Page 1

FormNo.3400-849RevC

TITAN

®

ZX4800,ZX5400,or

ZX6000Zero-Turn-RadiusRiding

Mower

ModelNo.74861—SerialNo.316000001andUp

ModelNo.74862—SerialNo.316000001andUp

ModelNo.74863—SerialNo.316000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3400-849*C

Page 2

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

ThissparkignitionsystemcomplieswithCanadian

ICES-002

TheenclosedEngineOwner'sManualis

suppliedforinformationregardingtheUS

EnvironmentalProtectionAgency(EPA)and

theCaliforniaEmissionControlRegulationof

emissionsystems,maintenance,andwarranty.

Replacementsmaybeorderedthroughtheengine

manufacturer.

Introduction

Thismachineisaride-on,rotary-bladelawnmower

intendedtobeusedbyhomeownersinresidential

applications.Itisprimarilydesignedforcuttinggrass

onwell-maintainedlawns.Itisnotdesignedforcutting

brush,mowinggrassandothergrowthalongside

highways,orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactT orodirectlyatwww.T oro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

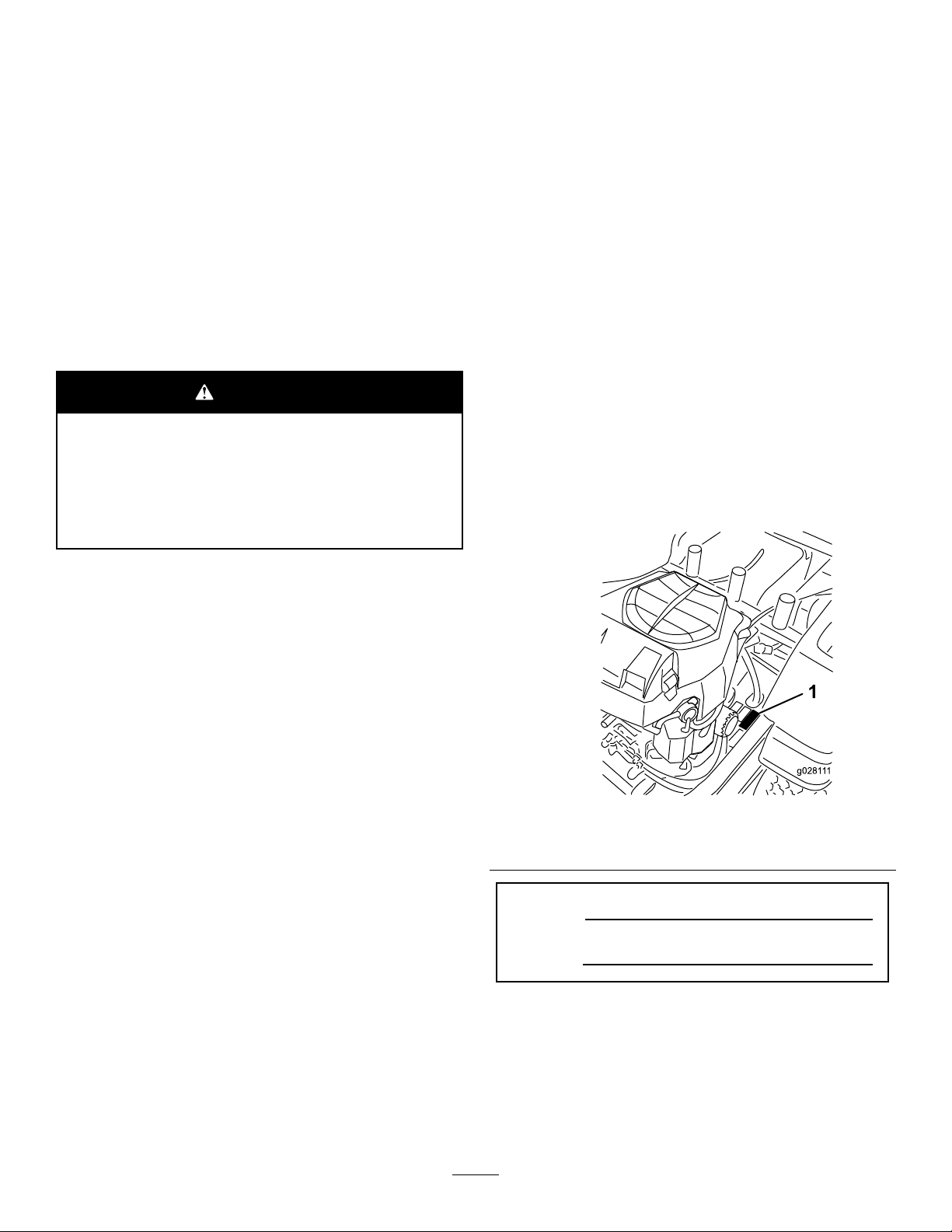

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

g02811 1

Figure1

1.Modelandserial-numberlocation

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

ModelNo.

SerialNo.

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

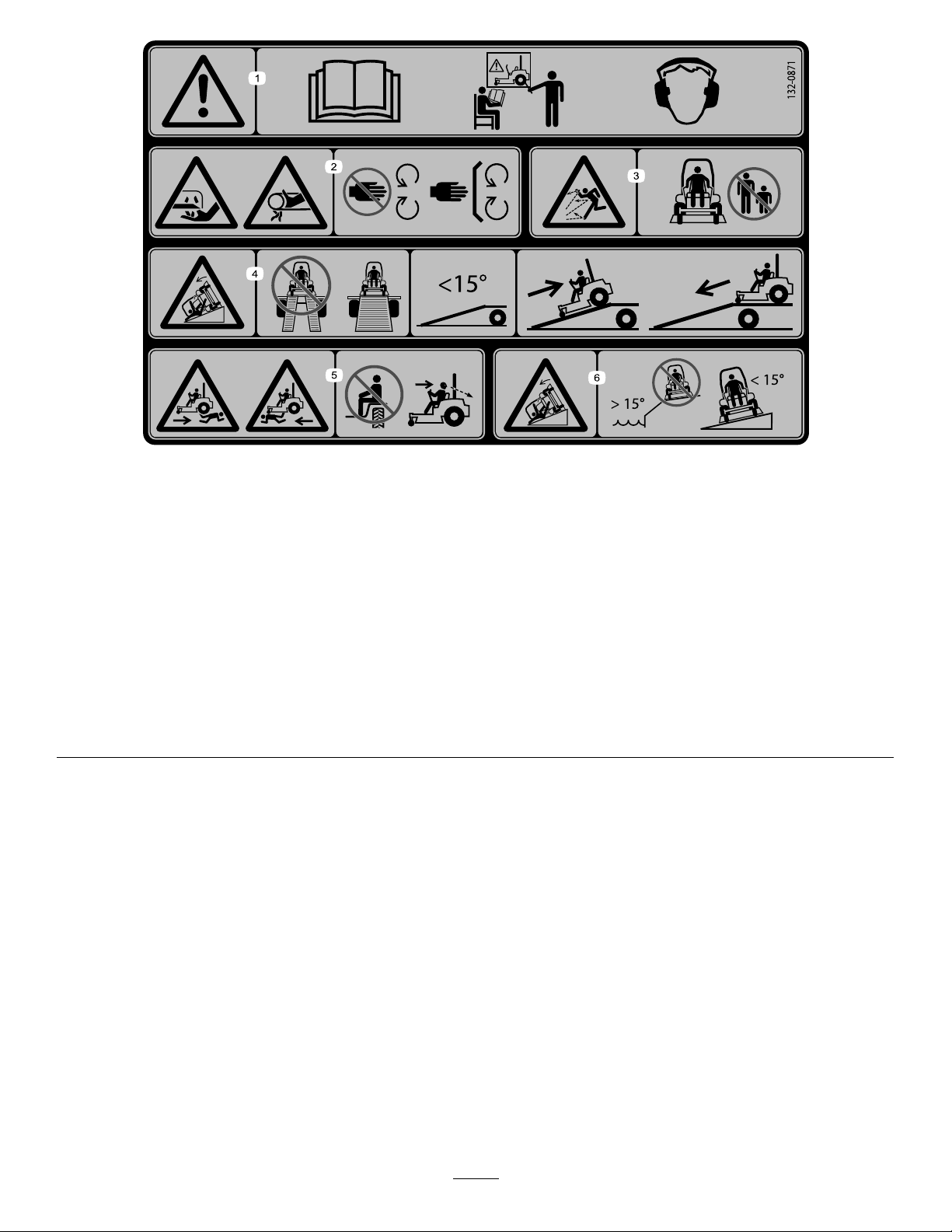

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

WARNING

Removingstandardoriginalequipmentparts

andaccessoriesmayalterthewarranty,

traction,andsafetyofthemachine.Failureto

useoriginalT oropartscouldcauseserious

injuryordeath.Makingunauthorizedchanges

totheengine,fuelorventingsystem,may

violateEPAandCARBregulations.

Replaceallpartsincluding,butnotlimited

to,tires,belts,blades,andfuelsystem

componentswithoriginalToroparts.

Formodelswithstatedenginehorsepower,thegross

horsepoweroftheenginewaslaboratorytestedby

theenginemanufacturerinaccordancewithSAE

J1995andratedtoJ2723.

Donottamperwiththeenginecontrolsoralterthe

governorspeed;doingsomaycreateanunsafe

conditionresultinginpersonalinjury.

Contents

Safety.......................................................................4

SafeOperatingPractices....................................4

ToroRidingMowerSafety...................................6

SlopeIndicator...................................................7

SafetyandInstructionalDecals..........................8

g000502

ProductOverview...................................................13

Controls...........................................................14

Operation................................................................15

AddingFuel......................................................15

ThinkSafetyFirst..............................................17

UsingtheRollover-ProtectionSystem

(ROPS).........................................................17

UnderstandingtheSafety-Interlock

System..........................................................18

TestingtheSafety-InterlockSystem..................18

CheckingtheEngine-OilLevel..........................18

BreakinginaNewMachine..............................18

OperatingtheParkingBrake.............................18

OperatingtheThrottle.......................................19

OperatingtheChoke.........................................19

OperatingtheIgnitionSwitch............................19

StartingandStoppingtheEngine......................19

OperatingtheBlade-ControlSwitch

(PTO)............................................................20

DrivingtheMachine..........................................21

StoppingtheMachine.......................................22

AdjustingtheHeightofCut...............................22

AdjustingtheAnti-ScalpRollers........................23

PositioningtheSeat..........................................24

AdjustingtheMotion-ControlLevers.................24

PushingtheMachinebyHand..........................24

UsingtheSideDischarge.................................25

TransportingtheMachine.................................26

LoadingtheMachine........................................26

OperatingTips.................................................28

Maintenance...........................................................29

RecommendedMaintenanceSchedule(s)...........29

Pre-MaintenanceProcedures..............................30

Service-IntervalChart.......................................30

RaisingtheSeat...............................................30

Lubrication..........................................................31

GreasingtheBearings......................................31

EngineMaintenance...........................................31

ServicingtheAirCleaner..................................31

ServicingtheEngineOil....................................32

ServicingtheSparkPlug...................................34

CleaningtheBlowerHousing............................35

FuelSystemMaintenance...................................36

ReplacingtheFuelFilter...................................37

ElectricalSystemMaintenance...........................37

ServicingtheBattery.........................................37

ServicingtheFuses..........................................38

DriveSystemMaintenance..................................39

CheckingtheTirePressure...............................39

HydraulicSystemMaintenance...........................40

CheckingtheHydraulic-FluidLevel...................40

3

Page 4

ChangingtheHydraulicFilterand

Fluid..............................................................40

MowerDeckMaintenance....................................42

ServicingtheCuttingBlades.............................42

LevelingtheMowerDeck..................................44

InspectingtheBelts..........................................46

ReplacingtheMowerBelt.................................46

RemovingtheMower........................................47

InstallingtheMowerDeck.................................48

ReplacingtheGrassDeector..........................48

Cleaning..............................................................49

WashingtheUndersideoftheMower................49

DisposingofWaste...........................................50

Storage...................................................................51

CleaningandStorage.......................................51

Troubleshooting......................................................52

Schematics.............................................................54

Safety

Improperlyusingormaintainingthemachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafetyalertsymbol,which

meansCaution,Warning,orDanger—personal

safetyinstruction.Failuretocomplywiththe

instructionmayresultinpersonalinjuryordeath.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Thisproductisdesignedforcuttingandrecycling

grassor,whenequippedwithagrassbagger,for

catchingcutgrass.Anyuseforpurposesotherthan

thesecouldprovedangeroustouserandbystanders.

SafeOperatingPractices

ThefollowinginstructionsareadaptedfromANSI

standardB71.4-2012.

Training

•ReadtheOperator'sManualandothertraining

material.Iftheoperator(s)ormechanic(s)cannot

readEnglishitistheowner'sresponsibilityto

explainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtopeopleor

damagetoproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Useonlyaccessoriesand

attachmentsapprovedbythemanufacturer.

•Wearappropriateclothingincludingsubstantial

slip-resistantfootwear,ahardhat,eyeprotection,

andhearingprotection.Tiebacklonghair.Donot

wearjewelry.

•Inspecttheareawheretheequipmentistobe

usedandremoveallobjectssuchasrocks,toys

andwirewhichcanbethrownbythemachine.

•Checkthatoperator-presencecontrols,safety

switchesandshieldsareattachedandfunctioning

4

Page 5

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

Operation

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfrom

holesandhiddenhazards.

•EnsurethatalldrivesareinNEUTRALandthatthe

parkingbrakeisengagedbeforestartingengine.

Starttheengineonlyfromtheoperator'sposition.

•Slowdownanduseextracareonhillsides.Be

suretotravelsidetosideonhillsides.Turf

conditionscanaffectthemachine'sstability .Use

cautionwhileoperatingneardrop-offs.

•Slowdownandusecautionwhenmakingturns

andwhenchangingdirectionsonslopes.

•Neverraisethedeckwiththebladesrunning.

•NeveroperatewiththePTOshield,orotherguards

notsecurelyinplace.Ensurethatallinterlocks

areattached,adjustedproperly,andfunctioning

properly.

•Neveroperatewiththedischargedeectorraised,

removedoraltered,unlessusingagrasscatcher.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Stoponlevelground,disengagethedrives,

engagetheparkingbrake(ifprovided),shutoff

theenginebeforeleavingtheoperator'sposition

foranyreasonincludingemptyingthecatchersor

uncloggingthechute.

•Stopequipmentandinspectbladesafterstriking

objectsorifanabnormalvibrationoccurs.Make

necessaryrepairsbeforeresumingoperations.

•Keephandsandfeetawayfromthecuttingunit.

•Lookbehindanddownbeforebackinguptobe

sureofaclearpath.

•Keeppetsandbystandersaway.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalks.Stopthe

bladesifyouarenotmowing.

•Beawareofthemowerdischargedirectionand

donotpointitatanyone.

•Donotoperatethemowerwhiletiredorunderthe

inuenceofalcoholordrugs.

•Usecarewhenloadingorunloadingthemachine

intoorfromatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

Rollover-ProtectionSystem (ROPS)

•DonotremovetheROPS.

•TheROPSisanintegralandeffectivesafety

device.KeeptheROPSonthemachineanduse

theseatbeltwhenoperatingthemachine.

•Becertainthattheseatbeltcanbereleased

quicklyintheeventofanemergency.

•Checktheareatobemowedwherethereare

slopes,dropoffs,orwater.

•Carefullycheckforoverheadclearances(i.e.,

branches,doorways,electricalwires)before

drivingunderanyobjectsanddonotcontactthem.

•KeeptheROPSinsafeoperatingconditionby

periodicallythoroughlyinspectingfordamageand

keepingallmountingfastenerstight.

•ReplaceadamagedROPS.Donotrepairor

revise.

•AnyalterationstoaROPSmustbeapprovedby

themanufacturer.

SafeHandlingofFuel

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineis

extremelyammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlightsuchas

onawaterheateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruck

ortrailerbedwithaplasticliner.Alwaysplace

containersonthegroundawayfromyourvehicle

beforelling.

•Removeequipmentfromthetruckortrailerand

fuelitontheground.Ifthisisnotpossible,then

refuelsuchequipmentwithaportablecontainer

ratherthanfromafueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimesuntilfueling

iscomplete.Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothing

immediately.

•Neveroverllthefueltank.Replacethefuelcap

andtightenitsecurely.

5

Page 6

MaintenanceandStorage

•Disengagedrives,setparkingbrake,stopengine

andremovekeyordisconnectspark-plugwire.

Waitforallmovementtostopbeforeadjusting,

cleaningorrepairing.

•Cleangrassanddebrisfromcuttingunit,drives,

mufers,andenginetohelppreventres.Clean

upoilorfuelspillage.

•Lettheenginecoolbeforestoringanddonotstore

nearame.

•Shutoffthefuelwhilestoringortransporting.Do

notstorefuelnearamesordrainindoors.

ToroRidingMowerSafety

Thefollowinglistcontainssafetyinformationspecic

toT oroproductsorothersafetyinformationthatyou

mustknowthatmaynotbeincludedintheANSI

standards.

•UseonlyToroapprovedattachments.Warranty

maybevoidedifusedwithunapproved

attachments.

•Ifloadingthemachineontoatrailerortruck,use

asingle,full-widthramponly.Therampangle

shouldnotexceed15degrees.

•Parkthemachineonlevelground.Settheparking

brake.Neverallowuntrainedpersonneltoservice

themachine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectthebatteryorremovespark-plug

wirebeforemakinganyrepairs.Disconnect

thenegativeterminalrstandthepositivelast.

Reconnectthepositiverstandnegativelast.

•Usecarewhencheckingblades.Wrapthe

blade(s)orwearthickly-paddedgloves,anduse

cautionwhenservicingthem.Onlyreplaceblades.

Neverstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

TowingSafety

•Donotattachtowedequipmentexceptatthehitch

point.

•Followtheattachmentmanufacturer's

recommendationforweightlimitsfortowed

equipmentandtowingonslopes.Towedweight

mustnotexceedtheweightofthemachine,

operator,andballast.Usecounterweightsor

wheelweightsasdescribedintheattachment,or

inthepullingmachineOperator’sManual.

•Neverallowchildrenorothersinorontowed

equipment.

•Onslopes,theweightofthetowedequipmentmay

causelossoftraction,increasedriskofrollover,

andlossofcontrol.Reducethetowedweightand

slowdown.

•Stoppingdistanceincreaseswiththeweightofthe

towedload.Travelslowlyandallowextradistance

tostop.

•Makewideturnstokeeptheattachmentclearof

themachine.

Hauling

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Usefullwidthrampsforloadingmachineinto

trailerortruck.

•Tiethemachinedownsecurelyusingstraps,

chains,cable,orropes.Bothfrontandrearstraps

shouldbedirecteddownandoutwardfromthe

machine.

6

Page 7

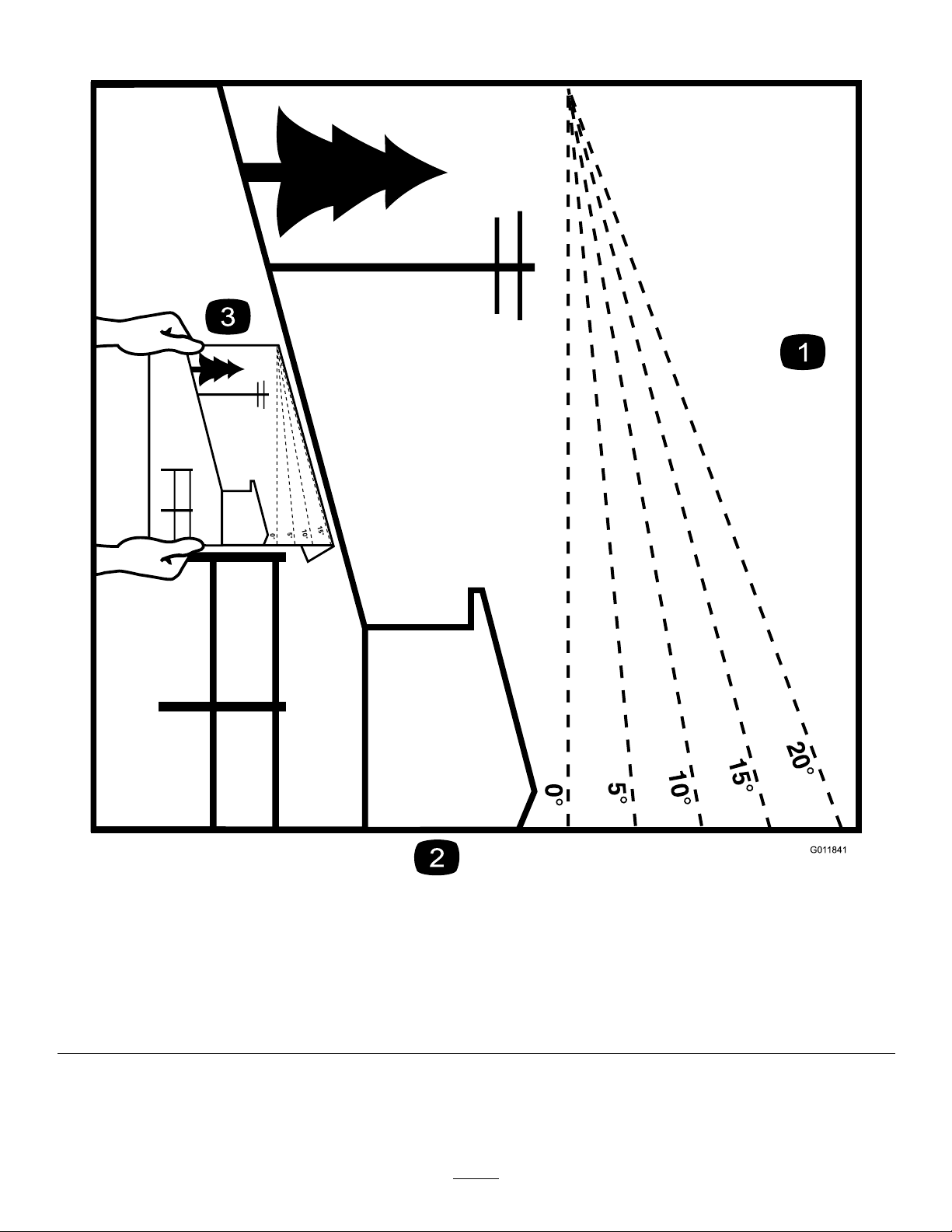

SlopeIndicator

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

7

r:\g011841

Page 8

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedorlost.

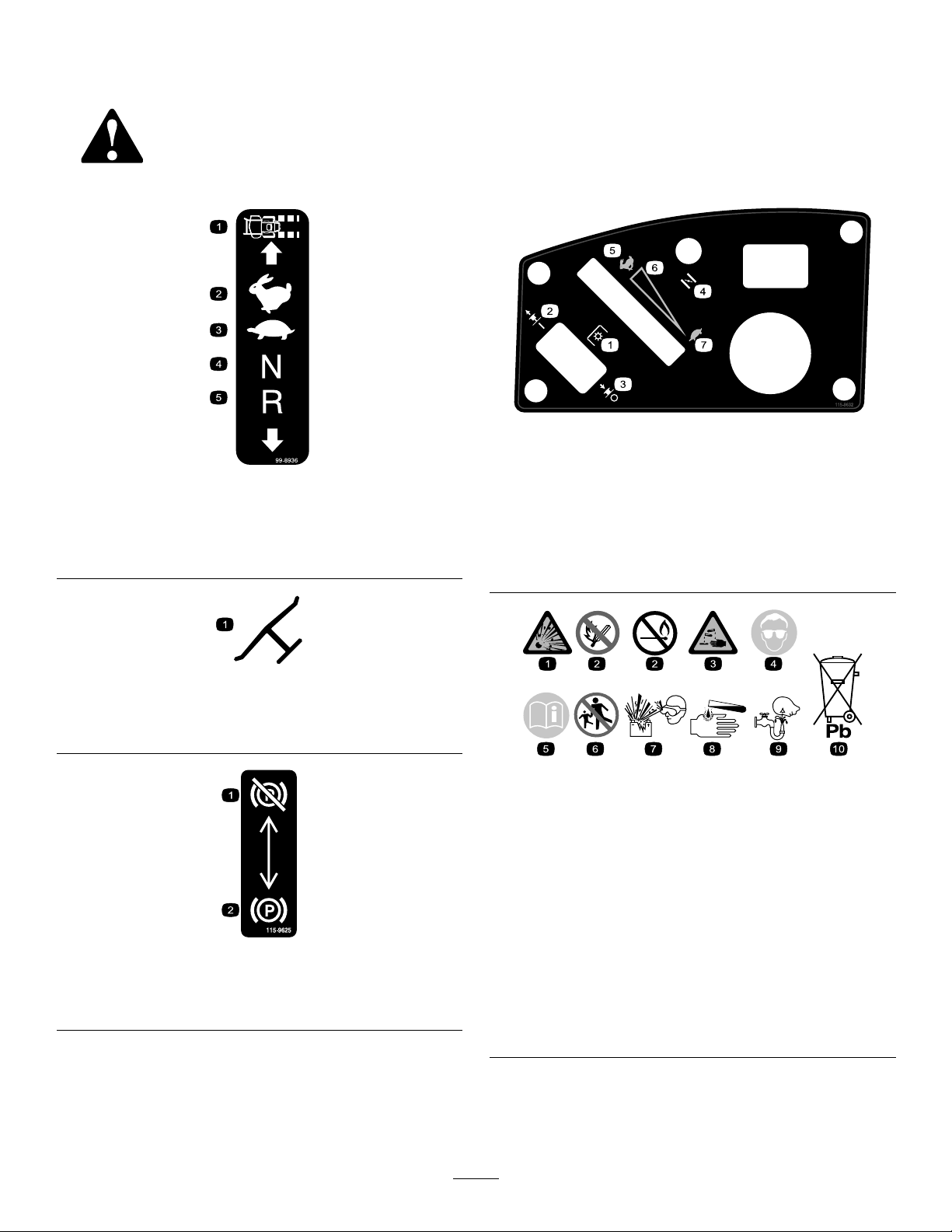

decal115-9632

115-9632

99-8936

1.Machinespeed4.Neutral

2.Fast5.Reverse

3.Slow

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

115-9625

1.Parking

brake—disengaged

2.Parkingbrake—engaged

decal99-8936

decaloemmarkt

1.Powertake-off(PTO),

Bladecontrolswitchon

somemodels

2.Bladecontrolswitch—On

3.Bladecontrolswitch—Off7.Slow

4.Choke

5.Fast

6.Continuousvariable

setting

decalbatterysymbols

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

decal115-9625

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

distancefromthebattery.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard.

8

Page 9

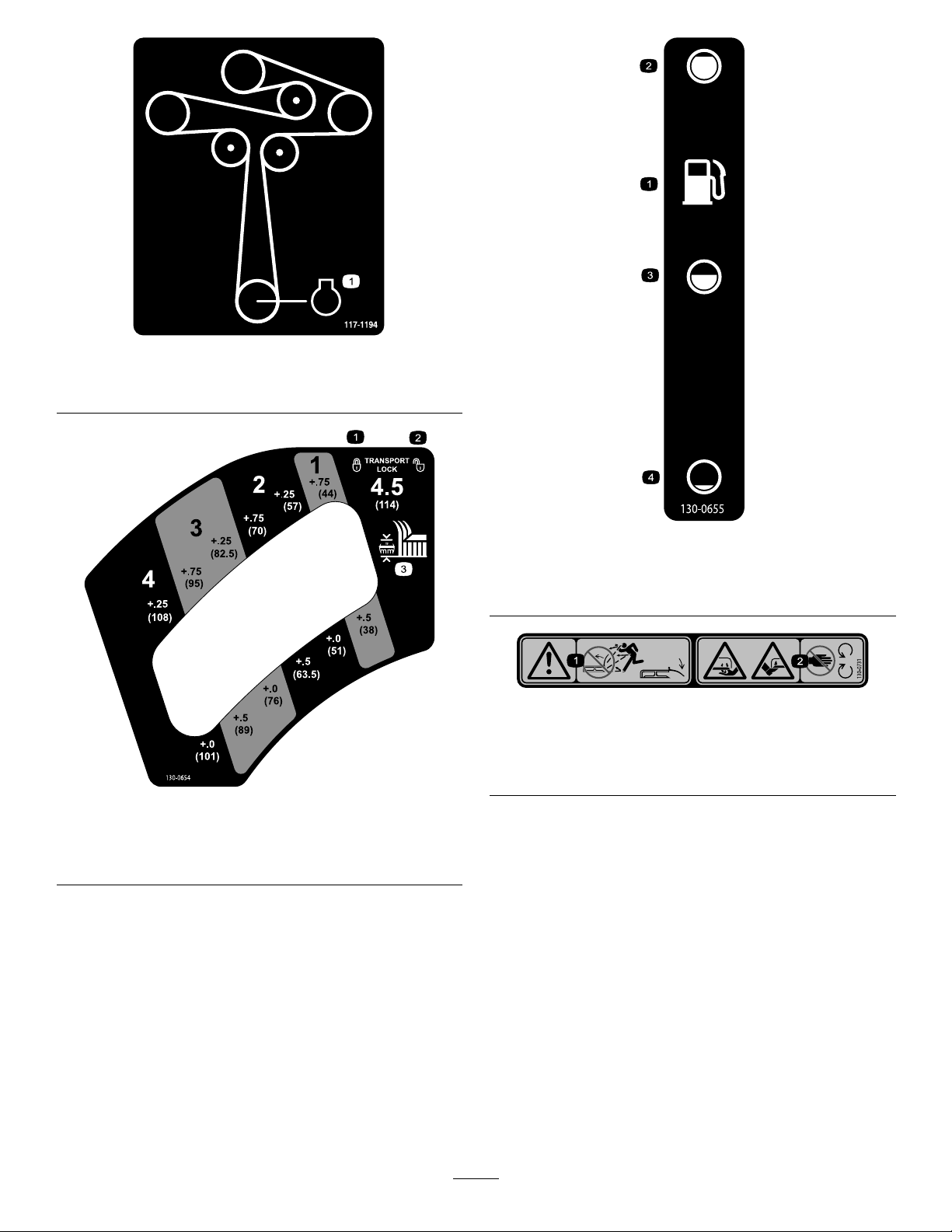

decal117-1 194

117-1194

1.Engine

decal130-0655

130-0655

1.Fueltank

3.Half

2.Full4.Empty

decal130-0731

130-0731

1.Warning—thrownobject

hazard;keepthedeector

shieldinplace.

decal130-0654

2.Cuttinghazardofhandor

foot,mowerblade—keep

awayfrommovingparts.

130-0654

1.Transport—lock

2.Transport—unlock

3.Height-of-cut

9

Page 10

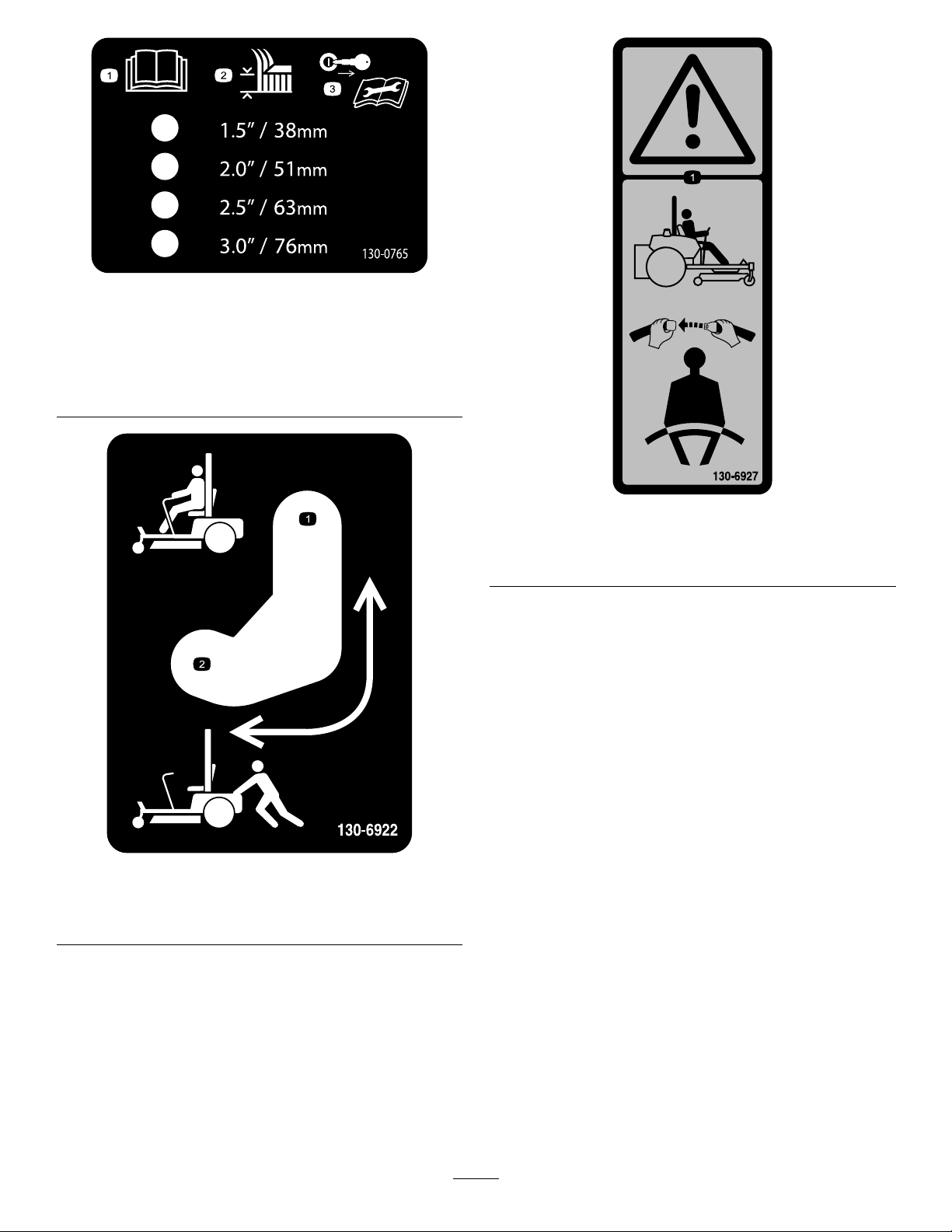

decal130-0765

130-0765

1.ReadtheOperator's

Manual.

2.Height-of-cutselection

3.Removethekeyfrom

theignitionandreadthe

Operator'sManualbefore

permorningmaintenance.

decal130-6927

130-6927

1.Warning—alwaysusetheROPSandweartheseatbelt

whenseatedintheoperator'sposition.

1.Bypassleverpositionfor

operatingthemachine.

decal130-6922

130-6922

2.Bypassleverpositionfor

pushingthemachine.

10

Page 11

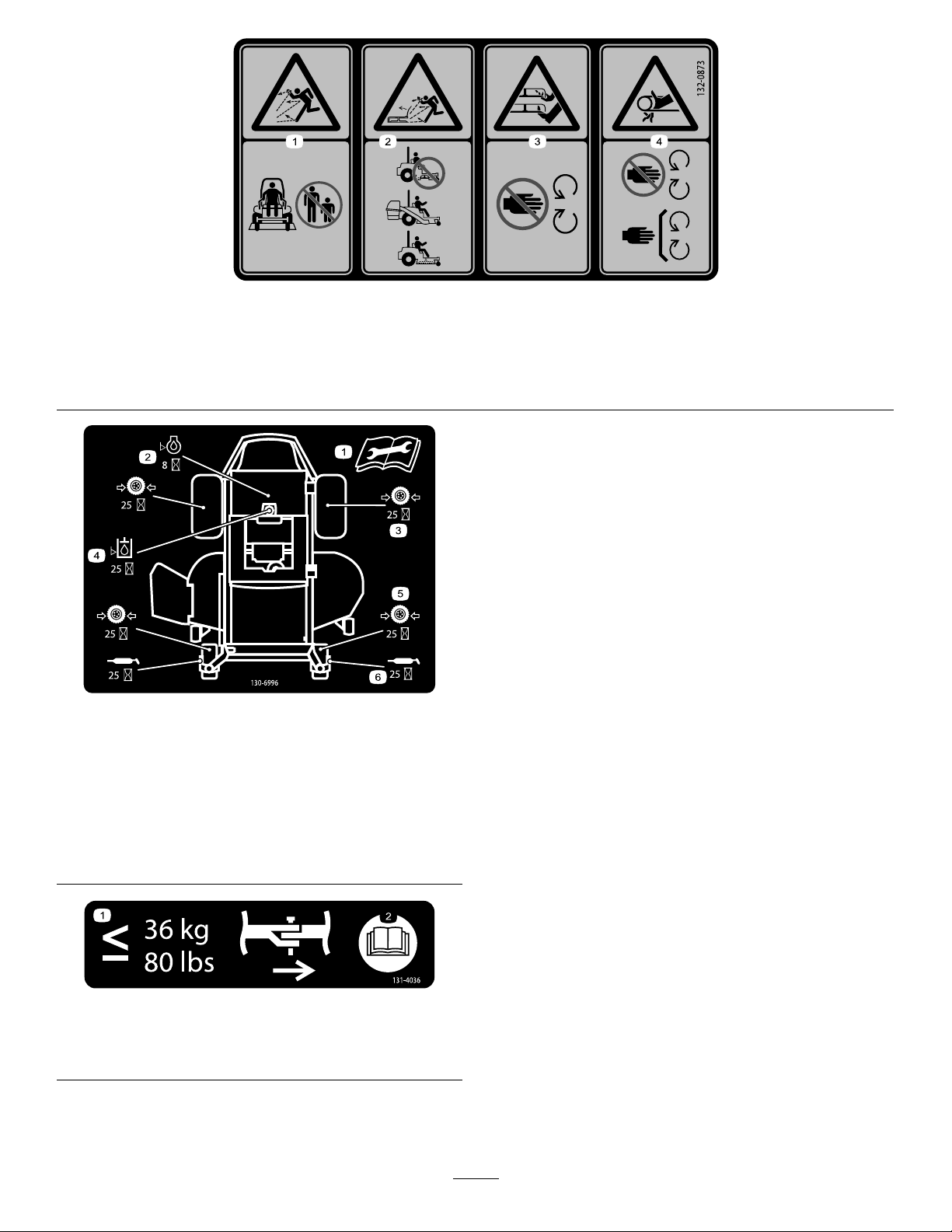

decal132-0873

132-0873

1.Thrownobjecthazard—keepbystandersawayfromthe

machine.

2.Thrownobjecthazard,mower—donotoperatethewithout

deector,dischargecover,orgrasscollectionsysteminplace.

130-6996

1.ReadtheOperator's

Manualforinformationon

maintenance.

2.Checktheengineoilevery

8hours

3.Checkthedrivewheeltire

pressureevery25hours

4.Checkthehydraulicoil

every25hours

5.Checkthecasterwheel

tirepressureevery25

hours

6.Lubricatethecasterwheel

every25hours

3.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

4.Entanglementhazard,belt—keepallguardsinplace.

decal130-6996

1.Themaximumdrawbar

pullis36kg(80lb).

decal131-4036

131-4036

2.ReadtheOperator's

Manual.

11

Page 12

132-0871

Note:Thismachinecomplieswiththeindustrystandardstabilitytestinthestaticlateralandlongitudinaltestswiththemaximum

recommendedslopeindicatedonthedecal.ReviewtheinstructionsforoperatingthemachineonslopesintheOperator’sManualas

wellastheconditionsinwhichyouwouldoperatethemachinetodeterminewhetheryoucanoperatethemachineinthoseconditions

onthatdayandatthatsite.Changesintheterraincanresultinachangeinslopeoperationforthemachine.Ifpossible,keepthe

cuttingunitsloweredtothegroundwhileoperatingthemachineonslopes.Raisingthecuttingunitswhileoperatingonslopescan

causethemachinetobecomeunstable.

decal132-0871

1.Warning—readtheOperator’sManual;donotoperatethis

machineunlessyouaretrained;wearhearingprotection.

2.Cutting,dismembering,andentanglementhazard—keep

handsawayfrommovingparts;keepallguardsandshieldsin

place.

3.Thrownobjecthazard—keepbystandersaway.6.Tippinghazardonslopes—donotuseonslopesnearopen

4.Ramphazard—whenloadingontoatrailer,donotusedual

ramps;onlyuseasingularrampwideenoughforthemachine

andthathasaninclinelessthan15°;backuptheramp(in

reverse)anddriveforwardofftheramp.

5.Bodilyharmhazard—donotcarrypassengers;lookbehind

youwhenmowinginreverse.

water;donotuseonslopesgreaterthan15°.

12

Page 13

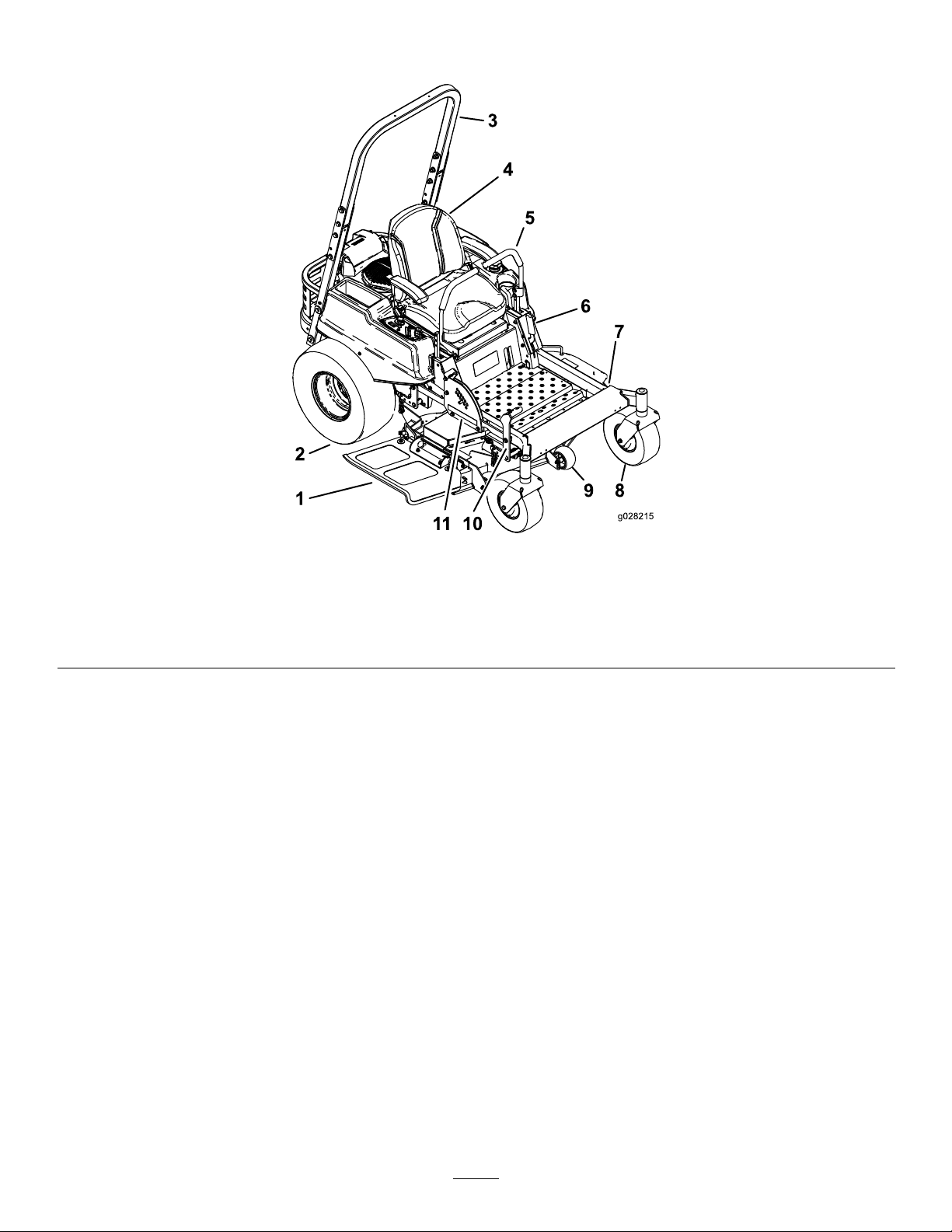

ProductOverview

Figure4

1.Grassdeector4.Operatorseat

2.Drivewheel5.Motion-controllevers8.Frontcasterwheel

3.Rollover-ProtectionSystem

(ROPS)

6.Parkingbrake9.Anti-scalproller

7.Footrest

g028215

10.Mower-deck-liftpedal

11.Height-of-cutlever

13

Page 14

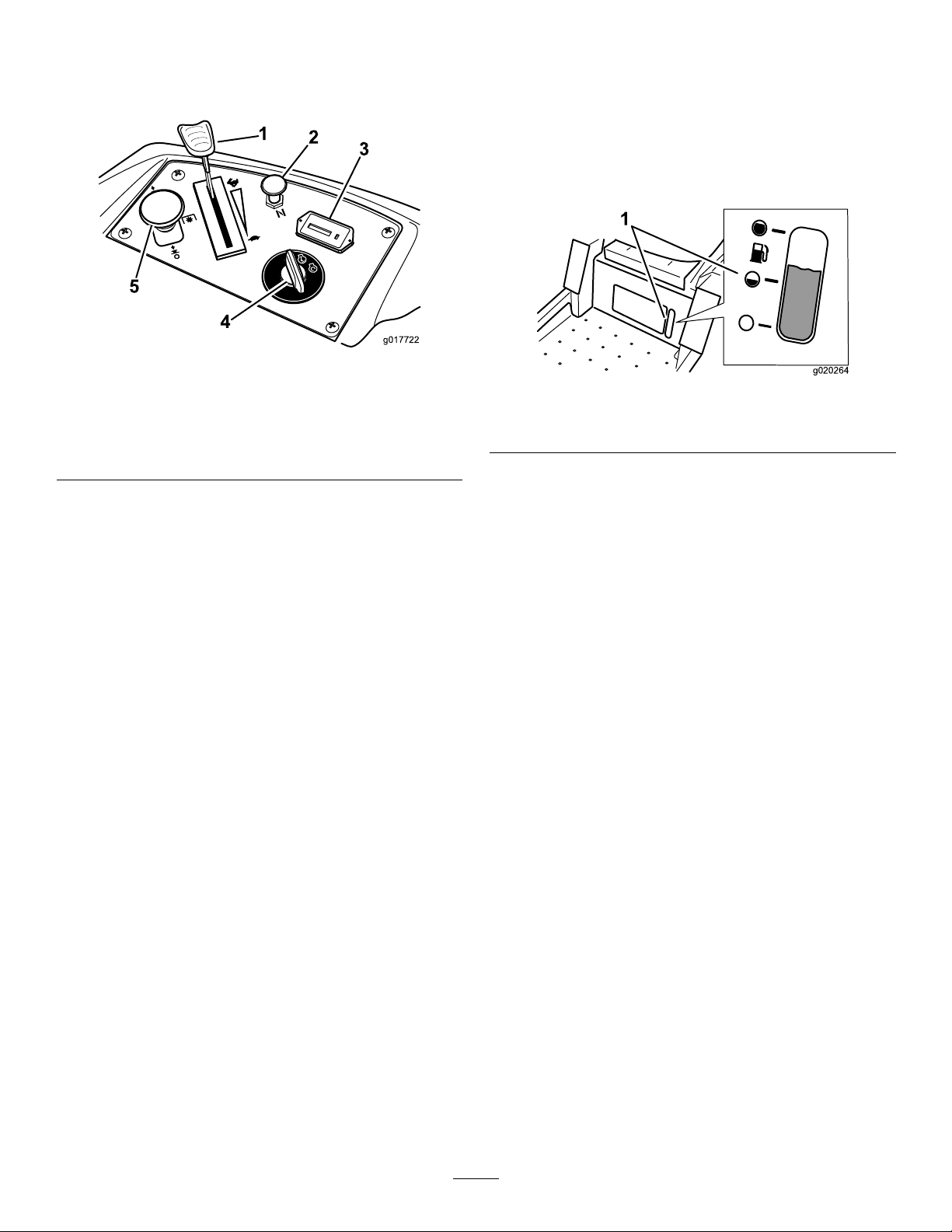

Controls

Becomefamiliarwithallthecontrolsbeforeyoustart

theengineandoperatethemachine(Figure5).

Figure5

1.Throttlecontrol4.Ignitionswitch

2.Choke

3.Hourmeter

5.Blade-controlswitch

(PTO)

switch(PTO)isengaged.Usethesetimesfor

schedulingregularmaintenance(Figure5).

FuelGauge

Thefuelwindowlocatedbelowtheoperatorposition

canbeusedtoverifythelevelofgasolineinthetank

(Figure6).

g017722

g020264

Figure6

1.Fuel-gaugewindow

IgnitionSwitch

Theignitionswitchhas3positions:START,RUN,and

OFF..ThekeywillturntotheSTARTpositionandmove

backtotheRUNpositionuponrelease.Turningthe

keytotheOFFpositionshutsofftheengine;however,

alwaysremovethekeywhenleavingthemachineto

preventtheenginefromaccidentallystarting(Figure

5).

ThrottleControl

ThethrottlecontrolisvariablebetweentheFASTand

SLOWposition.Movingthrottleleverforwardincreases

enginespeedandmovingthrottlelevertotherear

decreasesenginespeed.Movingthethrottleforward

intothedetentisfullthrottle(Figure5).

Choke

Usethechoketostartacoldengine.Pullthechoke

knobuptoengageit.Pushdownonthechokeknob

todisengageit.

Blade-ControlSwitch(Power

Takeoff)

Motion-ControlLevers

Themotion-controlleversarespeed-sensitivecontrols

ofindependent-wheelmotors.Movingaleverforward

orbackwardturnsthewheelonthesamesideforward

orinreverse;wheelspeedisproportionaltothe

amounttheleverismoved.Movethecontrollevers

outwardfromthecentertotheNEUTRAL-LOCKposition

andexitthemachine(Figure4).Alwayspositionthe

motion-controlleversintotheNEUTRAL-LOCKposition

whenyoustopthemachineorleaveitunattended.

Parking-BrakeLever

Theparking-brakeleverislocatedonleftsideofthe

console(Figure4).hebrakeleverengagesaparking

brakeonthedrivewheels.Pulltheleverupand

rearwardtoengagethebrake.Pushtheleverforward

anddowntodisengagethebrake.

FootPedalDeck-LiftSystem

Thefootpedaldeck-liftsystemallowstheoperator

tolowerandraisethedeckfromtheseatedposition.

Theoperatorcanusethefootpedaltoliftthedeck

brieytoavoidobstaclesorlockthedeckinthe

highestheightofcutortransportposition(Figure4).

Theblade-controlswitchengagesanddisengages

powertothemowerblades(Figure5).

HourMeter

Thehourmeterrecordsthenumberofhoursthe

bladesoperate.Itoperateswhentheblade-control

Height-of-CutLever

Theheight-of-cutleverworkswiththefootpedalto

lockthedeckinaspeciccuttingheight.Onlyadjust

theheightofcutwhilemachineisnotmoving(Figure

4).

14

Page 15

Attachments/Accessories

AselectionofT oroapprovedattachmentsand

accessoriesisavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.T oro.comforalistofallapprovedattachments

andaccessories.

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

AddingFuel

•Forbestresults,useonlyclean,fresh,unleaded

gasolinewithanoctaneratingof87orhigher

((R+M)/2ratingmethod).

•Oxygenatedfuelwithupto10%ethanolor15%

MTBEbyvolumeisacceptable.

•Donotuseethanolblendsofgasoline(such

asE15orE85)withmorethan10%ethanolby

volume.Performanceproblemsand/orengine

damagemayresultwhichmaynotbecovered

underwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessafuelstabilizer

isused.

•Donotaddoiltogasoline.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitethegasolinevapors.Are

orexplosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebefore

lling.

•Donotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowthe

lossofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

ground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbe

used,keepthenozzleincontactwiththe

rimofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.

15

Page 16

WARNING

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporscancause

seriousinjuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastank

orconditioneropening.

•Keepgasawayfromeyesandskin.

Addthecorrectamountofgasstabilizer/conditioner

tothegas.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.T ominimizethe

chanceofvarnishdepositsinthefuelsystem,usefuel

stabilizeratalltimes.

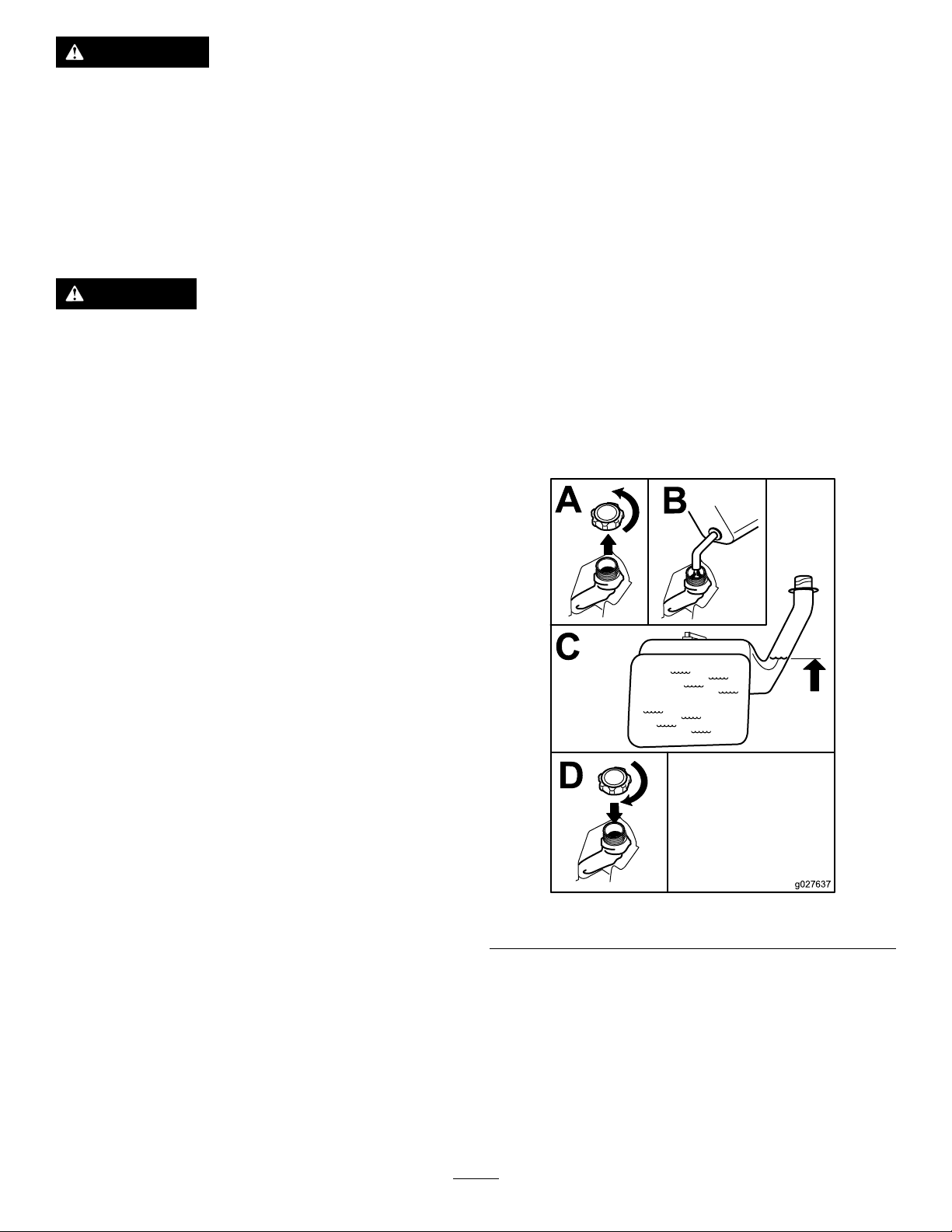

FillingtheFuelTank

Shutofftheengineandmovethemotioncontrolsto

thePARKposition.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areor

explosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupany

gasolinethatspills.

•Neverllthefueltankinsideanenclosed

trailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6

to13mm(1/4to1/2inch)belowthebottom

ofthellerneck.Thisemptyspaceinthe

tankallowsgasolinetoexpand.

•Neversmokewhenhandlinggasoline,and

stayawayfromanopenameorwhere

gasolinefumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainer

andkeepitoutofthereachofchildren.

Neverbuymorethana30-daysupplyof

gasoline.

Important:Donotoverllfueltank.Fillthefuel

tanktothebottomofthellerneck.Theempty

spaceinthetankallowsthefueltoexpand.

Overllingmayresultinfuelleakageordamageto

theengineoremissionsystem.

1.Cleanaroundthefuel-tankcapandremovethe

cap.

2.Slowlyaddregular,unleadedgasolineuntilthe

fuelreachesthebaseofthellerneck(Figure7).

•Donotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysor

less.Forlongerstorageitisrecommendedthat

thefueltankbedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

g027637

Figure7

3.Installthefuel-tankcapsecurelyandtighten

untilitclicks.

Note:Wipeupanygasolinethatmayhave

spilled.

16

Page 17

ThinkSafetyFirst

CAUTION

Pleasereadallsafetyinstructionsandsymbolsinthe

safetysection.Knowingthisinformationcouldhelp

youorbystandersavoidinjury.

DANGER

Operatingthemachineonwetgrassorsteep

slopescancauseslidingandlossofcontrol.

•Donotoperateonslopesgreaterthan15

degrees.

•Reducespeedanduseextremecautionon

slopes.

•Donotoperatethemachinenearwater.

DANGER

Wheelsdroppingoveredgescancause

rollovers,whichmayresultinseriousinjury,

death,ordrowning.

Donotoperatethemachineneardrop-offs.

Thismachineproducessoundlevelsin

excessof85dBAattheoperatorsearandcan

causehearinglossthroughextendedperiods

ofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Wearprotectiveequipmentforyoureyes,ears,hands,

andfeetwhenusingthismachine(Figure9).

g009027

Figure9

1.Weareyeprotection.2.Wearhearingprotection.

Usingthe

DANGER

Operatingthemachinewhiletherollbaris

downmayleadtoseriousinjuryordeathin

theeventofarollover.

Alwayskeeptherollbarinthefullyraisedand

lockedpositionandusetheseatbelt.

Figure8

Rollover-ProtectionSystem

(ROPS)

WARNING

Toavoidinjuryordeathfromrollover:keep

therollbarinstalledandusetheseatbelt.

WARNING

Thereisnorolloverprotectionwhentheroll

barisremoved.

•Driveslowlyandcarefully.

•Checkcarefullyforoverheadclearances

(i.e.,branches,doorways,electricalwires)

beforedrivingunderanyobjectsanddo

notcontactthem.

g000963

1.Safezone—usethe

machinehere.

2.Useawalk-behindmower

and/orhandtrimmernear

drop-offsandwater.

3.Water

17

Page 18

Understandingthe

CheckingtheEngine-Oil

Safety-InterlockSystem

WARNING

Ifthesafety-interlockswitchesare

disconnectedordamaged,themachinecould

operateunexpectedly,causingpersonal

injury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

Thesafety-interlocksystemisdesignedtopreventthe

enginefromstartingunless:

•Thebladesaredisengaged.

•Themotion-controlleversareinthePARKposition.

Thesafety-interlocksystemalsoisdesignedtoshut

offtheenginewheneverthecontrolleversareoutof

thePARKpositionandyourisefromtheseat.

Level

Beforeyoustarttheengineandusethemachine,

checktheoillevelintheenginecrankcase;referto

CheckingtheEngine-OilLevel(page32).

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mower

decksanddrivesystemshavehigherfrictionwhen

new,placingadditionalloadontheengine.Allow

40to50hoursofbreak-intimefornewmachinesto

developfullpowerandbestperformance.

OperatingtheParking Brake

Alwayssettheparkingbrakewhenyoustopthe

machineorleaveitunattended.

SettingtheParkingBrake

TestingtheSafety-Interlock System

Testthesafety-interlocksystembeforeyouusethe

machineeachtime.Ifthesafetysystemdoesnot

operateasdescribedbelow,haveanAuthorized

ServiceDealerrepairthesafetysystemimmediately .

1.Whilesittingontheseat,withthecontrollevers

inthePARKposition,andmovetheblade-control

switchtotheONposition.Trystartingthe

engine;theengineshouldnotstart.

2.Whilesittingontheseat,movetheblade-control

switchtotheOFFposition.Moveeithermotion

controllevertothecenter,unlockedposition.

Trystartingtheengine;theengineshouldnot

start.Repeatwiththeothermotion-controllever.

3.Whilesittingontheseat,movetheblade

controlswitchtotheOFFposition,andlockthe

motion-controlleversinthePARKposition.Start

theengine.Whiletheengineisrunning,engage

theblade-controlswitch,andriseslightlyfrom

theseat;theengineshouldshutoff.

g027638

Figure10

ReleasingtheParkingBrake

4.Whilesittingontheseat,movetheblade-control

switchtotheOFFposition,andlockthe

motion-controlleversinthePARKposition.Start

theengine.Whiletheengineisrunning,move

themotion-controlleverstothecenter,unlocked

position,engagetheblade-controlswitch,and

riseslightlyfromtheseat;theengineshould

shutoff.

g027639

Figure11

18

Page 19

OperatingtheThrottle

OperatingtheIgnition

ThethrottlecontrolcanbemovedbetweentheSLOW

andFASTpositions(Figure12).

AlwaysusetheFASTpositionwhenturningonthe

mowerdeckwiththeblade-controlswitch(PTO).

Figure12

OperatingtheChoke

Usethechoketostartacoldengine.

1.Iftheengineiscold,usethechoketostartthe

engine.

2.Pulluponthechokeknobtoengagethechoke

beforeusingtheignitionswitch(Figure13).

3.Pushdownonthechoketodisengagethechoke

aftertheenginestarts(Figure13).

Switch

1.TurntheignitionkeytotheSTARTposition

(Figure14).

Note:Whentheenginesstarts,releasethekey.

Note:Additionalstartingcyclesmaybe

requiredwhenstartingtheenginefortherst

timeafterthefuelsystemhasbeenwithoutfuel

completely.

g028222

g008947

Figure14

2.TurntheignitionkeytotheSTOPposition.

Figure13

1.ONposition2.OFFposition

StartingandStoppingthe Engine

StartingtheEngine

StarttheengineasshowninFigure15.

Note:Awarmorhotenginemaynotrequirechoking.

Important:Donotengagestarterformorethan5

secondsatatime.Iftheenginefailstostartallow

a15secondcool-downperiodbetweenattempts.

Failuretofollowtheseinstructionscanburnout

thestartermotor.

Note:Ifthefuelsystemwasdepletedoffuel—add

fueltothemachineanduseadditionalstartingcycles

whenstartingtheengine.

g008959

19

Page 20

Figure15

g028224

Figure16

g028223

Operatingthe

Blade-ControlSwitch

StoppingtheEngine

CAUTION

Injurycanoccurifchildrenorbystanders

moveorattempttooperatethemachinewhile

itisunattended.

Alwaysremovetheignitionkeyandsetthe

parkingbrakewhenleavingthemachine

unattended,evenifjustforafewminutes.

StoptheengineasshowninFigure16.

(PTO)

Theblade-controlswitch(PTO)startsandstopsthe

mowerbladesandanypoweredattachments.

EngagingtheBlade-Control Switch(PTO)

Engagetheblade-controlswitch(PTO)withthe

throttlepositionatFAST.

Note:Engagingtheblade-controlswitch(PTO)with

thethrottlepositionathalforlesswillcauseexcessive

weartothedrivebelts.

20

Page 21

DisengagingtheBlade-Control Switch(PTO)

g008945

Figure17

Figure18

DrivingtheMachine

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Place

thethrottlecontrolintheFASTpositionforbest

performance.Alwaysoperateinthefull-throttle

positionwhenmowing.

CAUTION

Machinecanspinveryrapidly.Operatormay

losecontrolofmachineandcausepersonal

injuryordamagetomachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemaking

sharpturns.

g009174

Figure19

1.Motion-control

lever—NEUTRAL-LOCK

position

2.Center,unlockedposition5.Frontofthemachine

3.Forward

4.Backward

g004532

DrivingForward

Note:Theenginekillsifthetraction-controllevers

aremovedwiththeparkingbrakeengaged.

1.Releasetheparkingbrake.

2.Movetheleverstothecenter,unlockedposition.

3.Tomoveforward,slowlypushthemotion-control

leversforward(Figure20).

UsingtheMotion-ControlLevers

Usethemotion-controlleversasshowninFigure19.

21

Page 22

StoppingtheMachine

WARNING

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

Alwaysremovetheignitionkeyandmove

themotion-controlleversoutwardtothe

PARKpositionwhenleavingthemachine

unattended,evenifjustforafewminutes.

Tostopthemachine,movethetraction-controllevers

totheNEUTRALpositionandmovetothelocked

position,disengagetheblade-controlswitch(PTO),

andturntheignitionkeytotheOFFposition.

Settheparkingbrakewhenyouleavethemachine.

Remembertoremovethekeyfromtheignitionswitch.

Figure20

DrivingBackward

Note:Alwaysusecautionwhenbackingupand

turning.

1.Movetheleverstothecenter,unlockedposition.

2.Togobackward,slowlypullthemotion-control

leversrearward(Figure21).

g008952

AdjustingtheHeightofCut

Themachineisequippedwithafootpedaldeck-lift

system.Theoperatorcanusethefootpedaltolift

thedeckbrieytoavoidobstaclesorlockthedeckin

thehighestheightofcutortransportposition.The

operatorcanusetheheight-of-cutleverwiththefoot

pedaltolockthedeckinaspeciccuttingheight.

UsingtheFootPedalDeck-Lift System

•Pressthepedaldowntoraisethedeck;continue

topressthepedaluntilthedeckislockedinthe

transportposition(Figure22).

•Pushonthedeck-liftpedalwithyourfootandpull

thetransportlockhandlerearwardtodisengage

thetransportlock(Figure22).

Figure21

g008953

22

Page 23

Figure22

TransportLockPosition

AdjustingtheHeightofCut

Theheightofcutcanbeadjustedfrom38to114mm

(1-1/2to4-1/2inch)in6mm(1/4inch)increments

byrelocatingtheheight-of-cutpinintodifferenthole

locations.

1.Pushonthedeck-liftpedalwithyourfootand

raisethemowerdecktothetransport-lock

position(alsothe114mm(4-1/2inch)cutting

heightposition)asshowninFigure23.

2.Toadjust,removethepinfromtheheight-of-cut

bracket(Figure23).

3.Selectaholeintheheight-of-cutsystem

correspondingtothedesiredheightofcutand

insertthepin(Figure23).

g024410

Figure23

1.Deck-liftpedal3.Height-of-cutpositions

g024409

2.Handle4.Pin

AdjustingtheAnti-Scalp Rollers

Wheneveryouchangetheheightofcut,itis

recommendedtoadjusttheheightoftheanti-scalp

rollers.

1.Disengagetheblade-controlswitch(PTO),move

themotion-controlleverstotheNEUTRAL-LOCK

position,andsettheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removetheangenut,anti-scalproller,andbolt

fromthebracket(Figure24).

Note:Keeptheboltandanti-scalproller

togetherwhenremoving.

4.Pushonthedeck-liftpedalwithyourfootand

pullthehandlerearwardtodisengagethe

transportlock(Figure22).

5.Lowerthedeckslowlyuntilthelevermakes

contactwiththepin.

1.Flangenut4.Bushing

2.Spacer

3.Anti-scalproller

23

g024312

Figure24

5.Bolt

Page 24

4.Aligntheboltandanti-scalprollerinthe

holeofthebracketthatmatchedtheclosest

height-of-cutposition(Figure24).

5.Inserttheboltintothebracketholeandsecure

theboltandanti-scalprollerwiththeangenut

(Figure24).

PositioningtheSeat

Theseatcanmoveforwardandbackward(Figure25).

Positiontheseatwhereyouhavethebestcontrolof

themachineandaremostcomfortable.

g027252

Figure26

AdjustingtheTilt

Themotion-controlleverscanbetiltedforwardor

rearwardformaximumoperatorcomfort.

1.Loosentheupperboltholdingthecontrollever

tothecontrol-armshaft.

Figure25

Adjustingthe Motion-ControlLevers

AdjustingtheHeight

Note:Repeattheadjustmentfortheoppositecontrol

lever.

Themotion-controlleverscanbeadjustedhigheror

lowerformaximumoperatorcomfort(Figure26).

2.Loosenthelowerboltjustenoughtopivotthe

controlleverforwardorrearward.

3.Tightenbothboltstosecurethecontrolinthe

newposition.

g027632

4.Repeattheadjustmentfortheoppositecontrol

lever.

PushingtheMachineby Hand

Important:Alwayspushthemachinebyhand.

Nevertowthemachinebecausedamagemay

occur.

1.Parkthemachineonalevelsurfaceand

disengagethebladecontrolswitch.

2.Movethemotioncontrolleversoutwardto

neutrallockposition,shutofftheengine,remove

thekey,andwaitforallmovingpartstostop

beforeleavingtheoperatingposition.Makesure

theparkingbrakeisdisengaged.

3.Dothisprocedureoneachsideofthe

machineFigure27.

24

Page 25

Figure27

4.Movethebypasstothepositionforoperating

themachine(Figure27)toengagethewheel

motors.

UsingtheSideDischarge

Themowerhasahingedgrassdeectorthat

dispersesclippingstothesideanddowntowardthe

turf.

DANGER

Withoutagrassdeector,dischargecover,or

completegrasscatcherassemblymountedin

place,youandothersareexposedtoblade

contactandthrowndebris.Contactwith

rotatingmowerblade(s)andthrowndebris

willcauseinjuryordeath.

•Neverremovethegrassdeectorfrom

themowerbecausethegrassdeector

routesmaterialdowntowardtheturf.Ifthe

g027642

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthe

mower.

•Nevertrytoclearthedischargearea

ormowerbladesunlessyoumovethe

blade-controlswitch(PTO)totheOFF

position,rotatetheignitionkeytotheOFF

position,andremovethekey .

•Makesurethatthegrassdeectorisinthe

downposition.

25

Page 26

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthe

machine.Ensurethatthetrailerortruckhasall

necessarybrakes,lighting,andmarkingasrequired

bylaw.Pleasecarefullyreadallthesafetyinstructions.

Knowingthisinformationcouldhelpyou,yourfamily,

pets,orbystandersavoidinjury.

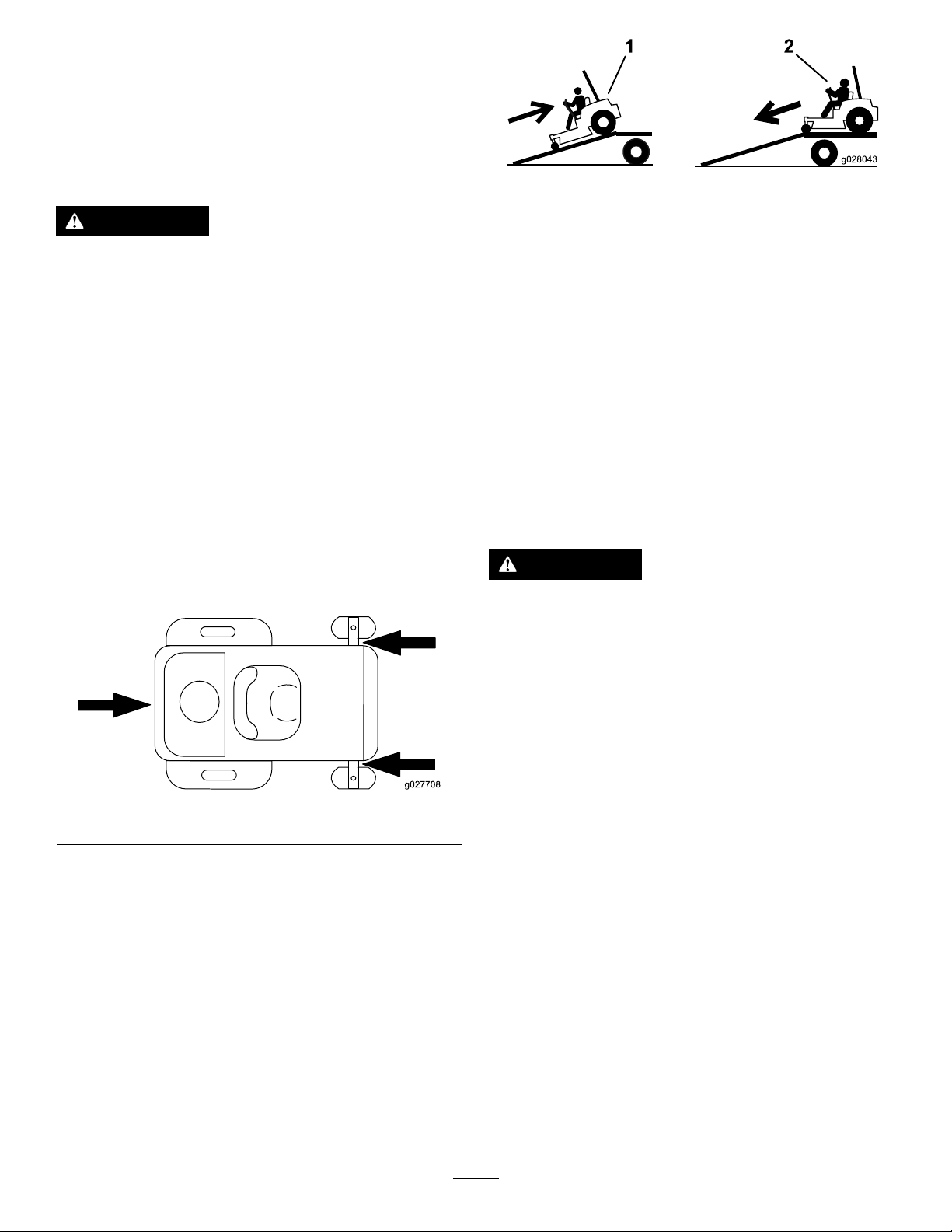

g028043

Figure29

WARNING

Drivingonthestreetorroadwaywithout

turnsignals,lights,reectivemarkings,ora

slow-moving-vehicleemblemisdangerous

andcanleadtoaccidents,causingpersonal

injury.

Donotdrivethemachineonapublicstreet

orroadway.

1.Ifyouareusingatrailer,connectittothetowing

vehicleandconnectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Loadthemachineontothetrailerortruck.

4.Shutofftheengine,removethekey,setthe

brake,andclosethefuelvalve.

5.Tiedownthemachinenearthefrontcaster

wheelsandtherearbumper(Figure28).

1.Backthemachineupthe

ramp.

2.Drivethemachineforward

downtheramp.

Important:Donotusenarrowindividualramps

foreachsideofthemachine.

Ensuretherampislongenoughsothattheanglewith

thegrounddoesnotexceed15degrees(Figure30).

Onatground,thisrequiresaramptobeatleast4

timesaslongastheheightofthetrailerortruckbed

totheground.Asteeperanglemaycausemower

componentstogetcaughtastheunitmovesfromthe

ramptothetrailerortruck.Steeperanglesmayalso

causethemachinetotiporlosecontrol.Ifloadingon

ornearaslope,positionthetrailerortrucksothatitis

onthedownsideoftheslopeandtherampextends

uptheslope.Thiswillminimizetherampangle.

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath.

•Useextremecautionwhenoperatinga

machineonaramp.

Figure28

LoadingtheMachine

Useextremecautionwhenloadingorunloading

machinesontoatraileroratruck.Useafull-width

rampthatiswiderthanthemachineforthisprocedure.

Backthemachineuptherampanddriveitforward

downtheramp(Figure29).

•Useonlyafull-widthramp;donotuse

individualrampsforeachsideofthe

machine.

g027708

•Donotexceeda15-degreeanglebetween

therampandthegroundorbetweenthe

rampandthetrailerortruck.

•Ensurethelengthoframpisatleast4

timesaslongastheheightofthetrailer

ortruckbedtotheground.Thiswill

ensurethatrampangledoesnotexceed15

degreesonatground.

•Backuprampsanddriveforwarddown

ramps.

•Avoidsuddenaccelerationordeceleration

whiledrivingthemachineonarampas

thiscouldcausealossofcontrolora

tip-oversituation.

26

Page 27

Figure30

g027996

1.Full-widthrampinstowed

position

2.Sideviewoffull-width

rampinloadingposition

3.Notgreaterthan

15degrees

4.Rampisatleast4times

aslongastheheightof

thetrailerortruckbedto

theground

5.H=heightofthetraileror

truckbedtotheground

6.Trailer

27

Page 28

OperatingTips

UsingtheFastThrottleSetting

raisethecuttingheighthigherthanusualandcutthe

grassatthissetting.Thencutthegrassagainusing

thelower,normalsetting.

Forbestmowingandmaximumaircirculation,operate

theengineattheFASTposition.Airisrequiredto

thoroughlycutgrassclippings,sodonotsetthe

height-of-cutsolowastototallysurroundthemower

inuncutgrass.Alwaystrytohave1sideofthemower

freefromuncutgrass,whichallowsairtobedrawn

intothemower.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethat

thecuttingheightofthemowerdoesnotscalpany

unevenground.However,thecuttingheightusedin

thepastisgenerallythebestonetouse.Whencutting

grasslongerthan15cm(6inches)tall,youmaywant

tocutthelawntwicetoensureanacceptablequality

ofcut.

CuttingaThirdoftheGrassBlade

Itisbesttocutonlyaboutathirdofthegrassblade.

Cuttingmorethanthatisnotrecommendedunless

grassissparse,oritislatefallwhengrassgrows

moreslowly.

AlternatingtheMowingDirection

Alternatethemowingdirectiontokeepthegrass

standingstraight.Thisalsohelpsdisperseclippings

whichenhancesdecompositionandfertilization.

Stopping

Ifyoumuststoptheforwardmotionofthemachine

whilemowing,aclumpofgrassclippingsmay

dropontoyourlawn.Toavoidthis,moveontoa

previouslycutareawiththebladesengagedoryou

candisengagethemowerdeckwhilemovingforward.

KeepingtheUndersideofthe

MowerClean

Cleanclippingsanddirtfromtheundersideofthe

moweraftereachuse.Ifgrassanddirtbuildupinside

themower,cuttingqualitywilleventuallybecome

unsatisfactory.

MaintainingtheBlade(s)

Maintainasharpbladethroughoutthecuttingseason

becauseasharpbladecutscleanlywithouttearingor

shreddingthegrassblades.Tearingandshredding

turnsgrassbrownattheedges,whichslowsgrowth

andincreasesthechanceofdisease.Checkthe

mowerbladesaftereachuseforsharpness,and

foranywearordamage.Filedownanynicksand

sharpenthebladesasnecessary .Ifabladeis

damagedorworn,replaceitimmediatelywitha

genuineT ororeplacementblade.

MowingatCorrectIntervals

Grassgrowsatdifferentratesatdifferenttimesof

theyear.Tomaintainthesamecuttingheight,mow

moreofteninearlyspring.Asthegrassgrowthrate

slowsinmidsummer,mowlessfrequently.Ifyou

cannotmowforanextendedperiod,rstmowata

highcuttingheight,thenmowagain2dayslaterata

lowerheightsetting.

UsingaSlowerCuttingSpeed

Toimprovecutquality ,useaslowergroundspeed

incertainconditions.

AvoidingCuttingTooLow

Whenmowinguneventurf,raisethecuttingheight

toavoidscalpingtheturf.

CuttingLongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,

28

Page 29

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst50hours

Beforeeachuseordaily

Aftereachuse

Every25hours

Every50hours

Every100hours

Every400hours

MaintenanceProcedure

•Changethehydrauliclteranduid.

•Checkthesafety-interlocksystem.

•Checktheaircleanerfordirty,looseordamagedparts.

•Checktheengine-oillevel.

•Cleantheblowerhousing(moreoftenunderextremelydusty,dirtyconditions).

•Checkthemowerblades.

•Inspectthegrassdeectorfordamage.

•Cleanthemowerhousing.

•Greasealllubricationpoints.

•Serviceorreplacetheair-cleanerfoamelement(moreoftenunderextremelydusty,

dirtyconditions).

•Checktirepressure.

•Checkthehydraulic-uidlevelintheexpansiontank.

•Inspectthebeltsforcracksandwear.

•Replacetheair-cleanerpaperelement(moreoftenunderextremelydusty,dirty

conditions).

•Changetheengineoilandtheengine-oillter.

•Cleanthecoolingns(moreoftenunderextremelydusty ,dirtyconditions).

•Replacethefuellter(moreoftenunderdusty ,dirtyconditions).

•Changethehydrauliclteranduid.

Every500hours

Monthly

Yearlyorbeforestorage

•Replacethesparkplug(s).

•Checkthebatterycharge.

•Paintchippedsurfaces.

•Checkallmaintenanceprocedureslistedabovebeforestorage.

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineand

seriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudo

anymaintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

29

Page 30

Pre-Maintenance

Procedures

Service-IntervalChart

decal130-6996

Figure31

Locatedontheseatpanunderside

1.ReadtheOperator'sManualbeforeperformingany

maintenance.

2.Checktheengineoilevery8hours.5.Checkthecasterwheeltirepressureevery25hours.

3.Checkthedrivewheeltirepressureevery25hours.

4.Checkthehydraulicoilevery25hours.

6.Lubricatethecasterwheelevery25hours.

RaisingtheSeat

Ensurethatthemotion-controlleversarelockedinthe

NEUTRAL-LOCKpositionandlifttheseatforward.

Thefollowingcomponentscanbeaccessedbyraising

theseat:

•Servicedecal

•Fuses

•Batteryandcables

30

Page 31

Lubrication

EngineMaintenance

GreasingtheBearings

ServiceInterval:Every25hours—Greaseall

lubricationpoints.

GreaseType:No.2lithiumgrease

1.Parkthemachineonalevelsurfaceand

disengagetheblade-controlswitch.

2.Movethemotion-controlleversoutwardtothe

NEUTRAL-LOCKposition,shutofftheengine,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Cleanthegreasettings(Figure32andFigure

31)witharag.

Note:Makesuretoscrapeanypaintoffthe

frontofthetting(s).

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandother

bodypartsawaythemuferandotherhot

surfaces.

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Check

theaircleanerfordirty,looseor

damagedparts.

Every25hours—Serviceorreplacethe

air-cleanerfoamelement(moreoftenunder

extremelydusty,dirtyconditions).

Every100hours—Replacetheair-cleaner

paperelement(moreoftenunderextremely

dusty,dirtyconditions).

Thisengineisequippedwithareplaceable,

high-densitypaperandfoamair-cleanerelement.

Checktheaircleanerdailyorbeforestartingthe

engine.Checkforabuildupofdirtanddebrisaround

theair-cleanersystem.Keepthisareaclean.Also,

checkforlooseordamagedcomponents.Replaceall

bentordamagedair-cleanercomponents.

Figure32

1.Frontcastertire

4.Connectagreaseguntoeachttingandpump

greaseintothettingsuntilgreasebeginsto

oozeoutofthebearings(Figure31andFigure

32).

Note:Operatingtheenginewithlooseordamaged

air-cleanercomponentscouldallowunlteredairinto

theengine,causingprematurewearandfailure.

Note:Servicetheaircleanermoreoftenunder

extremelydusty,dirtyconditions.

g009949

RemovingtheElements

1.Rotatethelatchesoutward.

2.Removethecovertoaccesstheair-cleaner

elements(Figure33).

31

Page 32

donotuseifthesealingsurfacesarebentor

damaged.

2.Cleantheair-cleanerbaseasrequired,and

checkthecondition.

InstallingtheElements

1.Installthefoamelementontothepaperelement.

2.Installtheelementsontotheair-cleanerbase

(Figure34).

3.Installthecover,andsecureitwiththelatches

(Figure33).

Figure33

1.Air-cleanercover2.Air-cleanerlatch

3.Removethefoamandpaperelements(Figure

34).

4.Removethefoamelementfromthepaper

element(Figure34).

Figure34

1.Air-cleanercover3.Paperelement

2.Foamelement

g028105

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSJorhigher)

CrankcaseCapacity:1.9L(64oz)whenthelter

ischanged

Viscosity:Seethetablebelow.

g028106

g017552

Figure35

ServicingtheFoamElement

1.Washthefoamelementinwarmwaterand

detergent.

2.Rinseandallowittoairdry.

3.Lightlyoilthefoamelementwithnewoiland

squeezeoutexcessoil.

ServicingthePaperElement

1.Gentlytapthepaperelementtodislodgedirt.

Note:Donotwashthepaperelementoruse

pressurizedair,asthiswilldamagetheelement.

Note:Replaceadirty,bent,ordamaged

element.Handlethenewelementcarefully;

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily—Check

theengine-oillevel.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,shutofftheengine,

andremovethekey.

2.Makesurethattheengineisstopped,level,and

iscool,sotheoilhastimetodrainintothesump.

3.Checktheengine-oillevel(Figure36).

32

Page 33

Figure36

ChangingtheEngineOilandthe Engine-OilFilter

ServiceInterval:Every100hours—Changethe

engineoilandtheengine-oillter.

Note:Thedrainplugisattachedtothedrainhose.

Note:Disposeoftheusedoilatarecyclingcenter.

Fillwithoilasspeciedinthe“ViscosityGrades”table

(Figure35).

1.Parkthemachine,sothatthedrainsideis

slightlylowerthantheoppositeside,toensure

thattheoildrainscompletely.

2.Disengagetheblade-controlswitchandmove

themotioncontrolsoutwardtothePARKposition.

3.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

g027515

g027934

Figure37

4.Torquetheplugto14N•m(10ft-lb).

5.Changetheengine-oillterasshowninFigure

38.

33

Page 34

Figure39

ServicingtheSparkPlug

ServiceInterval:Every500hours—Replacethe

sparkplug(s).

g027517

Figure38

6.Slowlypourapproximately80%ofthespecied

oilintothellertube(Figure39).

g028127

ThesparkplugisRFIcompliant.Equivalentalternate

brandplugscanalsobeused.

Type:ChampionXC12YC

AirGap:0.76mm(0.03inch)

RemovingtheSparkPlug

1.Disengagetheblade-controlswitch,movethe

motioncontrolsoutwardtotheparkposition,

shutofftheengine,andremovethekey .

2.Beforeremovingthesparkplug(s),cleanthe

areaaroundthebaseoftheplugtokeepdirt

anddebrisoutoftheengine.

3.Removethesparkplug(Figure40).

34

Page 35

g027478

Figure40

CheckingtheSparkPlug

Important:Donotcleanthesparkplug(s).

Alwaysreplacethesparkplug(s)whenithas:a

blackcoating,wornelectrodes,anoilylm,or

cracks.

Note:Ifyouseelightbrownorgrayontheinsulator,

theengineisoperatingproperly.Ablackcoatingon

theinsulatorusuallymeanstheaircleanerisdirty.

Setthegapto0.76mm(0.03inch).

InstallingtheSparkPlug

Tightenthesparkplugto27N•m(20ft-lb)asshown

inFigure42.

g028109

Figure42

Figure41

CleaningtheBlower Housing

Every100hours/Yearly(whichevercomesrst)

g027479

Toensurepropercooling,ensurethatthegrass

screen,coolingns,andotherexternalsurfacesofthe

enginearekeptcleanatalltimes.

Annually,orevery100hoursofoperation(moreoften

underextremelydusty ,dirtyconditions),removethe

blowerhousing,andanyothercoolingshrouds.Clean

thecoolingnsandexternalsurfacesasnecessary.

Makesurethecoolingshroudsareinstalled.

Important:Operatingtheenginewithablocked

grassscreen,dirtyorpluggedcoolingns,and/or

35

Page 36

coolingshroudsremoved,willcauseengine

damageduetooverheating.

FuelSystem

Maintenance

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areor

explosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Performanyfuelrelatedmaintenance

whentheengineiscold.Dothisoutdoors

inanopenarea.Wipeupanygasolinethat

spills.

•Neversmokewhendraininggasoline,and

stayawayfromanopenameorwherea

sparkmayignitethegasolinefumes.

36

Page 37

ReplacingtheFuelFilter

ElectricalSystem

ServiceInterval:Every100hours/Yearly(whichever

comesrst)(moreoftenunder

dusty,dirtyconditions).

1.Disengagetheblade-controlswitch(PTO),move

themotion-controlleverstotheNEUTRAL-LOCK

position,andsettheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.ReplacethefuellterasshowninFigure43.

Maintenance

ServicingtheBattery

ServiceInterval:Monthly

DANGER

Batteryelectrolytecontainssulfuricacid

whichisadeadlypoisonandcausessevere

burns.

Donotdrinkelectrolyteandavoidcontact

withskin,eyesorclothing.Wearsafety

glassestoshieldyoureyesandrubbergloves

toprotectyourhands.

g028110

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetalmachinecomponentscausing

sparks.Sparkscancausethebatterygasses

toexplode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,

donotallowthebatteryterminalstotouch

anymetalpartsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

Figure43

WARNING

Incorrectbatterycableroutingcoulddamage

themachineandcablescausingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysreconnectthepositive(red)battery

cablebeforereconnectingthenegative

(black)cable.

g027753

1.Disengagetheblade-controlswitch(PTO),move

themotion-controlleverstotheNEUTRAL-LOCK

position,andsettheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removethewingnutsecuringthebatteryclamp

(Figure44).

37

Page 38

Figure44

4.Removetheclamp(Figure44).

5.Firstdisconnectthenegativebatterycable

(black)fromthenegative(-)(black)battery

terminal(Figure44).

6.Slidetheredterminalbootoffthepositive(red)

batteryterminalandremovethepositive(+)(red)

batterycable(Figure44).

7.Removethebattery.

1.Chargebatteryfor10to15minutesat25to30

ampsor30minutesat10amps.

2.Whenthebatteryisfullycharged,unplug

thechargerfromtheelectricaloutlet,then

disconnectthechargerleadsfromthebattery

posts(Figure45).

3.Installthebatteryinthemachineandconnect

thebatterycables.

g020310

g000960

Figure45

1.Positivebatterypost

2.Negativebatterypost

3.Red(+)chargerlead

4.Black(-)chargerlead

InstallingtheBattery

1.Positionthebatteryinthetraywiththeterminal

postsoppositefromthefueltank(Figure44).

2.Installthepositive(red)batterycabletopositive

(+)batteryterminal.

3.Installthenegativebatterycabletothenegative

(-)batteryterminal.

4.Securethecableswith2bolts,2washers,and

2locknuts(Figure44).

5.Slidetheredterminalbootontothepositive

(red)batterypost.

6.Installtheclampandsecureitwiththewingnut

(Figure44).

ChargingtheBattery

WARNING

Chargingthebatteryproducesgassesthat

canexplode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery .

ServicingtheFuses

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;however,ifafuseblows,checkthe

component/circuitforamalfunctionorshort.

Note:Thefusesarelocatedonrighthandconsole

nexttotheseat(Figure46).

Fusetype:

•Main—30A,blade-type

•Engine—20A,blade-type

1.Toreplacethemainfuse,graspthefuseandpull

itstraightandawayfromthefuseblock(Figure

46).

Important:Alwayskeepthebatteryfullycharged.

Thisisespeciallyimportanttopreventbattery

damagewhenthetemperatureisbelow32°F(0°C).

38

Page 39

Figure46

1.Fuseblock2.Main—30A

DriveSystem

Maintenance

CheckingtheTirePressure

ServiceInterval:Every25hours—Checktire

pressure.

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseuneven

cut.Checkthepressureatthevalvestem(Figure48).

Checkthetireswhentheyarecoldtogetthemost

accuratepressurereading.

Refertothemaximumpressuresuggestedbythetire

manufactureronthesidewallofthecasterwheeltires.

Inatethereardrivewheeltiresto90kPa(13psi).

g024411

Important:Ensurethatthenewfusesare

thesametypeandamperageasthefuses

removed.

2.Toreplacetheenginefuse,removetheconsole

fromtheplasticfender.

Figure47

1.Enginefuse—25A

g000554

Figure48

1.V alvestem

g024412

3.Grasptheenginefuseandpullitstraightand

awayfromthefuseblock(Figure47).

4.Alignanewfusewiththeslotinthefuseblock

(Figure46).

5.Pushthefuseintothefuseblockuntilthefuse

isseated(Figure46).

39

Page 40

HydraulicSystem

Maintenance

OilType:T oroHYPR-OIL®500or20W-50motoroil.

SystemCapacity:4.495L(152oz)withalter

change.

Important:Useoilspeciedorequivalent.Other

uidscouldcausesystemdamage.

Checkingthe Hydraulic-FluidLevel

ServiceInterval:Every25hours

Checktheexpansionreservoir,and,ifnecessary,add

uidtotheFullColdline.

drainout.Useacontainerthatholds4.5L(152

oz)orlarger.

1.Shutofftheengine,waitforallmovingpartsto

stop,allowtheenginetocool,removethekey,

andengagetheparkingbrake.

2.Locatethelterandguardsoneachtransaxle

drivesystemandremovethe3screwssecuring

thelterguard(Figure50).

Figure49

1.Expansionreservoir3.Engine

2.FullColdline

ChangingtheHydraulic FilterandFluid

Thelteranduidarechangedatthesametime.

Oncethenewlterisinstalledanduidisadded,any

airinthesystemmustbepurged.

Thebleedingprocessisrepeateduntiltheuid

remainsattheFullColdlineinthereservoirafter

purging.Failuretoproperlyperformthisprocedure

canresultinirreparabledamagetothetransaxle

drivesystem.

RemovingtheHydraulicFilters

Important:Whenthehydrauliclterisremoved,

allofthehydraulicuidineachtransaxlewill

g010254

Figure50

Rightsideshown

1.Transaxledrive

2.Hydrauliclter

3.Filterguard

3.Carefullycleantheareaaroundthelters.

g020323

Important:Donotallowdirttoenterthe

hydraulicsystem,asitmaycausedamage.

4.Placeacontainerbelowthelteranddrainthe

uid.

5.Locateandremovetheventplugoneach

transmission.

6.Unscrewthelterandallowtheuidtodrain

fromthedrivesystem.

7.Repeatthisprocedureforbothlters.

4.Screws

5.Ventplug

InstallingtheHydraulicFilter

ServiceInterval:Aftertherst50hours

Every400hours

1.Usingthe3screwstoinstallthelterguards

overeachlterremovedpreviously.

2.Verifythattheventplugsareremovedbefore

addingtheuid.

3.Slowlypourthespecieduidthroughthe

expansionreservoiruntiluidcomesoutofa

vent-plughole.

40

Page 41

4.Installtheventplugandtorqueitto20N•m(180

in-lb).

5.Continuetoadduidthroughtheexpansion

reservoiruntiluidcomesoutoftheremaining

vent-plugholeonthesecondtransmission.

6.Installthesecondventplugandtorqueitto20

N•m(180in-lb).

7.Continuetoadduidthroughtheexpansion

reservoiruntilitreachestheFullColdlineonthe

expansionreservoir.

Important:FailuretoperformtheBleeding

theHydraulicSystemprocedureafter

changinghydraulicltersandoilcanresult

inirreparabledamagetothetransaxledrive

system.

BleedingtheHydraulicSystem

1.Raisetherearofmachineupandsupportitwith

jackstands(orequivalentsupport)justhigh

enoughtoallowthedrivewheelstoturnfreely.

g010333

Figure52

1.Jackingpoints

2.Entertheoperator'sposition,starttheengine,

movethethrottlecontrolto1/2throttleposition,

anddisengagetheparkingbrake.

Figure51

A.Movethebypassleversintothepushing

themachineposition;refertoPushingthe

MachinebyHand(page24).Withthe

bypassvalvesopenandtheenginerunning,

slowlymovethemotion-controlleversin

bothforwardandreversedirections(5or

6times).

B.Movethebypassleversintotheoperating

themachineposition.Withthebypassvalve

closedandtheenginerunning,slowlymove

thedirectionalcontrolinbothforwardand

reversedirections(5to6times).

C.Shutofftheengineandchecktheuid

levelintheexpansionreservoir.Addthe

specieduidasuntilitreachestheFull

Coldlineontheexpansionreservoir.

g027477

3.Repeatstep2untilalloftheairiscompletely

purgedfromthesystem.

Note:Whenthetransaxleoperatesatnormal

noiselevelsandmovessmoothlyforwardand

reverseatnormalspeeds,thenthetransaxleis

consideredpurged.

41

Page 42

MowerDeck Maintenance

ServicingtheCutting Blades

Maintainsharpbladesthroughoutthecuttingseason,

becausesharpbladescutcleanlywithouttearingor

shreddingthegrassblades.Tearingandshredding

turnsgrassbrownattheedges,whichslowsgrowth,

andincreasesthechanceofdisease.

Checkthecutterbladesdailyforsharpness,and

foranywearordamage.Filedownanynicksand

sharpenthebladesasnecessary .Ifabladeis

damagedorworn,replaceitimmediatelywitha

genuineTororeplacementblade.Forconvenient

sharpeningandreplacement,youmaywanttokeep

extrabladesonhand.

WARNING

Awornordamagedbladecanbreak,anda

pieceofthebladecouldbethrownatyou

orbystanders,resultinginseriouspersonal

injuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

Figure53

1.Cuttingedge3.Wear/slotforming

2.Curvedarea

4.Damage

CheckingforBentBlades

Note:Themachinemustbeonalevelsurfacefor

thefollowingprocedure.

1.Raisethemowerdecktothehighest

height-of-cutposition.

2.Whilewearingthickly-paddedgloves,orother

adequatehandprotection,slowlyrotatethe

bladetobemeasureintoapositionthatallows

effectivemeasurementofthedistancebetween

thecuttingedgeandthelevelsurfacethe

machineison(Figure54).

g006530

BeforeInspectingorServicingthe Blades

Parkthemachineonalevelsurface,disengagethe

blade-controlswitch,movethemotion-controllevers

outwardtothePARKposition,shutofftheengine,and

removethekey.

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily

1.Inspectthecuttingedges(Figure53).

Note:Iftheedgesarenotsharporhave

nicks,removeandsharpentheblades;referto

SharpeningtheBlades(page44).

2.Inspecttheblades,especiallythecurvedarea

(Figure53).

Note:Ifyounoticeanydamage,wear,oraslot

forminginthisarea(items3and4inFigure53),

immediatelyinstallanewblade.

g009679

Figure54

1.Deck3.Blade

2.Spindlehousing

42

Page 43

3.Measurefromthetipofthebladetotheat

surface(Figure55).

g009680

Figure57

Figure55

1.Blade(inpositionformeasuring)

2.Levelsurface

3.Measureddistancebetweenbladeandthesurface(A)

4.Rotatethesameblade180degreessothat

theopposingcuttingedgeisnowinthesame

position(Figure56).

Figure56

1.Blade(sidepreviouslymeasured)

2.Measurement(positionusedpreviously)

3.Opposingsideofbladebeingmovedintomeasurement

position

5.Measurefromthetipofthebladetotheat

surface(Figure57).

Note:Thevarianceshouldbenomorethan

3mm(1/8inch).

g009680

1.Oppositebladeedge(inpositionformeasuring)

2.Levelsurface

3.Secondmeasureddistancebetweenbladeandsurface(B)

A.IfthedifferencebetweenAandBisgreater

than3mm(1/8inch),replacethebladewith

anewblade;refertoRemovingtheBlades

(page43)andInstallingtheBlades(page

44).

Note:Ifabentbladeisreplacedwitha

newblade,andthedimensionobtained

continuestoexceed3mm(1/8inch),the

bladespindlecouldbebent.Contactan

AuthorizedT oroDealerforservice.

B.Ifthevarianceiswithinconstraints,moveto

thenextblade.

Repeatthisprocedureoneachblade.

g009681

RemovingtheBlades

Thebladesmustbereplacedifasolidobjectishit,if

thebladeisoutofbalance,orifthebladeisbent.T o

ensureoptimumperformanceandcontinuedsafety

conformanceofthemachine,usegenuineT oro

replacementblades.Replacementbladesmadeby

othermanufacturersmayresultinnon-conformance

withsafetystandards.

1.Holdthebladeendusingaragorthickly-padded

glove.

2.Removethebladebolt,curvedwasher,and

bladefromthespindleshaft(Figure58).

43

Page 44

Figure58

1.SailAreaofBlade3.Curvedwasher

2.Blade4.Bladebolt

3.Repeatthisprocedureuntilthebladeis

balanced.

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure

58).

Important:Thecurvedpartoftheblade

mustbepointingupwardtowardtheinside

ofthemowertoensurepropercutting.

2.Installthespringdiskandbladeboltwiththe

springdiskconeinstalledtowardthebolthead

(Figure58).

3.T orquethebladeboltto135to150N•m(100

to110ft-lb).

g010341

LevelingtheMowerDeck

Ensurethatthemowerdeckislevelanytimeyou

installthemowerdeckorwhenyouseeanuneven

cutonyourlawn.

SharpeningtheBlades

1.Usealetosharpenthecuttingedgeatboth

endsoftheblade(Figure59).

Note:Maintaintheoriginalangle.

Note:Thebladeretainsitsbalanceifthesame

amountofmaterialisremovedfrombothcutting

edges.

Figure59

1.Sharpenatoriginalangle.

2.Checkthebalanceofthebladebyputtingitona

bladebalancer(Figure60).

Note:Ifthebladestaysinahorizontalposition,

thebladeisbalanced,andcanbeused.

Note:Ifthebladeisnotbalanced,lesome

metalofftheendofthesailareaonly(Figure59).

Checkthemowerdeckforbentbladespriorto

leveling;removeandreplaceanybentblades;referto

CheckingforBentBlades(page42)beforecontinuing.

Levelthemowerdeckside-to-sidebeforeadjusting

thefront-to-rearslope.

Requirements:

•Themachinemustbeonalevelsurface.

•All4tiresmustbeproperlyinated;referto

CheckingtheTirePressure(page39).

CheckingtheSide-to-SideLevel

g000552

Themowerbladesmustbelevelfromsidetoside.

Checktheside-to-sidelevelanytimeyouinstallthe

mowerorwhenyouseeanunevencutonyourlawn.

1.Parkthemachineonalevelsurfaceand

disengagetheblade-controlswitch.

2.Movethemotion-controlleversoutwardtothe

NEUTRAL-LOCKposition,shutofftheengine,

removethekey,settheparkingbrake,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Carefullyrotatethebladessidetoside.

Figure60

1.Blade2.Balancer

4.Measurebetweentheoutsidecuttingedgesand

theatsurface(Figure61).

g000553

44

Note:Ifbothmeasurementsarenotwithin5

mm(3/16inch),anadjustmentisrequired;refer

toLevelingtheMowerDeck(page45).

Page 45

1.Bladessidetoside

2.Outsidecuttingedges

Figure61

3.Measurefromthetipofthe

bladetotheatsurface

here.

g007202

Figure62

1.Bladesfronttorear3.Measurefromthetipofthe

bladetotheatsurface

here.

2.Outsidecuttingedges

g007199

CheckingtheFront-to-RearBlade Slope

Checkthefront-to-rearbladelevelanytimeyouinstall

themower.Ifthefrontofthemowerismorethan

7.9mm(5/16inch)lowerthantherearofthemower,

adjustthebladelevelusingthefollowinginstructions:

1.Parkthemachineonalevelsurfaceand

disengagetheblade-controlswitch.

2.Movethemotion-controlleversoutwardtothe

NEUTRAL-LOCKposition,engagetheparking

brake,shutofftheengine,removethekey ,and

waitforallmovingpartstostopbeforeleaving

theoperatingposition.

3.Carefullyrotatethebladessotheyarefacing

fronttorear(Figure62).

4.Measurefromthetipofthefrontbladetothe

atsurfaceandthetipoftherearbladetothe

atsurface(Figure62).

Note:Ifthefrontbladetipisnot1.6to7.9mm

(1/16to5/16inch)lowerthantherearbladetip,

continuetotheLevelingtheMowerDeck(page

45)procedure.

LevelingtheMowerDeck

1.Setanti-scalprollerstotopholesorremove

themcompletelyforthisprocedure;referto

AdjustingtheAnti-ScalpRollers(page23).

2.Settheheight-of-cutlevertothe76mm(3inch)

position;refertoAdjustingtheHeightofCut

(page22).

3.Place26.6cm(2-5/8inches)blocksundereach

sideofthefrontedgeofthedeck,butnotunder

theanti-scalprollerbrackets(Figure63).

4.Place27.3cm(2-7/8inches)thickblocksunder

therearedgeofthecuttingdeckskirt;oneon

eachsideofthecuttingdeck(Figure63).

Figure63

1.Woodblock—6.6cm

(2-5/8inches)thick

2.Woodblock—7.3cm

(2-7/8inches)thick

3.Frontedge

5.Loosentheadjustmentboltsonall4cornersso

thatthedeckissittingsecurelyonall4blocks

(Figure64).

45

g024428

Page 46

Figure64

1.Deck-liftarm

2.Chain

3.Hook

4.Adjustmentbolt

6.Ensurethatthereistensiononall4chains

(Figure64).

ReplacingtheMowerBelt

Squealingwhenthebeltisrotating,bladesslipping

whencuttinggrass,frayedbeltedges,burnmarks,

andcracksaresignsofawornmowerbelt.Replace

themowerbeltifanyoftheseconditionsareevident.

1.Disengagetheblade-controlswitch(PTO),move

themotion-controlleverstotheNEUTRAL-LOCK

position,andsettheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Lowerthemowertothe76mm(3inch)

height-of-cutposition.

4.Foreachofthebeltcovers,loosenthe2bolts,

butdonotremovethem.

5.Slidethecoveruntilitisclearoftheboltsandlift

g024313

itupandouttoremoveit.

6.Removetheoorpantoaccesstheidlerpulley .

7.Usingaspringremovaltool,(T oroPartNo.

92-5771),removetheidlerspringfromthe

deckposttoremovetensionontheidlerpulley

(Figure65).

7.Tightenthe4adjustmentbolts(Figure64).

8.Ensurethattheblockstsnuglyunderthedeck

skirtandthatallboltsaretight.

9.Verifythatthedeckislevelbycheckingthe

side-to-sidelevelandfront-to-rearbladeslope;

repeatthedecklevelingprocedureifnecessary.

InspectingtheBelts

ServiceInterval:Every50hours

Checkthebeltsforsquealingwhenthebeltisrotating,

bladesslippingwhencuttinggrass,frayedbeltedges,

burnmarksandcracksaresignsofawornmower

belt.Replacethemowerbeltifanyoftheseconditions

areevident.

Figure65

1.Spring-removaltool(T oro

PartNo.92-5771)

2.Idlerspring5.Mowerbelt

3.Deckpost

4.Idlerarm

8.Lowerthemowertothelowestheightofcutand

placetheheight-of-cutpininthelockpositionfor

thelowestheight-of-cut.

9.Removethebeltfromthemower-deckpulleys

andremovetheexistingbelt.

10.Installthenewbeltaroundthemowerpulleys