Page 1

FormNo.3394-232RevB

TITAN

®

ZX4800andZX5400

Zero-Turn-RadiusRidingMower

ModelNo.74846—SerialNo.315000001andUp

ModelNo.74848—SerialNo.315000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3394-232*B

Page 2

Thismachineisaride-on,rotary-bladelawnmower

intendedtobeusedbyhomeownersinresidential

applications.Itisprimarilydesignedforcuttinggrass

onwell-maintainedlawns.Itisnotdesignedforcutting

brush,mowinggrassandothergrowthalongside

highways,orforagriculturaluses.

ThisproductcomplieswithallrelevantEuropean

directives,fordetailspleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactT orodirectlyatwww.T oro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

g015453

g010228

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizesgeneral

informationworthyofspecialattention.

g000502

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

WARNING

Removingstandardoriginalequipmentparts

andaccessoriesmayalterthewarranty ,

traction,andsafetyofthemachine.Failureto

useoriginalToropartscouldcauseserious

injuryordeath.Makingunauthorizedchanges

totheengine,fuelorventingsystem,may

violateEPAandCARBregulations.

Replaceallpartsincluding,butnotlimited

to,tires,belts,blades,andfuelsystem

componentswithoriginalToroparts.

Formodelswithstatedenginehorsepower,thegross

horsepoweroftheenginewaslaboratoryratedbythe

enginemanufacturerinaccordancewithSAEJ1940

andratedtoJ2723.

Donottamperwiththeenginecontrolsoralterthe

governorspeed;doingsomaycreateanunsafe

conditionresultinginpersonalinjury.

3

Page 4

Contents

Safety.......................................................................5

SafeOperationPracticesforRide-On(riding)

RotaryLawnmowerMachines.........................5

SafeOperatingPractices....................................5

ToroRidingMowerSafety...................................6

Model74846.......................................................7

Model74848.......................................................7

SlopeIndicator...................................................9

SafetyandInstructionalDecals........................10

ProductOverview...................................................15

Controls...........................................................16

Operation................................................................17

AddingFuel......................................................17

ThinkSafetyFirst..............................................19

UsingtheRolloverProtectionSystem

(ROPS).........................................................20

TheSafetyInterlockSystem.............................20

CheckingtheEngineOilLevel..........................20

BreakinginaNewMachine..............................21

OperatingtheParkingBrake.............................21

OperatingtheThrottle.......................................21

OperatingtheChoke.........................................21

OperatingtheIgnitionSwitch............................21

StartingandStoppingtheEngine......................22

OperatingtheMowerBladeControlSwitch

(PTO)............................................................23

DrivingForwardorBackward............................23

StoppingtheMachine.......................................25

AdjustingtheHeight-of-Cut...............................25

AdjustingtheAnti-ScalpRollers........................26

PositioningtheSeat..........................................27

AdjustingtheMotionControlLevers..................27

PushingtheMachinebyHand..........................27

Convertingthe48inchMowertoSide

Discharge......................................................28

Convertingthe54inchMowertoSide

Discharge......................................................29

UsingtheSideDischarge.................................31

TransportingtheMachine.................................32

LoadingtheMachine........................................32

OperatingTips.................................................34

Maintenance...........................................................35

RecommendedMaintenanceSchedule(s)...........35

Pre-MaintenanceProcedures..............................37

RaisingtheSeat...............................................37

ReleasingtheMower-DeckCurtain..................37

Lubrication..........................................................37

GreasingtheBearings......................................37

EngineMaintenance...........................................38

ServicingtheAirCleaner..................................38

ServicingtheEngineOil....................................38

ServicingtheSparkPlug...................................41

CleaningtheCoolingSystem............................42

FuelSystemMaintenance...................................42

ReplacingtheFuelFilter...................................42

ElectricalSystemMaintenance...........................43

ServicingtheBattery.........................................43

ServicingtheFuses..........................................44

DriveSystemMaintenance..................................45

CheckingtheTirePressure...............................45

HydraulicSystemMaintenance...........................45

CheckingtheHydraulicOilLevel......................45

ChangingtheHydraulicSystemFilterand

Oil.................................................................45

MowerDeckMaintenance....................................48

ServicingtheCuttingBlades.............................48

MowerDeckLeveling.......................................51

InspectingtheBelts..........................................52

ReplacingtheMowerBelt.................................52

RemovingtheMower........................................53

InstallingtheMowerDeck.................................54

ReplacingtheGrassDeector..........................54

Cleaning..............................................................56

WashingtheUndersideoftheMower................56

WasteDisposal.................................................57

Storage...................................................................57

CleaningandStorage.......................................57

Troubleshooting......................................................59

Schematics.............................................................61

4

Page 5

Safety

◊incorrecthitchingandloaddistribution.

ThefollowinginstructionsarefromtheENstandard

ENISO5395:2013.

SafeOperationPractices forRide-On(riding)Rotary LawnmowerMachines

ThismachinemeetsorexceedsEuropeanStandards

ineffectatthetimeofproduction.However,improper

useormaintenancebytheoperatororownercan

resultininjury .Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafetyalertsymbol,whichmeans

Caution,Warning,orDanger-“personalsafety

instruction.”Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

SafeOperatingPractices

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Training

•Readtheinstructionscarefully .Befamiliarwiththe

controlsandtheproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwith

theseinstructionstousethelawnmower.Local

regulationscanrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,or

petsarenearby.

•Keepinmindthattheoperatororuseris

responsibleforaccidentsorhazardsoccurringto

otherpeopleortheirproperty.

•Donotcarrypassengers.

•Alldriversshouldseekandobtainprofessional

andpracticalinstruction.Suchinstructionshould

emphasize:

–theneedforcareandconcentrationwhen

workingwithride-onmachines;

–controlofaride-onmachineslidingonaslope

willnotberegainedbytheapplicationofthe

brake.Themainreasonsforlossofcontrolare:

◊insufcientwheelgrip;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforits

task;

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

Preparation

•Whilemowing,alwayswearsubstantial,

slip-resistantfootwearandlongtrousers.Donot

operatetheequipmentwhenbarefootorwearing

opensandals.

•Thoroughlyinspecttheareawheretheequipment

istobeusedandremoveallobjectswhichmaybe

thrownbythemachine.

•Warning-Fuelishighlyammable.

–Storefuelincontainersspecicallydesigned

forthispurpose.

–Refueloutdoorsonlyanddonotsmokewhile

refueling.

–Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoraddfuel

whiletheengineisrunningorwhentheengine

ishot.

–Iffuelisspilled,donotattempttostartthe

enginebutmovethemachineawayfromthe

areaofspillageandavoidcreatinganysource

ofignitionuntilfuelvaporshavedissipated.

–Replaceallfueltanksandcontainercaps

securely.

•Replacefaultysilencers.

•Beforeusing,alwaysvisuallyinspecttoseethat

theblades,bladeboltsandcutterassemblyare

notwornordamaged.Replacewornordamaged

bladesandboltsinsetstopreservebalance.

•Onmulti-bladedmachines,takecareasrotating

onebladecancauseotherbladestorotate.

Operation

•Bealert,slowdownandusecautionwhenmaking

turns.Lookbehindandtothesidebeforechanging

directions.

•Donotoperatetheengineinaconnedspace

wheredangerouscarbonmonoxidefumescan

collect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengage

allbladeattachmentclutchesandshiftintoneutral.

•Donotuseonslopesofmorethan15degrees.

•Rememberthereisnosuchthingasasafeslope.

Travelongrassslopesrequiresparticularcare.T o

guardagainstoverturning:

–donotstoporstartsuddenlywhengoingup

ordownhill;

–uselowspeedsonslopesandduringtight

turns;

–stayalertforhumpsandhollowsandother

hiddenhazards;

5

Page 6

•Usecarewhenpullingloads.

–Useonlyapproveddrawbarhitchpoints.

–Limitloadstothoseyoucansafelycontrol.

–Donotturnsharply.Usecarewhenreversing.

•Watchoutfortrafcwhencrossingornear

roadways.

•Stopthebladesrotatingbeforecrossingsurfaces

otherthangrass.

•Whenusinganyattachments,neverdirect

dischargeofmaterialtowardbystandersnorallow

anyonenearthemachinewhileinoperation.

•Neveroperatethemachinewithdamagedguards

orwithoutsafetyprotectivedevicesinplace.

•Donotchangetheenginegovernorsettingsor

overspeedtheengine.Operatingtheengine

atexcessivespeedcanincreasethehazardof

personalinjury.

•Beforeleavingtheoperator'sposition:

–disengagethepowertake-offandlowerthe

attachments;

–changeintoneutralandsettheparkingbrake;

–stoptheengineandremovethekey .

•Disengagedrivetoattachments,stoptheengine,

anddisconnectthesparkplugwire(s)orremove

theignitionkey.

–beforeclearingblockagesoruncloggingchute;

–beforechecking,cleaningorworkingonthe

lawnmower;

–afterstrikingaforeignobject.Inspectthe

lawnmowerfordamageandmakerepairs

beforerestartingandoperatingtheequipment;

–ifthemachinestartstovibrateabnormally

(checkimmediately).

•Disengagedrivetoattachmentswhentransporting

ornotinuse.

•Stoptheengineanddisengagedriveto

attachment.

–beforerefuelling;

–beforeremovingthegrasscatcher;

–beforemakingheightadjustmentunless

adjustmentcanbemadefromtheoperator's

position.

•Reducethethrottlesettingduringenginerun-out

and,iftheengineisprovidedwithashut-offvalve,

turnthefueloffattheconclusionofmowing.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetank

insideabuildingwherefumescanreachanopen

ameorspark.

•Allowtheenginetocoolbeforestoringinany

enclosure.

•Toreducetherehazard,keeptheengine,

silencer,batterycompartmentandfuelstorage

areafreeofgrass,leaves,orexcessivegrease.

•Checkthegrasscatcherfrequentlyforwearor

deterioration.

•Replacewornordamagedpartsforsafety.

•Ifthefueltankhastobedrained,thisshouldbe

doneoutdoors.

•Whenmachineistobeparked,storedorleft

unattended,lowerthecuttingmeans.

ToroRidingMowerSafety

Thefollowinglistcontainssafetyinformationspecic

toT oroproductsorothersafetyinformationthatyou

mustknowthatisnotincludedintheCENstandard.

•Donotoperatetheengineinaconnedspace

wheredangerouscarbonmonoxideandother

exhaustgassescancollect.

•Keephands,feet,hairandlooseclothingaway

fromattachmentdischargearea,undersideof

mowerandanymovingpartswhileengineis

running.

•Donottouchequipmentorattachmentpartswhich

maybehotfromoperation.Allowtocoolbefore

attemptingtomaintain,adjust,orservice.

•Batteryacidispoisonousandcancauseburns.

Avoidcontactwithskin,eyesandclothing.Protect

yourface,eyes,andclothingwhenworkingwitha

battery.

•Batterygasescanexplode.Keepcigarettes,

sparks,andamesawayfrombattery .

•UseonlygenuineT ororeplacementpartsto

ensurethatoriginalstandardsaremaintained.

•UseonlyToro-approvedattachments.

SlopeOperation

•Donotmowslopesgreaterthan15degrees.

•Donotmowneardrop-offs,ditches,steepbanks,

orwater.Wheelsdroppingoveredgescancause

rollovers,whichmayresultinseriousinjury,death,

ordrowning.

•Donotmowslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcausesliding

andlossofcontrol.

•Donotmakesuddenturnsorrapidspeedchanges.

•Useawalkbehindmowerand/orahandtrimmer

neardrop-offs,ditches,steepbanks,orwater.

6

Page 7

•Reducespeedanduseextremecautiononslopes.

•Removeormarkobstaclessuchasrocks,tree

limbs,etc.frommowingarea.T allgrasscanhide

obstacles.

•Watchforditches,holes,rocksdips,andrisesthat

changetheoperatingangle,asroughterraincould

overturnthemachine.

•Avoidsuddenstartswhenmowinguphillbecause

themowermaytipbackwards.

SoundPressure

Thisunithasasoundpressurelevelattheoperator’s

earof92dBA,whichincludesanUncertaintyValue

(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO5395:2013.

Hand-ArmVibration

•Beawarethatlossoftractionmayoccurgoing

downhill.Weighttransfertothefrontwheels

maycausedrivewheelstoslipandcauselossof

brakingandsteering.

•Alwaysavoidsuddenstartingorstoppingona

slope.Iftireslosetraction,disengagetheblades

andproceedslowlyofftheslope.

•Followthemanufacturer'srecommendations

forwheelweightsorcounterweightstoimprove

stability.

•Useextremecarewithgrasscatchersorother

attachments.Thesecanchangethestabilityofthe

machineandcauselossofcontrol.

UsingtheRolloverProtection System(ROPS)

•Keeptherollbarintheraisedandlockedposition

andusetheseatbeltwhenoperatingthemachine.

•Becertainthattheseatbeltcanbereleased

quicklyintheeventofanemergency.

•Beawarethereisnorolloverprotectionwhenthe

rollbarisdown.

•Checktheareatobemowedandneverfoldthe

ROPSinareaswherethereareslopes,dropoffs

orwater.

Measuredvibrationlevelforlefthand=4.8m/s2

Measuredvibrationlevelforrighthand=4.4m/s2

UncertaintyValue(K)=2.4m/s2

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinENISO5395:2013.

WholeBodyVibration

Measuredvibrationlevel=0.39m/s2

UncertaintyValue(K)=0.19m/s2

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinENISO5395:2013(Riding&

Stand-Ons).

Model74848

SoundPower

Thisunithasaguaranteedsoundpowerlevelof105

dBA,whichincludesanUncertaintyValue(K)of1

dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO1 1094.

•Lowertherollbaronlywhenabsolutelynecessary.

Donotweartheseatbeltwiththerollbarfolded

down.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)before

drivingunderanyobjectsanddonotcontactthem.

Model74846

SoundPower

Thisunithasaguaranteedsoundpowerlevelof105

dBA,whichincludesanUncertaintyValue(K)of1

dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO1 1094.

SoundPressure

Thisunithasasoundpressurelevelattheoperator’s

earof92dBA,whichincludesanUncertaintyValue

(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO5395:2013.

Hand-ArmVibration

Measuredvibrationlevelforlefthand=5.8m/s2

Measuredvibrationlevelforrighthand=3.6m/s2

UncertaintyValue(K)=2.3m/s2

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinENISO5395:2013.

7

Page 8

WholeBodyVibration

Measuredvibrationlevel=0.45m/s2

UncertaintyValue(K)=0.22m/s2

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinENISO5395:2013(Riding&

Stand-Ons).

8

Page 9

SlopeIndicator

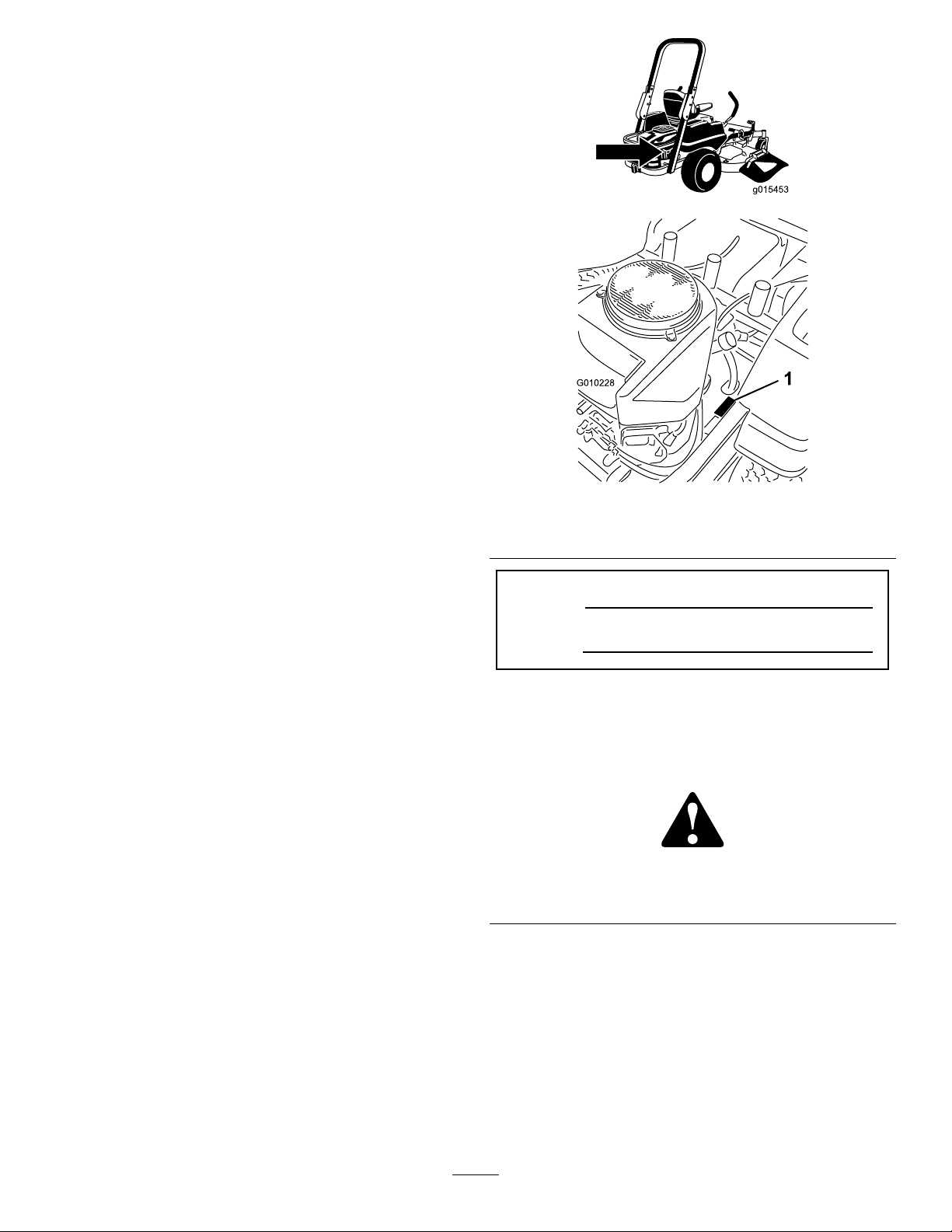

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

9

g011841

Page 10

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedorlost.

decaloemmarkt

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

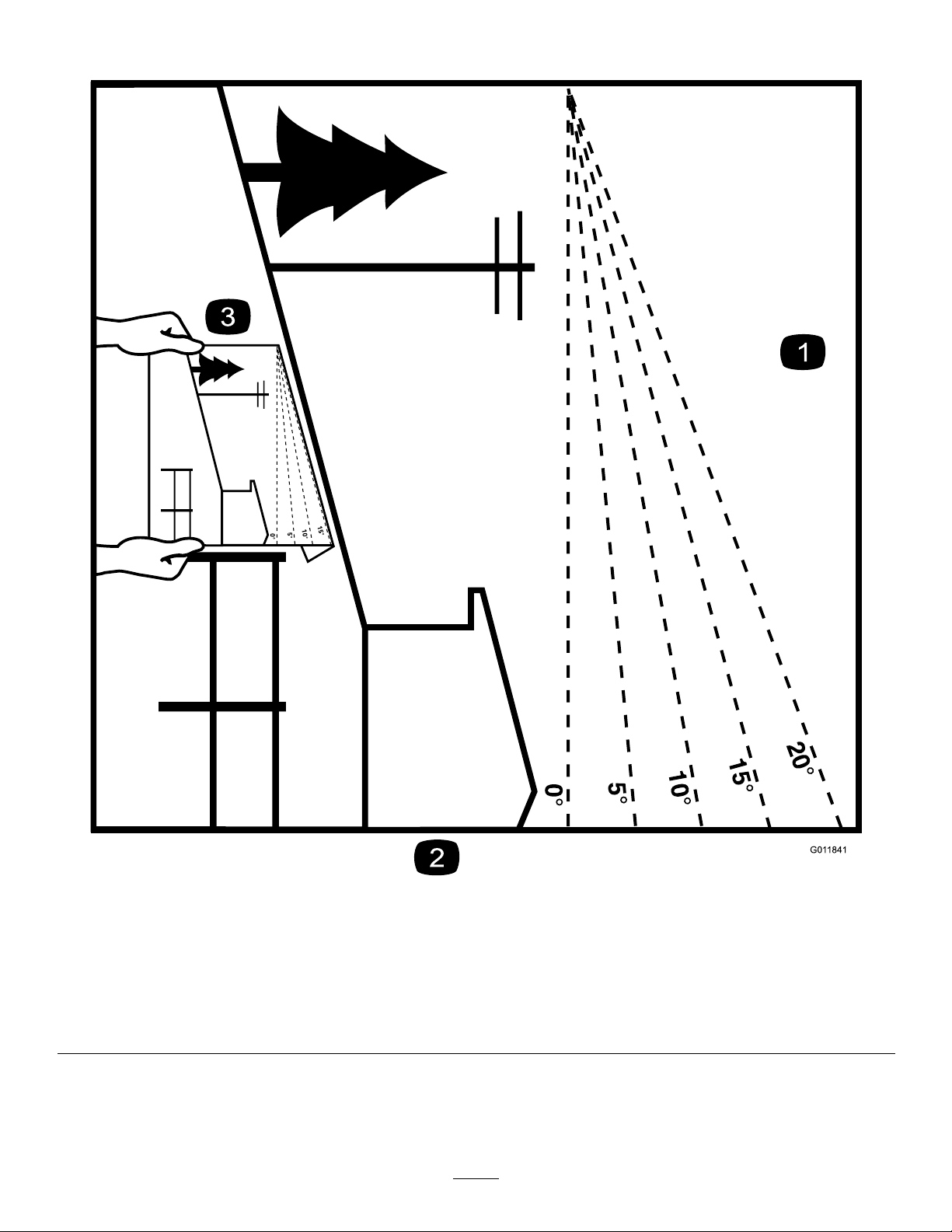

99-8936

1.Machinespeed4.Neutral

2.Fast5.Reverse

3.Slow

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

decal99-8936

decalbatterysymbols

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries.

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

114-1606

1.Entanglementhazard,belt—keepallguardsinplace.

115-9625

1.Parking

brake—disengaged

2.Parkingbrake—engaged

decal114-1606

decal115-9625

10

Page 11

decal115-9632

115-9632

1.Powertake-off(PTO),

5.Fast

Bladecontrolswitchon

somemodels

2.Bladecontrolswitch—On6.Continuousvariable

setting

3.Bladecontrolswitch—Off7.Slow

4.Choke

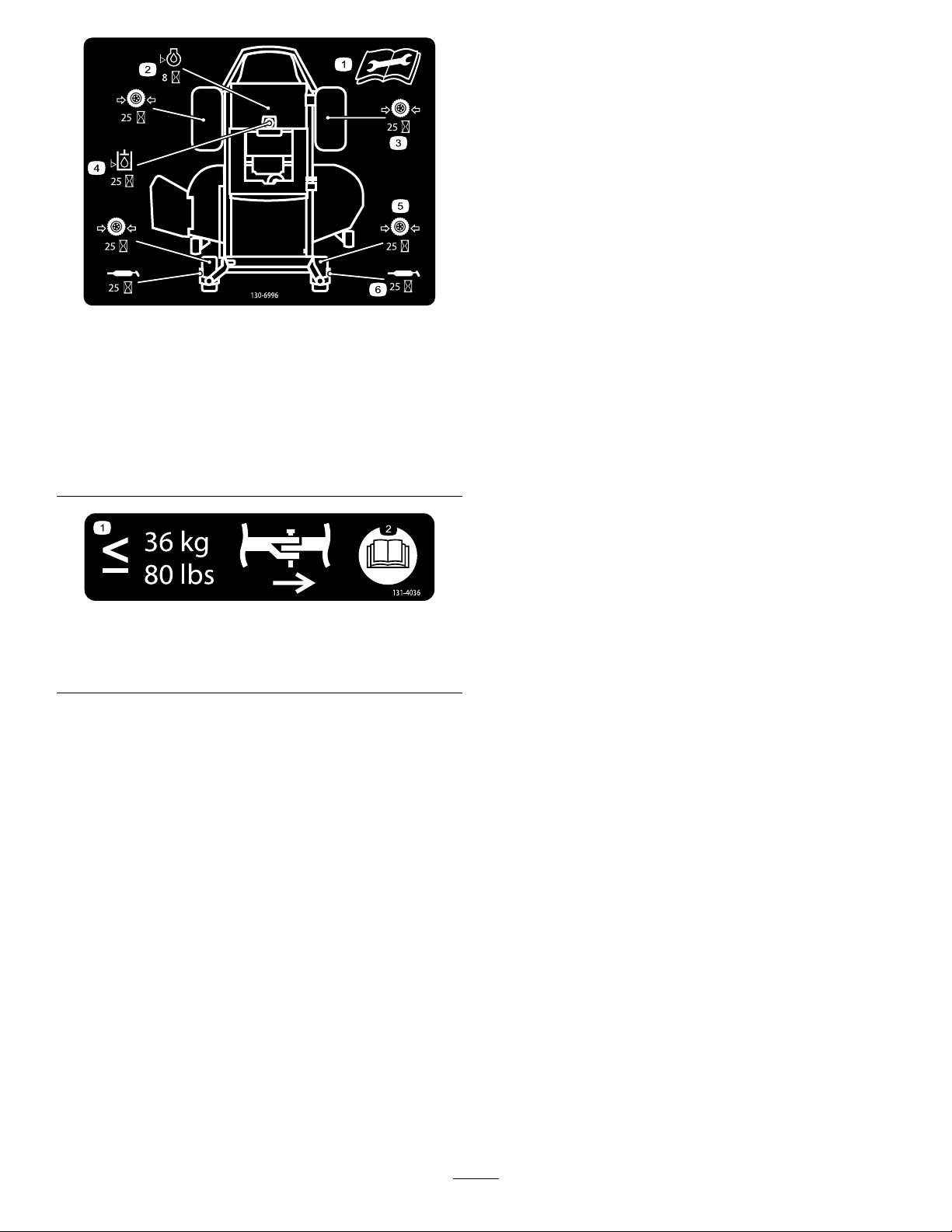

117-1194

decal117-1 194

decal130-0654

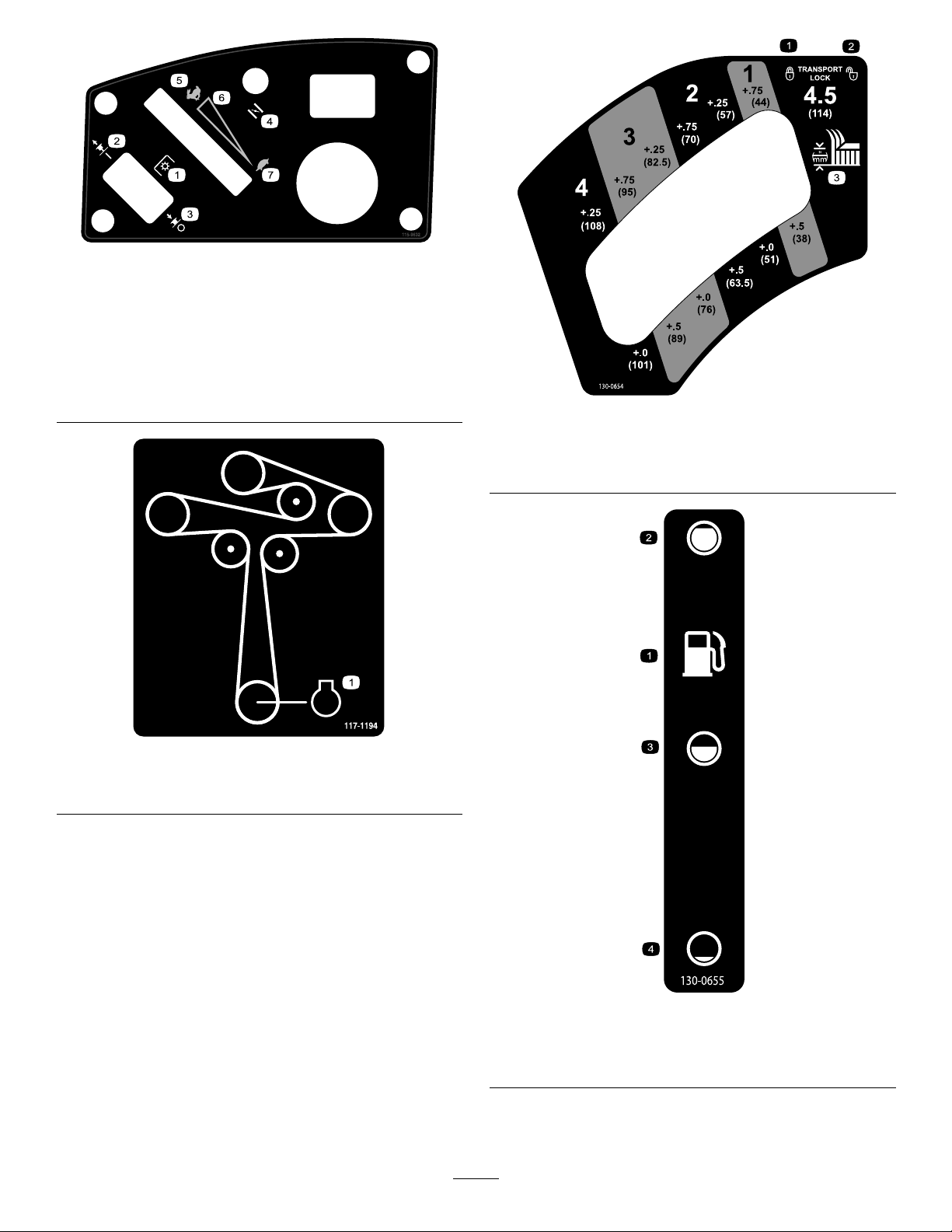

130-0654

1.Transport—lock

2.Transport—unlock

3.Height-of-cut

1.Engine

decal130-0655

130-0655

1.Fueltank

2.Full4.Empty

3.Half

11

Page 12

decal130-0731

130-0731

1.Warning—thrownobject

hazard;keepthedeector

shieldinplace.

1.ReadtheOperator's

Manual.

2.Height-of-cutselection

2.Cuttinghazardofhandor

foot,mowerblade—keep

awayfrommovingparts.

130-0765

3.Removethekeyfrom

theignitionandreadthe

Operator'sManualbefore

permorningmaintenance.

decal130-0765

decal130-6927

130-6927

1.Warning—alwaysusetheROPSandweartheseatbelt

whenseatedintheoperator'sposition.

1.Bypassleverpositionfor

operatingthemachine.

130-6922

2.Bypassleverpositionfor

pushingthemachine.

decal130-6928

130-6928

1.Thrownobject

hazard—keepbystanders

awayfromthemachine.

2.Thrownobjecthazard,

mower—donotoperate

thewithoutdeector,

dischargecover,orgrass

collectionsysteminplace.

decal130-6922

3.Cutting/dismembermentof

handorfoot—stayaway

frommovingparts.

12

Page 13

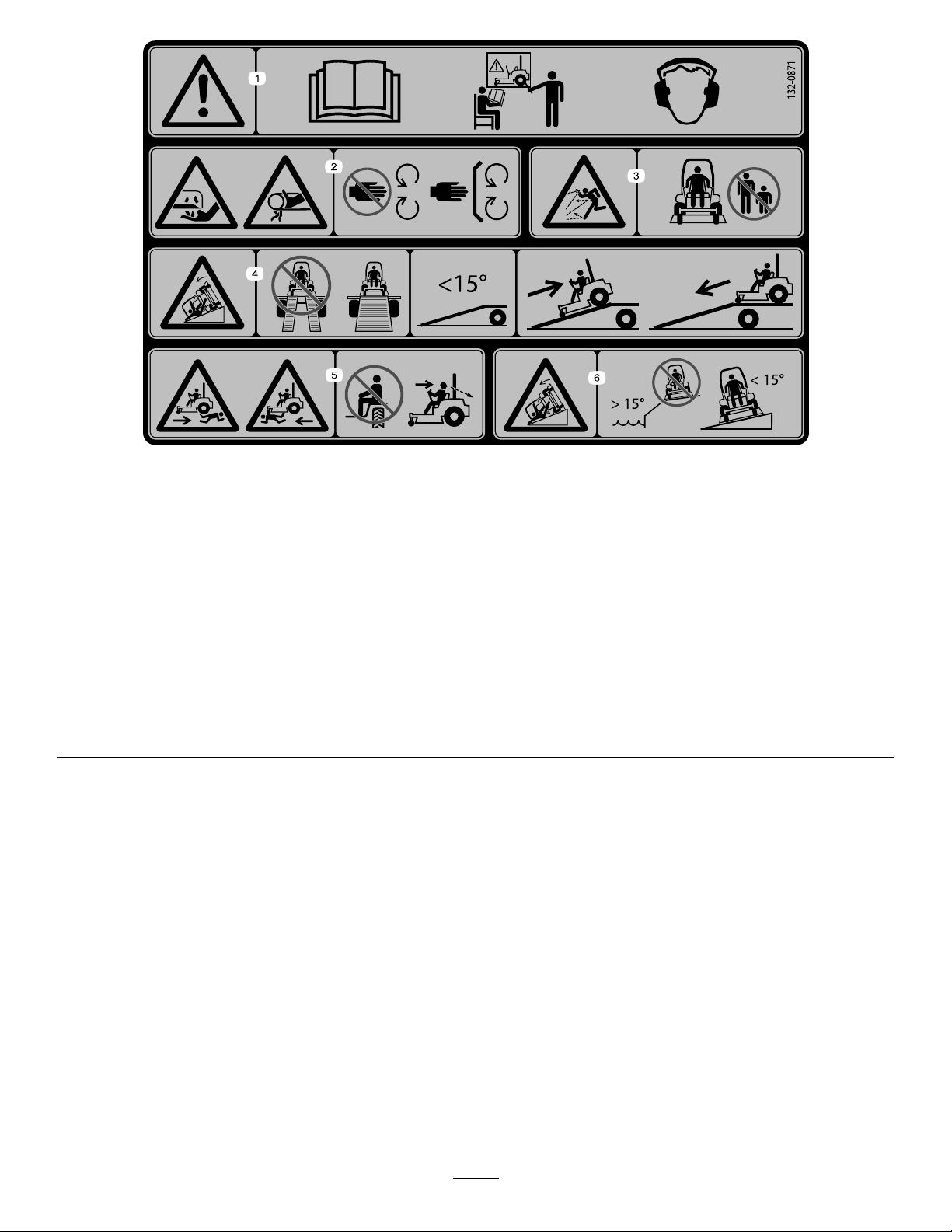

decal130-6996

130-6996

1.ReadtheOperator's

Manualforinformationon

maintenance.

2.Checktheengineoilevery

8hours

3.Checkthedrivewheeltire

pressureevery25hours

1.Themaximumdrawbar

pullis36kg(80lb).

4.Checkthehydraulicoil

every25hours

5.Checkthecasterwheel

tirepressureevery25

hours

6.Lubricatethecasterwheel

every25hours

decal131-4036

131-4036

2.ReadtheOperator's

Manual.

13

Page 14

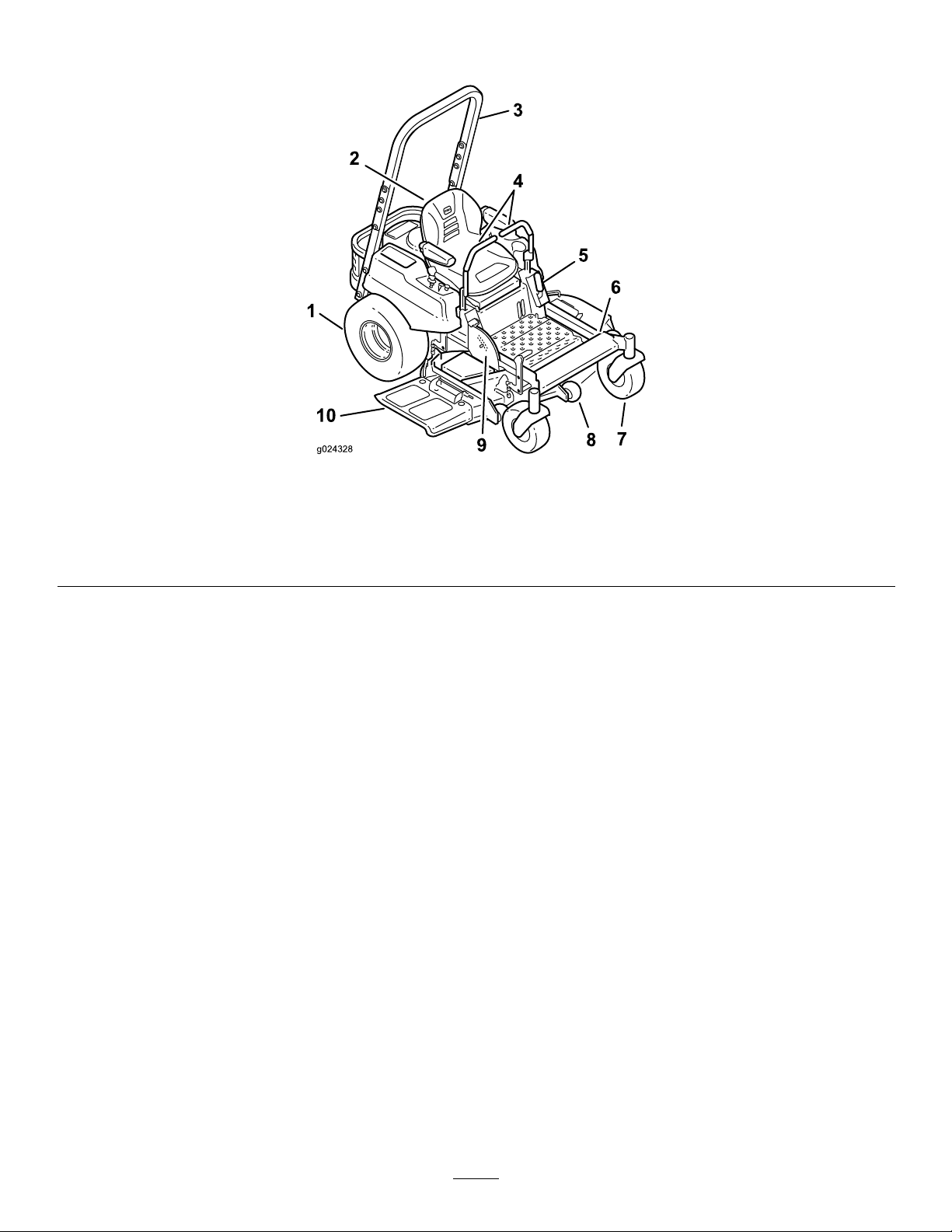

132-0871

Note:Thismachinecomplieswiththeindustrystandardstabilitytestinthestaticlateralandlongitudinaltestswiththemaximum

recommendedslopeindicatedonthedecal.ReviewtheinstructionsforoperatingthemachineonslopesintheOperator’sManualas

wellastheconditionsinwhichyouwouldoperatethemachinetodeterminewhetheryoucanoperatethemachineinthoseconditions

onthatdayandatthatsite.Changesintheterraincanresultinachangeinslopeoperationforthemachine.Ifpossible,keepthe

cuttingunitsloweredtothegroundwhileoperatingthemachineonslopes.Raisingthecuttingunitswhileoperatingonslopescan

causethemachinetobecomeunstable.

decal132-0871

1.Warning—readtheOperator’sManual;donotoperatethis

machineunlessyouaretrained;wearhearingprotection.

2.Cutting,dismembering,andentanglementhazard—keep

handsawayfrommovingparts;keepallguardsandshieldsin

place.

3.Thrownobjecthazard—keepbystandersaway .6.Tippinghazardonslopes—donotuseonslopesnearopen

4.Ramphazard—whenloadingontoatrailer,donotusedual

ramps;onlyuseasingularrampwideenoughforthemachine

andthathasaninclinelessthan15°;backuptheramp(in

reverse)anddriveforwardofftheramp.

5.Bodilyharmhazard—donotcarrypassengers;lookbehind

youwhenmowinginreverse.

water;donotuseonslopesgreaterthan15°.

14

Page 15

ProductOverview

g024328

Figure4

1.Drivewheel4.Motioncontrollevers7.Frontcasterwheel

2.Operatorseat

3.Rolloverprotectionsystem

(ROPS)

5.Parkingbrake8.Anti-scalproller

6.Footrest

9.Footpedaldeckliftand

height-of-cut

10.Deector

15

Page 16

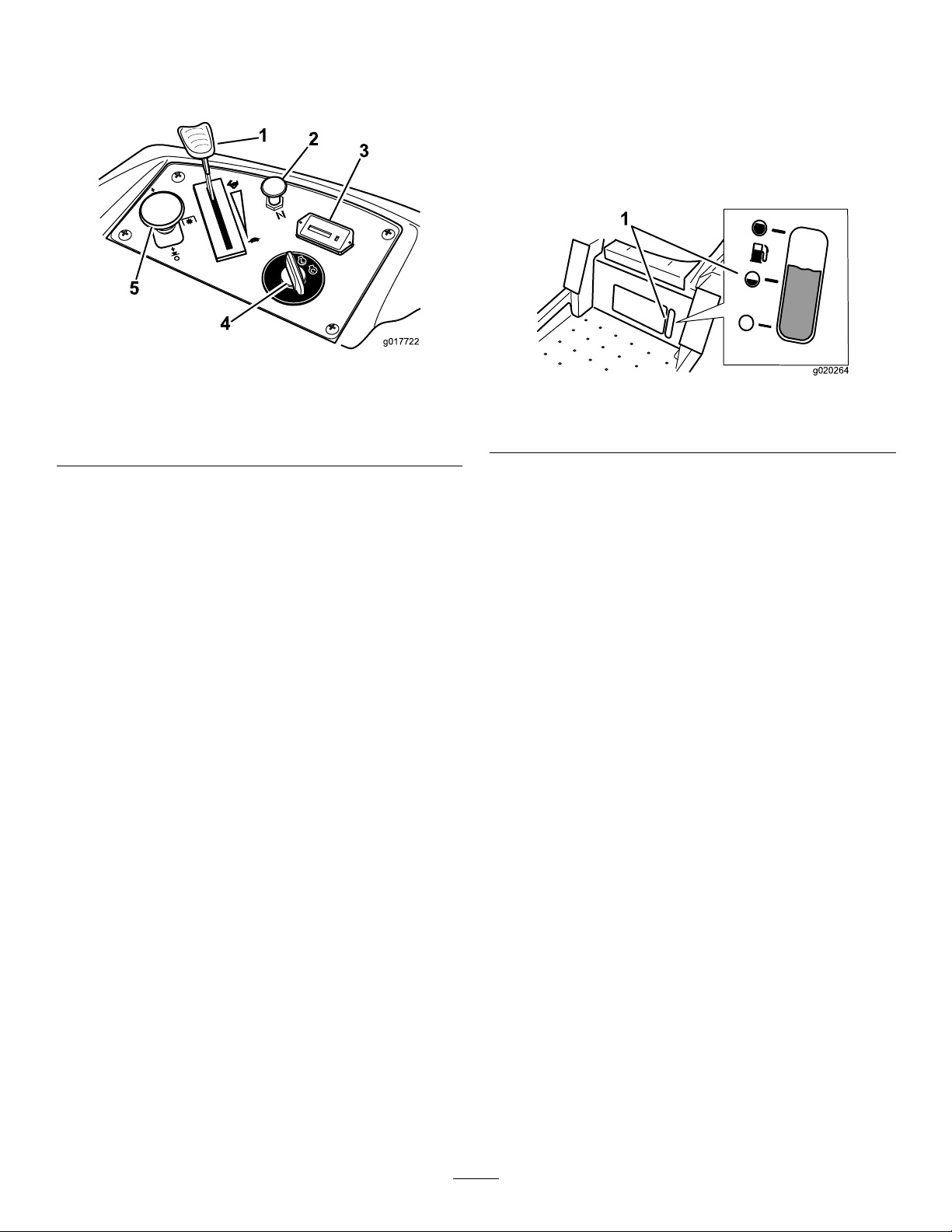

Controls

Becomefamiliarwithallthecontrolsbeforeyoustart

theengineandoperatethemachine(Figure5).

Figure5

1.Throttlecontrol4.Ignitionswitch

2.Choke5.Bladecontrolswitch(PTO)

3.Hourmeter

controlswitch(PTO)isengaged.Usethesetimesfor

schedulingregularmaintenance(Figure5).

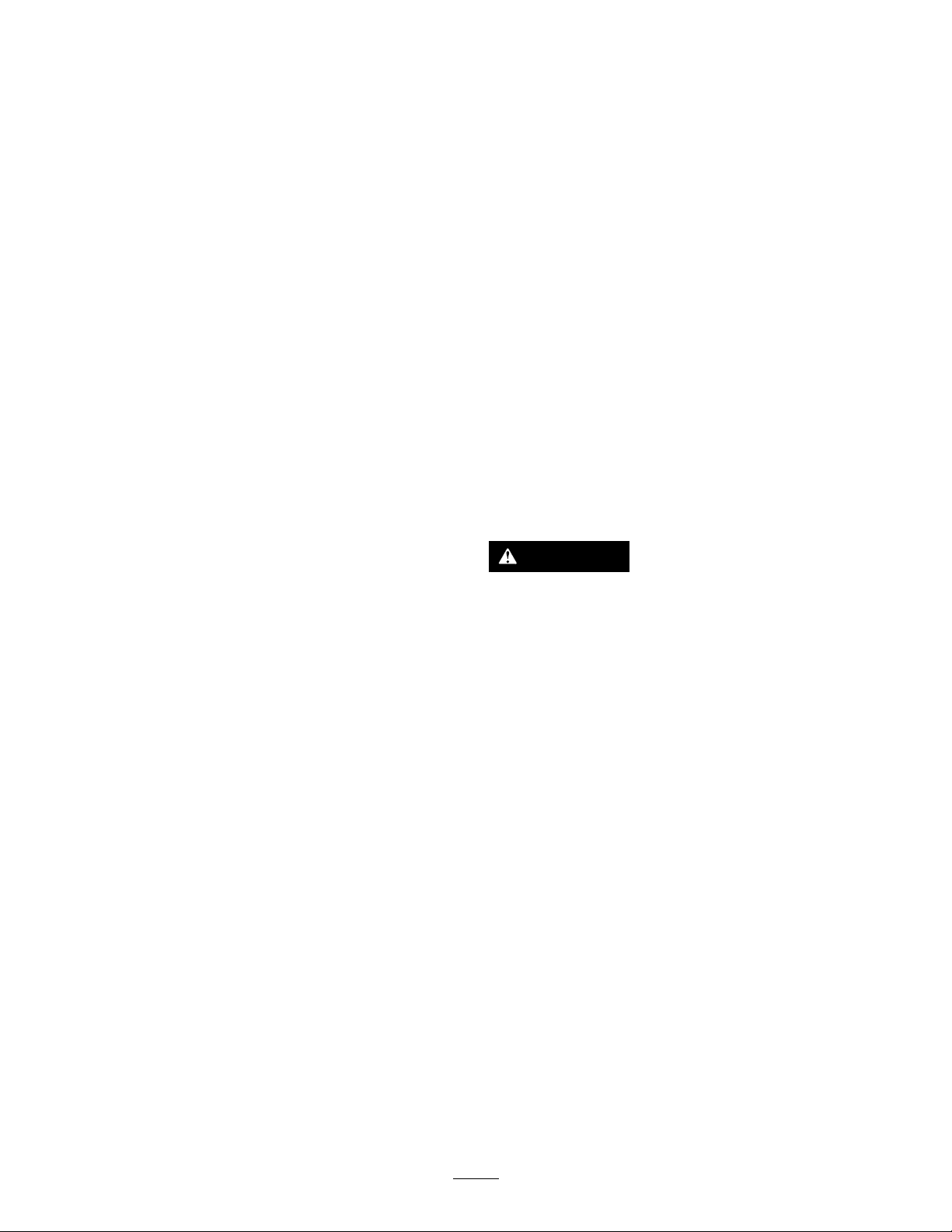

FuelGauge

Thefuelwindowlocatedbelowtheoperatorposition

canbeusedtoverifythelevelofgasolineinthetank

(Figure6).

g017722

g020264

Figure6

1.Fuelgaugewindow

IgnitionSwitch

Theignitionswitchhasthreepositions:Start,Run

andOff.ThekeywillturntoStartandmovebackto

Runuponrelease.TurningthekeytotheOffposition

willstoptheengine;however,alwaysremovethekey

whenleavingthemachinetopreventtheenginefrom

accidentallystarting(Figure5).

ThrottleControl

ThethrottlecontrolisvariablebetweenFastand

Slow.Movingthrottleleverforwardwillincrease

enginespeedandmovingthrottlelevertotherearwill

decreaseenginespeed.Movingthethrottleforward

intothedetentisfullthrottle(Figure5).

Choke

Usethechoketostartacoldengine.Pullthechoke

knobuptoengageit.Pushdownonthechokeknob

todisengageit.

Blade-ControlSwitch(Power

Take-Off)

Thebladecontrolswitch,representedbyapower

take-off(PTO)symbol,engagesanddisengages

powertothemowerblades(Figure5).

MotionControlLevers

Themotioncontrolleversarespeedsensitivecontrols

ofindependentwheelmotors.Movingaleverforward

orbackwardturnsthewheelonthesamesideforward

orinreverse;wheelspeedisproportionaltothe

amounttheleverismoved.Movethecontrollevers

outwardfromthecentertotheneutrallockposition

andexitthemachine(Figure4).Alwayspositionthe

motioncontrolleversintotheneutrallockposition

whenyoustopthemachineorleaveitunattended.

ParkingBrakeLever

Locatedonleftsideoftheconsole(Figure4).The

brakeleverengagesaparkingbrakeonthedrive

wheels.Pulltheleverupandrearwardtoengagethe

brake.Pushtheleverforwardanddowntodisengage

thebrake.

FootPedalDeckLiftSystem

Thefootpedaldeckliftsystemallowstheoperator

tolowerandraisethedeckfromtheseatedposition.

Theoperatorcanusethefootpedaltoliftthedeck

brieytoavoidobstaclesorlockthedeckinthe

highestheight-of-cutortransportposition(Figure4).

Height-of-CutLever

HourMeter

Thehourmeterrecordsthenumberofhoursthe

bladeshaveoperated.Itoperateswhentheblade

Theheight-of-cutleverworkswiththefootpedalto

lockthedeckinaspeciccuttingheight.Onlyadjust

theheightofcutwhilemachineisnotmoving(Figure

4).

16

Page 17

Attachments/Accessories

AselectionofT oroapprovedattachmentsand

accessoriesisavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.T oro.comforalistofallapprovedattachments

andaccessories.

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

AddingFuel

•Forbestresults,useonlyclean,fresh,unleaded

gasolinewithanoctaneratingof87orhigher

((R+M)/2ratingmethod).

•Oxygenatedfuelwithupto10%ethanolor15%

MTBEbyvolumeisacceptable.

•DoNotuseethanolblendsofgasoline(such

asE15orE85)withmorethan10%ethanolby

volume.Performanceproblemsand/orengine

damagemayresultwhichmaynotbecovered

underwarranty.

•DoNotusegasolinecontainingmethanol.

•DoNotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessafuelstabilizer

isused.

•DoNotaddoiltogasoline.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitethegasolinevapors.Are

orexplosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebefore

lling.

•Donotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowthe

lossofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

ground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbe

used,keepthenozzleincontactwiththe

rimofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.

17

Page 18

WARNING

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporscancause

seriousinjuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastank

orconditioneropening.

•Keepgasawayfromeyesandskin.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areor

explosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupany

gasolinethatspills.

•Neverllthefueltankinsideanenclosed

trailer.

Addthecorrectamountofgasstabilizer/conditioner

tothegas.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.T ominimizethe

chanceofvarnishdepositsinthefuelsystem,usefuel

stabilizeratalltimes.

FuelGauge

Usethefuelwindowbelowtheoperatortoverifythe

levelofgasolinebeforellingthetank(Figure7).

g020264

Figure7

1.Fuelgaugewindow

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6

to13mm(1/4to1/2inch)belowthebottom

ofthellerneck.Thisemptyspaceinthe

tankallowsgasolinetoexpand.

•Neversmokewhenhandlinggasoline,and

stayawayfromanopenameorwhere

gasolinefumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainer

andkeepitoutofthereachofchildren.

Neverbuymorethana30-daysupplyof

gasoline.

•Donotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysor

less.Forlongerstorageitisrecommendedthat

thefueltankbedrained.

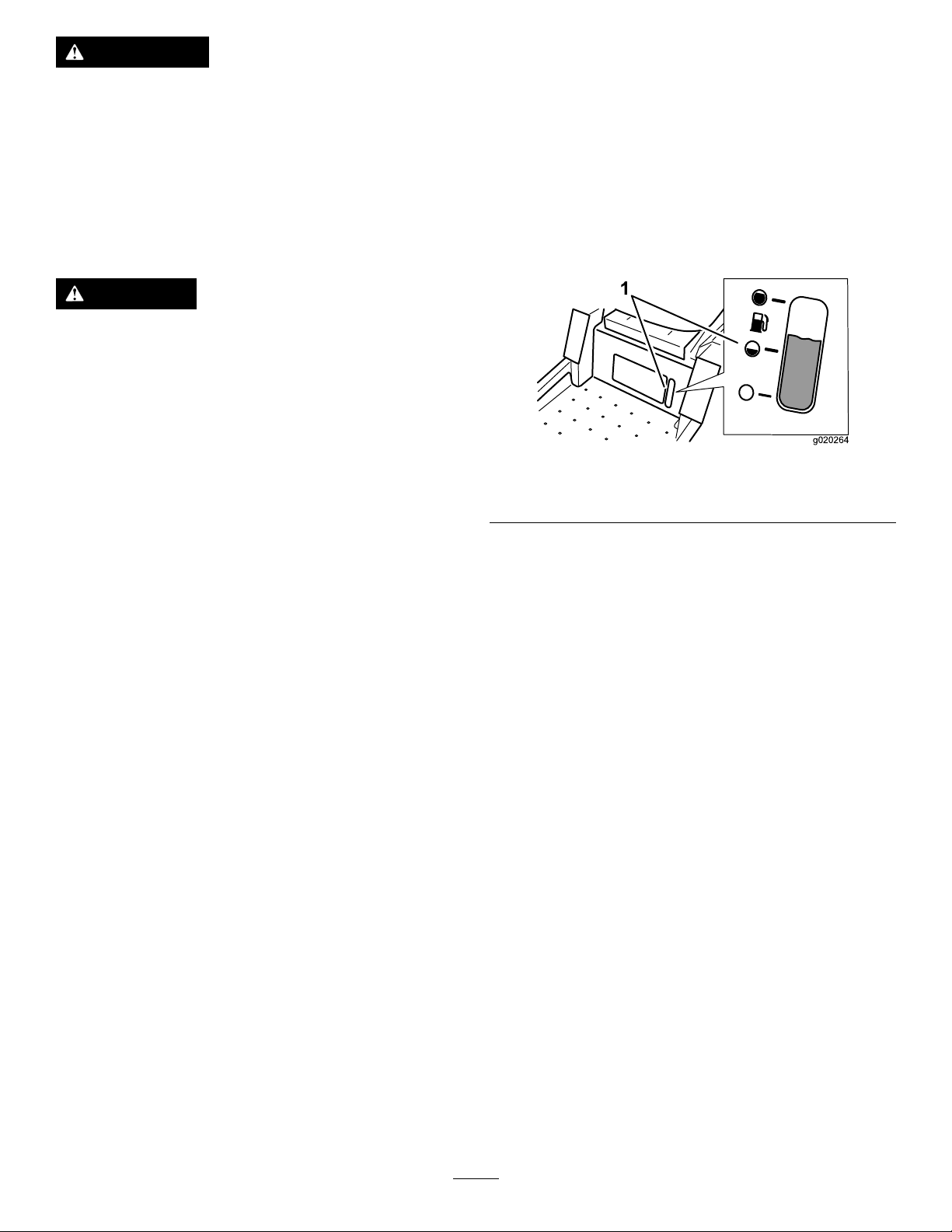

FillingtheFuelTank

Makesuretheengineisshutoffandthemotion

controlsareintheparkposition.

Important:DoNotoverllfueltank.Fillthe

fueltanktothebottomofthellerneck.The

emptyspaceinthetankallowsthefueltoexpand.

Overllingmayresultinfuelleakageordamageto

theengineoremissionsystem.

1.Cleanaroundthefueltankcapandremovethe

cap.

Note:Y oucanusethefuelwindowbelow

theoperatingpositionverifythepresenceof

gasolinebeforellingthetank(Figure7).

2.Slowlyaddregular,unleadedgasolineuntilthe

fuelreachesthebaseofthellerneckFigure8.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

18

Page 19

DANGER

Mowingonwetgrassorsteepslopescan

causeslidingandlossofcontrol.

Wheelsdroppingoveredgescancause

rollovers,whichmayresultinseriousinjury,

deathordrowning.

Alossoftractionisalossofsteeringcontrol.

Toavoidlossofcontrolandpossibilityof

rollover:

•Donotmowneardrop-offsornearwater.

•Donotmowslopesgreaterthan15degrees.

•Reducespeedanduseextremecautionon

slopes.

•Whenmowingslopes,graduallyworkfrom

lowertohigherareasontheincline.

Figure8

3.Installthefueltankcapsecurelyandtighten

untilit“clicks”.Wipeupanygasolinethatmay

havespilled.

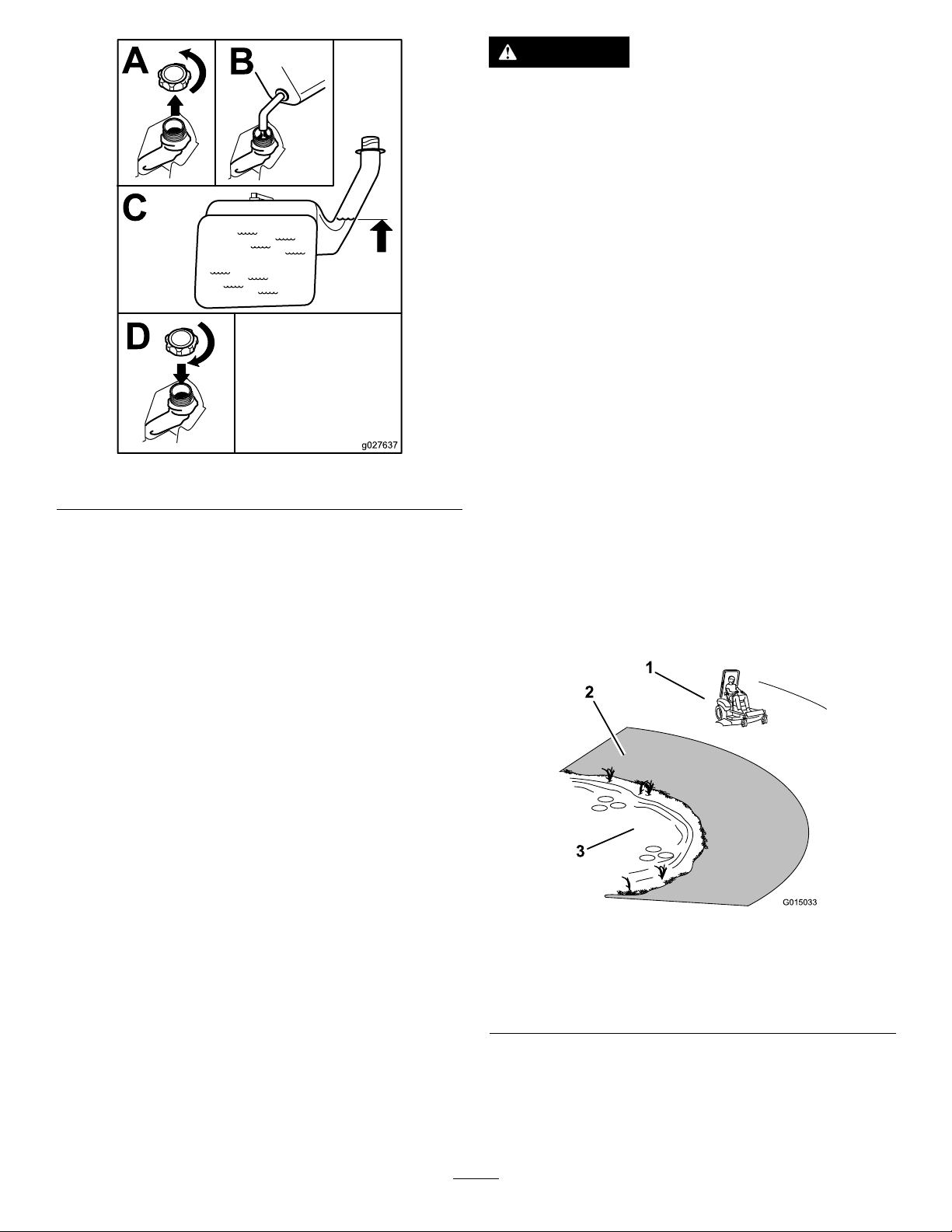

ThinkSafetyFirst

Pleasecarefullyreadallofthesafetyinstructionsand

decalsinthesafetysection.Knowingthisinformation

couldhelpyou,yourfamily,petsorbystandersavoid

injury.

g027637

•Avoidsuddenturnsorrapidspeed

changes.

•Turnup,intoaninclinewhenchanging

directionsonslopes.T urningdownthe

slopereducestraction.

•Attachmentschangethehandling

characteristicsofthemachine.Useextra

cautionwhenusingattachmentswiththe

machine.

Figure9

1.SafeZone-usethemachinehere

2.Usewalkbehindmowerand/orhandtrimmerneardrop-offs

andwater .

3.Water

19

g015033

Page 20

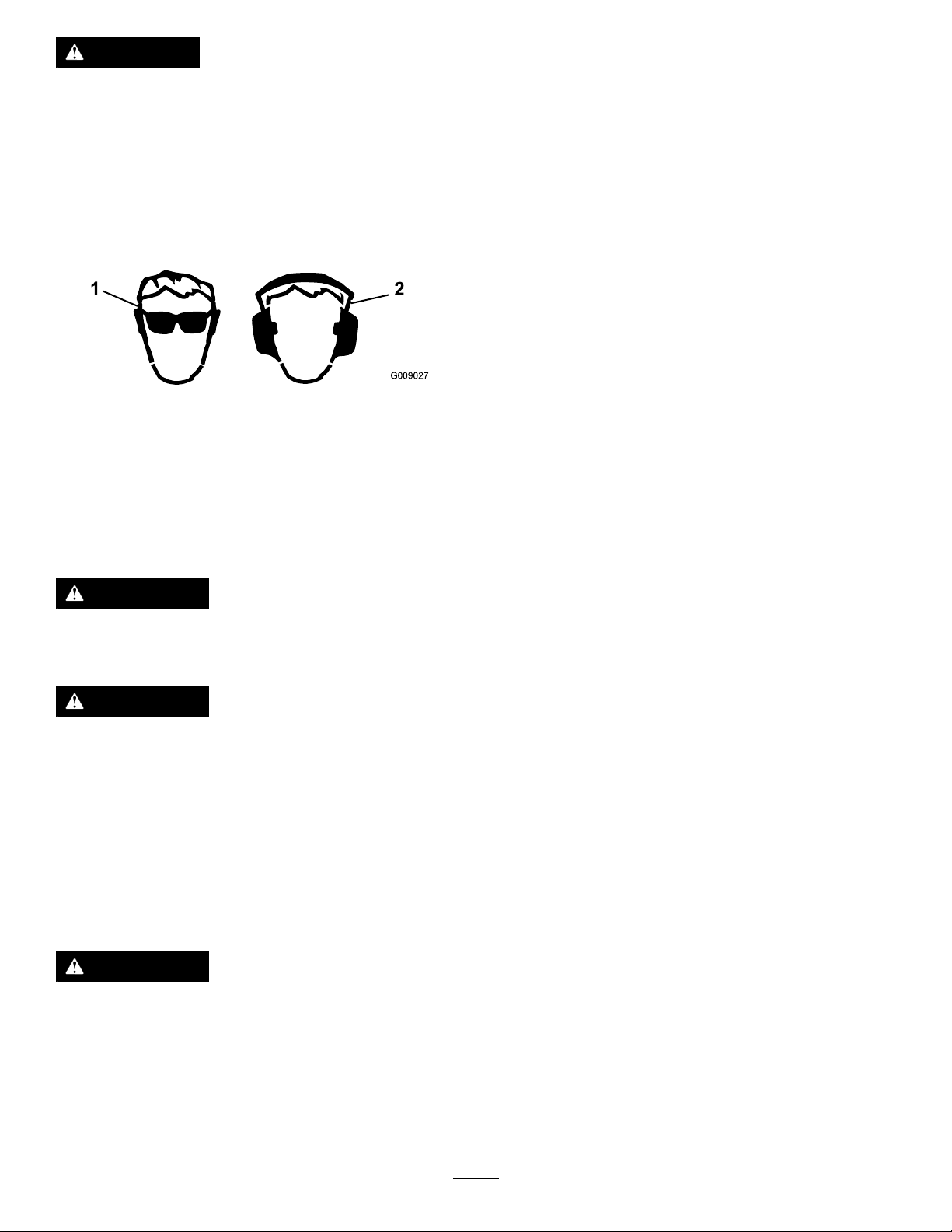

CAUTION

Thismachineproducessoundlevelsin

excessof85dBAattheoperatorsearandcan

causehearinglossthroughextendedperiods

ofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Theuseofprotectiveequipmentforeyes,ears,

hands,feet,andheadisrecommended.

Figure10

1.Wearsafetyglasses

2.Wearhearingprotection

UnderstandingtheSafetyInterlock System

Thesafetyinterlocksystemisdesignedtopreventthe

enginefromstartingunless:

•Theparkingbrakeisengaged.

•Thebladesaredisengaged.

•Themotioncontrolleversareintheneutrallock

position.

Thesafetyinterlocksystemalsoisdesignedtostop

theenginewhenthecontrolleversareoutofthe

neutrallockpositionwiththeparkingbrakeonorif

yourisefromtheseatwhenthebladesareengaged.

TestingtheSafetyInterlock

g009027

System

Testthesafetyinterlocksystembeforeyouusethe

machineeachtime.Ifthesafetysystemdoesnot

operateasdescribedbelow,haveanAuthorized

ServiceDealerrepairthesafetysystemimmediately .

UsingtheRollover ProtectionSystem(ROPS)

WARNING

Toavoidinjuryordeathfromrollover:keep

therollbarinstalledandusetheseatbelt.

WARNING

Thereisnorolloverprotectionwhentheroll

barisremoved.

•Driveslowlyandcarefully.

•Checkcarefullyforoverheadclearances

(i.e.branches,doorways,electricalwires)

beforedrivingunderanyobjectsanddo

notcontactthem.

TheSafetyInterlockSystem

1.Whilesittingontheseat,engagetheparking

brakeandmovethebladecontrolswitchtoOn.

Trystartingtheengine;theengineshouldnot

crank.

2.Whilesittingontheseat,engagetheparking

brakeandmovethebladecontrolswitchtoOff.

Moveeithermotioncontrollever(forwardor

reverse).Trystartingtheengine;theengine

shouldnotcrank.Repeatwiththeothermotion

controllever.

3.Whilesittingontheseat,engagetheparking

brake,movethebladecontrolswitchtoOff,

andlockthemotioncontrolleversinneutral.

Starttheengine.Whiletheengineisrunning,

releasetheparkingbrake,engagetheblade

controlswitch,andriseslightlyfromtheseat;

theengineshouldstop.

4.Whilesittingontheseat,engagetheparking

brake,movethebladecontrolswitchtoOff,and

lockthemotioncontrolleversinneutral.Start

theengine.Whiletheengineisrunning,center

themotioncontrols;theengineshouldstop.

WARNING

Ifsafetyinterlockswitchesaredisconnected

ordamagedthemachinecouldoperate

unexpectedlycausingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

CheckingtheEngineOil Level

Beforeyoustarttheengineandusethemachine,

checktheoillevelintheenginecrankcase;referto

CheckingtheEngineOilLevel(page38).

20

Page 21

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mower

decksanddrivesystemshavehigherfrictionwhen

new,placingadditionalloadontheengine.Allow

40to50hoursofbreak-intimefornewmachinesto

developfullpowerandbestperformance.

OperatingtheParking Brake

g008946

Figure13

Alwayssettheparkingbrakewhenyoustopthe

machineorleaveitunattended.

SettingtheParkingBrake

Figure11

ReleasingtheParkingBrake

OperatingtheChoke

Usethechoketostartacoldengine.

1.Iftheengineiscold,usethechoketostartthe

engine.

2.Pulluponthechokeknobtoengagethechoke

beforeusingtheignitionswitch(Figure14).

3.Pushdownonthechoketodisengagethechoke

aftertheenginehasstarted(Figure14).

g027638

Figure12

OperatingtheThrottle

ThethrottlecontrolcanbemovedbetweenFastand

Slowpositions(Figure13).

Alwaysusethefastpositionwhenturningonthe

mowerdeckwiththebladecontrolswitch(PTO).

g027639

1.On2.Off

Figure14

g008959

OperatingtheIgnition Switch

1.TurntheignitionkeytotheStartposition(Figure

15).Whentheenginesstarts,releasethekey.

Note:Additionalstartingcyclesmaybe

requiredwhenstartingtheenginefortherst

timeafterthefuelsystemhasbeenwithoutfuel

completely.

21

Page 22

Figure15

2.Turntheignitionkeytostoptostoptheengine.

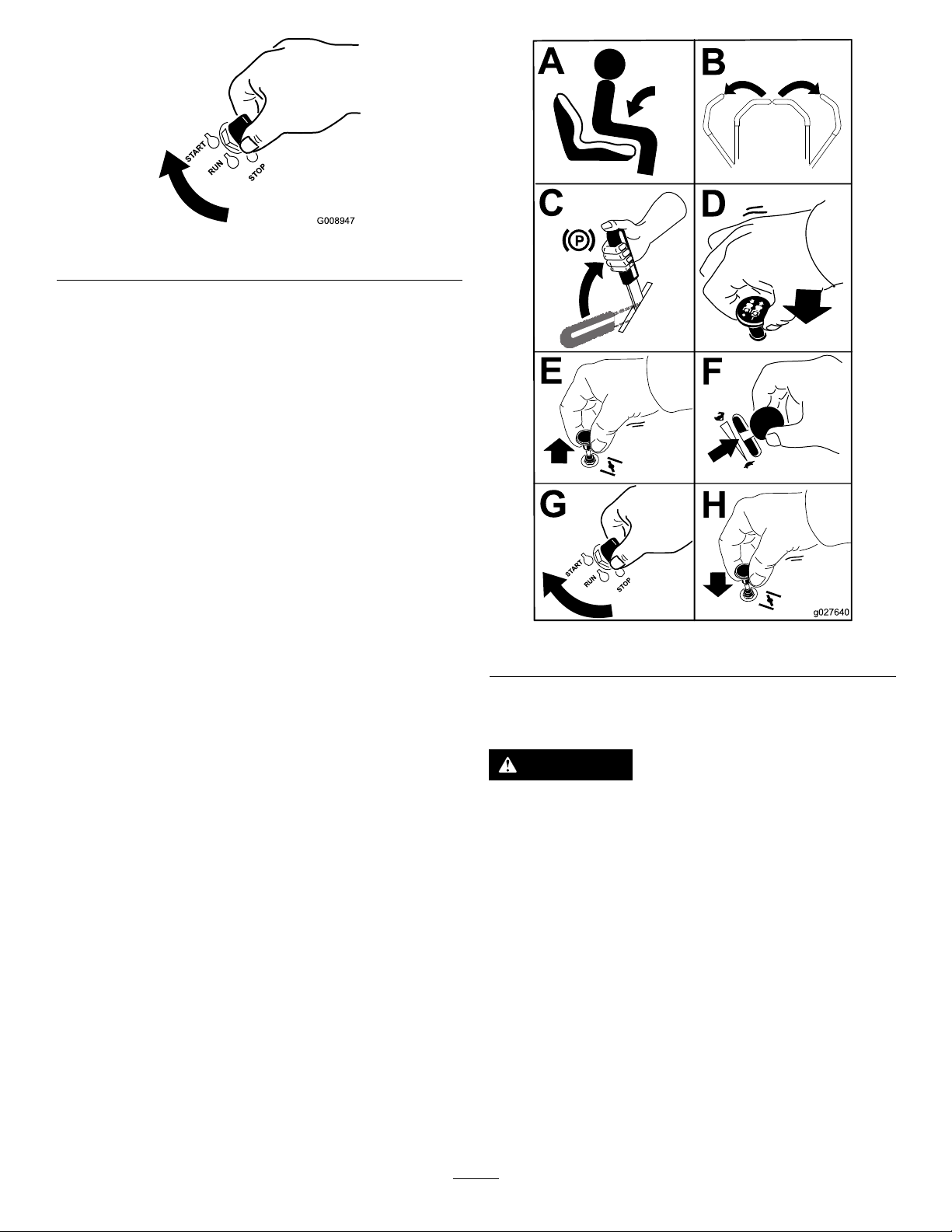

StartingandStoppingthe Engine

StartingtheEngine

Note:Awarmorhotenginemaynotrequirechoking

(Figure16).

Important:Donotengagestarterformorethan5

secondsatatime.Iftheenginefailstostartallow

a15secondcool-downperiodbetweenattempts.

Failuretofollowtheseinstructionscanburnout

thestartermotor.

Note:Ifthefuelsystemwasdepletedoffuel—add

fueltothemachineanduseadditionalstartingcycles

whenstartingtheengine.

g008947

g027640

Figure16

StoppingtheEngine

CAUTION

Injurycanoccurifchildrenorbystanders

moveorattempttooperatethemachinewhile

itisunattended.

Alwaysremovetheignitionkeyandsetthe

parkingbrakewhenleavingthemachine

unattended,evenifjustforafewminutes.

22

Page 23

OperatingtheMowerBlade ControlSwitch(PTO)

Thebladecontrolswitch(PTO)startsandstopsthe

mowerbladesandanypoweredattachments.

EngagingtheBladeControl Switch(PTO)

Engagethebladecontrolswitch(PTO)withthe

throttlepositionatFast.

Note:Engagingthebladecontrolswitch(PTO)with

thethrottlepositionathalforlesswillcauseexcessive

weartothedrivebelts.

Figure17

g008945

Figure18

g027641

DisengagingtheBladeControl Switch(PTO)

g009174

Figure19

DrivingForwardor Backward

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Place

thethrottlecontrolinthefastpositionforbest

23

Page 24

performance.Alwaysoperateinthefullthrottle

positionwhenmowing.

CAUTION

Machinecanspinveryrapidly.Operatormay

losecontrolofmachineandcausepersonal

injuryordamagetomachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemaking

sharpturns.

UsingtheMotionControlLevers

g008952

Figure21

Figure20

1.Motioncontrol

lever-neutrallockposition

2.Center,unlockedposition5.Frontofmachine

3.Forward

4.Backward

DrivingForward

Note:Theenginewillkillifthetractioncontrollevers

aremovedwiththeparkingbrakeengaged.

DrivingBackward

Note:Alwaysusecautionwhenbackingupand

turning.

1.Movetheleverstothecenter,unlockedposition.

2.Togobackward,slowlypullthemotioncontrol

leversrearward(Figure22).

g004532

1.Releasetheparkingbrake;refertoReleasing

theParkingBrakeinOperation.

2.Movetheleverstothecenter,unlockedposition.

3.Togoforward,slowlypushthemotioncontrol

leversforward(Figure21).

g008953

Figure22

24

Page 25

StoppingtheMachine

UsingtheFootPedalDeckLift System

WARNING

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

Alwaysremovetheignitionkeyandmove

themotioncontrolleversoutwardtothe

parkpositionwhenleavingthemachine

unattended,evenifjustforafewminutes.

Tostopthemachine,movethetractioncontrollevers

toneutralandmovetolockedposition,disengagethe

bladecontrolswitch(PTO),andturntheignitionkey

tooff.

Settheparkingbrakewhenyouleavethemachine;

refertoSettingtheParkingBrake.Rememberto

removethekeyfromtheignitionswitch.

AdjustingtheHeight-of-Cut

Themachineisequippedwithafootpedaldecklift

system.Theoperatorcanusethefootpedaltolift

thedeckbrieytoavoidobstaclesorlockthedeckin

thehighestheight-of-cutortransportposition.The

operatorcanusetheheightofcutleverwiththefoot

pedaltolockthedeckinaspeciccuttingheight.

•Pressthepedaldowntoraisethedeck;continue

topressthepedaluntilthedeckislockedinthe

transportposition(Figure23).

•Pushonthedeckliftpedalwithyourfootandpull

thetransportlockhandlerearwardtodisengage

thetransportlock(Figure23).

g024409

Figure23

TransportLockPosition

AdjustingtheHeight-of-Cut

Theheight-of-cutcanbeadjustedfrom38to114mm

(1-1/2to4-1/2inch)in6mm(1/4inch)increments

byrelocatingtheheight-of-cutpinintodifferenthole

locations.

1.Pushonthedeckliftpedalwithyourfootand

raisethemowerdecktothetransportlock

position(alsothe114mm(4-1/2inch)cutting

heightposition)(Figure24).

2.Toadjust,removethepinfromtheheight-of-cut

bracket(Figure24).

3.Selectaholeintheheight-of-cutsystem

correspondingtotheheight-of-cutdesiredand

insertthepin(Figure24).

4.Pushonthedeckliftpedalwithyourfootandpull

thehandlerearwardtodisengagethetransport

lock(Figure23).

5.Lowerthedeckslowlyuntilthelevermakes

contactwiththepin.

25

Page 26

Figure24

1.Deckliftpedal3.Height-of-cutpositions

2.Handle4.Pin

AdjustingtheAnti-Scalp Rollers

Wheneveryouchangetheheight-of-cut,itis

recommendedtoadjusttheheightoftheanti-scalp

rollers.

1.Disengagethebladecontrolswitch(PTO),move

themotioncontrolleverstotheneutrallock

positionandsettheparkingbrake.

2.Stoptheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removetheangenut,anti-scalprollerandbolt

fromthebracket(Figure25).

g024410

Note:Keeptheboltandanti-scalproller

togetherwhenremoving.

Figure25

1.FlangeNut4.Bushing

2.Spacer

3.Anti-scalproller

5.Bolt

4.Aligntheboltandanti-scalprollerintheholeof

thebracketthatmatchedtheclosestheightof

cutposition(Figure25).

5.Inserttheboltintothebracketholeandsecure

theboltandanti-scalprollerwiththeangenut

(Figure25).

g024312

26

Page 27

PositioningtheSeat

Theseatcanmoveforwardandbackward.Position

theseatwhereyouhavethebestcontrolofthe

machineandaremostcomfortable.

Figure26

AdjustingtheMotion

1.Loosentheupperboltholdingthecontrollever

tothecontrolarmshaft.

2.Loosenthelowerboltjustenoughtopivotthe

controlleverforeoraft.Tightenbothboltsto

securethecontrolinthenewposition.

3.Repeattheadjustmentfortheoppositecontrol

lever.

PushingtheMachineby Hand

Important:Alwayspushthemachinebyhand.

Nevertowthemachinebecausedamagemay

occur.

ToPushtheMachine

1.Parkthemachineonalevelsurfaceand

g027632

disengagethebladecontrolswitch.

2.Movethemotioncontrolleversoutwardto

neutrallockposition,stoptheengine,remove

thekey,andwaitforallmovingpartstostop

beforeleavingtheoperatingposition.Makesure

theparkingbrakeisdisengaged.

ControlLevers

AdjustingtheHeight

Note:Repeattheadjustmentfortheoppositecontrol

lever.

Themotioncontrolleverscanbeadjustedhigheror

lowerformaximumoperatorcomfort(Figure27).

Figure27

3.Dothisprocedureoneachsideofthe

machineFigure28.

g027642

g027252

Figure28

AdjustingtheTilt

Themotioncontrolleverscanbetiltedforeoraftfor

maximumoperatorcomfort.

ToOperatetheMachine

Movethebypasstothepositionforoperatingthe

machine(Figure28)toengagethewheelmotors.

27

Page 28

Convertingthe48inch MowertoSideDischarge

Themowerdeckandmowerbladesshippedwiththis

machineweredesignedforoptimummulchingand

sidedischargeperformance.

Installthefastenersintothesameholesinthedeck

theywereoriginallyremovedfrom.Thisensureno

holesareleftopenwhenthedeckisoperated.

DANGER

Openholesinthemowerexposeyouand

otherstothrowndebris.Debristhrownoutof

holesinthemowercancauseinjury.

•Neveroperatethemowerwithouthardware

mountedinallholesinthemower.

•Installhardwareinmountingholeswhen

thebafeisremoved.

RemovingtheMulchBafe

1.Parkthemachineonalevelsurfaceand

disengagethebladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothe

neutrallockposition,settheparkingbrake,

stoptheengine,removethekey ,andwaitfor

allmovingpartstostopbeforeleavingthe

operatingposition.

3.Removethemowerasdescribedinthe

RemovingtheMowerprocedureinthe

Maintenancesectionformoreinformation.

g012841

Figure29

1.Locknut(5/16inch)3.Leftbafe

2.Carriagebolt(5/16x3/4

inch)

7.Removetheleftbafefromthemowerdeckas

showninFigure29.

8.Removethecarriagebolt(5/16x3/4inch)and

locknut(5/16inch)ontherearwallofthemower

decksecuringthebafetothedeck(Figure30).

4.Turnthemowerupsidedown.

5.Removetheexistingmowerbladesinstalledon

yourdeck.RefertotheRemovingtheBlades

procedureintheMaintenancesectionformore

information.

6.Removethetwolocknuts(5/16inch)securedto

theweldedpostsoftheleftbafeonthetopof

themowerdeckatthecenterandleftofcenter

positions(Figure29).Removethecarriagebolt

andlocknutonthesidewallofthemowerdeck

securingtheleftbafetothedeck.

g012806

Figure30

1.Bafeguard3.Carriagebolt(5/16x3/4

inch)

2.Locknut(5/16inch)4.Rightbafe

9.Locatethebafeguardatthefrontedgeofthe

sidedischargeopening.Removethefasteners

securingthebafeguardandtherightbafeto

themowerdeckasshowninFigure30.Remove

thebafeguardandretainallfasteners.

10.Removethetwolocknuts(5/16inch)tosecuring

theweldedpostsoftherightbafetothetopof

themowerdeckatcenterandrightofcenter

positions(Figure31).Removetherightbafe

fromthemowerdeck.

28

Page 29

Figure31

1.Locknut(5/16inch)3.Weldedposts,rightbafe

2.Rightbafe

Convertingthe54inch MowertoSideDischarge

Installthefastenersintothesameholesinthedeck

theywereoriginallyremovedfrom.Thisensureno

holesareleftopenwhenthedeckisoperated.

DANGER

Openholesinthemowerexposeyouand

otherstothrowndebris.Debristhrownoutof

holesinthemowercancauseinjury.

•Neveroperatethemowerwithouthardware

mountedinallholesinthemower.

g012805

•Installhardwareinmountingholeswhen

thebafeisremoved.

RemovingtheMulchBafe

11.Locatethecutoffbafeintheloosepartsbag.

Removethefastenersattherearholesofthe

dischargeplate.Installthebafeattheside

dischargeopeningonthemowerdeck(Figure

32).

Figure32

1.Carriagebolt,existing3.Cutoffbafe,shipped

2.Rearholesinthe

dischargeplate

loose

4.Locknut,existing

1.Parkthemachineonalevelsurfaceand

disengagethebladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothe

neutrallockposition,settheparkingbrake,

stoptheengine,removethekey ,andwaitfor

allmovingpartstostopbeforeleavingthe

operatingposition.

3.Removethemowerasdescribedinthe

RemovingtheMowerprocedureinthe

Maintenancesectionformoreinformation.

4.Turnthemowerupsidedown.

5.Removetheexistingmowerbladesinstalledon

yourdeck.RefertotheRemovingtheBlades

procedureintheMaintenancesectionformore

information.

6.Removethethreelocknuts(5/16inch)secured

totheweldedpostsoftheleftbafeonthetopof

g012800

themowerdeckatthecenter,leftofcenterand

leftpositions(Figure33).Removethecarriage

boltandlocknutonthesidewallofthemower

decksecuringtheleftbafetothedeck.

12.Usethefastenersremovedtosecurethecutoff

bafetothedeck.

13.Installthebladestothedeck.Referto

theInstallingtheBladesprocedureinthe

Maintenancesectionformoreinformation.

14.InstallthemowerasdescribedintheInstalling

theMowerprocedureintheMaintenancesection

formoreinformation.

29

Page 30

Figure33

1.Locknut(5/16inch)3.Leftbafe

2.Carriagebolt(5/16x3/4

inch)

4.Installfastenershere

7.Removetheleftbafefromthemowerdeckas

showninFigure33.

8.Locatethetwoboltsinloosepartsandusethe

existinglocknuts.Installthesefastenersintothe

holesshowninFigure33onthemowerdeckto

preventyingdebris.Installtheboltup,through

theundersideofthedeckanduseanexisting

locknuttosecurefromthetopside.

WARNING

g011 149

g010712

Figure34

1.Carriagebolt(5/16x3/4

inch)

2.Locknuts,frontof

dischargeplate(reinstall

afterbafeisremoved)

3.Locknut,forwardholein

deck(reinstallafterbafe

isremoved)

4.Bafeguard,54inch

decks

5.Hexheadbolt,forward

holeindeck(reinstallafter

bafeisremoved)

6.Carriagebolts,frontof

dischargeplate(reinstall

afterbafeisremoved)

7.Locknut(5/16inch)

Openholesinthemowerexposeyouand

otherstothrowndebriswhichcancause

severeinjury.

•Neveroperatethemowerwithout

hardwaremountedinallholesinthe

mowerhousing.

•Installthehardwareinthemounting

holeswhenyouremovethemulching

bafe.

9.Removethecarriagebolt(5/16x3/4inch)and

locknut(5/16inch)ontherearwallofthemower

decksecuringthebafetothedeck(Figure34).

10.Locatethebafeguardatthefrontedgeofthe

sidedischargeopening.Removethefasteners

securingthebafeguardandtherightbafeto

themowerdeckasshowninFigure34.Remove

thebafeguardandretainallfasteners.

11.Removethetwolocknuts(5/16inch)securing

theweldedpostsoftherightbafetothetopof

themowerdeckatcenterandrightofcenter

positions(Figure35).

12.Removethecarriageboltandlocknutsecuring

therightbafetothetopofthemowerdeck.

Removetherightbafefromthemowerdeck

(Figure35).

30

Page 31

Figure35

1.Locknut(5/16inch)3.Weldedposts,rightbafe

2.Rightbafe4.Carriagebolt

13.Installthefastenersremovedpreviouslyatthe

frontholesinthedischargeplateandforward

holeinthedeck(Figure34).

14.Locatethecutoffbafeintheloosepartsbag.

Removethefastenersattherearholesofthe

dischargeplate.Installthebafeattheside

dischargeopeningonthemowerdeck(Figure

36).

17.InstallthemowerasdescribedintheInstalling

theMowerprocedureintheMaintenancesection

formoreinformation.

UsingtheSideDischarge

Themowerhasahingedgrassdeectorthat

dispersesclippingstothesideanddowntowardthe

turf.

DANGER

Withoutagrassdeector,dischargecover,or

completegrasscatcherassemblymountedin

place,youandothersareexposedtoblade

g010704

contactandthrowndebris.Contactwith

rotatingmowerblade(s)andthrowndebris

willcauseinjuryordeath.

•Neverremovethegrassdeectorfrom

themowerbecausethegrassdeector

routesmaterialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthe

mower.

•Nevertrytoclearthedischargeareaor

mowerbladesunlessyoumovetheblade

controlswitch(PTO)totheoffposition,

rotatetheignitionkeytooffandremove

thekey.

g010703

Figure36

1.Carriagebolt3.Cutoffbafe

2.Rearholesinthe

dischargeplate

15.Usethefastenersremovedtosecurethecutoff

bafetothedeck.

16.Installthebladestothedeck.Referto

theInstallingtheBladesprocedureinthe

Maintenancesectionformoreinformation.

4.Locknut

•Makesurethegrassdeectorisinthe

downposition.

31

Page 32

TransportingtheMachine

LoadingtheMachine

Useaheavy-dutytrailerortrucktotransportthe

machine.Ensurethatthetrailerortruckhasall

necessarybrakes,lighting,andmarkingasrequired

bylaw.Pleasecarefullyreadallthesafetyinstructions.

Knowingthisinformationcouldhelpyou,yourfamily,

pets,orbystandersavoidinjury.

WARNING

Drivingonthestreetorroadwaywithoutturn

signals,lights,reectivemarkings,oraslow

movingvehicleemblemisdangerousandcan

leadtoaccidentscausingpersonalinjury.

Donotdrivemachineonapublicstreetor

roadway.

Totransportthemachine:

1.Ifusingatrailer,connectittothetowingvehicle

andconnectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Loadthemachineontothetrailerortruck.

4.Stoptheengine,removethekey,setthebrake,

andclosethefuelvalve.

5.Tiedownthemachinenearthefrontcaster

wheelsandtherearbumper(Figure37).

Useextremecautionwhenloadingorunloading

machinesontoatraileroratruck.Useafull-width

rampthatiswiderthanthemachineforthisprocedure.

Backuprampsanddriveforwarddownramps(Figure

38).

Figure38

1.Backupramps

2.Driveforwarddownramps

Important:Donotusenarrowindividualramps

foreachsideofthemachine.

Ensuretherampislongenoughsothattheanglewith

thegrounddoesnotexceed15degrees(Figure39).

Onatground,thisrequiresaramptobeatleastfour

times(4X)aslongastheheightofthetrailerortruck

bedtotheground.Asteeperanglemaycausemower

componentstogetcaughtastheunitmovesfromthe

ramptothetrailerortruck.Steeperanglesmayalso

causethemachinetotiporlosecontrol.Ifloadingon

ornearaslope,positionthetrailerortrucksothatitis

onthedownsideoftheslopeandtherampextends

uptheslope.Thiswillminimizetherampangle.

g028043

Figure37

g027708

32

Page 33

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath.

•Useextremecautionwhenoperatinga

machineonaramp.

•EnsurethattheROPSisintheupposition

andusetheseatbeltwhenloadingor

unloadingthemachine.Ensurethatthe

ROPSwillclearthetopofanenclosed

trailer.

•Useonlyafull-widthramp;donotuse

individualrampsforeachsideofthe

machine.

•Donotexceeda15-degreeanglebetween

therampandthegroundorbetweenthe

rampandthetrailerortruck.

•Ensurethelengthoframpisatleastfour

times(4X)aslongastheheightofthe

trailerortruckbedtotheground.Thiswill

ensurethatrampangledoesnotexceed15

degreesonatground.

•Backuprampsanddriveforwarddown

ramps.

•Avoidsuddenaccelerationordeceleration

whiledrivingthemachineonarampas

thiscouldcausealossofcontrolora

tip-oversituation.

1.Full-widthrampinstowed

position

2.Sideviewoffull-width

rampinloadingposition

3.Notgreaterthan

15degrees

g027996

Figure39

4.Rampisatleastfourtimes

(4X)aslongastheheight

ofthetrailerortruckbed

totheground

5.H=heightofthetraileror

truckbedtotheground

6.Trailer

33

Page 34

OperatingTips

FastThrottleSetting

Forbestmowingandmaximumaircirculation,operate

theengineatthefastthrottleposition.Airisrequired

tothoroughlycutgrassclippings,sodonotsetthe

height-of-cutsolowastototallysurroundthemower

byuncutgrass.Alwaystrytohaveonesideofthe

mowerfreefromuncutgrass,whichallowsairtobe

drawnintothemower.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethe

cuttingheightofthemowerdoesnotscalpanyuneven

ground.However,thecuttingheightusedinthepast

isgenerallythebestonetouse.Whencuttinggrass

longerthan15.24cm(6inches)tall,youmaywant

tocutthelawntwicetoensureanacceptablequality

ofcut.

Cut1/3oftheGrassBlade

LongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,

raisethecuttingheighthigherthanusualandcutthe

grassatthissetting.Thencutthegrassagainusing

thelower,normalsetting.

WhenStopping

Ifthemachine'sforwardmotionmustbestoppedwhile

mowing,aclumpofgrassclippingsmaydroponto

yourlawn.Toavoidthis,moveontoapreviouslycut

areawiththebladesengagedoryoucandisengage

themowerdeckwhilemovingforward.

KeeptheUndersideoftheMower

Clean

Cleanclippingsanddirtfromtheundersideofthe

moweraftereachuse.Ifgrassanddirtbuildupinside

themower,cuttingqualitywilleventuallybecome

unsatisfactory.

Itisbesttocutonlyabout1/3ofthegrassblade.

Cuttingmorethanthatisnotrecommendedunless

grassissparse,oritislatefallwhengrassgrows

moreslowly.

MowingDirection

Alternatemowingdirectiontokeepthegrassstanding

straight.Thisalsohelpsdisperseclippingswhich

enhancesdecompositionandfertilization.

MowatCorrectIntervals

Normally,moweveryfourdays.Butremember,

grassgrowsatdifferentratesatdifferenttimes.So

tomaintainthesamecuttingheight,whichisagood

practice,mowmoreofteninearlyspring.Asthe

grassgrowthrateslowsinmidsummer,mowless

frequently.Ifyoucannotmowforanextendedperiod,

rstmowatahighcuttingheight;thenmowagaintwo

dayslateratalowerheightsetting.

CuttingSpeed

BladeMaintenance

Maintainasharpbladethroughoutthecuttingseason

becauseasharpbladecutscleanlywithouttearingor

shreddingthegrassblades.Tearingandshredding

turnsgrassbrownattheedges,whichslowsgrowth

andincreasesthechanceofdisease.Checkthe

cutterbladesdailyforsharpness,andforanywearor

damage.Filedownanynicksandsharpentheblades

asnecessary.Ifabladeisdamagedorworn,replaceit

immediatelywithagenuineTOROreplacementblade.

Toimprovecutquality ,useaslowergroundspeed

incertainconditions.

AvoidCuttingTooLow

Ifthecuttingwidthofthemoweriswiderthanthe

moweryoupreviouslyused,raisethecuttingheightto

ensurethatuneventurfisnotcuttooshort.

34

Page 35

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst50hours

Beforeeachuseordaily

Aftereachuse

Every25hours

Every50hours

Every100hours

Every200hours

Every400hours

MaintenanceProcedure

•Changetheengineoil.

•Changethehydraulicsystemlterandoil.

•Checkthesafetyinterlocksystem.

•Checktheengineoillevel.

•Cleantheairintakescreen.

•Checkthemowerblades.

•Inspectthegrassdeectorfordamage

•Cleanthemowerhousing.

•Greasealllubricationpoints.

•Checktirepressure.

•Checkthehydraulicoillevelintheexpansiontank.

•Inspectthebeltsforcracksandwear.

•Servicethepaperelement(moreoftenindusty,dirtyconditions).

•Changetheengineoil(moreoftenindusty ,dirtyconditions).

•Checkthesparkplug(s).

•Replacethefuellters(moreoftenunderdusty,dirtyconditions).

•Replacethepaperelement(moreoftenindusty,dirtyconditions).

•Changetheoillter.(moreoftenindusty ,dirtyconditions)

•Changethehydraulicsystemlterandoil.

Monthly

Yearlyorbeforestorage

•Checkthebatterycharge.

•Paintchippedsurfaces.

•Checkallmaintenanceprocedureslistedabovebeforestorage.

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineand

seriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudo

anymaintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

35

Page 36

Figure40

Locatedontheseatpanunderside

decal115-9630

1.ReadtheOperator'sManualbeforeperformingany

4.Checkthehydraulicoilevery25hours

maintenance.

2.Checktheengineoilevery8hours5.Checkthecasterwheeltirepressureevery25hours

3.Checkthedrivewheeltirepressureevery25hours

6.Lubricatethecasterwheelevery25hours

36

Page 37

Pre-Maintenance

Lubrication

Procedures

GreasingtheBearings

RaisingtheSeat

Makesurethemotioncontrolleversarelockedinthe

neutrallockposition.Lifttheseatforward.

Thefollowingcomponentscanbeaccessedbyraising

theseat:

•Servicedecal

•Fuses

•Batteryandcables

ReleasingtheMower-Deck Curtain

Loosenthe2bottomboltsofthecurtaintogainaccess

tothetopofthemowerdeck(Figure41).

ServiceInterval:Every25hours—Greaseall

lubricationpoints.

GreaseType:No.2generalpurposelithiumbase

grease

1.Parkthemachineonalevelsurfaceand

disengagethebladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothe

neutrallockposition,stoptheengine,remove

thekey,andwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.Cleanthegreasettings(Figure42andFigure

40)witharag.Makesuretoscrapeanypaintoff

ofthefrontofthetting(s).

1.Bottombolt

Figure41

g027673

Figure42

2.Curtain

1.Frontcastertire

4.Connectagreaseguntoeachtting(Figure40

andFigure42).Pumpgreaseintothettings

untilgreasebeginstooozeoutofthebearings.

5.Wipeupanyexcessgrease.

37

g009949

Page 38

EngineMaintenance

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandother

bodypartsawaythemuferandotherhot

surfaces.

ServicingtheAirCleaner

CleaningtheElement

ServiceInterval:Every100hours—Servicethe

paperelement(moreoftenindusty,

dirtyconditions).

Every200hours/Y early(whichevercomes

rst)—Replacethepaperelement(moreoften

industy,dirtyconditions).

1.Lightlytaptheelementonaatsurfaceto

removedustanddirt.

2.Inspecttheelementfortears,anoilylm,and

damagetotheseal.

Note:Servicetheaircleanermorefrequently(every

fewhours)ifoperatingconditionsareextremelydusty

orsandy .

RemovingtheElement

1.Parkthemachineonalevelsurfaceand

disengagethebladecontrol(PTO).

2.Movethemotioncontrolleverstotheneutrallock

position,settheparkingbrake,stoptheengine,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Cleanaroundtheaircleanercovertoprevent

dirtfromgettingintotheengineandcausing

damage.Liftthecoverandremovethehose

clampsecuringtheaircleanerassemblytothe

engine(Figure43).

4.Loosenthehoseclampandremovethepaper

element(Figure43).

Important:Nevercleanthepaperelement

withpressurizedairorliquids,suchas

solvent,gas,orkerosene.Replacethepaper

elementifitisdamagedorcannotbecleaned

thoroughly.

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSF ,SG,SH,SJ,

orSL)

CrankcaseCapacity:1.8liter(61ounce);whenoil

lterisremoved:2.1liter(70ounce)

Viscosity:Seethetablebelow.

1.Cover

2.Paperelement

Figure43

3.Hoseclamp

g010686

Figure44

Note:Usingmultigradeoils(5W-20,10W-30,and

10W-40)willincreaseoilconsumption.Checkoillevel

morefrequentlywhenusingthem.

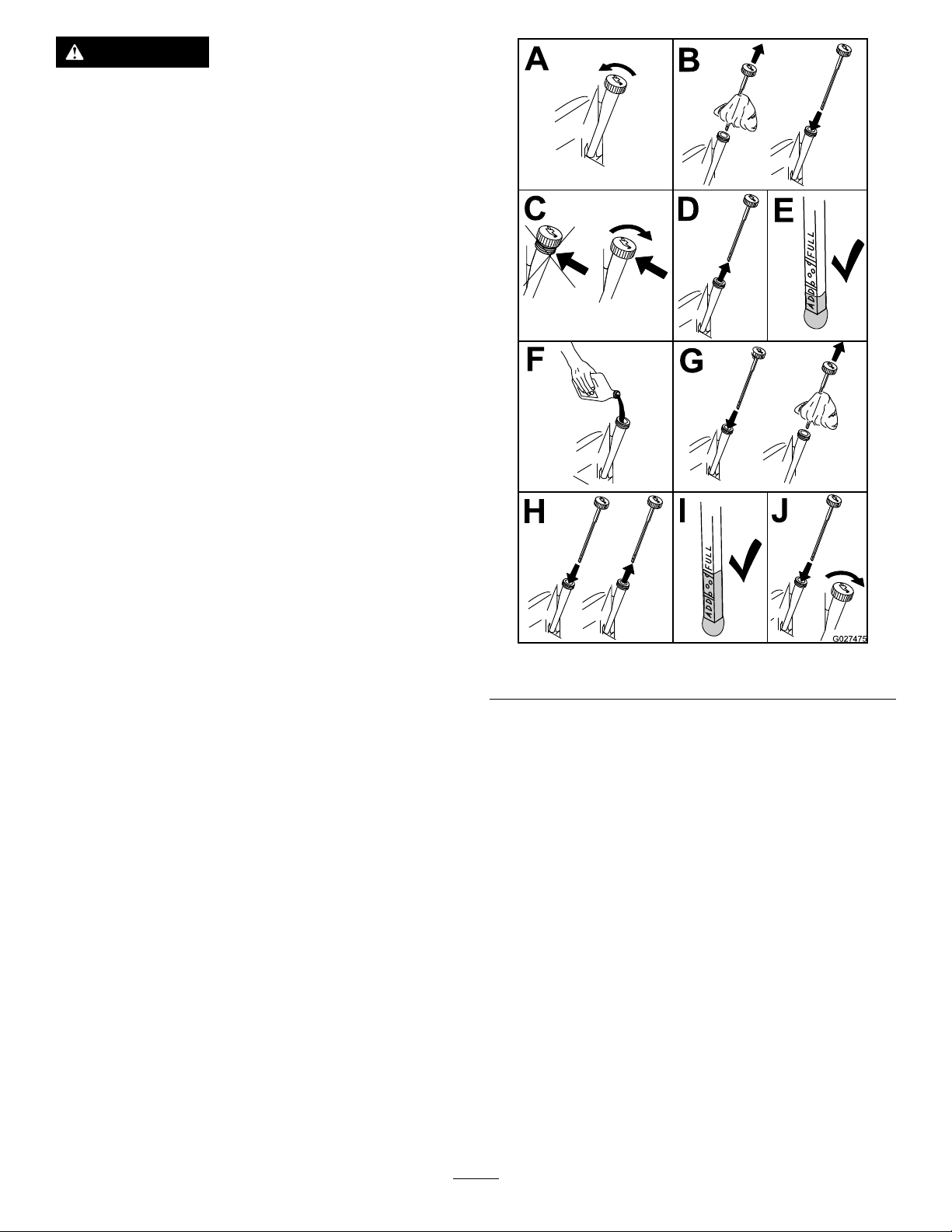

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

g015155

Note:Checktheoilwhentheengineiscold.

38

Page 39

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandother

bodypartsawaythemuferandotherhot

surfaces.

Important:Donotoverllthecrankcasewithoil

becausedamagetotheenginemayresult.Donot

runenginewithoilbelowthelowmarkbecause

theenginemaybedamaged.

1.Parkthemachineonalevelsurface,disengage

thebladecontrolswitch,stoptheengine,

engageparkingbrake,andremovethekey.

2.Makesuretheengineisstopped,level,andis

coolsotheoilhashadtimetodrainintothe

sump.

3.T okeepdirt,grassclippings,etc.,outof

theengine,cleantheareaaroundtheoilll

cap/dipstickbeforeremovingit.

4.Stoptheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition(Figure45).

Figure45

g027475

39

Page 40

ChangingtheEngineOil

ServiceInterval:Aftertherst8hours—Changethe

engineoil.

Every100hours—Changetheengineoil(more

oftenindusty ,dirtyconditions).

Note:Disposeoftheusedoilatarecyclingcenter.

1.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoensuretheoil

drainscompletely.

2.DisengagethePTO,movethemotioncontrol

leverstotheneutrallockedpositionandsetthe

parkingbrake.

3.Stoptheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition(Figure46).

g027660

Figure47

Figure46

4.Slowlypourapproximately80%ofthespecied

oilintothellertubeandslowlyaddthe

additionaloiltobringittotheFullmark(Figure

47).

ChangingtheEngineOilFilter

ServiceInterval:Every200hours—Changetheoil

lter.(moreoftenindusty,dirty

conditions)

Note:Changetheengineoilltermorefrequently

whenoperatingconditionsareextremelydustyor

sandy.

1.Draintheoilfromtheengine;refertoChanging

theEngineOil.

2.Changetheengineoillter(Figure48).

g027539

40

Page 41

Figure48

2.Stoptheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

g027478

Figure49

Note:Duetothedeeprecessaroundthespark

plug,blowingoutthecavitywithcompressedair

isusuallythemosteffectivemethodforcleaning.

Thesparkplugismostaccessiblewhenthe

blowerhousingisremovedforcleaning.

CheckingtheSparkPlug

Important:Nevercleanthesparkplug(s).Always

replacethesparkplug(s)whenithas:ablack

coating,wornelectrodes,anoilylm,orcracks.

g027477

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeanstheaircleanerisdirty .

Note:Ensuretheoilltergaskettouchesthe

engineandthenanextra3/4turniscompleted.

3.Fillthecrankcasewiththepropertypeofnew

oil;refertoChangingtheOil.

ServicingtheSparkPlug

ServiceInterval:Every100hours—Checkthespark

plug(s).

Makesuretheairgapbetweenthecenterandside

electrodesiscorrectbeforeinstallingthesparkplug.

Useasparkplugwrenchforremovingandinstalling

thesparkplug(s)andagappingtool/feelergaugeto

checkandadjusttheairgap.Installanewspark

plug(s)ifnecessary.

Type:NGKBPR4ES(orequivalent)

AirGap:0.76mm(0.030inch)

RemovingtheSparkPlug

1.DisengagethePTO,movethemotioncontrol

leverstotheneutrallockedpositionandsetthe

parkingbrake.

Setthegapto0.030inches(0.76mm).

g027479

Figure50

InstallingtheSparkPlug

Tightenthesparkplug(s)to22N-m(16ft-lb).

41

Page 42

CleaningtheCooling

Figure51

FuelSystem

Maintenance

ReplacingtheFuelFilter

ServiceInterval:Every100hours/Yearly(whichever

comesrst)(moreoftenunder

dusty,dirtyconditions).

1.Disengagethebladecontrolswitch(PTO),move

themotioncontrolleverstotheneutrallock

position,andsettheparkingbrake.

2.Stoptheengine,removethekey ,andwait

g027661

forallmovingpartstostopbeforeleavingthe

operatingposition.

System

Cleantheairintakescreenfromgrassanddebris

beforeeachuse.

1.Disengagethebladecontrolswitchandmove

thecontrolleverstotheneutrallockedposition

andapplytheparkingbrake.

2.Stoptheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removetheairintakescreen,aircleanercover,

andfanhousing.

4.Cleandebrisandgrassfromtheparts.

5.Installtheairintakescreen,aircleanercover,

andfanhousing.

g027590

g027518

Figure52

42

Page 43

ElectricalSystem

Maintenance

ServicingtheBattery

ServiceInterval:Monthly

DANGER

Batteryelectrolytecontainssulfuricacid

whichisadeadlypoisonandcausessevere

burns.

Donotdrinkelectrolyteandavoidcontact

withskin,eyesorclothing.Wearsafety

glassestoshieldyoureyesandrubbergloves

toprotectyourhands.

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetalmachinecomponentscausing

sparks.Sparkscancausethebatterygasses

toexplode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,

donotallowthebatteryterminalstotouch

anymetalpartsofthemachine.

3.Removethewingnutsecuringthebatteryclamp

(Figure53).

Figure53

1.Removethewingnutand

clamp

2.Removethenegative

batterycablebeforethe

positive

4.Removetheclamp(Figure53).

5.Firstdisconnectthenegativebatterycable

(black)fromthenegative(-)(black)battery

terminal(Figure53).

3.Removethepositive

batterycable

4.Removebattery

g027672

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

WARNING

Incorrectbatterycableroutingcoulddamage

themachineandcablescausingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•AlwaysDisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•AlwaysReconnectthepositive(red)

batterycablebeforereconnectingthe

negative(black)cable.

1.Disengagethebladecontrolswitch(PTO),move

themotioncontrolleverstotheneutrallock

positionandsettheparkingbrake.

2.Stoptheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

6.Slidetheredterminalbootoffthepositive(red)

batteryterminalandremovethepositive(+)(red)

batterycable(Figure53).

7.Removethebattery.

InstallingtheBattery

1.Positionbatteryinthetraywiththeterminal

postsoppositefromthefueltank(Figure53).

2.First,installthepositive(red)batterycableto

positive(+)batteryterminal.

3.Theninstallthenegativebatterycabletothe

negative(-)batteryterminal.

4.Securethecableswith2bolts,2washers,and

2locknuts(Figure53).

5.Slidetheredterminalbootontothepositive

(red)batterypost.

6.Installtheclampandsecureitwiththewingnut

(Figure53).

43

Page 44

ChargingtheBattery

WARNING

Chargingthebatteryproducesgassesthat

canexplode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged.

Thisisespeciallyimportanttopreventbattery

damagewhenthetemperatureisbelow32°F(0°C).

1.Chargebatteryfor10to15minutesat25to30

ampsor30minutesat10amps.

2.Whenthebatteryisfullycharged,unplug

thechargerfromtheelectricaloutlet,then

disconnectthechargerleadsfromthebattery

posts(Figure54).

3.Installthebatteryinthemachineandconnect

thebatterycables,refertoInstallingtheBattery.

1.Fuseblock

g024411

Figure55

2.30ampmainfuse

Figure54

1.PositiveBatteryPost

2.NegativeBatteryPost

3.Red(+)ChargerLead

4.Black(-)ChargerLead

ServicingtheFuses

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;howeverifafuseblows,checkthe

component/circuitforamalfunctionorshort.

Important:Ensurethatthenewfusesare

thesametypeandamperageasthefuses

removed.

2.T oreplacetheenginefuse,removetheconsole

fromtheplasticfender.

g000960

g024412

Figure56

1.Enginefuse

Note:Thefusesarelocatedonrighthandconsole

nexttotheseat(Figure55).

Fuses:

•Main,30amp,blade-type

•Engine,20amp,blade-type

1.T oreplacethemainfuse,graspthefuseandpull

itstraightandawayfromthefuseblock.

3.Grasptheenginefuseandpullitstraightand

awayfromthefuseblock(Figure56).

4.Alignanewfusewiththeslotinthefuseblock

(Figure55).

5.Pushthefuseintothefuseblockuntilthefuse

isseated(Figure55).

44

Page 45

DriveSystem

HydraulicSystem

Maintenance

CheckingtheTirePressure

ServiceInterval:Every25hours—Checktire

pressure.

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseuneven

cut.Checkthepressureatthevalvestem(Figure57).

Checkthetireswhentheyarecoldtogetthemost

accuratepressurereading.

Refertothemaximumpressuresuggestedbythetire

manufactureronthesidewallofthecasterwheeltires.

Inatethereardrivewheeltiresto13psi(90kPa).

Maintenance

HydraulicSystemOilSpecication

OilType:T oroHYPR-OIL®500or20w-50motoroil.

SystemCapacity:approximately4.495liter(152

oz)withalterchange.

Important:Useoilspeciedorequivalent.Other

uidscouldcausesystemdamage.

CheckingtheHydraulicOil Level

ServiceInterval:Every25hours

Checkexpansionreservoirandifnecessaryaddoil

totheFULLCOLDline.

1.Valvestem

g000554

Figure57

g010253

Figure58

1.Expansionreservoir3.Engine

2.FullColdline

ChangingtheHydraulic SystemFilterandOil

Thelterandoilarechangedatthesametime.Do

Notreuseoil.Oncethenewlterisinstalledandoilis

addedanyairinthesystemmustbepurged.

Thebleedingprocessisrepeateduntiltheoilremains

attheFULLCOLDlineinthereservoirafterpurging.

Failuretoproperlyperformthisprocedurecan

resultinirreparabledamagetothetransaxledrive

system.

45

Page 46

RemovingHydraulicSystem Filters

Important:Whenthehydraulicoillteris

removed,allofthehydraulicoilineachtransaxle

willdrainout.Useacontainerthatwillhandle

4.495liters(152oz)orlarger.

1.Stopengine,waitforallmovingpartstostop,

andallowenginetocool.Removethekeyand

engagetheparkingbrake.

2.Locatethelterandguardsoneachtransaxle

drivesystem(Figure59).Removethreescrews

securingthelterguardandguard.

Figure59

Rightsideshown

1.Transaxledrive

2.Oillter

3.Filterguard

4.Screws

5.Ventplug

3.Carefullycleantheareaaroundthelters.Itis

importantthatnodirtorcontaminationenterthe

hydraulicsystem.

4.Placeacontainerbelowtheltertocatchthe

oilthatdrainswhenthelterandventplugsare

removed.

5.Locateandremovetheventplugoneach

transmission

6.Unscrewtheltertoremoveandallowoilto

drainfromthedrivesystem.

Repeatthisprocedureforbothlters.

InstallingtheHydraulicSystem Filters

ServiceInterval:Aftertherst50hours

Every400hours

g027477

Figure60

g010254

1.Applyathincoatofoilonthesurfaceofthe

rubbersealofeachlter.

2.Turnthelterclockwiseuntilrubberseal

contactsthelteradapterthentightenthelter

anadditional3/4to1fullturn.Repeatforthe

otherlter

3.Installthelterguardsovereachlteras

previouslyremoved.Usethethreescrewsto

securethelterguards.

4.Verifytheventplugsareremovedbeforeadding

theoil.

5.Slowlypourthespeciedoilthroughexpansion

reservoiruntiloilcomesoutofoneofthevent

plugholes.Stopandinstallthatventplug.

Torquetheplugto20.3N-m(180in-lb).

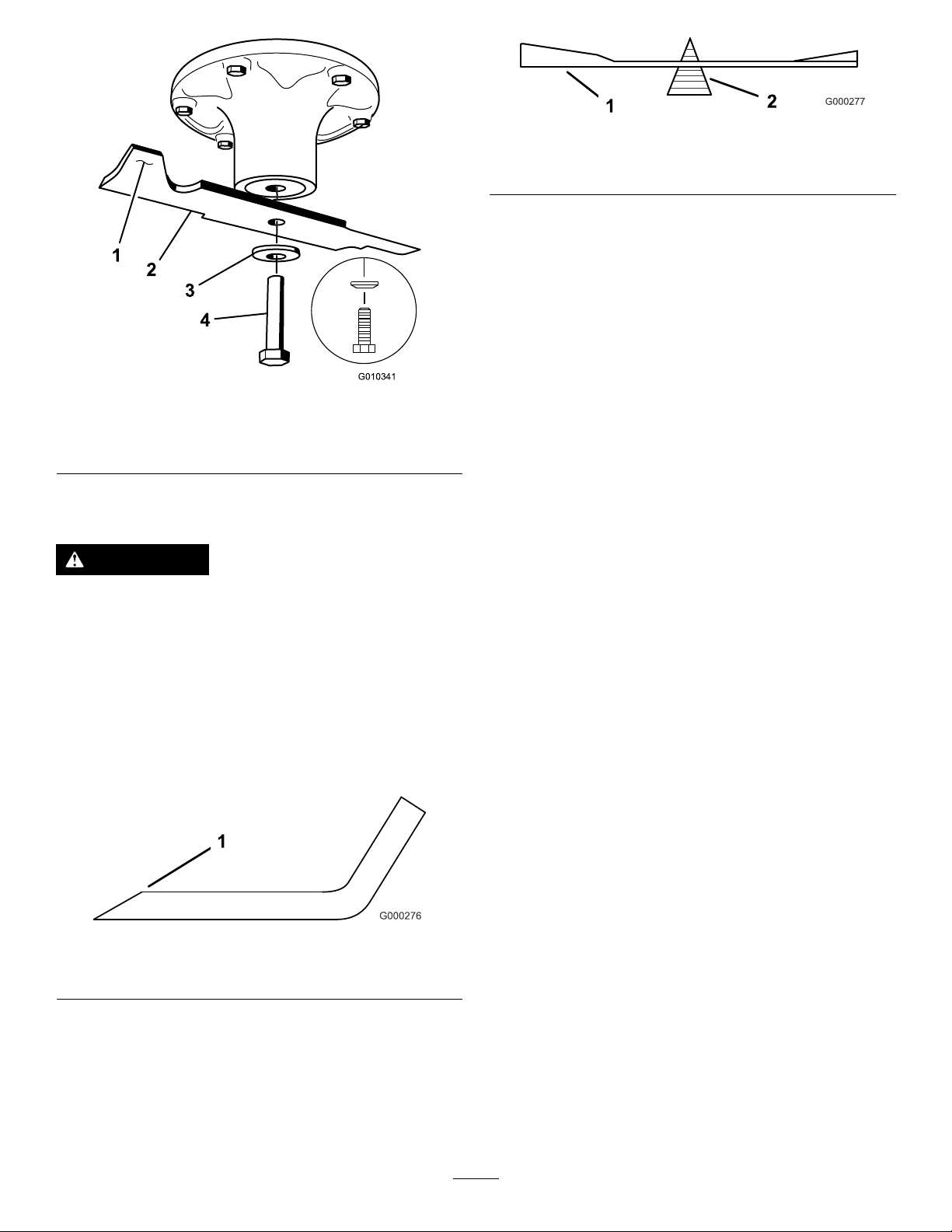

6.Continuetoaddoilthroughtheexpansion

reservoiruntiloilcomesoutoftheremaining

ventplugholeonthesecondtransmission.Stop

andinstallthatventplug.Torquetheplugto

20.3N-m(180in-lb).

7.Continuetoaddoilthroughtheexpansion

reservoiruntilitreachestheFULLCOLDline

ontheexpansionreservoir.Proceedtothe

BleedingtheHydraulicSystemsection.

46

Page 47

Important:FailuretoperformtheBleeding

theHydraulicSystemprocedureafter

changinghydraulicltersandoilcanresult

inirreparabledamagetothetransaxledrive

system.

BleedingtheHydraulicSystem

1.Raisetherearofmachineupandsupportwith

jackstands(orequivalentsupport)justhigh

enoughtoallowdrivewheelstoturnfreely.

reachestheFULLCOLDlineontheexpansion

reservoirifnecessary.

Figure61

1.Jackingpoints

2.Entertheoperator'sposition.Startengine

andmovethrottlecontrolaheadto1/2throttle

position.Disengageparkingbrake.

A.Movethebypassleversintothepushing

themachineposition;refertothePushing

theMachinebyHandsectioninOperation.

Withthebypassvalvesopenandtheengine

running,slowlymovethemotioncontrol

leversinbothforwardandreverse(5or6

times).

B.Movethebypassleversintotheoperating

themachineposition.Withthebypassvalve

closedandtheenginerunning,slowlymove

thedirectionalcontrolinbothforwardand

reversedirections(5to6times).

C.Stoptheengineandchecktheoillevelin

theexpansionreservoir.Addthespecied

oilasuntilitreachestheFULLCOLDline