Page 1

TITAN

ModelNo.74846—SerialNo.315000001andUp

ModelNo.74848—SerialNo.315000001andUp

®

ZXRidingMower

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

FormNo.3394-403RevA

SetupInstructions

ProcedureDescription

1

2

3

4

Nopartsrequired

Rearhitch1

Bolt(5/16x2-1/2inches)

Locknut(5/16inch)

Nopartsrequired

Rollbar1

Rollbarsupport2

Reinforcingbracket

ROPSplates

Bolt(1/2x3–1/2inches)

Bolt(1/2x4–1/2inches)

Hexlocknut(1/2inch)

Flatwasher(1/2inch)

Thrustwasher4

Flangelocknut(1/2inch)

Bolt(5/16x3–3/4inches)

Flangelocknut(5/16inch,maybe

pre-installed)

Flatwasher(5/16inch)

Qty.

10

10

Use

–

2

2

–

2

4

2

8

8

2

2

2

Connectthebattery.

Installtherearhitch.

Setupthemotion-controlleversandthe

seat.

InstalltheRollOverProtectionSystem

(ROPS).

5

6

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

©2015—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Nopartsrequired

Ignitionkey1

Operator'sManual

EngineOperator'sManual

Registeratwww.Toro.com.

–

1

1

Checkthemoweradjustment.

Completethesetup.

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

*3394-403*A

Page 2

1

g028541

2

1

4

3

6

5

g015397

1

2

2

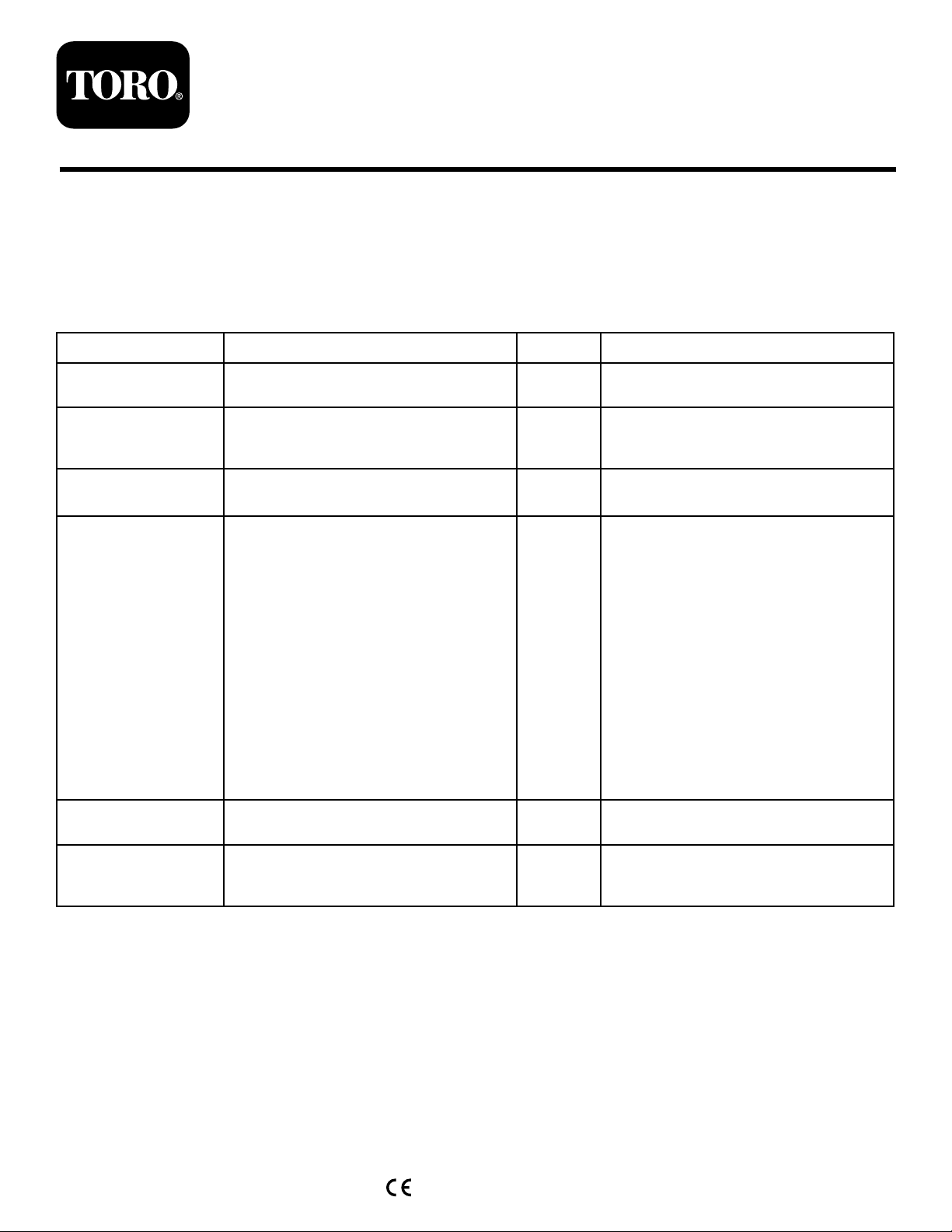

ConnectingtheBattery

NoPartsRequired

Procedure

1.Locatethebatteryandnegativebatterycable.

2.Removetheplasticcapfromthenegativebatterypost.

3.Removethefastenersonthenegativebatterycable,

andusethemtosecurethenegativebatterycableto

thenegativebatterypost(Figure1).

InstallingtheRearHitch

Partsneededforthisprocedure:

1Rearhitch

2

Bolt(5/16x2-1/2inches)

2

Locknut(5/16inch)

Procedure

InstallthebrackettotheframeasshowninFigure2and

Figure3.

Figure2

Beforeassembly

1.Bolts2.Locknuts

Figure1

1.Negativebatterycable4.Negativebatterypostcap

2.Nut5.Bolt

3.Washer6.Negativebatterypost

Figure3

Afterassembly

2

Page 3

3

g028542

A

B

C D

E

F

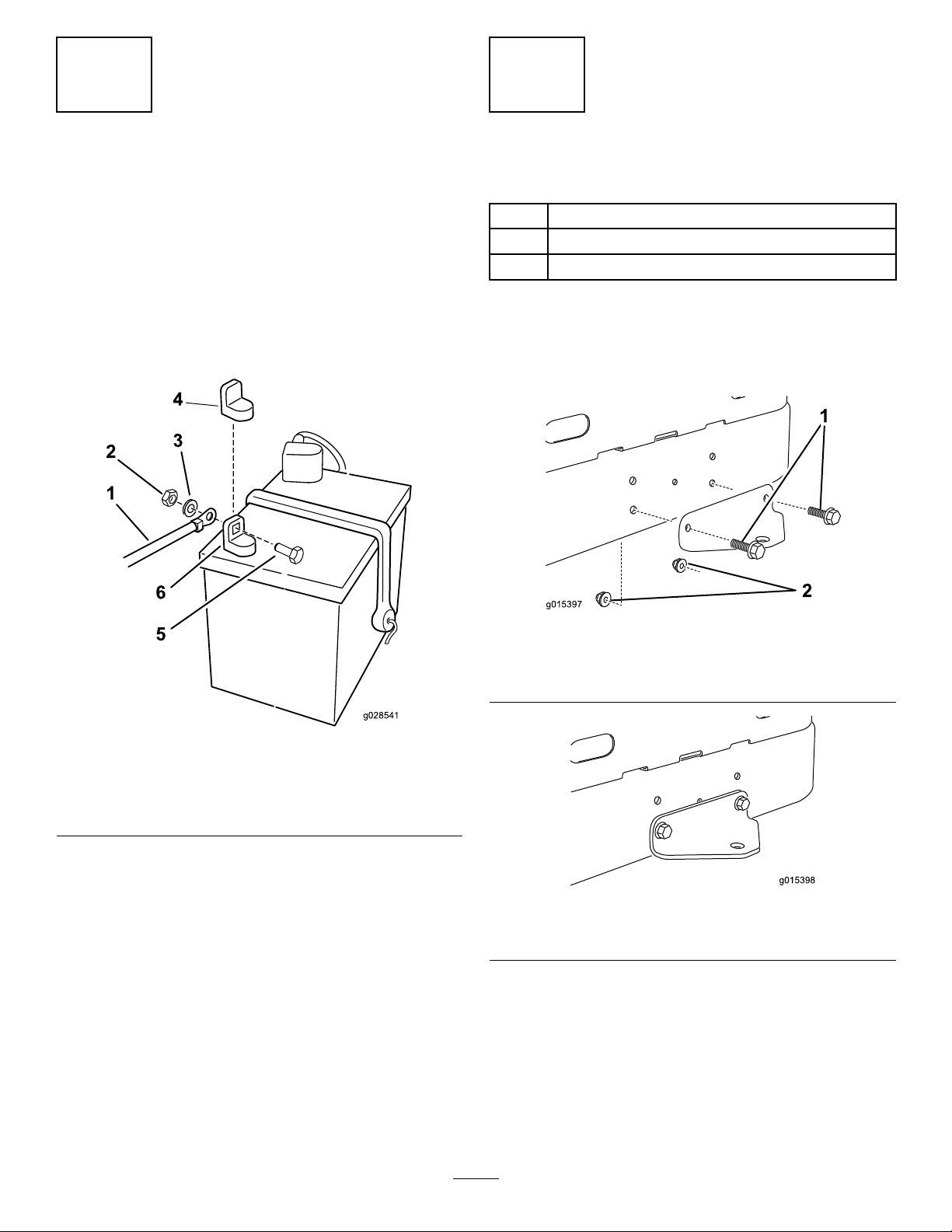

SettinguptheMotion-control

LeversandtheSeat

NoPartsRequired

Procedure

1.Locatethemotion-controlleversattached,butfolded

downonthemachine.

2.Removetheupperbolt(3/8x1inch)andwasher;

loosenthelowerbolt(3/8x1inch).

3.Raisethemotioncontrolleverstotheuprightposition.

4.Aligntheholesinthemotion-controlleverwiththe

holesinthecontrol-armshaft,andinstallthebolt

andwasherremovedpreviously.Repeatthisforboth

controlslevers.

Note:Handtightenallfasteners.

5.Setuptheseatasfollows(Figure4):

Figure4

A.Withthemotioncontrolleversintheoutward,

neutrallockposition,removethehairpincotter

pinsontheseatrodsecuringtheseattothe

machine.

B.Slidetheseatrodoutfromthebracketsandseat

frame.

C.Rotatetheseat180degreesandinstallitintothe

bracketyouremoveditfrom,usingtherodand

hairpincotterpinsremovedpreviously.

D.Connecttheinterlockswitchcabletotheseat.

E.Lowertheseatintotheoperatingposition.

6.Movethecontrolleversbacktothecenterposition

(neutral).

7.Verifythemotioncontrolleversareproperlyaligned.

Adjustasnecessary.Tightenallfasteners.

3

Page 4

4

13

14

15

g028588

InstallingtheRollOver

ProtectionSystem(ROPS)

Partsneededforthisprocedure:

1Rollbar

2Rollbarsupport

2

Reinforcingbracket

4

ROPSplates

10

Bolt(1/2x3–1/2inches)

2

Bolt(1/2x4–1/2inches)

8

Hexlocknut(1/2inch)

8

Flatwasher(1/2inch)

4Thrustwasher

10

Flangelocknut(1/2inch)

2

Bolt(5/16x3–3/4inches)

2

Flangelocknut(5/16inch,maybepre-installed)

2

Flatwasher(5/16inch)

InstallingtheRollbarSupports

Completethefollowingstepsforbothleftandrightrollbar

supports.

1.Locatethefactoryinstalledbraceattachedtotheframe

betweentheengineandtherearwheel(seeFigure5

andFigure6).

Note:Ifpreferred,therearwheelsmayberemoved

foreasieraccesstothebrace.

Figure6

1.Bolt(1/2x3–1/2inches)

(2)

2.Thrushwasher(4)10.Reinforcingbracket(2)

3.Rollbarsupport

4.Cutoutfacestherear12.Bolt(5/16x3–3/4inch)(2)

5.Brace,existing

6.Bolt(1/2x1–1/4inch)and

locknut(1/2inch),existing

7.Seatbeltassembly,

existing

8.Hexlocknut(1/2inch)(2)

9.Flangelocknut(1/2inch)

(2)

11.Bolt(1/2x4–1/2inch)(2)

13.Flatwasher(5/16inch)(2)

14.Flangelocknut(5/16inch)

(2)

15.Engineguard

2.Loosenthelocknutthatsecuresthebracetotheframe.

Stopwhenthebraceswingsfreely(Figure6).

3.Attachtherollbarsupporttotheframeandthebrace

totherollbarsupportasshowninFigure6.Leave

theboltslooseenoughthatthepartsarefreetoshift

around.

Figure5

Locationofthebraces

Note:Ensurethatthecutoutatthetopofthesupport

tubefacestherearofthemachine.

Note:Notetheorientationofthereinforcingbracket.

4.Attachtherollbarsupporttotheengineguardas

showninFigure6.

AttachingtheROPSPlates

AssembletheROPSplatestotherollbarasshowninFigure

7.Leavetheboltslooseenoughthatthepartsarefreeto

shiftaround.

Note:Ensurethatthelocknutsareontheinsideofthe

supporttube.

4

Page 5

g028544

1 2 3

2 4 5

1 2

3

2 1

4

g028545

MakingFinalAdjustments

1.Tightenthefastenersintheorderspeciedinthe

followingtable.Figure6,Figure7,andFigure8will

helpidentifytheparts.

Figure7

1.Flangelocknut(4)4.Flatwasher(4)

2.ROPSplates(4)5.Bolt(1/2x3–1/2inches)

(4)

3.Rollbar

InstallingtheRollbar

1.Lifttherollbarwiththecutoutsinendsofthetube

facingupandaligntheholeswiththerollbarsupports.

Note:Asecondpersontoperformthenextstepwill

behelpful.

2.Attachtherollbartotherollbarsupportsasshownin

Figure8.Leavetheboltsloose.

Sequence

1Fourboltsoneach

2Twoboltsoneach

3

4

DescriptionTorque

sideattachingthe

pivotbracketsto

therollbarand

rollbarsupport.

sideattachingthe

rollbarsupportto

theframeandthe

rollbarsupportto

thebrace.

Oneboltoneach

sideattaching

thebracestothe

machineframe.

Oneboltoneach

sideattachingthe

rollbartotheengine

guard.

400±40in-lbs

(45±.4N-m)

300±30in-lbs

(34±3N-m)

75±8ft-lbs

(102±11N-m)

60to80in-lbs.

(7to9N-m)

Note:Donotexceedtorquespecications.Doingso

maycausestructuraldamagetotheROPSortheframe

ofthemachine.

1.Bolt(1/2x3–1/2inches)

2.Flatwasher(4)

Figure8

(4)

3.Flangelocknut(4)

4.Rollbar

5

Page 6

5

CheckingtheMower

Adjustment

NoPartsRequired

Procedure

Adjusttheside-to-sidelevelandthefront-to-rearbladeslope.

UsetherelevantproceduresintheOperator'sManualtoverify

thatthedeckislevel,andmakeanyadjustmentsasnecessary.

RefertotheOperator'sManualformoreinformation.

6

CompletingtheSetup

Partsneededforthisprocedure:

1Ignitionkey

1

Operator'sManual

1

EngineOperator'sManual

Procedure

CheckingtheTirePressure

Checkthefrontandreartiresforproperination;referto

CheckingtheTirePressureintheOperator'sManualforthe

recommendedinationpressure.

CheckingtheSide-DischargeChute

Removethepackingrestraintholdingthesidedischargechute

upandlowerthechuteintoplace.

CheckingtheEngine-OilLevel

Beforeyoustarttheengineandusethemachine,checkthe

oillevelintheenginecrankcase;refertoCheckingtheOil

LevelintheOperator'sManual.

Keepallthefollowingitemswiththemachine:

•Ignitionkey

•Operator'sManual

•EngineOperator'sManual

6

Page 7

Notes:

7

Page 8

Loading...

Loading...