Page 1

FormNo.3372-551RevA

TITANZX4820Zero-Turn-Radius

RidingMower

ModelNo.74845—SerialNo.312000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

Thismachineisaride-on,rotary-bladelawnmower

1

G015032

intendedtobeusedbyhomeownersinresidential

applications.Itisprimarilydesignedforcuttinggrass

onwell-maintainedlawns.Itisnotdesignedforcutting

brush,mowinggrassandothergrowthalongside

highways,orforagriculturaluses.

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

WARNING

CALIFORNIA

Proposition65Warning

Thisengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Thisengineisnotequippedwitha

sparkarrestermufer.ItisaviolationofCalifornia

PublicResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-coverd,or

grasss-coveredland.Otherstatesorfederalareas

mayhavesimilarlaws.

ThissparkignitionsystemcomplieswithCanadian

ICES-002

WARNING

Removingstandardoriginalequipmentpartsand

accessoriesmayalterthewarranty,traction,and

safetyofthemachine.FailuretouseoriginalT oro

partscouldcauseseriousinjuryordeath.Making

unauthorizedchangestotheengine,fuelorventing

system,mayviolateEPAandCARBregulations.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndingadealer,

ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorToroCustomerServiceandhave

themodelandserialnumbersofyourproductready.

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

Figure1

1.Modelandserialnumberlocation

Replaceallpartsincluding,butnotlimitedto,tires,

belts,blades,andfuelsystemcomponentswith

originalT oroparts.

Theenclosed

Engine Owner's Man ual

issupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCalifornia

EmissionControlRegulationofemissionsystems,

maintenance,andwarranty.Replacementsmaybe

orderedthroughtheenginemanufacturer.

Formodelswithstatedenginehorsepower,thegross

horsepoweroftheenginewaslaboratorytestedbythe

enginemanufacturerinaccordancewithSAEJ1995and

ratedtoJ2723.

©2012—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

ModelNo.

SerialNo.

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

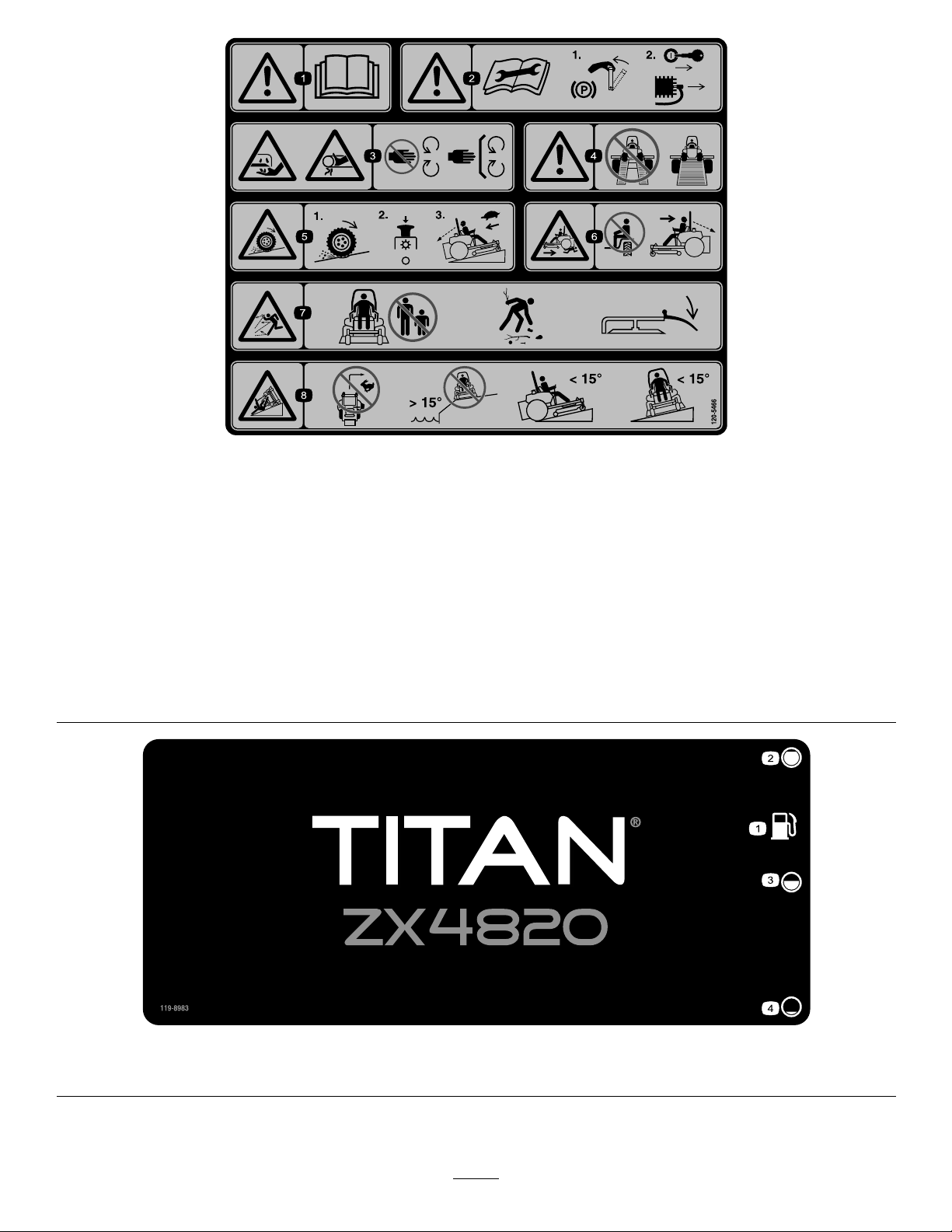

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjury

ordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

ToroRidingMowerSafety....................................6

SlopeIndicator.....................................................7

SafetyandInstructionalDecals.............................8

Setup.........................................................................13

1ConnectingtheBattery....................................13

2CheckingtheMowerAdjustment.....................13

3CompletingtheSetup......................................14

ProductOverview......................................................15

Controls.............................................................16

Operation...................................................................17

ThinkSafetyFirst...............................................17

UsingtheRolloverProtectionSystem

(ROPS)..........................................................18

AddingFuel.......................................................19

CheckingtheEngineOilLevel............................20

OperatingtheParkingBrake...............................20

OperatingtheThrottle.......................................21

OperatingtheChoke..........................................21

OperatingtheIgnitionSwitch.............................21

StartingandStoppingtheEngine........................22

OperatingtheMowerBladeControlSwitch

(PTO)............................................................23

TheSafetyInterlockSystem................................23

DrivingForwardorBackward.............................24

StoppingtheMachine.........................................25

AdjustingtheHeightofCut................................25

AdjustingtheAnti-ScalpRollers.........................26

PositioningtheSeat............................................27

AdjustingtheMotionControlLevers..................27

PushingtheMachinebyHand.............................28

UsingtheSideDischarge....................................28

OperatingTips...................................................28

Maintenance...............................................................30

RecommendedMaintenanceSchedule(s)................30

PremaintenanceProcedures....................................32

RaisingtheSeat..................................................32

Lubrication.............................................................32

GreasingtheBearings.........................................32

EngineMaintenance...............................................33

ServicingtheAirCleaner....................................33

ServicingtheEngineOil.....................................33

ServicingtheSparkPlug.....................................35

CleaningtheCoolingSystem...............................36

FuelSystemMaintenance.......................................37

ReplacingtheFuelFilter.....................................37

ElectricalSystemMaintenance................................38

ServicingtheBattery...........................................38

ServicingtheFuses.............................................39

DriveSystemMaintenance.....................................40

CheckingtheTirePressure.................................40

HydraulicSystemMaintenance...............................41

CheckingtheHydraulicOilLevel........................41

ChangingtheHydraulicSystemFilterand

Oil..................................................................41

MowerDeckMaintenance......................................43

ServicingtheCuttingBlades...............................43

MowerDeckLeveling.........................................45

InspectingtheBelts............................................47

ReplacingtheMowerBelt...................................47

RemovingtheMowerDeck................................48

InstallingtheMowerDeck..................................49

ReplacingtheGrassDeector.............................49

Cleaning.................................................................50

WashingtheUndersideoftheMower..................50

WasteDisposal...................................................51

Storage.......................................................................51

CleaningandStorage..........................................51

Troubleshooting.........................................................53

Schematics.................................................................55

3

Page 4

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructions

andalwayspayattentiontothesafetyalert

symbol,whichmeansCAUTION,WARNING,or

DANGER-"personalsafetyinstruction."Failureto

complywiththeinstructionmayresultinpersonal

injuryordeath.

•Neverleavearunningmachineunattended.Always

turnoffblades,setparkingbrake,stopengine,and

removekeybeforedismounting.

•Turnoffbladeswhennotmowing.Stoptheengine,

waitforallpartstocometoacompletestop

andremovethekeybeforecleaningthemachine,

removingthegrasscatcheroruncloggingthe

dischargechute.

•Operatethemachineonlyindaylightorgood

articiallight.

SafeOperatingPractices

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

ThefollowingsafetyinstructionsarebasedonANSI

standardB71.1-2003.Safetyinformationinaddition

totheinstructionsfoundintheANSIstandardbelow

canbefoundinToroRidingMowerSafetyattheend

ofthissection.

GeneralOperation

•Read,understand,andfollowallinstructionsin

theoperator'smanualandonthemachinebefore

starting.

•Donotplacehandsorfeetnearrotatingpartsor

underthemachine.Keepclearofthedischarge

openingatalltimes.

•Allowonlyresponsibleadultswhoarefamiliarwith

theinstructionstooperatethemachine.

•Donotoperatethemachinewhileunderthe

inuenceofalcoholordrugs.

•Watchfortrafcwhenoperatingnearorcrossing

roadways.

•Useextracarewhenloadingorunloadingthe

machineintoatrailerortruck.

•Alwaysweareyeprotectionwhenoperatingthe

mower.

•Dataindicatesthatoperators,age60yearsand

above,areinvolvedinalargepercentageofriding

mower-relatedinjuries.Operatorsshouldevaluate

theirabilitytooperatetheridingmowersafely

enoughtoprotectthemselvesandothersfrom

seriousinjury.

•Alwaysfollowtherecommendationsforany

applicationofcounterweights.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

•Cleartheareaofobjectssuchasrocks,toys,wire,etc.,

whichcouldbepickedupandthrownbytheblade.

•Besuretheareaisclearofotherpeoplebefore

mowing.Stopthemachineifanyoneentersthearea.

•Nevercarrypassengers.

•Donotmowinreverseunlessabsolutelynecessary.

Alwayslookdownandbehindbeforeandwhile

backingup.

•Beawareofthemowerdischargedirectionanddo

notpointitatanyone.Avoiddischargingmaterial

againstawallorobstruction.Materialmayricochet

backtowardtheoperator.Stoptheblade(s)when

crossinggravelsurfaces.

•Donotoperatethemachinewithoutdeector,

dischargecoverorentiregrasscollectionsystemin

placeandworking.

•Bealert,slowdownandusecautionwhenmaking

turns.Lookbehindandtothesidebeforechanging

directions.

SlopeOperation

Slopesareamajorfactorrelatedtolossofcontroland

tip-overaccidents,whichcanresultinsevereinjuryor

death.Operationonallslopesrequiresextracaution.If

youcannotbackuptheslopeorifyoufeeluneasyonit,

donotmowit.

•Donotmowslopesgreaterthan15degrees.

•Watchforditches,holes,rocks,dips,andrisesthat

changetheoperatingangle,asroughterraincould

overturnthemachine.

•Choosealowgroundspeedsoyouwillnothaveto

stopwhileoperatingonaslope.

•Donotmowslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcausesliding

andlossofcontrol.

•Alwayskeepthedrivewheelsengagedwhengoing

downslopes.

•Reducespeedanduseextremecautiononslopes.

4

Page 5

•Donotmakesuddenturnsorrapidspeedchanges.

•Removeormarkobstaclessuchasrocks,treelimbs,

etc.fromthemowingarea.Tallgrasscanhide

obstacles.

•Avoidsuddenstartswhenmowinguphillbecausethe

mowermaytipbackwards.

•Beawarethatlossoftractionmayoccurgoing

downhill.Weighttransfertothefrontwheelsmay

causedrivewheelstoslipandcauselossofbraking

andsteering.

•Alwaysavoidsuddenstartingorstoppingonaslope.

Iftireslosetraction,stopthemachine,disengagethe

bladesandproceedslowlyofftheslope.

•Useextremecarewithgrasscatchersorother

attachments.Thesecanchangethestabilityofthe

machineandcauselossofcontrol.

•Donottrytostabilizethemachinebyputtingyour

footontheground.

•Keepchildrenoutofthemowingareaandunderthe

watchfulcareofanotherresponsibleadult,notthe

operator.

•Bealertandturnthemachineoffifchildrenenter

thearea.

•Beforeandwhilebackingorchangingdirection,look

behind,down,andside-to-sideforsmallchildren.

•Nevercarrychildren,evenwiththebladesoff.They

mayfalloffandbeseriouslyinjuredorinterferewith

safemachineoperation.

•Childrenwhohavebeengivenridesinthepastmay

suddenlyappearinthemowingareaforanotherride

andberunoverorbackedoverbythemower.

•Neverallowchildrentooperatethemachine.

•Useextracarewhenapproachingblindcorners,

shrubs,trees,theendofafenceorotherobjectsthat

mayobscurevision.

•Donotmowneardrop-offs,ditches,steepbanks

orwater.Wheelsdroppingoveredgescancause

rollovers,whichmayresultinseriousinjury,death

ordrowning.

•Useawalkbehindmowerand/orahandtrimmer

neardrop-offs,ditches,steepbanksorwater.

UsingtheRolloverProtectionSystem

(ROPS)

•Keeptherollbarinthefullyraisedandlocked

positionandusetheseatbeltwhenoperatingthe

machine.

•Becertainthattheseatbeltcanbereleasedquickly

intheeventofanemergency.

•Beawarethereisnorolloverprotectionwhenthe

rollbarisdown.

•Checktheareatobemowedandneverfoldthe

ROPSinareaswherethereareslopes,dropoffsor

water.

•Lowertherollbaronlywhenabsolutelynecessary.

Donotweartheseatbeltwiththerollbarfolded

down.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)beforedriving

underanyobjectsanddonotcontactthem.

Children

Tragicaccidentscanoccuriftheoperatorisnotalertto

thepresenceofchildren.Childrenareoftenattractedto

themachineandthemowingactivity.Neverassumethat

childrenwillremainwhereyoulastsawthem.

Towing

Ahitchkitisavailableforthismachineandcanbe

obtainedbycontactinganAuthorizedToroDealer.

Donottowwithoutrstinstallingthismanufacturer

approvedhitch.Thefollowingguidelinesapplywhen

towingwiththeapprovedhitchkitinstalled.

•Towonlywithamachinethathasahitchdesigned

fortowing.Donotattachtowedequipmentexcept

atthehitchpoint.

•Followthemanufacturer'srecommendationfor

weightlimitsfortowedequipmentandtowingon

slopes.

•Neverallowchildrenorothersinorontowed

equipment.

•Onslopes,theweightofthetowedequipmentmay

causelossoftractionandlossofcontrol.

•Travelslowlyandallowextradistancetostop.

Service

SafeHandlingofGasoline:

Toavoidpersonalinjuryorpropertydamage,useextra

carewhenhandlinggasolineandotherfuels.Theyare

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipesandother

sourcesofignition.

•Useonlyanapprovedcontainer.

•Neverremovethegascaporaddfuelwhenthe

engineisrunning.Allowtheenginetocoolbefore

refueling.

5

Page 6

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

•Neverllcontainersinsideavehicleoronatruckor

trailerwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removegas-poweredequipmentfromthetruck

ortrailerandrefuelitontheground.Ifthisisnot

possible,thenrefuelsuchequipmentwithaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Keepthenozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimesuntilthefueling

iscomplete.Donotuseanozzlelock-opendevice.

•Iffuelisspilledonclothing,changeclothing

immediately.

•Neveroverllthefueltank.Replacegascapand

tightensecurely .

GeneralService:

•Maintainorreplacesafetyandinstructiondecalsas

necessary.

•UseonlygenuineTororeplacementpartstoensure

thatoriginalstandardsaremaintained.

ToroRidingMowerSafety

Thefollowinglistcontainssafetyinformationspecicto

Toroproductsorothersafetyinformationthatyoumust

knowthatmaynotbeincludedintheANSIstandards.

•Stoptheengine,movethemotioncontrolleversto

neutralandoutwardtotheparkposition,disengage

thebladecontrolswitch,removekeybeforeand

disconnectsparkplugwire(s)performinganyservice,

repairs,maintenanceoradjustments.

•Keephands,feet,hair,andlooseclothingawayfrom

attachmentdischargearea,undersideofmowerand

anymovingpartswhileengineisrunning.

•Donottouchequipmentorattachmentpartswhich

maybehotfromoperation.Allowtocoolbefore

attemptingtomaintain,adjustorservice.

•Neveroperateamachineinsideaclosedarea.Engine

exhaustcontainscarbonmonoxide,whichisan

odorless,deadlypoisonthatcankillyou.

•Keepnutsandboltstight,especiallytheblade

attachmentbolts.Keepequipmentingood

condition.

•Nevertamperwithsafetydevices.Checktheir

properoperationregularly.

•Keepthemachinefreeofgrass,leaves,orother

debrisbuild-up.Cleanupoilorfuelspillagefuel

soakeddebris.Allowthemachinetocoolbefore

storing.

•Stopandinspecttheequipmentifyoustrikean

object.Repair,ifnecessary,beforerestarting.

•Nevermakeanyadjustmentsorrepairswiththe

enginerunning.

•Grasscatchercomponentsaresubjecttowear,

damageanddeterioration,whichcouldexpose

movingpartsorallowobjectstobethrown.

Frequentlycheckcomponentsandreplacewith

manufacturers'recommendedparts,whennecessary.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyes,andclothing.Protectyour

face,eyes,andclothingwhenworkingwithabattery.

•Batterygasescanexplode.Keepcigarettes,sparks

andamesawayfrombattery.

•UseonlyToroapprovedattachments.W arrantymay

bevoidedifusedwithunapprovedattachments.

•Ifloadingthemachineontoatrailerortruck,usea

single,full-widthramponly.Therampangleshould

notexceed15degrees.

•Mowerbladesaresharpandcancut.Wrapthe

blade(s)orweargloves,anduseextracautionwhen

servicingthem.

•Checkforproperbrakeoperationfrequently.Adjust

andserviceasrequired.

6

Page 7

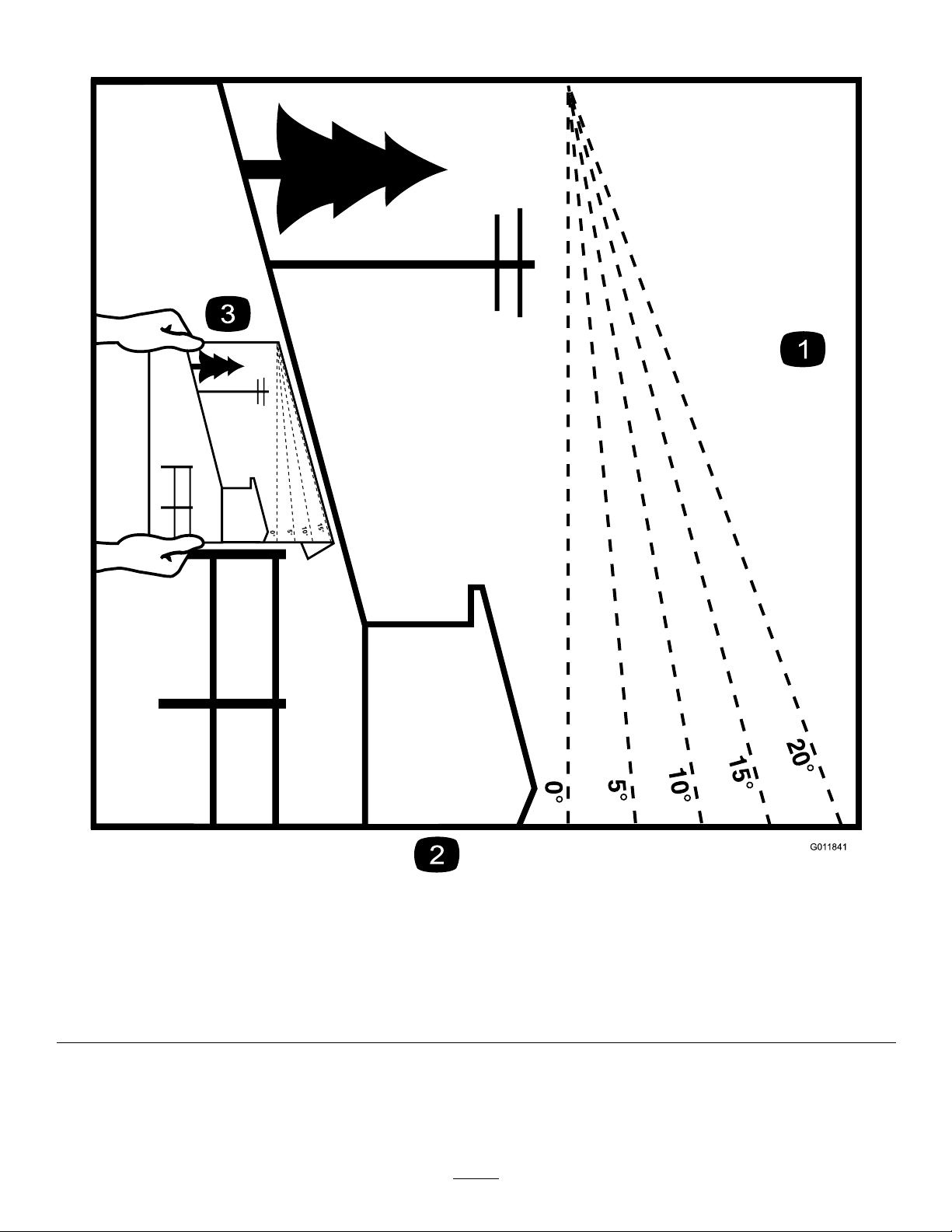

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

7

Page 8

SafetyandInstructional

Decals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

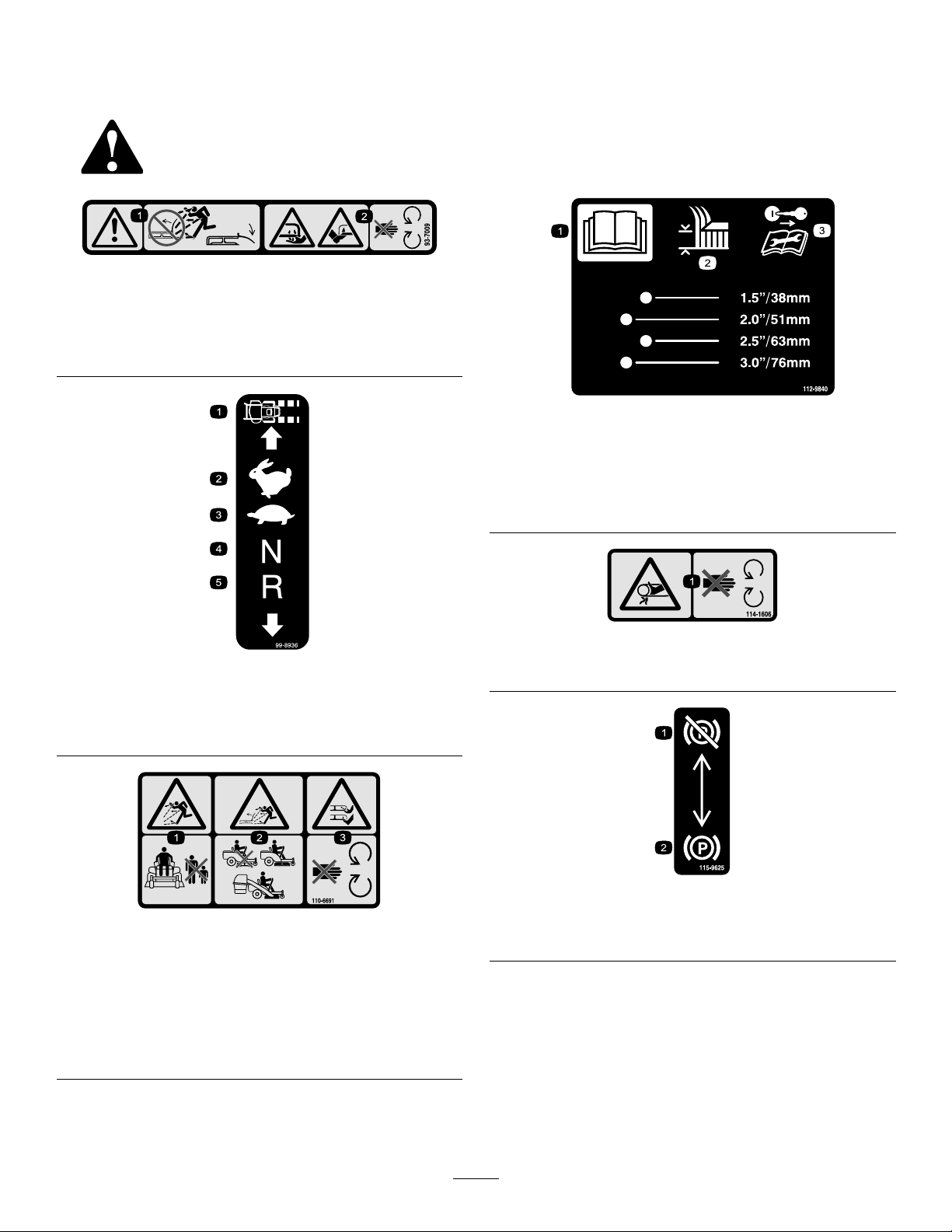

93-7009

1.Warning—don'toperatethemowerwiththedeectorupor

removed;keepthedeectorinplace.

2.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

112-9840

99-8936

1.Machinespeed4.Neutral

2.Fast5.Reverse

3.Slow

1.ReadtheOperator's

Manual.

2.Heightofcut

3.Removetheignitionkey

andreadtheinstructions

beforeservicingor

performingmaintenance.

114-1606

1.Entanglementhazard,belt—keepallguardsinplace.

110-6691

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Thrownobjecthazard,mower—donotoperatewithoutthe

deector,dischargecover,orgrasscollectionsystemin

place.

3.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

115-9625

1.Parking

brake—disengaged

2.Parkingbrake—engaged

8

Page 9

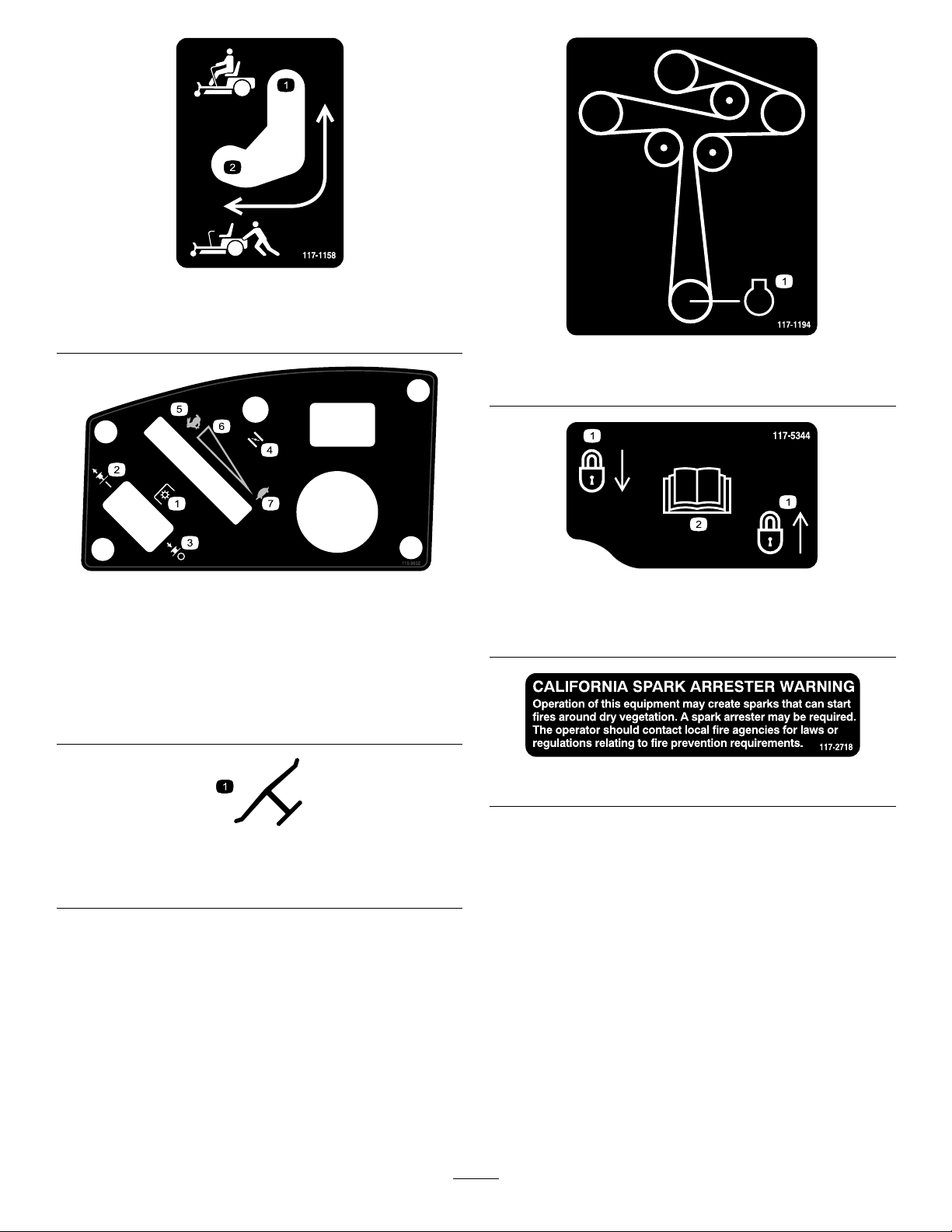

117-1158

1.Bypassleverpositionfor

operatingthemachine

2.Bypassleverpositionfor

pushingthemachine

115-9632

1.Powertake-off(PTO),

Bladecontrolswitchon

somemodels

2.Bladecontrolswitch—On6.Continuousvariable

3.Bladecontrolswitch—Off7.Slow

4.Choke

5.Fast

setting

117-1194

1.Engine

117-5344

1.Lock

2.ReadtheOperator'sManual

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

117–2718

9

Page 10

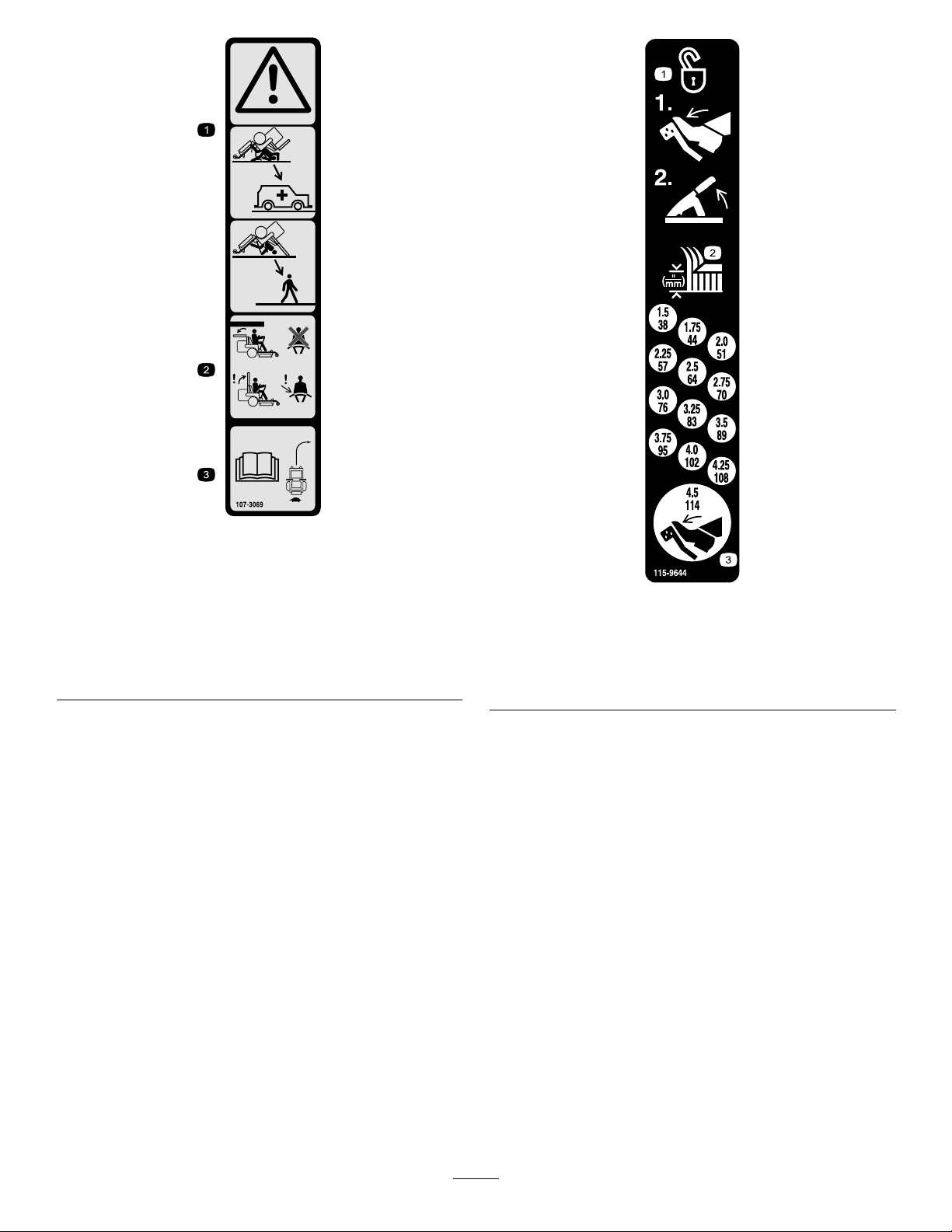

107-3069

1.Warning–thereisnorolloverprotectionwhentherollbaris

down.

2.Toavoidinjuryordeathfromarolloveraccident,keepthe

rollbarinthefullyraisedandlockedpositionandwear

theseatbelt.Lowertherollbaronlywhenabsolutely

necessary;donotwearthetheseatbeltwhentherollbaris

down.

3.ReadtheOperator'sManual;driveslowlyandcarefully.

115-9644

1.Pressthepedalandlifttheheightofcutlevertounlockthe

deckposition.

2.Heightofcut

3.Pressthepedaltomovethedecktothetransportposition

10

Page 11

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

115-9630

1.ReadtheOperator'sManualbeforeperformingany

maintenance.

2.Checktheengineoilevery8hours5.Checkthecasterwheeltirepressureevery25hours

3.Checkthedrivewheeltirepressureevery25hours

4.Checkthehydraulicoilevery25hours

6.Lubricatethecasterwheelevery25hours

11

Page 12

120-5466

1.Warning—readtheOperator'sManual.5.Lossoftraction/controlhazard,slopes—lossoftraction/control

2.Warning—readtheinstructionsbeforeservicingorperforming

maintenance;movethemotioncontrolleverstothepark

(brake)position,removetheignitionkeyanddisconnectthe

sparkplugwire.

3.Cutting/dismembermenthazard,mowerblade;entanglement

hazard,belt—stayawayfrommovingparts,keepallguards

andshieldsinplace.

4.Warning—donotusesplitramps,useafullrampswhen

transportingmachine.

onaslope,disengagethebladecontrolswitch(PTO),

proceedofftheslopeslowly.

6.Crushing/dismembermenthazardofbystanders,

reversing—donotcarrypassengers,lookbehindanddown

whenreversing.

7.Thrownobjecthazard—keepbystandersasafedistancefrom

themachine,pickupdebrisbeforeoperating,keepdeector

inplace.

8.Tippinghazard—donotturnathighspeeds,donotoperate

neardrop-offsonslopesgreaterthan15degrees,donotmow

slopesgreaterthan15degrees,avoidsuddenandsharp

turnswhileonslopes.

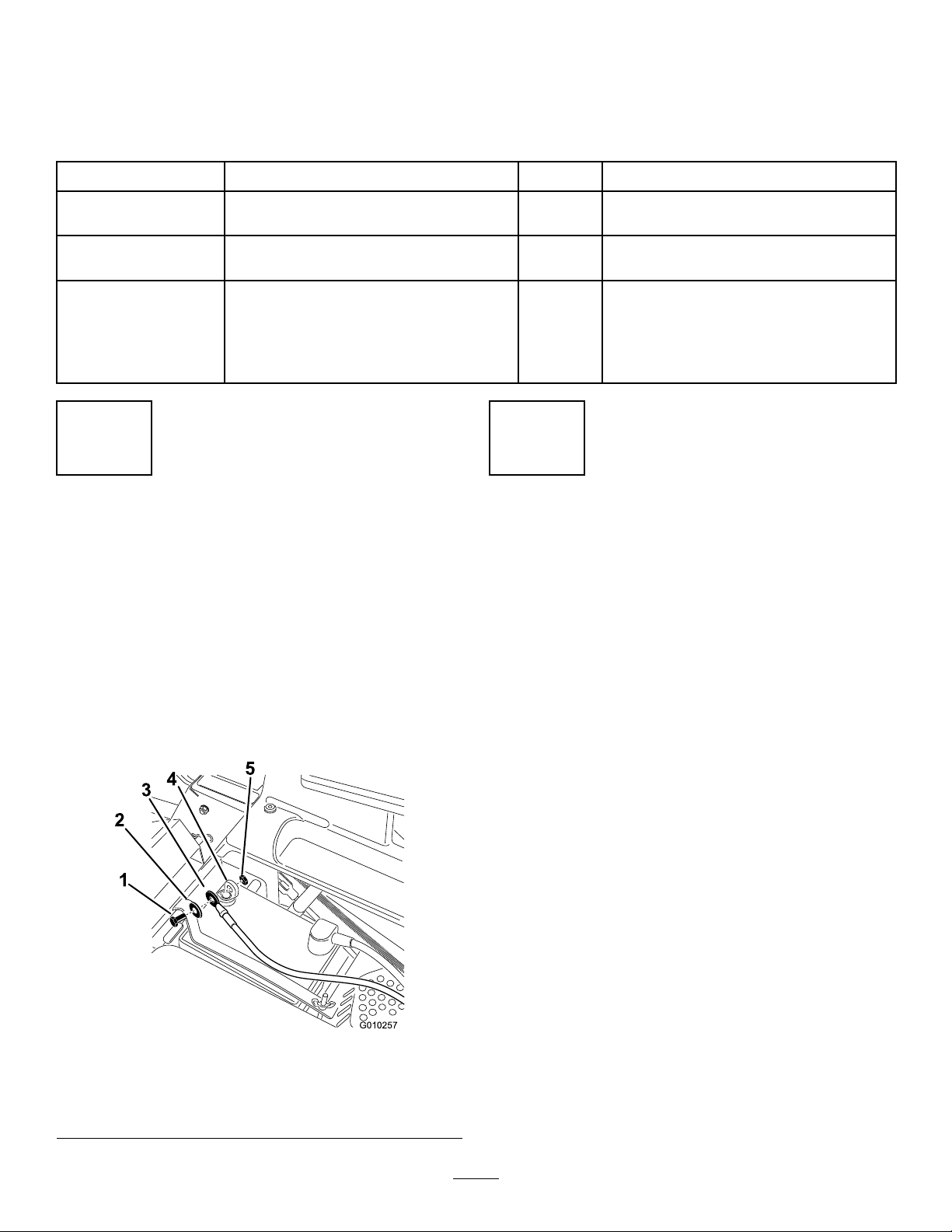

1.Fuel2.Full

119-8983

3.Half

4.Empty

12

Page 13

Setup

G010257

1

2

3

5

4

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

Nopartsrequired

Nopartsrequired

IgnitionKey1

Hosecoupling1

Operator'sManual

EngineOperator'sManual

OperatorTrainingMaterial

1

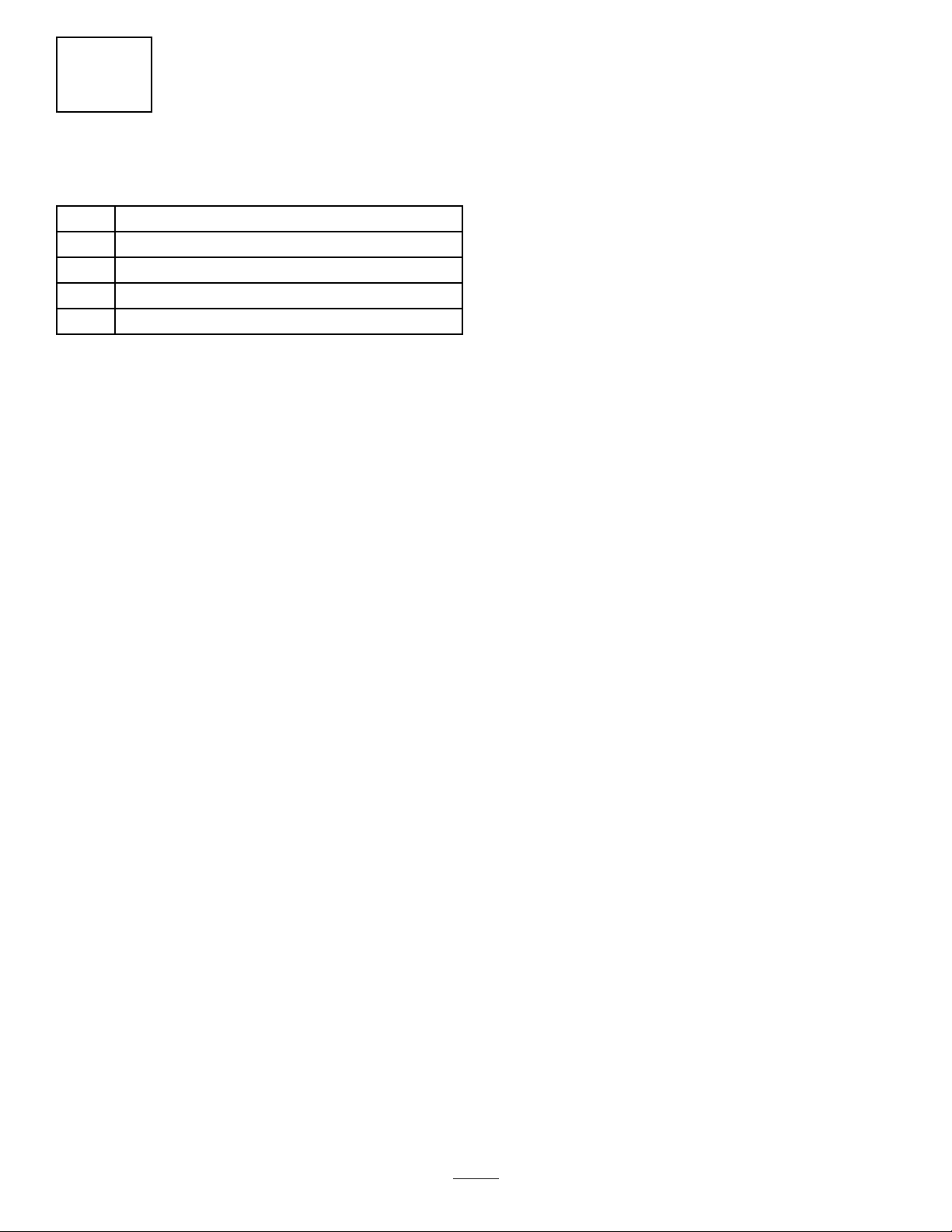

ConnectingtheBattery

NoPartsRequired

Procedure

1.Locatethebatteryandnegativebatterycableinthe

centerofthemachine.

2.Removetheblackplasticcapfromthenegative

batterypost.Removethefastenersfromthenegative

batterycableandusethemtosecurethenegative

batterycabletothenegativebatterypost(

Figure4).

Qty.

–

–

1

1

1

Connectthebattery .

Checkthemoweradjustment.

CompletetheSetup.

Use

2

CheckingtheMower

Adjustment

NoPartsRequired

Procedure

Adjusttheside-to-sidelevelandthefront-to-rearblade

slope.UsetherelevantproceduresintheOperator's

Manualtoverifythedeckislevelandmakeany

adjustmentsasnecessary.RefertotheOperator'sManual

formoreinformation.

1.Bolt4.Negativebatterypost

2.Washer5.Nut

3.Negativebatterycable

Figure4

13

Page 14

ReviewtheRemainingParts

Keepallthefollowingitemswiththemachine:

3

•IgnitionKey

CompletingtheSetup

Partsneededforthisprocedure:

1IgnitionKey

1Hosecoupling

1

Operator'sManual

1

EngineOperator'sManual

1

OperatorTrainingMaterial

Procedure

SettingUptheMotionControlLevers

Ifneeded,removetheupperbolt,washerandnutand

raisethemotioncontrolleverstotheuprightposition.

Securethemotioncontrollevers.RefertoAdjustingthe

MotionControlLeversintheOperationSection.

RaisingtheROPS

RaisetheROPSintotheuprightpositionandsecureit

inplace.RefertoUsingtheRolloverProtectionSystem

(ROPS)intheOperationSection.

•Hosecoupling

•Operator'sManual

•EngineOperator'sManual

•ViewtheOperatortrainingmaterial.

CheckingtheTirePressure

Checkthefrontandreartiresforproperination.Refer

toCheckingtheTirePressureintheOperator'sManual

fortherecommendedinationpressure.

CheckingtheSideDischargeChute

Removethepackingrestraintholdingthesidedischarge

chuteupandlowerthechuteintoplace.

CheckingtheEngineOilLevel

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoChecking

theOilLevelintheOperator'sManual.

CheckingtheHydraulicOilLevel

Beforeyoustarttheengineandusethemachine,check

thehydraulicoillevelinthereservoirbehindtheseat;

refertoCheckingtheOilLevelintheOperator'sManual.

CheckingtheMowerAdjustment

Themowerdeckwasleveledatthefactory.Ifthemower

isnotcuttinglevel,adjusttheside-to-sidelevelandthe

front-to-rearbladeslope.SeetheOperator'sManual

fortheproperprocedure.

14

Page 15

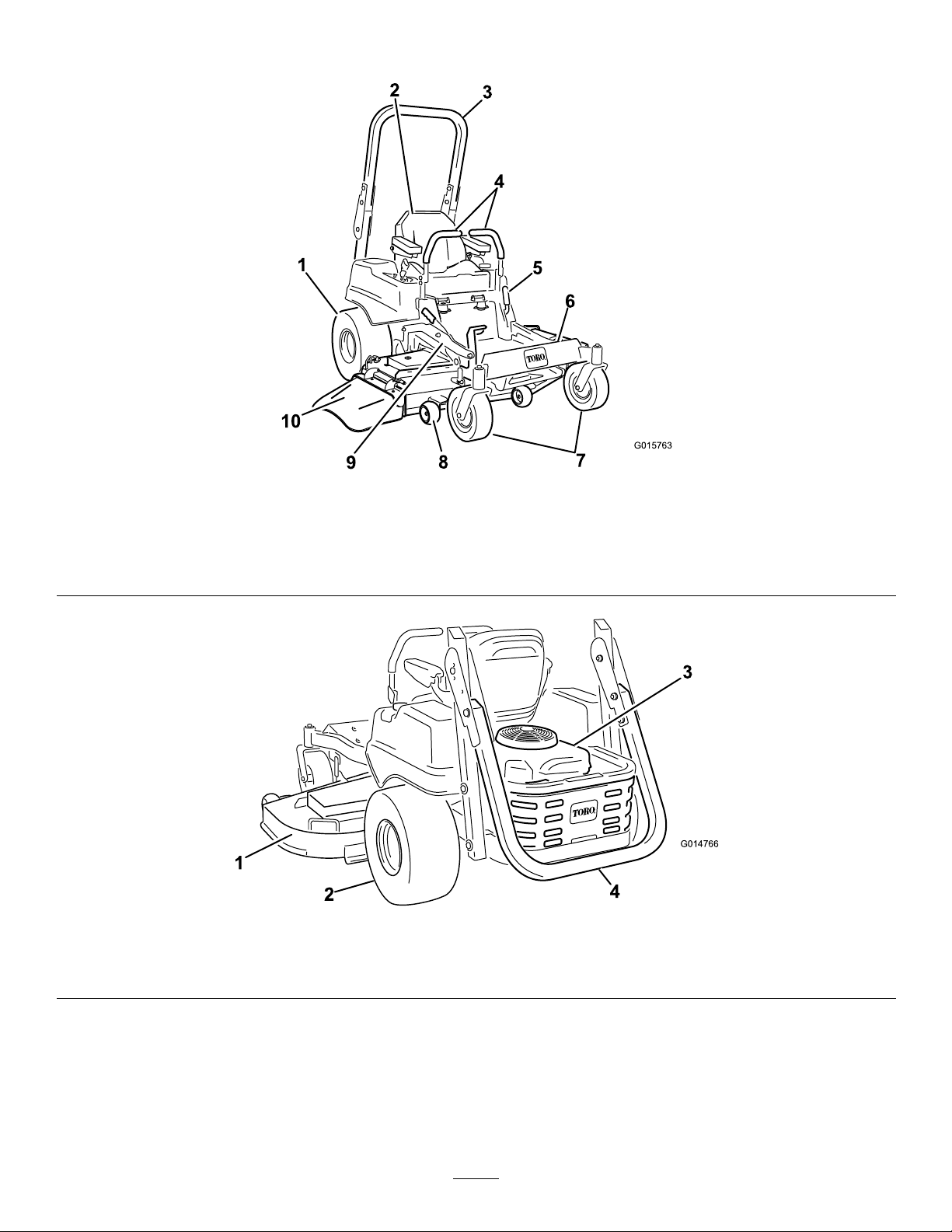

ProductOverview

G015763

1

2

3

4

5

6

7

8

9

10

G014766

1

2

3

4

Figure5

1.Drivewheel4.Motioncontrollevers7.Frontcasterwheel

2.Operatorseat

3.Rolloverprotectionsystem

(ROPS)

1.MowerDeck3.Engine

2.Drivewheel

5.Parkingbrake8.Anti-scalproller

6.Footrest

9.Footpedaldeckliftand

height-of-cut

Figure6

4.Rolloverprotectionsystem(ROPS),foldeddown

10.Deector

15

Page 16

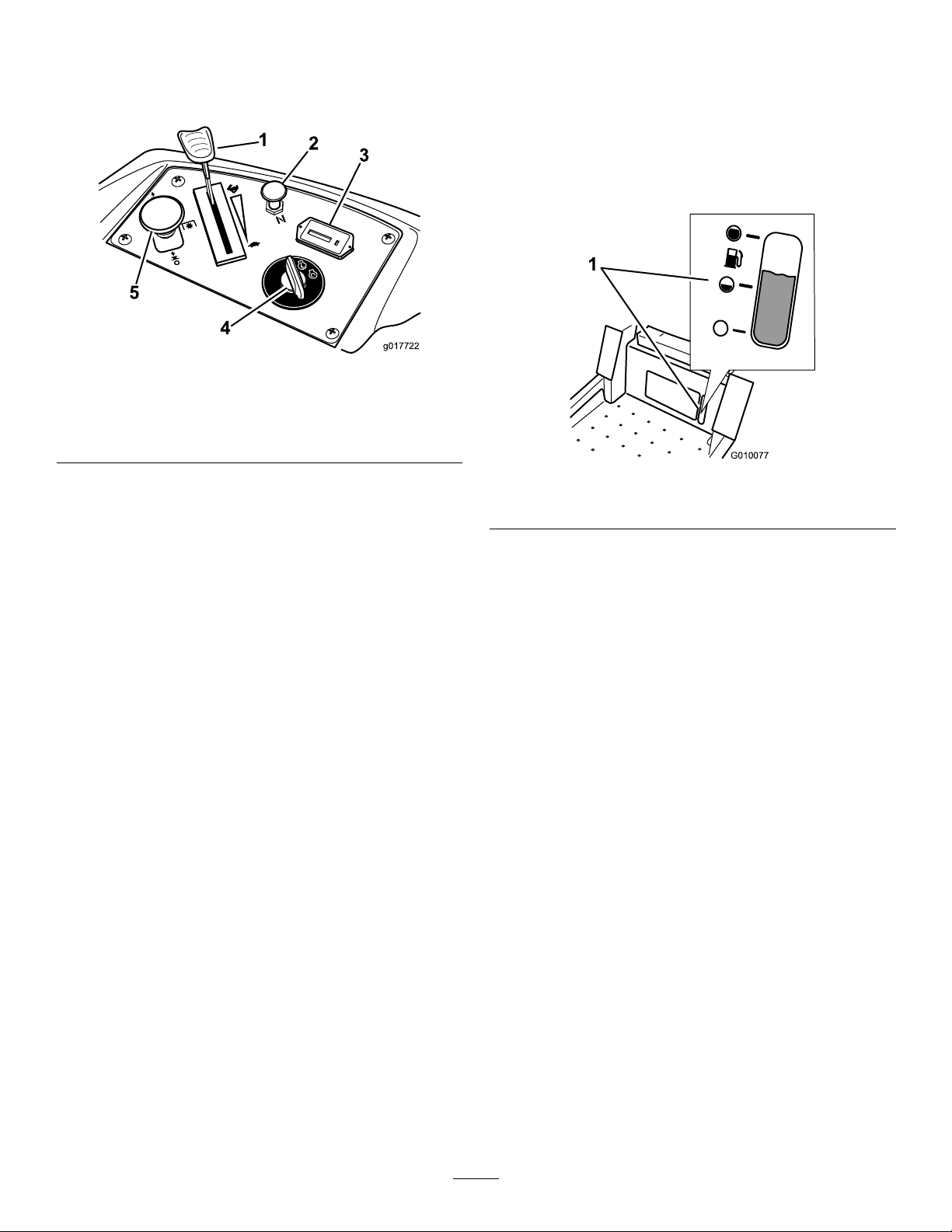

Controls

g017722

1

2

3

4

5

G010077

1

Becomefamiliarwithallthecontrolsbeforeyoustart

theengineandoperatethemachine(Figure7).

Figure7

1.Throttlecontrol4.Ignitionswitch

2.Choke5.Bladecontrolswitch(PTO)

3.Hourmeter

switch(PTO)isengaged.Usethesetimesforscheduling

regularmaintenance(

Figure7).

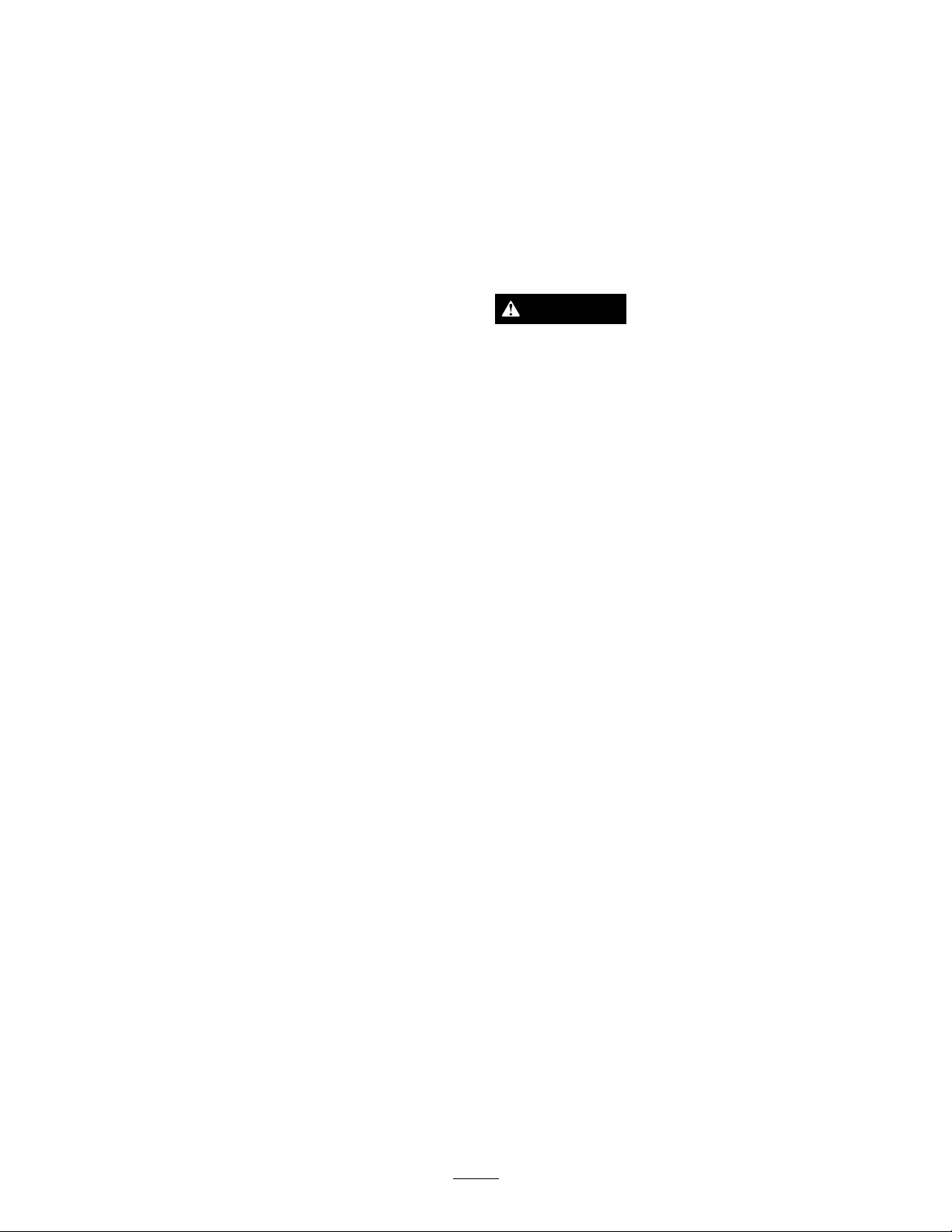

FuelGauge

Thefuelwindowlocatedbelowtheoperatorposition

canbeusedtoverifythelevelofgasolineinthetank

(Figure8).

Figure8

IgnitionSwitch

Theignitionswitchhasthreepositions:Start,Run

andOff.ThekeywillturntoStartandmovebackto

Runuponrelease.TurningthekeytotheOffposition

willstoptheengine;however,alwaysremovethekey

whenleavingthemachinetopreventtheenginefrom

accidentallystarting(

Figure7).

ThrottleControl

ThethrottlecontrolisvariablebetweenFastandSlow.

Movingthrottleleverforwardwillincreaseenginespeed

andmovingthrottlelevertotherearwilldecreaseengine

speed.Movingthethrottleforwardintothedetentis

fullthrottle(

Figure7).

Choke

Usethechoketostartacoldengine.Pullthechoke

knobuptoengageit.Pushdownonthechokeknob

todisengageit.

1.Fuelgaugewindow

MotionControlLevers

Themotioncontrolleversarespeedsensitivecontrols

ofindependentwheelmotors.Movingaleverforward

orbackwardturnsthewheelonthesamesideforward

orinreverse;wheelspeedisproportionaltotheamount

theleverismoved.Movethecontrolleversoutward

fromthecentertotheneutrallockpositionandexitthe

machine(

Figure5).Alwayspositionthemotioncontrol

leversintotheneutrallockpositionwhenyoustopthe

machineorleaveitunattended.

ParkingBrakeLever

Locatedonleftsideoftheconsole(Figure5).Thebrake

leverengagesaparkingbrakeonthedrivewheels.Pull

theleverupandrearwardtoengagethebrake.Pushthe

leverforwardanddowntodisengagethebrake.

BladeControlSwitch(PowerTake-Off)

Thebladecontrolswitch,representedbyapower

take-off(PTO)symbol,engagesanddisengagespower

tothemowerblades(Figure7).

HourMeter

Thehourmeterrecordsthenumberofhourstheblades

haveoperated.Itoperateswhenthebladecontrol

FootPedalDeckLiftSystem

Thefootpedaldeckliftsystemallowstheoperator

tolowerandraisethedeckfromtheseatedposition.

Theoperatorcanusethefootpedaltoliftthedeck

brieytoavoidobstaclesorlockthedeckinthehighest

height-of-cutortransportposition(Figure5).

16

Page 17

Height-of-CutLever

Theheight-of-cutleverworkswiththefootpedalto

lockthedeckinaspeciccuttingheight.Onlyadjustthe

heightofcutwhilemachineisnotmoving(Figure5).

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

ThinkSafetyFirst

Pleasecarefullyreadallofthesafetyinstructionsand

decalsinthesafetysection.Knowingthisinformation

couldhelpyou,yourfamily,petsorbystandersavoid

injury.

DANGER

Mowingonwetgrassorsteepslopescancause

slidingandlossofcontrol.

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,deathor

drowning.

Alossoftractionisalossofsteeringcontrol.

Toavoidlossofcontrolandpossibilityofrollover:

•Donotmowneardrop-offsornearwater.

•Donotmowslopesgreaterthan15degrees.

•Reducespeedanduseextremecautionon

slopes.

•Whenmowingslopes,graduallyworkfrom

lowertohigherareasontheincline.

•Avoidsuddenturnsorrapidspeedchanges.

•Turnup,intoaninclinewhenchanging

directionsonslopes.Turningdowntheslope

reducestraction.

•Attachmentschangethehandling

characteristicsofthemachine.Use

extracautionwhenusingattachmentswiththe

machine.

17

Page 18

G015033

1

2

3

Figure9

G015034

G015035

1

2

3

2

1.SafeZone-usethemachinehere

2.Usewalkbehindmowerand/orhandtrimmerneardrop-offs

andwater.

3.Water

UsingtheRolloverProtection

System(ROPS)

WARNING

Toavoidinjuryordeathfromrollover:keepthe

rollbarinthefullyraisedlockedpositionanduse

theseatbelt.

WARNING

Thereisnorolloverprotectionwhentherollbar

isinthedownposition.

•Lowertherollbaronlywhenabsolutely

necessary.

Figure10

Important:Alwaysusetheseatbeltwiththe

rollbarinthefullyraisedposition.

3.Installthelockingpins.Securethepinsbyinstalling

thehaircotterpin(Figure11).

Figure11

1.HoleinROPS

2.Lockingpin

3.Hairpincotter

•Donotweartheseatbeltwhentherollbaris

inthedownposition.

•Driveslowlyandcarefully.

•Raisetherollbarassoonasclearancepermits.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)before

drivingunderanyobjectsanddonotcontact

them.

Important:Lowertherollbaronlywhen

absolutelynecessary.

1.Toraisetherollbar,removethehaircotterpinand

removethelockingpins.

2.Raisetherollbartotheuprightposition(Figure10).

4.Twolowertherollbar,removethehaircotterpin

andremovethelockingpin.(Figure11).

5.Lowertherollbartothedownposition.

6.Usethetwolockingandcotterpinstosecurethe

bar.

18

Page 19

AddingFuel

DANGER

•Forbestresults,useonlyclean,fresh,unleaded

gasolinewithanoctaneratingof87orhigher

((R+M)/2ratingmethod).

•Oxygenatedfuelwithupto10%ethanolor15%

MTBEbyvolumeisacceptable.

•DoNotuseethanolblendsofgasoline(suchasE15

orE85)withmorethan10%ethanolbyvolume.

Performanceproblemsand/orenginedamagemay

resultwhichmaynotbecoveredunderwarranty.

•DoNotusegasolinecontainingmethanol.

•DoNotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessafuelstabilizeris

used.

•DoNotaddoiltogasoline.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmayinsulate

thecontainerandslowthelossofanystatic

charge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerandrefuel

theequipmentwithitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis1/4to

1/2inch(6to13mm)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystem

inplaceandinproperworkingcondition.

WARNING

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporscancauseserious

injuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening .

•Keepgasawayfromeyesandskin.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysor

less.Forlongerstorageitisrecommendedthatthe

fueltankbedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditioner

tothegas.

19

Page 20

Note:Afuelstabilizer/conditionerismosteffective

G010077

1

G010475

1

2

4

3

G010078

1

2

whenmixedwithfreshgasoline.Tominimizethe

chanceofvarnishdepositsinthefuelsystem,usefuel

stabilizeratalltimes.

FuelGauge

Usethefuelwindowbelowtheoperatortoverifythe

levelofgasolinebeforellingthetank(Figure12).

Figure12

Figure13

1.Fuelgaugewindow

FillingtheFuelT ank

Makesuretheengineisshutoffandthemotion

controlsareintheparkposition.

Important:DoNotoverllfueltank.Fillthe

fueltanktothebottomofthellerneck.The

emptyspaceinthetankallowsthefueltoexpand.

Overllingmayresultinfuelleakageordamageto

theengineoremissionsystem.

1.Cleanaroundthefueltankcapandremovethecap.

Note:Youcanusethefuelwindowbelowthe

operatingpositionverifythepresenceofgasoline

beforellingthetank(

2.Slowlyaddregular,unleadedgasolineuntilthefuel

reachesthebaseofthellerneck

Figure12).

Figure13.

3.Installthefueltankcapsecurelyandtightenuntilit

“clicks”.Wipeupanygasolinethatmayhavespilled.

CheckingtheEngineOilLevel

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoChecking

theEngineOilLevel.

OperatingtheParkingBrake

Alwayssettheparkingbrakewhenyoustopthe

machineorleaveitunattended.

SettingtheParkingBrake

Figure14

20

Page 21

ReleasingtheParkingBrake

G010079

1

2

G008946

G008959

1

2

START

RUN

STOP

G008947

Figure15

OperatingtheThrottle

ThethrottlecontrolcanbemovedbetweenFastand

Slowpositions(Figure16).

Alwaysusethefastpositionwhenturningonthe

mowerdeckwiththebladecontrolswitch(PTO).

Figure16

OperatingtheChoke

Usethechoketostartacoldengine.

1.Iftheengineiscold,usethechoketostartthe

engine.

2.Pulluponthechokeknobtoengagethechoke

beforeusingtheignitionswitch(

Figure17).

Figure17

1.On2.Off

OperatingtheIgnitionSwitch

1.TurntheignitionkeytotheStartposition

(Figure18).Whentheenginesstarts,releasethekey.

Important:Donotengagestarterformore

than5secondsatatime.Iftheenginefails

tostartallowa15secondcool-downperiod

betweenattempts.Failuretofollowthese

instructionscanburnoutthestartermotor.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthe

fuelsystemhasbeenwithoutfuelcompletely.

3.Pushdownonthechoketodisengagethechoke

aftertheenginehasstarted(

Figure17).

Figure18

2.Turntheignitionkeytostoptostoptheengine.

21

Page 22

StartingandStoppingthe

g017965

2

3

4

5

1

6

START

RUN

STOP

G008947

Engine

ontheChokecontrolandlettheenginerunfora

fewseconds.ThenpushdowntheChokecontrol.

Repeatasrequired.

StartingtheEngine

1.Sitdownontheseat(Figure19)andfastentheseat

belt.

2.Movethemotioncontrolsoutwardtotheneutral

lockposition(Figure19).

3.Settheparkingbrake(

theParkingBrake.

4.Movethebladecontrolswitch(PTO)totheOff

position(Figure19).

5.PullupontheChokecontrolbeforestartingacold

engine.

Note:Awarmorhotenginemaynotrequire

choking.

Figure19);refertoSetting

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthe

fuelsystemhasbeenwithoutfuelcompletely.

Figure20

1.Off3.Start

2.Run

StoppingtheEngine

CAUTION

Figure19

6.TurntheignitionkeytotheStartposition

(Figure18).Whentheenginesstarts,releasethekey.

Important:Donotengagestarterformore

than5secondsatatime.Iftheenginefails

tostartallowa15secondcool-downperiod

betweenattempts.Failuretofollowthese

instructionscanburnoutthestartermotor.

7.Aftertheenginestarts,pushdownontheChoke

control.Iftheenginestallsorhesitates,pullup

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethetractorwhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

22

Page 23

S

T

A

R

T

R

U

N

S

T

O

P

2

3

4

5

1

00:60 Sec

g017981

G008945

DisengagingtheBladeControlSwitch

G009174

(PTO)

Figure23

TheSafetyInterlockSystem

WARNING

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

Figure21

OperatingtheMowerBlade

ControlSwitch(PTO)

Thebladecontrolswitch(PTO)startsandstopsthe

mowerbladesandanypoweredattachments.

EngagingtheBladeControlSwitch

(PTO)

Engagethebladecontrolswitch(PTO)withthethrottle

positionatFast.

Note:Engagingthebladecontrolswitch(PTO)with

thethrottlepositionathalforlesswillcauseexcessive

weartothedrivebelts.

Figure22

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

UnderstandingtheSafetyInterlock

System

Thesafetyinterlocksystemisdesignedtopreventthe

enginefromstartingunless:

•Theparkingbrakeisengaged.

•Thebladesaredisengaged.

•Themotioncontrolleversareintheneutrallock

position.

Thesafetyinterlocksystemalsoisdesignedtostopthe

enginewhenthecontrolleversareoutoftheneutral

lockpositionwiththeparkingbrakeonorifyourise

fromtheseatwhenthebladesareengaged.

TestingtheSafetyInterlockSystem

Testthesafetyinterlocksystembeforeyouusethe

machineeachtime.Ifthesafetysystemdoesnot

operateasdescribedbelow,haveanAuthorizedService

Dealerrepairthesafetysystemimmediately.

1.Whilesittingontheseat,engagetheparkingbrake

andmovethebladecontrolswitchtoOn.Try

startingtheengine;theengineshouldnotcrank.

2.Whilesittingontheseat,engagetheparkingbrake

andmovethebladecontrolswitchtoOff.Move

eithermotioncontrollever(forwardorreverse).

23

Page 24

Trystartingtheengine;theengineshouldnotcrank.

Repeatwiththeothermotioncontrollever.

3.Whilesittingontheseat,engagetheparkingbrake,

movethebladecontrolswitchtoOff,andlockthe

motioncontrolleversinneutral.Starttheengine.

Whiletheengineisrunning,releasetheparking

brake,engagethebladecontrolswitch,andrise

slightlyfromtheseat;theengineshouldstop.

4.Whilesittingontheseat,engagetheparkingbrake,

movethebladecontrolswitchtoOff,andlockthe

motioncontrolleversinneutral.Starttheengine.

Whiletheengineisrunning,centerthemotion

controls;theengineshouldstop.

DrivingForwardorBackward

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Place

thethrottlecontrolinthefastpositionforbest

performance.Alwaysoperateinthefullthrottle

positionwhenmowing.

UsingtheMotionControlLevers

CAUTION

Machinecanspinveryrapidly.Operatormaylose

controlofmachineandcausepersonalinjuryor

damagetomachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

Figure24

1.Motioncontrol

lever-neutrallockposition

2.Center,unlockedposition

3.Forward

4.Backward

DrivingForward

Note:Theenginewillkillifthetractioncontrollevers

aremovedwiththeparkingbrakeengaged.

1.Releasetheparkingbrake;refertoReleasingthe

ParkingBrakeinOperation.

2.Movetheleverstothecenter,unlockedposition.

3.Togoforward,slowlypushthemotioncontrol

leversforward(

Figure25).

24

Page 25

G008952

Figure25

G008953

G010219

bladecontrolswitch(PTO),andturntheignitionkey

tooff.

Settheparkingbrakewhenyouleavethemachine;refer

toSettingtheParkingBrake.Remembertoremovethe

keyfromtheignitionswitch.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethetractorwhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

AdjustingtheHeightofCut

Themachineisequippedwithafootpedaldecklift

system.Theoperatorcanusethefootpedaltolift

thedeckbrieytoavoidobstaclesorlockthedeckin

thehighestheight-of-cutortransportposition.The

operatorcanusetheheightofcutleverwiththefoot

pedaltolockthedeckinaspeciccuttingheight.

DrivingBackward

1.Movetheleverstothecenter,unlockedposition.

2.Togobackward,slowlypullthemotioncontrol

leversrearward(Figure26).

UsingtheFootPedalDeckLiftSystem

Pressthepedaldowntoraisethedeck;continueto

pressthepedaluntilthedeckislockedinthetransport

positionFigure27.Pushonthedeckliftpedalwith

yourfootandraisetheheight-of-cutleverslightlyto

disengagethetransportlock.

Figure26

StoppingtheMachine

Tostopthemachine,movethetractioncontrollevers

toneutralandmovetolockedposition,disengagethe

Figure27

TransportLockPosition

25

Page 26

AdjustingtheHeight-of-Cut

G010236

1

2

3

4

5

G010233

1

2

3

4

Theheight-of-cutcanbeadjustedfrom1-1/2to

4-1/2inch(38to114mm)in1/4inch(6mm)

incrementsbyrelocatingtheheight-of-cutpininto

differentholelocations.

1.Pushonthedeckliftpedalwithyourfootandraise

themowerdecktothetransportposition(also

the4-1/2inch(114mm)cuttingheightposition)

Figure28).

(

2.Toadjust,removethepinfromtheheight-of-cut

bracket(Figure28).

3.Selectaholeintheheight-of-cutsystem

correspondingtotheheight-of-cutdesiredand,

insertthepin(

4.Pushonthedeckliftpedalwithyourfootandraise

theheight-of-cutleverslightlytodisengagethe

transportlock.Lowerthedeckslowlyuntilthepin

makescontactwiththelever.

Figure28).

2.Removethepinfromtheheight-of-cutbracket

(Figure28).

3.Selectthelowerholeonthelockdecalandinsert

thepin(

Figure28).

Tolockthedeckinthelowestheight-of-cut

position:

1.Pushonthedeckliftpedalwithyourfootand

raisethemowerdecktothetransportposition

(alsothe4.5inch(114mm)cuttingheightposition)

Figure28).

(

2.Removethepinfromtheheight-of-cutbracket

Figure28).

(

3.Pushonthedeckliftpedalwithyourfootandlower

themowerdecktothelowestposition..

4.Selecttheupperholeonthelockdecalandinsert

thepin(

Figure28).

AdjustingtheAnti-Scalp

1.Deckliftpedal

2.Cutheightpin

3.Height-of-cutpositions

Rollers

Wheneveryouchangetheheight-of-cut,itis

recommendedtoadjusttheheightoftheanti-scalp

rollers.

1.Disengagethebladecontrolswitch(PTO),move

themotioncontrolleverstotheneutrallock

positionandsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

Figure28

4.Lockposition.lowest

height-of-cut(useonlyfor

deckremoval)

5.Lockposition.transport

position

UsingtheLockPositions

Thedeckcanbelockedinthehighestheight-of-cutor

transportpositionorthelowestheight-of-cutposition.

Tolockthedeckinthetransportposition:

1.Pushonthedeckliftpedalwithyourfootand

raisethemowerdecktothetransportposition

(alsothe4.5inch(114mm)cuttingheightposition)

(Figure28).

Figure29

1.Anti-scalproller3.FlangeNut

2.Bolt4.Holespacing

26

Page 27

PositioningtheSeat

G010232

1

4

1

2

G014970

3

AdjustingtheTilt

Theseatcanmoveforwardandbackward.Positionthe

seatwhereyouhavethebestcontrolofthemachine

andaremostcomfortable.

Whilesittingintheoperator'sposition,raisetheseat

adjustmentleverslightlyandmovetheseatforwardor

backwardtothedesiredposition(Figure30).

Figure30

1.Adjustmentlever

Themotioncontrolleverscanbetiltedforeoraftfor

maximumoperatorcomfort.

1.Loosentheupperboltholdingthecontrolleverto

thecontrolarmshaft.

2.Loosenthelowerboltjustenoughtopivotthe

controlleverforeoraft.Tightenbothboltsto

securethecontrolinthenewposition.

3.Repeattheadjustmentfortheoppositecontrol

lever.

AdjustingtheMotionControl

Levers

AdjustingtheHeight

Themotioncontrolleverscanbeadjustedhigheror

lowerformaximumoperatorcomfort.

1.Removethe2boltsand2washersholdingthe

controllevertothecontrolarmshaft(Figure31).

2.Movethecontrollevertothenextsetofholes.

Securetheleverwiththe2boltsand2washers

(Figure31).

Figure31

1.Controlarmshaft

2.Controllever

3.Slotted,upperhole

3.Repeattheadjustmentfortheoppositecontrol

4.Washer

5.Bolt

lever.

27

Page 28

PushingtheMachinebyHand

2

3

4

1

g017980

DANGER

Important:Alwayspushthemachinebyhand.

Nevertowthemachinebecausedamagemay

occur.

ToPushtheMachine

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrolswitch.

2.Movethemotioncontrolleversoutwardtoneutral

lockposition,stoptheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.Makesuretheparkingbrakeis

disengaged.

3.Locatethebypassleversattherearofthemachine,

ontheleftandrightsideoftheframe.

4.Movethebypassleversrearwardandthendown

tolocktheminplaceasshownin

disengagethewheelmotors.Repeatthisoneach

sideofthemachine.

Themachineisnowabletobepushedbyhand.

Figure32to

Withoutagrassdeector,dischargecover,or

completegrasscatcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriswillcauseinjuryor

death.

•Neverremovethegrassdeectorfromthe

mowerbecausethegrassdeectorroutes

materialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthemower.

•Nevertrytoclearthedischargeareaormower

bladesunlessyoumovethebladecontrolswitch

(PTO)totheoffposition,rotatetheignition

keytooffandremovethekey.

•Makesurethegrassdeectorisinthedown

position.

OperatingTips

Figure32

ToOperatetheMachine

Movethebypasstothepositionforoperatingthe

machine(Figure32)toengagethewheelmotors.

FastThrottleSetting

Forbestmowingandmaximumaircirculation,operate

theengineatthefastthrottleposition.Airisrequired

tothoroughlycutgrassclippings,sodonotsetthe

height-of-cutsolowastototallysurroundthemower

byuncutgrass.Alwaystrytohaveonesideofthe

mowerfreefromuncutgrass,whichallowsairtobe

drawnintothemower.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethe

cuttingheightofthemowerdoesnotscalpanyuneven

ground.However,thecuttingheightusedinthepastis

generallythebestonetouse.Whencuttinggrasslonger

thansixinchestall,youmaywanttocutthelawntwice

toensureanacceptablequalityofcut.

Cut1/3oftheGrassBlade

Itisbesttocutonlyabout1/3ofthegrassblade.

Cuttingmorethanthatisnotrecommendedunless

grassissparse,oritislatefallwhengrassgrowsmore

slowly.

UsingtheSideDischarge

Themowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

MowingDirection

Alternatemowingdirectiontokeepthegrassstanding

straight.Thisalsohelpsdisperseclippingswhich

enhancesdecompositionandfertilization.

28

Page 29

MowatCorrectIntervals

Normally,moweveryfourdays.Butremember,

grassgrowsatdifferentratesatdifferenttimes.So

tomaintainthesamecuttingheight,whichisagood

practice,mowmoreofteninearlyspring.Asthegrass

growthrateslowsinmidsummer,mowlessfrequently.

Ifyoucannotmowforanextendedperiod,rstmow

atahighcuttingheight;thenmowagaintwodayslater

atalowerheightsetting.

CuttingSpeed

Toimprovecutquality ,useaslowergroundspeedin

certainconditions.

AvoidCuttingTooLow

Ifthecuttingwidthofthemoweriswiderthanthe

moweryoupreviouslyused,raisethecuttingheightto

ensurethatuneventurfisnotcuttooshort.

LongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,raise

thecuttingheighthigherthanusualandcutthegrassat

thissetting.Thencutthegrassagainusingthelower,

normalsetting.

WhenStopping

Ifthemachine'sforwardmotionmustbestoppedwhile

mowing,aclumpofgrassclippingsmaydropontoyour

lawn.Toavoidthis,moveontoapreviouslycutarea

withthebladesengaged.

KeeptheUndersideoftheMower

Clean

Cleanclippingsanddirtfromtheundersideofthe

moweraftereachuse.Ifgrassanddirtbuildupinside

themower,cuttingqualitywilleventuallybecome

unsatisfactory.

BladeMaintenance

Maintainasharpbladethroughoutthecuttingseason

becauseasharpbladecutscleanlywithouttearingor

shreddingthegrassblades.Tearingandshreddingturns

grassbrownattheedges,whichslowsgrowthand

increasesthechanceofdisease.Checkthecutterblades

dailyforsharpness,andforanywearordamage.File

downanynicksandsharpenthebladesasnecessary.If

abladeisdamagedorworn,replaceitimmediatelywith

agenuineTOROreplacementblade.

29

Page 30

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst50hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

Every200hours

Every400hours

MaintenanceProcedure

•Changetheengineoil.

•Changethehydraulicsystemlterandoil.

•Checkthesafetyinterlocksystem.

•Checktheengineoillevel.

•Cleantheairintakescreen.

•Checkthemowerblades.

•Inspectthegrassdeectorfordamage

•Cleanthemowerhousing.

•Greasealllubricationpoints.

•Checktirepressure.

•Checkthehydraulicoillevelintheexpansiontank.

•Inspectthebeltsforcracksandwear.

•Servicethepaperelement.(moreoftenindusty,dirtyconditions)

•Changetheengineoil.(moreoftenindusty ,dirtyconditions)

•Checkthesparkplug(s).

•Replacethefuellters(moreoftenunderdusty,dirtyconditions).

•Replacethepaperelement.(moreoftenindusty ,dirtyconditions)

•Changetheoillter.(moreoftenindusty,dirtyconditions)

•Changethehydraulicsystemlterandoil.

Monthly

Yearlyorbeforestorage

•Checkthebatterycharge.

•Paintchippedsurfaces.

•Checkallmaintenanceprocedureslistedabovebeforestorage.

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

30

Page 31

Figure33

Locatedontheseatpanunderside

1.ReadtheOperator'sManualbeforeperformingany

maintenance.

2.Checktheengineoilevery8hours5.Checkthecasterwheeltirepressureevery25hours

3.Checkthedrivewheeltirepressureevery25hours

4.Checkthehydraulicoilevery25hours

6.Lubricatethecasterwheelevery25hours

31

Page 32

Premaintenance

G009949

1

Lubrication

Procedures

GreasingtheBearings

RaisingtheSeat

Makesurethemotioncontrolleversarelockedinthe

neutrallockposition.Lifttheseatforward.

Thefollowingcomponentscanbeaccessedbyraising

theseat:

•Servicedecal

•Fuses

•Batteryandcables

ServiceInterval:Every25hours—Greaseall

lubricationpoints.

GreaseType:No.2GeneralPurposeLithiumBase

Grease

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothe

neutrallockposition,stoptheengine,removethe

key,andwaitforallmovingpartstostopbefore

leavingtheoperatingposition.

3.Cleanthegreasettings(

witharag.Makesuretoscrapeanypaintoffofthe

frontofthetting(s).

Figure34andFigure34)

Figure34

1.Frontcastertire

4.Connectagreaseguntoeachtting(Figure34and

Figure33).Pumpgreaseintothettingsuntilgrease

beginstooozeoutofthebearings.

5.Wipeupanyexcessgrease.

32

Page 33

EngineMaintenance

G015155

1

2

3

g017470

SAE V iscosity Grades

SAE 40

SAE 30

SAE 10W– 30/ SAE 10W– 40

-20 0 20 32 40 60 80 100

-30 -20 -10 0 10 20 30 40

°F

°C

STARTING TEMPERA TURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

SAE 5W– 20

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawaythemuferandotherhotsurfaces.

ServicingtheAirCleaner

CleaningtheElement

ServiceInterval:Every100hours—Servicethepaper

element.(moreoftenindusty ,dirty

conditions)

Every200hours/Y early(whichever

comesrst)—Replacethepaper

element.(moreoftenindusty ,dirty

conditions)

1.Lightlytaptheelementonaatsurfacetoremove

dustanddirt.

Note:Servicetheaircleanermorefrequently(every

fewhours)ifoperatingconditionsareextremelydusty

orsandy .

RemovingtheElement

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrol(PTO).

2.Movethemotioncontrolleverstothebrakeposition,

stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Cleanaroundtheaircleanercovertopreventdirt

fromgettingintotheengineandcausingdamage.

Liftthecoverandremovethehoseclampsecuring

theaircleanerassemblytotheengine(

4.Loosenthehoseclampandremovethepaper

element(

Figure35).

Figure35).

2.Inspecttheelementfortears,anoilylm,and

damagetotheseal.

Important:Nevercleanthepaperelementwith

pressurizedairorliquids,suchassolvent,gas,

orkerosene.Replacethepaperelementifitis

damagedorcannotbecleanedthoroughly.

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSF ,SG,SH,SJ,

orSL)

CrankcaseCapacity:61ounces(1.8l),[whenoillter

isremoved:70ounces(2.1l)]

Viscosity:Seethetablebelow .

1.Cover

2.Paperelement

Figure35

3.Hoseclamp

Figure36

Note:Usingmultigradeoils(5W -20,10W-30,and10W

-40)willincreaseoilconsumption.Checkoillevelmore

frequentlywhenusingthem.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

33

Page 34

WARNING

G008792

1

2

5

6

7

3

9

10

4

8

G012153

1

2

3

4

5 6

Contactwithhotsurfacesmaycausepersonal

injury.

ChangingtheEngineOil

ServiceInterval:Aftertherst8hours—Changethe

engineoil.

Keephands,feet,face,clothingandotherbody

partsawaythemuferandotherhotsurfaces.

Important:Donotoverllthecrankcasewithoil

becausedamagetotheenginemayresult.Donot

runenginewithoilbelowthelowmarkbecausethe

enginemaybedamaged.

1.Parkthemachineonalevelsurface,disengagethe

bladecontrolswitch,stoptheengine,engageparking

brake,andremovethekey .

2.Makesuretheengineisstopped,level,andiscoolso

theoilhashadtimetodrainintothesump.

3.Tokeepdirt,grassclippings,etc.,outoftheengine,

cleantheareaaroundtheoilllcap/dipstickbefore

removingit(

Figure37).

Every100hours—Changetheengine

oil.(moreoftenindusty,dirty

conditions)

Note:Disposeoftheusedoilatarecyclingcenter.

1.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoassuretheoildrains

completely.

2.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

3.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position(

Figure38).

Figure37

Figure38

34

Page 35

4.Slowlypourapproximately80%ofthespeciedoil

G008796

2

3

4

5

6

1

G008748

3/4

1

2

3

4

5

6

intothellertubeandslowlyaddtheadditionaloil

tobringittotheFullmark(Figure39).

Figure39

ChangingtheEngineOilFilter

ServiceInterval:Every200hours—Changetheoil

lter.(moreoftenindusty,dirty

conditions)

Note:Changetheengineoilltermorefrequently

whenoperatingconditionsareextremelydustyorsandy.

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil.

2.Changetheengineoillter(

Figure40).

Figure40

Note:Ensuretheoilltergaskettouchestheengine

andthenanextra3/4turniscompleted.

3.Fillthecrankcasewiththepropertypeofnewoil;

refertoChangingtheOil.

ServicingtheSparkPlug

ServiceInterval:Every100hours—Checkthespark

plug(s).

Makesuretheairgapbetweenthecenterandside

electrodesiscorrectbeforeinstallingthesparkplug.

Useasparkplugwrenchforremovingandinstalling

thesparkplug(s)andagappingtool/feelergaugeto

checkandadjusttheairgap.Installanewsparkplug(s)

ifnecessary.

Type:NGKBPR4ES(orequivalent)

AirGap:0.030inch(0.76mm)

35

Page 36

RemovingtheSparkPlug

G008794

1

2

16ft-lb

22N-m

G010687

InstallingtheSparkPlug

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

Figure41

Note:Duetothedeeprecessaroundthespark

plug,blowingoutthecavitywithcompressedair

isusuallythemosteffectivemethodforcleaning.

Thesparkplugismostaccessiblewhentheblower

housingisremovedforcleaning.

Tightenthesparkplug(s)to16ft-lb(22N-m).

Figure43

CleaningtheCoolingSystem

CheckingtheSparkPlug

Important:Nevercleanthesparkplug(s).Always

replacethesparkplug(s)whenithas:ablack

coating,wornelectrodes,anoilylm,orcracks.

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeanstheaircleanerisdirty.

Setthegapto0.030inches(0.76mm).

Figure42

Cleantheairintakescreenfromgrassanddebrisbefore

eachuse.

1.Disengagethebladecontrolswitchandmovethe

controlleverstotheneutrallockedpositionand

applytheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Removetheairintakescreen,aircleanercover,and

fanhousing.

4.Cleandebrisandgrassfromtheparts.

5.Installtheairintakescreen,aircleanercover,and

fanhousing.

36

Page 37

FuelSystem

g017723

1

2

3

4

5

G008963

12

3

Maintenance

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Performanyfuelrelatedmaintenancewhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

5.Squeezetheendsofthehoseclampstogetherand

slidethemawayfromthelter(Figure45).

ReplacingtheFuelFilter

ServiceInterval:Every100hours/Yearly(whichever

comesrst)(moreoftenunderdusty,

dirtyconditions).

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockposition,

andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Allowthemachinetocooldown.

4.Raisetheseatandlocatethefuelltersasshownin

Figure44.

Figure45

1.Fuellter

2.Hoseclamp

3.Fuelline

6.Removethelterfromthefuellines.

7.Installanewlterwiththeowdirectionarrow

comingfromthefueltankandpointingtothe

engine.Movethehoseclampsclosetothelter

Figure44)tosecureitinplace.

(

1.Fuellinefromtank

2.In-lineFuellter

3.Flowdirectionarrow

Figure44

4.Fuellinetoengine

5.Hoseclamp

37

Page 38

ElectricalSystem

G010240

1

2

3

4

Maintenance

ServicingtheBattery

ServiceInterval:Monthly

WARNING

CALIFORNIA

Proposition65Warning

WARNING

Incorrectbatterycableroutingcoulddamagethe

machineandcablescausingsparks.Sparkscan

causethebatterygassestoexplode,resultingin

personalinjury.

•AlwaysDisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

•AlwaysReconnectthepositive(red)battery

cablebeforereconnectingthenegative(black)

cable.

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling .

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing.Wearsafetyglassestoshield

youreyesandrubberglovestoprotectyourhands.

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockposition

andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Removethewingnutsecuringthebatteryclamp

Figure46).

(

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

Figure46

1.Removethewingnutand

clamp

2.Removethenegative

batterycablebeforethe

positive

4.Removetheclamp(Figure46).

5.Firstdisconnectthenegativebatterycable(black)

fromthenegative(-)(black)batteryterminal

Figure46).

(

6.Slidetheredterminalbootoffthepositive(red)

batteryterminalandremovethepositive(+)(red)

batterycable(

7.Removethebattery.

38

Figure46).

3.Removethepositive

batterycable

4.Removebattery

Page 39

InstallingtheBattery

1.Positionbatteryinthetraywiththeterminalposts

oppositefromthefueltank(

Figure46).

2.First,installthepositive(red)batterycableto

positive(+)batteryterminal.

3.Theninstallthenegativebatterycabletothenegative

(-)batteryterminal.

4.Securethecableswith2bolts,2washers,and

2locknuts(

Figure46).

5.Slidetheredterminalbootontothepositive(red)

batterypost.

6.Installtheclampandsecureitwiththewingnut

Figure46).

(

ChargingtheBattery

1.PositiveBatteryPost

2.NegativeBatteryPost

Figure47

3.Red(+)ChargerLead

4.Black(-)ChargerLead

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparksand

amesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged.

Thisisespeciallyimportanttopreventbattery

damagewhenthetemperatureisbelow32°F(0°C).

1.Chargebatteryfor10to15minutesat25to30amps

or30minutesat10amps.

2.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthe

chargerleadsfromthebatteryposts(

3.Installthebatteryinthemachineandconnectthe

batterycables,refertoInstallingtheBattery.

Note:Donotrunthemachinewiththebattery

disconnected,electricaldamagemayoccur.

Figure47).

ServicingtheFuses

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance,however,ifafuseblowscheckthe

component/circuitforamalfunctionorshort.

Fuses:

•Main,30amp,blade-type

•Engine,20amp,blade-type

1.Thefusesarelocatedonrighthandconsolenextto

theseat(

2.Toreplacethefuses,pulloutonthefusetoremove

it.

3.Installanewfuseofthesameamperageremoved

Figure48).

(

Figure48).

39

Page 40

30

25

1 2

3

G015037

4

Figure48

1.30amp

2.25amp4.Fuseblock

3.Openaccessoryslot

DriveSystem

Maintenance

CheckingtheTirePressure

ServiceInterval:Every25hours—Checktirepressure.

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseunevencut.

Checkthepressureatthevalvestem(

thetireswhentheyarecoldtogetthemostaccurate

pressurereading.

Refertothemaximumpressuresuggestedbythetire

manufactureronthesidewallofthecasterwheeltires.

Inatethereardrivewheeltiresto13psi.

Figure49).Check

Figure49

1.Valvestem

40

Page 41

HydraulicSystem

G010253

1

2

3

G010254

1

2

3

4

5

Maintenance

OilType:20w-50engineoil.

Important:Useoilspeciedorequivalent.Other

uidscouldcausesystemdamage.

CheckingtheHydraulicOil

Level

ServiceInterval:Every25hours

Checkexpansionreservoirandifnecessaryadd20W-50

engineoiltotheFULLCOLDline

2.Locatethelterandguardsoneachtransaxledrive

system(Figure51).Removethreescrewssecuring

thelterguardandguard.

Figure51

Rightsideshown

Figure50

1.Expansionreservoir3.Engine

2.FullColdline

ChangingtheHydraulic

SystemFilterandOil

Thelterandoilarechangedatthesametime.DoNot

reuseoil.Oncethenewlterisinstalledandoilisadded

anyairinthesystemmustbepurged.

Thebleedingprocessisrepeateduntiltheoilremains

attheFULLCOLDlineinthereservoirafterpurging.

Failuretoproperlyperformthisprocedurecan

resultinirreparabledamagetothetransaxledrive

system.

1.Transaxledrive

2.Oillter

3.Filterguard

3.Carefullycleanareaaroundlters.Itisimportant

thatnodirtorcontaminationenterhydraulicsystem.

4.Placeacontainerbelowtheltertocatchtheoilthat

drainswhenthelterandventplugsareremoved.

5.Locateandremovetheventplugoneach

transmission

6.Unscrewtheltertoremoveandallowoiltodrain

fromdrivesystem.

Repeatthisprocedureforbothlters.

4.Screws

5.Ventplug

InstallingtheHydraulicSystemFilters

ServiceInterval:Aftertherst50hours

Every400hours

RemovingHydraulicSystemFilters

1.Stopengine,waitforallmovingpartstostop,and

allowenginetocool.Removethekeyandengage

theparkingbrake.

41

Page 42

G008748

3/4

1

2

3

4

5

6

hydraulicltersandoilcanresultinirreparable

G010333

1

damagetothetransaxledrivesystem.

BleedingtheHydraulicSystem

1.Raisetherearofmachineupandsupportwithjack

stands(orequivalentsupport)justhighenoughto

allowdrivewheelstoturnfreely.

Figure53

1.Jackingpoints

Figure52

1.Applyathincoatofoilonthesurfaceoftherubber

sealofeachlter.

2.Turnthelterclockwiseuntilrubbersealcontacts

thelteradapterthentightenthelteranadditional

3/4to1fullturn.Repeatfortheotherlter

3.Installthelterguardsovereachlteraspreviously

removed.Usethethreescrewstosecurethelter

guards.

4.Verifytheventplugsareremovedbeforeaddingthe

oil.

5.Slowlypourthespeciedoilthroughexpansion

reservoiruntiloilcomesoutofoneoftheventplug

holes.Stopandinstallthatventplug.Torquethe

plugto180in-lb(20.3N-m).

6.Continuetoaddoilthroughtheexpansionreservoir

untiloilcomesoutoftheremainingventplughole

onthesecondtransmission.Stopandinstallthat

ventplug.Torquetheplugto180in-lb(20.3N-m).

7.Continuetoaddoilthroughtheexpansionreservoir

untilitreachestheFULLCOLDlineonthe

expansionreservoir.ProceedtotheBleedingthe

HydraulicSystemsection.

Important:Failuretoperformthe

the Hy draulic System

Bleeding

procedureafterchanging

2.Entertheoperator'sposition.Startengineand

movethrottlecontrolaheadto1/2throttleposition.

Disengageparkingbrake.

A.Movethebypassleversintothepushingthe

machineposition;refertothePushingthe

MachinebyHandsectioninOperation.With

thebypassvalvesopenandtheenginerunning,

slowlymovethemotioncontrolleversinboth

forwardandreverse(5or6times).

B.Movethebypassleversintotheoperating

themachineposition.Withthebypassvalve

closedandtheenginerunning,slowlymovethe

directionalcontrolinbothforwardandreverse

directions(5to6times).

C.Stoptheengineandchecktheoillevelinthe

expansionreservoir.Addthespeciedoilas

untilitreachestheFULLCOLDlineonthe

expansionreservoir.

3.Repeatstep2untilalltheairiscompletelypurged

fromthesystem.

Whenthetransaxleoperatesatnormalnoiselevels

andmovessmoothlyforwardandreverseatnormal

speeds,thenthetransaxleisconsideredpurged.

4.Checktheoillevelintheexpansionreservoirone

lasttime.Addthespeciedoilasuntilitreaches

theFULLCOLDlineontheexpansionreservoir

ifnecessary.

42

Page 43

MowerDeck

G014972

1

2

3

Maintenance

ServicingtheCuttingBlades

Maintainsharpbladesthroughoutthecuttingseason

becausesharpbladescutcleanlywithouttearingor

shreddingthegrassblades.Tearingandshreddingturns

grassbrownattheedges,whichslowsgrowthand

increasesthechanceofdisease.

Checkthecutterbladesdailyforsharpness,andforany

wearordamage.Filedownanynicksandsharpenthe

bladesasnecessary.Ifabladeisdamagedorworn,

replaceitimmediatelywithagenuineTororeplacement

blade.Forconvenientsharpeningandreplacement,you

maywanttokeepextrabladesonhand.

WARNING

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownintotheoperator's

orbystander'sarea,resultinginseriouspersonal

injuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

Figure54

1.CuttingEdge3.Wear/slotForming

2.CurvedArea4.Crack

CheckingforBentBlades

Note:Themachinemustbeonalevelsurfaceforthe

followingprocedure.

1.Raisethemowerdecktothehighestheight-of-cut

position;alsoconsideredthe'transport'position.

2.Whilewearingthicklypaddedglovesorother

adequatehandprotectionslowlyrotatebladeto

bemeasuredintoapositionthatallowseffective

measurementofthedistancebetweenthecutting

edgeandthelevelsurfacethemachineison.

•Replaceawornordamagedblade.

BeforeInspectingorServicingthe

Blades

Parkthemachineonalevelsurface,disengagetheblade

controlswitch(PTO),andsettheparkingbrake.Turn

theignitionkeytoOff.Removethekey.

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily

1.Inspectthecuttingedges(Figure54).Iftheedges

arenotsharporhavenicks,removeandsharpenthe

blades.RefertoSharpeningtheBlades.

2.Inspecttheblades,especiallythecurvedarea

(Figure54).Ifyounoticeanydamage,wear,oraslot

forminginthisarea(Figure54),immediatelyinstalla

newblade.

Figure55

1.Deck3.Blade

2.Spindlehousing

43

Page 44

3.Measurefromthetipofthebladetotheatsurface

G014973

1

2

3

G014974

1

2

3

G014973

1

2

3

here.

Figure56

1.Blade,inpositionformeasuring

2.Levelsurface

3.Measureddistancebetweenbladeandsurface(A)

Figure58

1.Opposingbladeedge,inpositionformeasuring

2.Levelsurface

3.Secondmeasureddistancebetweenbladeandsurface(B)

WARNING

4.Rotatethesameblade180degreessothatthe

opposingcuttingedgeisnowinthesameposition.

Figure57

1.Blade,sidepreviouslymeasured

2.Measurementpositionusedpreviously

3.Opposingsideofbladebeingmovedintomeasurement

position

5.Measurefromthetipofthebladetotheatsurface

here.Thevarianceshouldbenomorethan1/8inch

(3mm).

Abladethatisbentordamagedcouldbreak

apartandcouldseriouslyinjureorkillyouor

bystanders.

•Alwaysreplacebentordamagedbladewith

anewblade.

•Neverleorcreatesharpnotchesinthe

edgesorsurfacesofblade.

A.IfthedifferencebetweenAandBisgreater