Page 1

FormNo.3363-818RevA

G009968

TITANZX6030Zero-Turn-Radius

RidingMower

ModelNo.74833—SerialNo.310000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

Thismachineisaride-on,rotary-bladelawnmower

G009950

G010228

1

intendedtobeusedbyhomeownersinresidential

applications.Itisprimarilydesignedforcuttinggrass

onwell-maintainedlawns.Itisnotdesignedforcutting

brush,mowinggrassandothergrowthalongside

highways,orforagriculturaluses.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Thisengineisnotequippedwitha

sparkarrestermufer.ItisaviolationofCalifornia

PublicResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,or

grass-coveredland.Otherstatesorfederalareas

mayhavesimilarlaws.

andserialnumbersofyourproductready .

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

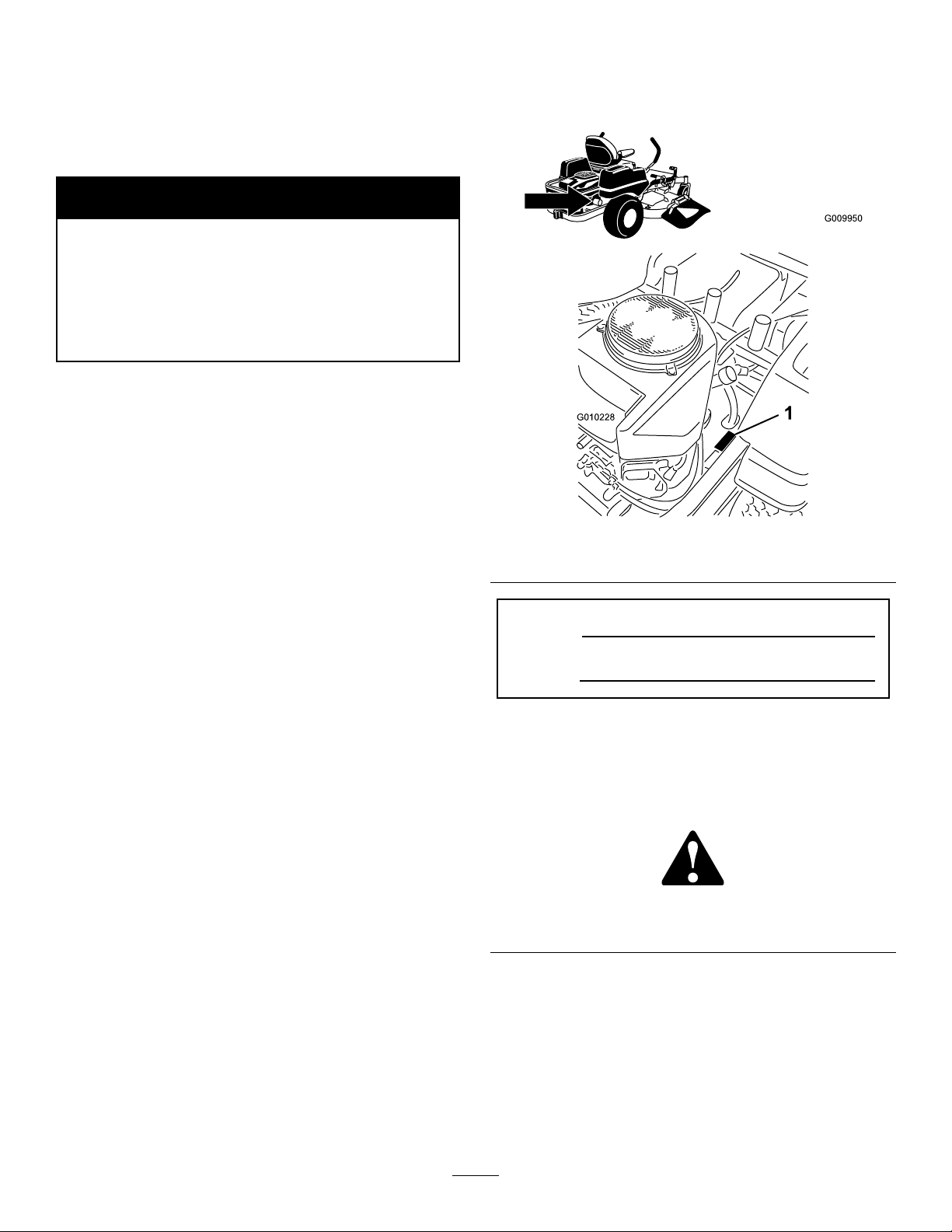

Figure1

ThissparkignitionsystemcomplieswithCanadian

ICES-002.

Theenclosed

Engine Owner’ s Man ual

issupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCalifornia

EmissionControlRegulationofemissionsystems,

maintenance,andwarranty.Replacementsmaybe

orderedthroughtheenginemanufacturer.

Formodelswithstatedenginehorsepower,thegross

horsepoweroftheenginewaslaboratoryratedbythe

enginemanufacturerinaccordancewithSAEJ1940.

Asconguredtomeetsafety,emission,andoperating

requirements,theactualenginehorsepoweronthisclass

oflawnmowerwillbesignicantlylower.

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .T oro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

©2010—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

ToroRidingMowerSafety....................................6

SlopeIndicator.....................................................7

SafetyandInstructionalDecals.............................8

ProductOverview......................................................12

Controls.............................................................13

Operation...................................................................14

ThinkSafetyFirst...............................................14

AddingFuel.......................................................15

CheckingtheEngineOilLevel............................17

OperatingtheParkingBrake...............................17

OperatingtheThrottle.......................................17

OperatingtheChoke..........................................17

OperatingtheIgnitionSwitch.............................18

StartingandStoppingtheEngine........................18

OperatingtheMowerBladeControlSwitch

(PTO)............................................................19

TheSafetyInterlockSystem................................19

DrivingForwardorBackward.............................20

StoppingtheMachine.........................................21

AdjustingtheHeightofCut................................21

AdjustingtheAnti-ScalpRollers.........................22

PositioningtheSeat............................................23

ChangingtheSeatRideSuspension.....................23

AdjustingtheMotionControlLevers..................23

PushingtheMachinebyHand.............................24

UsingtheSideDischarge....................................25

OperatingTips...................................................25

Maintenance...............................................................27

RecommendedMaintenanceSchedule(s)................27

PremaintenanceProcedures....................................28

RaisingtheSeat..................................................28

Lubrication.............................................................28

GreasingtheBearings.........................................28

EngineMaintenance...............................................29

ServicingtheAirCleaner....................................29

ServicingtheEngineOil.....................................30

ServicingtheSparkPlug.....................................33

CleaningtheBlowerHousing..............................33

FuelSystemMaintenance.......................................34

ReplacingtheFuelFilter.....................................34

ElectricalSystemMaintenance................................34

ServicingtheBattery...........................................34

ServicingtheFuses.............................................36

DriveSystemMaintenance.....................................37

CheckingtheTirePressure.................................37

HydraulicSystemMaintenance...............................37

CheckingtheHydraulicOilLevel........................37

ChangingtheHydraulicSystemFilterand

Oil..................................................................37

MowerDeckMaintenance......................................39

ServicingtheCuttingBlades...............................39

MowerDeckLeveling.........................................42

InspectingtheBelts............................................43

ReplacingtheMowerBelt...................................43

RemovingtheMower.........................................43

InstallingtheMower...........................................44

ReplacingtheGrassDeector.............................44

Cleaning.................................................................46

WashingtheUndersideoftheMower..................46

WasteDisposal...................................................46

Storage.......................................................................47

CleaningandStorage..........................................47

Troubleshooting.........................................................48

Schematics.................................................................50

3

Page 4

Safety

ThismachinemeetsorexceedstheB71.1-2003

specicationsoftheAmericanNationalStandards

Institute,ineffectatthetimeofproduction.

However,improperuseormaintenancebythe

operatororownercanresultininjury.Toreduce

thepotentialforinjury,complywiththesesafety

instructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeansCAUTION,

WARNING,orDANGER-"personalsafety

instruction."Failuretocomplywiththeinstruction

mayresultinpersonalinjuryordeath.

•Neverleavearunningmachineunattended.Always

turnoffblades,setparkingbrake,stopengine,and

removekeybeforedismounting.

•Turnoffbladeswhennotmowing.Stoptheengine

andwaitforallpartstocometoacompletestop

beforecleaningthemachine,removingthegrass

catcheroruncloggingthedischargechute.

•Operatethemachineonlyindaylightorgood

articiallight.

•Donotoperatethemachinewhileunderthe

inuenceofalcoholordrugs.

•Watchfortrafcwhenoperatingnearorcrossing

roadways.

SafeOperatingPractices

ThefollowinginstructionsarefromANSIstandard

B71.1-2003.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

GeneralOperation

•Read,understand,andfollowallinstructionsin

theoperator’smanualandonthemachinebefore

starting.

•Donotplacehandsorfeetnearrotatingpartsor

underthemachine.Keepclearofthedischarge

openingatalltimes.

•Allowonlyresponsibleadultswhoarefamiliarwith

theinstructionstooperatethemachine.

•Cleartheareaofobjectssuchasrocks,toys,wire,

etc.,whichcouldbepickedupandthrownbythe

blade.

•Besuretheareaisclearofotherpeoplebefore

mowing.Stopthemachineifanyoneentersthearea.

•Nevercarrypassengers.

•Donotmowinreverseunlessabsolutelynecessary.

Alwayslookdownandbehindbeforeandwhile

backingup.

•Beawareofthemowerdischargedirectionanddo

notpointitatanyone.Avoiddischargingmaterial

againstawallorobstruction.Materialmayricochet

backtowardtheoperator.Stoptheblade(s)when

crossinggravelsurfaces.

•Donotoperatethemachinewithoutdeector,

dischargecoverorentiregrasscollectionsystemin

placeandworking.

•Bealert,slowdownandusecautionwhenmaking

turns.Lookbehindandtothesidebeforechanging

directions.

•Useextracarewhenloadingorunloadingthe

machineintoatrailerortruck.

•Alwaysweareyeprotectionwhenoperatingthe

mower.

•Dataindicatesthatoperators,age60yearsand

above,areinvolvedinalargepercentageofriding

mower-relatedinjuries.Theseoperatorsshould

evaluatetheirabilitytooperatetheridingmower

safelyenoughtoprotectthemselvesandothersfrom

seriousinjury.

•Alwaysfollowtherecommendationsforwheel

weightsorcounterweights.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

SlopeOperation

Slopesareamajorfactorrelatedtolossofcontroland

tip-overaccidents,whichcanresultinsevereinjuryor

death.Operationonallslopesrequiresextracaution.If

youcannotbackuptheslopeorifyoufeeluneasyonit,

donotmowit.

•Donotmowslopesgreaterthan15degrees.

•Watchforditches,holes,rocks,dips,andrisesthat

changetheoperatingangle,asroughterraincould

overturnthemachine.

•Choosealowgroundspeedsoyouwillnothaveto

stopwhileoperatingonaslope.

•Donotmowslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcausesliding

andlossofcontrol.

•Alwayskeepthewheelmotorsengagedwhengoing

downslopes.

•Reducespeedanduseextremecautiononslopes.

•Donotmakesuddenturnsorrapidspeedchanges.

4

Page 5

•Removeormarkobstaclessuchasrocks,treelimbs,

etc.fromthemowingarea.Tallgrasscanhide

obstacles.

•Avoidsuddenstartswhenmowinguphillbecause

themowermaytipbackwards.

•Beawarethatlossoftractionmayoccurgoing

downhill.Weighttransfertothefrontwheelsmay

causedrivewheelstoslipandcauselossofbraking

andsteering.

•Alwaysavoidsuddenstartingorstoppingona

slope.Iftireslosetraction,disengagethebladesand

proceedslowlyofftheslope.

•Useextremecarewithgrasscatchersorother

attachments.Thesecanchangethestabilityofthe

machineandcauselossofcontrol.

•Donottrytostabilizethemachinebyputtingyour

footontheground.

Towing

Ahitchkitisavailableforthismachineandcanbe

obtainedbycontactinganAuthorizedToroDealer.

Donottowwithoutrstinstallingthismanufacturer

approvedhitch.Thefollowingguidelinesapplywhen

towingwiththeapprovedhitchkitinstalled.

•Towonlywithamachinethathasahitchdesigned

fortowing.Donotattachtowedequipmentexcept

atthehitchpoint.

•Followthemanufacturer’srecommendationfor

weightlimitsfortowedequipmentandtowingon

slopes.

•Neverallowchildrenorothersinorontowed

equipment.

•Onslopes,theweightofthetowedequipmentmay

causelossoftractionandlossofcontrol.

•Travelslowlyandallowextradistancetostop.

•Donotmowneardrop-offs,ditches,steepbanks

orwater.Wheelsdroppingoveredgescancause

rollovers,whichmayresultinseriousinjury,death

ordrowning.

•Useawalkbehindmowerand/orahandtrimmer

neardrop-offs,ditches,steepbanksorwater.

Children

Tragicaccidentscanoccuriftheoperatorisnotalertto

thepresenceofchildren.Childrenareoftenattractedto

themachineandthemowingactivity.Neverassumethat

childrenwillremainwhereyoulastsawthem.

•Keepchildrenoutofthemowingareaandunder

thewatchfulcareofanotherresponsibleadult,not

theoperator.

•Bealertandturnthemachineoffifchildrenenter

thearea.

•Beforeandwhilebackingorchangingdirection,look

behind,down,andside-to-sideforsmallchildren.

•Nevercarrychildren,evenwiththebladesoff.They

mayfalloffandbeseriouslyinjuredorinterferewith

safemachineoperation.

•Childrenwhohavebeengivenridesinthepastmay

suddenlyappearinthemowingareaforanotherride

andberunoverorbackedoverbythemower.

•Neverallowchildrentooperatethemachine.

•Useextracarewhenapproachingblindcorners,

shrubs,trees,theendofafenceorotherobjectsthat

mayobscurevision.

Service

SafeHandlingofGasoline:

Toavoidpersonalinjuryorpropertydamage,useextra

carewhenhandlinggasolineandotherfuels.Theyare

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipesandother

sourcesofignition.

•Useonlyanapprovedcontainer.

•Neverremovethegascaporaddfuelwhenthe

engineisrunning.Allowtheenginetocoolbefore

refueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

•Neverllcontainersinsideavehicleoronatruckor

trailerwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removegas-poweredequipmentfromthetruck

ortrailerandrefuelitontheground.Ifthisisnot

possible,thenrefuelsuchequipmentwithaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Keepthenozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimesuntilthefueling

iscomplete.Donotuseanozzlelock-opendevice.

•Iffuelisspilledonclothing,changeclothing

immediately.

•Neveroverllthefueltank.Replacegascapand

tightensecurely .

5

Page 6

GeneralService:

•Neveroperateamachineinsideaclosedarea.Engine

exhaustcontainscarbonmonoxide,whichisan

odorless,deadlypoisonthatcankillyou.

•Keepnutsandboltstight,especiallytheblade

attachmentbolts.Keepequipmentingood

condition.

•Nevertamperwithsafetydevices.Checktheir

properoperationregularly .

•Keepthemachinefreeofgrass,leaves,orother

debrisbuild-up.Cleanupoilorfuelspillagefuel

soakeddebris.Allowthemachinetocoolbefore

storing.

•Stopandinspecttheequipmentifyoustrikean

object.Repair,ifnecessary,beforerestarting.

•Nevermakeanyadjustmentsorrepairswiththe

enginerunning.

•Grasscatchercomponentsaresubjecttowear,

damageanddeterioration,whichcouldexpose

movingpartsorallowobjectstobethrown.

Frequentlycheckcomponentsandreplacewith

manufacturers’recommendedparts,whennecessary.

•Batterygasescanexplode.Keepcigarettes,sparks

andamesawayfrombattery.

•UseonlyToroapprovedattachments.W arrantymay

bevoidedifusedwithunapprovedattachments.

•Ifloadingthemachineontoatrailerortruck,usea

single,full-widthramponly.Therampangleshould

notexceed15degrees.

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

•Mowerbladesaresharpandcancut.Wrapthe

blade(s)orweargloves,anduseextracautionwhen

servicingthem.

•Checkforproperbrakeoperationfrequently.Adjust

andserviceasrequired.

•Maintainorreplacesafetyandinstructiondecalsas

necessary.

•UseonlygenuineTororeplacementpartstoensure

thatoriginalstandardsaremaintained.

ToroRidingMowerSafety

Thefollowinglistcontainssafetyinformationspecicto

Toroproductsorothersafetyinformationthatyoumust

knowthatisnotincludedintheANSIstandards.

•Stoptheengine,disconnectsparkplugwire(s)and

removekeybeforeperforminganyservice,repairs,

maintenanceoradjustments.

•Keephands,feet,hair,andlooseclothingawayfrom

attachmentdischargearea,undersideofmowerand

anymovingpartswhileengineisrunning.

•Donottouchequipmentorattachmentpartswhich

maybehotfromoperation.Allowtocoolbefore

attemptingtomaintain,adjustorservice.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyes,andclothing.Protectyour

face,eyes,andclothingwhenworkingwithabattery.

6

Page 7

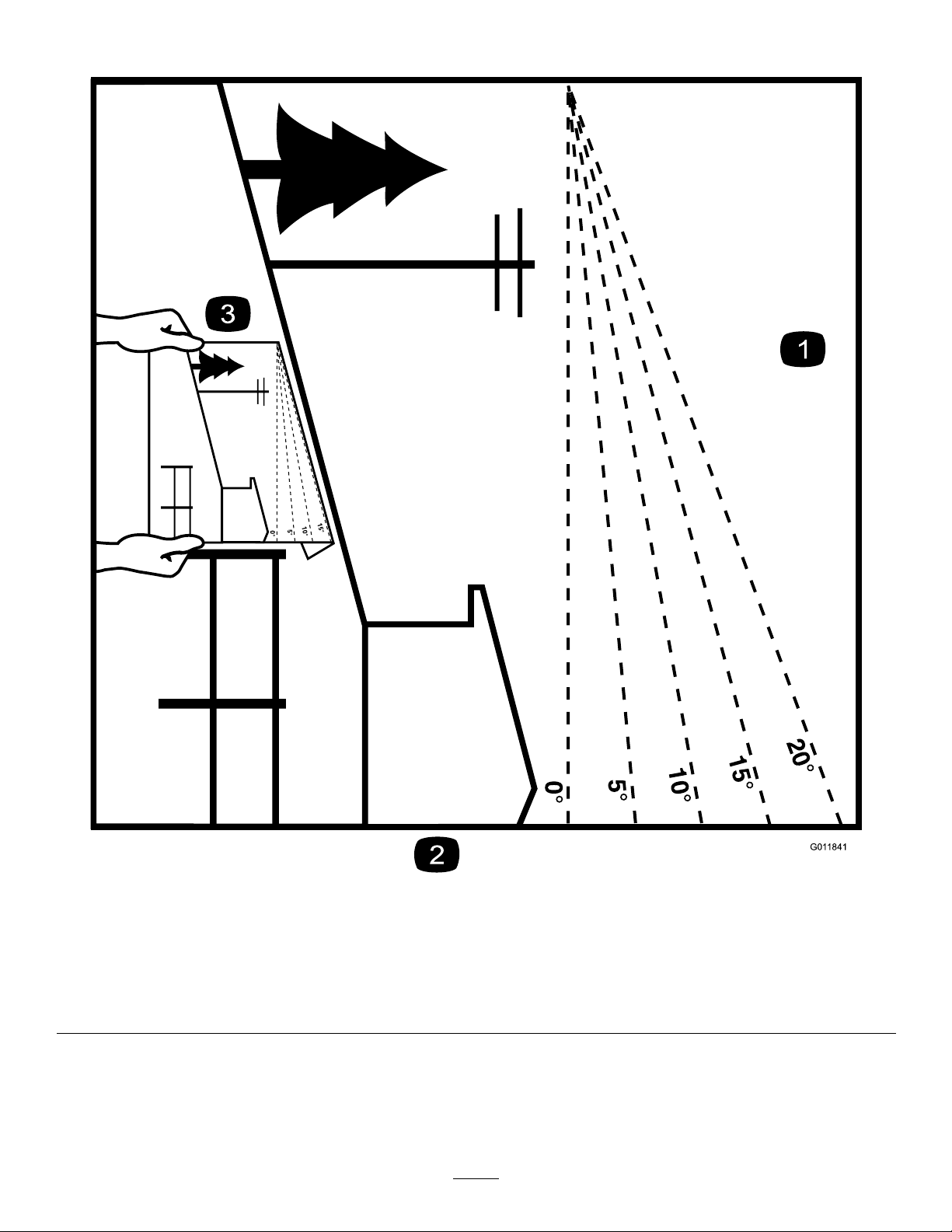

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

7

Page 8

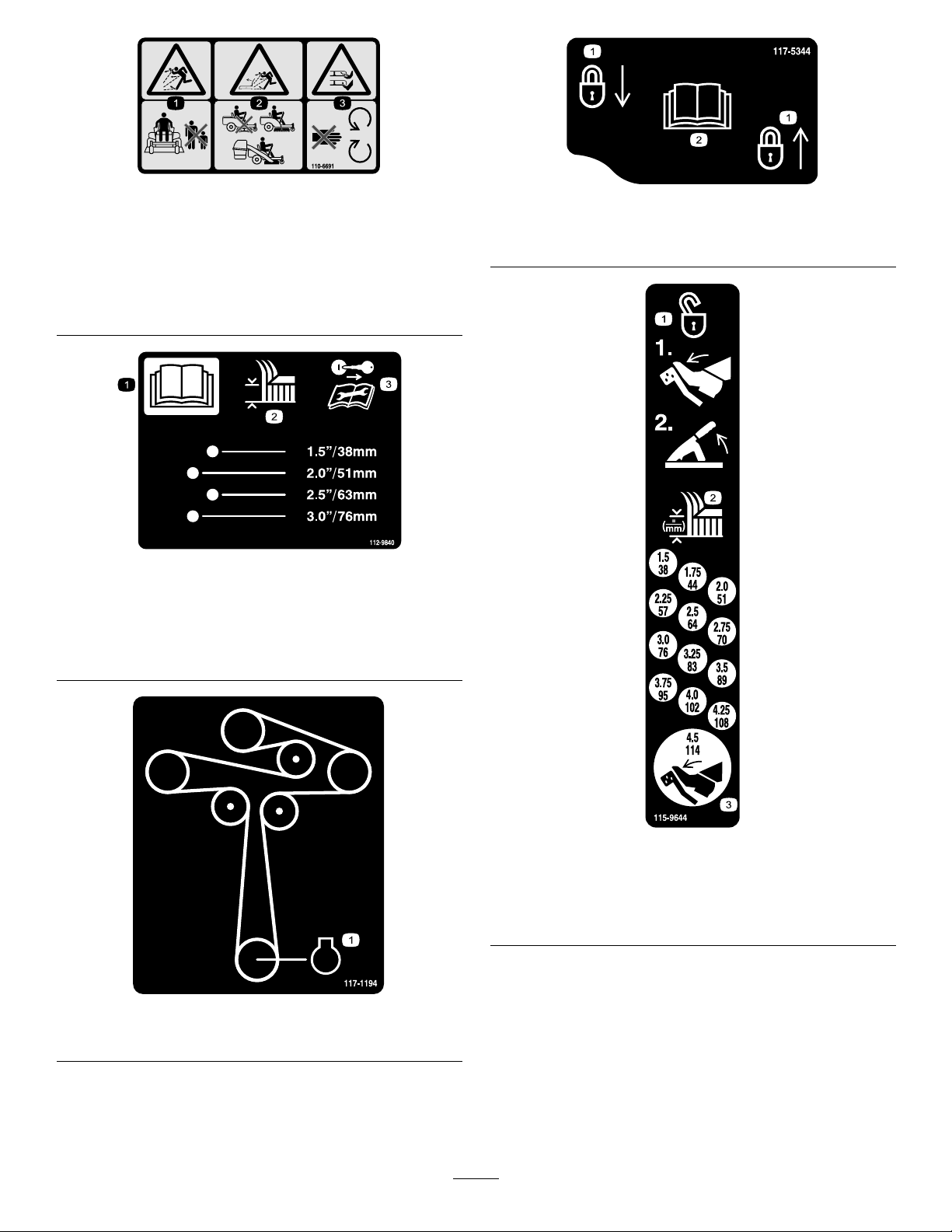

SafetyandInstructional

Decals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

1.Machinespeed4.Neutral

2.Fast5.Reverse

3.Slow

115-9631

1.Powertake-off(PTO),

99-8936

Bladecontrolswitchon

somemodels

2.Bladecontrolswitch—On6.Continuousvariable

3.Bladecontrolswitch—Off7.Slow

4.Choke

5.Fast

setting

1.Parking

brake—disengaged

1.Bypassleverpositionfor

operatingthemachine

114-1606

1.Entanglementhazard,belt—keepallguardsinplace.

115-9625

2.Parkingbrake—engaged

93-7009

1.Warning—don’toperatethemowerwiththedeectorupor

removed;keepthedeectorinplace.

2.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

Manufacturer’sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

117-1158

2.Bypassleverpositionfor

pushingthemachine

8

Page 9

110-6691

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Thrownobjecthazard,mower—donotoperatewithoutthe

deector,dischargecover,orgrasscollectionsystemin

place.

3.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

112-9840

1.ReadtheOperator’s

Manual.

2.Heightofcut

3.Removetheignitionkey

andreadtheinstructions

beforeservicingor

performingmaintenance.

117-5344

1.Lock

2.ReadtheOperator’sManual

115-9644

1.Pressthepedalandlifttheheightofcutlevertounlock

thedeckposition.

2.Heightofcut

3.Pressthepedaltomovethedecktothetransportposition

117-1194

1.Engine

9

Page 10

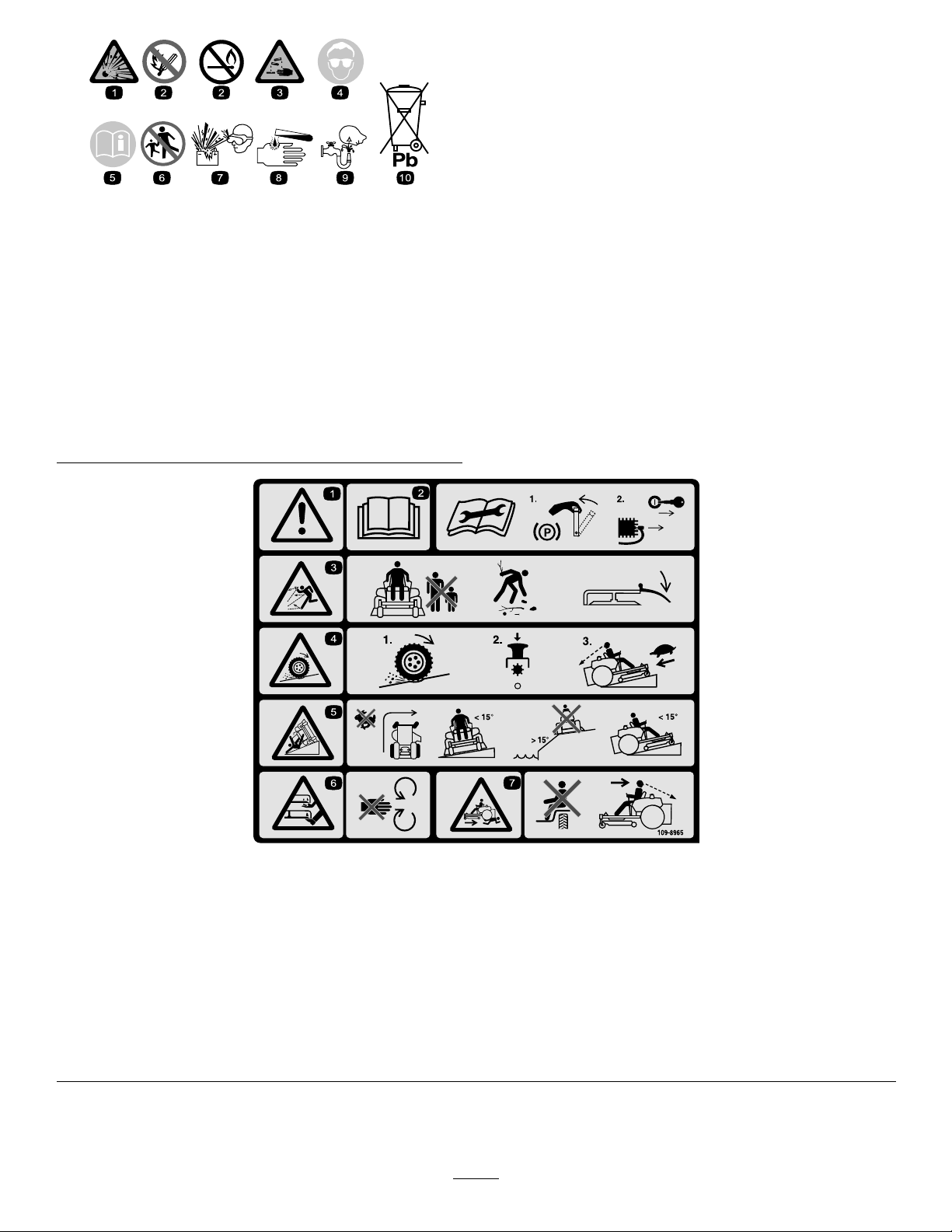

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator’s

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

109-8965

1.Warning–readtheOperator’sManual.

2.Readtheinstructionsbeforeservicingorperformingmaintenance;applyparkingbrake,removetheignitionkeyanddisconnect

thesparkplugwire.

3.Thrownobjecthazard—keepbystandersasafedistancefromthemachine,pickupdebrisbeforeoperating,keepthedischarge

deectorinplace.

4.Lossoftraction/controlhazard,slopes–lossoftraction/controlonslope,disengagethebladecontrolswitch(PTO),proceed

offtheslopeslowly.

5.Tippinghazard–avoidsuddenandsharpturnswhileonslopes,onlymowacrossslopeslessthan15degrees,keepasafe

distancefromwater,andonlymowupanddownslopeslessthan15degrees.

6.Cutting/dismembermenthazardofhandorfoot,mowerblade–stayawayfrommovingparts.

7.Crushing/dismembermenthazardofbystanders,reversing–DoNotcarrypassengers,lookbehindanddownwhenreversing.

10

Page 11

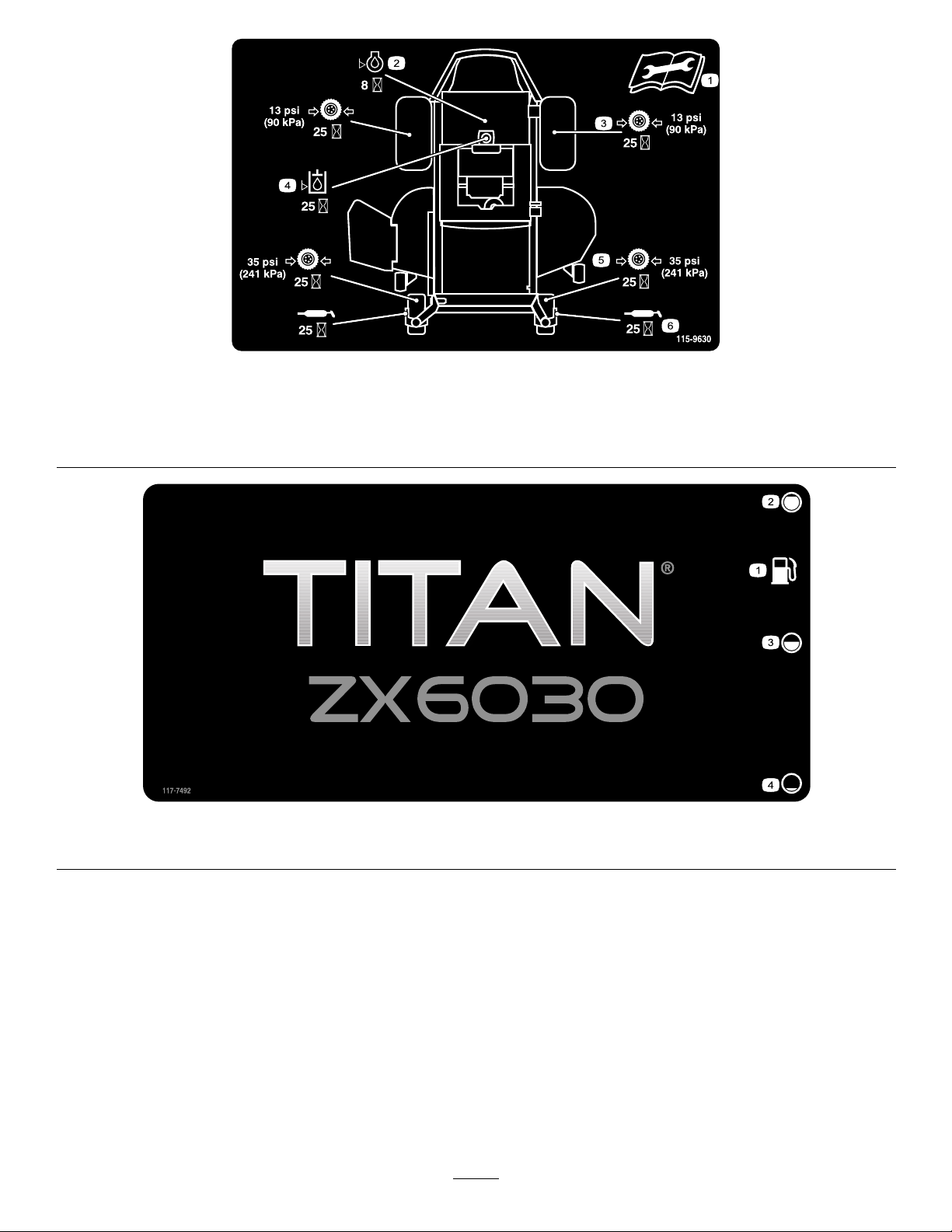

115-9630

1.ReadtheOperator’sManualbeforeperformingany

maintenance.

2.Checktheengineoilevery8hours5.Checkthecasterwheeltirepressureevery25hours

3.Checkthedrivewheeltirepressureevery25hours

4.Checkthehydraulicoilevery25hours

6.Lubricatethecasterwheelevery25hours

117-7492

1.Fuel2.Full

3.Half

4.Empty

11

Page 12

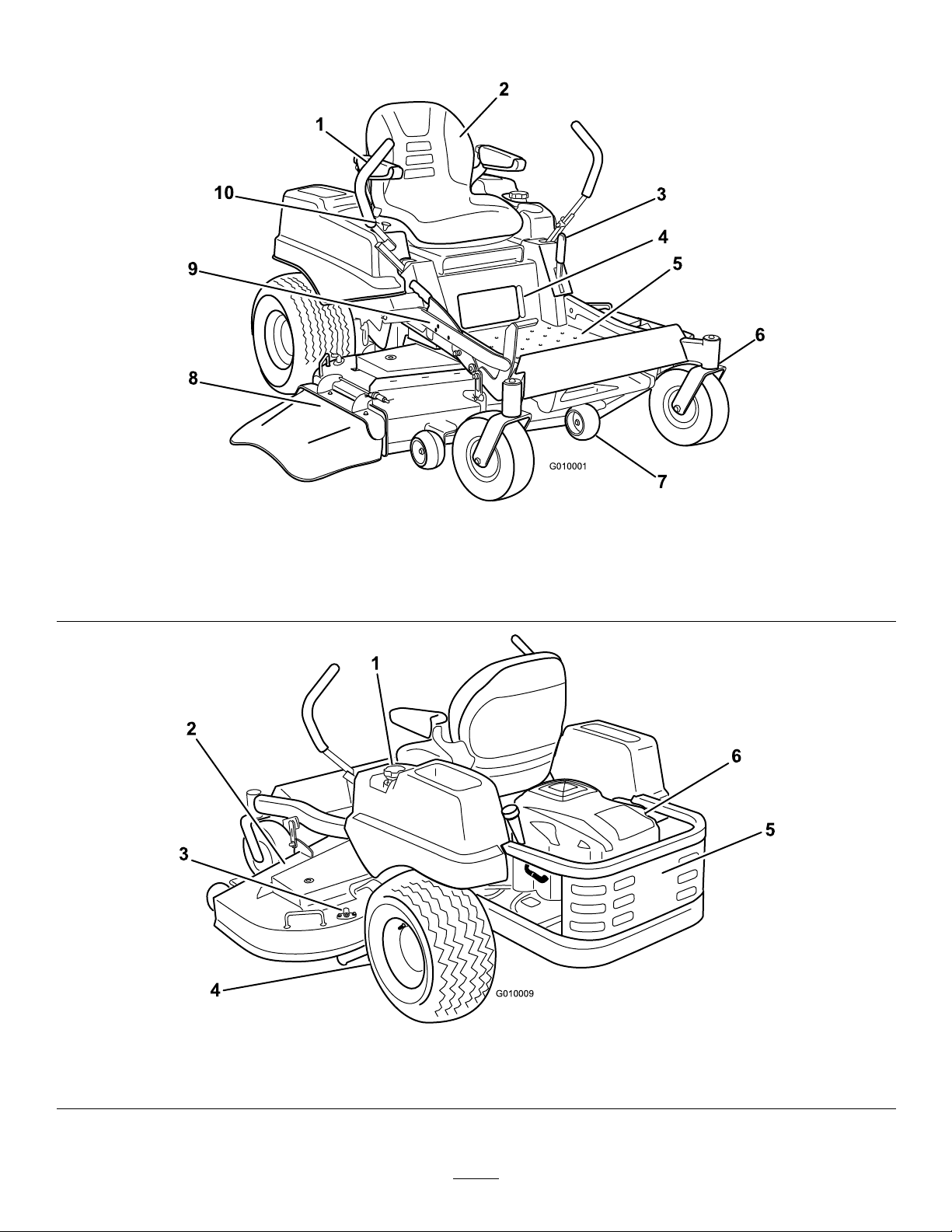

ProductOverview

G010001

1

2

3

4

5

6

7

8

9

10

G010009

1

2

3

4

5

6

Figure4

1.Motioncontrollevers4.Fuelgauge7.Anti-scalproller

2.Operatorseat

3.Parkingbrake6.Frontcasterwheel

5.Footrest

8.Deector

9.Footpedaldeckliftand

height-of-cut

10.Controlpanel

Figure5

1.Gastankcap

2.MowerDeck4.Drivewheel6.Engine

3.Washoutport5.Engineguard

12

Page 13

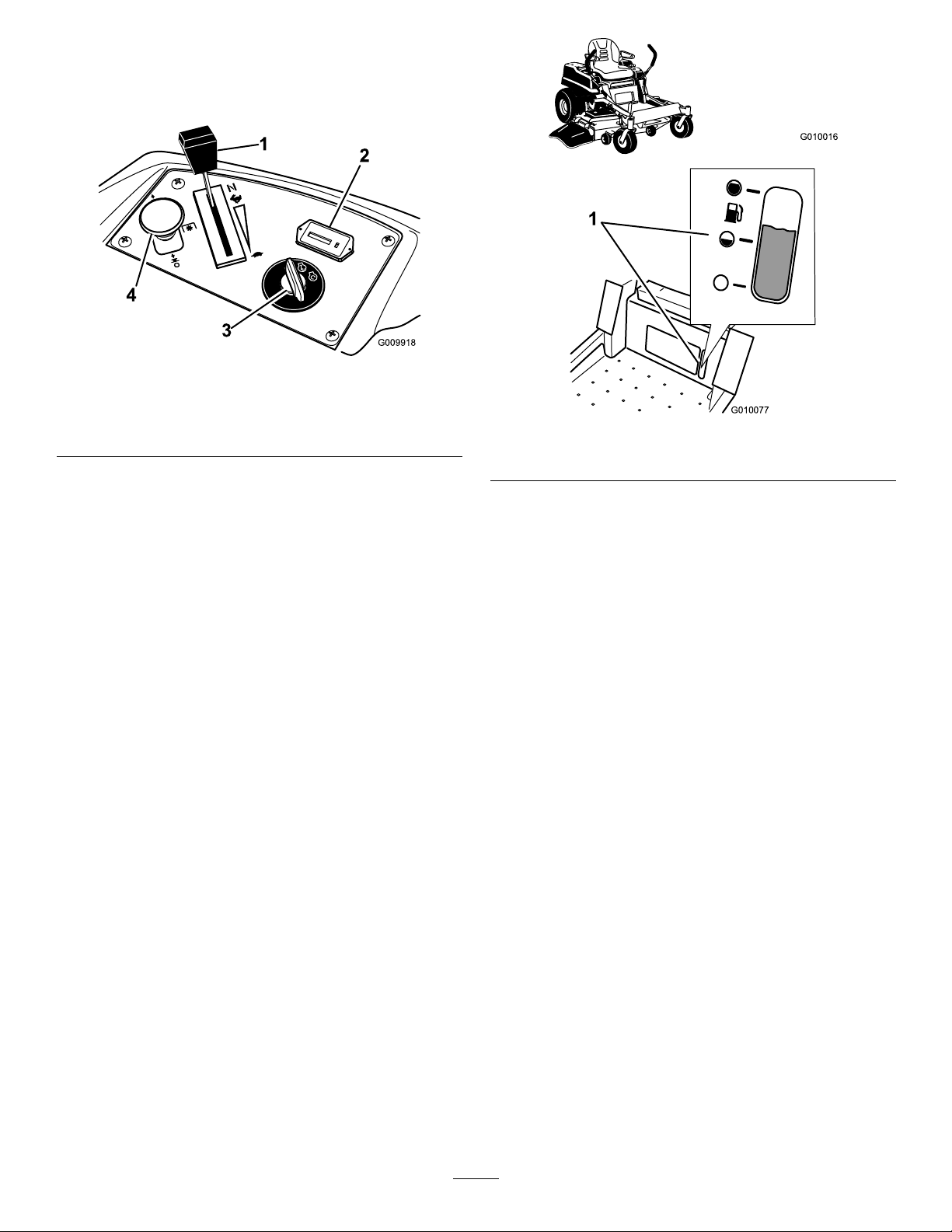

Controls

G009918

1

2

3

4

G010016

G010077

1

Becomefamiliarwithallthecontrolsbeforeyoustart

theengineandoperatethemachine(Figure6).

Figure6

1.Throttleandchokecontrol

2.Hourmeter5.Fuses

3.Ignitionswitch

IgnitionSwitch

4.Bladecontrolswitch(PTO)

Figure7

1.Fuelgaugewindow

Theignitionswitchhasthreepositions:Start,Run

andOff.ThekeywillturntoStartandmovebackto

Runuponrelease.TurningthekeytotheOffposition

willstoptheengine;however,alwaysremovethekey

whenleavingthemachinetopreventtheenginefrom

accidentallystarting(

Figure6).

Throttle/ChokeControl

Thethrottleandchokeiscombinedintoonecontrol

lever.ThethrottlecontrolisvariablebetweenFastand

Slow.Engagethechokebymovingtheleverpastthe

Fastsettinguntilitstops(

Figure6).

BladeControlSwitch(PowerTake-Off)

Thebladecontrolswitch,representedbyapower

take-off(PTO)symbol,engagesanddisengagespower

tothemowerblades(Figure6).

HourMeter

Thehourmeterrecordsthenumberofhourstheblades

haveoperated.Itoperateswhenthebladecontrol

switch(PTO)isengaged.Usethesetimesforscheduling

regularmaintenance(Figure6).

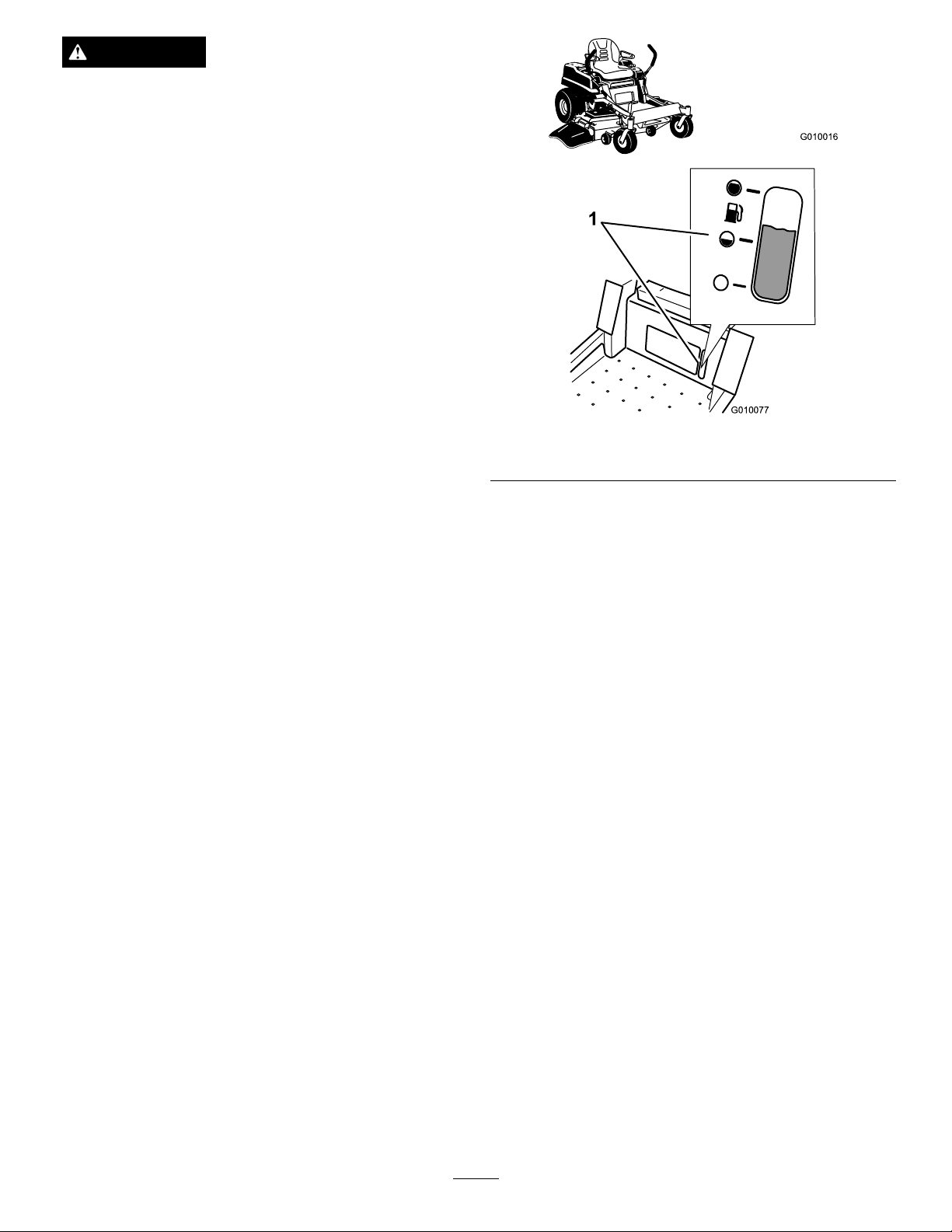

FuelGauge

Thefuelwindowlocatedbelowtheoperatorposition

canbeusedtoverifythelevelofgasolineinthetank

(Figure7).

MotionControlLevers

Themotioncontrolleversarespeedsensitivecontrols

ofindependentwheelmotors.Movingaleverforward

orbackwardturnsthewheelonthesamesideforward

orinreverse;wheelspeedisproportionaltotheamount

theleverismoved.Movethecontrolleversoutward

fromthecentertotheneutrallockpositionandexitthe

machine(

Figure4).Alwayspositionthemotioncontrol

leversintotheneutrallockpositionwhenyoustopthe

machineorleaveitunattended.

NeutralLockPosition

Theneutrallockpositionisusedwiththesafetyinterlock

systemtoengageanddisengagethemowerbladesand

todetermineneutralposition.

FootPedalDeckLiftSystem

Thefootpedaldeckliftsystemallowstheoperator

tolowerandraisethedeckfromtheseatedposition.

Theoperatorcanusethefootpedaltoliftthedeck

brieytoavoidobstaclesorlockthedeckinthehighest

height-of-cutortransportposition(Figure4).

Height-of-CutLever

Theheight-of-cutleverworkswiththefootpedalto

lockthedeckinaspeciccuttingheight.Onlyadjustthe

heightofcutwhilemachineisnotmoving(Figure4).

13

Page 14

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

ThinkSafetyFirst

Pleasecarefullyreadallofthesafetyinstructionsand

decalsinthesafetysection.Knowingthisinformation

couldhelpyou,yourfamily,petsorbystandersavoid

injury.

DANGER

Mowingonwetgrassorsteepslopescancause

slidingandlossofcontrol.

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,deathor

drowning.

Alossoftractionisalossofsteeringcontrol.

Toavoidlossofcontrolandpossibilityofrollover:

•Donotmowneardrop-offsornearwater.

•Donotmowslopesgreaterthan15degrees.

•Reducespeedanduseextremecautionon

slopes.

•Whenmowingslopes,graduallyworkfrom

lowertohigherareasontheincline.

•Avoidsuddenturnsorrapidspeedchanges.

•Turnup,intoaninclinewhenchanging

directionsonslopes.Turningdowntheslope

reducestraction.

•Attachmentschangethehandling

characteristicsofthemachine.Use

extracautionwhenusingattachmentswiththe

machine.

14

Page 15

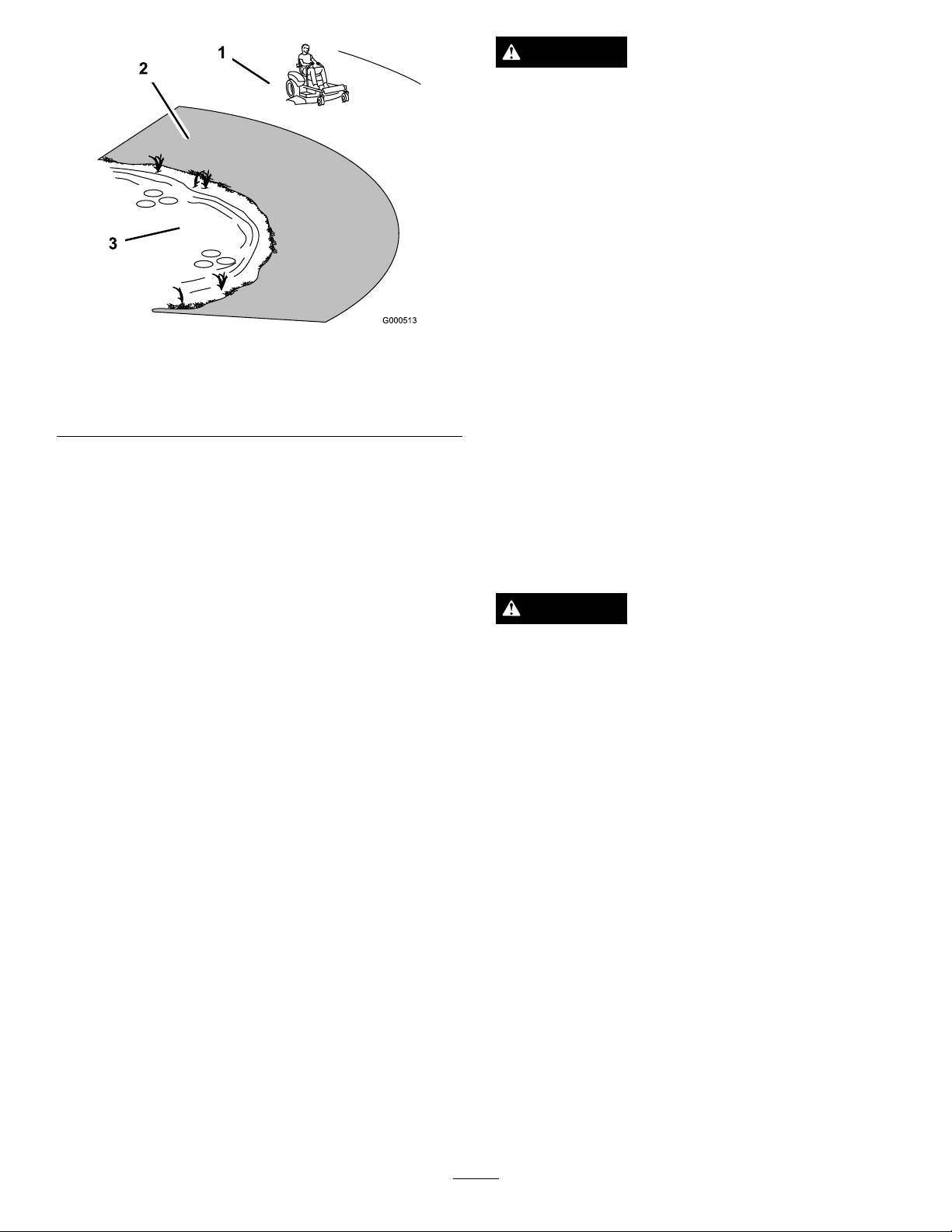

Figure8

1.SafeZone-usethemachinehere

2.Usewalkbehindmowerand/orhandtrimmerneardrop-offs

andwater.

3.Water

AddingFuel

Useunleadedregulargasolinesuitableforautomotive

use(85pumpoctaneminimum).Leadedregular

gasolinemaybeusedifunleadedregularisnotavailable.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis1/4to

1/2inch(6to13mm)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystem

inplaceandinproperworkingcondition.

Important:Neverusemethanol,gasoline

containingmethanol,orgasoholcontainingmore

than10%ethanolbecausethefuelsystemcouldbe

damaged.Donotmixoilwithgasoline.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmayinsulate

thecontainerandslowthelossofanystatic

charge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerandrefuel

theequipmentwithitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

15

Page 16

WARNING

G010016

G010077

1

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporscancauseserious

injuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening .

•Keepgasawayfromeyesandskin.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysor

less.Forlongerstorageitisrecommendedthatthe

fueltankbedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

Figure9

1.Fuelgaugewindow

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditioner

tothegas.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.Tominimizethe

chanceofvarnishdepositsinthefuelsystem,usefuel

stabilizeratalltimes.

Gasoline/Alcoholblends

Gasohol(upto10percentethylalcohol,90percent

unleadedgasolinebyvolume)isapprovedforfueluse

bytheenginemanufacturer.Othergasoline/alcohol

blends,suchasE85,arenotapproved.

Gasoline/Etherblends

MethylTertiaryButylEther(MTBE)andunleaded

gasolineblends(uptoamaximumof15percentMTBE

byvolume)areapprovedforfuelusebytheengine

manufacturer.Othergasoline/etherblendsarenot

approved.

FillingtheFuelT ank

Note:Donotllthefueltankcompletelyfull,thiswill

allowgasolinetoexpand.

1.Shuttheengineoffandsettheparkingbrake.

2.Cleanaroundthefueltankcap.

3.Fillthefueltanktothebottomoftheller

Figure10.

neck

FuelGauge

Usethefuelwindowbelowtheoperatortoverifythe

levelofgasolinebeforellingthetank(Figure9).

16

Page 17

G010016

G010475

1

2

4

3

G010078

1

2

ReleasingtheParkingBrake

G010079

1

2

G010289

G010288

Figure12

OperatingtheThrottle

ThethrottlecontrolcanbemovedbetweenFastand

Slowpositions(Figure13).

Alwaysusethefastpositionwhenturningonthe

mowerdeckwiththebladecontrolswitch(PTO).

Figure10

CheckingtheEngineOilLevel

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoChecking

theEngineOilLevel.

OperatingtheParkingBrake

Alwayssettheparkingbrakewhenyoustopthe

machineorleaveitunattended.

SettingtheParkingBrake

Figure13

OperatingtheChoke

Iftheengineiscold,usethechoketostarttheengine.

Engagethechokebymovingthethrottleleverpastthe

Fastsettinguntilitstops(Figure14).

Figure11

Figure14

Movethethrottleleverbacktodisengagethechoke

aftertheenginehasstarted.

17

Page 18

OperatingtheIgnitionSwitch

START

RUN

STOP

G008947

G010080

2

3

4

5

1

START

RUN

STOP

G008947

1.TurntheignitionkeytotheStartposition

(Figure15).Whentheenginesstarts,releasethekey.

Important:Donotengagestarterformore

than5secondsatatime.Iftheenginefails

tostartallowa15secondcool-downperiod

betweenattempts.Failuretofollowthese

instructionscanburnoutthestartermotor.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthe

fuelsystemhasbeenwithoutfuelcompletely.

Figure15

2.Turntheignitionkeytostoptostoptheengine.

StartingandStoppingthe

Engine

StartingtheEngine

1.Sitdownontheseat(Figure16).

2.Movethemotioncontrolsoutwardtotheneutral

lockposition(

3.Settheparkingbrake(Figure16);refertoSetting

theParkingBrake.

4.Movethebladecontrolswitch(PTO)totheOff

position(

5.MovethethrottlelevertoChokebeforestarting

acoldengine.

Figure16).

Figure16).

Figure16

6.TurntheignitionkeytotheStartposition

(Figure15).Whentheenginesstarts,releasethekey.

Important:Donotengagestarterformore

than5secondsatatime.Iftheenginefails

tostartallowa15secondcool-downperiod

betweenattempts.Failuretofollowthese

instructionscanburnoutthestartermotor.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthe

fuelsystemhasbeenwithoutfuelcompletely.

Note:Awarmorhotenginemaynotrequire

choking.

Figure17

1.Off3.Start

2.Run

18

Page 19

StoppingtheEngine

ST

ART

RUN

ST

OP

G010081

2

3

4

5

1

G008945

G009174

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethetractorwhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

Figure19

DisengagingtheBladeControlSwitch

(PTO)

Figure20

TheSafetyInterlockSystem

WARNING

Figure18

OperatingtheMowerBlade

ControlSwitch(PTO)

Thebladecontrolswitch(PTO)startsandstopsthe

mowerbladesandanypoweredattachments.

EngagingtheBladeControlSwitch

(PTO)

Note:Engagingthebladecontrolswitch(PTO)with

thethrottlepositionathalforlesswillcauseexcessive

weartothedrivebelts.

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

UnderstandingtheSafetyInterlock

System

Thesafetyinterlocksystemisdesignedtopreventthe

enginefromstartingunless:

•Theparkingbrakeisengaged.

•Thebladesaredisengaged.

•Themotioncontrolleversareintheneutrallock

position.

Thesafetyinterlocksystemalsoisdesignedtostopthe

enginewhenthecontrolleversareoutoftheneutral

lockpositionwiththeparkingbrakeonorifyourise

fromtheseatwhenthebladesareengaged.

19

Page 20

TestingtheSafetyInterlockSystem

Testthesafetyinterlocksystembeforeyouusethe

machineeachtime.Ifthesafetysystemdoesnot

operateasdescribedbelow,haveanAuthorizedService

Dealerrepairthesafetysystemimmediately .

1.Whilesittingontheseat,engagetheparkingbrake

andmovethebladecontrolswitchtoOn.Try

startingtheengine;theengineshouldnotcrank.

2.Whilesittingontheseat,engagetheparkingbrake

andmovethebladecontrolswitchtoOff.Move

eithermotioncontrollever(forwardorreverse).

Trystartingtheengine;theengineshouldnotcrank.

Repeatwiththeothermotioncontrollever.

3.Whilesittingontheseat,engagetheparkingbrake,

movethebladecontrolswitchtoOff,andlockthe

motioncontrolleversinneutral.Starttheengine.

Whiletheengineisrunning,releasetheparking

brake,engagethebladecontrolswitch,andrise

slightlyfromtheseat;theengineshouldstop.

4.Whilesittingontheseat,engagetheparkingbrake,

movethebladecontrolswitchtoOff,andlockthe

motioncontrolleversinneutral.Starttheengine.

Whiletheengineisrunning,centerthemotion

controlsandmove(forwardorreverse);theengine

shouldstop.

UsingtheMotionControlLevers

Figure21

1.Motioncontrol

lever-neutrallockposition

2.Center,unlockedposition

3.Forward

4.Backward

DrivingForwardorBackward

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Place

thethrottlecontrolinthefastpositionforbest

performance.Alwaysoperateinthefullthrottle

positionwhenmowing.

CAUTION

Machinecanspinveryrapidly.Operatormaylose

controlofmachineandcausepersonalinjuryor

damagetomachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

DrivingForward

Note:Theenginewillkillifthetractioncontrollevers

aremovedwiththeparkingbrakeengaged.

1.Releasetheparkingbrake;refertoReleasingthe

ParkingBrakeinOperation.

2.Movetheleverstothecenter,unlockedposition.

3.Togoforward,slowlypushthemotioncontrol

leversforward(

Figure22).

20

Page 21

G008952

G008953

StoppingtheMachine

Tostopthemachine,movethetractioncontrollevers

toneutralandmovetolockedposition,disengagethe

bladecontrolswitch(PTO),andturntheignitionkey

tooff.

Settheparkingbrakewhenyouleavethemachine;refer

toSettingtheParkingBrake.Remembertoremovethe

keyfromtheignitionswitch.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethetractorwhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

Figure22

DrivingBackward

1.Movetheleverstothecenter,unlockedposition.

2.Togobackward,slowlypullthemotioncontrol

leversrearward(

Figure23).

AdjustingtheHeightofCut

Themachineisequippedwithafootpedaldecklift

system.Theoperatorcanusethefootpedaltolift

thedeckbrieytoavoidobstaclesorlockthedeckin

thehighestheight-of-cutortransportposition.The

operatorcanusetheheightofcutleverwiththefoot

pedaltolockthedeckinaspeciccuttingheight.

UsingtheFootPedalDeckLiftSystem

Pressthepedaldowntoraisethedeck;continueto

pressthepedaluntilthedeckislockedinthetransport

positionFigure24.Pushonthedeckliftpedalwith

yourfootandraisetheheight-of-cutleverslightlyto

disengagethetransportlock.

Figure23

21

Page 22

G010016

G010219

G010236

1

2

3

4

5

1.Deckliftpedal

2.Cutheightpin

3.Height-of-cutpositions

UsingtheLockPositions

Figure25

4.Lockposition.lowest

height-of-cut(useonlyfor

deckremoval)

5.Lockposition.transport

position

Figure24

TransportLockPosition

Thedeckcanbelockedinthehighestheight-of-cutor

transportpositionorthelowestheight-of-cutposition.

1.Pushonthedeckliftpedalwithyourfootandraise

themowerdecktothetransportposition(also

the4.5inch(114mm)cuttingheightposition)

Figure25).

AdjustingtheHeight-of-Cut

(

2.Removethepinfromtheheight-of-cutbracket

Theheight-of-cutcanbeadjustedfrom1-1/2to

(Figure25).

4-1/2inch(38to114mm)in1/4inch(6mm)

incrementsbyrelocatingtheclevispinintodifferent

holelocations.

1.Pushonthedeckliftpedalwithyourfootandraise

themowerdecktothetransportposition(also

the4-1/2inch(114mm)cuttingheightposition)

Figure25).

(

2.Toadjust,removethepinfromtheheight-of-cut

bracket(Figure25).

3.Selectaholeintheheight-of-cutsystem

correspondingtotheheight-of-cutdesiredand,

insertthepin(Figure25).

4.Pushonthedeckliftpedalwithyourfootandraise

theheight-of-cutleverslightlytodisengagethe

transportlock.Lowerthedeckslowlyuntilthepin

makescontactwiththelever.

3.Selectaholeonthelockdecalandinsertthepin

(Figure25).

4.Pushonthedeckliftpedalwithyourfootandraise

theheight-of-cutleverslightlytodisengagethe

transportlock.Lowerthedecktoslowlyuntilthe

pinmakescontactwiththelever.

AdjustingtheAnti-Scalp

Rollers

Wheneveryouchangetheheight-of-cut,itis

recommendedtoadjusttheheightoftheanti-scalp

rollers.

1.Disengagethebladecontrolswitch(PTO),move

themotioncontrolleverstotheneutrallock

positionandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

22

Page 23

G010233

1

2

3

4

Figure26

G010016

G010232

1

G010484

4

4

1.Anti-scalproller3.FlangeNut

2.Bolt4.Holespacing

PositioningtheSeat

Theseatcanmoveforwardandbackward.Positionthe

seatwhereyouhavethebestcontrolofthemachine

andaremostcomfortable.

Whilesittingintheoperator’ sposition,raisetheseat

adjustmentleverslightlyandmovetheseatforwardor

backwardtothedesiredposition(

Figure27).

ChangingtheSeatRide

Suspension

Thenumberofseatspringscanbechangedto

maximizeridercomfort.Morespringsshouldbeused

withheavieroperatorsandonroughterrain.Fewer

springsshouldbeusedwithlighteroperatorsandwhen

mowingsmooth,wellestablishedlawns.Alwayskeep

thenumberofspringsontheleftandrightsidethe

samewhenaddingandremovingsprings.

1.Adjustmentlever

Figure28

1.Bolt3.Nut

2.Spring

4.Additionalmountingholes

Uptovespringscanbesecuredtotheseatsupport

withanutandbolt,seeFigure28.

RefertoyourPartsManualforspringandhardware

partnumbers.

AdjustingtheMotionControl

Levers

AdjustingtheHeight

Figure27

Themotioncontrolleverscanbeadjustedhigheror

lowerformaximumoperatorcomfort.

1.Removethe2boltsholdingthecontrollevertothe

controlarmshaft(Figure29).

2.Movethecontrollevertothenextsetofholes.

Securetheleverwiththe2bolts(

Figure29).

Note:Thecontrolleverscanalsobeinstalledon

theoutsideofthecontrolarmshafts.

23

Page 24

G010229

1

2

3

4

Figure29

G010337

G010230

G012087

2

3

4

1

1.Controlarmshaft3.Slotted,upperhole

2.Controllever

3.Repeattheadjustmentfortheoppositecontrol

lever.

4.Bolt

PushingtheMachinebyHand

Important:Alwayspushthemachinebyhand.

Nevertowthemachinebecausedamagemay

occur.

ToPushtheMachine

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrolswitch.

2.Movethemotioncontrolleversoutwardtoneutral

lockposition,stoptheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.Makesuretheparkingbrakeis

disengaged.

3.Locatethebypassleversattherearofthemachine,

ontheleftandrightsideoftheframe.

4.Movethebypassleversrearwardandthendown

tolocktheminplaceasshownin

disengagethewheelmotors.Repeatthisoneach

sideofthemachine.

Themachineisnowabletobepushedbyhand.

Figure31to

AdjustingtheTilt

Themotioncontrolleverscanbetiltedforeoraftfor

maximumoperatorcomfort.

1.Loosentheupperboltholdingthecontrolleverto

thecontrolarmshaft.

2.Loosenthelowerboltjustenoughtopivotthe

controlleverforeoraft(Figure29).Tightenboth

boltstosecurethecontrolinthenewposition.

3.Repeattheadjustmentfortheoppositecontrol

lever.

Figure30

Figure31

ToOperatetheMachine

Movethebypasstothepositionfordrivingthemachine

(Figure31)toengagethewheelmotors.

24

Page 25

UsingtheSideDischarge

MowingDirection

Themowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

DANGER

Withoutagrassdeector,dischargecover,or

completegrasscatcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriswillcauseinjuryor

death.

•Neverremovethegrassdeectorfromthe

mowerbecausethegrassdeectorroutes

materialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthemower.

•Nevertrytoclearthedischargeareaormower

bladesunlessyoumovethebladecontrolswitch

(PTO)totheoffposition,rotatetheignition

keytooffandremovethekey .

•Makesurethegrassdeectorisinthedown

position.

Alternatemowingdirectiontokeepthegrassstanding

straight.Thisalsohelpsdisperseclippingswhich

enhancesdecompositionandfertilization.

MowatCorrectIntervals

Normally,moweveryfourdays.Butremember,

grassgrowsatdifferentratesatdifferenttimes.So

tomaintainthesamecuttingheight,whichisagood

practice,mowmoreofteninearlyspring.Asthegrass

growthrateslowsinmidsummer,mowlessfrequently.

Ifyoucannotmowforanextendedperiod,rstmow

atahighcuttingheight;thenmowagaintwodayslater

atalowerheightsetting.

CuttingSpeed

Toimprovecutquality,useaslowergroundspeedin

certainconditions.

AvoidCuttingTooLow

Ifthecuttingwidthofthemoweriswiderthanthe

moweryoupreviouslyused,raisethecuttingheightto

ensurethatuneventurfisnotcuttooshort.

OperatingTips

FastThrottleSetting

Forbestmowingandmaximumaircirculation,operate

theengineatthefastthrottleposition.Airisrequired

tothoroughlycutgrassclippings,sodonotsetthe

height-of-cutsolowastototallysurroundthemower

byuncutgrass.Alwaystrytohaveonesideofthe

mowerfreefromuncutgrass,whichallowsairtobe

drawnintothemower.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethe

cuttingheightofthemowerdoesnotscalpanyuneven

ground.However,thecuttingheightusedinthepastis

generallythebestonetouse.Whencuttinggrasslonger

thansixinchestall,youmaywanttocutthelawntwice

toensureanacceptablequalityofcut.

Cut1/3oftheGrassBlade

LongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,raise

thecuttingheighthigherthanusualandcutthegrassat

thissetting.Thencutthegrassagainusingthelower,

normalsetting.

WhenStopping

Ifthemachine’sforwardmotionmustbestoppedwhile

mowing,aclumpofgrassclippingsmaydropontoyour

lawn.Toavoidthis,moveontoapreviouslycutarea

withthebladesengaged.

KeeptheUndersideoftheMower

Clean

Cleanclippingsanddirtfromtheundersideofthe

moweraftereachuse.Ifgrassanddirtbuildupinside

themower,cuttingqualitywilleventuallybecome

unsatisfactory.

Itisbesttocutonlyabout1/3ofthegrassblade.

Cuttingmorethanthatisnotrecommendedunless

grassissparse,oritislatefallwhengrassgrowsmore

slowly.

BladeMaintenance

Maintainasharpbladethroughoutthecuttingseason

becauseasharpbladecutscleanlywithouttearingor

25

Page 26

shreddingthegrassblades.Tearingandshreddingturns

grassbrownattheedges,whichslowsgrowthand

increasesthechanceofdisease.Checkthecutterblades

dailyforsharpness,andforanywearordamage.File

downanynicksandsharpenthebladesasnecessary.If

abladeisdamagedorworn,replaceitimmediatelywith

agenuineTOROreplacementblade.

26

Page 27

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst50hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

Every200hours

MaintenanceProcedure

•Changetheengineoil.

•Changethehydraulicsystemlterandoil.

•Checkthesafetyinterlocksystem.

•Checktheaircleanerfordirty,looseordamagedparts.

•Checktheengineoillevel.

•Checkairintakeandcoolingareas,cleanasnecessary.

•Checkthemowerblades.

•Inspectthegrassdeectorfordamage

•Cleanthemowerhousing.

•Greasealllubricationpoints.

•Servicethefoamelement.(moreoftenunderdusty ,dirtyconditions)

•Checktirepressure.

•Checkthehydraulicoillevelintheexpansiontank.

•Servicethepaperelement.(moreoftenunderdusty ,dirtyconditions)

•Inspectthebeltsforcracksandwear.

•Replacethepaperelement.(moreoftenunderdusty ,dirtyconditions)

•Changetheengineoil.(moreoftenunderdusty,dirtyconditions)

•Cleantheblowerhousing(moreoftenunderdusty,dirtyconditions).

•Changetheengineoillter.

•Checksparkplug(s)conditionandgap.

Every400hours

Every500hours

Monthly

Yearlyorbeforestorage

•Changethehydraulicsystemlterandoil.

•Replacethesparkplug(s).

•Replacethefuellters(moreoftenunderdusty,dirtyconditions).

•Checkthebatterycharge.

•Paintchippedsurfaces.

•Checkallmaintenanceprocedureslistedabovebeforestorage.

Important:Refertoyourengineoperator’smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

27

Page 28

Figure32

Locatedontheseatpanunderside

1.ReadtheOperator’sManualbeforeperformingany

maintenance.

2.Checktheengineoilevery8hours5.Checkthecasterwheeltirepressureevery25hours

3.Checkthedrivewheeltirepressureevery25hours

Premaintenance

4.Checkthehydraulicoilevery25hours

6.Lubricatethecasterwheelevery25hours

Lubrication

Procedures

GreasingtheBearings

RaisingtheSeat

Makesurethemotioncontrolleversarelockedinthe

neutrallockposition.Lifttheseatforward.

Thefollowingcomponentscanbeaccessedbyraising

theseat:

•Servicedecal

•Fuses

•Batteryandcables

ServiceInterval:Every25hours—Greaseall

lubricationpoints.

GreaseType:No.2GeneralPurposeLithiumBase

Grease

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrolswitch.

2.Movethemotioncontrolleverstotheneutrallock

position,settheparkingbrake,stoptheengine,

removethekey,andwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.Cleanthegreasettings(

witharag.Makesuretoscrapeanypaintoffofthe

frontofthetting(s).

28

Figure33andFigure32)

Page 29

G009949

1

EngineMaintenance

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawaythemuferandotherhotsurfaces.

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Checkthe

aircleanerfordirty,looseordamaged

parts.

Figure33

1.Frontcastertire

4.Connectagreaseguntoeachtting(Figure33and

Figure32).Pumpgreaseintothettingsuntilgrease

beginstooozeoutofthebearings.

5.Wipeupanyexcessgrease.

Every25hours/Yearly(whichever

comesrst)—Servicethefoam

element.(moreoftenunderdusty,

dirtyconditions)

Every50hours—Servicethepaper

element.(moreoftenunderdusty,

dirtyconditions)

Every100hours/Y early(whichever

comesrst)—Replacethepaper

element.(moreoftenunderdusty,

dirtyconditions)

Thisengineisequippedwithareplaceable,highdensity

paperaircleanerelement.Checktheaircleanerdailyor

beforestartingtheengine.Checkforabuildupofdirt

anddebrisaroundtheaircleanersystem.Keepthisarea

clean.Alsocheckforlooseordamagedcomponents.

Replaceallbentordamagedaircleanercomponents.

Note:Operatingtheenginewithlooseordamagedair

cleanercomponentscouldallowunlteredairintothe

enginecausingprematurewearandfailure.

Note:Servicetheaircleanermoreoftenunder

extremelydusty,dirtyconditions.

29

Page 30

G010338

1

2

3

4

5

6

Figure34

1.Aircleanercover4.Aircleanerbase

2.Aircleanerlatch5.Foamelement

3.Aircleaner6.Paperelement

ServicingFoamElement

Checkthefoamelementevery25hoursofoperation

(moreoftenunderextremelydustyordirtyconditions).

Cleanorreplacetheelementasnecessary.

Replacetheaircleanerelementyearly ,orevery100

hours.

1.Opentheaircleanercoverdoorontheblower

housingtoaccesstheaircleanerelement(Figure34).

2.Unhookthelatchandremovetheair

cleaner(Figure34).

3.Removethefoamelementandinspect.Cleanand

replaceasnecessary.

4.Gentlytapthepaperelementtodislodgedirt.Do

notwashthepaperelementorusepressurized

air,asthiswilldamagetheelement.Replaceadirty,

bent,ordamagedelement.Handlethenewelement

carefully;donotuseifthesealingsurfacesarebent

ordamaged.

5.Cleantheaircleanerbaseasrequiredandcheck

condition.

6.Installthepaperelementontotheaircleanerbase.

Securewiththelatch.

7.Closetheaircleanercoverdoor.

ServicingtheEngineOil

Replacetheaircleanerelementyearly ,orevery100

hours.

1.Opentheaircleanercoverdoorontheblower

housingtoaccesstheaircleanerelement(

2.Unhookthelatchandremovetheaircleaner

Figure34).

OilType:Detergentoil(APIserviceSG,SH,SJ,or

higher)

CrankcaseCapacity:1.6-1.8qt(1.7-1.9l)whenthe

lterischanged

Viscosity:Seethetablebelow .

(Figure34).

3.Washthefoamelementinwarmwaterwith

detergent.Rinsetheelementthoroughlyuntilall

tracesofdetergentareeliminated.Squeezeout

excesswater(donotwring)andallowthefoam

elementtoairdry.

4.Saturatethefoamelementwithnewengineoil.

Squeezeoutallexcessoil.

5.Reinstallthefoamelementoverthepaperaircleaner

element.

6.Cleantheaircleanerbaseasrequiredandcheck

condition.

7.Installtheaircleanerontotheaircleanerbase.

Figure35

Securewiththelatch.

8.Closetheaircleanercoverdoor.

Important:UseotherthanserviceclassSG,SH,SJ,

orhigheroilorextendingoilchangeintervalslonger

thanrecommendedcancauseenginedamage.

ServicingPaperElement

Checkthepaperelementevery50hoursofoperation

(moreoftenunderextremelydustyordirtyconditions).

Cleanorreplacetheelementasnecessary.

Note:Syntheticoilsmeetingthelistedclassications

maybeusedwithoilchangesperformedatthe

recommendedintervals.Howevertoallowpistonrings

toproperlyseat,aneworrebuiltengineshouldbe

30

Page 31

operatedforatleast50hoursusingstandardpetroleum

basedoilbeforeswitchingtosyntheticoil.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

“ADD”or“L”markorabovethe“FULL”or“F”

markonthedipstick.

8.Removedipstickandcheckoillevel.Thelevelshould

bebetweenthe“FullorF”and“ AddorL”marks.If

low,addoilofthepropertypeuptothefullmark.

Reinstalloilllcap/dipstickandscrewtight.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawaythemuferandotherhotsurfaces.

Important:Donotoverllthecrankcasewithoil

becausedamagetotheenginemayresult.Donot

runenginewithoilbelowthelowmarkbecausethe

enginemaybedamaged.

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockedposition

andsettheparkingbrake.

2.Makesuretheengineisstopped,level,andiscoolso

theoilhashadtimetodrainintothesump.

3.Tokeepdirt,grassclippings,etc.,outoftheengine,

cleantheareaaroundtheoilllcap/dipstickbefore

removingit.

4.Removethedipstickandwipetheoiloff.

ChangingtheEngineOil

ServiceInterval:Aftertherst8hours

Every100hours(moreoftenunder

dusty,dirtyconditions)

Note:Disposeoftheusedoilatarecyclingcenter.

1.Starttheengineandletitrunveminutes.This

warmstheoilsoitdrainsbetter.

2.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoassuretheoildrains

completely.

3.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockposition

andsettheparkingbrake.

4.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position(

Figure36).

Note:Checkthestyleofoildipstickfortheengine.

Dipstickswiththreadedcapsareuseddifferently

whencheckingtheoillevelthandipsticksthatare

seatedbypushingthemintoplace.

5.Reinsertthedipstickintothetubetochecktheoil

level:

•Threadeddipstickcaps:restthecaponthe

tube.Turnitcouterclockwiseuntiltheoildipstick

dropsdowntothelowestpointofthethread

leads.Donotscrewthecapontothetube.

•Unthreadeddipstickcaps:reinsertthedipstick

andpushrmlyintoplace.

6.Removethedipstickoutandchecktheoillevel.

Theoillevelshouldbeupto,butnotover,the

“FULL”or“F”markonthedipstick

7.Ifthelevelislow ,addoilofthepropertype,uptothe

“FULL”or“F”markonthedipstick.Alwayscheck

thelevelwiththedipstickbeforeaddingmoreoil.

Note:Topreventextensiveenginewearordamage,

alwaysmaintaintheproperoillevelinthecrankcase.

Neveroperatetheenginewiththeoillevelbelowthe

31

Page 32

G009950

G010457

1 2

3

4

5

6

5.Slowlypourapproximately80%ofthespeciedoil

G009950

G008748

3/4

1

2

3

4

5

6

intothellertubeandslowlyaddtheadditionaloil

tobringittotheFullmark.

6.Installtheoilllcap/dipstick.

7.Checktheoillevel;refertoCheckingtheOilLevel.

8.Slowlyaddadditionaloiltobringittothefullmark.

9.Installtheoilllcap/dipstick.

ChangingtheEngineOilFilter

ServiceInterval:Every200hours

Note:Changetheengineoilltermorefrequently

whenoperatingconditionsareextremelydustyorsandy.

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil.

Figure36

2.Changetheengineoillter(

Figure37).

Figure37

32

Page 33

Note:Ensuretheoilltergaskettouchestheengine

G010230

G008794

1

2

18-22ft-lb

25-29N-m

G010339

andthenanextra3/4turniscompleted.

3.Fillthecrankcasewiththepropertypeofnewoil;

refertoChangingtheOil.

ServicingtheSparkPlug

ServiceInterval:Every200hours—Checkspark

plug(s)conditionandgap.

Every500hours—Replacethespark

plug(s).

Setthegapto0.030inches(0.76mm).

Figure39

ThesparkplugisRFIcompliant.Equivalentalternate

brandplugscanalsobeused.Sparkplugreplacementis

recommendedat500hours.

Type:ChampionXC12YC(orequivalent)

AirGap:0.030inch(0.76mm)

RemovingtheSparkPlug

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockposition

andsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

InstallingtheSparkPlug

Tightenthesparkplugto18-22ft-lb(25-29N-m).

Figure40

Figure38

CheckingtheSparkPlug

Important:Nevercleanthesparkplug(s).Always

replacethesparkplug(s)whenithas:ablack

coating,wornelectrodes,anoilylm,orcracks.

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeanstheaircleanerisdirty.

CleaningtheBlowerHousing

Toensurepropercooling,makesurethegrassscreen,

coolingns,andotherexternalsurfacesoftheengine

arekeptcleanatalltimes.

Annuallyorevery100hoursofoperation(moreoften

underextremelydusty ,dirtyconditions),removethe

blowerhousingandanyothercoolingshrouds.Clean

thecoolingnsandexternalsurfacesasnecessary.Make

surethecoolingshroudsarereinstalled.Torquethe

blowerhousingscrewsto5.5ft-lb(7.5N-m).

Important:Operatingtheenginewithablocked

grassscreen,dirtyorpluggedcoolingns,and/or

coolingshroudsremoved,willcauseenginedamage

duetooverheating.

33

Page 34

FuelSystem

G008963

12

3

ElectricalSystem

Maintenance

ReplacingtheFuelFilter

ServiceInterval:Every500hours/Yearly(whichever

comesrst)(moreoftenunderdusty,

dirtyconditions).

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockposition,

andsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Allowthemachinetocooldown.

4.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

5.Squeezetheendsofthehoseclampstogetherand

slidethemawayfromthelter(

Figure41).

Maintenance

ServicingtheBattery

ServiceInterval:Monthly

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

Figure41

1.Fuellter

2.Hoseclamp

6.Removethelterfromthefuellines.

7.Installanewlterandmovethehoseclampsclose

tothelter(Figure41).

3.Fuelline

Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing.Wearsafetyglassestoshield

youreyesandrubberglovestoprotectyourhands.

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery ,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

8.Openthefuelshutoffvalve.

Note:Itisimportanttoreinstallthefuellinehosesand

securewithplastictiesthesameastheywereoriginally

installedatthefactorytokeepthefuellineawayfrom

componentsthatcouldcausefuellinedamage.

34

Page 35

WARNING

G010340

G010240

1

2

3

4

Incorrectbatterycableroutingcoulddamagethe

machineandcablescausingsparks.Sparkscan

causethebatterygassestoexplode,resultingin

personalinjury.

•AlwaysDisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

•AlwaysReconnectthepositive(red)battery

cablebeforereconnectingthenegative(black)

cable.

5.Slidetheredterminalbootoffthepositive(red)

batteryterminalandremovethepositive(+)(red)

batterycable(Figure42).

6.Removetheclamp(

7.Removethebattery.

Figure42).

InstallingtheBattery

1.Positionbatteryinthetraywiththeterminalposts

oppositefromthehydraulictank(Figure42).

2.First,installthepositive(red)batterycableto

positive(+)batteryterminal.

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockposition

andsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Removethewingnutsecuringthebatteryclamp

Figure42).

(

3.Theninstallthenegativebatterycableandground

wiretothenegative(-)batteryterminal.

4.Securethecableswith2bolts,2washers,and

2locknuts(

5.Slidetheredterminalbootontothepositive(red)

batterypost.

6.Installtheclampandsecureitwiththewingnut

Figure42).

(

Figure42).

ChargingtheBattery

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparksand

amesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged.

Thisisespeciallyimportanttopreventbattery

damagewhenthetemperatureisbelow32°F(0°C).

1.Removethewingnutand

clamp

2.Removethenegative

batterycablebeforethe

positive

4.Firstdisconnectthenegativebatterycable(black)

fromthenegative(-)(black)batteryterminal

(Figure42).

Figure42

3.Removethepositive

batterycable

4.Removebattery

1.Chargebatteryfor10to15minutesat25to30amps

or30minutesat10amps.

2.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthe

chargerleadsfromthebatteryposts(

3.Installthebatteryinthemachineandconnectthe

batterycables,refertoInstallingtheBattery.

Note:Donotrunthemachinewiththebattery

disconnected,electricaldamagemayoccur.

35

Figure43).

Page 36

Figure43

G010340

30

25

1 2

3

G010241

1.PositiveBatteryPost

2.NegativeBatteryPost

3.Red(+)ChargerLead

4.Black(-)ChargerLead

ServicingtheFuses

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance,however,ifafuseblowscheckthe

component/circuitforamalfunctionorshort.

Fuses:

•Main,30amp,blade-type

•Engine,20amp,blade-type

1.Thefusesarelocatedonrighthandconsolenextto

theseat(

2.Toreplacethefuses,pulloutonthefusetoremove

it.

3.Installanewfuse(Figure44).

Figure44).

Figure44

1.30amp3.Fuseblock

2.25amp

36

Page 37

DriveSystem

G010253

1

2

3

HydraulicSystem

Maintenance

CheckingtheTirePressure

ServiceInterval:Every25hours—Checktirepressure.

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseunevencut.

Checkthepressureatthevalvestem(Figure45).Check

thetireswhentheyarecoldtogetthemostaccurate

pressurereading.

RearTires:13psi(90kPa)

FrontTires(casterwheels):35psi(241kPa)

Maintenance

OilType:20w-50engineoil.

Important:Useoilspeciedorequivalent.Other

uidscouldcausesystemdamage.

CheckingtheHydraulicOil

Level

ServiceInterval:Every25hours

Checkexpansionreservoirandifnecessaryadd20W-50

engineoiltotheFULLCOLDline

Figure45

1.Valvestem

Figure46

1.Expansionreservoir3.Engine

2.FullColdline

ChangingtheHydraulic

SystemFilterandOil

Thelterandoilarechangedatthesametime.DoNot

reuseoil.Oncethenewlterisinstalledandoilisadded

anyairinthesystemmustbepurged.

Thebleedingprocessisrepeateduntiltheoilremains

attheFULLCOLDlineinthereservoirafterpurging.

Failuretoproperlyperformthisprocedurecan

37

Page 38

resultinirreparabledamagetothetransaxledrive

G010254

1

2

3

4

5

G008748

3/4

1

2

3

4

5

6

system.

RemovingHydraulicSystemFilters

1.Stopengine,waitforallmovingpartstostop,and

allowenginetocool.Removethekeyandengage

theparkingbrake.

2.Locatethelterandguardsoneachtransaxledrive

system(Figure47).Removethreescrewssecuring

thelterguardandguard.

Figure47

Rightsideshown

1.Transaxledrive

2.Oillter

3.Filterguard

3.Carefullycleanareaaroundlters.Itisimportant

thatnodirtorcontaminationenterhydraulicsystem.

4.Locateandremovetheventplugoneach

transmission

5.Placeacontainerbelowtheltertocatchtheoilthat

drainswhenthelterisremoved.Unscrewthelter

toremoveandallowoiltodrainfromdrivesystem.

Repeatthisprocedureforbothlters.

InstallingtheHydraulicSystemFilters

ServiceInterval:Aftertherst50hours

Every400hours

4.Screws

5.Ventplug

Figure48

1.Applyathincoatofoilonthesurfaceoftherubber

sealofeachlter.

2.Turnthelterclockwiseuntilrubbersealcontacts

thelteradapterthentightenthelteranadditional

3/4to1fullturn.Repeatfortheotherlter

3.Installthelterguardsovereachlteraspreviously

removed.Usethethreescrewstosecurethelter

guards.

4.Slowlypourthespeciedoilthroughexpansion

reservoiruntiloilcomesoutofventplugholes.Stop

andinstalltheventplugs.Torqueplugsto180in-lb

(20.3N-m).

5.ContinuetoaddoiluntilitreachestheFULLCOLD

lineontheexpansionreservoir.Proceedtothe

BleedingtheHydraulicSystemsection.

Important:Failuretoperformthe

the Hy draulic System

hydraulicltersandoilcanresultinirreparable

damagetothetransaxledrivesystem.

procedureafterchanging

Bleeding

BleedingtheHydraulicSystem

1.Raisetherearofmachineupandsupportwithjack

stands(orequivalentsupport)justhighenoughto

allowdrivewheelstoturnfreely.

38

Page 39

G010333

1

Figure49

1.Jackingpoints

2.Startengineandmovethrottlecontrolaheadto1/2

throttleposition.Disengageparkingbrake.

A.Movethebypassleversintothepushingthe

machineposition;refertothePushingthe

MachinebyHandsectioninOperation.With

thebypassvalvesopenandtheenginerunning,

slowlymovethemotioncontrolleversinboth

forwardandreverse(5or6times).

B.Movethebypassleversintotheoperating

themachineposition.Withthebypassvalve

closedandtheenginerunning,slowlymovethe

directionalcontrolinbothforwardandreverse

directions(5to6times).

C.Stoptheengineandchecktheoillevelinthe

expansionreservoir.Addthespeciedoilas

untilitreachestheFULLCOLDlineonthe

expansionreservoir.

3.Repeatstep2untilalltheairiscompletelypurged

fromthesystem.

MowerDeck

Maintenance

ServicingtheCuttingBlades

Maintainsharpbladesthroughoutthecuttingseason

becausesharpbladescutcleanlywithouttearingor

shreddingthegrassblades.Tearingandshreddingturns

grassbrownattheedges,whichslowsgrowthand

increasesthechanceofdisease.

Checkthecutterbladesdailyforsharpness,andforany

wearordamage.Filedownanynicksandsharpenthe

bladesasnecessary.Ifabladeisdamagedorworn,

replaceitimmediatelywithagenuineTororeplacement

blade.Forconvenientsharpeningandreplacement,you

maywanttokeepextrabladesonhand.

WARNING

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownintotheoperator’s

orbystander’sarea,resultinginseriouspersonal

injuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

BeforeInspectingorServicingthe

Blades

Parkthemachineonalevelsurface,disengagetheblade

controlswitch(PTO),andsettheparkingbrake.Turn

theignitionkeytoOff.Removethekey.

Whenthetransaxleoperatesatnormalnoiselevels

andmovessmoothlyforwardandreverseatnormal

speeds,thenthetransaxleisconsideredpurged.

4.Checktheoillevelintheexpansionreservoirone

lasttime.Addthespeciedoilasuntilitreaches

theFULLCOLDlineontheexpansionreservoir

ifnecessary.

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily

1.Inspectthecuttingedges(Figure50).Iftheedges

arenotsharporhavenicks,removeandsharpenthe

blades.RefertoSharpeningtheBlades.

2.Inspecttheblades,especiallythecurvedarea

(Figure50).Ifyounoticeanydamage,wear,oraslot

forminginthisarea(Figure50),immediatelyinstalla

newblade.

39

Page 40

Figure50

G009679

1

2

3

G009680

1

2

3

G009681

1

2

3

1.CuttingEdge3.Wear/slotForming

2.CurvedArea4.Crack

3.Measurefromthetipofthebladetotheatsurface

here.

CheckingforBentBlades

Note:Themachinemustbeonalevelsurfaceforthe

followingprocedure.

1.Raisethemowerdecktothehighestheight-of-cut

position;alsoconsideredthe’transport’position.

2.Whilewearingthicklypaddedglovesorother

adequatehandprotectionslowlyrotatebladeto

bemeasuredintoapositionthatallowseffective

measurementofthedistancebetweenthecutting

edgeandthelevelsurfacethemachineison.

Figure51

1.Deck3.Blade

2.Spindlehousing

Figure52

1.Blade,inpositionformeasuring

2.Levelsurface

3.Measureddistancebetweenbladeandsurface(A)

4.Rotatethesameblade180degreessothatthe

opposingcuttingedgeisnowinthesameposition.

Figure53

1.Blade,sidepreviouslymeasured

2.Measurementpositionusedpreviously

3.Opposingsideofbladebeingmovedintomeasurement

position

5.Measurefromthetipofthebladetotheatsurface

here.Thevarianceshouldbenomorethan1/8inch

(3mm).

40

Page 41

G009680

1

2

3

Figure54

1

2

3

4

G010341

1.Opposingbladeedge,inpositionformeasuring

2.Levelsurface

3.Secondmeasureddistancebetweenbladeandsurface(B)

WARNING

Abladethatisbentordamagedcouldbreak

apartandcouldseriouslyinjureorkillyouor

bystanders.

•Alwaysreplacebentordamagedbladewith

anewblade.

•Neverleorcreatesharpnotchesinthe

edgesorsurfacesofblade.

A.IfthedifferencebetweenAandBisgreater

than1/8inch(3mm)replacethebladewitha

newblade.RefertoRemovingtheBladesand

InstallingtheBlades.

Note:Ifabentbladeisreplacedwithanewone

andthedimensionobtainedcontinuestoexceed

1/8inch(3mm),thebladespindlecouldbebent.

ContactanAuthorizedToroDealerforservice.

B.Ifthevarianceiswithinconstraints,movetothe

nextblade..

Figure55

1.SailAreaofBlade3.Curvedwasher

2.Blade4.BladeBolt

SharpeningtheBlades

WARNING

Whensharpeningblade,piecesofbladecouldbe

thrownandcauseseriousinjury.

Wearpropereyeprotectionwhensharpeningblade.

1.Usealetosharpenthecuttingedgeatbothends

oftheblade(Figure56).Maintaintheoriginalangle.

Thebladeretainsitsbalanceifthesameamountof

materialisremovedfrombothcuttingedges.

Repeatthisprocedureoneachblade.

RemovingtheBlades

Bladesmustbereplacedifasolidobjectishit,ifthe

bladeisoutofbalanceorisbent.Toensureoptimum

performanceandcontinuedsafetyconformanceof

themachine,usegenuineT ororeplacementblades.

Replacementbladesmadebyothermanufacturersmay

resultinnon-conformancewithsafetystandards.

Holdthebladeendusingaragorthickly-paddedglove.

Removethebladebolt,curvedwasher,andbladefrom

thespindleshaft(Figure55).

Figure56

1.Sharpenatoriginalangle

2.Checkthebalanceofthebladebyputtingitona

bladebalancer(Figure57).Ifthebladestaysina

horizontalposition,thebladeisbalancedandcanbe

used.Ifthebladeisnotbalanced,lesomemetaloff

theendofthesailareaonly(Figure55).Repeatthis

procedureuntilthebladeisbalanced.

41

Page 42

Figure57

1.Blade2.Balancer

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure55).

Important:Thecurvedpartoftheblademust

bepointingupwardtowardtheinsideofthe

mowertoensurepropercutting.

2.Installthespringdiskandbladebolt.Thespring

diskconemustbeinstalledtowardthebolthead

Figure55).Torquethebladeboltto100-110ft-lb

(

(135-150N-m).

arenotwithin3/16inch(5mm),anadjustmentis

required;continuetotheLevelingprocedure.

Figure58

1.Bladessidetoside

2.Outsidecuttingedges

3.Measurefromthetipofthe

bladetotheatsurface

here

MowerDeckLeveling

Checktoensurethemowerdeckislevelanytimeyou

installthemowerorwhenyouseeanunevencuton

yourlawn.

Themowerdeckmustbecheckedforbentblades

priortoleveling;anybentbladesmustberemoved

andreplaced.RefertotheCheckingforBentBlades

procedurebeforecontinuing.

Themowerdeckmustbeleveledside-to-siderstthen

thefronttorearslopecanbeadjusted.

Requirements:

•Themachinemustbeonalevelsurface.

•Allfourtiremustbeproperlyinated.Referto

CheckingtheTirePressureintheDriveSystem

Maintenancesection.

CheckingSide-to-SideLevel

Themowerbladesmustbelevelfromsidetoside.

Checktheside-to-sidelevelanytimeyouinstallthe

mowerorwhenyouseeanunevencutonyourlawn.

CheckingtheFront-to-RearBlade

Slope

Checkthefront-to-rearbladelevelanytimeyouinstall

themower.Ifthefrontofthemowerismorethan

5/16inch(7.9mm)lowerthantherearofthemower,

adjustthebladelevelusingthefollowinginstructions:

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothe

neutralposition,engagetheparkingbrake,stopthe

engine,removethekey ,andwaitforallmovingparts

tostopbeforeleavingtheoperatingposition.

3.Carefullyrotatethebladessotheyarefacingfront

torear(

4.Measurefromthetipofthefrontbladetotheat

surfaceandthetipoftherearbladetotheatsurface

Figure59).Ifthefrontbladetipisnot1/16-5/16

(

inch(1.6-7.9mm)lowerthantherearbladetip,

continuetotheLevelingtheMowerDeckprocedure.

Figure59).

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothe

neutrallockposition,stoptheengine,removethe

key,andwaitforallmovingpartstostopbefore

leavingtheoperatingposition.

3.Carefullyrotatethebladessidetoside.

4.Measurebetweentheoutsidecuttingedgesand

theatsurface(Figure58).Ifbothmeasurements

42

Page 43

Figure59

G010336

1

2

3

G010321

1

2

3

1

2

3

4

4

1.Bladesfronttorear3.Measurefromthetipofthe

bladetotheatsurface

here

2.Outsidecuttingedges

LevelingtheMowerDeck

1.Setanti-scalprollerstotopholesorremove

completelyforthisprocedure.

2.Settheheight-of-cutlevertothe3inch(76mm)

position.

3.Placetwo2-5/8inch(6.66cm)blocksundereach