Page 1

TITANZero-Turn-RadiusRidingMowers

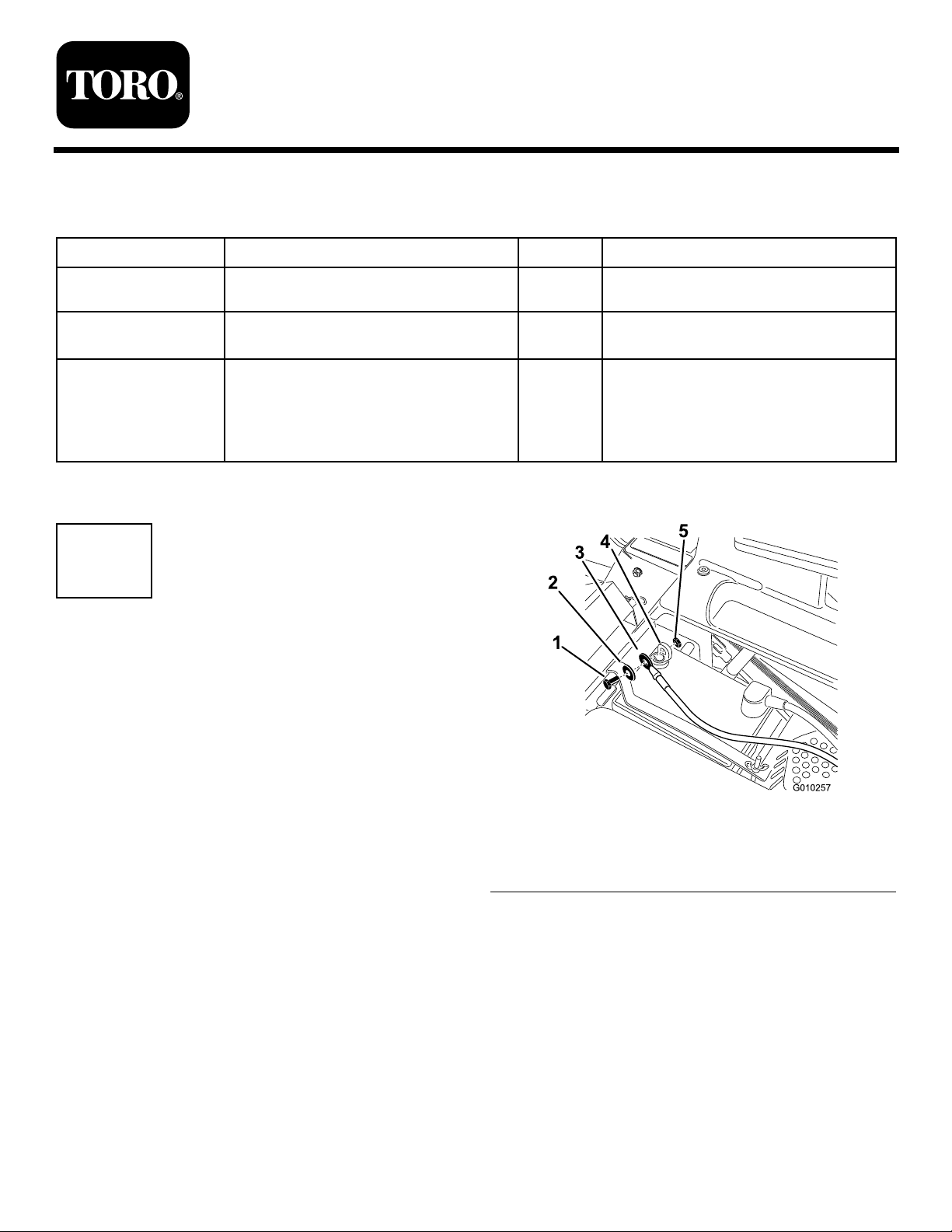

G010257

1

2

3

5

4

ModelNo.AllModels

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

FormNo.3360-964RevA

SetupInstructions

ProcedureDescription

1

2

3

Nopartsrequired

Nopartsrequired

IgnitionKey1

Hosecoupling1

Operator’sManual

EngineOperator’sManual

OperatorTrainingMaterial

Qty.

–

–

1

1

1

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

1

ConnectingtheBattery

NoPartsRequired

Use

Connectthebattery.

Setupthemotioncontrolleversandthe

Seat.

CompletetheSetup.

Procedure

1.Locatethebatteryandnegativebatterycableinthe

centerofthemachine.

2.Removetheblackplasticcapfromthenegative

batterypost.Removethefastenersfromthenegative

batterycableandusethemtosecurethenegative

batterycabletothenegativebatterypost(Figure1).

1.Bolt4.Negativebatterypost

2.Washer5.Nut

3.Negativebatterycable

©2009—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

Figure1

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

Page 2

2

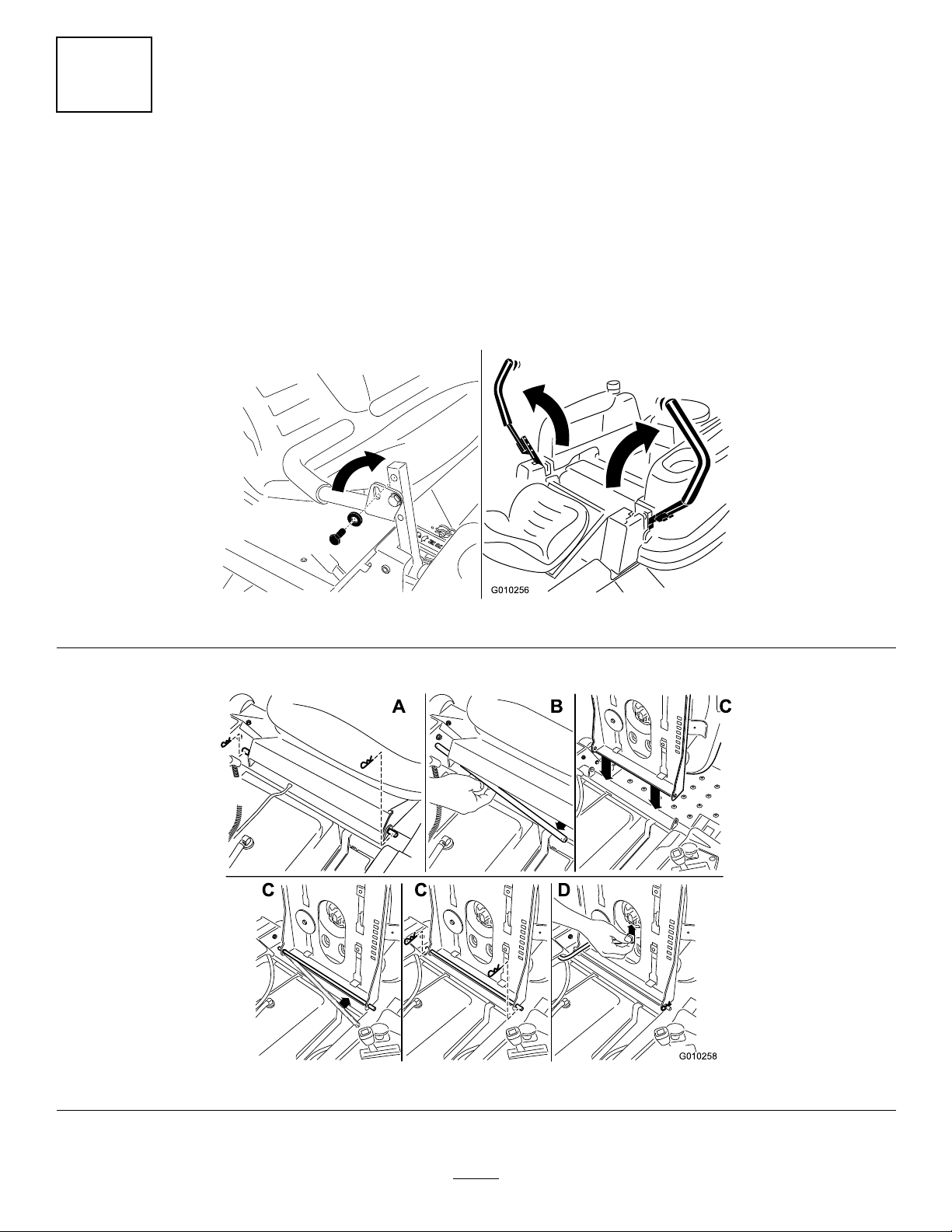

G010256

G010258

A B C

DC C

SettingUptheMotionControlLeversandtheSeat

NoPartsRequired

Procedure

1.Removetheupperbolt(3/8x1inch)andwasher;loosenthelowerbolt(3/8x1inch)asshowninFigure2.

2.Aligntheholesinthemotioncontrolleverwiththeholesinthecontrolarmshaftandinstalltheboltandwasher

removedpreviously(Figure2).Handtightenallfasteners.Repeatthisforbothcontrolslevers.Movethe

motioncontrolleversintotheneutrallockposition.

3.Setuptheseatasfollows(Figure3):

Figure2

Figure3

A.Removethehairpincottersontheseatrodsecuringtheseattothemachine.

2

Page 3

B.Slidetheseatrodoutfromthebracketsandseatframe.

G009802

E F

G009803

C.Rotatetheseat180degreesandinstallitintothebracketyouremoveditfrom,usingtherodandhairpin

cottersremovedpreviously.

D.Connecttheinterlockswitchcabletotheseat.

E.Lowertheseatintotheoperatingposition(Figure4).

F.Movethecontrolleversbacktothecenterposition(neutral)asshowninFigure4.

Figure4

4.Verifythemotioncontrolleversareproperlyaligned(Figure5).Adjustasnecessary.Tightenallfasteners.

Figure5

3

Page 4

3

CompletingtheSetup

Partsneededforthisprocedure:

1IgnitionKey

1Hosecoupling

1

Operator’sManual

1

EngineOperator’sManual

1

OperatorTrainingMaterial

Procedure

CheckingtheTirePressure

Checkthefrontandreartiresforproperination.Refer

toCheckingtheTirePressureintheOperator’sManualfor

therecommendedinationpressure.

CheckingtheSideDischargeChute

Removethepackingrestraintholdingthesidedischarge

chuteupandlowerthechuteintoplace.

CheckingtheEngineOilLevel

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoChecking

theOilLevelintheOperator’ sManual.

CheckingtheHydraulicOilLevel

Beforeyoustarttheengineandusethemachine,check

thehydraulicoillevelinthereservoirbehindtheseat;

refertoCheckingtheOilLevelintheOperator’sManual.

CheckingtheMowerAdjustment

Themowerdeckwasleveledatthefactory.Ifthemower

isnotcuttinglevel,adjusttheside-to-sidelevelandthe

front-to-rearbladeslope.SeetheOperator’sManual

fortheproperprocedure.

ReviewtheRemainingParts

Keepallthefollowingitemswiththemachine:

•IgnitionKey

•Hosecoupling

•Operator’sManual

•EngineOperator’sManual

•ViewtheOperatortrainingmaterial.

4

Loading...

Loading...