Page 1

ZeroTurnRadiusMowers

Allmodels

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

FormNo.3359-833RevA

SetupInstructions

ProcedureDescription

Deectorassembly

7

8

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Rod1

Spring

IgnitionKey1

Hosecoupling1

Operator’sManual

EngineOperator’sManual

OperatorTrainingMaterial

Qty.

1

1

1

1

1

Verifythatlanyardisfreetorotateonbothendsso

thatitpullsstraightwhilesupportingtheseat.

1

CheckingTirePressure

NoPartsRequired

Procedure

Use

Installthedischargedeector

CompletetheSetup.

1.Checkthetirepressureinthedrivetires.Proper

inationfordrivetiresis13psi(90kPa).

2.Adjustifnecessary.

2

FasteningtheSeat

NoPartsRequired

Procedure

1.Removethenutandboltfromthelooseendofthe

lanyard.

2.Tiltseatdownwardandalignlanyardtotheholein

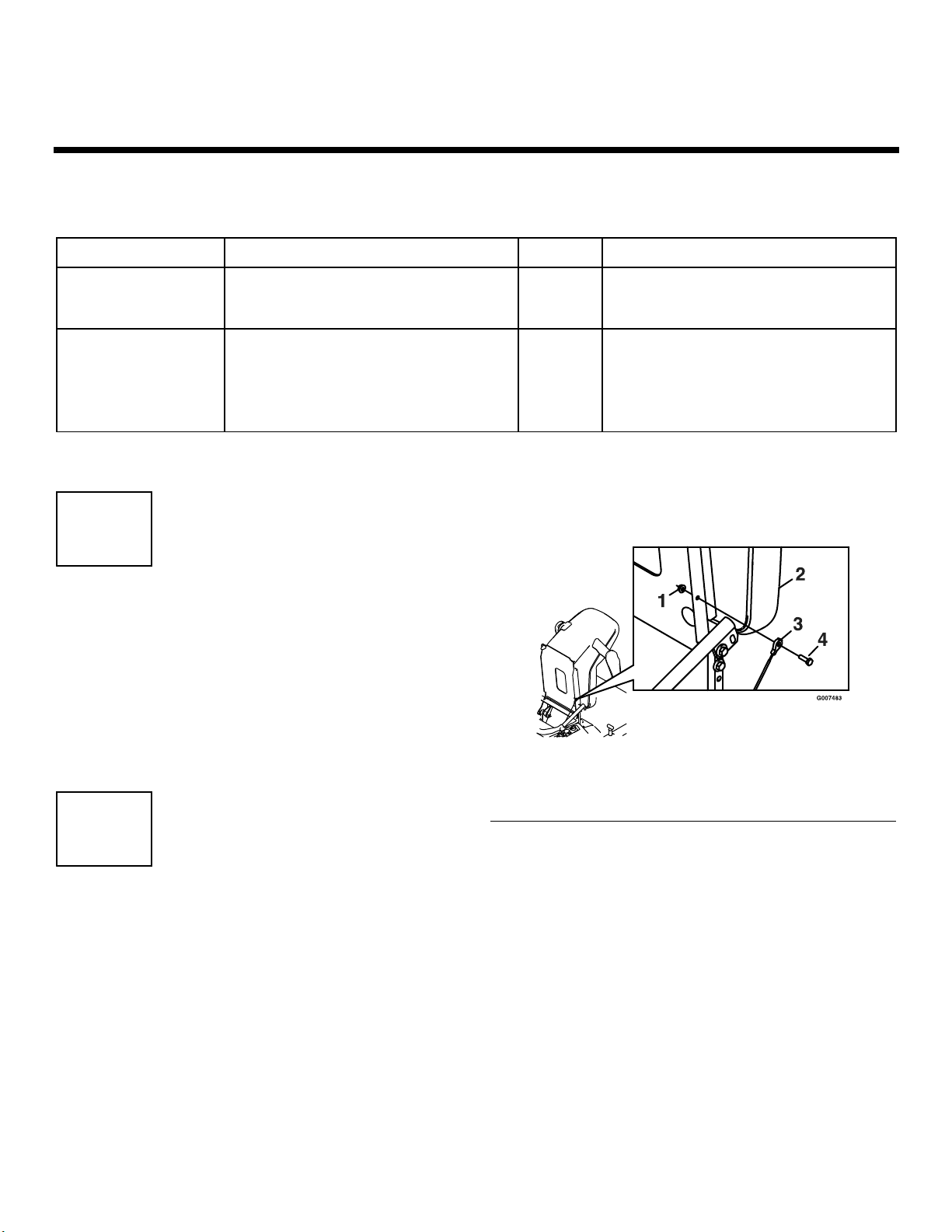

thesideoftheseat(Figure1).

3.Installboltandnut.Tightenboltandthenloosen

nut1/4-1/2turnsothatlanyardendrotatesfreely.

Figure1

1.Seatassembly3.5/16-18inchwhizlocknuts

2.Seattrackstuds

PrintedintheUSA.OriginalInstructions(EN)

AllRightsReserved

Page 2

3

ServicingtheBattery

NoPartsRequired

Procedure

Warning

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

Important:Themachineisshippedwithalled

leadacidbattery.

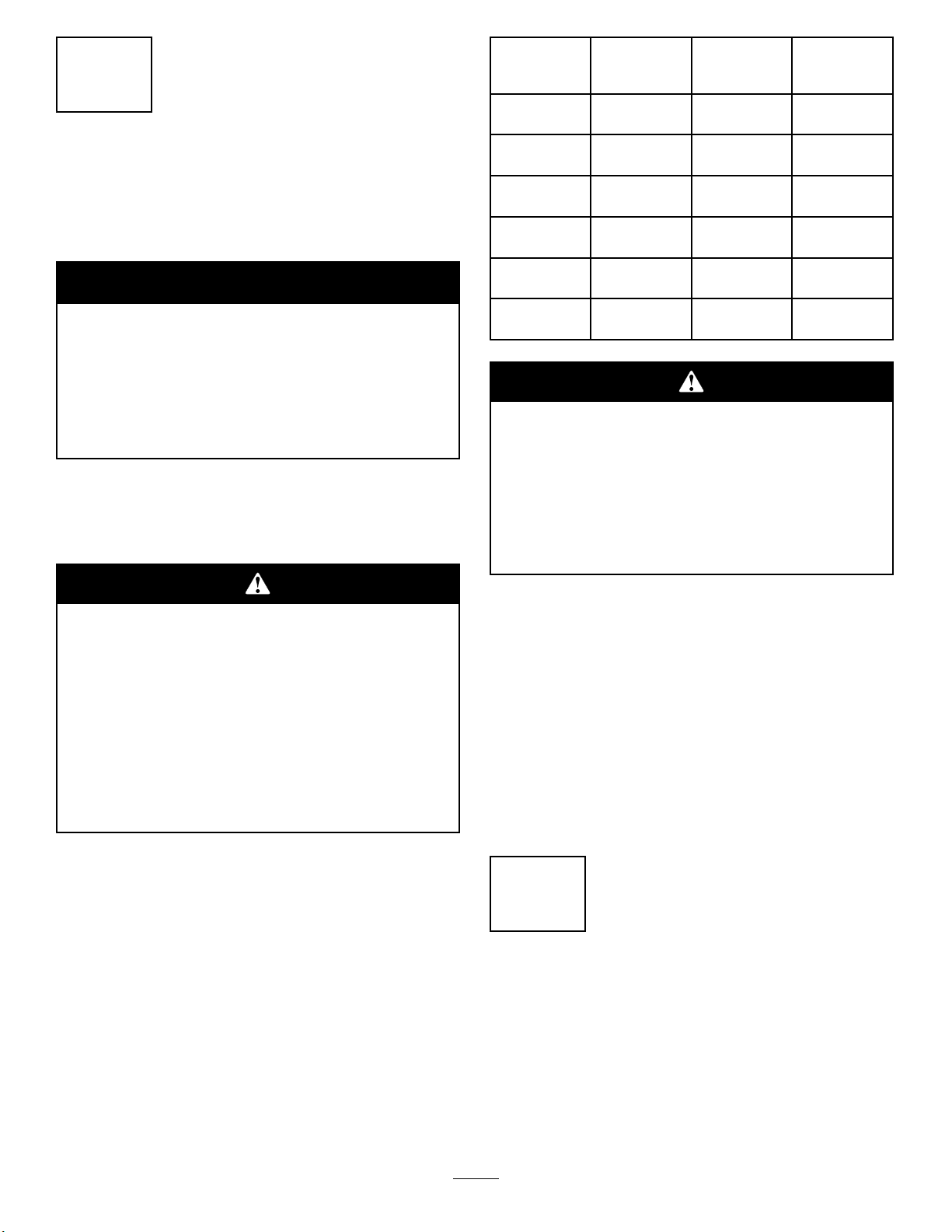

Voltage

Reading

12.6or

greater

12.4–12.6

12.2–12.4

12.0–12.2

11.7–12.0

11.7orless

Percent

Charge

100%16volts/7

75–100%16volts/7

50–75%16volts/7

25–50%14.4volts/4

0–25%14.4volts/4

0%14.4volts/2

Maximum

Charger

Settings

amps

amps

amps

amps

amps

amps

Charging

Interval

NoCharging

Required

30Minutes

1Hour

2Hours

3Hours

6Hoursor

More

Iftheignitionisinthe“ON”positionthere

ispotentialforsparksandengagementof

components.Sparkscouldcauseanexplosion

ormovingpartscouldaccidentallyengage

causingpersonalinjury

1.Tiltseatuptogainaccesstothebattery.

Chargingthebatterymayproduceexplosive

gasses.Batterygassescanexplodecausing

seriousinjury.

•Keepsparks,ames,orcigarettesawayfrom

battery.

•Ventilatewhenchargingorusingbatteryin

anenclosedspace.

•Makesureventingpathofbatteryisalways

openoncebatteryislledwithacid.

2.Checkthevoltageofthebatterywithadigital

voltmeter.Locatethevoltagereadingofthebattery

inthetablebelowandchargethebatteryforthe

recommendedtimeintervaltobringthechargeup

toafullchargeof12.6voltsorgreater.

Important:Makesurethenegativebattery

cablesaredisconnectedandthebatterycharger

usedforchargingthebatteryhasanoutputof

16voltsand7ampsorlesstoavoiddamaging

thebattery(chartforrecommendedcharger

settings).

Besureignitionswitchisinthe“OFF”position

beforechargingthebattery.

3.Connectthenegativebatterycables.

Note:Ifthepositivecableisalsodisconnected,

connectthepositive(red)cabletothepositive

batteryterminalrst,thenthenegative(black)cable

tothenegativebatteryterminal.Slipinsulatorboot

overthepositiveterminal.

Note:Iftimedoesnotpermitchargingthebattery,

orifchargingequipmentisnotavailable,connect

thenegativebatterycablesandrunthevehicle

continuouslyfor20to30minutestosufciently

chargethebattery.

4

InstallingtheMotionControl

Levers

NoPartsRequired

Procedure

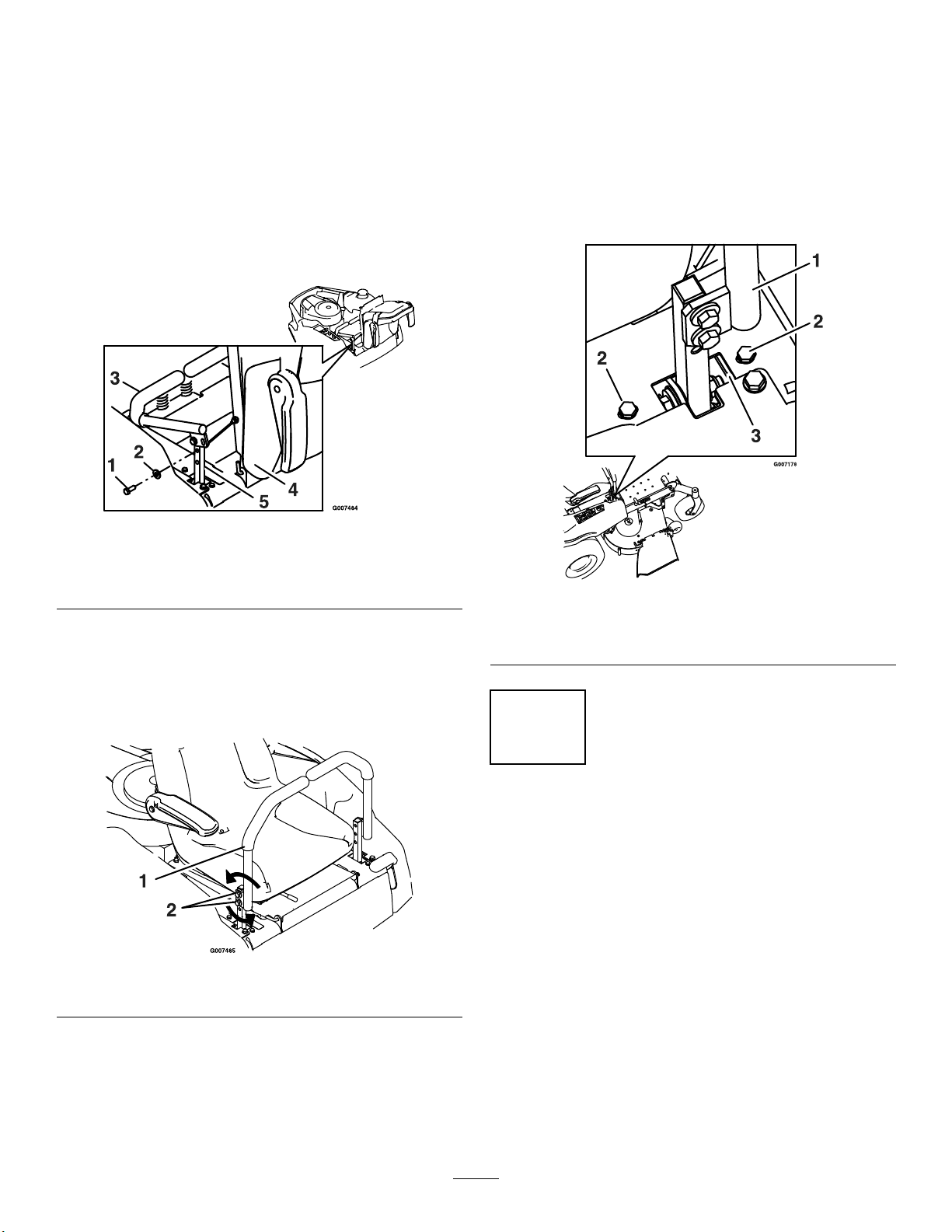

1.Removethebottom3/8x1inchboltandspring

discwasherfromthecontrolarmshaft.Loosenthe

2

Page 3

upper3/8x1inchboltandspringdiscwasherinthe

controlleversothatthelevercanrotate(Figure2).

bendingthemoutward.Movethembacktothedrive

positionandcheckforclearance.Repeatifnecessary.

2.Positiontheleversothebottomholealignswith

holeinthecontrolarmshaft.Installspringdisc

washerandbolt.

3.Repeatonoppositesideofunit.

Note:Therearetwoleverheightoptionsavailable.

Placetheleversinthetoptwoholestoincrease

heightofthelevers,orinthebottomtwoholesto

decreasetheheightofthelevers.

Figure2

1.Bolt

2.Springdiscwasher5.Controlarmshaft

3.Motioncontrollever

4.Aligntheleversfront/rearposition.Withthelevers

intheneutralposition,loosenthehardwareand

adjusttheleversslidingand/ortiltingthelever(s)

forwardorbackwarduntilproperlyalignedand

tightenhardware(Figure3).

4.Seat

6.Ifthemachineturnsrightorleftwhenhandlesare

pushedforwardtogether,adjustthestopontheside

oppositethedirectionofturn(Figure4).Loosen

thescrewsthatholdthemotioncontrollimiterstop.

Movethestopbackuntiltheunitdrivesstraight.

Tightenthescrewstolockthestopinplace.Readjust

handlesifnecessary.

Figure4

1.Controlarmshaft

2.Limiterstopscrews

3.Adjuststop

Figure3

1.Motioncontrollever2.Hardware

5.Iftheendsofthelevershitagainsteachother,

whileinthedriveposition(leversrotatedinasfaras

possible),makeadjustmentsbymovingthelevers

outwardstotheneutrallockpositionandcarefully

5

ServicingtheEngine

NoPartsRequired

Procedure

Engineisshippedwithoil;checkoillevelandif

necessarylltotheappropriatelevelwithoilasspecied

inEngineOwner’sManual.

3

Page 4

6

G006036

1

2

3

4

5

7

ServicingtheHydraulicOil

NoPartsRequired

Procedure

Themachineisshippedwithhydraulicoil.Verifylevel

onExpansionTank(Figure5).

1.Startengineanddrivethemachineforwardand

backwardforafewminutestoallowanyextraairto

purgeoutofthehydraulicsystem.

2.Stopengineandwaitforallmovingpartstostop.

Removekeyandengageparkingbrake.

3.CheckexpansiontankandifnecessaryaddMOBIL1

15W-50syntheticmotoroiltotheFULLCOLDline.

Note:Theproperamountofoilshouldhavebeen

addedatthefactory.Ifthereservoirisslightlyover

full,DoNotremoveuid.Thelevelwillgodown

oncealloftheairispurgedfromthesystem.

InstallingtheDischarge

Deector

Partsneededforthisprocedure:

1

Deectorassembly

1Rod

1

Spring

Procedure

1.Positionthedischargedeectorassemblywiththe

bracketendsbetweentheweldedbracketsonthe

deckasshowninFigure6.

1.Engine2.Expansiontank

4.Replaceexpansiontankcapandtightenuntilsnug.

DoNotovertighten.

Figure5

1.Deectorassembly4.Spring

2.Deckbrackets

3.Rod

2.Installthespringontothestraightendoftherod.

PositionthespringontherodasshowninFigure6

sotheshorterspringendiscomingfromunderthe

rodbeforethebendandgoingovertherodasit

returnsfromthebend.

4

Figure6

5.Springinstalledoverthe

rod

Page 5

3.Installthespringandrodassemblythroughthe

G006049

1

2

3

4

openingsinboththedeckbracketsandthedeector

bracket(Figure6).

4.Liftthelongendofthespringandplaceitintothe

notchonthedeectorassemblybracket(Figure7).

5.Securetherodandspringassemblybytwistingitso

theshortendoftherodcanbeplacedbehindthe

frontbracketweldedtothedeck(Figure7).

8

CompletingtheSetup

Partsneededforthisprocedure:

1IgnitionKey

1Hosecoupling

1

Operator’sManual

1

EngineOperator’sManual

1

OperatorTrainingMaterial

CheckingtheMowerAdjustment

Themowerdeckwasleveledatthefactory.Ifthemower

isnotcuttinglevel,adjusttheside-to-sidelevelandthe

front-to-rearbladeslope.SeetheOperator’sManualfor

theproperprocedure.

Figure7

1.Rodandspringassembly

partiallyinstalled

2.Longendofthespring

installedintothenotchin

thedeectorbracket

3.Rod,shortend,moved

behindmowerbracket

4.Shortend,retainedby

mowerbracket.

Important:Thedischargedeectormustbe

springloadedinthedownposition.Liftthe

deectoruptotestthatitsnapstothefulldown

position.

ReviewtheRemainingParts

Keepallthefollowingitemswiththemachine:

•IgnitionKey

•Hosecoupling

•Operator’sManual

•EngineOperator’sManual

•ViewtheOperatortrainingmaterial.

5

Page 6

Page 7

Page 8

Loading...

Loading...