Titan

®

Z4800andZ5200Zero-Turn-RadiusRiding

Mowers

ModelNo.74816—SerialNo.280000001andUp

ModelNo.74818—SerialNo.280000001andUp

FormNo.3360-705RevA

Addendum

Important:Thisaddendumreplacesthe“Servicing

theEngineOil”sectionfoundintheMaintenance

chapterofthe

Operator’ s Man ual

.

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSG,SH,SJ,or

higher)

CrankcaseCapacity:1.7qt(1.6l)whenthelteris

changed

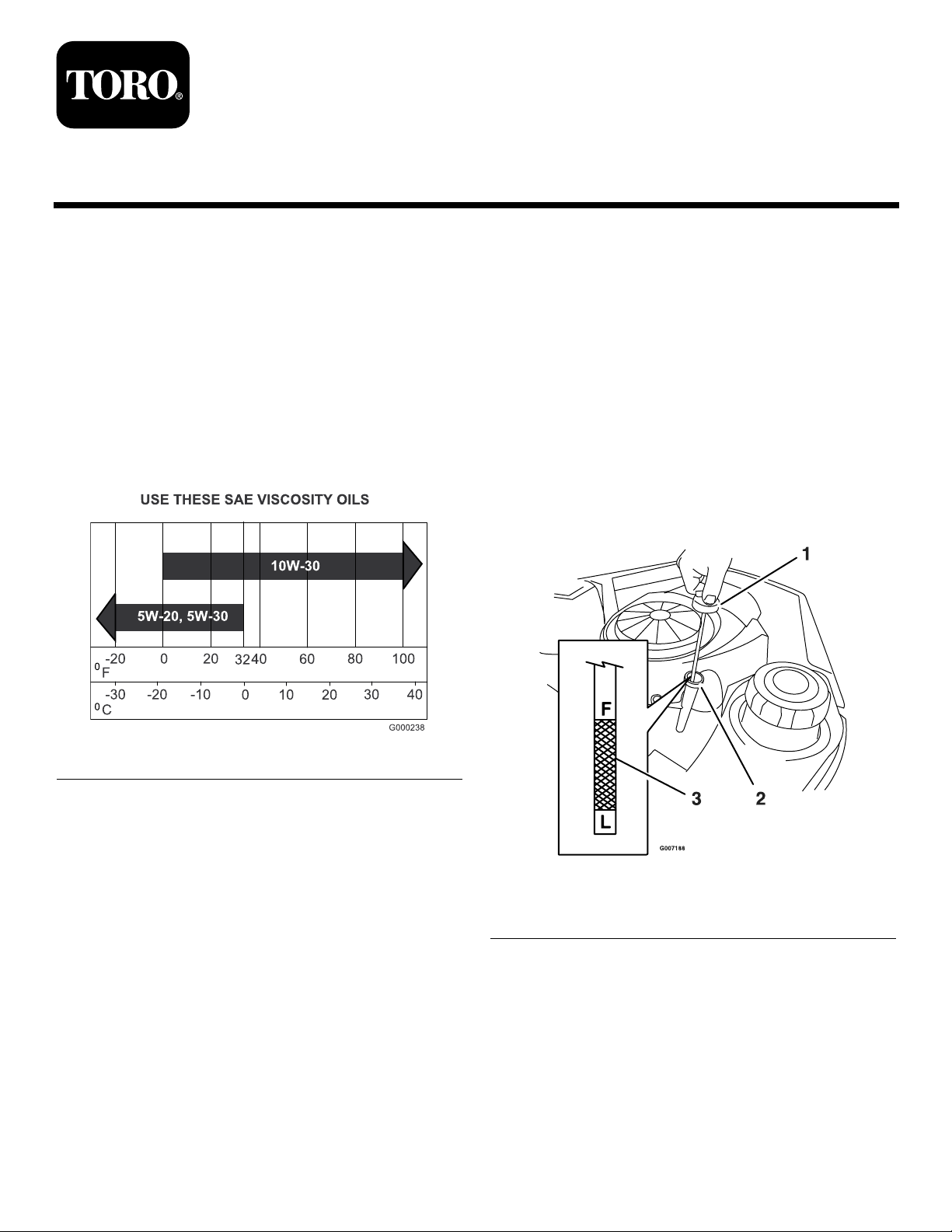

Viscosity:Seethetablebelow .

CheckingtheOilLevel

ServiceInterval:Beforeeachuseordaily

1.Parkthemachineonalevelsurface,disengagethe

bladecontrolswitch,stoptheengine,engageparking

brake,andremovethekey.

2.Makesuretheengineisstopped,level,andiscoolso

theoilhashadtimetodrainintothesump.

3.Tokeepdirt,grassclippings,etc.,outoftheengine,

cleantheareaaroundtheoilllcap/dipstickbefore

removingit.

4.Pullandremovetheoilllcap/dipstick;wipeoil

off.Reinsertthedipstickandpushrmlyintoplace

(Figure2).

Figure1

10W-30:0to100degreesF(-18to38degreesC)is

betterforvaryingtemperatureconditions.Thisviscosity

improvescoldweatherstarting,butmayincreaseoil

consumptionabove80degreesF(27degreesC).

5W-20,5W-30:Useofsyntheticoilhaving5W -20or

5W-30ratingisacceptable,upto40degreesF(4degrees

C).Syntheticoilswillprovidebetterstartinginextreme

coldbelow-10degreesF(23degreesC).

Note:Syntheticoilsmeetingthelistedclassications

maybeusedwithoilchangesperformedatthe

recommendedintervals.Howevertoallowpistonrings

toproperlyseat,aneworrebuiltengineshouldbe

operatedforatleast50hoursusingstandardpetroleum

basedoilbeforeswitchingtosyntheticoil.

©2008—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.Toro.com.

Figure2

1.Oildipstick3.Oillevel

2.Fillertube

5.Removethedipstickandchecktheoillevel.

Theoillevelshouldbeupto,butnotover,the“F”

markonthedipstick.

6.Ifthelevelislow,addoilofthepropertype,upto

the“F”markonthedipstick.Alwayscheckthelevel

withthedipstickbeforeaddingmoreoil.

Note:Topreventextensiveenginewearordamage,

alwaysmaintaintheproperoillevelinthecrankcase.

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

Neveroperatetheenginewiththeoillevelbelowthe

“L”markoroverthe“F”markonthedipstick.

ChangingtheOilandFilter

ServiceInterval:Every100hours/Yearly(whichever

comesrst)(morefrequentlyunder

extremelydusty,dirtyconditions).

Changetheoilandlterwhiletheengineisstillwarm.

Theoilwillowmorefreelyandcarryawaymore

impurities.Makesuretheengineislevelwhenlling,

checking,orchangingtheoil.

1.Starttheengineandletitrununtilwarm.This

warmstheoilsoitdrainsbetter.

2.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoassuretheoildrains

completely.

3.Disengagethebladecontrolswitchandmovethe

motioncontrolsoutwardtotheneutralpositionand

engageparkingbrake.

4.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

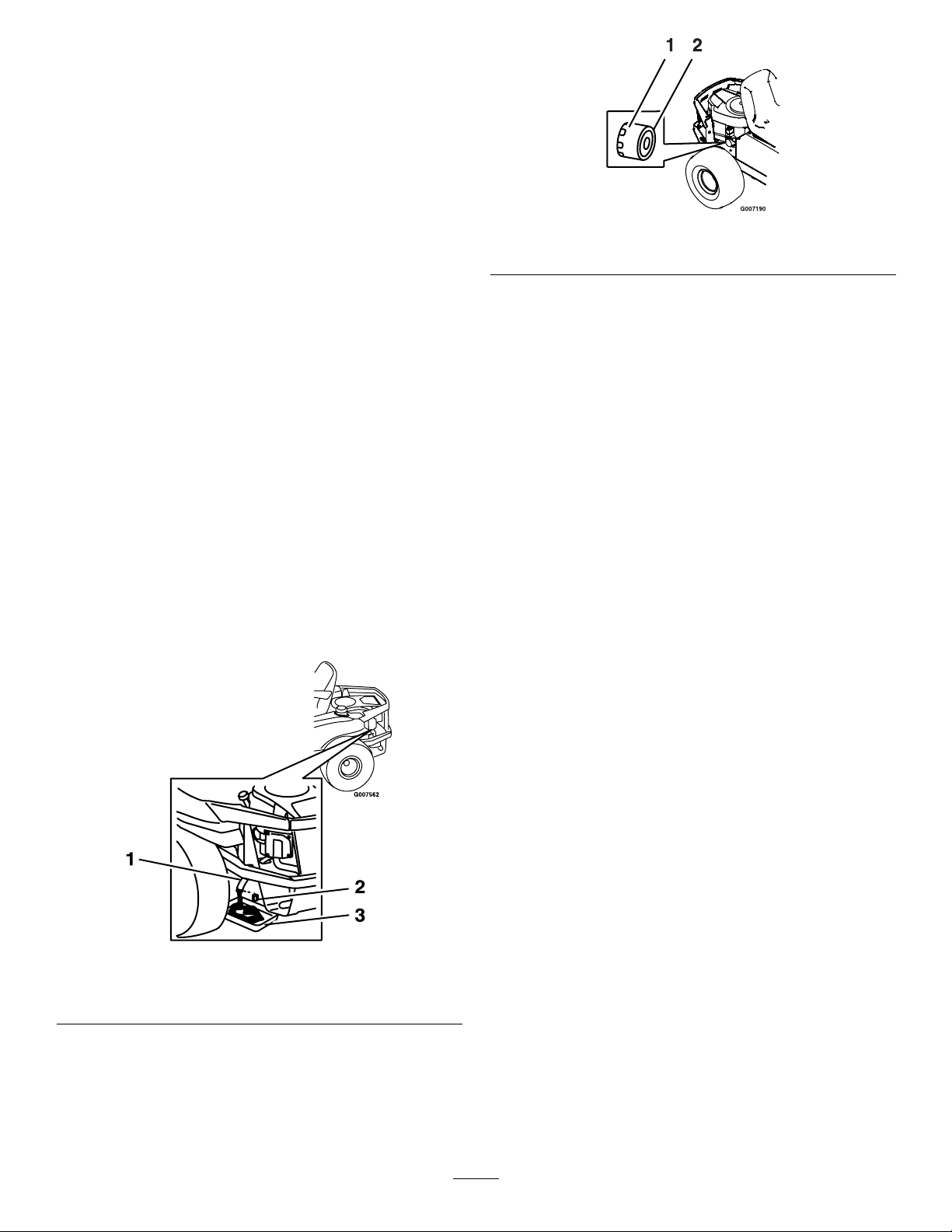

5.Cleantheareaaroundthedrainplugandonthe

machineframe.Placeapanunderneathmachine

directlybelowthedrainholeintheframeasshown

inFigure3

Figure4

1.Oillter2.Gasket

7.Besuretoallowampletimeforcompletedrainage.

8.Removetheoldlterandwipeoffthemountingpad

(Figure4).

9.Whentheoilhasdrainedcompletely,installthe

oildrainplug.Tightentheplugto14N-m(125

in-lb)torque.Wipeupanyexcessoilontheframe

(Figure3).

Note:Disposeoftheusedoilatarecyclingcenter.

10.Applyathinlmofcleanoiltotherubbergasketon

thenewlter.

11.Installthereplacementoilltertothemountingpad.

Turntheoillterclockwiseuntiltherubbergasket

contactsthepad,thentightenthelteranadditional

1/2to3/4turn(Figure3).

12.Slowlypourapproximately80%ofthespeciedoil

intothellertube.

Figure3

1.Oildrainhose

2.Oildrainplug

3.Pan

6.Removetheoildrainplug(Figure3).Removetheoil

llcap/dipstick(Figure2).

13.Installtheoilllcap/dipstickandpushrmlyinto

place.

14.Checktheoillevel(Figure2);refertotheChecking

theOilLevelsection.

15.Slowlyaddadditionaloiltobringittothefullmark.

16.Installtheoilllcap/dipstickandpushrmlyinto

place.

2

Loading...

Loading...