Page 1

ZeroTurnRadiusMowers

Allmodels

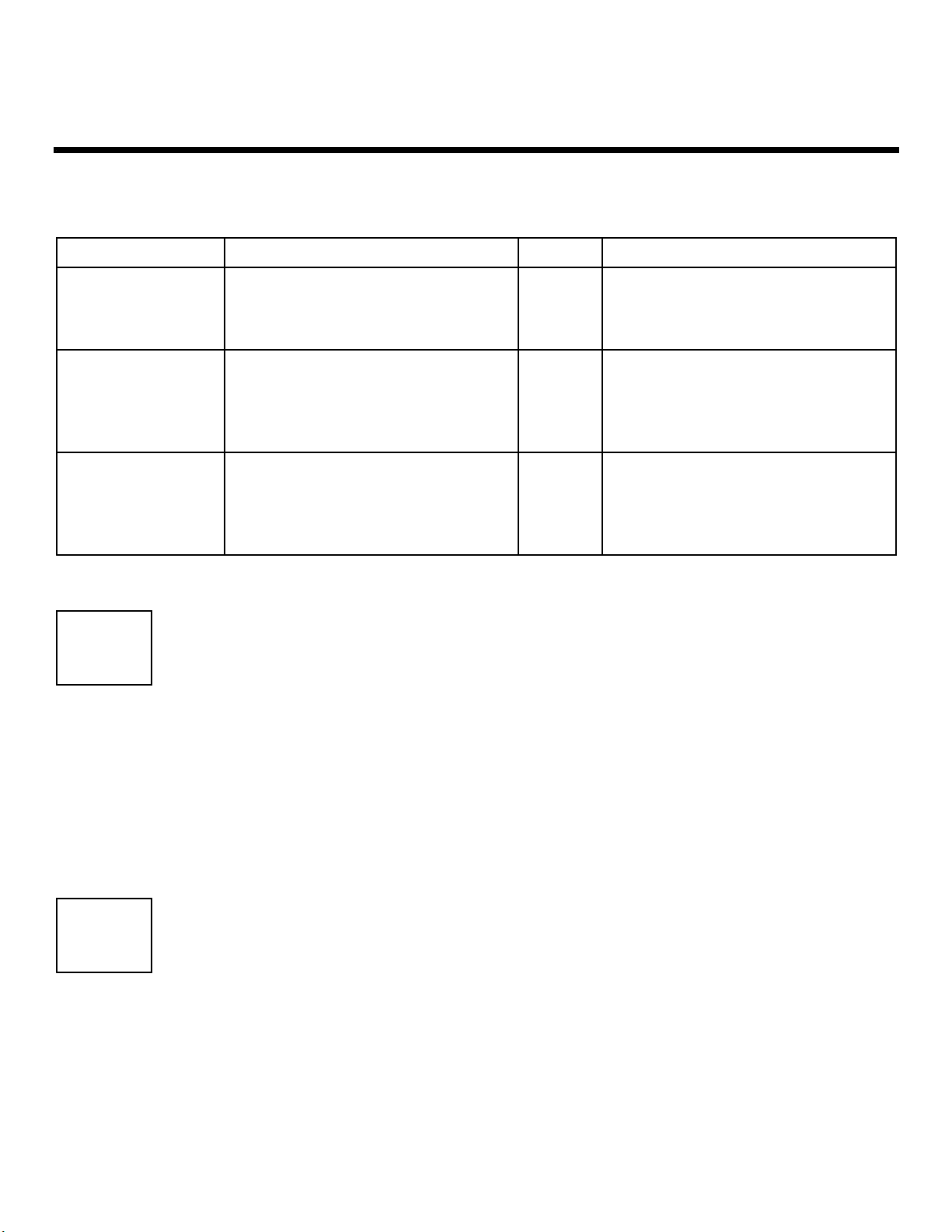

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

FormNo.3360-101RevA

SetupInstructions

ProcedureDescription

Deectorassembly

Rod1

7

8

9

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

1

Spring

Cotterpin

Sidedischargebafe

Carriagebolt(5/16x3/4inch)

Hex-headbolt(5/16x3/4inch)

Locknut(5/16inch)

Holecoverdecal3

IgnitionKey1

Hosecoupling1

Operator’sManual

EngineOperator’sManual

OperatorTrainingMaterial

2.Tiltseatdownwardandalignlanyardtotheholein

3.Installboltandnut.Tightenboltandthenloosen

CheckingTirePressure

Qty.

1

1

1

1

2

2

4

1

1

1

thesideoftheseat(seeFigure1).

nut1/4-1/2turnsothatlanyardendrotatesfreely.

Verifythatlanyardisfreetorotateonbothendsso

thatitpullsstraightwhilesupportingtheseat..

NoPartsRequired

Use

Installthedischargedeector.

Converttosidedischarge(optional).

Completethesetup.

Procedure

1.Checkthetirepressureinthedrivetires.Proper

inationfordrivetiresis13psi(90kPa).

2.Adjustifnecessary.

2

FasteningtheSeat

NoPartsRequired

Procedure

1.Removethenutandboltfromthelooseendofthe

lanyard.

PrintedintheUSA.OriginalInstructions(EN)

AllRightsReserved

Page 2

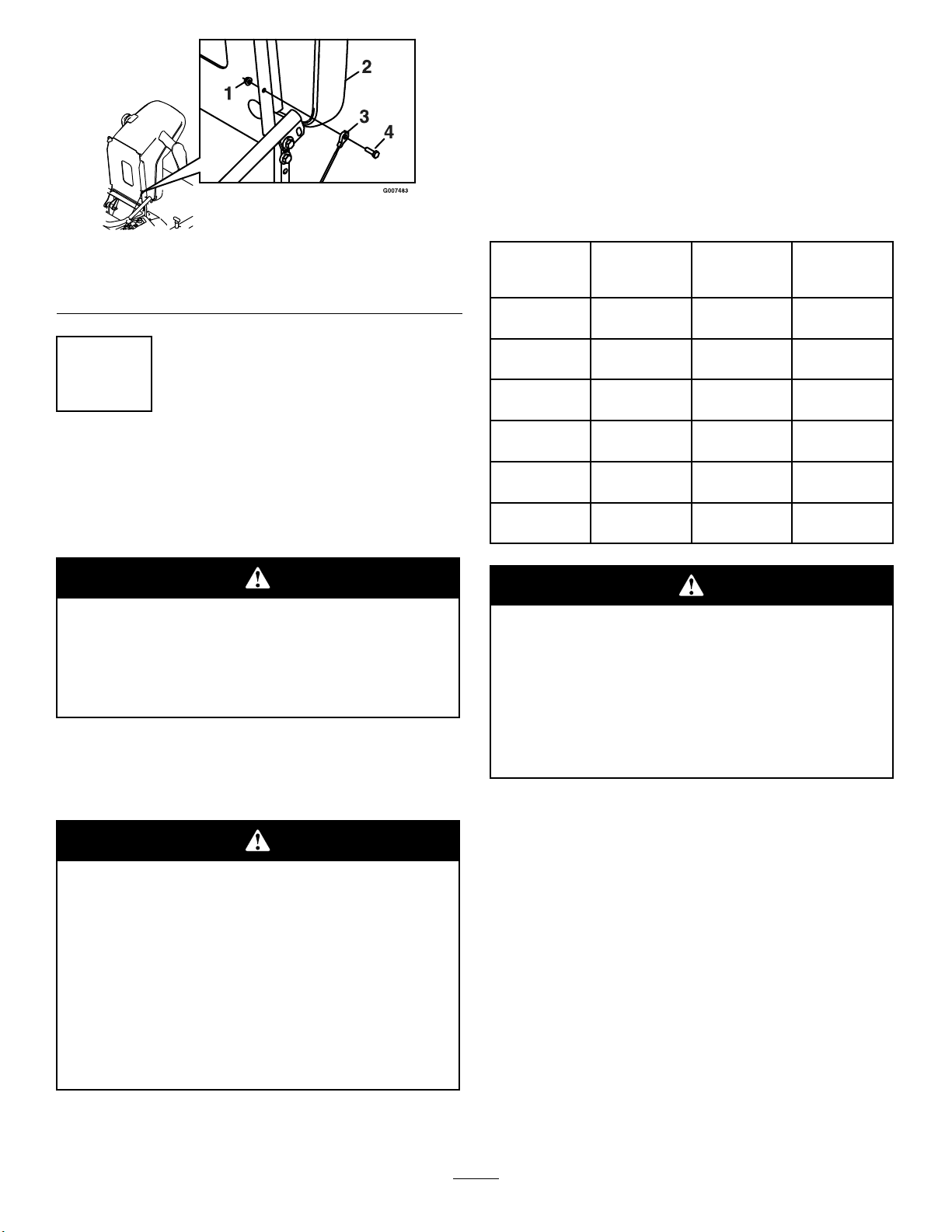

Figure1

1.Seatassembly3.5/16-18inchwhizlocknuts

2.Seattrackstuds

3

ServicingtheBattery

NoPartsRequired

Procedure

inthetablebelowandchargethebatteryforthe

recommendedtimeintervaltobringthechargeup

toafullchargeof12.6voltsorgreater.

Important:Makesurethenegativebattery

cablesaredisconnectedandthebatterycharger

usedforchargingthebatteryhasanoutputof

16voltsand7ampsorlesstoavoiddamaging

thebattery(seechartforrecommendedcharger

settings).

Voltage

Reading

12.6or

greater

12.4–12.6

12.2–12.4

12.0–12.2

11.7–12.0

11.7orless

Percent

Charge

100%16volts/7

75–100%16volts/7

50–75%16volts/7

25–50%14.4volts/4

0–25%14.4volts/4

0%14.4volts/2

Maximum

Charger

Settings

amps

amps

amps

amps

amps

amps

Charging

Interval

NoCharging

Required

30Minutes

1Hour

2Hours

3Hours

6Hoursor

More

Batteryposts,terminals,andrelatedaccessories

containleadandleadcompounds,chemicals

knowntotheStateofCaliforniatocausecancer

andreproductiveharm.Washhandsafter

handling.

Important:Themachineisshippedwithalled

leadacidbattery.

1.Tiltseatuptogainaccesstothebattery.

Chargingthebatterymayproduceexplosive

gasses.Batterygassescanexplodecausing

seriousinjury.

•Keepsparks,ames,orcigarettesawayfrom

battery.

•Ventilatewhenchargingorusingbatteryin

anenclosedspace.

•Makesureventingpathofbatteryisalways

openoncebatteryislledwithacid.

Iftheignitionisinthe“ON”positionthere

ispotentialforsparksandengagementof

components.Sparkscouldcauseanexplosion

ormovingpartscouldaccidentallyengage

causingpersonalinjury

Besureignitionswitchisinthe“OFF”position

beforechargingthebattery.

3.Connectthenegativebatterycables.

Note:Ifthepositivecableisalsodisconnected,

connectthepositive(red)cabletothepositive

batteryterminalrst,thenthenegative(black)cable

tothenegativebatteryterminal.Slipinsulatorboot

overthepositiveterminal.

Note:Iftimedoesnotpermitchargingthebattery,

orifchargingequipmentisnotavailable,connect

thenegativebatterycablesandrunthevehicle

continuouslyfor20to30minutestosufciently

chargethebattery.

2.Checkthevoltageofthebatterywithadigital

voltmeter.Locatethevoltagereadingofthebattery

2

Page 3

4

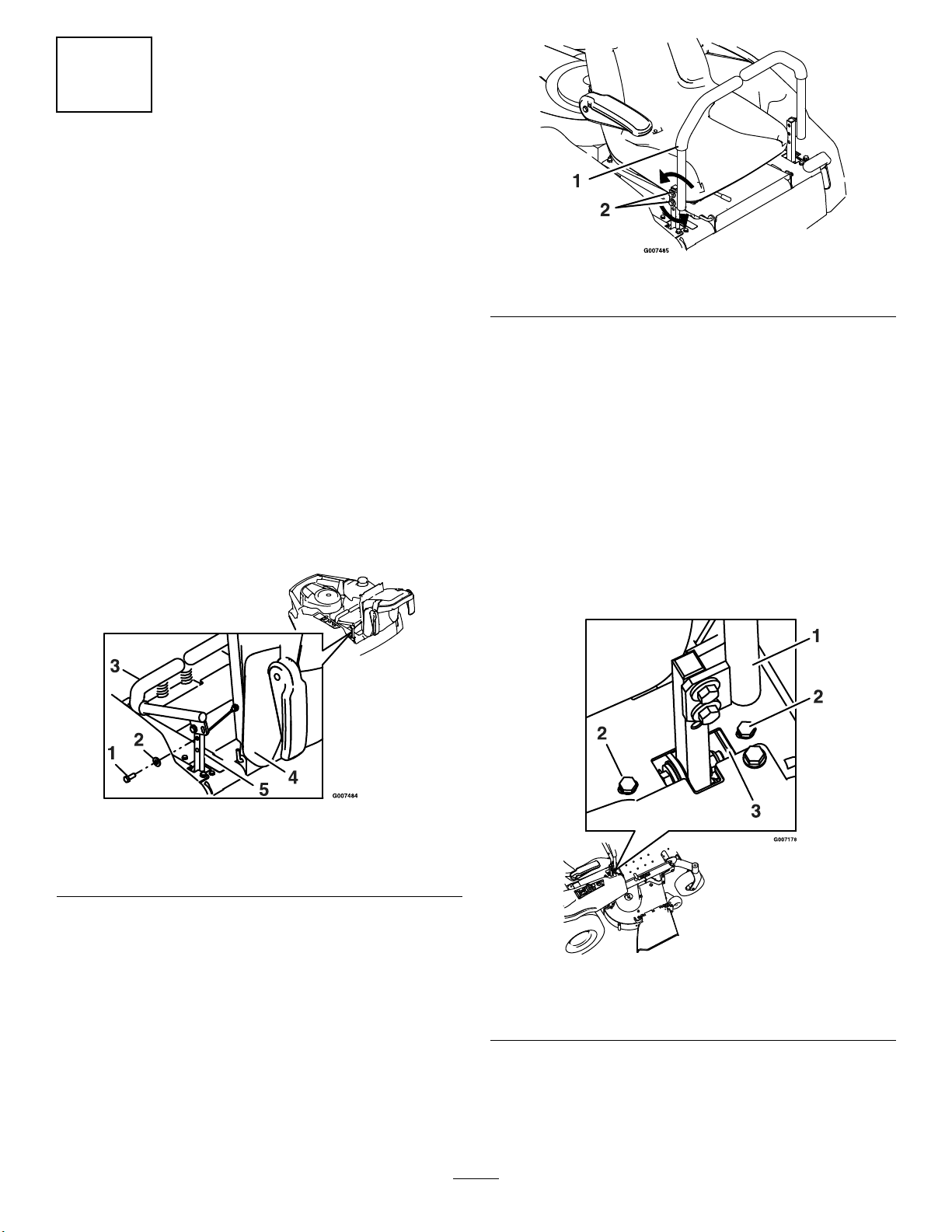

InstallingtheMotionControl

Levers

NoPartsRequired

Procedure

1.Removethebottom3/8x1inchboltandspring

discwasherfromthecontrolarmshaft.Loosenthe

upper3/8x1inchboltandspringdiscwasherinthe

controlleversothatthelevercanrotateFigure2.

2.Positiontheleversothebottomholealignswith

holeinthecontrolarmshaft.Installspringdisc

washerandbolt.

3.Repeatonoppositesideofunit.

Note:Therearetwoleverheightoptionsavailable.

Placetheleversinthetoptwoholestoincrease

heightofthelevers,orinthebottomtwoholesto

decreasetheheightofthelevers.

Figure3

1.Motioncontrollever2.Hardware

5.Iftheendsofthelevershitagainsteachother,

whileinthedriveposition(leversrotatedinasfaras

possible),makeadjustmentsbymovingthelevers

outwardstotheneutrallockpositionandcarefully

bendingthemoutward.Movethembacktothedrive

positionandcheckforclearance.Repeatifnecessary.

6.Ifthemachineturnsrightorleftwhenhandlesare

pushedforwardtogether,adjustthestoponthe

sideoppositethedirectionofturn(seeFigure4).

Loosenthescrewsthatholdthemotioncontrol

limiterstop.Movethestopbackuntiltheunitdrives

straight.Tightenthescrewstolockthestopinplace.

Readjusthandlesifnecessary.

Figure2

1.Bolt

2.Springdiscwasher5.Controlarmshaft

3.Motioncontrollever

4.Aligntheleversfront/rearposition.Withthelevers

intheneutralposition,loosenthehardwareand

adjusttheleversslidingand/ortiltingthelever(s)

forwardorbackwarduntilproperlyalignedand

tightenhardware(Figure3).

4.Seat

1.Controlarmshaft

2.Limiterstopscrews

3

Figure4

3.Adjuststop

Page 4

5

ServicingtheEngine

NoPartsRequired

Procedure

Engineisshippedwithoil;checkoillevelandif

necessarylltotheappropriatelevelwithoilasspecied

inEngineOwner’sManual.

Figure5

1.Engine2.Expansiontank

6

ServicingtheHydraulicOil

NoPartsRequired

Procedure

Themachineisshippedwithhydraulicoil.Verifylevel

onExpansionTank(seeFigure5).

1.Startengineanddrivethemachineforwardand

backwardforafewminutestoallowanyextraairto

purgeoutofthehydraulicsystem.

2.Stopengineandwaitforallmovingpartstostop.

Removekeyandengageparkingbrake.

3.CheckexpansiontankandifnecessaryaddMOBIL1

15W-50syntheticmotoroiltotheFULLCOLDline.

Note:Theproperamountofoilshouldhavebeen

addedatthefactory.Ifthereservoirisslightlyover

full,DoNotremoveuid.Thelevelwillgodown

oncealloftheairispurgedfromthesystem.

4.Replaceexpansiontankcapandtightenuntilsnug.

DoNotovertighten.

7

InstallingtheDischarge

Deector

Partsneededforthisprocedure:

1

Deectorassembly

1Rod

1

Spring

1

Cotterpin

Procedure

1.Installdischargedeector(Figure6).

4

Page 5

8

ConvertingtoSideDischarge

(optional)

Partsneededforthisprocedure:

1

Sidedischargebafe

2

Carriagebolt(5/16x3/4inch)

2

Hex-headbolt(5/16x3/4inch)

4

Locknut(5/16inch)

3Holecoverdecal

Procedure

Figure6

1.Rod4.Mowerdeck

2.Spring5.Dischargedeector

3.Dischargedeector

2.Orientthespringsothattheshortlegpointstowards

thedischargedeectorandthelongerlegpoints

towardsthedeckasshownin(Figure6).Placespring

onrodandsliderod,straightend,throughthefront

dischargedeectorbracket,dischargedeector,and

reardeectorbracket.

3.Makesurethatthespringandrodareinstalledso

thattherodisretainedfromslidingoutbythefront

bracketandthespringholdsthedischargedeector

inthedownposition.Referto(Figure6)forproper

orientation.

4.Securedeectorassemblybyinstallingacotterpin

throughtheholeinthestraightendoftherod.Bend

thestraightendsofthepinbacktosecurethepin.

bracket

6.Assembledview

Themowerdeckisbuiltforoptimummulching

performanceatthefactory.Ifthemoweristobe

convertedtosidedischarge,usetheloosepartslisted

aboveandSeetheOperator’sManualfortheproper

procedure.

5

Page 6

9

CompletingtheSetup

Partsneededforthisprocedure:

1IgnitionKey

1Hosecoupling

1

Operator’sManual

1

EngineOperator’sManual

1

OperatorTrainingMaterial

CheckingtheMowerAdjustment

Themowerdeckwasleveledatthefactory.Ifthemower

isnotcuttinglevel,adjusttheside-to-sidelevelandthe

front-to-rearbladeslope.SeetheOperator’sManualfor

theproperprocedure.

ReviewtheRemainingParts

Keepallthefollowingitemswiththemachine:

•IgnitionKey

•Hosecoupling

•Operator’sManual

•EngineOperator’sManual

•ViewtheOperatortrainingmaterial.

6

Page 7

Page 8

Loading...

Loading...