Page 1

Form No. 3358-267 Rev A

TM

Titan Z4800 and Z5200

Model No. 74812-Serial No. 270000001 and Up

Model No. 74814-Serial No. 270000001 and Up

Setup Instructions

Register your product at www.Toro.com

Original Instructions (EN)

Page 2

Loose Parts

Note: Use the chart below to verify that all loose parts have been shipped.

Description Qty Use

Warranty Registration Form 1 Fill out and return to Toro

Key, Toro Ignition

Key, Standard Ignition

Hose, Connector 1

Manual, Operator’s

Manual, Parts

DVD, Titan Safety

Manual, Engine Operator’s 1

1

Unit ignition

1

1

1

Read and view before operating machine

1

Checking Tire Pressure

1. Check the tire pressure in the drive and front

caster tires. Proper inflation for all tires is 13 psi

(90 kPa).

2. Adjust if necessary.

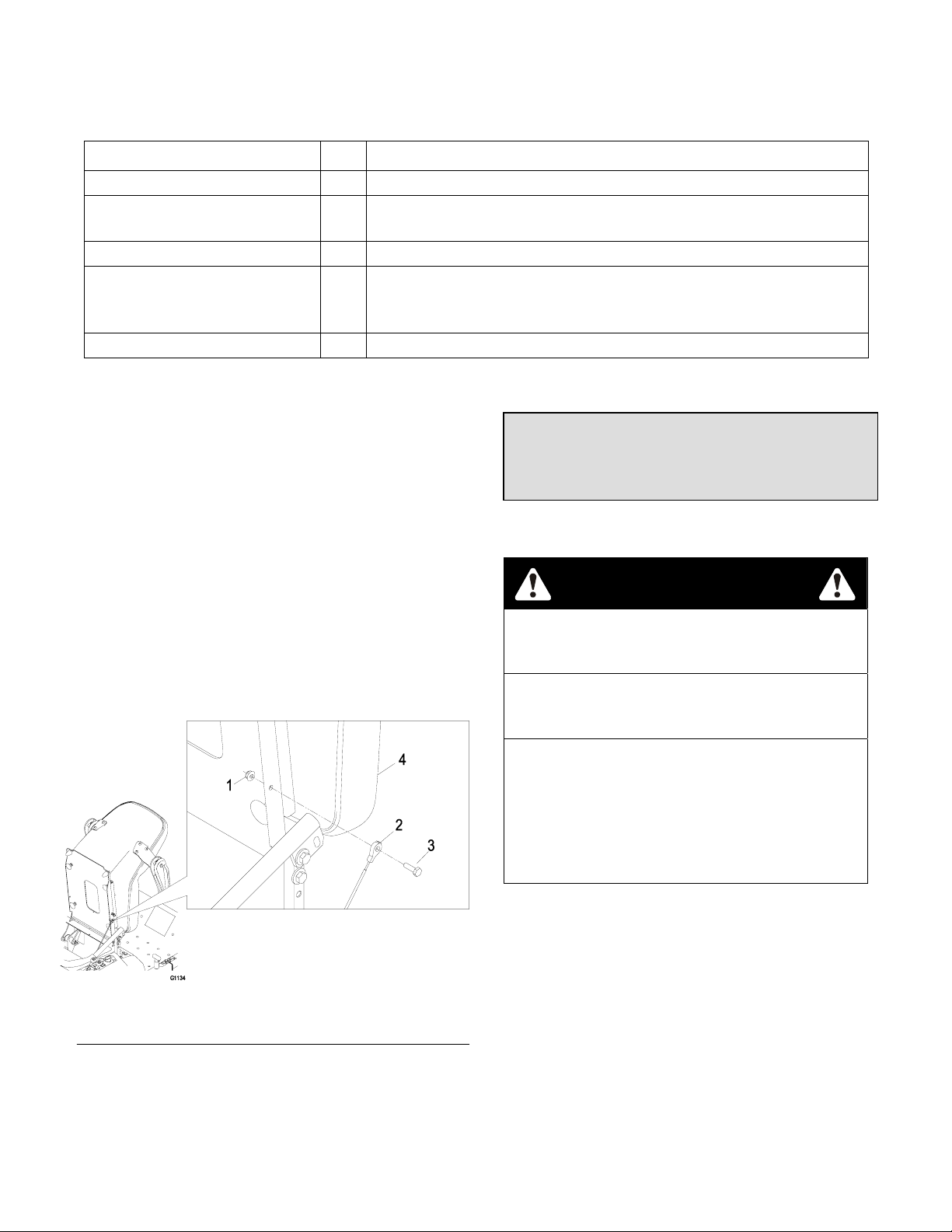

Fasten Seat

1. Remove the nut and bolt from the loose end of the

lanyard.

2. Tilt seat downward and align lanyard to the hole in

the side of the seat (See Figure 1).

3. Install bolt and nut. Tighten bolt and then loosen

nut 1/4-1/2 turn so that lanyard end rotates freely.

Verify that lanyard is free to rotate on both ends so

that it pulls straight while supporting the seat.

Figure 1

1. Nut 3. Bolt

2. Lanyard 4. Seat

Servicing the Battery

WARNING: Battery posts, terminals, and related

accessories contain lead compounds, chemicals

known to the State of California to cause cancer and

reproductive harm. Wash

hands after handling.

The machine is shipped with a filled lead

acid battery.

DANGER

POTENTIAL HAZARD

♦ Charging the battery may produce explosive

gasses

WHAT CAN HAPPEN

♦ Battery gasses can explode causing serious

injury.

HOW TO AVOID THE HAZARD

♦ Keep sparks, flames, or cigarettes away from

battery.

♦ Ventilate when charging or using battery in an

enclosed space.

♦ Make sure venting path of battery is always

open once battery is filled with acid.

1. Tilt seat up to gain access to the battery.

2. Check the voltage of the battery with a digital

voltmeter. Locate the voltage reading of the

battery in the table below and charge the battery

for the recommended time interval to bring the

charge up to a full charge of 12.6 volts or

greater.

Page 2

Page 3

IMPORTANT: Make sure the negative battery

cables are disconnected and the battery charger

used for charging the battery has an output of 16

volts and 7 amps or less to avoid damaging the

battery (see chart below for recommended charger

settings).

Voltage

Reading

Percent

Charge

12.6 or greater 100%

12.4 – 12.6 75 – 100%

12.2 – 12.4 50 – 75%

12.0 – 12.2 25 – 50%

11.7 – 12.0 0 – 25%

11.7 or less 0%

Maximum

Charger

Settings

16 volts /

7 amps

16 volts /

7 amps

16 volts /

7 amps

14.4 volts /

4 amps

14.4 volts /

4 amps

14.4 volts /

2 amps

Charging

Interval

No Charging

Required

30 Minutes

1 Hour

2 Hours

3 Hours

6 Hours

or More

2. Position the lever so the bottom hole aligns with

hole in the control arm shaft. Install spring disc

washer and bolt.

3. Repeat on opposite side of unit.

NOTE: There are two lever height options

available. Place the levers in the top two holes

to increase height of the levers, or in the bottom

two holes to decrease the height of the levers.

CAUTION

POTENTIAL HAZARD

♦ If the ignition is in the “ON” position there is

potential for sparks and engagement of

components.

WHAT CAN HAPPEN

♦ Sparks could cause an explosion or moving

parts could accidentally engage causing

personal injury.

HOW TO AVOID THE HAZARD

♦ Be sure ignition switch is in the “OFF” position

before charging the battery.

3. Connect the negative battery cables.

NOTE: If the positive cable is also disconnected,

connect the positive (red) cable to the positive

battery terminal first, then the negative (black)

cable to the negative battery terminal. Slip

insulator boot over the positive terminal.

NOTE: If time does not permit charging the

battery, or if charging equipment is not available,

connect the negative battery cables and run the

vehicle continuously for 20 to 30 minutes to

sufficiently charge the battery

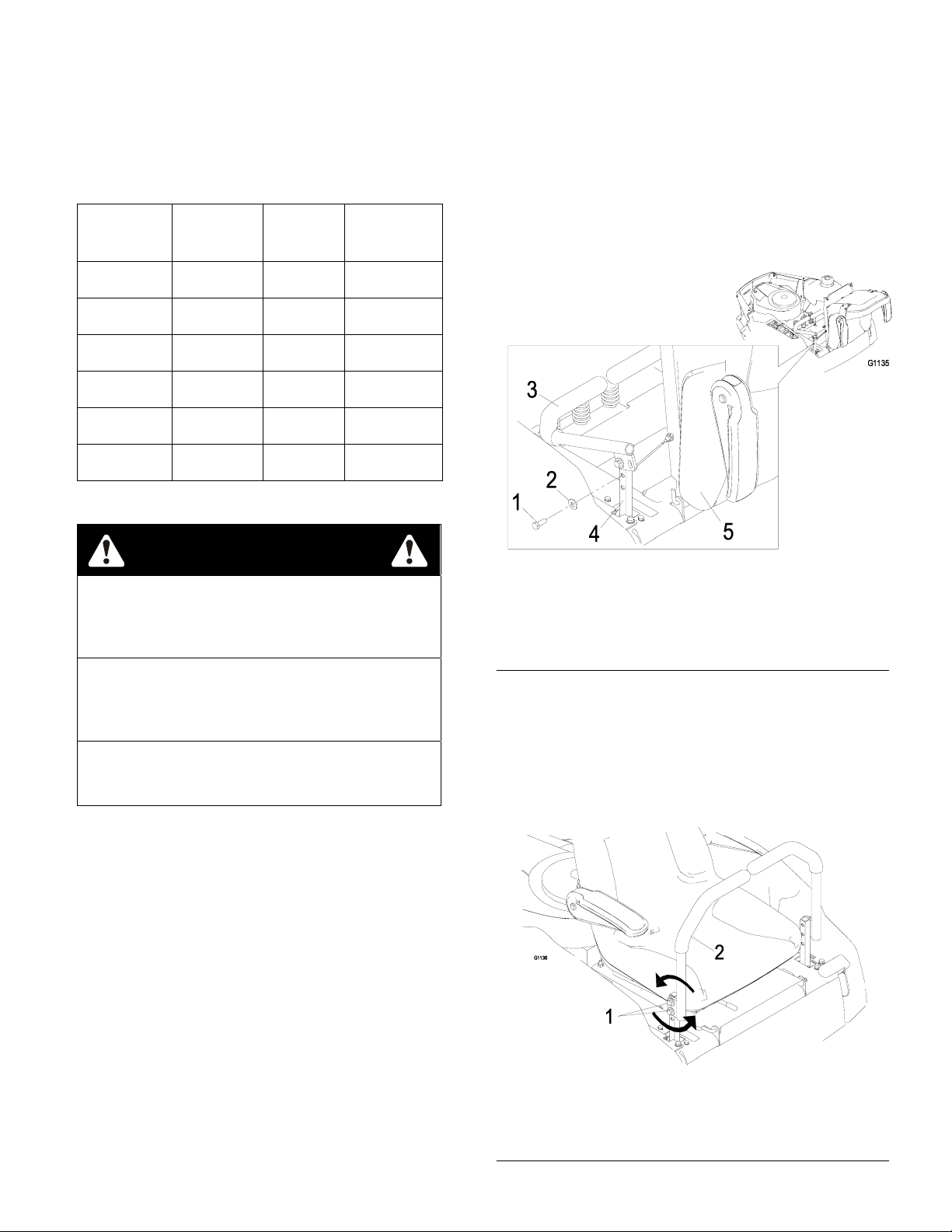

Installing the Motion Control Levers

1. Remove the bottom 3/8” x 1” bolt and spring disc

washer from the control arm shaft. Loosen the

upper 3/8” x 1” bolt and spring disc washer in the

control lever so that the lever can rotate (See

Figure 2).

.

Figure 2

1. Bolt 4. Control Arm Shaft

2. Spring Disc Washer 5. Seat

3. Motion Control Lever

4. Align the levers front/rear position. With the

levers in the neutral position, loosen the

hardware and adjust the levers sliding and/or

tilting the lever(s) forward or backward until

properly aligned and tighten hardware

(Figure. 3).

Figure 3

1. Hardware

2. Motion Control Lever

Page 3

Page 4

Servicing the Engine

Engine is shipped with oil; check oil level and if

necessary fill to the appropriate level with oil as

specified in Engine Owner’s Manual.

Servicing the Hydraulic Oil

The machine is shipped with hydraulic oil. Verify level

on Expansion Tank. (See Figure 5)

1. Start engine and drive the machine forward and

backward for a few minutes to allow any extra air

to purge out of the hydraulic system.

2. Stop engine and wait for all moving parts to stop.

Remove key and engage parking brake.

3. Check expansion tank and if necessary add

MOBIL 1 15W-50 synthetic motor oil to the FULL

COLD line.

NOTE: The proper amount of oil should have

been added at the factory. If the reservoir is

slightly over full, do not remove fluid. The level

will go down once all of the air is purged from the

system.

Figure 5

1. Seat 3. Expansion Tank

2. Engine

4. Replace expansion tank cap and tighten until

snug. Do not overtighten.

Installing the Discharge Deflector

1. Install discharge deflector (Figure 6).

2. Place the spring on the rod. Slide rod, straight

end, through the front discharge deflector

bracket, discharge deflector, and rear deflector

bracket.

3. Make sure that the spring and rod are installed

so that the rod is retained from sliding out by the

front bracket and the spring holds the discharge

deflector in the down position. Refer to

(Figure 6) for proper orientation.

Important: The discharge deflector must be

spring loaded in the down position. Lift the

deflector up to test that it snaps to the full

down position.

1. Mower deck 4. Spring

2. Discharge deflector 5. Rod

3. Discharge deflector bracket 6. Assembled view

Figure 6

© 2007 The Toro Company Contact us at www.Toro.com.

8111 Lyndale Ave. South All Rights Reserved

Bloomington, MN 55420 Printed in the USA.

Page 4

Loading...

Loading...