Page 1

FormNo.3425-432RevD

TimeCutter

ModelNo.74726—SerialNo.404314200andUp

ModelNo.74726TA—SerialNo.400000000andUp

ModelNo.74760—SerialNo.404314200andUp

ModelNo.74760TA—SerialNo.400000000andUp

ModelNo.74766—SerialNo.404314200andUp

ModelNo.74766TA—SerialNo.400000000andUp

ModelNo.74768—SerialNo.404314200andUp

ModelNo.74772—SerialNo.404314000andUp

ModelNo.74773—SerialNo.404314000andUp

ModelNo.74774—SerialNo.404310000andUp

ModelNo.74774TA—SerialNo.400000000andUp

ModelNo.74777—SerialNo.404314200andUp

ModelNo.74778—SerialNo.404314200andUp

®

RidingMowers

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3425-432*D

Page 2

GrossorNetTorque:Thegrossornettorque

ofthisenginewaslaboratoryratedbytheengine

manufacturerinaccordancewiththeSocietyof

AutomotiveEngineers(SAE)J1940orJ2723.As

conguredtomeetsafety,emission,andoperating

requirements,theactualenginetorqueonthisclass

ofmowerwillbesignicantlylower.Pleasereferto

theenginemanufacturer’sinformationincludedwith

themachine.

Gotowww.Toro.comtoviewspecicationsonyour

model.

Important:IfyouareusingamachinewithaToro

engineabove1500m(5,000ft)foracontinuous

period,ensurethattheHighAltitudeKithasbeen

installedsothattheenginemeetsCARB/EPA

emissionregulations.TheHighAltitudeKit

increasesengineperformancewhilepreventing

spark-plugfouling,hardstarting,andincreased

emissions.Onceyouhaveinstalledthekit,attach

thehigh-altitudelabelnexttotheserialdecalon

themachine.ContactanyAuthorizedToroService

DealertoobtaintheproperHighAltitudeKitand

high-altitudelabelforyourmachine.Tolocate

adealerconvenienttoyou,accessourwebsite

atwww.T oro.comorcontactourToroCustomer

CareDepartmentatthenumber(s)listedinyour

EmissionControlWarrantyStatement.

Removethekitfromtheengineandrestorethe

enginetoitsoriginalfactorycongurationwhen

runningtheengineunder1500m(5,000ft).Do

notoperateanenginethathasbeenconverted

forhigh-altitudeuseatloweraltitudes;otherwise,

youcouldoverheatanddamagetheengine.

Ifyouareunsurewhetherornotyourmachine

hasbeenconvertedforhigh-altitudeuse,lookfor

thefollowinglabel.

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

Visitwww.T oro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

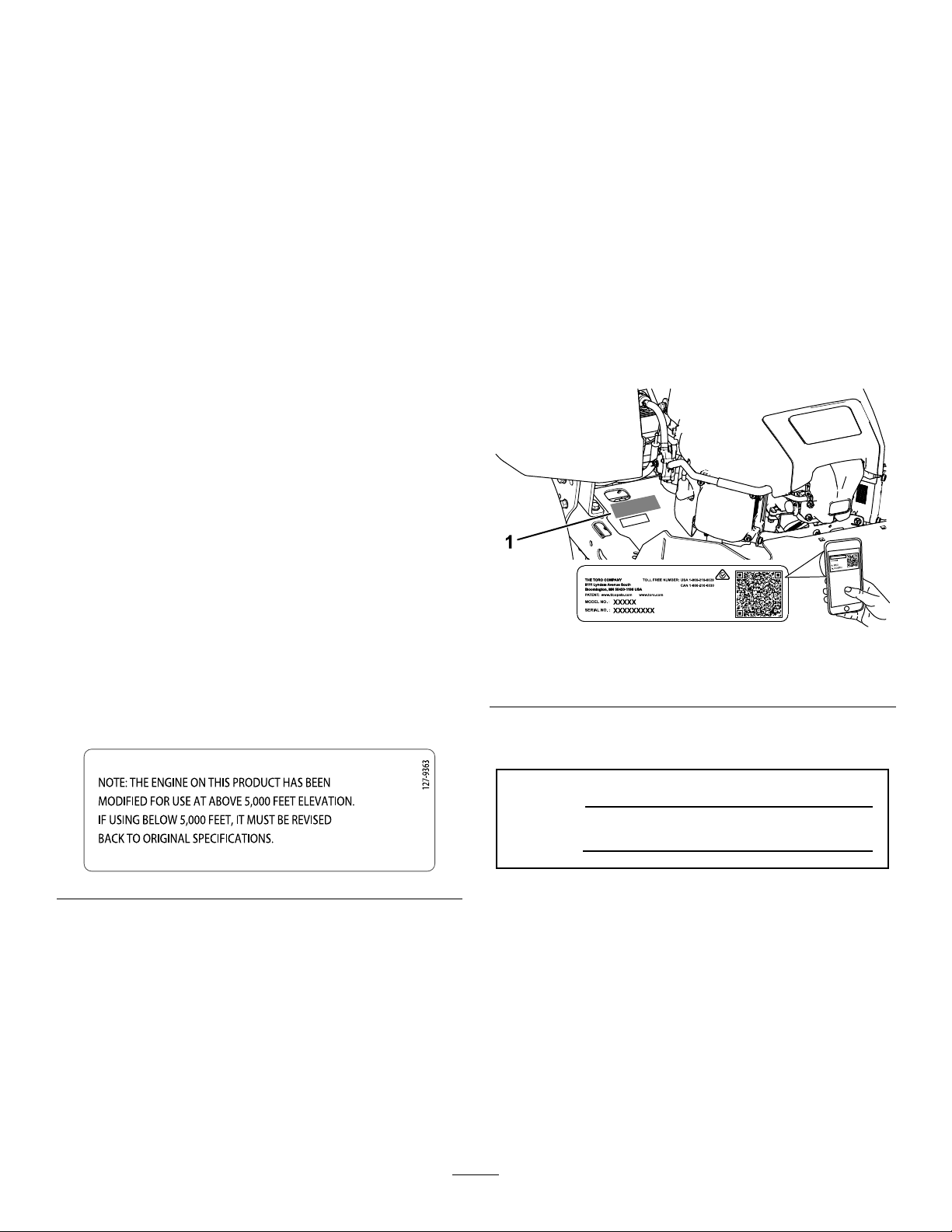

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

g234368

Figure1

1.Modelandserialnumberlocation

Writetheproductmodelandserialnumbersinthe

spacebelow:

decal127-9363

Introduction

Thisrotary-blade,ridinglawnmowerisintendedtobe

usedbyhomeownersinresidentialapplications.Itis

designedprimarilyforcuttinggrassonwell-maintained

lawns.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

©2019—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

ModelNo.

SerialNo.

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

2

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety.......................................................................4

SafetyAlertSymbol............................................4

GeneralSafety...................................................4

SlopeIndicator...................................................5

SafetyandInstructionalDecals..........................6

ProductOverview...................................................14

Controls...........................................................14

BeforeOperation.................................................16

BeforeOperationSafety...................................16

Pre-Start...........................................................16

FuelSafety.......................................................17

AddingFuel......................................................18

PerformingDailyMaintenance..........................18

BreakinginaNewMachine..............................18

UsingtheSafety-InterlockSystem....................19

PositioningtheSeat..........................................19

AdjustingtheMyRide™Suspension

System..........................................................21

AdjustingtheMotion-ControlLevers.................22

DuringOperation.................................................23

DuringOperationSafety...................................23

OperatingtheMowerBlade-ControlSwitch

(PTO)............................................................25

OperatingtheThrottle.......................................25

OperatingtheChoke.........................................25

StartingtheEngine...........................................26

ShuttingOfftheEngine.....................................26

UsingtheMotion-ControlLevers.......................26

DrivingtheMachine..........................................27

UsingtheSideDischarge.................................28

AdjustingtheHeightofCut...............................29

AdjustingtheAnti-ScalpRollers........................29

UsingAttachmentsandAccessories.................30

OperatingTips.................................................30

AfterOperation....................................................31

AfterOperationSafety......................................31

PushingtheMachinebyHand..........................33

Maintenance...........................................................35

RecommendedMaintenanceSchedule(s)...........35

MaintenanceSafety..........................................35

Pre-MaintenanceProcedures..............................37

RaisingtheSeat...............................................37

Lubrication..........................................................37

GreasingtheBearings......................................37

EngineMaintenance...........................................38

EngineSafety...................................................38

ServicingtheAirCleaner..................................38

ServicingtheEngineOil....................................40

ServicingtheSparkPlug...................................42

CleaningtheCoolingSystem............................43

FuelSystemMaintenance...................................43

ReplacingtheIn-LineFuelFilter.......................43

ElectricalSystemMaintenance...........................44

ElectricalSystemSafety...................................44

ServicingtheBattery.........................................44

ServicingtheFuses..........................................46

DriveSystemMaintenance..................................46

CheckingtheTirePressure...............................46

ReleasingtheElectricBrake.............................47

BeltMaintenance................................................47

ReplacingtheMower-DeckBelt........................47

MowerMaintenance.............................................49

BladeSafety.....................................................49

ServicingtheCuttingBlades.............................49

LevelingtheMowerDeck..................................51

RemovingtheMowerDeck...............................53

InstallingtheMower..........................................54

ReplacingtheGrassDeector..........................55

ReplacingtheGrassDeector..........................56

Cleaning..............................................................57

WashingtheUndersideoftheMower

Deck..............................................................57

CleaningtheSuspensionSystem.....................57

DisposingofWaste...........................................57

Storage...................................................................58

StorageSafety..................................................58

CleaningandStorage.......................................58

StoringtheBattery............................................59

Troubleshooting......................................................60

Schematics.............................................................62

3

Page 4

Safety

ThefollowinginstructionsarefromANSIstandard

B71.1-2017.

SafetyAlertSymbol

ThisSafetyAlertSymbol(Figure3)isusedbothin

thismanualandonthemachinetoidentifyimportant

safetymessageswhichmustbefollowedtoavoid

accidents.

Thissymbolmeans:ATTENTION!BECOMEALERT!

YOURSAFETYISINVOL VED!

Figure3

SafetyAlertSymbol

GeneralSafety

Thismachineiscapableofamputatinghandsandfeet

andofthrowingobjects.T orodesignedandtested

thislawnmowertoofferreasonablysafeservice;

however,failuretocomplywithsafetyinstructions

mayresultininjuryordeath.

•Read,understand,andfollowallinstructionsand

warningsintheOperator’sManualandother

trainingmaterial,onthemachine,engine,and

attachments.Alloperatorsandmechanicsshould

betrained.Iftheoperator(s)ormechanic(s)can

notreadthismanual,itistheowner’sresponsibility

toexplainthismaterialtothem;otherlanguages

maybeavailableonourwebsite.

•Onlyallowtrained,responsible,andphysically

capableoperatorsthatarefamiliarwiththesafe

g000502

operation,operatorcontrols,andsafetysignsand

instructionstooperatethemachine.Neverlet

childrenoruntrainedpeopleoperateorservicethe

equipment.Localregulationsmayrestricttheage

oftheoperator.

Thesafetyalertsymbolappearsaboveinformation

whichalertsyoutounsafeactionsorsituationsand

willbefollowedbythewordDANGER,WARNING,or

CAUTION.

DANGER:Indicatesanimminentlyhazardous

situationwhich,ifnotavoided,Willresultindeathor

seriousinjury.

WARNING:Indicatesapotentiallyhazardoussituation

which,ifnotavoided,Couldresultindeathorserious

injury.

CAUTION:Indicatesapotentiallyhazardoussituation

which,ifnotavoided,Mayresultinminorormoderate

injury.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizesgeneral

informationworthyofspecialattention.

•DoNotoperatethemachineneardrop-offs,

ditches,embankments,water,orotherhazards,or

onslopesgreaterthan15degrees.

•DoNotputyourhandsorfeetnearmoving

componentsofthemachine.

•Neveroperatethemachinewithdamagedguards,

shields,orcovers.Alwayshavesafetyshields,

guards,switchesandotherdevicesinplaceandin

properworkingcondition.

•Stopthemachine,shutofftheengine,andremove

thekeybeforeservicing,fueling,orunclogging

themachine.

4

Page 5

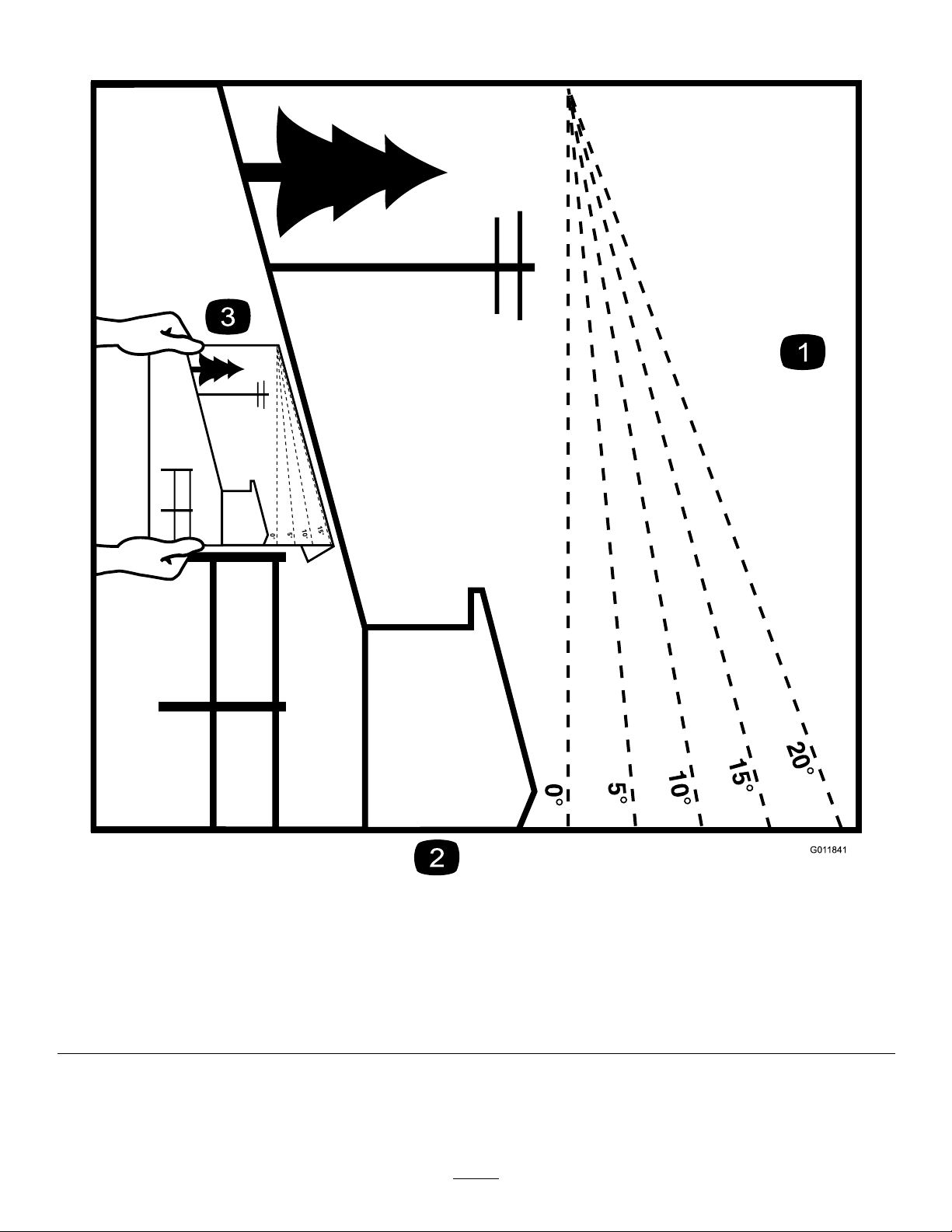

SlopeIndicator

Figure4

Youmaycopythispageforpersonaluse.

1.Themaximumslopeyoucanoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslopeof

hillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge

5

g011841

Page 6

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

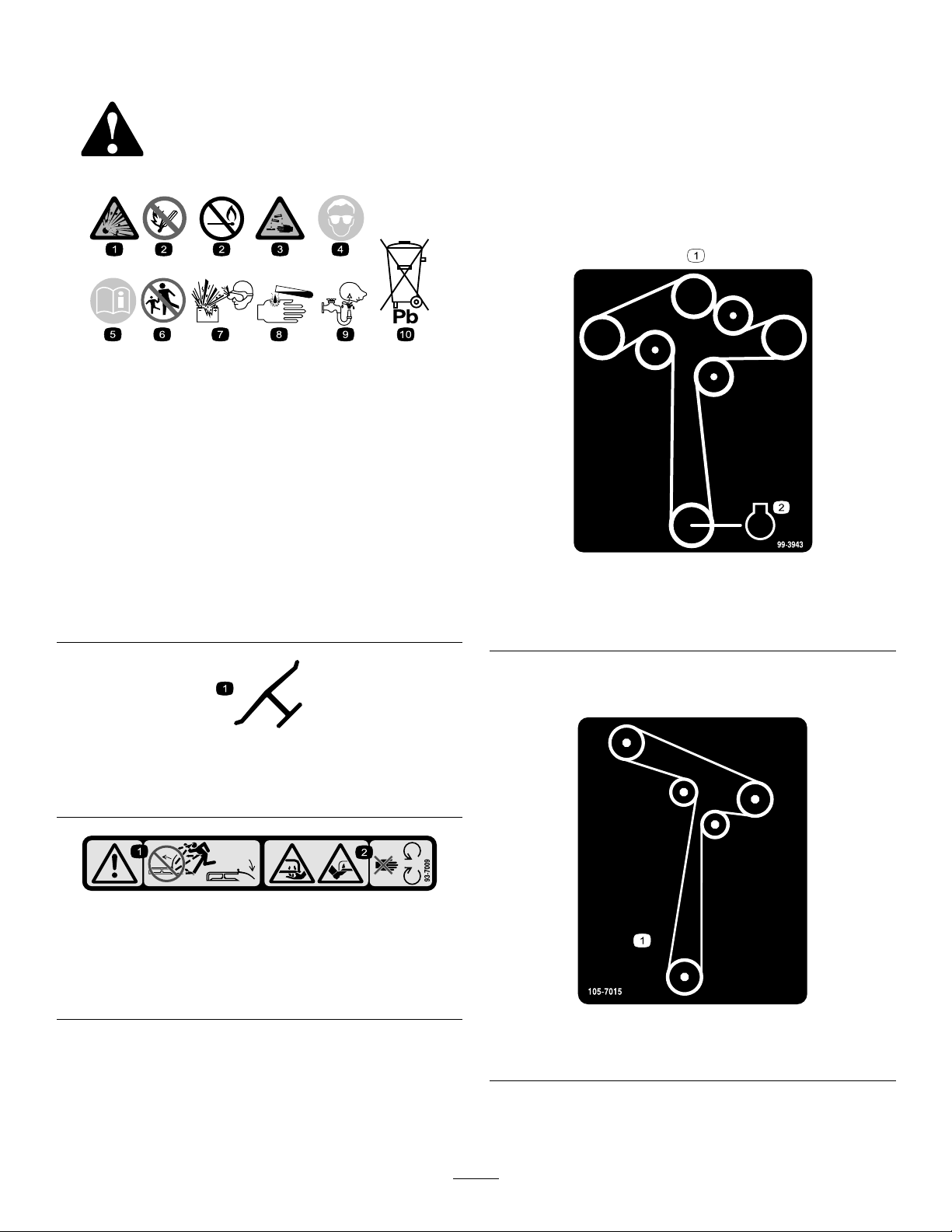

BatterySymbols

Someorallofthesesymbolsareonyourbattery .

Decal99-3943isformodelswith127cm(50inch),

137cm(54inch),or152cm(60inch)decks.

decalbatterysymbols

1.Explosionhazard6.Keepbystandersaway

2.Nore,opename,or

smoking

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

fromthebattery .

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

decal99-3943

99-3943

1.Beltrouting

2.Engine

Decal105-7015isformodelswith107cm(42-inch)

decks.

decaloemmarkt

93-7009

1.Warning—donotoperatethemowerwiththedeectorup

orremoved;keepthedeectorinplace.

2.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

decal93-7009

decal105-7015

105-7015

1.Beltrouting

6

Page 7

Decal106-8717isfornon-MyRidemodelswith107

cm(42inch),127cm(50inch),or137cm(54inch)

decks.

106-8717

1.Readtheinstructionsbeforeservicingorperforming

maintenance.

2.Checktirepressureevery25operatinghours.

3.Greaseevery25operatinghours.

4.Engine

Decal112-9840isformodelswith152cm(60inch)

mowerdecks.

decal119-8815

119-8815

decal106-8717

1.Parkingposition4.Neutral

2.Fast5.Reverse

3.Slow

Decal119-8870isforisformodelswith107cm(42

inch)mowerdecksortheMyRidesuspensionsystem.

112-9840

1.ReadtheOperator's

Manual.

2.Heightofcut

119-8814

1.Parkingposition4.Neutral

2.Fast5.Reverse

3.Slow

decal112-9840

3.Removetheignitionkey

andreadtheinstructions

beforeservicingor

performingmaintenance.

decal119-8870

119-8870

1.Heightofcut

decal119-8814

7

Page 8

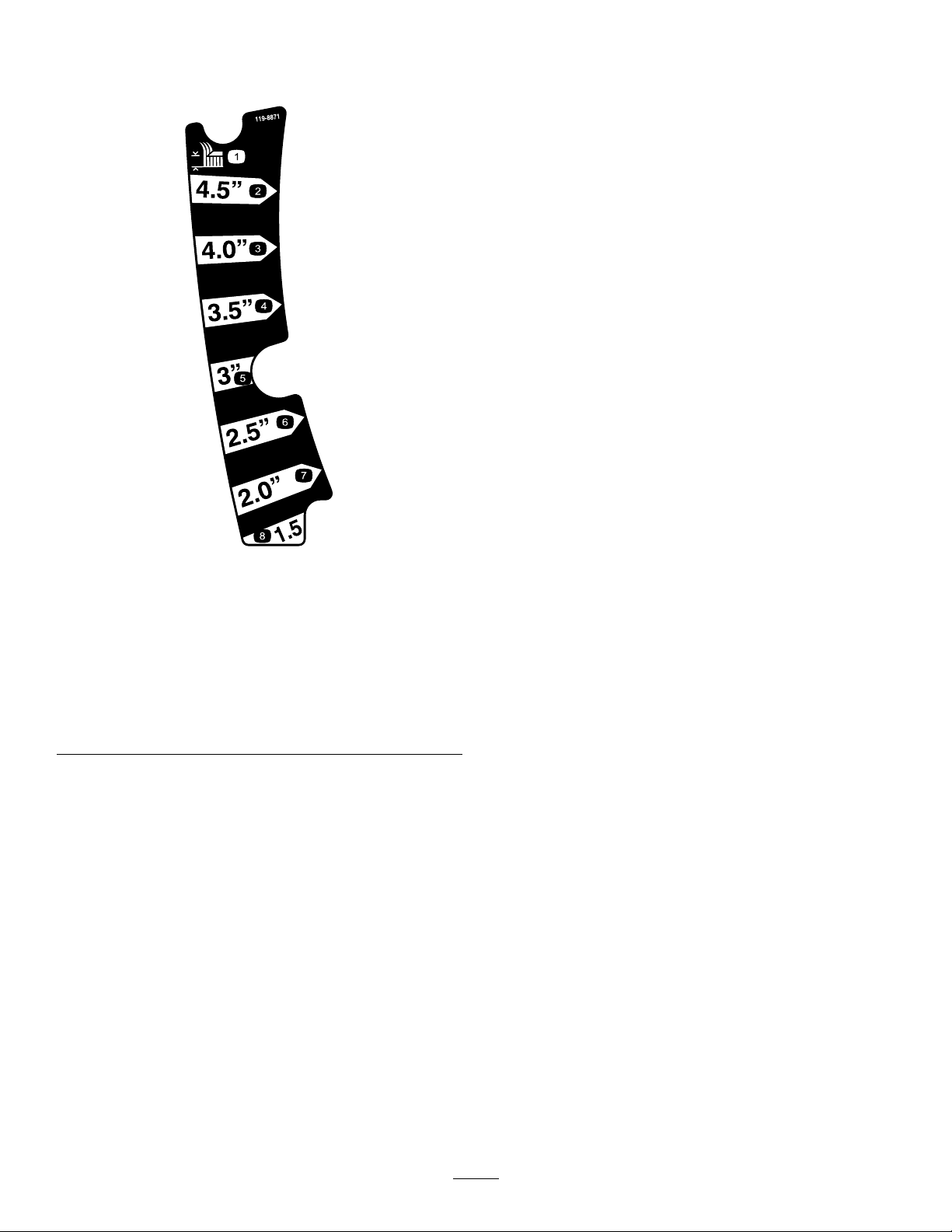

Decal119-8871isfornon-MyRidemodelswith127

cm(50inch),137cm(54inch),or152cm(60inch)

decks.

1.Heightofcut

2.4-1/2inches

3.4inches

4.3-1/2inches

5.3inches

6.2-1/2inches

7.2inches

8.1-1/2inches

decal119-8871

119-8871

8

Page 9

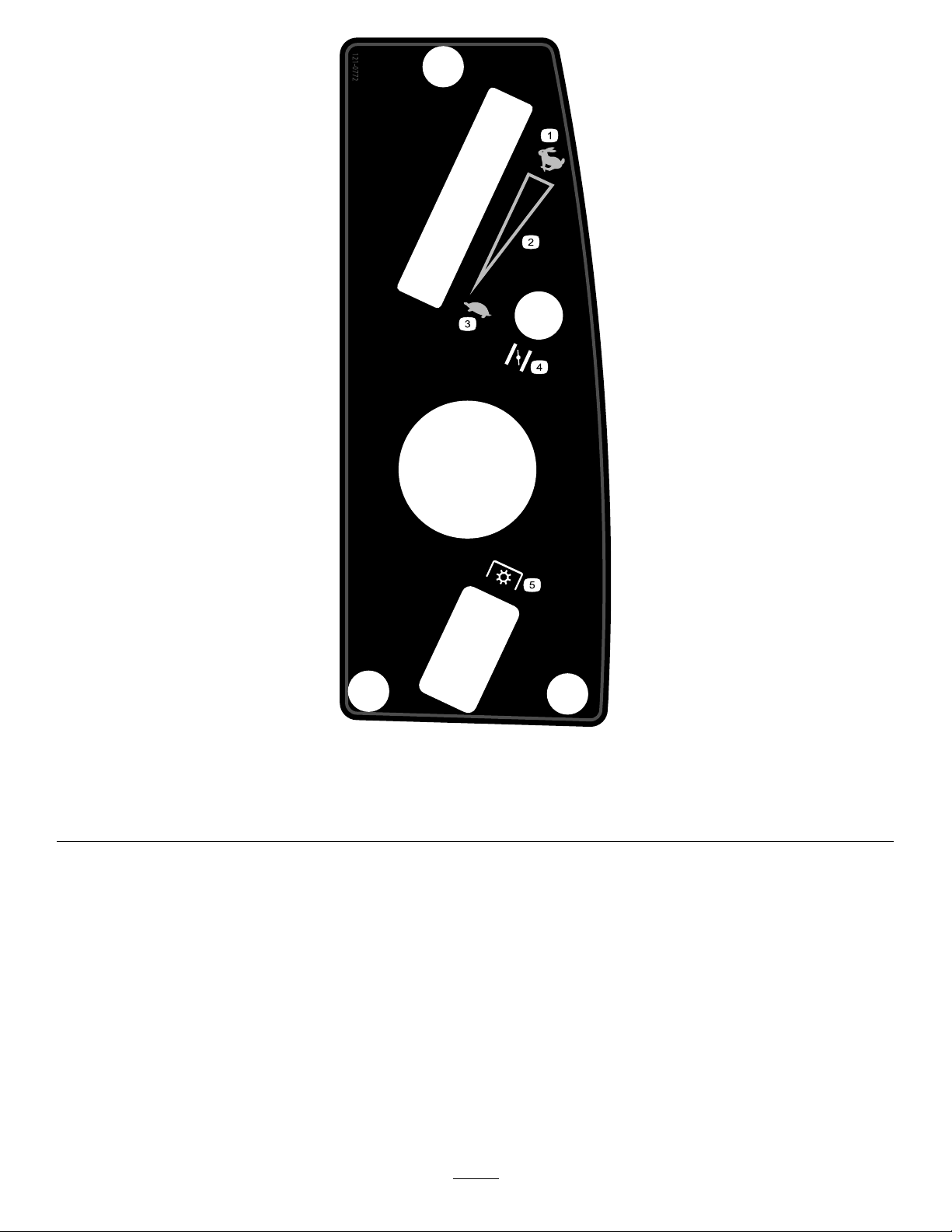

decal121-0772

121-0772

1.Fast

4.Choke

2.Continuousvariablesetting5.Powertake-off(PTO),Bladecontrolswitch

3.Slow

9

Page 10

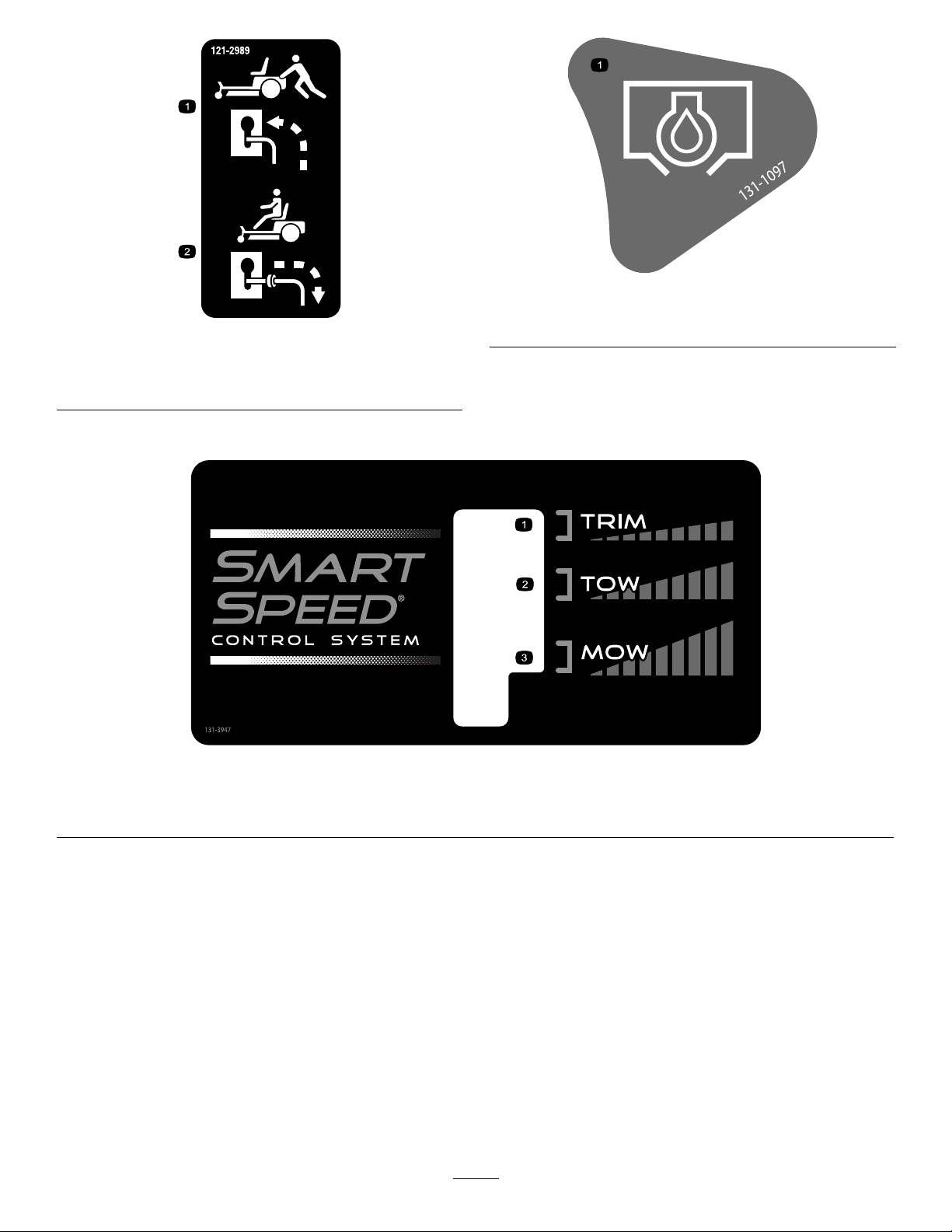

decal131-1097

131-1097

decal121-2989b

1.Oildrain

121-2989

1.Bypassleverpositionfor

pushingthemachine

2.Bypassleverpositionfor

operatingthemachine

Decal131-3947doesnotapplytomodelswithouttheMyRidesuspensionsystemormodel74773.

131–3947

decal131-3947

1.Trim—slow

3.Mow—fast

2.Tow—medium

10

Page 11

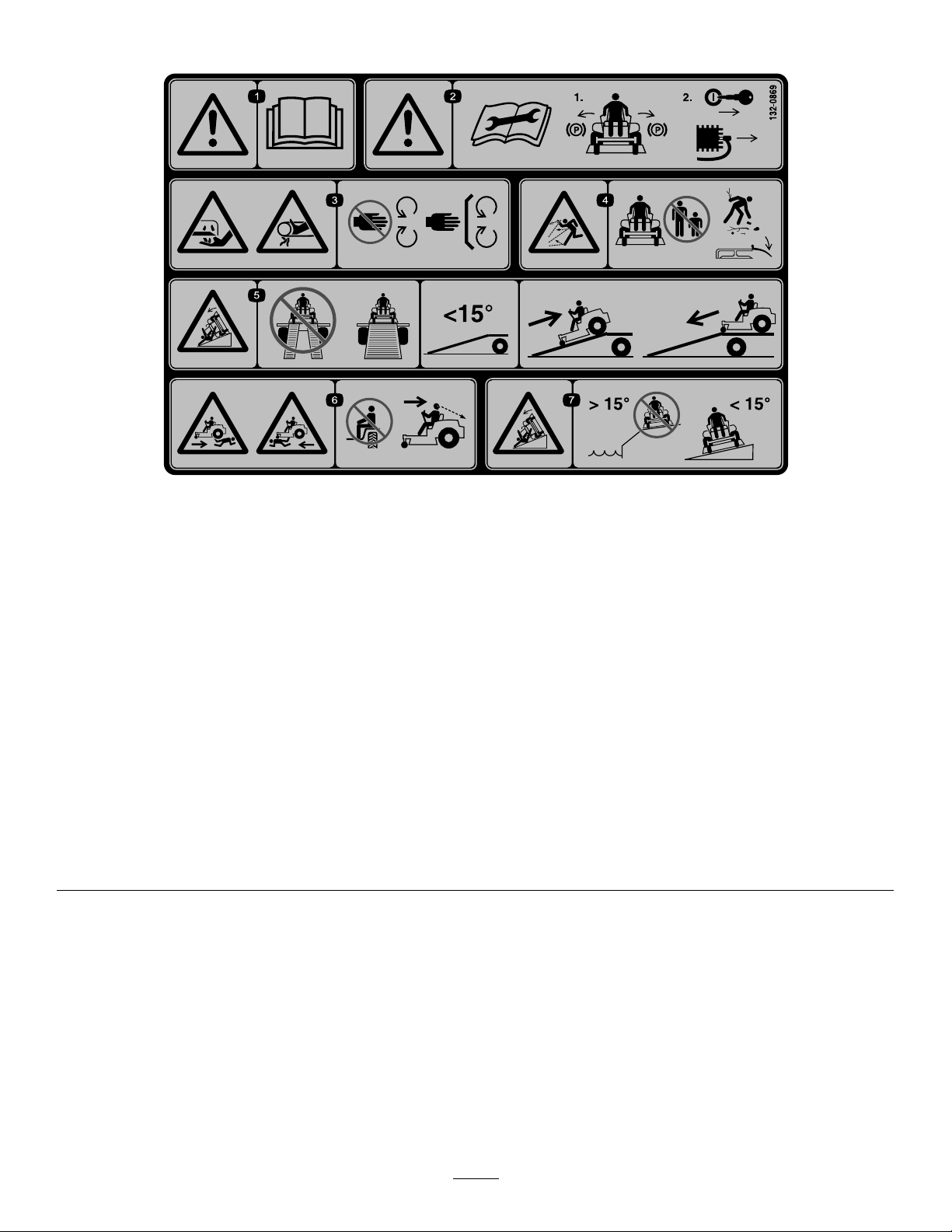

Decal132-0869isformodelswith107cm(42inch),127cm(50inch),or137cm(54inch)decks.

132-0869

Note:Thismachinecomplieswiththeindustrystandardstabilitytestinthestaticlateralandlongitudinaltestswiththemaximum

recommendedslopeindicatedonthedecal.ReviewtheinstructionsforoperatingthemachineonslopesintheOperator’sManualas

wellastheconditionsinwhichyouwouldoperatethemachinetodeterminewhetheryoucanoperatethemachineintheconditions

onthatdayandatthatsite.Changesintheterraincanresultinachangeinslopeoperationforthemachine.Ifpossible,keepthe

cuttingunitsloweredtothegroundwhileoperatingthemachineonslopes.Raisingthecuttingunitswhileoperatingonslopescan

causethemachinetobecomeunstable.

decal132-0869

1.Warning—readthe

Operator'sManual.

2.Warning—before

performingmaintenance,

readtheOperator'sManual;

engagetheparkingbrake,

removethekey ,and

disconnectthesparkplug.

3.Cutting/dismemberment

hazardofthehand,mower

blade;entanglement

hazardofthehand,

belt—stayawayfrom

movingparts;keepall

guardsandshieldsinplace.

4.Thrownobject

hazard—keepbystanders

away;pickupdebris

beforeoperating;lowerthe

deectorbeforeusingthe

machine.

5.Ramphazard—donot

usedualrampswhen

loadingontoatrailer;use

1rampwideenoughfor

themachine;usearamp

withaslopelessthan15°;

backuptherampwhen

loadingthemachineand

driveforwardofftheramp

whenunloading.

6.Runover/backover

hazard—donotcarry

passengers;lookbehind

youwhenmowingin

reverse.

7.Tippinghazard—donot

useonslopesnearopen

water;donotuseonslopes

greaterthan15°.

11

Page 12

decal132-0872

132-0872

1.Thrownobject

hazard—keepbystanders

awayfromthemachine.

2.Thrownobjecthazard,

raisedbafe—donot

operatethemachinewith

anopendeck;usea

baggerorabafe.

3.Severinghazardofhand

orfoot—keepawayfrom

movingparts.

4.Entanglement

hazard—keepaway

frommovingparts;keep

allguardsandshieldsin

place.

133-9255

Note:Thismachinecomplieswiththeindustrystandardstabilitytestinthestaticlateralandlongitudinaltestswiththemaximum

recommendedslopeindicatedonthedecal.ReviewtheinstructionsforoperatingthemachineonslopesintheOperator’sManualas

wellastheconditionsinwhichyouwouldoperatethemachinetodeterminewhetheryoucanoperatethemachineintheconditions

onthatdayandatthatsite.Changesintheterraincanresultinachangeinslopeoperationforthemachine.Ifpossible,keepthe

cuttingunitsloweredtothegroundwhileoperatingthemachineonslopes.Raisingthecuttingunitswhileoperatingonslopescan

causethemachinetobecomeunstable.

decal133-9255

1.Warning—readtheOperator'sManual.

2.Ramphazard—donotusedualrampswhenloadingontoa

trailer;use1rampwideenoughforthemachine;usearamp

withaslopelessthan15°;backuptherampwhenloadingthe

machineanddriveforwardofftherampwhenunloading.

3.Thrownobjecthazard—keepbystandersaway;pickup

debrisbeforeoperating;lowerthedeectorbeforeusingthe

machine.

4.Runover/backoverhazard—donotcarrypassengers;look

behindyouwhenmowinginreverse.

5.Tippinghazard—donotuseonslopesnearopenwater;do

notuseonslopesgreaterthan15°.

6.Cutting/dismembermenthazardofthehand,mowerblade;

entanglementhazardofthehand,belt—stayawayfrom

movingparts;keepallguardsandshieldsinplace.

7.Warning—beforeperformingmaintenance,readthe

Operator'sManual;engagetheparkingbrake,removethe

key,anddisconnectthesparkplug.

12

Page 13

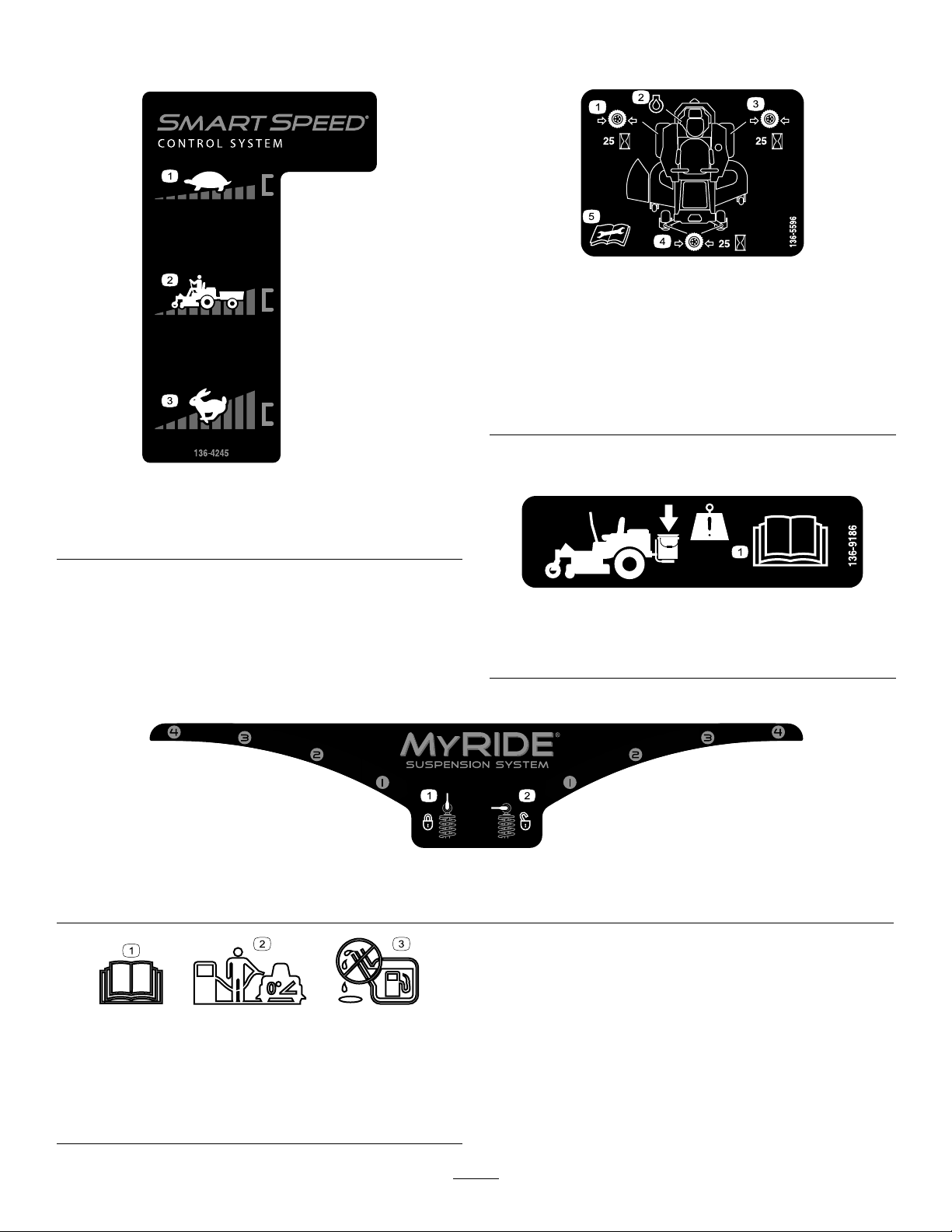

Decal136-4245isformodelswiththeMyRide

suspensionsystem.

Decal136-5596isformodelswiththeMyRide

suspensionsystemor152cm(60inch)decks.

decal136-5596

136-5596

decal136-4245

136-4245

1.Slow

2.Transport

3.Fast

Decal137-7044isformodelswiththeMyRidesuspensionsystem.

1.Checkthetirepressure

every25operatinghours.

2.Engineoil

4.Checkthetirepressure

every25operatinghours.

5.ReadtheOperator's

Manualbeforeperforming

maintenance.

3.Checkthetirepressure

every25operatinghours.

Decal136-9186isformodelswith152cm(60inch)

decks.

136-9186

1.ReadtheOperator'sManualbeforeaddingweighttothe

bucket.

decal136-9186

137-7044

1.Camlock2.Camunlock

decal138-2456

138-2456

1.ReadtheOperator’s

Manual.

2.Parkthemachineona

levelsurfacewhenlling

thefueltank.

3.Donotoverllthefuel

tank.

13

decal137-7044

Page 14

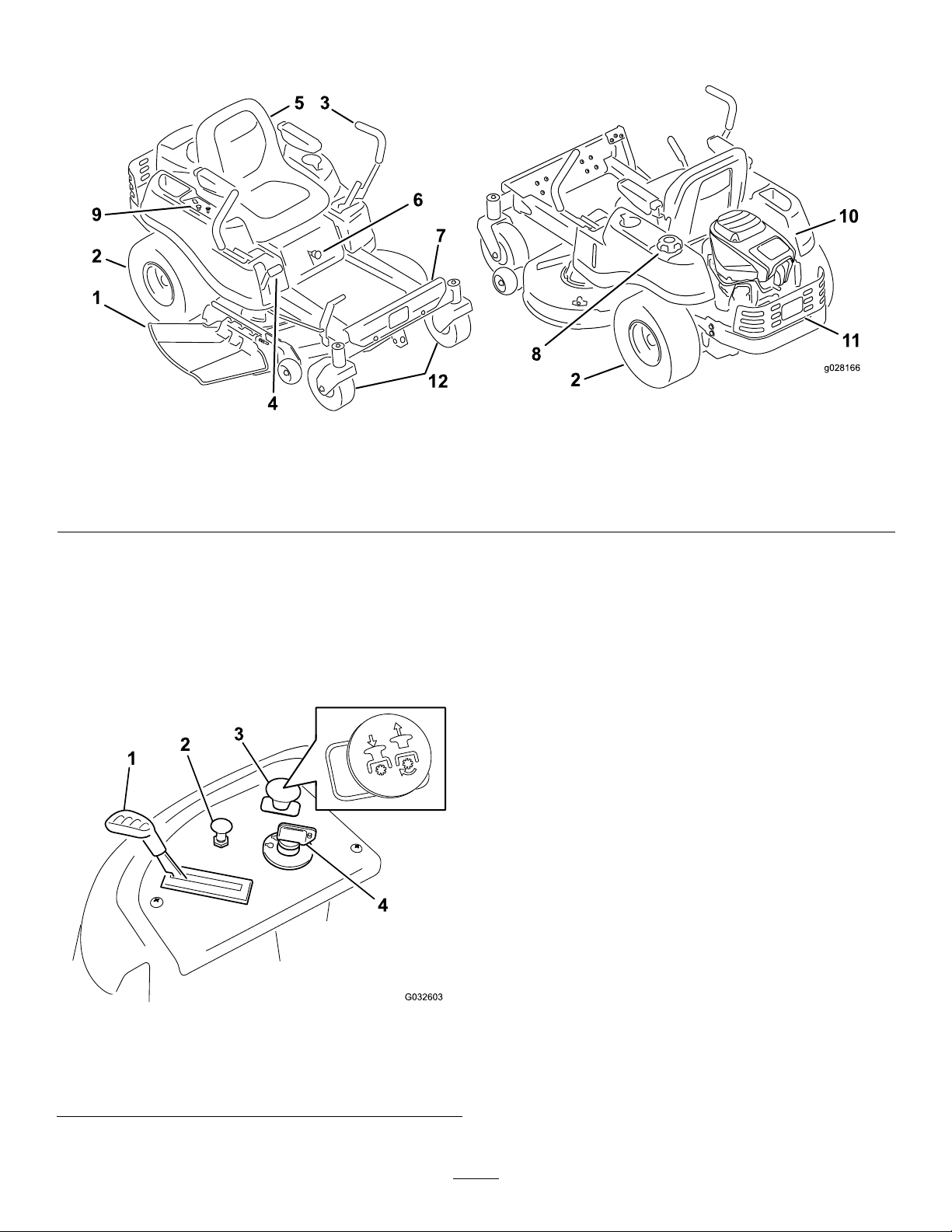

ProductOverview

g028166

Figure5

1.Deector4.Height-of-cutlever

2.Reardrivewheel

3.Motion-controllevers

5.Operatorseat

6.SmartSpeed™lever9.Controlpanel

Controls

Becomefamiliarwithallthecontrolsbeforeyoustart

theengineandoperatethemachine.

ControlPanel

7.Footrest10.Engine

8.Fuel-tankcap11.Engineguard

12.Frontcasterwheel

KeySwitch

Thekeyswitch,usedtostartandshutofftheengine,

has3positions:OFF,RUN,andST ART.Referto

StartingtheEngine(page26).

ThrottleControl

Thethrottlecontrolstheenginespeed,andithasa

continuous-variablesettingfromtheSLOWtoFAST

position(Figure6).

ChokeControl

Usethechokecontroltostartacoldengine.

Blade-ControlSwitch(Power

Figure6

1.Throttlecontrol3.Blade-controlswitch

2.Chokecontrol

(powertakeoff)

4.Keyswitch

Takeoff)

Theblade-controlswitch,representedbya

power-takeoff(PTO)symbol,engagesand

g032603

disengagespowertothemowerblades(Figure6).

14

Page 15

Motion-ControlLevers

Height-of-CutLever

Usethemotion-controlleverstodrivethemachine

forward,reverse,andturneitherdirection(Figure5).

ParkPosition

Movethemotion-controlleversoutwardfromthe

centertothePARKpositionwhenexitingthemachine

(Figure24).Alwayspositionthemotion-controllevers

intothePARKpositionwhenyoustopthemachineor

leaveitunattended.

SmartSpeed™ControlSystem

Lever

TheSmartSpeed™Control-Systemlever,located

belowtheoperatingposition,givesyouachoiceto

drivethemachineat3speedranges—trim,tow,and

mow(Figure27).

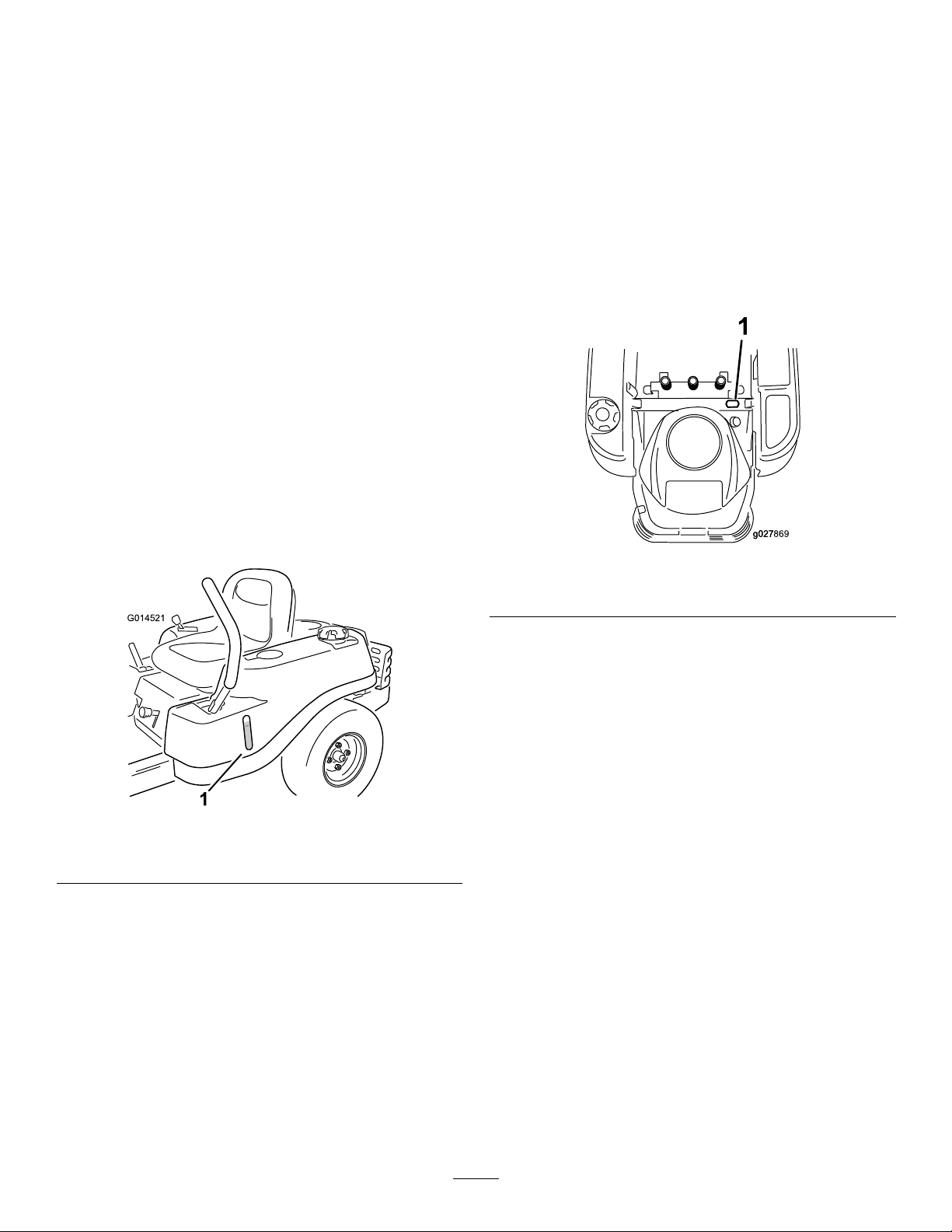

Fuel-PresenceWindow

Youcanusethefuelwindow,locatedontheleftside

ofthemachine,toverifythepresenceoffuelinthe

tank(Figure7).

Usetheheight-of-cutlevertolowerandraisethedeck

fromtheseatedposition.Movingtheleverup(toward

you)raisesthedeckfromthegroundandmovingthe

leverdown(awayfromyou)lowersthedecktoward

theground.Adjusttheheight-of-cutonlywhilethe

machineisnotmoving(Figure29).

HourMeter(IfEquipped)

Thehourmeterrecordsthenumberofhourswhen

youareintheseatandthekeyswitchisintheON

position(Figure8).

g027869

Figure8

1.Fuel-presencewindow

Figure7

1.Thehourmeterislocatedbehindtheseat.

Attachments/Accessories

AselectionofT oroapprovedattachmentsand

accessoriesisavailableforusewiththemachine

toenhanceandexpanditscapabilities.Contact

yourAuthorizedServiceDealerorauthorizedT oro

distributororgotowww.Toro.comforalistofall

approvedattachmentsandaccessories.

g014521

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

15

Page 16

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Pre-Start

Fillfueltankonlevelground.SeeFuel

RecommendationsintheSpecicationssectionfor

additionalgasolineinformation.

DoNotaddoiltogasoline.

BeforeOperation

BeforeOperationSafety

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbyToro.

•Inspecttheareawheretheequipmentistobe

usedandremoveallrocks,toys,sticks,wires,

bones,andotherforeignobjects.Thesecan

bethrownorinterferewiththeoperationofthe

machineandmaycausepersonalinjurytothe

operatororbystanders.

•Wearappropriatepersonalprotectiveequipment

suchassafetyglasses,substantialslip-resistant

footwear,andhearingprotection.Tiebacklong

hairandavoidlooseclothingandloosejewelry

whichmaygettangledinmovingparts.

CAUTION

Thismachineproducessoundlevelsin

excessof85dBAattheoperator’searand

cancausehearinglossthroughextended

periodsofexposure.

DoNotoverllfueltank.Fillthefueltanktothebottom

ofthellerneck.Theemptyspaceinthetankallows

gasolinetoexpand.Overllingmayresultinfuel

leakageordamagetotheengineoremissionsystem.

Makesureyouunderstandthecontrols,theirlocations,

theirfunctions,andtheirsafetyrequirements.

RefertotheMaintenancesectionandperformallthe

necessaryinspectionandmaintenancesteps.

Wearhearingprotectionwhenoperating

thismachine.

•Checkthattheoperatorpresencecontrols,

safetyswitches,andshieldsareattachedand

functioningproperly.DoNotoperateunlessthey

arefunctioningproperly.

•DoNotoperatethemowerwhenpeople,especially

children,orpetsareinthearea.Stopthemachine

andattachment(s)ifanyoneentersthearea.

•DoNotoperatethemachinewithouttheentire

grasscollectionsystem,dischargedeector,

orothersafetydevicesinplaceandinproper

workingcondition.Grasscatchercomponents

aresubjecttowear,damageanddeterioration,

whichcouldexposemovingpartsorallowobjects

tobethrown.Frequentlycheckforwornor

deterioratingcomponentsandreplacethemwith

themanufacturer’srecommendedpartswhen

necessary.

16

Page 17

FuelSafety

DANGER

Useextremecarewhenhandlingfuel.

DANGER

Incertainconditionsgasolineisextremely

ammableandvaporsareexplosive.

Areorexplosionfromgasolinecanburn

you,others,andcausepropertydamage.

•Fillthefueltankoutdoorsonlevelground,

inanopenarea,whentheengineiscold.

Wipeupanygasolinethatspills.

•Neverrellthefueltankordrainthe

machineindoorsorinsideanenclosed

trailer.

•DoNotllthefueltankcompletelyfull.

Fillthefueltanktothebottomoftheller

neck.Theemptyspaceinthetankallows

gasolinetoexpand.Overllingmayresult

infuelleakageordamagetotheengineor

emissionsystem.

•Neversmokewhenhandlinggasoline,and

stayawayfromanopenameorwhere

gasolinefumesmaybeignitedbyspark.

•Storegasolineinanapprovedcontainer

andkeepitoutofthereachofchildren.

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitegasolinevapors.Areor

explosionfromgasolinecanburnyouand

othersandcausepropertydamage.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebefore

lling.

•DoNotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowthe

lossofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

ground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbe

used,keepthenozzleincontactwiththe

rimofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.DoNot

useanozzlelockopendevice.

•Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoraddfuel

whenengineisrunningorwhentheengine

ishot.

•Iffuelisspilled,DoNotattempttostart

theengine.Moveawayfromtheareaof

thespillandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

•DoNotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

WARNING

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporshascaused

cancerinlaboratoryanimals.Failuretouse

cautionmaycauseseriousinjuryorillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgas

tank/containeropening.

•Keepawayfromeyesandskin.

•Neversiphonbymouth.

Tohelppreventres:

•Keepengineandengineareafreefrom

accumulationofgrass,leaves,excessivegrease

oroil,andotherdebriswhichcanaccumulatein

theseareas.

•Cleanupoilandfuelspillsandremovefuelsoaked

debris.

•Allowthemachinetocoolbeforestoringthe

machineinanyenclosure.DoNotstorenear

ameoranyenclosedareawhereopenpilotlights

orheatappliancesarepresent.

17

Page 18

AddingFuel

RecommendedFuel

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan

10%ethanolbyvolume,suchasE15(contains

15%ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

Note:Donotllthefueltankcompletelyfull.

Theemptyspaceinthetankallowsthefuelto

expand.

•Donotaddoiltogasoline.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsfuelfreshlongerwhenusedasdirectedby

thefuel-stabilizermanufacturer

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

Important:Donotusefueladditives

containingmethanolorethanol.

Addthecorrectamountoffuelstabilizer/conditioner

tothefuel.

Note:Afuelstabilizer/conditionerismost

effectivewhenmixedwithfreshfuel.T ominimize

thechanceofvarnishdepositsinthefuelsystem,

usefuelstabilizeratalltimes.

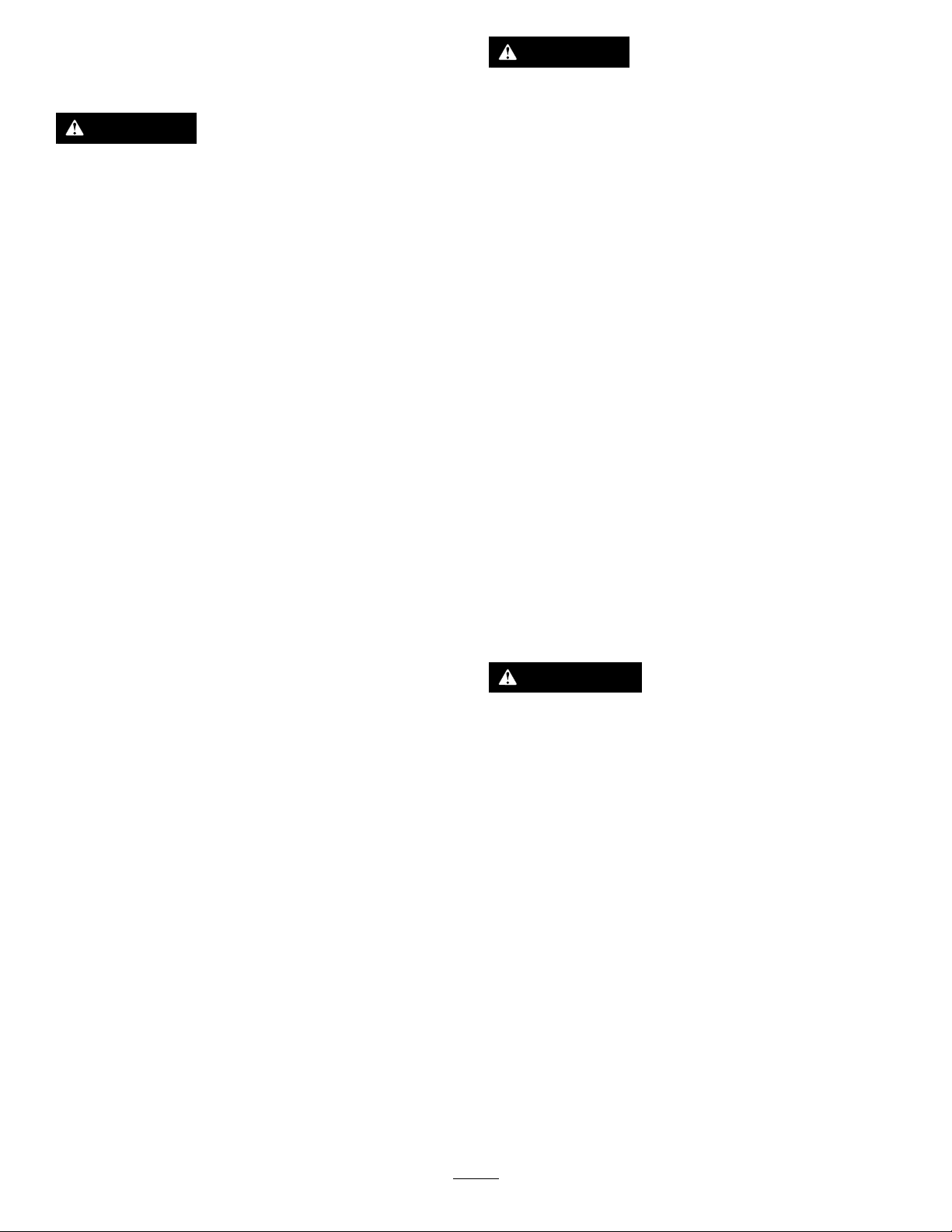

g027243

Figure9

PerformingDaily

Maintenance

Beforestartingthemachineeachday ,performthe

EachUse/DailyprocedureslistedinMaintenance

(page35).

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mower

decksanddrivesystemshavehigherfrictionwhen

new,placingadditionalloadontheengine.Allow

40to50hoursofbreak-intimefornewmachinesto

developfullpowerandbestperformance.

FillingtheFuelTank

1.Parkthemachineonalevelsurface.

2.Engagetheparkingbrake.

3.Shutofftheengineandremovethekey.

4.Cleanaroundthefuel-tankcap.

5.Fillthefueltanktothebottomofthellerneck

(Figure9).

18

Page 19

UsingtheSafety-Interlock

System

WARNING

Ifthesafety-interlockswitchesare

disconnectedordamaged,themachinecould

operateunexpectedly,causingpersonal

injury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

Understandingthe

Safety-InterlockSystem

Thesafety-interlocksystemisdesignedtopreventthe

enginefromstartingunless:

•Theblade-controlswitch(PTO)isdisengaged.

motion-controlleverstothecenter,unlocked

position,engagetheblade-controlswitch,and

riseslightlyfromtheseat;theengineshould

shutoff.

PositioningtheSeat

ForModels74726and74766

Theseatcanmoveforwardandbackward.Position

theseatwhereyouhavethebestcontrolofthe

machineandaremostcomfortable(Figure10).

•Themotion-controlleversareinthePARKposition.

Thesafety-interlocksystemalsoisdesignedtoshut

offtheenginewheneverthecontrolleversareoutof

thePARKpositionandyourisefromtheseat.

TestingtheSafety-Interlock

System

Testthesafety-interlocksystembeforeyouusethe

machineeachtime.Ifthesafetysystemdoesnot

operateasdescribedbelow,haveanAuthorized

ServiceDealerrepairthesafetysystemimmediately .

1.Sitontheseat,movethemotion-controllevers

inthePARKposition,andmovetheblade-control

switchtotheONposition.Trystartingthe

engine;theengineshouldnotcrank.

2.Sitontheseatandmovetheblade-controlswitch

totheOFFposition.Moveeithermotion-control

levertothecenter,unlockedposition.Try

startingtheengine;theengineshouldnotcrank.

Repeatwiththeothermotion-controllever.

3.Sitontheseat,movetheblade-controlswitch

totheOFFposition,andlockthemotion-control

leversinthePARKposition.Starttheengine.

Whiletheengineisrunning,engagethe

blade-controlswitch,andriseslightlyfromthe

seat;theengineshouldshutoff.

g027249

Figure10

4.Sitontheseat,movetheblade-controlswitch

totheOFFposition,andlockthemotion-control

leversinthePARKposition.Starttheengine.

Whiletheengineisrunning,movethe

19

Page 20

ForModels74760,74774,and

ForModels74772and74773

74777

Theseatcanmoveforwardandbackward.Position

theseatwhereyouhavethebestcontrolofthe

machineandaremostcomfortable(Figure11).

Theseatcanmoveforwardandbackward.Position

theseatwhereyouhavethebestcontrolofthe

machineandaremostcomfortable(Figure12).

Figure11

g265989

g265992

Figure12

20

Page 21

ForModels74768and74778

AdjustingtheMyRide™

Theseatcanmoveforwardandbackward.Position

theseatwhereyouhavethebestcontrolofthe

machineandaremostcomfortable(Figure13).

Figure13

SuspensionSystem

ForMachineswiththeMyRide™

SuspensionSystem

Note:T omakeadjustingtheMyRide™suspension

systemeasier,pivottheseatforwardandinstallthe

proprodtotakeweightofftheshockassemblies.

TheMyRide™suspensionsystemadjuststoprovide

asmoothandcomfortableride.Youcanadjustthe

rear2-shockassembliestoquicklyandeasilychange

thesuspensionsystem.Positionthesuspension

systemwhereyouaremostcomfortable.

AdjustingtheRear-Shock

Assemblies

g027632

Theslotsfortherear-shockassemblieshavedetent

positionsforreference.

Thefollowinggraphicshowsthepositionforasoftor

rmrideandthedifferentdetentpositions(Figure14).

Figure14

1.Firmestposition3.Detentsintheslots

2.Softestposition

Note:Ensurethattheleftandrightrear-shock

assembliesarealwaysadjustedtothesamepositions.

Adjusttherear-shockassemblies(Figure15).

21

g231347

Page 22

Adjustingthe

Motion-ControlLevers

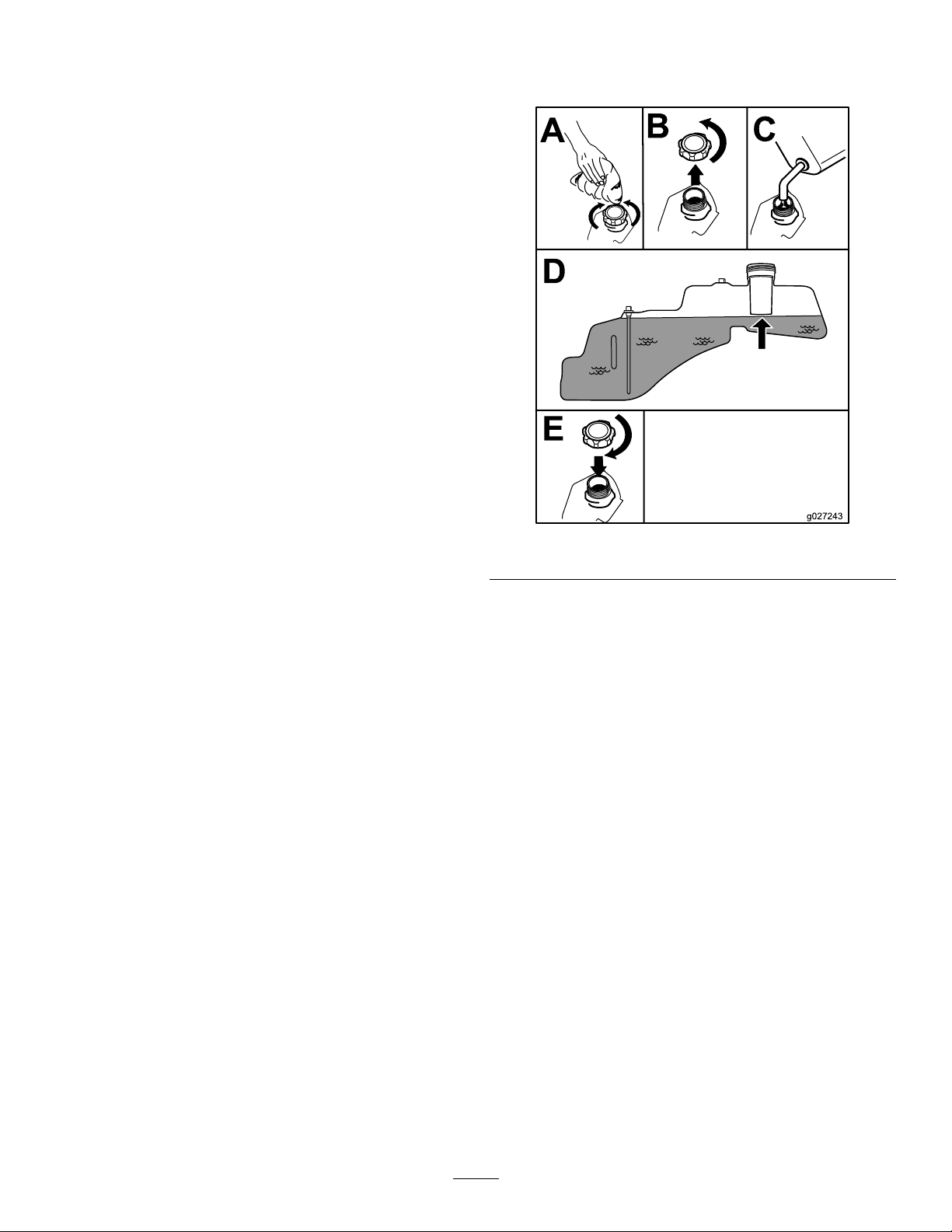

AdjustingtheHeight

Youcanadjustthemotion-controllevershigheror

lowerformaximumcomfort(Figure16).

Figure16

g027252

Figure15

AdjustingtheTilt

Youcanadjustthemotion-controlleversforwardor

rearwardforyourcomfort.

1.Loosentheupperboltholdingthecontrollever

tothecontrol-armshaft.

2.Loosenthelowerboltjustenoughtopivotthe

controlleverforwardorrearward(Figure16).

3.Tightenbothboltstosecurethecontrolleverin

g231392

thenewposition.

4.Repeattheadjustmentfortheothercontrollever.

22

Page 23

DuringOperation

DuringOperationSafety

GeneralSafety

Theoperatormustusetheirfullattentionwhen

operatingthemachine.DoNotengageinanyactivity

thatcausesdistractions;otherwise,injuryorproperty

damagemayoccur.

WARNING

Operatingengineparts,especiallythemufer,

becomeextremelyhot.Severeburnscan

occuroncontactanddebris,suchasleaves,

grass,brush,etc.cancatchre.

•Allowengineparts,especiallythemufer,

tocoolbeforetouching.

•Removeaccumulateddebrisfrommufer

andenginearea.

WARNING

Engineexhaustcontainscarbonmonoxide,

whichisanodorlessdeadlypoisonthatcan

killyou.

DoNotrunengineindoorsorinasmall

connedareawheredangerouscarbon

monoxidefumescancollect.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeopleorproperty .

•Thismowerwasdesignedforoneoperatoronly .

Donotcarrypassengersandkeepallothersaway

frommachineduringoperation.

•DoNotoperatethemachineundertheinuence

ofalcoholordrugs.

•Operateonlyindaylightorgoodarticiallight.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,

DoNotoperatethemachine;seekshelter.

•Useextracarewhileoperatingwithaccessoriesor

attachments,suchasgrasscollectionsystems.

Thesecanchangethestabilityofthemachine

andcausealossofcontrol.Followdirectionsfor

counterweightsifrequired.

•Keepawayfromholes,ruts,bumps,rocks,and

otherhiddenhazards.Usecarewhenapproaching

blindcorners,shrubs,trees,tallgrassorother

objectsthatmayhideobstaclesorobscurevision.

Uneventerraincouldoverturnthemachineor

causetheoperatortolosetheirbalanceorfooting.

•Besurealldrivesareinneutralandparkingbrake

isengagedbeforestartingengine.

•Starttheenginecarefullyaccordingtoinstructions

withfeetwellawayfromtheblades.

•Neveroperatethemowerwithdamagedguards,

shields,orcovers.Alwayshavesafetyshields,

guards,switchesandotherdevicesinplaceandin

properworkingcondition.

•Keepclearofthedischargeopeningatalltimes.

Nevermowwiththedischargedoorraised,

removedoralteredunlessthereisagrass

collectionsystemormulchkitinplaceandworking

properly.

•Keephandsandfeetawayfrommovingparts.

Ifpossible,DoNotmakeadjustmentswiththe

enginerunning.

WARNING

Hands,feet,hair,clothing,oraccessories

canbecomeentangledinrotatingparts.

Contactwiththerotatingpartscan

causetraumaticamputationorsevere

lacerations.

–DoNotoperatethemachinewithout

guards,shields,andsafetydevicesin

placeandworkingproperly .

–Keephands,feet,hair,jewelry,or

clothingawayfromrotatingparts.

•Neverraisethedeckwithbladesrunning.

•Beawareofthemowerdischargepathanddirect

dischargeawayfromothers.Avoiddischarging

materialagainstawallorobstructionasthe

materialmayricochetbacktowardtheoperator.

Stoptheblades,slowdown,andusecautionwhen

crossingsurfacesotherthangrassandwhen

transportingthemowertoandfromtheareatobe

mowed.

•Bealert,slowdownandusecautionwhen

makingturns.Lookbehindandtothesidebefore

changingdirections.DoNotmowinreverse

unlessabsolutelynecessary.

•DoNotchangetheenginegovernorsettingor

overspeedtheengine.

•Parkthemachineonlevelground.Stopengine,

waitforallmovingpartstostop,andremovethe

sparkplugwire(s).

–Beforechecking,cleaningorworkingonthe

mower.

–Afterstrikingaforeignobjectorabnormal

vibrationoccurs(inspectthemowerfor

damageandmakerepairsbeforerestarting

andoperatingthemower).

–Beforeclearingblockages.

23

Page 24

–Wheneveryouleavethemower.DoNotleave

arunningmachineunattended.

•Stopengine,waitforallmovingpartstostop:

–Beforerefueling.

–Beforedumpingthegrasscatcher.

–Beforemakingheightadjustments.

•Tragicaccidentscanoccuriftheoperatorisnot

alerttothepresenceofchildren.Childrenare

oftenattractedtothemachineandthemowing

activity.Neverassumethatchildrenwillremain

whereyoulastsawthem.

–Keepchildrenoutofthemowingareaand

underthewatchfulcareofanotherresponsible

adult,nottheoperator.

–Bealertandturnthemachineoffifchildren

enterthearea.

–Beforeandwhilebackingorchangingdirection,

lookbehind,down,andside-to-sideforsmall

children.

–Neverallowchildrentooperatethemachine.

–DoNotcarrychildren,evenwiththeblades

shutoff.Childrencouldfalloffandbeseriously

injuredorinterferewiththesafeoperationof

themachine.Childrenthathavebeengiven

ridesinthepastcouldsuddenlyappearinthe

workingareaforanotherrideandberunover

orbackedoverbythemachine.

distance(twicethewidthofthemachine)between

themachineandanyhazard.Useawalkbehind

machineorahandtrimmertomowthegrassin

theseareas.

g22911 1

Figure17

1.SafeZone-Usethemowerhereonslopeslessthan15

degrees

2.DangerZone-Useawalk-behindmowerand/orhand

trimmeronslopesgreaterthan15degrees

3.Water

4.W=widthofthemachine

5.Keepasafedistance(twicethewidthofthemachine)

betweenthemachineandanyhazard.

SlopeSafety

•Slopesareamajorfactorrelatedtolossofcontrol

androlloveraccidents,whichcanresultinsevere

injuryordeath.Theoperatorisresponsiblefor

safeslopeoperation.Operatingthemachineon

anysloperequiresextracaution.Beforeusingthe

machineonaslope,theoperatormust:

–Reviewandunderstandtheslopeinstructions

inthemanualandonthemachine.

–Useanangleindicatortodeterminethe

approximateslopeangleofthearea.

–Neveroperateonslopesgreaterthan15

degrees.

–Evaluatethesiteconditionsofthedayto

determineiftheslopeissafeformachine

operation.Usecommonsenseandgood

judgmentwhenperformingthisevaluation.

Changesintheterrain,suchasmoisture,can

quicklyaffecttheoperationofthemachineon

aslope.

•Identifyhazardsatthebaseoftheslope.Do

Notoperatethemachineneardropoffs,ditches,

embankments,waterorotherhazards.The

machinecouldsuddenlyrolloverifawheelgoes

overtheedgeortheedgecollapses.Keepasafe

•Avoidstarting,stoppingorturningthemachineon

slopes.Avoidmakingsuddenchangesinspeedor

direction;turnslowlyandgradually .

•DoNotoperateamachineunderanyconditions

wheretraction,steeringorstabilityisinquestion.

Beawarethatoperatingthemachineonwet

grass,acrossslopesordownhillmaycausethe

machinetolosetraction.Lossoftractiontothe

drivewheelsmayresultinslidingandalossof

brakingandsteering.Themachinecanslideeven

ifthedrivewheelsarestopped.

•Removeormarkobstaclessuchasditches,holes,

ruts,bumps,rocksorotherhiddenhazards.Tall

grasscanhideobstacles.Uneventerraincould

overturnthemachine.

•Useextracarewhileoperatingwithaccessoriesor

attachments,suchasgrasscollectionsystems.

Thesecanchangethestabilityofthemachine

andcausealossofcontrol.Followdirectionsfor

counterweights.

•Ifpossible,keepthedeckloweredtotheground

whileoperatingonslopes.Raisingthedeckwhile

operatingonslopescancausethemachineto

becomeunstable.

24

Page 25

OperatingtheMower

OperatingtheThrottle

Blade-ControlSwitch(PTO)

Theblade-controlswitch(PTO)startsandstopsthe

mowerbladesandanypoweredattachments.

EngagingtheBlade-Control

Switch(PTO)

Figure18

Note:Alwaysengagethebladeswiththethrottlein

theFASTposition(Figure19).

YoucanmovethethrottlecontrolbetweenFASTand

SLOWpositions(Figure21).

AlwaysusetheFASTpositionwhenengagingthePTO.

g187517

Figure21

g008945

OperatingtheChoke

Usethechoketostartacoldengine.

1.Pullupthechokeknobtoengagethechoke

beforeusingthekeyswitch(Figure22).

DisengagingtheBlade-Control

Switch(PTO)

Note:Ensurethatyoufullyengagethechoke.

Youmayneedtoholdtheknobupwhenyou

usethekeyswitch.

2.Pushdownthechoketodisengagethechoke

aftertheenginehasstarted(Figure22).

g187516

Figure19

Figure20

g009174

Figure22

1.ONposition2.OFFposition

25

g008959

Page 26

StartingtheEngine

ShuttingOfftheEngine

Note:Awarmorhotenginemaynotrequirechoking.

Important:Donotengagethestarterformore

than5secondsatatime.Engagingthestarter

motorformorethan5secondscandamagethe

startermotor.Iftheenginefailstostart,wait10

secondsbeforeoperatingtheenginestarteragain.

1.Disengagethebladesbymovingthe

blade-controlswitchtotheOFFposition(Figure

23).

2.Engagetheparkingbrake;refertoParkPosition

(page15).

3.MovethethrottlecontroltotheFASTposition.

4.TurnthekeytotheOFFpositionandremove

thekey .

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

Alwaysremovethekeyandengagethe

parkingbrakewhenleavingthemachine

unattended.

UsingtheMotion-Control

Levers

Figure23

g027581

g004532

Figure24

1.Motion-control

lever—PARKposition

2.Center,unlockedposition5.Frontofmachine

3.Forward

26

4.Backward

Page 27

DrivingtheMachine

Thedrivewheelsturnindependently,poweredby

hydraulicmotorsoneachaxle.Youcanturn1side

inreversewhileyouturntheotherforward,causing

themachinetospinratherthanturn.Thisgreatly

improvesthemachinemaneuverabilitybutmay

requiresometimeforyoutoadapttohowitmoves.

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Place

thethrottlecontrolintheFASTpositionforbest

performance.Alwaysoperateinthefullthrottle

positionwhenmowing.

WARNING

Themachinecanspinveryrapidly .You

maylosecontrolofthemachineandcause

personalinjuryordamagetothemachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemaking

sharpturns.

DrivingBackward

1.Movetheleverstothecenter,unlockedposition.

2.Togobackward,slowlypullthemotion-control

leversrearward(Figure26).

DrivingForward

Note:Alwaysusecautionwhenbackingupand

turning.

1.Movetheleverstothecenter,unlockedposition.

2.Togoforward,slowlypushthemotion-control

leversforward(Figure25).

Figure26

UsingtheSmartSpeed

TM

Control

System

TheSmartSpeed

27orFigure28)givestheoperatorachoicetodrive

themachineat3groundspeedranges—trim,tow,

andmow.

TM

Control-Systemlever(Figure

g008953

Figure25

g027625

Figure27

Non-MyRideMachines

g008952

1.Smart-speedlever

27

Page 28

Figure28

MyRideMachines

1.Smart-speedlever

Tochangespeeds,dothefollowing:

1.Movethemotion-controlleverstoneutraland

outwardtothePARKposition.

2.Disengagetheblade-controlswitch.

3.Adjustthelevertothedesiredposition.

Tow

Thisisthemediumspeed.Thesuggestedusesfor

thisspeedareasfollows:

•Bagging

•Mulching

•Towingattachments

Mow

g239348

Thisisthefastestspeed.Thesuggestedusesforthis

speedareasfollows:

•Normalmowing

•Movingthemachine

UsingtheSideDischarge

Themowerhasahingedgrassdeectorthat

dispersesclippingstothesideanddowntowardthe

turf.

Thefollowingareonlyrecommendationsforuse.

Adjustmentsvarybygrasstype,moisturecontent,

andtheheightofthegrass.

Suggested

uses:

ParkingX

Heavy,wet

grass

TrainingX

Trimming

grass

BaggingX

MulchingX

Towing

attachments

Normal

mowing

Movingthe

machine

TrimTowMow

X

X

X

X

X

Trim

Thisisthelowestspeed.Thesuggestedusesforthis

speedareasfollows:

DANGER

Withoutagrassdeector,dischargecover,or

acompletegrass-catcherassemblymounted

inplace,youandothersareexposedtoblade

contactandthrowndebris.Contactwith

rotatingmowerblade(s)andthrowndebris

willcauseinjuryordeath.

•Neverremovethegrassdeectorfromthe

mowerdeckbecausethegrassdeector

routesmaterialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthe

mowerdeck.

•Nevertrytoclearthedischargearea

ormowerbladesunlessyoumovethe

blade-controlswitch(PTO)totheOFF

position,rotatethekeyswitchtotheOFF

position,andremovethekeyfromthekey

switch.

•Makesurethatthegrassdeectorisinthe

downposition.

•Parking

•Heavy,wetgrassmowingconditions

•Training

•Trimminggrass

28

Page 29

AdjustingtheHeightofCut

AdjustingtheAnti-Scalp

Note:Thetransportpositionisthehighest

height-of-cutpositionorcuttingheightat1 15mm

(4-1/2inches)asshowninFigure29.

Heightofcutiscontrolledbytheleverlocatedtothe

rightoftheoperatingposition(Figure29).

Rollers

Machineswitha107cm(42inch),

127cm(50inch),or137cm(54

inch)MowerDeckOnly

Wheneveryouchangetheheightofcut,adjustthe

heightoftheanti-scalprollers.

Note:Adjusttheanti-scalprollerssothattherollers

donottouchthegroundinnormal,atmowingareas.

1.Disengagetheblade-controlswitch(PTO),move

themotion-controlleverstotheNEUTRAL-LOCK

position,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Adjusttheanti-scalprollersasshowninFigure

30tomatchtheclosestheight-of-cutposition.

Figure29

g010233

Figure30

g028025

1.Anti-scalproller3.Flangenut

2.Bolt4.Holespacing

Machineswitha152cm(60inch)

MowerDeckOnly

Wheneveryouchangetheheightofcut,itis

recommendedtoadjusttheheightoftheanti-scalp

rollers.

1.Disengagetheblade-controlswitch(PTO),move

themotion-controlleverstotheNEUTRAL-LOCK

position,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removetheangenut,anti-scalproller,andbolt

fromthebracket(Figure31).

Note:Keeptheboltandanti-scalproller

togetherwhenremoving.

29

Page 30

Figure31

OperatingTips

UsingtheFastThrottleSetting

Forbestmowingandmaximumaircirculation,operate

theengineattheFASTposition.Airisrequiredto

thoroughlycutgrassclippings,sodonotsetthe

height-of-cutsolowastototallysurroundthemower

deckinuncutgrass.Alwaystrytohave1sideofthe

g024312

mowerdeckfreefromuncutgrass,whichallowsair

tobedrawnintothemowerdeck.

1.Flangenut4.Bushing

2.Spacer

3.Anti-scalproller

4.Aligntheboltandanti-scalprollerinthe

holeofthebracketthatmatchedtheclosest

height-of-cutposition(Figure31).

5.Inserttheboltintothebracketholeandsecure

theboltandanti-scalprollerwiththeangenut

(Figure31).

5.Bolt

UsingAttachmentsand

Accessories

Machineswitha152cm(60inch)

MowerDeckOnly

Useonlyattachmentsandaccessoriesapprovedby

Toro.

Ifyouattachabuckettotheengineguard,useastrap

tosecureit.

Important:Ifyouarecarryingmorethan4.5kg

(10lb)inabucketattachedtotheengineguard,

youshouldequipyourmachinewiththeBucket

SupportKit.

ContactyourauthorizedToroservicedealer.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethat

thecuttingheightofthemowerdeckdoesnotscalp

anyunevenground.However,thecuttingheight

usedinthepastisgenerallythebestonetouse.

Whencuttinggrasslongerthan15cm(6inches)tall,

youmaywanttocutthelawntwicetoensurean

acceptablequalityofcut.

CuttingaThirdoftheGrassBlade

Itisbesttocutonlyaboutathirdofthegrassblade.

Cuttingmorethanthatisnotrecommendedunless

grassissparse,oritislatefallwhengrassgrows

moreslowly.

AlternatingtheMowingDirection

Alternatethemowingdirectiontokeepthegrass

standingstraight.Thisalsohelpsdisperseclippings,

whichenhancesdecompositionandfertilization.

MowingatCorrectIntervals

Grassgrowsatdifferentratesatdifferenttimesof

theyear.Tomaintainthesamecuttingheight,mow

moreofteninearlyspring.Asthegrassgrowthrate

slowsinmidsummer,mowlessfrequently.Ifyou

cannotmowforanextendedperiod,rstmowata

highcuttingheight,thenmowagain2dayslaterata

lowerheightsetting.

UsingaSlowerCuttingSpeed

Toimprovecutquality ,useaslowergroundspeed

incertainconditions.

AvoidingCuttingTooLow

Whenmowinguneventurf,raisethecuttingheight

toavoidscalpingtheturf.

StoppingtheMachine

Ifyoumuststoptheforwardmotionofthemachine

whilemowing,aclumpofgrassclippingsmay

30

Page 31

dropontoyourlawn.Toavoidthis,moveontoa

previouslycutareawiththebladesengagedoryou

candisengagethemowerdeckwhilemovingforward.

KeepingtheUndersideofthe

AfterOperation

AfterOperationSafety

MowerDeckClean

Cleanclippingsanddirtfromtheundersideofthe

mowerdeckaftereachuse.Ifgrassanddirtbuildup

insidethemowerdeck,cuttingqualitywilleventually

becomeunsatisfactory.

MaintainingtheBlade(s)

Maintainasharpbladethroughoutthecuttingseason

becauseasharpbladecutscleanlywithouttearingor

shreddingthegrassblades.Tearingandshredding

turnsgrassbrownattheedges,whichslowsgrowth

andincreasesthechanceofdisease.Checkthe

mowerbladesaftereachuseforsharpness,and

foranywearordamage.Filedownanynicksand

sharpenthebladesasnecessary.Ifabladeis

damagedorworn,replaceitimmediatelywitha

genuineT ororeplacementblade.

GeneralSafety

•Parkmachineonlevelground,disengagedrives,

setparkingbrake,stopengine,removekeyor

disconnectsparkplugwire.Waitforallmovement

tostopandallowthemachinetocoolbefore

adjusting,cleaning,repairing,orstoring.Never

allowuntrainedpersonneltoservicemachine.

•CleanthemachineasstatedintheMaintenance

section.Keepengineandengineareafreefrom

accumulationofgrass,leaves,excessivegrease

oroil,andotherdebriswhichcanaccumulate

intheseareas.Thesematerialscanbecome

combustibleandmayresultinare.

•Frequentlycheckforwornordeteriorating

componentsthatcouldcreateahazard.Tighten

loosehardware.

Transporting

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthe

machine.Ensurethatthetrailerortruckhasall

necessarylightingandmarkingasrequiredbylaw.

Thoroughlyreadallofthesafetyinstructions.Knowing

thisinformationcouldhelpyou,yourfamily ,pets,or

bystandersavoidinjury.

Totransportthemachine:

•Lockthebrakeandblockthewheels.

•Besurethefuelshut-offvalveisclosed.

•Securelyfastenthemachinetothetraileror

truckwithstraps,chains,cable,orropes.Only

usethefourdesignatedtie-downlocationson

themower–twoontheleftsideandtwoonthe

right(Figure32).Usetheselocationseven

whentransportingthemowerwithanattached

accessory.Usingnon-designatedlocationsmay

causedamagetothemowerand/orattachment.

31

Page 32

onthedownsideoftheslopeandtherampextends

uptheslope.Thiswillminimizetherampangle.

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath.

Figure32

1.Tie-downlocation

•Secureatrailertothetowingvehiclewithsafety

chains.

WARNING

Drivingonthestreetorroadwaywithout

turnsignals,lights,reectivemarkings,

oraslowmovingvehicleemblemis

dangerousandcanleadtoaccidents

causingpersonalinjury.

Donotdrivemachineonapublicstreetor

roadway.

LoadingtheMachine

Useextremecautionwhenloadingorunloading

machinesontoatraileroratruck.Useafull-width

rampthatiswiderthanthemachineforthisprocedure.

Backuprampsanddriveforwarddownramps(Figure

33).

g027708

•Useextremecautionwhenoperatinga

machineonaramp.

•Useonlyafull-widthramp;donotuse

individualrampsforeachsideofthe

machine.

•Donotexceeda15-degreeanglebetween

therampandthegroundorbetweenthe

rampandthetrailerortruck.

•Ensurethelengthoframpisatleastfour

times(4X)aslongastheheightofthe

trailerortruckbedtotheground.Thiswill

ensurethatrampangledoesnotexceed15

degreesonatground.

•Backuprampsanddriveforwarddown

ramps.

•Avoidsuddenaccelerationordeceleration

whiledrivingthemachineonarampas

thiscouldcausealossofcontrolora

tip-oversituation.

Figure33

1.Backupramps

2.Driveforwarddownramps

Important:Donotusenarrowindividualramps

foreachsideofthemachine.

Ensuretherampislongenoughsothattheanglewith

thegrounddoesnotexceed15degrees(Figure33).

Onatground,thisrequiresaramptobeatleastfour

times(4X)aslongastheheightofthetrailerortruck

bedtotheground.Asteeperanglemaycausemower

componentstogetcaughtastheunitmovesfromthe

ramptothetrailerortruck.Steeperanglesmayalso

causethemachinetotiporlosecontrol.Ifloadingon

ornearaslope,positionthetrailerortrucksothatitis

g027995

32

Page 33

andlossofcontrol.Reducethetowedweightand

slowdown.

•Stoppingdistanceincreaseswiththeweightofthe

towedload.Travelslowlyandallowextradistance

tostop.

•Makewideturnstokeeptheattachmentclearof

themachine.

PushingtheMachineby

Hand

Important:Alwayspushthemachinebyhand.

Donottowthemachine,becausetowingmay

damageit.

Thismachinehasanelectric-brakemechanism,and

topushthemachine,theignitionkeymustbeinthe

RUNposition.Thebatteryneedstobechargedand

functioningtodisengagetheelectricbrake.

PushingtheMachine

Figure34

1.Full-widthrampinstowed

position

2.Sideviewoffull-width

rampinloadingposition

3.Notgreaterthan

15degrees

4.Rampisatleastfourtimes

(4X)aslongastheheight

ofthetrailerortruckbed

totheground

5.H=heightofthetraileror

truckbedtotheground

6.Trailer

TowingtheMachine

•Donotattachtowedequipmentexceptatthehitch

point.

•Followtheattachmentmanufacturer's

recommendationforweightlimitsfortowed

equipmentandtowingonslopes.T owed

weightmustnotexceedtheweightofthe

machine,operator,andballast;otherwise

hydrostatictransmissionfailuremayoccur.Use

counterweightsorwheelweightsasdescribedin

theattachmentmanufacturer'smanual.

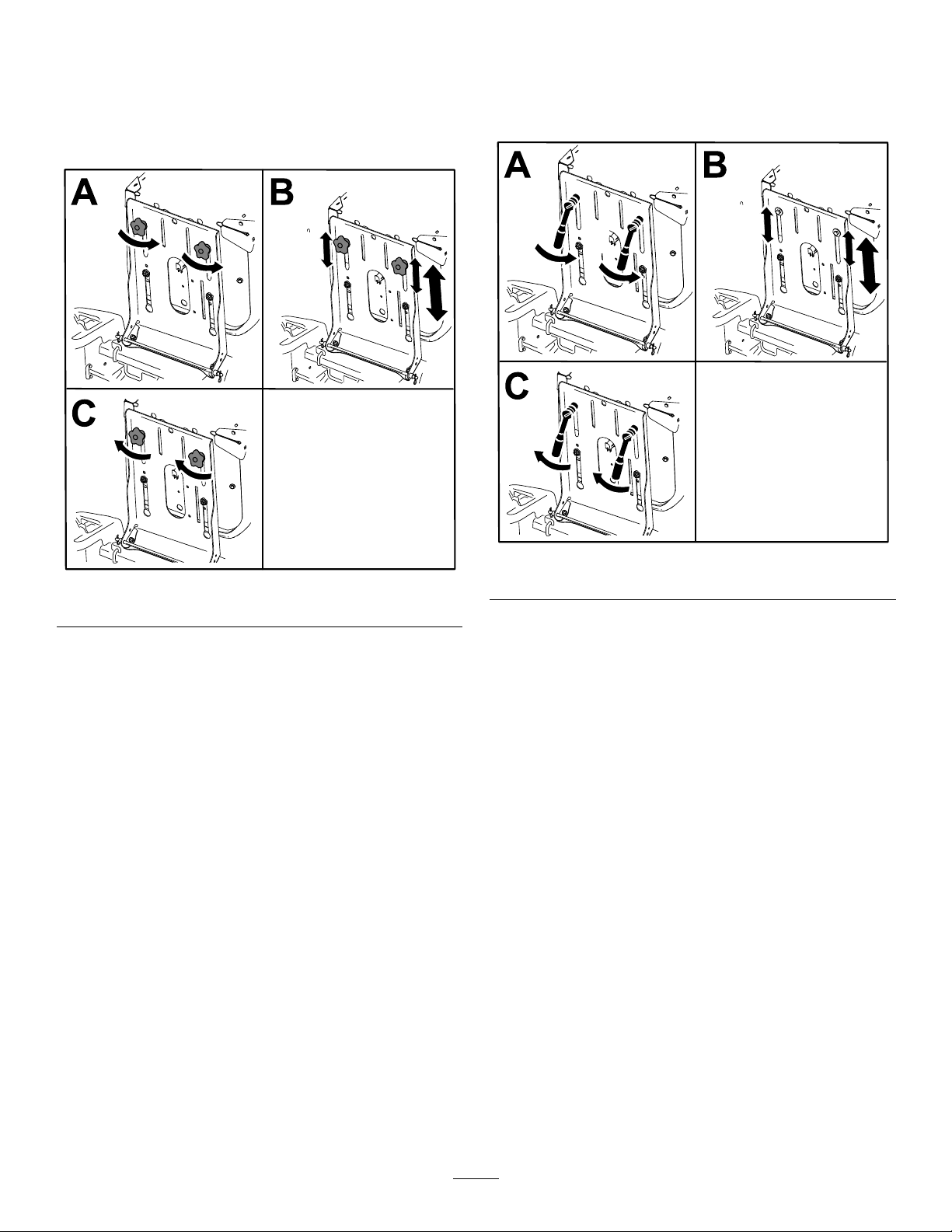

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake.

2.Shutofftheengine,removethekey,andwait

g027996

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Locatethebypassleversontheframeonboth

sidesoftheengine.

4.Movethebypassleversforwardthroughthekey

holeanddowntolocktheminplace(Figure35).

Note:Dothisforeachlever.

5.Turntheignitionkeyonanddisengagethe

parkingbrake.

Note:Donotstartthemachine.

•Neverallowchildrenorothersinorontowed

equipment.

•Onslopes,theweightofthetowedequipmentmay

causelossoftraction,increasedriskofrollover,

33

Page 34

Figure35

g017303

1.Bypass-leverlocations

2.Leverpositionfor

operatingthemachine

3.Leverpositionforpushing

themachine

6.Whennished,ensurethatthekeyhasbeen

returnedtotheSTOPpositiontoavoiddraining

thebatterycharge.

Note:Ifthemachinefailstomove,theelectricbrake

maystillbeengaged.Youcanreleasetheelectric

brakemanuallyifnecessary;refertoReleasingthe

ElectricBrake(page47).

OperatingtheMachine

Movethebypassleversrearwardthroughthekeyhole

anddowntolocktheminplaceasshowninFigure35.

Note:Dothisforeachlever.

34

Page 35

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Beforeeachuseordaily

Aftereachuse

Every25hours

Every100hours

Every200hours

Beforestorage

MaintenanceProcedure

•Changetheengineoilandlter.

•Checkthesafety-interlocksystem.

•Checktheaircleanerfordirty,loose,ordamagedparts.

•Checktheengine-oillevel.

•Cleantheairintakescreen.

•Inspecttheblades.

•Inspectthegrassdeectorfordamage.

•Cleanthemower-deckhousing.

•Greasealllubricationpoints(non-MyRidemodelsonly).

•Cleantheair-cleanerfoamelement(moreoftenindusty ,dirtyconditions).

•Checktirepressure.

•Replacetheair-cleanerfoamelement(moreoftenindusty,dirtyconditions).

•Cleanthepaperair-cleanerelement(moreoftenindirtyordustyconditions).

•Changetheengineoilandoillter(moreoftenindirtyordustyconditions).

•Checkthesparkplug(s).

•Checkthein-linefuellter.

•Replacethepaperair-cleanerelement(moreoftenindirtyordustyconditions).

•Replacethesparkplug(s).

•Replacethein-linefuellter.

•Chargethebatteryanddisconnectthebatterycables.

•Performallmaintenanceprocedureslistedabovebeforestorage.

•Paintanychippedsurfaces.

CAUTION

Ifyouleavethekeyintheswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Shutofftheengineandremovethekeyfromtheswitchbeforeyouperformanymaintenance.

MaintenanceSafety

WARNING

Whilemaintenanceoradjustmentsarebeingmade,someonecouldstarttheengine.Accidental

startingoftheenginecouldseriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionswitch,engageparkingbrake,andpullthewire(s)offthe

sparkplug(s)beforeyoudoanymaintenance.Alsopushthewire(s)asidesoitdoesnot

accidentallycontactthesparkplug(s).

WARNING

Theenginecanbecomeveryhot.Touchingahotenginecancausesevereburns.

Allowtheenginetocoolcompletelybeforeserviceormakingrepairsaroundtheenginearea.

35

Page 36

•Parkmachineonlevelground,disengagedrives,setparkingbrake,stopengine,removekeyordisconnect

sparkplugwire.Waitforallmovementtostopandallowthemachinetocoolbeforeadjusting,cleaningor

repairing.Neverallowuntrainedpersonneltoservicemachine.

•Disconnectbatteryorremovesparkplugwirebeforemakinganyrepairs.Disconnectthenegativeterminal

rstandthepositivelast.Reconnectpositiverstandnegativelast.

•Keepthemachine,guards,shieldsandallsafetydevicesinplaceandinsafeworkingcondition.Frequently

checkforwornordeterioratingcomponentsandreplacethemwiththemanufacturer’srecommended

partswhennecessary .

WARNING

Removalormodicationoforiginalequipment,partsand/oraccessoriesmayalterthe

warranty,controllability,andsafetyofthemachine.Unauthorizedmodicationstothe

originalequipmentorfailuretouseoriginalToropartscouldleadtoseriousinjuryor

death.Unauthorizedchangestothemachine,engine,fuelorventingsystem,mayviolate

applicablesafetystandardssuchas:ANSI,OSHAandNFPAand/orgovernmentregulations

suchasEPAandCARB.

•Usecarewhencheckingblades.Wraptheblade(s)orweargloves,andusecautionwhenservicingthem.

Onlyreplacedamagedblades.Neverstraightenorweldthem.

•Usejackstandstosupportthemachineand/orcomponentswhenrequired.

CAUTION

Raisingthemachineforserviceormaintenancerelyingsolelyonmechanicalorhydraulic

jackscouldbedangerous.Themechanicalorhydraulicjacksmaynotbeenoughsupportor

maymalfunctionallowingthemachinetofall,whichcouldcauseinjury.

Donotrelysolelyonmechanicalorhydraulicjacksforsupport.Useadequatejackstands

orequivalentsupport.

•Carefullyreleasepressurefromcomponentswithstoredenergy .

•Keephandsandfeetawayfrommovingparts.Ifpossible,DoNotmakeadjustmentswiththeengine

running.Ifthemaintenanceoradjustmentprocedurerequiretheenginetoberunningandcomponents

moving,useextremecaution.

WARNING

Contactwithmovingpartsorhotsurfacesmaycausepersonalinjury.

Keepyourngers,hands,andclothingclearofrotatingcomponentsandhotsurfaces.

•Checkallboltsfrequentlytomaintainpropertightness.

36

Page 37

Pre-Maintenance

Lubrication

Procedures

GreasingtheBearings

RaisingtheSeat

Ensurethattheparkingbrakeisengaged.Liftthe

seatforward.

Youcanaccessfollowingcomponentsbyraisingthe

seat:

•Serialplate

•Servicedecal

•Seat-adjustmentbolts(ifapplicable)

•Fuellter

•Batteryandbatterycables

AllModelswithoutMyRide

ServiceInterval:Every25hours—Greaseall

lubricationpoints(non-MyRide

modelsonly).

GreaseType:No.2lithiumgrease

1.Disengagetheblade-controlswitch(PTO),move

themotion-controlleverstotheNEUTRAL-LOCK

position,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanthegreasettings(Figure36andFigure

37)witharag.

Note:Makesuretoscrapeanypaintoffthe

frontofthetting(s).

Figure36

1.Frontcastertire

Figure37

Locatedontheseat-panunderside

1.Readtheinstructions

beforeservicingor

performingmaintenance.

2.Checkthetirepressure

every25operatinghours.

4.Connectagreaseguntoeachtting(Figure36

andFigure37).

5.Pumpgreaseintothettingsuntilgreasebegins

tooozeoutofthebearings.

3.Greaseevery25operating

hours.

4.Engine

g032432

decal106-8717

37

Page 38

EngineMaintenance

EngineSafety

•Shutofftheenginebeforecheckingtheoilor

addingoiltothecrankcase.

•Keepyourhands,feet,face,clothing,andother

bodypartsawaythemuferandotherhotsurfaces.

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily

Note:Servicetheaircleanermorefrequently(every

fewhours)ifoperatingconditionsareextremelydusty

orsandy .

RemovingtheFoamandPaper

Elements

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

g027800

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanaroundtheair-cleanercovertoprevent

dirtfromgettingintotheengineandcausing

damage.

4.Liftthecoverandrotatetheair-cleanerassembly

outoftheengine(Figure38).

g027801

Figure38

5.Separatethefoamandpaperelements(Figure

39).

g027802

Figure39

38

Page 39

ServicingtheFoamAir-Cleaner

InstallingtheAirCleaner

Element

ServiceInterval:Every25hours/Monthly(whichever

comesrst)—Cleantheair-cleaner

foamelement(moreoftenindusty,

dirtyconditions).

Every100hours/Y early(whichevercomes

rst)—Replacetheair-cleanerfoamelement

(moreoftenindusty ,dirtyconditions).

1.Washthefoamelementinliquidsoapand

warmwater.Whentheelementisclean,rinse

itthoroughly.

2.Drytheelementbysqueezingitinacleancloth.

Important:Replacethefoamelementifit

istornorworn.

ServicingthePaperAir-Cleaner

Element

ServiceInterval:Every100hours—Cleanthepaper

air-cleanerelement(moreoftenin

dirtyordustyconditions).

1.Installthefoamelementoverthepaperelement.

Note:Ensurethatyoudonotdamagethe

elements.

2.Aligntheholesofthelterintothemanifold

ports.

3.Rotatethelterdownintothechamberandfully

seatitagainstthemanifold(Figure40).

Every200hours—Replacethepaperair-cleaner

element(moreoftenindirtyordustyconditions).

1.Cleanthepaperelementbytappingitgentlyto

removedust.

Note:Ifitisverydirty ,replacethepaper

elementwithanewone.

2.Inspecttheelementfortears,anoilylm,or

damagetotherubberseal.

3.Replacethepaperelementifitisdamaged.

Important:Donotcleanthepaperlter.

g228022

Figure40

4.Closethecover.

39

Page 40

ServicingtheEngineOil

Engine-OilSpecications

OilType:Detergentoil(APIserviceSF ,SG,SH,SJ,

orSL)

CrankcaseCapacity:2.4L(81oz)withoillter

Viscosity:Seethetablebelow.

Figure41

g029683

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

Important:Ifyouoverllorunderlltheengine

crankcasewithoilandruntheengine,youmay

damagetheengine.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

Note:Ensurethattheengineiscoolsothatthe

oilhashadtimetodrainintothesump.

3.Tokeepdirt,grassclippings,etc.,outofthe

engine,cleantheareaaroundtheoil-llcapand

dipstickbeforeremovingit(Figure42).

g193541

Figure42

ChangingtheEngineOilandOil

Filter

ServiceInterval:Aftertherst5hours/Afterthe

rstmonth(whichevercomes

rst)—Changetheengineoiland

lter.

Every100hours/Y early(whichevercomes

rst)—Changetheengineoilandoillter(more

oftenindirtyordustyconditions).

1.Parkthemachineonalevelsurfacetoensure

thattheoildrainscompletely.

2.Disengagetheblade-controlswitch(PTO)and

engagetheparkingbrake.

3.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

4.Draintheoilfromtheengine.

40

Page 41

5.Changetheengine-oillter(Figure44).

Note:Ensurethattheoil-ltergaskettouches

theengineandthenturnthelteranextra3/4

turn.

g027799

Figure43

g027477

Figure44

6.Slowlypourapproximately80%ofthespecied

oilintothellertubeandslowlyaddthe

additionaloiltobringittotheFullmark(Figure

45).

g029570

41

Page 42

Figure45

RemovingtheSparkPlug

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleantheareaaroundthebaseoftheplugto

keepdirtanddebrisoutoftheengine.

4.Removethesparkplug(Figure46).

g027478

g193530

Figure46

7.Disposeoftheusedoilatarecyclingcenter.

ServicingtheSparkPlug

ServiceInterval:Every100hours/Yearly(whichever

comesrst)—Checkthespark

plug(s).

Every200hours/Every2years(whichever

comesrst)—Replacethesparkplug(s).

Ensurethattheairgapbetweenthecenterandside

electrodesiscorrectbeforeinstallingthesparkplug.

Useasparkplugwrenchforremovingandinstalling

thesparkplugandagappingtoolorfeelergaugeto

checkandadjusttheairgap.Installanewsparkplug

ifnecessary.

Type:Champion

®

Airgap:0.76mm(0.03inch)

RN9YCorNGK

®

BPR6ES

CheckingtheSparkPlug

Important:Donotcleanthesparkplug(s).

Alwaysreplacethesparkplug(s)whenithasa

blackcoating,wornelectrodes,anoilylm,or

cracks.

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeanstheaircleanerisdirty .

Setthegapto0.75mm(0.03inch).

g206628

Figure47

42

Page 43

InstallingtheSparkPlug

FuelSystem

Maintenance

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

RefertoAddingFuel(page18)foracomplete

listoffuelrelatedprecautions.

ReplacingtheIn-LineFuel

Figure48

CleaningtheCooling

System

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removetheairlterfromtheengine.

4.Removetheengineshroud.

5.Topreventdebrisenteringtheairintake,install

theairltertothelterbase.

6.Cleandebrisandgrassfromtheparts.

7.Removetheairlterandinstalltheengine

shroud.

g027960

Filter

ServiceInterval:Every100hours/Yearly(whichever

comesrst)—Checkthein-linefuel

lter.

Every200hours/Every2years(whichever

comesrst)—Replacethein-linefuellter.

Neverinstalladirtylterafterremovingitfromthe

fuelline.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

8.Installtheairlter.

43

Page 44

ElectricalSystem

Maintenance

ElectricalSystemSafety

g027939

•Disconnectthebatterybeforerepairingthe

machine.Disconnectthenegativeterminalrst

andthepositivelast.Connectthepositiveterminal

rstandthenegativelast.

•Chargethebatteryinanopen,well-ventilated

area,awayfromsparksandames.Unplugthe

chargerbeforeconnectingordisconnectingthe

battery.Wearprotectiveclothinganduseinsulated

tools.

ServicingtheBattery

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetalmachinecomponents,causing

sparks.Sparkscancausethebatterygasses

toexplode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,

donotallowthebatteryterminalstotouch

anymetalpartsofthemachine.

Figure49

•Donotallowmetaltoolstoshortbetween

g033082

thebatteryterminalsandmetalpartsofthe

machine.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Raisetheseattoaccessthebattery .

4.Disconnectthenegative(black)groundcable

fromthebatterypost(Figure50).

Note:Retainallfasteners.

44

Page 45

WARNING

Incorrectlyremovingthecablesfrom

batterycoulddamagethemachineand

cables,causingsparks.Sparkscan

causethebatterygassestoexplode,

resultinginpersonalinjury .

•Alwaysdisconnectthenegative

(black)batterycablebefore

disconnectingthepositive(red)

cable.

•Alwaysconnectthepositive(red)

batterycablebeforeconnectingthe

negative(black)cable.

5.Slidetherubbercoveroffthepositive(red)

cable.

6.Disconnectthepositive(red)cablefromthe

batterypost(Figure50).

Note:Retainallfasteners.

7.Removethebatteryhold-down(Figure50),and

liftthebatteryfromthebatterytray.

ChargingtheBattery

ServiceInterval:Beforestorage—Chargethebattery

anddisconnectthebatterycables.

1.Removethebatteryfromthechassis;referto

RemovingtheBattery(page44).

2.Chargethebatteryforaminimumof1hourat

6to10A.

Note:Donotoverchargethebattery .

3.Whenthebatteryisfullycharged,unplug

thechargerfromtheelectricaloutlet,then

disconnectthechargerleadsfromthebattery

posts(Figure51).

Figure50

1.Battery

2.Positive(+)batterypost

3.Bolt,washer,andnut7.Batteryhold-down

4.Terminalboot

5.Negative(–)batterypost

6.Wingnut,washer,andbolt

g000538

Figure51

1.Positive(+)batterypost3.Red(+)chargerlead

2.Negative(–)batterypost4.Black(–)chargerlead

InstallingtheBattery

1.Positionthebatteryinthetray(Figure50).

2.Usingthefastenerspreviouslyremoved,install

thepositive(red)batterycabletothepositive

(+)batteryterminal.

3.Usingthefastenerspreviouslyremoved,install

thenegativebatterycabletothenegative(-)

batteryterminal.

g017701

4.Slidetheredterminalbootontothepositive

(red)batterypost.

5.Securethebatterywiththehold-down(Figure

50).

6.Lowertheseat.

45

Page 46

ServicingtheFuses

DriveSystem

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;however,ifafuseblows,checkthe

component/circuitforamalfunctionorshort.

Fusetype:

•Main—F1(30A,blade-type)

•ChargeCircuit—F2(25A,blade-type)

1.Removethescrewssecuringthecontrolpanel

tothemachine.

Note:Retainallfasteners.

2.Liftthecontrolpaneuptoaccessthemainwire

harnessandfuseblock(Figure52).

3.Toreplaceafuse,pulloutthefusetoremove

it(Figure52).

Maintenance

CheckingtheTirePressure

ServiceInterval:Every25hours—Checktire

pressure.

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseuneven

cut.Checkthepressureatthevalvestem(Figure53).

Checkthetireswhentheyarecoldtogetthemost

accuratepressurereading.

Refertothemaximumpressuresuggestedbythetire

manufactureronthesidewallofthecasterwheeltires.

Formachineswith42-inchor50-inchdecks,inate

thereardrivewheeltiresto90kPa(13psi).

Formachineswith54-inchor60-inchdecks,inate

thefrontcastersandreardrivewheeltiresto103kPa

(15psi).

Figure52

1.Main(30A)2.Chargecircuit(25A)

4.Returnthecontrolpaneltoitsoriginalposition.

Note:Usethescrewsremovedpreviouslyto

securethepaneltothemachine.

g014921

1.Valvestem

Figure53

g000554

46

Page 47

ReleasingtheElectric

Brake

BeltMaintenance

Youcanmanuallyreleasetheelectricbrakeby

rotatingthelinkarmsforward.Oncetheelectricbrake

isenergized,thebrakeresets.

1.TurnthekeytotheOFFpositionordisconnect

thebattery.

2.Locatetheshaftontheelectricbrakewherethe

brakelinkarmsareconnected(Figure54).

3.Rotatetheshaftforwardtoreleasethebrake.

Figure54

ReplacingtheMower-Deck

Belt

Thesignsofawornbeltincludesquealingwhilethe

beltisrotating,bladesslippingwhilecuttinggrass,

andfrayededges,burnmarks,andcracksonthebelt.