Page 1

TimeCutter

ForTimeCutter

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

®

RidingMowers

®

RidingMowerswithMyRide

FormNo.3420-276RevB

®

Suspension

ProcedureDescription

1

2

3

4

5

6

7

Pin1

Roundclip2

Nopartsrequired

Nopartsrequired

Rearhitch1

Bolt(5/16x1inch)

Locknut(5/16inch)

Nopartsrequired

Nopartsrequired

Ignitionkey1

Hosecoupling(notincludedwithCE

models)

Operator'sManual

Engineowner’smanual(non-T oro

engines)

Operatortrainingmaterial

Qty.

Use

InstalltheMyRidesuspension.

–

–

2

2

–

–

1

1

1

1

Connectthebattery.

Installtheseat(machineswithMyRide

suspensionandshippedinawoodcrate

only).

Installtherearhitch.

Setupthemotion-controllevers.

Checkthemoweradjustment.

Completingthesetup.

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

©2018—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3420-276*B

Page 2

1

InstallingtheMyRide

Suspension

MachineswithMyRideSuspension

andShippedinaWoodCrateOnly

Partsneededforthisprocedure:

1Pin

2Roundclip

Procedure

1.Raisetheplatformandremovethewooden

blockfromabovethebattery.

Note:Youcandiscardthewoodenblock.

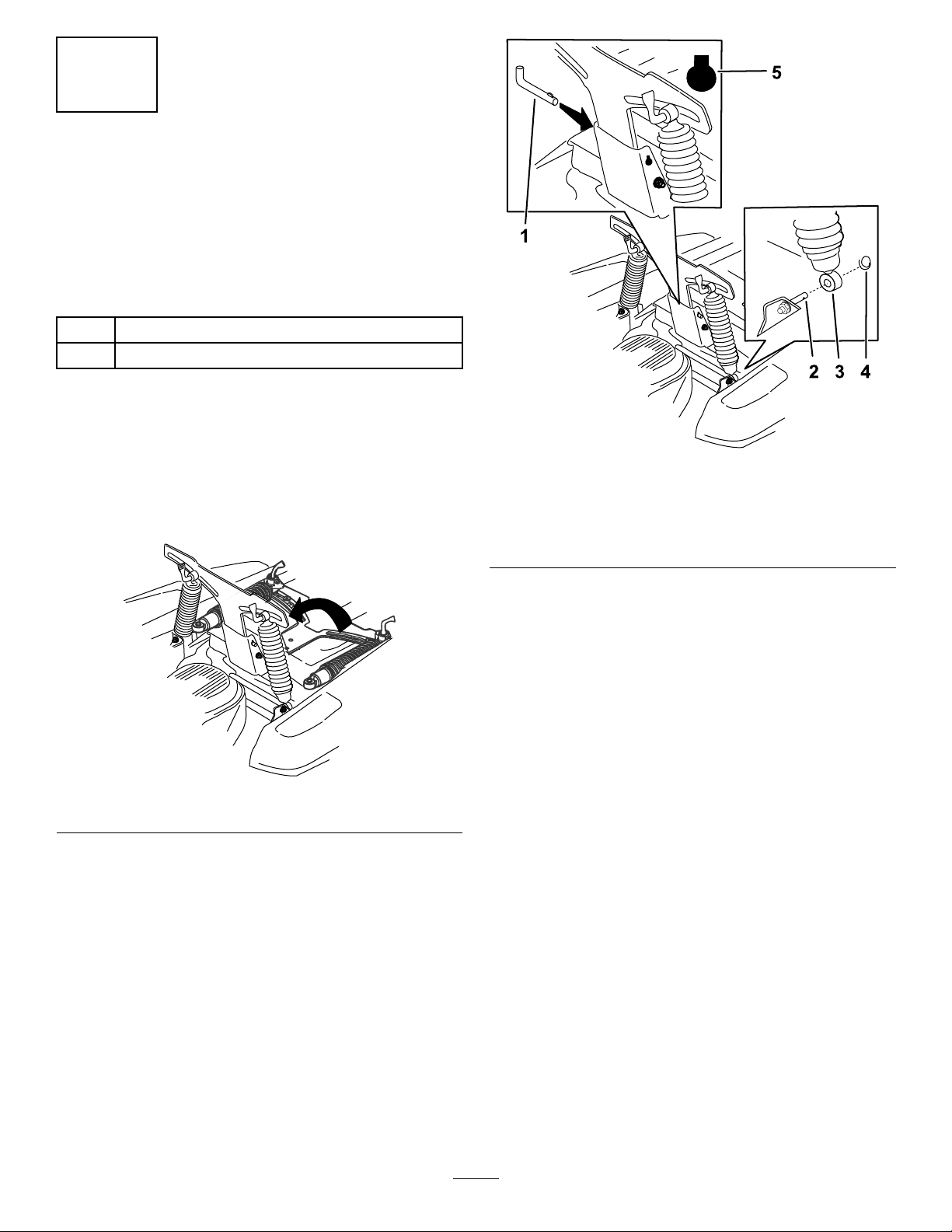

2.Rotatethesuspensionup(Figure1).

®

g233947

Figure2

1.Pin4.Roundclip

2.Post

3.Spring

5.Shapeofthekeyslot

Figure1

3.Placetheendsofthespringsontheposts

(Figure2).

4.Securethespringstothepostswiththe2round

clips(Figure2).

5.Installthepinintothebackbyusingtheindexed

keyslot(Figure2).

g233946

2

Page 3

2

3

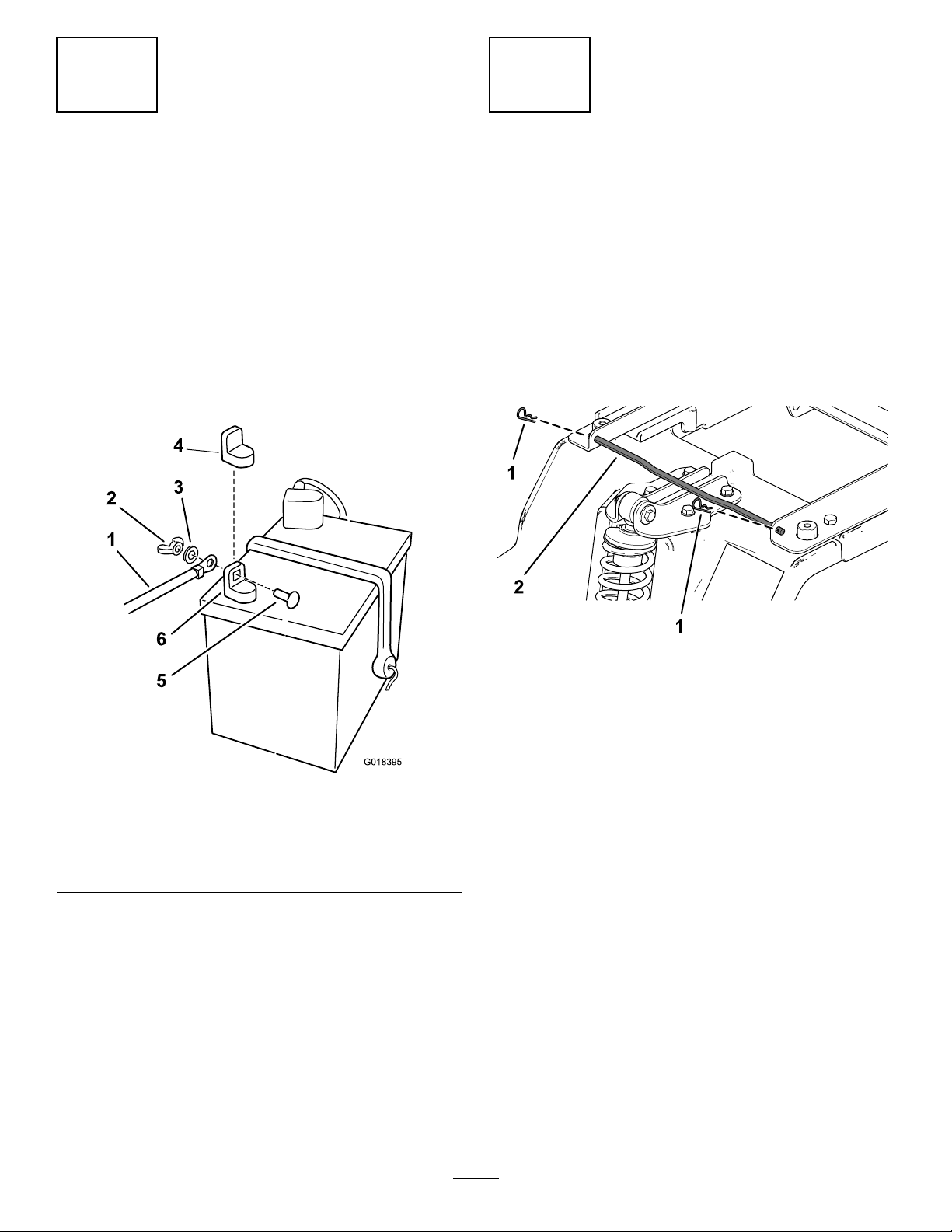

ConnectingtheBattery

NoPartsRequired

Procedure

1.Locatethebatteryandnegativebatterycable.

2.Removetheplasticcapfromthenegative

batterypost.

3.Removethefastenersonthenegativebattery

cable,andusethemtosecurethenegative

batterycabletothenegativebatterypost(Figure

3).

InstallingtheSeat

MachineswithMyRideSuspension

andShippedinaWoodCrateOnly

NoPartsRequired

Procedure

1.Removethe2hairpincottersfromtheseat-pivot

rod,andremovetheseat-pivotrodfromthe

platform(Figure4).

Figure3

1.Negativebatterycable4.Negativebatterypostcap

2.Wingnut

3.Washer6.Negativebatterypost

5.Carriagebolt

g233956

Figure4

1.Hairpincotter

g018395

2.Seat-pivotrod

3

Page 4

2.Placetheseatassemblyontotheplatform

(Figure5).

Figure5

4.Installahairpincotteron1sideoftheseat-pivot

rod,thenslidetheseat-pivotrodthroughthe

pivotbracketholeandseatpanhole(Figure7).

g233953

Figure7

5.Installtheotherhairpincotterontheotherside

oftheseat-pivotrod(Figure8).

g233955

3.Installtheseat-pivotrodbyinsertingtherod

fromthecenterandoutwardthroughthepivot

bracketholeandseatpanhole(Figure6).

Note:Ensurethattheseatpanisbetweenthe

2pivotbrackets.

Figure6

g233954

Figure8

g233952

4

Page 5

6.Rotatetheseatassemblyupwardandconnect

thewireharnesstotheseatswitchonthe

bottomoftheseat(Figure9).

Figure9

1.Seatswitch

4

g015398

Figure11

Afterassembly

g233951

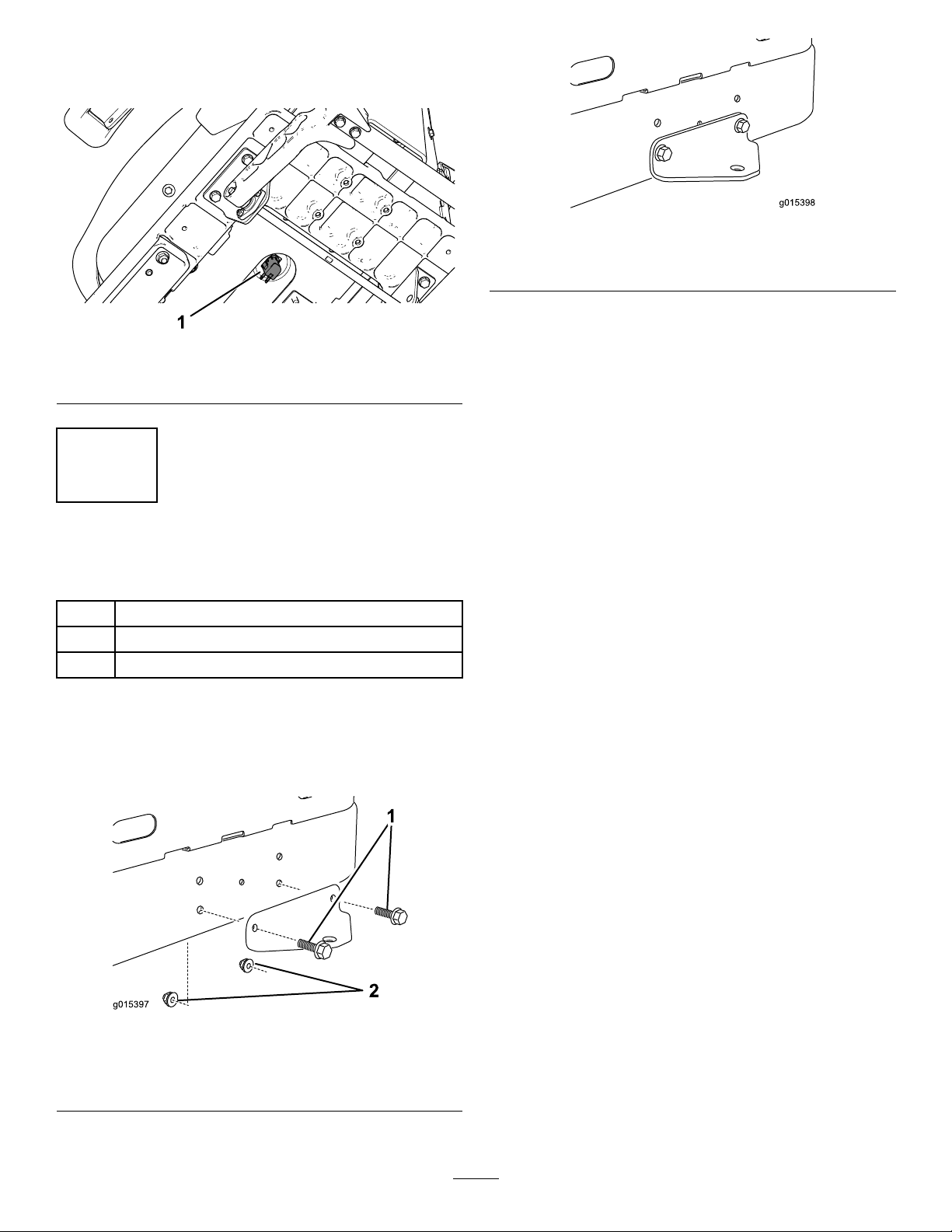

InstallingtheRearHitch

Partsneededforthisprocedure:

1Rearhitch

2

Bolt(5/16x1inch)

2

Locknut(5/16inch)

Procedure

InstallthebrackettotheframeasshowninFigure10

andFigure11.

Figure10

Beforeassembly

1.Bolts2.Locknuts

g015397

5

Page 6

5

7

SettingUpthe

Motion-ControlLevers

NoPartsRequired

Procedure

1.Locatethemotion-controlleversattached,but

foldeddownonthemachine.

2.Removetheupperbolt(3/8x1inch)and

washer;loosenthelowerbolt(3/8x1inch).

3.Raisethemotioncontrolleverstotheupright

position.

4.Aligntheholesinthemotion-controlleverwith

theholesinthecontrol-armshaft,andinstallthe

boltandwasherremovedpreviously.Repeat

thisforbothcontrollevers.

Note:Handtightenallfasteners.

5.Movethemotion-controlleverstothepark

position,raisetheseat,andmovethecontrol

leversbacktothecenterposition(neutral).

CompletingtheSetup

Partsneededforthisprocedure:

1Ignitionkey

1

Hosecoupling(notincludedwithCEmodels)

1

Operator'sManual

1

Engineowner’smanual(non-T oroengines)

1

Operatortrainingmaterial

CheckingtheTirePressure

Checkthefrontandreartiresforproperination;

refertoCheckingtheTirePressureintheOperator’s

Manualfortherecommendedinationpressure.

CheckingtheSide-Discharge

Chute

Removethepackingrestraintholdingtheside

dischargechuteupandlowerthechuteintoplace.

6.Verifythatthemotion-controlleversareproperly

aligned.

Note:Adjustasnecessary.Tightenall

fasteners.

6

CheckingtheMower

Adjustment

NoPartsRequired

Procedure

Adjusttheside-to-sidelevelandthefront-to-rearblade

slope.UsetherelevantproceduresintheOperator's

Manualtoverifythatthedeckislevel,andmakeany

adjustmentsasnecessary .RefertotheOperator's

Manualformoreinformation.

CheckingtheEngine-OilLevel

Beforeyoustarttheengineandusethemachine,

checktheoillevelintheenginecrankcase;referto

CheckingtheOilLevelintheOperator'sManual.

OrganizingtheMaterial

Keepallthefollowingitemswiththemachine:

•Ignitionkey

•Hosecoupling(notincludedinCEmodels)

•Operator'sManual

•Engineowners’smanual(non-T oroengines)

•Viewtheoperatortrainingmaterialbefore

operatingthemachine.

6

Page 7

Notes:

Page 8

Loading...

Loading...