Page 1

FormNo.3394-181RevA

TimeCutter

®

SS5425Riding

Mower

ModelNo.74740—SerialNo.315000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3394-181*A

Page 2

WARNING

registeryourproduct.

accessoryinformation,helpndingadealer,orto

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Thisengineisnotequippedwith

asparkarrestermufer.Itisaviolationof

CaliforniaPublicResourceCodeSection4442to

useoroperatetheengineonanyforest-covered,

brush-covered,orgrass-coveredland.Other

statesorfederalareasmayhavesimilarlaws.

ThissparkignitionsystemcomplieswithCanadian

ICES-002

TheenclosedEngineOwner'sManualis

suppliedforinformationregardingtheUS

EnvironmentalProtectionAgency(EPA)and

theCaliforniaEmissionControlRegulationof

emissionsystems,maintenance,andwarranty.

Replacementsmaybeorderedthroughtheengine

manufacturer.

Formodelswithstatedenginehorsepower,thegross

horsepoweroftheenginewaslaboratoryratedbythe

enginemanufacturerinaccordancewithSAEJ1940.

Asconguredtomeetsafety,emission,andoperating

requirements,theactualenginehorsepoweronthis

classoflawnmowerwillbesignicantlylower.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

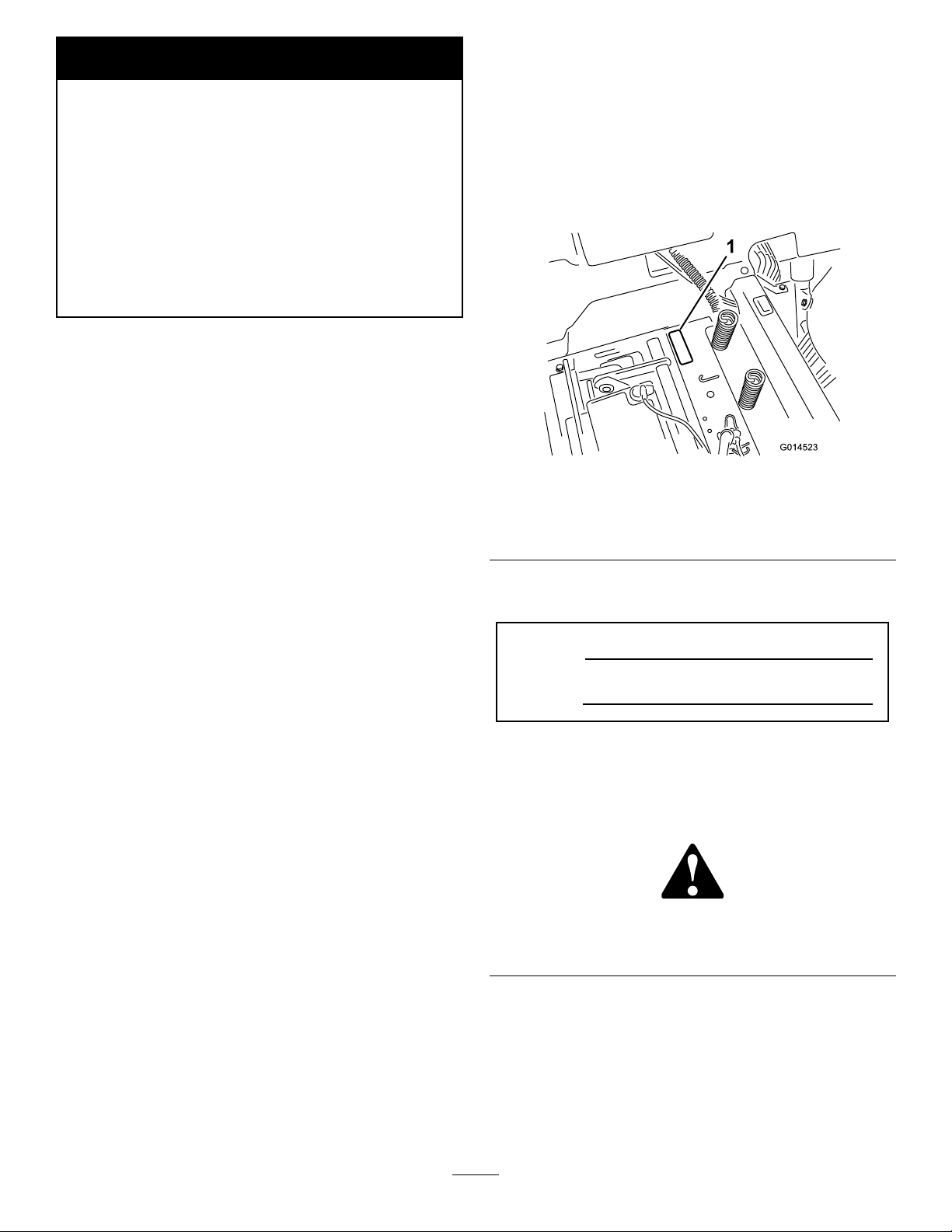

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

g014523

Figure1

Undertheseat

1.Modelandserialnumberplate

Writetheproductmodelandserialnumbersinthe

spacebelow:

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Introduction

Thismachineisaride-on,rotary-bladelawnmower

intendedtobeusedbyhomeownersinresidential

applications.Itisprimarilydesignedforcuttinggrass

onwell-maintainedlawns.Itisnotdesignedforcutting

brush,mowinggrassandothergrowthalongside

highways,orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactTorodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure2

1.Safetyalertsymbol.

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

2

g000502

Contactusatwww.Toro.com.

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Safety.......................................................................4

SafeOperatingPractices....................................4

SafetyandInstructionalDecals..........................6

ProductOverview....................................................11

Controls............................................................11

Operation................................................................13

AddingFuel......................................................13

CheckingtheEngine-OilLevel..........................14

BreakinginaNewMachine..............................14

ThinkSafetyFirst..............................................15

StartingtheEngine...........................................16

OperatingtheBlades........................................17

StoppingtheEngine.........................................17

Driving..............................................................17

StoppingtheMachine.......................................20

AdjustingtheHeight-of-Cut...............................20

AdjustingtheAnti-ScalpRollers........................20

PositioningtheSeat..........................................21

AdjustingtheMotion-ControlLevers.................21

PushingtheMachinebyHand..........................21

TransportingtheMachine.................................22

LoadingtheMachine........................................22

OperatingTips.................................................24

Maintenance...........................................................25

RecommendedMaintenanceSchedule(s)...........25

Pre-MaintenanceProcedures..............................26

RaisingtheSeat...............................................26

Lubrication..........................................................26

GreasingtheBearings......................................26

EngineMaintenance...........................................27

ServicingtheAirCleaner..................................27

ServicingtheEngineOil....................................28

ServicingtheSparkPlug...................................30

CleaningtheBlowerHousing............................31

FuelSystemMaintenance...................................31

ReplacingtheIn-LineFuelFilter.......................31

ElectricalSystemMaintenance...........................32

ChargingtheBattery.........................................32

ServicingtheFuses..........................................34

DriveSystemMaintenance..................................34

CheckingtheTirePressure...............................34

ReleasingtheElectricBrake.............................35

MowerMaintenance.............................................35

ServicingtheCuttingBlades.............................35

LevelingtheMowerDeck..................................38

RemovingtheMower........................................39

InstallingtheMower..........................................40

ReplacingtheGrassDeector..........................41

MowerBeltMaintenance......................................42

InspectingtheBelts..........................................42

ReplacingtheMowerBelt.................................42

Cleaning..............................................................43

WashingtheUndersideoftheMower................43

Storage...................................................................44

CleaningandStorage.......................................44

Troubleshooting......................................................45

Schematics.............................................................47

3

Page 4

Safety

Toreducethepotentialforinjury,comply

withthesesafetyinstructionsandalwayspay

attentiontothesafetyalertsymbol,whichmeans

CAUTION,WARNING,orDANGER-"personal

safetyinstruction."Failuretocomplywiththe

instructionmayresultinpersonalinjuryordeath.

SafeOperatingPractices

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

ThefollowinginstructionsareadaptedfromANSI

standardB71.1-2012.Allthelanguagewithinthis

ANSIstandardappliestothismachine;however,

duetotheapplicationofthestandardacrossmany

differenttypesofproductssomestatementscan

seemgeneralormisleading.Intheseinstances,T oro

hasrenedthestatementtoconveythemeaningof

thestandardwhilebettermatchingtheproductthis

Operator'sManualpertains.Safetyinformationin

additiontotheinstructionsfoundintheANSIstandard

belowcanbefoundinToroRidingMowerSafetyat

theendofthissection.

GeneralOperation

•Read,understand,andfollowallinstructionsin

theoperator'smanualandonthemachinebefore

starting.

•Donotplacehandsorfeetnearrotatingpartsor

underthemachine.Keepclearofthedischarge

openingatalltimes.

•Allowonlyresponsibleadultswhoarefamiliarwith

theinstructionstooperatethemachine.

•Cleartheareaofobjectssuchasrocks,toys,wire,

etc.,whichcouldbepickedupandthrownbythe

blade.

•Besuretheareaisclearofotherpeoplebefore

mowing.Stopthemachineifanyoneentersthe

area.

•Nevercarrypassengers.

•Donotmowinreverseunlessabsolutely

necessary.Alwayslookdownandbehindbefore

andwhilebackingup.

•Beawareofthemowerdischargedirectionanddo

notpointitatanyone.Avoiddischargingmaterial

againstawallorobstruction.Materialmayricochet

backtowardtheoperator.Stoptheblade(s)when

crossinggravelsurfaces.

•Donotoperatethemachinewithoutdeector,

dischargecoverorentiregrasscollectionsystem

inplaceandworking.

•Bealert,slowdownandusecautionwhenmaking

turns.Lookbehindandtothesidebeforechanging

directions.

•Neverleavearunningmachineunattended.

Alwaysturnoffblades,setparkingbrake,stop

engine,andremovekeybeforedismounting.

•Turnoffbladeswhennotmowing.Stoptheengine,

waitforallpartstocometoacompletestopand

removethekeybeforecleaningthemachine,

removingthegrasscatcheroruncloggingthe

dischargechute.

•Operatethemachineonlyindaylightorgood

articiallight.

•Donotoperatethemachinewhileunderthe

inuenceofalcoholordrugs.

•Watchfortrafcwhenoperatingnearorcrossing

roadways.

•Useextracarewhenloadingorunloadingthe

machineintoatrailerortruck.

•Alwaysweareyeprotectionwhenoperatingthe

mower.

•Alwaysfollowtherecommendationsforany

applicationofcounterweights.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

SlopeOperation

Slopesareamajorfactorrelatedtolossofcontroland

tip-overaccidents,whichcanresultinsevereinjuryor

death.Operationonallslopesrequiresextracaution.

Ifyoucannotbackuptheslopeorifyoufeeluneasy

onit,donotmowit.

•Donotmowslopesgreaterthan15degrees.

•Watchforditches,holes,rocks,dips,andrises

thatchangetheoperatingangle,asroughterrain

couldoverturnthemachine.

•Choosealowgroundspeedsoyouwillnothave

tostopwhileoperatingonaslope.

•Donotmowslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcausesliding

andlossofcontrol.

•Alwayskeepthedrivewheelsengagedwhen

goingdownslopes.

•Reducespeedanduseextremecautiononslopes.

•Donotmakesuddenturnsorrapidspeedchanges.

•Removeormarkobstaclessuchasrocks,tree

limbs,etc.fromthemowingarea.Tallgrasscan

hideobstacles.

•Avoidsuddenstartswhenmowinguphillbecause

themowermaytipbackwards.

4

Page 5

•Beawarethatlossoftractionmayoccurgoing

downhill.Weighttransfertothefrontwheels

maycausedrivewheelstoslipandcauselossof

brakingandsteering.

•Alwaysavoidsuddenstartingorstoppingona

slope.Iftireslosetraction,stopthemachine,

disengagethebladesandproceedslowlyoffthe

slope.

•Useextremecarewithgrasscatchersorother

attachments.Thesecanchangethestabilityofthe

machineandcauselossofcontrol.

•Donottrytostabilizethemachinebyputtingyour

footontheground.

•Donotmowneardrop-offs,ditches,steepbanks

orwater.Wheelsdroppingoveredgescancause

rollovers,whichmayresultinseriousinjury,death

ordrowning.

•Useawalkbehindmowerand/orahandtrimmer

neardrop-offs,ditches,steepbanksorwater.

Children

Tragicaccidentscanoccuriftheoperatorisnot

alerttothepresenceofchildren.Childrenareoften

attractedtothemachineandthemowingactivity.

Neverassumethatchildrenwillremainwhereyou

lastsawthem.

•Keepchildrenoutofthemowingareaandunder

thewatchfulcareofanotherresponsibleadult,not

theoperator.

•Bealertandturnthemachineoffifchildrenenter

thearea.

•Beforeandwhilebackingorchangingdirection,

lookbehind,down,andside-to-sideforsmall

children.

•Nevercarrychildren,evenwiththebladesoff.

Theymayfalloffandbeseriouslyinjuredor

interferewithsafemachineoperation.

•Childrenwhohavebeengivenridesinthepast

maysuddenlyappearinthemowingareafor

anotherrideandberunoverorbackedoverby

themower.

•Neverallowchildrentooperatethemachine.

•Useextracarewhenapproachingblindcorners,

shrubs,trees,theendofafenceorotherobjects

thatmayobscurevision.

TowingSafety

•Donotattachtowedequipmentexceptatthehitch

point.

•Followtheattachmentmanufacturer's

recommendationforweightlimitsfortowed

equipmentandtowingonslopes.Towedweight

mustnotexceedtheweightofthemachine,

operator,andballast.Usecounterweightsor

wheelweightsasdescribedintheattachment,or

inthepullingmachineOperator’sManual.

•Neverallowchildrenorothersinorontowed

equipment.

•Onslopes,theweightofthetowedequipmentmay

causelossoftraction,increasedriskofrollover,

andlossofcontrol.Reducethetowedweightand

slowdown.

•Stoppingdistanceincreaseswiththeweightofthe

towedload.Travelslowlyandallowextradistance

tostop.

•Makewideturnstokeeptheattachmentclearof

themachine.

Service

SafeHandlingofGasoline:

Toavoidpersonalinjuryorpropertydamage,use

extracarewhenhandlinggasolineandotherfuels.

Theyareammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipesandother

sourcesofignition.

•Useonlyanapprovedcontainer.

•Neverremovethegascaporaddfuelwhenthe

engineisrunning.Allowtheenginetocoolbefore

refueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasneara

waterheaterorfurnace.

•Neverllcontainersinsideavehicleorona

truckortrailerwithaplasticliner.Alwaysplace

containersonthegroundawayfromyourvehicle

beforelling.

•Removegas-poweredequipmentfromthetruck

ortrailerandrefuelitontheground.Ifthisis

notpossible,thenrefuelsuchequipmentwitha

portablecontainer,ratherthanfromagasoline

dispensernozzle.

•Keepthenozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimesuntilthe

fuelingiscomplete.Donotuseanozzlelock-open

device.

•Iffuelisspilledonclothing,changeclothing

immediately.

•Neveroverllthefueltank.Replacegascapand

tightensecurely.

GeneralService:

•Neveroperateamachineinsideaclosedarea.

Engineexhaustcontainscarbonmonoxide,which

isanodorless,deadlypoisonthatcankillyou.

•Keepnutsandboltstight,especiallytheblade

attachmentbolts.Keepequipmentingood

condition.

5

Page 6

•Neverinterferewiththeintendedfunctionofa

safetydeviceortoreducetheprotectionprovided

byasafetydevice.Checktheirproperoperation

regularly.

movingpartsorallowobjectstobethrown.

Frequentlycheckcomponentsandreplace

withmanufacturers'recommendedparts,when

necessary.

•Keepthemachinefreeofgrass,leaves,orother

debrisbuild-up.Cleanupoilorfuelspillagefuel

soakeddebris.Allowthemachinetocoolbefore

storing.

•Stopandinspecttheequipmentifyoustrikean

object.Repair,ifnecessary,beforerestarting.

•Nevermakeanyadjustmentsorrepairswiththe

enginerunning.

•Grasscatchercomponentsaresubjecttowear,

damageanddeterioration,whichcouldexpose

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedorlost.

•Mowerbladesaresharpandcancut.Wrapthe

blade(s)orwearthickly-paddedgloves,anduse

extracautionwhenservicingthem.

•Checkforproperbrakeoperationfrequently.

Adjustandserviceasrequired.

•Maintainorreplacesafetyandinstructiondecals

asnecessary.

•UseonlygenuineT ororeplacementpartsto

ensurethatoriginalstandardsaremaintained.

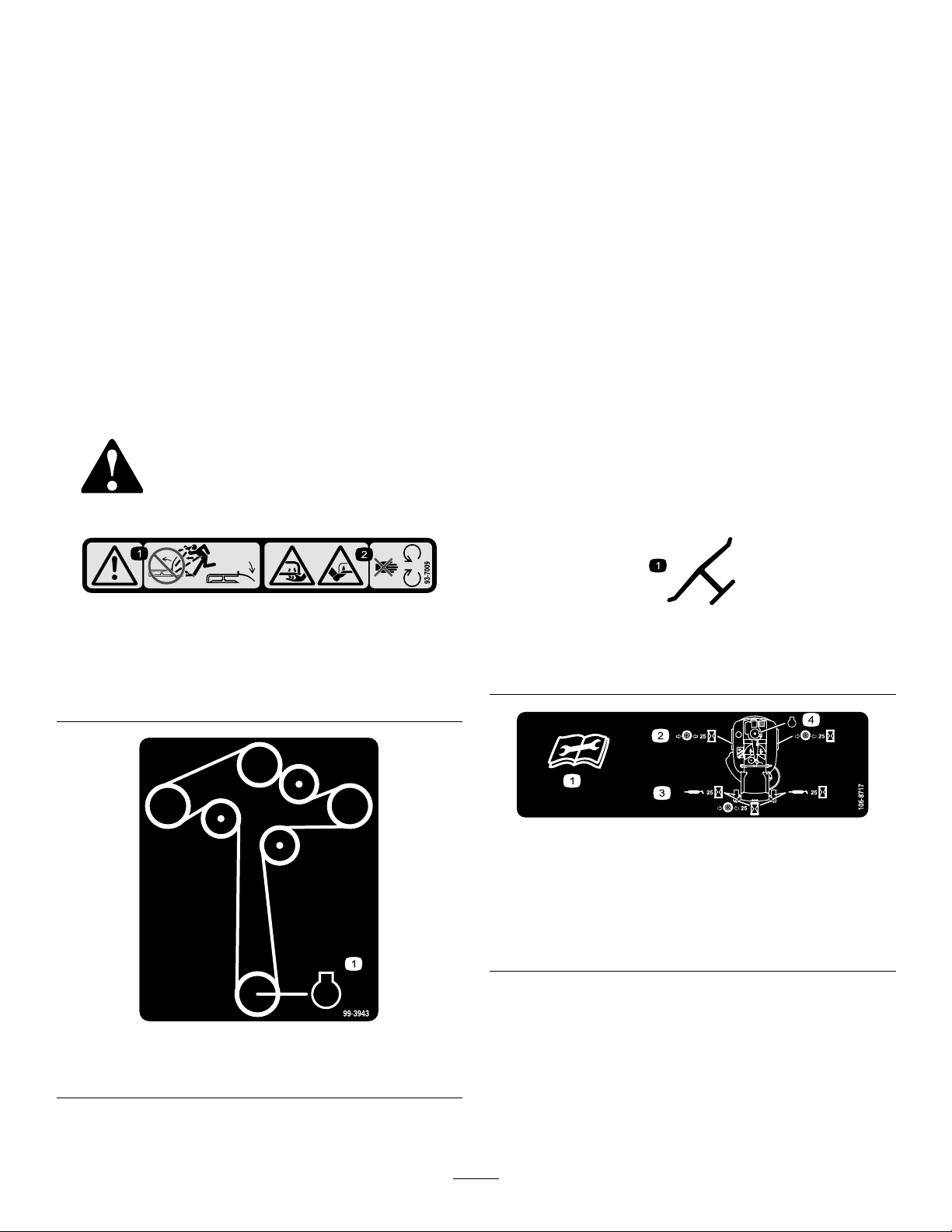

93-7009

1.Warning—don'toperatethemowerwiththedeectorupor

removed;keepthedeectorinplace.

2.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

99-3943

decal93-7009

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

106-8717

1.Readtheinstructionsbeforeservicingorperforming

maintenance.

2.Checktirepressureevery25operatinghours.

3.Greaseevery25operatinghours.

4.Engine

decal99-3943

decaloemmarkt

decal106-8717

1.Engine

6

Page 7

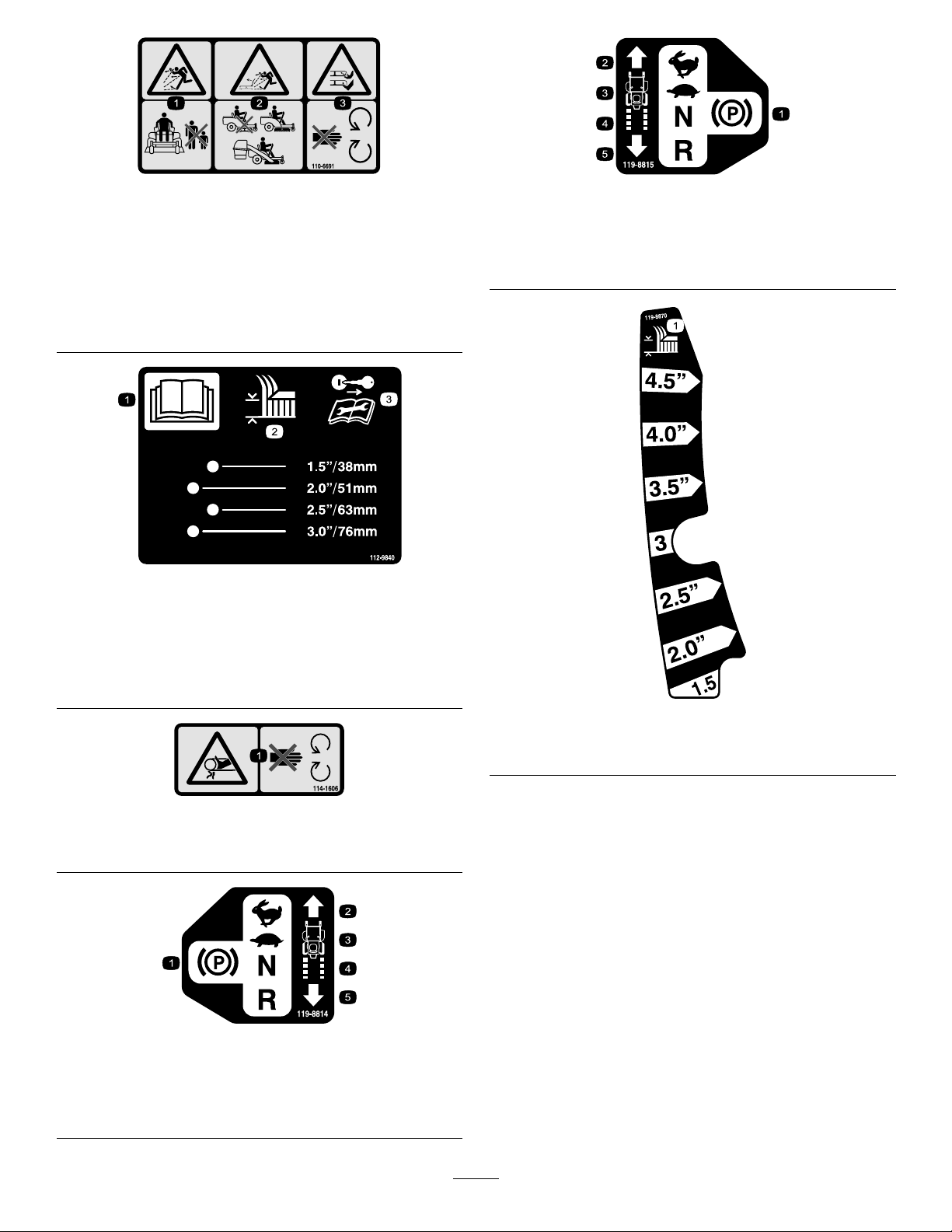

decal110-6691

110-6691

119-8815

decal119-8815

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Thrownobjecthazard,mower—donotoperatewithoutthe

deector,dischargecover,orgrasscollectionsystemin

place.

3.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

112-9840

1.ReadtheOperator's

Manual.

2.Height-of-cut

3.Removetheignitionkey

andreadtheinstructions

beforeservicingor

performingmaintenance.

1.Parkingposition4.Neutral

2.Fast5.Reverse

3.Slow

decal112-9840

decal119-8870

119-8870

114-1606

1.Entanglementhazard,belt—keepallguardsinplace.

119-8814

1.Parkingposition4.Neutral

2.Fast5.Reverse

3.Slow

1.Height-of-cut

decal114-1606

decal119-8814

7

Page 8

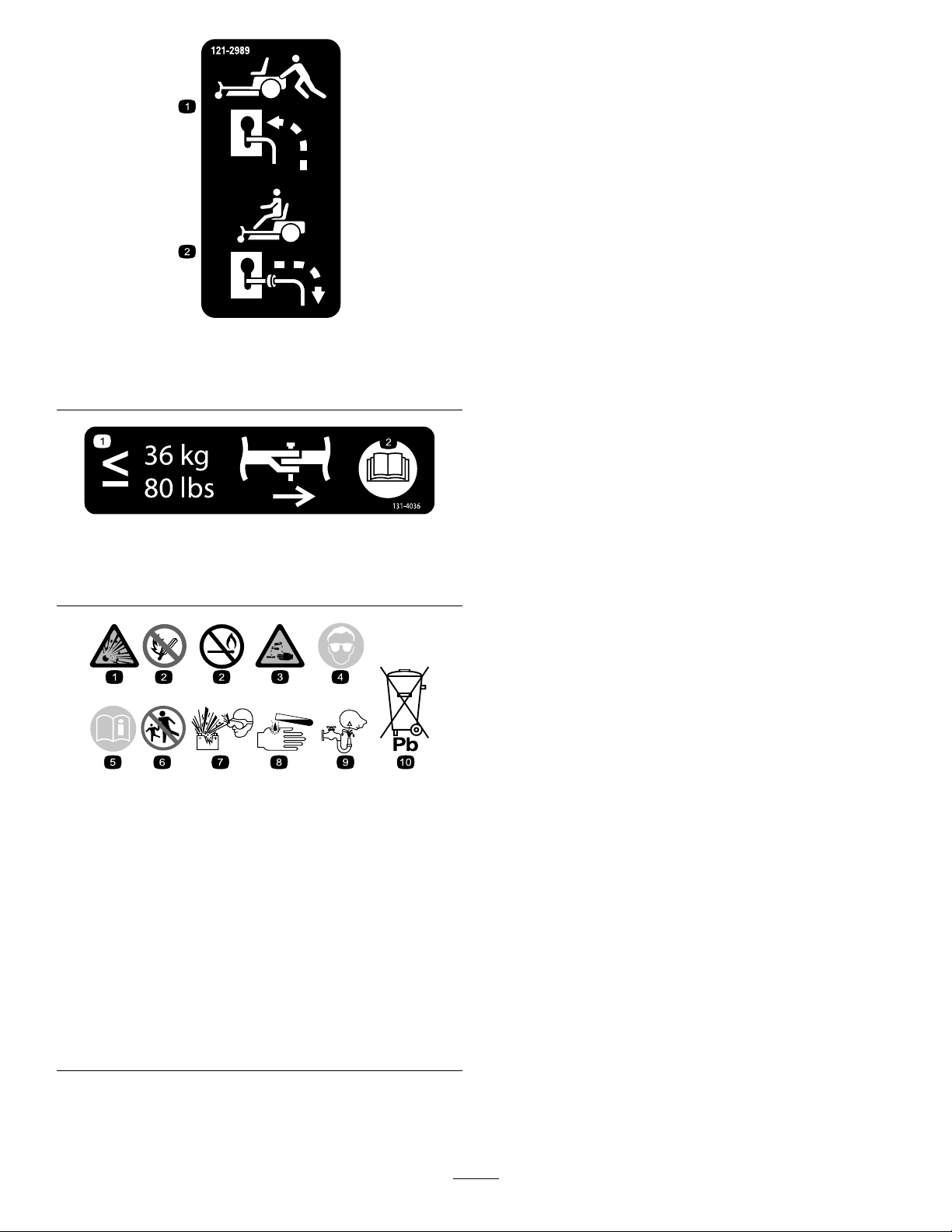

decal121-2989b

121-2989

1.Bypassleverpositionfor

pushingthemachine

131-4036

1.Maximumdrawbarpull36

kg(80lb)

BatterySymbols

Someorallofthesesymbolsareonyourbattery

2.Bypassleverpositionfor

operatingthemachine

decal131-4036

2.ReadtheOperator's

Manual.

decalbatterysymbols

1.Explosionhazard

2.Nore,opename,or

6.Keepbystandersasafe

7.Weareyeprotection;

smoking.

3.Causticliquid/chemical

8.Batteryacidcancause

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

10.Containslead;donot

Manual.

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

8

Page 9

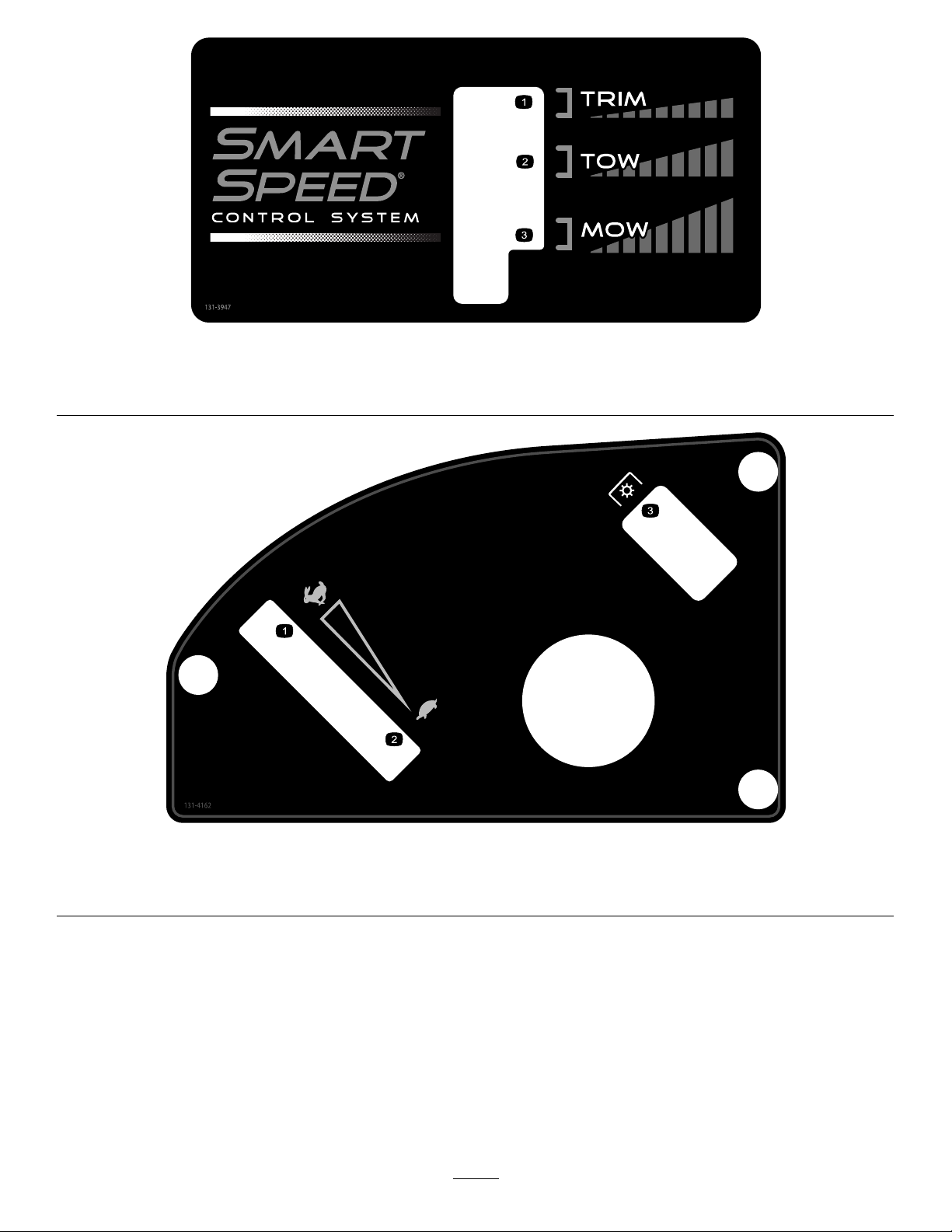

decal131-3947

131–3947

1.Trim—slow

3.Mow—fast

2.Tow—medium

decal131-4162

131-4162

1.Fast

2.Slow

3.Powertake-off

9

Page 10

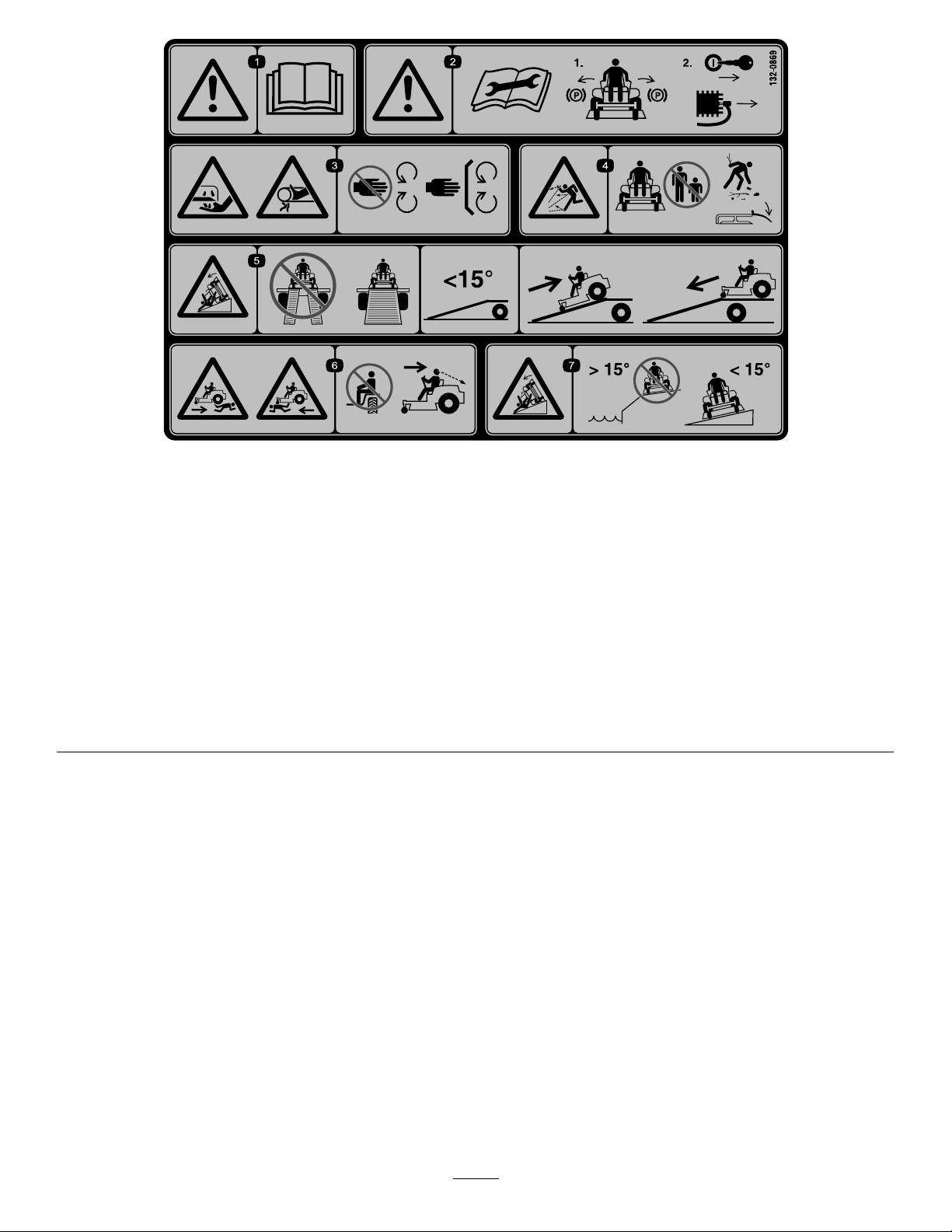

decal132-0869

132-0869

1.Warning—readthe

Operator'sManual.

2.Warning—beforeservicing,

engagetheparkingbrake,

removethekeyandthe

sparkplugconnection.

3.Cuttinghazardofhand,

mowerblade;pinching

hazardofhand,belt—keep

handsandfeetawayfrom

movingparts;keepall

guardsandshieldsinplace.

4.Thrownobject

hazard—keepbystanders

awayfromthemachine;

removedebrisfromthe

areabeforemowing;keep

thedeectorshielddown.

5.Ramptipping

hazard—whenloading

ontoatrailer,donotuse

dualramps;onlyusea

singlerampwideenough

forthemachineandthat

hasaninclinelessthan

15degrees;backupthe

ramp(inreverse)anddrive

forwardofftheramp.

6.Bodilyharmhazard—no

riders;lookbehindyou

whenmowinginreverse.

7.Tippinghazardon

slopes—donotuseon

slopesnearopenwater;do

notuseonslopesgreater

than15degrees.

10

Page 11

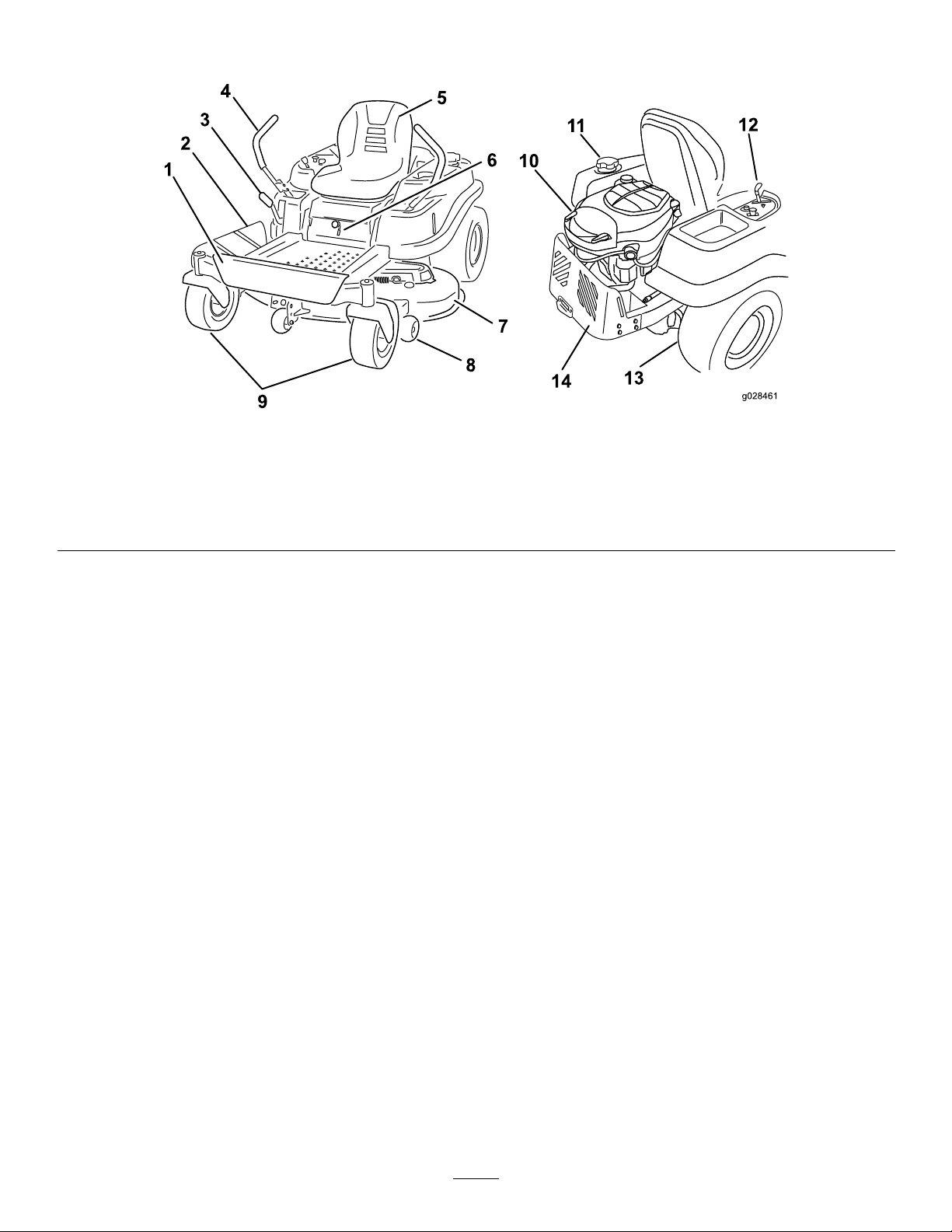

ProductOverview

g028461

Figure3

1.Footrest

2.Deector6.SmartSpeed™lever

3.Height-of-cutlever

4.Motion-controllevers8.Anti-scalproller

5.Operatorseat

7.Mowerdeck

Controls

BecomefamiliarwithallofthecontrolsinFigure3

andFigure4beforeyoustarttheengineandoperate

themachine.

9.Frontcasterwheel13.Reardrivewheel

10.Engine14.Engineguard

11.Fuel-tankcap

12.Controlpanel

11

Page 12

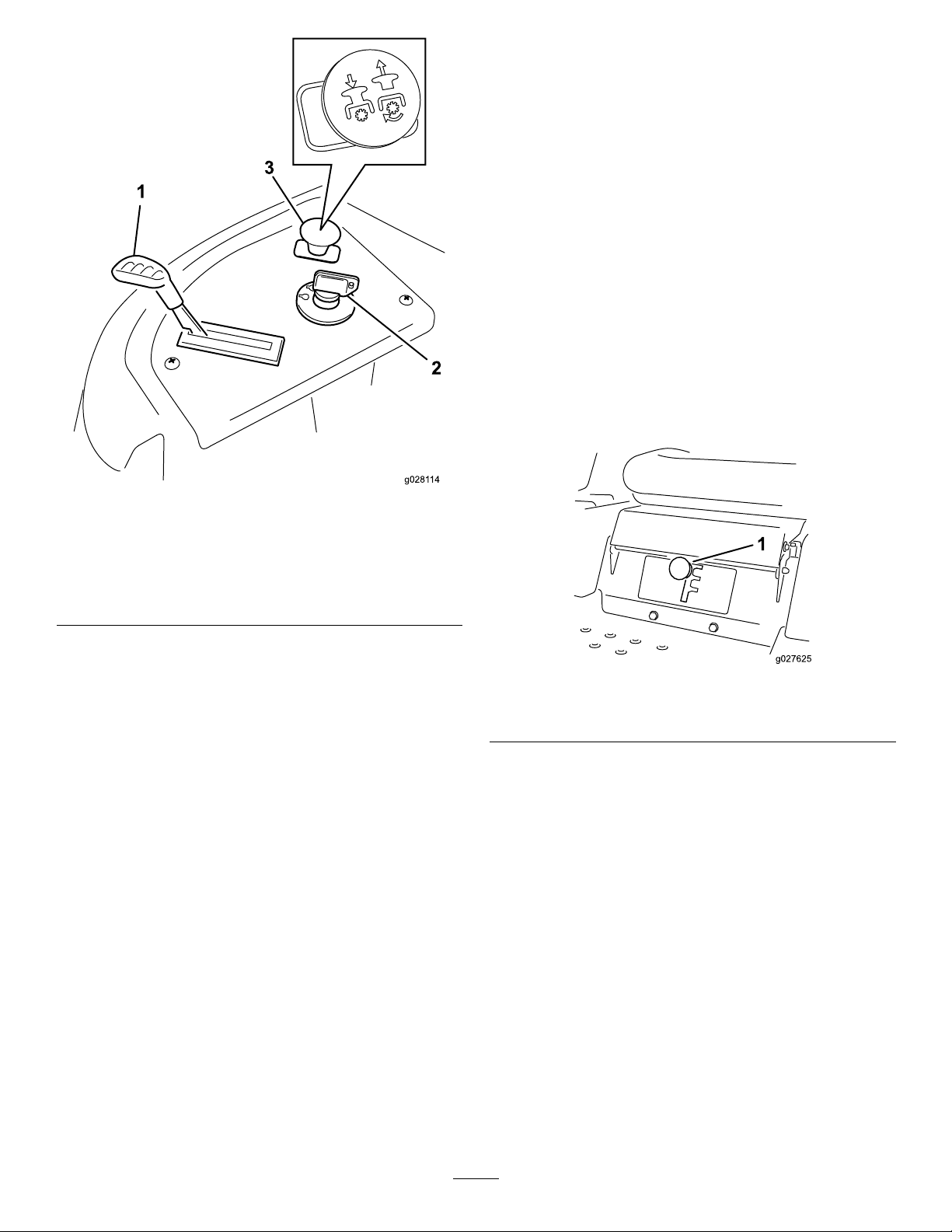

ControlPanel

Motion-ControlLeversandPark

Position

Themotion-controlleversarespeed-sensitivecontrols

ofindependent-wheelmotors.Movingaleverforward

orbackwardturnsthewheelonthesamesideforward

orinreverse;wheelspeedisproportionaltothe

amounttheleverismoved.Movethecontrollevers

outwardfromthecentertotheparkposition,and

exitthemachine(Figure13).Alwayspositionthe

motion-controlleversintotheparkpositionwhenyou

stopthemachineorleaveitunattended.

SmartSpeed™ControlSystem

Lever

TheSmartSpeed™Control-Systemlever,located

belowtheoperatingposition,givestheoperatora

choicetodrivethemachineat3speedranges—trim,

tow,andmow(Figure5).

g028114

Figure4

1.Throttle3.Blade-controlswitch

(powertake-off)

2.Ignitionswitch

IgnitionSwitch

Theignitionswitchhas3positions:Off,Run,and

Start.ThekeywillturntoStartandmovebacktoRun

uponrelease.TurningthekeytotheOffpositionwill

stoptheengine;however,alwaysremovethekey

whenleavingthemachinetopreventsomeonefrom

accidentallystartingtheengine(Figure4).

ThrottleControl

Thethrottlecontrolstheenginespeed,andithasa

continuous-variablesettingfromSlowtoFast(Figure

4).

Blade-ControlSwitch(Power

Take-off)

g027625

Figure5

1.Smart-speedlever

Fuel-PresenceWindow

Thefuelwindowlocatedontheleft-handsideof

themachinecanbeusedtoverifythepresenceof

gasolineinthetank(Figure6).

Theblade-controlswitch,representedbyapower

take-off(PTO)symbol,engagesanddisengages

powertothemowerblades(Figure4).

12

Page 13

Figure6

1.Fuel-presencewindow

Height-of-CutLever

Theheight-of-cutleverallowstheoperatortolower

andraisethedeckfromtheseatedposition.Whenthe

leverismovedup(towardtheoperator),thedeckis

raisedfromtheground,andwhenmoveddown(away

fromtheoperator),itisloweredtowardtheground.

Onlyadjusttheheight-of-cutwhilethemachineisnot

moving(Figure17).

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

AddingFuel

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

g014521

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan

10%ethanolbyvolume,suchasE15(contains

15%ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessafuelstabilizer

isused.

•Donotaddoiltogasoline.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areor

explosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupany

gasolinethatspills.

•Neverllthefueltankinsideanenclosed

trailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6

to13mm(1/4to1/2inch)belowthebottom

ofthellerneck.Thisemptyspaceinthe

tankallowsgasolinetoexpand.

•Neversmokewhenhandlinggasoline,and

stayawayfromanopenameorwhere

gasolinefumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainer

andkeepitoutofthereachofchildren.

Neverbuymorethana30-daysupplyof

gasoline.

•Donotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

13

Page 14

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitethegasolinevapors.Are

orexplosionfromgasolinecanburnyouand

othersandcandamageproperty.

Addthecorrectamountofgasstabilizer/conditioner

tothegas.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.T ominimizethe

chanceofvarnishdepositsinthefuelsystem,use

fuelstabilizeratalltimes.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebefore

lling.

•Donotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowthe

lossofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

ground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbe

used,keepthenozzleincontactwiththe

rimofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.

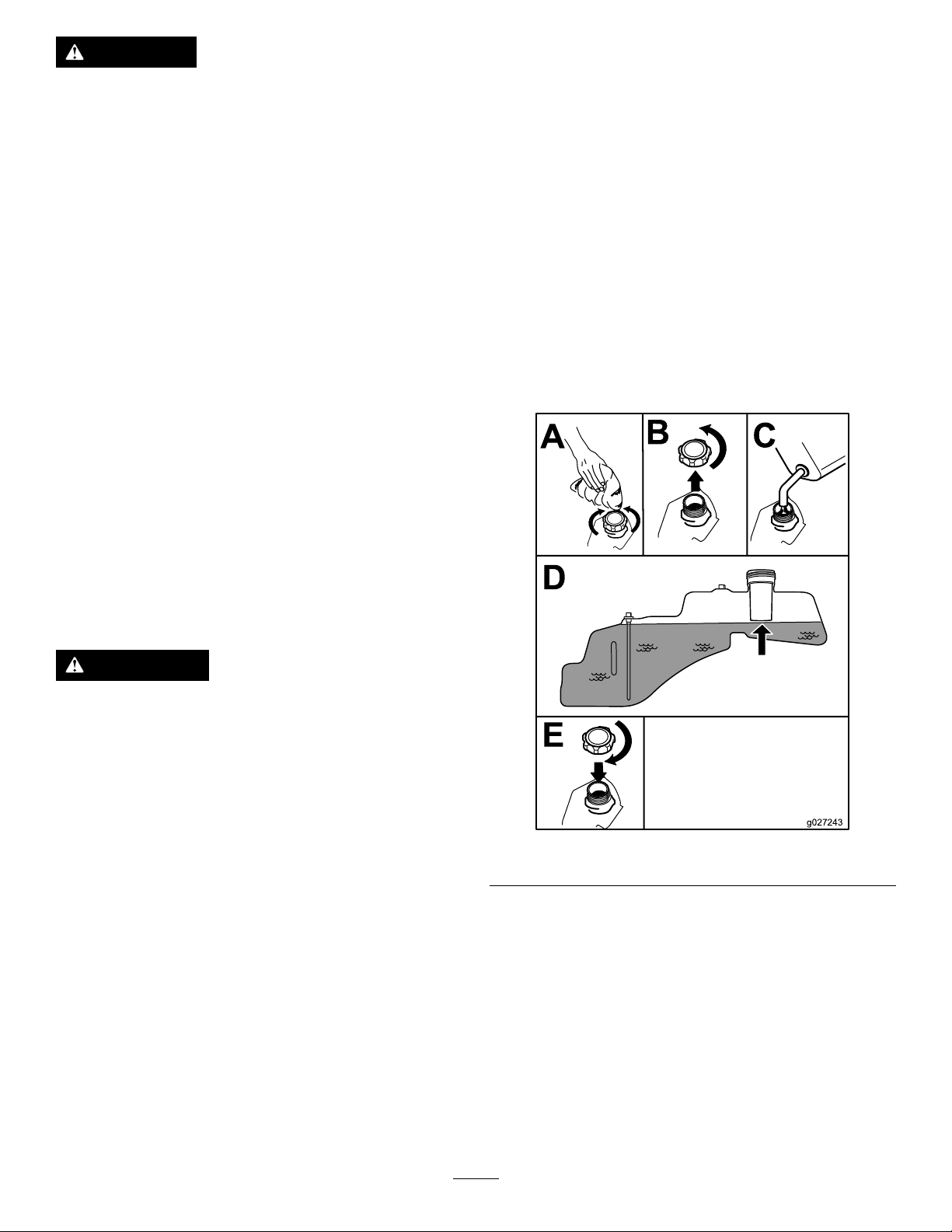

FillingtheFuelTank

Note:Ensurethattheengineisshutoffandthe

motioncontrolsareintheparkedposition.

Note:Y oucanusethefuelwindowtoverifythe

presenceofgasolinebeforellingthetank(Figure7).

Important:Donotoverllfueltank.Fillthefuel

tanktothebottomofthellerneck.Theempty

spaceinthetankallowsthefueltoexpand.

Overllingmayresultinfuelleakage,damageto

theengine,ordamagetotheemissionssystem.

WARNING

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporscancause

seriousinjuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastank

orconditionerbottleopening.

•Avoidcontactwithskin;washoffspillage

withsoapandwater.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysor

less.Forlongerstorageitisrecommendedthat

thefueltankbedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

Important:Donotusefueladditives

containingmethanolorethanol.

g027243

Figure7

CheckingtheEngine-Oil Level

Beforeyoustarttheengineandusethemachine,

checktheoillevelintheenginecrankcase;referto

CheckingtheEngine-OilLevel(page28).

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mower

decksanddrivesystemshavehigherfrictionwhen

14

Page 15

new,placingadditionalloadontheengine.Allow

40to50hoursofbreak-intimefornewmachinesto

developfullpowerandbestperformance.

ThinkSafetyFirst

OperatingSafety

Pleasecarefullyreadallofthesafetyinstructionsand

decalsinthesafetysection.Knowingthisinformation

couldhelpyou,yourfamily ,pets,orbystandersavoid

injury.

DANGER

Mowingonwetgrassorsteepslopescan

causeslidingandlossofcontrol.

Wheelsdroppingoveredgescancause

rollovers,whichmayresultinseriousinjury,

death,ordrowning.

Alossoftractionisalossofsteeringcontrol.

Toavoidlossofcontrolandpossibilityof

rollover:

•Donotmowneardrop-offsornearwater.

•Donotmowslopesgreaterthan15degrees.

•Reducethespeedanduseextremecaution

onslopes.

•Whenmowingslopes,graduallyworkfrom

lowertohigherareasontheincline.

•Avoidsuddenturnsorrapidspeed

changes.

•Turnup,intoaninclinewhenchanging

directionsonslopes.T urningdownthe

slopereducestraction.

Figure8

1.Safezone—usethe

TimeCutterhere

2.Useawalk-behindmower

and/orhandtrimmernear

drop-offsandwater.

3.Water

CAUTION

Thismachineproducessoundlevelsin

excessof85dBAattheoperatorsearandcan

causehearinglossthroughextendedperiods

ofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Theuseofprotectiveequipmentforeyes,ears,

hands,feet,andheadisrecommended.

g000513

•Attachmentschangethehandling

characteristicsofthemachine.Useextra

cautionwhenusingattachmentswiththe

machine.

15

1.Wearsafetyglasses

g009027

Figure9

2.Wearhearingprotection

Page 16

Understandingthe

Safety-InterlockSystem

WARNING

Ifsafety-interlockswitchesaredisconnected

ordamaged,themachinecouldoperate

unexpectedlycausingpersonalinjury.

11.Starttheengine.

12.Whiletheengineisrunning,movethe

motion-controlleverstothecenter,unlocked

position,engagetheblade-controlswitch,and

riseslightlyfromtheseat.

Note:Theengineshouldstop.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdaily,andreplaceanydamaged

switchesbeforeoperatingthemachine.

Thesafety-interlocksystemisdesignedtopreventthe

enginefromstartingunless:

•Thebladesaredisengaged.

•Themotion-controlleversareintheparkposition.

Thesafety-interlocksystemalsoisdesignedtostop

theenginewheneverthecontrolleversareoutofthe

parkpositionandyourisefromtheseat.

TestingtheSafety-Interlock

System

Testthesafety-interlocksystembeforeyouusethe

machineeachtime.Ifthesafetysystemdoesnot

operateasdescribedbelow,haveanAuthorized

ServiceDealerrepairthesafetysystemimmediately .

1.Whilesittingontheseat,withthecontrollevers

inparkposition,andmovetheblade-control

switchtoOn.

2.Trystartingtheengine;theengineshouldnot

crank.

3.Whilesittingontheseat,movetheblade-control

switchtoOff.

4.Moveeithermotion-controllevertothecenter,

unlockedposition.

5.Trystartingtheengine;theengineshouldnot

crank.

6.Repeatwiththeothermotion-controllever.

7.Whilesittingontheseat,movetheblade-control

switchtoOff,andlockthemotion-controllevers

intheparkposition.

8.Starttheengine.

9.Whiletheengineisrunning,engagethe

blade-controlswitch,andriseslightlyfromthe

seat.

StartingtheEngine

Important:Donotengagethestarterformore

than10secondsatatime.Iftheenginefailsto

start,allowa60secondcool-downperiodbetween

attempts.Failuretofollowtheseinstructionscan

damagethestartermotor.

g027578

Figure10

Note:Theengineshouldstop.

10.Whilesittingontheseat,movetheblade-control

switchtoOff,andlockthemotion-controllevers

intheparkposition.

16

Page 17

OperatingtheBlades

StoppingtheEngine

Theblade-controlswitch,representedbyapower

take-off(PTO)symbol,engagesanddisengages

powertothemowerblades.Thisswitchcontrols

powertoanyattachmentsthatdrawpowerfromthe

engine,includingthemowerdeckandcuttingblades.

EngagingtheBlades

Important:Donotengagethebladeswhen

parkedintallgrass.Beltorclutchdamagecan

occur.

Note:Alwaysengagethebladeswiththethrottlein

theFastposition(Figure11).

1.Disengagethebladesbymovingthe

blade-controlswitchtoOff(Figure12).

2.Movethethrottlelevertobetweenthehalfand

fullthrottleposition.

3.TurntheignitionkeytoOffandremovethekey.

Driving

Drivingthemachinebenetsfromanunderstanding

ofwhatzero-turn-radiusmowermeans.Thedrive

wheelsturnindependently,poweredbyhydraulic

motorsoneachaxle;henceonesidecanturnin

reversewhiletheotherturnsforwardcausingthe

machinetospinratherthanturn.Thisvastlyimproves

themachinemaneuverabilitybutmayrequiresome

adjustmentiftheoperatorisunfamiliar.

WARNING

Themachinecanspinveryrapidly.The

operatormaylosecontrolofthemachine

andcausepersonalinjuryordamagetothe

machine.

Figure11

DisengagingtheBlades

Figure12

1.Controlpanel2.Blade-controlswitch—Off

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemaking

sharpturns.

g027582

g027247

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Placing

thethrottlecontrolintheFastpositioncanbebestfor

performance.Formostapplications,operatinginthe

full-throttlepositionisdesirable.

17

Page 18

UsingtheSmartSpeed

System

TM

Control

Figure13

1.Park(brake)position

2.Center,unlockposition5.FrontoftheMachine

3.Forward

4.Backward

TheSmartSpeed

TM

Control-Systemlever,located

belowtheoperatingposition(Figure14),givesthe

operatorachoicetodrivethemachineat3ground

speedranges—trim,tow,andmow.

g027625

Figure14

1.Smartspeedlever

g004532

Tochangespeeds,dothefollowing:

1.Movethemotioncontrolleverstoneutraland

outwardtotheparkposition.

2.Disengagethebladecontrolswitch

3.Adjustthelevertothedesiredposition.

Thefollowingareonlyrecommendationsforuse.

Adjustmentswillvarybygrasstype,moisturecontent,

andtheheightofthegrass.

Suggested

uses:

ParkingX

Heavy,wet

grass

TrainingX

BaggingX

MulchingX

Normal

mowing

Transport

TrimTowMow

X

X

X

Trim

Thisisthelowestspeed.Thesuggestedusesforthis

speedareasfollows:

•Parking

•Heavy,wetgrassmowingconditions

•Training

Tow

18

Page 19

Thisisthemediumspeed.Thesuggestedusesfor

thisspeedareasfollows:

•Bagging

•Mulching

Mow

Thisisthefastestspeed.Thesuggestedusesforthis

speedareasfollows:

•Normalmowing

•Transportingthemachine

DrivingForward

1.Movetheleverstothecenter,unlockedposition.

2.T ogoforward,slowlypushthemotion-control

leversforward(Figure13).

g008952

Figure15

Togostraight,applyequalpressuretoboth

motion-controllevers(Figure13).

Toturn,releasepressureonthemotion-control

levertowardthedirectionyouwanttoturn

(Figure13).

Thefartheryoumovethemotion-controllevers

ineitherdirection,thefasterthemachinewill

moveinthatdirection.

Tostop,pullthemotion-controlleverstoneutral.

19

Page 20

DrivingBackward

Note:Alwaysusecautionwhenbackingupand

turning.

1.Movetheleverstothecenter,unlockedposition.

2.T ogobackward,lookbehindyouanddown,

asyouslowlypullthemotion-controllevers

rearward(Figure16).

AdjustingtheHeight-of-Cut

Thetransportpositionisthehighestheight-of-cut

positionorcuttingheight(115mm(4.5inches))as

showninFigure17.

Figure16

Togostraight,applyequalpressuretoboth

motion-controllevers(Figure16).

Toturn,releasethepressureonthe

motion-controllevertowardthedirectionyou

wanttoturn.

Tostop,pushthemotion-controlleversto

neutral.

StoppingtheMachine

Tostopthemachine,movethemotion-controllevers

toneutralandoutwardtotheparkposition,disengage

theblade-controlswitch,ensurethethrottleisbetween

halfandfullthrottle,andturntheignitionkeytooff.

Note:Remembertoremovethekeyfromtheignition

switch.

WARNING

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemowerwhile

itisunattended.

Alwaysremovetheignitionkeyandmove

themotion-controlleversoutwardtothe

parkpositionwhenleavingthemachine

unattended,evenifjustforafewminutes.

g008953

g028025

Figure17

AdjustingtheAnti-Scalp Rollers

Wheneveryouchangetheheight-of-cut,itis

recommendedtoadjusttheheightoftheanti-scalp

rollers.

Note:Adjusttheanti-scalprollerssotherollersdo

nottouchthegroundinnormal,atmowingareas.

1.Disengagethebladecontrolswitch(PTO),move

themotioncontrolleverstotheneutrallock

positionandsettheparkingbrake.

2.Stoptheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Adjusttheanti-scalprollersasshowninFigure

18tomatchtheclosestheight-of-cutposition.

20

Page 21

Figure18

1.Anti-scalproller3.FlangeNut

2.Bolt4.Holespacing

PositioningtheSeat

Adjustingthe Motion-ControlLevers

AdjustingtheHeight

Themotion-controlleverscanbeadjustedhigheror

lowerformaximumoperatorcomfort(Figure20).

g010233

g027252

Figure20

Figure19

AdjustingtheTilt

Themotion-controlleverscanbetiltedforeoraftfor

maximumoperatorcomfort.

1.Loosentheupperboltholdingthecontrollever

tothecontrol-armshaft.

2.Loosenthelowerboltjustenoughtopivotthe

controlleverforeoraft(Figure20).Tightenboth

boltstosecurethecontrolinthenewposition.

3.Repeattheadjustmentfortheoppositecontrol

lever.

g027249

PushingtheMachineby Hand

Important:Alwayspushthemachinebyhand.Do

nottowthemachine,becausedamagemayoccur.

Thismachinehasanelectric-brakemechanism,and

topushthemachine,theignitionkeyneedstobein

theRunposition.Thebatteryneedstobecharged

andfunctioningfortheelectricbraketobedisengage.

21

Page 22

PushingtheMachine

1.Parkthemachineonalevelsurface,and

disengagetheblade-controlswitch.

2.Movethemotion-controlleversoutwardto

theparkposition,stoptheengine,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Locatethebypassleversontheframeonboth

sidesoftheengine.

4.Movethebypassleversforwardthroughthekey

holeanddowntolocktheminplace(Figure21).

Note:Ensurethisisdoneforeachlever.

5.Movethemotion-controlleversinwardtothe

neutralpositionandturntheignitionkeytothe

Runposition.

Note:Donotstartthemachine.

Note:Themachineisnowabletobepushed

byhand.

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthe

machine.Ensurethatthetrailerortruckhasall

necessarybrakes,lighting,andmarkingasrequired

bylaw.Pleasecarefullyreadallthesafetyinstructions.

Knowingthisinformationcouldhelpyou,yourfamily,

pets,orbystandersavoidinjury.

WARNING

Drivingonthestreetorroadwaywithoutturn

signals,lights,reectivemarkings,oraslow

movingvehicleemblemisdangerousandcan

leadtoaccidentscausingpersonalinjury.

Donotdrivemachineonapublicstreetor

roadway.

Totransportthemachine:

1.Ifusingatrailer,connectittothetowingvehicle

andconnectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

Figure21

1.Bypass-leverlocations

2.Leverpositionfor

operatingthemachine

6.Whennished,ensurethatthekeyhasbeen

returnedtotheStoppositiontoavoiddraining

thebatterycharge.

3.Leverpositionforpushing

themachine

Note:Ifthemachinefailstomove,theelectricbrake

maystillbeengaged.Ifnecessary,theelectricbrake

canbereleasedmanually;refertoReleasingthe

ElectricBrake(page35).

3.Loadthemachineontothetrailerortruck.

4.Stoptheengine,removethekey,setthebrake,

andclosethefuelvalve.

5.Tiedownthemachinenearthefrontcaster

wheelsandtherearbumper(Figure22).

g017303

g027708

Figure22

LoadingtheMachine

Useextremecautionwhenloadingorunloading

machinesontoatraileroratruck.Useafull-width

rampthatiswiderthanthemachineforthisprocedure.

Backuprampsanddriveforwarddownramps(Figure

23).

OperatingtheMachine

Movethebypassleversrearwardthroughthekeyhole

anddowntolocktheminplaceasshowninFigure21.

Note:Ensurethisisdoneforeachlever.

22

Page 23

Figure23

g027995

1.Backupramps

2.Driveforwarddownramps

Important:Donotusenarrowindividualramps

foreachsideofthemachine.

Ensuretherampislongenoughsothattheanglewith

thegrounddoesnotexceed15degrees(Figure24).

Onatground,thisrequiresaramptobeatleastfour

times(4X)aslongastheheightofthetrailerortruck

bedtotheground.Asteeperanglemaycausemower

componentstogetcaughtastheunitmovesfromthe

ramptothetrailerortruck.Steeperanglesmayalso

causethemachinetotiporlosecontrol.Ifloadingon

ornearaslope,positionthetrailerortrucksothatitis

onthedownsideoftheslopeandtherampextends

uptheslope.Thiswillminimizetherampangle.

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath.

•Useextremecautionwhenoperatinga

machineonaramp.

•Useonlyafull-widthramp;donotuse

individualrampsforeachsideofthe

machine.

•Donotexceeda15-degreeanglebetween

therampandthegroundorbetweenthe

rampandthetrailerortruck.

1.Full-widthrampinstowed

position

2.Sideviewoffull-width

rampinloadingposition

3.Notgreaterthan

15degrees

g027996

Figure24

4.Rampisatleastfourtimes

(4X)aslongastheheight

ofthetrailerortruckbed

totheground

5.H=heightofthetraileror

truckbedtotheground

6.Trailer

•Ensurethelengthoframpisatleastfour

times(4X)aslongastheheightofthe

trailerortruckbedtotheground.Thiswill

ensurethatrampangledoesnotexceed15

degreesonatground.

•Backuprampsanddriveforwarddown

ramps.

•Avoidsuddenaccelerationordeceleration

whiledrivingthemachineonarampas

thiscouldcausealossofcontrolora

tip-oversituation.

23

Page 24

OperatingTips

rstmowatahighcuttingheight,thenmowagain2

dayslateratalowerheightsetting.

UsingtheFastThrottleSetting

Forbestmowingandmaximumaircirculation,operate

theengineattheFastthrottleposition.Airisrequired

tothoroughlycutgrassclippings,sodonotsetthe

height-of-cutsolowastototallysurroundthemower

byuncutgrass.Alwaystrytohaveonesideofthe

mowerfreefromuncutgrass,whichallowsairtobe

drawnintothemower.

UsingtheSmartSpeed™Control

System

TheSmartSpeed™Control-Systemlever,located

belowtheoperatingposition,givestheoperatora

choicetodrivethemachineat3speedranges—trim,

mow,andtow.Anoperatorcanbenetfromthetrim

speedsettingwhenmaneuveringthemachineintight

spacesoroperatingarounddelicatelandscapes.The

trimsettingcanalsobeusedtooperatethemachine

atahighthrottlesettingandbladespeed,whilestill

beingabletoreducethegroundspeedtoincrease

thequalityofcut.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethat

thecuttingheightofthemowerdoesnotscalpany

unevenground.However,thecuttingheightusedin

thepastisgenerallythebestonetouse.Whencutting

grasslongerthansixinchestall,youmaywanttocut

thelawntwicetoensureanacceptablequalityofcut.

AvoidingCuttingTooLow

Ifthecuttingwidthofthemoweriswiderthanthe

moweryoupreviouslyused,raisethecuttingheightto

ensurethatuneventurfisnotcuttooshort.

CuttingLongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,

raisethecuttingheighthigherthanusualandcutthe

grassatthissetting.Thencutthegrassagainusing

thelower,normalsetting.

StoppingtheMachine

Ifthemachine'sforwardmotionmustbestoppedwhile

mowing,aclumpofgrassclippingsmaydroponto

yourlawn.Toavoidthis,moveontoapreviouslycut

areawiththebladesengagedoryoucandisengage

themowerdeckwhilemovingforward.

KeepingtheUndersideofthe

MowerClean

Cleanclippingsanddirtfromtheundersideofthe

moweraftereachuse.Ifgrassanddirtbuildupinside

themower,cuttingqualitywilleventuallybecome

unsatisfactory.

MaintainingtheBlade(s)

Cutting1/3oftheGrassBlade

Itisbesttocutonlyabout1/3ofthegrassblade.

Cuttingmorethanthatisnotrecommendedunless

grassissparse,oritislatefallwhengrassgrows

moreslowly.

AlternatingtheMowingDirection

Alternatethemowingdirectiontokeepthegrass

standingstraight.Thisalsohelpsdisperseclippings

whichenhancesdecompositionandfertilization.

MowingatCorrectIntervals

Normally,mowevery4days.But,remember,grass

growsatdifferentratesatdifferenttimes.Soto

maintainthesamecuttingheight,whichisagood

practice,andmowmoreofteninearlyspring.Asthe

grassgrowthrateslowsinmidsummer,mowless

frequently.Ifyoucannotmowforanextendedperiod,

Maintainasharpbladethroughoutthecuttingseason

becauseasharpbladecutscleanlywithouttearingor

shreddingthegrassblades.Tearingandshredding

turnsgrassbrownattheedges,whichslowsgrowth

andincreasesthechanceofdisease.Checkthe

mowerbladesaftereachuseforsharpness,and

foranywearordamage.Filedownanynicksand

sharpenthebladesasnecessary.Ifabladeis

damagedorworn,replaceitimmediatelywitha

genuineT ororeplacementblade.

24

Page 25

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Beforeeachuseordaily

Aftereachuse

Every25hours

Every50hours

Every100hours

Every200hours

Every500hours

Beforestorage

MaintenanceProcedure

•Checkthesafety-interlocksystem.

•Checktheaircleanerfordirty,looseordamagedparts.

•Checktheengine-oillevel.

•Checkthecuttingblades.

•Inspectthegrassdeectorfordamage.

•Cleanthemower-deckhousing.

•Greaseallthelubricationpoints.

•Serviceorreplacetheprecleaner(moreoftenunderextremelydusty,dirty

conditions).

•Checktirepressure.

•Checkthebeltsforwearorcracks.

•Servicethepaperelement(moreoftenunderextremelydusty,dirtyconditions).

•Replacethepaperelement(moreoftenunderextremelydusty,dirtyconditions).

•Changetheengineoilandtheengine-oillter.

•Cleantheblowerhousing(moreoftenunderextremelydusty,dirtyconditions).

•Replacethein-linefuellter.

•Checksparkplug(s)conditionandgap.

•Replacethesparkplug(s).

•Chargethebatteryanddisconnectbatterycables.

•Performallmaintenanceprocedureslistedabovebeforestorage.

•Paintanychippedsurfaces.

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineand

seriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudo

anymaintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

25

Page 26

Pre-Maintenance

Lubrication

Procedures

GreasingtheBearings

RaisingtheSeat

Makesurethatthemotion-controlleversarelockedin

theparkposition.Lifttheseatforward.

Thefollowingcomponentscanbeaccessedbyraising

theseat:

•Serialplate

•Servicedecal

•Seatadjustmentbolts

•Fuellter

•Batteryandbatterycables

ServiceInterval:Every25hours—Greaseallthe

lubricationpoints.

GreaseType:No.2generalpurpose,lithium-based

grease

1.Parkthemachineonalevelsurface,and

disengagetheblade-controlswitch.

2.Movethemotion-controlleversoutwardtothe

parkposition,stoptheengine,removethekey,

andwaitforallmovingpartstostopbefore

leavingtheoperatingposition.

3.Cleanthegreasettings(Figure25andFigure

26)witharag.

Note:Makesuretoscrapeanypaintoffofthe

frontofthetting(s).

Figure25

1.Frontcastertire

Figure26

Locatedontheseat-panunderside

1.Readtheinstructions

beforeservicingor

performingmaintenance

2.Checkthetirepressure

every25operatinghours

4.Connectagreaseguntoeachtting(Figure25

andFigure26).

3.Greaseevery25operating

hours

4.Engine

g014522

decal106-8717

26

Page 27

5.Pumpgreaseintothettingsuntilgreasebegins

tooozeoutofthebearings.

EngineMaintenance

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Check

theaircleanerfordirty,looseor

damagedparts.

Every25hours—Serviceorreplacethe

precleaner(moreoftenunderextremelydusty,

dirtyconditions).

Every50hours—Servicethepaperelement

(moreoftenunderextremelydusty,dirty

conditions).

Every100hours—Replacethepaperelement

(moreoftenunderextremelydusty,dirty

conditions).

Thisengineisequippedwithareplaceable,high

densitypaperair-cleanerelement.Checktheair

cleanerdailyorbeforestartingtheengine.Checkfor

abuildupofdirtanddebrisaroundtheair-cleaner

system.Keepthisareaclean.Also,checkforlooseor

damagedcomponents.Replaceallbentordamaged

air-cleanercomponents.

Note:Operatingtheenginewithlooseordamaged

air-cleanercomponentscouldallowunlteredairinto

theengine,causingprematurewearandfailure.

Note:Servicetheaircleanermoreoftenunder

extremelydusty,dirtyconditions.

1.Rotatethelatchesoutward.

2.Removethecovertoaccesstheair-cleaner

element(Figure27).

3.Removetheprecleanerandpaperelement.

4.Removetheprecleanerfromthepaperelement,

andgentlytapthepaperelementtodislodgedirt

Note:Donotwashthepaperelementoruse

pressurizedair,asthiswilldamagetheelement.

Note:Replaceadirty,bent,ordamaged

element.Handlethenewelementcarefully;

donotuseifthesealingsurfacesarebentor

damaged.

5.Washtheprecleanerinwarmwaterwith

detergent,rinse,andairdry.

6.Lightlyoiltheprecleanerwithnewengineoiland

squeezeoutexcessoil.

7.Cleantheair-cleanerbaseasrequired,and

checkthecondition.

8.Installtheprecleaneroverthepaperelement.

9.Installtheprecleanerandpaperelementonto

theair-cleanerbase.

10.Installthecover,andsecureitwiththelatches

(Figure27).

27

Page 28

Figure27

1.Air-cleanerlatch4.Air-cleanerbase

2.Engine5.Precleaner

3.Paperelement

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSJorhigher)

CrankcaseCapacity:1.9L(64oz)whenthelter

ischanged

Viscosity:Seethetablebelow.

g028384

g027515

Figure29

ChangingtheEngineOilandthe

Engine-OilFilter

ServiceInterval:Every100hours—Changethe

engineoilandtheengine-oillter.

Figure28

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily—Check

theengine-oillevel.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,stoptheengine,and

removethekey.

2.Makesuretheengineisstopped,level,andis

cool,sotheoilhastimetodrainintothesump.

3.Checktheengine-oillevel(Figure29).

Note:Thedrainplugisattachedtothedrainhose.

Note:Disposeoftheusedoilatarecyclingcenter.

Fillwithoilasspeciedinthe“ViscosityGrades”table

g017552

(Figure28).

1.Parkthemachine,sothatthedrainsideis

slightlylowerthantheoppositeside,toensure

thattheoildrainscompletely.

2.Disengagetheblade-controlswitchandmove

themotioncontrolsoutwardtotheparkposition.

3.Stoptheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

28

Page 29

Figure31

g027477

Figure30

4.T orquetheplugto14N-m(125in-lb).

g027934

5.Slowlypourapproximately80%ofthespecied

oilintothellertube(Figure32).

29

Page 30

Figure32

ServicingtheSparkPlug

ServiceInterval:Every200hours—Checkspark

plug(s)conditionandgap.

Every500hours—Replacethesparkplug(s).

ThesparkplugisRFIcompliant.Equivalentalternate

brandplugscanalsobeused.

Type:ChampionXC12YC

AirGap:0.76mm(0.03inch)

RemovingtheSparkPlug

1.Disengagetheblade-controlswitch,movethe

motioncontrolsoutwardtotheparkposition,

stoptheengine,andremovethekey.

2.Beforeremovingthesparkplug(s),cleanthe

areaaroundthebaseoftheplugtokeepdirt

anddebrisoutoftheengine.

3.Removethesparkplug(Figure33).

g027517

g027478

Figure33

CheckingtheSparkPlug

Important:Donotcleanthesparkplug(s).

Alwaysreplacethesparkplug(s)whenithas:a

blackcoating,wornelectrodes,anoilylm,or

cracks.

Note:Ifyouseelightbrownorgrayontheinsulator,

theengineisoperatingproperly.Ablackcoatingon

theinsulatorusuallymeanstheaircleanerisdirty.

Setthegapto0.76mm(0.030inch).

30

Page 31

Figure34

InstallingtheSparkPlug

Tightenthesparkplugto25to29N-m(18to22ft-lb).

FuelSystem

Maintenance

DANGER

Incertainconditions,gasolineisextremely

g027479

ammableandhighlyexplosive.Areor

explosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Performanyfuelrelatedmaintenance

whentheengineiscold.Dothisoutdoors

inanopenarea.Wipeupanygasolinethat

spills.

•Neversmokewhendraininggasoline,and

stayawayfromanopenameorwherea

sparkmayignitethegasolinefumes.

ReplacingtheIn-LineFuel Filter

Figure35

CleaningtheBlower Housing

Toensurepropercooling,makesurethegrassscreen,

coolingns,andotherexternalsurfacesoftheengine

arekeptcleanatalltimes.

Annually,orevery100hoursofoperation(moreoften

underextremelydusty ,dirtyconditions),removethe

blowerhousing,andanyothercoolingshrouds.Clean

thecoolingnsandexternalsurfacesasnecessary.

Makesurethecoolingshroudsareinstalled.T orque

theblowerhousingscrewsto7.5N-m(5.5ft-lb).

ServiceInterval:Every100hours—Replacethe

in-linefuellter.

Neverinstalladirtylterifitisremovedfromthefuel

line.

1.Parkthemachineonalevelsurfaceand

disengagetheblade-controlswitch.

2.Movethemotion-controlleversoutwardtothe

parkposition,stoptheengine,removethekey,

g027938

andwaitforallmovingpartstostopbefore

leavingtheoperatingposition.

3.Replacethein-linelter(Figure36).

Important:Operatingtheenginewithablocked

grassscreen,dirtyorpluggedcoolingns,and/or

coolingshroudsremoved,willcauseengine

damageduetooverheating.

31

Page 32

ElectricalSystem

Maintenance

WARNING

CALIFORNIA

g027959

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

cancerandreproductiveharm.Wash

ChargingtheBattery

RemovingtheBattery

WARNING

Proposition65Warning

compounds,chemicalsknownto

theStateofCaliforniatocause

handsafterhandling.

Figure36

Batteryterminalsormetaltoolscouldshort

againstmetalmachinecomponentscausing

sparks.Sparkscancausethebatterygasses

toexplode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,

donotallowthebatteryterminalstotouch

anymetalpartsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

g027518

1.Parkthemachineonalevelsurfaceand

disengagetheblade-controlswitch.

2.Movethemotion-controlleversoutwardtothe

parkposition,stoptheengine,removethekey,

andwaitforallmovingpartstostopbefore

leavingtheoperatingposition.

3.Raisetheseattoaccessthebattery.

4.Disconnectthenegative(black)groundcable

fromthebatterypost(Figure37).

Note:Retainallfasteners.

32

Page 33

WARNING

Incorrectbattery-cableroutingcould

damagethemachineandcablescausing

sparks.Sparkscancausethebattery

gassestoexplode,resultinginpersonal

injury.

•Alwaysdisconnectthenegative

(black)batterycablebefore

disconnectingthepositive(red)

cable.

•Alwaysconnectthepositive(red)

batterycablebeforeconnectingthe

negative(black)cable.

5.Slidetherubbercoverupthepositive(red)

cable.

6.Disconnectthepositive(red)cablefromthe

batterypost(Figure37).

Note:Retainallfasteners.

7.Removethebatteryhold-down(Figure37),and

liftthebatteryfromthebatterytray.

ChargingtheBattery

ServiceInterval:Beforestorage—Chargethebattery

anddisconnectbatterycables.

1.Removethebatteryfromthechassis;referto

RemovingtheBattery(page32).

2.Chargethebatteryforaminimumof1hourat

6to10amps.

Note:Donotoverchargethebattery .

3.Whenthebatteryisfullycharged,unplug

thechargerfromtheelectricaloutlet,then

disconnectthechargerleadsfromthebattery

posts(Figure38).

Figure37

1.Battery

2.Positive(+)batterypost

3.Bolt,washer,andnut7.Batteryhold-down

4.Terminalboot

5.Negative(–)batterypost

6.Wingnut,washer,andbolt

g000538

Figure38

1.Positive(+)batterypost3.Red(+)chargerlead

2.Negative(–)batterypost4.Black(–)chargerlead

InstallingtheBattery

1.Positionthebatteryinthetray(Figure37).

2.Usingthefastenerspreviouslyremoved,install

thepositive(red)batterycabletothepositive

(+)batteryterminal.

3.Usingthefastenerspreviouslyremoved,install

thenegativebatterycabletothenegative(-)

batteryterminal.

g005072

4.Slidetheredterminalbootontothepositive

(red)batterypost.

5.Securethebatterywiththehold-down(Figure

37).

6.Lowertheseat.

33

Page 34

ServicingtheFuses

DriveSystem

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;however,ifafuseblows,checkthe

component/circuitforamalfunctionorshort.

Fusetype:

•Main—F1-30amp,blade-type

•ChargeCircuit—F2-25amp,blade-type

1.Removethescrewssecuringthecontrolpanel

tothemachine.

Note:Retainallfasteners.

2.Liftthecontrolpaneuptoaccessthemainwiring

harnessandfuseblock(Figure39).

3.T oreplaceafuse,pulloutonthefusetoremove

it(Figure39).

Maintenance

CheckingtheTirePressure

ServiceInterval:Every25hours—Checktire

pressure.

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseuneven

cut.Checkthepressureatthevalvestem(Figure40).

Checkthetireswhentheyarecoldtogetthemost

accuratepressurereading.

Refertothemaximumpressuresuggestedbythetire

manufactureronthesidewallofthecasterwheeltires.

Inatethereardrive-wheeltiresto90kPa(13psi).

Figure39

1.Main—30amp

4.Returnthecontrolpaneltoitsoriginalposition.

2.Chargecircuit—25amp

Note:Usethescrewsremovedpreviouslyto

securethepaneltothemachine.

g000554

Figure40

1.Valvestem

g014921

34

Page 35

ReleasingtheElectric Brake

MowerMaintenance

Theelectricbrakereleasesbymanuallyrotating

thelinkarmsforward.Oncetheelectricbrakeis

energizedthebrakewillreset.

Toreleasethebrake:

Figure41

1.Brakelinkarmontheelectricbrakecontrolmodule

2.Leftreartire

1.TurntheignitionkeytotheOffpositionor

disconnectthebattery.

2.Locatetheshaftontheelectricbrakewherethe

brake-linkarmsareconnected.

3.Rotatetheshaftforwardtoreleasethebrake.

g027911

ServicingtheCutting Blades

Maintainsharpbladesthroughoutthecuttingseason,

becausesharpbladescutcleanlywithouttearingor

shreddingthegrassblades.Tearingandshredding

turnsgrassbrownattheedges,whichslowsgrowth,

andincreasesthechanceofdisease.

Checkthecutterbladesdailyforsharpness,and

foranywearordamage.Filedownanynicksand

sharpenthebladesasnecessary.Ifabladeis

damagedorworn,replaceitimmediatelywitha

genuineTororeplacementblade.Forconvenient

sharpeningandreplacement,youmaywanttokeep

extrabladesonhand.

WARNING

Awornordamagedbladecanbreak,anda

pieceofthebladecouldbethrownintothe

operator'sorbystander'sarea,resultingin

seriouspersonalinjuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

BeforeInspectingorServicingthe

Blades

Parkthemachineonalevelsurface,disengagethe

blade-controlswitch,movethemotion-controllevers

outwardtotheparkposition,stoptheengine,and

removethekey.

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily—Check

thecuttingblades.

1.Inspectthecuttingedges(Figure42).

Note:Iftheedgesarenotsharporhave

nicks,removeandsharpentheblades;referto

SharpeningtheBlades(page37).

2.Inspecttheblades,especiallythecurvedarea

(Figure42).

Note:Ifyounoticeanydamage,wear,oraslot

forminginthisarea(items3and4inFigure42),

immediatelyinstallanewblade.

35

Page 36

Figure42

1.Cuttingedge3.Wear/slotforming

2.Curvedarea

4.Damage

CheckingforBentBlades

Note:Themachinemustbeonalevelsurfacefor

thefollowingprocedure.

1.Raisethemowerdecktothehighest

height-of-cutposition;alsoconsideredthe

'transport'position.

2.Whilewearingthicklypaddedgloves,orother

adequatehandprotection,slowlyrotatethe

bladetobemeasureintoapositionthatallows

effectivemeasurementofthedistancebetween

thecuttingedgeandthelevelsurfacethe

machineison(Figure43).

3.Measurefromthetipofthebladetotheat

surface(Figure44).

g006530

g014973

Figure44

1.Blade(inpositionformeasuring)

2.Levelsurface

3.Measureddistancebetweenbladeandthesurface(A)

4.Rotatethesameblade180degrees,sothat

theopposingcuttingedgeisnowinthesame

position(Figure45).

Figure43

1.Deck3.Blade

2.Spindlehousing

g014974

Figure45

1.Blade(sidepreviouslymeasured)

2.Measurement(positionusedpreviously)

g014972

3.Opposingsideofbladebeingmovedintomeasurement

position

5.Measurefromthetipofthebladetotheat

surface(Figure46).

Note:Thevarianceshouldbenomorethan

3mm(1/8inch).

36

Page 37

Figure46

1.Oppositebladeedge(inpositionformeasuring)

2.Levelsurface

3.Secondmeasureddistancebetweenbladeandsurface(B)

A.IfthedifferencebetweenAandBisgreater

than3mm(1/8inch),replacethebladewith

anewblade;refertoRemovingtheBlades

(page37)andInstallingtheBlades(page

38).

g014973

g027833

Figure47

1.Sailareaoftheblade3.Curvedwasher

2.Blade4.Bladebolt

SharpeningtheBlades

1.Usealetosharpenthecuttingedgeatboth

endsoftheblade(Figure48).

Note:Ifabentbladeisreplacedwithanew

one,andthedimensionobtainedcontinues

toexceed3mm(1/8inch),thebladespindle

couldbebent.ContactanAuthorizedToro

Dealerforservice.

B.Ifthevarianceiswithinconstraints,moveto

thenextblade.

Repeatthisprocedureoneachblade.

RemovingtheBlades

Thebladesmustbereplacedifasolidobjectishit,if

thebladeisoutofbalance,orifthebladeisbent.T o

ensureoptimumperformanceandcontinuedsafety

conformanceofthemachine,usegenuineT oro

replacementblades.Replacementbladesmadeby

othermanufacturersmayresultinnon-conformance

withsafetystandards.

1.Holdthebladeendusingaragorthickly-padded

glove.

2.Removethebladebolt,thecurvedwasher,and

thebladefromthespindleshaft(Figure47).

Note:Maintaintheoriginalangle.

Note:Thebladeretainsitsbalanceifthesame

amountofmaterialisremovedfrombothcutting

edges.

g000552

Figure48

1.Sharpenatoriginalangle

2.Checkthebalanceofthebladebyputtingitona

bladebalancer(Figure49).

Note:Ifthebladestaysinahorizontalposition,

thebladeisbalanced,andcanbeused.

Note:Ifthebladeisnotbalanced,lesome

metalofftheendofthesailareaonly(Figure48).

Figure49

1.Blade2.Balancer

3.Repeatthisprocedureuntilthebladeis

balanced.

37

g000553

Page 38

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure

47).

Important:Thecurvedpartoftheblade

mustbepointingupwardtowardtheinside

ofthemowertoensurepropercutting.

2.Installthethecurvedwasher(cuppedside

towardtheblade)andthebladebolt(Figure47).

3.T orquethebladeboltto47to88N-m(35to

65ft-lb).

LevelingtheMowerDeck

g005278

Figure50

Mowerdeckswith3blades

Checktoensurethatthemowerdeckislevelanytime

youinstallthemowerorwhenyouseeanunevencut

onyourlawn.

Themowerdeckmustbecheckedforbentblades

priortoleveling;anybentbladesmustberemoved

andreplaced;refertotheServicingtheCuttingBlades

(page35)beforecontinuing.

Themowerdeckmustbeleveledside-to-siderst

thenthefronttorearslopecanbeadjusted.

Requirements:

•Themachinemustbeonalevelsurface.

•All4tiresmustbeproperlyinated;referto

CheckingtheTirePressure(page34).

LevelingfromSidetoSide

1.Parkthemachineonalevelsurfaceand

disengagetheblade-controlswitch.

2.Movethemotion-controlleversoutwardtothe

parkposition,stoptheengine,removethekey,

andwaitforallmovingpartstostopbefore

leavingtheoperatingposition.

1.Bladesidetoside

2.Sailareaoftheblade4.Measurefromthetipofthe

3.Outsidecuttingedges

bladetotheatsurface

here

5.Measurebetweentheoutsidecuttingedges

andtheatsurface(Figure50).Ifboth

measurementsarenotwithin5mm(3/16inch),

anadjustmentisrequired;continuewiththis

procedure.

6.Movetotheleftsideofthemachine.

7.Loosentheside-lockingnut.

8.Raiseorlowertheleftsideofthemowerdeck

byrotatingtherearnut.(Figure51).

Note:Rotatetherearnutclockwiseto

raisethemowerdeck;rotatetherearnut

counter-clockwisetolowerthemowerdeck.

3.Settheheight-of-cutlevertomiddleposition.

4.Carefullyrotatetheblade(s)sothattheyareall

sidetoside(Figure50).

g027588

Figure51

1.Hangerbracket3.Rear-lockingnut

2.Side-lockingnut

38

Page 39

9.Checktheside-to-sideadjustmentsagain.

Repeatthisprocedureuntilthemeasurements

arecorrect.

10.Continuelevelingthedeckbycheckingthe

front-to-rearbladeslope;refertoAdjustingthe

Front-to-RearBladeSlope(page39).

AdjustingtheFront-to-RearBlade

Slope

Checkthefront-to-rearbladelevelanytimeyouinstall

themower.Ifthefrontofthemowerismorethan

7.9mm(5/16inch)lowerthantherearofthemower,

adjustthebladelevelusingthefollowinginstructions:

1.Parkthemachineonalevelsurfaceand

disengagetheblade-controlswitch.

2.Movethemotion-controlleversoutwardtothe

parkposition,stoptheengine,removethekey,

andwaitforallmovingpartstostopbefore

leavingtheoperatingposition.

3.Settheheight-of-cutlevertomiddleposition.

Note:Checkandadjusttheside-to-sideblade

levelifyouhavenotcheckedthesetting;referto

LevelingfromSidetoSide(page38).

4.Carefullyrotatethebladessotheyarefacing

fronttorear(Figure52).

Figure52

Mowerdeckswith3Blades

1.Bladesfronttorear3.Measurefromthetipofthe

bladetotheatsurface

here

2.Outsidecuttingedges

g014634

Figure53

1.Adjustingrod3.Locknut

2.Adjustingblock

7.T oraisethefrontofthemower,tightenthe

adjustmentnut.

8.T olowerthefrontofthemower,loosenthe

adjustmentnut.

9.Afteradjustment,checkthefront-to-rearslope

again,continueadjustingthenutuntilthefront

bladetipis1.6to7.9mm(1/16to5/16inch)

lowerthantherearbladetip(Figure52).

10.Whenthefront-to-rearbladeslopeiscorrect

checktheside-to-sidelevelofthemoweragain,

refertoLevelingfromSidetoSide(page38).

RemovingtheMower

1.Parkthemachineonalevelsurfaceand

g009659

disengagethebladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothe

parkposition,stoptheengine,removethekey,

andwaitforallmovingpartstostopbefore

leavingtheoperatingposition.

3.Lowertheheight-of-cutlevertothelowest

position.

5.Measurefromthetipofthefrontbladetothe

atsurface,andthetipoftherearbladetothe

atsurface(Figure52).

Note:Ifthefrontbladetipisnot1.6to7.9mm

(1/16to5/16inch)lowerthantherearbladetip,

adjustthefrontlocknut.

6.T oadjustthefront-to-rearbladeslope,rotatethe

adjustmentnutinthefrontofthemower(Figure

53).

4.Removethehairpincotterfromthefrontsupport

rodandremovetherodfromthedeckbracket

(Figure54).Carefullylowerthefrontofthe

mowerdecktotheground.

39

Page 40

Figure54

1.Frontsupportrod3.Deckbracket

2.Lockingnut

InstallingtheMower

1.Parkthemachineonalevelsurfaceand

disengagetheblade-controlswitch.

2.Movethemotion-controlleversoutwardtothe

parkposition,stoptheengine,removethekey,

andwaitforallmovingpartstostopbefore

leavingtheoperatingposition.

3.Slidethemowerunderthemachine.

4.Lowertheheight-of-cutlevertothelowest

position.

5.Lifttherearofthemowerdeckandguidethe

hangerbracketsovertherearliftrod(Figure55).

6.Attachthefrontsupportrodtothemowerdeck

withtheclevispinandhairpin-cotterpin(Figure

54).

7.Installthemowerbeltontotheenginepulley;

refertoReplacingtheMowerBelt(page42).

g014635

5.Liftthemowerdeckandhangerbracketsclear

oftherearliftrodandlowerthemowercarefully

totheground(Figure55).

Figure55

1.Mowerdeck

2.Hangerbracket

3.Rearliftrod

g005077

6.Slidethemowerdeckrearwardtoremovethe

mowerbeltfromtheenginepulley.

7.Slidethemowerdeckoutfromunderneaththe

machine.

Note:Retainallpartsforfutureinstallation.

40

Page 41

ReplacingtheGrass

Deector

ServiceInterval:Beforeeachuseordaily—Inspect

thegrassdeectorfordamage.

WARNING

Anuncovereddischargeopeningcould

allowthelawnmowertothrowobjectsin

theoperator'sorbystander'sdirectionand

resultinseriousinjury.Also,contactwiththe

bladecouldoccur.Neveroperatethemachine

withoutthegrassdeector,thedischarge

cover,orthegrass-collectionsysteminplace.

Neveroperatethemachinewithoutthe

grassdeector,thedischargecover,orthe

grass-collectionsysteminplace.

Inspectthegrassdeectorfordamagebeforeeach

use.Replaceanydamagedpartsbeforeuse.

1.Removethenut(3/8inch)fromtherodunder

themower(Figure56).

7.Sliderodthroughthesecondgrass-deector

bracket(Figure56).

8.Inserttherodatthefrontofthegrassdeector

intotheshortstandoffonthedeck.

9.Securetherearendoftherodintothemower

withanut(3/8inch)asshowninFigure56.

Important:Thegrassdeectormustbe

springloadedandinthedownposition.Lift

thedeectoruptotestthatitsnapstothe

fulldownposition.

Figure56

1.Mowerdeck

2.Grassdeector6.Nut(3/8inch)

3.Grass-deectorbracket7.Shortstandoff

4.Rod

2.Slidetherodoutoftheshortstandoff,thespring,

andthegrassdeector(Figure56).

3.Removethedamagedorworngrassdeector.

4.Replacethegrassdeector(Figure56).

5.Slidetherod(straightend),throughthe

rear-grass-deectorbracket.

6.Placethespringontherod,withtheendwires

downandbetweenthegrassdeectorbrackets.

5.Spring

g005192

41

Page 42

MowerBeltMaintenance

InspectingtheBelts

ServiceInterval:Every25hours—Checkthebelts

forwearorcracks.

Checkthebeltsforcracks,frayededges,burnmarks,

oranyotherdamage.Replacedamagedbelts.

ReplacingtheMowerBelt

Squealingwhenthebeltisrotating,bladesslipping

whencuttinggrass,frayedbeltedges,burnmarks,

andcracksaresignsofawornmowerbelt.Replace

themowerbeltifanyoftheseconditionsareevident.

1.Parkthemachineonalevelsurfaceand

disengagetheblade-controlswitch.

2.Movethemotion-controlleversoutwardtothe

parkposition,stoptheengine,removethekey,

andwaitforallmovingpartstostopbefore

leavingtheoperatingposition.

3.Settheheight-of-cutatthelowestcutting

positionof38mm(1-1/2inches).

4.Usingaspring-removaltool(T oropartno.

92-5771),removetheidlerspringfromthedeck

hooktoremovetensionontheidlerpulley,and

rollthebeltoffofthepulleys(Figure57).

WARNING

Thespringisundertensionwhen

installedandcancausepersonalinjury .

Becarefulwhenremovingthebelt.

Figure57

Mowerdeckswith3blades

1.Idlerpulley

2.Mowerbelt5.Enginepulley

3.Outsidepulley6.Spring-removaltool

5.Routethenewbeltaroundtheenginepulleyand

mowerpulleys(Figure57).

6.Usingaspring-removaltool(T oropartno.

92-5771),installtheidlerspringoverthedeck

hook,andplacetensionontheidlerpulleyand

mowerbelt(Figure57).

4.Spring

g014931

42

Page 43

Cleaning

7.Disengagetheblade-controlswitch,stopthe

engine,removetheignitionkey,andwaitforall

movingpartstostop.

WashingtheUndersideof theMower

ServiceInterval:Aftereachuse—Cleanthe

mower-deckhousing.

Washtheundersideofthemoweraftereachuseto

preventgrassbuildupforimprovedmulchactionand

clippingdispersal.

Important:Youcanwashthemachinewithmild

detergentandwater.Donotpressurewashthe

machine.Avoidexcessiveuseofwater,especially

nearthecontrolpanel,undertheseat,aroundthe

engine,hydraulicpumps,andmotors.

1.Parkthemachineonalevelsurfaceand

disengagetheblade-controlswitch.

2.Movethemotion-controlleversoutwardtothe

parkposition,stoptheengine,removethekey,

andwaitforallmovingpartstostopbefore

leavingtheoperatingposition.

3.Attachthehosecouplingtotheendofthe

mowerwashouttting,andturnthewateron

high(Figure58).

8.Turnthewateroffandremovethecouplingfrom

thewashouttting.

Note:Ifthemowerisnotcleanafterone

washing,soakitandletitstandfor30minutes.

Then,repeattheprocess.

9.Runthemoweragainfor1to3minutesto

removeexcesswater.

WARNING

Abrokenormissingwashouttting

couldexposeyouandotherstothrown

objectsorbladecontact.Contactwith

bladeorthrowndebriscancauseinjury

ordeath.

•Replacebrokenormissingwashout

ttingimmediately,beforeusing

moweragain.

•Neverputyourhandsorfeetunder

themowerorthroughopeningsinthe

mower.

Note:Spreadpetroleumjellyonthewashout

ttingO-ringtomakethecouplingslideon

easierandprotecttheO-ring.

Figure58

1.Washouttting3.O-ring

2.Hose

4.Coupling

g003934

4.Lowerthemowertothelowestheight-of-cut.

5.Sitontheseatandstarttheengine.

6.Engagetheblade-controlswitchandletthe

mowerrunfor1to3minutes.

43

Page 44

Storage

CleaningandStorage

1.Disengagethebladecontrolswitch,movethe

motioncontrolsoutwardtotheparkposition,

stoptheengine,andremovethekey.

2.Removegrassclippings,dirt,andgrimefromthe

externalpartsoftheentiremachine,especially

theengine.Cleandirtandchafffromtheoutside

oftheenginecylinderheadnsandblower

housing.

Important:Youcanwashthemachinewith

milddetergentandwater.Donotpressure

washthemachine.Avoidexcessiveuse

ofwater,especiallynearthecontrolpanel,

undertheseat,aroundtheengine,hydraulic

pumps,andmotors.

3.Servicetheaircleaner;refertoServicingtheAir

Cleaner(page27).

4.Greaseandoilthemachine;refertoLubrication

(page26).

5.Changethecrankcaseoilandlter;referto

ServicingtheEngineOil(page28).

6.Checkthetirepressure;refertoCheckingthe

TirePressure(page34).

7.Chargethebattery;refertoChargingtheBattery

(page32).

8.Checktheconditionoftheblades;referto

ServicingtheCuttingBlades(page35).

9.Preparethemachineforstoragewhennon-use

occursover30days.Preparethemachinefor

storageasfollows.

10.Addapetroleumbasedstabilizer/conditioner

tothefuelinthetank.Followthemixing

instructionsfromthestabilizermanufacturer.Do

notuseanalcoholbasedstabilizer(ethanolor

methanol).

11.Removethesparkplug(s)andcheckits

condition;refertoServicingtheSparkPlug

(page30).Withthesparkplug(s)removedfrom

theengine,pourtwotablespoonsofengine

oilintothesparkplughole.Usethestarterto

cranktheengineanddistributetheoilinsidethe

cylinder.Installthesparkplug(s).Donotinstall

thewireonthesparkplug(s).

12.Cleananydirtandchafffromthetopofthe

mower.

13.Scrapeanyheavybuildupofgrassanddirt

fromtheundersideofthemower,thenwashthe

mowerwithagardenhose.

14.Checktheconditionofthedriveandmower

belts.

15.Checkandtightenallbolts,nuts,andscrews.

Repairorreplaceanypartthatiswornor

damaged.

16.Paintallscratchedorbaremetalsurfaces.Paint

isavailablefromyourAuthorizedServiceDealer.

17.Storethemachineinaclean,drygarageor

storagearea.Removethekeyfromtheignition

switchandkeepitinamemorableplace.Cover

themachinetoprotectitandkeepitclean.

Note:Afuelstabilizer/conditionerismost

effectivewhenmixedwithfreshgasolineand

usedatalltimes.

Runtheenginetodistributetheconditionedfuel