Page 1

FormNo.3409-409RevB

TimeCutter

®

SS3225andSS4200

RidingMower

ModelNo.74710—SerialNo.400000000andUp

ModelNo.74720—SerialNo.400000000andUp

ModelNo.74725—SerialNo.400000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3409-409*B

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orotherreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadianICES-002

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineonany

forest-covered,brush-covered,orgrass-coveredlandunless

theengineisequippedwithasparkarrester,asdenedin

Section4442,maintainedineffectiveworkingorderorthe

engineisconstructed,equipped,andmaintainedforthe

preventionofre.

whilepreventingspark-plugfouling,hardstarting,and

increasedemissions.Onceyouhaveinstalledthekit,

attachthehigh-altitudelabelnexttotheserialdecal

onthemachine.ContactanyAuthorizedToroService

DealertoobtaintheproperHighAltitudeKitand

high-altitudelabelforyourmachine.Tolocateadealer

convenienttoyou,accessourwebsiteatwww .Toro.com

orcontactourToroCustomerCareDepartmentatthe

number(s)listedinyourEmissionControlWarranty

Statement.

Removethekitfromtheengineandrestoretheengine

toitsoriginalfactorycongurationwhenrunningthe

engineunder1500m(5,000ft).Donotoperateanengine

thathasbeenconvertedforhigh-altitudeuseatlower

altitudes;otherwise,youcouldoverheatanddamage

theengine.

Ifyouareunsurewhetherornotyourmachinehasbeen

convertedforhigh-altitudeuse,lookforthefollowing

label.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrester,contactyour

AuthorizedT oroDealer.

GenuineT orosparkarrestersareapprovedbytheUSDA

ForestryService.

WARNING

Removingstandardoriginalequipmentpartsand

accessoriesmayalterthewarranty,traction,and

safetyofthemachine.FailuretouseoriginalToro

partscouldcauseseriousinjuryordeath.Making

unauthorizedchangestotheengine,fuelorventing

system,mayviolateEPAandCARBregulations.

Replaceallpartsincluding,butnotlimitedto,tires,

belts,blades,andfuelsystemcomponentswith

originalToroparts.

ForallmodelsthatdonothaveT oroengines,please

refertotheenginemanufacturer’sinformationincluded

withthemachine.

decal127-9363

Labeledpowerratingsaresuppliedbytheengine

manufacturerinaccordancewithSAEtestingand

gross/netpowerratingstandards(J1940,J1995,J1349).

Important:IfyouareusingamachinewithaT oro

engineabove1500m(5,000ft)foracontinuousperiod,

ensurethattheHighAltitudeKithasbeeninstalledso

thattheenginemeetsCARB/EPAemissionregulations.

TheHighAltitudeKitincreasesengineperformance

©2016—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Introduction

Thisrotary-blade,ridinglawnmowerisintendedtobeused

byresidentialhomeownersorprofessional,hiredoperators.

Itisdesignedprimarilyforcuttinggrassonwell-maintained

lawnsonresidentialorcommercialproperties.Itisnot

designedforcuttingbrushorforagriculturaluses.

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safety-alertsymbol

Safety...........................................................................4

GeneralSafety.........................................................4

SlopeIndicator.......................................................5

SafetyandInstructionalDecals.................................6

ProductOverview.........................................................10

Controls...............................................................10

BeforeOperation......................................................11

BeforeOperationSafety..........................................11

RecommendedFuel................................................12

UsingStabilizer/Conditioner...................................12

FillingtheFuelTank...............................................12

CheckingtheEngine-OilLevel.................................13

BreakinginaNewMachine......................................13

ThinkSafetyFirst...................................................13

UsingtheSafety-InterlockSystem.............................14

PositioningtheSeat................................................14

AdjustingtheMotion-ControlLevers........................15

DuringOperation.....................................................15

DuringOperationSafety.........................................15

OperatingtheMowerBlade-ControlSwitch

(PTO)...............................................................16

OperatingtheThrottle............................................16

OperatingtheIgnitionSwitch..................................17

StartingandShuttingOfftheEngine.........................17

UsingtheMotion-ControlLevers.............................18

DrivingtheMachine...............................................18

g188142

g000502

StoppingtheMachine.............................................20

AdjustingtheHeightofCut.....................................20

AdjustingtheAnti-ScalpRollers...............................20

UsingtheSideDischarge.........................................21

OperatingTips......................................................21

AfterOperation........................................................22

AfterOperationSafety............................................22

PushingtheMachinebyHand..................................22

TransportingtheMachine........................................23

LoadingtheMachine..............................................24

Maintenance.................................................................25

RecommendedMaintenanceSchedule(s)......................25

Pre-MaintenanceProcedures......................................25

MaintenanceandStorageSafety................................25

RaisingtheSeat......................................................26

Lubrication...............................................................26

GreasingtheBearings.............................................26

EngineMaintenance..................................................27

EngineSafety.........................................................27

ServicingtheAirCleaner.........................................27

ServicingtheEngineOil..........................................28

ServicingtheSparkPlug..........................................30

CleaningtheBlowerHousing...................................31

FuelSystemMaintenance...........................................31

3

Page 4

ReplacingtheIn-LineFuelFilter...............................31

ElectricalSystemMaintenance....................................32

ElectricalSystemSafety...........................................32

ServicingtheBattery...............................................32

ServicingtheFuses.................................................34

DriveSystemMaintenance.........................................34

CheckingtheTirePressure......................................34

ReleasingtheElectricBrake.....................................35

MowerMaintenance...................................................35

ServicingtheCuttingBlades.....................................35

LevelingtheMowerDeck........................................37

RemovingtheMowerDeck.....................................39

InstallingtheMowerDeck.......................................40

ReplacingtheGrassDeector..................................40

MowerBeltMaintenance............................................42

InspectingtheBelts................................................42

ReplacingtheMowerBelt........................................42

Cleaning...................................................................43

WashingtheUndersideoftheMower........................43

Storage........................................................................44

CleaningandStorage..............................................44

Troubleshooting...........................................................46

Schematics...................................................................48

Safety

ThismachinehasbeendesignedinaccordancewithANSI

standardB71.1-2012.

GeneralSafety

Thisproductiscapableofamputatinghandsandfeetand

ofthrowingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriouspersonalinjury.

Usingthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustoyouandbystanders.

•ReadandunderstandthecontentsofthisOperator’ sManual

beforeyoustarttheengine.Ensurethateveryoneusing

thisproductknowshowtouseitandunderstandsthe

warnings.

•Donotputyourhandsorfeetnearmovingcomponents

ofthemachine.

•Donotoperatethemachinewithoutallguardsandother

safetyprotectivedevicesinplaceandworkingonthe

machine.

•Keepclearofanydischargeopening.Keepbystandersa

safedistanceawayfromthemachine.

•Keepchildrenoutoftheoperatingarea.Neverallow

childrentooperatethemachine.

•Stopthemachineandshutofftheenginebeforeservicing,

fueling,oruncloggingthemachine.

Improperlyusingormaintainingthismachinecanresult

ininjury.Toreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safety-alertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failuretocomplywith

theseinstructionsmayresultinpersonalinjuryordeath.

Youcanndadditionalitemsofsafetyinformationintheir

respectivesectionsthroughoutthismanual.

4

Page 5

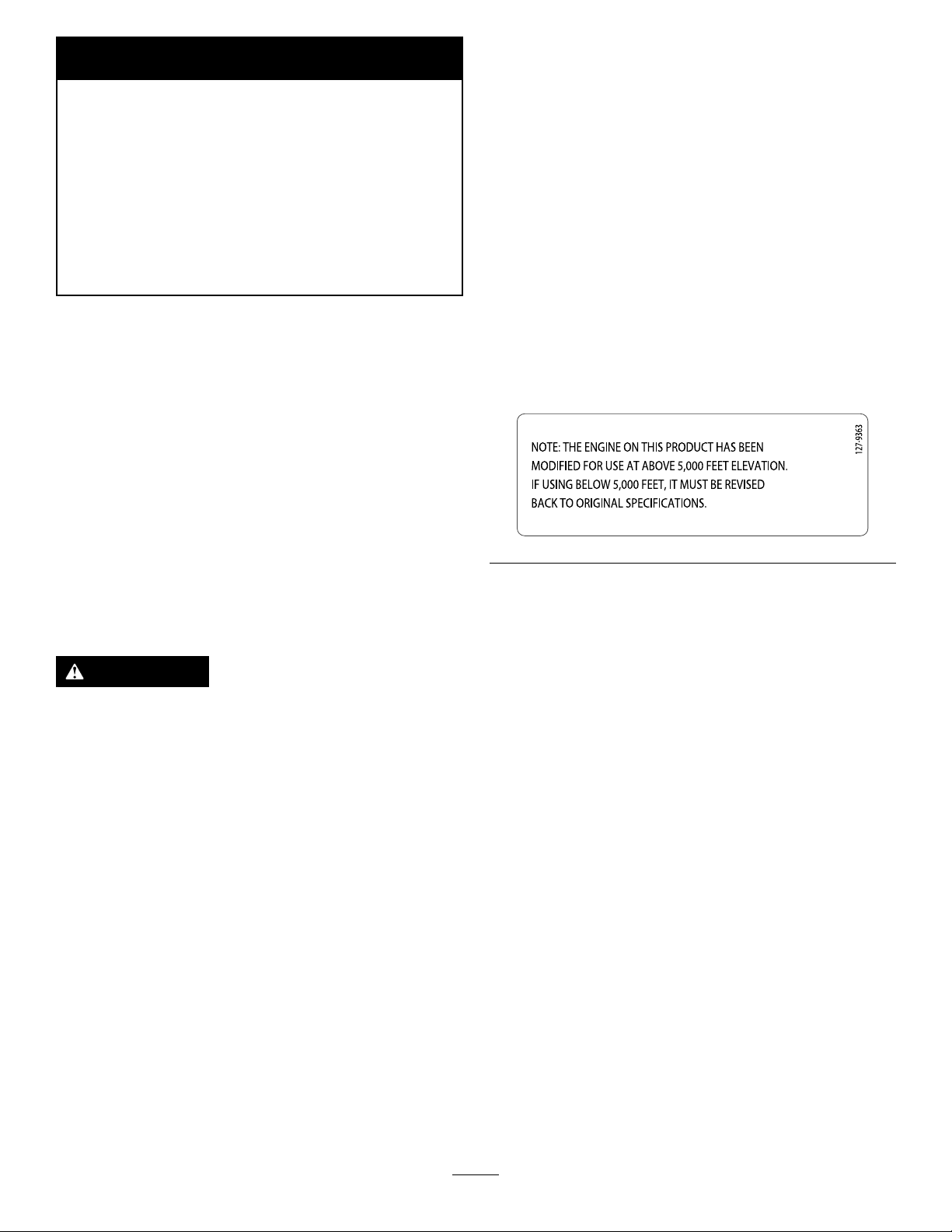

SlopeIndicator

G011841

Figure4

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge

5

g011841

Page 6

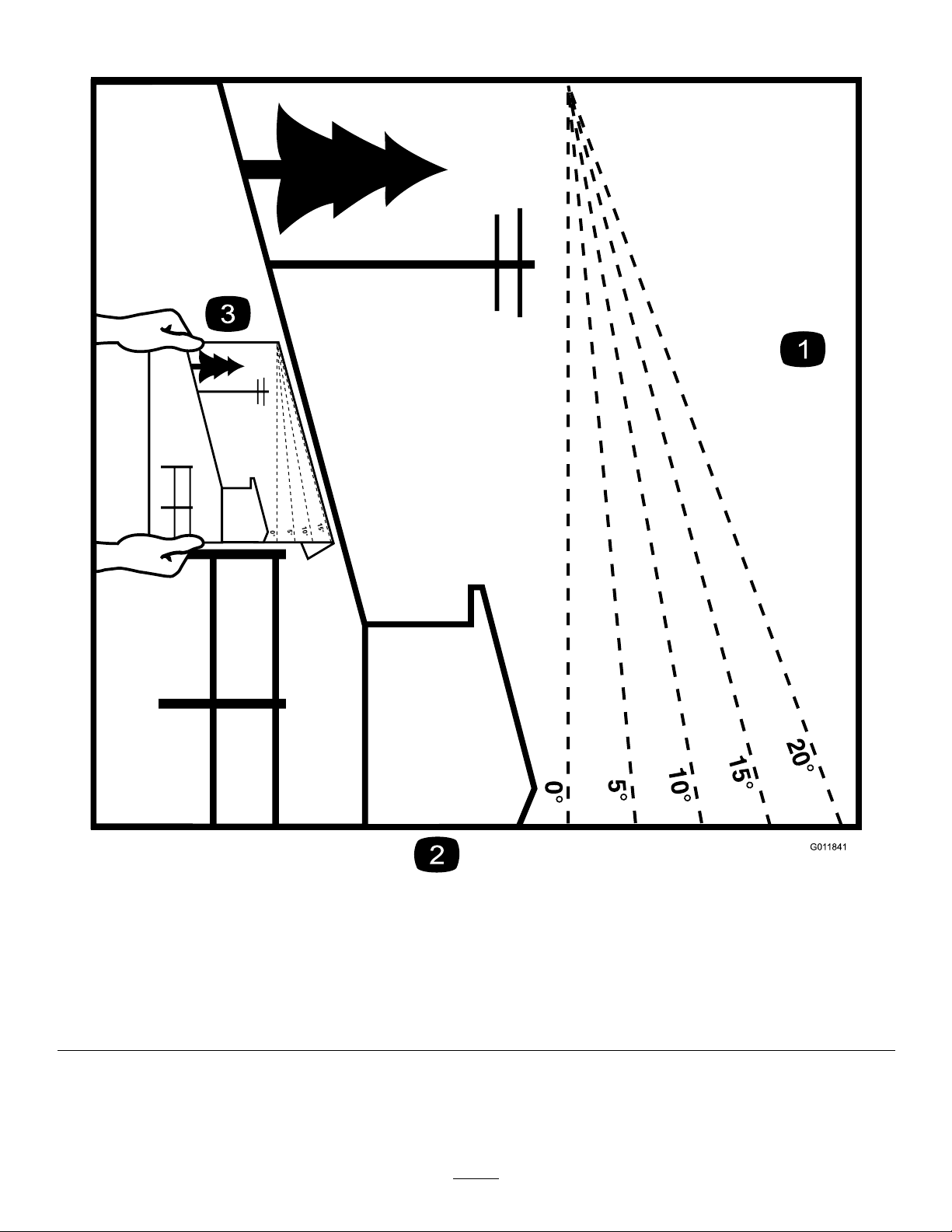

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedormissing.

93-7009

1.Warning—donotoperatethemowerwiththedeectorup

orremoved;keepthedeectorinplace.

2.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

decal93-7009

decal119-8814

119-8814

1.PARKINGposition4.NEUTRAL

2.FAST5.REVERSE

3.SLOW

105-7015

ForModelswith107cm(42-inch)Decks

1.Beltrouting

106-8717

1.Readtheinstructionsbeforeservicingorperforming

maintenance.

2.Checktirepressureevery25operatinghours.

3.Greaseevery25operatinghours.

4.Engine

decal119-8815

119-8815

1.PARKINGposition4.NEUTRAL

2.FAST5.REVERSE

decal105-7015

decal106-8717

3.SLOW

decal121-2989b

121-2989

1.Bypassleverpositionfor

pushingthemachine

6

2.Bypassleverpositionfor

operatingthemachine

Page 7

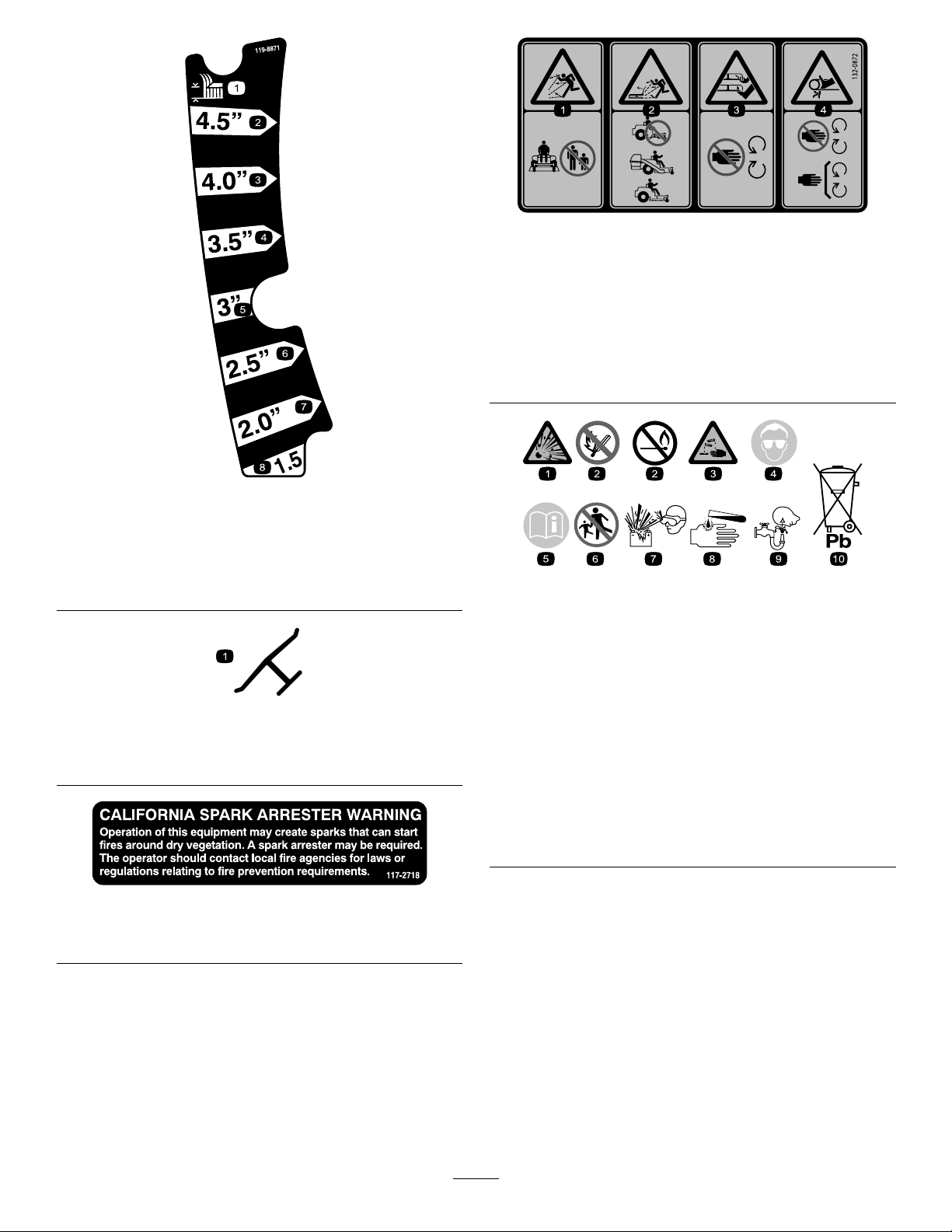

decal132-0872

132-0872

119-8871

1.Heightofcut

2.4-1/2inch6.2-1/2inch

3.4inch7.2inch

4.3-1/2inch8.1-1/2inch

5.3inch

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

1.Thrownobject

hazard—keepbystanders

awayfromthemachine.

2.Thrownobjecthazard,

raisedbafe—donot

operatethemachinewith

anopendeck;usea

baggerorabafe.

decal119-8871

3.Severinghazardofhand

orfoot—keepawayfrom

movingparts.

4.Entanglement

hazard—keepaway

frommovingparts;keep

allguardsandshieldsin

place.

decalbatterysymbols

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

decaloemmarkt

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

distancefromthebattery.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard.

117-2718

Model74725Only

decal117-2718

7

Page 8

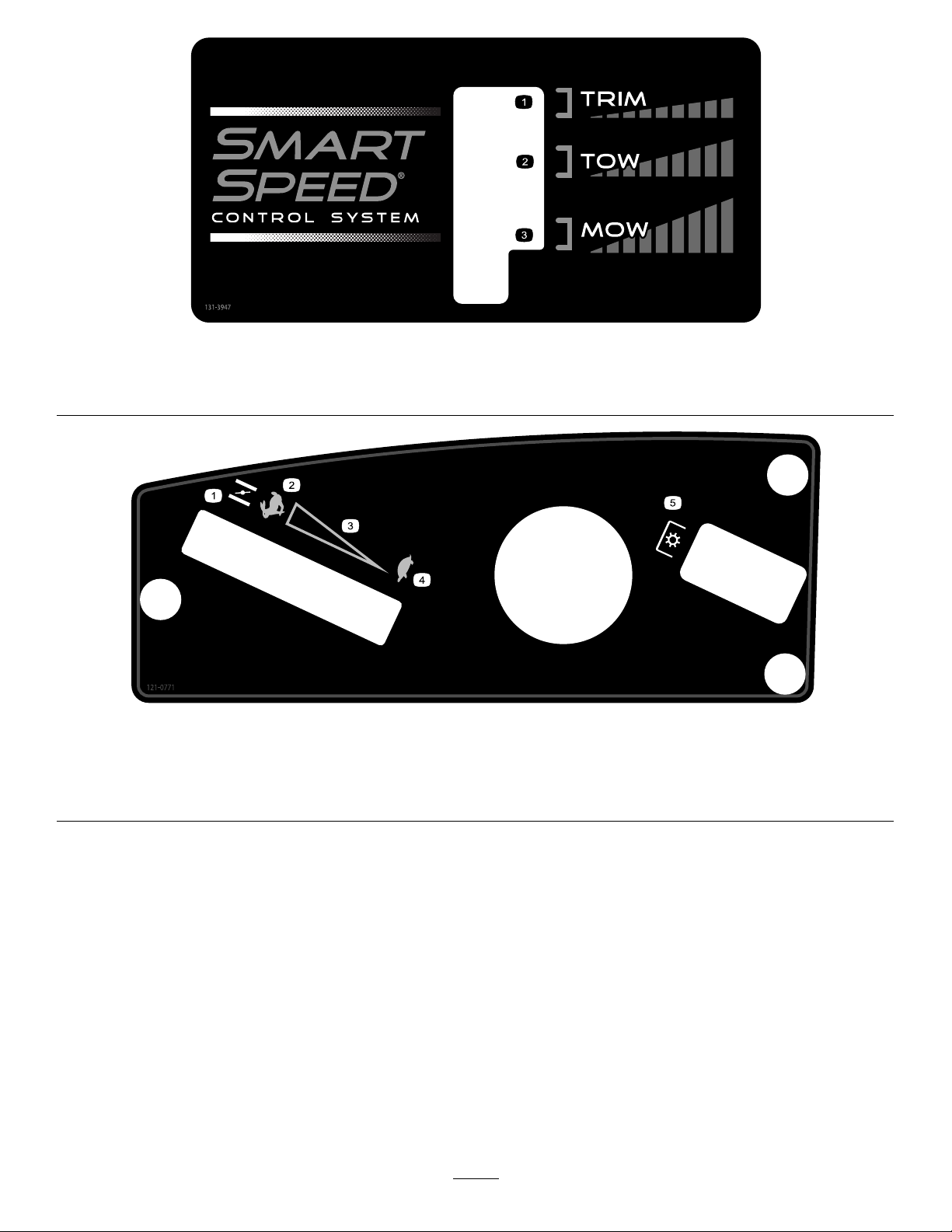

decal131-3947

131-3947

1.Trim—slow

2.Tow—medium

121-0771

1.Choke4.SLOW

2.FAST

3.Continuous-variablesetting

3.Mow—fast

decal121-0771

5.Powertake-off(PTO)—Blade-controlswitch

8

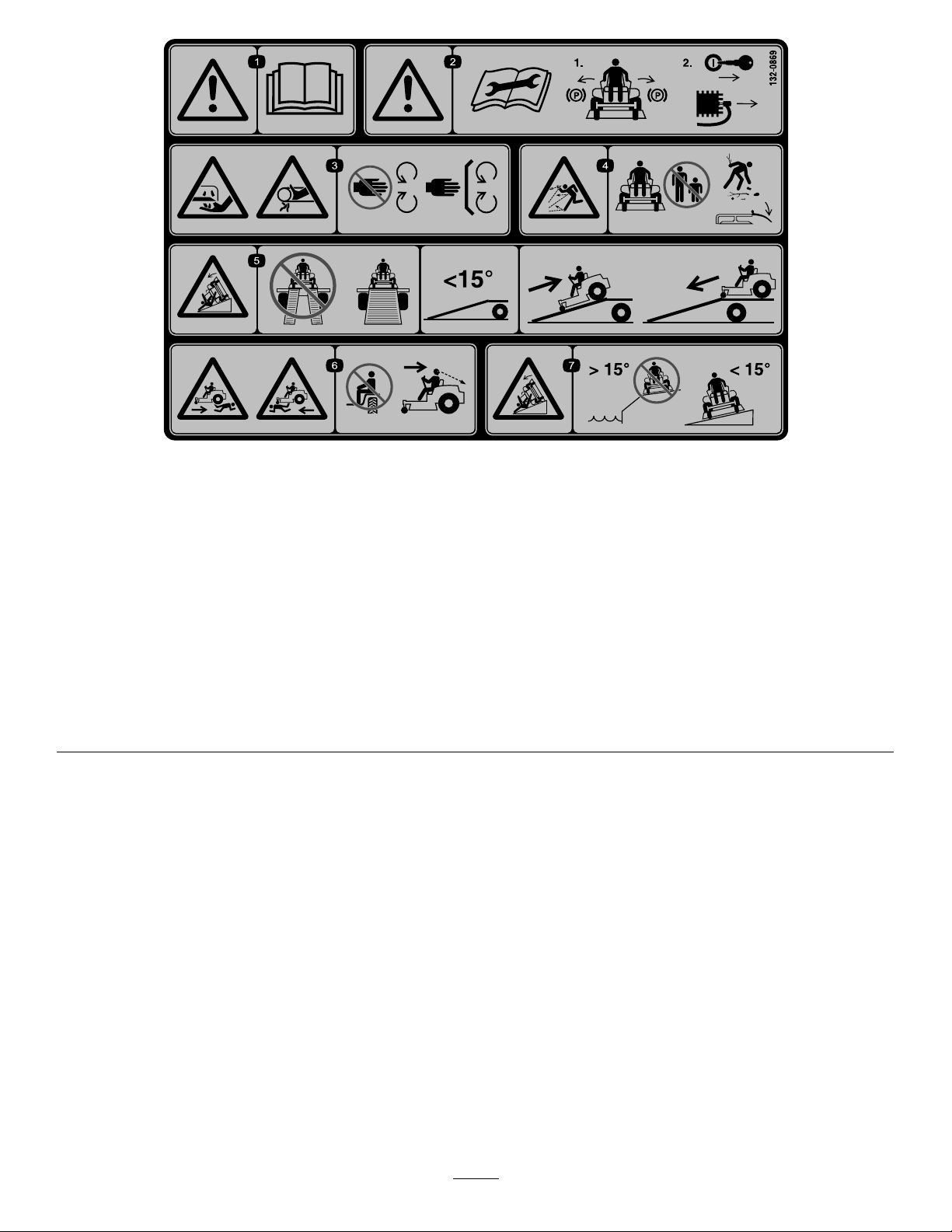

Page 9

decal132-0869

132-0869

1.Warning—readthe

Operator'sManual.

2.Warning—beforeservicing,

engagetheparkingbrake,

removethekeyandthe

sparkplugconnection.

3.Cuttinghazardofhand,

mowerblade;pinching

hazardofhand,belt—keep

handsandfeetawayfrom

movingparts;keepall

guardsandshieldsinplace.

4.Thrownobject

hazard—keepbystanders

awayfromthemachine;

removedebrisfromthe

areabeforemowing;keep

thedeectorshielddown.

5.Ramptipping

hazard—whenloading

ontoatrailer,donotuse

dualramps;onlyusea

singlerampwideenough

forthemachineandthat

hasaninclinelessthan

15degrees;backupthe

ramp(inreverse)anddrive

forwardofftheramp.

6.Bodilyharmhazard—no

riders;lookbehindyou

whenmowinginreverse.

7.Tippinghazardon

slopes—donotuseon

slopesnearopenwater;do

notuseonslopesgreater

than15degrees.

9

Page 10

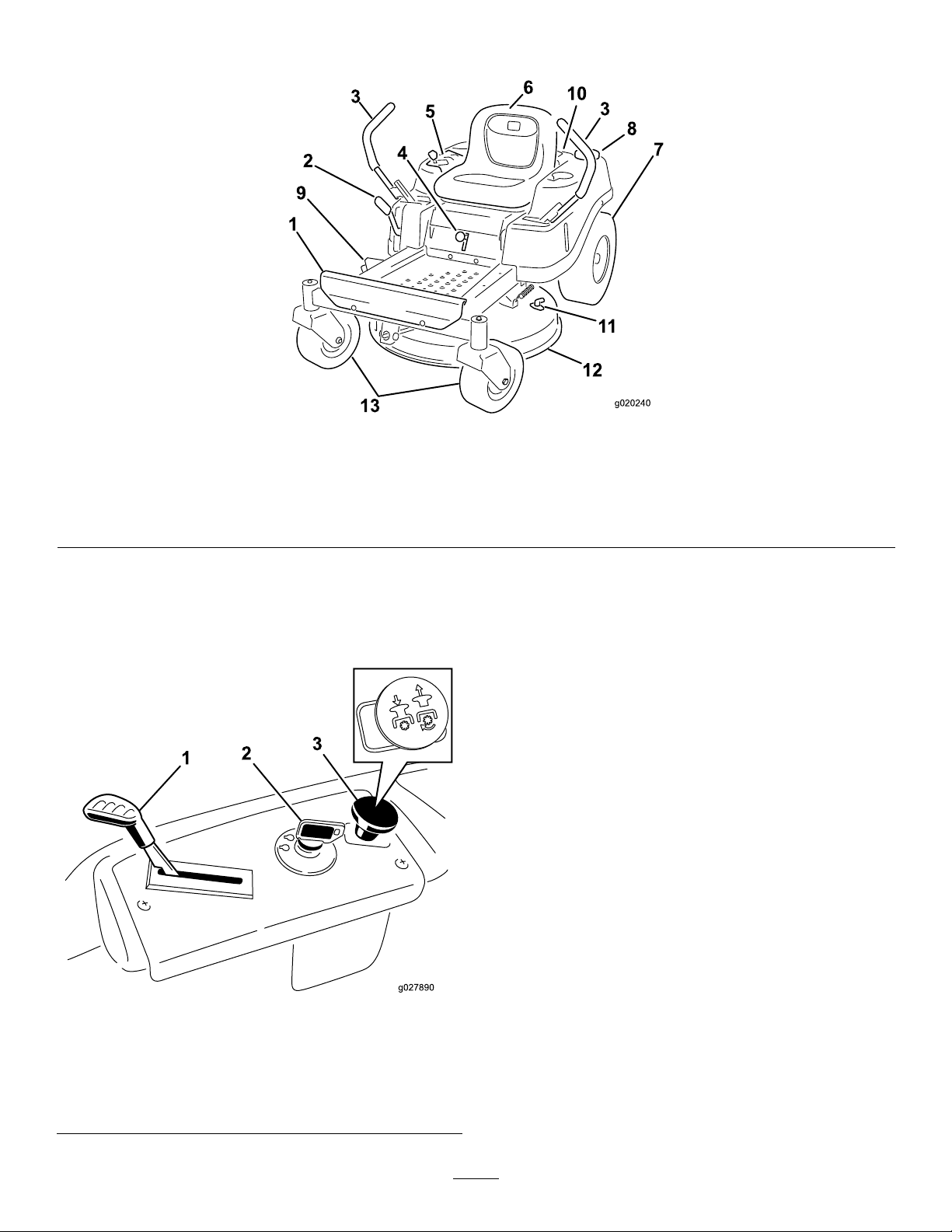

ProductOverview

g020240

1

2

3

4

5

6

7

8

10

11

12

13

9

3

Figure5

1.Footrest

2.Height-of-cutlever6.Operatorseat

3.Motion-controllever7.Reardrivewheel

4.Smart-speedlever

5.Controlpanel9.Deector

8.Fuel-tankcap12.Mowerdeck

Controls

BecomefamiliarwithallcontrolsinFigure5andFigure6

beforeyoustarttheengineandoperatethemachine.

10.Engine

11.Washouttting

IgnitionSwitch

Usethisswitchtostartthemowerengine.Ithas3positions:

START,RUN,andOFF.

13.Frontcasterwheels

Throttle/ChokeControl

Thethrottleandchokecontrolsarecombinedinto1control

lever.Thethrottlecontrolstheenginespeedandhasa

continuous-variablesettingfromSLOWtoFAST.Engagethe

chokebymovingtheleverpasttheFASTsettinguntilitstops

(Figure6).

Blade-ControlSwitch(PowerTakeoff)

Theblade-controlswitch,representedbyapower-takeoff

(PTO)symbol,engagesanddisengagespowertothemower

g027890

1.Throttle/Choke

2.Ignitionswitch

Figure6

ControlPanel

3.Blade-controlswitch

(powertakeoff)

blades(Figure6).

Motion-ControlLevers

Usethemotion-controlleverstodrivethemachineforward,

reverse,andturneitherdirection.

ParkPosition

Movethemotion-controlleversoutwardfromthecenterto

thePARKpositionwhenexitingthemachine(Figure18).

Alwayspositionthemotion-controlleversintothePARK

positionwhenyoustopthemachineorleaveitunattended.

10

Page 11

SmartSpeed™ControlSystemLever

G014521

1

TheSmartSpeed™Control-Systemlever,locatedbelowthe

operatingposition,givesyouachoicetodrivethemachineat

3speedranges—trim,tow ,andmow(Figure5).

Operation

BeforeOperation

Fuel-PresenceWindow

Youcanusethefuelwindow ,locatedontheleftsideofthe

machine,toverifythepresenceoffuelinthetank(Figure7).

Figure7

1.Fuel-presencewindow

Height-of-CutLever

Usetheheight-of-cutlevertolowerandraisethedeckfrom

theseatedposition.Movingtheleverup(towardyou)raises

thedeckfromthegroundandmovingtheleverdown(away

fromyou)lowersthedecktowardtheground.Adjustthe

height-of-cutonlywhilethemachineisnotmoving(Figure5).

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopletooperateor

servicethemachine.Localregulationsmayrestrictthe

ageoftheoperator.Theownerisresponsiblefortraining

alloperatorsandmechanics.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Knowhowtostopthemachineandshutofftheengine

quickly.

•Checkthatoperator-presencecontrols,safetyswitches,

andshieldsareattachedandfunctioningproperly.Donot

operatethemachineunlesstheyarefunctioningproperly.

g014521

•Beforemowing,alwaysinspectthemachinetoensurethat

theblades,bladebolts,andcuttingassembliesareingood

workingcondition.Replacewornordamagedbladesand

boltsinsetstopreservebalance.

•Inspecttheareawhereyouwillusethemachineand

removeallobjectsthatthemachinecouldthrow.

•Evaluatetheterraintodeterminetheappropriate

equipmentandanyattachmentsoraccessoriesrequiredto

operatethemachineproperlyandsafely.

FuelSafety

•Toavoidpersonalinjuryorpropertydamage,useextreme

careinhandlingfuel.Fuelvaporsareammableand

explosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfueltothefueltank

whiletheengineisrunningorwhilehot.

•Donotrefuelthemachineindoors.

•Donotstorethemachineorfuelcontainerwherethere

isanopename,spark,orpilotlight,suchasonawater

heateroronotherappliances.

•Donotllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

theground,awayfromyourvehiclebeforelling.

•Removetheequipmentfromthetruckortrailerand

refuelitwhileitisontheground.Ifthisisnotpossible,

thenrefuelfromaportablecontainerratherthana

fuel-dispensernozzle.

•Donotoperatethemachinewithouttheentireexhaust

systeminplaceandinproperworkingcondition.

11

Page 12

•Keepthefuel-dispensernozzleincontactwiththerimof

g027243

A

B

E

D

C

thefueltankorcontaineropeningatalltimesuntilfueling

iscomplete.Donotuseanozzlelock-opendevice.

•Ifyouspillfuelonyourclothing,changeyourclothing

immediately.Wipeupanyfuelthatspills.

•Neveroverllthefueltank.Replacethefuelcapand

tightenitsecurely.

•Storefuelinanapprovedcontainerandkeepitoutofthe

reachofchildren.Neverbuymorethana30-daysupply

offuel.

•Donotllthefueltankcompletelyfull.Addfueltothe

fueltankuntilthelevelis6to13mm(1/4to1/2inch)

belowthebottomofthellerneck.Thisemptyspacein

thetankallowsfueltoexpand.

–Avoidprolongedbreathingofvapors.

–Keepyourfaceawayfromthenozzleandfueltank

opening.

–Avoidcontactwithskin;washoffspillswithsoapand

water.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Keepsfuelfreshduringstorageof90daysorless(drain

thefueltankwhenstoringthemachineformorethan

90days)

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountoffuelstabilizer/conditioner

tothefuel.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshfuel.T ominimizethechanceof

varnishdepositsinthefuelsystem,usefuelstabilizerat

alltimes.

FillingtheFuelTank

RecommendedFuel

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontains

morethan10%ethanolbyvolume,suchasE15

(contains15%ethanol),E20(contains20%ethanol),or

E85(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/orengine

damagewhichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

•Donotaddoiltogasoline.

overthewinterunlessyouuseafuelstabilizer.

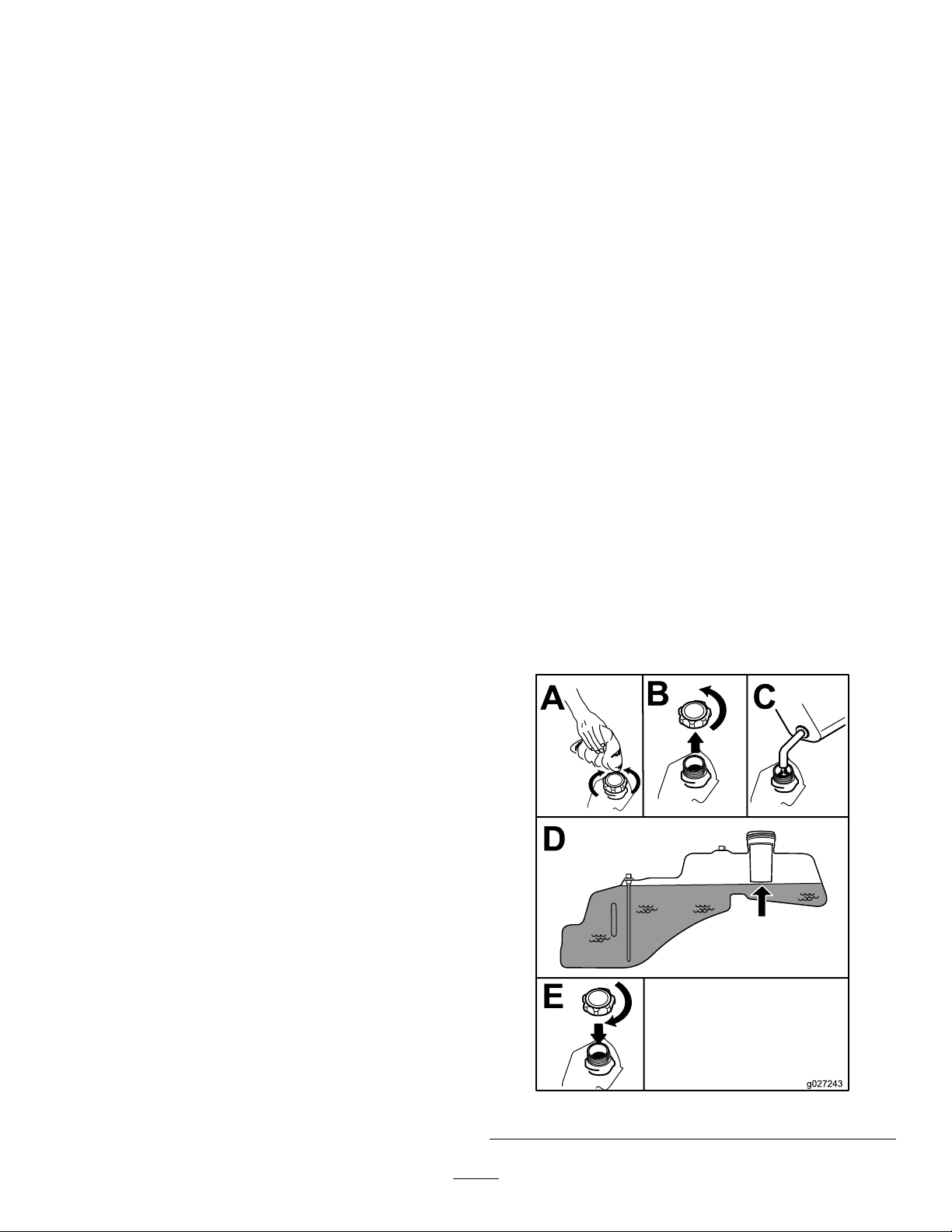

1.Parkthemachineonlevelground.

2.Shutofftheengineandengagetheparkingbrake.

3.Cleanaroundthefuel-tankcap.

4.Fillthefueltanktothebottomofthellerneck(Figure

8).

Note:Donotllthefueltankcompletelyfull.The

emptyspaceinthetankallowsthefueltoexpand.

Figure8

12

Page 13

CheckingtheEngine-OilLevel

G009027

1

2

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoCheckingthe

Engine-OilLevel(page13).

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mowerdecks

anddrivesystemshavehigherfrictionwhennew,placing

additionalloadontheengine.Allow40to50hoursof

break-intimefornewmachinestodevelopfullpowerand

bestperformance.

ThinkSafetyFirst

Pleasereadallsafetyinstructionsandsymbolsinthesafety

section.Knowingthisinformationcouldhelpyouor

bystandersavoidinjury.

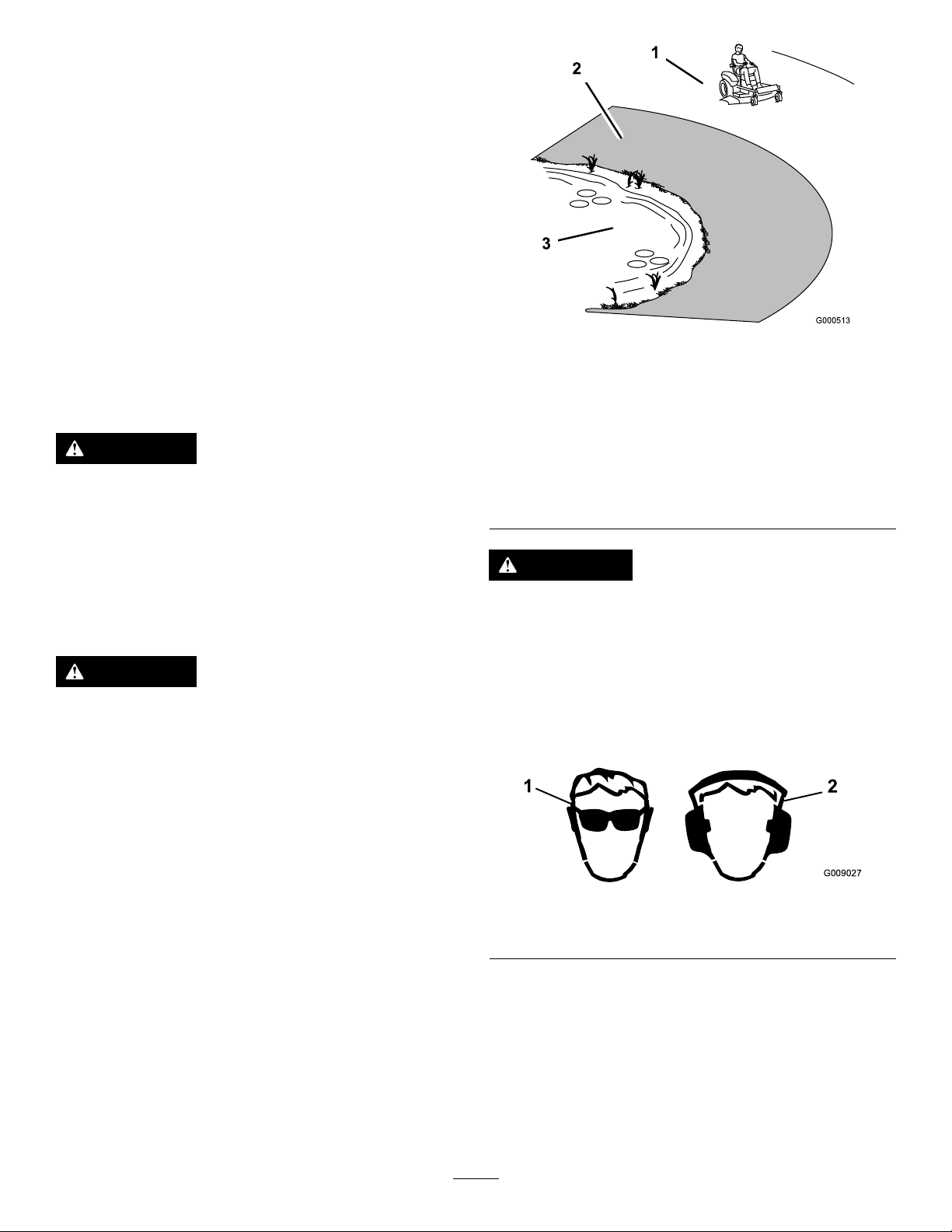

DANGER

Operatingthemachineonwetgrassorsteepslopes

cancauseslidingandlossofcontrol.

•Donotoperateonslopesgreaterthan15degrees.

•Reducespeedanduseextremecautionon

slopes.

•Donotoperatethemachinenearwater.

DANGER

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,death,or

drowning.

Donotoperatethemachineneardrop-offs.

Figure9

1.SafeZone—usethe

machinehereonslopes

lessthan15degreesor

atareas.

2.DangerZone—usea

walk-behindmowerand/or

ahandtrimmeronslopes

greaterthan15degrees,

neardrop-offsandwater.

3.Water

CAUTION

Thismachineproducessoundlevelsinexcessof

85dBAattheoperator’searandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Useprotectiveequipmentforyoureyes,ears,hands,feet,

andhead.

g000513

g009027

Figure10

1.Weareyeprotection.2.Wearhearingprotection.

13

Page 14

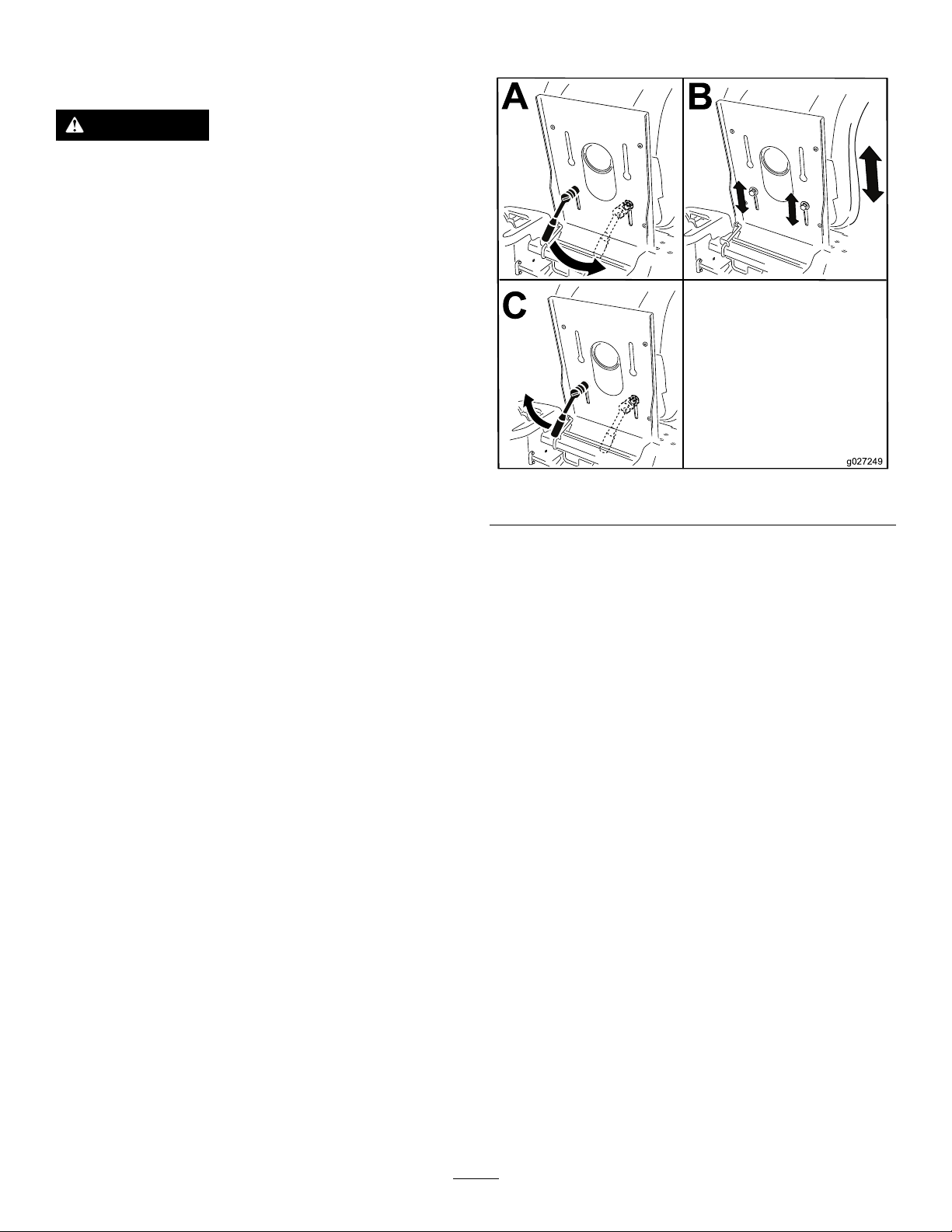

UsingtheSafety-Interlock

g027249

B

C

A

System

WARNING

Ifthesafety-interlockswitchesaredisconnectedor

damaged,themachinecouldoperateunexpectedly,

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

UnderstandingtheSafety-Interlock

System

Thesafety-interlocksystemisdesignedtopreventtheengine

fromstartingunless:

•Theblade-controlswitch(PTO)isdisengaged.

PositioningtheSeat

•Themotion-controlleversareinthePARKposition.

Thesafety-interlocksystemalsoisdesignedtoshutoffthe

enginewheneverthecontrolleversareoutofthePARK

positionandyourisefromtheseat.

TestingtheSafety-InterlockSystem

Testthesafety-interlocksystembeforeyouusethemachine

eachtime.Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthesafety

systemimmediately.

1.Sitontheseat,movethemotion-controlleversinthe

PARKposition,andmovetheblade-controlswitchto

theONposition.Trystartingtheengine;theengine

shouldnotcrank.

2.Sitontheseatandmovetheblade-controlswitchto

theOFFposition.Moveeithermotion-controlleverto

thecenter,unlockedposition.Trystartingtheengine;

theengineshouldnotcrank.Repeatwiththeother

motion-controllever.

3.Sitontheseat,movetheblade-controlswitchtothe

OFFposition,andlockthemotion-controlleversin

thePARKposition.Starttheengine.Whiletheengine

isrunning,engagetheblade-controlswitch,andrise

slightlyfromtheseat;theengineshouldshutoff.

g027249

Figure11

4.Sitontheseat,movetheblade-controlswitchtothe

OFFposition,andlockthemotion-controlleversinthe

PARKposition.Starttheengine.Whiletheengineis

running,movethemotion-controlleverstothecenter,

unlockedposition,engagetheblade-controlswitch,and

riseslightlyfromtheseat;theengineshouldshutoff.

14

Page 15

g027252

B

A

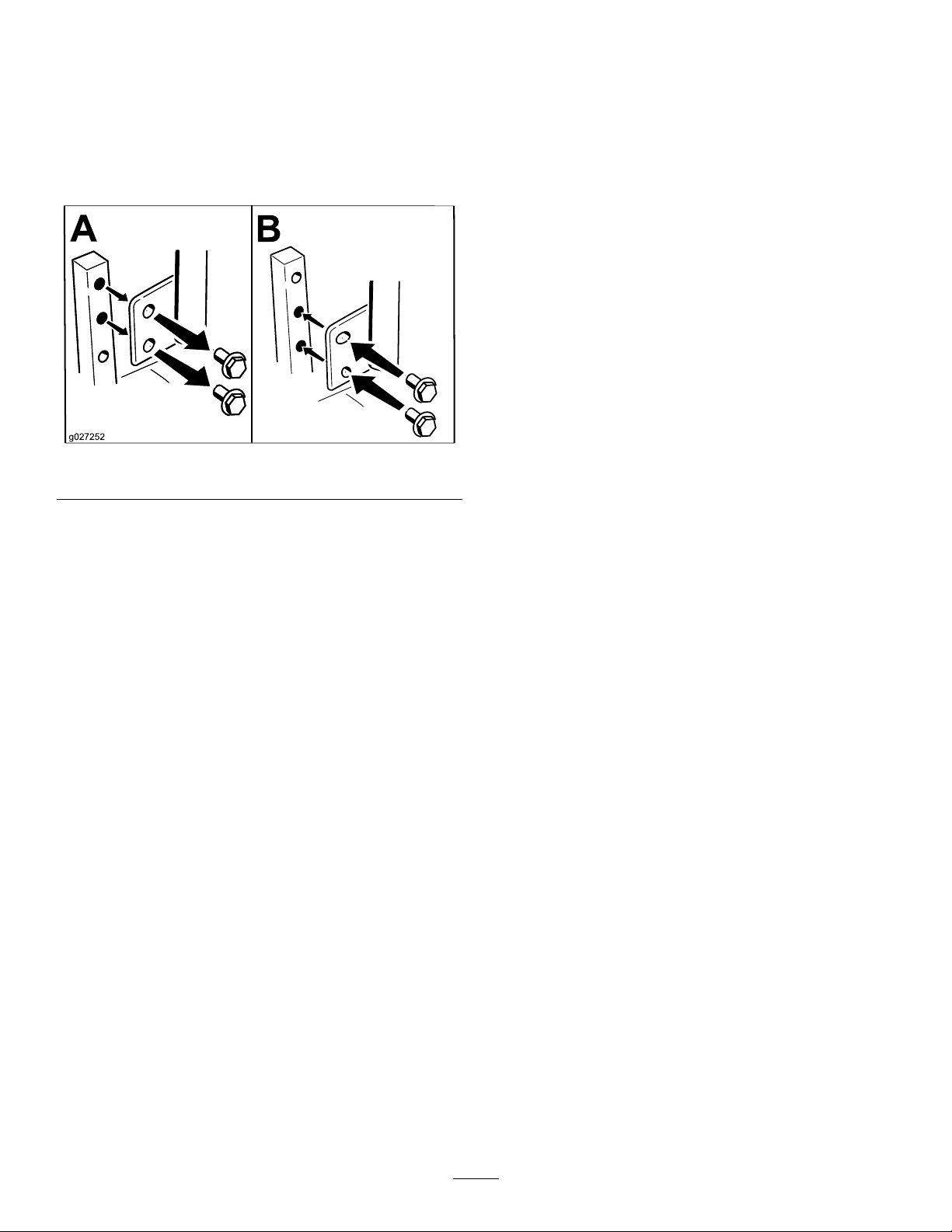

AdjustingtheMotion-Control Levers

AdjustingtheHeight

Youcanadjustthemotion-controllevershigherorlowerfor

maximumcomfort(Figure12).

Figure12

AdjustingtheTilt

Youcanadjustthemotion-controlleversforwardorrearward

foryourcomfort.

1.Loosentheupperboltholdingthecontrollevertothe

control-armshaft.

2.Loosenthelowerboltjustenoughtopivotthecontrol

leverforwardorrearward(Figure12).

3.Tightenbothboltstosecurethecontrolleverinthe

newposition.

4.Repeattheadjustmentfortheothercontrollever.

DuringOperation

DuringOperationSafety

GeneralSafety

•Theowner/operatorcanpreventandisresponsiblefor

accidentsthatmaycausepersonalinjuryorproperty

damage.

•Wearappropriateclothing,includingeyeprotection;

slip-resistant,substantialfootwear;andhearing

protection.Tiebacklonghairanddonotwearjewelry.

•Donotoperatethemachinewhileill,tired,orunderthe

inuenceofalcoholordrugs.

•Nevercarrypassengersonthemachineandkeep

bystandersandpetsawayfromthemachineduring

operation.

•Operatethemachineonlyingoodvisibilitytoavoidholes

orhiddenhazards.

g027252

•Avoidmowingonwetgrass.Reducedtractioncould

causethemachinetoslide.

•Ensurethatalldrivesareinneutral,theparkingbrake

isengaged,andyouareintheoperatingpositionbefore

youstarttheengine.

•Keepyourhandsandfeetawayfromthecuttingunits.

Keepclearofthedischargeopeningatalltimes.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscureyourvision.

•Donotmowneardrop-offs,ditches,orembankments.

Themachinecouldsuddenlyrolloverifawheelgoes

overtheedgeoriftheedgegivesway.

•Stopthebladeswheneveryouarenotmowing.

•Stopthemachineandinspectthebladesafterstrikingan

objectorifthereisanabnormalvibrationinthemachine.

Makeallnecessaryrepairsbeforeresumingoperation.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalkswiththemachine.Always

yieldtheright-of-way.

•Disengagethedrivetothecuttingunitandshutoffthe

enginebeforeadjustingtheheightofcut(unlessyoucan

adjustitfromtheoperatingposition).

•Neverrunanengineinanareawhereexhaustgasesare

enclosed.

•Neverleavearunningmachineunattended.

•Beforeleavingtheoperatingposition(includingtoempty

thecatchersortounclogthechute),dothefollowing:

–Stopthemachineonlevelground.

–Disengagethepowertake-offandlowerthe

attachments.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey .

15

Page 16

–Waitforallmovingpartstostop.

g027537

B

A

C

1

g027538

•Donotoperatethemachinewhenthereistheriskof

lightning.

•Donotusethemachineasatowingvehicle.

•Donotchangethegovernorspeedoroverspeedthe

engine.

•UseaccessoriesandattachmentsapprovedbyToroonly.

SlopeSafety

•Slowdownthemachineanduseextracareonhillsides.

Travelupanddownonhillsides.Turfconditionscan

affectthestabilityofthemachine.

•Avoidturningthemachineonslopes.Ifyoumustturnthe

machine,turnitslowlyandgraduallydownhill,ifpossible.

•Donotturnthemachinesharply .Usecarewhenreversing

themachine.

•Useextracarewhileoperatingthemachinewith

attachments;theycanaffectthestabilityofthemachine.

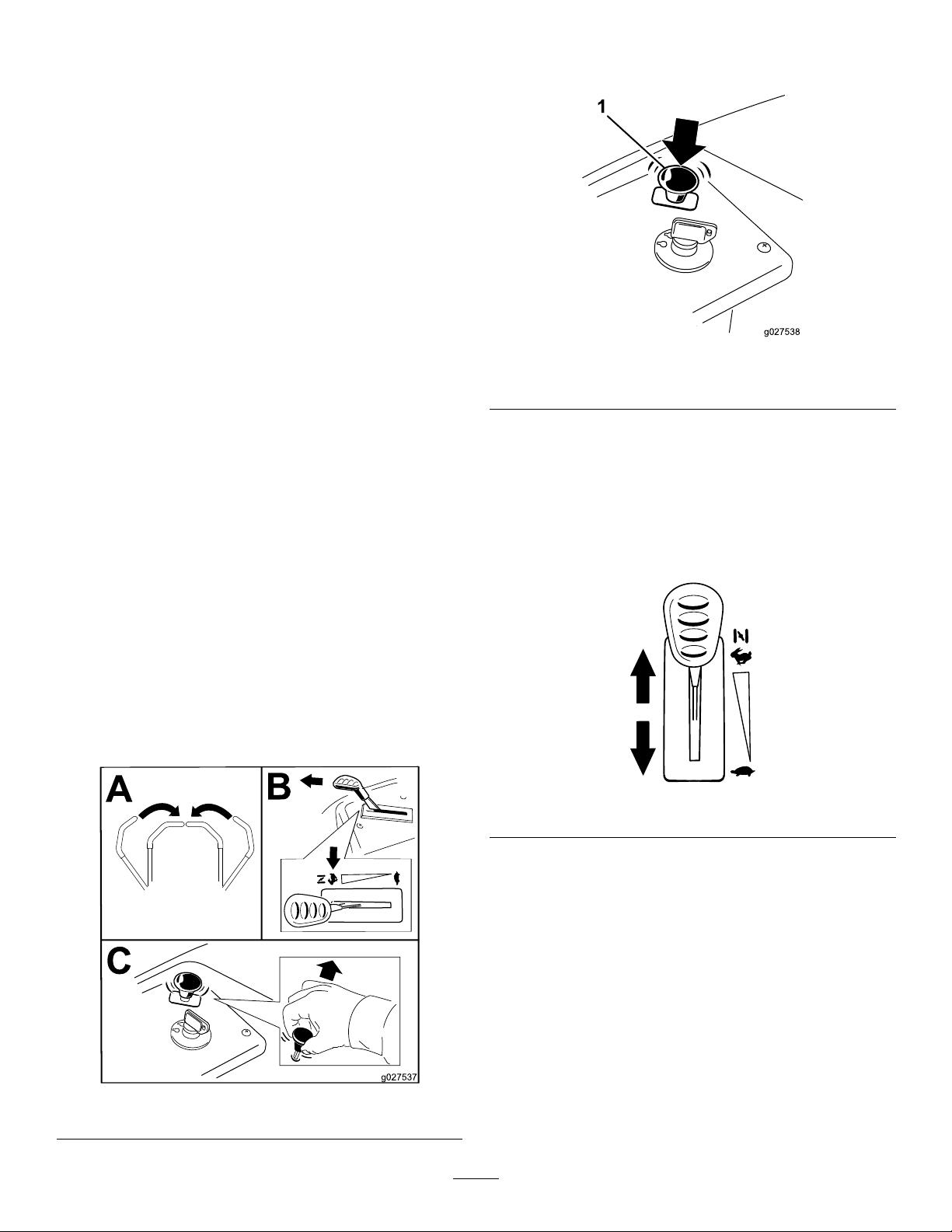

DisengagingtheBlade-ControlSwitch

(PTO)

g027538

Figure14

OperatingtheThrottle

OperatingtheMower Blade-ControlSwitch(PTO)

Theblade-controlswitch(PTO)startsandstopsthemower

bladesandanypoweredattachments.

EngagingtheBlade-ControlSwitch

(PTO)

Important:Donotengagethebladeswhenparkedin

tallgrass.Beltorclutchdamagecanoccur.

Note:Alwaysengagethebladeswiththethrottleinthe

FASTposition.

YoucanmovethethrottlecontrolbetweentheFASTand

SLOWpositions(Figure15).

AlwaysusetheFASTpositionwhenturningonthemower

deckwiththeblade-controlswitch(PTO).

g187361

Figure15

g027537

Figure13

16

Page 17

OperatingtheIgnitionSwitch

START

RUN

STOP

G008947

g027535

B

C

D

E

A

G

F

StartingandShuttingOffthe

1.TurntheignitionkeytotheSTARTposition(Figure16).

Note:Whentheenginestarts,releasethekey.

Important:Donotengagethestarterformore

than5secondsatatime.Iftheenginefailsto

start,wait15secondsbetweenattempts.Failureto

followtheseinstructionscanburnoutthestarter

motor.

Note:Youmayneedmultipleattemptstostartthe

enginewhenyoustartitthersttimeafterthefuel

systemhasbeenwithoutfuelcompletely.

Figure16

Engine

StartingtheEngine

Important:Donotengagethestarterformorethan

5secondsatatime.Engagingthestartermotorfor

morethan5secondscandamagethestartermotor.If

theenginefailstostart,wait10secondsbeforeoperating

theenginestarteragain.

Note:Itmaybenecessarytoholdtheleveragainstthestop,

inthechokeposition,whiletryingtostarttheengine(Figure

17).

g008947

2.TurntheignitionkeytotheSTOPpositiontoshutoff

theengine.

g027535

Figure17

17

Page 18

ShuttingOfftheEngine

G008952

1.Disengagethebladesbymovingtheblade-control

switchtotheOFFposition(Figure14).

2.MovethethrottlelevertotheFASTposition.

3.TurntheignitionkeytotheOFFpositionandremove

thekey.

UsingtheMotion-Control Levers

DrivingtheMachine

Thedrivewheelsturnindependently,poweredbyhydraulic

motorsoneachaxle.Youcanturn1sideinreversewhileyou

turntheotherforward,causingthemachinetospinrather

thanturn.Thisgreatlyimprovesthemachinemaneuverability

butmayrequiresometimeforyoutoadapttohowitmoves.

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placethethrottlecontrolin

theFASTpositionforbestperformance.Alwaysoperatein

thefullthrottlepositionwhenmowing.

WARNING

Themachinecanspinveryrapidly.Y oumaylose

controlofthemachineandcausepersonalinjuryor

damagetothemachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

DrivingForward

Figure18

1.Motion-control

lever—PARKposition

2.Center,unlockedposition5.Frontofmachine

3.Forward

4.Backward

Note:Alwaysusecautionwhenbackingupandturning.

1.Movetheleverstothecenter,unlockedposition.

2.Togoforward,slowlypushthemotion-controllevers

forward(Figure19).

c:\data\documentum\checkout\g004532

g008952

Figure19

18

Page 19

DrivingBackward

G008953

3.Adjustthelevertothedesiredposition.

1.Movetheleverstothecenter,unlockedposition.

2.Togobackward,slowlypullthemotion-controllevers

rearward(Figure20).

Figure20

Thefollowingareonlyrecommendationsforuse.

Adjustmentsvarybygrasstype,moisturecontent,andthe

heightofthegrass.

Suggested

uses:

ParkingX

Heavy,wet

grass

TrainingX

BaggingX

MulchingX

Normal

mowing

TransportX

TrimTowMow

X

X

Trim

Thisisthelowestspeed.Thesuggestedusesforthisspeed

areasfollows:

•Parking

g008953

•Heavy,wetgrassmowingconditions

•Training

UsingtheSmartSpeed

TM

Control

System

TheSmartSpeed

operatingposition(Figure21),givestheoperatorachoice

todrivethemachineat3groundspeedranges—trim,tow ,

andmow .

1.Smart-speedlever

TM

Control-Systemlever,locatedbelowthe

Figure21

Tow

Thisisthemediumspeed.Thesuggestedusesforthisspeed

areasfollows:

•Bagging

•Mulching

Mow

Thisisthefastestspeed.Thesuggestedusesforthisspeed

areasfollows:

•Normalmowing

•Transportingthemachine

g027625

Tochangespeeds,dothefollowing:

1.Movethemotion-controlleverstoneutralandoutward

tothePARKposition.

2.Disengagetheblade-controlswitch.

19

Page 20

StoppingtheMachine

g019929

1

2

3

4

5

AdjustingtheAnti-Scalp

Tostopthemachine,movethemotion-controlleversto

NEUTRALandoutwardtothePARKposition,disengagethe

blade-controlswitch,ensurethatthethrottleisintheFAST

position,andturntheignitionkeytoOFF.Removethekey

fromtheignitionswitch.

WARNING

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemowerwhileitis

unattended.

Alwaysremovetheignitionkeyandmovethe

motion-controlleversoutwardtothePARKposition

whenleavingthemachineunattended,evenifjust

forafewminutes.

AdjustingtheHeightofCut

Note:Thetransportpositionisthehighestheight-of-cut

positionorcuttingheightat115mm(4-1/2inches)asshown

inFigure22.

Heightofcutiscontrolledbytheleverlocatedtotherightof

theoperatingposition(Figure22).

Rollers

ForMachineswith107cm(42-inch)

MowerDecks

Wheneveryouchangetheheightofcut,adjusttheheight

oftheanti-scalprollers.

Note:Adjusttheanti-scalprollerssotherollersdonottouch

thegroundinnormal,atmowingareas.

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtoPARK

position,shutofftheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Adjusttheanti-scalprollersto1ofthefollowing

positions:

•Upperhole—usethispositionwiththemower

deckinthe63mm(2-1/2inch)andbelowthe

height-of-cutpositions(Figure23).

•Lowerhole—usethispositionwiththemowerdeck

inthe76mm(3inch)andabovetheheight-of-cut

positions(Figure23).

g019929

Figure23

1.Anti-scalproller4.Upperhole—themower

2.Lowerhole—themower

deckinthe76mm(3

inch)andabovethe

height-of-cutpositions

3.Flangenut

deckinthe63mm(2-1/2

inch)andbelowthe

height-of-cutpositions

5.Bolt

g028025

Figure22

20

Page 21

UsingtheSideDischarge

MowingatCorrectIntervals

Themowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

DANGER

Withoutagrassdeector,dischargecover,ora

completegrass-catcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriswillcauseinjuryor

death.

•Neverremovethegrassdeectorfromthemower

becausethegrassdeectorroutesmaterialdown

towardtheturf.Ifthegrassdeectorisever

damaged,replaceitimmediately .

•Neverputyourhandsorfeetunderthemower.

•Nevertrytoclearthedischargeareaormower

bladesunlessyoumovetheblade-controlswitch

(PTO)totheOFFposition,rotatetheignition

keytotheOFFposition,andremovethekey.

•Makesurethatthegrassdeectorisinthedown

position.

Grassgrowsatdifferentratesatdifferenttimesoftheyear.

Tomaintainthesamecuttingheight,mowmoreofteninearly

spring.Asthegrassgrowthrateslowsinmidsummer,mow

lessfrequently .Ifyoucannotmowforanextendedperiod,

rstmowatahighcuttingheight,thenmowagain2days

lateratalowerheightsetting.

UsingaSlowerCuttingSpeed

Toimprovecutquality,useaslowergroundspeedincertain

conditions.

AvoidingCuttingTooLow

Whenmowinguneventurf,raisethecuttingheighttoavoid

scalpingtheturf.

StoppingtheMachine

Ifyoumuststoptheforwardmotionofthemachinewhile

mowing,aclumpofgrassclippingsmaydropontoyour

lawn.Toavoidthis,moveontoapreviouslycutareawiththe

bladesengagedoryoucandisengagethemowerdeckwhile

movingforward.

OperatingTips

UsingtheFastThrottleSetting

Forbestmowingandmaximumaircirculation,operatethe

engineattheFASTposition.Airisrequiredtothoroughlycut

grassclippings,sodonotsettheheight-of-cutsolowasto

totallysurroundthemowerinuncutgrass.Alwaystrytohave

1sideofthemowerfreefromuncutgrass,whichallowsair

tobedrawnintothemower.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethatthe

cuttingheightofthemowerdoesnotscalpanyuneven

ground.However,thecuttingheightusedinthepastis

generallythebestonetouse.Whencuttinggrasslongerthan

15cm(6inches)tall,youmaywanttocutthelawntwiceto

ensureanacceptablequalityofcut.

CuttingaThirdoftheGrassBlade

Itisbesttocutonlyaboutathirdofthegrassblade.Cutting

morethanthatisnotrecommendedunlessgrassissparse,or

itislatefallwhengrassgrowsmoreslowly.

KeepingtheUndersideoftheMower

Clean

Cleanclippingsanddirtfromtheundersideofthemower

aftereachuse.Ifgrassanddirtbuildupinsidethemower,

cuttingqualitywilleventuallybecomeunsatisfactory.

MaintainingtheBlade(s)

Maintainasharpbladethroughoutthecuttingseasonbecause

asharpbladecutscleanlywithouttearingorshreddingthe

grassblades.Tearingandshreddingturnsgrassbrownat

theedges,whichslowsgrowthandincreasesthechanceof

disease.Checkthemowerbladesaftereachuseforsharpness,

andforanywearordamage.Filedownanynicksandsharpen

thebladesasnecessary.Ifabladeisdamagedorworn,replace

itimmediatelywithagenuineTororeplacementblade.

AlternatingtheMowingDirection

Alternatethemowingdirectiontokeepthegrassstanding

straight.Thisalsohelpsdisperseclippingswhichenhances

decompositionandfertilization.

21

Page 22

AfterOperation

g017303

1 2

3

AfterOperationSafety

GeneralSafety

•Cleangrassanddebrisfromthecuttingunits,mufers,

andenginecompartmenttohelppreventres.Cleanup

oilorfuelspills.

•Shutoffthefuelbeforestoringortransportingthe

machine.

•Disengagethedrivetotheattachmentwheneveryouare

transportingornotusingthemachine.

•Usefull-widthrampsforloadingthemachineintoa

trailerortruck.

Note:Donotstartthemachine.

Note:Youcannowpushthemachinebyhand.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

•Allowtheenginetocoolbeforestoringthemachinein

anyenclosure.

•Shutoffthefuelbeforestoringortransportingthe

machine.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlight,suchasonawater

heateroronotherappliances.

PushingtheMachinebyHand

Important:Alwayspushthemachinebyhand.Donot

towthemachine,becausedamagetothehydraulicdrive

systemmayoccur.

Thismachinehasanelectric-brakemechanism.Topushthe

machine,turntheignitionkeytotheRUNposition.The

batterymustbechargedandfunctioningtodisengagethe

electricbrake.

PushingtheMachine

Figure24

1.Bypass-leverlocations

2.Leverpositionfor

operatingthemachine

6.Whennished,turnthekeytotheSTOPpositionto

avoiddrainingthebatterycharge.

Note:Ifthemachinefailstomove,theelectricbrake

maystillbeengaged.Youcanreleasetheelectricbrakeif

necessary;refertoReleasingtheElectricBrake(page35).

3.Leverpositionforpushing

themachine

OperatingtheMachine

Movethebypassleversrearwardthroughthekeyholeand

downtolocktheminplaceasshowninFigure24.

Note:Dothisforeachlever.

g017303

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothePARK

position,shutofftheengine,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Locatethebypassleversontheframeonbothsidesof

theengine.

4.Movethebypassleversforwardthroughthekeyhole

anddowntolocktheminplace(Figure24).

Note:Dothisforeachlever.

5.Movethemotion-controlleversinwardtothe

NEUTRALpositionandturntheignitionkeytothe

RUNposition.

22

Page 23

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthemachine.

Ensurethatthetrailerortruckhasallnecessarybrakes,

lighting,andmarkingasrequiredbylaw .Pleasecarefullyread

allthesafetyinstructions.Knowingthisinformationcould

helpyou,yourfamily,pets,orbystandersavoidinjury.

WARNING

Drivingonthestreetorroadwaywithout

turnsignals,lights,reectivemarkings,ora

slow-moving-vehicleemblemisdangerousandcan

leadtoaccidents,causingpersonalinjury.

Donotdrivethemachineonapublicstreetor

roadway.

1.Ifyouareusingatrailer,connectittothetowing

vehicleandconnectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Loadthemachineontothetrailerortruck.

4.Shutofftheengine,removethekey,setthebrake,and

closethefuelvalve.

5.Tiedownthemachinenearthefrontcasterwheelsand

therearbumper(Figure25).

Figure25

g027708

23

Page 24

LoadingtheMachine

g027996

5

1

2

6

Useextremecautionwhenloadingorunloadingmachines

ontoatraileroratruck.Useafull-widthrampthatiswider

thanthemachineforthisprocedure.Backuptherampand

driveforwarddowntheramp(Figure26).

Figure26

g027995

1.Backthemachineupthe

ramp.

2.Drivethemachineforward

downtheramp.

Important:Donotusenarrowindividualrampsfor

eachsideofthemachine.

WARNING

Loadingamachineontoatrailerortruckincreases

thepossibilityoftip-overandcouldcauseserious

injuryordeath(Figure27).

•Useextremecautionwhenoperatingamachine

onaramp.

•Useonlyafull-widthramp;donotuseindividual

rampsforeachsideofthemachine.

•Donotexceeda15-degreeanglebetweenthe

rampandthegroundorbetweentherampand

thetrailerortruck.

•Ensurethatthelengthoframpisatleast4times

aslongastheheightofthetrailerortruckbed

totheground.Thisensuresthattherampangle

doesnotexceed15degreesonatground.

1.Full-widthrampinstowed

position

2.Sideviewoffull-width

rampinloadingposition

3.Notgreaterthan

15degrees

g027996

Figure27

4.Rampisatleast4times

aslongastheheightof

thetrailerortruckbedto

theground

5.H=heightofthetraileror

truckbedtotheground

6.Trailer

•Backuprampsanddriveforwarddownramps.

•Avoidsuddenaccelerationordecelerationwhile

drivingthemachineonarampasthiscould

causealossofcontroloratip-oversituation.

24

Page 25

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Beforeeachuseordaily

Aftereachuse

Every25hours

Every50hours

Every100hours

Every200hours

Beforestorage

MaintenanceProcedure

•Changetheengineoilandlter.

•Checkthesafety-interlocksystem.

•Cleanandchecktheaircleanerfoamelement.

•Checktheengine-oillevel.

•Inspecttheblades.

•Inspectthegrassdeectorfordamage.

•Cleanthemower-deckhousing.

•Greasealllubricationpoints.

•Checktirepressure.

•Checkthebeltsforwearorcracks.

•Replacetheaircleanerpaperelement.

•Checkthesparkplug.

•Changetheengineoil(changeitmoreoftenunderaheavyloadorinhigh

temperatures).

•Changetheengine-oillter.

•Replacethesparkplug.

•Cleantheblowerhousing(moreoftenunderextremelydusty,dirtyconditions).

•Checkthein-linefuellter.

•Replacethein-linefuellter.

•Chargethebatteryanddisconnectthebatterycables.

•Performallmaintenanceprocedureslistedabovebeforestorage.

•Paintanychippedsurfaces.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

Pre-Maintenance

Procedures

MaintenanceandStorage Safety

•Beforerepairingthemachinedothefollowing:

–Disengagethedrives.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey .

–Disconnectthespark-plugwire.

•Parkthemachineonalevelsurface.

•Cleangrassanddebrisfromthecuttingunit,drives,

mufers,andenginetohelppreventres.

•Cleanupoilorfuelspills.

•Lettheenginecoolbeforestoringthemachine.

•Donotstorethemachineorfuelnearamesordrain

thefuelindoors.

•Donotallowuntrainedpersonneltoservicethemachine.

•Usejackstandstosupportthemachineand/or

componentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatteryorremovethespark-plugwire

beforemakinganyrepairs.Disconnectthenegative

25

Page 26

terminalrstandthepositiveterminallast.Connectthe

positiveterminalrstandnegativelast.

•Usecarewhencheckingtheblades.Wraptheblade(s)

orwearthicklypaddedgloves,andusecautionwhen

servicingthem.Onlyreplaceblades;donotstraighten

orweldthem.

•Keepyourhandsandfeetawayfrommovingparts.

Ifpossible,donotmakeadjustmentswiththeengine

running.

•Keepallpartsingoodworkingconditionandallhardware

tightened,especiallytheblade-attachmentbolts.Replace

allwornordamageddecals.

•Neverinterferewiththeintendedfunctionofasafety

deviceorreducetheprotectionprovidedbyasafety

device.Checktheirproperoperationregularly.

•Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacementparts

andaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty.

•Checktheparkingbrakeoperationfrequently.Adjustand

serviceasrequired.

Lubrication

GreasingtheBearings

ServiceInterval:Every25hours—Greasealllubrication

points.

GreaseType:No.2lithiumgrease

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothePARK

position,shutofftheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanthegreasettings(Figure28andFigure29)with

arag.

Note:Makesuretoscrapeanypaintoffthefrontof

thetting(s).

RaisingtheSeat

Makesurethatthemotion-controlleversarelockedinthe

PARKposition.Lifttheseatforward.

Youcanaccessthefollowingcomponentsbyraisingtheseat:

•Serialplate

•Servicedecal

•Seat-adjustmentbolts

•Fuellter

•Batteryandbatterycables

g032432

Figure28

1.Frontcastertire

decal106-8717

Figure29

Locatedontheseat-panunderside

1.Readtheinstructionsbeforeservicingorperforming

maintenance.

2.Checkthetirepressureevery25operatinghours.

3.Greaseevery25operatinghours.

4.Engine

4.Connectagreaseguntoeachtting(Figure28and

Figure29).

5.Pumpgreaseintothettingsuntilgreasebeginsto

oozeoutofthebearings.

26

Page 27

EngineMaintenance

G017862

EngineSafety

Shutofftheenginebeforecheckingtheoiloraddingoilto

thecrankcase.

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Cleanandcheck

theaircleanerfoamelement.

Every50hours—Replacetheaircleanerpaper

element.

Note:Servicetheaircleanermorefrequently(everyfew

hours)ifoperatingconditionsareextremelydustyorsandy.

RemovingtheFoamandPaper

Elements

g015016

Figure31

1.Foamelement2.Paperelement

5.Separatethefoamandpaperelements.

CleaningtheFoamandPaperElements

1.Parkthemachineonalevelsurface,disengagethe

blade-controlswitch(PTO),engagetheparkingbrake,

shutofftheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

2.Cleanaroundtheaircleanertopreventdirtfrom

gettingintotheengineandcausingdamage.

3.Removetheair-cleanercoverbyunscrewingthe2

knobs(Figure30).

Figure30

1.Air-cleanercover2.Knobs

FoamElement:

1.Washthefoamelementinliquidsoapandwarmwater.

2.Whentheelementisclean,rinseitthoroughly.

3.Drytheelementbysqueezingitinacleancloth.

Note:Donotoiltheelement.

Important:Replacethefoamelementifitistorn

orworn.

4.Installthefoamelementontoacleanpaperelement.

PaperElement:

1.Tapthepaperelementonasolid,atsurface,andblow

itoutfromtheinsidewithcompressedairtoremove

dustanddirt.

2.Inspecttheelementfortears,anoilylm,anddamage

totherubberseal.

Important:Donotcleanthepaperelementwith

liquids,suchassolvents,gasoline,orkerosene.

Replacethepaperelementifitisdamagedor

g017862

cannotbecleanedthoroughly.

3.Cleantheinsideoftheair-cleanercoverofalldirt,dust,

anddebris.

4.Carefullyremovethefoamandpaperlterelements

fromtheair-cleanerhousing(Figure31).

27

Page 28

InstallingtheFoamandPaperElements

SAE 5W -30, 10W -30

SAE 30

SYNTHETIC 5W -20, 5W -30, 10W -30

g029683

Important:Topreventenginedamage,alwaysoperate

theenginewiththecompletefoamandpaperaircleaner

assemblyinstalled.

1.Installthefoamlterontothepaperlter(Figure31).

2.Installthefoamandpaperlterontotheair-cleaner

housing.

3.Installtheair-cleanercover,andtightenthe2knobs

(Figure30).

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSF ,SG,SH,SJ,or

higher)

CrankcaseCapacity:withlter—1.4L(1.5USqt)

Viscosity:Seethetablebelow.

3.Tokeepdirt,grassclippings,etc.,outoftheengine,

cleantheareaaroundtheoil-llcapanddipstickbefore

removingit(Figure33).

Figure32

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothing,andotherbody

partsawaythemuferandotherhotsurfaces.

Important:Donotoverllthecrankcasewithoil,

becausedamagetotheenginemayresult.Donotrun

enginewithoilbelowtheLowmark,becausetheengine

maybedamaged.

1.Parkthemachineonalevelsurface,disengagethe

blade-controlswitch,shutofftheengine,engagethe

parkingbrake,andremovethekey.

2.Makesurethattheengineisshutoff,level,andiscool,

sotheoilhashadtimetodrainintothesump.

g029683

g193541

Figure33

ChangingtheEngineOilandFilter

ServiceInterval:Aftertherst5hours

Every100hours(changeitmoreoftenunderaheavy

loadorinhightemperatures).

Every100hours

Note:Changetheengine-oilltermorefrequentlywhenthe

operatingconditionsareextremelydustyorsandy.

1.Parkthemachine,sothattherightsideisslightly

lowerthantheleftside,toensurethattheoildrains

completely.

2.DisengagethePTOandengagetheparkingbrake.

3.Shutofftheengine,waitforallmovingpartstostop,

andremovethekeybeforeleavingtheoperating

position.

4.Draintheoilfromtheengine.

28

Page 29

B

A

C

E F

D

G

H

g029369

B

A

C D

E

F

3/4

g027477

g027477

Figure35

6.Slowlypourapproximately80%ofthespeciedoil

intothellertubeandslowlyaddtheadditionaloilto

bringittotheFullmark(Figure36).

5.Changetheengine-oillter.

Note:Ensuretheoil-ltergaskettouchestheengine,

andthenturnthelteranextra3/4turn.

Figure34

g029369

29

Page 30

Figure36

B

A

g027478

B

A

g027479

ServicingtheSparkPlug

g027478

Figure37

CheckingtheSparkPlug

Important:Donotcleanthesparkplug(s).Always

replacethesparkplug(s)whenithas:ablackcoating,

wornelectrodes,anoilylm,orcracks.

Note:Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingontheinsulator

usuallymeanstheaircleanerisdirty.

Setthegapto0.76mm(0.030inch).

g193530

ServiceInterval:Every50hours—Checkthesparkplug.

Every100hours—Replacethesparkplug.

Ensurethattheairgapbetweenthecenterandsideelectrodes

iscorrectbeforeinstallingthesparkplug.Useasparkplug

wrenchforremovingandinstallingthesparkpluganda

gappingtoolorfeelergaugetocheckandadjusttheairgap.

Installanewsparkplugifnecessary.

Type:Champion

BCPR6ES

AirGap:0.76mm(0.03inch)

®

RC12YC,Autolite

®

3924,orNGK

®

RemovingtheSparkPlug

1.Disengagetheblade-controlswitch,engagetheparking

brake,shutofftheengine,andremovethekey.

2.Beforeremovingthesparkplug(s),cleanthearea

aroundthebaseoftheplugtokeepdirtanddebrisout

oftheengine.

3.Removethesparkplug(Figure37).

g027479

Figure38

InstallingtheSparkPlug

Tightenthesparkplugto20N∙m(15ft-lb).

30

Page 31

FuelSystem

Maintenance

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyou,others,andcandamageproperty.

•Performanyfuel-relatedmaintenancewhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanyfuelthatspills.

•Neversmokewhendrainingfuel,andstayaway

fromanopenameorwhereasparkmayignite

thefuelfumes.

Figure39

CleaningtheBlowerHousing

ServiceInterval:Every100hours/Yearly(whichevercomes

rst)

Toensurepropercooling,makesurethatthegrassscreen,

coolingns,andotherexternalsurfacesoftheengineare

keptcleanatalltimes.

Cleanthecoolingnsandexternalsurfacesasnecessary.

Makesurethatthecoolingshroudsareinstalled.Torquethe

blowerhousingscrewsto7.5N·m(5.5ft-lb).

Important:Operatingtheenginewithablocked

grassscreen,dirtyorpluggedcoolingns,and/or

coolingshroudsremoved,causesenginedamagedue

tooverheating.

g027480

ReplacingtheIn-LineFuel Filter

ServiceInterval:Every100hours/Yearly(whichevercomes

rst)—Checkthein-linefuellter.

Every200hours/Every2years(whichevercomes

rst)—Replacethein-linefuellter.

Neverinstalladirtylterifitisremovedfromthefuelline.

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Ensurethatthebrakeisengaged,shutofftheengine,

removethekey ,andwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

31

Page 32

g027590

ElectricalSystem

Maintenance

g027590

ElectricalSystemSafety

•Disconnectthebatterybeforerepairingthemachine.

Disconnectthenegativeterminalrstandthepositive

last.Connectthepositiveterminalrstandthenegative

last.

•Chargethebatteryinanopen,well-ventilatedarea,away

fromsparksandames.Unplugthechargerbefore

connectingordisconnectingthebattery.Wearprotective

clothinganduseinsulatedtools.

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

ServicingtheBattery

Figure40

RemovingtheBattery

g033082

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothePARK

position,shutofftheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Raisetheseattoaccessthebattery.

4.Disconnectthenegative(black)groundcablefromthe

batterypost(Figure41).

Note:Retainallfasteners.

32

Page 33

WARNING

G005072

1

2

3

4

5

6

7

Incorrectbattery-cableroutingcoulddamage

themachineandcablescausingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

3.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthecharger

leadsfromthebatteryposts(Figure42).

5.Slidetherubbercoverupthepositive(red)cable.

6.Disconnectthepositive(red)cablefromthebattery

post(Figure41).

Note:Retainallfasteners.

7.Removethebatteryhold-down(Figure41),andliftthe

batteryfromthebatterytray .

g000538

Figure42

1.Positive(+)batterypost3.Red(+)chargerlead

2.Negative(–)batterypost4.Black(–)chargerlead

InstallingtheBattery

1.Positionthebatteryinthetray(Figure41).

2.Usingthefastenerspreviouslyremoved,installthe

positive(red)batterycabletothepositive(+)battery

terminal.

3.Usingthefastenerspreviouslyremoved,installthe

negativebatterycabletothenegative(-)battery

terminal.

4.Slidetheredterminalbootontothepositive(red)

batterypost.

5.Securethebatterywiththehold-down(Figure41).

6.Lowertheseat.

Figure41

1.Battery

2.Positive(+)batterypost

3.Bolt,washer,andnut7.Batteryhold-down

4.Terminalboot

5.Negative(–)batterypost

6.Wingnut,washer,andbolt

ChargingtheBattery

ServiceInterval:Beforestorage—Chargethebatteryand

disconnectthebatterycables.

1.Removethebatteryfromthechassis;refertoRemoving

theBattery(page32).

2.Chargethebatteryforaminimumof1hourat6to

10A.

Note:Donotoverchargethebattery.

g005072

33

Page 34

ServicingtheFuses

30

25

30

25

G014540

2

1

DriveSystem

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;however,ifafuseblows,checkthe

component/circuitforamalfunctionorshort.

Fusetype:

•Main—F1(30A,blade-type)

•ChargeCircuit—F2(25A,blade-type)

1.Removethescrewssecuringthecontrolpaneltothe

machine.

Note:Retainallfasteners.

2.Liftthecontrolpaneuptoaccessthemainwireharness

andfuseblock(Figure43).

3.Toreplaceafuse,pulloutonthefusetoremoveit

(Figure43).

Maintenance

CheckingtheTirePressure

ServiceInterval:Every25hours—Checktirepressure.

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseunevencut.Check

thepressureatthevalvestem(Figure44).Checkthetires

whentheyarecoldtogetthemostaccuratepressurereading.

Refertothemaximumpressuresuggestedbythetire

manufactureronthesidewallofthecasterwheeltires.

Inatethereardrivewheeltiresto90kPa(13psi).

g000554

Figure44

Figure43

1.Main(30A)2.Chargecircuit(25A)

4.Returnthecontrolpaneltoitsoriginalposition.

Note:Usethescrewsremovedpreviouslytosecure

thepaneltothemachine.

1.Valvestem

g014540

34

Page 35

ReleasingtheElectricBrake

Youcanmanuallyreleasetheelectricbrakebyrotatingthe

linkarmsforward.Oncetheelectricbrakeisenergized,the

brakeresets.

1.TurntheignitionkeytotheOFFpositionordisconnect

thebattery.

2.Locatetheshaftontheelectricbrakewherethebrake

linkarmsareconnected(Figure45).

MowerMaintenance

ServicingtheCuttingBlades

Toensureasuperiorqualityofcut,keepthebladessharp.For

convenientsharpeningandreplacement,keepextrablades

onhand.

BladeSafety

3.Rotatetheshaftforwardtoreleasethebrake.

Figure45

1.Brake-linkarmontheelectricbrakecontrolmodule

2.Left,reartire

Awornordamagedbladecanbreak,andapieceoftheblade

couldbethrowntowardyouorbystanders,resultinginserious

personalinjuryordeath.Tryingtorepairadamagedblade

mayresultindiscontinuedsafetycerticationoftheproduct.

•Inspectthebladesperiodicallyforwearordamage.

•Usecarewhencheckingtheblades.Wrapthebladesor

weargloves,andusecautionwhenservicingtheblades.

Onlyreplaceorsharpentheblades;neverstraightenor

weldthem.

•Onmulti-bladedmachines,takecareasrotating1blade

cancauseotherbladestorotate.

BeforeInspectingorServicingthe

g027911

Blades

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andmovethe

motion-controlleversoutwardtothePARKposition.

2.Shutofftheengine,removethekey,anddisconnectthe

spark-plugwiresfromthesparkplugs.

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily

1.Inspectthecuttingedges(Figure46).

2.Iftheedgesarenotsharporhavenicks,removeand

sharpentheblade;refertoSharpeningtheBlades(page

37).

3.Inspecttheblades,especiallyinthecurvedarea.

4.Ifyounoticeanycracks,wear,oraslotforminginthis

area,immediatelyinstallanewblade(Figure46).

Figure46

1.Cuttingedge3.Wear/slotforming

2.Curvedarea4.Crack

35

g006530

Page 36

CheckingforBentBlades

G009679

1

2

3

G009680

1

2

3

G009681

1

2

3

G009680

1

2

3

Note:Themachinemustbeonalevelsurfaceforthe

followingprocedure.

1.Raisethemowerdecktothehighestheight-of-cut

position.

2.Whilewearingthicklypaddedgloves,orotheradequate

handprotection,slowlyrotatethebladetobemeasure

intoapositionthatallowseffectivemeasurementofthe

distancebetweenthecuttingedgeandthelevelsurface

themachineison(Figure47).

Figure47

1.Deck3.Blade

2.Spindlehousing

g009681

Figure49

1.Blade(sidepreviouslymeasured)

2.Measurement(positionusedpreviously)

3.Opposingsideofbladebeingmovedintomeasurement

position

5.Measurefromthetipofthebladetotheatsurface

(Figure50).

Note:Thevarianceshouldbenomorethan3mm

g009679

(1/8inch).

3.Measurefromthetipofthebladetotheatsurface

(Figure48).

Figure48

1.Blade(inpositionformeasuring)

2.Levelsurface

3.Measureddistancebetweenbladeandthesurface(A)

4.Rotatethesameblade180degreessothattheopposing

cuttingedgeisnowinthesameposition(Figure49).

g009680

Figure50

1.Oppositebladeedge(inpositionformeasuring)

2.Levelsurface

3.Secondmeasureddistancebetweenbladeandsurface(B)

g009680

A.IfthedifferencebetweenAandBisgreaterthan

3mm(1/8inch),replacethebladewithanew

blade;refertoRemovingtheBlades(page37)and

InstallingtheBlades(page37).

Note:Ifabentbladeisreplacedwithanew

blade,andthedimensionobtainedcontinuesto

exceed3mm(1/8inch),thebladespindlecould

bebent.ContactanAuthorizedToroDealerfor

service.

B.Ifthevarianceiswithinconstraints,movetothe

nextblade.

6.Repeatthisprocedureoneachblade.

36

Page 37

RemovingtheBlades

G027833

Thebladesmustbereplacedifasolidobjectishit,iftheblade

isoutofbalance,orifthebladeisbent.Forbestperformance

andcontinuedsafetyconformanceofthemachine,use

genuineT ororeplacementblades.Replacementbladesmade

byothermanufacturersmayresultinnon-conformancewith

safetystandards.

1.Holdthebladeendusingaragorthickly-paddedglove.

2.Removethebladestiffener(32-inchdecksonly),blade

bolt,thecurvedwasher,andthebladefromthespindle

shaft(Figure51andFigure52).

Note:Thebladeretainsitsbalanceifthesameamount

ofmaterialisremovedfrombothcuttingedges.

g000552

Figure53

1.Sharpenatoriginalangle.

2.Checkthebalanceofthebladebyputtingitonablade

balancer(Figure54).

Note:Ifthebladestaysinahorizontalposition,the

bladeisbalancedandcanbeused.

Note:Ifthebladeisnotbalanced,lesomemetaloff

theendofthesailareaonly(Figure53).

Figure51

81cm(32-Inch)Decks

1.Sailareaoftheblade

2.Blade

3.Curvedwasher

107cm(42-Inch)Decks

1.Sailareaoftheblade3.Curvedwasher

2.Blade4.Bladebolt

4.Bladebolt

5.Bladestiffener

Figure52

g000551

Figure54

1.Blade2.Balancer

g000553

3.Repeatthisprocedureuntilthebladeisbalanced.

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure52).

Important:Thecurvedpartoftheblademustbe

pointingupwardtowardtheinsideofthemowerto

ensurepropercutting.

2.Installthebladestiffener(32-inchdecksonly),curved

washer(cuppedsidetowardtheblade),andbladebolt

(Figure52).

3.Torquethebladeboltto47to88N∙m(35to65ft-lb).

LevelingtheMowerDeck

g027833

Checktoensurethatthemowerdeckislevelanytimeyou

installthemowerorwhenyouseeanunevencutonyour

lawn.

Themowerdeckmustbecheckedforbentbladespriorto

leveling;anybentbladesmustberemovedandreplaced;refer

totheCheckingforBentBlades(page36)beforecontinuing.

SharpeningtheBlades

1.Usealetosharpenthecuttingedgeatbothendsof

theblade(Figure53).

Note:Maintaintheoriginalangle.

Themowerdeckmustbeleveledside-to-siderstthenthe

fronttorearslopecanbeadjusted.

Requirements:

•Themachinemustbeonalevelsurface.

•Alltiresmustbeproperlyinated;refertoCheckingthe

TirePressure(page34).

37

Page 38

LevelingfromSidetoSide

G014630

1

2

3

4

4

G009682

1

2

2

3

3

4

4

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothePARK

position,shutofftheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Settheheight-of-cutlevertothemiddleposition.

4.Carefullyrotatetheblade(s)sothattheyareallsideto

side(Figure55andFigure56).

Note:Ifbothmeasurementsarenotwithin5mm

(3/16inch),anadjustmentisrequired;continuewith

thisprocedure.

6.Movetotheleftsideofthemachine.

7.Loosenthesidelockingnut.

8.Raiseorlowertheleftsideofthemowerdeckby

rotatingtherearnut(Figure57).

Note:Rotatetherearnutclockwisetoraisethemower

deck;rotatetherearnutcounter-clockwisetolowerthe

mowerdeck(Figure57).

g014630

Figure55

MowerDeckswith1Blade

1.Bladesidetoside

2.Sailareaoftheblade4.Measurefromthetipofthe

3.Outsidecuttingedges

bladetotheatsurface

here.

Figure57

1.Hangerbracket3.Rearlockingnut

2.Sidelockingnut

g027588

9.Checktheside-to-sideadjustmentsagain;repeatthis

procedureuntilthemeasurementsarecorrect.

10.Continuelevelingthedeckbycheckingthefront-to-rear

bladeslope;refertoAdjustingtheFront-to-RearBlade

Slope(page38).

AdjustingtheFront-to-RearBlade

Slope

Checkthefront-to-rearbladelevelanytimeyouinstallthe

mower.Ifthefrontofthemowerismorethan7.9mm

g009682

Figure56

MowerDeckswith2Blades

1.Bladessidetoside

2.Sailareaofblade4.Measurefromthetipofthe

3.Outsidecuttingedges

bladetotheatsurface

here.

5.Measurebetweentheoutsidecuttingedgesandtheat

surface(Figure55andFigure56).

(5/16inch)lowerthantherearofthemower,adjusttheblade

levelusingthefollowinginstructions:

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothePARK

position,shutofftheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Settheheight-of-cutlevertomiddleposition.

38

Page 39

Note:Checkandadjusttheside-to-sidebladelevel

G014631

1

2

2

G009658

1

2

2

G014634

1

2

3

ifyouhavenotcheckedthesetting;refertoLeveling

fromSidetoSide(page38).

4.Carefullyrotatethebladessotheyarefacingfrontto

rear(Figure58andFigure59).

Figure58

MowerDeckswith1Blade

1.Bladefronttorear

2.Measurefromthetipofthebladetotheatsurfacehere.

g014634

Figure60

1.Adjustingrod3.Locknut

2.Adjustingblock

g014631

7.Toraisethefrontofthemower,tightentheadjustment

nut.

8.Tolowerthefrontofthemower,loosentheadjustment

nut.

Figure59

MowerDeckswith2Blades

1.Bladesfronttorear

2.Measurefromthetipofthebladetotheatsurfacehere.

5.Measurefromthetipofthefrontbladetotheat

surface,andthetipoftherearbladetotheatsurface

(Figure58andFigure59).

Note:Ifthefrontbladetipisnot1.6to7.9mm(1/16

to5/16inch)lowerthantherearbladetip,adjustthe

frontlocknut.

6.Toadjustthefront-to-rearbladeslope,rotatethe

adjustmentnutinthefrontofthemower(Figure60).

9.Afteradjustment,checkthefront-to-rearslopeagain,

continueadjustingthenutuntilthefrontbladetipis

1.6to7.9mm(1/16to5/16inch)lowerthantherear

bladetip(Figure59andFigure60).

10.Whenthefront-to-rearbladeslopeiscorrectcheckthe

side-to-sidelevelofthemoweragain,refertoLeveling

fromSidetoSide(page38).

RemovingtheMowerDeck

g009658

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothePARK

position,shutofftheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Lowertheheight-of-cutlevertothelowestposition.

4.Removethehairpin-cotterpinfromthefrontsupport

rod,andremovetherodfromthedeckbracket(Figure

61).

39

Page 40

G014635

1

2

3

Figure61

G015338

2

2

3

1

2

2

3

1.Frontsupportrod3.Deckbracket

2.Lockingnut

8.Slidethemowerdeckoutfromunderneaththe

machine.

Note:Retainallpartsforfutureinstallation.

InstallingtheMowerDeck

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothePARK

position,shutofftheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Slidethemowerunderthemachine.

4.Lowertheheight-of-cutlevertothelowestposition.

5.Lifttherearofthemowerdeckandguidethehanger

bracketsovertherearliftrod(Figure62).

6.Attachthefrontsupportrodtothemowerdeckwith

g014635

theclevispinandhairpin-cotterpin(Figure61).

7.Installthemowerbeltontotheenginepulley;referto

ReplacingtheMowerBelt(page42).

5.Carefullylowerthefrontofthemowerdecktothe

ground.

6.Liftthemowerdeckandhangerbracketsclearof

therearliftrodandlowerthemowercarefullytothe

ground(Figure62).

Figure62

ReplacingtheGrassDeector

ServiceInterval:Beforeeachuseordaily—Inspectthegrass

deectorfordamage.

WARNING

Anuncovereddischargeopeningcouldallowthe

lawnmowertothrowobjectsatyouorbystanders,

resultinginseriousinjury.Also,contactwiththe

bladecouldoccur.Neveroperatethemachine

withoutthegrassdeector,thedischargecover,or

thegrass-collectionsysteminplace.

Neveroperatethemachinewithoutthegrass

deector,thedischargecover,orthegrass-collection

systeminplace.

1.Removethenut(3/8inch)fromtherodunderthe

mower(Figure63andFigure64).

g015338

1.Mowerdeck

2.Hangerbracket

7.Slidethemowerdeckrearwardtoremovethemower

beltfromtheenginepulley.

3.Rearliftrod

40

Page 41

G014636

1

2

3

4

5

6

7

Figure63

G005192

1

2

3

4

5

6

7

81cm(32-Inch)Deck

6.Placethespringontherod,withtheendwiresdown,

andbetweenthegrassdeectorbrackets.

7.Slidetherodthroughsecondgrassdeectorbracket

(Figure63andFigure64).

8.Inserttherodatthefrontofthegrassdeectorinto

theshortstandoffonthedeck.

9.Securetherearendoftherodintothemowerwitha

nut(3/8inch)asshowninFigure63andFigure64.

Important:Thegrassdeectormustbespring

loadedinthedownposition.Liftthedeectorup

totestthatitsnapstothefulldownposition.

g014636

1.Mowerdeck

2.Grassdeector6.Nut(3/8inch)

3.Grass-deectorbracket7.Shortstandoff

4.Rod

107cm(42-Inch)Deck

5.Spring

Figure64

g005192

1.Mowerdeck

2.Grassdeector6.Nut(3/8inch)

3.Grass-deectorbracket7.Shortstandoff

4.Rod

2.Slidetherodoutoftheshortstand-off,spring,and

grassdeector(Figure63andFigure64).

3.Removethedamagedorworngrassdeector.

5.Spring

4.Replacethegrassdeector(Figure63andFigure64).

5.Slidetherod(straightend),throughthe

rear-grass-deectorbracket.

41

Page 42

MowerBeltMaintenance

G015129

1

2

3

4

5

4

6

G014930

1

2

3

3

4

5

1

2

3

3

4

5

6

4

InspectingtheBelts

ServiceInterval:Every25hours—Checkthebeltsforwear

orcracks.

Checkthebeltsforcracks,frayededges,burnmarks,orany

otherdamage.Replacedamagedbelts.

ReplacingtheMowerBelt

Squealingwhenthebeltisrotating,bladesslippingwhen

cuttinggrass,frayedbeltedges,burnmarks,andcracksare

signsofawornmowerbelt.Replacethemowerbeltifanyof

theseconditionsareevident.

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothePARK

position,shutofftheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Settheheightofcutatthelowestcuttingposition(38

mm(1-1/2inches).

4.Removethepulleycovers(Figure65).

Figure66

MowerDeckswith1Blade

1.Idlerpulley

2.Mowerbelt5.Enginepulley

3.Outsidepulley6.Spring-removaltool

4.Spring

g015129

Figure65

Modelwith107cm(42-inch)DeckOnly

1.Cover2.Screw

5.Usingaspring-removaltool(ToroPartNo.92-5771),

removetheidlerspringfromthedeckhooktoremove

tensionontheidlerpulley,androllthebeltoffofthe

pulleys(Figure66andFigure67).