Page 1

FormNo.3394-169RevC

TimeCutter

®

SS3225Riding

Mower

ModelNo.74710—SerialNo.315000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3394-169*C

Page 2

Important:Thisengineisnotequippedwithaspark

G014523

1

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

ThissparkignitionsystemcomplieswithCanadianICES-002

Introduction

Thismachineisaride-on,rotary-bladelawnmowerintended

tobeusedbyhomeownersinresidentialapplications.Itis

primarilydesignedforcuttinggrassonwell-maintainedlawns.

Itisnotdesignedforcuttingbrush,mowinggrassandother

growthalongsidehighways,orforagriculturaluses.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orotherreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

GrossHorsepower

Thegrossornethorsepowerofthisenginewaslaboratory

ratedbytheenginemanufacturerinaccordancewiththe

SocietyofAutomotiveEngineers(SAE)J1940.Ascongured

tomeetsafety,emission,andoperatingrequirements,

theactualenginetorqueonthisclassofmowerwillbe

signicantlylower.

Gotowww .Toro.comtoviewspecicationsonyourmower

model.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationmaterials,accessoryinformation,help

ndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

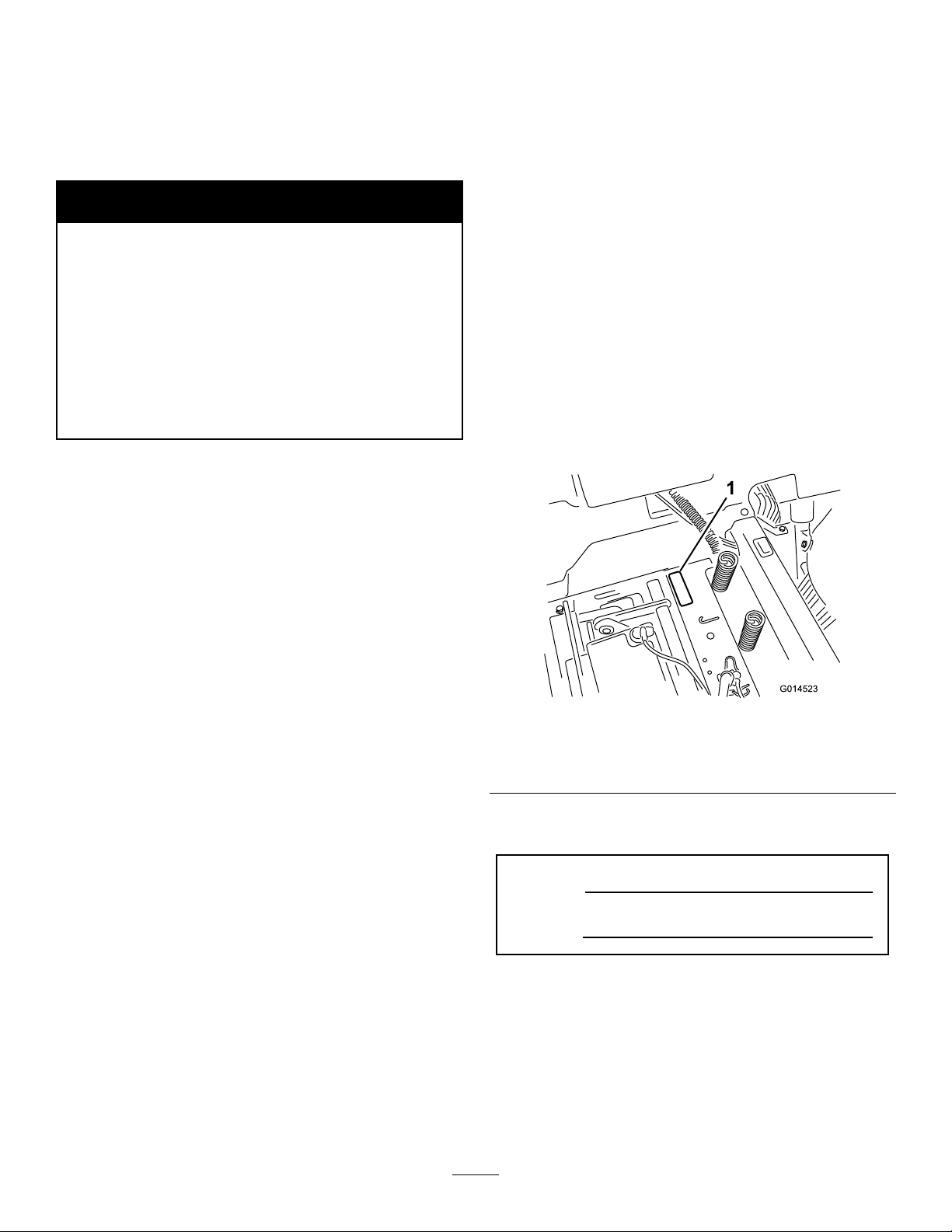

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

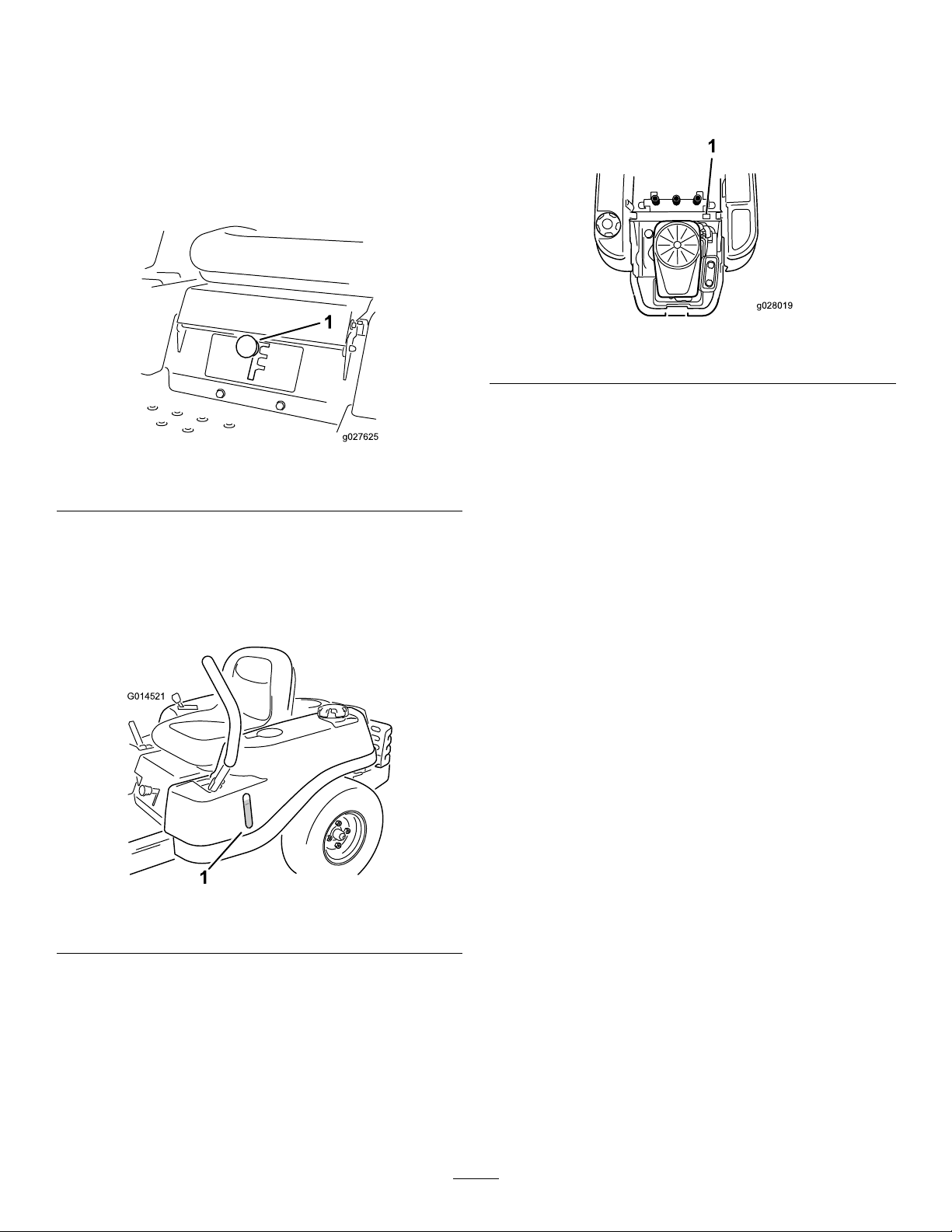

Figure1

Undertheseat

1.Modelandserialnumberplate

Writetheproductmodelandserialnumbersinthespace

below:

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Figure2

1.Safetyalertsymbol.

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroRidingMowerSafety........................................6

SlopeIndicator.......................................................7

SafetyandInstructionalDecals.................................8

ProductOverview.........................................................12

Controls...............................................................12

Operation....................................................................14

AddingFuel...........................................................14

CheckingtheEngine-OilLevel.................................15

BreakinginaNewMachine......................................15

ThinkSafetyFirst...................................................15

StartingtheEngine.................................................16

OperatingtheBlades...............................................17

StoppingtheEngine...............................................17

DrivingtheMachine...............................................17

StoppingtheMachine.............................................19

AdjustingtheHeight-of-Cut....................................20

PositioningtheSeat................................................20

AdjustingtheMotion-ControlLevers........................20

PushingtheMachinebyHand..................................21

TransportingtheMachine........................................21

LoadingtheMachine..............................................22

OperatingTips......................................................24

Maintenance.................................................................25

RecommendedMaintenanceSchedule(s)......................25

PremaintenanceProcedures........................................25

RaisingtheSeat......................................................25

Lubrication...............................................................25

GreasingtheBearings.............................................25

EngineMaintenance..................................................26

ServicingtheAirCleaner.........................................26

ServicingtheEngineOil..........................................27

ChangingtheEngineOilandFilter...........................28

ServicingtheSparkPlug..........................................29

FuelSystemMaintenance...........................................30

ReplacingtheIn-LineFuelFilter...............................30

ElectricalSystemMaintenance....................................31

ChargingtheBattery...............................................31

ServicingtheFuses.................................................33

DriveSystemMaintenance.........................................33

CheckingtheTirePressure......................................33

ReleasingtheElectricBrake.....................................34

CoolingSystemMaintenance......................................34

CleaningtheEngineScreen......................................34

CleaningtheEngine-CoolingFinsand

Shrouds.............................................................34

MowerMaintenance...................................................35

ServicingtheCuttingBlades.....................................35

LevelingtheMowerDeck........................................37

RemovingtheMower..............................................39

InstallingtheMower...............................................40

ReplacingtheGrassDeector..................................40

MowerBeltMaintenance............................................41

ServicingtheMowerBelt.........................................41

Cleaning...................................................................42

WashingtheUndersideoftheMower........................42

Storage........................................................................43

CleaningandStorage..............................................43

Troubleshooting...........................................................44

Schematics...................................................................46

3

Page 4

Safety

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructions,andpayattentionto

thesafetyalertsymbol,whichmeansCaution,Warning,or

Danger—“personalsafetyinstruction.”Failuretocomply

withtheinstructionsmayresultinpersonalinjuryor

death.

SafeOperatingPractices

•Neverleavearunningmachineunattended.Alwaysturn

offblades,setparkingbrake,stopengine,andremovekey

beforedismounting.

•Turnoffbladeswhennotmowing.Stoptheengine,wait

forallpartstocometoacompletestopandremovethe

keybeforecleaningthemachine,removingthegrass

catcheroruncloggingthedischargechute.

•Operatethemachineonlyindaylightorgoodarticial

light.

•Donotoperatethemachinewhileundertheinuence

ofalcoholordrugs.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

ThefollowinginstructionsareadaptedfromANSIstandard

B71.1-2012.AllthelanguagewithinthisANSIstandard

appliestothismachine;however,duetotheapplicationof

thestandardacrossmanydifferenttypesofproductssome

statementscanseemgeneralormisleading.Intheseinstances,

Torohasrenedthestatementtoconveythemeaningofthe

standardwhilebettermatchingtheproductthisOperator's

Manualpertains.Safetyinformationinadditiontothe

instructionsfoundintheANSIstandardbelowcanbefound

inToroRidingMowerSafetyattheendofthissection.

GeneralOperation

•Read,understand,andfollowallinstructionsinthe

operator'smanualandonthemachinebeforestarting.

•Donotplacehandsorfeetnearrotatingpartsorunder

themachine.Keepclearofthedischargeopeningatall

times.

•Allowonlyresponsibleadultswhoarefamiliarwiththe

instructionstooperatethemachine.

•Cleartheareaofobjectssuchasrocks,toys,wire,etc.,

whichcouldbepickedupandthrownbytheblade.

•Besuretheareaisclearofotherpeoplebeforemowing.

Stopthemachineifanyoneentersthearea.

•Watchfortrafcwhenoperatingnearorcrossing

roadways.

•Useextracarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Alwaysweareyeprotectionwhenoperatingthemower.

•Dataindicatesthatoperators,age60yearsandabove,are

involvedinalargepercentageofridingmower-related

injuries.Operatorsshouldevaluatetheirabilitytooperate

theridingmowersafelyenoughtoprotectthemselvesand

othersfromseriousinjury.

•Alwaysfollowtherecommendationsforanyapplication

ofcounterweights.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

SlopeOperation

Slopesareamajorfactorrelatedtolossofcontroland

tip-overaccidents,whichcanresultinsevereinjuryordeath.

Operationonallslopesrequiresextracaution.Ifyoucannot

backuptheslopeorifyoufeeluneasyonit,donotmowit.

•Donotmowslopesgreaterthan15degrees.

•Watchforditches,holes,rocks,dips,andrisesthatchange

theoperatingangle,asroughterraincouldoverturnthe

machine.

•Nevercarrypassengers.

•Donotmowinreverseunlessabsolutelynecessary.

Alwayslookdownandbehindbeforeandwhilebacking

up.

•Beawareofthemowerdischargedirectionanddonot

pointitatanyone.Avoiddischargingmaterialagainsta

wallorobstruction.Materialmayricochetbacktoward

theoperator.Stoptheblade(s)whencrossinggravel

surfaces.

•Donotoperatethemachinewithoutdeector,discharge

coverorentiregrasscollectionsysteminplaceand

working.

•Bealert,slowdownandusecautionwhenmakingturns.

Lookbehindandtothesidebeforechangingdirections.

•Choosealowgroundspeedsoyouwillnothavetostop

whileoperatingonaslope.

•Donotmowslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcauseslidingand

lossofcontrol.

•Alwayskeepthedrivewheelsengagedwhengoingdown

slopes.

•Reducespeedanduseextremecautiononslopes.

•Donotmakesuddenturnsorrapidspeedchanges.

•Removeormarkobstaclessuchasrocks,treelimbs,etc.

fromthemowingarea.Tallgrasscanhideobstacles.

•Avoidsuddenstartswhenmowinguphillbecausethe

mowermaytipbackwards.

4

Page 5

•Beawarethatlossoftractionmayoccurgoingdownhill.

Weighttransfertothefrontwheelsmaycausedrive

wheelstoslipandcauselossofbrakingandsteering.

•Alwaysavoidsuddenstartingorstoppingonaslope.If

tireslosetraction,stopthemachine,disengagetheblades

andproceedslowlyofftheslope.

•Useextremecarewithgrasscatchersorotherattachments.

Thesecanchangethestabilityofthemachineandcause

lossofcontrol.

•Donottrytostabilizethemachinebyputtingyourfoot

ontheground.

•Donotmowneardrop-offs,ditches,steepbanksor

water.Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,deathordrowning.

•Useawalkbehindmowerand/orahandtrimmernear

drop-offs,ditches,steepbanksorwater.

TowingSafety

•Donotattachtowedequipmentexceptatthehitchpoint.

•Followtheattachmentmanufacturer'srecommendation

forweightlimitsfortowedequipmentandtowingon

slopes.Towedweightmustnotexceedtheweightofthe

machine,operator,andballast.Usecounterweightsor

wheelweightsasdescribedintheattachment,orinthe

pullingmachineOperator’sManual.

•Neverallowchildrenorothersinorontowedequipment.

•Onslopes,theweightofthetowedequipmentmaycause

lossoftraction,increasedriskofrollover,andlossof

control.Reducethetowedweightandslowdown.

•Stoppingdistanceincreaseswiththeweightofthetowed

load.Travelslowlyandallowextradistancetostop.

•Makewideturnstokeeptheattachmentclearofthe

machine.

Children

Tragicaccidentscanoccuriftheoperatorisnotalerttothe

presenceofchildren.Childrenareoftenattractedtothe

machineandthemowingactivity.Neverassumethatchildren

willremainwhereyoulastsawthem.

•Keepchildrenoutofthemowingareaandunderthe

watchfulcareofanotherresponsibleadult,notthe

operator.

•Bealertandturnthemachineoffifchildrenenterthe

area.

•Beforeandwhilebackingorchangingdirection,look

behind,down,andside-to-sideforsmallchildren.

•Nevercarrychildren,evenwiththebladesoff.Theymay

falloffandbeseriouslyinjuredorinterferewithsafe

machineoperation.

•Childrenwhohavebeengivenridesinthepastmay

suddenlyappearinthemowingareaforanotherrideand

berunoverorbackedoverbythemower.

•Neverallowchildrentooperatethemachine.

•Useextracarewhenapproachingblindcorners,shrubs,

trees,theendofafenceorotherobjectsthatmayobscure

vision.

Service

SafeHandlingofGasoline:

Toavoidpersonalinjuryorpropertydamage,useextracare

whenhandlinggasolineandotherfuels.Theyareammable

andthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipesandothersources

ofignition.

•Useonlyanapprovedcontainer.

•Neverremovethegascaporaddfuelwhentheengineis

running.Allowtheenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerinsidewhere

thereisanopename,suchasnearawaterheateror

furnace.

•Neverllcontainersinsideavehicleoronatruckor

trailerwithaplasticliner.Alwaysplacecontainersonthe

groundawayfromyourvehiclebeforelling.

•Removegas-poweredequipmentfromthetruckortrailer

andrefuelitontheground.Ifthisisnotpossible,then

refuelsuchequipmentwithaportablecontainer,rather

thanfromagasolinedispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilthefuelingis

complete.Donotuseanozzlelock-opendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllthefueltank.Replacegascapandtighten

securely.

GeneralService:

•Neveroperateamachineinsideaclosedarea.Engine

exhaustcontainscarbonmonoxide,whichisanodorless,

deadlypoisonthatcankillyou.

•Keepnutsandboltstight,especiallythebladeattachment

bolts.Keepequipmentingoodcondition.

5

Page 6

•Neverinterferewiththeintendedfunctionofasafety

deviceortoreducetheprotectionprovidedbyasafety

device.Checktheirproperoperationregularly.

•Keepthemachinefreeofgrass,leaves,orotherdebris

build-up.Cleanupoilorfuelspillagefuelsoakeddebris.

Allowthemachinetocoolbeforestoring.

•Stopandinspecttheequipmentifyoustrikeanobject.

Repair,ifnecessary,beforerestarting.

•Nevermakeanyadjustmentsorrepairswiththeengine

running.

•Grasscatchercomponentsaresubjecttowear,damage

anddeterioration,whichcouldexposemovingpartsor

allowobjectstobethrown.Frequentlycheckcomponents

andreplacewithmanufacturers'recommendedparts,

whennecessary.

•Mowerbladesaresharpandcancut.Wraptheblade(s)or

wearthickly-paddedgloves,anduseextracautionwhen

servicingthem.

•Checkforproperbrakeoperationfrequently .Adjustand

serviceasrequired.

•Maintainorreplacesafetyandinstructiondecalsas

necessary.

•UseonlygenuineTororeplacementpartstoensurethat

originalstandardsaremaintained.

ToroRidingMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

maynotbeincludedintheANSIstandards.

•Stoptheengine,movethemotioncontrolleversto

neutralandoutwardtotheparkposition,disengagethe

bladecontrolswitch,removethekeyanddisconnectthe

sparkplugwire(s)beforeperforminganyservice,repairs,

maintenanceoradjustments.

•Keephands,feet,hair,andlooseclothingawayfrom

attachmentdischargearea,undersideofmowerandany

movingpartswhileengineisrunning.

•Donottouchequipmentorattachmentpartswhichmay

behotfromoperation.Allowtocoolbeforeattempting

tomaintain,adjustorservice.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyes,andclothing.Protectyourface,

eyes,andclothingwhenworkingwithabattery.

•Batterygasescanexplode.Keepcigarettes,sparksand

amesawayfrombattery.

•Ifloadingthemachineontoatrailerortruck,useasingle,

full-widthramponly.Therampangleshouldnotexceed

15degrees.

•Removingstandardoriginalequipmentpartsand

accessoriesmayalterthewarranty,traction,andsafety

ofthemachine.FailuretouseoriginalToropartscould

causeseriousinjuryordeath.Makingunauthorized

changestotheengine,fuelorventingsystem,mayviolate

EPAandCARBregulations.

•Replaceallpartsincluding,butnotlimitedto,tires,belts,

blades,andfuelsystemcomponentswithoriginalToro

parts.

6

Page 7

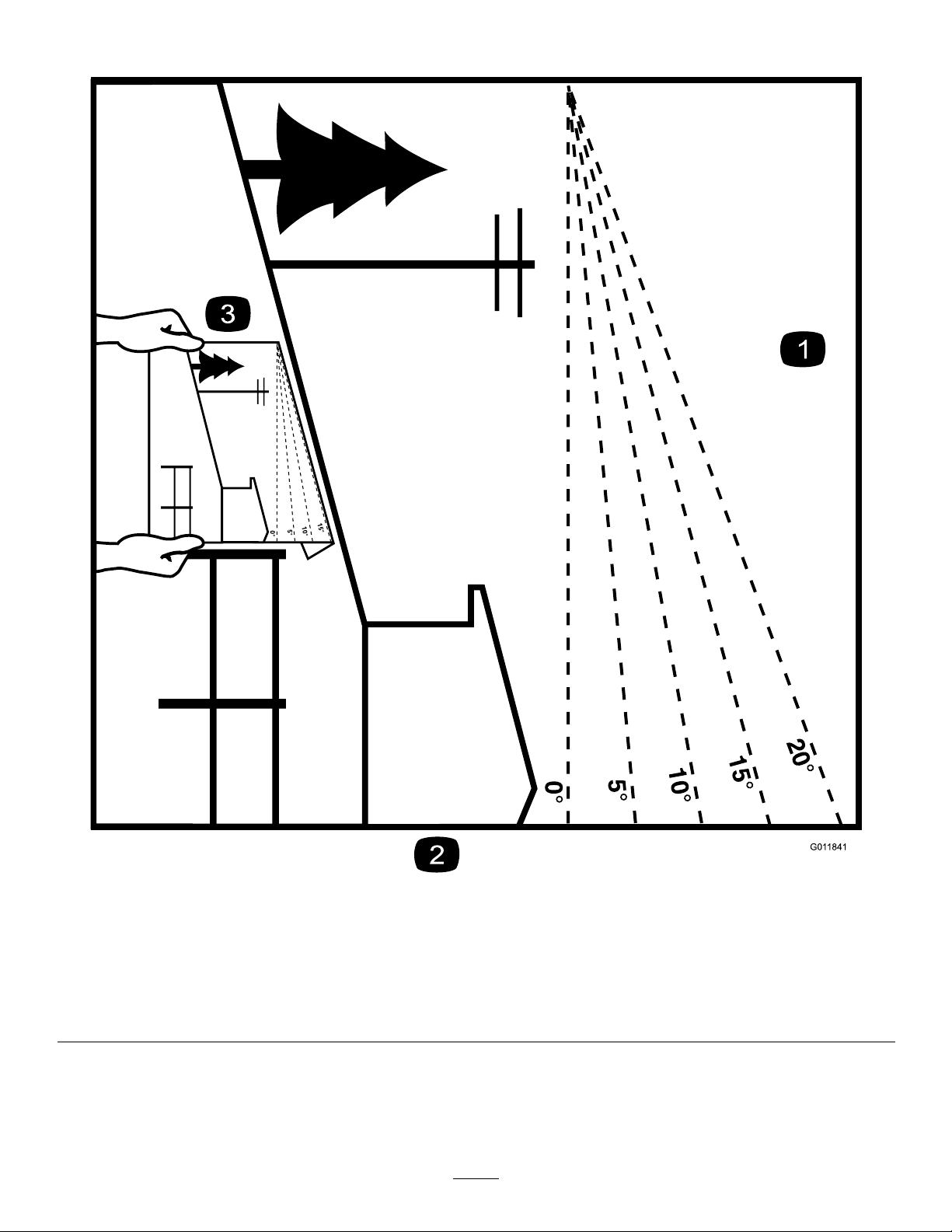

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

7

Page 8

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

93-7009

1.Warning—don'toperatethemowerwiththedeectorupor

removed;keepthedeectorinplace.

2.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

106-8717

1.Readtheinstructionsbeforeservicingorperforming

maintenance.

2.Checktirepressureevery25operatinghours.

3.Greaseevery25operatinghours.

4.Engine

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

119-8814

1.Parkingposition4.Neutral

2.Fast5.Reverse

3.Slow

110-6691

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Thrownobjecthazard,mower—donotoperatewithoutthe

deector,dischargecover,orgrasscollectionsystemin

place.

3.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

114-1606

1.Entanglementhazard,belt—keepallguardsinplace.

119-8815

1.Parkingposition4.Neutral

2.Fast5.Reverse

3.Slow

8

Page 9

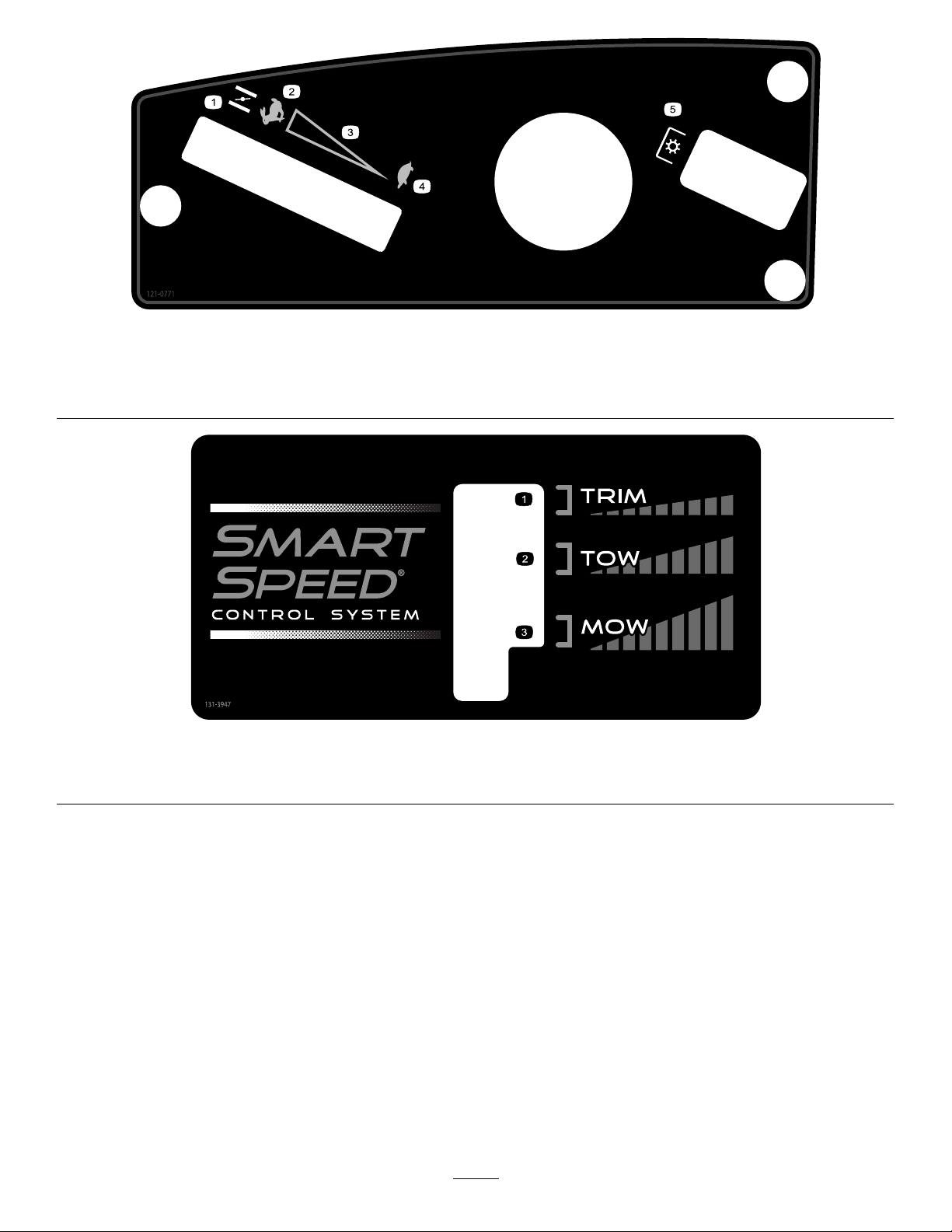

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

distancefromthebattery.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard.

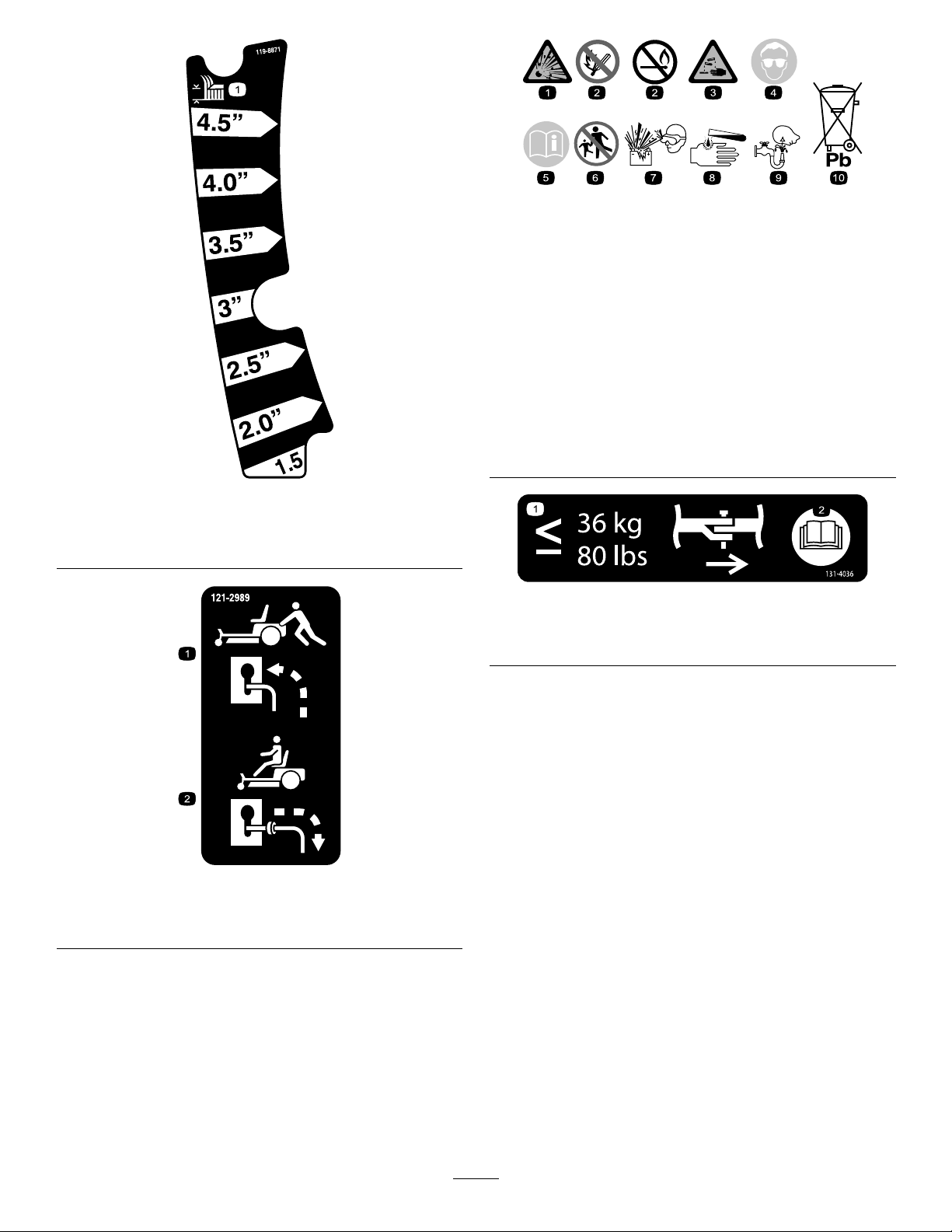

119-8871

Certainmodelsonly

1.Height-of-cut

131-4036

1.Maximumdrawbarpull36

kg(80lb)

2.ReadtheOperator's

Manual.

1.Bypassleverpositionfor

pushingthemachine

121-2989

2.Bypassleverpositionfor

operatingthemachine

9

Page 10

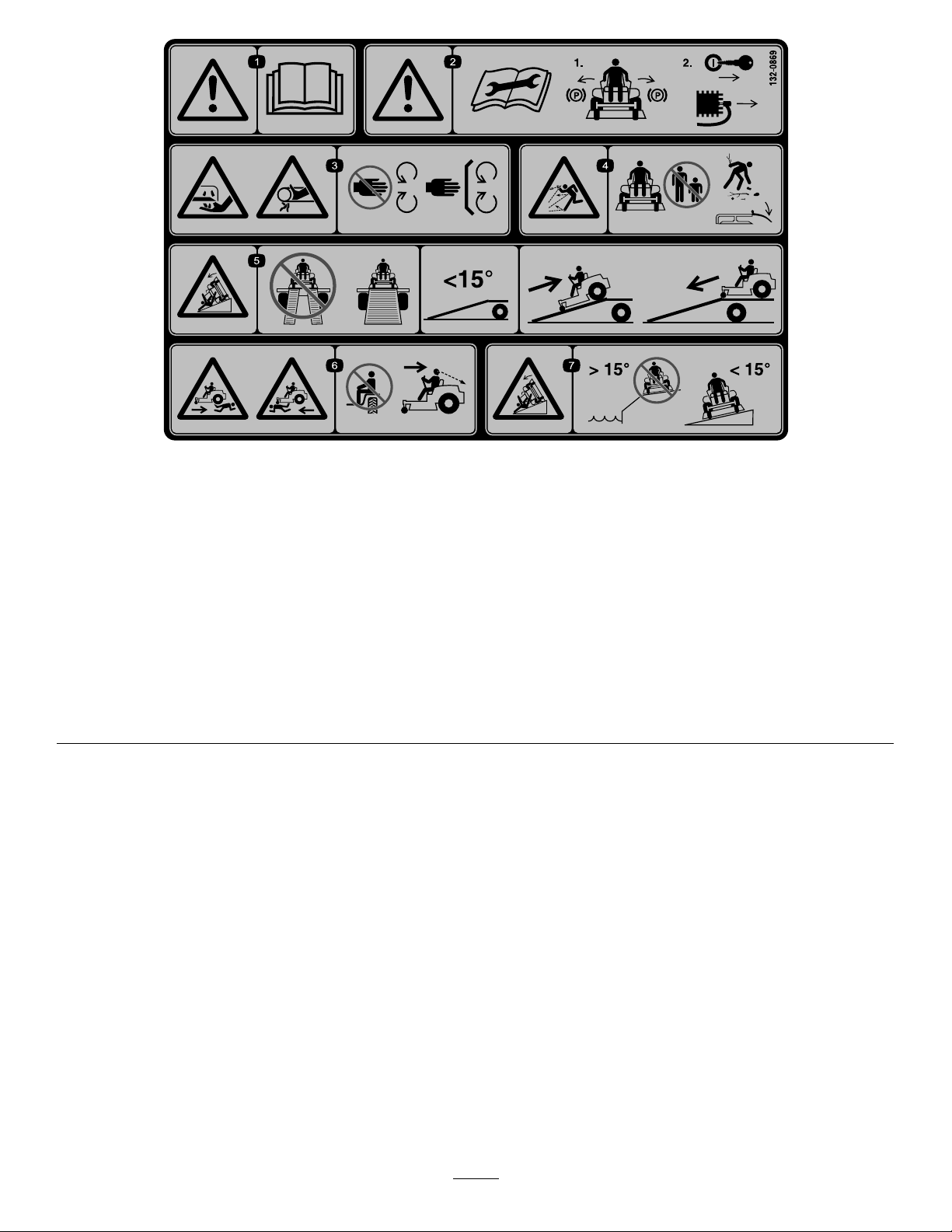

121-0771

1.Choke4.Slow

2.Fast

3.Continuousvariablesetting

131–3947

5.Powertake-off(PTO),Bladecontrolswitch

1.Trim—slow

2.Tow—medium

3.Mow—fast

10

Page 11

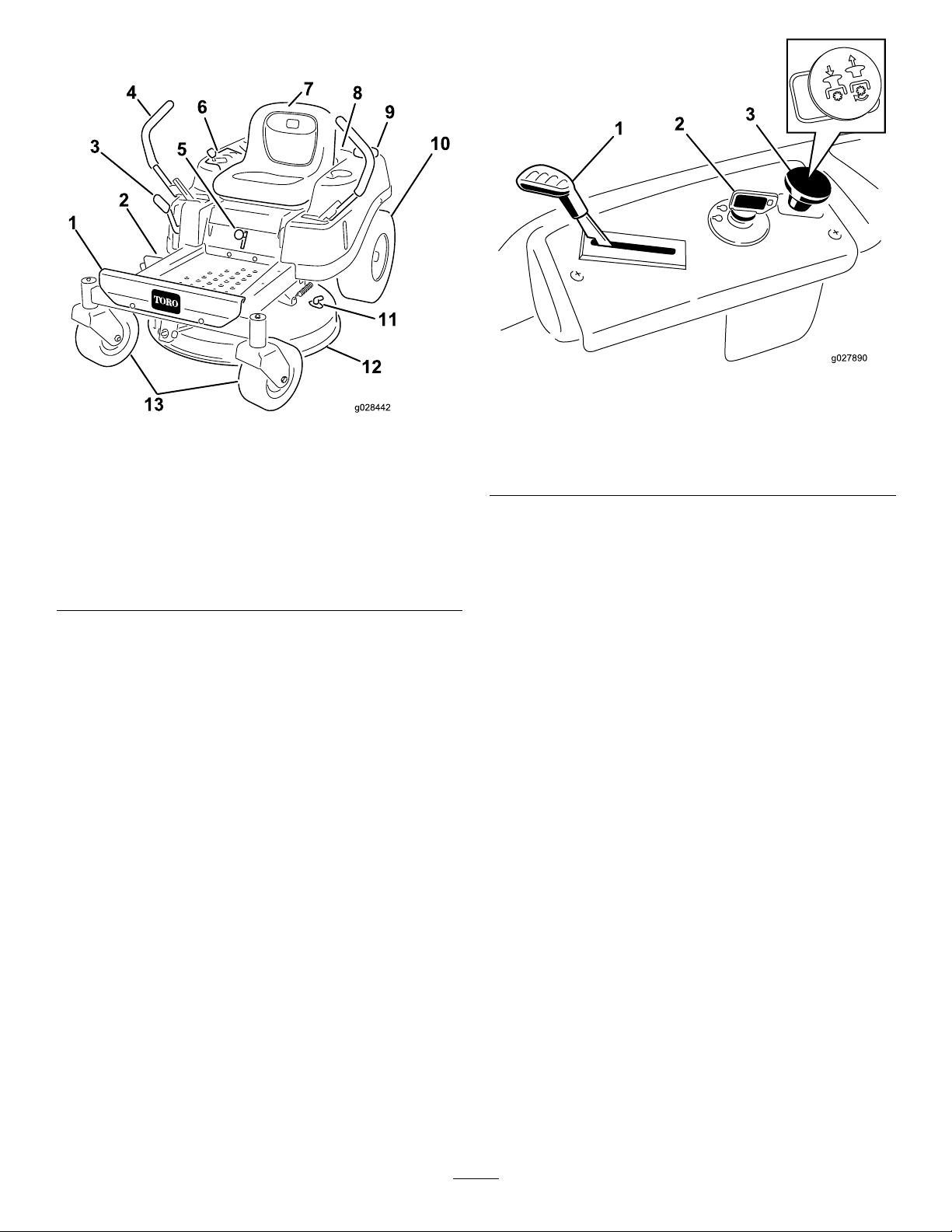

132-0869

1.Warning—readthe

Operator'sManual.

2.Warning—beforeservicing,

engagetheparkingbrake,

removethekeyandthe

sparkplugconnection.

3.Cuttinghazardofhand,

mowerblade;pinching

hazardofhand,belt—keep

handsandfeetawayfrom

movingparts;keepall

guardsandshieldsinplace.

4.Thrownobject

hazard—keepbystanders

awayfromthemachine;

removedebrisfromthe

areabeforemowing;keep

thedeectorshielddown.

5.Ramptipping

hazard—whenloading

ontoatrailer,donotuse

dualramps;onlyusea

singlerampwideenough

forthemachineandthat

hasaninclinelessthan

15degrees;backupthe

ramp(inreverse)anddrive

forwardofftheramp.

6.Bodilyharmhazard—no

riders;lookbehindyou

whenmowinginreverse.

7.Tippinghazardon

slopes—donotuseon

slopesnearopenwater;do

notuseonslopesgreater

than15degrees.

11

Page 12

ProductOverview

Figure5

ControlPanel

Figure4

1.Footrest8.Engine

2.Deector

3.Height-of-cutlever

4.Motion-controllever

5.Smart-speedlever

6.Controlpanel

7.Operatorseat

9.Fuel-tankcap

10.Reardrivewheel

11.Washouttting

12.Mowerdeck

13.Frontcasterwheels

Controls

BecomefamiliarwithallofthecontrolsinFigure4and

Figure5beforeyoustarttheengineandoperatethemachine.

1.Throttle/Choke

2.Ignitionswitch

3.Blade-controlswitch

(powertake-off)

IgnitionSwitch

Theignitionswitchhas3positions:Off,Run,andStart.The

keywillturntoStartandmovebacktoRunuponrelease.

TurningthekeytotheOffpositionwillstoptheengine;

however,alwaysremovethekeywhenleavingthemachine

topreventsomeonefromaccidentallystartingtheengine

(Figure5).

Throttle/ChokeControl

Thethrottleandchokearecombinedintoonecontrollever.

Thethrottlecontrolstheenginespeedandithasacontinuous

variablesettingfromSlowtoFast.Engagethechokeby

movingtheleverpasttheFastsettinguntilitstops(Figure5).

Itmaybenecessarytoholdtheleveragainstthestop,inthe

chokeposition,whiletryingtostarttheengine.

Note:Awarmorhotenginemaynotrequirechoking.

Blade-ControlSwitch(PowerTake-off)

Theblade-controlswitch,representedbyapowertake-off

(PTO)symbol,engagesanddisengagespowertothemower

blades(Figure5).

Motion-ControlLeversandPark

Position

Themotion-controlleversarespeed-sensitivecontrolsof

independent-wheelmotors.Movingaleverforwardor

backwardturnsthewheelonthesamesideforwardorin

reverse;wheelspeedisproportionaltotheamountthelever

ismoved.Movethecontrolleversoutwardfromthecenter

12

Page 13

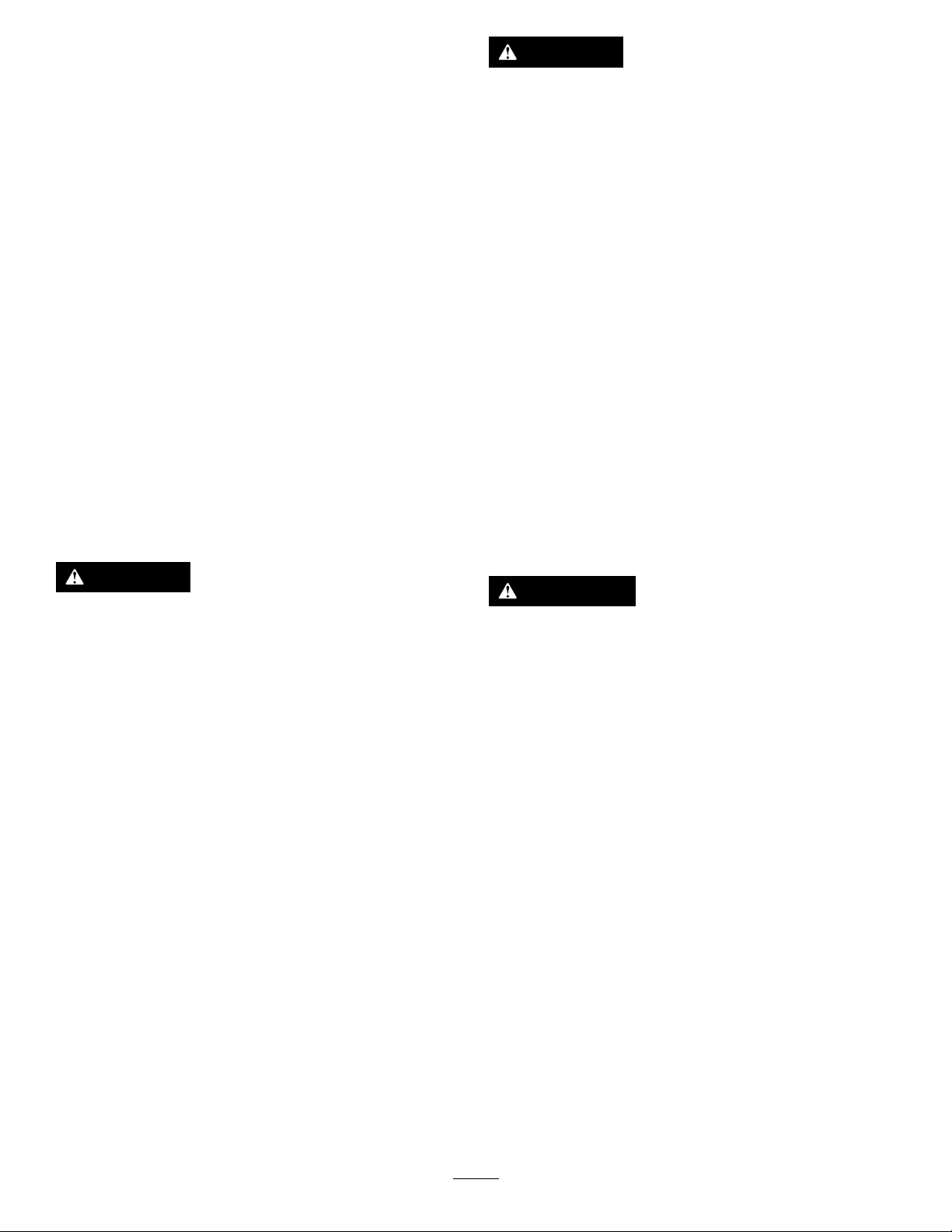

totheparkpositionandexitthemachine(Figure15).Always

G014521

1

g028019

1

positionthemotion-controlleversintotheparkposition

whenyoustopthemachineorleaveitunattended.

SmartSpeed™ControlSystemLever

TheSmartSpeed™Control-Systemlever,locatedbelowthe

operatingposition,givestheoperatorachoicetodrivethe

machineat3speedranges—trim,tow ,andmow(Figure6).

Figure6

1.Smart-speedlever

HourMeter

Thehourmeterrecordsthenumberofhourswhenthe

operatorisintheseatandtheignitionswitchisintheON

position(Figure8).

Figure8

1.Hourmeterlocationbehindtheseat

Fuel-PresenceWindow

Thefuelwindowlocatedontheleft-handsideofthemachine,

canbeusedtoverifythepresenceofgasolineinthetank

(Figure7).

Figure7

1.Fuel-presencewindow

Height-of-CutLever

Theheight-of-cutleverallowstheoperatortolowerand

raisethedeckfromtheseatedposition.Whentheleveris

movedup(towardtheoperator),thedeckisraisedfromthe

ground,andwhenmoveddown(awayfromtheoperator),it

isloweredtowardtheground.Onlyadjusttheheight-of-cut

whilethemachineisnotmoving(Figure4).

13

Page 14

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

AddingFuel

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontains

morethan10%ethanolbyvolume,suchasE15

(contains15%ethanol),E20(contains20%ethanol),or

E85(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/orengine

damagewhichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2inch)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

WARNING

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditionerbottleopening.

•Avoidcontactwithskin;washoffspillagewith

soapandwater.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysorless.

Forlongerstorageitisrecommendedthatthefueltank

bedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditionerto

thegas.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.T ominimizethechance

14

Page 15

ofvarnishdepositsinthefuelsystem,usefuelstabilizer

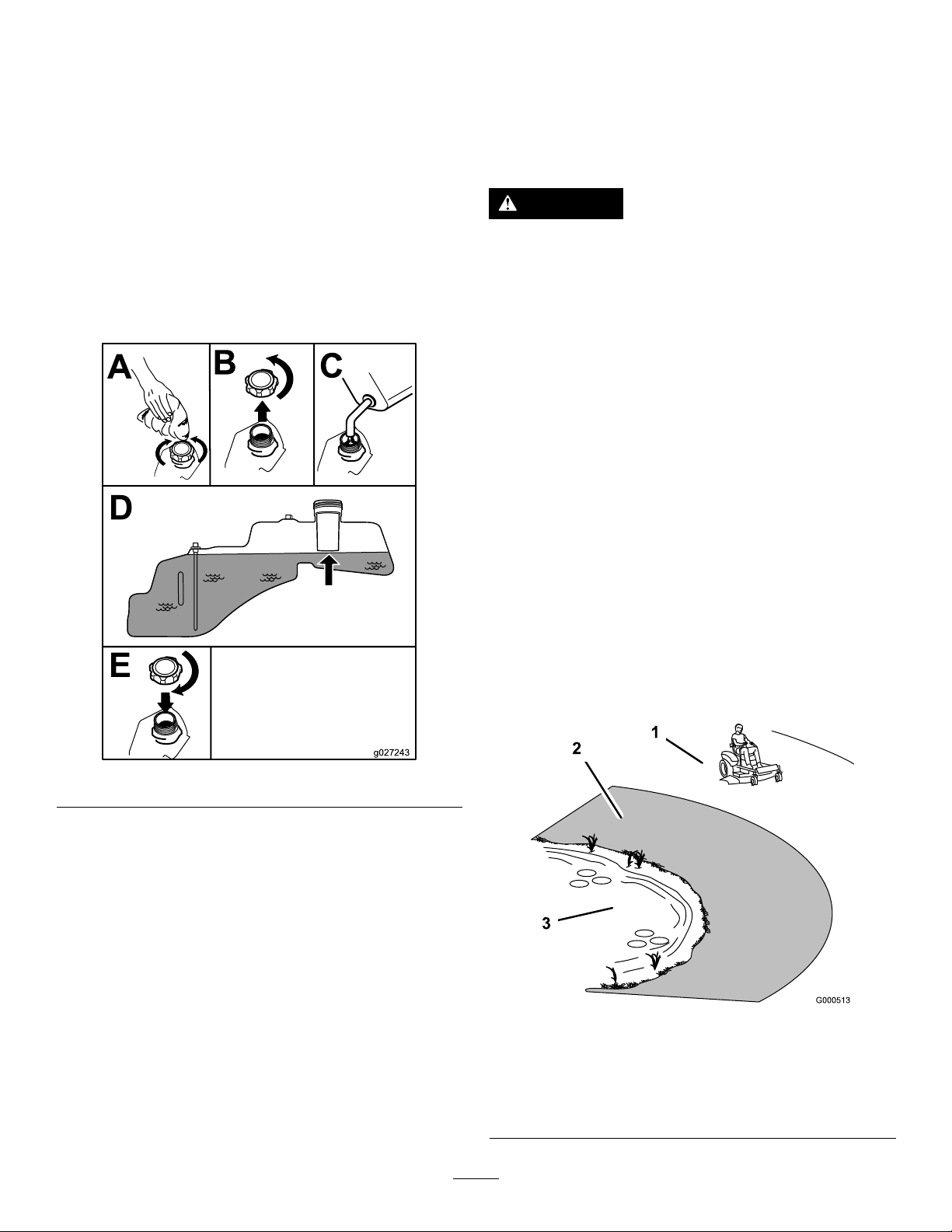

g027243

A

B

E

D

C

atalltimes.

FillingtheFuelTank

Note:Ensurethattheengineisshutoffandthemotion

controlsareintheparkedposition.

ThinkSafetyFirst

OperatingSafety

Pleasecarefullyreadallofthesafetyinstructionsanddecals

inthesafetysection.Knowingthisinformationcouldhelp

you,yourfamily ,pets,orbystandersavoidinjury.

Note:Youcanusethefuelwindowtoverifythepresenceof

gasolinebeforellingthetank(Figure9).

Important:Donotoverllfueltank.Fillthefueltank

tothebottomofthellerneck.Theemptyspaceinthe

tankallowsthefueltoexpand.Overllingmayresultin

fuelleakage,damagetotheengine,ordamagetothe

emissionssystem.

DANGER

Mowingonwetgrassorsteepslopescancause

slidingandlossofcontrol.

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,death,or

drowning.

Alossoftractionisalossofsteeringcontrol.

Toavoidlossofcontrolandpossibilityofrollover:

•Donotmowneardrop-offsornearwater.

•Donotmowslopesgreaterthan15degrees.

•Reducethespeedanduseextremecautionon

slopes.

•Whenmowingslopes,graduallyworkfrom

lowertohigherareasontheincline.

•Avoidsuddenturnsorrapidspeedchanges.

•Turnup,intoaninclinewhenchanging

directionsonslopes.Turningdowntheslope

reducestraction.

Figure9

CheckingtheEngine-OilLevel

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoCheckingthe

Engine-OilLevel(page27).

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mowerdecks

anddrivesystemshavehigherfrictionwhennew,placing

additionalloadontheengine.Allow40to50hoursof

break-intimefornewmachinestodevelopfullpowerand

bestperformance.

•Attachmentschangethehandlingcharacteristics

ofthemachine.Useextracautionwhenusing

attachmentswiththemachine.

Figure10

1.Safezone—usethe

TimeCutterhere

2.Useawalk-behindmower

and/orhandtrimmernear

drop-offsandwater.

3.Water

15

Page 16

CAUTION

G009027

1

2

Thismachineproducessoundlevelsinexcessof85

dBAattheoperatorsearandcancausehearingloss

throughextendedperiodsofexposure.

4.Moveeithermotion-controllevertothecenter,

unlockedposition.

5.Trystartingtheengine;theengineshouldnotcrank.

6.Repeatwiththeothermotion-controllever.

Wearhearingprotectionwhenoperatingthis

machine.

Theuseofprotectiveequipmentforeyes,ears,feet,andhead

isrecommended.

Figure11

1.Wearsafetyglasses

2.Wearhearingprotection

UnderstandingtheSafety-Interlock

System

WARNING

Ifsafety-interlockswitchesaredisconnectedor

damaged,themachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

daily,andreplaceanydamagedswitchesbefore

operatingthemachine.

7.Whilesittingontheseat,movetheblade-control

switchtoOff,andlockthemotion-controlleversin

theparkposition.

8.Starttheengine.

9.Whiletheengineisrunning,engagetheblade-control

switch,andriseslightlyfromtheseat.

Note:Theengineshouldstop.

10.Whilesittingontheseat,movetheblade-control

switchtoOff,andlockthemotion-controlleversin

theparkposition.

11.Starttheengine.

12.Whiletheengineisrunning,movethemotion-control

leverstothecenter,unlockedposition,engagethe

blade-controlswitch,andriseslightlyfromtheseat.

Note:Theengineshouldstop.

StartingtheEngine

Important:Donotengagethestarterformorethan

5secondsatatime.Engagingthestartermotorfor

morethan5secondscandamagethestartermotor.If

theenginefailstostart,wait10secondsbeforeoperating

theenginestarteragain.

Note:Itmaybenecessarytoholdtheleveragainstthestop,

inthechokeposition,whiletryingtostarttheengine(Figure

12).

Thesafety-interlocksystemisdesignedtopreventtheengine

fromstartingunless:

•Thebladesaredisengaged.

•Themotion-controlleversareintheparkposition.

Thesafety-interlocksystemalsoisdesignedtostoptheengine

wheneverthecontrolleversareoutoftheparkpositionand

yourisefromtheseat.

TestingtheSafety-InterlockSystem

Testthesafety-interlocksystembeforeyouusethemachine

eachtime.Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthesafety

systemimmediately.

1.Whilesittingontheseat,withthecontrolleversinpark

position,andmovetheblade-controlswitchtoOn.

2.Trystartingtheengine;theengineshouldnotcrank.

3.Whilesittingontheseat,movetheblade-control

switchtoOff.

16

Page 17

g027535

B

C

D

E

A

G

F

g027245

B

C

A

DisengagingtheBlades

g027247

Figure13

Figure12

OperatingtheBlades

Theblade-controlswitch,representedbyapowertake-off

(PTO)symbol,engagesanddisengagespowertothemower

blades.Thisswitchcontrolspowertoanyattachmentsthat

drawpowerfromtheengine,includingthemowerdeckand

cuttingblades.

EngagingtheBlades

Important:Donotengagethebladeswhenparkedin

tallgrass;beltorclutchdamagecanoccur.

Note:Alwaysengagethebladeswiththethrottleinthe

Fastposition.

Figure14

StoppingtheEngine

1.Disengagethebladesbymovingtheblade-control

switchtoOff(Figure14).

2.MovethethrottlelevertotheFastposition.

3.TurntheignitionkeytoOffandremovethekey.

DrivingtheMachine

Drivingthemachinebenetsfromanunderstandingof

whatzero-turn-radiusmowermeans.Thedrivewheelsturn

independently,poweredbyhydraulicmotorsoneachaxle;

henceonesidecanturninreversewhiletheotherturns

forwardcausingthemachinetospinratherthanturn.This

vastlyimprovesthemachinemaneuverabilitybutmayrequire

someadjustmentiftheoperatorisunfamiliar.

17

Page 18

WARNING

Themachinecanspinveryrapidly.Theoperator

maylosecontrolofthemachineandcausepersonal

injuryordamagetothemachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placingthethrottlecontrol

intheFastpositioncanbebestforperformance.Formost

applications,operatinginthefull-throttlepositionisdesirable.

UsingtheSmartSpeed

TM

Control

System

TheSmartSpeed

operatingposition(Figure16),givestheoperatorachoice

todrivethemachineat3groundspeedranges—trim,tow ,

andmow .

1.Smartspeedlever

Tochangespeeds,dothefollowing:

1.Movethemotioncontrolleverstoneutralandoutward

totheparkposition.

2.Disengagethebladecontrolswitch

3.Adjustthelevertothedesiredposition.

TM

Control-Systemlever,locatedbelowthe

Figure16

Figure15

1.Park(brake)position

2.Center,unlockposition5.Frontofthemachine

3.Forward

4.Backward

Thefollowingareonlyrecommendationsforuse.

Adjustmentswillvarybygrasstype,moisturecontent,and

theheightofthegrass.

Suggested

uses:

ParkingX

Heavy,wet

grass

TrainingX

BaggingX

MulchingX

Normal

mowing

TransportX

TrimTowMow

X

X

Trim

Thisisthelowestspeed.Thesuggestedusesforthisspeed

areasfollows:

•Parking

•Heavy,wetgrassmowingconditions

•Training

Tow

Thisisthemediumspeed.Thesuggestedusesforthisspeed

areasfollows:

18

Page 19

•Bagging

G008952

G008953

DrivingBackward

•Mulching

Mow

Thisisthefastestspeed.Thesuggestedusesforthisspeed

areasfollows:

•Normalmowing

•Transportingthemachine

DrivingForward

1.Movetheleverstothecenter,unlockedposition.

2.Togoforward,slowlypushthemotion-controllevers

forward(Figure17).

Note:Alwaysusecautionwhenbackingupandturning.

1.Movetheleverstothecenter,unlockedposition.

2.Togobackward,lookbehindyouanddown,asyou

slowlypullthemotion-controlleversrearward(Figure

18).

Figure18

Figure17

Togostraight,applyequalpressuretoboth

motion-controllevers(Figure17).

Toturn,releasepressureonthemotion-controllever

towardthedirectionyouwanttoturn(Figure17).

Thefartheryoumovethemotion-controlleversin

eitherdirection,thefasterthemachinewillmovein

thatdirection.

Tostop,pullthemotion-controlleverstoneutral.

Togostraight,applyequalpressuretoboth

motion-controllevers(Figure18).

Toturn,releasethepressureonthemotion-control

levertowardthedirectionyouwanttoturn.

Tostop,pushthemotion-controlleverstoneutral.

StoppingtheMachine

Tostopthemachine,movethemotion-controlleversto

neutralandoutwardtotheparkposition,disengagethe

blade-controlswitch,movethethrottletotheFastposition,

andturntheignitionkeytooff.

Note:Remembertoremovethekeyfromtheignitionswitch.

WARNING

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemowerwhileitis

unattended.

Alwaysremovetheignitionkeyandmovethe

motion-controlleversoutwardtotheparkposition

whenleavingthemachineunattended,evenifjust

forafewminutes.

19

Page 20

AdjustingtheHeight-of-Cut

g027249

B

C

A

g027252

B

A

Note:Thetransportpositionisthehighestheight-of-cut

positionorcuttingheight(115mm(4.5inches))asshown

inFigure19.

Height-of-cutiscontrolledbytheleverlocatedtotherightof

theoperatingposition(Figure19).

PositioningtheSeat

Figure20

AdjustingtheMotion-Control Levers

AdjustingtheHeight

Themotion-controlleverscanbeadjustedhigherorlowerfor

maximumoperatorcomfort(Figure21).

Figure19

Figure21

20

Page 21

AdjustingtheTilt

g017303

1 2

3

Themotion-controlleverscanbetiltedforeoraftfor

maximumoperatorcomfort.

1.Loosentheupperboltholdingthecontrollevertothe

control-armshaft.

2.Loosenthelowerboltjustenoughtopivotthecontrol

leverforeoraft(Figure21).Tightenbothboltsto

securethecontrolinthenewposition.

3.Repeattheadjustmentfortheoppositecontrollever.

PushingtheMachinebyHand

Important:Alwayspushthemachinebyhand.Donot

towthemachine,becausedamagemayoccur.

Thismachinehasanelectric-brakemechanism,andtopush

themachine,theignitionkeyneedstobeintheRunposition.

Thebatteryneedstobechargedandfunctioningforthe

electricbraketobedisengage.

PushingtheMachine

1.Parkthemachineonalevelsurface,anddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothepark

position,stoptheengine,andwaitforallmovingparts

tostopbeforeleavingtheoperatingposition.

3.Locatethebypassleversontheframeonbothsidesof

theengine.

4.Movethebypassleversforwardthroughthekeyhole

anddowntolocktheminplace(Figure22).

Note:Ensurethisisdoneforeachlever.

5.Movethemotion-controlleversinwardtotheneutral

positionandturntheignitionkeytotheRunposition.

Note:Donotstartthemachine.

Note:Themachineisnowabletobepushedbyhand.

Figure22

1.Bypass-leverlocations

2.Leverpositionfor

operatingthemachine

6.Whennished,ensurethatthekeyhasbeenreturnedto

theStoppositiontoavoiddrainingthebatterycharge.

Note:Ifthemachinefailstomove,theelectricbrakemay

stillbeengaged.Ifnecessary,theelectricbrakecanbereleased

manually;refertoReleasingtheElectricBrake(page34).

3.Leverpositionforpushing

themachine

OperatingtheMachine

Movethebypassleversrearwardthroughthekeyholeand

downtolocktheminplaceasshowninFigure22.

Note:Ensurethisisdoneforeachlever.

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthemachine.

Ensurethatthetrailerortruckhasallnecessarybrakes,

lighting,andmarkingasrequiredbylaw .Pleasecarefullyread

allthesafetyinstructions.Knowingthisinformationcould

helpyou,yourfamily,pets,orbystandersavoidinjury.

WARNING

Drivingonthestreetorroadwaywithoutturn

signals,lights,reectivemarkings,oraslow

movingvehicleemblemisdangerousandcanlead

toaccidentscausingpersonalinjury.

Donotdrivemachineonapublicstreetorroadway.

Totransportthemachine:

1.Ifusingatrailer,connectittothetowingvehicleand

connectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Loadthemachineontothetrailerortruck.

21

Page 22

4.Stoptheengine,removethekey,setthebrake,and

closethefuelvalve.

5.Tiedownthemachinenearthefrontcasterwheelsand

therearbumper(Figure23).

WARNING

Loadingamachineontoatrailerortruckincreases

thepossibilityoftip-overandcouldcauseserious

injuryordeath.

•Useextremecautionwhenoperatingamachine

onaramp.

•Useonlyafull-widthramp;donotuseindividual

rampsforeachsideofthemachine.

•Donotexceeda15-degreeanglebetweenthe

rampandthegroundorbetweentherampand

thetrailerortruck.

Figure23

LoadingtheMachine

Useextremecautionwhenloadingorunloadingmachines

ontoatraileroratruck.Useafull-widthrampthatiswider

thanthemachineforthisprocedure.Backuprampsand

driveforwarddownramps(Figure24).

Figure24

1.Backupramps

Important:Donotusenarrowindividualrampsfor

eachsideofthemachine.

2.Driveforwarddownramps

•Ensurethelengthoframpisatleastfourtimes

(4X)aslongastheheightofthetrailerortruck

bedtotheground.Thiswillensurethatramp

angledoesnotexceed15degreesonatground.

•Backuprampsanddriveforwarddownramps.

•Avoidsuddenaccelerationordecelerationwhile

drivingthemachineonarampasthiscould

causealossofcontroloratip-oversituation.

Ensuretherampislongenoughsothattheanglewiththe

grounddoesnotexceed15degrees(Figure25).Onat

ground,thisrequiresaramptobeatleastfourtimes(4X)as

longastheheightofthetrailerortruckbedtotheground.A

steeperanglemaycausemowercomponentstogetcaughtas

theunitmovesfromtheramptothetrailerortruck.Steeper

anglesmayalsocausethemachinetotiporlosecontrol.If

loadingonornearaslope,positionthetrailerortrucksothat

itisonthedownsideoftheslopeandtherampextendsup

theslope.Thiswillminimizetherampangle.

22

Page 23

g027996

5

1

2

6

Figure25

1.Full-widthrampinstowed

position

2.Sideviewoffull-width

rampinloadingposition

3.Notgreaterthan

15degrees

4.Rampisatleastfourtimes

(4X)aslongastheheight

ofthetrailerortruckbed

totheground

5.H=heightofthetraileror

truckbedtotheground

6.Trailer

23

Page 24

OperatingTips

UsingtheFastThrottleSetting

Forbestmowingandmaximumaircirculation,operate

theengineattheFastthrottleposition.Airisrequiredto

thoroughlycutgrassclippings,sodonotsettheheight-of-cut

solowastototallysurroundthemowerbyuncutgrass.

Alwaystrytohaveonesideofthemowerfreefromuncut

grass,whichallowsairtobedrawnintothemower.

UsingtheSmartSpeed™Control

System

TheSmartSpeed™Control-Systemlever,locatedbelowthe

operatingposition,givestheoperatorachoicetodrivethe

machineat3speedranges—trim,mow,andtow .Anoperator

canbenetfromthetrimspeedsettingwhenmaneuvering

themachineintightspacesoroperatingarounddelicate

landscapes.Thetrimsettingcanalsobeusedtooperatethe

machineatahighthrottlesettingandbladespeed,whilestill

beingabletoreducethegroundspeedtoincreasethequality

ofcut.

CuttingLongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,raisethe

cuttingheighthigherthanusualandcutthegrassatthis

setting.Thencutthegrassagainusingthelower,normal

setting.

Stopping

Ifyoumuststoptheforwardmotionofthemachinewhile

mowing,aclumpofgrassclippingsmaydropontoyour

lawn.Toavoidthis,moveontoapreviouslycutareawiththe

bladesengagedoryoucandisengagethemowerdeckwhile

movingforward.

KeepingtheUndersideoftheMower

Clean

Cleanclippingsanddirtfromtheundersideofthemower

aftereachuse.Ifgrassanddirtbuildupinsidethemower,

cuttingqualitywilleventuallybecomeunsatisfactory.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethatthe

cuttingheightofthemowerdoesnotscalpanyuneven

ground.However,thecuttingheightusedinthepastis

generallythebestonetouse.Whencuttinggrasslongerthan

sixinchestall,youmaywanttocutthelawntwicetoensure

anacceptablequalityofcut.

Cutting1/3oftheGrassBlade

Itisbesttocutonlyabout1/3ofthegrassblade.Cutting

morethanthatisnotrecommendedunlessgrassissparse,or

itislatefallwhengrassgrowsmoreslowly.

AlternatingtheMowingDirection

Alternatethemowingdirectiontokeepthegrassstanding

straight.Thisalsohelpsdisperseclippingswhichenhances

decompositionandfertilization.

MowingatCorrectIntervals

Normally,mowevery4days.But,remember,grassgrowsat

differentratesatdifferenttimes.Sotomaintainthesame

cuttingheight,whichisagoodpractice,andmowmoreoften

inearlyspring.Asthegrassgrowthrateslowsinmidsummer,

mowlessfrequently.Ifyoucannotmowforanextended

period,rstmowatahighcuttingheight,thenmowagain2

dayslateratalowerheightsetting.

MaintainingtheBlade(s)

Maintainasharpbladethroughoutthecuttingseasonbecause

asharpbladecutscleanlywithouttearingorshreddingthe

grassblades.Tearingandshreddingturnsgrassbrownat

theedges,whichslowsgrowthandincreasesthechanceof

disease.Checkthemowerbladesaftereachuseforsharpness,

andforanywearordamage.Filedownanynicksandsharpen

thebladesasnecessary.Ifabladeisdamagedorworn,replace

itimmediatelywithagenuineTororeplacementblade.

AvoidingCuttingTooLow

Ifthecuttingwidthofthemoweriswiderthanthemower

youpreviouslyused,raisethecuttingheighttoensurethat

uneventurfisnotcuttooshort.

24

Page 25

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Beforeeachuseordaily

Aftereachuse

Every25hours

Every50hours

Every100hours

Beforestorage

MaintenanceProcedure

•Changetheengineoilandlter.

•Checkthesafety-interlocksystem.

•Cleanandchecktheaircleanerfoamelement.

•Checktheengineoillevel.

•Cleantheengineair-intakescreen.

•Checkthecuttingblades.

•Inspectthegrassdeectorfordamage.

•Cleanthemower-deckhousing.

•Greaseallthelubricationpoints.

•Checktirepressure.

•Checkthebeltsforwear/cracks.

•Replacetheaircleanerpaperelement.

•Checkthesparkplug.

•Changetheengineoil(changeitmoreoftenunderaheavyloadorinhigh

temperatures).

•Changetheengine-oillter.

•Replacethesparkplug.

•Replacethein-linefuellter

•Cleantheengine-coolingnsandshrouds.

•Chargethebatteryanddisconnectbatterycables.

•Performallmaintenanceprocedureslistedabovebeforestorage.

•Paintanychippedsurfaces.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

Premaintenance

Lubrication

Procedures

GreasingtheBearings

RaisingtheSeat

Makesurethatthemotion-controlleversarelockedinthe

parkposition,andlifttheseatforward.

Thefollowingcomponentscanbeaccessedbyraisingtheseat:

•Serialplate

•Servicedecal

•Seat-adjustmentbolts

•Fuellter

•Batteryandbatterycables

ServiceInterval:Every25hours—Greaseallthelubrication

points.

GreaseType:No.2GeneralPurpose,Lithium-BaseGrease

1.Parkthemachineonalevelsurface,anddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothepark

position,stoptheengine,removethekey ,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

25

Page 26

3.Cleanthegreasettings(Figure26andFigure27)with

1

G014522

G017862

arag.

EngineMaintenance

Note:Makesuretoscrapeanypaintoffofthefront

ofthetting(s).

Figure26

1.Frontcastertire

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Cleanandcheck

theaircleanerfoamelement.

Every50hours—Replacetheaircleanerpaper

element.

Note:Servicetheaircleanermorefrequentlyiftheoperating

conditionsareextremelydustyorsandy.

RemovingtheFoamandPaper

Elements

1.Disengagetheblade-controlswitch(PTO).

2.Stoptheengine,waitforallmovingpartstostop,and

removethekeybeforeleavingtheoperatingposition.

3.Cleanaroundtheaircleanertopreventdirtfrom

gettingintotheengineandcausingdamage.

4.Removetheair-cleanercoverbyunscrewingthe2

knobs(Figure28).

Figure27

Locatedontheseat-panunderside

1.Readtheinstructions

beforeservicingor

performingmaintenance

2.Checkthetirepressure

every25operatinghours

3.Greaseevery25operating

hours

4.Engine

4.Connectagreaseguntoeachtting(Figure26and

Figure27).

5.Pumpgreaseintothettingsuntilgreasebeginsto

oozeoutofthebearings.

Figure28

1.Air-cleanercover2.Knobs

5.Carefullyremovethefoamandpaperlterelements

fromtheair-cleanerhousing(Figure29).

26

Page 27

Figure29

SAE 5W -30, 10W -30

SAE 30

SYNTHETIC 5W -20, 5W -30, 10W -30

g029683

1.Foamelement2.Paperelement

6.Separatethefoamandpaperelements.

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSF ,SG,SH,SJ,or

higher)

CrankcaseCapacity:1.0L(34oz)whenyoudonotchange

thelter;1.05L(36oz)whenyouchangethelter.

Viscosity:Seethetablebelow.

CleaningtheFoamandPaperElements

FoamElement:

1.Washthefoamelementinliquidsoapandwarmwater.

2.Whentheelementisclean,rinseitthoroughly.

3.Drytheelementbysqueezingitinacleancloth.

Note:Donotoiltheelement.

Important:Replacethefoamelementifitistorn

orworn.

4.Installthefoamelementontoacleanpaperelement.

PaperElement:

1.Tapthepaperelementonasolid,atsurface,andblow

itoutfromtheinsidewithcompressedairtoremove

dustanddirt.

2.Inspecttheelementfortears,anoilylm,anddamage

totherubberseal.

Important:Donotcleanthepaperelementwith

liquids,suchassolvents,gasoline,orkerosene.

Replacethepaperelementifitisdamagedor

cannotbecleanedthoroughly.

3.Cleantheinsideoftheair-cleanercoverofalldirt,dust,

anddebris.

Figure30

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawaythemuferandotherhotsurfaces.

Important:Donotoverllthecrankcasewithoiland

runtheengine;enginedamagemayresult.

1.Parkthemachineonalevelsurface.

2.Disengagetheblade-controlswitch(PTO).

3.Stoptheengine,waitforallmovingpartstostop,and

removethekeybeforeleavingtheoperatingposition.

4.Checktheengine-oillevel(Figure31).

InstallingtheFoamandPaperElements

Important:Topreventenginedamage,alwaysoperate

theenginewiththecompletefoamandpaperaircleaner

assemblyinstalled.

1.Installthefoamlterontothepaperlter(Figure29).

2.Installthefoamandpaperlterontotheair-cleaner

housing.

3.Installtheair-cleanercover,andtightenthe2knobs

(Figure28).

27

Page 28

B

A

C

D

E

G029368

F

G H

I J K

4.Draintheoilfromtheengine.

B

A

C

E F

D

G

H

g029369

ChangingtheEngineOiland Filter

ServiceInterval:Aftertherst5hours

Every100hours(changeitmoreoftenunderaheavy

loadorinhightemperatures).

Every100hours

Note:Changetheengine-oilltermorefrequentlywhenthe

operatingconditionsareextremelydustyorsandy.

Figure31

Figure32

5.Removetheengine-oillter.

Note:Ensuretheoil-ltergaskettouchestheengine,

andthenturnthelteranextra3/4turn.

1.Parkthemachine,sothattherightsideisslightly

lowerthantheleftside,toensurethattheoildrains

completely.

2.Disengagetheblade-controlswitch(PTO).

3.Stoptheengine,waitforallmovingpartstostop,and

removethekeybeforeleavingtheoperatingposition.

28

Page 29

B

A

C D

E

F

3/4

g027477

B

A

C

D

E

F

g027484

Figure33

6.Slowlypourapproximately80%ofthespecied

amountofoilintothellhole(Figure34).

7.Checktheoillevel;refertoFigure34.

Figure34

ServicingtheSparkPlug

ServiceInterval:Every50hours—Checkthesparkplug.

Every100hours—Replacethesparkplug.

Ensurethattheairgapbetweenthecenterandsideelectrodes

iscorrectbeforeinstallingthesparkplug.Useasparkplug

wrenchforremovingandinstallingthesparkpluganda

gappingtoolorfeelergaugetocheckandadjusttheairgap.

Installanewsparkplugifnecessary.

Type:Champion

BCPR6ES

AirGap:0.76mm(0.03inch)

RemovingtheSparkPlug

1.Disengagetheblade-controlswitch(PTO).

2.Stoptheengine,waitforallmovingpartstostop,and

removethekeybeforeleavingtheoperatingposition.

29

®

RC12YC,Autolite

®

3924,orNGK

®

Page 30

B

A

g027478

Figure35

B

A

g027479

B

A

15 ft-lb

20 N-m

g027480

C

D

CheckingtheSparkPlug

Important:Donotcleanthesparkplug.Always

replacethesparkplugwhenithasablackcoating,worn

electrodes,anoilylm,orcracks.

Note:Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingontheinsulator

usuallymeansthattheaircleanerisdirty.

Setthegapto0.76mm(0.030).

FuelSystem

Maintenance

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Performanyfuelrelatedmaintenancewhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

ReplacingtheIn-LineFuel Filter

ServiceInterval:Every100hours—Replacethein-linefuel

lter

Figure36

InstallingtheSparkPlug

Tightenthesparkplugto20N-m(15ft-lb).

Neverinstalladirtylterifitisremovedfromthefuelline.

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothepark

position,stoptheengine,removethekey ,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Replacethein-linefuellter(Figure38).

Figure37

30

Page 31

g027506

B

A

C

D

g029685

ElectricalSystem

Maintenance

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

ChargingtheBattery

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

Figure38

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothepark

position,stoptheengine,removethekey ,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Raisetheseattoaccessthebattery.

4.Disconnectthenegative(black)groundcablefromthe

batterypost(Figure39).

Note:Retainallfasteners.

31

Page 32

WARNING

G005072

1

2

3

4

5

6

7

Incorrectbattery-cableroutingcoulddamage

themachineandcablescausingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

ChargingtheBattery

ServiceInterval:Beforestorage—Chargethebatteryand

disconnectbatterycables.

1.Removethebatteryfromthechassis;refertoRemoving

theBattery(page31).

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

5.Slidetherubbercoverupthepositive(red)cable.

6.Disconnectthepositive(red)cablefromthebattery

post(Figure39).

Note:Retainallfasteners.

7.Removethebatteryhold-down(Figure39),andliftthe

batteryfromthebatterytray .

2.Chargethebatteryforaminimumof1hourat6to

10amps.

Note:Donotoverchargethebattery.

3.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthecharger

leadsfromthebatteryposts(Figure40).

Figure40

1.Positive(+)batterypost3.Red(+)chargerlead

2.Negative(–)batterypost4.Black(–)chargerlead

1.Battery

2.Positive(+)batterypost

3.Bolt,washer,andnut7.Batteryhold-down

4.Terminalboot

InstallingtheBattery

1.Positionthebatteryinthetray(Figure39).

2.Usingthefastenerspreviouslyremoved,installthe

positive(red)batterycabletothepositive(+)battery

terminal.

3.Usingthefastenerspreviouslyremoved,installthe

negativebatterycabletothenegative(-)battery

Figure39

5.Negative(–)batterypost

6.Wingnut,washer,andbolt

terminal.

4.Slidetheredterminalbootontothepositive(red)

batterypost.

5.Securethebatterywiththehold-down(Figure39).

6.Lowertheseat.

32

Page 33

ServicingtheFuses

30

25

30

25

G014540

2

1

DriveSystem

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;however,ifafuseblows,checkthe

component/circuitforamalfunctionorshort.

Fusetype:

•Main—F1-30amp,blade-type

•ChargeCircuit—F2-25amp,blade-type

1.Removethescrewssecuringthecontrolpaneltothe

machine.

Note:Retainallfasteners.

2.Liftthecontrolpaneuptoaccessthemainwiring

harnessandfuseblock(Figure41).

3.Toreplaceafuse,pulloutonthefusetoremoveit

(Figure41).

Maintenance

CheckingtheTirePressure

ServiceInterval:Every25hours—Checktirepressure.

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseunevencut.Check

thepressureatthevalvestem(Figure42).Checkthetires

whentheyarecoldtogetthemostaccuratepressurereading.

Refertothemaximumpressuresuggestedbythetire

manufactureronthesidewallofthecasterwheeltires.

Inatethereardrive-wheeltiresto90kPa(13psi).

Figure42

Figure41

1.Main—30amp

2.Chargecircuit—25amp

4.Returnthecontrolpaneltoitsoriginalposition.

Note:Usethescrewsremovedpreviouslytosecure

thepaneltothemachine.

1.Valvestem

33

Page 34

ReleasingtheElectricBrake

Theelectricbrakecanbereleasebymanuallyrotatingthe

linkarmsforward.Oncetheelectricbrakeisenergizedthe

brakewillreset.

CoolingSystem

Maintenance

Toreleasethebrake:

Figure43

1.Brakelinkarmontheelectricbrakecontrolmodule

2.Leftreartire

1.TurntheignitionkeytotheOffpositionordisconnect

thebattery.

2.Locatetheshaftontheelectricbrakewherethebrake

linkarmsareconnected.

3.Rotatetheshaftforwardtoreleasethebrake.

CleaningtheEngineScreen

ServiceInterval:Beforeeachuseordaily—Cleantheengine

air-intakescreen.

Toensurepropercooling,makesurethegrassscreen,cooling

ns,andotherexternalsurfacesoftheenginearekeptclean

atalltimes.

Useadrybrushtocleangrassandaccumulateddebrisfrom

theair-intakescreenandaroundtheengine.

Important:Topreventcontaminatingthefuelsystem,

donotusewatertocleantheengine.

CleaningtheEngine-Cooling FinsandShrouds

ServiceInterval:Every100hours—Cleantheengine-cooling

nsandshrouds.

1.Disengagetheblade-controlswitch,andmovethe

motion-controlleverstotheneutral-lockedposition

andapplytheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Removetheair-intakescreenandcoolingshrouds.

4.Cleanthedebrisandgrassfromtheengineparts.

5.Installtheair-intakescreenandcoolingshrouds.

34

Page 35

MowerMaintenance

G009679

1

2

3

ServicingtheCuttingBlades

Maintainsharpbladesthroughoutthecuttingseason,because

sharpbladescutcleanlywithouttearingorshreddingthegrass

blades.Tearingandshreddingturnsgrassbrownattheedges,

whichslowsgrowth,andincreasesthechanceofdisease.

Checkthecutterbladesdailyforsharpness,andforany

wearordamage.Filedownanynicksandsharpenthe

bladesasnecessary.Ifabladeisdamagedorworn,replace

itimmediatelywithagenuineT ororeplacementblade.For

convenientsharpeningandreplacement,youmaywantto

keepextrabladesonhand.

WARNING

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownintotheoperator's

orbystander'sarea,resultinginseriouspersonal

injuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

BeforeInspectingorServicingthe

Blades

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily—Checkthe

cuttingblades.

1.Inspectthecuttingedges(Figure44).

Note:Iftheedgesarenotsharporhavenicks,remove

andsharpentheblades;refertoSharpeningtheBlades

(page37).

2.Inspecttheblades,especiallythecurvedarea(Figure

44).

Note:Ifyounoticeanydamage,wear,oraslot

forminginthisarea(item3inFigure44),immediately

installanewblade.

Figure44

1.Cuttingedge3.Wear/slotforming

2.Curvedarea

4.Damage

Parkthemachineonalevelsurface,disengagethe

blade-controlswitch,movethemotion-controlleversoutward

totheparkposition,stoptheengine,andremovethekey .

CheckingforBentBlades

Note:Themachinemustbeonalevelsurfaceforthe

followingprocedure.

1.Raisethemowerdecktothehighestheight-of-cut

position;alsoconsideredthe'transport'position.

2.Whilewearingthicklypaddedgloves,orotheradequate

handprotection,slowlyrotatethebladetobemeasure

intoapositionthatallowseffectivemeasurementofthe

distancebetweenthecuttingedgeandthelevelsurface

themachineison(Figure45).

Figure45

1.Deck3.Blade

2.Spindlehousing

35

Page 36

3.Measurefromthetipofthebladetotheatsurface

G009680

1

2

3

G009681

1

2

3

G009680

1

2

3

(Figure46).

Figure46

1.Blade(inpositionformeasuring)

2.Levelsurface

3.Measureddistancebetweenbladeandthesurface(A)

4.Rotatethesameblade180degrees,sothattheopposing

cuttingedgeisnowinthesameposition(Figure47).

Figure48

1.Oppositebladeedge(inpositionformeasuring)

2.Levelsurface

3.Secondmeasureddistancebetweenbladeandsurface(B)

A.IfthedifferencebetweenAandBisgreaterthan

3mm(1/8inch),replacethebladewithanew

blade;refertoRemovingtheBlades(page36)and

InstallingtheBlades(page37).

Note:Ifabentbladeisreplacedwithanewone,

andthedimensionobtainedcontinuestoexceed

3mm(1/8inch),thebladespindlecouldbebent.

ContactanAuthorizedToroDealerforservice.

Figure47

1.Blade(sidepreviouslymeasured)

2.Measurement(positionusedpreviously)

3.Opposingsideofbladebeingmovedintomeasurement

position

5.Measurefromthetipofthebladetotheatsurface

(Figure48).

Note:Thevarianceshouldbenomorethan3mm

(1/8inch).

B.Ifthevarianceiswithinconstraints,movetothe

nextblade.

Repeatthisprocedureoneachblade.

RemovingtheBlades

Thebladesmustbereplacedifasolidobjectishit,ifthe

bladeisoutofbalance,orifthebladeisbent.T oensure

optimumperformanceandcontinuedsafetyconformance

ofthemachine,usegenuineTororeplacementblades.

Replacementbladesmadebyothermanufacturersmayresult

innon-conformancewithsafetystandards.

1.Holdthebladeendusingaragorthickly-paddedglove.

2.Removethebladebolt,thecurvedwasher,theblade

stiffener,andthebladefromthespindleshaft(Figure

49).

36

Page 37

2.Installthebladestiffener,thecurvedwasher(cupped

G014630

1

2

3

4

4

sidetowardtheblade),andthebladebolt(Figure49).

3.Torquethebladeboltto47to88N-m(35to65ft-lb).

LevelingtheMowerDeck

Checktoensurethatthemowerdeckislevelanytimeyou

installthemowerorwhenyouseeanunevencutonyour

lawn.

Figure49

1.Sailareaoftheblade

2.Blade

3.Curvedwasher

4.Bladebolt

5.Bladestiffener

SharpeningtheBlades

1.Usealetosharpenthecuttingedgeatbothendsof

theblade(Figure50).

Note:Maintaintheoriginalangle.

Note:Thebladeretainsitsbalanceifthesameamount

ofmaterialisremovedfrombothcuttingedges.

Figure50

1.Sharpenatoriginalangle

Themowerdeckmustbecheckedforbentbladespriorto

leveling;anybentbladesmustberemovedandreplaced;refer

toCheckingforBentBlades(page35)beforecontinuing.

Themowerdeckmustbeleveledside-to-siderstthenthe

fronttorearslopecanbeadjusted.

Requirements:

•Themachinemustbeonalevelsurface.

•Alltiresmustbeproperlyinated;refertoCheckingthe

TirePressure(page33).

LevelingfromSidetoSide

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Settheparkingbrake,stoptheengine,removethekey,

andwaitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Settheheight-of-cutlevertomiddleposition.

4.Carefullyrotatetheblade(s)sothattheyareallsideto

side(Figure52.

2.Checkthebalanceofthebladebyputtingitonablade

balancer(Figure51).

Note:Ifthebladestaysinahorizontalposition,the

bladeisbalanced,andcanbeused.

Note:Ifthebladeisnotbalanced,lesomemetaloff

theendofthesailareaonly(Figure50).

Figure51

1.Blade2.Balancer

3.Repeatthisprocedureuntilthebladeisbalanced.

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure49).

Important:Thecurvedpartoftheblademustbe

pointingupwardtowardtheinsideofthemowerto

ensurepropercutting.

Figure52

1.Bladesidetoside

2.Sailareaoftheblade4.Measurefromthetipofthe

3.Outsidecuttingedges

bladetotheatsurface

here

5.Measurebetweentheoutsidecuttingedgesandthe

atsurface(Figure52.Ifbothmeasurementsarenot

within5mm(3/16inch),anadjustmentisrequired;

continuewiththisprocedure.

37

Page 38

6.Movetotheleftsideofthemachine.

G014631

1

2

2

7.Loosenthesidelockingnut.

AdjustingtheFront-to-RearBlade

Slope

8.Raiseorlowertheleftsideofthemowerdeckby

rotatingtherearnut.(Figure53).

Note:Rotatetherearnutclockwisetoraisethemower

deck;rotatetherearnutcounter-clockwisetolower

themowerdeck.

Figure53

Checkthefront-to-rearbladeslopeanytimeyouinstallthe

mower.Ifthefrontofthemowerismorethan7.9mm

(5/16inch)lowerthantherearofthemower,adjusttheblade

levelusingthefollowinginstructions:

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Settheparkingbrake,stoptheengine,removethekey,

andwaitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Settheheight-of-cutlevertomiddleposition.

Note:Checkandadjusttheside-to-sidebladelevel

ifyouhavenotcheckedthesetting;refertoLeveling

fromSidetoSide(page37).

4.Carefullyrotatethebladessotheyarefacingfrontto

rear(Figure54.

1.Hangerbracket3.Rearnut

2.Sidelockingnut

9.Checktheside-to-sideadjustmentsagain.Repeatthis

procedureuntilthemeasurementsarecorrect.

10.Continuelevelingthedeckbycheckingthefront-to-rear

bladeslope;refertoAdjustingtheFront-to-RearBlade

Slope(page38).

Figure54

Mowerdeckswith1blade

1.Bladefronttorear

2.Measurefromthetipofthebladetotheatsurfacehere.

5.Measurefromthetipofthefrontbladetotheat

surfaceandthetipoftherearbladetotheatsurface

(Figure54).

Note:Ifthefrontbladetipisnot1.6to7.9mm(1/16

to5/16inch)lowerthantherearbladetip,adjustthe

frontlocknut.

6.Toadjustthefront-to-rearbladeslope,rotatethe

adjustmentnutinthefrontofthemower(Figure55).

38

Page 39

G014634

1

2

3

Figure55

G014635

1

2

3

G015338

2

2

3

1

2

2

3

1.Adjustingrod3.Locknut

2.Adjustingblock

7.Toraisethefrontofthemower,tightentheadjustment

nut.

8.Tolowerthefrontofthemower,loosentheadjustment

nut.

9.Afteradjustment,checkthefront-to-rearslopeagain,

continueadjustingthenutuntilthefrontbladetipis

1.6to7.9mm(1/16to5/16inch)lowerthantherear

bladetip(Figure54).

10.Whenthefront-to-rearbladeslopeiscorrectcheckthe

side-to-sidelevelofthemoweragain;refertoLeveling

fromSidetoSide(page37).

RemovingtheMower

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothepark

position,stoptheengine,removethekey ,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Lowertheheight-of-cutlevertothelowestposition.

Figure56

1.Frontsupportrod3.Deckbracket

2.Lockingnut

5.Liftthemowerdeckandhangerbracketsclearofthe

rearliftrod,andlowerthemowercarefullytothe

ground(Figure57).

4.Removethehairpincotterfromthefrontsupportrod,

andremovetherodfromthedeckbracket(Figure

56).Carefullylowerthefrontofthemowerdeckto

theground.

1.Mowerdeck

2.Hangerbracket

Figure57

3.Rearliftrod

6.Slidethemowerdeckrearwardtoremovethemower

beltfromtheenginepulley.

7.Slidethemowerdeckoutfromunderneaththe

machine.

Note:Retainallpartsforfutureinstallation.

39

Page 40

InstallingtheMower

G014636

1

2

3

4

5

6

7

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothepark

position,stoptheengine,removethekey ,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Slidethemowerunderthemachine.

4.Lowertheheight-of-cutlevertothelowestposition.

5.Lifttherearofthemowerdeckandguidethehanger

bracketsovertherearliftrod(Figure57).

2.Removethenut(3/8inch)fromtherodunderthe

mower(Figure58).

3.Slidetherodoutoftheshortstand-off,spring,and

grassdeector(Figure58).

4.Removethedamagedorworngrassdeector.

5.Replacethegrassdeector(Figure58).

6.Slidetherod,straightend,throughthereargrass

deectorbracket.

7.Placethespringontherod,withendwiresdown,and

betweenthegrassdeectorbrackets.Sliderodthrough

secondgrassdeectorbracket(Figure58).

6.Attachthefrontsupportrodtothemowerdeckwith

theclevispinandhairpincotter(Figure56).

7.Installthemowerbeltontotheenginepulley;referto

ReplacingtheMowerBelt(page41).

ReplacingtheGrassDeector

ServiceInterval:Beforeeachuseordaily—Inspectthegrass

deectorfordamage.

WARNING

Anuncovereddischargeopeningcouldallowthe

lawnmowertothrowobjectsintheoperator'sor

bystander'sdirectionandresultinseriousinjury.

Also,contactwiththebladecouldoccur.

Neveroperatethemachinewithoutgrassdeector,

dischargecoverorgrasscollectionsysteminplace.

1.LocateitemsshowninFigure58.

8.Insertrodatfrontofgrassdeectorintoshortstandoff

ondeck.

9.Securerearendofrodintothemowerwithanut

(3/8inch)asshowninFigure58.

Important:Thegrassdeectormustbespring

loadedinthedownposition.Liftthedeectorup

totestthatitsnapstothefulldownposition.

Figure58

1.Mowerdeck

2.Grassdeector6.Nut(3/8inch)

3.Grass-deectorbracket7.Shortstandoff

4.Rod

5.Spring

40

Page 41

MowerBeltMaintenance

G015129

1

2

3

4

5

4

6

ServicingtheMowerBelt

InspectingtheBelts

ServiceInterval:Every25hours—Checkthebeltsfor

wear/cracks.

Checkthebeltsforcracks,frayededges,burnmarks,orany

otherdamage.Replacedamagedbelts.

ReplacingtheMowerBelt

Squealingwhenthebeltisrotating,bladesslippingwhen

cuttinggrass,frayedbeltedges,burnmarks,andcracksare

signsofawornmowerbelt.Replacethemowerbeltifanyof

theseconditionsareevident.

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothepark

position,stoptheengine,removethekey ,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Settheheight-of-cutatthelowestcuttingposition(38

mm(1-1/2inches)).

4.Usingaspring-removaltool(Toropartno.92-5771),

removetheidlerspringfromthedeckhooktoremove

tensionontheidlerpulley,androllthebeltoffofthe

pulleys(Figure59).

WARNING

Figure59

1.Idlerpulley

2.Mowerbelt5.Enginepulley

3.Outsidepulley6.Spring-removaltool

5.Routethenewbeltaroundtheenginepulleyand

mowerpulleys(Figure59).

6.Usingaspringremovaltool(T oropartno.92-5771),

installtheidlerspringoverthedeckhookandplacing

tensionontheidlerpulleyandthemowerbelt(Figure

59).

4.Spring

Thespringisundertensionwheninstalled

andcancausepersonalinjury.

Becarefulwhenremovingthebelt.

41

Page 42

Cleaning

G020098

2

4

1

2

3

4

8.Turnthewateroffandremovethecouplingfromthe

washouttting.

WashingtheUndersideofthe Mower

ServiceInterval:Aftereachuse—Cleanthemower-deck

housing.

Washtheundersideofthemoweraftereachusetoprevent

grassbuildupforimprovedmulchactionandclipping

dispersal.

Important:Y oucanwashthemachinewithamild

detergentandwater.Donotpressurewashthemachine.

Avoidexcessiveuseofwater,especiallynearthecontrol

panel,undertheseat,aroundtheengine,hydraulic

pumps,andmotors.

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothepark

position,stoptheengine,removethekey ,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Attachthehosecouplingtotheendofthemower

washouttting,andturnthewateronhigh(Figure60).

Note:Ifthemowerisnotcleanafteronewashing,

soakitandletitstandfor30minutes.Then,repeat

theprocess.

9.Runthemoweragainfor1to3minutestoremove

excesswater.

WARNING

Abrokenormissingwashoutttingcould

exposeyouandotherstothrownobjectsor

bladecontact.Contactwithbladeorthrown

debriscancauseinjuryordeath.

•Replacebrokenormissingwashouttting

immediately,beforeusingmoweragain.

•Neverputyourhandsorfeetunderthe

mowerorthroughopeningsinthemower.

Note:Spreadpetroleumjellyonthewashouttting

O-ringtomakethecouplingslideoneasierandprotect

theO-ring.

Figure60

1.Washouttting3.O-ring

2.Hose

4.Lowerthemowertothelowestheight-of-cut.

5.Sitontheseatandstarttheengine.

6.Engagetheblade-controlswitchandletthemowerrun

for1to3minutes.

4.Coupling

7.Disengagetheblade-controlswitch,stoptheengine,

removetheignitionkey,andwaitforallmovingparts

tostop.

42

Page 43

Storage

CleaningandStorage