Page 1

FormNo.3394-276RevA

TimeCutter

®

ZS4200Tor5000

RidingMower

ModelNo.74656—SerialNo.315000001andUp

ModelNo.74660—SerialNo.315000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3394-276*A

Page 2

ThisproductcomplieswithallrelevantEuropeandirectives;

G014523

1

fordetails,pleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

GrossHorsepower

Formodelswithstatedenginehorsepower,thegross

horsepoweroftheenginewaslaboratorytestedbytheengine

manufacturerinaccordancewithSAEJ1995andratedto

J2723.Asconguredtomeetsafety,emission,andoperating

requirements,theactualenginehorsepoweronthisclassof

lawnmowerwillbesignicantlylower.

Gotowww .Toro.comtoviewspecicationsonyourmower

model.

ThissparkignitionsystemcomplieswithCanadianICES-002

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

Introduction

Thismachineisaride-on,rotary-bladeintendedtobeused

byhomeownersinresidentialapplications.Itisprimarily

designedforcuttinggrassonwell-maintainedlawns.Itisnot

designedforcuttingbrush,mowinggrassandothergrowth

alongsidehighways,orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

Figure1

Undertheseat

1.Modelandserialnumberplate

Writetheproductmodelandserialnumbersinthespace

below:

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroMowerSafety..................................................6

Model74656...........................................................7

Model74660...........................................................7

SlopeIndicator.......................................................8

SafetyandInstructionalDecals.................................9

ProductOverview.........................................................15

Controls...............................................................16

Operation....................................................................17

AddingFuel...........................................................17

CheckingtheEngine-OilLevel.................................18

BreakinginaNewMachine......................................18

ThinkSafetyFirst...................................................19

StartingtheEngine.................................................20

OperatingtheBlades...............................................21

StoppingtheEngine...............................................21

DrivingtheMachine...............................................21

StoppingtheMachine.............................................23

AdjustingtheHeight-of-Cut....................................24

AdjustingtheAnti-ScalpRollers(for107cm

(42-inch)MowerDecks)......................................24

AdjustingtheAnti-ScalpRollers(for127cm

(50-inch)MowerDecks)......................................24

PositioningtheSeat................................................25

AdjustingtheMotion-ControlLevers........................25

PushingtheMachinebyHand..................................25

ConvertingtoSideDischarge(formodelswith107

cm(42-inch)decks).............................................26

ConvertingtoSideDischarge(formodelswith127

cm(50-inch)decks).............................................27

TransportingtheMachine........................................29

LoadingtheMachine..............................................29

OperatingTips......................................................31

Maintenance.................................................................32

RecommendedMaintenanceSchedule(s)......................32

PremaintenanceProcedures........................................33

RaisingtheSeat......................................................33

ReleasingtheMower-DeckCurtain...........................33

Lubrication...............................................................33

GreasingtheBearings.............................................33

EngineMaintenance..................................................34

ServicingtheAirCleaner.........................................34

ServicingtheEngineOil..........................................35

ServicingtheSparkPlug..........................................37

CleaningtheCoolingSystem....................................38

FuelSystemMaintenance...........................................38

ReplacingtheIn-LineFuelFilter...............................38

ElectricalSystemMaintenance....................................39

ChargingtheBattery...............................................39

ServicingtheFuses.................................................41

DriveSystemMaintenance.........................................41

CheckingtheTirePressure......................................41

ReleasingtheElectricBrake.....................................41

MowerMaintenance...................................................42

ServicingtheCuttingBlades.....................................42

LevelingtheMowerDeck........................................45

RemovingtheMower..............................................47

InstallingtheMower...............................................47

ReplacingtheGrassDeector..................................48

MowerBeltMaintenance............................................49

InspectingtheBelts................................................49

ReplacingtheMowerBelt........................................49

Cleaning...................................................................50

WashingtheUndersideoftheMower........................50

Storage........................................................................51

CleaningandStorage..............................................51

Troubleshooting...........................................................53

Schematics...................................................................55

3

Page 4

Safety

ThismachinehasbeendesignedinaccordancewithENISO

5395:2013.

Improperlyusingormaintainingthismowercanresult

ininjury.T oreducethepotentialforinjury,complywith

thesesafetyinstructions.

Torodesignedandtestedthismowerforreasonablysafe

service;however,failuretocomplywiththefollowing

instructionsmayresultinpersonalinjury.

Toensuremaximumsafety ,bestperformance,and

togainknowledgeoftheproduct,itisessentialthat

youandanyotheroperatorofthemowerreadand

understandthecontentsofthismanualbeforethe

engineiseverstarted.Payparticularattentiontothe

safetyalertsymbol(Figure2)whichmeansCaution,

Warning,orDanger—“personalsafetyinstruction.”

Readandunderstandtheinstructionbecauseithasto

dowithsafety.Failuretocomplywiththeinstruction

mayresultinpersonalinjury.

SafeOperatingPractices

Training

•ReadtheOperator'sManualandothertrainingmaterial.

Note:Iftheoperator(s)ormechanic(s)cannotreadthe

manuallanguage,itistheowner'sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.

Note:Localregulationsmayrestricttheageofthe

operator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

people,ordamagetoproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothing;includingahardhat,safety

glasses,longpants,substantial,slip-resistantfootwear,

gloves,andhearingprotection.

Important:Longhair,looseclothingorjewelrymay

gettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeusedand

ensurethatallobjectsareremovedfromthemachine

beforeuse.

•Useextracarewhenhandlingfuels.Theyareammable

andvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Donotremovethefuelcaporaddfuelwiththe

enginerunning.Allowtheenginetocoolbefore

refueling.Donotsmokenearthemachinewhenthe

engineisrunning.

–Donotrefuelordrainthemachineindoors.

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlesstheyare

functioningproperly.

Operation

•Lightningcancausesevereinjuryordeath.Iflightning

isseen,orthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxideandotherexhaustgasses

cancollect.

•Onlyoperateinwell-litareas,keepingawayfromholes

andhiddenhazards.

•Ensurethatalldrivesareinneutralandthattheparking

brakeisengagedbeforestartingengine.Onlystartthe

enginefromtheoperator’ sposition.

•Slowdownanduseextracareonhillsides.Besureto

travelsidetosideonhillsides.Turfconditionscanaffect

thestabilityofthemachine.Usecautionwhileoperating

neardrop-offs.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Donotraisethemowerdeckwiththebladesrunning.

•DonotoperatethemachinewithoutthePTOshieldor

otherguardssecurelyinplace.Besureallinterlocksare

attached,adjustedproperly ,andfunctioningproperly.

•Donotoperatewiththedischargedeectorraised,

removedoraltered,unlessusingagrasscatcher.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

4

Page 5

•Stoponlevelground,disengagedrives,engagethe

parkingbrake(ifprovided),shutofftheenginebefore

leavingtheoperator'spositionforanyreason,including

emptyingthecatchersoruncloggingthechute.

•Stopequipmentandinspectthebladesafterstriking

objectsorifanabnormalvibrationoccurs.Makethe

necessaryrepairsbeforeresumingoperations.

•Keepyourhandsandfeetawayfromthecuttingunit.

•Lookbehindanddownbeforebackinguptoensurea

clearpath.

•Keeppetsandbystandersawayfromanoperating

machine.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopthebladesifyouare

notmowing.

•Beawareofthemower-dischargedirectionanddonot

pointitatanyone.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs.

•Usecarewhenloadingorunloadingthemachineinto

orfromatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfuelwiththeengine

running.

•Allowtheenginetocoolbeforefueling.

•Donotfuelthemachineindoors.

•Donotstorethemachineorfuelcontainerwherethere

isanopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Donotllcontainersinsideavehicle,onatruck,orona

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandfuelit

ontheground.Ifthisisnotpossible,thenaddfuelwith

suchequipmentasaportablecontainer,ratherthanfrom

afueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeyourclothing

immediately.

•Donotoverllfueltank.Replacefuelcapandtighten

securely.

MaintenanceandStorage

•Disengagedrives,settheparkingbrake,stoptheengine,

andremovethekeyordisconnectspark-plugwire.Wait

forallmovementtostopbeforeadjusting,cleaning,or

repairing.

•Cleangrassanddebrisfromthecuttingunit,drives,

mufers,andenginetohelppreventres.

•Cleanupoilorfuelspillage.

•Lettheenginecoolbeforestoring.

•Donotstorefuelnearamesordrainindoors.

•Donotallowuntrainedpersonneltoservicemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatteryorremovethespark-plugwire

beforemakinganyrepairs.Disconnectthenegative

terminalrstandthepositiveterminallast.Reconnect

thepositiverstandnegativelast.

•Usecarewhencheckingtheblades.Wraptheblade(s)

orwearthickly-paddedgloves,andusecautionwhen

servicingthem.Onlyreplaceblades;donotstraighten

orweldthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

traileroratruck.

•Usefull-widthrampsforloadingmachineintoatrailer

oratruck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

5

Page 6

ToroMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsandothersafetyinformationyoumustknow .

Thisproductiscapableofamputatinghandsandfeet,and

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Thisproductisdesignedforcuttingandrecyclinggrass,or,

whenequippedwithagrassbagger,forcatchingcutgrass.

Anyuseforpurposesotherthanthesecouldprovedangerous

totheuserandbystanders.

GeneralOperation

•Besurethattheareaisclearofbystandersbeforemowing.

Stopthemachineifanyoneentersthearea.

•Donottouchequipmentorattachmentpartswhichmay

behotfromoperation.Allowallofthepartstocool

beforeattemptingtomaintain,adjust,orservicethe

machine.

SlopeOperation

Allslopesandrampsrequireextracaution.Ifyoufeeluneasy

onaslope,donotmowit.

•Removeobstaclessuchasrocks,treelimbs,etc.fromthe

mowingarea.

•Watchforholes,rutsorbumps.

Note:Tallgrasscanhideobstacles.

•Usecautionneardrop-offs,ditches,orembankments.

Note:Themachinecouldsuddenlyturnoverifawheel

goesovertheedgeofaclifforditch,orifanedgecavesin.

•Useextracarewithgrasscatchersorotherattachments.

Note:Thesecanchangethestabilityofthemachine.

•Keepallmovementonslopesslowandgradual.

•Donotmakesuddenchangesinspeedordirection.

•Mowslopessidetoside.

•Donotmowslopesgreaterthan15degrees.

•UseonlyToro-approvedattachments.Warrantymaybe

voidedifusedwithanyunapprovedattachments.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires,etc.)beforeoperatingunder

anyobjects,anddonotcontactthem.

•Slowdownbeforemakingturnsanduseextracaution.

•Usecautionwhenridingtheplatformovercurbs,rocks,

roots,orotherobstructions.

•Lookbehindanddownbeforebackinguptoensurea

clearpath.Useextracarewhenoperatinginreverse.

•Donotjerkthecontrols;useasteadymotion.

•Whenloadingorunloadingthemachine,useone

full-widthrampthatiswideenoughtoextendbeyond

thewidthofthemachine.

•Donotcarrypassengers.

•Donotcarryequipmentonthemachine.

TowingSafety

•Donotattachtowedequipmentexceptatthehitchpoint.

•Followtheattachmentmanufacturer'srecommendation

forweightlimitsfortowedequipmentandtowingon

slopes.Towedweightmustnotexceedtheweightofthe

machine,operator,andballast.Usecounterweightsor

wheelweightsasdescribedintheattachment,orinthe

pullingmachineOperator’sManual.

•Neverallowchildrenorothersinorontowedequipment.

•Onslopes,theweightofthetowedequipmentmaycause

lossoftraction,increasedriskofrollover,andlossof

control.Reducethetowedweightandslowdown.

•Stoppingdistanceincreaseswiththeweightofthetowed

load.Travelslowlyandallowextradistancetostop.

•Makewideturnstokeeptheattachmentclearofthe

machine.

Service

•Donotstorethemachineorafuelcontainerinsidewhere

thereisanopename,suchasnearawaterheateror

furnace.

•Keepthenutsandboltstight,especiallythe

blade-attachmentbolts.

•Neverremoveortamperwithsafetydevices.Checktheir

properoperationregularly.Neverdoanythingtointerfere

withtheintendedfunctionofasafetydeviceortoreduce

theprotectionprovidedbyasafetydevice.

•Removingstandardoriginalequipmentpartsand

accessoriesmayalterthewarranty,traction,andsafety

ofthemachine.FailuretouseoriginalToropartscould

causeseriousinjuryordeath.Makingunauthorized

changestotheengine,fuelorventingsystem,mayviolate

regulations.

6

Page 7

•Replaceallpartsincluding,butnotlimitedto,tires,belts,

blades,andfuelsystemcomponentswithoriginalToro

parts.

•Checkthebrakeoperationfrequently.Adjustandservice

thebrakeasrequired.

Model74660

SoundPressure

Thisunithasasoundpressurelevelattheoperator’searof94

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Model74656

SoundPressure

Thisunithasasoundpressurelevelattheoperator’searof89

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO5395:2013.

SoundPower

Thisunithasaguaranteedsoundpowerlevelof100dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

Hand/ArmVibration

Measuredvibrationlevelforrighthand=2.6m/s

Measuredvibrationlevelforlefthand=3.2m/s

UncertaintyValue(K)=1.6m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO5395:2013.

2

WholeBodyVibration

2

2

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO5395:2013.

SoundPower

Thisunithasaguaranteedsoundpowerlevelof105dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

Hand/ArmVibration

Measuredvibrationlevelforrighthand=2.8m/s

Measuredvibrationlevelforlefthand=3.5m/s

UncertaintyValue(K)=1.7m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO5395:2013.

2

2

2

WholeBodyVibration

Measuredvibrationlevel=0.37m/s

UncertaintyValue(K)=0.18m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO5395:2013(RidingandStand-Ons).

2

2

Measuredvibrationlevel=0.82m/s

UncertaintyValue(K)=0.41m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO5395:2013(RidingandStand-Ons).

2

2

7

Page 8

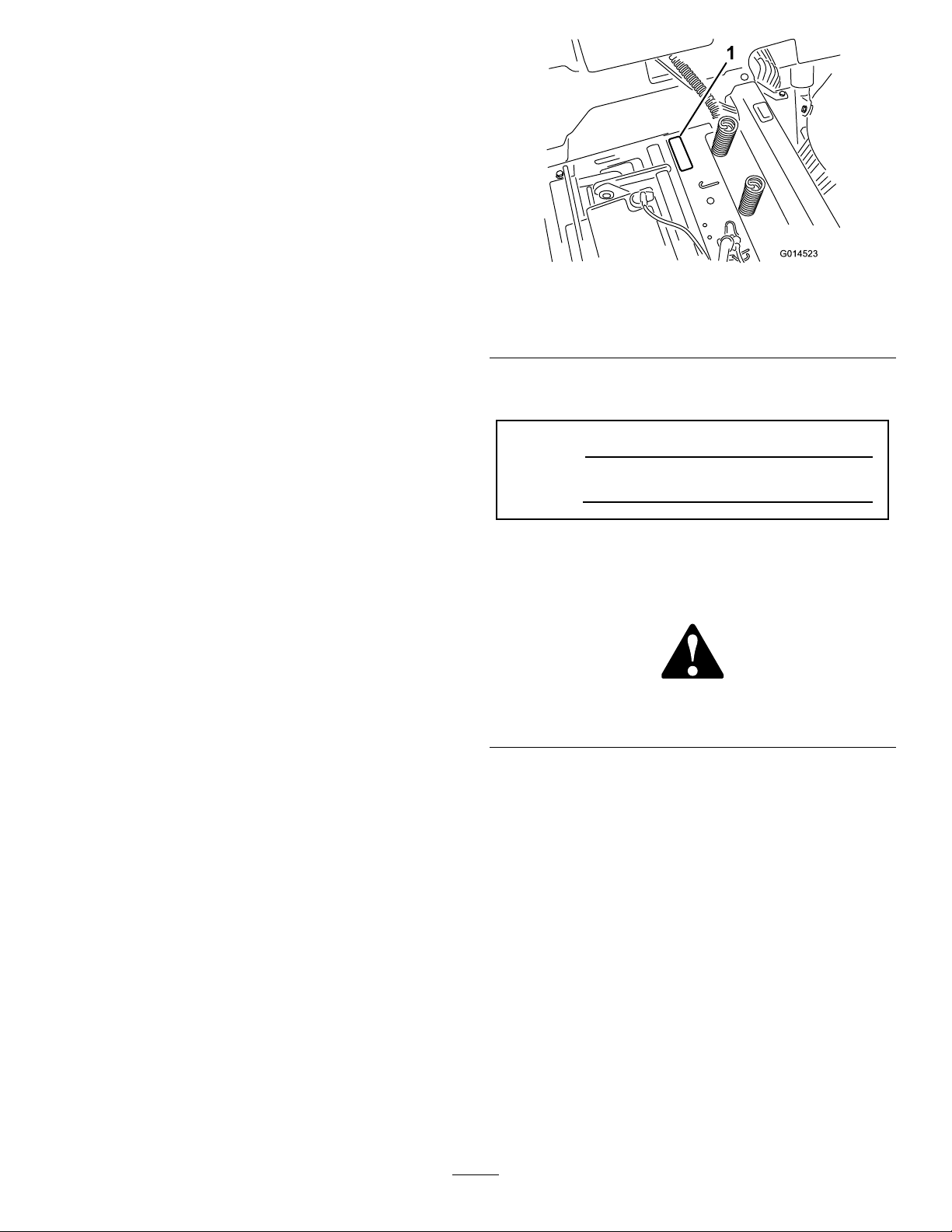

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

8

Page 9

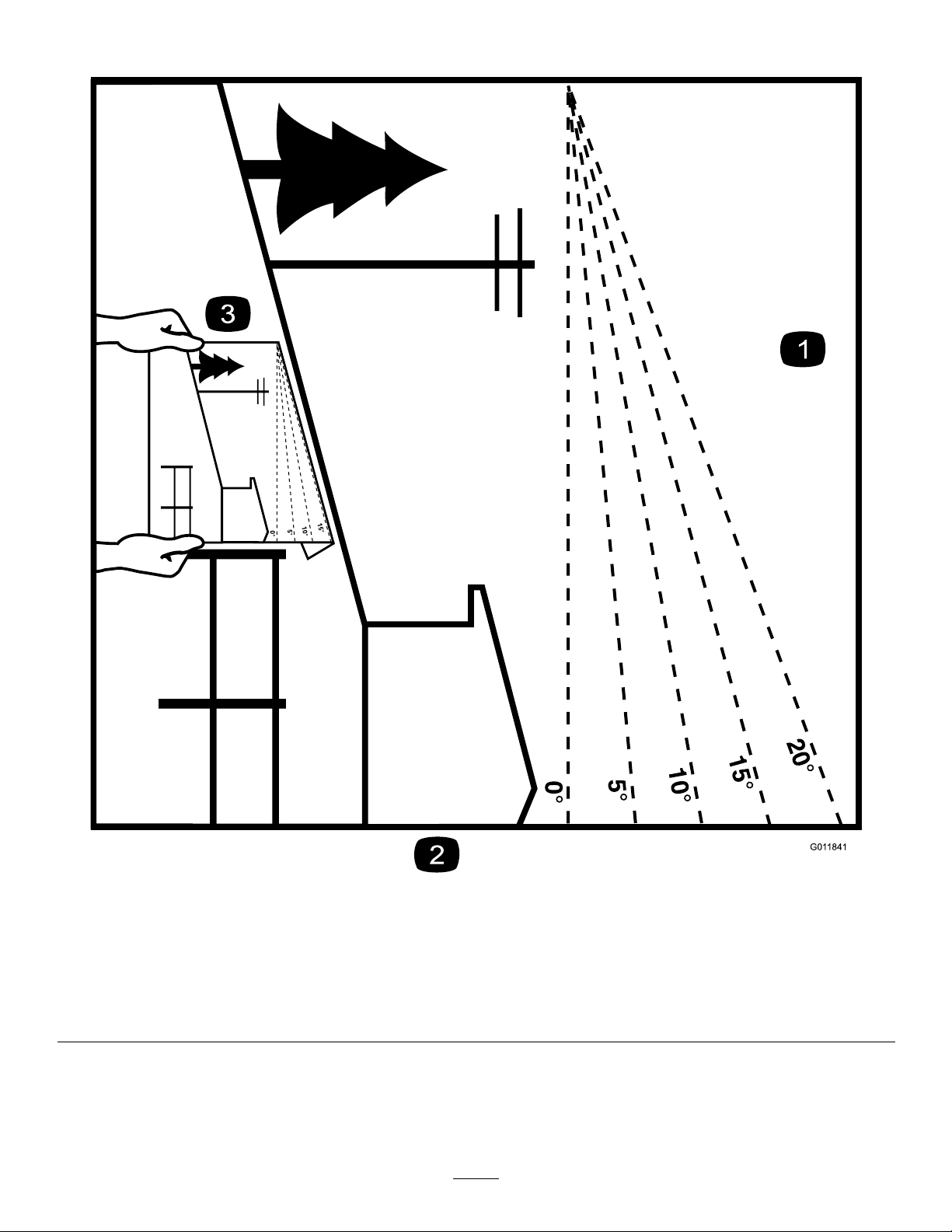

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

93-7009

1.Warning—don'toperatethemowerwiththedeectorupor

removed;keepthedeectorinplace.

2.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

105-7015

Formodelswith107cm(42inch)decks

106-8717

1.Readtheinstructionsbeforeservicingorperforming

maintenance.

2.Checktirepressureevery25operatinghours.

3.Greaseevery25operatinghours.

4.Engine

99-3943

Formodelswith127cm(50inch)decks

1.Engine

110-6691

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Thrownobjecthazard,mower—donotoperatewithoutthe

deector,dischargecover,orgrasscollectionsystemin

place.

3.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

9

Page 10

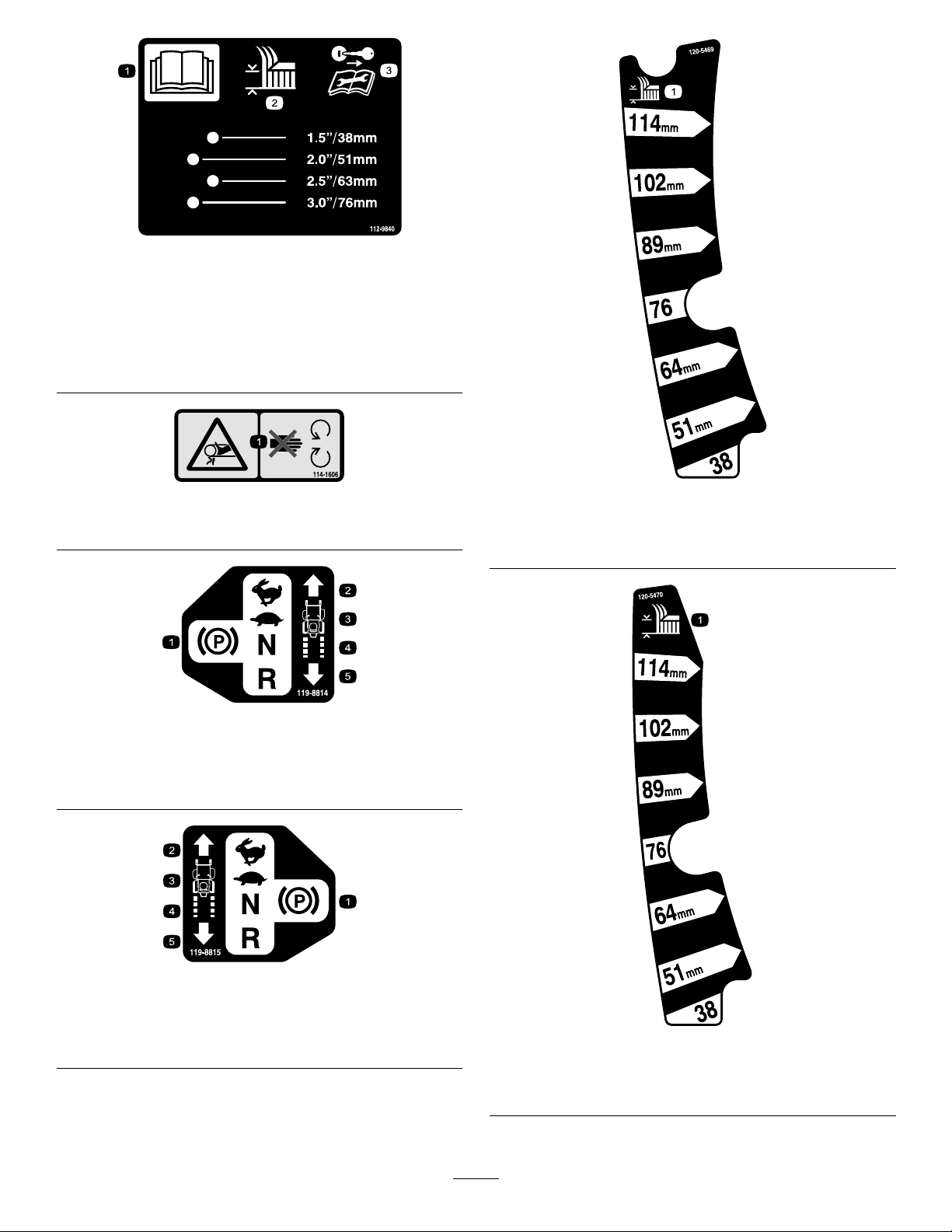

112-9840

Formodelswith127cm(50inch)decks

1.ReadtheOperator's

Manual.

2.Height-of-cut

3.Removetheignitionkey

andreadtheinstructions

beforeservicingor

performingmaintenance.

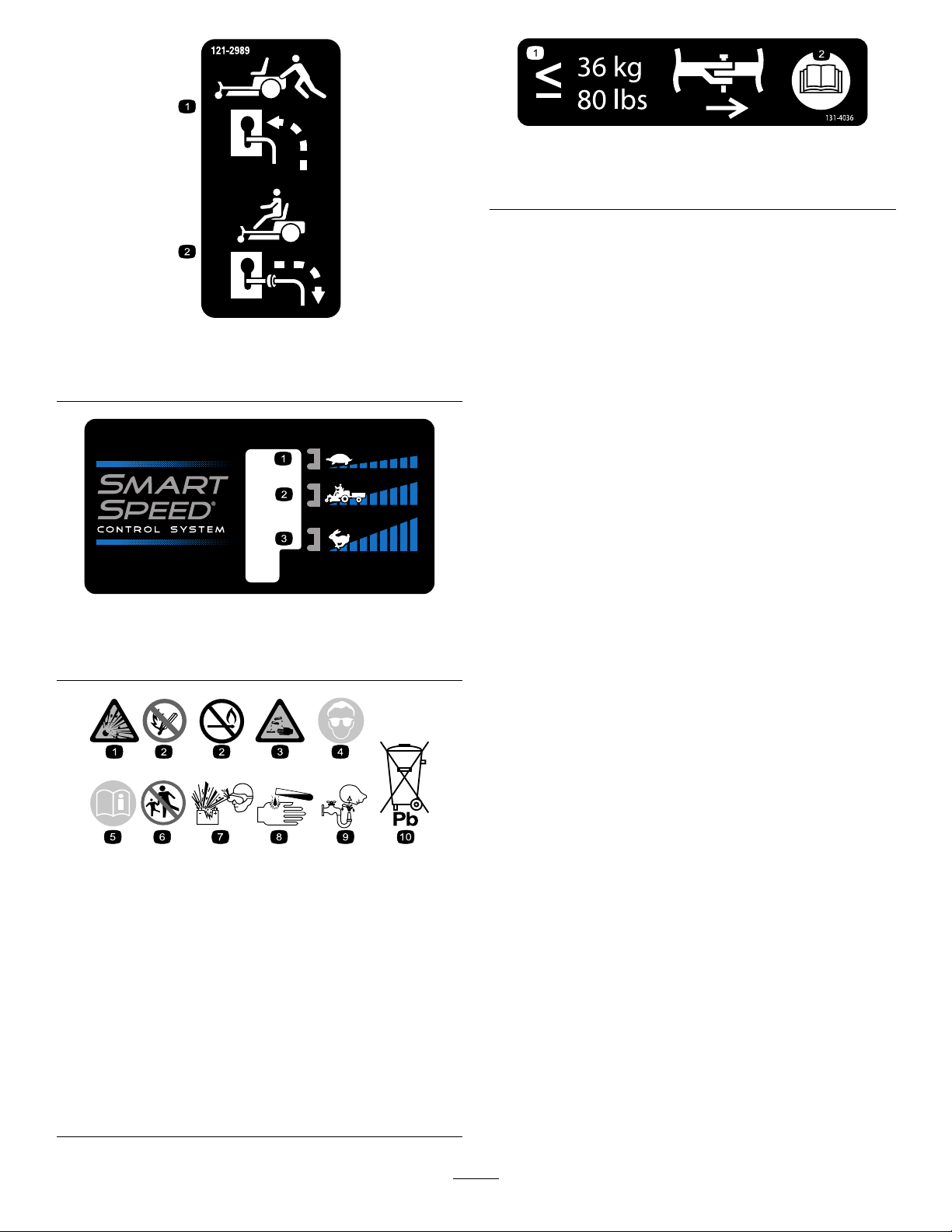

114-1606

1.Entanglementhazard,belt—keepallguardsinplace.

119-8814

1.Parkingposition4.Neutral

2.Fast5.Reverse

3.Slow

120-5469

Formodelswith107cm(42inch)decks

1.Height-of-cut

119-8815

1.Parkingposition4.Neutral

2.Fast5.Reverse

3.Slow

120-5470

Formodelswith127cm(50inch)decks

1.Height-of-cut

10

Page 11

131-3948

131-4036

1.Bypassleverpositionfor

pushingthemachine

121-2989

2.Bypassleverpositionfor

operatingthemachine

131-3948

1.Maximumdrawbarpull36

kg(80lb)

2.ReadtheOperator's

Manual.

1.Slow

2.Towing

3.Fast

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

11

Page 12

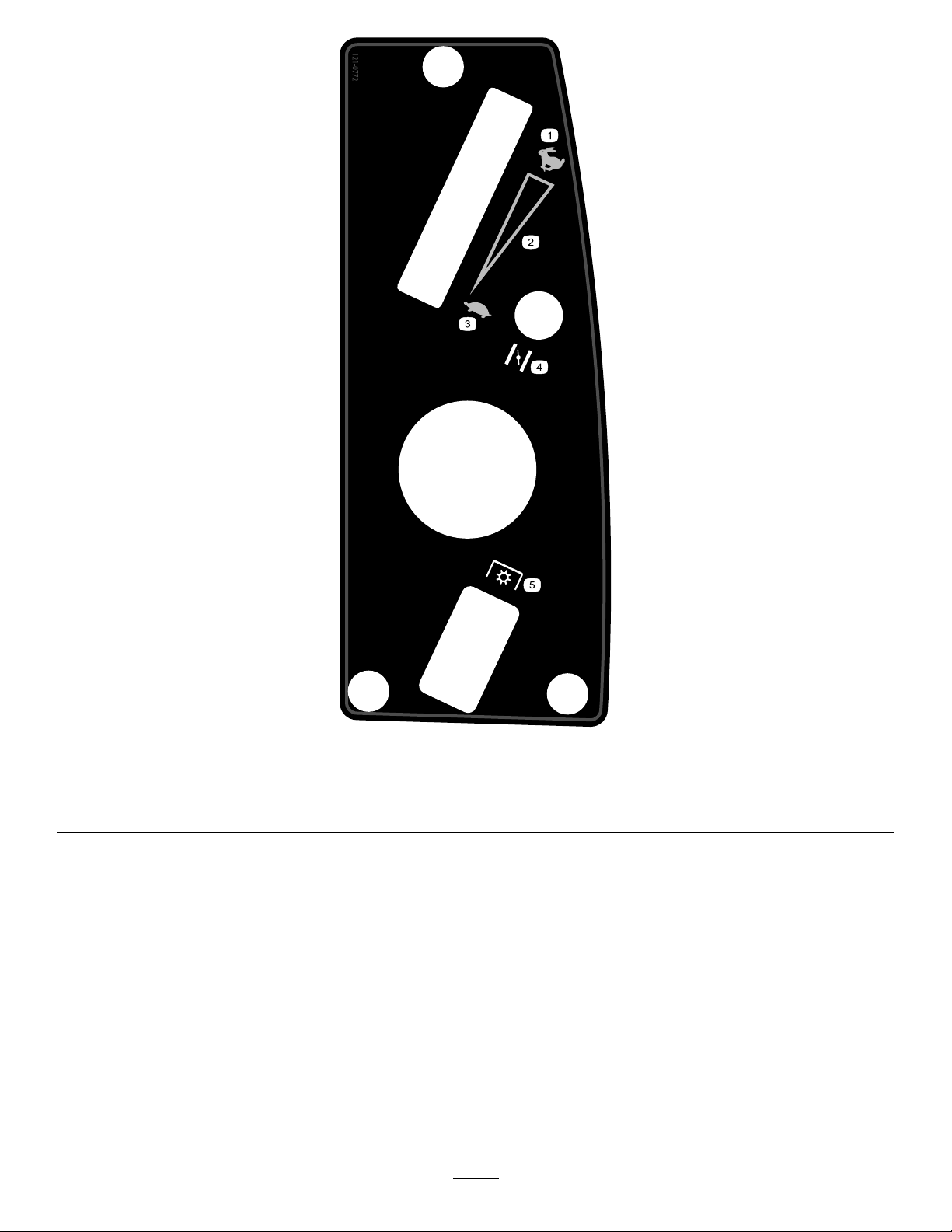

121-0772

1.Fast

2.Continuous-variablesetting5.Powertake-off(PTO),blade-controlswitch

3.Slow

4.Choke

12

Page 13

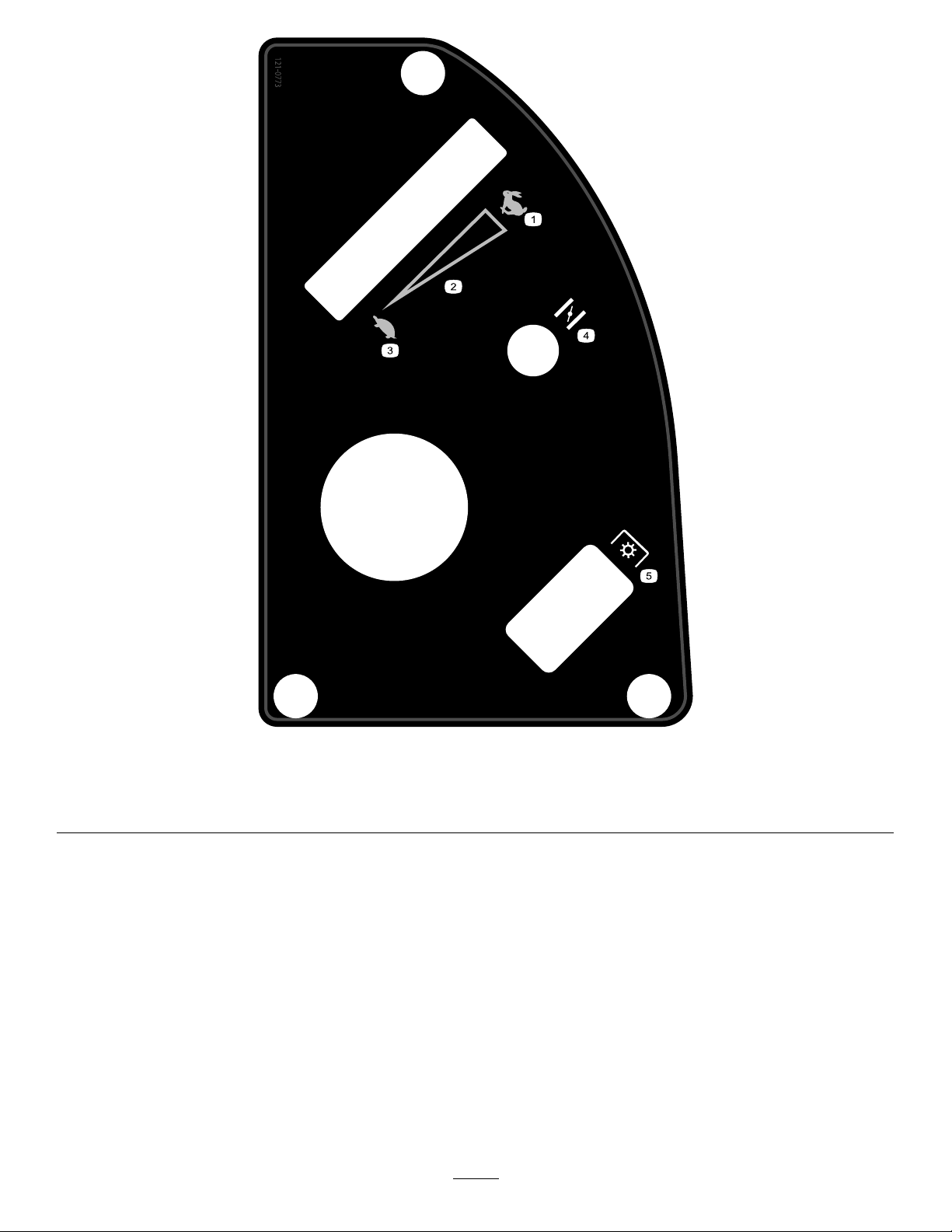

121-0773

1.Fast

2.Continuous-variablesetting5.Powertake-off(PTO),blade-controlswitch

3.Slow

4.Choke

13

Page 14

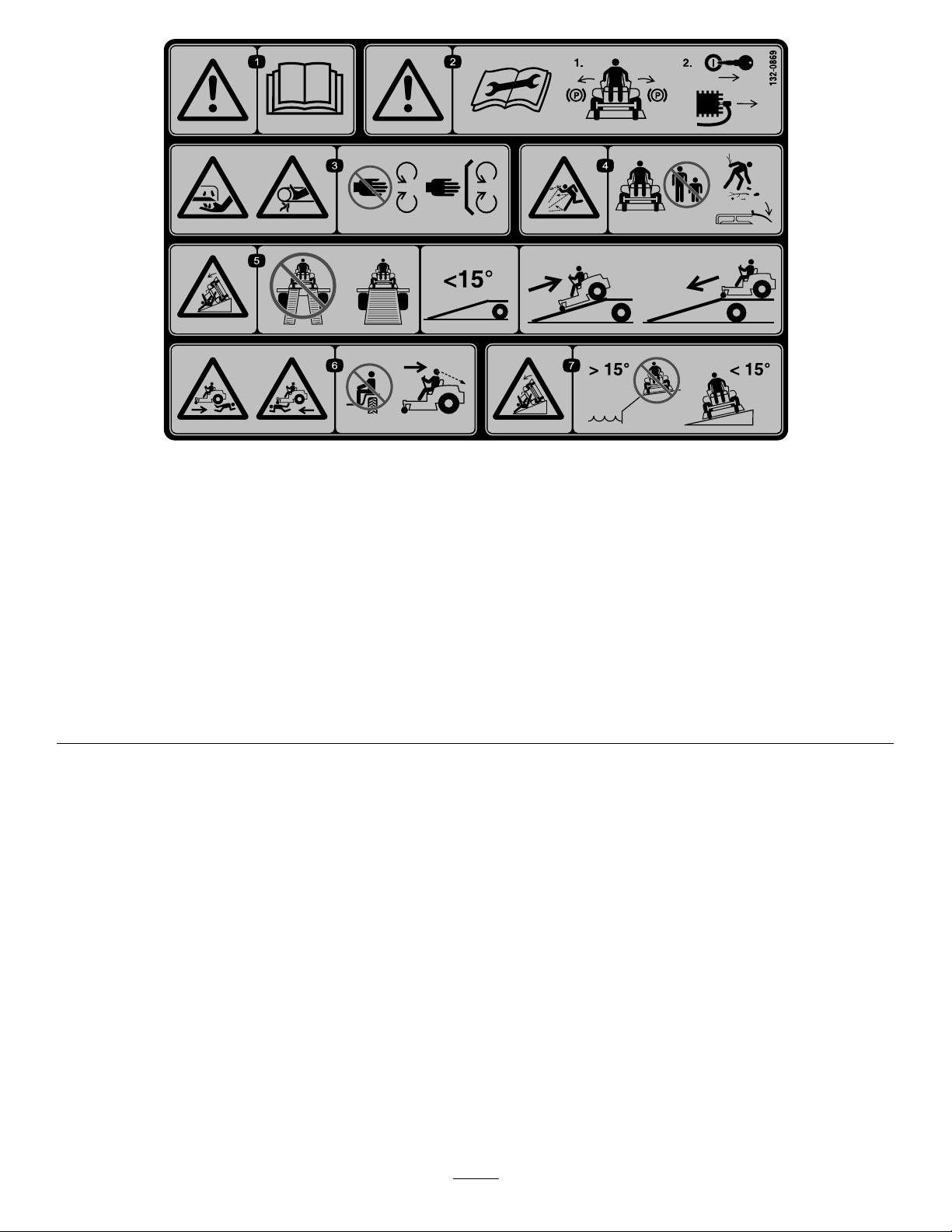

132-0869

1.Warning—readthe

Operator'sManual.

2.Warning—beforeservicing,

engagetheparkingbrake,

removethekeyandthe

sparkplugconnection.

3.Cuttinghazardofhand,

mowerblade;pinching

hazardofhand,belt—keep

handsandfeetawayfrom

movingparts;keepall

guardsandshieldsinplace.

4.Thrownobject

hazard—keepbystanders

awayfromthemachine;

removedebrisfromthe

areabeforemowing;keep

thedeectorshielddown.

5.Ramptipping

hazard—whenloading

ontoatrailer,donotuse

dualramps;onlyusea

singlerampwideenough

forthemachineandthat

hasaninclinelessthan

15degrees;backupthe

ramp(inreverse)anddrive

forwardofftheramp.

6.Bodilyharmhazard—no

riders;lookbehindyou

whenmowinginreverse.

7.Tippinghazardon

slopes—donotuseon

slopesnearopenwater;do

notuseonslopesgreater

than15degrees.

14

Page 15

ProductOverview

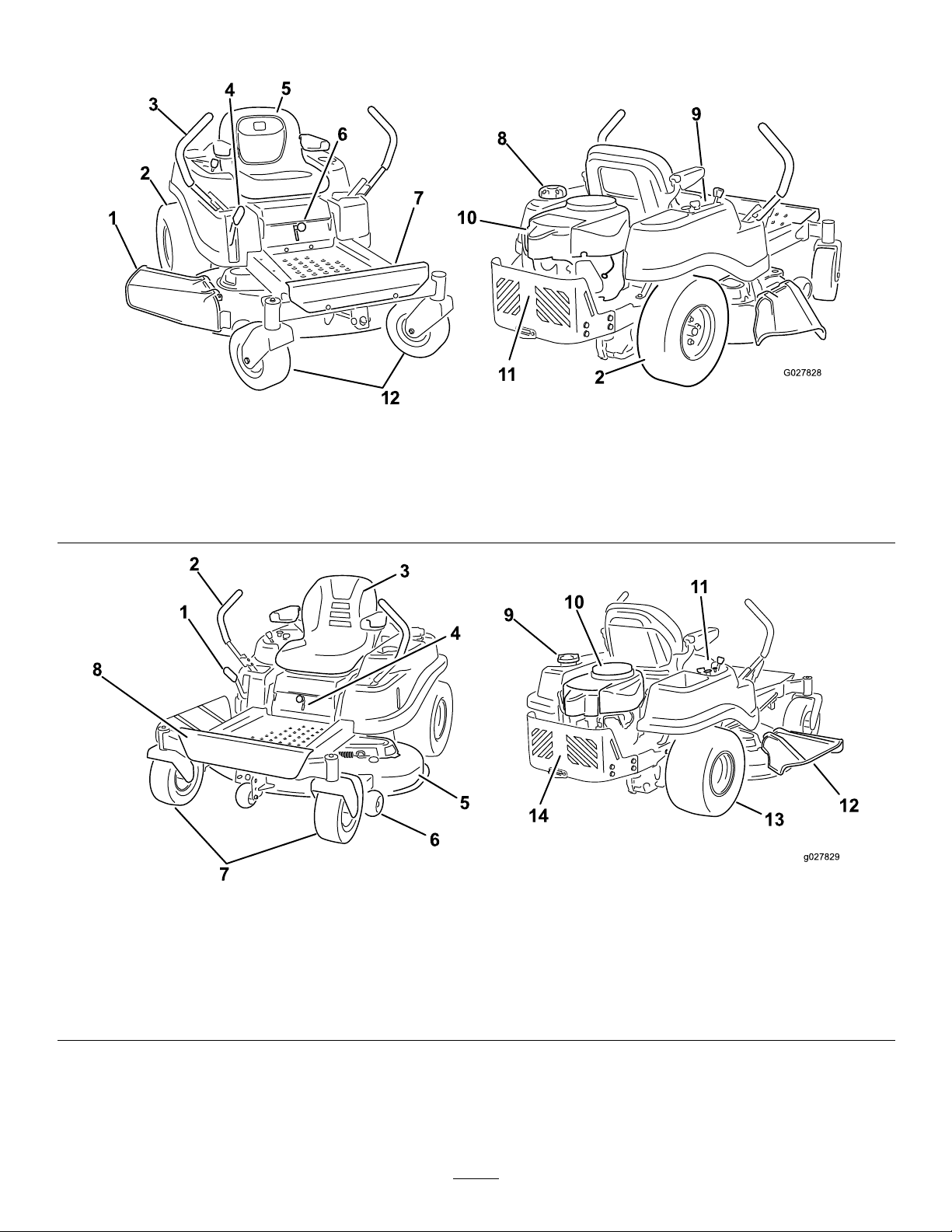

Figure4

Modelswith107cm(42-inch)decks

1.Deector4.Height-of-cutlever

2.Reardrivewheel

3.Motion-controllevers

5.Operatorseat

6.SmartSpeed™lever9.Controlpanel

7.Footrest10.Engine

8.Fuel-tankcap11.Engineguard

12.Frontcasterwheel

Figure5

Modelswith127cm(50-inch)decks

1.Height-of-cutlever

2.Motion-controllevers6.Anti-scalproller10.Engine14.Engineguard

3.Operatorseat

4.SmartSpeed™lever

5.Mowerdeck9.Fuel-tankcap13.Reardrivewheel

7.Frontcasterwheel

8.Footrest

11.Controlpanel

12.Deector

15

Page 16

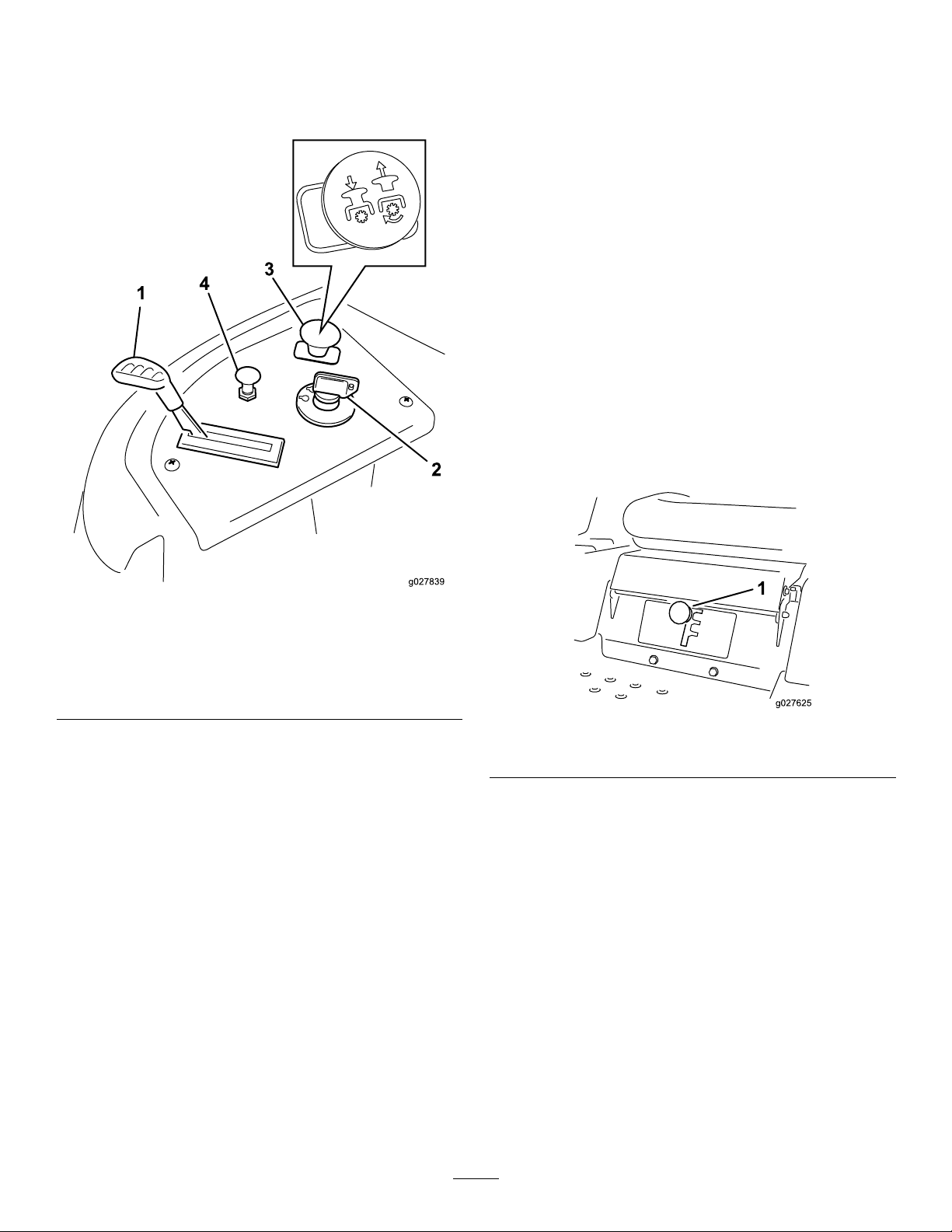

Controls

Blade-ControlSwitch(PowerTake-off)

BecomefamiliarwithallofthecontrolsinFigure4,Figure

5,andFigure6beforeyoustarttheengineandoperatethe

machine.

Theblade-controlswitch,representedbyapowertake-off

(PTO)symbol,engagesanddisengagespowertothemower

blades(Figure6).

Motion-ControlLeversandPark

Position

Themotion-controlleversarespeed-sensitivecontrolsof

independent-wheelmotors.Movingaleverforwardor

backwardturnsthewheelonthesamesideforwardorin

reverse;wheelspeedisproportionaltotheamountthelever

ismoved.Movethecontrolleversoutwardfromthecenter

totheparkposition,andexitthemachine(Figure15).Always

positionthemotion-controlleversintotheparkposition

whenyoustopthemachineorleaveitunattended.

SmartSpeed™ControlSystemLever

TheSmartSpeed™Control-Systemlever,locatedbelowthe

operatingposition,givestheoperatorachoicetodrivethe

machineat3speedranges—trim,tow ,andmow(Figure7).

Figure6

ControlPanel

1.Throttle3.Blade-controlswitch

2.Ignitionswitch

(powertake-off)

4.Choke

IgnitionSwitch

Theignitionswitchhas3positions:Off,Run,andStart.The

keywillturntoStartandmovebacktoRunuponrelease.

TurningthekeytotheOffpositionwillstoptheengine;

however,alwaysremovethekeywhenleavingthemachine

topreventsomeonefromaccidentallystartingtheengine

(Figure6).

ThrottleControl

Thethrottlecontrolstheenginespeed,andithasa

continuous-variablesettingfromSlowtoFast(Figure6).

ChokeControl

Figure7

1.Smart-speedlever

Fuel-PresenceWindow

Thefuelwindowlocatedontheleft-handsideofthemachine,

canbeusedtoverifythepresenceofgasolineinthetank

(Figure8).

Pulluponthechokecontroluntilitstopstochoketheengine

(Figure6).Pushdownonthechokecontrolfornormal

engineoperation

16

Page 17

G014521

1

Figure8

1.Fuel-presencewindow

Height-of-CutLever

Theheight-of-cutleverallowstheoperatortolowerand

raisethedeckfromtheseatedposition.Whentheleveris

movedup(towardtheoperator),thedeckisraisedfromthe

ground,andwhenmoveddown(awayfromtheoperator),it

isloweredtowardtheground.Onlyadjusttheheight-of-cut

whilethemachineisnotmoving.RefertoAdjustingthe

Height-of-Cut(page24).

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

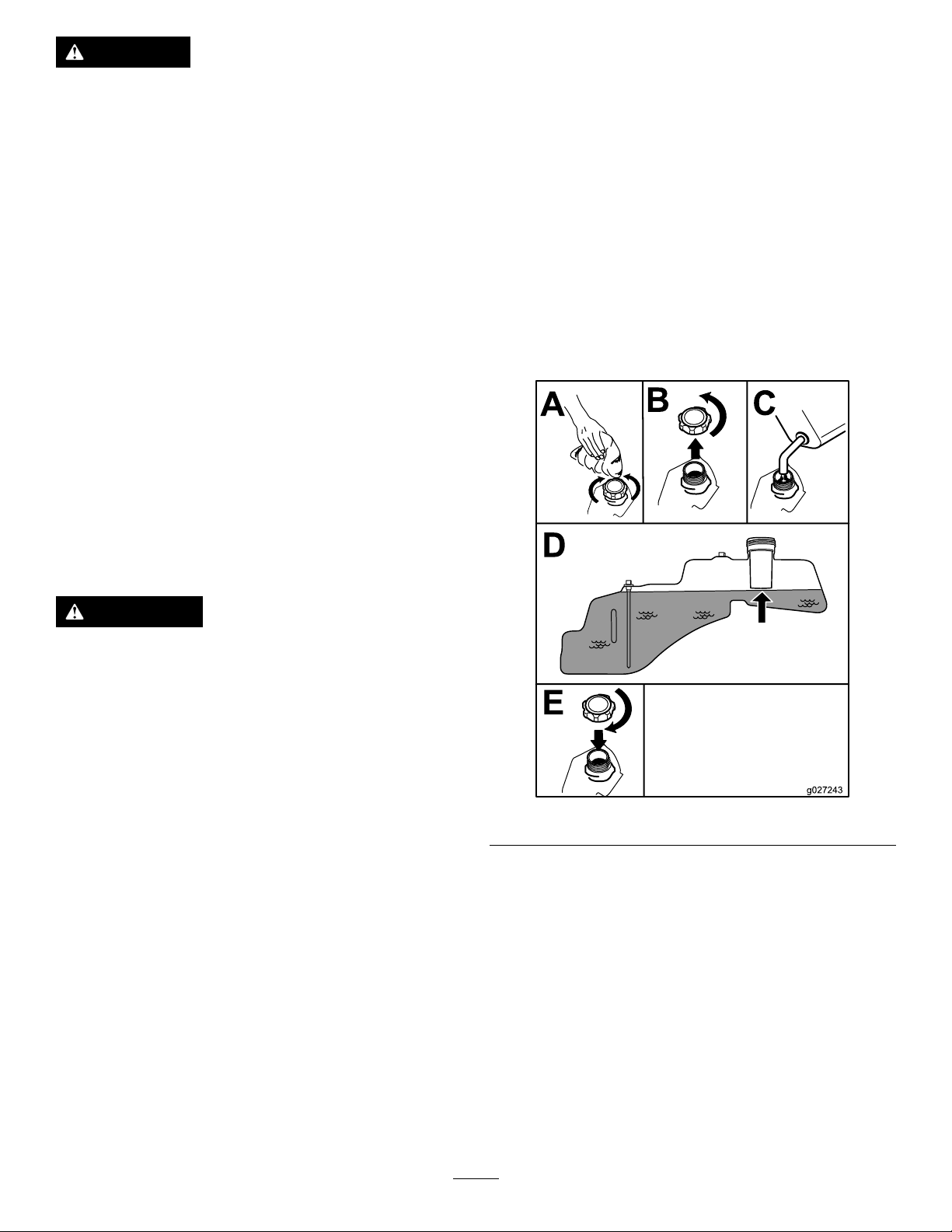

AddingFuel

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontains

morethan10%ethanolbyvolume,suchasE15

(contains15%ethanol),E20(contains20%ethanol),or

E85(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/orengine

damagewhichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2inch)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

17

Page 18

DANGER

g027243

A

B

E

D

C

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.T ominimizethechance

ofvarnishdepositsinthefuelsystem,usefuelstabilizer

atalltimes.

FillingtheFuelTank

Note:Ensurethattheengineisshutoffandthemotion

controlsareintheparkedposition.

Note:Youcanusethefuelwindowtoverifythepresenceof

gasolinebeforellingthetank(Figure9).

Important:Donotoverllfueltank.Fillthefueltank

tothebottomofthellerneck.Theemptyspaceinthe

tankallowsthefueltoexpand.Overllingmayresultin

fuelleakage,damagetotheengine,ordamagetothe

emissionssystem.

WARNING

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditionerbottleopening.

•Avoidcontactwithskin;washoffspillagewith

soapandwater.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysorless.

Forlongerstorageitisrecommendedthatthefueltank

bedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditionerto

thegas.

Figure9

CheckingtheEngine-OilLevel

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoCheckingthe

Engine-OilLevel(page35).

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mowerdecks

anddrivesystemshavehigherfrictionwhennew,placing

additionalloadontheengine.Allow40to50hoursof

break-intimefornewmachinestodevelopfullpowerand

bestperformance.

18

Page 19

ThinkSafetyFirst

G009027

1

2

CAUTION

OperatingSafety

Pleasecarefullyreadallofthesafetyinstructionsanddecals

inthesafetysection.Knowingthisinformationcouldhelp

you,yourfamily ,pets,orbystandersavoidinjury.

DANGER

Mowingonwetgrassorsteepslopescancause

slidingandlossofcontrol.

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,death,or

drowning.

Alossoftractionisalossofsteeringcontrol.

Toavoidlossofcontrolandpossibilityofrollover:

•Donotmowneardrop-offsornearwater.

•Donotmowslopesgreaterthan15degrees.

•Reducethespeedanduseextremecautionon

slopes.

•Whenmowingslopes,graduallyworkfrom

lowertohigherareasontheincline.

Thismachineproducessoundlevelsinexcessof85

dBAattheoperatorsearandcancausehearingloss

throughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Theuseofprotectiveequipmentforeyes,ears,hands,feet,

andheadisrecommended.

Figure11

1.Wearsafetyglasses

2.Wearhearingprotection

•Avoidsuddenturnsorrapidspeedchanges.

•Turnup,intoaninclinewhenchanging

directionsonslopes.Turningdowntheslope

reducestraction.

•Attachmentschangethehandlingcharacteristics

ofthemachine.Useextracautionwhenusing

attachmentswiththemachine.

Figure10

1.Safezone—usethe

TimeCutterhere

2.Useawalk-behindmower

and/orhandtrimmernear

drop-offsandwater.

3.Water

19

Page 20

UnderstandingtheSafety-Interlock

g027535

B

C

D

E

A

G

F

System

Note:Theengineshouldstop.

WARNING

Ifsafety-interlockswitchesaredisconnectedor

damaged,themachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

daily,andreplaceanydamagedswitchesbefore

operatingthemachine.

Thesafety-interlocksystemisdesignedtopreventtheengine

fromstartingunless:

•Thebladesaredisengaged.

•Themotion-controlleversareintheparkposition.

Thesafety-interlocksystemalsoisdesignedtostoptheengine

wheneverthecontrolleversareoutoftheparkpositionand

yourisefromtheseat.

TestingtheSafety-InterlockSystem

Testthesafety-interlocksystembeforeyouusethemachine

eachtime.Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthesafety

systemimmediately.

StartingtheEngine

Note:Awarmorhotenginemaynotrequirechoking

(Figure12).

Important:Donotengagethestarterformorethan

10secondsatatime.Iftheenginefailstostart,allowa

60-secondcool-downperiodbetweenattempts.Failure

tofollowtheseinstructionscandamagethestarter

motor.

1.Whilesittingontheseat,withthecontrolleversinpark

position,andmovetheblade-controlswitchtoOn.

2.Trystartingtheengine;theengineshouldnotcrank.

3.Whilesittingontheseat,movetheblade-control

switchtoOff.

4.Moveeithermotion-controllevertothecenter,

unlockedposition.

5.Trystartingtheengine;theengineshouldnotcrank.

6.Repeatwiththeothermotion-controllever.

7.Whilesittingontheseat,movetheblade-control

switchtoOff,andlockthemotion-controlleversin

theparkposition.

8.Starttheengine.

9.Whiletheengineisrunning,engagetheblade-control

switch,andriseslightlyfromtheseat.

Note:Theengineshouldstop.

10.Whilesittingontheseat,movetheblade-control

switchtoOff,andlockthemotion-controlleversin

theparkposition.

11.Starttheengine.

12.Whiletheengineisrunning,movethemotion-control

leverstothecenter,unlockedposition,engagethe

blade-controlswitch,andriseslightlyfromtheseat.

Figure12

20

Page 21

OperatingtheBlades

g027582

B

C

A

1

g027538

StoppingtheEngine

Theblade-controlswitch,representedbyapowertake-off

(PTO)symbol,engagesanddisengagespowertothemower

blades.Thisswitchcontrolspowertoanyattachmentsthat

drawpowerfromtheengine,includingthemowerdeckand

cuttingblades.

EngagingtheBlades

Important:Donotengagethebladeswhenparkedin

tallgrass;beltorclutchdamagecanoccur.

Note:AlwaysengagethebladeswiththethrottleintheFast

position(Figure13).

1.Disengagethebladesbymovingtheblade-control

switchtoOff(Figure14).

2.MovethethrottlelevertotheSlowposition.

Note:Runitatidlespeedforapproximatelyone

minute.

3.TurntheignitionkeytoOffandremovethekey.

DrivingtheMachine

Drivingthemachinebenetsfromanunderstandingof

whatzero-turn-radiusmowermeans.Thedrivewheelsturn

independently,poweredbyhydraulicmotorsoneachaxle;

henceonesidecanturninreversewhiletheotherturns

forwardcausingthemachinetospinratherthanturn.This

vastlyimprovesthemachinemaneuverabilitybutmayrequire

someadjustmentiftheoperatorisunfamiliar.

WARNING

Themachinecanspinveryrapidly.Theoperator

maylosecontrolofthemachineandcausepersonal

injuryordamagetothemachine.

DisengagingtheBlades

Figure13

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placingthethrottlecontrol

intheFastpositioncanbebestforperformance.Formost

applications,operatinginthefull-throttlepositionisdesirable.

Figure14

21

Page 22

Figure15

1.Park(brake)position

2.Center,unlockposition5.Frontofthemachine

3.Forward

4.Backward

UsingtheSmartSpeed

TM

Control

System

TheSmartSpeed

operatingposition(Figure16),givestheoperatorachoice

todrivethemachineat3groundspeedranges—trim,tow ,

andmow .

1.Smartspeedlever

Tochangespeeds,dothefollowing:

1.Movethemotioncontrolleverstoneutralandoutward

totheparkposition.

2.Disengagethebladecontrolswitch

3.Adjustthelevertothedesiredposition.

Thefollowingareonlyrecommendationsforuse.

Adjustmentswillvarybygrasstype,moisturecontent,and

theheightofthegrass.

TM

Control-Systemlever,locatedbelowthe

Figure16

Suggested

uses:

ParkingX

Heavy,wet

grass

TrainingX

BaggingX

MulchingX

Normal

mowing

TransportX

TrimTowMow

X

X

Trim

Thisisthelowestspeed.Thesuggestedusesforthisspeed

areasfollows:

•Parking

•Heavy,wetgrassmowingconditions

•Training

Tow

Thisisthemediumspeed.Thesuggestedusesforthisspeed

areasfollows:

22

Page 23

•Bagging

G008952

G008953

DrivingBackward

•Mulching

Mow

Thisisthefastestspeed.Thesuggestedusesforthisspeed

areasfollows:

•Normalmowing

•Transportingthemachine

DrivingForward

1.Movetheleverstothecenter,unlockedposition.

2.Togoforward,slowlypushthemotion-controllevers

forward(Figure17).

Note:Alwaysusecautionwhenbackingupandturning.

1.Movetheleverstothecenter,unlockedposition.

2.Togobackward,lookbehindyouanddown,asyou

slowlypullthemotion-controlleversrearward(Figure

18).

Figure18

Figure17

Togostraight,applyequalpressuretoboth

motion-controllevers(Figure17).

Toturn,releasepressureonthemotion-controllever

towardthedirectionyouwanttoturn(Figure17).

Thefartheryoumovethemotion-controlleversin

eitherdirection,thefasterthemachinewillmovein

thatdirection.

Tostop,pullthemotion-controlleverstoneutral.

Togostraight,applyequalpressuretoboth

motion-controllevers(Figure18).

Toturn,releasethepressureonthemotion-control

levertowardthedirectionyouwanttoturn.

Tostop,pushthemotion-controlleverstoneutral.

StoppingtheMachine

Tostopthemachine,movethemotion-controlleversto

neutralandoutwardtotheparkposition,disengagethe

blade-controlswitch,movethethrottletotheslowposition,

runitatidlespeedforapproximatelyforoneminute,and

turntheignitionkeytooff.

Note:Remembertoremovethekeyfromtheignitionswitch.

WARNING

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemowerwhileitis

unattended.

Alwaysremovetheignitionkeyandmovethe

motion-controlleversoutwardtotheparkposition

whenleavingthemachineunattended,evenifjust

forafewminutes.

23

Page 24

AdjustingtheHeight-of-Cut

g019929

1

2

3

4

5

Note:Thetransportpositionisthehighestheight-of-cut

positionorcuttingheight(115mm(4.5inches))asshown

inFigure19.

Height-of-cutiscontrolledbytheleverlocatedtotherightof

theoperatingposition(Figure19).

•Upperhole—usethispositionwiththemower

deckinthe63mm(2-1/2inches)andbelowthe

height-of-cutpositions(Figure20).

•Lowerhole—usethispositionwiththemower

deckinthe76mm(3inches)andabovethe

height-of-cutpositions(Figure20).

Figure20

Figure19

AdjustingtheAnti-Scalp Rollers(for107cm(42-inch) MowerDecks)

Wheneveryouchangetheheight-of-cut,itisrecommended

toadjusttheheightoftheanti-scalprollers.

1.Anti-scalproller4.Upperhole—themower

2.Lowerhole—themower

deckinthe76mm(3

inches)andabovethe

height-of-cutpositions

3.Flangenut

deckinthe63mm(2-1/2

inches)andbelowthe

height-of-cutpositions

5.Bolt

AdjustingtheAnti-Scalp Rollers(for127cm(50-inch) MowerDecks)

Wheneveryouchangetheheight-of-cut,itisrecommended

toadjusttheheightoftheanti-scalprollers.

Note:Adjusttheanti-scalprollerssotherollersdonottouch

thegroundinnormal,atmowingareas.

1.Disengagetheblade-controlswitch(PTO),movethe

motion-controlleverstotheneutral-lockposition,and

settheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Adjusttheanti-scalprollers(Figure21)tomatchthe

closestheight-of-cutposition.

Note:Adjusttheanti-scalprollerssotherollersdonottouch

thegroundinnormal,atmowingareas.

1.Disengagetheblade-controlswitch(PTO),movethe

motion-controlleverstotheneutral-lockposition,and

settheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Adjusttheanti-scalprollerstooneofthefollowing

positions:

24

Page 25

G010233

1

2

3

4

Figure21

g027249

B

C

A

g027252

B

A

1.Anti-scalproller3.Flangenut

2.Bolt4.Holespacing

PositioningtheSeat

Theseatcanmoveforwardandbackward.Positiontheseat

whereyouhavethebestcontrolofthemachineandaremost

comfortable(Figure22).

AdjustingtheMotion-Control Levers

AdjustingtheHeight

Themotion-controlleverscanbeadjustedhigherorlowerfor

maximumoperatorcomfort(Figure23).

Figure23

Figure22

AdjustingtheTilt

Themotion-controlleverscanbetiltedforeoraftfor

maximumoperatorcomfort.

1.Loosentheupperboltholdingthecontrollevertothe

control-armshaft.

2.Loosenthelowerboltjustenoughtopivotthecontrol

leverforeoraft(Figure23).Tightenbothboltsto

securethecontrolinthenewposition.

3.Repeattheadjustmentfortheoppositecontrollever.

PushingtheMachinebyHand

Important:Alwayspushthemachinebyhand.Donot

towthemachine,becausedamagemayoccur.

Thismachinehasanelectric-brakemechanism,andtopush

themachine,theignitionkeyneedstobeintheRunposition.

Thebatteryneedstobechargedandfunctioningforthe

electricbraketobedisengage.

PushingtheMachine

1.Parkthemachineonalevelsurface,anddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothepark

position,stoptheengine,andwaitforallmovingparts

tostopbeforeleavingtheoperatingposition.

3.Locatethebypassleversontheframeonbothsidesof

theengine.

4.Movethebypassleversforwardthroughthekeyhole

anddowntolocktheminplace(Figure24).

25

Page 26

Note:Ensurethisisdoneforeachlever.

g017303

1 2

3

G009660

1

2

3

4

5

5.Movethemotion-controlleversinwardtotheneutral

positionandturntheignitionkeytotheRunposition.

Note:Donotstartthemachine.

Note:Themachineisnowabletobepushedbyhand.

Figure24

ConvertingtoSideDischarge (formodelswith107cm (42-inch)decks)

Themowerdeckandmowerbladesshippedwiththismachine

weredesignedforoptimummulchingandsidedischarge

performance.

RemovingtheDischargeCoverforthe

SideDischarge

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtopark

position,stoptheengine,removethekey ,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Removethe2boltsandnutsthatsecurethedischarge

covertothemower(Figure25).

1.Bypass-leverlocations

2.Leverpositionfor

operatingthemachine

6.Whennished,ensurethatthekeyhasbeenreturnedto

theStoppositiontoavoiddrainingthebatterycharge.

Note:Ifthemachinefailstomove,theelectricbrakemay

stillbeengaged.Ifnecessary,theelectricbrakecanbereleased

manually;refertoReleasingtheElectricBrake(page41).

3.Leverpositionforpushing

themachine

OperatingtheMachine

Movethebypassleversrearwardthroughthekeyholeand

downtolocktheminplaceasshowninFigure24.

Note:Ensurethisisdoneforeachlever.

Figure25

1.Capnut(1/4inch)

2.Dischargecover5.Removethecover

3.Bolt(1/4x2-1/2inches)

4.Removethedischargecover.

5.Liftupthegrassdeector,andlocatethelocknuton

thedeectorpivotrod.

6.Removetheexistingthinnut(3/8inch).

7.Installthecutoffbafetotheexposedpivotrod

(Figure26).

4.Rotatethecoverup

Note:Usetheexistingthinnut(3/8inch)tosecure

thebafetothemower.

Note:Thecutoffbafewasshippedwiththemachine

asaloosepart.

26

Page 27

G005667

1

2

3

Figure26

1.Pivotrod

2.Cutoffbafe(originally

shippedwiththemachine)

8.Torquethefastenerto7to9N-m(14to18ft-lb).

9.Lowerthegrassdeectoroverthedischargeopening

Important:Ensurethatthemowerhasahinged

grassdeectorthatdispersesclippingstotheside

anddowntowardtheturf,whileinside-discharge

mode.

3.Existingthinnut(3/8inch)

InstallingtheDischargeCoverfor

Mulching

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothepark

position,stoptheengine,removethekey ,andwait

forallthemovingpartstostopbeforeleavingthe

operatingposition.

3.Removethecutoffbafefromthemowerdeck(Figure

26).

4.Liftthegrassdeectorandslidethetabsontopofthe

dischargecoverunderthegrassdeectorretainingrod.

5.Rotatethedischargecoverdownovertheopening,and

ontothelowerlipofthemower(Figure27).

Figure27

1.Dischargecover

2.Capnut(1/4inch)

6.Securethedischargecovertothelowerlipofthe

mowerwith2bolts(1/4x2-1/2inches)and2capnuts

(1/4inch)asshowninFigure27.

Note:Donotovertightenthenuts;thiscoulddistort

thecoverandcausebladecontact.

3.Bolt(1/4x2-1/2inches)

ConvertingtoSideDischarge (formodelswith127cm (50-inch)decks)

Themowerdeckandmowerbladesshippedwiththismachine

weredesignedforoptimummulchingandsidedischarge

performance.

RemovingtheRightBafeforSide

Discharge

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothepark

position,stoptheengine,removethekey ,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Removetherightmowerblade;refertoRemovingthe

27

Blades(page44).

Page 28

4.Removethe2knobsandcurvedwashersthatsecure

G015321

1

2

3

therightbafetothemower(Figure28).

Figure28

1.Knob

2.Curvedwasher

3.Bafestudcomingthrough

themower

5.Removetherightbafeandlowerthegrassdeector

overthedischargeopeningasshowninFigure28and

Figure29.

WARNING

Openholesinthemowerexposeyouand

otherstothrowndebriswhichcancause

severeinjury.

•Neveroperatethemowerwithouthardware

mountedinallholesinthemowerhousing.

•Installthehardwareinthemountingholes

whenyouremovethemulchingbafe.

7.Installtherightmowerblade;refertoRemovingthe

Blades(page44).

8.Liftupthegrassdeector.Install2bolts(5/16x3/4

inch)tothetwoholesalongthedeckcutout.

9.Installthecutoffbafetothemowerdeck(Figure30).

Note:Usethe2locknuts(5/16inch)tosecurethe

bafetothemowerdeck.

Note:Thecutoffbafewasshippedwiththemachine

asaloosepart.

Figure30

1.Bolt(5/16x3/4inch)3.Locknut(5/16inch)

2.Cutoffbafe

10.Torquethefastenersto7to9N-m(14to18ft-lb).

11.Lowerthegrassdeectoroverthedischargeopening.

Important:Ensurethatthemowerhasahinged

grassdeectorthatdispersesclippingstotheside

anddowntowardtheturf,whileinsidedischarge

mode.

1.Rightbafe

2.Curvedwasherandknob

Figure29

3.Dischargeopening

6.Installfastenersintotheholesinthetopofthemower

topreventyingdebris.

28

Page 29

InstallingtheRightBafeforMulching

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothepark

position,stoptheengine,removethekey ,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Removethecutoffbafefromthemowerdeck(Figure

30).

4.Removetherightmowerblade;refertoRemovingthe

Blades(page44).

Figure31

5.Slidetherightbafeunderthemowerdeck,andsecure

itusing2knobsandthecurvedwashers(cuppedside

facingthemower)asshowninFigure28andFigure29.

Important:Ensurethatthetabonthefarright

sideoftherightbafeisoutsideofthemowerand

isushwiththemowerwall.

6.Installtherightmowerblade;refertoRemovingthe

Blades(page44).

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthemachine.

Ensurethatthetrailerortruckhasallnecessarybrakes,

lighting,andmarkingasrequiredbylaw .Pleasecarefullyread

allthesafetyinstructions.Knowingthisinformationcould

helpyou,yourfamily,pets,orbystandersavoidinjury.

WARNING

Drivingonthestreetorroadwaywithoutturn

signals,lights,reectivemarkings,oraslow

movingvehicleemblemisdangerousandcanlead

toaccidentscausingpersonalinjury.

Donotdrivemachineonapublicstreetorroadway.

Totransportthemachine:

1.Ifusingatrailer,connectittothetowingvehicleand

connectthesafetychains.

LoadingtheMachine

Useextremecautionwhenloadingorunloadingmachines

ontoatraileroratruck.Useafull-widthrampthatiswider

thanthemachineforthisprocedure.Backuprampsand

driveforwarddownramps(Figure32).

Figure32

1.Backupramps

Important:Donotusenarrowindividualrampsfor

eachsideofthemachine.

Ensuretherampislongenoughsothattheanglewiththe

grounddoesnotexceed15degrees(Figure33).Onat

ground,thisrequiresaramptobeatleastfourtimes(4X)as

longastheheightofthetrailerortruckbedtotheground.A

steeperanglemaycausemowercomponentstogetcaughtas

theunitmovesfromtheramptothetrailerortruck.Steeper

anglesmayalsocausethemachinetotiporlosecontrol.If

loadingonornearaslope,positionthetrailerortrucksothat

itisonthedownsideoftheslopeandtherampextendsup

theslope.Thiswillminimizetherampangle.

2.Driveforwarddownramps

2.Ifapplicable,connectthetrailerbrakes.

3.Loadthemachineontothetrailerortruck.

4.Stoptheengine,removethekey,setthebrake,and

closethefuelvalve.

5.Tiedownthemachinenearthefrontcasterwheelsand

therearbumper(Figure31).

29

Page 30

WARNING

g027996

5

1

2

6

Loadingamachineontoatrailerortruckincreases

thepossibilityoftip-overandcouldcauseserious

injuryordeath.

•Useextremecautionwhenoperatingamachine

onaramp.

•Useonlyafull-widthramp;donotuseindividual

rampsforeachsideofthemachine.

•Donotexceeda15-degreeanglebetweenthe

rampandthegroundorbetweentherampand

thetrailerortruck.

•Ensurethelengthoframpisatleastfourtimes

(4X)aslongastheheightofthetrailerortruck

bedtotheground.Thiswillensurethatramp

angledoesnotexceed15degreesonatground.

•Backuprampsanddriveforwarddownramps.

•Avoidsuddenaccelerationordecelerationwhile

drivingthemachineonarampasthiscould

causealossofcontroloratip-oversituation.

Figure33

1.Full-widthrampinstowed

position

2.Sideviewoffull-width

rampinloadingposition

3.Notgreaterthan

15degrees

4.Rampisatleastfourtimes

(4X)aslongastheheight

ofthetrailerortruckbed

totheground

5.H=heightofthetraileror

truckbedtotheground

6.Trailer

30

Page 31

OperatingTips

UsingtheFastThrottleSetting

Forbestmowingandmaximumaircirculation,operate

theengineattheFastthrottleposition.Airisrequiredto

thoroughlycutgrassclippings,sodonotsettheheight-of-cut

solowastototallysurroundthemowerbyuncutgrass.

Alwaystrytohaveonesideofthemowerfreefromuncut

grass,whichallowsairtobedrawnintothemower.

UsingtheSmartSpeed™Control

System

TheSmartSpeed™Control-Systemlever,locatedbelowthe

operatingposition,givestheoperatorachoicetodrivethe

machineat3speedranges—trim,tow,andmow .Anoperator

canbenetfromthetrimspeedsettingwhenmaneuvering

themachineintightspacesoroperatingarounddelicate

landscapes.Thetrimsettingcanalsobeusedtooperatethe

machineatahighthrottlesettingandbladespeed,whilestill

beingabletoreducethegroundspeedtoincreasethequality

ofcut.

CuttingLongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,raisethe

cuttingheighthigherthanusualandcutthegrassatthis

setting.Thencutthegrassagainusingthelower,normal

setting.

Stopping

Ifthemachine'sforwardmotionmustbestoppedwhile

mowing,aclumpofgrassclippingsmaydropontoyour

lawn.Toavoidthis,moveontoapreviouslycutareawiththe

bladesengagedoryoucandisengagethemowerdeckwhile

movingforward.

KeepingtheUndersideoftheMower

Clean

Cleanclippingsanddirtfromtheundersideofthemower

aftereachuse.Ifgrassanddirtbuildupinsidethemower,

cuttingqualitywilleventuallybecomeunsatisfactory.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethatthe

cuttingheightofthemowerdoesnotscalpanyuneven

ground.However,thecuttingheightusedinthepastis

generallythebestonetouse.Whencuttinggrasslongerthan

15cm(6inches)tall,youmaywanttocutthelawntwiceto

ensureanacceptablequalityofcut.

Cutting1/3oftheGrassBlade

Itisbesttocutonlyabout1/3ofthegrassblade.Cutting

morethanthatisnotrecommendedunlessgrassissparse,or

itislatefallwhengrassgrowsmoreslowly.

AlternatingtheMowingDirection

Alternatethemowingdirectiontokeepthegrassstanding

straight.Thisalsohelpsdisperseclippingswhichenhances

decompositionandfertilization.

MowingatCorrectIntervals

Normally,mowevery4days.But,remember,grassgrowsat

differentratesatdifferenttimes.Sotomaintainthesame

cuttingheight,whichisagoodpractice,andmowmoreoften

inearlyspring.Asthegrassgrowthrateslowsinmidsummer,

mowlessfrequently.Ifyoucannotmowforanextended

period,rstmowatahighcuttingheight,thenmowagain2

dayslateratalowerheightsetting.

MaintainingtheBlade(s)

Maintainasharpbladethroughoutthecuttingseasonbecause

asharpbladecutscleanlywithouttearingorshreddingthe

grassblades.Tearingandshreddingturnsgrassbrownat

theedges,whichslowsgrowthandincreasesthechanceof

disease.Checkthemowerbladesaftereachuseforsharpness,

andforanywearordamage.Filedownanynicksandsharpen

thebladesasnecessary.Ifabladeisdamagedorworn,replace

itimmediatelywithagenuineTororeplacementblade.

AvoidingCuttingTooLow

Ifthecuttingwidthofthemoweriswiderthanthemower

youpreviouslyused,raisethecuttingheighttoensurethat

uneventurfisnotcuttooshort.

31

Page 32

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Beforeeachuseordaily

Aftereachuse

Every25hours

Every100hours

Every200hours

Beforestorage

MaintenanceProcedure

•Changetheengineoil.

•Checkthesafety-interlocksystem.

•Checktheengineoillevel.

•Cleantheair-intakescreen.

•Checkthecuttingblades.

•Inspectthegrassdeectorfordamage.

•Cleanthemower-deckhousing.

•Greaseallthelubricationpoints.

•Checktirepressure.

•Checkthebeltsforwearorcracks.

•Servicethepaperelement(moreoftenindusty ,dirtyconditions).

•Changetheengineoil(moreoftenindusty,dirtyconditions).

•Checkthesparkplug(s).

•Replacethein-linefuellter

•Replacethepaperelement(moreoftenindusty ,dirtyconditions).

•Changetheoillter(moreoftenindusty,dirtyconditions).

•Chargethebatteryanddisconnectbatterycables.

•Performallmaintenanceprocedureslistedabovebeforestorage.

•Paintanychippedsurfaces.

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

32

Page 33

Premaintenance

1

G014522

Lubrication

Procedures

GreasingtheBearings

RaisingtheSeat

Makesurethatthemotion-controlleversarelockedinthe

parkposition,andlifttheseatforward.

Thefollowingcomponentscanbeaccessedbyraisingtheseat:

•Serialplate

•Servicedecal

•Seat-adjustmentbolts

•Fuellter

•Batteryandbatterycables

ReleasingtheMower-Deck Curtain

Loosenthe2bottomboltsofthecurtaintogainaccesstothe

topofthemowerdeck(Figure34).

ServiceInterval:Every25hours—Greaseallthelubrication

points.

GreaseType:No.2generalpurpose,lithium-basedgrease

1.Parkthemachineonalevelsurface,anddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothepark

position,stoptheengine,removethekey ,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Cleanthegreasettings(Figure35andFigure36)with

arag.

Note:Makesuretoscrapeanypaintoffthefrontof

thetting(s).

Figure34

1.Bottombolt

Note:Alwaystightentheboltstoconnectthecurtainafter

maintenance.

2.Curtain

Figure35

1.Frontcastertire

Figure36

Locatedontheseat-panunderside

1.Readtheinstructions

beforeservicingor

performingmaintenance

2.Checkthetirepressure

every25operatinghours

4.Connectagreaseguntoeachtting(Figure35and

Figure36).

33

3.Greaseevery25operating

hours

4.Engine

Page 34

5.Pumpgreaseintothettingsuntilgreasebeginsto

G014908

1

2

3

oozeoutofthebearings.

EngineMaintenance

ServicingtheAirCleaner

Note:Servicetheaircleanermorefrequently(everyfew

hours)ifoperatingconditionsareextremelydustyorsandy.

RemovingtheElement

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch(PTO).

2.Movethemotion-controlleverstothebrakeposition,

stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Cleanaroundtheair-cleanercovertopreventdirtfrom

gettingintotheengineandcausingdamage.

4.Liftthecoverandremovethehoseclampsecuringthe

air-cleanerassemblytotheengine(Figure37).

5.Loosenthehoseclampandremovethepaperelement

(Figure37).

Figure37

1.Cover

2.Paperelement

3.Hoseclamp

CleaningthePaperElement

ServiceInterval:Every100hours—Servicethepaper

Every200hours/Yearly(whichevercomes

rst)—Replacethepaperelement(moreoftenin

dusty,dirtyconditions).

1.Lightlytaptheelementonaatsurfacetoremovedust

anddirt.

2.Inspecttheelementfortears,anoilylm,anddamage

totheseal.

34

element(moreoftenindusty,dirty

conditions).

Page 35

Important:Donotcleanthepaperelementwith

g017470

SAE V iscosity Grades

SAE 40

SAE 30

SAE 10W– 30/ SAE 10W– 40

-20 0 20 32 40 60 80 100

-30 -20 -10 0 10 20 30 40

°F

°C

STARTING TEMPERA TURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

SAE 5W– 20

B

A

C

D

E

G027659

F

G

H

I J

pressurizedairorliquids,suchassolvent,gas,

orkerosene.Replacethepaperelementifitis

damagedorcannotbecleanedthoroughly.

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSF,SG,SH,SJ,orSL)

CrankcaseCapacity:

Model

74656

74660

Viscosity:Seethetablebelow.

Note:Usingmultigradeoils(5W-20,10W -30,and10W-40)

willincreaseoilconsumption.Checkoillevelmorefrequently

whenusingthem.

OillternotremovedOillterremoved

1.5L(50.7oz)1.7L(57.5oz)

1.8L(60.9oz)2.1L(71oz)

Figure38

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawaythemuferandotherhotsurfaces.

Important:Donotoverllthecrankcasewithoiland

runtheengine;enginedamagemayresult.

1.Parkthemachineonalevelsurface.

2.Disengagetheblade-controlswitch(PTO).

3.Stoptheengine,waitforallmovingpartstostop,and

removethekeybeforeleavingtheoperatingposition.

4.Checktheengine-oillevel(Figure39).

Figure39

35

Page 36

ChangingtheEngineOil

A B

C

D

F

E

G027539

B

A

C

D

E

F

g027660

ServiceInterval:Aftertherst8hours—Changetheengine

oil.

Every100hours—Changetheengineoil(moreoften

industy ,dirtyconditions).

Note:Disposeoftheusedoilatarecyclingcenter.

1.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoassuretheoildrains

completely.

2.DisengagethePTO ,movethemotion-controlleversto

theneutral-lockedposition,andsettheparkingbrake.

3.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position(Figure40).

4.Slowlypourapproximately80%ofthespeciedoil

intothellertubeandslowlyaddtheadditionaloilto

bringittotheFullmark(Figure41).

Figure41

Figure40

36

Page 37

ChangingtheEngine-OilFilter

B

A

C D

E

F

3/4

g027477

B

A

g027478

B

A

g027479

RemovingtheSparkPlug

ServiceInterval:Every200hours—Changetheoillter

(moreoftenindusty,dirtyconditions).

Note:Changetheengine-oilltermorefrequentlywhen

operatingconditionsareextremelydustyorsandy.

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil(page36).

2.Changetheengineoillter(Figure42).

1.Disengagetheblade-controlswitch(PTO).

2.Stoptheengine,waitforallmovingpartstostop,and

removethekeybeforeleavingtheoperatingposition.

3.Removethesparkplug(Figure44).

Figure43

CheckingtheSparkPlug

Important:Donotcleanthesparkplug.Always

replacethesparkplugwhenithasablackcoating,worn

electrodes,anoilylm,orcracks.

Note:Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingontheinsulator

usuallymeansthattheaircleanerisdirty.

Note:Ensurethattheoil-ltergaskettouchesthe

engineandthenanextra3/4turniscompleted.

3.Fillthecrankcasewiththepropertypeofnewoil;refer

toChangingtheEngineOil(page36).

ServicingtheSparkPlug

ServiceInterval:Every100hours—Checkthesparkplug(s).

Makesuretheairgapbetweenthecenterandsideelectrodes

iscorrectbeforeinstallingthesparkplug.Useaspark-plug

wrenchforremovingandinstallingthesparkplug(s)anda

gappingtool/feelergaugetocheckandadjusttheairgap.

Installanewsparkplug(s)ifnecessary.

Setthegapto0.76mm(0.030).

Figure42

Figure44

Type:NGKBPR4ES(orequivalent)

AirGap:0.76mm(0.03inch)

37

Page 38

InstallingtheSparkPlug

B

A

16 ft-lb

22 N-m

g027661

C

D

Tightenthesparkplugto22N-m(16ft-lb).

FuelSystem

Maintenance

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyou,others,andcan

damageproperty.

•Performanyfuel-relatedmaintenancewhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

ReplacingtheIn-LineFuel

Figure45

CleaningtheCoolingSystem

Cleantheair-intakescreenfromgrassanddebrisbeforeeach

use.

1.Disengagetheblade-controlswitch,movethecontrol

leverstotheneutral-lockedposition,andapplythe

parkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Removetheair-intakescreen,theair-cleanercover,and

thefanhousing.

4.Cleandebrisandgrassfromtheparts.

5.Installtheair-intakescreen,air-cleanercover,andthe

fanhousing.

Filter

ServiceInterval:Every100hours—Replacethein-linefuel

lter

Neverinstalladirtylterifitisremovedfromthefuelline.

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothepark

position,stoptheengine,removethekey ,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Replacethein-linefuellter(Figure46).

38

Page 39

g027590

B

A

C

D

g027518

ElectricalSystem

Maintenance

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

ChargingtheBattery

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

Figure46

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothepark

position,stoptheengine,removethekey ,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Raisetheseattoaccessthebattery.

4.Disconnectthenegative(black)groundcablefromthe

batterypost(Figure47).

Note:Retainallfasteners.

39

Page 40

WARNING

G005072

1

2

3

4

5

6

7

Incorrectbattery-cableroutingcoulddamage

themachineandcablescausingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

ChargingtheBattery

ServiceInterval:Beforestorage—Chargethebatteryand

disconnectbatterycables.

1.Removethebatteryfromthechassis;refertoRemoving

theBattery(page39).

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

5.Slidetherubbercoverupthepositive(red)cable.

6.Disconnectthepositive(red)cablefromthebattery

post(Figure47).

Note:Retainallfasteners.

7.Removethebatteryhold-down(Figure47),andliftthe

batteryfromthebatterytray .

2.Chargethebatteryforaminimumof1hourat6to

10amps.

Note:Donotoverchargethebattery.

3.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthecharger

leadsfromthebatteryposts(Figure48).

Figure48

1.Positive(+)batterypost3.Red(+)chargerlead

2.Negative(–)batterypost4.Black(–)chargerlead

1.Battery

2.Positive(+)batterypost

3.Bolt,washer,andnut7.Batteryhold-down

4.Terminalboot

InstallingtheBattery

1.Positionthebatteryinthetray(Figure47).

2.Usingthefastenerspreviouslyremoved,installthe

positive(red)batterycabletothepositive(+)battery

terminal.

3.Usingthefastenerspreviouslyremoved,installthe

negativebatterycabletothenegative(-)battery

Figure47

5.Negative(–)batterypost

6.Wingnut,washer,andbolt

terminal.

4.Slidetheredterminalbootontothepositive(red)

batterypost.

5.Securethebatterywiththehold-down(Figure47).

6.Lowertheseat.

40

Page 41

ServicingtheFuses

30

25

30

25

G014921

2

1

DriveSystem

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;however,ifafuseblows,checkthe

component/circuitforamalfunctionorshort.

Fusetype:

•Main—F1-30amp,blade-type

•ChargeCircuit—F2-25amp,blade-type

1.Removethescrewssecuringthecontrolpaneltothe

machine.

Note:Retainallfasteners.

2.Liftthecontrolpaneuptoaccessthemainwiring

harnessandfuseblock(Figure49).

3.Toreplaceafuse,pulloutonthefusetoremoveit

(Figure49).

Maintenance

CheckingtheTirePressure

ServiceInterval:Every25hours—Checktirepressure.

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseunevencut.Check

thepressureatthevalvestem(Figure50).Checkthetires

whentheyarecoldtogetthemostaccuratepressurereading.

Refertothemaximumpressuresuggestedbythetire

manufactureronthesidewallofthecasterwheeltires.

Inatethereardrive-wheeltiresto82kPa(13psi).

Figure50

Figure49

1.Main—30amp

4.Returnthecontrolpaneltoitsoriginalposition.

Note:Usethescrewsremovedpreviouslytosecure

thepaneltothemachine.

2.Chargecircuit—25amp

1.Valvestem

ReleasingtheElectricBrake

Theelectricbrakereleasesbymanuallyrotatingthelinkarms

forward.Oncetheelectricbrakeisenergizedthebrakewill

reset.

Toreleasethebrake:

1.Turntheignitionkeytotheoffpositionordisconnect

thebattery.

2.Locatetheshaftontheelectricbrakewherethe

brake-linkarmsareconnected(Figure51).

3.Rotatetheshaftforwardtoreleasethebrake.

41

Page 42

Figure51

1.Brake-linkarmontheelectric-brake-controlmodule

MowerMaintenance

ServicingtheCuttingBlades

Maintainsharpbladesthroughoutthecuttingseason,because

sharpbladescutcleanlywithouttearingorshreddingthegrass

blades.Tearingandshreddingturnsgrassbrownattheedges,

whichslowsgrowth,andincreasesthechanceofdisease.

Checkthecutterbladesdailyforsharpness,andforany

wearordamage.Filedownanynicksandsharpenthe

bladesasnecessary.Ifabladeisdamagedorworn,replace

itimmediatelywithagenuineT ororeplacementblade.For

convenientsharpeningandreplacement,youmaywantto

keepextrabladesonhand.

WARNING

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownintotheoperator's

orbystander'sarea,resultinginseriouspersonal

injuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

BeforeInspectingorServicingthe

Blades

Parkthemachineonalevelsurface,disengagethe

blade-controlswitch,movethemotion-controlleversoutward

totheparkposition,stoptheengine,andremovethekey .

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily—Checkthe

cuttingblades.

1.Inspectthecuttingedges(Figure52).

Note:Iftheedgesarenotsharporhavenicks,remove

andsharpentheblades;refertoSharpeningtheBlades

(page44).

2.Inspecttheblades,especiallythecurvedarea(Figure

52).

Note:Ifyounoticeanydamage,wear,oraslot

forminginthisarea(items3and4inFigure52),

immediatelyinstallanewblade.

42

Page 43

Figure52

G014972

1

2

3

G014973

1

2

3

G014974

1

2

3

1.Cuttingedge3.Wear/slotforming

2.Curvedarea

4.Damage

CheckingforBentBlades

Note:Themachinemustbeonalevelsurfaceforthe

followingprocedure.

1.Raisethemowerdecktothehighestheight-of-cut

position;alsoconsideredthe'transport'position.

2.Whilewearingthicklypaddedgloves,orotheradequate

handprotection,slowlyrotatethebladetobemeasure

intoapositionthatallowseffectivemeasurementofthe

distancebetweenthecuttingedgeandthelevelsurface

themachineison(Figure53).

3.Measurefromthetipofthebladetotheatsurface

(Figure54).

Figure54

1.Blade(inpositionformeasuring)

2.Levelsurface

3.Measureddistancebetweenbladeandthesurface(A)

4.Rotatethesameblade180degrees,sothattheopposing

cuttingedgeisnowinthesameposition(Figure55).

Figure55

1.Blade(sidepreviouslymeasured)

2.Measurement(positionusedpreviously)

Figure53

1.Deck3.Blade

2.Spindlehousing

3.Opposingsideofbladebeingmovedintomeasurement

position

5.Measurefromthetipofthebladetotheatsurface

(Figure56).

Note:Thevarianceshouldbenomorethan3mm

(1/8inch).

43

Page 44

G014973

1

2

3

Figure56

G027833

1.Oppositebladeedge(inpositionformeasuring)

2.Levelsurface

3.Secondmeasureddistancebetweenbladeandsurface(B)

A.IfthedifferencebetweenAandBisgreaterthan

3mm(1/8inch),replacethebladewithanew

blade;refertoRemovingtheBlades(page44)and

InstallingtheBlades(page44).

Note:Ifabentbladeisreplacedwithanewone,

andthedimensionobtainedcontinuestoexceed

3mm(1/8inch),thebladespindlecouldbebent.

ContactanAuthorizedToroDealerforservice.

B.Ifthevarianceiswithinconstraints,movetothe

nextblade.

Repeatthisprocedureoneachblade.

RemovingtheBlades

Thebladesmustbereplacedifasolidobjectishit,ifthe

bladeisoutofbalance,orifthebladeisbent.T oensure

optimumperformanceandcontinuedsafetyconformance

ofthemachine,usegenuineTororeplacementblades.

Replacementbladesmadebyothermanufacturersmayresult

innon-conformancewithsafetystandards.

1.Holdthebladeendusingaragorthickly-paddedglove.

2.Removethebladebolt,thecurvedwasher,andthe

bladefromthespindleshaft(Figure57).

Figure57

1.Sailareaoftheblade3.Curvedwasher

2.Blade4.Bladebolt

SharpeningtheBlades

1.Usealetosharpenthecuttingedgeatbothendsof

theblade(Figure58).

Note:Maintaintheoriginalangle.

Note:Thebladeretainsitsbalanceifthesameamount

ofmaterialisremovedfrombothcuttingedges.

Figure58

1.Sharpenatoriginalangle

2.Checkthebalanceofthebladebyputtingitonablade

balancer(Figure59).

Note:Ifthebladestaysinahorizontalposition,the

bladeisbalanced,andcanbeused.

Note:Ifthebladeisnotbalanced,lesomemetaloff

theendofthesailareaonly(Figure58).

Figure59

1.Blade2.Balancer

3.Repeatthisprocedureuntilthebladeisbalanced.

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure57).

44

Page 45

Important:Thecurvedpartoftheblademustbe

G009682

1

2

2

3

3

4

4

G005278

1

2