Page 1

FormNo.3381-529RevB

TimeCutter

®

MX5060Riding

Mower

ModelNo.74641—SerialNo.314000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3381-529*B

Page 2

Thismachineisaride-on,rotary-bladelawnmowerintended

G014523

1

tobeusedbyhomeownersinresidentialapplications.Itis

primarilydesignedforcuttinggrassonwell-maintainedlawns.

Itisnotdesignedforcuttingbrush,mowinggrassandother

growthalongsidehighways,orforagriculturaluses.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

Introduction

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely .

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready .Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

ThissparkignitionsystemcomplieswithCanadianICES-002.

WARNING

Removingstandardoriginalequipmentpartsand

accessoriesmayalterthewarranty,traction,and

safetyofthemachine.FailuretouseoriginalToro

partscouldcauseseriousinjuryordeath.Making

unauthorizedchangestotheengine,fuelorventing

system,mayviolateEPAandCARBregulations.

Replaceallpartsincluding,butnotlimitedto,tires,

belts,blades,andfuelsystemcomponentswith

originalT oroparts.

Theenclosed

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Formodelswithstatedenginehorsepower,thegross

horsepoweroftheenginewaslaboratorytestedbytheengine

manufacturerinaccordancewithSAEJ1995andratedto

J2723.

Engine Owner's Man ual

issuppliedfor

Figure1

Undertheseat

1.Modelandserialnumberplate

Writetheproductmodelandserialnumbersinthespace

below:

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol.

©2013—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Thismanualusestwowordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contactusatwww.T oro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Introduction..................................................................2

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroRidingMowerSafety........................................6

SlopeIndicator.......................................................7

SafetyandInstructionalDecals.................................8

ProductOverview.........................................................13

Controls...............................................................13

Operation....................................................................15

ThinkSafetyFirst...................................................15

BeforeStarting.......................................................16

StartingtheEngine.................................................17

OperatingtheBlades...............................................18

TestingtheSafetyInterlockSystem...........................19

StoppingtheEngine...............................................19

Driving.................................................................19

StoppingtheMachine.............................................20

AdjustingtheHeightofCut.....................................21

AdjustingtheAnti-ScalpRollers...............................21

PositioningtheSeat................................................21

AdjustingtheMotionControlLevers........................21

PushingtheMachinebyHand..................................22

GrassDeector......................................................23

OperatingTips......................................................23

Maintenance.................................................................24

RecommendedMaintenanceSchedule(s)......................24

PremaintenanceProcedures........................................25

RaisingtheSeat......................................................25

Lubrication...............................................................25

GreasingtheBearings.............................................25

EngineMaintenance..................................................26

ServicingtheAirCleaner.........................................26

ServicingtheEngineOil..........................................26

ServicingtheSparkPlug..........................................28

CleaningtheCoolingSystem....................................29

FuelSystemMaintenance...........................................30

ReplacingtheIn-lineFuelFilter................................30

ElectricalSystemMaintenance....................................31

ChargingtheBattery...............................................31

ServicingtheFuses.................................................32

DriveSystemMaintenance.........................................33

CheckingtheTirePressure......................................33

ReleasingtheElectricBrake.....................................33

HydraulicSystemMaintenance....................................34

CheckingtheHydraulicOilLevel..............................34

ChangingtheHydraulicSystemOiland

Filters................................................................34

MowerMaintenance...................................................36

ServicingtheCuttingBlades.....................................36

LevelingtheMowerDeck........................................39

RemovingtheMower..............................................40

MowerBeltMaintenance.........................................41

InstallingtheMower...............................................41

ReplacingtheGrassDeector..................................42

Cleaning...................................................................43

WashingtheUndersideoftheMower........................43

Storage........................................................................44

CleaningandStorage..............................................44

Troubleshooting...........................................................46

Schematics...................................................................48

3

Page 4

Safety

Toreducethepotentialforinjury,complywiththese

safetyinstructionsandalwayspayattentiontothesafety

alertsymbol,whichmeansCAUTION,WARNING,

orDANGER-"personalsafetyinstruction."Failure

tocomplywiththeinstructionmayresultinpersonal

injuryordeath.

•Turnoffbladeswhennotmowing.Stoptheengine,wait

forallpartstocometoacompletestopandremovethe

keybeforecleaningthemachine,removingthegrass

catcheroruncloggingthedischargechute.

•Operatethemachineonlyindaylightorgoodarticial

light.

•Donotoperatethemachinewhileundertheinuence

ofalcoholordrugs.

SafeOperatingPractices

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

ThefollowinginstructionsareadaptedfromANSIstandard

B71.1-2012.AllthelanguagewithinthisANSIstandard

appliestothismachine;however,duetotheapplicationof

thestandardacrossmanydifferenttypesofproductssome

statementscanseemgeneralormisleading.Intheseinstances,

Torohasrenedthestatementtoconveythemeaningofthe

standardwhilebettermatchingtheproductthisOperator's

Manualpertains.Safetyinformationinadditiontothe

instructionsfoundintheANSIstandardbelowcanbefound

inToroRidingMowerSafetyattheendofthissection.

GeneralOperation

•Read,understand,andfollowallinstructionsinthe

operator'smanualandonthemachinebeforestarting.

•Donotplacehandsorfeetnearrotatingpartsorunder

themachine.Keepclearofthedischargeopeningatall

times.

•Allowonlyresponsibleadultswhoarefamiliarwiththe

instructionstooperatethemachine.

•Cleartheareaofobjectssuchasrocks,toys,wire,etc.,

whichcouldbepickedupandthrownbytheblade.

•Besuretheareaisclearofotherpeoplebeforemowing.

Stopthemachineifanyoneentersthearea.

•Nevercarrypassengers.

•Donotmowinreverseunlessabsolutelynecessary.

Alwayslookdownandbehindbeforeandwhilebacking

up.

•Beawareofthemowerdischargedirectionanddonot

pointitatanyone.Avoiddischargingmaterialagainsta

wallorobstruction.Materialmayricochetbacktoward

theoperator.Stoptheblade(s)whencrossinggravel

surfaces.

•Donotoperatethemachinewithoutdeector,discharge

coverorentiregrasscollectionsysteminplaceand

working.

•Bealert,slowdownandusecautionwhenmakingturns.

Lookbehindandtothesidebeforechangingdirections.

•Neverleavearunningmachineunattended.Alwaysturn

offblades,setparkingbrake,stopengine,andremovekey

beforedismounting.

•Watchfortrafcwhenoperatingnearorcrossing

roadways.

•Useextracarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Alwaysweareyeprotectionwhenoperatingthemower.

•Dataindicatesthatoperators,age60yearsandabove,are

involvedinalargepercentageofridingmower-related

injuries.Operatorsshouldevaluatetheirabilitytooperate

theridingmowersafelyenoughtoprotectthemselvesand

othersfromseriousinjury.

•Alwaysfollowtherecommendationsforanyapplication

ofcounterweights.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

SlopeOperation

Slopesareamajorfactorrelatedtolossofcontroland

tip-overaccidents,whichcanresultinsevereinjuryordeath.

Operationonallslopesrequiresextracaution.Ifyoucannot

backuptheslopeorifyoufeeluneasyonit,donotmowit.

•Donotmowslopesgreaterthan15degrees.

•Watchforditches,holes,rocks,dips,andrisesthatchange

theoperatingangle,asroughterraincouldoverturnthe

machine.

•Choosealowgroundspeedsoyouwillnothavetostop

whileoperatingonaslope.

•Donotmowslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcauseslidingand

lossofcontrol.

•Alwayskeepthedrivewheelsengagedwhengoingdown

slopes.

•Reducespeedanduseextremecautiononslopes.

•Donotmakesuddenturnsorrapidspeedchanges.

•Removeormarkobstaclessuchasrocks,treelimbs,etc.

fromthemowingarea.Tallgrasscanhideobstacles.

•Avoidsuddenstartswhenmowinguphillbecausethe

mowermaytipbackwards.

•Beawarethatlossoftractionmayoccurgoingdownhill.

Weighttransfertothefrontwheelsmaycausedrive

wheelstoslipandcauselossofbrakingandsteering.

4

Page 5

•Alwaysavoidsuddenstartingorstoppingonaslope.If

tireslosetraction,stopthemachine,disengagetheblades

andproceedslowlyofftheslope.

•Useextremecarewithgrasscatchersorotherattachments.

Thesecanchangethestabilityofthemachineandcause

lossofcontrol.

•Donottrytostabilizethemachinebyputtingyourfoot

ontheground.

•Donotmowneardrop-offs,ditches,steepbanksor

water.Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,deathordrowning.

•Useawalkbehindmowerand/orahandtrimmernear

drop-offs,ditches,steepbanksorwater.

Children

Tragicaccidentscanoccuriftheoperatorisnotalerttothe

presenceofchildren.Childrenareoftenattractedtothe

machineandthemowingactivity.Neverassumethatchildren

willremainwhereyoulastsawthem.

•Keepchildrenoutofthemowingareaandunderthe

watchfulcareofanotherresponsibleadult,notthe

operator.

•Bealertandturnthemachineoffifchildrenenterthe

area.

•Beforeandwhilebackingorchangingdirection,look

behind,down,andside-to-sideforsmallchildren.

•Nevercarrychildren,evenwiththebladesoff.Theymay

falloffandbeseriouslyinjuredorinterferewithsafe

machineoperation.

•Childrenwhohavebeengivenridesinthepastmay

suddenlyappearinthemowingareaforanotherrideand

berunoverorbackedoverbythemower.

•Neverallowchildrentooperatethemachine.

•Useextracarewhenapproachingblindcorners,shrubs,

trees,theendofafenceorotherobjectsthatmayobscure

vision.

TowingSafety

•Donotattachtowedequipmentexceptatthehitchpoint.

•Followtheattachmentmanufacturer'srecommendation

forweightlimitsfortowedequipmentandtowingon

slopes.Towedweightmustnotexceedtheweightofthe

machine,operator,andballast.Usecounterweightsor

wheelweightsasdescribedintheattachment,orinthe

pullingmachineOperator’sManual.

•Neverallowchildrenorothersinorontowedequipment.

•Onslopes,theweightofthetowedequipmentmaycause

lossoftraction,increasedriskofrollover,andlossof

control.Reducethetowedweightandslowdown.

•Stoppingdistanceincreaseswiththeweightofthetowed

load.Travelslowlyandallowextradistancetostop.

•Makewideturnstokeeptheattachmentclearofthe

machine.

Service

SafeHandlingofGasoline:

Toavoidpersonalinjuryorpropertydamage,useextracare

whenhandlinggasolineandotherfuels.Theyareammable

andthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipesandothersources

ofignition.

•Useonlyanapprovedcontainer.

•Neverremovethegascaporaddfuelwhentheengineis

running.Allowtheenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerinsidewhere

thereisanopename,suchasnearawaterheateror

furnace.

•Neverllcontainersinsideavehicleoronatruckor

trailerwithaplasticliner.Alwaysplacecontainersonthe

groundawayfromyourvehiclebeforelling.

•Removegas-poweredequipmentfromthetruckortrailer

andrefuelitontheground.Ifthisisnotpossible,then

refuelsuchequipmentwithaportablecontainer,rather

thanfromagasolinedispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilthefuelingis

complete.Donotuseanozzlelock-opendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllthefueltank.Replacegascapandtighten

securely.

GeneralService:

•Neveroperateamachineinsideaclosedarea.Engine

exhaustcontainscarbonmonoxide,whichisanodorless,

deadlypoisonthatcankillyou.

•Keepnutsandboltstight,especiallythebladeattachment

bolts.Keepequipmentingoodcondition.

•Neverinterferewiththeintendedfunctionofasafety

deviceortoreducetheprotectionprovidedbyasafety

device.Checktheirproperoperationregularly.

•Keepthemachinefreeofgrass,leaves,orotherdebris

build-up.Cleanupoilorfuelspillagefuelsoakeddebris.

Allowthemachinetocoolbeforestoring.

•Stopandinspecttheequipmentifyoustrikeanobject.

Repair,ifnecessary,beforerestarting.

•Nevermakeanyadjustmentsorrepairswiththeengine

running.

•Grasscatchercomponentsaresubjecttowear,damage

anddeterioration,whichcouldexposemovingpartsor

allowobjectstobethrown.Frequentlycheckcomponents

andreplacewithmanufacturers'recommendedparts,

whennecessary.

•Mowerbladesaresharpandcancut.Wraptheblade(s)or

weargloves,anduseextracautionwhenservicingthem.

•Checkforproperbrakeoperationfrequently.Adjustand

serviceasrequired.

5

Page 6

•Maintainorreplacesafetyandinstructiondecalsas

necessary.

•UseonlygenuineTororeplacementpartstoensurethat

originalstandardsaremaintained.

ToroRidingMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

maynotbeincludedintheANSIstandards.

•Stoptheengine,movethemotioncontrolleverstoneutral

andoutwardtotheparkposition,disengagetheblade

controlswitch,removekeybeforeanddisconnectspark

plugwire(s)performinganyservice,repairs,maintenance

oradjustments.

•Keephands,feet,hair,andlooseclothingawayfrom

attachmentdischargearea,undersideofmowerandany

movingpartswhileengineisrunning.

•Donottouchequipmentorattachmentpartswhichmay

behotfromoperation.Allowtocoolbeforeattempting

tomaintain,adjustorservice.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyes,andclothing.Protectyourface,

eyes,andclothingwhenworkingwithabattery.

•Batterygasescanexplode.Keepcigarettes,sparksand

amesawayfrombattery.

•UseonlyToroapprovedattachments.Warrantymaybe

voidedifusedwithunapprovedattachments.

•Ifloadingthemachineontoatrailerortruck,useasingle,

full-widthramponly.Therampangleshouldnotexceed

15degrees.

6

Page 7

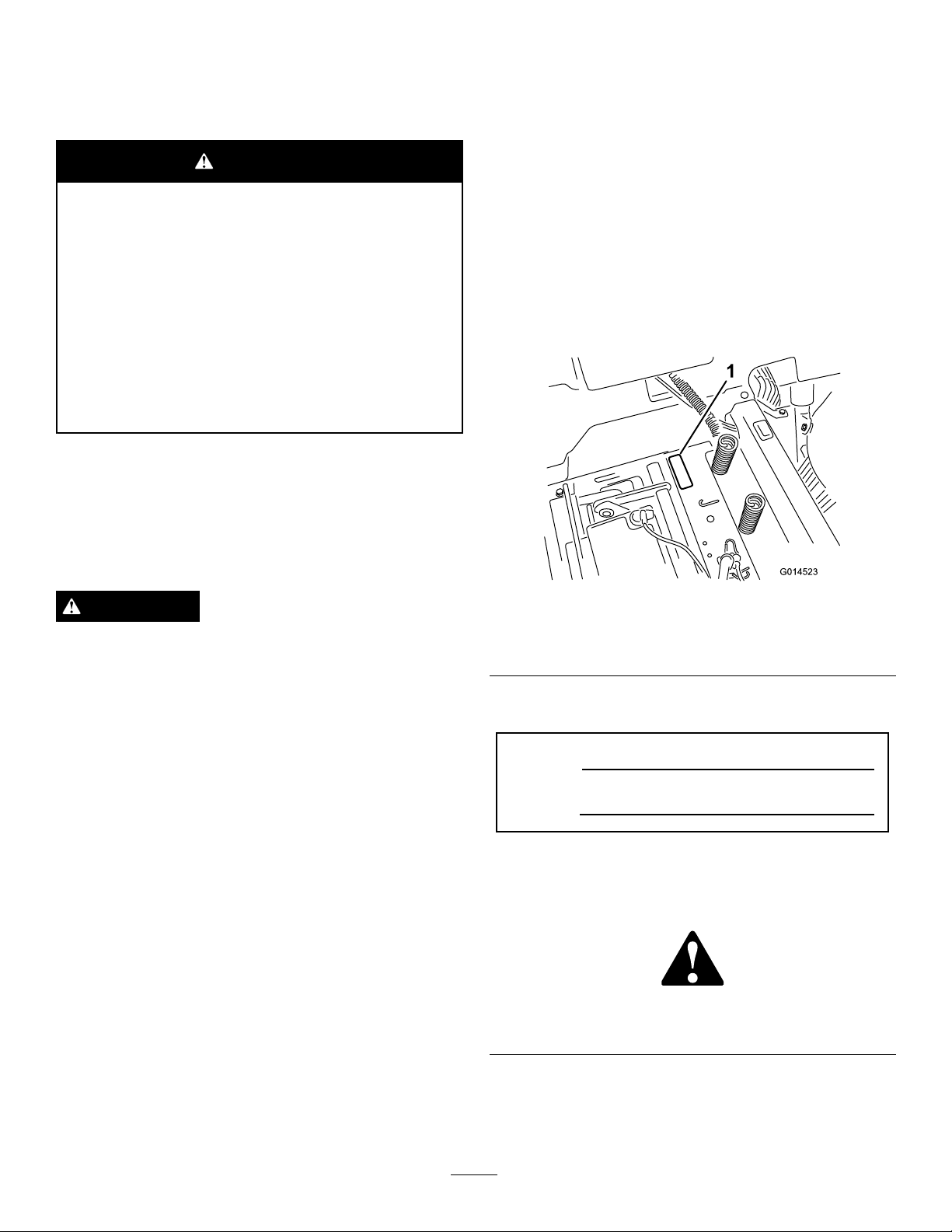

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

7

Page 8

SafetyandInstructional

Decals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

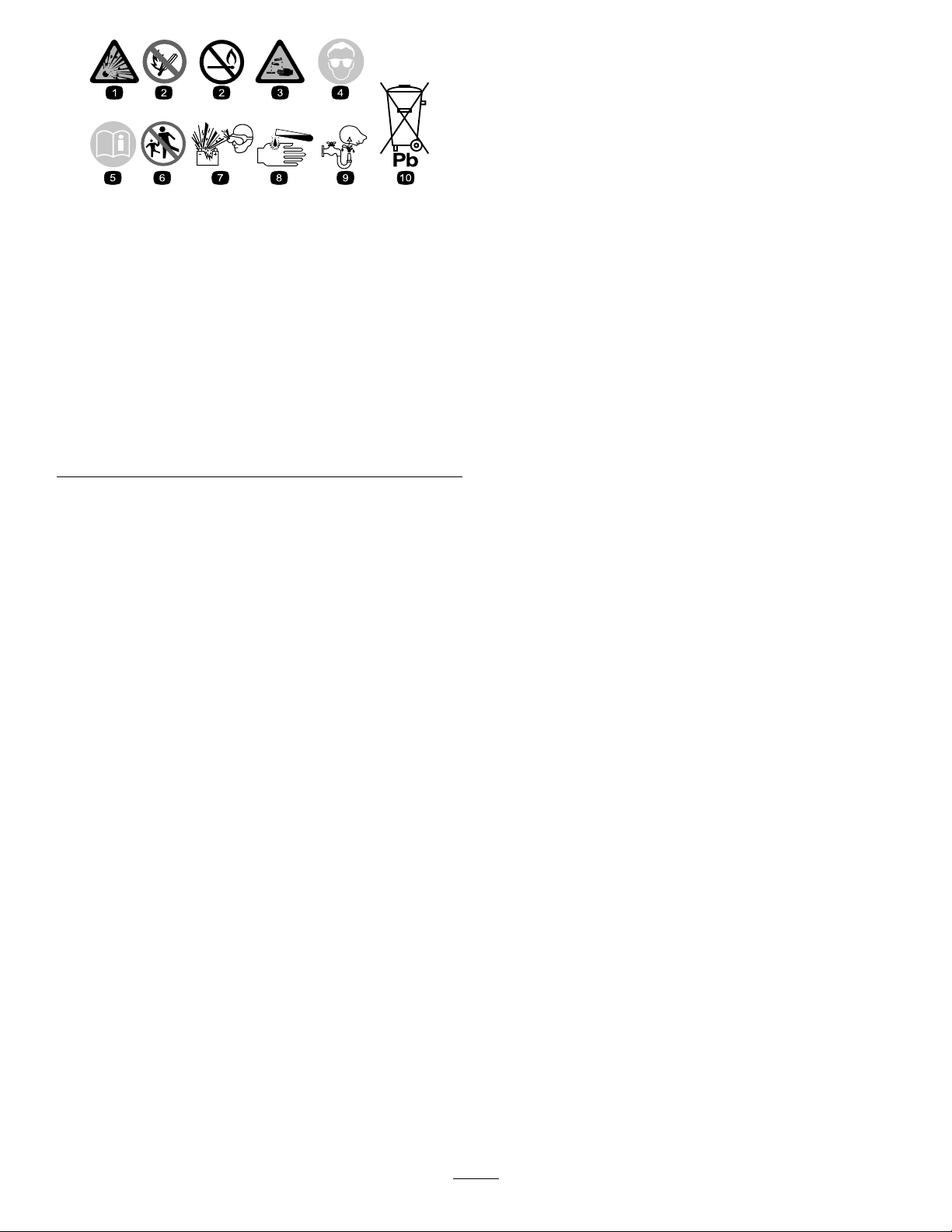

93-7009

1.Warning—don'toperatethemowerwiththedeectorupor

removed;keepthedeectorinplace.

2.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

109-7076

99-3943

1.Engine

106-8717

1.Readtheinstructionsbeforeservicingorperforming

maintenance.

2.Checktirepressureevery25operatinghours.

3.Greaseevery25operatinghours.

4.Engine

110-6691

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Thrownobjecthazard,mower—donotoperatewithoutthe

deector,dischargecover,orgrasscollectionsystemin

place.

3.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

8

Page 9

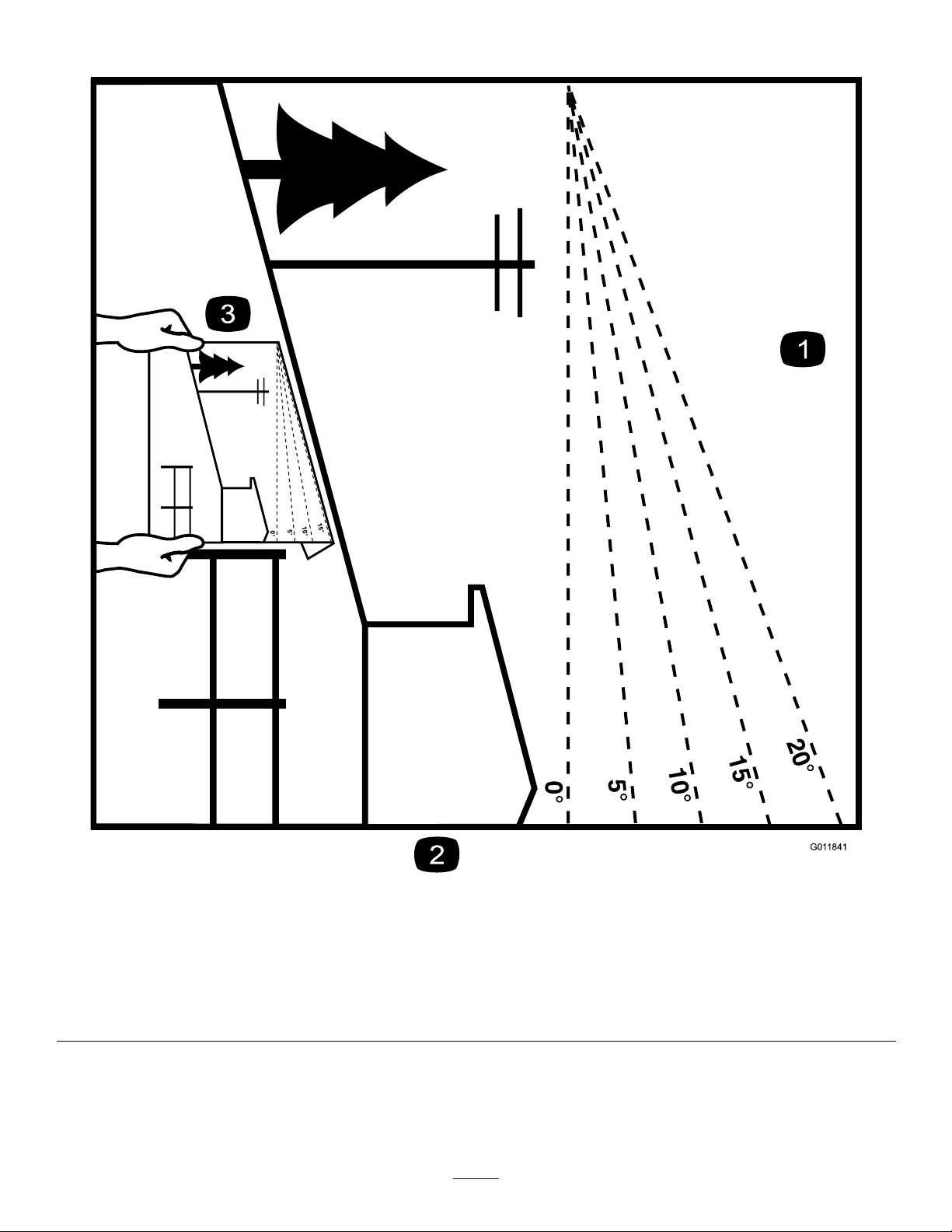

112-9840

1.ReadtheOperator's

Manual.

2.Heightofcut

3.Removetheignitionkey

andreadtheinstructions

beforeservicingor

performingmaintenance.

114-1606

1.Entanglementhazard,belt—keepallguardsinplace.

119-8814

1.Parkingposition4.Neutral

2.Fast5.Reverse

3.Slow

119-8870

50InchModel

1.Height-of-cut

121-2989

119-8815

1.Parkingposition4.Neutral

2.Fast5.Reverse

3.Slow

1.Bypassleverpositionfor

pushingthemachine

2.Bypassleverpositionfor

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

9

operatingthemachine

Page 10

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery .

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

10

Page 11

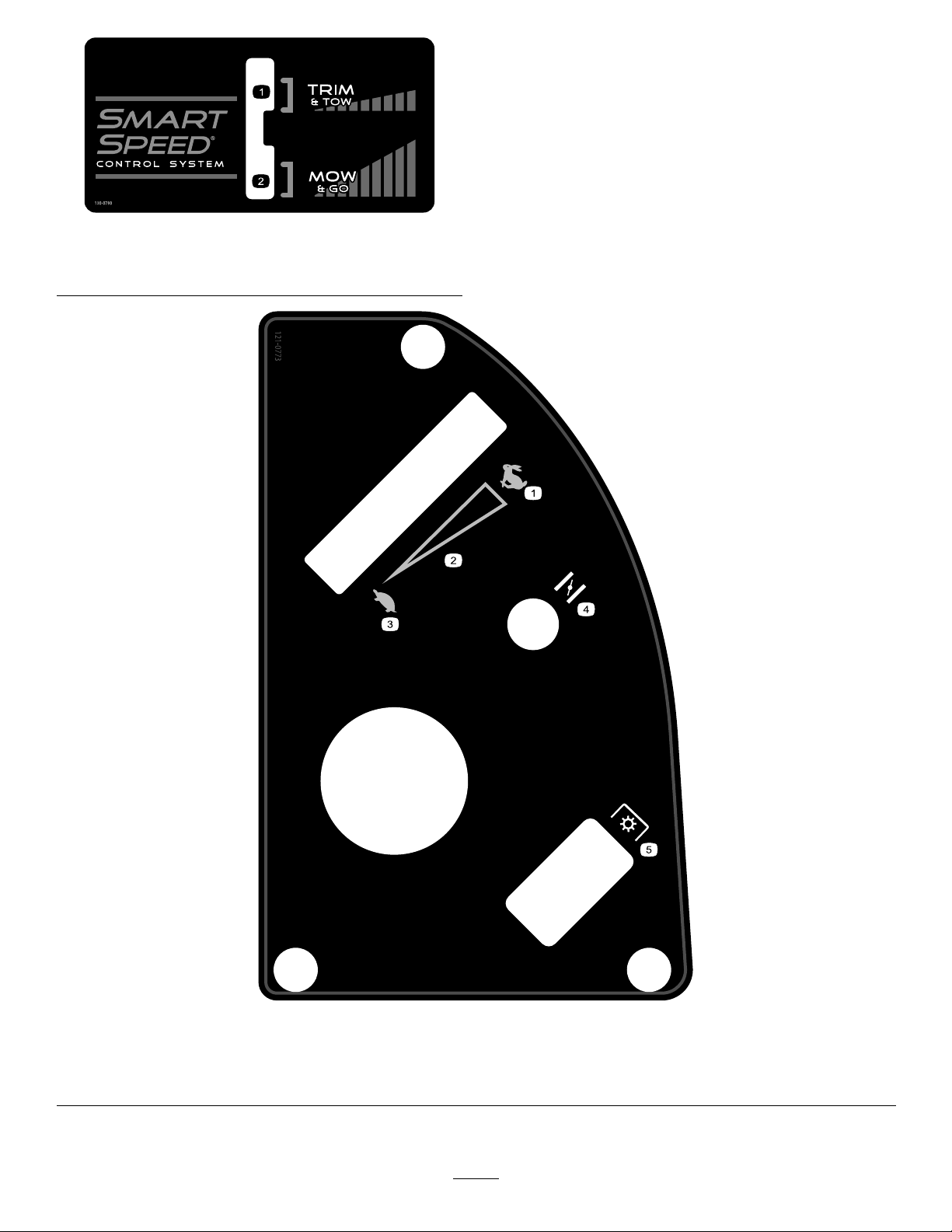

130-0780

1.Lowspeed—trimmingand

towing

2.Highspeed—mowingand

transport

121-0773

1.Fast

2.Continuousvariablesetting5.Powertake-off(PTO),Bladecontrolswitch

3.Slow

4.Choke

11

Page 12

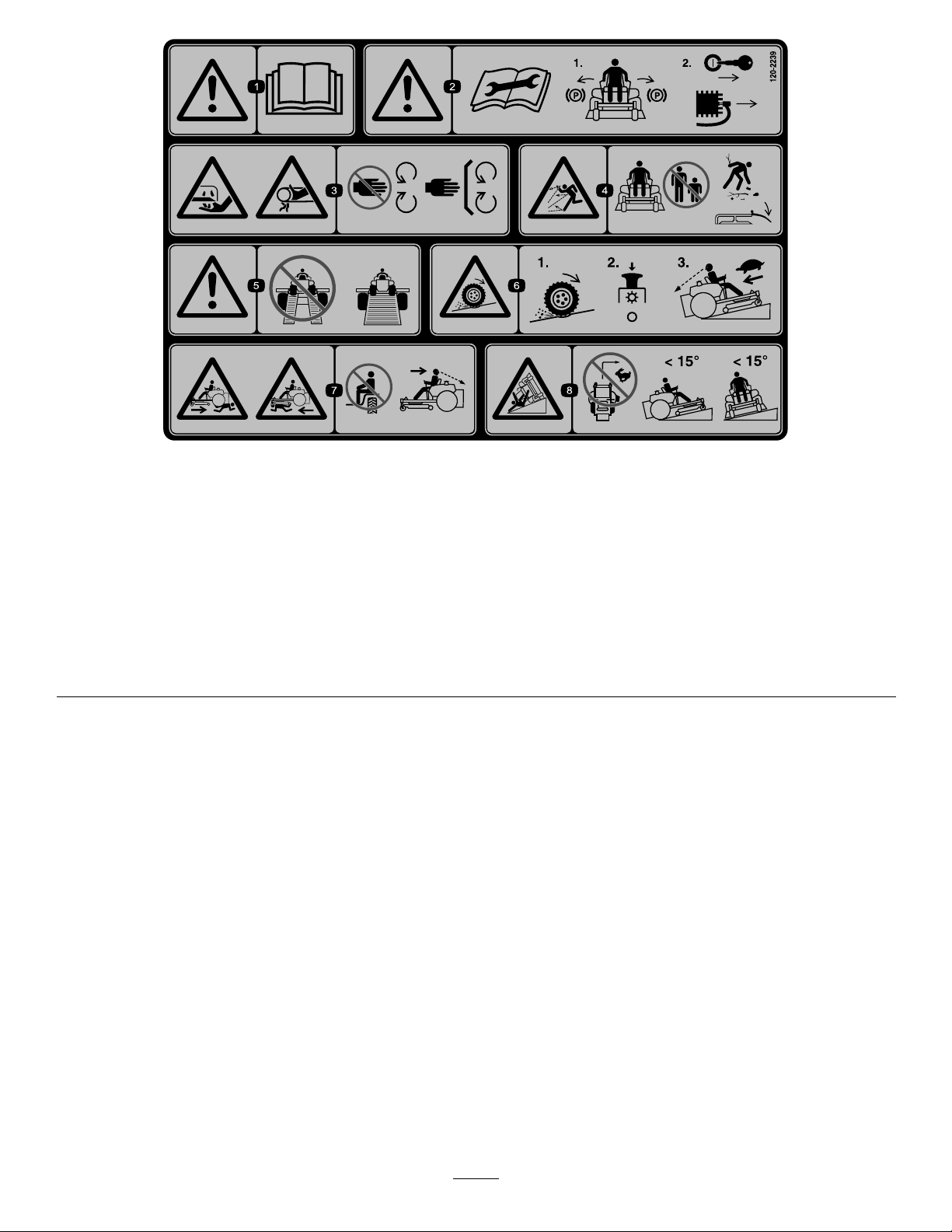

120-2239

1.Warning—readtheOperator'sManual.5.Warning—donotusesplitramps,useafullrampswhen

2.Warning—readtheinstructionsbeforeservicingorperforming

maintenance;movethemotioncontrolleverstothepark

(brake)position,removetheignitionkeyanddisconnectthe

sparkplugwire.

3.Cutting/dismembermenthazard,mowerblade;entanglement

hazard,belt—stayawayfrommovingparts,keepallguards

andshieldsinplace.

4.Thrownobjecthazard—keepbystandersasafedistancefrom

themachine,pickupdebrisbeforeoperating,keepdeector

inplace.

transportingmachine.

6.Lossoftraction/controlhazard,slopes—lossoftraction/control

onaslope,disengagethebladecontrolswitch(PTO),

proceedofftheslopeslowly .

7.Crushing/dismembermenthazardofbystanders,reversing;

crushing/dismembermenthazardofbystanders—donotcarry

passengers,lookbehindanddownwhenreversing.

8.Tippinghazard—donotmowslopesgreaterthan15degrees,

avoidsuddenandsharpturnswhileonslopes.

12

Page 13

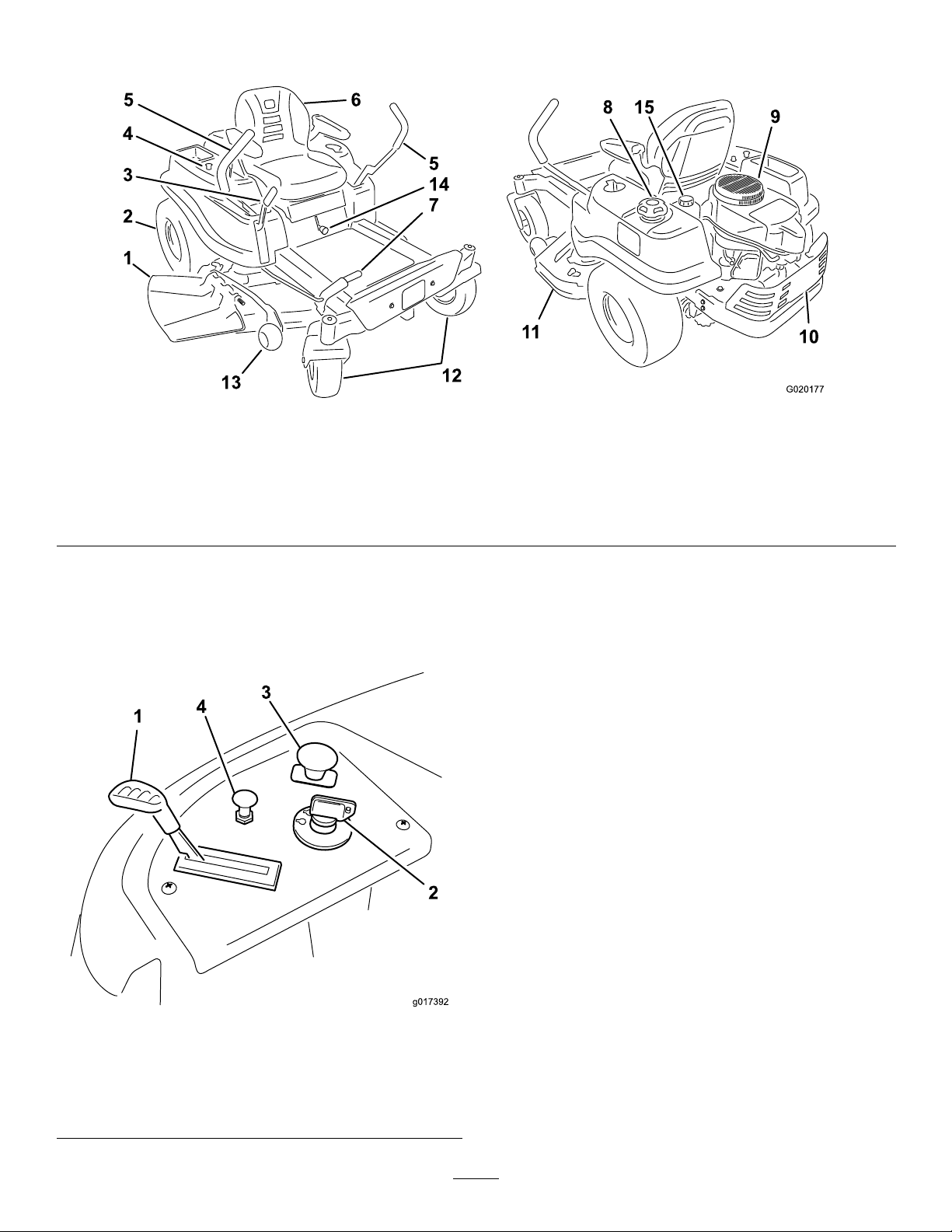

ProductOverview

G020177

4

3

2

1

8 15

9

10

11

12

13

6

5

14

7

5

Figure4

1.Deector

2.Reardrivewheel

3.Heightofcutlever7.Footassistlever(certain

4.Controlpanel8.Gastankcap

5.Motioncontrollevers9.Engine13.Anti-scalproller

6.Operatorseat

modelsonly)

Controls

BecomefamiliarwithallofthecontrolsinFigure4and

Figure5beforeyoustarttheengineandoperatethemachine.

10.Engineguard

11.Mowerdeck15.Hydraulicreservoir

12.Frontcasterwheel

14.SmartSpeed™lever

IgnitionSwitch

Theignitionswitchhasthreepositions,Off,RunandStart.

ThekeywillturntoStartandmovebacktoRunuponrelease.

TurningthekeytotheOffpositionwillstoptheengine;

however,alwaysremovethekeywhenleavingthemachine

topreventsomeonefromaccidentallystartingtheengine

(Figure5).

ThrottleControl

Thethrottlecontrolstheenginespeedandithasacontinuous

variablesettingfromSlowtoFast(Figure5).

ChokeControl

PullupontheChokecontroluntilitstopstochokethe

engine(Figure5).PushdownontheChokecontrolfor

normalengineoperation

1.Throttle3.Bladecontrolswitch

Figure5

ControlPanel

2.Ignitionswitch

(powertake-off)

4.Choke

BladeControlSwitch(PowerTake-Off)

Thebladecontrolswitch,representedbyapowertake-off

(PTO)symbol,engagesanddisengagespowertothemower

blades(

13

Figure5).

Page 14

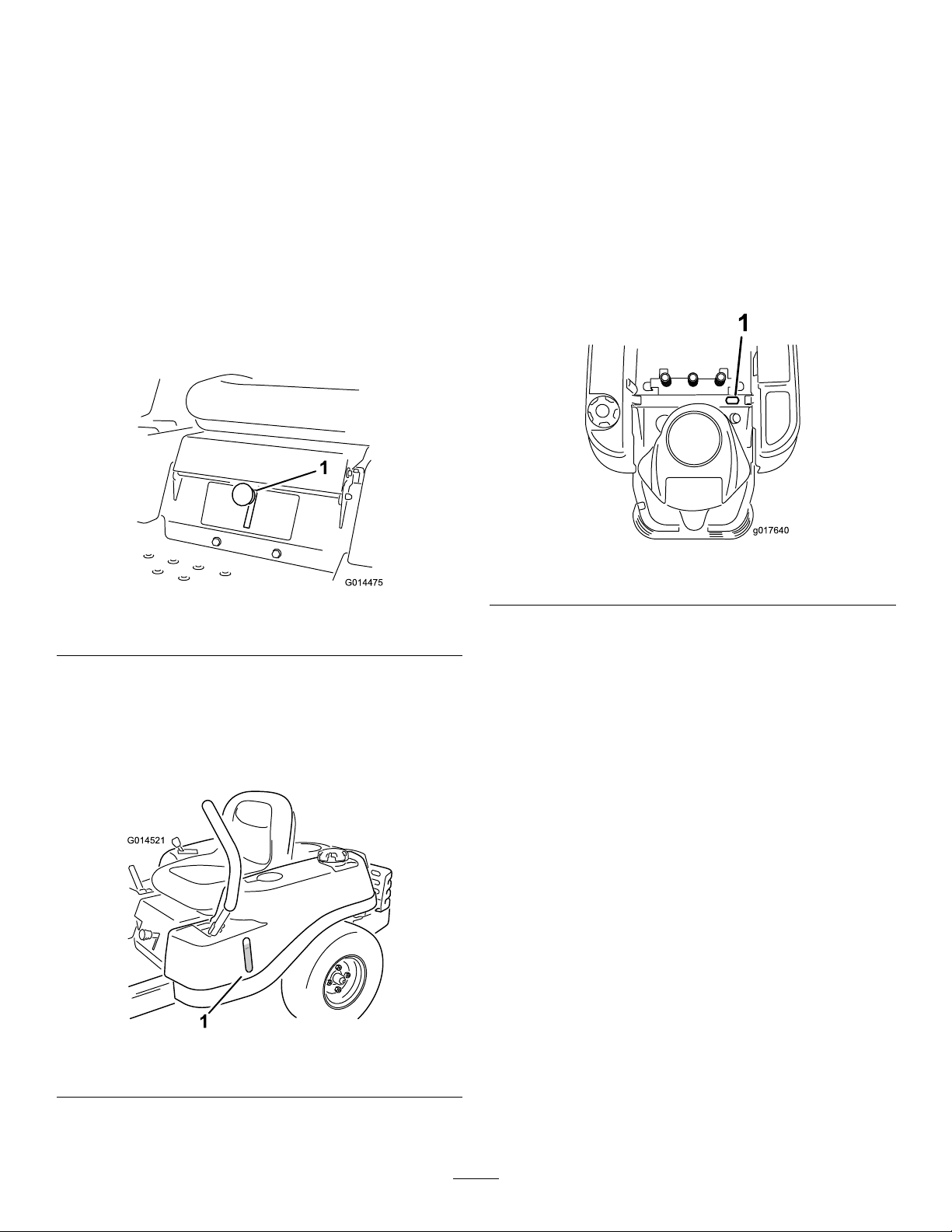

MotionControlLeversandParking

G014475

1

G014521

1

g017640

1

BrakePosition

Themotioncontrolleversarespeedsensitivecontrolsof

independentwheelmotors.Movingaleverforwardor

backwardturnsthewheelonthesamesideforwardorin

reverse;wheelspeedisproportionaltotheamountthelever

ismoved.Movethecontrolleversoutwardfromthecenter

totheparkpositionandexitthemachine(Figure17).Always

positionthemotioncontrolleversintotheparkposition

whenyoustopthemachineorleaveitunattended.

SmartSpeed™ControlSystemLever

TheSmartSpeed™ControlSystemlever,locatedbelowthe

operatingposition,givestheoperatorachoicetodrivethe

machineattwospeedranges,highandlow(Figure6).

Height-of-CutLever

Theheightofcutleverallowstheoperatortolowerand

raisethedeckfromtheseatedposition.Whentheleveris

movedup,towardtheoperatorthedeckisraisedfromthe

groundandwhenmoveddown,awayfromtheoperatoritis

loweredtowardtheground.Onlyadjusttheheightofcut

whilemachineisnotmoving(Figure4).

HourMeter

Thehourmeterrecordsthenumberofhourswhenthe

operatorisintheseatandtheignitionswitchisintheON

position(Figure8).

Figure6

1.Smartspeedlever

FuelWindow

Thefuelwindowlocatedonthelefthandsideofthemachine

canbeusedtoverifythepresenceofgasolineinthetank

(Figure7).

Figure8

1.Hourmeterlocationbehindtheseat

1.Fuelpresencewindow

Figure7

14

Page 15

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

ThinkSafetyFirst

OperatingSafety

Pleasecarefullyreadallofthesafetyinstructionsanddecals

inthesafetysection.Knowingthisinformationcouldhelp

you,yourfamily,petsorbystandersavoidinjury.

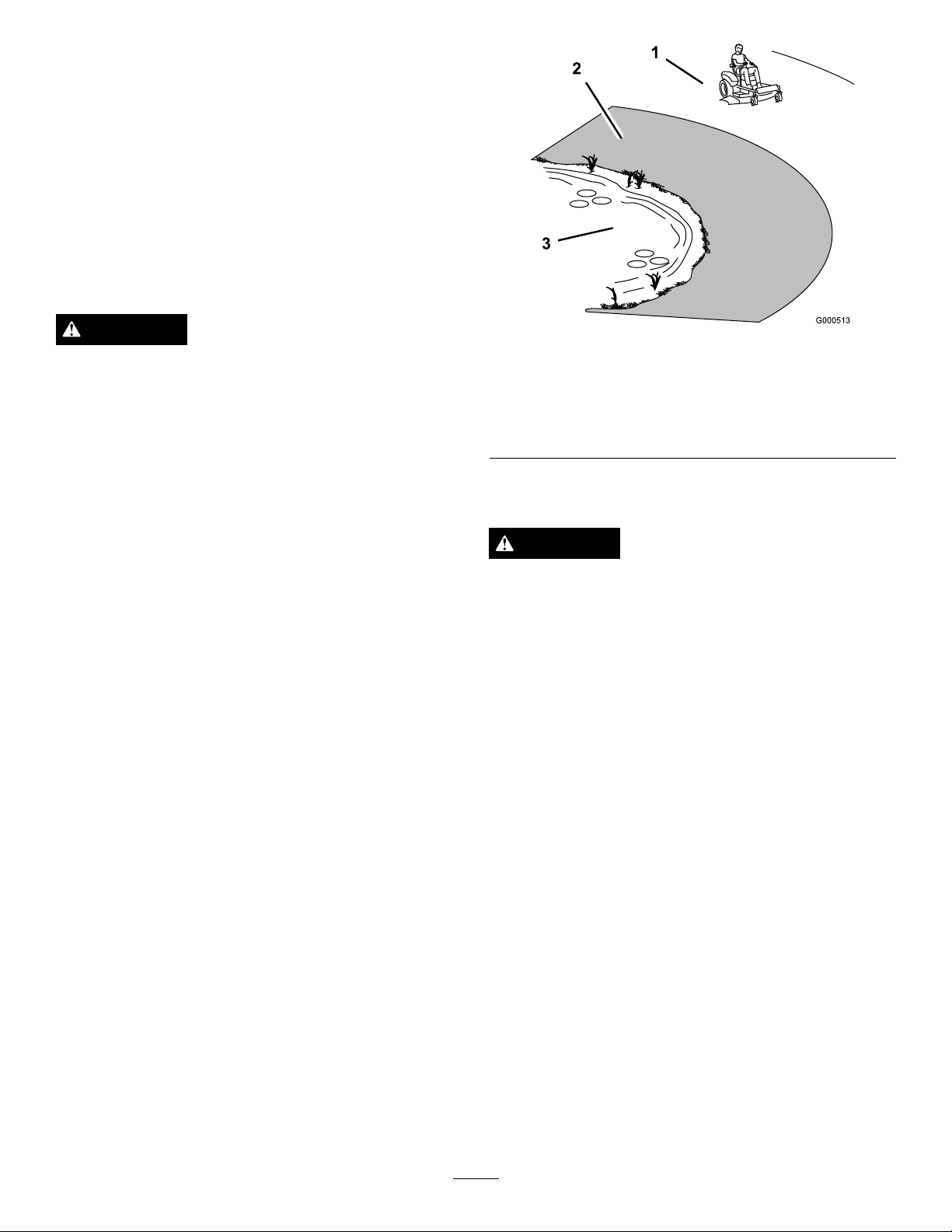

DANGER

Mowingonwetgrassorsteepslopescancause

slidingandlossofcontrol.

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,deathor

drowning.

Alossoftractionisalossofsteeringcontrol.

Toavoidlossofcontrolandpossibilityofrollover:

•Donotmowneardrop-offsornearwater.

•Donotmowslopesgreaterthan15degrees.

•Reducespeedanduseextremecautionon

slopes.

•Whenmowingslopes,graduallyworkfrom

lowertohigherareasontheincline.

•Avoidsuddenturnsorrapidspeedchanges.

•Turnup,intoaninclinewhenchanging

directionsonslopes.Turningdowntheslope

reducestraction.

•Attachmentschangethehandlingcharacteristics

ofthemachine.Useextracautionwhenusing

attachmentswiththemachine.

Figure9

1.SafeZone-usethe

TimeCutterhere

2.Usewalkbehindmower

and/orhandtrimmernear

drop-offsandwater .

3.Water

FuelSafety

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthefuelreaches

thebaseofthellerneck.Thisemptyspacein

thetankallowsgasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

15

Page 16

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

Thesafetyinterlocksystemalsoisdesignedtostoptheengine

wheneverthecontrolleversareoutoftheparkpositionand

yourisefromtheseat.

BeforeStarting

RecommendedFuel

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontains

morethan10%ethanolbyvolume,suchasE15

(contains15%ethanol),E20(contains20%ethanol),or

E85(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/orengine

damagewhichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

WARNING

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening .

•Keepgasawayfromeyesandskin.

UnderstandingtheSafetyInterlock

System

WARNING

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysorless.

Forlongerstorageitisrecommendedthatthefueltank

bedrained.

•Cleanstheenginewhileitruns.

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting.

Addthecorrectamountofgasstabilizer/conditionertothe

gas.

Note:Afuelstabilizer/conditionerismosteffectivewhen

mixedwithfreshgasoline.T ominimizethechanceofvarnish

depositsinthefuelsystem,usefuelstabilizeratalltimes.

CheckingtheEngineOilLevel

Beforeyoustarttheengineandusethemachine,checktheoil

levelintheenginecrankcase;refertoCheckingtheOilLevel

intheEngineMaintenancesection.

FillingtheFuelTank

Thesafetyinterlocksystemisdesignedtopreventtheengine

fromstartingunless:

•Thebladesaredisengaged.

•Themotioncontrolleversareintheparkposition.

Makesuretheengineisshutoffandthemotioncontrolsare

intheparkposition.Tankmaximumcapacityis2.9gallons.

Important:DoNotoverllfueltank.Fillthefueltank

tothebottomofthellerneck.Theemptyspaceinthe

16

Page 17

tankallowsthefueltoexpand.Overllingmayresultin

G014474

1

2

3

4

5

6

G014895

1

2

3

4

g017699

4

5

fuelleakageordamagetotheengineoremissionsystem.

1.Cleanaroundthefueltankcapandremovethecap.

Note:Youcanusethefuelwindowtoverifythe

presenceofgasolinebeforellingthetank(

Figure10).

2.Slowlyaddregular,unleadedgasolineuntilthefuel

reachesthebaseofthellerneck(Figure10).

Figure12

Figure10

1.Fueltankcap

2.Fillopening5.Fuelwindow

3.Fillerneck6.Fueltank

4.Baseofllerneck,DO

Figure11

NOTFILLP ASTHERE

1.Throttle

2.Bladecontrolswitch—Off

position

4.PullupontheChokecontrolbeforestartingacold

engine(Figure13).

Note:Awarmorhotenginemaynotrequirechoking.

1.Fillopening3.Fuel

2.Baseofllerneck,DO

NOTFILLP ASTHERE

4.Emptyspaceforfuel

expansion.

3.Installthefueltankcapsecurelyandtightenuntilit

“clicks”.Wipeupanygasolinethatmayhavespilled.

StartingtheEngine

1.Sitdownontheseatandmovethemotioncontrols

outwardtotheparkposition.

2.Movethethrottletothefastposition(Figure12).

3.Disengagethebladesbymovingthebladecontrol

switchtoOff(Figure12).

Figure13

1.Controlpanel4.Slow

2.Throttle

3.Fast

5.Chokecontrol

5.TurntheignitionkeytoStarttoenergizethestarter.

Whentheenginestarts,releasethekey(Figure14).

Important:Donotengagethestarterformore

than10secondsatatime.Iftheenginefailsto

start,allowa60secondcool-downperiodbetween

17

Page 18

attempts.Failuretofollowtheseinstructionscan

g017700

2

3

4

5

6

damagethestartermotor.

Figure15

Figure14

1.Controlpanel4.Off

2.Chokecontrol

3.Ignitionkey

5.Run

6.Start

6.Aftertheenginestarts,pushdownontheChoke

control(Figure14).Iftheenginestallsorhesitates,pull

upontheChokecontrolandlettheenginerunfora

fewseconds.ThenpushdownontheChokecontrol.

Repeatthisasrequired.

OperatingtheBlades

Thebladecontrolswitch,representedbyapowertake-off

(PTO)symbol,engagesanddisengagespowertothemower

blades.Thisswitchcontrolspowertoanyattachmentsthat

drawpowerfromtheengine,includingthemowerdeckand

cuttingblades.

1.Controlpanel2.Bladecontrolswitch—On

position

DisengagingtheBlades

PushdownonthebladecontrolswitchtomoveittotheOff

positionanddisengagetheblades(Figure16).

EngagingtheBlades

Important:Donotengagethebladeswhenparkedin

tallgrass.Beltorclutchdamagecanoccur.

1.Releasepressureonthemotioncontrolleversand

placethemachineinneutral.

2.MovethethrottletotheFastposition.

Note:Alwaysengagethebladeswiththethrottlein

theFastposition.

3.Pulluponthebladecontrolswitchtomoveittothe

Onpositionandengagetheblades(

Figure15).

Figure16

1.Controlpanel2.Bladecontrolswitch—Off

18

Page 19

TestingtheSafetyInterlock

G014475

1

System

Testthesafetyinterlocksystembeforeyouusethemachine

eachtime.Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthesafety

systemimmediately.

1.Whilesittingontheseat,withthecontrolleversinpark

position,andmovethebladecontrolswitchtoOn.Try

startingtheengine;theengineshouldnotcrank.

2.Whilesittingontheseat,movethebladecontrol

switchtoOff.Moveeithermotioncontrollevertothe

center,unlockedposition.Trystartingtheengine;the

engineshouldnotcrank.Repeatwiththeothermotion

controllever.

3.Whilesittingontheseat,movethebladecontrolswitch

toOff,andlockthemotioncontrolleversinthepark

position.Starttheengine.Whiletheengineisrunning,

engagethebladecontrolswitch,andriseslightlyfrom

theseat;theengineshouldstop.

4.Whilesittingontheseat,movethebladecontrolswitch

toOff,andlockthemotioncontrolleversinthepark

position.Starttheengine.Whiletheengineisrunning,

movethemotioncontrolleverstothecenter,unlocked

position,engagethebladecontrolswitch,andrise

slightlyfromtheseat;theengineshouldstop.

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placingthethrottlecontrol

intheFastpositioncanbebestforperformance.Formost

applications,operatinginthefullthrottlepositionisdesirable.

StoppingtheEngine

1.Disengagethebladesbymovingthebladecontrol

switchtoOff(Figure16).

2.MovethethrottlelevertobetweentheFastposition

(Figure13).

3.TurntheignitionkeytoOff(Figure14)andremove

thekey.

Driving

Drivingthemachinebenetsfromanunderstandingof

whatzeroturnradiusmowermeans.Thedrivewheelsturn

independently,poweredbyhydraulicmotorsoneachaxle;

henceonesidecanturninreversewhiletheotherturns

forwardcausingthemachinetospinratherthanturn.This

vastlyimprovesthemachinemaneuverabilitybutmayrequire

someadjustmentiftheoperatorisunfamiliar.

WARNING

Themachinecanspinveryrapidly .Theoperator

maylosecontrolofthemachineandcausepersonal

injuryordamagetothemachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

Figure17

1.Park(brake)position

2.Centerunlockposition5.Frontofmachine

3.Forward

4.Backward

UsingtheSmartSpeed™Control

System

TheSmartSpeed™ControlSystemlever,locatedbelowthe

operatingposition(

drivethemachineattwogroundspeedranges,highandlow .

1.Smartspeedlever

Figure18),givestheoperatorachoiceto

Figure18

19

Page 20

Tochangespeeds:

G008952

G008953

Backward

1.Movethemotioncontrolleverstoneutralandoutward

totheparkposition;disengagethebladecontrolswitch.

WARNING

Removingyourhandsfromthemotioncontrol

leverswhilethemachineisinmotioncan

resultinalossofcontrolcausingharmtoyou

orbystanders.

Alwaysstopthemachineandmovethemotion

controlleverstotheparkpositionbefore

adjustingtheSmartSpeed™ControlSystem.

2.Adjustthelevertothedesiredposition.

Forward

1.Movetheleverstothecenter,unlockedposition.

2.Togoforward,slowlypushthemotioncontrollevers

forward(

Figure17).

1.Movetheleverstothecenter,unlockedposition.

2.Togobackward,lookbehindyouanddownasyou

slowlypullthemotioncontrolleversrearward(Figure

20).

Figure20

Togostraight,applyequalpressuretobothmotion

controllevers(Figure20).

Figure19

Togostraight,applyequalpressuretobothmotion

controllevers(

Toturn,releasepressureonthemotioncontrollever

towardthedirectionyouwanttoturn(Figure19).

Thefartheryoumovethemotioncontrolleversin

eitherdirection,thefasterthemachinewillmovein

thatdirection.

Figure19).

Toturn,releasethepressureonthemotioncontrol

levertowardthedirectionyouwanttoturn.

Tostop,pushthemotioncontrolleverstoneutral.

StoppingtheMachine

Tostopthemachine,movethemotioncontrolleversto

neutralandoutwardtotheparkposition,disengagetheblade

controlswitch,ensurethethrottleisinthefastposition,and

turntheignitionkeytoOff.Remembertoremovethekey

fromtheignitionswitch.

WARNING

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemowerwhileitis

unattended.

Alwaysremovetheignitionkeyandmovethe

motioncontrolleversoutwardtotheparkposition

whenleavingthemachineunattended,evenifjust

forafewminutes.

Tostop,pullthemotioncontrolleverstoneutral.

20

Page 21

AdjustingtheHeightofCut

G014476

1

2

3

G010233

1

2

3

4

1

G014969

Height-of-cutiscontrolledbytheleverlocatedtotherightof

theoperatingposition(Figure21).

Figure21

1.Height-of-cutlever3.4.5inch(115mm),

Transportposition

2.Height-of-cutpositions

Figure22

1.Anti-scalproller3.FlangeNut

2.Bolt4.Holespacing

PositioningtheSeat

Whilesittingintheoperator’sposition,raisetheseat

adjustmentleverslightlyandmovetheseatforwardor

backwardtothedesiredposition(Figure23).

1.Pullupandinwardonthelevertomoveittothe

desiredcuttingposition.

2.Onceatthedesiredcuttingposition,slowlylowerthe

leveruntilitengagestheposition.

Thetransportpositionisthehighestheight-of-cutpositionor

cuttingheight4.5inch[115mm](Figure21).

AdjustingtheAnti-Scalp Rollers

Wheneveryouchangetheheight-of-cut,adjusttheheight

oftheanti-scalprollers.

Note:Adjusttheanti-scalprollerssotherollersdonottouch

thegroundinnormal,atmowingareas.

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockpositionand

settheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

3.Adjusttheanti-scalprollersasshownin

partstostopbeforeleavingtheoperatingposition.

matchtheclosestheight-of-cutposition.

Figure22to

Figure23

AdjustingtheMotionControl Levers

AdjustingtheHeight

Themotioncontrolleverscanbeadjustedhigherorlowerfor

maximumoperatorcomfort.

1.Removethe2boltsholdingthecontrollevertothe

controlarmshaft(

2.Movethecontrollevertothenextsetofholes.Secure

theleverwiththe2bolts(Figure24).

Figure24).

21

Page 22

4

1

2

G014970

3

Figure24

g017303

1 2

3

1.Controlarmshaft3.Slotted,upperhole

2.Controllever

4.Bolt

3.Repeattheadjustmentfortheoppositecontrollever.

AdjustingtheTilt

Themotioncontrolleverscanbetiltedforeoraftfor

maximumoperatorcomfort.

1.Loosentheupperboltholdingthecontrollevertothe

controlarmshaft.

2.Loosenthelowerboltjustenoughtopivotthecontrol

leverforeoraft(Figure24).Tightenbothboltsto

securethecontrolinthenewposition.

3.Repeattheadjustmentfortheoppositecontrollever.

PushingtheMachinebyHand

Important:Alwayspushthemachinebyhand.Never

towthemachinebecausedamagemayoccur.

Thismachinehasanelectricbrakemechanismandtopush

themachinetheignitionkeyneedstobeintheRunposition.

Thebatteryneedstobechargedandfunctioningforthe

electricbraketobedisengage.

Figure25

1.Bypassleverlocation

2.Leverpositionfor

operatingthemachine

3.Leverpositionforpushing

themachine

6.Whennished,ensurethekeyhasbeenreturnedtothe

Stoppositiontoavoiddrainingthebatterycharge.

Ifthemachinefailstomovetheelectricbrakemaystillbe

engaged.Ifnecessarytheelectricbrakecanbereleased

manually.RefertotheReleasingtheElectricBrake(page33)

procedureinDriveMaintenance.

ToOperatetheMachine

Movethebypassleversrearwardthroughthekeyholeand

downtolocktheminplaceasshowninFigure25.Ensure

thisisdoneforeachlever.

ToPushtheMachine

1.Parkthemachineonalevelsurfaceanddisengagethe

bladecontrolswitch.

2.Movethemotioncontrolleversoutwardtopark

position,stoptheengine,andwaitforallmovingparts

tostopbeforeleavingtheoperatingposition.

3.Locatethebypassleversontheframeonbothsidesof

theengine.

4.Movethebypassleversforwardthroughthekeyhole

anddowntolocktheminplaceasshownin

Ensurethisisdoneforeachlever.

5.Movethemotioncontrolleversinwardtotheneutral

positionandturntheignitionkeytotherunposition.

Donotstartthemachine.

Themachineisnowabletobepushedbyhand.

Figure25.

22

Page 23

GrassDeector

Themowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

Cut1/3oftheGrassBlade

Itisbesttocutonlyabout1/3ofthegrassblade.Cutting

morethanthatisnotrecommendedunlessgrassissparse,or

itislatefallwhengrassgrowsmoreslowly.

DANGER

Withoutthegrassdeector,dischargecover,or

completegrasscatcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriswillcauseinjuryor

death.

•Neverremovethegrassdeectorfromthemower

becausethegrassdeectorroutesmaterialdown

towardtheturf.Ifthegrassdeectorisever

damaged,replaceitimmediately .

•Neverputyourhandsorfeetunderthemower.

•Nevertrytocleardischargeareaormower

bladesunlessyoumovethebladecontrolswitch

toOffandrotatetheignitionkeytoOff.Also

removethekeyandpullthewireoffthespark

plug(s).

OperatingTips

MowingDirection

Alternatemowingdirectiontokeepthegrassstanding

straight.Thisalsohelpsdisperseclippingswhichenhances

decompositionandfertilization.

MowatCorrectIntervals

Normally,moweveryfourdays.Butremember,grassgrows

atdifferentratesatdifferenttimes.Sotomaintainthesame

cuttingheight,whichisagoodpractice,mowmoreoftenin

earlyspring.Asthegrassgrowthrateslowsinmidsummer,

mowlessfrequently .Ifyoucannotmowforanextended

period,rstmowatahighcuttingheight;thenmowagain

twodayslateratalowerheightsetting.

AvoidCuttingTooLow

Ifthecuttingwidthofthemoweriswiderthanthemower

youpreviouslyused,raisethecuttingheighttoensurethat

uneventurfisnotcuttooshort.

LongGrass

FastThrottleSetting

Forbestmowingandmaximumaircirculation,operatethe

engineattheFastposition.Airisrequiredtothoroughlycut

grassclippings,sodonotsettheheight-of-cutsolowasto

totallysurroundthemowerbyuncutgrass.Alwaystrytohave

onesideofthemowerfreefromuncutgrass,whichallowsair

tobedrawnintothemower.

UsingtheSmartSpeed™Control

System

TheSmartSpeed™ControlSystemlever,locatedbelowthe

operatingposition,givestheoperatorachoicetodrivethe

machineattwospeedranges,highandlow.Anoperator

canbenetfromthelowerspeedsettingwhenmaneuvering

themachineintightspacesoroperatingarounddelicate

landscapes.Thelowsettingcanalsobeusedtooperatethe

machineatahighthrottlesettingandbladespeedwhilestill

beingabletoreducegroundspeedtoincreasequalityofcut.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethatthe

cuttingheightofthemowerdoesnotscalpanyuneven

ground.However,thecuttingheightusedinthepastis

generallythebestonetouse.Whencuttinggrasslongerthan

sixinchestall,youmaywanttocutthelawntwicetoensure

anacceptablequalityofcut.

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,raisethe

cuttingheighthigherthanusualandcutthegrassatthis

setting.Thencutthegrassagainusingthelower,normal

setting.

WhenStopping

Ifthemachine'sforwardmotionmustbestoppedwhile

mowing,aclumpofgrassclippingsmaydropontoyourlawn.

Toavoidthis,moveontoapreviouslycutareawiththeblades

engaged.

KeeptheUndersideoftheMowerClean

Cleanclippingsanddirtfromtheundersideofthemower

aftereachuse.Ifgrassanddirtbuildupinsidethemower,

cuttingqualitywilleventuallybecomeunsatisfactory.

BladeMaintenance

Maintainasharpbladethroughoutthecuttingseasonbecause

asharpbladecutscleanlywithouttearingorshreddingthe

grassblades.Tearingandshreddingturnsgrassbrownat

theedges,whichslowsgrowthandincreasesthechanceof

disease.Checkthecutterbladesdailyforsharpness,andfor

anywearordamage.Filedownanynicksandsharpenthe

bladesasnecessary.Ifabladeisdamagedorworn,replaceit

immediatelywithagenuineTororeplacementblade.

23

Page 24

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst50hours

Beforeeachuseordaily

Aftereachuse

Every25hours

Every100hours

Every200hours

Every400hours

MaintenanceProcedure

•Changetheengineoil.

•Changetheoilandltersforthehydraulicsystem,andbleedthesystem.

•Checkthesafetyinterlocksystem.

•Checktheengineoillevel.

•Cleantheairintakescreen.

•Checkthecuttingblades.

•Inspectthegrassdeectorfordamage

•Cleanthemowerhousing.

•Greasealllubricationpoints.

•Checktirepressure.

•Checktheoillevelintheexpansiontank.

•Checkthebeltsforwear/cracks.

•Servicethepaperelement.(moreoftenindusty,dirtyconditions)

•Changetheengineoil.(moreoftenindusty,dirtyconditions)

•Checkthesparkplug(s).

•Replacethein-linefuellter

•Replacethepaperelement.(moreoftenindusty,dirtyconditions)

•Changetheoillter.(moreoftenindusty,dirtyconditions)

•Changetheoilandltersforthehydraulicsystem,andbleedthesystem.

•Chargethebatteryanddisconnectbatterycables.

Beforestorage

•Performallmaintenanceprocedureslistedabovebeforestorage.

•Paintanychippedsurfaces.

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

24

Page 25

Premaintenance

1

G014522

Lubrication

Procedures

GreasingtheBearings

RaisingtheSeat

Makesurethemotioncontrolleversarelockedinthepark

position.Lifttheseatforward.

Thefollowingcomponentscanbeaccessedbyraisingtheseat:

•Serialplate

•Servicedecal

•Seatadjustmentbolts

•Fuellter

•Batteryandbatterycables

ServiceInterval:Every25hours—Greasealllubrication

points.

GreaseType:No.2GeneralPurposeLithiumBaseGrease

1.Parkthemachineonalevelsurfaceanddisengagethe

bladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothepark

position,stoptheengine,removethekey,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Cleanthegreasettings(

arag.Makesuretoscrapeanypaintoffofthefront

ofthetting(s).

Figure26andFigure27)with

Figure26

1.Frontcastertire

Figure27

Locatedontheseatpanunderside

1.Readtheinstructions

beforeservicingor

performingmaintenance.

2.Checktirepressureevery

25operatinghours.

3.Greaseevery25operating

hours.

4.Engine

4.Connectagreaseguntoeachtting(Figure26and

Figure27).Pumpgreaseintothettingsuntilgrease

beginstooozeoutofthebearings.

5.Wipeupanyexcessgrease.

25

Page 26

EngineMaintenance

G014908

1

2

3

g017470

SAE V iscosity Grades

SAE 40

SAE 30

SAE 10W– 30/ SAE 10W– 40

-20 0 20 32 40 60 80 100

-30 -20 -10 0 10 20 30 40

°F

°C

STARTING TEMPERA TURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

SAE 5W– 20

ServicingtheAirCleaner

Note:Servicetheaircleanermorefrequently(everyfew

hours)ifoperatingconditionsareextremelydustyorsandy.

RemovingtheElement

1.Parkthemachineonalevelsurfaceanddisengagethe

bladecontrol(PTO).

2.Movethemotioncontrolleverstothebrakeposition,

stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Cleanaroundtheaircleanercovertopreventdirtfrom

gettingintotheengineandcausingdamage.Liftthe

coverandremovethehoseclampsecuringtheair

cleanerassemblytotheengine(Figure28).

4.Loosenthehoseclampandremovethepaperelement

(

Figure28).

Important:Nevercleanthepaperelementwith

pressurizedairorliquids,suchassolvent,gas,

orkerosene.Replacethepaperelementifitis

damagedorcannotbecleanedthoroughly.

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSF ,SG,SH,SJ,orSL)

CrankcaseCapacity:withalterchange,70ounces(2.1l);

withoutalterchange,61ounces(1.8l)

Viscosity:Seethetablebelow.

Figure29

Note:Usingmultigradeoils(5W -20,10W -30,and10W -40)

willincreaseoilconsumption.Checkoillevelmorefrequently

whenusingthem.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

WARNING

Figure28

1.Cover

2.Paperelement

3.Hoseclamp

CleaningtheElement

ServiceInterval:Every100hours—Servicethepaper

Every200hours/Yearly(whichevercomes

rst)—Replacethepaperelement.(moreoftenin

dusty,dirtyconditions)

1.Lightlytaptheelementonaatsurfacetoremovedust

anddirt.

2.Inspecttheelementfortears,anoilylm,anddamage

totheseal.

element.(moreoftenindusty ,dirty

conditions)

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawaythemuferandotherhotsurfaces.

Important:Donotoverllthecrankcasewithoil

becausedamagetotheenginemayresult.Donotrun

enginewithoilbelowthelowmarkbecausetheengine

maybedamaged.

1.Parkthemachineonalevelsurface,disengagethe

bladecontrolswitch,stoptheengine,engageparking

brake,andremovethekey.

2.Makesuretheengineisstopped,level,andiscoolso

theoilhashadtimetodrainintothesump.

3.Tokeepdirt,grassclippings,etc.,outoftheengine,

cleantheareaaroundtheoilllcap/dipstickbefore

removingit.

26

Page 27

4.Stoptheengine,removethekey ,andwaitforall

1

2

4

5

7

9

10

G0201 15

1

2

4

6

G0201 16

movingpartstostopbeforeleavingtheoperating

position(Figure30).

Figure31

Figure30

ChangingtheEngineOil

ServiceInterval:Aftertherst8hours—Changetheengine

oil.

Every100hours—Changetheengineoil.(moreoften

industy,dirtyconditions)

Note:Disposeoftheusedoilatarecyclingcenter.

1.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoassuretheoildrains

completely.

2.DisengagethePTO,movethemotioncontrolleversto

theneutrallockedpositionandsettheparkingbrake.

3.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position(

Figure31).

27

Page 28

4.Slowlypourapproximately80%ofthespeciedoil

1

2

4

6

G0201 17

1

2

4

6

3/4

G0201 18

intothellertubeandslowlyaddtheadditionaloilto

bringittotheFullmark(Figure32).

Figure32

Figure33

ChangingtheEngineOilFilter

ServiceInterval:Every200hours—Changetheoillter.

(moreoftenindusty ,dirtyconditions)

Note:Changetheengineoilltermorefrequentlywhen

operatingconditionsareextremelydustyorsandy.

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil.

2.Changetheengineoillter(Figure33).

Note:Ensuretheoilltergaskettouchestheengine

andthenanextra3/4turniscompleted.

3.Fillthecrankcasewiththepropertypeofnewoil;refer

toChangingtheOil.

ServicingtheSparkPlug

ServiceInterval:Every100hours—Checkthesparkplug(s).

Makesuretheairgapbetweenthecenterandsideelectrodes

iscorrectbeforeinstallingthesparkplug.Useasparkplug

wrenchforremovingandinstallingthesparkplug(s)anda

gappingtool/feelergaugetocheckandadjusttheairgap.

Installanewsparkplug(s)ifnecessary.

Type:NGKBPR4ES(orequivalent)

AirGap:0.030inch(0.76mm)

RemovingtheSparkPlug

1.DisengagethePTO,movethemotioncontrolleversto

28

theneutrallockedpositionandsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

Page 29

1

2

G020130

Figure34

1

2

G020131

16ft-lb

22N-m

G010687

Note:Duetothedeeprecessaroundthesparkplug,

blowingoutthecavitywithcompressedairisusually

themosteffectivemethodforcleaning.Thesparkplug

ismostaccessiblewhentheblowerhousingisremoved

forcleaning.

CheckingtheSparkPlug

Important:Nevercleanthesparkplug(s).Always

replacethesparkplug(s)whenithas:ablackcoating,

wornelectrodes,anoilylm,orcracks.

Ifyouseelightbrownorgrayontheinsulator,theengineis

operatingproperly.Ablackcoatingontheinsulatorusually

meanstheaircleanerisdirty.

InstallingtheSparkPlug

Tightenthesparkplug(s)to16ft-lb(22N-m).

Figure36

CleaningtheCoolingSystem

Setthegapto0.030inches(0.76mm).

Figure35

Cleantheairintakescreenfromgrassanddebrisbeforeeach

use.

1.Disengagethebladecontrolswitchandmovethe

controlleverstotheneutrallockedpositionandapply

theparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Removetheairintakescreen,aircleanercover,and

fanhousing.

4.Cleandebrisandgrassfromtheparts.

5.Installtheairintakescreen,aircleanercover,andfan

housing.

29

Page 30

FuelSystem

g017471

1

2

3

4

5

4.Squeezetheendsofthehoseclampstogetherandslide

themawayfromthelter(Figure37).

Maintenance

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Performanyfuelrelatedmaintenancewhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

ReplacingtheIn-lineFuel Filter

ServiceInterval:Every100hours—Replacethein-linefuel

lter

Neverinstalladirtylterifitisremovedfromthefuelline.

5.Removethelterfromthefuellines.

6.Installanewlterwiththeowdirectionarrowcoming

fromthefueltankandpointingtotheengine.Move

thehoseclampsclosetothelter(Figure37)tosecure

itinplace.

1.Parkthemachineonalevelsurfaceanddisengagethe

bladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothepark

position,stoptheengine,removethekey,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Locatethefuellteronthesideoftheengineasshown

Figure37.

in

Figure37

1.Fuellinefromtank

2.In-lineFuellter

3.Flowdirectionarrow

4.Fuellinetoengine

5.Hoseclamp

30

Page 31

ElectricalSystem

g017701

2

3

4

5

6

7

1

Maintenance

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

ChargingtheBattery

RemovingtheBattery

WARNING

5.Slidetherubbercoverupthepositive(red)cable.

Disconnectthepositive(red)cablefromthebattery

post(Figure38).Retainallfasteners.

6.Removethebatteryhold-down(Figure38)andliftthe

batteryfromthebatterytray .

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

1.Parkthemachineonalevelsurfaceanddisengagethe

bladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothepark

position,stoptheengine,removethekey,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Raisetheseattoaccessthebattery.

4.Disconnectthenegative(black)groundcablefromthe

batterypost(

WARNING

Incorrectbatterycableroutingcoulddamage

Figure38).Retainallfasteners.

themachineandcablescausingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

Figure38

1.Battery5.Negativebatterypost

2.Positivebatterypost6.Wingnut,washer,andbolt

3.Bolt,washer,andnut7.Batteryhold-down

4.T erminalboot

ChargingtheBattery

ServiceInterval:Beforestorage—Chargethebatteryand

disconnectbatterycables.

1.Removethebatteryfromthechassis;refertoRemoving

theBattery.

2.Chargethebatteryforaminimumof1hourat6to10

amps.Donotoverchargethebattery.

3.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthecharger

leadsfromthebatteryposts(

Figure39).

31

Page 32

Figure39

30

25

30

25

G014921

2

1

1.Positivebatterypost

2.Negativebatterypost

3.Red(+)chargerlead

4.Black(-)chargerlead

Note:Donotrunthemachinewiththebattery

disconnected,electricaldamagemayoccur.

InstallingtheBattery

1.Positionthebatteryinthetray(Figure38).

2.Installthepositive(red)batterycabletothepositive(+)

batteryterminalusingthefastenersremovedpreviously .

ServicingtheFuses

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;however,ifafuseblows,checkthe

component/circuitforamalfunctionorshort.

Fuse:

•MainF1-30amp,blade-type

•ChargeCircuitF2-25amp,blade-type

1.Removethescrewssecuringthecontrolpaneltothe

machine.Retainallfasteners

2.Liftthecontrolpaneuptoaccessthemainwiring

harnessandfuseblock(

3.Toreplaceafuse,pulloutonthefusetoremoveit

(Figure40).

Figure40).

3.Installthenegativebatterycabletothenegative(-)

batteryterminalusingthefastenersremovedpreviously .

4.Slidetheredterminalbootontothepositive(red)

batterypost.

5.Securethebatterywiththehold-down(

Figure38).

6.Lowertheseat.

Figure40

1.Main-30amp

2.Chargecircuit-25amp

4.Returnthecontrolpaneltoitsoriginalposition.Use

thescrewsremovedpreviouslytosecurethepanelto

themachine.

32

Page 33

DriveSystem

g017659

1

Maintenance

CheckingtheTirePressure

ServiceInterval:Every25hours—Checktirepressure.

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseunevencut.Check

thepressureatthevalvestem(Figure41).Checkthetires

whentheyarecoldtogetthemostaccuratepressurereading.

Refertothemaximumpressuresuggestedbythetire

manufactureronthesidewallofthecasterwheeltires.

Inatethereardrivewheeltiresto12psi.

2.Rotatetheshaftforwardtoreleasethebrake.

Figure41

1.V alvestem

ReleasingtheElectricBrake

Theelectricbrakecanbereleasebymanuallyrotatingthe

linkarmsforward.Oncetheelectricbrakeisenergizedthe

brakewillreset.

Toreleasethebrake:

Figure42

1.Brakelinkarmontheelectricbrakecontrolmodule

1.Locatetheshaftontheelectricbrakewherethebrake

linkarmsareconnected.

33

Page 34

HydraulicSystem

g017656

3

2

1

g017658

1

g017660

1 2 3

2 1

Maintenance

HydraulicSystemOilSpecication

OilType:T oroHYPR-OIL®500or20w-50motoroil.

SystemCapacity:approximately4.495liter(152oz)witha

lterchange.

CheckingtheHydraulicOil Level

ServiceInterval:Every25hours

Checkexpansionreservoirandifnecessaryaddthespecied

oiltotheFULLCOLDline.

RemovingHydraulicSystemFilters

1.Stopengine,waitforallmovingpartstostop,and

allowenginetocool.Removethekeyandengagethe

parkingbrake.

2.Raisetherearofmachineupandsupportwithjack

stands(orequivalentsupport)justhighenoughto

allowdrivewheelstoturnfreely.

Figure44

Figure43

1.Expansionreservoir3.Engine

2.FullColdline

ChangingtheHydraulic SystemOilandFilters

ServiceInterval:Aftertherst50hours

Every400hours

1.Jackingpoints

3.Removethenutsholdingthetransaxlesupportinplace

(Figure45).

Important:Thebleedingprocessisrepeateduntilthe

oilremainsattheFULLCOLDlineinthereservoirafter

purging.

can r esult in ir r epara ble dama ge to the transaxle dri v e

system.

Note:Thelterandoilarechangedatthesametime.Do

Notreuseoil.Oncethenewlterisinstalledandoilisadded

anyairinthesystemmustbepurged.

F ailur e to pr oper l y perf or m this pr ocedur e

1.Nut(5/16inch)(27to33

ft-lb)

2.Nut(3/8inch)(15to19

ft-lb)

34

Figure45

3.Transaxlesupport

Page 35

4.Locatethelterandlterguardsoneachtransaxle

G017657

5

1

2

3

4

1

2

4

6

3/4

G0201 18

drivesystem(Figure46).Removethreescrewssecuring

thelterguardandguard.

Figure46

Rightsideshown

InstallingtheHydraulicSystemFilters

1.Transaxledrive

2.Oillter

3.Filterguard

4.Screws

5.V entplug

5.Carefullycleanareaaroundlters.Itisimportantthat

nodirtorcontaminationenterhydraulicsystem.

6.Placeacontainerbelowtheltertocatchtheoilthat

Figure47

drainswhenthelterandventplugsareremoved.

7.Locateandremovetheventplugoneachtransmission

8.Unscrewtheltertoremoveandallowoiltodrain

fromdrivesystem.

Repeatthisprocedureforbothlters.

1.Applyathincoatofthespeciedoilonthesurfaceof

therubbersealofeachlter.

2.Turnthelterclockwiseuntilrubbersealcontactsthe

lteradapterthentightenthelteranadditional3/4to

1fullturn.Repeatfortheotherlter

3.Installthelterguardsovereachlteraspreviously

removed.Usethethreescrewstosecurethelter

guards.

4.Installthetransaxlesupport.RefertoFigure45forthe

correcttorquevaluesforthenutsandbolts.

Note:Ensurethetransaxlesupportisinstalled(

Figure

45).

5.Verifytheventplugsareremovedbeforeaddingtheoil.

6.Slowlypourthespeciedoilthroughexpansion

reservoiruntiloilcomesoutofoneoftheventplug

holes.Stopandinstallthatventplug.T orquetheplug

to180in-lb(20.3N-m).

7.Continuetoaddoilthroughtheexpansionreservoir

untiloilcomesoutoftheremainingventplugholeon

thesecondtransmission.Stopandinstallthatvent

plug.T orquetheplugto180in-lb(20.3N-m).

8.Continuetoaddoilthroughtheexpansionreservoir

untilitreachestheFULLCOLDlineontheexpansion

reservoir.

35

Page 36

9.ProceedtotheBleedingtheHydraulicSystemsection.

Important:Failuretoperformthe

the Hy draulic System

hydraulicltersandoilcanresultinirreparable

damagetothetransaxledrivesystem.

procedureafterchanging

Bleeding

BleedingtheHydraulicSystem

1.Entertheoperator'sposition.Startengineand

movethrottlecontrolaheadto1/2throttleposition.

Disengageparkingbrake.

A.Movethebypassleversintothepushingthe

machineposition;refertothePushingthe

MachinebyHandsectioninOperation.Withthe

bypassvalvesopenandtheenginerunning,slowly

movethemotioncontrolleversinbothforward

andreverse(5or6times).

B.Movethebypassleversintotheoperating

themachineposition.Withthebypassvalve

closedandtheenginerunning,slowlymovethe

directionalcontrolinbothforwardandreverse

directions(5to6times).

C.Stoptheengineandchecktheoillevelinthe

expansionreservoir.Addthespeciedoilasuntil

itreachestheFULLCOLDlineontheexpansion

reservoir.

2.Repeatstep1untilalltheairiscompletelypurgedfrom

thesystem.

Whenthetransaxleoperatesatnormalnoiselevelsand

movessmoothlyforwardandreverseatnormalspeeds,

thenthetransaxleisconsideredpurged.

3.Checktheoillevelintheexpansionreservoironelast

time.AddthespeciedoilasuntilitreachestheFULL

COLDlineontheexpansionreservoirifnecessary.

MowerMaintenance

ServicingtheCuttingBlades

Maintainsharpbladesthroughoutthecuttingseasonbecause

sharpbladescutcleanlywithouttearingorshreddingthegrass

blades.Tearingandshreddingturnsgrassbrownattheedges,

whichslowsgrowthandincreasesthechanceofdisease.

Checkthecutterbladesdailyforsharpness,andforany

wearordamage.Filedownanynicksandsharpenthe

bladesasnecessary.Ifabladeisdamagedorworn,replace

itimmediatelywithagenuineTororeplacementblade.For

convenientsharpeningandreplacement,youmaywantto

keepextrabladesonhand.

WARNING

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownintotheoperator's

orbystander'sarea,resultinginseriouspersonal

injuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

BeforeInspectingorServicingthe

Blades

Parkthemachineonalevelsurface,disengagetheblade

controlswitch,andmovethemotioncontrolleversoutward

totheparkposition.Stoptheengineandremovethekey .

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily—Checkthe

cuttingblades.

1.Inspectthecuttingedges(Figure48).Iftheedges

arenotsharporhavenicks,removeandsharpenthe

blades;refertoSharpeningtheBlades.

2.Inspecttheblades,especiallythecurvedarea(Figure

48).Ifyounoticeanydamage,wear,oraslotforming

inthisarea(item3inFigure48),immediatelyinstall

anewblade.

36

Page 37

Figure48

G014972

1

2

3

G014973

1

2

3

G014974

1

2

3

1.Cuttingedge3.Wear/slotforming

2.Curvedarea

4.Damage

CheckingforBentBlades

Note:Themachinemustbeonalevelsurfaceforthe

followingprocedure.

1.Raisethemowerdecktothehighestheight-of-cut

position;alsoconsideredthe'transport'position.

2.Whilewearingthicklypaddedglovesorotheradequate

handprotectionslowlyrotatebladetobemeasured

intoapositionthatallowseffectivemeasurementof

thedistancebetweenthecuttingedgeandthelevel

surfacethemachineison.

3.Measurefromthetipofthebladetotheatsurface

here.

Figure50

1.Blade,inpositionformeasuring

2.Levelsurface

3.Measureddistancebetweenbladeandsurface(A)

4.Rotatethesameblade180degreessothattheopposing

cuttingedgeisnowinthesameposition.

Figure51

1.Blade,sidepreviouslymeasured

2.Measurementpositionusedpreviously

Figure49

1.Deck3.Blade

2.Spindlehousing

3.Opposingsideofbladebeingmovedintomeasurement

position

5.Measurefromthetipofthebladetotheatsurface

here.Thevarianceshouldbenomorethan1/8inch

(3mm).

37

Page 38

G014973

1

2

3

g017645

1

2

3

4

Figure53

Figure52

1.Opposingbladeedge,inpositionformeasuring

2.Levelsurface

3.Secondmeasureddistancebetweenbladeandsurface(B)

WARNING

Abladethatisbentordamagedcouldbreak

apartandcouldseriouslyinjureorkillyouor

bystanders.

•Alwaysreplacebentordamagedblade

withanewblade.

•Neverleorcreatesharpnotchesinthe

edgesorsurfacesofblade.

A.IfthedifferencebetweenAandBisgreater

than1/8inch(3mm)replacethebladewitha

newblade.RefertoRemovingtheBladesand

InstallingtheBlades.

Note:Ifabentbladeisreplacedwithanewone

andthedimensionobtainedcontinuestoexceed

1/8inch(3mm),thebladespindlecouldbebent.

ContactanAuthorizedToroDealerforservice.

1.Sailareaofblade3.Curvedwasher

2.Blade4.Bladebolt

SharpeningtheBlades

1.Usealetosharpenthecuttingedgeatbothendsof

theblade(Figure54).Maintaintheoriginalangle.The

bladeretainsitsbalanceifthesameamountofmaterial

isremovedfrombothcuttingedges.

Figure54

1.Sharpenatoriginalangle

2.Checkthebalanceofthebladebyputtingitonablade

balancer(Figure55).Ifthebladestaysinahorizontal

position,thebladeisbalancedandcanbeused.Ifthe

bladeisnotbalanced,lesomemetalofftheendof

thesailareaonly(Figure54).Repeatthisprocedure

untilthebladeisbalanced.

B.Ifthevarianceiswithinconstraints,movetothe

nextblade..

Repeatthisprocedureoneachblade.

1.Blade2.Balancer

Figure55

RemovingtheBlades

Thebladesmustbereplacedifasolidobjectishit,ifthe

bladeisoutofbalance,orthebladeisbent.T oensure

optimumperformanceandcontinuedsafetyconformance

ofthemachine,usegenuineT ororeplacementblades.

Replacementbladesmadebyothermanufacturersmayresult

innon-conformancewithsafetystandards.

Holdthebladeendusingaragorthickly-paddedglove.

Removethebladebolt,curvedwasher,andbladefromthe

spindleshaft(

Figure53).

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure53).

Important:Thecurvedpartoftheblademustbe

pointingupwardtowardtheinsideofthemowerto

ensurepropercutting.

2.Installthecurvedwasher(cuppedsidetowardthe

blade)andthebladebolt(

3.Torquethebladeboltto35-65ft-lb(47-88N-m).

38

Figure53).

Page 39

LevelingtheMowerDeck

G005278

1

2

2

3

3

4

4

3

G005074

1

2

3

4

5

6

Checktoensurethemowerdeckislevelanytimeyouinstall

themowerorwhenyouseeanunevencutonyourlawn.

Themowerdeckmustbecheckedforbentbladespriorto

leveling;anybentbladesmustberemovedandreplaced.Refer

totheCheckingforBentBladesprocedurebeforecontinuing.

Themowerdeckmustbeleveledside-to-siderstthenthe

fronttorearslopecanbeadjusted.

Requirements:

•Themachinemustbeonalevelsurface.

•Allfourtiremustbeproperlyinated.RefertoChecking

theTirePressureintheDriveSystemMaintenance

section.

LevelingtheMowerfromSide-to-Side

Themowerbladesmustbelevelfromsidetoside.Checkthe

side-to-sidelevelanytimeyouinstallthemowerorwhenyou

seeanunevencutonyourlawn.

1.Parkthemachineonalevelsurfaceanddisengagethe

bladecontrolswitch.

6.Movetotheleftsideofthemachine.Loosen,butdo

notremove,therearlockingnutonthehangerbracket

(Figure57).

7.Loosenthesidelockingnutonthehangerbracket

justenoughtoallowtheeccentricplatetobeadjusted

(Figure57).Usea3/8inchdriveextensiononasocket

wrenchtomanipulatetheeccentricplate.Usethe

wrenchtorepositiontheheightofthemowerdeckand

adjustitsothatthemeasurementstakeninstep5are

within3/16inch(5mm).

8.Stopthedeckattheadjustedpositionandtightenthe

sidelockingnutonthehangerbrackettoholdthenew

position(Figure57).Tightentherearlockingnuton

thehangerbracket.

9.Continuelevelingthedeckbycheckingthefront-to-rear

bladeslope;refertoAdjustingtheFront-to-RearBlade

Slope.

2.Movethemotioncontrolleversoutwardtothepark

position,stoptheengine,removethekey,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Checktheairpressureofallfourtires.Ifneeded,adjust

totherecommendedination;refertoCheckingthe

TirePressureintheDriveSystemMaintenancesection.

4.Settheheight-of-cutlevertothe3inch(76mm)

position.

5.Carefullyrotatetheblade(s)sidetoside(Figure56).

Measurebetweentheoutsidecuttingedgesandthe

atsurface(

within3/16inch(5mm),anadjustmentisrequired;

continuewiththisprocedure.

Figure56).Ifbothmeasurementsarenot

Figure57

1.Hangerbracket4.Eccentricadjustmentplate

2.Rearlockingnut

3.Sidelockingnut6.Socketwrenchwith3/8

5.Socketwrenchhole

inchextension

AdjustingtheFront-to-RearBlade

1.Bladessidetoside

2.Sailareaofblade

Figure56

3.Outsidecuttingedges

4.Measurehere

Slope

Checkthefront-to-rearbladelevelanytimeyouinstallthe

mower.Ifthefrontofthemowerismorethan5/16inch

(7.9mm)lowerthantherearofthemower,adjusttheblade

levelusingthefollowinginstructions:

1.Parkthemachineonalevelsurfaceanddisengagethe

bladecontrolswitch.

39

Page 40

2.Movethemotioncontrolleversoutwardtothepark

G009659

1

2

3

2

3

G014634

1

2

3

G014635

1

2

3

position,stoptheengine,removethekey,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Settheheight-of-cutlevertomiddleposition.

Note:Checkandadjusttheside-to-sidebladelevel.If

youhavenotcheckedthesetting;refertoSide-to-Side

Leveling.

4.Carefullyrotatethebladessotheyarefacingfrontto

Figure58).

rear(

7.Toraisethefrontofthemower,tightentheadjustment

nut.T olowerthefrontofthemower,loosenthe

adjustmentnut.

8.Afteradjustment,checkthefront-to-rearslopeagain.

Continueadjustingthenutuntilthefrontbladetipis

1/16-5/16inch(1.6-7.9mm)lowerthantherearblade

tip(Figure58).

9.Whenthefront-to-rearbladeslopeiscorrectcheckthe

side-to-sidelevelofthemoweragain;refertoLeveling

theMowerfromSide-to-Side.

RemovingtheMower

1.Parkthemachineonalevelsurfaceanddisengagethe

bladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothepark

position,stoptheengine,removethekey,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

Figure58

MowerDeckswith3Blades

1.Bladesfronttorear3.Measurefromthetipofthe

bladetotheatsurface

here

2.Outsidecuttingedges

5.Measurefromthetipofthefrontbladetotheat

surfaceandthetipoftherearbladetotheatsurface

(Figure58).Ifthefrontbladetipisnot1/16-5/16inch

(1.6-7.9mm)lowerthantherearbladetip,adjustthe

frontlocknut.

6.Toadjustthefront-to-rearbladeslope,rotatethe

adjustmentnutinthefrontofthemower(Figure59).

3.Lowertheheight-of-cutlevertothelowestposition.

4.Removethehairpincotterfromthefrontsupportrod

andremovetherodfromthedeckbracket(Figure

60).Carefullylowerthefrontofthemowerdeckto

theground.

Figure60

1.Frontsupportrod3.Deckbracket

2.Lockingnut

1.Adjustingrod3.Locknut

2.Adjustingblock

Figure59

5.Usingthemowerdeckhandles,liftthemowerdeckand