Page 1

FormNo.3385-338RevA

TimeCutter

®

SS5000Riding

Mower

ModelNo.74637—SerialNo.314000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3385-338*A

Page 2

Thismachineisaride-on,rotary-bladelawnmowerintended

G014523

1

tobeusedbyhomeownersinresidentialapplications.Itis

primarilydesignedforcuttinggrassonwell-maintainedlawns.

Itisnotdesignedforcuttingbrush,mowinggrassandother

growthalongsidehighways,orforagriculturaluses.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orotherreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

Introduction

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Theenclosed

Engine Owner's Man ual

issuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Formodelswithstatedenginehorsepower,thegross

horsepoweroftheenginewaslaboratoryratedbytheengine

manufacturerinaccordancewithSAEJ1940.Ascongured

tomeetsafety,emission,andoperatingrequirements,the

actualenginehorsepoweronthisclassoflawnmowerwill

besignicantlylower.

Figure1

Undertheseat

1.Modelandserialnumberplate

Writetheproductmodelandserialnumbersinthespace

below:

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction..................................................................2

Safety...........................................................................4

SafeOperatingPractices...........................................4

SafetyandInstructionalDecals.................................6

ProductOverview.........................................................10

Controls...............................................................10

Operation....................................................................11

AddingFuel...........................................................11

CheckingtheEngine-oilLevel..................................13

BreakinginaNewMachine......................................13

ThinkSafetyFirst...................................................13

StartingtheEngine.................................................14

OperatingtheBlades...............................................15

TestingtheSafety-interlockSystem...........................16

StoppingtheEngine...............................................16

Driving.................................................................16

StoppingtheMachine.............................................18

AdjustingtheHeight-of-Cut....................................18

AdjustingtheAnti-scalpRollers................................18

PositioningtheSeat................................................19

AdjustingtheMotion-controlLevers.........................19

PushingtheMachinebyHand..................................19

OperatingTips......................................................21

Maintenance.................................................................22

RecommendedMaintenanceSchedule(s)......................22

PremaintenanceProcedures........................................23

RaisingtheSeat......................................................23

Lubrication...............................................................23

GreasingtheBearings.............................................23

EngineMaintenance..................................................24

ServicingtheAirCleaner.........................................24

ServicingtheEngineOil..........................................24

ServicingtheSparkPlug..........................................26

CleaningtheBlowerHousing...................................27

FuelSystemMaintenance...........................................27

ReplacingtheIn-lineFuelFilter................................27

ElectricalSystemMaintenance....................................28

ChargingtheBattery...............................................28

ServicingtheFuses.................................................30

DriveSystemMaintenance.........................................30

CheckingtheTirePressure......................................30

ReleasingtheElectricBrake.....................................31

MowerMaintenance...................................................31

ServicingtheCuttingBlades.....................................31

LevelingtheMowerDeck........................................34

RemovingtheMower..............................................36

InstallingtheMower...............................................37

ReplacingtheGrassDeector..................................37

MowerBeltMaintenance............................................38

InspectingtheBelts................................................38

ReplacingtheMowerBelt........................................38

Cleaning...................................................................40

WashingtheUndersideoftheMower........................40

Storage........................................................................41

CleaningandStorage..............................................41

Troubleshooting...........................................................42

Schematics...................................................................44

3

Page 4

Safety

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructions,andpayattentionto

thesafetyalertsymbol,whichmeansCaution,Warning,or

Danger—“personalsafetyinstruction.”Failuretocomply

withtheinstructionsmayresultinpersonalinjuryor

death.

Important:Thismachinewasmanufacturedaccording

totheappropriateregulatorystandardsineffectatthe

timeofmanufacture.Modifyingthismachineinany

waymaycauseittobeoutofcompliancewiththose

standardsandwiththeinstructionsinthis

Man ual

madebyeitherthemanufactureroranAuthorizedToro

Dealer.

Thisproductiscapableofamputatinghandsandfeet.Follow

allsafetyinstructionstoavoidseriousinjuryordeath.

Theowner/usercanpreventandisresponsibleforaccidents

orinjuriesoccurringtopeople,ordamagetoproperty.

Important:Theadditionofattachmentsmadeby

othermanufacturersthatdonotmeetAmerican

NationalStandardsInstitutecerticationwillcause

noncomplianceofthismachine.

.Modicationstothismachineshouldonlybe

Operator’ s

•Nevercarrypassengers.

•Donotmowinreverseunlessabsolutelynecessary.

Alwayslookdownandbehindbeforeandwhilebacking

up.

•Beawareofthemowerdischargedirectionanddonot

pointitatanyone.Avoiddischargingmaterialagainsta

wallorobstruction.Materialmayricochetbacktoward

theoperator.Stoptheblade(s)whencrossinggravel

surfaces.

•Donotoperatethemachinewithoutdeector,discharge

coverorentiregrasscollectionsysteminplaceand

working.

•Bealert,slowdownandusecautionwhenmakingturns.

Lookbehindandtothesidebeforechangingdirections.

•Neverleavearunningmachineunattended.Alwaysturn

offblades,setparkingbrake,stopengine,andremovekey

beforedismounting.

•Turnoffbladeswhennotmowing.Stoptheengine,wait

forallpartstocometoacompletestopandremovethe

keybeforecleaningthemachine,removingthegrass

catcheroruncloggingthedischargechute.

•Operatethemachineonlyindaylightorgoodarticial

light.

•Donotoperatethemachinewhileundertheinuence

ofalcoholordrugs.

SafeOperatingPractices

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

ThefollowinginstructionsareadaptedfromANSIstandard

B71.1-2012.AllthelanguagewithinthisANSIstandard

appliestothismachine;however,duetotheapplicationof

thestandardacrossmanydifferenttypesofproductssome

statementscanseemgeneralormisleading.Intheseinstances,

Torohasrenedthestatementtoconveythemeaningofthe

standardwhilebettermatchingtheproductthisOperator's

Manualpertains.Safetyinformationinadditiontothe

instructionsfoundintheANSIstandardbelowcanbefound

inToroRidingMowerSafetyattheendofthissection.

GeneralOperation

•Read,understand,andfollowallinstructionsinthe

operator'smanualandonthemachinebeforestarting.

•Donotplacehandsorfeetnearrotatingpartsorunder

themachine.Keepclearofthedischargeopeningatall

times.

•Allowonlyresponsibleadultswhoarefamiliarwiththe

instructionstooperatethemachine.

•Cleartheareaofobjectssuchasrocks,toys,wire,etc.,

whichcouldbepickedupandthrownbytheblade.

•Besuretheareaisclearofotherpeoplebeforemowing.

Stopthemachineifanyoneentersthearea.

•Watchfortrafcwhenoperatingnearorcrossing

roadways.

•Useextracarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Alwaysweareyeprotectionwhenoperatingthemower.

•Alwaysfollowtherecommendationsforanyapplication

ofcounterweights.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

SlopeOperation

Slopesareamajorfactorrelatedtolossofcontroland

tip-overaccidents,whichcanresultinsevereinjuryordeath.

Operationonallslopesrequiresextracaution.Ifyoucannot

backuptheslopeorifyoufeeluneasyonit,donotmowit.

•Donotmowslopesgreaterthan15degrees.

•Watchforditches,holes,rocks,dips,andrisesthatchange

theoperatingangle,asroughterraincouldoverturnthe

machine.

•Choosealowgroundspeedsoyouwillnothavetostop

whileoperatingonaslope.

•Donotmowslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcauseslidingand

lossofcontrol.

4

Page 5

•Alwayskeepthedrivewheelsengagedwhengoingdown

slopes.

•Reducespeedanduseextremecautiononslopes.

•Donotmakesuddenturnsorrapidspeedchanges.

•Removeormarkobstaclessuchasrocks,treelimbs,etc.

fromthemowingarea.Tallgrasscanhideobstacles.

•Avoidsuddenstartswhenmowinguphillbecausethe

mowermaytipbackwards.

•Beawarethatlossoftractionmayoccurgoingdownhill.

Weighttransfertothefrontwheelsmaycausedrive

wheelstoslipandcauselossofbrakingandsteering.

•Alwaysavoidsuddenstartingorstoppingonaslope.If

tireslosetraction,stopthemachine,disengagetheblades

andproceedslowlyofftheslope.

•Useextremecarewithgrasscatchersorotherattachments.

Thesecanchangethestabilityofthemachineandcause

lossofcontrol.

•Donottrytostabilizethemachinebyputtingyourfoot

ontheground.

•Donotmowneardrop-offs,ditches,steepbanksor

water.Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,deathordrowning.

•Useawalkbehindmowerand/orahandtrimmernear

drop-offs,ditches,steepbanksorwater.

Children

Tragicaccidentscanoccuriftheoperatorisnotalerttothe

presenceofchildren.Childrenareoftenattractedtothe

machineandthemowingactivity.Neverassumethatchildren

willremainwhereyoulastsawthem.

•Keepchildrenoutofthemowingareaandunderthe

watchfulcareofanotherresponsibleadult,notthe

operator.

•Bealertandturnthemachineoffifchildrenenterthe

area.

•Beforeandwhilebackingorchangingdirection,look

behind,down,andside-to-sideforsmallchildren.

•Nevercarrychildren,evenwiththebladesoff.Theymay

falloffandbeseriouslyinjuredorinterferewithsafe

machineoperation.

•Childrenwhohavebeengivenridesinthepastmay

suddenlyappearinthemowingareaforanotherrideand

berunoverorbackedoverbythemower.

•Neverallowchildrentooperatethemachine.

•Useextracarewhenapproachingblindcorners,shrubs,

trees,theendofafenceorotherobjectsthatmayobscure

vision.

TowingSafety

•Donotattachtowedequipmentexceptatthehitchpoint.

•Followtheattachmentmanufacturer'srecommendation

forweightlimitsfortowedequipmentandtowingon

slopes.Towedweightmustnotexceedtheweightofthe

machine,operator,andballast.Usecounterweightsor

wheelweightsasdescribedintheattachment,orinthe

pullingmachineOperator’sManual.

•Neverallowchildrenorothersinorontowedequipment.

•Onslopes,theweightofthetowedequipmentmaycause

lossoftraction,increasedriskofrollover,andlossof

control.Reducethetowedweightandslowdown.

•Stoppingdistanceincreaseswiththeweightofthetowed

load.Travelslowlyandallowextradistancetostop.

•Makewideturnstokeeptheattachmentclearofthe

machine.

SafeHandlingofGasoline

Toavoidpersonalinjuryorpropertydamage,useextracare

whenhandlinggasolineandotherfuels.Theyareammable

andthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipesandothersources

ofignition.

•Useonlyanapprovedcontainer.

•Neverremovethegascaporaddfuelwhentheengineis

running.Allowtheenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerinsidewhere

thereisanopename,suchasnearawaterheateror

furnace.

•Neverllcontainersinsideavehicleoronatruckor

trailerwithaplasticliner.Alwaysplacecontainersonthe

groundawayfromyourvehiclebeforelling.

•Removegas-poweredequipmentfromthetruckortrailer

andrefuelitontheground.Ifthisisnotpossible,then

refuelsuchequipmentwithaportablecontainer,rather

thanfromagasolinedispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilthefuelingis

complete.Donotuseanozzlelock-opendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllthefueltank.Replacegascapandtighten

securely.

GeneralService

•Neveroperateamachineinsideaclosedarea.Engine

exhaustcontainscarbonmonoxide,whichisanodorless,

deadlypoisonthatcankillyou.

•Keepnutsandboltstight,especiallythebladeattachment

bolts.Keepequipmentingoodcondition.

•Neverinterferewiththeintendedfunctionofasafety

deviceortoreducetheprotectionprovidedbyasafety

device.Checktheirproperoperationregularly.

•Keepthemachinefreeofgrass,leaves,orotherdebris

build-up.Cleanupoilorfuelspillagefuelsoakeddebris.

Allowthemachinetocoolbeforestoring.

•Stopandinspecttheequipmentifyoustrikeanobject.

Repair,ifnecessary,beforerestarting.

5

Page 6

•Nevermakeanyadjustmentsorrepairswiththeengine

running.

•Checkforproperbrakeoperationfrequently .Adjustand

serviceasrequired.

•Grasscatchercomponentsaresubjecttowear,damage

anddeterioration,whichcouldexposemovingpartsor

allowobjectstobethrown.Frequentlycheckcomponents

andreplacewithmanufacturers'recommendedparts,

whennecessary.

•Mowerbladesaresharpandcancut.Wraptheblade(s)or

weargloves,anduseextracautionwhenservicingthem.

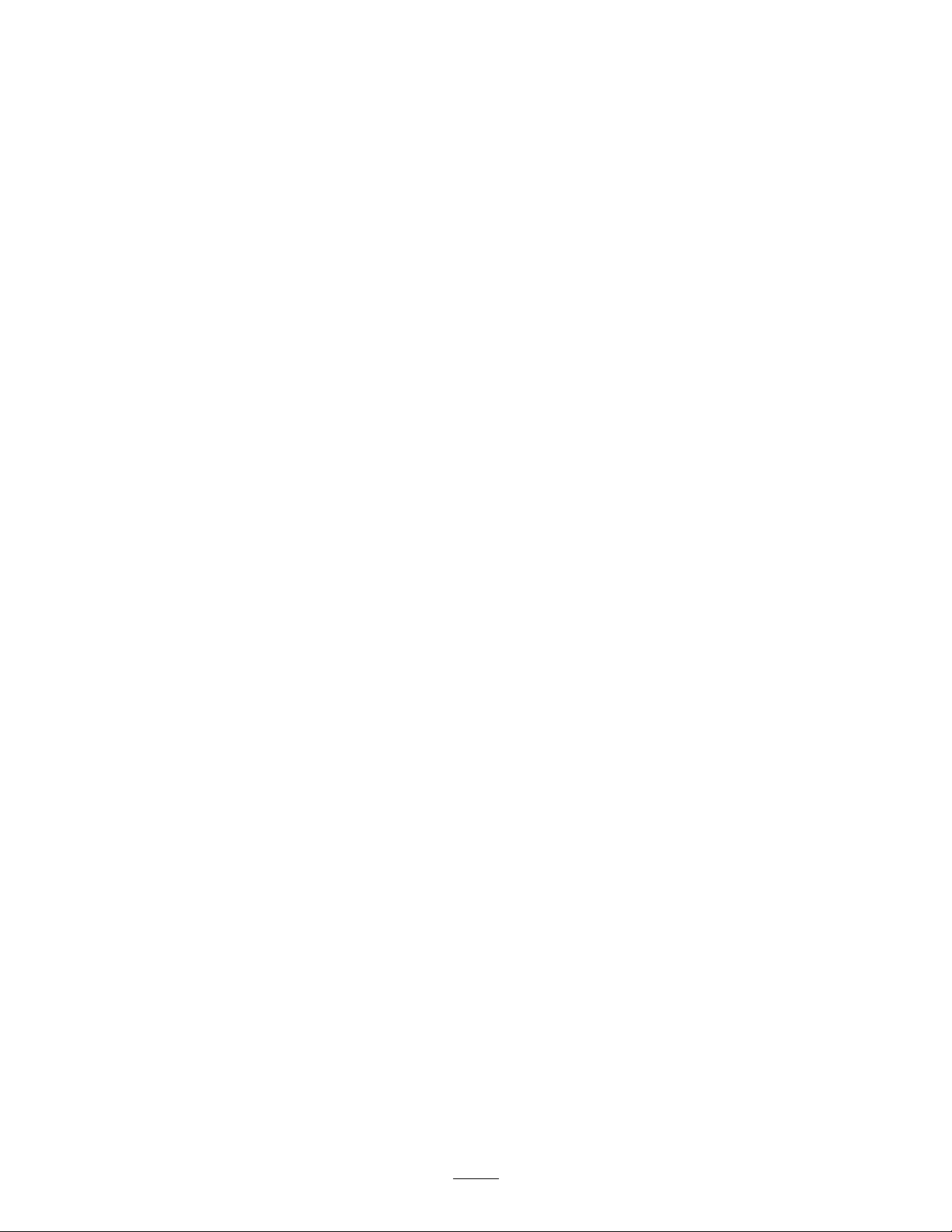

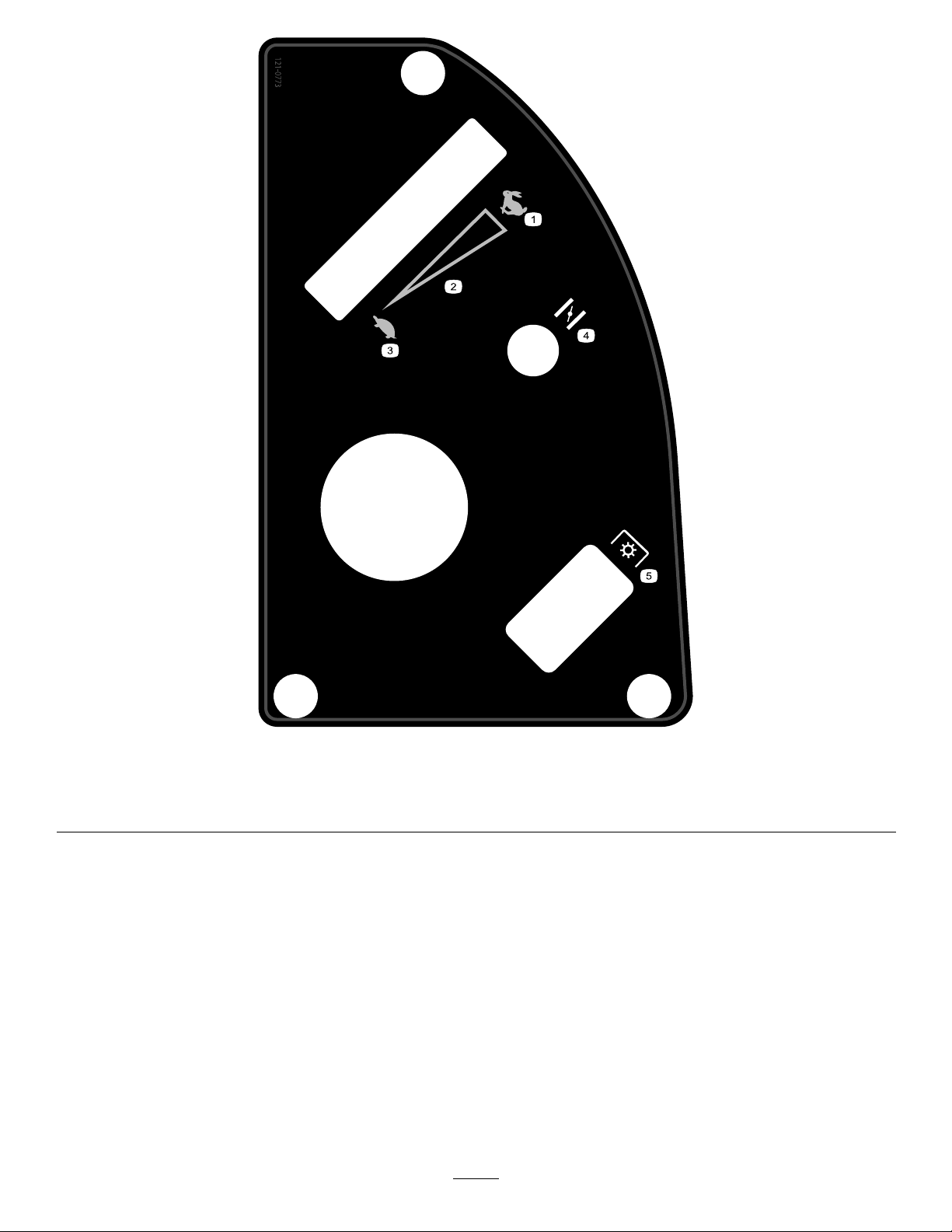

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

93-7009

1.Warning—don'toperatethemowerwiththedeectorupor

removed;keepthedeectorinplace.

2.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

•Maintainorreplacesafetyandinstructiondecalsas

necessary.

•UseonlygenuineTororeplacementpartstoensurethat

originalstandardsaremaintained.

110-6691

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

106-8717

1.Readtheinstructionsbeforeservicingorperforming

maintenance.

2.Checktirepressureevery25operatinghours.

3.Greaseevery25operatinghours.

4.Engine

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Thrownobjecthazard,mower—donotoperatewithoutthe

deector,dischargecover,orgrasscollectionsystemin

place.

3.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

114-1606

1.Entanglementhazard,belt—keepallguardsinplace.

119-8814

1.Parkingposition4.Neutral

2.Fast5.Reverse

3.Slow

6

Page 7

119-8815

1.Parkingposition4.Neutral

2.Fast5.Reverse

3.Slow

121-2989

119-8870

50-inchModel

1.Height-of-cut

1.Bypassleverpositionfor

pushingthemachine

2.Bypassleverpositionfor

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

operatingthemachine

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

1.ReadtheOperator's

Manual.

2.Heightofcut

112-9840

3.Removetheignitionkey

andreadtheinstructions

beforeservicingor

performingmaintenance.

130-0780

1.Slow(trimandtow)2.Fast(mowandgo)

7

Page 8

120-2239

1.Warning—readtheOperator'sManual.5.Warning—donotusesplitramps,useafullrampswhen

2.Warning—readtheinstructionsbeforeservicingorperforming

maintenance;movethemotioncontrolleverstothepark

(brake)position,removetheignitionkeyanddisconnectthe

sparkplugwire.

3.Cutting/dismembermenthazard,mowerblade;entanglement

hazard,belt—stayawayfrommovingparts,keepallguards

andshieldsinplace.

4.Thrownobjecthazard—keepbystandersasafedistancefrom

themachine,pickupdebrisbeforeoperating,keepdeector

inplace.

transportingmachine.

6.Lossoftraction/controlhazard,slopes—lossoftraction/control

onaslope,disengagethebladecontrolswitch(PTO),

proceedofftheslopeslowly.

7.Crushing/dismembermenthazardofbystanders,reversing;

crushing/dismembermenthazardofbystanders—donotcarry

passengers,lookbehindanddownwhenreversing.

8.Tippinghazard—donotmowslopesgreaterthan15degrees,

avoidsuddenandsharpturnswhileonslopes.

109-7076

99-3943

1.Engine

8

Page 9

121-0773

1.Fast

2.Continuousvariablesetting5.Powertake-off(PTO),Bladecontrolswitch

3.Slow

4.Choke

9

Page 10

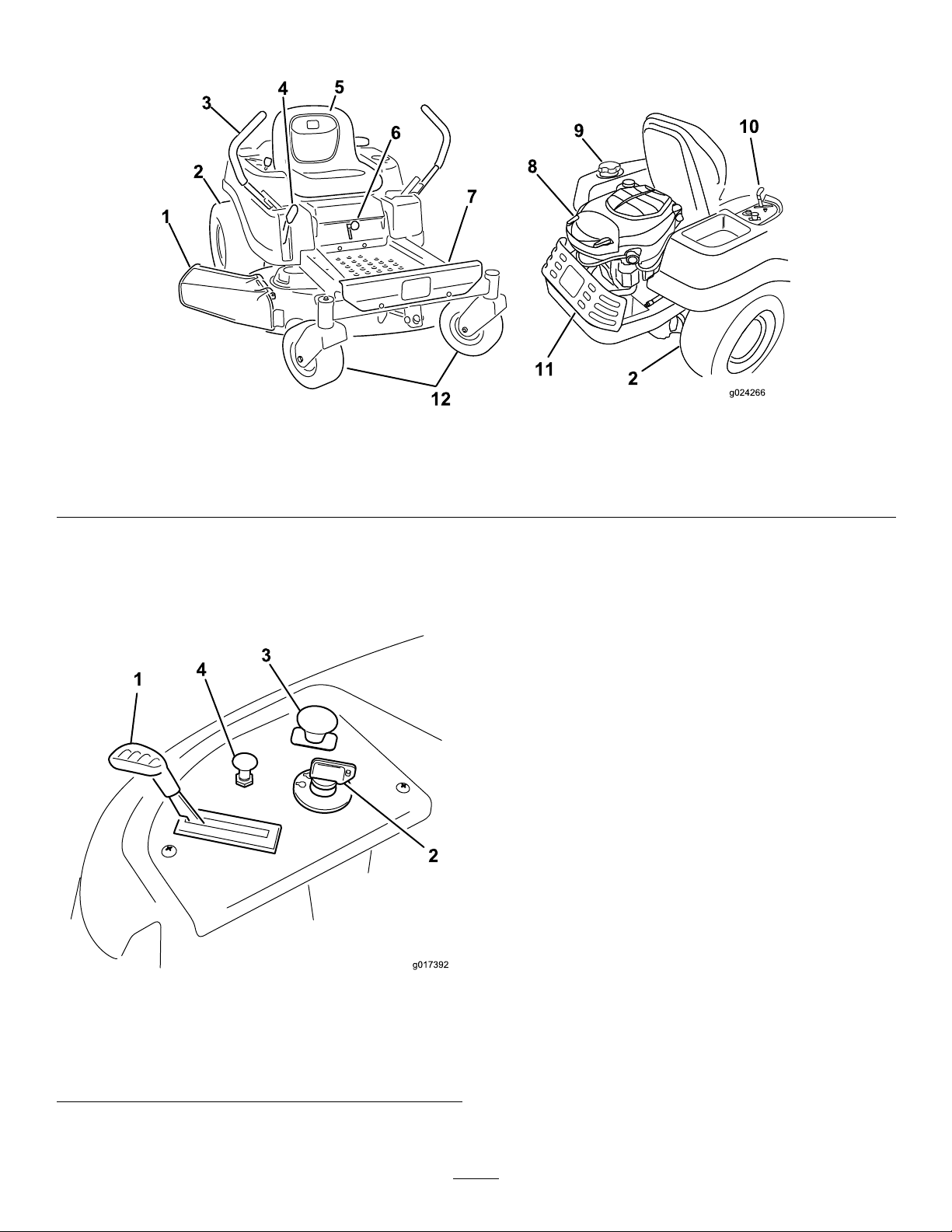

ProductOverview

Figure3

1.Deector4.Height-of-cutlever

2.Reardrivewheel

3.Motion-controllevers

5.Operatorseat

6.SmartSpeed™lever

Controls

BecomefamiliarwithallofthecontrolsinFigure3and

Figure4beforeyoustarttheengineandoperatethemachine.

7.Footrest

8.Engine11.Engineguard

9.Fuel-tankcap12.Frontcasterwheel

10.Controlpanel

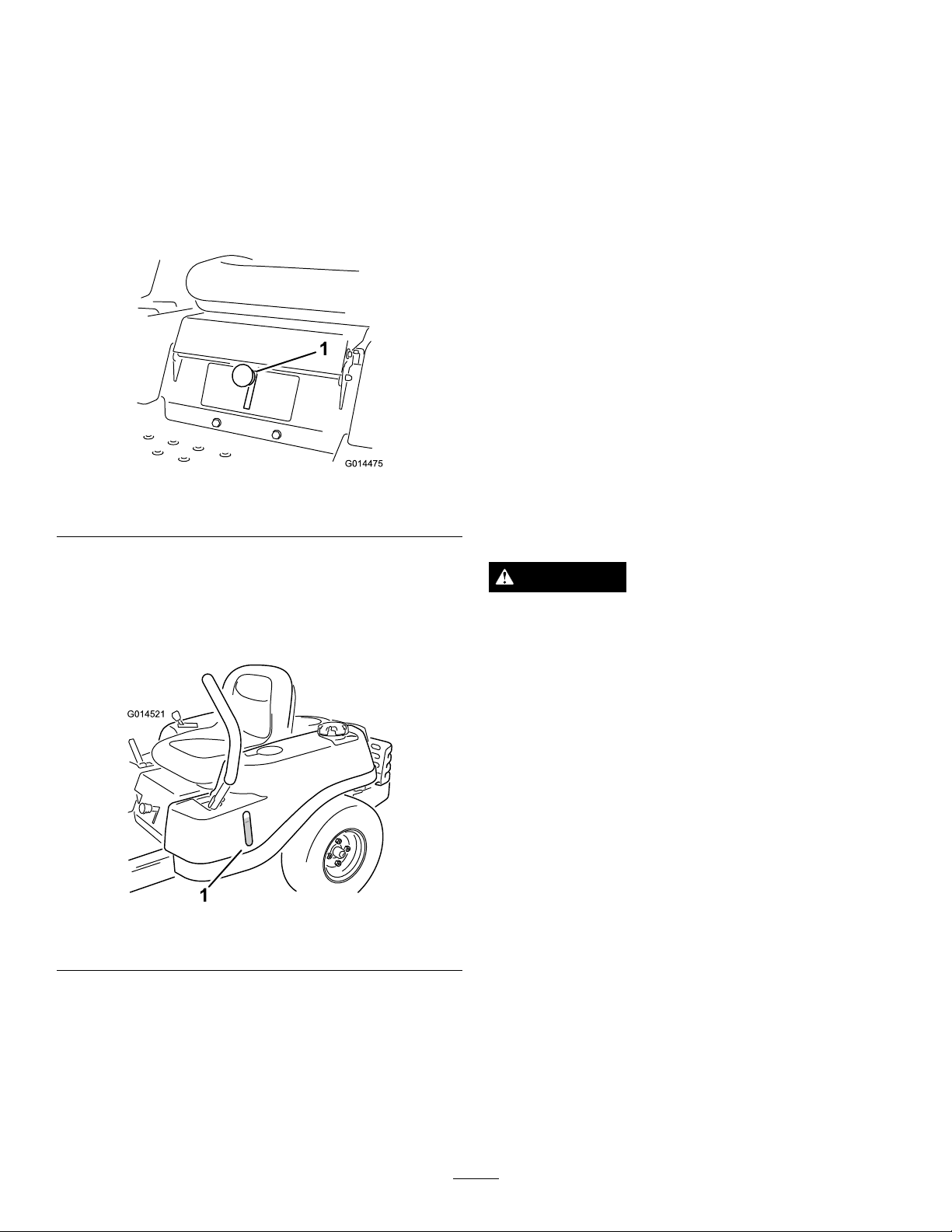

IgnitionSwitch

Theignitionswitchhas3positions:Off,Run,andStart.The

keywillturntoStartandmovebacktoRunuponrelease.

TurningthekeytotheOffpositionwillstoptheengine;

however,alwaysremovethekeywhenleavingthemachine

topreventsomeonefromaccidentallystartingtheengine

(Figure4).

ThrottleControl

Thethrottlecontrolstheenginespeed,andithasa

continuous-variablesettingfromSlowtoFast(Figure4).

ChokeControl

PullupontheChokecontroluntilitstopstochokethe

engine(Figure4).PushdownontheChokecontrolfor

normalengineoperation

Figure4

ControlPanel

1.Throttle3.Blade-controlswitch

2.Ignitionswitch

(powertake-off)

4.Choke

Blade-controlSwitch(PowerTake-Off)

Theblade-controlswitch,representedbyapowertake-off

(PTO)symbol,engagesanddisengagespowertothemower

blades(

Figure4).

Motion-controlLeversandPark

Position

Themotion-controlleversarespeed-sensitivecontrolsof

independent-wheelmotors.Movingaleverforwardor

backwardturnsthewheelonthesamesideforwardorin

10

Page 11

reverse;wheelspeedisproportionaltotheamountthelever

G014475

1

G014521

1

ismoved.Movethecontrolleversoutwardfromthecenter

totheparkposition,andexitthemachine(Figure16).Always

positionthemotion-controlleversintotheparkposition

whenyoustopthemachineorleaveitunattended.

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

SmartSpeed™ControlSystemLever

TheSmartSpeed™Control-Systemlever,locatedbelowthe

operatingposition,givestheoperatorachoicetodrivethe

machineat2speedranges—highandlow(Figure5).

Figure5

1.Smart-speedlever

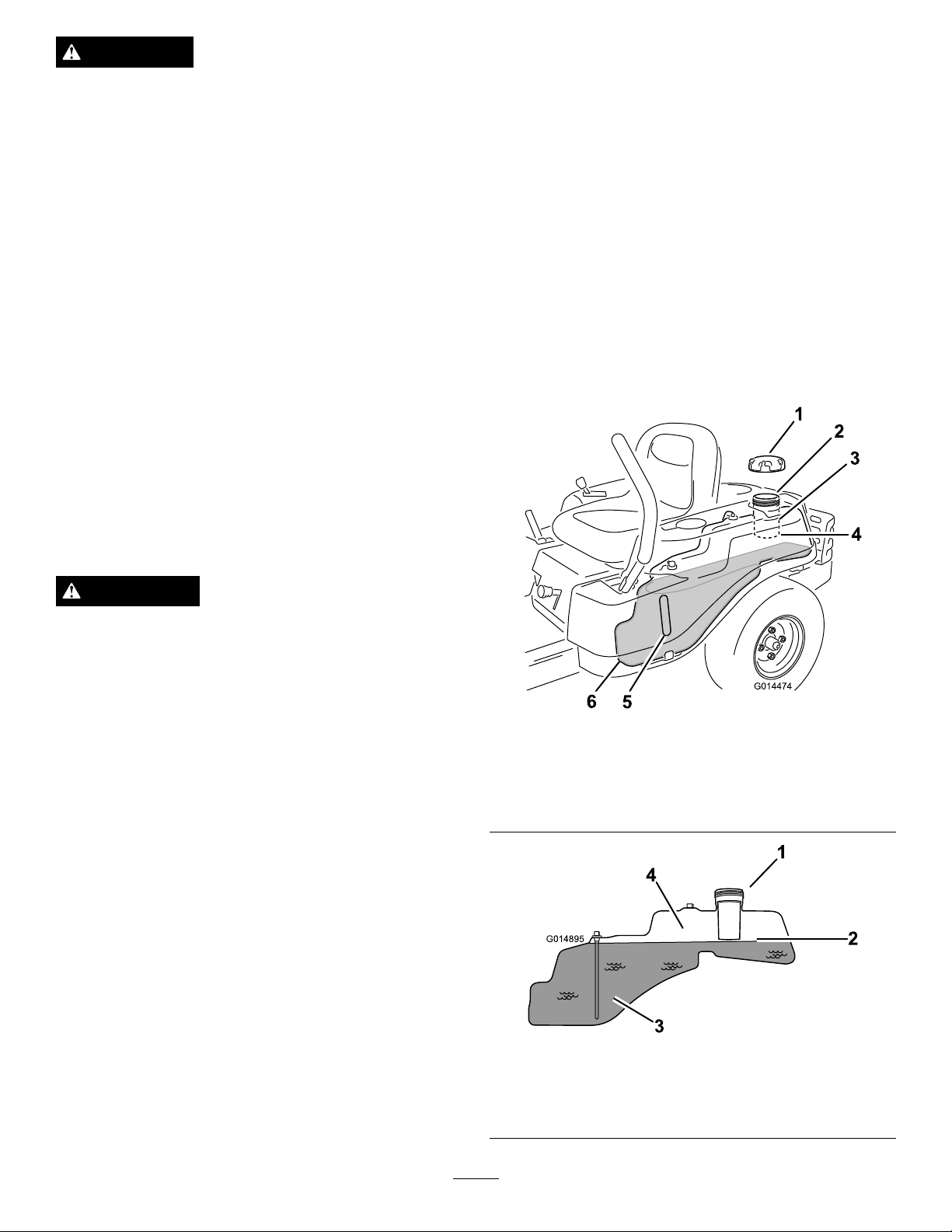

Fuel-presenceWindow

Thefuelwindowlocatedontheleft-handsideofthemachine

canbeusedtoverifythepresenceofgasolineinthetank

(Figure6).

AddingFuel

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontains

morethan10%ethanolbyvolume,suchasE15

(contains15%ethanol),E20(contains20%ethanol),or

E85(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/orengine

damagewhichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

Figure6

1.Fuel-presencewindow

Height-of-CutLever

Theheight-of-cutleverallowstheoperatortolowerand

raisethedeckfromtheseatedposition.Whentheleveris

movedup(towardtheoperator),thedeckisraisedfromthe

ground,andwhenmoveddown(awayfromtheoperator),it

isloweredtowardtheground.Onlyadjusttheheight-of-cut

whilethemachineisnotmoving(Figure20).

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2inch)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

11

Page 12

DANGER

G014474

1

2

3

4

5

6

G014895

1

2

3

4

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

ofvarnishdepositsinthefuelsystem,usefuelstabilizer

atalltimes.

FillingtheFuelTank

Ensurethattheengineisshutoffandthemotioncontrolsare

intheparkedposition.

Important:Donotoverllfueltank.Fillthefueltank

tothebottomofthellerneck.Theemptyspaceinthe

tankallowsthefueltoexpand.Overllingmayresultin

fuelleakage,damagetotheengine,ordamagetothe

emissionssystem.

1.Cleanaroundthefuel-tankcapandremovethecap.

Note:Youcanusethefuelwindowtoverifythe

presenceofgasolinebeforellingthetank(Figure7).

2.Slowlyaddgasolineuntilthefuelreachesthebaseof

thellerneck(Figure7).

WARNING

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditionerbottleopening.

•Avoidcontactwithskin;washoffspillagewith

soapandwater.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysorless.

Forlongerstorageitisrecommendedthatthefueltank

bedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditionerto

thegas.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.T ominimizethechance

Figure7

1.Fuel-tankcap

2.Fillopening5.Fuelwindow

3.Fillerneck

Figure8

1.Fillopening3.Fuel

2.Baseofthellerneck(do

notllpasthere)

4.Baseofthellerneck(do

notllpasthere)

6.Endofthefueltank

4.Emptyspace(forfuel

expansion)

12

Page 13

3.Installthefuel-tankcapsecurely ,andtightenuntilit

G009027

1

2

clicks.

CheckingtheEngine-oilLevel

Beforeyoustarttheengineandusethemachine,checktheoil

levelintheenginecrankcase;refertoCheckingtheEngine-oil

Level(page24).

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mowerdecks

anddrivesystemshavehigherfrictionwhennew,placing

additionalloadontheengine.Allow40to50hoursof

break-intimefornewmachinestodevelopfullpowerand

bestperformance.

ThinkSafetyFirst

OperatingSafety

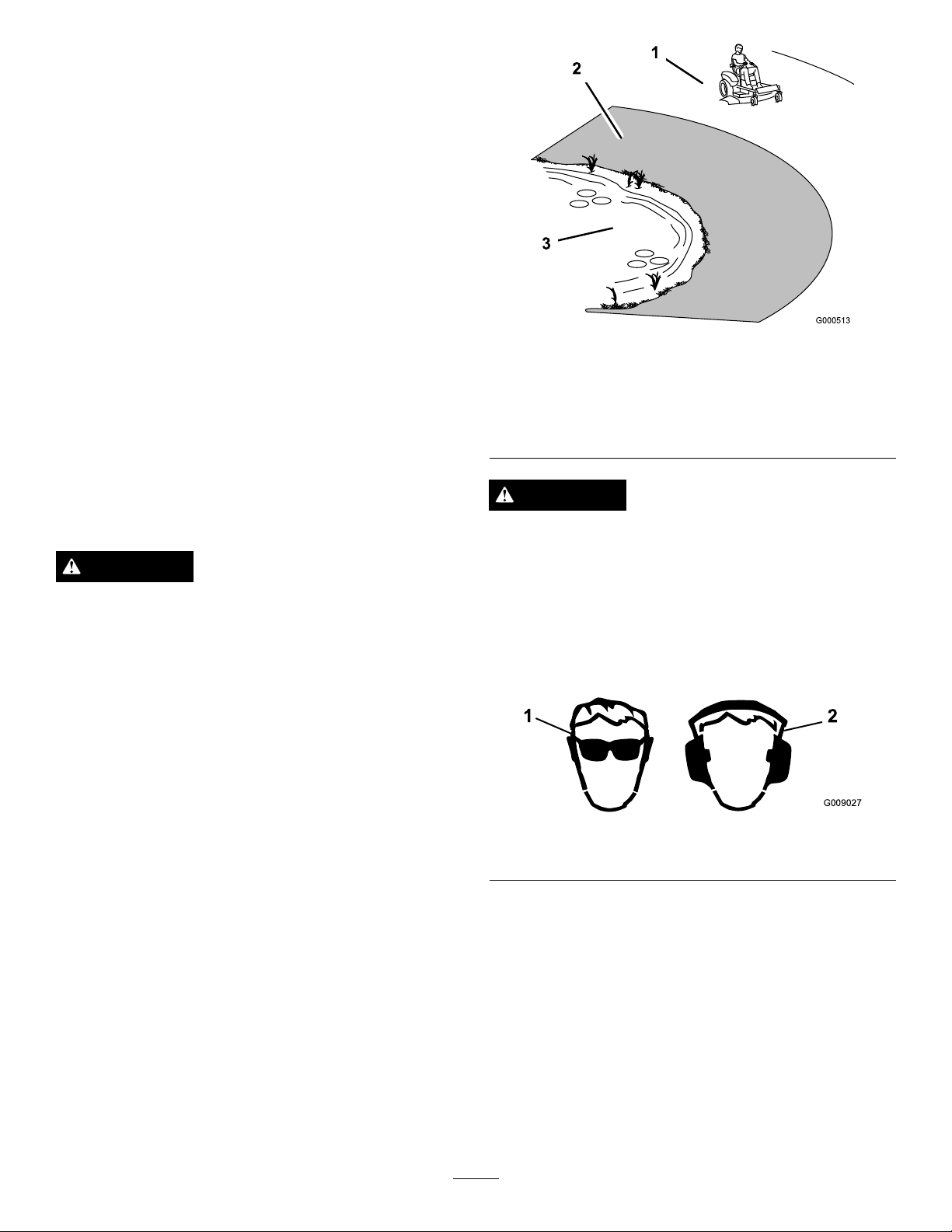

1.Safezone—usethe

TimeCutterhere

2.Useawalk-behindmower

and/orhandtrimmernear

drop-offsandwater.

Figure9

3.Water

Pleasecarefullyreadallofthesafetyinstructionsanddecals

inthesafetysection.Knowingthisinformationcouldhelp

you,yourfamily ,pets,orbystandersavoidinjury.

DANGER

Mowingonwetgrassorsteepslopescancause

slidingandlossofcontrol.

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,death,or

drowning.

Alossoftractionisalossofsteeringcontrol.

Toavoidlossofcontrolandpossibilityofrollover:

•Donotmowneardrop-offsornearwater.

•Donotmowslopesgreaterthan15degrees.

•Reducethespeedanduseextremecautionon

slopes.

•Whenmowingslopes,graduallyworkfrom

lowertohigherareasontheincline.

CAUTION

Thismachineproducessoundlevelsinexcessof85

dBAattheoperatorsearandcancausehearingloss

throughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Theuseofprotectiveequipmentforeyes,ears,feet,andhead

isrecommended.

Figure10

1.Wearsafetyglasses

2.Wearhearingprotection

•Avoidsuddenturnsorrapidspeedchanges.

•Turnup,intoaninclinewhenchanging

directionsonslopes.Turningdowntheslope

reducestraction.

•Attachmentschangethehandlingcharacteristics

ofthemachine.Useextracautionwhenusing

attachmentswiththemachine.

13

Page 14

UnderstandingtheSafety-interlock

System

WARNING

Ifsafety-interlockswitchesaredisconnectedor

damaged,themachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

daily,andreplaceanydamagedswitchesbefore

operatingthemachine.

Thesafety-interlocksystemisdesignedtopreventtheengine

fromstartingunless:

•Thebladesaredisengaged.

•Themotion-controlleversareintheparkposition.

Thesafety-interlocksystemalsoisdesignedtostoptheengine

wheneverthecontrolleversareoutoftheparkpositionand

yourisefromtheseat.

StartingtheEngine

1.Sitdownontheseat,andmovethemotioncontrols

outwardtotheparkposition.

2.Disengagethebladesbymovingthebladecontrol

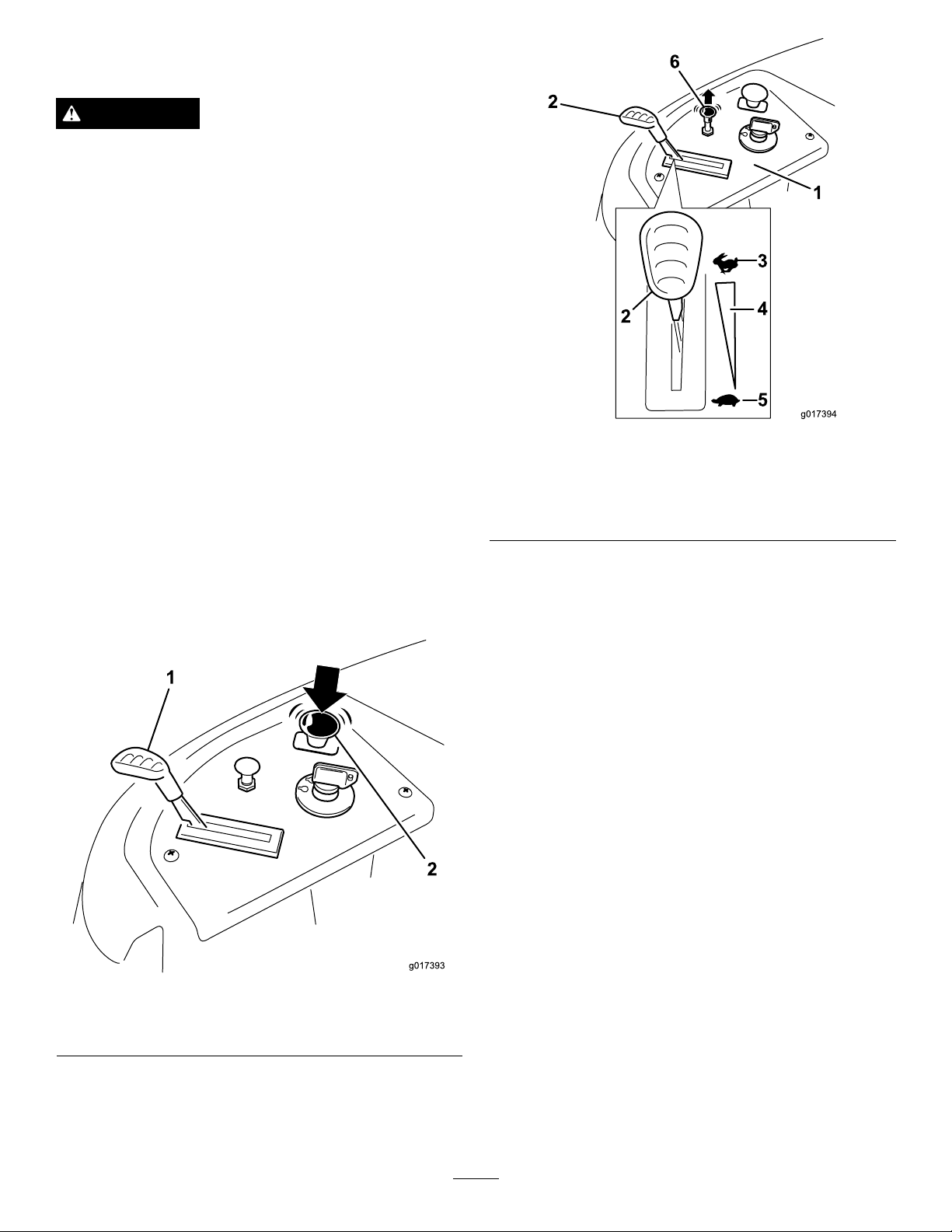

switchtoOff(Figure11)

Figure12

1.Controlpanel4.Continuous-variable

2.Throttle

3.Fast

4.TurntheignitionkeytoStarttoenergizethestarter

(Figure13).

Note:Whentheenginestarts,releasethekey.

Important:Donotengagethestarterformore

than10secondsatatime.Iftheenginefailsto

start,allowa60secondcooldownperiodbetween

attempts.Failuretofollowtheseinstructionscan

damagethestartermotor.

setting

5.Slow

6.Chokecontrol

Figure11

1.Controlpanel2.Blade-controlswitch—Off

position

3.PullupontheChokecontrolbeforestartingacold

engine(Figure12).

Note:Awarmorhotenginemaynotrequirechoking.

14

Page 15

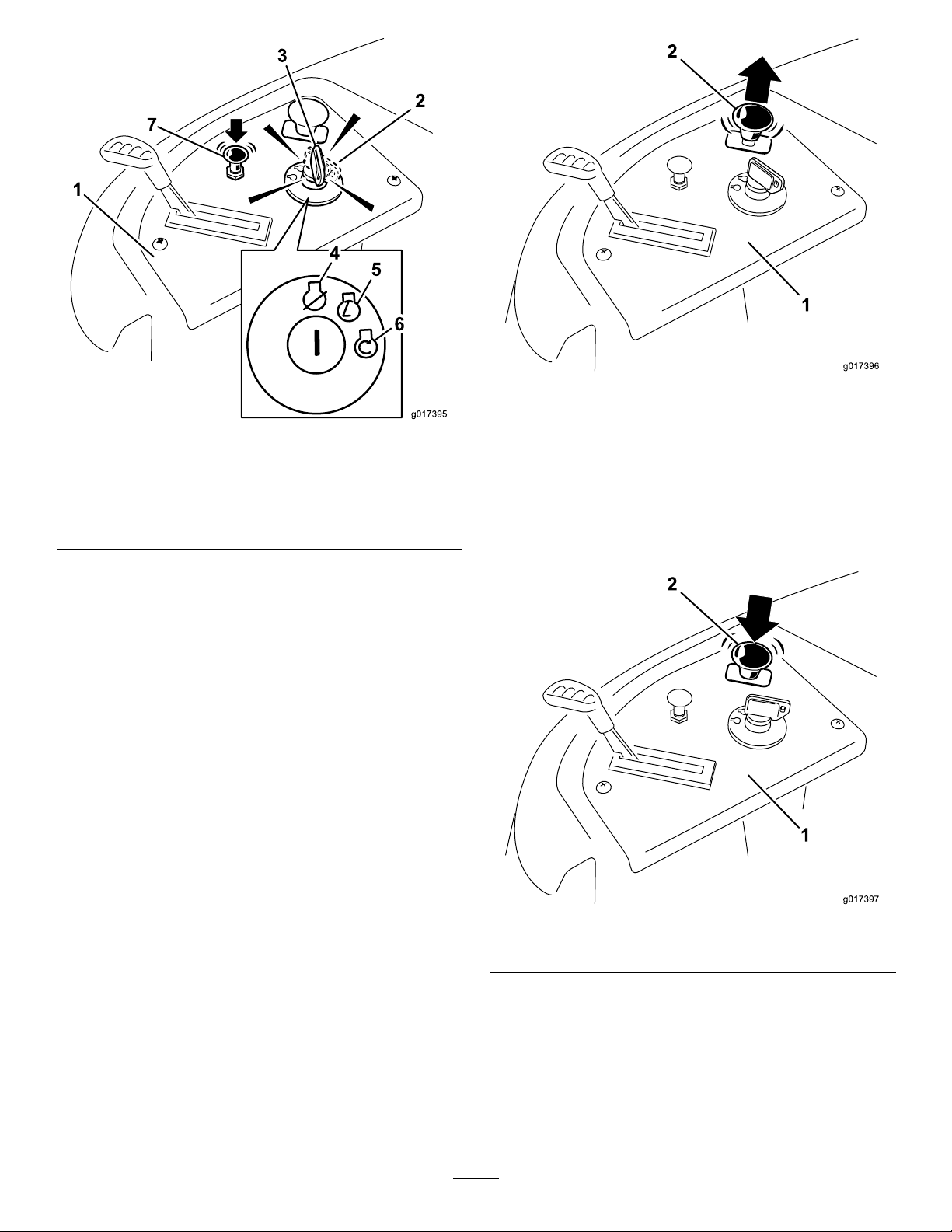

Figure14

Figure13

1.Controlpanel

2.Ignitionkey—runposition

3.Ignitionkey—startposition

4.Off

5.Run

6.Start

7.Chokecontrol

5.Aftertheenginestarts,pushdownontheChoke

control(

Figure13).

Note:Iftheenginestallsorhesitates,pullupon

theChokecontrol,andlettheenginerunforafew

seconds.Then,pushdownontheChokecontrol.

Repeatthisasrequired.

OperatingtheBlades

Theblade-controlswitch,representedbyapowertake-off

(PTO)symbol,engagesanddisengagespowertothemower

blades.Thisswitchcontrolspowertoanyattachmentsthat

drawpowerfromtheengine,includingthemowerdeckand

cuttingblades.

1.Controlpanel2.Blade-controlswitch—On

position

DisengagingtheBlades

Pushdownontheblade-controlswitchtomoveittotheOff

position,anddisengagetheblades(Figure15).

EngagingtheBlades

Important:Donotengagethebladeswhenparkedin

tallgrass.Beltorclutchdamagecanoccur.

1.Releasepressureonthemotion-controlleversand

placethemachineinneutral.

2.MovethethrottletotheFastposition.

Note:Alwaysengagethebladeswiththethrottlein

theFastposition.

3.Pullupontheblade-controlswitchtomoveittothe

Onposition,andengagetheblades(

Figure14).

Figure15

1.Controlpanel2.Blade-controlswitch—Off

15

Page 16

TestingtheSafety-interlock

Driving

System

Testthesafety-interlocksystembeforeyouusethemachine

eachtime.Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthesafety

systemimmediately.

1.Whilesittingontheseat,withthecontrolleversinpark

position,andmovetheblade-controlswitchtoOn.

2.Trystartingtheengine;theengineshouldnotcrank.

3.Whilesittingontheseat,movetheblade-control

switchtoOff.

4.Moveeithermotion-controllevertothecenter,

unlockedposition.

5.Trystartingtheengine;theengineshouldnotcrank.

6.Repeatwiththeothermotion-controllever.

7.Whilesittingontheseat,movetheblade-control

switchtoOff,andlockthemotion-controlleversin

theparkposition.

8.Starttheengine.

9.Whiletheengineisrunning,engagetheblade-control

switch,andriseslightlyfromtheseat.

Drivingthemachinebenetsfromanunderstandingof

whatzero-turn-radiusmowermeans.Thedrivewheelsturn

independently,poweredbyhydraulicmotorsoneachaxle;

henceonesidecanturninreversewhiletheotherturns

forwardcausingthemachinetospinratherthanturn.This

vastlyimprovesthemachinemaneuverabilitybutmayrequire

someadjustmentiftheoperatorisunfamiliar.

WARNING

Themachinecanspinveryrapidly.Theoperator

maylosecontrolofthemachineandcausepersonal

injuryordamagetothemachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placingthethrottlecontrol

intheFastpositioncanbebestforperformance.Formost

applications,operatinginthefull-throttlepositionisdesirable.

Note:Theengineshouldstop.

10.Whilesittingontheseat,movetheblade-control

switchtoOff,andlockthemotion-controlleversin

theparkposition.

11.Starttheengine.

12.Whiletheengineisrunning,movethemotion-control

leverstothecenter,unlockedposition,engagethe

blade-controlswitch,andriseslightlyfromtheseat.

Note:Theengineshouldstop.

StoppingtheEngine

1.MovethethrottlelevertotheSlowposition.

2.Lowertheenginespeedtoidlespeed,andallowitto

runforatleastoneminute.

3.Disengagethebladesbymovingtheblade-control

switchtoOff(Figure15).

4.TurntheignitionkeytoOff(Figure13)andremove

thekey.

1.Park(brake)position

2.Center,unlockposition

Figure16

3.Forward

4.Backward

16

Page 17

UsingtheSmartSpeed™Control

G014475

1

G008952

System

DrivingForward

1.Movetheleverstothecenter,unlockedposition.

TheSmartSpeed™Control-Systemlever,locatedbelowthe

operatingposition(Figure17),givestheoperatorachoiceto

drivethemachineat2groundspeedranges—highandlow .

Figure17

1.Smart-speedlever

Tochangespeeds:

1.Movethemotioncontrolleverstoneutralandoutward

totheparkposition;disengagethebladecontrolswitch.

WARNING

Removingyourhandsfromthemotion-control

leverswhilethemachineisinmotioncan

resultinalossofcontrolcausingharmtoyou

orbystanders.

Alwaysstopthemachineandmovethe

motion-controlleverstotheparkposition

beforeadjustingtheSmartSpeed™Control

System.

2.Togoforward,slowlypushthemotion-controllevers

forward(Figure16).

Figure18

Togostraight,applyequalpressuretoboth

motion-controllevers(Figure16).

Toturn,releasepressureonthemotion-controllever

towardthedirectionyouwanttoturn(Figure16).

Thefartheryoumovethemotion-controlleversin

eitherdirection,thefasterthemachinewillmovein

thatdirection.

Tostop,pullthemotion-controlleverstotheNeutral

position.

2.Adjustthelevertothedesiredposition.

17

Page 18

DrivingBackward

G008953

G014476

1

2

3

1.Movetheleverstothecenter,unlockedposition.

2.Togobackward,lookbehindyouanddown,asyou

slowlypullthemotion-controlleversrearward(Figure

19).

Figure19

AdjustingtheHeight-of-Cut

Height-of-cutiscontrolledbytheleverlocatedtotherightof

theoperatingposition(Figure20).

1.Pullupandinwardonthelevertomoveittothe

desiredcuttingposition.

2.Onceatthedesiredcuttingposition,slowlylowerthe

leveruntilitengagestheposition.

Thetransportpositionisthehighestheight-of-cutpositionor

cuttingheight115mm(4.5inches)asshownin

Figure20.

Togostraight,applyequalpressuretoboth

motion-controllevers(Figure19).

Toturn,releasethepressureonthemotion-control

levertowardthedirectionyouwanttoturn.

Tostop,pushthemotion-controlleverstotheNeutral

position.

StoppingtheMachine

Tostopthemachine,movethemotion-controlleversto

neutralandoutwardtotheparkposition,disengagethe

blade-controlswitch,ensurethethrottleisintheFast

position,andturntheignitionkeytooff.

Note:Remembertoremovethekeyfromtheignitionswitch.

WARNING

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemowerwhileitis

unattended.

Alwaysremovetheignitionkeyandmovethe

motion-controlleversoutwardtotheparkposition

whenleavingthemachineunattended,evenifjust

forafewminutes.

Figure20

1.Height-of-cutlever3.115mm(4.5inches),

2.Height-of-cutpositions

transportposition

AdjustingtheAnti-scalp Rollers

Wheneveryouchangetheheight-of-cut,itisrecommended

toadjusttheheightoftheanti-scalprollers.

Note:Adjusttheanti-scalprollerssotherollersdonottouch

thegroundinnormal,atmowingareas.

1.Disengagetheblade-controlswitch(PTO),movethe

motion-controlleverstotheneutral-lockpositionand

settheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Adjusttheanti-scalprollersasshownin

matchtheclosestheight-of-cutposition.

Figure21to

18

Page 19

G010233

1

2

3

4

G014477

1

AdjustingtheMotion-control

4

1

2

G014970

3

Levers

AdjustingtheHeight

Themotion-controlleverscanbeadjustedhigherorlowerfor

maximumoperatorcomfort.

1.Removethe2boltsholdingthecontrollevertothe

control-armshaft(Figure23).

Figure21

1.Anti-scalproller3.Flangenut

2.Bolt4.Holespacing

PositioningtheSeat

Theseatcanmoveforwardandbackward.Positiontheseat

whereyouhavethebestcontrolofthemachineandaremost

comfortable.

1.Raisetheseat,andloosentheadjustmentboltsjust

enoughsothattheseatcanmove(Figure22).

2.Movethecontrollevertothenextsetofholes.

3.Securetheleverwiththe2bolts(Figure23).

Figure23

1.Control-armshaft3.Slotted,upperhole

2.Controllever

4.Repeattheadjustmentfortheoppositecontrollever.

4.Bolt

AdjustingtheTilt

Themotion-controlleverscanbetiltedforeoraftfor

maximumoperatorcomfort.

Figure22

1.Adjustmentbolts

2.Movetheseattothedesiredpositionandtightenthe

bolts.

1.Loosentheupperboltholdingthecontrollevertothe

control-armshaft.

2.Loosenthelowerboltjustenoughtopivotthecontrol

leverforeoraft(Figure23).

Note:Tightenbothboltstosecurethecontrolinthe

newposition.

3.Repeattheadjustmentfortheoppositecontrollever.

PushingtheMachinebyHand

Important:Alwayspushthemachinebyhand.Donot

towthemachine,becausedamagemayoccur.

Thismachinehasanelectric-brakemechanism,andtopush

themachine,theignitionkeyneedstobeintheRunposition.

Thebatteryneedstobechargedandfunctioningforthe

electricbraketobedisengage.

19

Page 20

PushingtheMachine

g017303

1 2

3

1.Parkthemachineonalevelsurface,anddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothepark

position,stoptheengine,andwaitforallmovingparts

tostopbeforeleavingtheoperatingposition.

3.Locatethebypassleversontheframeonbothsidesof

theengine.

4.Movethebypassleversforwardthroughthekeyhole

anddowntolocktheminplace(

Note:Ensurethisisdoneforeachlever.

5.Movethemotion-controlleversinwardtotheneutral

positionandturntheignitionkeytotheRunposition.

Note:Donotstartthemachine.

Note:Youcannowpushthemachinebyhand.

Figure24).

Figure24

1.Bypass-leverlocations

2.Leverpositionfor

operatingthemachine

3.Leverpositionforpushing

themachine

6.Whennished,ensurethatthekeyreturnstotheStop

positiontoavoiddrainingthebatterycharge.

Note:Ifthemachinefailstomove,theelectricbrakemay

stillbeengaged.Ifnecessary,theelectricbrakecanrelease

manually;refertoReleasingtheElectricBrake(page31).

OperatingtheMachine

Movethebypassleversrearwardthroughthekeyholeand

downtolocktheminplaceasshowninFigure24.

Note:Ensurethisisdoneforeachlever.

20

Page 21

OperatingTips

UsingtheFastThrottleSetting

Forbestmowingandmaximumaircirculation,operate

theengineattheFastthrottleposition.Airisrequiredto

thoroughlycutgrassclippings,sodonotsettheheight-of-cut

solowastototallysurroundthemowerbyuncutgrass.

Alwaystrytohaveonesideofthemowerfreefromuncut

grass,whichallowsairtobedrawnintothemower.

UsingtheSmartSpeed™Control

System

TheSmartSpeed™Control-Systemlever,locatedbelow

theoperatingposition,givestheoperatorachoicetodrive

themachineat2speedranges—highandlow.Anoperator

canbenetfromthelowerspeedsettingwhenmaneuvering

themachineintightspacesoroperatingarounddelicate

landscapes.Thelowsettingcanalsooperatethemachineata

highthrottlesettingandbladespeed,whilestillbeingableto

reducethegroundspeedtoincreasethequalityofcut.

CuttingLongGrass

Ifthegrassisallowedtogrowslightlylongerthannormal,

orifitcontainsahighdegreeofmoisture,raisethecutting

heighthigherthanusualandcutthegrassatthissetting.Then

cutthegrassagainusingthelower,normalsetting.

StoppingtheMachine

Ifyoumuststoptheforwardmotionofthemachinewhile

mowing,aclumpofgrassclippingsmaydropontoyour

lawn.Toavoidthis,moveontoapreviouslycutareawiththe

bladesengagedoryoucandisengagethemowerdeckwhile

movingforward.

KeepingtheUndersideoftheMower

Clean

Cleanclippingsanddirtfromtheundersideofthemower

aftereachuse.Ifgrassanddirtbuildupinsidethemower,

cuttingqualitywilleventuallybecomeunsatisfactory.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethatthe

cuttingheightofthemowerdoesnotscalpanyuneven

ground.However,thecuttingheightusedinthepastis

generallythebestonetouse.Whencuttinggrasslongerthan

sixinchestall,youmaywanttocutthelawntwicetoensure

anacceptablequalityofcut.

Cutting1/3oftheGrassBlade

Itisbesttocutonlyabout1/3ofthegrassblade.Cutting

morethanthatisnotrecommendedunlessgrassissparse,or

itislatefallwhengrassgrowsmoreslowly.

AlternatingtheMowingDirection

Alternatethemowingdirectiontokeepthegrassstanding

straight.Thisalsohelpsdisperseclippingswhichenhances

decompositionandfertilization.

MowingatCorrectIntervals

Normally,mowevery4days.But,remember,grassgrowsat

differentratesatdifferenttimes.Sotomaintainthesame

cuttingheight,whichisagoodpractice,andmowmoreoften

inearlyspring.Asthegrassgrowthrateslowsinmidsummer,

mowlessfrequently.Ifyoucannotmowforanextended

period,rstmowatahighcuttingheight,thenmowagain2

dayslateratalowerheightsetting.

MaintainingtheBlade(s)

Maintainasharpbladethroughoutthecuttingseasonbecause

asharpbladecutscleanlywithouttearingorshreddingthe

grassblades.Tearingandshreddingturnsgrassbrownat

theedges,whichslowsgrowthandincreasesthechanceof

disease.Checkthemowerbladesaftereachuseforsharpness,

andforanywearordamage.Filedownanynicksandsharpen

thebladesasnecessary.Ifabladeisdamagedorworn,replace

itimmediatelywithagenuineTororeplacementblade.

AvoidingCuttingTooLow

Ifthecuttingwidthofthemoweriswiderthanthemower

youpreviouslyused,raisethecuttingheighttoensurethat

uneventurfisnotcuttooshort.

21

Page 22

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Beforeeachuseordaily

Aftereachuse

Every25hours

Every50hours

Every100hours

Every200hours

Every500hours

Beforestorage

MaintenanceProcedure

•Checkthesafety-interlocksystem.

•Checktheaircleanerfordirty,looseordamagedparts.

•Checktheengine-oillevel.

•Checkthecuttingblades.

•Inspectthegrassdeectorfordamage.

•Cleanthemower-deckhousing.

•Greaseallthelubricationpoints.

•Checktirepressure.

•Checkthebeltsforwearorcracks.

•Servicethepaperelement(moreoftenunderextremelydusty,dirtyconditions).

•Replacethepaperelement(moreoftenunderextremelydusty,dirtyconditions).

•Changetheengineoilandtheengine-oillter.

•Cleantheblowerhousing(moreoftenunderextremelydusty,dirtyconditions).

•Replacethein-linefuellter.

•Checksparkplug(s)conditionandgap.

•Replacethesparkplug(s).

•Chargethebatteryanddisconnectbatterycables.

•Performallmaintenanceprocedureslistedabovebeforestorage.

•Paintanychippedsurfaces.

Important:Refertoyourengine

Owner's Man ual

foradditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

22

Page 23

Premaintenance

1

G014522

Lubrication

Procedures

RaisingtheSeat

Makesurethatthemotion-controlleversarelockedinthe

parkposition.Lifttheseatforward.

Thefollowingcomponentscanbeaccessedbyraisingtheseat:

•Serialplate

•Servicedecal

•Seatadjustmentbolts

•Fuellter

•Batteryandbatterycables

GreasingtheBearings

ServiceInterval:Every25hours—Greaseallthelubrication

points.

GreaseType:No.2generalpurpose,lithium-basegrease

1.Parkthemachineonalevelsurface,anddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothepark

position,stoptheengine,removethekey ,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Cleanthegreasettings(Figure25andFigure26)with

arag.

Note:Makesuretoscrapeanypaintoffthefrontof

thetting(s).

Figure25

1.Frontcastertire

Figure26

Locatedontheseat-panunderside

1.Readtheinstructions

beforeservicingor

performingmaintenance

2.Checkthetirepressure

every25operatinghours

3.Greaseevery25operating

hours

4.Engine

4.Connectagreaseguntoeachtting(Figure25and

Figure26).

5.Pumpgreaseintothettingsuntilgreasebeginsto

oozeoutthebearings.

23

Page 24

EngineMaintenance

g023919

1 2

3

4

g017552

0

0

50

SAE 30

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Checktheair

cleanerfordirty,looseordamagedparts.

Every50hours—Servicethepaperelement(more

oftenunderextremelydusty,dirtyconditions).

Every100hours—Replacethepaperelement(more

oftenunderextremelydusty,dirtyconditions).

Thisengineisequippedwithareplaceable,highdensitypaper

air-cleanerelement.Checktheaircleanerdailyorbefore

startingtheengine.Checkforabuildupofdirtanddebris

aroundtheair-cleanersystem.Keepthisareaclean.Also,

checkforlooseordamagedcomponents.Replaceallbentor

damagedair-cleanercomponents.

Note:Operatingtheenginewithlooseordamaged

air-cleanercomponentscouldallowunlteredairintothe

engine,causingprematurewearandfailure.

Note:Servicetheaircleanermoreoftenunderextremely

dusty,dirtyconditions.

1.Rotatethelatchesoutward.

2.Removethecovertoaccesstheair-cleanerelement

(Figure27).

3.Removetheelement,andgentlytaptheelementto

dislodgedirt.

Note:Donotwashthepaperelementoruse

pressurizedair,asthiswilldamagetheelement.

Note:Replaceadirty,bent,ordamagedelement.

Handlethenewelementcarefully;donotuseifthe

sealingsurfacesarebentordamaged.

Figure27

1.Air-cleanerlatch3.Paperelement

2.Engine4.Air-cleanerbase

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSJorhigher)

CrankcaseCapacity:1.9L(64oz)whenthelterischanged

Viscosity:Seethetablebelow.

4.Cleantheair-cleanerbaseasrequired,andcheckthe

condition.

5.Installthepaperelementontotheair-cleanerbase.

6.Installthecover,andsecureitwiththelatches(Figure

27).

Figure28

CheckingtheEngine-oilLevel

ServiceInterval:Beforeeachuseordaily—Checkthe

engine-oillevel.

1.Parkthemachineonalevelsurface,disengagethe

blade-controlswitch,stoptheengine,andremovethe

key.

2.Makesurethattheengineisstopped,level,andiscool,

sotheoilhashastimetodrainintothesump.

3.Tokeepdirt,grassclippings,etc.,outoftheengine,

cleantheareaaroundtheoil-llcap/dipstickbefore

removingit.

4.Removethedipstickandwipetheoilofffromit

(

Figure29).

24

Page 25

5.Insertthedipstickintothetube.

g023855

1

2

3

4

Figure29

1.Oildipstick3.Oillevel—Lowmark

2.Oillevel—Fullmark

4.Fillertube

6.Pullthedipstickout,andchecktheoillevel(Figure29).

ChangingtheEngineOilandthe

Engine-oilFilter

ServiceInterval:Every100hours—Changetheengineoil

andtheengine-oillter.

Fillwithoilasspeciedinthe“ViscosityGrades”table

(Figure28).

Changetheengineoilandtheengine-oillterwhilethe

engineisstillwarm.Theoilwillowmorefreelyandcarry

awaymoreimpurities.Makesurethattheengineislevelwhen

lling,checking,orchangingtheoil.

Changetheengineoilandtheengine-oillterasfollows:

1.Parkthemachine,sothatthedrainsideisslightlylower

thantheoppositeside,toensurethattheoildrains

completely.

2.Disengagetheblade-controlswitchandmovethe

motioncontrolsoutwardtotheparkposition.

3.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

4.Locatetheoil-drainhoseontheleftsideoftheengine.

(Figure30).

Note:Theoillevelshouldbeupto,butnotover,the

FullorFmarkonthedipstick

7.Ifthelevelislow ,addoilofthepropertype,uptothe

FullorFmarkonthedipstick.

Note:Alwayscheckthelevelwiththedipstickbefore

addingmoreoil.

Note:Topreventextensiveenginewearordamage,

alwaysmaintaintheproperoillevelinthecrankcase.

Neveroperatetheenginewiththeoillevelbelowthe

AddorLmarkorabovetheFullorFmarkonthe

dipstick.

8.Removedipstickandcheckoillevel.

Note:ThelevelshouldbebetweentheFullorFand

AddorLmarks.Iflow ,addoilofthepropertypeup

tothefullmark.

9.Installtheoil-llcap/dipstick.

Note:Thedrainplugisattachedtothedrainhose.

5.Cleantheareaaroundtheoil-drainplugandthe

oil-drainhose.

6.Placeadrainpanunderneaththemachine,directly

belowtheoil-drainhoseasshownin

Figure30

1.Oil-drainplug3.Oil-drainhose

2.Pan

Figure30.

7.Using2wrenches(onetoholdtheoil-drainhoseand

onetoloosentheplug),removetheoil-drainplug

(

Figure30).

8.Removetheoil-llcap/dipstick(Figure29).

9.Allowampletimeforcompletedrainage.

25

Page 26

10.Locatetheoillterontherightsideoftheengine,and

G023857

1

2

removetheoldlterandwipeoffthelteradapter

withacleancloth(Figure31).

ServicingtheSparkPlug

ServiceInterval:Every200hours—Checksparkplug(s)

conditionandgap.

Every500hours—Replacethesparkplug(s).

ThesparkplugisRFIcompliant.Equivalentalternatebrand

plugscanalsobeused.

Type:ChampionXC12YC(orequivalent)

AirGap:0.76mm(0.03inch)

RemovingtheSparkPlug

1.Disengagetheblade-controlswitch,movethemotion

controlsoutwardtotheparkposition,stoptheengine,

andremovethekey.

2.Beforeremovingthesparkplug(s),cleanthearea

aroundthebaseoftheplugtokeepdirtanddebrisout

oftheengine.

Figure31

1.Oillter

11.Applyathinlmofcleanoiltotherubbergasketon

thenewlter.

12.Installthereplacementoilltertotheadapter.

13.Turntheoillterclockwiseuntiltherubbergasket

contactsthepad,thentightenthelteranadditional

3/4to1turn(

14.Wipeupanyexcessoilontheframe.

15.Whenoilhasdrainedcompletely ,installtheoildrain

plug.

16.Torquetheplugto14N-m(125in-lb).

17.Wipeupanyexcessoil(Figure30).

Note:Disposeoftheusedoilatarecyclingcenter.

18.Slowlypourapproximately80%ofthespeciedoil

intothellertube(Figure29).

19.Installtheoil-llcap/dipstick(

20.Checktheoillevel(

21.SlowlyaddadditionaloiltobringittotheFullmark.

22.Installtheoil-llcap/dipstick(Figure29).

Figure31).

2.Adapter

Figure29).

Figure29).

3.Pullthewireoffthesparkplug(s)(

4.Removethesparkplug(s)andthemetalwasher.

Figure32

1.Sparkplugandwirelocations

Figure32).

CheckingtheSparkPlug

Important:Donotcleanthesparkplug(s).Always

replacethesparkplug(s)whenithas:ablackcoating,

wornelectrodes,anoilylm,orcracks.

Ifyouseelightbrownorgrayontheinsulator,theengineis

operatingproperly .Ablackcoatingontheinsulatorusually

meanstheaircleanerisdirty.

Setthegapto0.76mm(0.030inch).

26

Page 27

G008794

1

2

Figure33

g023859

1

2

3

4

5

InstallingtheSparkPlug

1.Installthesparkplug.

Note:Makesurethattheairgapissetcorrectly.

2.Tightenthesparkplugto25to29N-m(18to22ft-lb).

3.Pushthewireontothesparkplug(Figure32).

FuelSystem

Maintenance

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Performanyfuelrelatedmaintenancewhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

ReplacingtheIn-lineFuel

CleaningtheBlowerHousing

Toensurepropercooling,makesurethegrassscreen,cooling

ns,andotherexternalsurfacesoftheenginearekeptclean

atalltimes.

Annually,orevery100hoursofoperation(moreoften

underextremelydusty,dirtyconditions),removetheblower

housing,andanyothercoolingshrouds.Cleanthecooling

nsandexternalsurfacesasnecessary.Makesurethatthe

coolingshroudsareinstalled.Torquetheblowerhousing

screwsto7.5N-m(5.5ft-lb).

Important:Operatingtheenginewithablockedgrass

screen,dirtyorpluggedcoolingns,and/orcooling

shroudsremoved,willcauseenginedamagedueto

overheating.

Filter

ServiceInterval:Every100hours—Replacethein-linefuel

lter.

Neverinstalladirtylterifitisremovedfromthefuelline.

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothepark

position,stoptheengine,removethekey ,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Locatethefuellteronthesideoftheengine(Figure

34).

Figure34

1.Fuellinefromtank

2.In-linefuellter

3.Flow-directionarrow

27

4.Fuellinetoengine

5.Hoseclamp

Page 28

4.Squeezetheendsofthehoseclampstogetherandslide

themawayfromthelter(Figure34).

ElectricalSystem

5.Removethelterfromthefuellines.

6.Installanewlterwiththeow-directionarrow

comingfromthefueltankandpointingtotheengine.

7.Movethehoseclampsclosetothelter(

tosecureitinplace.

Figure34)

Maintenance

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

ChargingtheBattery

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothepark

position,stoptheengine,removethekey ,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Raisetheseattoaccessthebattery.

4.Disconnectthenegative(black)groundcablefromthe

batterypost(

Note:Retainallfasteners.

Figure35).

28

Page 29

WARNING

G005072

1

2

3

4

5

6

7

Incorrectbattery-cableroutingcoulddamage

themachineandcablescausingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

ChargingtheBattery

ServiceInterval:Beforestorage—Chargethebatteryand

disconnectbatterycables.

1.Removethebatteryfromthechassis;referto

theBattery(page28)

.

Removing

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

5.Slidetherubbercoverupthepositive(red)cable.

6.Disconnectthepositive(red)cablefromthebattery

post(Figure35).

Note:Retainallfasteners.

7.Removethebatteryhold-down(

batteryfromthebatterytray .

Figure35),andliftthe

2.Chargethebatteryforaminimumof1hourat6to

10amps.

Note:Donotoverchargethebattery.

3.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthecharger

leadsfromthebatteryposts(

Figure36

1.Positive(+)batterypost3.Red(+)chargerlead

2.Negative(–)batterypost4.Black(–)chargerlead

Figure36).

1.Battery

2.Positive(+)batterypost

3.Bolt,washer,andnut7.Batteryhold-down

4.Terminalboot

Note:Donotrunthemachinewiththebattery

disconnected,electricaldamagemayoccur.

InstallingtheBattery

1.Positionthebatteryinthetray(Figure35).

2.Usingthefastenerspreviouslyremoved,installthe

positive(red)batterycabletothepositive(+)battery

terminal.

Figure35

5.Negative(–)batterypost

6.Wingnut,washer,andbolt

3.Usingthefastenerspreviouslyremoved,installthe

negativebatterycabletothenegative(-)battery

terminal.

4.Slidetheredterminalbootontothepositive(red)

batterypost.

5.Securethebatterywiththehold-down(Figure35).

6.Lowertheseat.

29

Page 30

ServicingtheFuses

30

25

30

25

G014921

2

1

DriveSystem

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;however,ifafuseblows,checkthe

component/circuitforamalfunctionorshort.

Fusetype:

•Main—F1-30amp,blade-type

•ChargeCircuit—F2-25amp,blade-type

1.Removethescrewssecuringthecontrolpaneltothe

machine.

Note:Retainallfasteners.

2.Liftthecontrolpaneuptoaccessthemainwiring

harnessandfuseblock(

3.Toreplaceafuse,pulloutonthefusetoremoveit

(Figure37).

Figure37).

Maintenance

CheckingtheTirePressure

ServiceInterval:Every25hours—Checktirepressure.

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseunevencut.Check

thepressureatthevalvestem(Figure38).Checkthetires

whentheyarecoldtogetthemostaccuratepressurereading.

Refertothemaximumpressuresuggestedbythetire

manufactureronthesidewallofthecasterwheeltires.

Inatethereardrive-wheeltiresto82kPa(12psi).

Figure38

Figure37

1.Main—30amp

2.Chargecircuit—25amp

4.Returnthecontrolpaneltoitsoriginalposition.

Note:Usethescrewsremovedpreviouslytosecure

thepaneltothemachine.

1.Valvestem

30

Page 31

ReleasingtheElectricBrake

G015000

1

Theelectricbrakereleasesbymanuallyrotatingthelinkarms

forward.Oncetheelectricbrakeisenergized,thebrakewill

reset.

1.Locatetheshaftontheelectricbrakewherethe

brake-linkarmsareconnected(Figure39).

2.Rotatetheshaftforwardtoreleasethebrake.

Figure39

1.Brake-linkarmontheelectric-brake-controlmodule

MowerMaintenance

ServicingtheCuttingBlades

Maintainsharpbladesthroughoutthecuttingseason,because

sharpbladescutcleanlywithouttearingorshreddingthegrass

blades.Tearingandshreddingturnsgrassbrownattheedges,

whichslowsgrowth,andincreasesthechanceofdisease.

Checkthecutterbladesdailyforsharpness,andforany

wearordamage.Filedownanynicksandsharpenthe

bladesasnecessary.Ifabladeisdamagedorworn,replace

itimmediatelywithagenuineT ororeplacementblade.For

convenientsharpeningandreplacement,youmaywantto

keepextrabladesonhand.

WARNING

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownintotheoperator's

orbystander'sarea,resultinginseriouspersonal

injuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

BeforeInspectingorServicingthe

Blades

Parkthemachineonalevelsurface,disengagethe

blade-controlswitch,movethemotion-controlleversoutward

totheparkposition,stoptheengine,andremovethekey .

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily—Checkthe

cuttingblades.

1.Inspectthecuttingedges(Figure40).

Note:Iftheedgesarenotsharporhavenicks,remove

andsharpentheblades;refertoSharpeningtheBlades

(page33).

2.Inspecttheblades,especiallythecurvedarea(Figure

40).

Note:Ifyounoticeanydamage,wear,oraslot

forminginthisarea(item3inFigure40),immediately

installanewblade.

31

Page 32

Figure40

G014972

1

2

3

G014973

1

2

3

G014974

1

2

3

1.Cuttingedge3.Wear/slotforming

2.Curvedarea

4.Damage

CheckingforBentBlades

Note:Themachinemustbeonalevelsurfaceforthe

followingprocedure.

1.Raisethemowerdecktothehighestheight-of-cut

position;alsoconsideredthe'transport'position.

2.Whilewearingthicklypaddedgloves,orotheradequate

handprotection,slowlyrotatethebladetobemeasure

intoapositionthatallowseffectivemeasurementofthe

distancebetweenthecuttingedgeandthelevelsurface

themachineison(Figure41).

3.Measurefromthetipofthebladetotheatsurface

(Figure42).

Figure42

1.Blade(inpositionformeasuring)

2.Levelsurface

3.Measureddistancebetweenbladeandthesurface(A)

4.Rotatethesameblade180degrees,sothattheopposing

cuttingedgeisnowinthesameposition(

Figure43).

Figure43

1.Blade(sidepreviouslymeasured)

2.Measurement(positionusedpreviously)

Figure41

1.Deck3.Blade

2.Spindlehousing

3.Opposingsideofbladebeingmovedintomeasurement

position

5.Measurefromthetipofthebladetotheatsurface

(Figure44).

Note:Thevarianceshouldbenomorethan3mm

(1/8inch).

32

Page 33

G014973

1

2

3

Figure45

Figure44

1.Oppositebladeedge(inpositionformeasuring)

2.Levelsurface

3.Secondmeasureddistancebetweenbladeandsurface(B)

A.IfthedifferencebetweenAandBisgreaterthan

3mm(1/8inch),replacethebladewithanew

blade;refertoRemovingtheBlades(page33)and

InstallingtheBlades(page33).

Note:Ifabentbladeisreplacedwithanewone,

andthedimensionobtainedcontinuestoexceed3

mm(1/8inch),thebladespindlecouldbebent.

ContactanAuthorizedToroDealerforservice.

B.Ifthevarianceiswithinconstraints,movetothe

nextblade.

Repeatthisprocedureoneachblade.

RemovingtheBlades

Thebladesmustbereplacedifasolidobjectishit,ifthe

bladeisoutofbalance,orifthebladeisbent.T oensure

optimumperformanceandcontinuedsafetyconformance

ofthemachine,usegenuineTororeplacementblades.

Replacementbladesmadebyothermanufacturersmayresult

innon-conformancewithsafetystandards.

1.Holdthebladeendusingaragorthickly-paddedglove.

2.Removethebladebolt,thecurvedwasher,theblade

stiffener,andthebladefromthespindleshaft(Figure

45).

1.Sailareaoftheblade

2.Blade

3.Curvedwasher

4.Bladebolt

5.Bladestiffener(42-inch

decksonly)

SharpeningtheBlades

1.Usealetosharpenthecuttingedgeatbothendsof

theblade(Figure46).

Note:Maintaintheoriginalangle.

Note:Thebladeretainsitsbalanceifthesameamount

ofmaterialisremovedfrombothcuttingedges.

Figure46

1.Sharpenatoriginalangle

2.Checkthebalanceofthebladebyputtingitonablade

balancer(

Note:Ifthebladestaysinahorizontalposition,the

bladeisbalanced,andcanbeused.

Note:Ifthebladeisnotbalanced,lesomemetaloff

theendofthesailareaonly(

Figure47).

Figure46).

Figure47

1.Blade2.Balancer

3.Repeatthisprocedureuntilthebladeisbalanced.

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure45).

Important:Thecurvedpartoftheblademustbe

33

pointingupwardtowardtheinsideofthemowerto

ensurepropercutting.

Page 34

2.Installthebladestiffener,thecurvedwasher(cupped

G009682

1

2

2

3

3

4

4

G005278

1

2

2

3

3

4

4

sidetowardtheblade),andthebladebolt(Figure45).

3.Torquethebladeboltto47to88N-m(35to65ft-lb).

LevelingtheMowerDeck

Checktoensurethatthemowerdeckislevelanytimeyou

installthemowerorwhenyouseeanunevencutonyour

lawn.

Themowerdeckmustbecheckedforbentbladespriorto

leveling;anybentbladesmustberemovedandreplaced;refer

to

CheckingforBentBlades(page32)beforecontinuing.

Themowerdeckmustbeleveledside-to-siderstthenthe

fronttorearslopecanbeadjusted.

Requirements:

•Themachinemustbeonalevelsurface.

Figure49

MowerDeckswith3Blades

1.Bladessidetoside

2.Sailareaofblade4.Measurefromthetipofthe

3.Outsidecuttingedges

bladetotheatsurface

here

•All4tiresmustbeproperlyinated;referto

theTirePressure(page30).

Side-to-SideLeveling

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothepark

position,stoptheengine,removethekey ,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Settheheight-of-cutlevertomiddleposition.

4.Carefullyrotatethebladessothattheyareallsideto

side(Figure48andFigure49).

Checking

5.Measurebetweentheoutsidecuttingedgesandtheat

surface(Figure48andFigure49).

Note:Ifbothmeasurementsarenotwithin5mm

(3/16inch),anadjustmentisrequired;continuewith

thisprocedure.

6.Supporttheweightofmowerdeckbyplacingwood

blocksundertheedgesofthemowerdeck.

Note:Avoidplacingthesupportsunderanyanti-scalp

rollersifpresentonthemowerdeck.

7.Movetotheleftsideofthemachine.

Note:Checkifthesidecarriageboltisinthexedor

slottedposition(Figure50).

8.Ifthesidecarriageboltisinthexedposition,remove

thesidecarriageboltandsidelockingnutfromthe

xedpositionandinstallitintotheslottedadjustment

position(Figure50).

Note:Iftheboltisintheslottedposition,thecarriage

boltandthesidelockingnutrequirenoremoval.

Figure48

1.Bladessidetoside

2.Sailareaofblade4.Measurefromthetipofthe

Mowerdeckswith2blades

3.Outsidecuttingedges

bladetotheatsurface

here

34

Page 35

G015323

1

2

3

4

5

G015324

1

2

3

4

G015325

1

2

Figure52

Figure50

1.Hangerbracket

2.Slottedadjustment

position

3.Fixedposition

4.Sidelockingnut.

5.Sidecarriagebolt

9.Loosentherearlockingnutonthehangerbracket

(Figure51).

Figure51

1.Hangerbracket

2.Rearlockingnut4.Adjustmentnotches

3.Sidelockingnut,slotted

position.

10.Loosenthesidelockingnutonthehangerbracketjust

enoughtoallowthehangertobeadjusted(Figure51).

Usethenotchesontheweldedbrackettomeasure

theamountofadjustment.Eachnotchsurfaceis

equivalentto6.35mm(1/4inch),whileasinglesideis

3.18mm(1/8inch)asshownin

Figure52).

11.Adjusttheheightofthemowerdecktothedesired

height.

1.0.25inch2.0.125inch

12.Stopthedeckattheadjustedpositionandtightenthe

sidelockingnutonthehangerbrackettoholdthenew

position(Figure51).

13.Tightentherearlockingnutonthehangerbracket.

14.Continuelevelingthedeckbycheckingthefront-to-rear

bladeslope;refertoAdjustingtheFront-to-RearBlade

Slope(page35).

AdjustingtheFront-to-RearBlade

Slope

Checkthefront-to-rearbladelevelanytimeyouinstallthe

mower.Ifthefrontofthemowerismorethan7.9mm

(5/16inch)lowerthantherearofthemower,adjusttheblade

levelusingthefollowinginstructions:

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothepark

position,stoptheengine,removethekey ,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Settheheight-of-cutlevertomiddleposition.

Note:Checkandadjusttheside-to-sidebladelevelif

youhavenotcheckedthesetting;refertoSide-to-Side

Leveling(page34).

4.Carefullyrotatethebladessotheyarefacingfrontto

rear(Figure53andFigure54).

35

Page 36

G009658

1

2

2

Figure53

G009659

1

2

3

2

3

G014634

1

2

3

Mowerdeckswith2blades

1.Bladesfronttorear

2.Measurefromthetipofthebladetotheatsurfacehere.

Figure54

Mowerdeckswith3blades

1.Bladesfronttorear3.Measurefromthetipofthe

bladetotheatsurface

here

2.Outsidecuttingedges

5.Measurefromthetipofthefrontbladetotheat

surfaceandthetipoftherearbladetotheatsurface

(Figure53andFigure54).

Figure55

1.Adjustingrod3.Locknut

2.Adjustingblock

7.Toraisethefrontofthemower,tightentheadjustment

nut.

Note:Tolowerthefrontofthemower,loosenthe

adjustmentnut.

8.Afteradjustment,checkthefront-to-rearslopeagain.

Note:Continueadjustingthenutuntilthefrontblade

tipis1.6to7.9mm(1/16to5/16inch)lowerthanthe

rearbladetip(Figure53andFigure54).

9.Whenthefront-to-rearbladeslopeiscorrectcheck

theside-to-sidelevelofthemoweragain;referto

Side-to-SideLeveling(page34).

RemovingtheMower

Note:Ifthefrontbladetipisnot1.6to7.9mm(1/16

to5/16inch)lowerthantherearbladetip,adjustthe

frontlocknut.

6.Toadjustthefront-to-rearbladeslope,rotatethe

adjustmentnutinthefrontofthemower(Figure55).

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothepark

position,stoptheengine,removethekey ,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Lowertheheight-of-cutlevertothelowestposition.

4.Removethehairpin-cotterpinfromthefrontsupport

rod,andremovetherodfromthedeckbracket(Figure

56).

36

Page 37

G014635

1

2

3

Figure56

2

2

3

G005077

1

2

2

3

1.Front-supportrod3.Deckbracket

2.Lockingnut

Note:Retainallpartsforfutureinstallation.

InstallingtheMower

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothepark

position,stoptheengine,removethekey ,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Slidethemowerunderthemachine.

4.Lowertheheight-of-cutlevertothelowestposition.

5.Lifttherearofthemowerdeckandguidethehanger

bracketsovertherearliftrod(Figure57).

6.Attachthefrontsupportrodtothemowerdeckwith

theclevispinandhairpin-cotterpin(

7.Installthemowerbeltontotheenginepulley.

Figure56).

ReplacingtheGrassDeector

ServiceInterval:Beforeeachuseordaily—Inspectthegrass

deectorfordamage.

5.Carefullylowerthefrontofthemowerdecktothe

ground.

6.Liftthemowerdeckandhangerbracketsclearof

therearliftrodandlowerthemowercarefullytothe

ground(Figure57).

Figure57

WARNING

Anuncovereddischargeopeningcouldallowthe

lawnmowertothrowobjectsintheoperator'sor

bystander'sdirectionandresultinseriousinjury.

Also,contactwiththebladecouldoccur.

Neveroperatethemachinewithoutthegrass

deector,thedischargecover,orthegrass-collection

systeminplace.

Inspectthegrassdeectorfordamagebeforeeachuse.

Replaceanydamagedpartsbeforeuse.

1.Removethenut(3/8inch)fromtherodunderthe

mower(Figure58).

1.Mowerdeck

2.Hangerbracket

7.Slidethemowerdeckrearwardtoremovethemower

beltfromtheenginepulley.

8.Slidethemowerdeckoutfromunderneaththe

machine.

3.Rearliftrod

37

Page 38

G005192

1

2

3

4

5

6

7

Figure58

1.Mowerdeck

2.Grassdeector6.Nut(3/8inch)

3.Grass-deectorbracket7.Shortstandoff

4.Rod

2.Slidetherodoutoftheshortstandoff,thespring,and

thegrassdeector(Figure58).

3.Removethedamagedorworngrassdeector.

4.Replacethegrassdeector(Figure58).

5.Slidetherod(straightend),throughthe

rear-grass-deectorbracket.

5.Spring

MowerBeltMaintenance

InspectingtheBelts

ServiceInterval:Every25hours—Checkthebeltsforwear

orcracks.

Checkthebeltsforcracks,frayededges,burnmarks,orany

otherdamage.Replacedamagedbelts.

ReplacingtheMowerBelt

Squealingwhenthebeltisrotating,bladesslippingwhen

cuttinggrass,frayedbeltedges,burnmarks,andcracksare

signsofawornmowerbelt.Replacethemowerbeltifanyof

theseconditionsareevident.

1.Parkthemachineonalevelsurfaceanddisengagethe

bladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothepark

position,stoptheengine,removethekey ,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Settheheight-of-cutatthelowestcuttingposition[38

mm(1-1/2inches)].

4.Usingaspring-removaltool,(Toropartno.92-5771),

removetheidlerspringfromthedeckhooktoremove

tensionontheidlerpulleyandrollthebeltoffthe

pulleys(Figure59andFigure60).

6.Placethespringontherod,withtheendwiresdown

andbetweenthegrassdeectorbrackets.

7.Sliderodthroughthesecondgrass-deectorbracket

(Figure58).

8.Inserttherodatthefrontofthegrassdeectorinto

theshortstandoffonthedeck.

9.Securetherearendoftherodintothemowerwitha

nut(3/8inch)asshownin

Important:Thegrassdeectormustbespring

loadedandinthedownposition.Liftthedeector

uptotestthatitsnapstothefulldownposition.

Figure58.

WARNING

Thespringisundertensionwheninstalled

andcancausepersonalinjury.

Becarefulwhenremovingthebelt.

38

Page 39

G014930

1

2

3

3

4

5

1

2

3

3

4

5

6

4

Figure59

G014931

1

2

3

3

4

5

6

MowerDeckswith2Blades

6.Usingaspring-removaltool,(Toropartno.92-5771),

installtheidlerspringoverthedeckhookandplacing

tensionontheidlerpulleyandmowerbelt(Figure59

andFigure60).

1.Idlerpulley

2.Mowerbelt5.Enginepulley

3.Outsidepulley6.Spring-removaltool

4.Spring

Figure60

MowerDeckswith3Blades

1.Idlerpulley