Page 1

LCE Products

Toro GrandStand

Stand-on Mower

Service Manual

Page 2

ABOUT THIS MANUAL

This service manual was written expressly for Toro and Lawn-Boy service technicians. The Toro Company has made

every effort to make the information in this manual complete and correct.

Basic shop safety knowledge and mechanical/electrical skills are assumed. The Table of Contents lists the systems

and the related topics covered in this manual.

For additional information on the electrical system, please refer to the Toro Electrical Demystication Guide (492-

4761) and subsequent. For service information on drive systems, please refer to the Hydro-Gear BDP service manual

(492-4779). For information specic to the engines used on this unit, refer to the appropriate engine manufacturer’s

service and repair instructions.

Toro GrandStand model years 2009 - 2010 are covered in this manual. The manual may also be specied for use on

later model products.

Both 2009 and 2010 models were used during the writing of this manual. You may see slight differences in the photos

depending on which model you are servicing.

Due to the compact design, parts were removed for photographic purposes when necessary.

The hydraulic components are sophisticated pieces of machinery. Maintain strict cleanliness control during all stages

of service and repair. Cover or cap all hose ends and ttings whenever they are exposed. Even a small amount of dirt

or other contamination can severely damage the system.

We are hopeful that you will nd this manual a valuable addition to your service shop. If you have any questions or

comments regarding this manual, please contact us at the following address:

The Toro Company

Residential and Landscape Contractor Service Training Department

8111 Lyndale Avenue South

Bloomington, MN 55420

The Toro Company reserves the right to change product specications or this manual without notice.

Copyright© All Rights Reserved

©2011 The Toro Company

Page 3

ABOUT THIS MANUAL

THIS PAGE INTENTIONALLY LEFT BLANK.

Page 4

TABLE OF CONTENTS

Safety Information

General Information ..................................................................................................................................... 1-1

Think Safety First......................................................................................................................................... 1-1

Specications

Torque Specications .................................................................................................................................. 2-1

Standard Torque for Dry, Zinc Plated & Steel Fasteners (Inch Series) ....................................................... 2-2

Standard Torque for Dry, Zinc & Steel Fasteners (Metric Fasteners) .......................................................... 2-3

Other Torque Specications ........................................................................................................................ 2-4

Equivalents & Conversions.......................................................................................................................... 2-5

Decimal & Millimeter Equivalents .......................................................................................................... 2-5

U.S. to Metric Conversions ................................................................................................................... 2-6

Domestic GrandStand Specications .......................................................................................................... 2-7

Domestic GrandStand Specications cont. ........................................................................................... 2-8

International GrandStand Specications ..................................................................................................... 2-9

International GrandStand Specications cont. .................................................................................... 2-10

Chassis

Parking Brake Assembly Replacement ....................................................................................................... 3-1

Parking Brake Assembly Removal ........................................................................................................ 3-1

Parking Brake Assembly Installation ..................................................................................................... 3-4

Height of Cut (HOC) Handle Assembly Replacement ............................................................................... 3-10

HOC Handle Assembly Removal ........................................................................................................ 3-10

HOC Handle Assembly Installation ..................................................................................................... 3-12

Caster Wheel Assembly Replacement ...................................................................................................... 3-17

Caster Wheel Assembly Removal ....................................................................................................... 3-17

Caster Wheel Assembly Installation .................................................................................................... 3-20

Fuel Tank Assembly Replacement ............................................................................................................ 3-26

Fuel Tank Assembly Removal ............................................................................................................. 3-26

Fuel Tank Assembly Installation .......................................................................................................... 3-29

Platform & Cushion Assembly Replacement ............................................................................................. 3-32

Platform & Cushion Assembly Removal ............................................................................................. 3-32

Platform & Cushion Assembly Installation .......................................................................................... 3-34

Lift Assist Cylinder Replacement (2009 only) ............................................................................................ 3-40

Lift Assist Cylinder Removal (2009 only) ............................................................................................ 3-40

Lift Assist Cylinder Installation (2009 only) ......................................................................................... 3-43

Lift Assist Spring Replacement (2010 only) ............................................................................................... 3-46

Lift Assist Spring Removal (2010 only) ............................................................................................... 3-46

Lift Assist Springs Installation (2010 only) .......................................................................................... 3-48

Wheel Motor Housing Assembly Replacement ......................................................................................... 3-49

Wheel Motor Housing Assembly Removal .......................................................................................... 3-49

Wheel Motor Housing Assembly Installation ....................................................................................... 3-53

Cross Shaft & Lift Assembly Replacement ................................................................................................ 3-57

Cross Shaft & Lift Assembly Removal ................................................................................................ 3-57

Cross Shaft & Lift Assembly Installation ............................................................................................. 3-62

Engine Base Replacement ........................................................................................................................ 3-71

Engine Base Removal ........................................................................................................................ 3-71

Engine Base Installation ..................................................................................................................... 3-92

Carrier Frame Replacement .................................................................................................................... 3-123

Carrier Frame Removal .................................................................................................................... 3-123

Carrier Frame Installation ................................................................................................................. 3-140

iToro GrandStand Service Manual

Page 5

TABLE OF CONTENTS

Controls

LH Motion Control Lever Replacement ...........................................................................................................4-1

LH Motion Control Lever Removal ............................................................................................................4-1

LH Motion Control Lever Installation .........................................................................................................4-3

RH Motion Control Lever Replacement ...........................................................................................................4-4

RH Motion Control Lever Removal ...........................................................................................................4-4

RH Motion Control Lever Installation ........................................................................................................4-7

RH Control Linkage Replacement ................................................................................................................. 4-11

RH Control Linkage Removal .................................................................................................................4-11

RH Control Linkage Installation ..............................................................................................................4-15

LH Control Linkage Replacement..................................................................................................................4-20

LH Control Linkage Removal ..................................................................................................................4-20

LH Control Linkage Installation ...............................................................................................................4-24

Speed Control Cable & Shifter Replacement ................................................................................................4-31

Speed Control Cable & Shifter Removal .................................................................................................4-31

Speed Control Cable & Shifter Installation ..............................................................................................4-34

Speed Control Adjustment .............................................................................................................................4-39

Control Cable Replacement ..........................................................................................................................4-42

Control Cable Removal ...........................................................................................................................4-42

Control Cable Installation ........................................................................................................................4-43

Choke Cable Replacement............................................................................................................................4-46

Choke Cable Removal ............................................................................................................................4-46

Choke Cable Installation .........................................................................................................................4-47

Throttle Cable Replacement ..........................................................................................................................4-50

Throttle Cable Removal ..........................................................................................................................4-50

Throttle Cable Installation .......................................................................................................................4-52

Engine

Engine Replacement .......................................................................................................................................5-1

Engine Removal ........................................................................................................................................5-1

Engine Installation .....................................................................................................................................5-9

Hydraulic Drive System

Pump Drive Belt Replacement ........................................................................................................................6-1

Pump Drive Belt Removal .........................................................................................................................6-1

Pump Drive Belt Installation ......................................................................................................................6-2

Pump Drive Belt Idler Replacement ................................................................................................................6-4

Pump Drive Belt Idler Removal .................................................................................................................6-4

Pump Drive Belt Idler Installation ..............................................................................................................6-6

Left Hydraulic Pump Replacement ..................................................................................................................6-9

Left Hydraulic Pump Removal ..................................................................................................................6-9

Left Hydraulic Pump Installation .............................................................................................................6-22

Right Hydraulic Pump Replacement..............................................................................................................6-35

Right Hydraulic Pump Removal ..............................................................................................................6-35

Right Hydraulic Pump Installation ...........................................................................................................6-48

Wheel Motor Replacement ............................................................................................................................6-62

Wheel Motor Removal ............................................................................................................................6-62

Wheel Motor Installation .........................................................................................................................6-69

Reservoir Tank Replacement ........................................................................................................................6-75

Reservoir Tank Removal .........................................................................................................................6-75

Reservoir Tank Installation ......................................................................................................................6-79

ii Toro GrandStand Service Manual

Page 6

TABLE OF CONTENTS

Hydraulic Drive System cont.

Hydraulic Filter Mount Replacement .............................................................................................................6-83

Hydraulic Filter Mount Removal ..............................................................................................................6-83

Hydraulic Filter Mount Installation ...........................................................................................................6-86

Hydraulic Testing ...........................................................................................................................................6-91

Bleeding the Hydraulic System......................................................................................................................6-95

Mower Deck

Mower Deck Belt Replacement .......................................................................................................................7-1

Mower Deck Belt Removal ........................................................................................................................7-1

Mower Deck Belt Installation .....................................................................................................................7-1

Spindle Replacement & Service ......................................................................................................................7-3

Mower Deck Spindle Removal ..................................................................................................................7-3

Mower Deck Spindle Installation ...............................................................................................................7-9

Spindle Service..............................................................................................................................................7-14

Spring Idler & Adjustment Idler Replacement ................................................................................................7-21

Spring Idler Removal ..............................................................................................................................7-21

Spring Idler Installation ...........................................................................................................................7-22

Adjustment Idler Removal .......................................................................................................................7-23

Adjustment Idler Installation ....................................................................................................................7-24

Bafes & Skid Plate Replacement .................................................................................................................7-26

Fixed Bafe Removal ..............................................................................................................................7-26

Fixed Bafe Installation ...........................................................................................................................7-27

Adjustable Bafe Removal ......................................................................................................................7-28

Adjustable Bafe Installation ...................................................................................................................7-30

Discharge Bafe Removal ......................................................................................................................7-31

Discharge Bafe Installation ...................................................................................................................7-32

Skid Plate Removal .................................................................................................................................7-33

Skid Plate Installation ..............................................................................................................................7-34

Anti-Scalp Roller Replacement (60” Models Only) ........................................................................................7-34

Single Anti-Scalp Roller Removal ...........................................................................................................7-34

Single Anti-Scalp Roller Installation ........................................................................................................7-36

Double Anti-Scalp Roller Removal ..........................................................................................................7-37

Double Anti-Scalp Roller Installation .......................................................................................................7-38

Belt Cover Brackets Replacement.................................................................................................................7-39

Early 2009 Belt Cover Bracket Removal .................................................................................................7-39

Early 2009 Belt Cover Bracket Installation ..............................................................................................7-40

Mid 2009 & Later Belt Cover Brackets Removal .....................................................................................7-41

Mid 2009 & Later Belt Cover Brackets Installation ..................................................................................7-42

Grass Deector Replacement .......................................................................................................................7-44

Grass Deector Removal ........................................................................................................................7-44

Grass Deector Installation .....................................................................................................................7-45

Mower Deck Replacement ............................................................................................................................7-47

Mower Deck Removal .............................................................................................................................7-47

Mower Deck Installation ..........................................................................................................................7-48

Mower Deck Adjustments - Correcting the Mower Quality of Cut..................................................................7-50

Checking the Mower Deck Side-to-Side Height ......................................................................................7-50

Changing the Mower Deck Side-to-Side Height .....................................................................................7-51

Checking the Mower Deck Front-to-Rear Pitch ......................................................................................7-51

Changing the Mower Deck Front-to-Rear Pitch ......................................................................................7-52

Matching Height-of-Cut ...........................................................................................................................7-53

iiiToro GrandStand Service Manual

Page 7

TABLE OF CONTENTS

Electrical

Component Testing ..........................................................................................................................................8-1

Ignition Switch .................................................................................................................................................8-1

Purpose .....................................................................................................................................................8-1

Location ....................................................................................................................................................8-1

How It Works .............................................................................................................................................8-1

Testing .......................................................................................................................................................8-1

Power Take Off (PTO) Switch ..........................................................................................................................8-2

Purpose .....................................................................................................................................................8-2

Location ....................................................................................................................................................8-2

How It Works .............................................................................................................................................8-2

Testing .......................................................................................................................................................8-2

Electric (PTO) Clutch .......................................................................................................................................8-3

Purpose .....................................................................................................................................................8-3

Location ....................................................................................................................................................8-3

How It Works .............................................................................................................................................8-3

Testing .......................................................................................................................................................8-3

Coil Resistance Measurement ..................................................................................................................8-3

Measuring Clutch Current Draw ................................................................................................................8-4

Solenoid...........................................................................................................................................................8-4

Purpose .....................................................................................................................................................8-4

Location ....................................................................................................................................................8-4

How It Works .............................................................................................................................................8-5

Testing .......................................................................................................................................................8-5

Operator Presence Control (OPC) Switch .......................................................................................................8-6

Purpose .....................................................................................................................................................8-6

Location ....................................................................................................................................................8-6

How It Works .............................................................................................................................................8-6

Testing .......................................................................................................................................................8-6

Neutral Switch .................................................................................................................................................8-7

Purpose .....................................................................................................................................................8-7

Location ....................................................................................................................................................8-7

How It Works .............................................................................................................................................8-7

Testing .......................................................................................................................................................8-7

Parking Brake Switch ......................................................................................................................................8-8

Purpose .....................................................................................................................................................8-8

Location ....................................................................................................................................................8-8

How It Works .............................................................................................................................................8-8

Testing .......................................................................................................................................................8-8

Fuse Block & Fuses.........................................................................................................................................8-9

Purpose .....................................................................................................................................................8-9

Location ....................................................................................................................................................8-9

How It Works .............................................................................................................................................8-9

Testing .......................................................................................................................................................8-9

Hour Meter/Control Module ...........................................................................................................................8-10

Purpose ...................................................................................................................................................8-10

Location ..................................................................................................................................................8-10

How It Works ...........................................................................................................................................8-10

Testing .....................................................................................................................................................8-10

iv Toro GrandStand Service Manual

Page 8

TABLE OF CONTENTS

Electrical cont.

Component Replacement .............................................................................................................................. 8-11

Ignition Switch Removal .......................................................................................................................... 8-11

Ignition Switch Installation .......................................................................................................................8-12

Power Take Off (PTO) Switch Removal ..................................................................................................8-13

Power Take Off (PTO) Switch Installation ...............................................................................................8-14

Electric PTO Clutch Removal..................................................................................................................8-14

Electric PTO Clutch Installation...............................................................................................................8-23

Electric PTO Clutch Burnishing Procedure .............................................................................................8-32

Solenoid Removal ...................................................................................................................................8-33

Solenoid Installation ................................................................................................................................8-34

Operator Presence Control (OPC) Switch Removal ............................................................................... 8-36

Operator Presence Control (OPC) Switch Installation ............................................................................ 8-36

Neutral Switch Removal ..........................................................................................................................8-38

Neutral Switch Installation .......................................................................................................................8-38

Parking Brake Switch Removal ...............................................................................................................8-39

Parking Brake Switch Installation ............................................................................................................8-39

Hour Meter/Control Module Removal .....................................................................................................8-41

Hour Meter/Control Module Installation ..................................................................................................8-42

Schematics

GrandStand Hydraulic Schematic ...................................................................................................................9-1

GrandStand Electrical Schematic ....................................................................................................................9-2

vToro GrandStand Service Manual

Page 9

TABLE OF CONTENTS

THIS PAGE INTENTIONALLY LEFT BLANK.

vi Toro GrandStand Service Manual

Page 10

General Information

SAFETY INFORMATION

This symbol means WARNING or

PERSONAL SAFETY INSTRUCTION read the instruction because if has to do

with your safety. Failure to comply with the

!

This manual is intended as a service and repair

manual only. The safety instructions provided herein

are for troubleshooting, service, and repair of the

Toro GrandStand Stand-on Mower. The GrandStand

instruction may result in personal injury or

even death.

Think Safety First

Avoid unexpected starting of engine...

Always turn off the engine and disconnect the spark plug

wire(s) before cleaning, adjusting, or repair.

Avoid lacerations and amputations...

Stay clear of all moving parts whenever the engine is

running. Treat all normally moving parts as if they were

moving whenever the engine is running or has the

potential to start.

mower and attachment operator’s manuals contain

safety information and operating tips for safe operating

practices. Operator’s manuals are available through your

Toro parts source or:

The Toro Company

Publications Department

8111 Lyndale Avenue South

Bloomington, MN 55420

Avoid injury from batteries...

Battery acid is poisonous and can cause burns. Avoid

contact with skin, eyes, and clothing. Battery gases can

explode. Keep cigarettes, sparks, and ames away from

the battery.

Avoid injury due to inferior parts...

Use only original equipment parts to ensure that

important safety criteria are met.

1

Avoid burns...

Do not touch the engine, mufer, or other components

which may increase in temperature during operation,

while the unit is running or shortly after it has been

running.

Avoid res and explosions...

Avoid spilling fuel and never smoke while working with

any type of fuel or lubricant. Wipe up any spilled fuel

or oil immediately. Never remove the fuel cap or add

fuel when the engine is running. Always use approved,

labeled containers for storing or transporting fuel and

lubricants.

Avoid asphyxiation...

Never operate an engine in a conned area without

proper ventilation.

Avoid injury to bystanders...

Always clear the area of bystanders before starting or

testing powered equipment.

Avoid injury due to projectiles...

Always clear the area of sticks, rocks, or any other

debris that could be picked up and thrown by the

powered equipment.

Avoid modications...

Never alter or modify any part unless it is a factory

approved procedure.

Avoid unsafe operation...

Always test the safety interlock system after making

adjustments or repairs on the machine. Refer to the

Electrical section in this manual for more information.

1-1Toro GrandStand Service Manual

Page 11

1

SAFETY INFORMATION

THIS PAGE INTENTIONALLY LEFT BLANK.

1-2 Toro GrandStand Service Manual

Page 12

SPECIFICATIONS

SPECIFICATIONS

Torque Specications

Torque Specifications

Recommended fastener torque values are listed in the

following tables. For critical applications, as

determined by Toro, either the recommended torque or

a torque that is unique to the application is clearly

identified and specified in the service manual.

These torque specifications for the installation and

tightening of fasteners shall apply to all fasteners which

do not have a specific requirement identified in the

service manual. The following factors shall be

considered when applying torque: cleanliness of the

fastener, use of a thread sealant (Loctite), degree of

lubrication on the fastener, presence of a prevailing

torque feature, hardness of the surface underneath of

the fastener’s head, or similar condition which affects

the installation.

As noted in the following tables, torque values should

be reduced by 25% for lubricated fasteners to

achieve the similar stress as a dry fastener. Torque

values may also have to be reduced when the fastener

is threaded into aluminum or brass. The specific

torque value should be determined based on the

aluminum or brass material strength, fastener size,

length of thread engagement, etc.

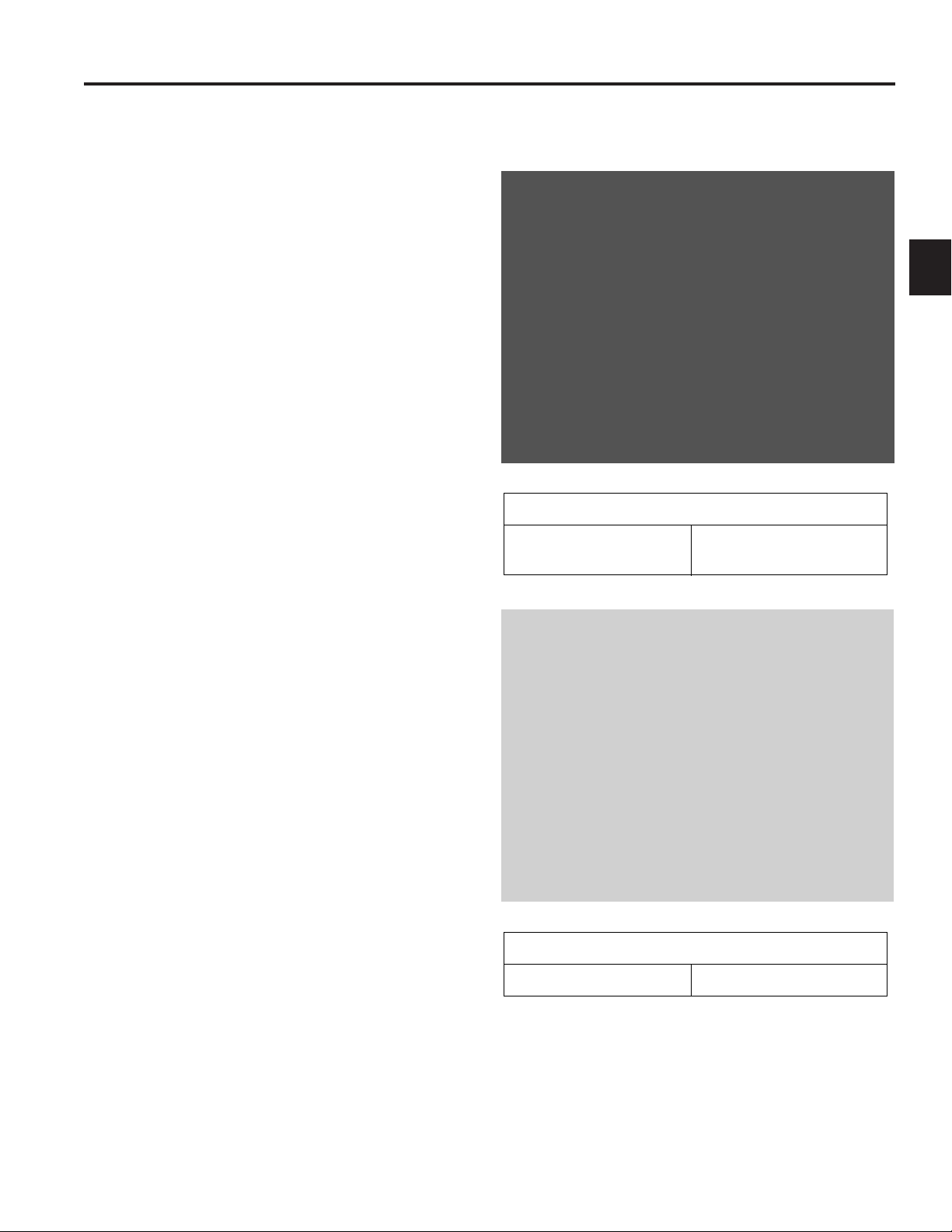

Fastener Identification

Inch Series Bolts and Screws

(A) Grade 1 & 2

(B) Grade 5

2

.

(C) Grade 8

The standard method of verifying torque shall be

performed by marking a line on the fastener (head or

nut) and mating part, then back off fastener 1/4 of a

turn. Measure the torque required to tighten the

fastener until the lines match up.

.

Metric Bolts and Screws

(A) Class 8.8 (B) Class 10.9

2-1Toro GrandStand Service Manual

Page 13

SPECIFICATIONS

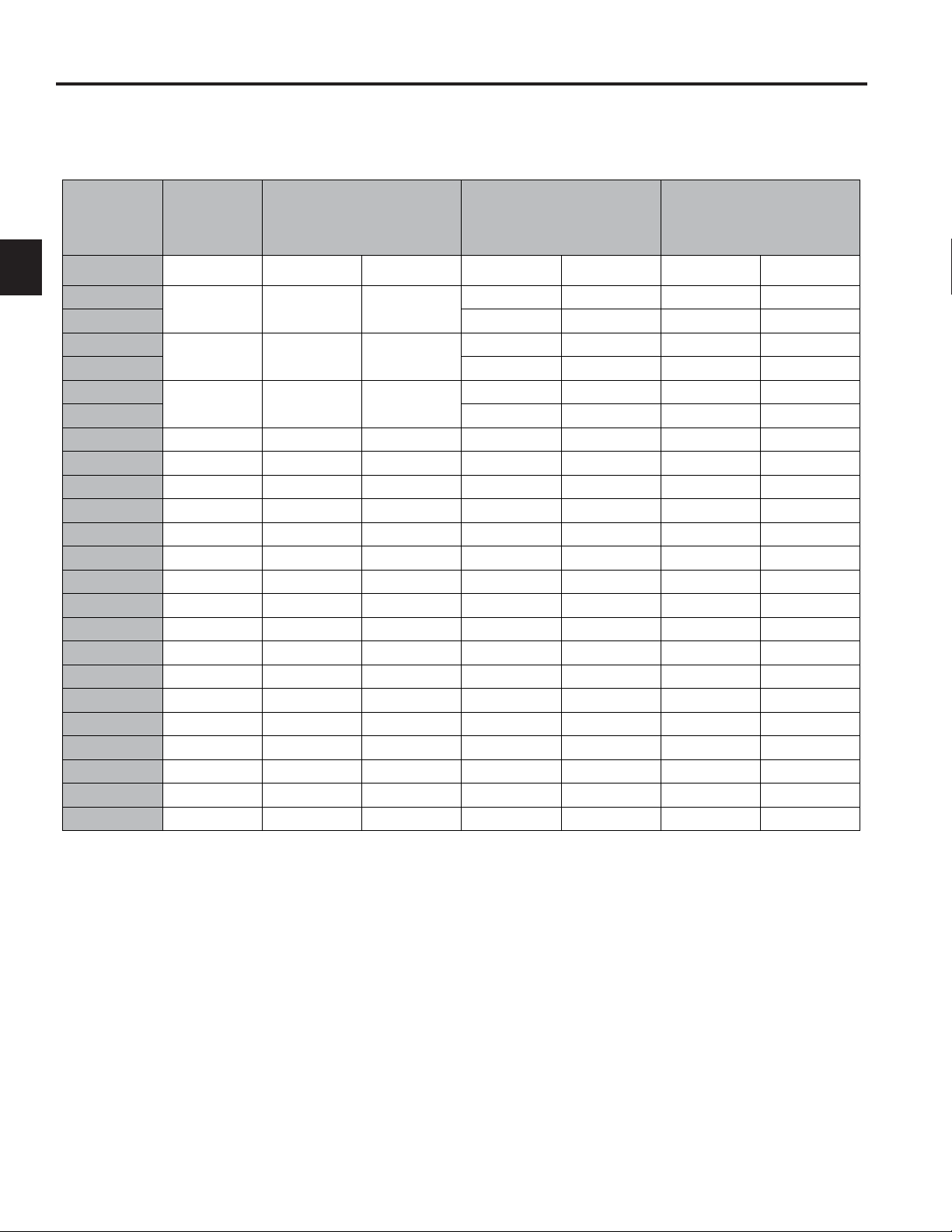

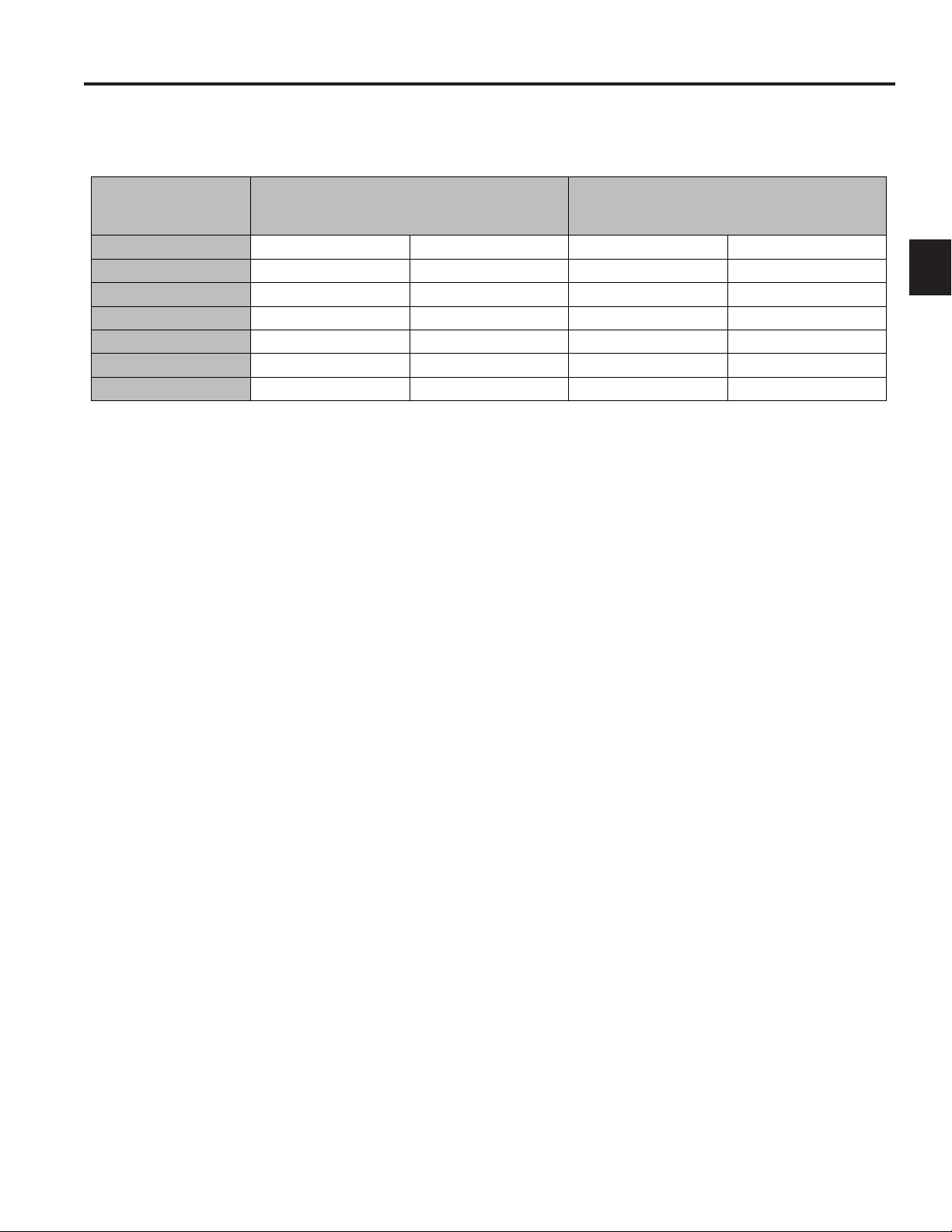

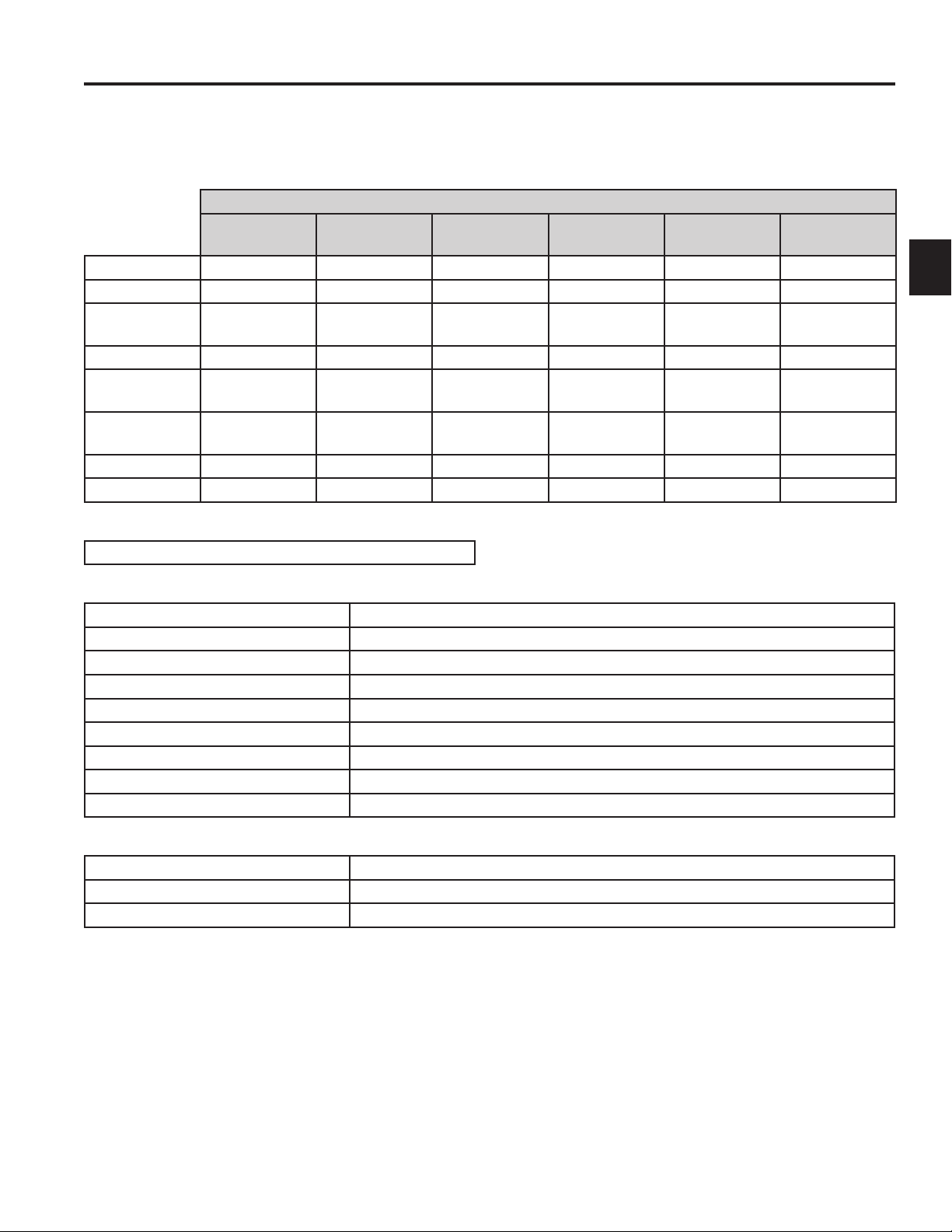

Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Inch Series)

Standard Torque for Dry, Zinc Plated & Steel Fasteners (Inch Series)

Grade 1, 5, &

Thread Size

2

# 6 - 32 UNC

# 6 - 40 UNF 17 ± 2 190 ± 20 25 ± 2 280 ± 20

# 8 - 32 UNC

# 8 - 36 UNF 31 ± 3 350 ± 30 43 ± 4 31 ± 3

# 10 - 24 UNC

#10 - 32 UNF 48 ± 4 540 ± 45 68 ± 6 765 ± 70

1/4 - 20 UNC 48 ± 7 53 ± 7 599 ± 79 100 ± 10 1125 ± 100 140 ± 15 1580 ± 170

1/4 - 28 UNF 53 ± 7 65 ± 10 734 ± 113 115 ± 10 1300 ± 100 160 ± 15 1800 ± 170

5/16 - 18 UNC 115 ± 15 105 ± 15 1186 ± 169 200 ± 25 2250 ± 280 300 ± 30 3390 ± 340

5/16 - 24 UNF 138 ± 17 128 ± 17 1446 ± 192 225 ± 25 2540 ± 280 325 ± 30 3670 ± 340

3/8 - 16 UNC 16 ± 2 16 ± 2 22 ± 3 30 ± 3 41 ± 4 43 ± 4 58 ± 5

3/8 - 24 UNF 17 ± 2 18 ± 2 24 ± 3 35 ± 3 47 ± 4 50 ± 4 68 ± 5

7/16 - 14 UNC 27 ± 3 27 ± 3 37 ± 4 50 ± 5 68 ± 7 70 ± 7 68 ± 9

7/16 - 20 UNF 29 ± 3 29 ± 3 39 ± 4 55 ± 5 75 ± 7 77 ± 7 104 ± 9

1/2 - 13 UNC 30 ± 3 48 ± 7 65 ± 9 75 ± 8 102 ± 11 105 ± 10 142 ± 14

1/2 - 20 UNF 32 ± 3 53 ± 7 72 ± 9 85 ± 8 115 ± 11 120 ± 10 163 ± 14

5/8 - 11 UNC 65 ± 10 88 ± 12 119 ± 16 150 ± 15 203 ± 20 210 ± 20 285 ± 27

5/8 - 18 UNF 75 ± 10 95 ± 15 129 ± 20 170 ± 15 230 ± 20 240 ± 20 325 ± 27

3/4 - 10 UNC 93 ± 12 140 ± 20 190 ± 27 265 ± 25 359 ± 34 374 ± 35 508 ± 47

3/4 - 16 UNF 115 ± 15 165 ± 25 224 ± 34 300 ± 25 407 ± 34 420 ± 35 569 ± 47

7/8 - 9 UNC 140 ± 20 225 ± 25 305 ± 34 430 ± 45 583 ± 61 600 ± 60 813 ± 81

7/8 - 14 UNF 155 ± 25 260 ± 30 353 ± 41 475 ± 45 644 ± 61 660 ± 60 895 ± 81

8 with Thin

Height Nuts

In-lb In-lb N-cm In-lb N-cm In-lb N-cm

10 ± 2 13 ± 2 147 ± 23

13 ± 2 25 ± 5 282 ± 30

18 ± 2 30 ± 5 339 ± 56

ft-lb ft-lb N-m ft-lb N-m ft-lb N-m

SAE Grade 1 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995

Grade 2 or Stronger Nuts)

SAE Grade 5 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995

Grade 2 or Stronger Nuts)

15 ± 2 169 ± 23 23 ± 2 260 ± 34

29 ± 3 330 ± 30 41 ± 4 460 ± 45

42 ± 4 475 ± 45 60 ± 6 674 ± 70

SAE Grade 8 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995

Grade 2 or Stronger Nuts)

Note: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

oil, graphite, or thread sealant such as Loctite.

Note: The nominal torque values listed above for

Grade 5 and 8 fasteners are based on 75% of the

minimum proof load specified in SAE J429. The

tolerance is approximately ± 10% of the nominal torque

value. Thin height nuts include jam nuts.

Note: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

2-2 Toro GrandStand Service Manual

Page 14

SPECIFICATIONS

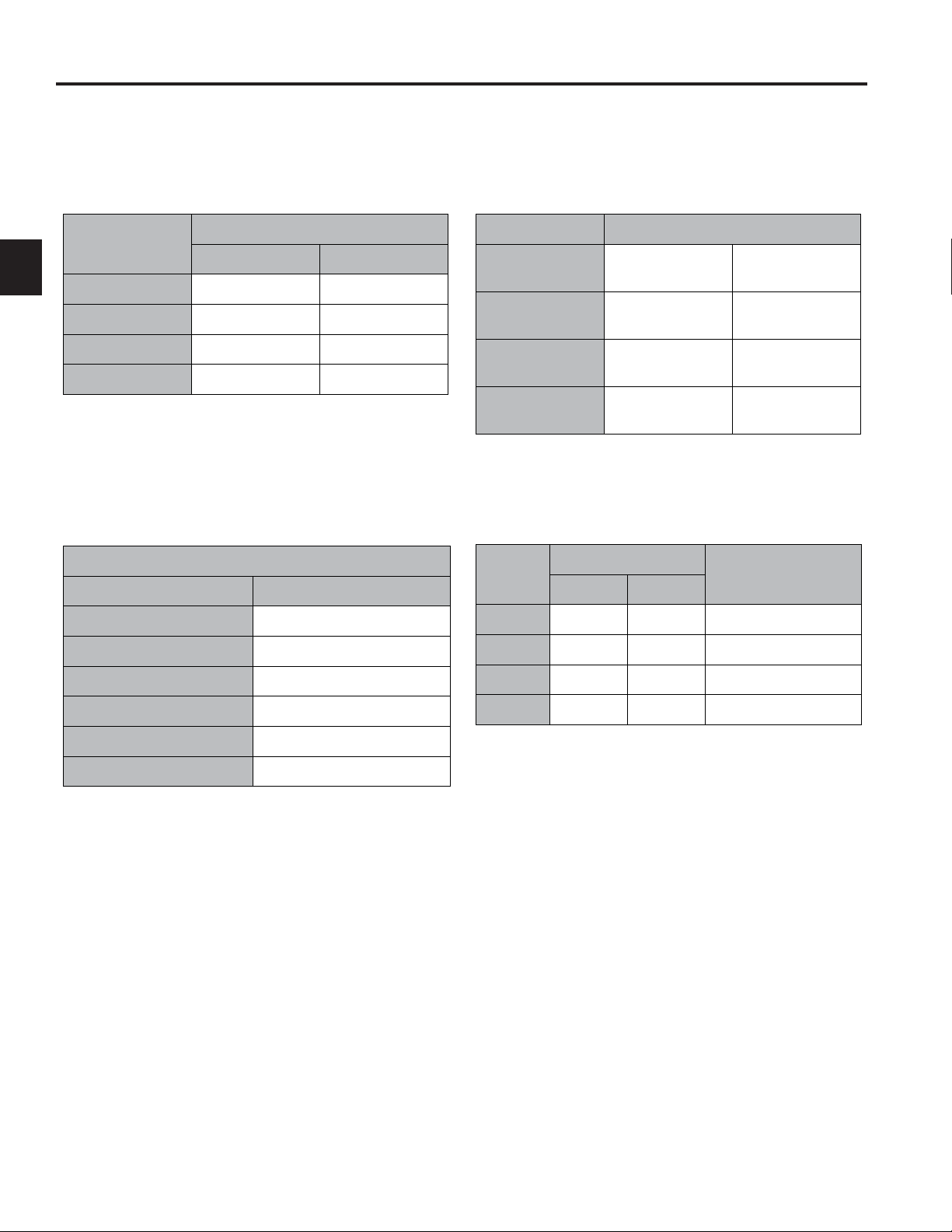

Standard Torque for Dry, Zinc, and Steel Fasteners (Metric Fasteners)

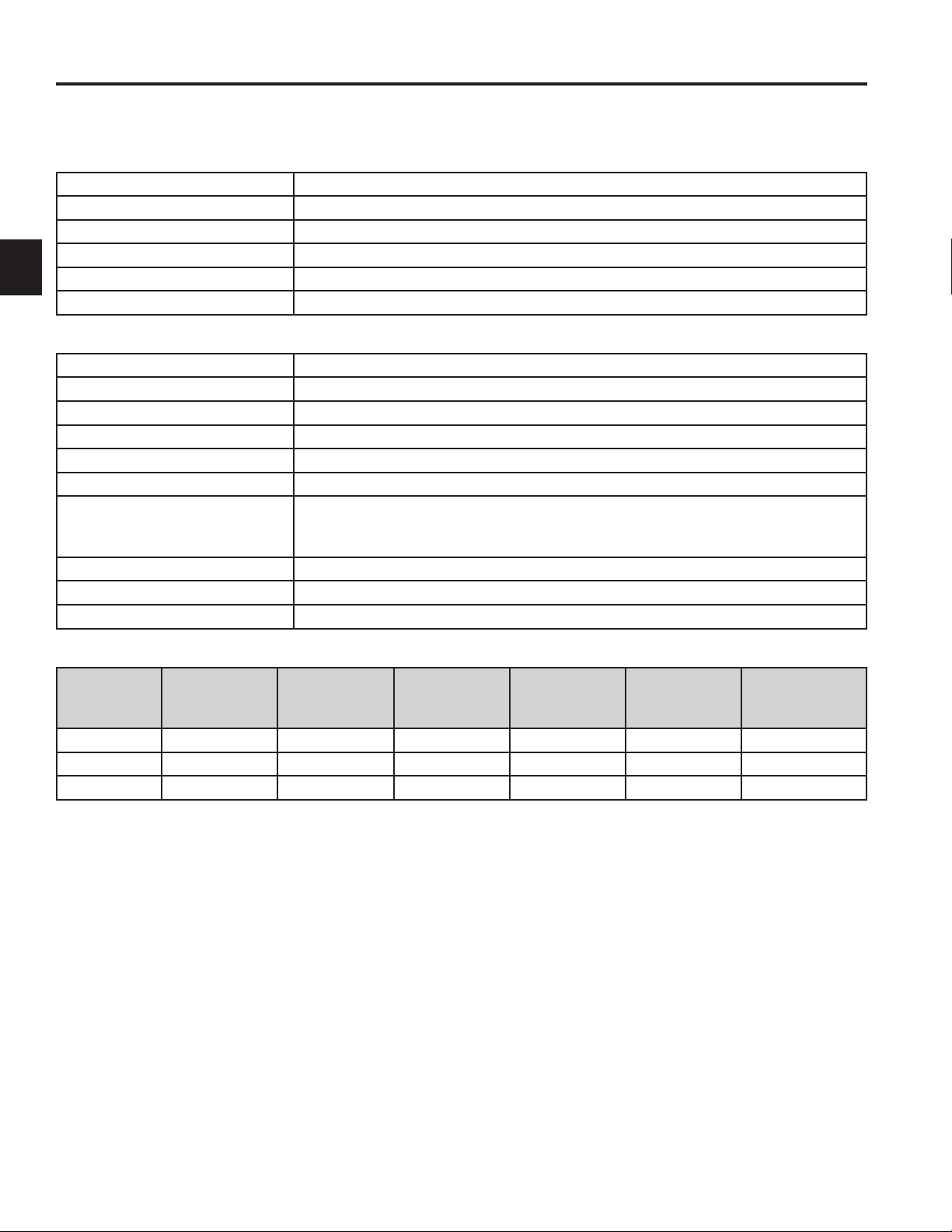

Standard Torque for Dry, Zinc & Steel Fasteners (Metric Fasteners)

Class 8.8 Bolts, Screws, and Studs with

Thread Size

M5 X 0.8 57 ± 5 in-lb 644 ± 68 N-cm 78 ± 8 in-lb 881 ± 90 N-cm

M6 X 1.0 96 ± 10 in-lb 1085 ± 113 N-cm 133 ± 14 in-lb 1503 ± 158 N-cm

M8 X 1.25 19 ± 2 ft-lb 26 ± 3 N-m 28 ± 3 ft-lb 38 ± 4 N-m

M10 X 1.5 38 ± 4 ft-lb 52 ± 5 N-m 54 ± 6 ft-lb 73 ± 8 N-m

M12 X 1.75 66 ± 7 ft-lb 90 ± 10 N-m 93 ± 10 ft-lb 126 ± 14 N-m

M16 X 2.0 166 ± 15 ft-lb 225 ± 23 N-m 229 ± 23 ft-lb 310 ± 31 N-m

M20 X 2.5 325 ± 33 ft-lb 440 ± 45 N-m 450 ± 36 ft-lb 610 ± 62 N-m

Note: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

oil, graphite, or thread sealant such as Loctite.

Note: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

Regular Height Nuts

(Class 8 or Strong Nuts)

Note: The nominal torque values listed above are

based on 75% of the minimum proof load specified in

SAE J1199. The tolerance is approximately ± 10% of

the nominal torque value. Thin height nuts include jam

nuts.

Class 10.9 Bolts, Screws, and Studs with

Regular Height Nuts (

Class 10 or Strong Nuts)

2

2-3Toro GrandStand Service Manual

Page 15

SPECIFICATIONS

Other Torque Specifications

Other Torque Specications

SAE Grade 8 Steel Set Screws

Recommended Torque

Square Head Hex Socket

2

Thread Size

1/4 - 20 UNC 140 ± 20 in-lb 73 ± 12 in-lb

5/16 - 18 UNC 215 ± 35 in-lb 145 ± 20 in-lb

3/8 - 16 UNC 35 ± 10 ft-lb 18 ± 3 ft-lb

1/2 - 13 UNC 75 ± 15 ft-lb 50 ± 10 ft-lb

Thread Cutting Screws

(Zinc Plated Steel)

Type 1, Type 23, or Type F

Thread Size Baseline Torque*

No. 6 - 32 UNC 20 ± 5 in-lb

Wheel Bolts and Lug Nuts

Thread Size Recommended Torque**

7/16 - 20 UNF

Grade 5

1/2 - 20 UNF

Grade 5

M12 X 1.25

Class 8.8

M12 X 1.5

Class 8.8

** For steel wheels and non-lubricated fasteners.

Thread Cutting Screws

Thread

Size

No. 6 18 20 20 ± 5 in-lb

Threads per Inch

Type A Type B

65 ± 10 ft-lb 88 ± 14 N-m

80 ± 10 ft-lb 108 ± 14 N-m

80 ± 10 ft-lb 108 ± 14 N-m

80 ± 10 ft-lb 108 ± 14 N-m

(Zinc Plated Steel)

Baseline Torque*

No. 8 - 32 UNC 30 ± 5 in-lb

No.10 - 24 UNC 38 ± 7 in-lb

1/4 - 20 UNC 85 ± 15 in-lb

5/16 - 18 UNC 110 ± 20 in-lb

3/8 - 16 UNC 200 ± 100 in-lb

Conversion Factors

in-lb X 11.2985 = N-cm

ft-lb X 1.3558 = N-m

No. 8 15 18 30 ± 5 in-lb

No. 10 12 16 38 ± 7 in-lb

No. 12 11 14 85 ± 15 in-lb

* Hole size, material strength, material thickness and

finish must be considered when determining specific

torque values. All torque values are based on nonlubricated fasteners.

N-cm X - 0.08851 = in-lb

N-cm X 0.73776 = ft-lb

2-4 Toro GrandStand Service Manual

Page 16

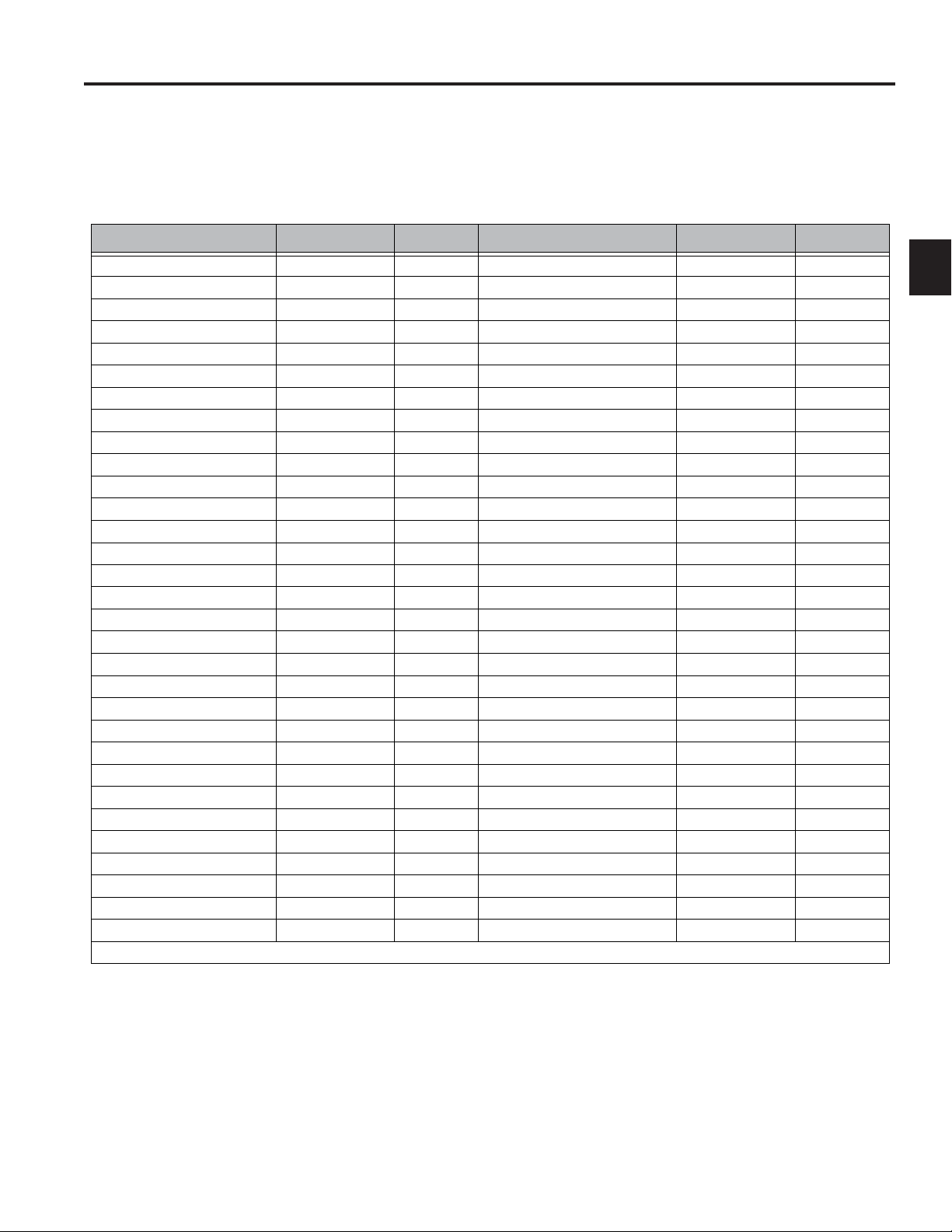

Equivalents & Conversions

Equivalents and Conversions

Decimal and Millimeter Equivalents

Decimal & Millimeter Equivalents

Fractions Decimals mm Fractions Decimals mm

1/64 0.015625 0.397 33/64 0.515625 13.097

1/32 0.03125 0.794 16/32 0.53125 13.484

3/64 0.046875 1.191 35/64 0.546875 13.891

1/16 0.0625 1.588 9/16 0.5625 14.288

5/64 0.078125 1.984 37/64 0.578125 14.684

3/32 0.9375 2.381 19/32 0.59375 15.081

1/8 0.1250 3.175 5/8 0.6250 15.875

5/32 0.15625 3.969 21/32 0.65625 16.669

3/16 0.1875 4.762 11/16 0.6875 17.462

7/32 0.21875 5.556 23/32 0.71875 18.256

1/4 0.2500 6.350 3/4 0.7500 19.050

9/32 0.28125 7.144 25/32 0.78125 19.844

5/16 0.3125 7.541 13/16 0.8125 20.638

11/32 0.34375 8.731 27/32 0.84375 21.431

3/8 0.3750 9.525 7/8 0.8750 22.225

13/32 0.40625 10.319 29/32 0.90625 23.019

7/16 0.4375 11.112 15/16 0.9375 23.812

15/32 0.46875 11.906 31/32 0.96875 24.606

1/2 0.5000 12.700 1 1.000 25.400

9/64 0.140625 3.572 41/64 0.640625 16.272

11/64 0.171875 4.366 43/64 0.671875 17.066

13/64 0.203125 5.159 45/64 0.703125 17.859

15/64 0.234375 5.953 47/64 0.734375 18.653

17/64 0.265625 6.747 49/64 0.765625 19.447

19/64 0.296875 7.541 51/64 0.796875 20.241

21/64 0.328125 8.334 53/64 0.828125 21.034

23/64 0.359375 9.128 55/64 0.859375 21.828

25/64 0.390625 9.922 57/64 0.890625 22.622

27/64 0.421875 10.716 59/64 0.921875 23.416

29/64 0.453125 11.509 61/64 0.953125 24.209

31/64 0.484375 12.303 63/64 0.984375 25.003

1 mm = 0.03937 in. 0.001 in. = 0.0254 mm

SPECIFICATIONS

2

2-5Toro GrandStand Service Manual

Page 17

2

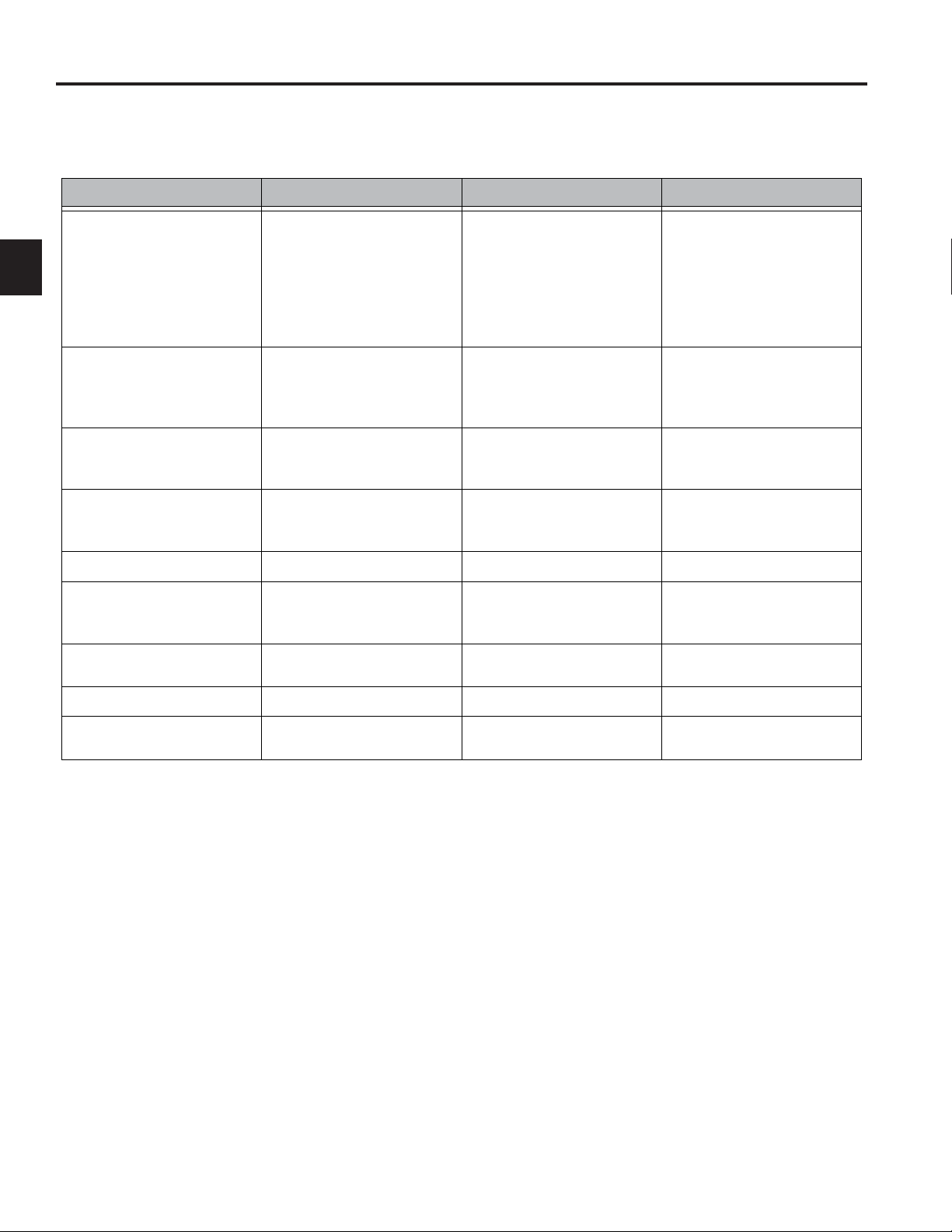

U.S. to Metric Conversions

SPECIFICATIONS

U.S. to Metric Conversions

To Convert Into Multiply By

Miles

Yards

Linear

Measurement

Area

Volume

Weight

Pressure

Work

Liquid Volume

Liquid Flows

Temperature

Feet

Feet

Inches

Inches

Inches

Square Miles

Square Feet

Square Inches

Acre

Cubic Yards

Cubic Feet

Cubic Inches

Tons (Short)

Pounds

Ounces

Pounds/Sq. In. Kilopascal

Foot-pounds

Foot-pounds

Inch-pounds

Quarts

Gallons

Gallons/Minute Liters/Minute

Fahrenheit Celsius

Kilometers

Meters

Meters

Centimeters

Meters

Centimeters

Millimeters

Square Kilometers

Square Meters

Square Centimeters

Hectare

Cubic Meters

Cubic Meters

Cubic Centimeters

Metric Tons

Kilograms

Grams

Newton-Meters

Kilogram-Meters

Kilogram-Centimeters

Liters

Liters

1.609

0.9144

0.3048

30.48

0.0254

2.54

25.4

2.59

0.0929

6.452

0.4047

0.7646

0.02832

16.39

0.9078

0.4536

28.3495

6.895

1.356

0.1383

1.152144

0.9463

3.785

3.785

1. Subtract 32°

2. Multiply by 5/9

2-6 Toro GrandStand Service Manual

Page 18

SPECIFICATIONS

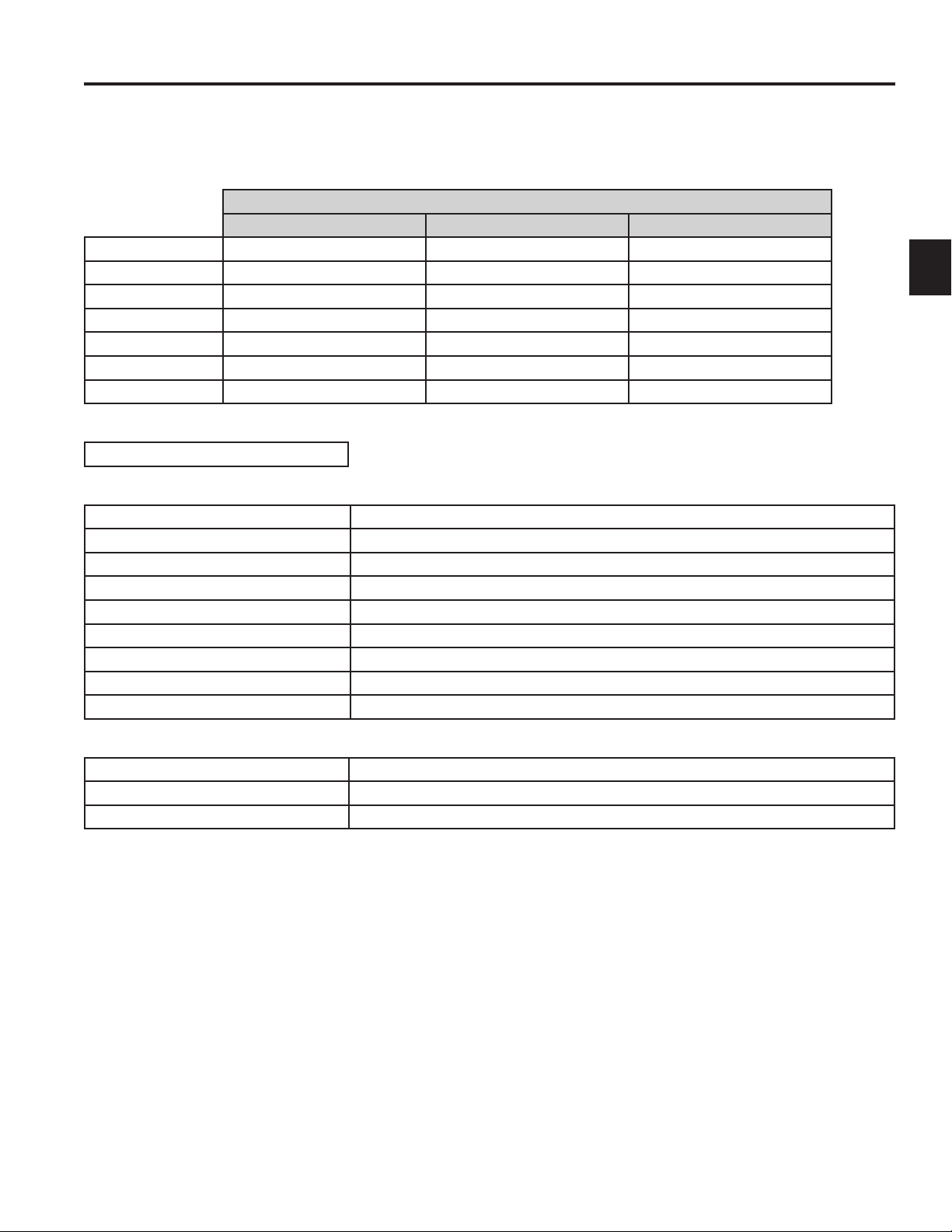

Domestic GrandStand Specications

Engines:

Output (Max. @ 3600 RPM’s)

18 hp

(13.4kW)

Make Kawasaki Kawasaki Kawasaki Kawasaki Kawasaki Kawasaki

Model FS541V FH580V FS600V FH680V FS691V FS730V

Hi-Idle 3600 ± 100

RPM

Starter Electric Electric Electric Electric Electric Electric

Spark Plug NGK BPR4ES Champion

Oil SAE 10w-30/

SAE10w-40

Oil Capacity 2.1 Qt. (2.0 L) 3.8 Pint (1.8L) 2.1 Qt. (2.0 L) 2.0 Qt. (1.9 L) 2.2 Qt. (2.2 L) 2.2 Qt. (2.2 L)

CARB 79534 / 79536 79558 / 79559 No Yes 79548 / 79549 79551

19 hp

(14.2kW)

3600 ± 100

RPM

RCJ8Y

SAE 10w-30/

SAE10w-40

20 hp

(14.9kW)

3600 ± 100

RPM

NGK BPR4ES NGK BPR4ES NGK BPR4ES NGK BPR4ES

SAE 10w-30/

SAE10w-40

23 hp

(17.2kW)

3600 ± 100

RPM

SAE 10w-30/

SAE10w-40

24 hp

(17.9kW)

3600 ± 100

RPM

SAE 10w-30/

SAE10w-40

26 hp

(19.4kW)

3600 ± 100

RPM

SAE 10w-30/

SAE10w-40

2

Fuel System:

7 or 12 Gallons (26.5 or 45.4L) fuel tank capacity

Traction Drives:

Traction Control: Toro “Split-Handle” Control Levers

Hydraulic Pump: Two Hydro-Gear Model PG 10cc (Same Part # / No Left & Right)

Hydraulic Wheel Motor: Two Parker TEO-195

Hydraulic Oil Filter: 25 Micron Automotive Spin-On Type

Hydraulic Fluid: Toro Hypr-Oil or Equivalent Synthetic 15w50

Hydraulic Fluid Capacity: 2.1 quarts (1.9 liters)

Parking Brake: Standard Equipment

Ground Speed: (Hydro-MPH) Variable, 3 (5 kph) to 8 (13 kph) MPH Fwd / 0 to 3 (5 kph) MPH Rev

Hourmeter with Service Indicator: Standard Equipment

Wheels & Tires:

Front Castors Tires: 11”x4” - 5”, 4 ply, Smooth Tread, Semi Pneumatic

Front Castors Fork: Heavy-Duty Design with 1” (25.4mm) Diameter Pivot Shaft

Rear Traction Tires: 20”x10”-8”, 4 ply with Turf Traction Tread

Mower Drive:

2-7Toro GrandStand Service Manual

Page 19

2

SPECIFICATIONS

Domestic GrandStand Specications cont.

Mower Engagement: Engine Mounted Electric Clutch

Clutch Adjustment: Periodic Air Gap Adjustment Required - .018” + .003” (0.45 + 0.0762 mm)

PTO Drive Belt: HB Section w/Aramid (Kevlar) Cords and Dry Clutching Envelope

PTO Idler: Spring Loaded Pivot Hub w/Friction Washer Dampening

Deck Drive Belt: HA Section with Aramid (Kevlar) Cords and Standard (Non-Clutching) Envelope

Deck Drive Idler: Spring Loaded Pivot Hub w/Friction Washer Dampening

Mower Decks:

HOC Range: 1” to 5” in 1/4” increments (25.4mm to 127mm in 6.3mm increments)

Blades: Three .250” (6.3mm) Thick Heat Treated Steel Blades

Spindles: Machined Steel 1.00” (25mm) Diameter Shaft

Spindle Housing: Ductile Cast Iron, 9-3/8” (24cm) Diameter Mounted with Six Bolts

Bearings: Greasable Ball Bearings with Grease Fitting for Lubrication

Construction: 7 gauge (.179” / 4.5mm) Steel Welded Construction

Blade Tip Speed: (Domestic) 48” - 18,750 ft/m calculated @ 3600 engine RPM

52” - 18,750 ft/m calculated @ 3600 engine RPM

60” - 18,750 ft/m calculated @ 3600 engine RPM

Skid Plate: Standard

Adjustable Discharge Bafe: Standard

Rubber Discharge Chute: Standard

Unit Dimensions:

Deck

Width

48” (122cm) 48” (122cm) 63.5” (161cm) 49.5” (126cm) 74” (188cm) 53” (135cm) 887 lbs (400kg)

52” (132cm) 48” (122cm) 67.5” (171cm) 53.5” (135cm) 74” (188cm) 53” (135cm) 900 lbs (408kg)

60” (152cm) 48” (122cm) 75.5” (191cm) 61.5” (156cm) 74” (188cm) 53” (135cm) 925 lbs (419kg)

* Estimated operating weight

Height

Width

Deector

Down

Width

Deector

Raised

Length

Platform

Down

Length

Platform Up

Weight*

2-8 Toro GrandStand Service Manual

Page 20

SPECIFICATIONS

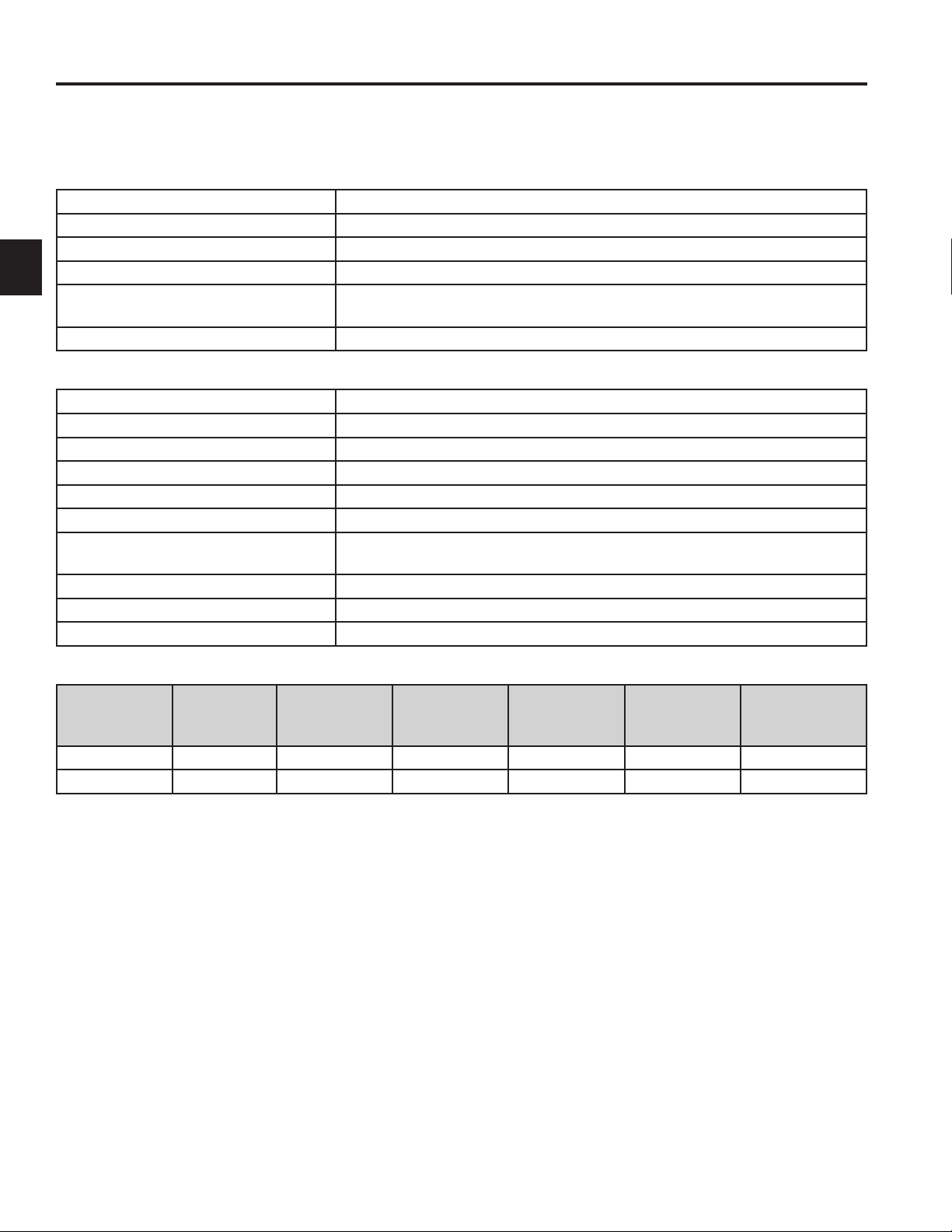

International GrandStand Specications

Engines:

Output (Max. @ 3000 RPM’s)

19 hp (14.2 kW) 20 hp (17.2 kW) 23 hp (17.2 kW)

Make Kawasaki Kawasaki Kawasaki

Model FH580V FS600V FH680V

Hi-Idle 2900 ± 100 RPM 2900 ± 100 RPM 2900 ± 100 RPM

Starter Electric Electric Electric

Spark Plug Champion RCJ8Y NGK BPR4ES NGK BPR4ES

Oil SAE 10w-30 / SAE10w-40 SAE 10w-30 / SAE10w-40 SAE 10w-30 / SAE10w-40

Oil Capacity 1.8 L (3.8 pint) 1.9 L (4.0 pint) 1.9 L (4.0 pint)

Fuel System:

26.5 L (7 gal.) Fuel Tank Capacity

Traction Drives:

Traction Control: Toro Twin Lever Control Levers

Hydraulic Pump: Two Hydro-Gear Model PG 10cc (Same Part # / No Left & Right)

Hydraulic Wheel Motor: Two Parker TEO-195

Hydraulic Oil Filter: 25 Micron Automotive Spin-On Type

Hydraulic Fluid: Toro Hypr-Oil or Equivalent Synthetic 15w50

Hydraulic Fluid Capacity: 1.9 L (2.1 quarts)

Parking Brake: Standard Equipment

Ground Speed: Variable, 3 (5 kph) to 8 (13 kph) MPH Fwd / 0 to 3 (5 kph) MPH Rev

Hourmeter with Service Indicator Standard Equipment

2

Wheels and Tires:

Front Castors Tires: 11”x4” - 5”, 4 ply, Smooth Tread, Semi Pneumatic

Front Castors Fork: Heavy-Duty Design with 25.4mm (1”) Diameter Pivot Shaft

Rear Traction Tires: 20”x10”-8”, 4 ply with Turf Traction Tread

2-9Toro GrandStand Service Manual

Page 21

2

SPECIFICATIONS

International GrandStand Specications cont.

Mower Drive:

Mower Engagement: Engine Mounted Electric Clutch

Clutch Adjustment: Periodic Air Gap Adjustment Required - 0.45 ± 0.0762 mm (.018” ± .003”)

PTO Drive Belt: HB Section W/ Aramid (Kevlar) Cords and Dry Clutching Envelope

PTO Idler: Spring Loaded Pivot Hub w/Friction Washer Dampening

Deck Drive Belt: HA Section with Aramid (Kevlar) Cords and Standard (Non-Clutching)

Envelope

Deck Drive Idler: Spring Loaded Pivot Hub w/Friction Washer Dampening

Mower Decks:

HOC Range: 25.4mm (1”) to 127mm (5”) in 6.3mm (1/4”) increments

Blades: Three 6.3mm (.250”) Thick Heat Treated Steel Blades

Spindles: Machined Steel 25.4mm (1”) Diameter Shaft

Spindle Housing: Ductile Cast Iron, Mounted with Six Bolts

Bearings: Greasable Ball Bearings with Grease Fitting for Lubrication

Construction: 7 gauge (.179” / 4.5mm) Steel Welded Construction

Blade Tip Speed: 122cm (48”) - 18,750 ft/m calculated @ 3600 engine RPM

132cm (52”) - 18,750 ft/m calculated @ 3600 engine RPM

Skid Plate: Standard

Adjustable Discharge Bafe: Standard

Rubber Discharge Chute: Standard

Unit Dimensions:

Width

Deck Width Height

122cm (48”) 122cm (48”) 161cm (63.5”) 126cm (49.5”) 135cm (53”) 188cm (74”) 400 kg (881 lbs)

132cm (52”) 122cm (48”) 171cm (67.5”) 135cm (53”) 135cm (53”) 188cm (74”) 408 kg (900 lbs)

* Estimated operating weight

Deector

Down

Width

Deector

Raised

Length

Platform Up

Length

Platform

Down

Weight*

2-10 Toro GrandStand Service Manual

Page 22

CHASSIS

Parking Brake Assembly Replacement

Parking Brake Assembly Removal

1. Move the parking brake lever to the “OFF” position

(Fig. 0001).

Fig. 0001 IMG-1302a

2. Remove the hairpin cotter and clevis pin securing

the linkage yoke at the lower end of the brake rod to

the brake assembly (Fig. 0002).

3

Fig. 0002 DSCN-0264a

3. Move the parking brake lever to the “ON” position

(Fig. 0003).

Fig. 0003 IMG-1310a

3-1Toro GrandStand Service Manual

Page 23

CHASSIS

3

4. Remove the hairpin cotter from the top end of the

parking brake rod. Slide the top end of the rod out of

the handle (Fig. 0004).

Fig. 0004 IMG-9347a

Note: 2010 models use a nut to secure the upper

end of the parking brake rod (Fig. 0005).

5. Remove the hairpin cotter and clevis pin securing

the top and bottom brake arms to the brake lever

(Fig. 0006).

Fig. 0006 DSCN-0268a

6. Disconnect the wire harness from the brake switch

(Fig. 0007).

Fig. 0005 DSCN-0261a

3-2 Toro GrandStand Service Manual

Fig. 0007 DSCN-0265a

Page 24

CHASSIS

7. Remove the carriage bolt and nut securing the brake

lever and brake switch plate to the control tower,

then remove the brake lever and brake switch plate

(Fig. 0008).

Fig. 0008 DSCN-0255a

8. Remove the bolt and nut securing the RH side of the

brake assembly and torsion spring assembly to the

chassis (Fig. 0009).

9. Remove the shoulder bolt, thick washer and nut

securing the LH side of the brake assembly to the

chassis, then remove the brake assembly (Fig.

0010).

3

Fig. 0010 IMG-1325a

Fig. 0009 IMG-1324a

3-3Toro GrandStand Service Manual

Page 25

CHASSIS

3

Parking Brake Assembly Installation

1. Secure the LH side of the brake assembly to the

chassis using the shoulder bolt, thick washer and nut

(Fig. 0011).

Fig. 0011 IMG-1325a

3. Position the bolt and spacer through the chassis

mount and brake assembly. The spacer must be

nested in the chassis mount (Fig. 0013).

Fig. 0013 IMG-1332a

4. Position the large spacer onto the bolt (Fig. 0014).

2. Place the small spacer onto the bolt that secures the

RH side of the brake assembly (Fig. 0012).

Fig. 0012 IMG-1329a

Fig. 0014 IMG-1334a

3-4 Toro GrandStand Service Manual

Page 26

CHASSIS

5. Position the torsion spring over the spacer and

bolt. The straight end of the spring is secured by

the chassis, the curved end hooks under the brake

assembly (Fig. 0015).

Fig. 0015 IMG-1336a

6. Secure the RH assembly using the washer and nut

(Fig. 0016).

7. Position the carriage bolt through the RH side of the

control tower (Fig. 0017).

3

Fig. 0017 IMG-1338a

8. Position the switch plate onto the carriage bolt (Fig.

0018).

Note: The switch plate has a square hole that

must be nested onto the square shank of the

carriage bolt.

Fig. 0016 IMG-1324a

Fig. 0018 IMG-1344a

3-5Toro GrandStand Service Manual

Page 27

CHASSIS

3

9. Position one of the large washers onto the carriage

bolt (Fig. 0019).

Fig. 0019 IMG-1348a

10. Position the shouldered spacer onto the carriage bolt

(Fig. 0020).

11. Position the brake lever through the control panel

and onto the shouldered spacer (Fig. 0021).

Fig. 0021 IMG-1355a

12. Secure the brake lever assembly with the large

washer and nut (Fig. 0022).

Fig. 0020 IMG-1351a

3-6 Toro GrandStand Service Manual

Fig. 0022 DSCN-0255a

Page 28

CHASSIS

13. Position the clevis pin through the bottom brake arm

(Fig. 0023).

Fig. 0023 IMG-1365a

14. Insert the clevis pin through the brake lever (Fig.

0024).

15. Position the top brake arm onto the clevis pin (Fig.

0025).

3

Fig. 0025 DSCN-0259a

16. Install the hairpin cotter to the clevis pin (Fig. 0026).

Fig. 0024 IMG-1367a

Fig. 0026 DSCN-0268a

3-7Toro GrandStand Service Manual

Page 29

CHASSIS

3

17. Plug the wire harness into the brake switch (Fig.

0027).

Fig. 0027 DSCN-0265a

18. Feed the brake rod up through the fuel tank base

and secure the upper end to the brake arm using a

hairpin cotter (Fig. 0028).

Fig. 0028 IMG-9347a

Note: 2010 models use a nut to secure the upper

end of the parking brake rod (Fig. 0029).

Fig. 0029 DSCN-0261a

3-8 Toro GrandStand Service Manual

Page 30

CHASSIS

19. Secure the yoke on the lower end of the brake rod

to the brake assembly using a clevis pin and hairpin

cotter (Fig. 0030).

Fig. 0030 DSCN-0264a

20. The brake assembly should contact the tires when

there is approximately 3/4” (1.9cm) gap between

the front edge of the control panel slot and the front

edge of the brake lever (Fig. 0031).

21. If adjustment is needed, remove the clevis pin securing the yoke to the brake arm. Rotate the yoke to

obtain the desired gap (Fig. 0032).

3

Fig. 0032 DSCN-0264a

A

Fig. 0031 DSCN-0263a

A. 3/4” (1.9cm)

3-9Toro GrandStand Service Manual

Page 31

CHASSIS

3

Height of Cut (HOC) Handle Assembly Replacement

HOC Handle Assembly Removal

1. Lower the deck onto two boards to support the

weight of the deck assembly (Fig. 0033).

Fig. 0033 IMG-1373a

3. 2010 only: Remove the dampener assembly from

the base of the lift bar (Fig. 0035).

Fig. 0035 DSCN-0272a

4. Remove the shoulder bolt, washer and spring

securing the height of cut (HOC) lever to the HOC

handle assembly (Fig. 0036).

2. 2009 only: Remove the nut at the base of the lift

bar (Fig. 0034).

Fig. 0034 DSCN-0274a

Fig. 0036 DSCN-0280a

3-10 Toro GrandStand Service Manual

Page 32

CHASSIS

5. Remove the HOC lever through the slot in the

control panel (Fig. 0037).

Fig. 0037 DSCN-0283a

6. Remove the “E” clip that secures the pivot hub in the

HOC handle assembly (Fig. 0038).

7. Remove the two sets of bolts, nuts and spacers

securing the HOC bracket to the side of the control

tower (Fig. 0039).

3

Fig. 0039 DSCN-0284a

8. Remove the carriage bolt and nut securing the HOC

handle assembly to the control tower (Fig. 0040).

Fig. 0038 DSCN-0285a

Fig. 0040 DSCN-0288a

3-11Toro GrandStand Service Manual

Page 33

CHASSIS

3

9. Move the HOC handle assembly from its frame

mount; then remove the lift bar pivot hub (Fig. 0041).

Fig. 0041 DSCN-0292a

10. Remove the lift bar by lowering it down through the

fuel tank base.

HOC Handle Assembly Installation

1. Install the plastic bushing into the upper end of the

lift bar (Fig. 0043).

Fig. 0043 DSCN-0297a

11. Remove the HOC handle assembly from the control

tower.

12. Remove the plastic bushing from the upper end of

the lift bar (Fig. 0042).

Fig. 0042 DSCN-0297a

3-12 Toro GrandStand Service Manual

Page 34

CHASSIS

2. Position the lift bar up through the slot in the fuel

tank base, to the approximate mounting location Fig.

0044).

Fig. 0044 DSCN-0307a

Note: 2010 only: The tube welded to the base of the

lift bar must face to the right (Fig. 0045).

3. Install the lift arm pivot hub into the HOC handle

assembly (Fig. 0046).

Note: Do not install the “E” clip. It will be installed

in a later step.

3

Fig. 0046 DSCN-0303a

4. Position the HOC handle assembly in the control

tower, just above its mounting bracket. Install the lift

bar onto the pivot hub (Fig. 0047).

Fig. 0045 DSCN-0304a

Fig. 0047 DSCN-0291a

3-13Toro GrandStand Service Manual

Page 35

CHASSIS

3

5. Secure the pivot hub with the “E” clip (Fig. 0048).

Fig. 0048 DSCN-0285a

6. Secure the HOC handle assembly to the control

tower using the carriage bolt and nut (Fig. 0049).

Note: Do not over-tighten. The HOC handle assem-

bly must move freely.

7. Place the two HOC bracket bolts through the side

of the control panel. The carriage bolt goes into the

upper hole (Fig. 0050).

Fig. 0050 DSCN-0323a

8. Place a spacer over each of the bolts (Fig. 0051).

Fig. 0051 DSCN-0325a

Fig. 0049 DSCN-0288a

3-14 Toro GrandStand Service Manual

Page 36

CHASSIS

9. Place the HOC bracket onto the two bolts and

secure with nuts (Fig. 0052).

Fig. 0052 DSCN-0330a

10. Position the HOC lever in through the control panel,

then onto the HOC handle assembly (Fig. 0053).

11. Place the washer, then the spring onto the HOC

lever shoulder bolt (Fig. 0054).

3

Fig. 0054 DSCN-0335a

12. Secure the HOC lever with the shoulder bolt

assembly (Fig. 0055).

Fig. 0053 DSCN-0333a

Fig. 0055 DSCN-0340a

3-15Toro GrandStand Service Manual

Page 37

CHASSIS

3

13. 2009 only: Secure the lower end of the lift bar to

the rear cross shaft assembly using a nut. Thread

the nut onto the bolt until there are 3 threads

protruding (Fig. 0056).

Fig. 0056 DSCN-0274a

14. 2010 only: Secure the lower end of the lift bar to

the rear cross shaft assembly using the dampener

assembly and nut. Thread the dampener assembly

bolt into the nut until there are 3 threads protruding

(Fig. 0057).

15. Remove the boards supporting the deck (Fig. 0058).

Fig. 0058 IMG-1373a

16. Place the HOC pin into the 3” (7.62cm) HOC

position, then verify that the blade tips are also at

3” (7.62cm).

Note: Use the dampener assembly bolt (2009 uses a

nut) to adjust as needed (Fig. 0059).

Fig. 0059 DSCN-0272a

Fig. 0057 DSCN-0793a

3-16 Toro GrandStand Service Manual

Page 38

CHASSIS

Caster Wheel Assembly Replacement

Caster Wheel Assembly Removal

1. Remove the grease cap from the top of the caster

wheel pivot tube (Fig. 0060).

Fig. 0060 DSCN-0357a

3. Remove the caster fork and wheel assembly.

4. Remove the three Bellville washers from the caster

wheel pivot tube (Fig. 0062).

3

Fig. 0062 DSCN-0362a

5. Remove the upper tapered roller bearing from the

caster wheel pivot tube (Fig. 0063).

2. Remove the nut from the caster fork shaft (Fig.

0061).

Fig. 0061 DSCN-0359a

Fig. 0063 DSCN-0364a

3-17Toro GrandStand Service Manual

Page 39

CHASSIS

3

6. Remove the grease seal from the bottom of the

caster wheel pivot tube (Fig. 0064).

Fig. 0064 DSCN-0370a

7. Remove the lower tapered roller bearing (Fig. 0065).

8. If replacing the wheel bearings, use a blunt punch to

remove the upper and lower bearing cups from the

caster wheel pivot tube (Fig. 0066).

Fig. 0066 DSCN-0392a

9. Remove the nut securing the caster wheel axle bolt,

then remove the axle bolt (Fig. 0067).

Fig. 0065 DSCN-0416a

Fig. 0067 DSCN-0376a

3-18 Toro GrandStand Service Manual

Page 40

CHASSIS

10. Remove the caster wheel assembly from the caster

fork.

11. Remove the seal guard from both sides of the wheel

hub (Fig. 0068).

Fig. 0068 DSCN-0377a

12. Remove the spacer nut from the caster axle (Fig.

0069).

3

Fig. 0069 DSCN-0379a

Note: The spacer nuts are both threaded onto the

caster axle. One of the spacer nuts will need

to be removed after it has been removed from

the caster wheel (Fig. 0070).

Fig. 0070 DSCN-0383a

3-19Toro GrandStand Service Manual

Page 41

CHASSIS

3

13. Remove the grease seal from both sides of the

caster wheel (Fig. 0071).

Fig. 0071 DSCN-0387a

14. Remove the LH and RH tapered bearings (Fig.

0072).

Caster Wheel Assembly Installation

1. Pack the caster wheel tapered roller bearing with

high temperature grease (Fig. 0073).

Fig. 0073 DSCN-0407a

2. Install the bearing into the wheel hub (Fig. 0074).

Fig. 0072 DSCN-0389a

Fig. 0074 DSCN-0389a

3-20 Toro GrandStand Service Manual

Page 42

CHASSIS

3. Install grease seal into the wheel hub (Fig. 0075). 6. Position the caster axle through the bearing and seal

assembly (Fig. 0077).

Fig. 0075 DSCN-0393a

Fig. 0077 DSCN-0398a

3

4. Repeat steps 1, 2, and 3 on the other side of the

caster wheel.

5. Fill the center of the wheel hub with high tempera-

ture grease (Fig. 0076).

Fig. 0076 DSCN-0406a

7. Install a spacer nut onto both ends of the caster axle

(Fig. 0078).

Note: There should be approximately 3 internal

spacer nut threads visible on both sides,

indicating the axle is centered.

Fig. 0078 DSCN-0379a

3-21Toro GrandStand Service Manual

Page 43

CHASSIS

3

8. Position the seal guard onto both sides of the caster

wheel hub (Fig. 0079).

Fig. 0079 DSCN-0377a

9. Secure the caster wheel assembly to the caster fork

using the axle bolt and nut (Fig. 0080).

10. Install the upper and lower bearing cups into the

pivot tube (Fig. 0081).

Fig. 0081 DSCN-0410a

Note: A socket can be used as a driver. Take care

not to scar the race surface (Fig. 0082).

Fig. 0080 DSCN-0376a

3-22 Toro GrandStand Service Manual

Fig. 0082 DSCN-0413a

Page 44

CHASSIS

11. Pack the pivot tube tapered roller bearings with high

temperature grease (Fig. 0083).

Fig. 0083 DSCN-0407a

12. Install the lower bearing into the pivot tube (Fig.

0084).

13. Install grease seal into the base of the pivot tube

(Fig. 0085).

3

Fig. 0085 DSCN-0414a

14. Install the upper bearing into the pivot tube (Fig.

0086).

Fig. 0084 DSCN-0416a

Fig. 0086 DSCN-0418a

3-23Toro GrandStand Service Manual

Page 45

CHASSIS

3

15. Install the 3 Bellville washers into the pivot tube (Fig.

0087).

Fig. 0087 DSCN-0428a

Note: Bottom: Crown Up / Middle: Crown Down /

Top: Crown up (Fig. 0088).

16. Insert the caster wheel and fork assembly through

the pivot hub (Fig. 0089).

Fig. 0089 DSCN-0431a

17. Secure the caster wheel and fork assembly with the

nut (Fig. 0090).

Fig. 0088 DSCN-0423a

3-24 Toro GrandStand Service Manual

Fig. 0090 DSCN-0360a

Page 46

CHASSIS

18. Tighten locknut until spring washers are at (15 ftlbs./20 Nm) and then back off a 1/4 turn to properly

set the pre-load on the bearings.

19. Remove the plug from the side of the pivot hub (Fig.

0091).

Fig. 0091 DSCN-0436a

21. Fill the pivot hub cavity until grease is purging out

through the upper bearing (Fig. 0093).

3

Fig. 0093 DSCN-0438a

22. Replace the grease zerk with the plug (Fig. 0094).

20. Install a grease zerk into the port on the side of the

pivot hub (Fig. 0092).

Fig. 0092 DSCN-0434a

Fig. 0094 DSCN-0436a

3-25Toro GrandStand Service Manual

Page 47

CHASSIS

3

23. Install the grease cap onto the top of the pivot hub

(Fig. 0095).

Fig. 0095 DSCN-0357a

Fuel Tank Assembly Replacement

Fuel Tank Assembly Removal

1. Turn the fuel shutoff valve to the “OFF” position (Fig.

0096).

Fig. 0096 DSCN-0457a

2. Siphon the fuel from the fuel tank.

Note: The only recommended way to remove the

fuel from the tank is by using a siphon pump.

3. Remove the height of cut (HOC) pin and lower the

deck (Fig. 0097).

Fig. 0097 DSCN-0459a

3-26 Toro GrandStand Service Manual

Page 48

CHASSIS

4. 2009 only: Remove the 90 degree fuel line vent

tting from the fuel tank (Fig. 0098).

Fig. 0098 IMG-9299a

5. 2009 only: Remove the rubber grommet from the

fuel tank (Fig. 0099).

6. 2009 only: Slide the hose clamp back from the fuel

tank tting, then slide the fuel line off the fuel tank

tting (Fig. 0100).

3

Fig. 0100 IMG-9292a

7. 2009 only: Remove the carriage bolt and nut

securing the fuel tank bracket to the frame bracket,

then remove the fuel tank support (Fig. 0101).

Fig. 0099 IMG-9530b

Fig. 0101 IMG-9304b

3-27Toro GrandStand Service Manual

Page 49

CHASSIS

3

8. 2010 only: Remove the vent line from the 90

degree vent tting (Fig. 0102).

Fig. 0102 DSCN-0461a

9. 2010 only: Remove the 90 degree vent tting, then

rubber grommet from the fuel tank (Fig. 0103).

10. 2010 only: Slide the hose clamp off the fuel pick-up

tube tting, then remove the fuel line from the tting

(Fig. 0104).

Fig. 0104 DSCN-0466a

11. 2010 only: Remove the four thread forming screws

securing the tank bracket to the control panel (Fig.

0105).

Fig. 0103 DSCN-0463a

Fig. 0105 DSCN-0467a

3-28 Toro GrandStand Service Manual

Page 50

CHASSIS

12. Remove the fuel tank from the control tower Fig.

0106).

Fig. 0106 IMG-9307a

Fuel Tank Assembly Installation

1. Position the fuel tank into the control tower (Fig.

0107).

3

Fig. 0107 IMG-9307a

2. 2009 only: Secure the fuel tank bracket to the

frame bracket using the carriage bolt and nut (Fig.

0108).

Fig. 0108 IMG-9304b

3-29Toro GrandStand Service Manual

Page 51

CHASSIS

3

3. 2009 only: Position the fuel line onto the pick-up

tube tting and secure with the hose clamp (Fig.

0109).

Fig. 0109 IMG-9292a

4. 2009 only: Install the rubber grommet into the fuel

tank (Fig. 0110).

5. 2009 only: Install the 90 degree fuel line vent tting

into the fuel tank (Fig. 0111).

Fig. 0111 IMG-9299a

6. 2010 only: Secure the tank bracket using four

thread forming screws (Fig. 0112).

Fig. 0112 DSCN-0467a

Fig. 0110 IMG-9530b

3-30 Toro GrandStand Service Manual

Page 52

CHASSIS

7. 2010 only: Slide the fuel line onto the pick-up tube

tting and secure with the hose clamp (Fig. 0113).

Fig. 0113 DSCN-0466a

8. 2010 only: Install the rubber grommet into the fuel

tank (Fig. 0114).

9. 2010 only: Install the 90 degree tting into the

rubber grommet (Fig. 0115).

Note: A thin lm of oil will ease installation of the

tting barb.

3

Fig. 0115 DSCN-0463a

Fig. 0114 DSCN-0469a

10. Install the vent hose onto vent tting (Fig. 0116).

Fig. 0116 DSCN-0461a

3-31Toro GrandStand Service Manual

Page 53

CHASSIS

3

Platform & Cushion Assembly Replacement

Platform & Cushion Assembly Removal

1. Remove both hairpin cotters securing the cushion

pad to the control tower, then lower the operator

cushion onto the operator platform (Fig. 0117).

Fig. 0117 DSCN-0478a

3. Remove the four sets of bolts and washers securing

the upper and lower pad hinges to the cushion pad

(Fig. 0119).

Fig. 0119 DSCN-0488a

4. Remove the two thread forming screws securing the

shield, foot mat bracket, and foot mat to the platform

(Fig. 0120).

2. Remove the carriage bolts, spacers, friction washers, washers and nuts securing the pad hinge to the

pad links (Fig. 0118).

Fig. 0118 DSCN-0577a

Fig. 0120 DSCN-0490a

3-32 Toro GrandStand Service Manual

Page 54

CHASSIS

5. Remove the RH and LH carriage bolts, washers,

spacers, and nuts securing the platform to the carrier

frame (Fig. 0121).

Fig. 0121 DSCN-0493a

6. Remove the carriage bolts, friction washers, spacers

and nuts securing the LH and RH pad links to the

platform (Fig. 0122).

7. Remove the knob from the platform latch pin (Fig.

0123).

3

Fig. 0123 DSCN-0500a

8. Remove the latch pin and spring from the platform

(Fig. 0124).

Fig. 0122 DSCN-0496a

Fig. 0124 DSCN-0501a

3-33Toro GrandStand Service Manual

Page 55

CHASSIS

3

9. Remove the four nuts securing the four rubber

bumpers to the platform (Fig. 0125).

Fig. 0125 DSCN-0505a

Platform & Cushion Assembly Installation

1. Secure the four rubber bumpers to the platform

using four nuts (Fig. 0126).

Fig. 0126 DSCN-0505a

2. Position the spring on the latch pin (Fig. 0127).

Fig. 0127 DSCN-0512a

3-34 Toro GrandStand Service Manual

Page 56

CHASSIS

3. Position the latch pin and spring assembly into the

platform (Fig. 0128).

Fig. 0128 DSCN-0517a

4. Apply thread-locking compound to the threads of the

knob (Fig. 0129).

5. Install the knob onto the latch pin (Fig. 0130).

3

Fig. 0130 DSCN-0498a

6. Position the carriage bolt and spacer into the tab on

the platform (Fig. 0131).

Fig. 0129 DSCN-0521a

Fig. 0131 DSCN-0548a

3-35Toro GrandStand Service Manual

Page 57

CHASSIS

3

7. Position the friction washer, then the pad link over

the spacer (Fig. 0132).

Fig. 0132 DSCN-0549a