Page 1

FormNo.3379-989RevB

g020526

GrandStand

®

Mower

With91cmor102cmTURBOFORCE

CuttingUnit

ModelNo.74534TE—SerialNo.314000001andUp

ModelNo.74536TE—SerialNo.314000001andUp

®

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3379-989*B

Page 2

WARNING

g020527

1

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThisproductcomplieswithallrelevantEuropeandirectives;

fordetailspleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

Introduction

Thisrotary-blade,ridinglawnmowerisintendedto

beusedbyprofessional,hiredoperatorsorresidential

homeowners.Itisdesignedprimarilyforcuttinggrass

onwell-maintainedlawnsonresidentialorcommercial

properties.Itisnotdesignedforcuttingbrushorfor

agriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely .

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready .

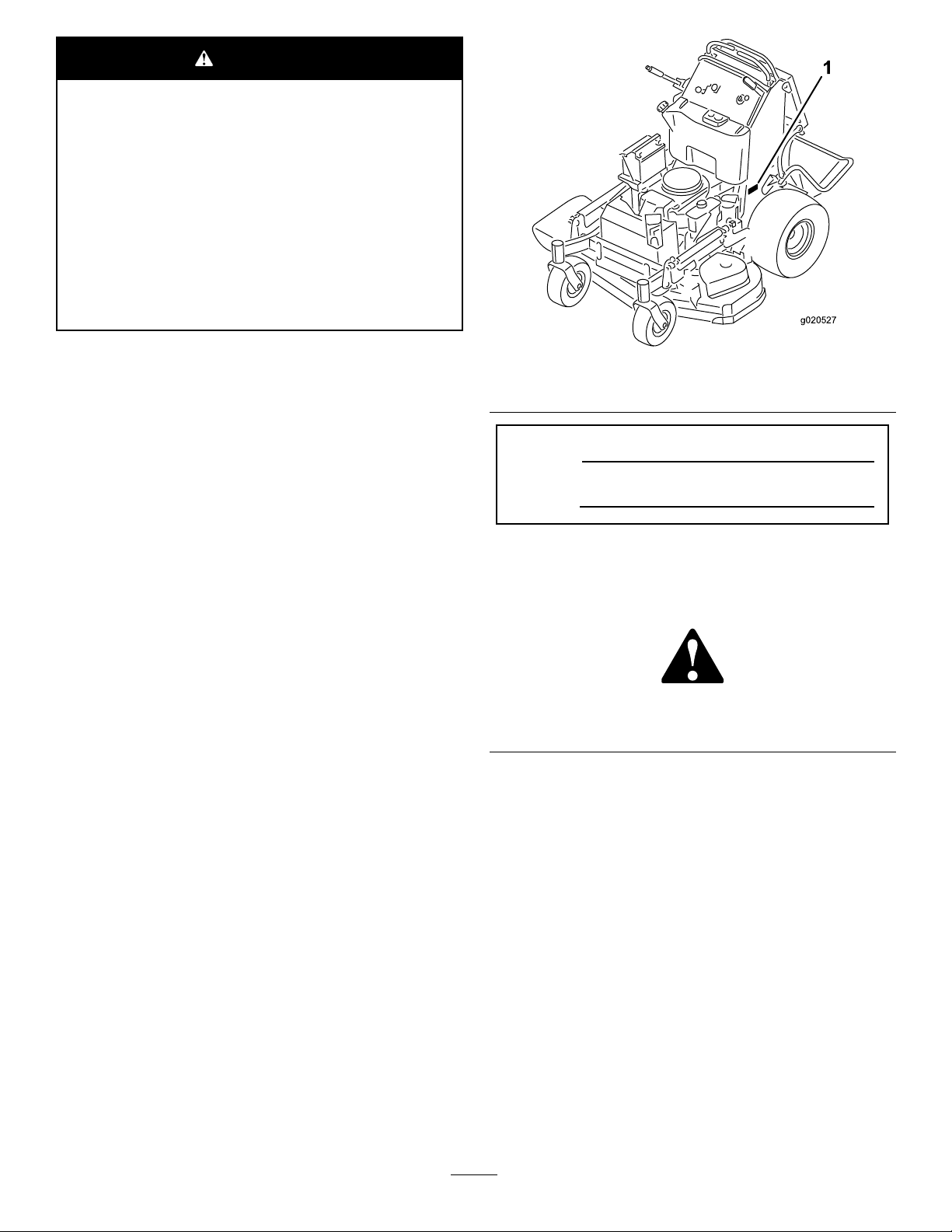

Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(

Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythefollowingwords:

•Dangersignalsanextremehazardthatwillcauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

•Warningsignalsahazardthatmaycauseseriousinjuryor

deathifyoudonotfollowtherecommendedprecautions.

•Cautionsignalsahazardthatmaycauseminoror

moderateinjuryifyoudonotfollowtherecommended

precautions.

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2013—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction..................................................................2

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroMowerSafety..................................................6

SoundPressure.......................................................7

SoundPower..........................................................7

VibrationLevelforModel74534TE...........................7

VibrationLevelforModel74536TE...........................7

SlopeIndicator.......................................................8

SafetyandInstructionalDecals.................................9

ProductOverview.........................................................14

Controls...............................................................14

Specications........................................................15

Operation....................................................................16

AddingFuel...........................................................16

CheckingtheEngine-oilLevel..................................17

BreakingInaNewMachine.....................................17

ThinkSafetyFirst...................................................17

OperatingtheParkingBrake....................................17

OperatingtheMower-blade-controlSwitch

(PTO)...............................................................18

OperatingtheThrottle............................................18

OperatingtheChoke...............................................19

OperatingtheIgnitionSwitch..................................19

UsingtheFuelShut-offValve...................................20

StartingandStoppingtheEngine..............................20

UsingtheSafety-interlockSystem.............................21

OperatingthePlatform...........................................22

DrivingForwardorBackward..................................23

StoppingtheMachine.............................................24

PushingtheMachinebyHand..................................24

TransportingtheMachine........................................25

LoadingMachines..................................................25

SideDischargingorMulchingtheGrass.....................26

AdjustingtheHeight-of-Cut....................................26

AdjustingtheFlowBafe........................................27

PositioningtheFlowBafe......................................27

UsingCounterweights.............................................28

Maintenance.................................................................29

RecommendedMaintenanceSchedule(s)......................29

PremaintenanceProcedures........................................30

RaisingtheMowerforAccess...................................30

ReleasetheCushionforRearAccess..........................31

Lubrication...............................................................32

LubricatingtheMachine..........................................32

GreasingtheFrontCasterPivots..............................32

LubricatingtheCaster-wheelHubs...........................33

EngineMaintenance..................................................34

ServicingtheAirCleaner.........................................34

ServicingtheEngineOil..........................................34

ServicingtheSparkPlug..........................................37

CheckingtheSparkArrester(ifequipped)..................38

FuelSystemMaintenance...........................................38

DrainingtheFuelTank...........................................38

ServicingtheFuelFilter...........................................39

ElectricalSystemMaintenance....................................39

ServicingtheBattery...............................................39

ServicingtheFuses.................................................41

DriveSystemMaintenance.........................................41

AdjustingtheTracking...........................................41

CheckingtheTirePressure......................................43

AdjustingtheCaster-pivotBearing............................43

AdjustingtheElectricClutch....................................43

CoolingSystemMaintenance......................................44

CleaningtheAir-intakeScreen..................................44

CleaningtheCoolingSystem....................................44

BrakeMaintenance....................................................45

ServicingtheBrake.................................................45

BeltMaintenance......................................................46

CheckingtheBelts..................................................46

ReplacingtheMower-deckBeltfor91cm

Mowers.............................................................46

ReplacingtheMower-deckBeltsfor102cm

Mowers.............................................................47

ReplacingtheRightMower-deckBelt........................47

ReplacingtheLeftMower-deckBelt..........................47

ReplacingthePump-driveBelt.................................48

ControlsSystemMaintenance.....................................49

AdjustingtheMotion-control-handle

Positions............................................................49

HydraulicSystemMaintenance....................................51

ServicingtheHydraulicSystem.................................51

MowerDeckMaintenance...........................................54

ServicingtheCuttingBlades.....................................54

LevelingtheMowerDeck........................................56

ReplacingtheGrassDeector..................................60

Cleaning...................................................................60

CleaningUndertheMower......................................60

DisposingofWaste.................................................60

Storage........................................................................61

CleaningandStorage..............................................61

Troubleshooting...........................................................62

Schematics...................................................................64

3

Page 4

Safety

Improperlyusingormaintainingthismowercanresult

ininjury.Toreducethepotentialforinjury,complywith

thesesafetyinstructions.

Torodesignedandtestedthismowerforreasonablysafe

service;however,failuretocomplywiththefollowing

instructionsmayresultinpersonalinjury.

Toensuremaximumsafety,bestperformance,and

togainknowledgeoftheproduct,itisessentialthat

youandanyotheroperatorofthemowerreadand

understandthecontentsofthismanualbeforethe

engineiseverstarted.Payparticularattentiontothe

safetyalertsymbol(

Warning,orDanger—“personalsafetyinstruction.”

Readandunderstandtheinstructionbecauseithasto

dowithsafety .Failuretocomplywiththeinstruction

mayresultinpersonalinjury.

SafeOperatingPractices

Thefollowinginstructionshavebeenadaptedfromthe

standardEN836:1997.

Training

•ReadtheOperator'sManualandothertrainingmaterial.

Note:Iftheoperator(s)ormechanic(s)cannotreadthe

manuallanguage,itistheowner'sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.

Note:Localregulationsmayrestricttheageofthe

operator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

people,ordamagetoproperty.

Figure2)whichmeansCaution,

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothing;includingahardhat,safety

glasses,longpants,safetyshoes,gloves,andhearing

protection.

Important:Longhair,looseclothingorjewelrymay

gettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeusedand

ensurethatallobjectsareremovedfromthemachine

beforeuse.

•Useextracarewhenhandlingfuels.Theyareammable

andvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Donotremovethefuelcaporaddfuelwiththe

enginerunning.Allowtheenginetocoolbefore

refueling.Donotsmokenearthemachinewhenthe

engineisrunning.

–Donotrefuelordrainthemachineindoors.

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlesstheyare

functioningproperly.

Operation

•Lightningcancausesevereinjuryordeath.Iflightning

isseen,orthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Donotrunanengineinanenclosedarea.

•Onlyoperateinwell-litareas,keepingawayfromholes

andhiddenhazards.

•Ensurethatalldrivesareinneutralandthattheparking

brakeisengagedbeforestartingengine.Onlystartthe

enginefromtheoperator’sposition.

•Makesurethatyouhavegoodfootingwhileusingthis

machine,especiallywhenbackingup.

Note:Reducedfootingcouldcauseslipping.

•Slowdownanduseextracareonhillsides.Besureto

travelsidetosideonhillsides.Turfconditionscanaffect

thestabilityofthemachine.Usecautionwhileoperating

neardrop-offs.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Donotraisethemowerdeckwiththebladesrunning.

•DonotoperatethemachinewithoutthePTOshieldor

otherguardssecurelyinplace.Besureallinterlocksare

attached,adjustedproperly,andfunctioningproperly .

•Donotoperatewiththedischargedeectorraised,

removedoraltered,unlessusingagrasscatcher.

4

Page 5

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Iffuelisspilledonclothing,changeyourclothing

immediately.

•Stoponlevelground,disengagedrives,engagethe

parkingbrake(ifprovided),shutofftheenginebefore

leavingtheoperator'spositionforanyreason,including

emptyingthecatchersoruncloggingthechute.

•Stopequipmentandinspectthebladesafterstriking

objectsorifanabnormalvibrationoccurs.Makethe

necessaryrepairsbeforeresumingoperations.

•Keepyourhandsandfeetawayfromthecuttingunit.

•Lookbehindanddownbeforebackinguptoensurea

clearpath.

•Keeppetsandbystandersawayfromanoperating

machine.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopthebladesifyouare

notmowing.

•Beawareofthemower-dischargedirectionanddonot

pointitatanyone.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs.

•Usecarewhenloadingorunloadingthemachineinto

orfromatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

Safehandlingoffuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Donotoverllfueltank.Replacefuelcapandtighten

securely.

MaintenanceandStorage

•Disengagedrives,settheparkingbrake,stoptheengine,

andremovethekeyordisconnectspark-plugwire.Wait

forallmovementtostopbeforeadjusting,cleaning,or

repairing.

•Cleangrassanddebrisfromthecuttingunit,drives,

mufers,andenginetohelppreventres.

•Cleanupoilorfuelspillage.

•Lettheenginecoolbeforestoring.

•Donotstorefuelnearamesordrainindoors.

•Donotallowuntrainedpersonneltoservicemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatteryorremovethespark-plugwire

beforemakinganyrepairs.Disconnectthenegative

terminalrstandthepositiveterminallast.Reconnect

thepositiverstandnegativelast.

•Usecarewhencheckingtheblades.Wraptheblade(s)or

weargloves,andusecautionwhenservicingthem.Only

replaceblades;donotstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfuelwiththeengine

running.

•Allowtheenginetocoolbeforefueling.

•Donotfuelthemachineindoors.

•Donotstorethemachineorfuelcontainerwherethere

isanopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Donotllcontainersinsideavehicle,onatruck,orona

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandfuelit

ontheground.Ifthisisnotpossible,thenaddfuelwith

suchequipmentasaportablecontainer,ratherthanfrom

afueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelockopendevice.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

traileroratruck.

•Usefull-widthrampsforloadingmachineintoatrailer

oratruck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

5

Page 6

ToroMowerSafety

SlopeOperation

ThefollowinglistcontainssafetyinformationspecictoToro

productsandothersafetyinformationyoumustknow.

Thisproductiscapableofamputatinghandsandfeet,and

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Thisproductisdesignedforcuttingandrecyclinggrass,or,

whenequippedwithagrassbagger,forcatchingcutgrass.

Anyuseforpurposesotherthanthesecouldprovedangerous

totheuserandbystanders.

GeneralOperation

•Besurethattheareaisclearofbystandersbeforemowing.

Stopthemachineifanyoneentersthearea.

•Donottouchequipmentorattachmentpartswhichmay

behotfromoperation.Allowallofthepartstocool

beforeattemptingtomaintain,adjust,orservicethe

machine.

•UseonlyToro-approvedattachments.Warrantymaybe

voidedifusedwithanyunapprovedattachments.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires,etc.)beforeoperatingunder

anyobjects,anddonotcontactthem.

•Slowdownbeforemakingturnsanduseextracaution.

•Usecautionwhenridingtheplatformovercurbs,rocks,

roots,orotherobstructions.

•Lookbehindanddownbeforebackinguptoensurea

clearpath.Useextracarewhenoperatinginreverse.

•Donotjerkthecontrols;useasteadymotion.

•Whenloadingorunloadingthemachine,useone

full-widthrampthatiswideenoughtoextendbeyond

thewidthofthemachine.

•Donotcarrypassengers.

•Donotcarryequipmentonthemachine.

Allslopesandrampsrequireextracaution.Ifyoufeeluneasy

onaslope,donotmowit.

•Removeobstaclessuchasrocks,treelimbs,etc.fromthe

mowingarea.

•Watchforholes,rutsorbumps.

Note:Tallgrasscanhideobstacles.

•Usecautionneardrop-offs,ditches,orembankments.

Note:Themachinecouldsuddenlyturnoverifawheel

goesovertheedgeofaclifforditch,orifanedgecavesin.

•Useextracarewithgrasscatchersorotherattachments.

Note:Thesecanchangethestabilityofthemachine.

•Keepallmovementonslopesslowandgradual.

•Donotmakesuddenchangesinspeedordirection.

•Mowslopessidetoside.

•Donotmowslopesgreaterthan15degrees.

Service

•Donotstorethemachineorafuelcontainerinsidewhere

thereisanopename,suchasnearawaterheateror

furnace.

•Keepthenutsandboltstight,especiallythe

blade-attachmentbolts.

•Neverremoveortamperwithsafetydevices.Checktheir

properoperationregularly .Neverdoanythingtointerfere

withtheintendedfunctionofasafetydeviceortoreduce

theprotectionprovidedbyasafetydevice.

•Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourToroequipment,countonToro

genuineparts.Whenitcomestoreliability ,T orodelivers

replacementpartsdesignedtotheexactengineering

specicationsofourequipment.Forpeaceofmind,insist

onTorogenuineparts.

•Checkbrakeoperationfrequently .Adjustandserviceas

required.

6

Page 7

SoundPressure

Model74534TEhasasoundpressurelevelattheoperator’s

earof88dBA,whichincludesanUncertaintyValue(K)of

1dBA.

Model74536TEhasasoundpressurelevelattheoperator’s

earof86dBA,whichincludesanUncertaintyValue(K)of

1dBA.

Thesoundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinEN836.

SoundPower

Model74534TEhasaguaranteedsoundpowerlevelof100

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Model74536TEhasaguaranteedsoundpowerlevelof100

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Thesoundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

Measuredvibrationlevel=0.79m/s

UncertaintyValue(K)=0.39m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836.

2

2

VibrationLevelforModel 74534TE

Hand-Arm

Measuredvibrationlevelforrighthand=0.8m/s

Measuredvibrationlevelforlefthand=0.6m/s

UncertaintyValue(K)=0.4m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836.

WholeBody

Measuredvibrationlevel=0.79m/s

UncertaintyValue(K)=0.39m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836.

2

2

2

VibrationLevelforModel 74536TE

2

2

Hand-Arm

Measuredvibrationlevelforrighthand=1.1m/s

Measuredvibrationlevelforlefthand=1.1m/s

UncertaintyValue(K)=0.6m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836.

WholeBody

2

2

2

7

Page 8

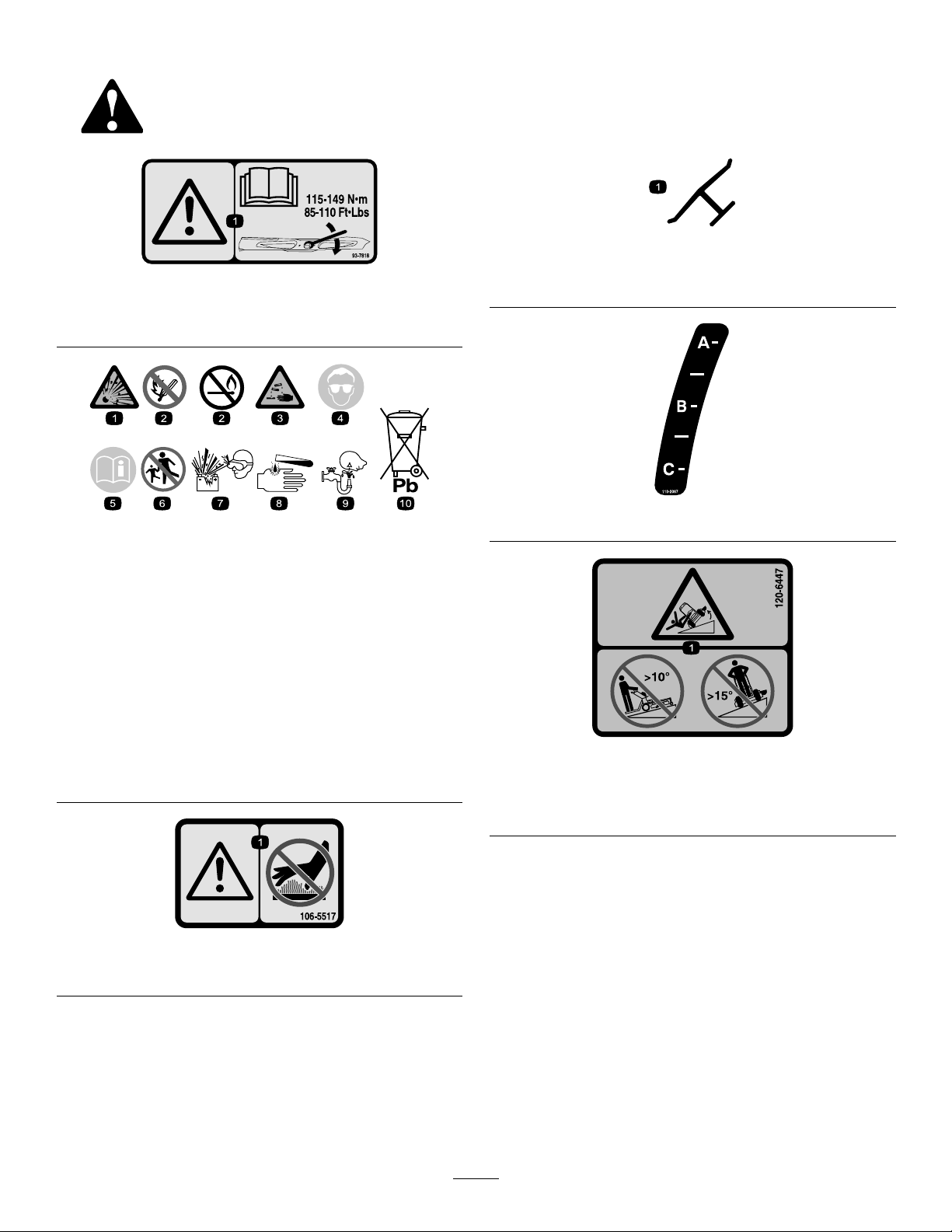

SlopeIndicator

G015791

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

8

Page 9

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

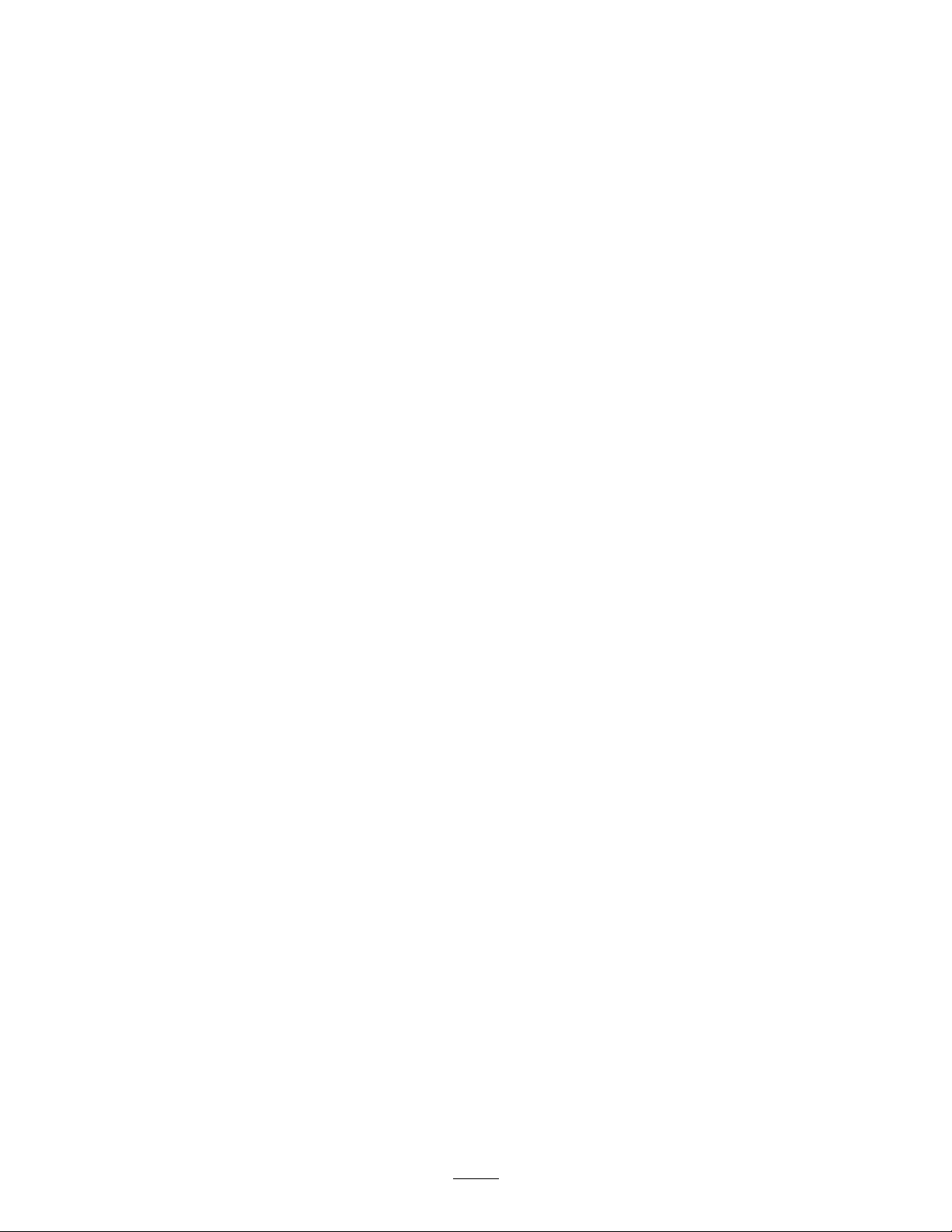

Manufacturer'sMark

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto1 15-149N-m(85-1 10ft-lb).

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

distancefromthebattery .

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard.

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

110-2067

120-6447

1.Tippinghazard—donotmowupanddownslopesgreater

than10degrees,donotmowacrossslopesgreaterthan

15degrees.

1.Warning—donottouchthehotsurface.

106-5517

9

Page 10

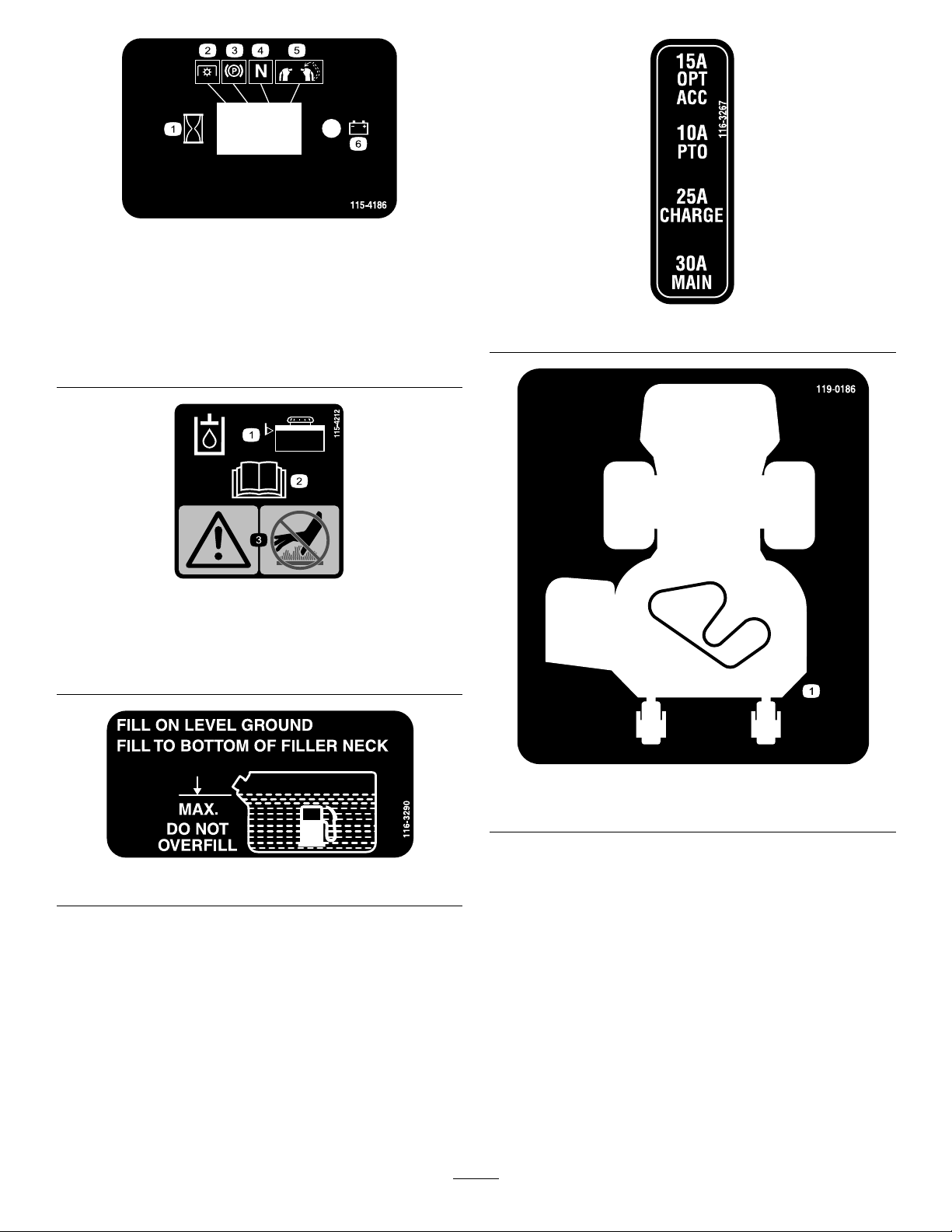

1.Interval

2.PowerT ake-off(PTO)

3.Parkingbrake

4.Neutral

5.Operatorpresenceswitch

6.Battery

115-4186

116-3267

115-4212

1.Hydraulicoillevel3.Warning—donottouchthe

hotsurface.

2.ReadtheOperator's

Manual.

116-3290

119-0186

1.Beltrouting

10

Page 11

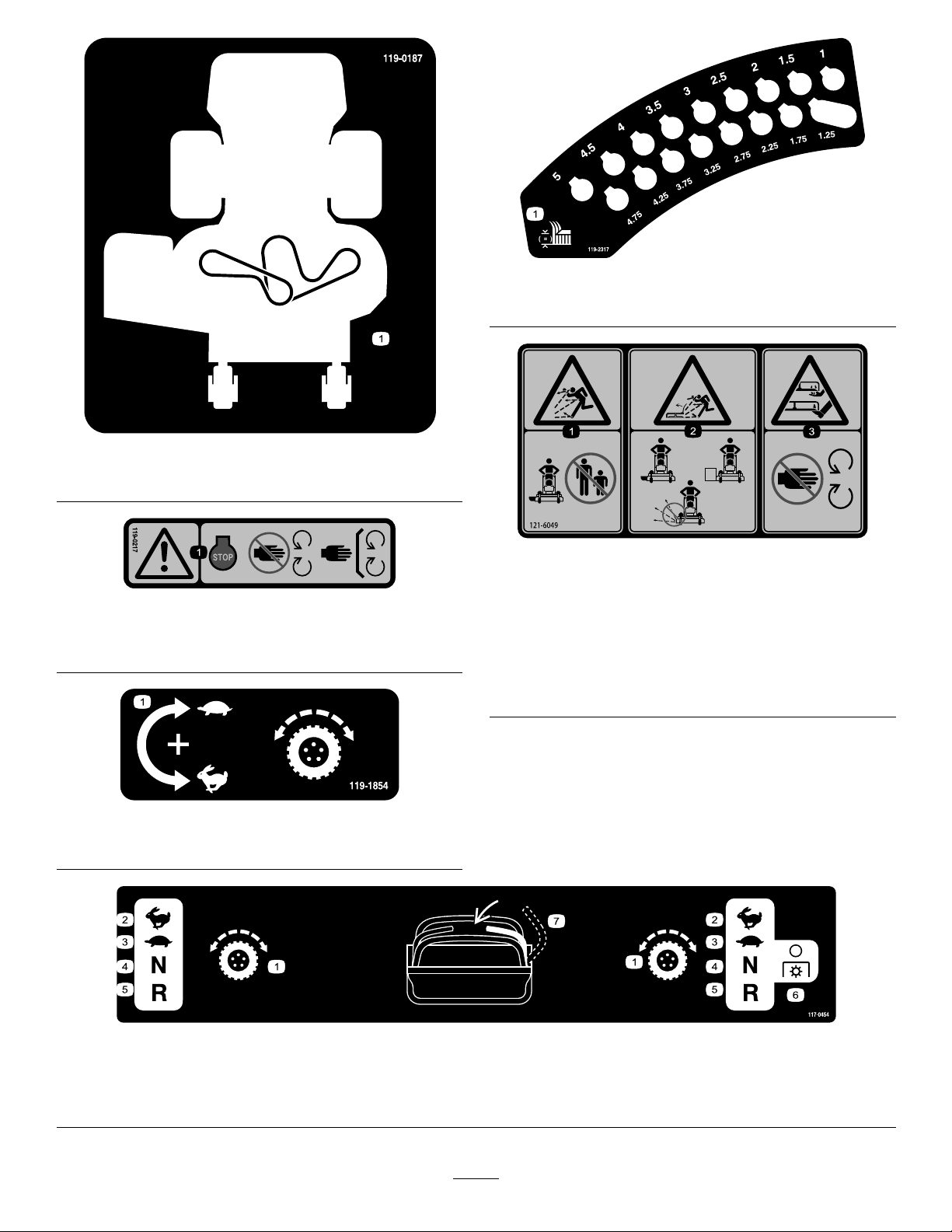

119-2317

1.Height-of-cut(inches)

119-0187

1.Beltrouting

121-6049

119-0217

1.Warning—stoptheengine;stayawayfrommovingparts;

keepallguardsandshieldsinplace.

119-1854

1.Adjustmentknobfortractiondrivespeed.

1.Thrownobject

hazard—keepbystanders

awayfromthemachine.

2.Thrownobjecthazard,

mower—donotoperate

themowerwithguardsor

shieldsremoved.

3.Cutting/dismemberment

hazardofhandorfoot,

mowerblade—keephands

awayfrommovingparts.

1.Tractioncontrol

2.Fast4.Neutral

117-0454

3.Slow

5.Reverse

6.PowerT ake-off

(PTO)—disengage

7.Operatorpresenceswitch

11

Page 12

117-3626

1.Warning—readtheOperator'sManual.5.Thrownobjecthazard—keepbystandersasafedistancefrom

2.Warning—donotoperatethismachineunlessyouaretrained.6.Warning—engagetheparkingbrake,stoptheengine

3.Thrownobjecthazard—keepdeectorinplace.

4.Cutting,dismembermenthazardofhandorfoot—stayaway

frommovingpartsandkeepallguardsandshieldsinplace.

themachine.

andremovethesparkplugwirebeforeperformingany

maintenanceonthemachine.

7.Warning—engagetheparkingbrakeandstoptheengine

beforeleavingthemachine.

8.Slidingandlossofcontrolhazard—donotoperatethe

machineneardrop-offsorwater;keepasafedistancefrom

drop-offs.

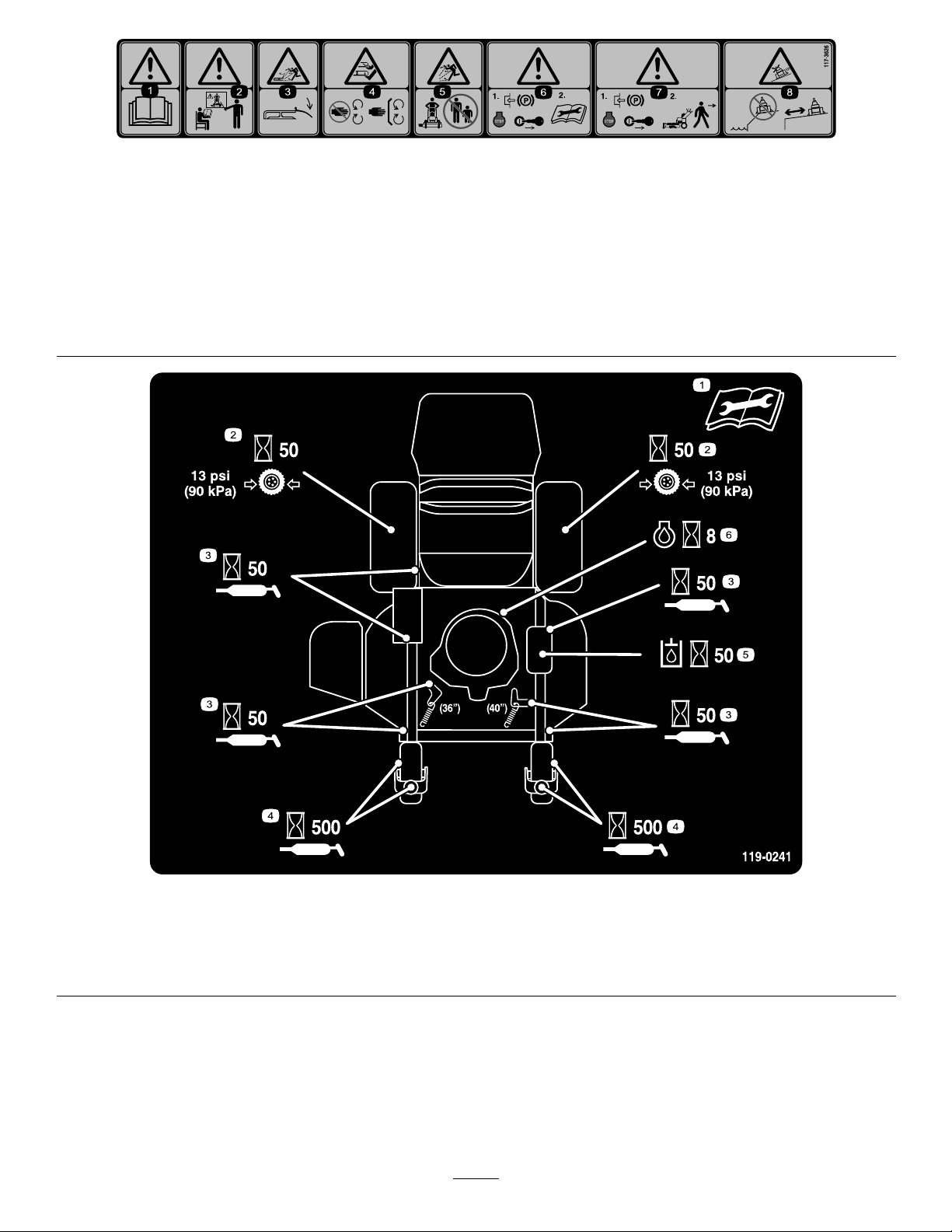

1.ReadtheOperator'sManualbefore

performinganymaintenance.

2.Checkthedrivewheeltirepressure

every50hours

119-0241

3.Lubricateevery50hours

4.Lubricatethecasterwheelevery500

hours

12

5.Checkthehydraulicoilevery50hours

6.Checktheengineoilevery8hours

Page 13

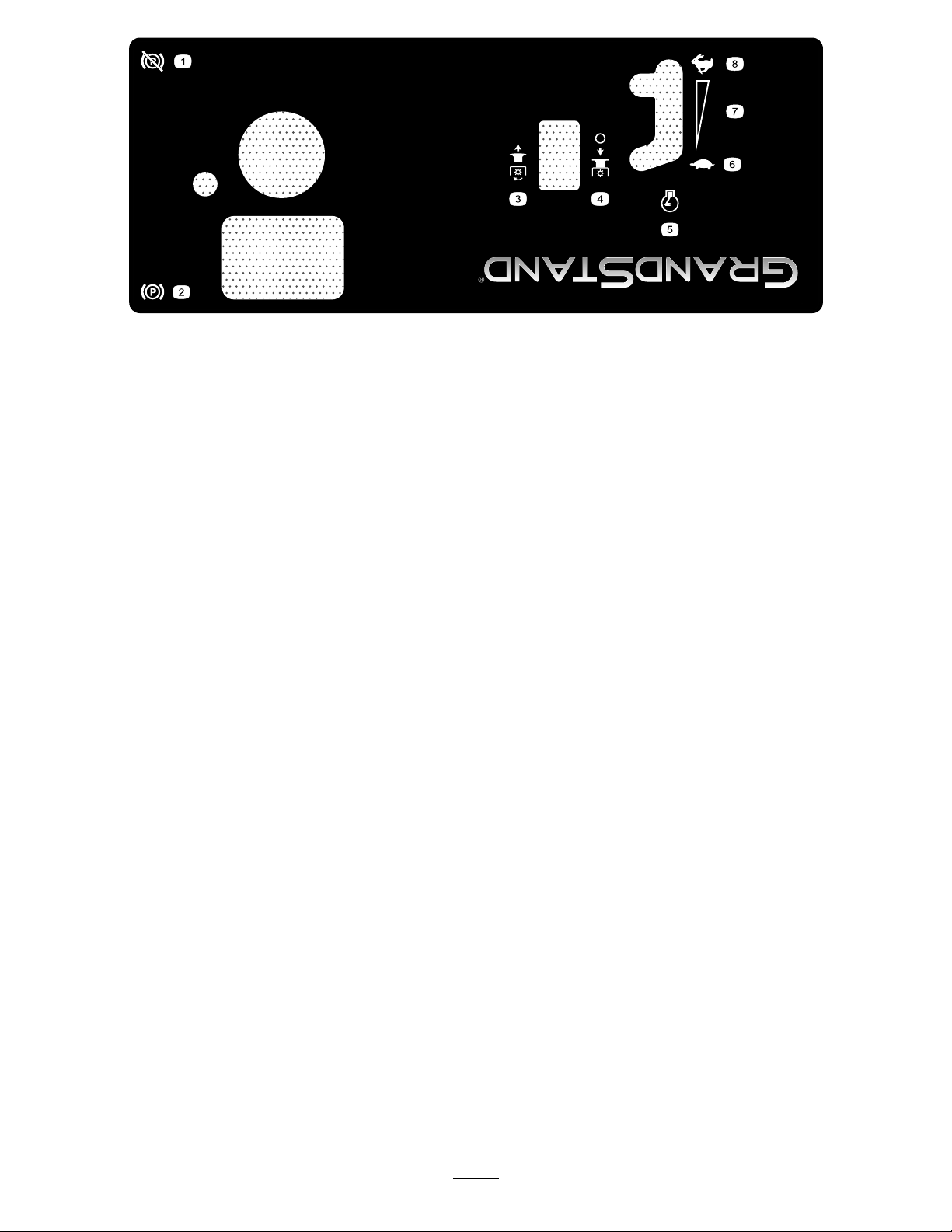

0

00

00

125-4679

1.Parkingbrake—disengaged5.Enginespeed

2.Parkingbrake—engaged

3.PTO—engaged7.Continuousvariablesetting

4.PTO—disengaged

6.Slow

8.Fast

13

Page 14

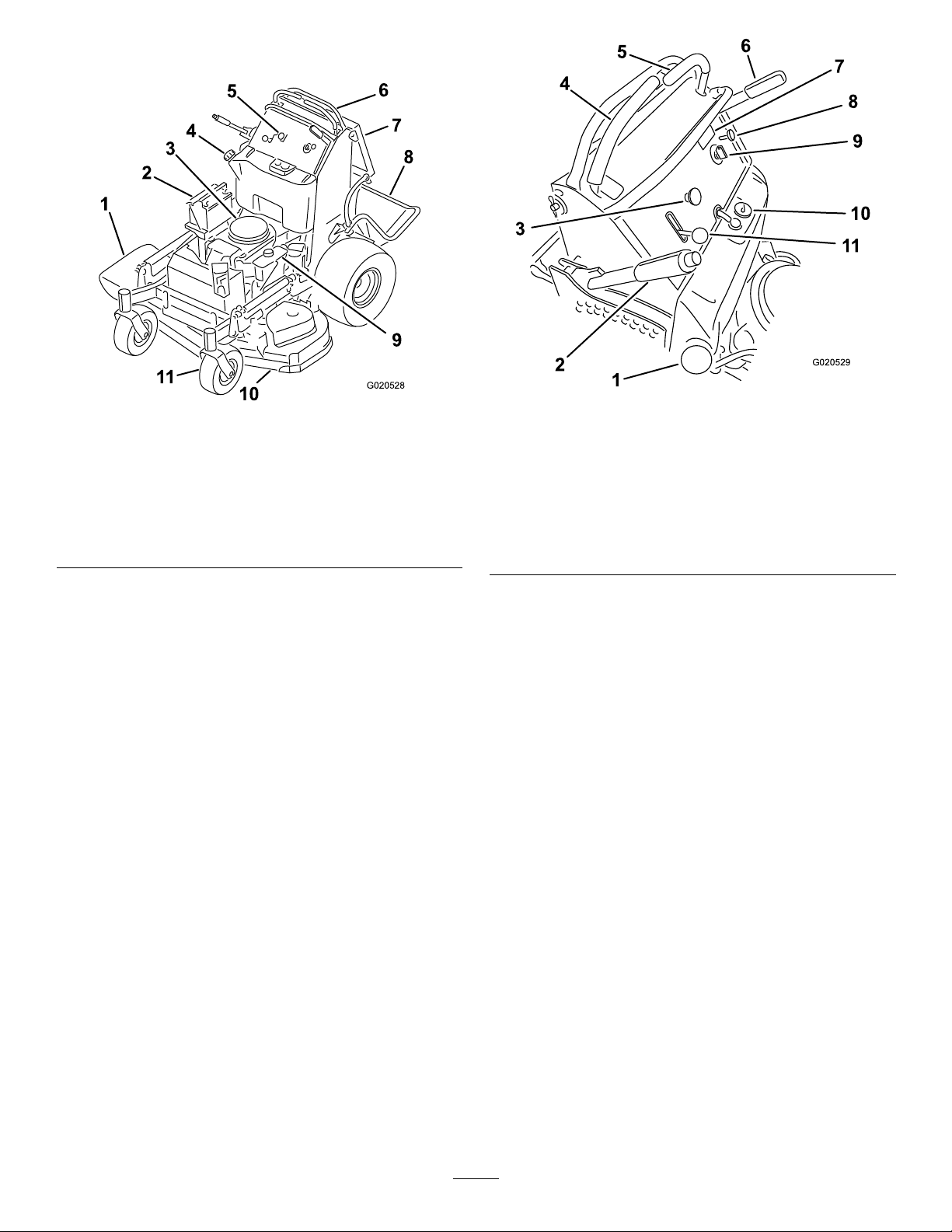

ProductOverview

G020528

7

8

9

10

11

1

7

2

8

3

9

4

10

5

11

6

G020529

Figure4

1.Side-dischargechute7.Operatorcushion

2.Battery

3.Engine9.Hydraulictank

4.Fueltank10.Mowerdeck

5.Controls

6.Motion-controllevers

8.Platform(downposition)

11.Frontcasterwheel

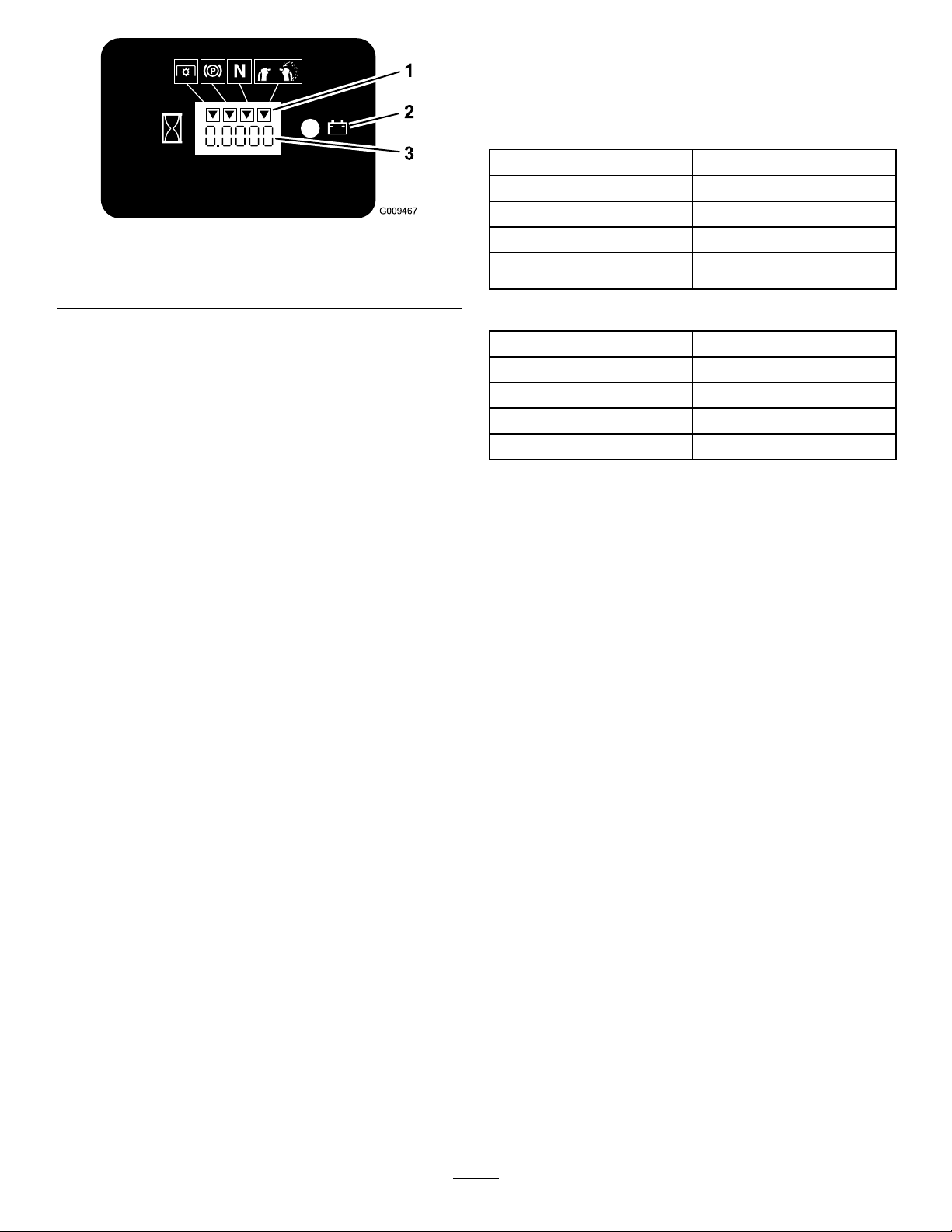

Controls

Becomefamiliarwithallthecontrols(Figure5)beforeyou

starttheengineandoperatethemachine.

Figure5

1.Fuelcap7.Hourmeter

2.Height-of-cutlever8.Choke

3.Blade-controlswitch

(PTO)

4.Rightmotion-controllever10.Fuelgauge

5.Leftmotion-controllever

6.Parking-brakelever

9.Ignitionswitch

11.Throttlecontrol

HourMeter

Thehourmeterrecordsthenumberofhourstheenginehas

operated.Itoperateswhentheengineisrunning.Usethese

timesforschedulingregularmaintenance(Figure6).

FuelGauge

Thefuelgaugeislocatedonthetop,middleofthetank

(Figure5).

Safety-interlockIndicators

Therearesymbolsonthehourmeterandindicatewitha

blacktrianglethattheinterlockcomponentisinthecorrect

position(Figure6).

Battery-indicatorLight

IftheignitionkeyisturnedtotheOnpositionforafew

seconds,thebatteryvoltagewillbedisplayedinthearea

wherethehoursarenormallydisplayed.

Thebatterylightturnsonwhentheignitionisturnedonand

whenthechargeisbelowthecorrectoperatinglevel(Figure

6

).

14

Page 15

1.Safety-interlocksymbols

2.Batterylight

Figure6

3.Hourmeter

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Model74534TE

Widthwithdeectordown131.1cm(51.62inches)

Lengthwithplatformdown188cm(74inches)

Lengthwithplatformup155cm(61inches)

Height

Weight

Model74536TE

121.9cm(48inches)

343kg(756lb)

ThrottleControl

ThethrottlecontrolisvariablebetweenFastandSlow.

Choke

Usethechoketostartacoldengine.

Blade-controlSwitch(PTO)

Theblade-controlswitch(PTO)isusedtoengagethe

electricclutchtodrivethemowerbladeswiththerightside

motion-controlleverinthecenter,unlockedposition.Pull

theswitchuptoengagethebladesandrelease.Todisengage

theblades,pushtheblade-controlswitch(PTO)downor

moveorreleasetherightsidemotion-controlleverintothe

neutral-lockposition.

IgnitionSwitch

Thisswitchisusedtostartthemowerengineandhasthree

positions:Off,RunandStart.

Widthwithdeectordown141.6cm(55.75inches)

Lengthwithplatformdown177.8cm(70inches)

Lengthwithplatformup144.8cm(57inches)

Height

Weight

121.9cm(48inches)

350.6kg(773lb)

Motion-controlLevers

Themotion-controlleversareusedtodrivethemachine

forward,reverse,andturneitherdirection.

FuelShut-offValve

Closethefuelshut-offvalve(locatedbehindtheoperator

cushionontherighthandsideoffueltank)whentransporting

orstoringthemower.

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .T oro.comforalistofallapproved

attachmentsandaccessories.

15

Page 16

Operation

AddingFuel

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontains

morethan10%ethanolbyvolume,suchasE15

(contains15%ethanol),E20(contains20%ethanol),or

E85(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/orengine

damagewhichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2inch)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

WARNING

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditionerbottleopening.

•Avoidcontactwithskin;washoffspillagewith

soapandwater.

UsingStabilizer/Conditioner

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysorless.

Forlongerstorageitisrecommendedthatthefueltank

bedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditionerto

thegas.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.Tominimizethechance

16

Page 17

ofvarnishdepositsinthefuelsystem,usefuelstabilizer

2

4

3

G012565

1

5

G009027

1

2

atalltimes.

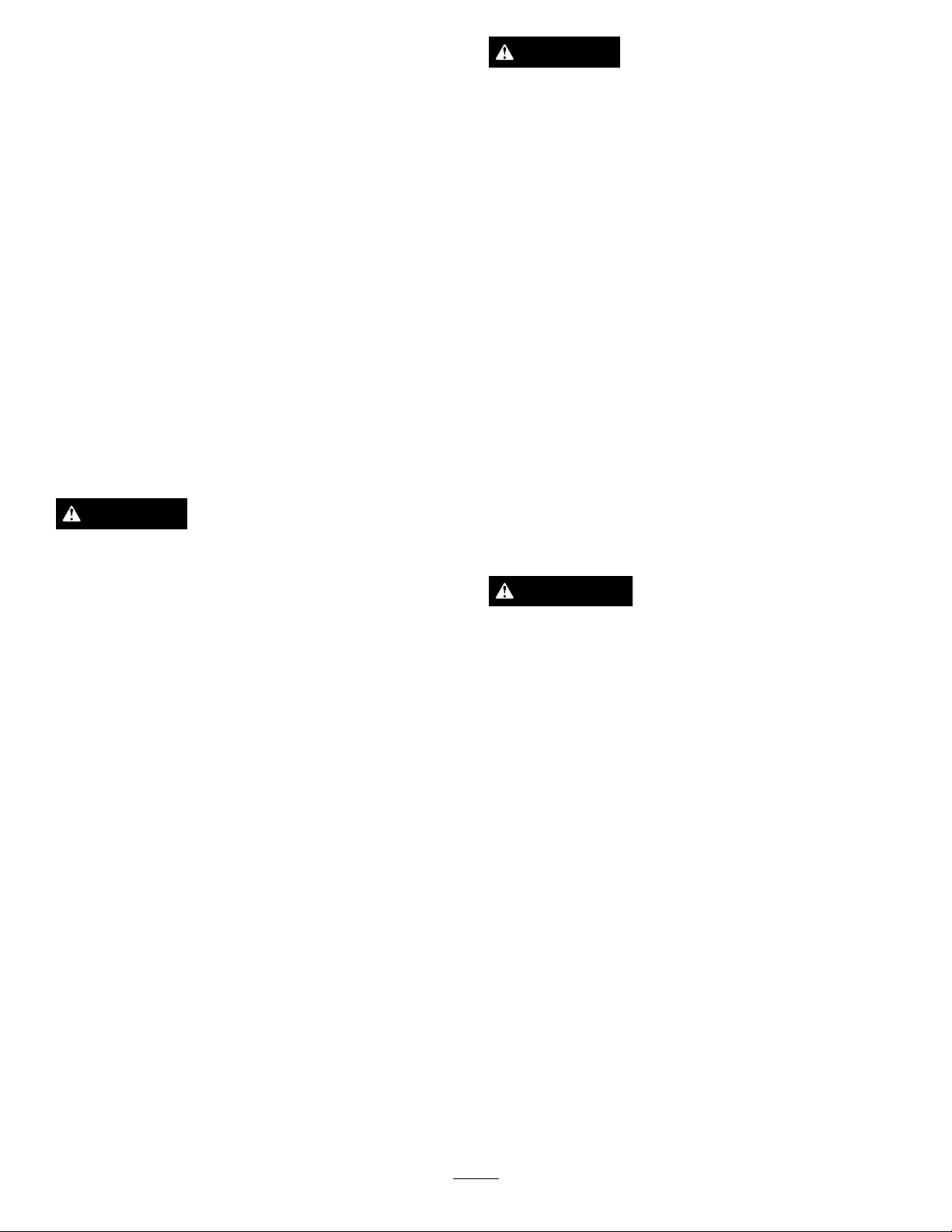

FillingtheFuelTank

Note:Donotllthefueltankcompletelyfull.Fillthefuel

tanktothebottomofthellerneck.Theemptyspaceinthe

tankallowsthegasolinetoexpand.

ThinkSafetyFirst

Carefullyreadallthesafetyinstructionsanddecalsinthe

safetysection.Knowingthisinformationcouldhelpyouor

anybystandersavoidinjury.

Theuseofprotectiveequipmentforeyes,hearing,feetand

headisrecommended.

1.Parkthemachineonlevelground.

2.Shuttheengineoffandsettheparkingbrake.

3.Cleanaroundthefuel-tankcap.

4.Fillthefueltanktothebottomofthellerneck.

Ensurethereisemptyspaceinthetanktoallowthe

gasolinetoexpand(

Figure7).

CAUTION

Thismachineproducessoundlevelsinexcessof

85dBAattheoperator'searandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Theuseofprotectiveequipmentforeyes,ears,feet,andhead

isrecommended.

Figure8

1.Wearsafetyglasses

2.Wearhearingprotection

OperatingtheParkingBrake

Alwayssettheparkingbrakewhenyoustopthemachineor

leaveitunattended.Beforeeachuse,checktheparkingbrake

forproperoperation.

Iftheparkingbrakedoesnotholdsecurely,adjustit;referto

Figure7

ServicingtheBrake(page45).

CAUTION

CheckingtheEngine-oilLevel

Beforeyoustarttheengineandusethemachine,checktheoil

levelintheenginecrankcase;refertoCheckingtheEngine-oil

Level(page35).

BreakingInaNewMachine

Newenginestaketimetodevelopfullpower.Mowerdecks

anddrivesystemshavehigherfrictionwhennew,placing

additionalloadontheengine.Allow40to50hoursof

break-intimefornewmachinestodevelopfullpowerand

bestperformance.

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

17

Page 18

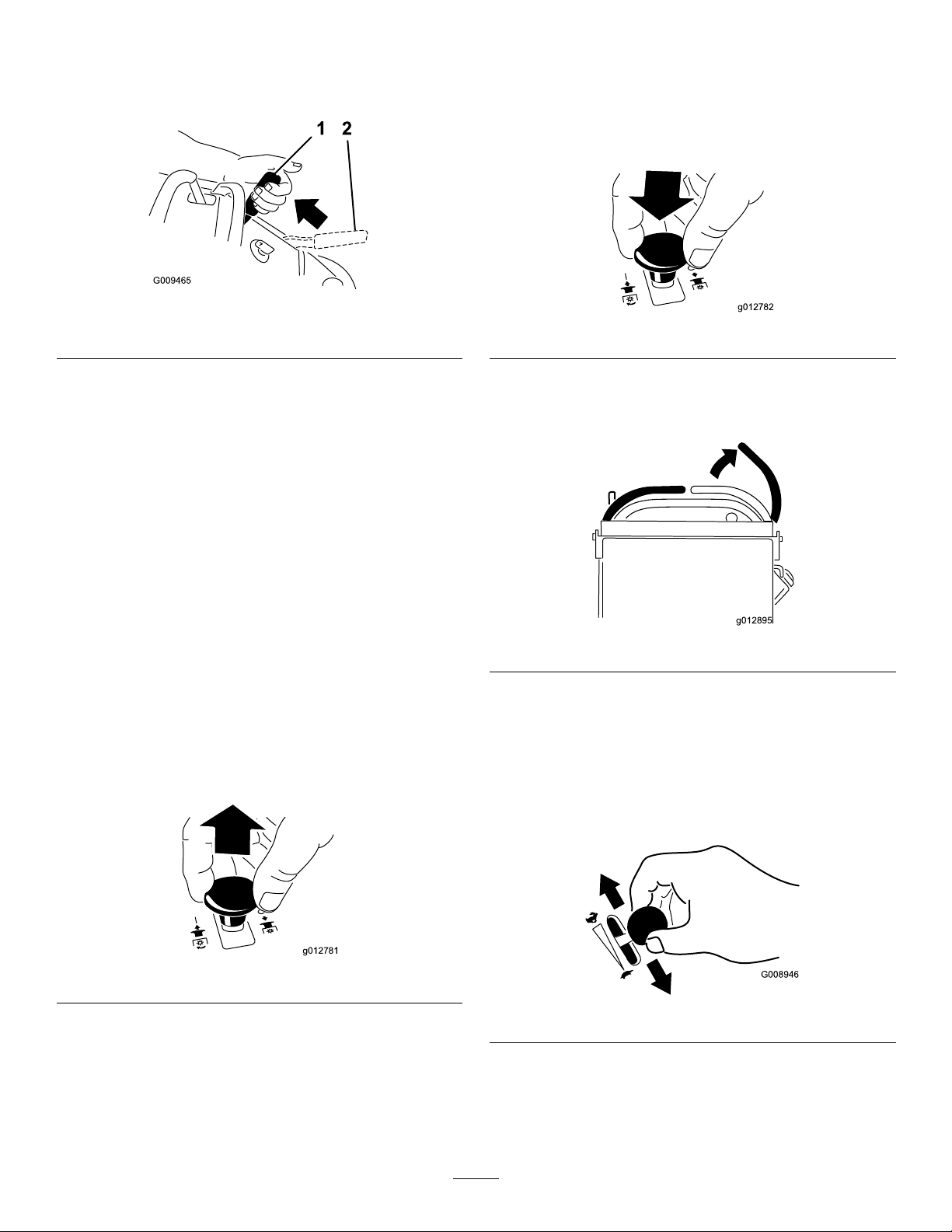

SettingtheParkingBrake

g012781

g012782

g012895

G008946

DisengagingtheMowerBlades(PTO)

Pulltheparking-brakeleverrearwardtotheengagedposition

(Figure9).

Figure9

1.Parkingbrakeengaged2.Parkingbrakereleased

ReleasingtheParkingBrake

Pushtheparking-brakeleverforward.

Operatingthe

Mower-blade-controlSwitch

Thefollowingaretwooptionsfordisengagingthemower

blades.

•Pushtheblade-controlswitch(PTO)downtotheOff

position(Figure11).

Figure11

•Movethemotion-controlleverstoneutralandmove

therightsidemotion-controlleverintotheneutral-lock

position(Figure12).

(PTO)

Theblade-controlswitch(PTO)isusedinconjunctionwith

therightsidemotion-controllevertoengageanddisengage

themowerblades.

EngagingtheMowerBlades(PTO)

1.Toengagethemowerblades,movetherightside

motion-controllevertothecenter,unlockedposition.

2.Pulltheblade-controlswitch(PTO)upandreleaseit

whileholdingdowntherightsidemotion-controllever

inthecenter,unlockedposition.

Figure10

Figure12

OperatingtheThrottle

ThethrottlecontrolcanbemovedbetweenFastandSlow

positions(Figure13).

AlwaysusetheFastpositionwhenturningonthemower

deckwiththeblade-controlswitch(PTO).

Figure13

18

Page 19

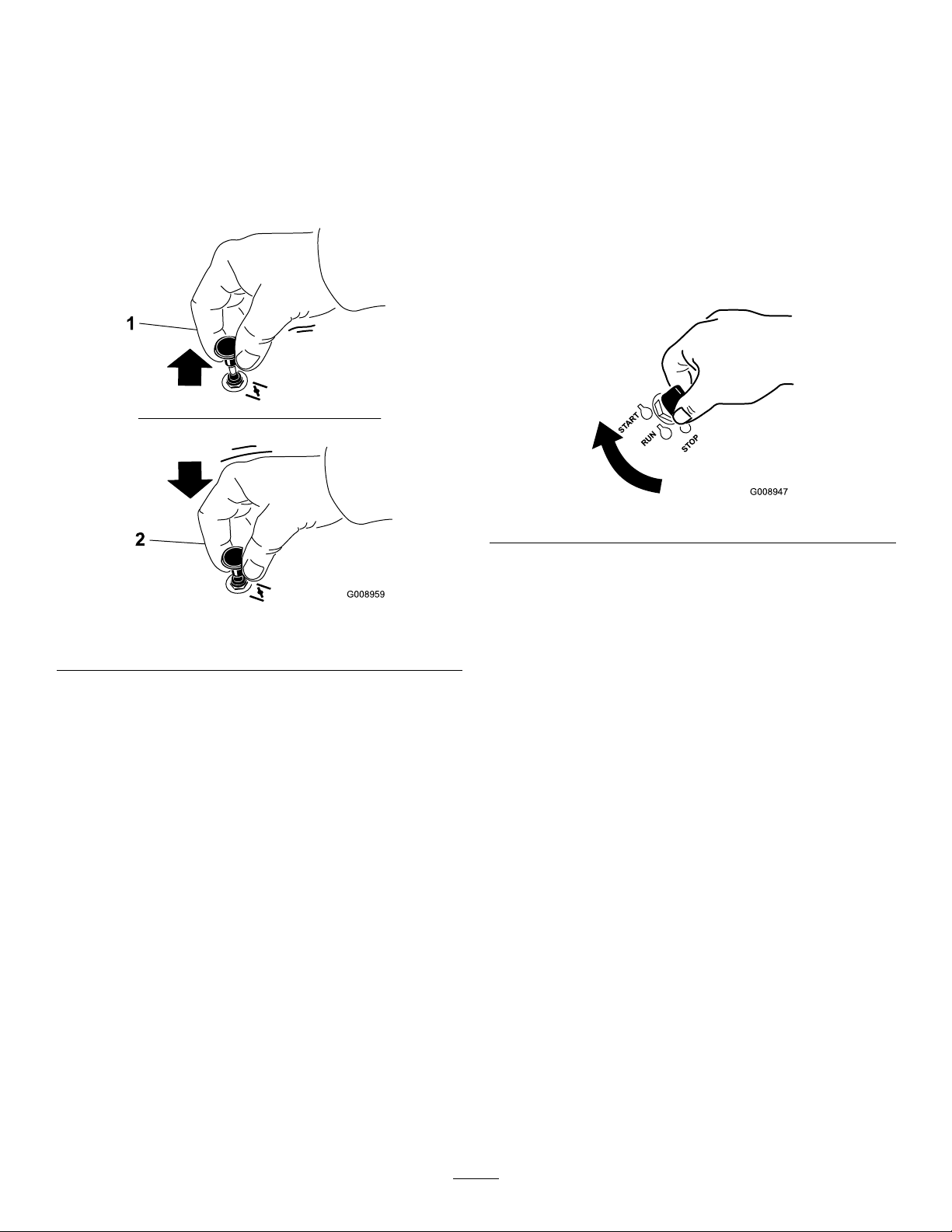

OperatingtheChoke

G008959

1

2

START

RUN

STOP

G008947

OperatingtheIgnitionSwitch

Usethechoketostartacoldengine.

1.Iftheengineiscold,usethechoketostarttheengine.

2.Pulluponthechokeknobtoengagethechokebefore

usingtheignitionswitch(

Figure14).

3.Pushdownonthechoketodisengagethechokeafter

theenginehasstarted(Figure14).

1.TurntheignitionkeytotheStartposition(Figure15).

Note:Whentheenginesstarts,releasethekey.

Important:Donotengagestarterformorethan5

secondsatatime.Iftheenginefailstostartallow

a15secondcool-downperiodbetweenattempts.

Failuretofollowtheseinstructionscanburnout

thestartermotor.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthefuel

systemhasbeenwithoutfuelcompletely.

Figure15

2.Turntheignitionkeytothestoppositiontostopthe

engine.

Figure14

1.Onposition2.Offposition

19

Page 20

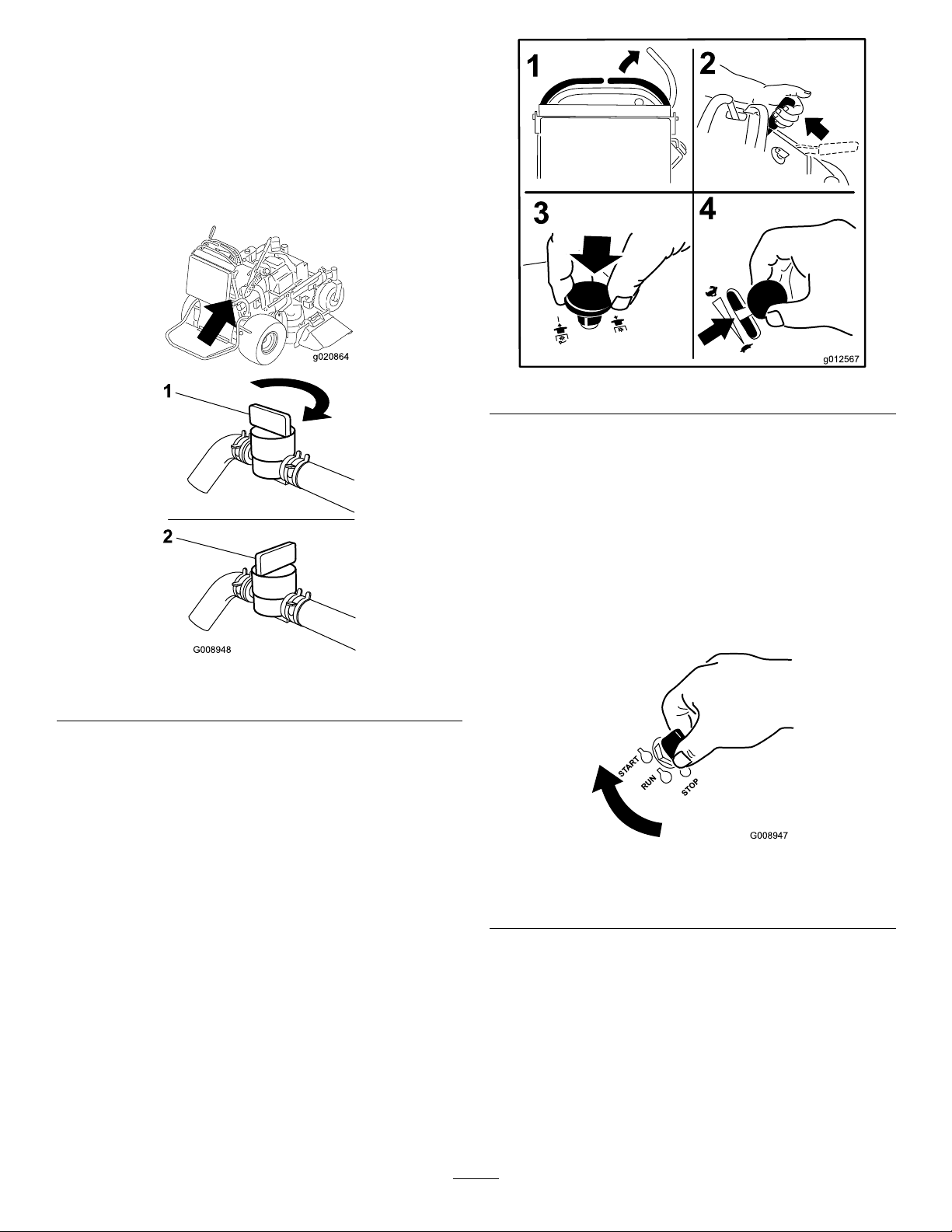

UsingtheFuelShut-offValve

g020864

G008948

1

2

START

RUN

STOP

G008947

Thefuelshut-offvalveislocatedbehindtherightsideofthe

operatorcushion.

Closethefuelshut-offvalvefortransport,maintenance,and

storage(Figure16).

Ensurethefuelshut-offvalveisopenwhenstartingthe

engine.

Figure17

7.TurntheignitionkeytotheStartposition(Figure18).

Whentheenginesstarts,releasethekey .

Important:Donotengagethestarterformore

than5secondsatatime.Iftheenginefailsto

start,allowa15secondcool-downperiodbetween

attempts.Failuretofollowtheseinstructionscan

burnoutthestartermotor.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthefuel

systemhasbeenwithoutfuelcompletely.

Figure16

1.Onposition2.Offpositon

StartingandStoppingthe Engine

StartingtheEngine

1.Connectthewirestothesparkplugs.

2.Openthefuelvalve.

3.Movetherightmotion-controllevertoneutrallocked

position.

4.Settheparkingbrake;refertoSettingtheParking

Brake(page18).

5.Movetheblade-controlswitch(PTO)totheOff

position.

1.Offposition3.Startposition

2.Runposition

Figure18

6.MovethethrottlelevermidwaybetweentheSlowand

Fastpositions.

Note:Awarmorhotenginemaynotrequirechoking.

20

Page 21

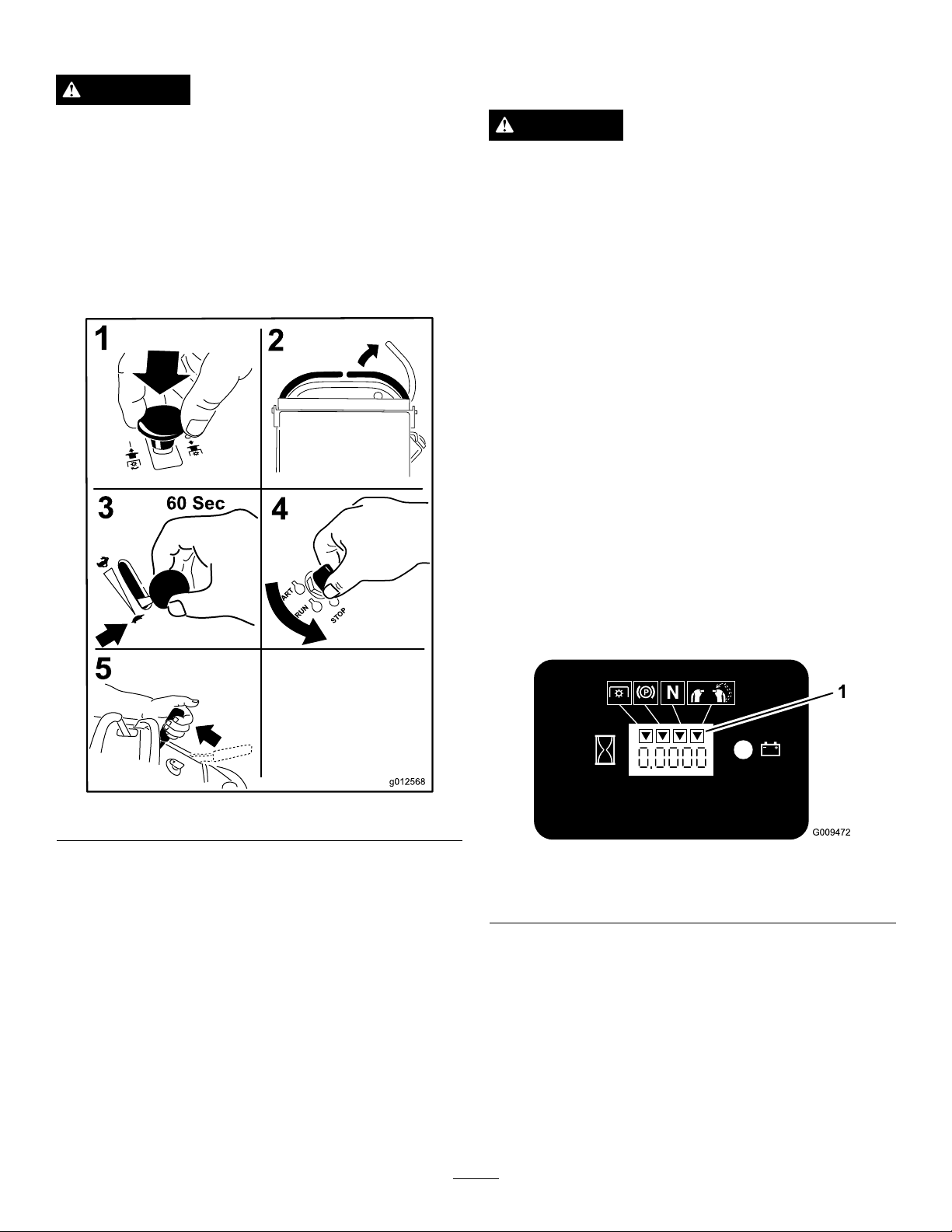

StoppingtheEngine

UsingtheSafety-interlock

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethetractorwhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

Lettheengineidleatslowthrottle(turtle)for60seconds

beforeturningtheignitionswitchoff.

System

CAUTION

Ifsafety-interlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

UnderstandingtheSafety-interlock

System

Thesafety-interlocksystemisdesignedtopreventthemower

bladesfromrotatingunless:

•Therightsidemotion-controlleverismovedtothe

center,unlockedposition.

•Theblade-controlswitch(PTO)ispulledon.

Thesafety-interlocksystemisdesignedtostopthemower

bladesifyoumoveorreleasetherightsidemotion-control

leverintotheneutral-lockposition.

Figure19

Important:Makesurethefuelshut-offvalveisclosed

beforetransportingorstoringthemachine,asfuel

leakagemayoccur.Beforestoringthemachine,pull

wireoffsparkplug(s)topreventpossibilityofaccidental

starting.

Thehourmeterhassymbolstonotifytheuserwhenthe

interlockcomponentisinthecorrectposition.Whenthe

componentisinthecorrectposition,atrianglewilllight

upinthecorrespondingsquare.

Figure20

1.Triangleslightupwhentheinterlockcomponentsareinthe

correctposition

21

Page 22

TestingtheSafety-interlockSystem

ServiceInterval:Beforeeachuseordaily

Testthesafety-interlocksystembeforeyouusethemachine

eachtime.

Note:Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthesafety

systemimmediately.

1.Starttheengine;refertoStartingtheEngine(page20).

2.Settheparkingbrake.

3.Movetherightsidemotion-controllevertothecenter,

unlockedposition.

Note:Thebladesshouldnotrotate.

4.Movethemotion-controlleversforward.

Note:Theengineshouldstoprunning.

5.Starttheengineandreleasetheparkingbrake.

6.Movetherightsidemotion-controllevertothecenter,

unlockedposition.

7.Continueholdingtherightsidemotion-controllever

inthecenter,unlockedposition,pulluponthe

blade-controlswitch(PTO),andrelease.

Note:Theclutchshouldengageandthemower

bladesrotate.

WARNING

Theoperatorplatformisheavyandmaycause

injurywhenloweringandraisingtheoperator

platform.Theplatformmaysuddenlydropifnot

supportedwhenthelatchpinispulledout.

•Donotputyourhandsorngersinthe

platform-pivotareawhenloweringorraisingthe

operatorplatform.

•Makesuretheplatformissupportedwhenthe

latchpinispulledout.

•Makesurethelatchsecurestheplatformwhen

foldingitintheupposition.Pushittightagainst

thecushionforthelatchpintolockintoplace.

•Keepbystandersawaywhenraisingorlowering

theplatform.

OperatingthePlatform

Themachinecanbeusedwiththeplatformintheupordown

position.Itistheoperator'spreferenceonwhichposition

touse.

OperatingtheMachinewiththe

PlatformUp

8.Moveorreleasetherightsidemotion-controlleverinto

theneutral-lockposition.

Note:Thebladesshouldstoprotatingandtheengine

continuestorun.

9.Pushtheblade-controlswitchdownandmovethe

rightsidemotion-controllevertothecenter,unlocked

position.

10.Continueholdingtherightsidemotion-controllever

inthecenter,unlockedposition,pulluponthe

blade-controlswitch(PTO),andrelease.

Note:Theclutchshouldengageandthemower

bladesrotate.

11.Pushtheblade-controlswitch(PTO)downtotheOff

position.

Note:Thebladesshouldstoprotating.

12.Withtheenginerunning,pulluptheblade-control

switch(PTO)andreleaseitwithoutholdingrightside

motion-controllevertothecenter,unlockedposition.

Note:Thebladesshouldnotrotate.

Operatingthemachinewiththeplatformupisrecommended

forthefollowing:

•Mowingneardrop-offs

•Mowingsmallareaswherethemachineistoolarge

•Areaswithlow ,over-hangingbranchesorobstacles

•Loadingthemachinefortransport

•Drivingupslopes

Toraisetheplatform,pullthebackoftheplatformupsothat

thelatchpinandknoblockitintoplace.Pushittightagainst

thecushionforthelatchpintolockitintoplace.

OperatingtheMachinewiththe

PlatformDown

Operatingthemachinewiththeplatformdownis

recommendedforthefollowing:

•Mowingmostareas

•Drivingacrossslopes

•Drivingdownslopes

Tolowertheplatform,pushtheplatformforwardagainstthe

cushiontoreleasepressureonthelatchpin,thenpullthe

knobout,andlowertheplatform(

22

Figure21).

Page 23

g020804

1.Platformup

G020531

4

5

1

2

3

2 4

2.Platformdown

Figure21

3.Pulltheknobouttorelease

theplatform.

1.Frontreferencebar

2.Leftcontrollever

3.Rearreferencebar

Figure22

4.Rightcontrollever

5.Rightcontrolleverinthe

neutral-lockposition

DrivingForwardorBackward

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placethethrottlecontrolin

theFastpositionforbestperformance.Alwaysoperateinthe

full-throttlepositionwhenmowing.

CAUTION

Machinecanspinveryrapidly.Operatormaylose

controlofmachineandcausepersonalinjuryor

damagetomachine.

Slowthemachinedownbeforemakingsharpturns.

DrivingForward

1.Releasetheparkingbrake;refertoReleasingthe

ParkingBrake(page18).

2.Movetherightsidemotion-controllevertothecenter,

unlockedposition.

3.Togoforward,movethespeed-controllevertothe

desiredspeed.

4.Slowlypushthemotion-controlleversforward(Figure

23).

Note:Theenginewillkillifamotion-controlleveris

movedwiththeparkingbrakeengaged.

Note:Thefartheryoumovethemotion-controllevers

ineitherdirection,thefasterthemachinewillmove

inthatdirection.

Note:T ostop,pullthemotion-controlleversbackto

theneutralposition.

23

Page 24

StoppingtheMachine

Tostopthemachine,movethemotion-controlleversto

neutral,movetherightsidemotion-controlleverintothe

neutral-lockposition,disengagethepowertakeoff(PTO),

andturntheignitionkeytooff.

Settheparkingbrakewhenyouleavethemachine;referto

SettingtheParkingBrake(page18).Remembertoremove

thekeyfromtheignitionswitch.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethetractorwhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

Figure23

DrivingBackward

1.Movetherightsidemotion-controllevertothecenter,

unlockedposition.

2.Slowlypullthemotion-controlleversrearward(Figure

24).

PushingtheMachinebyHand

Thebypassvalvesallowthemachinetobepushedbyhand

withouttheenginerunning.

Important:Alwayspushthemachinebyhand.Never

towthemachinebecausehydraulicdamagemayoccur.

1.DisengagethePTO,movethemotion-controlleversto

theneutral-lockedposition,andsettheparkingbrake.

2.Lowerthemowerdecktothelowestheight-of-cut

(HOC).

Note:Thiswillallowaccesstothebypassvalves.

3.Openthebypassvalveonbothpumpsbyturningthem

counterclockwise1to2turns(Figure25).

Note:Thisallowshydraulicuidtoby-passthe

pumpsandthewheelstoturn.

Note:Rotatethebypassvalvesamaximumof2turns

sothevalvedoesnotcomeoutofthebodycausing

uidtorunout.

Figure24

24

Page 25

g020805

1.Tractionunittie-downloop

Figure26

Figure25

1.Pump-bypassvalve

4.Releasetheparkingbrake.

5.Pushthemachinetothedesiredlocation.

6.Settheparkingbrake.

7.Closethebypassvalves,butdonotovertightenthem.

8.Torqueto12to15N-m(110to130in-lb).

Important:Donotstartoroperatethemachine

withthebypassvalvesopen.Damagetosystem

mayoccur.

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthemachine.

Ensurethatthetrailerortruckhasallnecessarybrakes,

lighting,andmarkingasrequiredbylaw.Pleasecarefullyread

allthesafetyinstructions.

Totransportthemachine:

1.Raisetheplatformofthemachinebeforedrivingup

ontothetrailerortruck.

2.Ifusingatrailer,connectittothetowingvehicleand

connectthesafetychains.

3.Ifapplicable,connectthetrailerbrakes.

LoadingMachines

Useextremecautionwhenloadingunitsontotrailersor

trucks.Onefull-widthrampthatiswideenoughtoextend

beyondthereartiresisrecommendedinsteadofindividual

rampsforeachsideoftheunit(Figure27).Theplatform

whendownandlockedintoposition,extendsbackbetween

therearwheelsandservesasastopfortippingbackward.

Havingafull-widthrampprovidesasurfacefortheplatform

tocontactiftheunitstartstotipbackward.Withtheplatform

up,afull-widthrampprovidesasurfacetowalkonbehindthe

unit.Theoperatorshoulddetermineifitisbesttohavethe

platformupordownwhenloading,dependingonconditions.

Ifitisnotpossibletouseonefull-widthramp,useenough

individualrampstosimulateafull-width,continuousramp.

Therampshouldbelongenoughsothattheanglesdonot

exceed15degrees(Figure27).Asteeperanglemaycause

mowercomponentstogetcaught,astheunitmovesfrom

ramptotrailerortruck.Steeperanglesmayalsocausethe

unittotipbackward.Ifloadingonornearaslope,position

thetrailerortrucksoitisonthedownsideoftheslopeand

therampextendsuptheslope.Thiswillminimizetheramp

angle.Thetrailerortruckshouldbeaslevelaspossible.

Important:Donotattempttoturntheunitwhileonthe

ramp;youmaylosecontrolanddriveofftheside.

Avoidsuddenaccelerationwhendrivinguparampand

suddendecelerationwhenbackingdownaramp.Both

maneuverscancausetheunittotipbackward.

4.Loadthemachineontothetrailerortruck.

5.Stoptheengine,removethekey,setthebrake,and

closethefuelvalve.

6.Usethemetaltie-downloopsonthemachineto

securelyfastenthemachinetothetrailerortruckwith

straps,chains,cable,orropes(

Figure26).

25

Page 26

WARNING

SideDischargingorMulching

Loadingaunitontoatrailerortruckincreasesthe

possibilityofbackwardtip-over,andcouldcause

seriousinjuryordeath.

•Useextremecautionwhenoperatingauniton

aramp.

•Useonlyasingle,full-widthramp;donotuse

individualrampsforeachsideoftheunit.

•Ifindividualrampsmustbeused,useenough

rampstocreateanunbrokenrampsurfacewider

thantheunit.

•Donotexceeda15-degreeanglebetweenramp

andground,orbetweenaramp,atrailer,ora

truck.

•Avoidsuddenaccelerationwhiledrivingunitup

aramptoavoidtippingbackward.

•Avoidsuddendecelerationwhilebackingunit

downaramptoavoidtippingbackward.

theGrass

Thismowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

DANGER

Withoutthegrassdeector,dischargecover,or

completegrasscatcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriswillcauseinjuryor

death.

•Donotremovethegrassdeectorfrom

themower,becausethegrassdeector

routesmaterialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthemower.

•Nevertrytoclearthedischargeareaormower

bladesunlessyoureleasethebailandthepower

takeoff(PTO)isoff.Rotatetheignitionkeyto

theOffposition.Alsoremovethekeyandpull

thewire(s)offthesparkplug(s).

Figure27

1.Trailer3.Notgreaterthan

2.Full-widthramp

15degrees

4.Full-widthramp(sideview)

AdjustingtheHeight-of-Cut

Theheight-of-cutcanbeadjustedfrom25to127mm(1to5

inches)in6mm(1/4inch)increments.

1.Movetheheight-of-cutlevertothetransportposition

(allthewayup).

2.Toadjust,rotatethepin90degreesandremovethepin

fromtheheight-of-cutbracket.

3.Selectaholeintheheight-of-cutbracketcorresponding

totheheight-of-cutdesiredandinsertthepin(Figure

28).

4.Pushthebuttonontopandlowertheheight-of-cut

levertothepin(Figure28).

26

Page 27

g020532

3

1

2

Figure28

g012676

1 2

G012677

1.Height-of-cutholes3.Height-of-cutlever

2.Height-of-cutpin

AdjustingtheFlowBafe

Themower-dischargeowcanbeadjustedfordifferenttypes

ofmowingconditions.Positionthecamlockandbafeto

givethebestqualityofcut.

PositioningtheFlowBafe

Thefollowingguresareonlyforrecommendeduse.

Adjustmentswillvarybygrasstype,moisturecontent,and

theheightofthegrass.

Note:Iftheenginepowerdrawsdown,andthemower

groundspeedisthesame,openupthebafe.

PositionA

Thisisthefull,rearposition(seeFigure30).Thesuggested

useforthispositionisasfollows:

•Inshort,lightgrassmowingconditions

•Indryconditions

•Smallergrassclippings

•Propelsgrassclippingsfartherawayfromthemower

1.DisengagethePTO,movethemotion-controlleversto

theneutral-lockedposition,andsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Toadjustthebafe,loosenthenut(

Figure29).

4.Adjustthebafeandnutintheslottothedesired

dischargeowandtightenthenut.

1.Slot

Figure29

2.Nut

Figure30

27

Page 28

PositionB

G012678

G012679

Usethispositionwhenbagging(Figure31).

Figure31

PositionC

UsingCounterweights

•Weightsareinstalledtoimprovehandling,balanceand

improveperformance.

•Weightscanbeaddedorremovedtocreateoptimized

performanceunderdifferentmowingconditionsandfor

operatorpreference.

•Itisrecommendedthatweightsbeaddedorremovedone

atatimeuntilthedesiredhandingandbalanceisachieved.

Note:ContactanAuthorizedServiceDealertoordera

WeightKit.

WARNING

Excessiveweightchangescaneffecthandlingand

operationofthemachine.Thiscouldcauseserious

injurytoyouorbystanders.

Makeweightchangesinsmallincrementsonly.

Evaluatethemoweraftereachweightchangeto

ensurethemachinecanbeoperatedsafely.

Thisisthefull,openposition(Figure32).Thesuggesteduse

forthispositionisasfollows:

•Intall,densegrassmowingconditions

•Inwetconditions

•Lowerstheengine-powerconsumption

•Allowsincreasedgroundspeedinheavyconditions

Figure32

28

Page 29

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthehydraulicuidlevel.

•Changethehydrauliclter.

•Checkthesafety-interlocksystem.

•Checktheengine-oillevel.

•Cleantheair-intakescreen.

•Checkthebrakes.

•Inspecttheblades.

•Cleanthemowerdeck.

•Cleanfoamair-cleanerelement.

•Greasethemower-deckidlerarms(moreoftenindirtyordustyconditions).

•Greasetheliftlinkage(moreoftenindirtyordustyconditions).

•Cleanthepaperair-cleanerelement.

•Checkthesparkarrester(ifequipped).

•Checkthetirepressure.

•Checkthehydraulicuidlevel.

•Changetheengineoil.(moreoftenindirtyordustyconditions)

•Check,cleanandgapthesparkplug.

•Checkthebattery .

•Checktheelectricclutch.

•Checkandcleanenginecoolingnsandshrouds.

•Checkthepump-drivebelt.

•Checkthemower-deckbelt(s).

•Checkthepump-drivebelt.

•Checkthehydraulichoses.

Every200hours

Every250hours

Every500hours

Beforestorage

Yearly

Important:Refertoyour

•Replacethepaperair-cleanerelement.

•Changetheengine-oillter.

•ChangethehydraulicoilwhenusingMobil®1oil.

•Adjustthecaster-pivotbearing.

•ChangethehydraulicoilwhenusingT oro®HYPR-OIL™500hydraulicoil.

•Changethehydrauliclter.

•Paintchippedsurfaces.

•Performallmaintenanceprocedureslistedabovebeforestorage.

•Greasethefrontcasterpivots(moreoftenindirtyordustyconditions).

•Lubricatethecaster-wheelhubs.

•Replacethefuellter.

Engine Operator's Man ual

foradditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthesparkplugwiresfromthesparkplugsbeforeyoudo

anymaintenance.Setthewiresasidesothattheydonotaccidentallycontactthesparkplugs.

29

Page 30

Premaintenance

Procedures

RaisingtheMowerforAccess

Thefrontofthemowercanberaisedandsupportedonits

backforaccessunderthemachineformaintenance.

1.Raisetheplatform;refertoOperatingthePlatform

(page22).

2.Removethebattery.

Figure34

Figure33

1.Wingnut

2.Batterycover5.Battery

3.Negative(–)batterycable

3.Drainthefuelfromthefueltank;refertoDraining

theFuelTank(page38).

4.Removethecapofthehydraulictankandplaceapiece

ofplasticovertheopeningandinstallthehydrauliccap.

Note:Thiswillsealthehydraulictankandprevent

itfromleakingout.

4.Positive(+)batterycable

1.Cap

2.Pieceofplastic

5.With2people,raisethefrontofthemowersoitrests

onthedrivetiresandtheplatformintheupposition.

6.Performanymaintenanceonthemachine.

7.With2people,lowerthefrontofthemowertothe

ground.

8.Removetheplasticunderthehydraulic-tankcap.

9.Installthebatteryforthemachine.

3.Hydraulictank

30

Page 31

Figure35

g012572

1

2

3

4

Figure36

1.Removebattery

2.With2people,liftthefront

ReleasetheCushionforRear Access

Thecushioncanbereleasedforrearaccesstothemachine

formaintenanceoradjustment.

1.Lowertheplatform.

2.Removethehairpin-cotterpinsoneachsideofthe

cushion.

3.Slidethelargewasherswithplasticbushingstothe

inside.

4.Removethecushionandlowerittotheplatform.

5.Performanymaintenanceoradjustmentonthe

machine.

6.Raisethecushionandslideitontothepinsonboth

sidesofthemachine(

Figure36).

endofthemower(ensure

theplatformisup)

7.Slidethelargewasherswithplasticbushingsintothe

cushionbracketandsecurethemwithahairpin-cotter

pin(

Figure36).

31

Page 32

Lubrication

GreasewithNo.2generalpurposelithiumbaseor

molybdenumbasegrease.

LubricatingtheMachine

ServiceInterval:Every50hours—Greasethemower-deck

idlerarms(moreoftenindirtyordusty

conditions).

Every50hours—Greasetheliftlinkage(moreoften

indirtyordustyconditions).

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Cleanthegreasettingswitharag.

Note:Makesuretoscrapeanypaintoffthefrontof

thetting(s).

4.Connectagreaseguntothetting.

5.Pumpgreaseintothettingsuntilgreasebeginsto

oozeoutofthebearings.

6.Wipeupanyexcessgrease.

Usethefollowinggraphicsforlocatingthegreasepoints.

Figure38

102cmMowerDeck

Figure39

GreasingtheFrontCaster

Figure37

91cmMowerDeck

Pivots

ServiceInterval:Yearly

Lubricatethefrontcasterpivotsonceayear.

1.Removethedustcapandadjustthecasterpivots;refer

toAdjustingtheCaster-pivotBearing(page43).

Note:Keepthedustcapoffuntilgreasingisdone.

2.Removethehexplug.

3.Threadagreasettingintothehole.

4.Pumpgreaseintothettinguntilitoozesoutaround

thetopbearing.

5.Removethegreasettinginthehole.

6.Installthehexplugandcap.

32

Page 33

LubricatingtheCaster-wheel Hubs

ServiceInterval:Yearly

1.Stoptheengine,waitforallmovingpartstostop,

engagetheparkingbrake,andremovethekey.

Figure40

13.Torquethenutto8to9N-m(71to80in-lb),loosen,

thentorqueitto2to3N-m(20to25in-lb).

Note:Makesureaxledoesnotextendbeyondeither

nut.

14.Installthesealguardsoverthewheelhubandinsert

wheelintocasterfork.

15.Installcasterboltandtightennutfully.

Important:T opreventsealandbearingdamage,check

thebearingadjustmentoftenbyspinningthecaster

tire.Thetireshouldnotspinfreely(morethan1or2

revolutions)orhaveanysideplay.Ifthewheelspins

freely,adjustthetorqueonthespacernutuntilthere

isaslightamountofdrag,andapplythread-locking

adhesive.

1.Sealguard2.Spacernutwithwrench

2.Removethecasterwheelfromthecasterforks.

3.Removethesealguardsfromthewheelhub.

4.Removeoneofthespacernutsfromtheaxleassembly

inthecasterwheel.

Note:Thread-lockingadhesivehasbeenappliedto

lockthespacernutstotheaxle.Removetheaxle(with

theotherspacernutstillassembledtoit)fromthe

wheelassembly.

5.Pryoutthesealsandinspectbearingsforwearor

damage,andreplaceifnecessary.

6.Packthebearingswithageneral-purposegrease.

7.Insert1bearingand1sealintothewheel.

Note:Thesealsmustbereplaced.

8.Iftheaxleassemblyhashadbothspacernutsremoved

(orbrokenloose),applyathread-lockingadhesiveto

onespacernutandthreaditontotheaxlewiththe

wrenchatsfacingoutward.

Note:DoNotthreadspacernutallofthewayonto

theendoftheaxle.Leaveapproximately3mm(1/8

inch)fromtheoutersurfaceofthespacernuttothe

endoftheaxleinsidethenut.

9.Inserttheassemblednutandaxleintothewheelonthe

sideofthewheelwiththenewsealandbearing.

10.Withtheopenendofthewheelfacingup,llthearea

insidethewheelaroundtheaxlefullofgeneral-purpose

grease.

11.Insertthesecondbearingandthenewsealintothe

wheel.

12.Applyathread-lockingadhesivetothesecondspacer

nut,andthreaditontotheaxlewiththewrenchats

facingoutward.

ats

33

Page 34

EngineMaintenance

ServicingtheAirCleaner

2.Drytheelementbysqueezingitinacleancloth.

Important:Replacethefoamelementifitistorn

orworn.

ServiceInterval/Specication

Inspectthefoamandpaperelementsandreplacethemifthey

aredamagedorexcessivelydirty.

Note:Servicetheaircleanermorefrequently(everyfew

operatinghours)iftheoperatingconditionsareextremely

dustyorsandy.

Important:Donotoilthefoamorpaperelement.

RemovingtheFoamandPaper

Elements

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Cleanaroundtheaircleanertopreventdirtfrom

gettingintotheengineandcausingdamage(

4.Unscrewthecoverknobsandremovetheair-cleaner

cover(Figure41).

5.Unscrewthehoseclampandremovetheair-cleaner

assembly(Figure41).

6.Carefullypullthefoamelementoffthepaperelement

(Figure41).

Figure41).

ServicingthePaperAir-cleanerElement

ServiceInterval:Every50hours—Cleanthepaper

air-cleanerelement.

Every200hours—Replacethepaperair-cleaner

element.

1.Cleanthepaperelementbytappinggentlytoremove

dust.

Note:Ifitisverydirty,replacethepaperelementwith

anewone(Figure41).

2.Inspecttheelementfortears,anoilylm,ordamageto

therubberseal.

InstallingtheFoamandPaperElements

Important:T opreventenginedamage,alwaysoperate

theenginewiththecompletefoamandpaperair-cleaner

assemblyinstalled.

1.Carefullyslidethefoamelementontothepaper

air-cleanerelement(

2.Placetheair-cleanerassemblyontotheaircleanerbase

orhoseandsecureit(Figure41).

3.Placetheair-cleanercoverintopositionandtighten

thecoverknob(Figure41).

Figure41).

Figure41

1.Cover

2.Hoseclamp4.Foamelement

3.Paperelement

CleaningtheFoamAir-cleanerElement

ServiceInterval:Every25hours

1.Washthefoamelementinliquidsoapandwarmwater.

Whentheelementisclean,rinseitthoroughly .

ServicingtheEngineOil

ServiceInterval:Beforeeachuseordaily—Checkthe

engine-oillevel.

Aftertherst8hours—Changetheengineoil.

Every100hours—Changetheengineoil.(moreoften

indirtyordustyconditions)

Every200hours—Changetheengine-oillter.

Note:Changetheoilmorefrequentlywhentheoperating

conditionsareextremelydustyorsandy.

Note:Therearedifferentoilcapacitiesforthedifferent

modelslistedinthismanual.Ensurethecorrectamountof

oilisused.

Important:Remembertoadd80%oftheoilandthen

graduallyllittotheFullmarkonthedipstick.

OilType:Detergentoil(APIserviceSF ,SG,SH,SJorSL)

EngineOilCapacity:1.7L(58oz)withthelterremoved;

1.5L(51oz)withoutthelterremoved

Viscosity:Refertothetablebelow:

34

Page 35

Figure42

g020534

G008792

1

2

5

6

7

3

9

10

4

8

CheckingtheEngine-oilLevel

Note:Checktheoilwhentheengineiscold.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawaythemuferandotherhotsurfaces.

Important:Donotoverllthecrankcasewithoil

becausedamagetotheenginemayresult.Donotrun

enginewithoilbelowthelowmarkbecausetheengine

maybedamaged.

1.DisengagethePTO,movethemotion-controlleversto

theneutral-lockedposition,andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position(Figure43).

Figure43

35

Page 36

ChangingtheEngineOil

g020534

g012596

2

3

4

1

G008796

2

3

4

5

6

1

Note:Disposeoftheusedoilatarecyclingcenter.

1.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoassuretheoildrains

completely.

2.DisengagethePTO,movethemotioncontrolleversto

theneutrallockedpositionandsettheparkingbrake.

3.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position(

4.ChangetheengineoilasshowninFigure44.

Figure44).

Figure45

Figure44

5.Slowlypourapproximately80%ofthespeciedoil

intothellertubeandslowlyaddtheadditionaloilto

bringittotheFullmark(Figure45).

ChangingtheEngine-oilFilter

Note:Changetheengine-oilltermorefrequentlywhen

operatingconditionsareextremelydustyorsandy.

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil(page36).

2.Placearagundertheoilltertosoakupanyspilledoil.

Important:Spilledoilmaydrainundertheengine

andontotheclutch.Oilspilledontheclutchmay

damagetheclutch,causethebladestostopslowly

whentheclutchisintheOffposition,andcause

theclutchtoslipwhentheclutchisswitchedto

theOnposition.Wipeupanyspilledoil.

3.Changetheengine-oillter(Figure46).

36

Page 37

g020534

G012845

3/4

2

3

4

5

6

1

RemovingtheSparkPlug

G008794

1

2

1.DisengagethePTO,movethemotion-controlleversto

theneutral-lockedposition,andsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.RemovethesparkplugasshowninFigure47.

Figure46

Note:Ensuretheoil-ltergaskettouchestheengine

andthenanextra3/4turniscompleted.

4.Fillthecrankcasewiththepropertypeofnewoil;refer

toChangingtheEngineOil(page36).

ServicingtheSparkPlug

ServiceInterval:Every100hours

Makesuretheairgapbetweenthecenterandsideelectrodes

iscorrectbeforeinstallingthesparkplug.

Figure47

CheckingtheSparkPlug

Important:Donotcleanthesparkplug(s).Always

replacethesparkplug(s)whenithasablackcoating,

wornelectrodes,anoilylm,orcracks.

Ifyouseelightbrownorgrayontheinsulator,theengineis

operatingproperly.Ablackcoatingontheinsulatorusually

meanstheaircleanerisdirty.

Setthegapto0.75mm(0.03inch).

Figure48

Useasparkplugwrenchforremovingandinstallingthespark

plug(s)andagappingtool/feelergaugetocheckandadjust

theairgap.Installanewsparkplug(s)ifnecessary.

TypeforallEngines:NGK

AirGap:0.75mm(0.03inch)

®

BPR4ESorequivalent

37

Page 38

InstallingtheSparkPlug

g020861

Tightenthesparkplug(s)to22N-m(16ft-lb).

FuelSystem

Maintenance

DrainingtheFuelTank

Note:Thereisnootherrecommendedwaytodrainfuel

fromthetank,otherthanusingasyphonpump.Asyphon

pumpcanbepurchasedatahardwarestore.

Figure49

CheckingtheSparkArrester (ifequipped)

ServiceInterval:Every50hours

WARNING

Hotexhaust-systemcomponentsmayignite

gasolinevaporsevenaftertheengineisstopped.

Hotparticlesexhaustedduringengineoperation

mayigniteammablematerials.Firemayresultin

personalinjuryorpropertydamage.

Donotrefuelorruntheengineunlessthespark

arresterisinstalled.

1.Stoptheengine,waitforallmovingpartstostop,

engagetheparkingbrake,andremovethekey.

2.Waitforthemufertocool.

3.Ifanybreaksinthescreenorweldsareobserved,

replacethearrester.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Draingasolinefromthefueltankwhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

1.Parkthemachineonalevelsurface,disengagethe

power-takeoff(PTO),settheparkingbrake,turnthe

ignitionkeytoOff,andremovethekey .

2.Cleanaroundthefuelcaptopreventdebrisfrom

gettingintothefueltank(

3.Removethefuelcap.

4.Insertasyphonpumpintothefueltank.

5.Usingthesyphonpump,drainthefuelintoacleangas

can(

Figure50).

6.Wipeupanyspilledfuel.

Figure51).

4.Ifpluggingofthescreenisobserved,removethe

arrester,shakelooseparticlesoutofthearrester,and

cleanthescreenwithawirebrush(soakinsolventif

necessary).

5.Installarresteronexhaustoutlet.

Figure50

1.Fuelcap

38

Page 39

ServicingtheFuelFilter

ElectricalSystem

ReplacingtheFuelFilter

ServiceInterval:Yearly

Neverinstalladirtylterifitisremovedfromthefuelline.

Note:Thefuellterisinstalledinordertoinstallthenew

ltercorrectly.

Note:Wipeupanyspilledfuel.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Closefuelshut-offvalve.

4.Squeezetheendsofthehoseclampstogetherandslide

themawayfromthelter(Figure51).

Maintenance

ServicingtheBattery

ServiceInterval:Every100hours

Alwayskeepthebatterycleanandfullycharged.Useapaper

toweltocleanthebatterycase.Ifthebatteryterminalsare

corroded,cleanthemwithasolutionoffourpartswaterand

onepartbakingsoda.Applyalightcoatingofgreasetothe

batteryterminalstopreventcorrosion.

Voltage:12V

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

Figure51

1.Fuellter

2.Hoseclamp

5.Removethelterfromthefuellines.

6.Installanewlterandmovethehoseclampscloseto

thelter.

7.Openthefuelshut-offvalve.

8.Checkforfuelleaksandrepairifneeded.

9.Wipeupanyspilledfuel.

3.Fuelline

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing.Wearsafetyglassestoshield

youreyesandrubberglovestoprotectyourhands.

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

39

Page 40

WARNING

g013199

1

2 3 4

5

6

Incorrectbatterycableroutingcoulddamagethe

machineandcablescausingsparks.Sparkscan

causethebatterygassestoexplode,resultingin

personalinjury.

•AlwaysDisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

•AlwaysReconnectthepositive(red)battery

cablebeforereconnectingthenegative(black)

cable.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Disconnectthenegativebatterycablefromthenegative

(-)batteryterminal(

4.Slidetheredterminalbootoffthepositive(red)battery

terminal.

5.Removethepositive(red)batterycable(Figure52).

Figure52).

6.Removethebatteryholddownplate(Figure52),and

removethebattery.

1.Wingnut

InstallingtheBattery

1.Placethebatteryontothemachine(Figure52).

2.Securethebatterywiththeholddownplate,thej-bolts,

andthelocknuts.

3.Installthepositive(red)batterycabletopositive(+)

batteryterminalwithanut,awasher,andabolt(

52).Slidetherubbercoveroverthepost.

4.Installthenegativebatterycableandgroundwireto

thenegative(-)batteryterminalwithanut,awasher,

andabolt(Figure52).

Note:Thebatterycableswillcrossovereachother

whentheyarecorrectlyinstalled(Figure52).

Figure

2.Batterycover5.Battery

3.Negative(–)batterycable

ChargingtheBattery

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparksand

amesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged

(1.265specicgravity)topreventbatterydamagewhen

thetemperatureisbelow32°F(0°C).

1.Removethebatteryfromthechassis;refertoRemoving

theBattery(page39).

Figure52

4.Positive(+)batterycable

6.Thebatterycablescross

wheninstalledcorrectly

2.Checktheelectrolytelevel.

3.Ensurethatthellercapsareinstalledonthebattery.

4.Chargethebatteryfor1hourat25to30ampsor6

hoursat4to6amps.

5.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,anddisconnectthecharger

leadsfromthebatteryposts(

40

Figure53).

Page 41

6.Installthebatteryontothemachineandconnectthe

g013015

g015241

batterycables;refertoInstallingtheBattery(page40).

DriveSystem

Note:Donotrunthemachinewiththebattery

disconnected;electricaldamagemayoccur.

Figure53

1.PositiveBatteryPost

2.NegativeBatteryPost

3.Red(+)ChargerLead

4.Black(-)ChargerLead

ServicingtheFuses

Theelectricalsystemisprotectedbyfuses.Itrequiresno

maintenance.Ifafuseblows,checkthecomponentorcircuit

foramalfunctionorshort.

Maintenance

AdjustingtheTracking

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

1.Pushbothcontrolleversforwardthesamedistance.

2.Checkifthemachinepullstooneside.

Note:Ifitdoes,stopthemachineandsettheparking

brake.

3.Releasethecushionfromtherearofthemachine.

4.Rotatetherightcableadjustmenttopositiontheright

motioncontrolinthecenterofthecontrolpanel

neutral-lockslot(

Figure56).

1.Releasetheoperatorcushionfromtherearofthe

machine.

2.Pulloutonthefusetoremoveandreplaceit(

54).

3.Installtheoperatorcushion.

Figure54

Figure

Figure55

1.Leftmotion-controllever

2.Rightmotion-controllever4.Alignthecontrollevers

5.Rotatetheleftcableadjustmenttomatchtheleft

wheelspeedtothepreviouslysetrightwheelspeed.

6.Adjustinquarter-turnincrementsuntilthemachine

tracksstraight.

Note:Onlyadjusttheleftcabletomatchtheleft

wheelspeedtotherightwheelspeed.Donotadjust

therightwheelspeedasthiswillpositiontheright

motion-controlleveroutofthecenterforthecontrol

panelneutral-lockslot.

3.Neutral-lockedposition

fronttoback

1.Controls

2.Wire

3.Fuses

41

Page 42

3

g017848

Figure56

G015609

1 6

2 3 4

4

2

5

6

6.Testthesafety-interlocksystembeforeoperation.

1.Leftcableadjustment

2.Cablelock

3.Rightcableadjustment

7.Checkforpropertracking.

Note:Ifthemachinewillnotstartafteradjusting

thetracking,makesureproximityswitchtargetaligns

withboltattachedtomotion-controllever;referto

AdjustingtheProximitySwitch(page42).

8.Repeatthecableadjustmentuntilthetrackingis

correct.

9.Checkthatthemachinedoesnotcreepfromneutral

withtheparkbrakesdisengaged.

Important:Donotrotatethelinkagetoofar,asthis

maycausethemachinetocreepinneutral.

AdjustingtheProximitySwitch

Usethisprocedureifthemachinewillnotstartafteradjusting

thetracking.

1.Ensurethattheboltattachedtothemotion-control

leveralignswiththeproximityswitchtarget(Figure57).

Figure57

1.Proximityswitchtarget4.Boltattachedtothe

motion-controllever

2.Proximityswitch5.Distancebetween0.51

to1.02mm(0.02to0.04

inches)isneeded

3.Boltsandnuts6.Jamnut

2.Ifneeded,loosentheboltsandadjusttheproximity

switchuntilthetargetalignswiththeboltattachedto

themotion-controllever(Figure57).

3.Checkthedistanceofthebolttotheproximityswitch;

itneedstobebetween0.51to1.02mm(0.02to0.04

inches)asshowninFigure57.

4.Ifadjustmentisneeded,loosenthejamnutandadjust

thebolttothecorrectdistance.

5.Tightenthejamnutafteradjustingthebolt(Figure57).

42

Page 43

CheckingtheTirePressure

ServiceInterval:Every50hours/Monthly(whichever

comesrst)

Maintaintheairpressureinthereartiresat83to97kPa(12

to14psi).

Important:Uneventirepressurecancauseanuneven

cut.

Note:Thefronttiresaresemi-pneumatictiresanddonot

requireair-pressuremaintenance.