Page 1

FormNo.3371-914RevA

GrandStand

®

Mower

With91cmor102cmTURBOFORCE

CuttingUnit

ModelNo.74534TE—SerialNo.312000001andUp

ModelNo.74536TE—SerialNo.312000001andUp

®

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

ThisproductcomplieswithallrelevantEuropean

directives,fordetailspleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

ThissparkignitionsystemcomplieswithCanadian

ICES-002.

Introduction

Thisrotary-blade,ridinglawnmowerisintended

tobeusedbyprofessional,hiredoperatorsor

residentialhomeowners.Itisdesignedprimarily

forcuttinggrassonwell-maintainedlawnson

residentialorcommercialproperties.Itisnot

designedforcuttingbrushorforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .T oro.comfor

productandaccessoryinformation,helpndingadealer,

ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorToroCustomerServiceandhave

themodelandserialnumbersofyourproductready .

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjury

ordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythefollowingwords:

•Dangersignalsanextremehazardthatwillcause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

•Warningsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

•Cautionsignalsahazardthatmaycauseminor

ormoderateinjuryifyoudonotfollowthe

recommendedprecautions.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizesgeneral

informationworthyofspecialattention.

1.Locationofthemodelandserialnumbers

©2011—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure1

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction.................................................................2

Safety...........................................................................4

GeneralLawnMowerSafety.................................4

ToroMowerSafety...............................................5

SoundPressure.....................................................6

SoundPower........................................................6

VibrationLevelforModel74534TE.....................6

VibrationLevelforModel74536TE.....................6

SlopeIndicator.....................................................8

SafetyandInstructionalDecals.............................9

ProductOverview......................................................14

Controls.............................................................14

Specications.....................................................15

Operation...................................................................16

AddingFuel.......................................................16

CheckingtheEngineOilLevel............................17

BreakingInaNewMachine................................17

ThinkSafetyFirst...............................................17

OperatingtheParkingBrake...............................17

OperatingtheMowerBladeControlSwitch

(PTO)............................................................18

OperatingtheThrottle.......................................18

OperatingtheChoke..........................................18

OperatingtheIgnitionSwitch.............................19

UsingtheSpeedControlLever...........................19

UsingtheFuelShut-OffValve............................19

StartingandStoppingtheEngine........................20

TheSafetyInterlockSystem................................21

OperatingthePlatform......................................22

DrivingForwardorBackward.............................23

StoppingtheMachine.........................................24

PushingtheMachinebyHand.............................24

TransportingMachines.......................................25

LoadingMachines..............................................25

SideDischargingorMulchingtheGrass..............26

AdjustingtheHeight-of-Cut...............................26

AdjustingtheFlowBafe...................................27

PositioningtheFlowBafe.................................27

UsingCounterweights........................................28

Maintenance...............................................................29

RecommendedMaintenanceSchedule(s)................29

PremaintenanceProcedures....................................30

RaisingtheMowerforAccess.............................30

ReleasetheCushionforRearAccess...................31

Lubrication.............................................................32

HowtoGrease...................................................32

LubricatingtheMachine.....................................32

GreasingtheFrontCasterPivots.........................33

LubricatetheCasterWheelHubs........................33

EngineMaintenance...............................................34

ServicingtheAirCleaner....................................34

ServicingtheEngineOil.....................................35

ServicingtheSparkPlug.....................................37

FuelSystemMaintenance.......................................39

DrainingtheFuelTank.......................................39

ServicingtheFuelFilter......................................39

ElectricalSystemMaintenance................................40

ServicingtheBattery...........................................40

ServicingtheFuses.............................................41

DriveSystemMaintenance.....................................42

AdjustingtheTracking.......................................42

CheckingtheTirePressure.................................43

AdjustingtheCasterPivotBearing......................43

AdjustingtheElectricClutch..............................44

CoolingSystemMaintenance..................................45

CleaningtheAirIntakeScreen............................45

CleaningtheCoolingSystem...............................45

BrakeMaintenance.................................................46

ServicingtheBrake.............................................46

BeltMaintenance....................................................47

CheckingtheBelts..............................................47

ReplacingtheMowerDeckBeltfor91cm

Mowers..........................................................47

ReplacingtheMowerDeckBeltsfor102cm

Mowers..........................................................47

ReplacingtheRightMowerDeckBelt.................47

ReplacingtheLeftMowerDeckBelt...................48

ReplacingthePumpDriveBelt...........................48

ControlsSystemMaintenance.................................49

AdjustingtheMotionControlHandle

Positions........................................................49

HydraulicSystemMaintenance...............................52

ServicingtheHydraulicSystem...........................52

MowerDeckMaintenance......................................55

ServicingtheCuttingBlades...............................55

LevelingtheMower............................................56

ReplacingtheGrassDeector.............................60

Cleaning.................................................................61

CleaningUndertheMower.................................61

WasteDisposal...................................................61

Storage.......................................................................61

CleaningandStorage..........................................61

Troubleshooting.........................................................63

Schematics.................................................................65

3

Page 4

Safety

Improperlyusingormaintainingthismowercan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructions.

Torodesignedandtestedthismowerforreasonablysafe

service;however,failuretocomplywiththefollowing

instructionsmayresultinpersonalinjury.

Toensuremaximumsafety,bestperformance,and

togainknowledgeoftheproduct,itisessential

thatyouandanyotheroperatorofthemowerread

andunderstandthecontentsofthismanualbefore

theengineiseverstarted.Payparticularattention

tothesafetyalertsymbol(

Caution,Warning,orDanger—“personalsafety

instruction.”Readandunderstandtheinstruction

becauseithastodowithsafety .Failuretocomply

withtheinstructionmayresultinpersonalinjury.

GeneralLawnMowerSafety

Thefollowinginstructionshavebeenadaptedfromthe

standardEN836:1997.

Figure2)whichmeans

–inadequatebraking

–thetypeofmachineisunsuitableforit'stask

–lackofawarenessoftheeffectofground

conditions,especiallyslopes

–incorrectloaddistribution

Gasoline

WARNING-Gasolineishighlyammable.Takethe

followingprecautions.

•Storefuelincontainersspecicallydesignedforthis

purpose.

•Refueloutdoorsonlyanddonotsmokewhile

refueling.

•Addfuelbeforestartingtheengine.Neverremove

thecapofthefueltankoraddgasolinewhilethe

engineisrunningorwhentheengineishot.

•Ifgasolineisspilled,donotattempttostartthe

enginebutmovethemowerawayfromtheareaof

spillageandavoidcreatinganysourceofignition

untilgasolinevaporshavedissipated.

•Replaceallfueltankandcontainercapssecurely.

Thiscuttingmachineiscapableofamputatinghands

andfeetandthrowingobjects.Failuretoobservethe

followingsafetyinstructionscouldresultinserious

injuryordeath.

Training

•Readtheinstructionscarefully.Befamiliarwiththe

controlsandtheproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstousethemower.Localregulationscan

restricttheageoftheoperator.

•Keepinmindthattheoperatororuserisresponsible

foraccidentsorhazardsoccurringtootherpeopleor

theirproperty.

•Understandexplanationsforallpictogramsusedon

themowerorintheinstructions.

•Donotcarrypassengers.

•Alloperatorsshouldseekandobtainprofessional

andpracticalinstruction.

•Usecareandconcentrationwhenworkingwith

machines.

•Thecontrolofamachineonaslopewillnotbe

regainedbytheapplicationofthebrake.

Themainreasonsforlossofcontrolare:

–insufcientwheelgrip

–beingdriventoofast

Preparation

•Whilemowing,alwayswearsubstantialfootwearand

longtrousers.Donotoperatetheequipmentwhen

barefootorwearingopensandals.

•Thoroughlyinspecttheareawheretheequipmentis

tobeusedandremoveallstones,sticks,wires,bones

andotherforeignobjects.

•Beforeusing,alwaysvisuallyinspecttoseethat

guards,andsafetydevices,suchasdeectorsand/or

grasscatchers,areinplaceandworkingcorrectly.

•Beforeusing,alwaysvisuallyinspecttoseethatthe

blades,bladeboltsandcutterassemblyarenotworn

ordamaged.Replacewornordamagedbladesand

boltsinsetstopreservebalance.

Starting

•Disengageallbladeanddriveclutchesandshiftinto

neutralbeforestartingtheengine.

•Starttheengineorswitchonthemotorcarefully

accordingtoinstructionsandwithfeetwellaway

fromtheblade(s)andnotinfrontofthedischarge

chute.

Operation

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

4

Page 5

•Nevermowwhilepeople,especiallychildren,orpets

arenearby .

•Mowonlyindaylightoringoodarticiallight.

•Avoidoperatingthelawnmowerinwetgrass,where

feasible.

•Stayalertforholesintheterrainandotherhidden

hazards.

•Neverdirectdischargeofmaterialtowards

bystanders.

•Donotputhandsorfeetnearorunderrotatingparts.

Keepclearofthedischargeopeningatalltimes.

•Useextremecautionwhenreversingorpullinga

pedestriancontrolledlawnmowertowardsyou.

•Walk,neverrun.

•Slopes:

–Donotmowexcessivelysteepslopes.Donot

mowslopesgreaterthan15degrees.

–Exerciseextremecautionwhenonslopes.

–Mowacrossthefaceofslopes,neverupand

downandexerciseextremecautionwhen

changingdirectiononslopes.

–Alwaysbesureofyourfootingonslopes.

•Uselowthrottlesettingswhenengagingthe

traction-clutch,especiallyinhighgears.Reduce

speedonslopesandinsharpturnstoprevent

overturningorlossofcontrol.

•Stopthebladewhencrossingsurfacesotherthan

grassandwhentransportingthelawnmowertoand

fromtheareatobemowed.

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Stoptheengine

–wheneveryouleavethelawnmower.

–beforerefueling.

–beforeremovingthegrasscatcher.

•Stoptheengineanddisconnectthespark-plugwire

orturnoffandremovethekey.

–beforeclearingblockagesoruncloggingchute.

–beforechecking,cleaningorworkingonthelawn

mower.

–afterstrikingaforeignobject,inspectthelawn

mowerfordamageandmakerepairsbefore

restartingandoperatingthelawnmower.

–iflawnmowerstartstovibrateabnormally(check

immediately).

•Watchoutfortrafcwhencrossingornearroadways.

•Beforeleavingtheoperator'sposition

–disengagethepowertake-offandlowerthe

attachments.

–changeintoneutralandsettheparkingbrake.

–stoptheengineandremovethekey.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Donotusepressurecleaningequipmentonmachine.

•Neverstoretheequipmentwithgasolineinthetank

andinsideabuildingwherefumescanreachanopen

ameorspark.

•Allowtheenginetocoolbeforestoringinany

enclosure.

•Toreducetherehazard,keeptheengine,silencer,

batterycompartmentandgasolinestoragefreeof

grass,leaves,orexcessivegrease.

•Checkgrasscatchercomponentsandthedischarge

guardfrequentlyandreplacewithmanufacturer's

recommendedparts,whennecessary.

•Replacewornordamagedpartsforsafety .

•Replacefaultysilencers.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Donotchangetheenginegovernorsettingsor

overspeedtheengine.Operatinganengineat

excessivespeedcanincreasethehazardofpersonal

injury.

•Onmultibladedlawnmowers,takecareasrotating

oneblademaycauseotherstorotate.

•Becarefulduringadjustmentofthelawnmowerto

prevententrapmentofthengersbetweenmoving

bladesandxedpartsofthelawnmower.

•Toensurethebestperformanceandsafety ,

purchaseonlygenuineT ororeplacementparts

andaccessories.Donotuse

accessories;theymaycauseasafetyhazard.

will t

partsand

ToroMowerSafety

Thefollowinglistcontainssafetyinformationspecic

toToroproductsandothersafetyinformationyoumust

know .

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Thisproductisdesignedforcuttingandrecyclinggrass

or,whenequippedwithagrassbagger,forcatchingcut

grass.Anyuseforpurposesotherthanthesecould

provedangeroustouserandbystanders.

5

Page 6

GeneralOperation

•Besuretheareaisclearofotherpeoplebefore

mowing.Stopthemachineifanyoneentersthearea.

•Donottouchequipmentorattachmentpartswhich

maybehotfromoperation.Allowtocoolbefore

attemptingtomaintain,adjustorservice.

•UseonlyToroapprovedattachments.Warrantymay

bevoidedifusedwithunapprovedattachments.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)beforeoperating

underanyobjectsanddonotcontactthem.

•Slowdownbeforemakingturnsanduseextra

caution.

•Usecautionwhenridingtheplatformovercurbs,

rocks,roots,orotherobstructions.

•Lookbehindanddownbeforebackinguptobesure

ofaclearpath.Useextracarewhenoperationin

reverse.

•Neverjerkthecontrols;useasteadymotion.

•Donotcarrypassengers.

SlopeOperation

Allslopesandrampsrequireextracaution.Ifyoufeel

uneasyonaslope,donotmowit.

•Removeobstaclessuchasrocks,treelimbs,etc.from

themowingarea.

•Watchforholes,rutsorbumps.Tallgrasscanhide

obstacles.

•Usecautionneardrop-offs,ditches,orembankments.

Themachinecouldsuddenlyturnoverifawheel

goesovertheedgeofaclifforditch,orifanedge

cavesin.

•Useextracarewithgrasscatchersorother

attachments.Thesecanchangethestabilityofthe

machine.

•Keepallmovementonslopesslowandgradual.Do

notmakesuddenchangesinspeedordirection.

•Mowslopessidetoside.

Service

•Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

•Keepnutsandboltstight,especiallytheblade

attachmentbolts.Keepequipmentingood

condition.

•Nevertamperwithsafetydevices.Checksafety

systemsforproperoperationbeforeeachuse.

•Useonlygenuinereplacementpartstoensurethat

originalstandardsaremaintained.

•Checkbrakeoperationfrequently.Adjustandservice

asrequired.

SoundPressure

Model74534TEhasasoundpressurelevelatthe

operator’searof88dBA,whichincludesanUncertainty

Value(K)of1dBA.

Model74536TEhasasoundpressurelevelatthe

operator’searof86dBA,whichincludesanUncertainty

Value(K)of1dBA.

Thesoundpressurelevelwasdeterminedaccordingto

theproceduresoutlinedinEN836.

SoundPower

Model74534TEhasaguaranteedsoundpowerlevel

of100dBA,whichincludesanUncertaintyValue(K)

of1dBA.

Model74536TEhasaguaranteedsoundpowerlevel

of100dBA,whichincludesanUncertaintyValue(K)

of1dBA.

Thesoundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

VibrationLevelforModel

74534TE

Hand-Arm

Measuredvibrationlevelforrighthand=0.8m/s

Measuredvibrationlevelforlefthand=0.6m/s

UncertaintyValue(K)=0.4m/s

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinEN836.

WholeBody

Measuredvibrationlevel=0.79m/s

UncertaintyValue(K)=0.39m/s

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinEN836.

2

2

2

2

VibrationLevelforModel

74536TE

Hand-Arm

Measuredvibrationlevelforrighthand=1.1m/s

2

2

6

Page 7

Measuredvibrationlevelforlefthand=1.1m/s

2

UncertaintyValue(K)=0.6m/s

2

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinEN836.

WholeBody

Measuredvibrationlevel=0.79m/s

UncertaintyValue(K)=0.39m/s

2

2

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinEN836.

7

Page 8

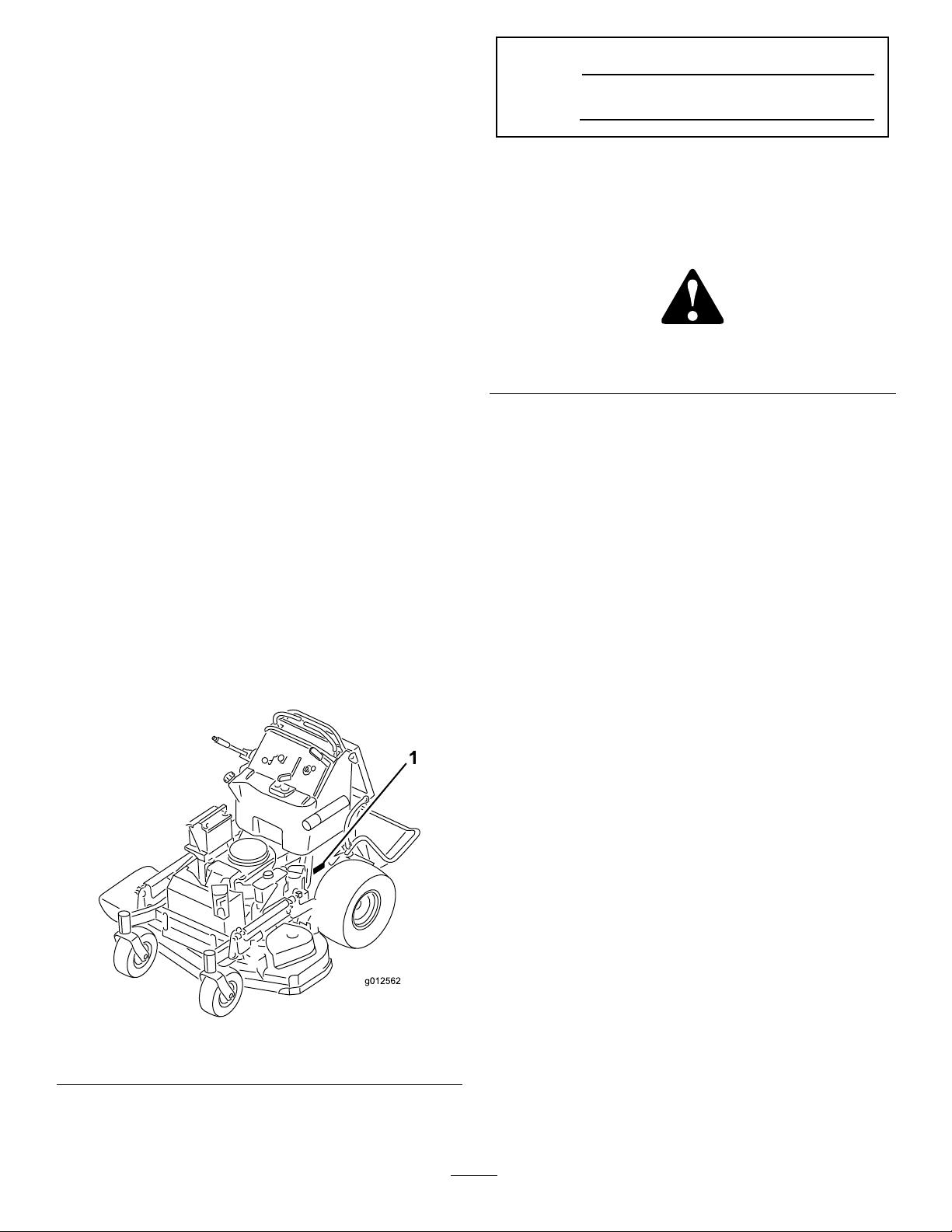

SlopeIndicator

G015791

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

8

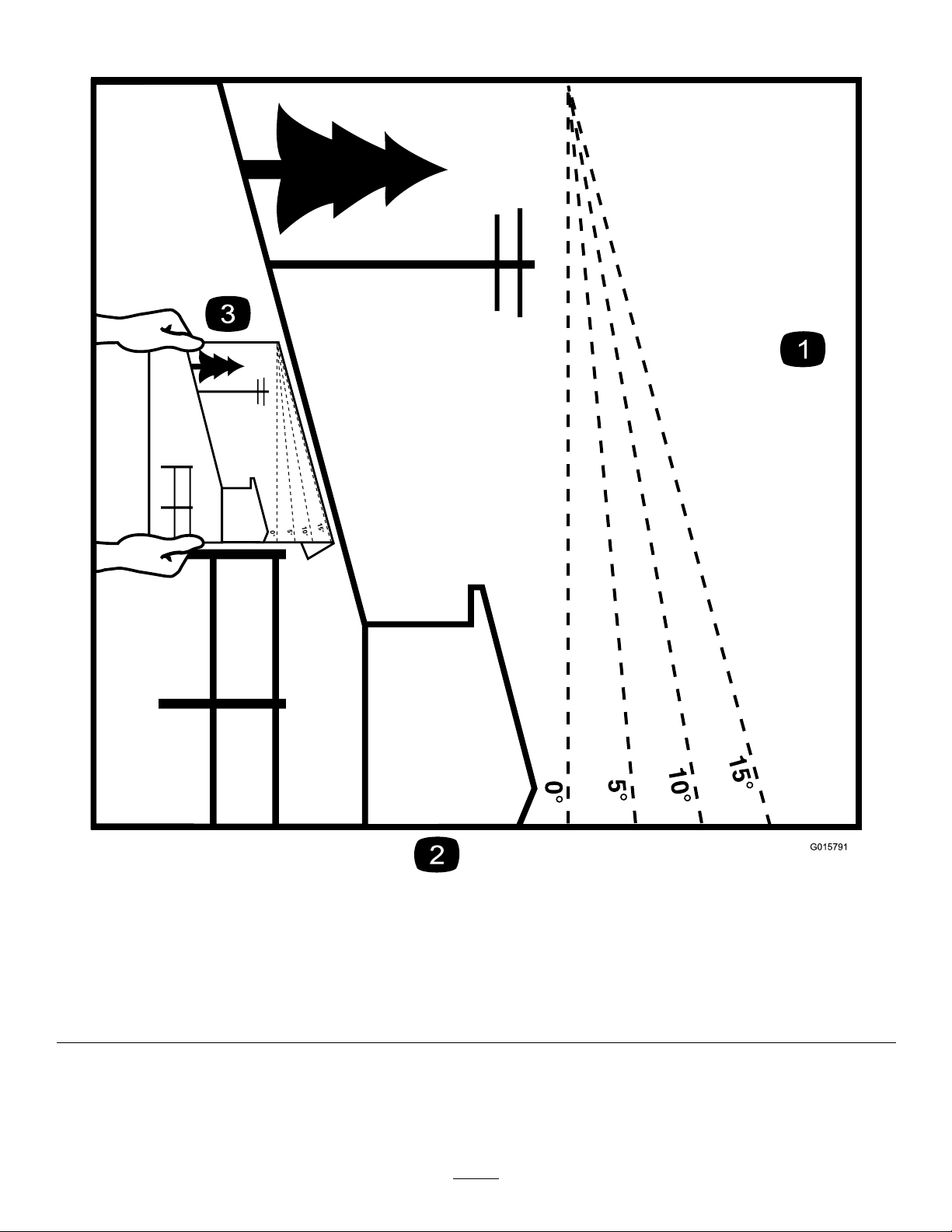

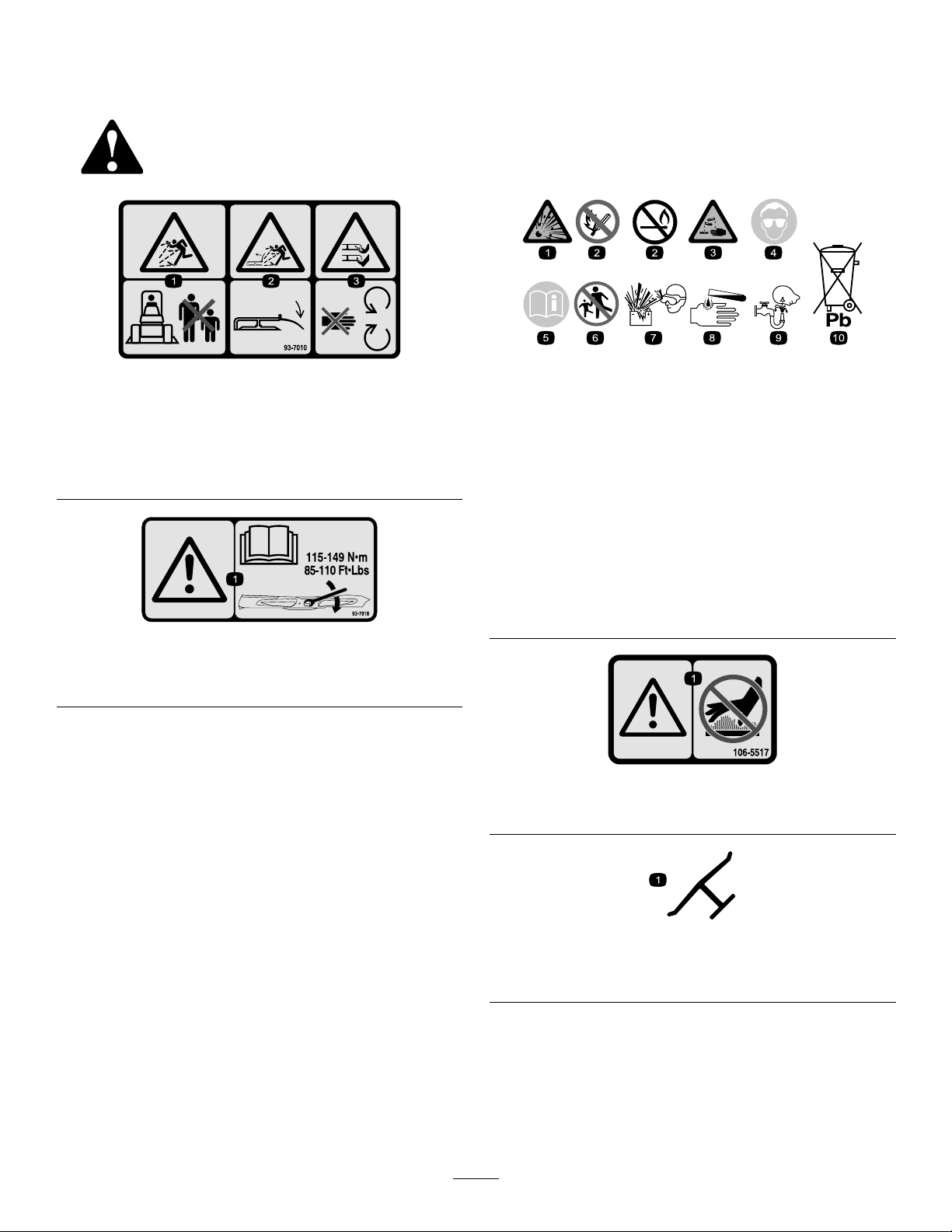

Page 9

SafetyandInstructional

Decals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

93-7010

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Thrownobjecthazard,mower—keepthedeectorinplace.

3.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto115-149N-m(85-110ft-lb).

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

106-5517

1.Warning—donottouchthehotsurface.

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

9

Page 10

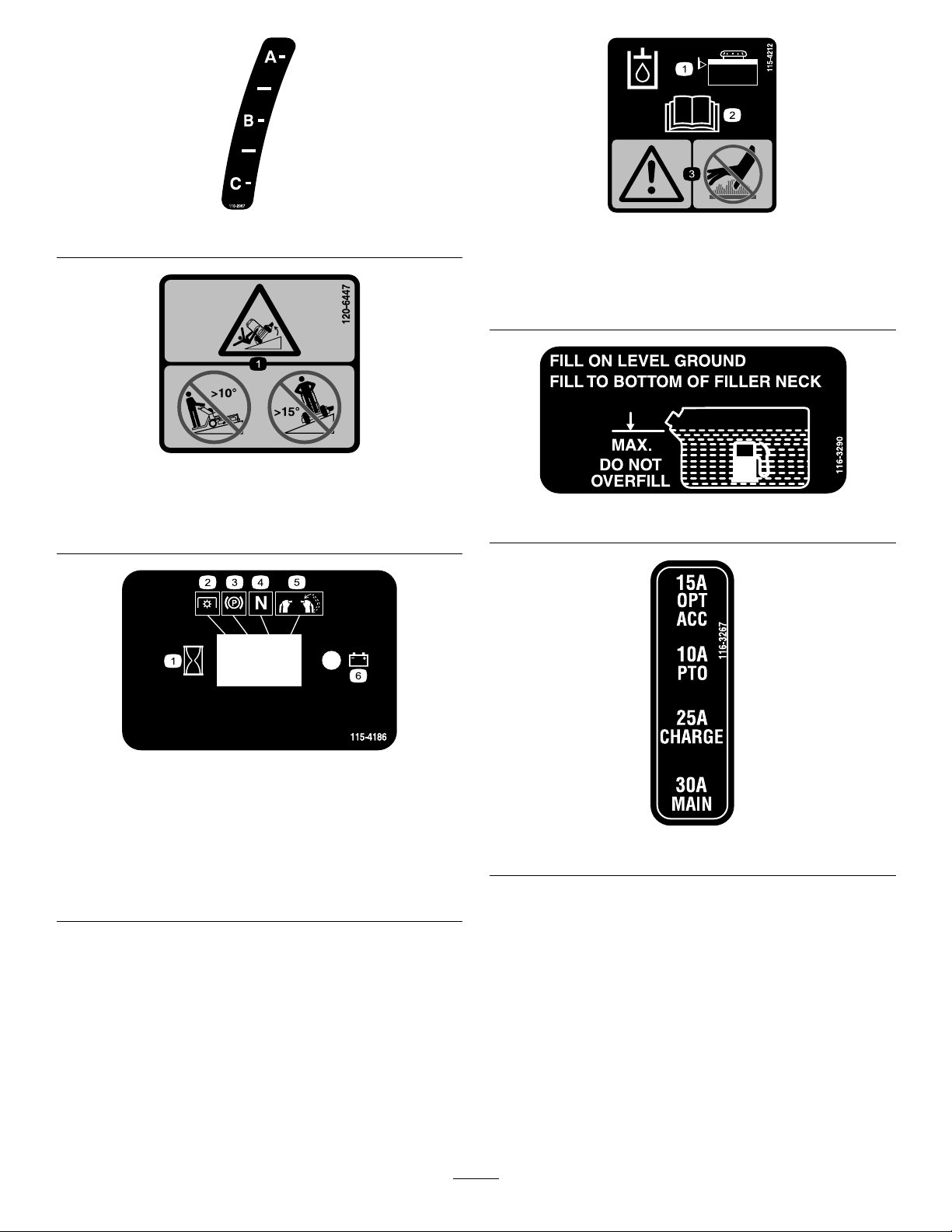

110-2067

115-4212

120-6447

1.Tippinghazard—donotmowupanddownslopesgreater

than10degrees,donotmowacrossslopesgreaterthan

15degrees.

1.Hydraulicoillevel3.Warning—donottouchthe

hotsurface.

2.ReadtheOperator's

Manual.

116-3290

1.Interval

2.PowerT ake-off(PTO)

3.Parkingbrake

4.Neutral

5.Operatorpresenceswitch

6.Battery

115-4186

116-3267

10

Page 11

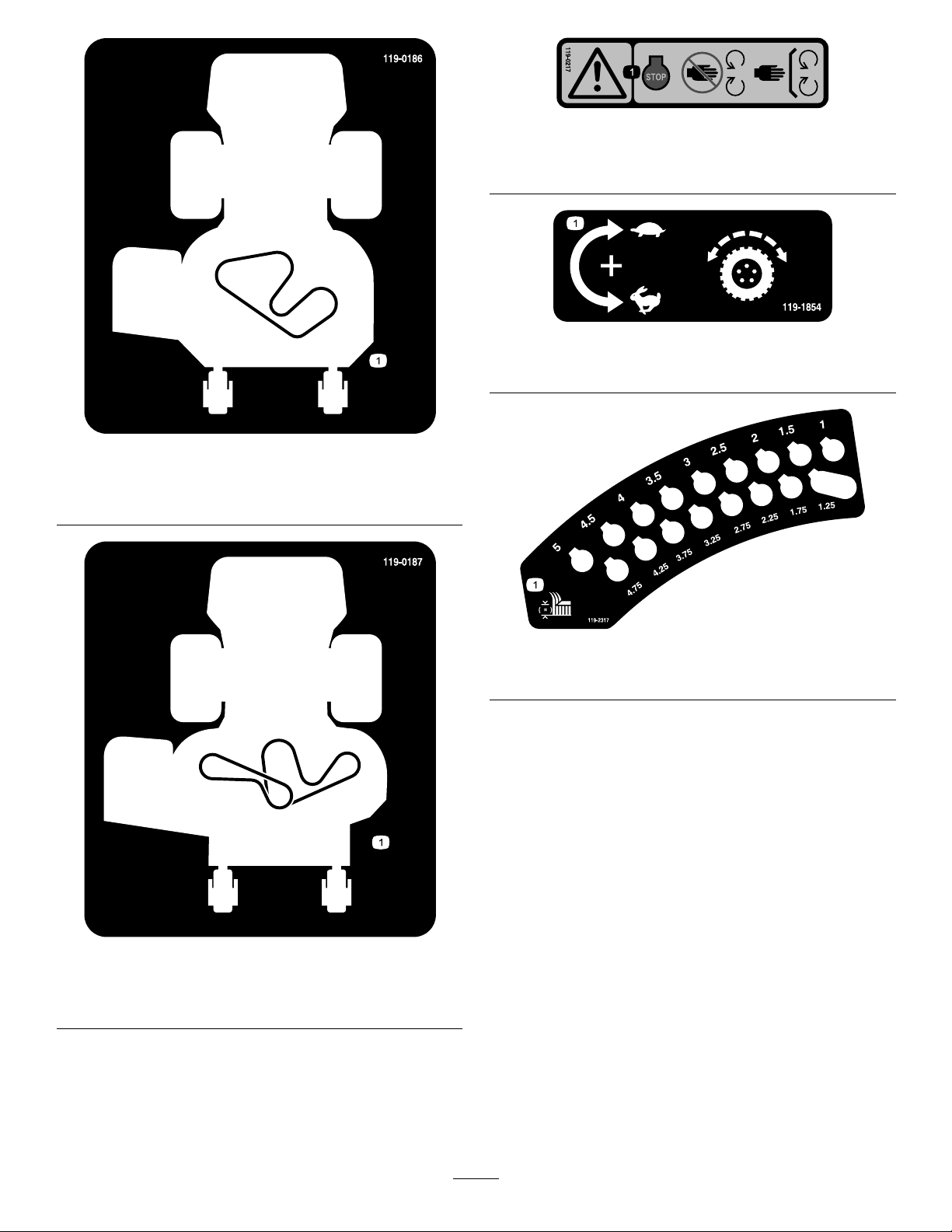

119-0217

1.Warning—stoptheengine;stayawayfrommovingparts;

keepallguardsandshieldsinplace.

119-1854

1.Adjustmentknobfortractiondrivespeed.

119-0186

91cmMowerDeck

1.Beltrouting

119-2317

1.Height-of-cut(inches)

119-0187

102cmMowerDeck

1.Beltrouting

11

Page 12

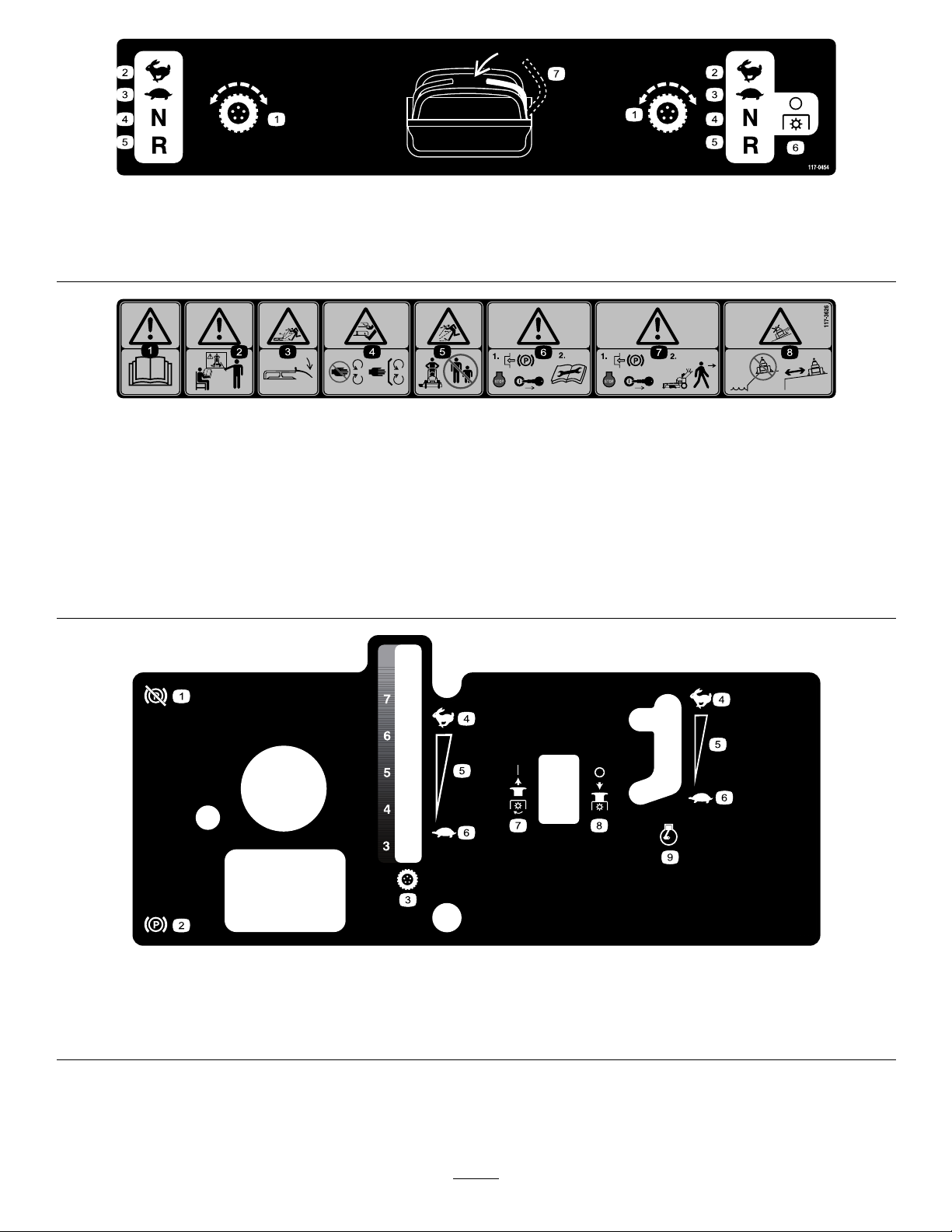

117-0454

1.Tractioncontrol

2.Fast4.Neutral

3.Slow

5.Reverse

6.PowerT ake-off

(PTO)—disengage

7.Operatorpresenceswitch

117–3626

1.Warning—readtheOperator'sManual.5.Thrownobjecthazard—keepbystandersasafedistancefrom

2.Warning—donotoperatethismachineunlessyouaretrained.6.Warning—engagetheparkingbrake,stoptheengine

3.Thrownobjecthazard—keepdeectorinplace.

4.Cutting,dismembermenthazardofhandorfoot—stayaway

frommovingpartsandkeepallguardsandshieldsinplace.

themachine.

andremovethesparkplugwirebeforeperformingany

maintenanceonthemachine.

7.Warning—engagetheparkingbrakeandstoptheengine

beforeleavingthemachine.

8.Slidingandlossofcontrolhazard—donotoperatethe

machineneardrop-offsorwater;keepasafedistancefrom

drop-offs.

1.Parkingbrake—disengaged4.Fast

2.Parkingbrake—engaged

3.Drivespeed

119-0234

5.Continuousvariablesetting8.PTO—disengaged

6.Slow

12

7.PTO—engaged

9.Enginespeed

Page 13

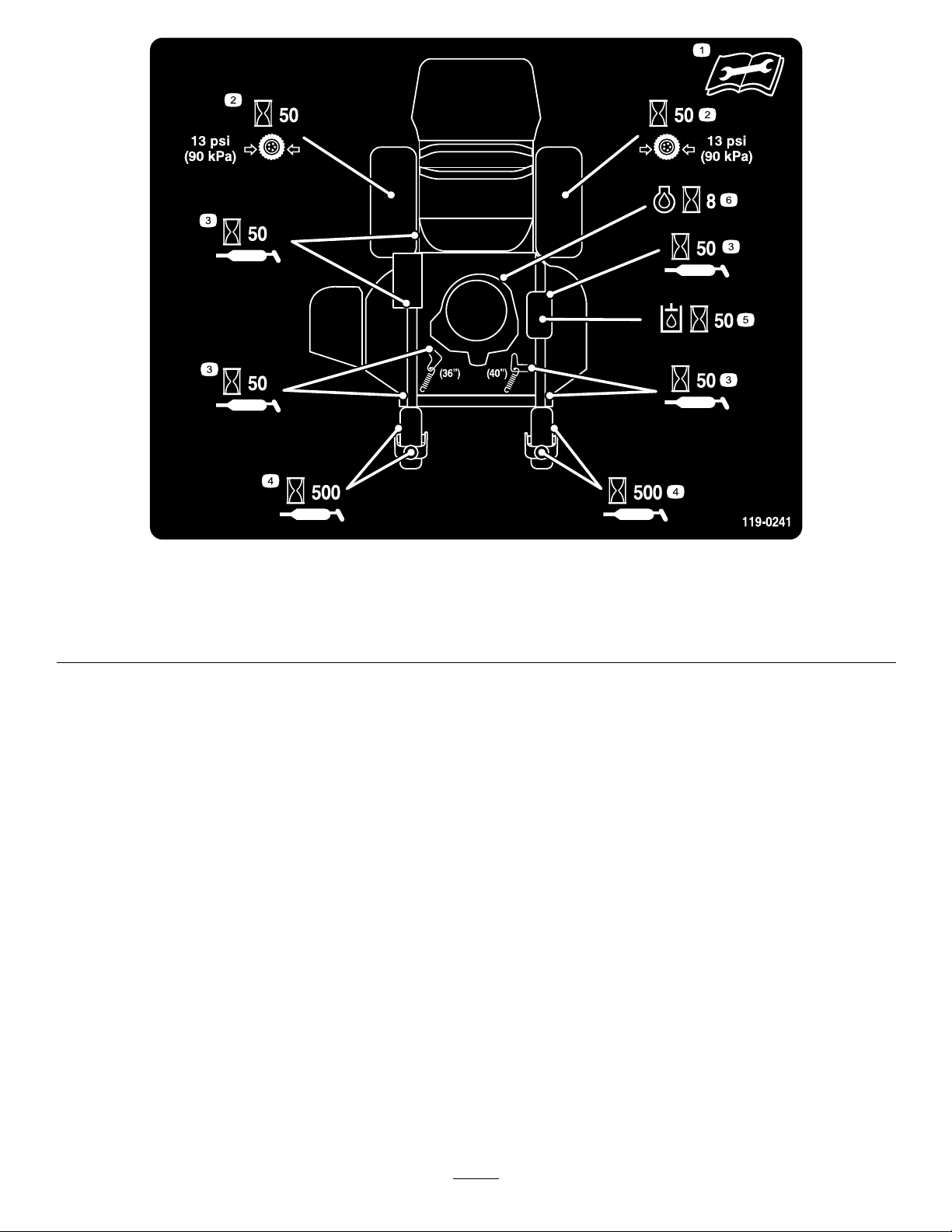

119–0241

1.ReadtheOperator'sManualbefore

performinganymaintenance.

2.Checkthedrivewheeltirepressure

every50hours

3.Lubricateevery50hours

4.Lubricatethecasterwheelevery500

hours

5.Checkthehydraulicoilevery50hours

6.Checktheengineoilevery8hours

13

Page 14

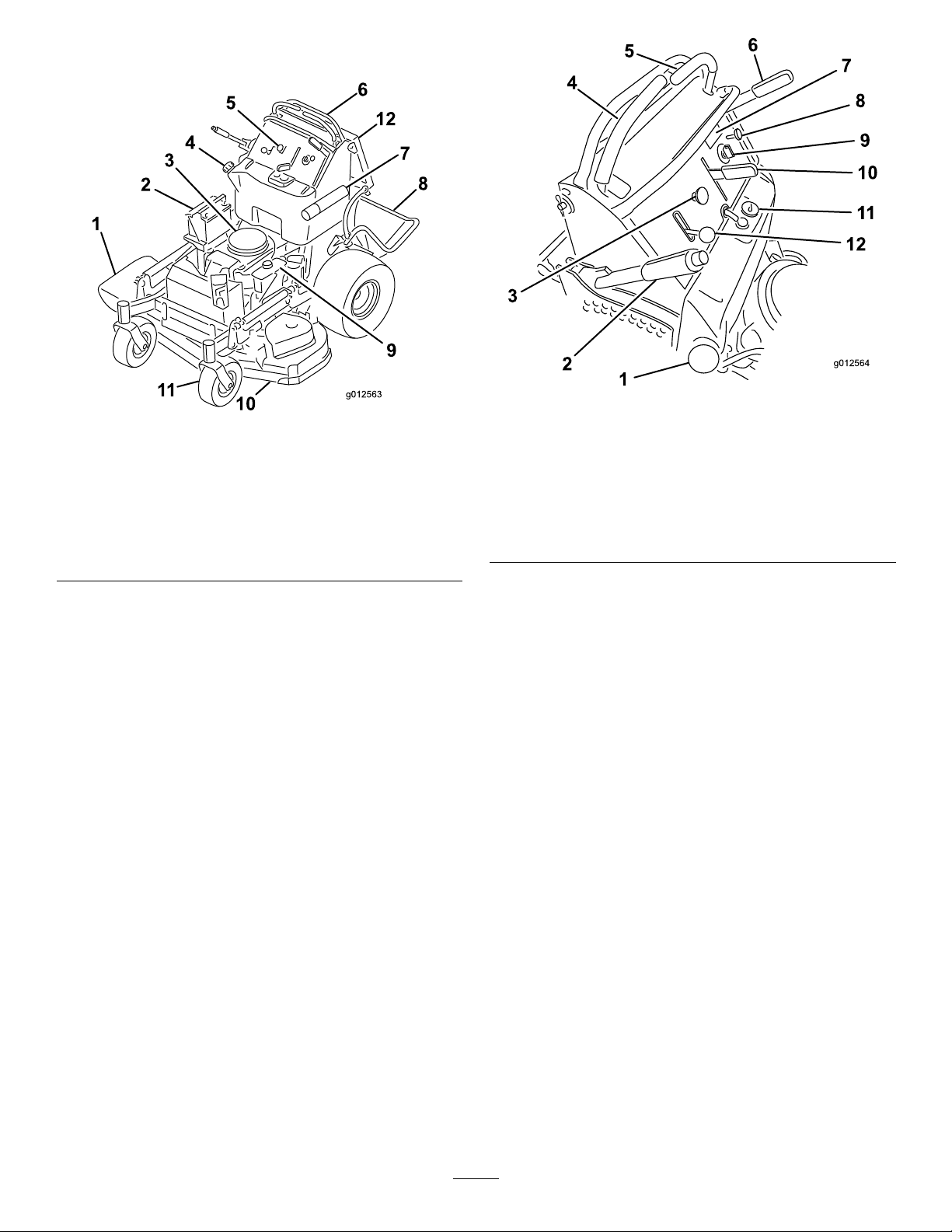

ProductOverview

g012564

1

7

2

8

3

9

4

10

5

11

6

12

Figure4

1.Sidedischargechute

2.Battery

3.Engine9.Hydraulictank

4.Fueltank10.Mowerdeck

5.Controls

6.Motioncontrollevers

7.Manualtube

8.Platform(downposition)

11.Frontcasterwheel

12.Operatorcushion

Figure5

1.Fuelcap7.Hourmeter

2.Height-of-cutlever8.Choke

3.Bladecontrolswitch(PTO)

4.Rightmotioncontrollever

5.Leftmotioncontrollever

6.Parkingbrakelever12.Throttlecontrol

9.Ignitionswitch

10.Speedcontrollever

11.Fuelgauge

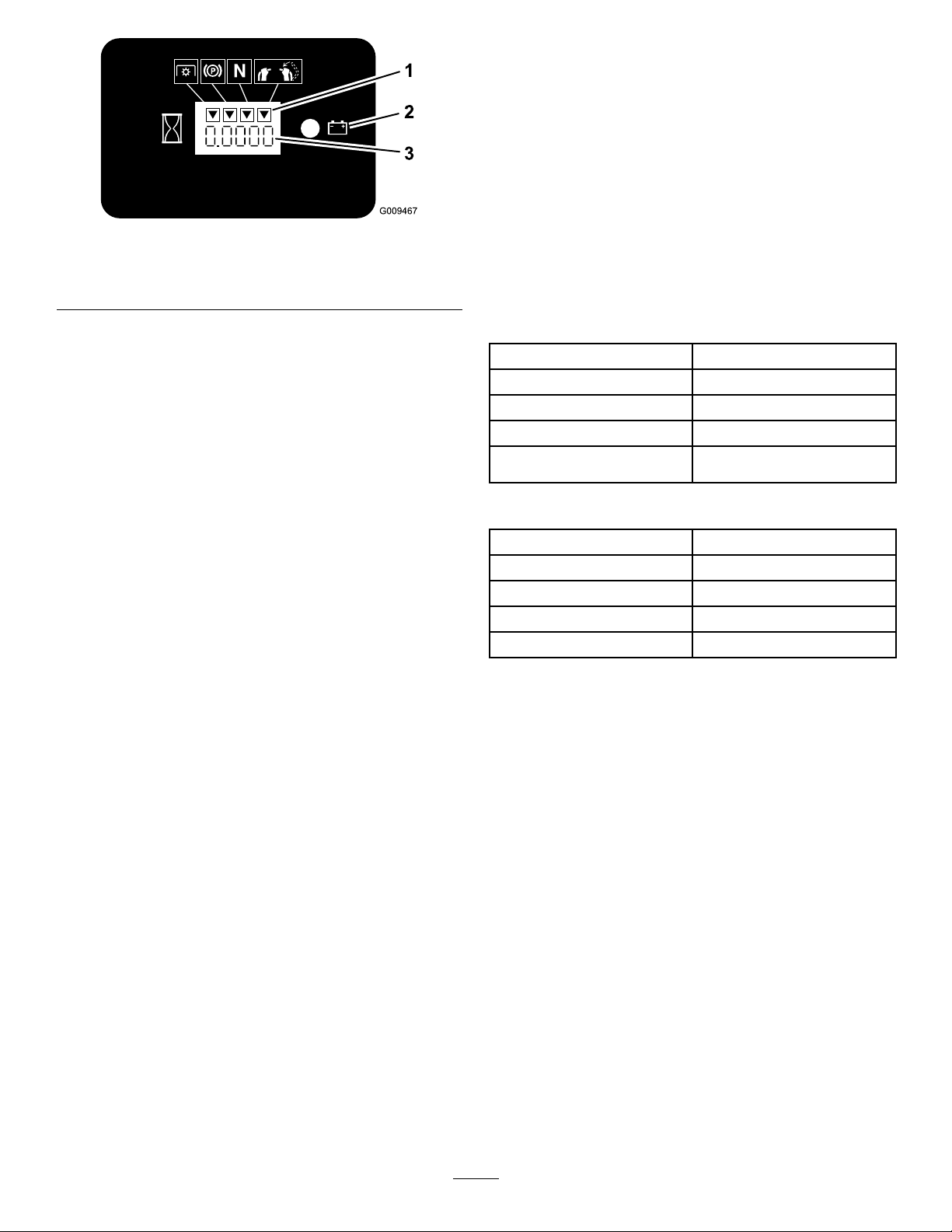

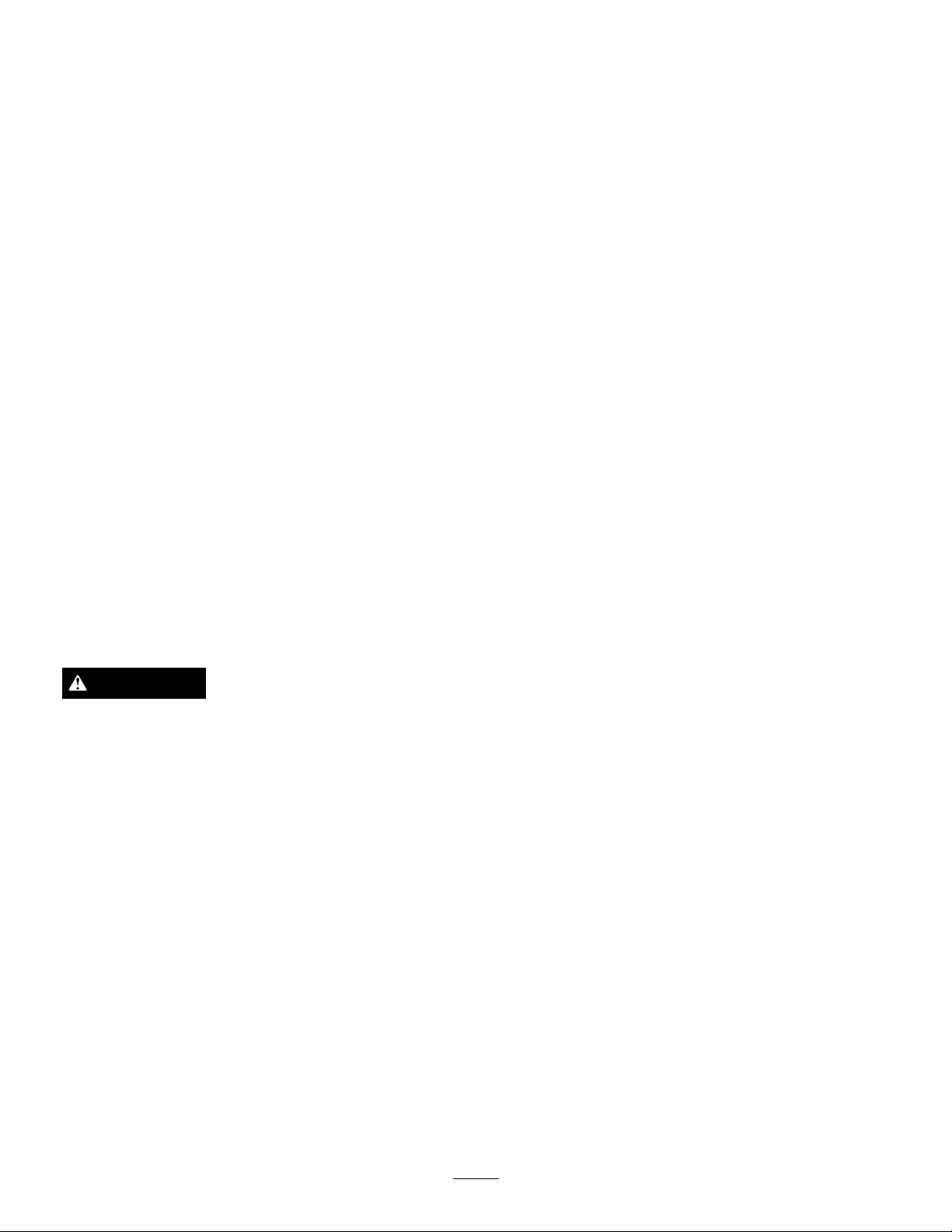

HourMeter

Controls

Becomefamiliarwithallthecontrols(Figure5)before

youstarttheengineandoperatethemachine.

Thehourmeterrecordsthenumberofhourstheengine

hasoperated.Itoperateswhentheengineisrunning.

Usethesetimesforschedulingregularmaintenance

Figure6).

(

FuelGauge

Thefuelgaugeislocatedonthetop,middleofthetank

(Figure5).

SafetyInterlockIndicators

Therearesymbolsonthehourmeterandindicatewith

ablacktrianglethattheinterlockcomponentisinthe

correctposition(

Figure6).

BatteryIndicatorLight

IftheignitionkeyisturnedtotheOnpositionforafew

seconds,thebatteryvoltagewillbedisplayedinthearea

wherethehoursarenormallydisplayed.

Thebatterylightturnsonwhentheignitionisturned

onandwhenthechargeisbelowthecorrectoperating

level(Figure6).

14

Page 15

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

Figure6

1.Safetyinterlocksymbols

2.Batterylight

3.Hourmeter

SpeedControlLever

Thismachinehasavariablespeedcontrol.Thiscontrols

howfastorslowthemachinewilltravelwiththemotion

controlleverspushedallthewayforward.

Note:Thenumbersnexttothespeedcontrolare

anapproximatemaximummilesperhour(mph)the

machinewilltravel.

ThrottleControl

ThethrottlecontrolisvariablebetweenFastandSlow.

Choke

Usethechoketostartacoldengine.

BladeControlSwitch(PTO)

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Model74534TE

Widthwithdeectordown51.62inches(131.1cm)

Lengthwithplatformdown74inches(188cm)

Lengthwithplatformup61inches(155cm)

Height

Weight

Model74536TE

Widthwithdeectordown55.75inches(141.6cm)

Lengthwithplatformdown70inches(177.8cm)

Lengthwithplatformup57inches(144.8cm)

Height

Weight

48inches(121.9cm)

756(343kg)

48inches(121.9cm)

773(350.6kg)

Thebladecontrolswitch(PTO)isusedtoengage

theelectricclutchtodrivethemowerbladeswiththe

rightsidemotioncontrolleverinthecenter,un-locked

position.Pulltheswitchuptoengagethebladesand

release.Todisengagetheblades,pushthebladecontrol

switch(PTO)downormoveorreleasetherightside

motioncontrolleverintotheneutrallockposition.

IgnitionSwitch

Thisswitchisusedtostartthemowerengineandhas

threepositions:Off,RunandStart.

MotionControlLevers

Themotioncontrolleversareusedtodrivethemachine

forward,reverse,andturneitherdirection.

FuelShut-offValve

Closethefuelshut-offvalve(locatedbehindthe

operatorcushionontherighthandsideoffueltank)

whentransportingorstoringthemower.

15

Page 16

Operation

AddingFuel

•Forbestresults,useonlyclean,fresh,unleaded

gasolinewithanoctaneratingof87orhigher

((R+M)/2ratingmethod).

•Oxygenatedfuelwithupto10%ethanolor15%

MTBEbyvolumeisacceptable.

•DoNotuseethanolblendsofgasoline(suchasE15

orE85)withmorethan10%ethanolbyvolume.

Performanceproblemsand/orenginedamagemay

resultwhichmaynotbecoveredunderwarranty.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmayinsulate

thecontainerandslowthelossofanystatic

charge.

•DoNotusegasolinecontainingmethanol.

•DoNotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessafuelstabilizeris

used.

•DoNotaddoiltogasoline.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoorsonlevelground,in

anopenarea,whentheengineiscold.Wipeup

anygasolinethatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Fill

thefueltanktothebottomofthellerneck.

Theemptyspaceinthetankallowsgasolineto

expand.Overllingmayresultinfuelleakage

ordamagetotheengineoremissionsystem(if

equipped).

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerandrefuel

theequipmentwithitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

WARNING

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporscancauseserious

injuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening .

•Keepgasawayfromeyesandskin.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysor

less.Forlongerstorageitisrecommendedthatthe

fueltankbedrained.

•Donotoperatewithoutentireexhaustsystem

inplaceandinproperworkingcondition.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

Important:Donotusefueladditives

containingmethanolorethanol.

Addthecorrectamountofgasstabilizer/conditioner

tothegas.

16

Page 17

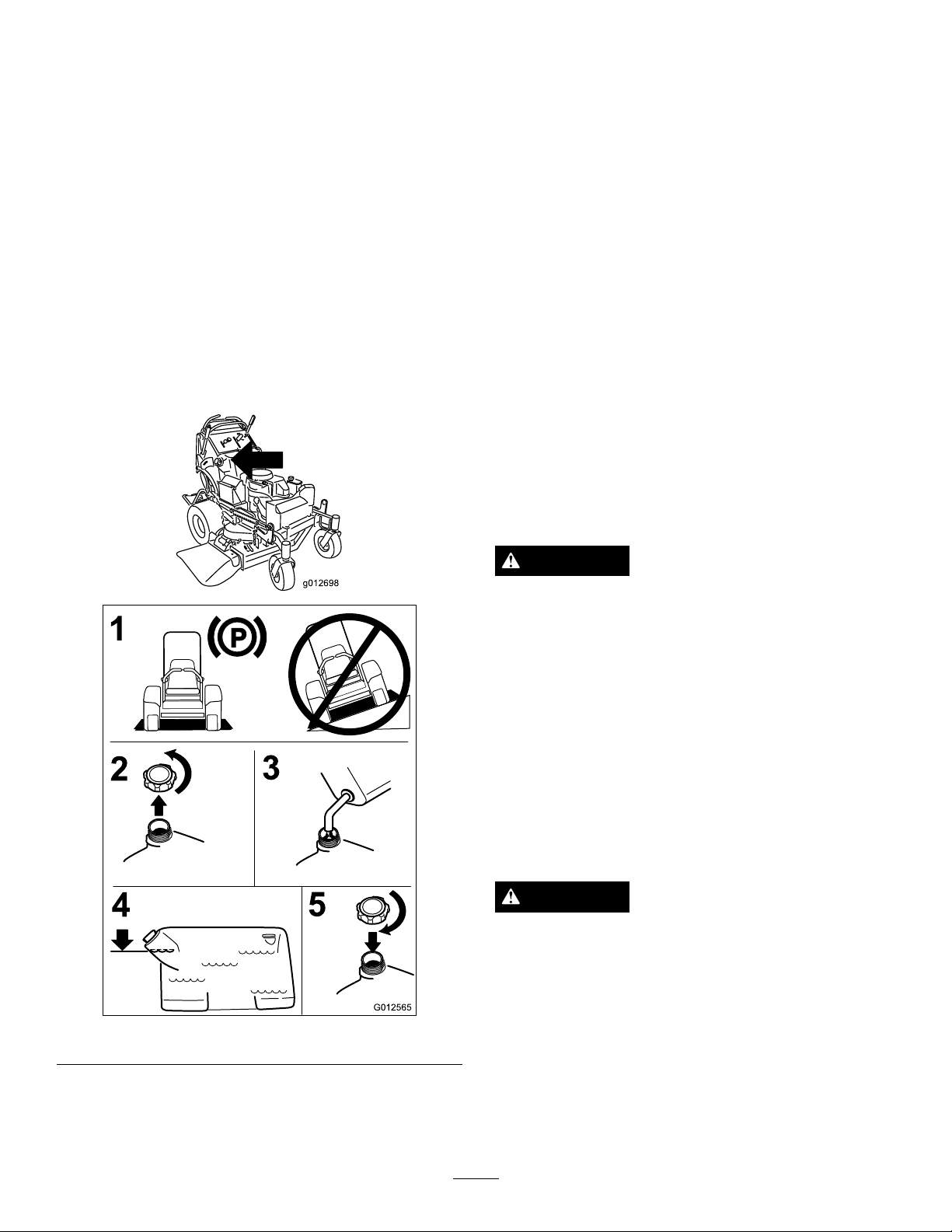

Note:Afuelstabilizer/conditionerismost

g012698

2

4

3

G012565

1

5

effectivewhenmixedwithfreshgasoline.To

minimizethechanceofvarnishdepositsinthefuel

system,usefuelstabilizeratalltimes.

CheckingtheEngineOilLevel

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoChecking

OilLevelinEngineMaintenance.

FillingtheFuelTank

Note:Donotllthefueltankcompletelyfull.Fillthe

fueltanktothebottomofthellerneck.Theempty

spaceinthetankallowsthegasolinetoexpand.

1.Parkthemachineonlevelground.

2.Shuttheengineoffandsettheparkingbrake.

3.Cleanaroundthefueltankcap.

4.Fillthefueltanktothebottomofthellerneck.

Ensurethereisemptyspaceinthetanktoallowthe

gasolinetoexpand(

Figure7).

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BreakingInaNewMachine

Newenginestaketimetodevelopfullpower.Mower

decksanddrivesystemshavehigherfrictionwhennew,

placingadditionalloadontheengine.Allow40to50

hoursofbreak-intimefornewmachinestodevelopfull

powerandbestperformance.

ThinkSafetyFirst

Carefullyreadallthesafetyinstructionsanddecalsin

thesafetysection.Knowingthisinformationcould

helpyouoranybystandersavoidinjury.

Theuseofprotectiveequipmentforeyes,hearing,feet

andheadisrecommended.

CAUTION

Thismachineproducessoundlevelsinexcessof

85dBAattheoperator'searandcancausehearing

lossthroughextendedperiodsofexposure.

Figure7

Wearhearingprotectionwhenoperatingthis

machine.

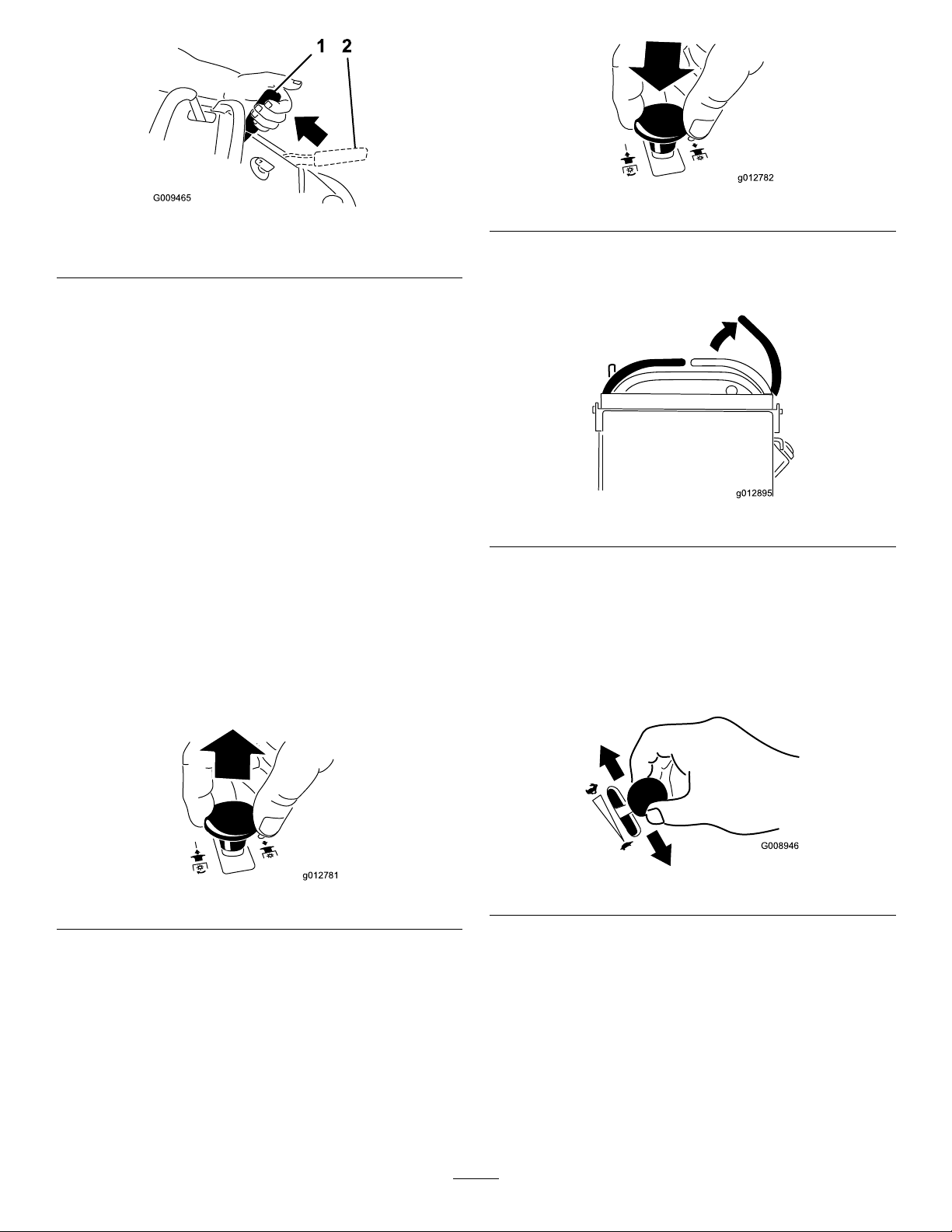

OperatingtheParkingBrake

Alwayssettheparkingbrakewhenyoustopthe

machineorleaveitunattended.Beforeeachuse,check

theparkingbrakeforproperoperation.

Iftheparkingbrakedoesnotholdsecurely,adjustit.

RefertoServicingtheParkingBrake.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileit

isunattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

SettingtheParkingBrake

Pulltheparkingbrakeleverrearwardtotheengaged

position(Figure8).

17

Page 18

Figure8

g012781

g012782

g012895

G008946

Figure10

1.Parkingbrakeengaged2.Parkingbrakereleased

ReleasingtheParkingBrake

Pushtheparkingbrakeleverforward.

OperatingtheMowerBlade

ControlSwitch(PTO)

Thebladecontrolswitch(PTO)isusedinconjunction

withtherightsidemotioncontrollevertoengageand

disengagethemowerblades.

EngagingtheMowerBlades(PTO)

1.Toengagethemowerblades,movetherightside

motioncontrollevertothecenter,un-locked

position.

2.Pullthebladecontrolswitch(PTO)upandrelease

itwhileholdingdowntherightsidemotioncontrol

leverinthecenter,un-lockedposition.

•Movethemotioncontrolleverstoneutralandmove

therightsidemotioncontrolleverintotheneutral

lockposition.

Figure11

OperatingtheThrottle

ThethrottlecontrolcanbemovedbetweenFastand

Slowpositions(Figure12).

Alwaysusethefastpositionwhenturningonthe

mowerdeckwiththebladecontrolswitch(PTO).

Figure9

DisengagingtheMowerBlades(PTO)

Thefollowingaretwooptionsfordisengagingthe

mowerblades.

•Pushthebladecontrolswitch(PTO)downtothe

offposition.

Figure12

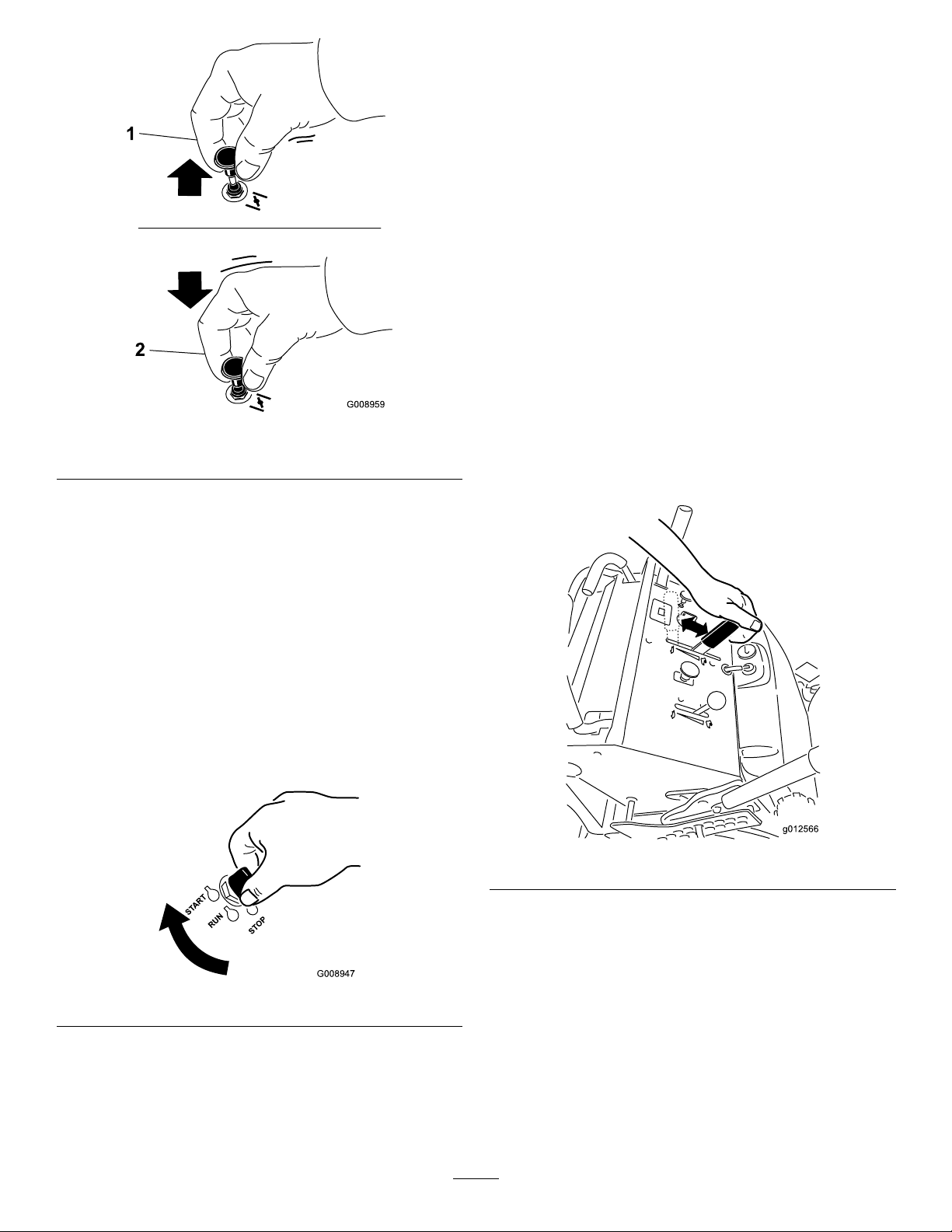

OperatingtheChoke

Usethechoketostartacoldengine.

1.Iftheengineiscold,usethechoketostartthe

engine.

2.Pulluponthechokeknobtoengagethechoke

beforeusingtheignitionswitch(Figure13).

3.Pushdownonthechoketodisengagethechoke

aftertheenginehasstarted(Figure13).

18

Page 19

G008959

1

2

START

RUN

STOP

G008947

UsingtheSpeedControlLever

Thismachinehasaspeedcontrolleverthatsets

themaximumgroundspeedofthemachine.This

canbeadjustedtotheoperator'sdesiredspeed.It

isrecommendedtousetheslowestspeedfornew

operator's.

Note:Thenumbersnexttothespeedcontrolarean

approximatemilesperhour(mph)themachinewill

travel.

1.Movethespeedcontrollevertosetthedesired

speed.

•Fullforwardhasquickresponseandmaximum

speed.

•Fullrearwardhassmoothresponseandslower

speed.

Figure13

1.On2.Off

OperatingtheIgnitionSwitch

1.TurntheignitionkeytotheStartposition

(Figure14).Whentheenginesstarts,releasethekey.

Important:Donotengagestarterformore

than5secondsatatime.Iftheenginefails

tostartallowa15secondcool-downperiod

betweenattempts.Failuretofollowthese

instructionscanburnoutthestartermotor.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthe

fuelsystemhasbeenwithoutfuelcompletely .

2.Movethecontrolleverstodrivethemachine.The

controlleversmaybepushedforwardtothefront

referencebarwhilethemaximumspeedofthe

machineissetbythespeedcontrollever.

Figure15

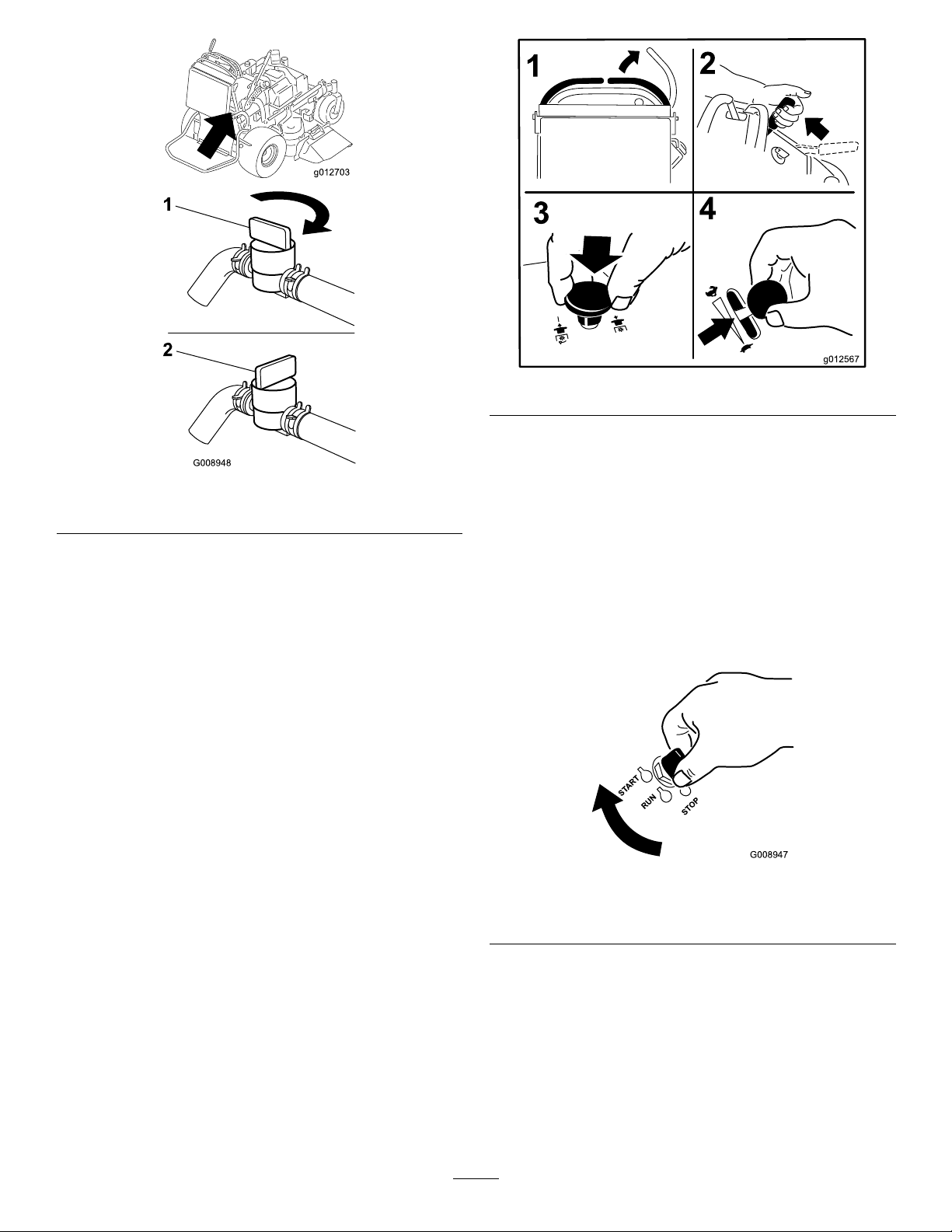

UsingtheFuelShut-OffValve

Thefuelshut-offvalveislocatedbehindtherightside

Figure14

2.Turntheignitionkeytothestoppositiontostop

theengine.

oftheoperatorcushion.

Closethefuelshut-offvalvefortransport,maintenance,

andstorage(Figure16).

Ensurethefuelshut-offvalveisopenwhenstarting

theengine.

19

Page 20

g012703

G008948

1

2

Figure16

START

RUN

STOP

G008947

1.On2.Off

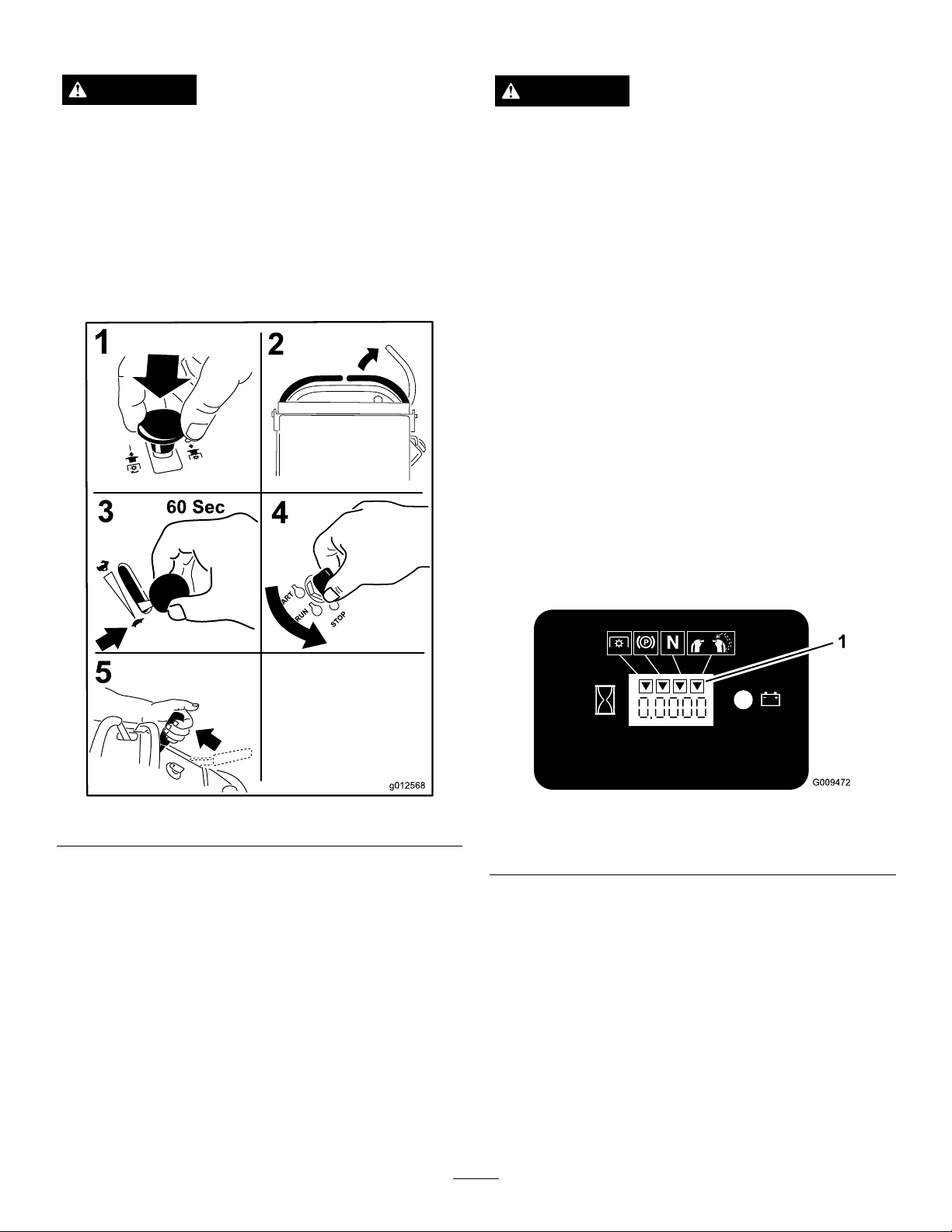

StartingandStoppingthe

Engine

StartingtheEngine

1.Connectthewirestothesparkplugs.

2.Openthefuelvalve.

3.Movetherightmotioncontrollevertoneutral

lockedposition.

4.Settheparkingbrake;refertoSettingtheParking

Brake.

Figure17

7.TurntheignitionkeytotheStartposition

(Figure14).Whentheenginesstarts,releasethekey.

Important:Donotengagestarterformore

than5secondsatatime.Iftheenginefails

tostartallowa15secondcool-downperiod

betweenattempts.Failuretofollowthese

instructionscanburnoutthestartermotor.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthe

fuelsystemhasbeenwithoutfuelcompletely .

5.Movethebladecontrolswitch(PTO)totheOff

position.

6.MovethethrottlelevermidwaybetweentheSlow

andFastpositions.

1.Off3.Start

2.Run

Figure18

Note:Awarmorhotenginemaynotrequire

choking.

20

Page 21

StoppingtheEngine

TheSafetyInterlockSystem

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethetractorwhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

Lettheengineidleatslowthrottle(turtle)for60

secondsbeforeturningtheignitionswitchoff.

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

UnderstandingtheSafetyInterlock

System

Thesafetyinterlocksystemisdesignedtopreventthe

mowerbladesfromrotatingunless:

•Therightsidemotioncontrolleverismovedtothe

center,un-lockedposition.

•Thebladecontrolswitch(PTO)ispulledon.

Thesafetyinterlocksystemisdesignedtostopthe

mowerbladesifyoumoveorreleasetherightside

motioncontrolleverintotheneutrallockposition.

Thehourmeterhassymbolstonotifytheuserwhen

theinterlockcomponentisinthecorrectposition.

Whenthecomponentisinthecorrectposition,a

trianglewilllightupinthecorrespondingsquare.

Figure19

Important:Makesurefuelshutoffvalveisclosed

beforetransportingorstoringthemachine,asfuel

leakagemayoccur.Beforestoringthemachine,

pullwireoffsparkplug(s)topreventpossibilityof

accidentalstarting.

Figure20

1.Triangleslightupwhentheinterlockcomponentsareinthe

correctposition

TestingtheSafetyInterlockSystem

ServiceInterval:Beforeeachuseordaily

Testthesafetyinterlocksystembeforeyouusethe

machineeachtime.

Note:Ifthesafetysystemdoesnotoperateas

describedbelow,haveanAuthorizedServiceDealer

repairthesafetysystemimmediately .

1.Starttheengine;refertoStartingandStoppingthe

Engine.

2.Settheparkingbrake.

21

Page 22

3.Movetherightsidemotioncontrollevertothe

center,un-lockedposition.Thebladesshould

notrotate.

4.Movethemotioncontrolleversforward.The

engineshouldkill.

5.Starttheengineandreleasetheparkingbrake.

6.Movetherightsidemotioncontrollevertothe

center,un-lockedposition.

7.Continueholdingtherightsidemotioncontrollever

inthecenter,un-lockedpositionandpulluponthe

bladecontrolswitch(PTO)andrelease.Theclutch

shouldengageandthemowerbladesbeginrotating.

8.Moveorreleasetherightsidemotioncontrollever

intotheneutrallockposition.Thebladesshould

stoprotatingandtheenginecontinuestorun.

9.Pushthebladecontrolswitchdownandmove

therightsidemotioncontrollevertothecenter,

un-lockedposition.

10.Continueholdingtherightsidemotioncontrollever

inthecenter,un-lockedpositionandpulluponthe

bladecontrolswitch(PTO)andrelease.Theclutch

shouldengageandthemowerbladesbeginrotating.

11.Pushthebladecontrolswitch(PTO)downtothe

offposition.Thebladesshouldstoprotating.

12.Withtheenginerunning,pullupthebladecontrol

switch(PTO)andreleasewithoutholdingright

sidemotioncontrollevertothecenter,un-locked

position.Thebladesshouldnotrotate.

WARNING

Theoperatorplatformisheavyandmaycause

injurywhenloweringandraisingtheoperator

platform.Theplatformmaysuddenlydropifnot

supportedwhenthelatchpinispulledout.

•Donotputhandsorngersintheplatform

pivotareawhenloweringorraisingtheoperator

platform.

•Makesuretheplatformissupportedwhenthe

latchpinispulledout.

•Makesurethelatchsecurestheplatformwhen

foldingitintheupposition.Pushittight

againstthecushionforthelatchpintolock

intoplace.

•Keepbystandersawaywhenraisingorlowering

theplatform.

OperatingtheMachinewiththe

PlatformUp

Operatingthemachinewiththeplatformupis

recommendedwhen:

•Mowingneardrop-off's

•Mowingsmallareaswherethemachineistoolong

•Areaswithlowoverhangingbranchesorobstacles

•Loadingthemachinefortransport

•Drivingupslopes

Toraisetheplatform,pullthebackoftheplatformup

sothelatchpinlocksitintoplace.Pushtheplatform

tightagainstthecushionforthelatchpintolockinto

place.

OperatingtheMachinewiththe

PlatformDown

Operatingthemachinewiththeplatformdownis

recommendedwhen:

•Mowingmostareas

•Drivingacrossslopes

•Drivingdownslopes

Tolowertheplatform,pushtheplatformforward

againstthecushiontoreleasepressureonthelatchpin

andthenpulltheknoboutandlowertheplatform.

Makesuretoholdontotheplatformwhenreleasing

thelatch.

OperatingthePlatform

Themachinecanbeusedwiththeplatformintheup

ordownposition.Itistheoperator'spreferenceon

whichpositiontouse.

22

Page 23

1.Platformup

g012570

4

5

1

2

3

2 4

2.Platformdown

Figure21

3.Pulltheknobouttorelease

theplatform

1.Frontreferencebar

2.Leftcontrollever

3.Rearreferencebar

Figure22

4.Rightcontrollever

5.Rightcontrolleverinthe

neutrallockposition

DrivingForwardorBackward

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Place

thethrottlecontrolinthefastpositionforbest

performance.Alwaysoperateinthefullthrottle

positionwhenmowing.

CAUTION

Machinecanspinveryrapidly.Operatormaylose

controlofmachineandcausepersonalinjuryor

damagetomachine.

Slowthemachinedownbeforemakingsharpturns.

DrivingForward

1.Releasetheparkingbrake;refertoReleasingthe

ParkingBrakeinOperation.

2.Togoforward,movethespeedcontrollevertothe

desiredspeed.

3.Movetherightsidemotioncontrollevertothe

center,un-lockedposition.

4.Slowlypushthemotioncontrolleversforward

(Figure23).

Note:Theenginewillkillifamotioncontrollever

ismovedwiththeparkingbrakeengaged.

Thefartheryoumovethemotioncontrolleversin

eitherdirection,thefasterthemachinewillmovein

thatdirection.

Tostop,pullthemotioncontrolleversbacktothe

neutralposition.

23

Page 24

Figure23

Settheparkingbrakewhenyouleavethemachine;refer

toSettingtheParkingBrakeinOperation.Remember

toremovethekeyfromtheignitionswitch.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethetractorwhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

PushingtheMachinebyHand

Theby-passvalvesallowthemachinetobepushedby

handwithouttheenginerunning.

Important:Alwayspushthemachinebyhand.

Nevertowthemachinebecausehydraulicdamage

mayoccur.

DrivingBackward

1.Movetherightsidemotioncontrollevertothe

center,un-lockedposition.

2.Slowlypullthemotioncontrolleversrearward

Figure24).

(

Figure24

ToPushtheMachine

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

2.Lowerthemowerdecktothelowestheight-of-cut

(HOC).Thiswillallowaccesstothebypassvalves.

3.Opentheby-passvalveonbothpumpsbyturning

themcounterclockwise1to2turns.Thisallows

hydraulicuidtoby-passthepumpsandthewheels

toturn(

Note:Rotatetheby-passvalvesamaximumof2

turnssothevalvedoesnotcomeoutofthebody

causinguidtorunout.

Figure25).

StoppingtheMachine

Tostopthemachine,movethemotioncontrolleversto

neutral,movetherightsidemotioncontrolleverinto

theneutrallockposition,disengagethepowertakeoff

(PTO),andturntheignitionkeytooff.

24

Page 25

5.Stoptheengine,removethekey,setthebrake,and

closethefuelvalve.

6.Usethemetaltiedownloopsonthemachineto

securelyfastenthemachinetothetrailerortruck

withstraps,chains,cable,orropes(

Figure26).

Figure25

1.Pumpby-passvalve

4.Releasetheparkingbrake.

5.Pushthemachinetothedesiredlocation.

6.Settheparkingbrake.

7.Closetheby-passvalves,butdonotovertighten

them.Torqueto110to130in-lb(12to15N-m).

Important:Donotstartoroperatethemachine

withtheby-passvalvesopen.Damageto

systemmayoccur.

TransportingMachines

Useaheavy-dutytrailerortrucktotransportthe

machine.Ensurethatthetrailerortruckhasall

necessarybrakes,lighting,andmarkingasrequiredby

law .Pleasecarefullyreadallthesafetyinstructions.

Knowingthisinformationcouldhelpyou,yourfamily,

petsorbystandersavoidinjury.

Totransportthemachine:

1.Raisetheplatformofthemachinebeforedrivingup

ontothetrailerortruck.

2.Ifusingatrailer,connectittothetowingvehicle

andconnectthesafetychains.

3.Ifapplicable,connectthetrailerbrakes.

4.Loadthemachineontothetrailerortruck.

Figure26

1.Tractionunittiedownloop

LoadingMachines

Useextremecautionwhenloadingunitsontrailersor

trucks.Onefullwidthrampthatiswideenoughto

extendbeyondthereartiresisrecommendedinsteadof

individualrampsforeachsideoftheunit(Figure27).

Theplatformwhendownandlockedintoposition,

extendsbackbetweentherearwheelsandservesasa

stopfortippingbackward.Havingafullwidthramp

providesasurfacefortheplatformtocontactifthe

unitstartstotipbackward.Withtheplatformup,afull

widthrampprovidesasurfacetowalkonbehindthe

unit.Theoperatorshoulddetermineifitisbesttohave

theplatformupordownwhenloading,dependingon

conditions.Ifitisnotpossibletouseonefullwidth

ramp,useenoughindividualrampstosimulateafull

widthcontinuousramp.

Therampshouldbelongenoughsothattheangles

donotexceed20degrees(

maycausemowercomponentstogetcaughtastheunit

movesfromramptotrailerortruck.Steeperangles

mayalsocausetheunittotipbackward.Ifloadingon

ornearaslope,positionthetrailerortrucksoitison

thedownsideoftheslopeandtherampextendsupthe

slope.Thiswillminimizetherampangle.Thetraileror

truckshouldbeaslevelaspossible.

Figure27).Asteeperangle

25

Page 26

Important:DoNotattempttoturntheunitwhile

ontheramp;youmaylosecontrolanddriveoff

theside.

SideDischargingorMulching

theGrass

Avoidsuddenaccelerationwhendrivinguparampand

suddendecelerationwhenbackingdownaramp.Both

maneuverscancausetheunittotipbackward.

WARNING

Loadingaunitontoatrailerortruckincreasesthe

possibilityofbackwardtip-overandcouldcause

seriousinjuryordeath.

•Useextremecautionwhenoperatingauniton

aramp.

•Useonlyasingle,fullwidthramp;DoNotuse

individualrampsforeachsideoftheunit.

•Ifindividualrampsmustbeused,useenough

rampstocreateanunbrokenrampsurface

widerthantheunit.

•Donotexceeda15degreeanglebetweenramp

andgroundorbetweenrampandtraileror

truck.

•Avoidsuddenaccelerationwhiledrivingunitup

aramptoavoidtippingbackward.

Thismowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

DANGER

Withoutthegrassdeector,dischargecover,or

completegrasscatcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriswillcauseinjuryor

death.

•Neverremovethegrassdeectorfromthe

mowerbecausethegrassdeectorroutes

materialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthemower.

•Nevertrytocleardischargeareaormower

bladesunlessyoureleasethebailandthepower

takeoff(PTO)isoff.Rotatetheignitionkeyto

Off.Alsoremovethekeyandpullthewire(s)

offthesparkplug(s).

•Avoidsuddendecelerationwhilebackingunit

downaramptoavoidtippingbackward.

Figure27

1.Trailer3.Notgreaterthan

15degrees

2.Fullwidthramp4.Fullwidthramp—sideview

AdjustingtheHeight-of-Cut

Theheight-of-cutcanbeadjustedfrom1to5inches

(25to127mm)in1/4inch(6mm)increments.

1.Movetheheight-of-cutlevertothetransport

position(allthewayup).

2.Toadjust,rotatethepin90degreesandremovethe

pinfromtheheight-of-cutbracket

3.Selectaholeintheheight-of-cutbracket

correspondingtotheheight-of-cutdesiredand,

insertthepin(

4.Pushthebuttonontopandlowertheheight-of-cut

levertothepin(

Figure28).

Figure28).

26

Page 27

g012676

1 2

PositioningtheFlowBafe

G012677

Thefollowingguresareonlyrecommendationsfor

use.Adjustmentswillvarybygrasstype,moisture

content,andheightofgrass.

Note:Iftheenginepowerdrawsdownandthemower

groundspeedisthesame,openupthebafe.

PositionA

Thisisthefullrearposition(seeFigure30).The

suggesteduseforthispositionisafollows.

Figure28

1.Height-of-cutholes3.Height-of-cutlever

2.Height-of-cutpin

AdjustingtheFlowBafe

Themowerdischargeowcanbeadjustedfordifferent

typesofmowingconditions.Positionthecamlockand

bafetogivethebestqualityofcut.

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Toadjustthebafe,loosenthenut(

4.Adjustthebafeandnutintheslottothedesired

dischargeowandtightenthenut.

Figure29).

•Useforshort,lightgrassmowingconditions.

•Useindryconditions.

•Forsmallergrassclippings.

•Propelsgrassclippingsfartherawayfromthe

mower.

Figure30

PositionB

Usethispositionwhenbagging(Figure31).

Figure29

1.Slot

2.Nut

27

Page 28

G012678

Figure31

G012679

PositionC

Thisisthefullopenposition.Thesuggestedusefor

thispositionisasfollows(Figure32).

•Useintall,densegrassmowingconditions.

•Useinwetconditions.

•Lowerstheenginepowerconsumption.

•Allowsincreasedgroundspeedinheavyconditions.

Note:ContactanAuthorizedServiceDealertoorder

aW eightKit.

WARNING

Excessiveweightchangescaneffecthandlingand

operationofthemachine.Thiscouldcauseserious

injurytoyouorbystanders.

Makeweightchangesinsmallincrementsonly.

Evaluatethemoweraftereachweightchangeto

ensurethemachinecanbeoperatedsafely.

Figure32

UsingCounterweights

•Weightsareinstalledtoimprovehandling,balance

andimproveperformance.Weightscanbeaddedor

removedtocreateoptimizedperformanceunder

differentmowingconditionsandforoperator

preference.

•Itisrecommendedthatweightsbeaddedor

removedoneatatimeuntilthedesiredhandingand

balanceisachieved.

28

Page 29

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthehydraulicuidlevel.

•Changethehydrauliclter.

•Checkthesafetyinterlocksystem.

•Checktheengineoillevel.

•Cleantheairintakescreen.

•Checkthebrakes.

•Inspecttheblades.

•Cleanthemowerdeck.

•Cleanfoamaircleanerelement.

•Greasethemowerdeckidlerarms(moreoftenindirtyordustyconditions).

•Greasetheliftlinkage(moreoftenindirtyordustyconditions).

•Lubricatethespeedcontrolslidingparts(moreoftenindirtyordustyconditions).

•Cleanthepaperaircleanerelement.

•Checkthetirepressure.

•Checkthehydraulicuidlevel.

•Changetheengineoil.(moreoftenindirtyordustyconditions)

•Check,cleanandregapthesparkplug.

•Checkthebattery .

•Checkandcleanenginecoolingnsandshrouds.

•Checkthepumpdrivebelt.

•Checkthemowerdeckbelt(s).

•Checkthehydraulichoses.

Every200hours

Every250hours

Every500hours

Beforestorage

Yearly

Important:Refertoyour

•Replacethepaperaircleanerelement.

•Changetheengineoillter.

•ChangethehydraulicoilwhenusingMobil®1oil.

•Adjustthecasterpivotbearing.

•Checktheelectricclutch.

•ChangethehydraulicoilwhenusingT oro®HYPR-OIL™500hydraulicoil.

•Changethehydrauliclter.

•Paintchippedsurfaces.

•Performallmaintenanceprocedureslistedabovebeforestorage.

•Greasethefrontcasterpivots(moreoftenindirtyordustyconditions).

•Lubricatethecasterwheelhubs.

•Replacethefuellter.

Engine Operator's Man ual

foradditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthesparkplugwiresfromthesparkplugsbeforeyoudo

anymaintenance.Setthewiresasidesothattheydonotaccidentallycontactthesparkplugs.

29

Page 30

Premaintenance

Procedures

RaisingtheMowerforAccess

Thefrontofthemowercanberaisedandsupportedon

itsbackforaccessunderthemachineformaintenance.

1.Raisetheplatform.RefertoOperatingthePlatform

inOperation.

2.Removethebattery.

Figure34

Figure33

1.Wingnut4.Positivebatterycable

2.Batterycover5.Battery

3.Negativebatterycable

3.Drainthefuelfromthefueltank.RefertoDraining

theFuelTankinMaintenance.

4.Removethecapofthehydraulictankandplace

apieceofplasticovertheopeningandinstallthe

hydrauliccap.Thiswillsealthehydraulictankand

preventitfromleakingout.

1.Cap

2.Pieceofplastic

5.Withtwopeople,raisethefrontofthemowersoit

restsonthedrivetiresandtheplatformintheup

position.

6.Performanymaintenanceonthemachine.

7.Withtwopeople,lowerthefrontofthemowerto

theground.

8.Removetheplasticunderthehydraulictankcap.

9.Installthebatteryforthemachine.

3.Hydraulictank

30

Page 31

Figure35

g012572

1

2

3

4

Figure36

1.Removebattery

2.Withtwopeople,liftthe

frontendofthemower

(ensuretheplatformisup)

ReleasetheCushionforRear

Access

Thecushioncanbereleasedforrearaccesstothe

machineformaintenanceoradjustment.

1.Lowertheplatform.

2.Removethehairpincotterpinsoneachsideofthe

cushion.

3.Slidethelargewasherswithplasticbushingstothe

inside.

4.Removethecushionandlowerittotheplatform.

5.Performanymaintenanceoradjustmentonthe

machine.

6.Raisethecushionandslideitontothepinsonboth

sidesofthemachine(

Figure36).

7.Slidethelargewasherswithplasticbushingsinto

thecushionbracketandsecurethemwithahairpin

cotterpin(Figure36).

31

Page 32

Lubrication

GreasewithNo.2generalpurposelithiumbaseor

molybdenumbasegrease.

Lubricatethespeed/tractioncontrollinkagewithadry

lubricant,PTFE(Polytetrauoroethylene)(

HowtoGrease

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Cleanthegreasettingswitharag.Makesureto

scrapeanypaintoffthefrontofthetting(s).

4.Connectagreaseguntothetting.Pumpgrease

intothettingsuntilgreasebeginstooozeoutof

thebearings.

5.Wipeupanyexcessgrease.

Figure40).

Figure38

102cmMowerDeck

LubricatingtheMachine

ServiceInterval:Every50hours—Greasethemower

deckidlerarms(moreoftenindirty

ordustyconditions).

Every50hours—Greasethelift

linkage(moreoftenindirtyordusty

conditions).

Every50hours/Yearly(whichever

comesrst)—Lubricatethespeed

controlslidingparts(moreoftenin

dirtyordustyconditions).

Usethefollowinggraphicsforlocatingthegreasepoints.

Figure39

Lubricatethespeed/tractioncontrollinkagewithadry

PTFE(Polytetrauoroethylene)lubricant.

Important:UseonlyadryPTFE

(Polytetrauoroethylene)lubricant.Donot

useawetoillm,whichwillattractdustanddirt.

Figure37

91cmMowerDeck

32

Page 33

Figure41

Figure40

GreasingtheFrontCaster

Pivots

ServiceInterval:Yearly—Greasethefrontcaster

pivots(moreoftenindirtyordusty

conditions).

Lubricatethefrontcasterpivotsonceayear.

1.Removethedustcapandadjustthecasterpivots.

Keepthedustcapoffuntilgreasingisdone.Referto

AdjustingtheCasterPivotBearinginMaintenance

Section.

2.Removethehexplug.Threadagreasezerkintothe

hole.

3.Pumpgreaseintothezerkuntilitoozesoutaround

thetopbearing.

4.Removethegreasezerkinthehole.Installthehex

plugandcap.

LubricatetheCasterWheel

Hubs

1.Sealguard2.Spacernutwithwrench

ats

2.Removethecasterwheelfromthecasterforks.

3.Removethesealguardsfromthewheelhub.

4.Removeoneofthespacernutsfromtheaxle

assemblyinthecasterwheel.Notethatthread

lockingadhesivehasbeenappliedtolockthespacer

nutstotheaxle.Removetheaxle(withtheother

spacernutstillassembledtoit)fromthewheel

assembly.

5.Pryoutseals,andinspectbearingsforwearor

damageandreplaceifnecessary.

6.Packthebearingswithageneral-purposegrease.

7.Insertonebearing,onenewsealintothewheel.

Note:Thesealsmustbereplaced.

8.Iftheaxleassemblyhashadbothspacernuts

removed(orbrokenloose),applyathreadlocking

adhesivetoonespacernutandthreadontotheaxle

withthewrenchatsfacingoutward.DoNotthread

spacernutallofthewayontotheendoftheaxle.

Leaveapproximately1/8inch(3mm)fromtheouter

surfaceofthespacernuttotheendoftheaxleinside

thenut.

9.Inserttheassemblednutandaxleintothewheelon

thesideofthewheelwiththenewsealandbearing.

10.Withtheopenendofthewheelfacingup,ll

theareainsidethewheelaroundtheaxlefullof

general-purposegrease.

11.Insertthesecondbearingandnewsealintothe

wheel.

ServiceInterval:Yearly—Lubricatethecasterwheel

hubs.

1.Stoptheengine,waitforallmovingpartstostop,

andremovethekey.Engagetheparkingbrake.

12.Applyathreadlockingadhesivetothe2ndspacer

nutandthreadontotheaxlewiththewrenchats

facingoutward.

33

Page 34

13.Torquethenutto75-80in-lb(8-9N-m),loosen,

thenre-torqueto20-25in-lb(2-3N-m).Makesure

axledoesnotextendbeyondeithernut.

14.Reinstallthesealguardsoverthewheelhuband

insertwheelintocasterfork.Reinstallcasterbolt

andtightennutfully .

EngineMaintenance

ServicingtheAirCleaner

ServiceInterval/Specication

Important:Topreventsealandbearingdamage,

checkthebearingadjustmentoften.Spinthecaster

tire.Thetireshouldnotspinfreely(morethan1or

2revolutions)orhaveanysideplay .Ifthewheel

spinsfreely,adjusttorqueonspacernutuntilthere

isaslightamountofdrag.Reapplythreadlocking

adhesive.

Inspectthefoamandpaperelementsandreplacethem

iftheyaredamagedorexcessivelydirty.

Note:Servicetheaircleanermorefrequently(every

fewoperatinghours)iftheoperatingconditionsare

extremelydustyorsandy .

Important:Donotoilthefoamorpaperelement.

RemovingtheFoamandPaper

Elements

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Cleanaroundtheaircleanertopreventdirt

fromgettingintotheengineandcausingdamage

Figure42).

(

4.Unscrewthecoverknobsandremovetheaircleaner

cover(Figure42).

5.Unscrewthehoseclampandremovetheaircleaner

assembly(

6.Carefullypullthefoamelementoffthepaper

element(Figure42).

1.Cover

2.Hoseclamp4.Foamelement

Figure42).

Figure42

3.Paperelement

34

Page 35

CleaningtheFoamAirCleanerElement

ServiceInterval:Every25hours

1.Washthefoamelementinliquidsoapandwarm

water.Whentheelementisclean,rinseitthoroughly.

2.Drytheelementbysqueezingitinacleancloth.

Important:Replacethefoamelementifitis

tornorworn.

ServicingthePaperAirCleaner

Element

ServiceInterval:Every50hours—Cleanthepaperair

cleanerelement.

Every200hours—Replacethepaper

aircleanerelement.

1.Cleanthepaperelementbytappinggentlytoremove

dust.Ifitisverydirty,replacethepaperelement

withanewone(

2.Inspecttheelementfortears,anoilylm,ordamage

totherubberseal.

Figure42).

Note:Therearedifferentoilcapacitiesforthedifferent

modelslistedinthismanual.Ensurethecorrectamount

ofoilisused.

Important:Remembertoadd80%oftheoiland

thengraduallyllittothefullmarkonthedipstick.

OilType:Detergentoil(APIserviceSF,SG,SH,SJ

orSL)

EngineOilCapacity:58ounces(1.7liter)withthe

lterremoved;51ounces(1.5liter)withoutthelter

removed

Viscosity:Refertothetablebelow

3.Replacethepaperelementifitisdamaged.

InstallingtheFoamandPaperElements

Important:Topreventenginedamage,always

operatetheenginewiththecompletefoamand

paperaircleanerassemblyinstalled.

1.Carefullyslidethefoamelementontothepaperair

cleanerelement(Figure42).

2.Placetheaircleanerassemblyontotheaircleaner

baseorhoseandsecureit(Figure42).

3.Placetheaircleanercoverintopositionandtighten

thecoverknob(Figure42).

ServicingtheEngineOil

ServiceInterval:Beforeeachuseordaily—Checkthe

engineoillevel.

Aftertherst8hours—Changethe

engineoil.

Every100hours—Changetheengine

oil.(moreoftenindirtyordusty

conditions)

Every200hours—Changetheengine

oillter.

Note:Changetheoilmorefrequentlywhenthe

operatingconditionsareextremelydustyorsandy.

Figure43

CheckingtheEngineOilLevel

Note:Checktheoilwhentheengineiscold.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawaythemuferandotherhotsurfaces.

Important:Donotoverllthecrankcasewithoil

becausedamagetotheenginemayresult.Donot

runenginewithoilbelowthelowmarkbecausethe

enginemaybedamaged.

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position(

Figure44).

35

Page 36

G008792

1

2

5

6

7

3

9

10

4

8

3.Stoptheengine,removethekey ,andwaitforall

g012596

2

3

4

1

movingpartstostopbeforeleavingtheoperating

position(Figure45).

Figure44

ChangingtheEngineOil

Note:Disposeoftheusedoilatarecyclingcenter.

1.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoassuretheoildrains

completely.

2.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

Figure45

4.Slowlypourapproximately80%ofthespeciedoil

intothellertubeandslowlyaddtheadditionaloil

tobringittotheFullmark(Figure46).

36

Page 37

G008796

2

3

4

5

6

1

G012845

3/4

2

3

4

5

6

1

Figure46

ChangingtheEngineOilFilter

Note:Changetheengineoilltermorefrequently

whenoperatingconditionsareextremelydustyorsandy.

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil.

2.Placearagundertheoilltertosoakupanyspilled

oil.

Important:Spilledoilmaydrainunderthe

engineandontotheclutch.Oilspilledonthe

clutchmaydamagetheclutch,causetheblades

tostopslowlywhentheclutchisswitchedoff

andcausetheclutchtoslipwhentheclutchis

switchedon.Wipeupanyspilledoil.

3.Changetheengineoillter(

Figure47).

Figure47

Note:Ensuretheoilltergaskettouchestheengine

andthenanextra3/4turniscompleted.

4.Fillthecrankcasewiththepropertypeofnewoil;

refertoChangingtheOil.

ServicingtheSparkPlug

ServiceInterval:Every100hours

Makesuretheairgapbetweenthecenterandside

electrodesiscorrectbeforeinstallingthesparkplug.

Useasparkplugwrenchforremovingandinstalling

thesparkplug(s)andagappingtool/feelergaugeto

checkandadjusttheairgap.Installanewsparkplug(s)

ifnecessary.

TypeforallEngines:NGK

AirGap:0.030inch(0.75mm)

37

®

BPR4ESorequivalent

Page 38

RemovingtheSparkPlug

G008794

1

2

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

Figure50

Figure48

CheckingtheSparkPlug

Important:Nevercleanthesparkplug(s).Always

replacethesparkplug(s)whenithas:ablack

coating,wornelectrodes,anoilylm,orcracks.

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeanstheaircleanerisdirty.

Setthegapto0.030inches(0.75mm).

Figure49

InstallingtheSparkPlug

Tightenthesparkplug(s)to16ft.-lb(22N-m).

38

Page 39

FuelSystem

ServicingtheFuelFilter

Maintenance

DrainingtheFuelTank

Note:Thereisnootherrecommendedwaytodrain

fuelfromthetank,otherthanusingasyphonpump.A

syphonpumpcanbepurchasedatahardwarestore.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Draingasolinefromthefueltankwhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

1.Parkthemachineonalevelsurface.Disengagethe

powertakeoff(PTO),settheparkingbrake,turnthe

ignitionkeytoOffandremovethekey .

2.Cleanaroundthefuelcaptopreventdebrisfrom

gettingintothefueltank(

3.Removethefuelcap.

4.Insertasyphonpumpintothefueltank.

5.Usingthesyphonpump,drainthefuelintoaclean

gascan(

6.Wipeupanyspilledfuel.

Figure51).

Figure52).

ReplacingtheFuelFilter

ServiceInterval:Yearly

Neverinstalladirtylterifitisremovedfromthefuel

line.

Note:Notehowthefuellterisinstalledinorderto

installthenewltercorrectly.

Note:Wipeupanyspilledfuel.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Closefuelshut-offvalve.

4.Squeezetheendsofthehoseclampstogetherand

slidethemawayfromthelter(

Figure52

Figure52).

1.Fuelcap

Figure51

1.Fuellter

2.Hoseclamp

5.Removethelterfromthefuellines.

6.Installanewlterandmovethehoseclampsclose

tothelter.

7.Openthefuelshut-offvalve.

8.Checkforfuelleaksandrepairifneeded.

9.Wipeupanyspilledfuel.

39

3.Fuelline

Page 40

ElectricalSystem

Maintenance

ServicingtheBattery

ServiceInterval:Every100hours

Alwayskeepthebatterycleanandfullycharged.Use

apapertoweltocleanthebatterycase.Ifthebattery

terminalsarecorroded,cleanthemwithasolutionof

fourpartswaterandonepartbakingsoda.Applyalight

coatingofgreasetothebatteryterminalstoprevent

corrosion.

Voltage:12V

WARNING

WARNING

Incorrectbatterycableroutingcoulddamagethe

machineandcablescausingsparks.Sparkscan

causethebatterygassestoexplode,resultingin

personalinjury.

•AlwaysDisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

•AlwaysReconnectthepositive(red)battery

cablebeforereconnectingthenegative(black)

cable.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling .

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing.Wearsafetyglassestoshield

youreyesandrubberglovestoprotectyourhands.

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

3.Disconnectthenegativebatterycablefromthe

negative(-)batteryterminal(

4.Slidetheredterminalbootoffthepositive(red)

batteryterminal.Thenremovethepositive(red)

batterycable(Figure53).

5.Removethebatteryholddownplate(

removethebattery.

Figure53).

Figure53)and

InstallingtheBattery

1.Placethebatteryontothemachine(Figure53).

2.Securethebatterywiththeholddownplate,j-bolts,

andlocknuts.

3.First,installthepositive(red)batterycableto

positive(+)batteryterminalwithanut,washerand

Figure53).Slidetherubbercoveroverthepost.

bolt(

4.Theninstallthenegativebatterycableandground

wiretothenegative(-)batteryterminalwithanut,

washerandbolt(Figure53).

Note:Thebatterycableswillcrossovereachother

whenthearecorrectlyinstalled(

Figure53).

•Whenremovingorinstallingthebattery ,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

40

Page 41

g013199

1

2 3 4

5

6

Note:Donotrunthemachinewiththebattery

g013015

disconnected,electricaldamagemayoccur.

Figure54

Figure53

1.Wingnut4.Positivebatterycable

2.Batterycover5.Battery

3.Negativebatterycable6.Thebatterycablescross

wheninstalledcorrectly

ChargingtheBattery

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

1.PositiveBatteryPost

2.NegativeBatteryPost

3.Red(+)ChargerLead

4.Black(-)ChargerLead

ServicingtheFuses

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance.Ifafuseblows,checkthecomponent

orcircuitforamalfunctionorshort.

1.Releasetheoperatorcushionfromtherearofthe

machine.

2.Pulloutonthefusetoremoveandreplaceit

Figure55).

(

3.Installtheoperatorcushion.

Neversmokenearthebatteryandkeepsparksand

amesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged

(1.265specicgravity).Thisisespeciallyimportant

topreventbatterydamagewhenthetemperatureis

below32°F(0°C).

1.Removethebatteryfromthechassis;referto

RemovingtheBattery.

2.Chargebatteryfor1hourat25to30ampsor6

hoursat4to6amps.

1.Controls

2.Wire

Figure55

3.Fuses

3.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthe

chargerleadsfromthebatteryposts(

Figure54).

4.Installthebatteryontothemachineandconnectthe

batterycables,refertoInstallingtheBattery.

41

Page 42

DriveSystem

g015241

g015369

1 2

Maintenance

AdjustingtheTracking

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

1.Pushbothcontrolleversforwardthesamedistance.

2.Checkifthemachinepullstooneside.Ifitdoes,

stopthemachineandsettheparkingbrake.

3.Releasethecushionfromtherearofthemachine.

4.Rotatetherightcableadjustmenttopositionthe

rightmotioncontrolinthecenterofthecontrol

panelneutrallockslot(

Figure57).

Figure57

Figure56

1.Leftmotioncontrollever

2.Rightmotioncontrollever4.Alignthecontrollevers

3.Neutrallockedposition

fronttoback

5.Rotatetheleftcableadjustmenttomatchtheleft

wheelspeedtothepreviouslysetrightwheelspeed.

Adjustinquarter-turnincrementsuntilthemachine

tracksstraight.

Note:Onlyadjusttheleftcabletomatchtheleft

wheelspeedtotherightwheelspeed.Donotadjust

therightwheelspeedasthiswillpositiontheright

motioncontrolleveroutofthecenterforthecontrol

panelneutrallockslot.

1.Leftcableadjustment

2.Rightcableadjustment

6.Checkforpropertracking.

Note:Ifthemachinewillnotstartafteradjusting

thetracking,makesureproximityswitchtargetaligns

withboltattachedtomotioncontrollever.Referto

AdjustingtheProximitySwitch(page42).

7.Repeatthecableadjustmentuntilthetrackingis

correct.

8.Checkthatthemachinedoesnotcreepfromneutral

withtheparkbrakesdisengaged.

Important:DoNotrotatethelinkagetoofar,as

thismaycausethemachinetocreepinneutral.

AdjustingtheProximitySwitch

Usethisprocedureifthemachinewillnotstartafter

adjustingthetracking.

1.Checkandensuretheboltattachedtothemotion

controlleveralignswiththeproximityswitchtarget

(Figure58).

2.Ifneeded,loosentheboltsandadjusttheproximity

switchuntilthetargetalignswithboltattachedtothe

motioncontrollever(

Figure58).

3.Checkthedistanceofthebolttotheproximity

switch.Itneedstobebetween0.050and0.090

inches(1.27to2.29mm)(Figure58).

42

Page 43

4.Ifadjustmentisneeded,loosenthejamnutand

G015609

1 6

2 3 4

4

2

5

6

adjustthebolttothecorrectdistance.Tightenthe

jamnutafteradjustingthebolt(Figure58).

5.Testthesafetyinterlocksystembeforeoperation.

Figure59

AdjustingtheCasterPivot

Bearing

ServiceInterval:Every500hours/Yearly(whichever

comesrst)

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockedposition

andsettheparkingbrake.

Figure58

1.Proximityswitchtarget4.Boltattachedtothemotion

controllever

2.Proximityswitch5.Distancebetween0.050

and0.090inches(1.27to

2.29mm)isneeded

3.Boltsandnuts6.Jamnut

CheckingtheTirePressure

ServiceInterval:Every50hours/Monthly(whichever

comesrst)

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Removethedustcapfromcasterandtightenlock

Figure60).

nut(

4.Tightenthelocknutuntilthespringwashersareat

andthenbackoffa1/4turntoproperlysetthe

pre-loadonthebearings(

Figure60).

Important:Makesurespringwashersare

installedcorrectlyasshowninFigure60.

5.Installthedustcap(

Figure60).

Maintaintheairpressureinthereartiresat12-14psi

(83-97kPa).Uneventirepressurecancauseanuneven

cut.

Note:Thefronttiresaresemi-pneumatictiresanddo

notrequireairpressuremaintenance.

43

Page 44

Figure60

1.SpringWashers3.DustCap

2.LockNut

AdjustingtheElectricClutch

ServiceInterval:Every500hours—Checktheelectric

clutch.

Theclutchisadjustabletoensureproperengagement

andproperbraking.

1.Inserta0.015–0.021inch(0.381–0.533mm)feeler

gaugethroughoneinspectionslotinthesideofthe

assembly.Makesureitisbetweenthearmatureand

therotorfrictionsurfaces.

Figure61

1.Adjustingnut3.Feelergauge

2.Slot

Thegapneedstobeatleast.015inches(0.381mm)

andnotmorethan.021inches(0.533mm).

2.Ifadjustmentisneeded,thensetat.015inches(0.381

mm)foreachofthethreeadjustmentslotpositions.

Tightenthelocknutsuntilthereisslightbindingon

thefeelergaugebutitcanbemovedeasilywithinthe