FormNo.3408-593RevB

GrandStand

®

MultiForceSnow

Machine

ModelNo.74527—SerialNo.4000000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3408-593*B

WARNING

accessoryinformation,helpndingadealer,orto

registeryourproduct.

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadian

ICES-002

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Pleaserefertotheenginemanufacturer’sinformation

includedwiththemachine.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

WARNING

Removingstandardoriginalequipmentparts

andaccessoriesmayalterthewarranty,

traction,andsafetyofthemachine.Failureto

useoriginalT oropartscouldcauseserious

injuryordeath.Makingunauthorizedchanges

totheengine,fuelorventingsystem,may

violateEPAandCARBregulations.

Replaceallpartsincluding,butnotlimited

to,tires,belts,blades,andfuelsystem

componentswithoriginalToroparts.

Introduction

Thissnowmachineisintendedtobeused

byprofessional,hiredoperatorsorresidential

homeowners.Itisdesignedtooperateattachmentsto

clearsnowonresidentialorcommercialproperties.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactTorodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

g235457

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2017—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SlopeIndicator...................................................5

SafetyandInstructionalDecals..........................6

ProductOverview.....................................................9

Controls.............................................................9

Specications..................................................10

Attachments/Accessories.................................10

BeforeOperation..................................................11

BeforeOperationSafety....................................11

AddingFuel.......................................................11

CheckingtheEngine-OilLevel..........................13

BreakinginaNewMachine..............................13

ThinkSafetyFirst..............................................13

UsingtheSafety-InterlockSystem....................13

DuringOperation.................................................15

DuringOperationSafety...................................15

OperatingtheParkingBrake.............................15

OperatingthePower-T akeoff(PTO)

Switch...........................................................16

OperatingtheThrottle.......................................16

OperatingtheIgnitionSwitch............................16

StartingtheEngine...........................................17

ShuttingOfftheEngine.....................................17

OperatingthePlatform......................................18

DrivingForwardorBackward............................18

StoppingtheMachine.......................................20

UsingWeights..................................................20

AfterOperation....................................................20

AfterOperationSafety......................................20

PreventingFreeze-upafterUse........................20

UsingtheFuel-ShutoffValve.............................21

PushingtheMachinebyHand..........................21

TransportingtheMachine.................................22

LoadingtheMachine........................................22

Maintenance...........................................................24

RecommendedMaintenanceSchedule(s)...........24

Pre-MaintenanceProcedures..............................25

MaintenanceandStorageSafety......................25

ReleasingtheCushionforRearAccess............25

Lubrication..........................................................26

GreasingtheAccessoryFrame.........................26

GreasingtheFrontCasterPivots......................26

GreasingtheCaster-WheelHubs.....................26

GreasingtheVoltageRegulator........................27

GreasingtheBrakeCalipers.............................27

GreasingtheMotionControls...........................28

EngineMaintenance...........................................28

EngineSafety...................................................28

ServicingtheAirCleaner..................................28

ServicingtheEngineOil....................................30

ServicingtheSparkPlug...................................33

CheckingtheSparkArrester.............................34

FuelSystemMaintenance...................................35

DrainingtheFuelT ank......................................35

RemovingtheFuelT ank...................................35

ServicingtheFuelFilter...................................36

ElectricalSystemMaintenance...........................36

ElectricalSystemSafety...................................36

ServicingtheBattery.........................................36

ServicingtheFuses..........................................38

DriveSystemMaintenance..................................39

AdjustingtheTracking......................................39

CheckingtheTirePressure...............................39

AdjustingtheCaster-PivotBearing...................40

ServicingtheCasterWheelsand

Bearings........................................................40

CheckingtheWheel-LugNuts..........................41

CheckingtheWheel-HubNuts..........................41

CoolingSystemMaintenance..............................41

CleaningtheAir-IntakeScreen.........................41

CleaningtheCoolingSystem............................41

BrakeMaintenance.............................................42

ServicingtheBrake..........................................42

BeltMaintenance................................................42

ReplacingtheTransmissionBelt......................42

ControlsSystemMaintenance.............................43

AdjustingtheMotion-ControlLevers.................43

HydraulicSystemMaintenance...........................44

HydraulicSystemSafety...................................44

HydraulicSystemSpecications.......................44

CheckingtheHydraulicFluid............................44

ReplacingtheHydraulicFluidand

Filters............................................................45

BleedingtheHydraulicSystem.........................46

Cleaning..............................................................47

DisposingoftheWaste.....................................47

Storage...................................................................47

CleaningandStorage.......................................47

Troubleshooting......................................................49

Schematics.............................................................51

3

Safety

Thefollowinginstructionshavebeenadaptedfrom

theANSIandISOstandards.

GeneralSafety

Alwaysfollowallsafetyinstructionstoavoidserious

personalinjury.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepclearofanydischargeopening.Keep

bystandersasafedistanceawayfromthe

machine.

•Keepchildrenoutoftheoperatingarea.Never

allowchildrentooperatethemachine.

•Stopthemachineandshutofftheenginebefore

servicing,fueling,oruncloggingthemachine.

Improperlyusingormaintainingthismachinecan

resultininjury .Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafety-alertsymbol,whichmeans

Caution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalsafetyinformationwhere

neededthroughoutthisOperator’sManual.

4

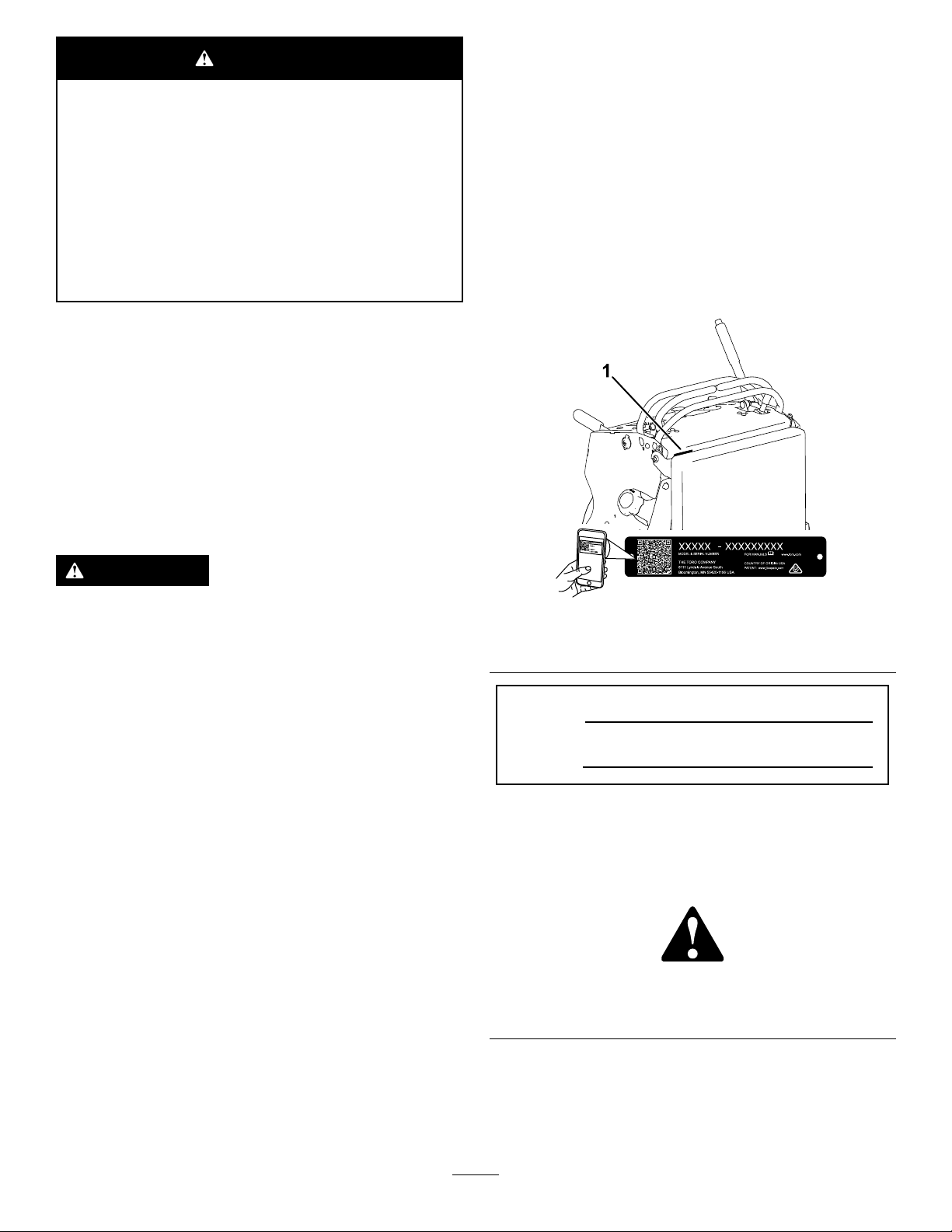

SlopeIndicator

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucanoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslopeof

hillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge

5

g011841

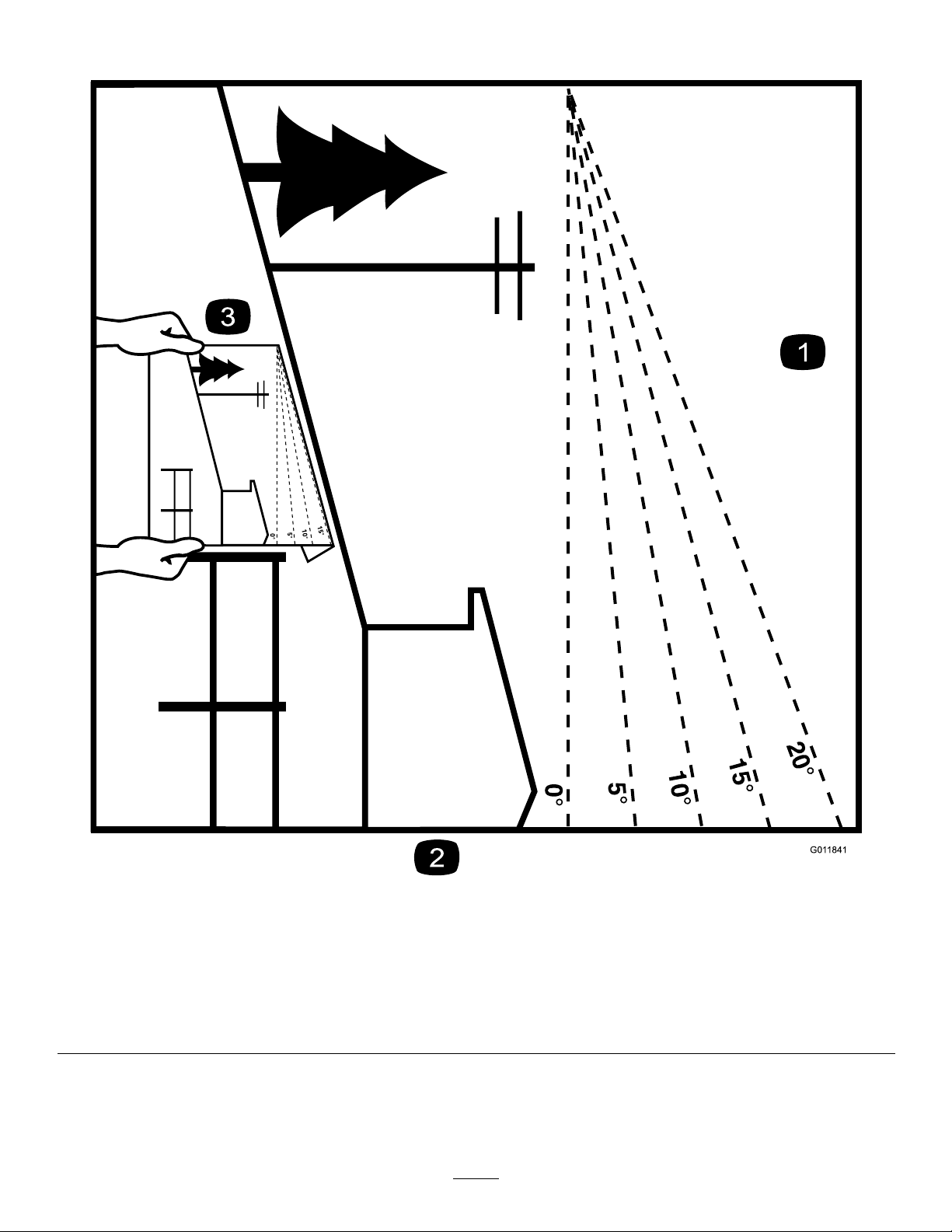

SafetyandInstructionalDecals

131-3528

15A 15A 10A

7.5A

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

BatterySymbols

Someorallofthesesymbolsareonyourbattery

decalbatterysymbols

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

106-5517

1.Warning—donottouchthehotsurface.

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

decal106-5517

1.ReadtheOperator's

Manual.

2.Transmissionoil

1.Ingition—15A

2.Accessoryport—15A

decal131-3524

131-3524

3.Oillevel

decal131-3528

131-3528

3.Powertakeoff(PTO)—10

A

4.Infocenter—7.5A

1.ReadtheOperator’s

Manual.

116-8775

decal116-8775

2.Filltobottomofllerneck;

warning—donotoverll

thetank.

6

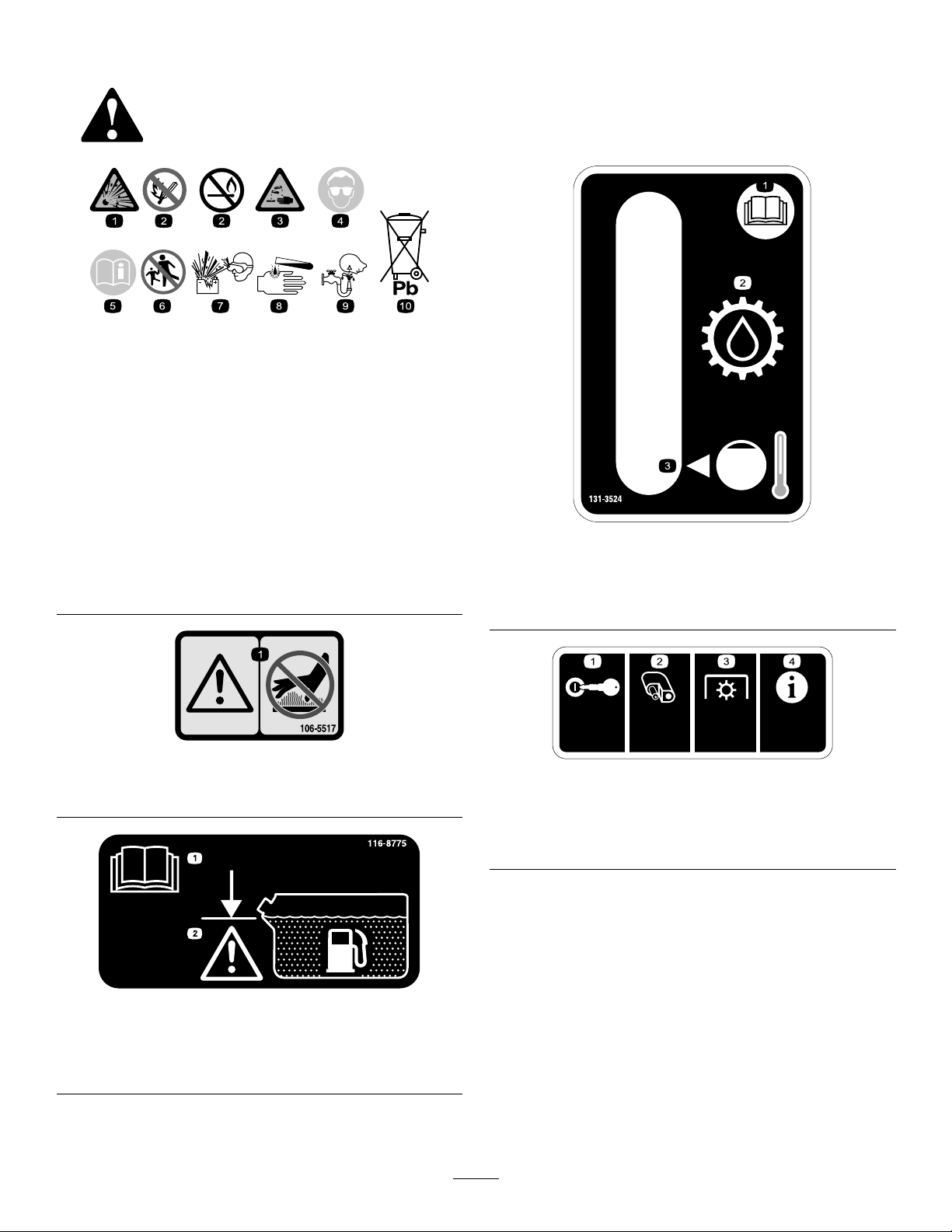

131-3536

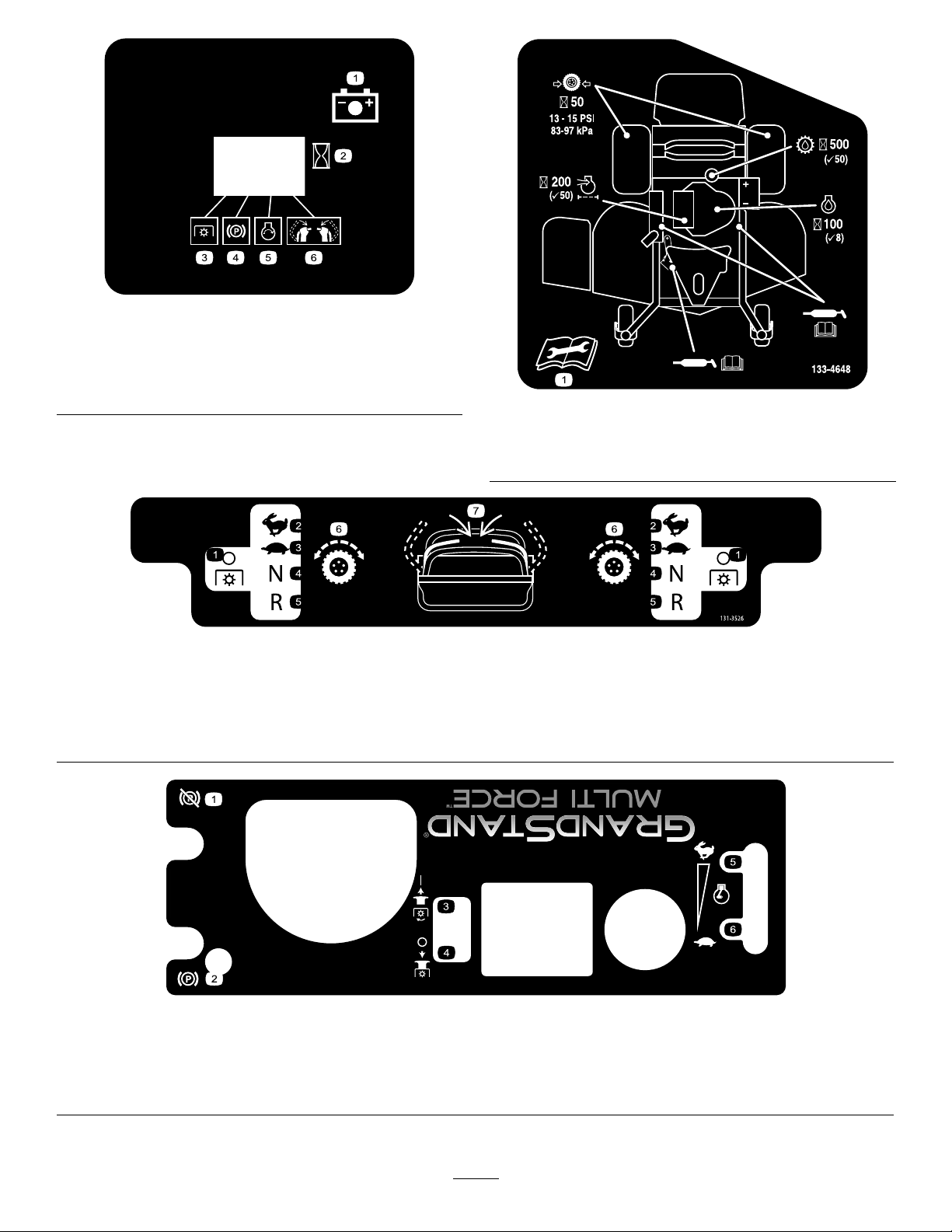

1.Battery4.Parkingbrake

2.Time5.Engine—start

3.Powertakeoff(PTO)

6.Engagethehandlebars.

decal131-3536

decal133-4648

133-4648

1.ReadtheOperator'sManualformoreinformationon

servicingthemachine.

decal131-3526

131-3526

1.Powertakeoff(PTO)—disengaged

5.Reverse

2.Fast6.Tractiondrive

3.Slow

7.Engagethehandles.

4.Neutral

133-1432

1.Disengagetheparkingbrake.

2.Engagetheparkingbrake.

3.PulluptoturnonthePTO.

4.PushdowntoturnoffthePTO.

5.Enginespeed—fast

6.Enginespeed—slow

decal133-1432

7

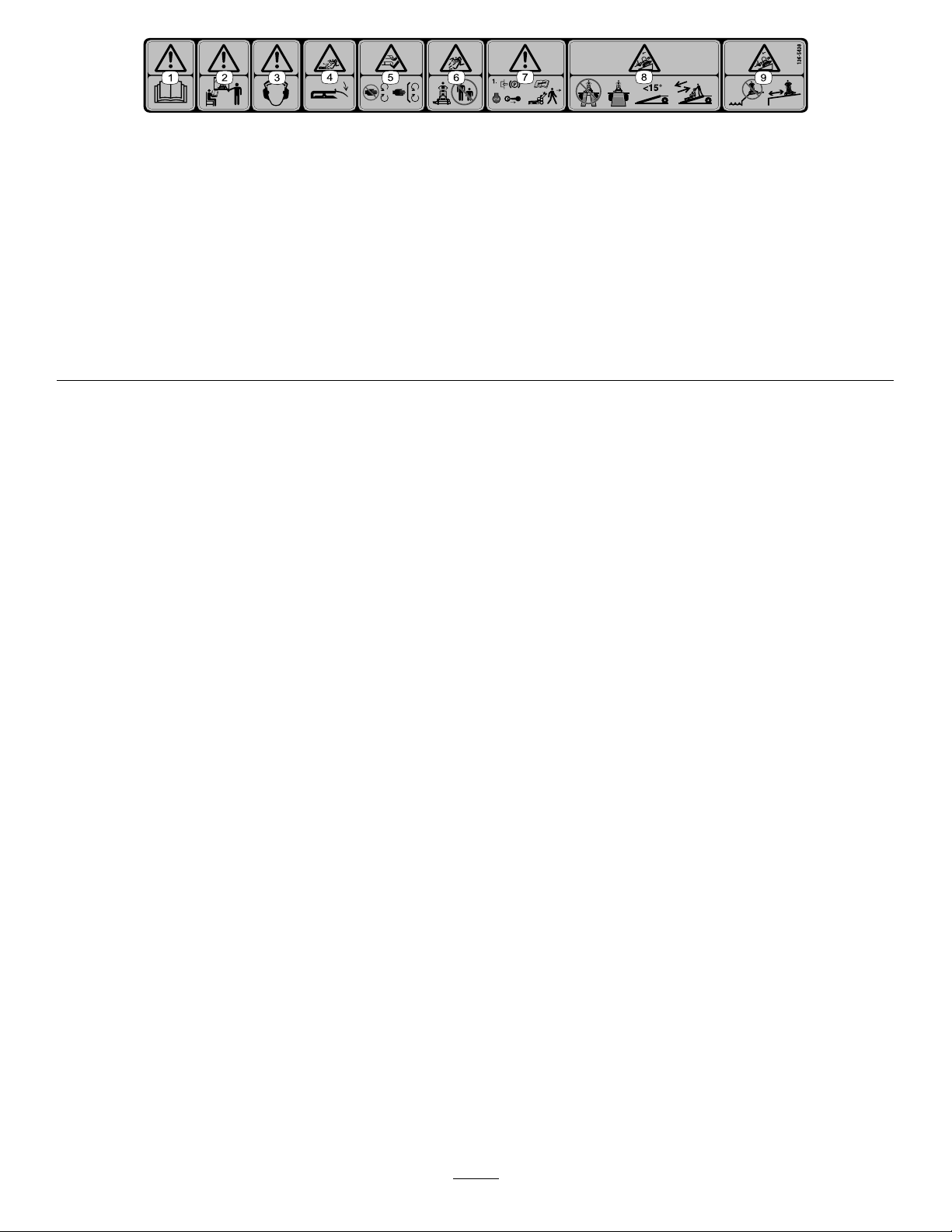

decal136-5438

136-5438

1.Warning—readtheOperator'sManual.6.Thrownobjecthazard—keepbystandersawayfromthe

machine.

2.Warning—receivetrainingbeforeoperatingthemachine.

7.Warning—engagetheparkingbrake,stoptheengine,and

removethekeyfromtheignitionbeforeleavingthemachine.

3.Warning—hearingprotectionmustbeworn.8.Ramphazard—donotusedualrampswhenloadingontoa

trailer;use1rampwideenoughforthemachine;usearamp

withaslopelessthan15°;backuptherampwhenloadingthe

machineanddriveforwardofftherampwhenunloading.

4.Thrownobjecthazard—keepthedeectorloweredduring

9.Tippinghazard—donotoperateneardrop-offsornearwater.

operation.

5.Cutting/severinghazardofhandorfoot—keepawayfrom

movingparts;keepallguardsandshieldsinplace.

8

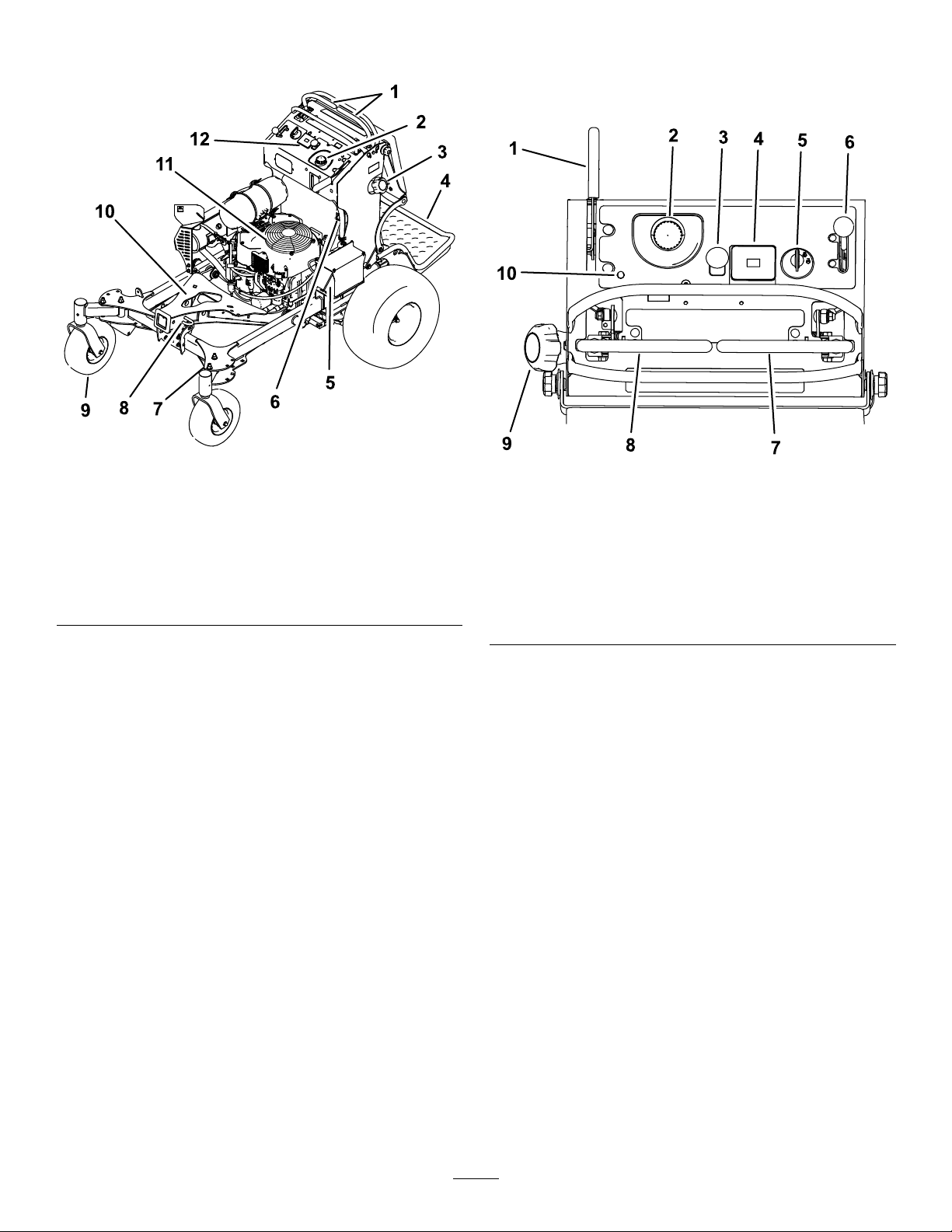

ProductOverview

Controls

Becomefamiliarwithallthecontrolsbeforeyoustart

theengineandoperatethemachine(Figure5).

Figure4

1.Controllevers

2.Hydraulictank

3.Fueltank9.Frontcasterwheel

4.Platform(downposition)10.Accessoryframe

5.Battery11.Engine

6.Fuel-shutoffvalve12.Controls

7.Adjustablecaster

8.Accessory-framelock

g192638

Figure5

1.Parking-brakelever

2.Hydraulic-tankcap7.Rightmotion-controllever

3.Power-takeoff(PTO)

switch

4.Hourmeter9.Fuelcap

5.Ignitionswitch

6.Throttlecontrol

8.Leftmotion-controllever

10.Malfunction-indicatorlight

(MIL)

g192637

HourMeter

Thehourmeterrecordsthenumberofhoursthe

enginehasoperated.Itoperateswhentheengine

isrunning.Usethesetimesforschedulingregular

maintenance(Figure5).

Safety-InterlockIndicators

Therearesymbolsonthehourmeterthatindicate

withablacktrianglethattheinterlockcomponentis

positionedcorrectly(Figure5).

Battery-IndicatorLight

IftheignitionkeyisturnedtotheONpositionfora

fewseconds,thebatteryvoltagedisplaysinthearea

wherethehoursarenormallydisplayed.

Thebatterylightturnsonwhentheignitionisturned

onandwhenthechargeisbelowthecorrectoperating

level(Figure5).

9

ThrottleControl

AdjustableCasters

Thethrottlecontrolstheenginespeed,andithasa

continuous-variablesettingfromtheSLOWtoFAST

position(Figure5).

Power-Takeoff(PTO)switch

Usethepower-takeoff(PTO)switchtostartandstop

poweredattachments(Figure5).

IgnitionSwitch

Usethisswitchtostarttheengine.Ithas3positions:

START,RUN,andOFF.

Motion-ControlLevers

Usethemotion-controlleverstodrivethemachine

forward,reverse,andturneitherdirection.

Fuel-ShutoffValve

Closethefuel-shutoffvalve(locatedontheleftside

ofthefueltank)whentransportingorstoringthe

machine(Figure4).

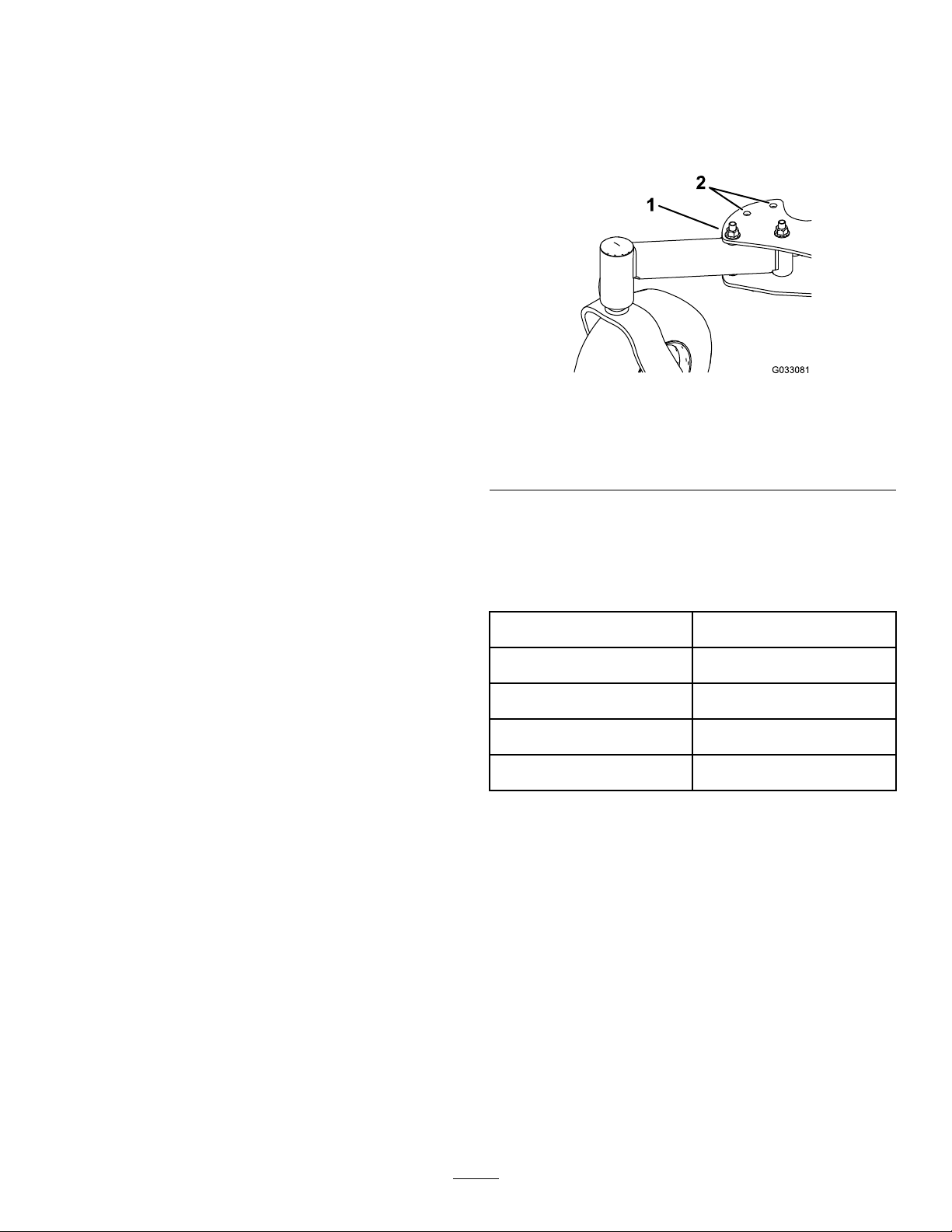

Whenusingthemachinewithanattachment,refer

totheOperator’sManualforthatattachmentforthe

correctcasterposition(Figure6).Donotoperatethe

machinewithoutanattachmentinstalledonthefront

ofthemachine.

Figure6

RightCasterShown

1.Casterboltandnutinfront

casterhole

2.Casterholes

Specications

g033081

AccessoryFrame

UsetheaccessoryframetoattachonlyToro-approved

accessoriestothemachine(Figure4).Refertothe

Operator’sManualfortheaccessoryforinstallation

instructions.

Accessory-FrameLock

Theaccessory-framelockholdstheframeinplaceon

themachineusingthelockpin.Alwayslocktheframe

unlessahydraulickitisinstalledwithanaccessory

onthemachine(Figure4).

Electronic-ControlUnit

Malfunction-IndicatorLight

Theelectronic-controlunit(ECU)continuously

monitorstheoperationoftheEFIsystem.

Ifaproblemorfaultwithinthesystemisdetected,the

malfunction-indicatorlight(MIL)isilluminated(Figure

5).

TheMIListheredlightlocatedintheconsolepanel.

WhentheMILilluminates,makeinitialtroubleshooting

checks.

Ifthesechecksdonotcorrecttheproblem,further

diagnosisandservicingbyanAuthorizedService

Dealerisnecessary.

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

Width

Lengthwithplatformdown191cm(75inches)

Lengthwithplatformup155cm(61inches)

Height

Weight

122cm(48inches)

122cm(48inches)

308kg(680lb)

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesisavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.T oro.comforalistofallapprovedattachments

andaccessories.

Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourToroequipment,countonT oro

genuineparts.Whenitcomestoreliability ,Toro

deliversreplacementpartsdesignedtotheexact

engineeringspecicationofourequipment.Forpeace

ofmind,insistonTorogenuineparts.

10

Operation

possible,thenrefuelfromaportablecontainer

ratherthanafuel-dispensernozzle.

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageoftheoperator.Theowner

isresponsiblefortrainingalloperatorsand

mechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Knowhowtostopthemachineandshutoffthe

enginequickly.

•Checkthatoperator-presencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

•Evaluatetheterraintodeterminetheappropriate

equipmentandanyattachmentsoraccessories

requiredtooperatethemachineproperlyand

safely.

•Donotoperatethemachinewithoutanattachment

installedonthefrontofthemachine.

•Donotoperatethemachinewithouttheentire

exhaustsysteminplaceandinproperworking

condition.

•Keepthefuel-dispensernozzleincontactwith

therimofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.Donotusea

nozzlelock-opendevice.

•Ifyouspillfuelonyourclothing,changeyour

clothingimmediately.Wipeupanyfuelthatspills.

•Neveroverllthefueltank.Replacethefuelcap

andtightenitsecurely.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymorethan

a30-daysupplyoffuel.

•Donotllthefueltankcompletelyfull.Addfuelto

thefueltankuntilthelevelis6to13mm(1/4to

1/2inch)belowthebottomofthellerneck.This

emptyspaceinthetankallowsfueltoexpand.

–Avoidprolongedbreathingofvapors.

–Keepyourfaceawayfromthenozzleandfuel

tankopening.

–Avoidcontactwithskin;washoffspillswith

soapandwater.

AddingFuel

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

FuelSafety

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlingfuel.Fuelvaporsare

ammableandexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfueltothefuel

tankwhiletheengineisrunningorwhilehot.

•Donotrefuelthemachineindoors.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

•Donotllcontainersinsideavehicleoronatruck

ortrailerbedwithaplasticliner.Alwaysplace

containersontheground,awayfromyourvehicle

beforelling.

•Removetheequipmentfromthetruckortrailer

andrefuelitwhileitisontheground.Ifthisisnot

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan

10%ethanolbyvolume,suchasE15(contains

15%ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagethatmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

•Donotaddoiltogasoline.

11

DANGER

WARNING

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanyfuel

thatspills.

•Neverllthefueltankinsideanenclosed

trailer.

•Donotllthefueltankcompletelyfull.

Addfueltothefueltankuntilthelevelis6

to13mm(1/4to1/2inch)belowthebottom

ofthellerneck.Thisemptyspaceinthe

tankallowsfueltoexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinanapprovedcontainerand

keepitoutofthereachofchildren.Never

buymorethana30-daysupplyoffuel.

•Donotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

Fuelisharmfulorfatalifswallowed.

Long-termexposuretovaporscancause

seriousinjuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepyourfaceawayfromthenozzleand

fueltankorconditionerbottleopening.

•Avoidcontactwithskin;washoffspills

withsoapandwater.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsfuelfreshduringstorageof90daysorless.

Forlongerstorage,drainthefueltank.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

Important:Donotusefueladditives

containingmethanolorethanol.

Addthecorrectamountoffuelstabilizer/conditioner

tothefuel.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark,

whichcanignitethefuelvapors.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Alwaysplacefuelcontainersontheground

awayfromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmay

insulatethecontainerandslowthelossof

anystaticcharge.

•Whenpractical,removeequipmentfrom

thetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainerratherthanfroma

fuel-dispensernozzle.

•Ifyoumustuseafuel-dispensernozzle,

keepthenozzleincontactwiththerimof

thefueltankorcontaineropeningatall

timesuntilfuelingiscomplete.

Note:Afuelstabilizer/conditionerismost

effectivewhenmixedwithfreshfuel.T ominimize

thechanceofvarnishdepositsinthefuelsystem,

usefuelstabilizeratalltimes.

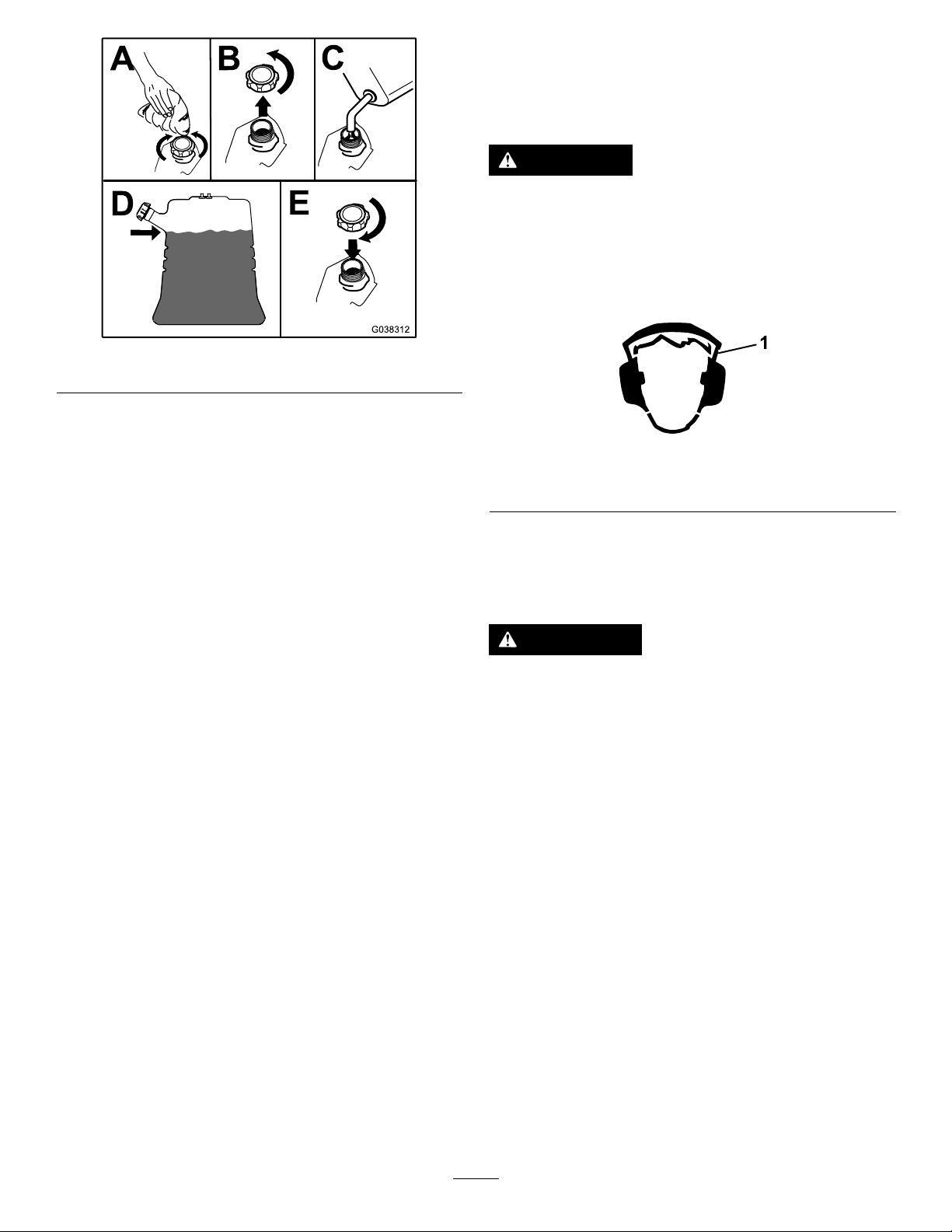

FillingtheFuelTank

1.Parkthemachineonalevelsurface,disengage

thePTO,movethemotion-controlleverstothe

NEUTRAL-LOCKposition,andengagetheparking

brake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanaroundthefuel-tankcapandremovethe

cap.

4.Fillthefueltanktothebottomofthellerneck.

Note:Donotllthefueltankcompletelyfull.

Theemptyspaceinthetankallowsthefuelto

expand.

5.Installthefuel-tankcapsecurely.Wipeupany

spilledfuel.

12

Figure7

ThinkSafetyFirst

Carefullyreadallthesafetyinstructionsanddecals

inthesafetysection.Knowingthisinformationcould

helpyouorbystandersavoidinjury.

CAUTION

Thismachineproducessoundlevelsin

excessof85dBAattheoperator'searand

cancausehearinglossfromextendedperiods

ofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

g038312

CheckingtheEngine-Oil Level

Beforeyoustarttheengineandusethemachine,

checktheoillevelintheenginecrankcase;referto

Maintenance(page24).

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Drive

systemshavehigherfrictionwhennew,placing

additionalloadontheengine.Allow40to50hoursof

break-intimefornewmachinestodevelopfullpower

andbestperformance.

g229846

Figure8

1.Wearhearingprotection.

UsingtheSafety-Interlock System

WARNING

Ifsafety-interlockswitchesaredisconnected

ordamaged,themachinecouldoperate

unexpectedlycausingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdaily,andreplaceanydamaged

switchesbeforeoperatingthemachine.

Understandingthe Safety-InterlockSystem

Thesafety-interlocksystemisdesignedtoprevent

poweringtheattachmentunlessyoudo1ofthe

following:

•Moveeithermotion-controllevertothecenter,

unlockedposition.

•PullthePTOswitchtotheONposition.

Thesafety-interlocksystemisdesignedtostop

theattachmentifyoumoveorreleaseboth

motion-controlleversintotheNEUTRAL-LOCK

position.

Thehourmeterhassymbolstonotifytheuser

wheneachinterlockcomponentisinthecorrect

13

position.Whenthecomponentisinthecorrect

position,atrianglelightsupinthecorresponding

square(Figure9).

8.Continueholdingthemotion-controlleverinthe

center,unlockedposition,pulluponthePTO

switch,andreleasetheswitch.

Note:Theclutchandattachmentshould

engage.

9.PushthePTOswitchdowntotheOFFposition.

Note:Theattachmentshouldstop.

10.Withtheenginerunning,pullupthePTO

switchandreleaseitwithoutholdingeither

motion-controllevertothecenter,unlocked

position.

Figure9

1.Triangleslightupwhentheinterlockcomponentsareinthe

correctposition.

TestingtheSafety-Interlock System

ServiceInterval:Beforeeachuseordaily

Testthesafety-interlocksystembeforeyouusethe

machineeachtime.

Note:Ifthesafetysystemdoesnotoperateas

describedbelow,haveanAuthorizedServiceDealer

repairthesafetysystemimmediately.

1.Starttheengine;refertoStartingtheEngine

(page17).

2.Movethemotion-controlleverstothecenter,

unlockedposition.

Note:Theattachmentshouldstopandthe

engineshouldstoprunning.

g031282

Note:Theattachmentshouldnotengage.

WARNING

Theoperatorplatformisheavyandmaycause

injurywhenyouraiseorlowerit.Carefully

lowerorraisetheoperatorplatform,as

suddenlydroppingitcouldinjureyou.

•Donotputyourhandsorngersinthe

platform-pivotareawhenloweringor

raisingtheoperatorplatform.

•Makesurethattheplatformissupported

whenyoupullthelatchpinout.

•Makesurethatthelatchsecuresthe

platformwhenfoldingitup.Pushittight

againstthecushionforthelatchpinto

lockintoplace.

•Keepbystandersawayfromthemachine

whenraisingorloweringtheplatform.

3.Starttheengineanddisengagetheparking

brake.

4.Moveeithermotion-controllevertothecenter,

unlockedposition.

5.Continueholdingthemotion-controlleverinthe

center,unlockedposition,pulluponthePTO

switch,andreleasetheswitch.

Note:Theclutchandattachmentshould

engage.

6.Moveorreleasethemotion-controlleversinto

theNEUTRAL-LOCKposition.

Note:Theattachmentshouldstopandthe

engineshouldcontinuetorun.

7.PushthePTOswitchdownandmoveeither

motion-controllevertothecenter,unlocked

position.

14

DuringOperation

DuringOperationSafety

–Waitforallmovingpartstostop.

•Donotoperatethemachinewhenthereistherisk

oflightning.

•Donotusethemachineasatowingvehicle.

GeneralSafety

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Wearappropriateclothing,includingadequate

wintergarmentseyeprotection;slip-resistant,

substantialfootwearthatwillimprovefootingon

slipperysurfaces;andhearingprotection.Tieback

longhairanddonotwearjewelry.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Nevercarrypassengersonthemachineandkeep

bystandersandpetsawayfromthemachine

duringoperation.

•Operatethemachineonlyingoodvisibilitytoavoid

holesorhiddenhazards.

•Ensurethatalldrivesareinneutral,theparking

brakeisengaged,andyouareintheoperating

positionbeforeyoustarttheengine.

•Lookbehindanddownbeforebackinguptobe

sureofaclearpath.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscureyour

vision.

•Donotusethemachineneardrop-offs,ditches,or

embankments.Themachinecouldsuddenlyroll

overifawheelgoesovertheedgeoriftheedge

givesway.

•Stopandinspectthemachineafterstrikingan

objectorifthereisanabnormalvibrationinthe

machine.Makeallnecessaryrepairsbefore

resumingoperation.

•Donotchangethegovernorspeedoroverspeed

theengine.

•Useaccessoriesandattachmentsapprovedby

Toroonly .

SlopeSafety

•Slowdownthemachineanduseextracareon

hillsides.Travelupanddownonhillsides.Turf

conditionscanaffectthestabilityofthemachine.

•Avoidturningthemachineonslopes.Ifyoumust

turnthemachine,turnitslowlyandgradually

downhill,ifpossible.

•Donotturnthemachinesharply.Usecarewhen

reversingthemachine.

•Useextracarewhileoperatingthemachinewith

attachments;theycanaffectthestabilityofthe

machine.

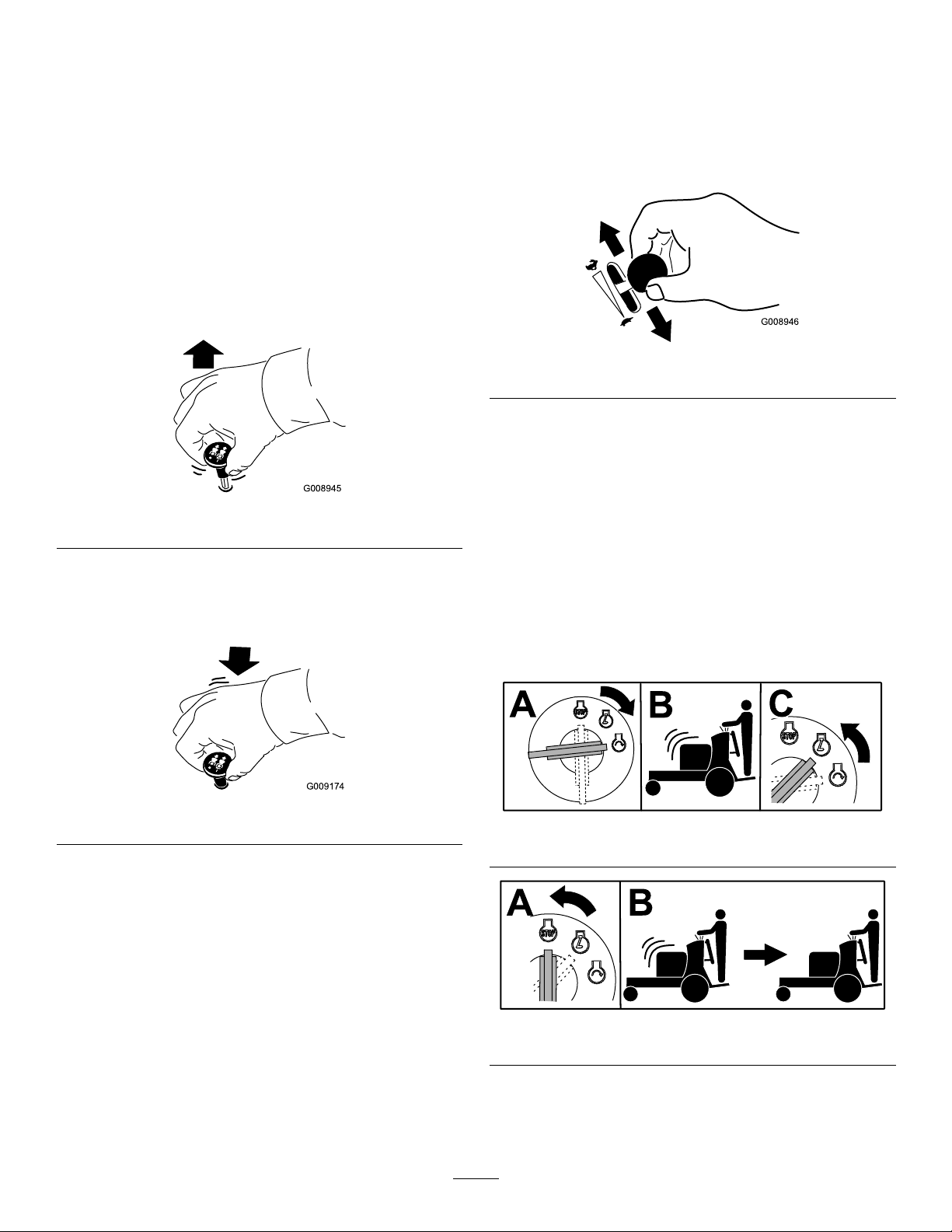

OperatingtheParking Brake

Alwaysengagetheparkingbrakewhenyoushutoff

themachineorleaveitunattended.Beforeeachuse,

checktheparkingbrakeforproperoperation.

Iftheparkingbrakedoesnotholdsecurely,adjustit;

refertoAdjustingtheBrakes(page42).

Pulltheparking-brakeleverrearwardtoengageit

(Figure10).

Pushtheparking-brakeleverforwardtodisengageit.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalkswiththe

machine.Alwaysyieldtheright-of-way.

•Neverrunanengineinanareawhereexhaust

gasesareenclosed.

•Neverleavearunningmachineunattended.

•Beforeleavingtheoperatingposition,dothe

following:

–Stopthemachineonlevelground.

–Disengagethepowertake-offandlowerthe

attachments.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey.

g009465

Figure10

1.Parkingbrake—engaged2.Parking

brake—disengaged

15

Operatingthe

OperatingtheThrottle

Power-Takeoff(PTO)

Switch

Thepower-takeoff(PTO)switchstartsandstopsany

poweredattachments.

EngagingthePower-Takeoff(PTO) Switch

Note:Engagingthepower-takeoff(PTO)switchwith

thethrottlepositionathalforlesscausesexcessive

weartothedrivebelts.

Figure11

DisengagingthePower-Takeoff

YoucanmovethethrottlecontrolbetweentheFAST

andSLOWpositions(Figure13).

AlwaysusetheFASTpositionwhenturningon

poweredattachmentswiththepower-takeoff(PTO)

switch.

g008946

Figure13

OperatingtheIgnition

g008945

Switch

Important:Donotengagethestarterformore

than5secondsatatime.Iftheenginefailsto

start,wait15secondsbetweenattempts.Failure

tofollowtheseinstructionscanburnoutthe

startermotor.

(PTO)Switch

g009174

Figure12

Note:Youmayneedtorepeatthecycleforstarting

theenginewhenyoustartitforthersttimeafteryou

havelledacompletelyemptyfuelsystemwithfuel.

g192743

Figure14

g192744

Figure15

16

StartingtheEngine

Important:Donotengagethestarterformore

than5secondsatatime.Iftheenginefailsto

start,wait15secondsbetweenattempts.Failure

tofollowtheseinstructionscanburnoutthe

startermotor.

Note:Youmayneedtorepeatthecycleforstarting

theenginewhenyoustartitforthersttimeafteryou

havelledacompletelyemptyfuelsystemwithfuel.

ShuttingOfftheEngine

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

Alwaysremovethekeyandengagethe

parkingbrakewhenleavingthemachine

unattended.

Lettheengineidleatslowthrottle(turtle)for60

secondsbeforeturningthekeyswitchtotheOFF

position.

Figure16

g192745

g030982

Figure17

Important:Makesurethatthefuel-shutoffvalve

isclosedbeforetransportingorstoringthe

machinetopreventafuelleak.Beforestoringthe

machine,disconnectthesparkplug(s)toprevent

thepossibilityofaccidentalstarting.

17

OperatingthePlatform

Youcanusethemachinewiththeplatforminthe

upordownposition.Itisyourpreferenceonwhich

positiontouse.

OperatingtheMachinewiththe PlatformUp

Operatethemachinewiththeplatformupforthe

followingconditions:

•Usingthemachineneardrop-offs

•Usingthemachineinsmallareaswherethe

machineistoolarge

•Areaswithlow-hangingbranchesorobstacles

•Loadingthemachinefortransport

•Drivingupslopes

Toraisetheplatform,pullthebackoftheplatformup

sothatthelatchpinandknoblockitintoplace.Push

ittightagainstthecushionforthelatchpintolockit

intoplace.

1.Platformup

2.Platformdown

g192759

Figure18

3.Pulltheknobouttorelease

theplatform.

OperatingtheMachinewiththe PlatformDown

Operatethemachinewiththeplatformdownforthe

followingconditions:

•Usingthemachineinmostareas

•Drivingacrossslopes

•Drivingdownslopes

Tolowertheplatform,pushtheplatformforward

againstthecushiontoreleasepressureonthelatch

pin,thenpulltheknoboutandlowertheplatform

(Figure18).

DrivingForwardor Backward

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Place

thethrottlecontrolintheFASTpositionforbest

performance.

Important:Backthemachineovercurbs,1wheel

atatime;drivingitforwardovercurbscould

damagethemachine.

CAUTION

Themachinecanspinveryrapidly,andyou

maylosecontrolofthemachine,causing

personalinjurytoyouanddamagetothe

machine.

Slowdownthemachinebeforemakingsharp

turns.

18

DrivingForward

1.Disengagetheparkingbrake;refertoOperating

theParkingBrake(page15).

2.Movethemotion-controlleverstothecenter,

unlockedposition.

g192742

Figure20

Figure19

1.Frontreferencebar

2.Leftcontrollever

3.Rearreferencebar6.Leftcontrolleverinthe

4.Rightcontrollever

5.Rightcontrolleverinthe

NEUTRAL-LOCKposition

NEUTRAL-LOCKposition

3.Slowlypushthemotion-controlleversforward

(Figure20).

Note:Theengineshutsoffifyoumovea

motion-controlleverwhiletheparkingbrakeis

engaged.

Note:Thefartheryoumovethemotion-control

leversineitherdirection,thefasterthemachine

movesinthatdirection.

Note:Tostop,pullthemotion-controllevers

backtotheNEUTRALposition.

g030983

DrivingBackward

1.Movebothmotion-controlleverstothecenter,

unlockedposition.

2.Slowlypullthemotion-controlleversrearward

(Figure21).

g192741

Figure21

19

StoppingtheMachine

Tostopthemachine,movethemotion-controllevers

toneutral,andthenmovethemtotheNEUTRAL-LOCK

position,disengagethepowertakeoff(PTO),andturn

theignitionkeytotheOFFposition.

Engagetheparkingbrakewhenyouleavethe

machine;refertoOperatingtheParkingBrake(page

15).

Note:Remembertoremovethekeyfromtheignition

switch.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

AfterOperation

AfterOperationSafety

GeneralSafety

•Cleansnowanddebrisfromthedrives,mufers,

andenginecompartmenttohelppreventres.

Cleanupoilorfuelspills.

•Shutoffthefuelbeforestoringortransportingthe

machine.

•Disengagethedrivetotheattachmentwhenever

youaretransportingornotusingthemachine.

•Usefull-widthrampsforloadingthemachineinto

atrailerortruck.

Alwaysremovetheignitionkeyandengage

theparkingbrakewhenleavingthemachine

unattended,evenifjustforafewminutes.

UsingWeights

•Installweightstoimprovebalance.Youcanaddor

removeweightstocreateoptimizedperformance

underdifferentoperatingconditionsandforyour

preference.

•Addorremoveweights1atatimeuntilyou

achievethedesiredhandlingandbalance.

•RefertotheOperator’sManualofattachmentsfor

recommendedweights.

Note:ContactanAuthorizedServiceDealertoorder

aweightkit.

WARNING

Excessiveweightchangescanaffectthe

handlingandoperationofthemachine.

Thiscouldcauseseriousinjurytoyouor

bystanders.

•Makeweightchangesinsmallincrements

only.

•Evaluatethemachineaftereachweight

changetoensurethatyoucanoperatethe

machinesafely .

•Tiethemachinedownsecurelyusingstraps,

chains,cable,orropes.Bothfrontandrearstraps

shouldbedirecteddownandoutwardfromthe

machine.

•Allowtheenginetocoolbeforestoringthemachine

inanyenclosure.

•Shutoffthefuelbeforestoringortransportingthe

machine.

•Neverstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

PreventingFreeze-upafter Use

•Insnowyandcoldconditions,somecontrolsand

movingpartsmayfreeze.Donotuseexcessive

forcewhentryingtooperatefrozencontrols.

Ifyouhavedifcultyoperatinganycontrolorpart,

starttheengineandletitrunforafewminutes.

Thawfrozenpartsbeforeoperatingthemachine.

•Afterusingthemachine,lettheenginerunfora

fewminutestopreventmovingpartsfromfreezing.

Shutofftheengine,waitforallmovingparts

tostop,andremovealliceandsnowfromthe

machine.

20

UsingtheFuel-Shutoff

PushingtheMachineby

Valve

Closethefuel-shutoffvalvefortransport,maintenance,

andstorage(Figure22).

Ensurethatthefuel-shutoffvalveisopenwhen

startingtheengine.

Hand

Thebypassvalvesallowyoutopushthemachineby

handwithouttheenginerunning.

Important:Alwayspushthemachinebyhand.

Donottowthemachine,becausehydraulic

damagemayoccur.

Important:Donotstartoroperatethemachine

withthebypassvalvesopen.Damagetosystem

mayoccur.

g192837

Figure22

1.ONposition2.OFFposition

g031238

g192836

Figure23

21

TransportingtheMachine

LoadingtheMachine

Useaheavy-dutytrailerortrucktotransportthe

machine.Ensurethatthetrailerortruckhasall

thenecessarybrakes,lighting,andmarkingas

requiredbylaw.Pleasecarefullyreadallthesafety

instructions.

1.Raisetheplatformofthemachinebeforedriving

ontothetrailerortruck.

2.Ifusingatrailer,connectittothetowingvehicle

andconnectthesafetychains.

3.Ifapplicable,connectthetrailerbrakes.

4.Loadthemachineontothetrailerortruck.

5.Shutofftheengine,removethekey,setthe

brake,andclosethefuelvalve.

6.Usethemetaltie-downloopsandthe

caster-wheelframestosecurelyfastenthe

machinetothetrailerortruckwithstraps,

chains,cable,orropes(Figure24).

Useextremecautionwhenloadingorunloadingthe

machineontoatraileroratruck.Useafull-widthramp

thatiswiderthanthemachineforthisprocedure.

Backthemachineuptherampandwalkitforward

downtheramp(Figure25).

Figure25

1.Backthemachineupthe

ramp.

2.Walkthemachinedown

theramp.

Important:Donotusenarrowindividualramps

foreachsideofthemachine.

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath(Figure26).

g192838

1.Tractionunittie-downloop

Figure24

2.Caster-wheelframe

•Useextremecautionwhenoperatinga

machineonaramp.

•Useonlyafull-widthramp;donotuse

individualrampsforeachsideofthe

machine.

•Donotexceeda15-degreeanglebetween

g192839

therampandthegroundorbetweenthe

rampandthetrailerortruck.

•Ensurethatthelengthoframpisatleast

4timesaslongastheheightofthetrailer

ortruckbedtotheground.Thisensures

thattherampangledoesnotexceed15

degreesonatground.

•Backuprampsanddriveforwarddown

ramps.

•Avoidsuddenaccelerationordeceleration

whiledrivingthemachineonarampas

thiscouldcausealossofcontrolora

tip-oversituation.

22

Figure26

g027996

1.Full-widthrampinstowed

position

2.Sideviewoffull-width

rampinloadingposition

3.Notgreaterthan

15degrees

4.Therampisatleast4

timesaslongastheheight

ofthetrailerortruckbed

totheground

5.H=heightofthetraileror

truckbedtotheground

6.Trailer

23

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst50hours

Aftertherst100hours

Beforeeachuseordaily

Every50hours

Every100hours

Every150hours

Every200hours

Every300hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthehydraulic-uidlevel.

•Changethehydraulicltersandhydraulicuid.

•Checkthewheel-lugnuts.

•Checkthewheel-hubnuts.

•Checkthesafety-interlocksystem.

•Checktheengine-oillevel.

•Cleantheair-intakescreen.

•Checkthebrakes.

•Checkthesparkarrester(ifequipped).

•Checkthetirepressure.

•Changetheengineoil.

•Checkthebattery.

•Checkandcleantheenginecoolingnsandshrouds.

•Inspecttheprimarylterandtheair-inletscreen.

•Changetheengine-oillter.

•Check,cleanandgapthesparkplug.

•Replacetheprimaryairlter(moreoftenindustyorsandyconditions).

•Checktheinnerairlter.

•Adjustthecaster-pivotbearing.

Every500hours

Every600hours

Every800hours

Every1,000hours

Beforestorage

Yearly

•Checkthewheel-hubnuts.

•Checkthehydraulic-uidlevel.

•Changethehydraulicltersandhydraulicuid.

•Replacetheinnerairlter.

•Replacethefuellter .

•Replacethetransmissionbelt.

•Paintchippedsurfaces.

•Performallmaintenanceprocedureslistedabovebeforestorage.

•Greasethefrontcasterpivots(moreoftenindirtyordustyconditions).

•Greasethecaster-wheelhubs.

•Greasethevoltageregulator.

•Greasethebrakecalipers.

•Greasethemotioncontrols.

•Applyanti-seizecompoundtothecushionknobs.

•Washthemachine.

Important:Refertoyourengineowner’smanualforadditionalmaintenanceprocedures.

24

CAUTION

Ifyouleavethekeyintheswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorbystanders.

Removethekeyfromtheswitchanddisconnectthespark-plugwiresfromthesparkplugs

beforeyoudoanymaintenance.Setthewiresasidesothattheydonotaccidentallycontact

thesparkplugs.

Pre-Maintenance

Procedures

MaintenanceandStorage Safety

•Beforerepairingthemachinedothefollowing:

–Disengagethedrives.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey.

–Disconnectthespark-plugwire.

•Parkthemachineonalevelsurface.

•Cleansnowanddebrisfromthedrives,mufers,

andenginetohelppreventres.

•Cleanupoilorfuelspills.

•Lettheenginecoolbeforestoringthemachine.

•Donotstorethemachineorfuelnearamesor

drainthefuelindoors.

•Donotallowuntrainedpersonneltoservicethe

machine.

•Usejackstandstosupportthemachineand/or

componentswhenrequired.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectthebatteryorremovethespark-plug

wirebeforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositiveterminal

last.Connectthepositiveterminalrstand

negativelast.

•Keepyourhandsandfeetawayfrommoving

parts.Ifpossible,donotmakeadjustmentswith

theenginerunning.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Neverinterferewiththeintendedfunctionofa

safetydeviceorreducetheprotectionprovided

byasafetydevice.Checktheirproperoperation

regularly.

•Toensureoptimumperformanceandcontinued

safetycerticationofthemachine,useonly

genuineT ororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadeby

othermanufacturerscouldbedangerous,and

suchusecouldvoidtheproductwarranty.

•Checktheparkingbrakeoperationfrequently.

Adjustandserviceasrequired.

ReleasingtheCushionfor RearAccess

Youcanreleasethecushionforrearaccesstothe

machineformaintenanceoradjustment.

1.Lowertheplatform.

2.Loosenthetwistknobsoneachsideofthe

machine(Figure27).

Figure27

1.Twistknob

3.Removethecushionandlowerittotheplatform.

4.Performanymaintenanceoradjustmentonthe

machine.

5.Raisethecushion,andslideitontothepinson

bothsidesofthemachine.

6.Tightenthetwistknobs.

2.Cushion

g032556

25

Lubrication

Usehigh-temperaturegrease.

1.DisengagethePTOandengagetheparking

brake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanthegreasettingswitharag.

Note:Makesuretoscrapeanypaintoffthe

frontofthetting(s).

4.Connectagreaseguntothetting.

5.Pumpgreaseintothettingsuntilgreasebegins

tooozeoutofthebearings.

6.Wipeupanyexcessgrease.

GreasingtheAccessory Frame

Greasethepivotsoftheaccessoryframeatthe

locationsshowninFigure28.

5.Removethegreasettingfromthehole.

6.Installthehexpluganddustcap.

GreasingtheCaster-Wheel Hubs

ServiceInterval:Yearly

1.Shutofftheengine,waitforallmovingpartsto

stop,engagetheparkingbrake,andremove

thekey.

2.Removethecasterwheelfromthecasterforks.

3.Removethesealguardsfromthewheelhub

(Figure29).

Figure28

1.Greasethesepivots.

GreasingtheFrontCaster Pivots

ServiceInterval:Yearly

1.Removethedustcapandadjustthecaster

pivots;refertoAdjustingtheCaster-Pivot

Bearing(page40).

Note:Keepthedustcapoffuntilyouhave

nishedgreasingthecasterpivots.

2.Removethehexplug.

3.Threadagreasettingintothehole.

4.Pumpgreaseintothettinguntilitoozesout

aroundthetopbearing.

g006115

Figure29

1.Sealguard2.Spacernutwithwrench

4.Remove1spacernutfromtheaxleassemblyin

thecasterwheel.

ats

Note:Thread-lockingadhesivehasbeen

g193333

appliedtolockthespacernutstotheaxle.

Removetheaxle(withtheotherspacernutstill

assembledtoit)fromthewheelassembly.

5.Pryouttheseals,inspectbearingsforwearor

damage,andreplacethemifnecessary.

6.Packthebearingswithageneral-purpose

grease.

7.Insert1bearingand1newsealintothewheel.

Note:Youmustreplacetheseals.

8.Ifbothspacernutsintheaxleassembly

havebeenremoved(orbrokenloose),apply

athread-lockingadhesiveto1spacernut,

threadingitontotheaxlewiththewrenchats

facingoutward.

Note:Donotthreadspacernutalloftheway

ontotheendoftheaxle.Leaveapproximately

3mm(1/8inch)fromtheoutersurfaceofthe

spacernuttotheendoftheaxleinsidethenut.

26

9.Inserttheassemblednutandaxleintothewheel

onthesideofthewheelwiththenewsealand

bearing.

10.Withtheopenendofthewheelfacingup,ll

theareainsidethewheelaroundtheaxlefullof

general-purposegrease.

11.Insertthesecondbearingandthenewsealinto

thewheel.

12.Applyathread-lockingadhesivetothesecond

spacernut,threadingitontotheaxlewiththe

wrenchatsfacingoutward.

13.Torquethenutto8to9N∙m(71to80in-lb),

loosenit,thentorqueitto2to3N∙m(20to25

in-lb).

Note:Makesurethataxledoesnotextend

beyondeithernut.

14.Installthesealguardsoverthewheelhuband

insertwheelintocasterfork.

g228035

Figure30

1.Voltageregulator2.Regulatorblades

15.Installthecasterboltandtightenthenutfully.

Important:Topreventsealandbearingdamage,

checkthebearingadjustmentoftenbyspinning

thecasterwheel.Thetireshouldnotspinfreely

(morethan1or2revolutions)orhaveanyside

play.Ifthewheelspinsfreely,adjustthetorque

onthespacernutuntilthereisaslightamountof

drag,andapplythread-lockingadhesive.

GreasingtheVoltage Regulator

ServiceInterval:Yearly

Greasetype:Dielectricgrease

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Disconnectthesparkplugwiresfromthespark

plug.

GreasingtheBrakeCalipers

ServiceInterval:Yearly

Applyarust-preventativespraytothebrakecalipers

yearly.

g228033

Figure31

1.Brakecaliper

4.Lightlyapplygreasetothevoltageregulator

blades(Figure30).

Important:T oomuchgreasecancause

watertopoolattheconnectorandshortthe

regulator.

5.Connectthesparkplug.

27

GreasingtheMotion Controls

ServiceInterval:Yearly

Greasetheoperator-presence-controlballjointand

themotion-controlbushingforbothlevers.

Note:Useanoildripbetweentheleverbracketsto

greasethebushing,locatedinthepivottube.

EngineMaintenance

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keepyourhands,feet,face,clothing,and

otherbodypartsawaythemuferandother

hotsurfaces.

EngineSafety

Shutofftheenginebeforecheckingtheoiloradding

oiltothecrankcase.

ServicingtheAirCleaner

ServiceInterval:Every150hours

Every300hours/Y early(whichevercomes

rst)—Replacetheprimaryairlter(moreoften

industyorsandyconditions).

1.Operator-presencecontrol

balljoint

Figure32

2.Pivottube

Every300hours—Checktheinnerairlter.

Every600hours—Replacetheinnerairlter.

Note:Checktheltersmorefrequentlyifthe

operatingconditionsareextremelydustyorsandy.

RemovingtheFilters

1.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,and

g228034

engagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Releasethelatchesontheaircleanerand

pulltheair-inletcoverofftheair-cleanerbody

(Figure33).

4.Cleantheair-inletscreenandcover.

5.Installtheair-inletcoverandsecureitwiththe

latches(Figure33).

28

Figure33

1.Air-inletcover3.Air-cleanerbody

2.Air-inletscreen4.Latch

g012996

g012997

Figure34

6.Releasethelatchesontheaircleanerandpull

theair-cleanercoverofftheair-cleanerbody

(Figure34).

7.Cleantheinsideoftheair-cleanercoverwith

compressedair.

8.Gentlyslidetheprimarylteroutofthe

air-cleanerbody(Figure34).

Note:Avoidknockingthelterintothesideof

thebody.

9.Removetheinnerlteronlyifyouintendto

replaceit.

Important:Neverattempttocleantheinner

lter.Ifthesafetylterisdirty,thenthe

primarylterisdamaged.Replaceboth

lters.

1.Innerlter

2.Primarylter

3.Air-cleanercover

4.Latch

5.Air-cleanerbody

10.Inspecttheprimarylterfordamagebylooking

intothelter,whileshiningabrightlightonthe

outsideofthelter.

Note:Holesinthelterwillappearasbright

spots.Ifthelterisdamaged,discardit.

ServicingthePrimaryFilter

•Iftheprimarylterisdirty,bent,ordamaged,

replaceit.

•Donotcleantheprimarylter.

ServicingtheSafetyFilter

Replacethesafetylter,nevercleanit.

Important:Donotattempttocleanthesafety

lter.Ifthesafetylterisdirty,thentheprimary

lterisdamaged.Replacebothlters.

InstallingtheFilters

Important:Topreventenginedamage,always

operatetheenginewithbothairltersandthe

coverinstalled.

1.Ifinstallingnewlters,checkeachlterfor

shippingdamage.

Note:Donotuseadamagedlter.

2.Iftheinnerlterisbeingreplaced,carefullyslide

itintothelterbody(Figure34).

3.Carefullyslidetheprimarylterovertheinner

lter(Figure34).

29

Note:Ensurethattheprimarylterisfully

seatedbypushingontheouterrimwhile

installingit.

Important:Donotpressonthesoft,inside

areaofthelter.

4.Installtheair-cleanercoverandsecurethe

latches(Figure34).

ServicingtheEngineOil

Engine-OilSpecications

OilType:Detergentoil(APIserviceSJorhigher)

OilCapacity:1.65L(56oz)withthelter;1.50L

(51oz)withoutthelter

Viscosity:Seethetablebelow.

g012991

Figure35

Note:Useasyntheticoilwith5W-20or5W-30rating,

upto4°C(40°F).

Note:Syntheticoilsprovidebetterstartingwhenthe

temperatureisbelow-23°C(-10°F).

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keepyourhands,feet,face,clothingand

otherbodypartsawaythemuferandother

hotsurfaces.

Important:Donotoverllthecrankcasewithoil

becausedamagetotheenginemayresult.Donot

runenginewithoilbelowthelowmarkbecause

theenginemaybedamaged.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Checktheengine-oillevelasshownin(Figure

36).

30

ChangingtheEngineOil

ServiceInterval:Aftertherst8hours

Every100hours

Note:Disposeoftheusedoilatarecyclingcenter.

1.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoassuretheoil

g193347

drainscompletely.

2.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,and

engagetheparkingbrake.

3.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

4.ChangetheengineoilasshowninFigure37.

Figure36

g194611

31

g193346

g194610

Figure38

6.Starttheengineanddrivetoaatarea.

7.Checktheoillevelagain.

Figure37

5.Slowlypourapproximately80%ofthespecied

oilintothellertubeandslowlyaddthe

additionaloiltobringittotheFullmark(Figure

38).

g027734

32

ChangingtheEngine-OilFilter

ServicingtheSparkPlug

ServiceInterval:Every200hours

Note:Changetheengine-oilltermorefrequently

whenoperatingconditionsareextremelydustyor

sandy.

1.Draintheoilfromtheengine;refertoChanging

theEngine-OilFilter(page33).

2.Changetheengine-oillter(Figure39).

ServiceInterval:Every200hours

Makesurethattheairgapbetweenthecenterand

sideelectrodesiscorrectbeforeinstallingthespark

plug.

Useasparkplugwrenchforremovingandinstalling

thesparkplug(s)andagappingtool/feelergaugeto

checkandadjusttheairgap.Installanewspark

plug(s)ifnecessary.

Typeforallengines:Kohler2513214-c,Champion

XC12YC,orequivalent

Airgap:0.75mm(0.03inch)

RemovingtheSparkPlug

g193346

1.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,and

engagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

Figure39

3.RemovethesparkplugasshowninFigure40.

g027478

Figure40

g027477

Note:Ensurethattheoil-ltergaskettouches

theengine,thenrotatethelteranextra3/4turn.

3.Fillthecrankcasewiththepropertypeofnew

oil;refertoEngine-OilSpecications(page30).

33

CheckingtheSparkPlug

CheckingtheSpark

Important:Donotcleanthesparkplug(s).

Alwaysreplacethesparkplug(s)whenithasa

blackcoating,wornelectrodes,anoilylm,or

cracks.

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeanstheaircleanerisdirty .

Setthegapto0.75mm(0.03inch).

Figure41

InstallingtheSparkPlug

Arrester

ForModelswithaSparkArrester

ServiceInterval:Every50hours

WARNING

Hotexhaustsystemcomponentsmayignite

fuelvaporsevenafteryoushutofftheengine.

Hotparticlesexhaustedduringengine

operationmayigniteammablematerials.

Firemayresultinpersonalinjuryorproperty

damage.

Donotfuelorruntheengineunlessaspark

arresterisinstalled.

g027479

1.Shutofftheengine,waitforallmovingpartsto

stop,removethekey ,andengagetheparking

brake.

2.Waitforthemufertocool.

3.Ifthereareanybreaksinthescreenorwelds

areobserved,replacethearrester.

Figure42

4.Ifthescreenisplugged,removethearrester

andshakelooseparticlesoutofthearrester,

andcleanthescreenwithawirebrush(soakin

solventifnecessary).

5.Installthearresterontheexhaustoutlet.

g027661

34

FuelSystem

Maintenance

DrainingtheFuelTank

Youcandrainthefueltankbyremovingitandpouring

thefueloutofthellneck;refertoRemovingtheFuel

Tank(page35).Y oucanalsodrainthefueltankby

usingasiphoninthefollowingprocedure.

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyou,others,and

candamageproperty.

•Performanyfuel-relatedmaintenance

whentheengineiscold.Dothisoutdoors

inanopenarea.Wipeupanyfuelthat

spills.

g193358

Figure43

1.Fuelcap

RemovingtheFuelTank

•Neversmokewhendrainingfuel,andstay

awayfromanopenameorwhereaspark

mayignitethefuelfumes.

1.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,and

engagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition

3.Cleanaroundthefuelcaptopreventdebrisfrom

gettingintothefueltank(Figure43).

4.Removethefuelcap.

5.Insertasyphonpumpintothefueltank.

6.Usingthesyphonpump,drainthefuelintoa

cleangascan(Figure43).

7.Wipeupanyspilledfuel.

1.Lowertheplatform.

2.Releasethecushion;refertoReleasingthe

CushionforRearAccess(page25).

3.Removethecrossbracket.

g031413

Figure44

4.Removethefueltankandsetitontheoperator

platform.

Note:Ifyouwanttomovethefueltankfurther

fromthemachine,removethefuelandvent

linesfromthetopofthetank.

35

ServicingtheFuelFilter

ElectricalSystem

ReplacingtheFuelFilter

ServiceInterval:Every800hours/Yearly(whichever

comesrst)

Donotinstalladirtylterifitisremovedfromthefuel

line.

Note:Wipeupanyspilledfuel.

1.DisengagethePTOandengagetheparking

brake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Closethefuel-shutoffvalve;refertoUsingthe

Fuel-ShutoffValve(page21).

4.ReplacethefuellterasshowninFigure45.

Maintenance

ElectricalSystemSafety

•Disconnectthebatterybeforerepairingthe

machine.Disconnectthenegativeterminalrst

andthepositivelast.Connectthepositiveterminal

rstandthenegativelast.

•Chargethebatteryinanopen,well-ventilated

area,awayfromsparksandames.Unplugthe

chargerbeforeconnectingordisconnectingthe

battery.Wearprotectiveclothinganduseinsulated

tools.

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

Figure45

ServicingtheBattery

ServiceInterval:Every100hours

Alwayskeepthebatterycleanandfullycharged.Use

apapertoweltocleanthebatterycase.Ifthebattery

terminalsarecorroded,cleanthemwithasolutionof

4partswaterand1partbakingsoda.Applyalight

coatingofgreasetothebatteryterminalstoprevent

corrosion.

Voltage:12V

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetalmachinecomponentscausing

g027518

sparks.Sparkscancausethebatterygasses

toexplode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,

donotallowthebatteryterminalstotouch

anymetalpartsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

36

WARNING

Incorrectbatterycableroutingcoulddamage

themachineandcablescausingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

1.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,and

engagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.RemovethebatteryasshowninFigure46.

InstallingtheBattery

InstallthebatteryasshowninFigure47.

Figure46

g030989

Figure47

g030988

37

ChargingtheBattery

ServicingtheFuses

WARNING

Chargingthebatteryproducesgassesthat

canexplode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery .

Important:Alwayskeepthebatteryfullycharged

(1.265specicgravity)topreventbatterydamage

whenthetemperatureisbelow0°C(32°F).

1.Removethebatteryfromthechassis;referto

RemovingtheBattery(page36).

2.Checktheelectrolytelevel.

3.Ensurethatthellercapsareinstalledonthe

battery.

4.Chargethebatteryfor1hourat25to30Aor6

hoursat4to6A.

5.Whenthebatteryisfullycharged,unplugthe

chargerfromtheelectricaloutlet,anddisconnect

thechargerleadsfromthebatteryposts(Figure

48).

Theelectricalsystemisprotectedbyfusesand

requiresnomaintenance.Ifafuseblows,checkthe

componentorcircuitforamalfunctionorshort.

1.Releasethecushionfromtherearofthe

machine.

2.Pulloutthefusetoremoveorreplaceit(Figure

49).

3.Installthecushiontotherearofthemachine.

Note:Ensurethatthecorrect-sizefuseis

installedFigure49.

6.Installthebatteryontothemachineandconnect

thebatterycables;refertoInstallingtheBattery

(page37).

Note:Donotrunthemachinewiththebattery

disconnected;electricaldamagemayoccur.

Figure48

1.Positivebatterypost

2.Negativebatterypost

3.Red(+)chargerlead

4.Black(-)chargerlead

g032693

Figure49

1.Ignitionfuse—15A3.Powertakeoff(PTO)

2.Accessory-portfuse—15

A

g000538

fuse—10A

4.Infocenterfuse—7.5A

38

DriveSystem

Maintenance

AdjustingtheTracking

Note:Ifyouareunabletoachieveproper

trackingbyadjustingtheleftcontrolrod,contact

yourAuthorizedServiceDealer.

6.Checkthatthemachinedoesnotcreepfrom

theneutralpositionwiththeparkbrakes

disengaged.

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

1.Pushbothcontrolleversforwardthesame

distance.

2.Checkifthemachinepullsto1side.

Note:Ifitdoes,stopthemachineandsetthe

parkingbrake.

3.Releasethecushionfromtherearofthe

machine;refertoReleasingtheCushionfor

RearAccess(page25).

Note:Foreasieraccess,youcanalsoremove

thefueltank;refertoRemovingtheFuelT ank

(page35).

4.Rotatetheleftcontrolrodinquarter-turn

incrementsuntilthemachinetracksstraight

(Figure50).

Note:Ifthemachinepullstotheright,shorten

thecontrolrodbyrotatingittotheright.Ifthe

machinepullstotheleft,lengthentherodby

rotatingittotheleft.

7.Installthefueltank,ifyouremovedit.

8.Installthecushion.

CheckingtheTirePressure

ServiceInterval:Every50hours/Monthly(whichever

comesrst)

Maintaintheairpressureinthereartiresat83to97

kPa(12to14psi).

Important:Uneventirepressurecancausean

unevencut.

Note:Thefronttiresaresemi-pneumatictiresanddo

notrequireair-pressuremaintenance.

Note:Onlyadjusttheleftcontrolrodtomatch

theleftwheelspeedtotherightwheelspeed.

Donotadjusttherightwheelspeed,asthis

positionstherightmotion-controlleveroutofthe

centerforthecontrolpanelneutral-lockslot.

Important:Donotrotatethecontrolrodtoo

far,asthismaycausethemachinetocreep

inneutral.

Figure50

1.Rotatelefttolengthenthe

rod.

2.Leftcontrolrod

3.Rotaterighttoshortenthe

rod.

g001055

Figure51

g031531

5.Checkforpropertracking,andadjusttherod

asnecessary.

39

AdjustingtheCaster-Pivot

ServicingtheCaster

Bearing

ServiceInterval:Every500hours/Yearly(whichever

comesrst)

1.DisengagethePTO,movethemotioncontrol

leverstotheNEUTRAL-LOCKposition,and

engagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removethedustcapfromthecasterandtighten

thelocknut(Figure52).

4.Tightenthelocknutuntilthespringwashersare

at,andthenbackoffa1/4turntoproperlyset

thepreloadonthebearings(Figure52).

Important:Makesurethatthespring

washersareinstalledcorrectlyasshownin

Figure52.

5.Installthedustcap(Figure52).

WheelsandBearings

Thecasterwheelsrotateonarollerbearingsupported

byaspannerbushing.Ifthebearingiskeptwell

lubricated,wearwillbeminimal.Failuretokeepthe

bearingwelllubricatedcausesrapidwear.Awobbly

casterwheelusuallyindicatesawornbearing.

1.Removethelocknutandwheelboltholdingthe

casterwheeltothecasterfork(Figure53).

1.Springwashers

2.Locknut

Figure52

3.Dustcap

g009453

Figure53

1.Locknut4.Rollerbearing

2.Bushing

3.Spannerbushing

2.Remove1bushing,thenpullthespanner

bushingandrollerbearingoutofthewheelhub

(Figure53).

3.Removetheotherbushingfromthewheelhub

andcleananygreaseanddirtfromthewheel

g001297

hub(Figure53).

4.Inspecttherollerbearing,bushings,spanner

bushingandtheinsideofthewheelhubforwear.

5.Casterwheel

6.Wheelbolt

Note:Replaceanydamagedorwornparts

(Figure53).

5.Place1bushingintothewheelhub(Figure53).

6.Greasetherollerbearingandspannerbushing,

andslidethemintothewheelhub(Figure53).

7.Placethesecondbushingintothewheelhub

(Figure53).

8.Installthecasterwheelintothecasterforkand

secureitwiththewheelboltandlocknut(Figure

53).

40

9.Tightenthelocknutuntilthespannerbushing

bottomsagainsttheinsideofthecasterforks

(Figure53).

10.Greasethettingonthecasterwheel.

CheckingtheWheel-Lug Nuts

ServiceInterval:Aftertherst100hours—Checkthe

wheel-lugnuts.

Checkandtorquethewheellugnutsto115to142

N∙m(85to105ft-lb).

CheckingtheWheel-Hub Nuts

ServiceInterval:Aftertherst100hours—Checkthe

wheel-hubnuts.

Every500hours—Checkthewheel-hubnuts.

Checkandtorquethewheelhubnutsto286to352

N∙m(211to260ft-lb).

CoolingSystem

Maintenance

CleaningtheAir-Intake Screen

ServiceInterval:Beforeeachuseordaily

Beforeeachuse,removeanybuildupofsnow,dirt,

orotherdebrisfromthecylinderandcylinder-head

coolingns,air-intakescreenontheywheelend,

andthecarburetor-governorleversandlinkage.This

helpsensurethatadequatecoolingandcorrectengine

speed,andreducesthepossibilityofoverheatingor

mechanicaldamagetotheengine.

CleaningtheCooling System

ServiceInterval:Every100hours—Checkandclean

theenginecoolingnsandshrouds.

1.DisengagethePTOandengagetheparking

brake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removetheair-intakescreenandfanhousing

(Figure54).

4.Cleanthedebrisandgrassfromtheengine

parts.

5.Installtheair-intakescreenandthefanhousing

(Figure54).

Figure54

g031439

41

1.Guardandengine

air-intakescreen

2.Fanhousing

3.Engine-oilcooler

BrakeMaintenance

BeltMaintenance

ServicingtheBrake

Beforeeachuse,checkthebrakesonalevelsurface

andslope.

Alwaysengagetheparkingbrakewhenyoushutoff

themachineorleaveitunattended.

Important:Iftheparkingbrakedoesnothold

securely,adjustit.

CheckingtheParkingBrake

ServiceInterval:Beforeeachuseordaily

1.Parkthemachineonalevelsurfaceand

disengagethePTO.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Disengagetheparkingbrake.

4.Engagetheparkingbrakeandensurethatthe

machinedoesnotmove.

5.Adjustthebrakeifneeded;refertoAdjustingthe

Brakes(page42).

ReplacingtheTransmission Belt

ServiceInterval:Every1,000hours—Replacethe

transmissionbelt.

1.Removethefueltank;refertoRemovingthe

FuelT ank(page35).

2.Removethehydraulic-reservoircap.

3.Locatethedrainplugsinthebottomofthe

transmissionandplaceadrainpanunderthe

plug(Figure56).

g193360

Figure56

AdjustingtheBrakes

1.Removethefueltank;refertoRemovingthe

FuelT ank(page35).

2.Loosentheboltonthecableclampontheleft

sideofthemachine.

Figure55

1.Cable

2.Cableclamp

3.Boltandnut

1.Drainplug

4.Allowthehydraulicuidtodrainfromthe

machine.

5.Removethelowerhydraulichose(Figure57).

g031396

1.Lowerhydraulichose3.Tensionspring

2.Transmissionbelt

Figure57

g031345

3.Pulldownonthecablesuntiltheyaretaut.

4.Tightenthenut.

5.Installthefueltank,crossbracket,andcushion.

6.Removethetensionspring(Figure57).

42

CAUTION

Thespringisundertensionwhen

installedandcancausepersonalinjury .

Wearsafetyglassesandbecarefulwhen

removingthespring.

ControlsSystem

Maintenance

Adjustingthe

7.Removethedeckbeltfromtheclutchandclutch

stop(Figure57).

8.Installthenewbelt.

9.Installthetensionspringandlowerhydraulic

hose.

10.Installthedrainplugsandtorqueto22to27

N∙m(16to20ft-lb).

11.Addhydraulicuidtothelllevel.

12.Installthehydraulic-reservoircap.

13.Runthemachinefor10minutesandverifythat

thehydraulicuidisatthecorrectlevel.

Motion-ControlLevers

Ifthemotion-controlleversdonotalignhorizontally ,

adjusttherightsidemotion-controllever.

1.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,and

engagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Pushthemotion-controlleversdownoutofthe

NEUTRAL-LOCKposition(Figure58).

4.Checkiftherightmotion-controlleveraligns

horizontallywiththeleftmotion-controllever

(Figure58).

Figure58

1.Leftmotion-controllever3.Checkthehorizontal

2.Rightmotion-controllever

intheNeutral-lockposition

5.Toadjustthemotion-controllevershorizontally,

youmustadjustthecam.

6.Releasethecushionfromtherearofthe

machine.

7.Loosenthenutholdingthecam(Figure59).

alignmenthere

4.Rightmotion-controllever

g009436

43

HydraulicSystem

Maintenance

HydraulicSystemSafety

•Ensurethatallhydraulic-uidhosesand

linesareingoodconditionandallhydraulic

connectionsandttingsaretightbefore

applyingpressuretothehydraulicsystem.

Figure59

1.Cam

8.Adjustthecamuntilitalignswiththeleft

motion-controlleverandtightenthenutforthe

cam.

2.Nut

Note:Movingthecamclockwise(inthevertical

position)lowersthehandle;movingthecam

counterclockwise(intheverticalposition)raises

thehandle.

Important:Ensurethattheatportionofthe

camdoesnotgoaboveaverticalposition

(rightorleft);otherwiseyoumaydamagethe

switch.

9.Repeatsteps3through8fortheleft

motion-controllever.

g031538

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthigh-pressure

hydraulicuid.

•Usecardboardorpapertondhydraulicleaks.

•Safelyrelieveallpressureinthehydraulic

systembeforeperforminganyworkonthe

hydraulicsystem.

•Seekimmediatemedicalattentionifuid

isinjectedintoskin.Injecteduidmustbe

surgicallyremovedwithinafewhoursbya

doctor.

HydraulicSystem

Specications

HydraulicFluidType:T oro

hydraulicuid

HydraulicSystemFluidCapacity:4.7L(159oz)

®

HYPR-OIL

Important:Usetheuidspecied.Otheruids

coulddamagethesystem.

™

500

CheckingtheHydraulic Fluid

ServiceInterval:Aftertherst8hours

Every500hours

Note:Checkthehydraulic-uidlevelwhentheuid

iscold.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleantheareaaroundthecapandthellerneck

ofthehydraulictank(Figure60).

44

ReplacingtheHydraulic FluidandFilters

ServiceInterval:Aftertherst50hours

Every500hours/Y early(whichevercomes

rst)—Changethehydraulicltersandhydraulic

uid.

Changethehydraulicuidmorefrequentlyinsevere

conditionsorinahotoperatingclimate.Contact

yourAuthorizedServiceDealerforahydraulickitto

replacethehydrauliclters.

Figure60

1.Hydraulic-tankcap2.Filllevel

4.Removethecapfromthellerneck(Figure60).

Note:Lookinsidetochecktheuidlevelin

thereservoir.

5.Adduidtothereservoiruntilitreachesthell

level.

6.Installthecaponthellerneck.

g193411

WARNING

Hothydraulicuidcancausesevereburns.

Allowthehydraulicuidtocoolbefore

performinganymaintenanceonthehydraulic

system.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removethefueltank;refertoRemovingthe

FuelT ank(page35).

4.Removethehydraulic-reservoircap.

5.Locatethedrainpluginthebottomofeach

transmissionandplaceadrainpanunderthe

plugs(Figure61).

Figure61

1.Drainplug

6.Removethedrainplugs.

7.Allowthehydraulicuidtofullydrainfromthe

machine.

8.Removethehydraulicltercapandlterfrom

eachtransmission.

9.Installnewhydrauliclterswiththespringside

facingoutandinstalltheltercaps.

45

2.Hydrauliclter

g193412

10.Installthedrainplugsandtorqueto22to27

N∙m(16to20ft-lb).

11.Loosentheventplugineachtransmissionso

thatitislooseandwobbles(Figure62).

Note:Thisallowsairtoescapethehydraulic

systemasyouaddhydraulicuid.

Figure62

Lefttransmissionshown

BleedingtheHydraulic System

Thetractionsystemisself-bleeding,however,itmay

benecessarytobleedthesystemifuidischanged

orafterworkisperformedonthesystem.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Raisetherearofthemachineontojackstands

highenoughtoraisethedrivewheelsoffthe

ground.

4.Starttheengineandmovethethrottlecontrolto

theidleposition.

g031544

Note:Ifthedrivewheeldoesnotrotate,assist

thepurgingofthesystembycarefullyrotating

thetireintheforwarddirection.

1.Ventplug

12.Slowlyadduidtothehydraulictankuntilit