Page 1

FormNo.3415-584RevB

GrandStand

®

MultiForceMower

With52inor60inTURBOFORCE

Unit

ModelNo.74523—SerialNo.316000001andUp

ModelNo.74529—SerialNo.316000001andUp

®

Cutting

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3415-584*B

Page 2

WARNING

accessoryinformation,helpndingadealer,orto

registeryourproduct.

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

WARNING

Removingstandardoriginalequipmentparts

andaccessoriesmayalterthewarranty,

traction,andsafetyofthemachine.Failureto

useoriginalToropartscouldcauseserious

injuryordeath.Makingunauthorizedchanges

totheengine,fuelorventingsystem,may

violateEPAandCARBregulations.

Replaceallpartsincluding,butnotlimited

to,tires,belts,blades,andfuelsystem

componentswithoriginalToroparts.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

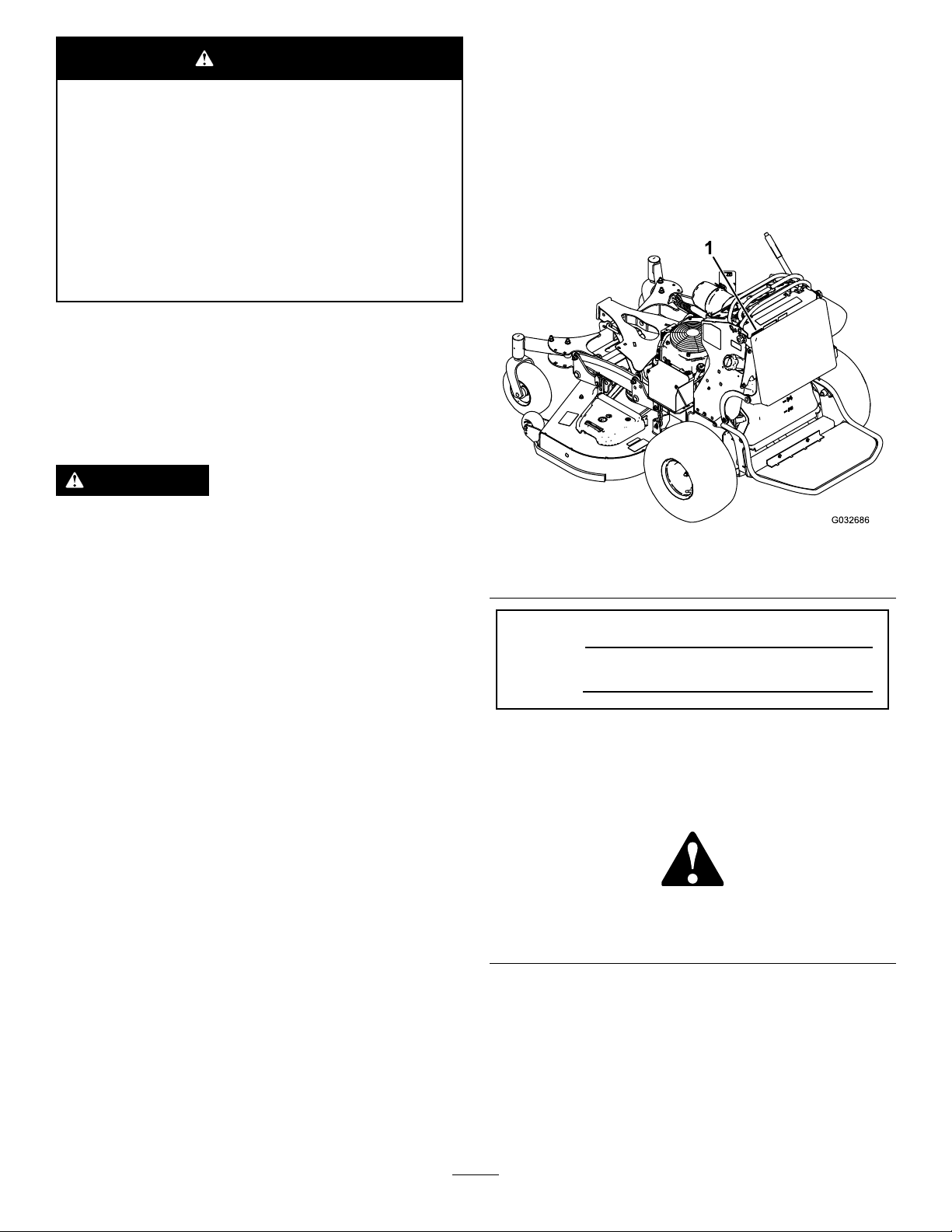

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

g032686

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Pleaserefertotheenginemanufacturer’sinformation

includedwiththemachine.

Introduction

Thisrotaryblade,ridinglawnmowerisintendedtobe

usedbyprofessional,hiredoperators,orresidential

homeowners.Itisdesignedprimarilyforcuttinggrass

onwell-maintainedlawnsonresidentialorcommercial

properties.Itisnotdesignedforcuttingbrushorfor

agriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactT orodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

©2017—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contactusatwww.Toro.com.

2

g000502

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety.......................................................................4

SafeOperatingPractices....................................4

ToroMowerSafety..............................................6

SlopeIndicator...................................................7

SafetyandInstructionalDecals..........................8

ProductOverview...................................................12

Controls...........................................................12

Specications..................................................13

Attachments/Accessories.................................14

Operation................................................................14

ThinkSafetyFirst..............................................14

AddingFuel......................................................14

CheckingtheEngine-OilLevel..........................16

BreakinginaNewMachine..............................16

OperatingtheParkingBrake.............................16

OperatingtheMower-Blade-ControlSwitch

(PTO)............................................................17

OperatingtheThrottle.......................................17

OperatingtheKeySwitch.................................17

UsingtheFuel-ShutoffValve.............................18

StartingtheEngine...........................................18

ShuttingOfftheEngine.....................................19

TheSafety-InterlockSystem.............................19

OperatingthePlatform......................................20

DrivingForwardorBackward............................21

StoppingtheMachine.......................................22

PushingtheMachinebyHand..........................22

TransportingtheMachine.................................23

LoadingtheMachine........................................24

SideDischargingorMulchingthe

Grass............................................................25

AdjustingtheHeight-of-Cut...............................25

AdjustingtheAnti-ScalpRollers........................26

AdjustingtheFlowBafe..................................26

UsingtheMid-SizeWeight................................27

Maintenance...........................................................28

RecommendedMaintenanceSchedule(s)...........28

Pre-MaintenanceProcedures..............................29

ReleasingtheCushionforRearAccess............29

Lubrication..........................................................29

GreasingtheAccessoryFrame.........................29

GreasingtheT orsionIdler.................................30

GreasingtheFrontCasterPivots......................30

GreasingtheCaster-WheelHubs.....................30

GreasingtheVoltageRegulator........................31

GreasingtheBrakeCalipers.............................31

GreasingtheMotionControls...........................32

EngineMaintenance...........................................32

ServicingtheAirCleaner..................................32

ServicingtheEngineOil....................................34

ServicingtheSparkPlug...................................36

CheckingtheSparkArrester.............................37

FuelSystemMaintenance...................................38

DrainingtheFuelT ank......................................38

RemovingtheFuelT ank...................................38

ServicingtheFuelFilter...................................39

ElectricalSystemMaintenance...........................39

ServicingtheBattery.........................................39

ServicingtheFuses..........................................41

DriveSystemMaintenance..................................42

AdjustingtheTracking......................................42

CheckingtheTirePressure...............................42

AdjustingtheCaster-PivotBearing...................43

ServicingtheCasterWheelsand

Bearings........................................................43

UsingtheClutchShim......................................44

CheckingtheWheel-LugNuts..........................46

CheckingtheWheel-HubNuts..........................46

CoolingSystemMaintenance..............................46

CleaningtheAir-IntakeScreen.........................46

CleaningtheCoolingSystem............................46

BrakeMaintenance.............................................47

ServicingtheBrake..........................................47

BeltMaintenance................................................47

ReplacingtheMower-DeckBelt........................47

ReplacingtheTransmissionBelt......................48

ControlsSystemMaintenance.............................49

AdjustingtheMotion-ControlLevers.................49

HydraulicSystemMaintenance...........................50

ServicingtheHydraulicSystem........................50

MowerDeckMaintenance....................................52

RemovingtheMowerDeck...............................52

InstallingtheMowerDeck.................................54

ServicingtheBlades.........................................54

CorrectingtheQualityofCut.............................56

AdjustingtheDeck-LiftSpring...........................59

ReplacingtheGrassDeector..........................59

Cleaning..............................................................60

CleaningundertheMowerDeck.......................60

DisposingoftheWaste.....................................60

Storage...................................................................60

CleaningandStorage.......................................60

Troubleshooting......................................................62

Schematics.............................................................64

3

Page 4

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.T oreducethepotential

forinjury,complywiththesesafetyinstructions,

andpayattentiontothesafetyalertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeinstructions

mayresultinpersonalinjuryordeath.

Thismachinewasmanufacturedaccordingtothe

appropriateregulatorystandardsineffectatthetime

ofmanufacture.Modifyingthismachineinanyway

maycauseittobeoutofcompliancewiththose

standardsandwiththeinstructionsinthisOperator’s

Manual.Modicationstothismachineshouldonly

bemadebyeitherthemanufactureroranAuthorized

ToroDealer.

Thisproductiscapableofamputatinghandsandfeet.

Followallsafetyinstructionstoavoidseriousinjury

ordeath.

Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtopeople,ordamage

toproperty.

Theadditionofattachmentsmadebyother

manufacturersthatdonotmeetAmericanNational

StandardsInstitutecerticationmaycause

noncomplianceofthismachine.

SafeOperatingPractices

ThefollowinginstructionsarefromANSIstandard

B71.4-2012.

Training

•ReadtheOperator'sManualandothertraining

material.Iftheoperator(s)ormechanic(s)cannot

readthemanuallanguage,itistheowner's

responsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeople,ordamagetoproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsyouneedtoproperlyandsafely

performthejob.Useonlyaccessoriesand

attachmentsapprovedbythemanufacturer.

•Wearappropriateclothing;includingsafety

glasses,longpants,substantialslip-resistant

footwear,gloves,andhearingprotection.Tieback

longhair.Donotwearjewelry .

•Inspecttheareawhereyouwillusetheequipment

andensurethatallobjectsareremovedfromthe

areabeforeuse.

•Useextracarewhenhandlingfuels.Theyare

ammableandvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Donotremovethefuelcaporaddfuelwiththe

enginerunning.Allowtheenginetocoolbefore

refueling.Donotsmokenearthemachine

whentheengineisrunning.

–Donotrefuelordrainthemachineindoors.

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

Operation

•Lightningcancausesevereinjuryordeath.If

lightningisseen,orthunderisheardinthearea,

donotoperatethemachine;seekshelter.

•Donotrunanengineinanenclosedarea.

•Operateonlyinwell-litareas,keepingawayfrom

holesandhiddenhazards.

•Ensurethatalldrivesareinneutralandthatthe

parkingbrakeisengagedbeforestartingengine.

Starttheengineonlyfromtheoperator’sposition.

•Makesurethatyouhavegoodfootingwhile

usingthismachine,especiallywhenbackingup.

Reducedfootingcouldcauseslipping.

•Slowdownanduseextracareonhillsides.Be

suretotravelsidetosideonhillsides.Turf

conditionscanaffectthestabilityofthemachine.

Usecautionwhileoperatingneardrop-offs.

•Slowdownandusecautionwhenmakingturns

andwhenchangingdirectionsonslopes.

•Donotraisethemowerdeckwiththeblades

running.

•DonotoperatethemachinewithoutthePTO

shieldorotherguardssecurelyinplace.Besure

thatallinterlocksareattached,adjustedproperly,

andfunctioningproperly.

•Donotoperatewiththedischargedeectorraised,

removedoraltered,unlessyouareusingagrass

catcher.

4

Page 5

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Stopthemachineonlevelground,disengagethe

drives,engagetheparkingbrake,andshutoffthe

enginebeforeleavingtheoperator'spositionfor

anyreason,includingemptyingthecatchersor

uncloggingthechute.

•Stopthemachineandinspectthebladesafter

strikingobjectsorifanabnormalvibrationoccurs.

Makethenecessaryrepairsbeforeresuming

operations.

•Keepyourhandsandfeetawayfromthecutting

unit.

•Lookbehindanddownbeforebackingupto

ensureaclearpath.

•Keeppetsandbystandersawayfromanoperating

machine.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalks.Stopthe

bladesifyouarenotmowing.

•Beawareofthemower-dischargedirectionand

donotpointitatanyone.

•Donotoperatethemachinewhiletired,ill,or

undertheinuenceofalcoholordrugs.

•Usecarewhenloadingorunloadingthemachine

intoorfromatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlingfuel.Fuelisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfuelwiththe

enginerunning.

•Allowtheenginetocoolbeforefueling.

•Donotfuelthemachineindoors.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

•Donotllcontainersinsideavehicle,onatruck,

oronatrailerbedwithaplasticliner.Alwaysplace

containersonthegroundawayfromyourvehicle

beforelling.

•Removeequipmentfromthetruckortrailerand

fuelitontheground.Ifthisisnotpossible,

thenaddfuelwithsuchequipmentasaportable

containerratherthanfromafuel-dispensernozzle.

•Keepthenozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimesuntilfueling

iscomplete.Donotuseanozzlelock-opendevice.

•Ifyouspillfuelonclothing,changeyourclothing

immediately.

•Donotoverllthefueltank.Replacethefuelcap

andtightenitsecurely.

MaintenanceandStorage

•Disengagedrives,engagetheparkingbrake,shut

offtheengine,andremovethekeyordisconnect

spark-plugwire.Waitforallmovementtostop

beforeadjusting,cleaning,orrepairing.

•Cleangrassanddebrisfromthecuttingunit,

drives,mufers,andenginetohelppreventres.

•Cleanupoilorfuelspills.

•Lettheenginecoolbeforestoringthemachine.

•Donotstorefuelnearamesordrainthefuel

indoors.

•Donotallowuntrainedpersonneltoservicethe

machine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectthebatteryorremovethespark-plug

wirebeforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositiveterminal

last.Connectthepositiveterminalrstand

negativelast.

•Usecarewhencheckingtheblades.Wrapthe

blade(s)orweargloves,andusecautionwhen

servicingthem.Onlyreplaceblades;donot

straightenorweldthem.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

Hauling

•Usecarewhenloadingorunloadingthemachine

intoatraileroratruck.

•Usefull-widthrampsforloadingmachineintoa

traileroratruck.

•Tiethemachinedownsecurelyusingstraps,

chains,cable,orropes.Bothfrontandrearstraps

shouldbedirecteddownandoutwardfromthe

machine.

5

Page 6

ToroMowerSafety

SlopeOperation

Thefollowinglistcontainssafetyinformationspecic

toT oroproductsandothersafetyinformationthatyou

mustknow.

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Thisproductisdesignedforcuttingandrecycling

grass,or,whenequippedwithagrassbagger,for

catchingcutgrass.Anyuseforpurposesother

thanthesecouldprovedangeroustotheuserand

bystanders.

GeneralOperation

•Besurethattheareaisclearofbystandersbefore

mowing.Stopthemachineifanyoneentersthe

area.

•Donottouchequipmentorattachmentpartswhich

maybehotfromoperation.Allowalloftheparts

tocoolbeforeattemptingtomaintain,adjust,or

servicethemachine.

•UseonlyToro-approvedattachments.Warranty

maybevoidedifusedwithanyunapproved

attachments.

•Checkcarefullyforoverheadclearances(i.e.,

branches,doorways,electricalwires,etc.)before

operatingunderanyobjects,anddonotcontact

them.

•Slowdownbeforemakingturnsanduseextra

caution.

•Usecautionwhenridingtheplatformovercurbs,

rocks,roots,orotherobstructions.

•Lookbehindanddownbeforebackinguptoensure

aclearpath.Useextracarewhenoperatingthe

machineinreverse.

•Donotjerkthecontrols;useasteadymotion.

•Whenloadingorunloadingthemachine,useone

full-widthrampthatiswideenoughtoextend

beyondthewidthofthemachine.

•Donotcarrypassengers.

Allslopesandrampsrequireextracaution.Ifyoufeel

uneasyonaslope,donotmowit.

•Removeobstaclessuchasrocks,treelimbs,etc.

fromthemowingarea.

•Watchforholes,rutsorbumps.T allgrasscan

hideobstacles.

•Usecautionneardrop-offs,ditches,or

embankments.Themachinecouldsuddenlyturn

overifawheelgoesovertheedgeofacliffor

ditch,orifanedgecavesin.

•Useextracarewithgrasscatchersorother

attachments.Thesecanchangethestabilityof

themachine.

•Keepallmovementonslopesslowandgradual.

•Donotmakesuddenchangesinspeedor

direction.

•Mowslopessidetoside.

•Donotmowslopesgreaterthan20degrees.

Service

•Donotstorethemachineorafuelcontainerinside

wherethereisanopename,suchasneara

waterheaterorfurnace.

•Keepthenutsandboltstight,especiallythe

blade-attachmentbolts.

•Neverremoveortamperwithsafetydevices.

Checktheirproperoperationregularly.Neverdo

anythingtointerferewiththeintendedfunctionofa

safetydeviceortoreducetheprotectionprovided

byasafetydevice.

•Tobestprotectyourinvestmentandmaintain

optimalperformanceofyourToroequipment,count

onT orogenuineparts.Whenitcomestoreliability ,

Torodeliversreplacementpartsdesignedtothe

exactengineeringspecicationsofourequipment.

Forpeaceofmind,insistonT orogenuineparts.

•Checktheoperationofthebrakesfrequently.

Adjustandservicethemasrequired.

•Donotcarryequipmentonthemachine.

6

Page 7

SlopeIndicator

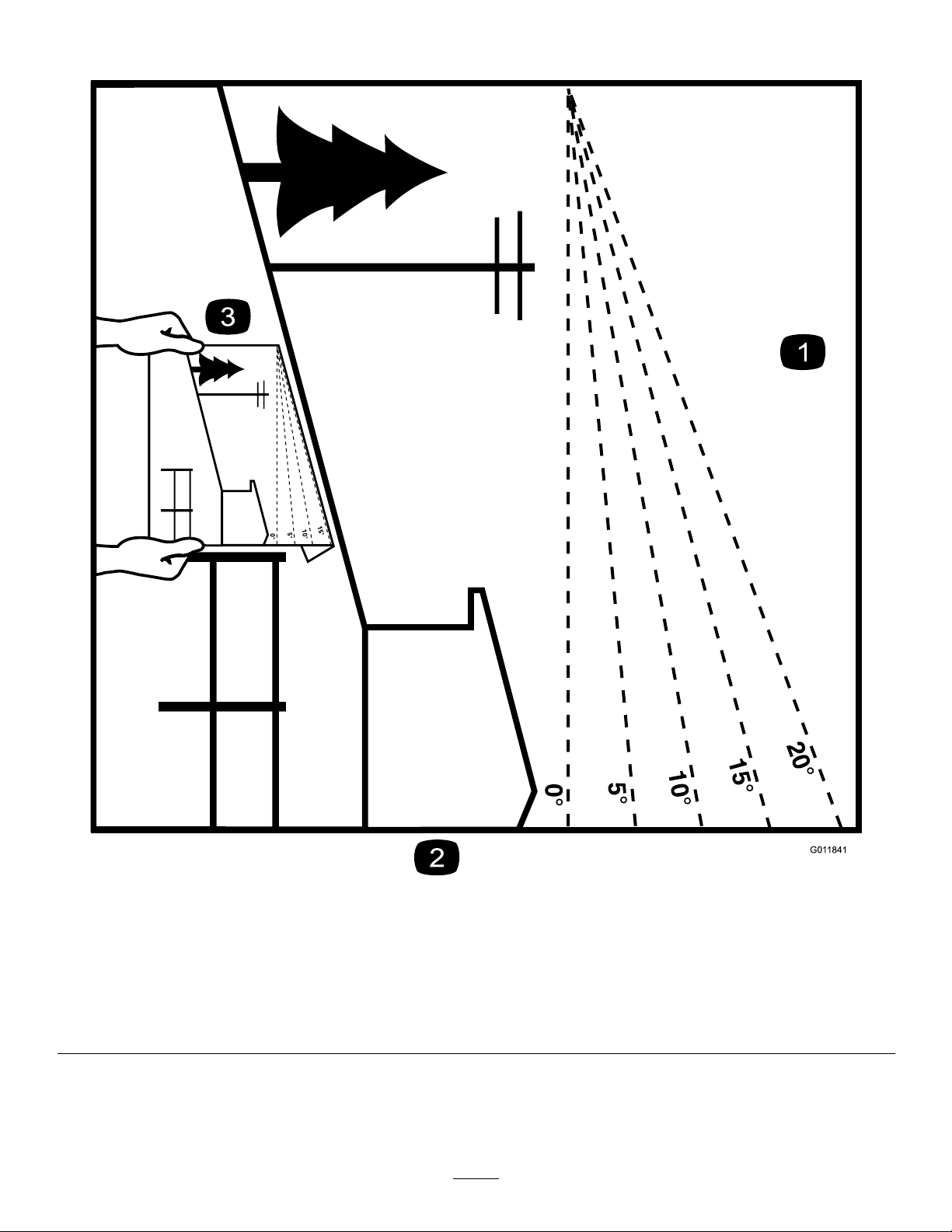

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis20degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan20degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge

7

g011841

Page 8

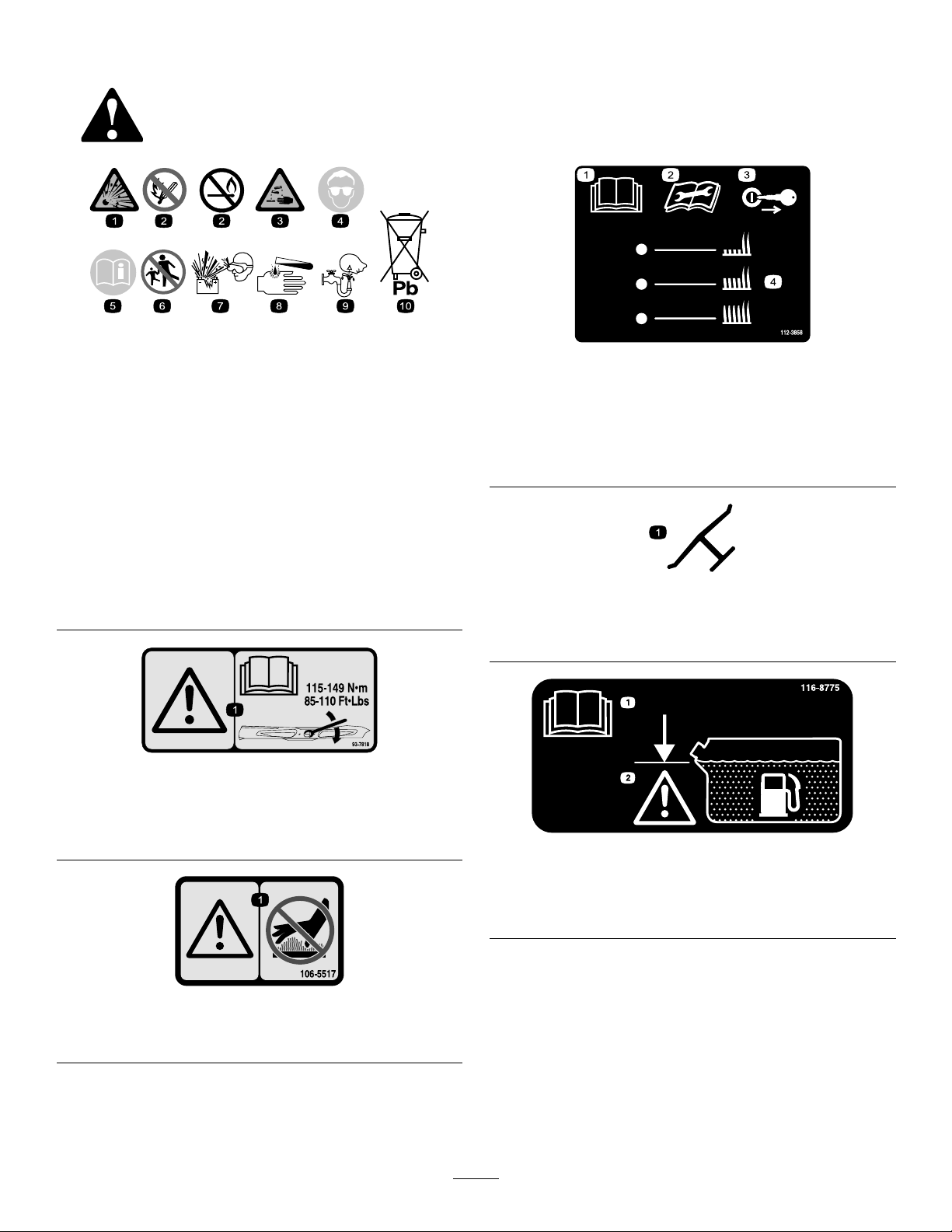

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

BatterySymbols

Someorallofthesesymbolsareonyourbattery .

1.Explosionhazard

2.Nore,opename,or

smoking

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

distanceawayfromthe

battery.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard

decalbatterysymbols

decal112-3858

112-3858

1.ReadtheOperator's

Manual.

2.Readtheinstructions

beforeservicingor

performingmaintenance.

3.Removethekeybefore

adjustingtheheightofcut.

4.Height-of-cutsettings.

decaloemmarkt

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto1 15to149N∙m(85to110

ft-lb).

106-5517

1.Warning—donottouchthehotsurface.

decal93-7818

decal116-8775

116-8775

1.ReadtheOperator’s

Manual.

decal106-5517

2.Filltobottomofllerneck;

warning—donotoverll

thetank.

8

Page 9

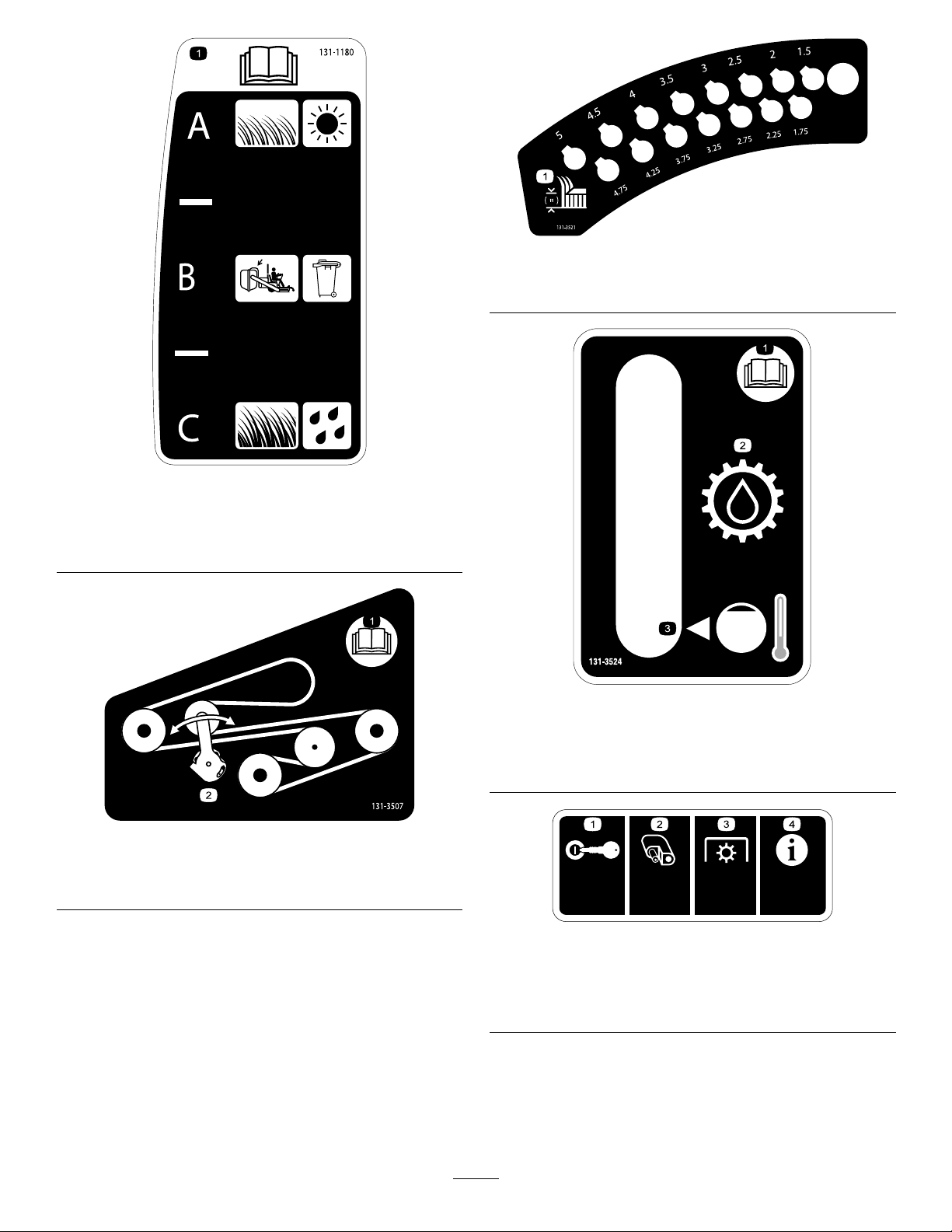

131-1180

131-3528

15A 15A 10A

7.5A

1.ReadtheOperator'sManual.(A)Short,lightgrass;dry

conditions;maximumdispersion;(B)Baggingsetting;(C)

Tall,densegrass;wetconditions;maximumgroundspeed

decal131-3521

131-3521

1.Heightofcut

decal131-1180

decal131-3524

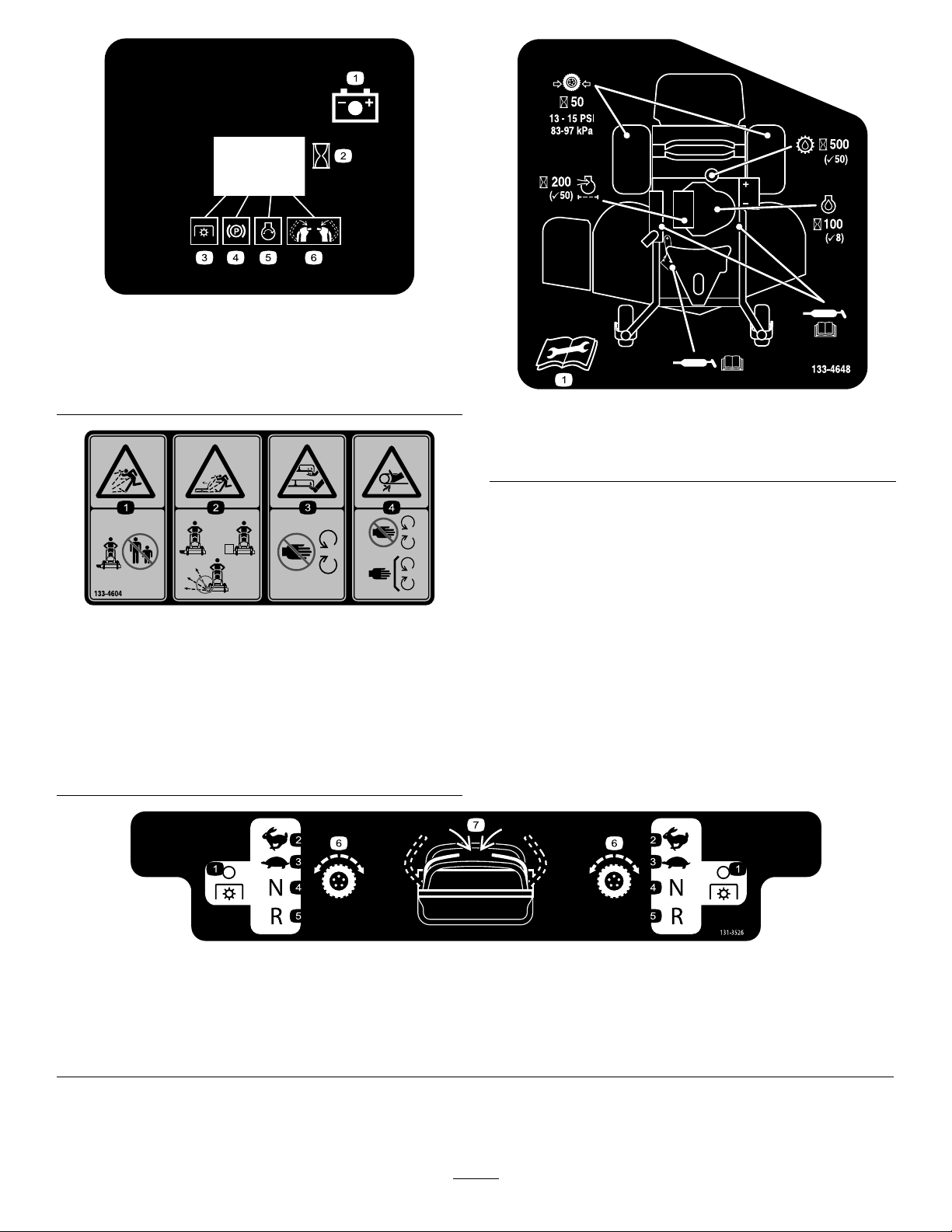

131-3524

1.ReadtheOperator's

Manual.

1.ReadtheOperator's

3.Fluidlevel

Manual.

2.Transmissionuid

decal131-3507

131-3507

2.Belttensioner

decal131-3528

131-3528

1.Keyswitch—15A

2.Accessoryport—15A

3.Powertakeoff(PTO)—10

A

4.Infocenter—7.5A

9

Page 10

131-3536

1.Battery4.Parkingbrake

2.Time5.Engine—start

3.Powertakeoff(PTO)

6.Engagethehandlebars.

133-4604

decal131-3536

decal133-4648

133-4648

1.ReadtheOperator'sManualformoreinformationon

servicingthemachine.

decal133-4604

1.Thrownobject

hazard—keepbystanders

awayfromthemachine.

2.Thrownobjecthazard,

openbafe—onlyoperate

themachinewithabafe

oragrasscollector.

3.Severinghazardofhand

orfoot—keepawayfrom

movingparts.

4.Entanglement

hazard—keepaway

frommovingparts;keep

allguardsandshieldsin

place.

131-3526

1.Powertakeoff(PTO)—disengaged

2.Fast6.Tractiondrive

3.Slow

4.Neutral

5.Reverse

7.Engagethehandles.

decal131-3526

10

Page 11

decal131-3527

131-3527

1.Warning—readtheOperator'sManual.5.Thrownobjecthazard—keepbystandersawayfromthe

machine.

2.Warning—receivetrainingbeforeoperatingthemachine.6.Warning—1)Engagetheparkingbrake,shutofftheengine,

andremovethekeyfromtheswitch;2)ReadtheOperator's

Manualbeforeservicingorperformingmaintenance.

3.Thrownobjecthazard—keepthedeectorloweredduring

operation.

4.Cutting/severinghazardofhandorfoot—keepawayfrom

7.Warning—engagetheparkingbrake,shutofftheengine,and

removethekeyfromtheswitchbeforeleavingthemachine.

8.Tippinghazard—donotoperateneardrop-offsornearwater.

movingparts;keepallguardsandshieldsinplace.

133-1432

1.Disengagetheparkingbrake.

2.Engagetheparkingbrake.

3.PulluptoturnonthePTO.

4.PushdowntoturnoffthePTO.

5.Enginespeed—fast

6.Enginespeed—slow

decal133-1432

11

Page 12

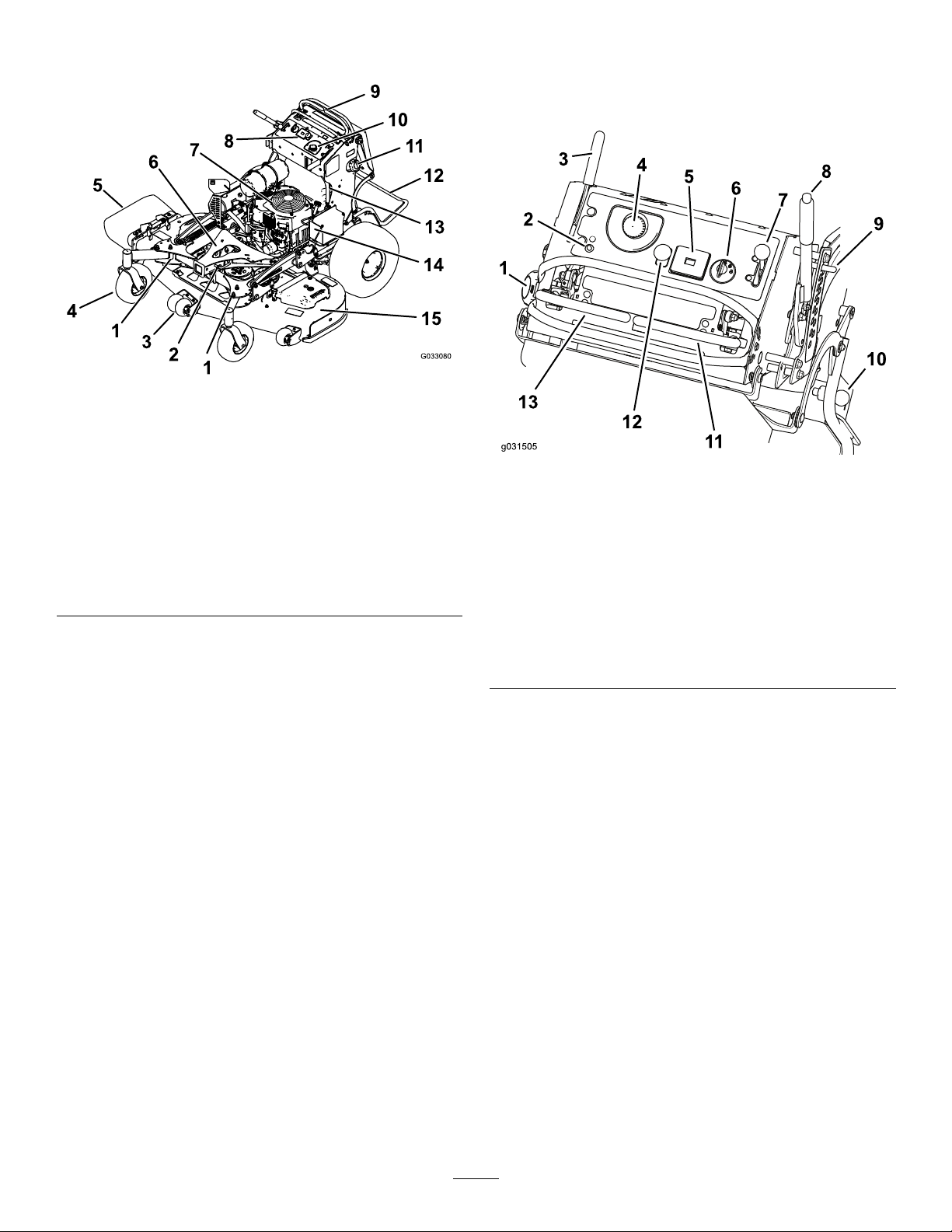

ProductOverview

Controls

Becomefamiliarwithallthecontrolsbeforeyoustart

theengineandoperatethemachine(Figure5).

g033080

Figure4

1.Adjustablecaster

2.Accessory-framelock

3.Anti-scalproller(60-inch

decksonly)

4.Frontcasterwheel

5.Side-dischargechute13.Fuel-shutoffvalve

6.Accessoryframe

7.Engine15.Mowerdeck

8.Controls

9.Controllevers

10.Hydraulictank

11.Fueltank

12.Platform(downposition)

14.Battery

Figure5

1.Fuelcap

2.Malfunction-indicatorlight

(MIL)

3.Parking-brakelever

4.Hydraulic-tankcap11.Rightmotion-controllever

5.Hourmeter12.Blade-controlswitch

6.Keyswitch

7.Throttlecontrol

8.Height-of-cutlever

9.Height-of-cutpin

10.Platformlatch

(PTO)

13.Leftmotion-controllever

Electronic-ControlUnit

Malfunction-IndicatorLight

Theelectronic-controlunit(ECU)continuously

monitorstheoperationoftheEFIsystem.

Ifaproblemorfaultwithinthesystemisdetected,the

malfunction-indicatorlight(MIL)isilluminated(Figure

5).

g031505

TheMIListheredlightlocatedintheconsolepanel.

WhentheMILilluminates,makeinitialtroubleshooting

checks.

Ifthesechecksdonotcorrecttheproblem,further

diagnosisandservicingbyanAuthorizedService

Dealerisnecessary.

HourMeter

Thehourmeterrecordsthenumberofhoursthe

enginehasoperated.Itoperateswhentheengine

12

Page 13

isrunning.Usethesetimesforschedulingregular

maintenance(Figure5).

Safety-InterlockIndicators

Symbolsonthehourmeterindicatewithablack

trianglethattheinterlockcomponentisinthecorrect

position(Figure5).

Battery-IndicatorLight

IfthekeyisturnedtotheONpositionforafew

seconds,thebatteryvoltagedisplaysinthearea

wherethehoursarenormallydisplayed.

Thebatterylightturnsonwhenthekeyisturnedtothe

ONpositionandwhenthechargeisbelowthecorrect

operatinglevel(Figure5).

ThrottleControl

ThethrottlecontrolisvariablebetweenFastand

Slow(Figure5).

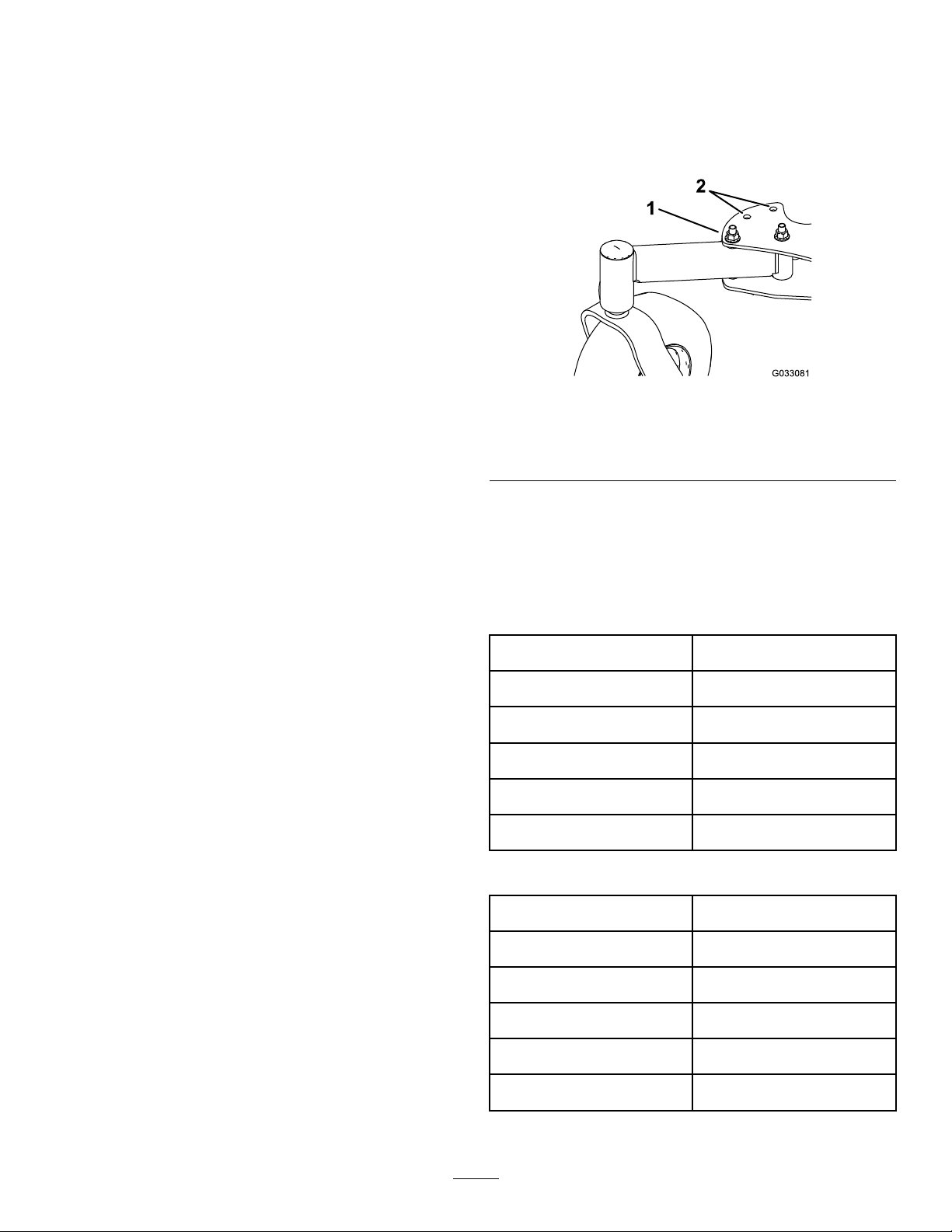

AdjustableCasters

Whenusingthemachinewithoutanaccessory,place

theadjustablecastersinthemowingposition(front

hole)asshowninFigure6.Whenusingthemachine

withanaccessory,refertotheOperator’sManualfor

thataccessoryforthecorrectcasterposition.

g033081

Figure6

RightCasterShown

1.Mowingposition2.Accessorypositions

Blade-ControlSwitch(PTO)

Usetheblade-controlswitch(PTO)toengageand

disengagethemowerblades(Figure5).

KeySwitch

Thekeyswitch,usedtostartandshutofftheengine,

has3positions:OFF,RUN,andSTART.Referto

OperatingtheKeySwitch(page17).

Motion-ControlLevers

Usethemotion-controlleverstodrivethemachine

forward,reverse,andturneitherdirection(Figure5).

Fuel-ShutoffValve

Closethefuel-shutoffvalvewhentransportingor

storingthemachine;refertoUsingtheFuel-Shutoff

Valve(page18).

AccessoryFrame

UsetheaccessoryframetoattachonlyToro-approved

accessoriestothemachine(Figure4).Refertothe

Operator’sManualfortheaccessoryforinstallation

instructions.

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

52-inchMowers

Widthwithdeectordown173cm(68inches)

Widthwithdeectorraised137cm(54inches)

Lengthwithplatformdown191cm(75inches)

Lengthwithplatformup155cm(61inches)

Height

Weight

60-inchMowers

Widthwithdeectordown193cm(76inches)

Widthwithdeectorraised157cm(62inches)

Lengthwithplatformdown201cm(79inches)

Lengthwithplatformup165cm(65inches)

122cm(48inches)

412kg(908lb)

Accessory-FrameLock

Theaccessory-framelockholdstheframeinplaceon

themachineusingthelockpin.Alwayslocktheframe

unlessahydraulickitisinstalledwithanaccessory

onthemachine(Figure4).

Height

Weight

13

122cm(48inches)

427kg(941lb)

Page 14

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesisavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.T oro.comforalistofallapprovedattachments

andaccessories.

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

ThinkSafetyFirst

Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourToroequipment,countonT oro

genuineparts.Whenitcomestoreliability,T oro

deliversreplacementpartsdesignedtotheexact

engineeringspecicationofourequipment.Forpeace

ofmind,insistonTorogenuineparts.

Carefullyreadallthesafetyinstructionsanddecals

inthesafetysection.Knowingthisinformationcould

helpyouorbystandersavoidinjury.

CAUTION

Thismachineproducessoundlevelsin

excessof85dBAattheoperator'searand

cancausehearinglossfromextendedperiods

ofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

g229846

Figure7

1.Wearhearingprotection.

AddingFuel

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan

10%ethanolbyvolume,suchasE15(contains

15%ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

•Donotaddoiltogasoline.

14

Page 15

DANGER

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty .

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanyfuel

thatspills.

•Neverllthefueltankinsideanenclosed

trailer.

•Donotllthefueltankcompletelyfull.

Addfueltothefueltankuntilthelevelis6

to13mm(1/4to1/2inch)belowthebottom

ofthellerneck.Thisemptyspaceinthe

tankallowsfueltoexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinanapprovedcontainerand

keepitoutofthereachofchildren.Never

buymorethana30-daysupplyoffuel.

•Donotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark,

whichcanignitethefuelvapors.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty .

•Alwaysplacefuelcontainersontheground

awayfromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmay

insulatethecontainerandslowthelossof

anystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

ground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainerratherthanfroma

fuel-dispensernozzle.

•Ifyoumustuseafuel-dispensernozzle,

keepthenozzleincontactwiththerimof

thefueltankorcontaineropeningatall

timesuntilfuelingiscomplete.

WARNING

Fuelisharmfulorfatalifswallowed.

Long-termexposuretovaporscancause

seriousinjuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandfueltank

orconditionerbottleopening.

•Avoidcontactwithskin;washoffspills

withsoapandwater.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsfuelfreshduringstorageof90daysorless.

Forlongerstorage,drainthefueltank.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

Important:Donotusefueladditives

containingmethanolorethanol.

Addthecorrectamountoffuelstabilizer/conditioner

tothefuel.

15

Page 16

Note:Afuelstabilizer/conditionerismost

effectivewhenmixedwithfreshfuel.T ominimize

thechanceofvarnishdepositsinthefuelsystem,

usefuelstabilizeratalltimes.

FillingtheFuelTank

OperatingtheParking Brake

Alwaysengagetheparkingbrakewhenyoustopthe

machineorleaveitunattended.Beforeeachuse,

checktheparkingbrakeforproperoperation.

1.Parkthemachineonalevelsurface,disengage

thePTO,movethemotion-controlleverstothe

NEUTRAL-LOCKposition,andengagetheparking

brake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanaroundthefuel-tankcapandremovethe

cap.

4.Fillthefueltanktothebottomofthellerneck.

Note:Donotllthefueltankcompletelyfull.

Theemptyspaceinthetankallowsthegasoline

toexpand.

5.Installthefuel-tankcapsecurely.Wipeupany

spilledfuel.

CheckingtheEngine-Oil Level

Beforeyoustarttheengineandusethemachine,

checktheoillevelintheenginecrankcase;referto

CheckingtheEngine-OilLevel(page34).

Iftheparkingbrakedoesnotholdsecurely,adjustit;

refertoAdjustingtheBrakes(page47).

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

Alwaysremovethekeyandengagethe

parkingbrakewhenleavingthemachine

unattended.

EngagingtheParkingBrake

Pulltheparking-brakeleverrearwardintothe

ENGAGEDposition(Figure8).

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mower

decksanddrivesystemshavehigherfrictionwhen

new,placingadditionalloadontheengine.Allow

40to50hoursofbreak-intimefornewmachinesto

developfullpowerandbestperformance.

g009465

Figure8

1.Parkingbrake—engaged2.Parking

brake—disengaged

DisengagingtheParkingBrake

Pushtheparking-brakeleverforward(Figure8).

16

Page 17

Operatingthe

OperatingtheThrottle

Mower-Blade-Control

Switch(PTO)

Usetheblade-controlswitch(PTO)inconjunctionwith

themotion-controlleverstoengageanddisengage

themowerblades.

EngagingtheMowerBlades(PTO)

Figure9

YoucanmovethethrottlecontrolbetweenFASTand

SLOWpositions(Figure12).

AlwaysusetheFASTpositionwhenengagingthePTO.

g008946

Figure12

OperatingtheKeySwitch

Important:Donotengagethestarterformore

than5secondsatatime.Iftheenginefailsto

start,wait15secondsbetweenattempts.Failure

tofollowtheseinstructionscanburnoutthe

startermotor.

g031592

Note:Y oumayneedtorepeatthecycleforstarting

theenginewhenyoustartitforthersttimeafteryou

havelledacompletelyemptyfuelsystemwithfuel.

DisengagingtheMowerBlades (PTO)

Figure10andFigure11show2waystodisengage

themowerblades.

Figure10

Figure11

g031239

Figure13

g009174

g031281

Figure14

g031593

17

Page 18

UsingtheFuel-Shutoff

StartingtheEngine

Valve

Closethefuel-shutoffvalvefortransport,maintenance,

andstorage(Figure15).

Ensurethatthefuel-shutoffvalveisopenwhen

startingtheengine.

Important:Donotengagethestarterformore

than5secondsatatime.Iftheenginefailsto

start,wait15secondsbetweenattempts.Failure

tofollowtheseinstructionscanburnoutthe

startermotor.

Note:Y oumayneedtorepeatthecycleforstarting

theenginewhenyoustartitforthersttimeafteryou

havelledacompletelyemptyfuelsystemwithfuel.

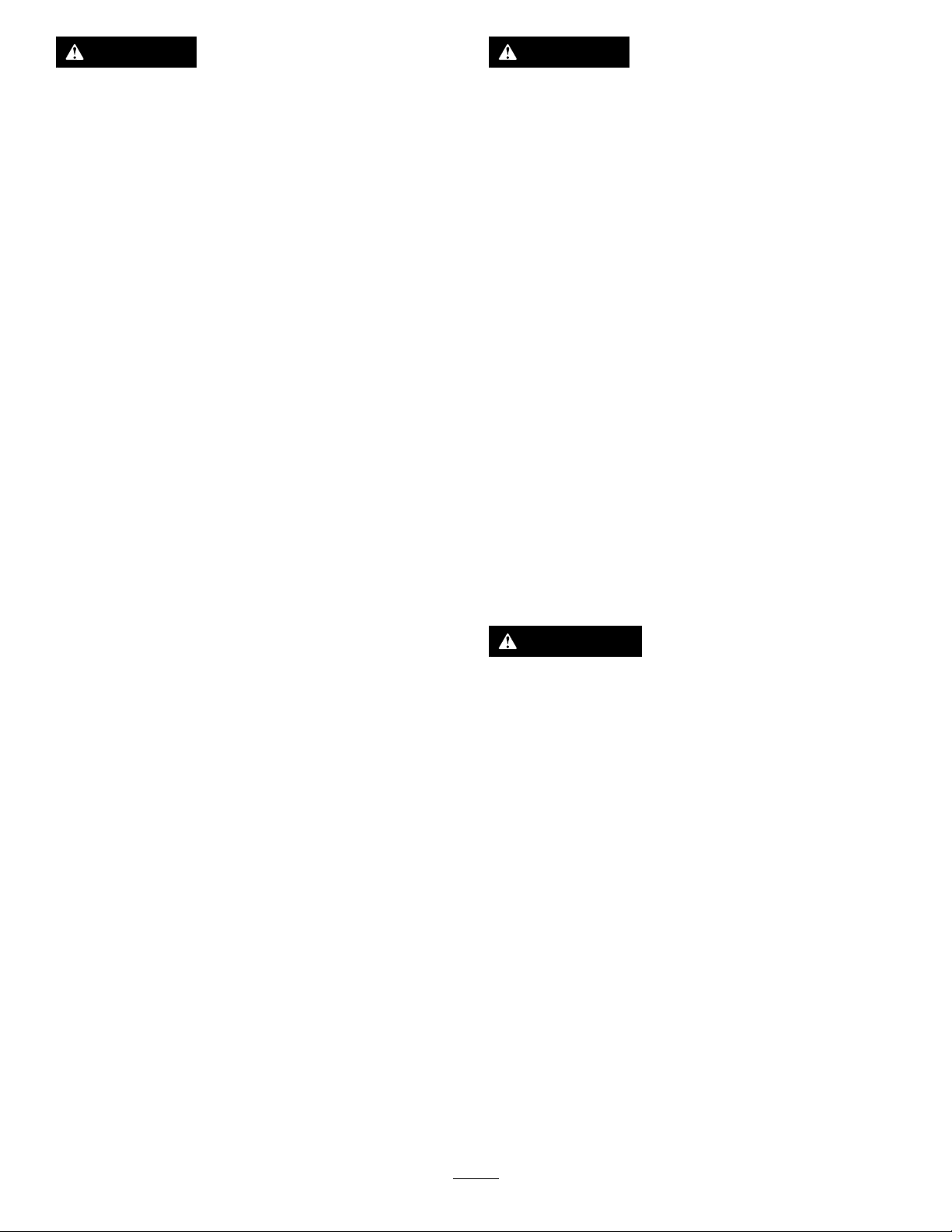

g032688

Figure15

1.ONposition2.OFFposition

g031238

g032689

Figure16

18

Page 19

ShuttingOfftheEngine

CAUTION

TheSafety-Interlock

System

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

Alwaysremovethekeyandengagethe

parkingbrakewhenleavingthemachine

unattended.

Lettheengineidleatslowthrottle(turtle)for60

secondsbeforeturningthekeyswitchtotheOFF

position.

CAUTION

Ifthesafety-interlockswitchesare

disconnectedordamaged,themachinecould

operateunexpectedly,causingpersonal

injury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

Understandingthe Safety-InterlockSystem

Thesafety-interlocksystemisdesignedtoprevent

themowerbladesfromrotatingunlessyoudo1of

thefollowing:

•Moveeithermotion-controllevertothecenter,

unlockedposition.

•Pulltheblade-controlswitch(PTO)totheON

position.

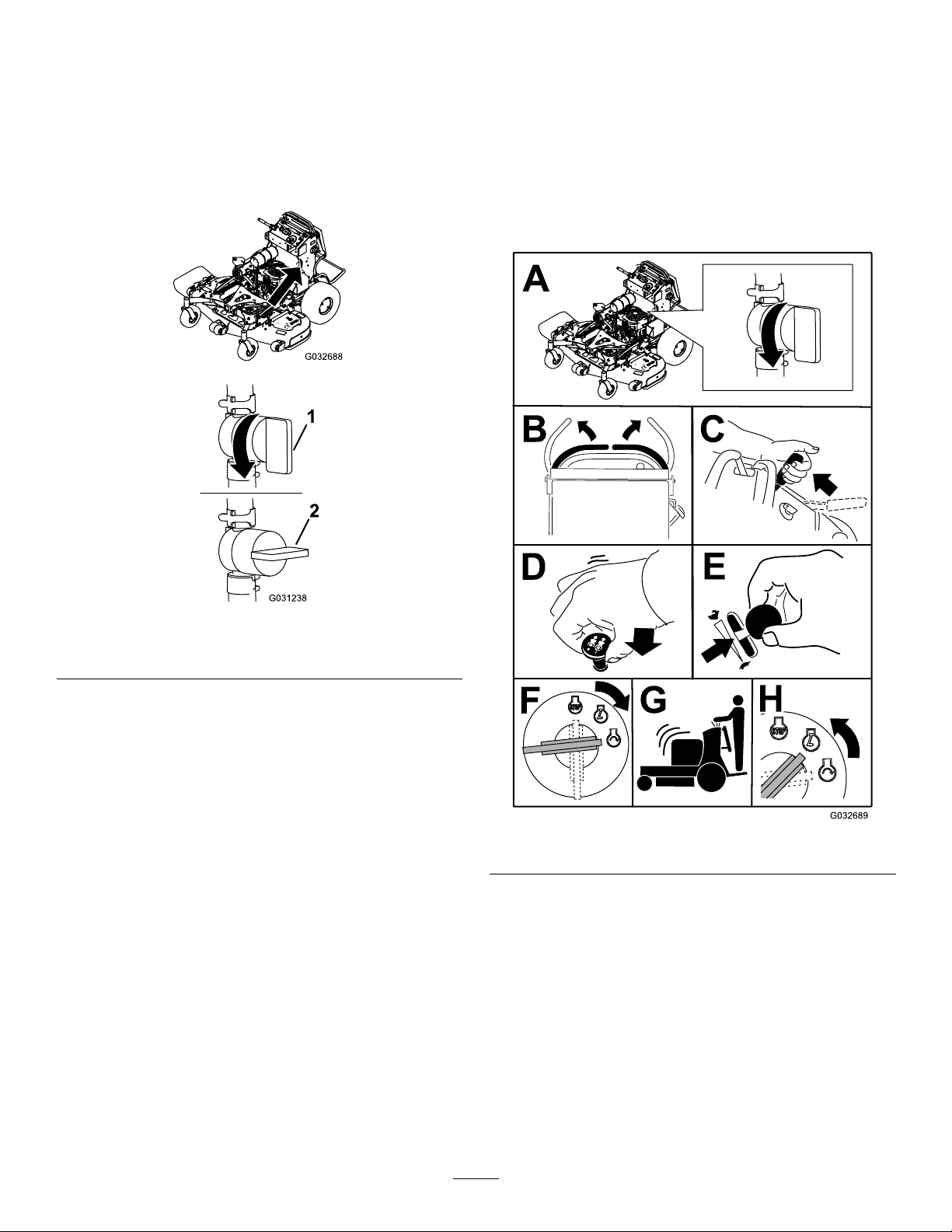

Figure17

Important:Makesurethatthefuel-shutoffvalve

isclosedbeforetransportingorstoringthe

machinetopreventafuelleak.Beforestoringthe

machine,disconnectthesparkplug(s)toprevent

thepossibilityofaccidentalstarting.

Thesafety-interlocksystemisdesignedtostop

themowerbladesifyoumoveorreleaseboth

motion-controlleversintotheNEUTRAL-LOCK

position.

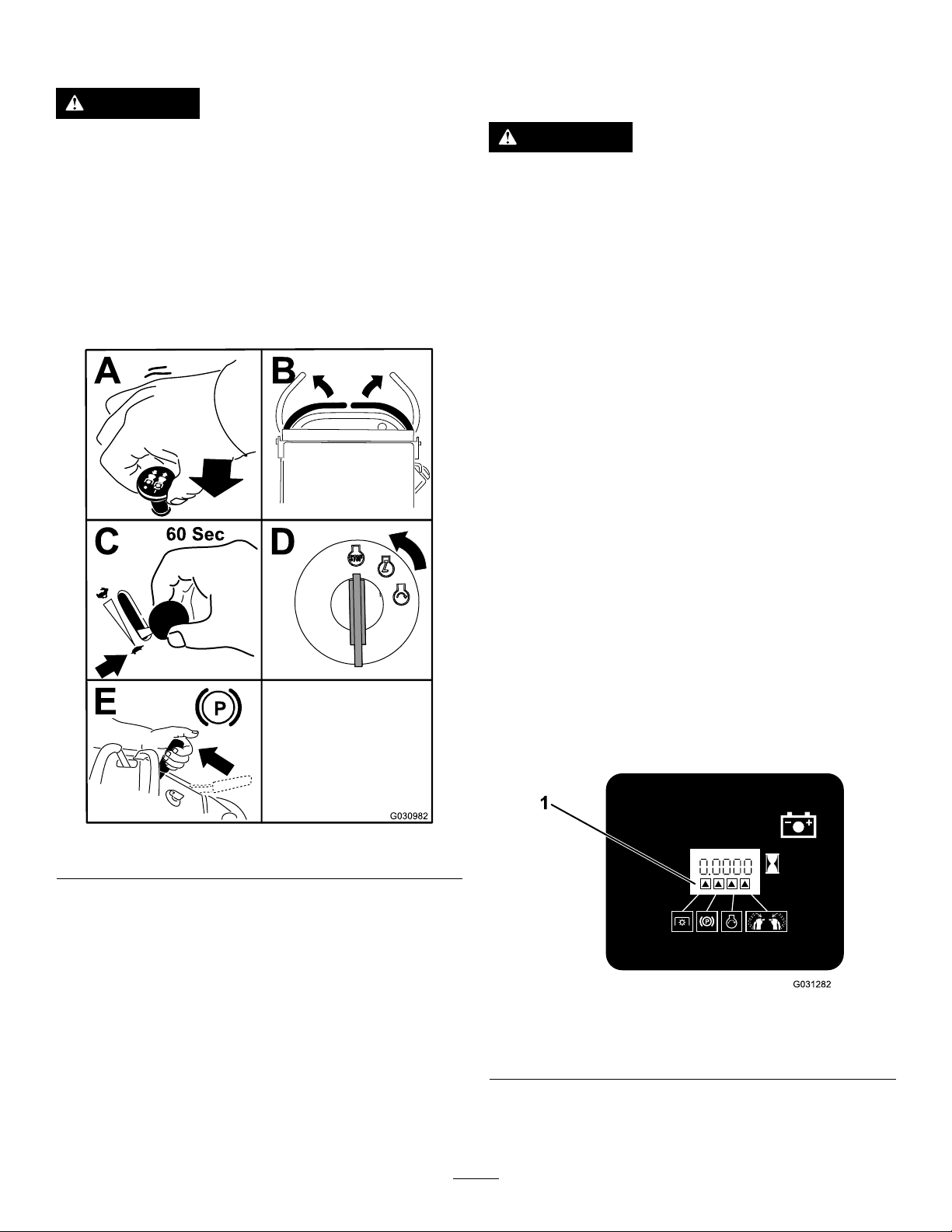

Thehourmeterhassymbolstonotifytheuser

wheneachinterlockcomponentisinthecorrect

position.Whenthecomponentisinthecorrect

position,atrianglelightsupinthecorresponding

square(Figure18).

g030982

g031282

Figure18

1.Triangleslightupwhentheinterlockcomponentsareinthe

correctposition.

19

Page 20

TestingtheSafety-Interlock System

ServiceInterval:Beforeeachuseordaily

Testthesafety-interlocksystembeforeyouusethe

machineeachtime.

Note:Ifthesafetysystemdoesnotoperateas

describedbelow,haveanAuthorizedServiceDealer

repairthesafetysystemimmediately.

1.Starttheengine;refertoStartingtheEngine

(page18).

2.Movethemotion-controlleverstothecenter,

unlockedposition.

Note:Thebladesshouldnotrotateandthe

engineshouldshutoff.

3.Starttheengineandreleasetheparkingbrake.

4.Moveeithermotion-controllevertothecenter,

unlockedposition.

5.Continueholdingthemotion-controlleverin

thecenter,unlockedposition,pulluponthe

blade-controlswitch(PTO),andreleasethe

switch.

WARNING

Theoperatorplatformisheavyandmaycause

injurywhenloweringandraisingtheoperator

platform.Carefullylowerorraisetheoperator

platform,assuddenlydroppingitcouldinjure

you.

•Donotputyourhandsorngersinthe

platform-pivotareawhenloweringor

raisingtheoperatorplatform.

•Makesurethattheplatformissupported

whenyoupullthelatchpinout.

•Makesurethatthelatchsecuresthe

platformwhenfoldingitup.Pushittight

againstthecushionforthelatchpinto

lockintoplace.

•Keepbystandersawaywhenraisingor

loweringtheplatform.

OperatingthePlatform

Youcanusethemachinewiththeplatforminthe

upordownposition.Itisyourpreferenceonwhich

positiontouse.

Note:Theclutchshouldengageandthemower

bladesrotate.

6.Moveorreleasethemotion-controlleversinto

theNEUTRAL-LOCKposition.

Note:Thebladesshouldstoprotatingandthe

engineshouldcontinuetorun.

7.Pushtheblade-controlswitchdownand

moveeithermotion-controllevertothecenter,

unlockedposition.

8.Continueholdingthemotion-controlleverin

thecenter,unlockedposition,pulluponthe

blade-controlswitch(PTO),andreleasethe

switch.

Note:Theclutchshouldengageandthemower

bladesshouldrotate.

9.Pushtheblade-controlswitch(PTO)downto

theOFFposition.

Note:Thebladesshouldstoprotating.

10.Withtheenginerunning,pulluptheblade-control

switch(PTO)andreleaseitwithoutholding

eithermotion-controllevertothecenter,

unlockedposition.

Note:Thebladesshouldnotrotate.

OperatingtheMachinewiththe PlatformUp

Operatethemachinewiththeplatformupforthe

followingconditions:

•Mowingneardrop-offs

•Mowingsmallareaswherethemachineistoo

large

•Areaswithlow,over-hangingbranchesor

obstacles

•Loadingthemachinefortransport

•Drivingupslopes

Toraisetheplatform,pullthebackoftheplatformup

sothatthelatchpinandknoblockitintoplace.Push

ittightagainstthecushionforthelatchpintolockit

intoplace.

OperatingtheMachinewiththe PlatformDown

Operatethemachinewiththeplatformdownforthe

followingconditions:

•Mowingmostareas

•Drivingacrossslopes

•Drivingdownslopes

Tolowertheplatform,pushtheplatformforward

againstthecushiontoreleasepressureonthelatch

20

Page 21

pin,thenpulltheknoboutandlowertheplatform

(Figure19).

Figure19

1.Platformup

2.Platformdown

3.Pulltheknobouttorelease

theplatform.

DrivingForwardor

DrivingForward

1.Disengagetheparkingbrake;referto

DisengagingtheParkingBrake(page16).

2.Movethemotion-controlleverstothecenter,

unlockedposition.

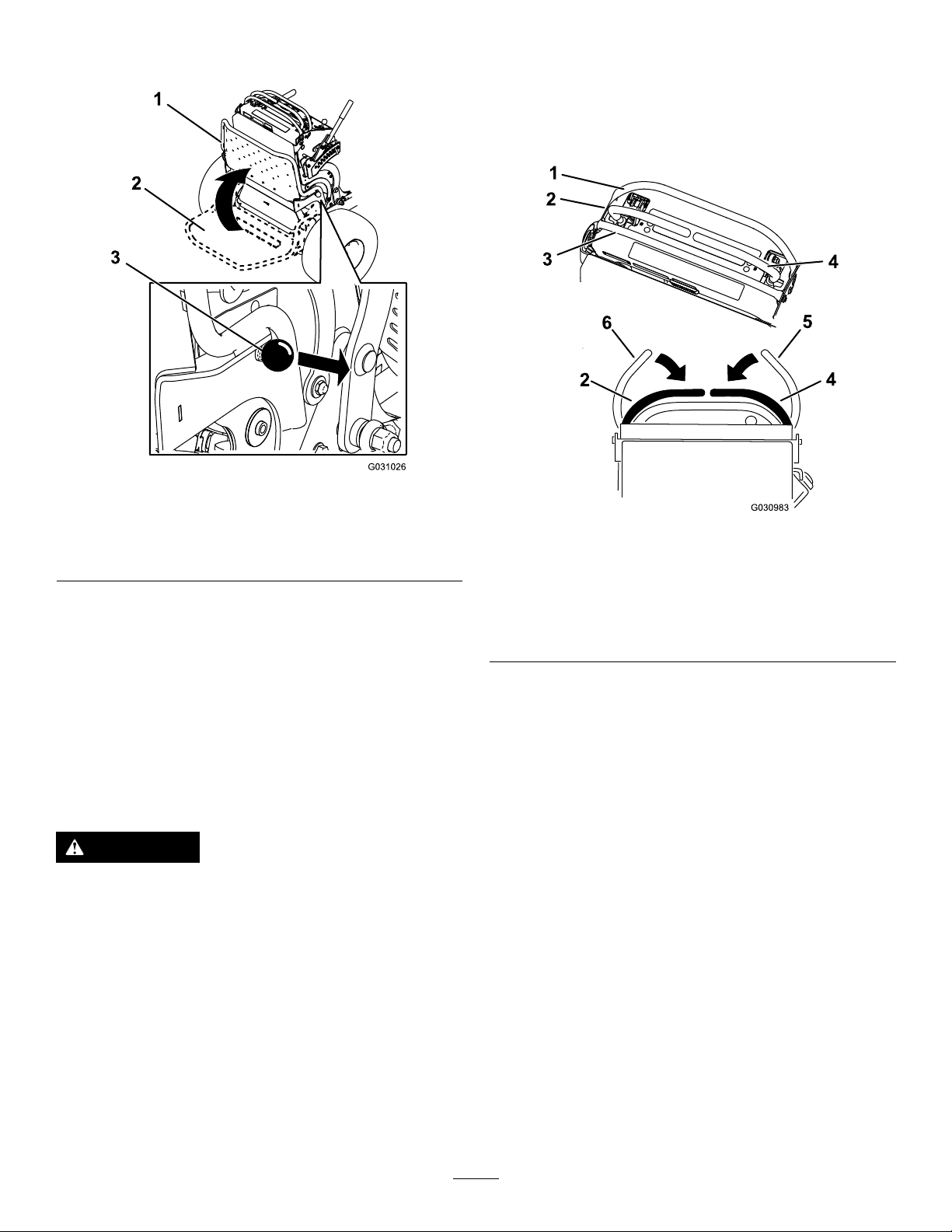

g031026

g030983

Figure20

1.Frontreferencebar

2.Leftcontrollever

3.Rearreferencebar6.Leftcontrolleverinthe

4.Rightcontrollever

5.Rightcontrolleverinthe

NEUTRAL-LOCKposition

NEUTRAL-LOCKposition

Backward

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Place

thethrottlecontrolintheFASTpositionforbest

performance.

Important:Backthemachineovercurbs;driving

itforwardovercurbscoulddamagethemachine.

CAUTION

Themachinecanspinveryrapidly,andyou

maylosecontrolofthemachine,causing

personalinjurytoyouanddamagetothe

machine.

Slowdownthemachinebeforemakingsharp

turns.

3.Slowlypushthemotion-controlleversforward

(Figure21).

Note:Theengineshutsoffifyoumovea

motion-controlleverwhiletheparkingbrakeis

engaged.

Note:Thefartheryoumovethemotion-control

leversineitherdirection,thefasterthemachine

movesinthatdirection.

Note:T ostop,pullthemotion-controllevers

backtotheNEUTRALposition.

21

Page 22

Figure21

StoppingtheMachine

Tostopthemachine,movethemotion-controllevers

toneutral,thenmovetherightmotion-controllever

intotheNEUTRAL-LOCKposition,disengagethepower

takeoff(PTO),andturnthekeytotheOFFposition.

Engagetheparkingbrakewhenyouleavethe

machine;refertoEngagingtheParkingBrake(page

16).Remembertoremovethekeyfromtheswitch.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

Alwaysremovethekeyandengagethe

parkingbrakewhenleavingthemachine

unattended.

g009473

PushingtheMachineby Hand

DrivingBackward

1.Movebothmotion-controlleverstothecenter,

unlockedposition.

2.Slowlypullthemotion-controlleversrearward

(Figure22).

Figure22

Thebypassvalvesallowyoutopushthemachineby

handwithouttheenginerunning(Figure23).

Important:Alwayspushthemachinebyhand.

Donottowthemachine,becausehydraulic

damagemayoccur.

Important:Donotstartoroperatethemachine

withthebypassvalvesopen.Damagetothe

systemmayoccur.

g009474

22

Page 23

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthe

machine.Ensurethatthetrailerortruckhasall

necessarybrakes,lighting,andmarkingsasrequired

bylaw.Pleasecarefullyreadallthesafetyinstructions.

1.Raisetheplatformofthemachinebeforedriving

upontothetrailerortruck.

2.Ifusingatrailer,connectittothetowingvehicle

andconnectthesafetychains.

3.Ifapplicable,connectthetrailerbrakes.

4.Loadthemachineontothetrailerortruck.

5.Shutofftheengine,removethekey,setthe

brake,andclosethefuelvalve.

6.Usethemetaltie-downloopsonthemachineto

securelyfastenthemachinetothetrailerortruck

withstraps,chains,cable,orropes(Figure24).

Figure23

g032703

Figure24

g031434

1.Tractionunittie-downloop

23

Page 24

LoadingtheMachine

Useextremecautionwhenloadingorunloadingthe

machineontoatraileroratruck.Useafull-widthramp

thatiswiderthanthemachineforthisprocedure.

Backthemachineuptherampandwalkitforward

downtheramp(Figure25).

Figure25

g031405

1.Backthemachineupthe

ramp.

2.Walkthemachinedown

theramp.

Important:Donotusenarrowindividualramps

foreachsideofthemachine.

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath(Figure26).

•Useextremecautionwhenoperatinga

machineonaramp.

•Useonlyafull-widthramp;donotuse

individualrampsforeachsideofthe

machine.

•Donotexceeda15-degreeanglebetween

therampandthegroundorbetweenthe

rampandthetrailerortruck.

•Ensurethatthelengthoframpisatleast

4timesaslongastheheightofthetrailer

ortruckbedtotheground.Thisensures

thattherampangledoesnotexceed15

degreesonatground.

1.Full-widthrampinstowed

position

2.Sideviewoffull-width

rampinloadingposition

3.Notgreaterthan

15degrees

g027996

Figure26

4.Therampisatleast4

timesaslongastheheight

ofthetrailerortruckbed

totheground

5.H=heightofthetraileror

truckbedtotheground

6.Trailer

•Backthemachineuptherampanddriveit

forwarddowntheramp.

•Avoidsuddenaccelerationordeceleration

whiledrivingthemachineonarampas

thiscouldcausealossofcontrolora

tip-oversituation.

24

Page 25

SideDischargingor

AdjustingtheHeight-of-Cut

MulchingtheGrass

Thismachinehasahingedgrassdeectorthat

dispersesclippingstothesideanddowntowardthe

turf.

DANGER

Withoutthegrassdeector,dischargecover,

orcompletegrasscatcherassemblymounted

inplace,youandothersareexposedtoblade

contactandthrowndebris.Contactwith

rotatingmowerblade(s)andthrowndebris

causeinjuryordeath.

•Donotremovethegrassdeectorfrom

themachine,becausethegrassdeector

routesmaterialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthe

machine.

•Nevertrytoclearthedischargeareaor

mowerbladesunlessyoureleasethebail

andthepowertakeoff(PTO)isoff.Rotate

thekeytotheOFFposition.Alsoremove

thekeyanddisconnectthewire(s)from

thesparkplug(s).

Theheight-of-cutcanbeadjustedfrom38to127mm

(1-1/2to5inches)in6mm(1/4inch)increments.

Note:Usingaheight-of-cutunder51mm(2inches)

increasesthewearonthemower-deckbelt.Usea

height-of-cutthatisgreaterthan51mm(2inches)

wheneverpossible.

Figure27

g030985

25

Page 26

AdjustingtheAnti-Scalp

AdjustingtheFlowBafe

Rollers

Modelswitha60-InchDeckOnly

Wheneveryouchangetheheight-of-cut,adjustthe

heightoftheanti-scalprollers.

1.Disengagetheblade-controlswitch(PTO),move

themotion-controlleverstotheNEUTRAL-LOCK

position,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removethenutandboltpositiontheanti-scalp

rollersandinstallthenutandbolt.

4.Ensurethatthespacersandbushingsare

installed(Figure28).

Youcanadjustthemower-dischargeowfordifferent

typesofmowingconditions.Positionthecamlock

andbafetoprovidethebestqualityofcut.

1.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,and

engagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Toadjustthebafe,loosenthenut(Figure29).

4.Adjustthebafeandnutintheslottothedesired

dischargeowandtightenthenut.

Figure28

1.Bushing4.Bolt

2.Anti-scalproller5.Nut

3.Spacer

g012676

Figure29

1.Slot

g018324

2.Nut

26

Page 27

UsingtheMid-SizeWeight

•Installweightstoimprovebalance.Youcanaddor

removeweightstocreateoptimizedperformance

underdifferentmowingconditionsandforyour

preference.

•Addorremoveweights1atatimeuntilyou

achievethedesiredhandlingandbalance.

Note:ContactanAuthorizedServiceDealertoorder

aWeightKit.

WARNING

Excessiveweightchangescanaffectthe

handlingandoperationofthemachine.

Thiscouldcauseseriousinjurytoyouor

bystanders.

•Makeweightchangesinsmallincrements

only.

•Evaluatethemachineaftereachweight

changetoensurethatyoucanoperateit

safely.

27

Page 28

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst50hours

Aftertherst100hours

Beforeeachuseordaily

Every50hours

Every100hours

Every150hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthehydraulic-uidlevel.

•Changethehydraulicltersandhydraulicuid.

•Checkthewheel-lugnuts.

•Checkthewheel-hubnuts.

•Checkthesafety-interlocksystem.

•Checktheengine-oillevel.

•Cleantheair-intakescreen.

•Checkthebrakes.

•Inspecttheblades.

•Cleanunderthemowerdeck.

•Washthemachine,especiallyafterwinterapplications.

•Checkthesparkarrester(ifequipped).

•Checkthetirepressure.

•Changetheengineoil(moreoftenindirtyordustyconditions).

•Checkthebattery.

•Checktheclutch.

•Checkandcleantheenginecoolingnsandshrouds.

•Checkthemower-deckbelt.

•Inspecttheprimarylterandtheair-inletscreen.

Every200hours

Every300hours

Every500hours

Every600hours

Every800hours

Every1,000hours

Beforestorage

•Changetheengine-oillter.

•Check,cleanandgapthesparkplug.

•Replacetheprimaryairlter(moreoftenindustyorsandyconditions).

•Checktheinnerairlter.

•Adjustthecaster-pivotbearing.

•Checkthewheel-hubnuts.

•Checkthehydraulic-uidlevel.

•Changethehydraulicltersandhydraulicuid.

•Replacetheinnerairlter.

•Replacethefuellter.

•Replacethetransmissionbelt.

•Paintchippedsurfaces.

•Performallmaintenanceprocedureslistedabovebeforestorage.

•Greasethetorsionidler.

•Greasethefrontcasterpivots(moreoftenindirtyordustyconditions).

•Greasethecaster-wheelhubs.

Yearly

•Greasethevoltageregulator.

•Greasethebrakecalipers.

•Greasethemotioncontrols.

•Applyanti-seizecompoundtothecushionknobs.

•Applydielectricgreasetothebatteryterminals.

Important:Refertoyourengineowner’smanualforadditionalmaintenanceprocedures.

28

Page 29

CAUTION

Ifyouleavethekeyinthekeyswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromthekeyswitchanddisconnectthewiresfromthesparkplugsbefore

youdoanymaintenance.Setthewiresasidesothattheydonotaccidentallycontactthe

sparkplugs.

Pre-Maintenance

Procedures

ReleasingtheCushionfor RearAccess

Youcanreleasethecushionforrearaccesstothe

machineformaintenanceoradjustment.

1.Lowertheplatform.

2.Loosenthetwistknobsoneachsideofthe

machine(Figure30).

Figure30

Lubrication

GreasewithNo.2lithiumormolybdenumgrease.

1.DisengagethePTOandengagetheparking

brake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanthegreasettingswitharag.

Note:Makesuretoscrapeanypaintoffthe

frontofthetting(s).

4.Connectagreaseguntothetting.

5.Pumpgreaseintothettingsuntilgreasebegins

tooozeoutofthebearings.

6.Wipeupanyexcessgrease.

GreasingtheAccessory Frame

g032556

Greasethepivotsoftheaccessoryframeatthe

locationsshowninFigure31.

1.Twistknob

3.Removethecushionandlowerittotheplatform.

4.Performanymaintenanceoradjustmentonthe

machine.

5.Raisethecushion,andslideitontothepinson

bothsidesofthemachine.

6.Tightenthetwistknobs.

2.Cushion

g032690

Figure31

1.Greasethesepivots.

29

Page 30

GreasingtheTorsionIdler

GreasingtheCaster-Wheel

ServiceInterval:Yearly

Greasethetorsionidleronthemowerdeckusing

high-temperaturegreaseatthegreasettingshown

inFigure32.

Important:Useonlyhigh-temperaturegrease.

Figure32

1.Greasetting

Hubs

ServiceInterval:Yearly

Greasetype:Lithiumormolybdenumgrease

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removethecasterwheelfromthecasterforks.

4.Removethesealguardsfromthewheelhub

(Figure33).

g031462

GreasingtheFrontCaster Pivots

ServiceInterval:Yearly

1.Removethedustcapandadjustthecaster

pivots;refertoAdjustingtheCaster-Pivot

Bearing(page43).

Note:Keepthedustcapoffuntilyouhave

nishedgreasingthecasterpivots.

2.Removethehexplug.

3.Threadagreasettingintothehole.

4.Pumpgreaseintothettinguntilitoozesout

aroundthetopbearing.

5.Removethegreasettingfromthehole.

6.Installthehexpluganddustcap.

g006115

Figure33

1.Sealguard2.Spacernutwithwrench

ats

5.Remove1spacernutfromtheaxleassemblyin

thecasterwheel.

Note:Thread-lockingadhesivehasbeen

appliedtolockthespacernutstotheaxle.

Removetheaxle(withtheotherspacernutstill

assembledtoit)fromthewheelassembly.

6.Pryouttheseals,inspectbearingsforwearor

damage,andreplacethemifnecessary.

7.Packthebearingswithageneral-purpose

grease.

8.Insert1bearingand1newsealintothewheel.

Note:Y oumustreplacetheseals.

9.Ifbothspacernutsintheaxleassembly

havebeenremoved(orbrokenloose),apply

athread-lockingadhesiveto1spacernut,

threadingitontotheaxlewiththewrenchats

facingoutward.

Note:Donotthreadthespacernutallof

thewayontotheendoftheaxle.Leave

approximately3mm(1/8inch)fromtheouter

surfaceofthespacernuttotheendoftheaxle

insidethenut.

30

Page 31

10.Inserttheassemblednutandaxleintothewheel

onthesideofthewheelwiththenewsealand

bearing.

11.Withtheopenendofthewheelfacingup,ll

theareainsidethewheelaroundtheaxlefullof

general-purposegrease.

12.Insertthesecondbearingandthenewsealinto

thewheel.

13.Applyathread-lockingadhesivetothesecond

spacernut,threadingitontotheaxlewiththe

wrenchatsfacingoutward.

14.T orquethenutto8to9N∙m(71to80in-lb),

loosenit,thentorqueitto2to3N∙m(20to25

in-lb).

Note:Makesurethattheaxledoesnotextend

beyondeithernut.

15.Installthesealguardsoverthewheelhuband

insertthewheelintothecasterfork.

g228035

Figure34

1.Voltageregulator2.Regulatorblades

16.Installthecasterboltandtightenthenutfully.

Important:Topreventsealandbearingdamage,

checkthebearingadjustmentoftenbyspinning

thecasterwheel.Thewheelshouldnotspinfreely

(morethan1or2revolutions)orhaveanyside

play.Ifthewheelspinsfreely,adjustthetorque

onthespacernutuntilthereisaslightamountof

drag,andapplythread-lockingadhesive.

GreasingtheVoltage Regulator

ServiceInterval:Yearly

Greasetype:Dielectricgrease

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Disconnectthesparkplugwiresfromthespark

plug.

GreasingtheBrakeCalipers

ServiceInterval:Yearly

Applyarust-preventativespraytothebrakecalipers

yearly.

g228033

Figure35

1.Brakecaliper

4.Lightlyapplygreasetothevoltageregulator

blades(Figure34).

Important:T oomuchgreasecancause

watertopoolattheconnectorandshortthe

regulator.

5.Connectthesparkplug.

31

Page 32

GreasingtheMotion Controls

ServiceInterval:Yearly

Greasetheoperator-presence-controlballjointand

themotion-controlbushingforbothlevers.

Note:Useanoildripbetweentheleverbracketsto

greasethebushing,locatedinthepivottube.

EngineMaintenance

ServicingtheAirCleaner

ServiceInterval:Every150hours

Every300hours/Y early(whichevercomes

rst)—Replacetheprimaryairlter(moreoften

industyorsandyconditions).

Every300hours—Checktheinnerairlter.

Every600hours—Replacetheinnerairlter.

Note:Checktheltersmorefrequentlyifthe

operatingconditionsareextremelydustyorsandy .

RemovingtheFilters

1.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,and

engagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

1.Operator-presencecontrol

balljoint

3.Releasethelatchesontheaircleanerand

pulltheair-inletcoverofftheair-cleanerbody

(Figure37).

4.Cleantheair-inletscreenandcover.

5.Installtheair-inletcoverandsecureitwiththe

latches(Figure37).

g228034

Figure36

2.Pivottube

g012996

Figure37

1.Air-inletcover3.Air-cleanerbody

2.Air-inletscreen4.Latch

6.Releasethelatchesontheaircleanerandpull

theair-cleanercoverofftheair-cleanerbody

(Figure38).

7.Cleantheinsideoftheair-cleanercoverwith

compressedair.

8.Gentlyslidetheprimarylteroutofthe

air-cleanerbody(Figure38).

32

Page 33

Note:Avoidknockingthelterintothesideof

thebody.

9.Removethesafetylteronlyifyouintendto

replaceit.

Figure38

1.Safetylter

2.Primarylter

3.Air-cleanercover

10.Inspecttheprimarylterfordamagebylooking

intothelterwhileshiningabrightlightonthe

outsideofthelter.

4.Latch

5.Air-cleanerbody

Note:Holesinthelterappearasbrightspots.

Ifthelterisdamaged,discardit.

ServicingthePrimaryFilter

•Iftheprimarylterisdirty,bent,ordamaged,

replaceit.

•Donotcleantheprimarylter.

ServicingtheSafetyFilter

Replacethesafetylter,nevercleanit.

Important:Donotattempttocleanthesafety

lter.Ifthesafetylterisdirty,thentheprimary

lterisdamaged.Replacebothlters.

InstallingtheFilters

Important:Topreventenginedamage,always

operatetheenginewithbothairltersandthe

coverinstalled.

1.Ifinstallingnewlters,checkeachlterfor

g012997

shippingdamage.

Note:Donotuseadamagedlter.

2.Ifyouarereplacingthesafetylter,carefully

slideitintothelterbody(Figure38).

3.Carefullyslidetheprimarylteroverthesafety

lter(Figure38).

Note:Ensurethattheprimarylterisfully

seatedbypushingontheouterrimwhile

installingit.

Important:Donotpressonthesoft,inside

areaofthelter.

4.Installtheair-cleanercoverandsecurethe

latches(Figure38).

33

Page 34

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSJorhigher)

OilCapacity:1.65L(56oz)withalterchange;

1.50L(51oz)withoutalterchange

Viscosity:Seethetablebelow.

Figure39

g032691

g012991

Note:Useasyntheticoilwith5W-20or5W-30rating,

upto4°C(40°F).

Note:Syntheticoilsprovidebetterstartingwhenthe

temperatureisbelow-23°C(-10°F).

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keepyourhands,feet,face,clothingand

otherbodypartsawaythemuferandother

hotsurfaces.

Important:Donotruntheenginewiththeoil

levelabovetheFullmarkorbelowtheLowmark.

Otherwise,doingsomaydamagetheengine.

1.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,and

engagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition(Figure40).

g027659

Figure40

ChangingtheEngineOil

ServiceInterval:Aftertherst8hours

Every100hours(moreoftenindirtyordusty

conditions).

Note:Disposeoftheusedoilatarecyclingcenter.

1.Starttheengineandletitrunfor5minutes.

Note:Thiswarmstheoilsoitdrainsbetter.

2.Parkthemachinesothattherearisslightly

lowerthanthefronttoensurethattheoildrains

completely.

34

Page 35

3.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,and

engagetheparkingbrake.

4.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition(Figure41).

5.Slowlypourapproximately80%ofthespecied

oilintothellertubeandslowlyaddthe

additionaloiltobringittotheFullmark(Figure

42).

g032710

Figure41

g027660

Figure42

6.Starttheengineanddrivetoaatarea.

7.Checktheoillevelagain.

g027734

35

Page 36

ChangingtheEngine-OilFilter

ServicingtheSparkPlug

ServiceInterval:Every200hours

Note:Changetheengine-oilltermorefrequently

whenoperatingconditionsareextremelydustyor

sandy.

1.Draintheoilfromtheengine;refertoChanging

theEngine-OilFilter(page36).

2.Changetheengine-oillter(Figure43).

ServiceInterval:Every200hours

Makesurethattheairgapbetweenthecenterand

sideelectrodesiscorrectbeforeinstallingthespark

plug.

Useasparkplugwrenchforremovingandinstalling

thesparkplug(s)andagappingtool/feelergaugeto

checkandadjusttheairgap.Installanewspark

plug(s)ifnecessary.

TypeforallEngines:Kohler2513214-c,Champion

XC12YC,orequivalent

AirGap:0.75mm(0.03inch)

RemovingtheSparkPlug

g032710

1.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,and

engagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

Figure43

3.RemovethesparkplugasshowninFigure44.

g027478

Figure44

g027477

Note:Ensurethattheoil-ltergaskettouches

theengine,thenrotatethelteranextra3/4turn.

3.Fillthecrankcasewiththepropertypeofnew

oil;refertoChangingtheEngineOil(page34).

36

Page 37

CheckingtheSparkPlug

CheckingtheSpark

Important:Donotcleanthesparkplug(s).

Alwaysreplacethesparkplug(s)whenithasa

blackcoating,wornelectrodes,anoilylm,or

cracks.

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeanstheaircleanerisdirty .

Setthegapto0.75mm(0.03inch).

Figure45

InstallingtheSparkPlug

Arrester

IfEquipped

ServiceInterval:Every50hours

WARNING

Hotexhaust-systemcomponentsmayignite

fuelvaporsevenaftertheengineisshut

off.Hotparticlesexhaustedduringengine

operationmayigniteammablematerials.

Firemayresultinpersonalinjuryorproperty

damage.

Donotrefuelorruntheengineunlessthe

sparkarresterisinstalled.

g027479

1.Shutofftheengine,waitforallmovingpartsto

stop,engagetheparkingbrake,andremove

thekey.

2.Waitforthemufertocool.

3.Ifanybreaksinthescreenorweldsare

observed,replacethearrester.

Figure46

4.Ifpluggingofthescreenisobserved,remove

thearrester,shakelooseparticlesoutofthe

arrester,andcleanthescreenwithawirebrush

(soakinsolventifnecessary).

5.Installarresteronexhaustoutlet.

g027661

37

Page 38

FuelSystem

Maintenance

DrainingtheFuelTank

Youcandrainthefueltankbyremovingitandpouring

thefueloutofthellneck;refertoRemovingtheFuel

Tank(page38).Youcanalsodrainthefueltankby

usingasiphoninthefollowingprocedure.

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty .

•Drainfuelfromthefueltankwhenthe

engineiscold.Dothisoutdoorsinanopen

area.Wipeupanyfuelthatspills.

•Neversmokewhendrainingfuel,andstay

awayfromanopename,orwhereaspark

mayignitethefuelfumes.

1.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,and

engagetheparkingbrake.

g032692

Figure47

1.Fuelcap

RemovingtheFuelTank

1.Lowertheplatform.

2.Releasethecushion;refertoReleasingthe

CushionforRearAccess(page29).

3.Removethecrossbracket.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition

3.Cleanaroundthefuelcaptopreventdebrisfrom

gettingintothefueltank(Figure47).

4.Removethefuelcap.

5.Insertasyphonpumpintothefueltank.

6.Usingthesyphonpump,drainthefuelintoa

cleangascan(Figure47).

7.Wipeupanyspilledfuel.

g031413

Figure48

4.Removethefueltankandsetitontheoperator

platform.

Note:Ifyouwanttomovethefueltankfurther

fromthemachine,removethefuelandvent

linesfromthetopofthetank.

38

Page 39

ServicingtheFuelFilter

ElectricalSystem

ReplacingtheFuelFilter

ServiceInterval:Every800hours/Yearly(whichever

comesrst)

Donotinstalladirtylterifitisremovedfromthefuel

line.

Note:Wipeupanyspilledfuel.

1.DisengagethePTOandengagetheparking

brake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Closethefuel-shutoffvalve;refertoUsingthe

Fuel-ShutoffValve(page18).

4.ReplacethefuellterasshowninFigure49.

Maintenance

ServicingtheBattery

ServiceInterval:Every100hours

Yearly

Alwayskeepthebatterycleanandfullycharged.Use

apapertoweltocleanthebatterycase.Ifthebattery

terminalsarecorroded,cleanthemwithasolutionof

4partswaterand1partbakingsoda.Applyalight

coatingofgreasetothebatteryterminalstoprevent

corrosion.

Voltage:12V

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

Figure49

DANGER

Donotdrinkelectrolyte,andavoidcontact

withskin,eyesorclothing.Wearsafety

glassestoshieldyoureyesandrubbergloves

toprotectyourhands.

Batteryelectrolytecontainssulfuricacid,a

deadlypoisonthatcausessevereburns.

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetalmachinecomponents,causing

sparks.Sparkscancausethebatterygasses

g027518

toexplode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,

donotallowthebatteryterminalstotouch

anymetalpartsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

39

Page 40

WARNING

Incorrectbattery-cableroutingcoulddamage

themachineandcables,causingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

1.DisengagethePTOandengagetheparking

brake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.RemovethebatteryasshowninFigure50.

InstallingtheBattery

InstallthebatteryasshowninFigure51.

Figure50

g030989

Figure51

g030988

40

Page 41

ChargingtheBattery

ServicingtheFuses

WARNING

Chargingthebatteryproducesgassesthat

canexplode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged

(1.265specicgravity)topreventbatterydamage

whenthetemperatureisbelow0°C(32°F).

1.Removethebatteryfromthechassis;referto

RemovingtheBattery(page39).

2.Checktheelectrolytelevel.

3.Ensurethatthellercapsareinstalledonthe

battery.

4.Chargethebatteryfor1hourat25to30Aor6

hoursat4to6A.

5.Whenthebatteryisfullycharged,unplugthe

chargerfromtheelectricaloutlet,anddisconnect

thechargerleadsfromthebatteryposts(Figure

52).

Theelectricalsystemisprotectedbyfusesand

requiresnomaintenance.Ifafuseblows,checkthe

componentorcircuitforamalfunctionorshort.

1.Releasethecushionfromtherearofthe

machine.

2.Pulloutthefusetoremoveorreplaceit(Figure

53).

3.Installthecushiontotherearofthemachine.

Note:Ensurethatthecorrect-sizefuseis

installedFigure53.

6.Installthebatteryontothemachineandconnect

thebatterycables;refertoInstallingtheBattery

(page40).

Note:Donotrunthemachinewiththebattery

disconnected;electricaldamagemayoccur.

Figure52

1.Positivebatterypost

2.Negativebatterypost

3.Red(+)chargerlead

4.Black(-)chargerlead

g032693

Figure53

1.Keyswitchfuse—15A3.Powertakeoff(PTO)

2.Accessory-portfuse—15

A

g000538

fuse—10A

4.Infocenterfuse—7.5A

41

Page 42

DriveSystem

Maintenance

AdjustingtheTracking

Note:Ifyouareunabletoachieveproper

trackingbyadjustingtheleftcontrolrod,contact

yourAuthorizedServiceDealer.

6.Checkthatthemachinedoesnotcreepfrom

theneutralpositionwiththeparkbrakes

disengaged.

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

1.Pushbothcontrolleversforwardthesame

distance.

2.Checkifthemachinepullsto1side.

Note:Ifitdoes,shutoffthemachineand

engagetheparkingbrake.

3.Releasethecushionfromtherearofthe

machine;refertoReleasingtheCushionfor

RearAccess(page29).

Note:Foreasieraccess,youcanalsoremove

thefueltank;refertoRemovingtheFuelT ank

(page38).

4.Rotatetheleftcontrolrodinquarter-turn

incrementsuntilthemachinetracksstraight

(Figure54).

Note:Ifthemachinepullstotheright,shorten

thecontrolrodbyrotatingittotheright.Ifthe

machinepullstotheleft,lengthentherodby

rotatingittotheleft.

7.Installthefueltank,ifyouremovedit.

8.Installthecushion.

CheckingtheTirePressure

ServiceInterval:Every50hours/Monthly(whichever

comesrst)

Maintaintheairpressureinthereartiresat83to97

kPa(12to14psi).

Important:Uneventirepressurecancausean

unevencut.

Note:Thefronttiresaresemi-pneumatictiresanddo

notrequireair-pressuremaintenance.

Note:Onlyadjusttheleftcontrolrodtomatch

theleftwheelspeedtotherightwheelspeed.

Donotadjusttherightwheelspeed,asthis

positionstherightmotion-controlleveroutofthe

centerforthecontrolpanelneutral-lockslot.

Important:Donotrotatethecontrolrodtoo

far,asthismaycausethemachinetocreep

inneutral.

Figure54

1.Rotatelefttolengthenthe

rod.

2.Leftcontrolrod

3.Rotaterighttoshortenthe

rod.

g001055

Figure55

g031531

5.Checkforpropertracking,andadjusttherod

asnecessary.

42

Page 43

AdjustingtheCaster-Pivot

ServicingtheCaster

Bearing

ServiceInterval:Every500hours/Yearly(whichever

comesrst)

1.Disengagetheblade-controlswitch(PTO),move

themotioncontrolleverstotheNEUTRAL-LOCK

position,andengagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removethedustcapfromthecasterandtighten

thelocknut(Figure56).

4.Tightenthelocknutuntilthespringwashersare

at,andthenbackoffa1/4turntoproperlyset

thepreloadonthebearings(Figure56).

Important:Makesurethatthespring

washersareinstalledcorrectlyasshownin

Figure56.

5.Installthedustcap(Figure56).

WheelsandBearings

Thecasterwheelsrotateonarollerbearingsupported

byaspannerbushing.Ifthebearingiskeptwell

lubricated,wearwillbeminimal.Failuretokeepthe

bearingwelllubricatedcausesrapidwear.Awobbly

casterwheelusuallyindicatesawornbearing.

1.Removethelocknutandwheelboltholdingthe

casterwheeltothecasterfork(Figure57).

1.Springwashers

2.Locknut

Figure56

3.Dustcap

g009453

Figure57

1.Locknut4.Rollerbearing

2.Bushing

3.Spannerbushing

2.Remove1bushing,thenpullthespanner

bushingandrollerbearingoutofthewheelhub

(Figure57).

3.Removetheotherbushingfromthewheelhub

andcleananygreaseanddirtfromthewheel

g001297

hub(Figure57).

4.Inspecttherollerbearing,bushings,spanner

bushingandtheinsideofthewheelhubforwear.

5.Casterwheel

6.Wheelbolt

Note:Replaceanydamagedorwornparts

(Figure57).

5.Place1bushingintothewheelhub(Figure57).

6.Greasetherollerbearingandspannerbushing,

andslidethemintothewheelhub(Figure57).

7.Placethesecondbushingintothewheelhub

(Figure57).

8.Installthecasterwheelintothecasterforkand

secureitwiththewheelboltandlocknut(Figure

57).

43

Page 44

9.Tightenthelocknutuntilthespannerbushing

bottomsagainsttheinsideofthecasterforks

(Figure57).

10.Greasethettingonthecasterwheel.

RemovingtheClutchShim

1.Shutofftheengine,waitforallmovingpartsto

stop,andremovethekey .

2.Engagetheparkingbrakeandwaitformachine

tocoolcompletely.

UsingtheClutchShim

ServiceInterval:Every100hours

Somelatermodelyearunitshavebeenbuiltwith

clutchesthatcontainabrakeshim.Whentheclutch

brakehasworntothepointwheretheclutchnolonger

engagesconsistently,youcanremovetheshimto

extendtheclutchlife.

Figure58

1.Armature5.Brakespacer

2.Fieldshell6.Regaptheshim.

3.Rotor7.Brakepole

4.Brake-mountingbolt

3.Usinganaircompressor,blowoutanydebris

underthebrakepoleandaroundthebrake

spacers.

g010868

Figure59

4.Checktheconditionofthewire-harnessleads,

connectors,andterminals.Cleanorrepairthem

g010869

asnecessary.

5.Verifythat12Vispresentattheclutchconnector

whentheyouengagetheblade-controlswitch

(PTO).

6.Measurethegapbetweentherotorand

armature.Ifthegapisgreaterthan1mm(0.04

inch),proceedwiththefollowingsteps:

A.Loosenbothbrakemountingbolts1/2to1

fullturnasshowninFigure60.

Note:Donotremovethebrakepolefrom

theeldshell/armature.Thebrakepole

hasworntomatchthearmatureandneeds

tocontinuetomatchafteryouremovethe

shimtoensuretheproperbraketorque.

44

Page 45

Figure62

g010872

Figure60

1.Brake-mountingbolt

B.Usingneedle-nosepliers,orbyhand,

removetheshim.

Note:Donotdiscardtheshimuntilyou

conrmthattheclutchfunctionsproperly.

Figure61

1.Shim

g010870

1.Feelergauge

g010873

Figure63

1.Feelergauge

•Ifthegapislessthan0.010inch,

theninstalltheshimandreferto

Troubleshooting(page62).

g010871

•Ifthegapissufcient,proceedtothe

safetycheckinstepF.

F.Performthefollowingsafetycheck:

C.Usingapneumaticline,blowoutanydebris

underthebrakepoleandaroundthebrake

spacers.

D.T orqueeachbolt(M6x1)to12.3to13.7

N∙m(9.5to10.5ft-lb).

E.Usinga0.010inchthick-feelergauge,verify

thatagapispresentbetweentherotorand

armaturefaceonbothsidesofthebrake

poleasshowninFigure62andFigure63.

Note:Duetothewaytherotorand

armaturefaceswear(peaksandvalleys),it

issometimesdifculttomeasurethetrue

gap.