FormNo.3449-144RevA

2000SeriesHDXRD122cmRidingMower

74456TE

122cmAufsitzrasenmäher2000derSerieHDXRD

74456TE

TondeuseautoportéeHDXSDsérie2000de122cm

74456TE

HDXRD2000seriezitmaaiervan122cm

74456TE

www.T oro.com.

*3449-144*

FormNo.3449-129RevA

2000SeriesHDXRD122cm

RidingMower

ModelNo.74456TE—SerialNo.410020000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3449-129*

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

Pleaserefertotheenginemanufacturer’sinformation

includedwiththemachine.

GrossorNetTorque:Thegrossornettorque

ofthisenginewaslaboratoryratedbytheengine

manufacturerinaccordancewiththeSocietyof

AutomotiveEngineers(SAE)J1940orJ2723.As

conguredtomeetsafety,emission,andoperating

requirements,theactualenginetorqueonthisclass

ofmowerwillbesignicantlylower.Pleasereferto

theenginemanufacturer’sinformationincludedwith

themachine.

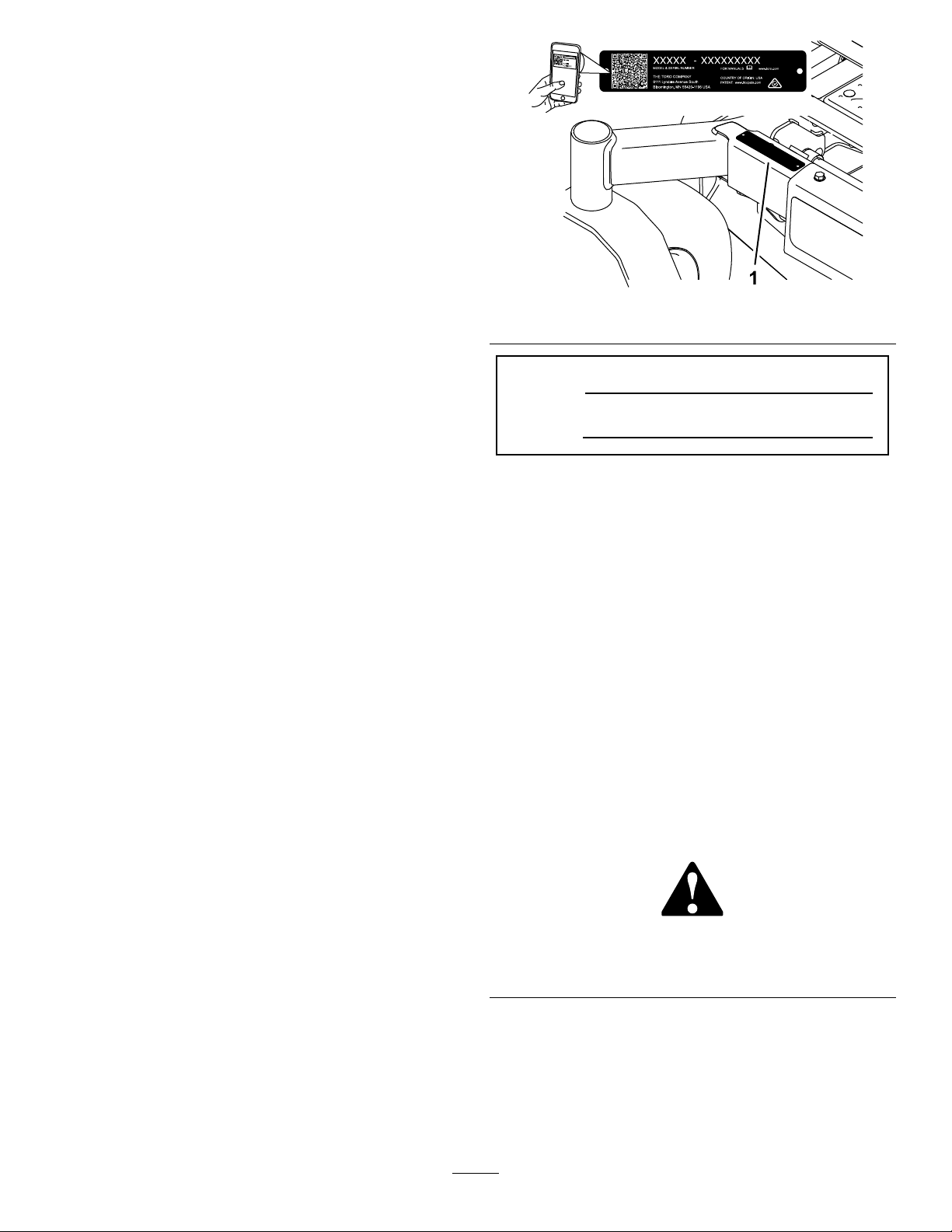

g233855

Figure1

ModelNo.

Introduction

Thisrotary-blade,ridinglawnmowerisintendedtobe

usedbyprofessional,hiredoperators.Itisdesigned

primarilyforcuttinggrassonwell-maintainedlawns

onresidentialorcommercialproperties.Usingthis

productforpurposesotherthanitsintendedusecould

provedangeroustoyouandbystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Y ouareresponsiblefor

operatingtheproductproperlyandsafely.

Visitwww.T oro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready .Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

SerialNo.

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Thesafety-alertsymbol(Figure2)appearsbothin

thismanualandonthemachinetoidentifyimportant

safetymessagesthatyoumustfollowtoavoid

accidents.Thissymbolwillappearwiththeword

Danger,Warning,orCaution.

•Dangerindicatesanimminentlyhazardous

situationwhich,ifnotavoided,willresultindeath

orseriousinjury.

•Warningindicatesapotentiallyhazardous

situationwhich,ifnotavoided,couldresultin

deathorseriousinjury.

•Cautionindicatesapotentiallyhazardoussituation

which,ifnotavoided,mayresultinminoror

moderateinjury .

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

©2021—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

sa-black

Figure2

Safety-alertsymbol

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SlopeIndicator...................................................5

SafetyandInstructionalDecals..........................6

ProductOverview...................................................12

Controls...........................................................12

Specications..................................................14

Attachments/Accessories.................................14

BeforeOperation.................................................15

BeforeOperationSafety...................................15

AddingFuel......................................................16

PerformingDailyMaintenance..........................16

BreakinginaNewMachine..............................16

UsingtheRollover-ProtectionSystem

(ROPS).........................................................17

UsingtheSafety-InterlockSystem....................18

PositioningtheSeat..........................................19

AdjustingtheRear-ShockAssemblies..............19

UsingAttachmentsandAccessories.................20

DuringOperation.................................................20

DuringOperationSafety...................................20

EnteringtheOperator’sPosition.......................23

OperatingtheParkingBrake.............................23

OperatingtheMowerBlade-ControlSwitch

(PTO)............................................................24

OperatingtheThrottle.......................................24

OperatingtheChoke........................................24

StartingtheEngine...........................................25

ShuttingOfftheEngine.....................................25

UsingtheMotion-ControlLevers.......................26

DrivingtheMachine..........................................26

AdjustingtheHeightofCut...............................27

AdjustingtheAnti-ScalpRollers........................28

OperatingTips.................................................29

AfterOperation....................................................29

AfterOperationSafety......................................29

UsingtheFuel-ShutoffValve.............................29

UsingtheDrive-WheelReleaseValves.............30

TransportingtheMachine.................................31

Maintenance...........................................................33

MaintenanceSafety..........................................33

RecommendedMaintenanceSchedule(s)...........33

Pre-MaintenanceProcedures..............................34

ReleasingtheMower-DeckCurtain..................34

RemovingtheSheet-MetalGuard.....................34

Lubrication..........................................................35

GreasingtheMachine.......................................35

EngineMaintenance...........................................35

EngineSafety...................................................35

ServicingtheAirCleaner..................................35

ServicingtheEngineOil....................................36

ServicingtheSparkPlug(s)..............................38

CleaningtheCoolingSystem............................39

CleaningtheEngineScreen.............................39

CheckingtheSparkArrester.............................40

ReplacingtheEmissions-AirIntake

Filter..............................................................40

FuelSystemMaintenance...................................40

ReplacingtheFuelFilter...................................40

ServicingtheFuelTank.....................................41

ElectricalSystemMaintenance...........................41

ElectricalSystemSafety...................................41

ServicingtheBattery.........................................41

ServicingtheFuses..........................................43

DriveSystemMaintenance..................................44

CheckingtheSeatBelt.....................................44

CheckingtheRoll-BarKnobs............................44

AdjustingtheTracking......................................45

CheckingtheTirePressure...............................45

CheckingtheWheelLugNuts...........................45

BrakeMaintenance.............................................46

AdjustingtheParkingBrake..............................46

BeltMaintenance................................................47

InspectingtheBelts..........................................47

ReplacingtheMowerBelt.................................47

ReplacingtheHydraulic-Pump-Drive

Belt................................................................48

ControlsSystemMaintenance.............................49

AdjustingtheControl-HandlePosition..............49

AdjustingtheMotion-ControlLinkage...............50

HydraulicSystemMaintenance...........................51

HydraulicSystemSafety...................................51

HydraulicFluidSpecications...........................51

CheckingtheHydraulicFluidLevel...................52

ChangingtheHydraulicFluidand

Filters............................................................52

BleedingtheHydraulicSystem.........................54

MowerDeckMaintenance....................................54

BladeSafety.....................................................54

ServicingtheCuttingBlades.............................54

AdjustingtheSide-to-SideLevelingandthe

BladeSlope..................................................57

RemovingtheMowerDeck...............................59

Cleaning..............................................................59

CleaningundertheMowerDeck.......................59

CleaningtheSuspensionSystem.....................59

DisposingofWaste...........................................59

Storage...................................................................60

StorageSafety..................................................60

CleaningandStorage.......................................60

Troubleshooting......................................................61

Schematics.............................................................63

3

Safety

Thismachinehasbeendesignedinaccordancewith

ENISO5395.

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjuryordeath.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Keepbystandersandchildrenaway.

•Donotallowchildrenoruntrainedpeopleto

operateorservicethemachine.Allowonlypeople

whoareresponsible,trained,familiarwiththe

instructions,andphysicallycapabletooperateor

servicethemachine.

•Alwayskeeptherollbarinthefullyraisedand

lockedpositionandusetheseatbelt.

•Donotoperatethemachineneardrop-offs,

ditches,embankments,water,orotherhazards,or

onslopesgreaterthan15°.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards,

safetyswitches,andothersafetyprotective

devicesinplaceandfunctioningproperly .

•Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operator’sposition.Allowthemachinetocool

beforeservicing,adjusting,fueling,cleaning,or

storingit.

4

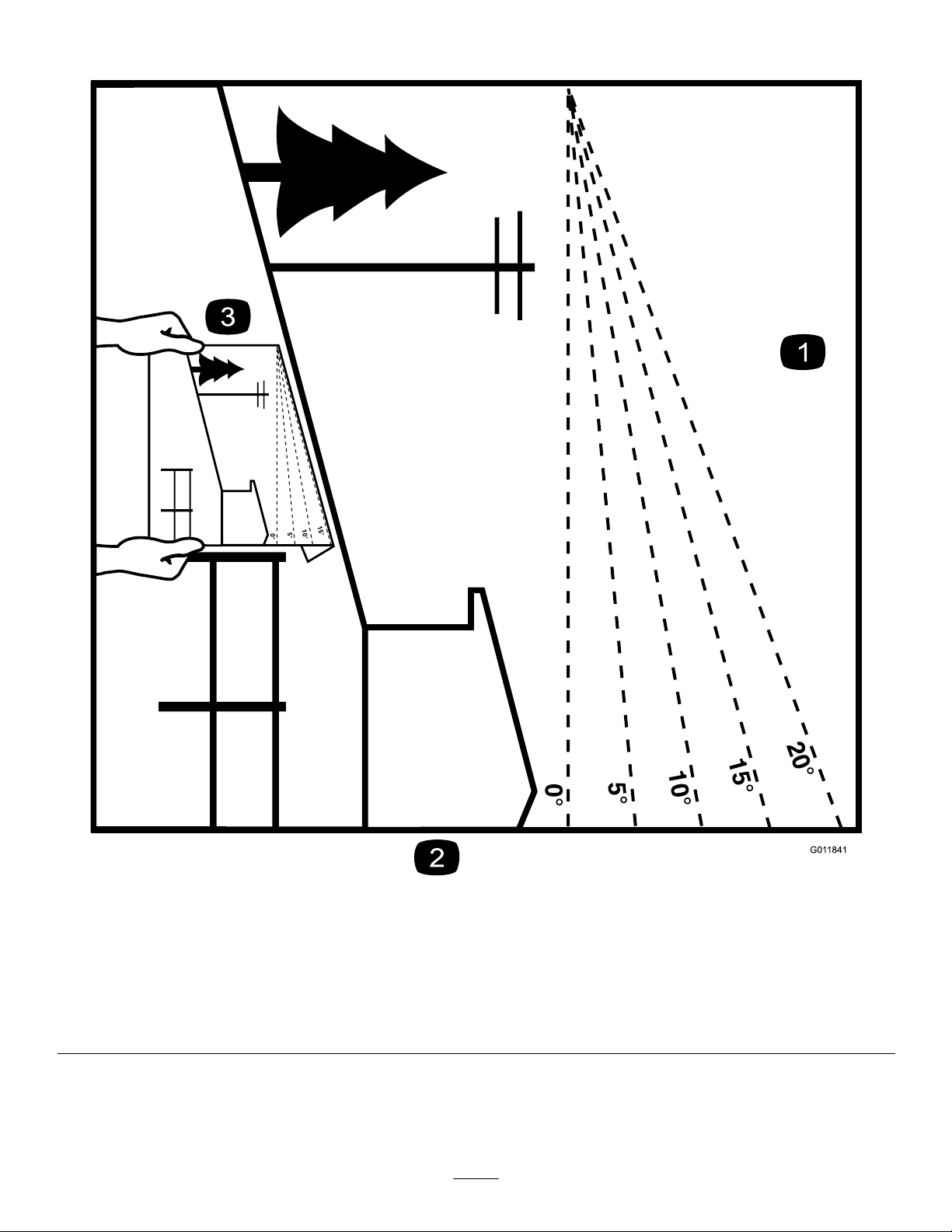

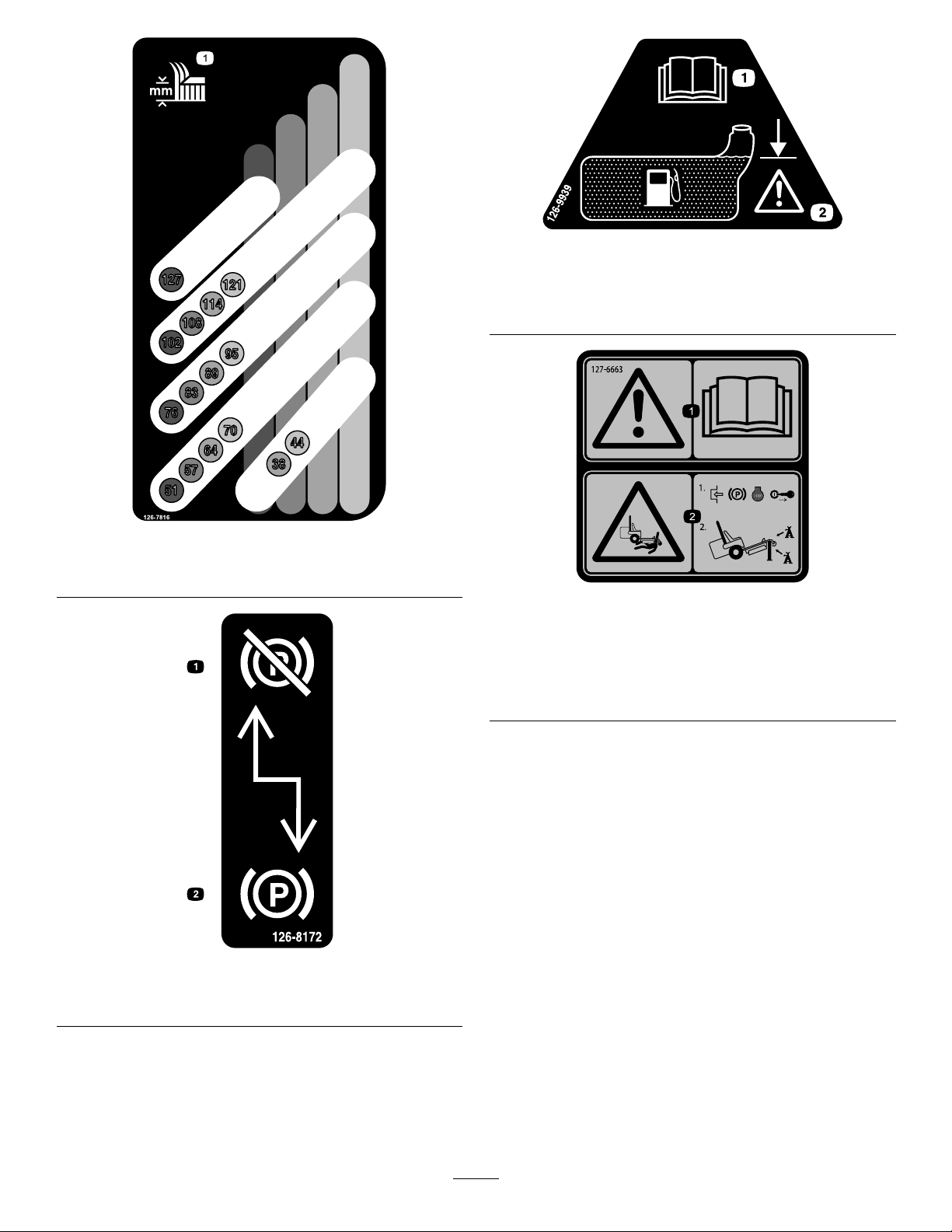

SlopeIndicator

Figure3

Youmaycopythispageforpersonaluse.

1.Themaximumslopeyoucanoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslopeof

hillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge

5

g011841

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

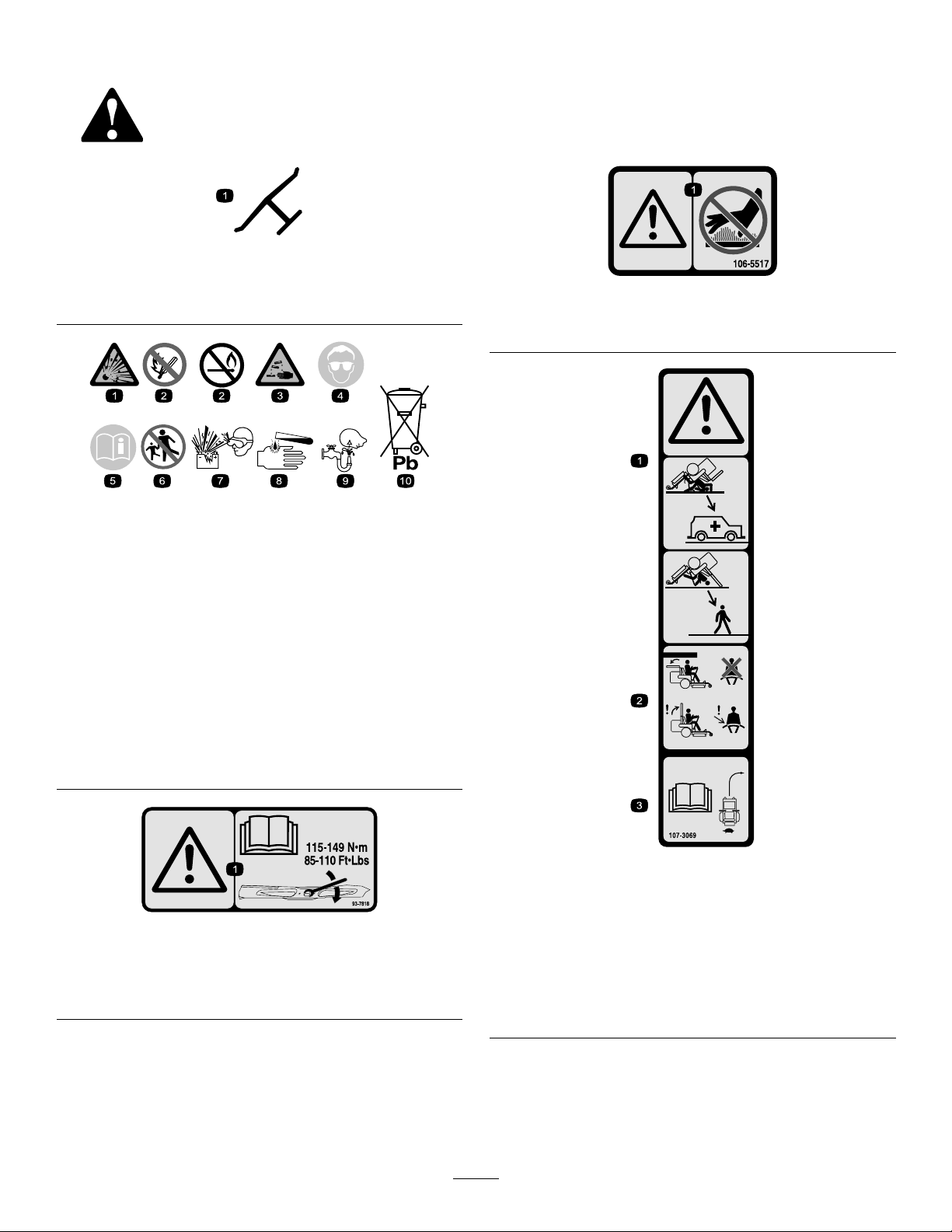

BatterySymbols

Someorallofthesesymbolsareonyourbattery.

decaloemmarkt

decal106-5517

106-5517

1.Warning—donottouchthehotsurface.

decalbatterysymbols

1.Explosionhazard6.Keepbystandersaway

2.Nore,opename,or

smoking

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

fromthebattery.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard

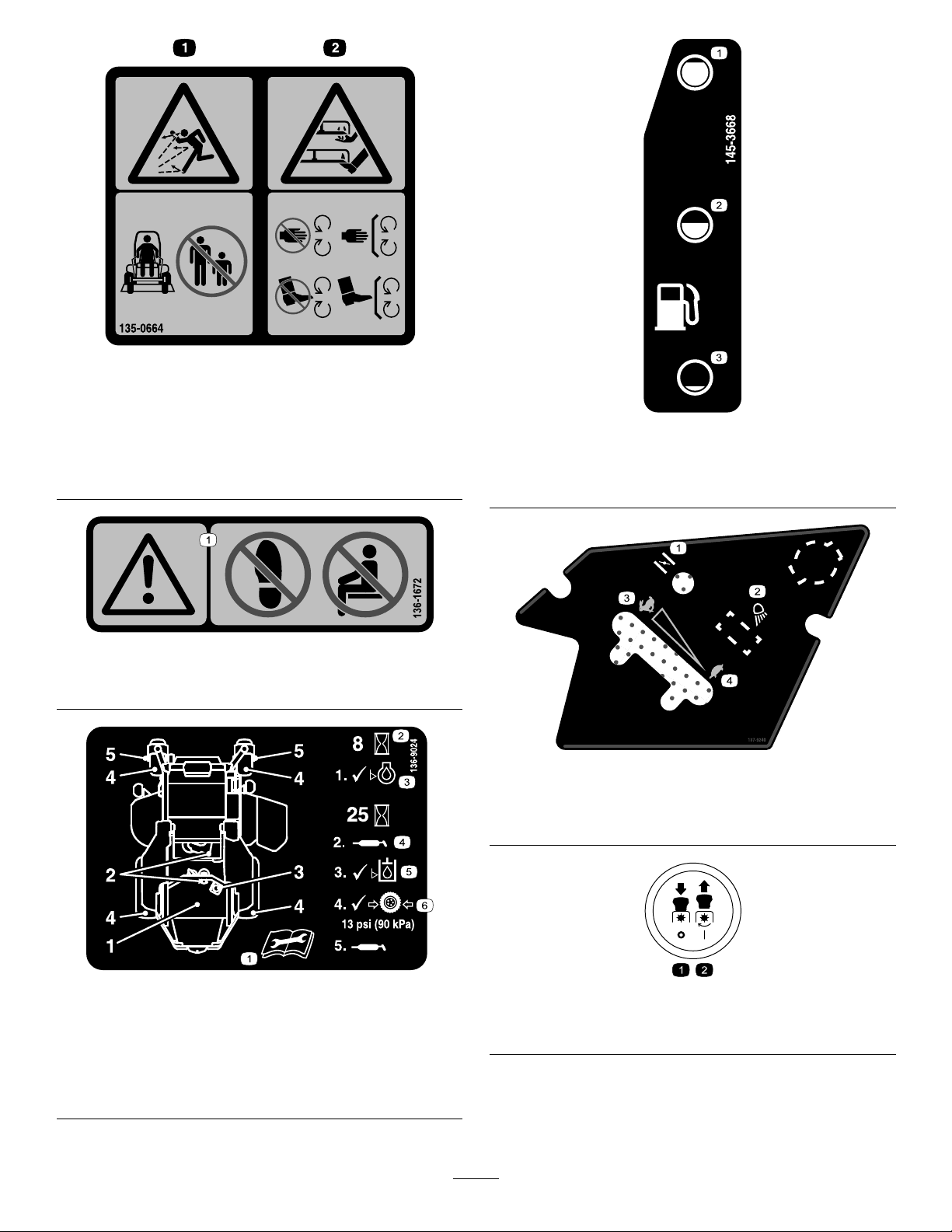

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto115to149N∙m(85to1 10

ft-lb).

decal107-3069

107-3069

1.Warning—thereisnorolloverprotectionwhentherollbaris

decal93-7818

down.

2.Toavoidinjuryordeathfromarolloveraccident,keepthe

rollbarinthefullyraisedandlockedpositionandwear

theseatbelt.Lowertherollbaronlywhenabsolutely

necessary;donotweartheseatbeltwhentherollbaris

down.

3.ReadtheOperator'sManual;driveslowlyandcarefully.

6

decal112-3858

112-3858

1.ReadtheOperator's

Manual.

2.ReadtheOperator's

3.Removethekeybefore

adjustingtheheightofcut.

4.Height-of-cutsettings

Manualbeforeperforming

maintenance.

112-9028

1.Warning—stayawayfrommovingparts;keepallguards

andshieldsinplace.

decal116-8588

116-8588

1.ReadtheOperator’sManual.

2.Rotatethedrivereleaseknobtoloosen,slidetheknob,

decal112-9028

andtighten.

3.Pushthemachine.

116–5610

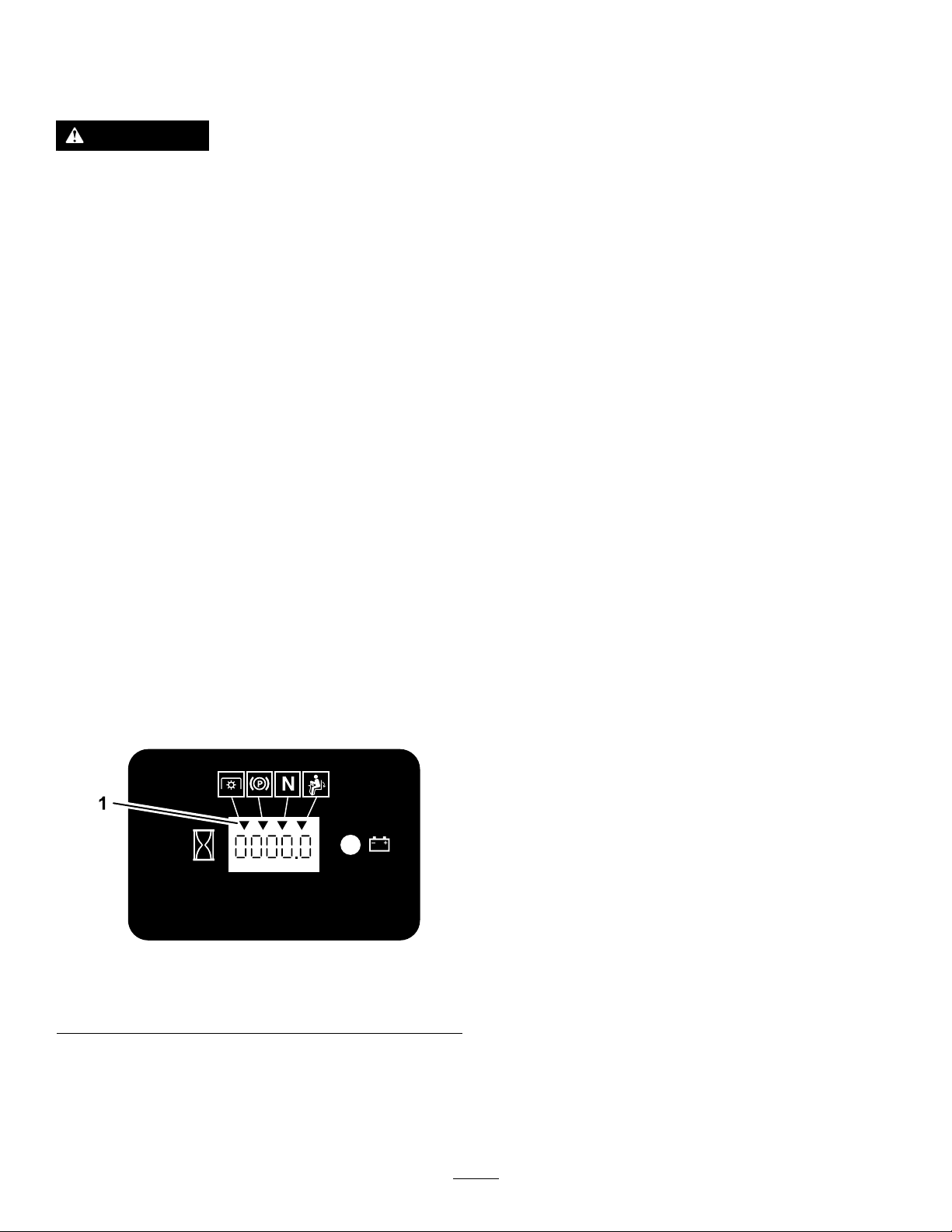

1.Hourmeter4.Neutral

2.Powertake-off(PTO)5.Operator-presenceswitch

3.Parkingbrake6.Battery

decal116-5610

decal117-1 194

117-1194

1.Beltrouting2.Engine

decal126-4363

126-4363

1.Cutting/dismembermenthazard,fanandentanglement

hazard,belt.Shutofftheengineandremovethekeybefore

adjusting,servicingorcleaningthemachine.

7

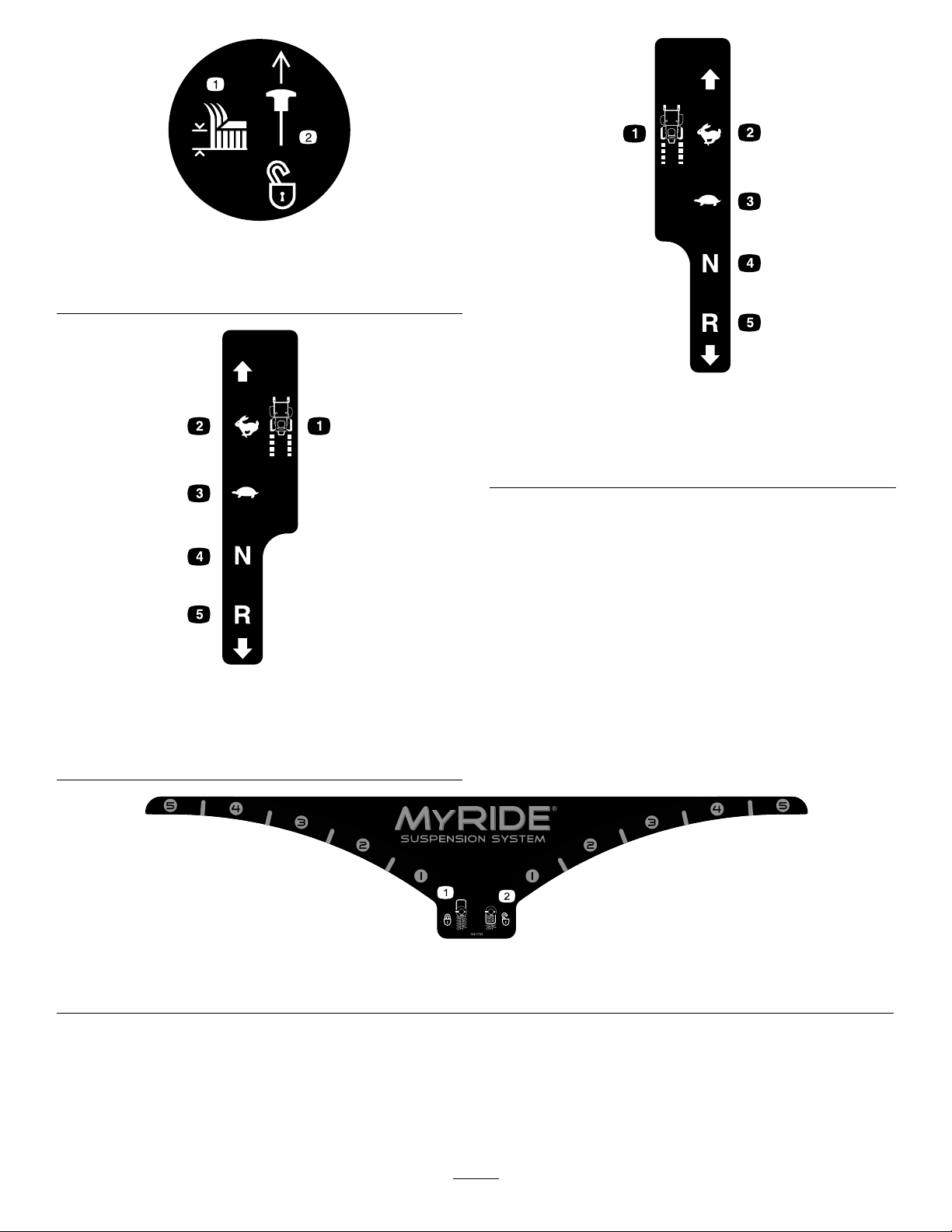

decal126-9939

126-9939

1.Heightofcut

1.ReadtheOperator’s

Manual.

2.Filltothebottomofthe

llerneck;warning—do

notoverllthetank.

decal126-7816

126-7816

decal127-6663

127-6663

1.Warning—readthe

Operator'sManual.

2.Crushinghazard—engage

theparkingbrake,shutoff

theengine,andremove

thekey;supportthe

machineusingjackstands.

126-8172

1.Parkingbrakedisengaged2.Parkingbrakeengaged

decal126-8172

8

decal135-0664

135-0664

1.Thrownobject

hazard—keepbystanders

away.

2.Cutting/dismemberment

hazardofhandsand

feet—stayawayfrom

movingparts;keepall

guardsandshieldsin

place.

136-1672

1.Warning—donotstep;donotcarrypassenger.

decal145-3668

145-3668

1.Fuel—full

2.Fuel—50%

decal136-1672

3.Fuel—empty

decal137-9240

137-9240

1.Choke

2.Worklight

3.Fast

4.Slow

136-9024

1.ReadtheOperator’s

Manualbeforeperforming

maintenance.

2.Operatinghours5.Hydraulic-uidlevel

3.Engine-oillevel6.Tirepressure

4.Greasepoint

decal136-9024

decalptosymbols

PTOSwitchSymbols

1.PTO–disengage2.PTO–engage

9

TransportLock

decaltransportlock

1.Heightofcut

LeftMotionControl

1.Machinespeed4.Neutral

2.Fast5.Reverse

3.Slow

2.Pulluptounlockthe

transportlock.

decalmotioncntrlrh-126-6183

RightMotionControl

1.Machinespeed4.Neutral

2.Fast5.Reverse

3.Slow

decalmotioncntrllh-126-6194

136-1720

1.Camlock2.Camunlock

10

decal136-1720

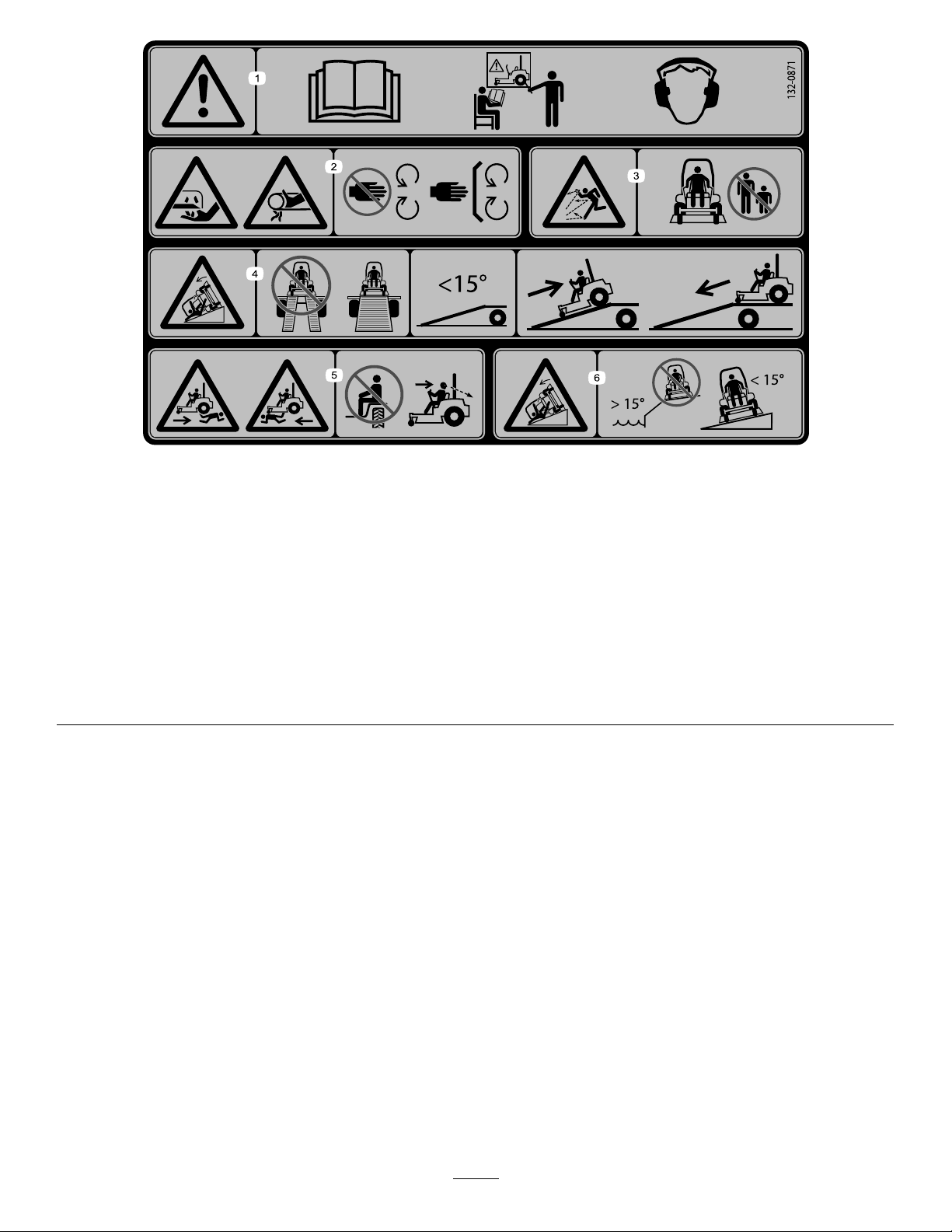

132-0871

Note:Thismachinecomplieswiththeindustrystandardstabilitytestinthestaticlateralandlongitudinaltestswiththemaximum

recommendedslopeindicatedonthedecal.ReviewtheinstructionsforoperatingthemachineonslopesintheOperator’sManualas

wellastheconditionsinwhichyouwouldoperatethemachinetodeterminewhetheryoucanoperatethemachineintheconditionson

thatdayandatthatsite.Changesintheterraincanresultinachangeinslopeoperationforthemachine.

decal132-0871

1.Warning—readtheOperator’sManual;alloperatorsshould

betrainedbeforeoperatingthemachine;wearhearing

protection.

2.Cutting/dismembermenthazardofhand—stayawayfrom

movingparts;keepallguardsandshieldsinplace.

3.Thrownobjecthazard—keepbystandersaway.

4.Tippinghazard—donotusedualrampswhenloadingontoa

trailer;use1rampwideenoughforthemachine;usearamp

withaslopelessthan15°;backuptheramp(inreverse)and

driveforwardofftheramp.

5.Runoverhazard—donotcarrypassengers;lookbehindyou

whenmovinginreverse.

6.Tippinghazard—donotusethemachineneardrop-offsor

onslopesgreaterthan15°;onlyoperateacrossslopesless

than15°.

11

ProductOverview

Controls

Becomefamiliarwithallthecontrolsbeforeyoustart

theengineandoperatethemachine.

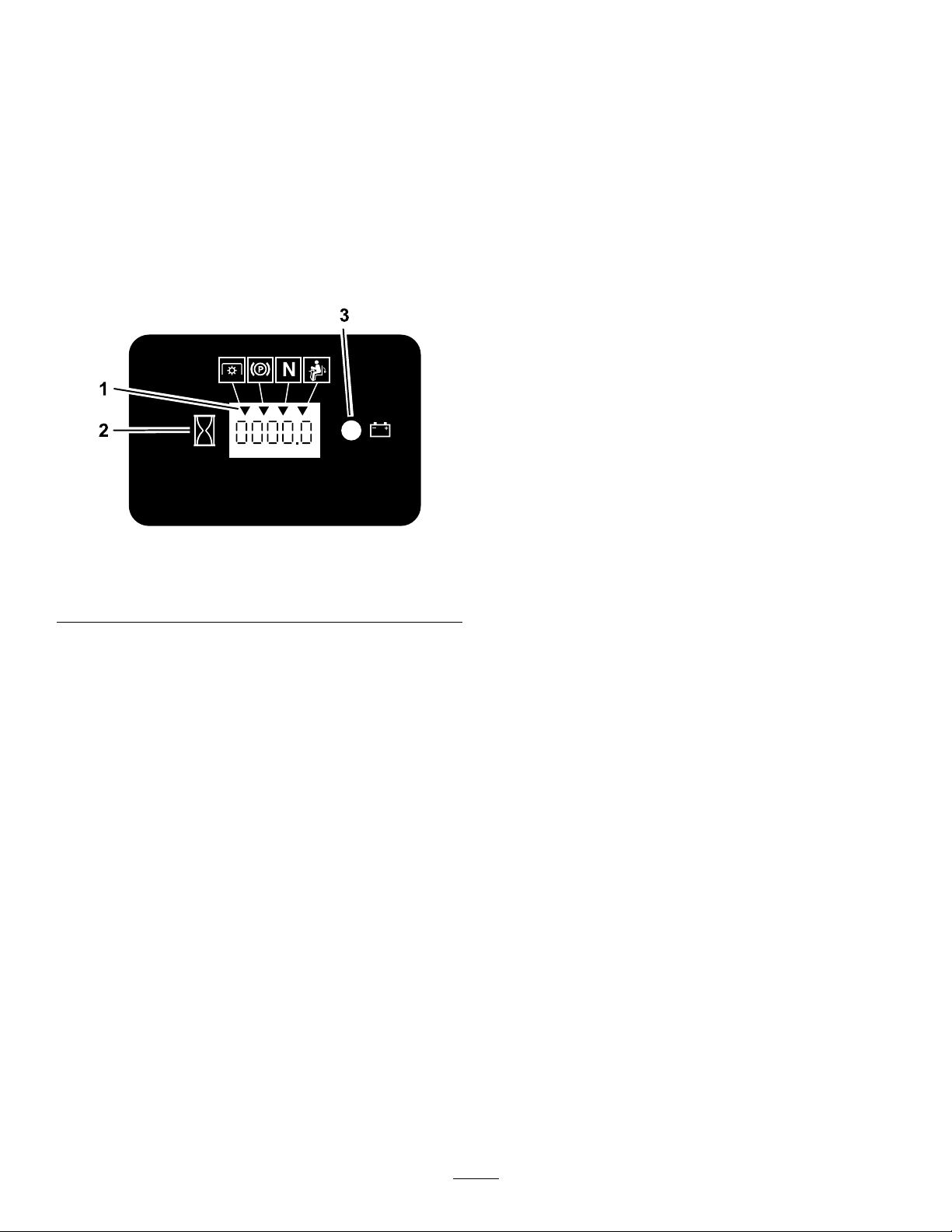

ControlPanel

g271171

Figure5

Figure4

1.Height-of-cutdeck-lift

pedal

2.Height-of-cutpositions

3.Transportlock9.Parking-brakelever

4.Controls

5.Motion-controllevers

6.Rollbar

7.Shockassembly

8.Fuelcap

10.Mowerdeck

11.Casterwheel

1.Positionforoptionalpower

point

2.Chokecontrol

3.Throttlecontrol

g327985

4.Hourmeter

5.Blade-controlswitch

(powertakeoff)

6.Keyswitch

7.Switchpositionforoptional

lightkit

KeySwitch

Thekeyswitch,usedtostartandshutofftheengine,

has3positions:OFF,RUN,andSTART.Referto

StartingtheEngine(page25).

ChokeControl

Usethechokecontroltostartacoldengine.

ThrottleControl

Thethrottlecontrolstheenginespeed,andithasa

continuous-variablesettingfromtheSLOWtoFAST

position(Figure5).

12

Blade-ControlSwitch(Power

Battery-IndicatorLight

Takeoff)

Theblade-controlswitch,representedbya

power-takeoff(PTO)symbol,engagesand

disengagespowertothemowerblades(Figure5).

HourMeter

Thehourmeterrecordsthenumberofhoursthe

enginehasoperated.Itoperateswhentheengine

isrunning.Usethesetimesforschedulingregular

maintenance(Figure6).

IfyouturnthekeyswitchtotheONpositionfora

fewseconds,thebatteryvoltagedisplaysinthearea

wherethehoursarenormallydisplayed.

Thebatterylightturnsonwhenthekeyswitchis

turnedonandwhenthechargeisbelowthecorrect

operatinglevel(Figure6).

Motion-ControlLevers

Usethemotion-controlleverstodrivethemachine

forward,reverse,andturneitherdirection(Figure4).

Neutral-LockPosition

Movethemotion-controlleversoutwardfromthe

centertotheNEUTRAL-LOCKpositionwhenexiting

themachine(Figure25).Alwayspositionthe

motion-controlleversintotheNEUTRAL-LOCKposition

whenyoustopthemachineorleaveitunattended.

Parking-BrakeLever

Figure6

1.Safety-interlocksymbols

2.Hourmeter

3.Batterylight

Safety-InterlockIndicators

Therearesymbolsonthehourmeterthatindicate

withablacktrianglethattheinterlockcomponentis

positionedcorrectly(Figure6).

g187133

Wheneveryoushutofftheengine,engagetheparking

braketopreventaccidentalmovementofthemachine.

Fuel-ShutoffValve

Closethefuel-shutoffvalvewhentransportingor

storingthemachine;refertoUsingtheFuel-Shutoff

Valve(page29).

13

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

Width

Withoutmowerdeck

Withmowerdeck

121cm(47-1/2inches)

125cm(49-3/16inches)

Length

Length

208cm(82inches)

Height

RollBar—UpRollBar—Down

179cm(70-1/2inches)125cm(49inches)

Weight

Withfullfueltank450kg(992lb)

Withoutfuel430kg(948lb)

Attachments/Accessories

AselectionofT oroapprovedattachmentsandaccessoriesisavailableforusewiththemachinetoenhance

andexpanditscapabilities.ContactyourAuthorizedServiceDealerorauthorizedT orodistributororgoto

www.T oro.comforalistofallapprovedattachmentsandaccessories.

Toensureoptimumperformanceandcontinuedsafetycerticationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacementpartsandaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty.

14

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Donotallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageoftheoperator.Theowner

isresponsiblefortrainingalloperatorsand

mechanics.

•Inspecttheareawhereyouwillusethemachine,

andremoveallobjectsthatcouldinterferewith

theoperationofthemachineorthatthemachine

couldthrow.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Checkthatoperator-presencecontrols,safety

switches,andguardsareattachedandworking

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

•Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operator’sposition.Allowthemachinetocool

beforeservicing,adjusting,fueling,cleaning,or

storingit.

FuelSafety

•Fuelisextremelyammableandhighlyexplosive.

Areorexplosionfromfuelcanburnyouand

othersandcandamageproperty.

–T opreventastaticchargefromignitingthe

fuel,removethemachinefromthetruckor

trailerandrefuelitontheground,awayfrom

allvehicles.Ifthisisnotpossible,placea

portablefuelcontainerontheground,away

fromallvehicles,andllit;thenrefuelthe

machinefromthefuelcontainerratherthan

fromafuel-dispensernozzle.

–Fillthefueltankoutdoorsonlevelground,in

anopenarea,andwhentheengineiscold.

Wipeupanyfuelthatspills.

–Donothandlefuelwhensmokingoraroundan

openameorsparks.

–Donotremovethefuelcaporaddfueltothe

tankwhiletheengineisrunningorhot.

–Ifyouspillfuel,donotattempttostartthe

engine.Avoidcreatingasourceofignitionuntil

thefuelvaporshavedissipated.

–Storefuelinanapprovedcontainerandkeep

itoutofthereachofchildren.

•Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

–Avoidprolongedbreathingofvapors.

–Keepyourhandsandfaceawayfromthe

nozzleandthefuel-tankopening.

–Keepfuelawayfromyoureyesandskin.

•Beforemowing,inspectthemachinetoensure

thatthecuttingassembliesareworkingproperly.

•Evaluatetheterraintodeterminetheappropriate

equipmentandanyattachmentsoraccessories

requiredtooperatethemachineproperlyand

safely.

•Wearappropriateclothing,includingeye

protection;longpants;substantial,slip-resistant

footwear;andhearingprotection.Tiebacklong

hairanddonotwearlooseclothingorloose

jewelry.

•Donotcarrypassengersonthemachine.

•Keepbystandersandpetsawayfromthemachine

duringoperation.Shutoffthemachineand

attachment(s)ifanyoneentersthearea.

•Donotoperatethemachineunlessallguards

andsafetydevices,suchasthedeectors,arein

placeandfunctioningproperly.Replacewornor

deterioratedpartswhennecessary .

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

•Donotoperatethemachinewithouttheentire

exhaustsysteminplaceandinproperworking

condition.

•Keepthefuel-dispensernozzleincontactwith

therimofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.Donotusea

nozzlelock-opendevice.

•Ifyouspillfuelonyourclothing,changeyour

clothingimmediately .

•Donotoverllthefueltank.Replacethefuelcap

andtightenitsecurely.

•Cleangrassanddebrisfromthecuttingunit,

mufer,drives,andenginecompartmenttohelp

preventres.Cleanupoilorfuelspills.

15

AddingFuel

RecommendedFuel

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan

10%ethanolbyvolume,suchasE15(contains

15%ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

Note:Donotllthefueltankcompletelyfull.

Theemptyspaceinthetankallowsthefuelto

expand.

•Donotaddoiltogasoline.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsfuelfreshlongerwhenusedasdirectedby

thefuel-stabilizermanufacturer

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

Important:Donotusefueladditives

containingmethanolorethanol.

Addthecorrectamountoffuelstabilizer/conditioner

tothefuel.

Note:Afuelstabilizer/conditionerismost

effectivewhenmixedwithfreshfuel.T ominimize

thechanceofvarnishdepositsinthefuelsystem,

usefuelstabilizeratalltimes.

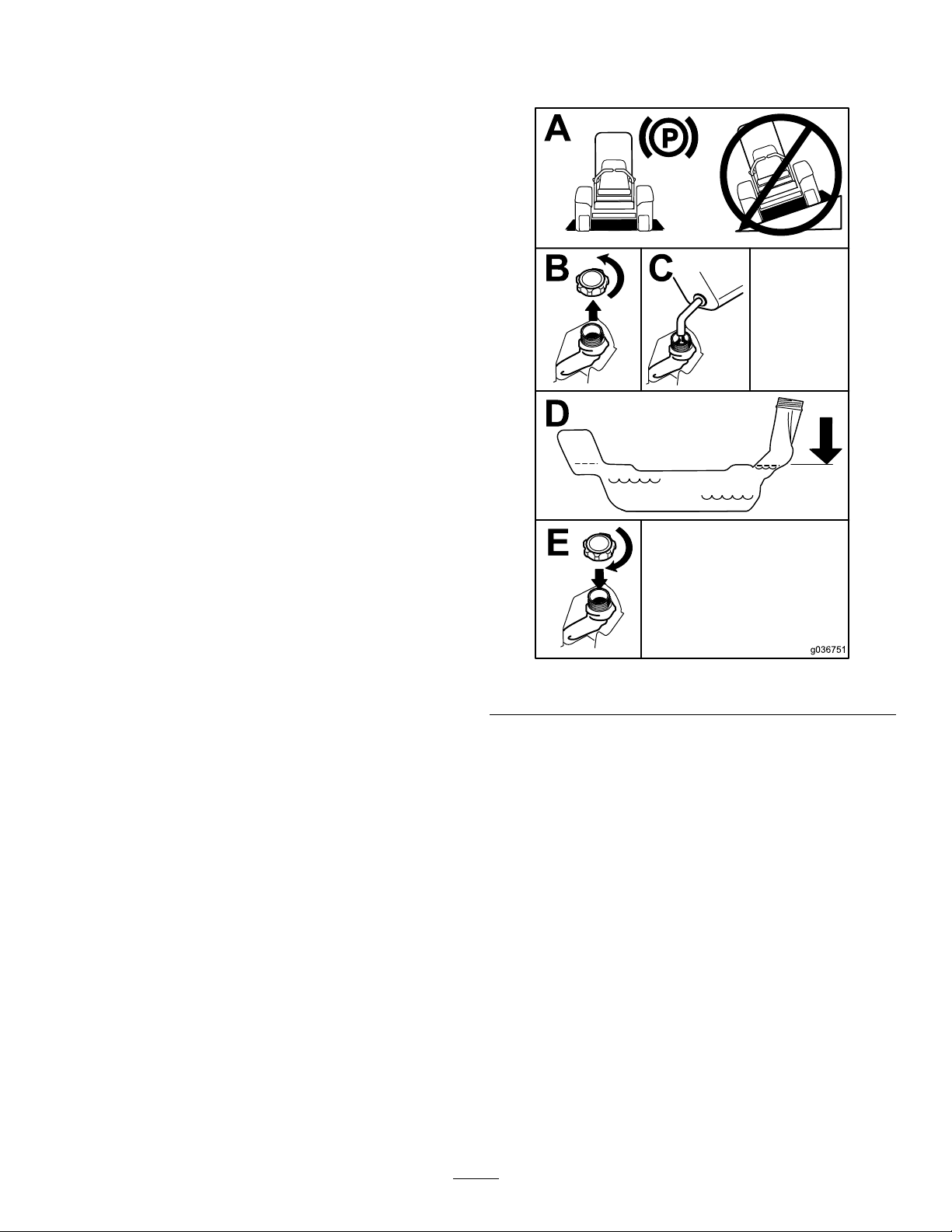

FillingtheFuelTank

1.Parkthemachineonalevelsurface.

2.Engagetheparkingbrake.

3.Shutofftheengineandremovethekey.

g036751

Figure7

PerformingDaily

Maintenance

Beforestartingthemachineeachday,performthe

EachUse/DailyprocedureslistedinMaintenance

(page33).

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mower

decksanddrivesystemshavehigherfrictionwhen

new,placingadditionalloadontheengine.Allow

40to50hoursofbreak-intimefornewmachinesto

developfullpowerandbestperformance.

4.Cleanaroundthefuel-tankcap.

5.Fillthefueltanktothebottomofthellerneck

(Figure7).

16

Usingthe

Rollover-ProtectionSystem

(ROPS)

WARNING

Toavoidinjuryordeathfromrollover,keep

therollbarinthefullyraised,lockedposition

andusetheseatbelt.

Ensurethattheseatissecuredtothe

machine.

WARNING

Thereisnorolloverprotectionwhentheroll

barisinthedownposition.

•Lowertherollbaronlywhenabsolutely

necessary.

•Donotweartheseatbeltwhentherollbar

isinthedownposition.

•Driveslowlyandcarefully.

g036746

Figure8

•Raisetherollbarassoonasclearance

permits.

•Checkcarefullyforoverheadclearances

(i.e.,branches,doorways,electricalwires)

beforedrivingunderanyobjectsanddo

notcontactthem.

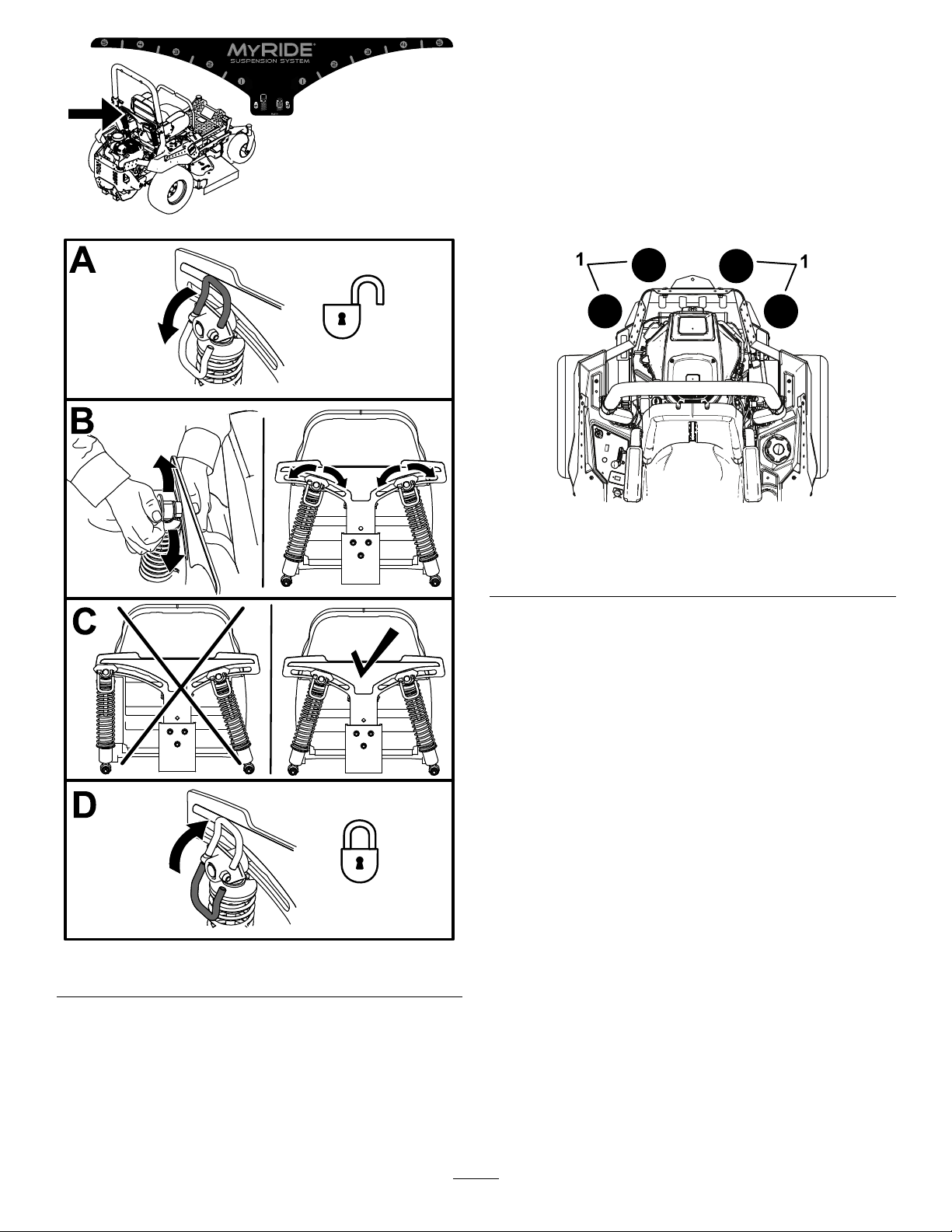

LoweringtheRollBar

Important:Lowertherollbaronlywhen

absolutelynecessary .

1.T olowertherollbar,applyforwardpressureto

theupperpartoftherollbar.

2.Pullbothknobsoutandrotatethem90degrees

sothattheyarenotengaged(Figure8).

3.Lowertherollbartothedownposition(Figure

8).

1.Rollbarintheupright

position

2.ROPSknobinthelatched

position

3.PulltheROPSknobout.6.Rollbarinthefolded

4.RotatetheROPSknob90

degrees.

5.ROPSknobinthe

unlatchedposition

position

RaisingtheRollBar

Important:Alwaysusetheseatbeltwiththeroll

barintheraisedposition.

1.Raisetherollbartotheoperatingpositionand

rotatetheknobsuntiltheymovepartiallyinto

thegrooves(Figure8).

2.Raisetherollbartothefulluprightpositionwhile

pushingontheupperrollbarsothatthepins

snapintopositionwhentheholesalignwiththe

pins(Figure8).

3.Pushontherollbarandensurethatbothpins

areengaged.

17

UsingtheSafety-Interlock

System

Testthesafety-interlocksystembeforeyouusethe

machineeachtime.Ifthesafetysystemdoesnot

operateasdescribedbelow,haveanAuthorized

ServiceDealerrepairthesafetysystemimmediately.

WARNING

Ifthesafety-interlockswitchesare

disconnectedordamaged,themachinecould

operateunexpectedly,causingpersonal

injury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

Understandingthe

Safety-InterlockSystem

Thesafety-interlocksystemisdesignedtopreventthe

enginefromstartingunlessthefollowingoccurs:

•Theparkingbrakeisengaged.

•Theblade-controlswitch(PTO)isdisengaged.

•Themotion-controlleversareintheNEUTRAL-LOCK

position.

Thesafety-interlocksystemalsoisdesignedtoshut

offtheenginewhenthemotion-controlleversare

movedfromtheNEUTRAL-LOCKpositionwiththe

parkingbrakeengagedorifyourisefromtheseat

whenthePTOisengaged.

Thehourmeterhasindicatorstonotifytheuserwhen

theinterlockcomponentisinthecorrectposition.

Whenthecomponentisinthecorrectposition,an

indicatordisplaysonthescreen.

1.Sitontheseat,engagetheparkingbrake,and

movetheblade-controlswitch(PTO)totheON

position.Trystartingtheengine;theengine

shouldnotstart.

2.Sitontheseat,engagetheparkingbrake,and

movetheblade-controlswitch(PTO)totheOFF

position.Moveeithermotion-controlleverout

oftheNEUTRAL-LOCKposition.Trystartingthe

engine;theengineshouldnotstart.Repeatfor

theothercontrollever.

3.Sitontheseat,engagetheparkingbrake,

movetheblade-controlswitch(PTO)totheOFF

position,andmovethemotion-controllevers

totheNEUTRAL-LOCKposition.Nowstartthe

engine.Whiletheengineisrunning,disengage

theparkingbrake,engagetheblade-control

switch(PTO),andriseslightlyfromtheseat;the

engineshouldshutoff.

4.Sitontheseat,engagetheparkingbrake,

movetheblade-controlswitch(PTO)totheOFF

position,andmovethemotion-controllevers

totheNEUTRAL-LOCKposition.Nowstartthe

engine.Whiletheengineisrunning,center

eithermotioncontrolandmove(forwardor

reverse);theengineshouldshutoff.Repeatfor

othermotioncontrol.

5.Sitontheseat,disengagetheparkingbrake,

movetheblade-controlswitch(PTO)totheOFF

position,andmovethemotion-controllevers

totheNEUTRAL-LOCKposition.Trystartingthe

engine;theengineshouldnotstart.

Figure9

1.Indicatorsdisplaywhentheinterlockcomponentsareinthe

correctposition

TestingtheSafety-Interlock

System

ServiceInterval:Beforeeachuseordaily

g187670

18

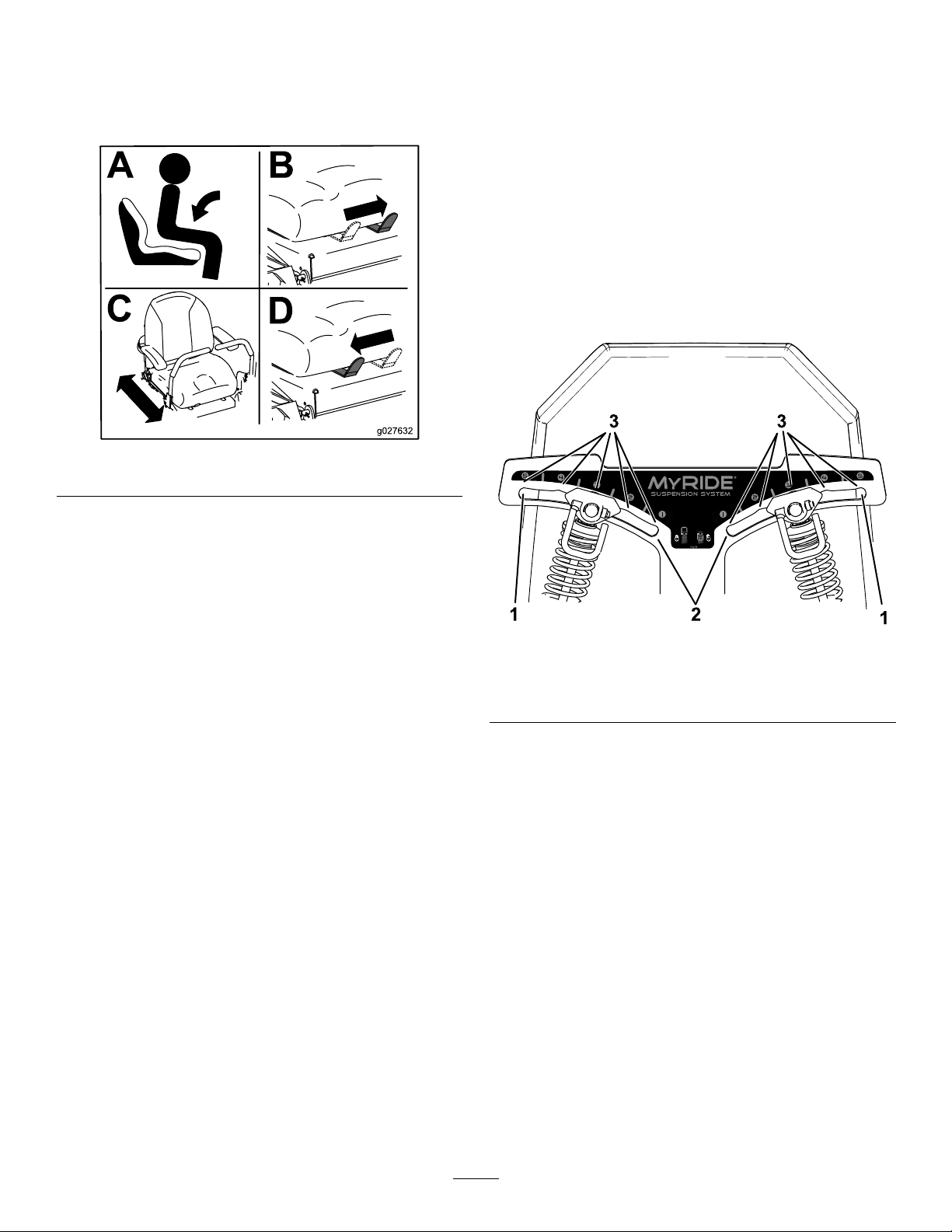

PositioningtheSeat

AdjustingtheRear-Shock

Theseatcanmoveforwardandbackward.Position

theseatwhereyouhavethebestcontrolofthe

machineandaremostcomfortable(Figure10).

Figure10

Assemblies

TheMyRide™suspensionsystemadjuststoprovide

asmoothandcomfortableride.Y oucanadjustthe

rear2-shockassembliestoquicklyandeasilychange

thesuspensionsystem.Positionthesuspension

systemwhereyouaremostcomfortable.

Theslotsfortherear-shockassemblieshave

detentpositionsforreference.Youcanpositionthe

rear-shockassembliesanywhereintheslot,notjustin

thedetentpositions.Thefollowinggraphicshowsthe

positionforasoftorrmrideandthedifferentdetent

positions(Figure11).

g027632

Figure11

1.Firmestposition3.Detentsintheslots

2.Softestposition

Note:Ensurethattheleftandrightrear-shock

assembliesarealwaysadjustedtothesamepositions.

Adjusttherear-shockassemblies(Figure12).

g227753

19

UsingAttachmentsand

Accessories

UseonlyToroapprovedattachmentsandaccessories.

Ifyouaddmorethan1accessory-mountkit(i.e.,

bucketkitoruniversalmountkit)isaddedtoanyof

the4locationsshowninFigure13,addafront-weight

g329642

kit.ContactanAuthorizedServiceDealerforthe

front-weightkit.

Figure12

g037417

Figure13

1.Addafront-weightkitwhen2ormoreaccessory-mountkits

areinstalledatthesepositions.

DuringOperation

DuringOperationSafety

GeneralSafety

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

g227751

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Contactingthebladecanresultinseriouspersonal

injury.Shutofftheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.Whenyouturnthekeytothe

OFFposition,theengineshouldshutoffandthe

bladeshouldstop.Ifnot,stopusingyourmachine

immediatelyandcontactanAuthorizedService

Dealer.

20

•Operatethemachineonlyingoodvisibilityand

appropriateweatherconditions.Donotoperate

themachinewhenthereistheriskoflightning.

•Keepyourhandsandfeetawayfromthecutting

units.Keepclearofthedischargeopening.

•Donotmowinreverseunlessitisabsolutely

necessary.Alwayslookdownandbehindyou

beforemovingthemachineinreverse.

•Useextremecarewhenapproachingblind

corners,shrubs,trees,orotherobjectsthatmay

blockyourview.

•Stopthebladeswheneveryouarenotmowing.

•Ifthemachinestrikesanobjectorstartstovibrate,

immediatelyshutofftheengine,removethekey

(ifequipped),andwaitforallmovingpartstostop

beforeexaminingthemachinefordamage.Make

allnecessaryrepairsbeforeresumingoperation.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalkswiththe

machine.Alwaysyieldtheright-of-way.

•Beforeyouleavetheoperatingposition,dothe

following:

–Parkthemachineonalevelsurface.

–Disengagethepowertakeoffandlowerthe

attachments.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey.

–Waitforallmovingpartstostop.

•Operatetheengineonlyinwell-ventilatedareas.

Exhaustgasescontaincarbonmonoxide,which

islethalifinhaled.

•Neverleavearunningmachineunattended.

•Attachtowedequipmenttothemachineonlyat

thehitchpoint.

•Donotoperatethemachineunlessallguards

andsafetydevices,suchasthedeectors,arein

placeandfunctioningproperly.Replacewornor

deterioratedpartswhennecessary .

•Useonlyaccessoriesandattachmentsapproved

byT oro.

•Thismachineproducessoundlevelsinexcess

of85dBAattheoperator’searandcancause

hearinglossthroughextendedperiodsof

exposure.

g229846

Figure14

1.Wearhearingprotection.

•Cleangrassanddebrisfromthecuttingunit,

drives,mufer,andenginetohelppreventres.

•Starttheenginewithyourfeetwellawayfromthe

blades.

•Beawareofthemowerdischargepathanddirect

thedischargeawayfromothers.Avoiddischarging

materialagainstawallorobstructionbecausethe

materialmayricochetbacktowardyou.

•Stoptheblades,slowdownthemachine,anduse

cautionwhencrossingsurfacesotherthangrass

orwhentransportingthemachinetoandfromthe

operatingarea.

•Donotchangetheenginegovernorspeedor

overspeedtheengine.

•Childrenareoftenattractedtothemachineand

themowingactivity .Neverassumethatchildren

willremainwhereyoulastsawthem.

•Keepchildrenoutoftheoperatingareaandunder

thewatchfulcareofaresponsibleadultotherthan

theoperator.

•Bealertandshutoffthemachineifchildrenenter

theoperatingarea.

•Beforebackinguporturningthemachine,look

downandallaroundforsmallchildren.

•Donotcarrychildrenonthemachine,evenwhen

thebladesarenotmoving.Childrencouldfall

offandbeseriouslyinjuredorpreventyoufrom

safelyoperatingthemachine.Childrenwhohave

beengivenridesinthepastcouldappearinthe

operatingareawithoutwarningandberunoveror

backedoverbythemachine.

RolloverProtectionSystem

(ROPS)Safety

•TheROPSisanintegralsafetydevice.Donot

removeanyoftheROPScomponentsfromthe

machine.

•Ensurethattheseatbeltisattachedandthatyou

canreleaseitquicklyinanemergency.

•Keeptherollbarinthefullyraisedandlocked

positionandalwayswearyourseatbeltwhenever

therollbarisup.

•Checkcarefullyforoverheadobjectsbeforeyou

driveunderthem,anddonotcontactthem.

21

•ReplacedamagedROPScomponents.Donot

repairoralterthem.

•Thereisnorolloverprotectionwhentherollbar

isdown.

•Wheelsdroppingoveredges,oversteepbanks,or

intowatercancausearollover,whichmayresult

inseriousinjuryordeath.

•Donotweartheseatbeltwhentherollbarisdown.

•Lowertherollbaronlywhenabsolutelynecessary;

raiseitassoonasclearancepermits.

drivewheelsmayresultinslidingandalossof

brakingandsteering.Themachinecanslideeven

ifthedrivewheelsarestopped.

•Removeormarkobstaclessuchasditches,holes,

ruts,bumps,rocks,orotherhiddenhazards.T all

grasscanhideobstacles.Uneventerraincould

overturnthemachine.

•Useextracarewhileoperatingwithaccessoriesor

attachments.Thesecanchangethestabilityof

themachineandcausealossofcontrol.Follow

directionsforcounterweights.

•Intheeventofarollover,takethemachinetoan

AuthorizedServiceDealertoinspecttheROPS.

•UseonlyT oroapprovedaccessoriesand

attachmentsfortheROPS.

SlopeSafety

•Slopesareamajorfactorrelatedtolossofcontrol

androlloveraccidents,whichcanresultinsevere

injuryordeath.Theoperatorisresponsiblefor

safeslopeoperation.Operatingthemachineon

anysloperequiresextracaution.Beforeusingthe

machineonaslope,dothefollowing:

–Reviewandunderstandtheslopeinstructions

inthemanualandonthemachine.

–Useanangleindicatortodeterminethe

approximateslopeangleofthearea.

–Neveroperateonslopesgreaterthan15°.

–Evaluatethesiteconditionsofthedayto

determineiftheslopeissafeformachine

operation.Usecommonsenseandgood

judgmentwhenperformingthisevaluation.

Changesintheterrain,suchasmoisture,can

quicklyaffecttheoperationofthemachineon

aslope.

•Identifyhazardsatthebaseoftheslope.Do

notoperatethemachineneardrop-offs,ditches,

embankments,water,orotherhazards.The

machinecouldsuddenlyrolloverifawheelgoes

overtheedgeortheedgecollapses.Keepasafe

distance(twicethewidthofthemachine)between

themachineandanyhazard.Useawalk-behind

machineorahandtrimmertomowthegrassin

theseareas.

•Ifpossible,keepthedeckloweredtotheground

whileoperatingonslopes.Raisingthedeckwhile

operatingonslopescancausethemachineto

becomeunstable.

Figure15

1.SafeZone—usethe

machinehereonslopes

lessthan15°oratareas.

2.DangerZone—usea

walk-behindmowerand/or

ahandtrimmeronslopes

greaterthan15°andnear

drop-offsorwater.

3.Water

4.W=Widthofthemachine

5.Keepasafedistance

(twicethewidthofthe

machine)betweenthe

machineandanyhazard.

g221745

•Avoidstarting,stopping,orturningthemachineon

slopes.Avoidmakingsuddenchangesinspeedor

direction;turnslowlyandgradually.

•Donotoperateamachineunderanyconditions

wheretraction,steering,orstabilityisinquestion.

Beawarethatoperatingthemachineonwet

grass,acrossslopes,ordownhillmaycausethe

machinetolosetraction.Lossoftractiontothe

22

EnteringtheOperator’s

Position

Usethemowerdeckasasteptogetintothe

operator’sposition(Figure16).

DisengagingtheParkingBrake

Figure16

1.Stephere.

OperatingtheParking

Brake

Alwaysengagetheparkingbrakewhenyoustopthe

machineorleaveitunattended.

EngagingtheParkingBrake

Parkthemachineonalevelsurface.

g029797

Figure18

g192635

Figure17

g036754

23

OperatingtheMower

OperatingtheThrottle

Blade-ControlSwitch(PTO)

Theblade-controlswitch(PTO)startsandstopsthe

mowerbladesandanypoweredattachments.

EngagingtheBlade-Control

Switch(PTO)

Note:Engagingtheblade-controlswitch(PTO)with

thethrottlepositionathalforlesscausesexcessive

weartothedrivebelts.

Figure19

DisengagingtheBlade-Control

YoucanmovethethrottlecontrolbetweenFASTand

SLOWpositions(Figure21).

AlwaysusetheFASTpositionwhenengagingthePTO.

g008946

Figure21

OperatingtheChoke

Usethechoketostartacoldengine.

g008945

1.Pullupthechokeknobtoengagethechoke

beforeusingthekeyswitch(Figure22).

2.Pushdownthechokeknobtodisengagethe

chokeaftertheenginehasstarted(Figure22).

Switch(PTO)

g009174

Figure20

g008959

Figure22

1.ONposition2.OFFposition

24

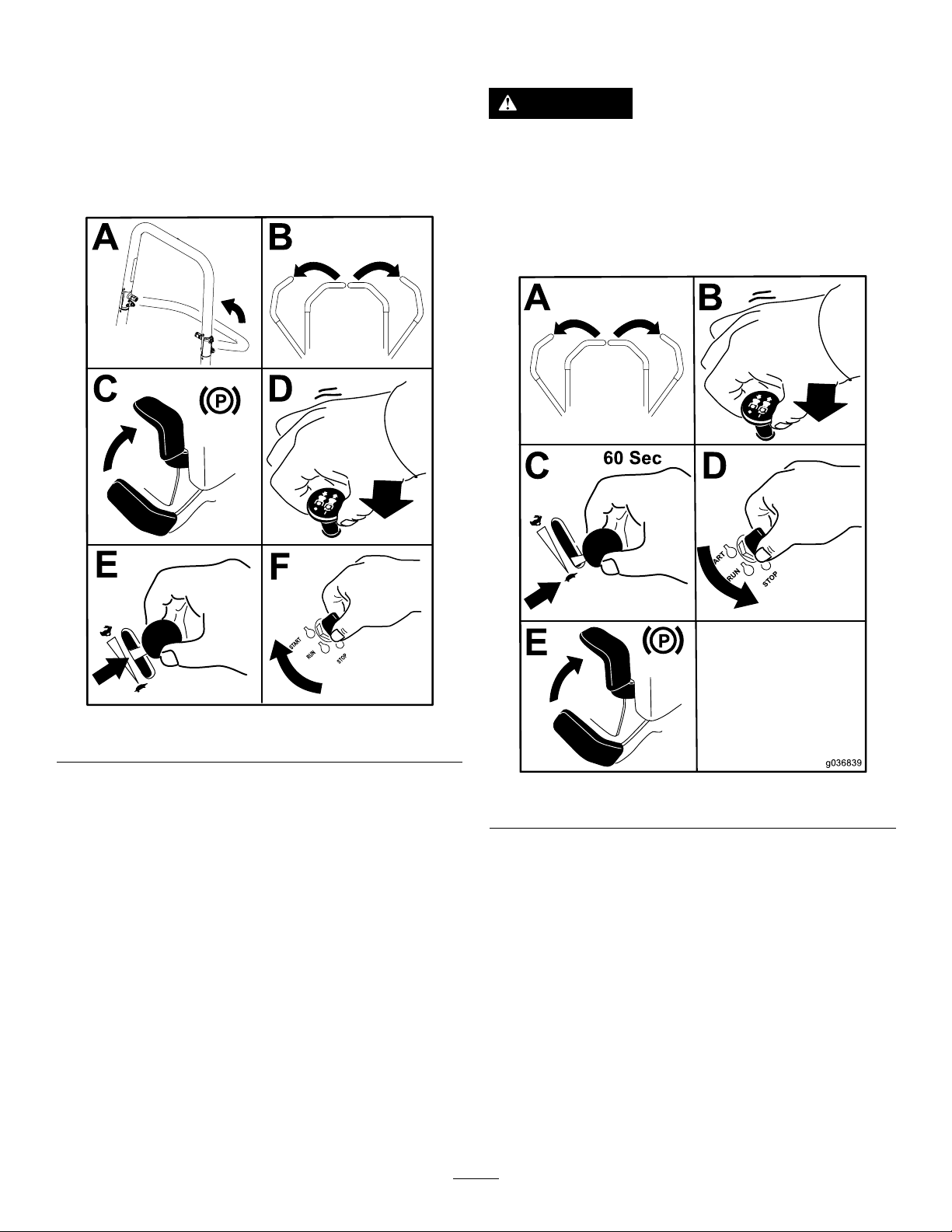

StartingtheEngine

Note:Awarmorhotenginemaynotrequirechoking.

Important:Donotengagethestarterformore

than5secondsatatime.Engagingthestarter

motorformorethan5secondscandamagethe

startermotor.Iftheenginefailstostart,wait10

secondsbeforeoperatingtheenginestarteragain.

ShuttingOfftheEngine

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

Alwaysremovethekeyandengagethe

parkingbrakewhenleavingthemachine

unattended.

Figure23

g227548

g036839

Figure24

Important:Makesurethatthefuel-shutoffvalve

isclosedbeforetransportingorstoringthe

machine,asfuelleakagemayoccur.Engagethe

parkingbrakebeforetransporting.Makesurethat

youremovethekeyasthefuelpumpmayrunand

causethebatterytolosecharge.

25

UsingtheMotion-Control

WARNING

Levers

Themachinecanspinveryrapidly.You

maylosecontrolofthemachineandcause

personalinjuryordamagetothemachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemaking

sharpturns.

DrivingForward

Note:Theengineshutsoffwhenyoumovethe

traction-controlwiththeparkingbrakeengaged.

Tostopthemachine,pullthemotion-controllevers

totheNEUTRALposition.

1.Disengagetheparkingbrake.

2.Movethemotion-controlleverstothecenter,

unlockedposition.

3.T ogoforward,slowlypushthemotion-control

leversforward(Figure26).

Figure25

1.Motion-control

levers—NEUTRAL-LOCK

position

2.Center,unlockedposition5.Frontofthemachine

3.Forward

4.Reverse

DrivingtheMachine

Thedrivewheelsturnindependently,poweredby

hydraulicmotorsoneachaxle.Youcanturn1side

inreversewhileyouturntheotherforward,causing

themachinetospinratherthanturn.Thisgreatly

improvesthemachinemaneuverabilitybutmay

requiresometimeforyoutoadapttohowitmoves.

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Place

thethrottlecontrolintheFASTpositionforbest

performance.Alwaysoperateinthefullthrottle

positionwhenmowing.

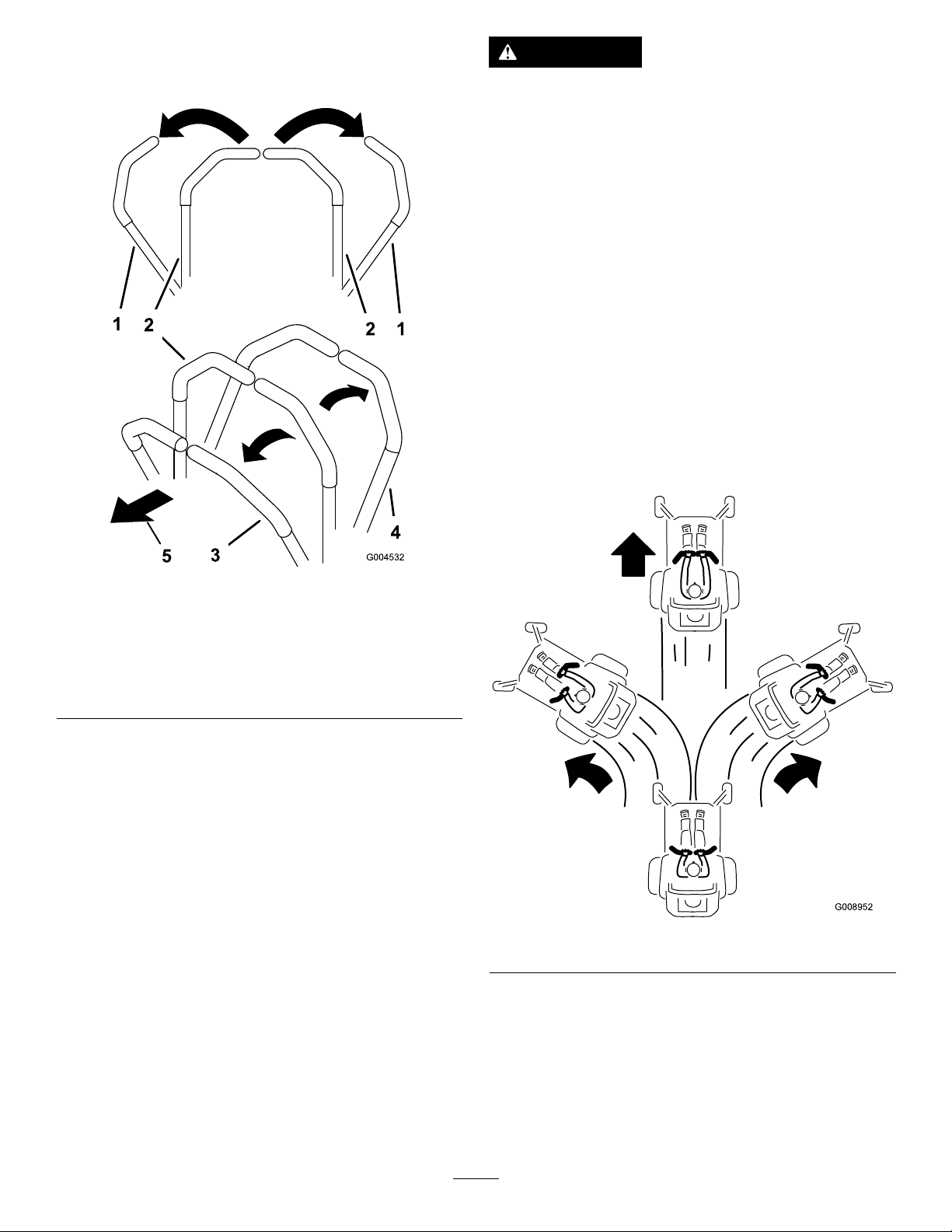

g004532

g008952

Figure26

DrivinginReverse

1.Movethemotion-controlleverstothecenter,

unlockedposition.

2.T ogoinreverse,slowlypullthemotion-control

leversrearward(Figure27).

26

Figure27

AdjustingtheHeightofCut

UsingtheTransportLock

Thetransportlockhas2positions,andisusedwith

thedeck-liftpedal.ThereisaLOCKpositionand

anUNLOCKpositionforthetransportpositionofthe

mowerdeck(Figure28).

g008953

Transport-LockPositions

1.Transportlockknob3.UNLOCKposition—The

2.LOCKposition—The

mowerdecklocksintothe

transportposition.

27

g037050

Figure28

mowerdeckdoesnotlock

intothetransportposition.

AdjustingtheHeight-of-CutPin

AdjustingtheAnti-Scalp

Adjusttheheight-of-cutfrom38to127mm(1-1/2to5

inches)in6mm(1/4inch)incrementsbymovingthe

height-of-cutpinintodifferentholelocations.

1.MovethetransportlocktotheLOCKposition.

2.Pushonthedeck-liftpedalwithyourfootand

raisethemowerdecktotheTRANSPORTposition

(alsothe127mmor5inchcutting-height

position)asshowninFigure29.

3.Removethepinfromtheheight-of-cutbracket

(Figure29).

4.Selectaholeintheheight-of-cutbracket

correspondingtotheheight-of-cutdesired,and

insertthepin(Figure29).

5.Pushonthedecklift,pulluponthetransport

lockknob,andslowlylowerthemowerdeck.

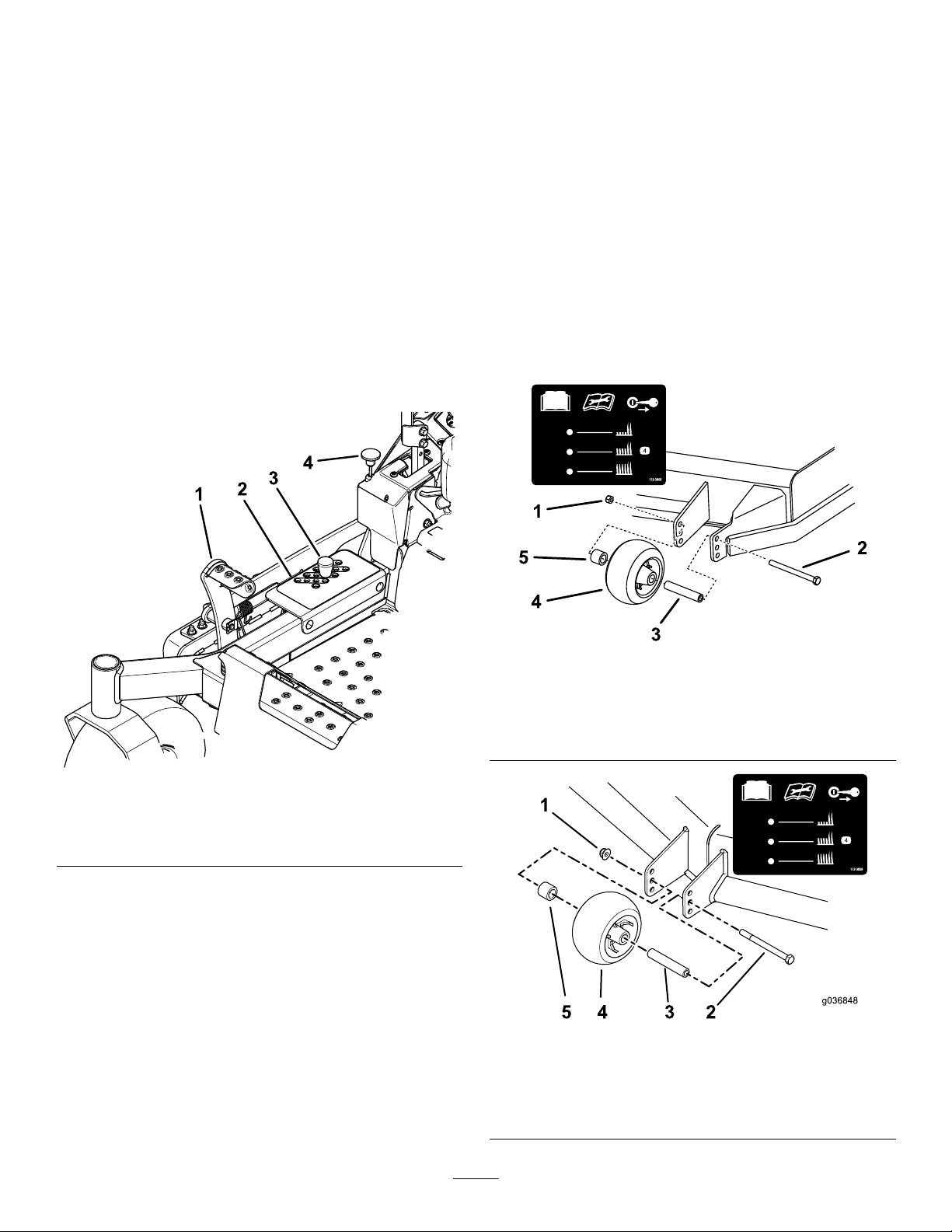

Rollers

Wheneveryouchangetheheightofcut,adjustthe

heightoftheanti-scalprollers.

Note:Adjusttheanti-scalprollerssothattherollers

donottouchthegroundinnormal,atmowingareas.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitchandengagetheparking

brake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Adjusttheanti-scalprollersasshowninFigure

30andFigure31.

Figure29

1.Deck-liftpedal3.Height-of-cutpin

2.Height-of-cutholes

4.Transportlockknob

g321510

Figure30

1.Flangenut4.Anti-scalproller

2.Bolt

3.Bushing

g327983

1.Flangenut4.Anti-scalproller

2.Bolt

3.Bushing

5.Spacer

g036848

Figure31

5.Spacer

28

Loading...

Loading...