Page 1

FormNo.3426-574RevB

48in,52in,or60inTITAN

1500,2000,or2500SeriesRiding

Mower

ModelNo.74452—SerialNo.404315000andUp

ModelNo.74453—SerialNo.400000000andUp

ModelNo.74454—SerialNo.400000000andUp

ModelNo.74463—SerialNo.404315000andUp

ModelNo.74465—SerialNo.404315000andUp

ModelNo.74466—SerialNo.404315000andUp

ModelNo.74467—SerialNo.404315000andUp

ModelNo.74470—SerialNo.404315000andUp

ModelNo.74471—SerialNo.404315000andUp

ModelNo.74472—SerialNo.404315000andUp

ModelNo.78450—SerialNo.404315000andUp

ModelNo.78472—SerialNo.404315000andUp

®

HD

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3426-574*B

Page 2

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

GrossorNetTorque:Thegrossornettorque

ofthisenginewaslaboratoryratedbytheengine

manufacturerinaccordancewiththeSocietyof

AutomotiveEngineers(SAE)J1940orJ2723.As

conguredtomeetsafety,emission,andoperating

requirements,theactualenginetorqueonthisclass

ofmowerwillbesignicantlylower.Pleasereferto

theenginemanufacturer’sinformationincludedwith

themachine.

Important:IfyouareusingamachinewithaToro

engineabove1500m(5,000ft)foracontinuous

period,ensurethattheHighAltitudeKithasbeen

installedsothattheenginemeetsCARB/EP A

emissionregulations.TheHighAltitudeKit

increasesengineperformancewhilepreventing

spark-plugfouling,hardstarting,andincreased

emissions.Onceyouhaveinstalledthekit,attach

thehigh-altitudelabelnexttotheserialdecalon

themachine.ContactanyAuthorizedToroService

DealertoobtaintheproperHighAltitudeKitand

high-altitudelabelforyourmachine.Tolocate

adealerconvenienttoyou,accessourwebsite

atwww.T oro.comorcontactourToroCustomer

CareDepartmentatthenumber(s)listedinyour

EmissionControlWarrantyStatement.

Removethekitfromtheengineandrestorethe

enginetoitsoriginalfactorycongurationwhen

runningtheengineunder1500m(5,000ft).Do

notoperateanenginethathasbeenconverted

forhigh-altitudeuseatloweraltitudes;otherwise,

youcouldoverheatanddamagetheengine.

Ifyouareunsurewhetherornotyourmachine

hasbeenconvertedforhigh-altitudeuse,lookfor

thefollowinglabel.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

Thisrotary-blade,ridinglawnmowerisintendedtobe

usedbyprofessional,hiredoperators.Itisdesigned

primarilyforcuttinggrassonwell-maintainedlawns

onresidentialorcommercialproperties.Usingthis

productforpurposesotherthanitsintendedusecould

provedangeroustoyouandbystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

Visitwww.Toro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

©2019—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

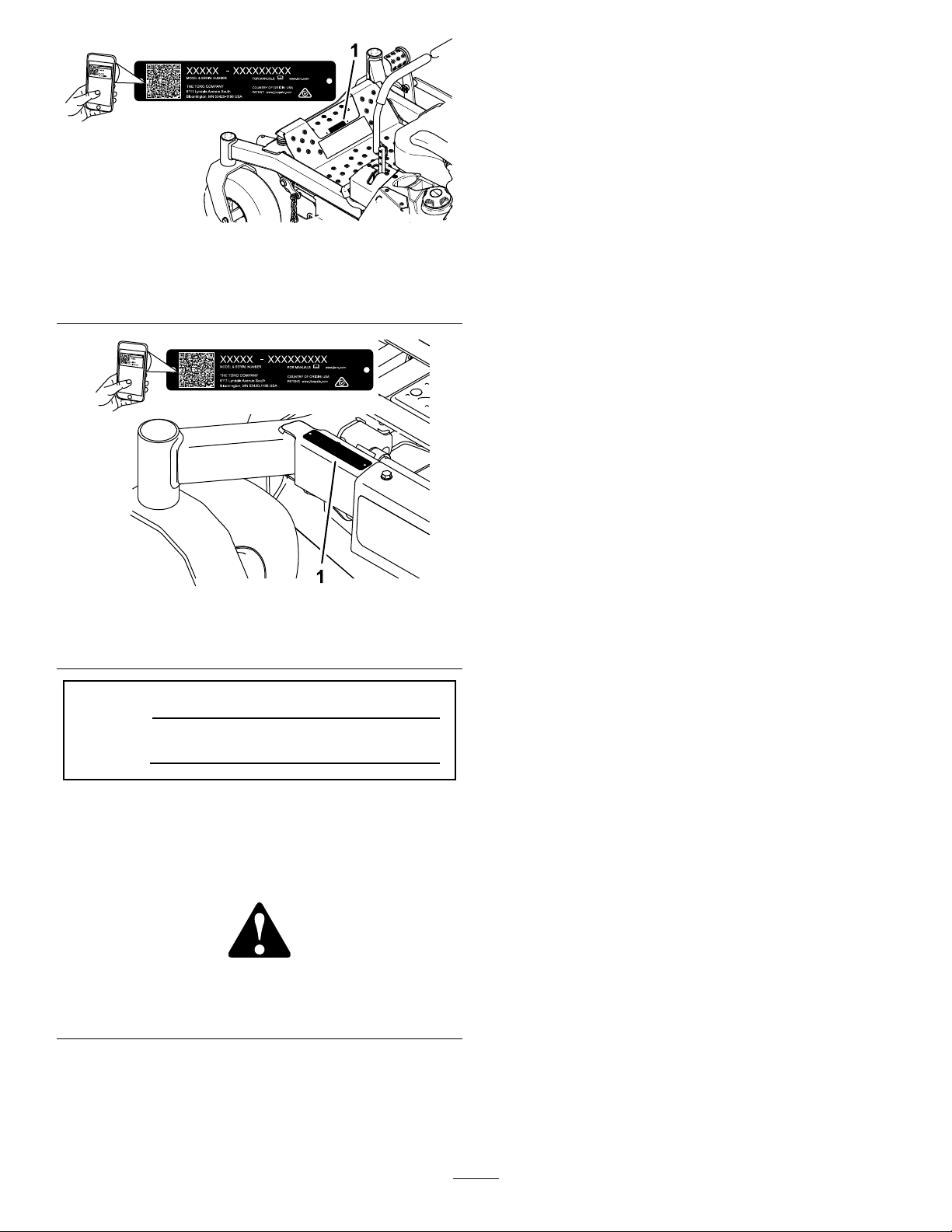

Figure4

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

orFigure2identiesthelocationofthemodeland

serialnumbersontheproduct.Writethenumbersin

decal127-9363

thespaceprovided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

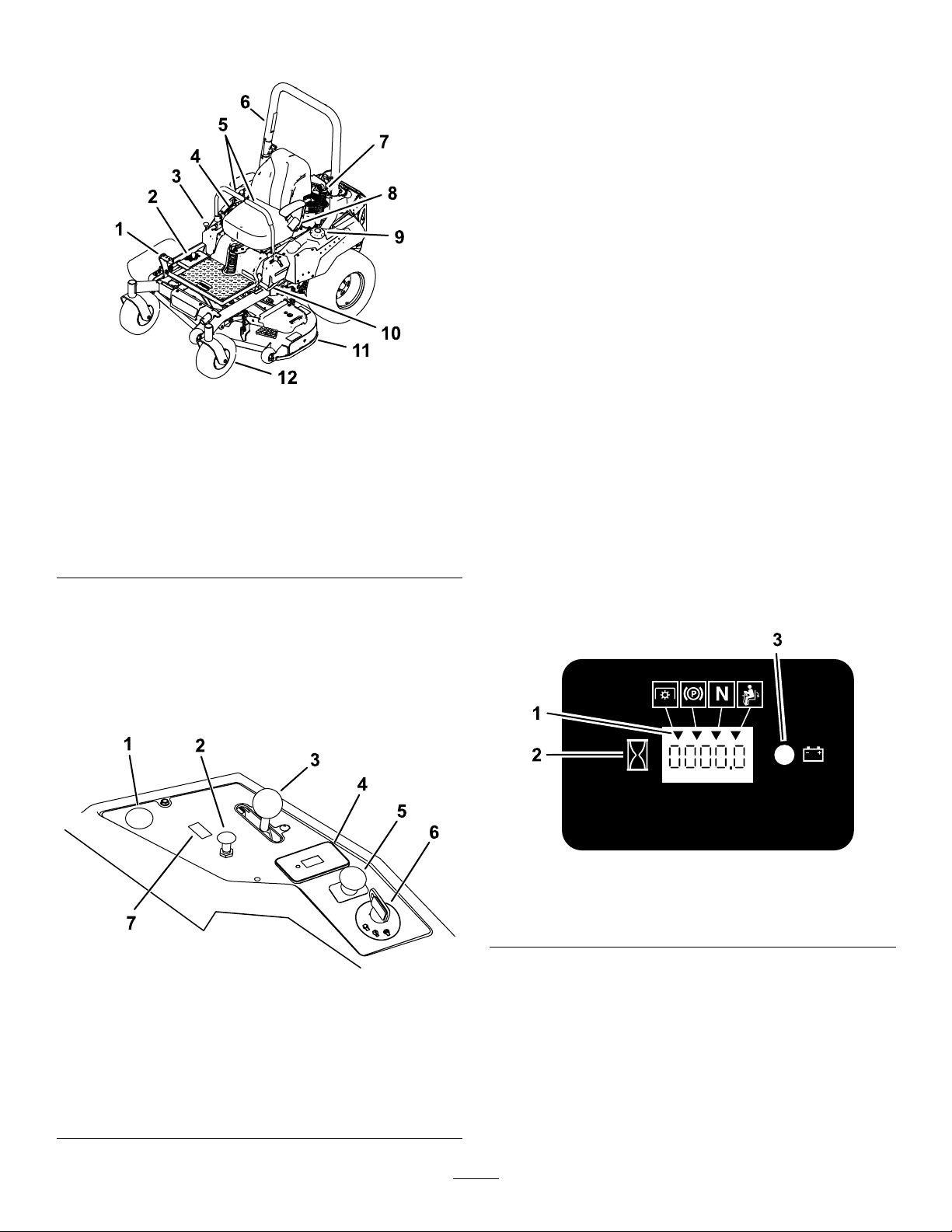

Figure1

MachineswithoutMyRide

1.Modelandserialnumberlocation

Figure2

MachineswithMyRide

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure3),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Figure3

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................5

SafetyAlertSymbol............................................5

GeneralSafety...................................................5

SlopeIndicator...................................................6

SafetyandInstructionalDecals..........................7

ProductOverview...................................................16

Controls...........................................................16

g233854

g233855

g000502

Specications..................................................18

Attachments/Accessories.................................18

BeforeOperation.................................................19

BeforeOperationSafety...................................19

AddingFuel......................................................20

PerformingDailyMaintenance..........................21

BreakinginaNewMachine..............................21

UsingtheRollover-ProtectionSystem

(ROPS).........................................................21

UsingtheSafety-InterlockSystem....................22

PositioningtheSeat..........................................23

ChangingtheSeatSuspension.........................23

AdjustingtheRear-ShockAssemblies..............24

UsingAttachmentsandAccessories.................25

DuringOperation.................................................25

DuringOperationSafety...................................25

EnteringtheOperator’sPosition.......................27

OperatingtheParkingBrake.............................28

OperatingtheMowerBlade-ControlSwitch

(PTO)............................................................28

OperatingtheThrottle.......................................29

OperatingtheChoke........................................29

StartingtheEngine...........................................30

ShuttingOfftheEngine.....................................30

UsingtheMotion-ControlLevers.......................32

DrivingtheMachine..........................................32

UsingtheSideDischarge.................................33

AdjustingtheHeightofCut...............................33

AdjustingtheAnti-ScalpRollers........................34

AdjustingtheSideBumpers..............................35

OperatingTips.................................................36

AfterOperation....................................................36

AfterOperationSafety......................................36

UsingtheFuel-ShutoffValve.............................37

UsingtheDrive-WheelReleaseValves.............37

TransportingtheMachine.................................38

Maintenance...........................................................40

MaintenanceSafety..........................................40

RecommendedMaintenanceSchedule(s)...........41

Lubrication..........................................................43

GreasingtheMachine.......................................43

GreasingtheCaster-WheelHubs.....................43

EngineMaintenance...........................................44

EngineSafety...................................................44

IdentifyingtheEngine.......................................44

ServicingaKawasaki

ServicingaKohler

®

Engine..........................45

®

Engine...............................50

ServicingaT oroEngine....................................54

CleaningtheBlowerHousing............................59

3

Page 4

CleaningtheCoolingSystem............................59

CheckingtheSparkArrester.............................60

ReplacingtheEmissions-AirIntake

Filter..............................................................60

FuelSystemMaintenance...................................60

ReplacingtheFuelFilter...................................60

ServicingtheFuelT ank.....................................61

ElectricalSystemMaintenance...........................61

ElectricalSystemSafety...................................61

ServicingtheBattery.........................................61

ServicingtheFuses..........................................63

DriveSystemMaintenance..................................64

CheckingtheSeatBelt.....................................64

CheckingtheRoll-BarKnobs............................64

AdjustingtheTracking......................................65

CheckingtheTirePressure...............................65

CheckingtheWheelLugNuts...........................65

CoolingSystemMaintenance..............................66

CleaningtheEngineScreen.............................66

BrakeMaintenance.............................................66

AdjustingtheParkingBrake..............................66

BeltMaintenance................................................68

InspectingtheBelts..........................................68

ReplacingtheMowerBeltforSide-Discharge

MowerDecks................................................68

ReplacingtheMowerBeltforRear-Discharge

MowerDecks................................................69

ReplacingtheHydraulicPump-Drive

Belt................................................................71

ControlsSystemMaintenance.............................72

AdjustingtheControl-HandlePosition..............72

AdjustingtheMotion-ControlLinkage...............73

HydraulicSystemMaintenance...........................74

HydraulicSystemSafety...................................74

HydraulicFluidSpecications...........................74

CheckingtheHydraulicFluidLevel...................74

ChangingtheHydraulicFluidand

Filters............................................................74

BleedingtheHydraulicSystem.........................76

MowerDeckMaintenance....................................77

ServicingtheCuttingBlades.............................77

AdjustingtheSide-to-SideLevelingandthe

BladeSlope..................................................80

RemovingtheMowerDeck...............................82

ReplacingtheGrassDeector..........................83

Cleaning..............................................................84

CleaningundertheMowerDeck.......................84

CleaningtheSuspensionSystem.....................84

DisposingofWaste...........................................84

Storage...................................................................85

StorageSafety..................................................85

CleaningandStorage.......................................85

Troubleshooting......................................................86

Schematics.............................................................88

4

Page 5

Safety

Thismachinehasbeendesignedinaccordancewith

ANSIstandardB71.4-2017.

SafetyAlertSymbol

ThisSafetyAlertSymbol(Figure5)isusedbothin

thismanualandonthemachinetoidentifyimportant

safetymessageswhichmustbefollowedtoavoid

accidents.

Thissymbolmeans:ATTENTION!BECOMEALERT!

YOURSAFETYISINVOL VED!

Figure5

SafetyAlertSymbol

Thesafetyalertsymbolappearsaboveinformation

whichalertsyoutounsafeactionsorsituationsand

willbefollowedbythewordDANGER,WARNING,or

CAUTION.

•Onlyallowtrained,responsible,andphysically

capableoperatorsthatarefamiliarwiththesafe

operation,operatorcontrols,andsafetysignsand

instructionstooperatethemachine.Neverlet

childrenoruntrainedpeopleoperateorservicethe

equipment.Localregulationsmayrestricttheage

oftheoperator.

•Alwayskeeptherollbarinthefullyraisedand

lockedpositionandusetheseatbelt.

•Donotoperatethemachineneardrop-offs,

ditches,embankments,water,orotherhazards,or

onslopesgreaterthan15degrees.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Neveroperatethemachinewithdamagedguards,

g000502

shields,orcovers.Alwayshavesafetyshields,

guards,switchesandotherdevicesinplaceandin

properworkingcondition.

•Stopthemachine,shutofftheengine,andremove

thekeybeforeservicing,fueling,orunclogging

themachine.

DANGER:Indicatesanimminentlyhazardous

situationwhich,ifnotavoided,Willresultindeathor

seriousinjury.

WARNING:Indicatesapotentiallyhazardoussituation

which,ifnotavoided,Couldresultindeathorserious

injury.

CAUTION:Indicatesapotentiallyhazardoussituation

which,ifnotavoided,Mayresultinminorormoderate

injury.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizesgeneral

informationworthyofspecialattention.

GeneralSafety

Thismachineiscapableofamputatinghandsandfeet

andofthrowingobjects.T orodesignedandtested

thislawnmowertoofferreasonablysafeservice;

however,failuretocomplywithsafetyinstructions

mayresultininjuryordeath.

•Read,understand,andfollowallinstructionsand

warningsintheOperator’sManualandother

trainingmaterial,onthemachine,engine,and

attachments.Alloperatorsandmechanicsshould

betrained.Iftheoperator(s)ormechanic(s)can

notreadthismanual,itistheowner’sresponsibility

toexplainthismaterialtothem;otherlanguages

maybeavailableonourwebsite.

5

Page 6

SlopeIndicator

Figure6

Youmaycopythispageforpersonaluse.

1.Themaximumslopeyoucanoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslopeof

hillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge

6

g011841

Page 7

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

BatterySymbols

Someorallofthesesymbolsareonyourbattery .

decaloemmarkt

decal106-5517

106-5517

1.Warning—donottouchthehotsurface.

decalbatterysymbols

1.Explosionhazard6.Keepbystandersaway

2.Nore,opename,or

smoking

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

fromthebattery .

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto1 15to149N∙m(85to110

ft-lb).

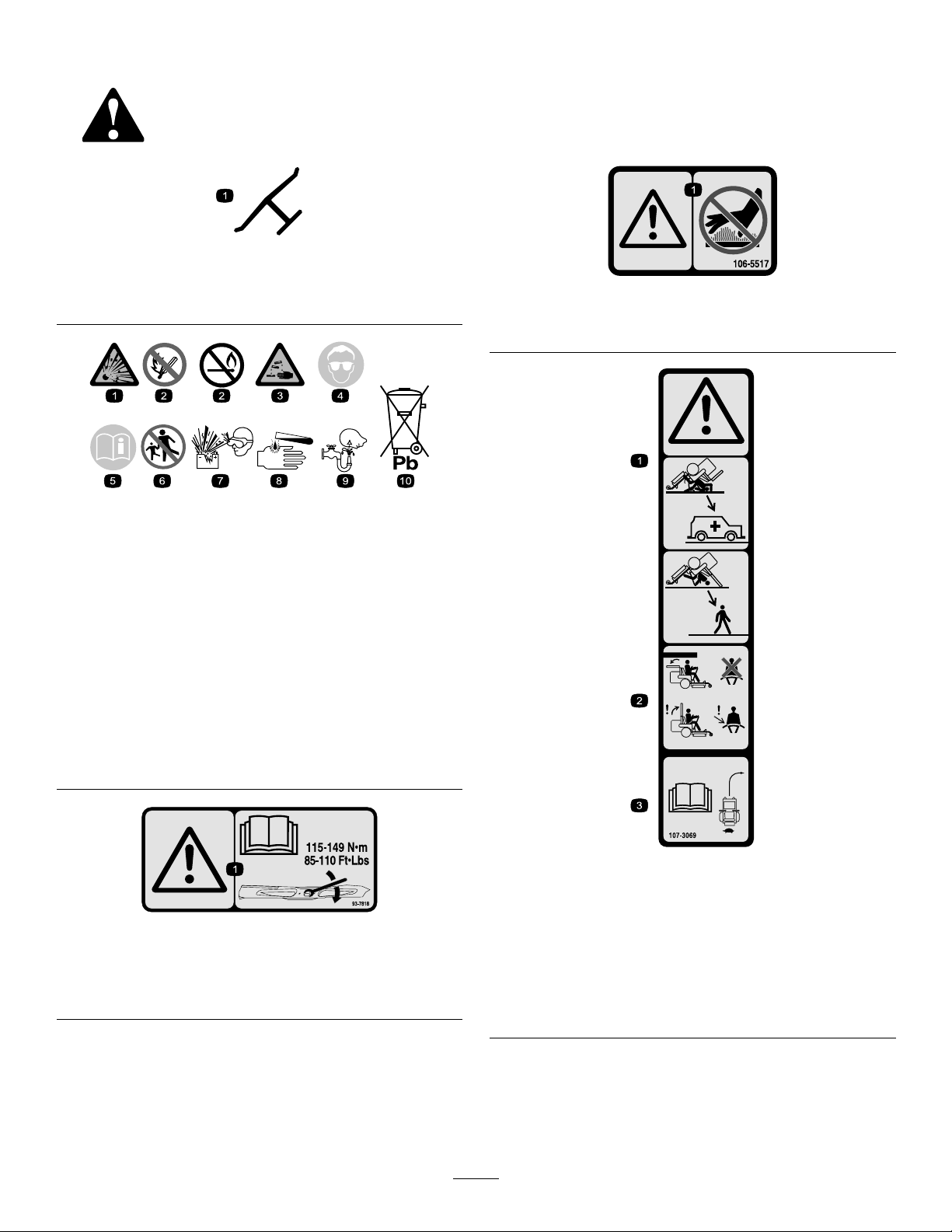

decal107-3069

107-3069

1.Warning—thereisnorolloverprotectionwhentherollbaris

decal93-7818

down.

2.Toavoidinjuryordeathfromarolloveraccident,keepthe

rollbarinthefullyraisedandlockedpositionandwear

theseatbelt.Lowertherollbaronlywhenabsolutely

necessary;donotweartheseatbeltwhentherollbaris

down.

3.ReadtheOperator'sManual;driveslowlyandcarefully.

7

Page 8

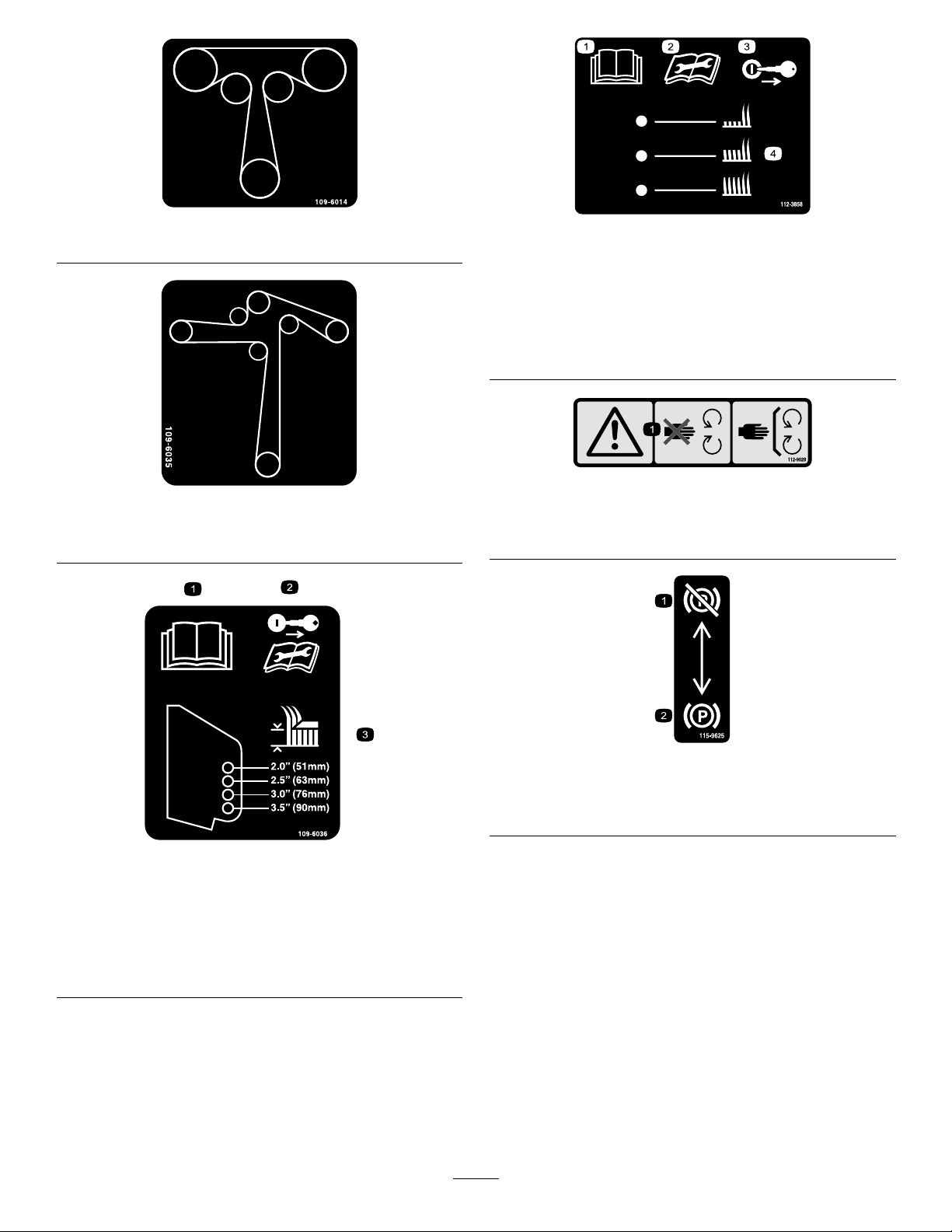

decal109-6014

109-6014

112-3858

decal112-3858

1500and2000SeriesSideDischargeMachinesOnly

109-6035

2500SeriesSideDischargeMachinesOnly

1.ReadtheOperator's

Manual.

2.Readtheinstructions

3.Removethekeybefore

adjustingtheheightofcut.

4.Height-of-cutsettings.

beforeservicingor

performingmaintenance.

decal112-9028

decal109-6035

112-9028

1.Warning—stayawayfrommovingparts;keepallguards

andshieldsinplace.

109-6036

RearDischargeMachinesOnly

1.ReadtheOperator’sManual.

2.Removethekeyandreadtheinstructionsbeforeservicing

orperformingmaintenance.

3.Heightofcut

decal115-9625

115-9625

1.Parking

brake—disengaged

decal109-6036

2.Parkingbrake—engaged

8

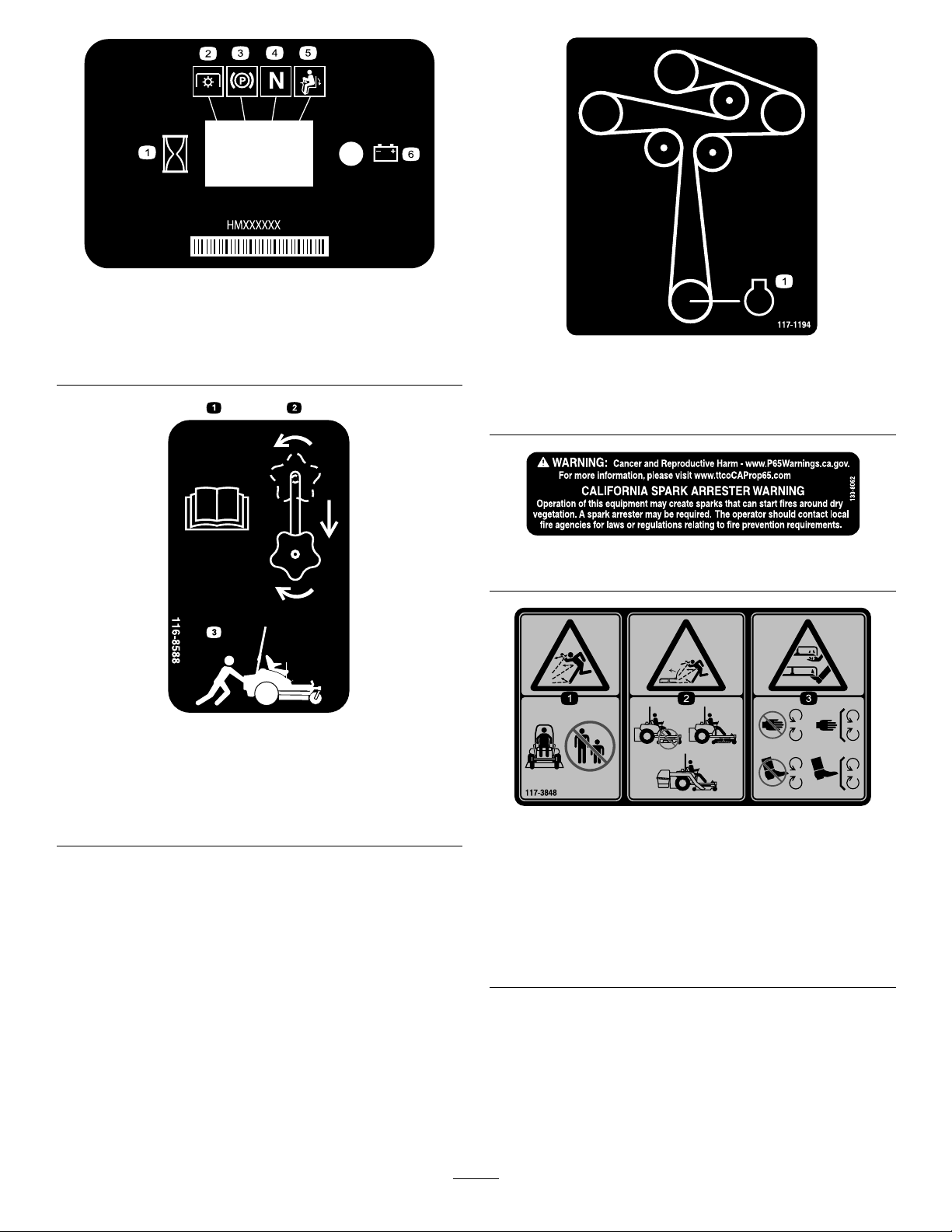

Page 9

116-5610

1.Hourmeter4.Neutral

2.Powertakeoff(PTO)5.Operator-presenceswitch

3.Parkingbrake6.Battery

116-8588

decal116-5610

decal117-1 194

117-1194

1500and2000SeriesSide-DischargeMachinesOnly

1.Engine

decal133-8062

133-8062

decal116-8588

1.ReadtheOperator’sManual.

2.Rotatethedrivereleaseknobtoloosen,slidetheknob,

andtighten.

3.Pushthemachine.

decal117-3848

117-3848

1.Thrownobjecthazard—keepbystandersaway.

2.Thrownobjecthazard,raiseddeector—donotoperate

withoutthedeector ,dischargecover ,orgrasscollection

systeminplace.

3.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts;keepallguardsand

shieldsinplace.

9

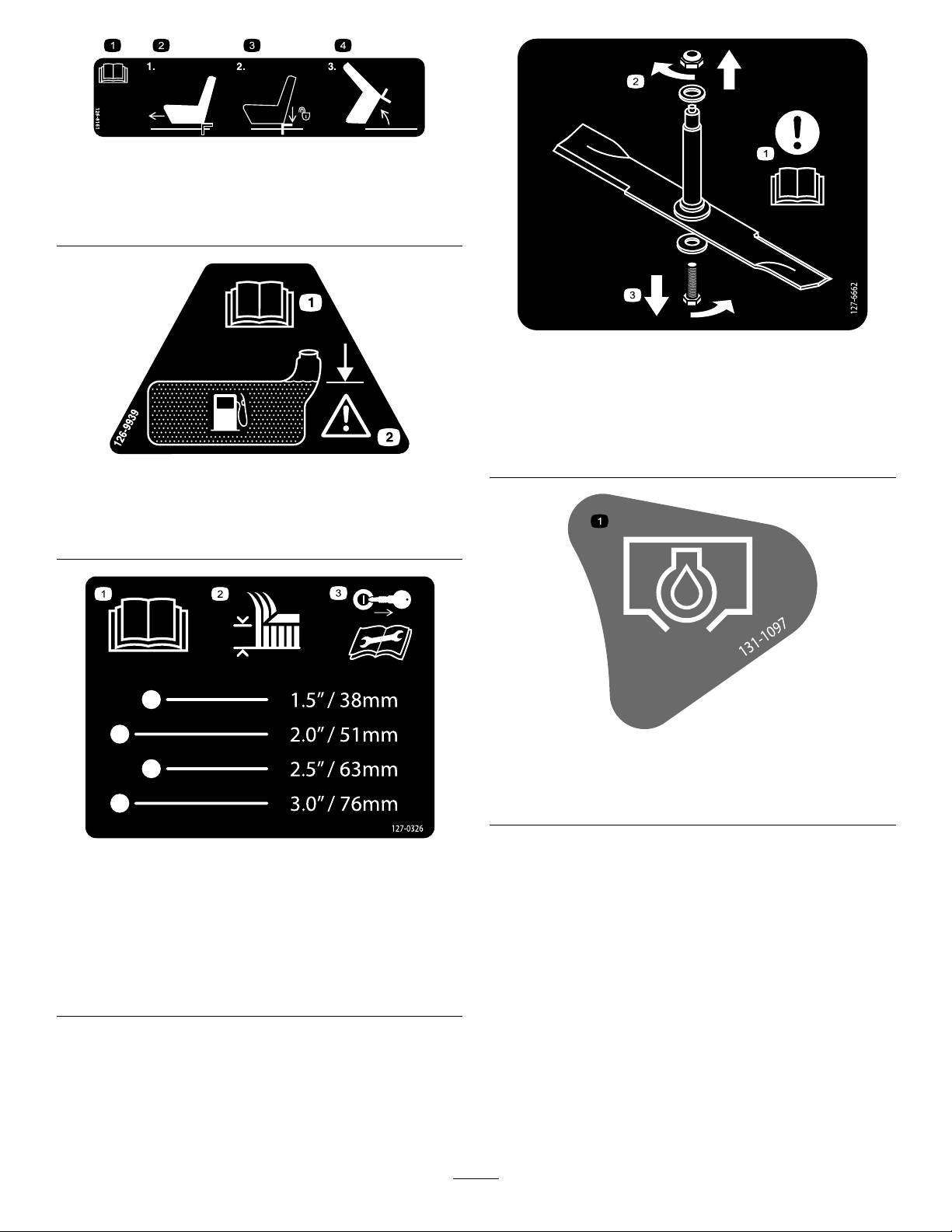

Page 10

126-0768

126-4363

1.Cutting/dismembermenthazard,fanandentanglement

hazard,belt.Shutofftheengineandremovethekeybefore

adjusting,servicingorcleaningthemachine.

decal126-0768

decal126-4784

126-4784

1.Heightofcut

decal126-4363

decal126-6599

126-6599

RearDischargeMachinesOnly

1.Thrownobjects

hazard—keepbystanders

away.

2.Cutting/dismemberment

ofhand—stayawayfrom

movingparts;keepall

guardsandshieldsin

place.

10

Page 11

decal126-8161

126-8161

1.ReadtheOperator’s

Manual.

2.Slideseatforward

1.ReadtheOperator’s

Manual.

3.Pressdownonlatchto

unlockseat

4.Rotateseat

126-9939

2.Filltothebottomofthe

llerneck;warning—do

notoverllthetank.

decal127-6662

127-6662

RearDischargeMowersOnly

1.Attention—readthe

Operator'sManual.

2.Removethenutbyturning

decal126-9939

itclockwise.

3.Removetheboltbyturning

itcounterclockwise.

127-0326

2500SeriesSideDischargeMachinesOnly

1.ReadtheOperator's

Manual.

2.Heightofcut

decal131-1097

131-1097

ToroEnginesOnly

1.Oildrain

decal127-0326

3.Removethekeyand

readtheOperator's

Manualbeforeperforming

maintenanceorservicing

themachine.

11

Page 12

PTOSwitchSymbols

1.PTO–disengage2.PTO–engage

decalptosymbols

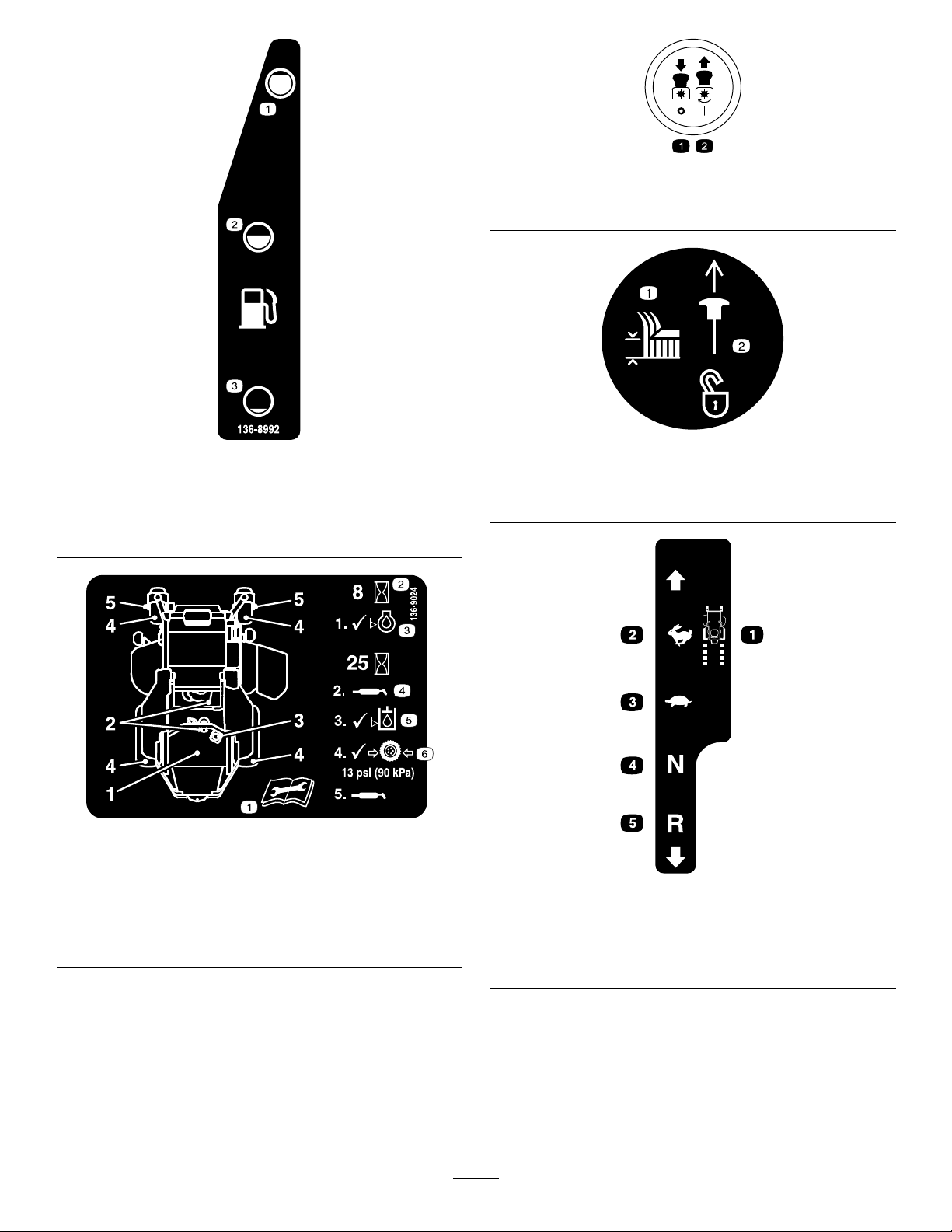

136-8992

MachineswithMyRideOnly

1.Fuel—full

2.Fuel—50%

3.Fuel—empty

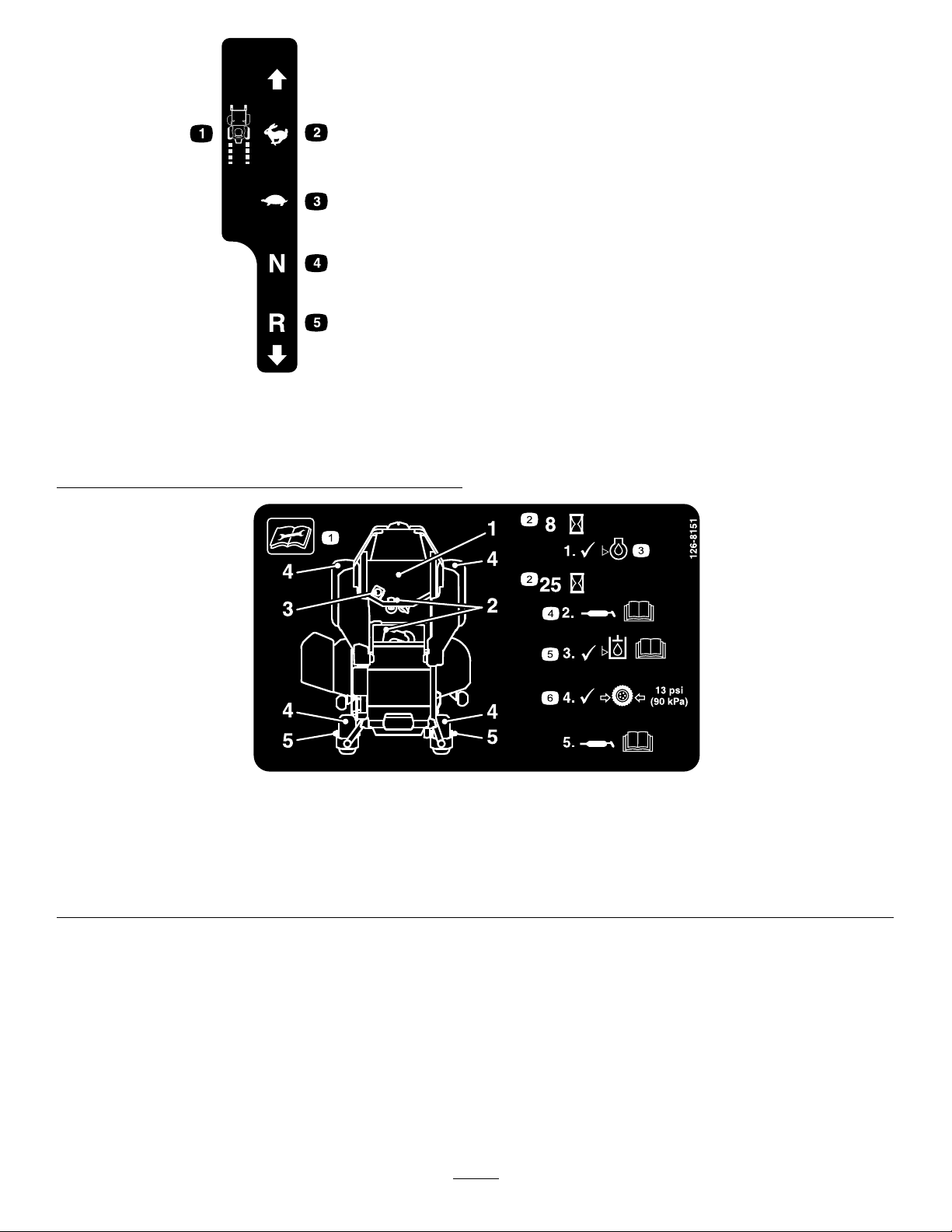

136-9024

1.ReadtheOperator’s

Manualbeforeperforming

maintenance.

2.Operatinghours5.Hydraulic-uidlevel

3.Engine-oillevel6.Tirepressure

4.Greasepoint

decal136-8992

1.Heightofcut

TransportLock

2.Pulluptounlockthe

decaltransportlock

transportlock.

decal136-9024

decalmotioncntrllh-126-6194

LeftMotionControl

1.Machinespeed4.Neutral

2.Fast5.Reverse

3.Slow

12

Page 13

RightMotionControl

1.Machinespeed4.Neutral

2.Fast5.Reverse

3.Slow

decalmotioncntrlrh-126-6183

decal126-8151

126-8151

1.Readtheinstructionsbeforeservicingorperforming

4.RefertotheOperator'sManualforgreaseinstructions.

maintenanceonthemachine.

2.Timeinterval

5.Checkthehydraulic-uidlevelandrefertotheOperator's

Manualforfurtherinstructions.

3.Checktheoillevel.6.Checkthetirepressure.

13

Page 14

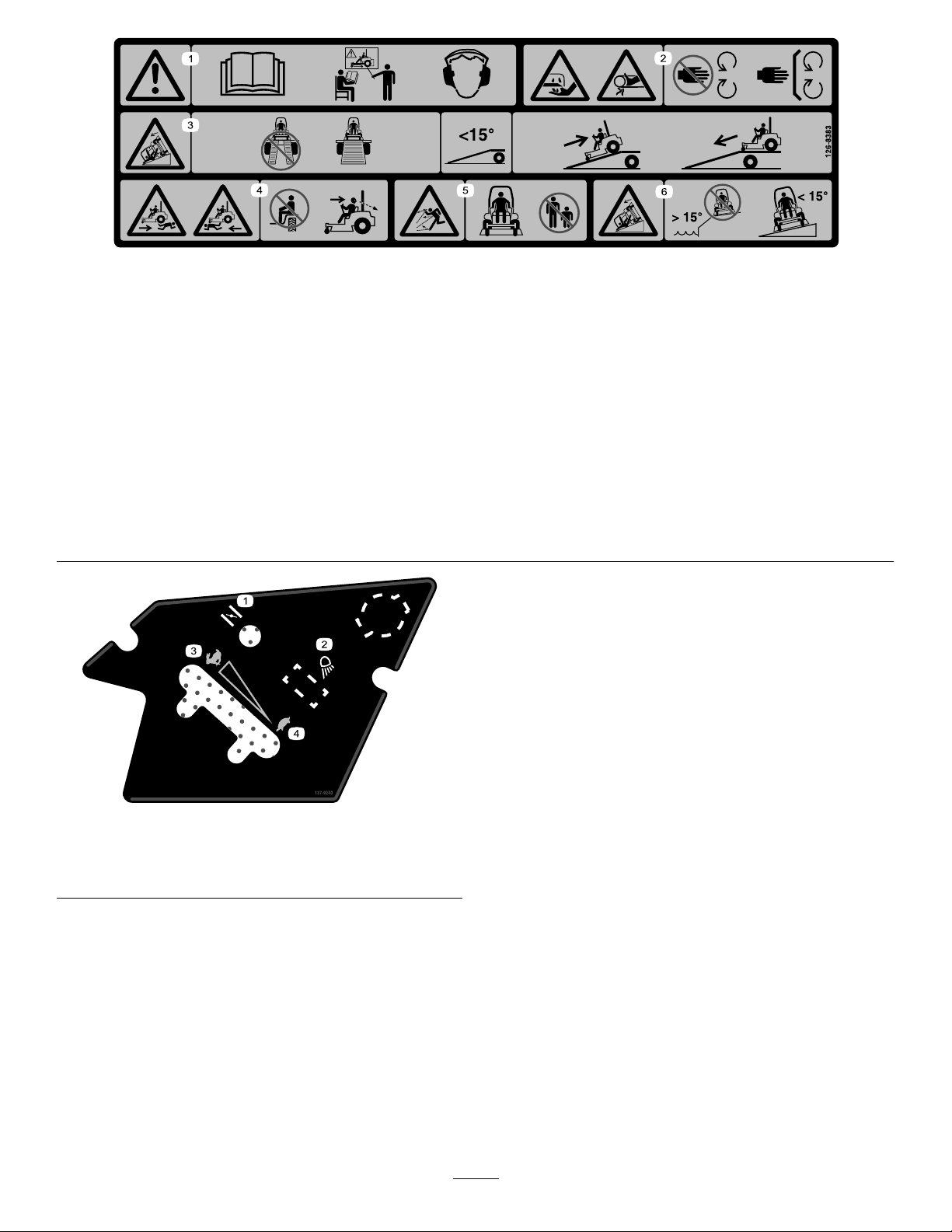

126-8383

Note:Thismachinecomplieswiththeindustrystandardstabilitytestinthestaticlateralandlongitudinaltestswiththemaximum

recommendedslopeindicatedonthedecal.ReviewtheinstructionsforoperatingthemachineonslopesintheOperator’sManualas

wellastheconditionsinwhichyouwouldoperatethemachinetodeterminewhetheryoucanoperatethemachineintheconditions

onthatdayandatthatsite.Changesintheterraincanresultinachangeinslopeoperationforthemachine.Ifpossible,keepthe

cuttingunitsloweredtothegroundwhileoperatingthemachineonslopes.Raisingthecuttingunitswhileoperatingonslopescan

causethemachinetobecomeunstable.

decal126-8383

1.Warning—readtheOperator’sManual;donotoperatethis

machineunlessyouaretrained;wearhearingprotection.

2.Cutting/dismembermenthazardofthehand,mowerblade;

entanglementhazardofthehand,belt—stayawayfrom

movingparts;keepallguardsandshieldsinplace.

3.Ramphazard—donotusedualrampswhenloadingontoa

trailer;use1rampwideenoughforthemachine;usearamp

withaslopelessthan15°;backuptherampwhenloadingthe

machineanddriveforwardofftherampwhenunloading.

decal137-9240

137-9240

4.Runover/backoverhazard—donotcarrypassengers;look

behindyouwhenmowinginreverse.

5.Thrownobjecthazard—keepbystandersaway.

6.Tippinghazard—donotuseonslopesnearopenwater;do

notuseonslopesgreaterthan15°.

1.Choke

2.Worklight

3.Fast

4.Slow

14

Page 15

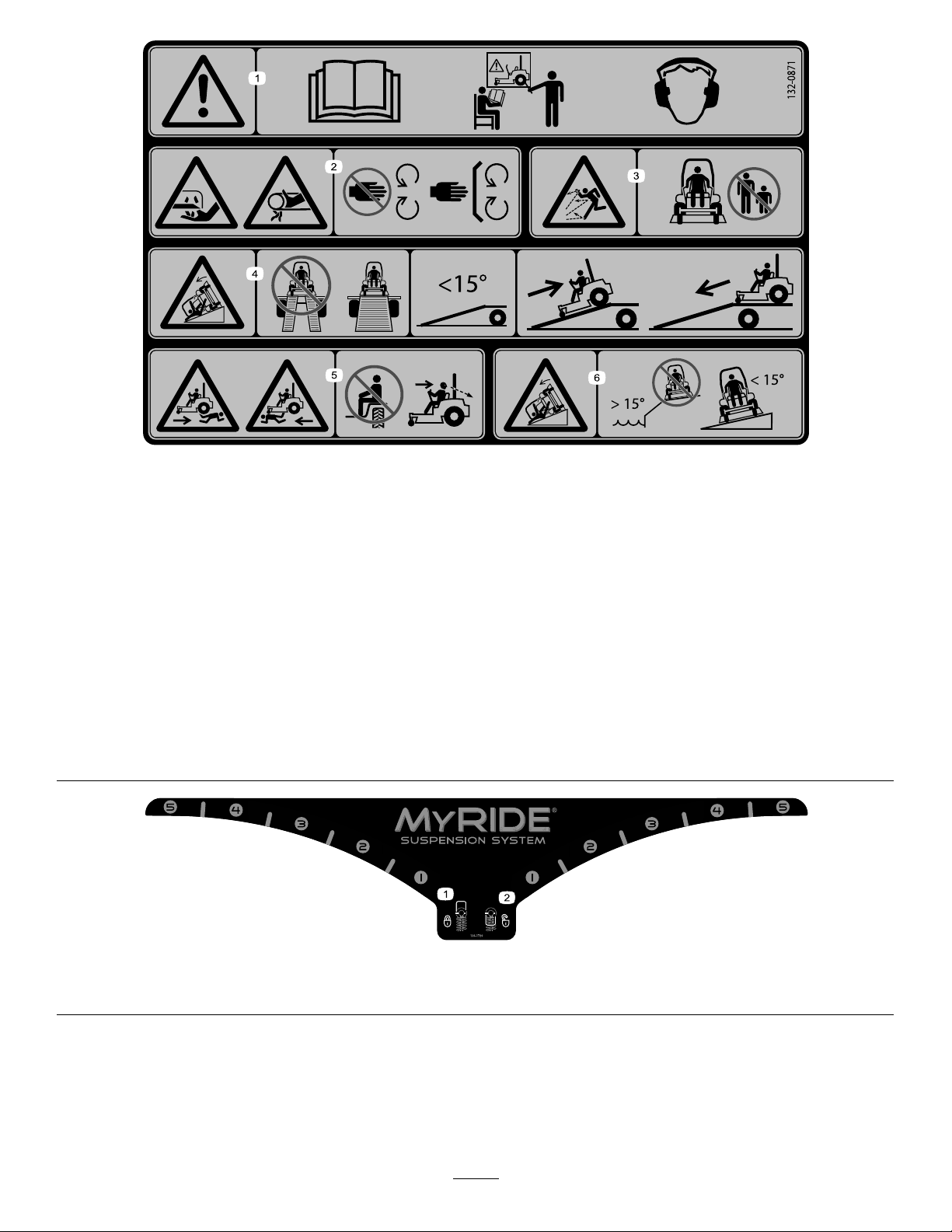

132-0871

MachineswithMyRideOnly

Note:Thismachinecomplieswiththeindustrystandardstabilitytestinthestaticlateralandlongitudinaltestswiththemaximum

recommendedslopeindicatedonthedecal.ReviewtheinstructionsforoperatingthemachineonslopesintheOperator’sManualas

wellastheconditionsinwhichyouwouldoperatethemachinetodeterminewhetheryoucanoperatethemachineinthoseconditions

onthatdayandatthatsite.Changesintheterraincanresultinachangeinslopeoperationforthemachine.Ifpossible,keepthe

cuttingunitsloweredtothegroundwhileoperatingthemachineonslopes.Raisingthecuttingunitswhileoperatingonslopescan

causethemachinetobecomeunstable.

decal132-0871

1.Warning—readtheOperator’sManual;donotoperatethis

machineunlessyouaretrained;wearhearingprotection.

4.Ramphazard—whenloadingontoatrailer,donotusedual

ramps;onlyuseasingularrampwideenoughforthemachine

andthathasaninclinelessthan15°;backuptheramp(in

reverse)anddriveforwardofftheramp.

2.Cutting,dismembering,andentanglementhazard—keep

handsawayfrommovingparts;keepallguardsandshieldsin

5.Bodilyharmhazard—donotcarrypassengers;lookbehind

youwhenmowinginreverse.

place.

3.Thrownobjecthazard—keepbystandersaway.6.Tippinghazardonslopes—donotuseonslopesnearopen

water;donotuseonslopesgreaterthan15°.

136-1720

1.Camlock2.Camunlock

decal136-1720

15

Page 16

ProductOverview

KeySwitch

Thekeyswitch,usedtostartandshutofftheengine,

has3positions:OFF,RUN,andST ART.Referto

StartingtheEngine(page30).

ChokeControl

Usethechokecontroltostartacoldengine.

ThrottleControl

Thethrottlecontrolstheenginespeed,andithasa

continuous-variablesettingfromtheSLOWtoFAST

position(Figure8).

Figure7

1.Height-of-cutdeck-lift

pedal

2.Height-of-cutpositions8.Seatbelt

3.Transportlock9.Fuelcap

4.Controls

5.Motion-controllevers11.Mowerdeck

6.Rollbar

7.Shockassembly

10.Parking-brakelever

12.Casterwheel

Controls

Becomefamiliarwithallthecontrolsbeforeyoustart

theengineandoperatethemachine.

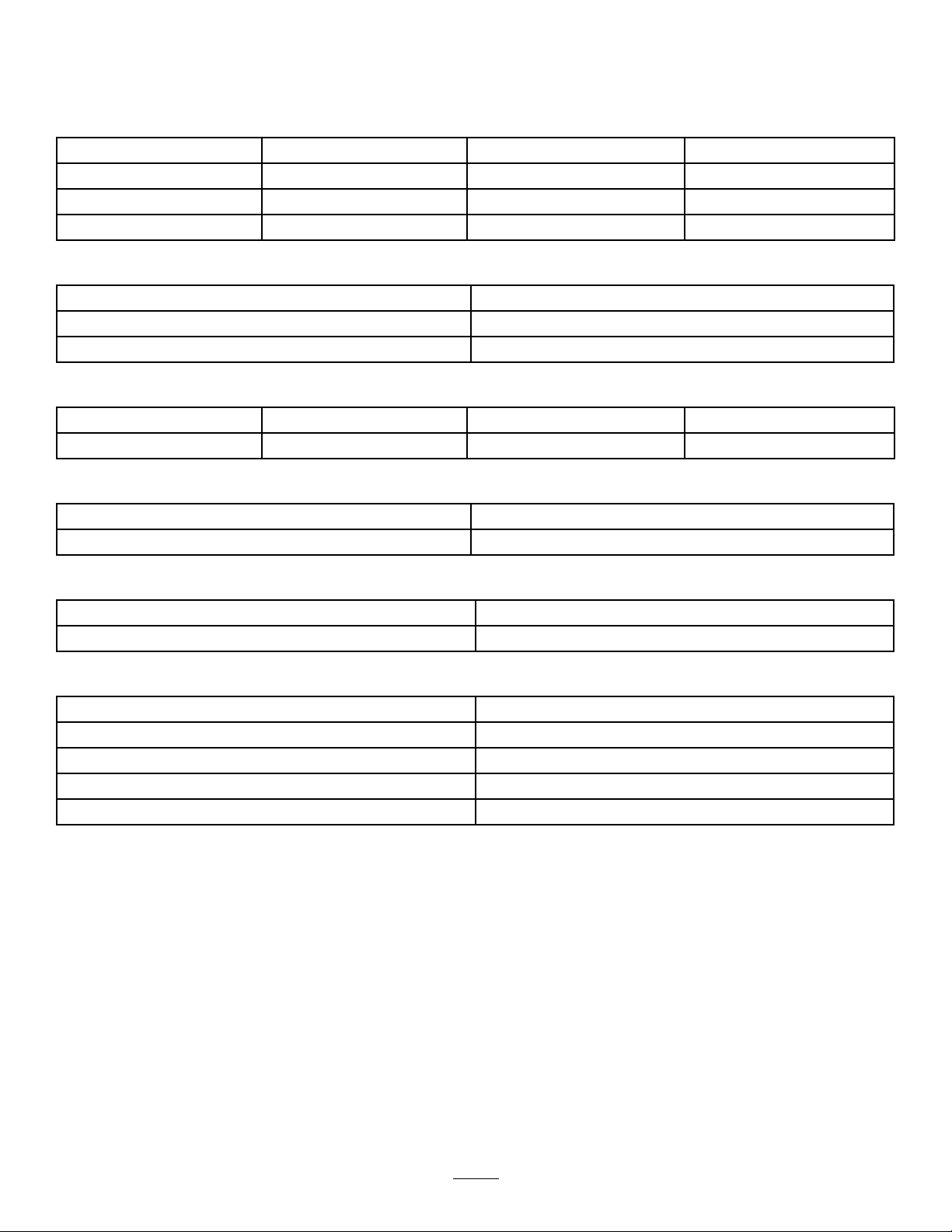

ControlPanel

g227688

Blade-ControlSwitch(Power

Takeoff)

Theblade-controlswitch,representedbya

power-takeoff(PTO)symbol,engagesand

disengagespowertothemowerblades(Figure8).

HourMeter

Thehourmeterrecordsthenumberofhoursthe

enginehasoperated.Itoperateswhentheengine

isrunning.Usethesetimesforschedulingregular

maintenance(Figure9).

1.Positionforoptionalpower

point

2.Chokecontrol

3.Throttlecontrol

4.Hourmeter

Figure8

5.Blade-controlswitch

(powertakeoff)

6.Keyswitch

7.Switchpositionforoptional

lightkit

g187133

Figure9

1.Safety-interlocksymbols

2.Hourmeter

g271171

3.Batterylight

Safety-InterlockIndicators

Therearesymbolsonthehourmeterthatindicate

withablacktrianglethattheinterlockcomponentis

positionedcorrectly(Figure9).

16

Page 17

Battery-IndicatorLight

IfyouturnthekeyswitchtotheONpositionfora

fewseconds,thebatteryvoltagedisplaysinthearea

wherethehoursarenormallydisplayed.

Thebatterylightturnsonwhenthekeyswitchis

turnedonandwhenthechargeisbelowthecorrect

operatinglevel(Figure9).

Motion-ControlLevers

Usethemotion-controlleverstodrivethemachine

forward,reverse,andturneitherdirection(Figure7).

Neutral-LockPosition

Movethemotion-controlleversoutwardfromthe

centertotheNEUTRAL-LOCKpositionwhenexiting

themachine(Figure30).Alwayspositionthe

motion-controlleversintotheNEUTRAL-LOCKposition

whenyoustopthemachineorleaveitunattended.

Parking-BrakeLever

Wheneveryoushutofftheengine,engagetheparking

braketopreventaccidentalmovementofthemachine.

Fuel-ShutoffValve

Closethefuel-shutoffvalvewhentransportingor

storingthemachine;refertoUsingtheFuel-Shutoff

Valve(page37).

17

Page 18

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

Width—MachineswithSideDischargeMowerDecks

48-inchDeck52-inchDeck60-inchDeck

Withoutmowerdeck

Deectorup133cm(53inches)144cm(56-3/4inches)161cm(63-1/2inches)

Deectordown160cm(63-1/4inches)171cm(67-1/4inches)191cm(75-1/4inches)

Width—MachineswithRearDischargeMowerDecks

Withoutmowerdeck

Withmowerdeck

Length—MachineswithSideDischargeMowerDecks

Length

Length—MachineswithRearDischargeMowerDecks

121cm(47-1/2inches)124cm(49inches)133cm(52inches)

60-inchDeck

133cm(52inches)

168cm(66inches)

48-inchDeck52-inchDeck60-inchDeck

208cm(82inches)208cm(82inches)209cm(83inches)

60-inchDeck

Withmowerdeck

215cm(84-1/2inches)

Height

RollBar-UpRollBar-Down

179cm(70-1/2inches)125cm(49inches)

Weight

MachinesWeight

48-inchside-dischargemachines

52-inchside-dischargemachines

60-inchside-dischargemachines

60-inchrear-dischargemachines

385to425kg(849to937lb)

391to434kg(862to957lb)

409to456kg(901to1,006lb)

459kg(1,012lb)

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesisavailableforusewiththemachinetoenhance

andexpanditscapabilities.ContactyourAuthorizedServiceDealerorauthorizedT orodistributororgoto

www.T oro.comforalistofallapprovedattachmentsandaccessories.

Toensureoptimumperformanceandcontinuedsafetycerticationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacementpartsandaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty .

18

Page 19

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbyToro.

FuelSafety

Useextremecarewhenhandlingfuel.

DANGER

Incertainconditionsgasolineisextremely

ammableandvaporsareexplosive.

Areorexplosionfromgasolinecanburn

you,others,andcausepropertydamage.

•Fillthefueltankoutdoorsonlevelground,

inanopenarea,whentheengineiscold.

Wipeupanygasolinethatspills.

•Neverrellthefueltankordrainthe

machineindoorsorinsideanenclosed

trailer.

•Inspecttheareawheretheequipmentistobe

usedandremoveallrocks,toys,sticks,wires,

bones,andotherforeignobjects.Thesecan

bethrownorinterferewiththeoperationofthe

machineandmaycausepersonalinjurytothe

operatororbystanders.

•Wearappropriatepersonalprotectiveequipment

suchassafetyglasses,substantialslip-resistant

footwear,andhearingprotection.Tiebacklong

hairandavoidlooseclothingandloosejewelry

whichmaygettangledinmovingparts.

CAUTION

Thismachineproducessoundlevelsin

excessof85dBAattheoperator’searand

cancausehearinglossthroughextended

periodsofexposure.

Wearhearingprotectionwhenoperating

thismachine.

•Checkthattheoperatorpresencecontrols,

safetyswitches,andshieldsareattachedand

functioningproperly.Donotoperateunlessthey

arefunctioningproperly.

•DoNotllthefueltankcompletelyfull.

Fillthefueltanktothebottomoftheller

neck.Theemptyspaceinthetankallows

gasolinetoexpand.Overllingmayresult

infuelleakageordamagetotheengineor

emissionsystem.

•Neversmokewhenhandlinggasoline,and

stayawayfromanopenameorwhere

gasolinefumesmaybeignitedbyspark.

•Storegasolineinanapprovedcontainer

andkeepitoutofthereachofchildren.

•Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoraddfuel

whenengineisrunningorwhentheengine

ishot.

•Iffuelisspilled,DoNotattempttostart

theengine.Moveawayfromtheareaof

thespillandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

•DoNotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

•Donotoperatethemowerwhenpeople,especially

children,orpetsareinthearea.Stopthemachine

andattachment(s)ifanyoneentersthearea.

•Donotoperatethemachinewithouttheentire

grasscollectionsystem,dischargedeector,

orothersafetydevicesinplaceandinproper

workingcondition.Grasscatchercomponents

aresubjecttowear,damageanddeterioration,

whichcouldexposemovingpartsorallowobjects

tobethrown.Frequentlycheckforwornor

deterioratingcomponentsandreplacethemwith

themanufacturer’srecommendedpartswhen

necessary.

19

Page 20

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitegasolinevapors.Areor

explosionfromgasolinecanburnyouand

othersandcausepropertydamage.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebefore

lling.

•DoNotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowthe

lossofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

ground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbe

used,keepthenozzleincontactwiththe

rimofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.DoNot

useanozzlelockopendevice.

WARNING

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporshascaused

cancerinlaboratoryanimals.Failuretouse

cautionmaycauseseriousinjuryorillness.

Tohelppreventres:

•Keepengineandengineareafreefrom

accumulationofgrass,leaves,excessivegrease

oroil,andotherdebriswhichcanaccumulatein

theseareas.

•Cleanupoilandfuelspillsandremovefuelsoaked

debris.

•Allowthemachinetocoolbeforestoringthe

machineinanyenclosure.DoNotstorenear

ameoranyenclosedareawhereopenpilotlights

orheatappliancesarepresent.

AddingFuel

RecommendedFuel

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan

10%ethanolbyvolume,suchasE15(contains

15%ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

•Donotaddoiltogasoline.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgas

tank/containeropening.

•Keepawayfromeyesandskin.

•Neversiphonbymouth.

CAUTION

Fueltankventislocatedinsidetheroll

bartube.Removingormodifyingtheroll

barcouldresultinfuelleakageandviolate

emissionsregulations.

•DoNotremoverollbar.

•DoNotweld,drill,ormodifyrollbarinany

way.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsfuelfreshlongerwhenusedasdirectedby

thefuel-stabilizermanufacturer

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

Important:Donotusefueladditives

containingmethanolorethanol.

Addthecorrectamountoffuelstabilizer/conditioner

tothefuel.

Note:Afuelstabilizer/conditionerismost

effectivewhenmixedwithfreshfuel.T ominimize

20

Page 21

thechanceofvarnishdepositsinthefuelsystem,

usefuelstabilizeratalltimes.

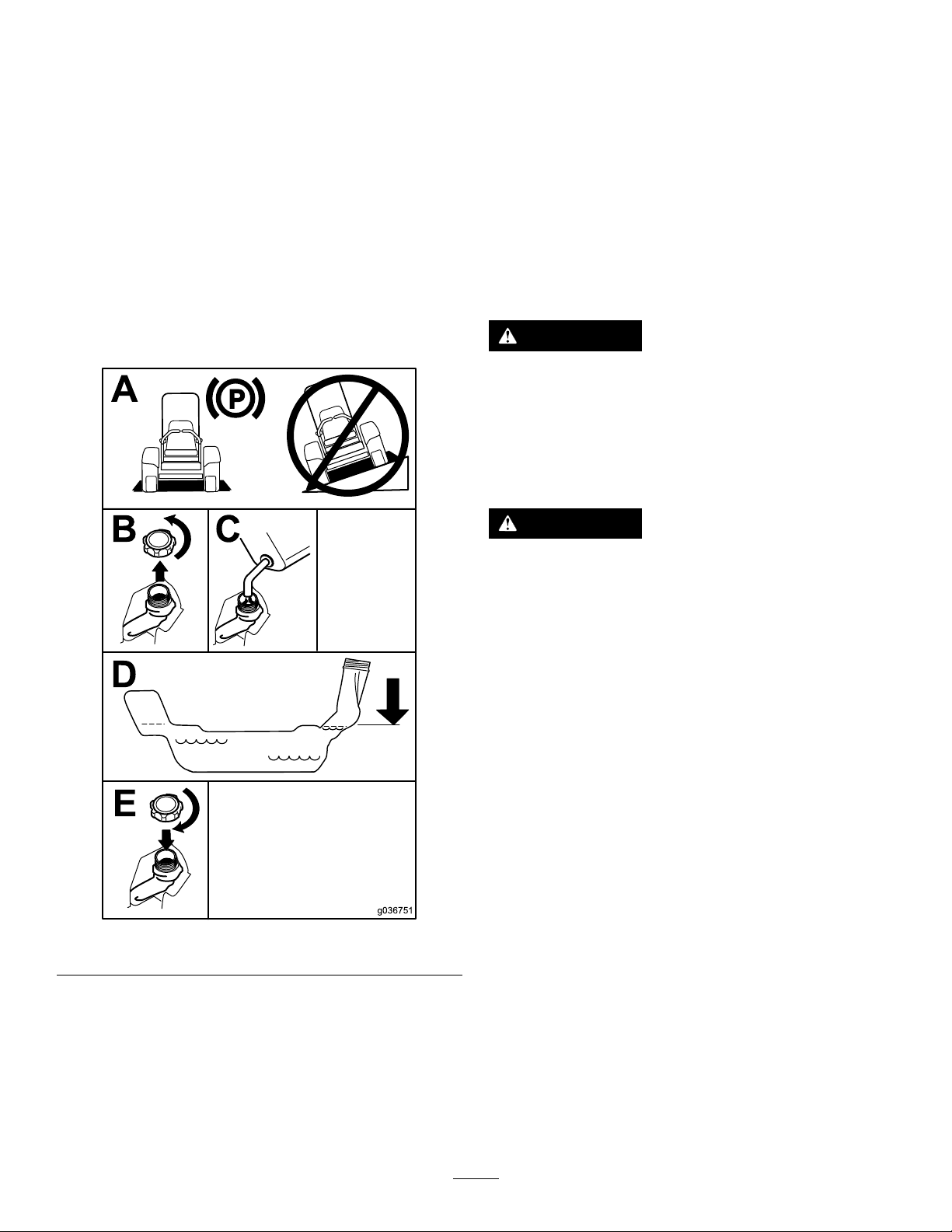

FillingtheFuelTank

1.Parkthemachineonalevelsurface.

2.Engagetheparkingbrake.

3.Shutofftheengineandremovethekey.

4.Cleanaroundthefuel-tankcap.

5.Fillthefueltanktothebottomofthellerneck

(Figure10).

Note:Donotllthefueltankcompletelyfull.

Theemptyspaceinthetankallowsthefuelto

expand.

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mower

decksanddrivesystemshavehigherfrictionwhen

new,placingadditionalloadontheengine.Allow

40to50hoursofbreak-intimefornewmachinesto

developfullpowerandbestperformance.

Usingthe

Rollover-ProtectionSystem

(ROPS)

WARNING

Toavoidinjuryordeathfromrollover,keep

therollbarinthefullyraised,lockedposition

andusetheseatbelt.

Ensurethattheseatissecuredtothe

machine.

Figure10

WARNING

Thereisnorolloverprotectionwhentheroll

barisinthedownposition.

•Lowertherollbaronlywhenabsolutely

necessary.

•Donotweartheseatbeltwhentherollbar

isinthedownposition.

•Driveslowlyandcarefully.

•Raisetherollbarassoonasclearance

permits.

•Checkcarefullyforoverheadclearances

(i.e.,branches,doorways,electricalwires)

beforedrivingunderanyobjectsanddo

notcontactthem.

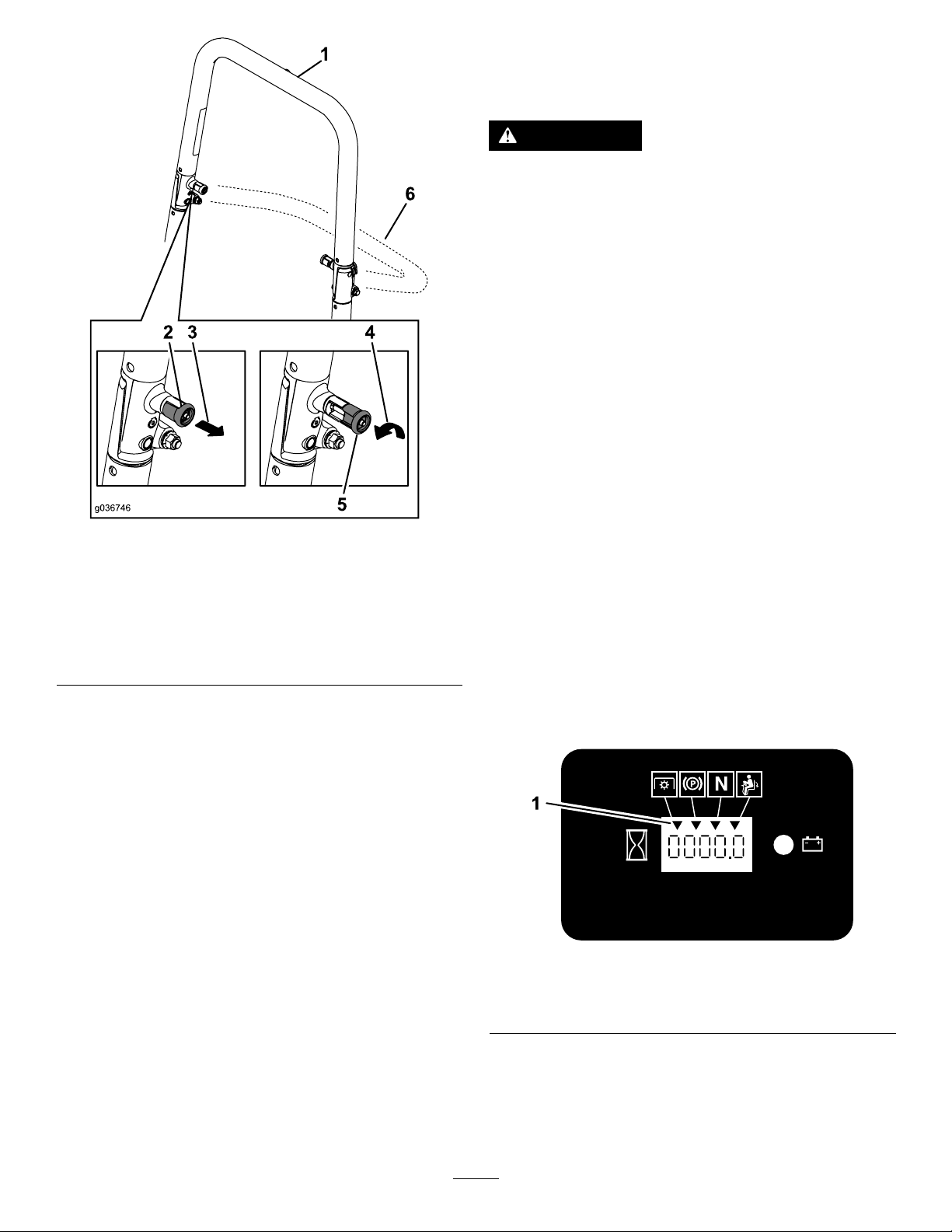

LoweringtheRollBar

g036751

Important:Lowertherollbaronlywhen

absolutelynecessary.

1.T olowertherollbar,applyforwardpressureto

theupperpartoftherollbar.

PerformingDaily

Maintenance

Beforestartingthemachineeachday ,performthe

EachUse/DailyprocedureslistedinMaintenance

(page40).

2.Pullbothknobsoutandrotatethem90degrees

sothattheyarenotengaged(Figure1 1).

3.Lowertherollbartothedownposition(Figure

11).

21

Page 22

Figure11

UsingtheSafety-Interlock

System

WARNING

Ifthesafety-interlockswitchesare

disconnectedordamaged,themachinecould

operateunexpectedly,causingpersonal

injury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

Understandingthe

Safety-InterlockSystem

Thesafety-interlocksystemisdesignedtopreventthe

enginefromstartingunlessthefollowingoccurs:

•Theparkingbrakeisengaged.

•Theblade-controlswitch(PTO)isdisengaged.

g036746

•Themotion-controlleversareintheNEUTRAL-LOCK

position.

1.Rollbarintheupright

position

2.ROPSknobinthelatched

position

3.PulltheROPSknobout.6.Rollbarinthefolded

4.RotatetheROPSknob90

degrees.

5.ROPSknobinthe

unlatchedposition

position

RaisingtheRollBar

Important:Alwaysusetheseatbeltwiththeroll

barintheraisedposition.

1.Raisetherollbartotheoperatingpositionand

rotatetheknobsuntiltheymovepartiallyinto

thegrooves(Figure11).

2.Raisetherollbartothefulluprightpositionwhile

pushingontheupperrollbarsothatthepins

snapintopositionwhentheholesalignwiththe

pins(Figure11).

3.Pushontherollbarandensurethatbothpins

areengaged.

Thesafety-interlocksystemalsoisdesignedtoshut

offtheenginewhenthemotion-controlleversare

movedfromtheNEUTRAL-LOCKpositionwiththe

parkingbrakeengagedorifyourisefromtheseat

whenthePTOisengaged.

Thehourmeterhasindicatorstonotifytheuserwhen

theinterlockcomponentisinthecorrectposition.

Whenthecomponentisinthecorrectposition,an

indicatordisplaysonthescreen.

g187670

Figure12

1.Indicatorsdisplaywhentheinterlockcomponentsareinthe

correctposition

TestingtheSafety-Interlock

System

ServiceInterval:Beforeeachuseordaily

22

Page 23

Testthesafety-interlocksystembeforeyouusethe

machineeachtime.Ifthesafetysystemdoesnot

operateasdescribedbelow,haveanAuthorized

ServiceDealerrepairthesafetysystemimmediately .

1.Sitontheseat,engagetheparkingbrake,and

movetheblade-controlswitch(PTO)totheON

position.Trystartingtheengine;theengine

shouldnotstart.

2.Sitontheseat,engagetheparkingbrake,and

movetheblade-controlswitch(PTO)totheOFF

position.Moveeithermotion-controlleverout

oftheNEUTRAL-LOCKposition.Trystartingthe

engine;theengineshouldnotstart.Repeatfor

theothercontrollever.

3.Sitontheseat,engagetheparkingbrake,

movetheblade-controlswitch(PTO)totheOFF

position,andmovethemotion-controllevers

totheNEUTRAL-LOCKposition.Nowstartthe

engine.Whiletheengineisrunning,disengage

theparkingbrake,engagetheblade-control

switch(PTO),andriseslightlyfromtheseat;the

engineshouldshutoff.

4.Sitontheseat,engagetheparkingbrake,

movetheblade-controlswitch(PTO)totheOFF

position,andmovethemotion-controllevers

totheNEUTRAL-LOCKposition.Nowstartthe

engine.Whiletheengineisrunning,center

eithermotioncontrolandmove(forwardor

reverse);theengineshouldshutoff.Repeatfor

othermotioncontrol.

5.Sitontheseat,disengagetheparkingbrake,

movetheblade-controlswitch(PTO)totheOFF

position,andmovethemotion-controllevers

totheNEUTRAL-LOCKposition.Trystartingthe

engine;theengineshouldnotstart.

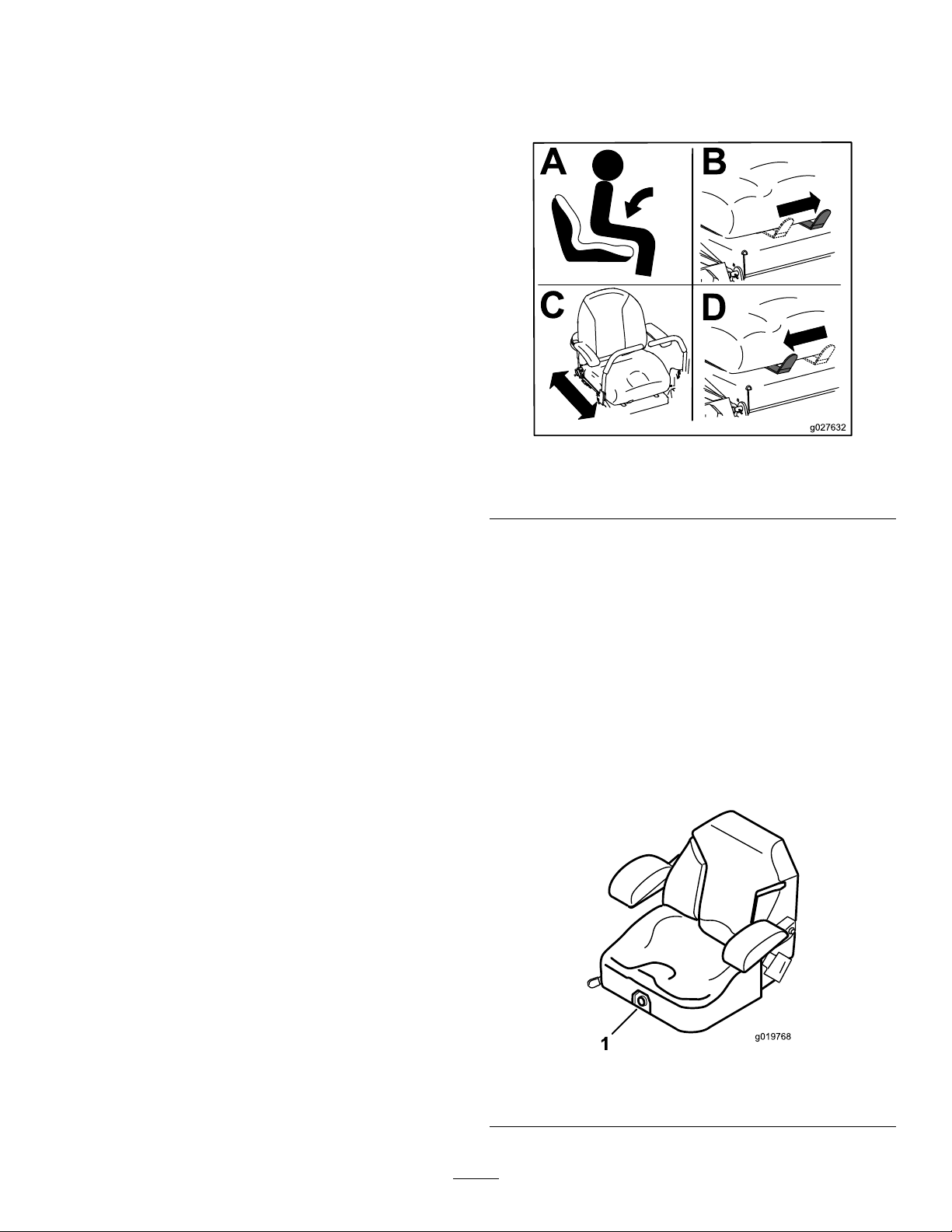

PositioningtheSeat

Theseatcanmoveforwardandbackward(Figure13).

Positiontheseatwhereyouhavethebestcontrolof

themachineandaremostcomfortable.

g027632

Figure13

SeatformachineswithMyRideshown.

ChangingtheSeat

Suspension

MachineswithoutMyRide™

SuspensionSystemOnly

Theseatisadjustabletoprovideasmoothand

comfortableride.Positiontheseatwhereyouare

mostcomfortable.

Toadjustit,turntheknobinfronteitherdirectionto

providethebestcomfort(Figure14).

Figure14

1.Seat-suspensionknob

23

g019768

Page 24

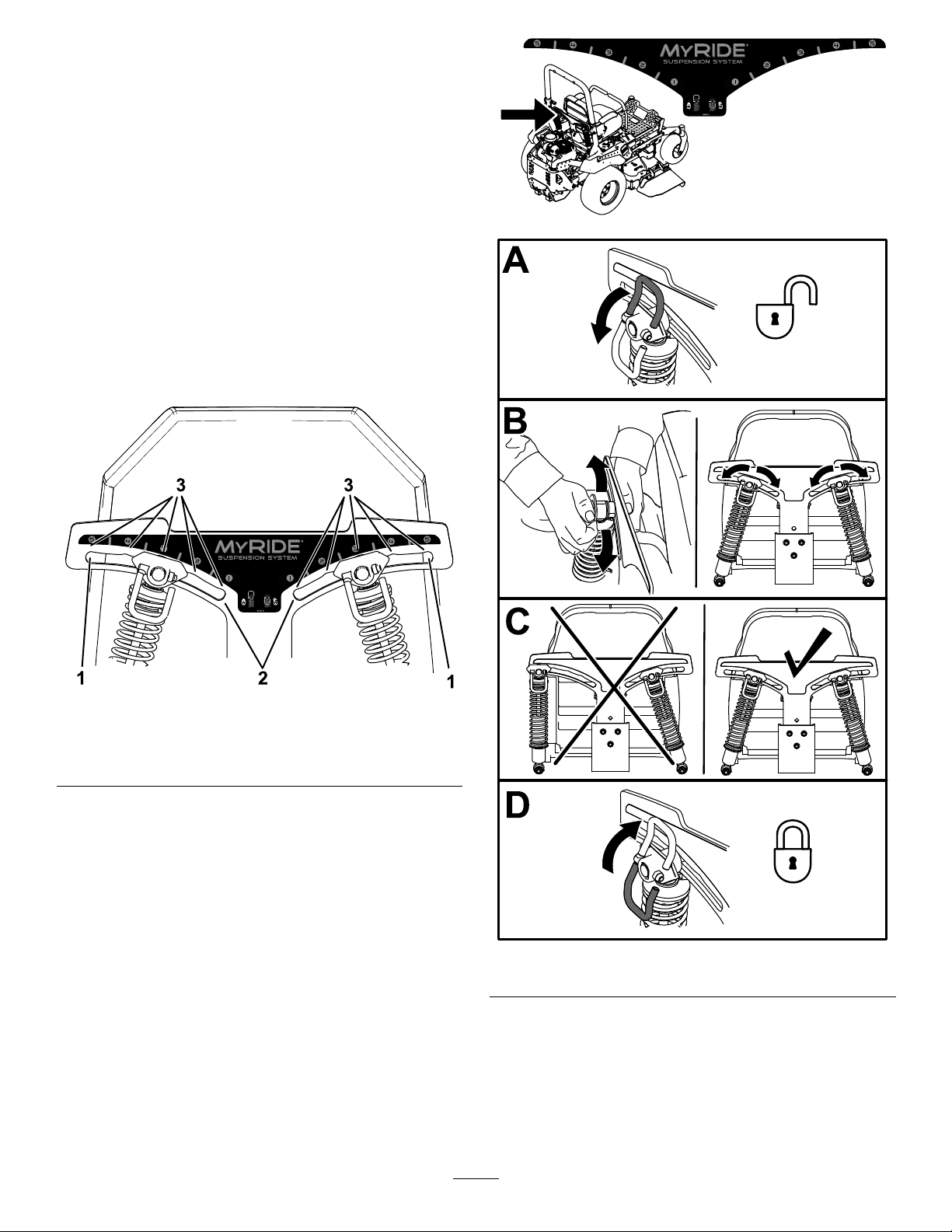

AdjustingtheRear-Shock

Assemblies

MachineswithMyRide™

SuspensionSystemOnly

TheMyRide™suspensionsystemadjuststoprovide

asmoothandcomfortableride.Youcanadjustthe

rear2-shockassembliestoquicklyandeasilychange

thesuspensionsystem.Positionthesuspension

systemwhereyouaremostcomfortable.

Theslotsfortherear-shockassemblieshave

detentpositionsforreference.Youcanpositionthe

rear-shockassembliesanywhereintheslot,notjustin

thedetentpositions.Thefollowinggraphicshowsthe

positionforasoftorrmrideandthedifferentdetent

positions(Figure15).

g227752

Figure15

1.Firmestposition3.Detentsintheslots

2.Softestposition

Note:Ensurethattheleftandrightrear-shock

assembliesarealwaysadjustedtothesamepositions.

Adjusttherear-shockassemblies(Figure16).

g227753

g227751

Figure16

24

Page 25

UsingAttachmentsand

WARNING

Accessories

UseonlyToroapprovedattachmentsandaccessories.

Ifyouaddmorethan1accessory-mountkit(i.e.,

bucketkitoruniversalmountkit)isaddedtoanyof

the4locationsshowninFigure17,addafront-weight

kit.ContactanAuthorizedServiceDealerforthe

front-weightkit.

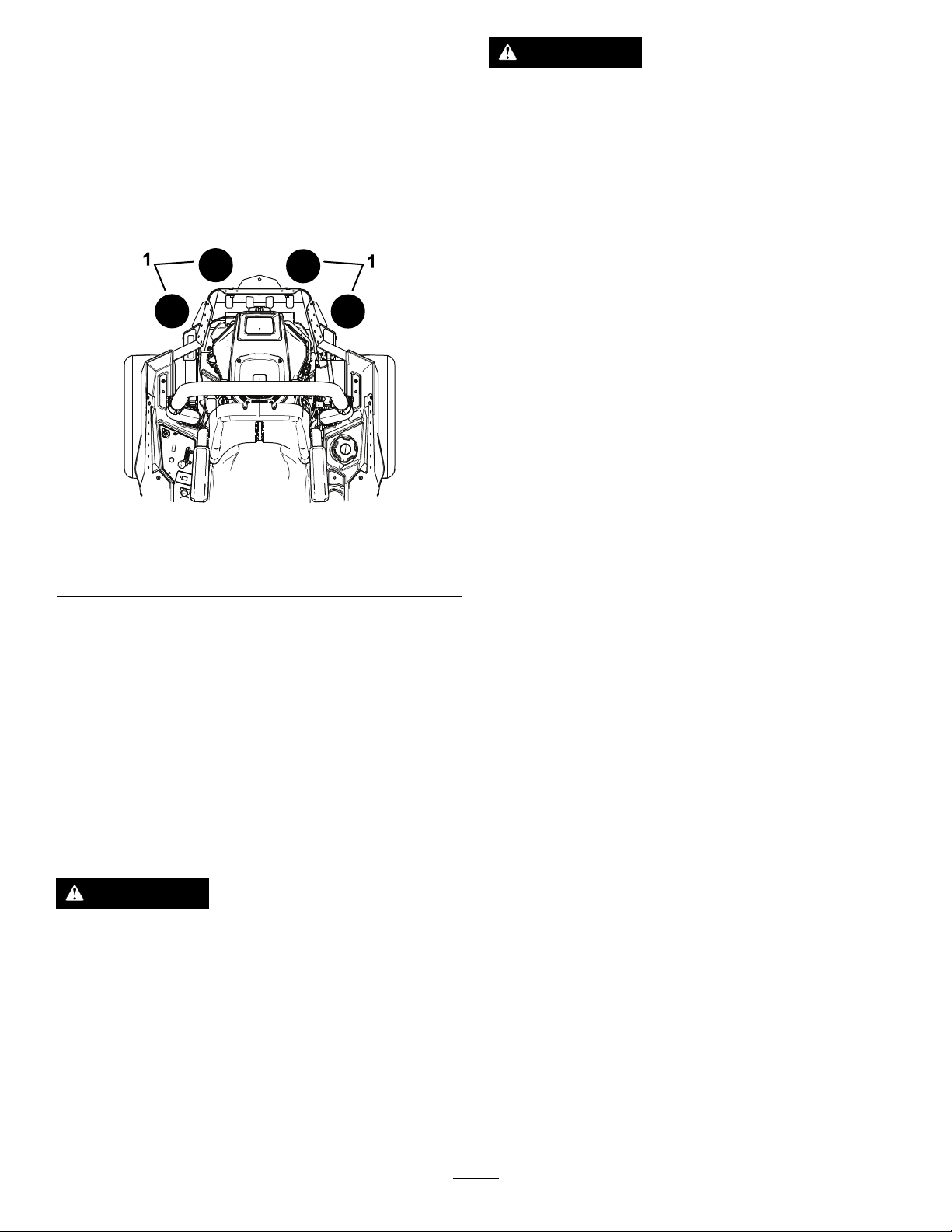

Figure17

1.Addafront-weightkitwhen2ormoreaccessory-mountkits

areinstalledatthesepositions.

Engineexhaustcontainscarbonmonoxide,

whichisanodorlessdeadlypoisonthatcan

killyou.

DoNotrunengineindoorsorinasmall

connedareawheredangerouscarbon

monoxidefumescancollect.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeopleorproperty .

•Thismowerwasdesignedforoneoperatoronly .

Donotcarrypassengersandkeepallothersaway

frommachineduringoperation.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Operateonlyindaylightorgoodarticiallight.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,

DoNotoperatethemachine;seekshelter.

g037417

•Useextracarewhileoperatingwithaccessoriesor

attachments,suchasgrasscollectionsystems.

Thesecanchangethestabilityofthemachine

andcausealossofcontrol.Followdirectionsfor

counterweightsifrequired.

DuringOperation

DuringOperationSafety

GeneralSafety

Theoperatormustusetheirfullattentionwhen

operatingthemachine.DoNotengageinanyactivity

thatcausesdistractions;otherwise,injuryorproperty

damagemayoccur.

WARNING

Operatingengineparts,especiallythemufer,

becomeextremelyhot.Severeburnscan

occuroncontactanddebris,suchasleaves,

grass,brush,etc.cancatchre.

•Allowengineparts,especiallythemufer,

tocoolbeforetouching.

•Removeaccumulateddebrisfrommufer

andenginearea.

•Keepawayfromholes,ruts,bumps,rocks,and

otherhiddenhazards.Usecarewhenapproaching

blindcorners,shrubs,trees,tallgrassorother

objectsthatmayhideobstaclesorobscurevision.

Uneventerraincouldoverturnthemachineor

causetheoperatortolosetheirbalanceorfooting.

•Besurealldrivesareinneutralandparkingbrake

isengagedbeforestartingengine.Useseatbelts

withtherollbarintheraisedandlockedposition.

•Starttheenginecarefullyaccordingtoinstructions

withfeetwellawayfromtheblades.

•Neveroperatethemowerwithdamagedguards,

shields,orcovers.Alwayshavesafetyshields,

guards,switchesandotherdevicesinplaceandin

properworkingcondition.

•Keepclearofthedischargeopeningatalltimes.

Nevermowwiththedischargedoorraised,

removedoralteredunlessthereisagrass

collectionsystemormulchkitinplaceandworking

properly.

•Keephandsandfeetawayfrommovingparts.

Ifpossible,DoNotmakeadjustmentswiththe

enginerunning.

25

Page 26

WARNING

Hands,feet,hair,clothing,oraccessories

canbecomeentangledinrotatingparts.

Contactwiththerotatingpartscan

causetraumaticamputationorsevere

lacerations.

–DoNotoperatethemachinewithout

guards,shields,andsafetydevicesin

placeandworkingproperly.

–Keephands,feet,hair,jewelry ,or

clothingawayfromrotatingparts.

•Neverraisethedeckwithbladesrunning.

•Beawareofthemowerdischargepathanddirect

dischargeawayfromothers.Avoiddischarging

materialagainstawallorobstructionasthe

materialmayricochetbacktowardtheoperator.

Stoptheblades,slowdown,andusecautionwhen

crossingsurfacesotherthangrassandwhen

transportingthemowertoandfromtheareatobe

mowed.

•Bealert,slowdownandusecautionwhen

makingturns.Lookbehindandtothesidebefore

changingdirections.DoNotmowinreverse

unlessabsolutelynecessary.

•DoNotchangetheenginegovernorsettingor

overspeedtheengine.

•Parkthemachineonlevelground.Stopengine,

waitforallmovingpartstostop,andremovethe

sparkplugwire(s).

–Beforechecking,cleaningorworkingonthe

mower.

–Afterstrikingaforeignobjectorabnormal

vibrationoccurs(inspectthemowerfor

damageandmakerepairsbeforerestarting

andoperatingthemower).

–Beforeclearingblockages.

–Wheneveryouleavethemower.DoNotleave

arunningmachineunattended.

•Stopengine,waitforallmovingpartstostop:

–Beforerefueling.

–Beforedumpingthegrasscatcher.

–Beforemakingheightadjustments.

•Tragicaccidentscanoccuriftheoperatorisnot

alerttothepresenceofchildren.Childrenare

oftenattractedtothemachineandthemowing

activity.Neverassumethatchildrenwillremain

whereyoulastsawthem.

–Keepchildrenoutofthemowingareaand

underthewatchfulcareofanotherresponsible

adult,nottheoperator.

–Bealertandturnthemachineoffifchildren

enterthearea.

–Beforeandwhilebackingorchangingdirection,

lookbehind,down,andside-to-sideforsmall

children.

–Neverallowchildrentooperatethemachine.

–DoNotcarrychildren,evenwiththeblades

shutoff.Childrencouldfalloffandbeseriously

injuredorinterferewiththesafeoperationof

themachine.Childrenthathavebeengiven

ridesinthepastcouldsuddenlyappearinthe

workingareaforanotherrideandberunover

orbackedoverbythemachine.

SlopeSafety

•Slopesareamajorfactorrelatedtolossofcontrol

androlloveraccidents,whichcanresultinsevere

injuryordeath.Theoperatorisresponsiblefor

safeslopeoperation.Operatingthemachineon

anysloperequiresextracaution.Beforeusingthe

machineonaslope,theoperatormust:

–Reviewandunderstandtheslopeinstructions

inthemanualandonthemachine.

–Useanangleindicatortodeterminethe

approximateslopeangleofthearea.

–Neveroperateonslopesgreaterthan15

degrees.

–Evaluatethesiteconditionsofthedayto

determineiftheslopeissafeformachine

operation.Usecommonsenseandgood

judgmentwhenperformingthisevaluation.

Changesintheterrain,suchasmoisture,can

quicklyaffecttheoperationofthemachineon

aslope.

•Identifyhazardsatthebaseoftheslope.Do

Notoperatethemachineneardropoffs,ditches,

embankments,waterorotherhazards.The

machinecouldsuddenlyrolloverifawheelgoes

overtheedgeortheedgecollapses.Keepasafe

distance(twicethewidthofthemachine)between

themachineandanyhazard.Useawalkbehind

machineorahandtrimmertomowthegrassin

theseareas.

26

Page 27

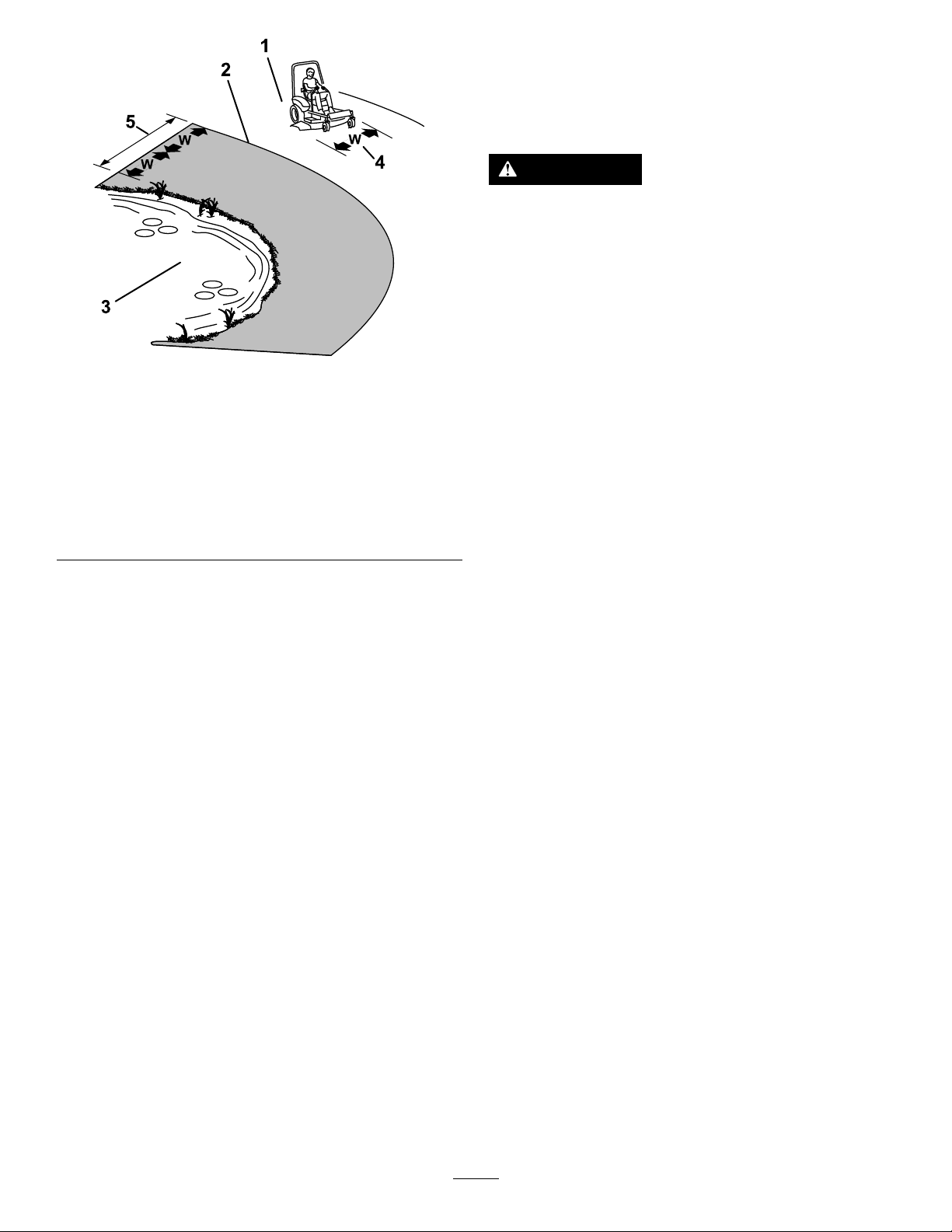

Figure18

1.SafeZone-Usethemowerhereonslopeslessthan15

degrees

2.DangerZone-Useawalk-behindmowerand/orhand

trimmeronslopesgreaterthan15degrees

3.Water

4.W=widthofthemachine

5.Keepasafedistance(twicethewidthofthemachine)

betweenthemachineandanyhazard.

RolloverProtectionSystem

(ROPS)Safety

ARolloverProtectionSystem(rollbar)isinstalledon

themachine.

WARNING

Thereisnorolloverprotectionwhentheroll

barisdown.Wheelsdroppingoveredges,

ditches,steepbanks,orwatercancause

rollovers,whichmayresultinseriousinjury,

deathordrowning.

•DoNotremovetheROPS.

•Keeptherollbarintheraisedandlocked

g221745

positionanduseseatbelt.

•Lowertherollbaronlywhenabsolutely

necessary.

•DoNotwearseatbeltwhentherollbaris

down.

•Driveslowlyandcarefully.

•Raisetherollbarassoonasclearance

permits.

•Avoidstarting,stoppingorturningthemachineon

slopes.Avoidmakingsuddenchangesinspeedor

direction;turnslowlyandgradually.

•DoNotoperateamachineunderanyconditions

wheretraction,steeringorstabilityisinquestion.

Beawarethatoperatingthemachineonwet

grass,acrossslopesordownhillmaycausethe

machinetolosetraction.Lossoftractiontothe

drivewheelsmayresultinslidingandalossof

brakingandsteering.Themachinecanslideeven

ifthedrivewheelsarestopped.

•Removeormarkobstaclessuchasditches,holes,

ruts,bumps,rocksorotherhiddenhazards.T all

grasscanhideobstacles.Uneventerraincould

overturnthemachine.

•Useextracarewhileoperatingwithaccessoriesor

attachments,suchasgrasscollectionsystems.

Thesecanchangethestabilityofthemachine

andcausealossofcontrol.Followdirectionsfor

counterweights.

•Ifpossible,keepthedeckloweredtotheground

whileoperatingonslopes.Raisingthedeckwhile

operatingonslopescancausethemachineto

becomeunstable.

•Becertainthattheseatbeltcanbereleased

quicklyintheeventofanemergency.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,andelectricalwires)before

drivingunderanyobjectsandDoNotcontact

them.

•Intheeventofarollover,taketheunittoan

AuthorizedServiceDealertohavetheROPS

inspected.

•ReplaceadamagedROPS.DoNotrepairor

revise.

•Anyaccessories,alterations,orattachments

addedtotheROPSmustbeapprovedbyT oro.

EnteringtheOperator’s

Position

Usethemowerdeckasasteptogetintothe

operator’sposition(Figure19).

27

Page 28

1.Stephere.

DisengagingtheParkingBrake

g029797

Figure19

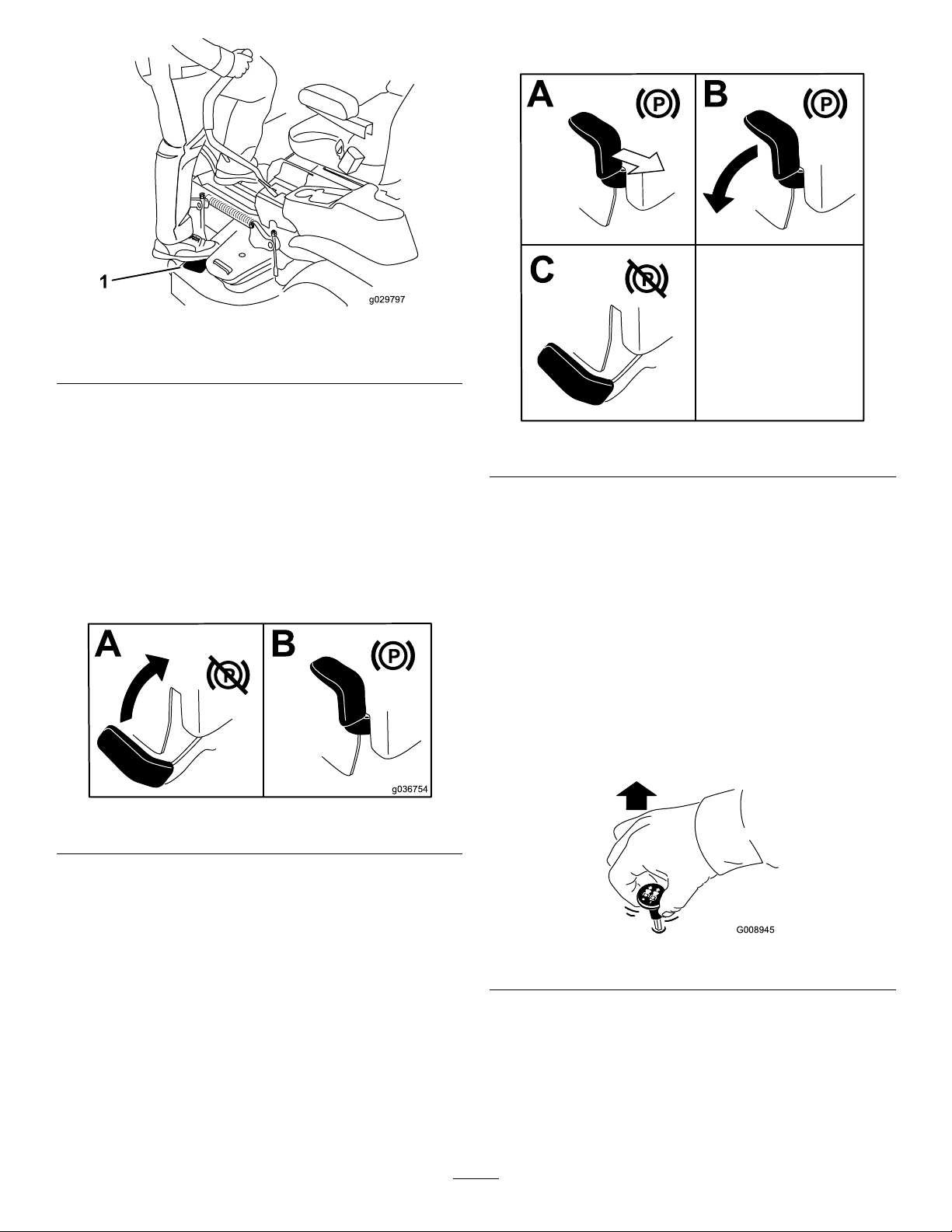

OperatingtheParking

Brake

Alwaysengagetheparkingbrakewhenyoustopthe

machineorleaveitunattended.

EngagingtheParkingBrake

Parkthemachineonalevelsurface.

Figure20

g192635

Figure21

OperatingtheMower

Blade-ControlSwitch(PTO)

Theblade-controlswitch(PTO)startsandstopsthe

mowerbladesandanypoweredattachments.

EngagingtheBlade-Control

Switch(PTO)

Note:Engagingtheblade-controlswitch(PTO)with

thethrottlepositionathalforlesscausesexcessive

weartothedrivebelts.

g036754

g008945

Figure22

28

Page 29

DisengagingtheBlade-Control

Switch(PTO)

Figure23

OperatingtheThrottle

YoucanmovethethrottlecontrolbetweenFASTand

SLOWpositions(Figure24).

AlwaysusetheFASTpositionwhenengagingthePTO.

OperatingtheChoke

Usethechoketostartacoldengine.

1.Pullupthechokeknobtoengagethechoke

beforeusingthekeyswitch(Figure25).

2.Pushdownthechokeknobtodisengagethe

chokeaftertheenginehasstarted(Figure25).

g009174

Figure24

g008959

Figure25

g008946

1.ONposition2.OFFposition

29

Page 30

StartingtheEngine

ShuttingOfftheEngine

Note:Awarmorhotenginemaynotrequirechoking.

Important:Donotengagethestarterformore

than5secondsatatime.Engagingthestarter

motorformorethan5secondscandamagethe

startermotor.Iftheenginefailstostart,wait10

secondsbeforeoperatingtheenginestarteragain.

Note:RefertoFigure45todeterminewhichengine

youhave.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

Alwaysremovethekeyandengagethe

parkingbrakewhenleavingthemachine

unattended.

ShuttingOffKawasakiEngines

Lettheengineidleatslowthrottlefor60seconds

beforeturningtheswitchoff.

Figure26

g227548

g036839

Figure27

Important:Makesurethatthefuel-shutoff

valveisclosedbeforetransportingorstoring

themachinetopreventfuelleakage.Engage

theparkingbrakebeforetransporting.Remove

thekeyasthefuelpumpmayrunandcausethe

batterytolosecharge.

30

Page 31

ShuttingOffKohlerEngines

ShuttingOffToroEngines

Lettheengineidleatmid-throttlefor60seconds

beforeturningtheswitchoff.

Note:EnsurethethrottleisintheFASTposition

beforeshuttingofftheengine.

Figure28

Important:Makesurethatthefuel-shutoff

valveisclosedbeforetransportingorstoring

themachinetopreventfuelleakage.Engage

theparkingbrakebeforetransporting.Remove

thekeyasthefuelpumpmayrunandcausethe

batterytolosecharge.

g231028

Figure29

g037049

Important:Makesurethatthefuel-shutoff

valveisclosedbeforetransportingorstoring

themachinetopreventfuelleakage.Engage

theparkingbrakebeforetransporting.Remove

thekeyasthefuelpumpmayrunandcausethe

batterytolosecharge.

31

Page 32

UsingtheMotion-Control

WARNING

Levers

Themachinecanspinveryrapidly.You

maylosecontrolofthemachineandcause

personalinjuryordamagetothemachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemaking

sharpturns.

DrivingForward

Note:Theengineshutsoffwhenyoumovethe

traction-controlwiththeparkingbrakeengaged.

Tostopthemachine,pullthemotion-controllevers

totheNEUTRALposition.

1.Disengagetheparkingbrake;referto

DisengagingtheParkingBrake(page28).

2.Movetheleverstothecenter,unlockedposition.

3.T ogoforward,slowlypushthemotion-control

leversforward(Figure31).

c:\data\documentum\checkout\g004532

Figure30

1.Motion-control

lever—NEUTRAL-LOCK

position

2.Center,unlockedposition5.Frontofmachine

3.Forward

4.Backward

DrivingtheMachine

Thedrivewheelsturnindependently,poweredby

hydraulicmotorsoneachaxle.Youcanturn1side

inreversewhileyouturntheotherforward,causing

themachinetospinratherthanturn.Thisgreatly

improvesthemachinemaneuverabilitybutmay

requiresometimeforyoutoadapttohowitmoves.

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Place

thethrottlecontrolintheFASTpositionforbest

performance.Alwaysoperateinthefullthrottle

positionwhenmowing.

g008952

Figure31

DrivingBackward

1.Movetheleverstothecenter,unlockedposition.

2.T ogobackward,slowlypullthemotion-control

leversrearward(Figure32).

32

Page 33

Figure32

UsingtheSideDischarge

Themowerhasahingedgrassdeectorthat

dispersesclippingstothesideanddowntowardthe

turf.

DANGER

Withoutagrassdeector,dischargecover,or

acompletegrass-catcherassemblymounted

inplace,youandothersareexposedtoblade

contactandthrowndebris.Contactwith

rotatingmowerblade(s)andthrowndebris

willcauseinjuryordeath.

•Neverremovethegrassdeectorfromthe

mowerdeckbecausethegrassdeector

routesmaterialdowntowardtheturf.Ifthe

g008953

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthe

mowerdeck.

•Nevertrytoclearthedischargearea

ormowerbladesunlessyoumovethe

blade-controlswitch(PTO)totheOFF

position,rotatethekeyswitchtotheOFF

position,andremovethekeyfromthekey

switch.

•Makesurethatthegrassdeectorisinthe

downposition.

AdjustingtheHeightofCut

UsingtheTransportLock

Thetransportlockhas2positions,andisusedwith

thedeck-liftpedal.ThereisaLOCKpositionand

anUNLOCKpositionforthetransportpositionofthe

mowerdeck(Figure33).

33

Page 34

4.Selectaholeintheheight-of-cutbracket

correspondingtotheheight-of-cutdesired,and

insertthepin(Figure34).

5.Pushonthedecklift,pulluponthetransport

lockknob,andslowlylowerthemowerdeck.

Figure34

1.Deck-liftpedal3.Height-of-cutpin

2.Height-of-cutholes

4.Transportlockknob

g036745

Figure33

Transport-LockPositions

1.Transportlockknob3.UNLOCKposition—The

mowerdeckdoesnotlock

intothetransportposition.

2.LOCKposition—The

mowerdecklocksintothe

transportposition.

AdjustingtheHeight-of-CutPin

Adjusttheheight-of-cutfrom38to127mm(1-1/2to5

inches)in6mm(1/4inch)incrementsbymovingthe

height-of-cutpinintodifferentholelocations.

1.MovethetransportlocktotheLOCKposition.

2.Pushonthedeck-liftpedalwithyourfootand

raisethemowerdecktotheTRANSPORTposition

(alsothe127mmor5inchcutting-height

position)asshowninFigure34.

AdjustingtheAnti-Scalp

Rollers

Wheneveryouchangetheheightofcut,adjustthe

g037050

heightoftheanti-scalprollers.

Note:Adjusttheanti-scalprollerssothattherollers

donottouchthegroundinnormal,atmowingareas.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitchandengagetheparking

brake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Adjusttheanti-scalprollersasshowninFigure

35orFigure36.

3.Removethepinfromtheheight-of-cutbracket

(Figure34).

34

Page 35

Figure35

2500Seriesmowerdeckshown

1.Anti-scalproller4.Flangenut

2.Spacer

3.Bushing

5.Bolt

AdjustingtheSideBumpers

Rear-DischargeMachinesOnly

Installthesidebumpersinthetopholeswhen

operatinginaheightofcuthigherthan64mm(2-1/2

inches)andinthecenterholeswhenoperatingina

heightofcutlowerthan64mm(2-1/2inches).

Note:Whenthebumpersbecomeworn,switchthe

bumperstotheoppositesidesofthemowerandip

themover.Thisallowsyoutousethebumperslonger

g038079

beforereplacingthem.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitchandengagetheparking

brake;refertoEngagingtheParkingBrake

(page28).

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Raisethemowertothetransportposition.

4.Removetheboltsandnutsfromeachbumper

(Figure37).

Figure36

1500and2000Seriesmowerdeckshown

1.Flangenut4.Anti-scalproller

2.Bolt

3.Bushing

5.Spacer

g036848

g037862

Figure37

1.Bolt(3)3.Nut(3)

2.Bumper

5.Moveeachbumpertothedesiredpositionand

securethemwiththeboltsandnuts.

Note:Useonlythetoporcentersetsofholes

toadjustthebumpers.Youusethebottom

holeswhenswitchingsides,atwhichtimethey

becomethetopholesontheothersideofthe

mower.

35

Page 36

OperatingTips

UsingtheFastThrottleSetting

dropontoyourlawn.Toavoidthis,moveontoa

previouslycutareawiththebladesengagedoryou

candisengagethemowerdeckwhilemovingforward.

Forbestmowingandmaximumaircirculation,operate

theengineattheFASTposition.Airisrequiredto

thoroughlycutgrassclippings,sodonotsetthe

height-of-cutsolowastototallysurroundthemower

deckinuncutgrass.Alwaystrytohave1sideofthe

mowerdeckfreefromuncutgrass,whichallowsair

tobedrawnintothemowerdeck.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethat

thecuttingheightofthemowerdeckdoesnotscalp

anyunevenground.However,thecuttingheight

usedinthepastisgenerallythebestonetouse.

Whencuttinggrasslongerthan15cm(6inches)tall,

youmaywanttocutthelawntwicetoensurean

acceptablequalityofcut.

CuttingaThirdoftheGrassBlade

Itisbesttocutonlyaboutathirdofthegrassblade.

Cuttingmorethanthatisnotrecommendedunless

grassissparse,oritislatefallwhengrassgrows

moreslowly.

KeepingtheUndersideofthe

MowerDeckClean

Cleanclippingsanddirtfromtheundersideofthe

mowerdeckaftereachuse.Ifgrassanddirtbuildup

insidethemowerdeck,cuttingqualitywilleventually

becomeunsatisfactory.

MaintainingtheBlade(s)

Maintainasharpbladethroughoutthecuttingseason

becauseasharpbladecutscleanlywithouttearingor

shreddingthegrassblades.Tearingandshredding

turnsgrassbrownattheedges,whichslowsgrowth

andincreasesthechanceofdisease.Checkthe

mowerbladesaftereachuseforsharpness,and

foranywearordamage.Filedownanynicksand

sharpenthebladesasnecessary .Ifabladeis

damagedorworn,replaceitimmediatelywitha

genuineT ororeplacementblade.

AfterOperation

AlternatingtheMowingDirection

Alternatethemowingdirectiontokeepthegrass

standingstraight.Thisalsohelpsdisperseclippings,

whichenhancesdecompositionandfertilization.

MowingatCorrectIntervals

Grassgrowsatdifferentratesatdifferenttimesof

theyear.Tomaintainthesamecuttingheight,mow

moreofteninearlyspring.Asthegrassgrowthrate

slowsinmidsummer,mowlessfrequently.Ifyou

cannotmowforanextendedperiod,rstmowata

highcuttingheight,thenmowagain2dayslaterata

lowerheightsetting.

UsingaSlowerCuttingSpeed

Toimprovecutquality ,useaslowergroundspeed

incertainconditions.

AvoidingCuttingTooLow

Whenmowinguneventurf,raisethecuttingheight

toavoidscalpingtheturf.

AfterOperationSafety

GeneralSafety

•Parkmachineonlevelground,disengagedrives,

setparkingbrake,stopengine,removekeyor

disconnectsparkplugwire.Waitforallmovement

tostopandallowthemachinetocoolbefore

adjusting,cleaning,repairing,orstoring.Never

allowuntrainedpersonneltoservicemachine.

•CleanthemachineasstatedintheMaintenance

section.Keepengineandengineareafreefrom

accumulationofgrass,leaves,excessivegrease

oroil,andotherdebriswhichcanaccumulate

intheseareas.Thesematerialscanbecome

combustibleandmayresultinare.

•Frequentlycheckforwornordeteriorating

componentsthatcouldcreateahazard.Tighten

loosehardware.

StoppingtheMachine

Ifyoumuststoptheforwardmotionofthemachine

whilemowing,aclumpofgrassclippingsmay

36

Page 37

UsingtheFuel-Shutoff

WARNING

Valve

Closethefuel-shutoffvalvefortransport,maintenance,

andstorage(Figure38).

Ensurethatthefuel-shutoffvalveisopenwhen

startingtheengine.

Theengineandhydraulic-driveunitscan

becomeveryhot.Touchingahotengineor

hydraulic-driveunitscancausesevereburns.

Allowtheengineandhydraulic-driveunits

tocoolcompletelybeforeaccessingthe

drive-wheelreleasevalves.

Thedrive-wheelreleasevalvesarelocatedontheleft

andrightsidesunderneaththeenginedeck.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake.

2.Shutofftheengine,removethekey ,andwait

g036849

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Locatethebypassleversbehindtheseat,down

ontheleftandrightsideoftheframe.

4.T opushthemachine,movebothbypassknobs

rearwardandlockthemintoplace(Figure39).

5.Disengagetheparkingbrakebeforepushing

themachine.

Figure38

1.ONposition2.OFFposition

UsingtheDrive-Wheel

ReleaseValves

WARNING

Handsmaybecomeentangledintherotating

drivecomponentsbelowtheenginedeck,

whichcouldresultinseriousinjury.

Shutofftheengine,removethekey,andallow

allmovingpartstostopbeforeaccessingthe

drive-wheelreleasevalves.

g008948

g035062

Figure39

1.Frontofthemachine

2.Rotatebypassreleaseknobcounterclockwisetoloosen.

3.Leverpositionforoperatingthemachine

4.Pulltheleverinthisdirectiontopushthemachine.

5.Leverpositionforpushingthemachine

6.Rotatethebypass-releaseknobclockwisetotighten.

7.Engine

8.Releaselever

37

Page 38

6.T orunthemachine,movethebypassknobsto

theFORWARDpositionandlockthemintoplace

(Figure39).

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthe

machine.Useafull-widthramp.Ensurethatthetrailer

ortruckhasallthenecessarybrakes,lighting,and

markingasrequiredbylaw.Pleasecarefullyreadall

thesafetyinstructions.Knowingthisinformationcould

helpyouorbystandersavoidinjury.Refertoyour

localordinancesfortrailerandtie-downrequirements.

WARNING

Drivingonthestreetorroadwaywithout

turnsignals,lights,reectivemarkings,ora

slow-moving-vehicleemblemisdangerous

andcanleadtoaccidents,causingpersonal

injury.

Donotdrivethemachineonapublicstreet

orroadway.

SelectingaTrailer

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath(Figure40).

•Useonlyafull-widthramp;donotuse

individualrampsforeachsideofthe

machine.

•Donotexceeda15-degreeanglebetween

therampandthegroundorbetweenthe

rampandthetrailerortruck.

•Ensurethatthelengthoftherampisat

least4timesaslongastheheightofthe

trailerortruckbedtotheground.This

ensuresthattherampangledoesnot

exceed15degreesonatground.

Figure40

1.Full-widthrampinstowed

position

2.Sideviewoffull-width

rampinloadingposition

3.Notgreaterthan

15degrees

4.Rampisatleast4times

aslongastheheightof

thetrailerortruckbedto

theground

5.H=heightofthetraileror

truckbedtotheground

6.Trailer

LoadingtheMachine

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath.

•Useextremecautionwhenoperatinga

machineonaramp.

g027996

•Backthemachineuptherampanddriveit

forwarddowntheramp.

•Avoidsuddenaccelerationordeceleration

whiledrivingthemachineonarampas

thiscouldcausealossofcontrolora

tip-oversituation.

38

Page 39

1.Ifusingatrailer,connectittothetowingvehicle

andconnectthesafetychains.

2.Ifapplicable,connectthetrailerbrakesand

lights.

3.Lowertheramp,ensuringthattheangle

betweentherampandthegrounddoesnot

exceed15degrees(Figure40).

4.Backthemachineuptheramp(Figure41).

Figure41

g028043

1.Backthemachineupthe

ramp.

2.Drivethemachineforward

downtheramp.

5.Shutofftheengine,removethekey,andengage

theparkingbrake.

6.Tiedownthemachinenearthefrontcaster

wheelsandtherearbumperwithstraps,chains,

cable,orropes(Figure42).Refertolocal

regulationsfortie-downrequirements.

Figure42

1.Tie-downloops

UnloadingtheMachine

1.Lowertheramp,ensuringthattheangle

betweentherampandthegrounddoesnot

exceed15degrees(Figure40).

2.Drivethemachineforwarddowntheramp

(Figure41).

g227761

39

Page 40

Maintenance

MaintenanceSafety

WARNING

Whilemaintenanceoradjustmentsarebeing

made,someonecouldstarttheengine.

Accidentalstartingoftheenginecould

seriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionswitch,

engageparkingbrake,andpullthewire(s)

offthesparkplug(s)beforeyoudoany

maintenance.Alsopushthewire(s)asideso

itdoesnotaccidentallycontactthespark

plug(s).

WARNING

Theenginecanbecomeveryhot.Touchinga

hotenginecancausesevereburns.

Allowtheenginetocoolcompletelybefore

serviceormakingrepairsaroundtheengine

area.

•Parkmachineonlevelground,disengagedrives,

setparkingbrake,stopengine,removekeyor

disconnectsparkplugwire.Waitforallmovement

tostopandallowthemachinetocoolbefore

adjusting,cleaningorrepairing.Neverallow

untrainedpersonneltoservicemachine.

•Disconnectbatteryorremovesparkplugwire

beforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositivelast.

Reconnectpositiverstandnegativelast.

•Keepthemachine,guards,shieldsandall

safetydevicesinplaceandinsafeworking

condition.Frequentlycheckforwornor

deterioratingcomponentsandreplacethemwith

themanufacturer’srecommendedpartswhen

necessary.

WARNING

Removalormodicationoforiginal

equipment,partsand/oraccessories

mayalterthewarranty ,controllability,

andsafetyofthemachine.Unauthorized

modicationstotheoriginalequipmentor

failuretouseoriginalToropartscouldlead

toseriousinjuryordeath.Unauthorized

changestothemachine,engine,fuelor

ventingsystem,mayviolateapplicable

safetystandardssuchas:ANSI,OSHAand

NFPAand/orgovernmentregulationssuch

asEP AandCARB.

WARNING

Hydraulicuidescapingunderpressure

canpenetrateskinandcauseinjury.Fluid

accidentallyinjectedintotheskinmustbe

surgicallyremovedwithinafewhoursby

adoctorfamiliarwiththisformofinjuryor

gangrenemayresult.

–Ifequipped,makesureallhydraulic

uidhosesandlinesareingood

conditionandallhydraulicconnections

andttingsaretightbeforeapplying

pressuretohydraulicsystem.

–Keepbodyandhandsawayfrom

pinholeleaksornozzlesthatejecthigh

pressurehydraulicuid.

–Usecardboardorpaper,notyourhands,

tondhydraulicleaks.

–Safelyrelieveallpressureinthe

hydraulicsystembyplacingthemotion

controlleversinneutralandshuttingoff

theenginebeforeperforminganywork

onthehydraulicsystem.

WARNING

Fuelsystemcomponentsareunder

highpressure.Theuseofimproper

componentscanresultinsystemfailure,

gasolineleakageandpossibleexplosion.

Useonlyapprovedfuellinesandfuellters

forhighpressuresystems.

•Usecarewhencheckingblades.Wrapthe

blade(s)orweargloves,andusecautionwhen

servicingthem.Onlyreplacedamagedblades.

Neverstraightenorweldthem.

40

Page 41

•Usejackstandstosupportthemachineand/or

componentswhenrequired.

CAUTION

Raisingthemachineforserviceor

maintenancerelyingsolelyonmechanical

orhydraulicjackscouldbedangerous.

Themechanicalorhydraulicjacksmaynot

beenoughsupportormaymalfunction

allowingthemachinetofall,whichcould

causeinjury.

Donotrelysolelyonmechanicalor

hydraulicjacksforsupport.Useadequate

jackstandsorequivalentsupport.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

RecommendedMaintenanceSchedule(s)

•Keephandsandfeetawayfrommovingparts.

Ifpossible,DoNotmakeadjustmentswiththe

enginerunning.Ifthemaintenanceoradjustment

procedurerequiretheenginetoberunningand

componentsmoving,useextremecaution.

WARNING

Contactwithmovingpartsorhotsurfaces

maycausepersonalinjury .

Keepyourngers,hands,andclothing

clearofrotatingcomponentsandhot

surfaces.

•Checkallboltsfrequentlytomaintainproper

tightness.

MaintenanceService

Interval

Aftertherst5hours

Aftertherst75hours

Beforeeachuseordaily

Every25hours

Every25hoursormonthly,

whichevercomesrst

MaintenanceProcedure

•ForToroengines—changetheengineoilandlter.

•Changethehydraulic-systemltersanduid.

•Checkthesafety-interlocksystem.

•ForKawasakiengines—checktheengine-oillevel.

•ForKohlerengines—checktheaircleanerfordirty,loose,ordamagedparts.

•ForKohlerengines—checktheengine-oillevel.

•ForToroengines—checktheengine-oillevel.

•Cleantheblowerhousing(moreoftenunderdusty,dirtyconditions).

•Cleantheairintakescreen.

•Checktheseatbelt.

•Checktherollbarknobs.

•Cleantheenginescreenandtheareaaroundtheengine.

•Cleanaroundtheengine-exhaustsystem.

•Checkthehydraulicuidlevelintheexpansiontank.

•Inspecttheblades.

•Cleanthemowerdeck.

•Cleanthesuspensionsystem.

•For1500and2000Seriesmachines—Greasethefrontcasteraxles(moreoftenin

dirtyordustyconditions).

•ForKohlerengines—serviceorreplacetheair-cleanerfoamelement(moreoften

underdusty,dirtyconditions).

•ForT oroengineswithastandardaircleaner—cleantheair-cleanerfoamelement

(moreoftenindirtyordustyconditions).

Every50hours

•For2500Seriesmachines—Greasethemowerdeck-idlerpivot.

•Greasethepump-idlerpivot.

•Checkthesparkarrester(ifequipped).

•Checkthetirepressure.

•Inspectthebeltsforcracksandwear.

41

Page 42

MaintenanceService

Interval

Every100hours

Every100hoursoryearly,

whichevercomesrst

Every200hours

Every250hours

MaintenanceProcedure

•ForKawasakiengines—changetheengineoil(moreoftenindirtyordusty

conditions).

•ForKawasakiengines—replaceorcleanandgapthesparkplug.

•ForKohlerengines—replacetheair-cleanerpaperelement(moreoftenunderdusty ,

dirtyconditions).

•ForKohlerengines—changetheengineoilandtheengine-oillter.

•ForToroengineswithastandardaircleaner—replacetheair-cleanerfoamand

paperelements(moreoftenindirtyordustyconditions).

•ForT oroengines—changetheengineoilandoillter(moreoftenindirtyordusty

conditions).

•ForToroengines—checkthesparkplug(s).

•ForKohlerengines—cleanthecoolingns(moreoftenunderdusty,dirtyconditions).

•ForKawasakiengines—changetheengine-oillter(moreoftenindirtyordusty

conditions).

•ForKohlerengines—checkthesparkplug(s).

•ForToroengines—replacethesparkplug(s).

•ForKawasakiengines—replacetheprimaryairlter(moreoftenindirtyordusty

conditions).

•ForKawasakiengines—checkthesafetyairlter(moreoftenindirtyordusty

conditions).

•ForT oroengineswithaheavy-dutyaircleaner—replacetheairlter(moreoftenin

dirtyordustyconditions).

•Aftertheinitialchange—changethehydraulic-systemltersanduidwhenusing

Mobil115W50uid.(Changeitmoreoftenunderdirtyordustyconditions)

•ForKawasakiengines—Checkandadjustthevalveclearance.SeeanAuthorized

Every300hours

Every500hours

Monthly

Yearly

Yearlyorbeforestorage

ServiceDealer.

•ForToroengines—Checkandadjustthevalveclearance.SeeanAuthorized

ServiceDealer.

•ForKawasakiengines—replacethesafetyairlter(moreoftenindirtyordusty

conditions).

•ForKohlerengines—Checkandadjustthevalveclearance.SeeanAuthorized

ServiceDealer.

•ForKohlerengines—replacethesparkplug(s).

•Replacetheemissions-airintakelter.

•Replacethefuellter(moreoftenindusty,dirtyconditions).

•Checktheparkingbrakeadjustment.

•Aftertheinitialchange—changethehydraulic-systemltersanduidwhenusing

Toro®HYPR-OIL™500uid.(Changeitmoreoftenunderdirtyordustyconditions)

•Checkthebatterycharge.

•For2500Seriesmachines—Greasethecaster-wheelhubs.

•Paintchippedsurfaces.

•CompletealltheproceduresintheStoragechapter.

Important:Refertoyourengineowner'smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Shutofftheengineandremovethekeyfromtheswitchbeforeyouperformanymaintenance.

42

Page 43

Lubrication

GreasingtheCaster-Wheel

Hubs

GreasingtheMachine

ServiceInterval:Every25hours—For1500and

2000Seriesmachines—Greasethe

frontcasteraxles(moreoftenin

dirtyordustyconditions).

Every50hours—For2500Series

machines—Greasethemowerdeck-idler

pivot.

Every50hours—Greasethepump-idlerpivot.

Greasethemachinemoreoftenindirtyordusty

conditions.

GreaseType:No.2lithiumormolybdenumgrease

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake;refertoParking-BrakeLever(page17).

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanthegreasettingswitharag.

2500SeriesMachinesOnly

ServiceInterval:Yearly—For2500Series

machines—Greasethe

caster-wheelhubs.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Raisethemowerforaccess.

4.Removethecasterwheelfromthecasterforks.

5.Removethesealguardsfromthewheelhub

(Figure44).

Note:Scrapeanypaintoffthefrontofthe

tting(s).

4.Greasethepumpidler-pulleypivotwith1or2

pumpsofgrease(Figure43).

5.Greasethefrontcasteraxles(Figure43).

Figure43

1.Pump-idlerpivot3.Mowerdeckidler-pulley

pivot(2500Series

machinesonly)

2.Casteraxle(1500and

2000Seriesmachines

only)

g006115

Figure44

1.Sealguard2.Spacernutwithwrench