Page 1

TITAN

ModelNo.AllModels

®

HDSeriesRidingMower

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

FormNo.3421-130RevA

SetupInstructions

ProcedureDescription

1

2

3

4

5

6

7

8

9

10

11

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

No.2lithiumormolybdenum-based

grease(purchaseseparately)

Locknut(3/8inch)

Carriagebolt(3/8x2-1/4inches)

1tube

Qty.

Use

–

–

–

–

–

–

–

–

–

3

3

Removethemachinefromthecrate.

Addfueltothemachine.

Checktheengine-oillevel.

Servicethehydraulicuid.

Checkthetirepressure.

Servicingthebattery.

Raisetherolloverprotectionsystem

(ROPS).

Checkthegrassdeector.

Removetheshippingstrap(s).

Checkthemachineforgrease.

Installtherightbumper(reardischarge

modelsonly).

12

13

14

Nopartsrequired

Nopartsrequired

Operator'sManual

Engineowner'smanual(non-Toro

engines)

Operator-trainingmaterial

Key2

Registrationcard1

–

–

1

1

1

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

©2017—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

Checkthemoweradjustment.

Checkthemachinebeforedeliveryto

thecustomer(allmachines).

Deliverthemachinetothecustomer(all

machines).

PrintedintheUSA

AllRightsReserved

*3421-130*A

Page 2

1

4

RemovingtheMachine

fromtheCrate

NoPartsRequired

Procedure

Ifremovingthemachinefromametalcrate,referto

theDealer/DistributorPortalforfurtherinformation.

2

AddingFueltotheMachine

NoPartsRequired

Procedure

ServicingtheHydraulic

Fluid

NoPartsRequired

Procedure

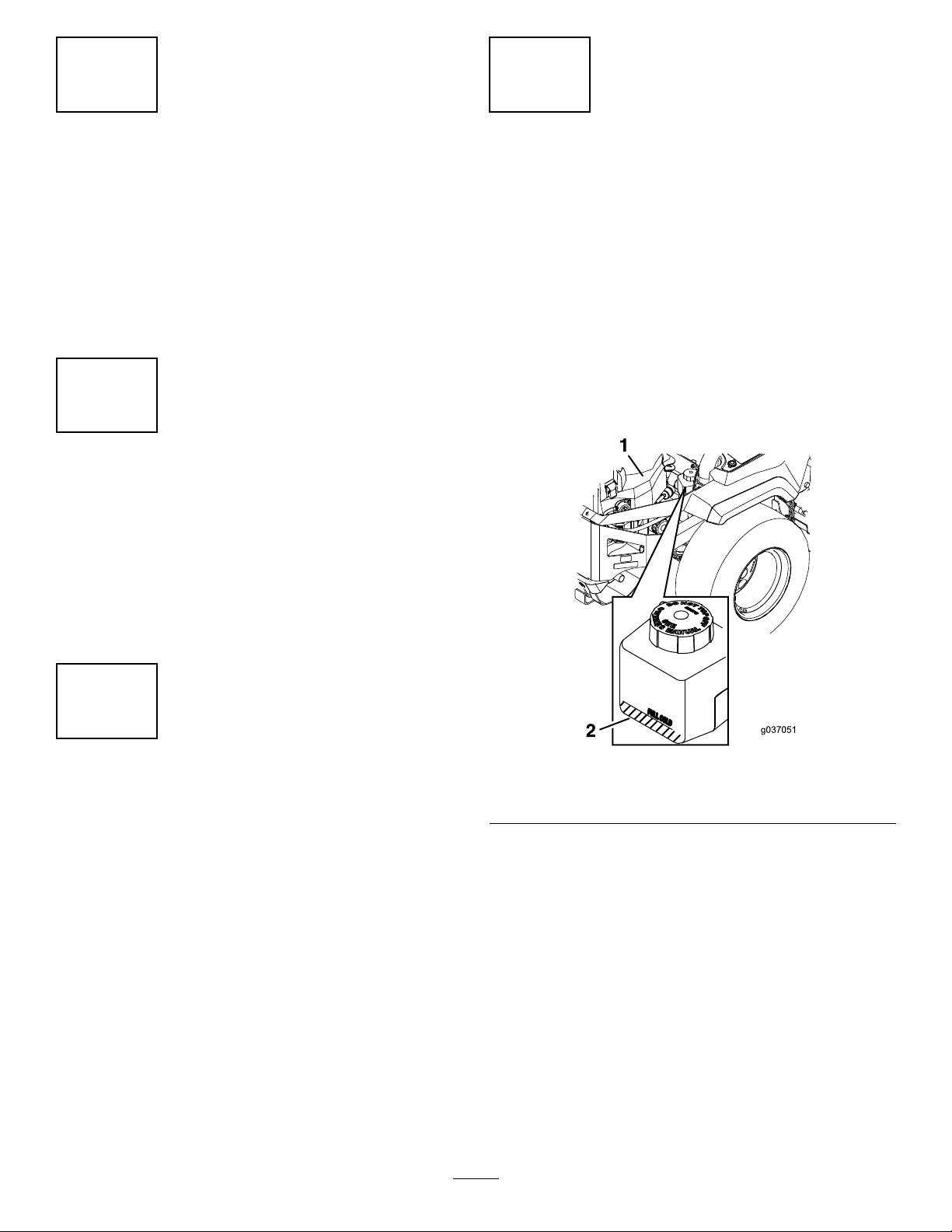

Thismachineisshippedlledwithhydraulicuidin

thereservoirs.

Checktheexpansiontank;ifnecessary,addT oro

HYPR-OIL

theOperator'sManual,totheFULLCOLDline(Figure

1).

™

500hydraulicuid,asrecommendedin

®

Addfueltothemachinebeforestartingit.Refer

toyourOperator’sManualforthecorrectfueland

procedure.

3

CheckingtheEngine-Oil

Level

NoPartsRequired

Procedure

Beforeyoustarttheengineandusethemachine,

checktheoillevelintheenginecrankcase;refer

toServicingtheEngine-OilLevelintheOperator's

Manual.

g037051

Figure1

1.Engine2.Expansiontank

2

Page 3

5

CheckingtheTirePressure

NoPartsRequired

Procedure

Pressure:13psi(90kPa)

Note:Checkthetirepressurebeforestartingthe

machine.RefertoyourOperator’sManualforthe

correcttiretypeandprocedure.

6

ServicingtheBattery

NoPartsRequired

Procedure

Important:Donotrunthemachinewiththe

batterydisconnected;electricaldamagemay

occurtotheengine.

1.Chargethebattery.RefertotheOperator's

Manualforinstructions.

2.Connectthenegativebatterycable.

Note:Ifthepositivecableisalsodisconnected,

connectthepositive(red)cabletothepositive

batteryterminalrst,thenthenegative(black)

cabletothenegativebatteryterminal.Slipthe

insulatorbootoverthepositiveterminal.

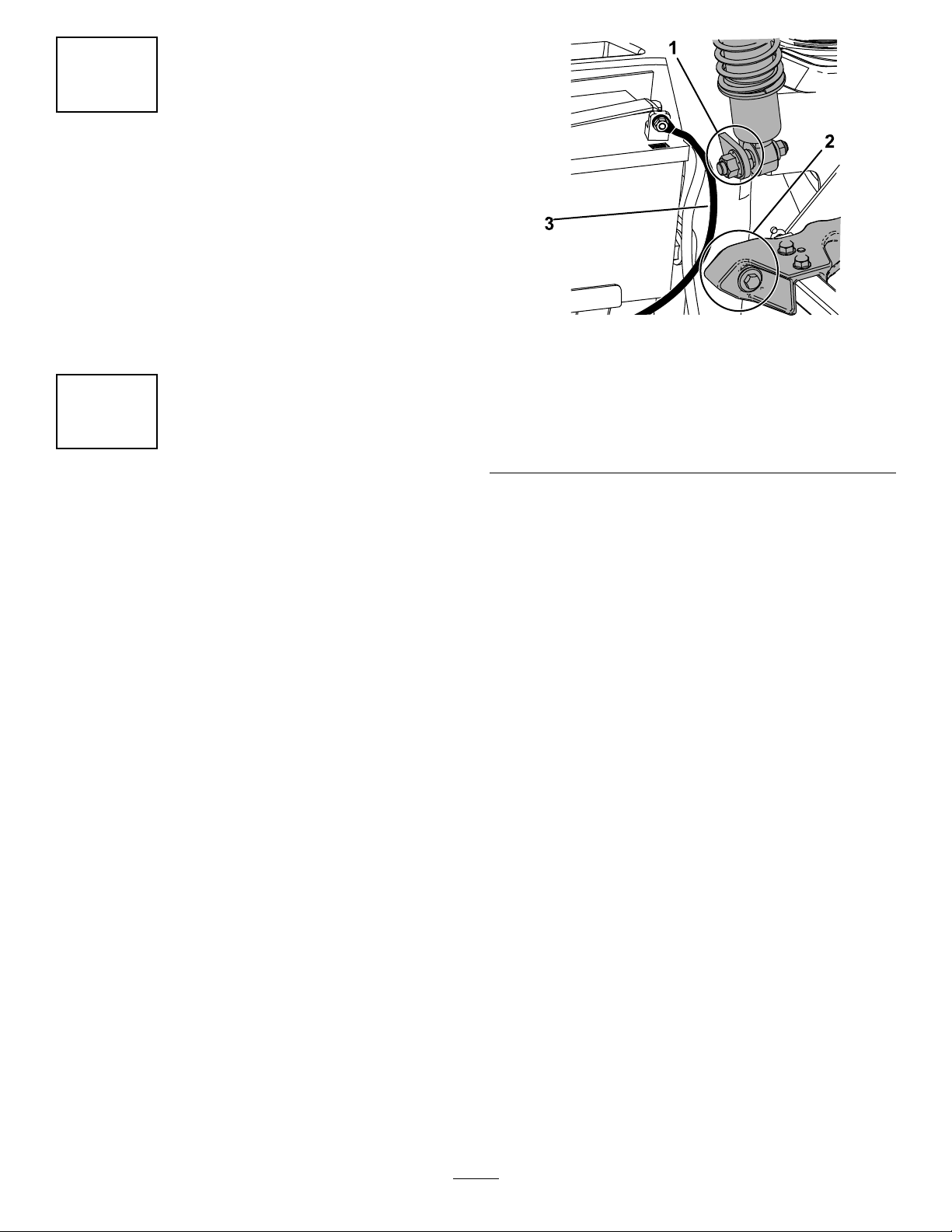

1.Ensurethattheground

cabledoesnotrubagainst

thelowershockmount.

2.Ensurethattheground

cabledoesnotrubagainst

thetrailingarm.

g236732

Figure2

3.Groundcable

Note:ForMyRidemachines,ensurethatthe

groundcabledoesnotrubagainstthetrailing

armorlowershockmount(Figure2).

3

Page 4

7

RaisingtheRollover

ProtectionSystem(ROPS)

NoPartsRequired

Procedure

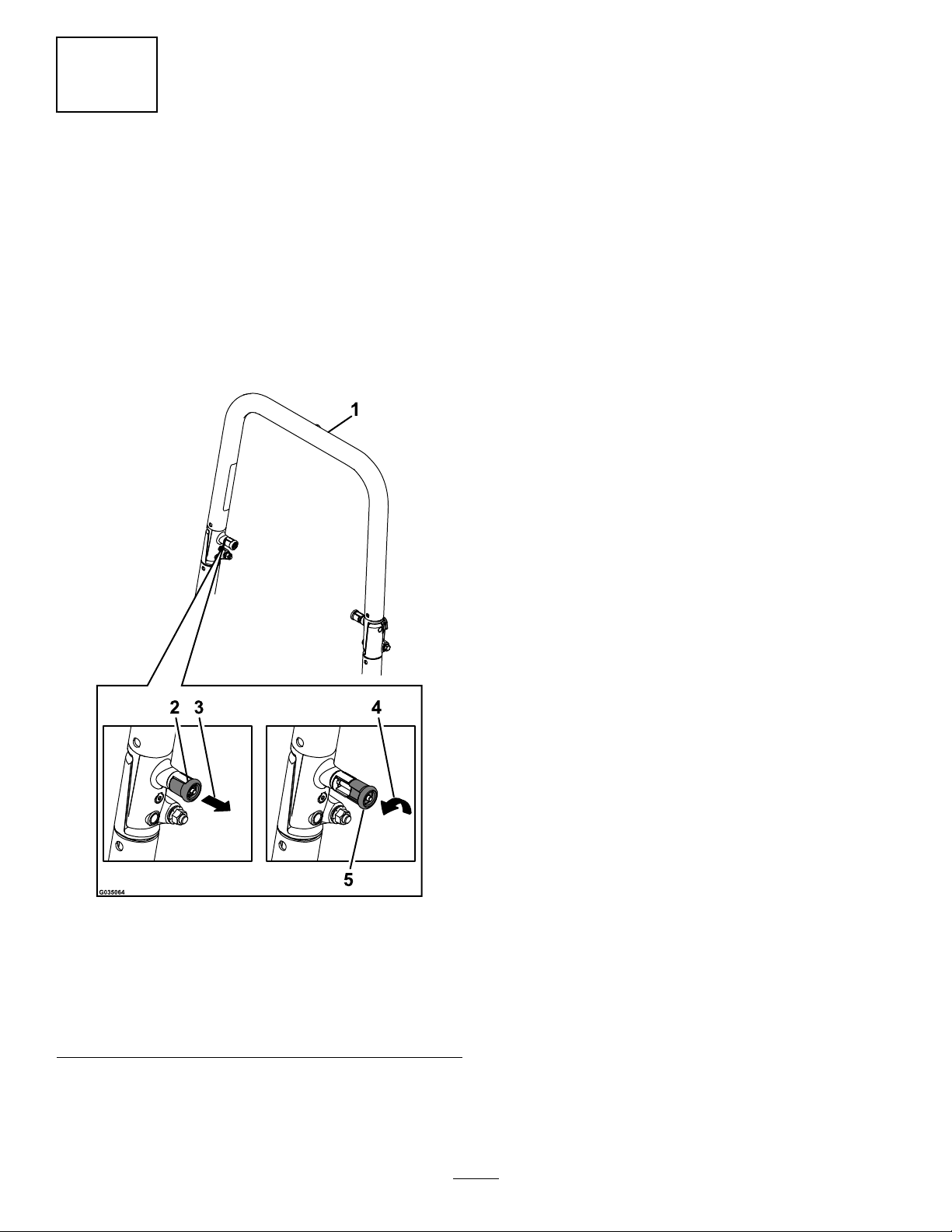

1.Pullbothknobsoutandrotatethem90degrees

sothattheyarenotengaged(Figure3).

2.Raisetherollbartotheoperatingpositionand

rotatetheknobsuntiltheymovepartiallyinto

thegrooves(Figure3).

4.Pushontherollbarandensurethatbothpins

areengaged(Figure3).

Figure3

1.Rollbarintheuprightposition

2.ROPSknobinthelatchedposition

3.PulltheROPSknobout.

4.RotatetheROPSknob90degrees.

5.ROPSknobintheunlatchedposition

3.Raisetherollbartothefulluprightpositionwhile

pushingontheupperrollbarsothatthepins

snapintopositionwhentheholesalignwiththe

pins.

g035064

4

Page 5

8

CheckingtheGrass

Deector

NoPartsRequired

Procedure

Ifthereareplastictiesholdingthegrassdeectorup,

removethemandlowerthedeectorintoplace.

WARNING

Anuncovereddischargeopeningcouldallow

themachinetothrowobjectstowardyouor

bystanders,resultinginseriousinjuryor

death.Also,contactwiththebladecould

occur.

Neveroperatethemachinewithoutacover

plate,amulchplate,grassdeector,orbagger

installed.

Figure4

1.Grassdeector3.Endofspring

2.Spring

4.Deckedge

g021181

1.Makesurethat1endofthespringisinstalled

behindthedeckedgebeforeinstallingthebolt

asshowninFigure4.

2.Placetheotherendofthespringaroundgrass

deector(Figure4).

Important:Thegrassdeectormustbefree

torotatewithdownwardtension.Liftthe

deectoruptothefullopenpositionand

ensurethatitrotatesfreely,withoutbinding

intothefulldownposition.

5

Page 6

9

10

RemovingtheShipping

Strap(s)

NoPartsRequired

Procedure

Note:Thisprocedureisonlyformachineswitha

MyRide™suspensionsystem.

WARNING

Thespringsarecompressedbytheshipping

strap(s).Whenthestrap(s)areremoved,the

seatwillraiseupquicklybyapproximately8.9

cm(3-1/2inches).

Note:Ensurethestrap(s)areremovedinthearea

showninFigure5beforeoperatingthemachine.

CheckingtheMachinefor

Grease

Partsneededforthisprocedure:

1tube

Procedure

Beforeyouusethemachine,checkthemachinefor

grease;refertoLubricationintheOperator'sManual.

No.2lithiumormolybdenum-basedgrease(purchase

separately)

Figure5

g228153

6

Page 7

11

12

InstallingtheRightBumper

Rear-DischargeMachinesOnly

Partsneededforthisprocedure:

3

Locknut(3/8inch)

3

Carriagebolt(3/8x2-1/4inches)

Procedure

Mountthesidebumpersinthetopholeswhen

operatinginheightofcuthigherthan64mm(2-1/2

inches)andinthecenterholeswhenoperatingin

heightofcutlowerthan64mm(2-1/2inches).

1.Raisethemowerdecktothe12.7cm(5inch)

heightposition(alsothetransportposition).

2.Therightbumperissecuredtothemachinewith

acabletieforshipping.Removeanddiscard

thecableties.

CheckingtheMower

Adjustment

NoPartsRequired

Procedure

Adjusttheside-to-sidelevelandthefront-to-rearblade

slope.UsetherelevantproceduresintheOperator's

Manualtoverifythatthedeckislevel,andmakeany

adjustmentsasneeded.

Figure6

1.Carriagebolt

2.Bumper(center-holemountingshown)

3.Locknut

3.Moveeachbumpertothedesiredposition

andsecureitwith3carriagebolts(3/8x2-1/4

inches)and3locknuts(3/8inch).

4.Torquetheboltsto14to16N∙m(10to12ft-lb).

g035120

7

Page 8

13

CheckingtheMachineBeforeDeliverytotheCustomer

(AllMachines)

NoPartsRequired

Procedure

Beforedeliveringthemachinetothecustomer,ensurethatyouhaveperformedtheprocedureslistedinthe

followingtableandinitialeachwhennished.RefertotheOperator'sManualforinstructionsonperforming

theseprocedures.

Initial

Checkthetirepressure.

Checkthelevelofthemowerdeck.

Checktheengine-oillevel.

Checkthehydraulic-uidlevel.

CheckthattheROPSissecure.

Checktheadjustmentoftheparkingbrake.

Ensurethatthemachinetrackscorrectly;refertotheOperator'sManualfortheadjustmentprocedure.

Checkthesafetyinterlocksystem;refertotheOperator'sManual.

EnsurethatthePTOworks.

Checkallfastenersthatyouinstalledtoensurethattheyaretight.

Whenyounishsettingupthemachine,signanddateinthespaceprovidedbelow:

Signature:

CheckProcedure

Date:

8

Page 9

14

DeliveringtheMachinetotheCustomer(AllMachines)

Partsneededforthisprocedure:

1

Operator'sManual

1

Engineowner'smanual(non-T oroengines)

1

Operator-trainingmaterial

2Key

1Registrationcard

Procedure

Atdelivery,llinthemodelandserialnumber,completetheitemslistedinthefollowingtable,andinitial

eachwhennished.

ModelNo.

SerialNo.

DealerInitial

CustomerInitialCheckProcedure

Showthecustomerwherethefollowingfeaturesarelocatedandhowtheyfunction:

•

Fueltank

•

Oil-llcap/Oildipstick

•

Sparkplug(s)

•

Engine-oillter

•

Engine-oildrain

•

Fuelgauge,valve,andhose

•

Airlter

•

Hydraulic-uidreservoir

•

Hydrauliclter

•

Battery

•

Ignitionswitch

•

Throttlelever

•

Choke(ifapplicable)

•

Powertakeoffswitch(PTO)

•

Motion-controllevers

•

Parkingbrake

•

Heightofcut

•

Lift-assistlever(ifapplicable)

•

Adjustableseat

•

Hydraulic-bypassvalves

•

RolloverProtectionSystem(ROPS)

9

Page 10

DealerInitial

CustomerInitialCheckProcedure

RefertotheOperator'sManualtopointoutsafetyprocedures,operation,and

maintenanceprocedures.

ReviewthewarrantystatementasshownintheOperator'sManual.

Describethepost-saleserviceproceduresforyourstore.

Assistthecustomerinllingoutandmailingtheregistrationcardorregisteronline

atwww.Toro.com.

MakesurethatthecustomerreceivestheOperator'sManual,engineowner'smanual

(non-Toroengines),SetUpInstructions,andoperatortrainingmaterial.

MakesurethecustomerknowsthatthePartsCatalogisavailableatwww .Toro.com.

Assistthecustomerinloadingthemachine.

Note:Whenyou,thedealerrepresentative,havenisheddeliveringthemachinetothecustomer,signand

dateinthespaceprovidebelowandkeepacopyofthispagefordealerrecords.Also,thedealermustremind

thecustomertouseafull-widthtrailerramptoloadthemachine.

Signature:

Signature:Date:

Date:

10

Page 11

Notes:

Page 12

Loading...

Loading...