Page 1

TITAN

ModelNo.Allmodels

®

HDSeriesRidingMowers

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

FormNo.3407-539RevA

SetupInstructions

ProcedureDescription

1

2

3

4

5

6

7

8

9

10

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

No.2lithiumormolybdenum-based

grease(purchaseseparately)

Locknut(3/8inch)

Carriagebolt(3/8x2-1/4inches)

1tube

Qty.

Use

–

–

–

–

–

–

–

–

3

3

Removethemachinefromthecrate.

Addfueltothemachine.

Checktheengine-oillevel.

Servicethehydraulicoil.

Checkthetirepressure.

Servicingthebattery.

Raisetherolloverprotectionsystem

(ROPS).

Checkthegrassdeector.

Checkthemachineforgrease.

Installtherightbumper(reardischarge

modelsonly).

11

12

13

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

©2016—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Nopartsrequired

Nopartsrequired

Operator'sManual

Engineowner'smanual(non-Toro

engines)

Operator-trainingmaterial

Key2

Registrationcard1

Registeratwww.T oro.com.

–

–

1

1

1

Checkthemoweradjustment.

Checkthemachinebeforedeliveryto

thecustomer(allmachines).

Deliverthemachinetothecustomer(all

machines).

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3407-539*A

Page 2

1

4

RemovingtheMachinefrom

theCrate

NoPartsRequired

Procedure

Ifremovingthemachinefromametalcrate,refertothe

Dealer/DistributorPortalforfurtherinformation.

2

AddingFueltotheMachine

NoPartsRequired

Procedure

Addfueltothemachinebeforestartingit.Refertoyour

Operator’sManualforthecorrectfuelandprocedure.

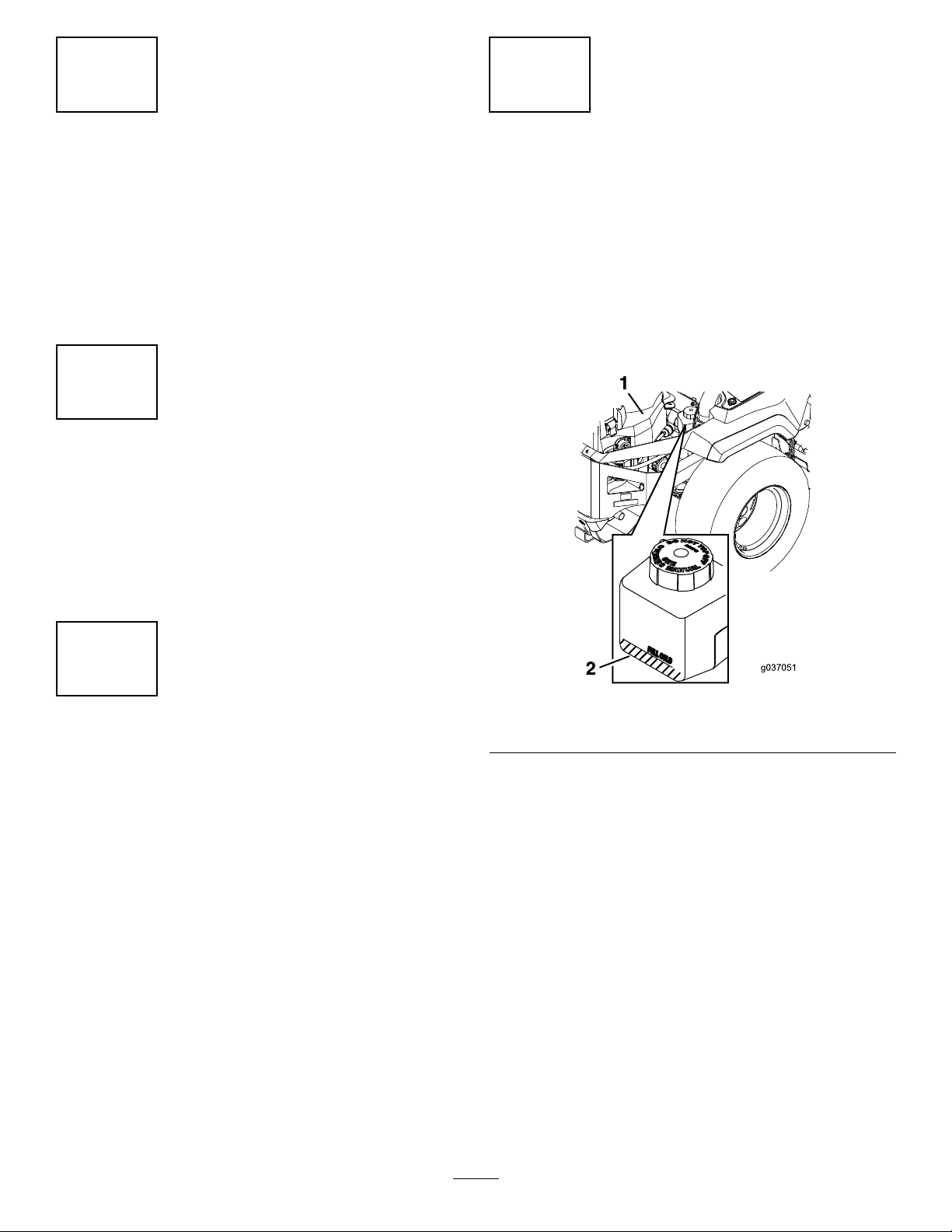

ServicingtheHydraulicOil

NoPartsRequired

Procedure

Thismachineisshippedlledwithhydraulicuidinthe

reservoirs.

Checktheexpansiontank;ifnecessary,addToro

HYPR-OIL

Operator'sManual,totheFULLCOLDline(Figure1).

™

500hydraulicuid,asrecommendedinthe

®

3

CheckingtheEngine-OilLevel

NoPartsRequired

Procedure

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoServicingthe

Engine-OilLevelintheOperator'sManual.

Figure1

1.Engine2.Expansiontank

2

Page 3

5

CheckingtheTirePressure

NoPartsRequired

Procedure

Pressure:13psi(90kPa)

Note:Checkthetirepressurebeforestartingthemachine.

RefertoyourOperator’ sManualforthecorrecttiretypeand

procedure.

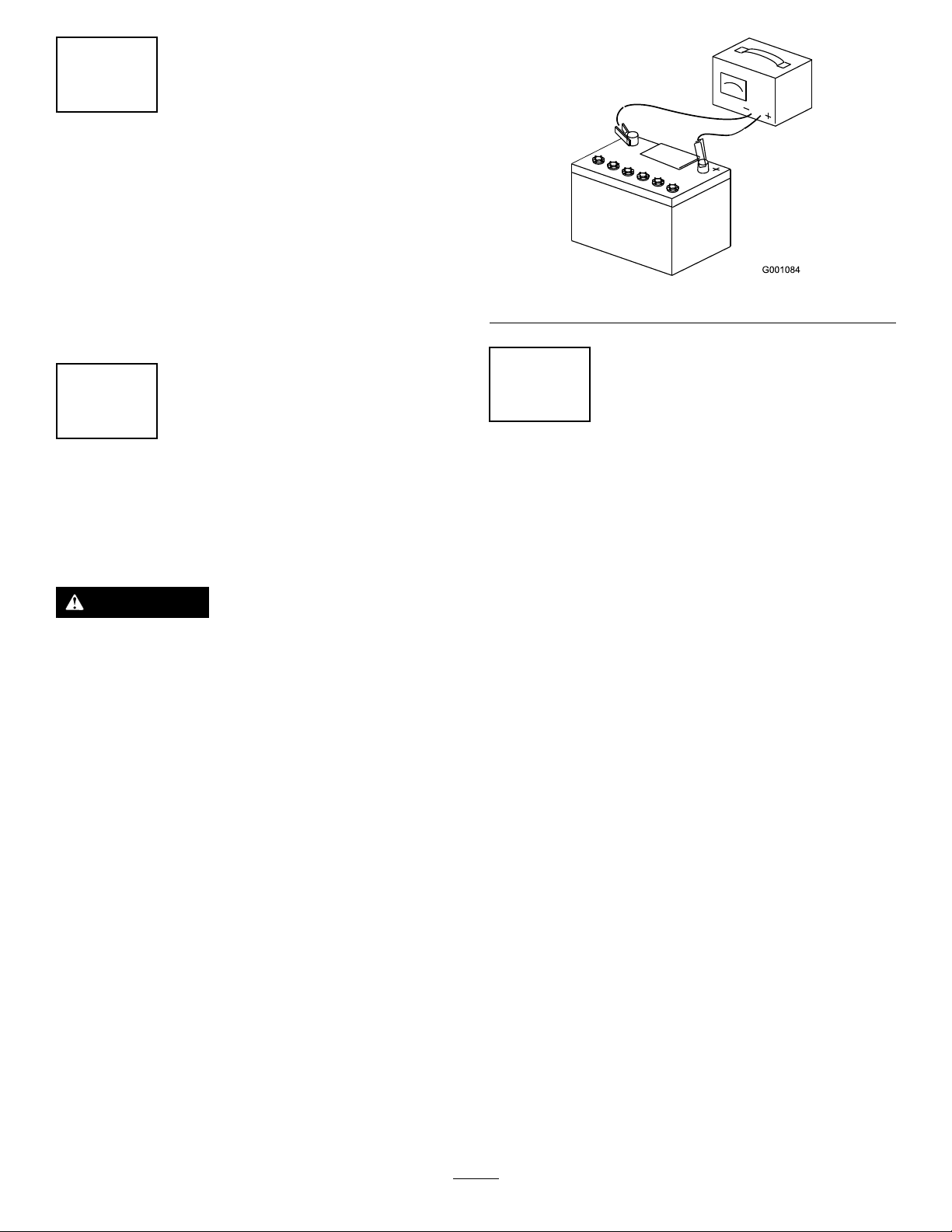

6

ServicingtheBattery

Figure2

7

RaisingtheRollover

ProtectionSystem(ROPS)

NoPartsRequired

Procedure

WARNING

Chargingthebatteryproducesgassesthatcan

explodeandcauseseriousinjury.

•Keepcigarettes,sparks,andamesawayfrom

thebattery.

•Makesurethattheignitionswitchisoff.

•Ventilatewhenchargingorusingthebatteryin

anenclosedspace.

Important:Donotrunthemachinewiththebattery

disconnected;electricaldamagemayoccurtothe

engine.

1.Chargethebattery.RefertotheOperator'sManualfor

instructions.

2.Connectthenegativebatterycable.

NoPartsRequired

Procedure

1.Pullbothknobsoutandrotatethem90degreessothat

theyarenotengaged(Figure3).

2.Raisetherollbartotheoperatingpositionandrotate

theknobsuntiltheymovepartiallyintothegrooves

(Figure3).

Note:Ifthepositivecableisalsodisconnected,

connectthepositive(red)cabletothepositivebattery

terminalrst,thenthenegative(black)cabletothe

negativebatteryterminal.Slipinsulatorbootoverthe

positiveterminal.

3

Page 4

1.Rollbarintheuprightposition

1

2

3

2

4

G021 181

4

3

3

2.ROPSknobinthelatchedposition

3.PulltheROPSknobout.

4.RotatetheROPSknob90degrees.

5.ROPSknobintheunlatchedposition

Figure3

8

CheckingtheGrassDeector

NoPartsRequired

Procedure

Ifthereareplastictiesholdingthegrassdeectorup,remove

themandlowerthedeectorintoplace.

WARNING

Anuncovereddischargeopeningcouldallowthe

machinetothrowobjectsintheoperator'sor

bystander'sdirectionandresultinseriousinjuryor

death.Also,contactwiththebladecouldoccur.

Neveroperatethemachinewithoutacoverplate,a

mulchplate,grassdeector,orbaggerinstalled.

1.Makesurethatoneendofthespringisinstalledbehind

thedeckedgebeforeinstallingtheboltasshownin

Figure4.

2.Placetheotherendofthespringaroundgrassdeector

(Figure4).

Important:Thegrassdeectormustbefreeto

rotatewithdownwardtension.Liftthedeectorup

tothefullopenpositionandensurethatitrotates

freely,withoutbindingintothefulldownposition.

3.Raisetherollbartothefulluprightpositionwhile

pushingontheupperrollbarsothatthepinssnapinto

positionwhentheholesalignwiththepins.

4.Pushontherollbarandensurethatbothpinsare

engaged(Figure3).

Figure4

1.Grassdeector3.Endofspring

2.Spring

4.Deckedge

4

Page 5

9

10

CheckingtheMachinefor

Grease

Partsneededforthisprocedure:

1tube

Procedure

Beforeyouusethemachine,checkthemachineforgrease;

refertoLubricationintheOperator'sManual.

No.2lithiumormolybdenum-basedgrease(purchase

separately)

InstallingtheRightBumper

Partsneededforthisprocedure:

3

Locknut(3/8inch)

3

Carriagebolt(3/8x2-1/4inches)

Procedure

Mountthesidebumpersinthetopholeswhenoperatingin

heightofcuthigherthan64mm(2-1/2inches)andinthe

centerholeswhenoperatinginheightofcutlowerthan64

mm(2-1/2inches).

1.Raisethemowerdecktothe12.7cm(5inch)height

position(alsothetransportposition).

2.Therightbumperisziptiedtothemachinefor

shipping.Removeanddiscardtheplasticzipties.

Figure5

1.Carriagebolt

2.Bumper(center-holemountingshown)

3.Locknut

3.Moveeachbumpertothedesiredpositionandsecure

itwith3carriagebolts(3/8x2-1/4inches)and3

locknuts(3/8inch).

4.Torquetheboltsto14to16N∙m(10to12ft-lb).

5

Page 6

11

CheckingtheMower

Adjustment

NoPartsRequired

Procedure

Adjusttheside-to-sidelevelandthefront-to-rearbladeslope.

UsetherelevantproceduresintheOperator'sManualtoverify

thatthedeckislevel,andmakeanyadjustmentsasnecessary.

6

Page 7

12

CheckingtheMachineBeforeDeliverytotheCustomer(All

Machines)

NoPartsRequired

Procedure

Beforedeliveringthemachinetothecustomer,ensurethatyouhaveperformedtheprocedureslistedinthefollowingtableand

initialeachwhennished.RefertotheOperator'sManualforinstructionsonperformingtheseprocedures.

Initial

Checkthetirepressure.

Checkthelevelofthemowerdeck.

Checktheengine-oillevel.

Checkthehydraulic-uidlevel.

CheckthattheROPSissecure.

Checktheadjustmentoftheparkingbrake.

Ensurethatthemachinetrackscorrectly;refertotheOperator'sManualfortheadjustmentprocedure.

Checkthesafetyinterlocksystem;refertotheOperator'sManual.

EnsurethatthePTOworks.

Checkallfastenersthatyouinstalledtoensurethattheyaretight.

Whenyounishsettingupthemachine,signanddateinthespaceprovidedbelow:

Signature:

CheckProcedure

Date:

13

DeliveringtheMachinetotheCustomer(AllMachines)

Partsneededforthisprocedure:

1

Operator'sManual

1

Engineowner'smanual(non-T oroengines)

1

Operator-trainingmaterial

2Key

1Registrationcard

Procedure

Atdelivery,llinthemodelandserialnumber,completetheitemslistedinthefollowingtable,andinitialeachwhennished.

ModelNo.SerialNo.

7

Page 8

DealerInitial

CustomerInitialCheckProcedure

Showthecustomerwherethefollowingfeaturesarelocatedandhowtheyfunction:

•

Fueltank

•

Oil-llcap/Oildipstick

•

Sparkplug(s)

•

Engine-oillter

•

Engine-oildrain

•

Fuelgauge,valve,andhose

•

Airlter

•

Hydraulic-uidreservoir

•

Hydrauliclter

•

Battery

•

Ignitionswitch

•

Throttlelever

•

Choke(ifapplicable)

•

Powertakeoffswitch(PTO)

•

Motion-controllevers

•

Parkingbrake

•

Heightofcut

•

Lift-assistlever(ifapplicable)

•

Adjustableseat

•

Hydraulic-bypassvalves

•

RolloverProtectionSystem(ROPS)

RefertotheOperator'sManualtopointoutsafetyprocedures,operation,and

maintenanceprocedures.

ReviewthewarrantystatementasshownintheOperator'sManual.

Describethepost-saleserviceproceduresforyourstore.

Assistthecustomerinllingoutandmailingtheregistrationcardorregisteronline

atwww.Toro.com.

MakesurethatthecustomerreceivestheOperator'sManual,engineowner'smanual

(non-Toroengines),SetUpInstructions,andoperatortrainingmaterial.

MakesurethecustomerknowsthatthePartsCatalogisavailableatwww .Toro.com.

Assistthecustomerinloadingthemachine.

Note:Whenyou,thedealerrepresentative,havenisheddeliveringthemachinetothecustomer,signanddateinthespace

providebelowandkeepacopyofthispagefordealerrecords.Also,thedealermustremindthecustomertouseafull-width

trailerramptoloadthemachine.

Signature:

Signature:Date:

Date:

8

Loading...

Loading...