Page 1

FormNo.3414-620RevB

122cmTITAN

®

HD1500Series

RidingMower

ModelNo.74447TE—SerialNo.400000000andUp

ModelNo.74451TE—SerialNo.400000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3414-620*B

Page 2

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

ThissparkignitionsystemcomplieswithCanadian

ICES-002.

WARNING

Removingstandardoriginalequipmentparts

andaccessoriesmayalterthewarranty,

traction,andsafetyofthemachine.Failureto

useoriginalToropartscouldcauseserious

injuryordeath.Makingunauthorizedchanges

totheengine,fuelorventingsystem,may

violateregulations.

Replaceallpartsincluding,butnotlimited

to,tires,belts,blades,andfuelsystem

componentswithoriginalToroparts.

Important:IfyouareusingamachinewithaT oro

engineabove1500m(5,000ft)foracontinuous

period,ensurethattheHighAltitudeKithasbeen

installedsothattheenginemeetsCARB/EPA

emissionregulations.TheHighAltitudeKit

increasesengineperformancewhilepreventing

spark-plugfouling,hardstarting,andincreased

emissions.Onceyouhaveinstalledthekit,attach

thehigh-altitudelabelnexttotheserialdecalon

themachine.ContactanyAuthorizedT oroService

DealertoobtaintheproperHighAltitudeKitand

high-altitudelabelforyourmachine.Tolocate

adealerconvenienttoyou,accessourwebsite

atwww.T oro.comorcontactourToroCustomer

CareDepartmentatthenumber(s)listedinyour

EmissionControlWarrantyStatement.

Removethekitfromtheengineandrestorethe

enginetoitsoriginalfactorycongurationwhen

runningtheengineunder1500m(5,000ft).Do

notoperateanenginethathasbeenconverted

forhigh-altitudeuseatloweraltitudes;otherwise,

youcouldoverheatanddamagetheengine.

Ifyouareunsurewhetherornotyourmachinehas

beenconvertedforhigh-altitudeuse,lookforthe

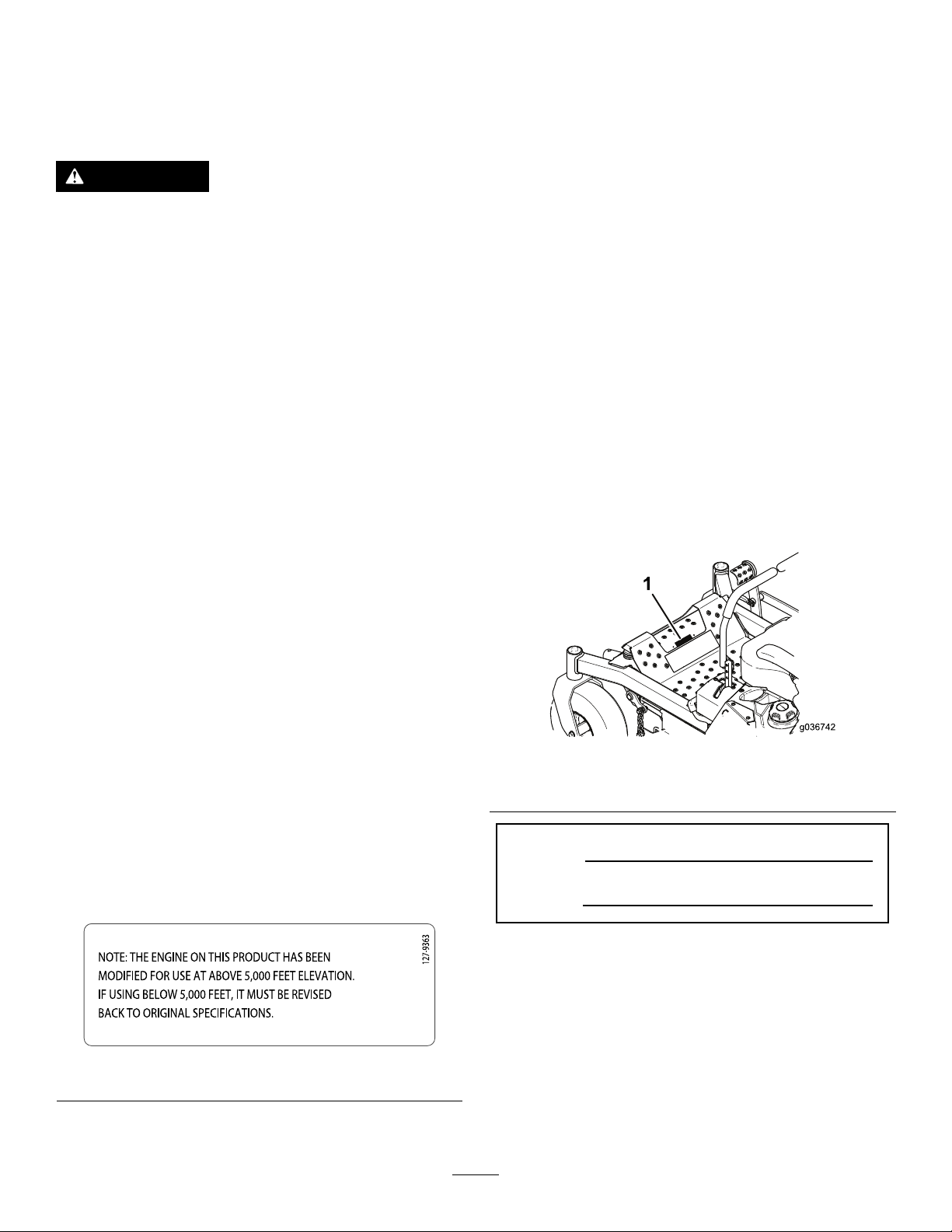

followinglabel(Figure3).

Introduction

Thisrotary-blade,ridinglawnmowerisintendedtobe

usedbyresidentialhomeownersorprofessional,hired

operators.Itisdesignedprimarilyforcuttinggrasson

well-maintainedlawnsonresidentialorcommercial

properties.Itisnotdesignedforcuttingbrushorfor

agriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

YoumaycontactT orodirectlyatwww.T oro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineT oroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

g036742

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure3

decal127-9363

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SlopeIndicator...................................................5

SafetyandInstructionalDecals..........................6

ProductOverview...................................................12

g000502

Controls...........................................................12

Specications..................................................14

BeforeOperation.................................................14

BeforeOperationSafety...................................14

RecommendedFuel.........................................15

UsingStabilizer/Conditioner.............................15

FillingtheFuelTank..........................................15

CheckingtheEngine-OilLevel..........................16

BreakinginaNewMachine..............................16

UsingtheRollover-ProtectionSystem

(ROPS).........................................................16

ThinkSafetyFirst..............................................17

UsingtheSafety-InterlockSystem....................18

PositioningtheSeat..........................................19

ChangingtheSeatSuspension.........................19

UsingAttachmentsandAccessories.................19

DuringOperation.................................................19

DuringOperationSafety...................................19

OperatingtheParkingBrake.............................20

OperatingtheMowerBlade-ControlSwitch

(PTO)............................................................21

OperatingtheThrottle.......................................21

OperatingtheChoke.........................................21

OperatingtheIgnitionSwitch............................22

StartingandShuttingOfftheEngine.................22

UsingtheMotion-ControlLevers.......................24

DrivingtheMachine..........................................24

AdjustingtheHeight-of-Cut...............................26

AdjustingtheAnti-ScalpRollers........................26

StoppingtheMachine.......................................27

UsingtheSideDischarge.................................27

OperatingTips.................................................27

AfterOperation....................................................28

AfterOperationSafety......................................28

UsingtheFuel-ShutoffValve.............................28

UsingtheDrive-Wheel-ReleaseV alves............29

TransportingtheMachine.................................30

LoadingtheMachine........................................30

Maintenance...........................................................32

RecommendedMaintenanceSchedule(s)...........32

Pre-MaintenanceProcedures..............................33

MaintenanceandStorage.................................33

ReleasingtheMower-DeckCurtain..................33

RemovingtheSheet-MetalGuard.....................33

Lubrication..........................................................35

GreasingtheMachine.......................................35

EngineMaintenance...........................................36

EngineSafety...................................................36

ServicingtheEngine.........................................36

CheckingtheSparkArrester.............................41

3

Page 4

ReplacingtheEmissions-AirIntake

Filter..............................................................41

FuelSystemMaintenance...................................41

ReplacingtheFuelFilter...................................41

ServicingtheFuelT ank.....................................42

ElectricalSystemMaintenance...........................42

ElectricalSystemSafety...................................42

ServicingtheBattery.........................................42

ServicingtheFuses..........................................44

DriveSystemMaintenance..................................45

CheckingtheSeatBelt.....................................45

CheckingtheRoll-BarKnobs............................45

AdjustingtheTracking......................................46

CheckingtheTirePressure...............................46

CheckingtheWheelLugNuts...........................46

CoolingSystemMaintenance..............................47

CleaningtheEngineScreen.............................47

BrakeMaintenance.............................................47

AdjustingtheParkingBrake..............................47

BeltMaintenance................................................49

InspectingtheBelts..........................................49

ReplacingtheMowerBeltforSideDischarge

MowerDecks................................................49

ReplacingtheHydraulic-Pump-Drive

Belt................................................................50

ControlsSystemMaintenance.............................51

AdjustingtheControl-HandlePosition..............51

AdjustingtheMotion-ControlLinkage...............51

HydraulicSystemMaintenance...........................53

HydraulicSystemSafety...................................53

ServicingtheHydraulicSystem........................53

ChangingtheHydraulic-SystemFiltersand

Fluid..............................................................54

MowerDeckMaintenance....................................57

LevelingtheMowerDeck..................................57

ServicingtheCuttingBlades.............................58

RemovingtheMowerDeck...............................61

ReplacingtheGrassDeector..........................61

Cleaning..............................................................62

CleaningundertheMower................................62

DisposingofWaste...........................................62

Storage...................................................................62

CleaningandStoringtheMachine....................62

Troubleshooting......................................................64

Schematics.............................................................66

Safety

Thismachinehasbeendesignedinaccordancewith

ENISO5395:2013.

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury .

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

•Readandunderstandthecontentsofthis

Operator’sManualbeforeyoustarttheengine.

Ensurethateveryoneusingthisproductknows

howtouseitandunderstandsthewarnings.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepclearofanydischargeopening.Keep

bystandersasafedistancefromthemachine.

•Keepchildrenoutoftheoperatingarea.Never

allowchildrentooperatethemachine.

•Stopthemachineandshutofftheenginebefore

servicing,fueling,oruncloggingthemachine.

Improperlyusingormaintainingthismachinecan

resultininjury .Toreducethepotentialforinjury ,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafety-alertsymbol,whichmeans

Caution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalitemsofsafetyinformationin

theirrespectivesectionsthroughoutthismanual.

4

Page 5

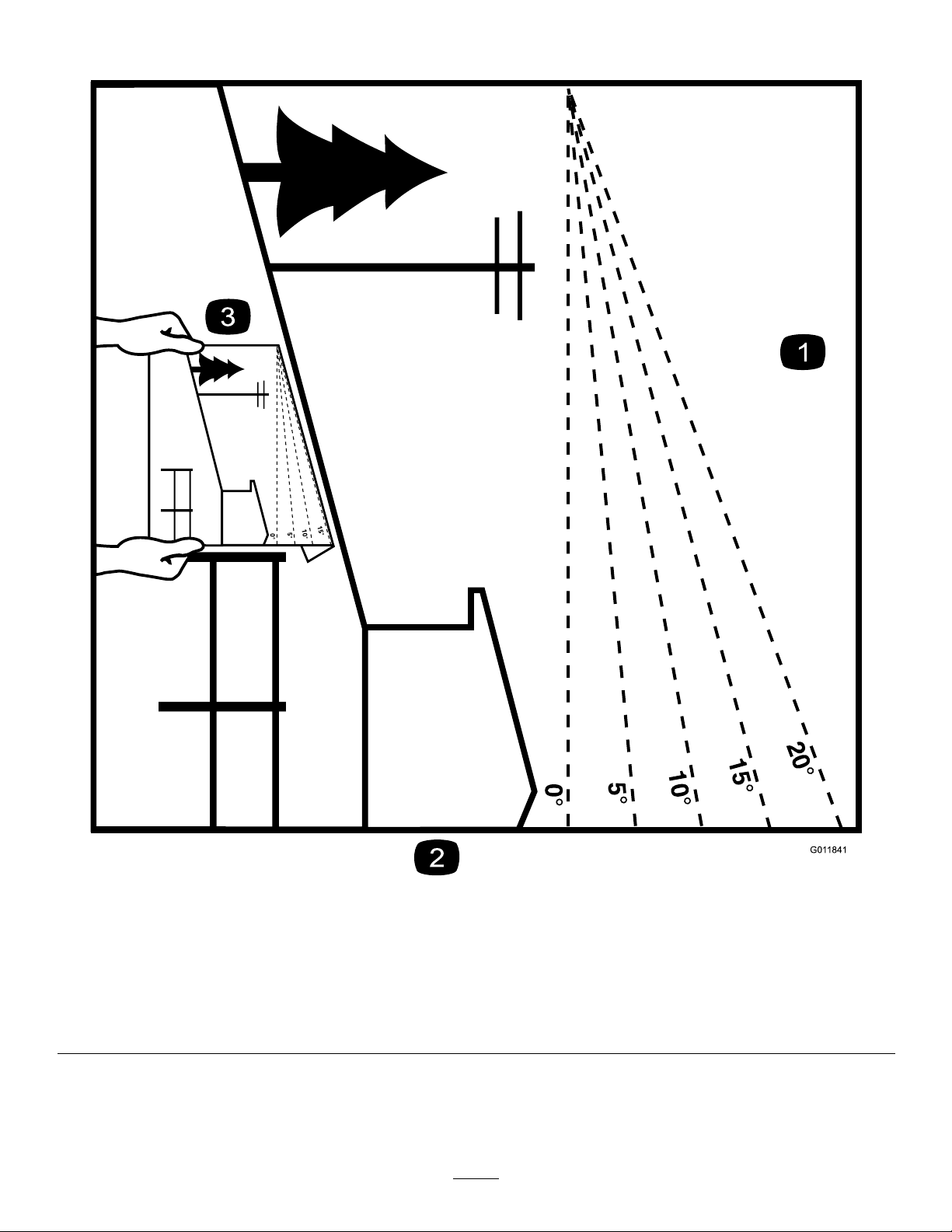

SlopeIndicator

Figure4

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

5

g011841

Page 6

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedorlost.

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto115-149N∙m(85-110ft-lb).

decaloemmarkt

decal93-7818

1.Warning—donottouchthehotsurface.

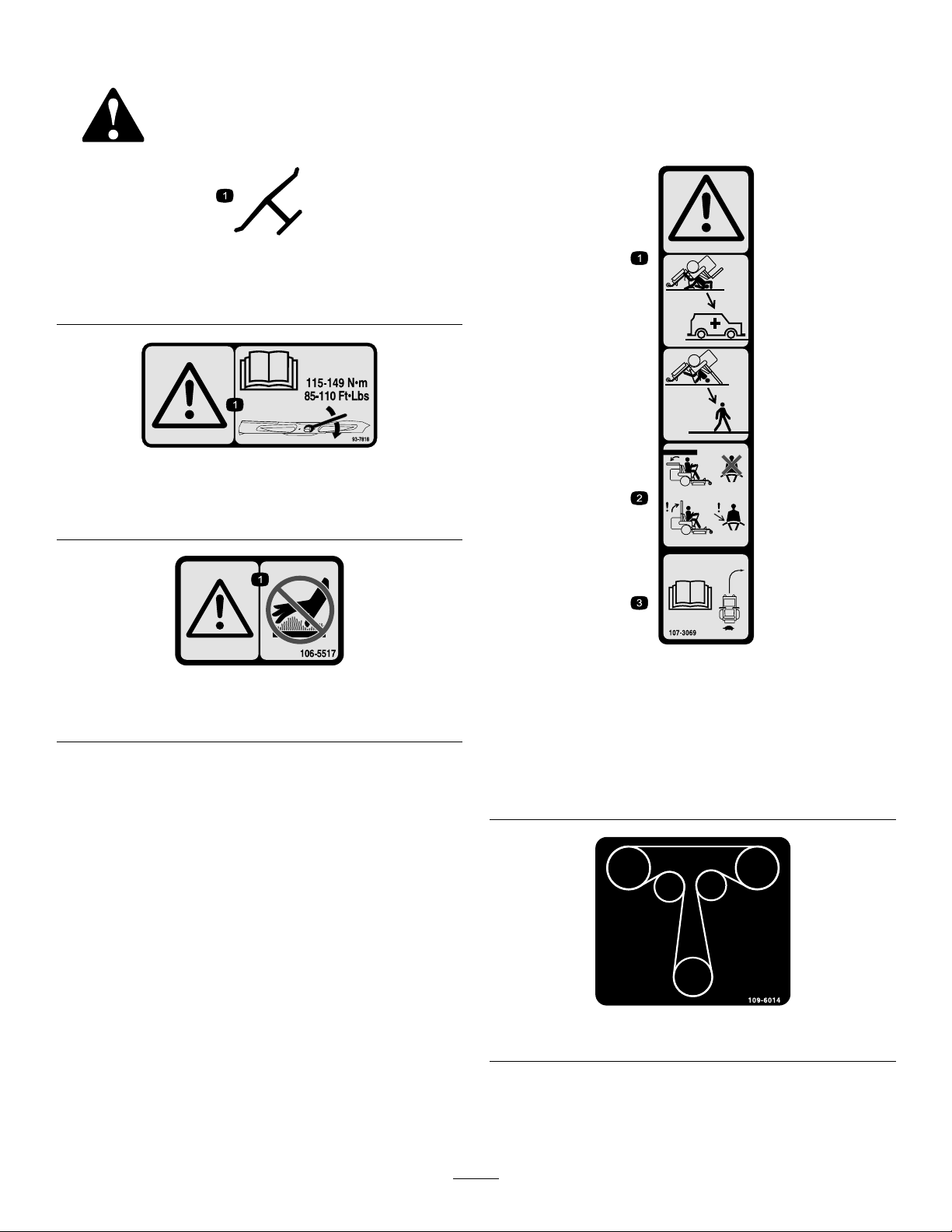

decal107-3069

decal106-5517

106-5517

1.Warning–thereisnorolloverprotectionwhentherollbaris

down.

2.Toavoidinjuryordeathfromarolloveraccident,keepthe

rollbarintheraisedandlockedpositionandweartheseat

belt.Lowertherollbaronlywhenabsolutelynecessary;do

notweartheseatbeltwhentherollbarisdown.

3.ReadtheOperator'sManual;driveslowlyandcarefully .

107-3069

decal109-6014

109-6014

6

Page 7

decal112-3858

112-3858

1.ReadtheOperator's

Manual.

3.Removetheignitionkey

beforeadjustingtheheight

ofcut.

2.Readtheinstructions

4.Height-of-cutsettings.

beforeservicingor

performingmaintenance.

decal112-9028

112-9028

1.Warning—stayawayfrommovingparts;keepallguardsin

place.

decal116-8588

116-8588

1.ReadtheOperator’smanual.

2.Rotatethedrivereleaseknobtoloosen,slidetheknob,

andtighten.

3.Pushthemachine.

decalhourmessagedisplay-116-5610

MessageDisplay

1.Hour4.Neutral

2.PTO5.Operatorpresenceswitch

3.Parkingbrake6.Battery

decal117-1 194

117-1194

1.Engine

7

Page 8

117-3848

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Thrownobjecthazard,mower—donotoperatethemachine

withoutdeector,dischargecover,orgrasscollection

systeminplace.

3.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts;keepallguardsandshieldsinplace.

decal117-3848

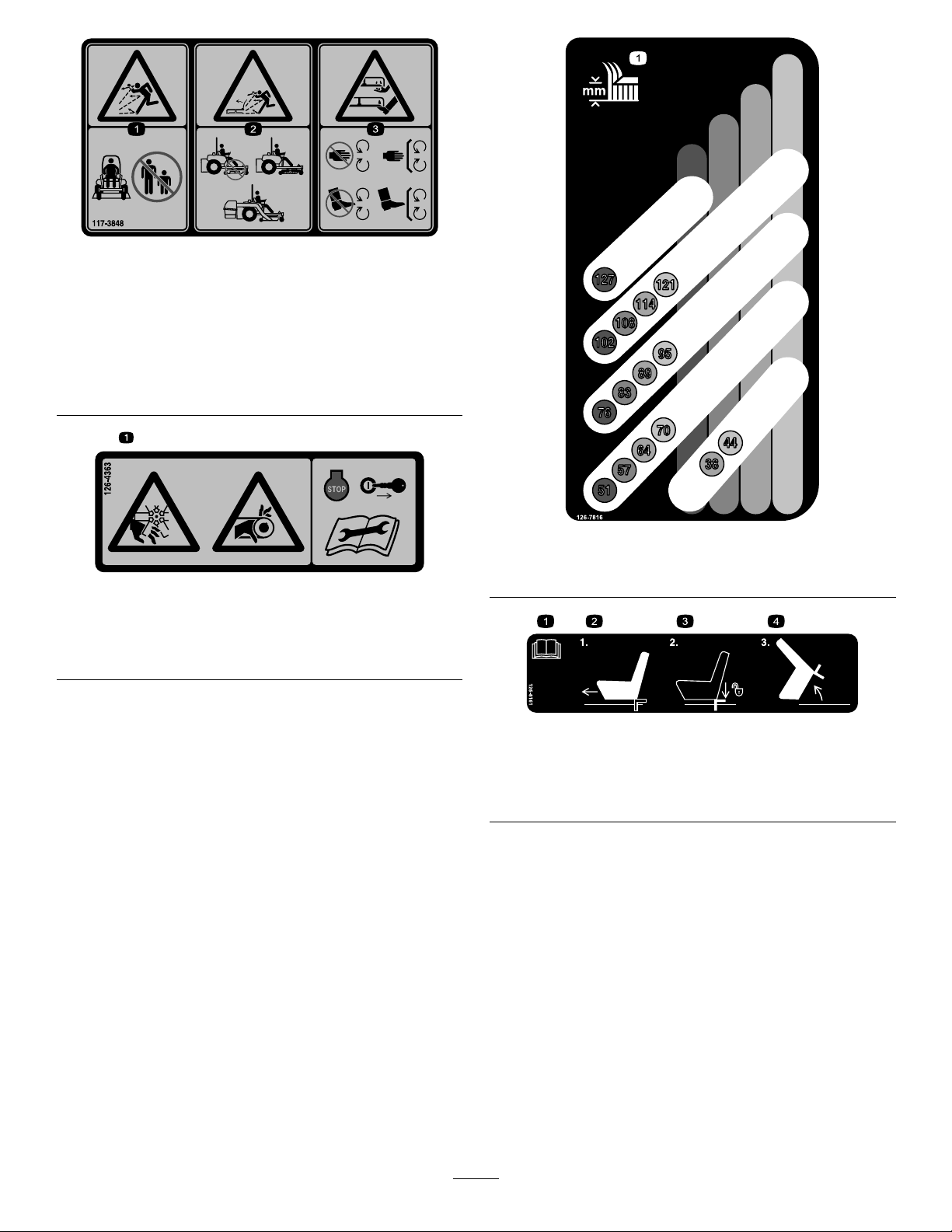

decal126-7816

126-7816

126-4363

1.Cutting/dismembermenthazard,fanandentanglement

hazard,belt.Shutofftheengineandremovekeybefore

adjusting,servicingorcleaning.

decal126-4363

1.Height-of-cut

decal126-8161

126-8161

1.ReadOperator’smanual

2.Slideseatforward

3.Pressdownonlatchto

unlockseat

4.Rotateseat

8

Page 9

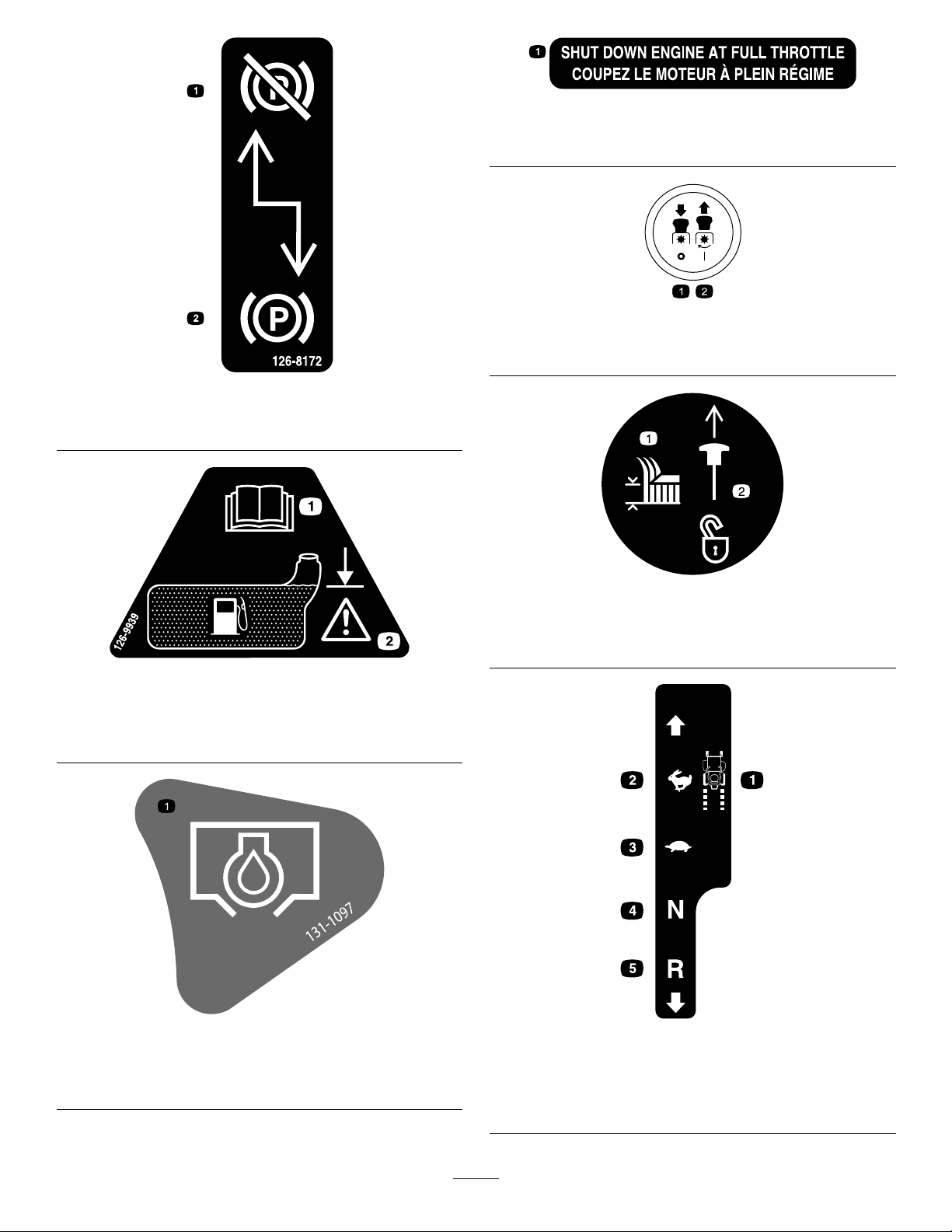

126–8172

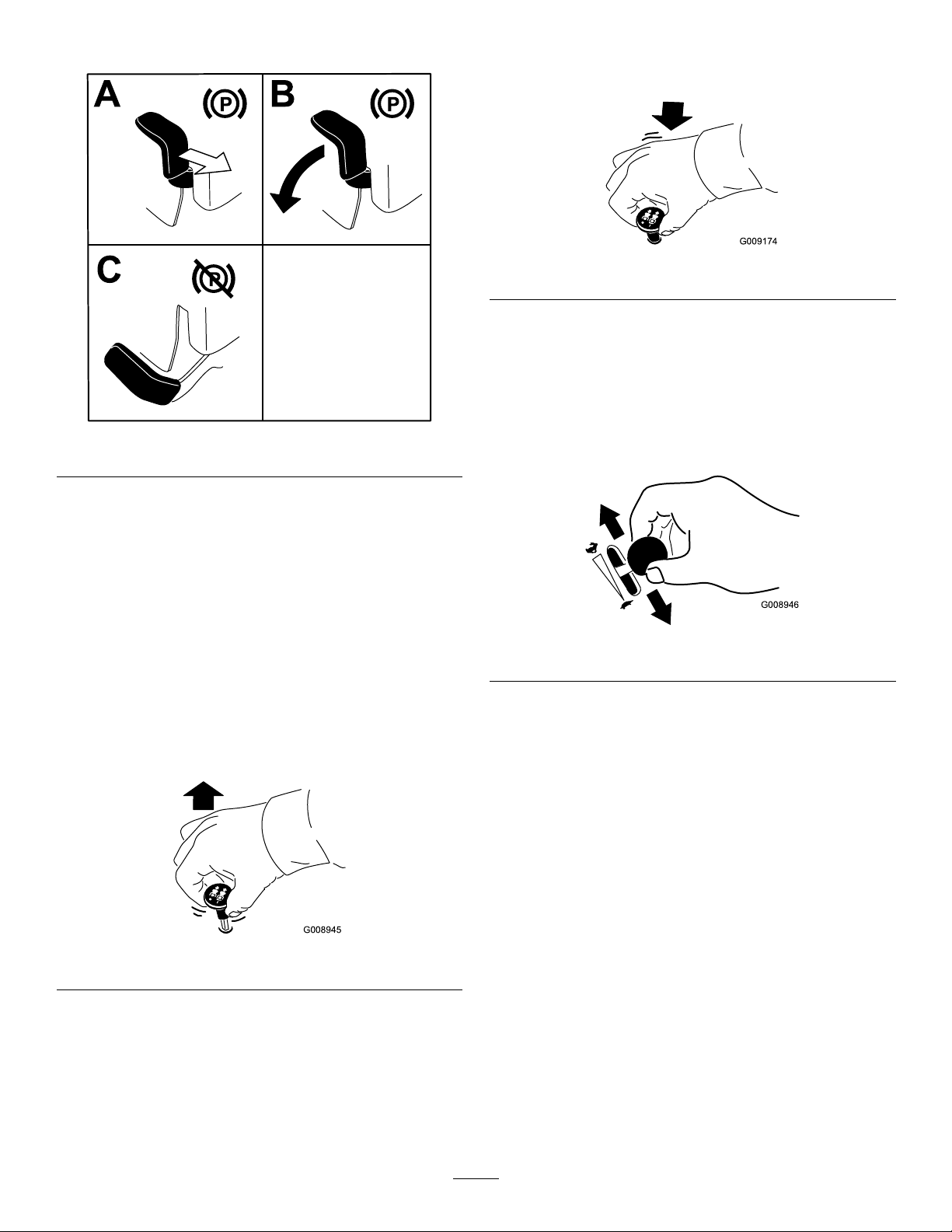

1.Parkingbrakedisengaged2.Parkingbrakeengaged

decal132-0904

ToroEngineOnly

1.Shutdownengineatfullthrottle

decalptosymbols

PTOSwitchSymbols

1.PTO–disengage2.PTO–engage

decal126-8172

1.ReadtheOperator’s

Manual

1.Oildrain

126-9939

131-1097

ToroEnginesOnly

2.Filltobottomofllerneck;

warning–donotoverllthe

tank

decaltransportlock

TransportLock

1.Heightofcut

decal126-9939

decal131-1097

2.Pulluptounlockthe

transportlock

decalmotioncntrllh-126-6194

LeftMotionControl

1.Machinespeed4.Neutral

2.Fast5.Reverse

3.Slow

9

Page 10

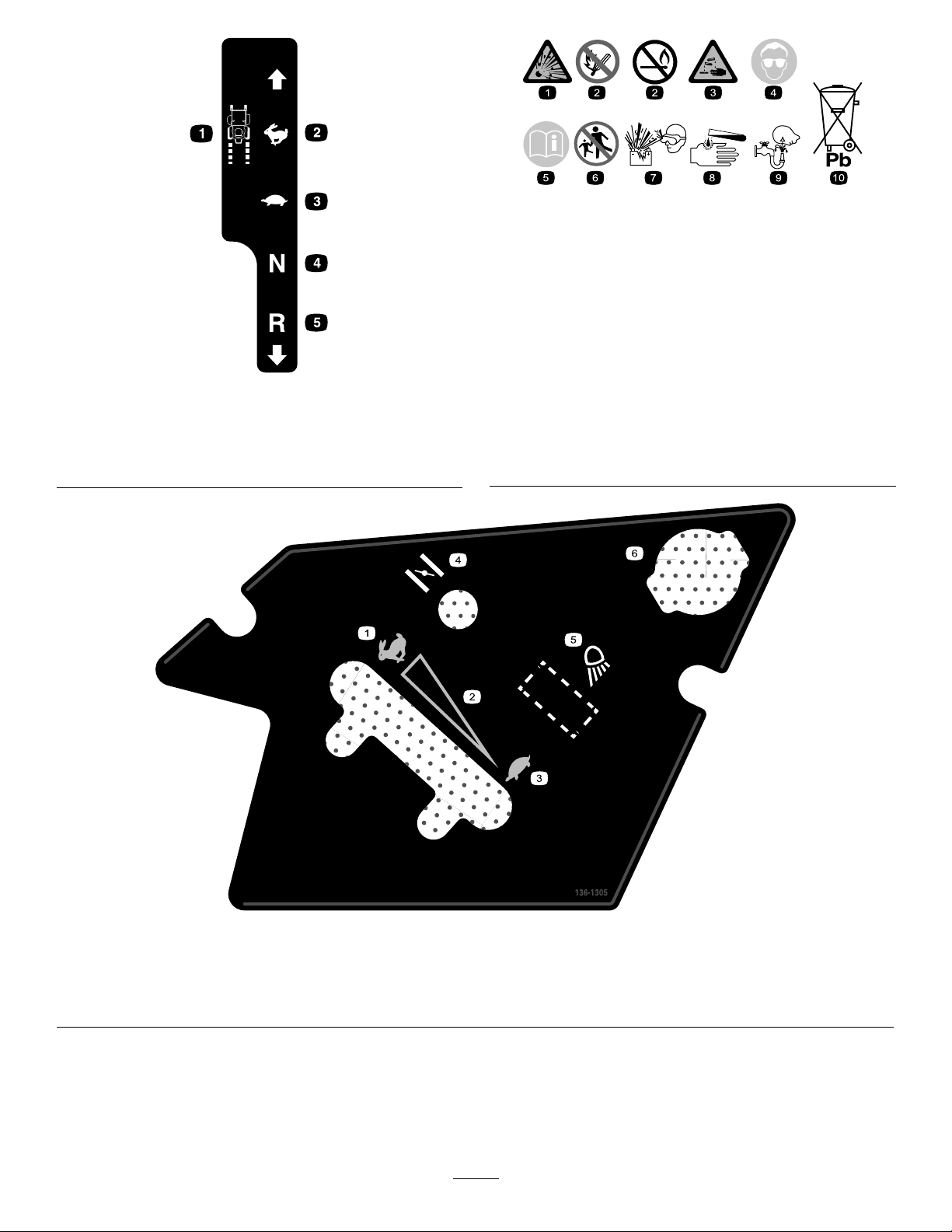

decalbatterysymbols

BatterySymbols

Someorallofthesesymbolsareonyourbattery.

RightMotionControl

1.Machinespeed4.Neutral

2.Fast5.Reverse

3.Slow

1.Explosionhazard

6.Keepbystandersasafe

distancefromthebattery.

2.Nore,opename,or

smoking

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

3.Causticliquid/chemical

decalmotioncntrlrh-126-6183

burnhazard

8.Batteryacidcancause

blindnessorsevereburns.

4.Weareyeprotection.9.Flusheyesimmediately

withwaterandgetmedical

helpfast.

5.ReadtheOperator's

Manual.

10.Containslead;donot

discard

136-1305

1.Fast

2.Continuousvariablesetting5.Worklight(optional)

3.Slow

4.Choke

6.Powerpoint

10

decal136-1305

Page 11

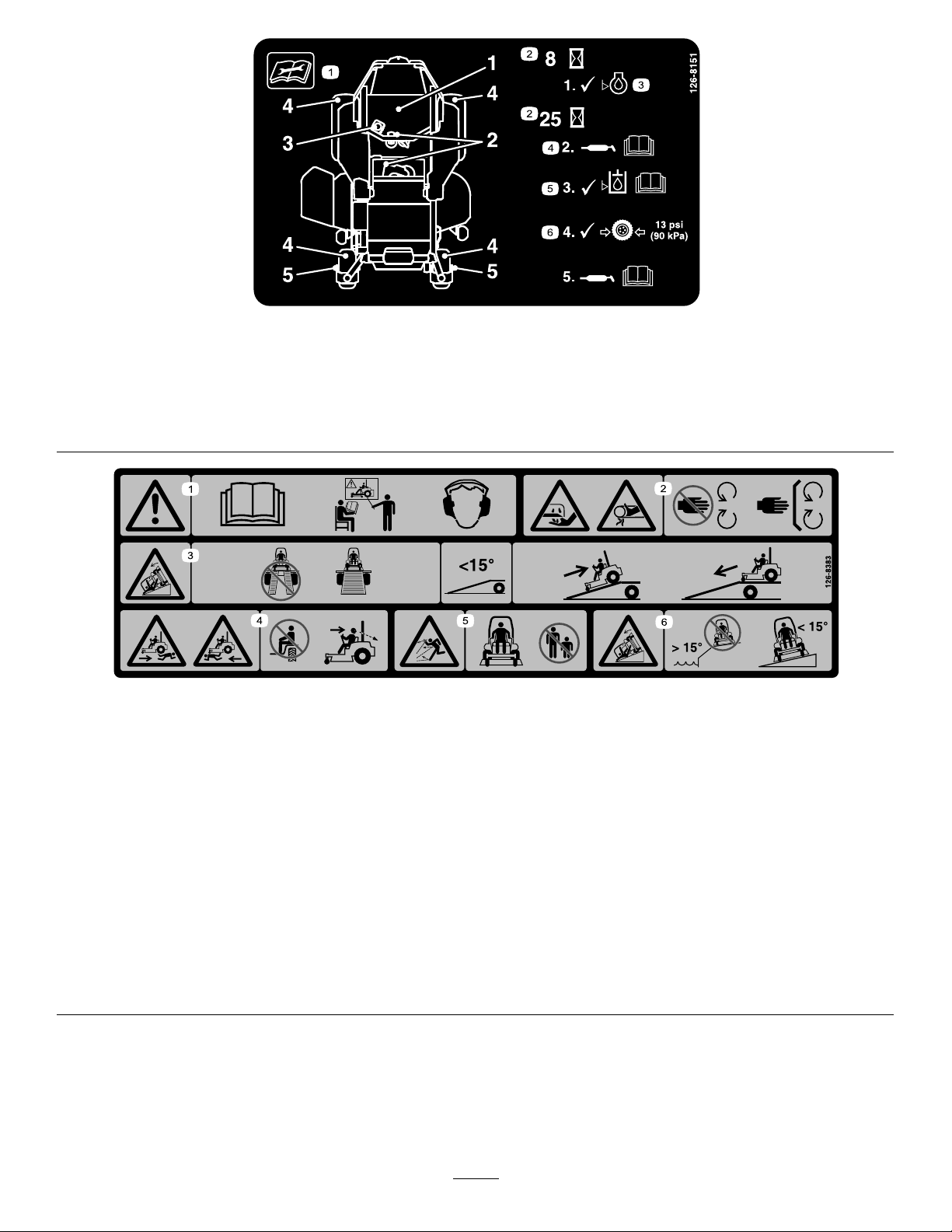

decal126-8151

126-8151

1.Readtheinstructionsbeforeservicingorperforming

4.RefertotheOperator'smanualforgreaseinstructions

maintenance

2.Timeinterval

5.CheckhydraulicoillevelandrefertotheOperator'smanual

forfurtherinstructions

3.Checkoillevel6.Checktirepressure

126-8383

MachineswithoutMyRideOnly

Note:Thismachinecomplieswiththeindustrystandardstabilitytestinthestaticlateralandlongitudinaltestswiththemaximum

recommendedslopeindicatedonthedecal.ReviewtheinstructionsforoperatingthemachineonslopesintheOperator’sManualas

wellastheconditionsinwhichyouwouldoperatethemachinetodeterminewhetheryoucanoperatethemachineinthoseconditions

onthatdayandatthatsite.Changesintheterraincanresultinachangeinslopeoperationforthemachine.Ifpossible,keepthe

cuttingunitsloweredtothegroundwhileoperatingthemachineonslopes.Raisingthecuttingunitswhileoperatingonslopescan

causethemachinetobecomeunstable.

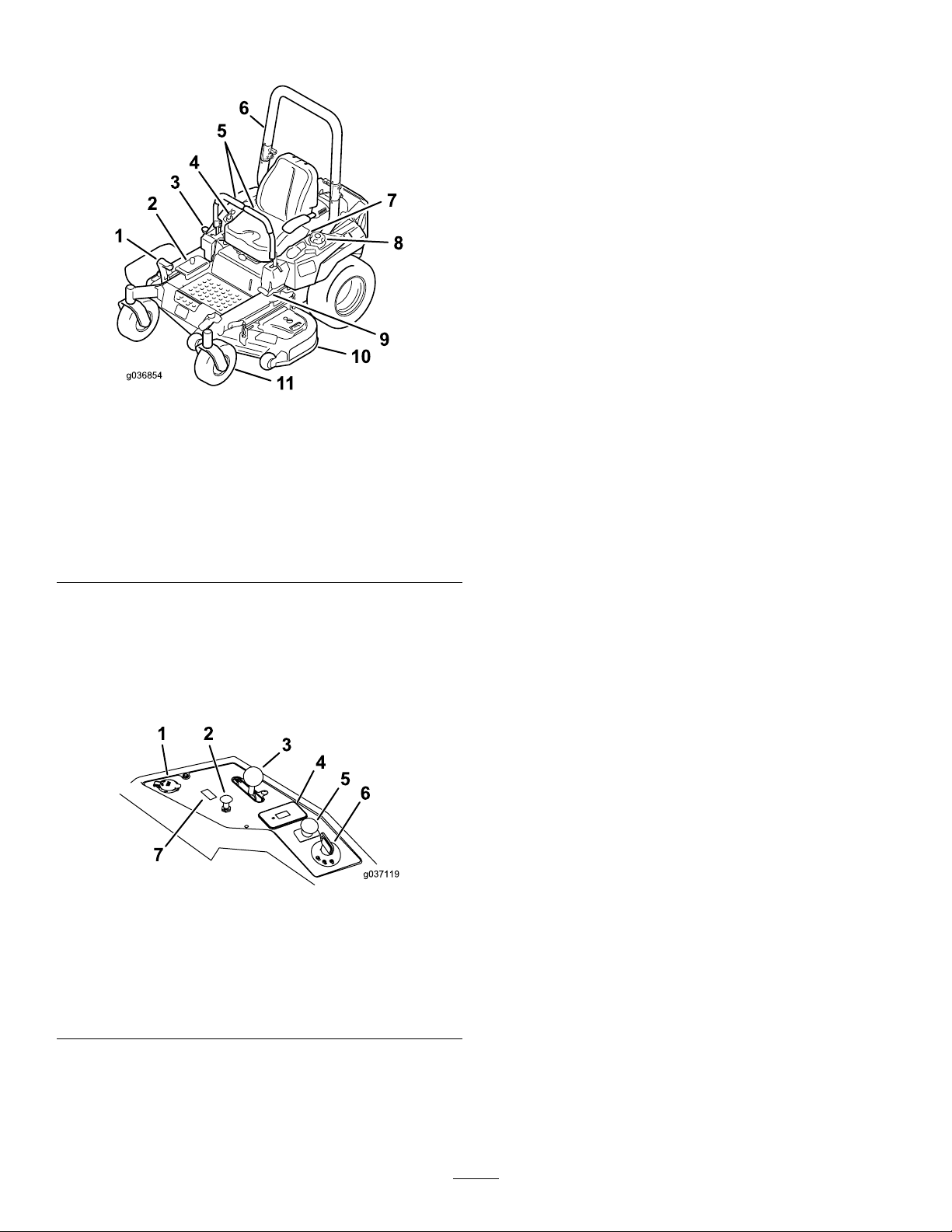

decal126-8383

1.Warning—readtheOperator’sManual;donotoperatethis

machineunlessyouaretrained;wearhearingprotection.

2.Cutting,dismembering,andentanglementhazard—keep

handsawayfrommovingparts;keepallguardsandshieldsin

place.

3.Ramphazard—whenloadingontoatrailer,donotusedual

ramps;onlyuseasingularrampwideenoughforthemachine

andthathasaninclinelessthan15°;backuptheramp(in

reverse)anddriveforwardofftheramp.

4.Bodilyharmhazard—donotcarrypassengers;lookbehind

youwhenmowinginreverse.

5.Thrownobjecthazard—keepbystandersaway.

6.Tippinghazardonslopes—donotuseonslopesnearopen

water;donotuseonslopesgreaterthan15°.

11

Page 12

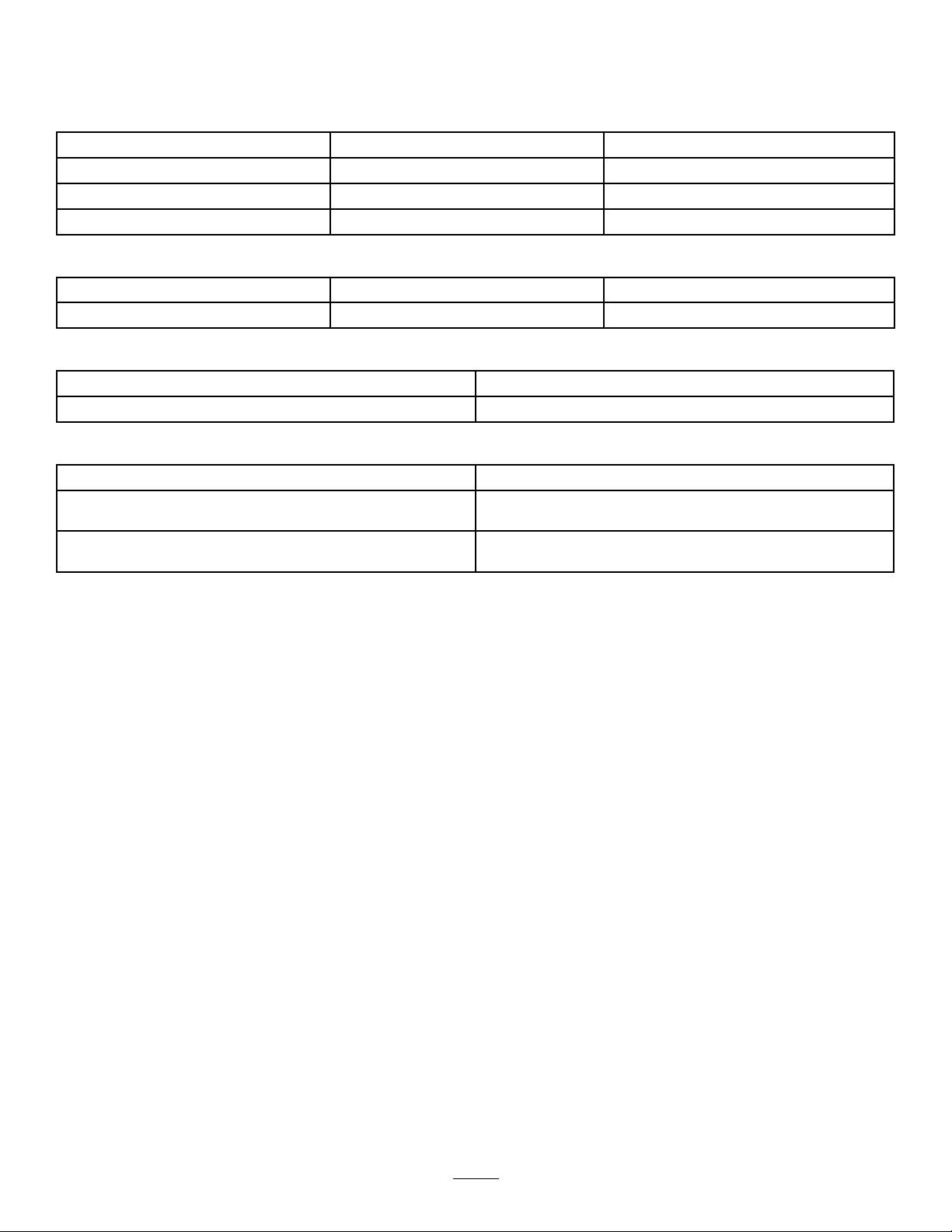

ProductOverview

IgnitionSwitch

Usethisswitchtostartthemowerengine.Ithas3

positions:START,RUN,andOFF.

ChokeControl

Usethechoketostartacoldengine.Pullthechoke

knobuptoengageit.Pushthechokeknobdownto

disengageit(Figure6).

ThrottleControl

Thethrottlecontrolstheenginespeed,andithasa

continuous-variablesettingfromtheSLOWtoFAST

position(Figure6).

Figure5

1.Height-of-cutdeck-lift

pedal

2.Height-of-cutpositions

3.Transportlock9.Parking-brakelever

4.Controls

5.Motion-controllevers

6.Rollbar

7.Seatbelt

8.Fuelcap

10.Mowerdeck

11.Casterwheel

Controls

Becomefamiliarwithallthecontrolsbeforeyoustart

theengineandoperatethemachine(Figure5and

Figure6).

g036854

Blade-ControlSwitch(Power

Takeoff)

Theblade-controlswitch(PTO)engagesand

disengagespowertothemowerblades(Figure6).

HourMeter

Thehourmeterrecordsthenumberofhoursthe

enginehasoperated.Itoperateswhentheengine

isrunning.Usethesetimesforschedulingregular

maintenance(Figure6).

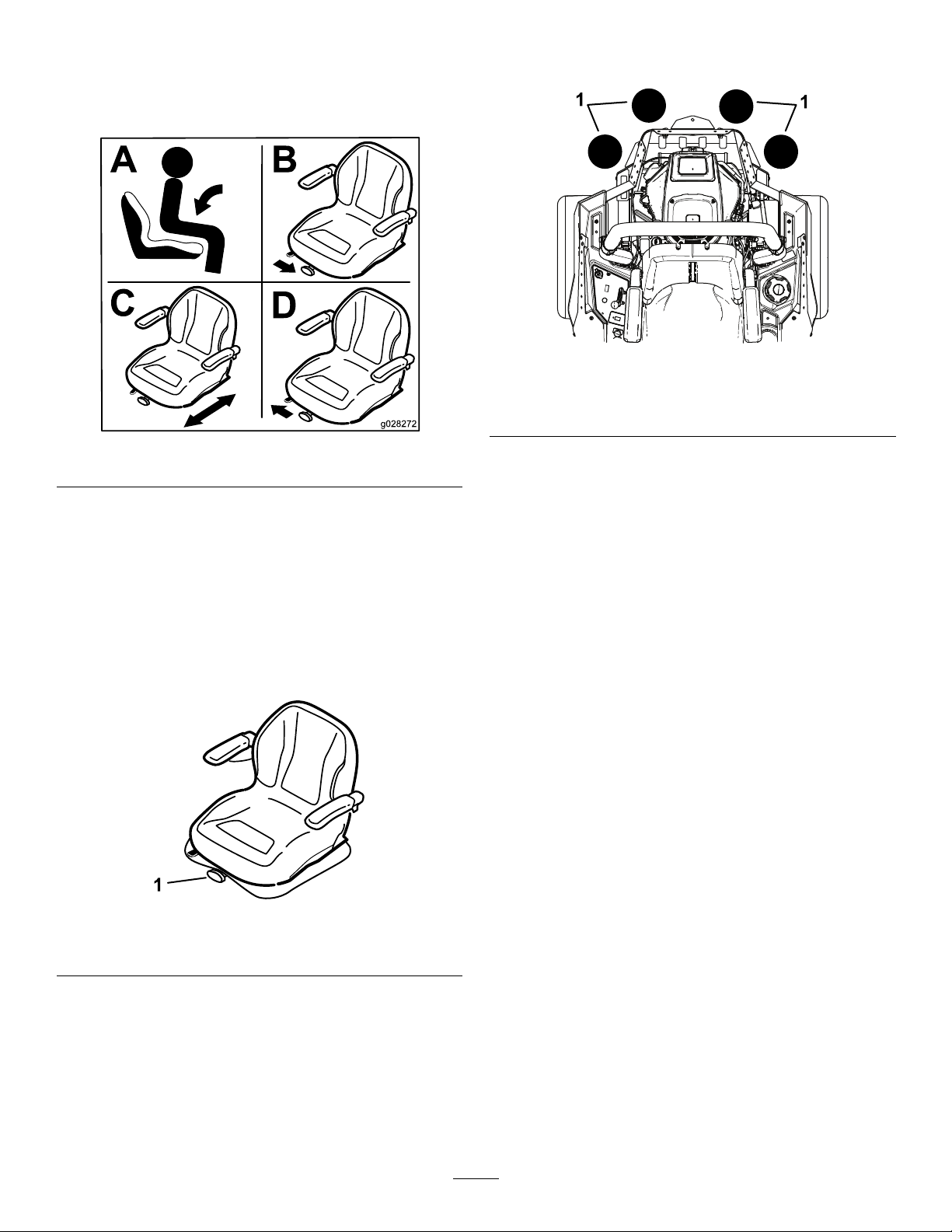

Safety-InterlockIndicators

Therearesymbolsonthehourmeterthatindicate

withablacktrianglethattheinterlockcomponentis

positionedcorrectly(Figure7).

Battery-IndicatorLight

IfyouturntheignitionkeytotheONpositionfora

fewseconds,thebatteryvoltagedisplaysinthearea

wherethehoursarenormallydisplayed.

1.Powerport

2.Chokecontrol

3.Throttlecontrol

4.Hourmeter

Figure6

5.PTOSwitch

6.Ignitionswitch

7.Switchpositionforoptional

lightkit

g037119

Thebatterylightturnsonwhentheignitionisturned

onandwhenthechargeisbelowthecorrectoperating

level(Figure7).

12

Page 13

Figure7

g187133

1.Safety-interlocksymbols

2.Hourmeter

3.Batterylight

Motion-ControlLevers

Usethemotion-controlleverstodrivethemachine

forward,reverse,andturneitherdirection.

Neutral-LockPosition

UsetheNEUTRAL-LOCKpositionwiththe

safety-interlocksystemtodeterminetheNEUTRAL

position.

Fuel-ShutoffValve

Closethefuel-shutoffvalve(behindtheseat)when

transportingorstoringthemower.

Attachments/Accessories

AselectionofT oroapprovedattachmentsand

accessoriesisavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.T oro.comforalistofallapprovedattachments

andaccessories.

13

Page 14

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

Width—SideDischargeMowerDecks:

122cmmowerdeck132cmmowerdeck

Withoutmowerdeck

Deectorup133cm(53inches)144cm(56-3/4inches)

Deectordown160cm(63-1/4inches)171cm(67-1/4inches)

Length—SideDischargeMowerDecks:

Length

Height:

RollBar-UpRollBar-Down

179cm(70-1/2inches)125cm(49inches)

Weight:

MachinesWeight

122cmsidedischargemachines849-937lb

132cmsidedischargemachines862-957lb

121cm(47-1/2inches)124cm(49inches)

122cmmowerdeck132cmmowerdeck

208cm(82inches)208cm(82inches)

(385-425kg)

(391–434kg)

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageoftheoperator.Theowner

isresponsiblefortrainingalloperatorsand

mechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Knowhowtostopthemachineandenginequickly.

•Checkthatoperator-presencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

•Beforemowing,alwaysinspectthemachineto

ensurethattheblades,bladebolts,andcutting

assembliesareingoodworkingcondition.

Replacewornordamagedbladesandboltsinsets

topreservebalance.

•Inspecttheareawhereyouwillusethemachine

andremoveallobjectsthatthemachinecould

throw.

•Evaluatetheterraintodeterminetheappropriate

equipmentandanyattachmentsoraccessories

requiredtooperatethemachineproperlyand

safely.

FuelSafety

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlingfuel.Fuelvaporsare

ammableandexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfueltothefuel

tankwhiletheengineisrunningorwhilehot.

•Donotrefuelthemachineindoors.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

14

Page 15

•Donotllcontainersinsideavehicleoronatruck

ortrailerbedwithaplasticliner.Alwaysplace

containersontheground,awayfromyourvehicle

beforelling.

•Removetheequipmentfromthetruckortrailer

andrefuelitwhileitisontheground.Ifthisisnot

possible,thenrefuelfromaportablecontainer

ratherthanafuel-dispensernozzle.

•Donotoperatethemachinewithouttheentire

exhaustsysteminplaceandinproperworking

condition.

•Keepthefuel-dispensernozzleincontactwith

therimofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.Donotusea

nozzlelock-opendevice.

•Ifyouspillfuelonyourclothing,changeyour

clothingimmediately.Wipeupanyfuelthatspills.

•Neveroverllthefueltank.Replacethefuelcap

andtightenitsecurely.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymorethan

a30-daysupplyoffuel.

RecommendedFuel

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan

10%ethanolbyvolume,suchasE15(contains

15%ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

•Donotaddoiltogasoline.

•Donotllthefueltankcompletelyfull.Addfuelto

thefueltankuntilthelevelis6to13mm(1/4to

1/2inch)belowthebottomofthellerneck.This

emptyspaceinthetankallowsfueltoexpand.

–Avoidprolongedbreathingofvapors.

–Keepyourfaceawayfromthenozzleandgas

tankopening.

–Avoidcontactwithskin;washoffspillswith

soapandwater.

Using Stabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsfuelfreshduringstorageof90daysorless

(drainthefueltankwhenstoringthemachinefor

morethan90days)

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

Important:Donotusefueladditives

containingmethanolorethanol.

Addthecorrectamountoffuelstabilizer/conditioner

tothefuel.

Note:Afuelstabilizer/conditionerismost

effectivewhenmixedwithfreshfuel.T ominimize

thechanceofvarnishdepositsinthefuelsystem,

usefuelstabilizeratalltimes.

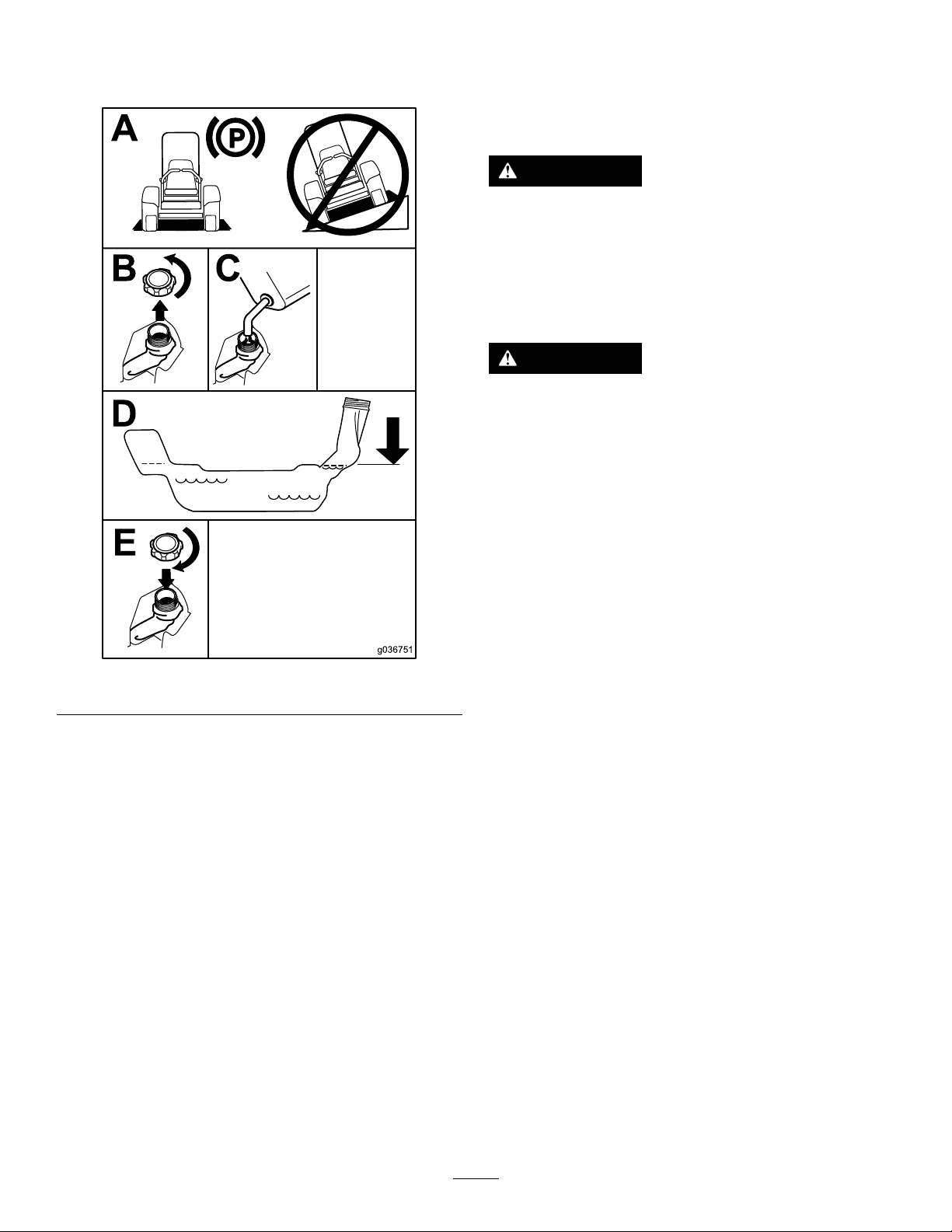

FillingtheFuelTank

1.Parkthemachineonlevelground.

2.Shutofftheengineandengagetheparking

brake.

3.Cleanaroundthefuel-tankcap.

4.Fillthefueltanktothebottomofthellerneck

(Figure8).

15

Page 16

Note:Donotllthefueltankcompletelyfull.

Theemptyspaceinthetankallowsthegasoline

toexpand.

Usingthe Rollover-ProtectionSystem (ROPS)

WARNING

Toavoidinjuryordeathfromrollover:keep

therollbarinthefullyraisedlockedposition

andusetheseatbelt.

Ensurethattheseatissecuredtothe

machine.

WARNING

Thereisnorolloverprotectionwhentheroll

barisinthedownposition.

•Lowertherollbaronlywhenabsolutely

necessary.

•Donotweartheseatbeltwhentherollbar

isinthedownposition.

Figure8

CheckingtheEngine-Oil Level

Beforeyoustarttheengineandusethemachine,

checktheoillevelintheenginecrankcase;referto

CheckingtheEngine-OilLevel(page37).

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mower

decksanddrivesystemshavehigherfrictionwhen

new,placingadditionalloadontheengine.Allow

40to50hoursofbreak-intimefornewmachinesto

developfullpowerandbestperformance.

•Driveslowlyandcarefully.

•Raisetherollbarassoonasclearance

permits.

•Checkcarefullyforoverheadclearances

(i.e.,branches,doorways,electricalwires)

g036751

beforedrivingunderanyobjectsanddo

notcontactthem.

Important:Lowertherollbaronlywhen

absolutelynecessary.

1.T olowertherollbar,applyforwardpressureto

theupperpartoftherollbar.

2.Pullbothknobsoutandrotatethem90degrees

sotheyarenotengaged(Figure9).

3.Lowertherollbartothedownposition(Figure

9).

16

Page 17

ThinkSafetyFirst

Pleasereadallsafetyinstructionsandsymbolsinthe

safetysection.Knowingthisinformationcouldhelp

youorbystandersavoidinjury .

DANGER

Operatingthemachineonwetgrassorsteep

slopescancauseslidingandlossofcontrol.

•Donotoperateonslopesgreaterthan15

degrees.

•Reducespeedanduseextremecautionon

slopes.

•Donotoperatethemachinenearwater.

DANGER

Wheelsdroppingoveredgescancause

rollovers,whichmayresultinseriousinjury ,

death,ordrowning.

Donotoperatethemachineneardrop-offs.

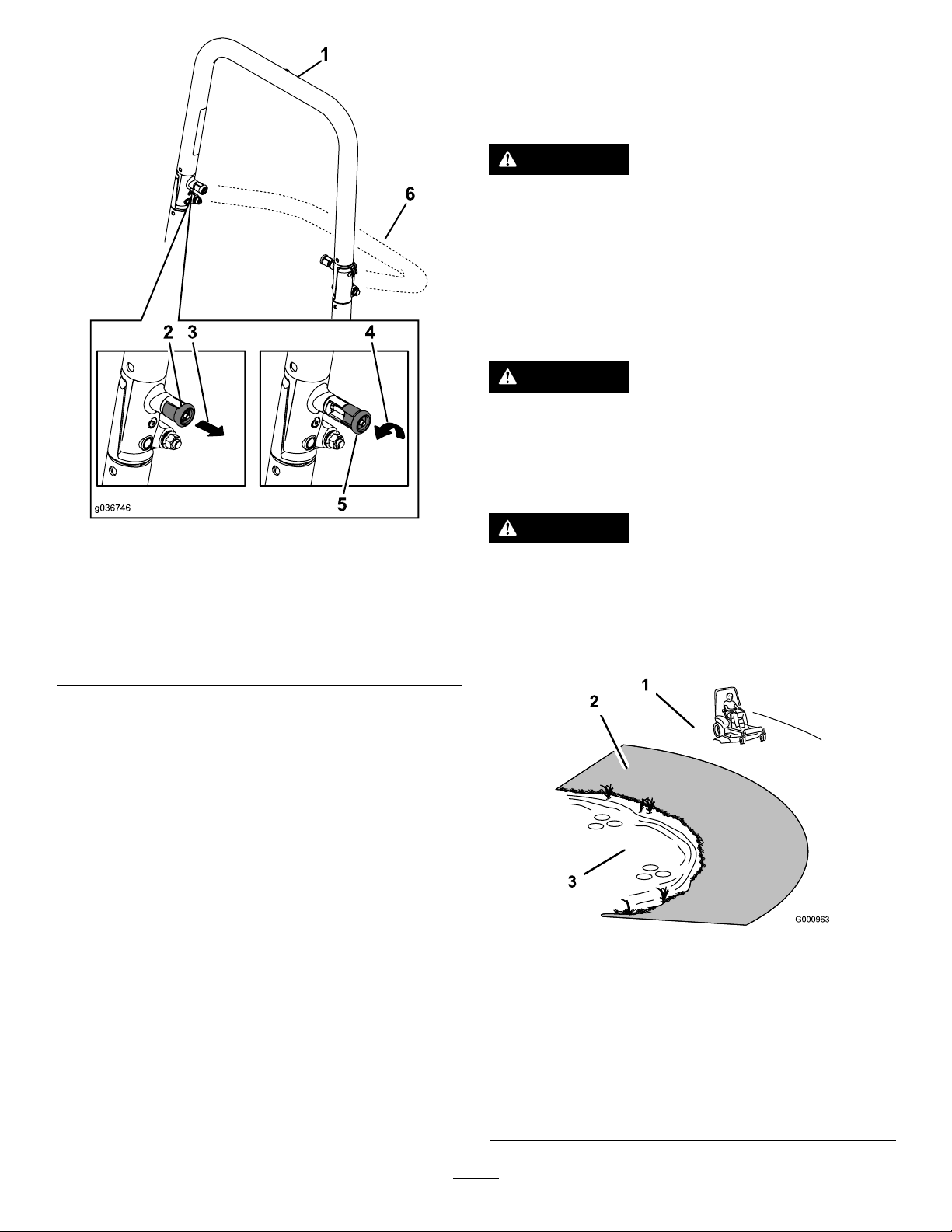

Figure9

1.Rollbarintheupright

position

2.ROPSknobinthelatched

position

3.PulltheROPSknobout.6.Rollbarinthefolded

4.RotatetheROPSknob90

degrees.

5.ROPSknobinthe

unlatchedposition

position

4.T oraisetherollbar,raisetherollbartothe

operatingpositionandrotatetheknobsuntil

theymovepartiallyintothegrooves(Figure9).

5.Raisetherollbartothefulluprightpositionwhile

pushingontheupperrollbarsothatthepins

snapintopositionwhentheholesalignwiththe

pins(Figure9).

Important:Alwaysusetheseatbeltwiththe

rollbarintheraisedposition.

6.Pushontherollbarandensurethatbothpins

areengaged.

g036746

DANGER

Operatingthemachinewhiletherollbaris

downmayleadtoseriousinjuryordeathin

theeventofarollover.

Alwayskeeptherollbarinthefullyraisedand

lockedpositionandusetheseatbelt.

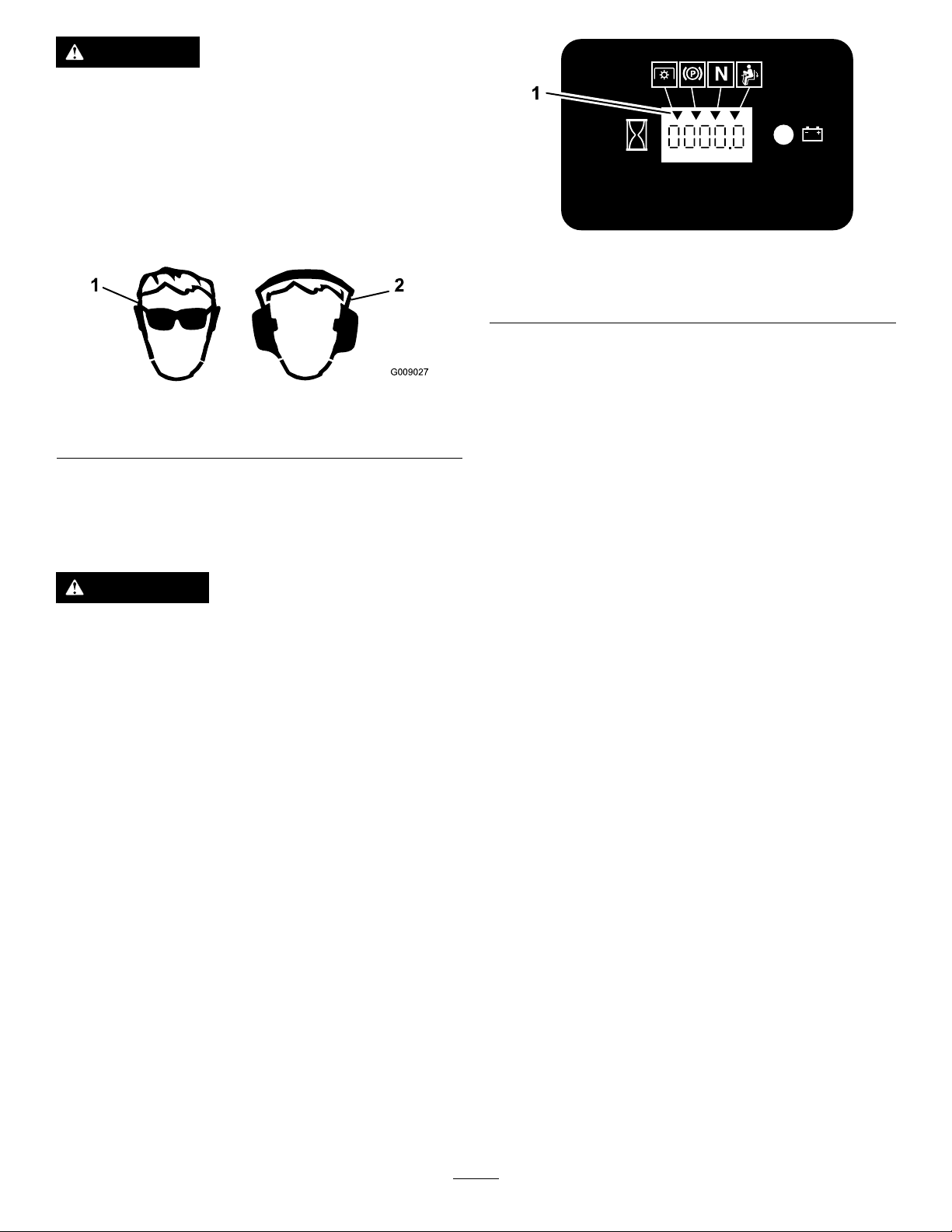

g000963

Figure10

1.SafeZone—usethe

machinehereonslopes

lessthan15degreesor

atareas.

2.DangerZone—usea

walk-behindmowerand/or

ahandtrimmeronslopes

greaterthan15degrees

andneardrop-offsor

water.

17

3.Water

Page 18

CAUTION

Thismachineproducessoundlevelsin

excessof85dBAattheoperator’searand

cancausehearinglossthroughextended

periodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Useprotectiveequipmentforyoureyes,ears,hands,

feet,andhead.

g009027

Figure11

1.Weareyeprotection.2.Wearhearingprotection.

UsingtheSafety-Interlock System

WARNING

Ifsafety-interlockswitchesaredisconnected

ordamaged,themachinecouldoperate

unexpectedlycausingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdaily ,andreplaceanydamaged

switchesbeforeoperatingthemachine.

Understandingthe Safety-InterlockSystem

Thesafety-interlocksystemisdesignedtopreventthe

enginefromstartingunless:

•Theparkingbrakeisengaged.

•Theblade-controlswitch(PTO)isdisengaged.

•Themotion-controlleversareintheNEUTRAL-LOCK

position.

Thesafety-interlocksystemisalsodesignedtoshutoff

theenginewhenthetractioncontrolsaremovedfrom

thelockedpositionwiththeparkingbrakeengagedor

ifyourisefromtheseatwhenthePTOisengaged.

Thehourmeterhassymbolstonotifytheuserwhen

theinterlockcomponentisinthecorrectposition.

Whenthecomponentisinthecorrectposition,a

trianglelightsupinthecorrespondingsquare.

g187670

Figure12

1.Triangleslightupwhentheinterlockcomponentsareinthe

correctposition

TestingtheSafety-Interlock System

ServiceInterval:Beforeeachuseordaily

Testthesafety-interlocksystembeforeyouusethe

machineeachtime.Ifthesafetysystemdoesnot

operateasdescribedbelow,haveanAuthorized

ServiceDealerrepairthesafetysystemimmediately .

1.Sittingontheseat,engagetheparkingbrake

andmovetheblade-controlswitch(PTO)tothe

ONposition.Trystartingtheengine;theengine

shouldnotstart.

2.Sittingontheseat,engagetheparkingbrake

andmovetheblade-controlswitch(PTO)tothe

OFFposition.Moveeithermotion-controllever

(outoftheNEUTRAL-LOCKposition).Trystarting

theengine;theengineshouldnotstart.Repeat

fortheothercontrollever.

3.Sittingontheseat,engagetheparkingbrake,

movetheblade-controlswitch(PTO)totheOFF

position,andmovethemotion-controllevers

totheNEUTRAL-LOCKposition.Nowstartthe

engine.Whiletheengineisrunning,disengage

theparkingbrake,engagetheblade-control

switch(PTO),andriseslightlyfromtheseat;the

engineshouldshutoff.

4.Sittingontheseat,engagetheparkingbrake,

movetheblade-controlswitch(PTO)totheOFF

position,andmovethemotion-controllevers

totheNEUTRAL-LOCKposition.Nowstartthe

engine.Whiletheengineisrunning,center

eithermotioncontrolandmove(forwardor

reverse);theengineshouldshutoff.Repeatfor

othermotioncontrol.

5.Sittingontheseat,disengagetheparkingbrake,

movetheblade-controlswitch(PTO)totheOFF

position,andmovethemotion-controllevers

totheNEUTRAL-LOCKposition.Trystartingthe

engine;theengineshouldnotstart.

18

Page 19

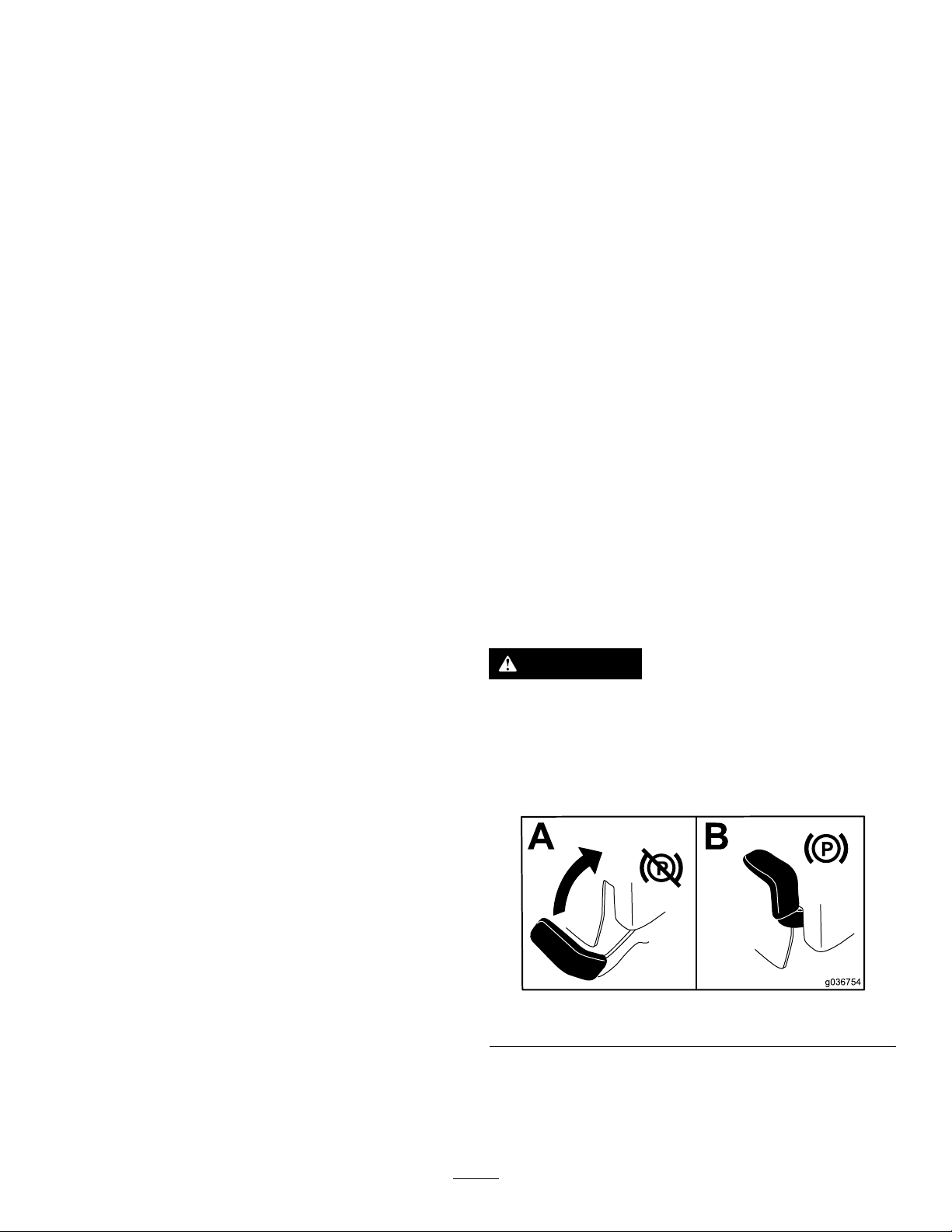

PositioningtheSeat

Theseatcanmoveforwardandbackward(Figure13).

Positiontheseatwhereyouhavethebestcontrolof

themachineandaremostcomfortable.

Figure13

showninFigure15,addafront-weightkit.Contact

yourauthorizedservicedealerforthefront-weightkit.

g037417

Figure15

1.Addafront-weightkitwhen2ormoreaccessory-mountkits

areinstalledatthesepositions.

g028272

DuringOperation

ChangingtheSeat Suspension

Theseatisadjustabletoprovideasmoothand

comfortableride.Positiontheseatwhereyouare

mostcomfortable.

Toadjustit,turntheknobinfronteitherdirectionto

providethebestcomfort(Figure14).

Figure14

1.Seat-suspensionknob

UsingAttachmentsand Accessories

UseonlyT oroapprovedattachmentsandaccessories.

DuringOperationSafety

GeneralSafety

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Wearappropriateclothing,includingeye

protection;slip-resistant,substantialfootwear;and

hearingprotection.Tiebacklonghairanddonot

wearjewelry.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Nevercarrypassengersonthemachineandkeep

bystandersandpetsawayfromthemachine

duringoperation.

g024881

•Operatethemachineonlyingoodvisibilitytoavoid

holesorhiddenhazards.

•Avoidmowingonwetgrass.Reducedtraction

couldcausethemachinetoslide.

•Ensurethatalldrivesareinneutral,theparking

brakeisengaged,andyouareintheoperating

positionbeforeyoustarttheengine.

•Keepyourhandsandfeetawayfromthecutting

units.Keepclearofthedischargeopeningatall

times.

Ifmorethanoneaccessory-mountkit(i.e.bucketkitor

universalmountkit)isaddedtoanyofthe4locations

•Lookbehindanddownbeforebackinguptobe

sureofaclearpath.

19

Page 20

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscureyour

vision.

•Keeptherollbarinsafeoperatingconditionby

thoroughlyinspectingitperiodicallyfordamage

andkeepingallthemountingfastenerstight.

•Donotmowneardrop-offs,ditches,or

embankments.Themachinecouldsuddenlyroll

overifawheelgoesovertheedgeoriftheedge

givesway .

•Stopthebladeswheneveryouarenotmowing.

•Stopthemachineandinspectthebladesafter

strikinganobjectorifthereisanabnormal

vibrationinthemachine.Makeallnecessary

repairsbeforeresumingoperation.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalkswiththe

machine.Alwaysyieldtheright-of-way.

•Disengagethedrivetothecuttingunitandshut

offtheenginebeforeadjustingtheheightof

cut(unlessyoucanadjustitfromtheoperating

position).

•Neverrunanengineinanareawhereexhaust

gasesareenclosed.

•Neverleavearunningmachineunattended.

•Beforeleavingtheoperatingposition(including

toemptythecatchersortounclogthechute),do

thefollowing:

•Replaceadamagedrollbar.Donotrepairoralter

it.

SlopeSafety

•Slowdownthemachineanduseextracareon

hillsides.Travelupanddownonhillsides.Turf

conditionscanaffectthestabilityofthemachine.

•Avoidturningthemachineonslopes.Ifyoumust

turnthemachine,turnitslowlyandgradually

downhill,ifpossible.

•Donotturnthemachinesharply .Usecarewhen

reversingthemachine.

•Useextracarewhileoperatingthemachinewith

attachments;theycanaffectthestabilityofthe

machine.

OperatingtheParking Brake

Alwaysengagetheparkingbrakewhenyoustopthe

machineorleaveitunattended.

–Stopthemachineonlevelground.

–Disengagethepowertake-offandlowerthe

attachments.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey.

–Waitforallmovingpartstostop.

•Donotoperatethemachinewhenthereistherisk

oflightning.

•Donotusethemachineasatowingvehicle.

•Donotchangethegovernorspeedoroverspeed

theengine.

•Useaccessoriesandattachmentsapprovedby

Toroonly.

RolloverProtectionSystem (ROPS)Safety

•Donotremovetherollbarfromthemachine.

•Ensurethattheseatbeltisattachedandthatyou

canreleaseitquicklyinanemergency.

EngagingtheParkingBrake

WARNING

Theparkingbrakemaynotholdthemachine

parkedonaslopeandcouldcausepersonal

injuryorpropertydamage.

Donotparkonslopesunlessthewheelsare

chockedorblocked.

g036754

Figure16

•Alwayswearyourseatbeltwhentherollbarisup.

•Checkcarefullyforoverheadobstructionsanddo

notcontactthem.

20

Page 21

DisengagingtheParkingBrake

Figure17

DisengagingtheBlade-Control Switch(PTO)

g009174

Figure19

OperatingtheThrottle

YoucanmovethethrottlecontrolbetweentheFAST

andSLOWpositions(Figure20).

g192635

AlwaysusetheFASTpositionwhenturningonthe

mowerdeckwiththeblade-controlswitch(PTO).

OperatingtheMower Blade-ControlSwitch(PTO)

Theblade-controlswitch(PTO)startsandstopsthe

mowerbladesandanypoweredattachments.

EngagingtheBlade-Control Switch(PTO)

Note:Engagingtheblade-controlswitch(PTO)with

thethrottlepositionathalforlesscausesexcessive

weartothedrivebelts.

Figure18

g008946

Figure20

OperatingtheChoke

Usethechoketostartacoldengine.

1.Iftheengineiscold,usethechoketostartthe

engine.

2.Pullupthechokeknobtoengagethechoke

beforeusingtheignitionswitch(Figure21).

3.Pushdownthechokeknobtodisengagethe

chokeafterstartingtheengine(Figure21).

g008945

21

Page 22

Figure21

1.ONposition2.OFFposition

StartingandShuttingOff theEngine

StartingtheEngine

1.Raisetherollbarupandlockintoplace,siton

theseat,andfastentheseatbelt.

2.MovethemotioncontrolstotheNEUTRAL-LOCK

position.

3.Engagetheparkingbrake;refertoEngagingthe

ParkingBrake(page20).

4.Movetheblade-controlswitch(PTO)totheOFF

position(Figure23).

5.Movethethrottlelevermidwaybetweenthe

SLOWandFASTpositions.

g008959

OperatingtheIgnition Switch

1.TurntheignitionkeytotheSTARTposition

(Figure22).

Note:Whentheenginestarts,releasethekey.

Important:Donotengagethestarterfor

morethan5secondsatatime.Iftheengine

failstostart,wait15secondsbetween

attempts.Failuretofollowtheseinstructions

canburnoutthestartermotor.

Note:Youmayneedmultipleattemptstostart

theenginewhenyoustartitthersttimeafter

thefuelsystemhasbeenwithoutfuelcompletely.

g036838

Figure23

6.TurntheignitionkeytotheSTARTposition

(Figure24).

Note:Whentheenginesstarts,releasethekey.

Figure22

2.TurntheignitionkeytotheSTOPpositiontoshut

offtheengine.

Important:Donotengagestarterformore

g008947

than5secondsatatime.Iftheenginefails

tostartallowa15-secondcool-downperiod

betweenattempts.Failuretofollowthese

instructionscanburnoutthestartermotor.

Note:Additionalstartingcyclesmaybe

requiredwhenstartingtheenginefortherst

22

Page 23

timeafterthefuelsystemhasbeenwithoutfuel

completely.

Figure24

ShuttingOfftheEngine

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

g008947

Alwaysremovetheignitionkeyandengage

theparkingbrakewhenleavingthemachine

unattended,evenifjustforafewminutes.

MovethethrottletotheFASTpositionandturnthe

switchtotheOFFposition.

g037049

Figure25

Important:Makesurethatthefuel-shutoffvalve

isclosedbeforetransportingorstoringthe

machine,asfuelleakagemayoccur.Engagethe

parkingbrakebeforetransporting.Makesurethat

youremovethekeyasthefuelpumpmayrunand

causethebatterytolosecharge.

23

Page 24

UsingtheMotion-Control

DrivingtheMachine

Levers

Thedrivewheelsturnindependently ,poweredby

hydraulicmotorsoneachaxle.Youcanturn1side

inreversewhileyouturntheotherforward,causing

themachinetospinratherthanturn.Thisgreatly

improvesthemachinemaneuverabilitybutmay

requiretimeforyoutoadapttohowitmoves.

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Place

thethrottlecontrolintheFASTpositionforbest

performance.Alwaysoperateinthefullthrottle

positionwhenmowing.

CAUTION

Machinecanspinveryrapidly.Operatormay

losecontrolofmachineandcausepersonal

injuryordamagetomachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemaking

sharpturns.

Figure26

1.Motion-control

lever—NEUTRAL-LOCK

position

2.Center,unlockedposition5.Frontofmachine

3.Forward

4.Backward

c:\data\documentum\checkout\g004532

24

Page 25

DrivingForward

DrivingBackward

Note:Theenginestopswhenyoumovethe

traction-controlwiththeparkingbrakeengaged.

Tostop,pullthemotion-controlleverstotheNEUTRAL

position.

1.Disengagetheparkingbrake;referto

DisengagingtheParkingBrake(page21).

2.Movetheleverstothecenter,unlockedposition.

3.T ogoforward,slowlypushthemotion-control

leversforward(Figure27).

1.Movetheleverstothecenter,unlockedposition.

2.T ogobackward,slowlypullthemotion-control

leversrearward(Figure28).

g008953

Figure28

Figure27

g008952

25

Page 26

AdjustingtheHeight-of-Cut

UsingtheTransportLock

Thetransportlockhas2positions,andisusedwith

thedeck-liftpedal.ThereisaLOCKpositionand

anUNLOCKpositionforthetransportpositionofthe

mowerdeck(Figure29).

AdjustingtheHeight-of-CutPin

Adjusttheheight-of-cutfrom38to127mm(1-1/2to5

inches)in6mm(1/4inch)incrementsbymovingthe

height-of-cutpinintodifferentholelocations.

1.MovethetransportlocktotheLOCKposition.

2.Pushonthedeck-liftpedalwithyourfootand

raisethemowerdecktotheTRANSPORTposition

(alsothe127mmor5inchcutting-height

position)asshowninFigure30.

3.T oadjust,removethepinfromtheheight-of-cut

bracket(Figure30).

4.Selectaholeintheheight-of-cutbracket

correspondingtotheheight-of-cutdesired,and

insertthepin(Figure30).

5.Pushonthedecklift,pulluponthetransport

lockknob,andslowlylowerthemowerdeck.

Figure29

Transport-LockPositions

1.Transportlockknob3.UNLOCKposition—The

2.LOCKposition—The

mowerdecklocksintothe

transportposition.

mowerdeckdoesnotlock

intothetransportposition.

g036745

Figure30

1.Deck-liftpedal3.Height-of-cutpin

2.Height-of-cutholes

g037050

AdjustingtheAnti-Scalp

4.Transportlockknob

Rollers

Wheneveryouchangetheheight-of-cut,adjustthe

heightoftheanti-scalprollers.

1.Disengagetheblade-controlswitch(PTO),move

themotion-controlleverstotheNEUTRAL-LOCK

position,andengagetheparkingbrake.

2.Stoptheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

26

Page 27

Figure31

1.Anti-scalproller4.Flangenut

2.Spacer

3.Bushing

1.Flangenut4.Anti-scalproller

2.Bolt5.Bushing

3.Spacer

5.Bolt

Figure32

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

Alwaysremovetheignitionkeyandengage

theparkingbrakewhenleavingthemachine

unattended,evenifjustforafewminutes.

UsingtheSideDischarge

g192815

g036848

Themowerhasahingedgrassdeectorthat

dispersesclippingstothesideanddowntowardthe

turf.

DANGER

Withoutagrassdeector,dischargecover,or

acompletegrass-catcherassemblymounted

inplace,youandothersareexposedtoblade

contactandthrowndebris.Contactwith

rotatingmowerblade(s)andthrowndebris

willcauseinjuryordeath.

•Neverremovethegrassdeectorfrom

themowerbecausethegrassdeector

routesmaterialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthe

mower.

•Nevertrytoclearthedischargearea

ormowerbladesunlessyoumovethe

blade-controlswitch(PTO)totheOFF

position,rotatetheignitionkeytotheOFF

position,andremovethekey.

•Makesurethatthegrassdeectorisinthe

downposition.

StoppingtheMachine

Tostopthemachine,movethemotion-controllevers

toneutralandthentotheNEUTRAL-LOCKposition,

disengagetheblade-controlswitch(PTO),andturn

theignitionkeytotheOFFposition.

Engagetheparkingbrakewhenyouleavethe

machine;refertoEngagingtheParkingBrake(page

20).Removethekeyfromtheignitionswitch.

OperatingTips

UsingtheFastThrottleSetting

Forbestmowingandmaximumaircirculation,operate

theengineattheFASTposition.Airisrequiredto

thoroughlycutgrassclippings,sodonotsetthe

height-of-cutsolowastototallysurroundthemower

inuncutgrass.Alwaystrytohave1sideofthemower

freefromuncutgrass,whichallowsairtobedrawn

intothemower.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethat

thecuttingheightofthemowerdoesnotscalpany

unevenground.However,thecuttingheightusedin

27

Page 28

thepastisgenerallythebestonetouse.Whencutting

grasslongerthan15cm(6inches)tall,youmaywant

tocutthelawntwicetoensureanacceptablequality

ofcut.

CuttingaThirdoftheGrassBlade

Itisbesttocutonlyaboutathirdofthegrassblade.

Cuttingmorethanthatisnotrecommendedunless

grassissparse,oritislatefallwhengrassgrows

moreslowly .

AlternatingtheMowingDirection

Alternatethemowingdirectiontokeepthegrass

standingstraight.Thisalsohelpsdisperseclippings

whichenhancesdecompositionandfertilization.

MowingatCorrectIntervals

Grassgrowsatdifferentratesatdifferenttimesof

theyear.T omaintainthesamecuttingheight,mow

moreofteninearlyspring.Asthegrassgrowthrate

slowsinmidsummer,mowlessfrequently .Ifyou

cannotmowforanextendedperiod,rstmowata

highcuttingheight,thenmowagain2dayslaterata

lowerheightsetting.

shreddingthegrassblades.T earingandshredding

turnsgrassbrownattheedges,whichslowsgrowth

andincreasesthechanceofdisease.Checkthe

mowerbladesaftereachuseforsharpness,and

foranywearordamage.Filedownanynicksand

sharpenthebladesasnecessary.Ifabladeis

damagedorworn,replaceitimmediatelywitha

genuineT ororeplacementblade.

AfterOperation

AfterOperationSafety

GeneralSafety

•Cleangrassanddebrisfromthecuttingunits,

mufers,andenginecompartmenttohelpprevent

res.Cleanupoilorfuelspills.

•Shutoffthefuelbeforestoringortransportingthe

machine.

•Disengagethedrivetotheattachmentwhenever

youaretransportingornotusingthemachine.

•Usefull-widthrampsforloadingthemachineinto

atrailerortruck.

UsingaSlowerCuttingSpeed

Toimprovecutquality,useaslowergroundspeed

incertainconditions.

AvoidingCuttingTooLow

Whenmowinguneventurf,raisethecuttingheight

toavoidscalpingtheturf.

StoppingtheMachine

Ifyoumuststoptheforwardmotionofthemachine

whilemowing,aclumpofgrassclippingsmay

dropontoyourlawn.Toavoidthis,moveontoa

previouslycutareawiththebladesengagedoryou

candisengagethemowerdeckwhilemovingforward.

KeepingtheUndersideofthe

MowerClean

Cleanclippingsanddirtfromtheundersideofthe

moweraftereachuse.Ifgrassanddirtbuildupinside

themower,cuttingqualitywilleventuallybecome

unsatisfactory.

•Tiethemachinedownsecurelyusingstraps,

chains,cable,orropes.Bothfrontandrearstraps

shouldbedirecteddownandoutwardfromthe

machine.

•Allowtheenginetocoolbeforestoringthemachine

inanyenclosure.

•Shutoffthefuelbeforestoringortransportingthe

machine.

•Neverstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

UsingtheFuel-Shutoff Valve

Thefuel-shutoffvalveislocatedbehindtheseat.

Closethefuel-shutoffvalvefortransport,maintenance,

andstorage.

Ensurethatthefuel-shutoffvalveisopenwhen

startingtheengine.

MaintainingtheBlade(s)

Maintainasharpbladethroughoutthecuttingseason

becauseasharpbladecutscleanlywithouttearingor

28

Page 29

Figure33

NEUTRAL-LOCKposition,applytheparkingbrake,

andremovethekey.

2.Locatethebypassleversbehindtheseat,down

ontheleftandrightsideoftheframe.

3.T opushthemachine,movebothbypassknobs

rearwardandlockthemintoplace(Figure34).

g036849

g008948

4.Disengagetheparkingbrakebeforepushing

themachine.

1.Onposition2.Offposition

Usingthe Drive-Wheel-Release Valves

WARNING

Handsmaybecomeentangledintherotating

drivecomponentsbelowtheenginedeck,

whichcouldresultinseriousinjury.

Shutofftheengine,removethekey,andallow

allmovingpartstostopbeforeaccessingthe

drive-wheel-releasevalves.

WARNING

Theengineandhydraulic-driveunitscan

becomeveryhot.Touchingahotengineor

hydraulic-driveunitscancausesevereburns.

g035062

Figure34

1.Frontofthemachine

2.Rotatebypassreleaseknobcounterclockwisetoloosen.

3.Leverpositionforoperatingthemachine

4.Pulltheleverinthisdirectiontopushthemachine.

5.Leverpositionforpushingthemachine

6.Rotatethebypass-releaseknobclockwisetotighten.

7.Engine

8.Releaselever

5.T orunthemachine,movethebypassknobsto

theFORWARDpositionandlockthemintoplace

(Figure34).

Allowtheengineandhydraulic-driveunits

tocoolcompletelybeforeaccessingthe

drive-wheel-releasevalves.

Thedrive-wheel-releasevalvesarelocatedontheleft

andrightsidesunderneaththeenginedeck.

1.Disengagetheblade-controlswitch(PTO),turn

theignitionkeytooff,movetheleverstothe

29

Page 30

TransportingtheMachine

LoadingtheMachine

Useaheavy-dutytrailerortrucktotransportthe

machine.Ensurethatthetrailerortruckhasall

necessarybrakes,lighting,andmarkingasrequired

bylaw.Pleasecarefullyreadallthesafetyinstructions.

Knowingthisinformationcouldhelpyou,yourfamily,

pets,orbystandersavoidinjury .

WARNING

Drivingonthestreetorroadwaywithout

turnsignals,lights,reectivemarkings,ora

slow-moving-vehicleemblemisdangerous

andcanleadtoaccidents,causingpersonal

injury.

Donotdrivethemachineonapublicstreet

orroadway.

Totransportthemachine:

1.Ifyouareusingatrailer,connectittothetowing

vehicleandconnectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Loadthemachineontothetrailerortruck.

4.Shutofftheengine,removethekey,setthe

brake,andclosethefuelvalve.

5.Usethemetaltie-downloopsonthemachineto

securelyfastentheittothetrailerortruckwith

straps,chains,cable,orropes(Figure35).

Useextremecautionwhenloadingorunloading

machinesontoatraileroratruck.Useafull-width

rampthatiswiderthanthemachineforthisprocedure.

Backuptherampanddriveforwarddowntheramp

(Figure36).

Figure36

1.Backthemachineupthe

ramp.

2.Drivethemachineforward

downtheramp.

Important:Donotusenarrowindividualramps

foreachsideofthemachine.

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath(Figure37).

•Useextremecautionwhenoperatinga

machineonaramp.

•Useonlyafull-widthramp;donotuse

individualrampsforeachsideofthe

machine.

g028043

1.Tie-downloops

Figure35

•Donotexceeda15-degreeanglebetween

therampandthegroundorbetweenthe

rampandthetrailerortruck.

•Ensurethatthelengthoframpisatleast

4timesaslongastheheightofthetrailer

ortruckbedtotheground.Thisensures

thattherampangledoesnotexceed15

degreesonatground.

•Backuprampsanddriveforwarddown

ramps.

g036851

•Avoidsuddenaccelerationordeceleration

whiledrivingthemachineonarampas

thiscouldcausealossofcontrolora

tip-oversituation.

30

Page 31

Figure37

g027996

1.Full-widthrampinstowed

position

2.Sideviewoffull-width

rampinloadingposition

3.Notgreaterthan

15degrees

4.Rampisatleast4times

aslongastheheightof

thetrailerortruckbedto

theground

5.H=heightofthetraileror

truckbedtotheground

6.Trailer

31

Page 32

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Aftertherst75hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

MaintenanceProcedure

•ForToroengines—changetheengineoilandlter.

•Changethehydraulic-systemltersanduid.

•Checkthesafetysystem.

•ForToroengines—checktheengine-oillevel.

•Cleantheair-intakescreen.

•Checktheseatbelt.

•Checktherollbarknobs.

•Cleantheenginescreenandtheareaaroundtheengine.

•Cleanaroundtheengine-exhaustsystem.

•Checkthehydraulicuidlevelintheexpansiontank.

•Inspecttheblades.

•Cleanthemowerdeck.

•Greasethefrontcasteraxles.(moreoftenindirtyordustyconditions).

•ForToroengines—cleantheair-cleanerfoamelement(moreoftenindusty,dirty

conditions).

•Greasethepump-idlerpivot.

•Checksparkarrester(ifequipped).

•Checkthetirepressure.

•Inspectthebeltsforcracksandwear.

•ForToroengines—replacetheair-cleanerfoamelement(moreoftenindusty,

dirtyconditions).

•ForToroengines—servicetheair-cleanerpaperelement(moreoftenindusty,

dirtyconditions).

•ForToroengines—changetheengineoilandoillter(moreoftenindusty,dirty

conditions).

•ForToroengines—checkthesparkplug(s).

•ForToroengines—replacetheair-cleanerpaperelement(moreoftenindusty ,

Every200hours

Every250hours

Every500hours

Monthly

Yearlyorbeforestorage

dirtyconditions).

•ForToroengines—replacethesparkplug(s).

•Aftertheinitialchange—changethehydraulic-systemltersanduidwhenusing

Mobil115W50uid(changeitmoreoftenundersevereconditions).

•Replacetheemissions-airintakelter.

•Replacethefuellter(moreoftenindusty,dirtyconditions).

•Checktheparkingbrakeadjustment.

•Aftertheinitialchange—changethehydraulic-systemltersanduidwhenusing

Toro®HYPR-OIL™500oil(changeitmoreoftenundersevereconditions).

•Checkthebatterycharge.

•Paintchippedsurfaces.

•Checkallmaintenanceprocedureslistedabovebeforestorage.

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineand

seriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

32

Page 33

Pre-Maintenance

ReleasingtheMower-Deck

Procedures

MaintenanceandStorage

•Beforerepairingthemachinedothefollowing:

–Disengagethedrives.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey.

–Disconnectthespark-plugwire.

•Parkthemachineonalevelsurface.

•Cleangrassanddebrisfromthecuttingunit,

drives,mufers,andenginetohelppreventres.

•Cleanupoilorfuelspills.

•Lettheenginecoolbeforestoringthemachine.

•Donotstorethemachineorfuelnearamesor

drainthefuelindoors.

•Donotallowuntrainedpersonneltoservicethe

machine.

•Usejackstandstosupportthemachineand/or

componentswhenrequired.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectthebatteryorremovethespark-plug

wirebeforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositiveterminal

last.Connectthepositiveterminalrstand

negativelast.

•Usecarewhencheckingtheblades.Wrapthe

blade(s)orwearthicklypaddedgloves,anduse

cautionwhenservicingthem.Onlyreplaceblades;

donotstraightenorweldthem.

•Keepyourhandsandfeetawayfrommoving

parts.Ifpossible,donotmakeadjustmentswith

theenginerunning.

•Keepallpartsingoodworkingcondition

andallhardwaretightened,especiallythe

blade-attachmentbolts.Replaceallwornor

damageddecals.

•Neverinterferewiththeintendedfunctionofa

safetydeviceorreducetheprotectionprovided

byasafetydevice.Checktheirproperoperation

regularly.

•Toensureoptimumperformanceandcontinued

safetycerticationofthemachine,useonly

genuineT ororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadeby

othermanufacturerscouldbedangerous,and

suchusecouldvoidtheproductwarranty.

•Checktheparkingbrakeoperationfrequently.

Adjustandserviceasrequired.

Curtain

Loosenthetopboltofthecurtaintoreleasethe

mower-deckcurtainandaccessthetopofthemower

deck(Figure38).Tightentheboltaftermaintenance

toinstallthecurtain.

Figure38

1.Bolt

2.Curtain

RemovingtheSheet-Metal Guard

1.Removetheoorpanandtheboltsattachedto

it(Figure39).

Figure39

1.Bolts

2.Loosenthe2frontboltsandremovethe

sheet-metalguardtoaccessthemowerbelts

andspindles(Figure40).Installthesheet-metal

guardandtightentheboltsaftermaintenance.

g193016

g193174

33

Page 34

Figure40

g192921

1.Sheet-metalguard

2.Bolt

34

Page 35

Lubrication

GreasingtheMachine

Greasemorefrequentlywhenoperatingconditions

areextremelydustyorsandy .

GreaseType:No.2general-purposelithium-based

ormolybdenum-basedgrease

1.Disengagetheblade-controlswitch(PTO),move

themotion-controlleverstotheNEUTRAL-LOCK

position,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanthegreasettingswitharag.

Note:Makesurethatyouscrapeanypaintoff

thefrontofthetting(s).

4.Connectagreaseguntothetting.

5.Pumpgreaseintothettingsuntilgreasebegins

tooozeoutofthebearings.

6.Wipeupanyexcessgrease.

ServiceInterval:Every25hours—Greasethefront

casteraxles.(moreoftenindirtyor

dustyconditions).

Every50hours—Greasethepump-idlerpivot.

1.Disengagetheblade-controlswitch(PTO),move

themotion-controlleverstotheNEUTRAL-LOCK

position,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Greasethepumpidler-pulleypivotwith1or2

pumpsofgrease(Figure41).

4.Greasethefrontcasteraxles(Figure41).

1.Pump-idlerpivot

g188563

Figure41

2.Casteraxle

35

Page 36

EngineMaintenance

WARNING

Contactwithhotsurfacesmaycausepersonalinjury.

Keephands,feet,face,clothingandotherbodypartsawaythemuferandotherhotsurfaces.

EngineSafety

Shutofftheenginebeforecheckingtheoiloradding

oiltothecrankcase.

ServicingtheEngine

ServicingtheAirCleaner

ServiceInterval:Every25hours/Monthly

(whichevercomesrst)—For

Toroengines—cleantheair-cleaner

foamelement(moreoftenindusty,

dirtyconditions).

Every100hours/Y early(whichevercomes

rst)—ForT oroengines—replacethe

air-cleanerfoamelement(moreoftenindusty ,

dirtyconditions).

g027800

Every100hours/Y early(whichevercomes

rst)—ForToroengines—servicetheair-cleaner

paperelement(moreoftenindusty,dirty

conditions).

Every200hours/Every2years(whichever

comesrst)—ForT oroengines—replacethe

air-cleanerpaperelement(moreoftenindusty,

dirtyconditions).

RemovingtheElements

1.Parkthemachineonalevelsurfaceand

disengagetheblade-controlswitch(PTO).

2.Engagetheparkingbrake,shutofftheengine,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Cleanaroundtheair-cleanercovertoprevent

dirtfromgettingintotheengineandcausing

damage.

4.Liftthecoverandrotatetheair-cleanerassembly

outoftheengine(Figure42).

g027801

Figure42

5.Removethefoamelementfromthepaper

element(Figure43).

g027802

Figure43

ServicingtheFoamElement

Washthefoamelementwithwaterandreplaceitif

itisdamaged.

36

Page 37

ServicingthePaperElement

1.Lightlytaptheelementonaatsurfaceto

removedustanddirt.

2.Inspecttheelementfortears,anoilylm,and

damagetotheseal.

Important:Donotcleanthepaperelement

withpressurizedairorliquids,suchas

solvent,gas,orkerosene.Replacethepaper

elementifitisdamagedorcannotbecleaned

thoroughly.

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSF ,SG,SH,SJ,

orSL)

CrankcaseCapacity:2.4L(80oz)withlter

Viscosity:Seethetablebelow.

2.Makesurethattheengineisshutoff,level,and

iscoolsothattheoilhashadtimetodraininto

thesump.

3.T okeepdirt,grassclippings,etc.,outofthe

engine,cleantheareaaroundtheoil-llcapand

dipstickbeforeremovingit(Figure45).

Figure44

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily—ForT oro

engines—checktheengine-oillevel.

Note:Checktheoilwhentheengineiscold.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothing,andother

bodypartsawaythemuferandotherhot

surfaces.

Important:Donotoverllthecrankcasewithoil,

becausedamagetotheenginemayresult.Donot

runenginewithoilbelowtheLowmark,because

theenginemaybedamaged.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,shutofftheengine,

engagetheparkingbrake,andremovethekey.

g029683

g029368

Figure45

ChangingtheEngineOilandOilFilter

ServiceInterval:Aftertherst5hours/Aftertherst

month(whichevercomesrst)—For

Toroengines—changetheengine

oilandlter.

Every100hours/Y early(whichevercomes

rst)—ForToroengines—changetheengine

oilandoillter(moreoftenindusty ,dirty

conditions).

Note:Disposeoftheusedoilatarecyclingcenter.

1.Parkthemachineonalevelsurfacetoensure

theoildrainscompletely.

37

Page 38

2.DisengagethePTOandengagetheparking

brake.

3.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

4.Draintheengineoil(Figure46).

g027799

g029570

Figure46

38

Page 39

5.Changetheengine-oillter(Figure47).

6.Slowlypourapproximately80%ofthespecied

oilintothellertubeandslowlyaddthe

additionaloiltobringittotheFullmark(Figure

48).

Figure47

Note:Ensurethattheoil-ltergaskettouches

theengineandthenturnthelteranextra3/4

turn.

g027484

Figure48

g027477

ServicingtheSparkPlug

ServiceInterval:Every100hours/Y early

(whichevercomesrst)—For

Toroengines—checkthespark

plug(s).

Every200hours/Every2years(whichever

comesrst)—ForT oroengines—replacethe

sparkplug(s).

Makesurethattheairgapbetweenthecenterand

sideelectrodesiscorrectbeforeinstallingthespark

plug.Useaspark-plugwrenchtoremoveandinstall

thesparkplug(s)andagappingtool/feelergaugeto

checkandadjusttheairgap.Installanewspark

plug(s)ifnecessary.

Type:ChampionRN9YCorNGKBPR6ES

Airgap:0.76mm(0.03inch)

39

Page 40

RemovingtheSparkPlug

InstallingtheSparkPlug

1.DisengagethePTOandengagetheparking

brake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

Figure49

Note:Duetothedeeprecessaroundthespark

plug,blowingoutthecavitywithcompressedair

isusuallythemosteffectivemethodforcleaning.

Thesparkplugismostaccessiblewhenthe

blowerhousingisremovedforcleaning.

CheckingtheSparkPlug

Tightenthesparkplug(s)to25to30N∙m(19to22

ft-lb).

g027478

g027735

Figure51

Important:Donotcleanthesparkplug(s).

Alwaysreplacethesparkplug(s)whenithas:a

blackcoating,wornelectrodes,anoilylm,or

cracks.

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeanstheaircleanerisdirty.

Setthegapto0.76mm(0.030inch).

Figure50

CleaningtheCoolingSystem

Cleantheair-intakescreenfromgrassanddebris

beforeeachuse.

1.Disengagetheblade-controlswitchandengage

theparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removetheairlterfromtheengine.

4.Removetheengineshroud.

5.T opreventdebrisenteringtheairintake,install

theairltertothelterbase.

6.Cleandebrisandgrassfromtheparts.

g027479

7.Removetheairlterandinstalltheengine

shroud.

8.Installtheairlter.

40

Page 41

CheckingtheSpark

FuelSystem

Arrester

ForaModelwithaSparkArrester

ServiceInterval:Every50hours

WARNING

Hotexhaustsystemcomponentsmayignite

gasolinevaporsevenafteryoushutoffthe

engine.Hotparticlesexhaustedduringengine

operationmayigniteammablematerials.

Firemayresultinpersonalinjuryorproperty

damage.

Donotrefuelorruntheengineunlessaspark

arresterisinstalled.

1.Shutofftheengine,waitforallmovingpartsto

stop,andremovethekey .Engagetheparking

brake.

2.Waitforthemufertocool.

3.Ifthereareanybreaksinthescreenorwelds,

replacethearrester.

4.Ifthescreenisplugged,removethearrester

andshakethelooseparticlesoutofthearrester

andcleanthescreenwithawirebrush(soakit

insolventifnecessary).Installthearresteron

theexhaustoutlet.

Maintenance

ReplacingtheFuelFilter

ServiceInterval:Every500hours/Yearly(whichever

comesrst)(moreoftenindusty ,

dirtyconditions).

Important:Installthefuellinehosesandsecure

withplastictiesthesameastheywereoriginally

installedatthefactorytokeepthefuellineaway

fromcomponentsthatcancausefuellinedamage.

Thefuellterislocatedneartheengineontheleft

frontoftheengine.

1.Disengagetheblade-controlswitch(PTO),move

themotion-controlleverstotheNEUTRAL-LOCK

position,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Allowthemachinetocooldown.

4.Closethefuel-shutoffvalvebehindtheseat

(Figure33).

Replacingthe Emissions-AirIntakeFilter

ServiceInterval:Every500hours

1.Shutofftheengine,waitforallmovingpartsto

stop,andremovethekey .Engagetheparking

brake.

2.Removethelterfromtheventhose.

3.Insertanewlterintotheendoftheventhose.

g033082

Figure52

5.Openthefuel-shutoffvalve.

41

Page 42

ServicingtheFuelTank

ElectricalSystem

Donotattempttodrainthefueltank.Ensurethatan

AuthorizedServiceDealerdrainsthefueltankand

servicesanycomponentsofthefuelsystem.

Maintenance

ElectricalSystemSafety

•Disconnectthebatterybeforerepairingthe

machine.Disconnectthenegativeterminalrst

andthepositivelast.Connectthepositiveterminal

rstandthenegativelast.

•Chargethebatteryinanopen,well-ventilated

area,awayfromsparksandames.Unplugthe

chargerbeforeconnectingordisconnectingthe

battery.Wearprotectiveclothinganduseinsulated

tools.

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

ServicingtheBattery

ServiceInterval:Monthly

DANGER

Batteryelectrolytecontainssulfuricacid,

whichisadeadlypoisonandcausessevere

burns.

Donotdrinkelectrolyteandavoidcontact

withskin,eyes,orclothing.Wearsafety

glassestoshieldyoureyesandwearrubber

glovestoprotectyourhands.

42

Page 43

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetalmachinecomponents,causing

sparks.Sparkscancausethebatterygasses

toexplode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery ,

donotallowthebatteryterminalstotouch

anymetalpartsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

WARNING

Incorrectbatterycableroutingcoulddamage

themachineandcables,causingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

g036853

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

1.Disengagetheblade-controlswitch(PTO),move

themotion-controlleverstotheNEUTRAL-LOCK

position,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Disconnectthenegativebatterycable(black)

fromthenegative(-)batteryterminal(Figure53).

4.Slidetheredterminalbootoffthepositive(red)

batteryterminal,andremovethepositive(+)

batterycable(Figure53).

5.Removetherubberstrap(Figure53).

6.Removethebattery .

g036855

Figure53

43

Page 44

InstallingtheBattery

1.Positionthebatteryinthetraywiththeterminal

postsoppositefromthehydraulictank(Figure

53).

2.Installthepositive(red)batterycabletothe

positive(+)batteryterminal.

3.Installthenegative(black)batterycableand

groundwiretothenegative(-)batteryterminal.

4.Securethecableswith2bolts,2washers,and

2locknuts(Figure53).

5.Slidetheredterminalbootontothepositive(+)

batteryterminal.

6.Securethebatterywiththerubberstrap(Figure

53).

ChargingtheBattery

1.Positivebatterypost

2.Negativebatterypost

g000960

Figure54

3.Red(+)chargerlead

4.Black(-)chargerlead

WARNING

Chargingthebatteryproducesgassesthat

canexplode.

Neversmokenearthebatteryandkeepsparks

andamesawayfromthebattery .

Important:Alwayskeepthebatteryfullycharged

(1.265specicgravity).Thisisespecially

importanttopreventbatterydamagewhenthe

temperatureisbelow0°C(32°F).

1.Chargebatteryfor10to15minutesat25to30

Aorfor30minutesat10A.

2.Whenthebatteryisfullycharged,unplug

thechargerfromtheelectricaloutlet,then

disconnectthechargerleadsfromthebattery

posts(Figure54).

3.Installthebatteryinthemachineandconnect

thebatterycables;refertoInstallingtheBattery

(page44).

Note:Donotrunthemachinewiththebattery

disconnected;electricaldamagemayoccur.

ServicingtheFuses

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance,however,ifafuseblowscheckthe

componentandcircuitforamalfunctionorshort.

Thefusesarelocatedontherightconsolenexttothe

seat(Figure55).

1.T oreplacethefuses,pulloutthefusetoremove

it.

2.Installanewfuse(Figure55).

g036858

Figure55

1.Fusecover

2.Fuseholder

44

3.Fuel-shutoffvalve

Page 45

DriveSystem

Maintenance

CheckingtheSeatBelt

ServiceInterval:Beforeeachuseordaily

Inspecttheseatbeltforwear,cuts,andproper

operationoftheretractorandbuckle.Replacethe

seatbeltifitisdamaged.

CheckingtheRoll-Bar Knobs

ServiceInterval:Beforeeachuseordaily

WARNING

Toavoidinjuryordeathfromrollover,keep

therollbarinthefullyraised,lockedposition

andusetheseatbelt.

Ensurethattheseatissecuredtothe

machine.

•Checkthatboththemountinghardwareandthe

knobsareingoodworkingcondition.

•Makesurethattheknobsarefullyengagedwith

therollbarintheraisedposition.

Note:Theupperhoopoftherollbarmayneed

tobepushedforwardorpulledrearwardtofully

engagebothknobs(Figure56andFigure57).

1.Rollbarintheupright

position

2.Roll-barknobinthe

latchedposition

3.Pulltheroll-barknobout

androtateit90degrees.

g036746

Figure56

4.Rotatetheroll-barknob90

degrees.

5.Roll-barknobinthe

unlatchedposition

6.Rollbarinthefolded

position

g034593

Figure57

1.Engaged2.Partiallyengaged—donot

45

operatewiththerollbarin

thisposition.

Page 46

AdjustingtheTracking

CheckingtheTirePressure

1.Disengagetheblade-controlswitch(PTO).

2.Drivetoanopen,atareaandmovethe

motion-controlleverstotheNEUTRAL-LOCK

position.

3.MovethethrottlemidwaybetweentheFASTand

SLOWpositions.

4.Movebothmotion-controlleversforwarduntil

theybothhitthestopsintheT-slot.

5.Checkwhichwaythemachinetracks.

6.Ifthemachinetrackstotheright,inserta3/16

inchhexwrenchthroughtheaccessholeinthe

rightfrontcoverpanelandrotatethetracking

screwclockwiseorcounterclockwisetoadjust

thetravelofthelever(Figure58).

7.Ifthemachinetrackstotheleft,inserta3/16

inchhexwrenchthroughtheaccessholeinthe

rightfrontcoverpanelandrotatethetracking

screwclockwiseorcounterclockwisetoadjust

thetravelofthelever(Figure58).

8.Drivethemachineandcheckthefullforward

tracking.

9.Repeattheadjustmentuntilthedesiredtracking

isobtained.

ServiceInterval:Every50hours/Monthly(whichever

comesrst)

Maintaintheairpressureinthefrontandreartires

at90kPa(13psi).Uneventirepressurecancause

unevencut.Checkthetireswhentheyarecoldtoget

themostaccuratepressurereading.

g001055

Figure59

CheckingtheWheelLug Nuts

Rightcontrollevershown

1.Accessholeonfrontcover

panel

Checkandtorquethewheellugnutsto122to136

N∙m(90to100ft-lb).

g035859

Figure58

2.Trackingscrew

46

Page 47

CoolingSystem

Maintenance

BrakeMaintenance

AdjustingtheParking

CleaningtheEngineScreen

ServiceInterval:Beforeeachuseordaily

Beforeeachuseordaily

Beforeeachuseremoveanybuildupofgrass,dirt,or

otherdebrisfromtheenginescreen,engineexhaust,

andtheareaaroundtheengine.Thishelpsensure

adequatecoolingandcorrectenginespeedand

reducesthepossibilityofoverheatingandmechanical

damagetotheengine.

Brake

ServiceInterval:Every500hours

Note:Makesuretofollowthisprocedurewhena

brakecomponenthasbeenremovedorreplaced.

1.Drivethemachineontoalevelsurface.

2.Disengagetheblade-controlswitch(PTO),move

themotion-controlleverstotheNEUTRAL-LOCK

position,andengagetheparkingbrake.

3.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

4.Setupthemachinetobepushedbyhand.Refer

toUsingtheDrive-Wheel-ReleaseV alves(page

29).

5.Raisethebackofthemachineupandsupport

themachinewithjackstands.

CAUTION

Raisingthemachineforservice

ormaintenancerelyingsolelyon

mechanicalorhydraulicjackscouldbe

dangerous.Themechanicalorhydraulic

jacksmaynotbeenoughsupportormay

malfunctionallowingthemachinetofall,

whichcouldcauseinjury.

Donotrelysolelyonmechanical

orhydraulicjacksforsupport.Use

adequatejackstandsorequivalent

support.

6.Engageanddisengagetheparkingbrakeand

checkeachdrivetiretoensurethateachbrake

engagesanddisengages.

7.Ifanadjustmentisnecessary,disengagethe

parkingbrake.Removethecotterpinfromthe

brakelinkageshaft(Figure60).

47

Page 48

Figure60

1.Cotterpin3.Brakelinkageshaft

2.Parkingbrake

8.CheckbothspringlengthsasshowninFigure

61.Ifanadjustmentisnecessary,turnthe

topnutclockwisetoshortenthespringand

counterclockwisetolengthenit.

10.Rotatethebrake-linkageshaftuntiltheend

alignswiththeholeinthelever.

•Shortenthelinkagebyturningitclockwise.

•Lengthenthelinkagebyturningit

counterclockwise.

11.Insertthebrake-linkageshaftintothe

parking-brakeholeandsecurewiththecotter

pin.Repeatstep6andadjustifnecessary.

12.Whenadjustmentiscomplete,removethejack

standsorequivalentsupportandlowerthe

machine.

13.PlacethemachineintotheOPERATINGposition.

g036752

RefertoUsingtheDrive-Wheel-ReleaseValves

(page29).

Figure61

1.Topnut

2.Spring

3.44mm(1-3/4inches)

9.Pushtheparkingbrakeleverallthewayforward

anddown.

g036100

48