Page 1

Z400 Series Z Master® Mowers

Model No. For all Z400 Series Z Master Mowers

Loose Parts

Use the chart below to verify that all parts have been shipped.

Form No. 3354-664 Rev A

Setup Instructions

Step

1

2

3

4

No parts required

No parts required

Rear wheels

Roll bar, right section

Roll bar, left section

Roll bar, center section

Bolt, (3/8 x 1 inch)

Curved washer

Flange nut, (3/8 inch)

Bolt, (1/2 x 3–1/4 inch)

Flange nut, (1/2 inch)

Description

Qty.

–

–

2

1

1

1

8

8

8

2

2

Remove parts from the crate.

Check the tire pressure.

Install the drive wheels.

Install the Rollover Protection

System (ROPS).

Use

5

Right control lever

Left control lever

6

Bolt (3/8 x 1 inch) (2 are assembled)

Curved washer (3/8 inch) (2 are

assembled)

1

1

4

4

Install the motion control levers.

7

8

9

10

11

12

13

© 2005—The Toro® Company

8111 Lyndale Avenue South

Bloomington, MN 55420

No parts required

No parts required

Air cleaner cap

Hose clamp

Number 2 general purpose lithium

base or molybdenum base grease.

(Purchase separately.)

No parts required

No parts required

No parts required

Register at www.Toro.com. Original Instructions (EN)

–

–

1

1

1 tube Check the machine for grease.

–

–

–

Adding fuel to the machine.

Charge the battery.

Install the air cleaner cap.

Check the engine oil level.

Prepare the side discharge chute.

Check the machine before delivery

to the customer.

Printed in the USA.

All Rights Reserved

Page 2

Step

Operator’s Manual

Parts Catalog

Engine Owner’s Manual

14

Registration Card

Safety Video

Key 2

Description

Qty.

1

1

1

1

1

Delivering the machine to the

customer.

Use

Step

1

Removing Parts from the

Crate

No Parts Required

Procedure

R emo v e the tires , the seat and the par ts for the

R OPS from the shipping crate .

Step

2

Checking the Tire Pressure

Step

3

Raising the Machine Up and

Installing the Drive Wheels

Parts needed for this step:

2

Rear wheels

Procedure

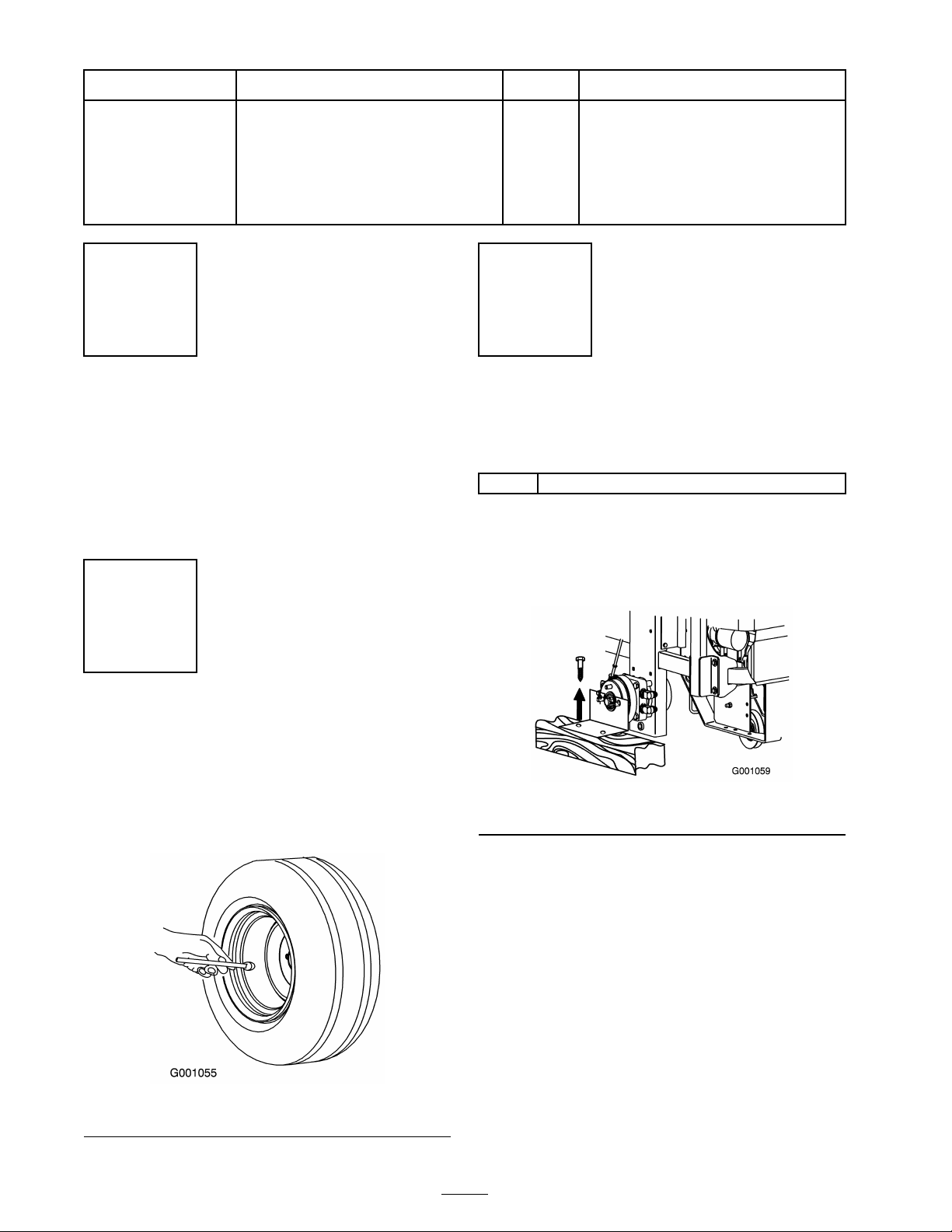

1. R emo v e the screws holding the right angle

retaining plate to the crate .

No Parts Required

Procedure

Chec k the air pressure in the front and rear tires .

Pressure: 13 psi (90 kP a)

Figure 1

Figure 2

2. Raise the bac k of the mac hine up and suppor t

it with jac k-stands .

2

Page 3

Figure 3

3. R emo v e the wheel n uts from both sides of the

v ehicle and remo v e the right angle retaining

plate . Discard the screws and retaining plate .

Step

4

Installing the Roll Over

Protection System

Parts needed for this step:

1

Roll bar, right section

1

Roll bar, left section

1

Roll bar, center section

8

Bolt, (3/8 x 1 inch)

8

Curved washer

8

Flange nut, (3/8 inch)

2

Bolt, (1/2 x 3–1/4 inch)

2

Flange nut, (1/2 inch)

Procedure

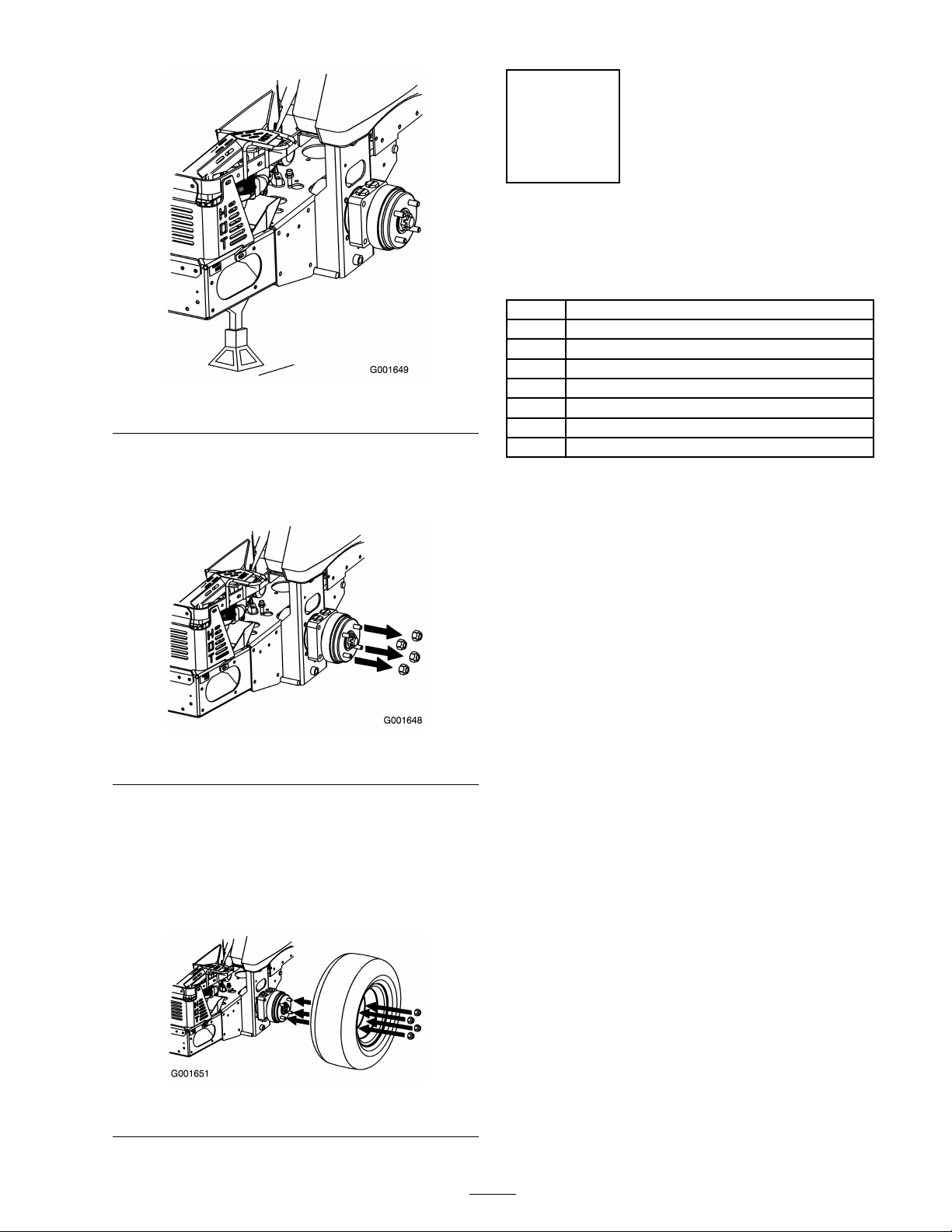

1. Loosely install the right and left roll bar section

to the frame , with 8 bolts (3/8 x 1 inc h), 8

cur v ed w ashers , and 8 flang e n uts (3/8 inc h).

Figure 4

4. Mount the wheels with the v alv e stem to the

outside and secure them with the wheel n uts

previously remo v ed.

5. T or que the wheel n uts to 95 ft-lb (128 N·m).

6. R emo v e the jac k-stands .

Note: T he cur v e w asher cone m ust be

installed to w ard the bolt head.

Figure 5

3

Page 4

Figure 8

Figure 6

2. Install the lanyard clips onto the long bolts

(1/2 x 3-1/4 inc h).

Note: Mak e sure the bent tab points to w ard

the head of the bolt.

Figure 7

3. Lightly oil the ends of the center roll bar

section.

4. Loosely install the center roll bar section using

2 bolts (1/2 x 3-1/4 inc h) and 2 flang e n uts

(1/2 inc h).

Note: Mak e sure the bolts are installed from

the outside of the roll bar .

Note: Mak e sure the lanyard tab is installed

as sho w and points forw ard.

5. Raise the roll bar into the upright position and

secure it with the pins and hair pin cotter pins

fastened to the lanyards

Figure 9

6. T or que all lo w er fasteners , attac hed to the

mac hine frame , to 30 ft-lb .

7. Tighten the center roll bar bolts (1/2 x 3-1/4

inc h) so it rotates freely with some resistance .

Note: No more than one thread should be

exposed outside the n ut.

4

Page 5

Figure 10

Step

5

Installing the Seat

Parts needed for this step:

Procedure

1. R emo v e the bolt and n ut from the seat frame .

2. R emo v e the n uts from the studs under the seat.

3. Secure the seat rod to the seat with the bolt

and n ut.

4. Install the seat to the seat frame with the

previously remo v ed n uts .

8. Tighten the front knobs ag ainst the center roll

bar ends .

Figure 11

Figure 12

5. Install the seat rod to the seat frame .

Figure 13

5

Page 6

Step

Step

6

Installing the Motion

Control Levers

Parts needed for this step:

1

Right control lever

1

Left control lever

4

Bolt (3/8 x 1 inch) (2 are assembled)

4

Curved washer (3/8 inch) (2 are assembled)

Procedure

Step

7

Adding Fuel to the Machine

No Parts Required

Procedure

8

Charging the Battery

No Parts Required

Procedure

Charging the batter y pr oduces gasses that

can explode and cause serious injur y .

• K eep cigar ettes, spar ks and flames a w ay

fr om the batter y .

• Mak e sur e the ignition s witch is of f.

• V entilate when charging or using the

batter y in an enclosed space.

Important: Do not r un the machine with

the batter y disconnected; electrical dama ge

may occur to the engine.

Charg e the batter y . R efer to the Operator’ s Manual

for instr uctions .

Add fuel to the mac hine before star ting it. R efer

to y our Operator’ s Manual. for the cor rect fuel and

procedure .

Figure 14

6

Page 7

Step

9

Installing the Air Cleaner

Cap

Parts needed for this step:

1

Air cleaner cap

1

Hose clamp

Procedure

1. R emo v e the plastic plug .

Figure 16

4. Install the air cleaner cap onto the air cleaner

and secure it with the hose clamp .

Figure 15

2. R emo v e the air cleaner cap from the mac hine .

3. Install the hose clamp onto the air cleaner cap .

Figure 17

7

Page 8

Step

Step

10

Checking the Machine for

Grease

Parts needed for this step:

1 tube

Procedure

1. R emo v e the belt co v ers .

2. Chec k the tensioning ar m for g rease .

3. Chec k the g rease for the three spindle bearings .

4. Install the belt co v ers .

Number 2 general purpose lithium base

or molybdenum base grease. (Purchase

separately.)

If needed, add g rease until it comes out of the

lo w er seals .

11

Checking the Engine Oil

Level

No Parts Required

Procedure

Before y ou star t the engine and use the mac hine ,

c hec k the oil lev el in the engine crankcase; refer to

Chec king Oil Lev el in Operator’ s Manual.

Step

12

Preparing the Side

Discharge Chute

No Parts Required

Procedure

R emo v e the plastic tie holding the side disc harg e

c hute up and lo w er the c hute into place .

Figure 18

8

Page 9

Step

13

Checking the Machine Before Delivery to the Customer

No Parts Required

Procedure

Before deli v ering the mac hine to the customer , ensure that y ou perfor m or ha v e perfor med the

procedures listed in the follo wing table and initial eac h when finished. R efer to the Operator’ s Man ual

for instr uctions on perfor ming these procedures .

Initial

Check the tire pressure.

Check the level of the mower.

Check that all mower spindles are greased.

Check the engine oil level.

Check the hydraulic uid level.

Check ROPS is secure.

Check the adjustment of the parking brake.

Ensure that the machine tracks correctly; refer to the Operator’s Manual for the adjustment

procedure.

Check the safety interlock system; refer to the Operator’s Manual .

Ensure that the PTO works.

Check all fasteners you installed to ensure that they are tight.

Check Procedure

W hen y ou finish setting up the mac hine , sign and date in the space pro vided belo w:

Signature: Date:

9

Page 10

Step

14

Delivering the Machine to the Customer

Parts needed for this step:

1

Operator’s Manual

1

Parts Catalog

1

Engine Owner’s Manual

1

Registration Card

1

Safety Video

2 Key

Procedure

At deli v er y , complete the items listed in the follo wing table and initial eac h when finished.

Model No. Serial No.

10

Page 11

Dealer Initial Customer Initial Check Procedure

Show the customer where the following features are located and how

they function:

Fuel tank caps

Oil ll cap/ Oil dipstick

Engine oil lter

Engine oil drain

Fuel lters

Air lter

Hydraulic uid reservoir

Hydraulic lter

Battery

Ignition switch

Throttle lever

Power take off switch (PTO)

Motion control levers

Parking brake

Mower height-of-cut

Adjustable seat

Hydraulic bypass valves

Rollover Protection System (ROPS)

Mower deck ow bafe

Refer to the Operator’s Manual to point out safety procedures, operation,

and maintenance procedures.

Review the warranty statement as shown in the Operator’s Manual.

Describe the post sale service procedures for your store.

Assist the customer in lling out and mailing the registration card or

register online at www.Toro.com

Make sure that the customer receives the Operator’s Manual, Parts Catalog,

and Engine Owner’s Manual, Set Up Instructions, and safety video.

Assist the customer in loading the mower.

Note: W hen y ou, the dealer re presentati v e , ha v e finished deli v ering the mac hine to the customer , sign

and date in the space pro vide belo w and k ee p a copy of this pag e for dealer records .

Signature: Date:

Signature: Date:

11

Page 12

Loading...

Loading...