Page 1

FormNo.3362-127RevA

Z300ZMaster

®

witha34inor40in

7-GaugeSideDischargeMower

ModelNo.74408—SerialNo.290000001andUp

ModelNo.74408CP—SerialNo.290000001andUp

ModelNo.74409—SerialNo.290000001andUp

ModelNo.74409CP—SerialNo.290000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

Warning

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Thisengineisnotequippedwitha

sparkarrestermufer.ItisaviolationofCalifornia

PublicResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,or

grass-coveredland.Otherstatesorfederalareas

mayhavesimilarlaws.

ThissparkignitionsystemcomplieswithCanadian

ICES-002.

Theenclosed

Engine Owner’ s Man ual

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCalifornia

EmissionControlRegulationofemissionsystems,

maintenance,andwarranty.Replacementsmaybe

orderedthroughtheenginemanufacturer.

issupplied

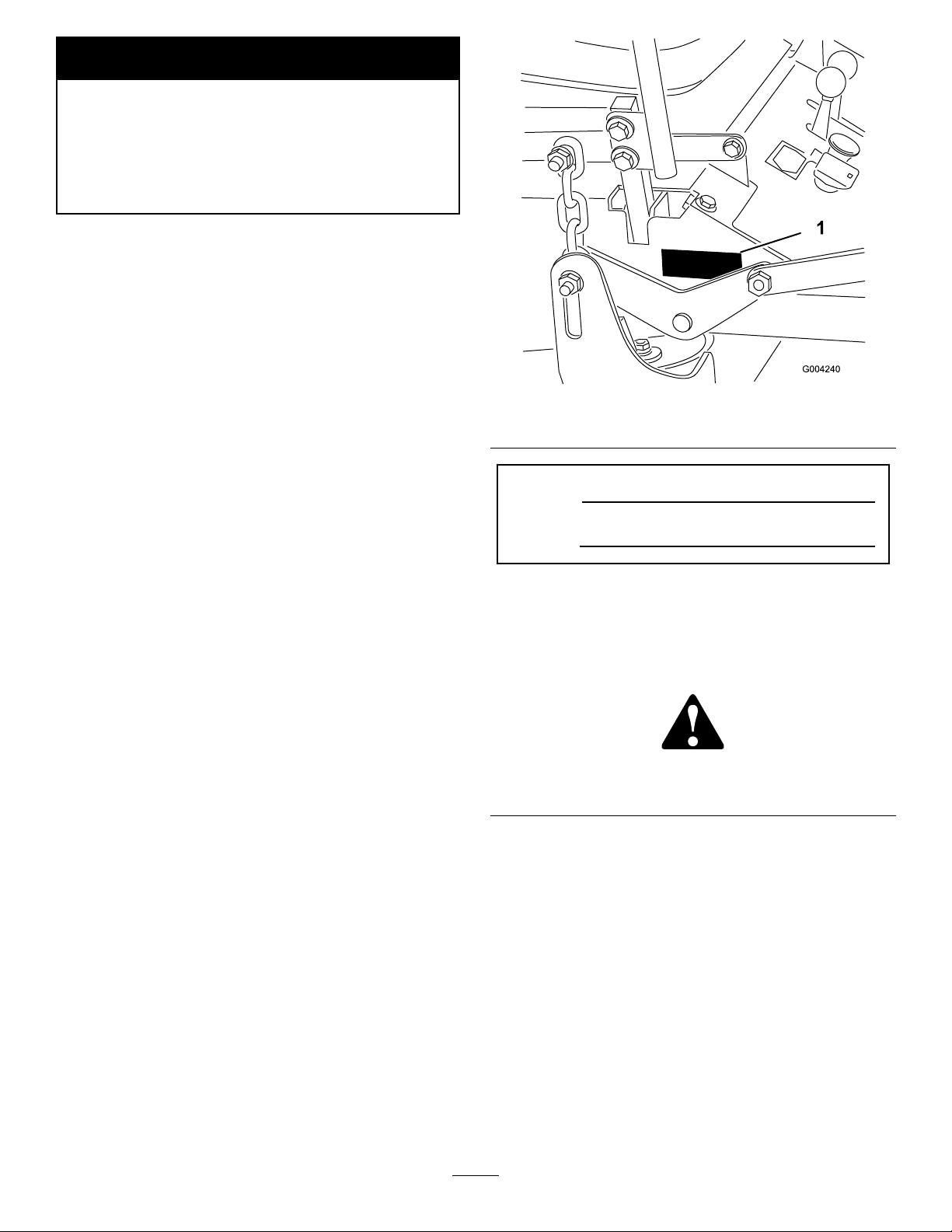

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .T oro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready .Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

ToroRidingMowerSafety....................................5

SlopeChart..........................................................7

SafetyandInstructionalDecals.............................8

ProductOverview......................................................10

©2008—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Controls.............................................................10

Operation...................................................................12

AddingFuel.......................................................12

CheckingtheEngineOilLevel............................13

ThinkSafetyFirst...............................................13

OperatingtheParkingBrake...............................14

StartingandStoppingtheEngine........................14

OperatingthePowerTakeOff(PTO).................15

TheSafetyInterlockSystem................................16

DrivingForwardorBackward.............................16

StoppingtheMachine.........................................17

AdjustingtheHeight-of-Cut...............................18

UsingtheLiftAssistPedal..................................18

AdjustingtheAnti-ScalpRollers.........................18

PositioningtheSeat............................................19

PushingtheMachinebyHand.............................19

UsingtheSideDischarge....................................20

TransportingMachines.......................................20

LoadingMachines..............................................21

OperatingTips...................................................21

Maintenance...............................................................23

RecommendedMaintenanceSchedule(s)................23

Lubrication.............................................................23

GreasingandLubrication...................................23

LubricatingtheCasterWheelHubs.....................25

EngineMaintenance...............................................27

ServicingtheAirCleaner....................................27

ServicingtheEngineOil.....................................28

ServicingtheSparkPlugs....................................29

FuelSystemMaintenance.......................................30

DrainingtheFuelTank.......................................30

ReplacingtheFuelFilter.....................................30

ElectricalSystemMaintenance................................31

ServicingtheBattery...........................................31

ServicingtheFuses.............................................33

DriveSystemMaintenance.....................................34

CheckingtheTirePressure.................................34

AdjustingtheCasterPivotBearing......................34

CoolingSystemMaintenance..................................35

CleaningtheAirIntakeScreen............................35

CleaningtheEngineCoolingSystem...................35

BrakeMaintenance.................................................35

ServicingtheBrakes...........................................35

BeltMaintenance....................................................36

InspectingtheBelts............................................36

ReplacingtheMowerBelt...................................36

CheckingandReplacingthePumpDrive

Belt................................................................36

ControlsSystemMaintenance.................................37

AdjustingtheControlHandleNeutral

Position..........................................................37

AdjustingtheTracking........................................38

HydraulicSystemMaintenance...............................39

ServicingtheHydraulicSystem...........................39

MowerDeckMaintenance......................................41

LevelingtheMower............................................41

ServicingtheCuttingBlades...............................42

ReplacingtheGrassDeector.............................45

Cleaning.................................................................46

CleaningUndertheMower.................................46

WasteDisposal...................................................46

Storage.......................................................................46

Troubleshooting.........................................................48

Schematics.................................................................50

3

Page 4

Safety

•Useextracarewhenhandlinggasolineandother

fuels.Theyareammableandvaporsareexplosive.

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafetyalertsymbol,whichmeans

CAUTION,WARNING,orDANGER-“personal

safetyinstruction."Failuretocomplywiththe

instructionmayresultinpersonalinjuryordeath.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Thisproductisdesignedforcuttingandrecyclinggrass

or,whenequippedwithagrassbagger,forcatching

cutgrass.Anyuseforpurposesotherthanthesecould

provedangeroustouserandbystanders.

SafeOperatingPractices

ThefollowinginstructionsarefromANSIstandard

B71.4-2004.

Training

•ReadtheOperator’sManualandothertraining

material.Iftheoperator(s)ormechanic(s)cannot

readEnglishitistheowner’sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmayrestrict

theageoftheoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,

otherpeopleorproperty.

–Useonlyanapprovedcontainer

–Neverrefuelordrainthemachineindoors.

–Neverremovegascaporaddfuelwithengine

running.Allowenginetocoolbeforerefueling.

Donotsmoke.

•Checkthatoperator’spresencecontrols,safety

switchesandshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholes

andhiddenhazards.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingengine.Starttheengineonly

fromtheoperator’sposition.Useseatbelts.

•Neverraisemowerwiththebladesrunning.

•NeveroperatewithoutthePTOshield,orother

guardssecurelyinplace.Besureallinterlocksare

attached,adjustedproperly,andfunctioningproperly .

•Neveroperatewiththedischargedeectorraised,

removedoraltered,unlessusingagrasscatcher.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Stoponlevelground,lowerimplements,disengage

drives,engageparkingbrake,shutoffenginebefore

leavingtheoperator’spositionforanyreason

includingemptyingthecatchersoruncloggingthe

chute.

•Stopequipmentandinspectbladesafterstriking

objectsorifanabnormalvibrationoccurs.Make

necessaryrepairsbeforeresumingoperations.

•Keephandsandfeetawayfromthecuttingunits.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Wearappropriateclothingincludinghardhat,safety

glassesandhearingprotection.Longhair,loose

clothingorjewelrymaygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeused

andremoveallobjectssuchasrocks,toysandwire

whichcanbethrownbythemachine.

•Nevercarrypassengersandkeeppetsandbystanders

away.

•Bealert,slowdownandusecautionwhenmaking

turns.Lookbehindandtothesidebeforechanging

directions.

•Slowdownandusecautionwhencrossingroadsand

sidewalks.Stopbladesifnotmowing.

•Beawareofthemowerdischargedirectionanddo

notpointitatanyone.

•Donotoperatethemowerundertheinuenceof

alcoholordrugs.

4

Page 5

•Useextremecarewhenloadingorunloadingthe

machineintoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

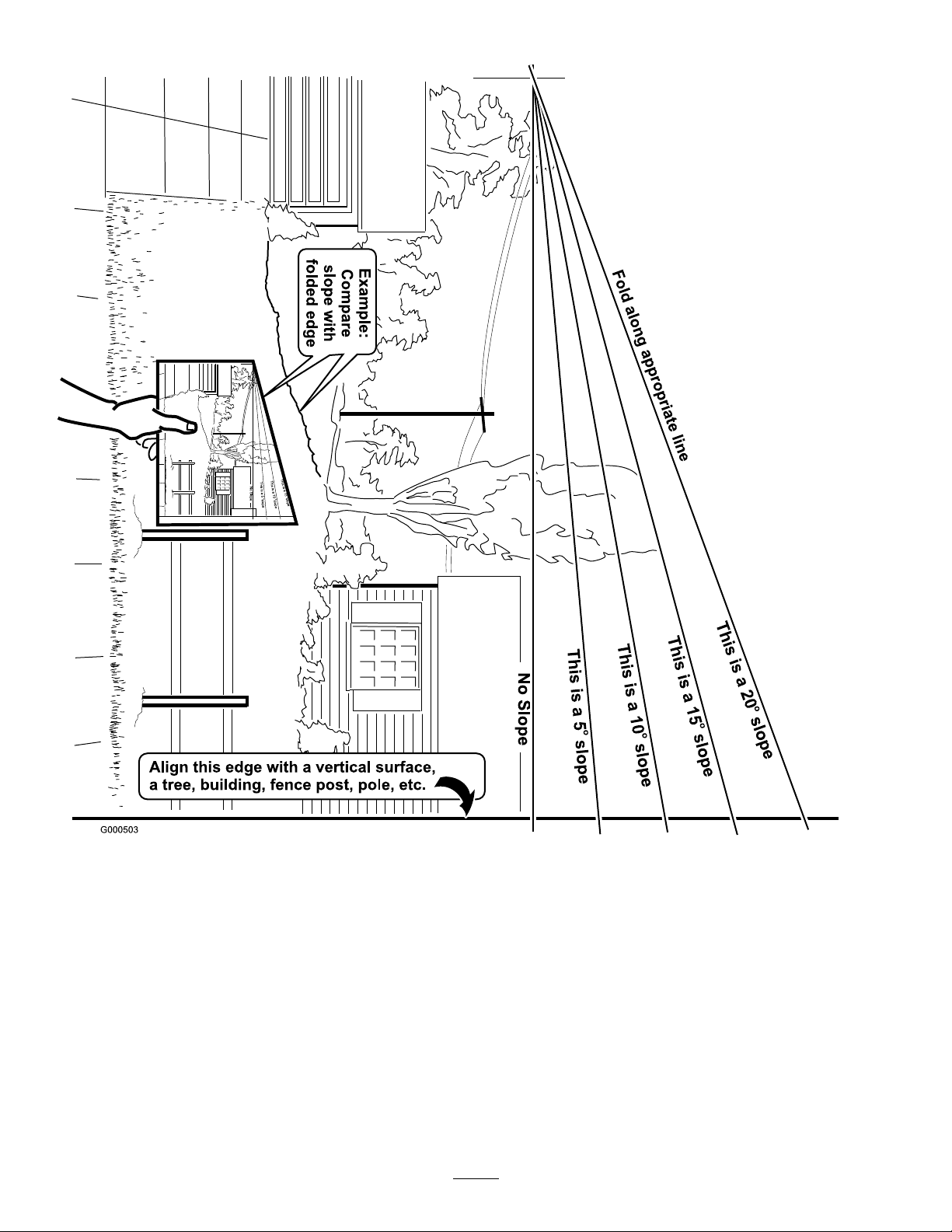

SlopeOperation

•Donotmowslopesgreaterthan15degrees.

•Donotmowneardrop-offs,ditches,steepbanks

orwater.Wheelsdroppingoveredgescancause

rollovers,whichmayresultinseriousinjury,death

ordrowning.

•Donotmowslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcausesliding

andlossofcontrol.

•Donotmakesuddenturnsorrapidspeedchanges.

•Useawalkbehindmowerand/orahandtrimmer

neardrop-offs,ditches,steepbanksorwater.

•Reducespeedanduseextremecautiononslopes.

•Removeormarkobstaclessuchasrocks,treelimbs,

etc.fromthemowingarea.Tallgrasscanhide

obstacles.

•Watchforditches,holes,rocks,dips,andrisesthat

changetheoperatingangle,asroughterraincould

overturnthemachine.

•Avoidsuddenstartswhenmowinguphillbecause

themowermaytipbackwards.

•Beawarethatlossoftractionmayoccurgoing

downhill.Weighttransfertothefrontwheelsmay

causedrivewheelstoslipandcauselossofbraking

andsteering.

•Alwaysavoidsuddenstartingorstoppingona

slope.Iftireslosetraction,disengagethebladesand

proceedslowlyofftheslope.

•Followthemanufacturer’srecommendationsfor

wheelweightsorcounterweightstoimprovestability.

•Useextremecarewithgrasscatchersorother

attachments.Thesecanchangethestabilityofthe

machineandcauselossofcontrol.

Maintenanceandstorage

•Disengagedrives,lowerimplement,setparking

brake,stopengineandremovekeyordisconnect

sparkplugwire.Waitforallmovementtostop

beforeadjusting,cleaningorrepairing.

•Cleangrassanddebrisfromcuttingunits,drives,

mufers,andenginetohelppreventres.Cleanup

oilorfuelspillage.

•Letenginecoolbeforestoringanddonotstorenear

ame.

•Shutofffuelwhilestoringortransporting.Donot

storefuelnearamesordrainindoors.

•Parkmachineonlevelground.Neverallowuntrained

personneltoservicemachine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectbatteryorremovesparkplugwirebefore

makinganyrepairs.Disconnectthenegativeterminal

rstandthepositivelast.Reconnectpositiverst

andnegativelast.

•Usecarewhencheckingblades.Wraptheblade(s)or

weargloves,andusecautionwhenservicingthem.

Onlyreplaceblades.Neverstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Chargebatteriesinanopenwellventilatedarea,

awayfromsparkandames.Unplugchargerbefore

connectingordisconnectingfrombattery.W ear

protectiveclothinganduseinsulatedtools.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•UseonlyToroapprovedattachments.Warrantymay

bevoidedifusedwithunapprovedattachments.

ToroRidingMowerSafety

•Engineexhaustcontainscarbonmonoxide,whichis

anodorless,deadlypoisonthatcankillyou.Donot

runengineindoorsorinanenclosedarea.

•Stoptheengine,disconnectsparkplugwire(s)and

removekeybeforeperforminganyservice,repairs,

maintenanceoradjustments.

•Keephands,feet,hair,andlooseclothingawayfrom

attachmentdischargearea,undersideofmowerand

anymovingpartswhileengineisrunning.

•Donottouchequipmentorattachmentpartswhich

maybehotfromoperation.Allowtocoolbefore

attemptingtomaintain,adjustorservice.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyes,andclothing.Protectyour

face,eyes,andclothingwhenworkingwithabattery.

•Batterygasescanexplode.Keepcigarettes,sparks

andamesawayfrombattery.

•Ifloadingthemachineontoatrailerortruck,usea

single,full-widthramponly.Therampangleshould

notexceed15degrees.

5

Page 6

SafeHandlingofGasoline:

Toavoidpersonalinjuryorpropertydamage,useextra

carewhenhandlinggasolineandotherfuels.Theyare

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipesandother

sourcesofignition.

•Neverremovethegascaporaddfuelwhenthe

engineisrunning.Allowtheenginetocoolbefore

refueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

•Neverllcontainersinsideavehicleoronatruckor

trailerwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Keepthenozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimesuntilthefueling

iscomplete.Donotuseanozzlelock-opendevice.

•Iffuelisspilledonclothing,changeclothing

immediately.

•Neveroverllthefueltank.Replacegascapand

tightensecurely .

•Keepnutsandboltstight,especiallytheblade

attachmentbolts.Keepequipmentingood

condition.

•Checkforproperbrakeoperationfrequently.Adjust

andserviceasrequired.

6

Page 7

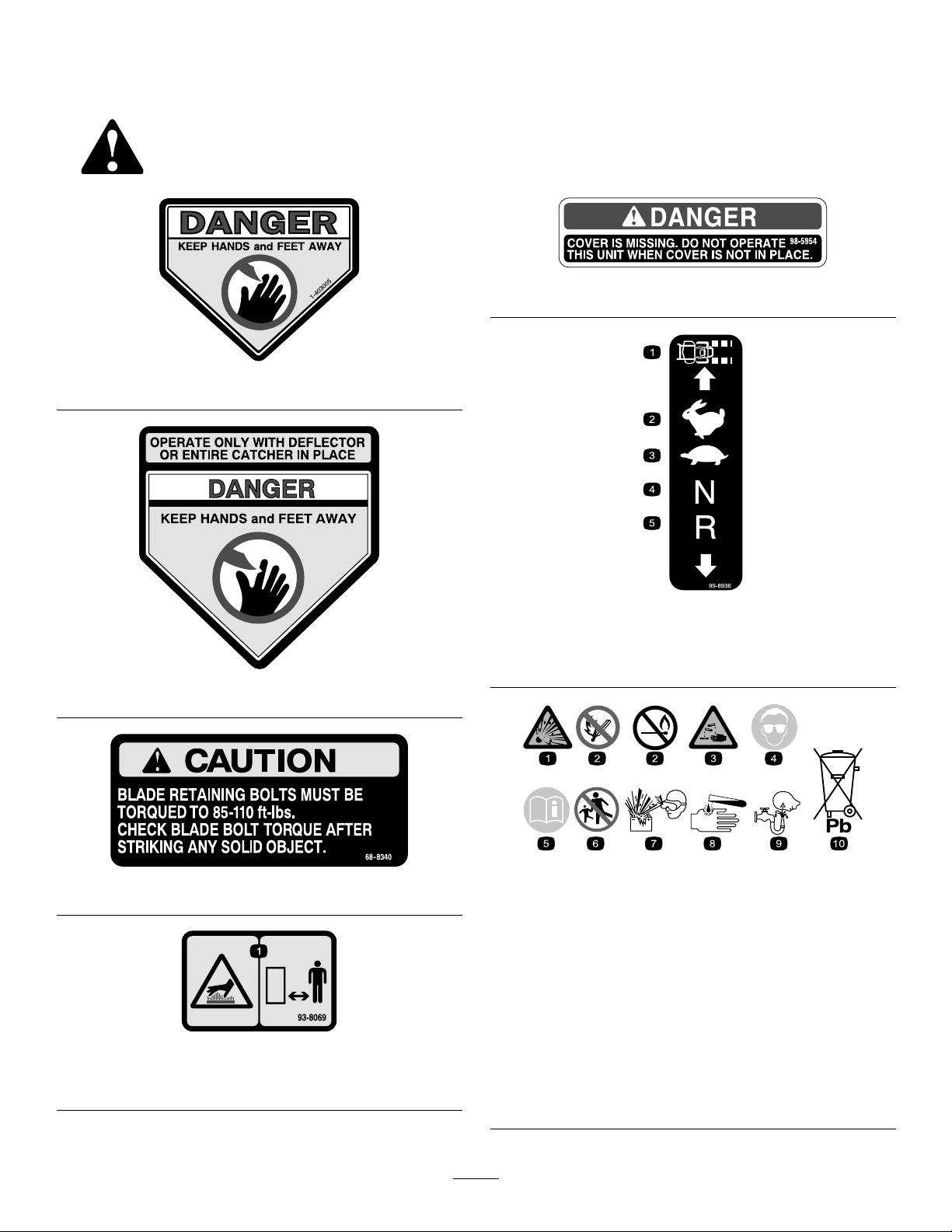

SlopeChart7SafetyandInstructional

Decals

Page 8

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

98-5954

1-403005

54-9220

68-8340

93-8069

1.Hotsurface/burnhazard—stayasafedistancefromthe

hotsurface.

99-8936

1.Machinespeed4.Neutral

2.Fast5.Reverse

3.Slow

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator’s

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

8

Page 9

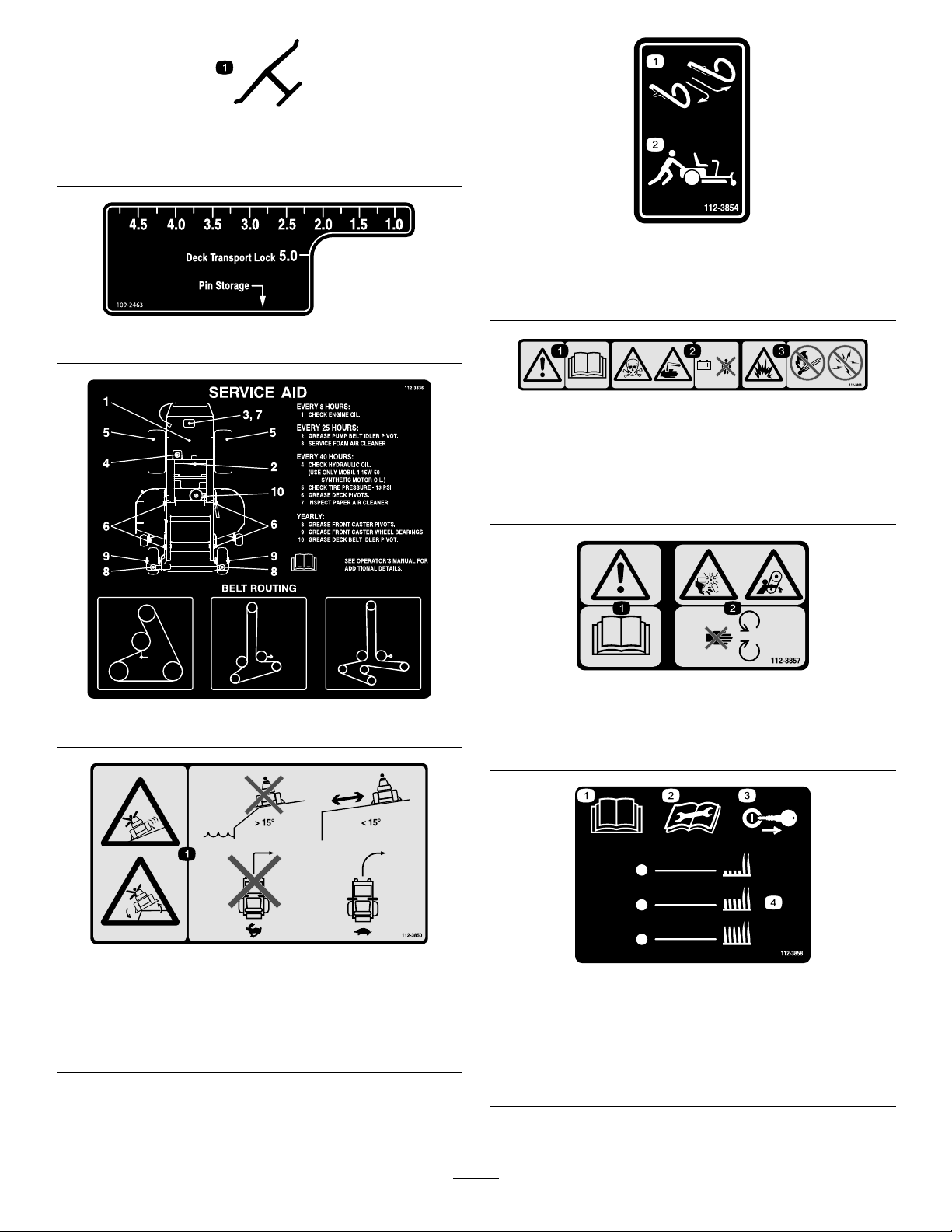

Manufacturer’sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

109-2463

112-3854

1.Pulltowbypasslevers

rearwardandthenoutto

lockintoplace.

2.Pushthemachine.

112-3856

1.Warning—readtheOperator’sManualformoreinformation.

2.Poisonhazard;causticliquid/chemicalburnhazard—keep

childrenawayfromthebattery.

3.Explosionhazard—nore,openames,orsmoking;avoid

sparks.

112-3836

112-3850

1.Slidingandlossofcontrolhazardandtippinghazard,

drop-offs—donotoperatethemachineneardrop-offs,

slopesgreaterthan15degrees,orwater;keepasafe

distancefromdrop-offs;donotturnsharplywhiletraveling

fast,instead,slowdownandturngradually .

112-3857

1.Warning—readtheOperator’sManual.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

112-3858

1.ReadtheOperator’s

Manual.

2.Readtheinstructions

beforeservicingor

performingmaintenance.

3.Removetheignitionkey

beforeadjustingtheheight

ofcut.

4.Heightofcutsettings.

9

Page 10

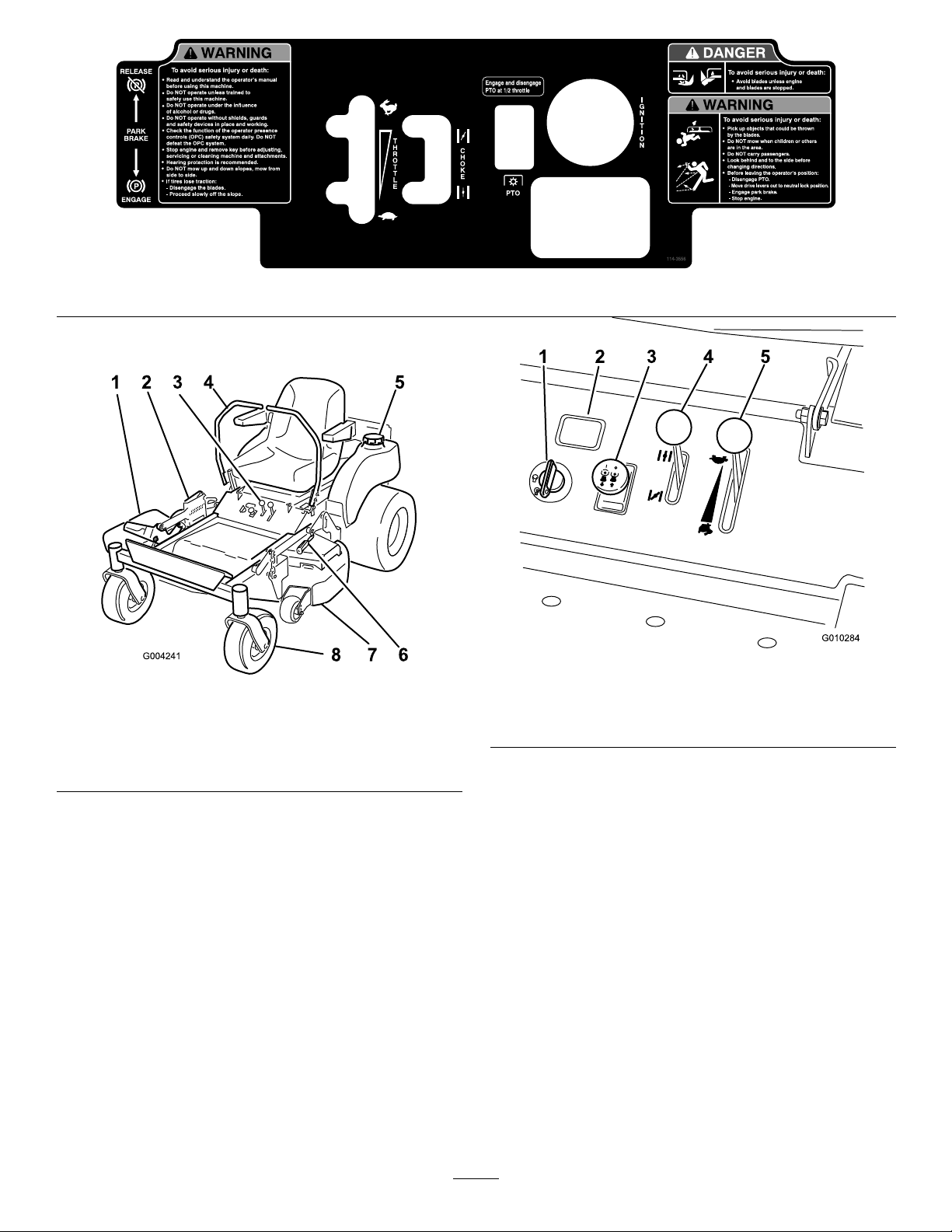

ProductOverview

Figure3

1.Sidedischargechute5.Fuelcap(bothsides)

2.Height-of-cutselectionpin

3.Controls

4.Motioncontrollever8.Frontcasterwheel

6.Parkingbrakelever

7.Mowerdeck

114–3556

Figure4

1.Ignitionswitch

2.Hourmeter5.Throttlecontrol

3.PTOSwitch

4.Chokelever

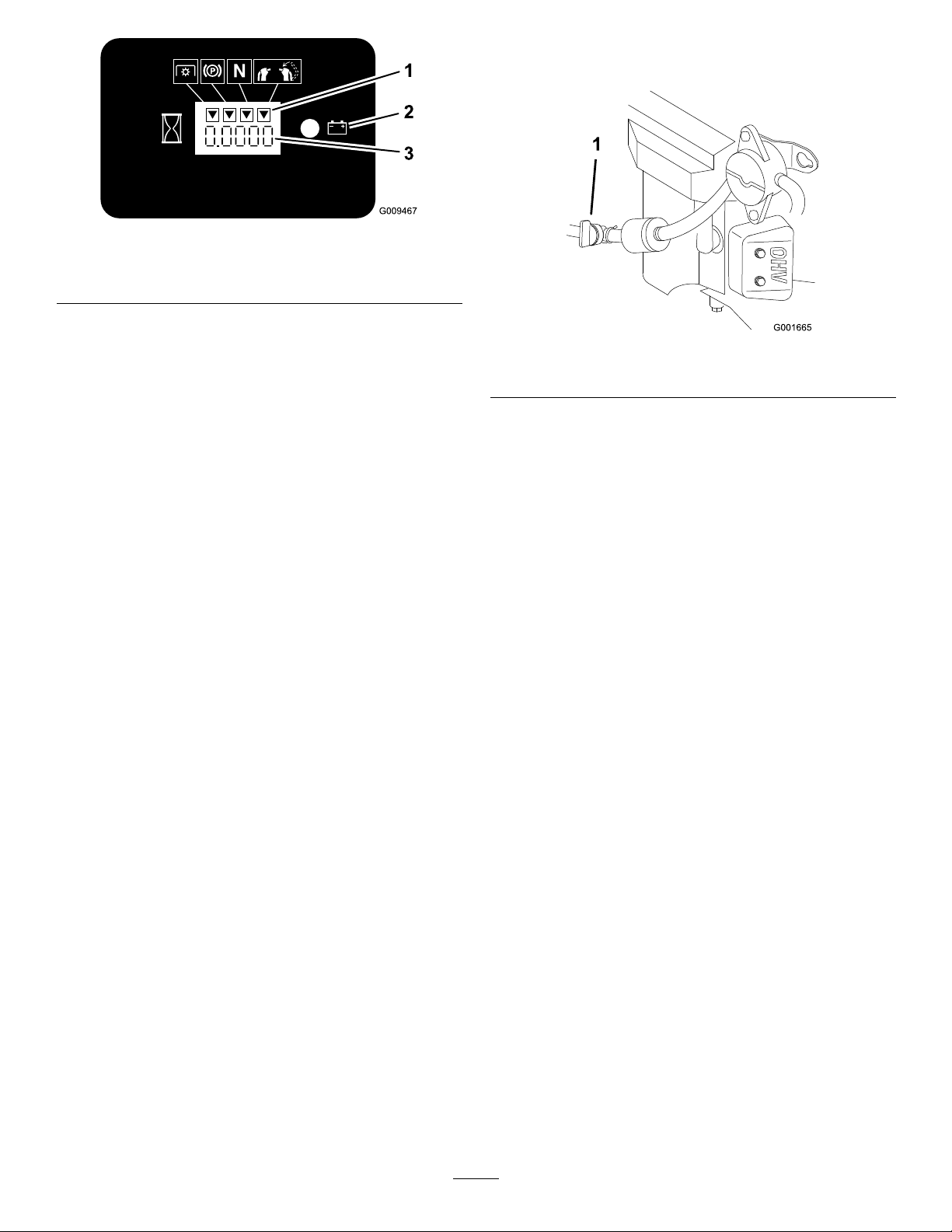

BatteryIndicatorLight

Controls

Becomefamiliarwithallthecontrolsbeforeyoustartthe

engineandoperatethemachine(Figure3andFigure4).

WhentheignitionkeyisinitiallyturnedtotheOn

positionforafewseconds,thebatteryvoltagewillbe

displayedintheareawherethehoursarenormally

displayed.

Thebatterylightturnsonwhentheignitionisturned

onandwhenthechargeisbelowthecorrectoperating

level(Figure5).

10

Page 11

1.Safetyinterlocksymbols

2.Batterylight

Closethefuelshutoffvalvebeforetransportingor

storingthemachine.

Figure5

3.Hourmeter

UsingtheHourMeter

Thehourmeter(@@@5)recordsthenumberofhours

theenginehasoperated.Itoperateswhentheengine

isrunning.Usethesetimesforschedulingregular

maintenance.

ThrottleControl

ThethrottlecontrolisvariablebetweenFastandSlow.

Choke

Usethechoketostartacoldengine.

BladeControlSwitch(PTO)

Thebladecontrolswitch(PTO)isusedtoengage

theelectricclutchtodrivethemowerbladeswiththe

rightsidemotioncontrolleverinthecenter,un-locked

position.Pulltheswitchuptoengagethebladesand

release.Todisengagetheblades,pushthebladecontrol

switch(PTO)downormoveorreleasetherightside

motioncontrolleverintotheneutrallockposition.

Figure6

1.Fuelshutoffvalve

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

IgnitionSwitch

Thisswitchisusedtostartthemowerengineandhas

threepositions:Off,RunandStart.

MotionControlLevers

Themotioncontrolleversareusedtodrivethemachine

forward,reverse,andturneitherdirection.

UsingtheFuelShutoffValve

Themachinehas2fueltanks,oneontheleftsideand

theotherontherightside.Eachtankconnectstoa

checkvalveandthentoatee.Fromthereacommon

fuellineleadstotheengine(Figure6).

11

Page 12

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

AddingFuel

UseUnleadedRegularGasolinesuitablefor

automotiveuse(85pumpoctaneminimum).Leaded

regulargasolinemaybeusedifunleadedregularisnot

available.

Important:Neverusemethanol,gasoline

containingmethanol,orgasoholcontainingmore

than10%ethanolbecausethefuelsystemcouldbe

damaged.Donotmixoilwithgasoline.

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areor

explosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupany

gasolinethatspills.

•Neverllthefueltankinsideanenclosed

trailer.

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitethegasolinevapors.Are

orexplosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowtheloss

ofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

ground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimof

thefueltankorcontaineropeningatall

timesuntilfuelingiscomplete.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis1/4

to1/2inch(6to13mm)belowthebottomof

thellerneck.Thisemptyspaceinthetank

allowsgasolinetoexpand.

•Neversmokewhenhandlinggasoline,and

stayawayfromanopenameorwhere

gasolinefumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Never

buymorethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporscancauseserious

injuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening.

•Keepgasawayfromeyesandskin.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysor

less.Forlongerstorageitisrecommendedthatthe

fueltankbedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

12

Page 13

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditioner

tothegas.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.Tominimizethe

chanceofvarnishdepositsinthefuelsystem,usefuel

stabilizeratalltimes.

FillingtheFuelTank

1.Shuttheengineoffandsettheparkingbrake.

2.Cleanaroundeachfueltankcapandremovethecap.

3.Addunleadedregulargasolinetobothfueltanks,

untilthelevelis1/4to1/2inch(6mmto13mm)

belowthebottomofthellerneck.

Thisspaceinthetankallowsgasolinetoexpand.

Donotllthefueltankscompletelyfull.

4.Installfueltankcapssecurely.

5.Wipeupanygasolinethatmayhavespilled.

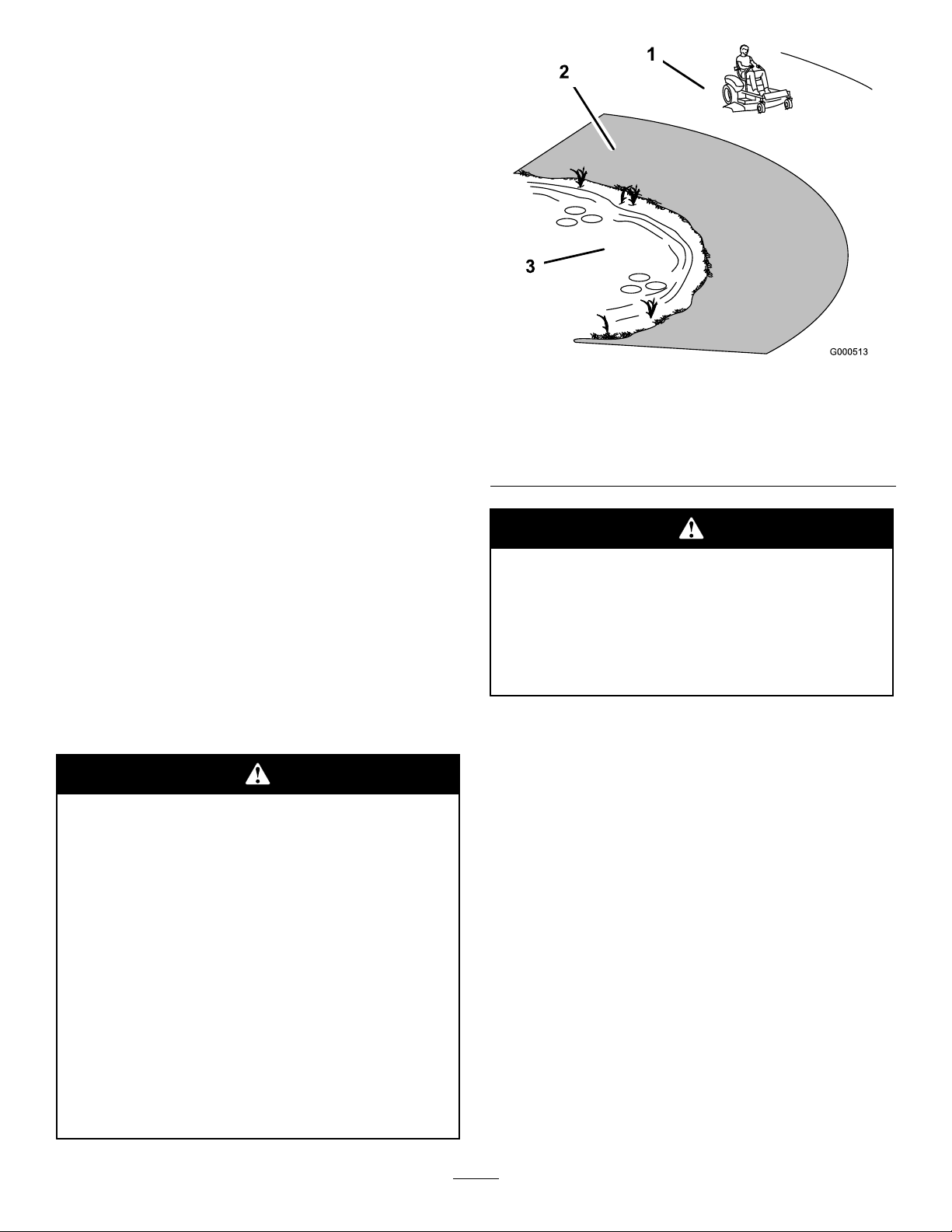

Figure7

1.SafeZone-usetheZMasterhereonslopeslessthan

15degreesoratareas.

2.Usewalkbehindmowerand/orhandtrimmerneardrop-offs

andwater.

3.Water

CheckingtheEngineOilLevel

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoChecking

OilLevelin,page

ThinkSafetyFirst

Pleasereadallsafetyinstructionsandsymbolsinthe

safetysection.Knowingthisinformationcouldhelp

youorbystandersavoidinjury.

Operatingonwetgrassorsteepslopescan

causeslidingandlossofcontrol.

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,deathor

drowning.

Toavoidlossofcontrolandpossibilityof

rollover:

Thismachineproducessoundlevelsinexcess

of85dBAattheoperatorsearandcancause

hearinglossthroughextendedperiodsof

exposure.

Wearhearingprotectionwhenoperatingthis

machine.

Useprotectiveequipmentforyoureyes,hearing,feet,

andhead.

•Donotoperateneardrop-offsornearwater.

•Donotoperateonslopesgreaterthan

15degrees.

•Reducespeedanduseextremecautionon

slopes.

•Avoidsuddenturnsorrapidspeedchanges.

13

Page 14

Figure8

1.Warningwearhearingprotection

OperatingtheParkingBrake

Alwayssettheparkingbrakewhenyoustopthe

machineorleaveitunattended.

SettingtheParkingBrake

1.Movethemotioncontrollevers(Figure15)outto

theneutrallockposition.

2.Pullupandbackontheparkingbrakelevertoset

theparkingbrake(Figure9).Theparkingbrake

levershouldstayrmlyintheengagedposition.

Parkingbrakemaynotholdmachineparked

onaslopeandcouldcausepersonalinjuryor

propertydamage.

Donotparkonslopesunlesswheelsare

chockedorblocked

ReleasingtheParkingBrake

Pushforwardanddownontheparkingbrakeleverto

releasetheparkingbrake(Figure9).

Figure9

1.Parkingbrake–Set/ON

2.Parkingbrake–

Released/OFF

StartingandStoppingthe

Engine

StartingtheEngine

1.Sitontheseatandmovethemotioncontrolsto

neutrallockedposition.

2.Settheparkingbrake;refertoSettingtheParking

Brake.

3.MovethePTO(powertakeoff)switchtotheOff

position(Figure10).

Figure10

1.PTOon(knobout)2.PTOoff(knobin)

4.Movethechokecontroltotheonpositionbefore

startingacoldengine(Figure11).

Note:Awarmorhotenginemaynotrequire

choking.Afterenginestarts,movechokecontrolto

Runposition.

14

Page 15

5.Movethethrottlecontroltothefastpositionbefore

startingacoldengine(Figure11).

Figure11

1.Chokeon

2.Chokeoff4.Throttlefast

3.Throttleslow

6.TurntheignitionkeytoStart.Whentheengines

starts,releasethekey(Figure12).

Important:Donotengagestarterformore

than10secondsatatime.Ifenginefailsto

startallow30secondcool-downperiodbetween

attempts.Failuretofollowtheseinstructions

canburnoutstartermotor.

3.Lettheengineidlefor60seconds.

4.Turntheignitionkeytotheoffpositionandremove

thekey(Figure12).

5.Closethefuelshutoffvalvebeforetransportingor

storingthemachine(Figure6).

Important:Makesurethatthefuelshutoff

valveisclosedbeforetransportingorstoring

themachine,asfuelleakagemayoccur.Setthe

parkingbrakebeforetransporting.Makesure

toremovethekeyasthefuelpumpmayrun

andcausethebatterytolosecharge.

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethetractorwhileit

isunattended.

Alwaysremovetheignitionkeyandsetthe

parkingbrakewhenleavingthemachine

unattended,evenifjustforafewminutes.

OperatingthePowerTakeOff

(PTO)

Thepowertakeoff(PTO)switchstartsandstopsthe

mowerbladesandanypoweredattachments.

Figure12

1.Off3.Start

2.Run

7.Aftertheenginestarts,movethechoketooff

(Figure11).Iftheenginestallsorhesitates,move

thechokebacktoonforafewseconds,thenmove

thethrottlelevertodesiredsetting.Repeatthisas

required.

StoppingtheEngine

1.PushthePTOtotheoffposition(Figure10).

2.Movethethrottlelevermidwaybetweentheslow

andfastpositions(Figure11).

EngagingthePTO

1.Iftheengineiscold,allowtheenginetowarmup5

to10minutesbeforeengagingthePTO.

2.Whileseatedintheseat,releasethepressureonthe

tractioncontrolleversandplaceinneutral.

3.Placethethrottleinthefastposition.

Note:EngagingthePTOwiththethrottleatthe

halforlesspositionwillcauseexcessiveweartothe

drivebelts.

4.Pulloutonthepowertakeoff(PTO)switchto

engageit(Figure13).

15

Page 16

Figure13

1.PTO-On(knobout)2.PTO-Off(knobin)

Figure14

1.Triangleslightupwhentheinterlockcomponentsareinthe

correctposition

DisengagingthePTO

Todisengage,pushthePTOswitchtotheoffposition

(Figure13).

TheSafetyInterlockSystem

Ifsafetyinterlockswitchesaredisconnected

ordamagedthemachinecouldoperate

unexpectedlycausingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

UnderstandingtheSafetyInterlock

System

Thesafetyinterlocksystemisdesignedtopreventthe

enginefromstartingunless:

•Theparkingbrakeisengaged.

•Thepowertakeoff(PTO)isoff.

•Themotioncontrolleversareintheneutrallocked

position

Thesafetyinterlocksystemalsoisdesignedtostopthe

enginewhenthetractioncontrolsaremovedfromthe

lockedpositionwiththeparkingbrakeengagedorif

yourisefromtheseatwhenthePTOswitchison.

TestingtheSafetyInterlockSystem

ServiceInterval:Beforeeachuseordaily

Note:Ifthesafetysystemdoesnotoperateas

describedbelow,haveanAuthorizedServiceDealer

repairthesafetysystemimmediately .

1.Sittingontheseat,engagetheparkingbrakeand

movethePTOtoon.Trystartingtheengine;the

engineshouldnotcrank.

2.Sittingontheseat,engagetheparkingbrakeand

movethePTOtooff.Moveeithermotioncontrol

lever(outofneutrallockedposition).Trystarting

theengine;theengineshouldnotcrank.Repeatfor

othercontrollever.

3.Sittingontheseat,engagetheparkingbrake,move

thePTOswitchtooffandmovethemotioncontrol

leverstoneutrallockposition.Nowstartthe

engine.Whiletheengineisrunning,releasethe

parkingbrake,movethePTOtoonandriseslightly

fromtheseat;theengineshouldstop.

4.Sittingontheseat,engagetheparkingbrake,move

thePTOswitchtooffandmovethemotioncontrol

leverstoneutrallockposition.Nowstarttheengine.

Whiletheengineisrunning,centereithermotion

controlandmove(forwardorreverse);theengine

shouldstop.Repeatforothermotioncontrol.

5.Sittingontheseat,disengagetheparkingbrake,

movethePTOswitchtooffandmovethemotion

controlleverstoneutrallockposition.Trystarting

theengine;theengineshouldnotcrank.

DrivingForwardorBackward

Thehourmeterhassymbolstonotifytheuserwhenthe

interlockcomponentisinthecorrectposition.When

thecomponentisinthecorrectposition,atrianglewill

lightupinthecorrespondingsquare.

Thethrottlecontrolregulatestheenginespeedas

measuredinRPM(revolutionsperminute).Place

thethrottlecontrolinthefastpositionforbest

performance.Alwaysoperateinthefullthrottle

positionwhenmowing.

16

Page 17

Machinecanspinveryrapidly.Operatormay

losecontrolofmachineandcausepersonal

injuryordamagetomachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemaking

sharpturns.

DrivingForward

1.Releasetheparkingbrake;refertoReleasingthe

ParkingBrakein,page.

2.Movetheleverstothecenter,theun-locked

position.

3.Togoforward,slowlypushthemotioncontrol

leversforward(Figure15).

Note:Theenginewillkillifthetractioncontrol

leversaremovedwiththeparkingbrakeengaged.

Togostraight,applyequalpressuretobothmotion

controllevers(Figure15).

Toturn,movethemotioncontrollevertoward

neutralinthedirectionyouwanttoturn(Figure15).

Thefartheryoumovethetractioncontrolleversin

eitherdirection,thefasterthemachinewillmovein

thatdirection.

Tostop,pullthemotioncontrolleverstothecenter

position.

Figure15

1.Motioncontrol

lever-neutrallockposition

2.Centerun-lockposition

3.Forward

4.Backward

DrivingBackward

1.Movetheleverstothecenter,un-lockedposition.

2.Togobackward,slowlypullthemotioncontrol

leversrearward(Figure15).

Togostraight,applyequalpressuretobothmotion

controllevers(Figure15).

Toturn,releasepressureonthemotioncontrollever

towardthedirectionyouwanttoturn(Figure15).

Tostop,pushthemotioncontrolleverstothe

neutralposition.

StoppingtheMachine

Tostopthemachine,movethetractioncontrollevers

tothecenterpositionandmovethemouttothelocked

position,disengagethepowertakeoff(PTO),andturn

theignitionkeytooff.

Settheparkingbrakewhenyouleavethemachine;refer

toSettingtheParkingBrakein,page.Rememberto

removethekeyfromtheignitionswitch.

17

Page 18

UsingtheLiftAssistPedal

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethetractorwhileit

isunattended.

Alwaysremovetheignitionkeyandsetthe

parkingbrakewhenleavingthemachine

unattended,evenifjustforafewminutes.

AdjustingtheHeight-of-Cut

Theheight-of-cutisadjustedfrom1to5inch

(25to127mm)in1/4inch(6mm)incrementsby

relocatingtheclevispinintodifferentholelocations.

1.Raisetheheight-of-cutlevertothetransport

position(alsothe5inch(127mm)cuttingheight

position)(Figure16).

2.Toadjust,removetheclevispinfromthe

height-of-cutbracket(Figure16).

3.Selectaholeintheheight-of-cutbracket

correspondingtotheheight-of-cutdesiredand,

inserttheclevispin(Figure16).

4.Movethelevertotheselectedheight.

Theliftassistpedalisusedforraisingthemowerdeck.

Thisallowsforeasierraisingofthemowerdeck.

1.Placeyourfootontoliftassistlever.

2.Pressontheliftassistleverwhilepullinguponthe

height-of-cutlever(Figure17).

Figure17

1.LiftAssistpedal2.Height-of-cutlever

AdjustingtheAnti-Scalp

Rollers

Wheneveryouchangetheheight-of-cut,adjustthe

heightoftheanti-scalprollers.

1.DisengagethePTO,movethemotioncontrol

leverstotheneutrallockedpositionandsetthe

parkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Afteradjustingtheheight-of-cut,adjusttherollers

byremovingtheangenut,bushing,spacer,and

bolt(Figure18).

4.Selectaholesotheanti-scalprollerispositionedto

thenearestcorrespondingheight-of-cutdesired.

5.Installtheangenutbushing,spacer,andbolt.

Torqueto40-45ft-lb(54-61N•m)(Figure18).

6.Repeatthisadjustmentontheotheranti-scalp

rollers.

Figure16

1.Heightofcutholes2.ClevisPin

18

Page 19

Figure18

1.Bolt4.Anti-scalproller

2.Anti-scalprollerbracket

3.FlangeNut6.Bushing

5.Spacer

PushingtheMachinebyHand

Important:Alwayspushthemachinebyhand.

Nevertowthemachinebecausedamagemay

occur.

ToPushtheMachine

1.Disengagethebladecontrolswitchandmovethe

controlleverstotheneutrallockedpositionand

applytheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Pullthetwobypassleversrearwardandpushthem

totheoutsideintotheslottolockthemintoplace.

(Figure20).

Note:Makesurebothbypassleversaredisengaged

beforepushingthemachine.

4.Disengagetheparkingbraketopushthemachine.

PositioningtheSeat

Theseatcanmoveforwardandbackward.Positionthe

seatwhereyouhavethebestcontrolofthemachine

andaremostcomfortable.

1.Raisetheseatandloosentheadjustmentbolts

(Figure19).

2.Movetheseattothedesiredpositionandtighten

thebolts.

1.Adjustmentbolts

Figure19

2.Seat

19

Page 20

G004250

1

1

3

21

Withoutthegrassdeector,dischargecover,

orcompletegrasscatcherassemblymounted

inplace,youandothersareexposedtoblade

contactandthrowndebris.Contactwith

rotatingmowerblade(s)andthrowndebriswill

causeinjuryordeath.

•Neverremovethegrassdeectorfrom

themowerbecausethegrassdeector

routesmaterialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthe

mower.

•Nevertrytoclearthedischargeareaor

mowerbladesunlessyoumovethepower

takeoff(PTO)totheoffposition,rotatethe

ignitionkeytooffandremovethekey .

•Makesurethegrassdeectorisinthedown

position.

TransportingMachines

Useaheavy-dutytrailerortrucktotransportthe

machine.Ensurethatthetrailerortruckhasall

Figure20

1.Bypasslever

2.Topviewofengine

3.Slot

ToOperatetheMachine

Pusheachbypasslevertotheinsideandpushthem

forward(Figure20).

Note:Themachinewillnotdriveunlessthebypass

leversarepushedforward.

UsingtheSideDischarge

necessarylightingandmarkingasrequiredbylaw .

Pleasecarefullyreadallthesafetyinstructions.

Knowingthisinformationcouldhelpyou,yourfamily,

petsorbystandersavoidinjury.

Totransportthemachine:

•Lockthebrakeandblockthewheels.

•Securelyfastenthemachinetothetrailerortruck

withstraps,chains,cable,orropes.

•Secureatrailertothetowingvehiclewithsafety

chains.

Drivingonthestreetorroadwaywithoutturn

signals,lights,reectivemarkings,oraslow

movingvehicleemblemisdangerousandcan

leadtoaccidentscausingpersonalinjury.

Themowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

Donotdrivemachineonapublicstreetor

roadway.

20

Page 21

LoadingMachines

Useextremecautionwhenloadingunitsontrailersor

trucks.Onefullwidthrampthatiswideenoughto

extendbeyondthereartiresisrecommendedinsteadof

individualrampsforeachsideoftheunit(Figure21).

Thelowerrearsectionofthetractorframeextends

backbetweentherearwheelsandservesasastopfor

tippingbackward.Havingafullwidthrampprovides

asurfacefortheframememberstocontactifthe

unitstartstotipbackward.Ifitisnotpossibletouse

onefullwidthramp,useenoughindividualrampsto

simulateafullwidthcontinuousramp.

Therampshouldbelongenoughsothattheangles

donotexceed15degrees(Figure21).Asteeperangle

maycausemowercomponentstogetcaughtastheunit

movesfromramptotrailerortruck.Steeperangles

mayalsocausetheunittotipbackward.Ifloadingon

ornearaslope,positionthetrailerortrucksoitison

thedownsideoftheslopeandtherampextendsupthe

slope.Thiswillminimizetherampangle.Thetraileror

truckshouldbeaslevelaspossible.

Figure21

1.Trailer3.Notgreaterthan

15degrees

2.Fullwidthramp4.Fullwidthrampsideview

Important:DoNotattempttoturntheunitwhile

ontheramp;youmaylosecontrolanddriveoff

theside.

Avoidsuddenaccelerationwhendrivinguparampand

suddendecelerationwhenbackingdownaramp.Both

maneuverscancausetheunittotipbackward.

Loadingaunitontoatrailerortruckincreases

thepossibilityofbackwardtip-overandcould

causeseriousinjuryordeath.

•Useextremecautionwhenoperatingaunit

onaramp.

•Useonlyasingle,fullwidthramp;DoNot

useindividualrampsforeachsideofthe

unit.

•Ifindividualrampsmustbeused,use

enoughrampstocreateanunbrokenramp

surfacewiderthantheunit.

OperatingTips

FastThrottleSetting

Forbestmowingandmaximumaircirculation,operate

theengineatthefastthrottleposition.Airisrequired

tothoroughlycutgrassclippings,sodonotsetthe

height-of-cutsolowastototallysurroundthemower

byuncutgrass.Alwaystrytohaveonesideofthe

mowerfreefromuncutgrass,whichallowsairtobe

drawnintothemower.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethe

cuttingheightofthemowerdoesnotscalpanyuneven

ground.However,thecuttingheightusedinthepastis

generallythebestonetouse.Whencuttinggrasslonger

thansixinchestall,youmaywanttocutthelawntwice

toensureanacceptablequalityofcut.

•Donotexceeda15degreeanglebetween

rampandgroundorbetweenrampand

trailerortruck.

•Avoidsuddenaccelerationwhiledrivingunit

uparamptoavoidtippingbackward.

•Avoidsuddendecelerationwhilebacking

unitdownaramptoavoidtippingbackward.

Cut1/3oftheGrassBlade

Itisbesttocutonlyabout1/3ofthegrassblade.

Cuttingmorethanthatisnotrecommendedunless

grassissparse,oritislatefallwhengrassgrowsmore

slowly.

21

Page 22

MowingDirection

Alternatemowingdirectiontokeepthegrassstanding

straight.Thisalsohelpsdisperseclippingswhich

enhancesdecompositionandfertilization.

MowatCorrectIntervals

Normally,moweveryfourdays.Butremember,

grassgrowsatdifferentratesatdifferenttimes.So

tomaintainthesamecuttingheight,whichisagood

practice,mowmoreofteninearlyspring.Asthegrass

growthrateslowsinmidsummer,mowlessfrequently.

Ifyoucannotmowforanextendedperiod,rstmow

atahighcuttingheight;thenmowagaintwodayslater

atalowerheightsetting.

CuttingSpeed

Toimprovecutquality,useaslowergroundspeedin

certainconditions.

AvoidCuttingTooLow

shreddingthegrassblades.Tearingandshreddingturns

grassbrownattheedges,whichslowsgrowthand

increasesthechanceofdisease.Checkthecutterblades

dailyforsharpness,andforanywearordamage.File

downanynicksandsharpenthebladesasnecessary.If

abladeisdamagedorworn,replaceitimmediatelywith

agenuineTOROreplacementblade.

Ifthecuttingwidthofthemoweriswiderthanthe

moweryoupreviouslyused,raisethecuttingheightto

ensurethatuneventurfisnotcuttooshort.

LongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,raise

thecuttingheighthigherthanusualandcutthegrassat

thissetting.Thencutthegrassagainusingthelower,

normalsetting.

WhenStopping

Ifthemachine’sforwardmotionmustbestoppedwhile

mowing,aclumpofgrassclippingsmaydropontoyour

lawn.T oavoidthis,moveontoapreviouslycutarea

withthebladesengaged.

KeeptheUndersideoftheMower

Clean

Cleanclippingsanddirtfromtheundersideofthe

moweraftereachuse.Ifgrassanddirtbuildupinside

themower,cuttingqualitywilleventuallybecome

unsatisfactory.

BladeMaintenance

Maintainasharpbladethroughoutthecuttingseason

becauseasharpbladecutscleanlywithouttearingor

22

Page 23

Maintenance

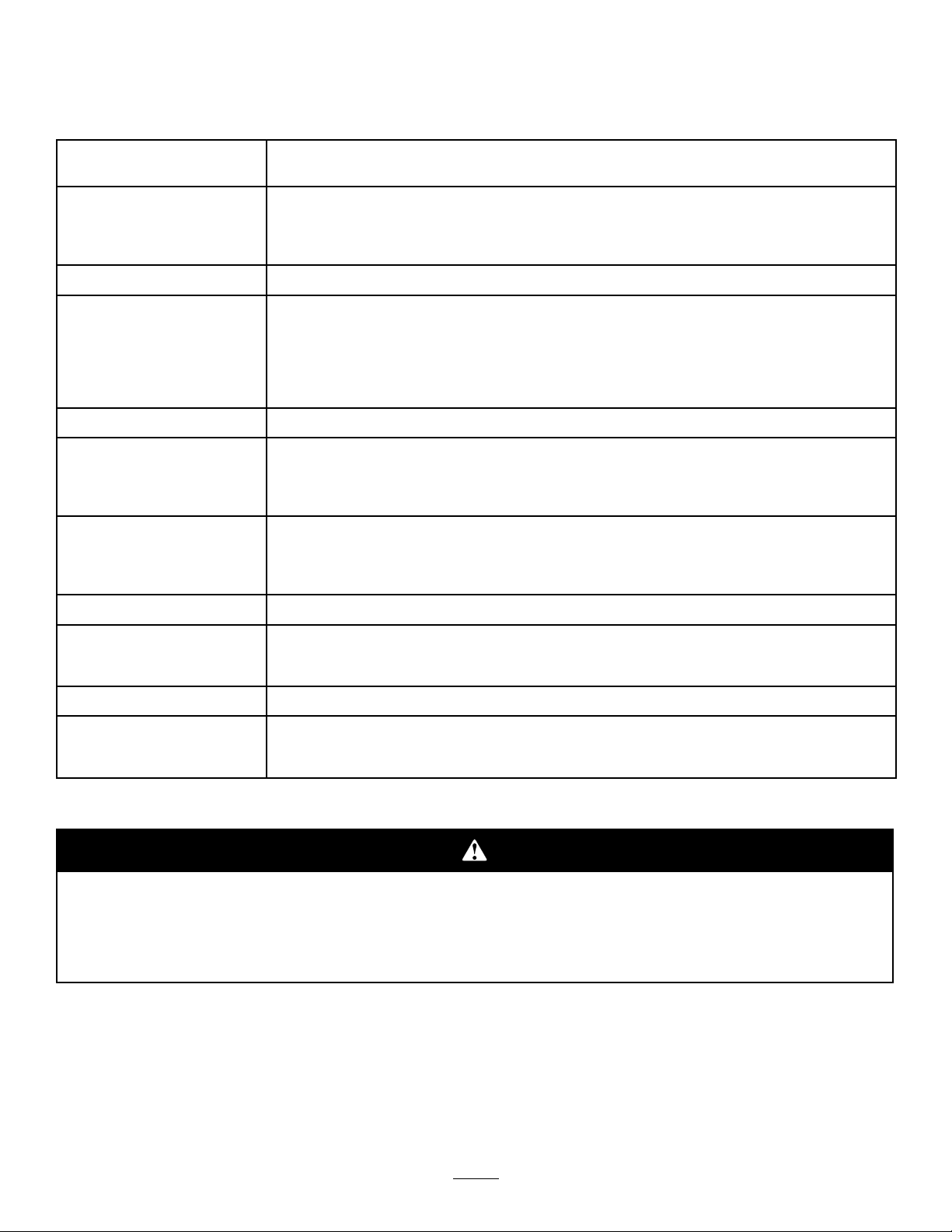

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst250hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

MaintenanceProcedure

•Checkforanyloosefastenersandtightenthem.

•Changetheengineoil.

•Tightenthewheellugnuts.

•Checkthehydraulicuid.

•Changethehydraulicltersandoil.

•Checkthesafetysystem.

•Checktheengineoillevel.

•Cleantheairintakescreen.

•Checkthebrake.

•Checkthemowerblades.

•Cleanthemowerdeck.

•Cleanfoamaircleanerelement.(moreoftenindirtyordustyconditions)

•Checkthepaperaircleanerelement.(moreoftenindirtyordustyconditions)

•Checkthetirepressure.

•Checkpumpdrivebelt.

•Checkthehydraulicuid.

•Changetheengineoil.(moreoftenindirtyordustyconditions)

•Checkthesparkplugs.

•Checkandcleanenginecoolingnsandshrouds.

•Inspectallbeltsforcracksandwear.

Every150hours

Every200hours

Every500hours

Yearly

Important:Refertoyour

•Lubricatethemachinewithlightoil

•Replacethepaperaircleanerelement.

•Replacetheoillter

•Replacethefuellter .

•Adjustthecasterpivotbearing.

•Greasethefrontcasterpivots(moreoftenindirtyordustyconditions)

•Lubricatethecasterwheelhubs.

•Changethehydraulicltersandoil.

Engine Operator’ s Man ual

foradditionalmaintenanceprocedures.

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplug(s)beforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

Lubrication

frequentlywhenoperatingconditionsareextremely

dustyorsandy.

GreasingandLubrication

LubricatethemachinewhenshownontheCheck

ServiceReferenceAiddecal(Figure22).Greasemore

GreaseType:General-purposegrease.

23

Page 24

HowtoGrease

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Cleanthegreasettingswitharag.Makesureto

scrapeanypaintoffthefrontofthetting(s).

4.Connectagreaseguntothetting.Pumpgrease

intothettingsuntilgreasebeginstooozeoutof

thebearings.

5.Wipeupanyexcessgrease.

GreasingtheFrontCasterPivots

Figure23

Brakehandlepivot

ServiceInterval:Yearly(moreoftenindirtyordusty

conditions)

1.Removethedustcapandadjustthecasterpivots.

Keepthedustcapoffuntilgreasingisdone.Refer

toAdjustingtheCasterPivotBearingin,page.

2.Removethehexplug.Threadagreasezerkintothe

hole.

3.Pumpgreaseintothezerkuntilitoozesoutaround

thetopbearing.

4.Removethegreasezerkinthehole.Installthehex

plugandcap.

WheretoAddGrease

LubricatethegreasettingsasshownontheCheck

ServiceReferenceAiddecal(Figure22).

GreaseandoilthelinkagesasshowninFigure24and

Figure25.

Figure22

WheretoAddLightOilorSpray

Lubrication

ServiceInterval:Every150hours(Referto

Lubrication).

Lubricatethemachineinthefollowingareaswithspray

typelubricantorlightoil.

•Seatswitchactuator.

•Brakecontrollinks.

•Motioncontrolpivots.

Figure24

24

Page 25

Figure25

LubricatingtheCasterWheel

Hubs

ServiceInterval:Yearly

Figure26

1.Casterfork4.Casterwheel

2.Bolt5.Nut

3.Sealguard

Note:Whenperformingthisprocedure,theoldseals

willneedtobereplacedwithnewseals.Contactan

AuthorizedServiceDealerforthecorrectseals.

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Raisethefrontofthemachineandsupportitwith

jackstands.

4.Removethennutandboltholdingthecasterwheel

tothefrontcasterfork(Figure26).

5.Removethesealguardfromthewheelhub

(Figure26).

6.Removeoneofthespacernuts(withwrenchats)

fromtheaxle(Figure28).

Note:Threadlockingadhesivehasbeenapplied

tothespacernuts.

7.Removetheaxlewithoutremovingtheopposite

spacernut(Figure28).

8.Removethesealsandinspectthebearingsforwear

ordamage.Replacethebearingsifneeded.

9.Packthebearingswithgeneralpurposegrease.

10.Insertthebearingandanewsealintothewheel

(Figure28).

Note:Donotinstallthenutallthewayontothe

axle.

11.Ifbothspacernutswereremovedfromtheaxle,

applythreadlockingadhesivetothespacernut.

Installthespacernutsontotheaxleleavingan1/8

inch(3mm)ofthenutpasttheaxle(Figure27).

25

Page 26

Figure27

1.1/8inch(3mm)ofthenutpasttheaxle

12.Installtheassemblednutandaxleintothewheelon

thesidewiththebearingandanewseal(Figure28).

13.Placethewheelwiththeopenendfacingupandll

theareainsidethewheelwithmulti-purposegrease.

14.Installthesecondbearingandanewsealintothe

wheel(Figure28).

15.Applythreadlockingadhesivetothesecondspacer

nutandinstallitontotheaxlewiththewrenchats

facingoutward.

16.Torquethespacernutto75-80in-lb(8-9N⋅m)then

loosenitandtorqueitto20–25in-lb(2-3N⋅m).

Makesuretheaxledoesnotextendpasteithernut

(Figure27).

Figure28

1.Spacernut4.Casterwheel

2.Bearingseal(newseals

required)

3.Bearing

5.Nutandaxleassembled

17.Installthesealguardsoverthewheelhubsandinsert

thewheelintothecasterfork(Figure26).

18.Installthecasterboltandtightenthenut(Figure26).

Important:Checkthebearingadjustmentoften

topreventsealandbearingdamage.Spinthe

castertire.Thetireshouldnotspinfreelymore

than1to2revolutionsorhaveanyside-to-side

playbetweenthecasterfork.Ifthewheelspins

freely,adjustthetorqueonthespacernutuntil

thereisaslightamountofdrag.

26

Page 27

EngineMaintenance

ServicingtheAirCleaner

Important:Donotoilthefoamorpaperelement.

Note:Servicetheaircleanermorefrequently(every

fewoperatinghours)iftheoperatingconditionsare

extremelydustyorsandy .

RemovingtheFoamandPaper

Elements

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Cleanaroundtheaircleanertopreventdirt

fromgettingintotheengineandcausingdamage

(Figure29).

4.Unscrewthecoverknobandremovetheaircleaner

cover(Figure29).

5.Removethe2wingnutsandremovetheaircleaner

assembly(Figure29).

6.Carefullypullthefoamelementoffthepaper

element(Figure29).

Figure29

1.Engine4.Foamelement

2.Cover

3.Wingnut

5.Paperelement

6.Coverknob

CleaningtheFoamAirCleanerElement

ServiceInterval:Every25hours(moreoftenindirty

ordustyconditions)

1.Washthefoamelementinliquidsoapandwarm

water.Whentheelementisclean,rinseitthoroughly.

2.Drytheelementbysqueezingitinacleancloth.

Important:Replacethefoamelementifitis

tornorworn.

ServicingthePaperAirCleaner

Element

ServiceInterval:Every50hours(moreoftenindirty

ordustyconditions)

Every200hoursoryearly ,whichever

occursrst.

1.Donotcleanthepaperlter,replaceit.(Figure29).

2.Inspecttheelementfortears,anoilylm,ordamage

totherubberseal.

3.Replacethepaperelementifitisdamaged.

27

Page 28

InstallingtheFoamandPaperElements

Important:Topreventenginedamage,always

operatetheenginewiththecompletefoamand

paperaircleanerassemblyinstalled.

1.Carefullyslidethefoamelementontothepaperair

cleanerelement(Figure29).

2.Placetheaircleanerassemblyontotheaircleaner

baseandsecureitwiththe2wingnuts(Figure29).

3.Placetheaircleanercoverintopositionandtighten

thecoverknob(Figure29).

ServicingtheEngineOil

Note:Changetheoilmorefrequentlywhenthe

operatingconditionsareextremelydustyorsandy.

OilType:Detergentoil(APIserviceSF ,SG,SH,orSJ)

CrankcaseCapacity:58ounces(1.7liter)withthelter

removed;51ounces(1.5liter)withoutthelterremoved

Viscosity:Refertothetablebelow

Figure31

1.Oildipstick

2.Fillertube

5.Unscrewtheoildipstickandwipetheendclean

(Figure31).

6.Slidetheoildipstickfullyintothellertube,butdo

notthreadontotube(Figure31).

7.Pullthedipstickoutandlookatthemetalend.Ifthe

oillevelislow,slowlypouronlyenoughoilintothe

llertubetoraisetheleveltotheFullmark.

Important:Donotoverllthecrankcasewith

oilandruntheengine;enginedamagecan

result.

ChangingtheOil

ServiceInterval:Aftertherst8hours

Every100hours(moreoftenindirty

ordustyconditions)

Figure30

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

1.Parkthemachineonalevelsurface.

2.DisengagethePTO,turntheignitionkeytooff,and

removethekey.

3.Waitforallmovingpartstostopbeforeleavingthe

operatingpositionandthenchockorblocktires.

4.Cleanaroundtheoildipstick(Figure31)sothatdirt

cannotfallintothellerholeanddamagetheengine.

1.Starttheengineandletitrunveminutes.This

warmstheoilsoitdrainsbetter.

2.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoassuretheoildrains

completely.

3.DisengagethePTOandsettheparkingbrake.

4.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

5.Slidethedrainhoseovertheoildrainvalve.

6.Placeapanbelowthedrainhose.Rotateoildrain

valvetoallowoiltodrain(Figure32).

7.Whenoilhasdrainedcompletely,closethedrain

valve.

8.Removethedrainhose(Figure32).

Note:Disposeoftheusedoilatarecyclingcenter.

28

Page 29

3.Applyathincoatofnewoiltotherubbergasketon

thereplacementlter(Figure33).

4.Installthereplacementoilltertothelteradapter,

turntheoillterclockwiseuntiltherubbergasket

contactsthelteradapter,thentightenthelteran

additional3/4turn(Figure33).

5.Fillthecrankcasewiththepropertypeofnewoil;

refertoServicingtheEngineOil.

6.Runtheengineforabout3minutes,stoptheengine,

andcheckforoilleaksaroundtheoillter.

7.Checktheengineoillevelandaddoilifneeded.

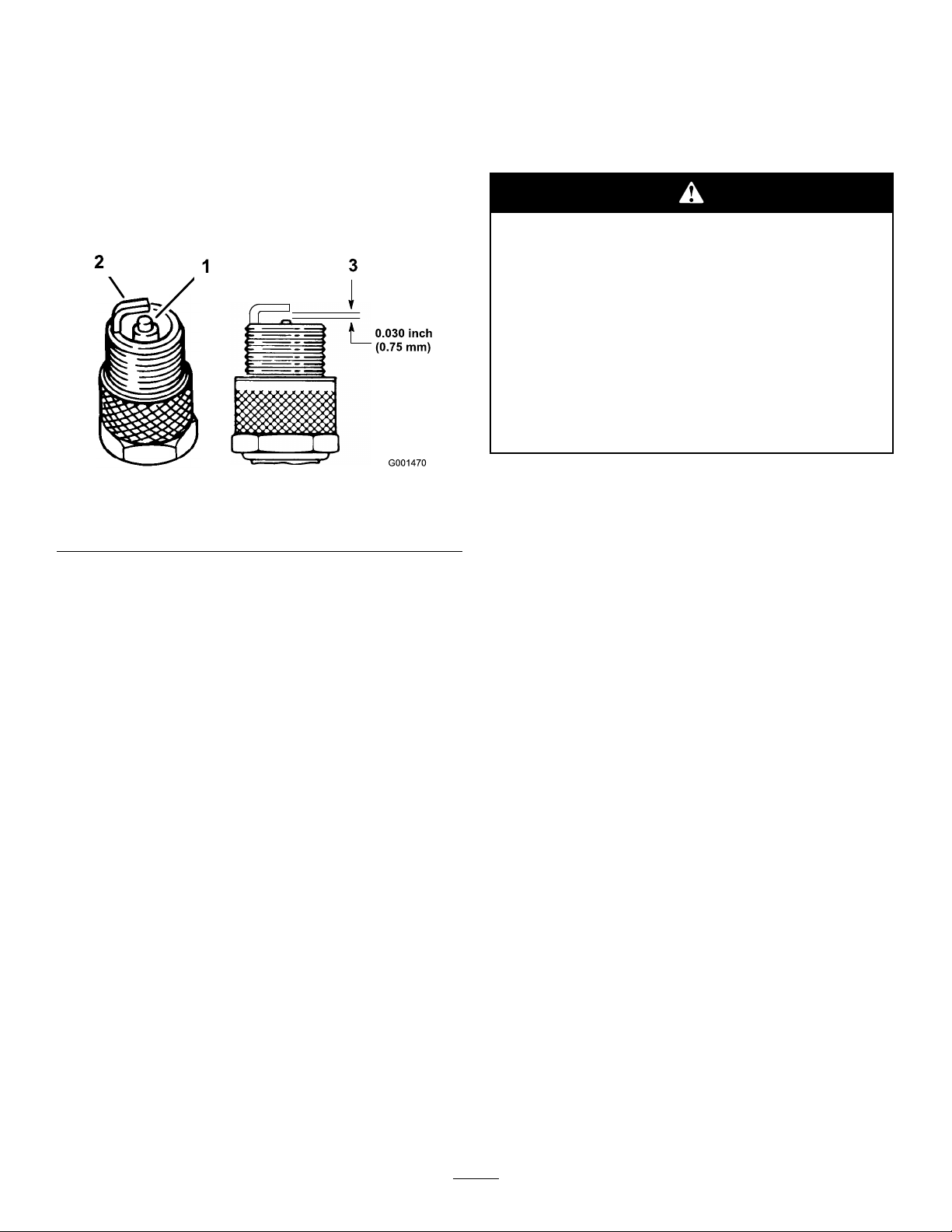

ServicingtheSparkPlugs

ServiceInterval/Specication

Figure32

1.Oildrainvalve2.Oildrainhose

9.Slowlypourapproximately80%ofthespeciedoil

intothellertube(Figure31).

10.Checktheoillevel;refertoCheckingtheEngineOil

Level.

11.SlowlyaddtheadditionaloiltobringittotheFull

mark.

ChangingtheOilFilter

ServiceInterval:Every200hoursoreveryotheroil

change.

Note:Changetheoilltermorefrequentlywhenthe

operatingconditionsareextremelydustyorsandy.

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil.

2.Removetheoldlter(Figure33).

Ensurethattheairgapbetweenthecenterandside

electrodesiscorrectbeforeinstallingthesparkplug.

Useasparkplugwrenchforremovingandinstallingthe

sparkplugsandagappingtool/feelergaugetocheckand

adjusttheairgap.Installanewsparkplugsifnecessary.

Type:Champion®RCJ8YorequivalentAirGap:

0.030inch(0.75mm)

RemovingtheSparkPlugs

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Disconnectthewiresfromthesparkplugs

(Figure34).

1.Oillter

Figure33

Figure34

1.Spark-plugwire/sparkplug

4.Cleanaroundthesparkplugstopreventdirtfrom

fallingintotheengineandpotentiallycausing

2.Adapter

damage.

5.Removethesparkplugsandthemetalwashers.

29

Page 30

CheckingtheSparkPlugs

ServiceInterval:Every100hours

1.Lookatthecenterofthesparkplugs(Figure35).

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly .Ablackcoatingonthe

insulatorusuallymeansthattheaircleanerisdirty.

2.Ifneeded,cleanthesparkplugwithawirebrushto

removecarbondeposits.

FuelSystem

Maintenance

DrainingtheFuelTank

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areor

explosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Draingasolinefromthefueltankwhenthe

engineiscold.Dothisoutdoorsinanopen

area.Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,and

stayawayfromanopenameorwherea

sparkmayignitethegasolinefumes.

Figure35

1.Centerelectrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

Important:Alwaysreplacethesparkplugs

whenithasablackcoating,wornelectrodes,

anoilylm,orcracks.

3.Checkthegapbetweenthecenterandsideelectrodes

(Figure35).Bendthesideelectrode(Figure35)if

thegapisnotcorrect.

InstallingtheSparkPlugs

1.Installthesparkplugsandthemetalwasher.Ensure

thattheairgapissetcorrectly.

2.Tightenthesparkplugsto16ft-lb(22N•m).

3.Connectthewirestothesparkplugs(Figure35).

1.Parkthemachineonalevelsurface,toensurethat

thefueltankdrainscompletely.

2.Disengagethebladecontrolswitchandmovethe

controlleverstotheneutrallockedpositionand

applytheparkingbrake.

3.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.Closethefuelshut-offvalvelocatedunderthefront

ofthefueltank.

5.Loosenthehoseclampatthefuellterandslideit

upthefuellineawayfromthefuellter(Figure36).

6.Pullthefuellineoffofthefuellter(Figure36).

7.Openthefuelshut-offvalve.Allowgasolinetodrain

intoagascanordrainpan.

Note:Nowisthebesttimetoinstallanewfuel

lterbecausethefueltankisempty.

ReplacingtheFuelFilter

ServiceInterval:Every200hoursoryearly ,whichever

occursrst.

Neverinstalladirtylterifitisremovedfromthefuel

line.

1.Disengagethebladecontrolswitchandmovethe

controlleverstotheneutrallockedpositionand

applytheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

30

Page 31

3.Closethefuelshut-offvalvelocatedunderthefront

ofthefueltank.

4.Squeezetheendsofthehoseclampstogetherand

slidethemawayfromthelter(Figure36).

ElectricalSystem

Maintenance

5.Removethelterfromthefuellines.

6.Installanewlterandmovethehoseclampsclose

tothelter(Figure36).

Important:Installtheltersothedirectionof

theowarrowisconsistentwiththeowoffuel;

fromthegastanktotheengine.

7.Openthefuelshut-offvalve.

Figure36

1.Fuellter

2.Hoseclamp

3.Fuelline

ServicingtheBattery

Warning

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling .

Batteryelectrolytecontainssulfuricacidwhich

isadeadlypoisonandcausessevereburns.

Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing.Wearsafetyglassesto

shieldyoureyesandrubberglovestoprotect

yourhands.

RemovingtheBattery

Batteryterminalsormetaltoolscouldshort

againstmetalmachinecomponentscausing

sparks.Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery ,do

notallowthebatteryterminalstotouchany

metalpartsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

31

Page 32

Incorrectbatterycableroutingcoulddamage

themachineandcablescausingsparks.Sparks

cancausethebatterygassestoexplode,

resultinginpersonalinjury.

•AlwaysDisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•AlwaysReconnectthepositive(red)battery

cablebeforereconnectingthenegative

(black)cable.

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedposition,andsettheparking

brake.

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Unlatchtheseatandtilttheseatup.

4.Firstdisconnectthenegativebatterycableand

groundwirefromthenegative(-)batteryterminal

(Figure37).

5.Slidetheredterminalbootoffthepositive(red)

batteryterminal.Thenremovethepositive(red)

batterycable(Figure37).

Figure37

1.Battery7.J-bolts

2.Positivebatterypost

3.Negativebatterypost

4.Terminalboot10.Negativebatterycable

5.Batteryclamp

6.Wingnut(1/4inch)

8.Bolt(1/4x3/4inch)

9.Groundwire

11.Locknut(1/4inch)

12.Positivebatterycable

6.Removebothwingnuts(1/4inch)securingthe

batteryclamp(Figure37).

7.Removethebattery.

InstallingtheBattery

1.Positionbatteryinthetraywiththeterminalposts

towardtheengine(Figure37).

2.First,installthepositive(red)batterycableto

positive(+)batteryterminal.

3.Theninstallthenegativebatterycableandground

wiretothenegative(-)batteryterminal.

4.Securethecableswith2bolts(1/4x3/4inch),

2washers(1/4inch),and2locknuts(1/4inch)

(Figure37).

5.Slidetheredterminalbootontothepositive(red)

batterypost.

6.SecurebatterywithJ-bolts,holddownclampand

2washers(1/4inch),and2wingnuts(1/4inch)

(Figure37).

32

Page 33

ChargingtheBattery

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged

(1.265specicgravity).Thisisespeciallyimportant

topreventbatterydamagewhenthetemperatureis

below32°F(0°C).

1.Chargebatteryfor10to15minutesat25to30amps

or30minutesat4-6amps.

2.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthe

chargerleadsfromthebatteryposts(Figure38).

Figure39

1.Fuseblock

2.Clutch,10amp(F3)4.Main,30amp(F1)

3.Chargecircuit,25amp

(F2)

Figure38

3.Installthebatteryinthemachineandconnectthe

batterycables;refertoInstallingtheBattery.

Note:Donotrunthemachinewiththebattery

disconnected,electricaldamagemayoccur.

ServicingtheFuses

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance,however,ifafuseblowscheck

component/circuitformalfunctionorshort.

1.Raisetheseattogainaccesstothefusesontheleft

sideofthemachine(Figure39).

2.Toreplacethefuses,pulloutonthefusetoremove

it.

3.Installanewfuse(Figure39).

33

Page 34

DriveSystem

Maintenance

CheckingtheTirePressure

ServiceInterval:Every50hoursormonthly ,whichever

occursrst.

Checkthepressureatthevalvestemafterevery

50operatinghoursormonthly,whicheveroccursrst

(Figure40).

Maintaintheairpressureinthereartiresat13psi(90

kPa).Uneventirepressurecancauseunevencut.Check

thetireswhentheyarecoldtogetthemostaccurate

pressurereading.

Note:Thefronttiresaresemi-pneumatictiresanddo

notrequireairpressuremaintenance.

Figure40

AdjustingtheCasterPivot

Figure41

1.SpringWashers3.DustCap

2.LockNut

Bearing

ServiceInterval:Every500hours

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Removethedustcapfromcasterandtightenlock

nut(Figure41).

4.Tightenthelocknutuntilthespringwashersareat

andthenbackoffa1/4turntoproperlysetthe

pre-loadonthebearings(Figure41).

Important:Makesurespringwashersare

installedcorrectlyasshowninFigure41.

5.Installthedustcap(Figure41).

34

Page 35

CoolingSystem

Maintenance

BrakeMaintenance

ServicingtheBrakes

CleaningtheAirIntakeScreen

ServiceInterval:Beforeeachuseordaily

Beforeeachuseremoveanybuild-upofgrass,dirt

orotherdebrisfromthecylinderandcylinderhead

coolingns,airintakescreenonywheelend,and

carburetor-governorleversandlinkage.Thiswillhelp

insureadequatecoolingandcorrectenginespeedand

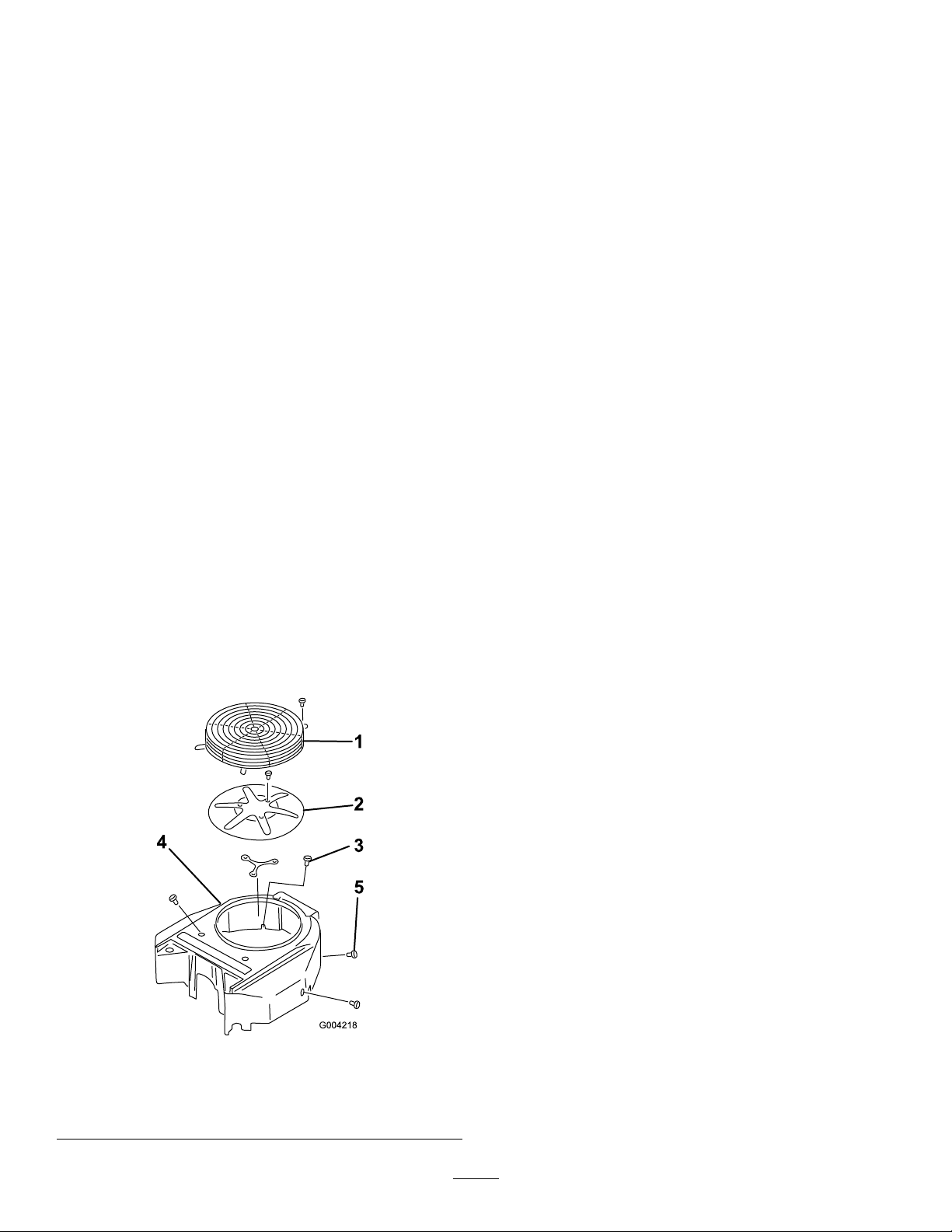

willreducethepossibilityofoverheatingandmechanical

damagetotheengine.

CleaningtheEngineCooling

System

ServiceInterval:Every100hoursoryearly ,whichever

occursrst.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Removetheengineguard,theengineairintake

screen,andthefanhousing(Figure42).

4.Cleanthedebrisandgrassfromtheengineparts.

5.Installtheengineguard,theengineairintakescreen,

andthefanhousing(Figure42).

Beforeeachuse,checkthebrakesonbothalevelsurface

andslope.

Alwayssettheparkingbrakewhenyoustopthemachine

orleaveitunattended.Iftheparkingbrakedoesnot

holdsecurely ,seeanAuthorizedServiceDealerfor

maintenance.

CheckingtheBrake

ServiceInterval:Beforeeachuseordaily

1.Parkthemachineonalevelsurface,disengagethe

bladecontrol(PTO).

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Applytheparkingbrake.Thewheelsmustlock

whenyoutrytopushthemachineforward.

4.Ifthewheelsdonotlock,seeanAuthorizedService

Dealerformaintenance.

5.Releasethebrakesandmovetheneutral/brake

lockstotheneutralposition.Thewheelsshould

rotate,ifnot;seeanAuthorizedServiceDealerfor

maintenance.

Figure42

1.Engineguard4.Bolt

2.Engineairintakescreen

3.Fanhousing

5.Screw

35

Page 36

BeltMaintenance

InspectingtheBelts

ServiceInterval:Every100hours—Inspectallbelts

forcracksandwear.

Checkbeltsforcracks,frayededges,burnmarksorany

otherdamage.Replacedamagedbelts.

ReplacingtheMowerBelt

Thesignsofawornmowerbeltaresquealingwhilethe

beltisrotating,bladesslippingwhileyouarecutting

grass,frayedbeltedges,burnmarks,andcracks.Replace

themowerbeltifyoudetectanyofthesesigns.

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedposition,andsettheparking

brake.

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Remove2boltsandwashersineachbeltcoverand

removethebeltcoversovertheoutsidespindles

(Figure45).

Figure44

40inchMower

1.Fixedidlerpulley3.Mowerbelt

2.Leftspindlepulley4.Spring-loadedidlerarm

8.Installthebeltcoversovertheoutsidespindles

(Figure45).

Note:Non-commercialownerswillneedtoinstall

thefrontwasherandboltthatholdsthebeltcover

inplace.

4.Pullontheidlerarmtorelievethebelttensionon

theleftspindlepulley(Figure43orFigure44).

5.Removetheoldbelt.

6.Installthenewbeltaroundthepulleys(Figure43

orFigure44).

7.Installthebeltontothespringloadedidlerpulley.

Figure43

34inchMower

1.Fixedidlerpulley3.Mowerbelt

2.Leftspindlepulley4.Spring-loadedidlerarm

Figure45

40inchmowershown

1.Leftbeltcover

2.Rightbeltcover4.Bolt

3.Washer

CheckingandReplacingthe

PumpDriveBelt

ServiceInterval:Every50hours—Checkpumpdrive

belt.

1.Pushtheseatforwadandlocatethepumpdrivebelt.

36

Page 37

Note:Non-commercialownerswillneedtoloosen

theseatretainerclipthatholdstheseatinplace.

2.Checkthebeltforwearandreplaceitifneeded.

3.Toreplacethebelt,removetheboltfromtheclutch

stopandunplugtheclutchelectricalwire(Figure46).

ControlsSystem

Maintenance

AdjustingtheControlHandle

4.Pullontheidlerpulleytorelievethebelttensionon

theidlerpulley(Figure46).

5.Removethepumpdrivebeltfromtheengineandthe

hydraulicpumppulleys(Figure46).

6.Installthenewbeltaroundtheengineandthe

hydraulicpumppulleys(Figure46).

7.Pullthespring-loadedidlertothesideandalignthe

belt.

8.Releasethepressureonthespringloadedidler

(Figure46).

NeutralPosition

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedposition,andsettheparking

brake.

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Loosentheboltsandcurvedwashersinstalledinthe

levers(Figure47).

4.Aligntheleversfronttorearpositionbybringthe

leverstogethertotheneutralpositionandslide

themuntiltheyarealigned,thentightenthebolts

(Figure48).

Figure46

1.Belt3.Enginepulley

2.Transmissionpump

pulleys

4.Springloadedidlerpulley

Figure47

37

Page 38

Figure48

5.Iftheendsofthelevershitagainsteachother,adjust

theleversbyrotatingthemouttotheneutrallocked

positionandcarefullybendthemoutward.Repeat

thisstepasneeded.

AdjustingtheTracking

1.Ifthemachineturnsrightorleftwhenthehandles

arepushedforwardtogether,adjustthestoponthe

sideoppositethatthemachineturns.

2.Loosentheboltlocatedinfrontofthecontrollever.

3.Movethestopuntilthemachinedrivesstraight

(Figure49).

4.Tightentheboltlocatedinfrontofthecontrollever

(Figure49).

Figure49

1.Controllever3.Boltinfrontofthecontrol

lever

2.Stop

38

Page 39

HydraulicSystem

Maintenance

ServicingtheHydraulic

System

CheckingtheHydraulicFluid

ServiceInterval:Aftertherst8hours

Every50hours

FluidType:Mobil115W -50syntheticmotoroilor

equivalentsyntheticoil.

Important:Useoilspeciedorequivalent.Other

uidscouldcausesystemdamage.

Note:Therearetwowaysofcheckingthehydraulic

oil;whentheoiliswarmorwhentheoiliscold.The

tankhastwolevelsdependingiftheoiliswarmorcold

(Figure50).

1.Positionthemachineonalevelsurfaceandsetthe

parkingbrake.

2.Cleantheareaaroundthehydraulictank(Figure50).

3.Ifthemachinehasnotbeenstartedandiscold,

ensuretheuidisuptothecoldlineonthesideof

thehydraulictank.

4.Ifthemachinehasbeenrunandisuptonormal

operatingtemperature,ensuretheuidisuptothe

hotlineonthesideofthehydraulictank.

5.Ifuidisneeded,removethecapfromtheller

neck(Figure50).

6.Adduidtothereservoiruntilitreachesthecoldor

hotlineofthetankdependingonthetemperature

oftheuid.

7.Installthecaponllerneck.

Figure50

1.Cap3.Colduidlevel-full

2.Bafe4.Hotuidlevel-full

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

•Ifhydraulicuidisinjectedintotheskin

itmustbesurgicallyremovedwithinafew

hoursbyadoctorfamiliarwiththistypeof

injury.Gangrenemayresultifthisisnot

done.

•Keepbodyandhandsawayfrompinhole

leaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulic

leaks.

•Safelyrelieveallpressureinthehydraulic

systembeforeperforminganyworkonthe

hydraulicsystem.

•Makesureallhydraulicuidhosesand

linesareingoodconditionandallhydraulic

connectionsandttingsaretightbefore

applyingpressuretohydraulicsystem.

ReplacingtheHydraulicFiltersandOil

ServiceInterval:Aftertherst250hours

Yearly—Changethehydrauliclters

andoil.

39

Page 40

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

Important:Donotsubstituteautomotiveoil

lterorseverehydraulicsystemdamagemay

result.

3.Locatethetwolters,oneundereachtransmission

andremovethelterguards.

4.Carefullycleantheareaaroundthelters.Itis

importantthatnodirtorcontaminationenterthe

hydraulicsystem(Figure51).

5.Unscrewtheltersandallowtheoiltodrainfrom

thedrivesystem(Figure51).

Important:Beforereinstallingnewlters,

applyathincoatofoilonthesurfaceofthe

ltersrubberseal.

6.Installthenewltersclockwiseuntilrubberseal

contactsthelteradapterandthentightenthelter

anadditional3/4to1fullturn.

changinglter),unlessitisfelttheoilhasbeen

contaminatedorbeenextremelyhot.Changing

theoilunnecessarilycoulddamagethehydraulic

systembyintroducingcontaminatesintothe

system.

7.Removetheventplugoneachtransmissionandll

throughthehydraulictank,whenoilcomesoutof

ventreinstallplug.T orquetheplugsto180in-lb

(244N⋅m).

8.Addoiluntilitreachesthecoldlineonthehydraulic

tank(Figure50).

9.Raisetherearofmachineupjustenoughtoallow

thedrivewheelstoturnfreelyandsupportitwith

jackstands.

10.Starttheengineandmovethethrottlecontrolahead

tothe1/2throttleposition.Disengagetheparking

brake.

11.Withthebypassvalveopenandtheenginerunning,

slowlymovethedirectionalcontrolinbothforward

andreverse5or6times.

12.Withthebypassvalveclosedandtheengine

running,slowlymovethedirectionalcontrolinboth

forwardandreversedirections5to6times.Stop

theengineandchecktheoillevel,andaddoilas

requiredtothehotline.

13.Repeatitems11and12asnecessaryuntilalltheair

iscompletelypurgedfromthesystem.Whenthe

transaxleoperatesatnormalnoiselevelsandmoves

smoothlyforwardandreverseatnormalspeeds,then

thetransaxleispurged.

1.Leftreartire

2.Hydrauliclter

Figure51

3.Ventplug

Important:Donotchangehydraulicsystem

oil(exceptforwhatcanbedrainedwhen

40

Page 41

MowerDeck

Maintenance

LevelingtheMower

Important:Thereareonlythreemeasuring

positionsneededtolevelthemower.

1.Positionmoweronaatsurface.

2.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

3.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.Checktirepressureofthereartires.Ifneeded,adjust

to13psi(90kPa)

5.Placetwothickblocksunderrearleftandrightlower

edgeofthemowerdecksotheweightofthedeck

restsontheblocks.

6.Lowerthemowertothe3inch(76mm)height-of-cut

position.

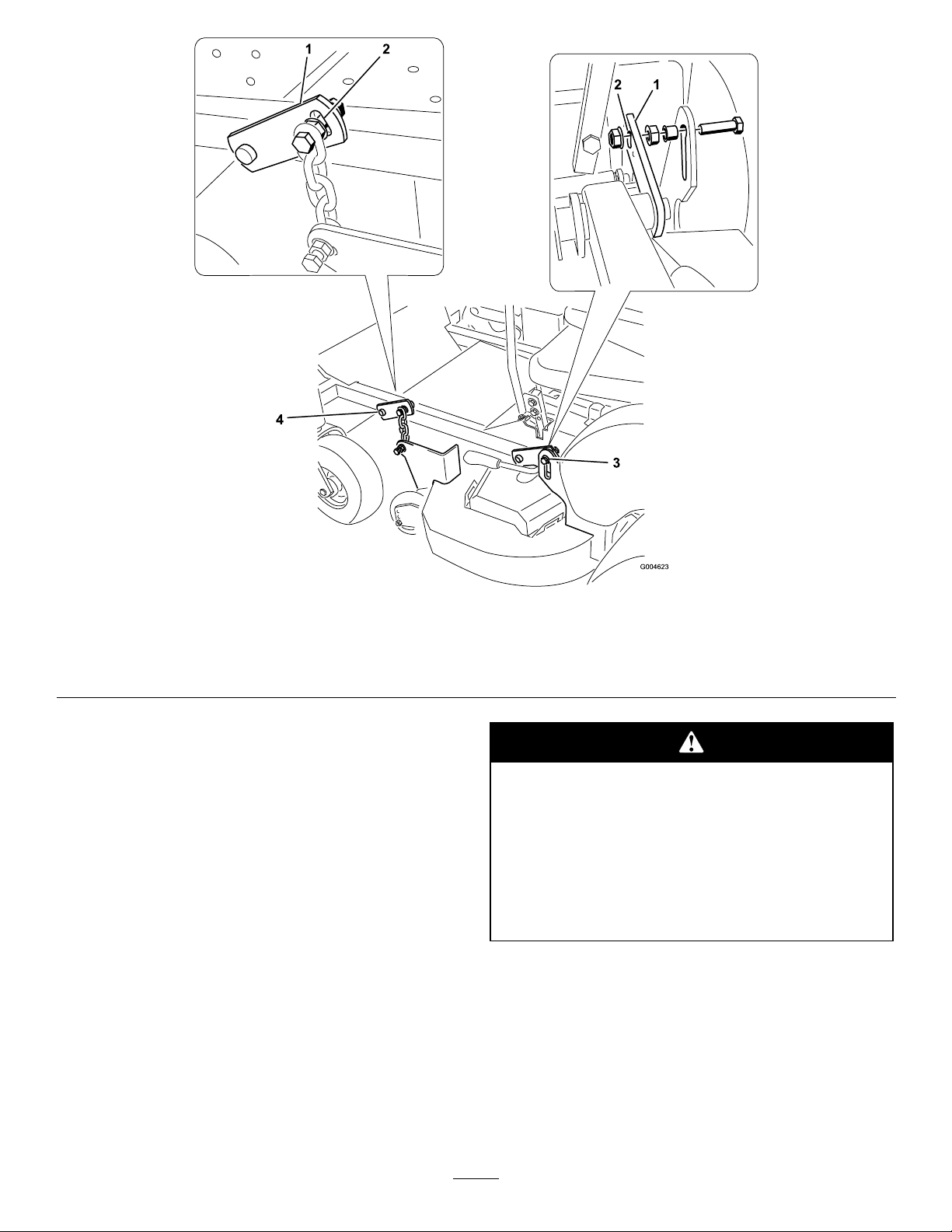

7.Loosentheboltsconnectingthetwochainsandthe

tworearbracketstothemower(Figure53).

8.Adjustthetworearboltssotheyareinthemiddleof

theslotlocatedinthepivotbracket(Figure53).

9.Adjusttheboltssotheendoftheboltisushwith

thenut.Thiswillallowthebushingtorollintheslot

inthemowerdeckbracket(Figure52).

10.Adjustthedischargesidefrontboltsoitisinthe

middleoftheslotlocatedinthepivotbracket

(Figure53).

11.Raisethemowerdeckandremovetheblocksholding

upthemowerdeck.

12.Adjusttheleftfrontboltinthepivotbracketsothe

chainhasnoslackinit.

13.Inspectthefourchains.Thechainsneedtohave

tension.

Note:Themowerdeckcuttingheightcanbe

adjusted.Loosentheheightofcutbracketandadjust

itforwardorbackwardtogetthecorrectheight.

Tightenthebracketaftertheadjustmentismade.

Figure52

1.Keeptheendofthebolt

ushwiththenut

2.Rearpivotbracket4.Bolt

3.Nut

Note:Whenproperlyadjusted,thefrontbladetip

willbea1/4inch(6mm)lowerfor34inchmowers

and3/16(4mm)lowerfor40inchmowersthanthe

rearbladetip.RefertoCheckingforBentBladesfor

theproceduretomeasurethebladetipheight.

14.Therightbladeatthefrontposition(Figure55or

Figure56)needstobethesameheightastheleft

bladeatthefrontposition.

Ifthereismorethanan1/8inch(3mm)difference

betweenleftandright,thenadjustthemounting

boltsintheslottolevelthemowerdecklefttoright.

41

Page 42

Figure53

Leftsideshown

1.Pivotbracket3.Rearpivotbracket

2.Boltinstalledinthemiddleoftheslot

4.Frontpivotbracket

ServicingtheCuttingBlades

Maintainsharpbladesthroughoutthecuttingseason

becausesharpbladescutcleanlywithouttearingor

shreddingthegrassblades.Tearingandshreddingturns

grassbrownattheedges,whichslowsgrowthand

increasesthechanceofdisease.

Checkthecutterbladesdailyforsharpness,andforany

wearordamage.Filedownanynicksandsharpenthe

bladesasnecessary.Ifabladeisdamagedorworn,

replaceitimmediatelywithagenuineTororeplacement

blade.Forconvenientsharpeningandreplacement,you

maywanttokeepextrabladesonhand.

Awornordamagedbladecanbreak,anda

pieceofthebladecouldbethrownintothe

operator’sorbystander’sarea,resultingin

seriouspersonalinjuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

BeforeInspectingorServicingthe

Blades

Parkthemachineonalevelsurface,disengagetheblade

control(PTO),andsettheparkingbrake.Turnthe

ignitionkeytoOff.Removethekey .

42

Page 43

InspectingtheBlades

A

1

G004621

A

A

2

ServiceInterval:Beforeeachuseordaily

1.Inspectthecuttingedges(Figure54).Iftheedges

arenotsharporhavenicks,removeandsharpenthe

blades.RefertoSharpeningtheBlades.

2.Inspecttheblades,especiallythecurvedarea

(Figure54).Ifyounoticeanydamage,wear,oraslot

forminginthisarea(Figure54),immediatelyinstalla