Page 1

Form No. 3328-454 Rev A

TimeCutter ZX Riding Mowers

Setup Instructions

Note: If needed, a Decal Kit, 106–6412, and French manual are available for the customer. Order the Decal Kit from the Toro

Parts Department and the French manual from either the Toro Parts Department or online at www.toro.com.

Loose Parts

Note: Use the chart below to verify that all parts have been shipped.

Description Qty. Use

Bolt, 1/4 x 3/4 inch

Washer, 1/4 inch

Nut, 1/4 inch

Seat

Spacer

Knob

Flat washer, 5/16 inch

Left-hand control lever

Right-hand control lever

Bolt, 3/8 x 1 inch

Curved washer, 3/8 inch

Hose coupling 1 Washing the underside of the mower

Key 1

Operator’s Manual

Engine Operator’s Manual

Registration card 1 Fill out and return to Toro.

2

2

2

1

2

2

2

1

1

4

4

1

1

Installing the battery

Installing the seat

Installing the motion control levers

Read before operating the machine.

Warning

CALIFORNIA

Proposition 65 Warning

Battery posts, terminals, and related accessories

contain lead and lead compounds, chemicals

known to the State of California to cause cancer

and reproductive harm. Wash hands after

handling.

2004 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

Original Instructions (EN)

Contact us at www.Toro.com

All Rights Reserved

Printed in the USA

Page 2

Installing the Battery

Bulk electrolyte with 1.260 specific gravity must be

purchased from a local battery supply outlet.

4. Wait five to ten minutes after filling the battery cells.

Add electrolyte, if necessary, until the electrolyte level

is up to the Upper line (Fig. 1) on the battery case.

5. Install the battery vent caps.

Danger

Battery electrolyte contains sulfuric acid which is a

deadly poison and causes severe burns.

• Do not drink electrolyte and avoid contact with

skin, eyes or clothing. Wear safety glasses to

shield your eyes and rubber gloves to protect

your hands.

• Fill the battery where clean water is always

available for flushing the skin.

• Follow all instructions and comply with all

safety messages on the electrolyte container.

1. Remove the battery from the machine and place it on a

level surface; refer to the Operator’s Manual,

Removing the Battery.

Important Never fill the battery with electrolyte while

the battery is installed in the tractor. Electrolyte could be

spilled on other parts and cause corrosion.

2. Clean the top of the battery with a paper towel.

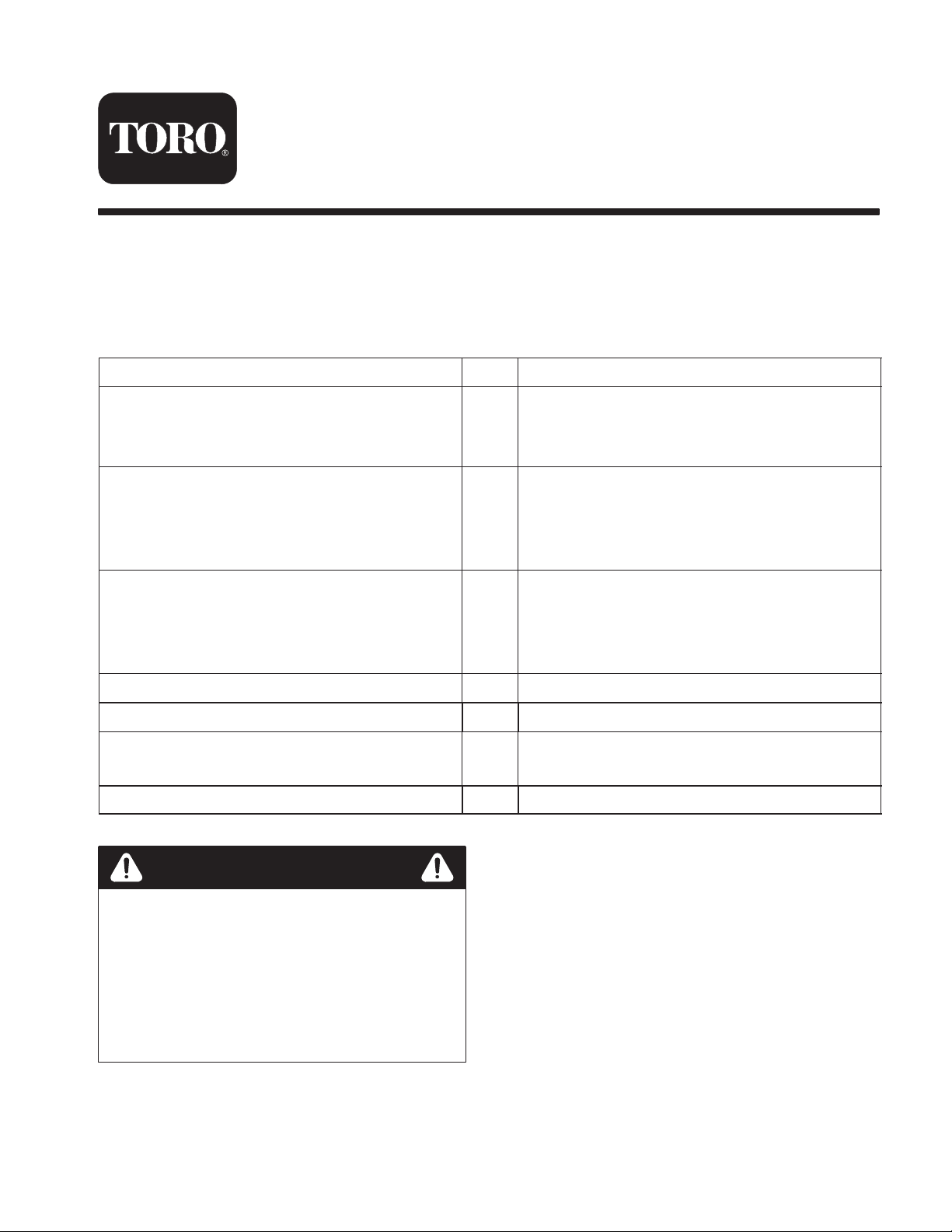

3. Remove the vent caps from the battery (Fig. 1). Slowly

pour electrolyte into each battery cell until the

electrolyte level is up to the Upper line on the battery

case (Fig. 1).

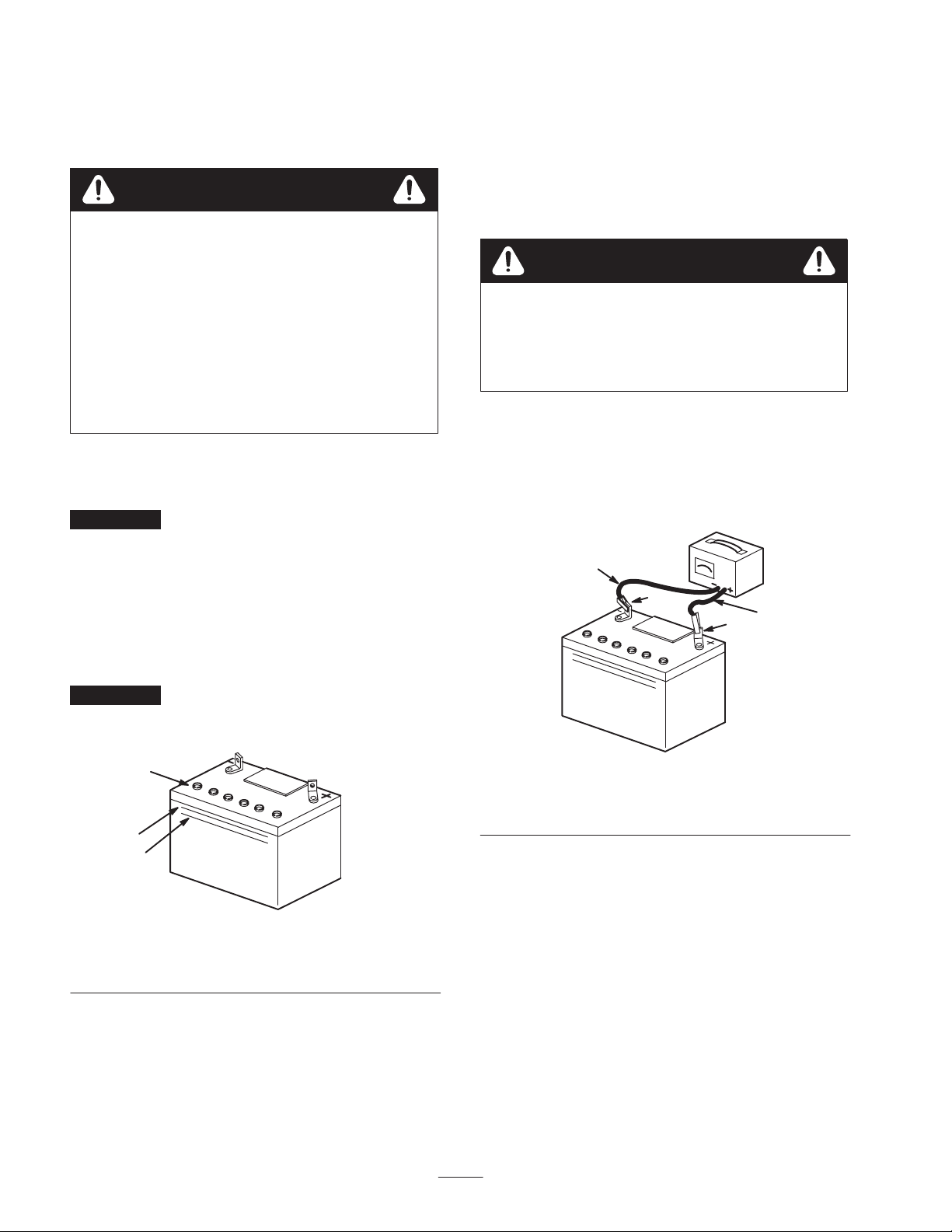

6. Charge the battery for 1 hour at 25 to 30 amps or

6 hours at 4 to 6 amps (Fig. 2). Do not overcharge the

battery.

Warning

Charging the battery produces gasses that can

explode.

Never smoke near the battery and keep sparks and

flames away from battery.

7. When the battery is fully charged, unplug the charger

from the electrical outlet, then disconnect the charger

leads from the battery posts (Fig. 2).

8. Install the battery in the tractor and connect the battery

cables; refer to the Operator’s Manual, Installing the

Battery.

4

2

3

1

Important Do not overfill the battery because

electrolyte (sulfuric acid) can cause severe corrosion and

damage to the chassis.

1

2

3

m-5004

Figure 1

1. Vent caps

2. Upper line

3. Lower line

Figure 2

1. Positive post

2. Negative post

3. Charger red (+) wire

4. Charger black (–) wire

Installing the Motion Control

Levers

1. Remove the 4 bolts (3/8 x 1 inch) and 4 curved washers

(3/8 inch) which attach the motion control levers to the

control arm shafts for shipping (Fig. 3).

2

Page 3

2. Place the levers (with the mounting plates toward the

rear of the machine) on the outside of the control arm

shaft and loosely secure them with the 4 bolts and

curved washers removed in step 1 (Fig. 3).

1

4

2

3

m–5215

Figure 3

1. Control arm

2. Bolt, 3/8 x 1 inch

3. Curved washer, 3/8 inch

4. Control arm shaft

2. Remove the knobs and flat washers (5/16 inch) from the

seat support.

3. Remove the spacers between the seat and seat support.

4. Raise the seat support on the machine (Fig. 5).

5. Slide the shoulder bolts on the bottom of the seat into

the slots on the seat support (Fig. 5).

6. Secure the seat to the seat support with the spacers, flat

washers and knobs removed in step 2 and 3 (Fig. 5).

2

3. Position the levers so that the bolts are in the center of

the slots on the lever mounting plate and tighten the

bolts until they are snug.

4. Align the front/rear position of the levers with each

other while in the neutral position. Loosen the bolts and

adjust the levers by sliding and/or tilting the lever(s)

forward or backward until they are properly aligned.

5. If the ends of the motion control levers hit against each

other while they are in the drive position (Fig. 4) (the

levers are rotated in as far as possible), make

adjustments by moving the levers outward to the neutral

lock position and carefully bend them outward. Move

them back to the drive position and check for clearance.

Repeat if necessary.

FRONT

OF

UNIT

LEVERS IN

ALIGNMENT

Figure 4

Installing the Seat

3

1

m–5579

Figure 5

1. Seat support

2. Shoulder bolt

3. Knob

Important Make sure the spacers are between the seat

and support, and the knobs pass through the washers, seat

support, spacers and into the seat (Fig. 6).

1

2

5

4

3

m–7546

Figure 6

1. Seat

2. Seat support

3. Knob

4. Washer

5. Spacer

1. Cut the plastic ties securing the seat to the machine for

shipping. Remove the seat.

7. Lower the seat and adjust it if necessary; refer to

Positioning the Seat in the Operator’s Manual.

3

Page 4

Washing the Underside of the

Mower

A hose coupling is included in loose parts for washing the

underside of the mower. See the Operator’s Manual for the

proper procedure.

Checking the Mower

Adjustment

The mower deck was leveled at the factory. If the mower is

not cutting level, adjust the side-to-side level and the

front-to-rear blade slope. See the Operator’s Manual for the

proper procedure.

Checking the Side Discharge

Chute

Remove the plastic tie holding the side discharge chute up,

and lower the chute into place.

Checking the Engine Oil Level

Before you start the engine and use the machine, check the

oil level in the engine crankcase; refer to Checking the Oil

Level in the Operator’s Manual.

Checking the Tire Pressure

Check the front and rear tires for proper inflation. Refer to

Tire Pressure in the Operator’s Manual for the

recommended inflation pressure.

4

Loading...

Loading...