Page 1

TORO TIMECUTTER Z SERVICE MANUAL

Table of Contents – Page 1 of 2

QUICK REFERENCE

SAFETY INFORMATION

GENERAL INFORMATION

THINK SAFETY FIRST

SPECIFICATIONS

ENGINE SPECIFICATIONS - (Z16-44 & Z17-44)

ENGINE SPECIFICATIONS - (Z17-52 & Z18-52)

BOLT TORQUES

MAINTENANCE SCHEDULE

Z16-44

Z17-44 & Z17-52

Z18-52

MODEL/SERIAL NUMBER LOCATION

GREASING AND LUBRICATION

SERVICE INTERVAL/SPECIFICATION

LUBRICATION POINTS

ENGINE

BRIGGS & STRATTON ENGINE

KOHLER ENGINE

KAWASAKI ENGINE

BRIGGS & STRATTON AIR CLEANER

KOHLER AIR CLEANER

KAWASAKI AIR CLEANER

SPARK PLUG

ENGINE REMOVE AND REPLACE

TRANSAXLE

TROUBLESHOOTING CHECKLIST

FLUIDS

REMOVE AND REPLACE TRANSAXLE

REASSEMBLY

CONTROL HANDLE-RETURN TO NEUTRAL ADJUSTMENT

PURGING THE SYSTEM

NEUTRAL ADJUSTMENT

TRACKING ADJUSTMENT

CONTROL HANDLE ADJUSTMENT

CHASSIS

REMOVE AND REPLACE DAMPERS

REMOVE AND REPLACE CONTROL LINKAGE

REPLACE CONTROL LINKAGE

REMOVE AND REPLACE BRAKE LINKAGE

REPLACE BRAKE LINKAGE

PARKING BRAKE ADJUSTMENT

REPLACE TRACTION BELT

Page 2

TORO TIMECUTTER Z SERVICE MANUAL

Table of Contents – Page 2 of 2

MOWER DECKS: 44” AND 52” DECK ASSEMBLIES

BELT REMOVAL AND REPLACEMENT

MOWER DECK REMOVE AND REPLACE

MOWER DECK SIDE TO SIDE ADJUSTMENT

MOWER DECK FRONT TO REAR ADJUSTMENT

SPINDLE BEARING REPLACEMENT

ELECTRICAL SYSTEMS

SAFETY INTERLOCK SYSTEM

INTERLOCK COMPONENTS

ELECTRICAL COMPONENTS

ELECTRIC CLUTCH

ELECTRICAL SCHEMATICS

BRIGGS & STRATTON

KAWASAKI

KOHLER

Page 3

TimeCutter® Z

TimeCutter® ZX

Service Manual

Page 4

ABOUT THIS MANUAL

This service manual was written expressly for Toro service technician. The Toro Company has made every effort

to make the information in this manual complete and correct.

Basic mechanical/electrical skills are assumed. The Table of Contents lists the systems and the related topics

covered in this manual.

For additional information on the electrical system, please refer to the Toro Electrical Demystification Guide (492-

4404). For information on the hydrostatic drive units, refer to the Integrated Zero-Turn Transaxle Service and

Repair Manual (492-4737). For information specific to the engines used on this unit, refer to the appropriate

engine manufacturer’s service and repair instructions.

We are hopeful that you will find this manual a valuable addition to your service shop. If you have any questions or

comments regarding this manual, please contact us at the following address:

The Toro Company

Consumer Service Training Department

8111 Lyndale Avenue South

Bloomington, MN 55420

The Toro Company reserves the right to change product specifications or this manual without notice.

The automatic transmission and transaxle are sophisticated pieces of machinery. Maintain strict cleanliness

control during all stages of service and repair. Cover or cap all hose ends and fittings whenever they are exposed.

Even a small amount of dirt or other contamination can severely damage the system.

Copyright© All Rights Reserved

©2001 The Toro Company

Page 5

QUICK REFERENCE SECTION

TABLE OF CONTENTS

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE SECTION

Model/Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Greasing and Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1a

1b

1c

2

3

4

5

Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mower Decks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

7

8

TimeCutter™ Z Service Manual 1 - 1

Page 6

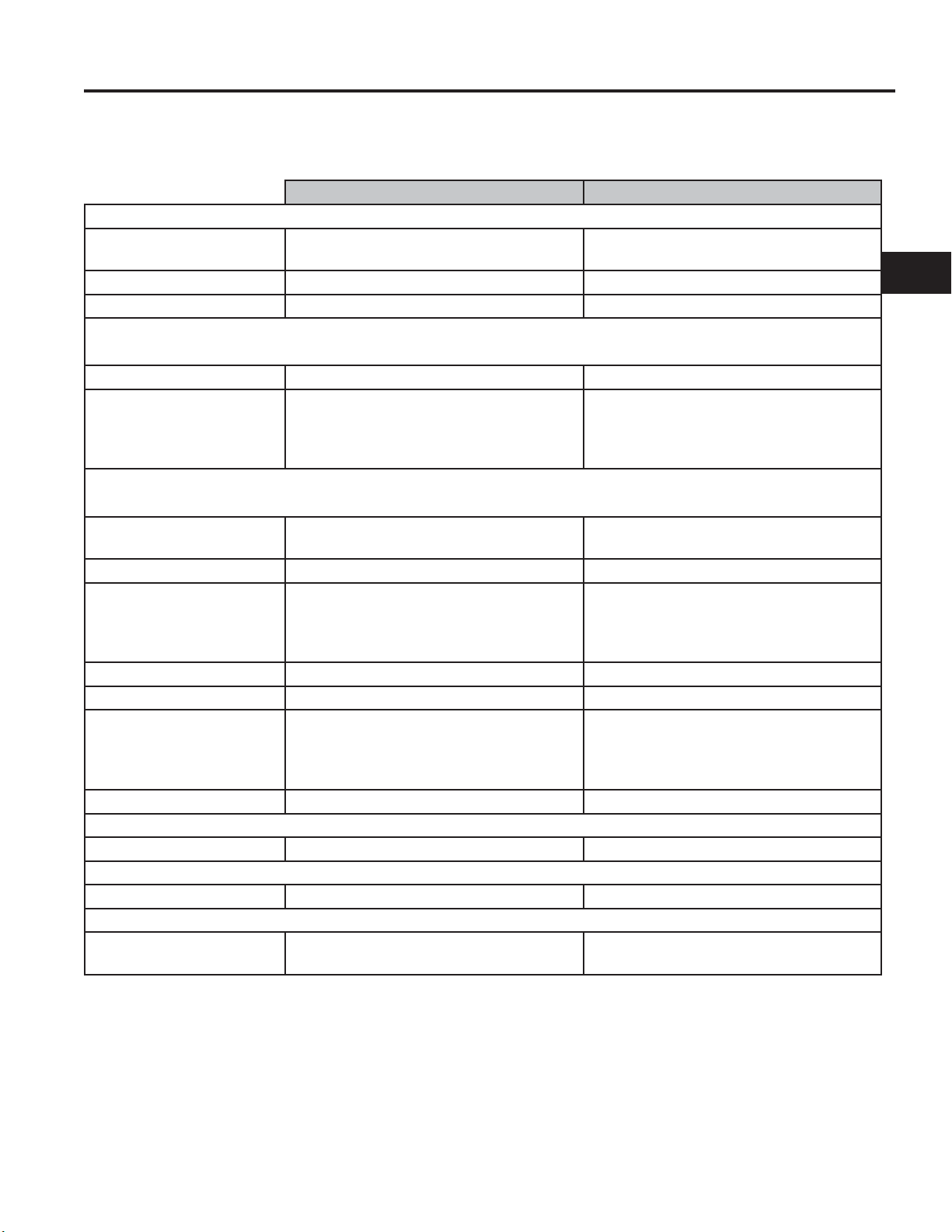

QUICK REFERENCE

SAFETY INFORMATION

General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Think Safety First. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

SPECIFICATIONS

Engine Specifications - (Z16-44 & Z17-44) . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

Engine Specifications - (Z17-52 & Z18-52) . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5

BOLT TORQUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 6

MAINTENANCE SCHEDULE

Table of Contents

Z16-44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 7

Z17-44 & Z17-52 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 8

Z18-52 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 9

1 - 2 TimeCutter™ Z Service Manual

Page 7

SAFETY INFORMATION

This symbol means WARNING or

PERSONAL SAFETY INSTRUCTION

- read the instruction because it has to

do with your safety. Failure to comply

with the instruction may result in

personal injury or even death.

This manual is intended as a service and repair manual

only. The safety instructions provided herein are for

troubleshooting, service, and repair of the TimeCutter Z

zero radius tractor. The TimeCutter Z zero radius

THINK SAFETY FIRST

Avoid unexpected starting of engine...

Always turn off the engine and disconnect the spark

plug wire(s) before cleaning, adjusting, or repair.

Avoid lacerations and amputations...

Stay clear of all moving parts whenever the engine is

running. Treat all normally moving parts as if they were

moving whenever the engine is running or has the

potential to start.

tractor and attachment operator’s manuals contain

safety information and operating tips for safe operating

practices. Operator’s manuals are available through

your Toro parts source or:

1a

The Toro Company

Publications Department

8111 Lyndale Avenue South

Bloomington, MN 55420

Avoid injury from batteries...

Battery acid is poisonous and can cause burns. Avoid

contact with skin, eyes, and clothing. Battery gases can

explode. Keep cigarettes, sparks, and flames away

from the battery.

Avoid injury due to inferior parts...

Use only original equipment parts to ensure that

important safety criteria are met.

Avoid burns...

Do not touch the engine, muffler, or other components

which may increase in temperature during operation,

while the unit is running or shortly after it has been

running.

Avoid fires and explosions...

Avoid spilling fuel and never smoke while working with

any type of fuel or lubricant. Wipe up any spilled fuel or

oil immediately. Never remove the fuel cap or add fuel

when the engine is running. Always use approved,

labeled containers for storing or transporting fuel and

lubricants.

Avoid asphyxiation...

Never operate an engine in a confined area without

proper ventilation.

Avoid injury to bystanders...

Always clear the area of bystanders before starting or

testing powered equipment.

Avoid injury due to projectiles...

Always clear the area of sticks, rocks, or any other

debris that could be picked up and thrown by the

powered equipment.

Avoid modifications...

Never alter or modify any part unless it is a factory

approved procedure.

Avoid unsafe operation...

Always test the safety interlock system after making

adjustments or repairs on the machine. Refer to the

Electrical section in this manual for more information.

TimeCutter™ Z Service Manual 1 - 3

Page 8

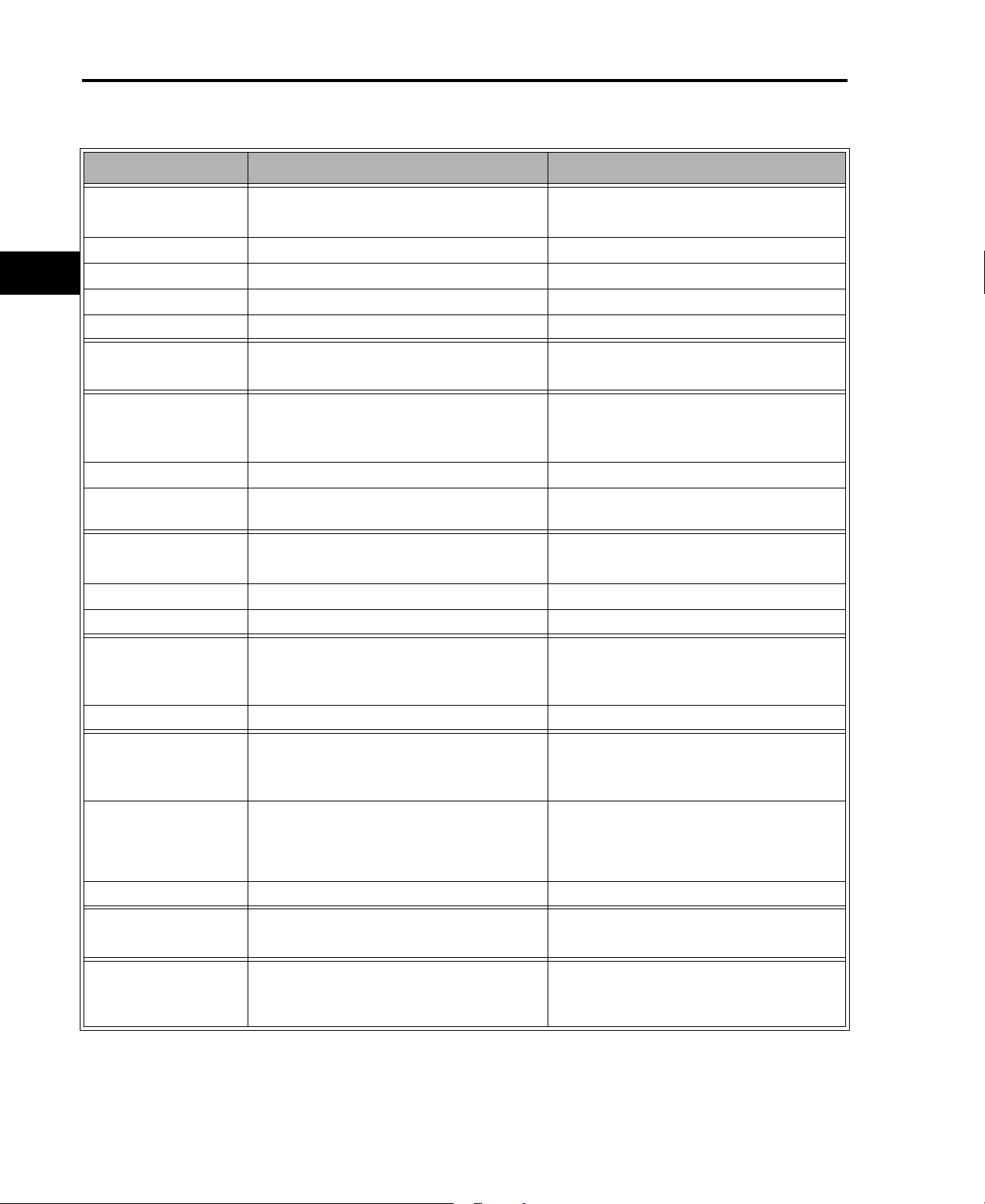

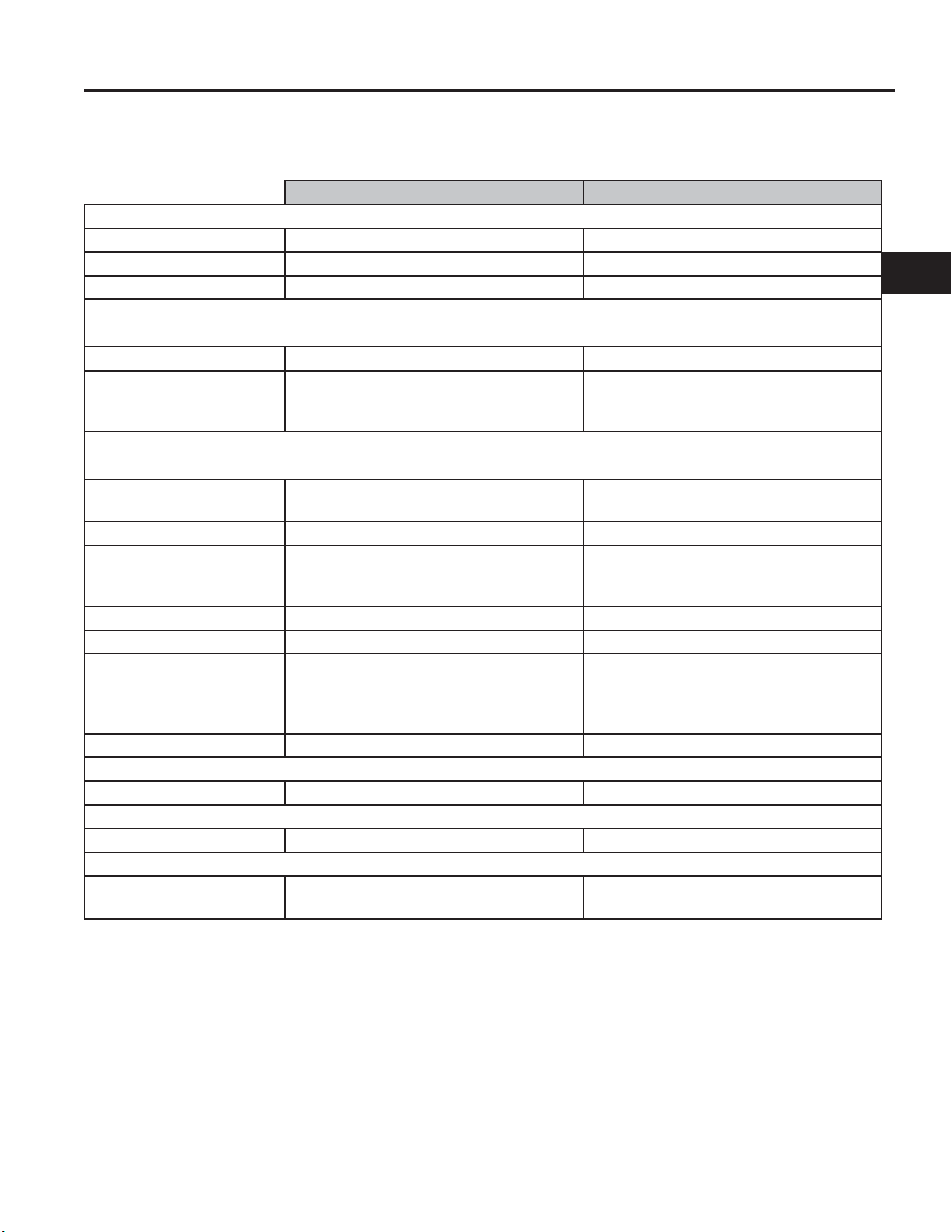

SPECIFICATIONS

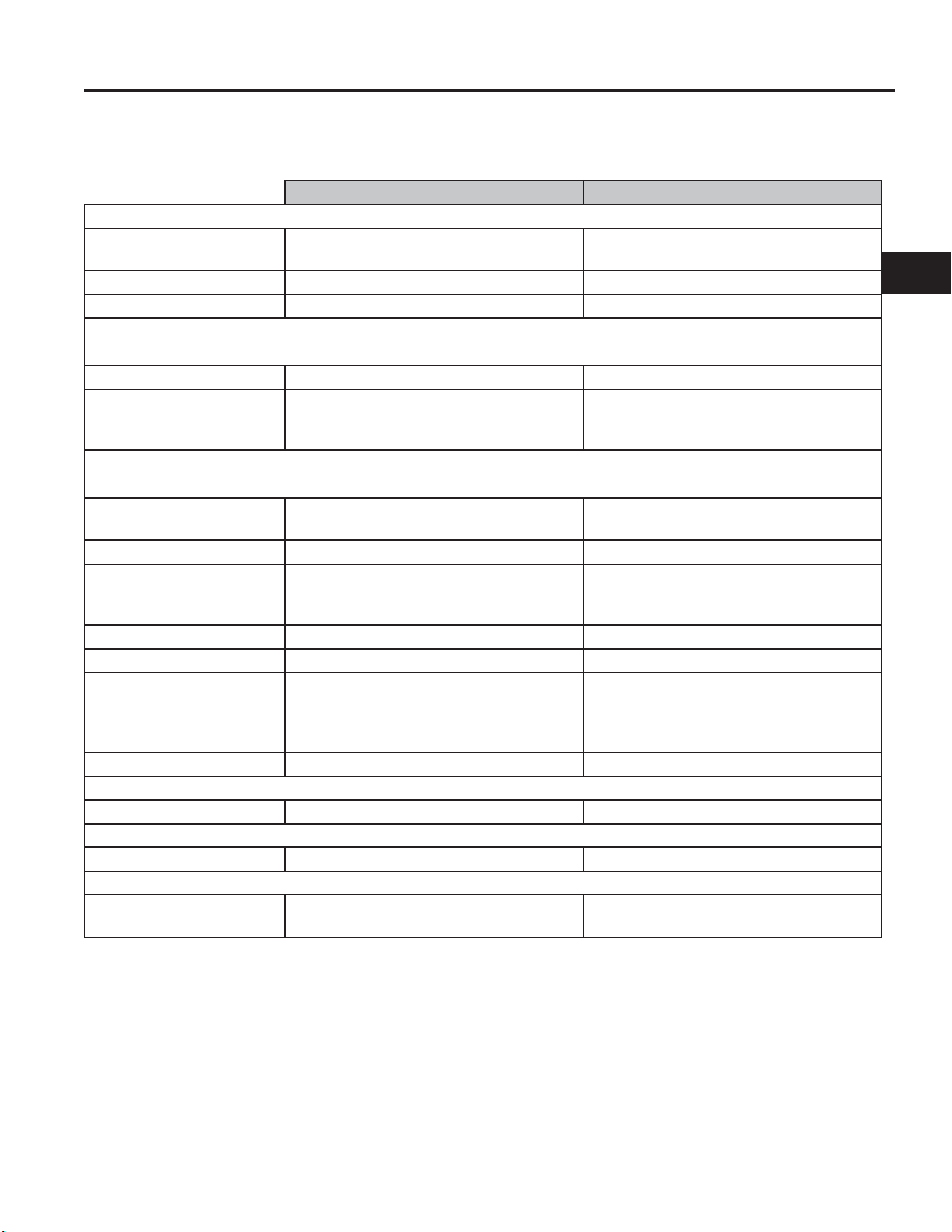

Specifications

ENGINE:

High Idle 3400 ± 100 RPM 3400 ± 100 RPM

Low Idle 1400 RPM 1400 RPM

1b

FUEL SYSTEM:

TRACTION SYSTEM:

Manufacturer Briggs & Stratton Kohler

Horsepower (kW) 16.5 HP (12.3kW) @ 3600 RPM 17 HP (12.7 kW) @ 3600 RPM

Capacity 5 Gallon (18.9 L) 5 Gallon (18.9 L)

Transaxles Twin Hydro-Gear IZT Hydrostatic

Transaxle Drive Belt drive with self-tensioning system Belt drive with self-tensioning system

Z16-44 Z17-44

Fuel Unleaded Gasoline 87 octane min. Unleaded Gasoline 87 octane min.

Twin Hydro-Gear IZT Hydrostatic

Transaxles

Transaxles

Ground Speed Infinite, 0 to 6.5 MPH (10.5-km/hr) forward

0 to 3.4 MPH (5.5-km/hr) reverse

TIRES:

Rear Drive Tires 18x10-8 4 ply with “Multitrac CS” Tread 18x10-8 4 ply with “Multitrac CS” Tread

Front Caster Tires 410/350 x 4 - 4.25 IS with “sawtooth” tread 410/350 x 4 - 4.25 IS with “sawtooth” tread

Tire Pressure 13 psi (90 kPa) rear, 35 psi (241 kPa) front 13 psi (90 kPa), rear 35 psi (241 kPa) front

ELECTRICAL

SYSTEM:

Battery Voltage 12 volt, negative ground 12 volt, negative ground

Battery Type BCI Group U1 BCI Group U1

DIMENSIONS:

Wheel Base 52.1 in. (132.3 cm) center of caster to

center of drive tires

Overall Width 55 in. (139.7 cm) with deck deflector down

46.6 in. (118.4 cm) gate width with deck

deflector up

Overall Length 77.5 in. (196.9 cm) 77.5 in. (196.9 cm)

WEIGHT:

Net Weight 635 lbs. (approx.) 635 lbs. (approx.)

Infinite, 0 to 6.5 MPH (10.5-km/hr) forward

0 to 3.4 MPH (5.5-km/hr) reverse

52.1 in. (132.3 cm) center of caster to

center of drive tires

55 in. (139.7 cm) with deck deflector down

46.6 in. (118.4 cm) gate width with deck

deflector up

HEIGHT OF CUT:

Adjusts from 1.5” (3.8 cm) to

4.5” (11.4 cm) (7 positions)

1 - 4 TimeCutter™ Z Service Manual

Adjusts from 1.5” (3.8 cm) to

4.5” (11.4 cm) (7 positions)

Page 9

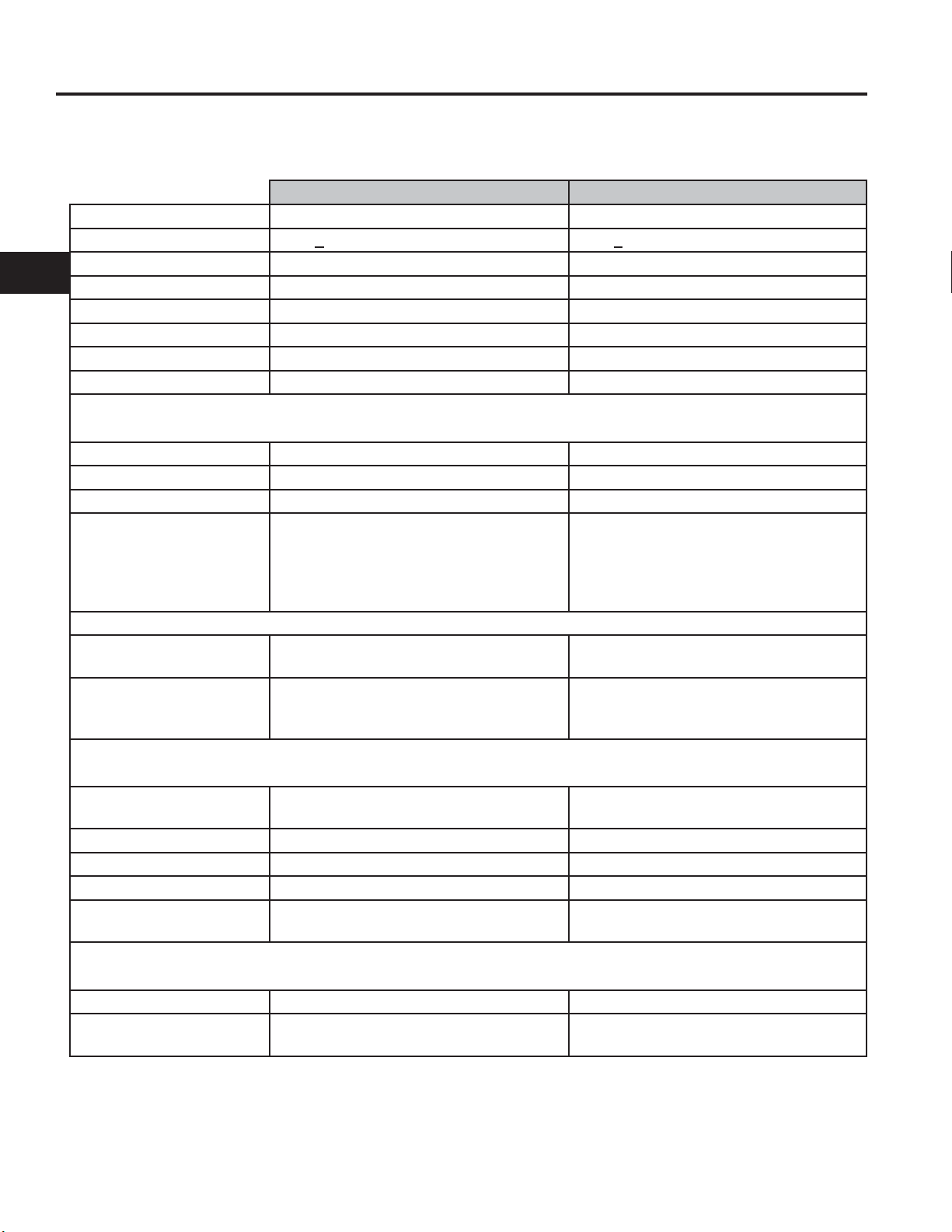

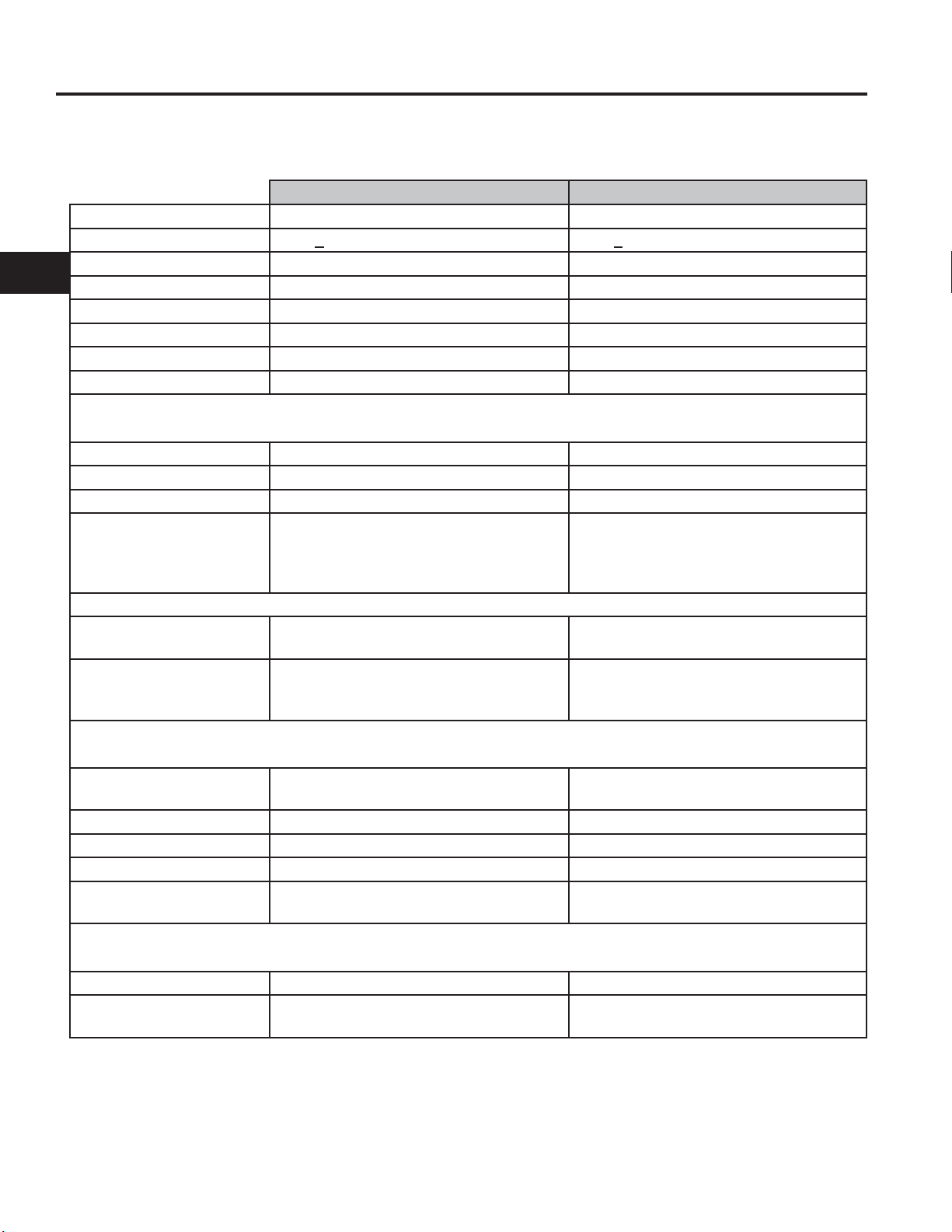

Specifications (cont’d)

ENGINE:

High Idle 3400 ± 100 RPM 3400 ± 100 RPM

Low Idle 1400 RPM 1400 RPM

Manufacturer Kohler Kawasaki

Horsepower (kW) 17 HP (12.7kW) @ 3600 RPM 18 HP (13.4kW) @ 3600 RPM

Fuel Unleaded Gasoline 87 octane min. Unleaded Gasoline 87 octane min.

FUEL SYSTEM:

Capacity 5 Gallon (18.9 L) 5 Gallon (18.9 L)

TRACTION SYSTEM:

Transaxles Twin Hydro-Gear IZT Hydrostatic

Transaxles

Transaxle Drive Belt drive with self-tensioning system Belt drive with self-tensioning system

SPECIFICATIONS

Z17-52 Z18-52

1b

Twin Hydro-Gear IZT Hydrostatic

Transaxles

Ground Speed Infinite, 0 to 6.5 MPH (10.5-km/hr) forward

TIRES:

Rear Drive Tires 18x10-10-10.5 4 ply with “Multitrac CS”

Front Caster Tires 410/350 x 4 - 4.25 IS with “sawtooth” tread 410/350 x 4 - 4.25 IS with “sawtooth” tread

Tire Pressure 13 psi (90 kPa) rear, 35 psi (241 kPa) front 13 psi (90 kPa) rear, 35 psi (241 kPa) front

ELECTRICAL SYSTEM:

Battery Voltage 12 volt, negative ground 12 volt, negative ground

Battery Type BCI Group U1 BCI Group U1

DIMENSIONS:

Wheel Base 52.1 in. (132.3 cm) center of caster to

Overall Width 65 in. (165.1 cm) with deck deflector down

Overall Length 77.5 in. (196.9 cm) 77.5 in. (196.9 cm)

WEIGHT:

Net Weight 680 lbs. (approx.) 680 lbs. (approx.)

0 to 3.4 MPH (5.5-km/hr) reverse

Tread

center of drive tires

58 in. (147.3 cm) gate width with deck

deflector up

Infinite, 0 to 6.5 MPH (10.5-km/hr) forward

0 to 3.4 MPH (5.5-km/hr) reverse

18x10-10-10.5 4 ply with “Multitrac CS”

Tread

52.1 in. (132.3 cm) center of caster to

center of drive tires

65 in. (165.1 cm) with deck deflector down

58 in. (147.3 cm) gate width with deck

deflector up

HEIGHT OF CUT:

Adjusts from 1.5” (3.8 cm) to 4.5” (11.4 cm)

(7 positions)

TimeCutter™ Z Service Manual 1 - 5

Adjusts from 1.5” (3.8 cm) to 4.5” (11.4 cm)

(7 positions)

Page 10

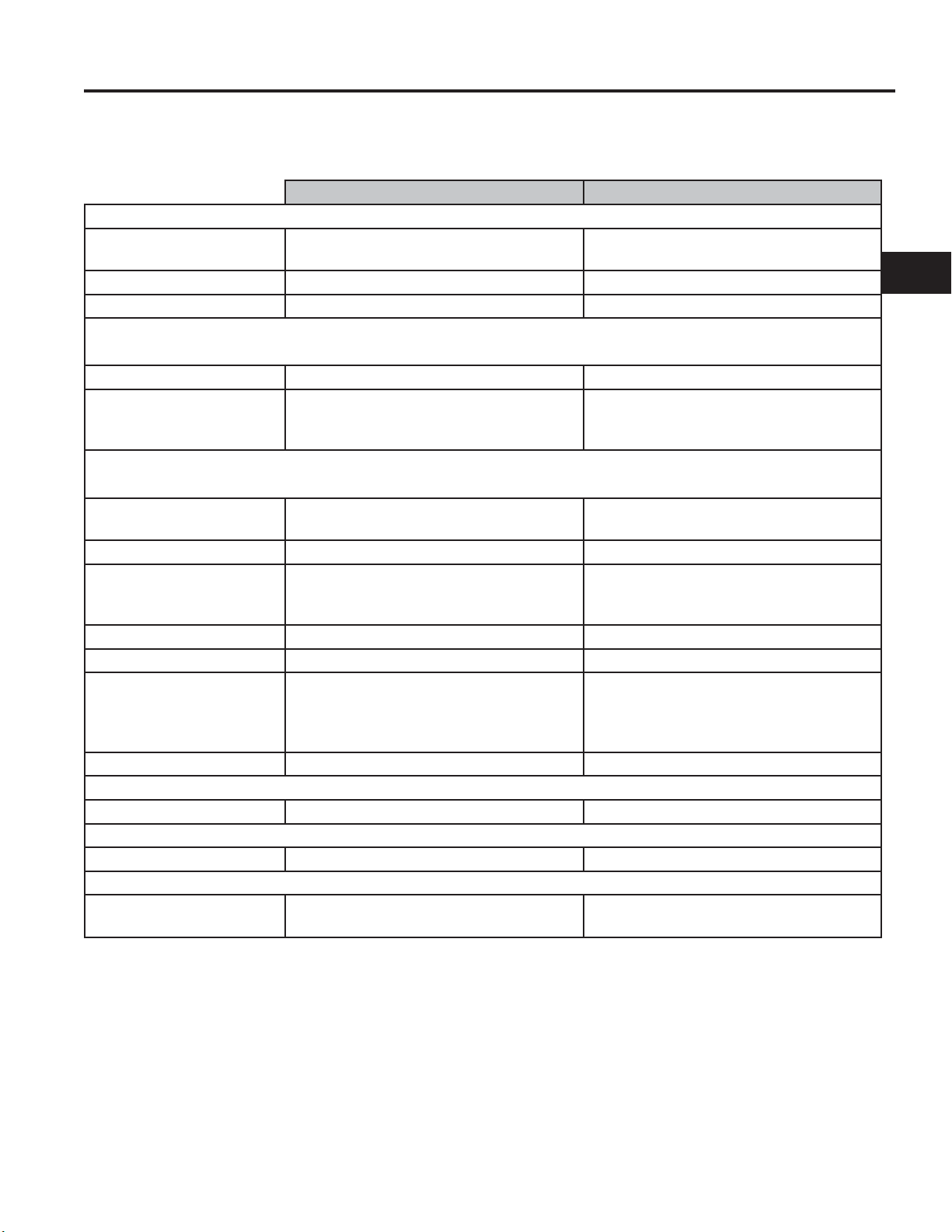

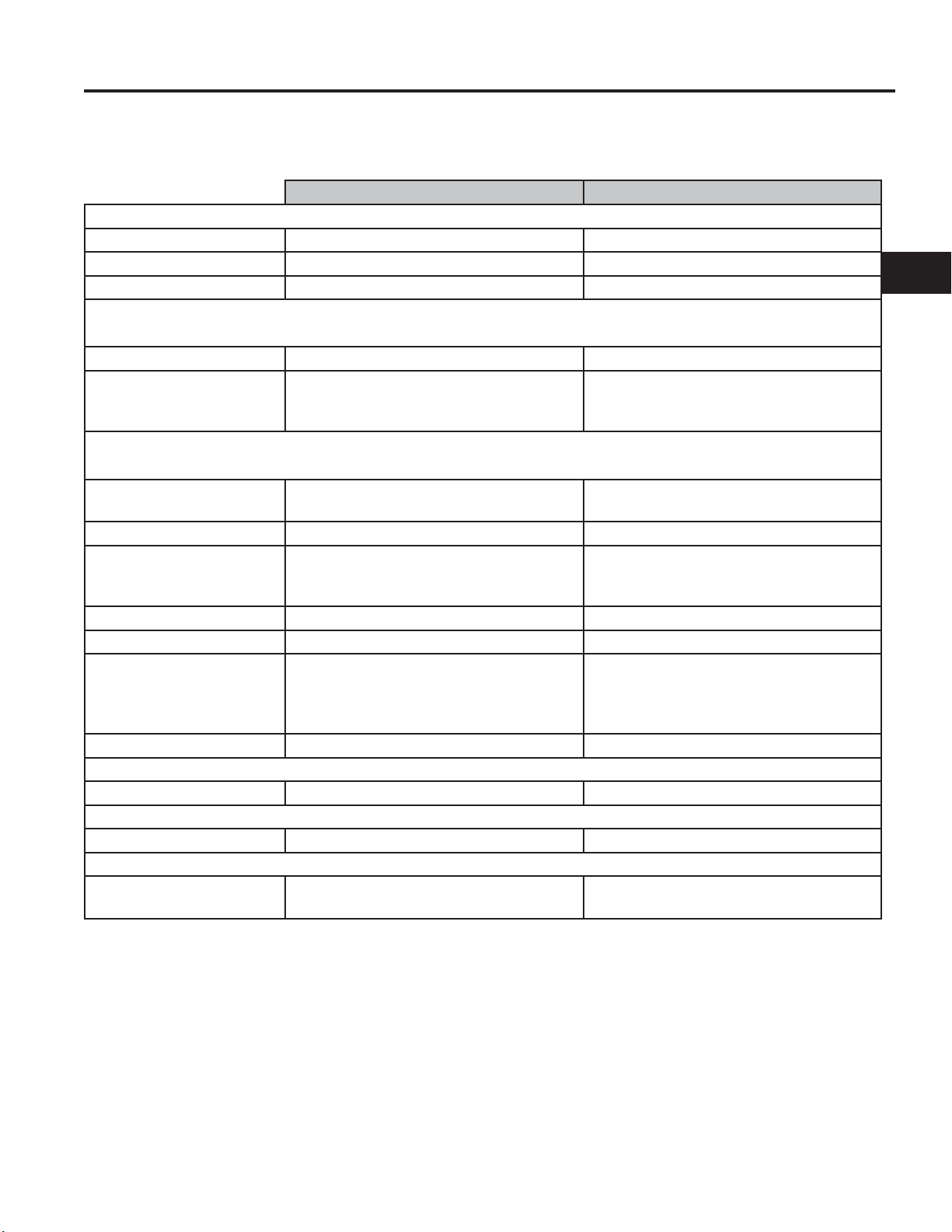

1b

SPECIFICATIONS

Specifi cations cont.

ZX 17K-44 ZX 17-44

Engine: 17 hp Kohler® OHV, CV490S 17 hp Briggs & Stratton OHV, 31F777

High Idle 3400 + 100 RPM 3400 + 100 RPM

Low Idle 1400 RPM N/A

Horse Power 17 (12.7kW) @3600 RPM 17 (12.7kW) @3600 RPM

Cubic Centimeter’s (cc’s) 490 Dispacement 500 Dispacement

Fuel Unleaded Gasoline 87 octane min. Unleaded Gasoline 87 octane min.

Oil Capacity 2 qts. (1.9 L) 1.75 qt. (1.7 L)

Charge coil 12v - 15 amp 12v - 16 amp

Construction:

Front Frame Welded 1x2x.120” structural steel tube Welded 1x2x.120” structural steel tube

Rear Frame Welded 7 & 10 ga. High strength steel Welded 7 & 10 ga. High strength steel

Frame Assembly Front & rear frames bolted together. Front & rear frames bolted together.

Deck Right side discharge, 44 in. cut, three

blade mid-mounted rotary. Drawn 13

gauge steel with welded mounting

brackets and gauge wheel brackets.

Frame supported.

Right side discharge, 44 in. cut, three

blade mid-mounted rotary. Drawn 13

gauge steel with welded mounting

brackets and gauge wheel brackets.

Frame supported.

Fuel System: Single fuel tank fender type mounted on

the left side.

Capacity 5 Gallons (18.9 L)

Fuel tank shut off

In-line fuel fi lter

Traction System:

Transaxles Twin Hydro-Gear IZT Hydrostatic

Transaxles

Transaxle Drive Belt Drive with self-tensioning system Belt Drive with self-tensioning system

Ground speed forward Infi nite, 0 to 6.5-MPH (10.5-km/hr) Infi nite, 0 to 6.5-MPH (10.5-km/hr)

Ground speed reverse 0 to 3.4-MPH (5.5-km/hr) 0 to 3.4-MPH (5.5-km/hr)

Transport rods Allows unit to be moved without engine

running.

Attachment Drive:

Clutch Electric Electric

Type Vertical Drive with Single Deep B-Groove

Pulley

Single fuel tank fender type mounted on

the left side.

5 Gallons (18.9 L)

Fuel tank shut off

In-line fuel fi lter

Twin Hydro-Gear IZT Hydrostatic

Transaxles

Allows unit to be moved without engine

running.

Vertical Drive with Single Deep B-Groove

Pulley

A1-6 TimeCutter ZX Service Manual

Page 11

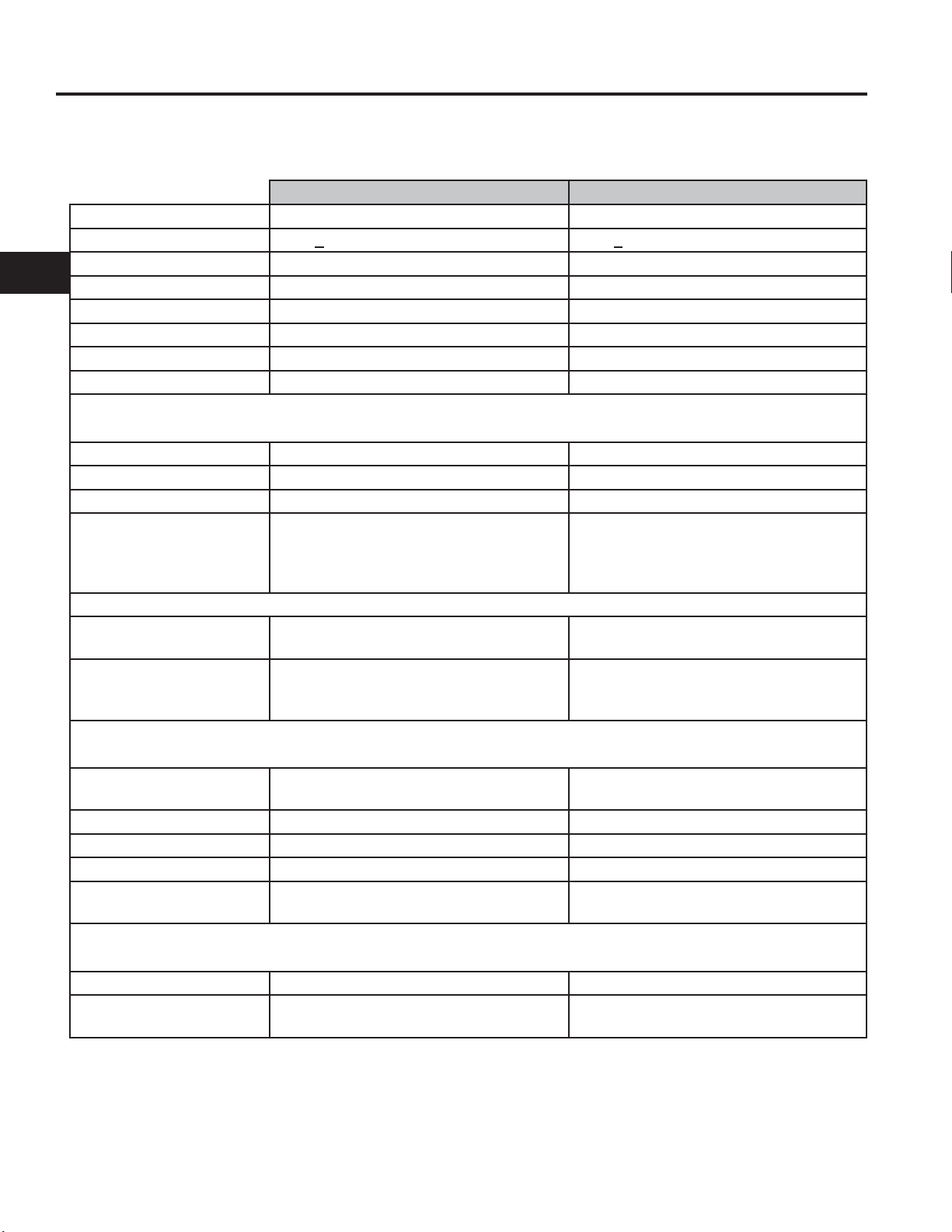

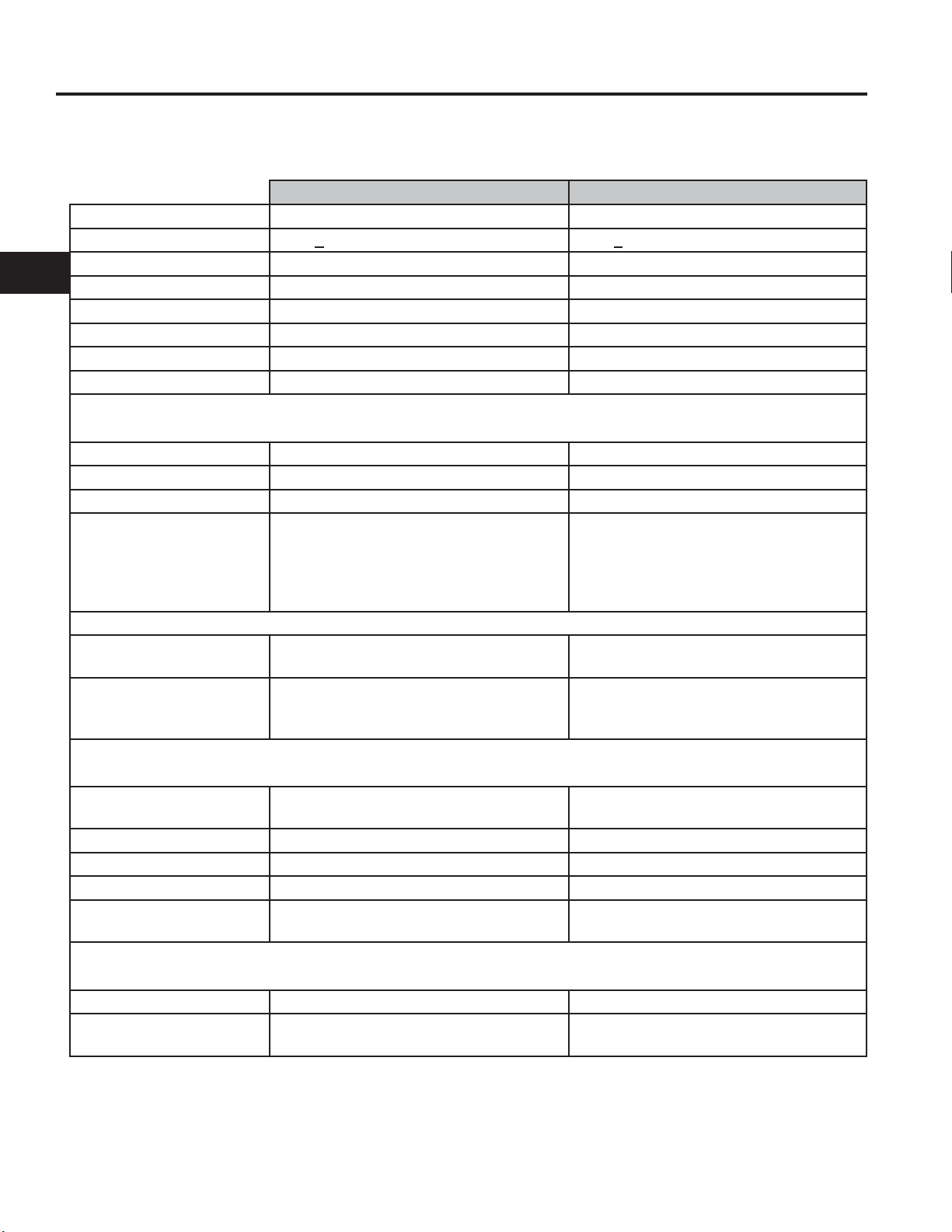

SPECIFICATIONS

Specifi cations cont.

ZX 17K-44 ZX 17-44

Tires:

Rear Drive Tires 18x10-8 4 ply with “Multitrac CS” Tread 18x10-8 4 ply with “Multitrac CS” Tread

Front Castor Tires 410/350x4 - 4.25 IS with “sawtooth” tread 410/350x4 - 4.25 IS with “sawtooth” tread

Tire Pressure 13 psi (90kPa) rear, 35 psi (241kPa) front 13 psi (90kPa) rear, 35 psi (241kPa) front

Electrical System:

Battery voltage 12 volt negative ground. 12 volt negative ground.

Fused (1) 30 amp blade type main.

(1) 25 amp blade type charge system.

(1) 10 amp included with optional light kit.

Dimensions:

Wheel Base 52.1” (132.3cm) center of castor wheel to

center of drive tires.

Width 43” (109.2cm) outside rear tires. 43” (109.2cm) outside rear tires.

Overall Width 55” (139.7cm) with deck defl ector down.

46.6” (188.4cm) Gate width with deck

defl ector up.

Overall Length 77.5” (196.9cm) 77.5” (196.9cm)

Overall Height 40” (101.6cm) 40” (101.6cm)

Track Width 35.2” (89.4cm) center to center of rear

tires.

30.4” (77.2cm) center to center of castor

tires.

Deck Width 55” (139.7cm) with defl ector down. 55” (139.7cm) with defl ector down.

(1) 30 amp blade type main.

(1) 25 amp blade type charge system.

(1) 10 amp included with optional light kit.

52.1” (132.3cm) center of castor wheel to

center of drive tires.

55” (139.7cm) with deck defl ector down.

46.6” (188.4cm) Gate width with deck

defl ector up.

35.2” (89.4cm) center to center of rear

tires.

30.4” (77.2cm) center to center of castor

tires.

1b

Weight: 635 lbs. (288kg) (estimated) 635 lbs. (288kg) (estimated)

Height of Cut: Adjusts from 1.5” to 4.5” (7 postions) Adjusts from 1.5” to 4.5” (7 postions)

Tip Speed: 18,160 ft/min @ 3400 RPM nominal

18,770 ft/min @ 3500 RPM max

18,160 ft/min @ 3400 RPM nominal

18,770 ft/min @ 3500 RPM max

A1-7TimeCutter ZX Service Manual

Page 12

1b

SPECIFICATIONS

Specifi cations cont.

ZX 17-52 ZX 18-52

Engine: 17 hp Kohler® OHV, CV490S 18 hp Kawasaki OHV, FH531V

High Idle 3400 + 100 RPM 3400 + 100 RPM

Low Idle 1400 RPM 1400 RPM

Horse Power 17 (12.7kW) @3600 RPM 18 HP (13.4kW) @3600 RPM

Cubic Centimeter’s (cc’s) 490 Dispacement 494 Displacement

Fuel Unleaded Gasoline 87 octane min. Unleaded Gasoline 87 octane min.

Oil Capacity 2 qts. (1.9 L) 1.9 qts (1.8 L)

Charge coil 12v - 15 amp 12v - 13 amp

Construction:

Front Frame Welded 1x2x.120” structural steel tube Welded 1x2x.120” structural steel tube

Rear Frame Welded 7 & 10 ga. High strength steel Welded 7 & 10 ga. High strength steel

Frame Assembly Front & rear frames bolted together. Front & rear frames bolted together.

Deck Right side discharge, 52 in. cut, three

blade mid-mounted rotary. Drawn 12

gauge steel with welded mounting

brackets and gauge wheel brackets.

Frame supported.

Right side discharge, 52 in. cut, three

blade mid-mounted rotary. Drawn 12

gauge steel with welded mounting

brackets and gauge wheel brackets.

Frame supported.

Fuel System: Single fuel tank fender type mounted on

the left side.

Capacity 5 Gallons (18.9 L)

Fuel tank shut off

In-line fuel fi lter

Traction System:

Transaxles Twin Hydro-Gear IZT Hydrostatic

Transaxles

Transaxle Drive Belt Drive with self-tensioning system Belt Drive with self-tensioning system

Ground speed forward Infi nite, 0 to 6.5-MPH (10.5-km/hr) Infi nite, 0 to 6.5-MPH (10.5-km/hr)

Ground speed reverse 0 to 3.4-MPH (5.5-km/hr) 0 to 3.4-MPH (5.5-km/hr)

Transport rods Allows unit to be moved without engine

running.

Attachment Drive:

Clutch Electric Electric

Type Vertical Drive with Single Deep B-Groove

Pulley

Single fuel tank fender type mounted on

the left side.

5 Gallons (18.9 L)

Fuel tank shut off

In-line fuel fi lter

Twin Hydro-Gear IZT Hydrostatic

Transaxles

Allows unit to be moved without engine

running.

Vertical Drive with Single Deep B-Groove

Pulley

A1-8 TimeCutter ZX Service Manual

Page 13

SPECIFICATIONS

Specifi cations cont.

ZX 17-52 ZX 18-52

Tires:

Rear Drive Tires 18x10-8 4 ply with “Multitrac CS” Tread 18x10-10.5 4 ply with “Multitrac CS”

Tread

Front Castor Tires 410/350x4 - 4.25 IS with “sawtooth” tread 410/350x4 - 4.25 IS with “sawtooth” tread

Tire Pressure 13 psi (90kPa) rear, 35 psi (241kPa) front 13 psi (90kPa) rear, 35 psi (241kPa) front

Electrical System:

Battery voltage 12 volt negative ground. 12 volt negative ground.

Fused (1) 30 amp blade type main.

(1) 25 amp blade type charge system.

(1) 10 amp included with optional light kit.

Dimensions:

Wheel Base 52.1” (132.3cm) center of castor wheel to

center of drive tires.

Width 47.6” (120.9cm) outside rear tires. 47.6” (120.9cm) outside rear tires.

Overall Width 65” (165.1cm) with deck defl ector down.

58” (147.3cm) Gate width with deck

defl ector up.

Overall Length 77.5” (196.9cm) 77.5” (196.9cm)

Overall Height 41” (104.1cm) 41” (104.1cm)

Track Width 37.5” (95.3cm) center to center of rear

tires.

30.4” (77.2cm) center to center of castor

tires.

Deck Width 65” (165.1cm) with deck defl ector down. 65” (165.1cm) with defl ector down.

(1) 30 amp blade type main.

(1) 25 amp blade type charge system.

(1) 10 amp included with optional light kit.

52.1” (132.3cm) center of castor wheel to

center of drive tires.

65” (165.1cm) with deck defl ector down.

58” (147.3cm) Gate width with deck

defl ector up.

37.5” (95.3cm) center to center of rear

tires.

30.4” (77.2cm) center to center of castor

tires.

1b

Weight: 680 lbs. (308.4kg) (estimated) 680 lbs. (308.4kg) (estimated)

Height of Cut: Adjusts from 1.5” to 4.5” (7 postions) Adjusts from 1.5” to 4.5” (7 postions)

Tip Speed: 17,410 ft/min @ 3400 RPM nominal

17,980 ft/min @ 3400 RPM max

17,410 ft/min @ 3400 RPM nominal

17,980 ft/min @ 3500 RPM max

A1-9TimeCutter ZX Service Manual

Page 14

1b

SPECIFICATIONS

Specifi cations cont.

ZX 18-52 ZX 19-52

Engine: 18 hp Kohler® CV4925 19 hp Kawasaki OHV, FH580V

High Idle 3400 + 100 RPM 3400 + 100 RPM

Low Idle 1400 RPM 1400 RPM

Horse Power 18 (13.4kW) @3600 RPM 19 HP (14.2kW) @3600 RPM

Cubic Centimeter’s (cc’s) 490 Displacement 585 Displacement

Fuel Unleaded Gasoline 87 octane min. Unleaded Gasoline 87 octane min.

Oil Capacity 2 qts. (1.9 L) 1.9 qts. (1.8 L)

Charge coil 12v - 15 amp 12v - 15 amp

Construction:

Front Frame Welded 1x2x.120” structural steel tube Welded 1x2x.120” structural steel tube

Rear Frame Welded 7 & 10 ga. High strength steel Welded 7 & 10 ga. High strength steel

Frame Assembly Front & rear frames bolted together. Front & rear frames bolted together.

Deck Right side discharge, 52” cut, three blade

mid-mounted rotary. Drawn 12 gauge

steel with welded mounting brackets and

gauge wheel brackets. Frame supported.

Right side discharge, 52” cut, three blade

mid-mounted rotary. Drawn 12 gauge

steel with welded mounting brackets and

gauge wheel brackets. Frame supported.

Fuel System: Single fuel tank fender type mounted on

the left side.

Capacity 5 Gallons (18.9 L)

Fuel tank shut off

In-line fuel fi lter

Traction System:

Transaxles Twin Hydro-Gear IZT Hydrostatic

Transaxles

Transaxle Drive Belt Drive with self-tensioning system Belt Drive with self-tensioning system

Ground speed forward Infi nite, 0 to 6.5-MPH (10.5-km/hr) Infi nite, 0 to 6.5-MPH (10.5-km/hr)

Ground speed reverse 0 to 3.4-MPH (5.5-km/hr) 0 to 3.4-MPH (5.5-km/hr)

Transport rods Allows unit to be moved without engine

running.

Attachment Drive:

Clutch Electric Electric

Type Vertical Drive with Single Deep B-Groove

Pulley

Single fuel tank fender type mounted on

the left side.

5 Gallons (18.9 L)

Fuel tank shut off

In-line fuel fi lter

Twin Hydro-Gear IZT Hydrostatic

Transaxles

Allows unit to be moved without engine

running.

Vertical Drive with Single Deep B-Groove

Pulley

A1-10 TimeCutter ZX Service Manual

Page 15

SPECIFICATIONS

Specifi cations cont.

ZX 18-52 ZX 19-52

Tires:

Rear Drive Tires 18x10.5-10 4 ply with “Multitrac CS”

Tread

Front Castor Tires 410/350x4 with “sawtooth” tread 410/350x4 with “sawtooth” tread

Tire Pressure 13 psi (90kPa) rear, 35 psi (241kPa) front 13 psi (90kPa) rear, 35 psi (241kPa) front

Electrical System:

Battery voltage 12 volt negative ground. 12 volt negative ground.

Fused (1) 30 amp blade type main.

(1) 25 amp blade type charge system.

(1) 10 amp included with optional light kit.

Dimensions:

Wheel Base 52.1” (132.3cm) center of castor wheel to

center of drive tires.

Width 47.6” (120.9cm) outside rear tires. 47.6” (120.9cm) outside rear tires.

Overall Width 65” (165.1cm) with deck defl ector down.

58” (147.3cm) Gate width with deck

defl ector up.

Overall Length 77.5” (196.9cm) 77.5” (196.9cm)

Overall Height 41” (104.1cm) 41” (104.1cm)

Track Width 37.5” (95.3cm) center to center of rear

tires.

30.4” (77.2cm) center to center of castor

tires.

Deck Width 65” (165.1cm) with defl ector down. 66” (165.1cm) with defl ector down.

18x10.5-10 4 ply with “Multitrac CS”

Tread

(1) 30 amp blade type main.

(1) 25 amp blade type charge system.

(1) 10 amp included with optional light kit.

52.1” (132.3cm) center of castor wheel to

center of drive tires.

65” (165.1cm) with deck defl ector down.

58” (147.3cm) Gate width with deck

defl ector up.

37.5” (95.3cm) center to center of rear

tires.

30.4” (77.2cm) center to center of castor

tires.

1b

Weight: 680 lbs. (308.4kg) (estimated) 680 lbs. (308.4kg) (estimated)

Height of Cut: Adjusts from 1.5” to 4.5” (7 postions) Adjusts from 1.5” to 4.5” (7 postions)

Tip Speed: 17,500 ft/min @ 3400 RPM nominal

18,070 ft/min @ 3500 RPM max

17,500 ft/min @ 3400 RPM nominal

18,070 ft/min @ 3500 RPM max

A1-11TimeCutter ZX Service Manual

Page 16

1b

SPECIFICATIONS

Specifi cations cont.

ZX 18-44 ZX 440

Engine: 18 hp Briggs & Stratton OHV, 31M777 18 hp Kohler® OHV, CV492S

High Idle 3400 + 100 RPM 3400 + 50/- 0 RPM

Low Idle 1400 RPM 1400 RPM

Horse Power 18 (13.4kW) @3600 RPM 10 HP (13.4kW) @ 3600 RPM

Cubic Centimeter’s (cc’s) 500 Displacement 490 Displacement

Fuel Unleaded Gasoline 87 octane min. Unleaded Gasoline 87 octane min.

Oil Capacity 1.75 qts. (1.7 L) 2 qts. (1.9 L)

Charge coil 12v - 16 amp 12v - 15 amp

Construction:

Front Frame Welded 1x2x.120” structural steel tube Welded 1x2x.120” structural steel tube

Rear Frame Welded 7 & 10 ga. High strength steel Welded 7 & 10 ga. High strength steel

Frame Assembly Front & rear frames bolted together. Front & rear frames bolted together.

Deck Right side discharge, 44” cut, three blade

mid-mounted rotary. Drawn 13 gauge

steel with welded mounting brackets and

gauge wheel brackets. Frame supported.

Right side discharge, 44” cut, three blade

mid-mounted rotary. Drawn 13 gauge

steel with welded mounting brackets and

gauge wheel brackets. Frame supported.

Fuel System: Single fuel tank fender type mounted on

the left side.

Capacity 5 Gallons (18.9 L)

Fuel tank shut off

In-line fuel fi lter

Traction System:

Transaxles Twin Hydro-Gear IZT Hydrostatic

Transaxles

Transaxle Drive Belt Drive with self-tensioning system Belt Drive with self-tensioning system

Ground speed forward Infi nite, 0 to 6.5-MPH (10.5-km/hr) Infi nite, 0 to 7.0-MPH (11.3-km/hr)

Ground speed reverse 0 to 3.4-MPH (5.5-km/hr) 0 to 3.4-MPH (5.5-km/hr)

Transport rods Allows unit to be moved without engine

running.

Attachment Drive:

Clutch Electric Electric

Type Vertical Drive with Single Deep B-Groove

Pulley

Single fuel tank fender type mounted on

the left side.

5 Gallons (18.9 L)

Fuel tank shut off

In-line fuel fi lter

Twin Hydro-Gear IZT Hydrostatic Transaxles with charge pumps & shock valves

Allows unit to be moved without engine

running.

Vertical Drive with Single Deep B-Groove

Pulley

A1-12 TimeCutter ZX Service Manual

Page 17

SPECIFICATIONS

Specifi cations cont.

ZX 18-44 ZX 440

Tires:

Rear Drive Tires 18x7.5-8 ply with “Multitrac CS” Tread 18x7.5-4 ply

Front Castor Tires 410/350x4 with “sawtooth” tread 410/350x4 “sawtooth” tread

Tire Pressure 13 psi (90kPa) rear, 35 psi (241kPa) front 13 psi (90kPa) rear, 35 psi (241kPa) front

Electrical System:

Battery voltage 12 volt negative ground. 12 volt negative ground.

Fused (1) 30 amp blade type main.

(1) 25 amp blade type charge system.

(1) 10 amp included with optional light kit.

Dimensions:

Wheel Base 52.1” (132.3cm) center of castor wheel to

center of drive tires.

Width 43” (109.2cm) outside rear tires. 43” (109.2cm) outside rear tires.

Overall Width 55” (139.7cm) with deck defl ector down.

46.6” (188.4cm) Gate width with deck

defl ector up.

Overall Length 77.5” (196.9cm) 77.5” (196.9cm)

Overall Height 40” (101.6cm) 40” (101.6cm)

Track Width 35.2” (89.4cm) center to center of rear

tires.

30.4” (77.2cm) center to center of castor

tires.

Deck Width 55” (139.7cm) with defl ector down. 60” (139.7cm) with deck defl ector down

(1) 30 amp blade type main.

(1) 25 amp blade type charge system.

(1) 10 amp included with optional light kit.

52.1” (132.3cm) center of castor wheel to

center of drive tires.

60” (139.7cm) with deck defl ector down

49” (118.4cm) Gate width with deck

defl ector up.

35.2” (89.4cm) center to center of rear

tires.

30.4” (77.2cm) center to center of castor

tires.

1b

Weight: 635 lbs. (288 kg) (estimated) 651 lbs. (295 kg) (estimated)

Height of Cut: Adjusts from 1.5” to 4.5” (7 postions) Adjusts from 1.5” to 4.5” (7 postions)

Tip Speed: 18,160 ft/min @ 3400 RPM nominal

18,770 ft/min @ 3500 RPM max

18,160 ft/min @ 3400 RPM nominal

18,770 ft/min @ 3500 RPM max

A1-13TimeCutter ZX Service Manual

Page 18

1b

SPECIFICATIONS

Specifi cations cont.

ZX 480 ZX 525

Engine: Briggs & Stratton Intek OHV, 441577 Kawasaki FH58V OHV

High Idle 3400 + 100 RPM 3400 + 100 RPM

Low Idle N/A 1400 RPM

Horse Power N/A N/A

Cubic Centimeter’s (cc’s) 725 Dispacement 585 Dispacement

Fuel Unleaded Gasoline 87 octane min. Unleaded Gasoline 87 octane min.

Oil Capacity 2 qts. (1.9 L) 1.9 qts. (1.8 L)

Charge coil 12v - 16 amp 12v - 13 amp

Construction:

Front Frame Welded 1x2x.120” structural steel tube Welded 1x2x.120” structural steel tube

Rear Frame Welded 7 & 10 ga. High strength steel Welded 7 & 10 ga. High strength steel

Frame Assembly Front & rear frames bolted together. Front & rear frames bolted together.

Deck Right side discharge, 48” cut, three

blade mid-mounted rotary. Drawn 12

gauge steel deck with gauge reinforced

plate and welded mounting brackets and

gauge.

Right side discharge, 44” cut, three blade

mid-mounted rotary. Drawn 12 gauge

steel with welded mounting brackets and

gauge wheel brackets. Frame supported.

Fuel System: Single fuel tank fender type mounted on

the left side.

Capacity 5 Gallons (18.9 L)

Fuel tank shut off

In-line fuel fi lter

Traction System:

Transaxles Twin Hydro-Gear IZT Hydrostatic Trans-

axles with charge pumps & shock valves.

Transaxle Drive Belt Drive with self-tensioning system Belt Drive with self-tensioning system

Ground speed forward Infi nite, 0 to 7.0-MPH (11.3-km/hr) Infi nite, 0 to 7.0-MPH (11.3-km/hr)

Ground speed reverse 0 to 3.4-MPH (5.5-km/hr) 0 to 3.4-MPH (5.5-km/hr)

Transport rods Allows unit to be moved without engine

running.

Attachment Drive:

Clutch Electric Electric

Type Vertical Drive with Single Deep B-Groove

Pulley

Single fuel tank fender type mounted on

the left side.

5 Gallons (18.9 L)

Fuel tank shut off

In-line fuel fi lter

Twin Hydro-Gear IZT Hydrostatic Transaxles with charge pumps & shock valves.

Allows unit to be moved without engine

running.

Vertical Drive with Single Deep B-Groove

Pulley

A1-14 TimeCutter ZX Service Manual

Page 19

SPECIFICATIONS

Specifi cations cont.

ZX 480 ZX 525

Tires:

Rear Drive Tires 18x10.5-4 ply 18x10.5-10 4 ply with “Multitrac CS”

Tread

Front Castor Tires 410/350x4 with “sawtooth” tread 410/350x4 with “sawtooth” tread

Tire Pressure 13 psi (90kPa) rear, 35 psi (241kPa) front 13 psi (90kPa) rear, 35 psi (241kPa) front

Electrical System:

Battery voltage 12 volt negative ground. 12 volt negative ground.

Fused (1) 30 amp blade type main.

(1) 25 amp blade type charge system.

(1) 25 amp blade type charge system.

Dimensions:

Wheel Base 52.1” (132.3cm) center of castor wheel to

center of drive tires.

Width 43” (109.2cm) outside rear tires. 47.6” (120.9cm) outside rear tires.

Overall Width 62.5” (158.8cm) with deck defl ector

down.

53.5” (135.9cm) Gate width with deck

defl ector up.

Overall Length 77.5” (196.9cm) 77.5” (196.9cm)

Overall Height 40” (101.6cm) 41” (101.6cm)

Track Width 35.2” (89.4cm) center to center of rear

tires.

30.4” (77.2cm) center to center of castor

tires.

Deck Width 62.5” (158.8cm) with defl ector down. 68” (165.1cm) with defl ector down.

(1) 30 amp blade type main.

(1) 25 amp blade type charge system.

(1) 10 amp (blade type) included with

optional light kit.

52.1” (132.3cm) center of castor wheel to

center of drive tires.

68” (165.1cm) with deck defl ector down.

55” (147.3cm) Gate width with deck

defl ector up.

37.5in. (95.3cm) center to center of rear

tires.

30.4” (77.2cm) center to center of castor

tires.

1b

Weight: 646 lbs. (293 kg) (estimated) 695 lbs. (315 kg) (estimated)

Height of Cut: Adjusts from 1.5” to 4.5” (7 postions) Adjusts from 1.5” to 4.5” (7 postions)

Tip Speed: 15,710 ft/min @ 3400 RPM nominal

16,170 ft/min @ 3400 RPM nominal

17,500 ft/min @ 3400 RPM nominal

18,070 ft/min @ 3500 RPM max

A1-15TimeCutter ZX Service Manual

Page 20

SPECIFICATIONS

Bolt Torques

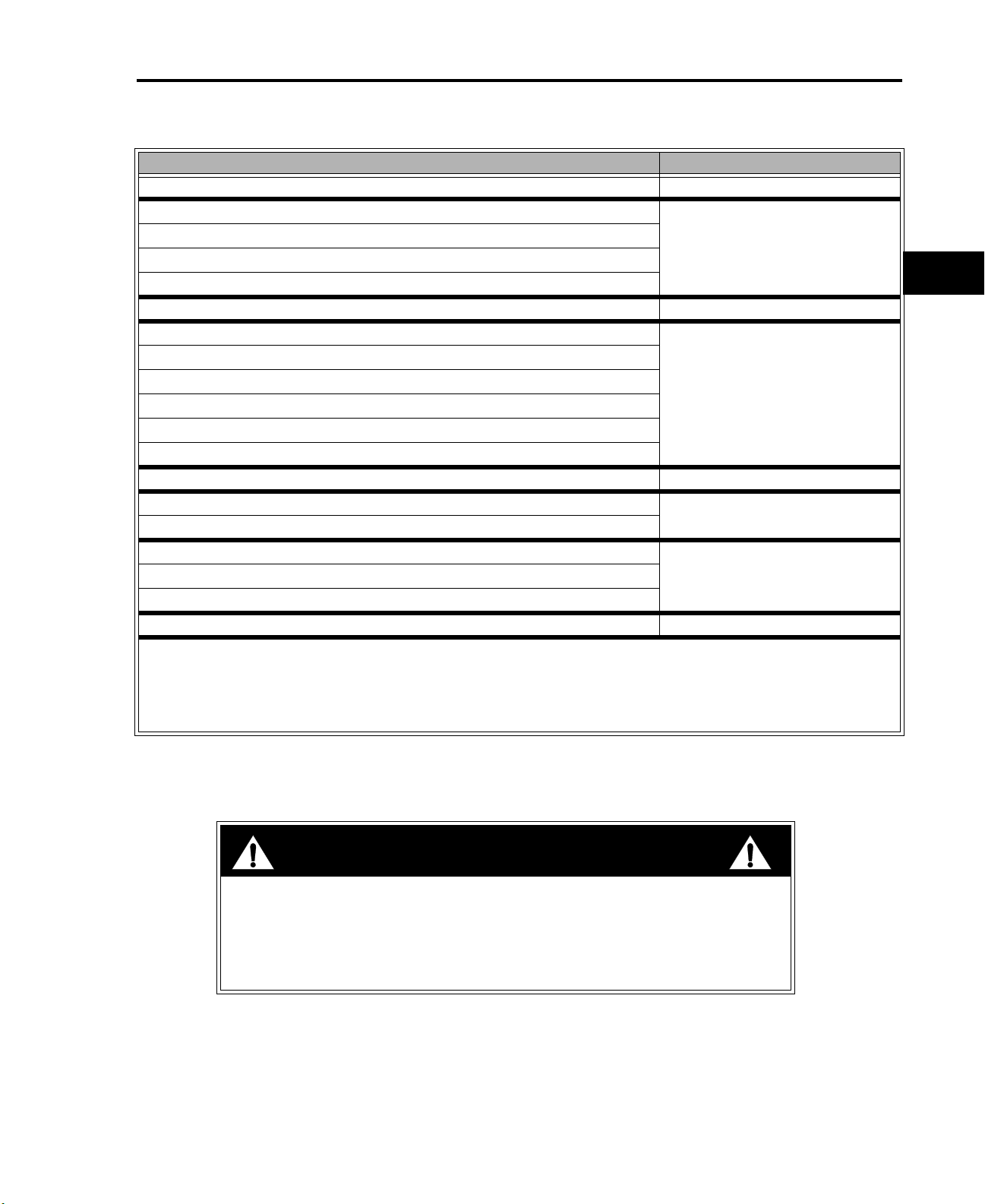

Description Torque - 52” Torque - 44”

Blade to Spindle 80 - 100 ft·lb (109 - 136 N·m) 40 - 60 ft·lb (54 - 82 N·m)

Caster Bolts 77 - 95 ft·lb (105 - 130 N·m) 77 - 95 ft·lb (105 - 130 N·m)

Clutch Bolt 50 - 60 ft·lb (68 - 82 N·m) 50 - 60 ft·lb (68 - 82 N·m)

1b

Engine Mounting Bolts 120 - 180 ft·lb (164 - 246 N·m) 120 - 180 ft·lb (164 - 246 N·m)

Spindle Pulley Nuts 80 - 100 ft·lb (109 - 136 N·m) 50 - 75 ft·lb (68 - 102 N·m)

Wheel Lug Nuts 70 - 90 ft·lb (95.5 - 123 N·m) 70 - 90 ft·lb (95.5 - 123 N·m)

1 - 6 TimeCutter™ Z Service Manual

Page 21

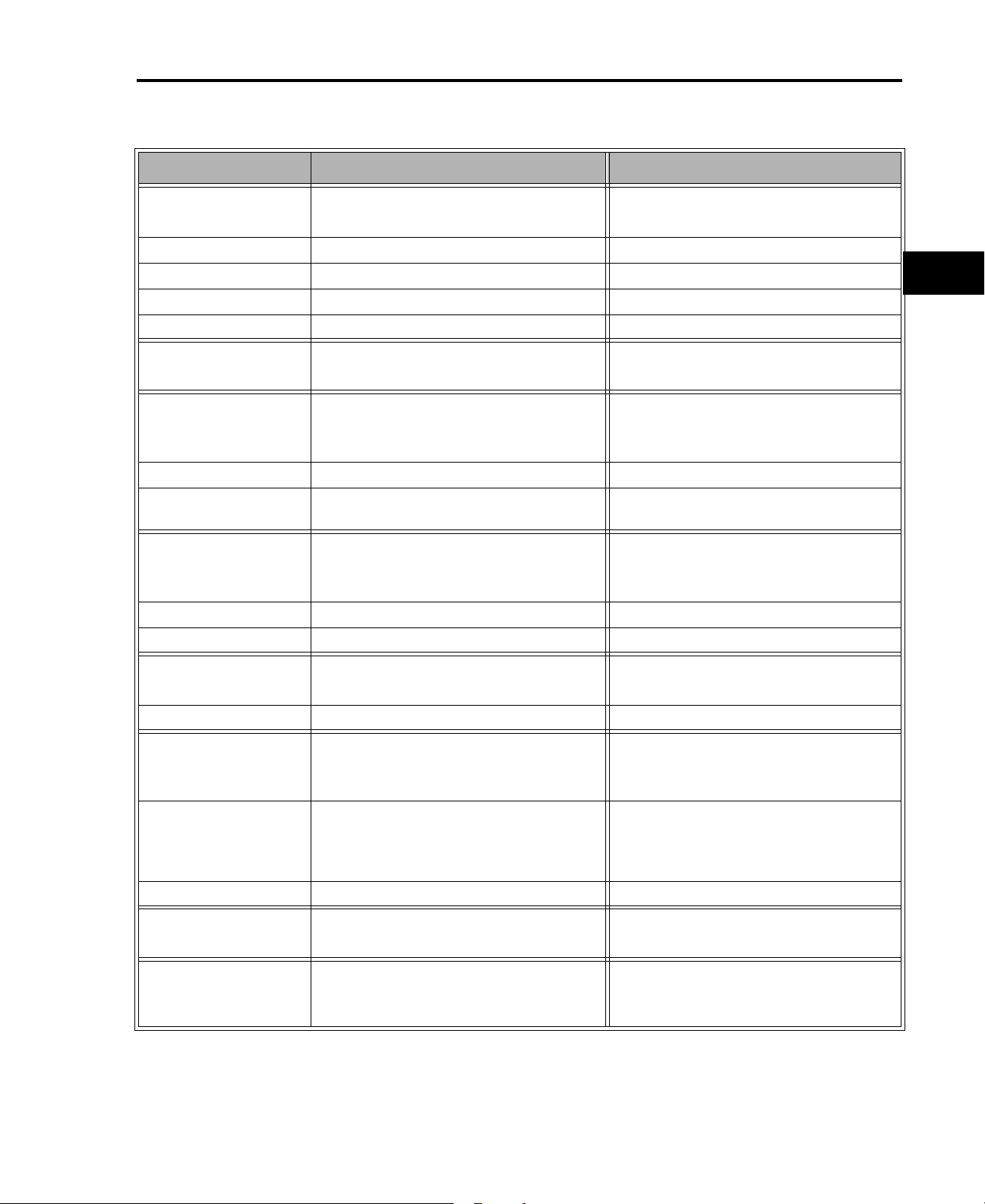

MAINTENANCE

Maintenance Schedule (Z16-44)

Maintenance Procedure Service Interval

Change the engine oil After first use

Check the engine oil level

Each useCheck the safety system

Clean the mower housing

Check the cutting blades Every 5 hours

Grease all lubrication points

Oil the linkage bushings

Service the foam air cleaner

Check the belts for wear/cracks

Check the battery electrolyte

Check the tire pressure

Change the engine oil

Clean the cooling system

Service the paper air cleaner

Change the oil filter

Replace the fuel filter

Replace the spark plug(s)

Before Storage:

• Perform all maintenance procedures listed above.

• Drain the fuel tank.

• Charge the battery and disconnect the battery cables.

• Paint any chipped surfaces.

2

1

1

1

Every 25 hours

2

1

1

Every 50 hours

Every 100 hours

1c

1

More often in dusty, dirty conditions

2

More often when operating the engine under heavy load or in high temperatures

IMPORTANT: Refer to your engine operator’s manual for additional maintenance procedures.

CAUTION

If you leave the key in the ignition switch, someone could accidently start the

engine and seriously injury you or other bystanders.

Remove the key from the ignition and disconnect the wire from the spark

plug(s) before you do any maintenance. Set the wire aside so that it does not

accidentally contact the spark plug.

TimeCutter™ Z Service Manual 1 - 7

Page 22

MAINTENANCE

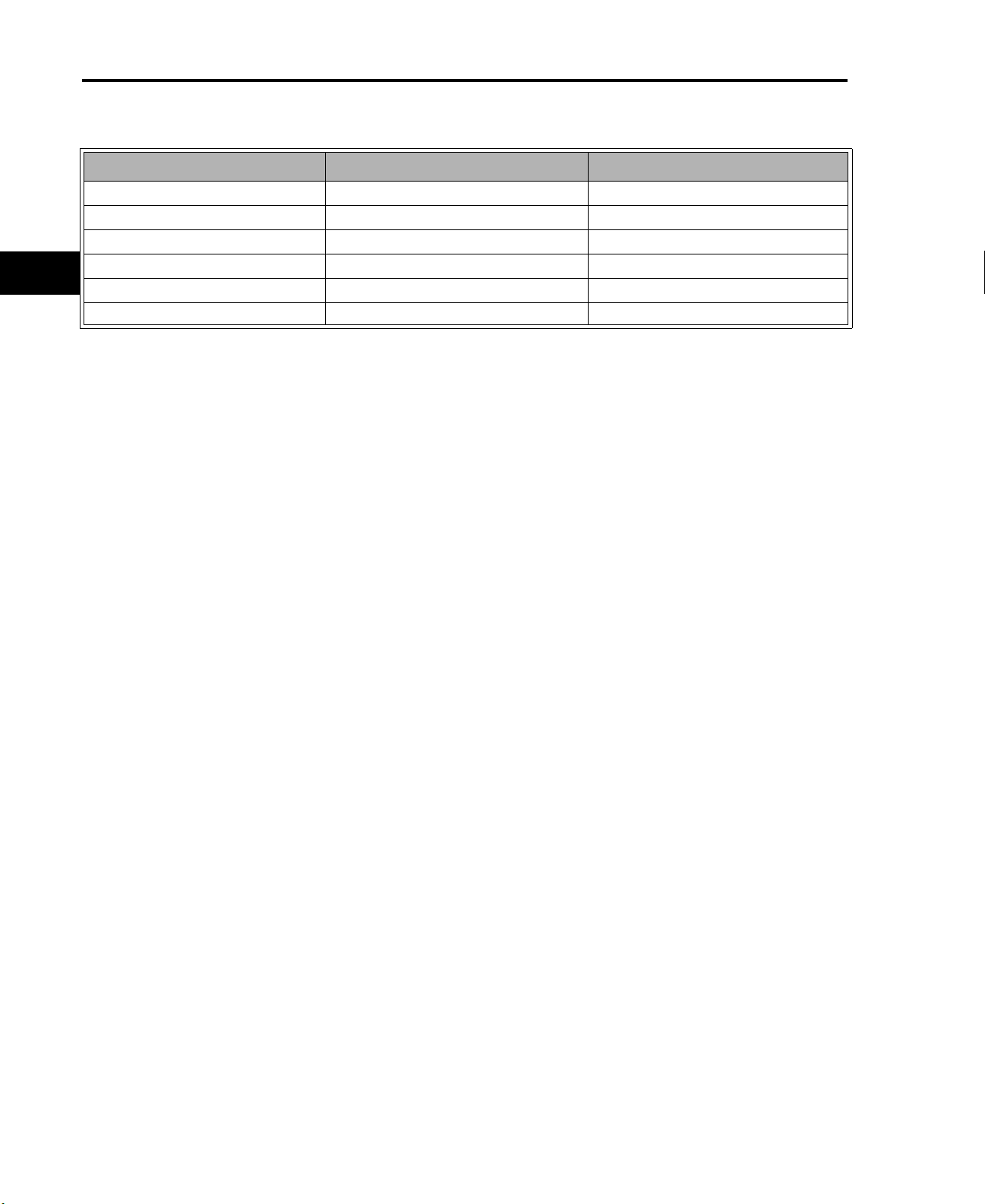

Maintenance Schedule (Z17-44 & Z17-52)

Maintenance Procedure Service Interval

Check the engine oil level

Check the safety system

1

1

1

1

1

1

1

1c

Clean the cooling system

Clean the mower housing

Check the air cleaner

Check the cutting blades Every 5 hours

Grease all lubrication points

Oil the linkage bushings

Service the foam air cleaner

Check the belts for wear/cracks

Check the battery electrolyte

Check the tire pressure

Change the engine oil

Replace the paper air cleaner

Change the oil filter

Check the spark plug(s)

Before Storage:

• Perform all maintenance procedures listed above.

• Drain the fuel tank.

• Charge the battery and disconnect the battery cables.

• Paint any chipped surfaces.

Each use

Every 25 hours

Every 100 hours

Every 200 hoursReplace the fuel filter

1

More often in dusty, dirty conditions

IMPORTANT: Refer to your engine operator’s manual for additional maintenance procedures.

CAUTION

If you leave the key in the ignition switch, someone could accidently start the

engine and seriously injury you or other bystanders.

Remove the key from the ignition and disconnect the wire from the spark

plug(s) before you do any maintenance. Set the wire aside so that it does not

accidentally contact the spark plug.

1 - 8 TimeCutter™ Z Service Manual

Page 23

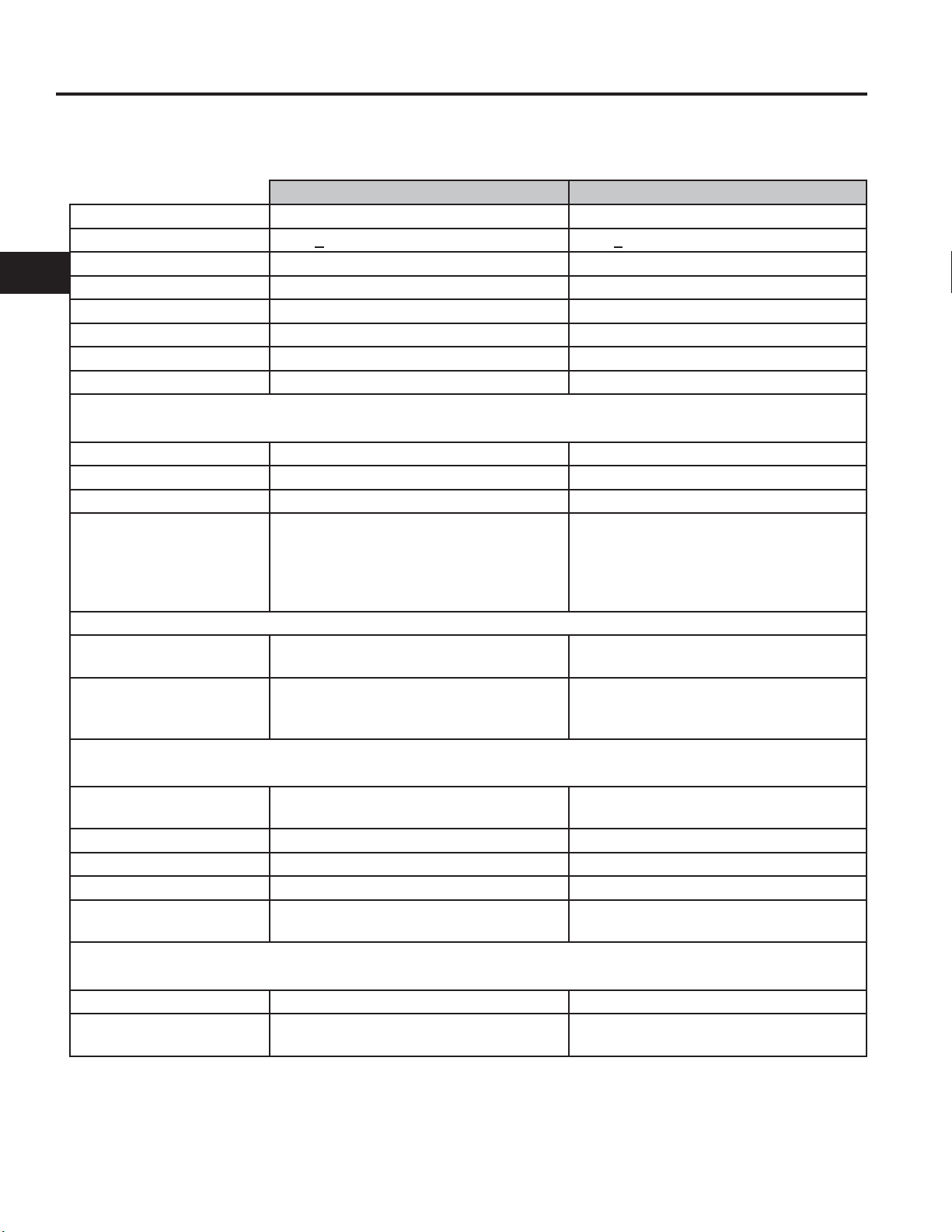

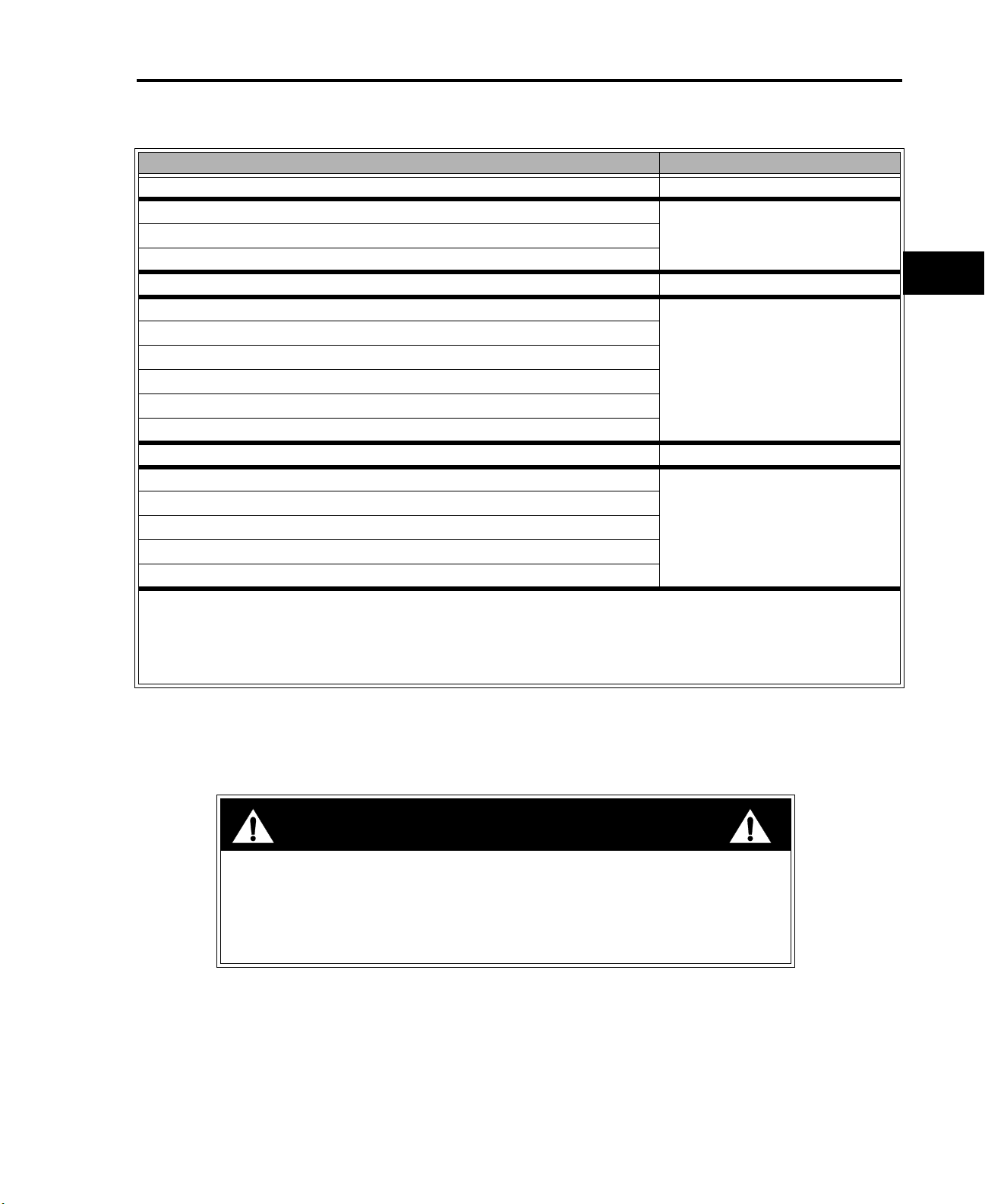

MAINTENANCE

Maintenance Schedule (Z18-52)

Maintenance Procedure Service Interval

Change the engine oil After first use

Check the engine oil level

Check the safety system

Clean the air intake screen

Clean the mower housing

Check the cutting blades Every 5 hours

Grease all lubrication points

Oil the linkage bushings

Service the foam air cleaner

Check the belts for wear/cracks

Check the battery electrolyte

Check the tire pressure

Service the paper air cleaner

Change the engine oil

Check the spark plug(s)

Change the oil filter

Replace the paper air cleaner

Clean the engine shrouds and cooling fins

Before Storage:

• Perform all maintenance procedures listed above.

• Drain the fuel tank.

• Charge the battery and disconnect the battery cables.

• Paint any chipped surfaces.

1

1

1

1

1

1

Each use

Every 25 hours

Every 50 hours

Every 100 hours

Every 200 hoursReplace the fuel filter

Every 300 hours

1c

1

More often in dusty, dirty conditions

IMPORTANT: Refer to your engine operator’s manual for additional maintenance procedures.

CAUTION

If you leave the key in the ignition switch, someone could accidently start the

engine and seriously injury you or other bystanders.

Remove the key from the ignition and disconnect the wire from the spark

plug(s) before you do any maintenance. Set the wire aside so that it does not

accidentally contact the spark plug.

TimeCutter™ Z Service Manual 1 - 9

Page 24

THIS PAGE INTENTIONALLY LEFT BLANK

1 - 10 TimeCutter™ Z Service Manual

Page 25

MODEL/SERIAL NUMBER LOCATION

QUICK REFERENCE SECTION

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE SECTION

Model/Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Greasing and Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1a

1b

1c

2

3

4

5

Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mower Decks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

7

8

TimeCutter™ Z Service Manual 2 - 1

Page 26

MODEL/SERIAL NUMBER LOCATION

Table of Contents

MODEL/SERIAL NUMBER LOCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

2 - 2 TimeCutter™ Z Service Manual

Page 27

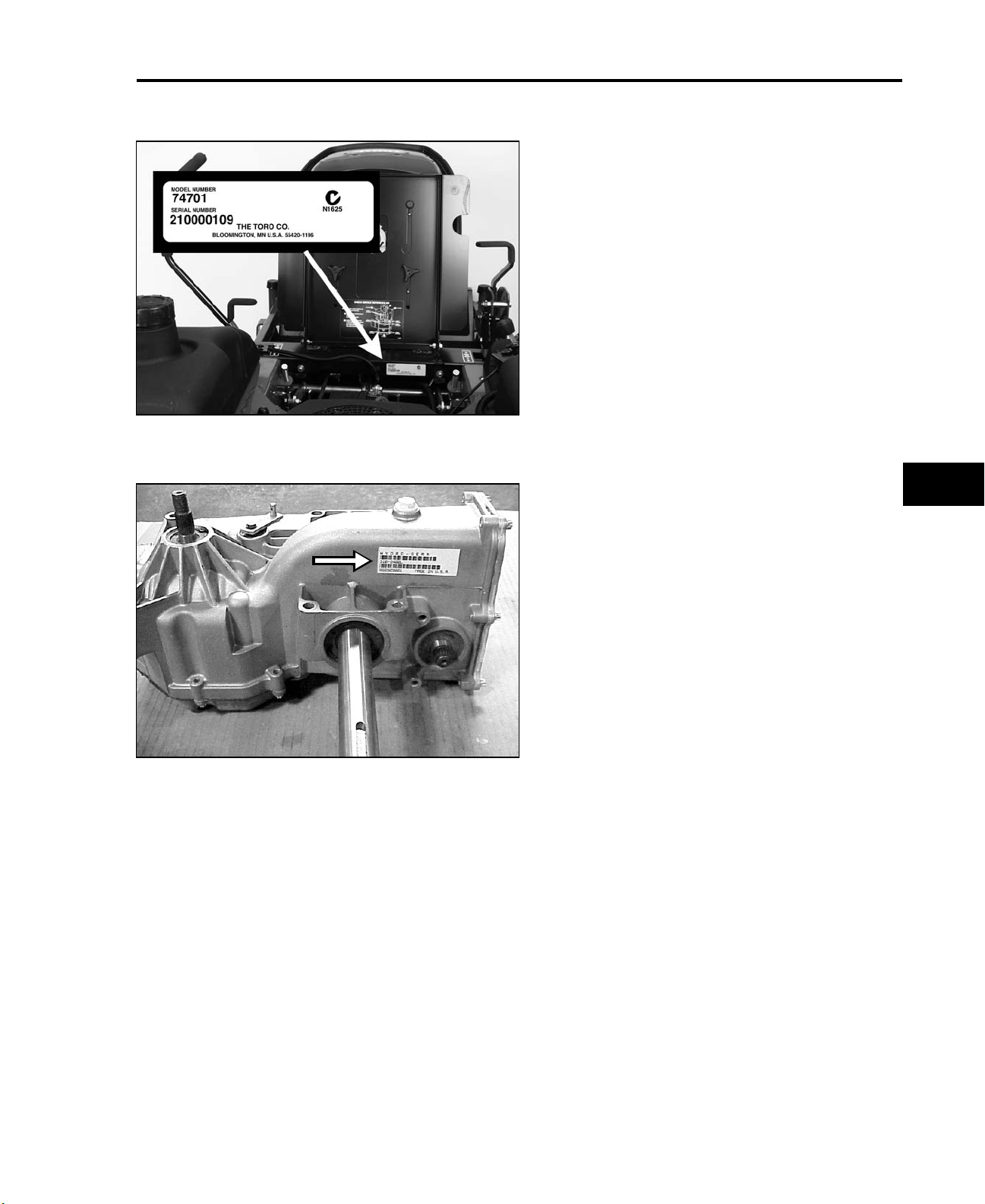

0702-0201

MODEL/SERIAL NUMBER LOCATION

MODEL/SERIAL NUMBER LOCATION

The unit model and serial number plate is on the

frame under the seat as shown in the illustration.

The engine has its own model and serial number

identification. Consult the appropriate engine

manufacturer’s service literature for the location

and translation of the engine model and serial

number information.

0702-0202

Transaxles also have their own model/serial

number.

2

TimeCutter™ Z Service Manual 2 - 3

Page 28

THIS PAGE INTENTIONALLY LEFT BLANK

2 - 4 TimeCutter™ Z Service Manual

Page 29

QUICK REFERENCE SECTION

GREASING AND LUBRICATION

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE SECTION

Model/Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Greasing and Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1a

1b

1c

2

3

4

5

Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mower Decks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

7

8

TimeCutter™ Z Service Manual 3 - 1

Page 30

GREASING AND LUBRICATION

Table of Contents

Service Interval/Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

Lubrication Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 4

3 - 2 TimeCutter™ Z Service Manual

Page 31

0702-0301

GREASING AND LUBRICATION

Service Interval/Specification

The unit should be greased every 25 hours;

more often when operating in dirty, dusty, or

sandy conditions.

A decal located under the seat shows the

location of all the grease zerks.

Grease Type: General-purpose lithium base

grease.

3

0702-0302

TimeCutter™ Z Service Manual 3 - 3

Page 32

GREASING AND LUBRICATION

Lubrication Points

There is a grease fitting on the mower for right

and left outer spindle.

0702-0303

3

The grease zerk for the center mower spindle.

0702-0304

There is a grease fitting for the deck idler arm

bushing.

0702-0305

3 - 4 TimeCutter™ Z Service Manual

Page 33

0702-0306

GREASING AND LUBRICATION

There are 2 grease fittings for the deck raising

pivot bushings - one on each side of the unit.

0702-0307

The grease zerk for the deck height adjustment

lever is on the right side of the machine.

There are grease fittings for each front castor

bushing,

3

0702-0308

TimeCutter™ Z Service Manual 3 - 5

Page 34

GREASING AND LUBRICATION

as well as the castor wheel bearings.

0702-0309

3

The zerk fitting for the traction belt idler bushing

is located under the seat.

0702-0310

Also under the seat are the fittings for the motion

control lever pivot bushings - one for each lever.

0702-0311

3 - 6 TimeCutter™ Z Service Manual

Page 35

QUICK REFERENCE SECTION

ENGINE

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE SECTION

Model/Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Greasing and Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1a

1b

1c

2

3

4

5

Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mower Decks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

7

8

TimeCutter™ Z Service Manual 4 - 1

Page 36

ENGINE

Briggs & Stratton Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

Kohler Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

Kawasaki Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

Briggs & Stratton Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 4

Kohler Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 4

Kawasaki Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 4

Spark Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 5

Engine Remove and Replace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 6

Table of Contents

4 - 2 TimeCutter™ Z Service Manual

Page 37

ENGINE

Briggs & Stratton Engine

Oil Type: Detergent oil (API service SF, SG, SH,

SJ, or higher).

0702-0401

5W-20, 5W-30

5W-30, 10W-30

SYNTHETIC 5W-20, 5W-30

SAE 30

10W-30

Crankcase Capacity (with filter): 1.75 qt. (1.7 l).

Crankcase Capacity (without filter): 1.5 qt. (1.4 l).

Viscosity: See table.

Change Oil:

• After the first use.

• Every 100 hours.

Change oil filter every 200 hours.

Kohler Engine

Oil Type: Detergent oil (API service SG, SH, SJ,

or higher).

Crankcase Capacity (with filter): 2.1 qt. (2 l).

Viscosity: See table.

Change Oil (Kohler):

• Every 50 hours.

4

0702-0402

0702-0403

USE THESE SAE VISCOSITY OILS

Change oil filter every 100 hours.

Kawasaki Engine

Oil Type: Detergent oil (API service SC, SD, SE,

SF, SG, or SH).

Crankcase Capacity (with filter): 1.6 qt. (1.5 l).

Viscosity: See table.

Change Oil (Kawasaki):

• After the first use.

• Every 100 hours.

Change oil filter every 200 hours.

TimeCutter™ Z Service Manual 4 - 3

Page 38

ENGINE

Briggs & Stratton Air Cleaner

The air cleaner assembly consists of a paper

filter element and a foam precleaner.

To clean the paper element, tap lightly on a flat

surface to remove dust and dirt. Inspect the

element for tears, oil contamination, and damage

to the rubber seal.

NOTE: Never clean the paper element with

compressed air or solvents. If the element is

dirty or damaged, replace it immediately.

(A) Paper Element

(B) Foam Precleaner

(C) Cover

Kohler Air Cleaner

The air cleaner assembly consists of a paper

filter element and a foam precleaner.

C

B

A

0702-0404

C

4

To clean the paper element, tap lightly on a flat

surface to remove dust and dirt. Inspect the

element for tears, oil contamination, and damage

to the rubber seal.

NOTE: Never clean the paper element with

compressed air or solvents. If the element is

dirty or damaged, replace it immediately.

(A) Paper Element

(B) Foam Precleaner

(C) Cover

Kawasaki Air Cleaner

The air cleaner assembly consists of a paper

filter element and a foam precleaner.

To clean the paper element, tap lightly on a flat

surface to remove dust and dirt. Inspect the

element for tears, oil contamination, and damage

to the rubber seal.

NOTE: Never clean the paper element with

compressed air or solvents. If the element is

dirty or damaged, replace it immediately.

(A) Cover

(B) Air Filter

B

A

0702-0405

A

B

0702-0406

4 - 4 TimeCutter™ Z Service Manual

Page 39

0702-0407

N

E

W

P

H

O

T

O

ENGINE

Every 25 hours (more often in dusty, dirty

conditions) wash the foam element in liquid soap

and warm water. When the element is clean,

rinse it thoroughly.

Dry the element by squeezing it in a clean cloth

(do not wring). Allow the element to air dry.

Follow engine manufacturer’s recommendation

for treatment of pre cleaner prior to installation.

Spark Plug

On Briggs & Stratton and Kawasaki engines,

replace the spark plug(s) every 100 operating

hours.

On Kohler engines, check the spark plug(s) every

200 operating hours.

If the insulator on the spark plug(s) is light brown or

gray, the engine is running properly. A black

coating on the insulator indicates the air cleaner

may be dirty.

IMPORTANT: Never clean the spark plug(s).

Always replace the spark plug(s) when it has a

black coating, worn electrodes, an oily film, or

cracks.

4

Gap (all engines): .030” (0.76 mm)

Typ e:

0144-011

TimeCutter™ Z Service Manual 4 - 5

Kohler / Briggs & Stratton:Champion RC12YC

(or equivalent)

Kawasaki: Champion RCJ86 (or equivalent)

Page 40

ENGINE

Engine Remove and Replace

Disconnect the negative battery cable.

Close the fuel shut-off.

0702-0408

N

E

W

P

H

O

T

O

4

0702-0409

Remove the fuel line from the fuel filter.

0702-0410

4 - 6 TimeCutter™ Z Service Manual

Page 41

0702-0411

ENGINE

Disconnect the clutch PTO wiring.

Disconnect the engine wiring harness plug.

0702-0412

4

Loosen the throttle/choke cable clamp and

remove the cable from the governor linkage.

0702-0413

TimeCutter™ Z Service Manual 4 - 7

Page 42

ENGINE

Remove the ground cable from the engine block.

On Kohler engines, loosen the oil filter base bolts

and remove the filter base.

0702-0414

4

0702-0415

Remove the starter cable.

0702-0416

4 - 8 TimeCutter™ Z Service Manual

Page 43

0702-0417

ENGINE

Remove mower drive belt. See complete

procedure in Chapter 8.

Remove the clutch bolt and lower the clutch

assembly.

0702-0418

4

Remove traction drive belt.

Move the idler pulley to lessen the tension on the

traction drive belt and slip the belt up off the

engine drive pulley. Then remove the clutch and

drive pulley from the crankshaft.

0702-0419

TimeCutter™ Z Service Manual 4 - 9

Page 44

ENGINE

Remove the 4 engine mounting bolts.

Lift the engine from the chassis.

0702-0420

4

Reverse the above steps to replace.

0702-0421

4 - 10 TimeCutter™ Z Service Manual

Page 45

QUICK REFERENCE SECTION

TRANSAXLE

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE SECTION

Model/Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Greasing and Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1a

1b

1c

1c

2

3

4

5

Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mower Decks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

7

8

TimeCutter™ Z Service Manual 5 - 1

Page 46

TRANSAXLE

Troubleshooting Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 3

Fluids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 4

Remove and Replace Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 5

Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 10

Control Handle-Return To Neutral Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 14

Purging the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 16

Neutral Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 18

Tracking Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 22

Table of Contents

Control Handle Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 24

5 - 2 TimeCutter™ Z Service Manual

Page 47

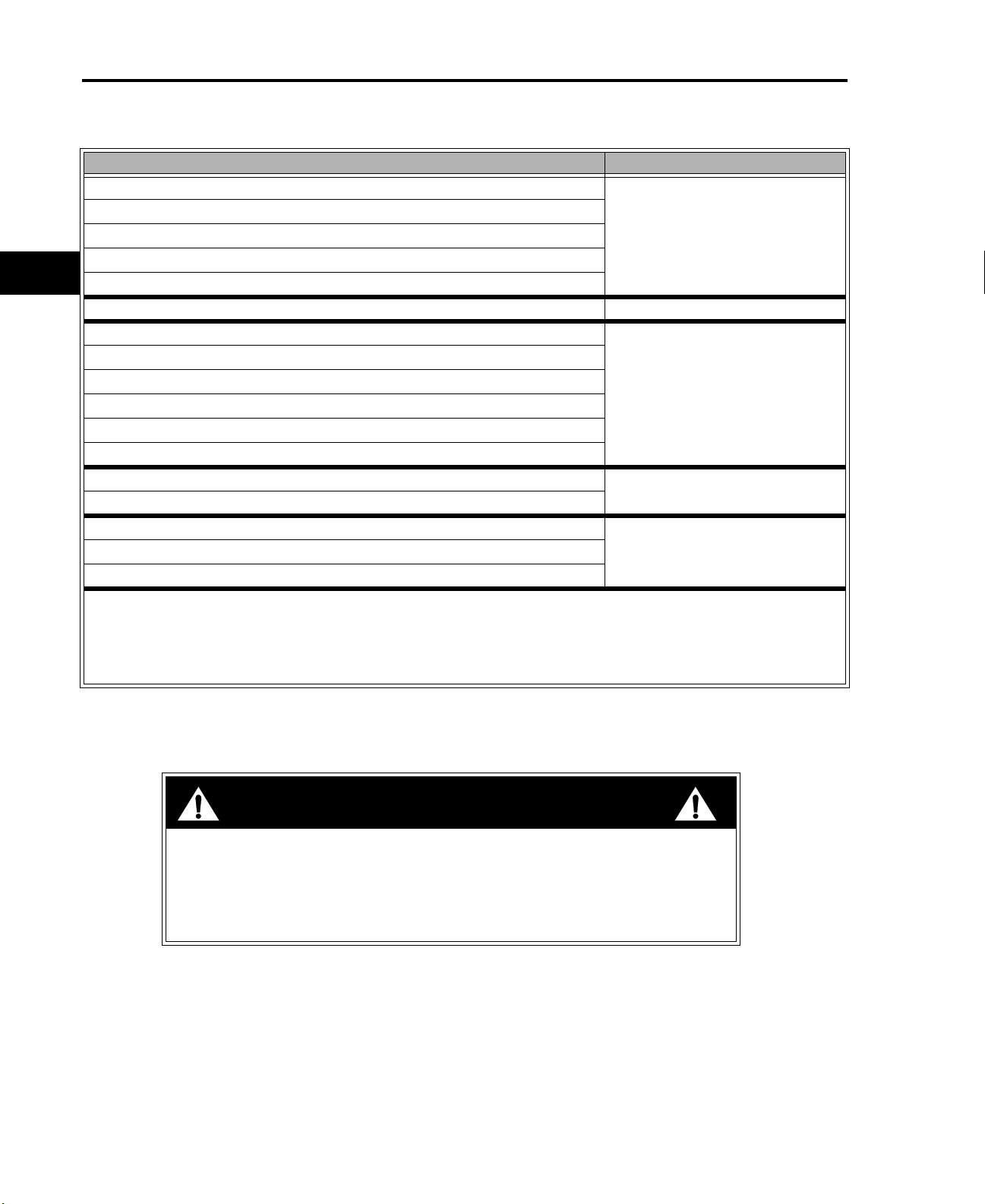

TROUBLESHOOTING CHECKLIST

Possible Cause Corrective Action

UNIT OPERATES IN ONE DIRECTION ONLY

TRANSAXLE

Control linkage bent or out of adjustment.

Drive belt slipping or pulley damaged.

VEHICLE DOES NOT DRIVE/TRACK STRAIGHT

Vehicle tires improperly inflated.

Control linkage bent, loose, or out of adjustment.

Bypass partially engaged.

Oil level low or contaminated oil.

Excessive loading.

Brake setting incorrect.

Loose parts.

Bypass assembly sticking.

Air trapped in hydraulic system.

UNIT HAS NO/LOW POWER

Engine speed low.

Control linkage bent or out of adjustment.

Brake setting incorrect.

Drive belt slipping or pulley damaged.

Oil level low or contaminated oil.

Excessive loading.

Bypass assembly sticking.

Air trapped in hydraulic system.

Repair or replace linkage.

Repair or replace drive belt or pulley.

Inflate to recommended pressure. Check tire

diameters are approximately equal, side-to-side.

Repair, adjust, or replace vehicle linkage.

Adjust bypass linkage.

UNIT IS NOISY

Fill to proper level or change oil.

Reduce vehicle loading.

Adjust brake to proper setting.

Repair or replace loose parts.

Repair or replace valve or linkage.

Purge hydraulic system.

Adjust to correct setting.

Repair or replace linkage.

Adjust brake to proper setting.

Repair or replace drive belt or pulley.

Fill to proper level or change oil.

Reduce vehicle loading.

Repair or replace valve or linkage.

Purge hydraulic system.

5

UNIT OPERATING HOT

Debris buildup around transaxle.

Brake setting incorrect.

Cooling fan damaged.

Oil level low or contaminated oil.

Excessive loading.

Air trapped in hydraulic system.

TRANSAXLE LEAKS OIL

Damaged seals, housing, or gaskets.

Air trapped in hydraulic system.

TimeCutter™ Z Service Manual 5 - 3

Clean off debris.

Adjust brake to proper setting.

Repair or replace cooling fan.

Fill to proper level or change oil.

Reduce vehicle loading.

Purge hydraulic system.

Replace damaged component.

Purge hydraulic system.

Page 48

TRANSAXLE

Fluids

Engine oil with a minimum rating of 55 SUS at

212 F° and an API classification of SH/CD is

recommended. A 20W-50 engine oil has been

selected for use by the factory and is

recommended for normal operating

temperatures.

Check oil level when cold. To check the

transaxle fluid level, remove the vent. Oil level

should be 1-7/8” - 2-3/16” (4.8 cm - 5.56 cm)

from the top of the vent port.

0702-0501

5

The oil level can only be checked when the

transaxle is removed from the machine.

0702-0502

5 - 4 TimeCutter™ Z Service Manual

Page 49

0702-0408

TRANSAXLE

Remove and Replace Transaxle

Disconnect the battery.

Close the fuel shut-off.

0702-0409

5

Raise the rear of the unit and support it with jack

stands.

0702-0505

TimeCutter™ Z Service Manual 5 - 5

Page 50

TRANSAXLE

Remove the clip that secures the vent hose to

the chassis.

If necessary, engage the parking brake to

facilitate wheel removal.

0702-0506

5

0702-0507

Remove the wheel assembly.

0702-0508

5 - 6 TimeCutter™ Z Service Manual

Page 51

0702-0509

TRANSAXLE

Remove the parking brake link from the brake

arm.

Disconnect the motion control link from the

transaxle.

0702-0510

5

Remove the hairpin cotter and washer from the

bypass valve lever. Leave the rod in place.

0702-0511

TimeCutter™ Z Service Manual 5 - 7

Page 52

TRANSAXLE

Move the idler pulley to lessen the tension on the

traction drive belt and slip the belt up off the

engine drive pulley.

Remove the belt from the transaxle being

removed.

0702-0419

5

0702-0512

Loosen and remove the 6 bolts and washer

between both transaxles. Remove the hydro

lower plate. Note the orientation of the hydro

lower plate. It must be reinstalled with the lip

facing down, toward the front.

0702-0513

5 - 8 TimeCutter™ Z Service Manual

Page 53

0702-0514

TRANSAXLE

Support the transaxle with a jack while removing

the last bolts.

Guide the transaxle as it is lowered. Make sure

the cooling fan and vent hose clear the chassis.

0702-0515

5

TimeCutter™ Z Service Manual 5 - 9

Page 54

TRANSAXLE

Reassembly

IMPORTANT: Before installing a new transaxle,

check

the oil level and check the torque on the

nut retaining the input pulley. Torque to 30 - 35

ft. lbs. (40.7 N·m - 47.5 N·m).

Use a jack to lift the transaxle into the chassis.

Carefully guide it into position so that the cooling

fan does not catch on the chassis and the

bypass rod is properly positioned in the lever.

Insert the vent hose through the slot provided for

it in the frame.

0702-0516

5

Install the two axle bolts, washer, and nuts to the

frame. Do not tighten the bolts. Reinstall the

rest of the bolts, washers, and nuts in the lower

hydro plate. If the plate was completely

removed, make sure the lip of the plate is

pointing to the front and down. Tighten the

transaxle bolts and nuts following the sequence

shown in the photo. Torque the bolts and nuts to

200 in. lbs. (22.6 N·m)

0702-0515

5

2

3

1

4

0702-0513

5 - 10 TimeCutter™ Z Service Manual

Page 55

1s-0802

TRANSAXLE

Place the traction belt on the pulley. Check for

correct belt routing.

(A) Engine Pulley

(B) Idler Pulley

(C) Right Hydro

(D) Left Hydro

Install the hairpin cotter pin and washer on the

bypass valve lever.

0702-0511

5

Reinstall the motion control link.

0702-0517

TimeCutter™ Z Service Manual 5 - 11

Page 56

TRANSAXLE

NOTE: The length of the link is set at the factory

and should not normally require adjustment in

the field.

If the link has been tampered with, the distance

between bolt centers is:

• Left side 3.6” (9.14 cm)

• Right side 3.1” (7.9 cm)

Install the parking brake linkage.

0702-0517

5

0702-0509

Replace the wheel assembly.

0702-0508

5 - 12 TimeCutter™ Z Service Manual

Page 57

0702-0506

TRANSAXLE

Secure the vent hose to the chassis.

Recheck to make sure the brake arm clears the

teeth of the brake cog when the park brake is

disengaged.

0702-0518

5

TimeCutter™ Z Service Manual 5 - 13

Page 58

TRANSAXLE

Control Handle-Return To Neutral Adjustment

1. With the engine off, move the directional

control handles to the reverse position.

2. Let the handles go. They should return to

the neutral position, which means the handle

should line up with the neutral slot (neutral

lockout position).

0702-0519

5

0702-0520

3. If adjustment is needed:

A. Lift the seat and located the adjusters.

Loosen the jam nut on the yoke.

0702-0521

5 - 14 TimeCutter™ Z Service Manual

Page 59

0702-0522

TRANSAXLE

B. Turn the top bolt head until the

directional control handle is lined up with

the neutral slot (Neutral Lockout

Position).

C. Tighten the jam nut and then test the

directional control handle by pulling the

handle in reverse and then let the handle

go. It should return to the neutral slot.

0702-0520

D. Before starting the unit, follow the

procedures on Purging the System.

5

TimeCutter™ Z Service Manual 5 - 15

Page 60

TRANSAXLE

Purging the System

Due to the effects air has on efficiency in

hydrostatic drive applications, it is critical that it

be purged from the system.

These purge procedures should be implemented

any time a hydrostatic system has been opened

to facilitate maintenance or any additional oil has

been added to the system.

Air creates inefficiency because its compression

and expansion rate is higher than that of the oil

normally approved for use in hydrostatic drive

systems.

0702-0516

5

2001-027

The following procedures should be performed

with the vehicle drive wheels off the ground, the

seat switch temporarily bypassed, and the brake

arm completely disengaged from the brake cog,

(see Parking Brake Adjustment page 6 - 18).

The procedure may need to be repeated under

normal operating conditions.

1. With the bypass valves open (hand push

mode) and the engine running, slowly move

the directional control handles in both

forward and reverse directions 5 to 6 times,

to purge trapped air from the unit.

0702-0523

5 - 16 TimeCutter™ Z Service Manual

Page 61

0702-0524

TRANSAXLE

2. Place the bypass valves in the closed

position (operating). With the engine

running, slowly move the directional control

handles through the forward and reverse

directions (5 to 6 times).

3. It may be necessary to repeat steps 1 and 2

until all the air is completely purged from the

system. When the transaxle moves forward

and reverse at normal speed, purging is

complete.

5

TimeCutter™ Z Service Manual 5 - 17

Page 62

TRANSAXLE

Neutral Adjustment

1. If the unit creeps in neutral, it will be

necessary to make an adjustment to the

transaxle.

2. Operate the unit to determine which

transaxle needs adjustment.

3. Raise the unit and place it on jack stands.

0702-0525

5

4. Warm the transaxle fluid by running for at

least 10 minutes.

0702-0505

5. Unplug the seat switch and temporarily

connect a jumper wire across the plug

connector.

2001-050

5 - 18 TimeCutter™ Z Service Manual

Page 63

0702-0526

TRANSAXLE

6. Place the directional control handles in the

neutral lockout position. Start the engine

and run at half throttle.

7. The rear traction wheels should remain

stationary or creep slightly in reverse.

0702-0527

5

8. If necessary, loosen the jam nuts (A) and

turn the control rod until the wheel stops

between forward and reverse. In some

cases, you may have a slight creep in

reverse. When you lower the unit to the

ground, it should stop.

A

0702-05028

TimeCutter™ Z Service Manual 5 - 19

Page 64

TRANSAXLE

9. After you have adjusted the rods, move the

directional control handle in reverse position,

then let go of the handles. The handles

should move to the neutral position and the

drive wheels should remain stationary, or

have a very slight amount of creep in

reverse. The wheels should not creep in the

forward direction when the control handles

are in the neutral lock out position.

10. Run the engine at full throttle. Check neutral

again by moving the directional control

handles in reverse, then let go of the

handles. The handles should move to the

neutral position and the drive wheels should

not move. A slight creep could be observed

when the machine is elevated. However,

when lowering the unit to the ground, the

5

weight of the unit should stop the creep.

0702-0529

0702-0530

11. When the adjustment is complete, hold the

control rod stationary with pliers and tighten

the jam nuts. Always test again to make

sure the unit is still neutralized.

0702-0531

5 - 20 TimeCutter™ Z Service Manual

Page 65

0702-0532

TRANSAXLE

12. Remove the jumper wire on the seat switch

and plug the switch into the harness. Lower

the unit to the ground.

5

TimeCutter™ Z Service Manual 5 - 21

Page 66

TRANSAXLE

Tracking Adjustment

When operating the unit in forward, it is not

unusual for the unit to track slightly right or left

when going for a distance. This is because of

the different tolerances between two different

hydrostatic pumps. If the tracking deviation is

large, check the following.

NOTE: Ground surface should be level when

checking the tracking.

1. Check the tire pressure in each tire. 13 psi

(90 kPa) rear, 35 psi (241 kPa) front. Tire

pressure has a great influence on the

tracking of these units.

0702-0525

5

It is advisable to check for a large deviation

in outside diameter of the tires, side-to-side,

if the tracking error is severe. Also, check

that the front casters rotate freely, and the

front wheel bearings are in good condition.

0702-0533

2. You may be able to make a slight tracking

adjustment by turning the neutral control

rods without affecting the neutral position.

IMPORTANT: Be sure to recheck the

neutral adjustment to be sure the machine

does not creep after correcting the tracking.

0702-0528

5 - 22 TimeCutter™ Z Service Manual

Page 67

0702-0527

TRANSAXLE

NOTE: All of the control linkage is set up for

forward motion. It is not unusual to have a large

tracking error when going a distance in reverse.

Do not try to adjust reverse tracking. If you do, it

will misadjust the forward linkage.

3. After attempting any tracking change with

the unit, make sure it is still neutralized.

5

TimeCutter™ Z Service Manual 5 - 23

Page 68

TRANSAXLE

Control Handle Adjustment

If the directional control handles do not line up

with each other, they require adjustment.

1. Loosen the bolts attaching the handles to the

control linkage.

2. Adjust the position of the handles so that

they are aligned. Tighten the bolts after

adjustment.

0702-0534

5

0702-0535

5 - 24 TimeCutter™ Z Service Manual

Page 69

PICT-6171

TRANSAXLE

Transaxle Identifi cation Model Year 2001 - 2004

Hydro-Gear Model 310-2400 IZT Transaxles

Transaxle Identifi cation Model Year 2005 and Later

Hydro-Gear Model 310-2600 IZT with a Charge Pump

MVC-353X

5

A5-25TimeCutter ZX Service Manual

Page 70

TRANSAXLE

THIS PAGE INTENTIONALLY LEFT BLANK.

5

A5-26 TimeCutter ZX Service Manual

Page 71

QUICK REFERENCE SECTION

CHASSIS

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE SECTION

Model/Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Greasing and Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1a

1b

1c

2

3

4

5

Chassis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mower Decks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

7

8

TimeCutter™ Z Service Manual 6 - 1

Page 72

CHASSIS

Table of Contents

Remove and Replace Dampers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 3

Remove and Replace Control Linkage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 4

Replace Control Linkage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 8

Remove and Replace Brake Linkage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 11

Replace Brake Linkage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 15

Parking Brake Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 18

Replace Traction Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 20

TimeCutter™ Z Service Manual 6 - 2

Page 73

0702-0601

CHASSIS

Remove and Replace Dampers

Remove the E-clip and washer at the bottom of

the damper.

Remove the bolt at the top of the damper and

remove the damper.

0702-0602

6

TimeCutter™ Z Service Manual 6 - 3

Page 74

CHASSIS

Remove and Replace Control Linkage

Remove the control arm.

Remove the electrical connector from the motion

control switch.

0702-0603

6

Remove the pin from the return to neutral yoke.

N

0702-0604

E

W

P

H

O

T

O

0702-0605

6 - 4 TimeCutter™ Z Service Manual

Page 75

0702-0606

CHASSIS

Remove the link between the front and rear

bellcranks.

NOTE: All the ball joint assemblies are installed

with a flat washer between the ball joint and

lever.

0702-0607

0702-0608

6

Disconnect the steering damper.

TimeCutter™ Z Service Manual 6 - 5

Page 76

CHASSIS

Remove the bolts securing the bushings at each

end of the control shaft.

Remove the control shaft.

0702-0609

6

0702-0610

Disconnect the link between the transaxle and

the bellcrank.

NOTE: Do not change the length of the link.

0702-0611

6 - 6 TimeCutter™ Z Service Manual

Page 77

0702-0612

CHASSIS

Use a small punch to drive the roll pin out of the

upper bellcrank lever, then remove the lever and

thrust washer.

Pull the lower lever and shaft from the bushing.

0702-0613

6

TimeCutter™ Z Service Manual 6 - 7

Page 78

CHASSIS

Replace Control Linkage

Lubricate the bellcrank shaft and install in

bushing. The lever welded to the shaft goes on

the underside of the chassis.

Carefully position the top lever on the shaft and

secure with roll pin.

0702-0613

6

0702-0614

Install the link between the transaxle and

bellcrank lever.

0702-0517

6 - 8 TimeCutter™ Z Service Manual

Page 79

0702-0609

CHASSIS

Place the motion control shaft in position in the

console and secure with nuts and bolts.

NOTE: Make sure shaft is rotating freely after

installation.

Reconnect the steering damper.

0702-0608

0702-0606

6

Replace the link connecting the control shaft and

bellcrank.

TimeCutter™ Z Service Manual 6 - 9

Page 80

CHASSIS

Attach the return to neutral adjustment yoke to

the control shaft lever.

Connect the wiring to the neutral switch.

0702-0605

6

0702-0604

Position the motion control handle and secure

with 2 bolts.

0702-0603

6 - 10 TimeCutter™ Z Service Manual

Page 81

0702-0509

CHASSIS

Remove and Replace Brake Linkage

Remove the brake link from the brake arm.

Remove the clip and yoke from the brake shaft

lever.

0702-0615

0702-0616

6

Remove the cotter pin and washer from the

actuator rod.

NOTE: The actuator rod cannot be removed

from the lever at this time.

TimeCutter™ Z Service Manual 6 - 11

Page 82

CHASSIS

Remove the two clamps securing the brake

shaft.

NOTE: During reassembly, the wiring harness is

routed below the brake shaft, throttle cable is

routed above.

Remove the brake shaft from the chassis and

actuator rod.

0702-0617

6