Page 1

FormNo.3375-707RevA

TimeCutter

®

ZS4200or5000

RidingMower

ModelNo.74386—SerialNo.313000001andUp

ModelNo.74387—SerialNo.313000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3375-707*A

Page 2

Thismachineisaride-on,rotary-bladeintendedtobeused

G014523

1

byhomeownersinresidentialapplications.Itisprimarily

designedforcuttinggrassonwell-maintainedlawns.Itisnot

designedforcuttingbrush,mowinggrassandothergrowth

alongsidehighways,orforagriculturaluses.

ThisproductcomplieswithallrelevantEuropeandirectives,

fordetailspleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

GrossHorsepower

Thegrossornethorsepowerofthisenginewaslaboratory

ratedbytheenginemanufacturerinaccordancewiththe

SocietyofAutomotiveEngineers(SAE)J1940.Ascongured

tomeetsafety,,andoperatingrequirements,theactualengine

torqueonthisclassofmowerwillbesignicantlylower.

Gotowww.Toro.comtoviewspecicationsonyourmower

model.

Introduction

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely .

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

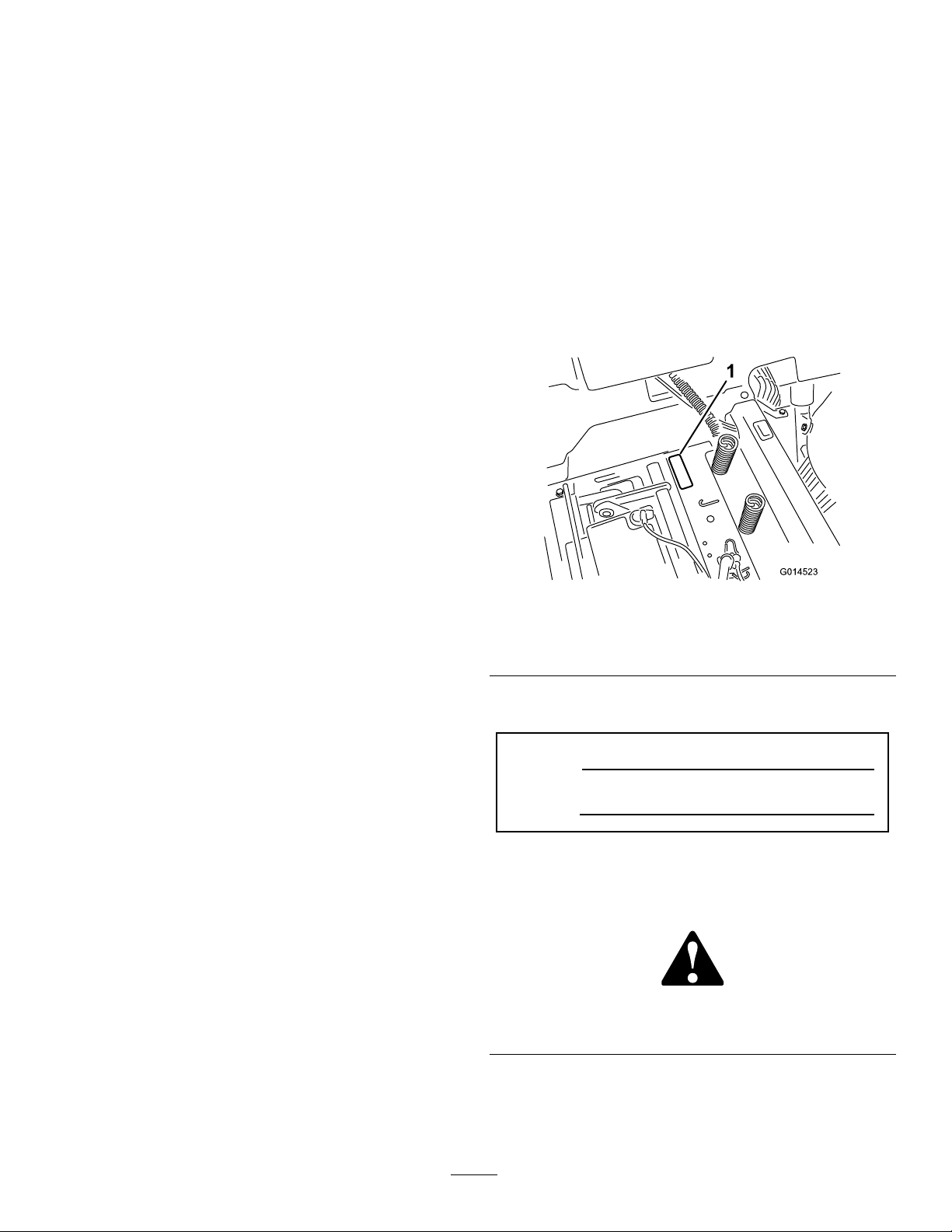

yourproductready .Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Figure1

Undertheseat

1.Modelandserialnumberplate

Writetheproductmodelandserialnumbersinthespace

below:

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol.

©2012—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Thismanualusestwootherwordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction..................................................................2

Safety...........................................................................4

SafeOperationPracticesforRide-on(riding)

RotaryLawnMowerMachines...............................4

SafeOperatingPractices...........................................4

ToroRidingMowerSafety........................................5

Model74386...........................................................6

Model74387...........................................................6

SlopeIndicator.......................................................7

SafetyandInstructionalDecals.................................8

ProductOverview.........................................................14

Controls...............................................................15

Operation....................................................................16

ThinkSafetyFirst...................................................16

BeforeStarting.......................................................18

StartingtheEngine.................................................19

OperatingtheBlades...............................................20

TestingtheSafetyInterlockSystem...........................20

StoppingtheEngine...............................................21

Driving.................................................................21

StoppingtheMachine.............................................22

AdjustingtheHeightofCut.....................................23

AdjustingtheAnti-ScalpRollers(For42inch

MowerDecks)....................................................23

AdjustingtheAnti-ScalpRollers(For50inch

MowerDecks)....................................................23

PositioningtheSeat................................................24

AdjustingtheMotionControlLevers........................24

PushingtheMachinebyHand..................................25

GrassDeector......................................................26

ConvertingtoSideDischarge(ForModelswith42

InchDecks).......................................................26

ConvertingtoSideDischarge(ForModelswith50

InchDecks).......................................................27

OperatingTips......................................................29

Maintenance.................................................................30

RecommendedMaintenanceSchedule(s)......................30

PremaintenanceProcedures........................................31

RaisingtheSeat......................................................31

Lubrication...............................................................31

GreasingtheBearings.............................................31

EngineMaintenance..................................................32

ServicingtheAirCleaner.........................................32

ServicingtheEngineOil..........................................32

ServicingtheSparkPlug..........................................34

CleaningtheCoolingSystem....................................35

FuelSystemMaintenance...........................................36

ReplacingtheIn-lineFuelFilter................................36

ElectricalSystemMaintenance....................................37

ChargingtheBattery...............................................37

ServicingtheFuses.................................................38

DriveSystemMaintenance.........................................39

CheckingtheTirePressure......................................39

ReleasingtheElectricBrake.....................................39

MowerMaintenance...................................................40

ServicingtheCuttingBlades.....................................40

LevelingtheMowerDeck........................................42

RemovingtheMower..............................................45

MowerBeltMaintenance.........................................46

InstallingtheMower...............................................47

ReplacingtheGrassDeector..................................47

Cleaning...................................................................48

WashingtheUndersideoftheMower........................48

Storage........................................................................49

CleaningandStorage..............................................49

Troubleshooting...........................................................50

Schematics...................................................................52

3

Page 4

Safety

SafeOperationPracticesfor

Ride-on(riding)RotaryLawn

MowerMachines

ThismachinemeetsorexceedsEuropeanStandardsin

effectatthetimeofproduction.However,improperuseor

maintenancebytheoperatororownercanresultininjury.

Toreducethepotentialforinjury,complywiththesesafety

instructionsandalwayspayattentiontothesafetyalert

symbol,whichmeansCAUTION,WARNING,orDANGER

-“personalsafetyinstruction.”Failuretocomplywiththe

instructionmayresultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsarefromtheENstandardEN

836:1997.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Training

•Readtheinstructionscarefully.Befamiliarwiththe

controlsandtheproperuseoftheequipment.

Preparation

•Whilemowing,alwayswearsubstantialfootwearandlong

trousers.Donotoperatetheequipmentwhenbarefoot

orwearingopensandals.

•Thoroughlyinspecttheareawheretheequipmentisto

beusedandremoveallobjectswhichmaybethrownby

themachine.

•Warning-Fuelishighlyammable.

–Storefuelincontainersspecicallydesignedforthis

purpose.

–Refueloutdoorsonlyanddonotsmokewhile

refuelling.

–Addfuelbeforestartingtheengine.Neverremove

thecapofthefueltankoraddfuelwhiletheengineis

runningorwhentheengineishot.

–Iffuelisspilled,donotattempttostarttheengine

butmovethemachineawayfromtheareaofspillage

andavoidcreatinganysourceofignitionuntilfuel

vaporshavedissipated.

–Replaceallfueltanksandcontainercapssecurely.

•Replacefaultysilencers.

•Beforeusing,alwaysvisuallyinspecttoseethattheblades,

bladeboltsandcutterassemblyarenotwornordamaged.

Replacewornordamagedbladesandboltsinsetsto

preservebalance.

•Onmulti-bladedmachines,takecareasrotatingoneblade

cancauseotherbladestorotate.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstousethelawnmower.Localregulationscan

restricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpetsare

nearby.

•Keepinmindthattheoperatororuserisresponsiblefor

accidentsorhazardsoccurringtootherpeopleortheir

property.

•Donotcarrypassengers.

•Alldriversshouldseekandobtainprofessionaland

practicalinstruction.Suchinstructionshouldemphasize:

–theneedforcareandconcentrationwhenworking

withride-onmachines;

–controlofaride-onmachineslidingonaslopewill

notberegainedbytheapplicationofthebrake.The

mainreasonsforlossofcontrolare:

◊insufcientwheelgrip;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforitstask;

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

◊incorrecthitchingandloaddistribution.

Operation

•Bealert,slowdownandusecautionwhenmakingturns.

Lookbehindandtothesidebeforechangingdirections.

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageallblade

attachmentclutchesandshiftintoneutral.

•Donotuseonslopesofmorethan15degrees.

•Rememberthereisnosuchthingasasafeslope.Travel

ongrassslopesrequiresparticularcare.Toguardagainst

overturning:

–donotstoporstartsuddenlywhengoingupor

downhill;

–uselowspeedsonslopesandduringtightturns;

–stayalertforhumpsandhollowsandotherhidden

hazards;

•Usecarewhenpullingloads.

–Useonlyapproveddrawbarhitchpoints.

–Limitloadstothoseyoucansafelycontrol.

–Donotturnsharply.Usecarewhenreversing.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesrotatingbeforecrossingsurfacesother

thangrass.

4

Page 5

•Whenusinganyattachments,neverdirectdischargeof

materialtowardbystandersnorallowanyonenearthe

machinewhileinoperation.

•Neveroperatethemachinewithdamagedguardsor

withoutsafetyprotectivedevicesinplace.

•Donotchangetheenginegovernorsettingsoroverspeed

theengine.Operatingtheengineatexcessivespeedcan

increasethehazardofpersonalinjury.

•Beforeleavingtheoperator'sposition:

–disengagethepowertake-offandlowerthe

attachments;

–changeintoneutralandsettheparkingbrake;

–stoptheengineandremovethekey.

•Disengagedrivetoattachments,stoptheengine,and

disconnectthesparkplugwire(s)orremovetheignition

key

–beforeclearingblockagesoruncloggingchute;

–beforechecking,cleaningorworkingonthelawn

mower;

–afterstrikingaforeignobject.Inspectthelawn

mowerfordamageandmakerepairsbeforerestarting

andoperatingtheequipment;

–ifthemachinestartstovibrateabnormally(check

immediately).

•Disengagedrivetoattachmentswhentransportingornot

inuse.

•Stoptheengineanddisengagedrivetoattachment

–beforerefuelling;

–beforeremovingthegrasscatcher;

–beforemakingheightadjustmentunlessadjustment

canbemadefromtheoperator'sposition.

•Reducethethrottlesettingduringenginerun-outand,if

theengineisprovidedwithashut-offvalve,turnthefuel

offattheconclusionofmowing.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetankinsidea

buildingwherefumescanreachanopenameorspark.

•Allowtheenginetocoolbeforestoringinanyenclosure.

•Toreducetherehazard,keeptheengine,silencer,

batterycompartmentandfuelstorageareafreeofgrass,

leaves,orexcessivegrease.

•Checkthegrasscatcherfrequentlyforwearor

deterioration.

•Replacewornordamagedpartsforsafety .

•Ifthefueltankhastobedrained,thisshouldbedone

outdoors.

•Whenmachineistobeparked,storedorleftunattended,

lowerthecuttingmeans.

ToroRidingMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedintheCENstandard.

•Engineexhaustcontainscarbonmonoxide,whichisan

odorless,deadlypoisonthatcankillyou.Donotrun

engineindoorsorinanenclosedarea.

•Keephands,feet,hairandlooseclothingawayfrom

attachmentdischargearea,undersideofmowerandany

movingpartswhileengineisrunning.

•Donottouchequipmentorattachmentpartswhichmay

behotfromoperation.Allowtocoolbeforeattempting

tomaintain,adjust,orservice.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyesandclothing.Protectyourface,

eyes,andclothingwhenworkingwithabattery.

•Batterygasescanexplode.Keepcigarettes,sparks,and

amesawayfrombattery.

•UseonlygenuineTororeplacementpartstoensurethat

originalstandardsaremaintained.

•UseonlyT oro-approvedattachments.

SlopeOperation

•Donotmowslopesgreaterthan15degrees.

•Donotmowneardrop-offs,ditches,steepbanks,or

water.Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,death,ordrowning.

•Donotmowslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcauseslidingand

lossofcontrol.

•Donotmakesuddenturnsorrapidspeedchanges.

•Useawalkbehindmowerand/orahandtrimmernear

drop-offs,ditches,steepbanks,orwater.

•Reducespeedanduseextremecautiononslopes.

•Removeormarkobstaclessuchasrocks,treelimbs,etc.

frommowingarea.Tallgrasscanhideobstacles.

•Watchforditches,holes,rocksdips,andrisesthatchange

theoperatingangle,asroughterraincouldoverturnthe

machine.

•Avoidsuddenstartswhenmowinguphillbecausethe

mowermaytipbackwards.

•Beawarethatlossoftractionmayoccurgoingdownhill.

Weighttransfertothefrontwheelsmaycausedrive

wheelstoslipandcauselossofbrakingandsteering.

•Alwaysavoidsuddenstartingorstoppingonaslope.

Iftireslosetraction,disengagethebladesandproceed

slowlyofftheslope.

5

Page 6

•Followthemanufacturer'srecommendationsforwheel

weightsorcounterweightstoimprovestability.

•Useextremecarewithgrasscatchersorotherattachments.

Thesecanchangethestabilityofthemachineandcause

lossofcontrol.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

Vibration

Measuredvibrationlevelforrighthand=1.9m/s

2

Model74386

SoundPressure

Thisunithasasoundpressurelevelattheoperator’searof89

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinEN836.

SoundPower

Thisunithasaguaranteedsoundpowerlevelof100dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

Vibration

Measuredvibrationlevelforrighthand=1.3m/s

Measuredvibrationlevelforlefthand=1.3m/s

UncertaintyValue(K)=0.7m/s

2

2

2

Measuredvibrationlevelforlefthand=2.8m/s

UncertaintyValue(K)=1.4m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836.

2

WholeBodyVibration

Measuredvibrationlevel=0.37m/s

UncertaintyValue(K)=0.19m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836(Riding&Stand-Ons).

2

2

2

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836.

WholeBodyVibration

Measuredvibrationlevel=0.33m/s

UncertaintyValue(K)=0.16m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836(Riding&Stand-Ons).

2

2

Model74387

SoundPressure

Thisunithasasoundpressurelevelattheoperator’searof94

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinEN836.

SoundPower

Thisunithasaguaranteedsoundpowerlevelof105dBA,

whichincludesanUncertaintyValue(K)of1dBA.

6

Page 7

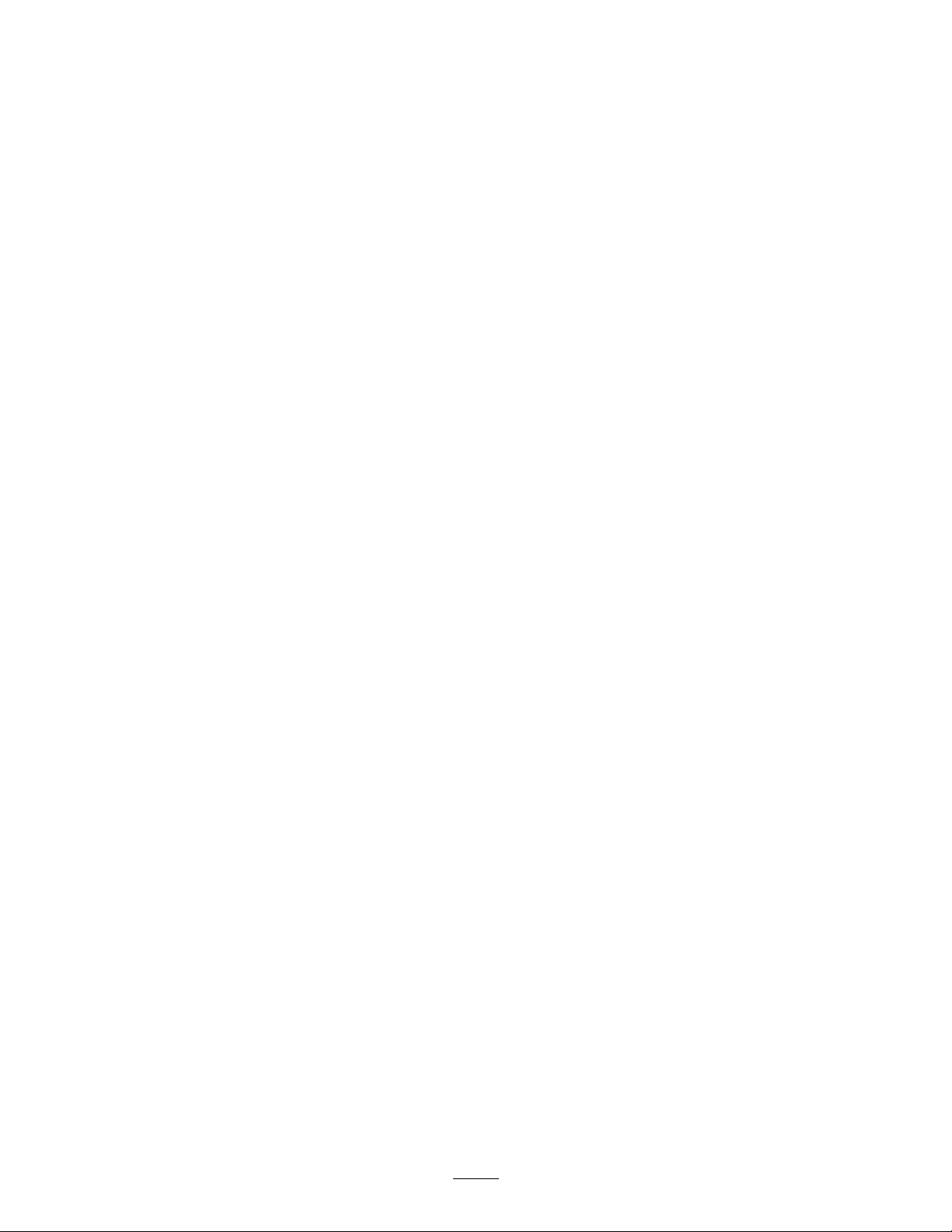

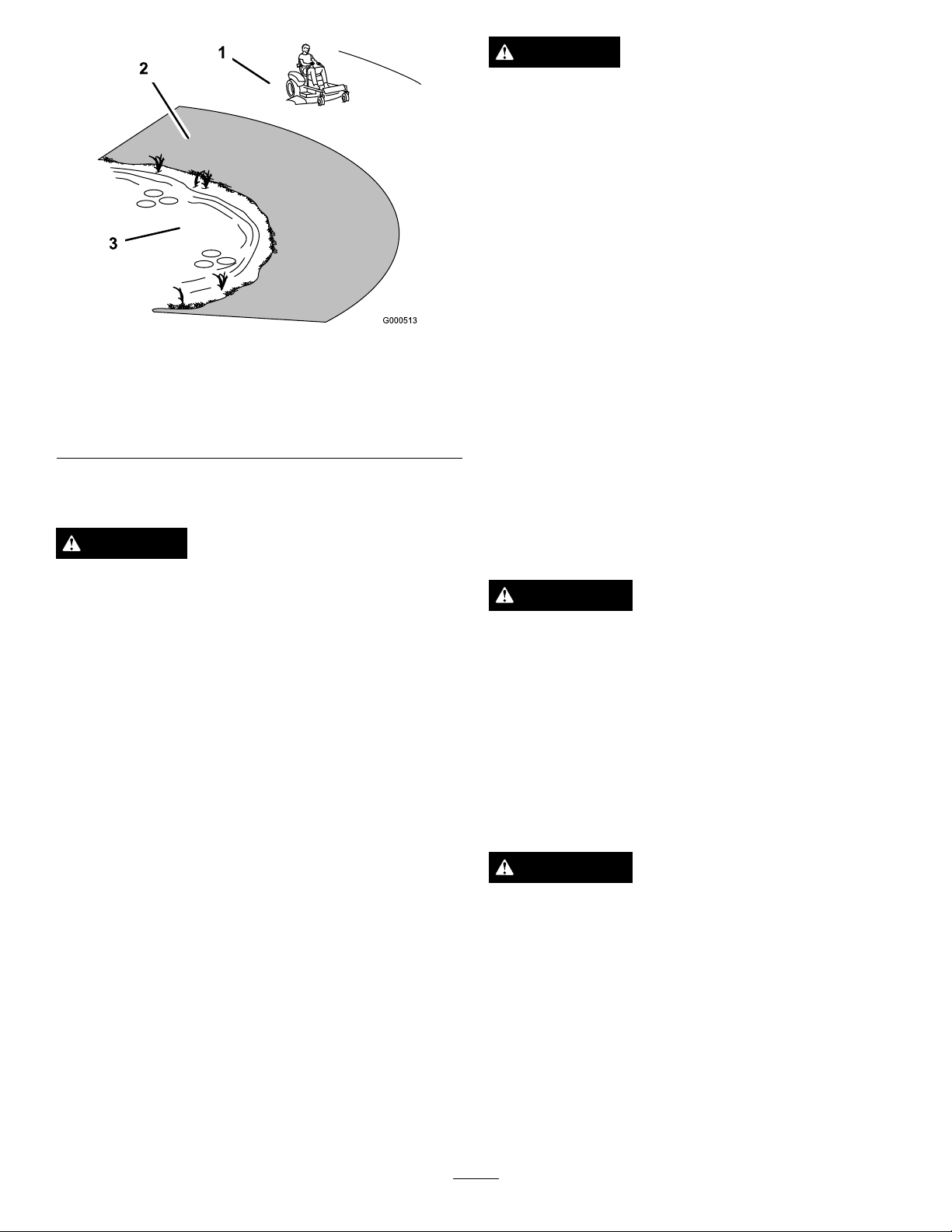

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

7

Page 8

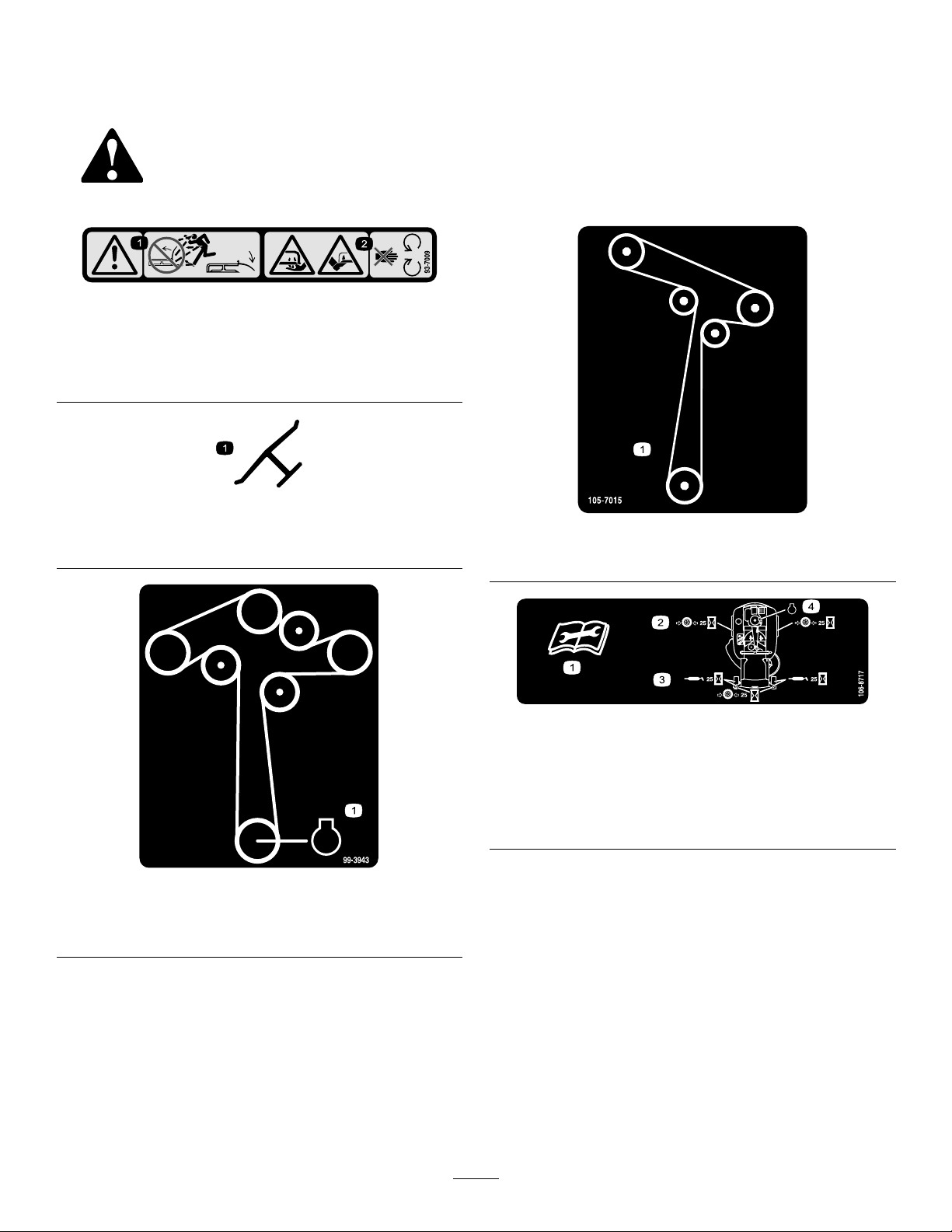

SafetyandInstructional

Decals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

93-7009

1.Warning—don'toperatethemowerwiththedeectorupor

removed;keepthedeectorinplace.

2.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

105-7015

ForModelswith42InchDecks

106-8717

1.Readtheinstructionsbeforeservicingorperforming

maintenance.

2.Checktirepressureevery25operatinghours.

3.Greaseevery25operatinghours.

4.Engine

99-3943

ForModelswith50InchDecks

1.Engine

8

Page 9

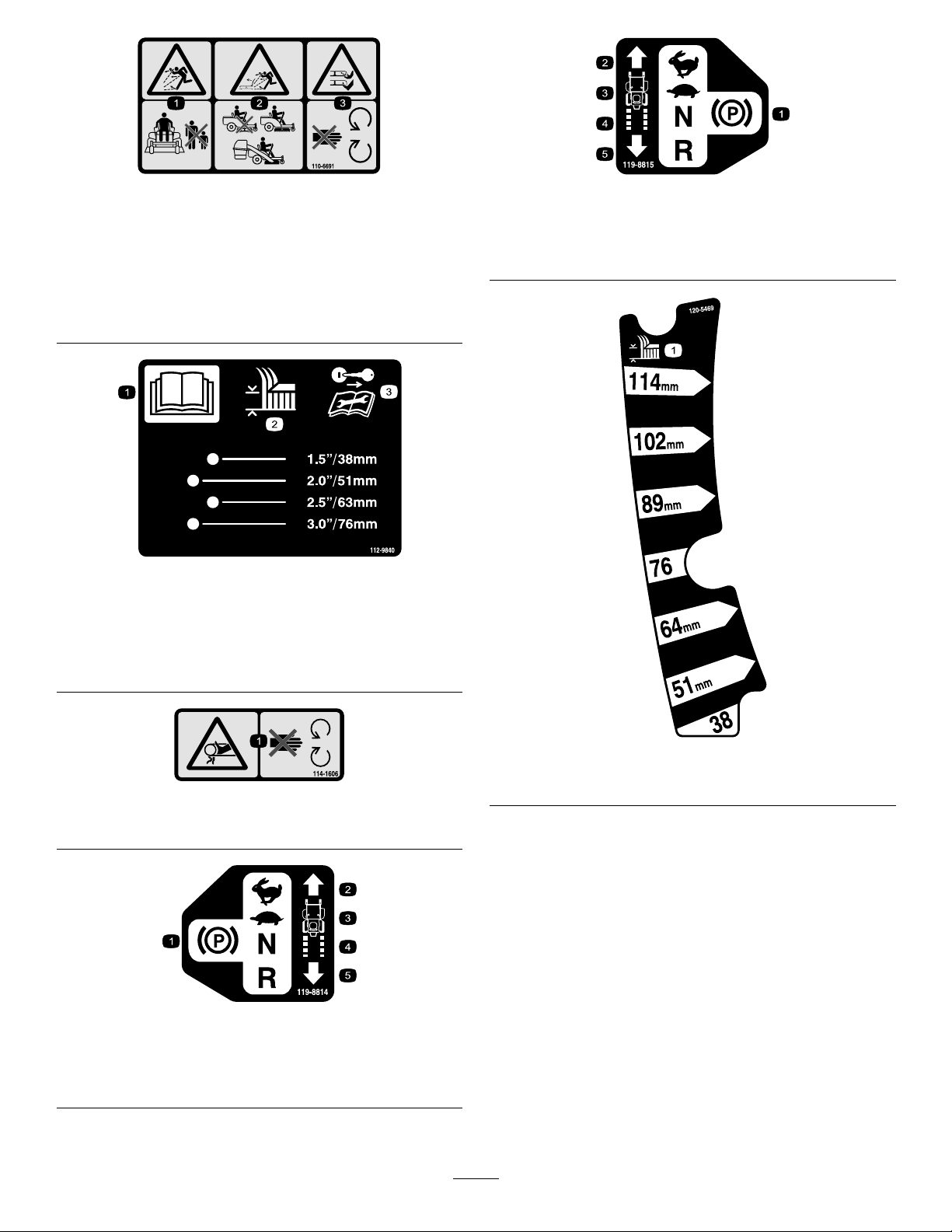

110-6691

119-8815

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Thrownobjecthazard,mower—donotoperatewithoutthe

deector,dischargecover,orgrasscollectionsystemin

place.

3.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

112-9840

1.ReadtheOperator's

Manual.

2.Heightofcut

3.Removetheignitionkey

andreadtheinstructions

beforeservicingor

performingmaintenance.

1.Parkingposition4.Neutral

2.Fast5.Reverse

3.Slow

114-1606

1.Entanglementhazard,belt—keepallguardsinplace.

119-8814

1.Parkingposition4.Neutral

2.Fast5.Reverse

3.Slow

120-5469

1.Height-of-cut

9

Page 10

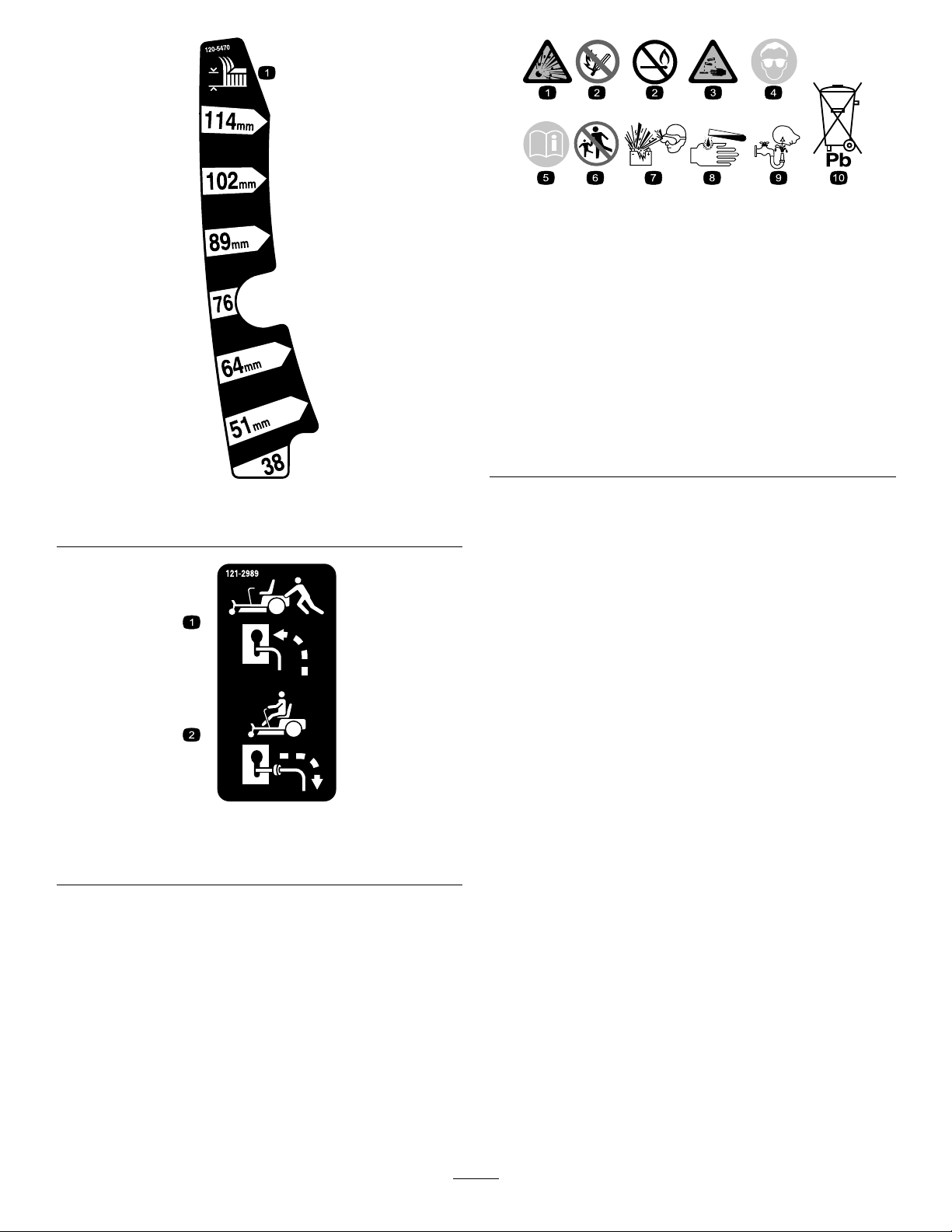

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

distancefromthebattery .

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard.

120-5470

1.Height-of-cut

1.Bypassleverpositionfor

pushingthemachine

121-2989

2.Bypassleverpositionfor

operatingthemachine

10

Page 11

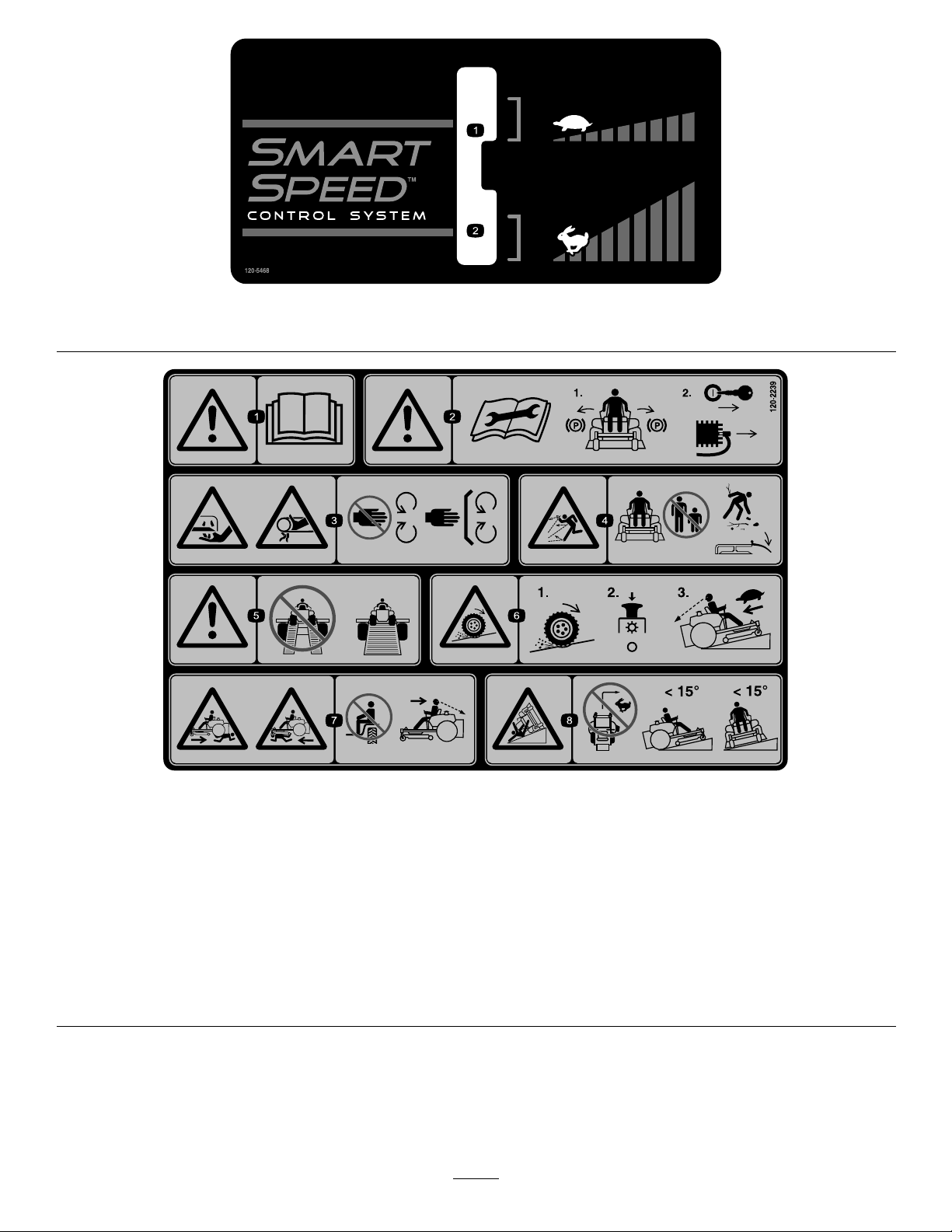

120-5468

1.Slowspeed

2.Fastspeed

120-2239

1.Warning—readtheOperator'sManual.5.Warning—donotusesplitramps,useafullrampswhen

2.Warning—readtheinstructionsbeforeservicingorperforming

maintenance;movethemotioncontrolleverstothepark

(brake)position,removetheignitionkeyanddisconnectthe

sparkplugwire.

3.Cutting/dismembermenthazard,mowerblade;entanglement

hazard,belt—stayawayfrommovingparts,keepallguards

andshieldsinplace.

4.Thrownobjecthazard—keepbystandersasafedistancefrom

themachine,pickupdebrisbeforeoperating,keepdeector

inplace.

transportingmachine.

6.Lossoftraction/controlhazard,slopes—lossoftraction/control

onaslope,disengagethebladecontrolswitch(PTO),

proceedofftheslopeslowly .

7.Crushing/dismembermenthazardofbystanders,reversing;

crushing/dismembermenthazardofbystanders—donotcarry

passengers,lookbehindanddownwhenreversing.

8.Tippinghazard—donotmowslopesgreaterthan15degrees,

avoidsuddenandsharpturnswhileonslopes.

11

Page 12

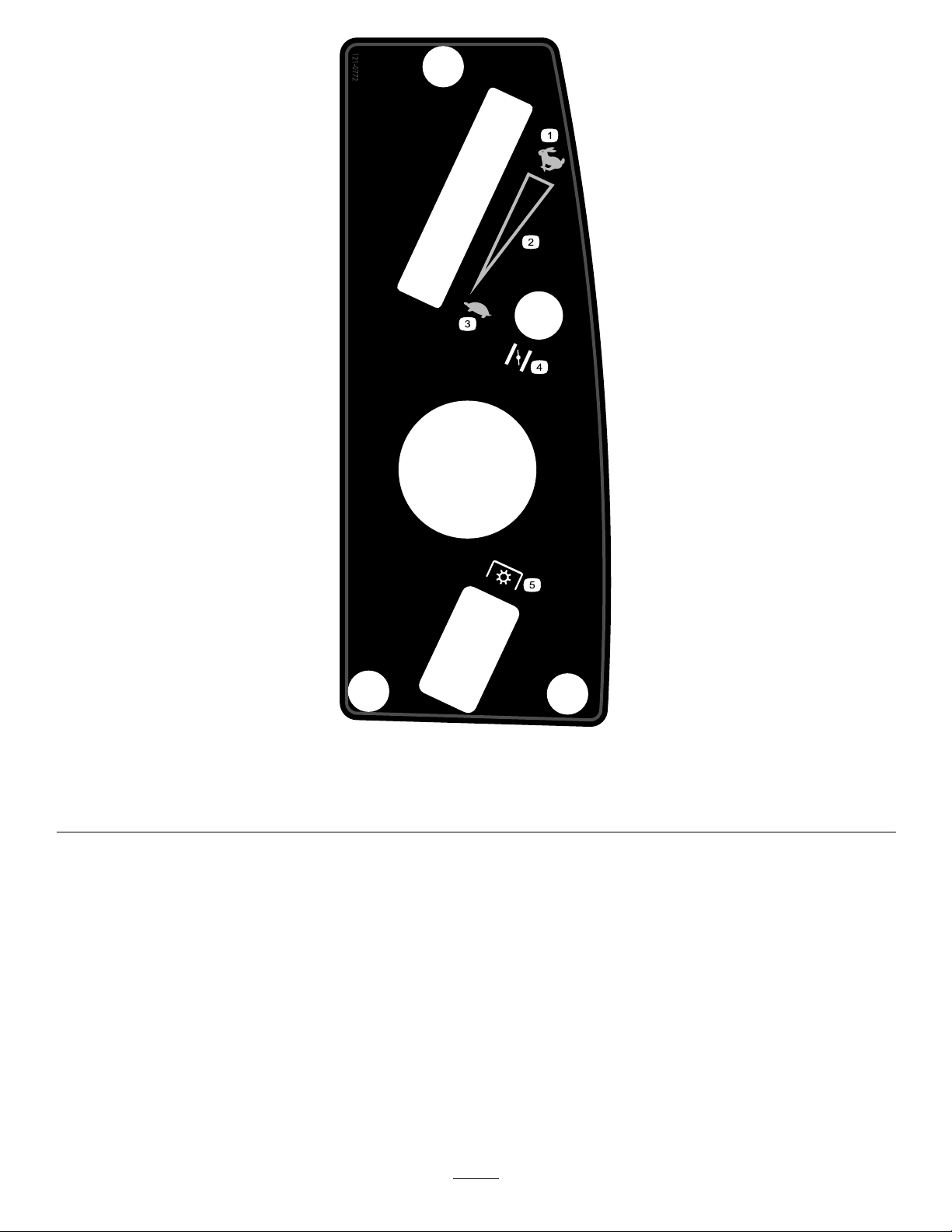

121-0772

1.Fast

2.Continuousvariablesetting5.Powertake-off(PTO),Bladecontrolswitch

3.Slow

4.Choke

12

Page 13

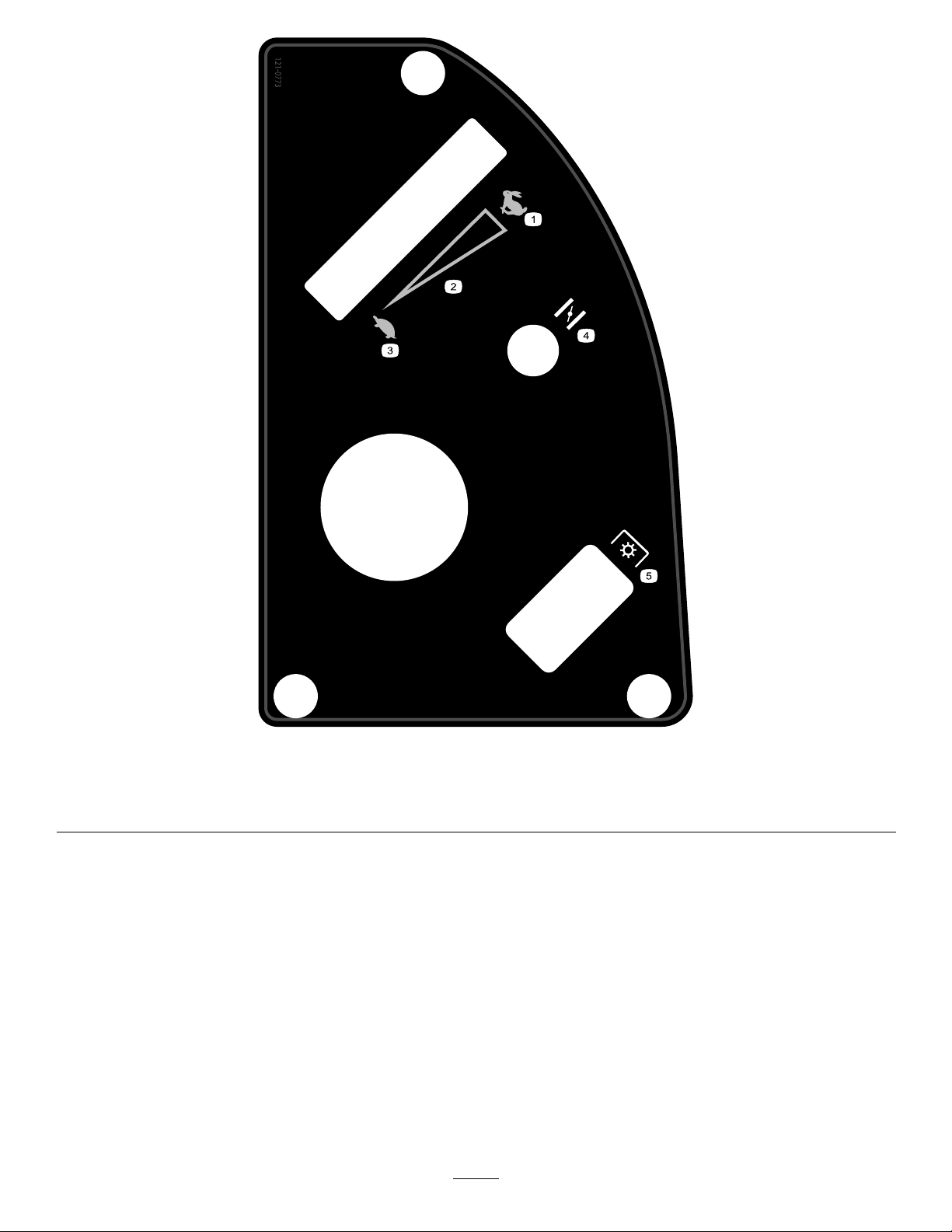

121-0773

1.Fast

2.Continuousvariablesetting5.Powertake-off(PTO),Bladecontrolswitch

3.Slow

4.Choke

13

Page 14

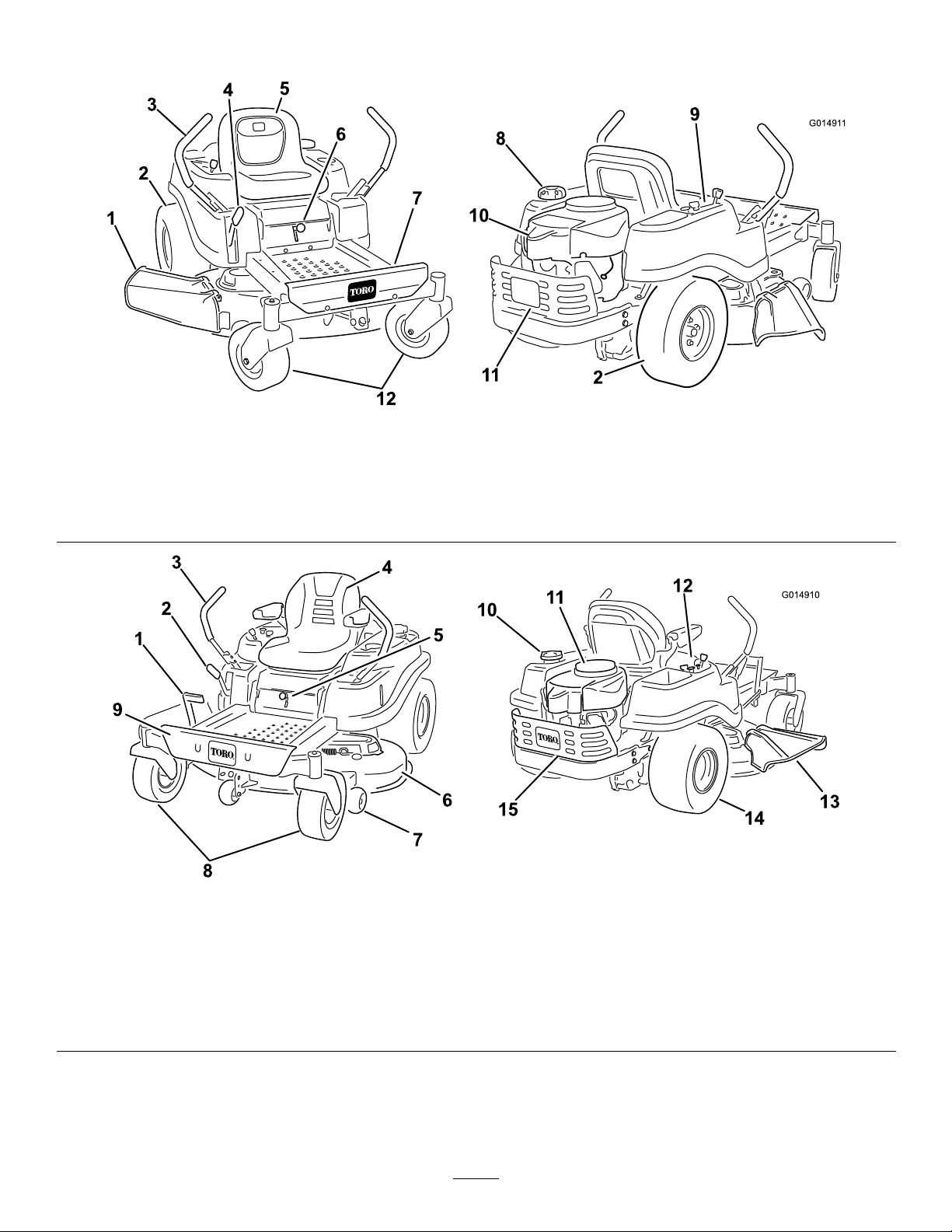

ProductOverview

G01491 1

1

2

3

4

5

6

7

8

9

10

11

2

12

G014910

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Figure4

Modelswith42inchdecks

1.Deector4.Heightofcutlever

2.Reardrivewheel

3.Motioncontrollevers

1.Footassistlever

2.Heightofcutlever

3.Motioncontrollevers7.Anti-scalproller11.Engine15.Engineguard

4.Operatorseat(armrests

optional)

5.Operatorseat

6.SmartSpeed™lever9.Controlpanel

Modelswith50inchdecks

5.SmartSpeed™lever

6.Mowerdeck

8.Frontcasterwheel

7.Footrest10.Engine

8.Fueltankcap11.Engineguard

Figure5

9.Footrest

10.Gastankcap

12.Controlpanel

12.Frontcasterwheel

13.Deector

14.Reardrivewheel

14

Page 15

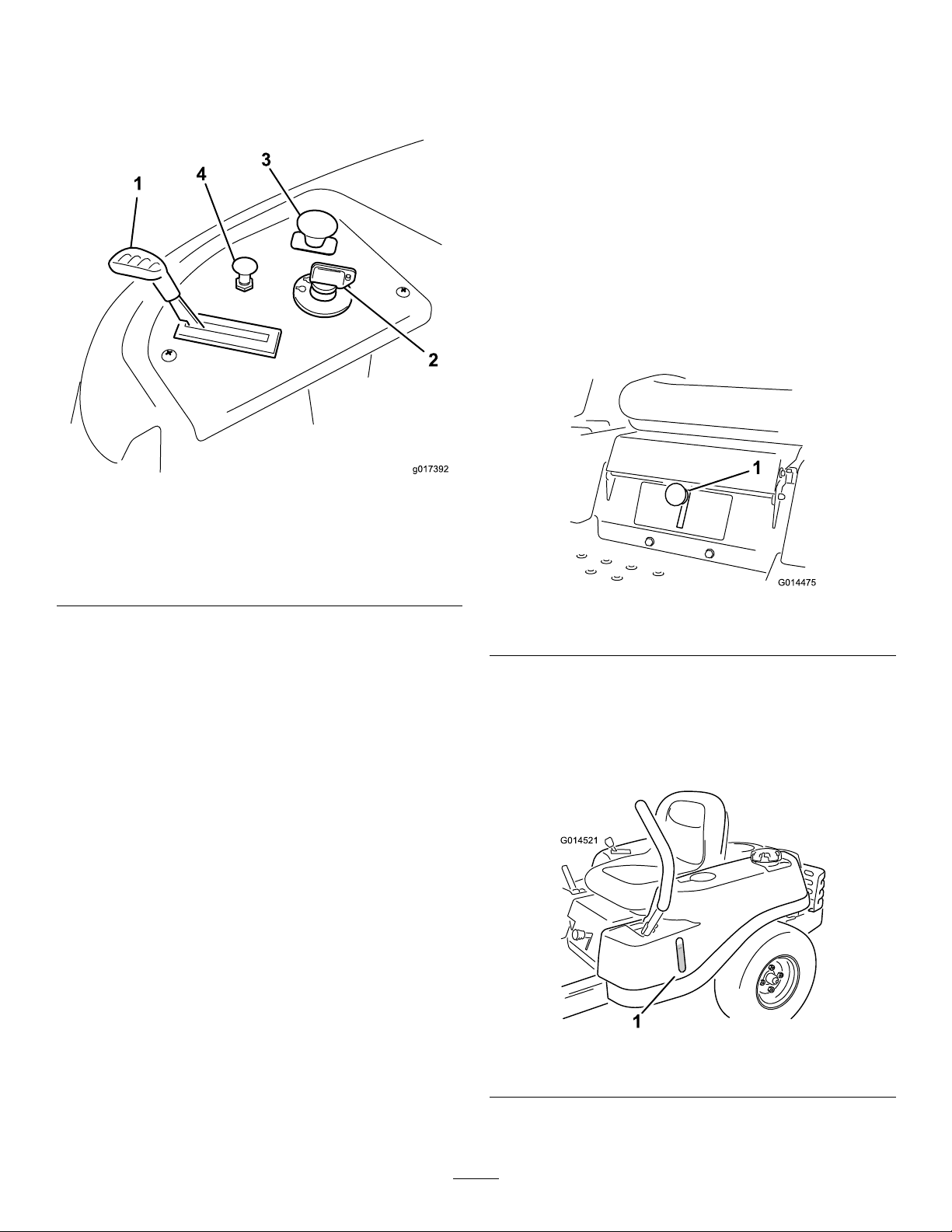

Controls

G014475

1

G014521

1

BecomefamiliarwithallofthecontrolsinFigure4,Figure5,

andFigure6beforeyoustarttheengineandoperatethe

machine.

Figure6

ControlPanel

MotionControlLeversandPark

Position

Themotioncontrolleversarespeedsensitivecontrolsof

independentwheelmotors.Movingaleverforwardor

backwardturnsthewheelonthesamesideforwardorin

reverse;wheelspeedisproportionaltotheamountthelever

ismoved.Movethecontrolleversoutwardfromthecenter

totheparkpositionandexitthemachine(Figure17).Always

positionthemotioncontrolleversintotheparkposition

whenyoustopthemachineorleaveitunattended.

SmartSpeed™ControlSystemLever

TheSmartSpeed™ControlSystemlever,locatedbelowthe

operatingposition,givestheoperatorachoicetodrivethe

machineattwospeedranges,highandlow(Figure7).

1.Throttle3.Bladecontrolswitch

2.Ignitionswitch

(powertake-off)

4.Choke

IgnitionSwitch

Theignitionswitchhasthreepositions,Off,RunandStart.

ThekeywillturntoStartandmovebacktoRunuponrelease.

TurningthekeytotheOffpositionwillstoptheengine;

however,alwaysremovethekeywhenleavingthemachine

topreventsomeonefromaccidentallystartingtheengine

(Figure6).

ThrottleControl

Thethrottlecontrolstheenginespeedandithasacontinuous

variablesettingfromSlowtoFast(Figure6).

ChokeControl

PullupontheChokecontroluntilitstopstochokethe

engine(Figure6).PushdownontheChokecontrolfor

normalengineoperation

Figure7

1.Smartspeedlever

FuelWindow

Thefuelwindowlocatedonthelefthandsideofthemachine

canbeusedtoverifythepresenceofgasolineinthetank

(Figure8).

BladeControlSwitch(PowerTake-Off)

Thebladecontrolswitch,representedbyapowertake-off

(PTO)symbol,engagesanddisengagespowertothemower

blades(Figure6).

Figure8

1.Fuelpresencewindow

15

Page 16

Height-of-CutLever

Theheightofcutleverallowstheoperatortolowerand

raisethedeckfromtheseatedposition.Whentheleveris

movedup,towardtheoperatorthedeckisraisedfromthe

groundandwhenmoveddown,awayfromtheoperatoritis

loweredtowardtheground.Onlyadjusttheheightofcut

whilemachineisnotmoving(Figure21).

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

ThinkSafetyFirst

OperatingSafety

Pleasecarefullyreadallofthesafetyinstructionsanddecals

inthesafetysection.Knowingthisinformationcouldhelp

you,yourfamily,petsorbystandersavoidinjury.

DANGER

Mowingonwetgrassorsteepslopescancause

slidingandlossofcontrol.

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,deathor

drowning.

Alossoftractionisalossofsteeringcontrol.

Toavoidlossofcontrolandpossibilityofrollover:

•Donotmowneardrop-offsornearwater.

•Donotmowslopesgreaterthan15degrees.

•Reducespeedanduseextremecautionon

slopes.

•Whenmowingslopes,graduallyworkfrom

lowertohigherareasontheincline.

•Avoidsuddenturnsorrapidspeedchanges.

•Turnup,intoaninclinewhenchanging

directionsonslopes.Turningdowntheslope

reducestraction.

•Attachmentschangethehandlingcharacteristics

ofthemachine.Useextracautionwhenusing

attachmentswiththemachine.

16

Page 17

1.SafeZone-usethe

TimeCutterhere

2.Usewalkbehindmower

and/orhandtrimmernear

drop-offsandwater .

FuelSafety

DANGER

Figure9

3.Water

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthefuelreaches

thebaseofthellerneck.Thisemptyspacein

thetankallowsgasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

WARNING

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening .

•Keepgasawayfromeyesandskin.

UnderstandingtheSafetyInterlock

System

WARNING

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

Thesafetyinterlocksystemisdesignedtopreventtheengine

fromstartingunless:

•Thebladesaredisengaged.

•Themotioncontrolleversareintheparkposition.

17

Page 18

Thesafetyinterlocksystemalsoisdesignedtostoptheengine

G014474

1

2

3

4

5

6

G014895

1

2

3

4

wheneverthecontrolleversareoutoftheparkpositionand

yourisefromtheseat.

BeforeStarting

RecommendedFuel

1.Forbestresults,useonlyclean,fresh,unleadedgasoline

withanoctaneratingof87orhigher((R+M)/2rating

method).

2.Oxygenatedfuelwithupto10%ethanolor15%

MTBEbyvolumeisacceptable.

3.DoNotuseethanolblendsofgasoline(suchasE15

orE85)withmorethan10%ethanolbyvolume.

Performanceproblemsand/orenginedamagemay

resultwhichmaynotbecoveredunderwarranty.

4.DoNotusegasolinecontainingmethanol.

5.DoNotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessafuelstabilizeris

used.

6.DoNotaddoiltogasoline.

2.Slowlyaddregular,unleadedgasolineuntilthefuel

reachesthebaseofthellerneck(Figure10).

Figure10

1.Fueltankcap

2.Fillopening5.Fuelwindow

3.Fillerneck

4.Baseofllerneck,DO

NOTFILLP ASTHERE

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysorless.

Forlongerstorageitisrecommendedthatthefueltank

bedrained.

•Cleanstheenginewhileitruns.

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting.

Addthecorrectamountofgasstabilizer/conditionertothe

gas.

Note:Afuelstabilizer/conditionerismosteffectivewhen

mixedwithfreshgasoline.Tominimizethechanceofvarnish

depositsinthefuelsystem,usefuelstabilizeratalltimes.

FillingtheFuelTank

Makesuretheengineisshutoffandthemotioncontrolsare

intheparkposition.Tankmaximumcapacityis2.9gallons.

Important:DoNotoverllfueltank.Fillthefueltank

tothebottomofthellerneck.Theemptyspaceinthe

tankallowsthefueltoexpand.Overllingmayresult

infuelleakageordamagetotheengineoremissions

system.

1.Cleanaroundthefueltankcapandremovethecap.

Figure11

1.Fillopening3.Fuel

2.Baseofllerneck,DO

NOTFILLP ASTHERE

4.Emptyspaceforfuel

expansion.

Important:DoNotoverllfueltank.Fillthe

fueltanktothebottomofthellerneck.The

emptyspaceinthetankallowsthefueltoexpand.

Overllingmayresultinfuelleakageordamage

totheengine.

3.Installthefueltankcapsecurelyandtightenuntilit

“clicks”.Wipeupanygasolinethatmayhavespilled.

CheckingtheEngineOilLevel

Beforeyoustarttheengineandusethemachine,checktheoil

levelintheenginecrankcase;refertoCheckingtheOilLevel

intheEngineMaintenancesection.

Note:Youcanusethefuelwindowtoverifythe

presenceofgasolinebeforellingthetank(

Figure10).

18

Page 19

StartingtheEngine

1.Sitdownontheseatandmovethemotioncontrols

outwardtotheparkposition.

2.Disengagethebladesbymovingthebladecontrol

switchtoOff(Figure12)

Figure13

Figure12

1.Controlpanel2.Bladecontrolswitch—Off

position

3.PullupontheChokecontrolbeforestartingacold

engine(Figure13).

Note:Awarmorhotenginemaynotrequirechoking.

1.Controlpanel4.Continuousvariable

2.Throttle

3.Fast

setting

5.Slow

6.Chokecontrol

4.TurntheignitionkeytoStarttoenergizethestarter.

Whentheenginestarts,releasethekey(Figure14).

Important:Donotengagethestarterformore

than10secondsatatime.Iftheenginefailsto

start,allowa60secondcool-downperiodbetween

attempts.Failuretofollowtheseinstructionscan

damagethestartermotor.

19

Page 20

Figure15

Figure14

1.Controlpanel

2.Ignitionkey—runposition

3.Ignitionkey—startposition

4.Off

5.Aftertheenginestarts,pushdownontheChoke

control(

upontheChokecontrolandlettheenginerunfora

fewseconds.ThenpushdownontheChokecontrol.

Repeatthisasrequired.

Figure14).Iftheenginestallsorhesitates,pull

5.Run

6.Start

7.Chokecontrol

OperatingtheBlades

Thebladecontrolswitch,representedbyapowertake-off

(PTO)symbol,engagesanddisengagespowertothemower

blades.Thisswitchcontrolspowertoanyattachmentsthat

drawpowerfromtheengine,includingthemowerdeckand

cuttingblades.

EngagingtheBlades

1.Controlpanel2.Bladecontrolswitch—On

position

DisengagingtheBlades

PushdownonthebladecontrolswitchtomoveittotheOff

positionanddisengagetheblades(Figure16).

Important:Donotengagethebladeswhenparkedin

tallgrass.Beltorclutchdamagecanoccur.

1.Releasepressureonthemotioncontrolleversand

placethemachineinneutral.

2.MovethethrottletotheFastposition.

Note:Alwaysengagethebladeswiththethrottlein

theFastposition.

3.Pulluponthebladecontrolswitchtomoveittothe

Onpositionandengagetheblades(

Figure15).

Figure16

1.Controlpanel2.Bladecontrolswitch—Off

TestingtheSafetyInterlock System

Testthesafetyinterlocksystembeforeyouusethemachine

eachtime.Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthesafety

systemimmediately.

20

Page 21

1.Whilesittingontheseat,withthecontrolleversinpark

G014475

1

position,andmovethebladecontrolswitchtoOn.Try

startingtheengine;theengineshouldnotcrank.

2.Whilesittingontheseat,movethebladecontrol

switchtoOff.Moveeithermotioncontrollevertothe

center,unlockedposition.Trystartingtheengine;the

engineshouldnotcrank.Repeatwiththeothermotion

controllever.

3.Whilesittingontheseat,movethebladecontrolswitch

toOff,andlockthemotioncontrolleversinthepark

position.Starttheengine.Whiletheengineisrunning,

engagethebladecontrolswitch,andriseslightlyfrom

theseat;theengineshouldstop.

4.Whilesittingontheseat,movethebladecontrolswitch

toOff,andlockthemotioncontrolleversinthepark

position.Starttheengine.Whiletheengineisrunning,

movethemotioncontrolleverstothecenter,unlocked

position,engagethebladecontrolswitch,andrise

slightlyfromtheseat;theengineshouldstop.

StoppingtheEngine

1.Disengagethebladesbymovingthebladecontrol

switchtoOff(Figure16).

Figure17

2.MovethethrottlelevertoFast(Figure13).

3.TurntheignitionkeytoOff(Figure14)andremove

thekey.

Driving

Drivingthemachinebenetsfromanunderstandingof

whatzeroturnradiusmowermeans.Thedrivewheelsturn

independently,poweredbyhydraulicmotorsoneachaxle;

henceonesidecanturninreversewhiletheotherturns

forwardcausingthemachinetospinratherthanturn.This

vastlyimprovesthemachinemaneuverabilitybutmayrequire

someadjustmentiftheoperatorisunfamiliar.

WARNING

Themachinecanspinveryrapidly .Theoperator

maylosecontrolofthemachineandcausepersonal

injuryordamagetothemachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placingthethrottlecontrol

intheFastpositioncanbebestforperformance.Formost

applications,operatinginthefullthrottlepositionisdesirable.

1.Park(brake)position

2.Centerunlockposition

3.Forward

4.Backward

UsingtheSmartSpeed™Control

System

TheSmartSpeed™ControlSystemlever,locatedbelowthe

operatingposition(),givestheoperatorachoicetodrivethe

machineattwogroundspeedranges,highandlow.

Figure18

1.Smartspeedlever

Tochangespeeds:

1.Movethemotioncontrolleverstoneutralandoutward

totheparkposition;disengagethebladecontrolswitch.

21

Page 22

WARNING

G008952

G008953

Removingyourhandsfromthemotioncontrol

leverswhilethemachineisinmotioncan

resultinalossofcontrolcausingharmtoyou

orbystanders.

Alwaysstopthemachineandmovethemotion

controlleverstotheparkpositionbefore

adjustingtheSmartSpeed™ControlSystem.

2.Adjustthelevertothedesiredposition.

Forward

1.Movetheleverstothecenter,unlockedposition.

2.Togoforward,slowlypushthemotioncontrollevers

forward(Figure17).

Backward

1.Movetheleverstothecenter,unlockedposition.

2.Togobackward,lookbehindyouanddownas

youslowlypullthemotioncontrolleversrearward

(Figure20).

Figure20

Figure19

Togostraight,applyequalpressuretobothmotion

controllevers(Figure17).

Toturn,releasepressureonthemotioncontrollever

towardthedirectionyouwanttoturn(Figure17).

Thefartheryoumovethemotioncontrolleversin

eitherdirection,thefasterthemachinewillmovein

thatdirection.

Tostop,pullthemotioncontrolleverstoneutral.

Togostraight,applyequalpressuretobothmotion

controllevers(Figure20).

Toturn,releasethepressureonthemotioncontrol

levertowardthedirectionyouwanttoturn.

Tostop,pushthemotioncontrolleverstoneutral.

StoppingtheMachine

Tostopthemachine,movethemotioncontrolleversto

neutralandoutwardtotheparkposition,disengagetheblade

controlswitch,ensurethethrottleisinthefastposition,and

turntheignitionkeytooff.Remembertoremovethekey

fromtheignitionswitch.

WARNING

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemowerwhileitis

unattended.

Alwaysremovetheignitionkeyandmovethe

motioncontrolleversoutwardtotheparkposition

whenleavingthemachineunattended,evenifjust

forafewminutes.

22

Page 23

AdjustingtheHeightofCut

G015319

1

2

3

g019929

1

2

3

4

5

Height-of-cutiscontrolledbytheleverlocatedtotherightof

theoperatingposition(Figure21).

•Upperhole—usethispositionwiththemowerdeck

inthe63mm(2-1/2inch)andbelowheight-of-cut

positions(

Figure22).

•Lowerhole—usethispositionwiththemower

deckinthe76mm(3inch)andaboveheight-of-cut

positions(Figure22).

Figure22

Figure21

1.Height-of-cutlever3.115mm(4.5inch),

2.Height-of-cutpositions

1.Pullupandinwardonthelevertomoveittothe

desiredcuttingposition.

2.Onceatthedesiredcuttingposition,slowlylowerthe

leveruntilitengagestheposition.

Thetransportpositionisthehighestheight-of-cutpositionor

cuttingheight115inch[4.5mm](Figure21).

Transportposition

AdjustingtheAnti-Scalp Rollers(For42inchMower Decks)

Wheneveryouchangetheheight-of-cut,itisrecommended

toadjusttheheightoftheanti-scalprollers.

Note:Adjusttheanti-scalprollerssotherollersdonottouch

thegroundinnormal,atmowingareas.

1.Disengagethebladecontrolswitch(PTO),movethe

2.Stoptheengine,removethekey,andwaitforallmoving

motioncontrolleverstotheneutrallockpositionand

settheparkingbrake.

partstostopbeforeleavingtheoperatingposition.

1.Anti-scalproller4.Upperhole—themower

2.Lowerhole—themower

deckinthe76mm(3inch)

andaboveheight-of-cut

positions

3.FlangeNut

deckinthe63mm

(2-1/2inch)andbelow

height-of-cutpositions

5.Bolt

AdjustingtheAnti-Scalp Rollers(For50inchMower Decks)

Wheneveryouchangetheheight-of-cut,itisrecommended

toadjusttheheightoftheanti-scalprollers.

Note:Adjusttheanti-scalprollerssotherollersdonottouch

thegroundinnormal,atmowingareas.

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockpositionand

settheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Adjusttheanti-scalprollersasshowninFigure23to

matchtheclosestheight-of-cutposition.

3.Adjusttheanti-scalprollerstooneofthefollowing

positions:

23

Page 24

G010233

1

2

3

4

Figure23

G014477

1

1

G014969

4

1

2

G014970

3

1.Anti-scalproller3.FlangeNut

2.Bolt4.Holespacing

Figure25

AdjustingtheMotionControl

PositioningtheSeat

Theseatcanmoveforwardandbackward.Positiontheseat

whereyouhavethebestcontrolofthemachineandaremost

comfortable.

Modelswith42inchDecks

1.Raisetheseatandloosentheadjustmentboltsjust

enoughthatseatcanmove(Figure24).

Levers

AdjustingtheHeight

Themotioncontrolleverscanbeadjustedhigherorlowerfor

maximumoperatorcomfort.

1.Removethe2boltsholdingthecontrollevertothe

controlarmshaft(Figure26).

2.Movethecontrollevertothenextsetofholes.Secure

theleverwiththe2bolts(Figure26).

Figure26

1.Controlarmshaft3.Slotted,upperhole

2.Controllever

4.Bolt

Figure24

1.Adjustmentbolt

2.Movetheseattothedesiredpositionandtightenthe

bolts.

Modelswith50inchDecks

Whilesittingintheoperator’sposition,raisetheseat

adjustmentleverslightlyandmovetheseatforwardor

backwardtothedesiredposition(Figure25).

3.Repeattheadjustmentfortheoppositecontrollever.

AdjustingtheTilt

Themotioncontrolleverscanbetiltedforeoraftfor

maximumoperatorcomfort.

1.Loosentheupperboltholdingthecontrollevertothe

controlarmshaft.

2.Loosenthelowerboltjustenoughtopivotthecontrol

leverforeoraft(

securethecontrolinthenewposition.

3.Repeattheadjustmentfortheoppositecontrollever.

24

Figure26).Tightenbothboltsto

Page 25

PushingtheMachinebyHand

g017303

1 2

3

ToOperatetheMachine

Important:Alwayspushthemachinebyhand.Never

towthemachinebecausedamagemayoccur.

Thismachinehasanelectricbrakemechanismandtopush

themachinetheignitionkeyneedstobeintheRunposition.

Thebatteryneedstobechargedandfunctioningforthe

electricbraketobedisengage.

ToPushtheMachine

1.Parkthemachineonalevelsurfaceanddisengagethe

bladecontrolswitch.

2.Movethemotioncontrolleversoutwardtopark

position,stoptheengine,andwaitforallmovingparts

tostopbeforeleavingtheoperatingposition.

3.Locatethebypassleversontheframeonbothsidesof

theengine.

4.Movethebypassleversforwardthroughthekeyhole

anddowntolocktheminplaceasshowninFigure

23Figure27.Ensurethisisdoneforeachlever.

5.Movethemotioncontrolleversinwardtotheneutral

positionandturntheignitionkeytotherunposition.

Donotstartthemachine.

Movethebypassleversrearwardthroughthekeyholeand

downtolocktheminplaceasshowninFigure27.Ensure

thisisdoneforeachlever.

Themachineisnowabletobepushedbyhand.

Figure27

1.Bypassleverlocations

2.Leverpositionfor

operatingthemachine

3.Leverpositionforpushing

themachine

6.Whennished,ensurethekeyhasbeenreturnedtothe

Stoppositiontoavoiddrainingthebatterycharge.

Ifthemachinefailstomovetheelectricbrake

maystillbeengaged.Ifnecessarytheelectric

brakecanbereleasedmanually.Refertothe

ReleasingtheElectricBrake(page39)procedureinDrive

Maintenance.

25

Page 26

GrassDeector

G009660

1

2

3

4

5

G005667

1

2

3

Themowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

DANGER

Withoutthegrassdeector,dischargecover,or

completegrasscatcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriswillcauseinjuryor

death.

•Neverremovethegrassdeectorfromthemower

becausethegrassdeectorroutesmaterialdown

towardtheturf.Ifthegrassdeectorisever

damaged,replaceitimmediately .

•Neverputyourhandsorfeetunderthemower.

•Nevertrytocleardischargeareaormower

bladesunlessyoumovethebladecontrolswitch

toOffandrotatetheignitionkeytoOff.Also

removethekeyandpullthewireoffthespark

plug(s).

ConvertingtoSideDischarge (ForModelswith42Inch Decks)

Themowerdeckandmowerbladesshippedwiththismachine

weredesignedforoptimummulchingandsidedischarge

performance.

RemovingtheDischargeCoverforSide

Discharge

1.Parkthemachineonalevelsurfaceanddisengagethe

bladecontrolswitch.

2.Movethemotioncontrolleversoutwardtopark

position,stoptheengine,removethekey,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

Figure28

1.Capnut(1/4inch)

2.Dischargecover5.Removethecover

3.Bolt(1/4x2-1/2inches)

4.Removethedischargecover.

5.Liftupthegrassdeectorandlocatethelocknuton

thedeectorpivotrod.Removetheexistingthinnut

(3/8inch).

6.Installthecutoffbafetotheexposedpivotrod

(

Figure29).Usetheexistingthinnut(3/8inch)to

securethebafetothemower.

Note:Thecutoffbafewasshippedwiththemachine

asaloosepart.

4.Rotatethecoverup

3.Removethe2boltsandnutsthatsecurethedischarge

covertothemower(Figure28).

Figure29

1.Pivotrod

2.Cutoffbafe(originally

shippedwiththemachine)

7.Torquethefastenerto14-18ft-lb(7-9N-m).

8.Lowerthegrassdeectoroverthedischargeopening

26

3.Existingthinnut(3/8inch)

Page 27

Important:Ensurethemowerhasahingedgrass

deectorthatdispersesclippingstothesideand

downtowardtheturf,whileinsidedischarge

mode.

ConvertingtoSideDischarge (ForModelswith50Inch Decks)

InstallingtheDischargeCoverfor

Mulching

1.Parkthemachineonalevelsurfaceanddisengagethe

bladecontrolswitch.

2.Movethemotioncontrolleversoutwardtopark

position,stoptheengine,removethekey,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Liftthegrassdeectorandslidethetabsontopofthe

dischargecoverunderthegrassdeectorretainingrod.

Rotatethedischargecoverdownovertheopening,and

ontothelowerlipofthemower(Figure30).

Themowerdeckandmowerbladesshippedwiththismachine

weredesignedforoptimummulchingandsidedischarge

performance.

RemovingtheRightBafeforSide

Discharge

1.Parkthemachineonalevelsurfaceanddisengagethe

bladecontrolswitch.

2.Movethemotioncontrolleversoutwardtopark

position,stoptheengine,removethekey,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Removetherightmowerblade.RefertotheMower

Maintenancesection.

4.Removethe2knobsandcurvedwashersthatsecure

therightbafetothemowerasshowninFigure31.

Figure30

1.Dischargecover

2.Capnut(1/4inch)

4.Securethedischargecovertothelowerlipofthe

mowerwithtwobolts(1/4x2-1/2inches)andtwocap

nuts(1/4inch)asshownin

Note:Donotovertightenthenuts;thiscoulddistort

thecoverandcausebladecontact.

3.Bolt(1/4x2-1/2inches)

Figure30.

Figure31

1.Knob

2.Curvedwasher

5.Removetherightbafeandlowerthegrassdeector

overthedischargeopeningasshowninFigure32and

Figure31.

3.Bafestudcomingthrough

themower

27

Page 28

G006475

1

2

3

4

1

Figure32

G015321

1

2

3

1.Rightbafe

2.Curvedwasherandknob4.Tab(mustremainoutside

3.Dischargeopening

ofthemower)

6.Installfastenersintotheholesinthetopofthemower

topreventyingdebris.

WARNING

Openholesinthemowerexposeyouand

otherstothrowndebriswhichcancause

severeinjury.

Figure33

1.Bolt(5/16x3/4inch)3.Locknut(5/16inch)

2.Cutoffbafe

10.Torquethefastenersto14-18ft-lb(7-9N-m).

11.Lowerthegrassdeectoroverthedischargeopening.

Important:Ensurethemowerhasahingedgrass

deectorthatdispersesclippingstothesideand

downtowardtheturf,whileinsidedischarge

mode.

InstallingtheRightBafeforMulching

1.Parkthemachineonalevelsurfaceanddisengagethe

bladecontrolswitch.

2.Movethemotioncontrolleversoutwardtopark

position,stoptheengine,removethekey,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Removethecutoffbafefromthemowerdeck

(Figure33).

•Neveroperatethemowerwithouthardware

mountedinallholesinthemowerhousing.

•Installthehardwareinthemountingholes

whenyouremovethemulchingbafe.

7.Installtherightmowerblade.RefertotheMower

Maintenancesection.

8.Liftupthegrassdeector.Installtwobolts(5/16x

3/4inch)tothetwoholesalongthedeckcutout.

9.Installthecutoffbafetothemowerdeck

Usethetwolocknuts(5/16inch)tosecurethebafe

tothemowerdeck.

Figure33.

4.Removetherightmowerblade.RefertotheMower

Maintenancesection.

5.Slidetherightbafeunderthemowerdeckandsecure

itusing2knobsandcurvedwashers(cuppedside

facingthemower)asshownin

Figure31andFigure32.

Important:Ensurethatthetabonthefarright

sideoftherightbafeisoutsideofthemowerand

isushwiththemowerwall.

6.Installtherightmowerblade.RefertotheMower

Maintenancesection.

Note:Thecutoffbafewasshippedwiththemachine

asaloosepart.

28

Page 29

OperatingTips

FastThrottleSetting

Forbestmowingandmaximumaircirculation,operatethe

engineattheFastposition.Airisrequiredtothoroughlycut

grassclippings,sodonotsettheheight-of-cutsolowasto

totallysurroundthemowerbyuncutgrass.Alwaystrytohave

onesideofthemowerfreefromuncutgrass,whichallowsair

tobedrawnintothemower.

UsingtheSmartSpeed™Control

System

TheSmartSpeed™ControlSystemlever,locatedbelowthe

operatingposition,givestheoperatorachoicetodrivethe

machineattwospeedranges,highandlow.Anoperator

canbenetfromthelowerspeedsettingwhenmaneuvering

themachineintightspacesoroperatingarounddelicate

landscapes.Thelowsettingcanalsobeusedtooperatethe

machineatahighthrottlesettingandbladespeedwhilestill

beingabletoreducegroundspeedtoincreasequalityofcut.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethatthe

cuttingheightofthemowerdoesnotscalpanyuneven

ground.However,thecuttingheightusedinthepastis

generallythebestonetouse.Whencuttinggrasslongerthan

sixinchestall,youmaywanttocutthelawntwicetoensure

anacceptablequalityofcut.

Cut1/3oftheGrassBlade

LongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,raisethe

cuttingheighthigherthanusualandcutthegrassatthis

setting.Thencutthegrassagainusingthelower,normal

setting.

WhenStopping

Ifthemachine'sforwardmotionmustbestoppedwhile

mowing,aclumpofgrassclippingsmaydropontoyour

lawn.Toavoidthis,moveontoapreviouslycutareawiththe

bladesengagedoryoucandisengagethemowerdeckwhile

movingforward.

KeeptheUndersideoftheMowerClean

Cleanclippingsanddirtfromtheundersideofthemower

aftereachuse.Ifgrassanddirtbuildupinsidethemower,

cuttingqualitywilleventuallybecomeunsatisfactory.

BladeMaintenance

Maintainasharpbladethroughoutthecuttingseasonbecause

asharpbladecutscleanlywithouttearingorshreddingthe

grassblades.Tearingandshreddingturnsgrassbrownat

theedges,whichslowsgrowthandincreasesthechanceof

disease.Checkthemowerbladesaftereachuseforsharpness,

andforanywearordamage.Filedownanynicksandsharpen

thebladesasnecessary.Ifabladeisdamagedorworn,replace

itimmediatelywithagenuineT ororeplacementblade.

Itisbesttocutonlyabout1/3ofthegrassblade.Cutting

morethanthatisnotrecommendedunlessgrassissparse,or

itislatefallwhengrassgrowsmoreslowly.

MowingDirection

Alternatemowingdirectiontokeepthegrassstanding

straight.Thisalsohelpsdisperseclippingswhichenhances

decompositionandfertilization.

MowatCorrectIntervals

Normally,moweveryfourdays.Butremember,grassgrows

atdifferentratesatdifferenttimes.Sotomaintainthesame

cuttingheight,whichisagoodpractice,mowmoreoftenin

earlyspring.Asthegrassgrowthrateslowsinmidsummer,

mowlessfrequently .Ifyoucannotmowforanextended

period,rstmowatahighcuttingheight;thenmowagain

twodayslateratalowerheightsetting.

AvoidCuttingTooLow

Ifthecuttingwidthofthemoweriswiderthanthemower

youpreviouslyused,raisethecuttingheighttoensurethat

uneventurfisnotcuttooshort.

29

Page 30

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Beforeeachuseordaily

Aftereachuse

Every25hours

Every100hours

Every200hours

Beforestorage

MaintenanceProcedure

•Changetheengineoil.

•Checkthesafetyinterlocksystem.

•Checktheengineoillevel.

•Cleantheairintakescreen.

•Checkthecuttingblades.

•Inspectthegrassdeectorfordamage

•Cleanthemowerdeckhousing.

•Greasealllubricationpoints.

•Checktirepressure.

•Checkthebeltsforwear/cracks.

•Servicethepaperelement.(moreoftenindusty ,dirtyconditions)

•Changetheengineoil.(moreoftenindusty,dirtyconditions)

•Checkthesparkplug(s).

•Replacethein-linefuellter

•Replacethepaperelement.(moreoftenindusty ,dirtyconditions)

•Changetheoillter.(moreoftenindusty,dirtyconditions)

•Chargethebatteryanddisconnectbatterycables.

•Performallmaintenanceprocedureslistedabovebeforestorage.

•Paintanychippedsurfaces.

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

30

Page 31

Premaintenance

1

G014522

Lubrication

Procedures

GreasingtheBearings

RaisingtheSeat

Makesurethemotioncontrolleversarelockedinthepark

position.Lifttheseatforward.

Thefollowingcomponentscanbeaccessedbyraisingtheseat:

•Serialplate

•Servicedecal

•Seatadjustmentbolts

•Fuellter

•Batteryandbatterycables

ServiceInterval:Every25hours—Greasealllubrication

points.

GreaseType:No.2GeneralPurposeLithiumBaseGrease

1.Parkthemachineonalevelsurfaceanddisengagethe

bladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothepark

position,stoptheengine,removethekey,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Cleanthegreasettings(

arag.Makesuretoscrapeanypaintoffofthefront

ofthetting(s).

Figure34andFigure35)with

Figure34

1.Frontcastertire

Figure35

Locatedontheseatpanunderside

1.Readtheinstructions

beforeservicingor

performingmaintenance.

2.Checktirepressureevery

25operatinghours.

3.Greaseevery25operating

hours.

4.Engine

4.Connectagreaseguntoeachtting(Figure34and

Figure35).Pumpgreaseintothettingsuntilgrease

beginstooozeoutofthebearings.

5.Wipeupanyexcessgrease.

31

Page 32

EngineMaintenance

G014908

1

2

3

g017470

SAE V iscosity Grades

SAE 40

SAE 30

SAE 10W– 30/ SAE 10W– 40

-20 0 20 32 40 60 80 100

-30 -20 -10 0 10 20 30 40

°F

°C

STARTING TEMPERA TURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

SAE 5W– 20

ServicingtheAirCleaner

Note:Servicetheaircleanermorefrequently(everyfew

hours)ifoperatingconditionsareextremelydustyorsandy.

RemovingtheElement

1.Parkthemachineonalevelsurfaceanddisengagethe

bladecontrol(PTO).

2.Movethemotioncontrolleverstothebrakeposition,

stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Cleanaroundtheaircleanercovertopreventdirtfrom

gettingintotheengineandcausingdamage.Liftthe

coverandremovethehoseclampsecuringtheair

cleanerassemblytotheengine(Figure36).

4.Loosenthehoseclampandremovethepaperelement

(

Figure36).

Important:Nevercleanthepaperelementwith

pressurizedairorliquids,suchassolvent,gas,

orkerosene.Replacethepaperelementifitis

damagedorcannotbecleanedthoroughly.

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSF ,SG,SH,SJ,orSL)

CrankcaseCapacity:

Model

74386

74387

Viscosity:Seethetablebelow .

OillternotremovedOillterremoved

1.6qt(1.5l)1.8qt(1.7l)

1.9qt(1.8l)2.2qt(2.1l)

Figure37

Note:Usingmultigradeoils(5W-20,10W-30,and10W-40)

willincreaseoilconsumption.Checkoillevelmorefrequently

whenusingthem.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Figure36

1.Cover

2.Paperelement

3.Hoseclamp

CleaningtheElement

ServiceInterval:Every100hours—Servicethepaper

Every200hours/Yearly(whichevercomes

rst)—Replacethepaperelement.(moreoftenin

dusty,dirtyconditions)

1.Lightlytaptheelementonaatsurfacetoremovedust

anddirt.

2.Inspecttheelementfortears,anoilylm,anddamage

totheseal.

element.(moreoftenindusty ,dirty

conditions)

Note:Checktheoilwhentheengineiscold.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawaythemuferandotherhotsurfaces.

Important:Donotoverllthecrankcasewithoil

becausedamagetotheenginemayresult.Donotrun

enginewithoilbelowthelowmarkbecausetheengine

maybedamaged.

1.Parkthemachineonalevelsurface,disengagethe

bladecontrolswitch,stoptheengine,engageparking

brake,andremovethekey.

32

Page 33

2.Makesuretheengineisstopped,level,andiscoolso

G008792

1

2

5

6

7

3

9

10

4

8

G014971

1

2

3

4

5 6

theoilhashadtimetodrainintothesump.

3.Tokeepdirt,grassclippings,etc.,outoftheengine,

cleantheareaaroundtheoilllcap/dipstickbefore

removingit.

4.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position(

Figure38).

3.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position(Figure39).

ChangingtheEngineOil

ServiceInterval:Aftertherst8hours—Changetheengine

Every100hours—Changetheengineoil.(moreoften

industy,dirtyconditions)

oil.

Figure38

Figure39

Note:Disposeoftheusedoilatarecyclingcenter.

1.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoassuretheoildrains

completely.

2.DisengagethePTO,movethemotioncontrolleversto

theneutrallockedpositionandsettheparkingbrake.

33

Page 34

4.Slowlypourapproximately80%ofthespeciedoil

G008796

2

3

4

5

6

1

G008748

3/4

1

2

3

4

5

6

intothellertubeandslowlyaddtheadditionaloilto

bringittotheFullmark(Figure40).

Figure40

ChangingtheEngineOilFilter

ServiceInterval:Every200hours—Changetheoillter.

(moreoftenindusty ,dirtyconditions)

Note:Changetheengineoilltermorefrequentlywhen

operatingconditionsareextremelydustyorsandy.

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil.

2.Changetheengineoillter(Figure41).

Figure41

Note:Ensuretheoilltergaskettouchestheengine

andthenanextra3/4turniscompleted.

3.Fillthecrankcasewiththepropertypeofnewoil;refer

toChangingtheOil.

ServicingtheSparkPlug

ServiceInterval:Every100hours—Checkthesparkplug(s).

Makesuretheairgapbetweenthecenterandsideelectrodes

iscorrectbeforeinstallingthesparkplug.Useasparkplug

wrenchforremovingandinstallingthesparkplug(s)anda

gappingtool/feelergaugetocheckandadjusttheairgap.

Installanewsparkplug(s)ifnecessary.

Type:NGKBPR4ES(orequivalent)

AirGap:0.030inch(0.76mm)

34

Page 35

RemovingtheSparkPlug

G008794

1

2

16ft-lb

22N-m

G010687

InstallingtheSparkPlug

1.DisengagethePTO,movethemotioncontrolleversto

theneutrallockedpositionandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

Figure42

Note:Duetothedeeprecessaroundthesparkplug,

blowingoutthecavitywithcompressedairisusually

themosteffectivemethodforcleaning.Thesparkplug

ismostaccessiblewhentheblowerhousingisremoved

forcleaning.

CheckingtheSparkPlug

Tightenthesparkplug(s)to16ft-lb(22N-m).

Figure44

CleaningtheCoolingSystem

Important:Nevercleanthesparkplug(s).Always

replacethesparkplug(s)whenithas:ablackcoating,

wornelectrodes,anoilylm,orcracks.

Ifyouseelightbrownorgrayontheinsulator,theengineis

operatingproperly.Ablackcoatingontheinsulatorusually

meanstheaircleanerisdirty.

Setthegapto0.030inches(0.76mm).

Figure43

Cleantheairintakescreenfromgrassanddebrisbeforeeach

use.

1.Disengagethebladecontrolswitchandmovethe

controlleverstotheneutrallockedpositionandapply

theparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Removetheairintakescreen,aircleanercover,and

fanhousing.

4.Cleandebrisandgrassfromtheparts.

5.Installtheairintakescreen,aircleanercover,andfan

housing.

35

Page 36

FuelSystem

g017471

1

2

3

4

5

4.Squeezetheendsofthehoseclampstogetherandslide

themawayfromthelter(Figure45).

Maintenance

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Performanyfuelrelatedmaintenancewhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

ReplacingtheIn-lineFuel Filter

ServiceInterval:Every100hours—Replacethein-linefuel

lter

Neverinstalladirtylterifitisremovedfromthefuelline.

5.Removethelterfromthefuellines.

6.Installanewlterwiththeowdirectionarrowcoming

fromthefueltankandpointingtotheengine.Move

thehoseclampsclosetothelter(Figure45)tosecure

itinplace.

1.Parkthemachineonalevelsurfaceanddisengagethe

bladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothepark

position,stoptheengine,removethekey,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Locatethefuellteronthesideoftheengineasshown

Figure45.

in

Figure45

1.Fuellinefromtank

2.In-lineFuellter

3.Flowdirectionarrow

4.Fuellinetoengine

5.Hoseclamp

36

Page 37

ElectricalSystem

G005072

1

2

3

4

5

6

7

Maintenance

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

ChargingtheBattery

RemovingtheBattery

WARNING

5.Slidetherubbercoverupthepositive(red)cable.

Disconnectthepositive(red)cablefromthebattery

post(Figure46).Retainallfasteners.

6.Removethebatteryhold-down(Figure46)andliftthe

batteryfromthebatterytray .

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

1.Parkthemachineonalevelsurfaceanddisengagethe

bladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothepark

position,stoptheengine,removethekey,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Raisetheseattoaccessthebattery.

4.Disconnectthenegative(black)groundcablefromthe

batterypost(

WARNING

Incorrectbatterycableroutingcoulddamage

Figure46).Retainallfasteners.

themachineandcablescausingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

Figure46

1.Battery5.Negativebatterypost

2.Positivebatterypost6.Wingnut,washer ,andbolt

3.Bolt,washer ,andnut7.Batteryhold-down

4.Terminalboot

ChargingtheBattery

ServiceInterval:Beforestorage—Chargethebatteryand

disconnectbatterycables.

1.Removethebatteryfromthechassis;refertoRemoving

theBattery.

2.Chargethebatteryforaminimumof1hourat6to10

amps.Donotoverchargethebattery.

3.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthecharger

leadsfromthebatteryposts(

Figure47).

37

Page 38

Figure47

30

25

30

25

G014921

2

1

1.Positivebatterypost

2.Negativebatterypost

3.Red(+)chargerlead

4.Black(-)chargerlead

Note:Donotrunthemachinewiththebattery

disconnected,electricaldamagemayoccur.

InstallingtheBattery

1.Positionthebatteryinthetray(Figure46).

2.Installthepositive(red)batterycabletothepositive(+)

batteryterminalusingthefastenersremovedpreviously .

3.Installthenegativebatterycabletothenegative(-)

batteryterminalusingthefastenersremovedpreviously .

4.Slidetheredterminalbootontothepositive(red)

batterypost.

5.Securethebatterywiththehold-down(

Figure46).

6.Lowertheseat.

ServicingtheFuses

Figure48

1.Main-30amp

2.Chargecircuit-25amp

4.Returnthecontrolpaneltoitsoriginalposition.Use

thescrewsremovedpreviouslytosecurethepanelto

themachine.

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;however,ifafuseblows,checkthe

component/circuitforamalfunctionorshort.

Fuse:

•MainF1-30amp,blade-type

•ChargeCircuitF2-25amp,blade-type

1.Removethescrewssecuringthecontrolpaneltothe

machine.Retainallfasteners

2.Liftthecontrolpaneuptoaccessthemainwiring

harnessandfuseblock(

3.Toreplaceafuse,pulloutonthefusetoremoveit

(

Figure48).

Figure48).

38

Page 39

DriveSystem

G015000

1

Maintenance

CheckingtheTirePressure

ServiceInterval:Every25hours—Checktirepressure.

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseunevencut.Check

thepressureatthevalvestem(Figure49).Checkthetires

whentheyarecoldtogetthemostaccuratepressurereading.

Refertothemaximumpressuresuggestedbythetire

manufactureronthesidewallofthecasterwheeltires.

Inatethereardrivewheeltiresto12psi.

2.Rotatetheshaftforwardtoreleasethebrake.

Figure49

1.Valvestem

ReleasingtheElectricBrake

Theelectricbrakecanbereleasebymanuallyrotatingthe

linkarmsforward.Oncetheelectricbrakeisenergizedthe

brakewillreset.

Toreleasethebrake:

Figure50

1.Brakelinkarmontheelectricbrakecontrolmodule

1.Locatetheshaftontheelectricbrakewherethebrake

linkarmsareconnected.

39

Page 40

MowerMaintenance

G014972

1

2

3

ServicingtheCuttingBlades

Maintainsharpbladesthroughoutthecuttingseasonbecause

sharpbladescutcleanlywithouttearingorshreddingthegrass

blades.Tearingandshreddingturnsgrassbrownattheedges,

whichslowsgrowthandincreasesthechanceofdisease.

Checkthecutterbladesdailyforsharpness,andforany

wearordamage.Filedownanynicksandsharpenthe

bladesasnecessary.Ifabladeisdamagedorworn,replace

itimmediatelywithagenuineT ororeplacementblade.For

convenientsharpeningandreplacement,youmaywantto

keepextrabladesonhand.

WARNING

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownintotheoperator's

orbystander'sarea,resultinginseriouspersonal

injuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

Figure51

1.Cuttingedge3.Wear/slotforming

2.Curvedarea

4.Damage

CheckingforBentBlades

Note:Themachinemustbeonalevelsurfaceforthe

followingprocedure.

1.Raisethemowerdecktothehighestheight-of-cut

position;alsoconsideredthe'transport'position.

2.Whilewearingthicklypaddedglovesorotheradequate

handprotectionslowlyrotatebladetobemeasureinto

apositionthatallowseffectivemeasurementofthe

distancebetweenthecuttingedgeandthelevelsurface

themachineison.

BeforeInspectingorServicingthe

Blades

Parkthemachineonalevelsurface,disengagetheblade

controlswitch,andmovethemotioncontrolleversoutward

totheparkposition.Stoptheengineandremovethekey .

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily—Checkthe

cuttingblades.

1.Inspectthecuttingedges(Figure51).Iftheedges

arenotsharporhavenicks,removeandsharpenthe

blades;refertoSharpeningtheBlades.

2.Inspecttheblades,especiallythecurvedarea

(Figure51).Ifyounoticeanydamage,wear,oraslot

forminginthisarea(item3inFigure51),immediately

installanewblade.

Figure52

1.Deck3.Blade

2.Spindlehousing

40

Page 41

3.Measurefromthetipofthebladetotheatsurface

G014973

1

2

3

G014974

1

2

3

G014973

1

2

3

here.

Figure53

1.Blade,inpositionformeasuring

2.Levelsurface

3.Measureddistancebetweenbladeandsurface(A)

Figure55

1.Opposingbladeedge,inpositionformeasuring

2.Levelsurface

3.Secondmeasureddistancebetweenbladeandsurface(B)

WARNING

4.Rotatethesameblade180degreessothattheopposing

cuttingedgeisnowinthesameposition.

Figure54

1.Blade,sidepreviouslymeasured

2.Measurementpositionusedpreviously

3.Opposingsideofbladebeingmovedintomeasurement

position

5.Measurefromthetipofthebladetotheatsurface

here.Thevarianceshouldbenomorethan1/8inch

(3mm).

Abladethatisbentordamagedcouldbreak

apartandcouldseriouslyinjureorkillyouor

bystanders.

•Alwaysreplacebentordamagedblade

withanewblade.

•Neverleorcreatesharpnotchesinthe

edgesorsurfacesofblade.

A.IfthedifferencebetweenAandBisgreater

than1/8inch(3mm)replacethebladewitha

newblade.RefertoRemovingtheBladesand

InstallingtheBlades.

Note:Ifabentbladeisreplacedwithanewone

andthedimensionobtainedcontinuestoexceed

1/8inch(3mm),thebladespindlecouldbebent.

ContactanAuthorizedToroDealerforservice.

B.Ifthevarianceiswithinconstraints,movetothe

nextblade..

Repeatthisprocedureoneachblade.

RemovingtheBlades

Thebladesmustbereplacedifasolidobjectishit,ifthe

bladeisoutofbalance,orthebladeisbent.Toensure

optimumperformanceandcontinuedsafetyconformance

ofthemachine,usegenuineT ororeplacementblades.

Replacementbladesmadebyothermanufacturersmayresult

innon-conformancewithsafetystandards.

Holdthebladeendusingaragorthickly-paddedglove.

Removethebladebolt,curvedwasher,bladestiffener,and

bladefromthespindleshaft(

41

Figure56).

Page 42

LevelingtheMowerDeck

G009682

1

2

2

3

3

4

4

Checktoensurethemowerdeckislevelanytimeyouinstall

themowerorwhenyouseeanunevencutonyourlawn.

Themowerdeckmustbecheckedforbentbladespriorto

leveling;anybentbladesmustberemovedandreplaced.Refer

totheCheckingforBentBladesprocedurebeforecontinuing.

Themowerdeckmustbeleveledside-to-siderstthenthe

fronttorearslopecanbeadjusted.

Figure56

1.Sailareaofblade

2.Blade

3.Curvedwasher

4.Bladebolt

5.Bladestiffener(Models

with42inchdecksonly)

SharpeningtheBlades

1.Usealetosharpenthecuttingedgeatbothendsof

theblade(Figure57).Maintaintheoriginalangle.The

bladeretainsitsbalanceifthesameamountofmaterial

isremovedfrombothcuttingedges.

Figure57

1.Sharpenatoriginalangle

2.Checkthebalanceofthebladebyputtingitonablade

balancer(Figure58).Ifthebladestaysinahorizontal

position,thebladeisbalancedandcanbeused.Ifthe

bladeisnotbalanced,lesomemetalofftheendof

thesailareaonly(Figure57).Repeatthisprocedure

untilthebladeisbalanced.

Requirements:

•Themachinemustbeonalevelsurface.

•Allfourtiremustbeproperlyinated.RefertoChecking

theTirePressureintheDriveSystemMaintenance

section.

Side-to-SideLeveling

1.Parkthemachineonalevelsurfaceanddisengagethe

bladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothepark

position,stoptheengine,removethekey,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Settheheight-of-cutlevertomiddleposition.

4.Carefullyrotatethebladessothattheyareallsideto

side(Figure59andFigure60).

Figure58

1.Blade2.Balancer

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure56).

MowerDeckswith2Blades

1.Bladessidetoside

2.Sailareaofblade4.Measurefromthetipofthe

Figure59

3.Outsidecuttingedges

bladetotheatsurface

here

Important:Thecurvedpartoftheblademustbe

pointingupwardtowardtheinsideofthemowerto

ensurepropercutting.

2.Installthebladestiffener,thecurvedwasher(cupped

sidetowardtheblade)andthebladebolt(Figure56).

3.Torquethebladeboltto35-65ft-lb(47-88N-m).

42

Page 43

G005278

1

2

2

3

3

4

4

Figure60

G015323

1

2

3

4

5

G015324

1

2

3

4

MowerDeckswith3Blades

Figure61

1.Bladessidetoside

2.Sailareaofblade4.Measurefromthetipofthe

3.Outsidecuttingedges

bladetotheatsurface

here

5.Measurebetweentheoutsidecuttingedgesand

theatsurface(Figure59andFigure60).Ifboth

measurementsarenotwithin3/16inch(5mm),an

adjustmentisrequired;continuewiththisprocedure.

6.Supporttheweightofmowerdeckbyplacingwood

blocksundertheedgesofthemowerdeck.

Note:Avoidplacingthesupportsunderanyanti-scalp

rollersifpresentonthemowerdeck.

7.Movetotheleftsideofthemachine.Checkifthe

sidecarriageboltisinthexedorslottedposition

(Figure61).

8.Ifthesidecarriageboltisinthexedposition,remove

thesidecarriageboltandsidelockingnutfromthe

xedpositionandinstallitintotheslottedadjustment

position(Figure61).

Iftheboltisintheslottedposition,thecarriagebolt

andsidelockingnutdonotneedtoberemoved.

1.Hangerbracket

2.Slottedadjustment

position

3.Fixedposition

4.Sidelockingnut.

5.Sidecarriagebolt

9.Loosentherearlockingnutonthehangerbracket

(Figure62).

Figure62

1.Hangerbracket

2.Rearlockingnut4.Adjustmentnotches

3.Sidelockingnut,slotted

position.

10.Loosenthesidelockingnutonthehangerbracketjust

enoughtoallowthehangertobeadjusted(Figure62).

Usethenotchesontheweldedbrackettomeasure

theamountofadjustment.Eachnotchsurfaceis

equivalentto0.25inch,whileasinglesideis0.125inch

(

Figure63).Adjusttheheightofthemowerdecktothe

desiredheight.

43

Page 44

G015325

1

2

Figure63

G009658

1

2

2

G009659

1

2

3

2

3

1.0.25inch2.0.125inch

11.Stopthedeckattheadjustedpositionandtightenthe

sidelockingnutonthehangerbrackettoholdthenew

position(Figure62).Tightentherearlockingnuton

thehangerbracket.

12.Continuelevelingthedeckbycheckingthefront-to-rear

bladeslope;refertoAdjustingtheFront-to-RearBlade