Toro 74373 (290004013 AND UP), 74373 Owner’s Manual

Count on it.

Form No. 3360-826 Rev A

TimeCutter_ Z5030 and Z5060

Riding Mower

Model No. 74373mSerial No. 290000001 and Up

Model No. 74375mSerial No. 290000001 and Up

0

CL

0

G007648

Register at www.Toro.com. Original Instructions (EN)

CALIFORNIA

Proposition 65 Warning

The engine exhaust from this product

contains chemicals known to the State of

California to cause cancer, birth defects,

or other reproductive harm.

Important: This engine is not equipped with a

spark arrester muffler. It is a violation of California

Public Resource Code Section 4442 to use or operate

the engine on any forest-covered, brush-covered, or

grass-covered land. Other states or federal areas

may have similar laws.

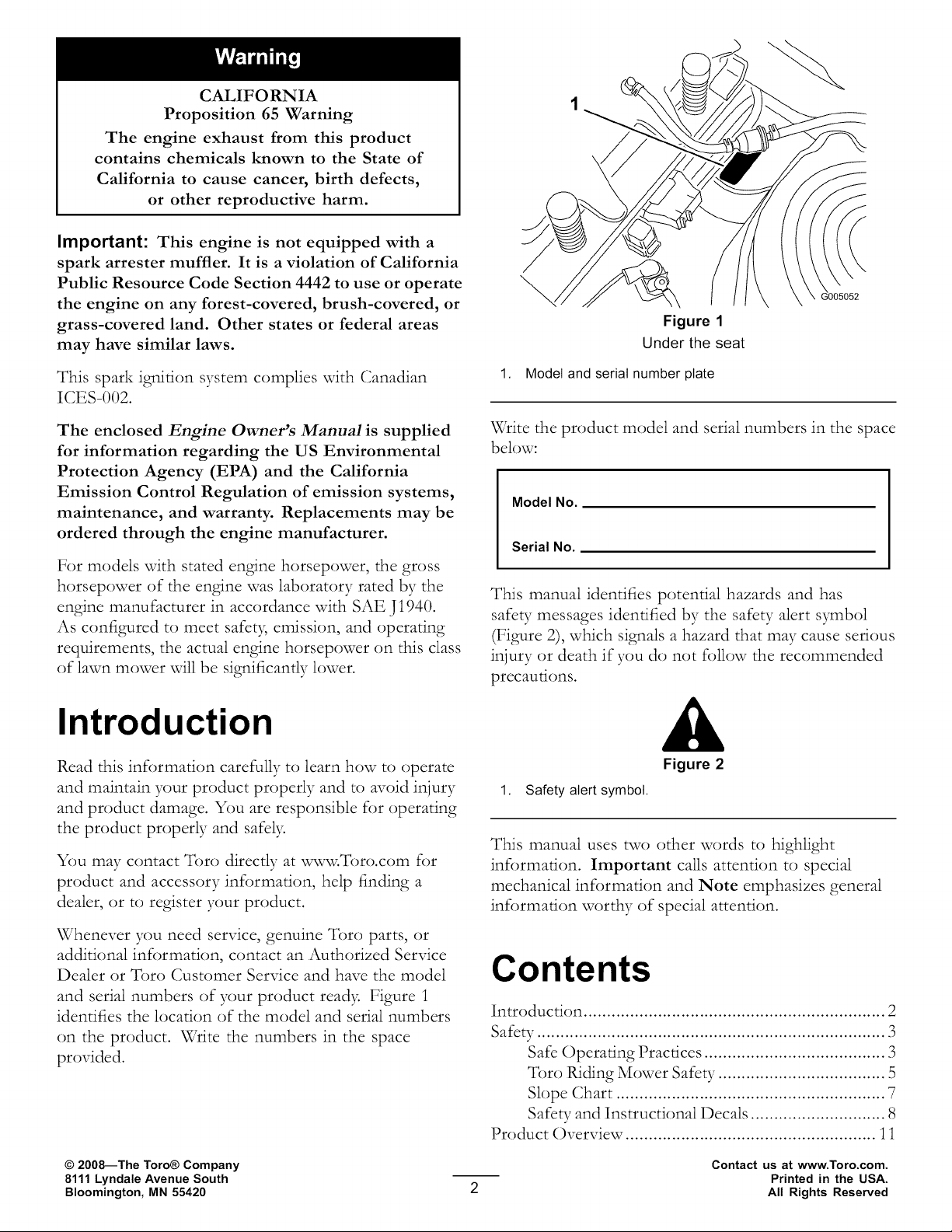

Figure 1

Under the seat

This spark ignition system complies with Canadian

ICES-002.

The enclosed Engine Owner's Manual is supplied

for information regarding the US Environmental

Protection Agency (EPA) and the California

Emission Control Regulation of emission systems,

maintenance, and warranty. Replacements may be

ordered through the engine manufacturer.

For models with stated engine horsepower, the gross

horsepower of the engine was laboratory rated by the

engine manufacturer in accordance with SAE J1940.

As configured to meet safer B emission, and operating

requirements, the actual engine horsepower on this class

of lawn mower will be significantly lower.

Introduction

Read this information carefully to learn how to operate

and maintain your product properly and to avoid injury

and product damage. You are responsible for operating

the product properly and safely.

You may contact Toro directly at www.Toro.com for

product and accessory information, help finding a

dealer, or to register your product.

1. Model and serial number plate

Write the product model and serial numbers in the space

below:

Model No.

Serial No.

This manual identifies potential hazards and has

safety messages identified by the safety alert symbol

(Figure 2), which signals a hazard that may cause serious

injury or death if you do not follow the recommended

precautions.

Figure 2

1. Safety alert symbol.

This manual uses two other words to highlight

information. Important calls attention to special

mechanical information and Note emphasizes general

information worthy of special attention.

Whenever you need service, genuine Toro parts, or

additional information, contact an Authorized Service

Dealer or Toro Customer Service and have the model

and serial numbers of your product read> Figure i

identifies the location of the model and serial numbers

on the product. Write the numbers in the space

provided.

© 2008--The Toro® Company

8111 Lyndale Avenue South

Bloomington, MN 55420

Contents

Introduction ................................................................. 2

Safety ........................................................................... 3

Safe Operating Practices ....................................... 3

Toro Riding Mower Safety .................................... 5

Slope Chart .......................................................... 7

Safety and Instructional Decals ............................. 8

Product Overview ...................................................... 11

Contact us at www.Toro.com.

Printed in the USA.

All Rights Reserved

Controls ............................................................. 12

Operation ................................................................... 13

Think Safety First ............................................... 13

Recommended Fuel ............................................ 13

Checking the Engine Oil Level ............................ 15

Starting and Stopping the Engine ........................ 15

Operating the Blades .......................................... 16

Stopping the Engine ........................................... 17

The Safety Interlock System ................................ 17

Driving Forward or Backward ............................. 18

Stopping the Machine ......................................... 19

Adjusting the Height of Cut ................................ 19

Positioning the Seat ............................................ 20

Adjusting the Motion Control Levers .................. 20

Pushing the Machine by Hand ............................. 2i

Side Discharge .................................................... 2i

Operating Tips ................................................... 22

Maintenance ............................................................... 24

Recommended Maintenance Schedule(s) ................ 24

Premaintenance Procedures .................................... 25

Raising the Seat .................................................. 25

Accessing the Battery ......................................... 25

Lubrication ............................................................. 25

Greasing the Bearings ......................................... 25

Engine Maintenance ............................................... 26

Servicing the Air Cleaner .................................... 26

Servicing the Engine Oil ..................................... 27

Servicing the Spark Plug ..................................... 29

Cleaning the Blower Housing .............................. 30

Fuel System Maintenance ....................................... 30

Replacing the Fuel Filter ..................................... 30

Electrical System Maintenance ................................ 3i

Charging the Battery ........................................... 3i

Servicing the Fuses ............................................. 32

Drive System Maintenance ..................................... 33

Checking the Tire Pressure ................................. 33

Mower Maintenance ............................................... 34

Servicing the Cutting Blades ............................... 34

Leveling the Mower Deck ................................... 36

Removing the Mower ......................................... 38

Mower Belt Maintenance .................................... 39

Instal_ng the Mower ........................................... 40

Replacing the Grass Deflector ............................. 40

Cleaning ................................................................. 41

Washing the Underside of the Mower .................. 4i

Storage ....................................................................... 42

Cleaning and Storage .......................................... 42

Troubleshooting ......................................................... 43

Schematics ................................................................. 45

Safety

This machine meets or exceeds the B71.1-2003

specifications of the American National Standards

Institute, in effect at the time of production.

However, improper use or maintenance by the

operator or owner can result in injury. To reduce

the potential for injury, comply with these safety

instructions and always pay attention to the

safety alert symbol, which means CAUTION,

WARNING, or DANGER-"personal safety

instruction." Failure to comply with the instruction

may result in personal injury or death.

Safe Operating Practices

The following instructions are from ANSI standard

B71.I-2003.

This product is capable of amputating hands and

feet and throwing objects. Always follow all safety

instructions to avoid serious injury or death.

General Operation

• Read, understand, and follow all instructions in

the operator's manual and on the machine before

starting.

• Do not place hands or feet near rotating parts or

under the machine. Keep clear of the discharge

opening at all times.

• Allow only responsible adults who are familiar with

the instructions to operate the machine.

• Clear the area of objects such as rocks, toys, wire,

etc., which could be picked up and thrown by the

blade.

• Be sure the area is clear of other people before

mowing. Stop the machine if awone enters the area.

• Never carry passengers.

• Do not mow in reverse unless absolutely necessar>

Always look down and behind before and while

backing up.

• Be aware of the mower discharge direction and do

not point it at anyone. Avoid discharging material

against a wall or obstruction. Material m W ricochet

back toward the operator. Stop the blade(s) when

crossing gravel surfaces.

• Do not operate the machine without deflector,

discharge cover or entire grass collection system in

place and working.

• Be alert, slow down and use caution when malting

turns. Look behind and to the side before changing

directions.

• Neverleavearunningmachineunattended.Always

turnoff blades,setparkingbrake,stopengine,and

removekeybeforedismounting.

• Turnoff bladeswhennotmowing.Stoptheengine

andwaitfor allpartsto cometoacompletestop

beforecleaningthemachine,removingthegrass

catcheror uncloggingthedischargechute.

• Operatethemachineonlyin daylightor good

artificiallight.

• Do not operatethemachinewhileunderthe

influenceof alcoholordrugs.

• Watchfor trafficwhenoperatingnearorcrossing

roadways.

• Useextracarewhenloadingor unloadingthe

machineinto atraileror truck.

Alwaysweareyeprotectionwhenoperatingthe

mower.

• Data indicates that operators, age 60 years and

above, are involved in a large percentage of riding

mower-related injuries. These operators should

evaluate their ability to operate the riding mower

safely enough to protect themselves and others from

serious injur):

• Always follow the recommendations for wheel

weights or counterweights.

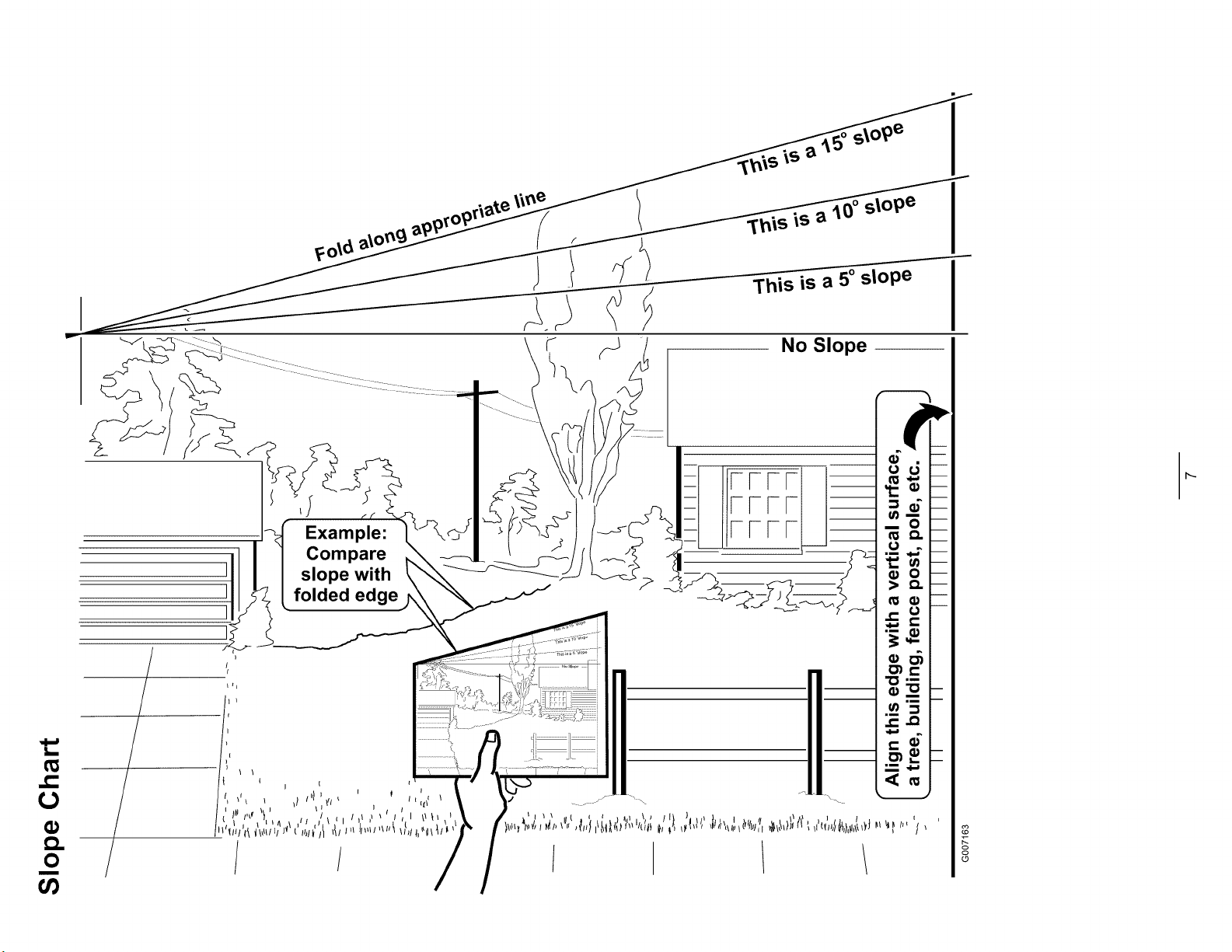

Slope Operation

Slopes are a major factor related to loss of control and

tip-over accidents, which can result in severe injury or

death. Operation on all slopes requires extra caution. If

you cannot back up the slope or if you feel uneasy on it,

do not mow it.

Do not mow slopes greater than 15 degrees.

Watch for ditches, holes, rocks, dips, and rises that

change the operating angle, as rough terrain could

overturn the machine.

• Choose a low ground speed so you will not have to

stop while operating on a slope.

• Do not mow slopes when grass is wet. Slippery

conditions reduce traction and could cause sliding

and loss of control.

• Always keep the wheel motors engaged when going

down slopes.

• Reduce speed and use extreme caution on slopes.

• Do not make sudden turns or rapid speed changes.

• Remove or mark obstacles such as rocks, tree limbs,

etc. from the mowing area. Tall grass can hide

obstacles.

• Avoid sudden starts when mowing uphill because

the mower may tip backwards.

• Be aware that loss of traction may occur going

downhill. \Vcight transfer to the front wheels may

cause drive wheels to slip and cause loss of braking

and steering.

• Always avoid sudden starting or stopping on a

slope. If tires lose traction, disengage the blades and

proceed slowly off the slope.

• Use extreme care with grass catchers or other

attachments. These can change the stability of the

machine and cause loss of control.

• Do not try to stabilize the machine by putting your

foot on the ground.

• Do not mow near drop-off-s, ditches, steep banks

or water. Wheels dropping over edges can cause

rollovers, which may result in serious injur B death

or drowning.

• Use a walk behind mower and/or a hand trimmer

near drop-off_, ditches, steep banks or water.

Children

Tragic accidents can occur if the operator is not alert to

the presence of children. Children are often attracted to

the machine and the mowing activit> Never assume that

children will remain where you last saw them.

• Keep children out of the mowing area and under

the watchful care of another responsible adult, not

the operator.

• Be alert and turn the machine off if children enter

the area.

Before and while backing or changing direction, look

behind, down, and side-to-side for small children.

• Never carry children, even with the blades off. They

may fall off and be seriously injured or interfere with

safe machine operation.

• Children who have been given rides in the past may

suddenly appear in the mowing area for another ride

and be run over or backed over by the mower.

• Never allow children to operate the machine.

• Use extra care when approaching blind corners,

shrubs, trees, the end of a fence or other objects that

may obscure vision.

Towing

A hitch kit is available for this machine and can be

obtained by contacting an Authorized Toro Dealer.

Do not tow without first installing this manufacturer

approvedhitch.Thefollowingguidelinesapplywhen

towingwith theapprovedhitchkit installed.

• Tow only with a machine that has a hitch designed

for towing. Do not attach towed equipment except

at the hitch point.

• Follow the manufacturer's recommendation for

weight limits for towed equipment and towing on

slopes.

• Never allow children or others in or on towed

equipment.

• On slopes, the weight of the towed equipment may

cause loss of traction and loss of control.

• Travel slowly and allow extra distance to stop.

Keep nuts and bolts tight, especially the blade

attachment bolts. Keep equipment in good

condition.

Never tamper with safcty devices. Check their

proper operation regularl 3.

Keep the machine free of grass, leaves, or other

debris build-up. Clean up oil or fuel spillage fuel

soaked debris. Allow the machine to cool before

storing.

Stop and inspect the equipment if you strike an

object. Repair, if necessar 5 before restarting.

Never make aW adjustments or repairs with the

engine running.

Service

Safe Handling of Gasoline:

To avoid personal injury or property damage, use extra

care when handling gasoline and other fuels. They are

flammable and the vapors are explosNe.

• Extinguish all cigarettes, cigars, pipes and other

sources of ignition.

• Use only an approved container.

• Never remove the gas cap or add fuel when the

engine is running. Allow the engine to cool before

refueling.

Never refuel the machine indoors.

Never store the machine or fuel container inside

where there is an open flame, such as near a water

heater or furnace.

Never fill containers inside a vehicle or on a truck or

trailer with a plastic liner. Always place containers on

the ground away from your vehicle before filling.

Remove gas-powered equipment from the truck

or trailer and refuel it on the ground. If this is not

possible, then refuel such equipment with a portable

container, rather than from a gasoline dispenser

nozzle.

• Keep the nozzle in contact with the rim of the fuel

tank or container opening at all times until the fueling

is complete. Do not use a nozzle lock-open device.

• If fuel is spilled on clothing, change clothing

immediatel>

• Never overfill the fuel tank. Replace gas cap and

tighten securely

General Service:

Never operate a machine inside a closed area. Engine

exhaust contains carbon monoxide, which is an

odorless, deadly poison that can kill you.

Grass catcher components are subject to wear,

damage and deterioration, which could expose

moving parts or allow objects to be thrown.

Frequently check components and replace with

manufacturers' recommended parts, when necessar>

Mower blades are sharp and can cut. Wrap the

blade(s) or wear gloves, and use extra caution when

servicing them.

Check for proper brake operation frequently Adjust

and service as required.

Maintain or replace safety and instruction decals as

necessary.

Use only genuine Toro replacement parts to ensure

that original standards are maintained.

Toro Riding Mower Safety

The following list contains safety information specific to

Toro products or other safety information that you must

know that is not included in the ANSI standards.

Stop the engine, disconnect spark plug wire(s) and

remove key before performing any service, repairs,

maintenance or adjustments.

Keep hands, feet, hair, and loose clothing away from

attachment discharge area, underside of mower and

any moving parts while engine is running.

Do not touch equipment or attachment parts which

may be hot from operation. Allow to cool before

attempting to maintain, adjust or service.

Battery acid is poisonous and can cause burns. Avoid

contact with skin, eyes, and clothing. Protect your

face, eyes, and clothing when working with a batter>

Battery gases can explode. Keep cigarettes, sparks

and flames away from batter>

Use only 7bro approved attachments. \K2arrantymay

be voided if used with unapproved attachments.

If loading the machine ontoa trailer or truck, use a

single, full-width ramp onl> The ramp angle should

not exceed i5 degrees.

Note: Determine the left and right sides of the

machine from the normal operating position.

_ _ _ No Slope

0

CO

FFFF

J

Example:

I

I

]

]

Compare

slope with

folded edge

FFFF

FFFF

b..

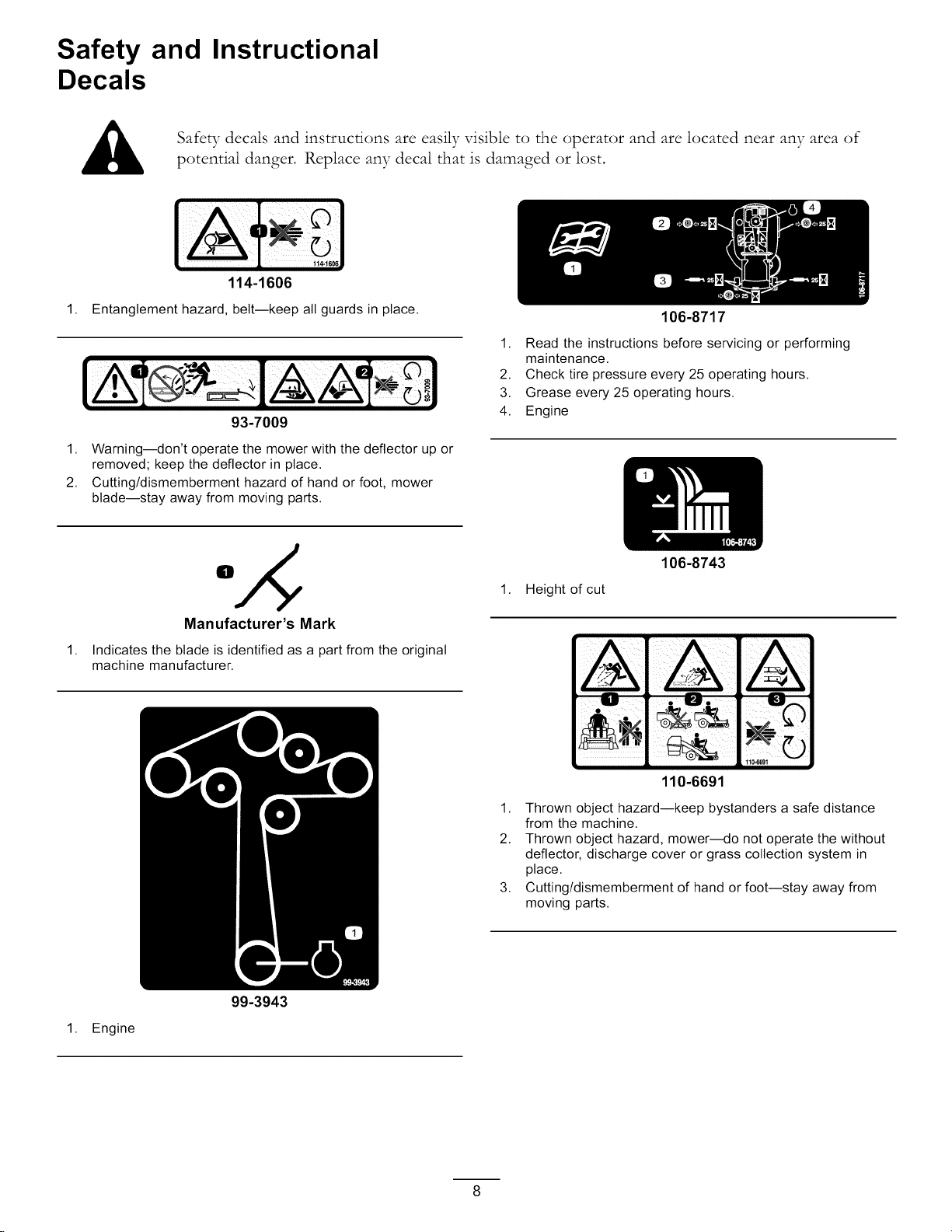

Safety and Instructional

Decals

Safety decals and instructions are easily visible to the operator and are located near any area of

potential danger. Replace any decal that is damaged or lost.

114-1606

1,

Entanglement hazard, belt--keep all guards in place.

93-7009

1. Warning--don't operate the mower with the deflector up or

removed; keep the deflector in place.

2. Cutting/dismemberment hazard of hand or foot, mower

blade--stay away from moving parts.

106-8717

1. Read the instructions before servicing or performing

maintenance.

2. Check tire pressure every 25 operating hours.

3. Grease every 25 operating hours.

4. Engine

Manufacturer's Mark

1,

Indicates the blade is identified as a part from the original

machine manufacturer.

99-3943

106-8743

1. Height of cut

110-6691

1. Thrown object hazard--keep bystanders a safe distance

from the machine.

2. Thrown object hazard, mower--do not operate the without

deflector, discharge cover or grass collection system in

place.

3. Cutting/dismemberment of hand or foot--stay away from

moving parts.

1. Engine

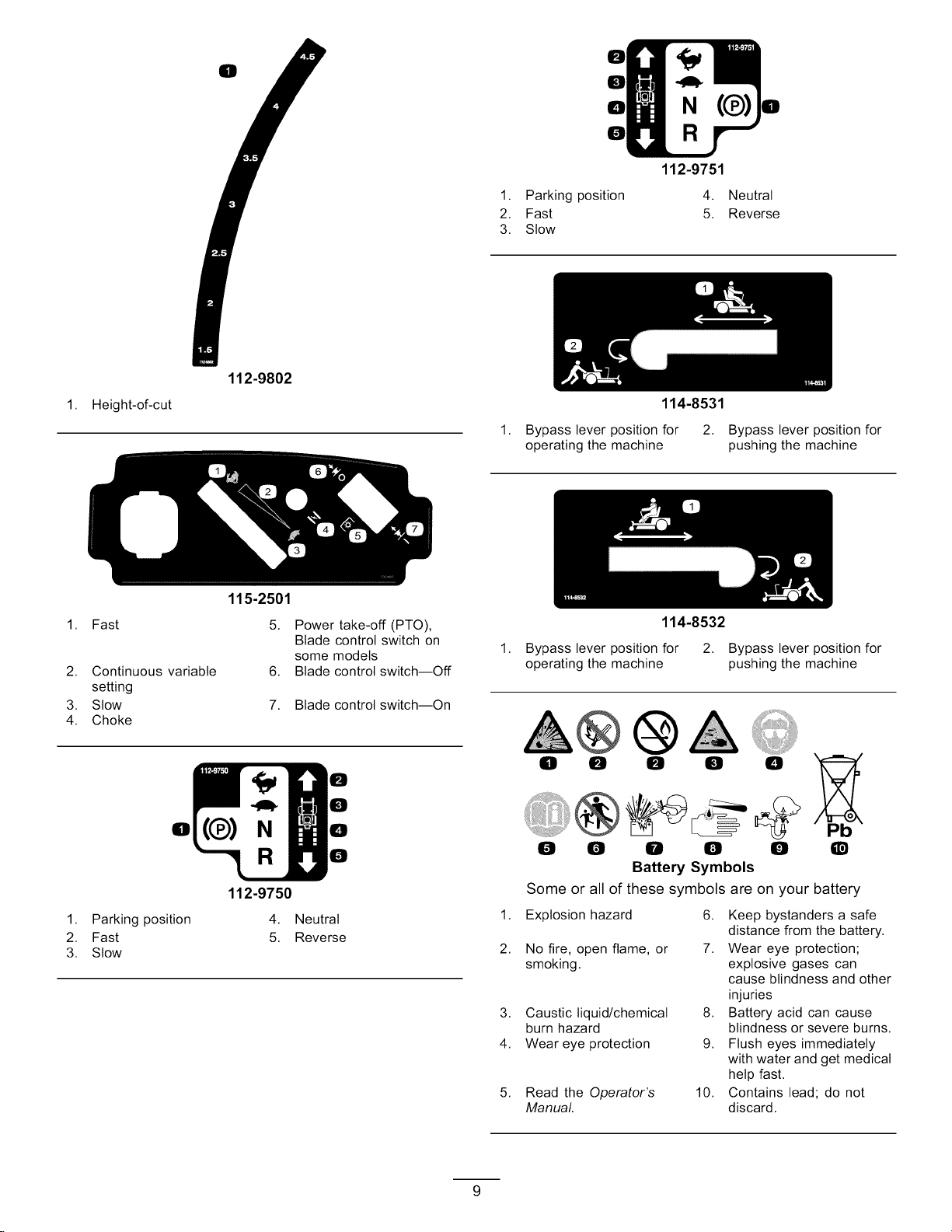

1. Height-of-cut

112-9802

0

0

0

N(Q)

0

0

112-9751

1. Parking position 4. Neutral

2. Fast 5. Reverse

3. Slow

114-8531

1. Bypass lever position for 2. Bypass lever position for

operating the machine pushing the machine

1. Fast

2. Continuous variable

setting

3. Stow

4. Choke

O

1. Parking position

2. Fast

3. Slow

115-2501

(Q) N

112-9750

5. Power take-off (PTO),

Blade control switch on

some models

6. Blade control switch--Off

7. Blade control switch--On

0

0

0

0

4.

Neutral

5.

Reverse

114-8532

1,

Bypass lever position for 2. Bypass lever position for

operating the machine pushing the machine

0 0 0 0 0

0 0 0 0 0

Battery Symbols

Some or all of these symbols

1. Explosion hazard 6. Keep bystanders a safe

2. No fire, open flame, or 7. Wear eye protection;

smoking, explosive gases can

3. Caustic liquid/chemical 8. Battery acid can cause

burn hazard blindness or severe burns.

4. Wear eye protection 9. Flush eyes immediately

5. Read the Operator's 10. Contains lead; do not

Manual. discard.

are on your battery

distance from the battery.

cause blindness and other

injuries

with water and get medical

help fast.

Q

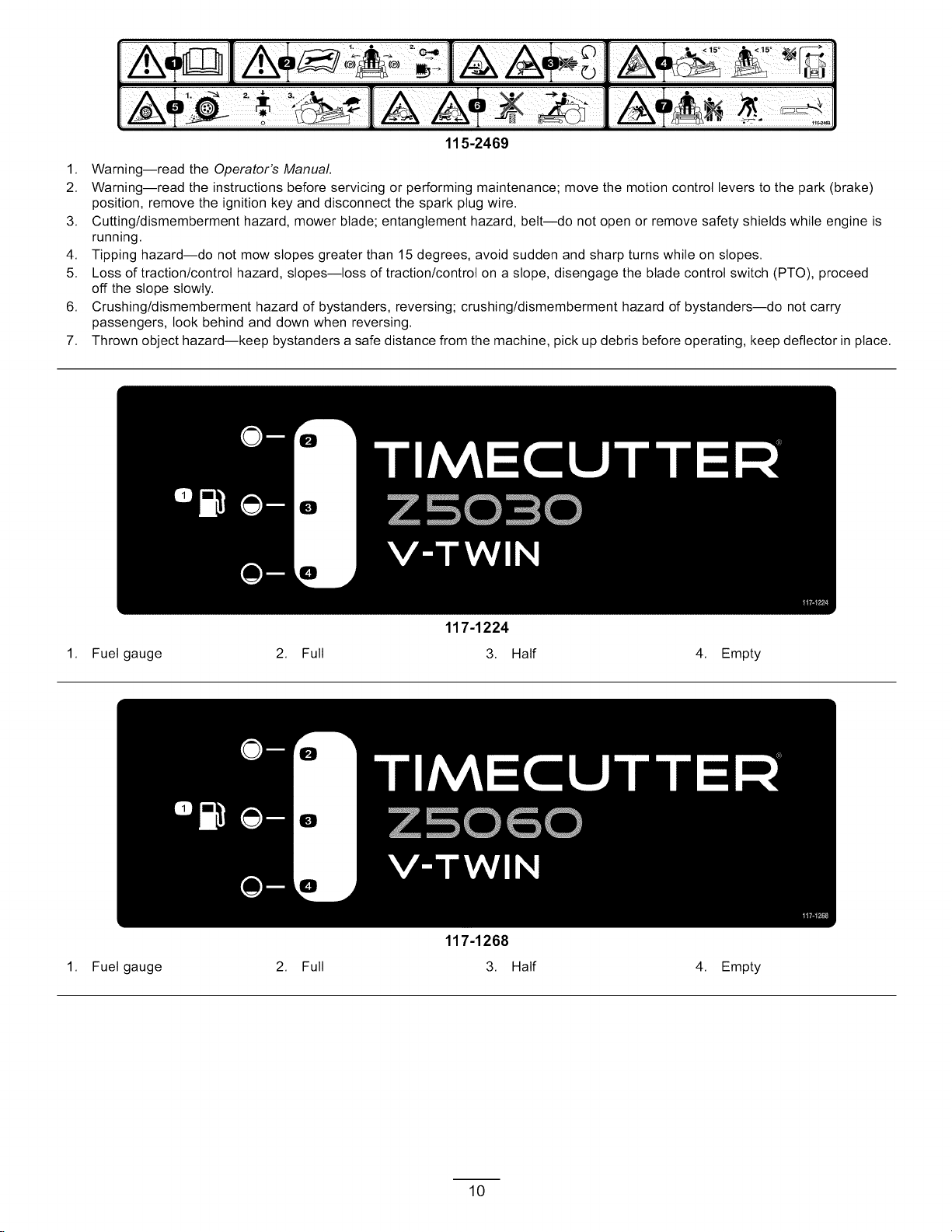

115-2469

1. Warning--read the Operator's ManuaL

2. Warning--read the instructions before servicing or performing maintenance; move the motion control levers to the park (brake)

position, remove the ignition key and disconnect the spark plug wire.

3. Cutting/dismemberment hazard, mower blade; entanglement hazard, belt--do not open or remove safety shields while engine is

running.

4. Tipping hazard--do not mow slopes greater than 15 degrees, avoid sudden and sharp turns while on slopes.

5. Loss of traction/control hazard, slopes--loss of traction/control on a slope, disengage the blade control switch (PTO), proceed

off the slope slowly.

6. Crushing/dismemberment hazard of bystanders, reversing; crushing/dismemberment hazard of bystanders--do not carry

passengers, look behind and down when reversing.

7. Thrown object hazard--keep bystanders a safe distance from the machine, pick up debris before operating, keep deflector in place.

117-1224

1. Fuel gauge 2. Full 3. Half 4. Empty

117-1268

1. Fuel gauge 2. Full 3. Half 4. Empty

10

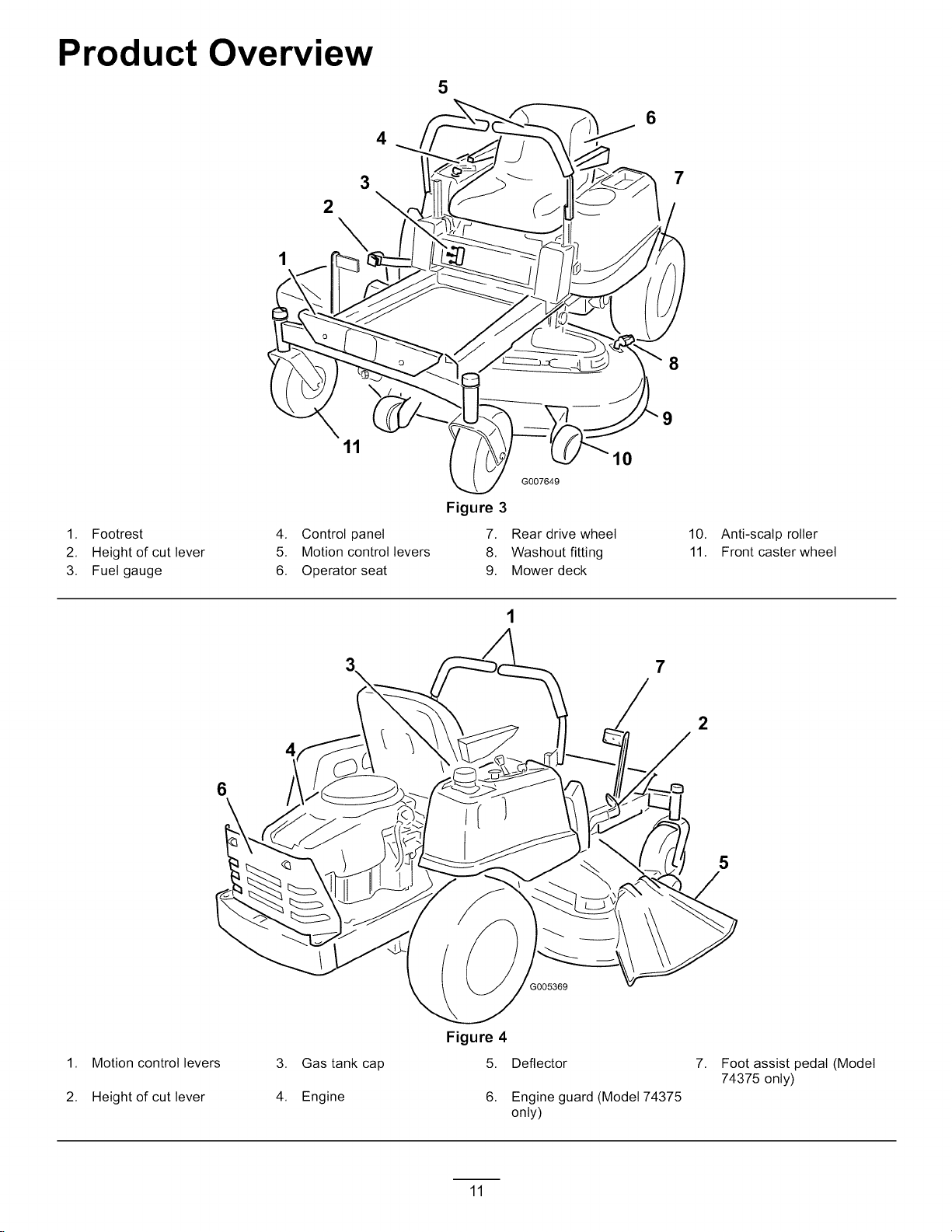

Product Overview

6

4

3

11

1. Footrest 4. Control panel

2. Height of cut lever 5. Motion control levers

3. Fuel gauge 6. Operator seat

Figure 3

7.

8.

9.

G007649

Rear drive wheel

Washout fitting

Mower deck

7

8

10

10. Anti-scalp roller

11. Front caster wheel

4

6

1. Motion control levers 3. Gas tank cap

2. Height of cut lever 4. Engine

Figure 4

5.

6,

7

.3005369

Deflector

Engine guard (Model 74375

only)

2

5

7. Foot assist pedal (Model

74375 only)

11

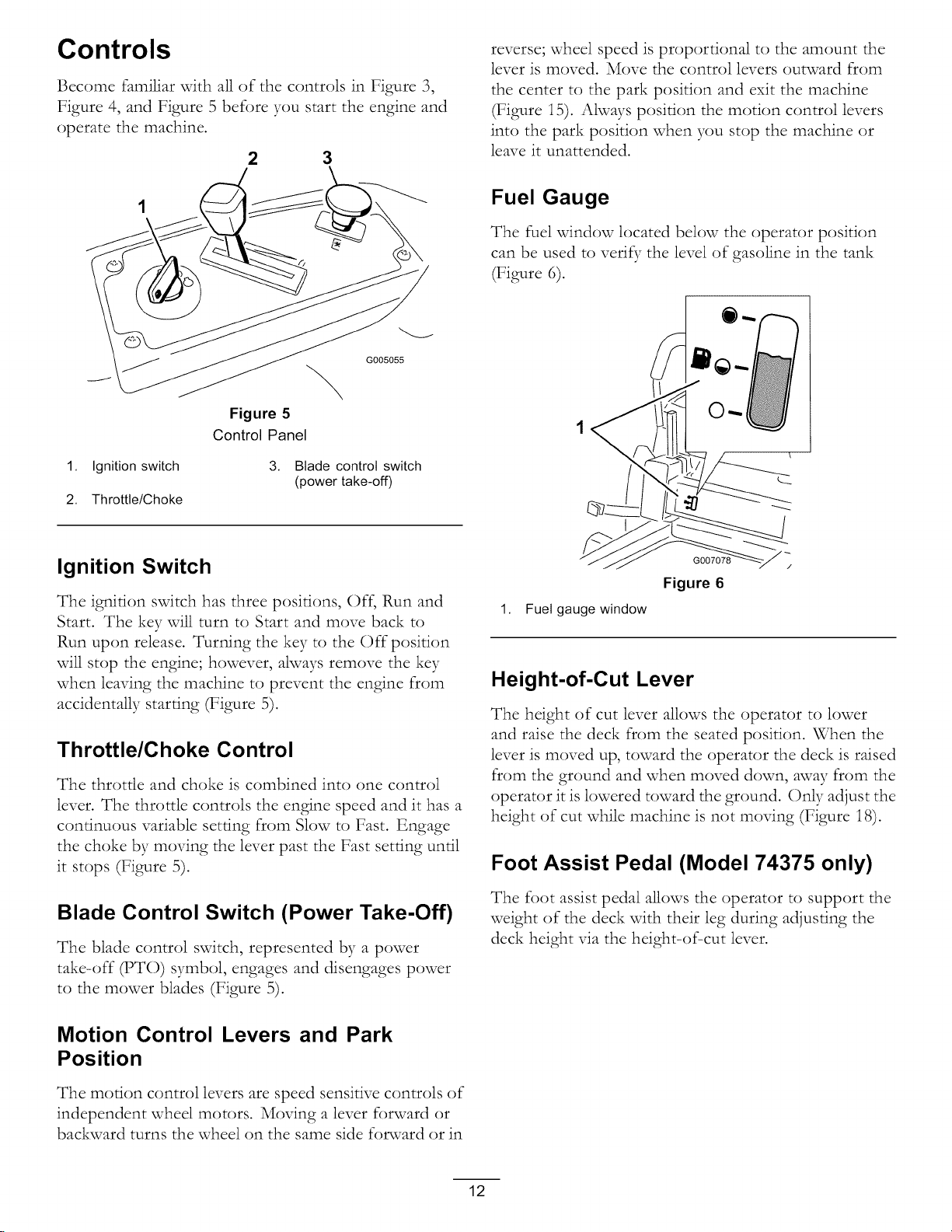

Controls

Become familiar with all of the controls in Figure 3,

Figure 4, and Figure 5 before you start the engine and

operate the machine.

2 3

G005055

Figure 5

Control Panel

1. Ignition switch 3. Blade control switch

(power take-off)

2. Throttle/Choke

reverse; wheel speed is proportional to the amount the

lever is moved. Move the control levers outward from

the center to the park position and exit the machine

(Figure i5). Always position the motion control levers

into the park position when you stop the machine or

leave it unattended.

Fuel Gauge

The fuel window located below the operator position

can be used to veri_T the level of gasoline in the tank

(Figure 6).

Ignition Switch

The ignition switch has three positions, ()f_; Run and

Start. The key will turn to Start and move back to

Run upon release. Turning the key to the Off position

will stop the engine; however, always remove the key

when leaving the machine to prevent the engine from

accidentally starting (Figure 5).

Throttle/Choke Control

The throttle and choke is combined into one control

lever. The throttle controls the engine speed and it has a

continuous variable setting from Slow to Fast. Engage

the choke by moving the lever past the Fast setting until

it stops (Figure 5).

Blade Control Switch (Power Take-Off)

The blade control switch, represented by a power

take-off _TO) symbol, engages and disengages power

to the mower blades (Figure 5).

G007078

Figure 6

1. Fuel gauge window

Height-of-Cut Lever

The height of cut lever allows the operator to lower

and raise the deck from the seated position. When the

lever is moved up, toward the operator the deck is raised

from the ground and when moved down, away from the

operator it is lowered toward the ground. Only adjust the

height of cut while machine is not moving (Figure 18).

Foot Assist Pedal (Model 74375 only)

The foot assist pedal allows the operator to support the

weight of the deck with their leg during adjusting the

deck height via the height-of-cut lever.

Motion Control Levers and Park

Position

The motion control levers are speed sensitive controls of

independent wheel motors. Moving a lever forward or

backward turns the wheel on the same side forward or in

12

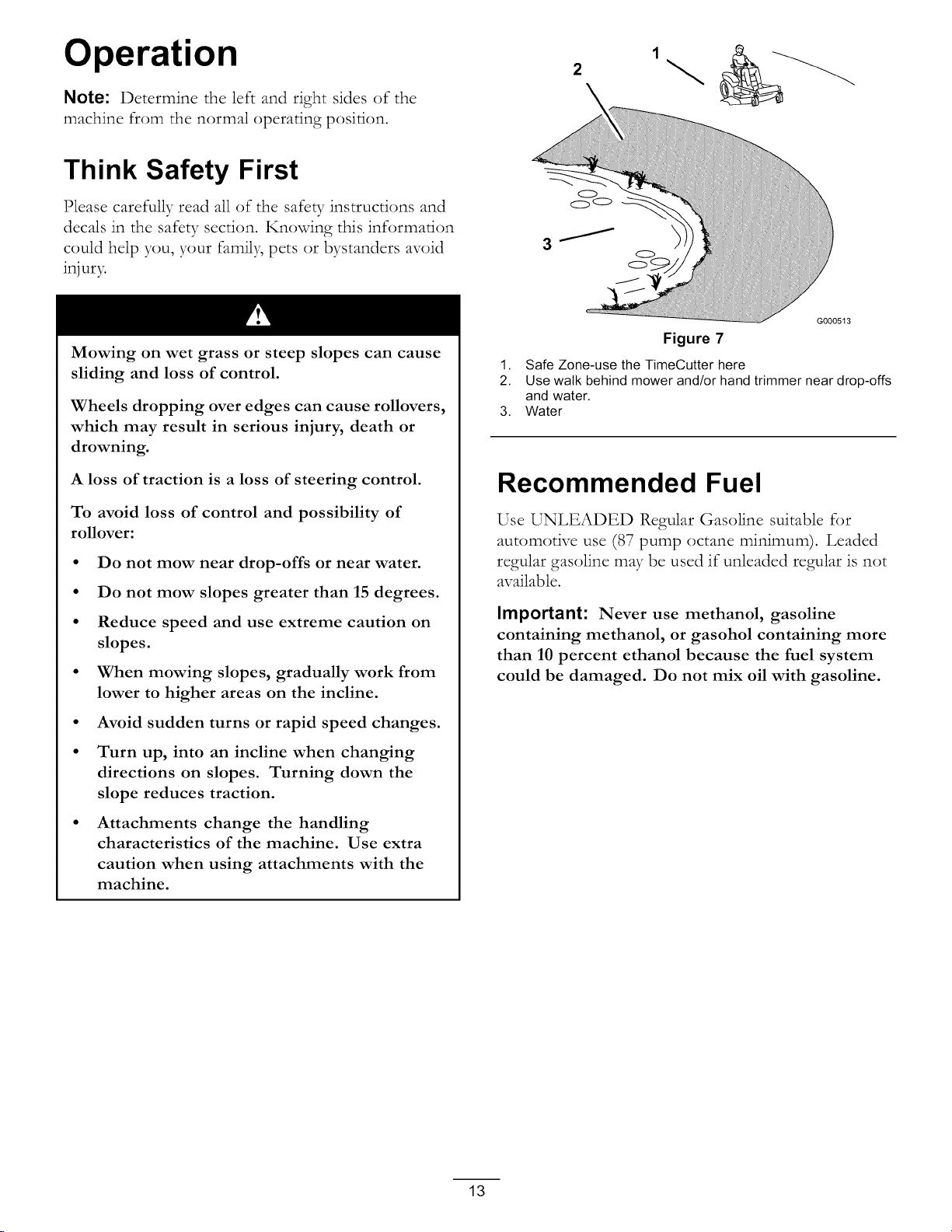

Operation

2

Note: Determine the leKt and right sides of the

machine from the normal operating position.

Think Safety First

Please carefully read all of the safety instructions and

decals in the safety section. Knowing this information

could help you, your famil5 pets or bystanders avoid

injur>

Mowing on wet grass or steep slopes can cause

sliding and loss of control.

Wheels dropping over edges can cause rollovers,

which may result in serious injury, death or

drowning.

A loss of traction is a loss of steering control.

To avoid loss of control and possibility of

rollover:

• Do not mow near drop-offs or near water.

• Do not mow slopes greater than 15 degrees.

• Reduce speed and use extreme caution on

slopes.

• When mowing slopes, gradually work from

lower to higher areas on the incline.

\

G000513

Figure 7

1. Safe Zone-use the TimeCutter here

2. Use walk behind mower and/or hand trimmer near drop-offs

and water.

3. Water

Recommended Fuel

Use UNLEADED Regular Gasoline suitable for

automotive use (87 pump octane minimum). Leaded

regular gasoline may be used if unleaded regular is not

available.

Important: Never use methanol, gasoline

containing methanol, or gasohol containing more

than 10 percent ethanol because the fuel system

could be damaged. Do not mix oil with gasoline.

• Avoid sudden turns or rapid speed changes.

• Turn up, into an incline when changing

directions on slopes. Turning down the

slope reduces traction.

• Attachments change the handling

characteristics of the machine. Use extra

caution when using attachments with the

machine.

13

In certain conditions, gasoline is extremely

flammable and highly explosive. A fire or

explosion from gasoline can burn you and

others and can damage property.

Fill the fuel tank outdoors, in an open area,

when the engine is cold. Wipe up any

gasoline that spills.

Never fill the fuel tank inside an enclosed

trailer.

Do not fill the fuel tank completely full. Add

gasoline to the fuel tank until the body of

the tank is full but fuel does not fill the neck

of the tank. This empty space in the tank

allows gasoline to expand.

Never smoke when handling gasoline, and

stay away from an open flame or where

gasoline fumes may be ignited by a spark.

Store gasoline in an approved container and

keep it out of the reach of children. Never

buy more than a 30-day supply of gasoline.

Do not operate without entire exhaust

system in place and in proper working

condition.

In certain conditions during fueling, static

electricity can be released causing a spark

which can ignite the gasoline vapors. A fire

or explosion from gasoline can burn you and

others and can damage property.

• Mways place gasoline containers on the

ground away from your vehicle before filling.

Do not fill gasoline containers inside a

vehicle or on a truck or trailer bed because

interior carpets or plastic truck bed liners

may insulate the container and slow the loss

of any static charge.

When practical, remove gas-powered

equipment from the truck or trailer and

refuel the equipment with its wheels on the

ground.

If this is not possible, then refuel such

equipment on a truck or trailer from a

portable container, rather than from a

gasoline dispenser nozzle.

If a gasoline dispenser nozzle must be used,

keep the nozzle in contact with the rim of

the fuel tank or container opening at all

times until fueling is complete.

Gasoline is harmful or fatal if swallowed.

Long-term exposure to vapors can cause serious

injury and illness.

• Avoid prolonged breathing of vapors.

• Keep face away from nozzle and gas tank or

conditioner opening.

• Keep gas away from eyes and skin.

Using Stabilizer/Conditioner

Use a fuel stabilizer/conditioner in the machine to

provide the following benefits:

• Keeps gasoline fresh during storage of 30 days or

less. For longer storage it is recommended that the

fuel tank be drained.

• Cleans the engine while it runs.

• Eliminates gum-like varnish buildup in the fuel

system, which causes hard starting.

14

Add the correct amount of gas stabilizer/conditioner

to the gas.

Note: A fuel stabilizer/conditioner is most effective

when mixed with fresh gasoline. To minimize the

chance of varnish deposits in the fuel system, use fuel

stabilizer at all rimes.

Gasoline/Alcohol blends

Gasohol (up to 10 percent ethyl alcohol, 90 percent

unleaded gasoline by volume) is approved for fuel use

by the engine manufacturer. Other gasoline/alcohol

blends, such as E85, are not approved.

Gasoline/Ether blends

Methyl Tertiary Butyl Ether (MTBE) and unleaded

gasoline blends (up to a maximum of i5 percent MTBE

by volume) are approved for fuel use by the engine

manufacturer. Other gasoline/ether blends are not

approved.

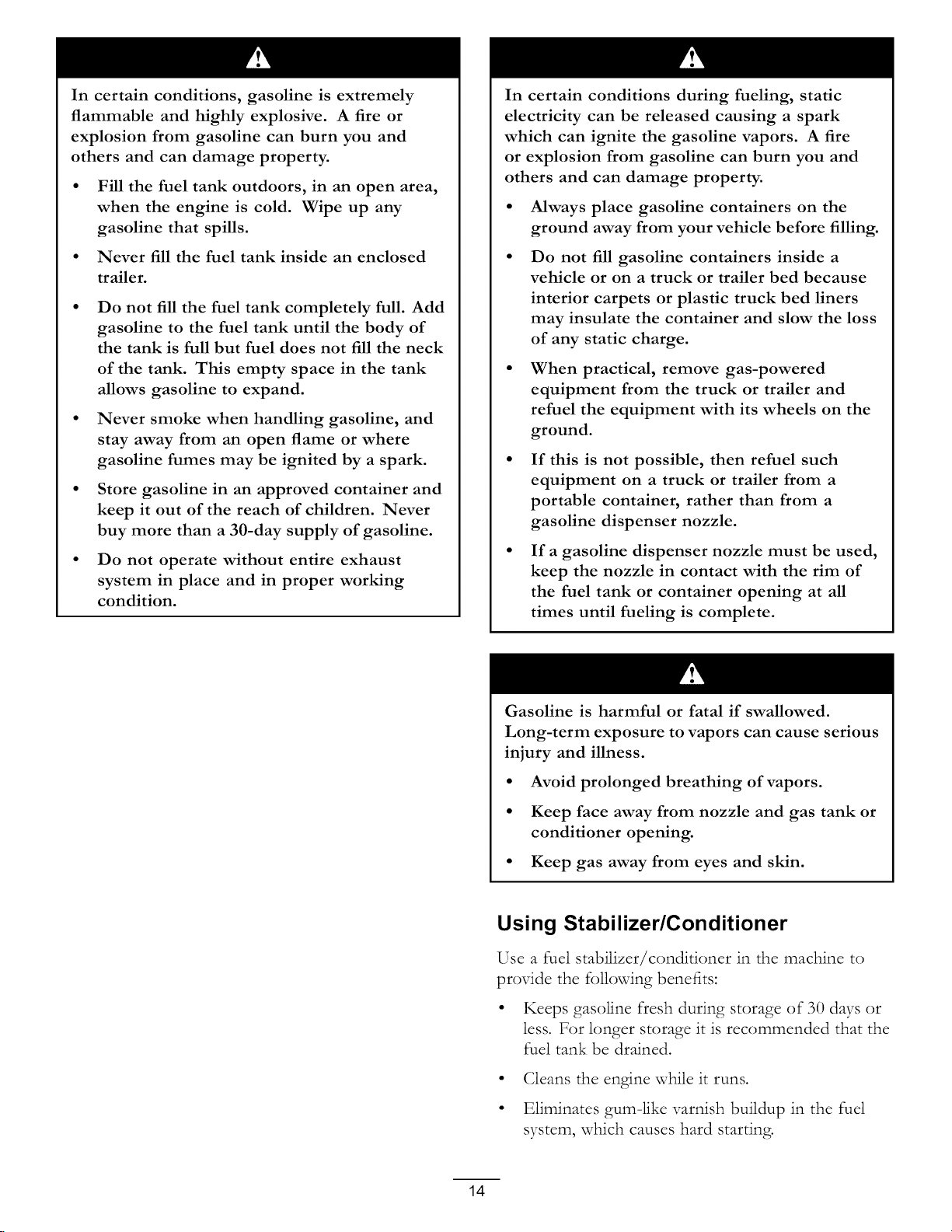

Fuel Gauge

Use the fuel window below the operator to veri_T the

level of gasoline before filling the tank (Figure 8).

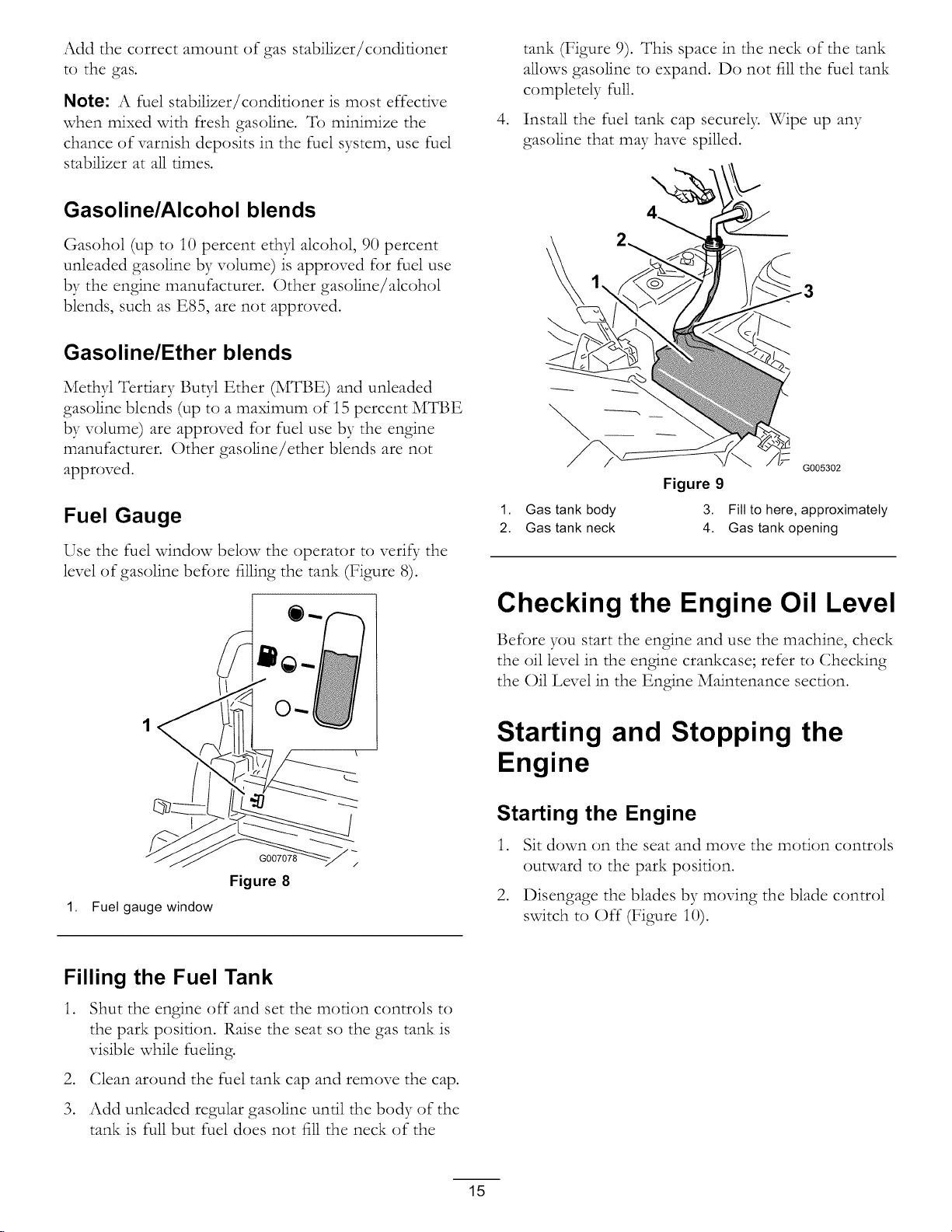

tank (Figure 9). This space in the neck of the tank

allows gasoline to expand. Do not fill the fuel tank

completely full.

.

Install the fuel tank cap securely. Wipe up any

gasoline that may have spilled.

\

G005302

Figure 9

1. Gas tank body 3.

2. Gas tank neck 4.

Fill to here, approximately

Gas tank opening

Figure 8

1. Fuel gauge window

Filling the Fuel Tank

1. Shut the engine off and set the morion controls to

the park position. Raise the seat so the gas tank is

visible while fueling.

Checking the Engine Oil Level

Before you start the engine and use the machine, check

the oil level in the engine crankcase; refer to Checking

the Oil Level in the Engine Maintenance section.

Starting and Stopping the

Engine

Starting the Engine

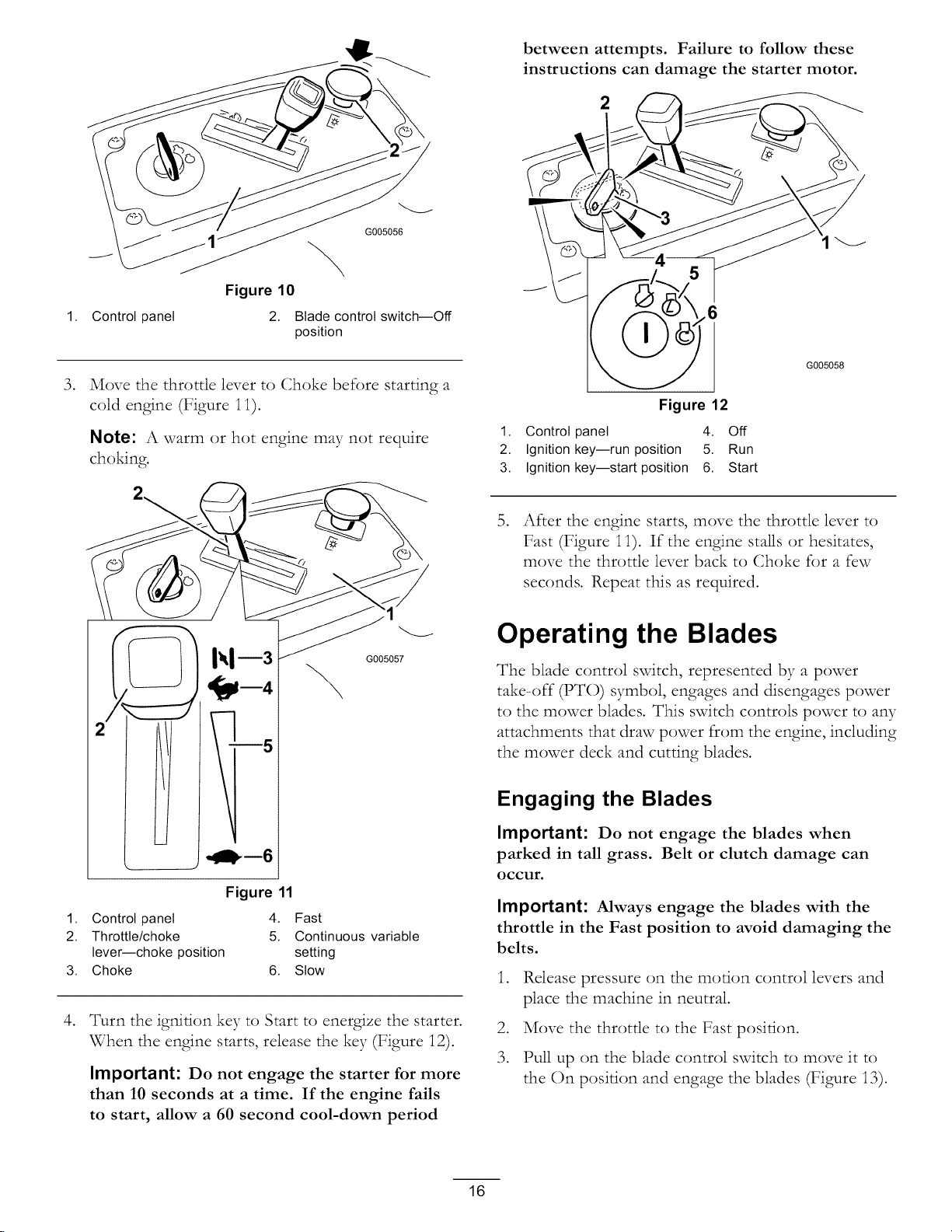

1. Sit down on the seat and move the motion controls

outward to the park position.

2. Disengage the blades by moving the blade control

switch to Off (Figure 10).

2. Clean around the fuel tank cap and remove the cap.

3. Add unleaded regular gasoline until the body of the

tank is full but fuel does not fill the neck of the

15

G005056

Figure 10

1,

Control panel

.

Move the throttle lever to Choke before starting a

2. Blade control switch--Off

position

cold engine (Figure 1i).

Note: A warm or hot engine may not require

choking.

between attempts. Failure to follow these

instructions can damage the starter motor.

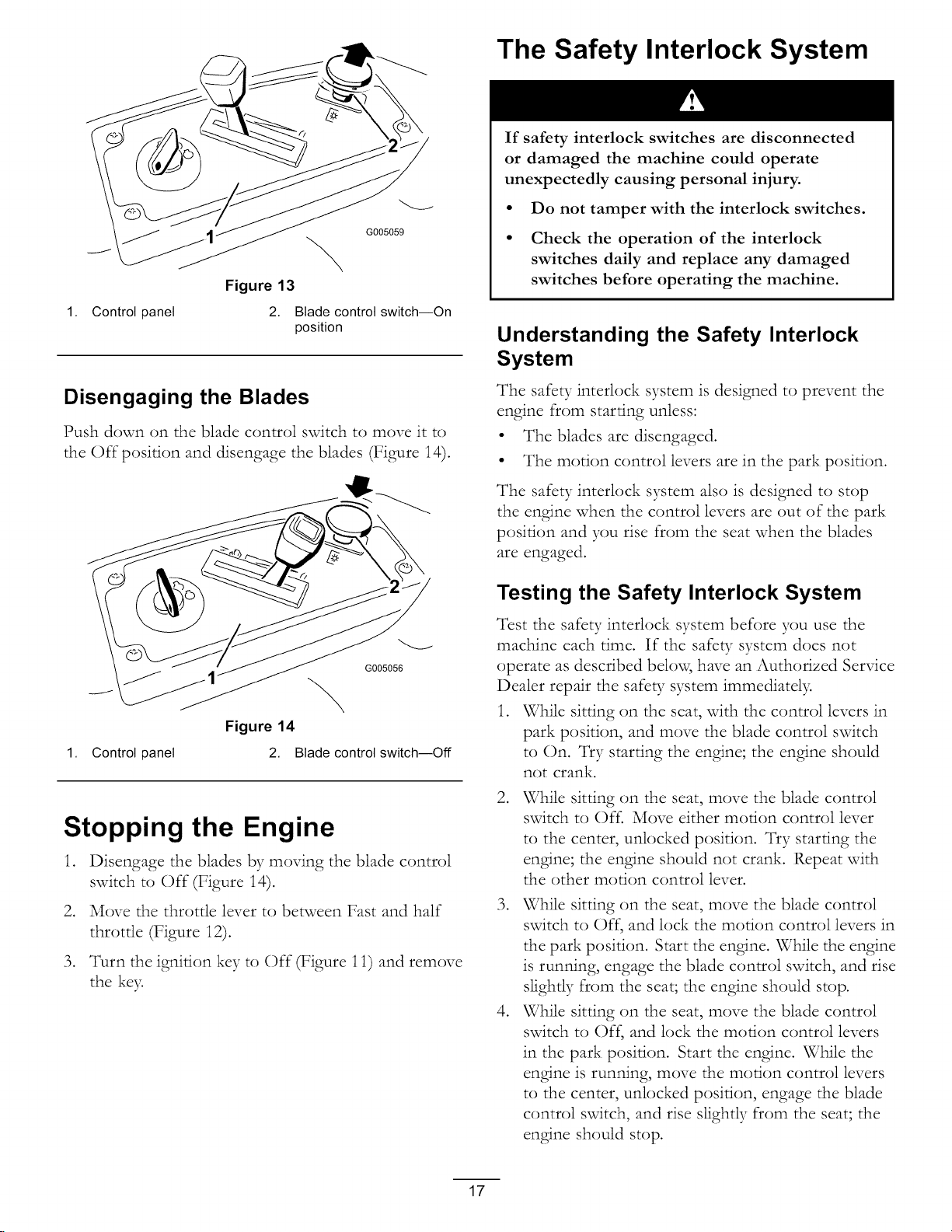

G005058

Figure 12

1. Control panel 4. Off

2. Ignition key--run position 5. Run

3. Ignition key--start position 6. Start

G005057

2 /

Figure 11

1,

Control panel

2.

Throttle/choke

lever--choke 3osition

3,

Choke

.

Turn the igmdon key to Start to energize the starter.

4. Fast

5. Continuous variable

setting

6. Slow

When the engine starts, release the key (Figure 12).

Important: Do not engage the starter for more

than 10 seconds at a time. If the engine fails

to start, allow a 60 second cool-down period

.

After the engine starts, move the throttle lever to

Fast (Figure 1i). If the engine stalls or hesitates,

move the throttle lever back to Choke for a few

seconds. Repeat this as required.

Operating the Blades

The blade control switch, represented by a power

take-off (PTO) symbol, engages and disengages power

to the mower blades. This switch controls power to aW

attachments that draw power from the engine, including

the mower deck and cutting blades.

Engaging the Blades

Important: Do not engage the blades when

parked in tall grass. Belt or clutch damage can

occur.

Important: Always engage the blades with the

throttle in the Fast position to avoid damaging the

belts.

1. Release pressure on the motion control levers and

place the machine in neutral.

2. Move the throttle to the Fast position.

3. Pull up on the blade control switch to move it to

the On posidon and engage the blades (Figure 13).

16

G005059

Figure 13

1. Control panel 2. Blade control switch--On

position

The Safety Interlock System

If safety interlock switches are disconnected

or damaged the machine could operate

unexpectedly causing personal injury.

• Do not tamper with the interlock switches.

• Check the operation of the interlock

switches daily and replace any damaged

switches before operating the machine.

Understanding the Safety Interlock

System

Disengaging the Blades

Push down on the blade control switch to move it to

the Off position and disengage the blades (Figure 14).

G005056

Figure 14

1. Control panel

2. Blade control switch--Off

Stopping the Engine

1. Disengage the blades by moving the blade control

switch to Off (Figure i4).

2. Move the throttle lever to between Fast and half

throttle (Figure i2).

3. Turn the ignition key to Off (Figure 11) and remove

the ke>

The safety interlock system is designed to prevent the

engine from starting unless:

• The blades are disengaged.

• The motion control levers are in the park position.

The safety interlock system also is designed to stop

the engine when the control levers are out of the park

position and you rise from the seat when the blades

are engaged.

Testing the Safety Interlock System

Test the safety interlock system before you use the

machine each time. If the safety system does not

operate as described below, have an Authorized Service

Dealer repair the safety system immediatel>

1. While sitting on the seat, with the control levers in

park position, and move the blade control switch

to On. Try starting the engine; the engine should

not crank.

.

While sitting on the seat, move the blade control

switch to Oft, Move either motion control lever

to the center, unlocked position. Try starting the

engine; the engine should not crank. Repeat with

the other morion control lever.

.

While sitting on the seat, move the blade control

switch to Off, and lock the motion control levers in

the park position. Start the engine. While the engine

is running, engage the blade control switch, and rise

slightly from the seat; the engine should stop.

.

While sitting on the seat, move the blade control

switch to Off, and lock the motion control levers

in the park position. Start the engine. While the

engine is running, move the morion control levers

to the center, unlocked position, engage the blade

control switch, and rise slightly from the seat; the

engine should stop.

17

Driving Forward or Backward

The throttle control regulates the engine speed as

measured in rpm (revolutions per minute). Place

the throttle control in the Fast position for best

performance. Always operate in the full throttle

position.

The machine can spin very rapidly. The

operator may lose control of the machine

and cause personal injury or damage to the

machine.

• Use caution when making turns.

• Slow the machine down before making

sharp turns.

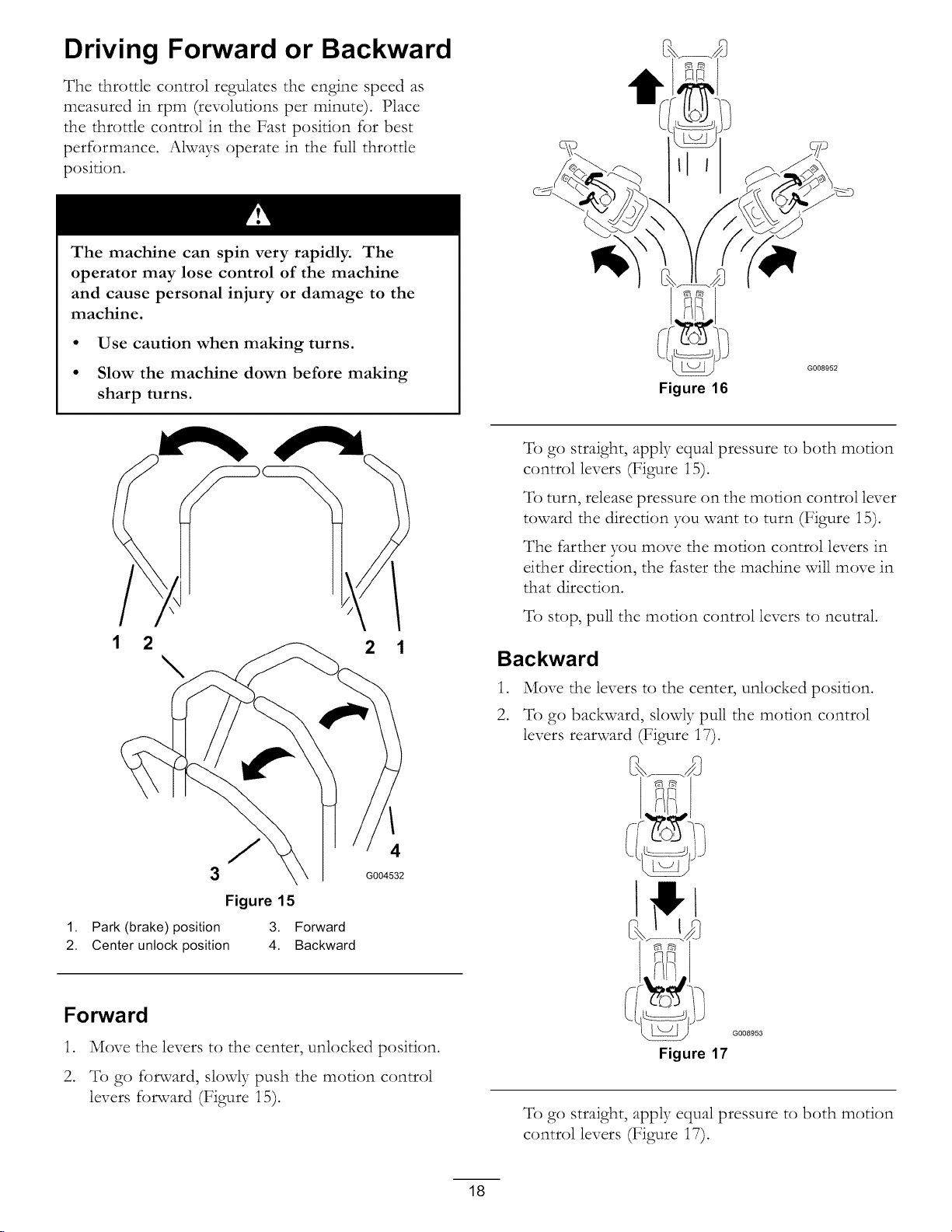

1 2

2 1

Figure 16

To go straight, apply equal pressure to both motion

control levers (Figure i5).

To turn, release pressure on the morion control lever

toward the direction you want to turn (Figure 15).

The farther you move the motion control levers in

either direction, the faster the machine will move in

that direction.

To stop, pull the motion control levers to neutral.

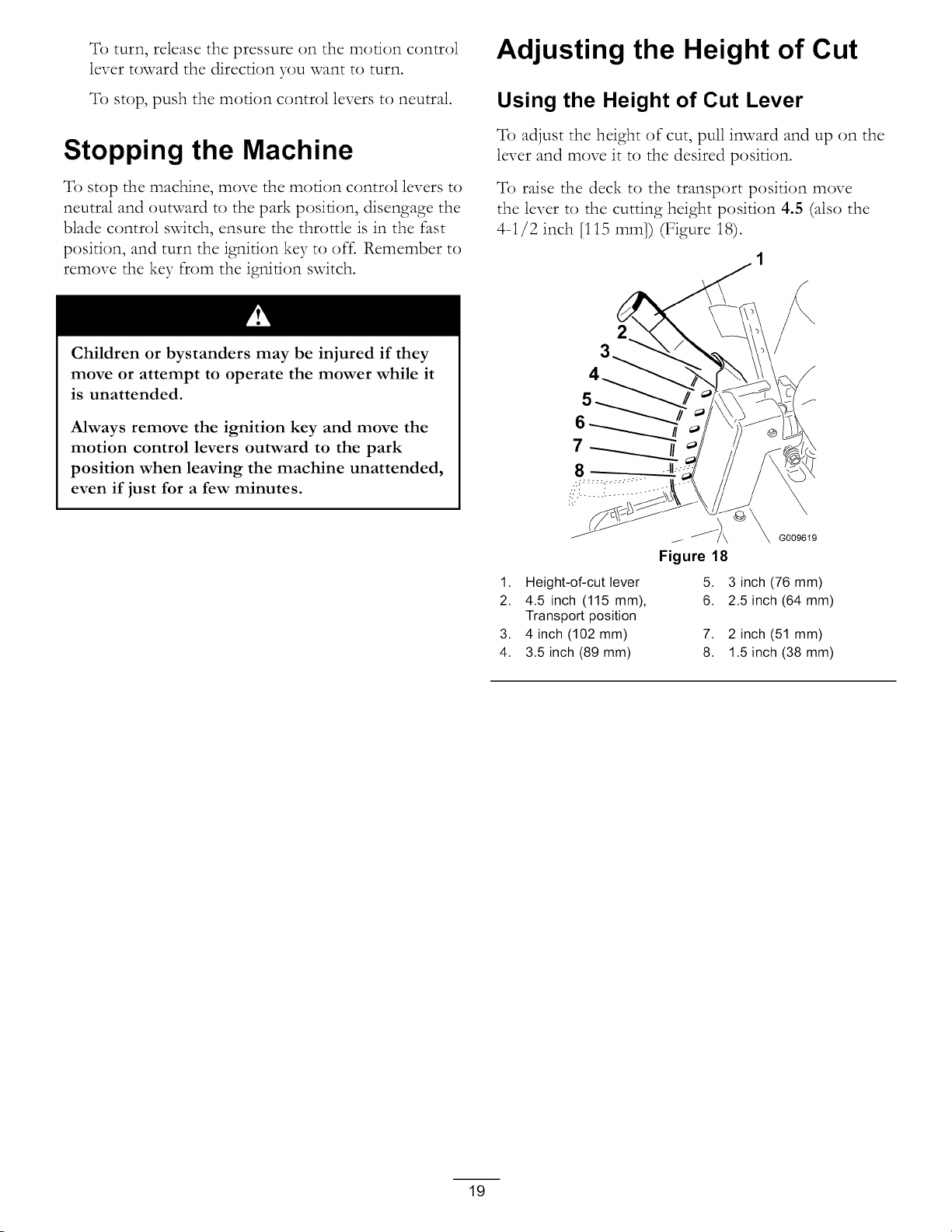

Backward

1. Move the levers to the center, unlocked position.

2. To go backward, slowly pull the morion control

levers rearward (Figure 17).

/

3

Figure 15

1. Park (brake) position 3. Forward

2. Center unlock position 4. Backward

4

G004532

Forward

1. Move the levers to the center, unlocked position.

2. To go forward, slowly push the motion control

levers forward (Figure 15).

I$1

G008953

Figure 17

To go straight, apply equal pressure to both motion

control levers (Figure 17).

18

Toturn,releasethepressureon the motion control

lever toward the direction you want to turn.

Adjusting the Height of Cut

To stop, push the motion control levers to neutral.

Stopping the Machine

To stop the machine, move the motion control levers to

neutral and outward to the park position, disengage the

blade control switch, ensure the throttle is in the fast

position, and turn the ignition key to of L Remember to

remove the key from the ignition switch.

Children or bystanders may be injured if they

move or attempt to operate the mower while it

is unattended.

Always remove the ignition key and move the

motion control levers outward to the park

position when leaving the machine unattended,

even if just for a few minutes.

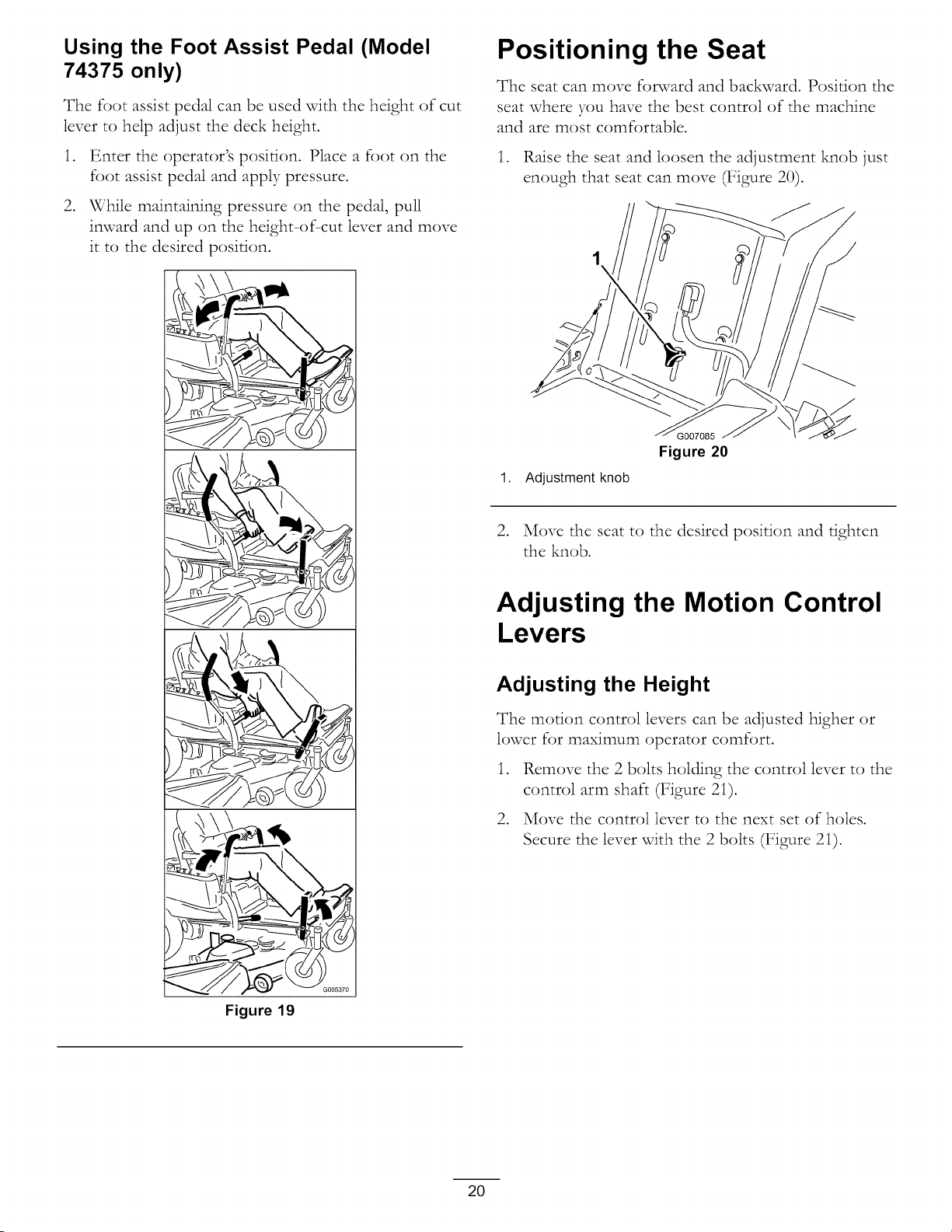

Using the Height of Cut Lever

To adjust the height of cut, pull inward and up on the

lever and move it to the desired position.

To raise the deck to the transport position move

the lever to the cutting height position 4.5 (also the

4-1/2 inch [115 mini) (Figure 18).

2

3

6

7

G009619

Figure 18

1. Height-of-cut lever

2. 4.5 inch (115 mm),

Transport position

3. 4 inch (102 mm)

4. 3.5 inch (89 mm)

5. 3 inch (76 mm)

6. 2.5 inch (64 mm)

7. 2 inch (51 mm)

8. 1.5 inch (38 mm)

19

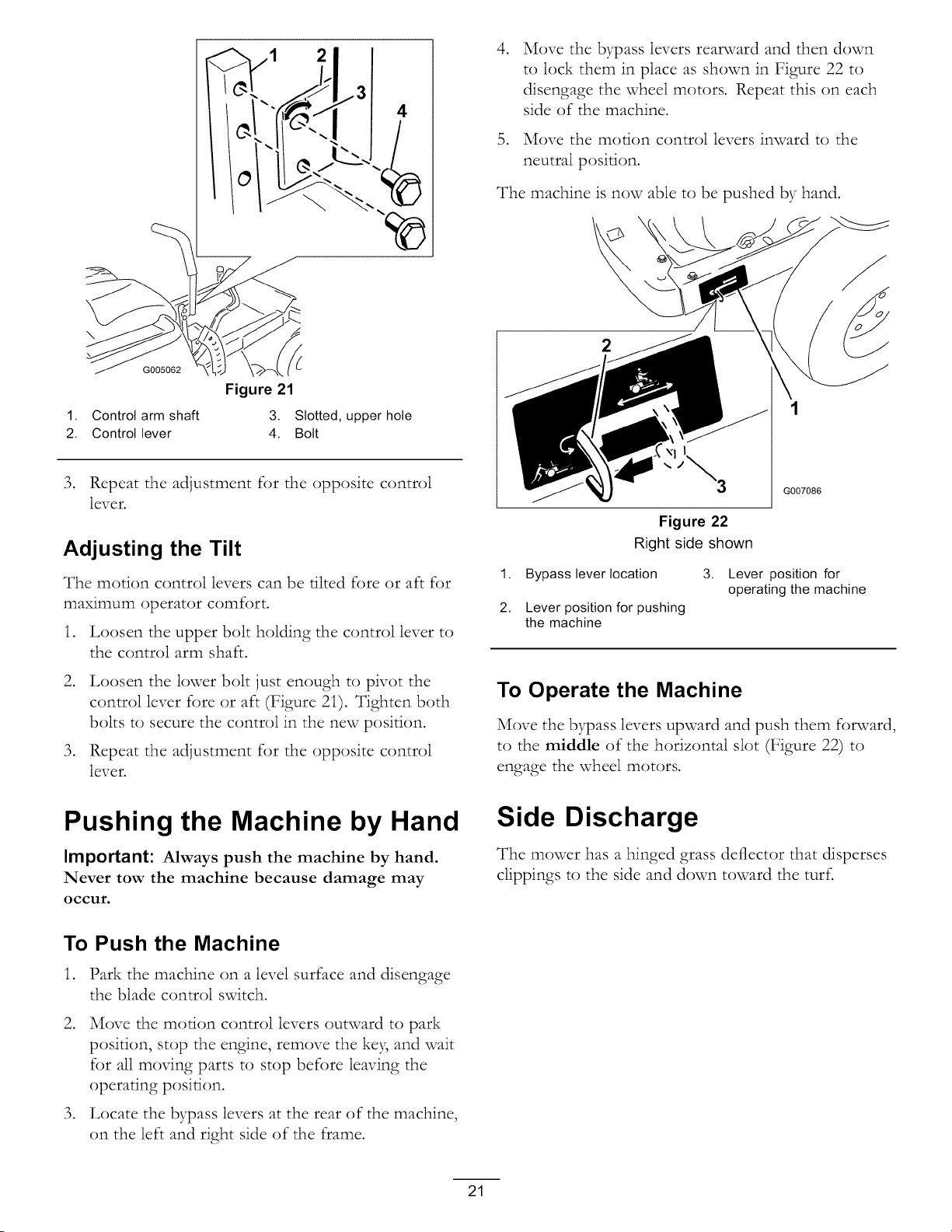

Using the Foot Assist Pedal (Model

74375 only)

The foot assist pedal can be used with the height of cut

lever to help adjust the deck height.

.

Enter the operator's position. Place a foot on the

foot assist pedal and apply pressure.

.

\While maintaining pressure on the pedal, pull

inward and up on the height-of-cut lever and move

it to the desired position.

Positioning the Seat

The seat can move forward and backward. Position the

seat where you have the best control of the machine

and are most comfortable.

1. Raise the seat and loosen the adjustment knob just

enough that seat can move (Figure 20).

1

\

Figure 20

1. Adjustment knob

2. Move the seat to the desired position and tighten

the knob.

Adjusting the Motion Control

Levers

Adjusting the Height

The motion control levers can be adjusted higher or

lower for maximum operator comfort.

1. Remove the 2 bolts holding the control lever to the

control arm shaft (Figure 2i).

2. Move the control lever to the next set of holes.

Secure the lever with the 2 bolts (Figure 2i).

Figure 19

2O

.

2

Move the bypass levers rearward and then down

to lock them in place as shown in Figure 22 to

disengage the wheel motors. Repeat this on each

side of the machine.

5. Move the motion control levers inward to the

neutral position.

The machine is now able to be pushed by hand.

\

G005062

Figure 21

1. Control arm shaft

2. Control lever

3. Slotted, upper hole

4. Bolt

3. Repeat the adjustment for the opposite control

lever.

Adjusting the Tilt

The motion control levers can be tilted fore or aft for

maximum operator comfort.

1. Loosen the upper bolt holding the control lever to

the control arm shaft.

2. Loosen the lower bolt just enough to pivot the

control lever fore or aft (Figure 2i). Tighten both

bolts to secure the control in the new position.

3. Repeat the adjustment for the opposite control

lever.

2

\1 I

G007086

Figure 22

Right side shown

1. Bypass lever location

2. Lever position for pushing

the machine

3. Lever position for

operating the machine

To Operate the Machine

Move the bypass levers upward and push them forward,

to the middle of the horizontal slot (Figure 22) to

engage the wheel motors.

Pushing the Machine by Hand

Important: Always push the machine by hand.

Never tow the machine because damage may

occur.

To Push the Machine

1. Park the machine on a level surface and disengage

the blade control switch.

.

Move the motion control levers outward to park

position, stop the engine, remove the keB and wait

for all moving parts to stop before leaving the

operating position.

.

Locate the bypass levers at the rear of the machine,

on the left and right side of the frame.

Side Discharge

"['he mower has a hinged grass deflector that disperses

clippings to the side and down toward the turf.

21

Without the grass deflector, discharge cover,

or complete grass catcher assembly mounted

in place, you and others are exposed to blade

contact and thrown debris. Contact with

rotating mower blade(s) and thrown debris will

cause injury or death.

Never remove the grass deflector from

the mower because the grass deflector

routes material down toward the turf. If the

grass deflector is ever damaged, replace it

immediately.

Never put your hands or feet under the

mower.

Never try to clear discharge area or mower

blades unless you move the blade control

switch to Off and rotate the ignition key to

Off. Mso remove the key and pull the wire

off the spark plug(s).

Operating Tips

Mowing Direction

Alternate mowing direction to keep the grass standing

straight. This also helps disperse clippings which

enhances decomposition and fertilization.

Mow at Correct Intervals

Normall3; mow every fi)ur days. But remember,

grass grows at different rates at different times. So

to maintain the same cutting height, which is a good

practice, mow more often in early spring. As the grass

growth rate slows in mid summer, mow less frequently.

If you cannot mow for an extended period, first mow

at a high cutting height; then mow again two days later

at a lower height setting.

Cutting Speed

To improve cut quality use a slower ground speed.

Avoid Cutting Too Low

If the cutting width of the mower is wider than the

mower you previously used, raise the cutting height to

ensure that uneven turf is not cut too short.

Fast Throttle Setting

For best mowing and maximum air circulation, operate

the engine at the Fast position. Air is required to

thoroughly cut grass clippings, so do not set the

height-of-cut so low as to totally surround the mower

by uncut grass. Always try to have one side of the

mower flee from uncut grass, which allows air to be

drawn into the mower.

Cutting a Lawn for the First Time

Cut grass slightly longer than normal to ensure that the

cutting height of the mower does not scalp any uneven

ground. However, the cutting height used in the past is

generally the best one to use. When cutting grass longer

than six inches tall, you may want to cut the lawn twice

to ensure an acceptable quality of cut.

Cut 113of the Grass Blade

It is best to cut only about i/3 of the grass blade.

Cutting more than that is not recommended unless

grass is sparse, or it is late fall when grass grows more

slowl>

Long Grass

If the grass is ever allowed to grow slightly longer than

normal, or if it contains a high degree of moisture, raise

the cutting height higher than usual and cut the grass at

this setting. Then cut the grass again using the lower,

normal setting.

When Stopping

If the machine's fi)rward motion must be stopped while

mowing, a clump of grass clippings may drop onto your

lawn. To avoid this, move onto a previously cut area

with the blades engaged.

Keep the Underside of the Mower

Clean

Clean clippings and dirt from the underside of the

mower after each use. If grass and dirt build up inside

the mower, cutting quality will eventually become

unsatisfactor).

Blade Maintenance

Maintain a sharp blade throughout the cutting season

because a sharp blade cuts cleanly without tearing or

shredding the grass blades. Tearing and shredding turns

grass brown at the edges, which slows growth and

increases the chance of disease. Check the cutter blades

22

daily for sharpness, and for aW wear or damage. File

down aW nicks and sharpen the blades as necessar> If

a blade is damaged or worn, replace it immediately with

a genuine Toro replacement blade.

23

Maintenance

Note: Determine the left and right sides of the machine from the normal operating position.

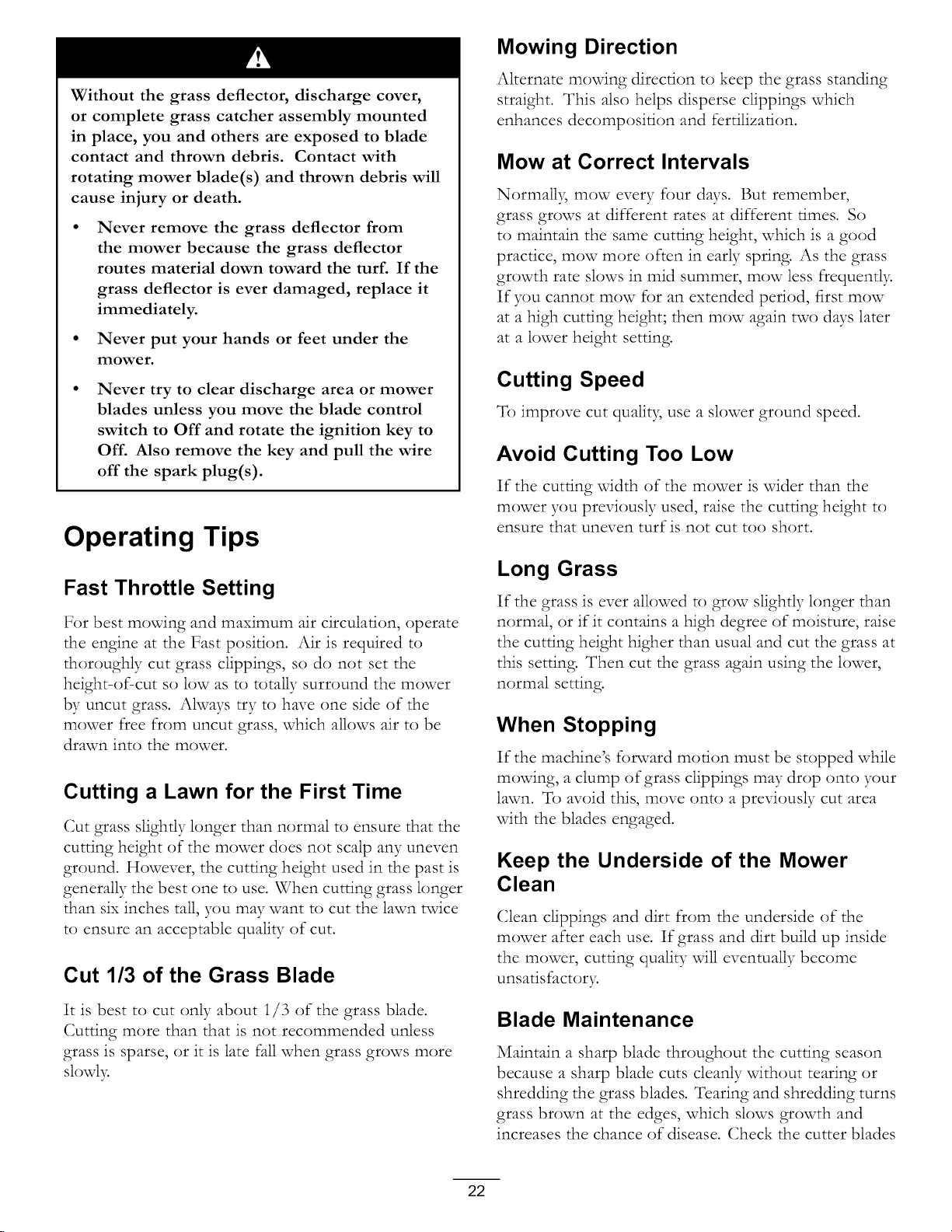

Recommended Maintenance Schedule(s)

Maintenance Service

Interval

Before each use or daily

Every 25 hours • Check tire pressure.

Every 50 hours • Service the paper element. (more often under extremely dusty, dirty conditions)

Every 100 hours

Every 200 hours • Check spark plug(s) condition and gap.

Every 500 hours • Replace the spark plug(s).

Before storage • Perform all maintenance procedures listed above before storage.

Maintenance Procedure

• Check the safety interlock system.

• Check the air cleaner for dirty, loose or damaged parts.

• Check the engine oil level.

• Check air intake and cooling areas, clean as necessary.

• Check the cutting blades.

• Inspect the grass deflector for damage

• Clean the mower housing.

• Grease all lubrication points.

• Check the belts for wear/cracks.

• Replace the paper element. (more often under extremely dusty, dirty conditions)

• Change the engine oil and filter.

• Clean the blower housing (more often under extremely dusty, dirty conditions).

• Replace the fuel filter.

• Charge the battery and disconnect battery cables.

• Paint any chipped surfaces.

Important: Refer to your engine operator's manual for additional maintenance procedures.

If you leave the key in the ignition switch, someone could accidently start the engine and seriously

injure you or other bystanders.

Remove the key from the ignition and disconnect the wire from the spark plug before you do any

maintenance. Set the wire aside so that it does not accidentally contact the spark plug.

24

Premaintenance

Procedures

Lubrication

Greasing the Bearings

Raising the Seat

Make sure the motion control levers are locked in the

park position. Lift the seat forward.

The following components can be accessed by raising

the seat:

• Serial plate

• Service decal

• Seat adjustment knob

• Fuel filter

• Fuses

• Battery cables

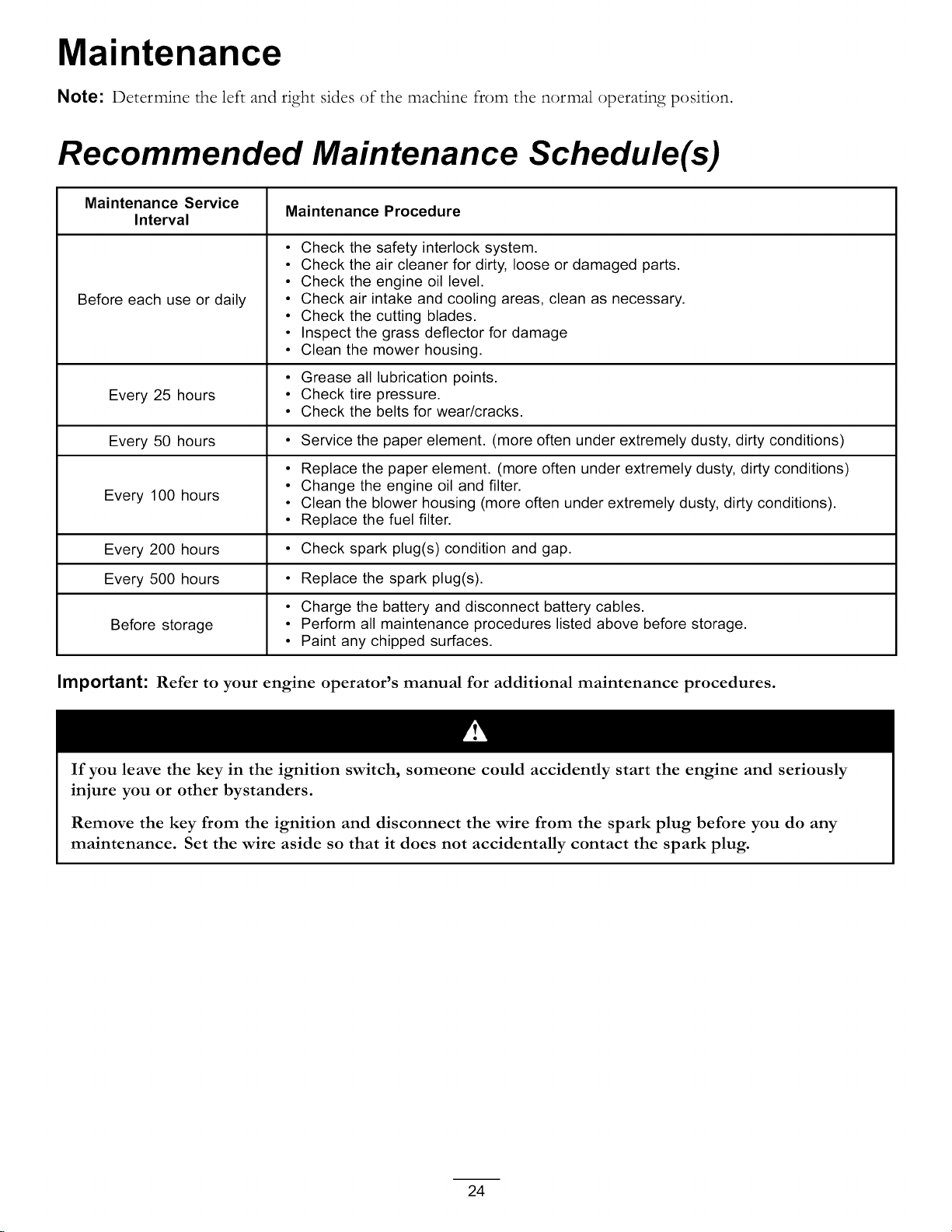

Accessing the Battery

1. Raise the seat.

2. Rcmove the TORX® head fasteners (T25) securing

the left cover to the frame as shown in Figure 23.

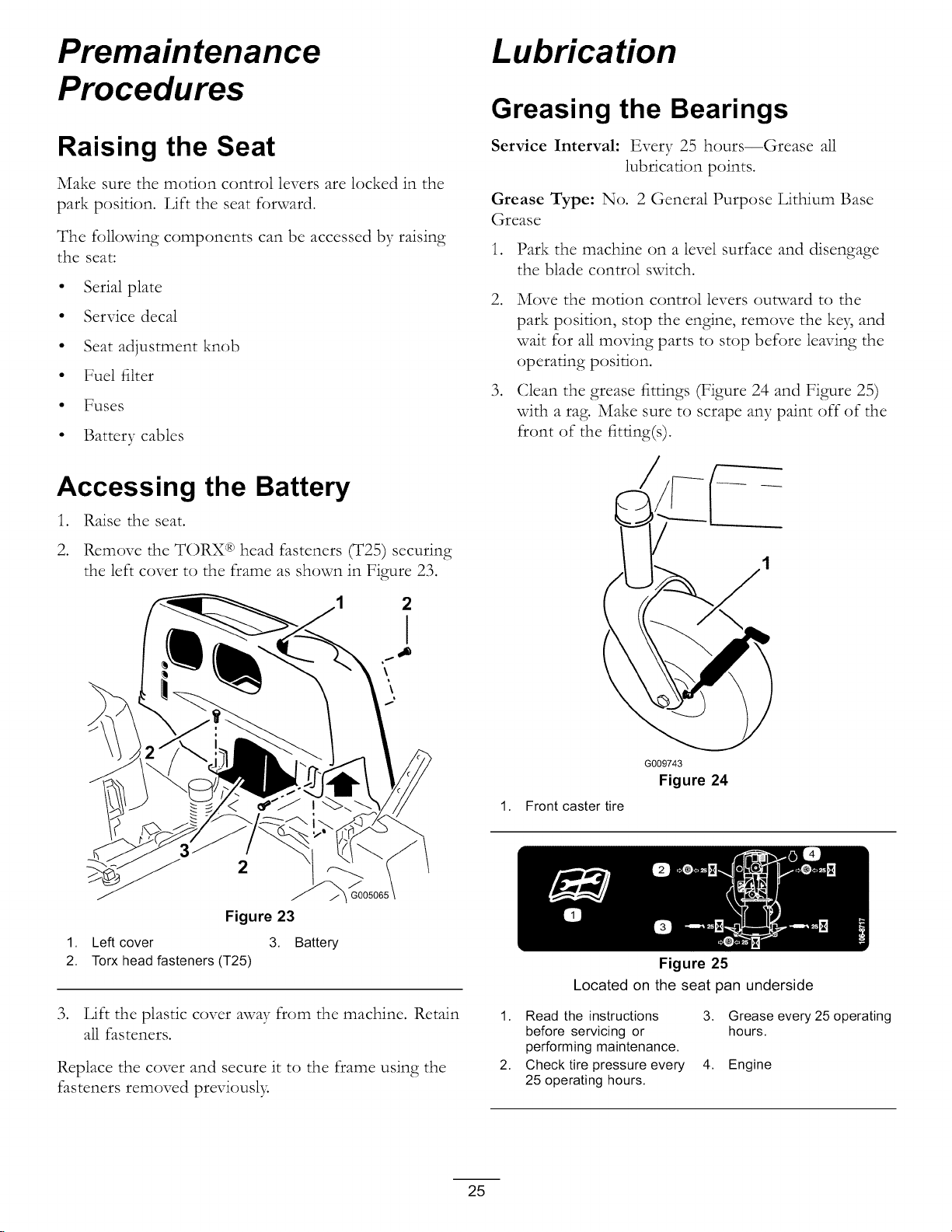

Service Interval: Ever3:25 hours--Grease all

lubrication points.

Grease Type: No. 2 General Purpose Lithium Base

Grease

1. Park the machine on a level surface and disengage

the blade control switch.

.

Move the motion control levers outward to the

park position, stop the engine, remove the ke3, and

wait for all moving parts to stop before leaving the

operating position.

.

Clean the grease fittings (Figure 24 and Figure 25)

with a rag. Make sure to scrape an): paint off of the

front of the fitting(s).

\

\

2

Figure 23

1,

Left cover 3. Battery

2.

Torx head fasteners (T25)

3. Lift the plastic cover away from the machine. Retain

all fasteners.

Replace the cover and secure it to the frame using the

fasteners removed previousl>

G009743

Figure 24

1. Front caster tire

Figure 25

Located on the seat pan underside

1. Read the instructions

before servicing or

performing maintenance.

2. Check tire pressure every

25 operating hours.

3. Grease every 25 operating

hours.

4. Engine

25

.

Connect a grease gun to each fitting (Figure 24 and

Figure 25). Pump grease into the fittings until grease

begins to ooze out of the bearings.

5. Wipe up any excess grease.

Engine Maintenance

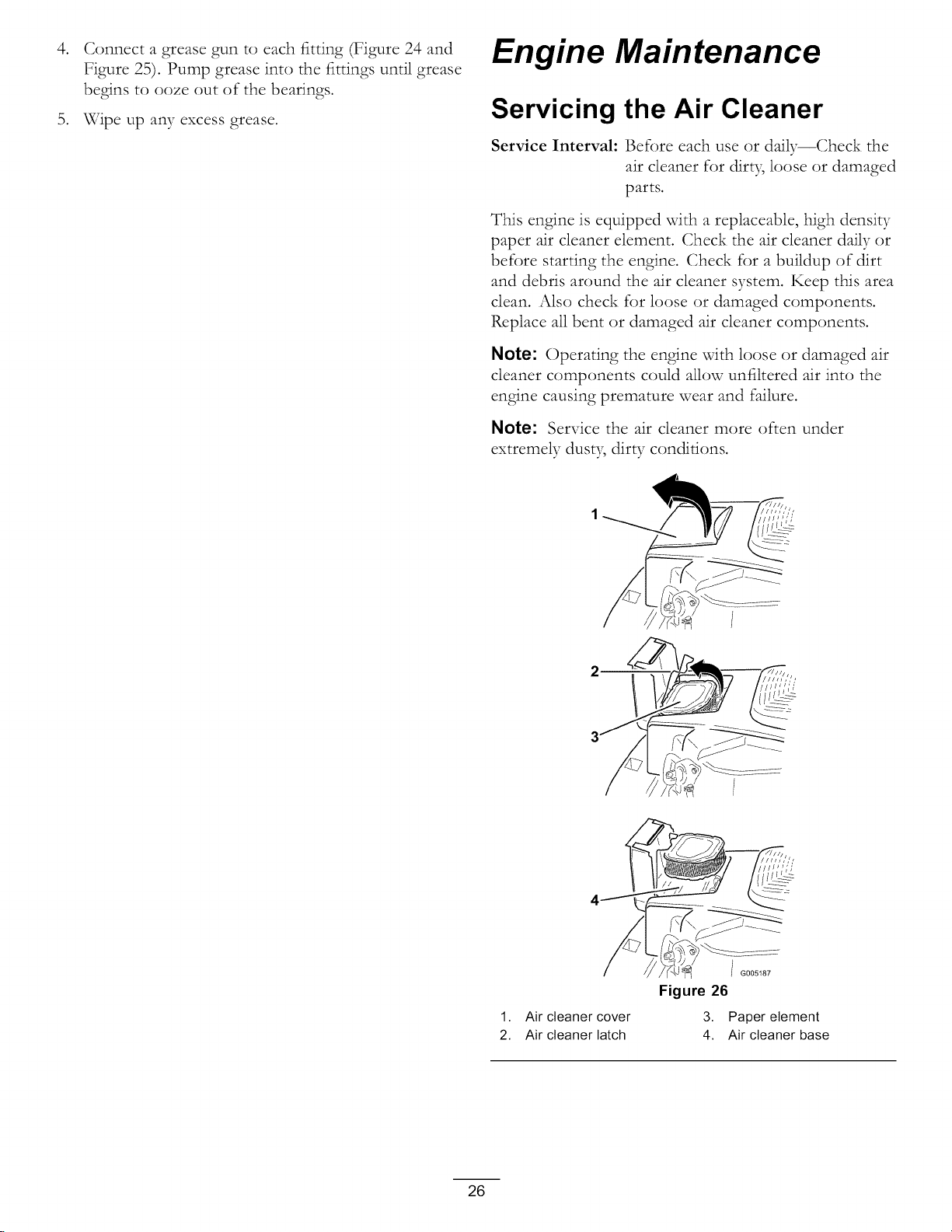

Servicing the Air Cleaner

Service Interval: Before each use or daily--Check the

air cleaner for dirty, loose or damaged

parts.

This engine is equipped with a replaceable, high density

paper air cleaner element. Check the air cleaner daily or

before starting the engine. Check for a buildup of dirt

and debris around the air cleaner system. Keep this area

clean. Also check for loose or damaged components.

Replace all bent or damaged air cleaner components.

Note: Operating the engine with loose or damaged air

cleaner components could allow unfiltered air into the

engine causing premature wear and failure.

Note: Service the air cleaner more often under

extremely dusty, dirty conditions.

2

1. Air cleaner cover

2. Air cleaner latch

G005187

Figure 26

3. Paper element

4. Air cleaner base

26

Servicing Paper Element

Checking the Oil Level

Service Interval: Every 50 hours--Service the paper

element. (more often under extremely

dust3; dirty conditions)

Every i00 hours--Replace the paper

element. (more often under extremely

dust3; dirty conditions)

Check the paper dement every 25 hours of operation

(more often under extremely dusty or dirty conditions).

Clean or replace the element as necessar> Replace the

air cleaner element yearl B or every 100 hours.

.

()pen the air cleaner cover door on the blower

housing to access the air cleaner element (Figure 26).

.

Unhook the latch and remove the air cleaner element

(Figure 26).

.

Gently tap the paper element to dislodge dirt. Do

not wash the paper element or use pressurized

air, as this will damage the element. Replace a dirt B

bent, or damaged element. Handle the new element

carefully; do not use if the sealing surfaces are bent

or damaged.

.

(;lean the air cleaner base as required and check

condition.

Service Interval: Before each use or daily--Check the

engine oil level.

.

Park the machine on a level surface, disengage the

blade control switch, stop the engine, and remove

the key.

.

Make sure the engine is stopped, level, and is cool so

the oil has had time to drain into the sump.

.

To keep dirt, grass clippings, etc., out of the engine,

clean the area around the oil fill cap/dipstick before

removing it.

.

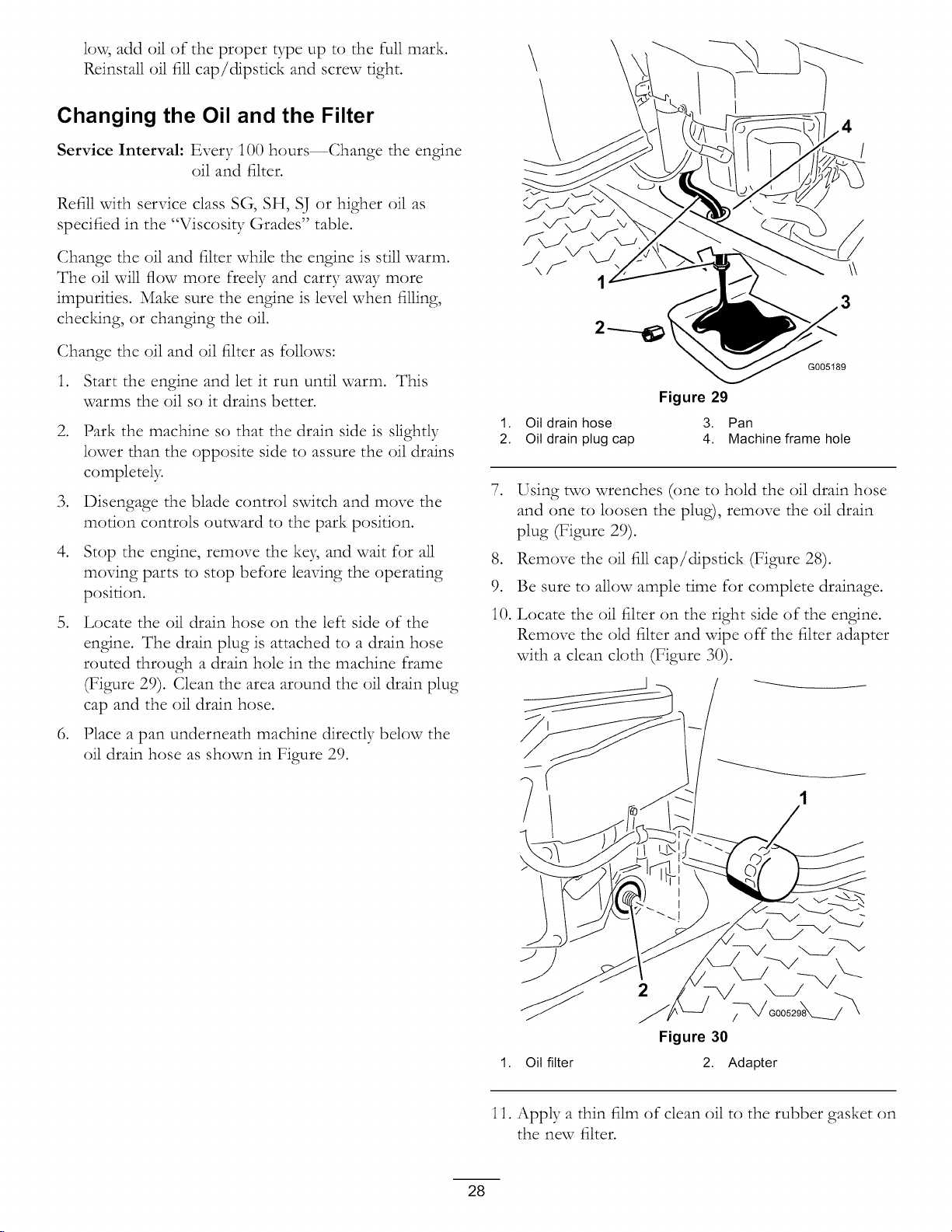

Unscrew and remove the dipstick; wipe oil off

(Figure 28). Reinsert the dipstick into the tube and

rest the cap on the tube. Do not screw the cap onto

the tube.

._ 1

3\

5. Install the paper element onto the air cleaner base.

Secure with the latch.

6. Close the air cleaner cover door.

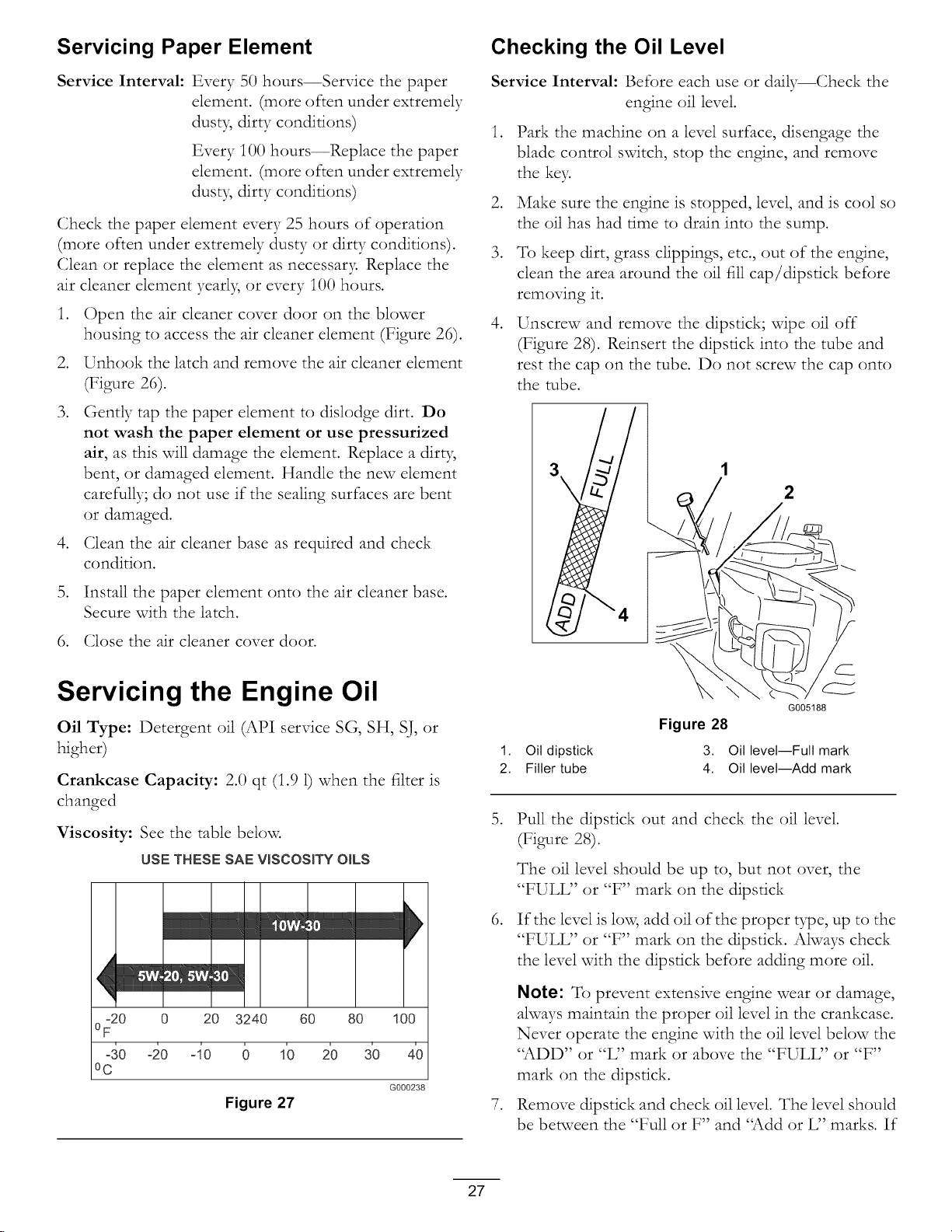

Servicing the Engine Oil

Oil Type: Detergent oil (API service SG, SH, SJ, or

higher)

Crankcase Capacity: 2.0 qt (1.9 1)when the filter is

changed

Viscosity: See the table below.

USE THESE SAE ViSCOSiTY OraLS

I

o

_20 0 20 3240 60 80 100

-30 -10 6 10 20 30 40

0C

G000238

Figure 27

G005188

Figure 28

1. Oil dipstick 3. Oil level--Full mark

2. Filler tube 4. Oil level--Add mark

.

Pull the dipstick out and check the oil level.

(Figure 28).

The oil level should be up to, but not over, the

"FULL" or "F" mark on the dipstick

.

If the level is low, add oil of the proper type, up to the

"FULL" or "F" mark on the dipstick. Always check

the level with the dipstick before adding more oil.

Note: To prevent extensive engine wear or damage,

always maintain the proper oil level in the crankcase.

Never operate the engine with the oil level below the

"ADD" or "L" mark or above the "FULL" or "F"

mark on the dipstick.

.

Remove dipstick and check oil level. The level should

be between the "Full or F" and "Add or L" marks. If

27

low,addoil oKthepropertypeupto theKullmark.

Reinstalloilfill cap/dipstickandscrewtight.

Changing the Oil and the Filter

Service Interval: Every I00 hours--Change the engine

oil and filter.

Refill with service class SG, SH, SJ or higher oil as

specified in the "Viscosity Grades" table.

Change the oil and filter while the engine is still warm.

The oil will flow more freely and carry away more

impurities. Make sure the engine is level when filling,

checldng, or changing the oil.

Change the oil and oil filter as follows:

1. Start the engine and let it run until warm. This

warms the oil so it drains better.

.

Park the machine so that the drain side is slightly

lower than the opposite side to assure the oil drains

completely

.

Disengage the blade control switch and move the

motion controls outward to the park position.

.

Stop the engine, remove the ke5 and wait for all

moving parts to stop before leaving the operating

position.

.

Locate the oil drain hose on the left side of the

engine. The drain plug is attached to a drain hose

routed through a drain hole in the machine frame

(Figure 29). Clean the area around the oil drain plug

cap and the oil drain hose.

.

Place a pan underneath machine directly below the

oil drain hose as shown in Figure 29.

Figure 29

1. Oil drain hose 3. Pan

2. Oil drain plug cap 4. Machine frame hole

7. Using two wrenches (one to hold the oil drain hose

and one to loosen the plug), remove the oil drain

plug (Figure 29).

8. Remove the oil fill cap/dipstick (Figure 28).

9. Be sure to allow ample time for complete drainage.

10. Locate the oil filter on the right side of the engine.

Remove the old filter and wipe off the filter adapter

with a clean cloth (Figure 30).

2

Figure 30

1. Oil filter 2. Adapter

11. Apply a thin film of clean oil to the rubber gasket on

the new filter.

28

12.Installthereplacementoil filterto the adapter.

Turntheoil filterclockwiseuntil therubbergasket

contactsthe pad, then tighten the filter an additional

3/4 to i turn (Figure 30). Wipe up aW excess oil

on the frame.

13. When oil has drained completely, install the oil drain

plug. Tighten the plug to 14 N-m (125 in-lb) torque.

Wipe up any excess oil (Figure 29).

Note: Dispose of the used oil at a recycling center.

14. Slowly pour approximately 80% of the specified oil

into the filler tube (Figure 28).

15. Install the oil fill cap/dipstick (Figure 28).

16. Check the oil level (Figure 28); refer to Checking

the Oil Level.

1"7. Slowly add additional oil to bring it to the full mark.

18. Install the oil fill cap/dipstick and screw tight

(Figure 28).

Servicing the Spark Plug

Service Interval:

The spark plug is RFI compliant. Equivalent alternate

brand plugs can also be used. Spark plug replacement is

recommended at 500 hours.

"[_pe: Champion XCI2YC (or equivalent)

Air Gap: 0.030 inch (0.76 ram)

Removing the Spark Plug

1. Disengage the blade control switch, move the

motion controls outward to the park position, stop

the engine, and remove the key.

Every 200 hours--Check spark

plug(s) condition and gap.

Every 500 hours--Replace the spark

plug(s).

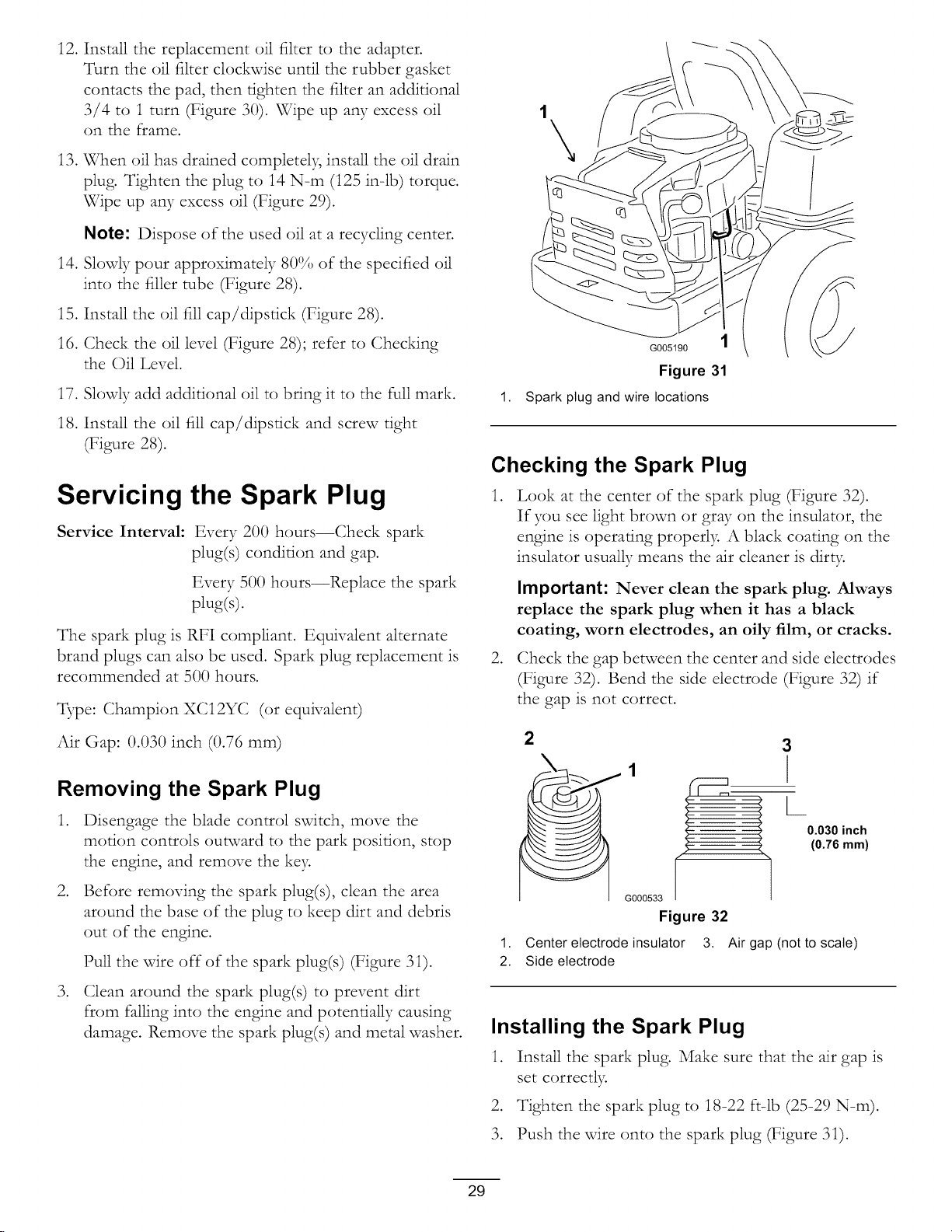

1

\

G005190 1

Figure 31

1,

Spark plug and wire locations

Checking the Spark Plug

.

Look at the center of the spark plug (Figure 32).

If you see light brown or gray on the insulator, the

engine is operating properl> A black coating on the

insulator usually means the air cleaner is dirt>

Important: Never clean the spark plug. Always

replace the spark plug when it has a black

coating, worn electrodes, an oily film, or cracks.

2. Check the gap between the center and side electrodes

(Figure 32). Bend the side electrode (Figure 32) if

the gap is not correct.

2

1

3

Li

0.030 inch

(0.76 mm)

2. Before removing the spark plug(s), clean the area

around the base of the plug to keep dirt and debris

out of the engine.

Pull the wire off of the spark plug(s) (Figure 3i).

3. (;lean around the spark plug(s) to prevent dirt

from falling into the engine and potentially causing

damage. Remove the spark plug(s) and metal washer.

G000533

Figure 32

1. Center electrode insulator 3. Air gap (not to scale)

2. Side electrode

Installing the Spark Plug

1. Install the spark plug. Make sure that the air gap is

set correctly.

2. Tighten the spark plug to 18-22 ft-lb (25-29 N-m).

3. Push the wire onto the spark plug (Figure 3i).

29

Loading...

Loading...