Page 1

FormNo.3361-179RevA

TimeCutter

®

Z4200,Z4220,and

Z5000RidingMowers

ModelNo.74360—SerialNo.290000001andUp

ModelNo.74363—SerialNo.290000001andUp

ModelNo.74370—SerialNo.290000001andUp

Registeratwww.T oro.com.OriginalInstructions(EN)

Page 2

Warning

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Thisengineisnotequippedwitha

sparkarrestermufer.ItisaviolationofCalifornia

PublicResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,or

grass-coveredland.Otherstatesorfederalareas

mayhavesimilarlaws.

Figure1

Undertheseat

ThissparkignitionsystemcomplieswithCanadian

ICES-002.

Theenclosed

Engine Owner’ s Man ual

issupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCalifornia

EmissionControlRegulationofemissionsystems,

maintenance,andwarranty.Replacementsmaybe

orderedthroughtheenginemanufacturer.

Formodelswithstatedenginehorsepower,thegross

horsepoweroftheenginewaslaboratoryratedbythe

enginemanufacturerinaccordancewithSAEJ1940.

Asconguredtomeetsafety,emission,andoperating

requirements,theactualenginehorsepoweronthisclass

oflawnmowerwillbesignicantlylower.

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

1.Modelandserialnumberplate

Writetheproductmodelandserialnumbersinthespace

below:

ModelNo.

SerialNo.

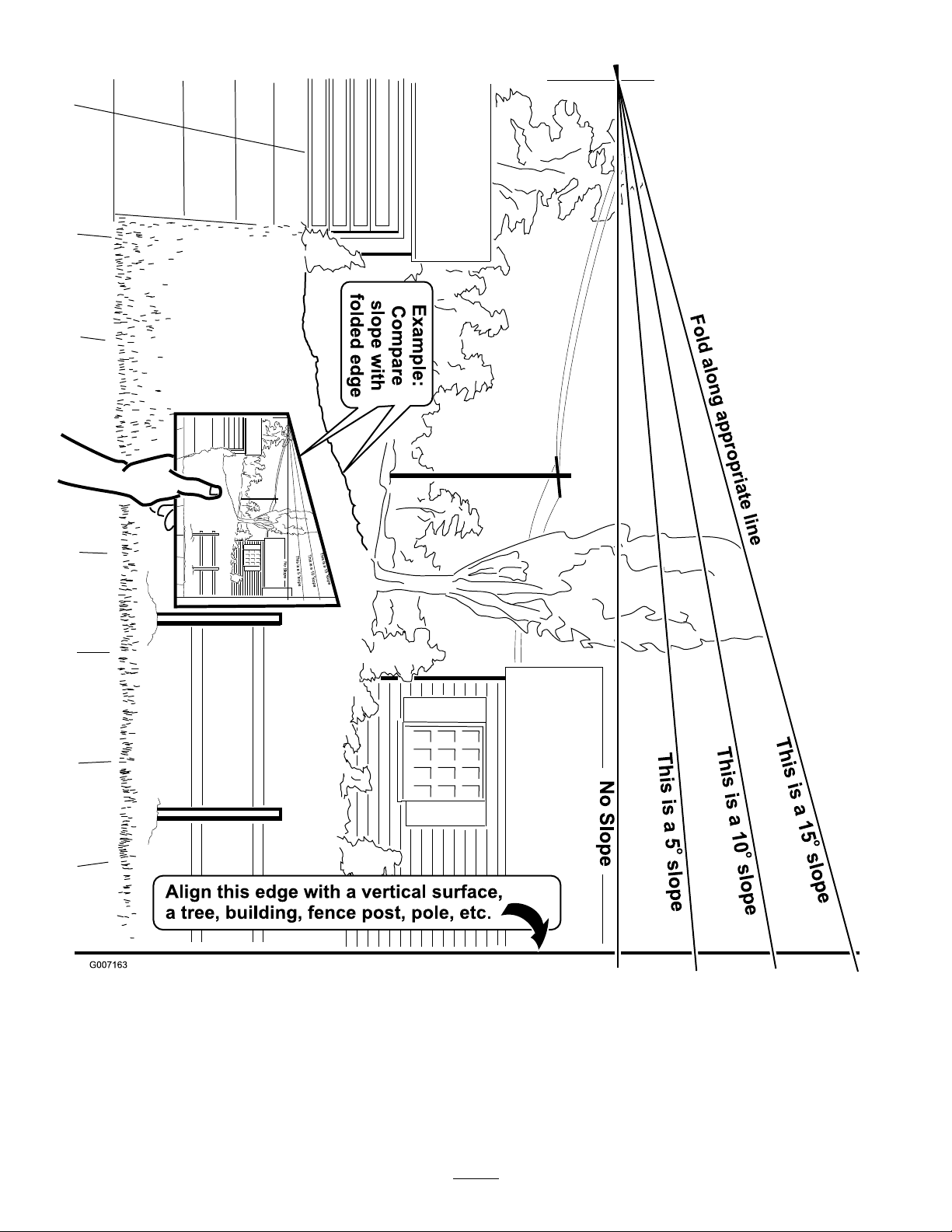

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizesgeneral

informationworthyofspecialattention.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready .Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

©2008—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contents

Introduction.................................................................2

Safety...........................................................................3

SafeOperatingPractices.......................................3

ToroRidingMowerSafety....................................5

SlopeChart..........................................................7

SafetyandInstructionalDecals.............................8

ProductOverview......................................................12

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Controls.............................................................13

Operation...................................................................14

ThinkSafetyFirst...............................................14

RecommendedGasoline.....................................14

CheckingtheEngineOilLevel............................16

StartingtheEngine.............................................16

OperatingtheBlades..........................................17

StoppingtheEngine...........................................18

TheSafetyInterlockSystem................................18

DrivingForwardorBackward.............................19

StoppingtheMachine.........................................20

AdjustingtheHeightofCut................................20

PositioningtheSeat............................................20

AdjustingtheMotionControlLevers..................20

PushingtheMachinebyHand.............................21

GrassDeector..................................................22

OperatingTips...................................................22

Maintenance...............................................................24

RecommendedMaintenanceSchedule(s)................24

PremaintenanceProcedures....................................25

RaisingtheSeat..................................................25

AccessingtheBattery.........................................25

Lubrication.............................................................25

GreasingtheBearings.........................................25

EngineMaintenance...............................................26

ServicingtheAirCleaner....................................26

ServicingtheEngineOil.....................................27

ServicingtheSparkPlug.....................................29

CleaningtheBlowerHousing..............................29

FuelSystemMaintenance.......................................30

ReplacingtheFuelFilter.....................................30

ElectricalSystemMaintenance................................31

ChargingtheBattery...........................................31

ServicingtheFuses.............................................32

DriveSystemMaintenance.....................................33

CheckingtheTirePressure.................................33

MowerMaintenance...............................................34

ServicingtheCuttingBlades...............................34

LevelingtheMowerDeck...................................36

RemovingtheMower.........................................38

MowerBeltMaintenance....................................39

InstallingtheMower...........................................40

ReplacingtheGrassDeector.............................40

Cleaning.................................................................41

WashingtheUndersideoftheMower..................41

Storage.......................................................................42

CleaningandStorage..........................................42

Troubleshooting.........................................................44

Schematics.................................................................46

Safety

ThismachinemeetsorexceedstheB71.1-2003

specicationsoftheAmericanNationalStandards

Institute,ineffectatthetimeofproduction.

However,improperuseormaintenancebythe

operatororownercanresultininjury.Toreduce

thepotentialforinjury,complywiththesesafety

instructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeansCAUTION,

WARNING,orDANGER-"personalsafety

instruction."Failuretocomplywiththeinstruction

mayresultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsarefromANSIstandard

B71.1-2003.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

GeneralOperation

•Read,understand,andfollowallinstructionsin

theoperator’smanualandonthemachinebefore

starting.

•Donotplacehandsorfeetnearrotatingpartsor

underthemachine.Keepclearofthedischarge

openingatalltimes.

•Allowonlyresponsibleadultswhoarefamiliarwith

theinstructionstooperatethemachine.

•Cleartheareaofobjectssuchasrocks,toys,wire,

etc.,whichcouldbepickedupandthrownbythe

blade.

•Besuretheareaisclearofotherpeoplebefore

mowing.Stopthemachineifanyoneentersthearea.

•Nevercarrypassengers.

•Donotmowinreverseunlessabsolutelynecessary.

Alwayslookdownandbehindbeforeandwhile

backingup.

•Beawareofthemowerdischargedirectionanddo

notpointitatanyone.Avoiddischargingmaterial

againstawallorobstruction.Materialmayricochet

backtowardtheoperator.Stoptheblade(s)when

crossinggravelsurfaces.

•Donotoperatethemachinewithoutdeector,

dischargecoverorentiregrasscollectionsystemin

placeandworking.

•Bealert,slowdownandusecautionwhenmaking

turns.Lookbehindandtothesidebeforechanging

directions.

3

Page 4

•Neverleavearunningmachineunattended.Always

turnoffblades,setparkingbrake,stopengine,and

removekeybeforedismounting.

•Turnoffbladeswhennotmowing.Stoptheengine

andwaitforallpartstocometoacompletestop

beforecleaningthemachine,removingthegrass

catcheroruncloggingthedischargechute.

•Operatethemachineonlyindaylightorgood

articiallight.

•Avoidsuddenstartswhenmowinguphillbecause

themowermaytipbackwards.

•Beawarethatlossoftractionmayoccurgoing

downhill.Weighttransfertothefrontwheelsmay

causedrivewheelstoslipandcauselossofbraking

andsteering.

•Alwaysavoidsuddenstartingorstoppingona

slope.Iftireslosetraction,disengagethebladesand

proceedslowlyofftheslope.

•Donotoperatethemachinewhileunderthe

inuenceofalcoholordrugs.

•Watchfortrafcwhenoperatingnearorcrossing

roadways.

•Useextracarewhenloadingorunloadingthe

machineintoatrailerortruck.

•Alwaysweareyeprotectionwhenoperatingthe

mower.

•Dataindicatesthatoperators,age60yearsand

above,areinvolvedinalargepercentageofriding

mower-relatedinjuries.Theseoperatorsshould

evaluatetheirabilitytooperatetheridingmower

safelyenoughtoprotectthemselvesandothersfrom

seriousinjury.

•Alwaysfollowtherecommendationsforwheel

weightsorcounterweights.

SlopeOperation

Slopesareamajorfactorrelatedtolossofcontroland

tip-overaccidents,whichcanresultinsevereinjuryor

death.Operationonallslopesrequiresextracaution.If

youcannotbackuptheslopeorifyoufeeluneasyonit,

donotmowit.

•Donotmowslopesgreaterthan15degrees.

•Watchforditches,holes,rocks,dips,andrisesthat

changetheoperatingangle,asroughterraincould

overturnthemachine.

•Choosealowgroundspeedsoyouwillnothaveto

stopwhileoperatingonaslope.

•Donotmowslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcausesliding

andlossofcontrol.

•Alwayskeepthewheelmotorsengagedwhengoing

downslopes.

•Reducespeedanduseextremecautiononslopes.

•Donotmakesuddenturnsorrapidspeedchanges.

•Useextremecarewithgrasscatchersorother

attachments.Thesecanchangethestabilityofthe

machineandcauselossofcontrol.

•Donottrytostabilizethemachinebyputtingyour

footontheground.

•Donotmowneardrop-offs,ditches,steepbanks

orwater.Wheelsdroppingoveredgescancause

rollovers,whichmayresultinseriousinjury,death

ordrowning.

•Useawalkbehindmowerand/orahandtrimmer

neardrop-offs,ditches,steepbanksorwater.

Children

Tragicaccidentscanoccuriftheoperatorisnotalertto

thepresenceofchildren.Childrenareoftenattractedto

themachineandthemowingactivity.Neverassumethat

childrenwillremainwhereyoulastsawthem.

•Keepchildrenoutofthemowingareaandunder

thewatchfulcareofanotherresponsibleadult,not

theoperator.

•Bealertandturnthemachineoffifchildrenenter

thearea.

•Beforeandwhilebackingorchangingdirection,look

behind,down,andside-to-sideforsmallchildren.

•Nevercarrychildren,evenwiththebladesoff.They

mayfalloffandbeseriouslyinjuredorinterferewith

safemachineoperation.

•Childrenwhohavebeengivenridesinthepastmay

suddenlyappearinthemowingareaforanotherride

andberunoverorbackedoverbythemower.

•Neverallowchildrentooperatethemachine.

•Useextracarewhenapproachingblindcorners,

shrubs,trees,theendofafenceorotherobjectsthat

mayobscurevision.

Towing

•Removeormarkobstaclessuchasrocks,treelimbs,

etc.fromthemowingarea.Tallgrasscanhide

obstacles.

Ahitchkitisavailableforthismachineandcanbe

obtainedbycontactinganAuthorizedToroDealer.

Donottowwithoutrstinstallingthismanufacturer

4

Page 5

approvedhitch.Thefollowingguidelinesapplywhen

towingwiththeapprovedhitchkitinstalled.

•Towonlywithamachinethathasahitchdesigned

fortowing.Donotattachtowedequipmentexcept

atthehitchpoint.

•Followthemanufacturer’srecommendationfor

weightlimitsfortowedequipmentandtowingon

slopes.

•Neverallowchildrenorothersinorontowed

equipment.

•Onslopes,theweightofthetowedequipmentmay

causelossoftractionandlossofcontrol.

•Travelslowlyandallowextradistancetostop.

•Keepnutsandboltstight,especiallytheblade

attachmentbolts.Keepequipmentingood

condition.

•Nevertamperwithsafetydevices.Checktheir

properoperationregularly.

•Keepthemachinefreeofgrass,leaves,orother

debrisbuild-up.Cleanupoilorfuelspillagefuel

soakeddebris.Allowthemachinetocoolbefore

storing.

•Stopandinspecttheequipmentifyoustrikean

object.Repair,ifnecessary,beforerestarting.

•Nevermakeanyadjustmentsorrepairswiththe

enginerunning.

Service

SafeHandlingofGasoline:

Toavoidpersonalinjuryorpropertydamage,useextra

carewhenhandlinggasolineandotherfuels.Theyare

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipesandother

sourcesofignition.

•Useonlyanapprovedcontainer.

•Neverremovethegascaporaddfuelwhenthe

engineisrunning.Allowtheenginetocoolbefore

refueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

•Neverllcontainersinsideavehicleoronatruckor

trailerwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removegas-poweredequipmentfromthetruck

ortrailerandrefuelitontheground.Ifthisisnot

possible,thenrefuelsuchequipmentwithaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Keepthenozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimesuntilthefueling

iscomplete.Donotuseanozzlelock-opendevice.

•Iffuelisspilledonclothing,changeclothing

immediately.

•Neveroverllthefueltank.Replacegascapand

tightensecurely .

GeneralService:

•Neveroperateamachineinsideaclosedarea.Engine

exhaustcontainscarbonmonoxide,whichisan

odorless,deadlypoisonthatcankillyou.

•Grasscatchercomponentsaresubjecttowear,

damageanddeterioration,whichcouldexpose

movingpartsorallowobjectstobethrown.

Frequentlycheckcomponentsandreplacewith

manufacturers’recommendedparts,whennecessary.

•Mowerbladesaresharpandcancut.Wrapthe

blade(s)orweargloves,anduseextracautionwhen

servicingthem.

•Checkforproperbrakeoperationfrequently.Adjust

andserviceasrequired.

•Maintainorreplacesafetyandinstructiondecalsas

necessary.

•UseonlygenuineTororeplacementpartstoensure

thatoriginalstandardsaremaintained.

ToroRidingMowerSafety

Thefollowinglistcontainssafetyinformationspecicto

Toroproductsorothersafetyinformationthatyoumust

knowthatisnotincludedintheANSIstandards.

•Stoptheengine,disconnectsparkplugwire(s)and

removekeybeforeperforminganyservice,repairs,

maintenanceoradjustments.

•Keephands,feet,hair,andlooseclothingawayfrom

attachmentdischargearea,undersideofmowerand

anymovingpartswhileengineisrunning.

•Donottouchequipmentorattachmentpartswhich

maybehotfromoperation.Allowtocoolbefore

attemptingtomaintain,adjustorservice.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyes,andclothing.Protectyour

face,eyes,andclothingwhenworkingwithabattery.

•Batterygasescanexplode.Keepcigarettes,sparks

andamesawayfrombattery.

5

Page 6

•UseonlyToroapprovedattachments.Warrantymay

bevoidedifusedwithunapprovedattachments.

•Ifloadingthemachineontoatrailerortruck,usea

single,full-widthramponly.Therampangleshould

notexceed15degrees.

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

6

Page 7

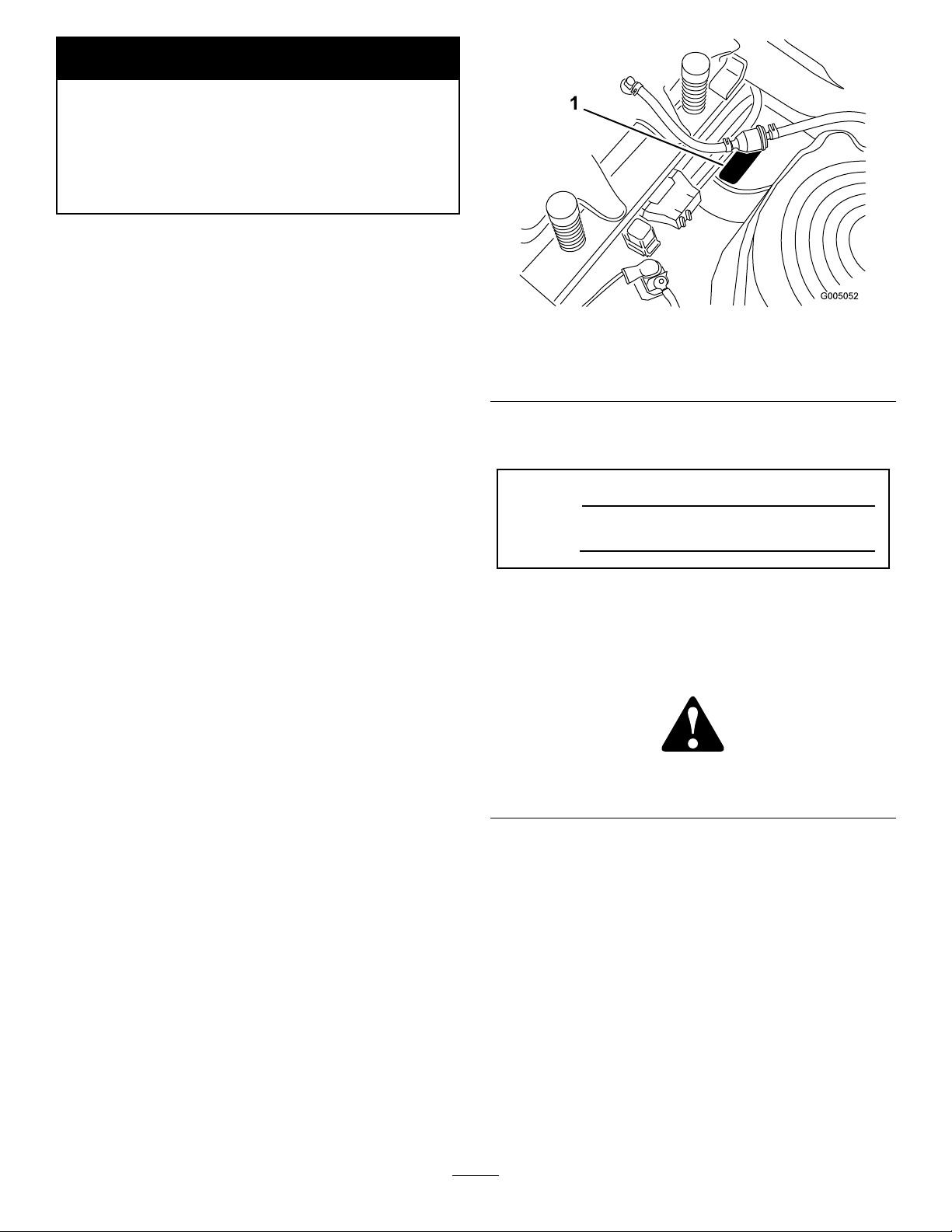

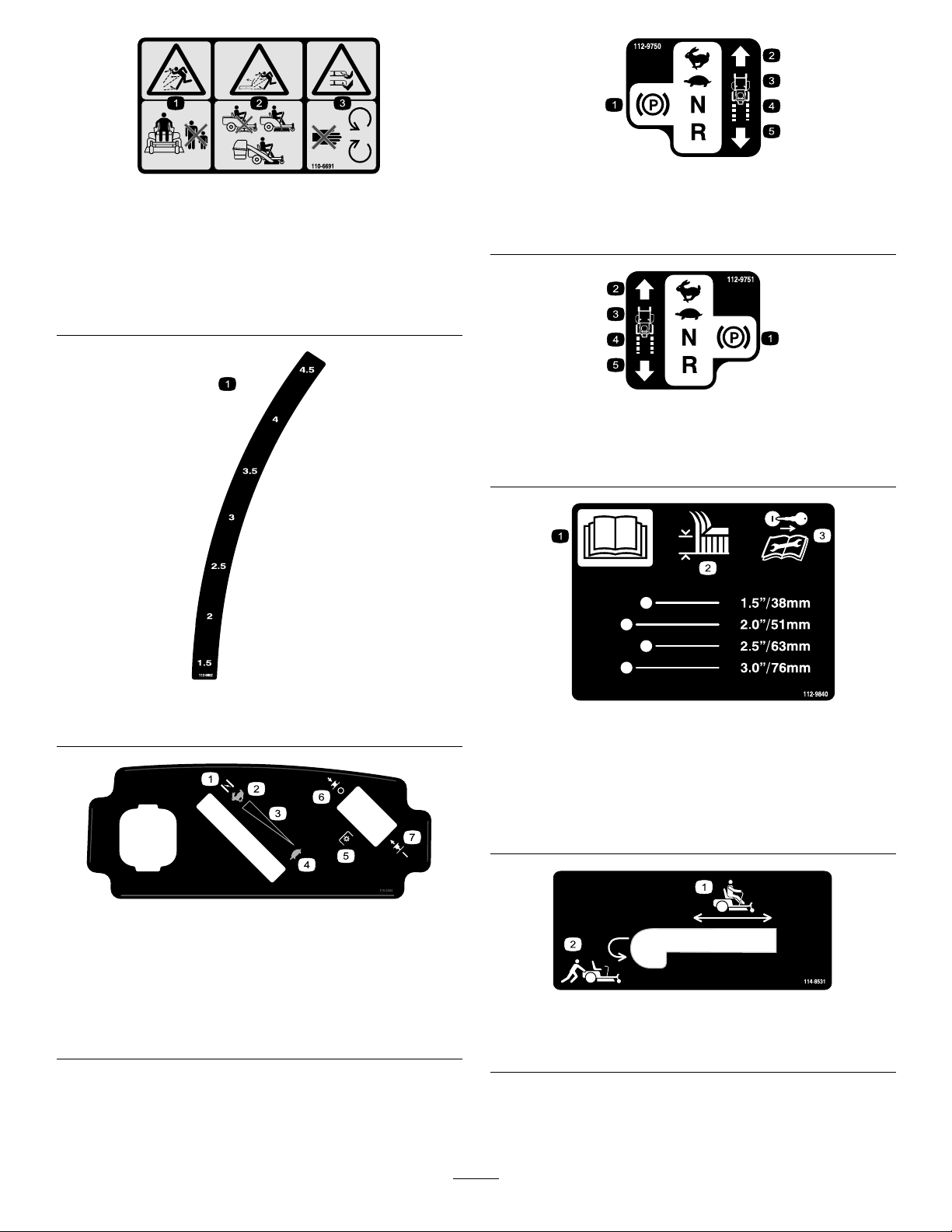

SlopeChart7SafetyandInstructional

Decals

Page 8

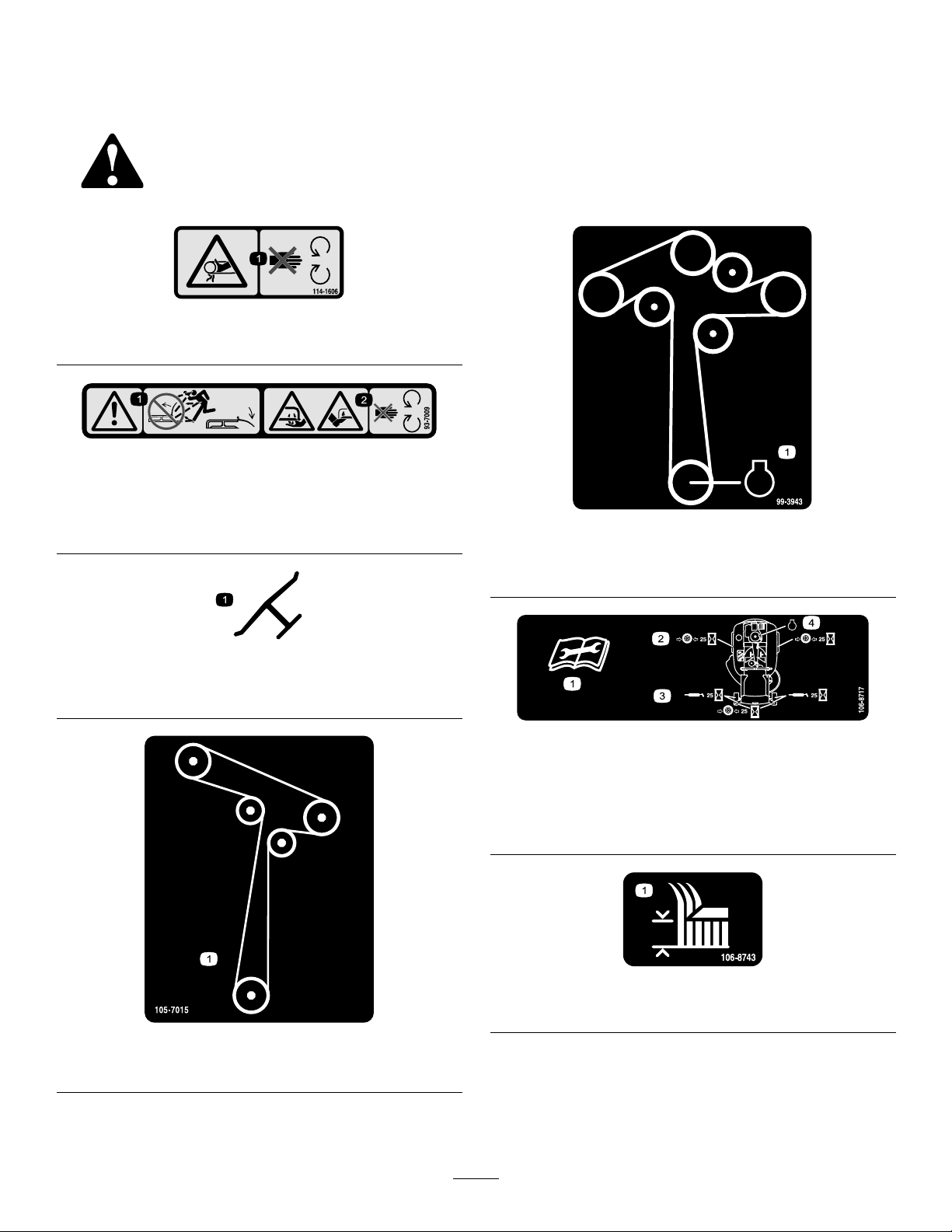

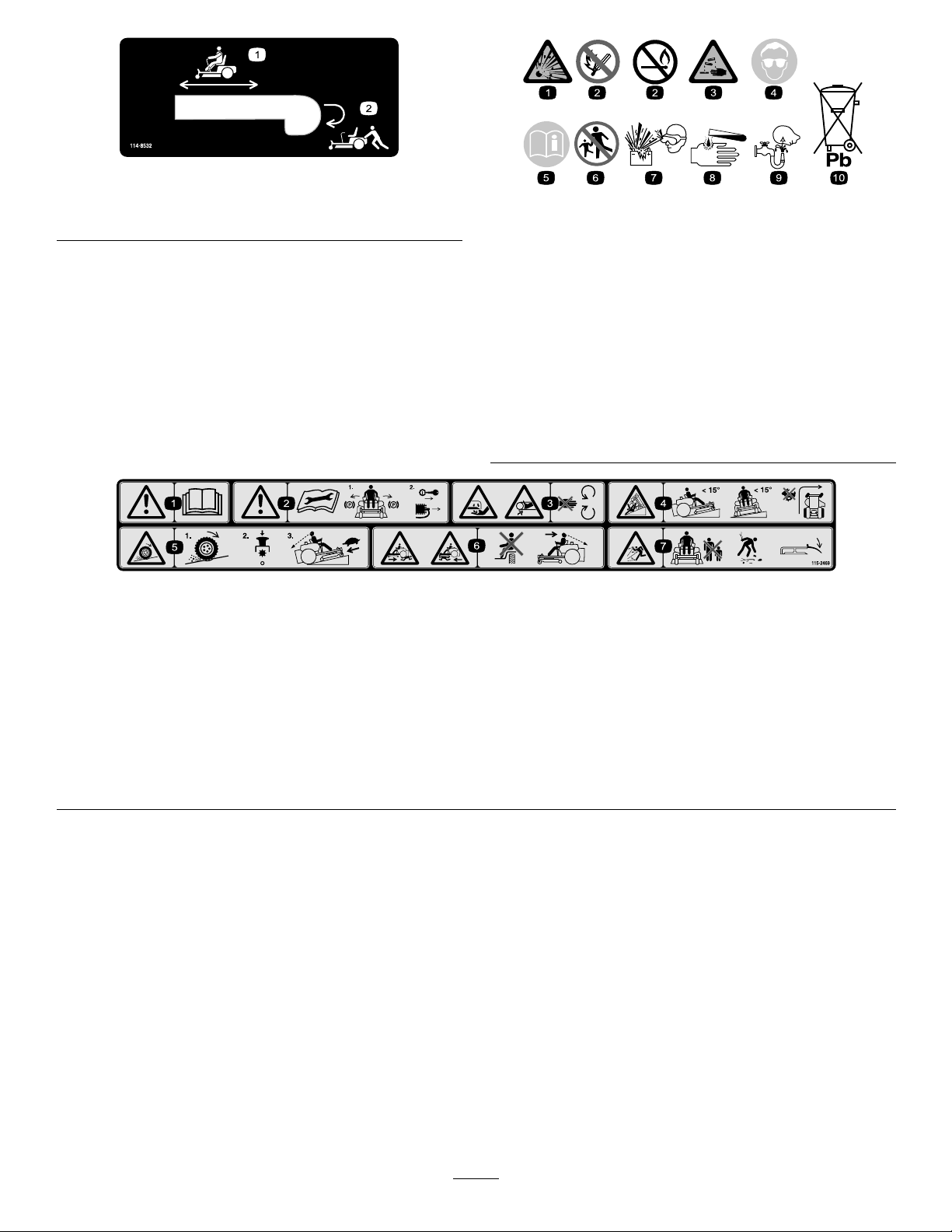

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

114-1606

1.Entanglementhazard,belt—keepallguardsinplace.

93-7009

1.Warning—don’toperatethemowerwiththedeectorupor

removed;keepthedeectorinplace.

2.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

99-3943

ForModelswith50InchDecks

1.Engine

Manufacturer’sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

105-7015

ForModelswith42InchDecks

106-8717

1.Readtheinstructionsbeforeservicingorperforming

maintenance.

2.Checktirepressureevery25operatinghours.

3.Greaseevery25operatinghours.

4.Engine

106-8743

1.Heightofcut

8

Page 9

110-6691

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Thrownobjecthazard,mower—donotoperatethewithout

deector,dischargecoverorgrasscollectionsystemin

place.

3.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

112-9750

1.Parkingposition4.Neutral

2.Fast5.Reverse

3.Slow

112-9751

1.Parkingposition4.Neutral

2.Fast5.Reverse

3.Slow

112-9802

1.Height-of-cut

115-2500

1.Choke5.Powertake-off(PTO),

2.Fast

3.Continuousvariable

setting

4.Slow

Bladecontrolswitchon

somemodels

6.Bladecontrolswitch—Off

7.Bladecontrolswitch—On

ForModelswith50InchDecks

1.ReadtheOperator’s

Manual.

2.Heightofcut

1.Bypassleverpositionfor

operatingthemachine

112-9840

3.Removetheignitionkey

andreadtheinstructions

beforeservicingor

performingmaintenance.

114-8531

2.Bypassleverpositionfor

pushingthemachine

9

Page 10

114-8532

1.Bypassleverpositionfor

operatingthemachine

2.Bypassleverpositionfor

pushingthemachine

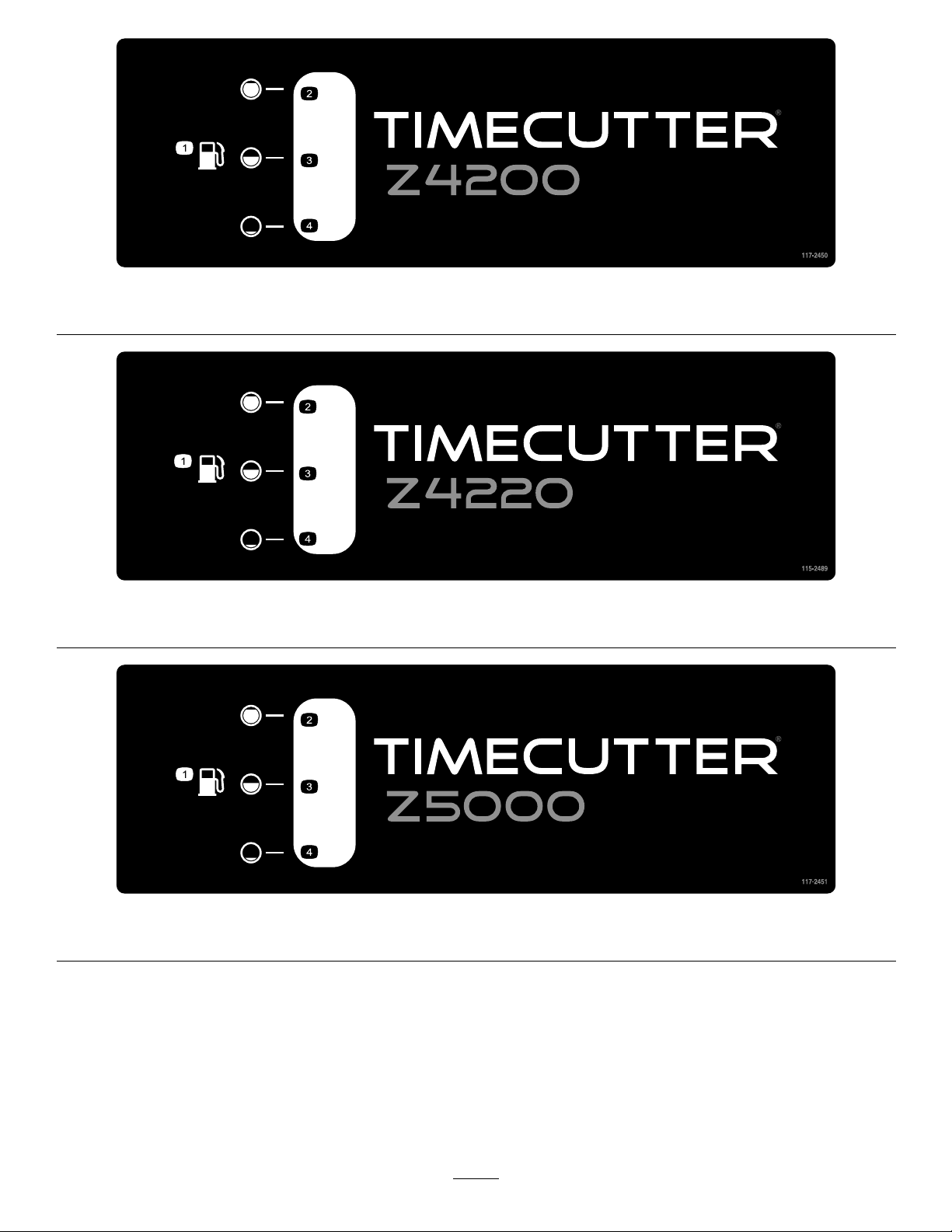

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator’s

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

115-2469

1.Warning—readtheOperator’sManual.

2.Warning—readtheinstructionsbeforeservicingorperformingmaintenance;movethemotioncontrolleverstothepark(brake)

position,removetheignitionkeyanddisconnectthesparkplugwire.

3.Cutting/dismembermenthazard,mowerblade;entanglementhazard,belt—donotopenorremovesafetyshieldswhileengineis

running.

4.Tippinghazard—donotmowslopesgreaterthan15degrees,avoidsuddenandsharpturnswhileonslopes.

5.Lossoftraction/controlhazard,slopes—lossoftraction/controlonaslope,disengagethebladecontrolswitch(PTO),proceed

offtheslopeslowly.

6.Crushing/dismembermenthazardofbystanders,reversing;crushing/dismembermenthazardofbystanders—donotcarry

passengers,lookbehindanddownwhenreversing.

7.Thrownobjecthazard—keepbystandersasafedistancefromthemachine,pickupdebrisbeforeoperating,keepdeectorinplace.

10

Page 11

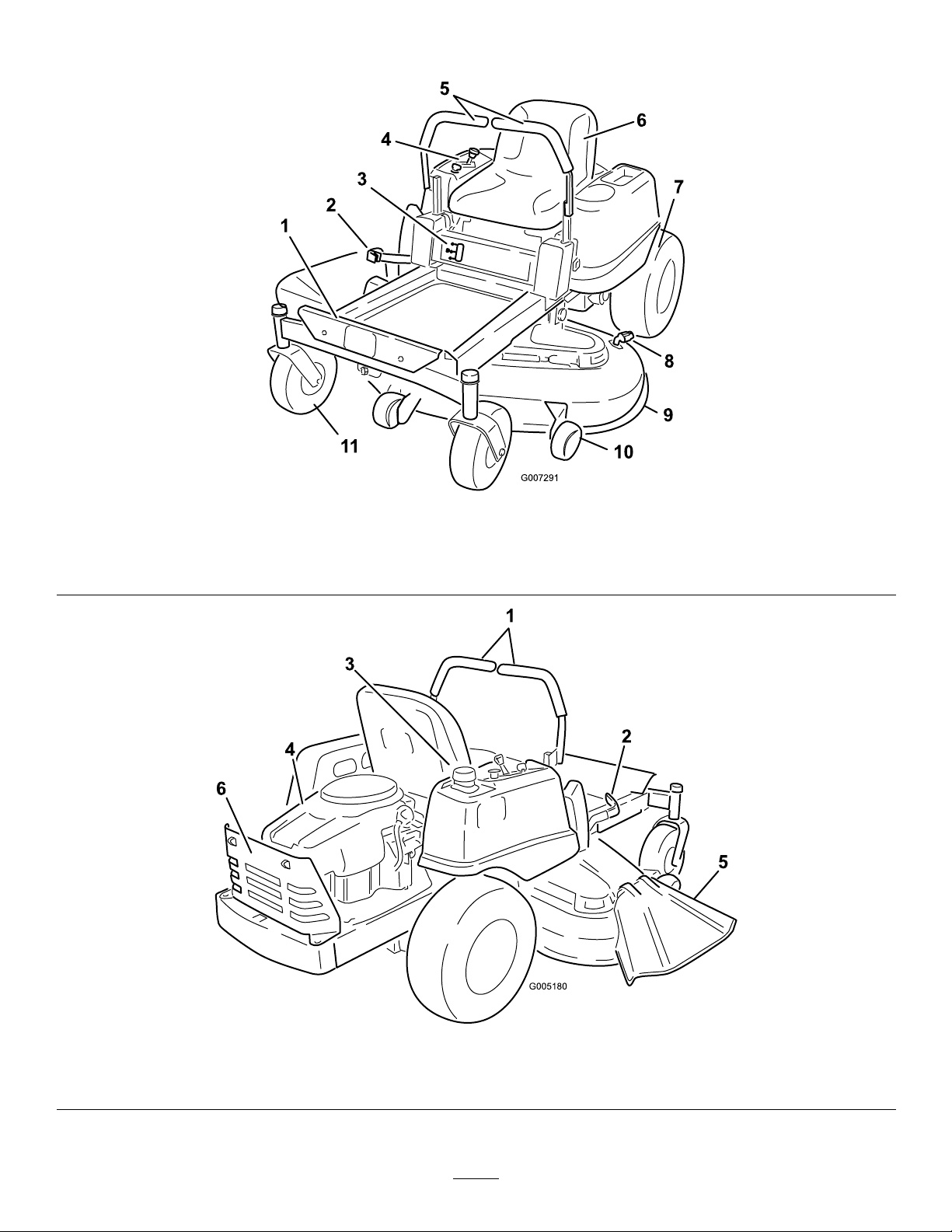

1.Fuelgauge2.Full

1.Fuelgauge2.Full

115-2450

3.Half

4.Empty

115-2489

3.Half

4.Empty

1.Fuelgauge2.Full

115-2451

3.Half

4.Empty

11

Page 12

ProductOverview

G005180

1

2

3

4

5

6

1.Footrest

2.Heightofcutlever

3.Fuelgauge

4.Controlpanel

5.Motioncontrollevers

6.Operatorseat

Figure3

7.Reardrivewheel10.Anti-scalproller

8.Washouttting

9.Mowerdeck

11.Frontcasterwheel

Figure4

1.Motioncontrollevers

2.Heightofcutlever

3.Gastankcap5.Deector

4.Engine

12

6.Engineguard(Model74370only)

Page 13

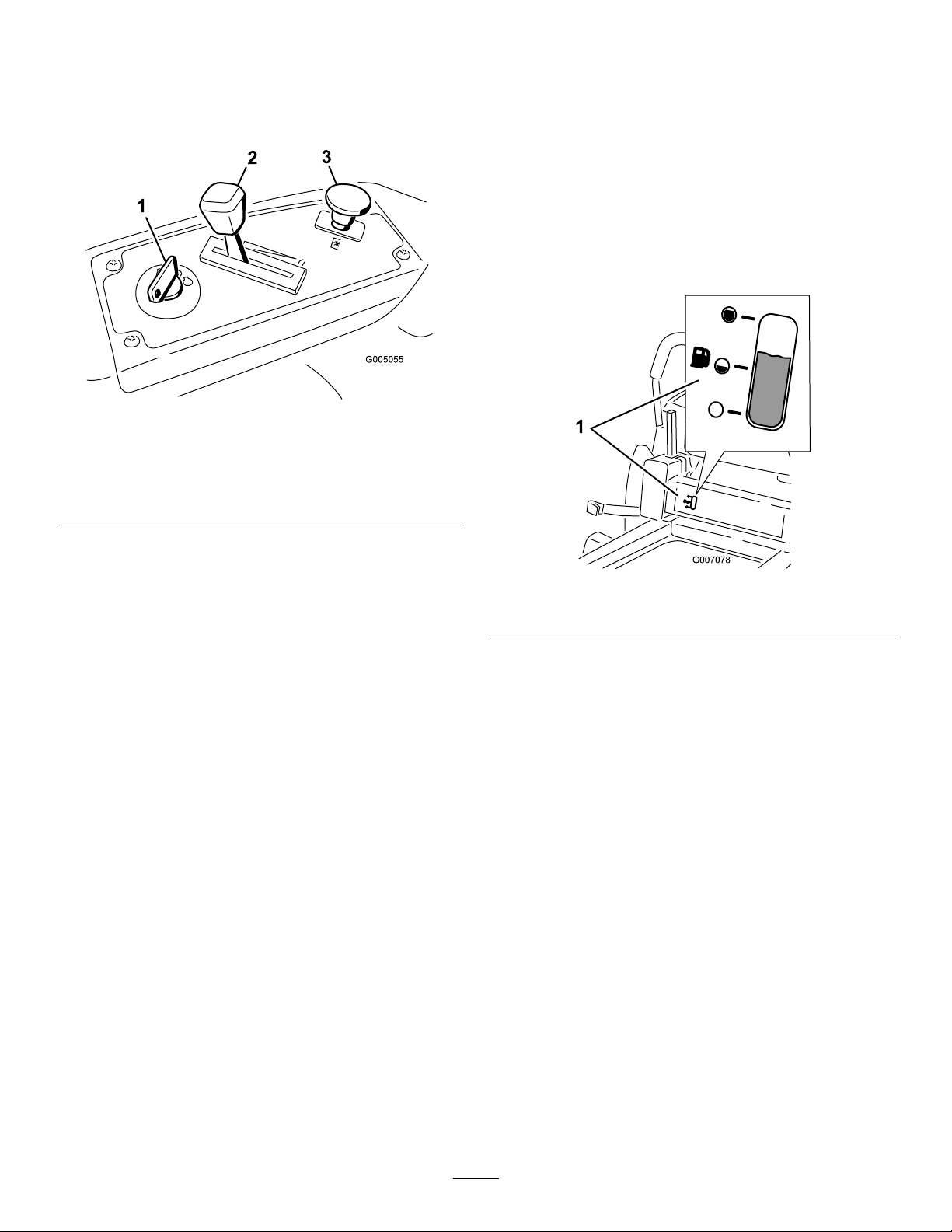

Controls

G005055

1

2

3

BecomefamiliarwithallofthecontrolsinFigure3,

Figure4,andFigure5beforeyoustarttheengineand

operatethemachine.

Figure5

ControlPanel

reverse;wheelspeedisproportionaltotheamountthe

leverismoved.Movethecontrolleversoutwardfrom

thecentertotheparkpositionandexitthemachine

(Figure15).Alwayspositionthemotioncontrollevers

intotheparkpositionwhenyoustopthemachineor

leaveitunattended.

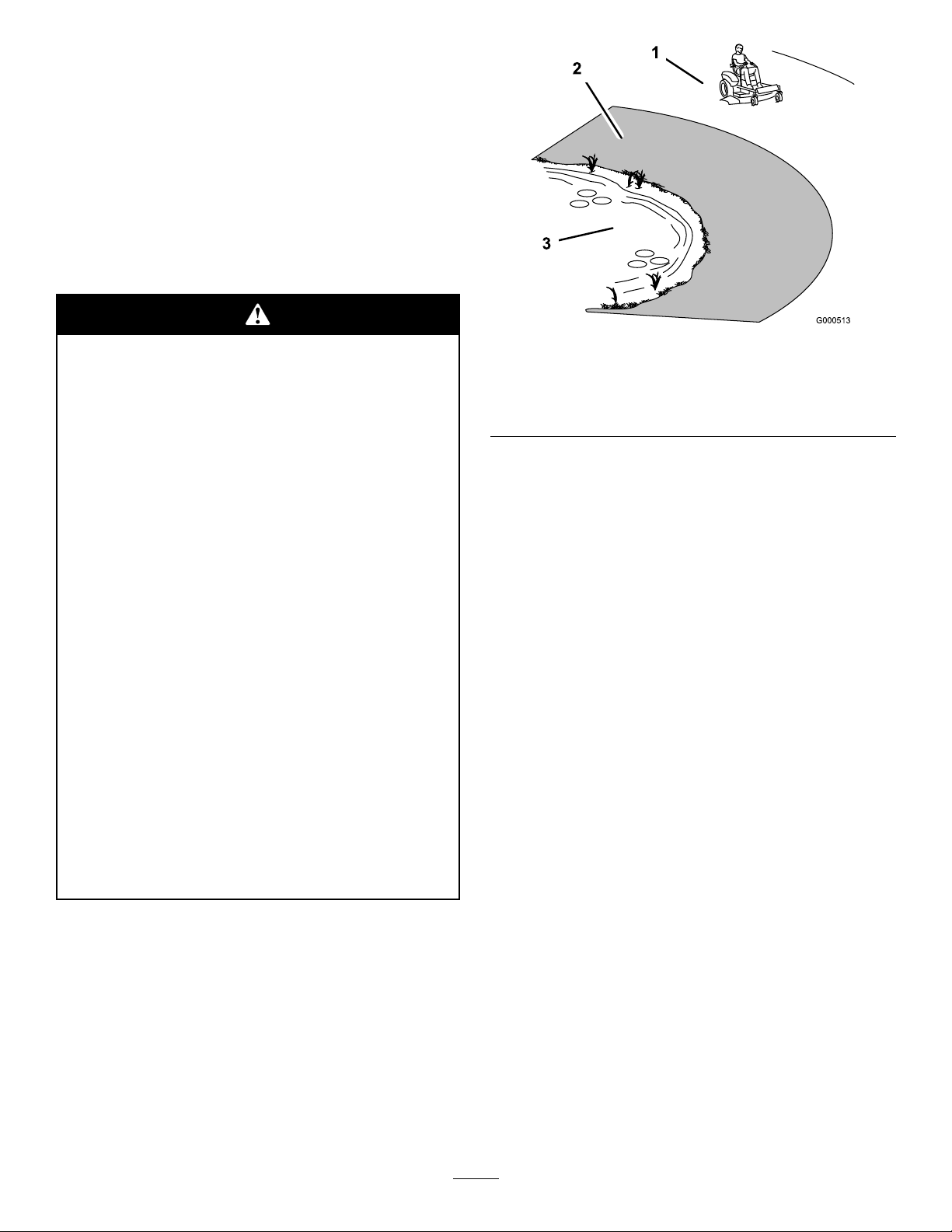

FuelGauge

Thefuelwindowlocatedbelowtheoperatorposition

canbeusedtoverifythelevelofgasolineinthetank

(Figure6).

1.Ignitionswitch3.Bladecontrolswitch

(powertake-off)

2.Throttle/Choke

IgnitionSwitch

Theignitionswitchhasthreepositions,Off,Runand

Start.ThekeywillturntoStartandmovebackto

Runuponrelease.TurningthekeytotheOffposition

willstoptheengine;however,alwaysremovethekey

whenleavingthemachinetopreventsomeonefrom

accidentallystartingtheengine(Figure5).

Throttle/ChokeControl

Thethrottleandchokeiscombinedintoonecontrol

lever.Thethrottlecontrolstheenginespeedandithasa

continuousvariablesettingfromSlowtoFast.Engage

thechokebymovingtheleverpasttheFastsettinguntil

itstops(Figure5).

BladeControlSwitch(PowerTake-Off)

Figure6

1.Fuelgaugewindow

Height-of-CutLever

Theheightofcutleverallowstheoperatortolower

andraisethedeckfromtheseatedposition.Whenthe

leverismovedup,towardtheoperatorthedeckisraised

fromthegroundandwhenmoveddown,awayfromthe

operatoritisloweredtowardtheground.Onlyadjustthe

heightofcutwhilemachineisnotmoving(Figure18).

Thebladecontrolswitch,representedbyapower

take-off(PTO)symbol,engagesanddisengagespower

tothemowerblades(Figure5).

MotionControlLeversandPark

Position

Themotioncontrolleversarespeedsensitivecontrolsof

independentwheelmotors.Movingaleverforwardor

backwardturnsthewheelonthesamesideforwardorin

13

Page 14

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

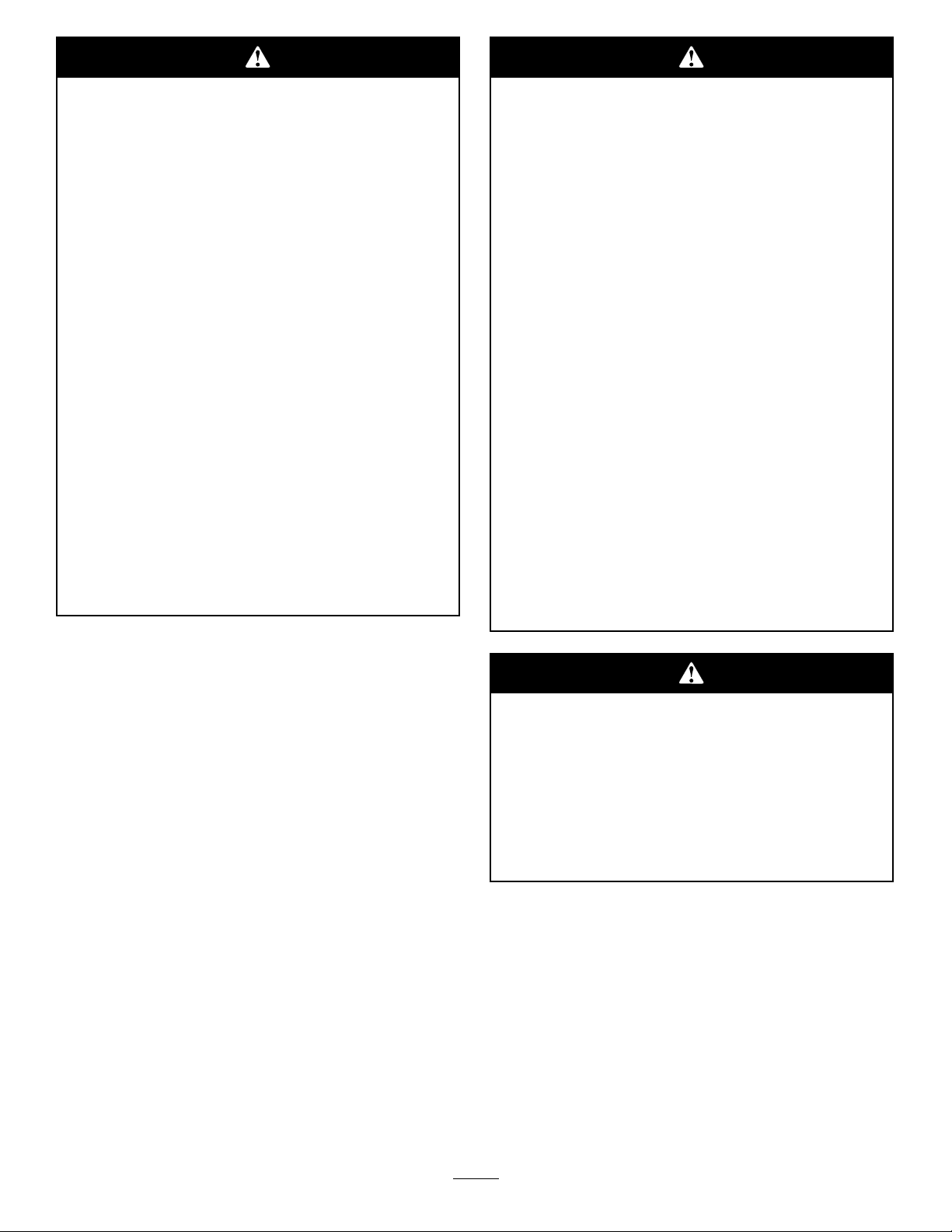

ThinkSafetyFirst

Pleasecarefullyreadallofthesafetyinstructionsand

decalsinthesafetysection.Knowingthisinformation

couldhelpyou,yourfamily,petsorbystandersavoid

injury.

Mowingonwetgrassorsteepslopescancause

slidingandlossofcontrol.

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,deathor

drowning.

Alossoftractionisalossofsteeringcontrol.

Toavoidlossofcontrolandpossibilityof

rollover:

•Donotmowneardrop-offsornearwater.

•Donotmowslopesgreaterthan15degrees.

•Reducespeedanduseextremecautionon

slopes.

•Whenmowingslopes,graduallyworkfrom

lowertohigherareasontheincline.

•Avoidsuddenturnsorrapidspeedchanges.

•Turnup,intoaninclinewhenchanging

directionsonslopes.Turningdownthe

slopereducestraction.

Figure7

1.SafeZone-usetheTimeCutterhere

2.Usewalkbehindmowerand/orhandtrimmerneardrop-offs

andwater.

3.Water

RecommendedGasoline

UseUNLEADEDRegularGasolinesuitablefor

automotiveuse(87pumpoctaneminimum).Leaded

regulargasolinemaybeusedifunleadedregularisnot

available.

Important:Neverusemethanol,gasoline

containingmethanol,orgasoholcontainingmore

than10percentethanolbecausethefuelsystem

couldbedamaged.Donotmixoilwithgasoline.

•Attachmentschangethehandling

characteristicsofthemachine.Useextra

cautionwhenusingattachmentswiththe

machine.

14

Page 15

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areor

explosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupany

gasolinethatspills.

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitethegasolinevapors.Are

orexplosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebeforelling.

•Neverllthefueltankinsideanenclosed

trailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthebodyof

thetankisfullbutfueldoesnotlltheneck

ofthetank.Thisemptyspaceinthetank

allowsgasolinetoexpand.

•Neversmokewhenhandlinggasoline,and

stayawayfromanopenameorwhere

gasolinefumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Never

buymorethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

•Donotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowtheloss

ofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

ground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimof

thefueltankorcontaineropeningatall

timesuntilfuelingiscomplete.

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporscancauseserious

injuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening.

•Keepgasawayfromeyesandskin.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsgasolinefreshduringstorageof30daysor

less.Forlongerstorageitisrecommendedthatthe

fueltankbedrained.

•Cleanstheenginewhileitruns.

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting.

15

Page 16

Addthecorrectamountofgasstabilizer/conditioner

G005302

1

2

3

4

1

2

G005056

1

2

tothegas.

allowsgasolinetoexpand.Donotllthefueltank

completelyfull.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.Tominimizethe

chanceofvarnishdepositsinthefuelsystem,usefuel

stabilizeratalltimes.

Gasoline/Alcoholblends

Gasohol(upto10percentethylalcohol,90percent

unleadedgasolinebyvolume)isapprovedforfueluse

bytheenginemanufacturer.Othergasoline/alcohol

blends,suchasE85,arenotapproved.

Gasoline/Etherblends

MethylTertiaryButylEther(MTBE)andunleaded

gasolineblends(uptoamaximumof15percentMTBE

byvolume)areapprovedforfuelusebytheengine

manufacturer.Othergasoline/etherblendsarenot

approved.

FuelGauge

Usethefuelwindowbelowtheoperatortoverifythe

levelofgasolinebeforellingthetank(Figure8).

4.Installthefueltankcapsecurely.Wipeupany

gasolinethatmayhavespilled.

Figure9

1.Gastankbody

2.Gastankneck4.Gastankopening

3.Filltohere,approximately

CheckingtheEngineOilLevel

Figure8

1.Fuelgaugewindow

FillingtheFuelTank

1.Shuttheengineoffandsetthemotioncontrolsto

theparkposition.Raisetheseatsothegastankis

visiblewhilefueling.

2.Cleanaroundthefueltankcapandremovethecap.

3.Addunleadedregulargasolineuntilthebodyofthe

tankisfullbutfueldoesnotlltheneckofthe

tank(Figure9).Thisspaceintheneckofthetank

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoChecking

theOilLevelintheEngineMaintenancesection.

StartingtheEngine

1.Sitdownontheseatandmovethemotioncontrols

outwardtotheparkposition.

2.Disengagethebladesbymovingthebladecontrol

switchtoOff(Figure10).

Figure10

1.Controlpanel2.Bladecontrolswitch—Off

position

16

Page 17

3.MovethethrottlelevertoChokebeforestartinga

1

2

2

3

4

5

6

G005057

1

2

2

3

4

5

6

1

2

3

4

5

6

G005058

1

2

3

4

5

6

coldengine(Figure11).

Note:Awarmorhotenginemaynotrequire

choking.

Figure12

1.Controlpanel4.Off

2.Ignitionkey—runposition5.Run

3.Ignitionkey—startposition

6.Start

5.Aftertheenginestarts,movethethrottleleverto

Fast(Figure11).Iftheenginestallsorhesitates,

movethethrottleleverbacktoChokeforafew

seconds.Repeatthisasrequired.

Figure11

1.Controlpanel

2.Throttle/choke

lever—chokeposition

3.Choke6.Slow

4.Fast

5.Continuousvariable

setting

4.TurntheignitionkeytoStarttoenergizethestarter.

Whentheenginestarts,releasethekey(Figure12).

Important:Donotengagethestarterformore

than10secondsatatime.Iftheenginefails

tostart,allowa60secondcool-downperiod

betweenattempts.Failuretofollowthese

instructionscandamagethestartermotor.

OperatingtheBlades

Thebladecontrolswitch,representedbyapower

take-off(PTO)symbol,engagesanddisengagespower

tothemowerblades.Thisswitchcontrolspowertoany

attachmentsthatdrawpowerfromtheengine,including

themowerdeckandcuttingblades.

EngagingtheBlades

Important:Donotengagethebladeswhen

parkedintallgrass.Beltorclutchdamagecan

occur.

1.Releasepressureonthemotioncontrolleversand

placethemachineinneutral.

2.MovethethrottletotheFastposition.

Note:Alwaysengagethebladeswiththethrottle

intheFastposition.

3.Pulluponthebladecontrolswitchtomoveitto

theOnpositionandengagetheblades(Figure13).

17

Page 18

G005059

121

2

Figure13

1

2

G005056

1

2

1.Controlpanel2.Bladecontrolswitch—On

position

TheSafetyInterlockSystem

Ifsafetyinterlockswitchesaredisconnected

ordamagedthemachinecouldoperate

unexpectedlycausingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

UnderstandingtheSafetyInterlock

System

DisengagingtheBlades

Pushdownonthebladecontrolswitchtomoveitto

theOffpositionanddisengagetheblades(Figure14).

Figure14

1.Controlpanel2.Bladecontrolswitch—Off

StoppingtheEngine

1.Disengagethebladesbymovingthebladecontrol

switchtoOff(Figure14).

2.MovethethrottlelevertobetweenFastandhalf

throttle(Figure12).

3.TurntheignitionkeytoOff(Figure11)andremove

thekey .

Thesafetyinterlocksystemisdesignedtopreventthe

enginefromstartingunless:

•Thebladesaredisengaged.

•Themotioncontrolleversareintheparkposition.

Thesafetyinterlocksystemalsoisdesignedtostop

theenginewhenthecontrolleversareoutofthepark

positionandyourisefromtheseatwhentheblades

areengaged.

TestingtheSafetyInterlockSystem

Testthesafetyinterlocksystembeforeyouusethe

machineeachtime.Ifthesafetysystemdoesnot

operateasdescribedbelow ,haveanAuthorizedService

Dealerrepairthesafetysystemimmediately .

1.Whilesittingontheseat,withthecontrolleversin

parkposition,andmovethebladecontrolswitch

toOn.Trystartingtheengine;theengineshould

notcrank.

2.Whilesittingontheseat,movethebladecontrol

switchtoOff.Moveeithermotioncontrollever

tothecenter,unlockedposition.Trystartingthe

engine;theengineshouldnotcrank.Repeatwith

theothermotioncontrollever.

3.Whilesittingontheseat,movethebladecontrol

switchtoOff,andlockthemotioncontrolleversin

theparkposition.Starttheengine.Whiletheengine

isrunning,engagethebladecontrolswitch,andrise

slightlyfromtheseat;theengineshouldstop.

4.Whilesittingontheseat,movethebladecontrol

switchtoOff,andlockthemotioncontrollevers

intheparkposition.Starttheengine.Whilethe

engineisrunning,movethemotioncontrollevers

tothecenter,unlockedposition,engagetheblade

controlswitch,andriseslightlyfromtheseat;the

engineshouldstop.

18

Page 19

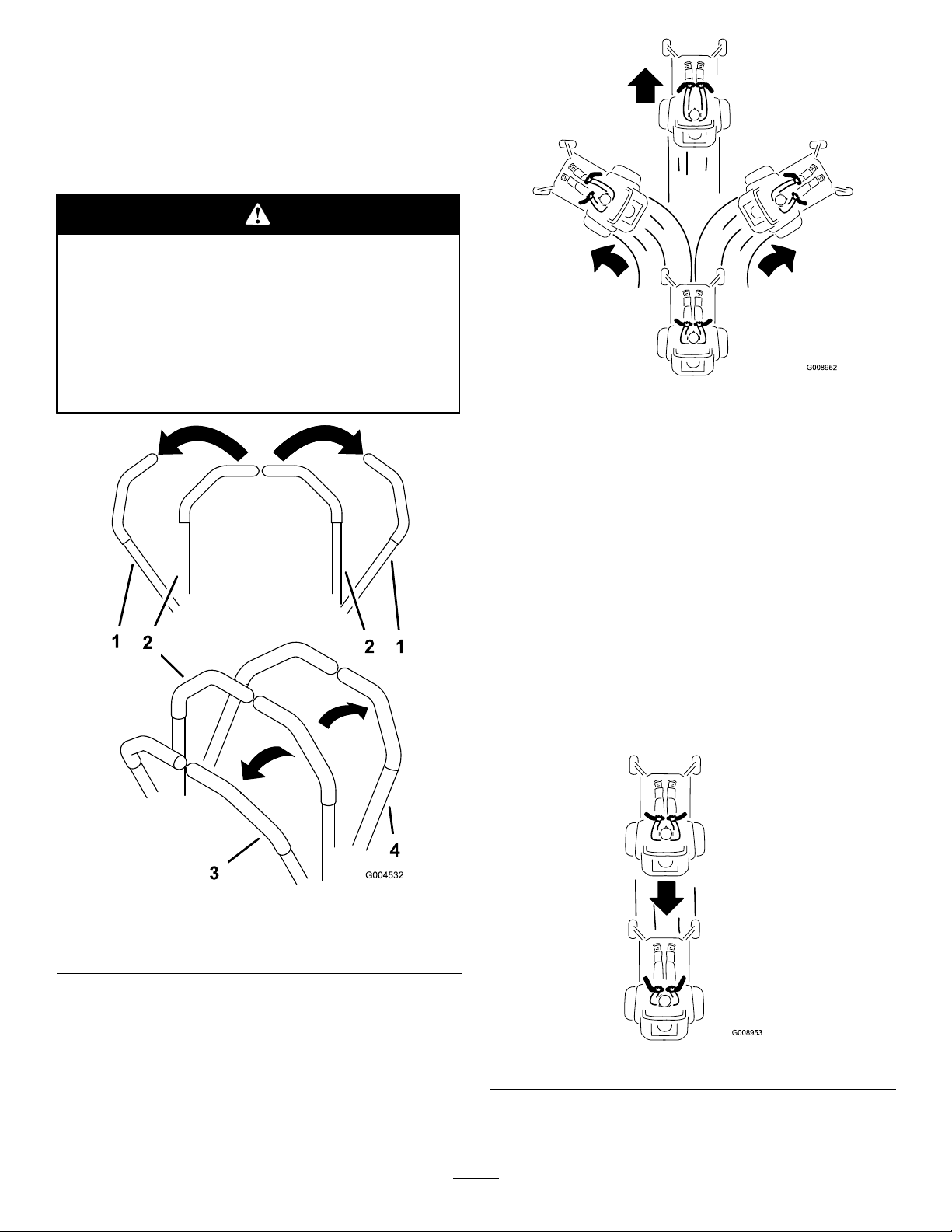

DrivingForwardorBackward

G008952

G008953

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Place

thethrottlecontrolintheFastpositionforbest

performance.Alwaysoperateinthefullthrottle

position.

Themachinecanspinveryrapidly .The

operatormaylosecontrolofthemachine

andcausepersonalinjuryordamagetothe

machine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemaking

sharpturns.

Figure16

Togostraight,applyequalpressuretobothmotion

controllevers(Figure15).

Toturn,releasepressureonthemotioncontrollever

towardthedirectionyouwanttoturn(Figure15).

Thefartheryoumovethemotioncontrolleversin

eitherdirection,thefasterthemachinewillmovein

thatdirection.

Tostop,pullthemotioncontrolleverstoneutral.

Backward

1.Movetheleverstothecenter,unlockedposition.

2.Togobackward,slowlypullthemotioncontrol

leversrearward(Figure17).

Figure15

1.Park(brake)position

2.Centerunlockposition

3.Forward

4.Backward

Forward

1.Movetheleverstothecenter,unlockedposition.

2.Togoforward,slowlypushthemotioncontrol

leversforward(Figure15).

Figure17

Togostraight,applyequalpressuretobothmotion

controllevers(Figure17).

19

Page 20

Toturn,releasethepressureonthemotioncontrol

G009619

1

2

3

4

5

6

7

8

levertowardthedirectionyouwanttoturn.

Tostop,pushthemotioncontrolleverstoneutral.

PositioningtheSeat

Theseatcanmoveforwardandbackward.Positionthe

seatwhereyouhavethebestcontrolofthemachine

andaremostcomfortable.

StoppingtheMachine

Tostopthemachine,movethemotioncontrolleversto

neutralandoutwardtotheparkposition,disengagethe

bladecontrolswitch,ensurethethrottleisinthefast

position,andturntheignitionkeytooff.Rememberto

removethekeyfromtheignitionswitch.

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemowerwhileit

isunattended.

Alwaysremovetheignitionkeyandmovethe

motioncontrolleversoutwardtothepark

positionwhenleavingthemachineunattended,

evenifjustforafewminutes.

AdjustingtheHeightofCut

1.Raisetheheight-of-cutlevertothetransport

position,cuttingheightposition4.5(alsothe

4-1/2inch[115mm])(Figure18).

1.Raisetheseatandloosentheadjustmentknobjust

enoughthatseatcanmove(Figure19).

Figure19

1.Adjustmentknob

2.Movetheseattothedesiredpositionandtighten

theknob.

AdjustingtheMotionControl

Levers

AdjustingtheHeight

Themotioncontrolleverscanbeadjustedhigheror

lowerformaximumoperatorcomfort.

1.Removethe2boltsholdingthecontrollevertothe

controlarmshaft(Figure20).

2.Movethecontrollevertothenextsetofholes.

Securetheleverwiththe2bolts(Figure20).

Figure18

1.Height-of-cutlever5.3inch(76mm)

2.4.5inch(1 15mm),

Transportposition

3.4inch(102mm)7.2inch(51mm)

4.3.5inch(89mm)8.1.5inch(38mm)

2.Toadjusttheheightofcut,pullinwardandupon

theleverandmoveittothedesiredposition.

6.2.5inch(64mm)

20

Page 21

G005062

1

2

3

4

Figure20

1.Controlarmshaft3.Slotted,upperhole

2.Controllever

4.Bolt

3.Repeattheadjustmentfortheoppositecontrol

lever.

AdjustingtheTilt

Themotioncontrolleverscanbetiltedforeoraftfor

maximumoperatorcomfort.

1.Loosentheupperboltholdingthecontrolleverto

thecontrolarmshaft.

4.Movethebypassleversrearwardandthendown

tolocktheminplaceasshowninFigure21to

disengagethewheelmotors.Repeatthisoneach

sideofthemachine.

5.Movethemotioncontrolleversinwardtothe

neutralposition.

Themachineisnowabletobepushedbyhand.

Figure21

Rightsideshown

1.Bypassleverlocation

2.Leverpositionforpushing

themachine

3.Leverpositionfor

operatingthemachine

2.Loosenthelowerboltjustenoughtopivotthe

controlleverforeoraft(Figure20).Tightenboth

boltstosecurethecontrolinthenewposition.

3.Repeattheadjustmentfortheoppositecontrol

lever.

PushingtheMachinebyHand

Important:Alwayspushthemachinebyhand.

Nevertowthemachinebecausedamagemay

occur.

ToPushtheMachine

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrolswitch.

2.Movethemotioncontrolleversoutwardtopark

position,stoptheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Locatethebypassleversattherearofthemachine,

ontheleftandrightsideoftheframe.

ToOperatetheMachine

Movethebypassleversupwardandpushthemforward,

tothemiddleofthehorizontalslot(Figure21)to

engagethewheelmotors.

21

Page 22

GrassDeector

MowingDirection

Themowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

Withoutthegrassdeector,dischargecover,

orcompletegrasscatcherassemblymounted

inplace,youandothersareexposedtoblade

contactandthrowndebris.Contactwith

rotatingmowerblade(s)andthrowndebriswill

causeinjuryordeath.

•Neverremovethegrassdeectorfrom

themowerbecausethegrassdeector

routesmaterialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthe

mower.

•Nevertrytocleardischargeareaormower

bladesunlessyoumovethebladecontrol

switchtoOffandrotatetheignitionkeyto

Off.Alsoremovethekeyandpullthewire

offthesparkplug(s).

Alternatemowingdirectiontokeepthegrassstanding

straight.Thisalsohelpsdisperseclippingswhich

enhancesdecompositionandfertilization.

MowatCorrectIntervals

Normally,moweveryfourdays.Butremember,

grassgrowsatdifferentratesatdifferenttimes.So

tomaintainthesamecuttingheight,whichisagood

practice,mowmoreofteninearlyspring.Asthegrass

growthrateslowsinmidsummer,mowlessfrequently.

Ifyoucannotmowforanextendedperiod,rstmow

atahighcuttingheight;thenmowagaintwodayslater

atalowerheightsetting.

CuttingSpeed

Toimprovecutquality,useaslowergroundspeed.

AvoidCuttingTooLow

Ifthecuttingwidthofthemoweriswiderthanthe

moweryoupreviouslyused,raisethecuttingheightto

ensurethatuneventurfisnotcuttooshort.

LongGrass

OperatingTips

FastThrottleSetting

Forbestmowingandmaximumaircirculation,operate

theengineattheFastposition.Airisrequiredto

thoroughlycutgrassclippings,sodonotsetthe

height-of-cutsolowastototallysurroundthemower

byuncutgrass.Alwaystrytohaveonesideofthe

mowerfreefromuncutgrass,whichallowsairtobe

drawnintothemower.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethatthe

cuttingheightofthemowerdoesnotscalpanyuneven

ground.However,thecuttingheightusedinthepastis

generallythebestonetouse.Whencuttinggrasslonger

thansixinchestall,youmaywanttocutthelawntwice

toensureanacceptablequalityofcut.

Cut1/3oftheGrassBlade

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,raise

thecuttingheighthigherthanusualandcutthegrassat

thissetting.Thencutthegrassagainusingthelower,

normalsetting.

WhenStopping

Ifthemachine’sforwardmotionmustbestoppedwhile

mowing,aclumpofgrassclippingsmaydropontoyour

lawn.T oavoidthis,moveontoapreviouslycutarea

withthebladesengaged.

KeeptheUndersideoftheMower

Clean

Cleanclippingsanddirtfromtheundersideofthe

moweraftereachuse.Ifgrassanddirtbuildupinside

themower,cuttingqualitywilleventuallybecome

unsatisfactory.

BladeMaintenance

Itisbesttocutonlyabout1/3ofthegrassblade.

Cuttingmorethanthatisnotrecommendedunless

grassissparse,oritislatefallwhengrassgrowsmore

slowly.

Maintainasharpbladethroughoutthecuttingseason

becauseasharpbladecutscleanlywithouttearingor

shreddingthegrassblades.Tearingandshreddingturns

grassbrownattheedges,whichslowsgrowthand

22

Page 23

increasesthechanceofdisease.Checkthecutterblades

dailyforsharpness,andforanywearordamage.File

downanynicksandsharpenthebladesasnecessary.If

abladeisdamagedorworn,replaceitimmediatelywith

agenuineTororeplacementblade.

23

Page 24

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Beforeeachuseordaily

Every25hours

Every100hours

Every200hours

Every500hours

Beforestorage

MaintenanceProcedure

•Checkthesafetyinterlocksystem.

•Checktheaircleanerfordirty,looseordamagedparts.

•Checktheengineoillevel.

•Checkairintakeandcoolingareas,cleanasnecessary.

•Checkthecuttingblades.

•Inspectthegrassdeectorfordamage

•Cleanthemowerhousing.

•Greasealllubricationpoints.

•Servicethepaperelement.(moreoftenunderextremelydusty,dirtyconditions)

•Checktirepressure.

•Checkthebeltsforwear/cracks.

•Replacethepaperelement.(moreoftenunderextremelydusty,dirtyconditions)

•Changetheengineoilandlter.

•Cleantheblowerhousing(moreoftenunderextremelydusty,dirtyconditions).

•Replacethefuellter.

•Checksparkplugconditionandgap.

•Replacethesparkplug.

•Chargethebatteryanddisconnectbatterycables.

•Performallmaintenanceprocedureslistedabovebeforestorage.

•Paintanychippedsurfaces.

Important:Refertoyourengineoperator’smanualforadditionalmaintenanceprocedures.

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

24

Page 25

Premaintenance

G005066

1

Lubrication

Procedures

GreasingtheBearings

RaisingtheSeat

Makesurethemotioncontrolleversarelockedinthe

parkposition.Lifttheseatforward.

Thefollowingcomponentscanbeaccessedbyraising

theseat:

•Serialplate

•Servicedecal

•Seatadjustmentknob

•Fuellter

•Fuses

•Batterycables

AccessingtheBattery

1.Raisetheseat.

2.RemovetheTORX

theleftcovertotheframeasshowninFigure22.

®

headfasteners(T25)securing

ServiceInterval:Every25hours—Greaseall

lubricationpoints.

GreaseType:No.2GeneralPurposeLithiumBase

Grease

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothe

parkposition,stoptheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanthegreasettings(Figure23andFigure24)

witharag.Makesuretoscrapeanypaintoffofthe

frontofthetting(s).

Figure22

1.Leftcover

2.Torxheadfasteners(T25)

3.Battery

3.Lifttheplasticcoverawayfromthemachine.Retain

allfasteners.

Replacethecoverandsecureittotheframeusingthe

fastenersremovedpreviously.

1.Frontcastertire

1.Readtheinstructions

beforeservicingor

performingmaintenance.

2.Checktirepressureevery

25operatinghours.

25

Figure23

Figure24

Locatedontheseatpanunderside

3.Greaseevery25operating

hours.

4.Engine

Page 26

4.Connectagreaseguntoeachtting(Figure23and

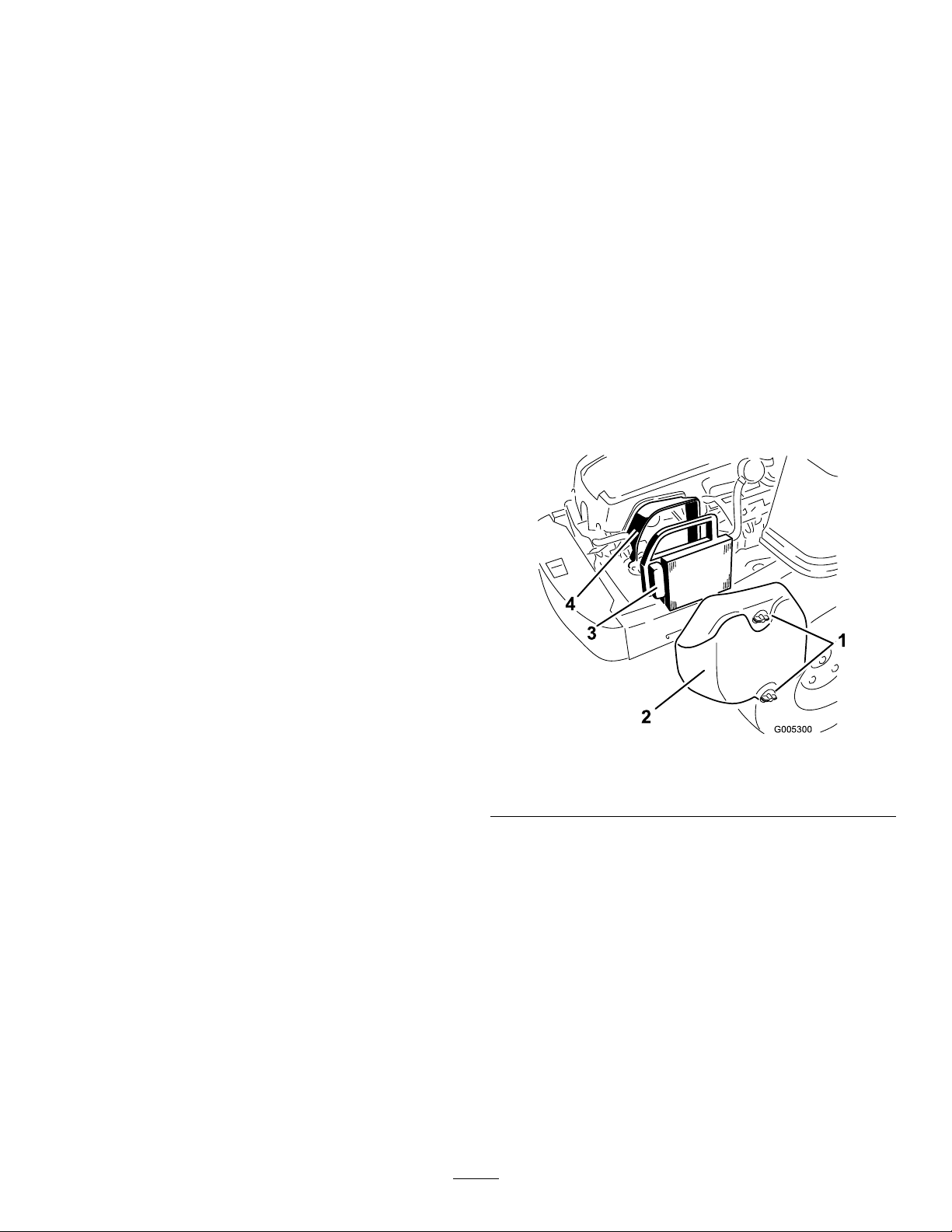

G005300

1

2

3

4

1

2

3

4

Figure24).Pumpgreaseintothettingsuntilgrease

beginstooozeoutofthebearings.

5.Wipeupanyexcessgrease.

EngineMaintenance

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Checkthe

aircleanerfordirty,looseordamaged

parts.

Thisengineisequippedwithareplaceable,highdensity

paperaircleanerelement.Checktheaircleanerdailyor

beforestartingtheengine.Checkforabuildupofdirt

anddebrisaroundtheaircleanersystem.Keepthisarea

clean.Alsocheckforlooseordamagedcomponents.

Replaceallbentordamagedaircleanercomponents.

Note:Operatingtheenginewithlooseordamagedair

cleanercomponentscouldallowunlteredairintothe

enginecausingprematurewearandfailure.

Note:Servicetheaircleanermoreoftenunder

extremelydusty,dirtyconditions.

Figure25

1.Knobs,aircleanercover3.Paperelement

2.Aircleanercover4.Aircleanerbase

ServicingPaperElement

ServiceInterval:Every25hours—Servicethepaper

element.(moreoftenunderextremely

dusty,dirtyconditions)

Every100hours—Replacethepaper

element.(moreoftenunderextremely

dusty,dirtyconditions)

1.Removetheaircleanercover(Figure25).

2.Removetheaircleanerelementwiththeintegral

rubberseal(Figure25).

3.Gentlytapthepleatedsideofthepaperelementto

dislodgedirt.Donotwashthepaperelementor

usepressurizedair,asthiswilldamagetheelement.

26

Page 27

Replaceadirty,bent,ordamagedelement.Handle

G005176

2

3

1

2

F

L

G005068

1

2

3

newelementscarefully;donotuseiftherubberseal

isdamaged.

4.Cleanallaircleanercomponentsofanyaccumulated

dirtorforeignmaterial.Preventanydirtfrom

enteringthecarburetor.

5.Installtheaircleanerelementwiththepleatedside

“out”andseattherubbersealontotheedgesofthe

aircleanerbase(Figure25).

6.Reinstalltheaircleanercoverandsecurewiththe

twoknobs(Figure25).

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSG,SH,SJ,or

higher)

CrankcaseCapacity:1.6qt(1.5l)whenthelteris

changed

Viscosity:Seethetablebelow .

Figure27

1.Oildipstick3.Oillevel

2.Fillertube

Figure26

CheckingtheOilLevel

ServiceInterval:Beforeeachuseordaily—Checkthe

engineoillevel.

1.Parkthemachineonalevelsurface,disengagethe

bladecontrolswitch,stoptheengine,andremove

thekey .

2.Makesuretheengineisstopped,level,andiscoolso

theoilhashadtimetodrainintothesump.

3.Tokeepdirt,grassclippings,etc.,outoftheengine,

cleantheareaaroundtheoilllcap/dipstickbefore

removingit.

4.Pullandremovetheoilllcap/dipstick;wipeoil

off.Reinsertthedipstickandpushrmlyintoplace

(Figure27).

5.Removethedipstickandchecktheoillevel.

(Figure27).

Theoillevelshouldbeupto,butnotover,theF

markonthedipstick.

6.Ifthelevelislow ,addoilofthepropertype,upto

theFmarkonthedipstick.Alwayscheckthelevel

withthedipstickbeforeaddingmoreoil.

Note:Topreventextensiveenginewearordamage,

alwaysmaintaintheproperoillevelinthecrankcase.

Neveroperatetheenginewiththeoillevelbelowthe

“L”markoroverthe“F”markonthedipstick.

ChangingtheOilandtheFilter

ServiceInterval:Every100hours—Changetheengine

oilandlter.

RellwithserviceclassSG,SH,SJorhigheroilas

speciedinthe“ViscosityGrades”table.

Changetheoilandlterwhiletheengineisstillwarm.

Theoilwillowmorefreelyandcarryawaymore

impurities.Makesuretheengineislevelwhenlling,

checking,orchangingtheoil.

Changetheoilandoillterasfollows:

1.Starttheengineandletitrununtilwarm.This

warmstheoilsoitdrainsbetter.

27

Page 28

2.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoassuretheoildrains

completely.

3.Disengagethebladecontrolswitchandmovethe

motioncontrolsoutwardtotheparkposition.

4.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

5.Cleantheareaaroundthedrainvalveandonthe

machineframe.Locatetheoildrainhoseandslide

itoverthedrainvalve(Figure28).

Figure29

1.Oildrainvalve

2.Machineframe5.Oillter

3.Oildrainhose

4.Pan

Figure28

1.Oildrainhose3.Holeinframe

2.Drainvalve

4.Oillter

6.Placetheoppositeendoftheoildrainhosethrough

thedrainholeintheframe(Figure28).

7.Placeapanunderneathmachinedirectlybelowthe

drainholeintheframeasshowninFigure29.

8.Turnthedrainvalve1/4counterclockwisetoopen

andallowtheoiltodrain(Figure29).Removethe

oilllcap/dipstick(Figure27).

9.Besuretoallowampletimeforcompletedrainage.

10.Removetheoldlterandwipeoffthemountingpad

(Figure29).

11.Whenoilhasdrainedcompletely,closetheoildrain

valve.Removetheoildrainhoseandwipeupany

excessoilontheframe(Figure29).

Note:Disposeoftheusedoilatarecyclingcenter.

12.Placethenewreplacementlterinashallowpan

withtheopenendup.Pournewoiloftheproper

type,inthroughthethreadedcenterhole.Stop

pouringwhentheoilreachesthebottomofthe

threads.Allowaminuteortwofortheoiltobe

absorbedbytheltermaterial.

13.Applyathinlmofcleanoiltotherubbergasketon

thenewlter.

14.Installthereplacementoilltertothemountingpad.

Turntheoillterclockwiseuntiltherubbergasket

contactsthepad,thentightenthelteranadditional

2/3to1turn(Figure30).

28

Page 29

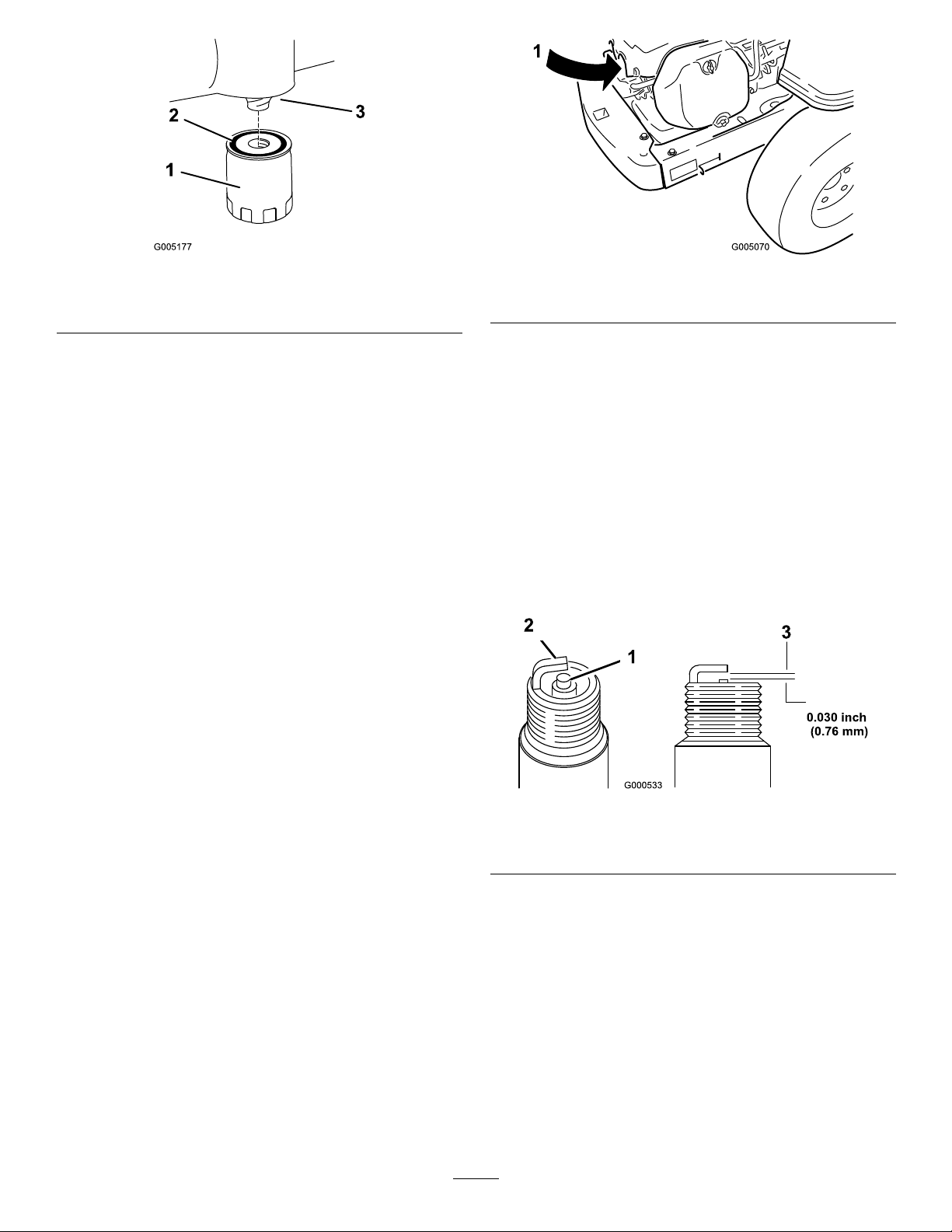

G005177

2

1

3

1.Oillter

G005070

1

2.Gasket

Figure30

Figure31

3.Adapter

1.Sparkplugandwirelocation

15.Slowlypourapproximately80%ofthespeciedoil

CheckingtheSparkPlug

intothellertube(Figure27).

1.Lookatthecenterofthesparkplug(Figure32).

16.Installtheoilllcap/dipstickandpushrmlyinto

place(Figure27).

17.Checktheoillevel(Figure27);refertoChecking

theOilLevel.

18.Slowlyaddadditionaloiltobringittothefullmark.

19.Installtheoilllcap/dipstickandpushrmlyinto

place(Figure27).

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly .Ablackcoatingonthe

insulatorusuallymeanstheaircleanerisdirty.

Important:Nevercleanthesparkplug.Always

replacethesparkplugwhenithasablack

coating,wornelectrodes,anoilylm,orcracks.

2.Checkthegapbetweenthecenterandsideelectrodes

(Figure32).Bendthesideelectrode(Figure32)if

ServicingtheSparkPlug

thegapisnotcorrect.

ServiceInterval:Every200hours—Checksparkplug

conditionandgap.

Every500hours—Replacethespark

plug.

ThesparkplugisRFIcompliant.Equivalentalternate

brandplugscanalsobeused.Sparkplugreplacementis

recommendedat500hours.

Type:ChampionXC12YC(orequivalent)

AirGap:0.030inch(0.76mm)

1.Centerelectrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

Figure32

RemovingtheSparkPlug

1.Disengagethebladecontrolswitch,movethe

motioncontrolsoutwardtotheparkposition,stop

theengine,andremovethekey.

2.Pullthewireoffofthesparkplug(Figure31).Clean

aroundthesparkplugtopreventdirtfromfalling

intotheengineandpotentiallycausingdamage.

Note:Duetothedeeprecessaroundthespark

plug,blowingoutthecavitywithcompressedair

isusuallythemosteffectivemethodforcleaning.

Thesparkplugismostaccessiblewhentheblower

housingisremovedforcleaning.

3.Removethesparkplugandmetalwasher.

InstallingtheSparkPlug

1.Installthesparkplug.Makesurethattheairgapis

setcorrectly.

2.Tightenthesparkplugto30ft-lb(41N-m).

3.Pushthewireontothesparkplug(Figure31).

CleaningtheBlowerHousing

Toensurepropercooling,makesurethegrassscreen,

coolingns,andotherexternalsurfacesoftheengine

arekeptcleanatalltimes.

29

Page 30

Annuallyorevery100hoursofoperation(moreoften

underextremelydusty ,dirtyconditions),removethe

blowerhousingandanyothercoolingshrouds.Clean

thecoolingnsandexternalsurfacesasnecessary.Make

surethecoolingshroudsarereinstalled.Torquethe

blowerhousingscrewsto5.5ft-lb(7.5N-m).

FuelSystem

Maintenance

Important:Operatingtheenginewithablocked

grassscreen,dirtyorpluggedcoolingns,and/or

coolingshroudsremoved,willcauseenginedamage

duetooverheating.

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areor

explosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Performanyfuelrelatedmaintenancewhen

theengineiscold.Dothisoutdoorsinan

openarea.Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,and

stayawayfromanopenameorwherea

sparkmayignitethegasolinefumes.

ReplacingtheFuelFilter

ServiceInterval:Every100hours—Replacethefuel

lter.

Neverinstalladirtylterifitisremovedfromthefuel

line.

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothe

parkposition,stoptheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Raisetheseatandlocatethefuellinecomingfrom

thefueltankbelow .Thefuellterisinthefuelline

betweenthetankandengine.

30

Page 31

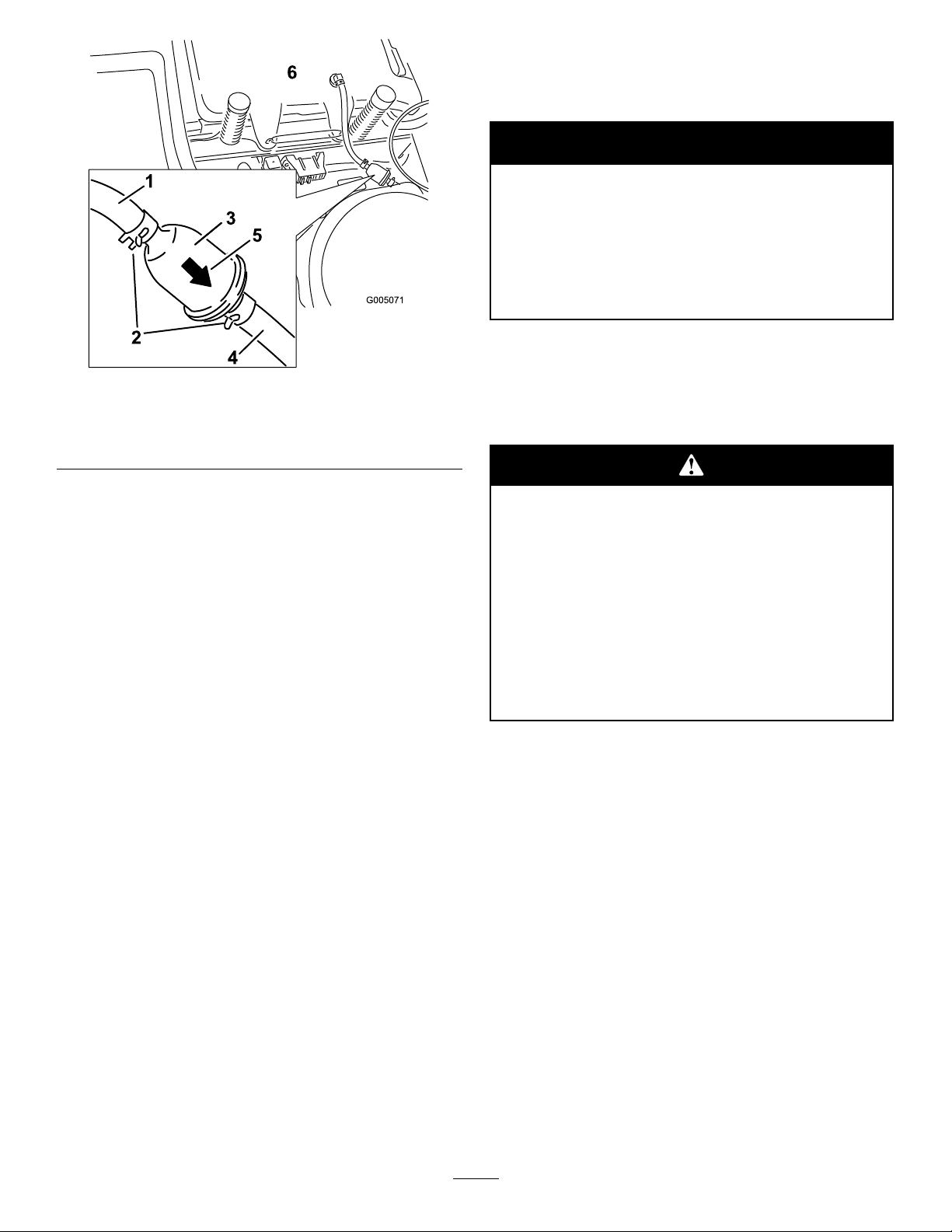

G005071

212

3

4

6

5

ElectricalSystem

Maintenance

Warning

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

Figure33

1.Fuellinefromtank

2.Hoseclamp5.Flowdirectionarrow

3.Filter6.Fueltank

4.Squeezetheendsofthehoseclampstogetherand

slidethemawayfromthelter(Figure33).

5.Removethelterfromthefuellines.

6.Installanewlterwiththeowdirectionarrow

comingfromthefueltankandpointingtothe

engine.Movethehoseclampsclosetothelter

(Figure33)tosecureitinplace.

4.Fuellinetoengine

ChargingtheBattery

RemovingtheBattery

Batteryterminalsormetaltoolscouldshort

againstmetalmachinecomponentscausing

sparks.Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,do

notallowthebatteryterminalstotouchany

metalpartsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothe

parkposition,stoptheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removetheleftsideconsoletoaccessthebattery.

RefertheAccessingtheBatteryprocedureinthe

31

PremaintenanceProceduresforinstructions.

4.Disconnectthenegative(black)groundcablefrom

thebatterypost(Figure34).Retainallfasteners.

Page 32

Incorrectbatterycableroutingcoulddamage

G005072

1

2

3

4

5

6

7

themachineandcablescausingsparks.Sparks

cancausethebatterygassestoexplode,

resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative(black)

cable.

5.Slidetherubbercoverupthepositive(red)cable.

Disconnectthepositive(red)cablefromthebattery

post(Figure34).Retainallfasteners.

6.Removethebatteryhold-down(Figure34)andlift

thebatteryfromthebatterytray.

Figure35

1.Positivebatterypost

2.Negativebatterypost

3.Red(+)chargerlead

4.Black(-)chargerlead

Note:Donotrunthemachinewiththebattery

disconnected,electricaldamagemayoccur.

InstallingtheBattery

1.Positionthebatteryinthetraywiththeterminal

poststowardtheoperatingposition(Figure34).

2.Installthepositive(red)batterycabletothepositive

(+)batteryterminalusingthefastenersremoved

previously.

Figure34

1.Battery5.Negativebatterypost

2.Positivebatterypost6.Wingnut,washer,andbolt

3.Bolt,washer ,andnut7.Batteryhold-down

4.Terminalboot

ChargingtheBattery

ServiceInterval:Beforestorage—Chargethebattery

anddisconnectbatterycables.

1.Removethebatteryfromthechassis;referto

RemovingtheBattery.

2.Chargethebatteryforaminimumof1hourat6to

10amps.Donotoverchargethebattery.

3.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthe

chargerleadsfromthebatteryposts(Figure35).

3.Installthenegativebatterycabletothenegative

(-)batteryterminalusingthefastenersremoved

previously.

4.Slidetheredterminalbootontothepositive(red)

batterypost.

5.Securethebatterywiththehold-down(Figure34).

6.Installtheleftsideconsole.RefertotheAccessing

theBatteryprocedureinPremaintenanceProcedures

forinstructions.

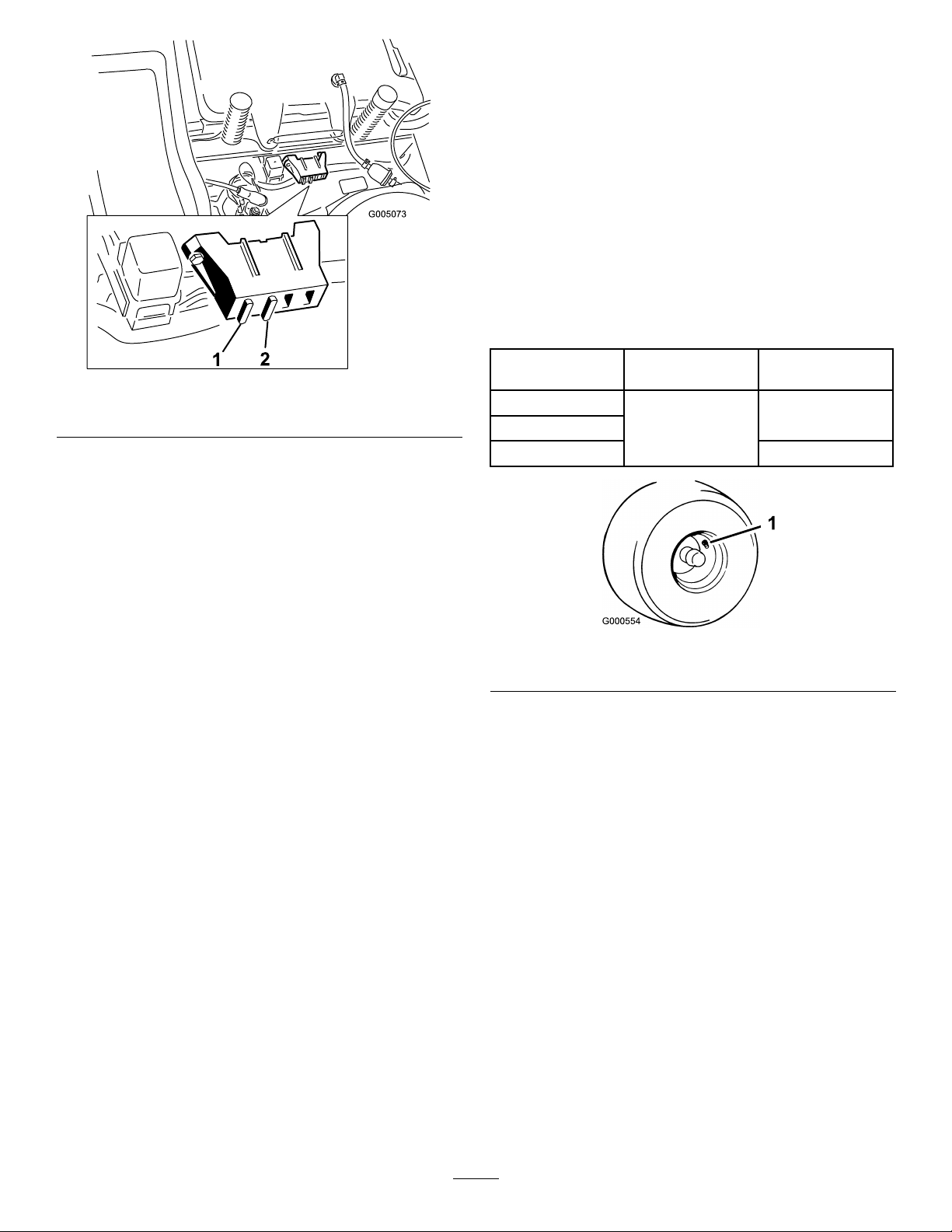

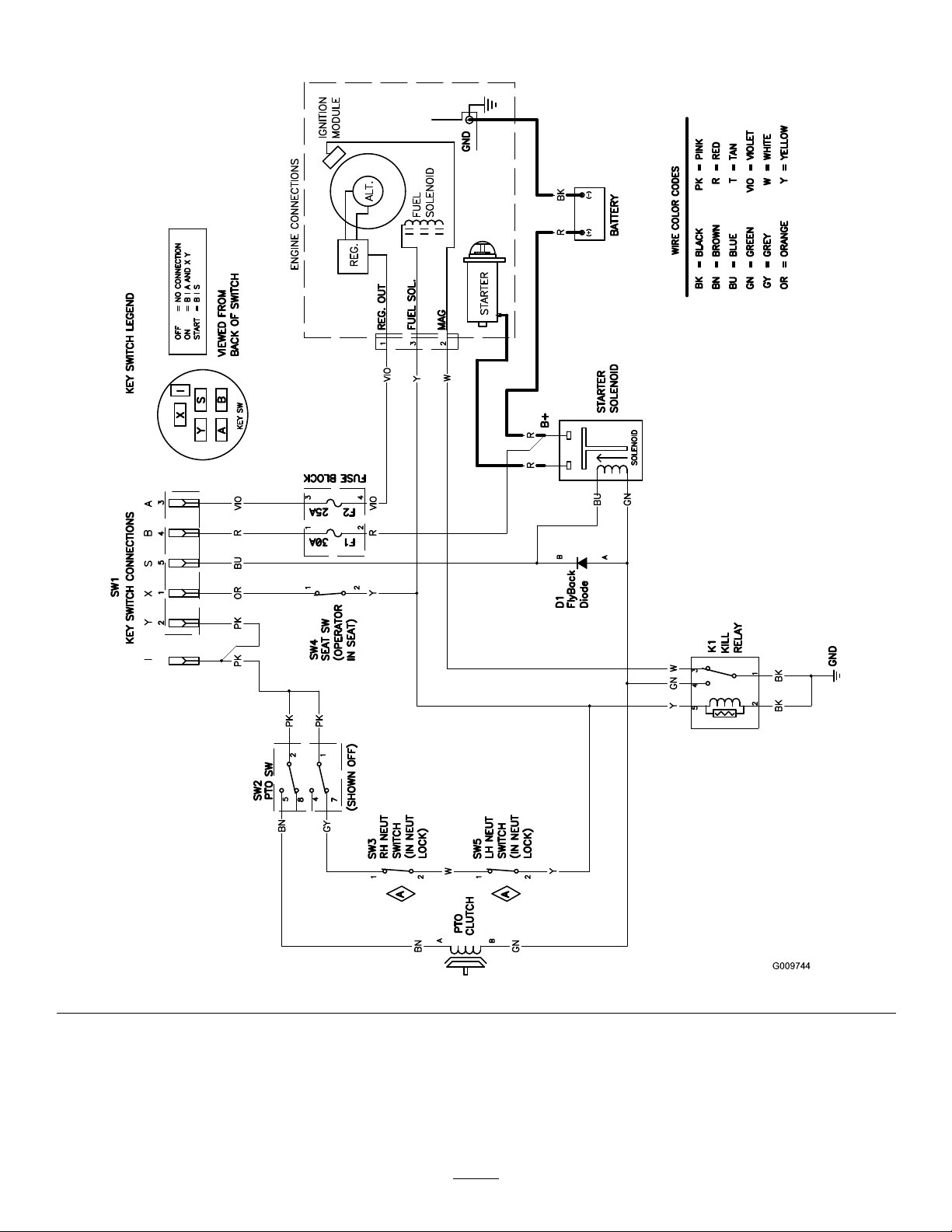

ServicingtheFuses

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;however,ifafuseblows,checkthe

component/circuitforamalfunctionorshort.

Fuse:

•MainF1-30amp,blade-type

•ChargeCircuitF2-25amp,blade-type

1.Raisetheseattogainaccesstothefuseholder

(Figure36).

2.Toreplaceafuse,pulloutonthefusetoremoveit

(Figure36).

32

Page 33

G005073

1

2

DriveSystem

Maintenance

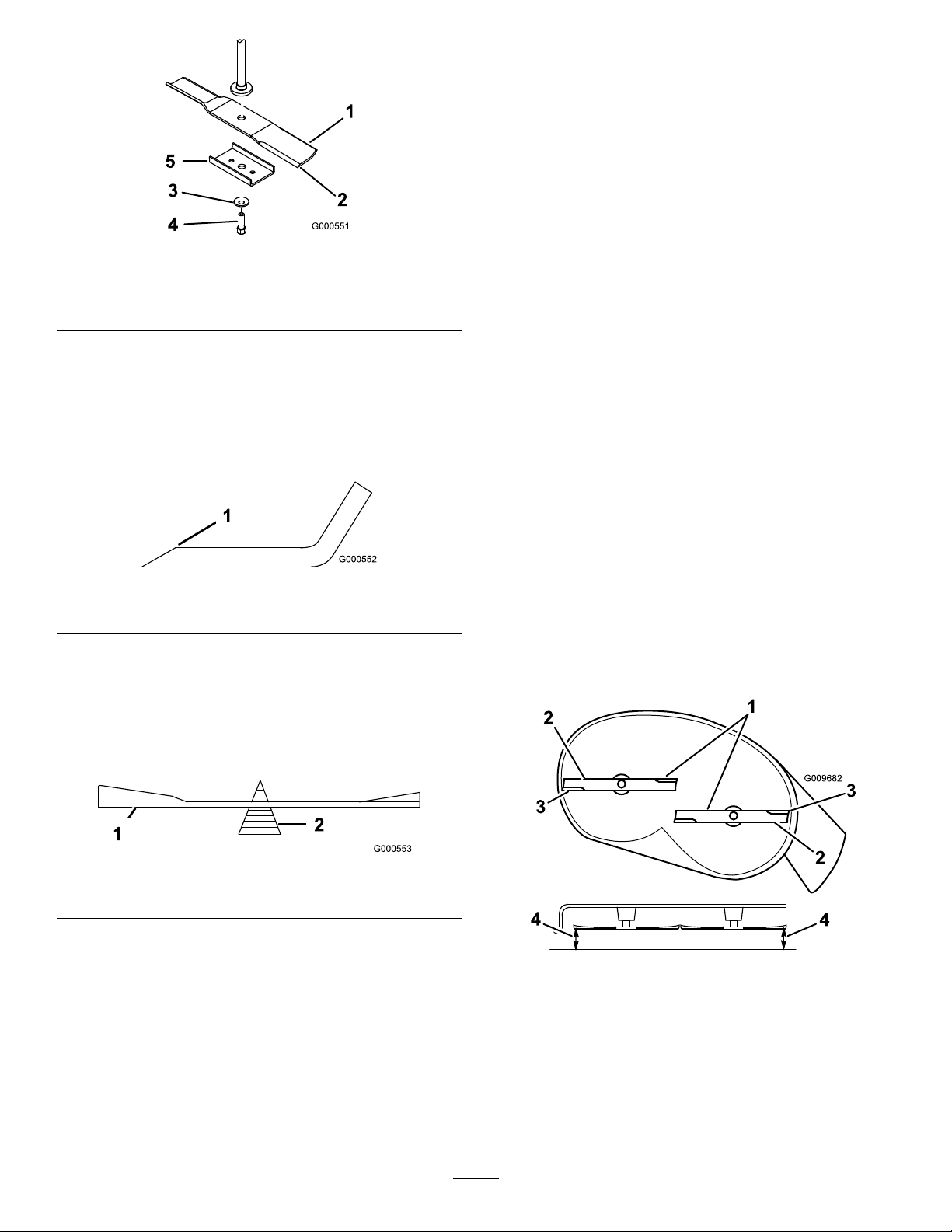

CheckingtheTirePressure

ServiceInterval:Every25hours—Checktirepressure.

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseunevencut.

Checkthepressureatthevalvestem(Figure37).Check

thetireswhentheyarecoldtogetthemostaccurate

pressurereading.

TirePressures

1.Main-30amp

Figure36

2.Chargecircuit-25amp

ModelRearTire

74360

74363

74370

1.Valvestem

13psi(90kPa)

FrontTire(caster

wheels)

35psi(241kPa)

20psi(138kPa)

Figure37

33

Page 34

MowerMaintenance

G009679

1

2

3

ServicingtheCuttingBlades

Maintainsharpbladesthroughoutthecuttingseason

becausesharpbladescutcleanlywithouttearingor

shreddingthegrassblades.Tearingandshreddingturns

grassbrownattheedges,whichslowsgrowthand

increasesthechanceofdisease.

Checkthecutterbladesdailyforsharpness,andforany

wearordamage.Filedownanynicksandsharpenthe

bladesasnecessary.Ifabladeisdamagedorworn,

replaceitimmediatelywithagenuineTororeplacement

blade.Forconvenientsharpeningandreplacement,you

maywanttokeepextrabladesonhand.

Awornordamagedbladecanbreak,anda

pieceofthebladecouldbethrownintothe

operator’sorbystander’sarea,resultingin

seriouspersonalinjuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

Figure38

1.Cuttingedge3.Wear/slotforming

2.Curvedarea

4.Damage

CheckingforBentBlades

Note:Themachinemustbeonalevelsurfaceforthe

followingprocedure.

1.Raisethemowerdecktothehighestheight-of-cut

position;alsoconsideredthe’transport’position.

2.Whilewearingthicklypaddedglovesorother

adequatehandprotectionslowlyrotatebladeto

bemeasureintoapositionthatallowseffective

measurementofthedistancebetweenthecutting

edgeandthelevelsurfacethemachineison.

•Replaceawornordamagedblade.

BeforeInspectingorServicingthe

Blades

Parkthemachineonalevelsurface,disengagetheblade

controlswitch,andmovethemotioncontrollevers

outwardtotheparkposition.Stoptheengineand

removethekey.

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily—Checkthe

cuttingblades.

1.Inspectthecuttingedges(Figure38).Iftheedges

arenotsharporhavenicks,removeandsharpenthe

blades;refertoSharpeningtheBlades.

2.Inspecttheblades,especiallythecurvedarea

(Figure38).Ifyounoticeanydamage,wear,or

aslotforminginthisarea(item3inFigure38),

immediatelyinstallanewblade.

Figure39

1.Deck3.Blade

2.Spindlehousing

34

Page 35

3.Measurefromthetipofthebladetotheatsurface

G009680

1

2

3

G009681

1

2

3

G009680

1

2

3

here.

Figure40

1.Blade,inpositionformeasuring

2.Levelsurface

3.Measureddistancebetweenbladeandsurface(A)

Figure42

1.Opposingbladeedge,inpositionformeasuring

2.Levelsurface

3.Secondmeasureddistancebetweenbladeandsurface(B)

4.Rotatethesameblade180degreessothatthe

opposingcuttingedgeisnowinthesameposition.

Figure41

1.Blade,sidepreviouslymeasured

2.Measurementpositionusedpreviously

3.Opposingsideofbladebeingmovedintomeasurement

position

5.Measurefromthetipofthebladetotheatsurface

here.Thevarianceshouldbenomorethan1/8inch

(3mm).

Abladethatisbentordamagedcouldbreak

apartandcouldseriouslyinjureorkillyouor

bystanders.

•Alwaysreplacebentordamagedbladewith

anewblade.

•Neverleorcreatesharpnotchesinthe

edgesorsurfacesofblade.

A.IfthedifferencebetweenAandBisgreater

than1/8inch(3mm)replacethebladewitha

newblade.RefertoRemovingtheBladesand

InstallingtheBlades.

Note:Ifabentbladeisreplacedwithanewone

andthedimensionobtainedcontinuestoexceed

1/8inch(3mm),thebladespindlecouldbebent.

ContactanAuthorizedToroDealerforservice.

B.Ifthevarianceiswithinconstraints,movetothe

nextblade..

Repeatthisprocedureoneachblade.

RemovingtheBlades

Thebladesmustbereplacedifasolidobjectishit,

ifthebladeisoutofbalance,orthebladeisbent.

Toensureoptimumperformanceandcontinued

safetyconformanceofthemachine,usegenuineToro

replacementblades.Replacementbladesmadebyother

manufacturersmayresultinnon-conformancewith

safetystandards.

Holdthebladeendusingaragorthickly-paddedglove.

Removethebladebolt,curvedwasher,bladestiffener,

andbladefromthespindleshaft(Figure43).

35

Page 36

LevelingtheMowerDeck

G009682

1

2

2

3

3

4

4

Checktoensurethemowerdeckislevelanytimeyou

installthemowerorwhenyouseeanunevencuton

yourlawn.

Themowerdeckmustbecheckedforbentblades

priortoleveling;anybentbladesmustberemoved

andreplaced.RefertotheCheckingforBentBlades

procedurebeforecontinuing.

Figure43

1.Sailareaofblade

2.Blade

3.Curvedwasher

4.Bladebolt

5.Bladestiffener

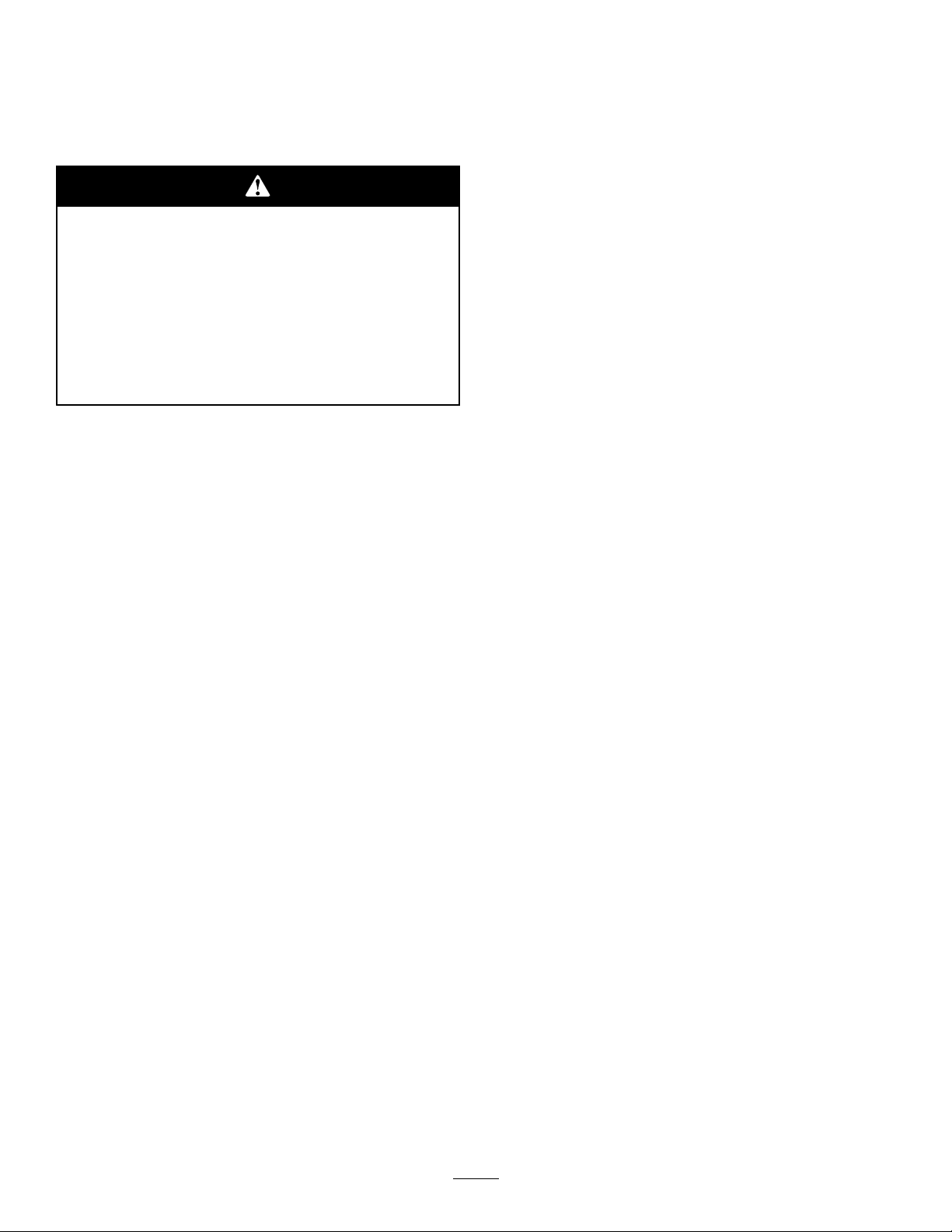

SharpeningtheBlades

1.Usealetosharpenthecuttingedgeatbothends

oftheblade(Figure44).Maintaintheoriginalangle.

Thebladeretainsitsbalanceifthesameamountof

materialisremovedfrombothcuttingedges.

Figure44

1.Sharpenatoriginalangle

2.Checkthebalanceofthebladebyputtingitona

bladebalancer(Figure45).Ifthebladestaysina

horizontalposition,thebladeisbalancedandcanbe

used.Ifthebladeisnotbalanced,lesomemetaloff

theendofthesailareaonly(Figure44).Repeatthis

procedureuntilthebladeisbalanced.

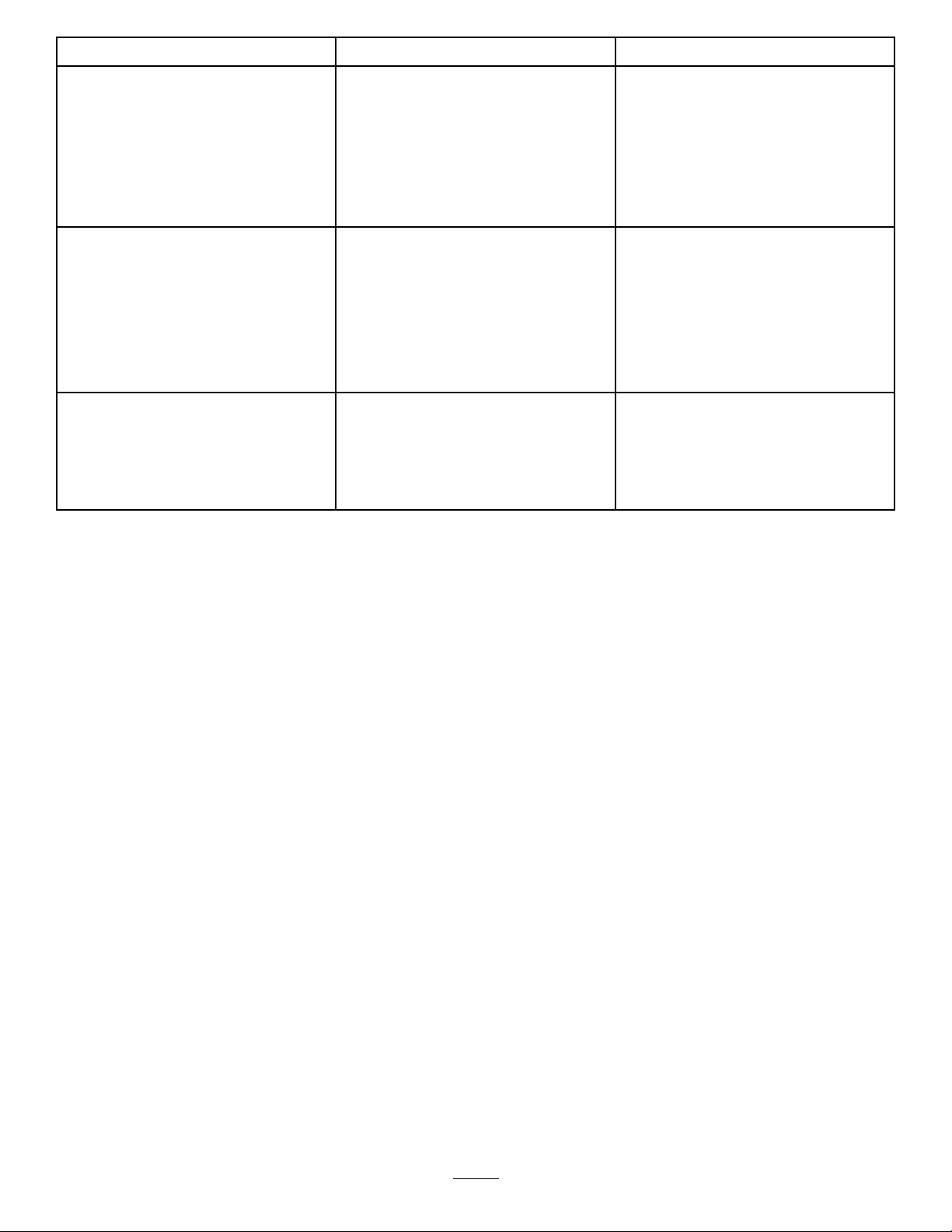

Themowerdeckmustbeleveledside-to-siderstthen

thefronttorearslopecanbeadjusted.

Requirements:

•Themachinemustbeonalevelsurface.

•Allfourtiremustbeproperlyinated.Referto

CheckingtheTirePressureintheDriveSystem

Maintenancesection.

Side-to-SideLeveling

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothe

parkposition,stoptheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Settheheight-of-cutlevertomiddleposition.

4.Carefullyrotatethebladessothattheyareallsideto

side(Figure46andFigure47).

Figure45

1.Blade2.Balancer

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure43).

Important:Thecurvedpartoftheblademust

bepointingupwardtowardtheinsideofthe

mowertoensurepropercutting.

1.Bladessidetoside

2.Sailareaofblade4.Measurefromthetipofthe

2.Installthebladestiffener,thecurvedwasher(cupped

MowerDeckswith2Blades

Figure46

3.Outsidecuttingedges

bladetotheatsurface

here

sidetowardtheblade)andthebladebolt(Figure43).

3.Torquethebladeboltto35-65ft-lb(47-88N-m).

36

Page 37

G005278

1

2

2

3

3

4

4

Figure47

3

G005074

1

2

3

4

5

6

MowerDeckswith3Blades

1.Bladessidetoside

2.Sailareaofblade4.Measurefromthetipofthe

3.Outsidecuttingedges

bladetotheatsurface

here

5.Measurebetweentheoutsidecuttingedgesand

theatsurface(Figure46andFigure47).Ifboth

measurementsarenotwithin3/16inch(5mm),an

adjustmentisrequired;continuewiththisprocedure.

6.Movetotheleftsideofthemachine.Loosen,but

donotremove,therearlockingnutonthehanger

bracket(Figure48).

7.Loosenthesidelockingnutonthehangerbracket

justenoughtoallowtheeccentricplatetobeadjusted

(Figure48).Usea3/8inchdriveextensionona

socketwrenchtomanipulatetheeccentricplate.Use

thewrenchtorepositiontheheightofthemower

deckandadjusttothedesiredheight.

8.Stopthedeckattheadjustedpositionandtightenthe

sidelockingnutonthehangerbrackettoholdthe

newposition(Figure48).Tightentherearlocking

nutonthehangerbracket.

Figure48

1.Hangerbracket4.Eccentricadjustmentplate

2.Rearlockingnut

3.Sidelockingnut6.Socketwrenchwith3/8

5.Socketwrenchhole

inchextension

AdjustingtheFront-to-RearBlade

Slope

Checkthefront-to-rearbladelevelanytimeyouinstall

themower.Ifthefrontofthemowerismorethan

5/16inch(7.9mm)lowerthantherearofthemower,

adjustthebladelevelusingthefollowinginstructions:

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrolswitch.

9.Continuelevelingthedeckbycheckingthe

front-to-rearbladeslope;refertoAdjustingthe

Front-to-RearBladeSlope.

2.Movethemotioncontrolleversoutwardtothe

parkposition,stoptheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Settheheight-of-cutlevertomiddleposition.

Note:Checkandadjusttheside-to-sideblade

levelifyouhavenotcheckedthesetting;referto

Side-to-SideLeveling.

4.Carefullyrotatethebladessotheyarefacingfrontto

rear(Figure49andFigure50).

37

Page 38

G009658

1

2

2

Figure49

G009659

1

2

3

2

3

MowerDeckswith2Blades

1.Bladesfronttorear

2.Measurefromthetipofthebladetotheatsurfacehere

Figure50

MowerDeckswith3Blades

1.Bladesfronttorear3.Measurefromthetipofthe

bladetotheatsurface

here

2.Outsidecuttingedges

5.Measurefromthetipofthefrontbladetotheat

surfaceandthetipoftherearbladetotheatsurface

(Figure49andFigure50).Ifthefrontbladetipis

not1/16-5/16inch(1.6-7.9mm)lowerthantherear

bladetip,adjustthefrontlocknut.

6.Toadjustthefront-to-rearbladeslope,rotatethe

adjustmentnutinthefrontofthemower(Figure51).

Figure51

1.Adjustingrod3.Locknut

2.Adjustingblock

7.Toraisethefrontofthemower,tightenthe

adjustmentnut.T olowerthefrontofthemower,

loosentheadjustmentnut.

8.Afteradjustment,checkthefront-to-rearslopeagain.

Continueadjustingthenutuntilthefrontbladetip

is1/16-5/16inch(1.6-7.9mm)lowerthantherear

bladetip(Figure49andFigure50).

9.Whenthefront-to-rearbladeslopeiscorrectcheck

theside-to-sidelevelofthemoweragain;referto

LevelingtheMowerfromSide-to-Side.

RemovingtheMower

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothe

parkposition,stoptheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Lowertheheight-of-cutlevertothelowestposition.

4.Removethehairpincotterandclevispinfromthe

frontsupportrod(Figure52).Carefullylowerthe

frontofthemowerdecktotheground.

38

Page 39

Figure52

2

2

3

G005077

1

2

2

3

1.Frontsupportrod3.Hairpincotterandclevis

pin

2.Lockingnut

5.Liftthemowerdeckandhangerbracketsclearof

therearliftrodandlowerthemowercarefullyto

theground(Figure53).

MowerBeltMaintenance

InspectingtheBelts

ServiceInterval:Every25hours—Checkthebeltsfor

wear/cracks.

Checkthebeltsforcracks,frayededges,burnmarks,or

anyotherdamage.Replacedamagedbelts.

ReplacingtheMowerBelt

Squealingwhenthebeltisrotating,bladesslippingwhen

cuttinggrass,frayedbeltedges,burnmarks,andcracks

aresignsofawornmowerbelt.Replacethemowerbelt

ifanyoftheseconditionsareevident.

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothe

parkposition,stoptheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Settheheight-of-cutatthelowestcuttingposition

[1-1/2inch(38mm)].

4.Removethebeltcoversovertheoutsidespindles.

5.Pulltheidlerpulleyinthedirectionshownin

Figure55androllthebeltoffofthepulleys.

Figure53

1.Mowerdeck

2.Hangerbracket

3.Rearliftrod

6.Slidethemowerdeckrearwardtoremovethemower

beltfromtheenginepulley .

7.Slidethemowerdeckoutfromunderneaththe

machine.

Note:Retainallpartsforfutureinstallation.

Thespringisundertensionwheninstalledand

cancausepersonalinjury.

Becarefulwhenremovingthebelt.

39

Page 40

G005078

1

2

3

3

4

5

1

2

3

3

4

5

G005191

1

2

3

3

4

5

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Slidethemowerunderthemachine.

4.Lowertheheight-of-cutlevertothelowestposition.

5.Lifttherearofthemowerdeckandguidethehanger

bracketsovertherearliftrod(Figure53).

6.Attachthefrontsupportrodtothemowerdeckwith

theclevispinandhairpincotter(Figure52).

7.Installthemowerbeltontotheenginepulley;refer

toReplacingtheMowerBelt.

Figure54

MowerDeckswith2Blades

1.Idlerpulley

2.Mowerbelt5.Enginepulley

3.Outsidepulley

MowerDeckswith3Blades

4.Spring

Figure55

ReplacingtheGrassDeector

ServiceInterval:Beforeeachuseordaily—Inspectthe

grassdeectorfordamage

Anuncovereddischargeopeningcouldallow

thelawnmowertothrowobjectsinthe

operator’sorbystander’sdirectionandresult

inseriousinjury.Also,contactwiththeblade

couldoccur.

Neveroperatethemachinewithoutgrass

deector,dischargecoverorgrasscollection

systeminplace.

Inspectthegrassdeectorfordamagebeforeeachuse.

Replaceanydamagedpartsbeforeuse.

1.LocateitemsshowninFigure56.

1.Idlerpulley

2.Mowerbelt5.Enginepulley

3.Outsidepulley

4.Spring

6.Routethenewbeltaroundtheenginepulleyand

mowerpulleys(Figure55).

7.Pulltheidlerpulleyinthedirectionshownin

Figure55androutethebeltontotheidlerpulley

(Figure55).

8.Installthebeltcoversovertheoutsidespindles.

InstallingtheMower

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothe

parkposition,stoptheengine,removethekey,and

40

Page 41

G005192

1

2

3

4

5

6

7

Figure56

1.Mowerdeck

2.Grassdeector6.Nut(3/8inch)

3.Grassdeectorbracket7.Shortstand-off

4.Rod

5.Spring

2.Removethenut(3/8inch)fromtherodunderthe

mower(Figure56).

3.Slidetherodoutoftheshortstand-off,spring,and

grassdeector(Figure56).Removethedamaged

orworngrassdeector.

Cleaning

WashingtheUndersideofthe

Mower

ServiceInterval:Beforeeachuseordaily—Cleanthe

mowerhousing.

Washtheundersideofthemoweraftereachuseto

preventgrassbuildupforimprovedmulchactionand

clippingdispersal.

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothe

parkposition,stoptheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Attachthehosecouplingtotheendofthemower

washouttting,andturnthewateronhigh

(Figure57).

Note:Spreadpetroleumjellyonthewashouttting

O-ringtomakethecouplingslideoneasierand

protecttheO-ring.

4.Replacethegrassdeector(Figure56).

5.Sliderod,straightend,throughthereargrass

deectorbracket.

6.Placethespringontherod,withendwiresdown,

andbetweenthegrassdeectorbrackets.Sliderod

throughsecondgrassdeectorbracket(Figure56).

7.Insertrodatfrontofgrassdeectorintoshort

stand-offondeck.Securerearendofrodintothe

mowerwithanut(3/8inch)(Figure56).

Important:Thegrassdeectormustbespring

loadedinthedownposition.Liftthedeector

uptotestthatitsnapstothefulldownposition.

Figure57

1.Washouttting3.O-ring

2.Hose

4.Coupling

4.Lowerthemowertothelowestheight-of-cut.

5.Sitontheseatandstarttheengine.Engagetheblade

controlswitchandletthemowerrunforoneto

threeminutes.

6.Disengagethebladecontrolswitch,stoptheengine,

andremovetheignitionkey.Waitforallmoving

partstostop.

7.Turnthewateroffandremovethecouplingfrom

thewashouttting.

41

Page 42

Note:Ifthemowerisnotcleanafteronewashing,

soakitandletitstandfor30minutes.Thenrepeat

theprocess.

8.Runthemoweragainforonetothreeminutesto

removeexcesswater.

Abrokenormissingwashoutttingcould

exposeyouandotherstothrownobjectsor

bladecontact.Contactwithbladeorthrown

debriscancauseinjuryordeath.

•Replacebrokenormissingwashouttting

immediately,beforeusingmoweragain.

•Neverputyourhandsorfeetunderthe

mowerorthroughopeningsinthemower.

Storage

CleaningandStorage

1.Disengagethebladecontrolswitch,movethe

motioncontrolsoutwardtotheparkposition,stop

theengine,andremovethekey.

2.Removegrassclippings,dirt,andgrimefromthe

externalpartsoftheentiremachine,especiallythe

engine.Cleandirtandchafffromtheoutsideofthe

enginecylinderheadnsandblowerhousing.

Important:Youcanwashthemachinewith

milddetergentandwater.Donotpressure

washthemachine.Avoidexcessiveuseof

water,especiallynearthecontrolpanel,engine,

hydraulicpumps,andmotors.

3.Servicetheaircleaner;refertoServicingtheAir

CleanerintheEngineMaintenancesection.

4.Greaseandoilthemachine;refertotheLubrication

section.

5.Changethecrankcaseoilandlter;refertoServicing

theEngineOilintheEngineMaintenancesection.

6.Checkthetirepressure;refertoCheckingtheTire

PressureintheDriveSystemMaintenancesection.

7.Chargethebattery;refertoServicingtheBattery

intheElectricalSystemMaintenancesection.

8.Checktheconditionoftheblades;refertoServicing

theCuttingBladesintheMowerMaintenance

section.

9.Preparethemachineforstoragewhennon-use

occursover30days.Preparethemachineforstorage

asfollows.

10.Addapetroleumbasedstabilizer/conditionertothe

fuelinthetank.Followthemixinginstructionsfrom

thestabilizermanufacturer.Donotuseanalcohol

basedstabilizer(ethanolormethanol).

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasolineandusedatalltimes.

Runtheenginetodistributetheconditionedfuel

throughthefuelsystem(5minutes).

Stoptheengine,allowittocool,anddrainthefuel

tank;refertoDrainingtheFuelTankintheFuel

SystemMaintenancesection.

Restarttheengineandrunituntilitstops.

Choketheengine.Startandruntheengineuntilit

willnotstart.