Page 1

FormNo.3389-840RevB

ZMaster

®

8000SeriesRiding

Mower

with42inor48inDirect-CollectCuttingUnit

ModelNo.74310—SerialNo.315000001andUp

ModelNo.74311—SerialNo.315000001andUp

ModelNo.74312—SerialNo.315000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3389-840*B

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrester,contactyour

AuthorizedToroServiceDealer.

GenuineT orosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

Theenclosedengineowner’smanualissuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughtheengine

manufacturer.

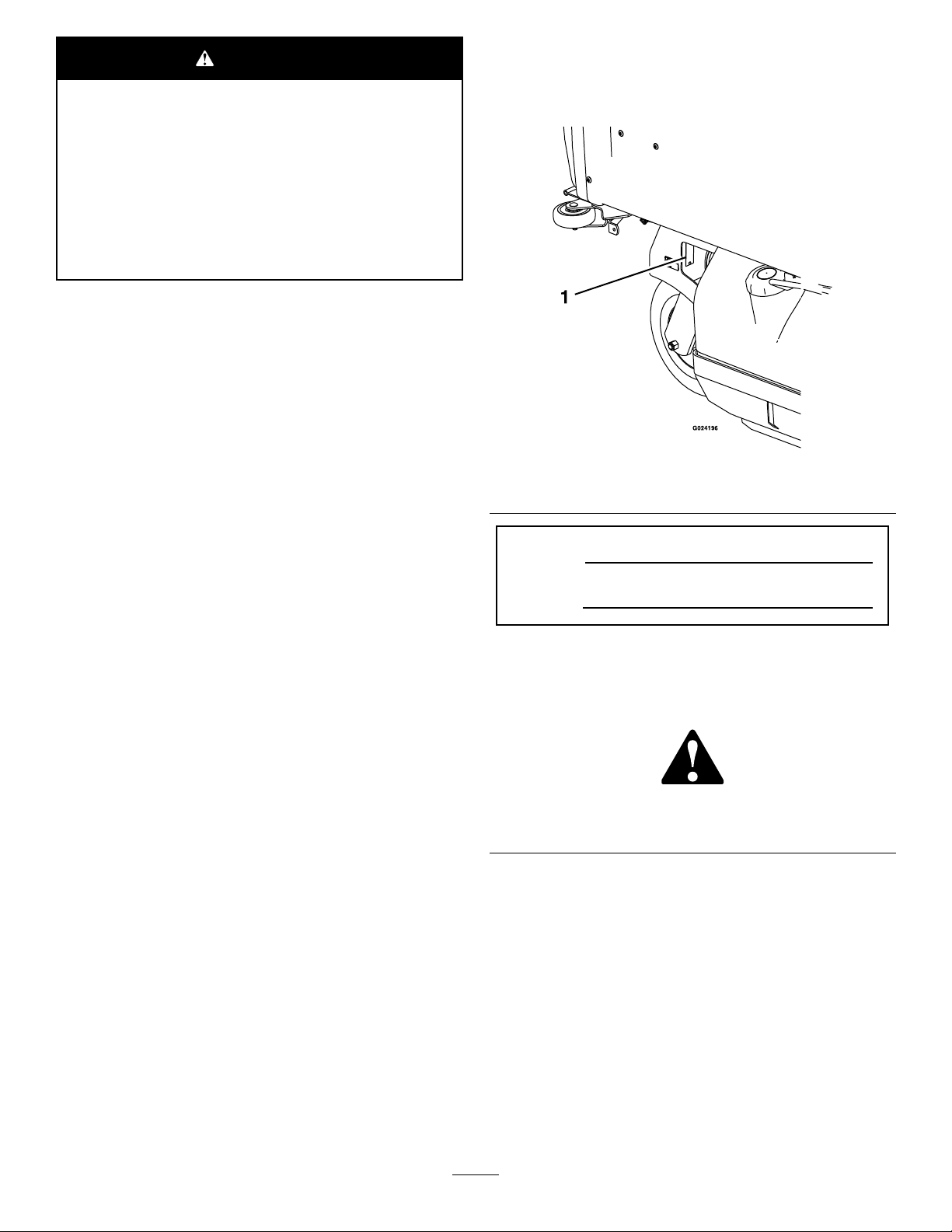

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Introduction

Thisrotary-blade,ridinglawnmowerisintendedtobeused

byresidentialhomeownersorprofessional,hiredoperators.

Itisdesignedprimarilyforcuttinggrassonwell-maintained

lawnsonresidentialorcommercialproperties.Itisnot

designedforcuttingbrushorforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .T oro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

©2016—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

SlopeIndicator.......................................................6

SafetyandInstructionalDecals.................................7

ProductOverview.........................................................14

Controls...............................................................14

Specications........................................................15

Operation....................................................................16

AddingFuel...........................................................16

CheckingtheEngine-OilLevel.................................17

BreakinginaNewMachine......................................17

ThinkSafetyFirst...................................................17

OperatingtheParkingBrake....................................18

OperatingtheThrottle............................................18

OperatingtheIgnitionSwitch..................................18

UsingtheFuel-ShutoffValve...................................19

OperatingthePTO-EngagementLever.....................19

StartingandStoppingtheEngine..............................19

TheSafetyInterlockSystem.....................................21

DrivingForwardorBackward..................................21

StoppingtheMachine.............................................22

RaisingtheMowerDeckintoServicePosition.............22

LoweringtheMowerDecktotheOperating

Position.............................................................23

AdjustingtheFillReductionSystem(FRS)

Bafes...............................................................23

AdjustingtheHeightofCut.....................................24

EmptyingtheHopper.............................................24

ClearingtheHopperScreen.....................................24

UsingtheDrive-Wheel-ReleaseValves.......................25

TransportingtheMachine........................................25

LoadingtheMachine..............................................26

OperatingTips......................................................27

Maintenance.................................................................28

RecommendedMaintenanceSchedule(s)......................28

Lubrication...............................................................29

LubricatingtheMachine..........................................29

EngineMaintenance..................................................32

ServicingtheAirCleaner.........................................32

ServicingtheEngineOil..........................................33

ServicingtheSparkPlugs.........................................35

CheckingtheSparkArrester(ifequipped)..................35

FuelSystemMaintenance...........................................36

ServicingtheElectronicFuelInjection

System..............................................................36

ReplacingtheFuelFilter..........................................36

ServicingtheFuelTank...........................................36

ElectricalSystemMaintenance....................................37

ServicingtheBattery...............................................37

ServicingtheFuses.................................................38

AdjustingtheSafetySwitches...................................38

JumpStartingtheMachine.......................................38

DriveSystemMaintenance.........................................40

AdjustingtheTracking............................................40

CheckingtheTirePressure......................................40

CheckingtheWheelLugNuts..................................40

CheckingtheWheelHubNuts.................................40

AdjustingtheCasterPivotBearings...........................40

CoolingSystemMaintenance......................................41

CleaningtheEngineScreenandEngine-Oil

Cooler...............................................................41

ServicingtheEngine-OilCooler...............................41

CleaningtheEngineCoolingFinsand

Shrouds.............................................................41

CheckandCleantheHydraulicPumps.......................42

BrakeMaintenance....................................................42

AdjustingtheParkingBrake.....................................42

BeltMaintenance......................................................44

InspectingtheBelts................................................44

ReplacingthePTOBelts.........................................44

ReplacingthePumpDriveBelt.................................44

AdjustingtheBeltGuides........................................45

ControlsSystemMaintenance.....................................45

AdjustingtheReverse-StopRod...............................45

AdjustingtheSpeed-ControlLeverTension...............46

AdjustingtheSpeed-ControlLinkage........................46

AligningthePTO-DrivePulley.................................47

AligningthePump-DrivePulley...............................47

AdjustingthePTOBrakeSpring...............................48

AdjustingtheHopperDoor.....................................48

AdjustingtheLocking-PinStopontheMower

Deck.................................................................48

HydraulicSystemMaintenance....................................49

ServicingtheHydraulicSystem.................................49

MowerDeckMaintenance...........................................50

LevelingtheMowerDeck........................................50

ServicingtheCuttingBlades.....................................51

RemovingtheMowerDeck.....................................53

InstallingtheMowerDeck.......................................54

AdjustingtheLocking-PinStopontheMower

Deck.................................................................55

Cleaning...................................................................55

CleaningundertheMower.......................................55

CleaningDebrisfromtheMachine............................55

DisposingofWaste.................................................55

Storage........................................................................56

CleaningandStorage..............................................56

Troubleshooting...........................................................57

Schematics...................................................................59

3

Page 4

Safety

ThismachinecompliestotheANSIB71.4–2012specication

oftheAmericanNationalStandardsInstitutewiththe

additionoftheoptionalROPSaccessory.

Improperlyusingormaintainingthemachinecanresult

ininjury.T oreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safety-alertsymbol,whichmeans

Danger

withtheinstructionmayresultinpersonalinjuryor

death.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Thisproductisdesignedforcuttingandrecyclinggrassor,

whenequippedwithagrassbagger,forcatchingcutgrass.

Anyuseforpurposesotherthanthesecouldprovedangerous

totheuserandbystanders.

—personalsafetyinstruction.Failuretocomply

SafeOperatingPractices

ThefollowinginstructionsareadaptedfromANSI

B71.4-2012.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadorunderstand

theinformationitistheowner'sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtopeopleordamageto

property.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothingincludinghardhat,safety

glasses,andhearingprotection.Longhair,looseclothing,

orjewelrymaygettangledinmovingparts.

Caution, W ar ning ,

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchasrocks,toys,andwirewhichcan

bethrownbythemachine.

•Checkthatoperator-presencecontrols,safetyswitches,

andshieldsareattachedandfunctioningproperly.Donot

operateunlesstheyarefunctioningproperly.

Operation

or

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•BesurethatalldrivesareinNEUTRALandtheparking

brakeisengagedbeforestartingtheengine.Onlystartthe

enginefromtheoperator'sposition.

•Slowdownanduseextracareonhillsides.Besureto

travelsidetosideonhillsides.Turfconditionscanaffect

thestabilityofthemachine.Usecautionwhileoperating

neardrop-offs.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Neverraisedeckwiththebladesrunning.

•NeveroperatewiththePTOshieldorotherguardsnot

securelyinplace.Besureallinterlocksareattached,

adjustedproperly ,andfunctioningproperly.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Stoponlevelground,disengagedrives,engagethe

parkingbrake(ifprovided),andshutofftheenginebefore

leavingtheoperator'spositionforanyreason,including

emptyingthehopperoruncloggingthechute.

•Stopequipmentandinspectbladesafterstrikingobjects

orifanabnormalvibrationoccurs.Makenecessary

repairsbeforeresumingoperations.

•Keepyourhandsandfeetawayfromthecuttingunit.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Nevercarrypassengersonthemachine.

•Keeppetsandbystandersaway .

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopbladesifnotmowing.

•Beawareofthemowerdischargedirectionanddonot

pointitatanyone.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs.

•Usecarewhenloadingorunloadingthemachineinto

orfromatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

4

Page 5

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforeaddingfuel.

•Neveraddfueltothemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Usecarewhencheckingtheblades.Wraptheblade(s)or

weargloves,andusecautionwhenservicingthem.Only

replaceblades.Neverstraightenorweldthem.

•Keepyourhandsandfeetawayfrommovingparts.

Ifpossible,donotmakeadjustmentswiththeengine

running.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourToroequipment,countonToro

genuineparts.Whenitcomestoreliability ,Torodelivers

replacementpartsdesignedtotheexactengineering

specicationsofourequipment.Forpeaceofmind,insist

onTorogenuineparts.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Removeequipmentfromthetruckortrailerandaddfuel

tothemachineitontheground.Ifthisisnotpossible,

thenrefuelsuchequipmentwithaportablecontainer,

ratherthanfromafuel-dispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

•Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

MaintenanceandStorage

•Disengagedrives,settheparkingbrake,shutoffthe

engine,andremovethekeyordisconnectthespark-plug

wire.Waitforallmovementtostopbeforeadjusting,

cleaningorrepairingthemachine.

•Cleangrassanddebrisfromthecuttingunit,thedrives,

themufers,andtheenginetohelppreventres.Clean

upoilorfuelspills.

•Lettheenginecoolbeforestoringanddonotstorenear

ame.

•Usefullwidthrampsforloadingmachineintotraileror

truck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

•Shutoffthefuelwhilestoringortransporting.Donot

storefuelnearamesordrainindoors.

•Parkthemachineonlevelground.Settheparkingbrake.

Neverallowuntrainedpersonneltoservicethemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatteryorthespark-plugwirebefore

makinganyrepairs.Disconnectthenegativeterminal

rstandthepositivelast.Connectthepositiverstand

negativelast.

5

Page 6

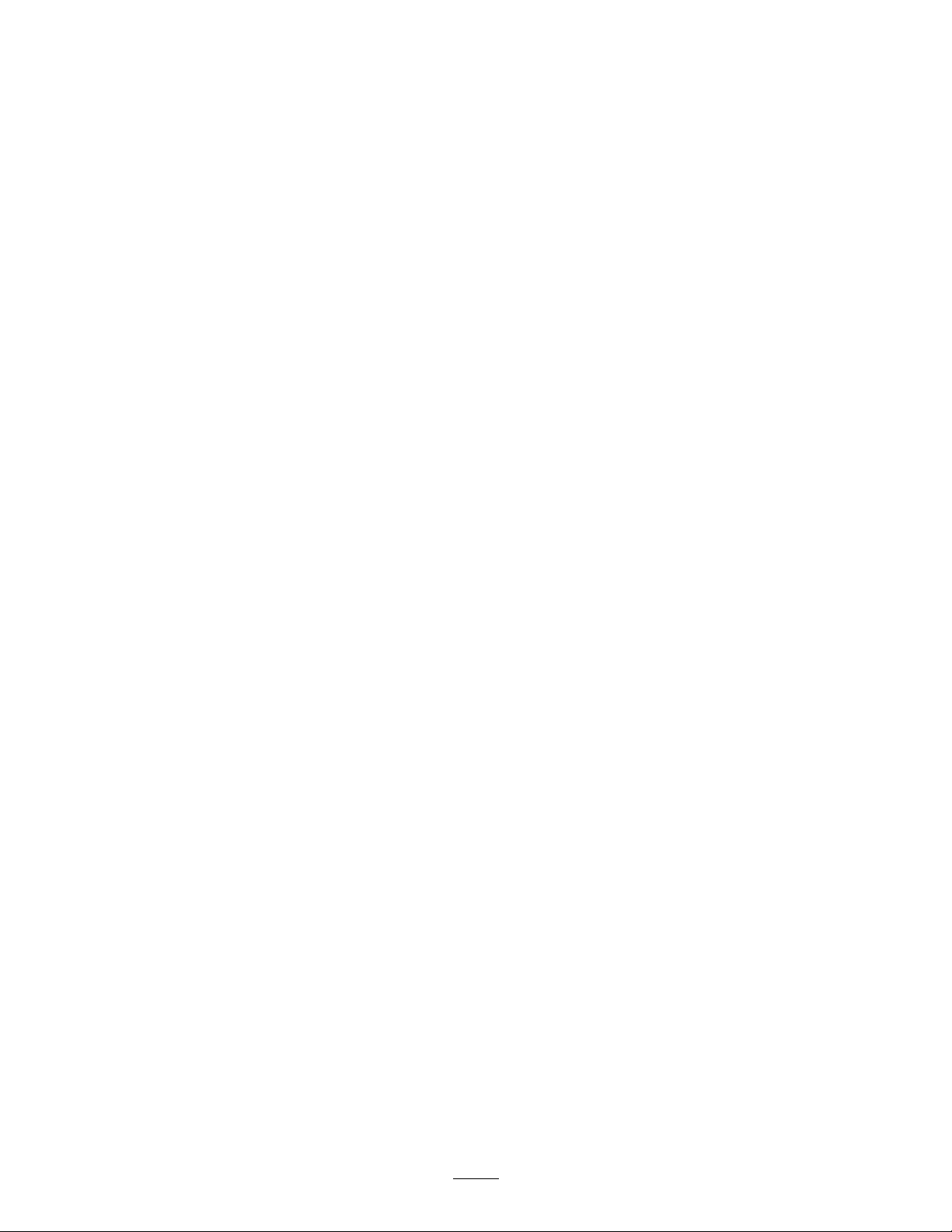

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

6

Page 7

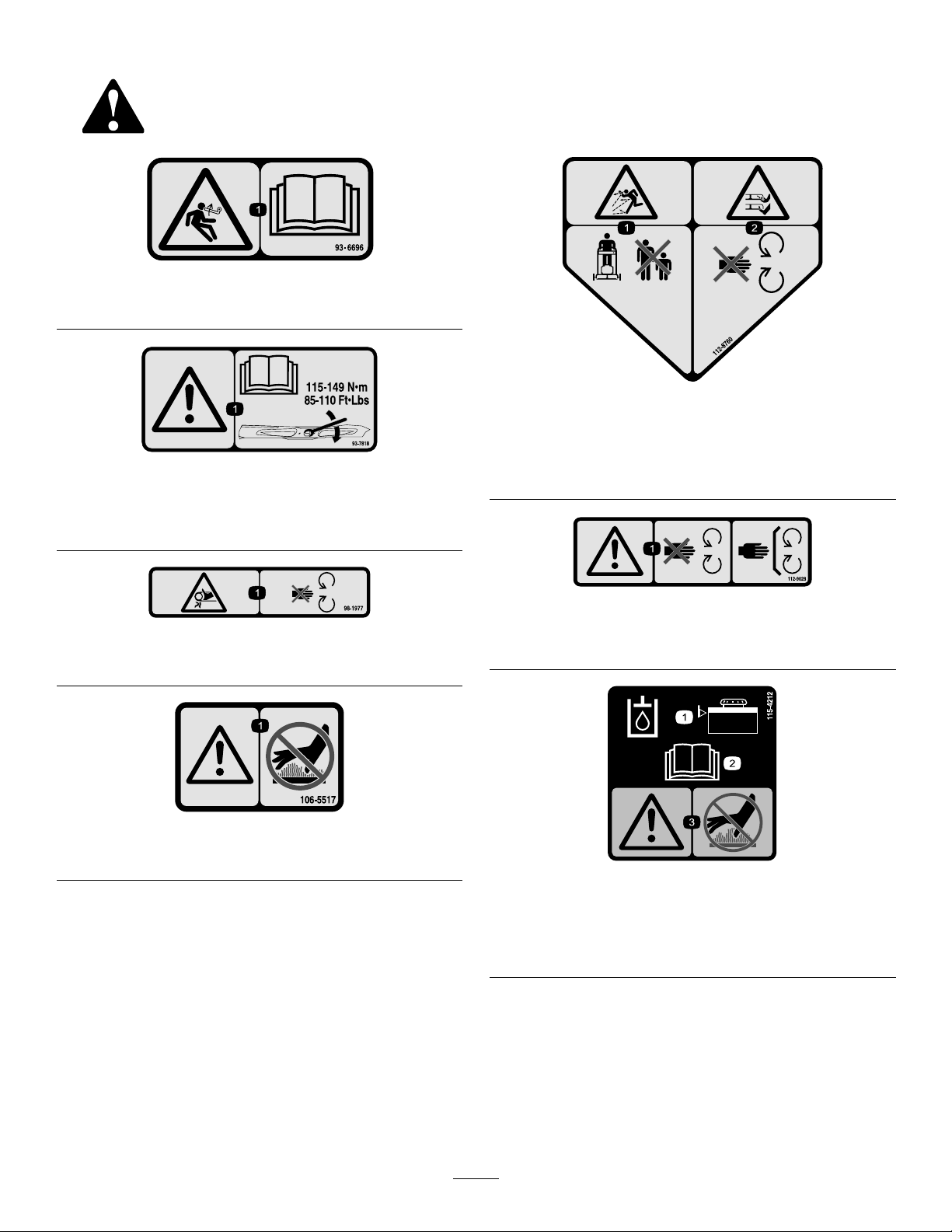

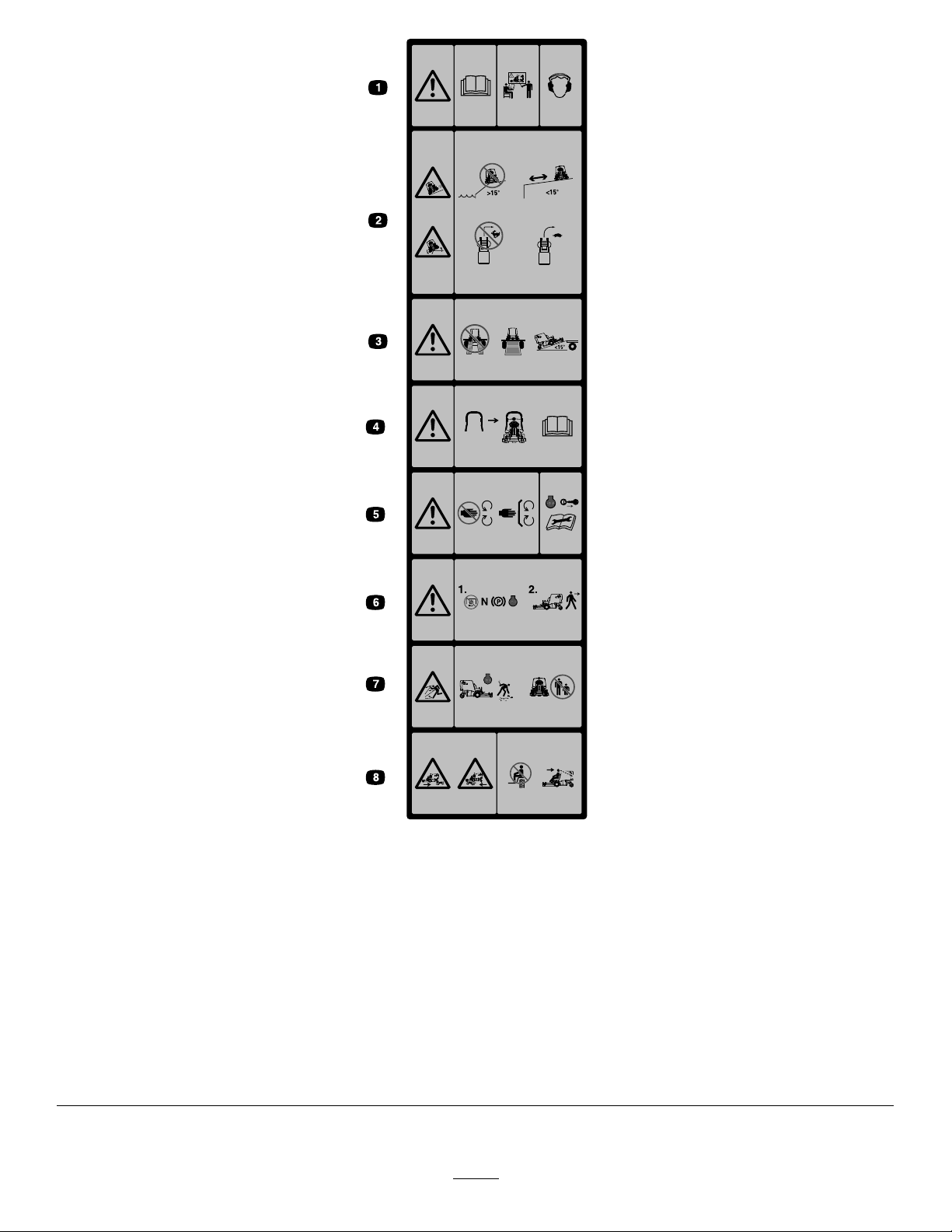

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

93–6696

1.Storedenergyhazard—readtheOperator'sManual.

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto1 15to149N∙m(85to110

ft-lb).

112-8760

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

98-1977

1.Entanglementhazard,belt—stayawayfrommovingparts.

106-5517

1.Warning—donottouchthehotsurface.

112-9028

1.Warning—stayawayfrommovingparts;keepallguardsin

place.

115-4212

1.Hydraulic-uidlevel

2.ReadtheOperator's

Manual.

3.Warning—donottouchthe

hotsurface.

7

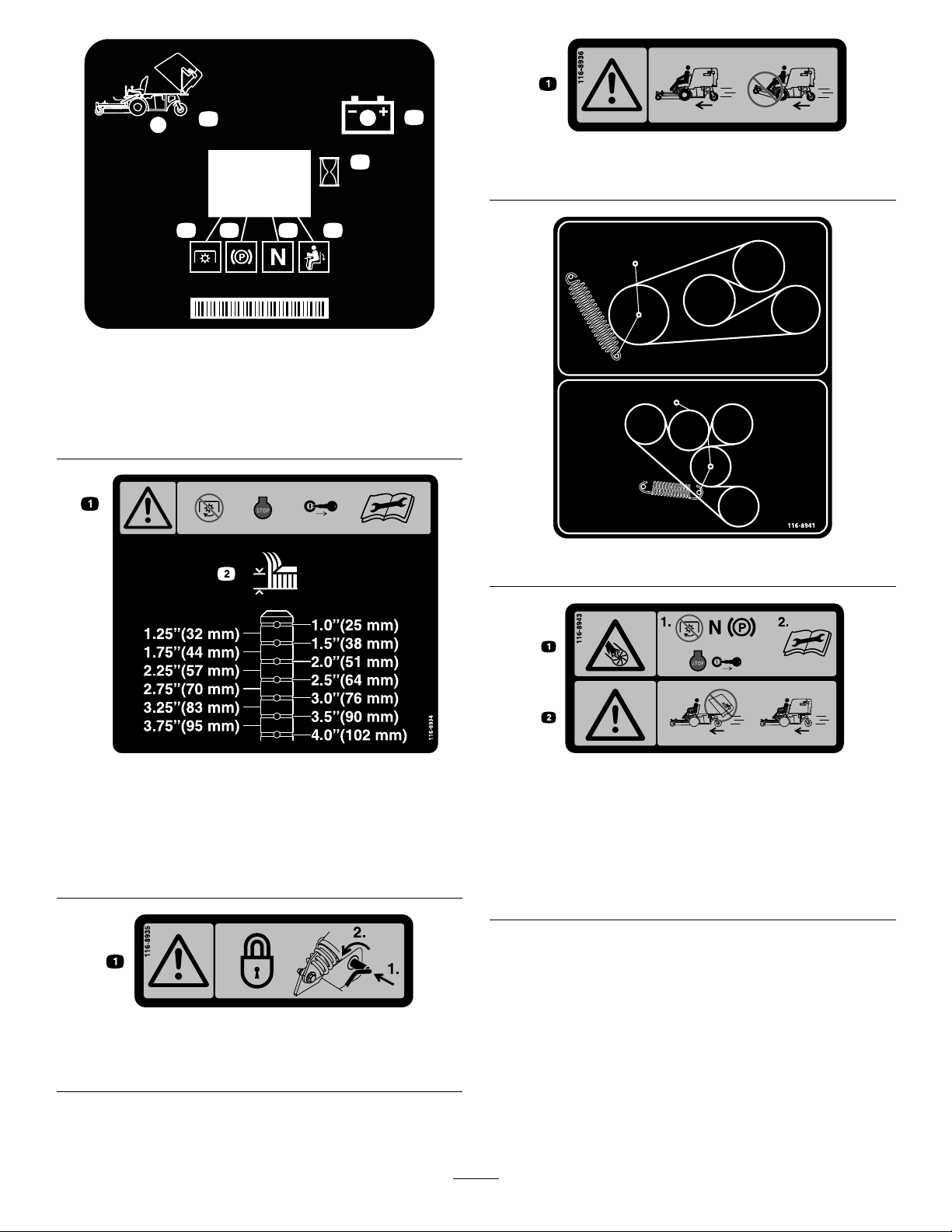

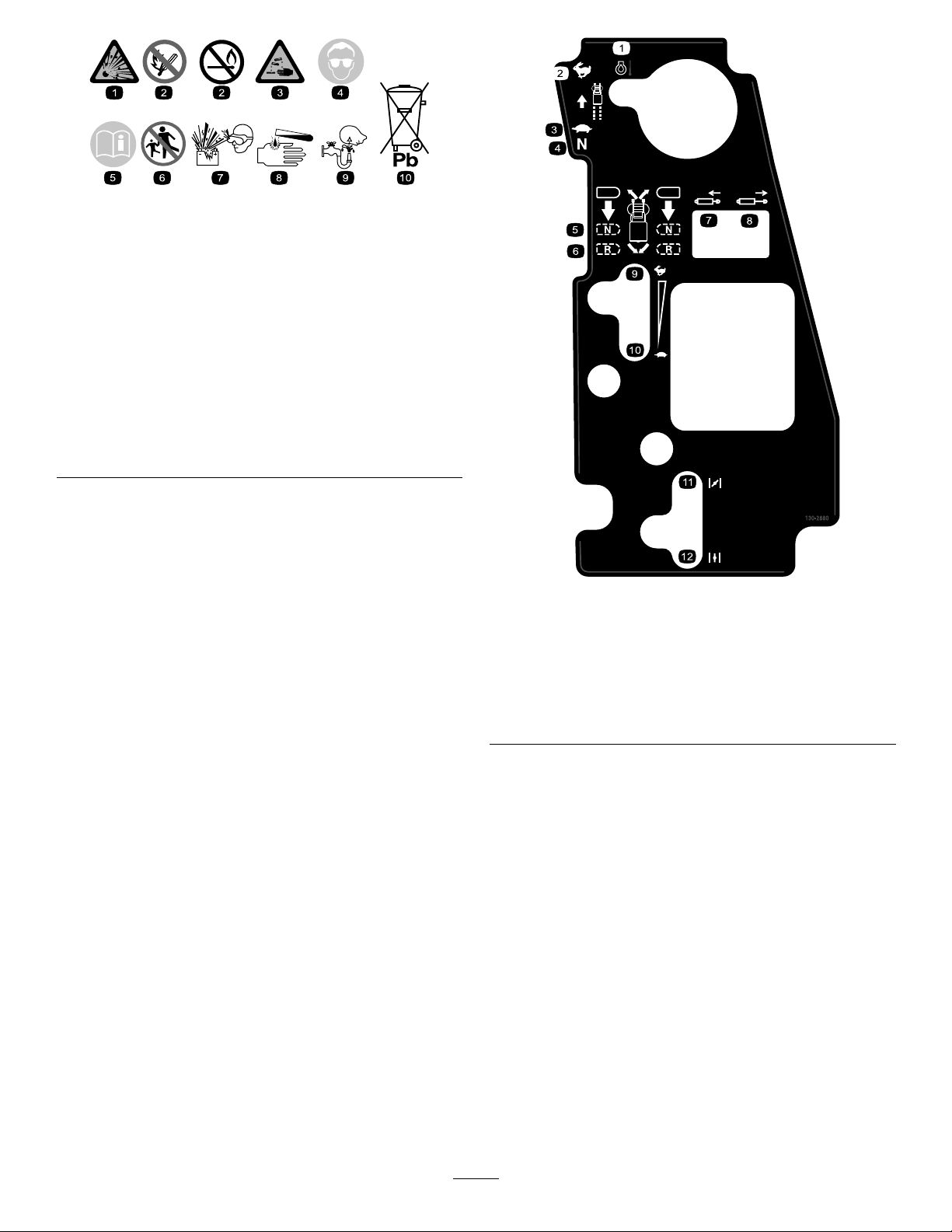

Page 8

NVXXXXXX

1

2

3

4 5 6 7

116-8813

1.Hopperupindicator5.Parkingbrake

2.Battery6.Neutral

3.Hourmeter

4.PTO

7.Operator-presenceswitch

116-8936

1.Danger—donotoperatewithdeckintilt-upposition.

116-8941

116-8934

1.Warning—disengage

bladeclutch,shutoff

theengine,andremove

thekeybeforemaking

adjustments,servicing,or

cleaningthedeck.

1.Warningfoldingdeckhazard—lockthepivotjointby

pushinginwardandrotatingtowardthefrontofthedeck.

116-8935

2.Heightofcut.

116-8943

1.Rotatingbladeshazard-DisengagePTO,movethe

speed-controllevertoNEUTRAL,engagetheparkingbrake,

shutofftheengine,andremovethekeybeforeleavingthe

operator’sposition.Readtheinstructionsbeforeservicing

orperformingmaintenance.

2.Danger—donotoperatewiththemowerhopperinthe

raisedposition.

8

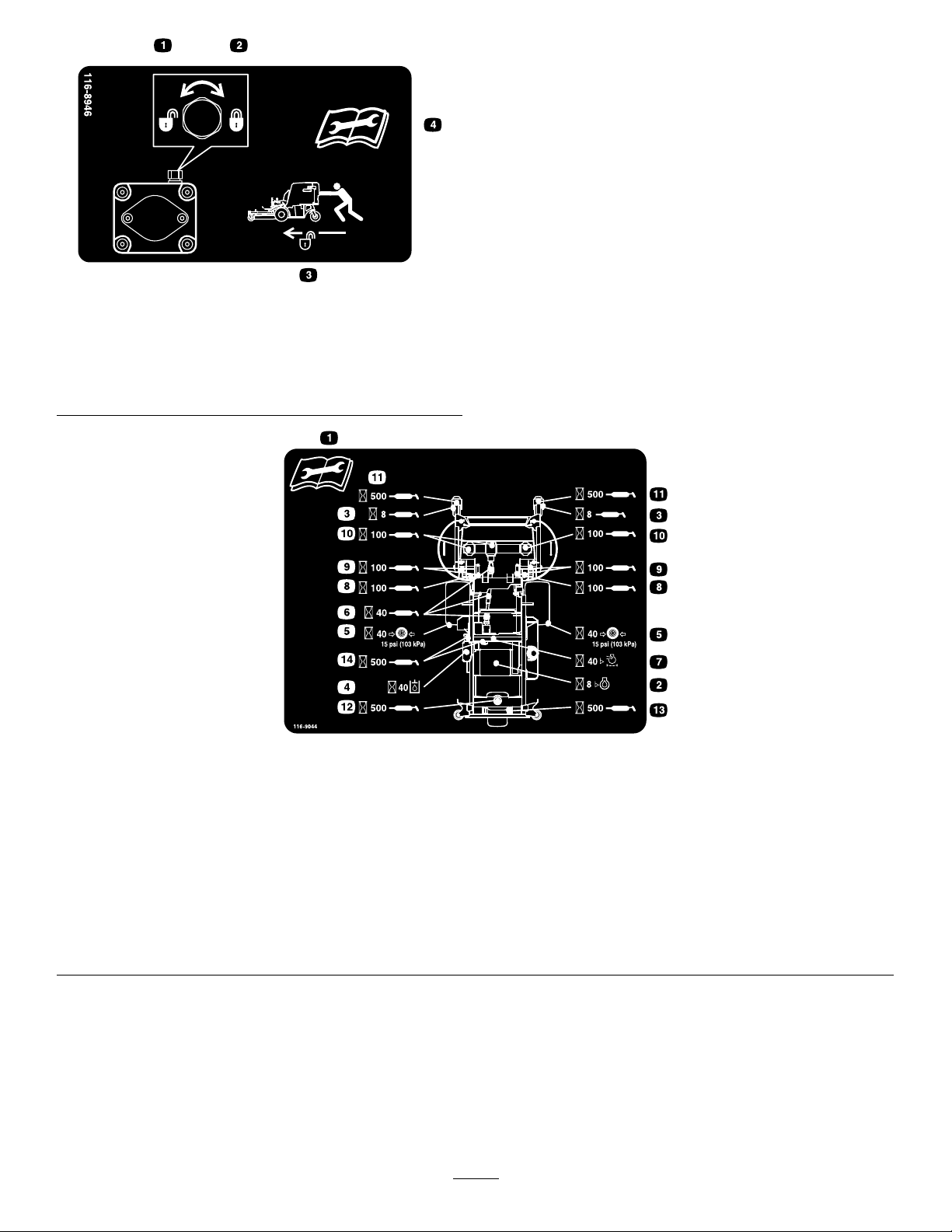

Page 9

116-8946

1.Rotatecounterclockwise

torelease

2.Rotateclockwisetolock4.Readtheinstructions

3.Unlocktopushthe

machine

beforeservicingor

performingmaintenance.

116-9044

1.ReadtheOperator’sManualbeforeperformingany

maintenance.

2.Checkengineoilevery8hours.9.Greasethedeckpivotsevery100hours.

3.Greasefrontcasterwheelbearingsevery8hours.10.Checkthegearboxoilevery100hours(useonlyMobil1

4.Checkthehydraulic-uidlevelevery40hours(onlyuse

recommendedhydrooil).

5.Checkthetirepressureevery40hours.12.Greasetherearcasterpivotevery500hours.

6.GreasethedeckdrivePTOevery40hours.13.Greasetherearcasterwheelevery500hours.

7.Checktheaircleanerevery40hours.14.Greasethebeltidlersevery500hours.

8.Greasethedecklockmechanismevery100hours.

75W-90gearoil).

11.Greasethefrontcasterpivotsevery500hours.

9

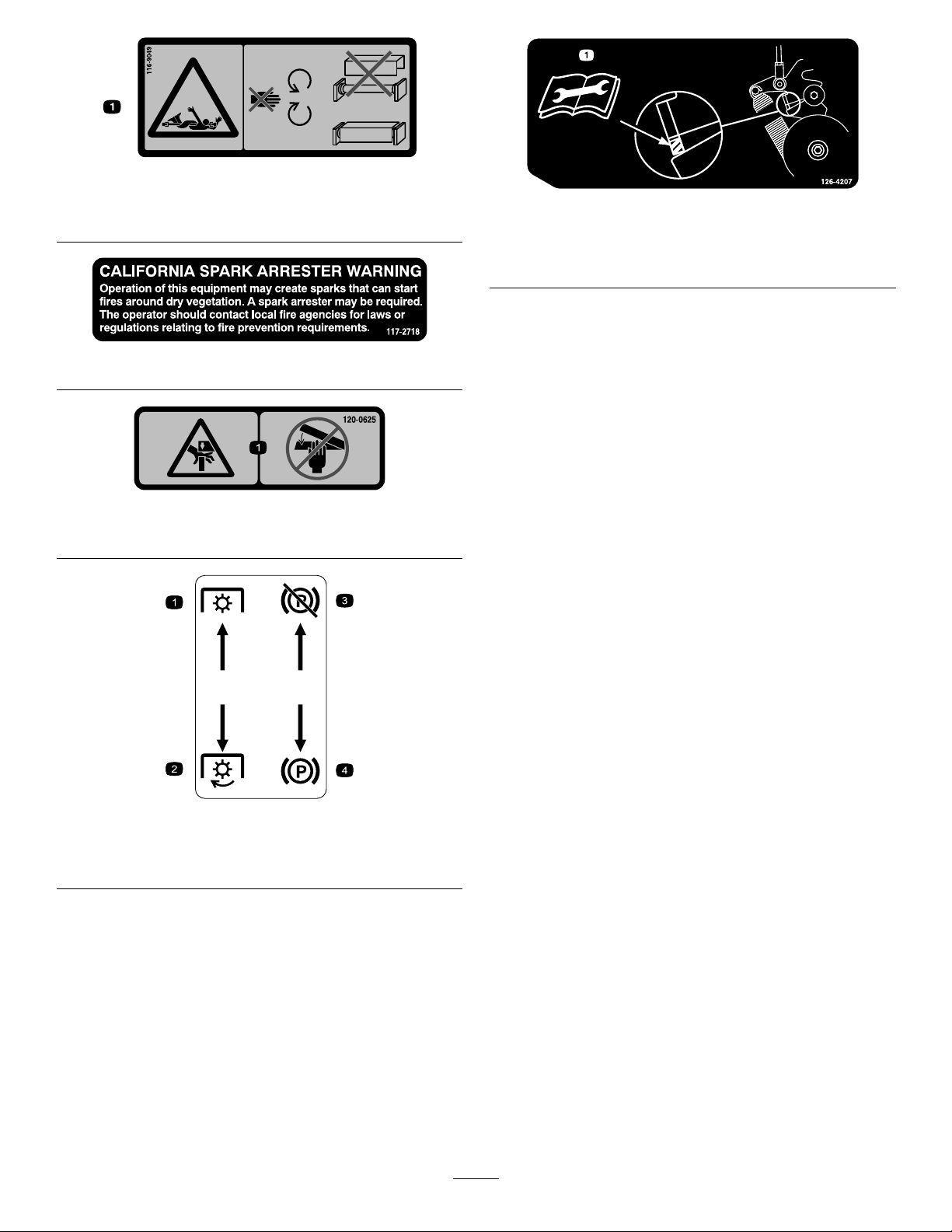

Page 10

116-9049

1.Rotatingdrivelinehazard—keepalldrivelinesshieldsin

place.Securelyattachbothendsofthedriveline.

117–2718

120-0625

1.Pinchpoint,hand—keephandsaway.

126-4207

1.RefertotheOperator’sManualforadjustmentprocedure.

WhenthePTOisengaged,theidlerarmpositionmustbe

inhatchedareaoranadjustmentisrequired.

MoldedinLHConsole

1.PTO—disengage

2.PTO—engage

3.Parkingbrake—release

4.Parkingbrake—engage

10

Page 11

MoldedintoFrontofHopper

1.Warning—ReadtheOperator’sManual.Donotoperatethis

machineunlessyouaretrained.Wearhearingprotection.

2.Sliding,tippinghazard—Donotusethemachinenear

drop-offswithslopesgreaterthan15degrees,usethe

machineasafedistanceformdrop-offsonslopeslessthan

15degrees;Donotturnsharplywhiletravelingfast,drive

slowlywhenturning.

3.Warning—Donotusedualramps,useonepiecerampswhen

transportingmachine;Donotuserampswithinclination

greaterthan15degrees.

4.Arollbarisavailable;useitforareaswherethereareslopes,

drop-offs,orwater.

5.Warning—Stayawayfrommovingparts;keepallguards

inplace.Shutofftheengineandremovethekeybefore

adjusting,servicing,orcleaning.

6.Warning—DisengagethePTO,movethespeed-controllever

toNEUTRALposition,engagetheparkingbrake,andshutoff

theenginebeforeleavingtheoperator’sposition.

7.Thrownobjecthazard—Pickupobjectsthatcouldbethrown

bymower.Donotoperatewhenpeopleandpetsareinthe

area.Keepthedeectorinplace.

8.Crushing/dismembermenthazardofbystanders—Donot

carrypassengers,andlookforwardanddownwhenoperating

themachine,andlookbehindanddownwhenreversing.

11

Page 12

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries.

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard

130-2880

1.Enginetemperature7.Retractthepiston

2.Fast8.Extendthepiston

3.Slow

4.Neutral

5.Neutral

6.Reverse

9.Fast

10.Slow

11.Choke—closed/on

12.Choke—open/off

12

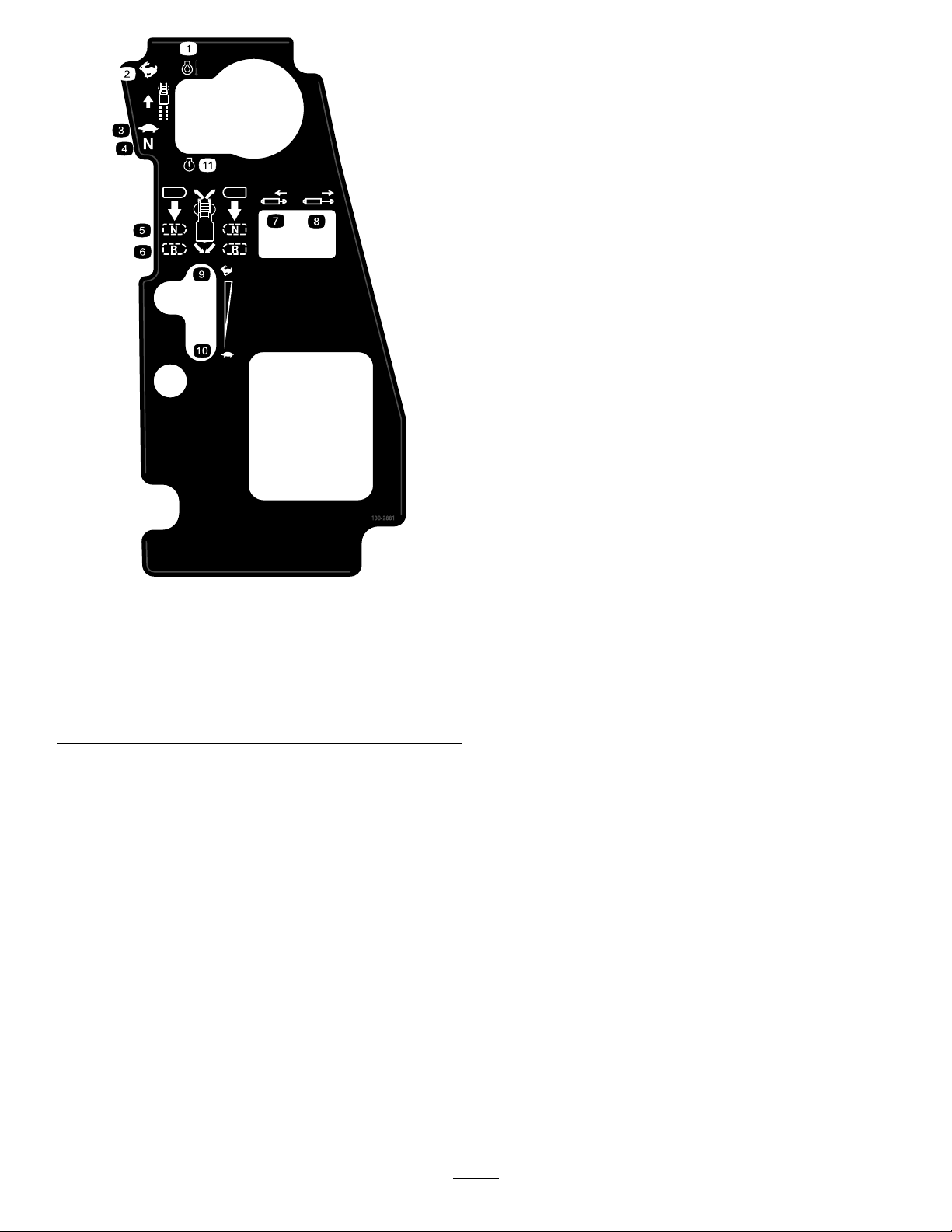

Page 13

130–2881

1.Enginetemperature7.Retractthepiston

2.Fast8.Extendthepiston

3.Slow

4.Neutral

5.Neutral11.MILtoggleswitch

6.Reverse

9.Fast

10.Slow

13

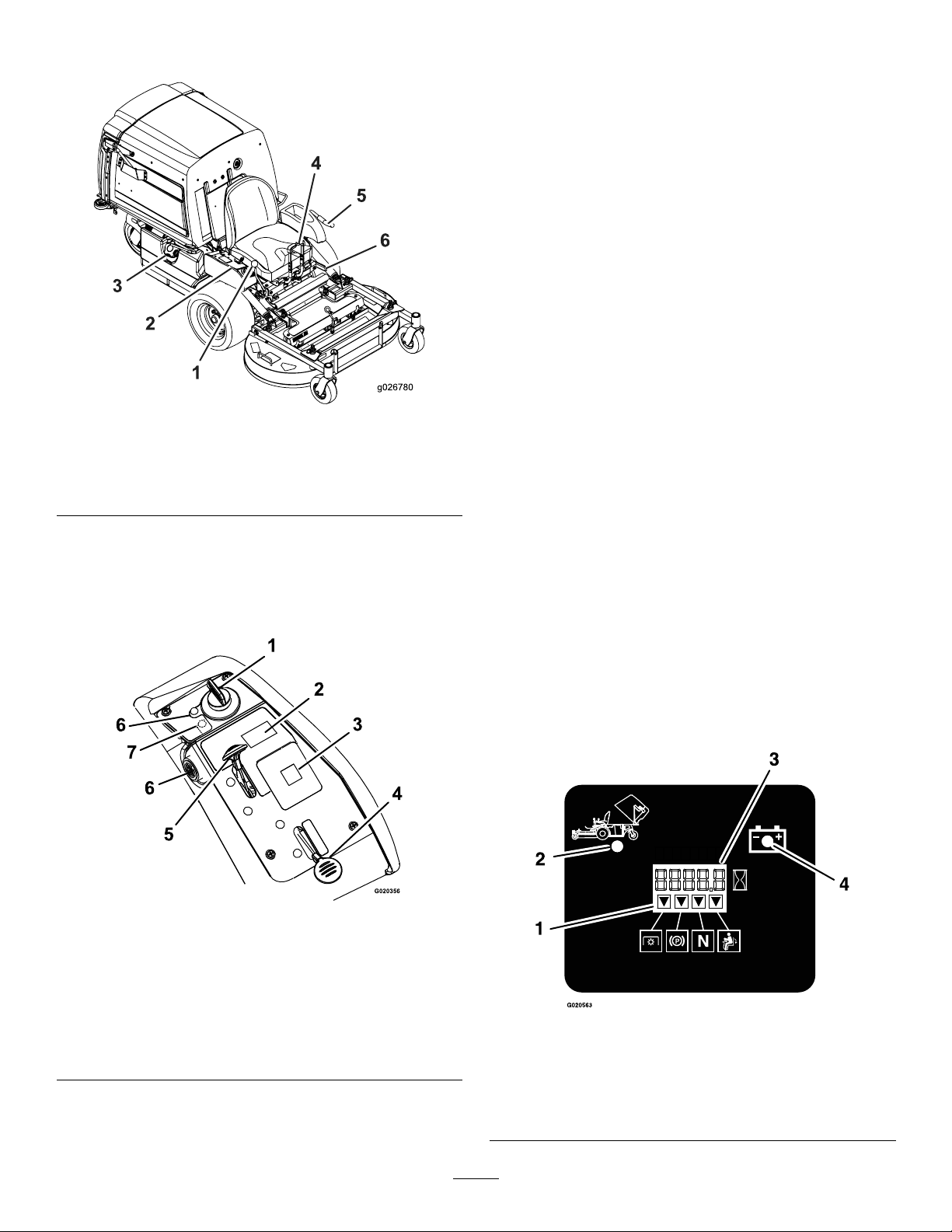

Page 14

ProductOverview

Motion-ControlLevers

Themotion-controlleversareusedtodrivethemachine

forward,reverse,andturneitherdirection(Figure4).

Speed-ControlLever

Thespeed-controlleversetsmaximumforwardspeedofthe

machine(Figure4).Movingspeed-controlleverrearwardto

theNEUTRALpositionplacesthedrivesystemintoneutral.

ThrottleControl

Thethrottleisusedtocontrolenginespeed.Thethrottle

controlisvariablebetweenFASTandSLOW.

ChokeControl(NotonEFImachines)

Thechokeisusedtoaidinstartingacoldengine.Movethe

choketotheCLOSED/ONpositiontostartacoldengine.

Figure4

1.Speed-controllever

2.Controls5.PTO-engagementlever

3.Fuelcap6.Parking-brakelever

4.Motion-controllevers

Controls

Becomefamiliarwithallthecontrolsbeforeyoustartthe

engineandoperatethemachine(Figure4andFigure5).

Note:DonotrunawarmenginewithchokeintheON

position.

BrakeLever

Thebrakeleverengagesaparkingbrakeonthedrivewheels

(Figure4).

IgnitionSwitch

Thisswitchisusedtostartthemowerengineandhas3

positions:START,RUN,andOFF.

HourMeter

Thehourmeterrecordsthenumberofhourstheenginehas

operated.Thehourmeterisrecordingwhenthedecimal

pointisashinginthehour/voltagedisplay.Usethesetimes

forschedulingregularmaintenance(Figure6).

Figure5

1.Ignitionswitch5.Throttle

2.Hopperswitch6.Engine-oiltemperature

3.Messagedisplay

4.Choke(notonEFI

machines)

7.Checkenginelight(EFI

lightandbuzzer

machinesonly)

Figure6

1.Safety-interlockindicators

2.Hopperup

3.Hour/voltagedisplay

4.Lowvoltageindicatorlight

14

Page 15

Safety-InterlockIndicators

Specications

Therearesymbolsonthehourmeterandtheindicatewitha

blacktrianglethattheinterlockcomponentisinthecorrect

position(Figure6).

Fuel-ShutoffValve

Closethefuel-shutoffvalve(underthehopper)when

transportingorstoringthemower.

PTO-EngagementLever

ThePTO-engagementleverisusedtoengagethebladesand

theblower.Pulltheleveruptoengagethebladesandblower.

Todisengagethebladesblower,pushthePTO-engagement

leverdown.

BatteryIndicatorLight

WhentheignitionkeyisinitiallyturnedtotheRUNposition

forafewseconds,thebatteryvoltagewillbedisplayedinthe

areawherethehoursarenormallydisplayed.

Thebatterylightturnsonwhentheignitionisturnedonand

whenthechargeisbelowthecorrectoperatinglevel(Figure

6).

EngineOilTemperatureLightand

Buzzer

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

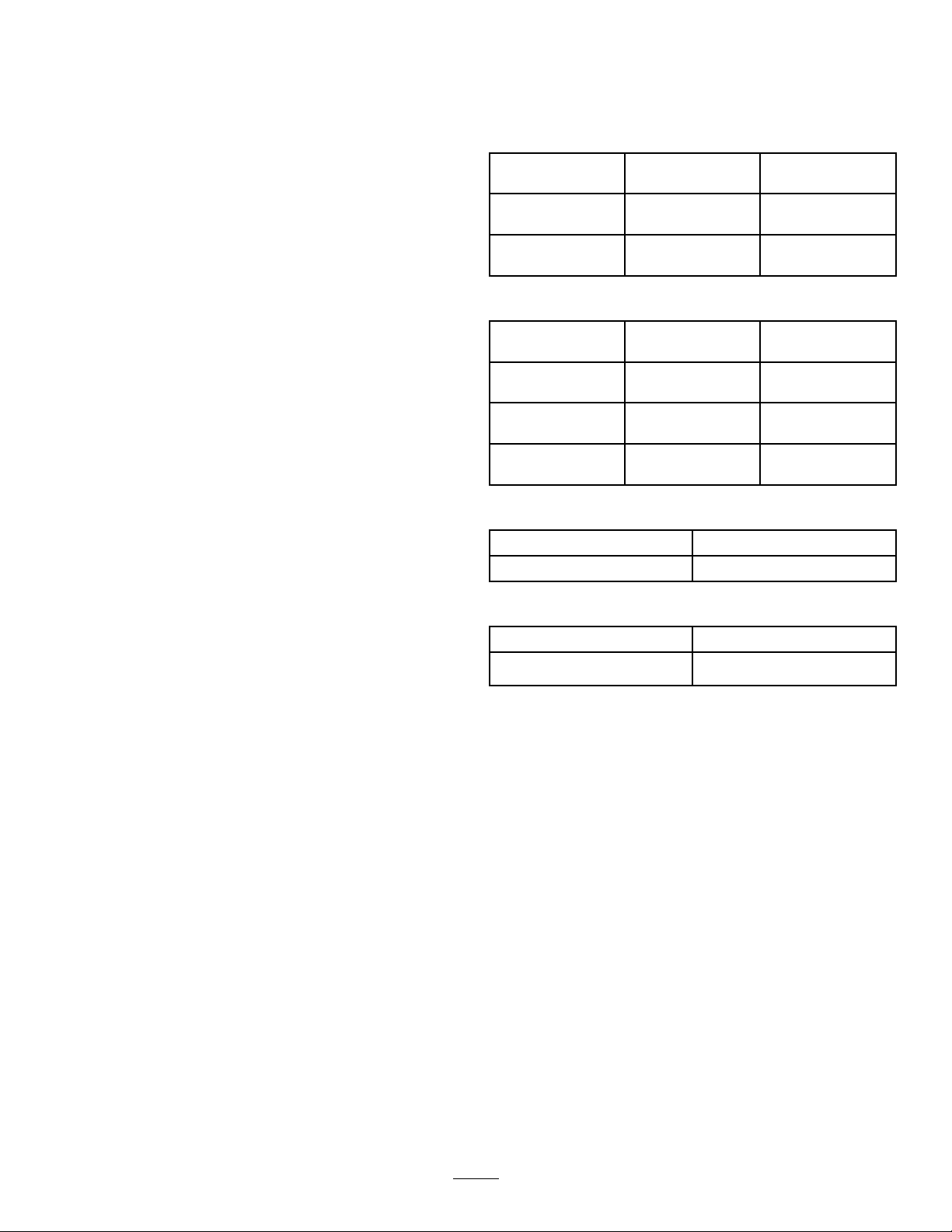

Width:

WithoutMower

Deck

WithMowerDeck

42-inchMower

Deck

108.2cm(42.6

inches)

109.7cm(43.2

inches)

48-inchMower

Deck

108.2cm(42.6

inches)

125.0cm(49.2

inches)

Length:

42-inchMower

Deck

WithoutMower

Deck

MowerDeck—Up

Mower

Deck—Down

170.9cm(67.3

inches)

209.3cm(82.4

inches)

233.2cm(91.8

inches)

48-inchMower

Deck

170.9cm(67.3

inches)

207.6cm(81.8

inches)

240.0cm(94.5

inches)

Height:

42-inchMowerDeck48-inchMowerDeck

130.0cm(51.2inches)130.0cm(51.2inches)

Weight:

Theengineoiltemperaturelightmonitorsthetemperatureof

theengineoil.Anilluminatedengineoiltemperaturelightand

intermittentbuzzingsoundsignalstheengineisoverheating.

ElectronicControlUnitMalfunction

IndicatorLight

Theelectroniccontrolunit(ECU)continuouslymonitorsthe

operationoftheEFIsystem.

Ifthesystemdetectsaproblemorfault,themalfunction

indicatorlight(MIL)illuminates.

TheMILislocatedintherightconsolepanel.

IftheMILilluminates,performtheinitialtroubleshooting

checks;refertotheMILsectioninTroubleshooting(page57).

Ifthesechecksdonotcorrecttheproblem,furtherdiagnosis

andservicingbyanAuthorizedServiceDealerisnecessary.

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

42-inchMowerDeck48-inchMowerDeck

517kg(1,140lb)531kg(1,170lb)

15

Page 16

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

DANGER

Incertainconditionsduringfueling,static

electricitycancauseasparkwhichcanignitethe

gasolinevapors.Areorexplosionfromgasoline

canburnyouandothersandcandamageproperty.

AddingFuel

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontainsmore

than10%ethanolbyvolume,suchasE15(contains15%

ethanol),E20(contains20%ethanol),orE85(contains

upto85%ethanol).Usingunapprovedgasolinemay

causeperformanceproblemsand/orenginedamage,

whichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessyouuseafuelstabilizer.

•Donotaddoiltogasoline.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2inch)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithouttheentireexhaust

systeminplaceandinproperworkingcondition.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbed,becauseinteriorcarpets

orplastictruck-bedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandfueltheequipment

withthewheelsontheground.

•Ifthisisnotpossible,thenfuelsuchequipment

onatruckortrailerfromaportablecontainer,

ratherthanfromagasoline-dispensernozzle.

•Ifagasolinedispensermustbeused,keepthe

nozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingis

complete.

WARNING

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditionerbottleopening.

•Avoidcontactwithskin;washoffspillswith

soapandwater.

UsingFuelStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetokeep

thefuelfreshduringstorageof90daysorless.Ifyouare

storingthemachineforlonger,drainthefueltank;seeyour

authorizedservicedealer.

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountoffuelstabilizer/conditionertothe

fuel,andfollowthedirectionsofthemanufacturer.

Note:Fuelstabilizer/conditionerismosteffectivewhen

mixedwithfreshgasoline.Tominimizethechanceofvarnish

depositsinthefuelsystem,usefuelstabilizeratalltimes.

16

Page 17

FillingtheFuelTank

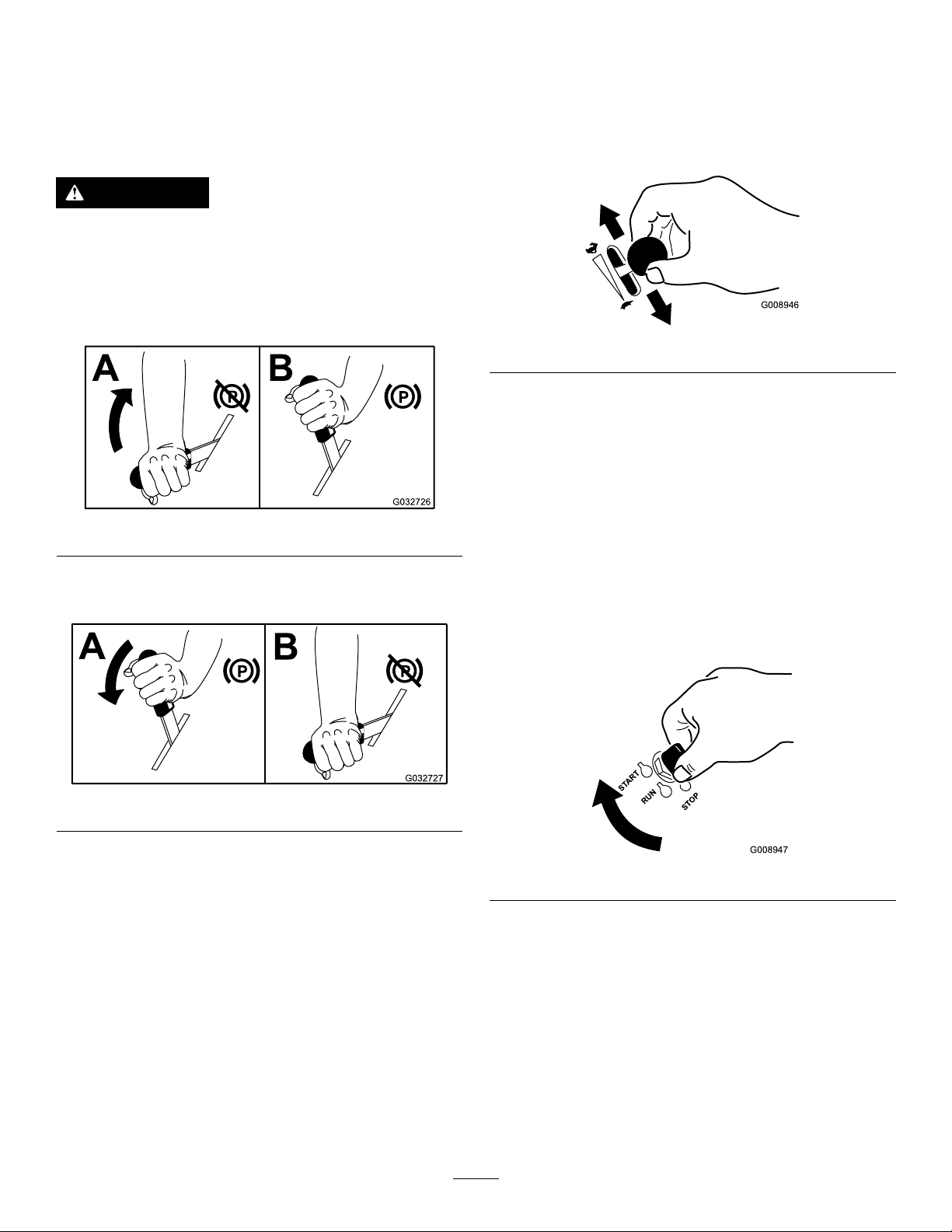

G009027

1

2

1.Parkthemachineonlevelground.

2.Shuttheengineoffandsettheparkingbrake.

3.Cleanaroundthefuel-tankcapandremoveit.Add

regularunleadedgasolinetothefueltankuntilthelevel

is6to13mm(1/4to1/2inch)belowthebottom

ofthellerneck.Thisspaceinthetankallowsthe

gasolinetoexpand.Donotllthefueltankcompletely

full;referto(Figure4).

CheckingtheEngine-OilLevel

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoCheckingthe

Engine-OilLevel(page33).

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mowerdecks

anddrivesystemshavehigherfrictionwhennew,placing

additionalloadontheengine.Allow40to50hoursof

break-intimefornewmachinestodevelopfullpowerand

bestperformance.

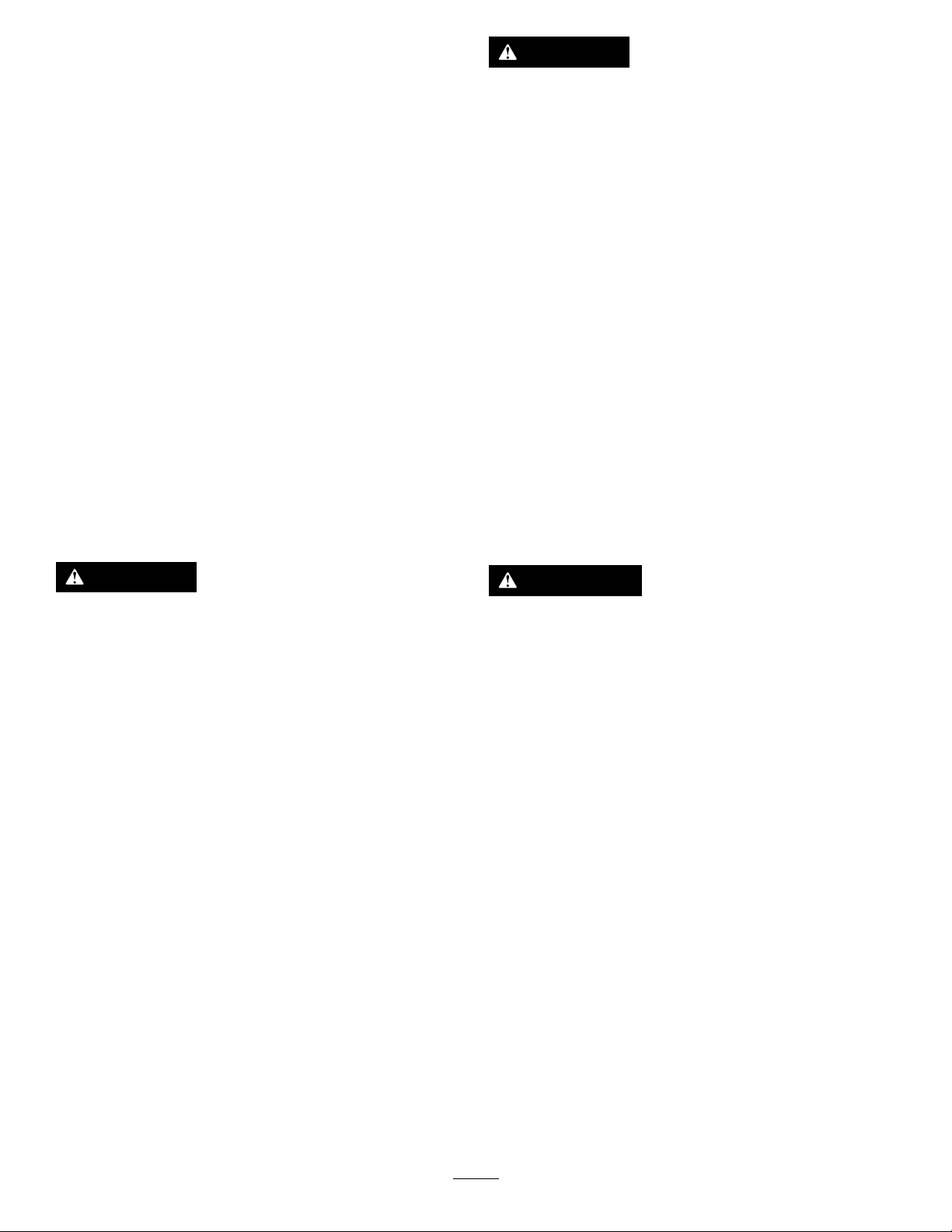

1.Safezone—usethe

machinehereonslopes

lessthan15degreesor

atareas.

2.Dangerzone—useawalk

behindmowerand/ora

handtrimmeronslopes

greaterthan15degrees,

neardrop-offsandwater.

CAUTION

Figure7

3.Water

ThinkSafetyFirst

Pleasereadallsafetyinstructionsandsymbolsinthesafety

section.Knowingthisinformationcouldhelpyouor

bystandersavoidinjury.

DANGER

Operatingonwetgrassorsteepslopescancause

slidingandlossofcontrol.

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,death,or

drowning.

Toavoidlossofcontrolandpossibilityofrollover:

•Donotoperateneardrop-offsornearwater.

•Donotoperateonslopesgreaterthan15degrees.

•Reducespeedanduseextremecautionon

slopes.

•Avoidsuddenturnsorrapidspeedchanges.

Thismachineproducessoundlevelsinexcessof

85dBAattheoperator’searandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Theuseofprotectiveequipmentforeyes,ears,feet,andhead

isrecommended.

Figure8

1.Weareyeprotection.2.Wearhearingprotection.

17

Page 18

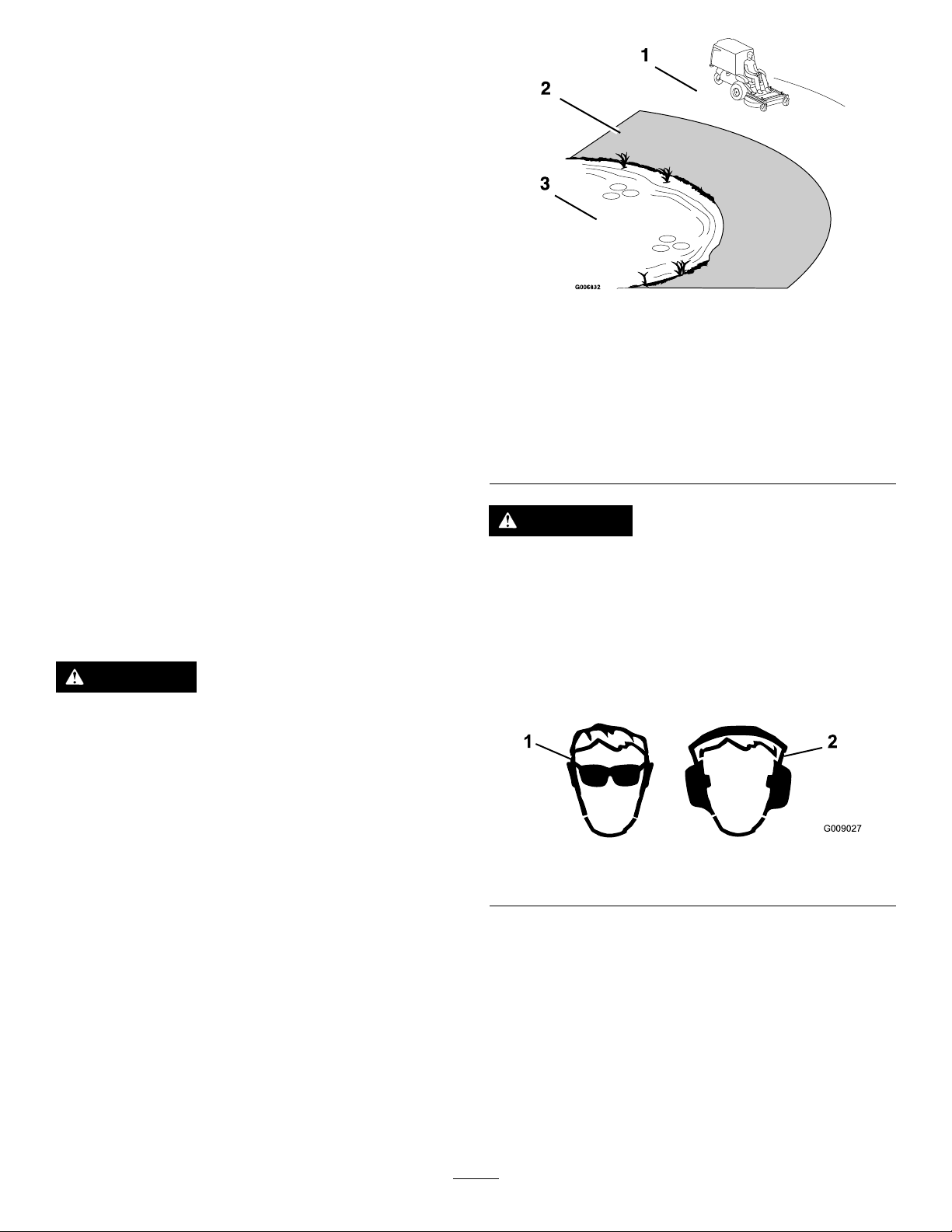

OperatingtheParkingBrake

G008946

START

RUN

STOP

G008947

OperatingtheThrottle

Alwayssettheparkingbrakewhenyoustopthemachineor

leaveitunattended.

SettingtheParkingBrake

WARNING

Theparkingbrakemaynotholdmachineparkedon

aslopeandcouldcausepersonalinjuryorproperty

damage.

Donotparkonslopesunlessthewheelsare

chockedorblocked.

Figure9

ReleasingtheParkingBrake

ThethrottlecontrolcanbemovedbetweentheFASTand

SLOWpositions(Figure11).

Alwaysusethemiddlepositionwhenturningonthemower

deckandblowerwiththePTO-engagementlever.

Figure11

OperatingtheIgnitionSwitch

1.TurntheignitionkeytotheSTARTposition(Figure

12).Whentheenginestarts,releasethekey.

Important:Donotengagethestarterformore

than10secondsatatime.Iftheenginefailsto

start,allowa60secondcool-downperiodbetween

attempts.Failuretofollowtheseinstructionscan

burnoutthestartermotor.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthefuel

systemhasbeencompletelywithoutfuel.

Figure10

Figure12

2.Toshutofftheengine,turntheignitionkeytothe

STOPposition.

18

Page 19

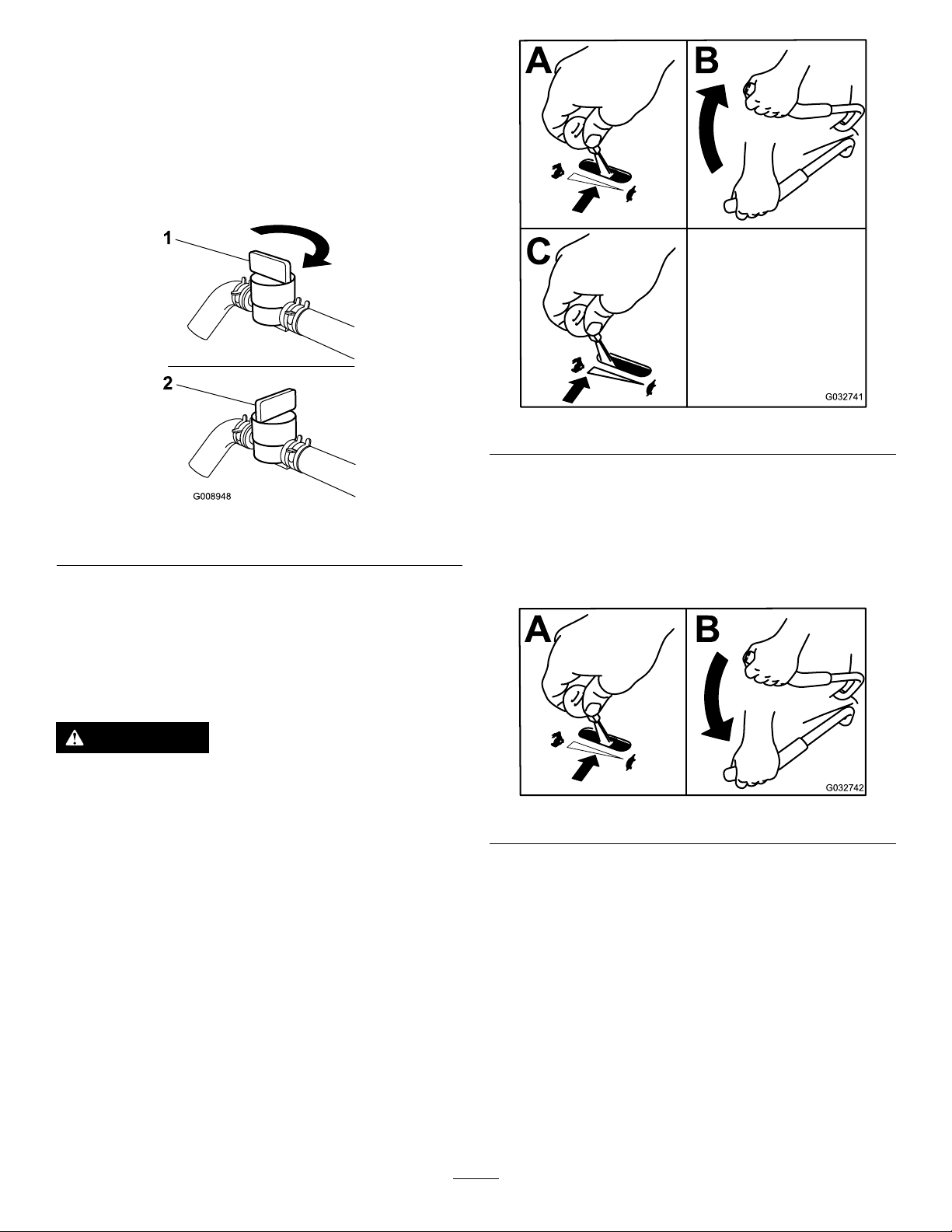

UsingtheFuel-ShutoffValve

G008948

1

2

Thefuel-shutoffvalveislocatedunderthehopper.Raisethe

hoppertoaccessit.

Closethefuel-shutoffvalvefortransport,maintenance,and

storage.

Ensurethatthefuel-shutoffvalveisopenwhenstartingthe

engine.

Figure13

1.On2.Off

Figure14

DisengagingthePTO-Engagement

Lever

1.SetthethrottletotheMIDDLEposition.

2.PushPTOleverdowntotheSTOPpositionstopping

thebladesandblower.

Operatingthe PTO-EngagementLever

ThePTO-engagementleverstartsandstopsthemower

bladesandblower.

WARNING

Anuncovereddischargeopeningallowsobjectsto

bethrownatyouorbystanders.Also,contactwith

theblowerbladescouldoccur.Thrownobjectsor

bladecontactcancauseseriousinjuryordeath.

Neveroperatethemachinewiththehopperor

hopperdoorraised,removed,oraltered.

EngagingthePTO-EngagementLever

1.SetthethrottletotheMIDDLEposition.

2.PullthePTOleverupwarduntillockedovercenter.

3.PlacethethrottleintheFASTpositiontobeginmowing.

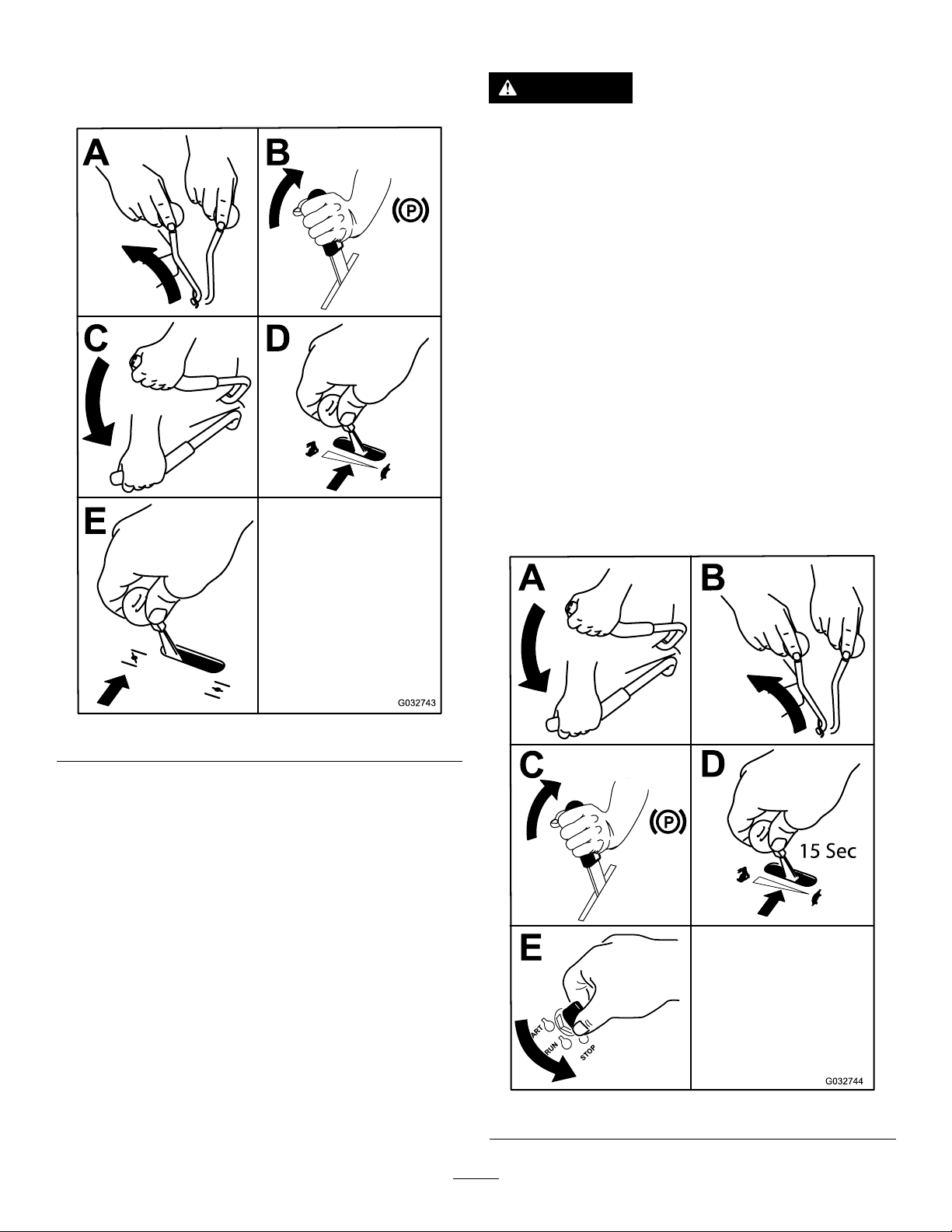

StartingandStoppingthe Engine

StartingtheEngine

1.Movethespeed-controllevertotheNEUTRALposition.

2.Settheparkingbrake;refertoSettingtheParking

Brake(page18).

Figure15

3.MovethePTO-engagementlevertotheOFFposition

(Figure16).

4.MovethethrottlelevermidwaybetweentheSLOWand

FASTpositions.

19

Page 20

5.Onacoldengine,pushthechokeleverforwardinto

theCLOSED/ONposition(notonEFIengines).On

awarmengine,leavethechokeintheOPEN/OFF

position.

StoppingtheEngine

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

Important:Makesurethatthefuel-shutoffvalveis

closedbeforetransportingorstoringthemachine,as

fuelleakagemayoccur.Settheparkingbrakebefore

transporting.Makesurethatyouremovethekeyasthe

fuelpumpmayrunandcausethebatterytolosecharge.

1.DisengagethePTO.

2.Movethespeed-controllevertotheNEUTRALposition.

3.Engagetheparkingbrake.

4.Placethethrottletothemiddleposition.

5.Allowtheenginetorunforaminimumof15seconds,

thenturntheignitionswitchtotheOFFpositionto

shutofftheengine.

6.Removethekey.

Figure16

6.TurntheignitionkeytotheSTARTposition(Figure

12).Whentheenginestarts,releasethekey.

Important:Donotcranktheenginecontinuously

formorethan10secondsatatime.Iftheengine

doesnotstart,wait60secondsbetweenstarting

attempts.Failuretofollowtheseguidelinescan

burnoutthestartermotor.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthefuel

systemhasbeenwithoutfuelcompletely.

7.IfthechokeisintheCLOSED/ONposition,gradually

returnchoketotheOPEN/OFFpositionastheengine

warmsup.

Figure17

20

Page 21

7.Closethefuelshut-offvalvewhenyoudonotusethe

machineforafewdays,whentransporting,orwhen

youparkthemachineinsideabuilding.

TheSafetyInterlockSystem

CAUTION

Ifthesafetyinterlockswitchesaredisconnectedor

damaged,themachinecouldoperateunexpectedly,

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

UnderstandingtheSafetyInterlock

System

Thesafetyinterlocksystemisdesignedtopreventtheengine

fromstartingunlessthefollowingoccurs:

•Theparkingbrakeisengaged.

•ThePTO-engagementleverisdisengaged.

•Thespeed-controlleverisintheNEUTRALposition.

Thesafetyinterlocksystemisdesignedtoshutofftheengine

whenyourisefromtheseatwhenthePTOisengaged.

Thehourmeterhassymbolstonotifytheuserwhenthe

interlockcomponentisinthecorrectposition.Whenthe

componentisinthecorrectposition,atrianglelightsupin

thecorrespondingsquare.

TestingtheSafetyInterlockSystem

ServiceInterval:Beforeeachuseordaily

Testthesafetyinterlocksystembeforeyouusethemachine

eachtime.Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthesafety

systemimmediately.

1.Sittingontheseat,engagetheparkingbrake,move

thePTO-engagementlevertoON,andmovethe

speed-controllevertotheNEUTRALposition.Try

startingtheengine;theengineshouldnotcrank.

2.Sittingontheseat,engagetheparkingbrakeand

movethePTO-engagementlevertoOFF.Movethe

speed-controlleveroutoftheNEUTRALposition.Try

startingtheengine;theengineshouldnotcrank.

3.Sittingontheseat,disengagetheparkingbrake,move

thePTO-engagementlevertoOFF,andmovethe

speed-controllevertotheNEUTRALposition.Try

startingtheengine;theengineshouldnotcrank.

4.Sittingontheseat,engagetheparkingbrake,move

thePTO-engagementlevertoOFF,andmovethe

speed-controllevertotheNEUTRALposition.Start

theengine.Whiletheengineisrunning,releasethe

parkingbrake,engagethePTO-engagementlever,and

riseslightlyfromtheseat;theengineshouldshutoff.

5.Sittingontheseat,engagetheparkingbrake,move

thePTO-engagementlevertoOFF,andmovethe

speed-controllevertotheNEUTRALposition.Start

theengine.Movethespeed-controlleverforward;the

engineshouldshutoff.

DrivingForwardorBackward

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placethethrottlecontrolin

theFASTpositionforbestperformance.Alwaysoperatein

thefullthrottlepositionwhenmowing.

Figure18

1.Triangleslightupwhen

theinterlockcomponents

areinthecorrectposition

2.Hopperup4.Lowvoltageindicatorlight

3.Hour/voltagedisplay

CAUTION

Machinecanspinveryrapidly.Youmaylosecontrol

ofmachineandcausepersonalinjuryordamage

tothemachine.

•Usecautionwhenmakingturns.

•Slowdownthemachinebeforemakingsharp

turns.

DrivingForward

Note:Tobeginmovement(forwardorbackward)youmust

beintheseat,thebrakelevermustbedisengaged(pushed

down)beforethespeed-controllevercanmoveforward;

otherwise,theengineshutsoff.

Tostopthemachine,pullthespeed-controllevertothe

NEUTRALposition.

1.Starttheengine.

21

Page 22

2.Releasetheparkingbrake;refertoReleasingthe

ParkingBrake(page18).

3.Tomoveforwardinastraightlinemovethe

speed-controlleverforward.

Note:Themachinemovesfasterthefartherthe

speed-controlleverismovedawayfromNEUTRAL.

4.Toturnleftorright,pull1ofthesteeringleversback

towardneutralinthedirectiondesired.

5.Tostopthemachine,pullthespeed-controlleverback

totheNEUTRALposition.

DrivingBackward

1.Tomoverearwardinastraightline,pullbothsteering

leversrearwardequally.

Toturnleftorright,releasepressureonthesteering

levertowardthedirectiondesired.

RaisingtheMowerDeckinto ServicePosition

1.Shutofftheengine,waitforallmovingpartstostop,

removethekey,andengagetheparkingbrake.

WARNING

Incorrectlyraisingorloweringamowerdeck

canbedangerous.Adroppedmowerdeckcan

resultinaseriousinjuryorpropertydamage.

•Alwaysraiseandlowerthemowerdeckon

at,dryground,freeofanyobstructions.

•Firmlygraspthemower-deck-lifthandle

andlowerinaslowcontrolledmanner.

•Alwaysmakesurethatthemowerdeckis

securelylatchedintheupordownposition.

2.Tostopthemachine,releasethesteeringleverstothe

NEUTRALposition.

StoppingtheMachine

1.Pullthespeed-controlleverbacktotheNEUTRAL

position,disengagethePTO-engagementlever,and

turntheignitionkeytotheOFFposition.

2.Settheparkingbrakewhenyouleavethemachine;

refertoSettingtheParkingBrake(page18).

3.Removethekeyfromtheignitionswitch.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

2.Releasethemowerdecklockingpinsoneachside

(Figure19).

Figure19

1.Deck-lifthandle

2.Rotatethemowerdecklockingpintowardtherearandpull

outwardtounlock.

3.Pushthedecklockingpininandrotateittowardthefront

tolock.

3.Usingthedeck-lifthandle,liftthedeckupandlatchit

intheupposition(Figure20).

Note:Thelatchislocatedatthefrontcenterofthe

seat.

22

Page 23

Figure20

•Bafesopenwithstandardblades—maximumcollection

•Bafesclosedwithstandardblades—partialmulching

•Bafesclosedwithmulchblades—intermediatemulching

•Mulchpluginstalledwithmulchblades—complete

mulching(requiresmulchkit)

1.Shutofftheengine,waitforallmovingpartstostop,

removethekey,andengagetheparkingbrake.

2.Removethehairpinsandclevispinsfrombothsidesof

thePTOguard(Figure21).

3.Foldtheguardforward.

1.Securethemower-deck

latchontothehook.

2.Hook

3.Deck-lifthandle

WARNING

EngagingthePTOwithadeckintheraised

positioncanresultinaseriousinjuryorproperty

damage.

Alwayslowerandlockmowerdeckintheoperating

positionbeforeengagingthePTO.

LoweringtheMowerDeckto theOperatingPosition

1.Whilermlyholdingontothedeck-lifthandle,unhook

themower-decklatchfromthemachineandslowly

lowerthemowerdecktotheground(Figure20).

2.Pushthedecklockingpinsinwardandrotatethem

forwardtosecurelylockthemowerdeckinthelowered

position(Figure19).

Figure21

1.Hairpinandclevispins

4.LoosenthelocknutsontherearstudsoftheFRS

bafes.

WARNING

Operatingmowerwithoutlockingpinssecurely

latchedcanresultinthemowerdeckfolding

upunexpectedly.Themowerdeckfoldingup

unexpectedlycancauseseriousinjury.

Alwaysoperatemowerwithlockingpinssecurely

latched.

AdjustingtheFillReduction

System(FRS)Bafes

Thellreductionsystemallowsyoutoreducetheamountof

clippingscollectedbyvaryingdegrees.

Theadvantagesincludelessfrequentemptyingofthehopper

andthereturnofnutrientstothesoil.

Thefollowingarepossiblecongurations:

Figure22

1.PTOguardremovedfor

clarity

5.Raisethemowerdeck;refertoRaisingtheMower

DeckintoServicePosition(page22).

6.RemovetheboltandwasheratthefrontofeachFRS

bafe(Figure23).

7.Rotatethebafesintothedesiredpositionandinstall

theboltandwasher.

23

2.Loosenlocknuts

Page 24

g025067

1

2

Figure24

Figure23

1.Bafesshowninclosedposition

2.Bafesshowninopenposition

3.Bolt

4.Washer

5.Bafes

8.Lowerthemowerdeck;refertoLoweringtheMower

DecktotheOperatingPosition(page23).

9.Slightlytightenthelocknutsontherearstudsofthe

FRSbafes.

Note:Thelocknutsontherearstudsmaybeleft

slightlylooseifyouexpecttoadjustthebafes

frequently.

10.InstallthePTOguardusingtheclevispinsandhair

pinsremovedinstep2.

AdjustingtheHeightofCut

Thecuttingheightofthemowerdeckisadjustedfrom2.5to

10.2cm(1to4inches)in6.3mm(1/4inch)increments.

1.Movethespeed-controllevertotheNEUTRALposition

tostopthemachine.

1.Cotterpin

2.Mower-deckhandle

EmptyingtheHopper

Afullhopperisindicatedbyabuzzerlocatedbehindthe

operatorinthehopper.Emptythehopperwhenthebuzzer

soundstopreventcloggingoftheblowerorthemowerdeck.

1.DisengagethePTO,movethespeedcontrolto

NEUTRAL,settheparkingbrake,anddismountthe

machinetodumpthehopper.

2.Makesurethatthemachineisonadry,levelsurface.

3.Liftthereardoorupandallowittorestontopof

hopper.

4.Usingthehandlesatthelowerfrontofthehopper,

raisethehoppertodumpthecontents.

5.Lowerthehopperandclosethehopperdoor.

ClearingtheHopperScreen

Removethescreenbyrmlyliftingthescreenhandles(Figure

25).

Pullthescreentowardthebacktoremoveit.Asneeded,

gentlytapthescreentoremovedebris.

Note:Excessivebuilduponthescreencancausetheblower

toplug.

2.DisengagethePTO ,engagetheparkingbrake,shutoff

theengine,andwaitforallmovingpartstostop.

3.Usingthemower-deckhandle,raisethemowerdeck

andmovethecotterpinstothedesiredheight-of-cut

position.Repeatfortheoppositeside.

Note:Inconditionswherethescreenclogsquickly,thefront

removablescreenpanelcanbeturnedandinstalledunderthe

primaryscreentoallowfreeairowfromthehopper.

24

Page 25

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthemachine.

Ensurethatthetrailerortruckhasallnecessarybrakes,

lighting,andmarkingasrequiredbylaw .Pleasecarefullyread

allthesafetyinstructions.Knowingthisinformationcould

helpyou,yourfamily,pets,orbystandersavoidinjury.

WARNING

Figure25

1.Frontremovablescreen

canberotatedandstored

forwetconditions

2.Frontremovablescreen4.Handles

3.Primaryscreen

UsingtheDrive-Wheel-Release Valves

WARNING

Handsmaybecomeentangledintherotatingdrive

componentsbelowtheenginedeck,whichcould

resultinseriousinjury.

Shutofftheengine,removethekey,andallow

allmovingpartstostopbeforeaccessingthe

drive-wheel-releasevalves.

WARNING

Theengineandhydraulic-driveunitscanbecome

veryhot.Touchingahotengineorhydraulic-drive

unitscancausesevereburns.

Drivingonthestreetorroadwaywithoutturn

signals,lights,reectivemarkings,oraslow-moving

vehicleemblemisdangerousandcanleadto

accidents,causingpersonalinjury.

Donotdrivethemachineonapublicstreetor

roadway.

1.Ifusingatrailer,connectittothetowingvehicleand

connectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Loadthemachineontothetrailerortruck.

4.Shutofftheengine,removethekey,setthebrake,and

closethefuelvalve.

5.Securelyfastenthemachinetothetrailerortruckwith

straps,chains,cable,orropes.

Allowtheengineandhydraulic-driveunitstocool

completelybeforeaccessingthedrive-wheel-release

valves.

Thedrive-wheel-releasevalvesarelocatedonthetop,left

frontcornerofhydrostaticpumps.

1.Movethespeed-controllevertotheNEUTRALposition

tostopthemachine.

2.DisengagethePTO ,engagetheparkingbrake,shutoff

theengine,andwaitforallmovingpartstostop.

3.Tilttheseatuptogainaccesstothepumps.

4.Rotatebothreleasevalves1turncounterclockwiseto

releasethedrivesystem.Thisallowsthehydraulicuid

tobypassthepump,enablingthewheelstoturn.

5.Disengagetheparkingbrakebeforepushingthe

machine.

Note:Donottowthemachine.

6.Rotatethevalvesclockwisetorunthemachine.

Note:Donotovertightenthevalves.

25

Page 26

LoadingtheMachine

Useextremecautionwhenloadingthemachineontoatrailer

ortruck.Onefull-widthrampthatiswideenoughtoextend

beyondthereartiresisrecommendedinsteadofindividual

rampsforeachsideofthemachine(Figure26).Thelower

rearsectionofthemachineframeextendsbackbetweenthe

rearwheelsandservesasastopfortippingbackward.Having

afull-widthrampprovidesasurfacefortheframemembers

tocontactifthemachinestartstotipbackward.Ifitisnot

possibletouse1full-widthramp,useenoughindividual

rampstosimulateafull-widthcontinuousramp.

Therampshouldbelongenoughsothattheanglesdonot

exceed15degrees(Figure26).Asteeperanglemaycause

mowercomponentstogetcaughtasthemachinemovesfrom

theramptothetrailerortruck.Steeperanglesmayalsocause

themachinetotipbackward.Ifloadingonornearaslope,

positionthetrailerortrucksothatitisonthedownside

oftheslopeandtherampextendsuptheslope.Thiswill

minimizetherampangle.Thetrailerortruckshouldbeas

levelaspossible.

Important:Donotattempttoturnthemachinewhile

ontheramp;youmaylosecontrolanddriveofftheside.

Figure26

1.Trailer3.Notgreaterthan

15degrees

2.Full-widthramp4.Full-widthramp—side

view

Avoidsuddenaccelerationwhendrivinguparampand

suddendecelerationwhenbackingdownaramp.Both

maneuverscancausethemachinetotipbackward.

WARNING

Loadingamachineontoatrailerortruckincreases

thepossibilityofbackwardtip-overandcouldcause

seriousinjuryordeath.

•Useextremecautionwhenoperatingamachine

onaramp.

•Useonlyasingle,full-widthramp;donotuse

individualrampsforeachsideofthemachine.

•Ifyoumustuseindividualramps,useenough

rampstocreateanunbrokenrampsurfacewider

thanthemachine.

•Donotexceeda15-degreeanglebetweenthe

rampandthegroundorbetweentherampand

thetrailerortruck.

•Avoidsuddenaccelerationwhiledrivingthe

machineuparamptoavoidtippingbackward.

•Avoidsuddendecelerationwhilebacking

themachinedownaramptoavoidtipping

backward.

26

Page 27

OperatingTips

FastThrottleSetting

Forbestmowingandmaximumaircirculation,operate

theengineatthefastthrottleposition.Airisrequiredto

thoroughlycutgrassclippings,sodonotsettheheightof

cutsolowastototallysurroundthemowerbyuncutgrass.

Alwaystrytohave1sideofthemowerfreefromuncutgrass,

whichallowsairtobedrawnintothemower.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethatthe

cuttingheightofthemowerdoesnotscalpanyuneven

ground.However,thecuttingheightusedinthepastis

generallythebestonetouse.Whencuttinggrasslongerthan

13cm(6inches)tall,youmaywanttocutthelawntwiceto

ensureanacceptablequalityofcut.

LongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,raisethe

cuttingheighthigherthanusualandcutthegrassatthis

setting.Thencutthegrassagainusingthelower,normal

setting.

WhenStopping

Ifyoumuststoptheforwardmotionofthemachinewhile

mowing,aclumpofgrassclippingsmaydropontoyourlawn.

Toavoidthis,moveontoapreviouslycutareawiththeblades

engaged.

KeeptheUndersideoftheMowerClean

Cleanclippingsanddirtfromtheundersideofthemower

aftereachuse.Ifgrassanddirtbuildupinsidethemower,

cuttingqualitywilleventuallybecomeunsatisfactory.

CutaThirdoftheGrassBlade

Itisbesttocutonlyabout1/3ofthegrassblade.Cutting

morethanthatisnotrecommendedunlessgrassissparse,or

itislatefallwhengrassgrowsmoreslowly.

MowingDirection

Alternatemowingdirectiontokeepthegrassstanding

straight.Thisalsohelpsdisperseclippings,whichenhances

decompositionandfertilization.

MowatCorrectIntervals

Normally,mowevery4days.Butremember,grassgrowsat

differentratesatdifferenttimes.Sotomaintainthesame

cuttingheight,whichisagoodpractice,mowmoreoftenin

earlyspring.Asthegrassgrowthrateslowsinmidsummer,

mowlessfrequently.Ifyoucannotmowforanextended

period,rstmowatahighcuttingheight;thenmowagain2

dayslateratalowerheightsetting.

CuttingSpeed

BladeMaintenance

Maintainasharpbladethroughoutthecuttingseasonbecause

asharpbladecutscleanlywithouttearingorshreddingthe

grassblades.Tearingandshreddingturnsgrassbrownat

theedges,whichslowsgrowthandincreasesthechanceof

disease.Checkthecutterbladesdailyforsharpness,andfor

anywearordamage.Filedownanynicksandsharpenthe

bladesasnecessary.Ifabladeisdamagedorworn,replaceit

immediatelywithagenuineT ororeplacementblade.

Toimprovecutquality,useaslowergroundspeedincertain

conditions.

AvoidCuttingTooLow

Ifthecuttingwidthofthemoweriswiderthanthemower

youpreviouslyused,raisethecuttingheighttoensurethat

uneventurfisnotcuttooshort.

27

Page 28

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst50hours

Aftertherst100hours

Beforeeachuseordaily

Every40hours

Every50hours

Every100hours

MaintenanceProcedure

•Changeoilinall3gearboxhousings.Addoilasneededuntilitislevelwiththe

oil-drainplug.

•Checkthewheellugnuttorque.

•Checkthewheelhubnuttorque.

•Checktheparkingbrakeadjustment.

•Changethehydrauliclterandreservoirhydraulicuidwhenusinganytypeofuid.

•Checkthesafetysystem.

•Greasethefrontcasterwheelhubs.

•Checktheengine-oillevel.

•Cleantheenginescreenandtheoilcooler.

•Cleanthehydraulicpumps.

•Checkthemowerblades.

•Cleanthemowerdeck.

•Cleandebrisfromthemachine.

•Greasethedriveshaft.

•Checkthetirepressure.

•Inspectthebeltsforcracksandwear.

•Checkthehydraulic-uidlevel.

•Checkthesparkarrester(ifequipped).

•Greasethemowerdeckip-uppivot.

•Greasethemowerdeckpush-armtubes.

•Changeoilinall3gearboxhousings.Addoilasneededuntilitislevelwiththe

oil-drainplug.

•Changetheengineoil(moreoftenindirtyordustyconditions).

•Cleantheengine-oilcooler.

•Checkandcleantheenginecoolingnsandshrouds.

Every150hours

Every160hours

Every200hours

Every250hours

Every500hours

•Inspecttheprimarylterandair-inletscreen.

•Lubricatethebrake-handlepivot.

•Lubricatethebrake-rodbushings.

•Lubricatethesteering-linkage-rodends.

•Changetheengine-oillter.

•Checkandgapthesparkplug(EFIenginesonly).

•Replacethefuellter(moreoftenindirtyordustyconditions).

•Replacetheprimaryairlterandcheckthesafetyairlter(moreoftenindustyor

sandyconditions).

•ChangethehydrauliclterandreservoirhydraulicuidwhenusingMobil®1uid

(moreoftenindirtyordustyconditions).

•Replacethesafetyairlter.

•Checkandgapthesparkplug(Non-EFIenginesonly).

•Checkthewheellugnuttorque.

•Checkthewheelhubnuttorque.

•Adjustthecasterpivotbearings.

•Checktheparkingbrakeadjustment.

•ChangethehydrauliclterandreservoirhydraulicuidwhenusingT oro®

HYPR-OIL™500hydraulicuid(moreoftenindirtyordustyconditions).

Monthly

•Checkthebattery.

28

Page 29

MaintenanceService

Interval

Yearly

MaintenanceProcedure

•Greasethefront-casterpivots.

•Greasetherear-casterhub.

•Greasethepump-beltidlerarm.

•GreasethePTO-beltidlerarm.(moreoftenindirtyordustyconditions).

•Greasetherear-casterpivot.(moreoftenindirtyordustyconditions).

•Lubricatethecasterwheelhubs.

Yearlyorbeforestorage

•Paintchippedsurfaces.

•Checkallmaintenanceprocedureslistedabovebeforestorage.

Important:Refertoyourengineowner’smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyouperformanymaintenance.

Lubrication

LubricatingtheMachine

GreasingtheMachine

ServiceInterval:Beforeeachuseordaily—Greasethefront

casterwheelhubs.

Every40hours—Greasethedriveshaft.

Every100hours—Greasethemowerdeckip-up

pivot.

Every100hours—Greasethemowerdeckpush-arm

tubes.

Yearly—Greasethefront-casterpivots.

Yearly—Greasetherear-casterhub.

Yearly—Greasethepump-beltidlerarm.

Yearly—GreasethePTO-beltidlerarm.(moreoften

indirtyordustyconditions).

Yearly—Greasetherear-casterpivot.(moreoftenin

dirtyordustyconditions).

Greasemorefrequentlywhenoperatingconditionsare

extremelydustyorsandy.

GreaseType:No.2lithiumormolybdenumgrease

1.DisengagethePTO,stopthemachine,shutoffthe

engine,removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

2.Cleanthegreasettingswitharag.Makesurethatyou

scrapeanypaintoffthefrontofthetting(s).

3.Connectagreaseguntothetting.Pumpgrease

intothettingsuntilgreasebeginstooozeoutofthe

bearings.

4.Wipeupanyexcessgrease.

1.Rear-casterpivot—grease

yearly

2.PTObeltidler

arm—greaseyearly

3.Pumpbeltidler

arm—greaseyearly

4.Rear-casterhub—grease

yearly

5.Driveshaft—greaseevery

40hours

Figure27

6.Front-casterwheel

hub—greaseevery8

hours

7.Deckip-uppivot—grease

every100hours

8.Push-armtubes—grease

every100hours

9.Front-caster

pivots—greaseyearly

29

Page 30

LubricatetheRearCasterWheelHub

ServiceInterval:Yearly

1.Shutofftheengine,waitforallmovingpartstostop,

removethekey,andengagetheparkingbrake.

14.Torquethenutto8to9N∙m(6.0to6.6ft-lb),loosen,

thenre-torqueto2to3N∙m(1.5to2.2ft-lb).

Note:Makesurethattheaxledoesnotextendbeyond

eithernut.

15.Installthesealguardsoverthewheelhubandinsert

thewheelintothecasterfork.Installthecasterbolt

andtightenthenutfully.

Important:Topreventsealandbearingdamage,check

thebearingadjustmentoften.Spinthecastertire.The

tireshouldnotspinfreely(morethan1or2revolutions)

orhaveanysideplay .Ifthewheelspinsfreely,adjustthe

torqueonthespacernutuntilthereisaslightamountof

drag.Applythread-lockingadhesive.

Figure28

1.Sealguard2.Spacernutwithwrench

ats

2.Raisethefrontofthemachineupandsupportitwith

jackstands.

3.Removethecasterwheelfromthecasterforks.

4.Removethesealguardsfromthewheelhub.

5.Remove1ofthespacernutsfromtheaxleassembly

inthecasterwheel.

Note:Notethatthread-lockingadhesivehasbeen

appliedtolockthespacernutstotheaxle.Remove

theaxle(withtheotherspacernutstillassembledtoit)

fromthewheelassembly.

6.Pryouttheseals,andinspectthebearingsforwearor

damageandreplaceifnecessary.

7.Packthebearingswithageneral-purposegrease.

8.Insert1bearingand1newsealintothewheel.

Note:Thesealsmustbereplaced.

9.Iftheaxleassemblyhashadbothspacernutsremoved

(orbrokenloose),applyathread-lockingadhesiveto1

spacernutandthreaditontotheaxlewiththewrench

atsfacingoutward.

Note:Donotthreadthespacernutalloftheway

ontotheendoftheaxle.Leaveapproximately3mm

(1/8inch)fromtheoutersurfaceofthespacernutto

theendoftheaxleinsidethenut.

10.Inserttheassemblednutandaxleintothewheelonthe

sideofthewheelwiththenewsealandbearing.

11.Withtheopenendofthewheelfacingup,llthearea

insidethewheelaroundtheaxlefullofgeneral-purpose

grease.

12.Insertthesecondbearingandnewsealintothewheel.

13.Applyathread-lockingadhesivetothesecondspacer

nutandthreaditontotheaxlewiththewrenchats

facingoutward.

LubricatetheBrake-HandlePivot

ServiceInterval:Every160hours

1.Shutofftheengine,waitforallmovingpartstostop,

removethekey,andengagetheparkingbrake.

2.Lubricatethebronzebushingsonthebrake-handle

pivotwithaspraytypelubricantorlightoil(Figure29).

Figure29

LeftSideofmachineshown

1.Brake-handlepivot

2.PTO-handlepivot

3.Spring-armpivot

4.Togglepivot

LubricatetheBrake-RodBushings

ServiceInterval:Every160hours

1.Shutofftheengine,waitforallmovingpartstostop,

removethekey,andengagetheparkingbrake.

2.Unhooktheseatlatchandtiltseatup.

3.Lubricatethebronzebushingsoneachendofthe

brakerodshaftwithaspraytypelubricantoralight

oil(bushingsarelocatedtotheinsideoftheange

bearings).

30

Page 31

LubricatetheSteering-Linkage-Rod

Ends

ServiceInterval:Every160hours

1.Shutofftheengine,waitforallmovingpartstostop,

removethekey,andengagetheparkingbrake.

2.Unhooktheseatlatchandtilttheseatup.

3.Lubricateeachendofbothsteering-linkagerodswitha

spraylubricantoralightoil.

ChangetheGearboxOil

ServiceInterval:Aftertherst50hours—Changeoilinall

3gearboxhousings.Addoilasneeded

untilitislevelwiththeoil-drainplug.

Every100hours—Changeoilinall3gearbox

housings.Addoilasneededuntilitislevelwiththe

oil-drainplug.

1.Placethemachineonalevelsurface.

2.Shutofftheengine,waitforallmovingpartstostop,

removethekey,andengagetheparkingbrake.

Note:Keepthemowerdeckleveltothegroundwhen

llingthegearboxwithoil.Donotllthrgearboxwith

themowerdeckraisedintheserviceposition.

9.ApplyaPTFEpipesealanttothe3largeoilplugsand

installthemintothegearbox.

3.Removethegearboxanddriveshaftassemblyfromthe

mowerdeck.Retainthehardwareforuselater.

4.Removethelargeoil-drainplugonthefrontofeachof

the3gearboxsectionsanddraintheoil(Figure30).

Figure30

1.Smallmagneticplugs

(frontandback)

2.Largeoildrain/llplug

3.Smallmagneticplug(front

only)

5.Removethesmallmagneticplugsandwipeawayany

materialaccumulatedontheplugs.

6.ApplyaPTFEpipesealanttoallsmallmagneticplugs

andinstallthemintothegearbox.

7.Installthegearboxanddriveshaftassemblytothe

mowerdeck.

8.FillthegearboxwithMobil

®

SHC(synthetic)75W-90

gearlubeoiluntillevelwithoildrain/llplug.

Note:Eachofthegearboxsectionsmustbelled

separately.

31

Page 32

EngineMaintenance

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keepyourhands,feet,face,clothing,andother

bodypartsawaythemuferandotherhotsurfaces.

6.Removethesafetylteronlyifyouintendtoreplaceit.

Important:Donotattempttocleanthesafety

lter.Ifthesafetylterisdirty,thentheprimary

lterisdamaged.Replacebothlters.

7.Inspecttheprimarylterfordamagebylookinginto

thelterwhileshiningabrightlightontheoutsideof

thelter.Holesinthelterwillappearasbrightspots.

Ifthelterisdamaged,discardit.

ServicingtheAirCleaner

ServiceInterval:Every150hours

Every250hours/Yearly(whichevercomes

rst)—Replacetheprimaryairlterandcheck

thesafetyairlter(moreoftenindustyorsandy

conditions).

Every500hours—Replacethesafetyairlter.

Note:Checktheltersmorefrequentlyiftheoperating

conditionsareextremelydustyorsandy.

RemovingtheFilters

1.Movethespeed-controllevertotheNEUTRALposition

tostopthemachine.

2.DisengagethePTO ,engagetheparkingbrake,shutoff

theengine,andwaitforallmovingpartstostop.

3.Releasethelatchesontheaircleanerandpullthe

air-cleanercoverofftheair-cleanerbody(Figure31).

4.Cleantheinsideoftheair-cleanercoverwith

compressedair.

5.Gentlyslidetheprimarylteroutoftheair-cleaner

body(Figure31).

ServicingthePrimaryFilter

•Iftheprimarylterisdirty,bent,ordamaged,replaceit.

•Donotcleantheprimarylter.

ServicingtheSafetyFilter

Replacethesafetylter,nevercleanit.

Important:Neverattempttocleanthesafetylter.

Ifthesafetylterisdirty,thentheprimarylteris

damaged.Replacebothlters.

InstallingtheFilters

Important:Topreventenginedamage,alwaysoperate

theenginewithbothairltersandcoverinstalled.

1.Ifinstallingnewlters,checkeachlterforshipping

damage.Donotuseadamagedlter.

2.Iftheinnerlterisbeingreplaced,carefullyslideitinto

thelterbody(Figure31).

3.Carefullyslidetheprimarylterovertheinnerlter

(Figure31).

Note:Avoidknockingthelterintothesideofthe

body.

Figure31

1.Air-cleanerbody4.Air-cleanercover

2.Primarylter5.Safetylter

3.Latch

Note:Ensurethattheprimarylterisfullyseatedby

pushingonitsouterrimwhileinstallingit.

Important:Donotpressonthesoftinsidearea

ofthelter.

4.Installtheair-cleanercoverandsecurethelatches

(Figure31).

32

Page 33

ServicingtheEngineOil

g012991

0

0

50

SAE 30

OilType:Detergentoil(APIserviceclassSJorhigher)

OilCapacity(Non-EFIengines):withalterchange,

1.8L(1.9USqt);withnolterchange,1.6L(1.7USqt)

OilCapacity(EFIengines):withalterchange,1.9L(2.0

USqt);withnolterchange,1.6L(1.7USqt)

Viscosity:Seethetablebelow.

8.Removethedipstickandreadtheoillevel.

9.Iftheoillevelislow ,wipeofftheareaaroundthe

oil-llcap,removecap,andlltotheFULLmarkon

thedipstick(Figure33).Donotoverll.

Important:Donotoperatetheenginewiththeoil

levelbelowtheLOW(oradd)markonthedipstick,

orovertheFULLmark.

Figure32

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keepyourhands,feet,face,clothingandotherbody

partsawayfromthemuferandotherhotsurfaces.

Important:Donotoverllthecrankcasewithoil

becausedamagetotheenginemayresult.Donotrun

enginewithoilbelowtheLOWmarkbecausetheengine

maybedamaged.

1.Movethespeed-controllevertotheNEUTRALposition

tostopthemachine.

Figure33

1.Oil-llcap2.Oildipstick

2.DisengagethePTO ,engagetheparkingbrake,shutoff

theengine,andwaitforallmovingpartstostop.

3.Allowtheenginetocool.

4.Raisethehopper

5.Cleantheareaaroundthedipstick(Figure33).

6.Removethedipstickandwipetheoiloff.

7.Insertthedipstickandpushitallthewaydowninto

thetube.

33

Page 34

ChangingtheEngineOil

2.Changetheengine-oillter(Figure35).

ServiceInterval:Every100hours(moreoftenindirtyor

dustyconditions).

Note:Disposeoftheusedoilatarecyclingcenter.

1.Parkthemachinesothattherearisslightlylowerthan

thefronttoensurethattheoildrainscompletely.

2.Movethespeed-controllevertotheNEUTRALposition

tostopthemachine.

3.DisengagethePTO ,engagetheparkingbrake,shutoff

theengine,andwaitforallmovingpartstostop.

Note:Allow2minutesforthenewoiltobeabsorbed

bythenewltermaterial.

Figure34

4.Slowlypourapproximately80%ofthespeciedoil

intothellertubeandslowlyaddtheadditionaloilto

bringittotheFULLmarkonthedipstick(Figure33).

5.Starttheengineanddrivetoaatarea.Checktheoil

levelagain(Figure33).

6.Ifneeded,addoiltotheFULLmarkonthedipstick.

ChangingtheEngine-OilFilter

ServiceInterval:Every200hours

Note:Changetheengine-oilltermorefrequentlywhen

operatingconditionsareextremelydustyorsandy.

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil(page34).

Figure35

3.Fillthecrankcasewiththepropertypeofnewoil;refer

toChangingtheEngineOil(page34).

34

Page 35

ServicingtheSparkPlugs

B

A

g027478

B

A

g027479

InstallingtheSparkPlugs

ServiceInterval:Every200hours—Checkandgapthe

sparkplug(EFIenginesonly).

Every500hours—Checkandgapthesparkplug

(Non-EFIenginesonly).

Makesurethattheairgapbetweenthecenterandside

electrodesiscorrectbeforeinstallingthesparkplugs.Usea

spark-plugwrenchforremovingandinstallingthesparkplugs

andagappingtool/feelergaugetocheckandadjusttheair

gap.Installnewsparkplugsifnecessary.

TypeforEFIengines:Champion

TypeforNon-EFIengines:Champion

equivalent

AirGap:0.76mm(0.030inch)

®

XC12YCorequivalent

®

RC12YCor

RemovingtheSparkPlugs

1.Movethespeed-controllevertotheNEUTRALposition

tostopthemachine.

2.DisengagethePTO ,engagetheparkingbrake,shutoff

theengine,andwaitforallmovingpartstostop.

3.Removethesparkplugs.

Tightenthesparkplugsto24.4to29.8N∙m(18to22ft-lb).

Figure38

CheckingtheSparkArrester (ifequipped)

Figure36

CheckingtheSparkPlugs

Important:Replacethesparkplugswhentheyhavea

blackcoating,wornelectrodes,anoilylm,orcracks.

Ifyouseelightbrownorgrayontheinsulator,theengineis

operatingproperly .Ablackcoatingontheinsulatorusually

meansthattheaircleanerisdirty.

Setthegapto0.76mm(0.030inch).

ServiceInterval:Every50hours

WARNING

Hotexhaustsystemcomponentsmayignite

gasolinevaporsevenaftertheengineisshutoff.

Hotparticlesexhaustedduringengineoperation

mayigniteammablematerials.Firemayresultin

personalinjuryorpropertydamage.

Donotfuelorruntheengineunlessasparkarrester

isinstalled.

1.Shutofftheengine,waitforallmovingpartstostop,

removethekey,andengagetheparkingbrake.

2.Waitforthemufertocool.

3.Ifanybreaksinthescreenorweldsareobserved,

replacethearrester.

4.Ifpluggingofthescreenisobserved,removethe

arresterandshakelooseparticlesoutofthearrester

andcleanthescreenwithawirebrush(soakinsolvent

ifnecessary).Installthearresterontheexhaustoutlet.

Figure37

35

Page 36

FuelSystem

G008963

12

3

Maintenance

WARNING

Fuelsystemcomponentsareunderhighpressure.

Theuseofimpropercomponentscanresultin

systemfailure,gasolineleakage,andpossible

explosion.

Useonlyapprovedfuellinesandfuellters.

ServicingtheElectronicFuel InjectionSystem

Thismachinecontainsanelectronicfuelinjectionsystem.It

controlsthefuelowunderdifferentoperatingconditions.

Theelectroniccontrolunit(ECU)continuouslymonitorsthe

operationoftheEFIsystem.

Ifaproblemorfaultwithinthesystemisdetected,the

malfunctionindicatorlight(MIL)isilluminated.TheMILis

theredlightlocatedintherightconsolepanel.

OncetheMILilluminates,initialtroubleshooting

checksshouldbemade.RefertotheMILsectionunder

Troubleshooting(page57).

Ifthesechecksdonotcorrecttheproblem,furtherdiagnosis

andservicingbyanAuthorizedServiceDealerisnecessary.

ReplacingtheFuelFilter

ServiceInterval:Every200hours/Yearly(whichevercomes

rst)(moreoftenindirtyordusty

conditions).

Thefuellterislocatedneartheengineonthefrontorrear

sideoftheengine.

Figure39

1.Fuellter

2.Hoseclamp

5.Squeezetheendsofthehoseclampstogetherandslide

themawayfromthelter(Figure39).

6.Removethelterfromthefuellines.

7.Installanewlterandmovethehoseclampscloseto

thelter(Figure39).

8.Openthefuel-shutoffvalve.

Note:Installthefuellinehosesandsecurethemwithplastic

tiesthesameastheywereoriginallyinstalledatthefactoryto

keepthefuellineawayfromcomponentsthatcoulddamage

thefuelline.

3.Fuelline

ServicingtheFuelTank

Donotattempttodrainthefueltank.HaveanAuthorized

ServiceDealerdrainthefueltank.

1.Movethespeed-controllevertotheNEUTRALposition

tostopthemachine.

2.DisengagethePTO ,engagetheparkingbrake,shutoff

theengine,andwaitforallmovingpartstostop.

3.Allowthemachinetocooldown.

4.Closethefuel-shutoffvalveundertheseat(Figure39).

36

Page 37

ElectricalSystem

1.Movethespeed-controllevertotheNEUTRALposition

tostopthemachine.

Maintenance

ServicingtheBattery

ServiceInterval:Monthly

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

W ash hands after handling .

DANGER

Batteryelectrolytecontainssulfuricacid,whichisa

deadlypoisonandcausessevereburns.

Donotdrinkelectrolyteandavoidcontactwith

skin,eyes,orclothing.Wearsafetyglassestoshield

youreyesandrubberglovestoprotectyourhands.

2.DisengagethePTO ,engagetheparkingbrake,shutoff

theengine,andwaitforallmovingpartstostop.

3.Firstdisconnectthenegativebatterycable(black)from

thenegative(black)batteryterminal(Figure40).

4.Slidetheredterminalbootoffthepositive(red)battery

terminalandremovethepositive(red)batterycable

(Figure40).

5.RemovethewingnutssecuringtheJ-hooks(Figure40).

6.Removetheclamp(Figure40).

7.Removethebattery.

Figure40

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygasestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

WARNING

Incorrectbatterycableroutingcoulddamagethe

machineandcablescausingsparks.Sparkscan

causethebatterygasestoexplode,resultingin

personalinjury.

•Alwaysdisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

•Alwaysconnectthepositive(red)batterycable

beforeconnectingthenegative(black)cable.

1.Negative(black)battery

cable

2.Wingnut

3.J-hook

4.Clamp

5.Positive(red)batterycable

InstallingtheBattery

1.Positionbatteryinthetraywiththeterminalposts

oppositefromthehydraulictank(Figure40).

2.First,installthepositive(red)batterycabletopositive

(+)batteryterminal.

3.Theninstallthenegative(black)batterycableand

groundwiretothenegative(-)batteryterminal.

4.Securethecableswith2bolts,2washers,and2

locknuts(Figure40).

5.Slidetheredterminalbootontothepositive(red)

batterypost.

6.Installtheclampandsecureitwiththewingnutsand

J-hooks(Figure40).

37

Page 38

ChargingtheBattery

ServicingtheFuses

WARNING

Chargingthebatteryproducesgasesthatcan

explode.

Neversmokenearthebatteryandkeepsparksand

amesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged(1.265

specicgravity).Thisisespeciallyimportanttoprevent

batterydamagewhenthetemperatureisbelow0°C

(32°F).

1.Chargebatteryfor10to15minutesat25to30Aor

30minutesat10A.

2.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet;thendisconnectthecharger

leadsfromthebatteryposts(Figure41).

3.Installthebatteryinthemachineandconnectthe

batterycables,refertoInstallingtheBattery(page37).

Note:Donotrunthemachinewiththebattery

disconnected;electricaldamagemayoccur.

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;however,ifafuseblows,checkthe

component/circuitforamalfunctionorshort.

1.Thefusesarelocatedonrightsideofthemachine,

behindtheseat.

2.Toreplacethefuses,pulloutthefusetoremoveit.

3.Installanewfuse.

AdjustingtheSafetySwitches

Adjustallsafetyswitchessothattheplungerextends4.8to

6.4mm(3/16to1/4inch)fromswitchbodywhenplungeris

compressed(Figure42).

1.Positivebatterypost

2.Negativebatterypost

Figure41

3.Red(+)chargerlead

4.Black(-)chargerlead

Figure42

1.4.8to6.4mm(3/16to1/4inch)

JumpStartingtheMachine

1.Checkandcleancorrosionfromthebatteryterminals

beforejump-starting.Ensurethattheconnectionsare

tight.

CAUTION

Corrosionorlooseconnectionscancause

unwantedelectricalvoltagespikesatanytime