Page 1

ZMaster

®

8000SeriesRidingMower

with42inor48inDirect-CollectCuttingUnit

ModelNo.74310—SerialNo.314000001andUp

ModelNo.74311—SerialNo.314000001andUp

ModelNo.74312—SerialNo.314000001andUp

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

FormNo.3383-798RevB

SetupInstructions

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

Nopartsrequired

Rearcasterwheel1

Bolt(1/2x13inches)

Locknut(1/2inch)

Nopartsrequired

Nopartsrequired

Nopartsrequired

Wingnut(1/4inch)

Nopartsrequired

Qty.

–

1

1

–

–

–

2Installthebattery.

–

Openthecrate.

Removethemachinefromthecrate.

Checkthetirepressure.

Checktheengine-oillevel.

Checkthewheellugnuttorque.

Chargethebattery.

Use

8

9

©2014—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Nopartsrequired

Number2general-purposelithium-base

ormolybdenum-basegrease.(Purchase

separately.)

Registeratwww.T oro.com.

–

1tube

Checkthehydraulicoil.

Checkthemachineforgrease.

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

*3383-798*B

Page 2

ProcedureDescription

Qty.

Use

10

11

Nopartsrequired

Operator'sManual

EngineOwner'sManual

Registrationcard1

Operator-trainingmaterial

Key2

1

OpeningtheCrate

NoPartsRequired

Procedure

1.Lowertheendsofthecrate.

2.Removetheretainingstraps.

3.Removetheplastictiesaroundthehopperhandles.

–

1

1

1

2.Removetheboltholdingtherear-framesupporttothe

frame(Figure1).

Checkthemachinebeforedeliveryto

thecustomer(Allmachines).

Deliveringthemachinetothecustomer

(Allmachines).

CAUTION

Raisingthemowerdeckforserviceor

maintenancerelyingsolelyonmechanical

orhydraulicjackscouldbedangerous.The

mechanicalorhydraulicjacksmaynotbe

enoughsupportormaymalfunctionallowing

theunittofall,whichcouldcauseinjury.

DoNotrelysolelyonmechanicalorhydraulic

jacksforsupport.Useadequatejackstands

orequivalentsupport.

2

RemovingtheMachinefrom

theCrate

Partsneededforthisprocedure:

1Rearcasterwheel

1

Bolt(1/2x13inches)

1

Locknut(1/2inch)

DrivingtheMachineOfftheCrate

CAUTION

ThemowerdeckisshippedintheUpposition,but

notlatched.Removingshippingreinforcements

withoutsupportingthefrontofthedeckwillcause

thedecktodropwhichmayresultininjuryor

propertydamage.

Alwayssecurelysupportthefrontofthedeckwhile

settinguptheunit.

3.Raisetherearoftheunitapproximately25.4to30.5

cm(10to12inches)andsupportitwithjackstandsor

equivalentsupport(Figure1).

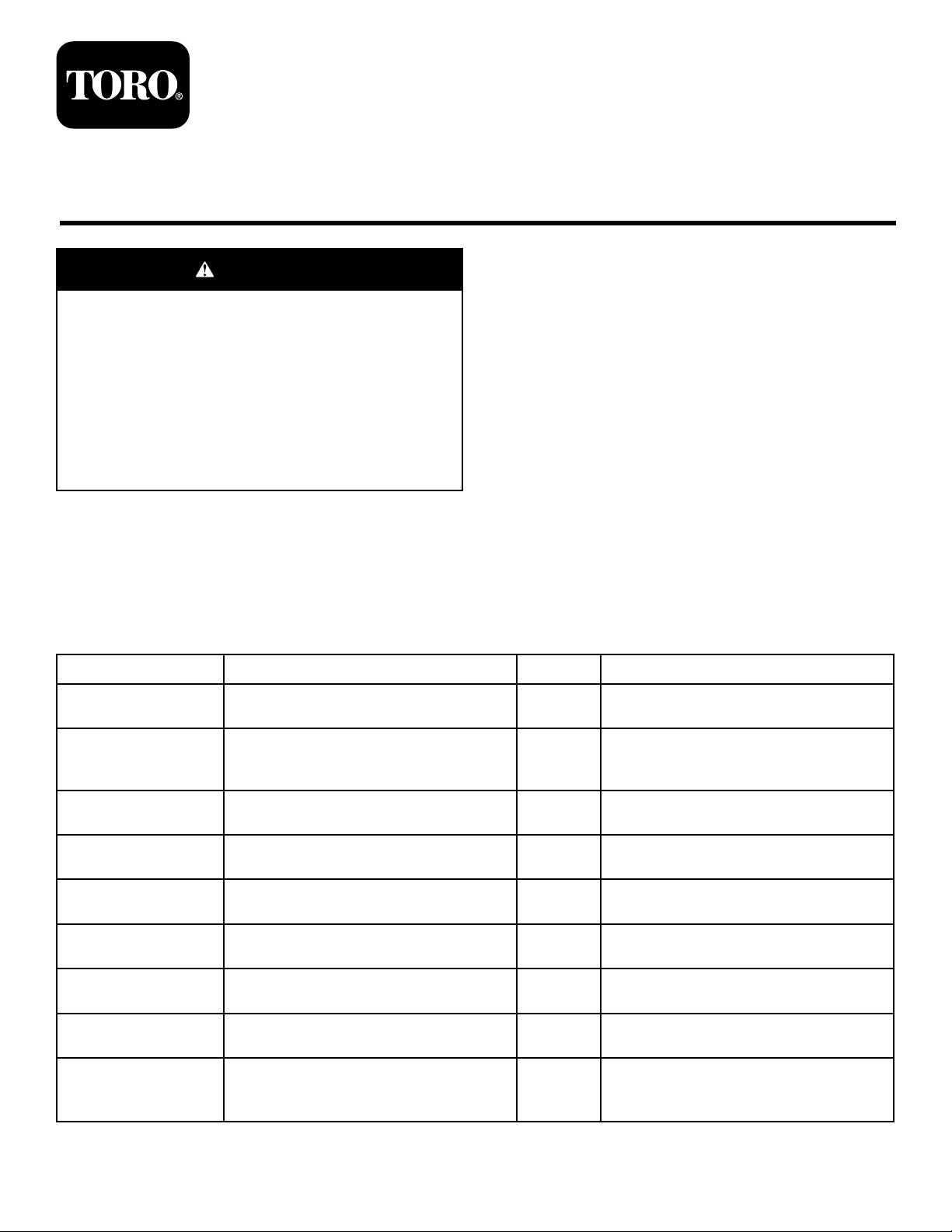

Figure1

1.Rearcasterfork

2.Boltholdingtherear-frame

support

4.Removeanddiscardtherear-framesupport,located

behindthedrivetires,fromthemachine.

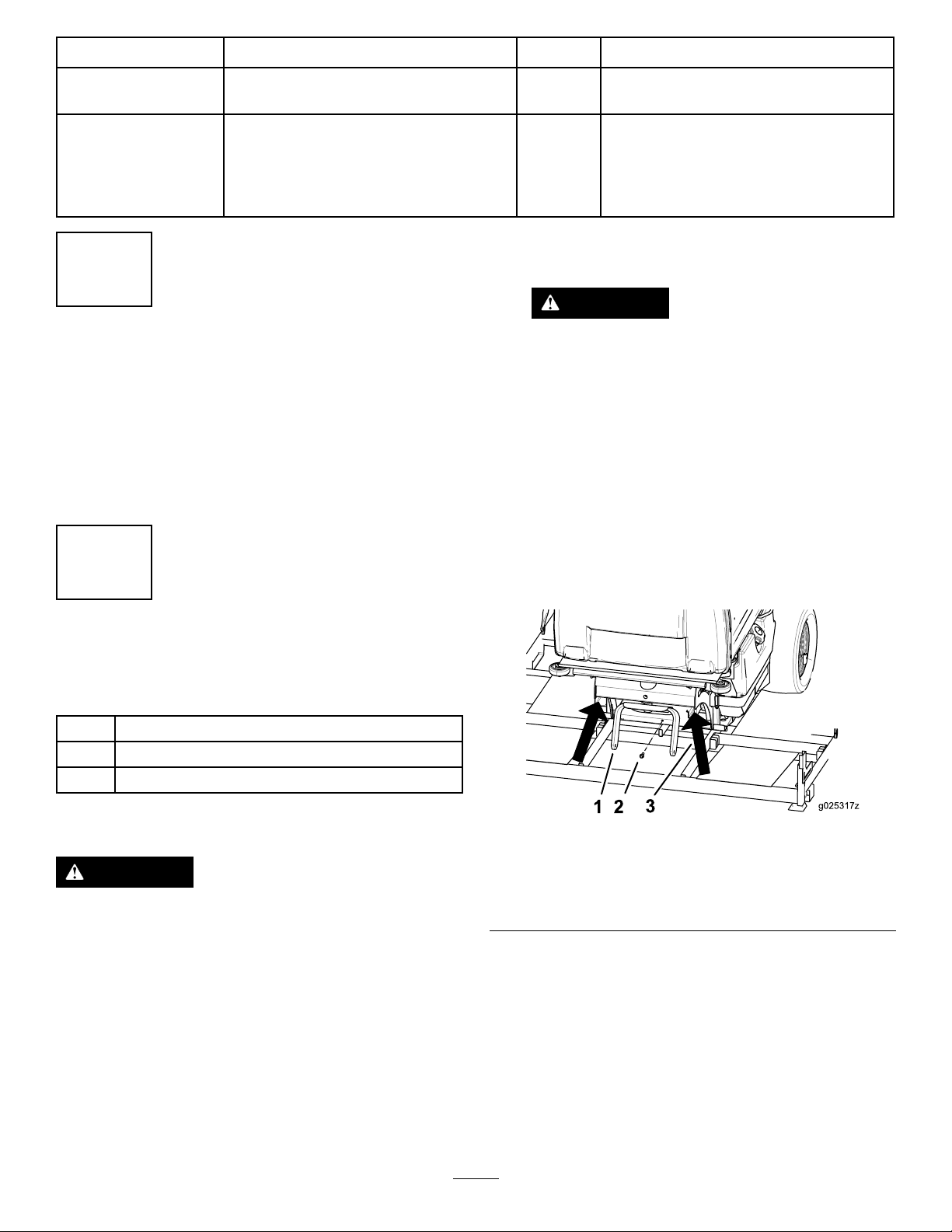

5.Installtherearcasterwheeltotherearcasterforkwith

abolt(1/2x13inches)andlocknut(1/2inch)(Figure

2).

3.Placethejackstandsat

thearrows

Note:Ensurethedischargetubedoesnotcatchonthecrate

whendrivingthemachineoffthecrate(Figure4).

1.Removetherearcasterwheelassemblyfrominside

thehopper.

6.Torquetheboltto90.8to112.5N-m(67to83ft-lb).

2

Page 3

Figure2

1 2 3

g026150

1.Bolt(1/2x13inches)3.Locknut(1/2inch)

2.Rearcasterwheel

providesupportforthedeckwhentheunitisdriven

offofthecrate(Figure4).

7.Carefullyremovethejackstandsandlowerthemachine.

Important:Ensurethemowerdeckisinthe

uprightpositionbeforeraisingthefrontofthe

machine.

8.Raisethefrontofthemachineandsupportitwithjack

standsoranequivalentsupport(Figure3).

Note:Liftthedeckjustenoughtoremovethedeck

supportandtoinsertothersupportsintothecrate

opening.

Figure4

1.Drivetire3.Plywoodsheetunderthe

reardeckrollers

2.Dischargetube

11.Carefullyremovethejackstandsandlowerthemachine.

12.Whilesupportingthemowerdeck,removeanddiscard

thetwosidestruts,mountingbrackets,andtheir

hardwareonbothsidesoftheseat(Figure5).

13.Removeanddiscardthestrutlocatedbetweenthefront

decksupportpins(Figure5).

Figure3

1.Placejackstandsatthearrows

9.Removeanddiscardthedecksupportfromunderthe

reardeckrollers.

Note:Beforethedeckisloweredintotheoperating

position(steps10through14),thecrateopeningunder

thedeckmustbefullycovered.

10.Placeaplywoodsheet(58.4cmx81.3cm(23inches

x32inches)),orsimilarsupport,overtheopeningto

Figure5

1.Decksupportpin

2.Strutbetweendeck

supportpins

3.Sidestruthardware

14.Withthedecklockingpinspulledoutintheunlock

position,carefullylowerthedeck(Figure6).

3

Page 4

Figure6

1 2

g026149

g026151

1

2

3

4

1.Decklifthandle

2.Rotatethedecklocking

pintowardtherearand

pulloutwardtounlock

3.Pushthedecklockingpin

inandrotatetowardthe

fronttolock

15.Pushthedeck-lockingpinsinwardandrotatethem

forwardtosecurelylockthedeckinthelowered

position.

16.Raisethemowerdecktothehighestheight-of-cut

position.

17.Installpiecesofwood,toformaramp,infrontofthe

reartire(Figure7).

Figure8

1.Frontcaster3.Plywoodbetweendrive

2.Reardeckrollers

wheels

4.Woodrampforfront

casters(2x4’s)

Note:Ensurethedischargetubedoesnotcatchonthe

cratewhendrivingthemachineoffthecrate(Figure4).

WARNING

Operatingmowerwithoutlockingpins

securelylatchedcanresultinthemowerdeck

foldingupunexpectedly.Themowerdeck

foldingupunexpectedlycancauseserious

injury.

Alwaysoperatemowerwithlockingpins

securelylatched.

19.Drivethemachineoffthecrate.

1.Reartire2.Woodramp

18.Toformaramp,place2longpiecesofwood(2x4’s)

Figure7

infrontofeachfront-castertire(Figure8).

RemovingtheMachinefromtheCrate

UsingaHoist

CAUTION

ThemowerdeckisshippedintheUpposition,but

notlatched.Removingshippingreinforcements

withoutsupportingthefrontofthedeckwillcause

thedecktodropwhichmayresultininjuryor

propertydamage.

Alwayssecurelysupportthefrontofthedeckwhile

settinguptheunit.

1.Removetherearcasterwheelassemblyfrominside

thehopper.

4

Page 5

2.Removetheboltholdingtherearframetothecrate

(Figure11).

3.Liftthefrontofthehopperup.

Note:Usecarewhenhoistingthemachinetoprevent

damagetothehopper.

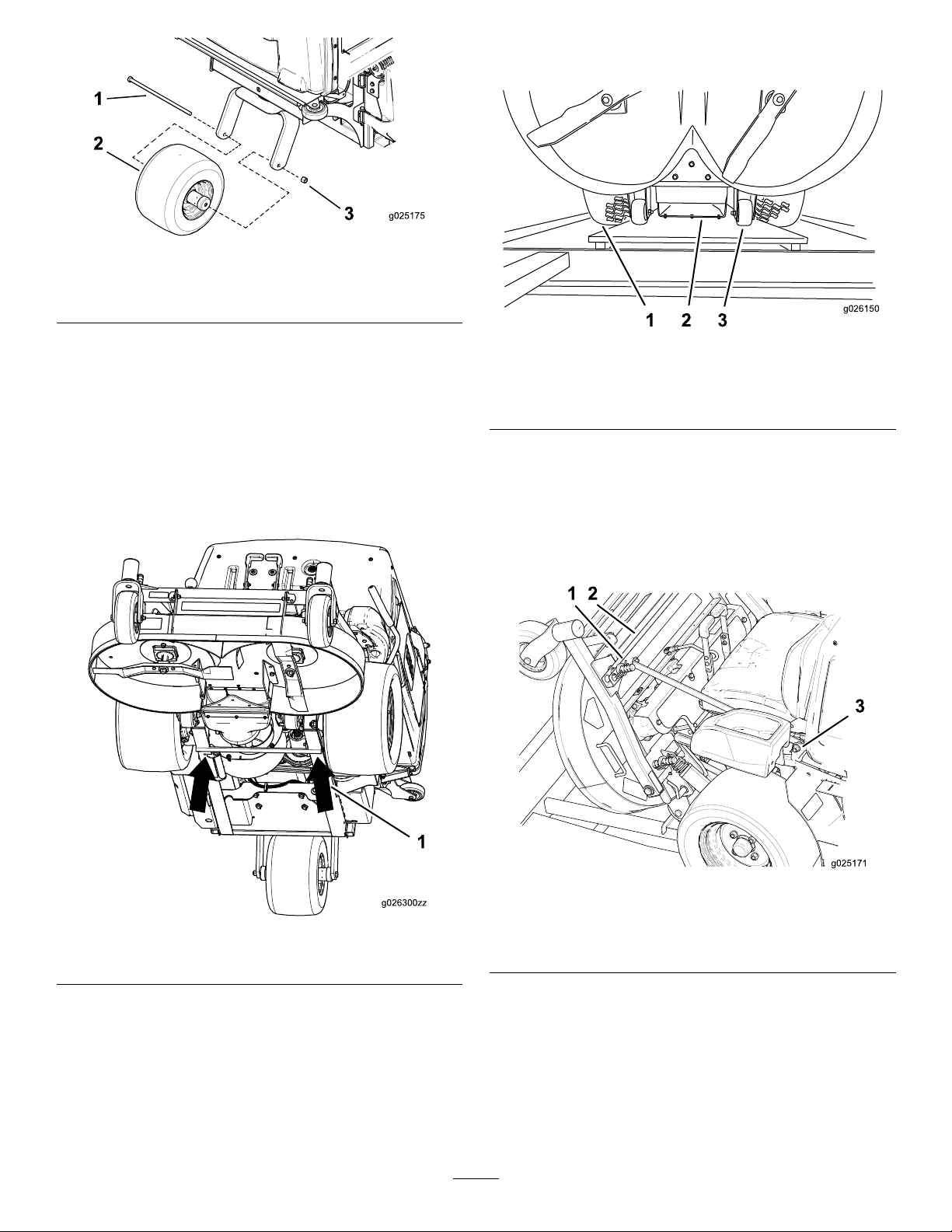

4.Usingthehoist,liftthemachineatthelocationshown

inFigure9.

Figure10

Figure9

1.Withthehopperup,liftthemachineoneachsidehere

CAUTION

Raisingthemowerdeckforserviceor

maintenancerelyingsolelyonmechanical

orhydraulicjackscouldbedangerous.The

mechanicalorhydraulicjacksmaynotbe

enoughsupportormaymalfunctionallowing

theunittofall,whichcouldcauseinjury.

DoNotrelysolelyonmechanicalorhydraulic

jacksforsupport.Useadequatejackstands

orequivalentsupport.

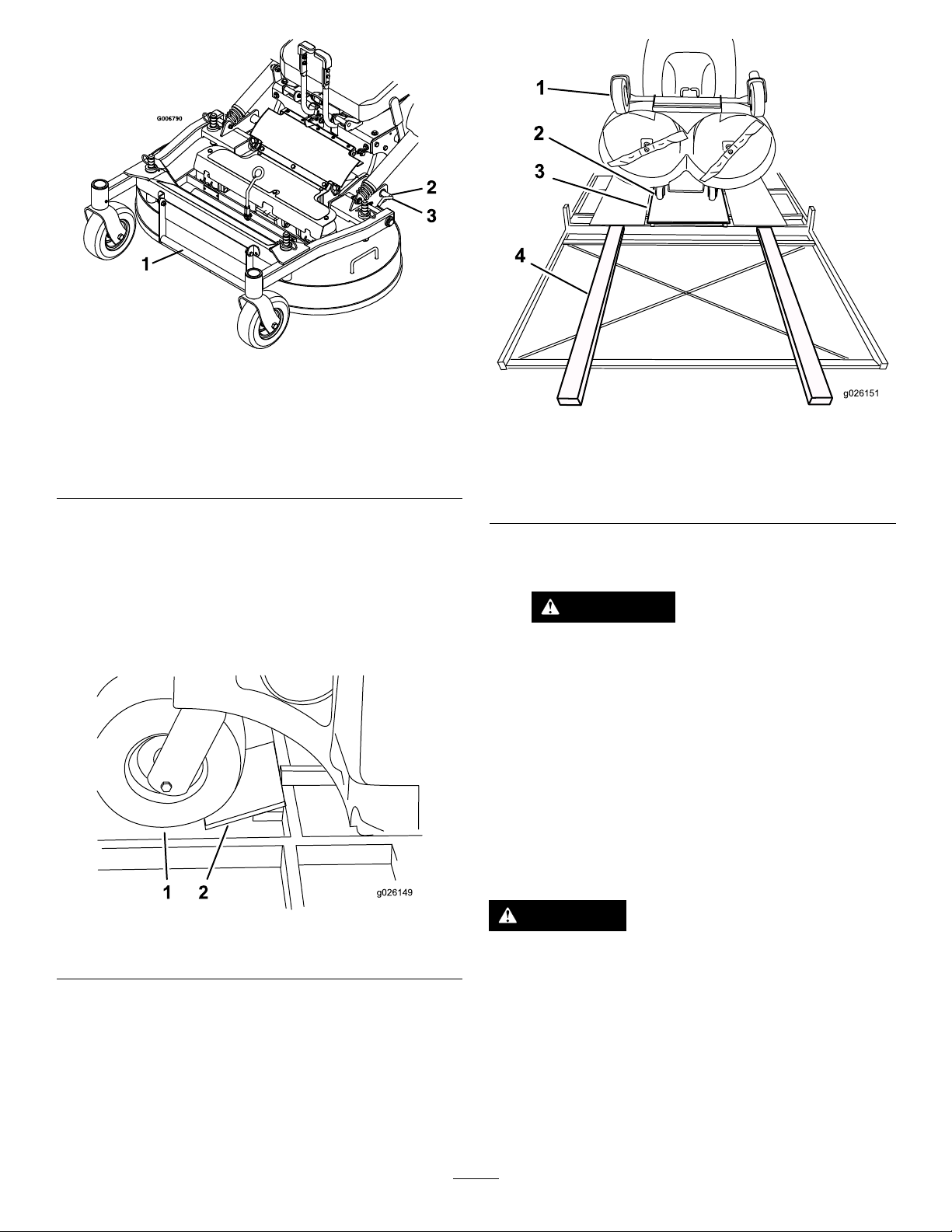

5.Raisetherearoftheunitapproximately25.4to30.5

cm(10to12inches)andsupportitwithjackstandsor

equivalentsupport(Figure10).

1.Rearcasterfork

2.Boltholdingrearframe

3.Placejackstandsatthe

arrows

6.Removeanddiscardtherear-framesupportandits

hardware,locatedbehindthedrivetires.

7.Installtherearcasterwheeltotherearcasterforkwith

abolt(1/2x13inches)andlocknut(1/2inch)(Figure

11).

8.Torquetheboltto90.8to112.5N-m(67to83ft-lb).

Figure11

1.Bolt(1/2x13inches)3.Locknut(1/2inch)

2.Rearcasterwheel

9.Carefullyremovethejackstandsandlowerthemachine.

10.Lowerthefrontofthehopper.

11.Tilttheseatup.

12.Placethehoisthooksoneachsideoftheseatasshown

inFigure12.

5

Page 6

Figure12

1.Liftpointsoneachsideoftheseat

1.Decksupportpin

2.Strutbetweenthe

deck-supportpins

Figure13

3.Side-struthardware

Important:Ensurethemowerdeckisinthe

uprightpositionbeforeraisingthefrontofthe

machine.

13.Raiseupthefrontofthemachine,justenoughto

removeanddiscardthedecksupportfromunderthe

reardeckrollers.

14.Lowerthemachinetotheground.

15.Liftthefrontofthehopperup.

16.Usingthehoist,liftthemachineatthelocationsshown

inFigure9andFigure12.

17.Removethecratefromunderthemachine.

18.Lowerthemachinetotheground.

19.Whilesupportingthemowerdeck,removeanddiscard

thetwosidestruts,mountingbrackets,andtheir

hardwareonbothsidesoftheseat(Figure13).

20.Removeanddiscardthestrutlocatedbetweenthefront

decksupportpins(Figure13).

21.Withthedecklockingpinspulledoutintheunlock

position,carefullylowerthedeck(Figure14).

Figure14

1.Decklifthandle

2.Rotatethedecklocking

pintowardtherearand

pulloutwardtounlock

3.Pushthedecklockingpin

inandrotatetowardthe

fronttolock

22.Pushthedecklockingpinsinwardandrotatethem

forwardtosecurelylockthedeckinthelowered

position.

6

Page 7

WARNING

Operatingmowerwithoutlockingpins

securelylatchedcanresultinthemowerdeck

foldingupunexpectedly.Themowerdeck

foldingupunexpectedlycancauseserious

injury.

Alwaysoperatemowerwithlockingpins

securelylatched.

6

InstallingtheBattery

Partsneededforthisprocedure:

2

Wingnut(1/4inch)

Procedure

3

CheckingtheTirePressure

NoPartsRequired

Procedure

Pressure:103kPa(15psi)

Note:Checkthetirepressurebeforestartingthemachine.

RefertoyourOperator’sManualforthecorrecttiretype,

correctairpressureneeded,andprocedure.

4

CheckingtheEngine-OilLevel

NoPartsRequired

Procedure

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoServicingthe

Engine-OilLevelintheOperator'sManual.

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling .

CAUTION

Batteryelectrolytecontainssulfuricacid,whichis

poisonousandcancausesevereburns.Swallowing

electrolytecanbefatalorifittouchesskincan

causesevereburns.

•Wearsafetyglassestoshieldeyes,andrubber

glovestoprotectskinandclothingwhen

handlingelectrolyte.

•DoNotswallowelectrolyte.

•Intheeventofanaccident,ushwithwaterand

calladoctorimmediately.

WARNING

5

CheckingtheWheelLugNut

Torque

NoPartsRequired

Procedure

Beforeyoustarttheengineandusethemachine,checkthe

wheellugnuttorque;refertoCheckingtheWheelLugNuts

intheOperator'sManual

IftheignitionisintheOnpositionthereispotential

forsparksandengagementofcomponents.Sparks

couldcauseanexplosionormovingpartscould

accidentallyengagecausingpersonalinjury.

BesureignitionswitchisintheOffpositionbefore

chargingthebattery.

Locatethebattery-mountinghardwareandinstallthenegative

batterycable.RefertoInstallingtheBatteryintheOperator's

Manual.

Note:Ifthepositivecableisalsodisconnected,connectthe

positive(red)cabletothepositivebatteryterminalrst,then

thenegative(black)cabletothenegativebatteryterminal.

Slipinsulatorbootoverthepositiveterminal.

7

Page 8

Note:Iftimedoesnotpermitchargingthebattery,orif

chargingequipmentisnotavailable,connectthenegative

batterycableandrunthevehiclecontinuouslyfor20to30

minutestosufcientlychargethebattery.

8

CheckingtheHydraulicOil

7

ChargingtheBattery

NoPartsRequired

Procedure

WARNING

Chargingthebatteryproducesgassesthatcan

explodeandcauseseriousinjury.

•Keepcigarettes,sparksandamesawayfrom

thebattery.

•Makesuretheignitionswitchisoff.

•Ventilatewhenchargingorusingthebatteryin

anenclosedspace.

Important:Donotrunthemachinewiththebattery

disconnected;electricaldamagemayoccurtothe

engine.

Chargethebattery.RefertotheOperator'sManualfor

instructions.

NoPartsRequired

Procedure

Themachineisshippedwithhydraulicoilinthereservoir.

1.Checkandensurethereservoirhashydraulicoil.

2.IfneededaddToroHYPR-OIL™500hydraulicoil.

3.Runthemachineforapproximately15minutestoallow

anyextraairtopurgeoutofthehydraulicsystem.

4.Waituntiltheunitcoolsbeforecheckingthehydraulic

oil.

5.Tiltthehopperup.

6.Removethehydraulicreservoircap.

7.Wipethedipstickcleanandinsertthecapbackinto

thehydro.

8.Lightlytightenthecap.

9.Removethecapagainandchecktheleveloftheoil

onthedipstick(Figure16).

10.Checkthehydraulicreservoirandifnecessaryll

thereservoirtotheappropriatelevelwithToro

HYPR-OIL™500hydraulicoil.

Figure15

Figure16

1.Full2.Add

11.IfthedipstickoillevelisattheAddmark,addhydraulic

oil.Donotoverll.

12.Replacehydraulicreservoircapandtightenuntilsnug.

Donotovertighten.

8

Page 9

9

CheckingtheMachinefor

Grease

Partsneededforthisprocedure:

1tube

Procedure

Beforeyouusethemachine,checkthemachineforgrease;

refertoLubricationintheOperator'sManual.

Number2general-purposelithium-baseor

molybdenum-basegrease.(Purchaseseparately.)

9

Page 10

10

CheckingtheMachineBeforeDeliverytotheCustomer

NoPartsRequired

Procedure

Beforedeliveringthemachinetothecustomer,ensurethatyouperformorhaveperformedtheprocedureslistedinthe

followingtableandinitialeachwhennished.RefertotheOperator'sManualforinstructionsonperformingtheseprocedures.

Initial

Checkthetirepressure.

Checkthelevelofthemachine.

Checkthemowerdeckgearboxesforoil.

Checktheengine-oillevel.

Checkthehydraulic-uidlevel.

Checktheadjustmentoftheparkingbrake.

Ensurethatthemachinetrackscorrectly;refertotheOperator'sManualfortheadjustmentprocedure.

Checkthesafetyinterlocksystem;refertotheOperator'sManual.

EnsurethatthePTOworks.

Checkallfastenersthatyouinstalledtoensurethattheyaretight.

Whenyounishsettingupthemachine,signanddateinthespaceprovidedbelow:

Signature:

CheckProcedure

Date:

10

Page 11

11

DeliveringtheMachinetotheCustomer

Partsneededforthisprocedure:

1

Operator'sManual

1

EngineOwner'sManual

1Registrationcard

1

Operator-trainingmaterial

2Key

Procedure

Atdelivery,llinthemodelandserialnumber,completetheitemslistedinthefollowingtable,andinitialeachwhennished.

ModelNo.

SerialNo.

11

Page 12

DealerInitial

CustomerInitialCheckProcedure

Showthecustomerwherethefollowingfeaturesarelocatedandhowtheyfunction:

•

Fueltank

•

Oilllcap/Oildipstick

•

Sparkplug(s)

•

Engine-oillter

•

Engine-oildrain

•

Fuelgauge,valveandhose

•

Airlter

•

Hydraulic-uidreservoir

•

Hydrauliclter

•

Battery

•

Ignitionswitch

•

Throttlelever

•

Choke(ifapplicable)

•

Powertakeoff(PTO)

•

Motion-controllevers

•

Parkingbrake

•

Height-of-cut

•

Adjustableseat

•

Hydraulic-bypassvalves

•

Mowerdeckbafe

RefertotheOperator'sManualtopointoutsafetyprocedures,operation,and

maintenanceprocedures.

ReviewthewarrantystatementasshownintheOperator'sManual.

Describethepostsaleserviceproceduresforyourstore.

Assistthecustomerinllingoutandmailingtheregistrationcardorregisteronlineat

www.T oro.com

MakesurethatthecustomerreceivestheOperator'sManual,EngineOwner'sManual,

SetUpInstructions,andoperatortrainingmaterial.

MakesurethecustomerknowsthePartsCatalogisavailableatwww.T oro.com.

Assistthecustomerinloadingthemachine.

Note:Whenyou,thedealerrepresentative,havenisheddeliveringthemachinetothecustomer,signanddateinthespace

providebelowandkeepacopyofthispagefordealerrecords.Also,thedealermustremindthecustomertouseafull-width

trailerramptoloadthemachine.

Signature:

Signature:Date:

Date:

12

Loading...

Loading...