FormNo.3424-708RevC

ZMaster

®

Professional7000

SeriesRidingMower

With132cmor152cmTURBOFORCE

Mower

ModelNo.74264TE—SerialNo.403138013andUp

ModelNo.74265TE—SerialNo.403227065andUp

ModelNo.74279TE—SerialNo.403320852andUp

®

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3424-708*

GrossorNetTorque:Thisproductcomplieswith

allrelevantEuropeandirectives;fordetails,please

seetheseparateproductspecicDeclarationof

Conformity(DOC)sheet.Thegrossornettorque

ofthisenginewaslaboratoryratedbytheengine

manufacturerinaccordancewiththeSocietyof

AutomotiveEngineers(SAE)J1940orJ2723.As

conguredtomeetsafety,emission,andoperating

requirements,theactualenginetorqueonthisclass

ofmowerwillbesignicantlylower.Pleasereferto

theenginemanufacturer’sinformationincludedwith

themachine.

Pleaserefertotheenginemanufacturer’sinformation

includedwiththemachine.

WARNING

CALIFORNIA

Proposition65Warning

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

FortheOperator’sManual,thecompletewarranty

details,ortoregisteryourproduct,usetheQR

codeorvisitwww.Toro.com.Youmayalsocallus

at1-888-384-9939torequestawrittencopyofthe

productwarranty.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcode(ifequipped)ontheserial

numberdecaltoaccesswarranty,parts,andother

productinformation.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

Thisrotary-blade,ridinglawnmowerisintendedtobe

usedbyprofessional,hiredoperators.Itisdesigned

primarilyforcuttinggrassonwell-maintainedlawnson

residentialorcommercialproperties.Itisnotdesigned

forcuttingbrushorforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

YoumaycontactT orodirectlyatwww.T oro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

g248729

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

Safety-alertsymbol

©2022—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SlopeIndicator...................................................5

SafetyandInstructionalDecals..........................6

ProductOverview...................................................16

Controls...........................................................16

BeforeOperation.................................................18

BeforeOperationSafety...................................18

PerformingDailyMaintenance..........................18

AddingFuel......................................................18

BreakinginaNewMachine..............................20

UsingtheRollover-ProtectionSystem

(ROPS).........................................................20

UsingtheSafety-InterlockSystem....................21

PositioningtheSeat..........................................22

UnlatchingtheSeat..........................................22

ChangingtheSeatSuspension.........................22

DuringOperation.................................................23

DuringOperationSafety...................................23

OperatingtheParkingBrake.............................25

OperatingtheMowerBlade-ControlSwitch

(PTO)............................................................25

OperatingtheThrottle.......................................25

StartingandShuttingOfftheEngine.................26

UsingtheMotion-ControlLevers.......................27

DrivingtheMachine..........................................27

UsingtheSideDischarge.................................29

AdjustingtheHeightofCut...............................29

AdjustingtheAnti-ScalpRollers........................30

AdjustingtheAnti-ScalpRollers........................31

AdjustingtheFlowBafeCamLocks................32

PositioningtheFlowBafe................................32

OperatingwiththeOverheatSensor.................33

OperatingTips.................................................33

AfterOperation....................................................34

AfterOperationSafety......................................34

UsingtheFuel-ShutoffValve.............................34

PushingtheMachinebyHand..........................35

TransportingtheMachine.................................35

UsingtheZStand

Maintenance...........................................................39

RecommendedMaintenanceSchedule(s)...........39

Pre-MaintenanceProcedures..............................40

MaintenanceSafety..........................................40

ReleasingtheMower-DeckCurtain..................41

RemovingtheSheet-MetalGuard.....................41

Lubrication..........................................................41

GreasingtheMachine.......................................41

GreasingtheFrontCasterPivots......................41

AddingGrease.................................................41

AddingLightOilorSprayLubrication................42

AddingLightOilorSprayLubrication................42

GreasingtheMowerDeckandBelt

Idlers.............................................................43

LubricatingtheCaster-WheelHubs..................44

EngineMaintenance...........................................45

TM

..........................................37

3

EngineSafety...................................................45

ServicingtheAirCleaner..................................45

ServicingtheEngineOil....................................46

FuelSystemMaintenance...................................50

ServicingtheFuelFilterandWater

Seperator......................................................50

ServicingtheFuelT ank.....................................51

ElectricalSystemMaintenance...........................52

ElectricalSystemSafety...................................52

ServicingtheBattery.........................................52

ServicingtheFuses..........................................53

DriveSystemMaintenance..................................54

AdjustingtheTracking......................................54

CheckingtheTirePressure...............................54

CheckingtheWheel-HubSlottedNut................55

AdjustingtheCaster-PivotBearing...................55

ServicingtheGearbox......................................55

AdjustingtheElectricClutch.............................56

CoolingSystemMaintenance..............................58

ServicingtheCoolingSystem...........................58

BrakeMaintenance.............................................59

AdjustingtheParkingBrake..............................59

BeltMaintenance................................................60

InspectingtheBelts..........................................60

ReplacingtheMowerBelt.................................60

ReplacingtheMowerBelt.................................61

ReplacingthePTO-DriveBelt...........................62

ReplacingthePumpDriveBelt.........................63

ReplacingandT ensioningtheAlternator

Belt................................................................63

ControlsSystemMaintenance.............................64

AdjustingtheControlHandleNeutral

Position.........................................................64

HydraulicSystemMaintenance...........................65

HydraulicSystemSafety...................................65

ServicingtheHydraulicSystem........................65

SettingtheHydraulicPumpNeutral

Position.........................................................68

MowerDeckMaintenance....................................70

LevelingtheMowerat3Positions.....................70

ServicingtheCuttingBlades.............................73

ReplacingtheGrassDeector..........................75

Cleaning..............................................................76

CleaningundertheMowerDeck.......................76

DisposingofWaste...........................................76

Storage...................................................................77

StorageSafety..................................................77

CleaningandStorage.......................................77

Troubleshooting......................................................78

Schematics.............................................................80

Safety

Thismachinehasbeendesignedinaccordancewith

ENISO5395:2013.

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury .

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

•Alwayskeeptherollbarinthefullyraisedand

lockedpositionandusetheseatbelt.

•Donotoperatethemachineneardrop-offs,

ditches,embankments,water,orotherhazards,or

onslopesgreaterthan15degrees.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepchildrenandbystandersoutoftheoperating

area.Neverallowchildrentooperatethemachine.

•Stopthemachine,shutofftheengine,andremove

thekeybeforeservicing,fueling,orunclogging

themachine.

Improperlyusingormaintainingthismachinecan

resultininjury .T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafety-alertsymbol,whichmeans

Caution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalsafetyinformationwhere

neededthroughoutthismanual.

4

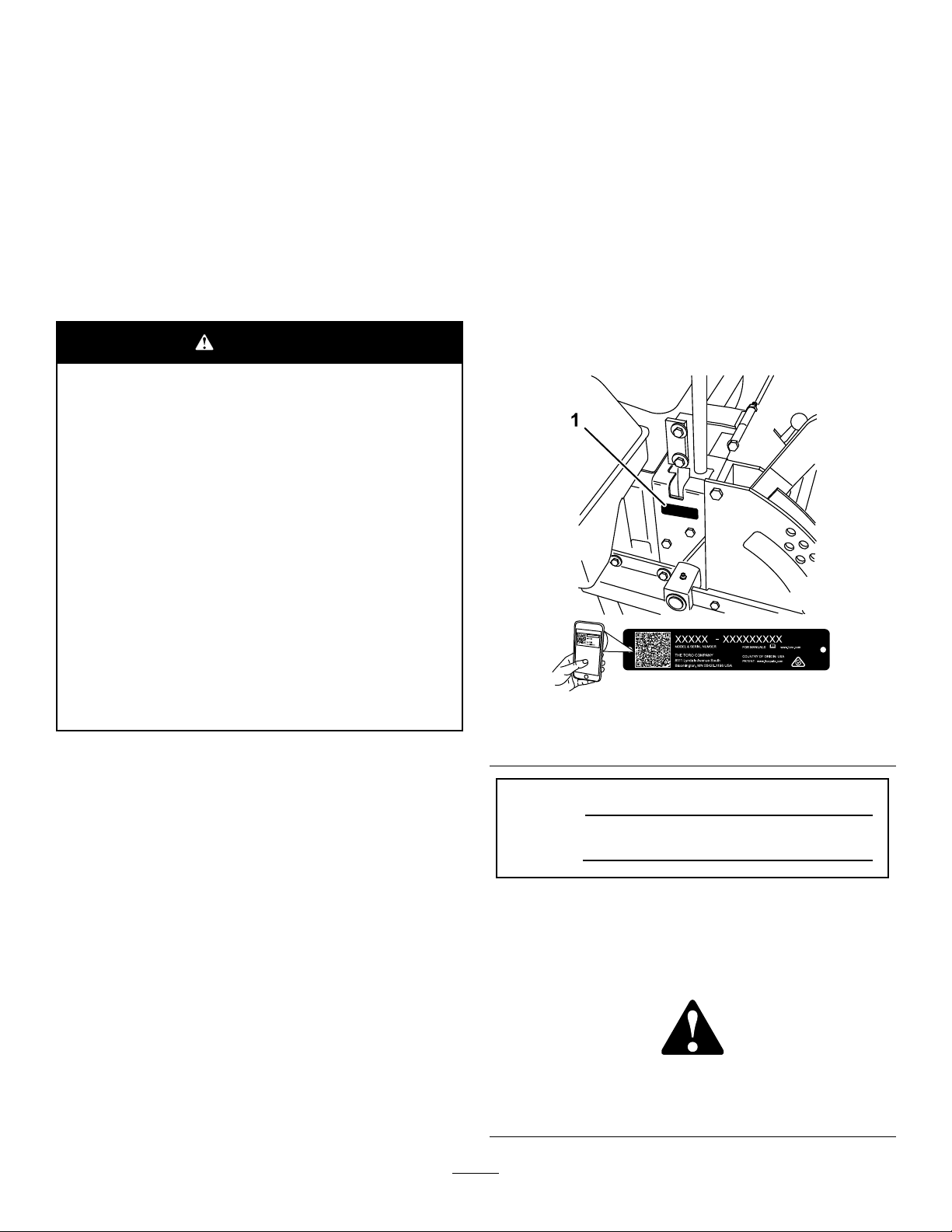

SlopeIndicator

Figure3

Youmaycopythispageforpersonaluse.

1.Themaximumslopeyoucanoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslopeof

hillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge

5

g011841

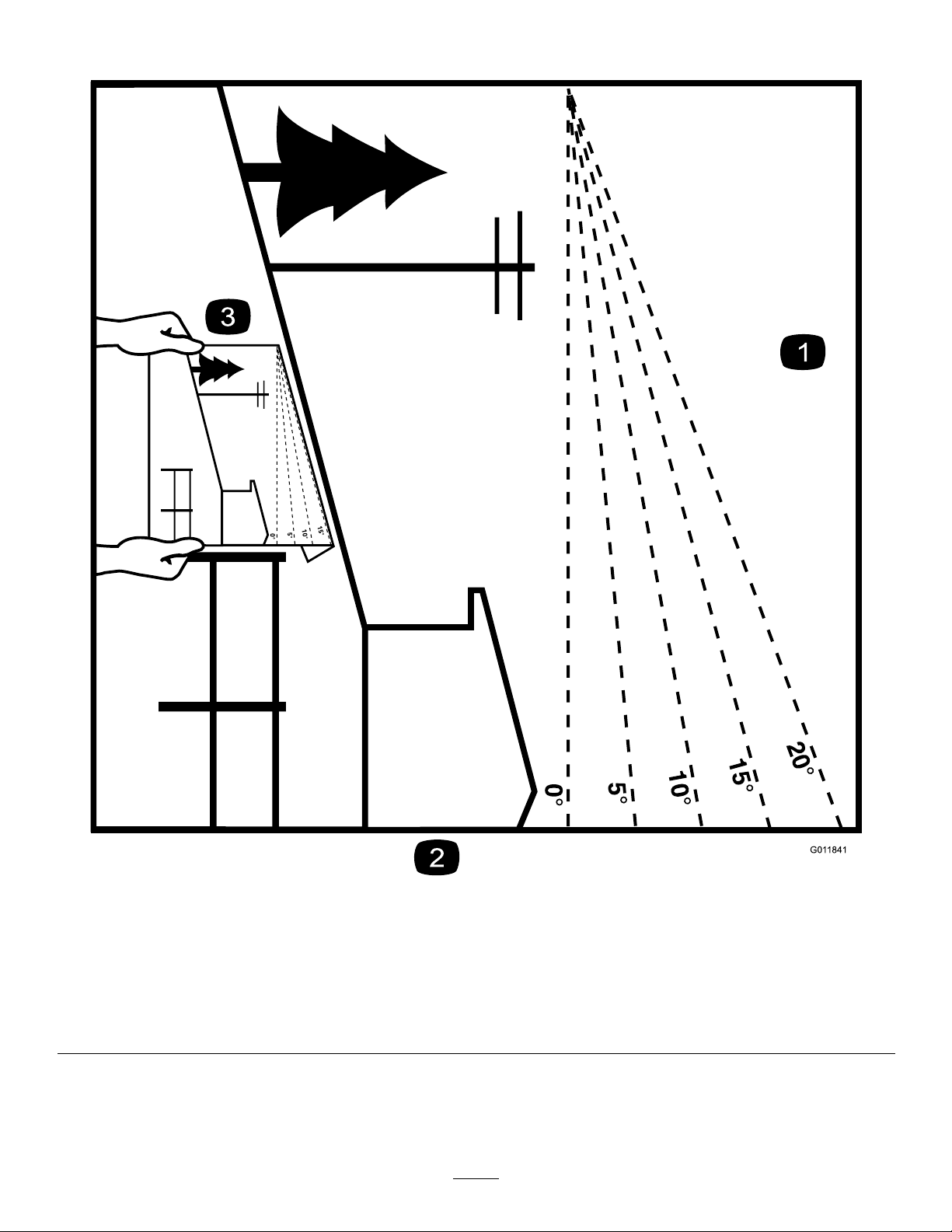

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

BatterySymbols

Someorallofthesesymbolsareonyourbattery.

1.Explosionhazard6.Keepbystandersaway

2.Nore,opename,or

smoking

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

fromthebattery .

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

decalbatterysymbols

decal93-7010

93-7010

1.Thrownobjecthazard—keepbystandersaway.

2.Thrownobjecthazard,mower—keepthedeectorinplace.

3.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

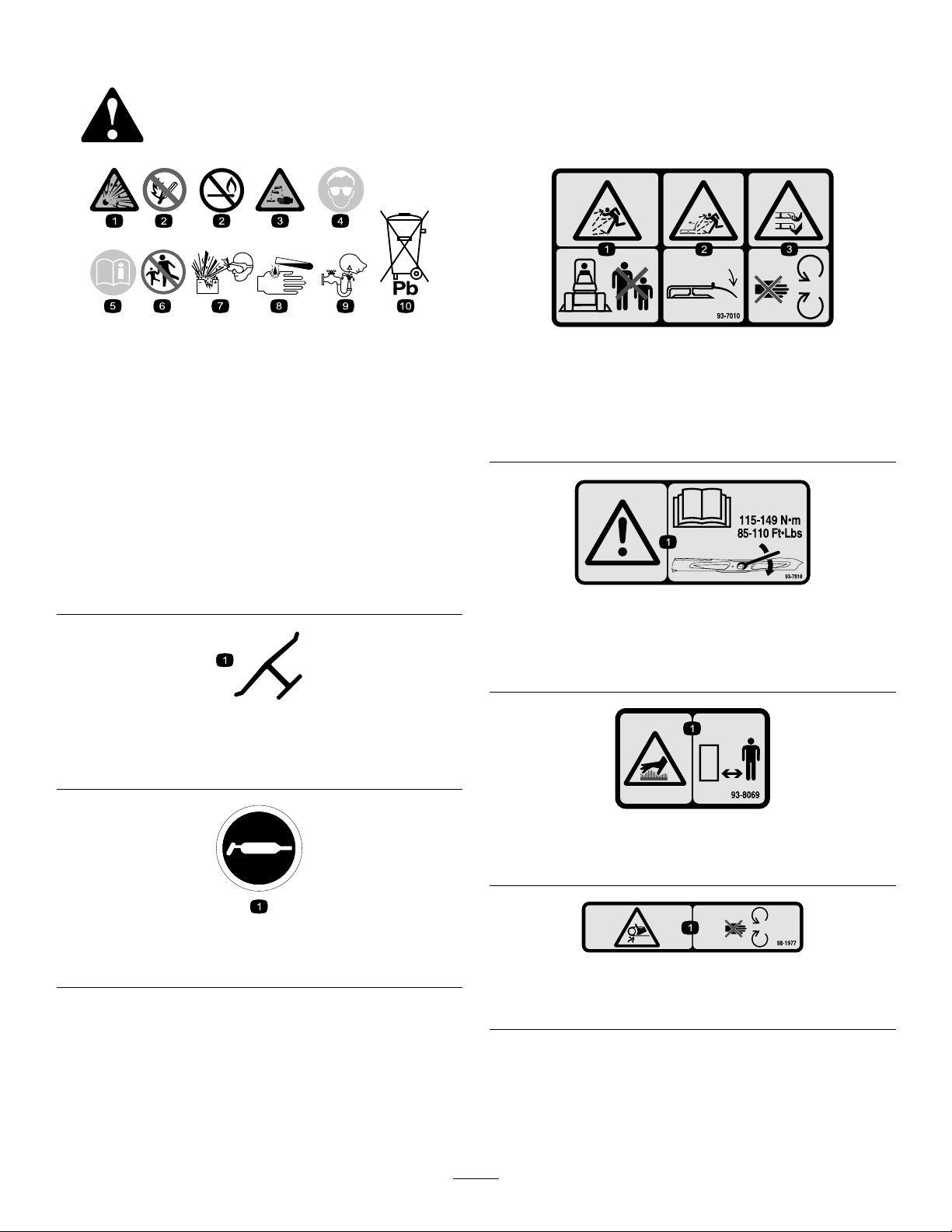

decal93-7818

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto1 15to149N∙m(85to110

ft-lb).

decaloemmarkt

decal93-8069

93-8069

1.Hotsurface/burnhazard—stayawayfromthehotsurface.

decal58-6520

58-6520

1.Grease

98-1977

1.Entanglementhazard,belt—stayawayfrommovingparts.

decal98-1977

6

1.Warning—wearhearingprotection.

decal98-4387

98-4387

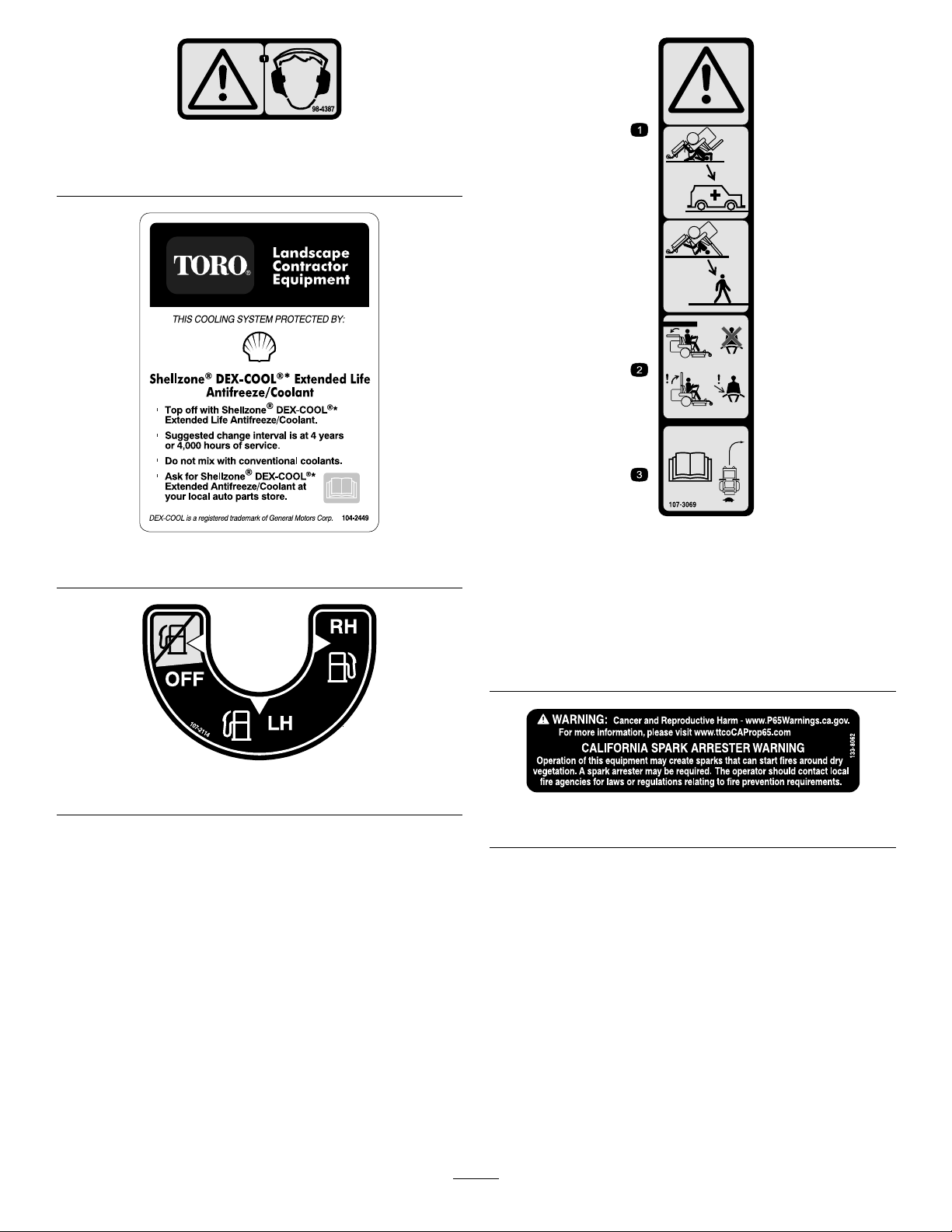

decal107-3069

decal104-2449

104-2449

1.Warning–thereisnorolloverprotectionwhentherollbaris

down.

2.Toavoidinjuryordeathfromarolloveraccident,keepthe

rollbarintheraisedandlockedpositionandweartheseat

belt.Lowertherollbaronlywhenabsolutelynecessary;do

notweartheseatbeltwhentherollbarisdown.

3.ReadtheOperator'sManual;driveslowlyandcarefully.

107-3069

107-2114

decal107-2114

decal133-8062

133-8062

7

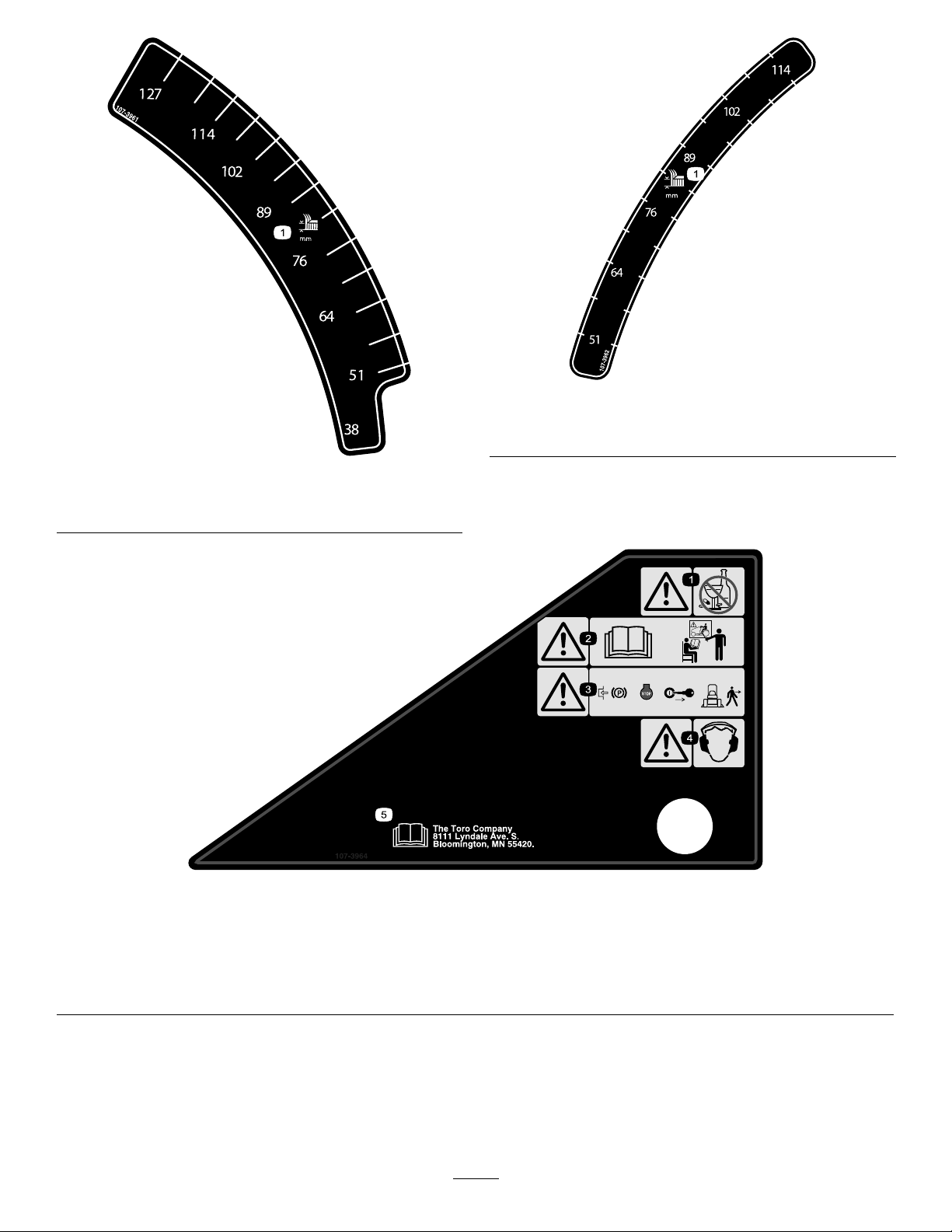

1.Heightofcutinmillimeters

decal107-3962

107-3962

1.Heightofcutinmillimeters

decal107-3961

107-3961

107-3964

1.Warning—donotusedrugsoralcohol.3.Warning—engagetheparkingbrake,

2.Warning—readtheOperator'sManual

andreceivetraining.

shutofftheengine,andremovethe

keybeforeleavingthemachine.

4.Warning—wearhearingprotection.

8

decal107-3964

5.ReadtheOperator'sManual.

107-3968

1.Disengage3.Parkingbrake

2.Engage

decal107-3969

107-3969

1.Warning—readtheOperator'sManual.

2.Crushinghazard,mower—engagetheparkingbrake,shut

offtheengine,andremovethekeybeforeworkingunder

themower.

decal107-3968

decal107-7719

107-7719

1.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

2.Beforestartingtheengine,cleangrassanddebrisfromthe

mowerbeltandpulleys,insertthekey,andstarttheengine.

107-9309

1.Warning—readtheOperator'sManualforinformationonchargingthebattery;containslead;donotdiscard.

2.ReadtheOperator'sManual.

decal108-5955

108-5955

decal107-9309

decal108-5957

108-5957

9

decal108-5981

108-5981

1.Beltrouting

2.Heightofcut

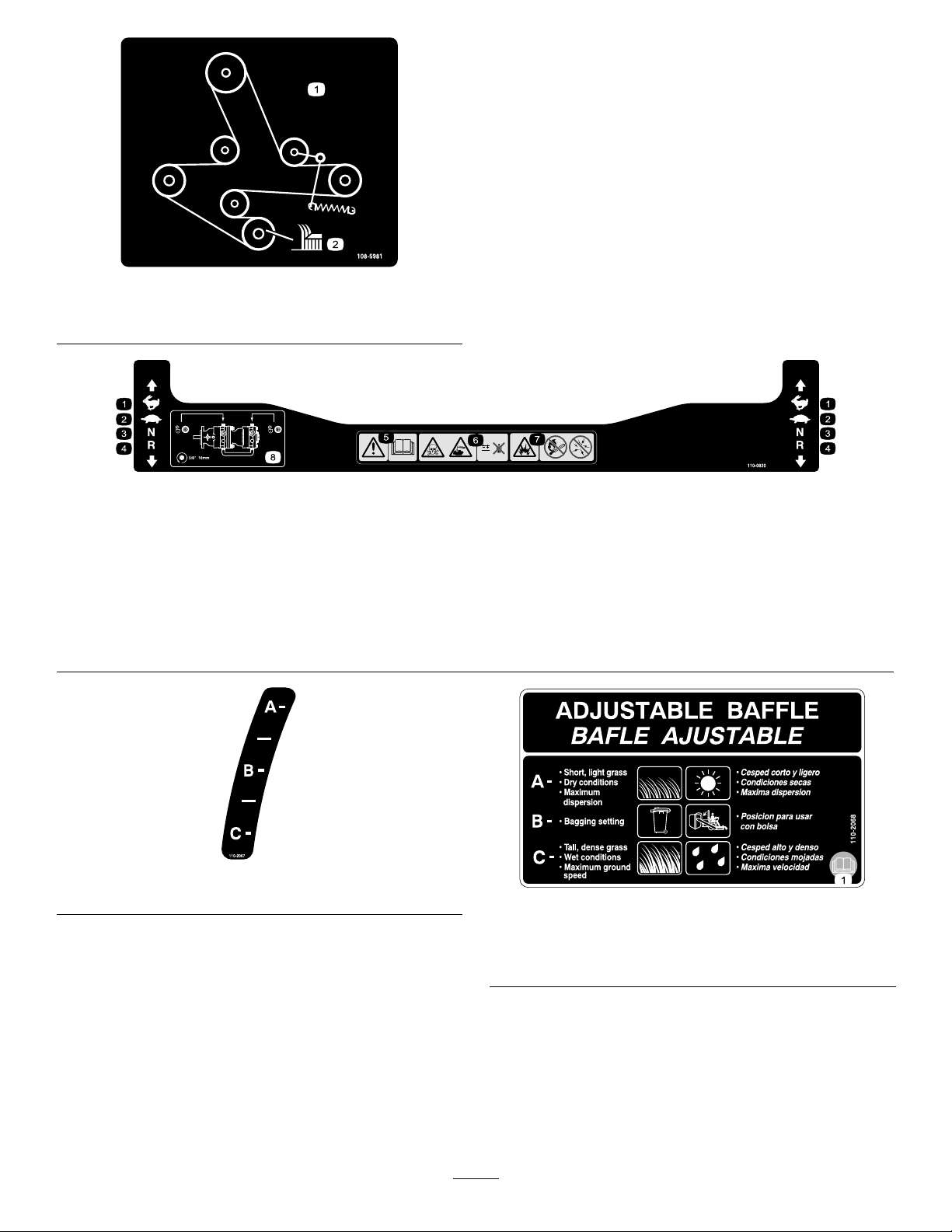

110-0820

1.Fast

2.Slow6.Poisonandcausticliquid/chemicalburnhazard—keepaway

3.Neutral

4.Reverse8.Tounlockthetractiondrive,turnthebypassvalve1complete

5.Warning—readtheOperator'sManual.

fromthebattery.

7.Explosionhazard—nore,openames,orsmoking;avoid

sparks.

revolutioncounterclockwiseusinga5/8inchor16mm

wrench.

decal110-0820

decal110-2067

110-2067

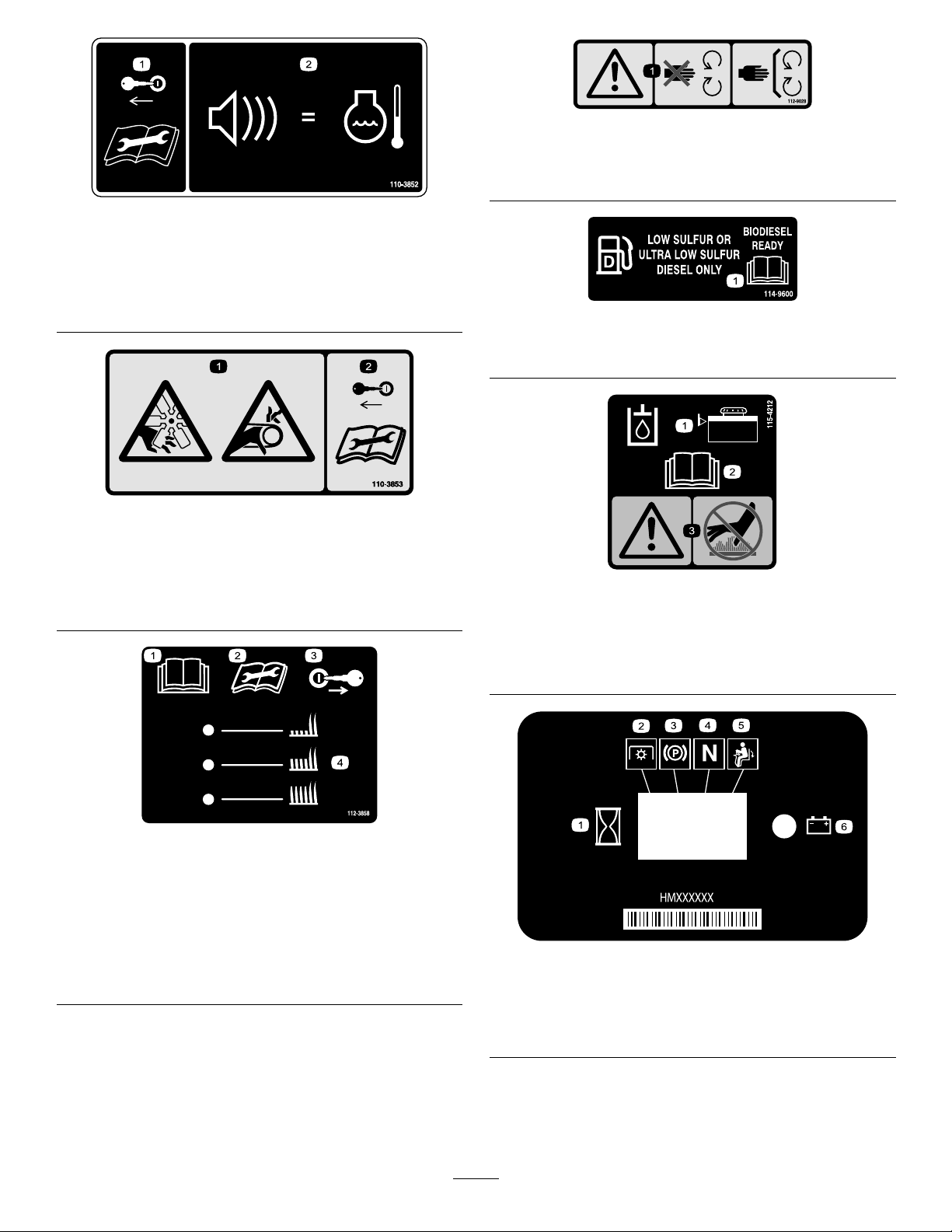

decal110-2068

110-2068

SideDischargeMachinesOnly

1.ReadtheOperator'sManual.

10

decal112-9028

112-9028

1.Warning—stayawayfrommovingparts;keepallguards

andshieldsinplace.

decal110-3852

110-3852

1.Removethekeyfrom

thekeyswitchandread

theinstructionsbefore

servicingorperforming

maintenance.

1.Cutting/dismemberment

hazard,fanand

entanglementhazard,

belt.

2.Continuoustonesignals

110-3853

2.Removethekeyfrom

theuserthattheengineis

overheating.

decal110-3853

thekeyswitchandread

theinstructionsbefore

servicingorperforming

maintenance.

1.ReadtheOperator'sManual.

1.Hydraulic-iudlevel

2.ReadtheOperator's

Manual.

decal114-9600

114-9600

decal115-4212

115-4212

3.Warning—donottouchthe

hotsurface.

1.ReadtheOperator's

Manual.

2.Readtheinstructions

beforeservicingor

performingmaintenance.

112-3858

RearDischargeMachinesOnly

3.Removethekeyfrom

4.Height-of-cutsettings.

decal112-3858

thekeyswitchbefore

adjustingtheheightofcut.

decal116-5610

116-5610

1.Hourmeter4.Neutral

2.Powertake-off(PTO)5.Operator-presenceswitch

3.Parkingbrake6.Battery

11

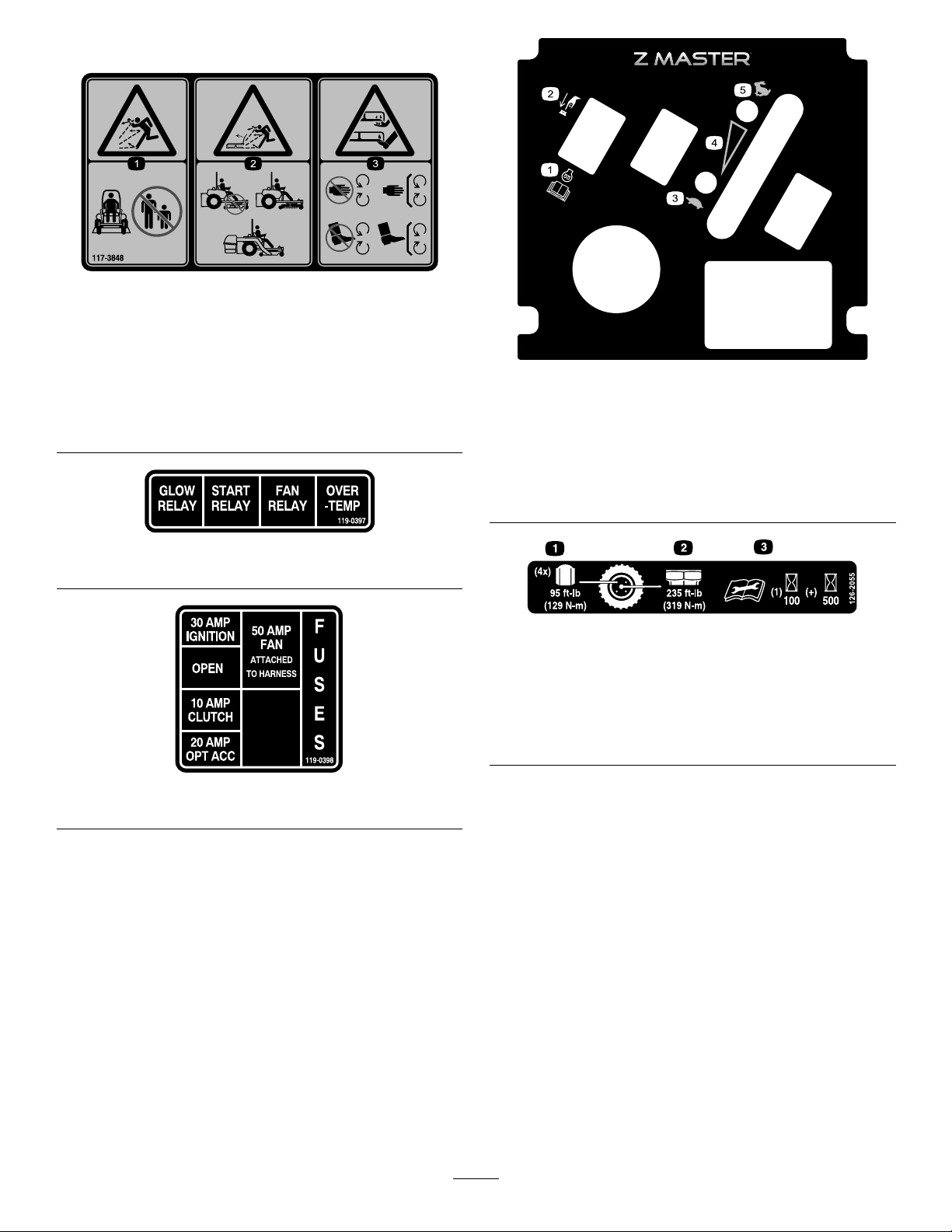

Reardischargemachinesonly:

117-3848

1.Thrownobjecthazard—keepbystandersaway.

2.Thrownobjecthazard,raiseddeector—donotoperate

withoutthedeector,dischargecover,orgrasscollection

systeminplace.

3.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts;keepallguardsand

shieldsinplace.

decal117-3848

decal121-7562

121-7562

1.Pushtostart4.Variablespeedcontrol

2.ReadtheOperator’s

Manualformore

informationonpreheating

theengine.

3.Slow

5.Fast

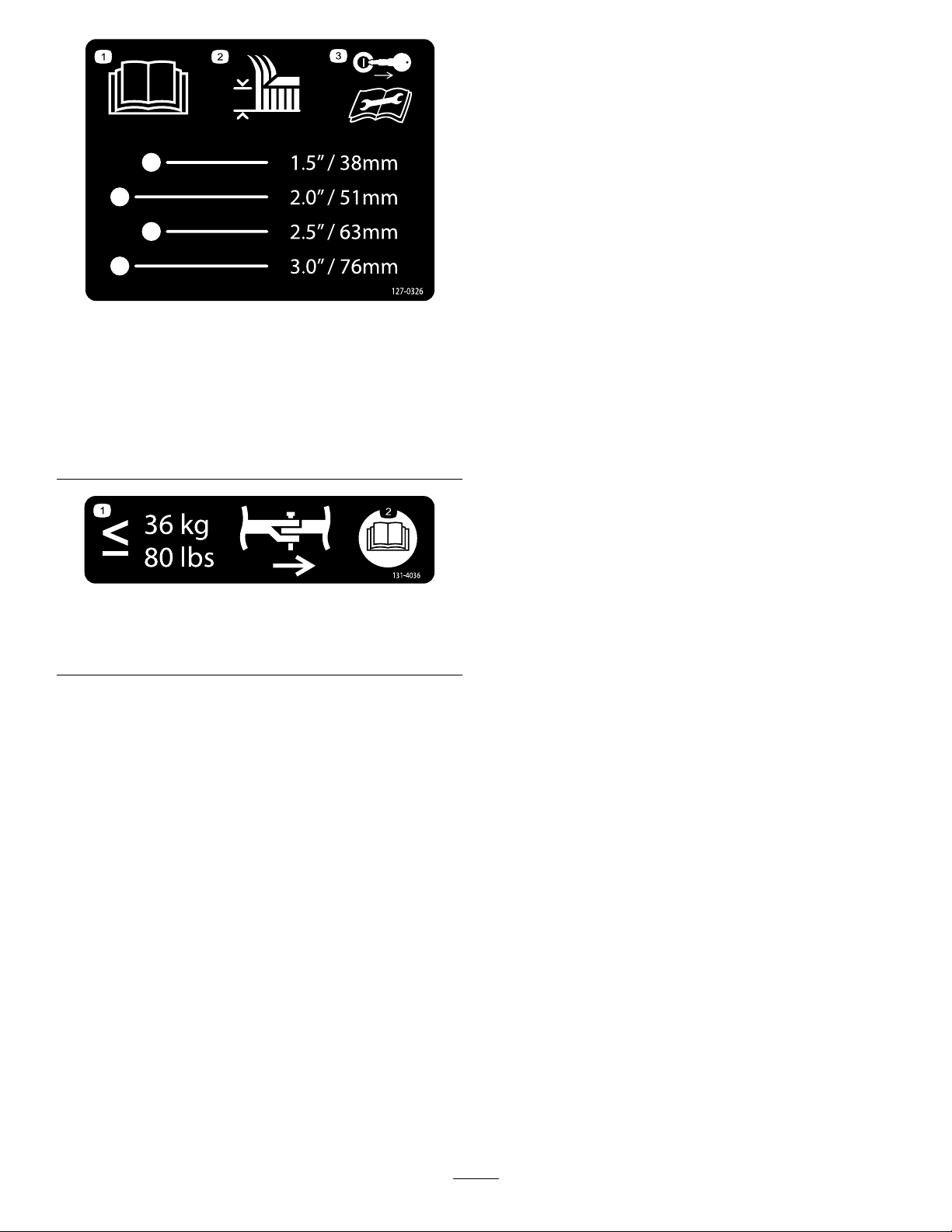

decal119-0397

119-0397

decal126-2055

126-2055

1.Wheellugnuttorque129N∙m(95ft-lb)(4x)

2.Wheelhubnuttorque319N∙m(235ft-lb)

3.ReadandunderstandtheOperator’sManualbefore

performinganymaintenance,checktorqueafterrst100

hoursthenevery500hoursthereafter.

decal119-0398

119-0398

12

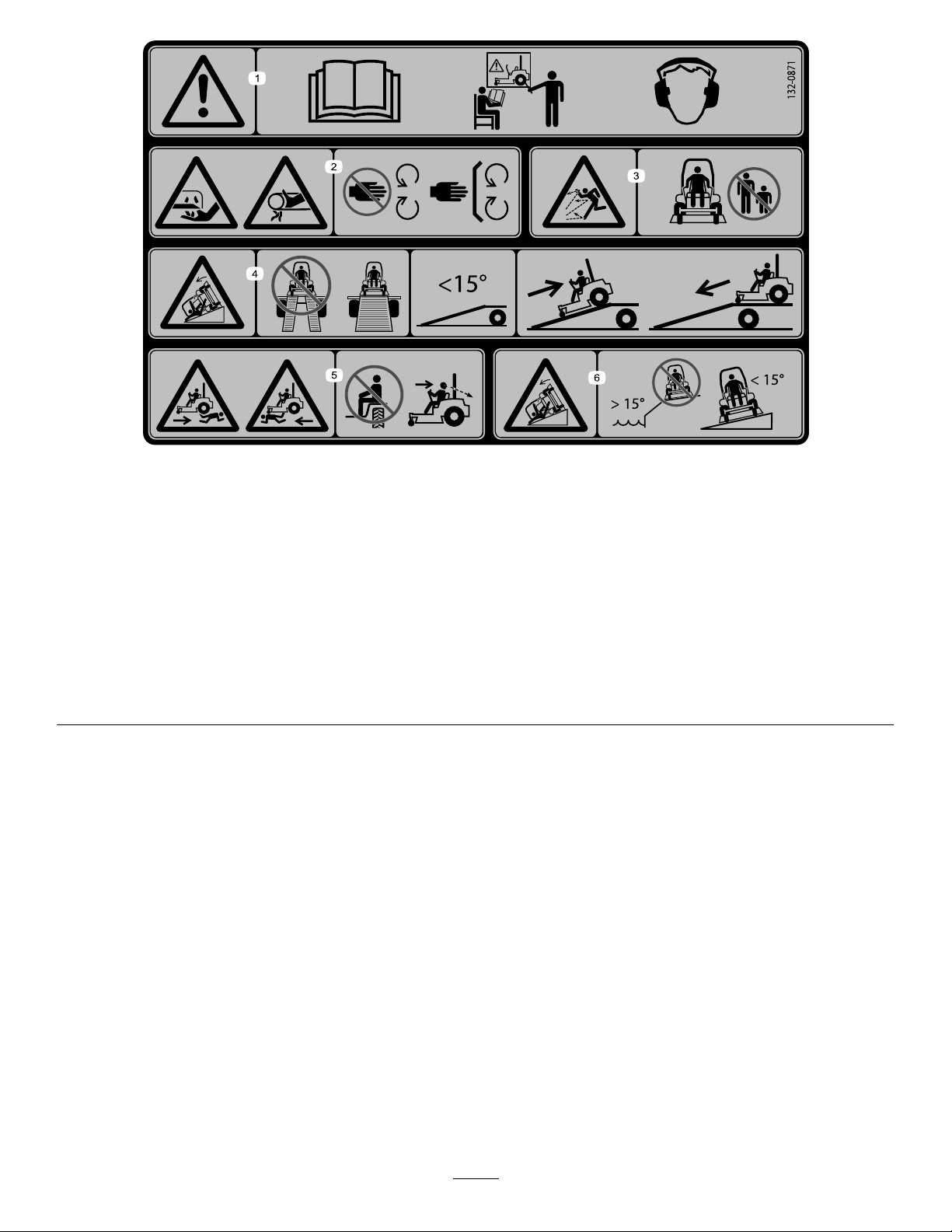

127-0326

SideDischargeMachinesOnly

decal127-0326

1.ReadtheOperator's

Manual.

2.Heightofcut

1.Maximumdrawbarpull36

kg(80lb).

3.Removethekeyand

readtheOperator's

Manualbeforeperforming

maintenanceorservicing

themachine.

decal131-4036

131-4036

2.ReadtheOperator's

Manual.

13

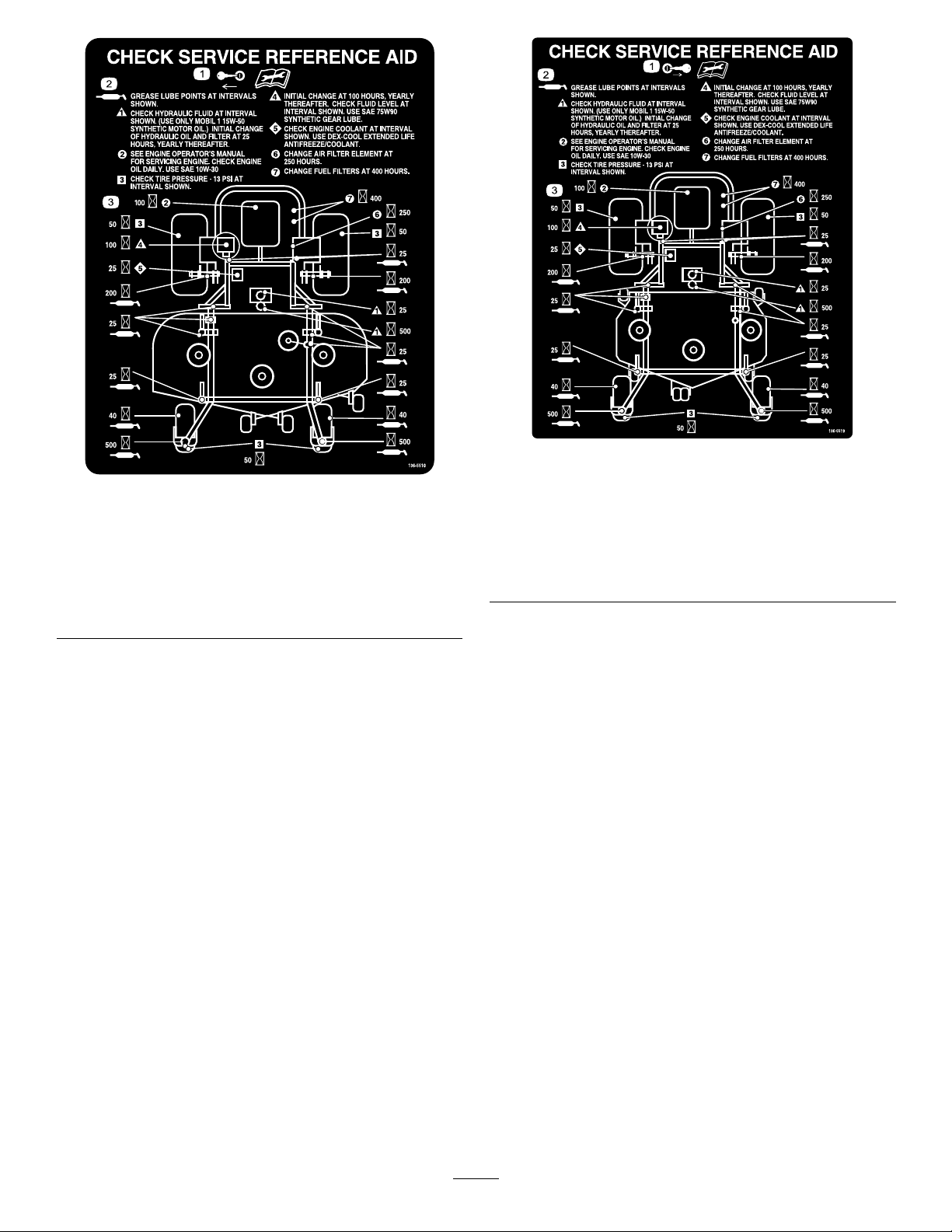

132-0871

Note:Thismachinecomplieswiththeindustrystandardstabilitytestinthestaticlateralandlongitudinaltestswiththemaximum

recommendedslopeindicatedonthedecal.ReviewtheinstructionsforoperatingthemachineonslopesintheOperator’sManualas

wellastheconditionsinwhichyouwouldoperatethemachinetodeterminewhetheryoucanoperatethemachineintheconditionson

thatdayandatthatsite.Changesintheterraincanresultinachangeinslopeoperationforthemachine.

decal132-0871

1.Warning—readtheOperator’sManual;alloperatorsshould

betrainedbeforeoperatingthemachine;wearhearing

protection.

2.Cutting/dismembermenthazardofhand—stayawayfrom

movingparts;keepallguardsandshieldsinplace.

3.Thrownobjecthazard—keepbystandersaway.

4.Tippinghazard—donotusedualrampswhenloadingontoa

trailer;use1rampwideenoughforthemachine;usearamp

withaslopelessthan15°;backuptheramp(inreverse)and

driveforwardofftheramp.

5.Runoverhazard—donotcarrypassengers;lookbehindyou

whenmovinginreverse.

6.Tippinghazard—donotusethemachineneardrop-offsor

onslopesgreaterthan15°;onlyoperateacrossslopesless

than15°.

14

SideDischargeMachinesOnly

1.Removethekeyand

readtheOperator's

Manualbeforeperforming

maintenance.

2.Greasepoint

decal136-5519

136-5519

decal136-5510

RearDischargeMachinesOnly

136-5510

3.Hourinterval

3.Hourinterval

1.Removethekeyand

readtheOperator's

Manualbeforeperforming

maintenance.

2.Greasepoint

15

ProductOverview

Controls

Becomefamiliarwithallthecontrolsbeforeyoustart

theengineandoperatethemachine.

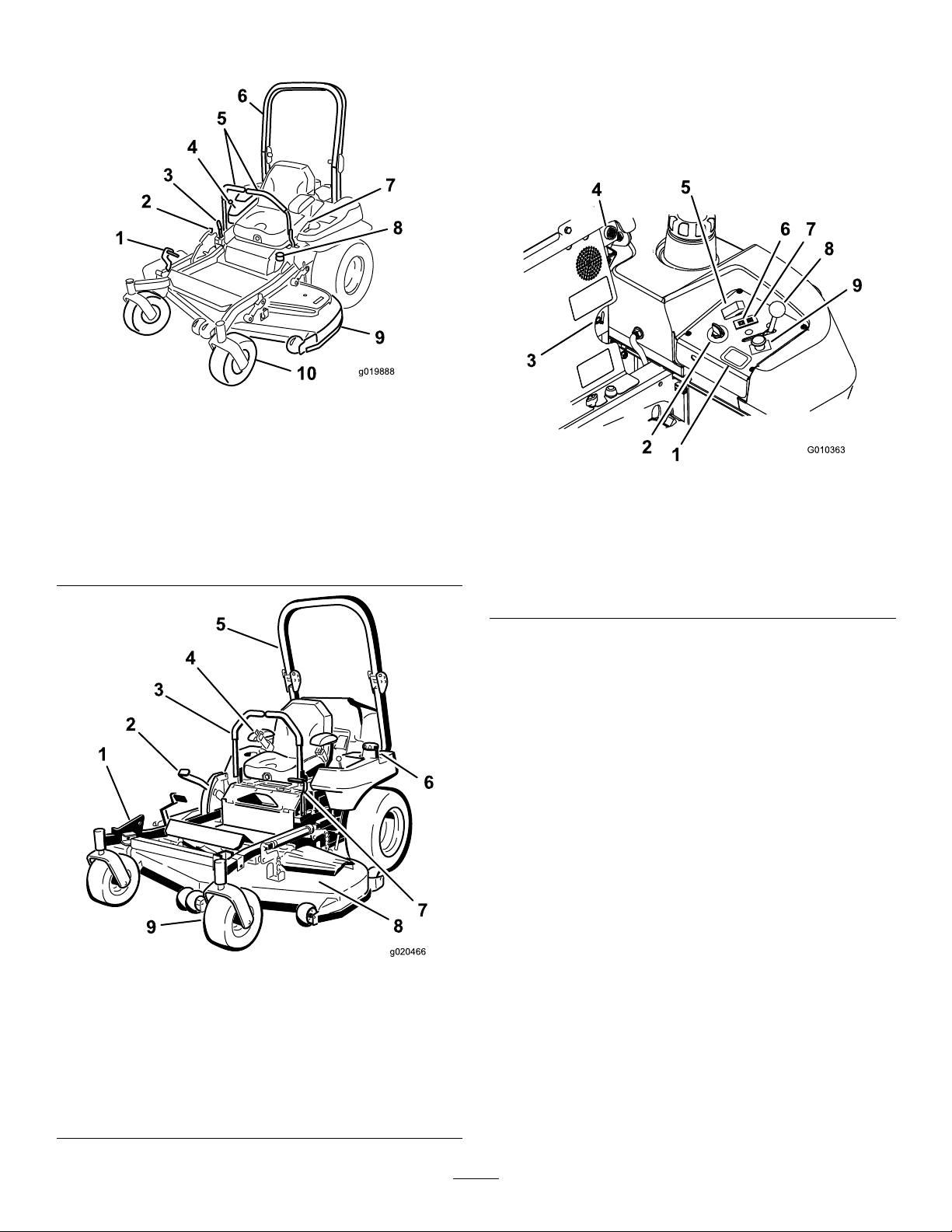

ControlPanel

g019888

Figure4

SideDischargeMachine

1.Height-of-cutdecklift

pedal

2.Transportlock

3.Parking-brakelever8.Fuelcap

4.Controls

5.Motion-controllever

6.Rollbar

7.Seatbelt

9.Mowerdeck

10.Casterwheel

Figure6

1.Hourmeter

2.Keyswitch7.Engine-temperaturelight

3.Fuel-selectorvalve8.Throttlecontrol

4.Audiblealarm

5.Glow-plugswitch

6.Glow-pluglight

9.PTOswitch

KeySwitch

Thekeyswitch,usedtostartandshutofftheengine,

has3positions:OFF,RUN,andSTART.Referto

StartingandShuttingOfftheEngine(page26).

HourMeter

Thehourmeterrecordsthenumberofhoursthe

enginehasoperated.Itoperateswhentheengine

isrunning.Usethesetimesforschedulingregular

maintenance(Figure6).

g010363

Figure5

RearDischargeMachine

1.ZStand

2.Height-of-cutlever

3.Motion-controllever8.Mowerdeck

4.Seatbelt9.Casterwheel

5.Rollbar

©

6.Fuelcap(bothsides)

7.Parking-brakelever

Safety-InterlockIndicators

g020466

Therearesymbolsonthehourmeterthatindicate

withablacktrianglethattheinterlockcomponentis

positionedcorrectly(Figure7).

16

Battery-IndicatorLight

AudibleAlarm

IfyouturnthekeyswitchtotheONpositionfora

fewseconds,thebatteryvoltagedisplaysinthearea

wherethehoursarenormallydisplayed.

Thebatterylightturnsonwhentheignitionisturned

onandwhenthechargeisbelowthecorrectoperating

level(Figure7).

Figure7

1.Safety-interlocksymbols

2.Hourmeter

3.Batterylight

ThrottleControl

Thethrottlecontrolstheenginespeed,andithasa

continuous-variablesettingfromtheSLOWtoFAST

position(Figure6).

Thismachinehasanaudiblealarmthatalertstheuser

toshutofftheengine;otherwise,enginedamagecan

occurfromoverheating.RefertoOperatingwiththe

OverheatSensor(page33).

Fuel-SelectorValve

Thefuel-selectorvalveislocatedbehindtheseat.

Closethefuel-selectorvalvewhentransportingor

storingmower.

Movetheselectorvalvetotheleftorrightpositionfor

operation.

Attachments/Accessories

g009610

AselectionofT oroapprovedattachmentsand

accessoriesisavailableforusewiththemachine

toenhanceandexpanditscapabilities.Contact

yourAuthorizedServiceDealerorauthorizedT oro

distributororgotowww.Toro.comforalistofall

approvedattachmentsandaccessories.

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

Neutral-LockPosition

UsetheNEUTRAL-LOCKpositionwiththe

safety-interlocksystemtoengageandtodetermine

theNEUTRALposition.

Glow-PlugLight

Theglow-plugindicatorlightturnsonwhenthe

glow-plugbuttonisengaged(Figure6).

Glow-PlugSwitch

Thisswitchactivatestheglowplugsandisindicated

bytheglow-pluglight.Holddowntheglow-plugswitch

for10secondspriortostartingthemachine.

TemperatureLight

Thetemperaturelightcomesonwhentheengineis

overheating(Figure6).

17

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageoftheoperator.Theowner

isresponsiblefortrainingalloperatorsand

mechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Knowhowtostopthemachineandshutoffthe

enginequickly.

•Checkthatoperator-presencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

•Beforemowing,alwaysinspectthemachineto

ensurethattheblades,bladebolts,andcutting

assembliesareingoodworkingcondition.

Replacewornordamagedbladesandboltsinsets

topreservebalance.

•Inspecttheareawhereyouwillusethemachine

andremoveallobjectsthatthemachinecould

throw.

•Evaluatetheterraintodeterminetheappropriate

equipmentandanyattachmentsoraccessories

requiredtooperatethemachineproperlyand

safely.

containersontheground,awayfromyourvehicle

beforelling.

•Removetheequipmentfromthetruckortrailer

andrefuelitwhileitisontheground.Ifthisisnot

possible,thenrefuelfromaportablecontainer

ratherthanafuel-dispensernozzle.

•Donotoperatethemachinewithouttheentire

exhaustsysteminplaceandinproperworking

condition.

•Keepthefuel-dispensernozzleincontactwith

therimofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.Donotusea

nozzlelock-opendevice.

•Ifyouspillfuelonyourclothing,changeyour

clothingimmediately.Wipeupanyfuelthatspills.

•Neveroverllthefueltank.Replacethefuelcap

andtightenitsecurely.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymorethan

a30-daysupplyoffuel.

•Donotllthefueltankcompletelyfull.Addfuelto

thefueltankuntilthelevelis6to13mm(1/4to

1/2inch)belowthebottomofthellerneck.This

emptyspaceinthetankallowsfueltoexpand.

–Avoidprolongedbreathingofvapors.

–Keepyourfaceawayfromthenozzleandfuel

tankopening.

–Avoidcontactwithskin;washoffspillswith

soapandwater.

PerformingDaily

Maintenance

Beforestartingthemachineeachday,performthe

EachUse/DailyprocedureslistedinMaintenance

(page39).

FuelSafety

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlingfuel.Fuelvaporsare

ammableandexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfueltothefuel

tankwhiletheengineisrunningorwhilehot.

•Donotrefuelthemachineindoors.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

•Donotllcontainersinsideavehicleoronatruck

ortrailerbedwithaplasticliner.Alwaysplace

AddingFuel

RecommendedFuel

Theenginerunsonclean,freshdieselfuelwith

aminimumoctaneratingof40.Purchasefuelin

quantitiesthatcanbeusedwithin30daystoensure

fuelfreshness.

Usesummer-gradedieselfuel(No.2-D)at

temperaturesabove-7°C(20°F)andwinter-grade

dieselfuel(No.1-DorNo.1-D/2-Dblend)below

-7°C(20°F).Useofwinter-gradedieselfuelatlower

temperaturesprovideslowerashpointandpour

pointcharacteristics,thereforeeasingstartabilityand

lesseningchancesofchemicalseparationofthefuel

duetolowertemperatures(waxappearance,which

maypluglters).

18

Usingsummer-gradedieselfuelabove-7°C

(20°F)contributestowardlongerlifeofthepump

components.

Important:Donotusekeroseneorgasoline

insteadofdieselfuel.Failuretoobservethis

cautionwilldamagetheengine.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuel

ofuptoB20(20%biodiesel,80%petrodiesel).The

petrodieselportionshouldbeloworultralowsulfur.

Observethefollowingprecautions:

•Thebiodieselportionofthefuelmeetspecication

ASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTM

D975orEN590.

•Paintedsurfacesmaybedamagedbybiodiesel

blends.

•UseB5(biodieselcontentof5%)orlesserblend

incoldweather.

•Monitorseals,hoses,gasketsincontactwithfuel

astheymaydegradeovertime.

•Fuellterpluggingmaybeexpectedforatime

afterconvertingtobiodieselblends.

•Contactyourdistributorformoreinformationon

biodiesel.

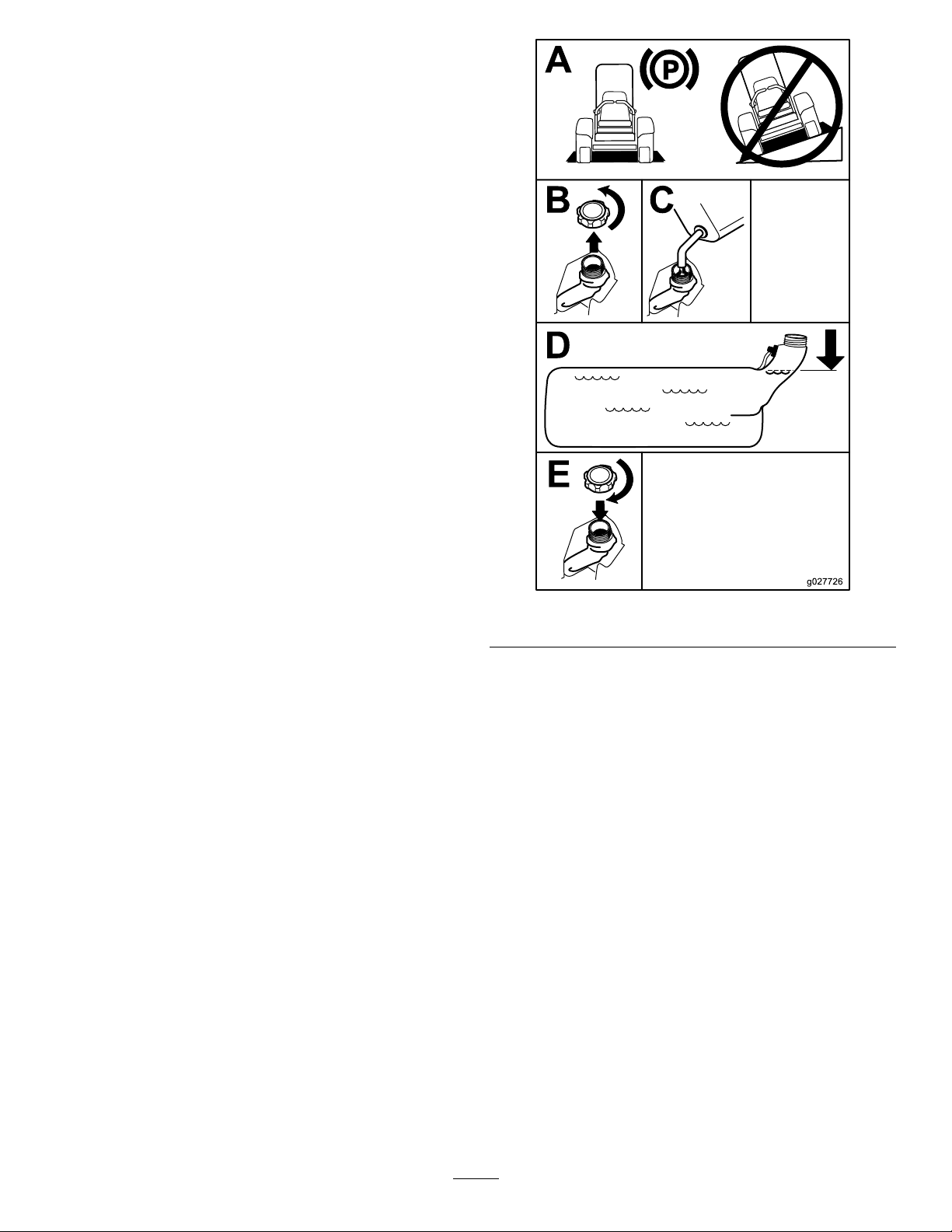

FillingtheFuelTank

1.Parkthemachineonalevelsurface.

2.Engagetheparkingbrake.

3.Shutofftheengineandremovethekey.

4.Cleanaroundthefuel-tankcap.

5.Fillthefueltanktothebottomofthellerneck

(Figure8).

Note:Donotllthefueltankcompletelyfull.

Theemptyspaceinthetankallowsthefuelto

expand.

g027726

Figure8

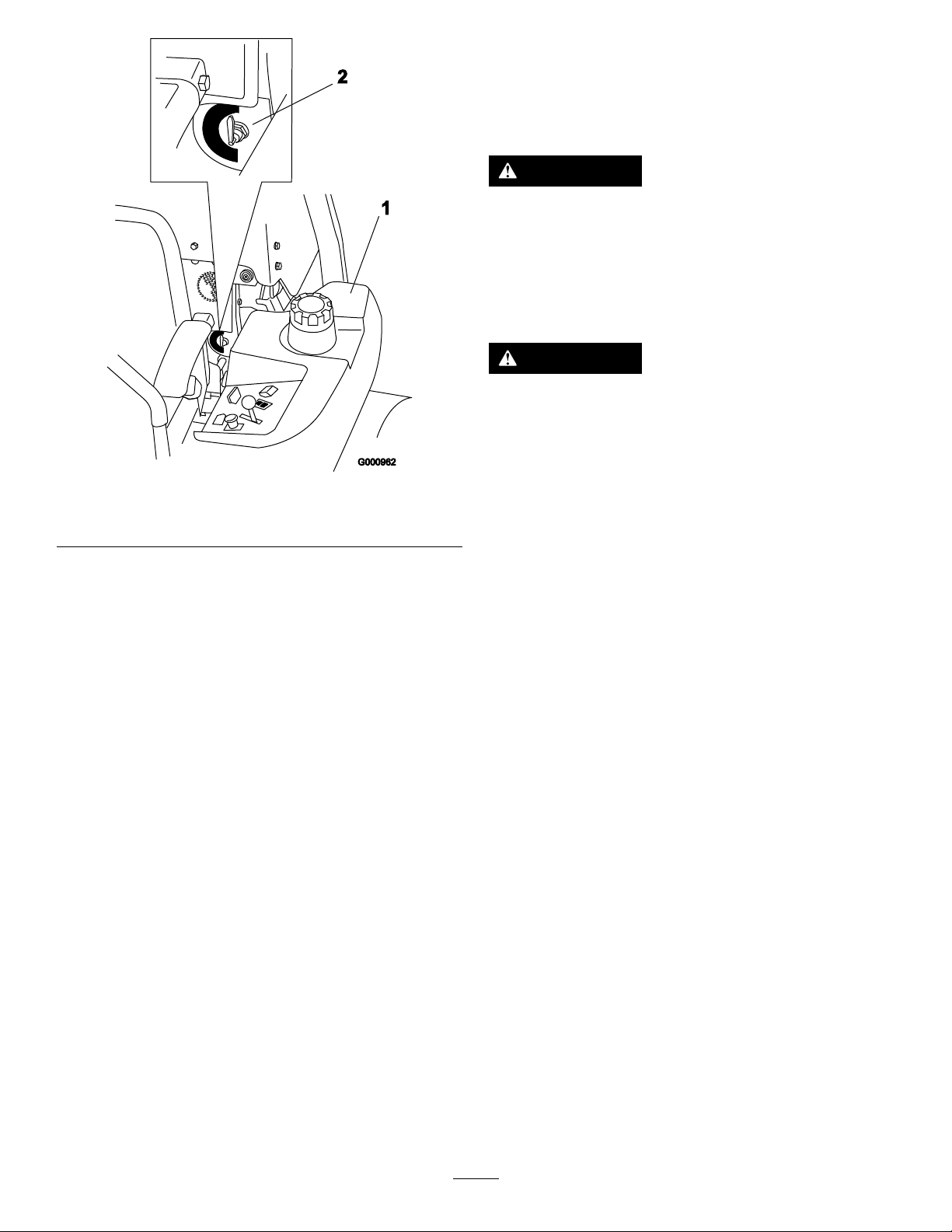

SwitchingtheFuelTanks

Important:Donotallowthemachinetorunout

offuel,asthiscandamagethemachine.

Thefuel-selectorvalveislocatedbehindtheleftside

oftheseat.

Themachinehas2fueltanks:1tankisontheleft

sideand1isontherightside.Eachtankconnectsto

thefuel-selectorvalve.Fromthere,acommonfuel

lineleadstotheengine(Figure9).

Tousetheleftfueltank,rotatethefuel-selector

valvetotheleft.T ousetherightfueltank,rotatethe

fuel-selectorvalvetotheright(Figure9).

Closethefuel-selectorvalvebeforetransportingor

storingthemachine.

19

1.Leftfueltank

Figure9

Usingthe

Rollover-ProtectionSystem

(ROPS)

WARNING

Toavoidinjuryordeathfromrollover,keep

therollbarinthefullyraised,lockedposition

andusetheseatbelt.

Ensurethattheseatissecuredtothe

machine.

WARNING

Thereisnorolloverprotectionwhentheroll

barisinthedownposition.

•Lowertherollbaronlywhenabsolutely

necessary.

g000962

•Donotweartheseatbeltwhentherollbar

isinthedownposition.

2.Fuel-selectorvalve

•Driveslowlyandcarefully.

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mower

decksanddrivesystemshavehigherfrictionwhen

new,placingadditionalloadontheengine.Allow

40to50hoursofbreak-intimefornewmachinesto

developfullpowerandbestperformance.

•Raisetherollbarassoonasclearance

permits.

•Checkcarefullyforoverheadclearances

(i.e.,branches,doorways,electricalwires)

beforedrivingunderanyobjectsanddo

notcontactthem.

LoweringtheRollBar

Important:Lowertherollbaronlywhen

absolutelynecessary.

1.Removethehairpincottersandremovethe2

pins(Figure11).

2.Lowertherollbartothedownposition(Figure

10).

Note:Thereare2downpositions;referto

Figure10.

3.Installthe2pinsandsecurethemwiththe

hairpincotters(Figure11).

20

Figure10

UsingtheSafety-Interlock

System

WARNING

Ifsafety-interlockswitchesaredisconnected

ordamaged,themachinecouldoperate

unexpectedlycausingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdaily,andreplaceanydamaged

g004954

switchesbeforeoperatingthemachine.

1.Full-downposition2.Downpositionwiththe

baggerinstalled

Important:Ensurethatyousecuretherear

partoftheseatwiththeseatlatch.

RaisingtheRollBar

Important:Alwaysusetheseatbeltwiththeroll

barintheraisedposition.

1.Removethehairpincottersandremovethe2

pins(Figure11).

2.Raisetherollbartotheuprightposition,install

the2pins,andsecurethemwiththehairpin

cotters(Figure11).

Understandingthe

Safety-InterlockSystem

Thesafety-interlocksystemisdesignedtopreventthe

enginefromstartingunless:

•Theparkingbrakeisengaged.

•Theblade-controlswitch(PTO)isdisengaged.

•Themotion-controlleversareintheNEUTRAL-LOCK

position.

Thesafety-interlocksystemalsoisdesignedtoshutoff

theenginewhenthetractioncontrolsaremovedfrom

thelockedpositionwiththeparkingbrakeengagedor

ifyourisefromtheseatwhenthePTOisengaged.

Thehourmeterhassymbolstonotifytheuserwhen

theinterlockcomponentisinthecorrectposition.

Whenthecomponentisinthecorrectposition,a

trianglelightsupinthecorrespondingsquare.

Figure11

1.Rollbar3.Pin

2.Raisedposition4.Hairpincotter

g009612

Figure12

1.Triangleslightupwhentheinterlockcomponentsareinthe

correctposition

TestingtheSafety-Interlock

g004955

System

ServiceInterval:Beforeeachuseordaily

Testthesafety-interlocksystembeforeyouusethe

machineeachtime.Ifthesafetysystemdoesnot

21

operateasdescribedbelow,haveanAuthorized

ServiceDealerrepairthesafetysystemimmediately .

1.Sittingontheseat,engagetheparkingbrake

andmovetheblade-controlswitch(PTO)tothe

ONposition.Trystartingtheengine;theengine

shouldnotstart.

2.Sittingontheseat,engagetheparkingbrake

andmovetheblade-controlswitch(PTO)tothe

OFFposition.Moveeithermotion-controllever

(outoftheNEUTRAL-LOCKposition).Trystarting

theengine;theengineshouldnotstart.Repeat

fortheothercontrollever.

3.Sittingontheseat,engagetheparkingbrake,

movetheblade-controlswitch(PTO)totheOFF

position,andmovethemotion-controllevers

totheNEUTRAL-LOCKposition.Nowstartthe

engine.Whiletheengineisrunning,disengage

theparkingbrake,engagetheblade-control

switch(PTO),andriseslightlyfromtheseat;the

engineshouldshutoff.

4.Sittingontheseat,engagetheparkingbrake,

movetheblade-controlswitch(PTO)totheOFF

position,andmovethemotion-controllevers

totheNEUTRAL-LOCKposition.Nowstartthe

engine.Whiletheengineisrunning,center

eithermotioncontrolandmove(forwardor

reverse);theengineshouldshutoff.Repeatfor

othermotioncontrol.

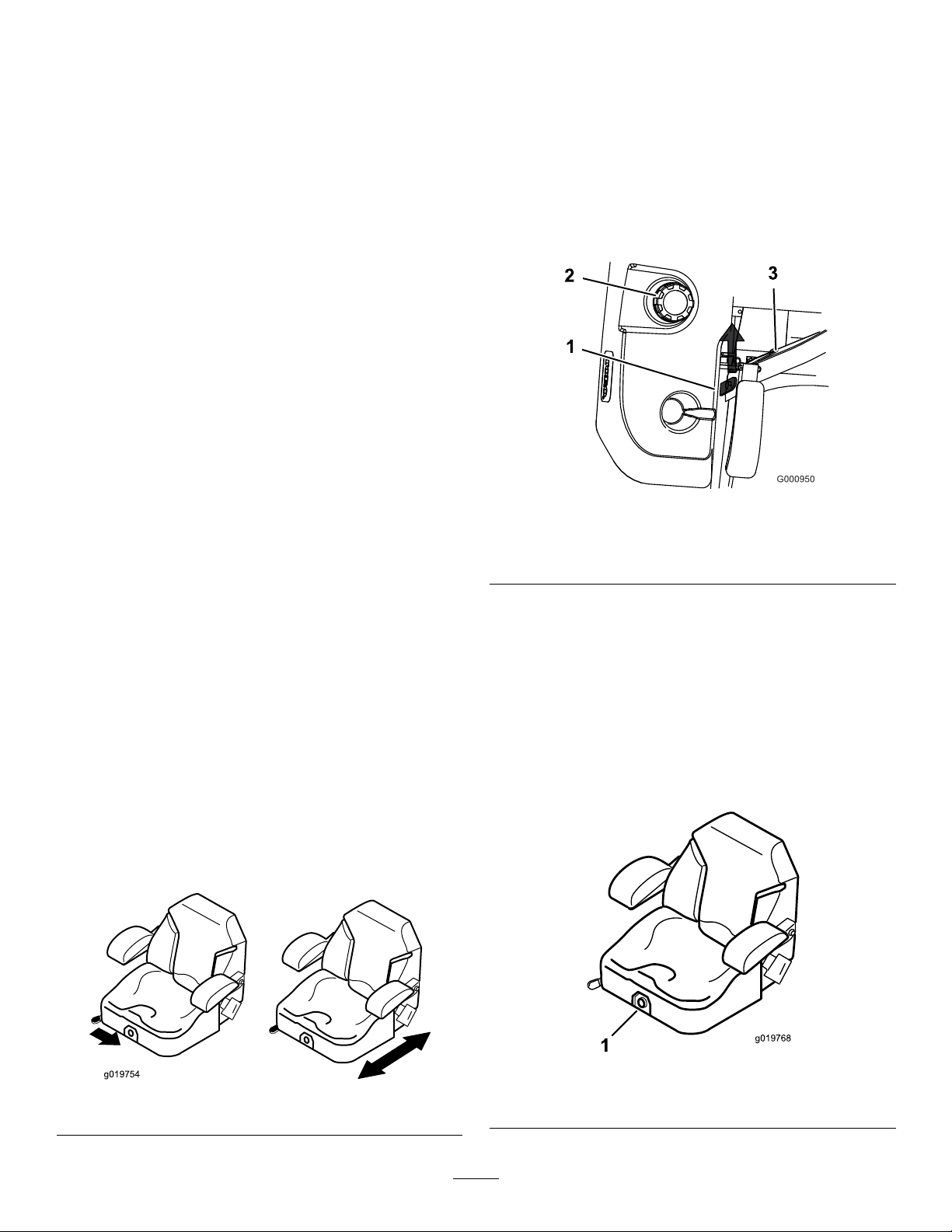

UnlatchingtheSeat

1.Movetheseattothemostrearwardposition.

Note:Thispreventsinterferencewhenyou

raisetheseat.

2.Pushtheseatlatchrearwardtounlatchtheseat.

3.Raisetheseatup(Figure14).

Note:Thisallowsaccesstothemachineunder

theseat.

g000950

Figure14

1.Seatlatch3.Seat

2.Fuelcap

5.Sittingontheseat,disengagetheparkingbrake,

movetheblade-controlswitch(PTO)totheOFF

position,andmovethemotion-controllevers

totheNEUTRAL-LOCKposition.Trystartingthe

engine;theengineshouldnotstart.

PositioningtheSeat

Theseatmovesforwardandbackward.Positionthe

seatwhereyouhavethebestcontrolofthemachine

andaremostcomfortable.

Toadjust,movetheleversidewaystounlocktheseat

(Figure13).

Figure13

ChangingtheSeat

Suspension

Theseatisadjustabletoprovideasmoothand

comfortableride.Positiontheseatwhereyouare

mostcomfortable.

Toadjustit,turntheknobinfronteitherdirectionto

providethebestcomfort(Figure15).

g019768

g019754

1.Seat-suspensionknob

Figure15

22

DuringOperation

DuringOperationSafety

GeneralSafety

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Wearappropriateclothing,includingeye

protection;longpants;slip-resistant,substantial

footwear;andhearingprotection.Tiebacklong

hairanddonotwearloosejewelry.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Nevercarrypassengersonthemachineandkeep

bystandersandpetsawayfromthemachine

duringoperation.

•Operatethemachineonlyingoodvisibilitytoavoid

holesorhiddenhazards.

•Avoidmowingonwetgrass.Reducedtraction

couldcausethemachinetoslide.

•Ensurethatalldrivesareinneutral,theparking

brakeisengaged,andyouareintheoperating

positionbeforeyoustarttheengine.

•Keepyourhandsandfeetawayfromthecutting

units.Keepclearofthedischargeopeningatall

times.

•Lookbehindanddownbeforebackinguptobe

sureofaclearpath.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscureyour

vision.

•Donotmowneardrop-offs,ditches,or

embankments.Themachinecouldsuddenlyroll

overifawheelgoesovertheedgeoriftheedge

givesway.

•Stopthebladeswheneveryouarenotmowing.

•Stopthemachine,shutofftheengine,remove

thekey,andinspectthebladesafterstrikingan

objectorifthereisanabnormalvibrationinthe

machine.Makeallnecessaryrepairsbefore

resumingoperation.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalkswiththe

machine.Alwaysyieldtheright-of-way.

•Disengagethedrivetothecuttingunit,shutoffthe

engine,andremovethekeybeforeadjustingthe

heightofcut(unlessyoucanadjustitfromthe

operatingposition).

•Neverrunanengineinanareawhereexhaust

gasesareenclosed.

•Neverleavearunningmachineunattended.

•Beforeleavingtheoperatingposition(including

toemptythecatchersortounclogthechute),do

thefollowing:

–Stopthemachineonlevelground.

–Disengagethepowertakeoffandlowerthe

attachments.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey .

–Waitforallmovingpartstostop.

•Donotoperatethemachinewhenthereistherisk

oflightning.

•Donotusethemachineasatowingvehicleunless

ithasahitchinstalled.

•Donotchangethegovernorspeedoroverspeed

theengine.

•Useonlyaccessoriesandattachmentsapproved

byToro.

•Thismachineproducessoundlevelsinexcess

of85dBAattheoperator’searandcancause

hearinglossthroughextendedperiodsof

exposure.

g229846

Figure16

1.Wearhearingprotection.

RolloverProtectionSystem

(ROPS)Safety

•Donotremovetherollbarfromthemachine.

•Ensurethattheseatbeltisattachedandthatyou

canreleaseitquicklyinanemergency.

•Alwayswearyourseatbeltwhentherollbarisup.

•Checkcarefullyforoverheadobstructionsanddo

notcontactthem.

•Keeptherollbarinsafeoperatingconditionby

thoroughlyinspectingitperiodicallyfordamage

andkeepingallthemountingfastenerstight.

•Replaceadamagedrollbar.Donotrepairoralter

it.

SlopeSafety

•Slopesareamajorfactorrelatedtolossofcontrol

androlloveraccidents,whichcanresultinsevere

23

injuryordeath.Theoperatorisresponsiblefor

safeslopeoperation.Operatingthemachineon

anysloperequiresextracaution.Beforeusingthe

machineonaslope,dothefollowing:

–Reviewandunderstandtheslopeinstructions

inthemanualandonthemachine.

–Useanangleindicatortodeterminethe

approximateslopeangleofthearea.

–Neveroperateonslopesgreaterthan15

degrees.

–Evaluatethesiteconditionsofthedayto

determineiftheslopeissafeformachine

operation.Usecommonsenseandgood

judgmentwhenperformingthisevaluation.

Changesintheterrain,suchasmoisture,can

quicklyaffecttheoperationofthemachineon

aslope.

•Identifyhazardsatthebaseoftheslope.Do

notoperatethemachineneardrop-offs,ditches,

embankments,water,orotherhazards.The

machinecouldsuddenlyrolloverifawheelgoes

overtheedgeortheedgecollapses.Keepasafe

distance(twicethewidthofthemachine)between

themachineandanyhazard.Useawalk-behind

machineorahandtrimmertomowthegrassin

theseareas.

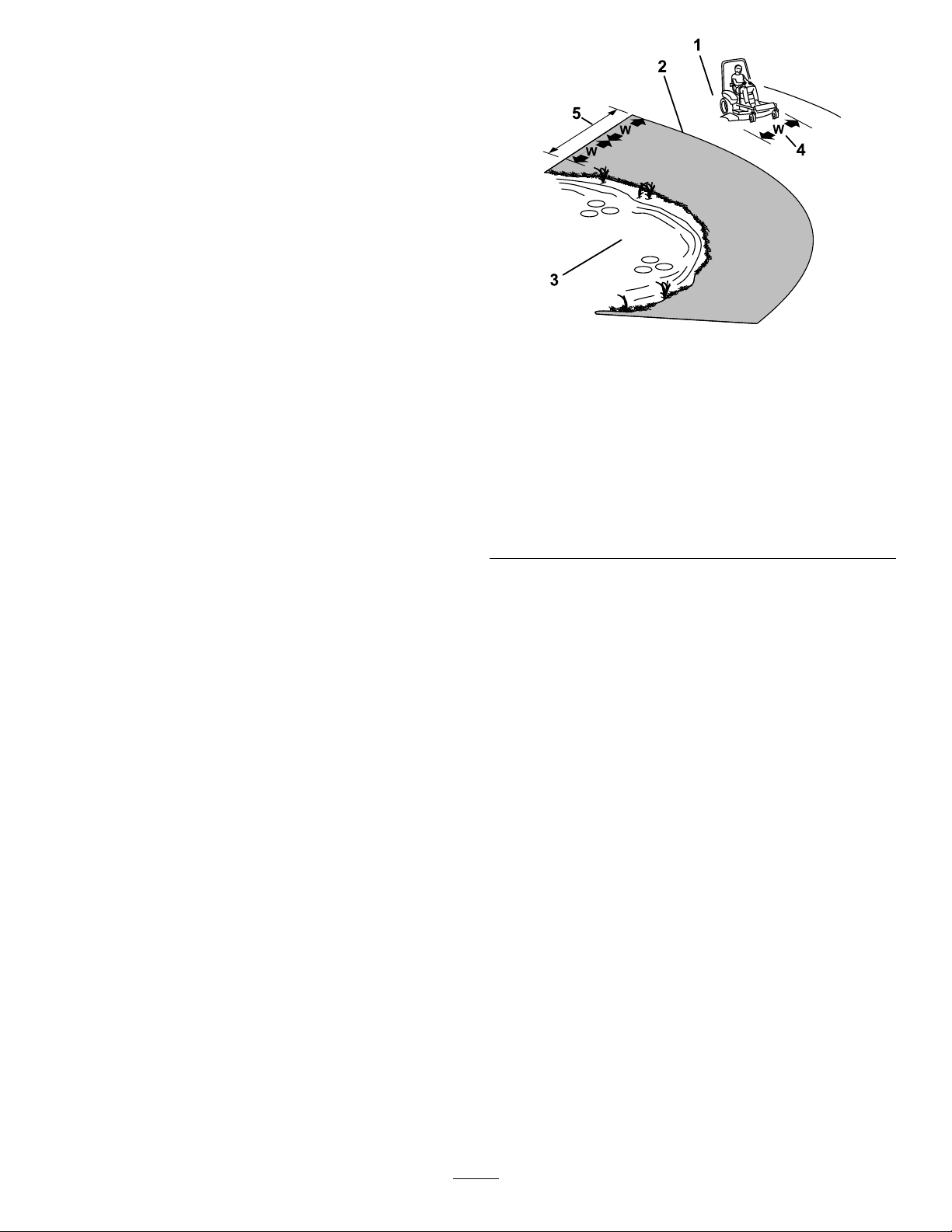

1.SafeZone—usethe

machinehereonslopes

lessthan15degreesor

atareas.

2.DangerZone—usea

walk-behindmowerand/or

ahandtrimmeronslopes

greaterthan15degrees

andneardrop-offsor

water.

3.Water

g221745

Figure17

4.W=widthofthemachine

5.Keepasafedistance

(twicethewidthofthe

machine)betweenthe

machineandanyhazard.

•Avoidstarting,stopping,orturningthemachineon

slopes.Avoidmakingsuddenchangesinspeedor

direction;turnslowlyandgradually.

•Donotoperateamachineunderanyconditions

wheretraction,steering,orstabilityisinquestion.

Beawarethatoperatingthemachineonwet

grass,acrossslopes,ordownhillmaycausethe

machinetolosetraction.Lossoftractiontothe

drivewheelsmayresultinslidingandalossof

brakingandsteering.Themachinecanslideeven

ifthedrivewheelsarestopped.

•Removeormarkobstaclessuchasditches,holes,

ruts,bumps,rocks,orotherhiddenhazards.Tall

grasscanhideobstacles.Uneventerraincould

overturnthemachine.

•Useextracarewhileoperatingwithaccessoriesor

attachments,suchasgrass-collectionsystems.

Thesecanchangethestabilityofthemachine

andcausealossofcontrol.Followdirectionsfor

counterweights.

•Ifpossible,keepthedeckloweredtotheground

whileoperatingonslopes.Raisingthedeckwhile

operatingonslopescancausethemachineto

becomeunstable.

24

OperatingtheParking

Brake

Alwaysengagetheparkingbrakewhenyoustopthe

machineorleaveitunattended.

EngagingtheParkingBrake

Parkthemachineonalevelsurface.

Figure18

EngagingtheBlade-Control

Switch(PTO)

Note:Engagingtheblade-controlswitch(PTO)with

thethrottlepositionathalforlesscausesexcessive

weartothedrivebelts.

g008945

Figure20

DisengagingtheBlade-Control

Switch(PTO)

g187227

DisengagingtheParkingBrake

Figure19

OperatingtheMower

Blade-ControlSwitch(PTO)

Theblade-controlswitch(PTO)startsandstopsthe

mowerbladesandanypoweredattachments.

g009174

Figure21

OperatingtheThrottle

YoucanmovethethrottlecontrolbetweentheFAST

andSLOWpositions(Figure22).

AlwaysusetheFASTpositionwhenturningonthe

mowerdeckwiththeblade-controlswitch(PTO).

g187226

g008946

Figure22

25

StartingandShuttingOff

theEngine

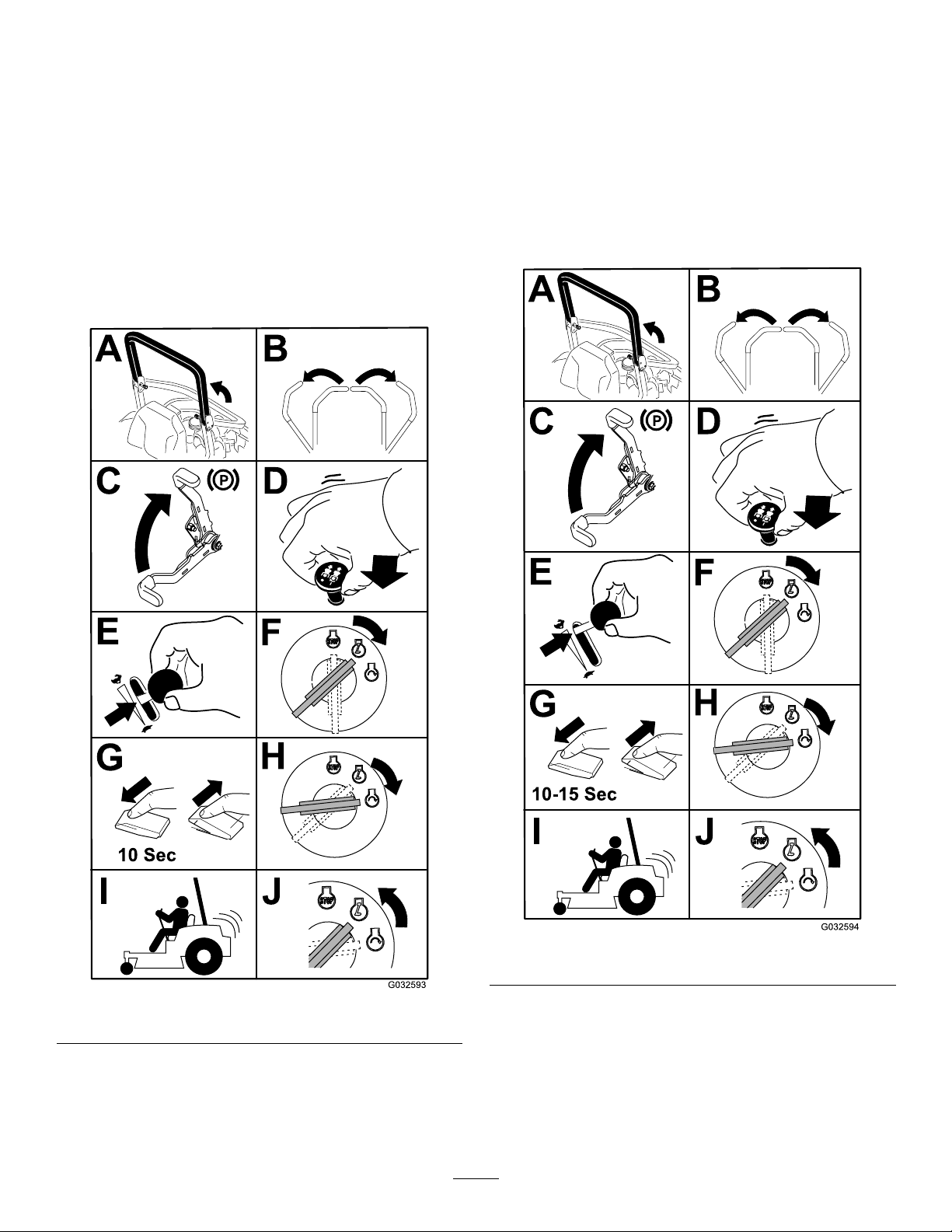

StartingtheEngineinNormal

Weather

Important:Usestartingcyclesofnomorethan

30secondsperminutetoavoidoverheatingthe

startermotor.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthefuel

systemhasbeencompletelywithoutfuel.

StartingtheEngineinCold

Weather(Below23°For-5°C)

Usethecorrectengineoilforthestartingtemperature;

refertoEngine-OilSpecications(page46).

Important:Usestartingcyclesofnomorethan

30secondsperminutetoavoidoverheatingthe

startermotor.

Note:Donotusefuelleftoverfromthesummer.Use

onlyfreshwinter-gradedieselfuel.

Figure23

g032594

Figure24

g032593

26

ShuttingOfftheEngine

UsingtheMotion-Control

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

Alwaysremovethekeyandengagethe

parkingbrakewhenleavingthemachine

unattended.

Levers

Figure25

Important:Makesurethatyouclosethe

fuel-shutoffvalvebeforetransportingorstoring

themachine,asfuelleakagemayoccur.Engage

theparkingbrakebeforetransportingthe

machine.Makesurethatyouremovethekeyas

thefuelpumpmayrunandcausethebatteryto

losecharge.

g004532

Figure26

1.Motion-control

lever—NEUTRAL-LOCK

position

2.Center,unlockedposition5.Frontofmachine

3.Forward

g032595

DrivingtheMachine

Thedrivewheelsturnindependently,poweredby

hydraulicmotorsoneachaxle.Youcanturn1side

inreversewhileyouturntheotherforward,causing

themachinetospinratherthanturn.Thisgreatly

improvesthemachinemaneuverabilitybutmay

requiresometimeforyoutoadapttohowitmoves.

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Place

thethrottlecontrolintheFASTpositionforbest

performance.Alwaysoperateinthefullthrottle

positionwhenmowing.

4.Backward

27

WARNING

Themachinecanspinveryrapidly.You

maylosecontrolofthemachineandcause

personalinjuryordamagetothemachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemaking

sharpturns.

DrivingForward

Note:Theengineshutsoffwhenyoumovethe

traction-controlwiththeparkingbrakeengaged.

Tostopthemachine,pullthemotion-controllevers

totheNEUTRALposition.

1.Disengagetheparkingbrake;referto

DisengagingtheParkingBrake(page25).

2.Movetheleverstothecenter,unlockedposition.

3.T ogoforward,slowlypushthemotion-control

leversforward(Figure27).

DrivingBackward

1.Movetheleverstothecenter,unlockedposition.

2.T ogobackward,slowlypullthemotion-control

leversrearward(Figure28).

Figure27

g008953

Figure28

g008952

28

UsingtheSideDischarge

AdjustingtheHeightofCut

MachineswithSideDischarge

Only

Themowerhasahingedgrassdeectorthat

dispersesclippingstothesideanddowntowardthe

turf.

DANGER

Withoutagrassdeector,dischargecover,or

acompletegrass-catcherassemblymounted

inplace,youandothersareexposedtoblade

contactandthrowndebris.Contactwith

rotatingmowerblade(s)andthrowndebris

willcauseinjuryordeath.

•Neverremovethegrassdeectorfromthe

mowerdeckbecausethegrassdeector

routesmaterialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthe

mowerdeck.

UsingtheTransportLock

Thetransportlockhas2positions,andisusedwith

thedeck-liftpedal.ThereisaLOCKpositionand

anUNLOCKpositionforthetransportpositionofthe

mowerdeck(Figure29).

•Nevertrytoclearthedischargearea

ormowerbladesunlessyoumovethe

blade-controlswitch(PTO)totheOFF

position,rotatethekeyswitchtotheOFF

position,andremovethekeyfromthekey

switch.

•Makesurethatthegrassdeectorisinthe

downposition.

g229103

Figure29

Transport-LockPositions

1.Transportlockknob3.UNLOCKposition—The

2.LOCKposition—The

mowerdecklocksintothe

transportposition.

29

mowerdeckdoesnotlock

intothetransportposition.

AdjustingtheHeight-of-CutPin

AdjustingtheAnti-Scalp

Theheight-of-cutisadjustedfrom25to140mm(1

to5-1/2inches)in6mm(1/4inch)incrementsby

relocatingtheclevispinintodifferentholelocations.

1.Movethetransportlocktothelockposition.

2.Pushonthedeck-liftpedalwithyourfoot,and

raisethemowerdecktothetransportposition

(alsothe140mm(5-1/2inch)cuttingheight

position)asshowninFigure30.

3.T oadjust,rotatethepin90degreesandremove

thepinfromtheheight-of-cutbracket(Figure

30).

4.Selectaholeintheheight-of-cutbracket

correspondingtotheheight-of-cutdesired,and

insertthepin(Figure30).

5.Pushonthedecklift,pullbackonthetransport

lock,andslowlylowerthemowerdeck.

Rollers

ForMachineswithSideDischarge

Wheneveryouchangetheheight-of-cut,adjustthe

heightoftheanti-scalprollers.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Adjusttheanti-scalprollersasshowninFigure

31,Figure32,andFigure33.

1.Deck-liftpedal

2.Cut-of-heightpin

Figure30

3.Transportlock

g029955

Figure31

1.Anti-scalproller4.Flangenut

2.Spacer

3.Bushing

g027343

1.Anti-scalproller3.Flangenut

2.Bushing4.Bolt

5.Bolt

g029956

Figure32

30

Figure33

1.Anti-scalproller4.Flangenut

2.Spacer

3.Bushing

5.Bolt

AdjustingtheAnti-Scalp

Rollers

ForMachineswithRearDischarge

Wheneveryouchangetheheightofcut,itis

recommendedtoadjusttheheightoftheanti-scalp

rollers.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

g029957

g024242

Figure34

1.Flangenut3.Bushing

2.Anti-scalproller4.Bolt

3.Adjusttheanti-scalprollersasshowninFigure

34andFigure35.

g024243

Figure35

1.Bolt3.Anti-scalproller

2.Bushing4.Flangenut

31

AdjustingtheFlowBafe

PositioningtheFlowBafe

CamLocks

ForMachineswithSideDischarge

Thisprocedureisapplicableonlytomachineswiththe

ow-bafelocks.Certainmodelshavenutsandbolts

inplaceoftheow-bafelocksandcanbeadjusted

thesame.

Youcanadjustthemower-dischargeowfordifferent

typesofmowingconditions.Positionthecamlocks

andbafetogivethebestqualityofcut.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.T oadjustthecamlocks,swingtheleverupto

loosenthecamlock(Figure36).

4.Adjustthebafeandcamlocksintheslotsto

thedesireddischargeow.

5.Swingtheleverbackovertotightenthebafe

andcamlocks(Figure36).

ForMachineswithSideDischarge

Thefollowingguresareonlyrecommendations

foruse.Adjustmentsvarybygrasstype,moisture

content,andtheheightofthegrass.

Note:Iftheenginepowerdrawsdownandthe

mowergroundspeedisthesame,openupthebafe.

PositionA

Thisisthefullrearposition.Thesuggestedusefor

thispositionisasfollows:

•Short,lightgrassmowingconditions

•Dryconditions

•Smallergrassclippings

•Propelsgrassclippingsfartherawayfromthe

mower

6.Ifthecamlocksdonotlockthebafeintoplace

oritistootight,loosentheleverandthenrotate

thecamlock.

Note:Adjustthecamlockuntilthedesired

lockingpressureisachieved.

Figure36

g005832

Figure37

PositionB

Usethispositionwhenbagging.Alwaysalignitwith

thebloweropening.

g027727

g005833

Figure38

32

PositionC

OperatingwiththeOverheat

Thisisthefullopenposition.Thesuggestedusefor

thispositionisasfollows:

•Tall,densegrassmowingconditions

•Wetconditions

•Lowerstheengine-powerconsumption

•Allowsincreasedgroundspeedinheavyconditions

Figure39

Sensor

Thismachinehasasensorthatturnsoffthemower

deckwhentheengineoverheats.Whentheengine

overheats,theaudiblealarmandlightalarmturnson

alongwiththemowerdeckturningoff.

Ifthemowerdeckturnsoffautomaticallybecauseof

overheating,youwillbeabletodrivethemachineto

asafeareaortoatruckortrailer.

Ifthemachineoverheats,ensurethattheareaaround

theengineandradiatorisclearofanydebris.Shutoff

theengineandallowittocoolbeforeyouengagethe

mowerdeck.Iftheenginecontinuestooverheat,take

yourmachinetoanAuthorizedServiceDealer.

OperatingTips

UsingtheFastThrottleSetting

Forbestmowingandmaximumaircirculation,operate

theengineattheFASTposition.Airisrequiredto

thoroughlycutgrassclippings,sodonotsetthe

g005834

height-of-cutsolowastototallysurroundthemower

deckinuncutgrass.Alwaystrytohave1sideofthe

mowerdeckfreefromuncutgrass,whichallowsair

tobedrawnintothemowerdeck.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethat

thecuttingheightofthemowerdeckdoesnotscalp

anyunevenground.However,thecuttingheight

usedinthepastisgenerallythebestonetouse.

Whencuttinggrasslongerthan15cm(6inches)tall,

youmaywanttocutthelawntwicetoensurean

acceptablequalityofcut.

CuttingaThirdoftheGrassBlade

Itisbesttocutonlyaboutathirdofthegrassblade.

Cuttingmorethanthatisnotrecommendedunless

grassissparse,oritislatefallwhengrassgrows

moreslowly.

AlternatingtheMowingDirection

Alternatethemowingdirectiontokeepthegrass

standingstraight.Thisalsohelpsdisperseclippings,

whichenhancesdecompositionandfertilization.

MowingatCorrectIntervals

Grassgrowsatdifferentratesatdifferenttimesof

theyear.Tomaintainthesamecuttingheight,mow

moreofteninearlyspring.Asthegrassgrowthrate

33

slowsinmidsummer,mowlessfrequently .Ifyou

cannotmowforanextendedperiod,rstmowata

highcuttingheight,thenmowagain2dayslaterata

lowerheightsetting.

AfterOperation

AfterOperationSafety

UsingaSlowerCuttingSpeed

Toimprovecutquality,useaslowergroundspeed

incertainconditions.

AvoidingCuttingTooLow

Whenmowinguneventurf,raisethecuttingheight

toavoidscalpingtheturf.

StoppingtheMachine

Ifyoumuststoptheforwardmotionofthemachine

whilemowing,aclumpofgrassclippingsmay

dropontoyourlawn.Toavoidthis,moveontoa

previouslycutareawiththebladesengagedoryou

candisengagethemowerdeckwhilemovingforward.

KeepingtheUndersideofthe

MowerDeckClean

Cleanclippingsanddirtfromtheundersideofthe

mowerdeckaftereachuse.Ifgrassanddirtbuildup

insidethemowerdeck,cuttingqualitywilleventually

becomeunsatisfactory.

GeneralSafety

•Cleangrassanddebrisfromthecuttingunits,

mufers,andenginecompartmenttohelpprevent

res.Cleanupoilorfuelspills.

•Shutoffthefuelandremovethekeybeforestoring

ortransportingthemachine.

•Disengagethedrivetotheattachmentwhenever

youaretransportingornotusingthemachine.

•Allowtheenginetocoolbeforestoringthemachine

inanyenclosure.

•Neverstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

UsingtheFuel-Shutoff

Valve

Thefuel-shutoffvalveislocatedundertheseat.Move

theseatforwardtoaccessit.

Closethefuel-shutoffvalvefortransport,maintenance,

andstorage.

MaintainingtheBlade(s)

Maintainasharpbladethroughoutthecuttingseason

becauseasharpbladecutscleanlywithouttearingor

shreddingthegrassblades.T earingandshredding

turnsgrassbrownattheedges,whichslowsgrowth

andincreasesthechanceofdisease.Checkthe

mowerbladesaftereachuseforsharpness,and

foranywearordamage.Filedownanynicksand

sharpenthebladesasnecessary .Ifabladeis

damagedorworn,replaceitimmediatelywitha

genuineT ororeplacementblade.

Ensurethatthefuel-shutoffvalveisopenwhen

startingtheengine.

g008948

Figure40

1.ONposition2.OFFposition

34

PushingtheMachineby

ChangingtoMachineOperation

Hand

Important:Alwayspushthemachinebyhand.

Nevertowthemachinebecausehydraulicdamage

mayoccur.

PushingtheMachine

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Rotatethebypassvalvescounterclockwise1

turntopush(Figure41).

Note:Thisallowshydraulicuidtobypassthe

pumpenablingthewheelstoturn.

Important:Donotrotatebypassvalves

morethan1turn.Thispreventsvalvesfrom

comingoutofthebodyandcausinguidto

runout.

4.Disengagetheparkingbrakebeforepushing.

Rotatethebypassvalvesclockwise1turntooperate

machine(Figure41).

Note:Donotover-tightenthebypassvalves.

Important:Themachinedoesnotdriveunless

bypassvalvesareturnedin.

Figure41

1.Sideconsolecontrols

2.Bypassvalve

3.Hydraulicpumps

g010371

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthe

machine.Useafull-widthramp.Ensurethatthetrailer

ortruckhasallthenecessarybrakes,lighting,and

markingasrequiredbylaw.Pleasecarefullyreadall

thesafetyinstructions.Knowingthisinformationcould

helpyouorbystandersavoidinjury.Refertoyour

localordinancesfortrailerandtie-downrequirements.

WARNING

Drivingonthestreetorroadwaywithout

turnsignals,lights,reectivemarkings,ora

slow-moving-vehicleemblemisdangerous

andcanleadtoaccidents,causingpersonal

injury.

Donotdrivethemachineonapublicstreet

orroadway.

35

SelectingaTrailer

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath(Figure42).

•Useonlyafull-widthramp;donotuse

individualrampsforeachsideofthe

machine.

•Donotexceeda15-degreeanglebetween

therampandthegroundorbetweenthe

rampandthetrailerortruck.

•Ensurethatthelengthoftherampisat

least4timesaslongastheheightofthe

trailerortruckbedtotheground.This

ensuresthattherampangledoesnot

exceed15degreesonatground.

Figure42

1.Full-widthrampinstowed

position

2.Sideviewoffull-width

rampinloadingposition

3.Notgreaterthan

15degrees

4.Rampisatleast4times

aslongastheheightof

thetrailerortruckbedto

theground

5.H=heightofthetraileror

truckbedtotheground

6.Trailer

LoadingtheMachine

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath.

•Useextremecautionwhenoperatinga

machineonaramp.

•Backthemachineuptherampanddriveit

forwarddowntheramp.

g027996

•Avoidsuddenaccelerationordeceleration

whiledrivingthemachineonarampas

thiscouldcausealossofcontrolora

tip-oversituation.

36

1.Ifusingatrailer,connectittothetowingvehicle

andconnectthesafetychains.

2.Ifapplicable,connectthetrailerbrakesand

lights.

UsingtheZStand

TM

TheZStandraisesthefrontendofthemachineto

allowyoutocleanthemowerandremovetheblades.

3.Lowertheramp,ensuringthattheangle

betweentherampandthegrounddoesnot

exceed15degrees(Figure42).

4.Backthemachineuptheramp(Figure43).

Figure43

1.Backthemachineupthe

ramp.

2.Drivethemachineforward

downtheramp.

5.Shutofftheengine,removethekey,andengage

theparkingbrake.

6.Tiedownthemachinenearthefrontcaster

wheelsandtherearbumperwithstraps,chains,

cable,orropes(Figure44).Refertolocal

regulationsfortie-downrequirements.

WARNING

Themachinecouldfallontosomeoneand

causeseriousinjuryordeath.

•Useextremecautionwhenoperatingthe

machineontheZStand.

•UsetheZStandonlyforcleaningthe

mowerandremovingtheblades.

•DonotkeepthemachineontheZStand

forextendedperiodsoftime.

g028043

•Alwaysshutofftheengine,setthe

parkingbrake,andremovethekeybefore

performinganymaintenancetothemower.

DrivingupontotheZStand

Important:UsetheZStandonalevelsurface.

1.Raisethemowerdecktothetransportposition.

2.Removethebracketpin(Figure45).

Figure44

1.Tie-downloops

UnloadingtheMachine

1.Lowertheramp,ensuringthattheangle

betweentherampandthegrounddoesnot

exceed15degrees(Figure42).

2.Drivethemachineforwarddowntheramp

(Figure43).

g001811

Figure45

1.ZStand4.Bottomofslot

2.Bracketpin5.Latch

g028622

3.Bracket

3.Raisethelatch.

37

4.Swingthestandfootoutfrontandslideit

towardmachine,intothebottomofslot(Figure

45andFigure46).

Figure46

DrivingofftheZStand

1.Removethechocksorblocks.

2.Raisethelatchtotheunlockedposition(Figure

47).

g001812

1.ZStand(positionedinslot)

2.Crackinsidewalkorturf

3.Latchrestingonpivottab

5.Setthefootofthestandonthegroundandrest

thelatchonthepivottab(Figure46).

6.Starttheengineandputitathalfthrottle.

Note:Forbestresults,placethefootofthe

standintotheseamsinsidewalksorintotheturf

(Figure46).

7.Drivethemachineontothestand.Stopwhen

thelatchdropsoverthetabintothelocked

position(Figure46).

8.Engagetheparkingbrakeandturnoffthe

engine.

9.Chockorblockthedrivewheels.

WARNING

Theparkingbrakemaynotholdthe

machineparkedontheZStandand

couldcausepersonalinjuryorproperty

damage.

Figure47

1.ZStand

2.Latch4.Unlockedposition

3.Lockedposition

3.Starttheengineandplaceitathalfthrottle.

Disengagetheparkingbrake.

4.Slowlydrivebackwardoffthestand.

5.Returnthestandtoitsrestposition(Figure45).

g001813

DonotparkontheZStandunlessthe

wheelsarechockedorblocked.

10.Performthemaintenance.

38

Maintenance

Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst25hours

Aftertherst50hours

Aftertherst100hours

Beforeeachuseordaily

Every25hours

MaintenanceProcedure

•Checktheenginecoolingsystemlevel.

•Checkthehydraulicuid.

•Changethehydrauliclter.

•Replacetheengineoil.

•Changetheengine-oillter.

•Changetheengineoil.

•Checkthewheel-hubslottednut.

•Changethegearboxoil.

•Checkthesafetysystem.

•Checktheengine-oillevel.

•Checktheenginecoolingsystemlevel.

•Cleantheengine-oilcooler.

•Inspecttheblades.

•Cleanthemowerdeck.

•Greasethemowerdeckandspindles.

•Greasethemowerbeltidlerarm.

•Greasethepumpbeltidlerarm.

•GreasethePTO-drivebeltidlerarm.

•Greasethebrakelever .

•Checkthehydraulicuid.

Every40hours

Every50hours

Every100hours

Every150hours

Every200hours

Every250hours

Every400hours

•Drainthewaterseparator.

•Checkthetirepressure

•CheckthePTO-drivebelt.

•Checkthepumpdrivebelt.

•Checkthealternatorbelt.

•Lubricatethedeck-liftpivots.

•Replacetheengineoil.

•Changetheengineoil.

•Checkthegearbox-oillevel.

•Checktheenginecoolingsystemhoses.

•Inspectthebeltsforcracksandwear.

•Checkthehydraulichoses.

•Addlightoilorspraylubricationtothemachine;refertolubrication.

•Changetheengine-oillter.

•Greasethebrakepivot.

•Checkand/orreplacetheairlter(moreoftenindirtyordustyconditions).

•ChangethehydrauliclterandhydraulicuidwhenusingMobil®1uid.

•Replacethefuellter(moreoftenindirtyordustyconditions).

39

MaintenanceService

Interval

Every500hours

Yearly

MaintenanceProcedure

•Checkthewheel-hubslottednut.

•Adjustthecaster-pivotbearing.

•Adjusttheelectricclutch.

•ChangethehydrauliclterandhydraulicuidwhenusingToro®HYPR-OIL™500

hydraulicuid.

•Greasethefrontcasterpivots(moreoftenindirtyordustyconditions).

•Lubricatethecaster-wheelhubs.

•Changethegearboxoil.

•Changetheenginecoolant.

Important:Refertoyourengineowner'smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheswitchbeforeyouperformanymaintenance.

Pre-Maintenance

Procedures

MaintenanceSafety

•Beforerepairingthemachinedothefollowing:

–Disengagethedrives.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey .

–Disconnectthespark-plugwire.

•Parkthemachineonalevelsurface.

•Cleangrassanddebrisfromthecuttingunit,

drives,mufers,andenginetohelppreventres.

•Cleanupoilorfuelspills.

•Donotallowuntrainedpersonneltoservicethe

machine.

•Usejackstandstosupportthemachineand/or

componentswhenrequired.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectthebatteryorremovethespark-plug

wirebeforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositiveterminal

last.Connectthepositiveterminalrstand

negativelast.

•Usecarewhencheckingtheblades.Wrapthe

blade(s)orwearthicklypaddedgloves,anduse

cautionwhenservicingthem.Onlyreplaceblades;

donotstraightenorweldthem.

•Keepyourhandsandfeetawayfrommoving

parts.Ifpossible,donotmakeadjustmentswith

theenginerunning.

•Keepallpartsingoodworkingcondition

andallhardwaretightened,especiallythe

blade-attachmentbolts.Replaceallwornor

damageddecals.

•Neverinterferewiththeintendedfunctionofa

safetydeviceorreducetheprotectionprovided

byasafetydevice.Checktheirproperoperation

regularly.

•UseonlygenuineT ororeplacementparts.

•Checktheparkingbrakeoperationfrequently.

Adjustandserviceasrequired.

40

ReleasingtheMower-Deck

Curtain

Lubrication

Loosenthebottomboltofthecurtaintorelease

themower-deckcurtainandgetaccesstothetop

ofthemowerdeck(Figure48).Afterperforming

maintenance,installthecurtainandtightenthebolt.

Figure48

1.Bolt

2.Curtain

GreasingtheMachine

Greasemorefrequentlywhenoperatingconditions

areextremelydustyorsandy .

GreaseType:No.2lithiumormolybdenumgrease

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanthegreasettingswitharag.

Note:Makesurethatyouscrapeanypaintoff

thefrontofthetting(s).

4.Connectagreaseguntothetting.

g027945

5.Pumpgreaseintothettingsuntilgreasebegins

tooozeoutofthebearings.

6.Wipeupanyexcessgrease.

RemovingtheSheet-Metal

Guard

Loosenthe2frontboltsandremovethesheet-metal

guardtoaccessthemowerbeltsandspindles

(Figure49).Afterperformingmaintenance,installthe

sheet-metalguardandtightenthebolts.

GreasingtheFrontCaster

Pivots

ServiceInterval:Yearly(moreoftenindirtyordusty

conditions).

1.Removethedustcapandadjustthecaster

pivotsandkeepthedustcapoffuntilgreasingis

done;refertoAdjustingtheCaster-PivotBearing

(page55).

2.Removethehexplug.

3.Threadagreasettingintothehole.

4.Pumpgreaseintothettinguntilitoozesout

aroundthetopbearing.

5.Removethegreasettingfromthehole.Install

thehexplugandcap.

AddingGrease

LubricatethegreasettingsasshownontheCheck

ServiceReferenceAiddecal(Figure50orFigure51).

1.Sheet-metalguard

g027946

Figure49

2.Bolt

41

SideDischargeMachines

AddingLightOilorSpray

Lubrication

SideDischargeMachines

ServiceInterval:Every100hours

Lubricatethedeck-liftpivots.

decal136-5510

Figure50

g017028

Figure52

RearDischargeMachines

AddingLightOilorSpray

Lubrication

RearDischargeMachines

ServiceInterval:Every150hours

Lubricatethemachineinthefollowingareaswith

spraytypelubricantorlightoil.

•Seat-switchactuator

•Brake-handlepivot

•Brake-rodbushings

•Motioncontrolbronzebushings

decal136-5519

Figure51

42

GreasingtheMowerDeck

andBeltIdlers

ServiceInterval:Every25hours—Greasethemower

deckandspindles.

GreasewithNo.2lithiumormolybdenumgrease.

Important:Makesurethatthecutting-unit

spindlesarefullofgreaseweekly.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Loosenthebottomboltholdingthemower-deck

curtaintothemowerdeck;refertoReleasing

theMower-DeckCurtain(page41).

4.Removethesheet-metalguard;referto

RemovingtheSheet-MetalGuard(page41)

5.Removethebeltcovers.

6.Greasetheidlerarmonthemowerdeck(Figure

53).

7.Greasethettingsonthepusharms(Figure53

orFigure54).

g194085

Figure54

RearDischargeMachines

8.GreasethePTO-drivebeltidlerarm(Figure55).

9.Greasethepumpbeltidlerarm(Figure55).

SideDischargeMachines

g007170

Figure55

10.Installthesheet-metalguard.

11.Tightenthebottomboltholdingthemower-deck

curtaintothemowerdeck.

g187362

Figure53

43

Lubricatingthe

Caster-WheelHubs

ServiceInterval:Yearly

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

12.Inserttheassemblednutandaxleintothewheel

onthesideofthewheelwiththenewsealand

bearing.

13.Withtheopenendofthewheelfacingup,ll

theareainsidethewheelaroundtheaxlefullof

general-purposegrease.

14.Insertthesecondbearingandnewsealintothe

wheel.

15.Applyathread-lockingadhesivetothesecond

spacernut,andthreaditontotheaxlewiththe

wrenchatsfacingoutward.

16.T orquethenutto8to9N∙m(75to80in-lb),

loosen,thentorqueto2to3N∙m(20to25in-lb).

Note:Makesurethattheaxledoesnotextend

beyondeithernut.

17.Installthesealguardsoverthewheelhub,and

insertthewheelintothecasterfork.

18.Installthecasterboltandtightenthenutfully.

Figure56

1.Sealguard2.Spacernutwithwrench

ats

3.Raisethemowerforaccess.

4.Removethecasterwheelfromthecasterforks.

5.Removethesealguardsfromthewheelhub.

6.Removeaspacernutfromtheaxleassemblyin

thecasterwheel.

Note:Thread-lockingadhesivehasbeen

appliedtolockthespacernutstotheaxle.

7.Removetheaxle(withtheotherspacernutstill

assembledtoit)fromthewheelassembly.

8.Pryoutsealsandinspectbearingsforwearor

damageandreplaceifnecessary.

9.Packthebearingswithageneral-purpose

grease.

10.Insert1bearingand1newsealintothewheel.

g006115

Important:Topreventsealandbearingdamage,

checkthebearingadjustmentoften.Spinthe

castertire.Thetireshouldnotspinfreely(more

than1or2revolutions)orhaveanysideplay.If

thewheelspinsfreely,adjustthetorqueonthe

spacernutuntilthereisaslightamountofdrag.

Applyanotherlayerofthread-lockingadhesive.

Note:Replacetheseals.

11.Iftheaxleassemblyismissingbothspacernuts,

applyathread-lockingadhesiveto1spacernut

andthreaditontotheaxlewiththewrenchats

facingoutward.

Note:Donotthreadthespacernutallof

thewayontotheendoftheaxle.Leave

approximately3mm(1/8inch)fromtheouter

surfaceofthespacernuttotheendoftheaxle

insidethenut.

44

EngineMaintenance

EngineSafety

•Shutofftheengineandremovethekeybefore

checkingtheoiloraddingoiltothecrankcase.

•Keepyourhands,feet,face,clothing,andother

bodypartsawaythemuferandotherhotsurfaces.

ServicingtheAirCleaner

Note:Checktheltersmorefrequentlyifoperating

conditionsareextremelydustyorsandy.

RemovingtheAirFilter

ServiceInterval:Every250hours(moreoftenindirty

ordustyconditions).

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Releasethelatchesontheaircleanerandpull

theair-cleanercoverofftheair-cleanerbody

(Figure57).

4.Cleantheinsideoftheair-cleanercoverwith

compressedair.

5.Gentlyslidethelteroutoftheair-cleanerbody

(Figure57).

Note:Avoidknockingthelterintothesideof

thebody.

6.Inspectthelterfordamagebylookingintothe

lterwhileshiningabrightlightontheoutside

ofthelter.

Note:Holesinthelterappearasbrightspots.

Ifthelterisdamaged,discardit.

Figure57

1.Air-lterbody

2.Airlter

3.Air-cleanercover

4.Latches

InstallingtheAirFilter

1.Ifinstallinganewlter,checkthelterfor

shippingdamage.Donotuseadamagedlter.

2.Carefullyslidethelterintothelterbody

(Figure58).

Note:Ensurethatitisfullyseatedbypushing

ontheouterrimofthelterwhileinstallingit.

Important:Donotpressonthesoftinside

areaofthelter.

3.Installtheair-cleanercoverandsecurethe

latches(Figure58).

g001049

45

Figure58

1.Air-lterbody

2.Airlter

3.Air-cleanercover

4.Latches

ServicingtheEngineOil

Engine-OilSpecications

OilType:High-qualitydetergentoilclassiedAPI

ServiceCJ-4orhigherfordieselengines.Donotuse

specialadditiveswithrecommendedoils.

g001061

Figure59

PreparingtoServicetheEngine

Oil

Important:Thefastenersforthefrontengine

g001048

panelaredesignedtoremainonthemachineafter

coverremoval.Loosenallofthefastenersafew

turnssothatthepanelisloosebutstillattached,

thengobackandloosenthemuntilthepanel

comesfree.Thispreventsyoufromaccidentally

strippingtheboltsfreeoftheretainers.

Tilttheseatforward,loosentheboltsholdingthefront

enginepanelandremoveit(Figure60).

CrankcaseCapacity:3.7L(3.9USqt)

Viscosity:Seethetablebelow.

g012347

Figure60

1.Bolt2.Frontenginepanel

Note:Afterservicingtheengineoil,installtheengine

panelandtilttheseatintoitsuprightposition.

46

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Checktheengine-oillevel(Figure61).

Important:Addtheoilveryslowlyand

donotblocktheopeningofthellerhole

(Figure40).Ifyouaddoiltoofastorblock

thehole,theoilcouldbackupandfoulthe

airintakes,causingenginedamage.

g000955

Figure62

1.Notetheclearanceleftinthelleropening.

Figure61

g032601

DrainingtheEngineOil

ServiceInterval:Aftertherst50hours

Every100hours

1.Starttheengineandletitrunfor5minutes.

Note:Thiswarmstheoilsoitdrainsbetter.

2.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),movethe

motion-controlleverstotheNEUTRAL-LOCK

position,andengagetheparkingbrake.

3.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

g032641

4.Starttheengine,runitatidlefor5minutes,

shutofftheengine,waitfor3minutes,andthen

checktheengine-oillevel.Ifneeded,addoilup

totheFULLmarkonthedipstick.

Important:Besuretokeeptheengine-oil

levelbetweentheupperandlowerlimitson

theoilgauge.Enginefailuremayoccuras

aresult.

47

ChangingtheEngine-OilFilter

ServiceInterval:Aftertherst50hours

Every200hours

1.Draintheoilfromtheengine;refertoDraining

theEngineOil(page47).

2.Changetheengine-oillter(Figure64).

g032646

g032649

Figure63

Note:Disposeoftheusedoilatarecycling

center.

g032642

g032644

Figure64

3.Addoil;refertoChangingtheEngineOil(page

49).

48

ChangingtheEngineOil

AddingEngineOil

ServiceInterval:Aftertherst50hours

Every100hours

1.Starttheengineandletitrunfor5minutes.

Note:Thiswarmstheoilsoitdrainsbetter.

2.Parkthemachineonalevelsurface.

3.Disengagetheblade-controlswitch(PTO),move

themotion-controlleverstotheNEUTRAL-LOCK

position,andengagetheparkingbrake.

4.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

5.Placeapanbelowtheoildrain.Removethe

drainplugandlettheoildraincompletely(Figure

65).

6.Removetheoilllercapfromthetopofthe

engine(Figure67).

Note:Thishelpstheoiltodrain.

7.Installthedrainplugandtightenitto35N∙m

(25-1/2ft-lb).

1.Tilttheseatforwardandremovethefrontengine

panel(Figure66).

g001312

Figure66

1.Knob2.Frontenginepanel

Note:Disposeoftheusedoilatarecycling

center.

1.Backofthemachine

Figure65

2.Drainplug

2.Removetheoil-llcapanddipstick(Figure67).

g001162

Figure67

1.Engine

g001058

2.Oil-llcap

3.Useahoseandfunneltoaddoiltotheengine

(Figure68).

4.Addoilslowly,checkingthelevelfrequentlywith

thedipstickuntilthelevelreachestheupper

holeonthedipstick.Forthecorrectoiltype

andviscositytouseindifferenttemperature

conditions,refertoServicingtheEngineOil

(page46).

49

FuelSystem

Maintenance

WARNING

Fuel-systemcomponentsareunderhigh

pressure.Theuseofimpropercomponents

canresultinsystemfailure,fuelleakage,and

possibleexplosion.

Useonlyapprovedfuellinesandfuellters.

ServicingtheFuelFilter

Figure68

1.Engineoil2.Funnelandhose

Important:Addtheoilveryslowlyand

donotblocktheopeningofthellerhole

(Figure69).Ifyouaddoiltoofastorblock

thehole,theoilcouldbackupandfoulthe

airintakes,causingenginedamage.

Figure69

1.Notetheclearanceleftinthelleropening.

g001163

andWaterSeperator

ServiceInterval:Every40hours—Drainthewater

separator.

Every400hours/Y early(whichevercomes

rst)—Replacethefuellter(moreoftenindirty

ordustyconditions).

DrainingtheWaterSeparator

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake.