Page 1

FormNo.3400-446RevB

ZMaster

®

Professional7000

SeriesRidingMower

With52inTURBOFORCE

Mower

ModelNo.74279TE—SerialNo.316000001andUp

®

RearDischarge

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3400-446*B

Page 2

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Introduction

Thisrotary-blade,ridinglawnmowerisintended

tobeusedbyresidentialhomeownersor

professional,hiredoperators.Itisdesigned

primarilyforcuttinggrassonwell-maintained

lawnsonresidentialorcommercialproperties.It

isnotdesignedforcuttingbrushorforagricultural

uses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Y ouareresponsiblefor

operatingtheproductproperlyandsafely.

YoumaycontactT orodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

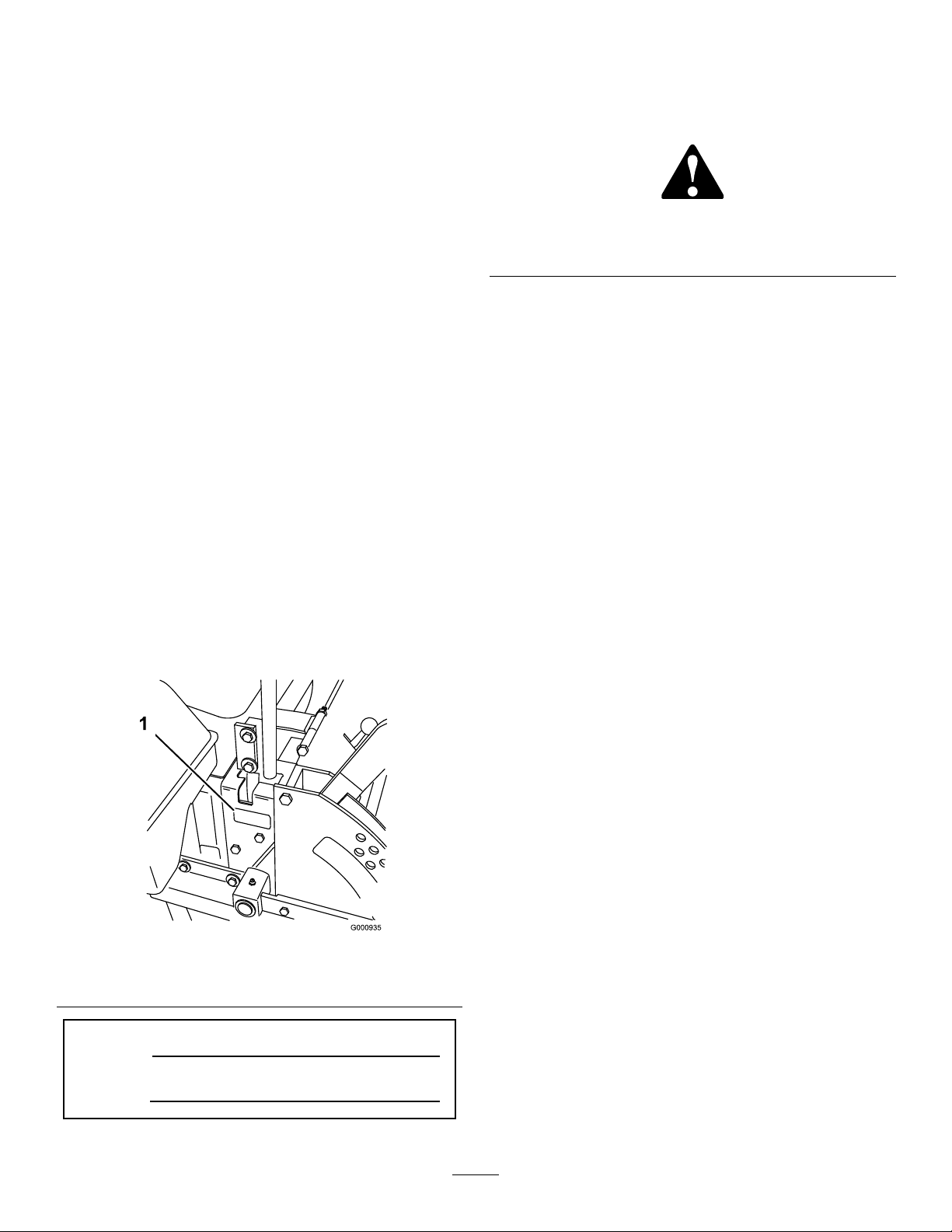

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure1

g000935

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety.......................................................................4

SafeOperatingPractices....................................4

ToroRidingMowerSafety...................................6

SoundPressureLevel........................................6

SoundPowerLevel............................................6

VibrationLevel....................................................6

SafetyandInstructionalDecals..........................7

ProductOverview...................................................14

Controls...........................................................14

Operation................................................................16

AddingFuel......................................................16

BiodieselReady...............................................16

FillingtheFuelTank..........................................17

CheckingtheEngine-OilLevel..........................17

SwitchingtheFuelT anks..................................17

UsingtheRolloverProtectionSystem

(ROPS).........................................................17

ThinkSafetyFirst..............................................18

OperatingtheParkingBrake.............................19

StartingandStoppingtheEngine......................20

OperatingthePowerT akeoff(PTO)..................21

UsingtheSafety-InterlockSystem....................22

DrivingForwardorBackward............................22

StoppingtheMachine.......................................24

AdjustingtheHeight-of-Cut...............................24

AdjustingtheAnti-ScalpRollers........................24

PositioningtheSeat..........................................25

ChangingtheSeatSuspension.........................26

UnlatchingtheSeat..........................................26

PushingtheMachinebyHand..........................26

OperatingwiththeOverheatSensor.................27

TransportingtheMachine.................................27

LoadingtheMachine........................................27

UsingtheZStand™.........................................29

OperatingTips.................................................30

Maintenance...........................................................31

RecommendedMaintenanceSchedule(s)...........31

Pre-MaintenanceProcedures..............................32

ReleasingtheMower-DeckCurtain..................32

RemovingtheSheet-MetalGuard.....................32

Lubrication..........................................................33

GreasingtheMachine.......................................33

GreasingtheFrontCasterPivots......................33

AddingGrease.................................................33

AddingLightOilorSprayLubrication................33

GreasingtheMowerDeckandBelt

Idlers.............................................................33

EngineMaintenance...........................................35

ServicingtheAirCleaner..................................35

ServicingtheEngineOil....................................36

FuelSystemMaintenance...................................40

ServicingtheFuelFilterandWater

Separator......................................................40

ServicingtheFuelT ank.....................................40

ElectricalSystemMaintenance...........................41

ServicingtheBattery.........................................41

ServicingtheFuses..........................................43

DriveSystemMaintenance..................................43

AdjustingtheTracking......................................43

CheckingtheTirePressure...............................44

CheckingtheWheelLugNuts...........................44

CheckingtheWheel-HubSlottedNut................44

AdjustingtheCaster-PivotBearing...................45

ServicingtheGearbox......................................45

AdjustingtheElectricClutch.............................45

CoolingSystemMaintenance..............................47

ServicingtheCoolingSystem...........................47

BrakeMaintenance.............................................49

AdjustingtheParkingBrake..............................49

BeltMaintenance................................................49

InspectingtheBelts..........................................49

ReplacingtheMowerBelt.................................49

ReplacingthePTODriveBelt...........................50

ReplacingthePumpDriveBelt.........................51

ReplacingandTensioningtheAlternator

Belt................................................................51

ControlsSystemMaintenance.............................52

AdjustingtheControlHandleNeutral

Position.........................................................52

HydraulicSystemMaintenance...........................53

ServicingtheHydraulicSystem........................53

SettingtheHydraulicPumpNeutral

Position.........................................................55

MowerDeckMaintenance....................................57

LevelingtheMower..........................................57

ServicingtheCuttingBlades.............................59

Cleaning..............................................................62

CleaningundertheMower................................62

DisposingofWaste...........................................62

Storage...................................................................62

CleaningandStorage.......................................62

Troubleshooting......................................................64

Schematics.............................................................66

3

Page 4

Safety

ThismachinewasdesignedinaccordancewithEN

ISO5395:2013.

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafety-alertsymbol,whichmeans

Caution,Warning,orDanger—”personalsafety

instruction”.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

SafeOperatingPractices

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Training

•Readtheinstructionscarefully.Befamiliarwiththe

controlsandtheproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwith

theseinstructionstousethelawnmower.Local

regulationscanrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,or

petsarenearby.

•Keepinmindthattheoperatororuseris

responsibleforaccidentsorhazardsoccurringto

otherpeopleortheirproperty.

•Donotcarrypassengers.

•Alldriversshouldseekandobtainprofessional

andpracticalinstruction.Suchinstructionshould

emphasize:

–theneedforcareandconcentrationwhen

workingwithride-onmachines;

–controlofaride-onmachineslidingonaslope

willnotberegainedbytheapplicationofthe

controllevers.Themainreasonsforlossof

controlare:

◊insufcientwheelgrip,especiallyonwet

grass;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforits

task;

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

◊incorrecthitchingandloaddistribution.

Preparation

•Whilemowing,alwayswearsubstantial,

slip-resistantfootwearandlongtrousers.

•Thoroughlyinspecttheareawheretheequipment

istobeusedandremoveallobjectswhichmaybe

thrownbythemachine.

•Warning–Fuelishighlyammable.

–Storefuelincontainersspecicallydesigned

forthispurpose.

–Refueloutdoorsonlyanddonotsmokewhile

refuelling.

–Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoraddfuel

whiletheengineisrunningorwhentheengine

ishot.

–Iffuelisspilled,donotattempttostartthe

enginebutmovethemachineawayfromthe

areaofspillageandavoidcreatinganysource

ofignitionuntilfuelvaporshavedissipated.

–Replaceallfueltanksandcontainercaps

securely.

•Replacefaultysilencers.

•Beforeusing,alwaysvisuallyinspecttoseethat

theblades,bladeboltsandcutterassemblyare

notwornordamaged.Replacewornordamaged

bladesandboltsinsetstopreservebalance.

•Onmulti-bladedmachines,takecareasrotating

onebladecancauseotherbladestorotate.

Operation

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

•Bealert,slowdownandusecautionwhenmaking

turns.Lookbehindandtothesidebeforechanging

directions.

•Donotoperatetheengineinaconnedspace

wheredangerouscarbonmonoxidefumescan

collect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengage

allbladeattachmentclutchesandshiftintoneutral.

•Donotuseonslopesgreaterthan15degrees.

•Rememberthereisnosuchthingasasafeslope.

Travelongrassslopesrequiresparticularcare.T o

guardagainstoverturning:

–donotstoporstartsuddenlywhenonaslope;

–useslowspeedsonslopesandduringtight

turns;

–stayalertforhumpsandhollowsandother

hiddenhazards;

•Usecarewhenpullingloadsorusingheavy

equipment.

–Useonlyapproveddrawbarhitchpoints.

4

Page 5

–Limitloadstothoseyoucansafelycontrol.

–Donotturnsharply.Usecarewhenreversing.

•Watchoutfortrafcwhencrossingornear

roadways.

•Stopthebladesrotatingbeforecrossingsurfaces

otherthangrass.

•Whenusinganyattachments,neverdirect

dischargeofmaterialtowardbystandersnorallow

anyonenearthemachinewhileinoperation.

•Neveroperatethemachinewithdamagedguards

orwithoutsafetyprotectivedevicesinplace.

•Donotchangetheenginegovernorsettingsor

overspeedtheengine.Operatingtheengine

atexcessivespeedcanincreasethehazardof

personalinjury.

•Beforeleavingtheoperator'sposition:

–disengagethepowertakeoffandlowerthe

attachments;

–changeintoneutralandsettheparkingbrake;

–shutofftheengineandremovethekey .

•Disengagedrivetoattachments,shutoffthe

engine,anddisconnectthesparkplugwire(s)or

removetheignitionkey

–beforeclearingblockagesoruncloggingchute;

–beforechecking,cleaningorworkingonthe

lawnmower;

–afterstrikingaforeignobject.Inspectthe

lawnmowerfordamageandmakerepairs

beforerestartingandoperatingtheequipment;

ifthemachinestartstovibrateabnormally

(checkimmediately).

•Disengagedrivetoattachmentswhentransporting

ornotinuse.

•Shutofftheengineanddisengagedriveto

attachment

–beforerefuelling;

–beforeremovingthegrasscatcher;

–beforemakingheightadjustmentunless

adjustmentcanbemadefromtheoperator's

position.

•Reducethethrottlesettingduringenginerun-out

and,iftheengineisprovidedwithashutoffvalve,

turnthefueloffattheconclusionofmowing.

•Allowtheenginetocoolbeforestoringinany

enclosure.

•Toreducetherehazard,keeptheengine,

silencer,batterycompartmentandfuelstorage

areafreeofgrass,leaves,orexcessivegrease.

•Checkthegrasscatcherfrequentlyforwearor

deterioration.

•Replacewornordamagedpartsforsafety .

•Ifyoumustdrainthefueltank,thisshouldbedone

outdoors.

•Onmulti-bladedmachines,takecareasrotating1

bladecancauseotherbladestorotate.

•Whenmachineistobeparked,storedorleft

unattended,lowerthecuttingmeansunlessa

positivemechanicallockisused.

MaintenanceandStorage

•Keepallnuts,bolts,andscrewstighttobesure

theequipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetank

insideabuildingwherefumescanreachanopen

ameorspark.

5

Page 6

ToroRidingMowerSafety

Thefollowinglistcontainssafetyinformationspecic

toT oroproductsorothersafetyinformationthatyou

mustknowthatisnotincludedintheCENstandard.

•Engineexhaustcontainscarbonmonoxide,which

isanodorless,deadlypoisonthatcankillyou.Do

notrunengineindoorsorinanenclosedarea.

•Keepyourhands,feet,hairandlooseclothing

awayfromattachmentdischargearea,underside

ofmowerandanymovingpartswhileengineis

running.

•Donottouchequipmentorattachmentpartswhich

maybehotfromoperation.Allowtocoolbefore

attemptingtomaintain,adjust,orservice.

•Batteryacidispoisonousandcancauseburns.

Avoidcontactwithskin,eyesandclothing.Protect

yourface,eyes,andclothingwhenworkingwitha

battery.

•Batterygasescanexplode.Keepcigarettes,

sparksandamesawayfrombattery.

maycausedrivewheelstoslipandcauselossof

brakingandsteering.

•Alwaysavoidsuddenstartingorstoppingona

slope.Iftireslosetraction,disengagetheblades

andproceedslowlyofftheslope.

•Followthemanufacturer'srecommendations

forwheelweightsorcounterweightstoimprove

stability.

•Useextremecarewithgrasscatchersorother

attachments.Thesecanchangethestabilityofthe

machineandcauselossofcontrol.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’s

earof90dBA,whichincludesanUncertaintyV alue

(K)of1dBA.

Thesoundpressurelevelwasdeterminedaccording

totheproceduresoutlinedinENISO5395:2013.

•UseonlygenuineTororeplacementpartsto

ensurethatoriginalstandardsaremaintained.

•UseonlyToro-approvedattachments.Warranty

maybevoidedifusedwithunapproved

attachments.

SlopeOperation

•Donotmowslopesgreaterthan15degrees.

•Donotmowneardrop-offs,ditches,steepbanks

orwater.Wheelsdroppingoveredgescancause

rollovers,whichmayresultinseriousinjury,death

ordrowning.

•Donotmowslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcausesliding

andlossofcontrol.

•Donotmakesuddenturnsorrapidspeedchanges.

•Useawalkbehindmowerand/orahandtrimmer

neardrop-offs,ditches,steepbanksorwater.

•Reducespeedanduseextremecautiononslopes.

•Removeormarkobstaclessuchasrocks,tree

limbs,etc.fromthemowingarea.T allgrasscan

hideobstacles.

•Watchforditches,holes,rocks,dips,andrises

thatchangetheoperatingangle,asroughterrain

couldoverturnthemachine.

SoundPowerLevel

Thisunithasaguaranteedsoundpowerlevelof105

dBA,whichincludesanUncertaintyValue(K)of1

dBA.

Thesoundpowerlevelwasdeterminedaccordingto

theproceduresoutlinedinISO11094.

VibrationLevel

Hand-Arm

Measuredvibrationlevelforrighthand=3.1m/s

Measuredvibrationlevelforlefthand=3.1m/s

UncertaintyValue(K)=1.6m/s

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinENISO5395:2013.

WholeBody

Measuredvibrationlevel=0.90m/s

UncertaintyValue(K)=0.45m/s

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinENISO5395:2013.

2

2

2

2

2

•Avoidsuddenstartswhenmowinguphillbecause

themowermaytipbackwards.

•Beawarethatlossoftractionmayoccurgoing

downhill.Weighttransfertothefrontwheels

6

Page 7

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedorlost.

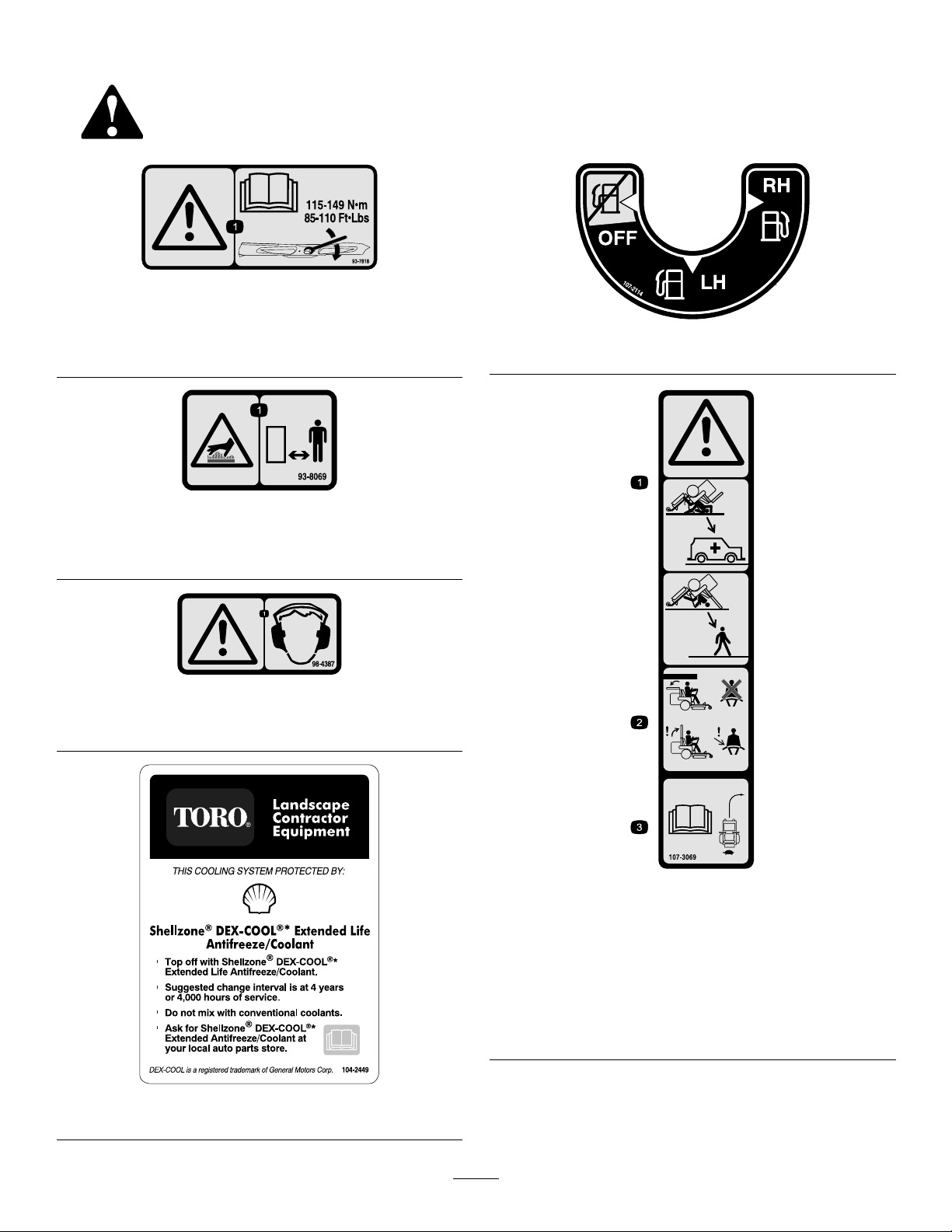

93-7818

decal93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto1 15to149N∙m(85to110

ft-lb).

93-8069

1.Hotsurface/burnhazard—stayasafedistancefromthe

hotsurface.

98-4387

1.Warning—wearhearingprotection.

decal107-2114

107-2114

decal93-8069

decal98-4387

decal107-3069

107-3069

1.Warning–thereisnorolloverprotectionwhentherollbaris

down.

2.Toavoidinjuryordeathfromarolloveraccident,keepthe

rollbarinthefullyraisedandlockedpositionandwear

theseatbelt.Lowertherollbaronlywhenabsolutely

necessary;donotwearthetheseatbeltwhentherollbaris

down.

3.ReadtheOperator'sManual;driveslowlyandcarefully.

decal104-2449

104-2449

7

Page 8

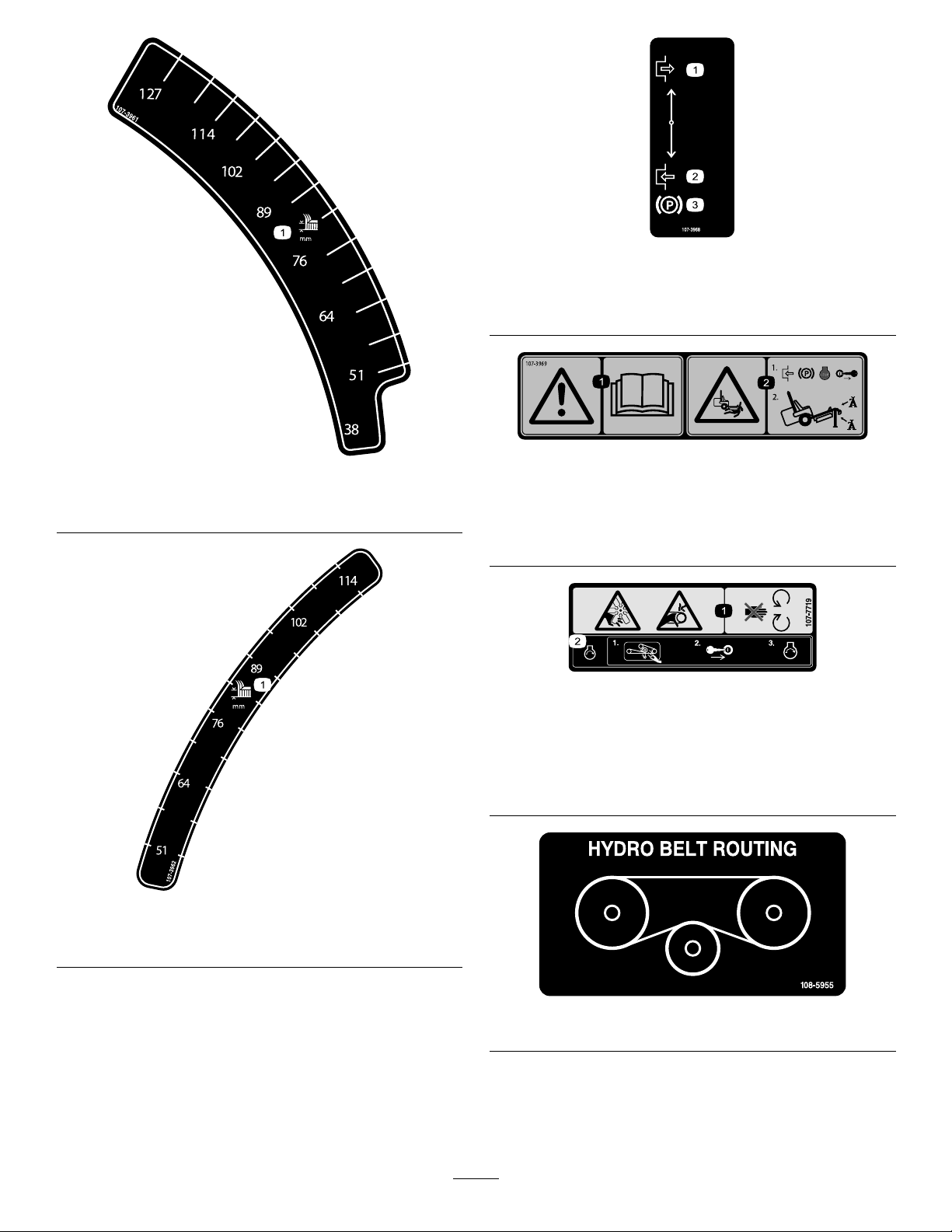

1.Heightofcutinmillimeters

decal107-3968

107-3968

1.Disengage3.Parkingbrake

2.Engage

decal107-3969

decal107-3961

107-3969

107-3961

1.Warning—readtheOperator'sManual.

2.Crushinghazard,mower—engagetheparkingbrake,stop

theengine,andremovetheignitionkeybeforeworking

underthemower.

decal107-7719

107-7719

1.Heightofcutinmillimeters

1.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

2.Beforestartingtheengine,cleangrassanddebrisfromthe

mowerbeltandpulleys,inserttheignitionkey,andstart

theengine.

decal107-3962

107-3962

decal108-5955

108-5955

8

Page 9

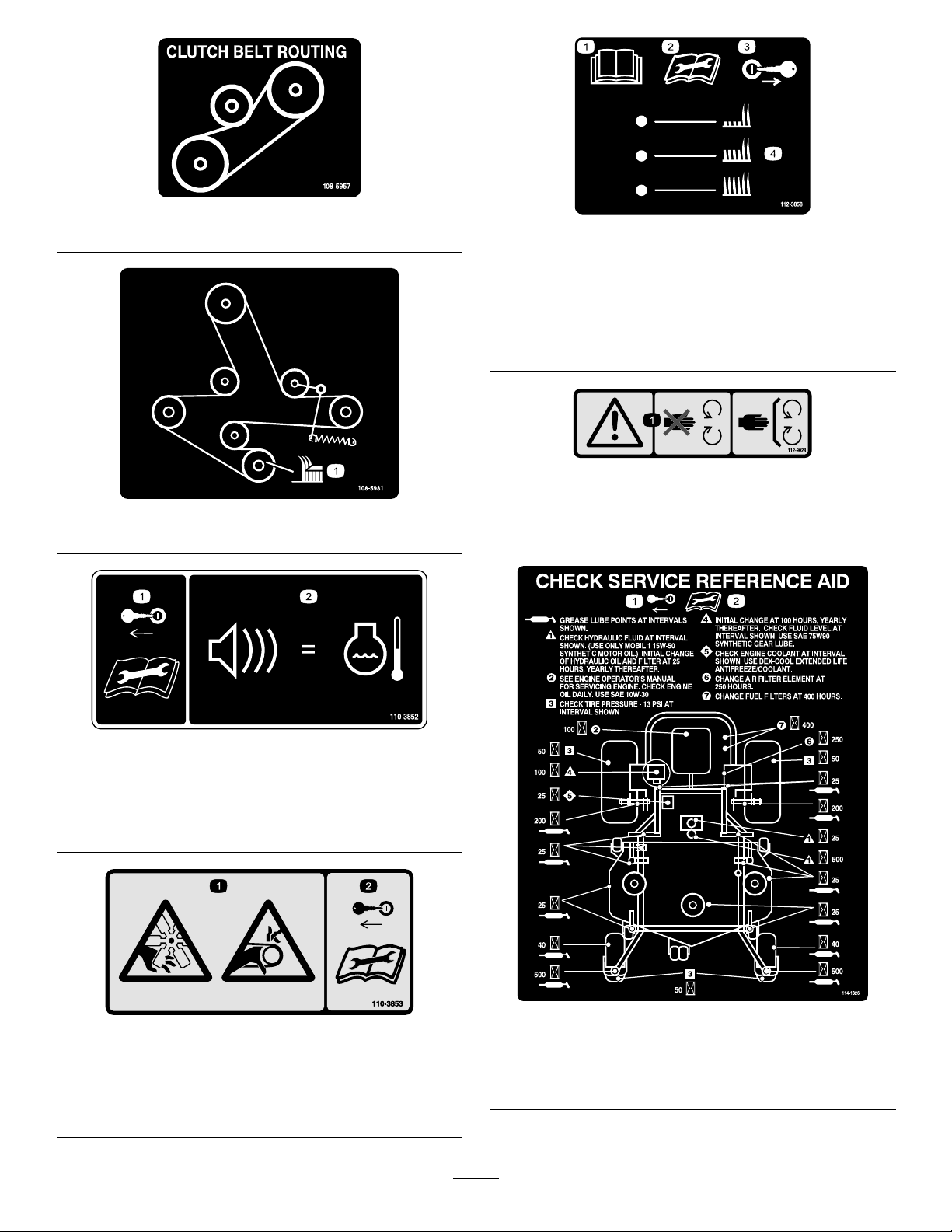

decal108-5957

108-5957

decal112-3858

112-3858

1.ReadtheOperator's

Manual.

3.Removetheignitionkey

beforeadjustingtheheight

ofcut.

2.Readtheinstructions

4.Heightofcutsettings.

beforeservicingor

performingmaintenance.

decal112-9028

112-9028

decal108-5981

108-5981

1.Warning—stayawayfrommovingparts;keepallguardsin

place.

1.Removetheignitionkey

andreadtheinstructions

beforeservicingor

performingmaintenance.

1.Cutting/dismemberment

hazard,fanand

entanglementhazard,

belt.

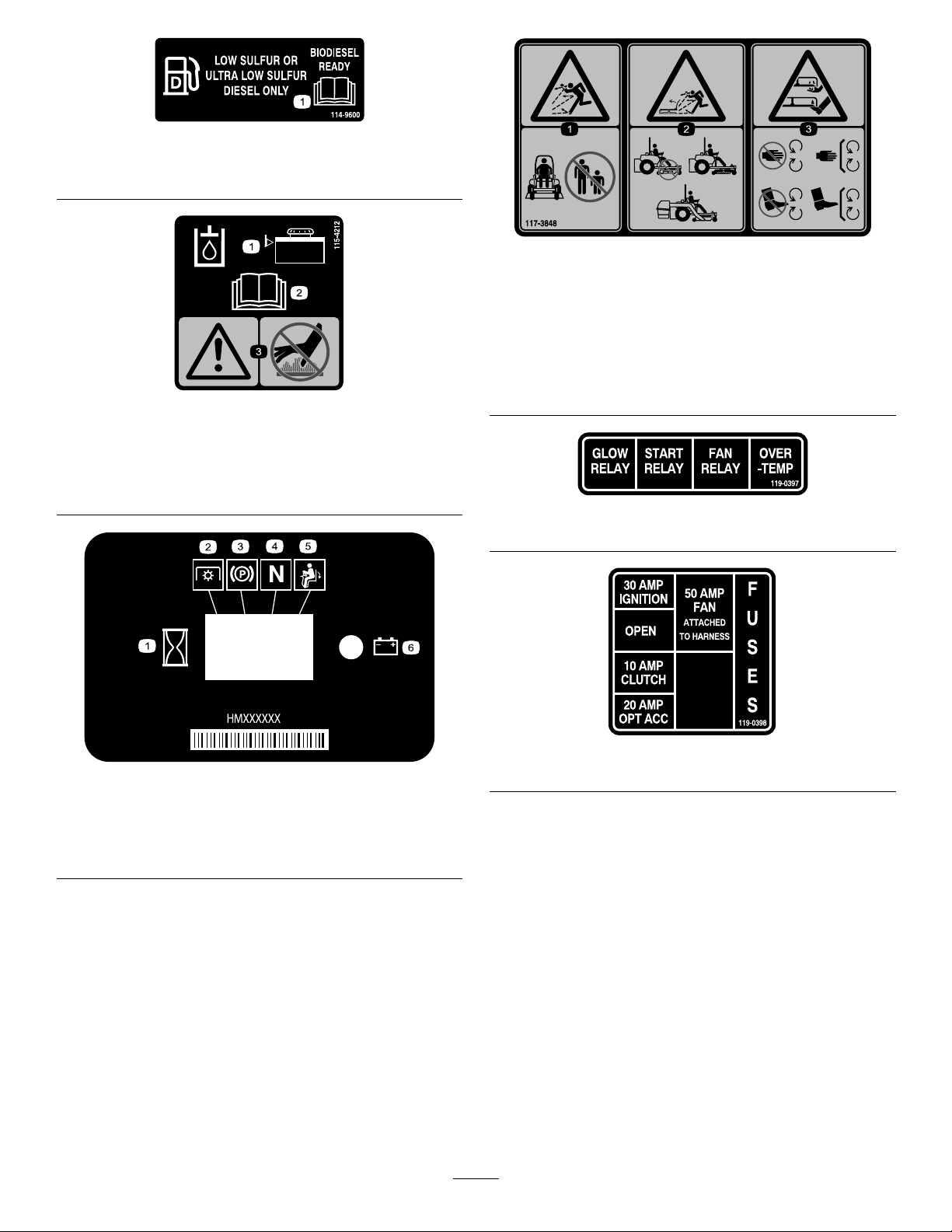

110-3852

2.Continuoustonesignals

theuserthatengineis

overheating.

110-3853

2.Removetheignitionkey

andreadtheinstructions

beforeservicingor

performingmaintenance.

decal110-3852

decal110-3853

114-1826

decal114-1826

1.Removetheignitionkey.2.Readtheinstructions

beforeservicingor

performingmaintenance.

9

Page 10

1.ReadtheOperator'sManual.

decal114-9600

114-9600

decal117-3848

117-3848

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine

2.Thrownobjecthazard,mower-donotoperatewithoutthe

deector,dischargecoverorgrasscollectionsystemin

place.

3.Cutting/dismembermentofhandorfoot—stayawayfrom

decal115-4212

movingparts;keepallguardsandshieldsinplace.

115-4212

1.Hydraulicoillevel3.Warning—donottouchthe

hotsurface.

2.ReadtheOperator's

Manual.

116–5610

1.Hourmeter4.Neutral

2.Powertakeoff(PTO)5.Operatorpresenceswitch

3.Parkingbrake6.Battery

decal119-0397

119–0397

decal119-0398

decal116-5610

119–0398

10

Page 11

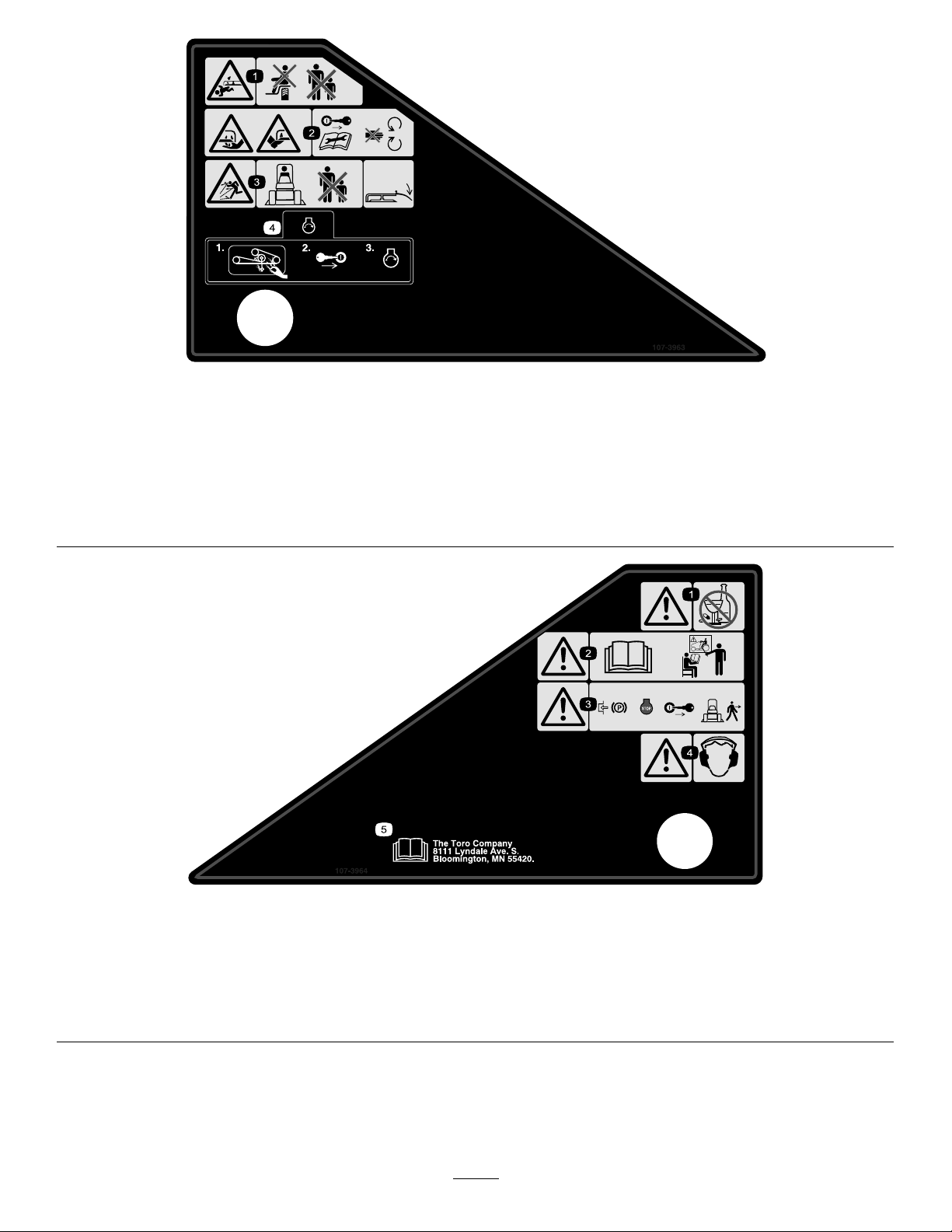

decal131-4036

131-4036

121–7562

1.Pushtostart4.Variablespeedcontrol

2.ReadtheOperator’s

5.Fast

Manualformore

informationonpreheating

theengine.

3.Slow

126-2055

1.Wheellugnuttorque129N∙m(95ft-lb)(4x)

2.Wheel-hubnuttorque319N∙m(235ft-lb)

3.ReadandunderstandtheOperator’smanualbefore

performinganymaintenance,checktorqueafterrst100

hoursthenevery500hoursthereafter.

1.Maximumdrawbarpull36

kg(80lb).

2.ReadtheOperator's

Manual.

decaloemmarkt

Manufacturer'sMark

decal121-7562

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

decalbatterysymbols

BatterySymbols

Someorallofthesesymbolsareonyourbattery

decal126-2055

1.Explosionhazard

2.Nore,opename,or

6.Keepbystandersasafe

7.Weareyeprotection;

smoking.

3.Causticliquid/chemical

8.Batteryacidcancause

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

10.Containslead;donot

Manual.

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

107-9309

1.Warning—readtheOperator'sManualforinformationonchargingthebattery;containslead;donotdiscard.

2.ReadtheOperator'sManual.

11

decal107-9309

Page 12

decal107-3963

107-3963

1.Cutting/dismemberment

hazard,mowerblade—do

notcarrypassengersand

keepbystandersaway.

2.Cutting/dismemberment

hazardofhandorfoot,

mowerblade—remove

theignitionkeyandread

theinstructionsbefore

servicingorperforming

maintenance;stayaway

frommovingparts.

3.Thrownobject

hazard—keepbystanders

asafedistancefromthe

machineandkeepthe

deectorinplace.

4.Beforestartingtheengine,

cleangrassanddebrisfrom

themowerbeltandpulleys,

inserttheignitionkey,and

starttheengine.

107-3964

1.Warning—donotusedrugsoralcohol.3.Warning—engagetheparkingbrake,

2.Warning—readtheOperator'sManual

andreceivetraining.

stoptheengine,andremovethe

ignitionkeybeforeleavingthe

machine.

4.Warning—wearhearingprotection.

12

decal107-3964

5.ReadtheOperator'sManual.

Page 13

decal110-0820

110-0820

1.Fast

5.Warning—readtheOperator'sManual.

2.Slow6.Poisonandcausticliquid/chemicalburnhazard—keep

childrenasafedistancefromthebattery.

3.Neutral

7.Explosionhazard—nore,openames,orsmoking;avoid

sparks.

4.Reverse8.Tounlockthetractiondrive,turntheby-passvalve1complete

revolutioncounterclockwiseusinga16mmor5/8inch

wrench.

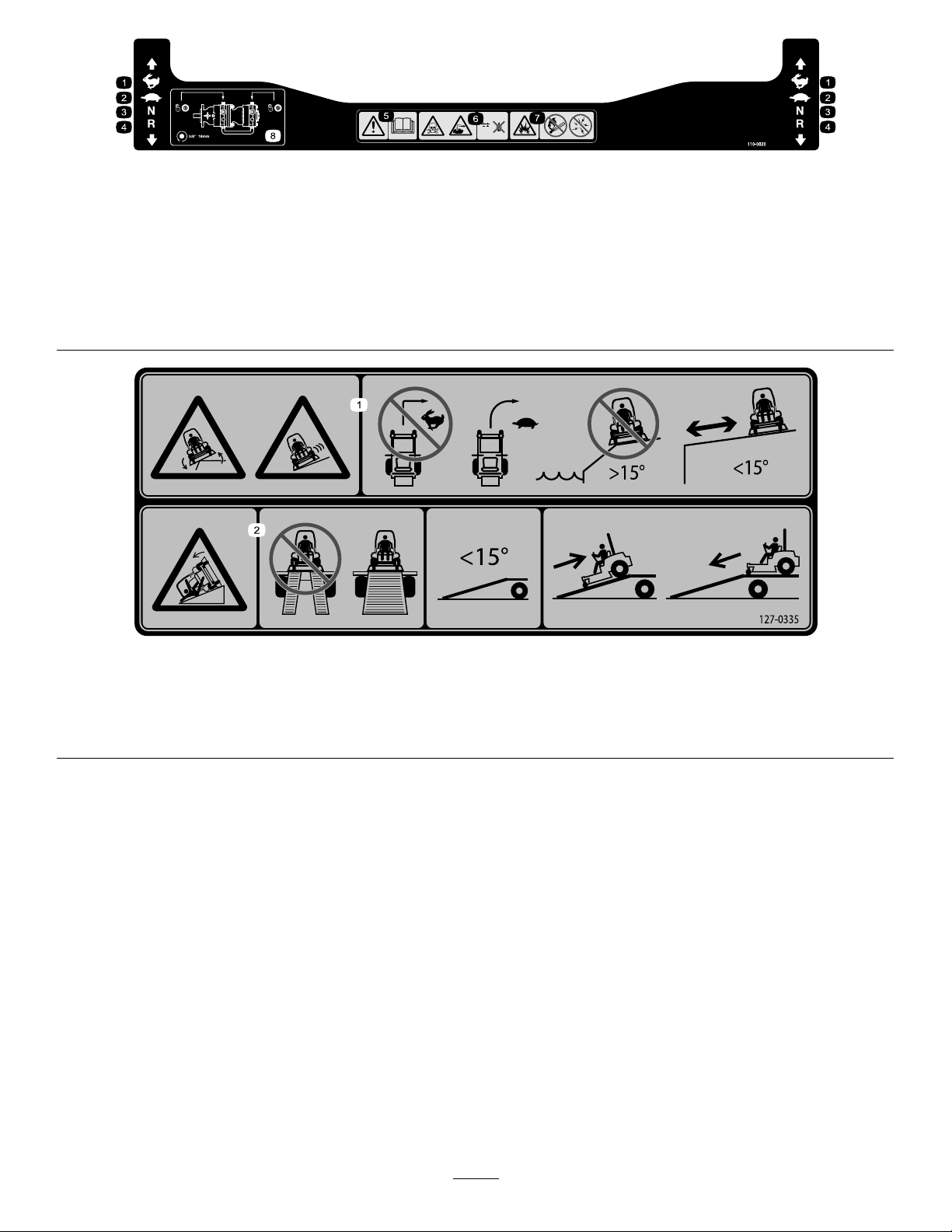

127–0335

decal127-0335

1.Tippinghazardonslopes—donotmakesudden,tightturns;

makeslow,wideturns;donotuseonslopesnearopenwater;

donotusethismachineonslopesgreaterthan15degrees.

2.Ramphazard—whenloadingontoatrailer,donotusedual

ramps;onlyuseasingularrampwideenoughforthemachine

andthathasaninclinelessthan15degrees;backupthe

ramp(inreverse)anddriveforwardofftheramp.

13

Page 14

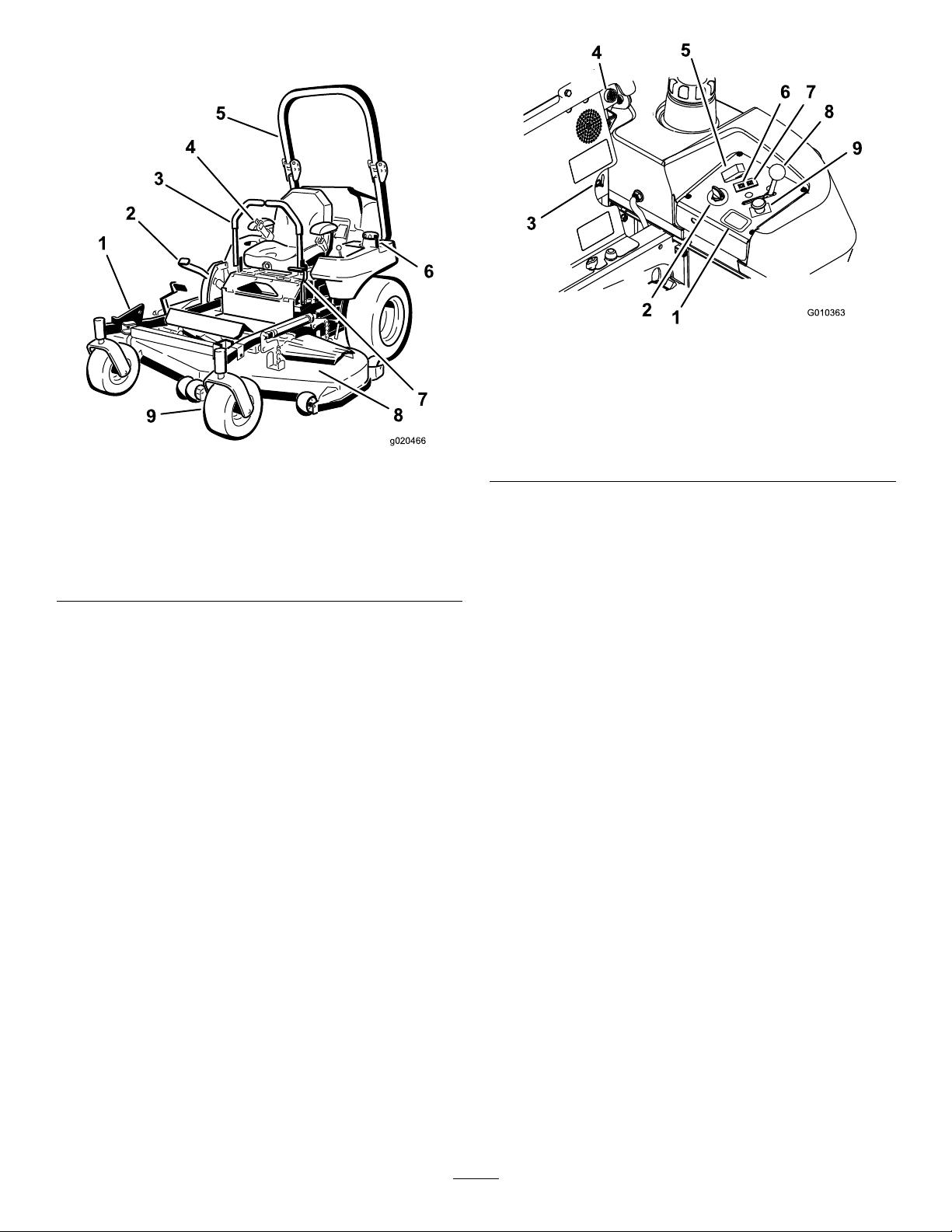

ProductOverview

g010363

Figure4

Figure3

1.ZStand

2.Height-of-cutlever

3.Motion-controllever8.Mowerdeck

4.Seatbelt9.Casterwheel

5.Rollbar

©

6.Fuelcap(bothsides)

7.Parking-brakelever

Controls

Becomefamiliarwithallthecontrolsbeforeyoustart

theengineandoperatethemachine(Figure3and

Figure4).

1.Hourmeter

2.Ignitionswitch7.Engine-temperaturelight

3.Fuel-selectorvalve8.Throttlecontrol

g020466

4.Audiblealarm

5.Glow-plugswitch

6.Glow-pluglight

9.PTOSwitch

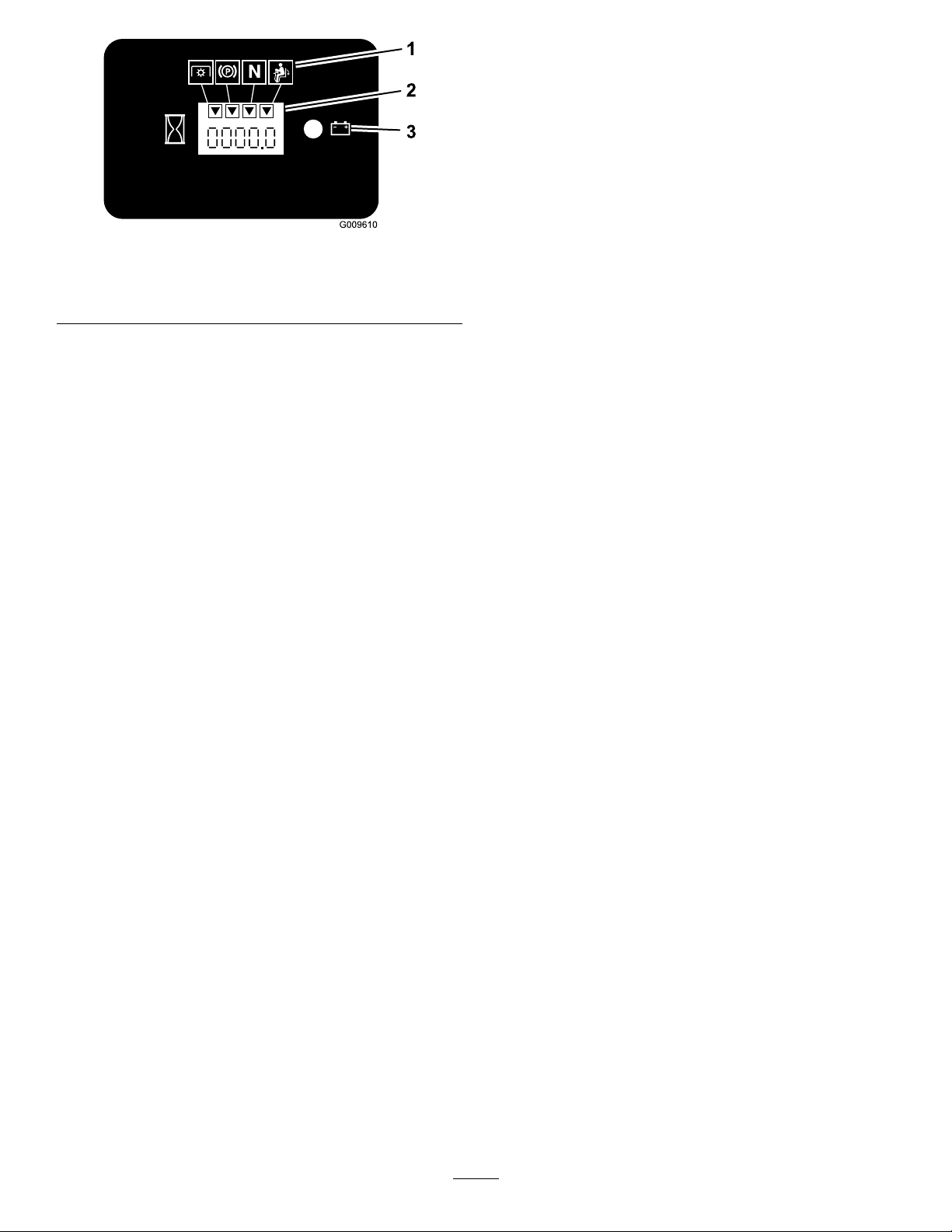

HourMeter

Thehourmeterrecordsthenumberofhoursthe

enginehasoperated.Itoperateswhentheengine

isrunning.Usethesetimesforschedulingregular

maintenance(Figure4).

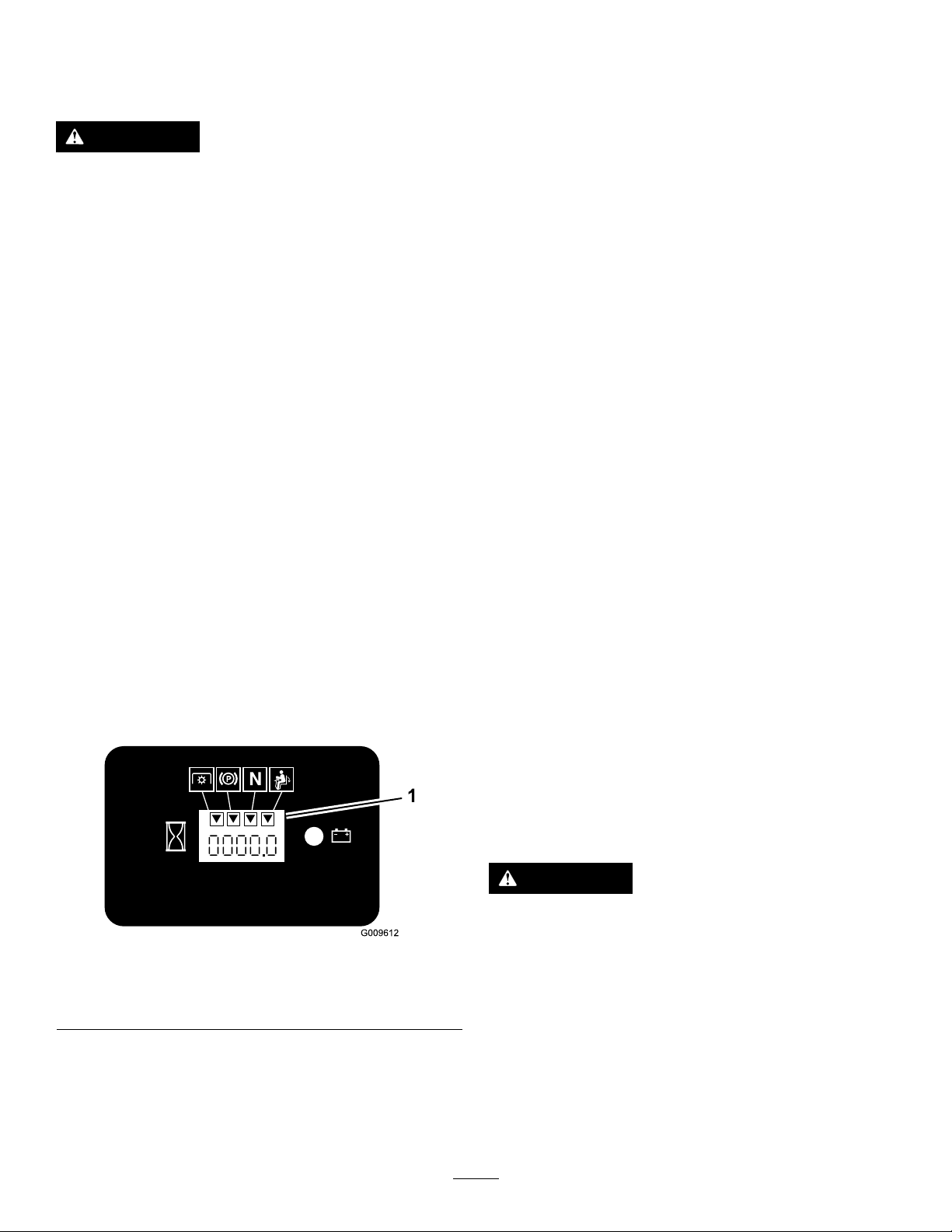

Safety-InterlockIndicators

Therearesymbolsonthehourmeterandtheyindicate

withablacktrianglethattheinterlockcomponentisin

thecorrectposition(Figure5).

BatteryIndicatorLight

WhentheignitionkeyisinitiallyturnedtotheRUN

positionforafewseconds,thebatteryvoltageis

displayedintheareawherethehoursarenormally

displayed.

Thebatterylightturnsonwhentheignitionisturned

onandwhenthechargeisbelowthecorrectoperating

level(Figure5).

14

Page 15

AudibleAlarm

Thismachinehasanaudiblealarmthatalertstheuser

toturnofftheengineorenginedamagecanoccur

fromoverheating.RefertoServicingtheCooling

SysteminCoolingSystemMaintenance(page47).

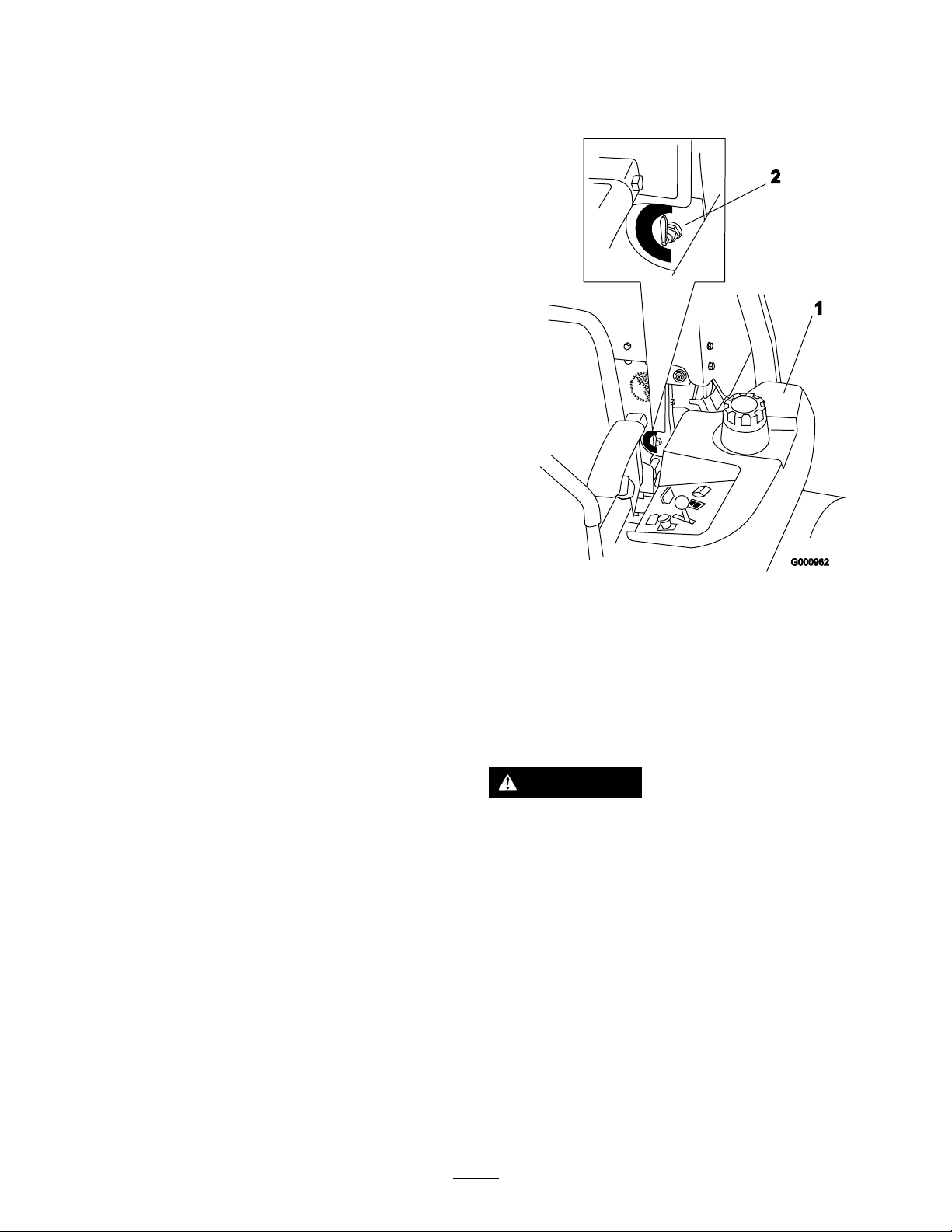

Fuel-SelectorValve

Figure5

1.Safety-interlocksymbols

2.Hourmeter

3.Batterylight

ThrottleControl

ThethrottlecontrolisvariablebetweenFASTand

SLOW.

Blade-ControlSwitch(PTO)

Theblade-controlswitch(PTO)isusedtoengage

theelectricclutchtodrivethemowerbladeswiththe

motion-controlleversinthecenter,unlockedposition.

Pulltheswitchuptoengagethebladesandrelease.

Todisengagetheblades,pushtheblade-control

switch(PTO)down.

Neutral-LockPosition

g009610

Thefuel-selectorvalveislocatedbehindtheseat.

Closethefuel-selectorvalvewhentransportingor

storingmower.

Movetheselectorvalvetotheleftorrightpositionfor

operation.

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesisavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.T oro.comforalistofallapprovedattachments

andaccessories.

Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourT oroequipment,countonT oro

genuineparts.Whenitcomestoreliability,T oro

deliversreplacementpartsdesignedtotheexact

engineeringspecicationofourequipment.Forpeace

ofmind,insistonTorogenuineparts.

TheNEUTRAL-LOCKpositionisusedwiththe

safety-interlocksystemandtodetermineNEUTRAL

position.

IgnitionSwitch

Thisswitchisusedtostartthemowerengineandhas

3positions:START,RUN,andOFF.

Glow-PlugLight

Theglowplugindicatorlightturnsonwhenthe

glow-plugbuttonisengaged(Figure4).

Glow-PlugSwitch

Thisswitchactivatestheglowplugsandisindicated

bytheglow-pluglight.Holddowntheglow-plugswitch

for10secondspriortostarting.

Engine-TemperatureLight

Theengine-temperaturelightcomesonwhenthe

engineisoverheating(Figure4).

15

Page 16

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty .

AddingFuel

Theenginerunsonclean,freshdieselfuelwith

aminimumoctaneratingof40.Purchasefuelin

quantitiesthatyoucanusewithin30daystoensure

fuelfreshness.

Usesummergradedieselfuel(No.2-D)at

temperaturesabove-7°C(20°F)andwintergrade

dieselfuel(No.1-DorNo.1-D/2-Dblend)below

-7°C(20°F).Useofwintergradedieselfuelatlower

temperaturesprovideslowerashpointandpour

pointcharacteristics,thereforeeasingstartabilityand

lesseningchancesofchemicalseparationofthefuel

duetolowertemperatures(waxappearance,which

maypluglters).

Useofsummergradedieselfuelabove-7°C

(20°F)contributestowardlongerlifeofthepump

components.

Important:Donotusekeroseneorgasoline

insteadofdieselfuel.Failuretoobservethis

cautionwilldamagetheengine.

WARNING

Fuelisharmfulorfatalifswallowed.

Long-termexposuretovaporscancause

seriousinjuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandfueltank

orconditioneropening.

•Keepfuelawayfromeyesandskin.

•Fillthefueltankoutdoorsonlevelground,

inanopenarea,whentheengineiscold.

Wipeupanyfuelthatspills.

•Neverllthefueltankinsideanenclosed

trailer.

•Donotllthefueltankcompletelyfull.

Fillthefueltanktothebottomoftheller

neck.Theemptyspaceinthetankallows

fueltoexpand.Overllingmayresultin

fuelleakageordamagetotheengineor

emissionsystem(ifequipped).

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinanapprovedcontainerand

keepitoutofthereachofchildren.Never

buymorethana30-daysupplyoffuel.

•Alwaysplacefuelcontainersontheground

awayfromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmay

insulatethecontainerandslowthelossof

anystaticcharge.

•Whenpractical,removefuel-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

ground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

fuel-dispensernozzle.

•Ifafuel-dispensernozzlemustbeused,

keepthenozzleincontactwiththerimof

thefueltankorcontaineropeningatall

timesuntilfuelingiscomplete.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuel

ofuptoB20(20%biodiesel,80%petrodiesel).The

petrodieselportionshouldbeloworultralowsulfur.

Observethefollowingprecautions:

•Thebiodieselportionofthefuelmeetspecication

ASTMD6751orEN14214.

16

Page 17

•TheblendedfuelcompositionshouldmeetASTM

D975orEN590.

fueltankrotatethefuel-selectorvalvetotheright-hand

location(Figure6)

•Paintedsurfacesmaybedamagedbybiodiesel

blends.

•UseB5(biodieselcontendof5%)orlesserblend

incoldweather.

•Monitorseals,hoses,gasketsincontactwithfuel

astheymaydegradeovertime.

•Fuellterpluggingmaybeexpectedforatime

afterconvertingtobiodieselblends.

•Contactyourdistributorifyouwishformore

informationonbiodiesel.

FillingtheFuelTank

Note:Donotllthefueltankcompletelyfull.Fillthe

fueltanktothebottomofthellerneck.Theempty

spaceinthetankallowsthegasolinetoexpand.

1.Shuttheengineoffandsettheparkingbrake.

2.Cleanaroundeachfuel-tankcapandremovethe

cap.Fillthefueltanktothebottomoftheller

neck.Thisspaceinthetankallowsthefuelto

expand.Donotllthefueltankcompletelyfull.

Closethefuel-selectorvalvebeforetransportingor

storingmachine.

3.Installthefuel-tankcapsecurely.Wipeupany

fuelthatmayhavespilled.

4.Ifpossible,llthefueltankaftereachuse.This

minimizespossiblebuildupofcondensation

insidethefueltank.

CheckingtheEngine-Oil Level

Beforeyoustarttheengineandusethemachine,

checktheoillevelintheenginecrankcase;referto

CheckingtheEngine-OilLevel(page37).

SwitchingtheFuelTanks

Important:Donotrunthemachineoutoffuel.

Thismaycauseenginedamageandrequirethe

fuelsystemtobechecked.

Thefuel-selectorvalveislocatedbehindtheleftside

oftheseat.

Figure6

1.Leftfueltank

2.Fuel-selectorvalve

UsingtheRollover ProtectionSystem(ROPS)

WARNING

Toavoidinjuryordeathfromrollover:keep

therollbarintheraisedlockedpositionand

usetheseatbelt.

Ensurethattherearpartoftheseatissecured

withtheseatlatch.

g000962

Theunithas2fueltanks.Onetankisontheleftside

andtheotherontherightside.Eachtankconnects

tothefuel-selectorvalve.Fromthereacommonfuel

lineleadstotheengine(Figure6).

Tousetheleftsidefueltankrotatethefuel-selector

valvetotheleft-handlocation.T ousetherightside

17

Page 18

WARNING

Thereisnorolloverprotectionwhentheroll

barisinthedownposition.

•Lowertherollbaronlywhenabsolutely

necessary.

•Donotweartheseatbeltwhentherollbar

isinthedownposition.

•Driveslowlyandcarefully.

•Raisetherollbarassoonasclearance

permits.

•Checkcarefullyforoverheadclearances

(i.e.,branches,doorways,electricalwires)

beforedrivingunderanyobjectsanddo

notcontactthem.

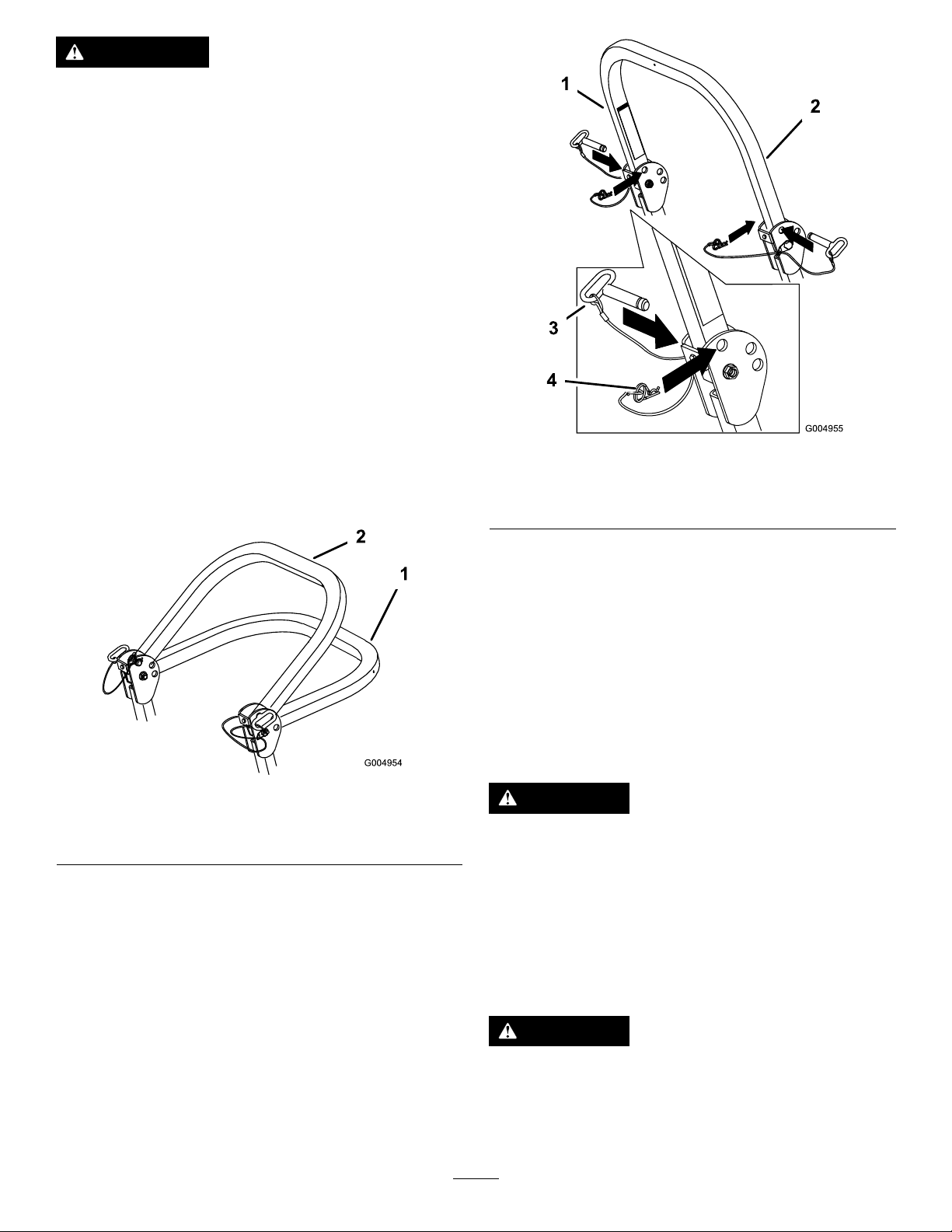

1.Removethehairpincottersandremovethe2

pins(Figure8).

2.Lowertherollbartothedownposition.There

are2downpositions.SeeFigure7forthe

positions.

g004955

Figure8

1.Rollbar3.Pin

2.Raisedposition4.Hairpincotter

Figure7

1.Fulldownposition2.Downpositionwithbagger

installed

3.Installthe2pinsandsecurethemwiththe

hairpincotters(Figure8).

4.Toraisetherollbar,removethehairpincotters

andremovethe2pins(Figure8).

5.Raisetherollbartotheuprightpositionand

installthe2pinsandsecurethemwiththe

hairpincotters(Figure8).

ThinkSafetyFirst

Pleasereadallsafetyinstructionsandsymbolsinthe

safetysection.Knowingthisinformationcouldhelp

youorbystandersavoidinjury .

g004954

DANGER

Operatingthemachineonwetgrassorsteep

slopescancauseslidingandlossofcontrol.

•Donotoperateonslopesgreaterthan15

degrees.

•Reducespeedanduseextremecautionon

slopes.

•Donotoperatethemachinenearwater.

DANGER

Wheelsdroppingoveredgescancause

rollovers,whichmayresultinseriousinjury,

death,ordrowning.

Donotoperatethemachineneardrop-offs.

18

Page 19

DANGER

OperatingtheParking

Operatingthemachinewhiletherollbaris

downmayleadtoseriousinjuryordeathin

theeventofarollover.

Alwayskeeptherollbarinthefullyraisedand

lockedpositionandusetheseatbelt.

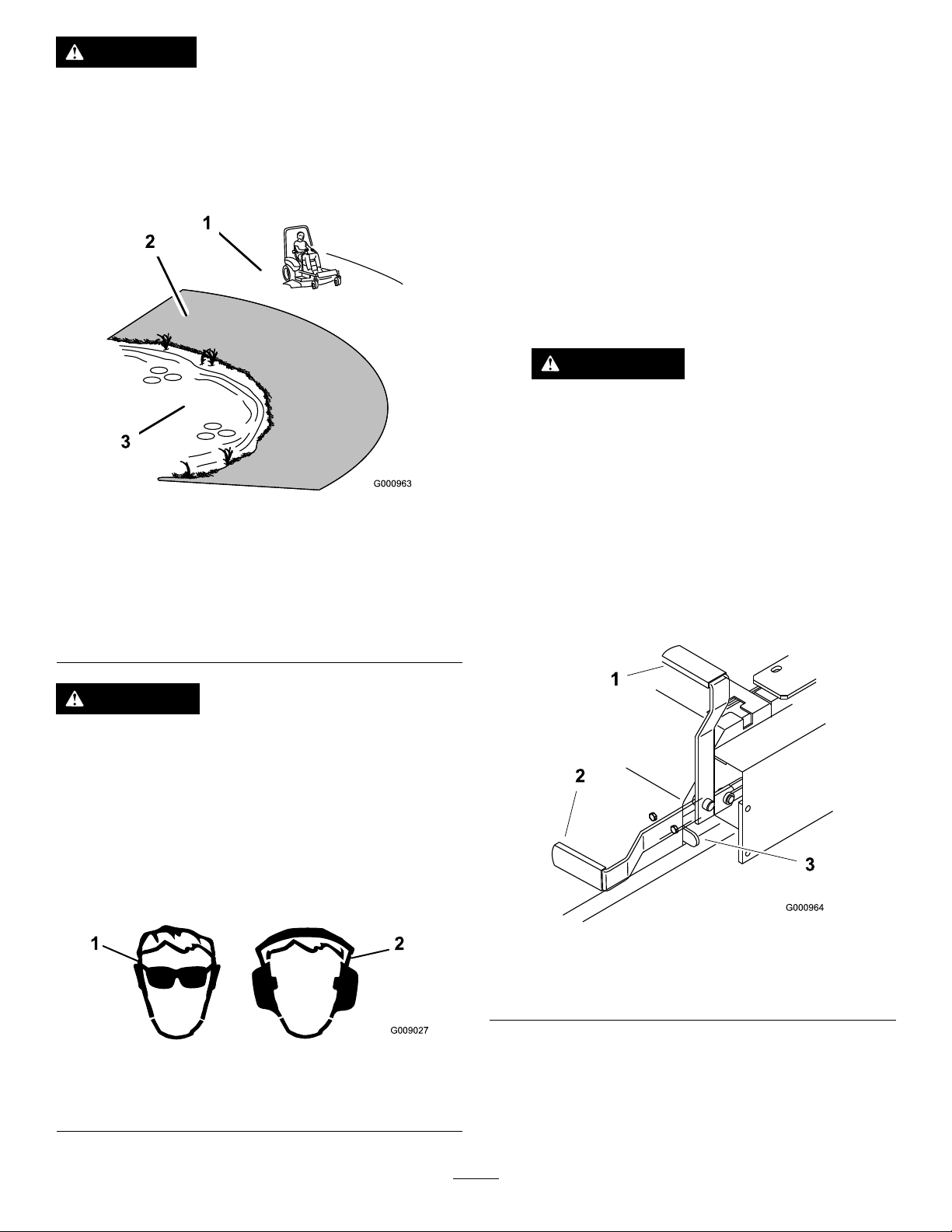

Figure9

1.SafeZone-usethe

ZMasterhereonslopes

lessthan15degreesor

atareas.

2.Usewalkbehindmower

and/orhandtrimmernear

drop-offsandwater.

3.Water

Brake

Alwayssettheparkingbrakewhenyoustopthe

machineorleaveitunattended.

SettingtheParkingBrake

1.Movethemotion-controllevers(Figure17)out

totheNEUTRAL-LOCKposition.

2.Pullupandbackontheparking-brakelever

tosettheparkingbrake(Figure11).The

parking-brakelevershouldstayrmlyinthe

engagedposition.

WARNING

Parkingbrakemaynotholdmachine

parkedonaslopeandcouldcause

personalinjuryorpropertydamage.

Donotparkonslopesunlesswheelsare

g000963

chockedorblocked

ReleasingtheParkingBrake

Pushforwardanddownontheparking-brakeleverto

releasetheparkingbrake(Figure1 1).Theparking

brakeisdisengagedandtheleverwillrestagainst

thebrakestop.

CAUTION

Thismachineproducessoundlevelsin

excessof85dBAattheoperatorsearandcan

causehearinglossthroughextendedperiods

ofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Wearprotectiveequipmentforyoureyes,ears,hands,

feet,andheadwhenusingthismachine.

Figure10

1.Warning—weareye

protection.

2.Warning—wearhearing

protection

g000964

Figure11

1.ONposition

2.OFFposition

g009027

3.Brakestop

19

Page 20

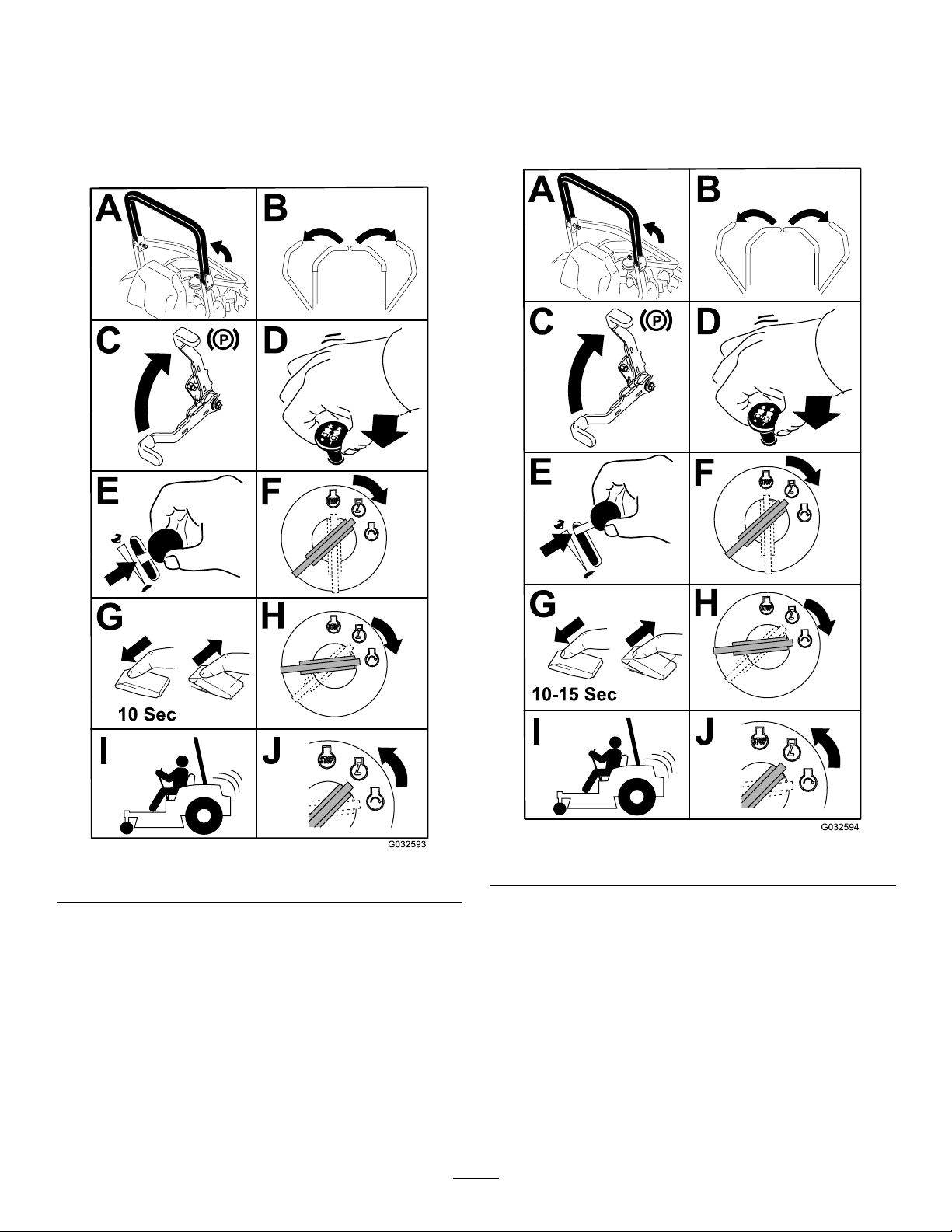

StartingandStoppingthe Engine

StartingtheEngineinNormal Weather

StartingtheEngineinCold Weather(Below-5°Cor23°F)

Note:Usethecorrectengineoilforthestarting

temperature;refertoServicingtheEngineOil(page

36).

Figure12

Important:Usestartingcyclesofnomorethan

30secondsperminutetoavoidoverheatingthe

startermotor.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthefuel

systemhasbeencompletelywithoutfuel.

g032594

g032593

Important:Usestartingcyclesofnomorethan

30secondsperminutetoavoidoverheatingthe

startermotor.

Note:Donotusefuelleftoverfromthesummer.Use

onlyfreshwintergradedieselfuel.

20

Figure13

Page 21

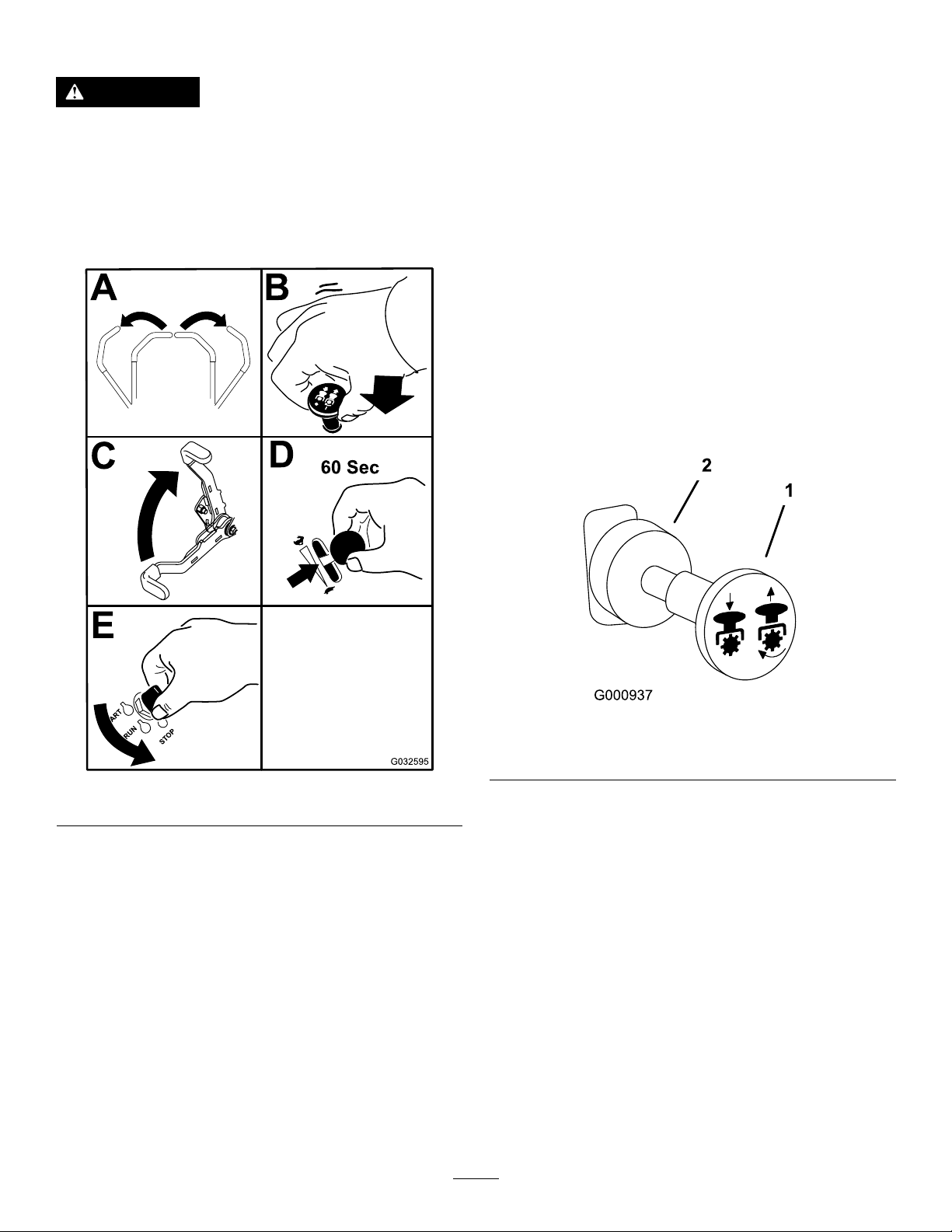

StoppingtheEngine

OperatingthePower

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

Alwaysremovetheignitionkeyandsetthe

parkingbrakewhenleavingthemachine

unattended,evenifjustforafewminutes.

Takeoff(PTO)

Thepowertakeoff(PTO)switchstartsandstopsthe

mowerbladesandanypoweredattachments.

EngagingthePTO

1.Iftheengineiscold,allowtheenginetowarm

up5to10minutesbeforeengagingthePTO.

2.Whileseatedintheseat,releasethepressureon

thetractioncontrolleversandplaceinNEUTRAL.

3.PlacethethrottleintheFASTposition.

Note:EngagingthePTOwiththethrottleat

thehalforlesspositioncausesexcessivewear

tothedrivebelts.

4.Pulloutonthepowertakeoff(PTO)switchto

engageit(Figure15).

Figure14

Important:Makesurethatyouclosethe

fuel-shutoffvalvebeforetransportingorstoring

themachine,asfuelleakagemayoccur.Setthe

parkingbrakebeforetransportingthemachine.

Makesurethatyouremovethekeyasthefuel

pumpmayrunandcausethebatterytolose

charge.

g000937

Figure15

1.PTOon2.PTOoff

g032595

DisengagingthePTO

Todisengage,pushthePTOswitchtotheOFF

position(Figure15).

21

Page 22

UsingtheSafety-Interlock System

CAUTION

Ifsafetyinterlockswitchesaredisconnected

ordamagedthemachinecouldoperate

unexpectedlycausingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

Understandingthe Safety-InterlockSystem

Thesafety-interlocksystemisdesignedtopreventthe

enginefromstartingunless:

•Theparkingbrakeisengaged.

•Thepowertakeoff(PTO)isdisengaged.

•Themotion-controlleversareintheNEUTRAL-LOCK

position

Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthe

safetysystemimmediately.

1.Sittingontheseat,engagetheparkingbrake

andmovethePTOtoON.Trystartingthe

engine;theengineshouldnotcrank.

2.Sittingontheseat,engagetheparkingbrake

andmovethePTOtoOFF.Moveeither

motion-controllever(outoftheNEUTRAL-LOCK

position).Trystartingtheengine;theengine

shouldnotcrank.Repeatforothercontrollever.

3.Sittingontheseat,engagetheparkingbrake,

movethePTOswitchtoOFFandmovethe

motion-controlleverstotheNEUTRAL-LOCK

position.Nowstarttheengine.Whiletheengine

isrunning,releasetheparkingbrake,engage

thePTOandriseslightlyfromtheseat;the

engineshouldstop.

4.Sittingontheseat,engagetheparkingbrake,

movethePTOswitchtoOFFandmovethe

motion-controlleverstotheNEUTRAL-LOCK

position.Nowstarttheengine.Whiletheengine

isrunning,centereithermotioncontroland

move(forwardorreverse);theengineshould

stop.Repeatfortheothermotioncontrol.

Thesafety-interlocksystemalsoisdesignedtoshut

offtheenginewhenthetractioncontrolsaremoved

fromtheLOCKEDpositionwiththeparkingbrake

engagedorifyourisefromtheseatwhenthePTO

isengaged.

Thehourmeterhassymbolstonotifytheuserwhen

theinterlockcomponentisinthecorrectposition.

Whenthecomponentisinthecorrectposition,a

trianglelightsupinthecorrespondingsquare.

Figure16

1.Triangleslightupwhentheinterlockcomponentsareinthe

correctposition

5.Sittingontheseat,disengagetheparkingbrake,

movethePTOswitchtoOFFandmovethe

motion-controlleverstoNEUTRAL-LOCKposition.

Trystartingtheengine;theengineshouldnot

crank.

DrivingForwardor Backward

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Place

thethrottlecontrolintheFASTpositionforbest

performance.AlwaysoperateintheFULLTHROTTLE

positionwhenmowing.

CAUTION

Machinecanspinveryrapidly.Operatormay

g009612

losecontrolofmachineandcausepersonal

injuryordamagetomachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemaking

sharpturns.

TestingtheSafety-Interlock System

ServiceInterval:Beforeeachuseordaily

DrivingForward

1.Releasetheparkingbrake;refertoAdjustingthe

ParkingBrake(page49).

22

Page 23

2.Movetheleverstothecenter,unlockedposition.

3.Togoforward,slowlypushthemotion-control

leversforward(Figure17).

Note:Theenginekillsifthetractioncontrol

leversaremovedwiththeparkingbrake

engaged.

Togostraight,applyequalpressuretoboth

motion-controllevers(Figure17).

Toturn,movethemotion-controllevertoward

neutralinthedirectionyouwanttoturn(Figure

17).

Thefartheryoumovethetractioncontrollevers

ineitherdirection,thefasterthemachinemoves

inthatdirection.

Tostop,pullthemotion-controlleverstothe

NEUTRALposition.

Togostraight,applyequalpressuretoboth

motion-controllevers(Figure17).

Toturn,releasepressureonthemotion-control

levertowardthedirectionyouwanttoturn

(Figure17).

Tostop,pushthemotion-controlleverstothe

NEUTRALposition.

Figure17

1.Motion-controlleverinthe

NEUTRAL-LOCKposition

2.Centerunlockposition5.Frontofthemachine

3.Forward

4.Backward

DrivingBackward

1.Movetheleverstothecenter,unlockedposition.

2.Togobackward,slowlypullthemotion-control

leversrearward(Figure17).

g004532

23

Page 24

StoppingtheMachine

AdjustingtheAnti-Scalp

Tostopthemachine,movethetraction-controllevers

totheNEUTRALpositionandthentotheLOCKED

position,disengagethepowertakeoff(PTO),andturn

theignitionkeytotheOFFposition.

Settheparkingbrakewhenyouleavethemachine.

Remembertoremovethekeyfromtheignitionswitch.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

Alwaysremovetheignitionkeyandsetthe

parkingbrakewhenleavingthemachine

unattended,evenifjustforafewminutes.

AdjustingtheHeight-of-Cut

Theheight-of-cutisadjustedfrom38to127mm

(1-1/2to5inches)in6mm(1/4inch)incrementsby

relocatingthepinintodifferentholelocations.

1.Raisetheheight-of-cutlevertotheTRANSPORT

position(alsothe127mm(5inch)cutting-height

position)(Figure18).

2.Toadjust,removethepinfromtheheight-of-cut

bracket(Figure18).

Rollers

Wheneveryouchangetheheight-of-cut,itis

recommendedtoadjusttheheightoftheanti-scalp

rollers.

1.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,andsetthe

parkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Afteradjustingtheheightofcut,adjusttherollers

byremovingtheangenut,bushing,spacer,

andbolt(Figure19orFigure20).

Note:The2middlerollersdonothaveaspacer

(Figure19orFigure20).

4.Selectaholesotheanti-scalprollerispositioned

tothenearestcorrespondingheight-of-cut

desired.

5.Installtheangenutbushing,spacer,andbolt.

Torqueto54to61N∙m(40to45ft-lb)(Figure

19orFigure20).

6.Repeatthisadjustmentontheotheranti-scalp

rollers.

3.Selectaholeintheheight-of-cutbracket

correspondingtotheheight-of-cutdesiredand,

insertthepin(Figure18).

4.Movethelevertotheselectedheight.

Figure18

1.Height-of-cutlever

2.Pin

g009568

24

Page 25

Figure20

g005960

Figure19

1.Anti-scalproller4.Flangenut

2.Spacer

3.Bushing

5.Bolt

g005887

1.Anti-scalproller4.Flangenut

2.Spacer

3.Bushing

5.Bolt

PositioningtheSeat

Theseatcanmoveforwardandbackward.Position

theseatwhereyouhavethebestcontrolofthe

machineandaremostcomfortable.

Toadjust,movetheleversidewaystounlockseat

(Figure21).

g019754

Figure21

25

Page 26

ChangingtheSeat

PushingtheMachineby

Suspension

Theseatisadjustabletoprovideasmoothand

comfortableride.Positiontheseatwhereyouare

mostcomfortable.

Toadjustit,turntheknobinfronteitherdirectionto

providethebestcomfort(Figure22).

Figure22

1.Seatsuspensionknob

Hand

Important:Alwayspushthemachinebyhand.

Nevertowthemachinebecausehydraulicdamage

mayoccur.

PushingtheMachine

1.Disengagethepowertakeoff(PTO)andturn

theignitionkeytooff.Movetheleversto

NEUTRAL-LOCKposition,applytheparkingbrake,

andremovethekey.

2.Rotatethebypassvalvescounterclockwise1

turn.Thisallowshydraulicuidtobypassthe

pumpenablingthewheelstoturn(Figure24).

Important:Donotrotatethebypassvalves

morethan1turn.Thispreventsvalvesfrom

comingoutofthebodyandcausinguidto

runout.

g019768

3.Disengageparkingbrakebeforepushingthe

machine.

UnlatchingtheSeat

1.Movetheseattothemostrearwardposition.

Thispreventsinterferencewhentheseatis

raised.

2.Pushtheseatlatchrearwardtounlatchtheseat.

3.Raisetheseatup.Thisallowsaccesstothe

machineundertheseat(Figure23).

ChangingtoMachineOperation

Rotatethebypassvalvesclockwise1turntooperate

themachine(Figure24).

Note:Donotovertightentheby-passvalves.

Themachinewillnotdriveunlessbypassvalvesare

turnedin.

Figure23

1.Seatlatch3.Seat

2.Fuelcap

g000950

g010371

Figure24

1.Sideconsolecontrols

2.Bypassvalve

26

3.Hydraulicpumps

Page 27

OperatingwiththeOverheat Sensor

ThismachinehasasensorthatturnsOFFthemower

deckwhentheengineoverheats.Whentheengine

overheats,theaudiblealarmandlightalarmturnsON

alongwiththemowerdeckturningOFF.

IfthemowerdeckturnsOFFautomaticallybecause

ofoverheating,drivethemachinetoasafeareaand

toatruckortrailer.

1.Backthemachineupthe

ramp.

g028043

Figure25

2.Drivethemachineforward

downtheramp.

Ifthemachineoverheats,ensurethattheareaaround

theengineandradiatorisclearofanydebris.Turnthe

engineoffandallowittocooldownbeforeyouengage

themowerdeck.Iftheenginecontinuestooverheat,

takeyourmachinetoanAuthorizedServiceDealer.

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthe

machine.Ensurethatthetrailerortruckhasall

necessarylightingandmarkingasrequiredbylaw.

Pleasecarefullyreadallthesafetyinstructions.

Knowingthisinformationcouldhelpyou,yourfamily,

petsorbystandersavoidinjury.

Totransportthemachine:

•Lockthebrakeandblockthewheels.

•Securelyfastenthemachinetothetrailerortruck

withstraps,chains,cable,orropes.

•Secureatrailertothetowingvehiclewithsafety

chains.

Important:Donotusenarrowindividualramps

foreachsideofthemachine.

WARNING

Drivingonthestreetorroadwaywithout

turnsignals,lights,reectivemarkings,

oraslowmovingvehicleemblemis

dangerousandcanleadtoaccidents

causingpersonalinjury.

Donotdrivemachineonapublicstreetor

roadway.

LoadingtheMachine

Useextremecautionwhenloadingortheunloading

machineontoatraileroratruck.Useafull-widthramp

thatiswiderthanthemachineforthisprocedure.

Backthemachineuptherampanddriveitforward

downtheramp(Figure25).

27

Page 28

Ensurethattherampislongenoughsothattheangle

withthegrounddoesnotexceed15degrees(Figure

26).Onatground,thisrequiresaramptobeatleast

4timesaslongastheheightofthetrailerortruckbed

totheground.Asteeperanglemaycausemower

componentstogetcaughtasthemachinemovesfrom

theramptothetrailerortruck.Steeperanglesmay

alsocausethemachinetotiporlosecontrol.Ifyou

areloadingthemachineonornearaslope,position

thetrailerortrucksothatitisonthedownsideof

theslopeandtherampextendsuptheslope.This

minimizestherampangle.

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath.

•Useextremecautionwhenoperatinga

machineonaramp.

•EnsurethattheROPSisintheupposition

andusetheseatbeltwhenloadingor

unloadingthemachine.Ensurethatthe

ROPSclearsthetopofanenclosedtrailer.

•Useonlyafull-widthramp;donotuse

individualrampsforeachsideofthe

machine.

•Donotexceeda15-degreeanglebetween

therampandthegroundorbetweenthe

rampandthetrailerortruck.

•Ensurethatthelengthoframpisatleast4

timesaslongastheheightofthetraileror

truckbedtotheground.Thisensuresthat

rampangledoesnotexceed15degreeson

atground.

•Backuprampsanddriveforwarddown

ramps.

•Avoidsuddenaccelerationordeceleration

whiledrivingthemachineonarampas

thiscouldcausealossofcontrolora

tip-oversituation.

1.Full-widthrampinstowed

position

2.Sideviewoffull-width

rampinloadingposition

3.Notgreaterthan

15degrees

g027996

Figure26

4.Rampisatleast4times

aslongastheheightof

thetrailerortruckbedto

theground

5.H=heightofthetraileror

truckbedtotheground

6.Trailer

28

Page 29

UsingtheZStand™

TheZStandraisesthefrontendofthemachineto

allowyoutocleanthemowerandremovetheblades.

WARNING

Themachinecouldfallontosomeoneand

causeseriousinjuryordeath.

•Useextremecautionwhenoperatingthe

machineontheZStand™.

•Useonlyforcleaningthemowerand

removingtheblades.

•DonotkeepthemachineontheZStand™

forextendedperiodsoftime.

•Alwaysturntheengineoff,setthe

parkingbrake,andremovethekeybefore

performinganymaintenancetothemower.

Figure28

1.ZStand(positionedinslot)

2.Crackinsidewalkorturf

4.Setthefootofstandonthegroundandrestthe

latchonthepivottab(Figure28).

5.Starttheengineandputitathalfthrottle.

3.Latchrestingonpivottab

Note:Forbestresults,placethefootofstand

intoseamsinsidewalksorintotheturf(Figure

28).

g001812

DrivingupontotheZStand™

Important:UsetheZStand™onalevelsurface.

1.RaisethemowertotheTRANSPORTposition.

2.Removethebracketpin(Figure27).

Figure27

1.ZStand™

2.Latch

3.Bracket

4.Bracketpin

5.Bottomofslot

6.Driveontothestand.Stopwhenthelatchdrops

overthetabintotheLOCKEDposition(Figure

28).Onceontothestand,engagetheparking

brakeandturnofftheengine.

7.Chockorblockthedrivewheels.

WARNING

Theparkingbrakemaynotholdmachine

parkedonZStand™andcouldcause

personalinjuryorpropertydamage.

DonotparkonZStand™unlesswheels

arechockedorblocked.

8.Performthemaintenance.

g001811

DrivingofftheZStand™

1.Removethechocksorblocks.

2.RaisethelatchtotheUNLOCKEDposition(Figure

29).

3.Raisethelatch.Swingthestandfootoutfront

andslidestandtowardmachine,intothebottom

ofslot(Figure27andFigure28).

29

Page 30

MowingatCorrectIntervals

Normally,mowevery4days.However,grassgrows

atdifferentratesatdifferenttimes.T omaintainthe

samecuttingheight,whichisagoodpractice,mow

moreofteninearlyspring.Asthegrassgrowthrate

slowsinmid-summer,mowlessfrequently .Ifyou

cannotmowforanextendedperiod,rstmowata

highcuttingheight;thenmowagain2dayslaterata

lowerheightsetting.

Figure29

1.ZStand™

2.Latch4.UNLOCKEDposition

3.Starttheengineandplaceitathalfthrottle.

Disengagetheparkingbrake.

4.Slowlydrivebackwardoffthestand.

5.ReturnthestandtoitsRESTposition(Figure27).

3.LOCKEDposition

OperatingTips

UsingtheFastThrottleSetting

Forbestmowingandmaximumaircirculation,operate

theengineattheFASTthrottleposition.Airisrequired

tothoroughlycutgrassclippings,sodonotsetthe

heightofcutsolowastototallysurroundthemower

inuncutgrass.Alwaystrytohave1sideofthemower

freefromuncutgrass,whichallowsairtobedrawn

intothemower.

CuttingaLawnfortheFirstTime

g001813

AdjustingtheCuttingSpeed

Toimprovecutquality,useaslowergroundspeed

incertainconditions.

AvoidingCuttingTooLow

Ifthecuttingwidthofthemoweriswiderthanthe

moweryoupreviouslyused,raisethecuttingheightto

ensurethatuneventurfisnotcuttooshort.

CuttingLongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,

raisethecuttingheighthigherthanusualandcutthe

grassatthissetting.Thencutthegrassagainusing

thelower,normalsetting.

Stopping

Ifyoumuststoptheforwardmotionofthemachine

whilemowing,aclumpofgrassclippingsmaydrop

ontoyourlawn.Toavoidthis,moveontoapreviously

cutareawiththebladesengaged.

Cutthegrassslightlylongerthannormaltoensure

thatthecuttingheightofthemowerdoesnotscalp

anyunevenground.However,thecuttingheightyou

haveusedinthepastisgenerallythebesttouse.

Whencuttinggrasslongerthan15.24cm(6inches)

tall,youmaywanttocutthelawntwicetoensurean

acceptablequalityofcut.

CuttingaThirdoftheGrassBlade

Itisbesttocutonlyaboutathirdofthegrassblade.

Cuttingmorethanthatisnotrecommendedunless

grassissparse,oritislatefallwhengrassgrows

moreslowly.

AlternatingtheMowingDirection

Alternatethemowingdirectiontokeepthegrass

standingstraight.Thisalsohelpsdisperseclippings,

whichenhancesdecompositionandfertilization.

KeepingtheUndersideofthe

MowerClean

Cleanclippingsanddirtfromtheundersideofthe

moweraftereachuse.Ifgrassanddirtbuildupinside

themower,cuttingqualitywilleventuallybecome

unsatisfactory.

MaintainingtheBlades

Maintainasharpbladethroughoutthecuttingseason

becauseasharpbladecutscleanlywithouttearingor

shreddingthegrassblades.T earingandshredding

turnsgrassbrownattheedges,whichslowsgrowth

andincreasesthechanceofdisease.Checkthe

cutterbladesdailyforsharpness,andforanywearor

damage.Filedownanynicksandsharpentheblades

asnecessary.Ifabladeisdamagedorworn,replace

itimmediatelywithagenuineT ororeplacementblade.

30

Page 31

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst25hours

Aftertherst50hours

Aftertherst100hours

Beforeeachuseordaily

Every25hours

MaintenanceProcedure

•Checktheenginecoolantlevel.

•Checkthehydraulicuid.

•Changethehydrauliclter.

•Changetheengineoil.

•Changetheengine-oillter.

•Checkthetorqueonthewheellugnuts.

•Checkthewheel-hubslottednut.

•Checkthewheellugnuts.

•Changethegearboxoil.

•Checkthesafetysystem.

•Checktheengineoil.

•Checktheenginecoolantlevel.

•Cleantheengineoilcooler.

•Checkthemowerblades.

•Cleanthemowerdeck.

•Greasethemowerdeckandspindles.

•Greasethepumpbeltidlerarm.

•Greasethedrivebeltidlerarm.

•Greasethebrakelever .

•Checkthehydraulicuid.

Every40hours

Every50hours

Every100hours

Every150hours

Every200hours

Every250hours

Every400hours

Every500hours

•Drainthewaterseparator.

•Checkthetirepressure.

•CheckthePTOdrivebelt.

•Checkthepumpdrivebelt.

•Checkthealternatorbelt.

•Changetheengineoil.

•Checkthegearbox-oillevel.

•Checktheenginecoolingsystemhoses.

•Inspectthebeltsforcracksandwear.

•Checkthehydraulichoses.

•Lubricatethemachinewithlightoil.

•Changetheengine-oillter.

•Greasethebrakepivot.

•Checkand/orreplacetheairlter(moreoftenindirtyordustyconditions).

•ChangethehydrauliclterandhydraulicoilwhenusingMobil®1oil.

•Replacethefuellter(moreoftenindirtyordustyconditions).

•Checkthetorqueonthewheellugnuts.

•Checkthewheel-hubslottednut.

•Checkthewheellugnuts.

•Adjustthecasterpivotbearing(oryearly,whichevercomesrst).

•Adjusttheelectricclutch.

•ChangethehydrauliclterandhydraulicoilwhenusingT oro®HYPR-OIL™500

hydraulicoil.

•Greasethefrontcasterpivots(moreoftenindirtyordustyconditions).

Yearly

•Changethegearboxoil.

•Changetheenginecoolant.

31

Page 32

Important:Refertoyourengineowner’smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineand

seriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplug(s)beforeyoudo

anymaintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

Pre-Maintenance

Procedures

ReleasingtheMower-Deck Curtain

Loosenthebottomboltofthecurtaintoreleasethe

mower-deckcurtainandaccessthetopofthemower

deck(Figure30).Tightentheboltaftermaintenance

toinstallthecurtain.

RemovingtheSheet-Metal Guard

Loosenthe2frontboltsandremovethesheet-metal

guardtoaccessthemowerbeltsandspindles(Figure

31).Placethesheet-metalguardandtightenthebolts

aftermaintenance.

g027946

Figure31

g027945

Figure30

1.Bolt

2.Curtain

1.Sheet-metalguard

2.Bolt

32

Page 33

Lubrication

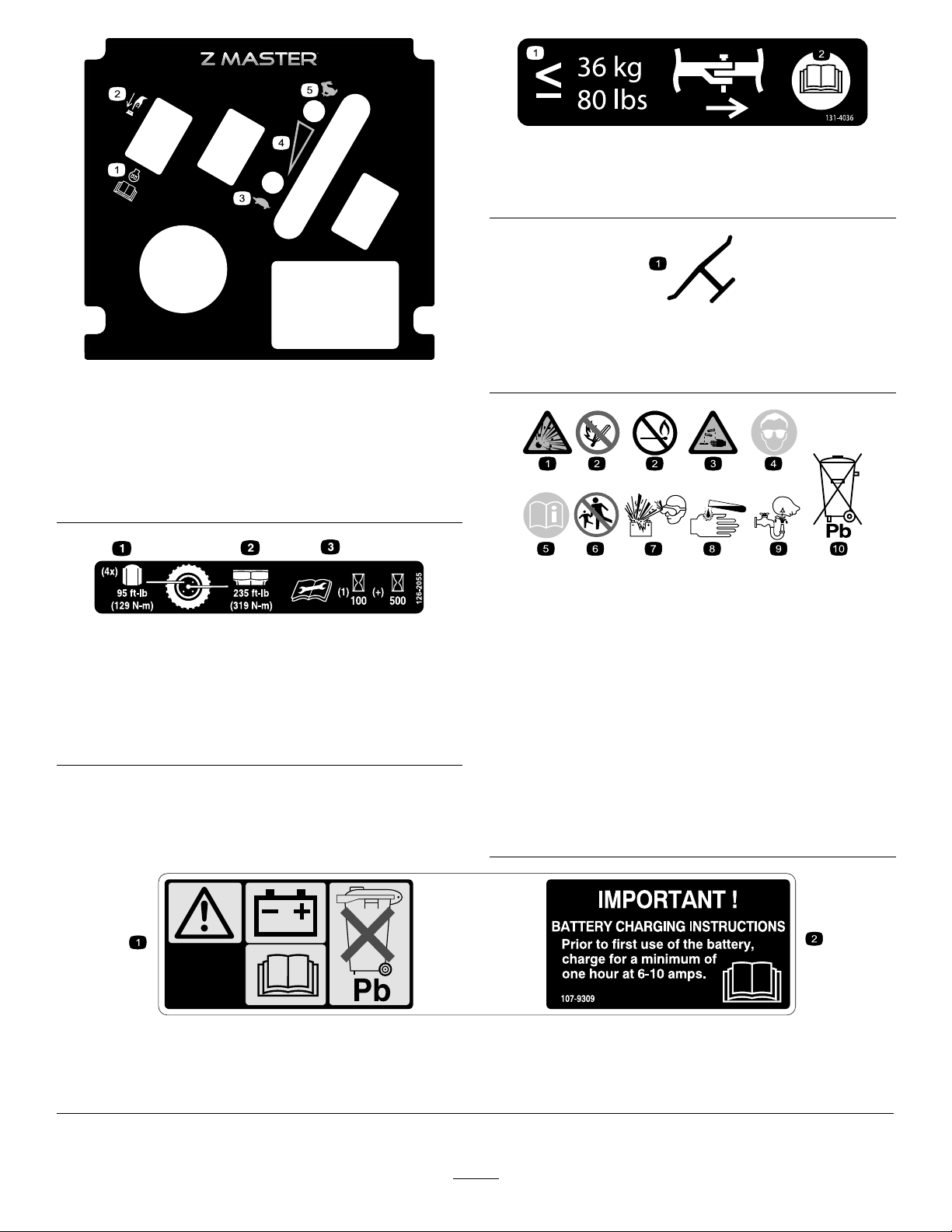

LubricatethemachinewhenshownontheCheck

ServiceReferenceAiddecal(Figure32).Grease

morefrequentlywhenoperatingconditionsare

extremelydustyorsandy.

GreaseType:General-purposegrease.

GreasingtheMachine

1.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,andsetthe

parkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanthegreasettingswitharag.Makesure

toscrapeanypaintoffthefrontofthetting(s).

4.Connectagreaseguntothetting.Pump

greaseintothettingsuntilgreasebeginsto

oozeoutofthebearings.

5.Wipeupanyexcessgrease.

g005930

Figure32

GreasingtheFrontCaster Pivots

Lubricatethefrontcasterpivotsonceayear.

1.Removethedustcapandadjustthecaster

pivots.Keepthedustcapoffuntilgreasing

isdone.RefertoAdjustingtheCaster-Pivot

Bearing(page45).

2.Removethehexplug.Threadagreasetting

intothehole.

3.Pumpgreaseintothettinguntilitoozesout

aroundthetopbearing.

4.Removethegreasettinginthehole.Installthe

hexplugandcap.

AddingGrease

LubricatethegreasettingsasshownontheCheck

ServiceReferenceAiddecal(Figure32).

AddingLightOilorSpray Lubrication

ServiceInterval:Every150hours

Lubricatethemachineinthefollowingareaswith

spraytypelubricantorlightoil.

•Seatswitchactuator.

•Brakehandlepivot.

•Brakerodbushings.

•Motioncontrolbronzebushings.

GreasingtheMowerDeck andBeltIdlers

ServiceInterval:Every25hours—Greasethemower

deckandspindles.

Every25hours—Greasethepumpbeltidler

arm.

Every25hours—Greasethedrivebeltidlerarm.

GreasewithNo.2lithiumormolybdenumgrease.

Important:Makesurecuttingunitspindlesare

fullofgreaseweekly.

1.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,andsetthe

parkingbrake.

33

Page 34

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Loosenthebottomboltholdingthemower-deck

curtaintothemowerdeck.RefertoReleasing

theMower-DeckCurtain(page32).

4.Removethesheetmetalguard.Referto

RemovingtheSheet-MetalGuard(page32)

5.Removethebeltcoversandtheboltsattached

tothem.

6.Greasethe3spindlebearingsuntilgrease

comesout(Figure33).

7.Greasethettingsonthepusharms(Figure33).

12.Tightentheboltforthemower-deckcurtain.

RefertoReleasingtheMower-DeckCurtain

(page32).

Figure33

8.GreasethePTOdrivebeltidlerarm(Figure34).

9.Greasethepumpbeltidlerarm(Figure34).

Figure34

g012504

g007170

10.Installthebeltcovers.

11.Installthesheetmetalguard.RefertoRemoving

theSheet-MetalGuard(page32).

34

Page 35

EngineMaintenance

ServicingtheAirCleaner

Note:Checktheltersmorefrequentlyifoperating

conditionsareextremelydustyorsandy.

RemovingtheAirFilter

ServiceInterval:Every250hours(moreoftenindirty

ordustyconditions).

1.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,andsetthe

parkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Releasethelatchesontheaircleanerandpull

theair-cleanercoverofftheair-cleanerbody

(Figure35).

4.Cleantheinsideoftheair-cleanercoverwith

compressedair.

5.Gentlyslidethelteroutoftheair-cleanerbody

(Figure35).Avoidknockingthelterintothe

sideofthebody.

6.Inspectthelterfordamagebylookingintothe

lterwhileshiningabrightlightontheoutside

ofthelter.Holesinthelterappearasbright

spots.Ifthelterisdamageddiscardit.

Figure35

1.Air-lterbody

2.Airlter

3.Air-cleanercover

4.Latches

InstallingtheAirFilter

1.Ifinstallinganewlter,checkthelterfor

shippingdamage.Donotuseadamagedlter.

2.Carefullyslidethelterintothelterbody(Figure

36).Ensurethatitisfullyseatedbypushingon

theouterrimofthelterwhileinstallingit.

Important:Donotpressonthesoftinside

areaofthelter.

3.Installtheair-cleanercoverandsecurethe

latches(Figure36).

g001049

35

Page 36

ServicingtheEngineOil

OilType:High-qualitydetergentoilclassiedAPI

ServiceCDorhigherfordieselengines.Donotuse

specialadditiveswithrecommendedoils.

CrankcaseCapacity:3.7L(3.9USqt)

Viscosity:Seethetablebelow:

1.Air-lterbody

2.Airlter

Figure36

3.Air-cleanercover

4.Latches

g001048

Figure37

g001061

PreparingtoServicetheEngine Oil

Important:Thefastenersforthefrontengine

panelaredesignedtoremainonthemachineafter

coverremoval.Loosenallofthefastenersafew

turnssothatthepanelisloosebutstillattached,

thengobackandloosenthemuntilthepanel

comesfree.Thispreventsyoufromaccidentally

strippingtheboltsfreeoftheretainers.

Tilttheseatforward,loosentheboltsholdingthefront

enginepanelandremoveit(Figure38).

36

Page 37

Figure38

1.Bolt2.Frontenginepanel

Note:Afterservicingtheengineoil,installtheengine

panelandtilttheseatintoitsuprightposition.

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

1.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,andsetthe

parkingbrake.

g032601

g012347

g032641

Figure39

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Checktheengine-oillevel(Figure39).

4.Starttheengine,runitatidlefor5minutes,

shutofftheengine,waitfor3minutes,andthen

checktheengine-oillevel.Ifneeded,addoilup

totheFULLmarkonthedipstick.

Important:Besuretokeeptheengine-oillevel

betweentheupperandlowerlimitsontheoil

gauge.Enginefailuremayoccurasaresultof

overllingorunderllingtheengineoil.

Important:Addtheoilveryslowlyanddonot

blocktheopeningofthellerhole(Figure40).If

youaddoiltoofastorblockthehole,theoilcould

backupandfoultheairintakes,causingengine

damage.

37

Page 38

Figure40

1.Notetheclearanceleftinthelleropening.

DrainingtheEngineOil

ServiceInterval:Aftertherst50hours

Every100hours

1.Starttheengineandletitrunfor5minutes.

Note:Thiswarmstheoilsoitdrainsbetter.

2.Parkthemachineonalevelsurface,disengage

thePTO,movethemotion-controlleverstothe

g000955

NEUTRAL-LOCKposition,andsettheparking

brake.

3.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

38

Page 39

ChangingtheEngine-OilFilter

ServiceInterval:Aftertherst50hours

Every200hours

1.Draintheoilfromtheengine;refertoDraining

theEngineOil(page38).

2.Changetheengine-oillter(Figure42).

g032646

g032649

Figure41

Note:Disposeoftheusedoilatarecyclingcenter.

g032642

g032644

Figure42

3.Addoil;refertoCheckingtheEngine-OilLevel

(page37).

39

Page 40

FuelSystem

Maintenance

ServicingtheFuelFilter andWaterSeparator

DrainingtheWaterSeparator

ServiceInterval:Every40hours

1.Positionthemachineonalevelsurface.

2.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,andsetthe

parkingbrake.

3.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

4.Locatethewaterseparatoratthebackleftof

themachine.

5.Placeadrainpanbelowthewaterseparator.

6.Openthedrainvalveonthewaterseparator

approximately1turntoallowwaterandother

contaminatestodrain(Figure43).

7.Closethedrainvalvewhenonlydieselfuel

comesout(Figure43).

1.Allowthemachinetocooldown.

2.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,andsetthe

parkingbrake.

3.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

4.Closethefuel-shutoffvalve(Figure44).

5.Loosenthe2hoseclampsanddisconnectthe

fuellinesfromthefuellter(Figure44).

6.Installanewlter.Connectthefuellinestothe

fuellterandinstallthe2hoseclamps(Figure

44).

7.Openthefuel-shutoffvalve.

8.Starttheengineandcheckforleaks.

Figure43

1.Drainvalve

2.Waterseparator

3.Backofmachine

ChangingtheFuelFilter

ServiceInterval:Every400hours/Yearly(whichever

comesrst)(moreoftenindirtyor

dustyconditions).

Neverinstalladirtyfuellterifitisremovedfromthe

fuelline.

g007169

g007697

Figure44

1.Fuellter4.Leftsideofthemachine

2.Hoseclamp

3.Fuelpump

5.Fuel-shutoffvalve

ServicingtheFuelTank

Donotattempttodrainthefueltank.Ensurethatan

AuthorizedServiceDealerdrainsthefueltankand

servicesanycomponentsofthefuelsystem.

40

Page 41

ElectricalSystem

Maintenance

ServicingtheBattery

WARNING

Incorrectbatterycableroutingcoulddamage

themachineandcablescausingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

WARNING

positive(red)cable.

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

DANGER

Batteryelectrolytecontainssulfuricacid

whichisadeadlypoisonandcausessevere

burns.

Donotdrinkelectrolyteandavoidcontact

withskin,eyesorclothing.Wearsafety

glassestoshieldyoureyesandrubbergloves

toprotectyourhands.

RemovingtheBattery

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

1.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,andsetthe

parkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Unlatchtheseatandtilttheseatup.

4.RemovethebatteryasshowninFigure49

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetalmachinecomponentscausing

sparks.Sparkscancausethebatterygasses

toexplode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery ,

donotallowthebatteryterminalstotouch

anymetalpartsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

g032750

Figure45

41

Page 42

InstallingtheBattery

ChargingtheBattery

Note:Positionthebatteryinthetraywiththeterminal

postsoppositefromthehydraulictank.

WARNING

Chargingthebatteryproducesgassesthat

canexplode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged

(1.265specicgravity).Thisisespecially

importanttopreventbatterydamagewhenthe

temperatureisbelow0°C(32°F).

1.Makesurethellercapsareinstalledinbattery .

Chargebatteryfor10to15minutesat25to30A

or30minutesat10A.

2.Whenthebatteryisfullycharged,unplug

thechargerfromtheelectricaloutlet,then

disconnectthechargerleadsfromthebattery

posts(Figure47).

3.Installthebatteryinthemachineandconnect

thebatterycables,refertoInstallingtheBattery

(page42).

Figure46

g032751

g000960

Figure47

1.Positivebatterypost

2.Negativebatterypost

3.Red(+)chargerlead

4.Black(-)chargerlead

42

Page 43

ServicingtheFuses

DriveSystem

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance,however,ifafuseblowscheck

component/circuitformalfunctionorshort.

1.Unlatchtheenginehoodandraisetheengine

hoodtogainaccesstofuseholder(Figure48).

2.T oreplacethefuses,pulloutonthefuseto

removeit.

3.Installanewfuse(Figure48).

Maintenance

AdjustingtheTracking

Themachinehasaknobforadjustingthetracking

locatedundertheseat.

Important:Adjustthehandleneutraland

hydraulicpumpneutralbeforeadjustingthe

tracking.RefertoAdjustingtheControlHandle

NeutralPosition(page52)andSettingthe

HydraulicPumpNeutralPosition(page55).

1.Pushbothcontrolleversforwardthesame

distance.

2.Checkifthemachinepullsto1side.Ifitdoes,

stopthemachineandsettheparkingbrake.

3.Unlatchtheseatandtilttheseatforwardto

accessthetrackingknob.

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

4.T omakethemachinegoright,turntheknob

towardtherightsideofthemachine.Referto

Figure49.

Figure48

1.Ignition—30A(F1)3.Clutch—10A(F3)

2.Radiatorfan—50A(large,

heavydutyfuse)

4.Leftfueltank

5.T omakethemachinegoleft,turntheknob

towardtheleftsideofthemachine.Referto

g012492

Figure49.

6.Repeatadjustmentuntilthetrackingiscorrect.

43

Page 44

Figure49

1.Trackingknob4.Turnthiswaytotrackright.

2.Hydraulictank

3.Hydraulicpumps

5.Turnthiswaytotrackleft.

CheckingtheWheelLug Nuts

Checkandtorquethewheellugnutsto122to129

N∙m(90to95ft-lb).

CheckingtheWheel-Hub SlottedNut

ServiceInterval:Aftertherst100hours—Checkthe

wheel-hubslottednut.

Every500hours—Checkthewheel-hubslotted

nut.

Aftertherst100hours—Checkthewheellug

nuts.

Every500hours—Checkthewheellugnuts.

Theslottednutneedstobetorquedto170N∙m(125

ft-lb).

1.DisengagethePTO,movethemotion-control

g001070

leverstotheNEUTRAL-LOCKposition,andsetthe

parkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removethecotterpin.

4.T orquetheslottednutto170N∙m(125ft-lb)

(Figure51).

CheckingtheTirePressure

ServiceInterval:Every50hours/Monthly(whichever

comesrst)

Maintaintheairpressureinthereartiresat90kPa

(13psi).Uneventirepressurecancauseunevencut.

Checkthetireswhentheyarecoldtogetthemost

accuratepressurereading.

Note:Thefronttiresaresemi-pneumatictiresanddo

notrequireairpressuremaintenance.

Figure50

g001051

Figure51

1.Slottednut3.Holeinthreadedshaft

2.2threadsorlessshowing

5.Checkthedistancefrombottomofslotinnut

toinsideedgeofhole.2threadsorlessshould

beshowing(Figure51).

6.Ifmorethan2threadsareshowingremovenut

andinstallwasherbetweenhubandnut.

7.T orquetheslottednutto170N∙m(125ft-lb)

(Figure51).

g001055

8.Tightenthenutuntilthenextsetofslotslineup

withtheholeintheshaft(Figure51).

9.Replacethecotterpin.

4.Washer(ifneeded)

44

Page 45

AdjustingtheCaster-Pivot Bearing

ServiceInterval:Every500hours(oryearly,which

evercomesrst).

1.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,andsetthe

parkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removethedustcapfromcasterandtighten

thelocknut(Figure52).

4.Tightenthelocknutuntilthespringwashersare

atandthenbackoffa1/4turntoproperlyset

thepre-loadonthebearings(Figure52).

Important:Makesurespringwashersare

installedcorrectlyasshowninFigure52.

5.Installthedustcap(Figure52).

3.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

4.Removethesideorrearplugonthegearbox

(Figure53).

5.Theoilshouldbeuptotheopeningofthe

gearbox.

6.Addoilifneededtobringittothecorrectlevel.

Figure52

1.Springwashers

2.Locknut

3.Dustcap

ServicingtheGearbox

CheckingtheGearbox-OilLevel

ServiceInterval:Every100hours

UseSAE75W–90SyntheticGearLube.

1.Parkthemachineonalevelsurface.

2.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,andsetthe

parkingbrake.

g001156

Figure53

1.Gearbox

2.Sideplug

g001297

ChangingtheGearboxOil

ServiceInterval:Aftertherst100hours

Yearly

ContactanAuthorizedServiceDealertochangethe

gearboxoil.

3.Rearplug

4.Pulley

AdjustingtheElectric Clutch

ServiceInterval:Every500hours

Theclutchisadjustabletoensureproperengagement

andproperbraking.

1.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,andsetthe

parkingbrake.

45

Page 46

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Unlatchtheseatandtipitforward.

4.Loosenthefrontenginepanelknobsand

removethepanel.

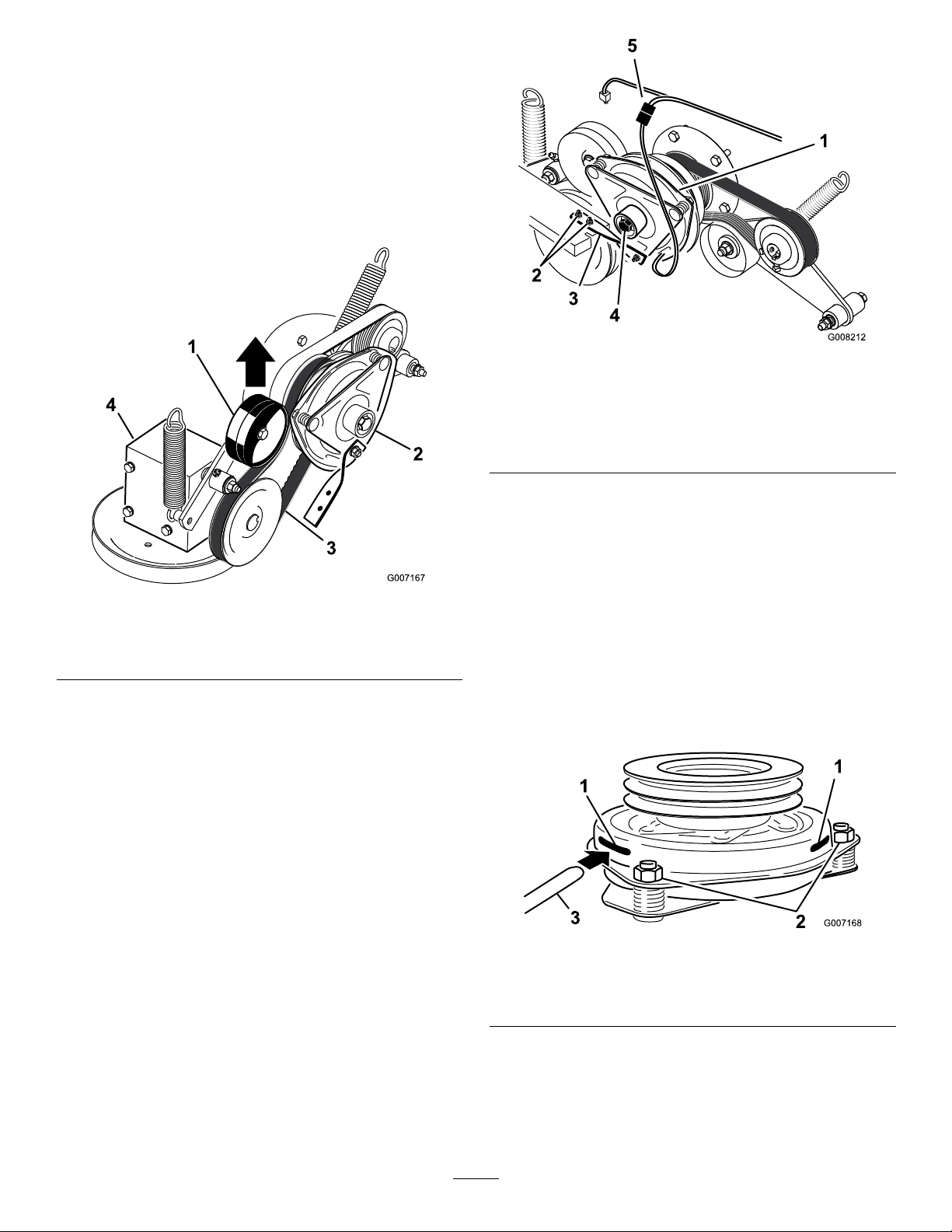

5.Pulluponthespringloadedidlerpulleyforthe

PTOdrivebeltandremovethebeltfromthe

clutchpulley(Figure54).

Figure54

1.Spring-loadedidlerpulley3.PTOdrivebelt

2.Clutch4.Gearbox

6.Unplugtheelectricconnectionfortheclutch

(Figure55).

7.Removetheboltsholdingtherubberclutchstrap

tothemowerframe(Figure55).

g008212

Figure55

1.Clutch4.Clutchcenterbolt

2.Bolts(2)andnutsfor

clutchstrap

3.Rubberclutchstrap

5.Electricalconnection

9.Inserta0.381to0.533mm(0.015to0.021inch)

feelergaugethrough1inspectionslotintheside

oftheassembly.Makesureitisbetweenthe

armatureandtherotorfrictionsurfaces(Figure

56).

g007167

10.Tightenthelocknutsuntilthereisslightbinding

onthefeelergaugebutitcanbemovedeasily

withintheairgap(Figure56).

11.Repeatthisfortheremainingslots.

12.Checkeachslotagainandmakeslight

adjustmentsuntilthefeelergaugebetween

therotorandarmaturehasveryslightcontact

betweenthem.

8.Removethecenterboltholdingtheclutchto

theengineshaftandremovetheclutchandkey

(Figure55).

Figure56

1.Slot

2.Adjustingnut

3.Feelergauge

13.Installtheclutchtotheengineshaftwiththekey.

14.Applythread-lockingadhesivetothecenterbolt.

15.Whileholdingthecrankshaftatthebackofthe

machine,installthecenterboltandtorqueitto

68N∙m(50ft-lb)(Figure55).

46

g007168

Page 47

16.Installtherubberclutchstraptothemower

framewiththe2previouslyremovedboltsand