Page 1

FormNo.3364-205RevA

Z590-DZMaster

®

Witha60inor72inTURBOFORCE

DischargeMower

ModelNo.74268—SerialNo.310000001andUp

ModelNo.74269—SerialNo.310000001andUp

®

Side

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Important:Thisengineisnotequippedwitha

sparkarrestermufer.ItisaviolationofCalifornia

PublicResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,or

grass-coveredland.Otherstatesorfederalareas

mayhavesimilarlaws.

Figure1

1.Modelandserialnumberlocation

ThissparkignitionsystemcomplieswithCanadian

ICES-002.

Theenclosed

Engine Owner’ s Man ual

issupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCalifornia

EmissionControlRegulationofemissionsystems,

maintenance,andwarranty.Replacementsmaybe

orderedthroughtheenginemanufacturer.

Introduction

Thisrotary-blade,ridinglawnmowerisintendedto

beusedbyresidentialhomeownersorprofessional,

hiredoperators.Itisdesignedprimarilyforcutting

grassonwell-maintainedlawnsonresidential

orcommercialproperties.Itisnotdesignedfor

cuttingbrushorforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

YoumaycontactTorodirectlyatwww .T oro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready .

Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

©2010—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

SlopeIndicator.....................................................6

SafetyandInstructionalDecals.............................7

ProductOverview......................................................14

Controls.............................................................14

Operation...................................................................16

AddingFuel.......................................................16

BiodieselReady..................................................16

FillingtheFuelTank...........................................17

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

CheckingtheEngineOilLevel............................17

SwitchingtheFuelTanks....................................17

UsingtheRolloverProtectionSystem

(ROPS)..........................................................17

ThinkSafetyFirst...............................................18

UnderstandingtheAudibleAlarms.....................19

OperatingtheParkingBrake...............................19

StartingandStoppingtheEngine........................19

OperatingthePowerTakeOff(PTO).................21

TheSafetyInterlockSystem................................21

DrivingForwardorBackward.............................22

StoppingtheMachine.........................................23

AdjustingtheControlLeverResistance...............23

AdjustingtheHeight-of-Cut...............................23

UsingtheLiftAssistLever..................................24

AdjustingtheAnti-ScalpRollers.........................24

AdjustingtheFlowBafe...................................25

PositioningtheFlowBafe.................................25

PositioningtheSeat............................................26

UnlatchingtheSeat.............................................27

PushingtheMachinebyHand.............................27

UsingtheSideDischarge....................................27

TransportingMachines.......................................28

LoadingMachines..............................................28

UsingtheZStand®............................................29

OperatingTips...................................................30

Maintenance...............................................................32

RecommendedMaintenanceSchedule(s)................32

Lubrication.............................................................33

GreasingandLubrication...................................33

GreasingtheMowerDeckandBelt

Idlers..............................................................33

WheretoAddLightOilorSpray

Lubrication.....................................................34

GreasetheIdlerArms........................................34

GreasingtheFrontCasterPivots.........................34

LubricateCasterWheelHubs.............................34

EngineMaintenance...............................................36

ServicingtheAirCleaner....................................36

ServicingtheEngineOil.....................................37

FuelSystemMaintenance.......................................39

ServicingtheFuelFilterandWater

Separator........................................................39

ServicingtheFuelTank......................................40

ElectricalSystemMaintenance................................40

ServicingtheBattery...........................................40

ServicingtheFuses.............................................41

DriveSystemMaintenance.....................................42

AdjustingtheTracking........................................42

CheckingtheTirePressure.................................43

CheckingtheWheelHubSlottedNut..................43

AdjustingtheCasterPivotBearing......................43

CoolingSystemMaintenance..................................44

ServicingtheCoolingSystem..............................44

BrakeMaintenance.................................................46

AdjustingtheParkingBrake................................46

BeltMaintenance....................................................47

InspectingtheBelts............................................47

ReplacingtheMowerBelt...................................47

ReplacingtheDriveBelts....................................47

AdjustingtheDriveBelts....................................48

CheckingandReplacingthePumpDrive

Belt................................................................49

ReplacingandTensioningtheAlternator

Belt................................................................49

ControlsSystemMaintenance.................................50

AdjustingtheControlHandleNeutral

Position..........................................................50

HydraulicSystemMaintenance...............................51

ServicingtheHydraulicSystem...........................51

SettingtheHydraulicPumpNeutral

Position..........................................................53

MowerDeckMaintenance......................................55

LevelingtheMoweratThreePositions................55

ServicingtheCuttingBlades...............................57

ReplacingtheGrassDeector.............................59

Cleaning.................................................................60

CleaningUndertheMower.................................60

WasteDisposal...................................................60

Storage.......................................................................60

CleaningandStorage..........................................60

Troubleshooting.........................................................62

Schematics.................................................................64

3

Page 4

Safety

•Useextracarewhenhandlingdieselandotherfuels.

Theyareammableandvaporsareexplosive.

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafetyalertsymbol,whichmeans

CAUTION,WARNING,orDANGER-“personal

safetyinstruction."Failuretocomplywiththe

instructionmayresultinpersonalinjuryordeath.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Thisproductisdesignedforcuttingandrecyclinggrass

or,whenequippedwithagrassbagger,forcatching

cutgrass.Anyuseforpurposesotherthanthesecould

provedangeroustouserandbystanders.

SafeOperatingPractices

ThefollowinginstructionsarefromANSIstandard

B71.4-2004.

Training

•ReadtheOperator’sManualandothertraining

material.Iftheoperator(s)ormechanic(s)cannot

readEnglishitistheowner’sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmayrestrict

theageoftheoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,

otherpeopleorproperty.

–Useonlyanapprovedcontainer

–Neverrefuelordrainthemachineindoors.

–Neverremovegascaporaddfuelwithengine

running.Allowenginetocoolbeforerefueling.

Donotsmoke.

•Checkthatoperator’spresencecontrols,safety

switchesandshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholes

andhiddenhazards.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingengine.Starttheengineonly

fromtheoperator’sposition.Useseatbelts.

•Neverraisemowerwiththebladesrunning.

•NeveroperatewithoutthePTOshield,orother

guardssecurelyinplace.Besureallinterlocksare

attached,adjustedproperly,andfunctioningproperly .

•Neveroperatewiththedischargedeectorraised,

removedoraltered,unlessusingagrasscatcher.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Stoponlevelground,lowerimplements,disengage

drives,engageparkingbrake,shutoffenginebefore

leavingtheoperator’spositionforanyreason

includingemptyingthecatchersoruncloggingthe

chute.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Wearappropriateclothingincludinghardhat,safety

glassesandhearingprotection.Longhair,loose

clothingorjewelrymaygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeused

andremoveallobjectssuchasrocks,toysandwire

whichcanbethrownbythemachine.

•Stopequipmentandinspectbladesafterstriking

objectsorifanabnormalvibrationoccurs.Make

necessaryrepairsbeforeresumingoperations.

•Keephandsandfeetawayfromthecuttingunits.

•Nevercarrypassengersandkeeppetsandbystanders

away.

•Bealert,slowdownandusecautionwhenmaking

turns.Lookbehindandtothesidebeforechanging

directions.

•Slowdownandusecautionwhencrossingroadsand

sidewalks.Stopbladesifnotmowing.

4

Page 5

•Beawareofthemowerdischargedirectionanddo

notpointitatanyone.

•Donotoperatethemowerundertheinuenceof

alcoholordrugs.

•Useextremecarewhenloadingorunloadingthe

machineintoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

SlopeOperation

•Donotmowslopesgreaterthan15degrees.

•Donotmowneardrop-offs,ditches,steepbanks

orwater.Wheelsdroppingoveredgescancause

rollovers,whichmayresultinseriousinjury,death

ordrowning.

•Donotmowslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcausesliding

andlossofcontrol.

•Donotmakesuddenturnsorrapidspeedchanges.

•Useawalkbehindmowerand/orahandtrimmer

neardrop-offs,ditches,steepbanksorwater.

•Reducespeedanduseextremecautiononslopes.

•Removeormarkobstaclessuchasrocks,treelimbs,

etc.fromthemowingarea.Tallgrasscanhide

obstacles.

•Watchforditches,holes,rocks,dips,andrisesthat

changetheoperatingangle,asroughterraincould

overturnthemachine.

•Avoidsuddenstartswhenmowinguphillbecause

themowermaytipbackwards.

•Beawarethatlossoftractionmayoccurgoing

downhill.Weighttransfertothefrontwheelsmay

causedrivewheelstoslipandcauselossofbraking

andsteering.

•Alwaysavoidsuddenstartingorstoppingona

slope.Iftireslosetraction,disengagethebladesand

proceedslowlyofftheslope.

•Followthemanufacturer’srecommendationsfor

wheelweightsorcounterweightstoimprovestability.

•Useextremecarewithgrasscatchersorother

attachments.Thesecanchangethestabilityofthe

machineandcauselossofcontrol.

UsingtheRolloverProtectionSystem

(ROPS)

•Keeptherollbarintheraisedandlockedposition

andusetheseatbeltwhenoperatingthemachine.

•Becertainthattheseatbeltcanbereleasedquickly

intheeventofanemergency.

•Beawarethereisnorolloverprotectionwhenthe

rollbarisdown.

•Checktheareatobemowedandneverfoldthe

ROPSinareaswherethereareslopes,dropoffsor

water.

•Lowertherollbaronlywhenabsolutelynecessary.

Donotweartheseatbeltwiththerollbarfolded

down.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)beforedriving

underanyobjectsanddonotcontactthem.

Maintenanceandstorage

•Disengagedrives,lowerimplement,setparking

brake,stopengineandremovekeyordisconnect

sparkplugwire.Waitforallmovementtostop

beforeadjusting,cleaningorrepairing.

•Cleangrassanddebrisfromcuttingunits,drives,

mufers,andenginetohelppreventres.Cleanup

oilorfuelspillage.

•Letenginecoolbeforestoringanddonotstorenear

ame.

•Shutofffuelwhilestoringortransporting.Donot

storefuelnearamesordrainindoors.

•Parkmachineonlevelground.Neverallowuntrained

personneltoservicemachine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectbatteryorremovesparkplugwirebefore

makinganyrepairs.Disconnectthenegativeterminal

rstandthepositivelast.Reconnectpositiverst

andnegativelast.

•Usecarewhencheckingblades.Wraptheblade(s)or

weargloves,andusecautionwhenservicingthem.

Onlyreplaceblades.Neverstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Chargebatteriesinanopenwellventilatedarea,

awayfromsparkandames.Unplugchargerbefore

connectingordisconnectingfrombattery.Wear

protectiveclothinganduseinsulatedtools.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•UseonlyToroapprovedattachments.W arrantymay

bevoidedifusedwithunapprovedattachments.

5

Page 6

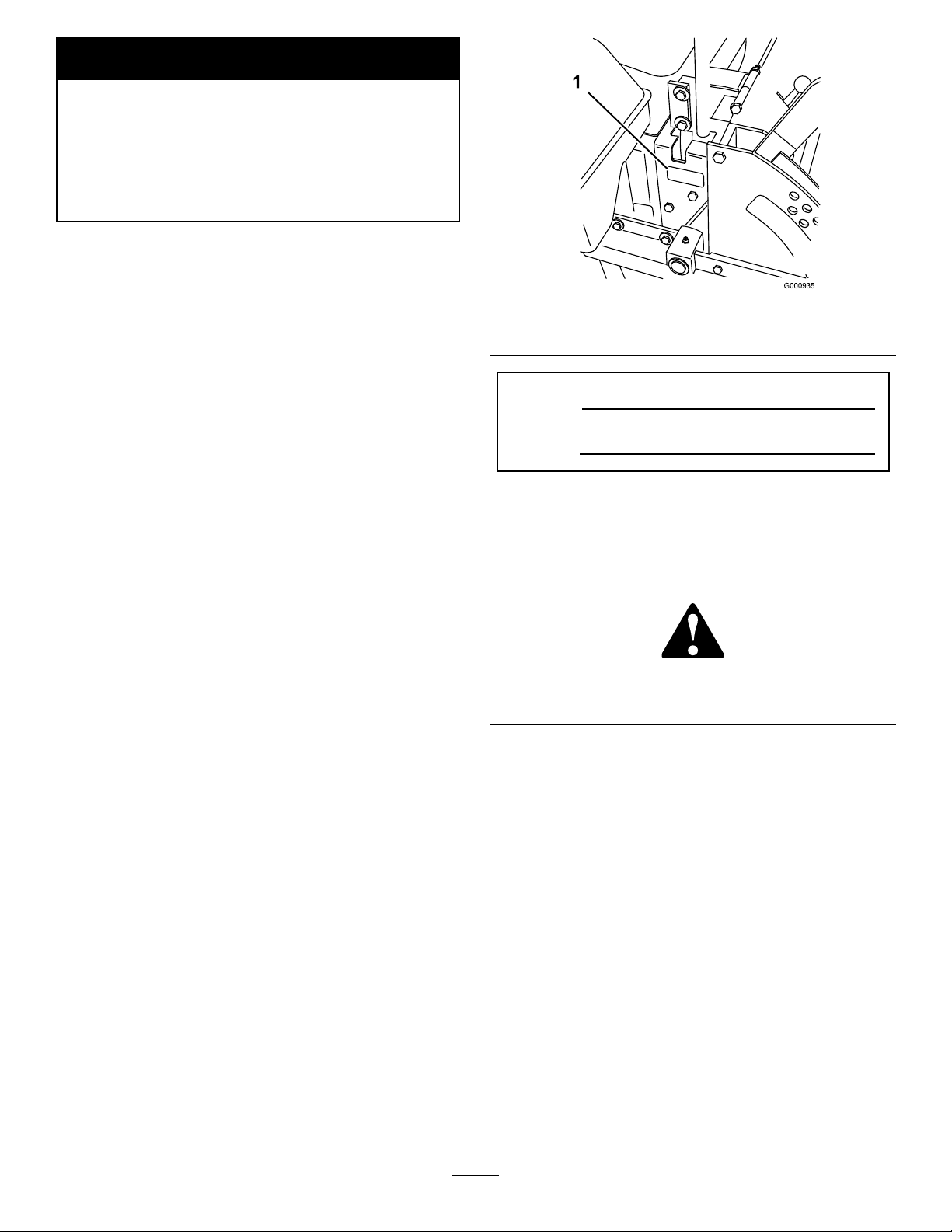

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

6

Page 7

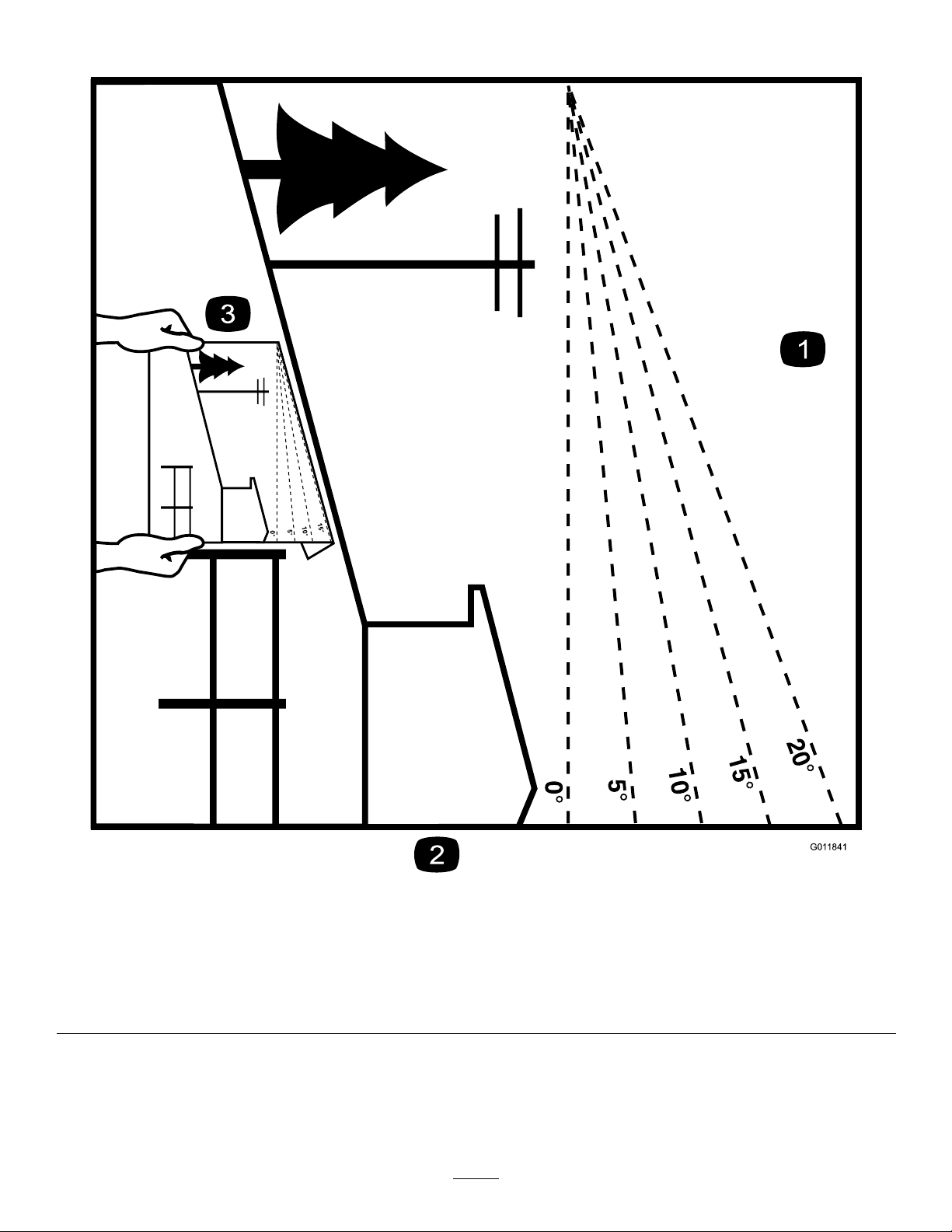

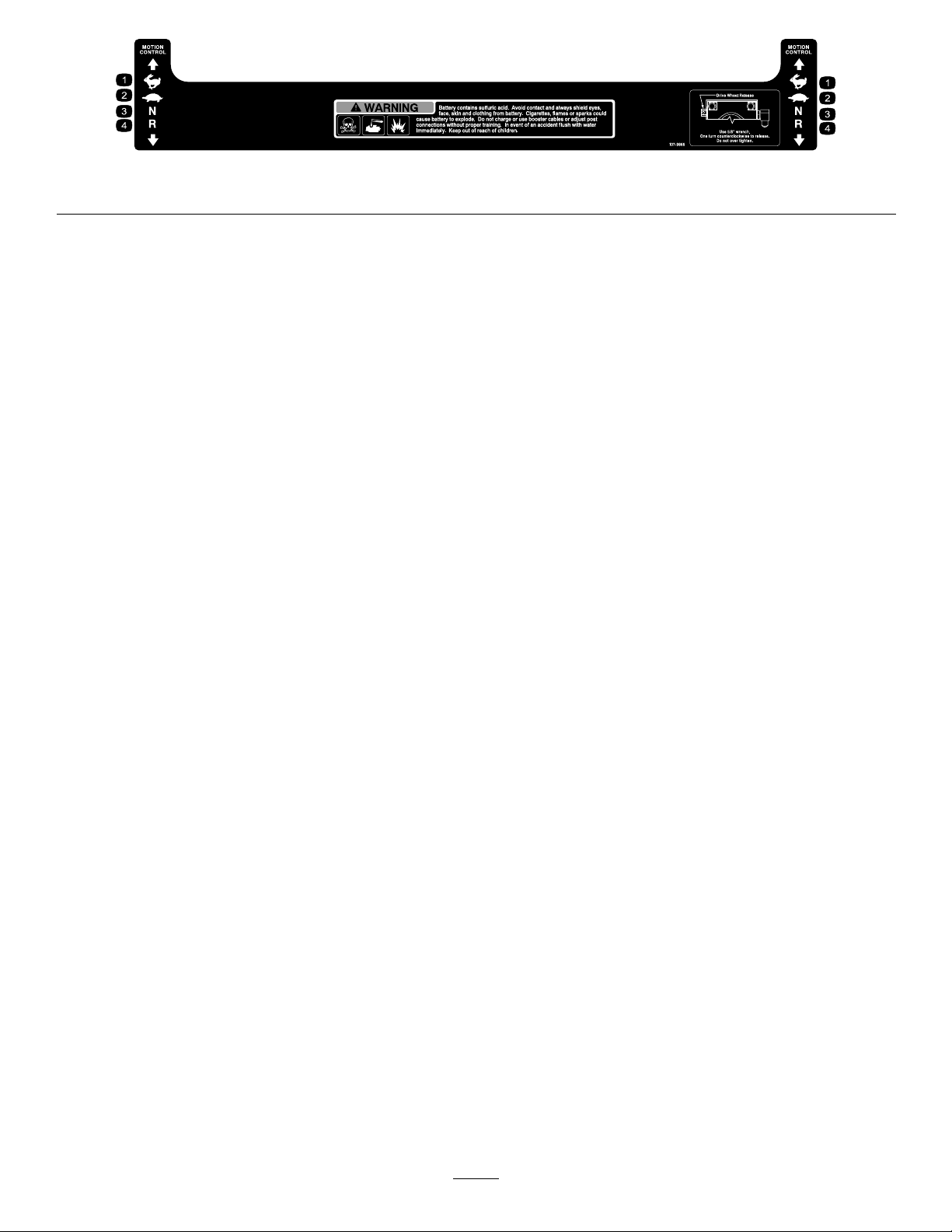

SafetyandInstructional

Decals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

58-6520

1.Grease

1-403005

66-1340

1-523552

65-2690

1-643253

68-8340

98-4387

54-9220

1.Warning—wearhearingprotection.

7

Page 8

98-5954

105-7798

103-3276

107-1613

103-5881

107-1857

104-2449

104-7759

107-1860

8

Page 9

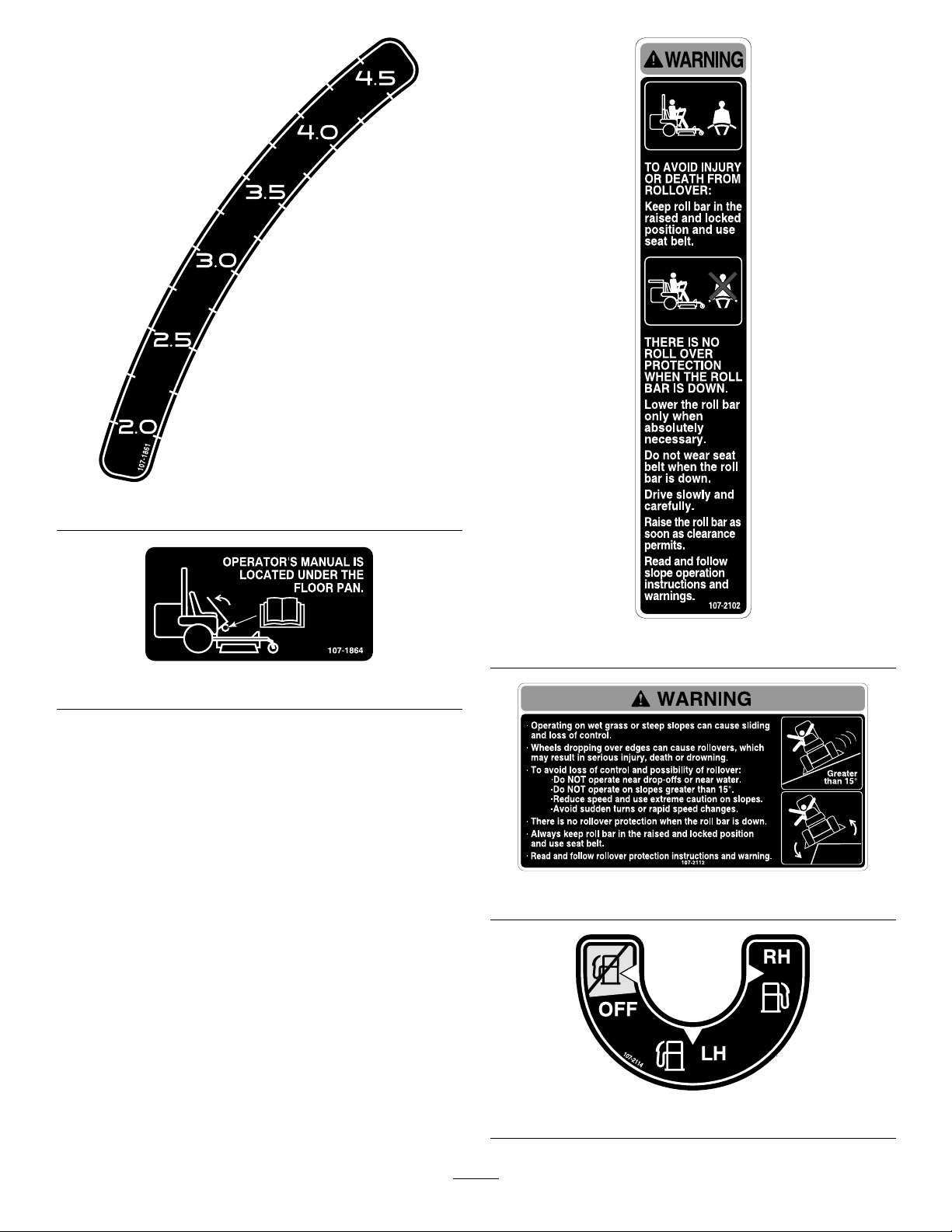

107-1861

107-2102

107-1864

107-2112

107-2114

9

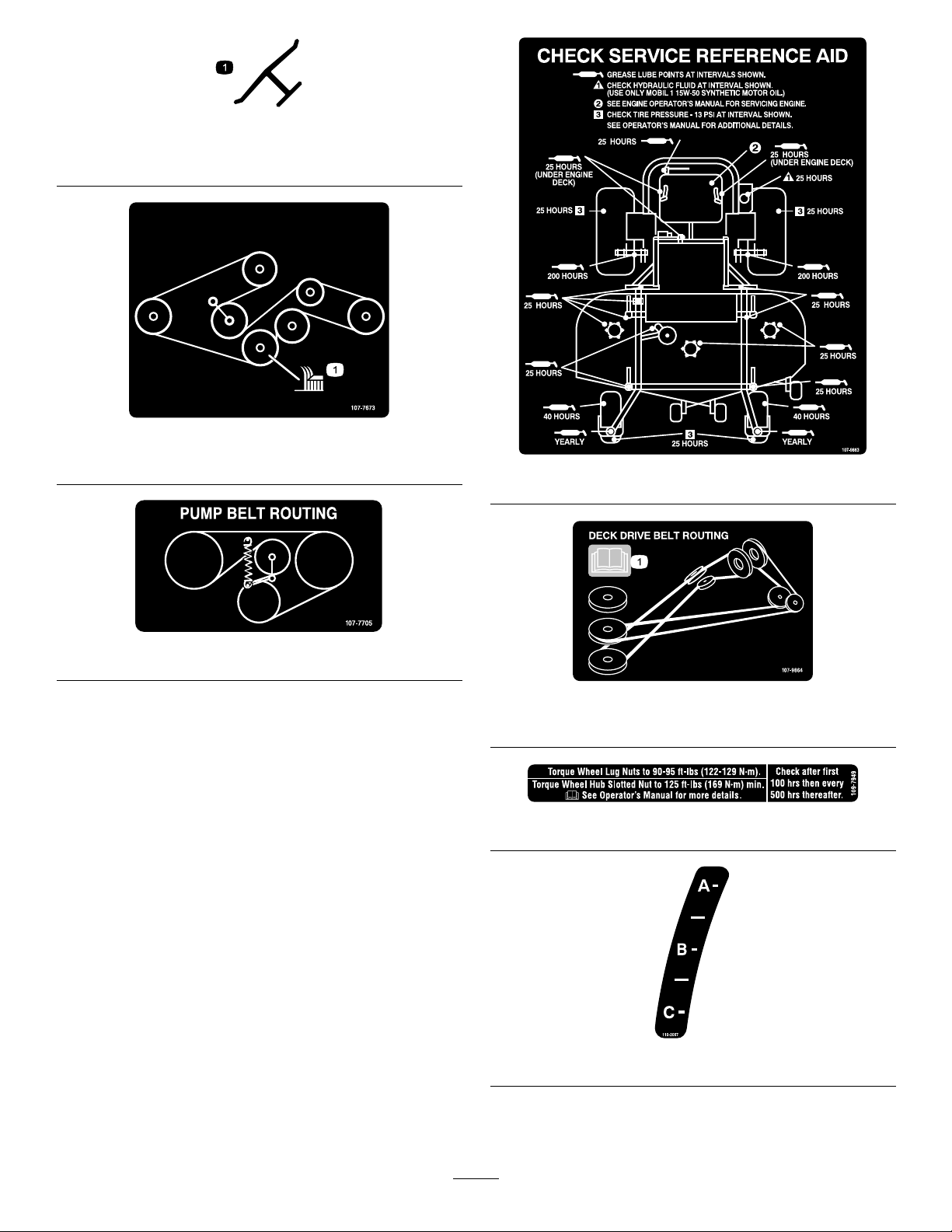

Page 10

Manufacturer’sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

107-7673

1.Cuttingblade

107-9863

107-7705

107-9864

1.ReadtheOperator’sManual.

109-7949

110-2067

10

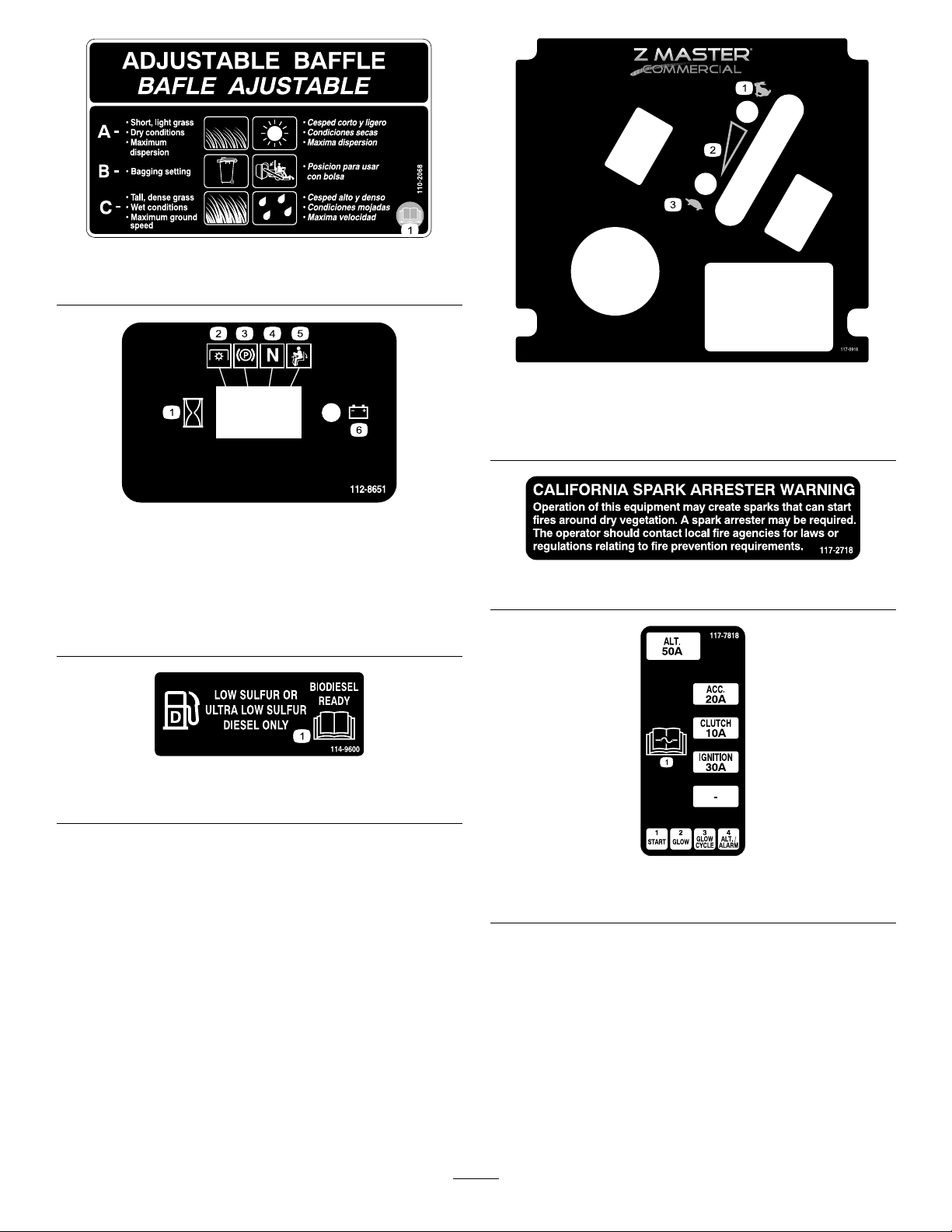

Page 11

110-2068

1.ReadtheOperator’sManual.

112-8651

1.Interval

2.PowerT ake-off(PTO)

3.Parkingbrake

4.Neutral

5.Operatorpresenceswitch

6.Battery

1.Fast

2.Continuousvariable

setting

117–0916

3.Slow

117–2718

1.ReadtheOperator’sManual.

114-9600

117-7818

1.ReadtheOperator’sManualforinformationonfuses.

11

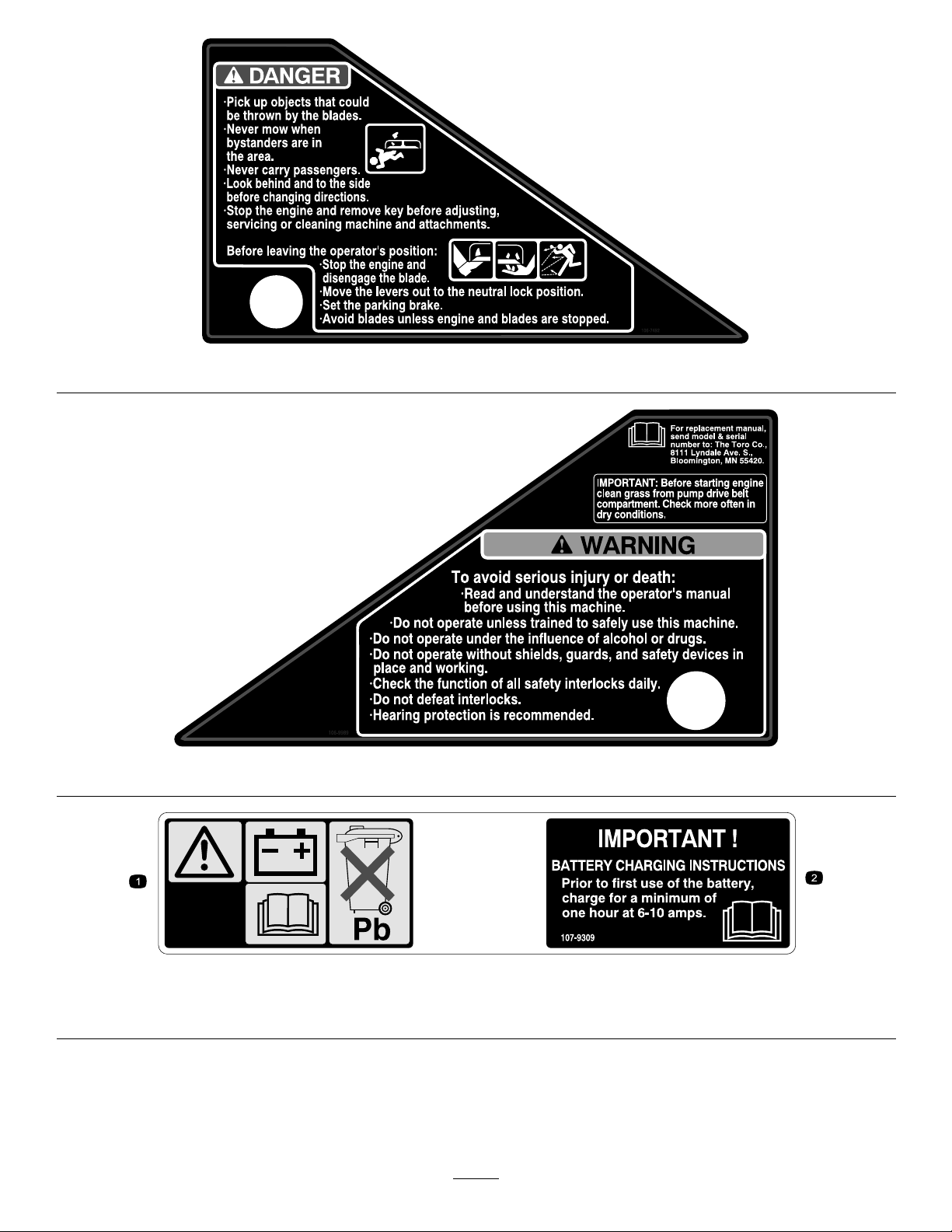

Page 12

106-7492

106-9989

107-9309

1.Warning—readtheOperator’sManualforinformationonchargingthebattery;containslead;donotdiscard.

2.ReadtheOperator’sManual.

12

Page 13

107-9866

1.Fast

2.Slow

3.Neutral4.Reverse

13

Page 14

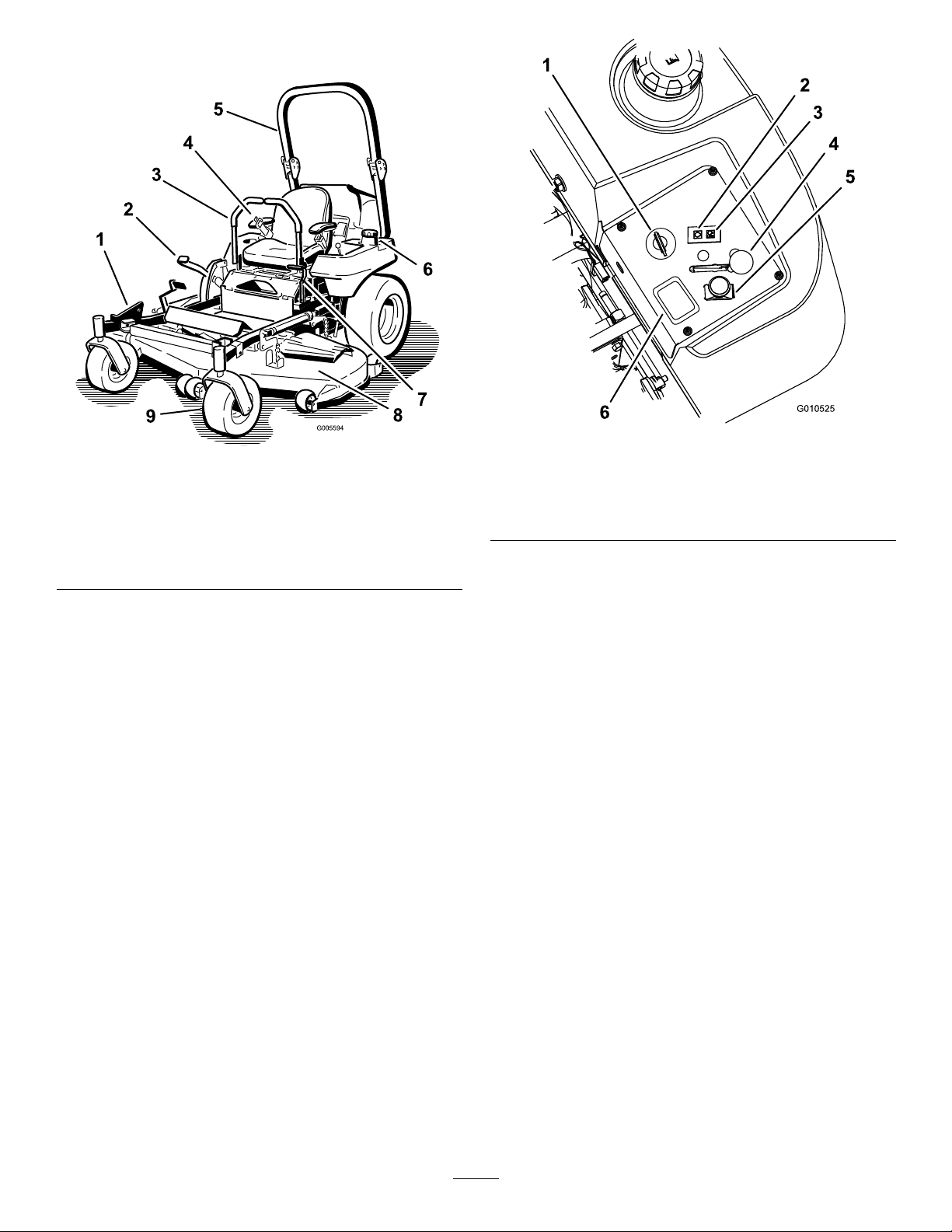

ProductOverview

Figure4

1.ZStand

2.Height-of-cutlever

3.Motioncontrollever8.Mowerdeck

4.Seatbelt9.Casterwheel

5.Rollbar

©

6.Fuelcap(bothsides)

7.Parkingbrakelever

Figure5

1.Ignitionswitch4.Throttlecontrol

2.Glowpluglight5.Powertakeoff(PTO)

Switch

3.EngineTemperaturelight6.Hourmeter

HourMeter

Controls

Becomefamiliarwithallthecontrolsbeforeyoustartthe

engineandoperatethemachine(Figure4andFigure5).

Thehourmeterrecordsthenumberofhourstheengine

hasoperated.Itoperateswhentheengineisrunning.

Usethesetimesforschedulingregularmaintenance

(Figure5).

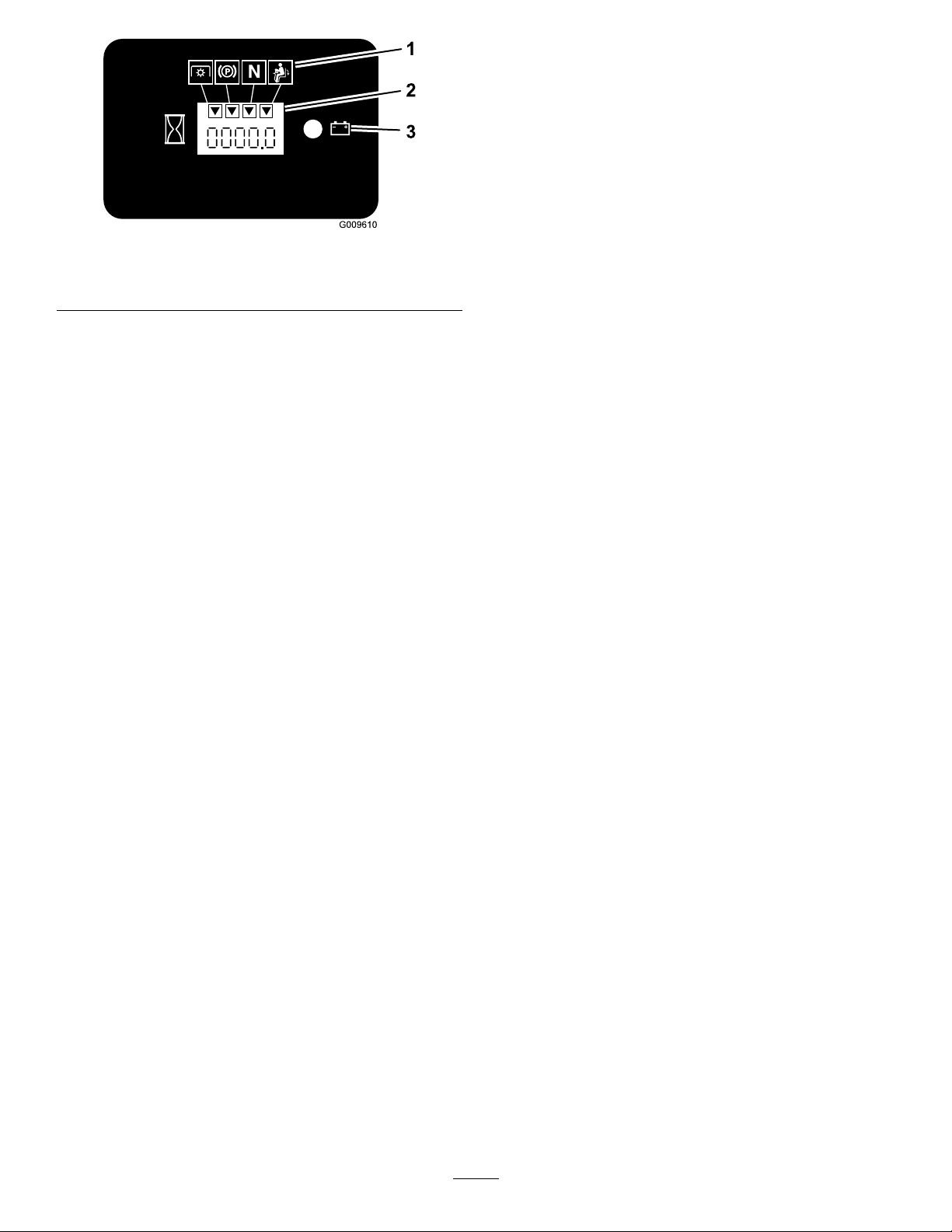

SafetyInterlockIndicators

Therearesymbolsonthehourmeterandtheyindicate

withablacktrianglethattheinterlockcomponentisin

thecorrectposition(

Figure6).

BatteryIndicatorLight

WhentheignitionkeyisinitiallyturnedtotheRun

positionforafewseconds,thebatteryvoltagewillbe

displayedintheareawherethehoursarenormally

displayed.

Thebatterylightturnsonwhentheignitionisturned

onandwhenthechargeisbelowthecorrectoperating

Figure6).

level(

14

Page 15

Figure6

1.Safetyinterlocksymbols

2.Hourmeter

3.Batterylight

ThrottleControl

ThethrottlecontrolisvariablebetweenFastandSlow.

BladeControlSwitch(PTO)

Thebladecontrolswitch(PTO)isusedtoengagethe

electricclutchtodrivethemowerbladeswiththemotion

controlleversinthecenter,un-lockedposition.Pullthe

switchuptoengagethebladesandrelease.Todisengage

theblades,pushthebladecontrolswitch(PTO)down.

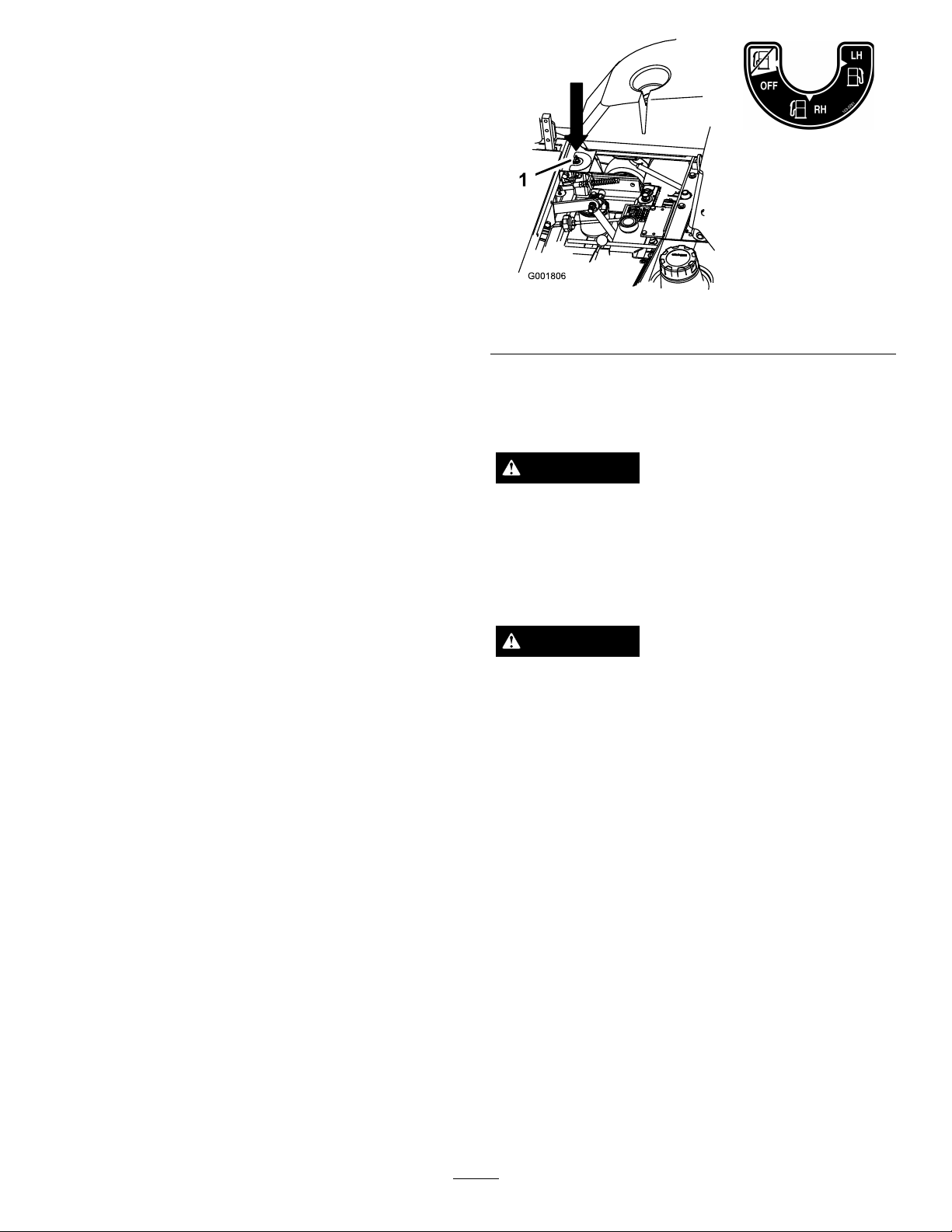

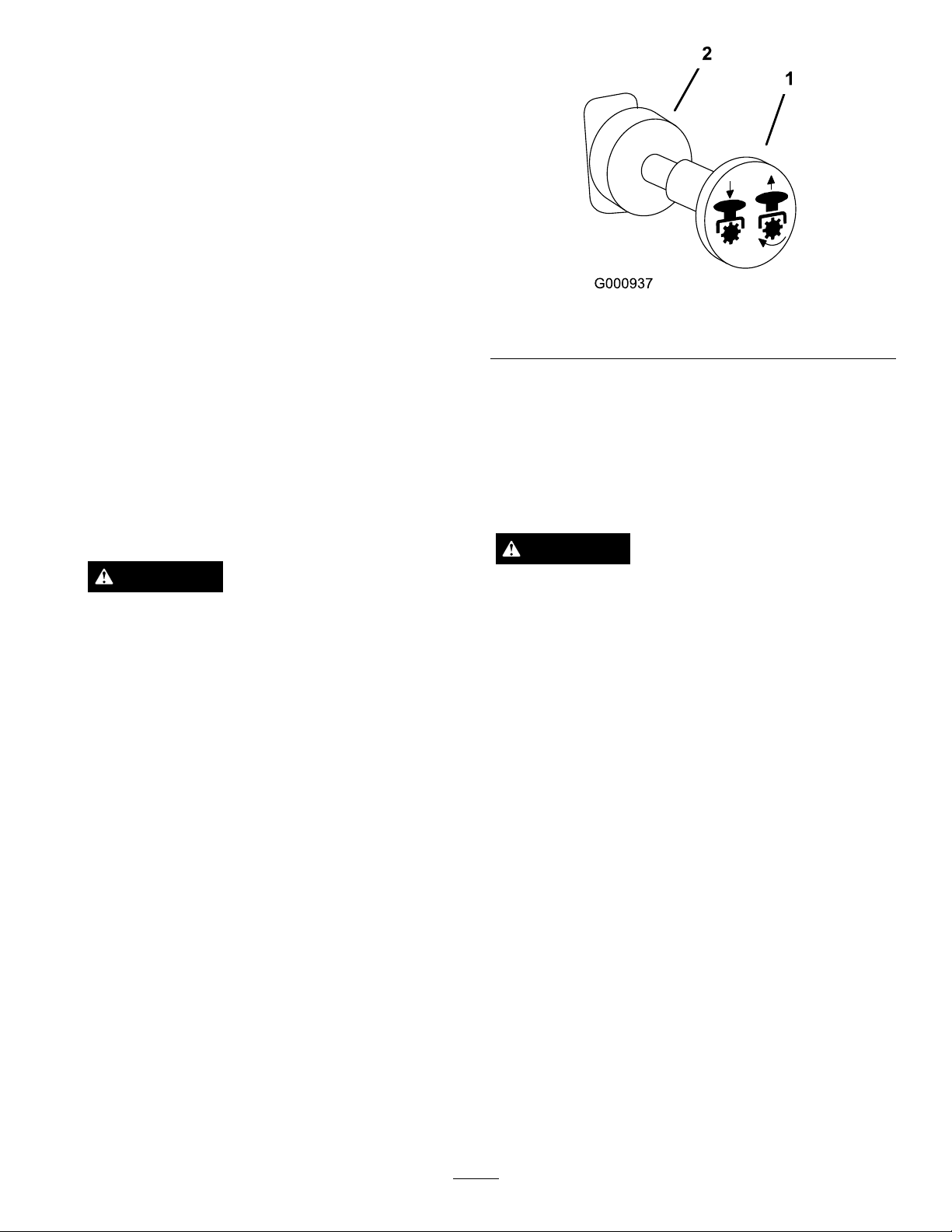

FuelSelectorValve

Thefuelselectorvalveislocatedbehindtheleftside

oftheseat.

Closethefuelselectorvalvewhentransportingor

storingmower.

Movetheselectorvalvetothelefthand(LH)or

righthand(RH)positionforoperation.

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

NeutralLockPosition

Theneutrallockpositionisusedwiththesafetyinterlock

systemandtodetermineneutralposition.

IgnitionSwitch

Thisswitchisusedtostartthemowerengineandhas

threepositions:Start,RunandOff.

GlowPlugLight(OrangeLight)

Theglowplugindicatorlightturnsonwhentheignition

switchisturnedtotheonposition.Whenthelightturns

off,theengineisreadytobestarted(

Figure5).

TemperatureLight

Thetemperaturelightcomesonwhentheengineisover

heating(Figure5).

AudibleAlarm

Thismachinehasanaudiblealarmthatalertstheuser

toturnofftheengineorenginedamagecanoccurfrom

overheating.RefertoServicingtheCoolingSystemin

Maintenance.

15

Page 16

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

AddingFuel

Theenginerunsonclean,freshdieselfuelwith

aminimumoctaneratingof40.Purchasefuelin

quantitiesthatcanbeusedwithin30daystoensure

fuelfreshness.

Usesummergradedieselfuel(No.2-D)attemperatures

above20°F(-7°C)andwintergradedieselfuel(No.

1-DorNo.1-D/2-Dblend)below20°F(-7°C).Useof

wintergradedieselfuelatlowertemperaturesprovides

lowerashpointandpourpointcharacteristics,

thereforeeasingstartabilityandlesseningchances

ofchemicalseparationofthefuelduetolower

temperatures(waxappearance,whichmaypluglters).

Useofsummergradedieselfuelabove20°F(-7°C)will

contributetowardlongerlifeofthepumpcomponents.

Important:Donotusekeroseneorgasoline

insteadofdieselfuel.Failuretoobservethis

cautionwilldamagetheengine.

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening .

•Keepgasawayfromeyesandskin.

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltankoutdoorsonlevelground,in

anopenarea,whentheengineiscold.Wipe

upanyfuelthatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Fill

thefueltanktothebottomofthellerneck.

Theemptyspaceinthetankallowsgasolineto

expand.Overllingmayresultinfuelleakage

ordamagetotheengineoremissionsystem(if

equipped).

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuelfumes

maybeignitedbyaspark.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymore

thana30-daysupplyoffuel.

•Alwaysplacefuelcontainersontheground

awayfromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicleoron

atruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerandrefuel

theequipmentwithitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromafueldispenser

nozzle.

•Ifafueldispensernozzlemustbeused,keep

thenozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimesuntil

fuelingiscomplete.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuel

ofuptoB20(20%biodiesel,80%petrodiesel).The

petrodieselportionshouldbeloworultralowsulfur.

Observethefollowingprecautions:

•Thebiodieselportionofthefuelmeetspecication

ASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTM

D975orEN590.

•Paintedsurfacesmaybedamagedbybiodiesel

blends.

16

Page 17

•UseB5(biodieselcontendof5%)orlesserblend

incoldweather.

•Monitorseals,hoses,gasketsincontactwithfuelas

theymaybedegradeovertime.

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblends.

•Contactyourdistributorifyouwishformore

informationonbiodiesel.

FillingtheFuelTank

Note:Donotllthefueltankcompletelyfull.Fillthe

fueltanktothebottomofthellerneck.Theempty

spaceinthetankallowsthegasolinetoexpand.

1.Shuttheengineoffandsettheparkingbrake.

2.Cleanaroundeachfueltankcapandremovethe

cap.Fillthefueltanktothebottomoftheller

neck.Thisspaceinthetankallowsthefuelto

expand.Donotllthefueltankcompletelyfull.

3.Installthefueltankcapsecurely .Wipeupanyfuel

thatmayhavespilled.

4.Ifpossible,llthefueltankaftereachuse.Thiswill

minimizepossiblebuildupofcondensationinside

thefueltank.

CheckingtheEngineOilLevel

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoChecking

theOilLevelinMaintenance.

SwitchingtheFuelTanks

Important:Donotrunthemachineoutoffuel.

Thefuelselectorvalveislocatedbehindtheleftside

oftheseat.

Theunithastwofueltanks.Onetankisontheleft

sideandoneontherightside.Eachtankconnectsto

thefuelselectorvalve.Fromthereacommonfuelline

leadstotheengine(

Tousetheleftsidefueltankrotatethefuelselector

valvetotheLHposition,lefthandlocation.Tousethe

rightsidefueltankrotatethefuelselectorvalvetothe

RHposition,righthandlocation(Figure7)

Closethefuelselectorvalvebeforetransportingor

storingmachine.

Figure7).

Figure7

1.Leftsidefueltank

2.Fuelselectorvalve

UsingtheRolloverProtection

System(ROPS)

WARNING

Toavoidinjuryordeathfromrollover:keepthe

rollbarintheraisedlockedpositionandusethe

seatbelt.

Ensurethattherearpartoftheseatissecuredwith

theseatlatch.

WARNING

Thereisnorolloverprotectionwhentherollbar

isinthedownposition.

•Lowertherollbaronlywhenabsolutely

necessary.

•Donotweartheseatbeltwhentherollbaris

inthedownposition.

•Driveslowlyandcarefully.

•Raisetherollbarassoonasclearancepermits.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)before

drivingunderanyobjectsanddonotcontact

them.

Important:Lowertherollbaronlywhen

absolutelynecessary.

1.Removethehairpincotterpinsandremovethetwo

pins(Figure9).

2.Lowerthetherollbartothedownposition.There

aretwodownpositions.SeeFigure8forthe

positions.

3.Installthetwopinsandsecurethemwiththe

hairpincotterpins(Figure9).

17

Page 18

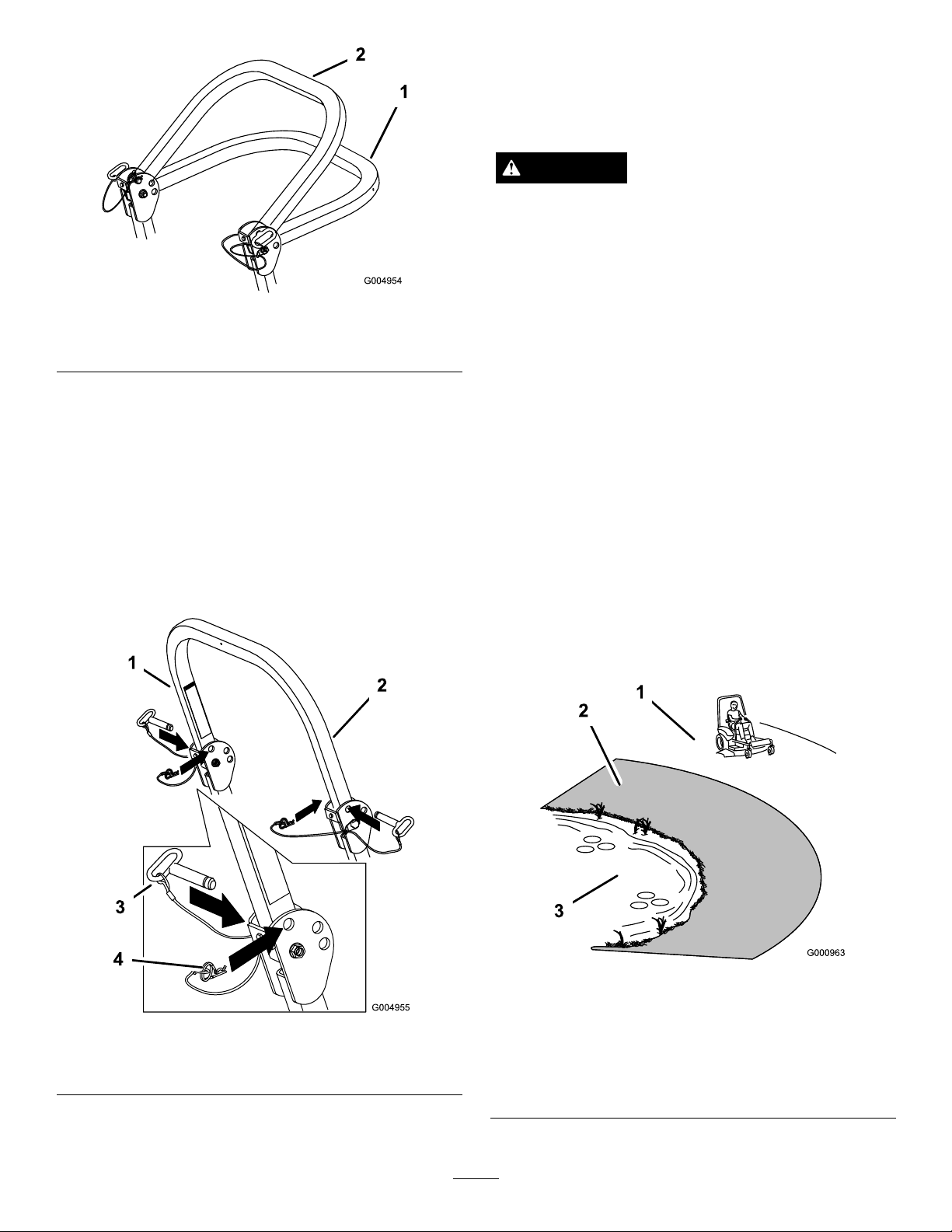

Figure8

G004955

1

2

3

4

1.Fulldownposition2.Downpositionwithbagger

installed

Important:Ensurethattherearpartofthe

seatissecuredwiththeseatlatch.

4.Toraisetherollbar,removethehairpincotterpins

andremovethetwopins(

Figure9).

5.Raisetherollbartotheuprightpositionandinstall

thetwopinsandsecurethemwiththehairpincotter

pins(Figure9).

Important:Alwaysusetheseatbeltwiththe

rollbarintheraisedposition.

ThinkSafetyFirst

Pleasereadallsafetyinstructionsandsymbolsinthe

safetysection.Knowingthisinformationcouldhelp

youorbystandersavoidinjury.

DANGER

Operatingonwetgrassorsteepslopescancause

slidingandlossofcontrol.

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,deathor

drowning.

Thereisnorolloverprotectionwhentherollbar

isdown.

Alwayskeeptherollbarintheraisedandlocked

positionandusetheseatbelt.

Readandfollowtherolloverprotectioninstructions

andwarnings.

Toavoidlossofcontrolandpossibilityofrollover:

•Donotoperateneardrop-offsornearwater.

•Donotoperateonslopesgreaterthan

15degrees.

•Reducespeedanduseextremecautionon

slopes.

Figure9

1.Rollbar3.Pin

2.Raisedposition4.Hairpincotterpin

•Avoidsuddenturnsorrapidspeedchanges.

Figure10

1.SafeZone-usethe

ZMasterhereonslopes

lessthan15degreesor

atareas.

2.Usewalkbehindmower

and/orhandtrimmernear

drop-offsandwater.

3.Water

18

Page 19

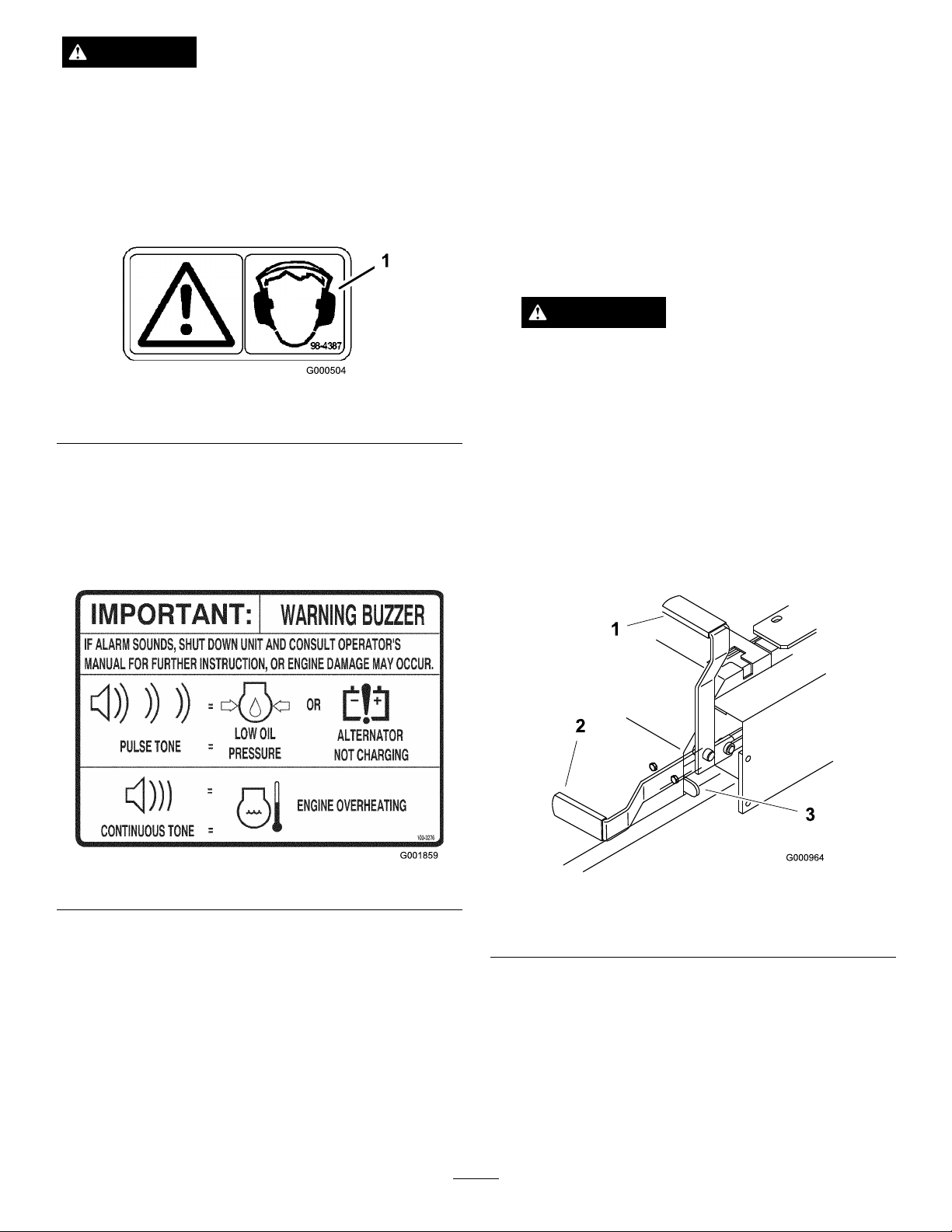

CAUTION

OperatingtheParkingBrake

Thismachineproducessoundlevelsinexcessof

85dBAattheoperatorsearandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Theuseofprotectiveequipmentforeyes,ears,feetand

headisrecommended.

Figure11

1.Warning—wearhearingprotection

UnderstandingtheAudible

Alarms

Thismachinehasanaudiblealarmthatalertstheuser

toturnofftheengineorenginedamagecanoccur.

Alwayssettheparkingbrakewhenyoustopthe

machineorleaveitunattended.

SettingtheParkingBrake

1.Movethemotioncontrollevers(Figure19)outto

theneutrallockposition.

2.Pullupandbackontheparkingbrakelevertoset

theparkingbrake(Figure13).Theparkingbrake

levershouldstayrmlyintheengagedposition.

WARNING

Parkingbrakemaynotholdmachineparked

onaslopeandcouldcausepersonalinjuryor

propertydamage.

Donotparkonslopesunlesswheelsare

chockedorblocked

ReleasingtheParkingBrake

Pushforwardanddownontheparkingbrakelever

toreleasetheparkingbrake(Figure13).Theparking

brakeisdisengagedandtheleverwillrestagainstthe

brakestop.

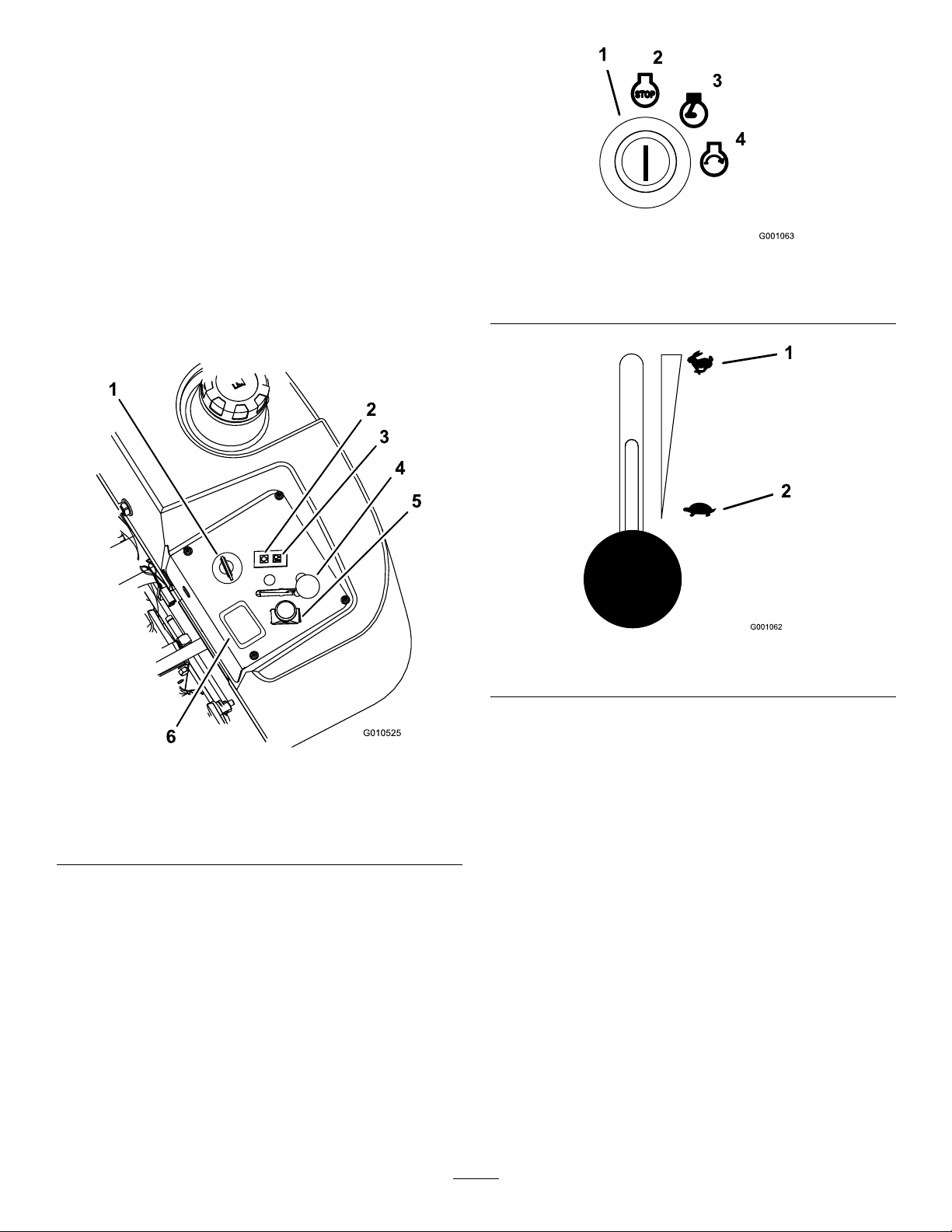

Figure12

ContinuousAudibleAlarm

Thecontinuousaudiblealarmalertstheuserthatthe

engineisoverheating.RefertoServicingtheCooling

System.

PulsingAudibleAlarm

Thepulsingaudiblealarmalertstheusertolowoil

pressureorthealternatorisnotcharging.Referto

CheckingtheEngineOilandcheckthealternatorbelt.

Figure13

1.Parkingbrake-ON3.BrakeStop

2.Parkingbrake-OFF

StartingandStoppingthe

Engine

StartingtheEngineinNormalWeather

1.RaisetheROPSupandlockintoplace,sitonthe

seatandfastentheseatbelt.

19

Page 20

2.Movethemotioncontrolstotheneutrallocked

position.

3.Settheparkingbrake;refertoSettingtheParking

Brake.

4.MovethePTO(powertakeoff)switchtotheoff

position(

Figure14).

5.Movethethrottlelevertothemiddleposition

(Figure14).

6.Turntheignitionkeyclockwisetotherunposition

Figure14).Theglowpluglightwillturnon.

(

7.Aftertheglowplugindicatorlightgoesout,turn

thekeytothestartposition.whentheenginesstarts

releasethekey .

Figure15

1.Ignitionswitch3.Run

2.Off4.Start

Figure16

1.Throttle—fast

2.Throttle—slow

Figure14

1.Ignitionswitch4.Throttlecontrol

2.Glowpluglight5.Powertakeoff(PTO)

Switch

3.EngineTemperaturelight6.Hourmeter

Important:Usestartingcyclesofnomorethan

30secondsperminutetoavoidoverheatingthe

startermotor.

8.Iftheenginedoesnotstartimmediately,movethe

throttlecontroltofastandturnthekeytothestart

position.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthe

fuelsystemhasbeencompletelywithoutfuel.

StartingtheEngineinColdWeather

(Below14°For-10°C)

Usethecorrectengineoilforthestarting

temperature.RefertoServicingtheEngineOilin

EngineMaintenance(page36).

1.StarttheenginewiththethrottleintheFast

position.

2.Turntheignitionkeyclockwisetotherunposition

Figure15).Theglowpluglightwillturnon.

(

3.Aftertheglowplugindicatorlightgoesout,turn

thekeytothestartposition.whentheenginesstarts

releasethekey .

Important:Usestartingcyclesofnomorethan

30secondsperminutetoavoidoverheatingthe

startermotor.

20

Page 21

StoppingtheEngine

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake(Figure17).

2.Movethethrottlelevermidwaybetweentheslow

andfastpositions(

3.Lettheengineidlefor60seconds.

Figure16).

4.Turntheignitionkeytotheoffposition(

Waitforallmovingpartstostopbeforeleavingthe

operatingposition.

5.Removethekeytopreventpossibilityofsomeone

accidentallystartingthemachinebeforetransporting

orstoringmachine.

6.Closethefuelselectorvalvebeforetransportingor

storingthemachine.

Important:Makesurethatthefuelselector

valveisclosedbeforetransportingorstoring

themachine,asfuelleakagemayoccur.Setthe

parkingbrakebeforetransporting.

Important:Makesuretoremovethekeyas

thefuelpumpmayrunandcausethebattery

tolosecharge.

Figure15).

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethetractorwhileit

isunattended.

Figure17

1.PTO-On2.PTO-Off

DisengagingthePTO

Todisengage,pushthePTOswitchtotheoffposition

(Figure17).

TheSafetyInterlockSystem

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

Alwaysremovetheignitionkeyandsetthe

parkingbrakewhenleavingthemachine

unattended,evenifjustforafewminutes.

OperatingthePowerTakeOff

(PTO)

Thepowertakeoff(PTO)switchstartsandstopsthe

mowerbladesandanypoweredattachments.

EngagingthePTO

1.Iftheengineiscold,allowtheenginetowarmup5

to10minutesbeforeengagingthePTO.

2.Whileseatedintheseat,releasethepressureonthe

tractioncontrolleversandplaceinneutral.

3.Placethethrottleinthefastposition.

Note:EngagingthePTOwiththethrottleatthe

halforlesspositionwillcauseexcessiveweartothe

drivebelts.

4.Pulloutonthepowertakeoff(PTO)switchto

engageit(

Figure17).

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

UnderstandingtheSafetyInterlock

System

Thesafetyinterlocksystemisdesignedtopreventthe

enginefromstartingunless:

•Theparkingbrakeisengaged.

•Thepowertakeoff(PTO)isdisengaged.

•Themotioncontrolleversareintheneutrallocked

position

Thesafetyinterlocksystemalsoisdesignedtostopthe

enginewhenthetractioncontrolsaremovedfromthe

lockedpositionwiththeparkingbrakeengagedorif

yourisefromtheseatwhenthePTOisengaged.

Thehourmeterhassymbolstonotifytheuserwhenthe

interlockcomponentisinthecorrectposition.When

thecomponentisinthecorrectposition,atrianglewill

lightupinthecorrespondingsquare.

21

Page 22

thethrottlecontrolinthefastpositionforbest

performance.Alwaysoperateinthefullthrottle

positionwhenmowing.

CAUTION

Machinecanspinveryrapidly.Operatormaylose

controlofmachineandcausepersonalinjuryor

damagetomachine.

Figure18

1.Triangleslightupwhentheinterlockcomponentsareinthe

correctposition

TestingtheSafetyInterlockSystem

ServiceInterval:Beforeeachuseordaily

Testthesafetyinterlocksystembeforeyouusethe

machineeachtime.Ifthesafetysystemdoesnot

operateasdescribedbelow,haveanAuthorizedService

Dealerrepairthesafetysystemimmediately .

1.Sittingontheseat,engagetheparkingbrakeand

movethePTOtoon.Trystartingtheengine;the

engineshouldnotcrank.

2.Sittingontheseat,engagetheparkingbrakeand

movethePTOtooff.Moveeithermotioncontrol

lever(outofneutrallockedposition).Trystarting

theengine;theengineshouldnotcrank.Repeatfor

othercontrollever.

3.Sittingontheseat,engagetheparkingbrake,

movethePTOswitchtooffandmovethemotion

controlleverstoneutrallockposition.Nowstart

theengine.Whiletheengineisrunning,release

theparkingbrake,engagethePTOandriseslightly

fromtheseat;theengineshouldstop.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

•Lookbehindandtothesidebeforechanging

direction.

DrivingForward

1.Releasetheparkingbrake;refertoReleasingthe

ParkingBrake.

2.Movetheleverstothecenter,un-lockedposition.

3.Togoforward,slowlypushthemotioncontrol

leversforward(

Note:Theenginewillkillifthetractioncontrol

leversaremovedwiththeparkingbrakeengaged.

Togostraight,applyequalpressuretobothmotion

controllevers(Figure19).

Toturn,movethemotioncontrollevertoward

neutralinthedirectionyouwanttoturn(

Thefartheryoumovethetractioncontrolleversin

eitherdirection,thefasterthemachinewillmovein

thatdirection.

Tostop,pullthemotioncontrolleverstotheneutral

position.

Figure19).

Figure19).

4.Sittingontheseat,engagetheparkingbrake,move

thePTOswitchtooffandmovethemotioncontrol

leverstoneutrallockposition.Nowstarttheengine.

Whiletheengineisrunning,centereithermotion

controlandmove(forwardorreverse);theengine

shouldstop.Repeatforothermotioncontrol.

5.Sittingontheseat,disengagetheparkingbrake,

movethePTOswitchtooffandmovethemotion

controlleverstoneutrallockposition.Trystarting

theengine;theengineshouldnotcrank.

DrivingForwardorBackward

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Place

22

Page 23

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethetractorwhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

AdjustingtheControlLever

Resistance

Thetopdampermountingboltcanbeadjustedto

obtainadesiredmotioncontrolleverresistance.Refer

toFigure20forthemountingoptions.

Torquetheboltto200in-lb(22.6N-m).

Figure19

1.Motioncontrol

lever-neutrallockposition

2.Center,un-lockedposition5.Frontofmachine

3.Forward

4.Backward

DrivingBackward

1.Movetheleverstothecenter,un-lockedposition.

2.Togobackward,slowlypullthemotioncontrol

leversrearward(

Figure19).

Togostraight,applyequalpressuretobothmotion

controllevers(Figure19).

Toturn,releasepressureonthemotioncontrollever

towardthedirectionyouwanttoturn(Figure19).

Tostop,pushthemotioncontrolleverstothe

neutralposition.

StoppingtheMachine

Tostopthemachine,movethetractioncontrollevers

toneutralandmovetolockedposition,disengagethe

powertakeoff(PTO),andturntheignitionkeytooff.

Figure20

1.Damper4.Mediumresistanceor

2.Motioncontrolbracket

3.Mostresistanceorrmest

feel

mediumfeel

5.Leastresistanceorsoftest

feel

AdjustingtheHeight-of-Cut

Theheight-of-cutisadjustedfrom1-1/2to5inch

(38to127mm)in1/4inch(6mm)incrementsby

relocatingthepinintodifferentholelocations.

1.Raisetheheight-of-cutlevertothetransport

position(alsothe5inch(127mm)cuttingheight

position)(

Figure21).

Settheparkingbrakewhenyouleavethemachine;refer

toSettingtheParkingBrakeinOperation.Remember

toremovethekeyfromtheignitionswitch.

23

Page 24

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Afteradjustingtheheight-of-cut,adjusttherollers

byremovingtheangenut,bushing,spacer,and

Figure23,Figure24andFigure25).

bolt(

Note:Thetwomiddlerollerswillnothaveaspacer

(Figure24).

4.Selectaholesotheanti-scalprollerispositionedto

thenearestcorrespondingheight-of-cutdesired.

Figure21

1.Heightofcutlever

2.Pin

2.Toadjust,removethepinfromtheheight-of-cut

bracket(

Figure21).

3.Selectaholeintheheight-of-cutbracket

correspondingtotheheight-of-cutdesiredand,

insertthepin(

Figure21).

4.Movethelevertotheselectedheight.

UsingtheLiftAssistLever

Theliftassistleverisusedalongwiththeheight-of-cut

leverforraisingthemower.Thisallowsforeasier

raisingofthemower.

1.Placeyourfootontoliftassistlever.

2.Pressontheliftassistleverwhilepullinguponthe

height-of-cutlever(Figure22).

5.Installtheangenutbushing,spacer,andbolt.

Torqueto40-45ft-lb(54-61N-m)(

Figure23,

Figure24andFigure25).

6.Repeatthisadjustmentontheotheranti-scalp

rollers.

Figure23

1.Anti-scalproller4.FlangeNut

2.Spacer

3.Bushing

5.Bolt

Figure22

1.LiftAssistLever

AdjustingtheAnti-Scalp

Rollers

Wheneveryouchangetheheight-of-cut,itis

recommendedtoadjusttheheightoftheanti-scalp

rollers.

1.DisengagethePTO,movethemotioncontrol

leverstotheneutrallockedpositionandsetthe

parkingbrake.

Figure24

1.Anti-scalproller3.FlangeNut

2.Bushing4.Bolt

24

Page 25

Figure25

1.Anti-scalproller4.FlangeNut

2.Spacer

3.Bushing

5.Bolt

AdjustingtheFlowBafe

Figure26

1.Camlock

2.Lever

3.Rotatecamtoincreaseor

decreaselockingpressure

4.Slot

PositioningtheFlowBafe

Thefollowingguresareonlyrecommendationsfor

use.Adjustmentswillvarybygrasstype,moisture

content,andheightofgrass.

Themowerdischargeowcanbeadjustedfordifferent

typesofmowingconditions.Positionthecamlocks

andbafetogivethebestqualityofcut.

1.DisengagethePTO,movethemotioncontrol

leverstotheneutrallockedpositionandsetthe

parkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Toadjustthecamlocks,swingtheleverupto

loosenthecamlock(

Figure26).

4.Adjustthebafeandcamlocksintheslotstothe

desireddischargeow .

5.Swingtheleverbackovertotightenthebafeand

camlocks(Figure26).

6.Ifthecamsdonotlockthebafeintoplaceoritis

tootight,loosentheleverandthenrotatethecam

lock.Adjustthecamlockuntilthedesiredlocking

pressureisachieved.

Note:Iftheenginepowerdrawsdownandthemower

groundspeedisthesame,openupthebafe.

PositionA

Thisisthefullrearposition.Thesuggesteduseforthis

positionisafollows.

•Useforshort,lightgrassmowingconditions.

•Useindryconditions.

•Forsmallergrassclippings.

•Propelsgrassclippingsfartherawayfromthe

mower.

PositionB

Usethispositionwhenbagging.

25

Figure27

Page 26

PositionC

g012486

1.Toadjust,movetheleversidewaystounlockseat

(Figure30).

Figure28

Figure30

1.Seatsuspensionknob2.Seatpositionadjustment

lever

Thisisthefullopenposition.Thesuggestedusefor

thispositionisasfollows.

•Useintall,densegrassmowingconditions.

•Useinwetconditions.

•Lowerstheenginepowerconsumption.

•Allowsincreasedgroundspeedinheavyconditions.

•ThispositionissimilartothebenetsoftheT oro

SFSmower.

2.Slidetheseattothedesiredpositionandrelease

levertolockinposition.

ChangingtheSeatSuspension

Theseatcanbeadjustedtoprovideasmoothand

comfortableride.Positiontheseatwhereyouaremost

comfortable.

Toadjustit,turntheknobinfronteitherdirectionto

providethebestcomfort(Figure30).

ChangingtheBackPosition

Thebackoftheseatcanbeadjustedtoprovidea

comfortableride.Positionthebackoftheseatwhereit

ismostcomfortable.

Toadjustit,turntheknob,undertheright-sidearm

rest,ineitherdirectiontoprovidethebestcomfort

Figure31).

(

Figure29

PositioningtheSeat

ChangingtheSeatPosition

Theseatcanmoveforwardandbackward.Positionthe

seatwhereyouhavethebestcontrolofthemachine

andaremostcomfortable.

26

Page 27

g012487

PushingtheMachinebyHand

Important:Alwayspushthemachinebyhand.

Nevertowthemachinebecausehydraulicdamage

mayoccur.

PushingtheMachine

1.Disengagethepowertakeoff(PTO)andturnthe

ignitionkeytooff.Movetheleverstoneutrallocked

positionandapplyparkingbrake.Removethekey.

2.Rotatetheby-passvalvescounterclockwise1turn

topush.Thisallowshydraulicuidtoby-passthe

pumpenablingthewheelstoturn(Figure33).

Figure31

1.Backrestknob2.Right-sidearmrest

UnlatchingtheSeat

Pushtheseatlatchrearwardtounlatchtheseat.

Thiswillallowaccesstothemachineundertheseat

(Figure32).

Important:Donotrotateby-passvalvesmore

than1turn.Thispreventsvalvesfromcoming

outofthebodyandcausinguidtorunout.

3.Disengageparkingbrakebeforepushing.

ChangingtoMachineOperation

Rotatetheby-passvalvesclockwise1turntooperate

machine(Figure33).

Note:Donotovertightentheby-passvalves.

Themachinewillnotdriveunlessby-passvalvesare

turnedin.

Figure32

1.Seatlatch3.Seat

2.Fuelcap

Figure33

1.Sideconsolecontrols

2.By-passvalve

3.Hydraulicpumps

UsingtheSideDischarge

Themowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

27

Page 28

DANGER

Withoutthegrassdeector,dischargecover,or

completegrasscatcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriswillcauseinjuryor

death.

•Neverremovethegrassdeectorfromthe

mowerbecausethegrassdeectorroutes

materialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthemower.

•Nevertrytoclearthedischargeareaormower

bladesunlessyoumovethepowertakeoff

(PTO)totheoffposition,rotatetheignition

keytooffandremovethekey .

•Makesurethegrassdeectorisinthedown

position.

TransportingMachines

Useaheavy-dutytrailerortrucktotransportthe

machine.Ensurethatthetrailerortruckhasall

necessarylightingandmarkingasrequiredbylaw .

Pleasecarefullyreadallthesafetyinstructions.

Knowingthisinformationcouldhelpyou,yourfamily,

petsorbystandersavoidinjury.

Totransportthemachine:

•Lockthebrakeandblockthewheels.

•Securelyfastenthemachinetothetrailerortruck

withstraps,chains,cable,orropes.

•Secureatrailertothetowingvehiclewithsafety

chains.

individualrampsforeachsideoftheunit(

Thelowerrearsectionofthetractorframeextends

backbetweentherearwheelsandservesasastopfor

tippingbackward.Havingafullwidthrampprovides

asurfacefortheframememberstocontactifthe

unitstartstotipbackward.Ifitisnotpossibletouse

onefullwidthramp,useenoughindividualrampsto

simulateafullwidthcontinuousramp.

Therampshouldbelongenoughsothattheangles

donotexceed15degrees(

maycausemowercomponentstogetcaughtastheunit

movesfromramptotrailerortruck.Steeperangles

mayalsocausetheunittotipbackward.Ifloadingon

ornearaslope,positionthetrailerortrucksoitison

thedownsideoftheslopeandtherampextendsupthe

slope.Thiswillminimizetherampangle.Thetraileror

truckshouldbeaslevelaspossible.

Important:DoNotattempttoturntheunitwhile

ontheramp;youmaylosecontrolanddriveoff

theside.

Avoidsuddenaccelerationwhendrivinguparampand

suddendecelerationwhenbackingdownaramp.Both

maneuverscancausetheunittotipbackward.

Figure34).Asteeperangle

Figure34).

WARNING

Loadingaunitontoatrailerortruckincreasesthe

possibilityofbackwardtip-overandcouldcause

seriousinjuryordeath.

•Useextremecautionwhenoperatingauniton

aramp.

•Useonlyasingle,fullwidthramp;DoNotuse

individualrampsforeachsideoftheunit.

•Ifindividualrampsmustbeused,useenough

rampstocreateanunbrokenrampsurface

widerthantheunit.

WARNING

Drivingonthestreetorroadwaywithoutturn

signals,lights,reectivemarkings,oraslow

movingvehicleemblemisdangerousandcan

leadtoaccidentscausingpersonalinjury.

Donotdrivemachineonapublicstreetor

roadway.

LoadingMachines

Useextremecautionwhenloadingunitsontrailersor

trucks.Onefullwidthrampthatiswideenoughto

extendbeyondthereartiresisrecommendedinsteadof

•Donotexceeda15degreeanglebetweenramp

andgroundorbetweenrampandtraileror

truck.

•Avoidsuddenaccelerationwhiledrivingunitup

aramptoavoidtippingbackward.

•Avoidsuddendecelerationwhilebackingunit

downaramptoavoidtippingbackward.

28

Page 29

Figure34

1.Trailer3.Notgreaterthan

15degrees

2.Fullwidthramp4.Fullwidthramp—sideview

UsingtheZStand®

TheZStandraisesthefrontendofthemachineto

allowyoutocleanthemowerandremovetheblades.

WARNING

Themachinecouldfallontosomeoneandcause

seriousinjuryordeath.

Figure35

1.ZStand

2.Latch

3.Bracket

4.BracketPin

5.Bottomofslot

3.Raisethelatch.Swingthestandfootoutfrontand

slidestandtowardmachine,intothebottomofslot

(Figure35andFigure36).

4.LengthentheZStandbyremovingtheclevispin

andhairpincotterpinfromtheoutertubeand

slidingthefootout.

5.Aligntheholesandinstalltheclevispinandhairpin

cotterpin.

•Useextremecautionwhenoperatingthe

machineontheZStand®.

•Useonlyforcleaningthemowerandremoving

theblades.

•DonotkeepthemachineontheZStandfor

extendedperiodsoftime.

•Alwaysturntheengineoff,settheparking

brake,andremovethekeybeforeperforming

anymaintenancetothemower.

DrivingupontotheZStand

Important:UsetheZStandonalevelsurface.

1.Raisethemowertothetransportposition.

2.Removethebracketpin(

Figure35).

Figure36

1.ZStand(Positionedin

slot)

2.Crackinsidewalkorturf

3.Latchrestingonpivottab

6.Setthefootofstandonthegroundandrestthe

latchonthepivottab(Figure36).

7.Starttheengineandputitathalfthrottle.

Note:Forbestresults,placethefootofstandinto

seamsinsidewalksorintotheturf(Figure36).

8.Driveontothestand.Stopwhenthelatchdrops

overthetabintothelockedposition(

Figure36).

Onceontothestand,engagetheparkingbrakeand

tunofftheengine.

9.Chockorblockthedrivewheels.

29

Page 30

WARNING

Parkingbrakemaynotholdmachineparked

onZStandandcouldcausepersonalinjuryor

propertydamage.

DonotparkonZStandunlesswheelsare

chockedorblocked.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethe

cuttingheightofthemowerdoesnotscalpanyuneven

ground.However,thecuttingheightusedinthepastis

generallythebestonetouse.Whencuttinggrasslonger

thansixinchestall,youmaywanttocutthelawntwice

toensureanacceptablequalityofcut.

10.Performthemaintenance.

DrivingofftheZStand

1.Removethechocksorblocks.

2.Raisethelatchtotheunlockedposition(

Figure37

1.ZStand

2.Latch4.Unlockedposition

3.Starttheengineandplaceitathalfthrottle.

Disengagetheparkingbrake.

4.Slowlydrivebackwardsoffofthestand.

5.ShortentheZStandbyremovingtheclevispinand

hairpincotterpinfromtheoutertubeandsliding

thefootin.

6.Aligntheholesandinstalltheclevispinandhairpin

cotterpin.

7.Returnthestandtoitsrestposition(Figure35).

3.Lockedposition

Figure37).

Cut1/3oftheGrassBlade

Itisbesttocutonlyabout1/3ofthegrassblade.

Cuttingmorethanthatisnotrecommendedunless

grassissparse,oritislatefallwhengrassgrowsmore

slowly.

MowingDirection

Alternatemowingdirectiontokeepthegrassstanding

straight.Thisalsohelpsdisperseclippingswhich

enhancesdecompositionandfertilization.

MowatCorrectIntervals

Normally,moweveryfourdays.Butremember,

grassgrowsatdifferentratesatdifferenttimes.So

tomaintainthesamecuttingheight,whichisagood

practice,mowmoreofteninearlyspring.Asthegrass

growthrateslowsinmidsummer,mowlessfrequently.

Ifyoucannotmowforanextendedperiod,rstmow

atahighcuttingheight;thenmowagaintwodayslater

atalowerheightsetting.

CuttingSpeed

Toimprovecutquality,useaslowergroundspeedin

certainconditions.

AvoidCuttingTooLow

Ifthecuttingwidthofthemoweriswiderthanthe

moweryoupreviouslyused,raisethecuttingheightto

ensurethatuneventurfisnotcuttooshort.

OperatingTips

FastThrottleSetting

Forbestmowingandmaximumaircirculation,operate

theengineatthefastthrottleposition.Airisrequired

tothoroughlycutgrassclippings,sodonotsetthe

height-of-cutsolowastototallysurroundthemower

byuncutgrass.Alwaystrytohaveonesideofthe

mowerfreefromuncutgrass,whichallowsairtobe

drawnintothemower.

LongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,raise

thecuttingheighthigherthanusualandcutthegrassat

thissetting.Thencutthegrassagainusingthelower,

normalsetting.

WhenStopping

Ifthemachine’sforwardmotionmustbestoppedwhile

mowing,aclumpofgrassclippingsmaydropontoyour

30

Page 31

lawn.Toavoidthis,moveontoapreviouslycutarea

withthebladesengaged.

KeeptheUndersideoftheMower

Clean

Cleanclippingsanddirtfromtheundersideofthe

moweraftereachuse.Ifgrassanddirtbuildupinside

themower,cuttingqualitywilleventuallybecome

unsatisfactory.

BladeMaintenance

Maintainasharpbladethroughoutthecuttingseason

becauseasharpbladecutscleanlywithouttearingor

shreddingthegrassblades.Tearingandshreddingturns

grassbrownattheedges,whichslowsgrowthand

increasesthechanceofdisease.Checkthecutterblades

dailyforsharpness,andforanywearordamage.File

downanynicksandsharpenthebladesasnecessary.If

abladeisdamagedorworn,replaceitimmediatelywith

agenuineTOROreplacementblade.

31

Page 32

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst25hours

Aftertherst50hours

Aftertherst100hours

Beforeeachuseordaily

Every25hours

Every40hours

MaintenanceProcedure

•Checkcoolingsystemlevel.

•Checkthehydraulicuid.

•Changethehydrauliclter.

•Changetheengineoil.

•Changetheengineoillter.

•Checkthewheelhubslottednut.

•Checkthewheellugnuts.

•Checkthesafetysystem.

•Checktheengineoil.

•Checkcoolingsystemlevel.

•Cleanthecoolingsystem.

•Checkthemowerblades.

•Cleanthemowerdeck.

•Greasethemowerdeckandspindles.

•Greasethemowerbeltidlerarm.

•Greasethepumpbeltidlerarm.

•Greasethedrivebeltidlerarm.

•Greasethebrakelever.

•Checkthehydraulicuid.

•Drainthewaterseparator.

Every50hours

Every100hours

Every150hours

Every200hours

Every250hours

Every400hours

Every500hours

Every600hours

•Checkthetirepressure

•Checkthepumpdrivebelt.

•Checkthealternatorbelt.

•Changetheengineoil.

•Checkthecoolingsystemhoses.

•Inspectthebeltsforcracksandwear.

•Checkthehydraulichoses.

•Lubricatethemachinewithlightoil.

•Replacetheprimaryairlter.

•Changetheengineoillter.

•Greasethebrakepivot.

•ChangethehydrauliclterandhydraulicoilwhenusingMobil®1oil.

•Replacethefuellter(moreoftenindirtyordustyconditions).

•Checkthewheelhubslottednut.

•Checkthewheellugnuts.

•Adjustthecasterpivotbearingoratstorage,whichevercomesrst.

•ChangethehydrauliclterandhydraulicoilwhenusingT oro®HYPR-OIL™500

hydraulicoil.

•Replacethefanhydrauliclter

•Replacethesafetyairlter.

•Greasethefrontcasterpivots(moreoftenindirtyordustyconditions).

Yearly

•Lubricatethecasterwheelhubs

•Changetheenginecoolant.

Important:Refertoyour

Engine Operator’ s Man ual

foradditionalmaintenanceprocedures.

32

Page 33

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplug(s)beforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

Lubrication

GreasingandLubrication

LubricatethemachinewhenshownontheCheck

ServiceReferenceAiddecal(Figure38).Greasemore

frequentlywhenoperatingconditionsareextremely

dustyorsandy.

GreaseType:General-purposegrease.

HowtoGrease

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Cleanthegreasettingswitharag.Makesureto

scrapeanypaintoffthefrontofthetting(s).

4.Connectagreaseguntothetting.Pumpgrease

intothettingsuntilgreasebeginstooozeoutof

thebearings.

5.Wipeupanyexcessgrease.

WheretoAddGrease

LubricatethegreasettingsasshownontheCheck

ServiceReferenceAiddecal(Figure38).

Figure38

GreasingtheMowerDeckand

BeltIdlers

ServiceInterval:Every25hours—Greasethemower

deckandspindles.

Every25hours—Greasethemower

beltidlerarm.

Every25hours—Greasethepump

beltidlerarm.

Every25hours—Greasethedrive

beltidlerarm.

GreasewithNo.2generalpurposelithiumbaseor

molybdenumbasegrease.

Important:Makesurecuttingunitspindlesare

fullofgreaseweekly.

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

33

Page 34

2.Stoptheengine,removethekey ,andwaitforall

g012892

movingpartstostopbeforeleavingtheoperating

position.

3.Removethebeltcovers.

4.Greasethethreespindlebearingsuntilgreasecomes

Figure39).

out(

5.Greasetheidlerarmonthemowerdeck(Figure39).

6.Greasethettingsonthepusharms(Figure39).

Figure40

3.Greasethepumpbeltidlerarm.

Figure39

WheretoAddLightOilor

SprayLubrication

ServiceInterval:Every150hours

Lubricatethemachineinthefollowingareaswithspray

typelubricantorlightoil.

•Seatswitchactuator.

•Brakehandlepivot.

•Brakerodbushings.

•Motioncontrolbronzebushings.

GreasetheIdlerArms

1.Greasethecoolingfanbeltidlerarm(Figure40).

2.Greasethedrivebeltidlerarms(Figure40).

Figure41

GreasingtheFrontCaster

Pivots

ServiceInterval:Yearly

Lubricatethefrontcasterpivotsonceayear.

1.Removethedustcapandadjustthecasterpivots.

Keepthedustcapoffuntilgreasingisdone.Referto

AdjustingtheCasterPivotBearinginMaintenance

Section.

2.Removethehexplug.Threadagreasezerkintothe

hole.

3.Pumpgreaseintothezerkuntilitoozesoutaround

thetopbearing.

4.Removethegreasezerkinthehole.Installthehex

plugandcap.

LubricateCasterWheelHubs

ServiceInterval:Yearly

1.Stoptheengine,waitforallmovingpartstostop,

andremovethekey.Engagetheparkingbrake.

34

Page 35

Figure42

1.Sealguard2.Spacernutwithwrench

ats

2.Removethecasterwheelfromthecasterforks.

3.Removethesealguardsfromthewheelhub.

4.Removeoneofthespacernutsfromtheaxle

assemblyinthecasterwheel.Notethatthread

lockingadhesivehasbeenappliedtolockthespacer

nutstotheaxle.Removetheaxle(withtheother

spacernutstillassembledtoit)fromthewheel

assembly.

13.Torquethenutto75-80in-lb(8-9N-m),loosen,

thenre-torqueto20-25in-lb(2-3N-m).Makesure

axledoesnotextendbeyondeithernut.

14.Reinstallthesealguardsoverthewheelhuband

insertwheelintocasterfork.Reinstallcasterbolt

andtightennutfully .

Important:Topreventsealandbearingdamage,

checkthebearingadjustmentoften.Spinthecaster

tire.Thetireshouldnotspinfreely(morethan1or

2revolutions)orhaveanysideplay.Ifthewheel

spinsfreely,adjusttorqueonspacernutuntilthere

isaslightamountofdrag.Reapplythreadlocking

adhesive.

5.Pryoutseals,andinspectbearingsforwearor

damageandreplaceifnecessary.

6.Packthebearingswithageneral-purposegrease.

7.Insertonebearing,onenewsealintothewheel.

Note:Thesealsmustbereplaced.

8.Iftheaxleassemblyhashadbothspacernuts

removed(orbrokenloose),applyathreadlocking

adhesivetoonespacernutandthreadontotheaxle

withthewrenchatsfacingoutward.DoNotthread

spacernutallofthewayontotheendoftheaxle.

Leaveapproximately1/8inch(3mm)fromthe

outersurfaceofthespacernuttotheendoftheaxle

insidethenut.

9.Inserttheassemblednutandaxleintothewheelon

thesideofthewheelwiththenewsealandbearing.

10.Withtheopenendofthewheelfacingup,ll

theareainsidethewheelaroundtheaxlefullof

general-purposegrease.

11.Insertthesecondbearingandnewsealintothe

wheel.

12.Applyathreadlockingadhesivetothe2ndspacer

nutandthreadontotheaxlewiththewrenchats

facingoutward.

35

Page 36

EngineMaintenance

ServicingtheAirCleaner

Note:Servicetheaircleanermorefrequentlyif

operatingconditionsareextremelydustyorsandy.

RemovingtheFilters

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Tilttheseatforwardandremovethefrontengine

panel(

Figure43).

Figure44

1.Latches

2.Aircleanercover

3.Airlterbody

4.Primarylter

5.Safetylter

ServicingthePrimaryFilter

ServiceInterval:Every200hours—Replacethe

primaryairlter.

1.Donotcleanthepaperlter,replaceit(

2.Inspecttheelementfortears,anoilylm,ordamage

totherubberseal.

3.Replacethepaperelementifitisdamaged.

Figure44).

Figure43

1.Frontenginepanel2.Knob

4.Releasethelatchesontheaircleanerandpulltheair

cleanercoveroffoftheaircleanerbody(Figure44).

5.Cleantheinsideoftheaircleanercoverwith

compressedair.

6.Gentlyslidetheprimarylteroutoftheaircleaner

body(Figure44).Avoidknockingthelterintothe

sideofthebody.

7.Removethesafetylteronlyifyouintendtoreplace

it.

Important:Neverattempttocleanthesafety

lter.Ifthesafetylterisdirty,thentheprimary

lterisdamagedandyoushouldreplaceboth

lters.

8.Inspecttheprimarylterfordamagebylookinginto

thelterwhileshiningabrightlightontheoutside

ofthelter.Holesinthelterwillappearasbright

spots.Ifthelterisdamageddiscardit.

ServicingtheSafetyFilter

ServiceInterval:Every600hours—Replacethesafety

airlter.

Donotcleanthesafetylter,replaceit.

Important:Neverattempttocleanthesafetylter.

Ifthesafetylterisdirty,thentheprimarylteris

damagedandyoushouldreplacebothlters.

InstallingtheFilters

Important:Topreventenginedamage,always

operatetheenginewithbothairltersandcover

installed.

1.Ifinstallingnewlters,checkeachlterforshipping

damage.Donotuseadamagedlter.

2.Ifthesafetylterisbeingreplaced,carefullyslideit

intothelterbody(

3.Carefullyslidetheprimarylteroverthesafetylter

(Figure44).Ensurethatitisfullyseatedbypushing

ontheouterrimofthelterwhileinstallingit.

Important:Donotpressonthesoftinsidearea

ofthelter.

Figure44).

36

Page 37

4.Installtheaircleanercoverwiththesideindicatedas

UPfacingupandsecurethelatches(Figure44).

5.Installthefrontenginepanel.

ServicingtheEngineOil

OilType:High-qualitydetergentoilclassied“ API

ServiceCForCF-4"orhigherfordieselengines.Do

notusespecialadditiveswithrecommendedoils.

CrankcaseCapacity:3.5quarts(3.3liters)

Viscosity:Seethetablebelow .

Figure45

Figure46

1.Oildipstick3.Rightsideofmachine

2.Metalend

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Cleanaroundtheoildipstick(

cannotfallintothellerholeanddamagetheengine.

4.Pulltheoildipstickoutandwipethemetalendclean

(Figure46).

5.Slidetheoildipstickfullyintothetube.Pullthe

dipstickoutandlookatthemetalend(Figure46).If

theoillevelislow,slowlypouronlyenoughoilinto

thellholetoraisetheleveltothefullmark.

Important:Donotoverllthecrankcasewith

oilbecausethismaycauseenginedamage.Do

notruntheenginewithoilbelowthelowmark

becausetheenginemaybedamagedasaresult.

Figure46)sodirt

ChangingtheEngineOil

ServiceInterval:Aftertherst50hours

Every100hours

1.Starttheengineandletitrunforveminutes.This

warmstheoilsoitdrainsbetter.

2.Parkthemachineonalevelsurface.

3.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

4.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

5.Placeapanbelowtheoildrain.Removethedrain

plugandlettheoildraincompletely(

6.Removetheoilllercapfromthetopoftheengine

(Figure48).Thiswillhelptheoiltodrain.

7.Installthedrainplugandtightenitto25-1/2ft-lb

(35N-m).

Note:Disposeoftheusedoilatarecyclingcenter.

Figure50).

37

Page 38

AddingEngineOil

1.Tilttheseatforwardandremovethefrontengine

panel(Figure47).

Figure47

1.Frontenginepanel2.Knob

2.Removetheoilllercapandthedipstick(Figure48).

Figure49

1.Notetheclearanceleftinthelleropening.

5.Replacethedipstickandinstallthefrontengine

panel.

6.Starttheengineandrunitatidlefor5minutes.

7.Shutofftheengine.

8.Wait3minutesandchecktheoillevel.

9.Addoil,ifrequired,tobringtheleveltotheupper

holeonthedipstick.

Figure48

1.Engine

2.Oilllcap

3.Toaddoiltotheengine,locateanduseahoseand

funnelforaddingoil.

4.Addoilslowly ,checkingthelevelwiththedipstick

frequentlyuntilthelevelreachestheupperholeon

thedipstick.Forthecorrectoiltypeandviscosity

touseindifferenttemperatureconditions,referto

ServicingtheEngineOilinEngineMaintenance.

Important:Addtheoilveryslowlyanddonot

blocktheopeningofthellerhole(

Figure49).

Ifyouaddoiltoofastorblockthehole,theoil

couldbackupandfoultheairintakes,causing

enginedamage.

10.Replacethedipstickand,llercap,andthefront

enginepanel.

11.Checkforleaks.

Important:Donotoverllthecrankcasewith

oilbecausethismaycauseenginedamage.

ChangingtheEngineOilFilter

ServiceInterval:Aftertherst50hours

Every200hours

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil.

Placeadrippanbeneaththeoildriptraytoreceive

oilfromtheoillterandoilpassagesintheengine.

2.Turntheltercounterclockwisetoremoveit

Figure51andFigure51).

(

Note:Disposeoftheoillterproperly.Recyclein

accordancewithlocalcodes.

3.Beforeinstallingthelter,lightlyoilthegasketon

thelterwithfresh,cleanoil.Screwthelteronby

handuntilthegasketcontactstheoillteradapter.

Tighten1/2to3/4turnmore.

4.Addoil;refertoAddingEngineOil.

38

Page 39

FuelSystem

Maintenance

ServicingtheFuelFilterand

WaterSeparator

Figure50

1.Drainplug3.Dipstick

2.Oillter

Figure51

1.Oillter

2.Gasket

3.Adapter

DrainingtheWaterSeparator

ServiceInterval:Every40hours

1.Positionthemachineonalevelsurface.

2.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

3.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.Locatethewaterseparatoratthebackleftofthe

machine.

5.Placeadrainpanbelowthewaterseparator.

6.Openthedrainvalveonthewaterseparator

approximatelyoneturntoallowwaterandother

contaminatestodrain(

7.Closethedrainvalvewhenonlydieselfuelcomes

out(Figure52).

Figure52).

Figure52

1.Waterseparator

2.Drainvalve

39

3.Rightsideofmachine

Page 40

ChangingtheFuelFilter

ServiceInterval:Every400hours/Yearly(whichever

comesrst)—Replacethefuel

lter(moreoftenindirtyordusty

conditions).

Neverinstalladirtyfuellterifitisremovedfromthe

fuelline.

ElectricalSystem

Maintenance

ServicingtheBattery

WARNING

1.Allowthemachinetocooldown.

2.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

3.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.Closethefuelshut-offvalve.

5.Loosenthetwohoseclampsanddisconnectthefuel

linesfromthefuellter(

6.Installanewlter.Connectthefuellinestothefuel

lterandinstallthetwohoseclamps.

7.Openthefuelshut-offvalve.

8.Starttheengineandcheckforleaks.

Figure53).

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing.Wearsafetyglassestoshield

youreyesandrubberglovestoprotectyourhands.

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

Figure53

1.Fuellter3.Rightsideofmachine

2.Hoseclamps

ServicingtheFuelTank

Donotattempttodrainthefueltank.Ensurethatan

AuthorizedServiceDealerdrainsthefueltankand

servicesanycomponentsofthefuelsystem.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

WARNING

Incorrectbatterycableroutingcoulddamagethe

machineandcablescausingsparks.Sparkscan

causethebatterygassestoexplode,resultingin

personalinjury.

•AlwaysDisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

•AlwaysReconnectthepositive(red)battery

cablebeforereconnectingthenegative(black)

cable.

40

Page 41

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Unlatchtheseatandtilttheseatup.

4.Firstdisconnectthenegativebatterycablefromthe

negative(-)batteryterminal(

Figure54).

5.Slidetheredterminalbootoffthepositive(red)

batteryterminal.Thenremovethepositive(red)

batterycable(

Figure54).

ChargingtheBattery

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparksand

amesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged

(1.265specicgravity).Thisisespeciallyimportant

topreventbatterydamagewhenthetemperatureis

below32°F(0°C).

1.Makesurethellercapsareinstalledinbattery.

Chargebatteryfor10to15minutesat25to30amps

or30minutesat10amps.

2.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthe

chargerleadsfromthebatteryposts(

3.Installthebatteryinthemachineandconnectthe

batterycables,refertoInstallingtheBattery.

Figure55).

Figure54

1.Battery5.Batteryclamp

2.J-bolts

3.Terminalboot

4.Wingnut(1/4inch)8.Black(-)cable

6.Groundwire

7.Red(+)cable

6.Removethebattery.

InstallingtheBattery

1.Positionbatteryinthetraywiththeterminalposts

oppositefromthehydraulictank(Figure54).

2.First,installthepositive(red)batterycableto

positive(+)batteryterminal.

3.Theninstallthenegativebatterycableandground

wiretothenegative(-)batteryterminal.

4.Securethecableswith2bolts(1/4x3/4inch),

2washers(1/4inch),and2locknuts(1/4inch)

(Figure54).

5.Slidetheredterminalbootontothepositive(red)

batterypost.

6.SecurethebatterywithJ-bolts,holddownclamp,

2washers(1/4inch),and2wingnuts(1/4inch)

(Figure54).

Note:Donotrunthemachinewiththebattery

disconnected,electricaldamagemayoccur.

Figure55

1.PositiveBatteryPost

2.NegativeBatteryPost

3.Red(+)ChargerLead

4.Black(-)ChargerLead

ServicingtheFuses

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance,however,ifafuseblowscheck

component/circuitformalfunctionorshort.

1.Tilttheseatforwardandremovethefrontengine

panel(Figure56).

41

Page 42

Figure56

1.Frontenginepanel2.Knob

2.Toreplaceafuse,pulloutonthefusetoremoveit

(Figure57).

DriveSystem

Maintenance

AdjustingtheTracking

Themachinehasaknobforadjustingthetracking

locatedundertheseat.

Important:Adjustthehandleneutralandhydraulic

pumpneutralbeforeadjustingthetracking.Refer

toAdjustingtheHandleNeutralinControlsSystem

MaintenanceandAdjustingtheHydraulicPump

NeutralinHydraulicSystemMaintenance.

1.Pushbothcontrolleversforwardthesamedistance.

2.Checkifthemachinepullstooneside.Ifitdoes,

stopthemachineandsettheparkingbrake.

3.Unlatchtheseatandtilttheseatforwardtoaccess

thetrackingknob.

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Figure57

1.Accessory-20amp3.Ignition-30amp

2.Clutch-10amp

4.Alternator-50amp

4.Tomakethemachinegoright,turntheknobtowards

therightsideofthemachine.Referto

Figure58.

5.Tomakethemachinegoleft,turntheknobtowards

theleftsideofthemachine.Referto

Figure58.

6.Repeatadjustmentuntilthetrackingiscorrect.

Figure58

1.Trackingknob4.Turnthiswaytotrackright

2.Hydraulictank

3.Hydraulicpumps

5.Turnthiswaytotrackleft

42

Page 43

CheckingtheTirePressure

ServiceInterval:Every50hours/Monthly(whichever

comesrst)

Checkthepressureatthevalvestem(

Figure59).

5.Checkthedistancefrombottomofslotinnutto

insideedgeofhole.Twothreadsorlessshouldbe

showing(Figure60).

6.Ifmorethantwothreadsareshowingremovenut

andinstallwasherbetweenhubandnut.

Maintaintheairpressureinthereartiresat13psi(90

kPa).Uneventirepressurecancauseunevencut.Check

thetireswhentheyarecoldtogetthemostaccurate

pressurereading.

Note:Thefronttiresaresemi-pneumatictiresanddo

notrequireairpressuremaintenance.

Figure59

7.Torquetheslottednutto125ft-lb.(170N-m)

Figure60).

(

8.Tightenthenutuntilthenextsetofslotslineupwith

theholeintheshaft(

9.Replacethecotterpin.

1.SlottedNut3.Holeinthreadedshaft

2.Twothreadsorless

showing

Figure60).

Figure60

4.Washer(ifneeded)

CheckingtheWheelHub

SlottedNut

ServiceInterval:Aftertherst100hours—Checkthe

wheelhubslottednut.

Every500hours—Checkthewheel

hubslottednut.

Aftertherst100hours—Checkthe

wheellugnuts.

Every500hours—Checkthewheel

lugnuts.

Theslottednutneedstobetorquedto125ft-lb

(170N-m).

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

AdjustingtheCasterPivot

Bearing

ServiceInterval:Every500hoursoratstorage,which

evercomesrst.

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Removethedustcapfromcasterandtightenlock

Figure61).

nut(