Page 1

LCE Products

Z Master Z597

Diesel Series

Service Manual

Page 2

ABOUT THIS MANUAL

This service manual was written expressly for Toro service technicians. The Toro Company has

made every effort to make the information in this manual complete and correct.

Basic shop safety knowledge and mechanical/electrical skills are assumed. The Table of Contents

lists the systems and the related topics covered in this manual.

The following service materials are available in addition to this service manual:

Hydrostatic Pumps: Hydro-Gear BDP-10A/16A/21L - Service and Repair Manual

Form #492-4789

Wheel Motors: Parker/Ross Wheel Motor Service Manual

Form #492-4753

Diesel Engine: Briggs & Stratton Daihatsu 3 Cylinder Liquid-Cooled Engine Repair Manual

Form #492-0670

Hydraulic Troubleshooting: Interactive hydraulic troubleshooting and failure analysis on compact disk

Form #492-4777

Electrical Troubleshooting: Interactive electrical troubleshooting and wiring diagrams on compact disk

Form # 492-9143

The Z Master 597 model years 2004 and 2005 are covered in this manual. The manual may also

be specied for use on later model products.

The hydrostatic drive system is precision machinery. Maintain strict cleanliness control during all

stages of service and repair. Cover or cap all hose ends and ttings whenever they are exposed.

Even a small amount of dirt or other contamination can severely damage the system.

We are hopeful that you will nd this manual a valuable addition to your service shop. If you have

any questions or comments regarding this manual, please contact us at the following address:

The Toro Company

LCE Service Training Department

8111 Lyndale Avenue South

Bloomington, MN 55420

The Toro Company reserves the right to change product specications or this manual without

notice.

Copyright© All Rights Reserved

©2005 The Toro Company

Page 3

THIS PAGE INTENTIONALLY LEFT BLANK.

Page 4

TABLE OF CONTENTS

Safety Information

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Think Safety First . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specications

Machine Prole Photos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Available Service Manuals / Service Aids . . . . . . . . . . . . . . . . . . . . . . . . .

Torque Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Inch Series) . . . . . . . . . . . . .

Standard Torque for Dry, Zinc, and Steel Fasteners (Metric Fasteners) . . . . . . . . . . . . . .

Other Torque Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equivalents and Conversions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

U.S. to Metric Conversions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chassis

Caster Fork Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the Caster Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Caster Fork Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Wheel Removal and Bearing Replacement . . . . . . . . . . . . . . . . . . . . . .

Fuel Tank Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Right Side Fuel Tank Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Right Side Fuel Tank Installation . . . . . . . . . . . . . . . . . . . . . . . . . . .

Left Side Fuel Tank Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Left Side Fuel Tank Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hood Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hood Assembly Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Throttle Control Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake Lever Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake Lever Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake Band Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake Band Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake Cross Shaft Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake Shaft Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting the Parking Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Deck Lift Lever Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Deck Lift Lever Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motion Control Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motion Control Assembly Installation . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2

1-2

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

2-10

2-11

2-12

3-2

3-3

3-4

3-5

3-6

3-6

3-8

3-8

3-11

3-11

3-12

3-12

3-13

3-16

3-17

3-17

3-18

3-18

3-20

3-22

3-23

3-26

3-29

3-32

Hydraulic System

Hydrostatic Pump Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hydrostatic Pump Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wheel Motor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wheel Motor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purging the Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hydraulic Fan Pump Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hydraulic Fan Pump Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hydraulic Fan Motor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hydraulic Fan Motor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2

4-5

4-8

4-10

4-13

4-14

4-16

4-17

4-20

iZ Master Z597 Diesel Service Manual

Page 5

TABLE OF CONTENTS

Hydraulic System continued

Setting the Hydrostatic Pump Neutral . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting the Handle Neutral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the LH Hydrostatic Pump Neutral . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the RH Hydrostatic Pump Neutral . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting the Tracking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hydraulic Flow Testing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cooling Fan Pump Flow Testing Procedure . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the Traction Pump Drive Belt . . . . . . . . . . . . . . . . . . . . . . . . . .

Pushing the Machine by Hand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing to Machine Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hydraulic Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine

Engine Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Radiator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Radiator Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking the Radiator Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the Fan Pump Drive Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing and Tensioning the Alternator Belt . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the Alternator Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tensioning the Alternator Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Servicing the Fuel Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Draining Water from the Fuel Filter . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing the Fuel Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Priming the Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-23

4-24

4-25

4-26

4-27

4-28

4-30

4-31

4-32

4-33

4-34

5-2

5-11

5-21

5-21

5-25

5-28

5-29

5-29

5-30

5-31

5-32

5-32

5-33

5-34

Electrical

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PTO Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ignition Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Neutral Safety Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Park Brake Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Seat Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Delay Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dual-Tone Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glow Plug Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Temperature Sender . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pressure Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Water Temperature Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hour Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Volt Meter Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electric PTO Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Coil Resistance Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measuring Clutch Current Draw . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Filter Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2

6-2

6-2

6-4

6-5

6-6

6-7

6-9

6-10

6-11

6-13

6-15

6-16

6-17

6-18

6-19

6-20

6-20

6-21

6-22

6-24, 25

ii Z Master Z597 Diesel Service Manual

Page 6

TABLE OF CONTENTS

Mower Decks

Electric PTO Clutch Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PTO Clutch Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mower Deck Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mower Deck Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mower Spindle Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mower Spindle Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mower Spindle Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mower Jackshaft Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mower Jackshaft Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mower Jackshaft and Pulley Assembly . . . . . . . . . . . . . . . . . . . . . . . . . .

Right Hand Mower Idler Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . .

Right Hand Mower Idler Assembly Installation . . . . . . . . . . . . . . . . . . . . . . .

Left Hand Mower Idler Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . .

Left Hand Mower Idler Assembly Installation . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the Mower Spindle Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing Mower Drive Belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Leveling the Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting up the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Leveling the Mower Side-to-Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting the Front-to-Rear Mower Pitch . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting the Compression Spring . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-2

7-5

7-8

7-13

7-18

7-20

7-24

7-29

7-31

7-32

7-32

7-34

7-36

7-38

7-39

7-41

7-46

7-46

7-47

7-48

7-50

iiiZ Master Z597 Diesel Service Manual

Page 7

TABLE OF CONTENTS

THIS PAGE INTENTIONALLY LEFT BLANK.

iv Z Master Z597 Diesel Service Manual

Page 8

SAFETY INFORMATION

Safety Information . . . . . . . . .

Specications . . . . . . . . . . .

Chassis . . . . . . . . . . . . . .

Hydraulic System . . . . . . . . .

Engine . . . . . . . . . . . . . . .

1

2

3

4

5

Electrical . . . . . . . . . . . . . .

Mower Decks . . . . . . . . . . .

1-1Z Master Z597 Diesel Service Manual

6

7

Page 9

SAFETY INFORMATION

SAFETY INFORMATION

SAFETY INFORMATION

General Information

This symbol means WARNING or

PERSONAL SAFETY INSTRUCTION

- read the instruction because it has to

do with your safety. Failure to comply

with the instruction may result in

personal injury or even death.

This manual is intended as a service and repair

manual only. The safety instructions provided herein

are for troubleshooting, service, and repair of the

Z Master Z597 Zero-turn Riding Mower

The riding mower and attachment operator's manual

contain safety information and operating tips for safe

operating practices. Operator's manuals are available

through your Toro parts source or:

The Toro Company

Publications Department

8111 Lyndale Avenue South

Bloomington, MN 55420

General Information

This symbol means WARNING or

1

This manual is intended as a service and repair

manual only. The safety instructions provided herein

are for troubleshooting, service, and repair of the

Z Master Z597 Zero-turn Riding Mower

Think Safety First

Avoid unexpected starting of engine...

Always turn off the engine and disconnect the spark

plug wire(s) before cleaning, adjusting, or repair.

Avoid lacerations and amputations...

Stay clear of all moving parts whenever the engine is

running. Treat all normally moving parts as if they were

moving whenever the engine is running or has the

potential to start.

PERSONAL SAFETY INSTRUCTION

- read the instruction because it has to

do with your safety. Failure to comply

with the instruction may result in

personal injury or even death.

The riding mower and attachment operator's manual

contain safety information and operating tips for safe

operating practices. Operator's manuals are available

through your Toro parts source or:

The Toro Company

Publications Department

8111 Lyndale Avenue South

Bloomington, MN 55420

Avoid injury from batteries...

Battery acid is poisonous and can cause burns. Avoid

contact with skin, eyes, and clothing. Battery gases

can explode. Keep cigarettes, sparks, and flames away

from the battery.

Avoid injury due to inferior parts...

Use only original equipment parts to ensure that

important safety criteria are met.

Avoid burns...

Do not touch the engine, muffler, or other components

which may increase in temperature during operation,

while the unit is running or shortly after it has been

running.

Avoid fires and explosions...

Avoid spilling fuel and never smoke while working with

any type of fuel or lubricant. Wipe up any spilled fuel or

oil immediately. Never remove the fuel cap or add fuel

when the engine is running. Always use approved,

labeled containers for storing or transporting fuel and

lubricants.

Avoid asphyxiation...

Never operate an engine in a confined area without

proper ventilation.

Avoid injury to bystanders...

Always clear the area of bystanders before starting or

testing powered equipment.

Avoid injury due to projectiles...

Always clear the area of sticks, rocks, or any other

debris that could be picked up and thrown by the

powered equipment.

Avoid modifications...

Never alter or modify any part unless it is a factory

approved procedure.

Avoid unsafe operation...

Always test the safety interlock system after making

adjustments or repairs on the machine. Refer to the

Electrical section in this manual for more information.

1-2 Z Master Z597 Diesel Service Manual

Page 10

SPECIFICATIONS

Safety Information . . . . . . . . .

Specications . . . . . . . . . . .

Chassis . . . . . . . . . . . . . .

Hydraulic System . . . . . . . . .

Engine . . . . . . . . . . . . . . .

1

1

2

3

4

5

Electrical . . . . . . . . . . . . . .

Mower Decks . . . . . . . . . . .

2-1Z Master Z597 Diesel Service Manual

6

7

Page 11

2

SPECIFICATIONS

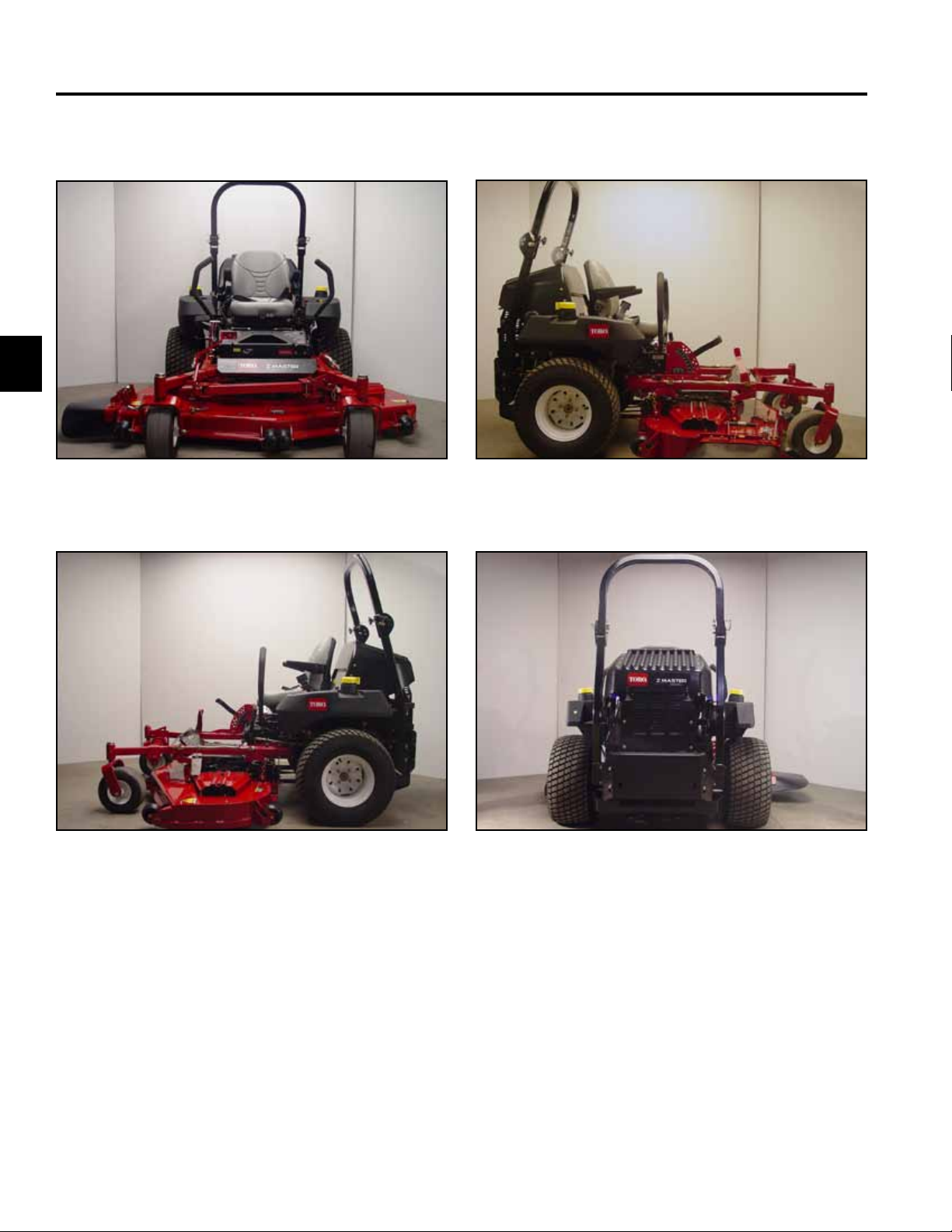

MACHINE PROFILE PHOTOS

Fig 001 DSC-2789

Fig 002 DSC-2790 Fig 004 DSC-2794

Fig 003 DSC-2792

2-2 Z Master Z597 Diesel Service Manual

Page 12

SPECIFICATIONS

Item Specication

Engine Briggs & Stratton® Vanguard™ Daihatsu® 27 Horsepower Diesel Engine

RPM setting High RPM Setting (no load) 3850 + 50 (International: 3450 + 50)

Low RPM Setting 1750

Fuel Capacity 12 gallons (45.4 liters) Diesel Fuel

Length Z597 – 60” (152.4cm) TF Deck - 81.5” (207cm)

Z597 – 72” (182.9cm) TF Deck - 84.5” (214.6cm)

Width Z597 – 60” (152.4cm) TF Deck - 61.7” (156.7cm) - Deector 76” (193cm)

Z597 – 72” (182.9cm) TF Deck - 73.6” (186.9cm) - Deector 88” (223.5cm)

Height 74” (188cm) ROPS Height Upright

55” (140cm) ROPS Folded

Weight Z597 – 60” (152.4cm) TF Deck - 1630 lbs. (739.36kg)

Z597 – 72” (182.9cm) TF Deck - 1695 lbs. (768.84kg)

Traction System (2) Hydro-Gear BDP-21A, 21cc/rev with system check relief (Pump)

(2) Parker/Ross MB18, 17.1 cir 1 ¼“ Tapered Shaft (Wheel Motor)

Ground Speed Forward: Innite 0 – 12 mph

Reverse: Innite 0 – 8 mph

Tires Rear: 26” x 12” – 12

Front: 13” x 6.5” – 6

Tire Pressure Rear: 13 psi (90kPa)

Front: 13 psi (90kPa)

Attachment Drive 200 ft-lb. electromagnetic clutch (271.16 Nm)

2

Battery BCI Group Size: 26

540 cold cranking amps.

2-3Z Master Z597 Diesel Service Manual

Page 13

2

SPECIFICATIONS

Item Specication

Mower Deck TURBO FORCE

Deck Construction Fabricated, High Strength 7-gauge Steel/with Bull-nose Bumper

Deck Depth 5 ½” (13.97cm)

Mower Bafes Adjustable Discharge Bafe

Spindle Housing 9 3/8” (23.8cm) Diameter Cast Iron

Spindle Shaft/Bearings 1” (2.54cm) Shaft / Tapered Roller

Blade Tip Speed 18,500+ ft/min (5,638+ m/min)

Blades ¼” (.635cm) Heat Treated Steel

Discharge Chute 5/16” (.79cm) Rubber

Cutting Height 1-1/2” – 5” (3.81 - 12.7cm)

Carrier Frame Construction 2” x 2” x 3/16” (5.08 x 5.08 x .476cm) Steel

Anti-scalp Rollers 6

Certication ANSI, CARB, EPA, OSHA

2-4 Z Master Z597 Diesel Service Manual

Page 14

SPECIFICATIONS

General Specications

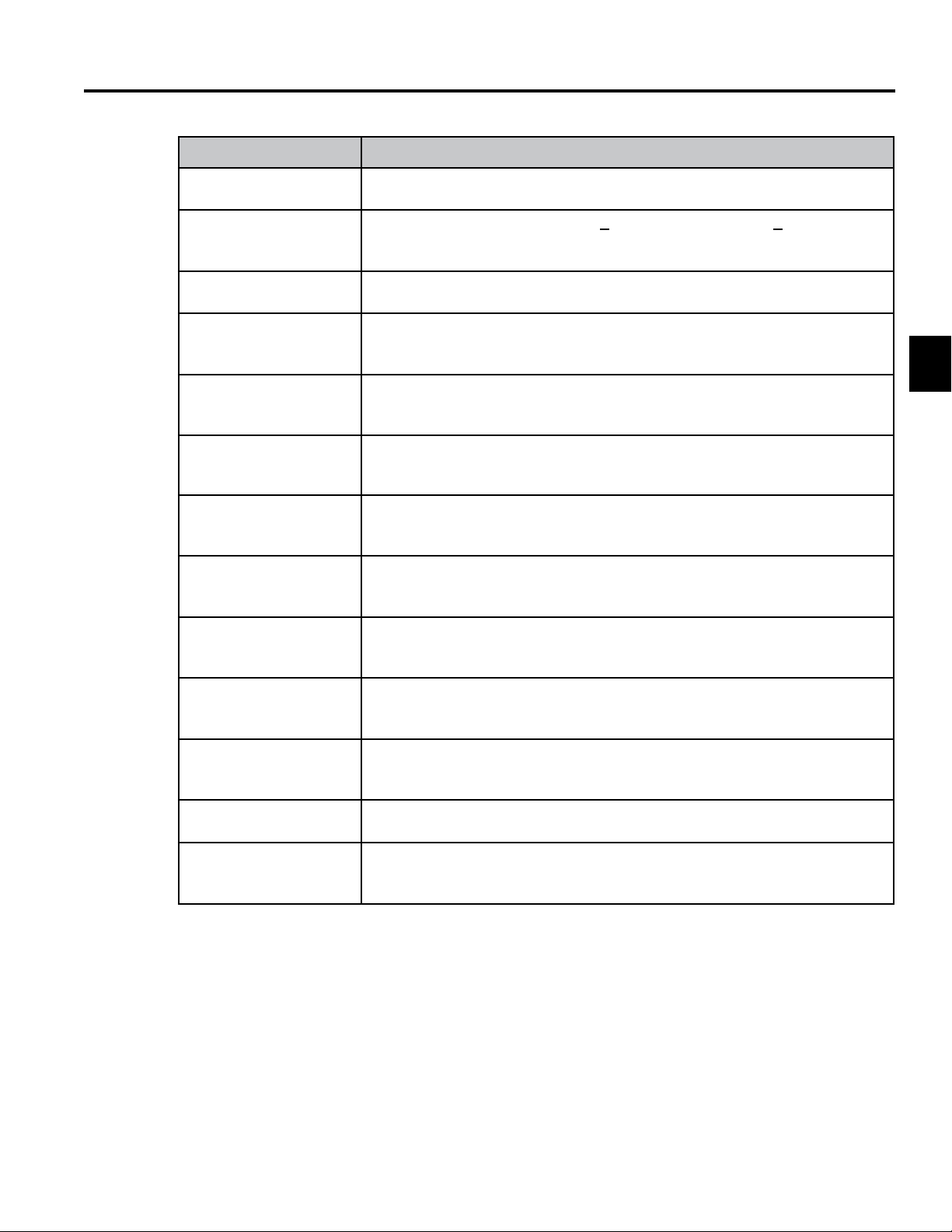

Greasing and Lubrication:

Grease: No. 2 general purpose lithium base or molybdenum grease.

Where to Add Grease: See Check Service Reference Aid decal below.

2

Fig 006 g. 55 m-5615

1. Cap 3. Cold uid level - full

2. Bafe 4. Hot uid level - full

Fig 005 g. 50 decal

Hydraulic System Oil Capacity: 4 quarts (3.8 l)

Fluid Type: Mobil 1 15W – 50 synthetic motor oil or equivalent synthetic oil

Fluid Level: Check the uid level while the uid is warm. The uid should be between cold

and hot.

Note: The uid level should be to the top of the hot level of the bafe,

when the uid is hot (Fig. 006 above).

2-5Z Master Z597 Diesel Service Manual

Page 15

SPECIFICATIONS

2

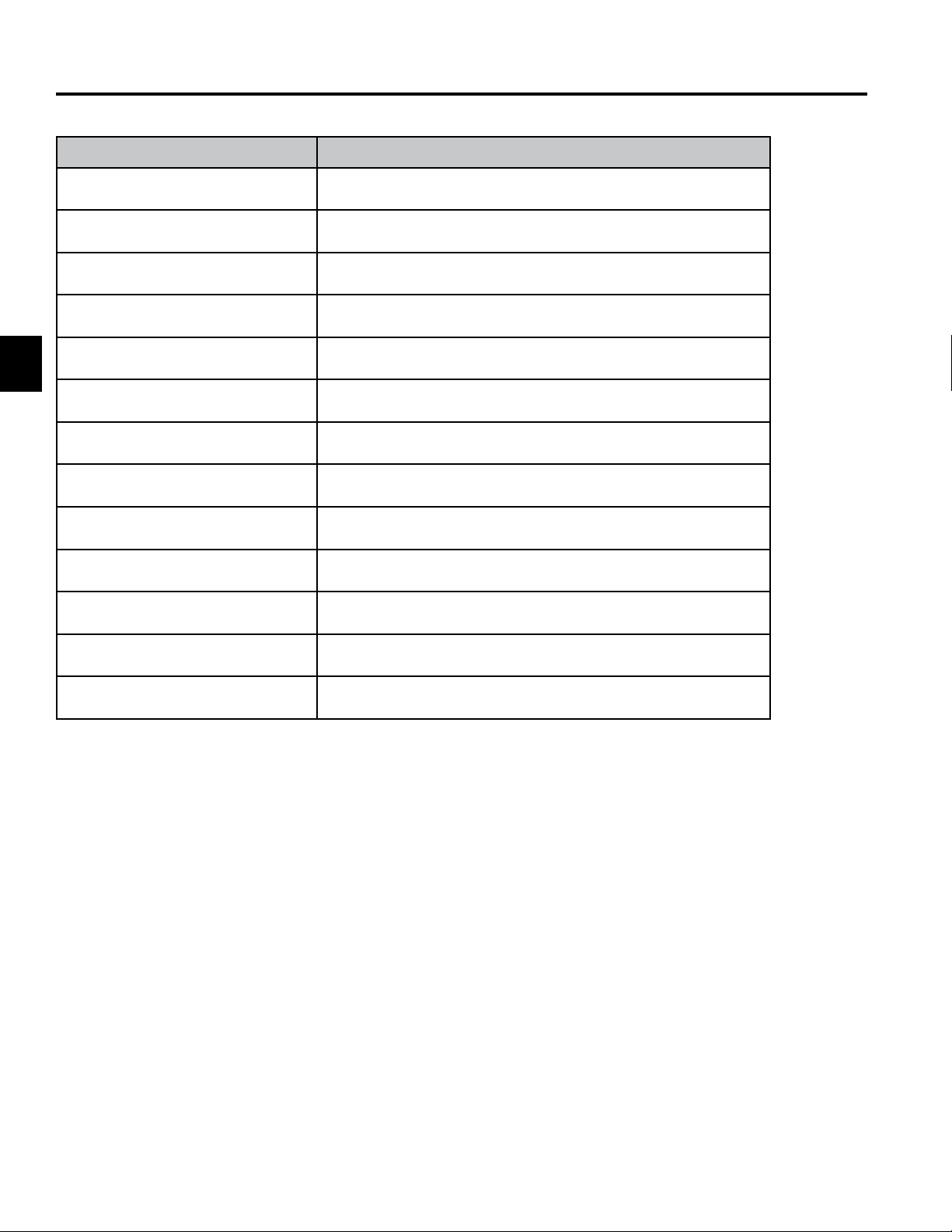

Model and Serial Number

Location

The unit model and serial number plate is located on the right hand side of the

unit, below the right side motion control lever (Fig. 007).

Fig 007 DSC-2351

Engine Model and Serial Number

Identication:

Consult the appropriate engine manufacture’s service literature for the

location and translation of the engine model and serial number information.

Fig 008 conguration

Hydrostatic Pumps Model and Serial

Number:

The label above (Fig. 008), can be located on the pump housing. It

identies the model and conguration of the BDP pump.

Available Service Manuals / Service Aids

Hydrostatic Pumps: Hydro-Gear BDP-10A/16A/21L – Service and Repair Manual

Form # 492-4789

Wheel Motors: Parker/Ross Wheel Motor Service Manual

Form # 492-4753

Diesel Engine: Briggs & Stratton Daihatsu 3 Cylinder Liquid-Cooled Engine Repair Manual

Form # 492-0670

Hydraulic Troubleshooting: Interactive hydraulic troubleshooting and failure analysis on compact disk

Form #492-4777

Electrical Troubleshooting: Interactive electrical troubleshooting and wiring diagrams on compact disk

Form #492-9143

2-6 Z Master Z597 Diesel Service Manual

Page 16

SPECIFICATIONS

Torque Specifications

Recommended fastener torque values are listed in the

following tables. For critical applications, as

determined by Toro, either the recommended torque or

a torque that is unique to the application is clearly

identified and specified in the service manual.

These torque specifications for the installation and

tightening of fasteners shall apply to all fasteners which

do not have a specific requirement identified in the

service manual. The following factors shall be

considered when applying torque: cleanliness of the

fastener, use of a thread sealant (Loctite), degree of

lubrication on the fastener, presence of a prevailing

torque feature, hardness of the surface underneath of

the fastener’s head, or similar condition which affects

the installation.

As noted in the following tables, torque values should

be reduced by 25% for lubricated fasteners to

achieve the similar stress as a dry fastener. Torque

values may also have to be reduced when the fastener

is threaded into aluminum or brass. The specific

torque value should be determined based on the

aluminum or brass material strength, fastener size,

length of thread engagement, etc.

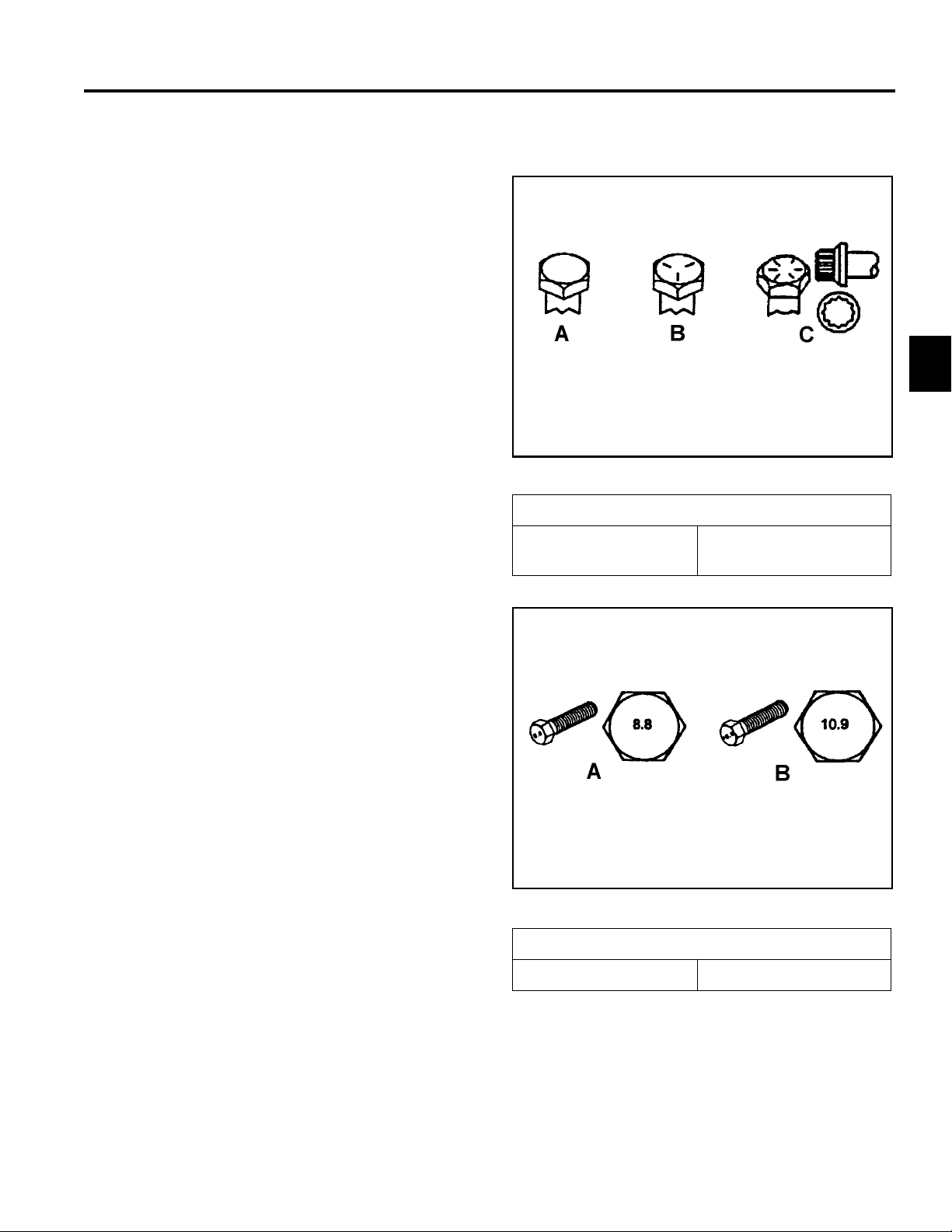

Fastener Identification

Inch Series Bolts and Screws

(A) Grade 1

(B) Grade 5

2

Figure A

(C) Grade 8

The standard method of verifying torque shall be

performed by marking a line on the fastener (head or

nut) and mating part, then back off fastener 1/4 of a

turn. Measure the torque required to tighten the

fastener until the lines match up.

Figure B

Metric Bolts and Screws

(A) Class 8.8 (B) Class 10.9

2-7Z Master Z597 Diesel Service Manual

Page 17

SPECIFICATIONS

SAE Grade 8 Bolts, Screws,

Studs, & Sems with Regular

2

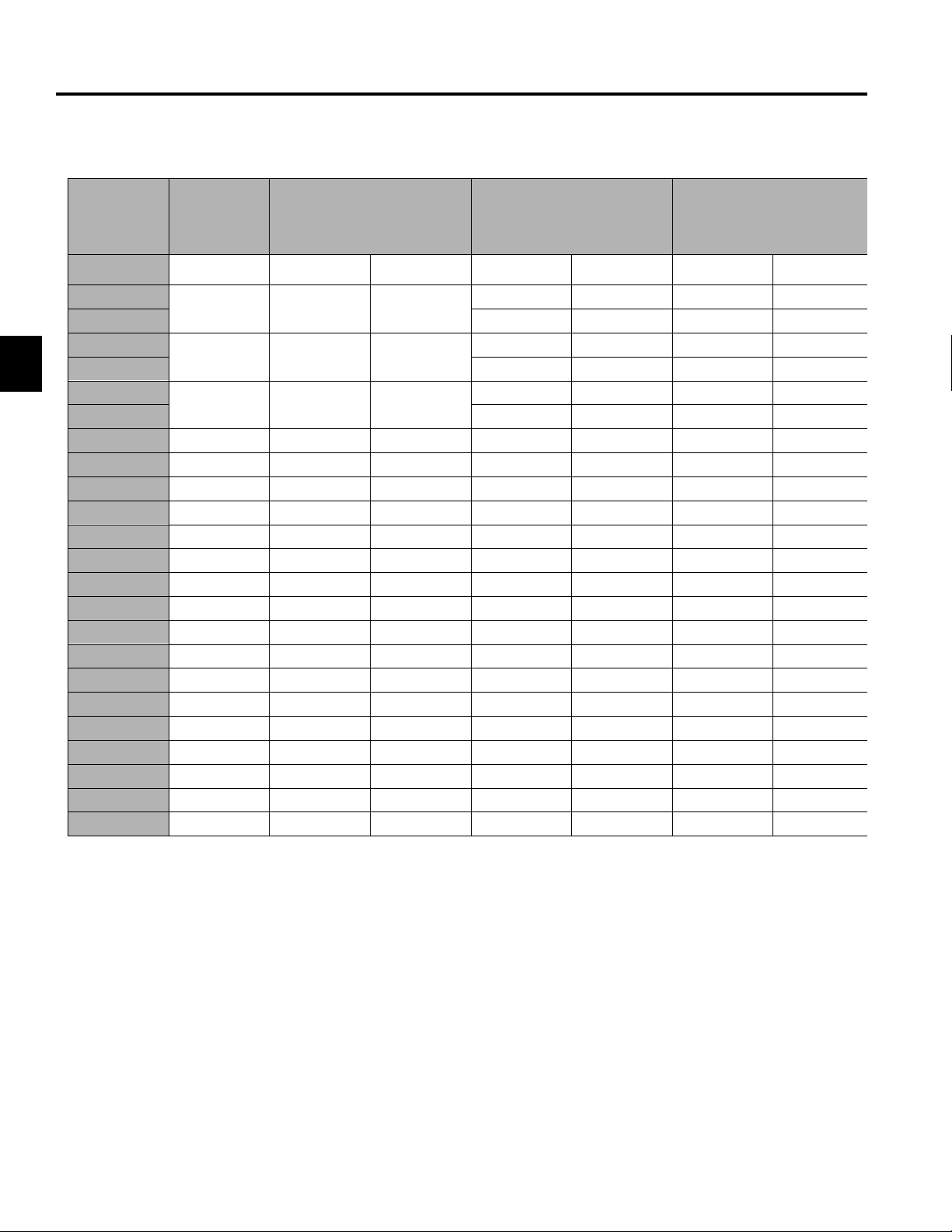

Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Inch Series)

2

Grade 1, 5, &

Thread Size

# 6 - 32 UNC

# 6 - 40 UNF 17 ± 2 190 ± 20 25 ± 2 280 ± 20

# 8 - 32 UNC

# 8 - 36 UNF 31 ± 3 350 ± 30 43 ± 4 31 ± 3

# 10 - 24 UNC

#10 - 32 UNF 48 ± 4 540 ± 45 68 ± 6 765 ± 70

1/4 - 20 UNC 48 ± 7 53 ± 7 599 ± 79 100 ± 10 1125 ± 100 140 ± 15 1580 ± 170

1/4 - 28 UNF 53 ± 7 65 ± 10 734 ± 113 115 ± 10 1300 ± 100 160 ± 15 1800 ± 170

5/16 - 18 UNC 115 ± 15 105 ± 17 1186 ± 169 200 ± 25 2250 ± 280 300 ± 30 3390 ± 340

5/16 - 24 UNF 138 ± 17 128 ± 17 1446 ± 192 225 ± 25 2540 ± 280 325 ± 30 3670 ± 340

3/8 - 16 UNC 16 ± 2 16 ± 2 22 ± 3 30 ± 3 41 ± 4 43 ± 4 58 ± 5

3/8 - 24 UNF 17 ± 2 18 ± 2 24 ± 3 35 ± 3 47 ± 4 50 ± 4 68 ± 5

7/16 - 14 UNC 27 ± 3 27 ± 3 37 ± 4 50 ± 5 68 ± 7 70 ± 7 68 ± 9

7/16 - 20 UNF 29 ± 3 29 ± 3 39 ± 4 55 ± 5 75 ± 7 77 ± 7 104 ± 9

1/2 - 13 UNC 30 ± 3 48 ± 7 65 ± 9 75 ± 8 102 ± 11 105 ± 10 142 ± 14

1/2 - 20 UNF 32 ± 3 53 ± 7 72 ± 9 85 ± 8 115 ± 11 120 ± 10 163 ± 14

5/8 - 11 UNC 65 ± 10 88 ± 12 119 ± 16 150 ± 15 203 ± 20 210 ± 20 285 ± 27

5/8 - 18 UNF 75 ± 10 95 ± 15 129 ± 20 170 ± 15 230 ± 20 240 ± 20 325 ± 27

3/4 - 10 UNC 93 ± 12 140 ± 20 190 ± 27 265 ± 25 359 ± 34 374 ± 35 508 ± 47

3/4 - 16 UNF 115 ± 15 165 ± 25 224 ± 34 300 ± 25 407 ± 34 420 ± 35 569 ± 47

7/8 - 9 UNC 140 ± 20 225 ± 25 305 ± 34 430 ± 45 583 ± 61 600 ± 60 813 ± 81

7/8 - 14 UNF 155 ± 25 260 ± 30 353 ± 41 475 ± 45 644 ± 61 660 ± 60 895 ± 81

8 with Thin

Height Nuts

In-lb In-lb N-cm In-lb N-cm In-lb N-cm

10 ± 2 13 ± 2 147 ± 23

13 ± 2 25 ± 5 282 ± 30

18 ± 2 30 ± 5 339 ± 56

ft-lb ft-lb N-m ft-lb N-m ft-lb N-m

SAE Grade 1 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995

Grade 2 or Stronger Nuts)

SAE Grade 5 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995

Grade 2 or Stronger Nuts)

15 ± 2 170 ± 20 23 ± 2 260 ± 20

29 ± 3 330 ± 30 41 ± 4 460 ± 45

42 ± 4 475 ± 45 60 ± 6 674 ± 70

Height Nuts (SAE J995

Grade 2 or Stronger Nuts)

Note: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

oil, graphite, or thread sealant such as Loctite.

Note: The nominal torque values listed above for

Grade 5 and 8 fasteners are based on 75% of the

minimum proof load specified in SAE J429. The

tolerance is approximately

value. Thin height nuts include jam nuts.

± 10% of the nominal torque

Note: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

2-8 Z Master Z597 Diesel Service Manual

Page 18

SPECIFICATIONS

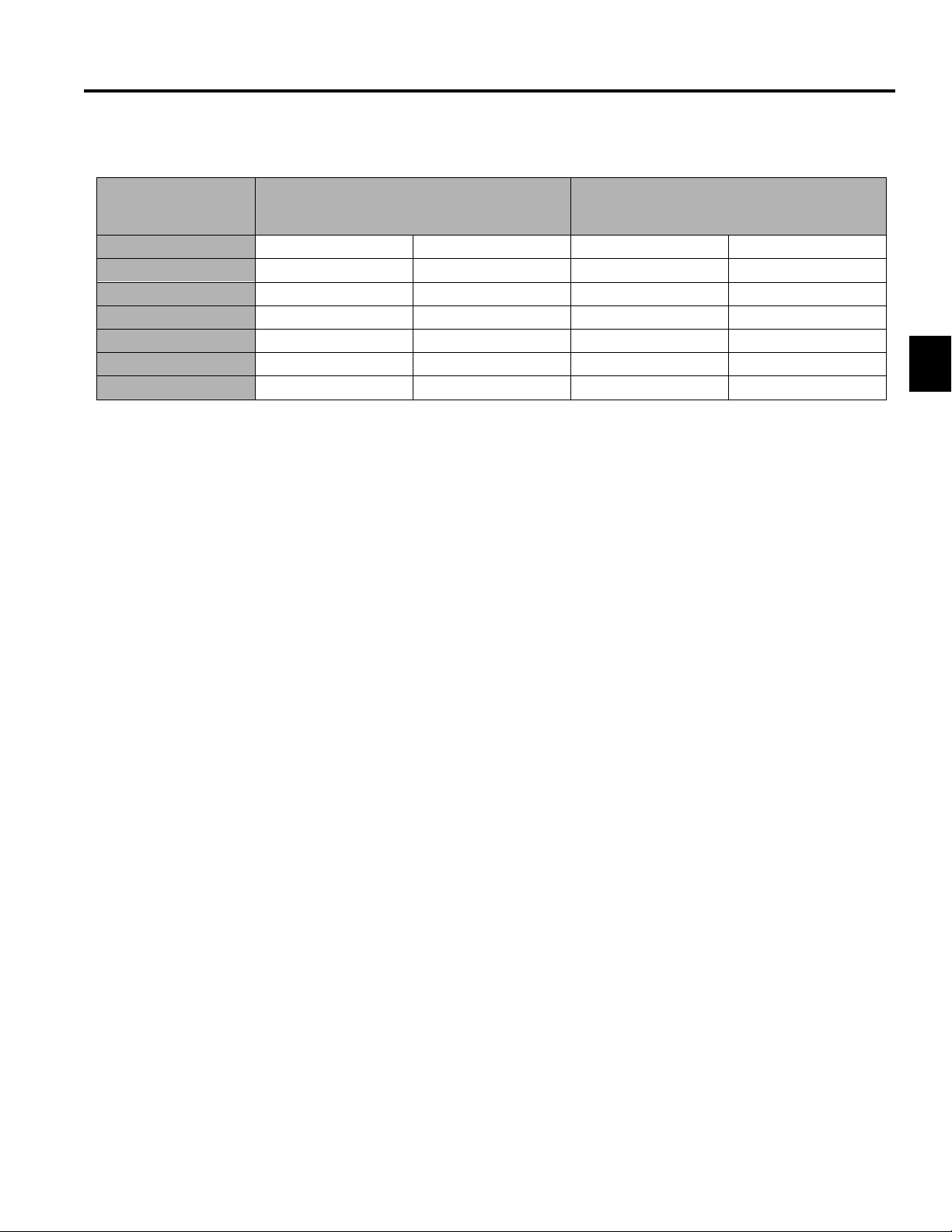

Standard Torque for Dry, Zinc, and Steel Fasteners (Metric Fasteners)

Class 8.8 Bolts, Screws, and Studs with

Thread Size

M5 X 0.8 57 ± 5 in-lb 640 ± 60 N-cm 78 ± 7 in-lb 885 ± 80 N-cm

M6 X 1.0 96 ± 9 in-lb 1018 ± 100 N-cm 133 ± 13 in-lb 1500 ± 150 N-cm

M8 X 1.25 19 ± 2 ft-lb 26 ± 3 N-m 27 ± 2 ft-lb 36 ± 3 N-m

M10 X 1.5 38 ± 4 ft-lb 52 ± 5 N-m 53 ± 5 ft-lb 72 ± 7 N-m

M12 X 1.75 66 ± 7 ft-lb 90 ± 10 N-m 92 ± 9 ft-lb 125 ± 12 N-m

M16 X 2.0 166 ± 15 ft-lb 225 ± 20 N-m 229 ± 22 ft-lb 310 ± 30 N-m

M20 X 2.5 325 ± 33 ft-lb 440 ± 45 N-m 450 ± 37 ft-lb 610 ± 50 N-m

Note: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

oil, graphite, or thread sealant such as Loctite.

Note: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

Regular Height Nuts

(Class 8 or Strong Nuts)

Note: The nominal torque values listed above are

based on 75% of the minimum proof load specified in

SAE J1199. The tolerance is approximately

the nominal torque value. Thin height nuts include jam nuts.

Class 10.9 Bolts, Screws, and Studs with

Regular Height Nuts (

Class 10 or Strong Nuts)

2

± 10% of

2-9Z Master Z597 Diesel Service Manual

Page 19

SPECIFICATIONS

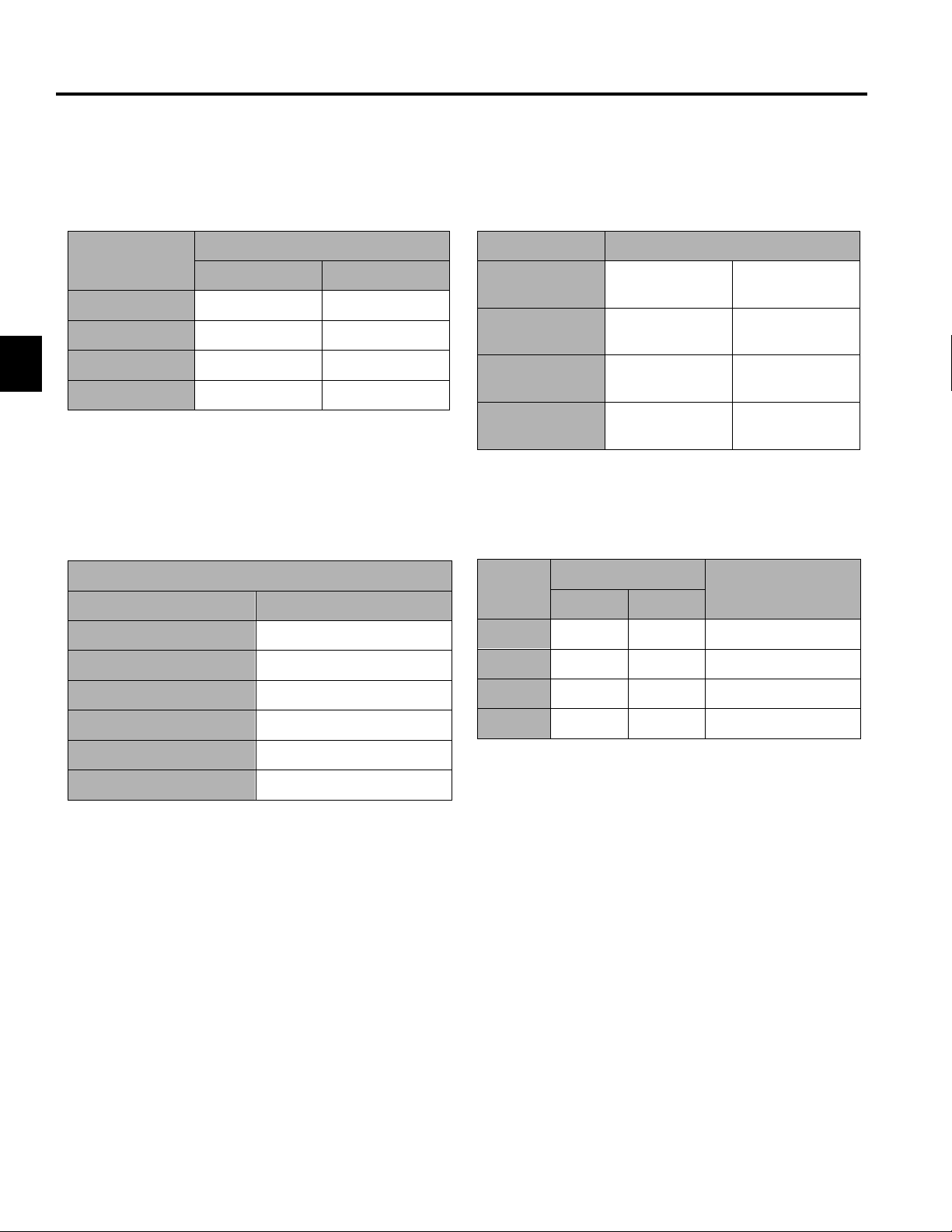

Other Torque Specifications

2

SAE Grade 8 Steel Set Screws

Recommended Torque

Thread Size

Square Head Hex Socket

1/4 - 20 UNC 140 ± 20 in-lb 73 ± 12 in-lb

5/16 - 18 UNC 215 ± 35 in-lb 145 ± 20 in-lb

3/8 - 16 UNC 35 ± 10 ft-lb 18 ± 3 ft-lb

1/2 - 13 UNC 75 ± 15 ft-lb 50 ± 10 ft-lb

Thread Cutting Screws

(Zinc Plated Steel)

Type 1, Type 23, or Type F

Thread Size Baseline Torque*

No. 6 - 32 UNC 20 ± 5 in-lb

Wheel Bolts and Lug Nuts

Thread Size Recommended Torque**

7/16 - 20 UNF

Grade 5

1/2 - 20 UNF

Grade 5

M12 X 1.25

Class 8.8

M12 X 1.5

Class 8.8

** For steel wheels and non-lubricated fasteners.

Thread Cutting Screws

Thread

Size

No. 6 18 20 20 ± 5 in-lb

Threads per Inch

Type A Type B

65 ± 10 ft-lb 88 ± 14 N-m

80 ± 10 ft-lb 108 ± 14 N-m

80 ± 10 ft-lb 108 ± 14 N-m

80 ± 10 ft-lb 108 ± 14 N-m

(Zinc Plated Steel)

Baseline Torque*

No. 8 - 32 UNC 30 ± 5 in-lb

No.10 - 24 UNC 38 ± 7 in-lb

1/4 - 20 UNC 85 ± 15 in-lb

5/16 - 18 UNC 110 ± 20 in-lb

3/8 - 16 UNC 200 ± 100 in-lb

Conversion Factors

in-lb X 11.2985 - N-cm

ft-lb X 1.3558 = N-m

No. 8 15 18 30 ± 5 in-lb

No. 10 12 16 38 ± 7 in-lb

No. 12 11 14 85 ± 15 in-lb

* Hole size, material strength, material thickness and

finish must be considered when determining specific

torque values. All torque values are based on nonlubricated fasteners.

N-cm X - 0.08851 = in-lb

N-cm X 0.73776 - ft-lb

2-10 Z Master Z597 Diesel Service Manual

Page 20

SPECIFICATIONS

Equivalents and Conversions

Decimal and Millimeter Equivalents

Fractions Decimals mm Fractions Decimals mm

1/64 0.015625 0.397 33/64 0.515625 13.097

1/32 0.03125 0.794 16/32 0.53125 13.484

3/64 0.046875 1.191 35/64 0.546875 13.891

1/16 0.0625 1.588 9/16 0.5625 14.288

5/64 0.078125 1.984 37/64 0.578125 14.684

3/32 0.9375 2.381 19/32 0.59375 15.081

1/8 0.1250 3.175 5/8 0.6250 15.875

9/64 0.140625 3.572 41/64 0.640625 16.272

5/32 0.15625 3.969 21/32 0.65625 16.669

11/64 0.171875 4.366 43/64 0.671875 17.066

3/16 0.1875 4.762 11/16 0.6875 17.462

13/64 0.203125 5.159 45/64 0.703125 17.859

7/32 0.21875 5.556 23/32 0.71875 18.256

15/64 0.234375 5.953 47/64 0.734375 18.653

1/4 0.2500 6.350 3/4 0.7500 19.050

17/64 0.265625 6.747 49/64 0.765625 19.447

9/32 0.28125 7.144 25/32 0.78125 19.844

19/64 0.296875 7.541 51/64 0.796875 20.241

5/16 0.3125 7.541 13/16 0.8125 20.638

21/64 0.328125 8.334 53/64 0.828125 21.034

11/32 0.34375 8.731 27/32 0.84375 21.431

23/64 0.359375 9.128 55/64 0.859375 21.828

3/8 0.3750 9.525 7/8 0.8750 22.225

25/64 0.390625 9.922 57/64 0.890625 22.622

13/32 0.40625 10.319 29/32 0.90625 23.019

27/64 0.421875 10.716 59/64 0.921875 23.416

7/16 0.4375 11.112 15/16 0.9375 23.812

29/64 0.453125 11.509 61/64 0.953125 24.209

15/32 0.46875 11.906 31/32 0.96875 24.606

31/64 0.484375 12.303 63/64 0.984375 25.003

1/2 0.5000 12.700 1 1.000 25.400

1 mm = 0.03937 in. 0.001 in. = 0.0254 mm

2

2-11Z Master Z597 Diesel Service Manual

Page 21

2

SPECIFICATIONS

U.S. to Metric Conversions

To Convert Into Multiply By

Miles

Yards

Linear

Measurement

Area

Volume

Weight

Pressure

Work

Liquid Volume

Liquid Flows

Temperature

Feet

Feet

Inches

Inches

Inches

Square Miles

Square Feet

Square Inches

Acre

Cubic Yards

Cubic Feet

Cubic Inches

Tons (Short)

Pounds

Ounces

Pounds/Sq. In. Kilopascal

Foot-pounds

Foot-pounds

Inch-pounds

Quarts

Gallons

Gallons/Minute Liters/Minute

Fahrenheit Celsius

Kilometers

Meters

Meters

Centimeters

Meters

Centimeters

Millimeters

Square Kilometers

Square Meters

Square Centimeters

Hectare

Cubic Meters

Cubic Meters

Cubic Centimeters

Metric Tons

Kilograms

Grams

Newton-Meters

Kilogram-Meters

Kilogram-Centimeters

Liters

Liters

1.609

0.9144

0.3048

30.48

0.0254

2.54

25.4

2.59

0.0929

6.452

0.4047

0.7646

0.02832

16.39

0.9078

0.4536

28.3495

6.895

1.356

0.1383

1.152144

0.9463

3.785

3.785

1. Subtract 32°

2. Multiply by 5/9

2-12 Z Master Z597 Diesel Service Manual

Page 22

CHASSIS

Safety Information . . . . . . . . .

Specications . . . . . . . . . . .

Chassis . . . . . . . . . . . . . .

Hydraulic System . . . . . . . . .

Engine . . . . . . . . . . . . . . .

1

1

2

3

4

5

Electrical . . . . . . . . . . . . . .

Mower Decks . . . . . . . . . . .

3-1Z Master Z597 Diesel Service Manual

6

7

Page 23

CHASSIS

3

Caster Fork Assembly Removal

1. Raise the front of the unit off the ground, allowing

enough clearance to remove the castor fork from the

bottom of the hub.

2. With a hammer and chisel, remove the top grease

cap (Fig. 009).

3. Remove the locknut (Fig. 010).

Fig 010 DSC-1532

4. Remove the Belleville washers, caster fork and

wheel assembly (Fig. 011).

Fig 009 mvc-1531

Fig 011 DSC-1533

3-2 Z Master Z597 Diesel Service Manual

Page 24

CHASSIS

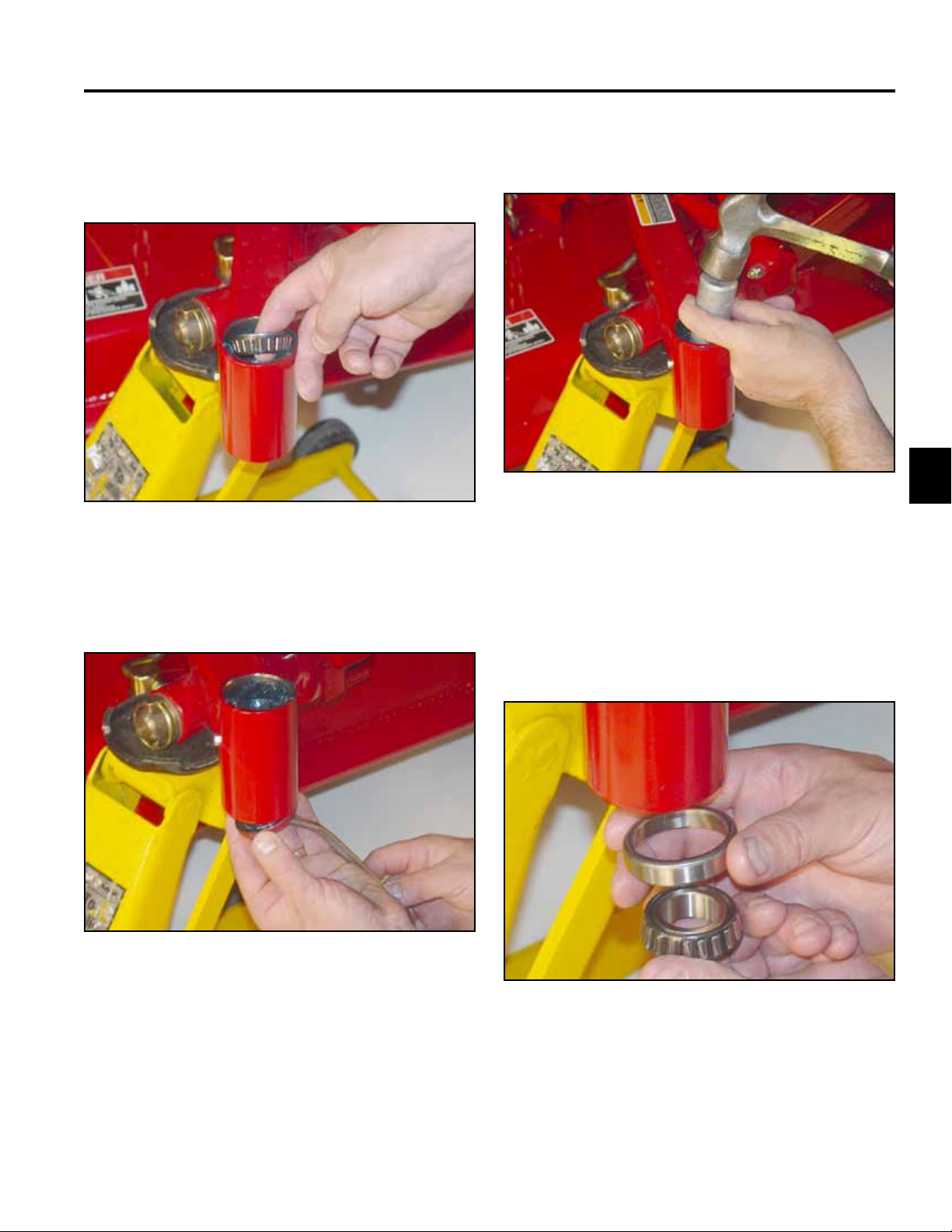

Replacing the Caster Bearings

1. Remove the top tapered roller bearing (Fig. 012).

Fig 012 DSC-1534

2. Remove bottom seal and tapered roller bearing (Fig.

013).

3. With a driver and hammer, remove both the bottom

and top tapered bearing cups (Fig. 014).

Fig 014 DSC-1536

4. With a driver and hammer, install new bearing

cups. The bearing cups are tapered; make sure the

tapered/thicker end of the cup is installed inward for

the top and bottom end (Fig. 015). Tap the bearing

cups in until they seat against the step in the caster

hub.

3

Fig 013 DSC-1535

Fig 015 DSC-1537

3-3Z Master Z597 Diesel Service Manual

Page 25

CHASSIS

3

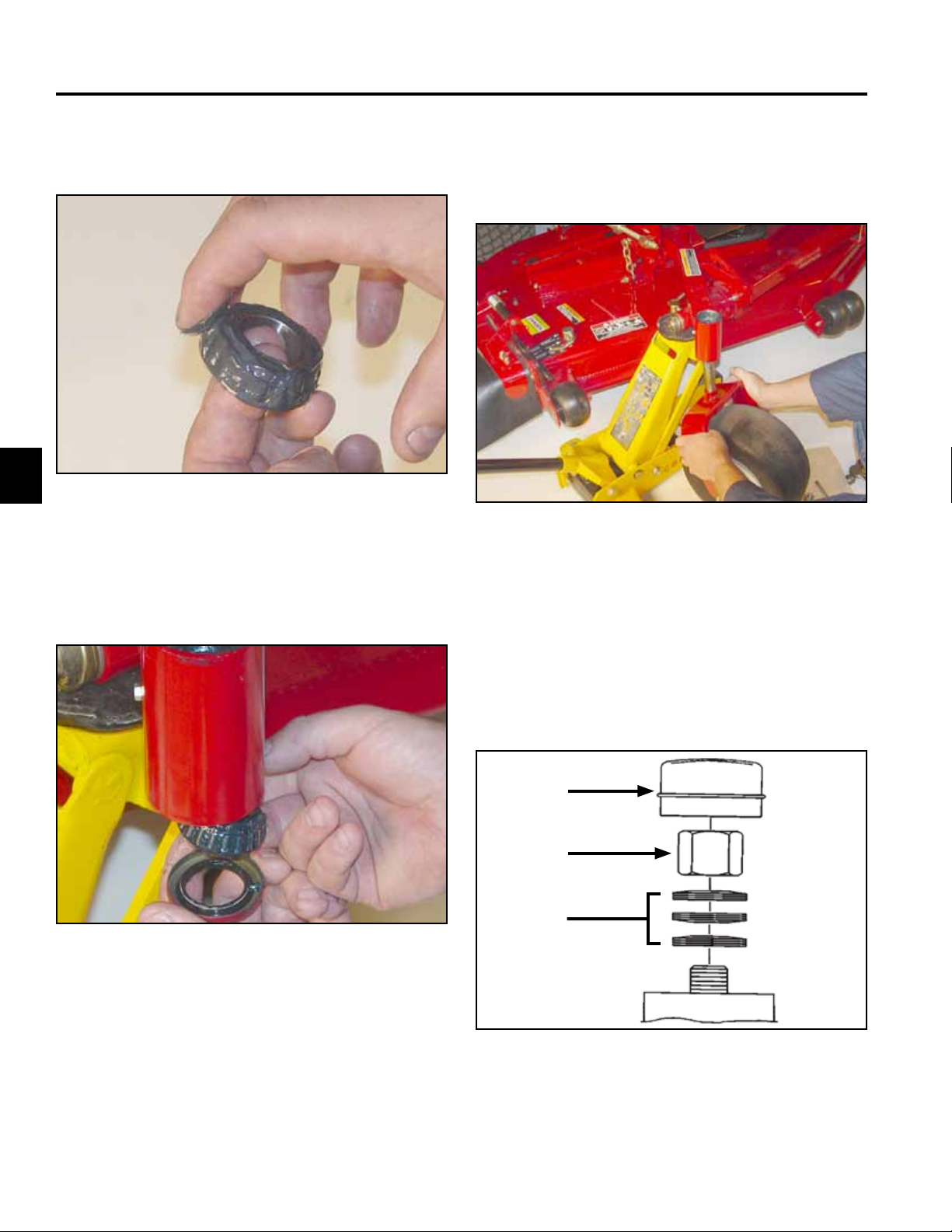

5. Pack the upper and lower tapered bearings prior to

installation (Fig. 016).

Fig 016 DSC-1539

6. Install the lower bearing and seal, with the open end

of the seal facing up (Fig. 017).

Castor Fork Assembly

1. Install the castor fork into the frame (Fig. 018).

Fig 018 DSC-1533

2. Install the upper bearing.

Fig 017 DSC-1538

3. Install the Belleville (spring) washers as shown in

(Fig. 019).

A. Dust Cap

B. Locknut

C. Spring Washers

A

B

C

Fig 019 washers line art

3-4 Z Master Z597 Diesel Service Manual

Page 26

CHASSIS

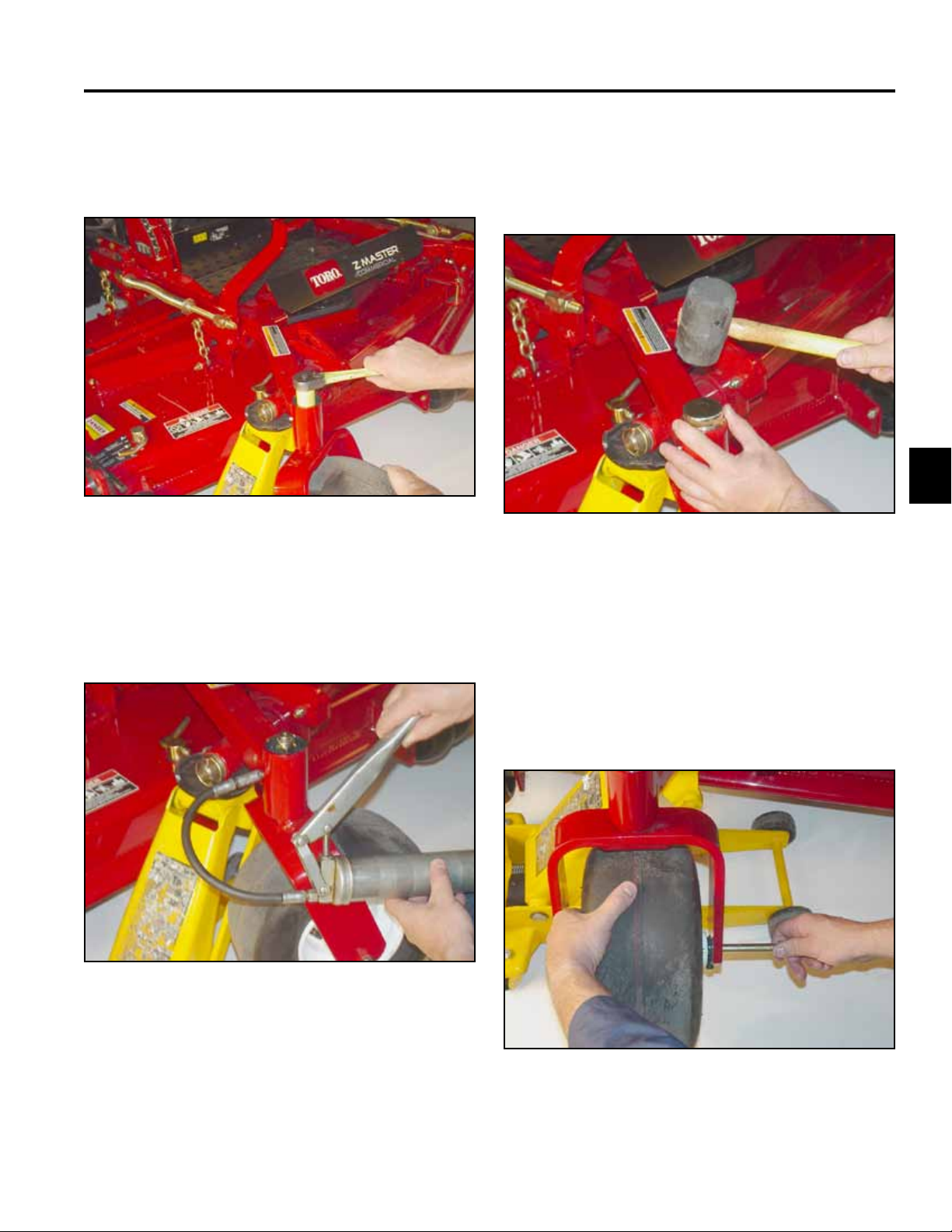

4. Install the locknut and tighten until the spring

washers are at, then back off 1/4 turn to properly

set the preload on the bearings (Fig. 020).

Fig 020 DSC-1532

6. Remove the grease tting and install the grease

plug.

7. Install the dust cap on the caster hub (Fig. 022).

3

Fig 022 DSC-1541

5. Remove the plug located on the side of the hub

on the frame for the castor fork. Install a grease

tting. Pump grease into the housing until grease is

passing through the upper bearing (Fig. 021).

Fig 021 DSC-1540

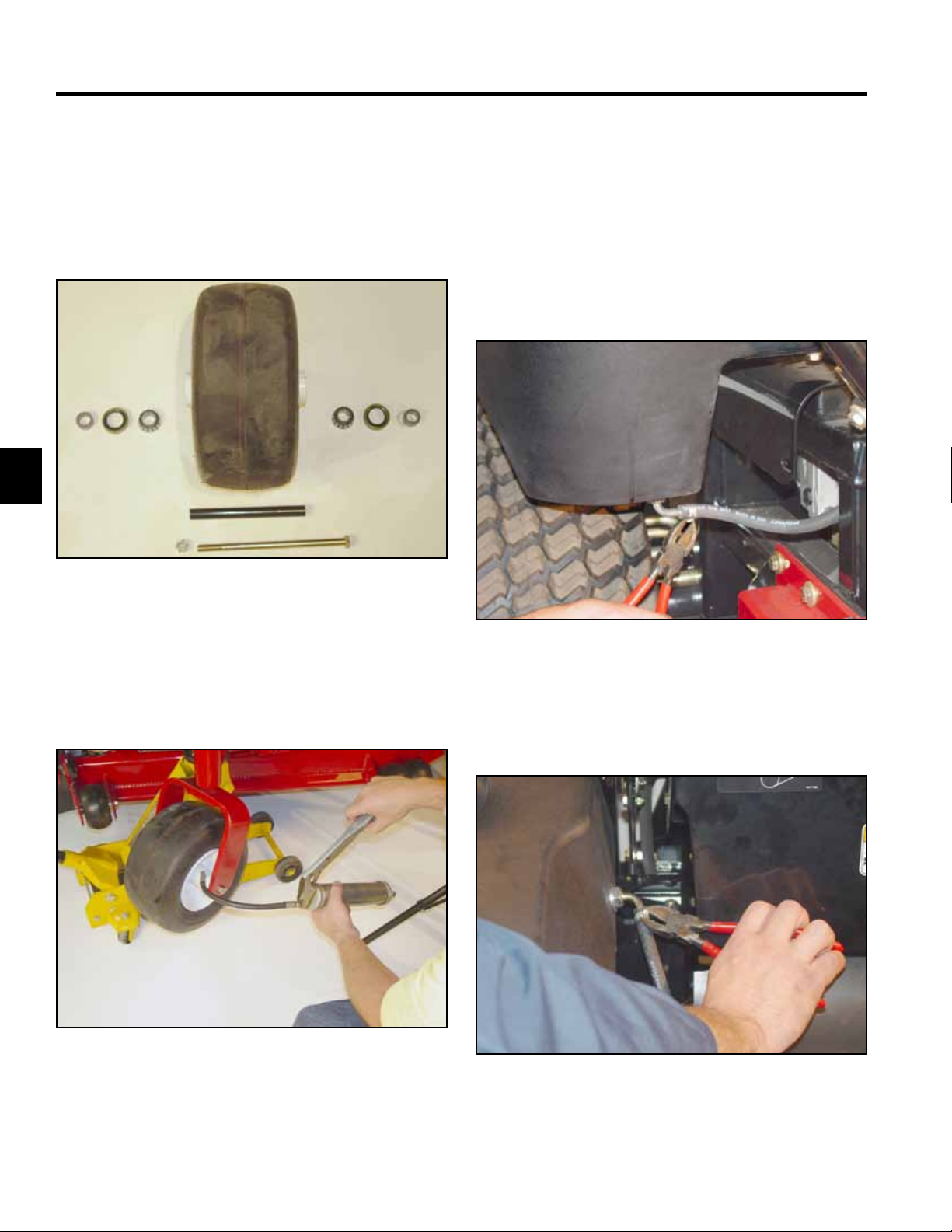

Front Wheel Removal and Bearing

Replacement

1. Raise the front of the unit off the ground.

2. Remove the wheel bolt from the fork (Fig. 023).

Fig 023 DSC-1543

3-5Z Master Z597 Diesel Service Manual

Page 27

CHASSIS

3

3. Remove bearing spacers and the front caster

spacer. Remove the seals located on each side of

the wheel and both the tapered bearings (Fig. 024).

A. Bearing Spacer D. Caster Spacer

B. Bearing Seal E. Retaining wheel nut

C. Taper Bearing F. Retaining wheel bolt

B

C

D

E

B

C

AA

F

Fig 024 DSC-1546

Fuel Tank Removal

Right Side Fuel Tank Removal

1. Disconnect the negative battery cable. Empty the

fuel tank.

2. Remove the fuel hose at the bottom of the fuel tank

(Fig. 026).

4. Pack both tapered wheel bearings. Reassemble

per Fig. 024. Pump grease into the wheel bearings

through the grease tting located on the rim (Fig.

025).

Fig 025 DSC-1547

Fig 026 DSC-1548

3. Remove the fuel return line located on the inside of

the fuel tank (Fig. 027).

Fig 027 DSC-1549

3-6 Z Master Z597 Diesel Service Manual

Page 28

CHASSIS

4. Remove the front bolt, spacer, washer, and nut that

secure the fuel tank bracket to the frame (Fig. 028).

Fig 028 DSC-1550

5. Remove the bolt, washer, and nut securing the left

rear of the fuel tank bracket to the frame (Fig. 029).

6. Remove bolt, washer, and nut securing the right rear

of the fuel tank bracket to the frame (Fig. 030).

3

Fig 030 DSC-1553

7. Remove the tank from the frame (Fig. 031).

Fig 029 DSC-1552

Fig 031 DSC-1555

3-7Z Master Z597 Diesel Service Manual

Page 29

CHASSIS

3

8. Remove the fuel tank bracket by removing 3

locknuts and springs and 1 bolt (Fig. 032).

Fig 032 DSC-1556

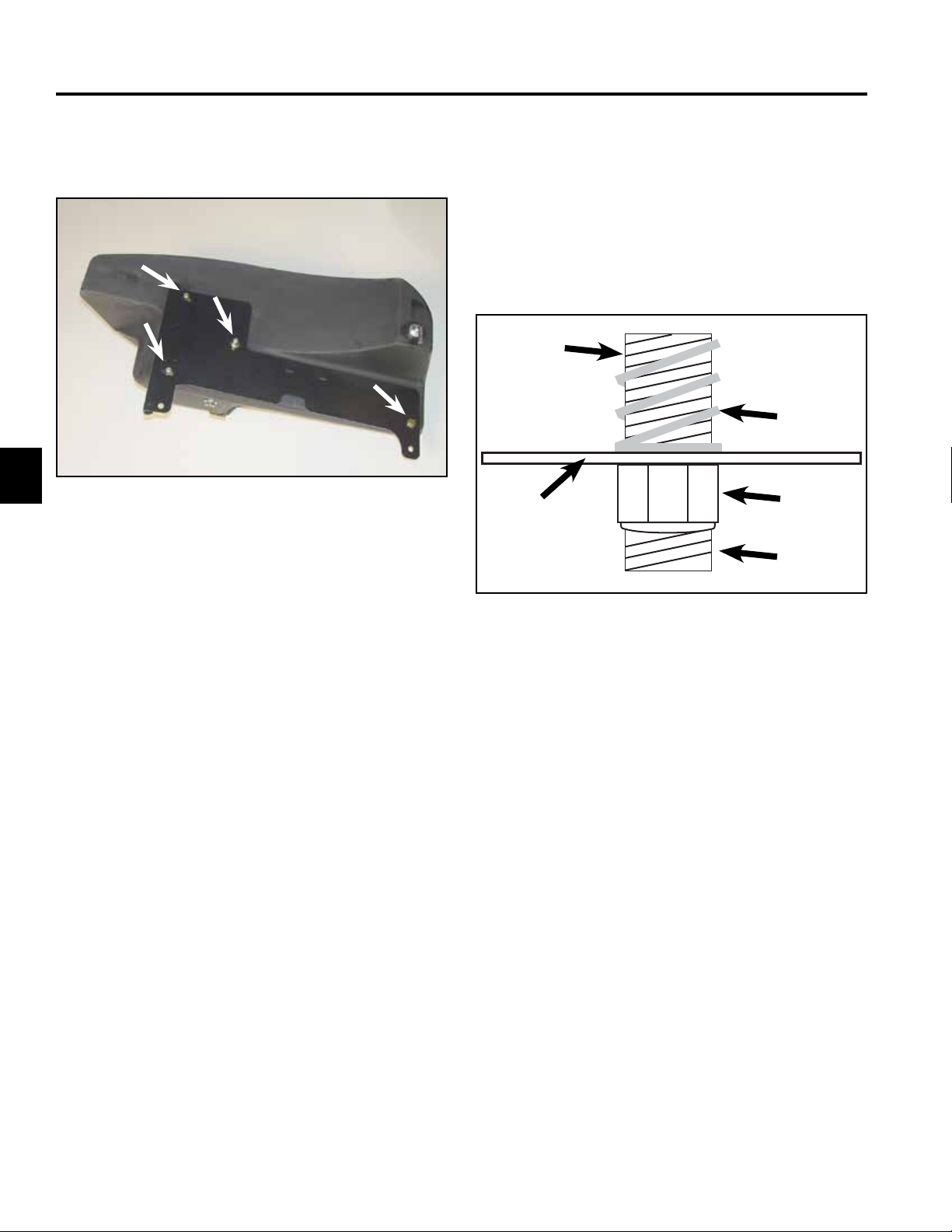

Right Side Fuel Tank Installation

Reverse the order of removal.

Note: When tightening the nuts and springs on the

fuel tank bracket, Do Not over-tighten the

nuts. Tighten the nuts until there are three

threads showing on the threaded stud (Fig.

033).

A

B

C

D

E

Fig 033 3 thread above nut

A. Tank Stud D. Nut

B. Compression Spring E. 3 Threads

C. Tank mounting Plate

Left Side Fuel Tank Removal

1. Disconnect the negative battery cable. Empty the

fuel tank.

3-8 Z Master Z597 Diesel Service Manual

Page 30

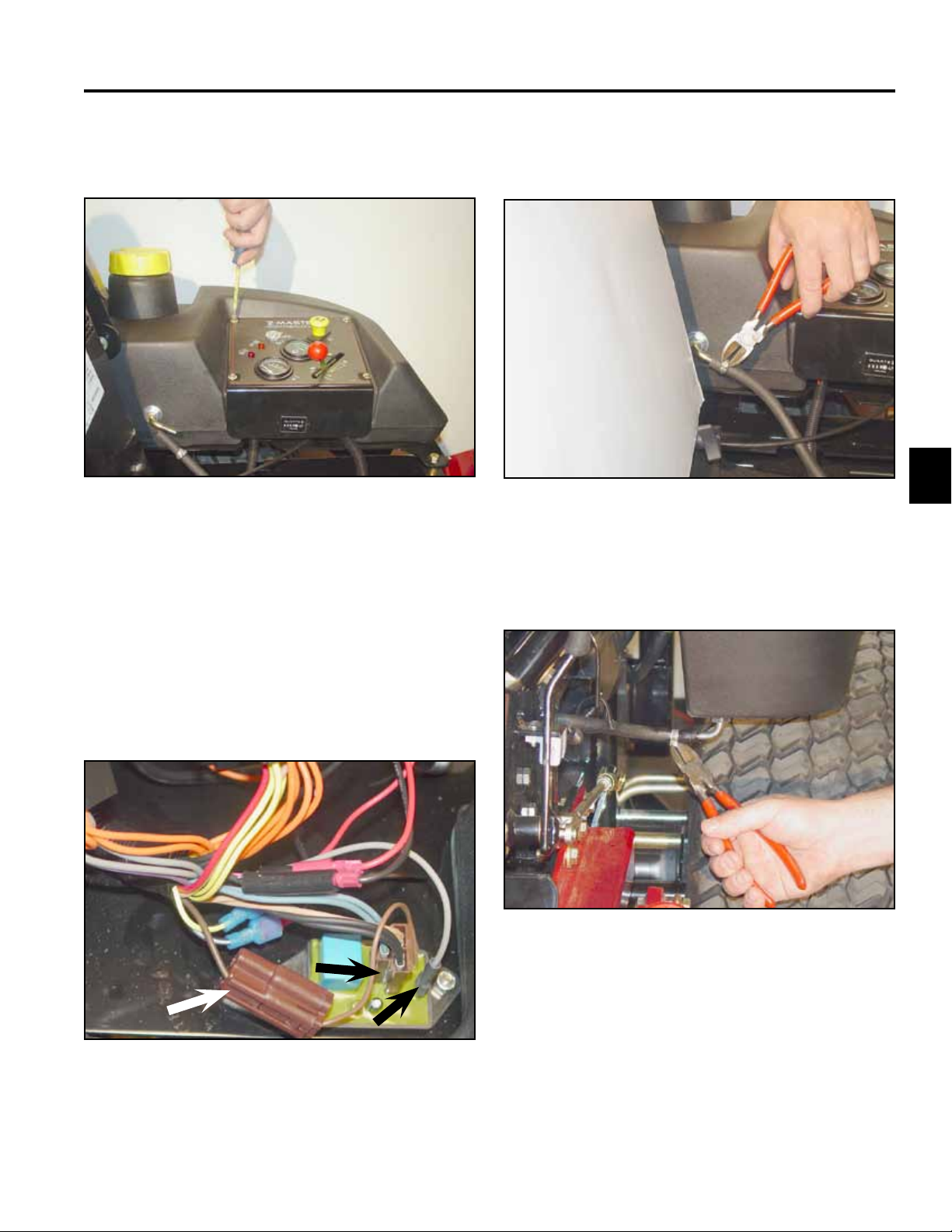

CHASSIS

2. Remove the 4 screws retaining the control panel and

control panel shield to the tank (Fig. 034).

Fig 034 DSC-1563

3. Carefully remove the control panel and control panel

shield by lifting the panel and sliding it to the middle

of the unit.

5. Remove the return fuel line, located on the inside of

the fuel tank (Fig. 036).

3

Fig 036 DSC-1565

6. Remove the fuel line, located under the front of the

fuel tank (Fig. 037).

NOTE: It is not necessary to disconnect any cables

or wiring.

4. Unplug the 3 connectors that plug into the delay

module (Fig. 035).

Fig 035 DSC-1578

Fig 037 DSC-1566

3-9Z Master Z597 Diesel Service Manual

Page 31

CHASSIS

3

7. Remove the front bolt, spacer, washer, and nut that

secure the fuel tank bracket to the frame (Fig. 038).

Fig 038 DSC-1568

8. Remove the bolt, washer, and nut that retain the fuel

tank bracket to the frame. They are located under

the right rear of the fuel tank (Fig. 039).

9. Remove the bolt, washer, and nut that retain the fuel

tank bracket to the frame. They are located under

the left rear of the fuel tank (Fig. 040).

Fig 040 DSC-1573

10. Remove the fuel tank from the frame (Fig. 041).

Fig 041 DSC-1575

Fig 039 DSC-1571

3-10 Z Master Z597 Diesel Service Manual

Page 32

CHASSIS

11. Remove the fuel tank bracket by removing 3

locknuts, springs, and 1 bolt (Fig. 042).

Fig 042 DSC-1576

Left Side Fuel Tank Installation

Hood Assembly Removal

1. Unhook the two rubber latches located on the rear of

the hood.

2. Remove the two hairpins, clevis pins, and washers

located in the front left and right side of the hood

(Fig. 044).

3

Reverse the order of removal.

Note: When tightening the nuts and bolts, Do Not

over-tighten the nuts. Tighten until there

are 3 threads showing on the threaded stud

(Fig. 043).

A

B

C

D

E

Fig 043 3 thread above nut

A. Tank Stud D. Nut

B. Compression Spring E. 3 Threads

C. Tank mounting Plate

Fig 044 DSC-1579

3. Lift the hood and remove the stop lanyards located

on each side of the hood. Remove the hood from the

frame of the unit (Fig. 045).

Fig 045 DSC-1581

3-11Z Master Z597 Diesel Service Manual

Page 33

CHASSIS

3

Hood Assembly Installation

Reverse the order of removal.

Throttle Control Replacement

1. Disconnect the negative battery cable.

2. Remove the 4 screws retaining the control panel to

the fuel tank (Fig. 046).

4. Remove the two locknuts and carriage bolts

retaining the throttle cable assembly (Fig. 048).

Fig 048 DSC-1591

5. Disconnect the end of throttle cable at the swivel

clamp, located on the throttle linkage at the injector

pump (Fig. 049).

Fig 046 DSC-1584

3. Remove the ball knob located on the throttle control

by applying upward pressure under the knob (Fig.

047).

Fig 049 DSC-1592

Fig 047 DSC-1586

3-12 Z Master Z597 Diesel Service Manual

Page 34

CHASSIS

6. Loosen the screw on the throttle casing clamp and

remove the throttle cable (Fig. 050).

Fig 050 DSC-1593

7. Keeping the tie straps in place, slide the throttle

cable through the two tie straps to remove it from the

machine. One tie strap is located at the radiator fan

motor mount, Ref. A, and the other is at the engine

removal bracket, Ref. B (Fig. 051).

NOTE: DO NOT cut or remove the tie straps.

Installation

1. Install the throttle control in the control plate. Install

the two carriage bolts and nuts and tighten (Fig.

052).

3

Fig 052 DSC-1596

2. Feed the throttle cable through the tie strap on the

radiator fan motor mount (Fig. 053).

A

B

Fig 051 DSC-1594

Fig 053 DSC-1597

3-13Z Master Z597 Diesel Service Manual

Page 35

CHASSIS

3

3. Route the throttle cable through the tie strap located

on the engine lifting bracket (Fig. 054).

Fig 054 DSC-1599

4. The throttle cable is then routed around the fuel

pump injector lines and through the swivel clamp.

5. Install the throttle cable on the inside of the casing

clamp, DO NOT tighten (Fig. 056).

Fig 056 DSC-1605

6. Install control panel to the fuel tank mount location

(Fig. 057).

Note: The cable wire should be routed through the

swivel clamp, with the swivel clamp washer

located under the cable wire (Fig. 055).

A

B

Fig 055 DSC-1600

A. Cable wire B. Washer

Fig 057 DSC-1606

3-14 Z Master Z597 Diesel Service Manual

Page 36

CHASSIS

7. Install throttle control knob and position throttle

control lever to the idle position (Fig. 058).

Fig 058 DSC-1608

8. Position the throttle cable swivel clamp until 1/4”

(6.35mm) of the throttle cable wire protrudes through

the opposite end of the clamp. Carefully tighten the

swivel clamp screw (Fig. 059).

9. Tighten the cable housing clamp (Fig. 060).

Fig 060 DSC-1616

10. Move the throttle control lever to the Full speed

position. Verify injector pump arm contacts the high

speed stop screw (Fig. 061).

3

Fig 059 DSC-1614

Fig 061 DSC-1617

3-15Z Master Z597 Diesel Service Manual

Page 37

CHASSIS

3

Brake Lever Removal

1. Release the parking brake (forward position).

2. Remove the cotter pin and clevis pin from the brake

rod yoke (Fig. 062).

Fig 062 DSC-1618

4. Remove the brake shaft cotter pin (Fig. 064).

Fig 064 DSC-1620

5. Slide the brake shaft out of the frame pivot bushings

(Fig 065).

3. Lift the oor pan assembly to access the brake lever

shaft and cotter pin (Fig. 063).

Fig 063 DSC-1619

Fig 065 DSC-1621

3-16 Z Master Z597 Diesel Service Manual

Page 38

CHASSIS

6. Using a hammer and punch, drive both brake lever

control bearings from the brake pivot (Fig. 066).

Fig 066 DSC-1622

7. Inspect the brake shaft and bushings for excessive

wear. Replace any worn or broken components

(Fig. 067).

Brake Lever Installation

Reverse the order of removal

Brake Band Removal

1. Raise the left rear tire off the ground (Fig. 068).

3

A

B

Fig 067 DSC-1623

A. Brake Lever C. Cotter Pin

B. Bushings

C

Fig 068 DSC-1624

2. Remove the four wheel lug bolts.

3-17Z Master Z597 Diesel Service Manual

Page 39

CHASSIS

3

3. Remove bolts, brake band retainer, spacers, and

brake band (Fig. 069).

A. 3 Bolts

B. Brake Band Retainer

C. 3 Spacers

D. Brake Band

A

B

C

D

Fig 069 DSC-1626

2. Install the 3 bolts, brake band retainer, brake band,

and spacers and tighten (Fig. 071).

Fig 071 DSC-1631

3. Install tire assembly and the 4 wheel bolts.

Brake Band Installation

1. Install the brake band around the wheel hub (Fig.

070).

Fig 070 DSC-1629

Brake Cross Shaft Removal

1. Raise the rear end of the unit and remove the right

and left rear tires.

Note: To prevent the unit from rolling, block the two

front tires.

3-18 Z Master Z597 Diesel Service Manual

Page 40

CHASSIS

2. Remove the clevis spring pin from the brake rod and

remove the rod (Fig. 072).

Fig 072 DSC-1632

3. Remove the cotter pin and clevis pin from the left

side lower brake linkage assembly (Fig. 073).

4. On the right side, remove the cotter pin and clevis

pin from the lower brake linkage assembly (Fig. 074).

3

Fig 074 DSC-1634

5. On the right side, remove the two bolts and nuts

holding the ange bearing (Fig. 075).

Fig 073 DSC-1633

Fig 075 DSC-1635

3-19Z Master Z597 Diesel Service Manual

Page 41

CHASSIS

3

6. On the left side, remove the two bolts, spacers, and

nuts holding the ange bearing (Fig. 076).

Fig 076 DSC-1636

7. Remove the brake shaft from the frame (Fig. 077).

8. Inspect brake shaft and ange bushings for

excessive wear (Fig. 078).

A

C

B

D

D

E

Fig 078 DSC-1638

A. RH Mounting Bolts D. Flange Bearing

B. Brake Shaft E. Spacers

C. LH Mounting Bolts

Fig 077 DSC-1637

Brake Shaft Installation

1. Install the ange bearing on the right side of the

shaft. From the outside of the frame, align the ange

bearing holes with the frame mounting holes. Install

mounting hardware and tighten (Fig. 079).

Fig 079 DSC-1640

3-20 Z Master Z597 Diesel Service Manual

Page 42

CHASSIS

2. Install the ange bearing over the left side of the

brake shaft, ange facing outward. Install mounting

bolts from the outside of the ange, through brake

retainer spacers, and through the frame.

Note: Before tightening the mounting hardware,

be sure that the brake lever arm is pointing

upward between the mounting hardware (Fig.

080).

A

B

C

Fig 080 DSC-1641

A. Brake Lever Arm C. Bolt

B. Spacer

3. Install clevis pin connecting the lower brake

assembly to brake shaft. Install cotter pin into clevis

pin (Fig. 081). Repeat procedure for right side.

3

Fig 081 DSC-1643

4. Install clevis spring pin connecting brake rod to

brake shaft. Rotate clevis spring pin until it clips onto

brake rod clevis (Fig. 082).

Fig 082 DSC-1644

5. Install left and right rear tires. Torque wheel

mounting bolts to 95 ft-lbs (128.8 Nm).

3-21Z Master Z597 Diesel Service Manual

Page 43

CHASSIS

3

Adjusting the Parking Brake

Check the parking brake for proper adjustment.

1. Disengage the brake lever (lever down).

2. Measure the length of the spring. The measurement

should be 2-3/4” (70mm) between the washers (Fig.

083).

11 11

10

Fig 083 m-7417

1. Brake lever - engaged 7. 1/4 - 5/16” (5 - 8mm)

2. Brake lever - disengaged 8. Spring bracket

3. Spring, 2-3/4” (70mm) 9. Lock nut below trunion

4. Jam nut above trunion roller roller

5. Nut below spring bracket 10. Brake rod

6. Trunion roller 11. Yoke

3. If an adjustment is necessary, loosen the jam nut

below the spring and tighten the nut directly below

the yoke (Fig. 083). Turn the nut until the correct

measurement is obtained. Tighten the two nuts

together and repeat on the opposite side of the unit.

4. Turn the nuts clockwise to shorten the spring length

and counterclockwise to lengthen the spring.

5. Engage the parking brake (lever up).

6. Measure the distance between the spring bracket

and the adjusting nut under spring bracket. The

measurement should be 1/4 - 5/16” (5 - 8mm) (Fig.

083).

7. If adjustment is necessary, loosen the jam nut

directly above the trunion roller. Turn the lock

nut below the trunion roller until the correct

measurement is obtained (Fig. 083).

8. Tighten the jam nut directly above the trunion roller

(Fig. 083).

Note: If the 1/4 - 5/16” (5 - 8mm) can not be

achieved, remove a pin from either yoke at the

ends of the brake rod. Adjust the length of the

rod so 1/4 - 5/16” (5 - 8mm) can be achieved

and install the brake rod.

3-22 Z Master Z597 Diesel Service Manual

Page 44

CHASSIS

Deck Lift Lever Removal

1. Park the machine on a level surface, disengage the

blade control (PTO), and turn the ignition key to OFF

to stop the engine. Remove the ignition key.

2. Remove the lower stop bolt from the deck lift plate

(Fig. 084).

Fig 084 DSC-1647

4. Loosen jam nuts on LH and RH deck lift rods until

deck support springs are fully extended (Fig. 086).

3

Fig 086 DSC-1649

5. Remove hex nut from RH rear deck lift assembly.

Repeat procedure for LH rear deck lift assembly

(Fig. 087).

3. With the mower deck in the transport position, place

a 4”x 4” block under each corner of the deck. Lower

the mower deck onto the support blocks to remove

the weight from the support chains (Fig. 085).

Fig 085 DSC-1648

Fig 087 DSC-1650

3-23Z Master Z597 Diesel Service Manual

Page 45

CHASSIS

3

6. Lower lift lever to its lowest position. Rear deck

swivel mounts should clear deck lift rods on both

sides. The mower deck lift linkage should now be

fully unloaded (Fig. 088).

A

Fig 088 DSC-1651

A. Lift Lever at lowest position

8. Loosen the top hex head ange nut at the deck lift

plate mounting location. Pivot the INNER deck lift

plate up and back toward the RH motion control

lever (Fig. 090).

Fig 090 DSC-1653

7. Remove hex bolt, nut, and lift lever bushing from the

lower deck lift plate mounting location (Fig. 089).

Fig 089 DSC-1652

9. Lift the oor pan assembly to its fully opened

position (Fig. 091).

Fig 091 DSC-1654

3-24 Z Master Z597 Diesel Service Manual

Page 46

CHASSIS

10. Remove hex bolt, bushing, and nylock nut

connecting the deck lift arm plates to the mower

deck rear cross-shaft lift assembly (Fig. 092).

Fig 092 DSC-1655

11. Remove retainer clip from lift lever (Fig. 093).

12. When removing the lift lever you may experience

interference with the RH oor pan hinge or the front

edge of the RH motion control plate, or both (Fig.

094).

A

Fig 094 DSC-1657

A. RH Floor pan hinge B. RH Motion control plate

B

3

Fig 093 DSC-1656

13. If the lift lever contacts the RH oor pan hinge,

loosen the RH oor pan hinge mounting hardware.

Push the RH hinge upward. Re-tighten the RH oor

pan hinge mounting hardware (Fig. 095).

A

Fig 095 DSC-1661

A. RH Floor pan hinge

3-25Z Master Z597 Diesel Service Manual

Page 47

CHASSIS

3

14. If the lift lever contacts the RH motion control plate,

tilt and hold the oor pan assembly slightly forward.

Move the RH motion control lever out of the neutral

lock position and push it in the full forward position.

Using a tie strap or wire, tie the oor pan assembly

to the motion control arm to hold the oor pan

assembly in place (Fig. 096).

Fig 096 DSC-1665

Deck Lift Lever Installation

1. For ease of installation, make sure deck lift arm

plates, bushing, and hardware are installed on the

lift lever grip assembly prior to installation as shown

(Fig. 098).

A

B

C

D

A

Fig 098 DSC-1668

A. Plate C. Bushing

B. Nut D. Bolt

15. Carefully slide the lift lever assembly out of its

carrier frame pivot (Fig. 097).

Fig 097 DSC-1667

2. Install lift lever assembly into front frame pivot

location (Fig. 099).

Fig 099 DSC-1670

3-26 Z Master Z597 Diesel Service Manual

Page 48

CHASSIS

3. Install retainer clip to lift lever shaft (Fig. 100).

Fig 100 DSC-1672

4. Install bushing into rear lift arm cross shaft (Fig.

101).

5. Install hex bolt through deck lift plates and rear

lift arm cross shaft bushing. Install nylock nut and

tighten (Fig. 102).

A

A

B

3

Fig 102 DSC-1675

A. Rear Lift Arm Plates B. Hex Bolt

A

Fig 101 DSC-1674

A. Bushing

6. Rotate deck lift plate (inner) downward until lower

mounting holes line up with hole in carrier frame and

deck lift plate (outer). From the outside of the frame,

install hex bolt, spacer, and anged lock nut as

shown. Tighten bolt (Fig. 103).

A B C

Fig 103 DSC-1677

A. Hex Bolt C. Flanged Lock Nut

B. Spacer

3-27Z Master Z597 Diesel Service Manual

Page 49

CHASSIS

3

7. Align rear deck mount swivels with ends of deck lift

rod (Fig. 104).

Fig 104 DSC-1680

8. Raise lift lever until deck mount swivels rest against

deck rod jam nuts. Install HOC pin into deck lift plate

height of cut holes to hold lift lever in this position

(Fig. 105).

9. Install lower “stop” bolt through inner and outer deck

lift plates. Install nylock nut and tighten until hex nut

and bolt are seated rmly against the deck lift plates.

DO NOT over-tighten or deck lift plates will deform

inward causing height of cut hitch pin assembly to

bind (Fig. 106).

Fig 106 DSC-1682

10. Install hex nut on end of deck lift rod. Tighten against

deck mount swivel. Repeat procedure for opposite

side deck lift rod (Fig. 107).

A

Fig 105 DSC-1681

A. HOC Pin

Fig 107 DSC-1683

3-28 Z Master Z597 Diesel Service Manual

Page 50

CHASSIS

11. Raise mower deck to the transport position. Remove

support blocks. Check deck level adjustment (refer

to the Leveling the Mower procedure, pg 7-46).

Readjust compression spring length by turning front

nut. Spring should be compressed to a length of

11-1/2” (29.2cm) between washers. Lock the front

nut into position by tightening the spring jam nut

(Fig. 108).

Motion Control Assembly Removal

1. Remove both oor pan assembly hinge bolts (Fig.

109).

3

Fig 109 DSC-1686

Fig 108 DSC-1685

12. Untie the oor pan assembly and lower. Return

motion control lever to its neutral locked position.

2. Remove oor pan assembly (Fig. 110).

Fig 110 DSC-1689

3-29Z Master Z597 Diesel Service Manual

Page 51

CHASSIS

3

3. Remove (4) pocket mounting bolts (Fig. 111).

Fig 111 DSC-1690

4. Remove pocket (Fig. 112).

5. Remove the two bolts retaining the lever assembly

to the control arm shaft (Fig. 113).

Fig 113 DSC-2062

6. Disconnect motion control dampener from motion

control assembly (Fig. 114).

Fig 112 DSC-1691

Fig 114 DSC-1695

3-30 Z Master Z597 Diesel Service Manual

Page 52

CHASSIS

7. Disconnect neutral switch wire harness from neutral

switch (Fig. 115).

Fig 115 DSC-1693

8. Remove bolt, spacer, and nut that retains the ball

joint to the motion control (Fig. 116).

9. Remove the cotter pin and clevis pin through the

adjustable yoke for the neutral return bolt (Fig. 117).

Fig 117 DSC-2064

10. Remove the two bolts and nuts that retain the ange

bearing on the inside of the motion control (Fig. 118).

3

Fig 116 DSC-2063

Fig 118 DSC-2066

3-31Z Master Z597 Diesel Service Manual

Page 53

CHASSIS

3

11. Remove the two bolts and nuts that retain the ange

bearing on the outside of the motion control (Fig.

119).

Fig 119 DSC-2067

Motion Control Assembly Installation

Reverse the order of removal

12. Remove the motion control from the frame (Fig.

120).

Fig 120 DSC-2068

3-32 Z Master Z597 Diesel Service Manual

Page 54

HYDRAULIC SYSTEM

Safety Information . . . . . . . . .

Specications . . . . . . . . . . .

Chassis . . . . . . . . . . . . . .

Hydraulic System . . . . . . . . .

Engine . . . . . . . . . . . . . . .

1

1

2

3

4

5

Electrical . . . . . . . . . . . . . .

Mower Decks . . . . . . . . . . .

4-1Z Master Z597 Diesel Service Manual

6

7

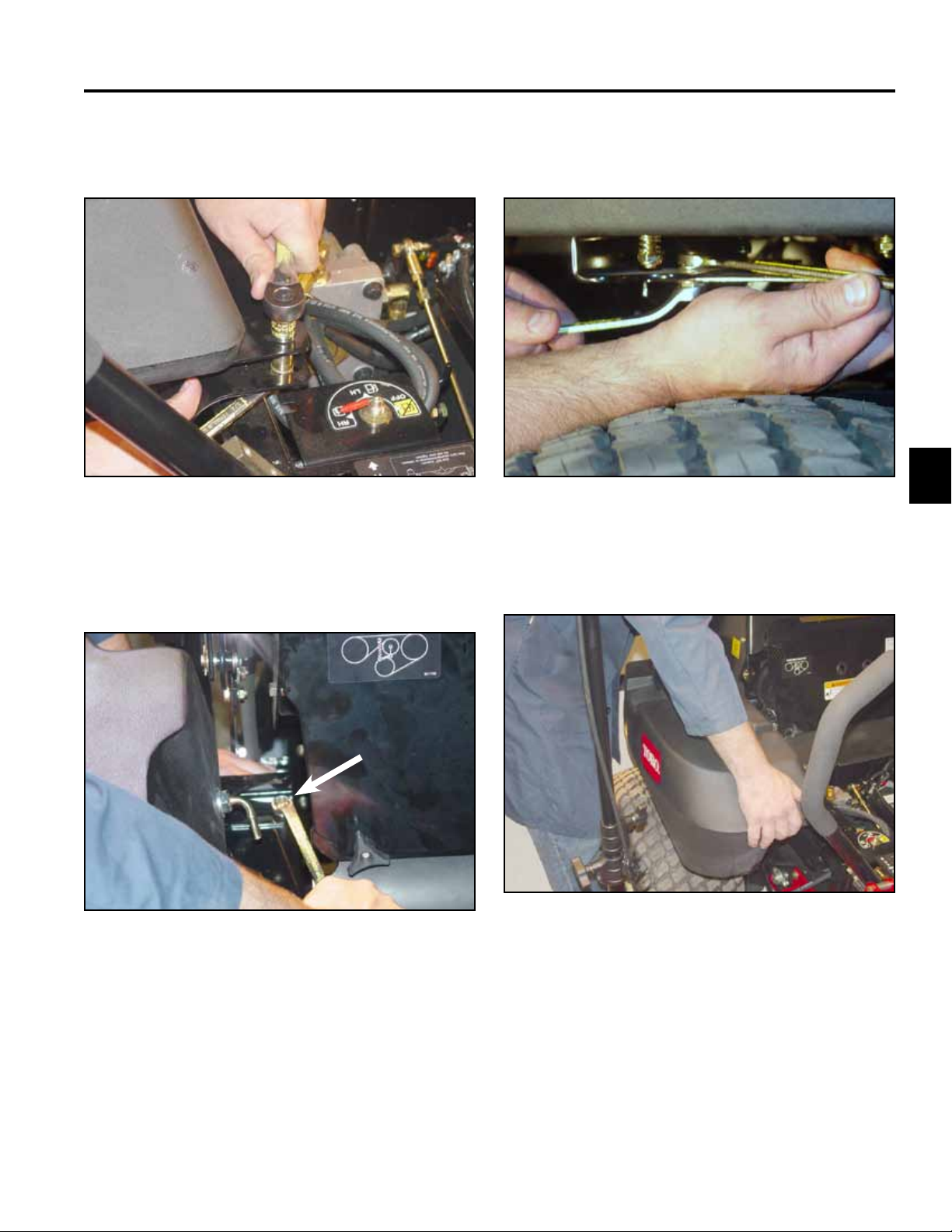

Page 55

HYDRAULIC SYSTEM

Hydrostatic Pump Removal

Note: Cleanliness is a key factor in a successful

repair of any hydrostatic system. Thoroughly

clean all exposed surfaces prior to any type

of maintenance. Cleaning all parts by using

a solvent wash and air drying is usually

adequate. As with any precision equipment,

all parts must be kept free of foreign material

and chemicals. Protect all exposed sealing

areas and open cavities from damage and

foreign material.

Upon removal, all seals, O-rings, and gaskets

should be replaced. Lightly lubricate all

seals, O-Rings and gaskets with clean

petroleum jelly prior to installation.

This procedure is showing the LH Hydrostatic Pump

being removed. Use these same procedures to remove

the RH Hydrostatic Pump.

1. Disconnect the negative and positive battery cables.

Remove the battery from the unit.

4. Using a 3/8” drive ratchet, insert the drive end into

the square hole in the pump belt tensioner arm.

Relieve the tension on the hydrostatic pump v-belt

and remove the belt (Fig. 122).

Fig 122 DSC-2073

4

2. Using compressed air, clean the area around the

hydrostatic pump. Perform additional cleaning as

needed to make sure it is free from any dirt and

debris.

3. Remove the two knobs located on the engine access

panel assembly. Remove both engine belt shield

and the engine access panel (Fig. 121).

5 Remove the bolt and nut retaining the hydro pump

control linkage to the hydro control arm (Fig. 123).

Fig 123 DSC-2081

Fig 121 DSC-2071

4-2 Z Master Z597 Diesel Service Manual

Page 56

HYDRAULIC SYSTEM

6. Remove the case drain hydraulic hose, located on

the left hand side of the hydrostatic pump (Fig. 124).

Note: When removing hydraulic hoses from the

pump, cap the hose and the tting on the

hydrostatic pump. This is to make sure dirt

and debris does not enter these areas.

7. Remove the two hydraulic hoses on the bottom of

the hydrostatic pump that go to the hydraulic motor

(Fig. 125). Install caps on the hydraulic hoses and

ttings.

Fig 125 DSC-2087

Fig 124 DSC-2083

Note: Before removing the hydraulic lines from

the hydrostatic pump, mark or tag one of the

hoses to make sure they are reconnected

correctly.

8. Remove the hydraulic suction line from the top of the

4

hydrostatic pump (Fig. 126). Install caps on the

hydraulic line and on the ttting.

Fig 126 DSC-2088

4-3Z Master Z597 Diesel Service Manual

Page 57

HYDRAULIC SYSTEM

4

9. Using a 12-point 3/8” socket, loosen the two set

screws located on the hydro pump hub Slide the

hydrostatic pump hub and pulley off the hydrostatic

pump shaft. Remove the key on the hydrostatic

pump shaft (Fig. 127).

Fig 127 DSC-2089

11. Cut the two cable ties that hold the fuel line and the

wiring harness (Fig. 129).

Fig 129 DSC-2092

12. Remove the hydrostatic pump from the frame (Fig.

130).

10. Loosen and remove the two bolts and nuts retaining

the hydrostatic pump to the frame (Fig. 128).

Fig 128 DSC-2091

Fig 130 DSC-2094

13. For service work on the hydrostatic pump refer to the

Hydro-Gear Service Manual, Form 492-4789.

4-4 Z Master Z597 Diesel Service Manual

Page 58

HYDRAULIC SYSTEM

Hydrostatic Pump Installation

Note: Prior to connecting the hydraulic lines,

replace the O-Rings with new ones and lightly

lubricate with petroleum jelly.

1. Install the hydrostatic pump to the frame. Install and

tighten the two bolts and nuts (Fig. 131).

Note: Before installing the pulley, replace the set

screws. The end of the set screws have a

knurled cup point for retention and must not

be re-used.

3. Install pulley and hydro pump hub on the hydrostatic

pump shaft and key. Align the center of the

hydrostatic pump pulley with the center of the idler

pulley (Fig. 133).

A

B

Fig 131 DSC-2091

2. Install the key on the hydrostatic pump shaft; make

sure the key is facing up on the shaft (Fig. 132).

4

Fig 133 DSC-2097

A. Pump pulley B. Idler Pulley

4. Tighten the two sets screws on the pulley using a 12point 3/8” (9.5mm) socket (Fig. 134).

Fig 132 DSC-2095

Fig 134 DSC-2089

4-5Z Master Z597 Diesel Service Manual

Page 59

HYDRAULIC SYSTEM

4

5. Install the hydraulic suction line on the top of the

hydrostatic pump (Fig. 135).

Fig 135 DSC-2088

6. Install the two hydraulic hoses that run from

the hydraulic wheel motor to the bottom of the

hydrostatic pump (Fig. 136).

7. Install the case drain hydraulic line, located on the

left hand side of the pump (Fig. 137).

Fig 137 DSC-2099

8. Install and tighten the bolt and nut retaining the

hydro pump control linkage to the hydro control arm

(Fig. 138).

Fig 136 DSC-2098

Remember to install the hydraulic hoses to the

correct port on the hydrostatic pump. If the lines are

reversed, the hydrostatic wheel motor will turn in the

direction opposite of motion control position.

Note: It may be easier to remove the rear tire

assembly for installation of the bottom and

side hydraulic hoses.

4-6 Z Master Z597 Diesel Service Manual

Fig 138 DSC-2081

Page 60

HYDRAULIC SYSTEM

9. Using a 3/8” drive ratchet, insert the wrench into

the square hole in the pump belt tensioner arm and

relieve the tension to install the hydrostatic pump

v-belt (Fig. 139).

Fig 139 DSC-2073

11. Install the battery in the unit and connect the positive

and negative battery cables.

12. Check the hydraulic uid in the reservoir tank. Add

oil if necessary, refer to Figure 006, page 2-5. Air

will need to be purged in the system. Follow the

procedures on Purging the Hydraulic System, page

4-13.

13. Check the neutral adjustment. Follow procedures

for Adjusting the Handle Neutral, page 4-24.

14. Install the engine belt shield and the engine access

panel. Install the two knobs (Fig. 141).

10. Install two cable ties for the fuel line and the wiring

harness (Fig. 140).

Fig 140 DSC-2101

4

Fig 141 DSC-2071

4-7Z Master Z597 Diesel Service Manual

Page 61

HYDRAULIC SYSTEM

4

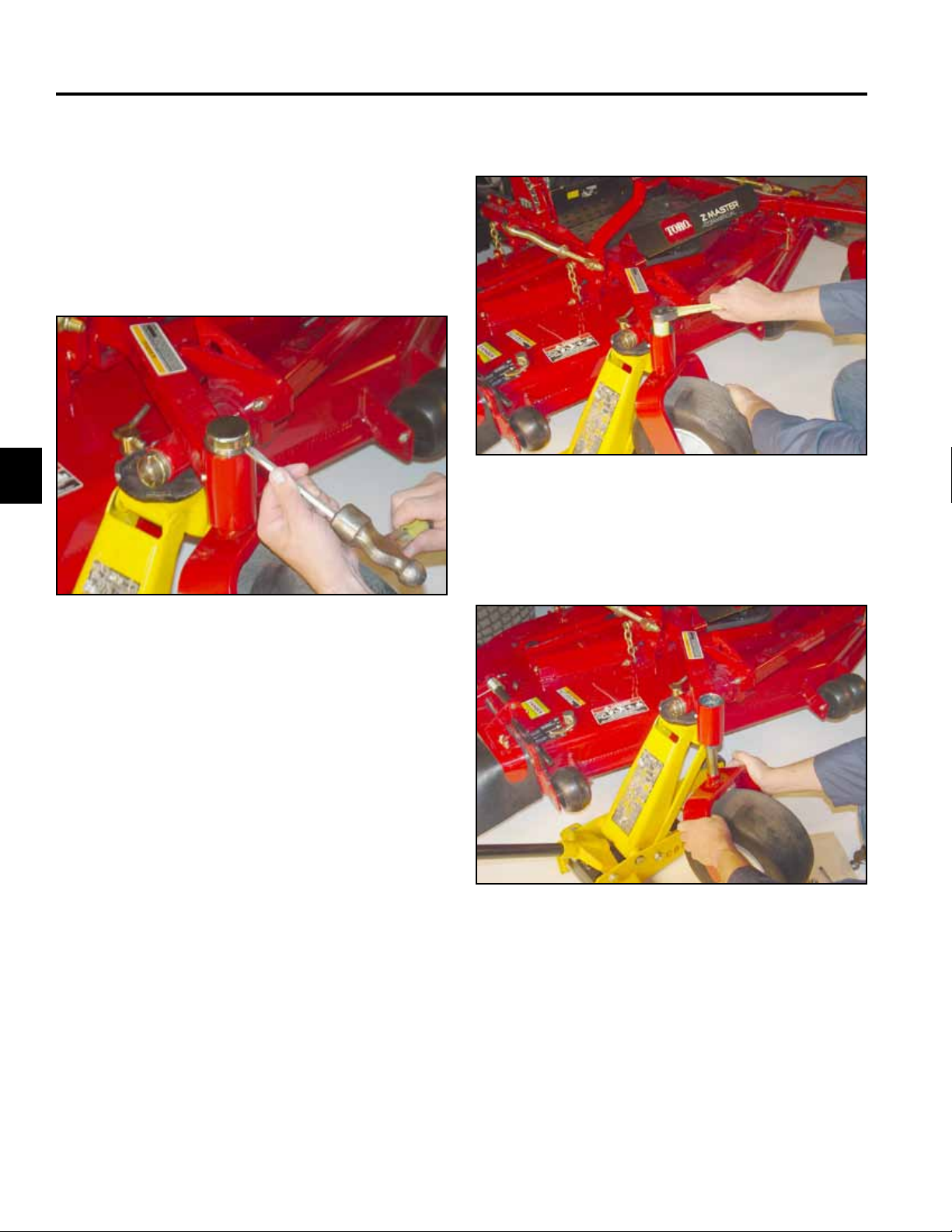

Wheel Motor Removal

1. Disconnect the battery negative cable.

2. Raise the rear wheels of the machine off the ground

and support frame with jackstands. Remove the rear

wheel (Fig. 142).

Fig 142 DSC-2102

4. Loosen and remove nut securing hub to the wheel

motor output shaft (Fig. 144).

Fig 144 DSC-2105

5. Remove the 3 bolts securing the brake band to the

actuator (Fig. 145).

3. Apply the parking brake and remove the cotter pin

from the wheel motor output shaft (Fig. 143).

Fig 143 DSC-2103

Fig 145 DSC-2106

4-8 Z Master Z597 Diesel Service Manual

Page 62

HYDRAULIC SYSTEM

6. Remove the brake band from the hub (Fig. 146).

Fig 146 DSC-2107

7. Install a wheel puller on to the hub and remove the

hub from the motor output shaft (Fig. 147).

8. Clean any dirt or debris away from the hydraulic line

ttings. Remove the hydraulic lines.

Note: Cap the ttings and hoses to prevent dirt from

entering the hydraulic system (Fig. 148).

Fig 148 DSC-2110

4

Fig 147 DSC-2108

Note: The Hub Removal Tool (TOR 4097) can also

be used and is available through your Toro

Distributor.

9. Remove the front two wheel motor mounting bolts,

lock washers, and nuts (Fig. 149).

Fig 149 DSC-2111

4-9Z Master Z597 Diesel Service Manual

Page 63

HYDRAULIC SYSTEM

10. Swing the brake linkage forward out of the way of

the wheel motor. It may be necessary to loosen the

back two bolts to remove the spacers (Fig. 150).

Fig 150 DSC-2113

Wheel Motor Installation

Note: As a reminder, prior to connecting the

hydraulic lines, the O-Rings should be

replaced with new ones and lightly lubricated

with petroleum jelly.

Note: There are two different spacers used on the

wheel motors (Fig. 152). The short spacers

are used in the front of the wheel motor (with

the brake linkage) and the long spacers are

used to retain the back of the wheel motor.

A

B

4

11. Remove the back two bolts, lock washers, spacers,

and nuts and remove the wheel motor from the

frame (Fig. 151).

Fig 152 DSC-2117

A. Short Spacer B. Long Spacer

Fig 151 DSC-2114

12. For service work on the wheel motor refer to the

Parker/Ross Service Manual, Form #492-4753.

4-10 Z Master Z597 Diesel Service Manual

Page 64

HYDRAULIC SYSTEM

1. Install wheel motor in the frame. Loosely install the

back two bolts, long spacers, lock washers and nuts

(Fig. 153).

Fig 153 DSC-2116

2. Align the brake linkage up with the two front bolt

holes (Fig. 154).

3. Install the two front bolts, short spacers, lock

washers, and nuts through the wheel motor, brake

linkage and frame (Fig. 155).

Fig 155 DSC-2120

4. Install the two rear bolts and long spacers through

the wheel motor and frame.

4

Fig 154 DSC-2119

5. Torque the bolts to 80 to 90 ft-lbs. (108 to 122 Nm)

(Fig. 156).

Fig 156 DSC-2122

4-11Z Master Z597 Diesel Service Manual

Page 65

HYDRAULIC SYSTEM

4

6. Install and tighten the hydraulic lines (Fig. 157).

Fig 157 DSC-2123

7. Install wheel hub assembly, making sure the

woodruff key is in place (Fig. 158).

8. Install the nut on the wheel motor shaft, DO NOT

tighten (Fig. 159).

Fig 159 DSC-2126

9. Install spacers, brake band retainer, and brake band

around the wheel hub and tighten all three retainer

bolts (Fig. 160).

Fig 158 DSC-2125

Fig 160 DSC-2106

4-12 Z Master Z597 Diesel Service Manual

Page 66

HYDRAULIC SYSTEM

10. Install rear wheel and wheel lug nuts and tighten.

11. Engage parking brake, torque the wheel hub nut

to 125 ft-lbs. (169 Nm) (Fig. 161). Install cotter key

through the nut and motor wheel shaft.

Note: Re-torque nut at 100 hours, and every 500

hours thereafter. Washer 1-523157 can be

added under nut to keep cotter pin engaged

with nut castellation.

Purging the Hydraulic System

The hydraulic system is self bleeding; however, it may

be necessary to bleed the system if uid is changed or

after work is performed on the system.

1. Raise the machine so wheels are off the ground and

support with jack stands (Fig. 162).

Fig 161 DSC-2128

12. Check the park brake and adjust park brake if

necessary. Refer to Adjusting the Parking Brake,

page 3-22.

13. Reconnect the battery negative cable.

14. Check the hydraulic uid in the reservoir tank.

Add oil if necessary. Air will need to be purged in

the system. Follow the procedures on Purging the

Hydraulic System, page 4-13.

4

Fig 162 DSC-2352

2. Start the engine and run at low idle speed. Slowly

engage the motion control lever. If the wheel does

not rotate immediately, it may be necessary to spin

the wheel by hand to start purging air that is trapped

in the system (Fig. 163).

Fig 163 DSC-2353

4-13Z Master Z597 Diesel Service Manual

Page 67

HYDRAULIC SYSTEM

3. When the wheel begins to spin on its own, keep it

engaged until the wheel drives smoothly. (Minimum

2 minutes)

4. Check the hydraulic uid level and add uid as

required to maintain proper level.

5. Repeat this procedure on the opposite wheel.

Hydraulic Fan Pump Removal

Note: Cleanliness is a key factor in a successful

repair of any hydraulic system. Thoroughly

clean all exposed surfaces prior to any type

of maintenance. Cleaning all parts by using

a solvent wash and air drying is usually

adequate. As with any precision equipment,

all parts must be kept free of foreign material

and chemicals. Protect all exposed sealing

areas and open cavities from damage and

foreign material.

2. Push down on the pump belt tensioner and remove

the drive belt from the pulley on the PTO clutch.

Remove the other end of the pump drive belt from

the hydraulic pump pulley (Fig. 165).

Fig 165 DSC-2360

4

Upon removal, all seals, O-rings, and gaskets

should be replaced. Lightly lubricate all

seals, O-rings and gaskets with clean

petroleum jelly prior to installation.

1. Loosen the 4 bolts on the rear bumper assembly and

remove.

Note: DO NOT remove the bolts (Fig. 164).

3. Loosen two hex set screws located on the hydraulic

pump pulley (Fig. 166).

Fig 166 DSC-2361

Fig 164 DSC-2359

4-14 Z Master Z597 Diesel Service Manual

Page 68

HYDRAULIC SYSTEM

4. Remove the hydraulic pump pulley.

Note: It may be necessary to use a puller to remove

the pulley (Fig. 167).

Fig 167 DSC-2362

Note: Cut a piece of cardboard approximately 8” x

18” (20.3 x 45.7cm) to be used as a deector

to channel oil away from the mower drive belt

and pulleys located under the hydraulic pump

fan (Fig. 168).

5. Disconnect the three hydraulic lines connected to

the hydraulic fan pump (Fig. 169).

Fig 169 DSC-2366

6. Remove the four bolts and nuts retaining the

hydraulic fan pump to the fan pump mounting plate

(Fig. 170).

4

Fig 168 DSC-2363

Fig 170 DSC-2367

4-15Z Master Z597 Diesel Service Manual

Page 69

HYDRAULIC SYSTEM

4

7. Remove the hydraulic fan pump from the unit (Fig.

171).

Fig 171 DSC-2368

Hydraulic Fan Pump Installation

Note: Prior to connecting the hydraulic lines,

replace the O-rings with new ones and lightly

lubricate with petroleum jelly.

2. Install the three hydraulic lines to the hydraulic fan

pump and tighten (Fig. 173).

Fig 173 DSC-2366

3. Install the square key in the hydraulic fan pump

shaft. Install the fan pump pulley on the shaft.

Before installing the set screws into the pulley, install

a thread locking compound on the set screws and

tighten (Fig. 174).

1. Install the hydraulic fan pump with four bolts and

nuts to the fan pump mounting plate (Fig. 172).

Fig 172 DSC-2367

Note: Always use new set screws when installing

the pump drive pulley.

Fig 174 DSC-2361

4-16 Z Master Z597 Diesel Service Manual

Page 70

HYDRAULIC SYSTEM

4. Install pump drive belt around the hydraulic pump

pulley. Push down the pump belt tensioner and

install the belt around the PTO clutch pulley (Fig.

175).

Fig 175 DSC-2360

Hydraulic Fan Motor Removal

Note: Cleanliness is a key factor in a successful

repair of any hydraulic system. Thoroughly

clean all exposed surfaces prior to any type

of maintenance. Cleaning all parts by using

a solvent wash and air drying is usually

adequate. As with any precision equipment,

all parts must be kept free of foreign material

and chemicals. Protect all exposed sealing

areas and open cavities from damage and

foreign material.

Upon removal all seals, O-rings, and gaskets

should be replaced. Lightly lubricate all seals,

O-rings, and gaskets with clean petroleum

jelly prior to installation.

1. Unlatch and open the engine hood. Loosen and

remove the rear heat shield from the frame (Fig.

177).

5. Install the rear bumper assembly and tighten the four

bolts (Fig. 176).

Fig 176 DSC-2369

6. Check the hydraulic uid in the reservoir tank. Add

oil of necessary. Air may need to be purged in the

system. Follow the procedures on Purging the

Hydraulic System, page 4-13.

4

Fig 177 DSC-2370

4-17Z Master Z597 Diesel Service Manual

Page 71

HYDRAULIC SYSTEM

4

2. There are 6 bolts and nuts, 3 on each side, retaining

the radiator and fan mounting plate assembly to the

right and left upper frame assembly. Loosen, DO

NOT remove, the two bolts and nuts at the front

right and left side; this will allow you to pivot the

assembly upward. Remove the rear 4 bolts and nuts

(Fig. 178).

A

A

B

Fig 178 DSC-2371

A. Remove B. Loosen

4. Loosen and remove the clamp on the hydraulic

return line located on the left side of the unit (Fig.

180).

Fig 180 DSC-2372

5. Remove the tie strap holding the throttle control

cable. Remove the clamps holding the inlet cooling

hose and the overow hose to the radiator (Fig.

181).

3. Remove the two knobs located on the engine access