Toro 74266CP, 74267CP, 74274CP Operator's Manual

FormNo.3364-201RevA

Z580-DZMaster

®

With52in,60inor72inTURBOFORCE

DischargeMower

ModelNo.74266CP—SerialNo.310000001andUp

ModelNo.74267CP—SerialNo.310000001andUp

ModelNo.74274CP—SerialNo.310000001andUp

®

Side

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Thisengineisnotequippedwitha

sparkarrestermufer.ItisaviolationofCalifornia

PublicResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,or

grass-coveredland.Otherstatesorfederalareas

mayhavesimilarlaws.

Figure1

1.Modelandserialnumberlocation

Theenclosed

Engine Owner’ s Man ual

issupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCalifornia

EmissionControlRegulationofemissionsystems,

maintenance,andwarranty.Replacementsmaybe

orderedthroughtheenginemanufacturer.

Introduction

Thisrotary-blade,ridinglawnmowerisintendedto

beusedbyresidentialhomeownersorprofessional,

hiredoperators.Itisdesignedprimarilyforcutting

grassonwell-maintainedlawnsonresidential

orcommercialproperties.Itisnotdesignedfor

cuttingbrushorforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww.Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Figure1

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

SlopeIndicator.....................................................6

SafetyandInstructionalDecals.............................7

ProductOverview......................................................14

Controls.............................................................14

Operation...................................................................15

AddingFuel.......................................................15

BiodieselReady..................................................16

FillingtheFuelTank...........................................16

©2010—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

CheckingtheEngineOilLevel............................16

SwitchingtheFuelTanks....................................16

UsingtheRolloverProtectionSystem

(ROPS)..........................................................17

ThinkSafetyFirst...............................................18

OperatingtheParkingBrake...............................19

StartingandStoppingtheEngine........................19

OperatingthePowerTakeOff(PTO).................21

TheSafetyInterlockSystem................................21

DrivingForwardorBackward.............................22

StoppingtheMachine.........................................23

AdjustingtheHeight-of-Cut...............................23

AdjustingtheAnti-ScalpRollers.........................23

AdjustingtheFlowBafe...................................24

PositioningtheFlowBafe.................................25

PositioningtheSeat............................................25

UnlatchingtheSeat.............................................26

PushingtheMachinebyHand.............................26

OperatingwiththeOverheatSensor...................27

UsingtheSideDischarge....................................27

TransportingMachines.......................................27

LoadingMachines..............................................28

UsingtheZStand®............................................28

OperatingTips...................................................29

Maintenance...............................................................31

RecommendedMaintenanceSchedule(s)................31

Lubrication.............................................................32

GreasingandLubrication...................................32

GreasingtheMowerDeckandBelt

Idlers..............................................................33

LubricateCasterWheelHubs.............................33

EngineMaintenance...............................................35

ServicingtheAirCleaner....................................35

ServicingtheEngineOil.....................................36

FuelSystemMaintenance.......................................39

ServicingtheFuelFilterandWater

Seperator........................................................39

ServicingtheFuelTank......................................40

ElectricalSystemMaintenance................................41

ServicingtheBattery...........................................41

ServicingtheFuses.............................................42

DriveSystemMaintenance.....................................43

AdjustingtheTracking........................................43

CheckingtheTirePressure.................................44

CheckingtheWheelHubSlottedNut..................44

AdjustingtheCasterPivotBearing......................44

ServicingtheGearBox.......................................45

AdjustingtheElectricClutch..............................45

CoolingSystemMaintenance..................................47

ServicingtheCoolingSystem..............................47

BrakeMaintenance.................................................48

AdjustingtheParkingBrake................................48

BeltMaintenance....................................................49

InspectingtheBelts............................................49

ReplacingtheMowerBelt...................................49

AdjustingtheMowerBeltTensionfor72in

MowersOnly..................................................50

ReplacingthePTODriveBelt.............................50

ReplacingthePumpDriveBelt...........................51

ReplacingandTensioningtheAlternator

Belt................................................................51

ControlsSystemMaintenance.................................53

AdjustingtheControlHandleNeutral

Position..........................................................53

HydraulicSystemMaintenance...............................54

ServicingtheHydraulicSystem...........................54

SettingtheHydraulicPumpNeutral

Position..........................................................56

MowerDeckMaintenance......................................58

LevelingtheMoweratThreePositions................58

ServicingtheCuttingBlades...............................59

ReplacingtheGrassDeector.............................61

Cleaning.................................................................62

CleaningUndertheMower.................................62

WasteDisposal...................................................62

Storage.......................................................................63

CleaningandStorage..........................................63

Troubleshooting.........................................................64

Schematics.................................................................66

3

Safety

•Useextracarewhenhandlingdieselandotherfuels.

Theyareammableandvaporsareexplosive.

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafetyalertsymbol,whichmeans

CAUTION,WARNING,orDANGER-“personal

safetyinstruction."Failuretocomplywiththe

instructionmayresultinpersonalinjuryordeath.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Thisproductisdesignedforcuttingandrecyclinggrass

or,whenequippedwithagrassbagger,forcatching

cutgrass.Anyuseforpurposesotherthanthesecould

provedangeroustouserandbystanders.

SafeOperatingPractices

ThefollowinginstructionsarefromANSIstandard

B71.4-2004.

Training

•ReadtheOperator’sManualandothertraining

material.Iftheoperator(s)ormechanic(s)cannot

readEnglishitistheowner’sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmayrestrict

theageoftheoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,

otherpeopleorproperty.

–Useonlyanapprovedcontainer

–Neverrefuelordrainthemachineindoors.

–Neverremovefuelcaporaddfuelwithengine

running.Allowenginetocoolbeforerefueling.

Donotsmoke.

•Checkthatoperator’spresencecontrols,safety

switchesandshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholes

andhiddenhazards.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingengine.Starttheengineonly

fromtheoperator’sposition.Useseatbelts.

•Neverraisemowerwiththebladesrunning.

•NeveroperatewithoutthePTOshield,orother

guardssecurelyinplace.Besureallinterlocksare

attached,adjustedproperly,andfunctioningproperly .

•Neveroperatewiththedischargedeectorraised,

removedoraltered,unlessusingagrasscatcher.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Stoponlevelground,lowerimplements,disengage

drives,engageparkingbrake,shutoffenginebefore

leavingtheoperator’ spositionforanyreason

includingemptyingthecatchersoruncloggingthe

chute.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Wearappropriateclothingincludinghardhat,safety

glassesandhearingprotection.Longhair,loose

clothingorjewelrymaygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeused

andremoveallobjectssuchasrocks,toysandwire

whichcanbethrownbythemachine.

•Stopequipmentandinspectbladesafterstriking

objectsorifanabnormalvibrationoccurs.Make

necessaryrepairsbeforeresumingoperations.

•Keephandsandfeetawayfromthecuttingunits.

•Nevercarrypassengersandkeeppetsandbystanders

away.

•Bealert,slowdownandusecautionwhenmaking

turns.Lookbehindandtothesidebeforechanging

directions.

•Slowdownandusecautionwhencrossingroadsand

sidewalks.Stopbladesifnotmowing.

4

•Beawareofthemowerdischargedirectionanddo

notpointitatanyone.

•Donotoperatethemowerundertheinuenceof

alcoholordrugs.

•Useextremecarewhenloadingorunloadingthe

machineintoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

SlopeOperation

•Donotmowslopesgreaterthan15degrees.

•Donotmowneardrop-offs,ditches,steepbanks

orwater.Wheelsdroppingoveredgescancause

rollovers,whichmayresultinseriousinjury,death

ordrowning.

•Donotmowslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcausesliding

andlossofcontrol.

•Donotmakesuddenturnsorrapidspeedchanges.

•Useawalkbehindmowerand/orahandtrimmer

neardrop-offs,ditches,steepbanksorwater.

•Reducespeedanduseextremecautiononslopes.

•Removeormarkobstaclessuchasrocks,treelimbs,

etc.fromthemowingarea.Tallgrasscanhide

obstacles.

•Watchforditches,holes,rocks,dips,andrisesthat

changetheoperatingangle,asroughterraincould

overturnthemachine.

•Avoidsuddenstartswhenmowinguphillbecause

themowermaytipbackwards.

•Beawarethatlossoftractionmayoccurgoing

downhill.Weighttransfertothefrontwheelsmay

causedrivewheelstoslipandcauselossofbraking

andsteering.

•Alwaysavoidsuddenstartingorstoppingona

slope.Iftireslosetraction,disengagethebladesand

proceedslowlyofftheslope.

•Followthemanufacturer’srecommendationsfor

wheelweightsorcounterweightstoimprovestability.

•Useextremecarewithgrasscatchersorother

attachments.Thesecanchangethestabilityofthe

machineandcauselossofcontrol.

UsingtheRolloverProtectionSystem

(ROPS)

•Keeptherollbarintheraisedandlockedposition

andusetheseatbeltwhenoperatingthemachine.

•Becertainthattheseatbeltcanbereleasedquickly

intheeventofanemergency.

•Beawarethereisnorolloverprotectionwhenthe

rollbarisdown.

•Checktheareatobemowedandneverfoldthe

ROPSinareaswherethereareslopes,dropoffsor

water.

•Lowertherollbaronlywhenabsolutelynecessary.

Donotweartheseatbeltwiththerollbarfolded

down.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)beforedriving

underanyobjectsanddonotcontactthem.

Maintenanceandstorage

•Disengagedrives,lowerimplement,setparking

brake,stopengineandremovekey .Waitforall

movementtostopbeforeadjusting,cleaningor

repairing.

•Cleangrassanddebrisfromcuttingunits,drives,

mufers,andenginetohelppreventres.Cleanup

oilorfuelspillage.

•Letenginecoolbeforestoringanddonotstorenear

ame.

•Shutofffuelwhilestoringortransporting.Donot

storefuelnearamesordrainindoors.

•Parkmachineonlevelground.Neverallowuntrained

personneltoservicemachine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectbatterybeforemakinganyrepairs.

Disconnectthenegativeterminalrstandthe

positivelast.Reconnectpositiverstandnegative

last.

•Usecarewhencheckingblades.Wraptheblade(s)or

weargloves,andusecautionwhenservicingthem.

Onlyreplaceblades.Neverstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Chargebatteriesinanopenwellventilatedarea,

awayfromsparkandames.Unplugchargerbefore

connectingordisconnectingfrombattery.W ear

protectiveclothinganduseinsulatedtools.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•UseonlyToroapprovedattachments.Warrantymay

bevoidedifusedwithunapprovedattachments.

5

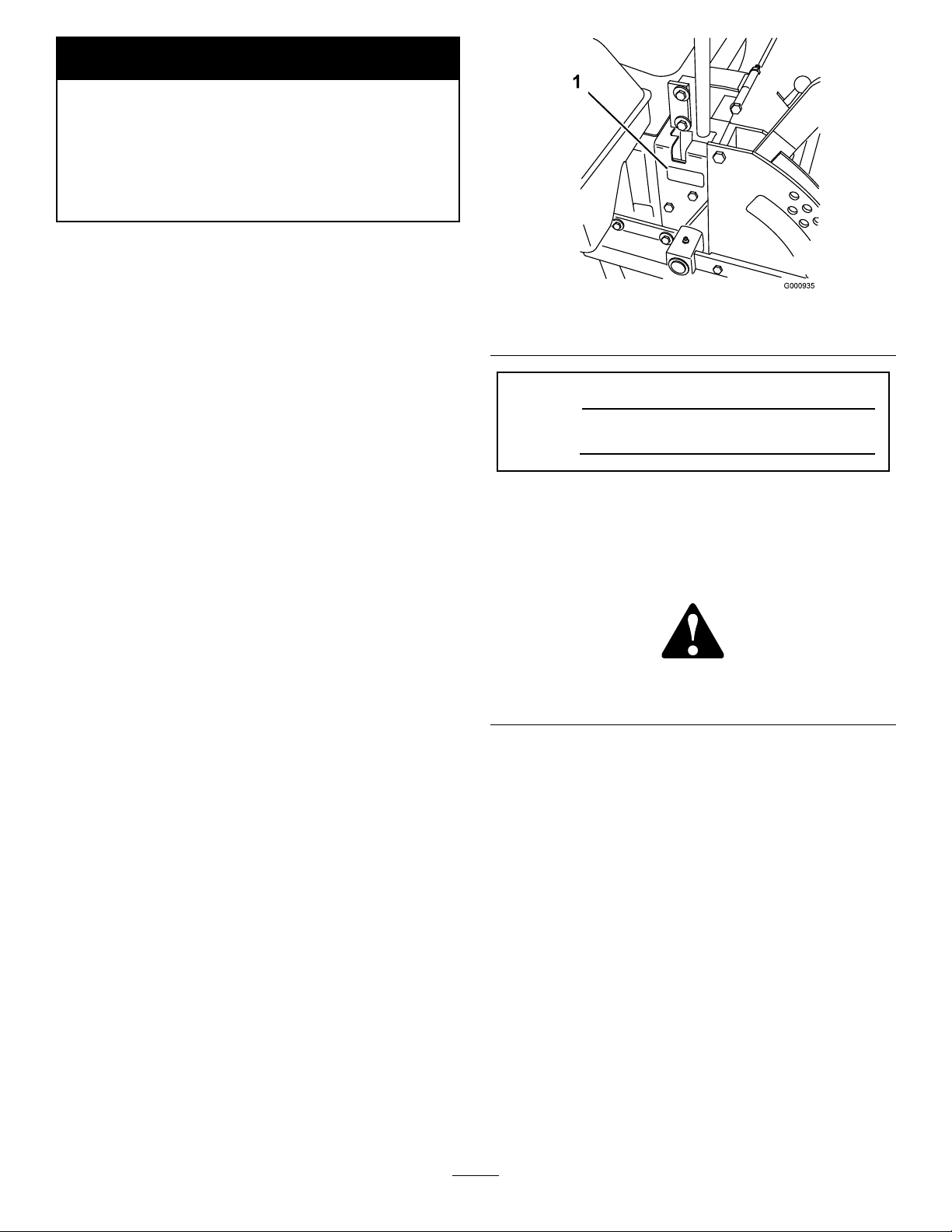

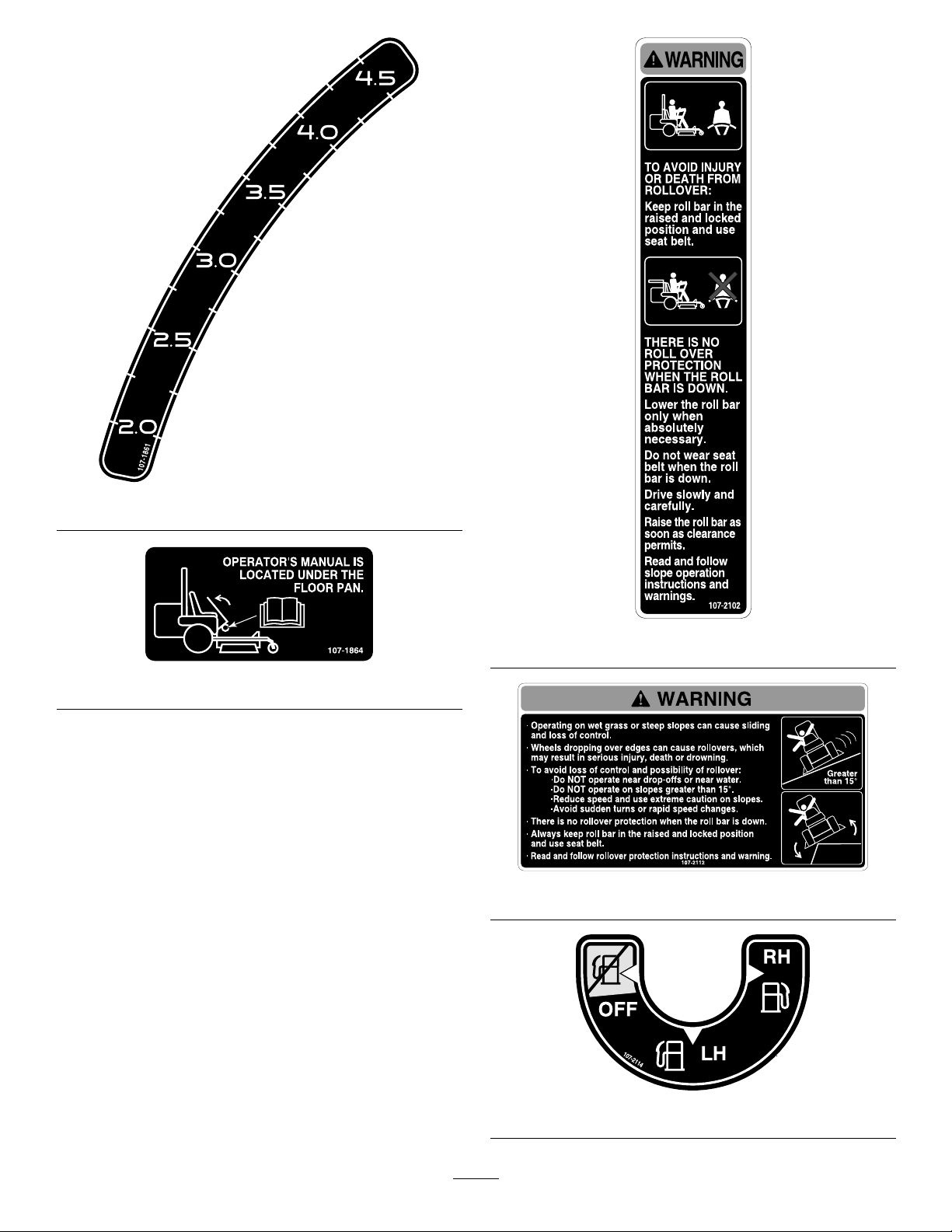

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

6

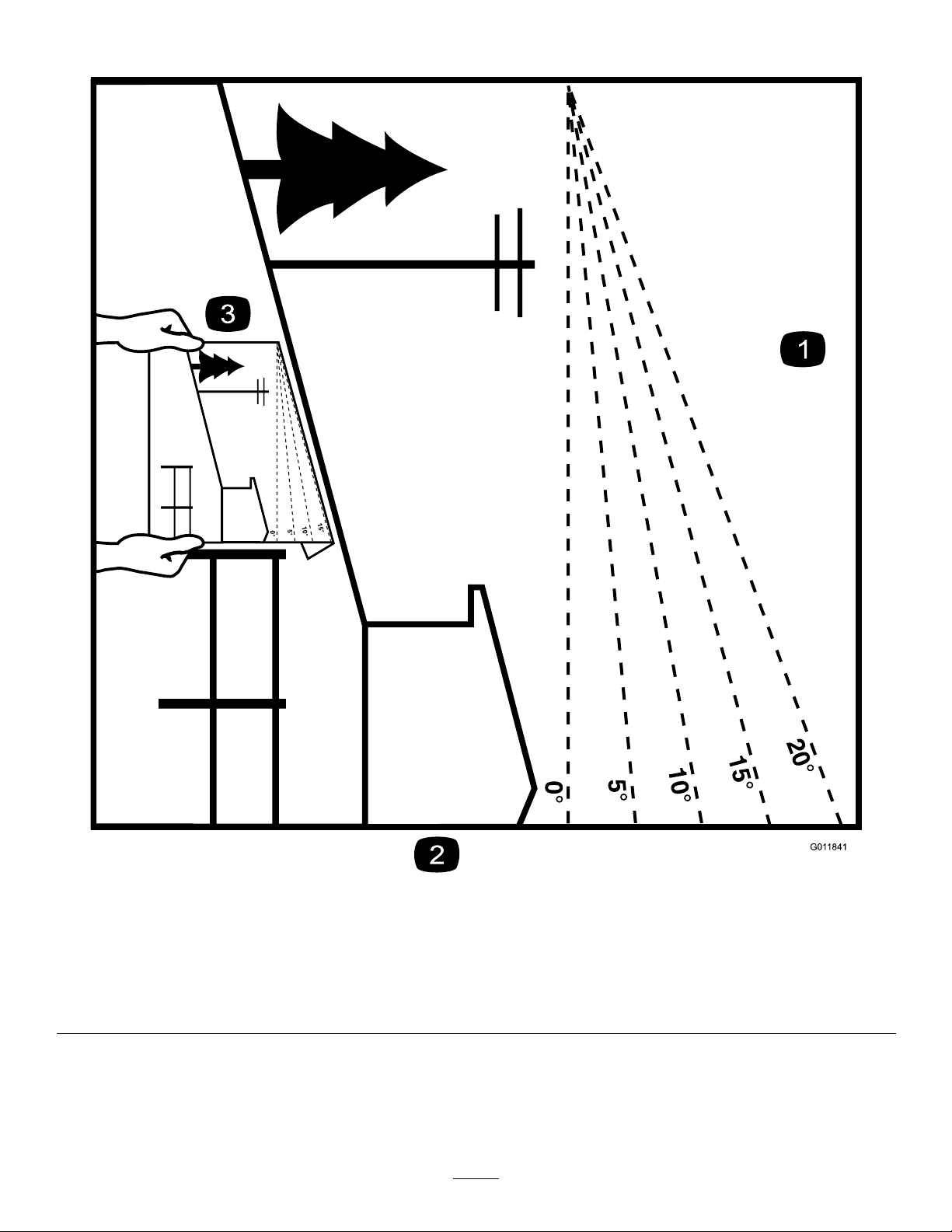

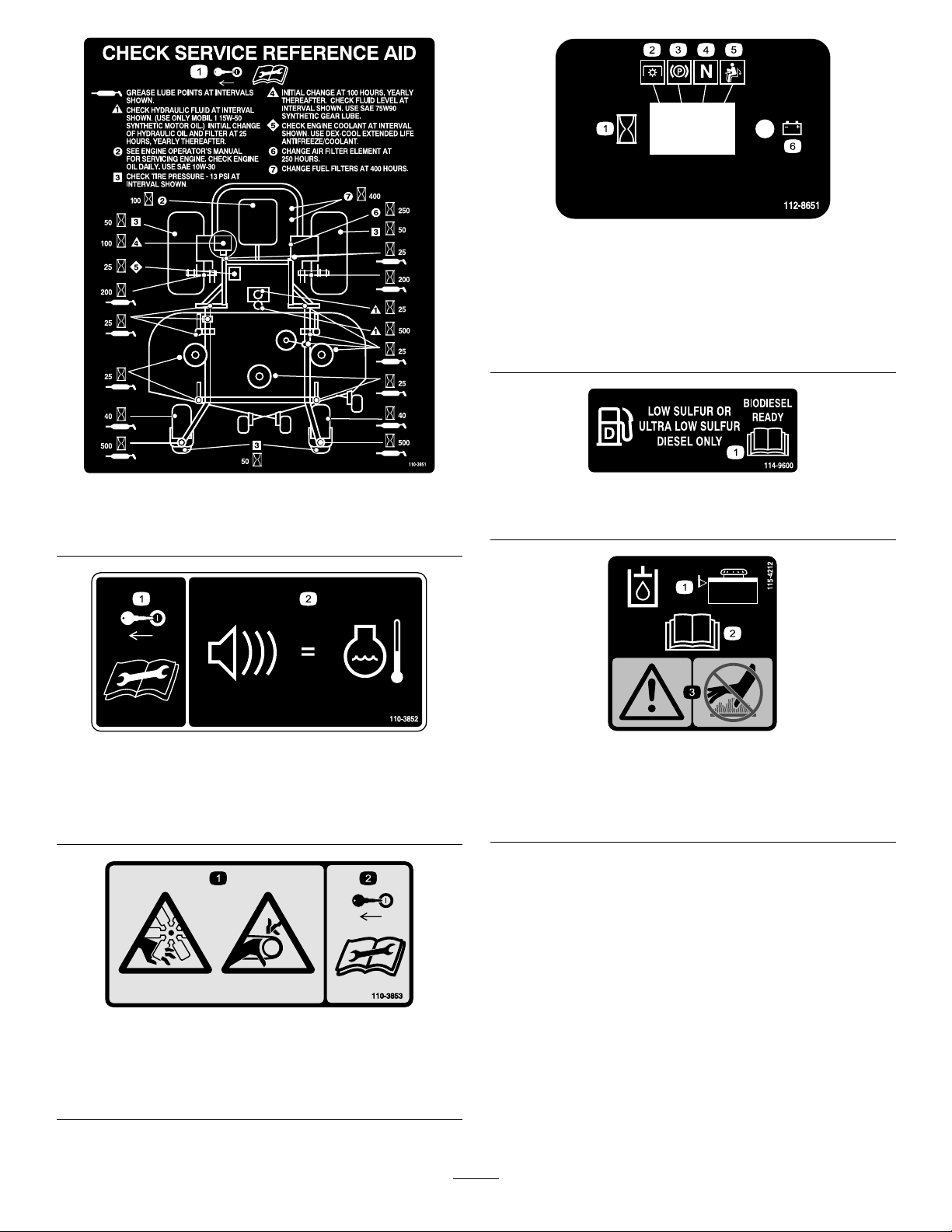

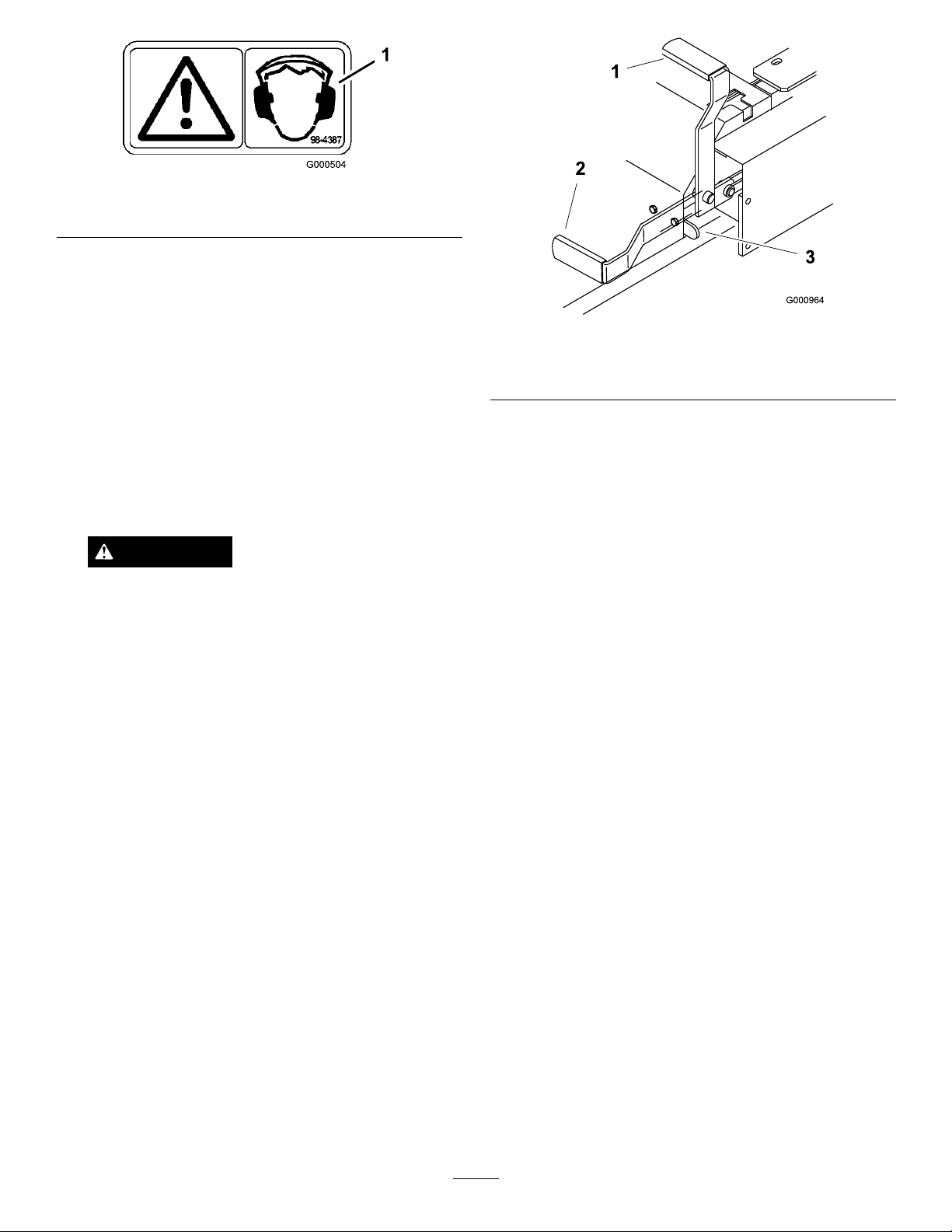

SafetyandInstructional

Decals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

65-2690

1-403005

66-1340

1-643253

68-8340

54-9220

1.Warning—wearhearingprotection.

98-4387

98-5954

58-6520

1.Grease

7

107-1857

104-2449

104-7759

107-1860

105-7798

107-1613

8

107-1861

107-2102

107-1864

107-2112

107-2114

9

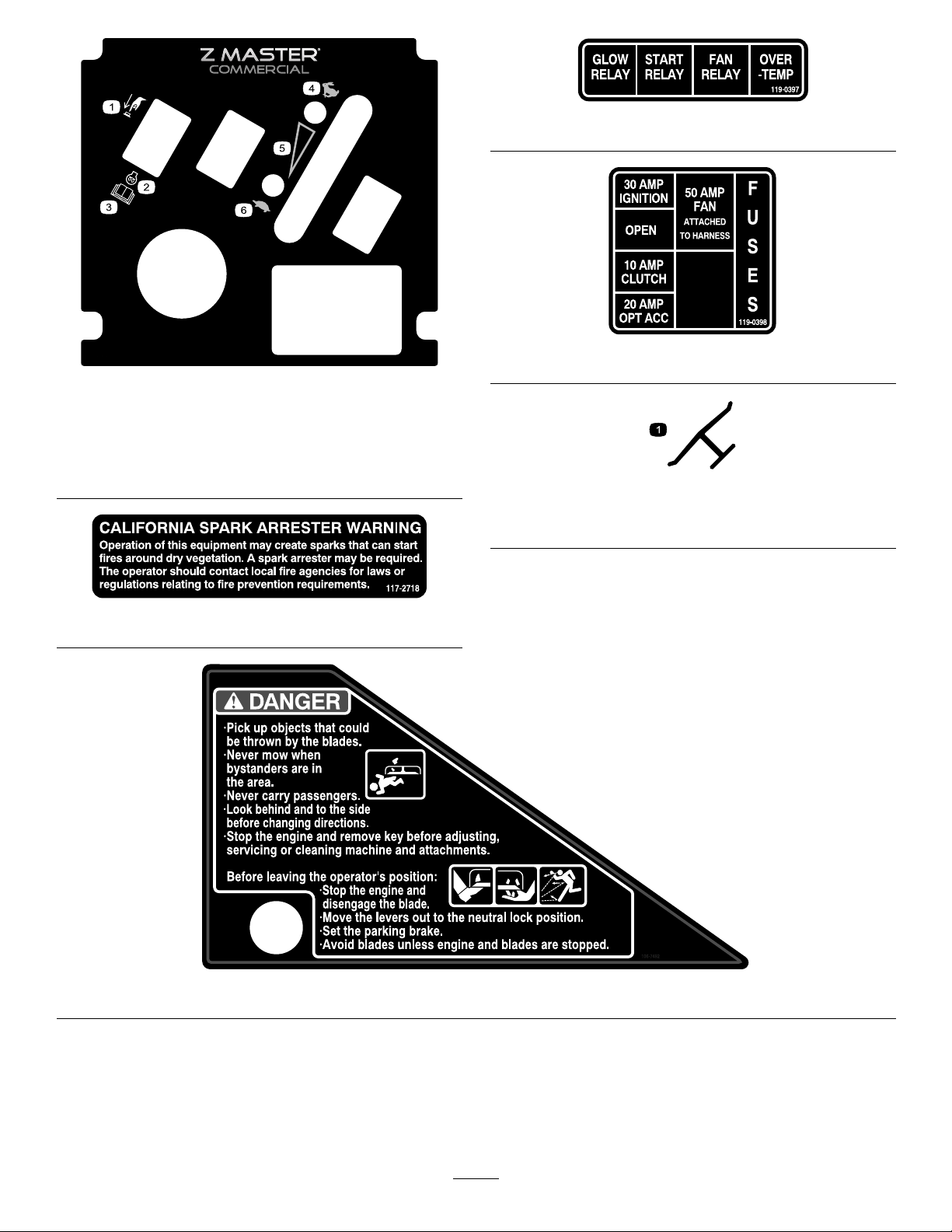

108-5955

110-2067

108-5957

110-2068

1.ReadtheOperator’sManual.

110–3842

108-5981

109-7949

110–0806

10

1.Interval

2.PowerT ake-off(PTO)

3.Parkingbrake

4.Neutral

5.Operatorpresenceswitch

6.Battery

112-8651

110-3851

1.Removetheignitionkeyandreadtheinstructionsbefore

servicingorperformingmaintenance.

110-3852

1.Removetheignitionkey

andreadtheinstructions

beforeservicingor

performingmaintenance.

2.Continuoustonesignals

theuserthatengineis

overheating.

114-9600

1.ReadtheOperator’sManual.

115-4212

1.Hydraulicoillevel3.Warning—donottouch

thehotsurface.

2.ReadtheOperator’s

Manual.

1.Cutting/dismemberment

hazard,fanand

entanglementhazard,

belt.

110-3853

2.Removetheignitionkey

andreadtheinstructions

beforeservicingor

performingmaintenance.

11

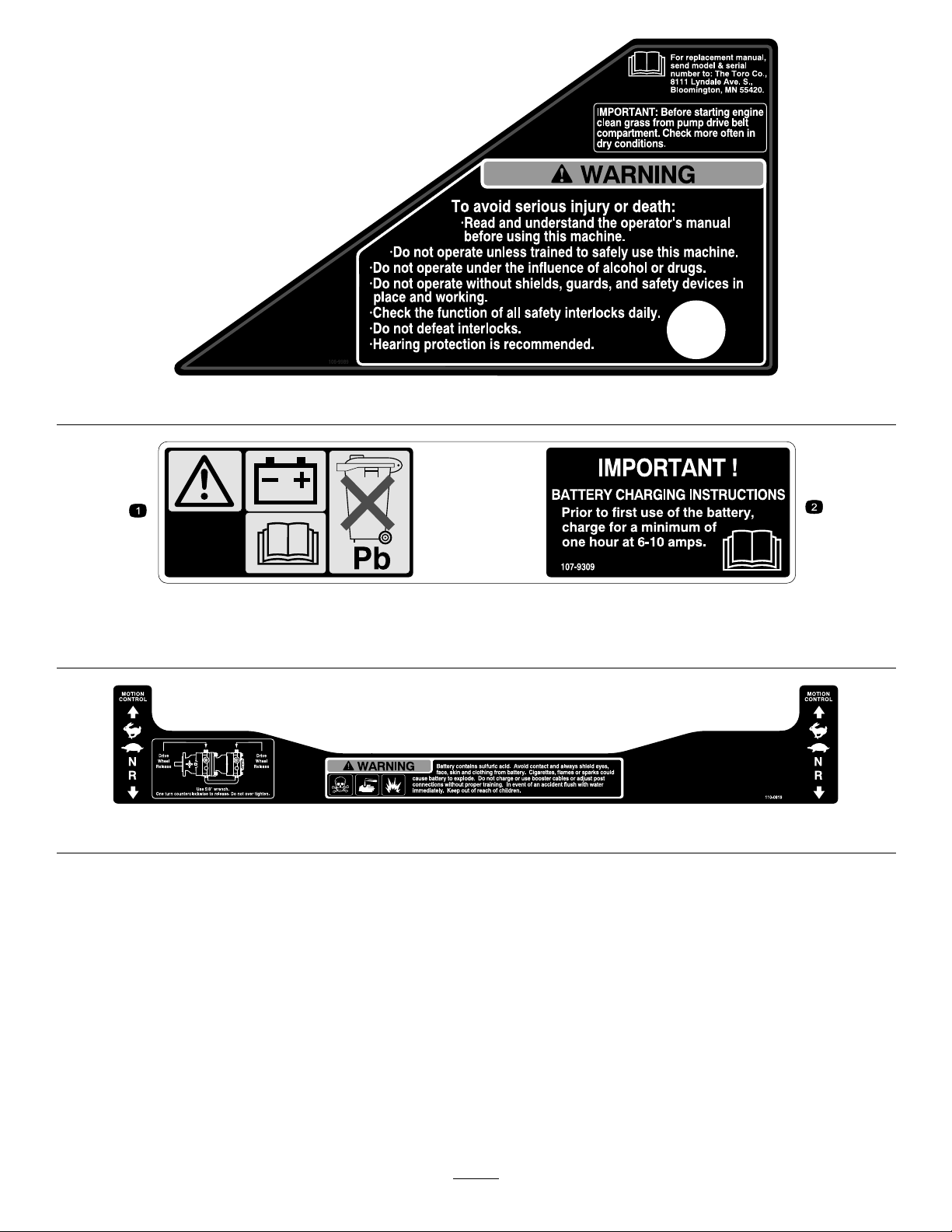

117-0912

1.Pushtoengage4.Fast

2.Engine—preheat

3.ReartheOperator’s

Manual.

119-0397

119-0398

5.Continuousvariable

setting

6.Slow

Manufacturer’sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

117–2718

106-7492

12

106-9989

107-9309

1.Warning—readtheOperator’sManualforinformationonchargingthebattery;containslead;donotdiscard.

2.ReadtheOperator’sManual.

110-0819

13

ProductOverview

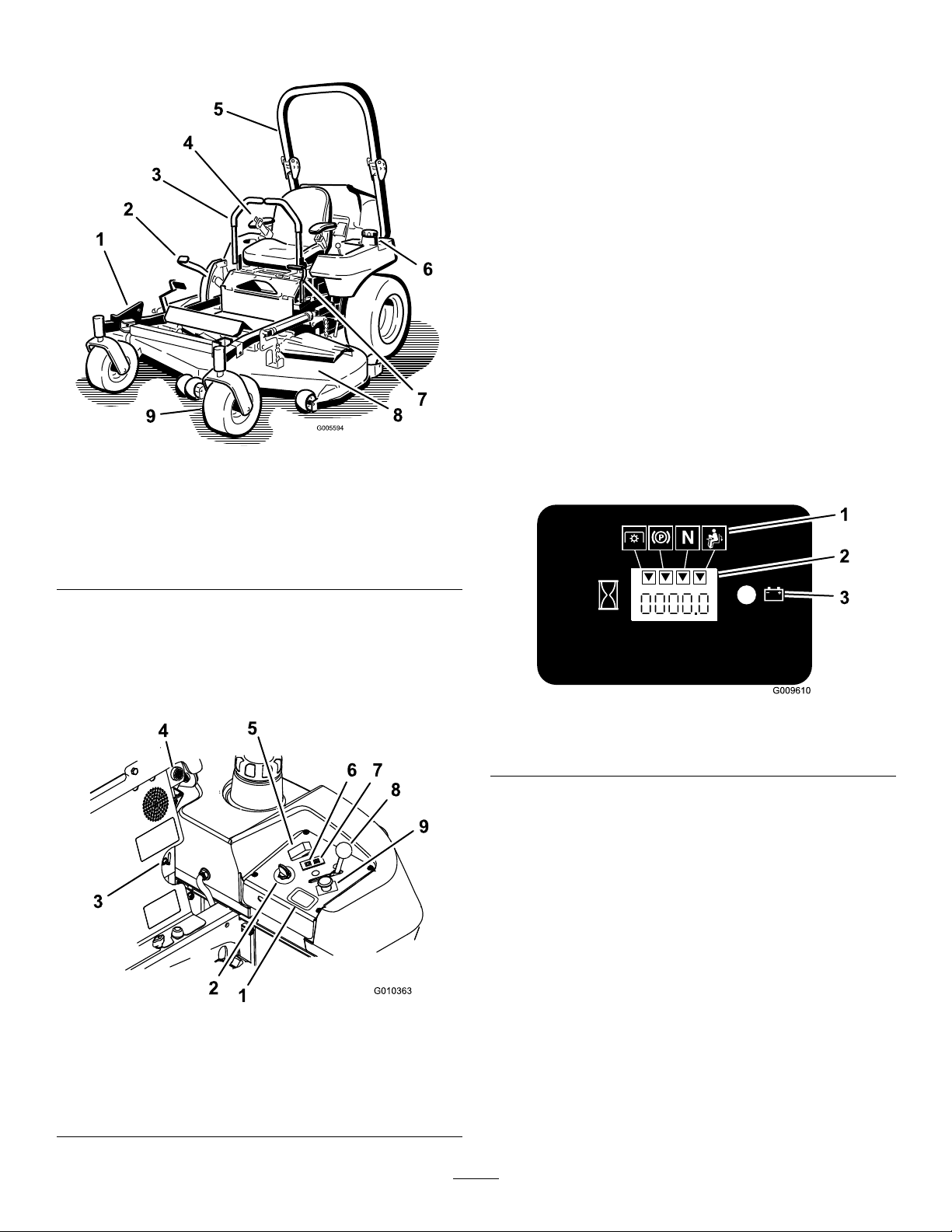

Figure4

1.ZStand

2.Height-of-cutlever

3.Motioncontrollever8.Mowerdeck

4.Seatbelt9.Casterwheel

5.Rollbar

©

6.Fuelcap(bothsides)

7.Parkingbrakelever

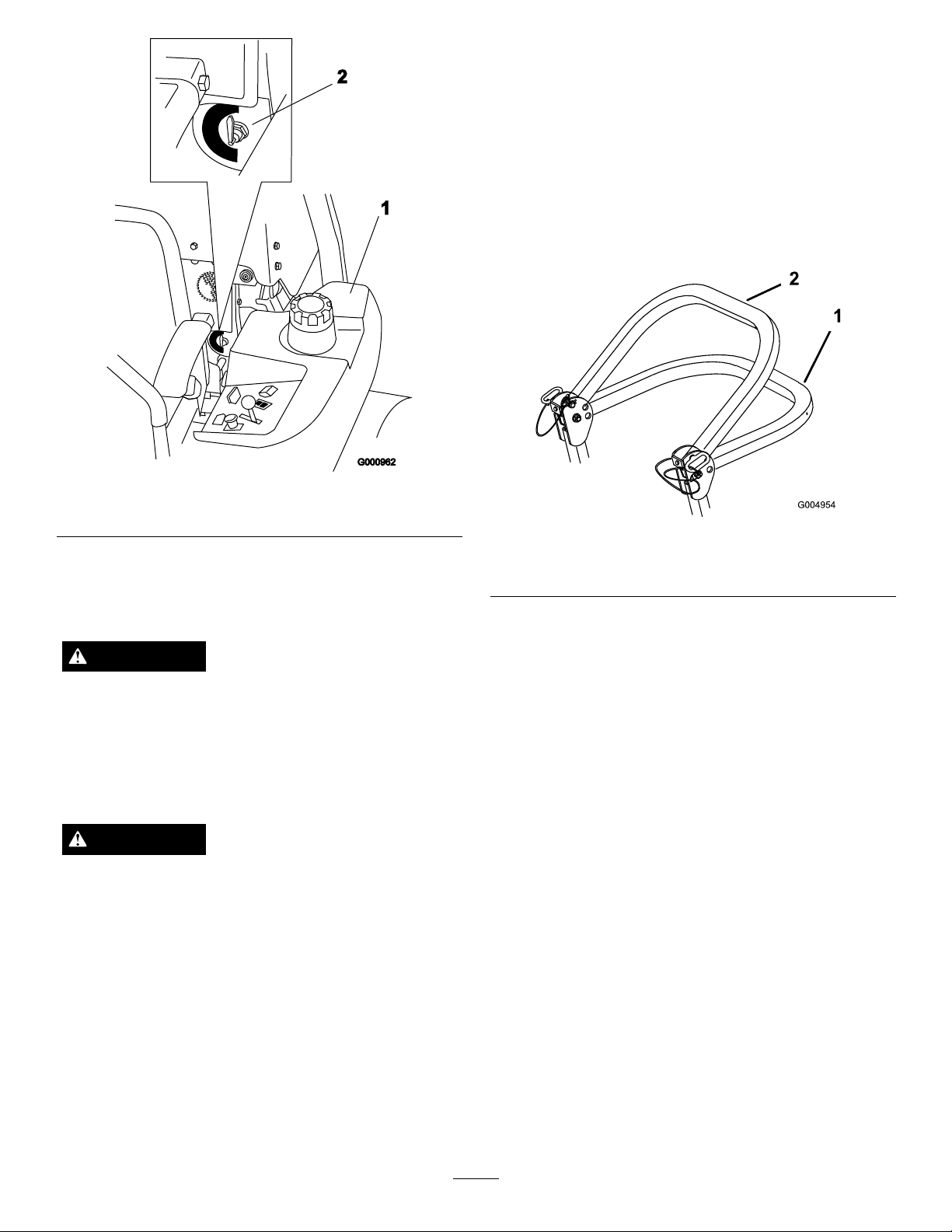

HourMeter

Thehourmeterrecordsthenumberofhourstheengine

hasoperated.Itoperateswhentheengineisrunning.

Usethesetimesforschedulingregularmaintenance

Figure5).

(

SafetyInterlockIndicators

Therearesymbolsonthehourmeterandtheyindicate

withablacktrianglethattheinterlockcomponentisin

thecorrectposition(

Figure6).

BatteryIndicatorLight

WhentheignitionkeyisinitiallyturnedtotheRun

positionforafewseconds,thebatteryvoltagewillbe

displayedintheareawherethehoursarenormally

displayed.

Thebatterylightturnsonwhentheignitionisturned

onandwhenthechargeisbelowthecorrectoperating

Figure6).

level(

Controls

Becomefamiliarwithallthecontrolsbeforeyoustartthe

engineandoperatethemachine(Figure4andFigure5).

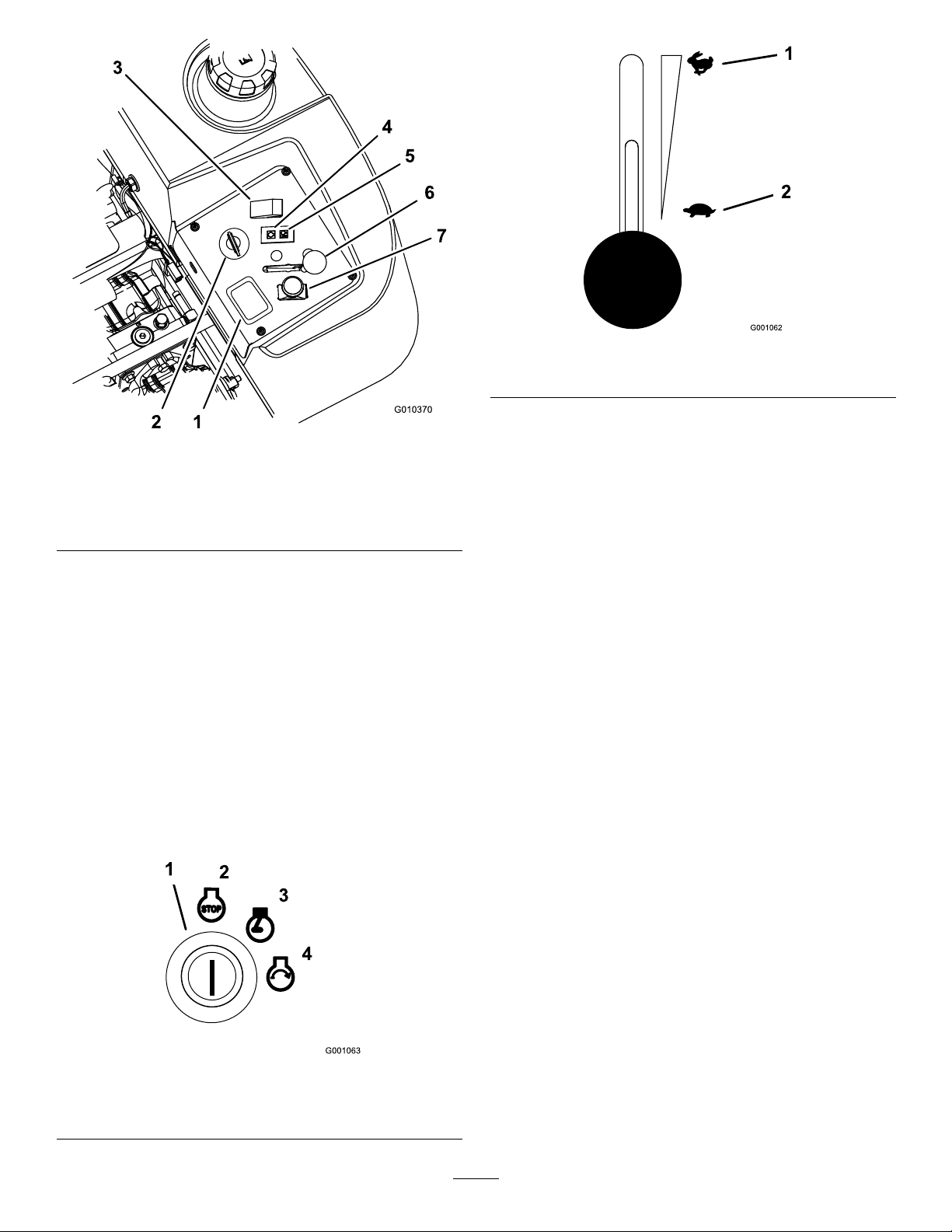

Figure5

1.Hourmeter

2.Ignitionswitch7.EngineTemperaturelight

3.Fuelselectorvalve8.Throttlecontrol

4.Audiblealarm

5.Glowplugswitch

6.Glowpluglight

9.PTOSwitch

Figure6

1.Safetyinterlocksymbols

2.Hourmeter

3.Batterylight

ThrottleControl

ThethrottlecontrolisvariablebetweenFastandSlow.

BladeControlSwitch(PTO)

Thebladecontrolswitch(PTO)isusedtoengagethe

electricclutchtodrivethemowerbladeswiththemotion

controlleversinthecenter,un-lockedposition.Pullthe

switchuptoengagethebladesandrelease.Todisengage

theblades,pushthebladecontrolswitch(PTO)down.

NeutralLockPosition

Theneutrallockpositionisusedwiththesafetyinterlock

systemandtodetermineneutralposition.

14

IgnitionSwitch

Thisswitchisusedtostartthemowerengineandhas

threepositions:Start,RunandOff.

GlowPlugLight

Theglowplugindicatorlightturnsonwhentheglow

plugbuttonisengaged(

Figure5).

GlowPlugSwitch

Thisswitchactivatestheglowplugsandisindicatedby

theglowpluglight.Holddowntheglowplugswitchfor

10secondspriortostarting.

TemperatureLight

Thetemperaturelightcomesonwhentheengineisover

heating(Figure5).

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

AddingFuel

Theenginerunsonclean,freshdieselfuelwith

aminimumoctaneratingof40.Purchasefuelin

quantitiesthatcanbeusedwithin30daystoensure

fuelfreshness.

Usesummergradedieselfuel(No.2-D)attemperatures

above20°F(-7°C)andwintergradedieselfuel(No.

1-DorNo.1-D/2-Dblend)below20°F(-7°C).Useof

wintergradedieselfuelatlowertemperaturesprovides

lowerashpointandpourpointcharacteristics,

thereforeeasingstartabilityandlesseningchances

ofchemicalseparationofthefuelduetolower

temperatures(waxappearance,whichmaypluglters).

AudibleAlarm

Thismachinehasanaudiblealarmthatalertstheuser

toturnofftheengineorenginedamagecanoccurfrom

overheating.RefertoServicingtheCoolingSystemin

CoolingSystemMaintenance(page47).

FuelSelectorValve

Thefuelselectorvalveislocatedbehindtheseat.

Closethefuelselectorvalvewhentransportingor

storingmower.

Movetheselectorvalvetothelefthand(LH)or

righthand(RH)positionforoperation.

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

Useofsummergradedieselfuelabove20°F(-7°C)will

contributetowardlongerlifeofthepumpcomponents.

Important:Donotusekeroseneorgasoline

insteadofdieselfuel.Failuretoobservethis

cautionwilldamagetheengine.

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening .

•Keepgasawayfromeyesandskin.

15

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltankoutdoorsonlevelground,in

anopenarea,whentheengineiscold.Wipe

upanyfuelthatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Fill

thefueltanktothebottomofthellerneck.

Theemptyspaceinthetankallowsgasolineto

expand.Overllingmayresultinfuelleakage

ordamagetotheengineoremissionsystem(if

equipped).

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuelfumes

maybeignitedbyaspark.

•Paintedsurfacesmaybedamagedbybiodiesel

blends.

•UseB5(biodieselcontendof5%)orlesserblend

incoldweather.

•Monitorseals,hoses,gasketsincontactwithfuelas

theymaybedegradeovertime.

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblends.

•Contactyourdistributorifyouwishformore

informationonbiodiesel.

FillingtheFuelTank

Note:Donotllthefueltankcompletelyfull.Fillthe

fueltanktothebottomofthellerneck.Theempty

spaceinthetankallowsthegasolinetoexpand.

1.Shuttheengineoffandsettheparkingbrake.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymore

thana30-daysupplyoffuel.

•Alwaysplacefuelcontainersontheground

awayfromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicleoron

atruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerandrefuel

theequipmentwithitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromafueldispenser

nozzle.

•Ifafueldispensernozzlemustbeused,keep

thenozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimesuntil

fuelingiscomplete.

2.Cleanaroundeachfueltankcapandremovethe

cap.Fillthefueltanktothebottomoftheller

neck.Thisspaceinthetankallowsthefuelto

expand.Donotllthefueltankcompletelyfull.

3.Installthefueltankcapsecurely .Wipeupanyfuel

thatmayhavespilled.

4.Ifpossible,llthefueltankaftereachuse.Thiswill

minimizepossiblebuildupofcondensationinside

thefueltank.

CheckingtheEngineOilLevel

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoChecking

OilLevelinEngineMaintenance(page35)

SwitchingtheFuelTanks

Important:Donotrunthemachineoutoffuel.

Thefuelselectorvalveislocatedbehindtheleftside

oftheseat.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuel

ofuptoB20(20%biodiesel,80%petrodiesel).The

petrodieselportionshouldbeloworultralowsulfur.

Observethefollowingprecautions:

•Thebiodieselportionofthefuelmeetspecication

ASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTM

D975orEN590.

Theunithastwofueltanks.Onetankisontheleft

sideandoneontherightside.Eachtankconnectsto

thefuelselectorvalve.Fromthereacommonfuelline

leadstotheengine(Figure7).

Tousetheleftsidefueltankrotatethefuelselector

valvetotheLH,lefthandlocation.Tousetheright

sidefueltankrotatethefuelselectorvalvetotheRH,

righthandlocation(Figure7)

Closethefuelselectorvalvebeforetransportingor

storingmachine.

16

1.Leftsidefueltank

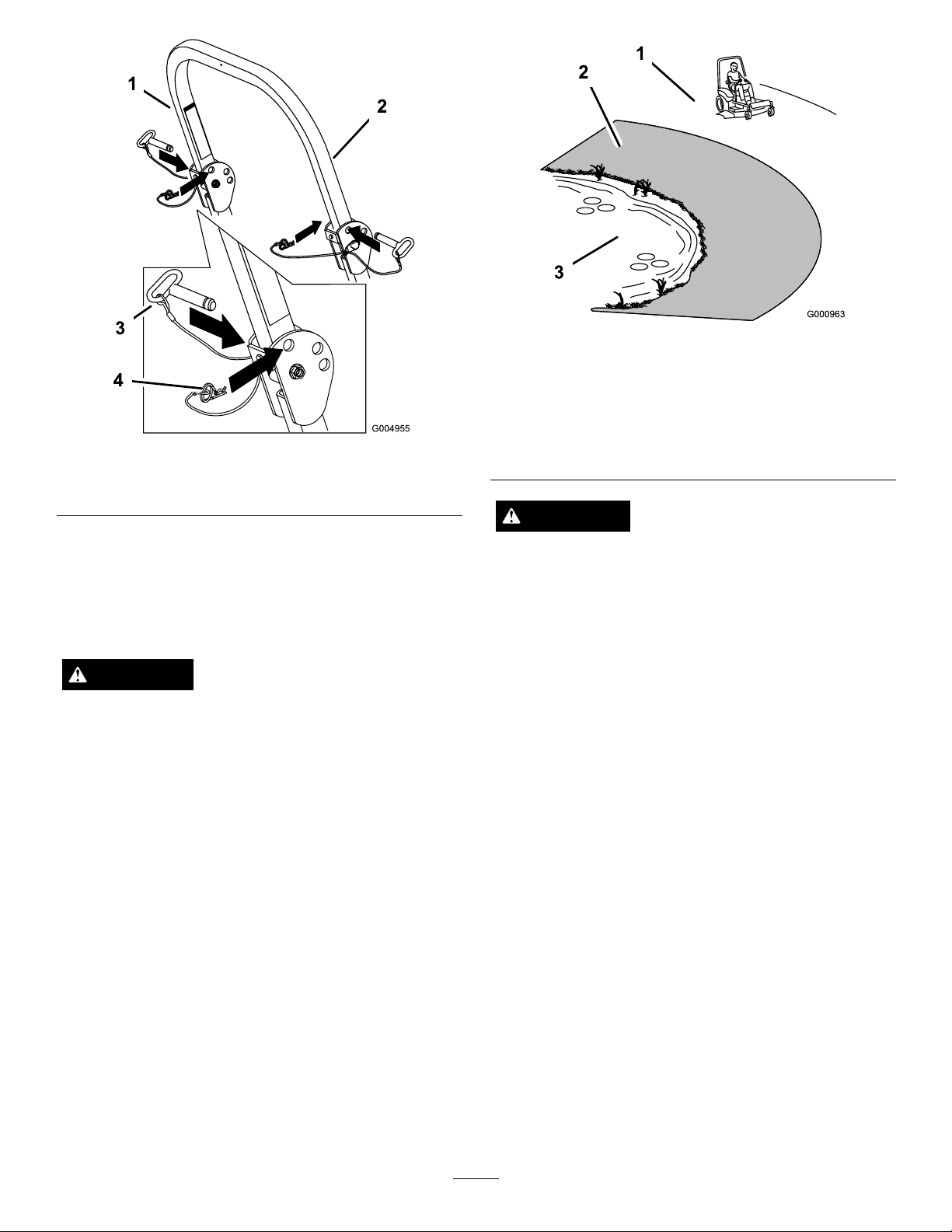

UsingtheRolloverProtection

Figure7

2.Fuelselectorvalve

Important:Lowertherollbaronlywhen

absolutelynecessary.

1.Removethehairpincotterpinsandremovethetwo

Figure9).

pins(

2.Lowerthetherollbartothedownposition.There

aretwodownpositions.SeeFigure8forthe

positions.

3.Installthetwopinsandsecurethemwiththe

hairpincotterpins(

1.Fulldownposition2.Downpositionwithbagger

Figure9).

Figure8

installed

System(ROPS)

WARNING

Toavoidinjuryordeathfromrollover:keepthe

rollbarintheraisedlockedpositionandusethe

seatbelt.

Ensurethattherearpartoftheseatissecuredwith

theseatlatch.

WARNING

Thereisnorolloverprotectionwhentherollbar

isinthedownposition.

•Lowertherollbaronlywhenabsolutely

necessary.

•Donotweartheseatbeltwhentherollbaris

inthedownposition.

•Driveslowlyandcarefully.

•Raisetherollbarassoonasclearancepermits.

Important:Ensurethattherearpartofthe

seatissecuredwiththeseatlatch.

4.Toraisetherollbar,removethehairpincotterpins

andremovethetwopins(Figure9).

5.Raisetherollbartotheuprightpositionandinstall

thetwopinsandsecurethemwiththehairpincotter

Figure9).

pins(

Important:Alwaysusetheseatbeltwiththe

rollbarintheraisedposition.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)before

drivingunderanyobjectsanddonotcontact

them.

17

G004955

1

2

3

4

Figure9

1.Rollbar3.Pin

2.Raisedposition4.Hairpincotterpin

ThinkSafetyFirst

Pleasereadallsafetyinstructionsandsymbolsinthe

safetysection.Knowingthisinformationcouldhelp

youorbystandersavoidinjury.

Figure10

1.SafeZone-usethe

ZMasterhereonslopes

lessthan15degreesor

atareas.

2.Usewalkbehindmower

and/orhandtrimmernear

drop-offsandwater.

3.Water

CAUTION

Thismachineproducessoundlevelsinexcessof

85dBAattheoperatorsearandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

DANGER

Operatingonwetgrassorsteepslopescancause

Theuseofprotectiveequipmentforeyes,ears,feetand

headisrecommended.

slidingandlossofcontrol.

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,deathor

drowning.

Thereisnorolloverprotectionwhentherollbar

isdown.

Alwayskeeptherollbarintheraisedandlocked

positionandusetheseatbelt.

Readandfollowtherolloverprotectioninstructions

andwarnings.

Toavoidlossofcontrolandpossibilityofrollover:

•Donotoperateneardrop-offsornearwater.

•Donotoperateonslopesgreaterthan

15degrees.

•Reducespeedanduseextremecautionon

slopes.

•Avoidsuddenturnsorrapidspeedchanges.

18

Figure11

1.Warning—wearhearingprotection

OperatingtheParkingBrake

Alwayssettheparkingbrakewhenyoustopthe

machineorleaveitunattended.

SettingtheParkingBrake

1.Movethemotioncontrollevers(Figure18)outto

theneutrallockposition.

2.Pullupandbackontheparkingbrakelevertoset

theparkingbrake(Figure12).Theparkingbrake

levershouldstayrmlyintheengagedposition.

WARNING

Parkingbrakemaynotholdmachineparked

onaslopeandcouldcausepersonalinjuryor

propertydamage.

Donotparkonslopesunlesswheelsare

chockedorblocked

ReleasingtheParkingBrake

Pushforwardanddownontheparkingbrakelever

toreleasetheparkingbrake(Figure12).Theparking

brakeisdisengagedandtheleverwillrestagainstthe

brakestop.

Figure12

1.Parkingbrake-ON3.BrakeStop

2.Parkingbrake-OFF

StartingandStoppingthe

Engine

StartingtheEngineinNormalWeather

1.RaisetheROPSupandlockintoplace,sitonthe

seatandfastentheseatbelt.

2.Movethemotioncontrolstotheneutrallocked

position.

3.Settheparkingbrake;refertoSettingtheParking

Brake.

4.MovethePTO(powertakeoff)switchtotheoff

position(

5.Movethethrottlelevertothemiddleposition

(Figure15).

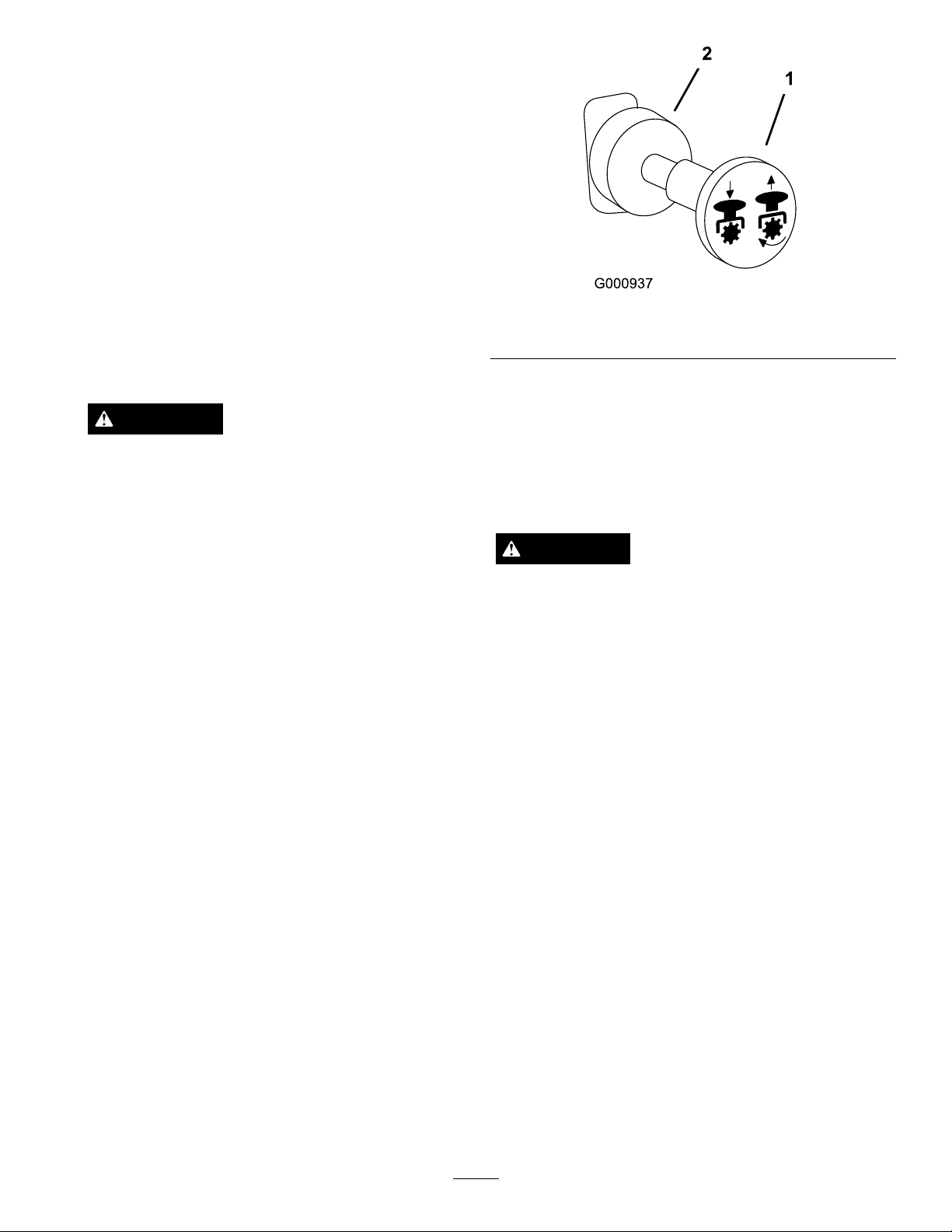

6.Turntheignitionkeyclockwisetotherunposition

Figure14).

(

Figure13).

7.Pushtheglowplugswitchfor10seconds.Thelight

willturnon.

8.Releasetheswitchafter10seconds.Thelightwill

turnoff.

19

Figure15

1.Throttle—fast

2.Throttle—slow

Figure13

1.Hourmeter5.EngineTemperaturelight

2.Ignitionswitch6.Throttlecontrol

3.Glowplugswitch7.PTOSwitch

4.Glowpluglight

9.Turnthekeytothestartpositionandtheglowplug

indicatorlightwillcomebackon.Whentheengine

starts,releasethekey(Figure14).

Important:Usestartingcyclesofnomorethan

30secondsperminutetoavoidoverheatingthe

startermotor.

10.Iftheenginedoesnotstartimmediately,movethe

throttlecontroltofastandturnthekeytothestart

position.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthe

fuelsystemhasbeencompletelywithoutfuel.

StartingtheEngineinColdWeather

(Below23°For-5°C)

Usethecorrectengineoilforthestarting

temperature.RefertoServicingtheEngineOilin

EngineMaintenance(page35).

1.StarttheenginewiththethrottleintheFast

position.

2.Turntheignitionkeyclockwisetotherunposition

(Figure14).

3.Pushtheglowplugswitchfor10to15seconds.

Thelightwillturnon.

4.Releasetheswitchafter10to15seconds.Thelight

willturnoff.

5.Turnthekeytothestartpositionandtheglowplug

indicatorlightwillcomebackon.Whentheengine

starts,releasethekey .

Important:Usestartingcyclesofnomorethan

30secondsperminutetoavoidoverheatingthe

startermotor.

Figure14

1.Ignitionswitch3.Run

2.Off4.Start

Note:Donotusefuelleftoverfromthesummer.

Useonlyfreshwintergradedieselfuel.

StoppingtheEngine

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake(Figure16).

2.Movethethrottlelevermidwaybetweentheslow

andfastpositions(Figure15).

3.Lettheengineidlefor60seconds.

20

4.Turntheignitionkeytotheoffposition(Figure14).

Waitforallmovingpartstostopbeforeleavingthe

operatingposition.

5.Removethekeytopreventpossibilityofsomeone

accidentallystartingthemachinebeforetransporting

orstoringmachine.

6.Closethefuelselectorvalvebeforetransportingor

storingthemachine.

Important:Makesurethatthefuelselector

valveisclosedbeforetransportingorstoring

themachine,asfuelleakagemayoccur.Setthe

parkingbrakebeforetransporting.

Important:Makesuretoremovethekeyas

thefuelpumpmayrunandcausethebattery

tolosecharge.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethetractorwhileit

isunattended.

Alwaysremovetheignitionkeyandsetthe

parkingbrakewhenleavingthemachine

unattended,evenifjustforafewminutes.

OperatingthePowerTakeOff

Figure16

1.PTO-On2.PTO-Off

DisengagingthePTO

Todisengage,pushthePTOswitchtotheoffposition

(Figure16).

TheSafetyInterlockSystem

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

(PTO)

Thepowertakeoff(PTO)switchstartsandstopsthe

mowerbladesandanypoweredattachments.

EngagingthePTO

1.Iftheengineiscold,allowtheenginetowarmup5

to10minutesbeforeengagingthePTO.

2.Whileseatedintheseat,releasethepressureonthe

tractioncontrolleversandplaceinneutral.

3.Placethethrottleinthefastposition.

Note:EngagingthePTOwiththethrottleatthe

halforlesspositionwillcauseexcessiveweartothe

drivebelts.

4.Pulloutonthepowertakeoff(PTO)switchto

engageit(Figure16).

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

UnderstandingtheSafetyInterlock

System

Thesafetyinterlocksystemisdesignedtopreventthe

enginefromstartingunless:

•Theparkingbrakeisengaged.

•Thepowertakeoff(PTO)isdisengaged.

•Themotioncontrolleversareintheneutrallocked

position

Thesafetyinterlocksystemalsoisdesignedtostopthe

enginewhenthetractioncontrolsaremovedfromthe

lockedpositionwiththeparkingbrakeengagedorif

yourisefromtheseatwhenthePTOisengaged.

Thehourmeterhassymbolstonotifytheuserwhenthe

interlockcomponentisinthecorrectposition.When

thecomponentisinthecorrectposition,atrianglewill

lightupinthecorrespondingsquare.

21

Loading...

Loading...