Page 1

LCE Products

Z580/Z589 DFI Z Master

Service Manual

Page 2

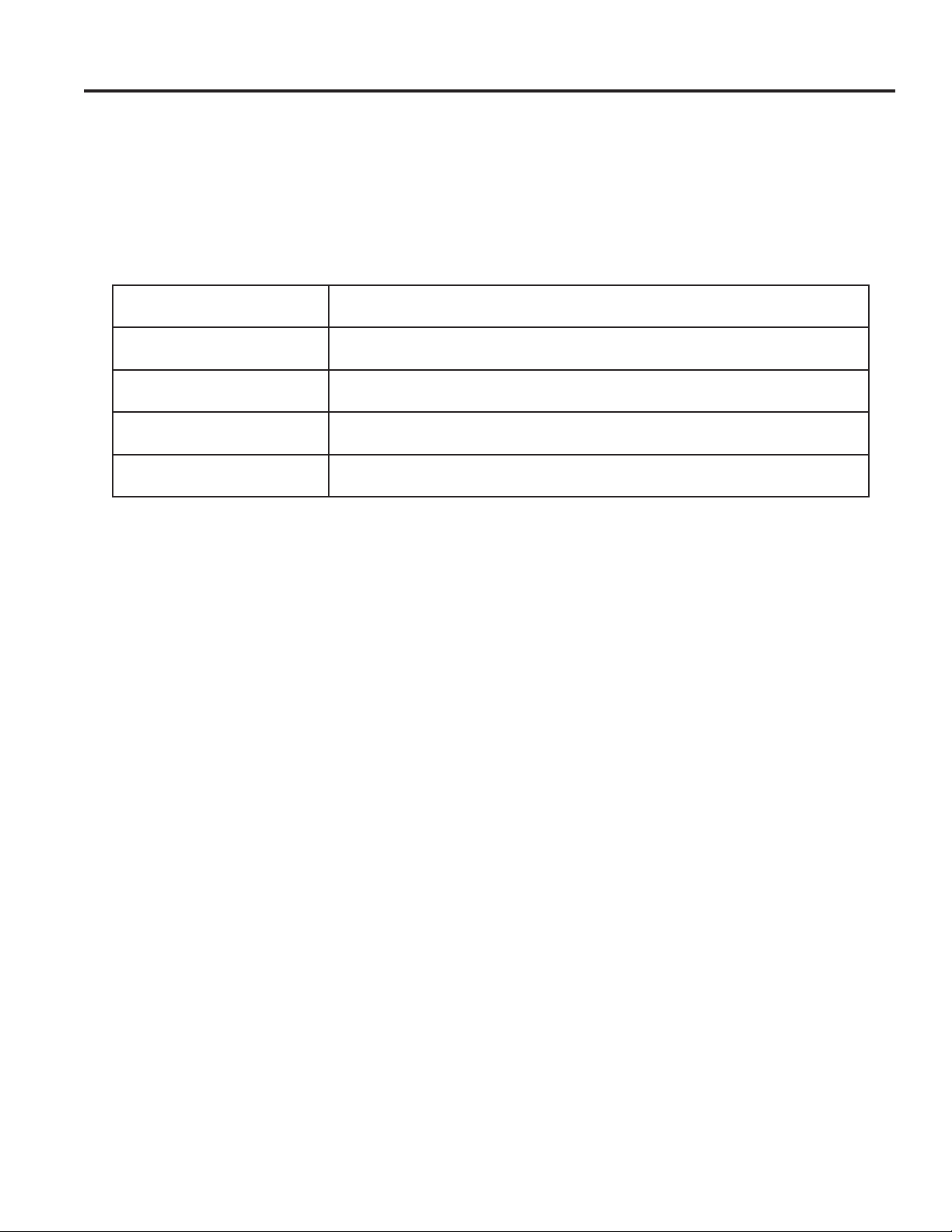

ABOUT THIS MANUAL

This service manual was written expressly for Toro service technicians. The Toro Company has made every effort to

make the information in this manual complete and correct.

Basic shop safety knowledge and mechanical/electrical skills are assumed. The Table of Contents lists the systems

and the related topics covered in this manual.

The following service materials are available in addition to this service manual:

Hydrostatic Pumps: Hydro-Gear P Series Pumps - Service and Repair Manual

Form #BLN 52503

Wheel Motors: Hydro-Gear HGM-E Wheel Motor Service Manual

Form #492-9139

Engine: Kawasaki FD791D Engine Service Manual (available through Kawasaki)

Form #99924-2061-03

Hydraulic Troubleshooting: Interactive hydraulic troubleshooting and failure analysis on DVD

Form #492-4777

Electrical Troubleshooting: Interactive electrical troubleshooting and wiring diagrams on DVD

Form # 492-9193

The Z Master Z580/Z589 with liquid-cooled DFI Kawasaki engine, model years 2007 to 2009, are covered in this

manual.

The hydrostatic drive system is precision machinery. Maintain strict cleanliness control during all stages of service

and repair. Cover or cap all hose ends and ttings whenever they are exposed. Even a small amount of dirt or other

contamination can severely damage the system.

We are hopeful that you will nd this manual a valuable addition to your service shop. If you have any questions or

comments regarding this manual, please contact us at the following address:

The Toro Company

LCE Service Training Department

8111 Lyndale Avenue South

Bloomington, MN 55420

The Toro Company reserves the right to change product specications or this manual without notice.

Copyright© All Rights Reserved

©2011 The Toro Company

Page 3

THIS PAGE INTENTIONALLY LEFT BLANK.

Page 4

TABLE OF CONTENTS

SAFETY INFORMATION

General Information ......................................................................................................................1-1

Think Safety First ...................................................................................................................1-1

SPECIFICATIONS

Specications ...............................................................................................................................2-1

Congurations ........................................................................................................................2-1

Power System ........................................................................................................................2-1

Electrical ................................................................................................................................2-2

Mowing Deck .........................................................................................................................2-2

Operator Zone ........................................................................................................................2-3

Dimensions ............................................................................................................................2-3

Torque Specications ...................................................................................................................2-4

Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Inch Series) ....................................2-5

Standard Torque for Dry, Zinc, and Steel Fasteners (Metric Fasteners) ......................................2-6

Other Torque Specications .........................................................................................................2-7

Equivalents and Conversions .......................................................................................................2-8

U.S. to Metric Conversions ...........................................................................................................2-9

CHASSIS

Castor Fork Assembly Replacement ............................................................................................3-1

Castor Fork Assembly Removal .............................................................................................3-1

Castor Bearing Replacement .................................................................................................3-2

Castor Fork Assembly Installation ..........................................................................................3-4

Front Wheel Bearing Replacement ..............................................................................................3-6

Fuel Tank Replacement ................................................................................................................ 3-9

Right Side Fuel Tank Removal ...............................................................................................3-9

Right Side Fuel Tank Installation .......................................................................................... 3-11

Left Side Fuel Tank Removal ...............................................................................................3-14

Left Side Fuel Tank Installation ............................................................................................3-17

Fuel Tank Fitting Replacement ...................................................................................................3-20

Hood Assembly Replacement ....................................................................................................3-22

Hood Assembly Removal .....................................................................................................3-22

Hood Assembly Installation ..................................................................................................3-23

Throttle Control Assembly Replacement ....................................................................................3-25

Throttle Control Assembly Removal .....................................................................................3-25

Throttle Control Assembly Installation ..................................................................................3-27

Brake Lever Replacement ..........................................................................................................3-31

Brake Lever Removal ..........................................................................................................3-31

Brake Lever Installation .......................................................................................................3-33

Brake Band Replacement...........................................................................................................3-34

Brake Band Removal ...........................................................................................................3-34

Brake Band Installation ........................................................................................................3-35

Brake Cross Shaft Replacement ................................................................................................3-37

Brake Cross Shaft Removal .................................................................................................3-37

Brake Cross Shaft Installation ..............................................................................................3-39

Deck Lift Lever Replacement .....................................................................................................3-41

Deck Lift Lever Removal ......................................................................................................3-41

Deck Lift Lever Installation ...................................................................................................3-45

iZ580/Z589 DFI Z Master Service Manual

Page 5

TABLE OF CONTENTS

CHASSIS cont.

Motion Control Assembly Replacement......................................................................................3-48

Motion Control Assembly Removal ......................................................................................3-48

Right Hand Motion Control Assembly Removal ...................................................................3-50

Left Hand Motion Control Assembly Removal .....................................................................3-52

Left Hand Motion Control Assembly Installation ..................................................................3-55

Right Hand Motion Control Assembly Installation ................................................................3-57

Motion Control Assembly Installation ...................................................................................3-61

Motion Control Damper Replacment ..........................................................................................3-62

Motion Control Damper Removal .........................................................................................3-62

Motion Control Damper Installation ......................................................................................3-64

Adjusting the Parking Brake .......................................................................................................3-65

HYDRAULIC SYSTEM

Hydrostatic Tandem Pump Replacement .....................................................................................4-1

Hydrostatic Tandem Pump Removal ......................................................................................4-1

Hydrostatic Tandem Pump Installation ...................................................................................4-8

Wheel Motor Replacement .........................................................................................................4-17

Wheel Motor Removal .........................................................................................................4-17

Wheel Motor Installation ......................................................................................................4-21

Purging the Hydraulic System ....................................................................................................4-26

Adjusting the Control Handle Neutral Position ...........................................................................4-27

Setting the Hydrostatic Pump Neutral ........................................................................................4-28

Setting the Right Hydraulic Pump Neutral Position ..............................................................4-29

Setting the Left Hydraulic Pump Neutral Position ................................................................4-30

Adjusting the Tracking ................................................................................................................4-32

Hydraulic Flow Testing ................................................................................................................4-33

Hydraulic Flow Testing Procedure........................................................................................4-33

Traction Pump Drive Belt Replacement .....................................................................................4-37

Traction Pump Drive Belt Removal ......................................................................................4-37

Traction Pump Drive Belt Installation ...................................................................................4-39

Hydraulic Oil Cooler Replacement .............................................................................................4-42

Hydraulic Oil Cooler Removal ..............................................................................................4-42

Hydraulic Oil Cooler Installation ...........................................................................................4-43

Hydraulic Reservoir Tank Replacement .....................................................................................4-44

Hydraulic Reservoir Tank Removal ......................................................................................4-44

Hydraulic Reservoir Tank Installation ...................................................................................4-47

Pushing the Machine by Hand....................................................................................................4-50

Switching from Hand Pushing the Machine to Machine Operation ............................................4-50

ENGINE

Engine Replacement ....................................................................................................................5-1

Engine Removal .....................................................................................................................5-1

Engine Installation ..................................................................................................................5-9

Radiator Replacement ................................................................................................................5-19

Radiator Removal ................................................................................................................5-19

Radiator Installation .............................................................................................................5-22

Cooling Fan Replacement ..........................................................................................................5-26

Cooling Fan Removal ..........................................................................................................5-26

Cooling Fan Installation .......................................................................................................5-27

Fuel Pump Replacement ............................................................................................................5-29

Fuel Pump Removal ............................................................................................................5-29

Fuel Pump Installation .........................................................................................................5-31

Checking the Radiator Coolant...................................................................................................5-32

ii Z580/Z589 DFI Z Master Service Manual

Page 6

TABLE OF CONTENTS

ELECTRICAL

General .........................................................................................................................................6-1

Relays...........................................................................................................................................6-1

Purpose ..................................................................................................................................6-1

Location .................................................................................................................................6-1

How It Works ..........................................................................................................................6-2

Testing ....................................................................................................................................6-2

PTO Switch ...................................................................................................................................6-3

Purpose ..................................................................................................................................6-3

Location .................................................................................................................................6-3

How It Works ..........................................................................................................................6-3

Testing ....................................................................................................................................6-4

Ignition Switch ..............................................................................................................................6-5

Purpose ..................................................................................................................................6-5

Location .................................................................................................................................6-5

How It Works ..........................................................................................................................6-5

Testing ....................................................................................................................................6-6

Neutral Safety Switch ...................................................................................................................6-6

Purpose ..................................................................................................................................6-6

Location .................................................................................................................................6-6

How It Works ..........................................................................................................................6-7

Testing ....................................................................................................................................6-7

Parking Brake Switch ...................................................................................................................6-7

Purpose ..................................................................................................................................6-7

Location .................................................................................................................................6-7

How It Works ..........................................................................................................................6-8

Testing ....................................................................................................................................6-8

Seat Switch...................................................................................................................................6-9

Purpose ..................................................................................................................................6-9

Location .................................................................................................................................6-9

How It Works ..........................................................................................................................6-9

Testing ....................................................................................................................................6-9

Delay Module..............................................................................................................................6-10

Purpose ................................................................................................................................6-10

Location ...............................................................................................................................6-10

How It Works ........................................................................................................................6-10

Testing .................................................................................................................................. 6-11

High Temperature Audible Alarm (Solid Tone) ............................................................................6-12

Purpose ................................................................................................................................6-12

Location ...............................................................................................................................6-12

How It Works ........................................................................................................................6-12

Testing ..................................................................................................................................6-12

Temperature Sender ................................................................................................................... 6-13

Purpose ................................................................................................................................6-13

Location ...............................................................................................................................6-13

How It Works ........................................................................................................................6-13

Testing ..................................................................................................................................6-13

Oil Pressure Switch ....................................................................................................................6-14

Purpose ................................................................................................................................6-14

Location ...............................................................................................................................6-14

How It Works ........................................................................................................................6-14

Testing ..................................................................................................................................6-14

iiiZ580/Z589 DFI Z Master Service Manual

Page 7

TABLE OF CONTENTS

ELECTRICAL cont.

Engine High Temperature & Malfunction Indicator Light Cluster ................................................6-15

Purpose ................................................................................................................................6-15

Location ...............................................................................................................................6-15

How It Works ........................................................................................................................6-15

Testing ..................................................................................................................................6-16

Hour Meter..................................................................................................................................6-16

Purpose ................................................................................................................................6-16

Location ...............................................................................................................................6-16

How It Works ........................................................................................................................6-17

Testing ..................................................................................................................................6-17

Electric PTO Clutch ....................................................................................................................6-17

Purpose ................................................................................................................................6-17

Location ...............................................................................................................................6-17

How It Works ........................................................................................................................6-18

Testing ..................................................................................................................................6-18

Clutch Coil Continuity Test ...................................................................................................6-19

MOWER DECKS

Mower Belt Replacement .............................................................................................................7-1

Mower Deck Removal ............................................................................................................7-3

Mower Deck Installation .........................................................................................................7-6

Mower Spindle Replacement........................................................................................................7-9

Mower Spindle Removal ........................................................................................................7-9

Mower Deck Spindle Rebuild ...............................................................................................7-12

Mower Spindle Installation ...................................................................................................7-20

Mower Deck Idler Assembly Replacement .................................................................................7-24

Mower Deck Idler Assembly Removal .................................................................................7-24

Mower Deck Idler Assembly Installation ..............................................................................7-26

Fixed Pulley Replacement ..........................................................................................................7-30

Fixed Pulley Removal ..........................................................................................................7-30

Fixed Pulley Installation .......................................................................................................7-32

Electric PTO Clutch Replacement ..............................................................................................7-34

Electric PTO Clutch Removal...............................................................................................7-34

Electric PTO Clutch Installation............................................................................................7-36

Gearbox Assembly Replacement ...............................................................................................7-39

Gearbox Assembly Removal ................................................................................................7-39

Gearbox Assembly Installation .............................................................................................7-43

Checking the Gearbox Oil Level .................................................................................................7-48

Changing Gearbox Oil ................................................................................................................7-49

Strut Replacement ......................................................................................................................7-50

Strut Removal ......................................................................................................................7-50

Strut Installation ...................................................................................................................7-53

72” Mower Deck Belt Tension Adjustment Plate Replacement ...................................................7-56

72” Mower Deck Belt Tension Adjustment Plate Removal ...................................................7-56

72” Mower Deck Belt Tension Adjustment Plate Installation ................................................7-59

72” Mower Deck Belt Tension Adjustment .................................................................................. 7-62

iv Z580/Z589 DFI Z Master Service Manual

Page 8

TABLE OF CONTENTS

MOWER DECKS cont.

Gearbox Rebuild.........................................................................................................................7-63

Pinion Shaft Teardown .........................................................................................................7-66

Cross Shaft Teardown ..........................................................................................................7-69

Open End Cap Teardown .....................................................................................................7-70

Closed End Cap Teardown ..................................................................................................7-70

Closed End Cap Rebuild ......................................................................................................7-71

Open End Cap Rebuild ........................................................................................................7-71

Cross Shaft Rebuild .............................................................................................................7-72

Pinion Shaft Rebuild ............................................................................................................7-73

Gearbox Assembly ...............................................................................................................7-75

Leveling the Mower ....................................................................................................................7-79

Setting up the Machine ........................................................................................................7-79

Leveling the Mower Side to Side ................................................................................................7-80

Adjusting the Front to Rear Mower Pitch ....................................................................................7-81

Adjusting the Compression Spring .............................................................................................7-82

vZ580/Z589 DFI Z Master Service Manual

Page 9

TABLE OF CONTENTS

THIS PAGE INTENTIONALLY LEFT BLANK.

vi Z580/Z589 DFI Z Master Service Manual

Page 10

General Information

SAFETY INFORMATION

This symbol means WARNING or

PERSONAL SAFETY INSTRUCTION

- read the instruction because it has to

do with your safety. Failure to comply

with the instruction may result in

personal injury or even death.

!

troubleshooting, service, and repair of the Z Master

Z580/Z589 with liquid-cooled DFI Kawasaki engine.

This manual is intended as a service

and repair manual only. The safety

instructions provided herein are for

Think Safety First

Avoid unexpected starting of engine...

Always turn off the engine and disconnect the spark plug

wire(s) before cleaning, adjusting, or repair.

Avoid lacerations and amputations...

The riding mower and attachment operator’s manual

contain safety information and operating tips for safe

operating practices. Operator’s manuals are available

online at www.toro.com, through your Toro parts source

or:

The Toro Company

Publications Department

8111 Lyndale Avenue South

Bloomington, MN 55420

Avoid injury from batteries...

Battery acid is poisonous and can cause burns. Avoid

contact with skin, eyes, and clothing. Battery gases can

explode. Keep cigarettes, sparks, and ames away from

the battery.

1

Stay clear of all moving parts whenever the engine is

running. Treat all normally moving parts as if they were

moving whenever the engine is running or has the

potential to start.

Avoid burns...

Do not touch the engine, mufer, or other components

which may increase in temperature during operation,

while the unit is running or shortly after it has been

running.

Avoid res and explosions...

Avoid spilling fuel and never smoke while working with

any type of fuel or lubricant. Wipe up any spilled fuel

or oil immediately. Never remove the fuel cap or add

fuel when the engine is running. Always use approved

labeled containers for storing or transporting fuel and

lubricants.

Avoid asphyxiation...

Never operate an engine in a conned area without

proper ventilation.

Avoid injury due to inferior parts...

Use only original equipment parts to ensure that

important safety criteria are met.

Avoid injury to bystanders...

Always clear the area of bystanders before starting or

testing powered equipment.

Avoid injury due to projectiles...

Always clear the area of sticks, rocks, or any other

debris that could be picked up and thrown by the

powered equipment.

Avoid modications...

Never alter or modify any part unless it is a factory

approved procedure.

Avoid unsafe operation...

Always test the safety interlock system after making

adjustments or repairs on the machine. Refer to the

Electrical section in this manual for more information.

1-1Z580/Z589 DFI Z Master Service Manual

Page 11

1

SAFETY INFORMATION

THIS PAGE INTENTIONALLY LEFT BLANK.

1-2 Z580/Z589 DFI Z Master Service Manual

Page 12

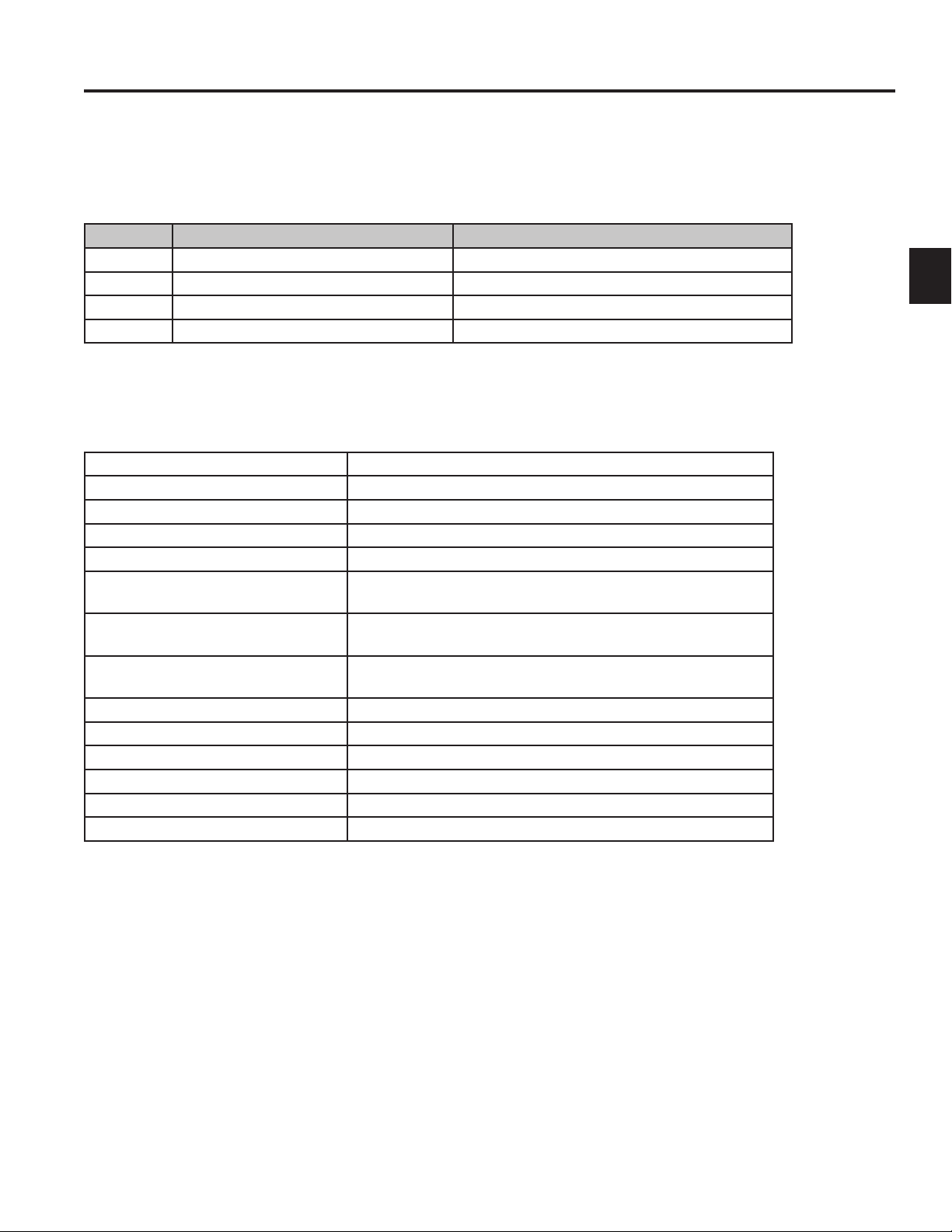

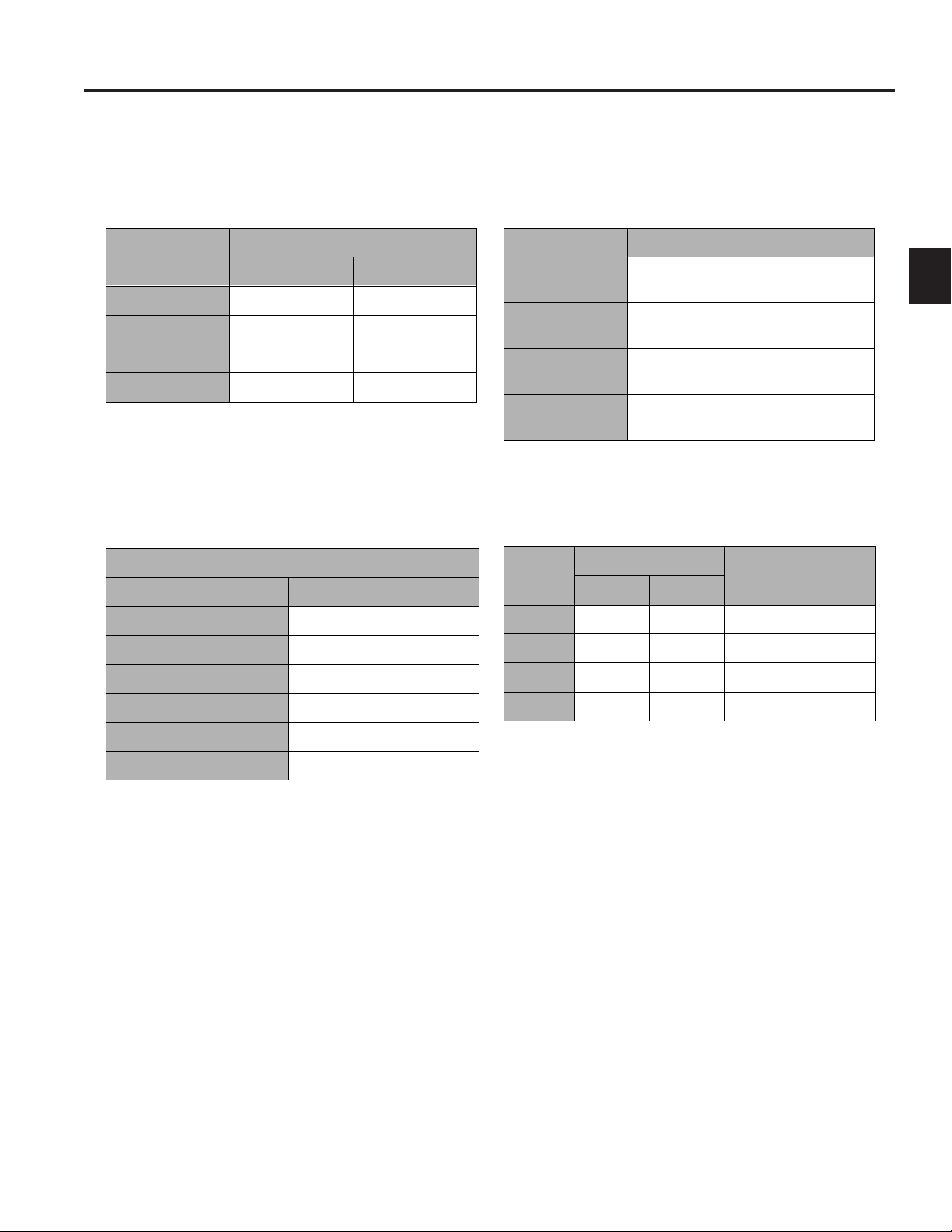

SPECIFICATIONS

Specications

Congurations

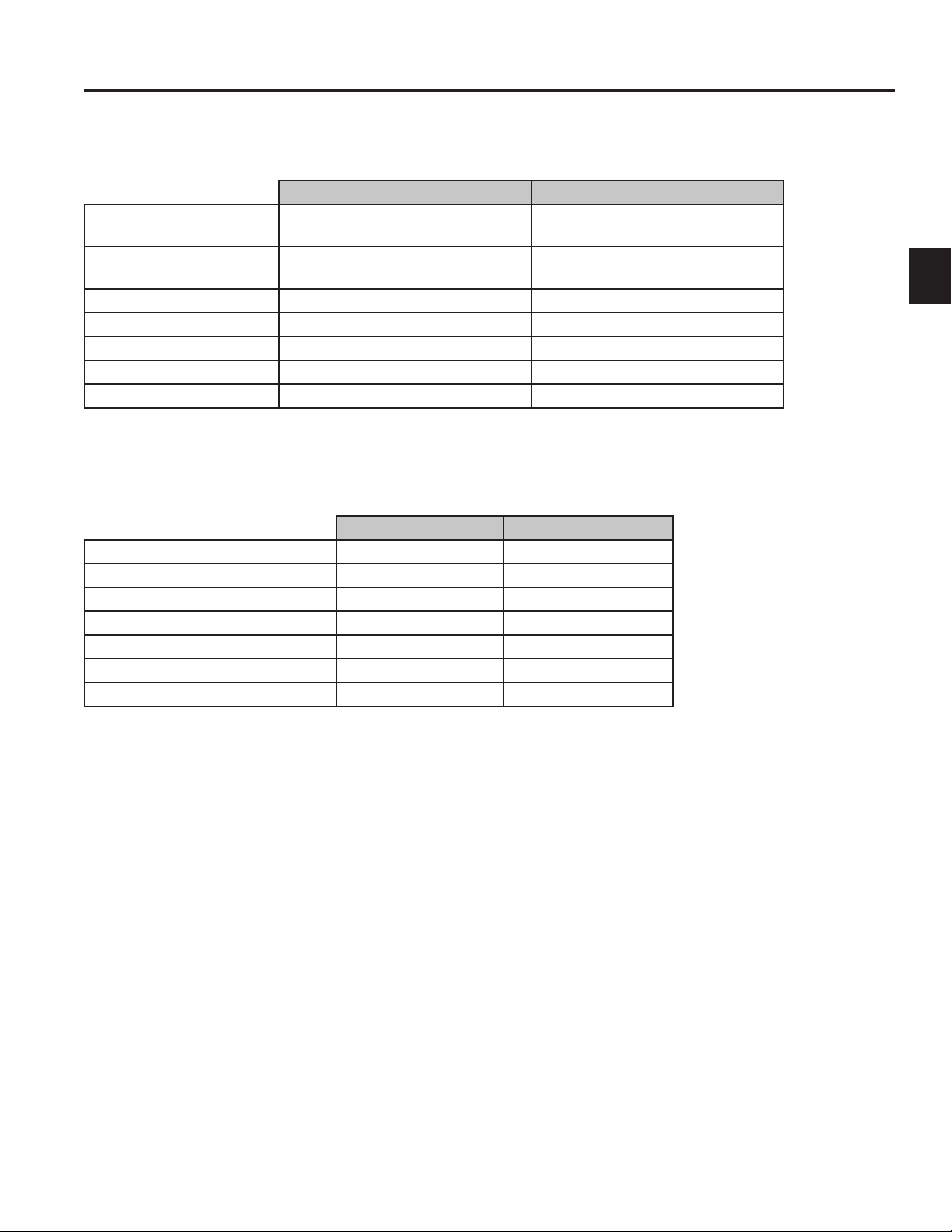

Model Engine Deck

74253 29 hp Kawasaki Liquid Cool DFI 60” (152.4cm) Turbo Force SD Mower

74254 29 hp Kawasaki Liquid Cool DFI 72” (182.8cm) Turbo Force SD Mower

74253CP 29 hp Kawasaki Liquid Cool DFI 60” (152.4cm) Turbo Force SD Mower

74254CP 29 hp Kawasaki Liquid Cool DFI 72” (182.8cm) Turbo Force SD Mower

Power System

Engine Kawasaki FD791D-AS07

High Idle 3800 ± 100 RPM

Low Idle 2250 ± 150 RPM

Engine Oil Capacity 2.1 qt. (1.98 L)

Heavy Duty Canister Air Cleaner Standard

Hydraulic Pumps Hydro-Gear variable displacement 16 cc/rev hydrostatic

with shock valves

Wheel Motors Twin Hydro-Gear HGM 18E positive displacement with

1.25” (3.175cm) heavy duty tapered shafts

Ground Speed Forward: 0 - 11 mph (0 - 17.7 k/hr)

Reverse: 0 - 6.3 mph (0 - 10.1 k/hr)

Hour Meter Standard

Rear Drive Tires 24” x 12.0 -12” 4 ply

Front Caster Tires 13” x 6.5 - 6” Semi-pneumatic with smooth tread

Tire Pressure 13 psi (89.6 kPa) (rear drive tires only)

Fuel / Capacity 12 gallons (6 gallons per tank) (45.4 L / 22.7 L per tank)

Cooling System Capacity 5.5 qt. (5.2 liter)

2

2-1Z580/Z589 DFI Z Master Service Manual

Page 13

2

SPECIFICATIONS

Electrical

Engine Charging Coil 40 Amp

Voltage 12 volt, negative ground

Battery BCI group 26, 540 CCA

Gauges and Alarms • Top panel mounted hour meter

• Audio alarm for excess engine temperature

• Lighted indicators for engine malfunction and excess engine temperature

• Push/pull PTO switch

Fuses Blade type, 30 Amp ignition, 30 Amp cooling fan and 10 Amp engine

Mowing Deck

60” (152.4cm) 72” (182.8cm)

Type Turbo Force™ Turbo Force™

Deck Construction Fabricated, 7-gauge high-strength

steel

Deck Depth 5-1/2” (13.97cm) 5-1/2” (13.97cm)

Adjustable Discharge Bafe Standard Standard

Spindle Housings Reinforced cast iron Reinforced cast iron

Spindle Shaft / Bearings 1” (2.54cm) Steel shaft/tapered roller

bearings

Blade Tip Speed 18,500 ft/min (5,638.8 meters/min) at

high idle

Height of Cut 1.5” - 5” in .25” increments

(3.81 - 12.7cm in .635cm increments)

Anti-Scalp Rollers 6 Adjustable 6 Adjustable

Fabricated, 7-gauge high-strength

steel

1” (2.54cm) Steel shaft/tapered roller

bearings

18,500 ft/min (5,638.8 meters/min) at

high idle

1.5” - 5” in .25” increments

(3.81 - 12.7cm in .635cm increments)

2-2 Z580/Z589 DFI Z Master Service Manual

Page 14

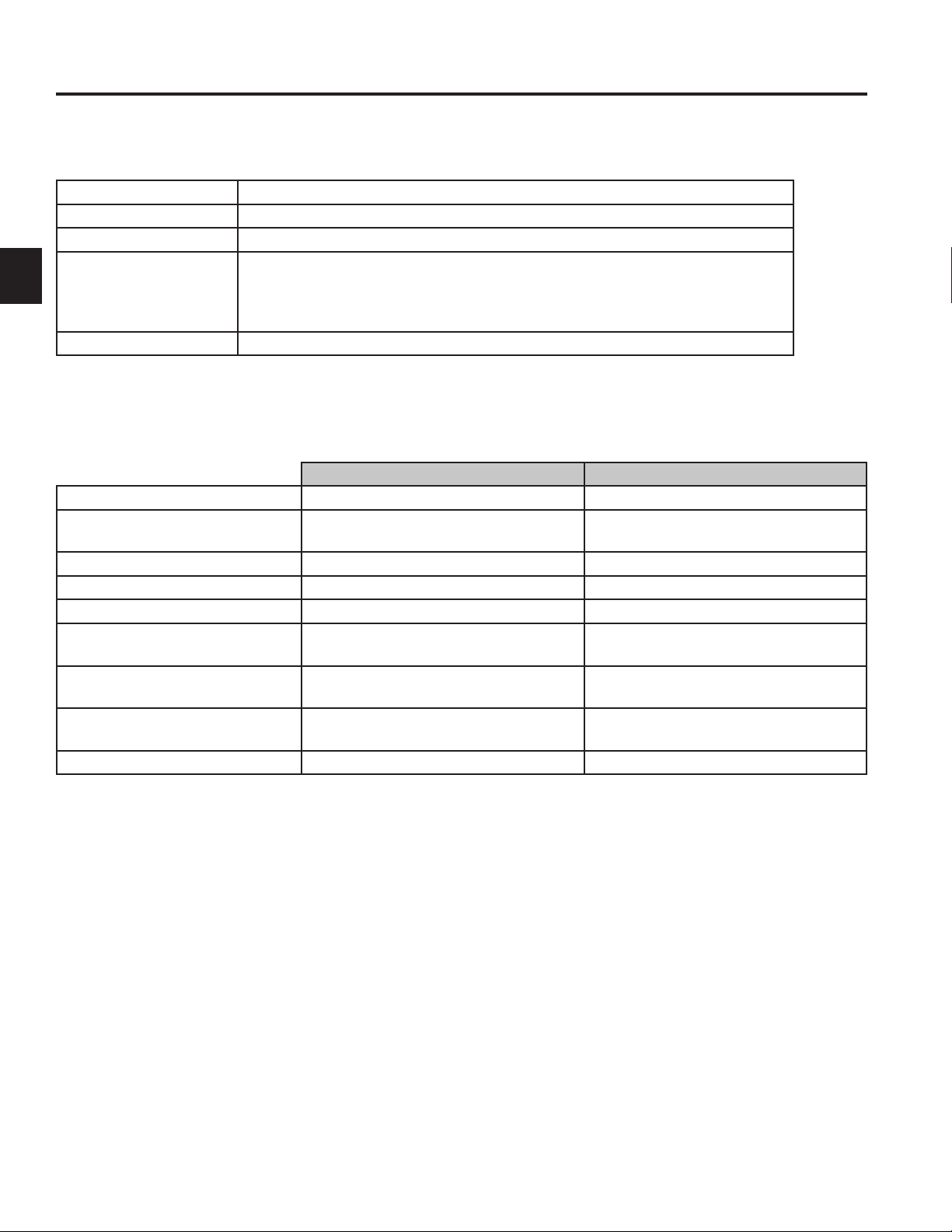

SPECIFICATIONS

Operator Zone

60” (152.4cm) 72” (182.8cm)

Steering Levers Dual, wrap-around hydraulically

dampened, with cushioned grips

Parking Brake Left hand operated lever with

cushioned grip

Folding ROPS Standard Standard

Deck Lift Assist Pedal Standard Standard

Arm Rests Standard Standard

Seat Belt Retractable Retractable

Z Stand Optional Optional

Dimensions

60” (152.4cm) 72” (182.8cm)

Weight 1423 lbs. (645kg) 1482 lbs. (672kg)

Wheel Base 53.6” (136cm) 56.8” (144.3kg)

Overall Length 81.6” (207cm) 84.6” (215cm)

Width Outside Tires 53.2” (135cm) 57.2” (145cm)

Overall Width (outside deck) 76” (193cm) 88” (224cm)

Gate Width 62” (157.5cm) 74” (188cm)

Overall Height 72” (183cm) 72” (183cm)

Dual, wrap-around hydraulically

dampened, with cushioned grips

Left hand operated lever with

cushioned grip

2

2-3Z580/Z589 DFI Z Master Service Manual

Page 15

SPECIFICATIONS

2

Torque Specications

Torque Specifications

Recommended fastener torque values are listed in the

following tables. For critical applications, as

determined by Toro, either the recommended torque or

a torque that is unique to the application is clearly

identified and specified in the service manual.

These torque specifications for the installation and

tightening of fasteners shall apply to all fasteners which

do not have a specific requirement identified in the

service manual. The following factors shall be

considered when applying torque: cleanliness of the

fastener, use of a thread sealant (Loctite), degree of

lubrication on the fastener, presence of a prevailing

torque feature, hardness of the surface underneath of

the fastener’s head, or similar condition which affects

the installation.

As noted in the following tables, torque values should

be reduced by 25% for lubricated fasteners to

achieve the similar stress as a dry fastener. Torque

values may also have to be reduced when the fastener

is threaded into aluminum or brass. The specific

torque value should be determined based on the

aluminum or brass material strength, fastener size,

length of thread engagement, etc.

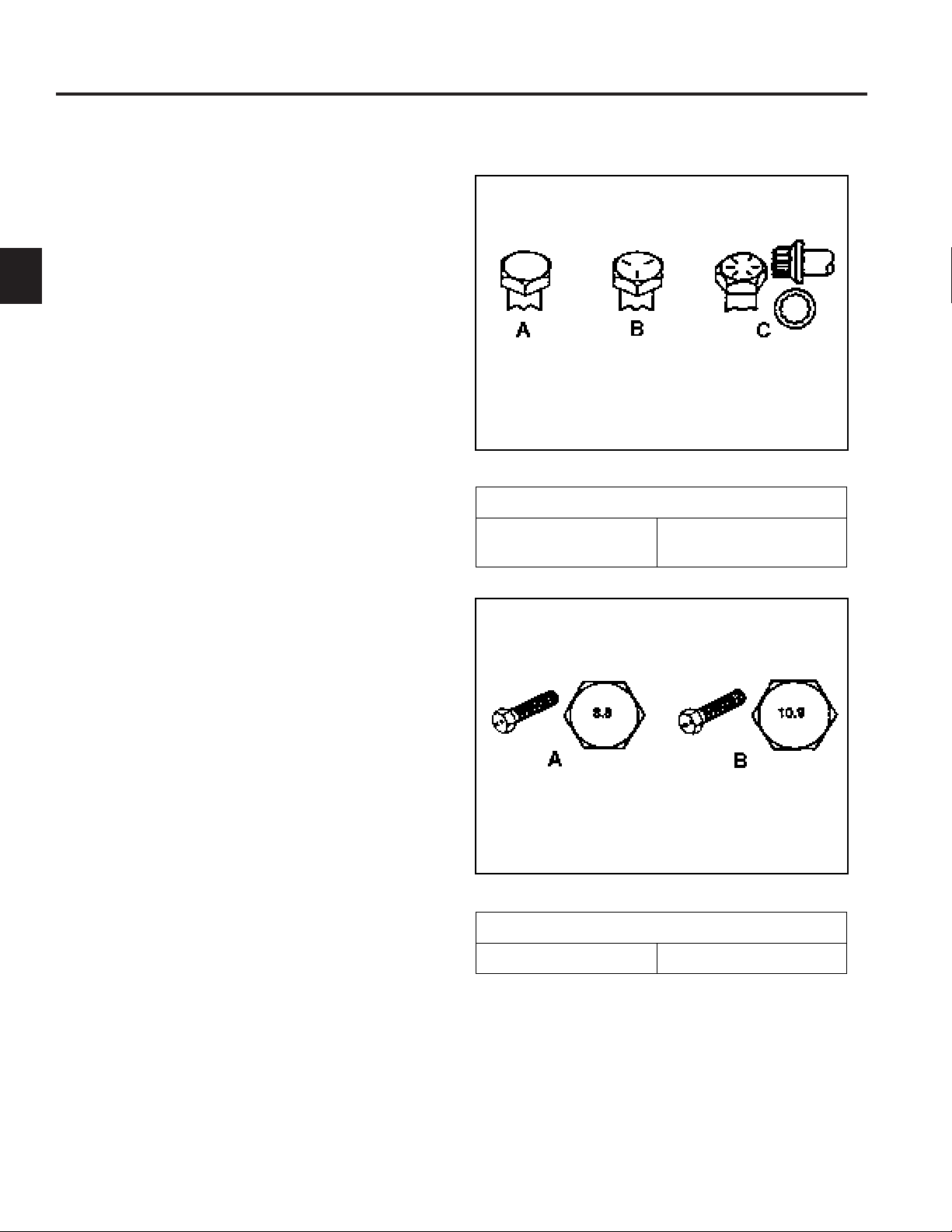

Fastener Identification

Inch Series Bolts and Screws

(A) Grade 1

(B) Grade 5

Figure A

(C) Grade 8

The standard method of verifying torque shall be

performed by marking a line on the fastener (head or

nut) and mating part, then back off fastener 1/4 of a

turn. Measure the torque required to tighten the

fastener until the lines match up.

Figure B

Metric Bolts and Screws

(A) Class 8.8 (B) Class 10.9

2-4 Z580/Z589 DFI Z Master Service Manual

Page 16

SPECIFICATIONS

2

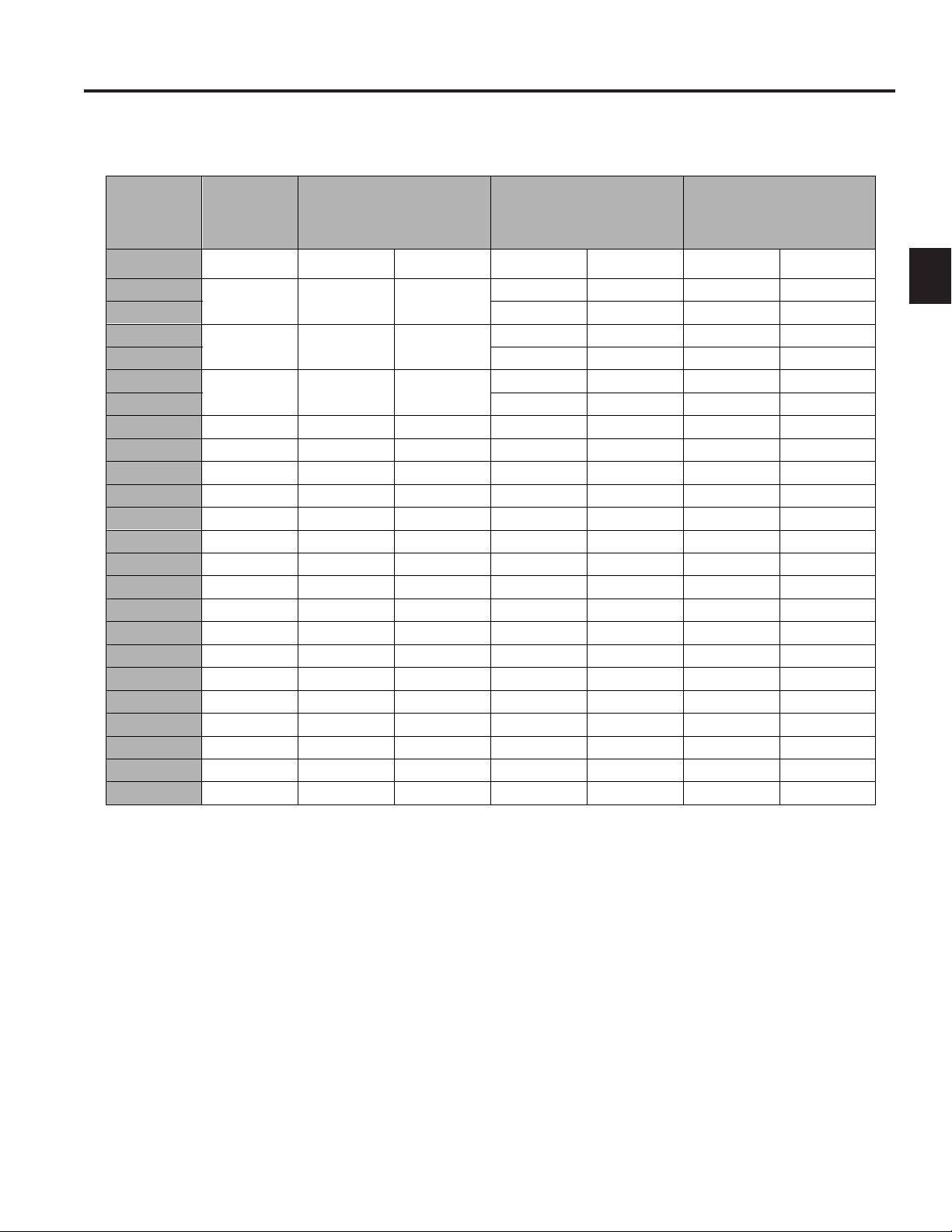

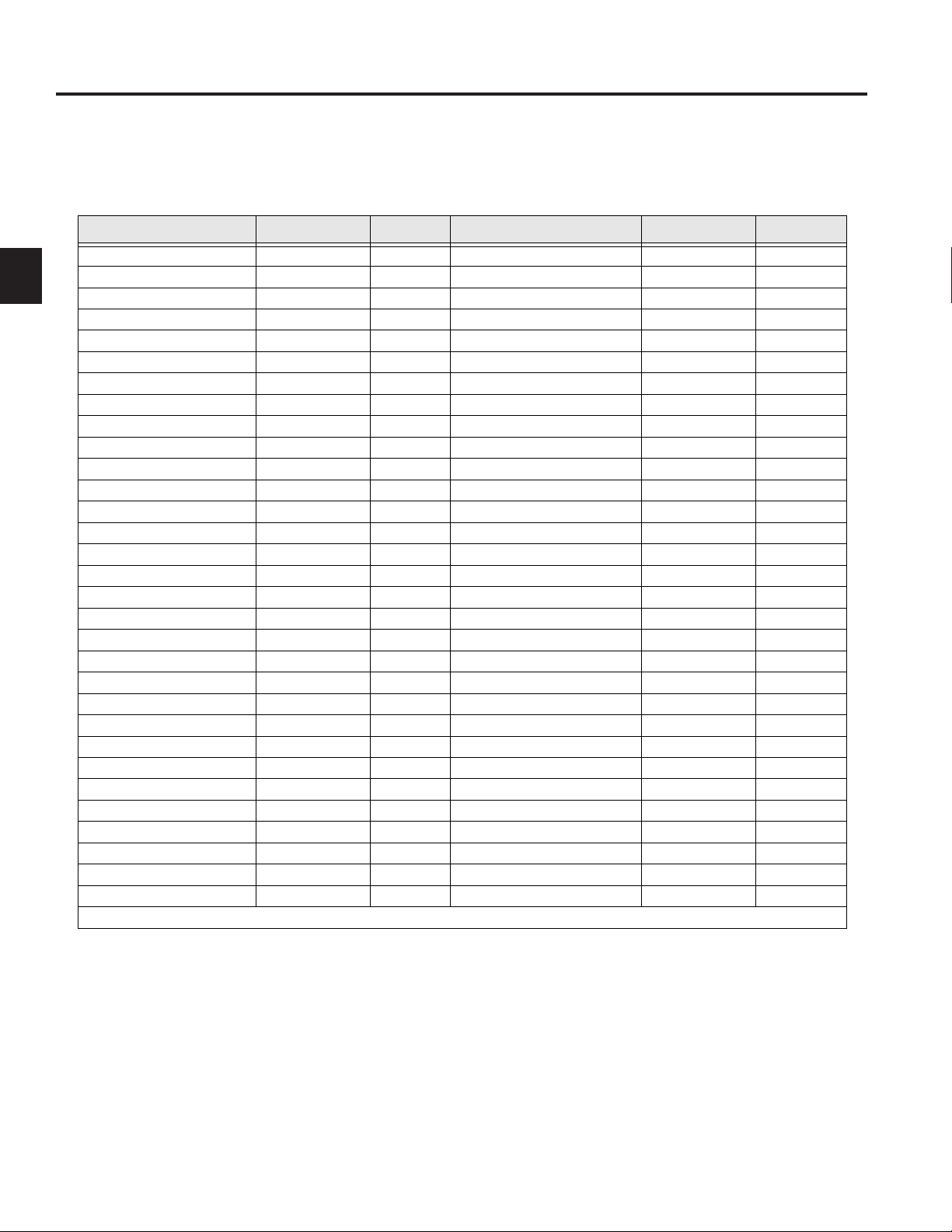

Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Inch Series)

Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Inch Series)

Grade 1, 5, &

Thread Size

# 6 - 32 UNC

# 6 - 40 UNF 17 ± 2 190 ± 20 25 ± 2 280 ± 20

# 8 - 32 UNC

# 8 - 36 UNF 31 ± 3 350 ± 30 43 ± 4 31 ± 3

# 10 - 24 UNC

#10 - 32 UNF 48 ± 4 540 ± 45 68 ± 6 765 ± 70

1/4 - 20 UNC 48 ± 7 53 ± 7 599 ± 79 100 ± 10 1125 ± 100 140 ± 15 1580 ± 170

1/4 - 28 UNF 53 ± 7 65 ± 10 734 ± 113 115 ± 10 1300 ± 100 160 ± 15 1800 ± 170

5/16 - 18 UNC 115 ± 15 105 ± 17 1186 ± 169 200 ± 25 2250 ± 280 300 ± 30 3390 ± 340

5/16 - 24 UNF 138 ± 17 128 ± 17 1446 ± 192 225 ± 25 2540 ± 280 325 ± 30 3670 ± 340

3/8 - 16 UNC 16 ± 2 16 ± 2 22 ± 3 30 ± 3 41 ± 4 43 ± 4 58 ± 5

3/8 - 24 UNF 17 ± 2 18 ± 2 24 ± 3 35 ± 3 47 ± 4 50 ± 4 68 ± 5

7/16 - 14 UNC 27 ± 3 27 ± 3 37 ± 4 50 ± 5 68 ± 7 70 ± 7 68 ± 9

7/16 - 20 UNF 29 ± 3 29 ± 3 39 ± 4 55 ± 5 75 ± 7 77 ± 7 104 ± 9

1/2 - 13 UNC 30 ± 3 48 ± 7 65 ± 9 75 ± 8 102 ± 11 105 ± 10 142 ± 14

1/2 - 20 UNF 32 ± 3 53 ± 7 72 ± 9 85 ± 8 115 ± 11 120 ± 10 163 ± 14

5/8 - 11 UNC 65 ± 10 88 ± 12 119 ± 16 150 ± 15 203 ± 20 210 ± 20 285 ± 27

5/8 - 18 UNF 75 ± 10 95 ± 15 129 ± 20 170 ± 15 230 ± 20 240 ± 20 325 ± 27

3/4 - 10 UNC 93 ± 12 140 ± 20 190 ± 27 265 ± 25 359 ± 34 374 ± 35 508 ± 47

3/4 - 16 UNF 115 ± 15 165 ± 25 224 ± 34 300 ± 25 407 ± 34 420 ± 35 569 ± 47

7/8 - 9 UNC 140 ± 20 225 ± 25 305 ± 34 430 ± 45 583 ± 61 600 ± 60 813 ± 81

7/8 - 14 UNF 155 ± 25 260 ± 30 353 ± 41 475 ± 45 644 ± 61 660 ± 60 895 ± 81

8 with Thin

Height Nuts

In-lb In-lb N-cm In-lb N-cm In-lb N-cm

10 ± 2 13 ± 2 147 ± 23

13 ± 2 25 ± 5 282 ± 30

18 ± 2 30 ± 5 339 ± 56

ft-lb ft-lb N-m ft-lb N-m ft-lb N-m

SAE Grade 1 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995

Grade 2 or Stronger Nuts)

SAE Grade 5 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995

Grade 2 or Stronger Nuts)

15 ± 2 170 ± 20 23 ± 2 260 ± 20

29 ± 3 330 ± 30 41 ± 4 460 ± 45

42 ± 4 475 ± 45 60 ± 6 674 ± 70

SAE Grade 8 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995

Grade 2 or Stronger Nuts)

2

Note: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

oil, graphite, or thread sealant such as Loctite.

Note: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

Note: The nominal torque values listed above for

Grade 5 and 8 fasteners are based on 75% of the

minimum proof load specified in SAE J429. The

tolerance is approximately

value. Thin height nuts include jam nuts.

± 10% of the nominal torque

2-5Z580/Z589 DFI Z Master Service Manual

Page 17

SPECIFICATIONS

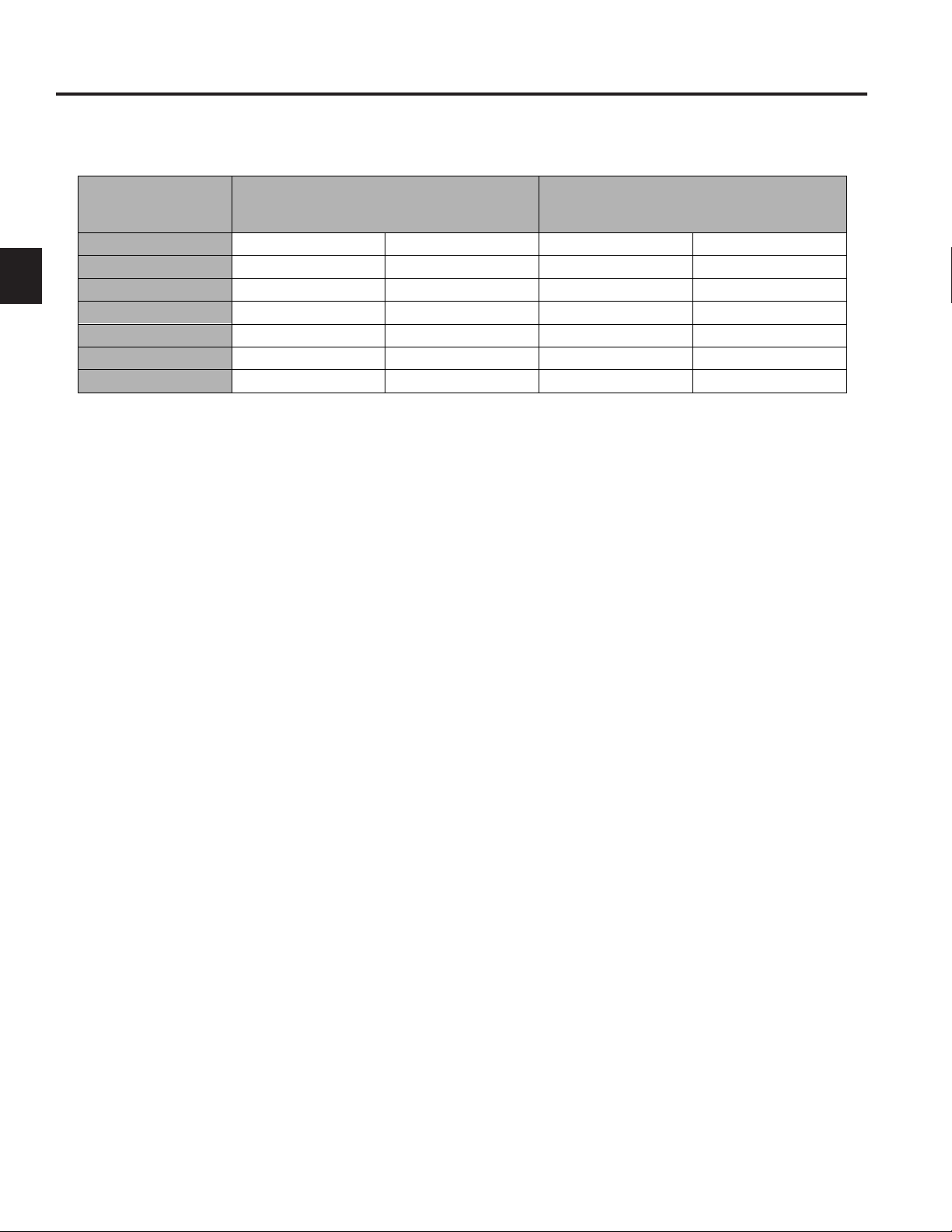

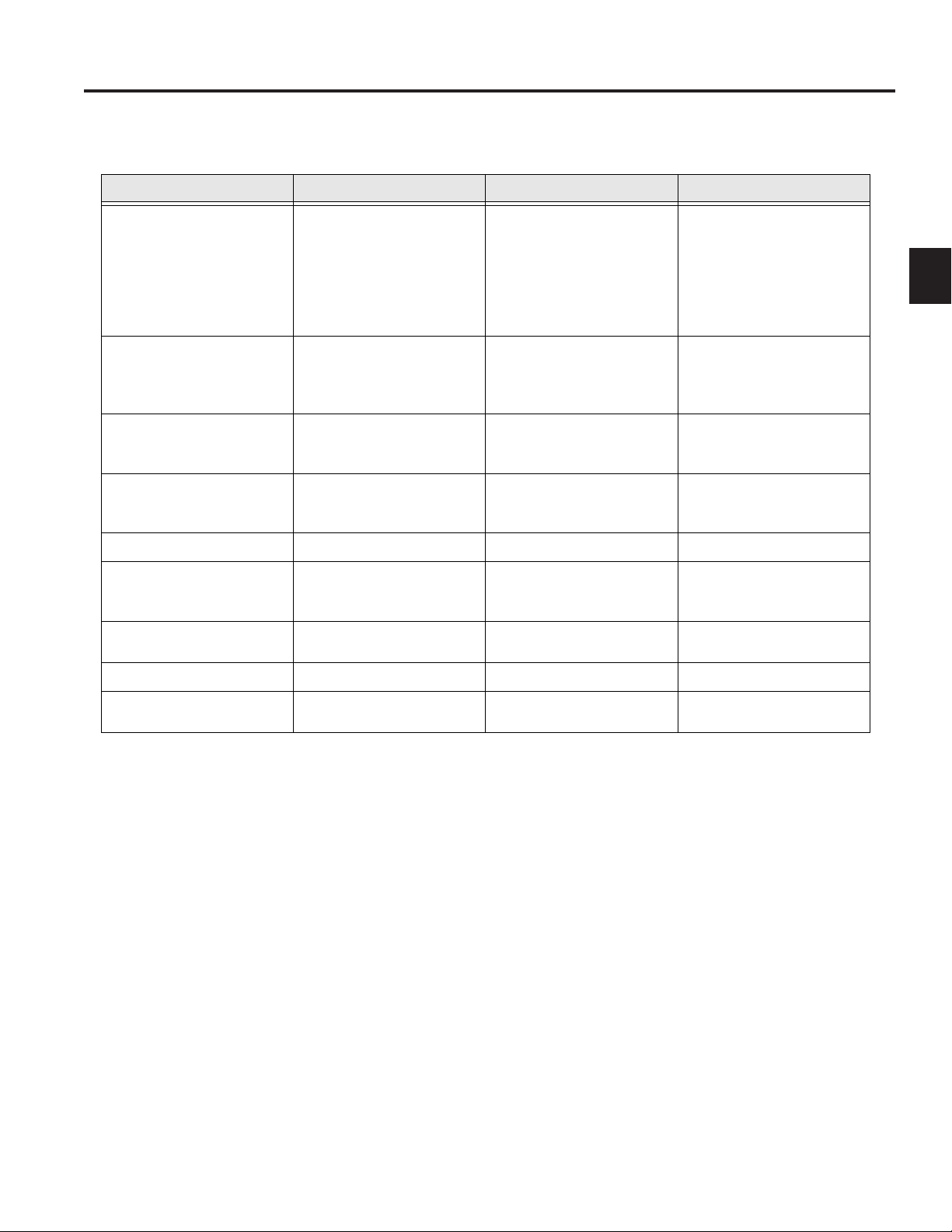

Standard Torque for Dry, Zinc, and Steel Fasteners (Metric Fasteners)

Standard Torque for Dry, Zinc, and Steel Fasteners (Metric Fasteners)

2

Class 8.8 Bolts, Screws, and Studs with

Thread Size

M5 X 0.8 57 ± 5 in-lb 640 ± 60 N-cm 78 ± 7 in-lb 885 ± 80 N-cm

M6 X 1.0 96 ± 9 in-lb 1018 ± 100 N-cm 133 ± 13 in-lb 1500 ± 150 N-cm

M8 X 1.25 19 ± 2 ft-lb 26 ± 3 N-m 27 ± 2 ft-lb 36 ± 3 N-m

M10 X 1.5 38 ± 4 ft-lb 52 ± 5 N-m 53 ± 5 ft-lb 72 ± 7 N-m

M12 X 1.75 66 ± 7 ft-lb 90 ± 10 N-m 92 ± 9 ft-lb 125 ± 12 N-m

M16 X 2.0 166 ± 15 ft-lb 225 ± 20 N-m 229 ± 22 ft-lb 310 ± 30 N-m

M20 X 2.5 325 ± 33 ft-lb 440 ± 45 N-m 450 ± 37 ft-lb 610 ± 50 N-m

Note: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

oil, graphite, or thread sealant such as Loctite.

Note: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

Regular Height Nuts

(Class 8 or Strong Nuts)

Note: The nominal torque values listed above are

based on 75% of the minimum proof load specified in

SAE J1199. The tolerance is approximately

the nominal torque value. Thin height nuts include jam nuts.

Class 10.9 Bolts, Screws, and Studs with

Regular Height Nuts (

Class 10 or Strong Nuts)

± 10% of

2-6 Z580/Z589 DFI Z Master Service Manual

Page 18

Other Torque Specications

Other Torque Specifications

SPECIFICATIONS

SAE Grade 8 Steel Set Screws

Recommended Torque

Thread Size

Square Head Hex Socket

1/4 - 20 UNC 140 ± 20 in-lb 73 ± 12 in-lb

5/16 - 18 UNC 215 ± 35 in-lb 145 ± 20 in-lb

3/8 - 16 UNC 35 ± 10 ft-lb 18 ± 3 ft-lb

1/2 - 13 UNC 75 ± 15 ft-lb 50 ± 10 ft-lb

Thread Cutting Screws

(Zinc Plated Steel)

Type 1, Type 23, or Type F

Thread Size Baseline Torque*

No. 6 - 32 UNC 20 ± 5 in-lb

No. 8 - 32 UNC 30 ± 5 in-lb

Wheel Bolts and Lug Nuts

Thread Size Recommended Torque**

7/16 - 20 UNF

Grade 5

1/2 - 20 UNF

Grade 5

M12 X 1.25

Class 8.8

M12 X 1.5

Class 8.8

** For steel wheels and non-lubricated fasteners.

Thread Cutting Screws

Thread

Size

No. 6 18 20 20 ± 5 in-lb

No. 8 15 18 30 ± 5 in-lb

Threads per Inch

Type A Type B

65 ± 10 ft-lb 88 ± 14 N-m

80 ± 10 ft-lb 108 ± 14 N-m

80 ± 10 ft-lb 108 ± 14 N-m

80 ± 10 ft-lb 108 ± 14 N-m

(Zinc Plated Steel)

Baseline Torque*

2

No.10 - 24 UNC 38 ± 7 in-lb

1/4 - 20 UNC 85 ± 15 in-lb

5/16 - 18 UNC 110 ± 20 in-lb

3/8 - 16 UNC 200 ± 100 in-lb

Conversion Factors

in-lb X 11.2985 - N-cm

ft-lb X 1.3558 = N-m

No. 10 12 16 38 ± 7 in-lb

No. 12 11 14 85 ± 15 in-lb

* Hole size, material strength, material thickness and

finish must be considered when determining specific

torque values. All torque values are based on nonlubricated fasteners.

N-cm X - 0.08851 = in-lb

N-cm X 0.73776 - ft-lb

2-7Z580/Z589 DFI Z Master Service Manual

Page 19

2

SPECIFICATIONS

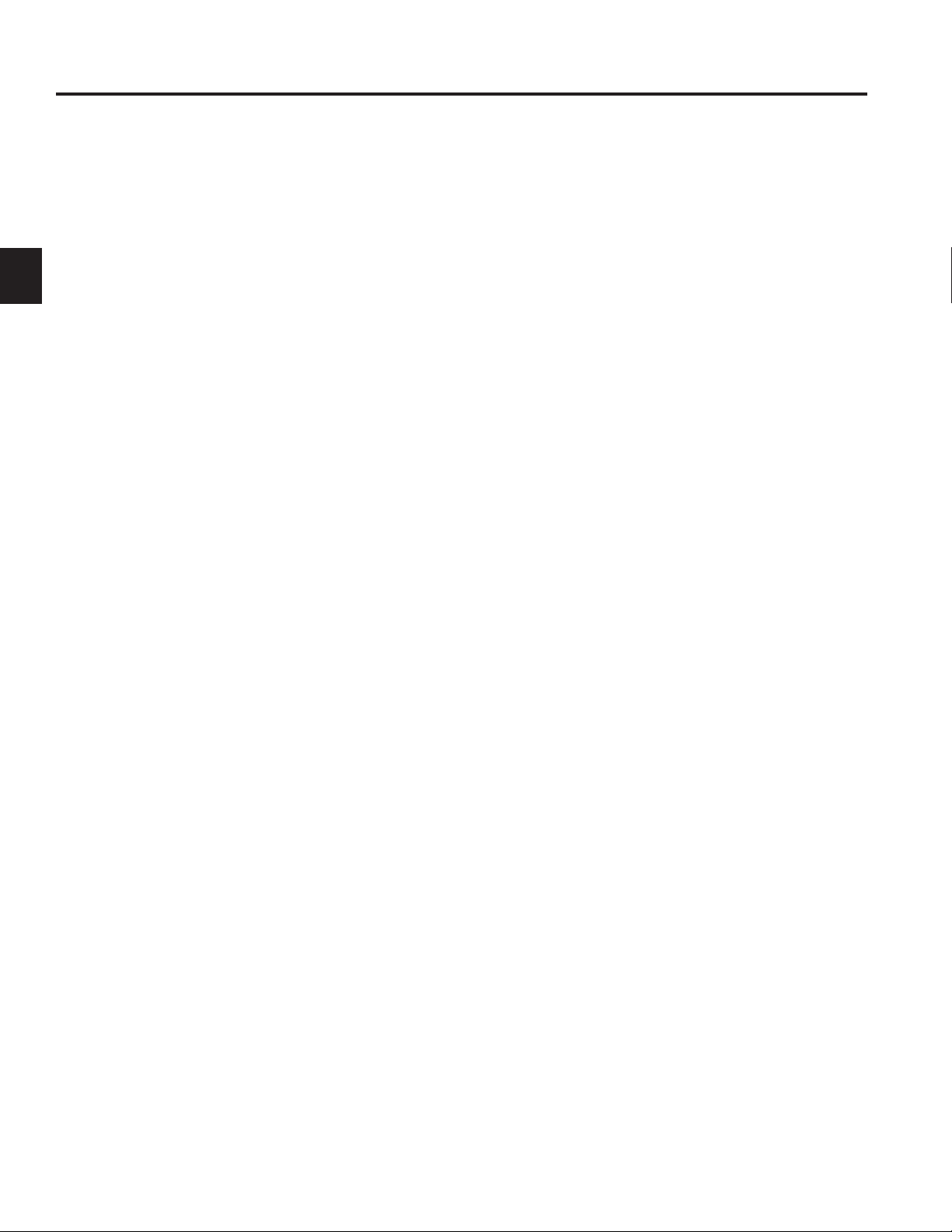

Equivalents and Conversions

Equivalents and Conversions

Decimal and Millimeter Equivalents

Decimal and Millimeter Equivalents

Fractions Decimals mm Fractions Decimals mm

1/64 0.015625 0.397 33/64 0.515625 13.097

1/32 0.03125 0.794 16/32 0.53125 13.484

3/64 0.046875 1.191 35/64 0.546875 13.891

1/16 0.0625 1.588 9/16 0.5625 14.288

5/64 0.078125 1.984 37/64 0.578125 14.684

3/32 0.9375 2.381 19/32 0.59375 15.081

1/8 0.1250 3.175 5/8 0.6250 15.875

9/64 0.140625 3.572 41/64 0.640625 16.272

5/32 0.15625 3.969 21/32 0.65625 16.669

11/64 0.171875 4.366 43/64 0.671875 17.066

3/16 0.1875 4.762 11/16 0.6875 17.462

13/64 0.203125 5.159 45/64 0.703125 17.859

7/32 0.21875 5.556 23/32 0.71875 18.256

15/64 0.234375 5.953 47/64 0.734375 18.653

1/4 0.2500 6.350 3/4 0.7500 19.050

17/64 0.265625 6.747 49/64 0.765625 19.447

9/32 0.28125 7.144 25/32 0.78125 19.844

19/64 0.296875 7.541 51/64 0.796875 20.241

5/16 0.3125 7.541 13/16 0.8125 20.638

21/64 0.328125 8.334 53/64 0.828125 21.034

11/32 0.34375 8.731 27/32 0.84375 21.431

23/64 0.359375 9.128 55/64 0.859375 21.828

3/8 0.3750 9.525 7/8 0.8750 22.225

25/64 0.390625 9.922 57/64 0.890625 22.622

13/32 0.40625 10.319 29/32 0.90625 23.019

27/64 0.421875 10.716 59/64 0.921875 23.416

7/16 0.4375 11.112 15/16 0.9375 23.812

29/64 0.453125 11.509 61/64 0.953125 24.209

15/32 0.46875 11.906 31/32 0.96875 24.606

31/64 0.484375 12.303 63/64 0.984375 25.003

1/2 0.5000 12.700 1 1.000 25.400

1 mm = 0.03937 in. 0.001 in. = 0.0254 mm

2-8 Z580/Z589 DFI Z Master Service Manual

Page 20

Linear

Measurement

Area

Volume

Weight

Pressure

Work

Liquid Volume

Liquid Flows

Temperature

SPECIFICATIONS

U.S. to Metric Conversions

U.S. to Metric Conversions

To Convert Into Multiply By

Miles

Yards

Feet

Feet

Inches

Inches

Inches

Square Miles

Square Feet

Square Inches

Acre

Cubic Yards

Cubic Feet

Cubic Inches

Tons (Short)

Pounds

Ounces

Pounds/Sq. In. Kilopascal

Foot-pounds

Foot-pounds

Inch-pounds

Quarts

Gallons

Gallons/Minute Liters/Minute

Fahrenheit Celsius

Kilometers

Meters

Meters

Centimeters

Meters

Centimeters

Millimeters

Square Kilometers

Square Meters

Square Centimeters

Hectare

Cubic Meters

Cubic Meters

Cubic Centimeters

Metric Tons

Kilograms

Grams

Newton-Meters

Kilogram-Meters

Kilogram-Centimeters

Liters

Liters

1.609

0.9144

0.3048

30.48

0.0254

2.54

25.4

2.59

0.0929

6.452

0.4047

0.7646

0.02832

16.39

0.9078

0.4536

28.3495

6.895

1.356

0.1383

1.152144

0.9463

3.785

3.785

1. Subtract 32°

2. Multiply by 5/9

2

2-9Z580/Z589 DFI Z Master Service Manual

Page 21

2

SPECIFICATIONS

THIS PAGE INTENTIONALLY LEFT BLANK.

2-10 Z580/Z589 DFI Z Master Service Manual

Page 22

CHASSIS

Castor Fork Assembly Replacement

Castor Fork Assembly Removal

1. Raise the front of the machine off the ground leaving

enough clearance to remove the castor fork from the

carrier frame.

2. Remove the grease cap from the frame (Fig. 001).

3. Remove the locknut (Fig. 002).

3

Fig 002 IMG-7874a

4. Slide the castor fork assembly out of the frame (Fig.

003).

Fig 001 IMG-7694a

Fig 003 IMG-7700a

3-1Z580/Z589 DFI Z Master Service Manual

Page 23

CHASSIS

3

Castor Bearing Replacement

1. Remove the 3 Belleville washers (Fig. 004).

Fig 004 IMG-7703a

3. Remove the bottom grease seal (Fig. 006).

Fig 006 IMG-7709a

4. Remove the bottom tapered bearing (Fig. 007).

2. Remove the top tapered bearing (Fig. 005).

Fig 005 IMG-7706a

Fig 007 IMG-7711a

3-2 Z580/Z589 DFI Z Master Service Manual

Page 24

CHASSIS

5. Drive the top and bottom tapered bearing cups out of

the caster fork hub (Fig. 008).

Fig 008 IMG-7714a

6. Install new tapered bearing cups by pressing each

bearing cup into the caster fork hub so that the thick-

er part of the taper is pressed in rst. The bearing

cups should seat against the shoulder inside the

frame.

Section view of caster fork hub (Fig. 009):

7. Pack the upper and lower tapered bearings with

grease (No. 2 general purpose lithium base or

molybdenum grease).

8. Install the lower bearing into the caster fork hub (Fig.

010).

3

Fig 010 IMG-7722a

9. Install the grease seal into the caster fork hub (Fig.

011).

A

B

C

A

Fig 009 tapered bearing cup install

A. Tapered Bearing Cup (2)

B. Caster fork hub (sectioned)

C. Machined shoulder inside caster fork hub (2)

Fig 011 IMG-7725a

3-3Z580/Z589 DFI Z Master Service Manual

Page 25

CHASSIS

3

10. Install the upper bearing into the caster fork hub

(Fig. 012).

Fig 012 IMG-7731a

Castor Fork Assembly Installation

1. Install 3 Bellville washers as shown (Fig. 013):

A

Fig 013 g. 49 G001297

A. Belleville washers

2. Slide the castor fork assembly into the hub (Fig.

014).

Fig 014 IMG-7700a

3-4 Z580/Z589 DFI Z Master Service Manual

Page 26

CHASSIS

3. Install the locknut. Tighten the locknut until the

Belle ville washers are at, then back the nut off 1/4

turn to properly set the preload on the bearings (Fig.

015).

Fig 015 IMG-7874a Fig 017 IMG-7734a

5. Remove the grease tting and install the grease

plug.

6. Install the dust cap onto the frame (Fig. 017).

3

4. Remove the plug located on the side of the castor

hub. Install a grease tting. Apply grease (No.

2 general purpose lithium base or molybdenum

grease) into the hub until it passes through the upper

bear ing. Fill the top cavity with grease (Fig. 016).

Fig 016 PICT-2897a

3-5Z580/Z589 DFI Z Master Service Manual

Page 27

CHASSIS

3

Front Wheel Bearing Replacement

1. Raise the front of the machine off the ground.

2. Remove the wheel axle bolt and nut (Fig. 018).

Fig 018 IMG-7736a

4. Remove the castor spacer from the wheel assembly

(Fig. 020).

Fig 020 IMG-7742a

5. Remove both bearing spacers (one on each side)

from the wheel assembly (Fig. 021).

3. Remove the wheel assembly from the fork (Fig.

019).

Fig 019 IMG-7878a

Fig 021 IMG-7744a

3-6 Z580/Z589 DFI Z Master Service Manual

Page 28

CHASSIS

6. Drive the bearing cup, bearing and bearing seal out

of the wheel assembly. Repeat on the opposite side

(Fig. 022).

Fig 022 IMG-7748a

Wheel Assembly (Fig. 023)

7. Install a new tapered bearing cup into the wheel

assembly by pressing each bearing cup into the

wheel hub so that the thicker part of the taper is

pressed into the wheel hub rst. The bearing cups

should seat against the shoulder divots inside the

wheel hub (Fig. 024).

3

Fig 024 IMG-7881a

E

A AB BC CD D

F

H

Fig 023 IMG-7880a

A. Bearing spacer (2) E. Wheel and tire

B. Grease seal (2) assembly

C. Tapered bearing (2) F. Caster spacer

D. Tapered bearing G. Wheel assembly axle

cup (2) bolt

H. Nut

G

8. Pack both tapered bearings with grease (No. 2 general purpose lithium base or molybdenum grease).

9. Install the tapered bearings into each side of the

wheel hub (Fig. 025).

Fig 025 IMG-7882a

3-7Z580/Z589 DFI Z Master Service Manual

Page 29

CHASSIS

3

10. Install the grease seals into each side of the wheel

hub (Fig. 026).

Fig 026 IMG-7883a

11. Install a bearing spacer into each side of the wheel

hub (Fig. 027).

12. Install the castor spacer into the wheel hub (Fig.

028).

Fig 028 IMG-7885a

13. Position the wheel assembly into the caster fork (Fig.

029).

Fig 027 IMG-7884a

3-8 Z580/Z589 DFI Z Master Service Manual

Fig 029 IMG-7878a

Page 30

CHASSIS

14. Install the axle bolt and nut securing the wheel as-

sembly to the fork (Fig. 030).

Fig 030 IMG-7736a

15. Apply grease (No. 2 general purpose lithium base or

molybdenum grease) to the wheel assembly grease

tting (Fig. 031).

Fuel Tank Replacement

Right Side Fuel Tank Removal

1. Raise the seat and remove the front engine shield

(Fig. 032).

3

Fig 032 IMG-0303a

Fig 031 IMG-7886a

2. Turn the fuel shut-off valve to OFF position (Fig.

033).

Fig 033 IMG-0304a

3-9Z580/Z589 DFI Z Master Service Manual

Page 31

CHASSIS

3

3. Disconnect the negative battery cable.

4. Remove the right rear wheel assembly (Fig. 034).

Fig 034 IMG-0307a

6. Remove the clamp securing the return fuel line to

the tting on the operator’s side of the fuel tank.

Slide the fuel hose off the tting (Fig. 036).

Fig 036 IMG-0309a

5. Remove the clamp securing the fuel line to the tting

on the bottom of the fuel tank. Slide the fuel hose off

the tting and drain the fuel from the tank (Fig. 035).

Fig 035 IMG-0308a

7. Remove the nuts, springs and washers from the 3

studs on the underside of the fuel tank (Fig. 037).

A

B

B

C

C C

Fig 037 RH fuel tank fasteners a

A. Fuel tank C. Mounting stud fastener

B. Frame assembly (3)

3-10 Z580/Z589 DFI Z Master Service Manual

Page 32

CHASSIS

8. Remove the bolt, lockwasher and washer securing

the left front corner of the fuel tank to the frame (Fig.

038).

Fig 038 IMG-0310a

Right Side Fuel Tank Installation

1. Position the fuel tank onto the frame (Fig. 040).

3

Fig 040 IMG-0313a

9. Lift the fuel tank off the frame (Fig. 039).

Fig 039 IMG-0313a

2. Slide a hose clamp onto the return fuel line. Slide

the return fuel line onto the tting located on the

operator’s side of the fuel tank (Fig. 041).

Fig 041 IMG-0317a

3-11Z580/Z589 DFI Z Master Service Manual

Page 33

CHASSIS

3

3. Position the hose clamp and tighten (Fig. 042).

Fig 042 IMG-0320a

4. Slide a hose clamp onto the intake fuel line. Slide

the intake fuel line onto the tting located on the

bottom of the fuel tank. Position the hose clamp and

tighten (Fig. 043).

5. Loosely install a bolt, lock washer, and washer

through the frame and into the front left corner of the

fuel tank (Fig. 044).

Fig 044 IMG-0310a

6. Loosely install a washer, spring and nut onto each

of the three studs on the underside of the fuel tank

(Fig. 045).

Fig 043 IMG-0321a

A

B

B

C

C C

Fig 045 RH fuel tank fasteners a

3-12 Z580/Z589 DFI Z Master Service Manual

Page 34

CHASSIS

7. Tighten the 3 nuts until three threads protrude past

the nut. Do not over-tighten (Fig. 046).

Fig 046 PICT-3290a

8. Tighten the bolt located in the front corner of the

tank to frame (Fig. 047).

9. Install the right rear wheel assembly (Fig. 048).

3

Fig 048 IMG-0307a

10. Install the negative battery cable.

11. Install the front engine shield (Fig. 049).

Fig 047 IMG-0310a

Fig 049 IMG-0303a

3-13Z580/Z589 DFI Z Master Service Manual

Page 35

CHASSIS

3

Left Side Fuel Tank Removal

1. Raise the seat and remove the front engine shield

(Fig. 050).

Fig 050 IMG-0303a

3. Disconnect the negative battery cable.

4. Remove the left rear wheel assembly (Fig. 052).

Fig 052 IMG-0322a

2. Turn the fuel shut-off valve to the “OFF” position

(Fig. 051).

Fig 051 IMG-0304a

5. Remove the 4 screws and washers securing the

control panel to the fuel tank (Fig. 053).

Fig 053 IMG-0327a

3-14 Z580/Z589 DFI Z Master Service Manual

Page 36

CHASSIS

6. Remove the cable tie securing the throttle cable to

the fuel tting (Fig. 054).

Fig 054 IMG-0328a

7. Move the control panel assembly away from the fuel

tank (Fig. 055).

8. Remove the hose clamp from the fuel return line and

tting located on the operator’s side of the fuel tank

(Fig. 056).

3

Fig 056 IMG-0333a

9. Remove the return fuel line from the fuel tting (Fig.

057).

Fig 055 IMG-0331a

Fig 057 IMG-0335a

3-15Z580/Z589 DFI Z Master Service Manual

Page 37

CHASSIS

3

10. Remove the hose clamp from the fuel intake line and

tting located on the underside of the fuel tank (Fig.

058).

Fig 058 IMG-0338a

11. Remove the fuel line from the fuel tting and drain

the fuel from the fuel tank (Fig. 059).

12. Remove the nuts, springs and washers from the 3

fuel tank mounting studs located on the underside of

the fuel tank (Fig. 060).

A

B

C

C

C

Fig 060 LH fuel tank fasteners a

A. Fuel tank C. Mounting stud fastener

B. Frame assembly (3)

Fig 059 IMG-0341a

13. Remove the nut and washer retaining the fuel shutoff valve to the fuel valve bracket (Fig. 061).

Fig 061 IMG-0351a

3-16 Z580/Z589 DFI Z Master Service Manual

Page 38

CHASSIS

14. Remove the bolt and washers securing the right

front corner of the fuel tank to the frame (Fig. 062).

Fig 062 IMG-0350a

15. Remove the fuel tank from the frame (Fig. 063).

Left Side Fuel Tank Installation

1. Position the fuel tank onto the frame (Fig. 064).

3

Fig 064 IMG-0345a

2. Slide a hose clamp onto the return fuel hose. Install

the fuel return hose onto the fuel-tting barb located

on the operator’s side of the fuel tank. Slide the hose

clamp into position and tighten (Fig. 065).

Fig 063 IMG-0345a

Fig 065 IMG-0354a

3-17Z580/Z589 DFI Z Master Service Manual

Page 39

CHASSIS

3

3. Slide the hose clamp onto the fuel intake hose.

Install the fuel intake hose onto the fuel-tting barb

located on the underside of the fuel tank. Slide the

hose clamp into position and tighten (Fig. 066).

Fig 066 IMG-0338a

5. Loosely install a washer, spring and nut onto each

of the three studs on the underside of the fuel tank

(Fig. 068).

A

B

C

C

C

Fig 068 lh fuel tank fasteners

A. Fuel tank C. Mounting stud fastener

B. Frame assembly (3)

4. Install a bolt, lock washer, and washer into the right

front corner of the fuel tank securing it to the frame

(Fig. 067).

Fig 067 IMG-0350a

6. Tighten the nuts until three threads protrude past the

nut. Do not over-tighten (Fig. 069).

Fig 069 PICT-3290

3-18 Z580/Z589 DFI Z Master Service Manual

Page 40

CHASSIS

7. Install the fuel shut-off valve to the fuel valve bracket

with a washer and nut (Fig. 070).

Fig 070 IMG-0351a

8. Install 4 screws and washers securing the control

panel to the fuel tank (Fig. 071).

9. Install a cable tie securing the throttle cable to the

fuel tank tting located on the operator’s side of the

fuel tank (Fig. 072).

3

Fig 072 IMG-0416a

10. Install the left rear tire assembly and lower the

machine to the ground.

Fig 071 IMG-0327a

11. Install the negative battery cable.

12. Install the front engine shroud (Fig. 073).

Fig 073 IMG-0303a

13. Lower the seat.

3-19Z580/Z589 DFI Z Master Service Manual

Page 41

CHASSIS

3

Fuel Tank Fitting Replacement

There are 2 fuel ttings located on each of the fuel tanks.

The following procedure can be used to replace any of

the ttings (Fig. 074).

Fig 074 IMG-7771a

2. Using a magnet tool, remove the tting from the

inside of the fuel tank (Fig. 076).

Fig 076 IMG-7774a

3. Using a magnet tool, install a fuel tank tting by

inserting it through the fuel tank opening (Fig. 077).

1. Remove the nut and washer securing the tting to

the fuel tank (Fig. 075).

Fig 075 IMG-7772a

Fig 077 IMG-7775a

3-20 Z580/Z589 DFI Z Master Service Manual

Page 42

CHASSIS

4. Loosely install a washer and nut to secure the fuel

tank tting to the fuel tank (Fig. 078).

Fig 078 IMG-7772a

5. Position the fuel tank ttings as shown (Fig. 079, Fig.

080 and Fig. 081):

Right side fuel tank operator’s side tting

3

Fig 080 DSC-4856a

Left side fuel tank operator’s side tting

Right and left fuel tank bottom tting

Fig 079 IMG-7781a

Fig 081 DSC-4854a

6. Tighten the tting nut.

3-21Z580/Z589 DFI Z Master Service Manual

Page 43

CHASSIS

3

Hood Assembly Replacement

Hood Assembly Removal

1. Unhook the rubber latch that is located on the rear of

the hood (Fig. 082).

Fig 082 IMG-0361a

3. Lift the hood and remove from the machine (Fig.

084).

Fig 084 IMG-0369a

2. Remove the two hairpin cotters, clevis pins, and

washers in the left and right hinges (Fig. 083).

Fig 083 IMG-0365a

3-22 Z580/Z589 DFI Z Master Service Manual

Page 44

CHASSIS

Hood Assembly Installation

1. Align the hood pivot brackets with holes in the pivot

bracket on the frame (Fig. 085).

Fig 085 IMG-0370a

2. Install a clevis pin, washer and hairpin cotter into

each of the pivot brackets (Fig. 086).

Note: The hood screen can contact the radiator cap.

The pressure on the cap can result in a crack

at the cap adapter joint, resulting in loss of

radiator pressure and overheating.

Check the clearance between the hood screen

and the radiator cap. If there is any interfer

ence, the hood can be adjusted using the

slotted holes in the hood mounting brackets.

3

Fig 086 IMG-0365a

3-23Z580/Z589 DFI Z Master Service Manual

Page 45

CHASSIS

3

Hood hinge plate adjustment slots (Fig. 087).

Fig 087 IMG-0381a

Hood pivot plate adjustment slots (Fig. 088).

3. Lower the hood and hook the rubber latch located at

the rear of the hood (Fig. 089).

Fig 089 IMG-0361a

Fig 088 IMG-0382a

3-24 Z580/Z589 DFI Z Master Service Manual

Page 46

CHASSIS

Throttle Control Assembly Replacement

Throttle Control Assembly Removal

1. Raise the seat.

2. Disconnect the negative battery cable from the

battery terminal.

3. Remove the knob from the throttle control assembly

(Fig. 090).

4. Remove the 4 screws securing the control panel to

the left hand fuel tank (Fig. 091).

3

Fig 091 IMG-0385a

5. Remove the locknuts and carriage bolts securing the

throttle control to the control panel (Fig. 092).

Fig 090 IMG-0383a

Fig 092 IMG-0386a

3-25Z580/Z589 DFI Z Master Service Manual

Page 47

CHASSIS

3

6. Remove the front engine panel shield assembly (Fig.

093).

Fig 093 IMG-0303a

7. Remove the cable tie securing the throttle cable to

the fuel tank tting (Fig. 094).

8. Remove the cable tie securing the throttle cable to

the bracket located behind the voltage regulator (Fig.

095).

Fig 095 IMG-0387a

9. Loosen the cable clamp and remove the throttle

cable (Fig. 096).

Fig 094 IMG-0328a

Fig 096 IMG-0388a

3-26 Z580/Z589 DFI Z Master Service Manual

Page 48

CHASSIS

10. Remove the z-bend end of the cable from the throttle

arm assembly (Fig. 097).

Fig 097 IMG-0390a

11. Remove the throttle cable from the unit.

Throttle Control Assembly Installation

1. Slide the throttle cable through the slot in the side of

the control panel (Fig. 098).

3

Fig 098 IMG-0392a

2. Install the throttle cable assembly into the slot in the

control panel (Fig. 099).

Fig 099 IMG-0393a

3-27Z580/Z589 DFI Z Master Service Manual

Page 49

CHASSIS

3

3. Install the carriage bolts and locknuts securing the

throttle control assembly to the control panel (Fig.

100).

Fig 100 IMG-0386a

4. Route the throttle cable behind the fuel tank tting

(Fig. 101).

5. Route the throttle cable behind the engine breather

tube (Fig. 102).

Fig 102 IMG-0397a

6. Then route the cable back on the right side of the

engine to the throttle linkage (Fig. 103).

Fig 103 IMG-0405a

Fig 101 IMG-0396a

3-28 Z580/Z589 DFI Z Master Service Manual

Page 50

CHASSIS

7. Insert the z-bend of the throttle cable into the throttle

arm assembly (Fig. 104).

Fig 104 IMG-0406a

8. Install the throttle cable into the cable clamp on the

engine throttle linkage (Fig. 105).

9. Install the 4 screws securing the control panel to the

left hand fuel tank. Install the knob for the throttle

control assembly. Move the throttle control to the low

idle speed setting (Fig. 106).

3

Fig 106 IMG-0408a

10. Adjust the throttle linkage on the engine. Lightly

push the cable toward the Z-bend end of the cable

and tighten the cable clamp (Fig. 107).

Fig 105 IMG-0407a

Fig 107 IMG-0410a

3-29Z580/Z589 DFI Z Master Service Manual

Page 51

CHASSIS

3

11. Install a cable tie securing the throttle cable to the

bracket located behind the voltage regulator (Fig.

108).

Fig 108 IMG-0414a

12. Install a cable tie securing the throttle cable to the

fuel tank tting located on the operator’s side of the

fuel tank (Fig. 109).

13. Install the front engine shield assembly (Fig. 110).

Fig 110 IMG-0303a

14. Connect the negative battery cable.

15. Start the unit and operate the throttle control, to

check for proper function and adjustment.

Fig 109 IMG-0416a

3-30 Z580/Z589 DFI Z Master Service Manual

Page 52

CHASSIS

Brake Lever Replacement

The left fuel tank and hood have been removed for photo

purposes.

Brake Lever Removal

1. Raise the seat.

2. Disconnect the negative battery cable from the

battery terminal.

3. Lower the seat.

4. Release the parking brake (forward position).

5. Remove the cotter pin and clevis pin securing the

brake linkage yoke to the brake lever assembly (Fig.

111).

6. Lift the oor pan assembly.

7. Remove the brake lever pivot shaft cotter pin (Fig.

112).

3

Fig 112 IMG-7922a

Fig 111 PICT-2915a

8. Slide the brake lever out of the pivot bushings (Fig.

113).

Fig 113 PICT-2913a

3-31Z580/Z589 DFI Z Master Service Manual

Page 53

3

CHASSIS

9. With a hammer and punch tap out the two pivot

bushings (Fig. 114).

Fig 114 PICT-2883a

10. Inspect the brake shaft and bushings for excessive

wear. Replace any worn or damaged components

(Fig. 115).

Fig 115 PICT-2887a

3-32 Z580/Z589 DFI Z Master Service Manual

Page 54

CHASSIS

Brake Lever Installation

1. Raise the oor pan assembly.

2. Install the two bushings into the brake lever pivot

mounting hole (Fig. 116).

Fig 116 PICT-2891a

4. Install a cotter pin into the pivot shaft (Fig. 118).

3

Fig 118 IMG-7922a

5. Lower the oor pan assembly.

6. Move the parking brake lever into the released

(forward) position.

3. Slide the brake lever assembly pivot through the

bushings (Fig. 117).

Fig 117 PICT-2892a

7. Position the brake linkage yoke to the brake lever.

Install a clevis and cotter pin to secure (Fig. 119).

Fig 119 PICT-2895a

3-33Z580/Z589 DFI Z Master Service Manual

Page 55

CHASSIS

3

Brake Band Replacement

Note: The following procedures can be followed for

both right and left brake band removal and

installation.

Brake Band Removal

1. Remove the rear tire (Fig. 120).

2. Remove the 3 bolts, spacer and retainer from the

brake band assembly (Fig. 121).

Fig 121 PICT-2920a

3. Remove the 2 spacers from the brake band (Fig.

122).

Fig 120 PICT-2919a

Fig 122 PICT-2935a

3-34 Z580/Z589 DFI Z Master Service Manual

Page 56

CHASSIS

4. Remove the brake band from the wheel and hub

assembly (Fig. 123).

Fig 123 PICT-2933a

5. Inspect the brake band. Replace if worn or

damaged.

Brake Band Assembly (Fig. 124)

Brake Band Installation

1. Slide the brake band onto the wheel hub assembly

(Fig. 125).

3

Fig 125 PICT-2933a

2. Slide a spacer into each end of the brake band (Fig.

126).

A

B

C

D

Fig 124 PICT-2926a

A. Shoulder bolt (3) C. Retainer

B. Spacer (3) D. Brake band

Fig 126 PICT-2935a

3-35Z580/Z589 DFI Z Master Service Manual

Page 57

CHASSIS

3

3. Position the brake band retainer and loosely install 2

bolts through the retainer, brake band spacers and

into the brake bracket (Fig. 127).

Fig 127 PICT-2941a

4. Position the third spacer between the retainer and

the brake bracket. Loosely install the third bolt

through the retainer and spacer and into the brake

bracket (Fig. 128).

5. Tighten the 3 brake band retainer bolts (Fig. 129).

Fig 129 PICT-2942a

6. Install the rear tire (Fig. 130).

Fig 130 PICT-2919a

7. Check operation/adjustment of the parking brake.

Fig 128 PICT-2936a

3-36 Z580/Z589 DFI Z Master Service Manual

See “Adjusting the Parking Brake” on page 3-65.

Page 58

CHASSIS

Brake Cross Shaft Replacement

Note: The front engine shield has been removed for

photo purposes.

Brake Cross Shaft Removal

1. Raise the seat.

2. Remove the negative battery cable from the battery.

3. Raise the rear tires off the ground and remove the

left and right tires (Fig. 131).

Note: To prevent the unit from rolling, block the

front tires.

4. Remove the two clevis spring pins securing the

brake rod linkage yokes to the left side of the brake

cross shaft (Fig. 132).

3

Fig 132 PICT-2954a

Fig 131 PICT-2919a

5. Remove the clevis spring pin securing the brake rod

linkage yoke to the right side of the brake cross shaft

(Fig. 133).

Fig 133 PICT-2956a

3-37Z580/Z589 DFI Z Master Service Manual

Page 59

CHASSIS

3

6. Remove the 2 bolts and nuts securing the right side

ange bearing to the frame. Remove the ange

bearing from the cross shaft (Fig. 134).

Fig 134 PICT-2958a

7. Remove the 2 bolts and nuts securing the left side

ange bearing to the frame. Remove the ange

bearing from the cross shaft (Fig. 135).

8. Remove brake cross shaft (Fig. 136).

Fig 136 PICT-2964a

9. Inspect brake cross shaft and bearings. Replace if

worn or damaged (Fig. 137).

B B

Fig 135 PICT-2960a

D

C C

A A

Fig 137 PICT-2968a

A. Bolt (4) C. Nuts (4)

B. Side ange bearing (2) D. Brake cross shaft

3-38 Z580/Z589 DFI Z Master Service Manual

Page 60

CHASSIS

Brake Cross Shaft Installation

1. Slide the brake cross shaft into position (Fig. 138).

Note: The end of the cross shaft with two tabs is

installed on the left side of the machine.

Fig 138 PICT-2964a

2. Position a ange bearing onto each end of the cross

shaft with the ange facing outward (Fig. 139).

3. Position the ange bearing on the right end of the

cross shaft and install 2 bolts and nuts securing the

ange bearing to the frame (Fig. 140).

3

Fig 140 PICT-2958a

4. Position the ange bearing to the left side of the

frame and install 2 bolts and nuts to secure the

ange bearing to the frame (Fig. 141).

Fig 139 PICT-2970a

Fig 141 PICT-2960a

3-39Z580/Z589 DFI Z Master Service Manual

Page 61

CHASSIS

3

5. Ensure the brake cross shaft rotates freely in the

ange bearings.

6. Install the clevis spring pin securing the brake rod

linkage yoke to the right side of the brake cross shaft

(Fig. 142).

Fig 142 PICT-2956a

8. Install the left and right rear tires and lower the

machine to the ground (Fig. 144).

Fig 144 PICT-2919a

9. Lower the seat.

7. Install the two clevis spring pins securing the brake

rod linkage yokes to the left side of the brake cross

shaft (Fig. 143).

Fig 143 PICT-2954a

10. Adjust the parking brake. Refer to “Adjusting the

Parking Brake” on page 3-65.

3-40 Z580/Z589 DFI Z Master Service Manual

Page 62

CHASSIS

Deck Lift Lever Replacement

Deck Lift Lever Removal

1. Park the machine on a level surface, disengage the

PTO, turn the ignition off and remove the key.

2. Raise the seat.

3. Remove the negative battery cable from the battery.

4. Place the mower deck in the transport position.

Position wood blocks under each corner of the

mower deck (Fig. 145).

5. Lower the mower deck onto the blocks to remove

tension from the deck lift chains (Fig. 146).

3

Fig 146 PICT-2973a

6. Remove the lower stop bolt from the deck lift plate

(Fig. 147).

Fig 145 PICT-2971a

Fig 147 PICT-2978a

3-41Z580/Z589 DFI Z Master Service Manual

Page 63

CHASSIS

3

7. Loosen the jam nut and hex nut on the right hand

and left hand deck lift rods until the deck support

springs are fully extended (Fig. 148).

Fig 148 PICT-2980a

9. Lower the deck lift lever to its lowest position. The

rear deck swivel mounts should clear the deck lift

rods on both sides. The mower deck lift linkage

should now be fully unloaded (Fig. 150).

Fig 150 PICT-2984a

8. Remove the hex nut from the back end of the right

and left deck lift assemblies (Fig. 149).

Fig 149 PICT-2982a

10. Remove the bolt, nut and lift lever bushing that

secures the inner deck lift plate to the frame (Fig.

151).

Fig 151 PICT-2987a

3-42 Z580/Z589 DFI Z Master Service Manual

Page 64

CHASSIS

11. Remove the outside hex head ange nut at the top

of the inner deck lift plate. Remove the hitch pin

assembly from the bolt (Fig. 152).

Fig 152 PICT-2988a

13. Raise the oor pan.

14. Remove the front bolt and nut that secure the 2

deck lift arms to the deck lift cross shaft assembly.

Pivot the deck lift arms away from the cross shaft

assembly and remove the bushing from the hole in

the cross shaft assembly tab (Fig. 154).

3

12. Loosen the inner hex head ange nut. Pivot the

inner deck lift plate up (Fig. 153).

Fig 153 PICT-2991a

Fig 154 PICT-3000a

15. Remove the E-clip from the deck lift arm pivot (Fig.

155).

Fig 155 PICT-3002a

3-43Z580/Z589 DFI Z Master Service Manual

Page 65

CHASSIS

3

16. Remove the deck lift lever assembly from the pivot