Toro 74242, 74246TE, 74250 Setup Instructions

Z500 Series Z Master Mowers

Loose Parts

Use the chart below to verify all parts have been shipped.

Step Description Qty. Use

Form No. 3351–148 Rev A

Setup Instructions

1

2

3

4

5

No parts needed – Raising the machine up

Roll bar, right section

Roll bar, left section

Roll bar, center section

Bolt, 3/8 x 4–1/2 inches

Bolt, 3/8 x 1 inch

Curved washer

Flange nut, 3/8 inch

Bolt, 1/2 x 3-1/4 inches

Flange nut, 1/2 inch

Lock nut, 3/8 inch

Lanyard

Wheels 2 Installing the drive wheels

No parts needed – Checking the tire pressure

Control lever–right

Control lever–left

Bolt, 3/8 x 1 inch

Curved washer, 3/8 inch

1

1

1

2

4

8

6

2

2

2

2

1

1

4

4

Installing the roll over protection system

(ROPS)

Installing the motion control levers

Seat

6

7

8

9

10

11

2003—The Toro Company

8111 Lyndale A ve., Blomington, MN 55420, USA

Nuts (installed on the seat)

Bulk electrolyte with 1.265 specific gravity

(Purchase from a battery supply outlet.)

Air cleaner

Hose clamp

Air cleaner

Hose clamp

Number 2 general purpose lithium base or

molybdenum base grease. (Purchase

separately.)

No parts needed – Preparing the side discharge chute

1

4

1 US

Gallon

1

1

1

1

1 tube Greasing the bearings

Printed in the USA

All Rights Reserved

Installing the seat

Activating the battery

Installing the air cleaner on Kohler engines

Installing the air cleaner on 25hp Kawasaki

engines

Original Instructions (EN)

Register your product at www.Toro.com

Step UseQty.Description

2

12

13

No parts needed. – Checking the machine before delivery

Key

Operator’s Manual

Engine Owner’s Manual

Parts Catalog

Safety video

Registration card

Step

1

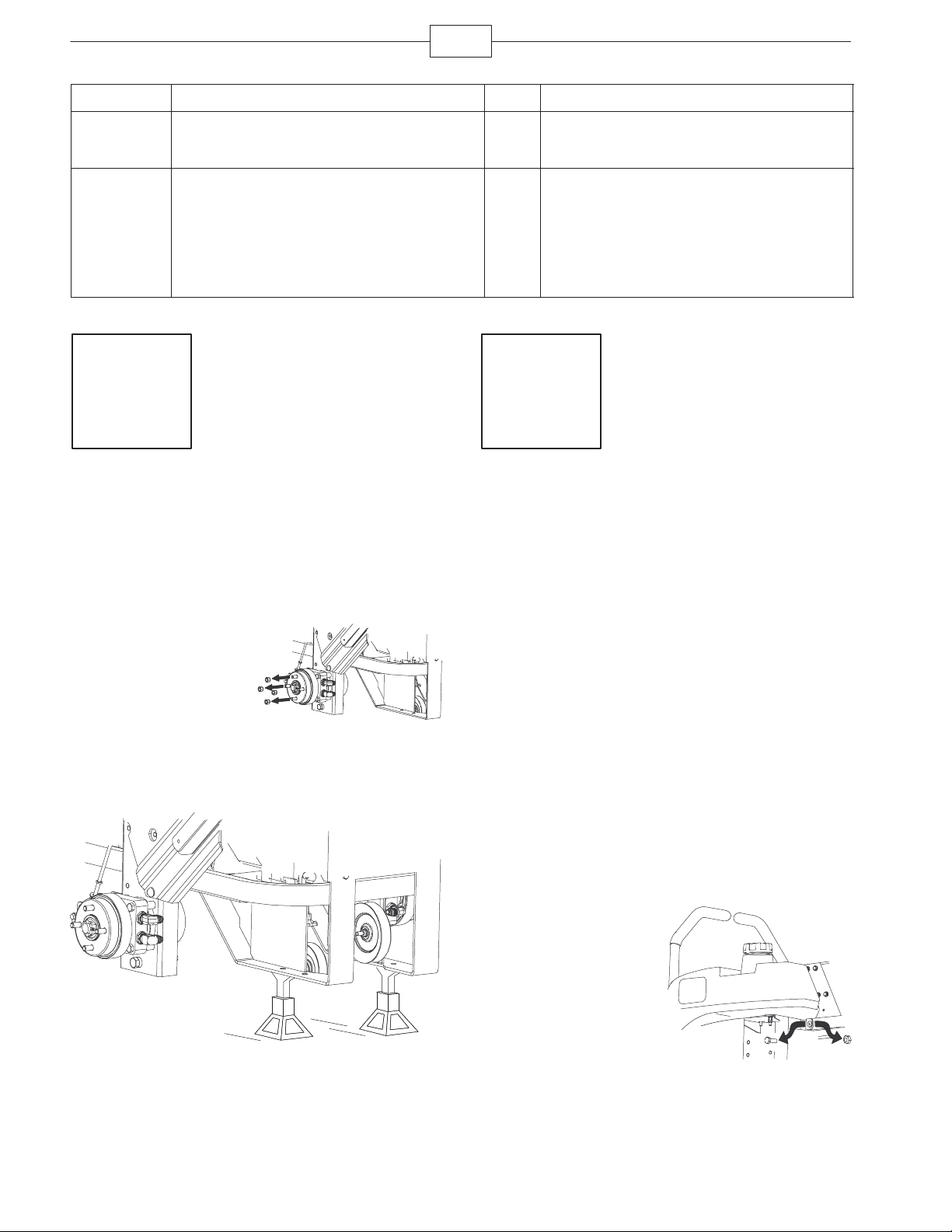

Raising the Machine Up

Parts needed for this step:

None

2

1

1

1

1

1

Delivering the Machine to the Customer

Step

2

Installing the Roll Over

Protection System (ROPS)

Parts needed for this step:

Procedure

1. Remove the wheel

nuts from both sides of

the vehicle.

2. Remove the right

angle retaining plate

from the crate and the

wheel hub.

3. Raise the back of the machine up and support it

with jack-stands.

m–6858

Qty. Part

1 Roll bar, right section

1 Roll bar, left section

1 Roll bar, center section

2 Bolt, 3/8 x 4–1/2 inches

2 Lock nut, 3/8 inch

4 Bolt, 3/8 x 1 inch

8 Curved washer

6 Flange nut, 3/8 inch

2 Bolt, 1/2 x 3-1/4 inches

2 Flange nut, 1/2 inch

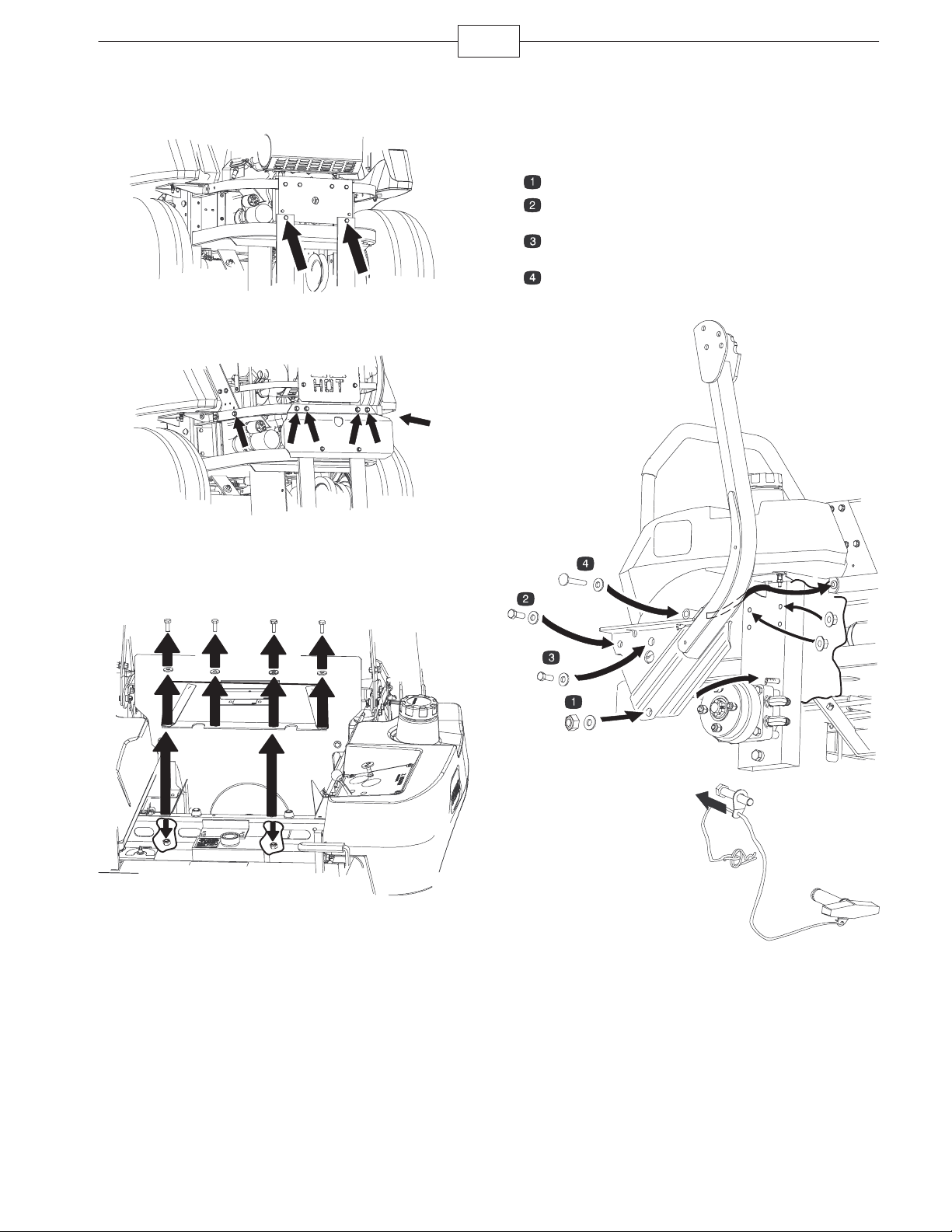

Procedure

1. Remove and discard

the fuel tank mounting

bolt and nut from under

the tank on each side.

m–6857

3

2. For an air cooled machine, loosen the two bottom

bolts in the rear bumper.

m–6886

3. For a liquid cooled machine, loosen the two side

and four back bolts in the rear bumper.

m–6885

Note: Step 4 is needed for international mowers only.

4. For internationl mowers, remove the bolts,

washers and nuts holding the rubber flap in front of

the motor.

5. Install the bolts in the order shown in the figure

below.

6. Loosely install the right and left roll bar sections

to the frame, in numbered order as follows:

Lock nut (3/8 inch), curved washer

Bolt (3/8 x 1 inch), curved washer, and flange nut

(3/8 inch)

Bolt (3/8 x 1 inch), curved washer, and flange nut

(3/8 inch)

Bolt (3/8 x 4-1/2 inches), curved washer, and

flange nut (3/8 inch)

m–7655

m–6854

7. Install the lanyard

clips onto the 2 bolts

(1/2 x 3-1/4 inches).

Note: Make sure the

bent tab points toward

the head of the bolt.

m–6892

4

5

8. Lightly oil the ends

of the center roll bar

section.

9. Loosely install the

center roll bar section,

using 2 bolts

(1/2 x 3-1/4 inches) and

2 flange nuts (1/2 inch).

Note: Make sure the

bolts are installed on the

outside of the roll bar.

Note: Make sure the

lanyard tab is install as

shown and points

forward.

10. Raise the roll bar

into the upright position

and secure it with the

pins and hairpin cotter

pins fastened to the

lanyards.

m–6891

m–6893

11. Tighten the center

roll bar bolts

(1/2 x 3-1/4 inches) so it

rotates freely with some

resistance.

Note: No more than one

thread should be

exposed outside the nut.

12. Torque all lower

fasteners, attached to

the machine frame, to

30 ft–lb.

13. Tighten the front

handles against the

center roll bar ends.

14. Tighten the rear

bumper bolts.

m–6891

m–683

Note: Step 15 is needed for international mowers

only.

15. For internationl mowers, install the rubber flap

with the previously removed bolts, washers and nuts.

5

Step

4

Checking the Tire Pressure

Parts needed for this step:

None

m–7656

Step

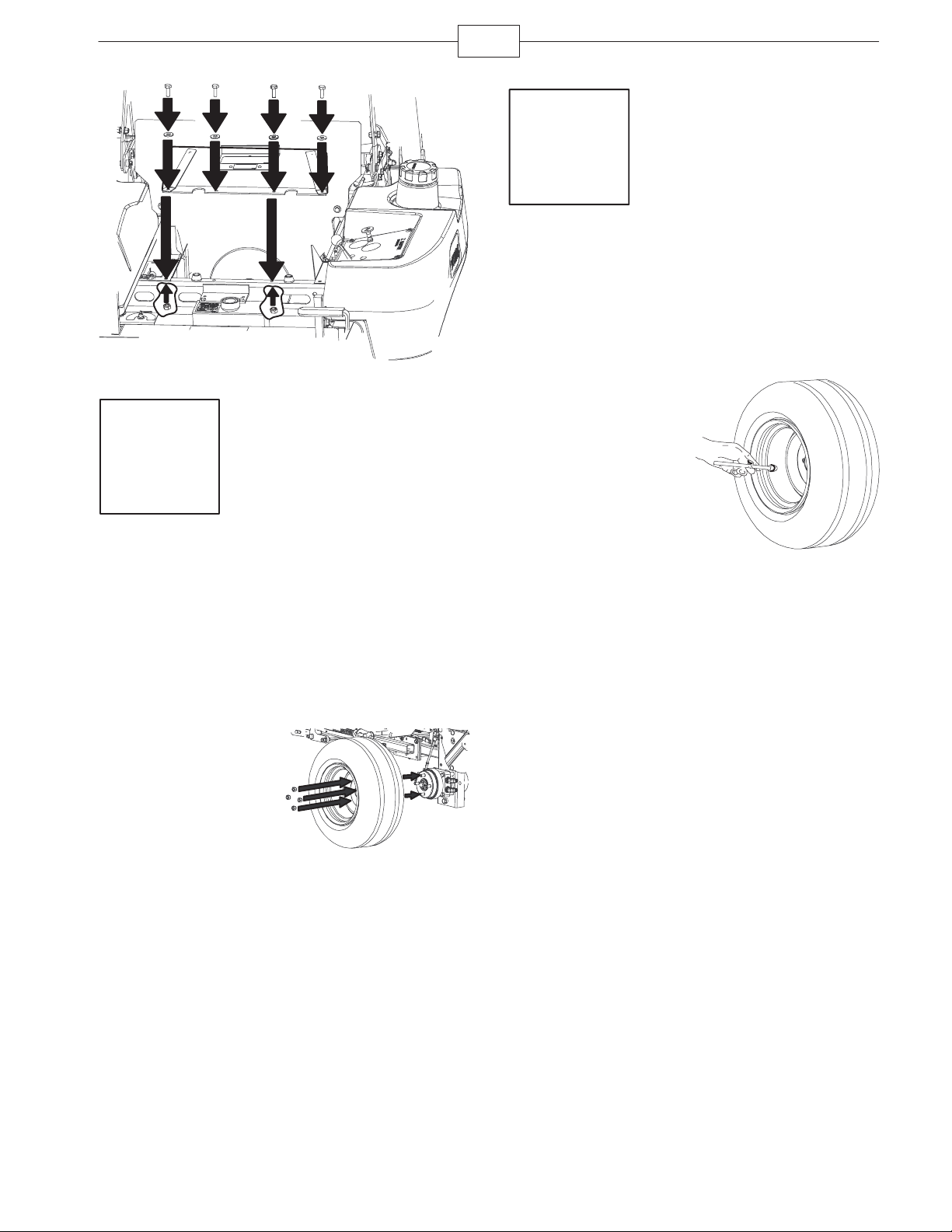

3

Installing the Drive Wheels

Parts needed for this step:

Qty. Part

2 Rear wheels

Procedure

1. Mount the wheels

with the valve stem to

the outside and secure

them with the nuts

previously removed in

Step 1.

2. Torque the nuts to

95 ft-lb (128 N⋅m).

m–6859

Procedure

Check the air pressure

in the front and rear

tires.

Pressure: 13 psi

(90 kPa)

m–6873

Loading...

Loading...