Page 1

Spindle Repair Module 1

Page 2

Page 3

Z Master 200 Series

1. Stop the engine, remove the key, and

engage the parking brake.

Zerk

2. Remove covers from the cutting unit.

3. Using a floor jack raise the machine until

you can access the underside of the cutting unit.

4. Support the machine using a properly

rated jack stand.

5. Inspect the assembly before removing.

Look for the following:

A. Bent or damaged blade.

B. Missing or unused grease zerk.

C. String, wire, rope, etc. wrapped

around the spindle under the deck.

6. Remove the drive belt(s) from the pulley.

Consult the machine owner's manual for

this procedure.

7. Remove the nut and washer retaining the

spindle pulley. Then remove the pulley

from the shaft.

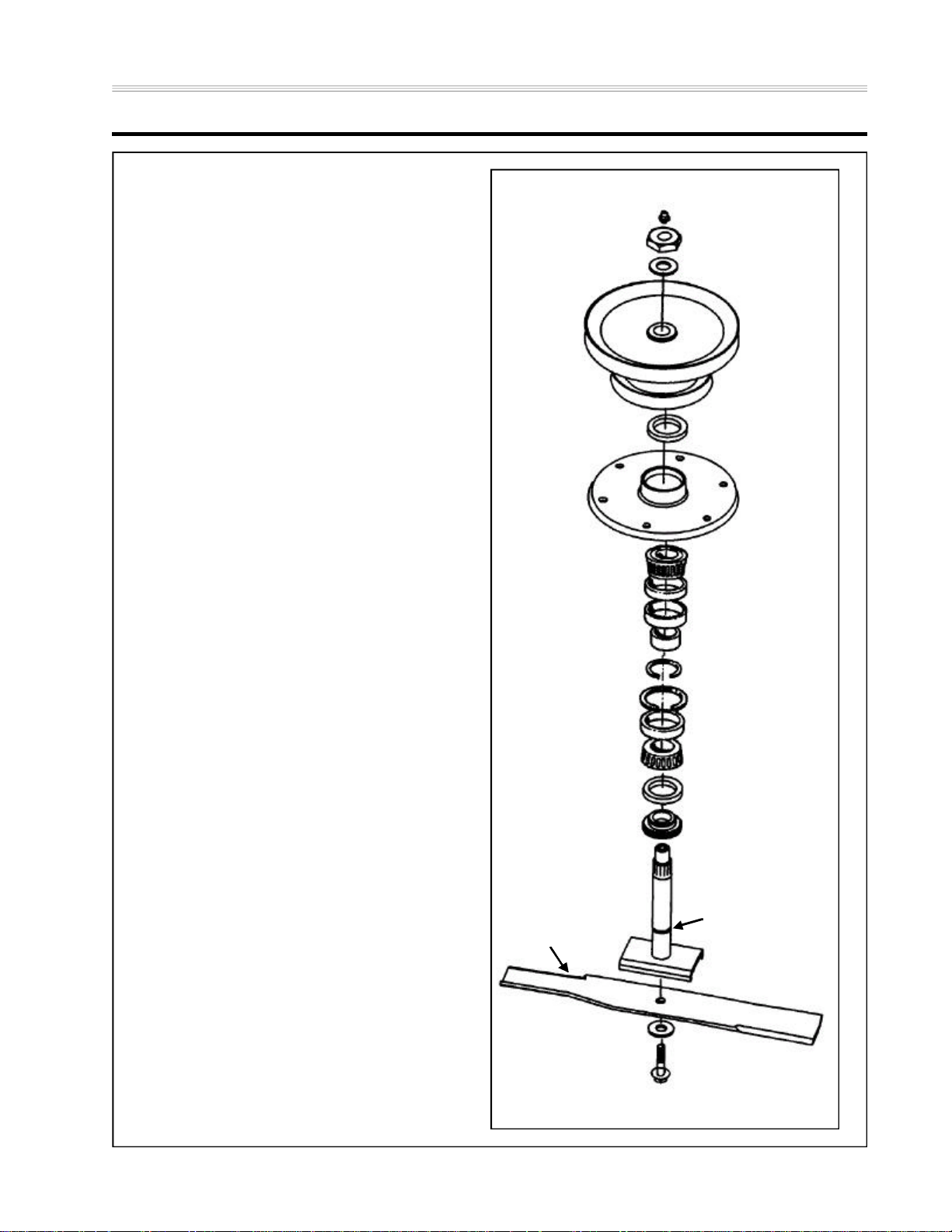

Nut

Hardened Washer

Pulley

Seal

Spindle

Housing

Bearing Cone

Bearing Cup

Large Spacer

Small Spacer

Machine “C” Spacer

8. Unbolt the spindle housing from the deck.

Place spindle assembly on a bench or in a

vise and remove the blade.

9. Remove the spindle shaft from the spindle

housing; it may need to be pressed out of

the housing.

Note: The lower bearing spacer will remain

on the spindle shaft.

10. Inspect the spindle shaft for the

following:

A. Elongated grease axis hole. Normally

this hole is perfectly round, if it is

deformed it is directly a result of

impact.

B. Damaged splines - If the splines are

twisted, it is a sign of impact. If they

are worn, it's an indication that the

assembly was running with the pulley

loose.

Bearing Cup

Spindle Shaft

Blade

Spring Washer

Snap Ring

Bearing Cone

Seal

Bearing Spacer

Grease Axis Hole

Blade Bolt

3Spindle Repair Module

Page 4

Z Master 200 Series

C. Damaged shaft - When the shaft is

worn at the point where the upper

bearing is located in the assembly, it

is a result of the assembly running

loose.

There are two causes for this:

1. Improper torque on the pulley retention nut. This allows individual components of the assembly to move

and wear against other components.

2. Impacts cause the shaft to stretch,

which will lessen the clamp load and

cause the assembly to wear as if

the nut did not have proper torque.

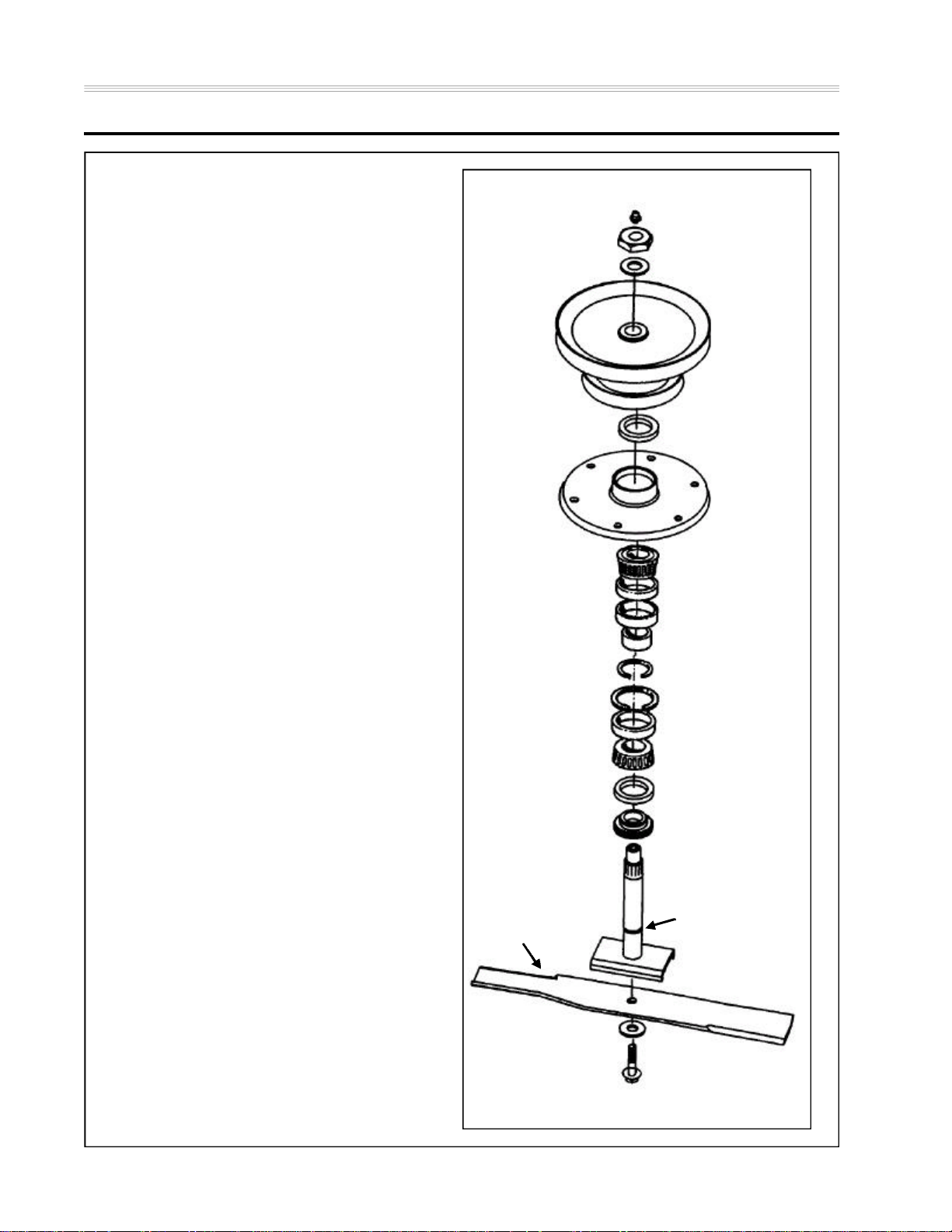

Zerk

Nut

Hardened Washer

Pulley

Seal

11. Remove the seals, note the direction of the

seals, this will be important during reassembly. The upper seal faces inward,

and the lower seal faces outward. If the

lower seal is installed incorrectly, the lower

bearing spacer will crush the seal and

allow dirt into the assembly, causing bearing failure to occur.

12. Remove the bearings and the two small

diameter spacers from the housing. One of

the two spacers removed will look like a

"C" slip and the other will be a thicker

spacer with a hole in it. The open side on

the “C” shaped spacer, in addition to the

lubrication hole in the thicker spacer,

allows grease to pass from the spindle

shaft to the bearings.

Note: When removing the bearings, mark or

isolate the top bearing from the lower

bearing. This will allow the bearings to

be installed in their original operating

position. Failure to do this may cause

premature bearing failure when

reassembled.

Spindle

Housing

Bearing Cone

Bearing Cup

Large Spacer

Small Spacer

Machine “C” Spacer

Snap Ring

Bearing Cup

Bearing Cone

Seal

Bearing Spacer

Spindle Shaft

Grease Axis Hole

Blade

Inspect the bearings as follows:

A. Look for the presence of grease, par-

ticularly in the upper bearing. Dry or

cooked grease indicates a lack of

maintenance

B. Look for dirt in the grease. This indi-

cates a bad seal or worn lower bearing spacer. If the unit was recently

4 Spindle Repair Module

Spring Washer

Blade Bolt

Page 5

Z Master 200 Series

rebuilt, look for proper installation of

the lower seal.

C. Clean the bearings and look for any

pitting or flaking on the rollers.

D. Roll the clean bearings in your hand

and feel for rough spots. If the bearing catches or the rollers get stuck in

the cage, replace the bearing.

Note: With this spindle design, both bearings

and bearing cups must be replaced as

a set. Even if only one of the two bearings is damaged.

13. If replacing the bearings, use a punch and

hammer to drive both of the bearing cups

out of the spindle housing. Also, remove

the large diameter spacer at this time.

Caution: Do not use old bearing cups with

new bearings. This may cause premature bearing wear and result in

failure.

Zerk

Nut

Hardened Washer

Pulley

Seal

Spindle

Housing

Bearing Cone

Bearing Cup

14. A large snap ring is still inside the spindle

housing. It locates the matched bearing

set in the bore of the spindle housing.

There is no need to remove and replace

this snap ring.

Assembly

15. Thoroughly clean and inspect the parts

prior to assembly:

A. Spindle shaft for bearing surface

damage or signs of impact. Also

check for damage to the threaded

areas for both the blade bolt and the

pulley retention nut.

B. Bottom bearing spacer for wear. If

the spacer is damaged the seal may

not be able to keep dirt out properly.

C. Bearings for wear. If reusing bear-

ings, you must examine them carefully for wear. Also, make sure to put

the same bearing and bearing saddle

together as they were. As noted

above, look for pitting on the rollers

of the bearings and replace the bearing set if any pitting is present.

Large Spacer

Machine “C” Spacer

Bearing Cup

Seal

Spindle Shaft

Blade

Spring Washer

Small Spacer

Snap Ring

Bearing Cone

Bearing Spacer

Grease Axis Hole

Blade Bolt

5Spindle Repair Module

Page 6

Z Master 200 Series

Note: If using compressed air to dry the

bearing after cleaning, DO NOT allow

it to spin. The bearing could come

apart and cause serious injury. Always

wear safety glasses.

D. Spindle housing for damage or wear.

E. Pulley assembly, if the shaft shows

signs of wear inspect the pulley for

excessive wear in the splines. If

excessive wear is found, replace the

pulley. Excessive wear of the splines

will show up as sharp edges on the

splines.

Note: New bearings are only available in

matched sets. The matched set is

necessary because the bearing endplay is not adjustable. The small "C"

shaped spacer is machined to specifically match the bearings in the set.

The advantage of a matched set is the

ability to torque the assembly to a

specified value and have a pre-set

endplay. Alternatively, most tapered

bearing applications use either a crush

washer or a castle nut with key as a

means to set endplay.

16. Install the snap ring into spindle housing.

Discard the new snap ring if the spindle

housing is being reused.

17. Press in lower bearing cup until it firmly

contacts the snap ring.

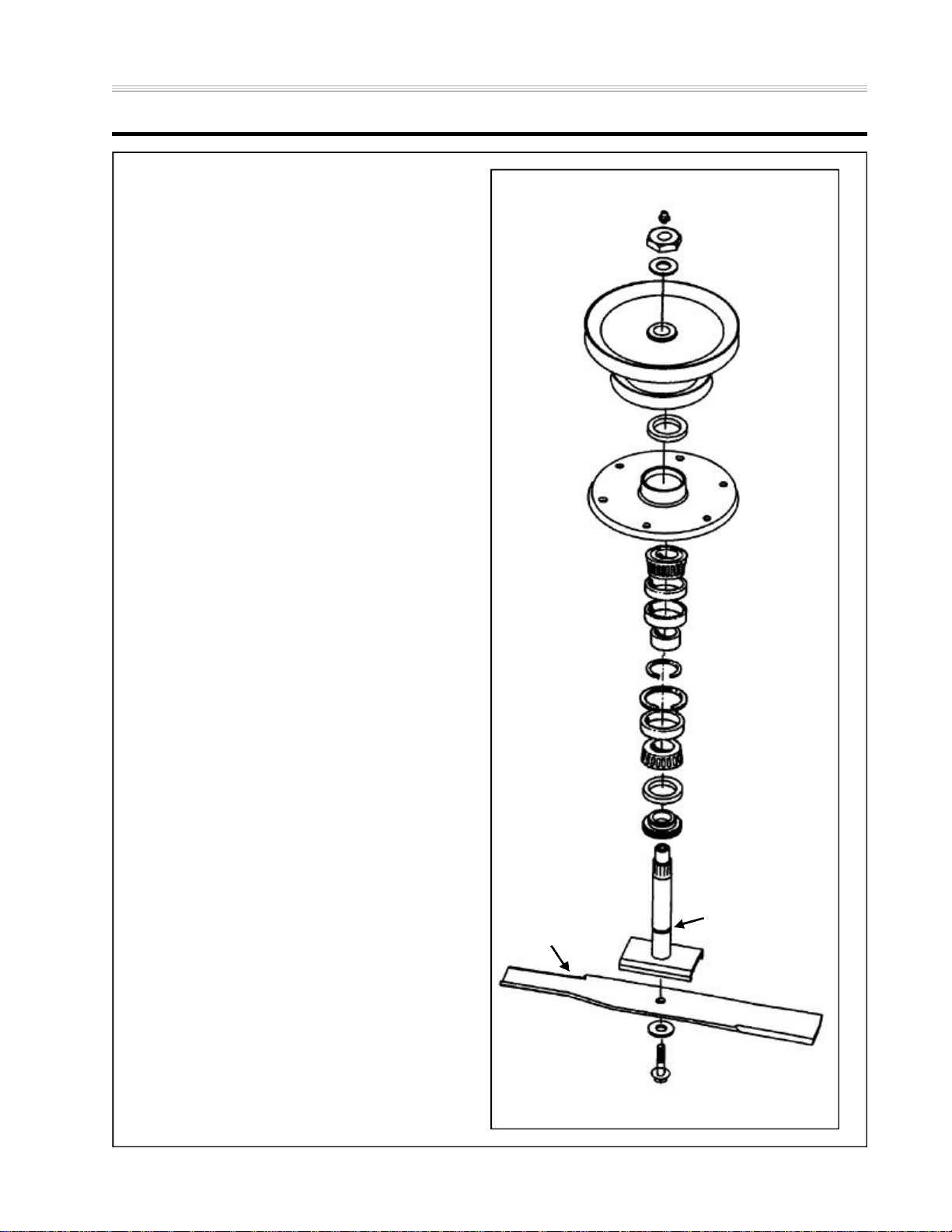

Zerk

Nut

Hardened Washer

Pulley

Seal

Spindle

Housing

Bearing Cone

Bearing Cup

Large Spacer

Small Spacer

Machine “C” Spacer

Snap Ring

Bearing Cup

Bearing Cone

Seal

Bearing Spacer

Note: The machined stop for the seal may

cause your driver to stop before the

bearing cup is seated completely.

NEVER use a punch to drive in a bearing cup, this will damage the cup.

18. Slide the large spacer in from the top until

it also contacts the snap ring. Now press

the upper bearing cup in against the spacer. Apply a layer of grease to both bearing

surfaces.

19. Pack both bearings with grease. Smearing

grease on the outside of the bearing is not

6 Spindle Repair Module

Spindle Shaft

Blade

Spring Washer

Grease Axis Hole

Blade Bolt

Page 7

Z Master 200 Series

enough lubrication. Pack the bearing by

hand or use a bearing packing tool.

Zerk

20. With the spindle upside down, set the

lower bearing in the bearing cup. Now

install the lower seal. Use a seal driver to

prevent damage.

Note: Remember to install the seal with the

lip facing out.

21. With the spindle right side up, install the

small "C" shaped spacer first, then the

small thick spacer. The order of these two

is not critical to the performance of the

spindle, but putting the thinner spacer in

first it prevents the possibility of the open

part of the spacer from dropping down on

the thicker spacer.

22. Now install the upper bearing and seal.

The upper seal must face inward. Again,

be sure to use a seal driver.

23. Lubricate both seal lips with grease and

insert the bearing spacer into the lower

seal. By inserting the spacer individually,

and not with the shaft, you will prevent

possible damage to the lower seal.

24. Bolt the assembly back into the deck shell.

25. Install the spindle shaft.

Note: The shaft will slide out if not supported.

Nut

Hardened Washer

Pulley

Seal

Spindle

Housing

Bearing Cone

Bearing Cup

Large Spacer

Small Spacer

Machine “C” Spacer

Snap Ring

Bearing Cup

Bearing Cone

Seal

Bearing Spacer

26. Slide the pulley down onto the shaft and

secure with the washer and nut. Be certain

to only use the washer specified because

it is hardened, a softer washer will deform

and spindle damage will occur. Torque the

nut to 100-120 ft/lbs and rotate the assembly to make sure that it turns smoothly and

freely.

27. Pump grease into the assembly until

grease is relieved pass the lower seal.

The ability to relieve grease without pushing out the seal is why to lower seal is

installed with the lip facing out. Make sure

the blade bolt is threaded into the spindle

Spindle Shaft

Blade

Spring Washer

Grease Axis Hole

Blade Bolt

7Spindle Repair Module

Page 8

Z Master 200 Series

shaft or grease will push out that opening.

28. Install the blade and torque the blade bolt

to 85-110 ft/lbs.

29. Install the drive belts. Consult the machine

owner's manual for this procedure.

Zerk

Nut

Hardened Washer

30. Replace the deck covers.

31. Remove the machine from the jack

stands.

Pulley

Seal

Spindle

Housing

Bearing Cone

Bearing Cup

Large Spacer

Small Spacer

Machine “C” Spacer

Snap Ring

Bearing Cup

Bearing Cone

Seal

Bearing Spacer

Spindle Shaft

Blade

Spring Washer

8 Spindle Repair Module

Grease Axis Hole

Blade Bolt

Page 9

Z Master 500 Series

1. Stop the engine, remove the key, and

engage the parking brake.

2. Remove covers from the cutting unit.

3. Using a floor jack and properly rated jack

stands or the Z Stand®, raise the machine

until you can access the underside of the

cutting unit.

4. Inspect the assembly before removing it

from the mower. Look for the following:

Nut

Heavy Washer

Square Key

Pulley Hub

Bearing

Shield

Seal Spacer

A. Bent or damaged blade.

B. Missing or unused grease zerk.

C. String, wire, rope, etc. wrapped

around the spindle under the deck.

5. Remove the drive belt from the pulley.

Consult the machine operator's manual for

this procedure.

6. Remove the bolts retaining the spindle

pulley. Then remove the pulley from the

hub.

7. Unbolt the spindle housing from the deck.

Place spindle assembly on a bench or in a

vise and remove the blade.

8. Remove the spindle nut, heavy washer,

pulley hub, square key, and bearing

shield.

9. Inspect the pulley hub and square key for

damage. Carefully check the pulley hub

for cracks.

10. Remove the spindle shaft from the spindle

housing. If corrosion has bonded spacers

or bearings to the shaft, it may need to be

pressed out.

Seal

Spindle

Housing

Bearing Cone

Bearing Cup

Inner Spacer

Outer Spacer

Machine “C” Spacer

Snap Ring

Bearing Cup

Bearing Cone

Seal

Seal Spacer

Bearing

Shield

Note: The lower bearing spacer may remain

on the spindle shaft.

11. Inspect the spindle shaft. Check for the

following:

A. Worn or damaged keyway. Impacts

cause key and keyway damage.

Spindle

Shaft

9Spindle Repair Module

Page 10

Z Master 500 Series

B. Damaged Shaft - when the shaft is

worn at the point where the upper

bearing is located in the assembly, it

is a result of the assembly running

loose. The cause for this is improper

torque on the pulley hub retention

nut. This allows individual components of the assembly to move and

wear.

12. Remove the seals, note the direction the

seals face. This will be important during

re-assembly. The upper seal faces

inward, and the lower seal faces outward.

If the lower seal is installed incorrectly, the

lower bearing spacer will crush the seal

and allow dirt into the assembly causing

bearing failure to occur. This orientation of

the lower seal also allows grease to

bypass the seal, purging old grease from

the spindle when fresh grease is supplied.

Nut

Heavy Washer

Square Key

Pulley Hub

Bearing

Shield

Seal Spacer

Seal

Spindle

Housing

13. Remove the bearing cones and inner

spacers.

Note: There is a long spacer and then a

machined "C" spacer.

Note: When removing the bearings, tag or

isolate the top bearing from the lower

bearing. This will allow the bearings to

be installed in their original operating

position. Failure to do this may cause

premature bearing failure when

reassembled.

Inspect the bearings as follows:

A. Look for the presence of grease, par-

ticularly in the upper bearing. Dry or

cooked grease indicates a lack of

maintenance.

B. Look for dirt in the grease. This indi-

cates a bad seal or worn lower bearing spacer. If the unit was recently

rebuilt, look for proper installation of

the lower seal.

C. Clean the bearings and look for any

pitting or flaking on the rollers.

D. Roll the clean bearings in your hand

and feel for rough spots. If the bearing catches or the rollers get stuck in

Bearing Cone

Bearing Cup

Inner Spacer

Outer Spacer

Machine “C” Spacer

Snap Ring

Bearing Cup

Bearing Cone

Seal

Seal Spacer

Bearing

Shield

Spindle

Shaft

10 Spindle Repair Module

Page 11

Z Master 500 Series

the cage, replace the bearing set.

Note: With this spindle design, both bearings

and bearing cups must be replaced as

a set.

14. If replacing the bearings, use a punch and

hammer to drive both of the bearing cups

out of the spindle housing. Also remove

the large diameter spacer at this time if

spacers are to be replaced.

Caution: Do not use old bearing cups with

new bearings. This may cause premature bearing wear and result in

failure.

15. A large snap ring is still inside the spindle

housing. It locates the matched bearing

set in the spindle housing. Unless this is

damaged or worn, there is no need to

remove and replace this snap ring. A

replacement snap ring comes with the

replacement bearing set. If the snap ring is

damaged, look for damage to the housing.

Replace as needed.

Nut

Heavy Washer

Square Key

Pulley Hub

Bearing

Shield

Seal Spacer

Seal

Spindle

Housing

Bearing Cone

Bearing Cup

Inner Spacer

Assembly

16. Thoroughly clean and inspect the spindle

assembly parts prior to assembly. Always

wear safety glasses.

A. Check spindle shaft for bearing sur-

face damage or signs of impact. Also

check for damage to the threaded

areas for both the blade bolt and the

spindle retention nut.

B. Check lower bearing spacer for wear.

If the spacer is damaged, the seal

may not be able to keep dirt out

properly.

C. Check bearings for wear. If reusing

bearings, you must examine them

carefully for wear. Also, make sure to

put the same bearing cone and bearing cup together as they were when

disassembled. Look for pitting on the

rollers of the bearings and replace the

bearing set if any pitting is present.

Outer Spacer

Machine “C” Spacer

Snap Ring

Bearing Cup

Bearing Cone

Seal

Seal Spacer

Bearing

Shield

Spindle

Shaft

11Spindle Repair Module

Page 12

Z Master 500 Series

Note: If using compressed air to dry the

bearing after cleaning, DO NOT allow

it to spin. The bearing could come

apart and cause serious injury.

Note: New bearings are only available in

matched sets. The matched set is

necessary because the bearing endplay is not adjustable. The small "C"

shaped spacer is machined to specifically match the bearings in the set.

The advantage of a matched set is the

ability to torque the assembly to a

specified value and have a preset endplay.

D. Check spindle housing for any dam-

age or wear.

E. Check pulley hubs for wear marks or

worn keyway. A worn or cracked hub

should be replaced.

Nut

Heavy Washer

Square Key

Pulley Hub

Bearing

Shield

Seal Spacer

Seal

Spindle

Housing

17. If the snap ring is being replaced, install it

into the spindle housing. If the old snap

ring is being reused, discard the new snap

ring.

18. Press in lower bearing cup until it firmly

contacts the snap ring.

Note: The machined stop for the seal may

cause your driver to stop before the

bearing cup is seated completely.

NEVER use a punch to drive in a bearing cup. This will damage the cup.

19. Slide the large diameter spacer in from the

top until it also contacts the snap ring.

Now press the upper bearing cup in

against the spacer. Apply a layer of grease

to both bearing surfaces.

20. Pack both bearings with grease. Smearing

grease on the outside of the bearing is not

enough lubrication. Pack the bearing by

hand or use a bearing packing tool.

Bearing Cone

Bearing Cup

Inner Spacer

Outer Spacer

Machine “C” Spacer

Snap Ring

Bearing Cup

Bearing Cone

Seal

Seal Spacer

Bearing

Shield

Spindle

Shaft

21. With the spindle upside down, set the

lower bearing in the bearing cup. Now

install the lower seal. Use a seal driver to

prevent damage.

12 Spindle Repair Module

Page 13

Z Master 500 Series

Note: Remember to install the seal with the

lip facing out.

22. With the spindle right side up, install the

small "C" shaped spacer first, then the

long inner spacer. The order of these two

is not critical to the performance of the

spindle, but putting the thin spacer in first

prevents the possibility of the open part of

the spacer dropping down on the long

spacer.

23. Now install the upper bearing and seal.

The upper seal must face inward. Again,

use a seal driver.

24. Lubricate both seal lips with grease and

insert the bearing spacer into the lower

seal.

25. Place the bearing shield on the spindle

shaft with the cup up.

26. Slide the spindle shaft up through the

bearing spacer, lower bearing, spacers,

and upper bearing.

27. Install the upper bearing spacer on the

shaft and into the upper seal. By inserting

the upper spacer individually rather than

with the shaft, you will prevent possible

damage to the lower seal.

28. Place the bearing shield, cup down, on the

shaft.

29. Install the pulley hub, square key, heavy

cupped washer, and nut on the top of the

spindle. Torque the nut to 85-110 ft.-lbs.

30. Grease the spindle until grease flows from

the lower seal.

Nut

Heavy Washer

Square Key

Pulley Hub

Bearing

Shield

Seal Spacer

Seal

Spindle

Housing

Bearing Cone

Bearing Cup

Inner Spacer

Outer Spacer

Machine “C” Spacer

Snap Ring

Bearing Cup

Bearing Cone

Seal

Seal Spacer

Bearing

Shield

31. Bolt the assembly back into the deck shell.

The screws are self-tapping with a nut

backup on top of the deck. This design

makes it easier for one person alone to

install the spindle assembly and also provides a method of retention if a hole is

stripped out by overtorquing or repeated

replacement.

Spindle

Shaft

13Spindle Repair Module

Page 14

Z Master 500 Series

32. Install the pulley on the pulley hub and

torque the bolts to 27-33 ft.-lbs.

33. Install the blade and torque the blade bolt

to 85-110 ft.-lbs.

Nut

Heavy Washer

Square Key

34. Install the drive belt. Consult the operator's manual for the proper procedure.

35. Replace the deck covers. Remove the

machine from the jack stands or Z Stand®.

Pulley Hub

Bearing

Shield

Seal Spacer

Seal

Spindle

Housing

Bearing Cone

Bearing Cup

Inner Spacer

Outer Spacer

Machine “C” Spacer

Snap Ring

Bearing Cup

Bearing Cone

Seal

Seal Spacer

Bearing

Shield

Spindle

Shaft

14 Spindle Repair Module

Page 15

Page 16

492-4752

October 2003

Loading...

Loading...