Toro 74183 Operator's Manual

FORM NO. 3319–951

Z–325

OUT FRONT Z

Traction Unit

Model No. 74182 – 890184 & Up

Operator’s Manual

IMPORTANT: Read this manual carefully. It contains information about your

safety and the safety of others. Also become familiar with the controls and

their proper use before you operate the product.

Introduction

Thank you for purchasing a Toro product.

All of us at Toro want you to be completely satisfied

with your new product, so feel free to contact your

local Authorized Service Dealer for help with service,

genuine replacement parts, or other information you

may require.

Whenever you contact your Authorized Service

Dealer or the factory, always know the model and

serial numbers of your product. These numbers will

help the Service Dealer or Service Representative

provide exact information about your specific

product. You will find the model and serial number

plate located in a unique place on the product as

shown below.

Read this manual carefully to learn how to operate

and maintain your product correctly. Reading this

manual will help you and others avoid personal injury

and damage to the product. Although we design,

produce and market safe, state-of-the-art products,

you are responsible for using the product properly

and safely. You are also responsible for training

persons, who you allow to use the product, about safe

operation.

The warning system in this manual identifies

potential hazards and has special safety messages that

help you and others avoid personal injury, even death.

DANGER, WARNING and CAUTION are signal

words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

DANGER signals an extreme hazard that will cause

serious injury or death if the recommended

precautions are not followed.

WARNING signals a hazard that may cause serious

injury or death if the recommended precautions are

not followed.

1

1. Model and Serial Number Plate

For your convenience, write the product model and

serial numbers in the space below.

Model No:

Serial No.

CAUTION signals a hazard that may cause minor or

moderate injury if the recommended precautions are

not followed.

Two other words are also used to highlight

information. “Important” calls attention to special

mechanical information and “Note” emphasizes

general information worthy of special attention.

The left and right side of the machine is determined

by sitting on the seat in the normal operator’s

position.

The engine exhaust from this product

contains chemicals known to the State of

California to cause cancer, birth defects,

or other reproductive harm.

The Toro Company – 1997

All Rights Reserved

Contents

Safety 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safe Operating Practices 2. . . . . . . . . . . . . .

Slope Chart 5. . . . . . . . . . . . . . . . . . . . . . . . .

Safety and Instruction Decals 6. . . . . . . . . .

Gasoline and Oil 7. . . . . . . . . . . . . . . . . . . . . . . .

Recommended Gasoline 7. . . . . . . . . . . . . .

Stabilizer/Conditioner 7. . . . . . . . . . . . . . . .

Filling the Fuel Tank 7. . . . . . . . . . . . . . . . .

Check Engine Oil Level 7. . . . . . . . . . . . . . .

Assembly 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loose Parts 8. . . . . . . . . . . . . . . . . . . . . . . . .

Install Castor Wheel 9. . . . . . . . . . . . . . . . . .

Activate the Battery 9. . . . . . . . . . . . . . . . . .

Install Battery 10. . . . . . . . . . . . . . . . . . . . . . .

Install Drive Shaft 11. . . . . . . . . . . . . . . . . . .

Remove Drive Shaft 11. . . . . . . . . . . . . . . . . .

Operation 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Think Safety First 12. . . . . . . . . . . . . . . . . . .

Controls 12. . . . . . . . . . . . . . . . . . . . . . . . . . .

Parking Brake 13. . . . . . . . . . . . . . . . . . . . . . .

Starting and Stopping Engine 14. . . . . . . . . .

Operating Power Take Off (PTO) 15. . . . . . .

The Safety Interlock System 16. . . . . . . . . . .

Instruments 16. . . . . . . . . . . . . . . . . . . . . . . . .

Page

Page

Driving Forward or Backward 17. . . . . . . . . .

Stopping the Machine 18. . . . . . . . . . . . . . . .

Positioning the Seat 18. . . . . . . . . . . . . . . . . .

Pushing the Machine by Hand 19. . . . . . . . . .

Maintenance 20. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Interval Chart 20. . . . . . . . . . . . . . . .

Air Cleaner 21. . . . . . . . . . . . . . . . . . . . . . . . .

Engine Oil 23. . . . . . . . . . . . . . . . . . . . . . . . .

Spark Plug 25. . . . . . . . . . . . . . . . . . . . . . . . .

Greasing and Lubrication 26. . . . . . . . . . . . . .

Cleaning the Cooling Systems 27. . . . . . . . . .

Tire Pressure 27. . . . . . . . . . . . . . . . . . . . . . . .

Fuel Filter 28. . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Tank 28. . . . . . . . . . . . . . . . . . . . . . . . . .

Hydraulic System 29. . . . . . . . . . . . . . . . . . . .

Adjusting Motion Controls 31. . . . . . . . . . . .

Adjusting Mowing Speed Reference Position 32

Replacing Power Take Off (PTO) Belts 33. . .

Replacing the Traction Belt 34. . . . . . . . . . . .

Fuse 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery 35. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Diagram 36. . . . . . . . . . . . . . . . . . . . .

Hydraulic Diagram 37. . . . . . . . . . . . . . . . . . .

Cleaning and Storage 38. . . . . . . . . . . . . . . . .

Troubleshooting 39. . . . . . . . . . . . . . . . . . . . . . . . .

1

Safety

Improper use or maintenance by the operator or

owner can result in injury. To reduce the potential

for injury, comply with these safety instructions

and always pay attention to the safety alert

symbol, which means CAUTION, WARNING, or

DANGER—“personal safety instruction.” Failure

to comply with the instruction may result in

personal injury or death.

Safe Operating Practices

This product is capable of amputating hands and feet

and throwing objects. Always follow all safety

instructions to avoid serious injury or death.

POTENTIAL HAZARD

• Engine exhaust contains carbon monoxide,

which is an odorless, deadly poison.

WHAT CAN HAPPEN

• Carbon monoxide can kill you and is also

known to the State of California to cause

birth defects.

HOW TO AVOID THE HAZARD

• Do not run engine indoors or in an enclosed

area.

This product is designed for cutting and recycling

grass or, when equipped with a grass bagger, for

catching cut grass. Any use for purposes other than

these could prove dangerous to user and bystanders.

Note: This engine is NOT equipped with a

spark arrestor muffler. Use or operation

of this mower in the State of California

on any forest-covered or unimproved

grass-covered land, without an

approved spark arrester muffler, is a

violation of the law. Other states may

have similar laws.

General Operation

1. Read, understand, and follow all instructions in

the operator’s manual and on the machine before

starting.

2. Allow only responsible adults who are familiar

with the instructions to operate the machine.

3. Clear the area of objects such as rocks, toys,

wire, etc., which could be picked up and thrown

by the blade.

4. Be sure the area is clear of other people before

mowing. Stop the machine if anyone enters the

area.

5. Never carry passengers.

6. Do not mow in reverse unless absolutely

necessary. Always look down and behind before

and while backing.

7. Be aware of the mower discharge direction and

do not point it at anyone. Do not operate the

mower without either the entire grass catcher or

the guard in place.

8. Slow down before turning. Sharp turns on any

terrain may cause loss of control.

9. Never leave a running machine unattended.

Always turn off blades, set parking brake, stop

engine, and remove key before dismounting.

10. Turn off blades when not mowing.

11. Keep hands, feet, hair and loose clothing away

from attachment discharge area, underside of

mower and any moving parts while engine is

running.

12. Stop the engine before removing the grass

catcher or unclogging the chute.

13. Mow only in daylight or good artificial light.

2

Safety

14. Do not operate the machine while under the

influence of alcohol or drugs.

15. Watch for traffic when operating near or crossing

roadways.

16. Use extra care when loading or unloading the

machine onto a trailer or truck.

17. Do not touch equipment or attachment parts

which may be hot from operation. Allow to cool

before attempting to maintain, adjust or service.

18. Wear seat belt when operating a machine with

ROPS (roll over protection).

19. Wear ear protection when operating this

machine.

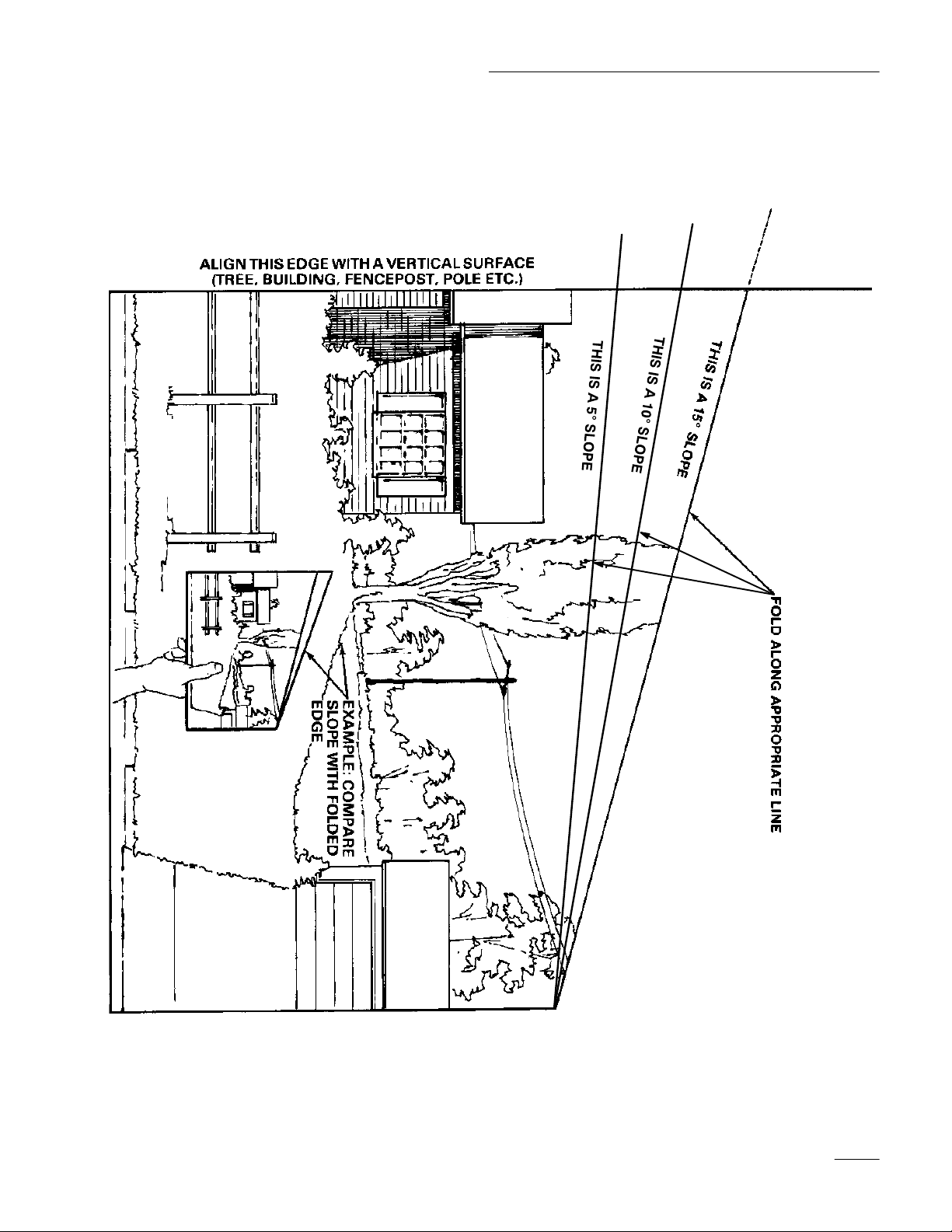

Slope Operation

Slopes are a major factor related to loss-of-control

and tip-over accidents, which can result in severe

injury or death. All slopes require extra caution. If

you cannot back up the slope or if you feel uneasy on

it, do not mow it.

DO

• Mow up and down slopes greater than 5°, not

across.

• Mow downhill only on slopes less than 10°,

Mow uphill only on slopes less than 15°

• Remove obstacles such as rocks, tree limbs, etc.

from the mowing area. Watch for holes, ruts or

bumps, as uneven terrain could overturn the

machine. Tall grass can hide obstacles.

• Use slow speed. Choose a low gear so that you

will not have to stop or shift while on the slope.

• Follow the manufacturer’s recommendations for

wheel weight or counterweights to improve

stability.

• Keep all movement on slopes slow and gradual.

Do not make sudden changes in speed or

direction.

• Avoid starting or stopping on a slope. If tires

lose traction, disengage the blades and proceed

slowly straight down the slope.

• When operating machine on slopes, banks or

near drop offs, always have ROPS (roll over

protection) installed.

• When operating a machine with ROPS (roll over

protection) always use seat belt.

• Be certain that the seat belt can be released

quickly if the machine is driven or rolls into

ponds of water.

• Check carefully for overhead clearances (i.e.

branches, doorways, electrical wires) before

driving under any objects and do not contact

them.

DO NOT

• Do not operate machine on hillsides or slopes

exceeding 15°.

• Avoid turning on slopes. If you must turn, turn

slowly and gradually downhill, if possible.

• Do not mow near drop-offs, ditches, or

embankments. The machine could suddenly turn

over if a wheel goes over the edge of a cliff or

ditch, or if an edge caves in.

• Do not mow on wet grass. Reduced traction

could cause sliding.

• Do not try to stabilize the machine by putting

your foot on the ground.

• Do not use a grass catcher on steep slopes.

Heavy grass bags could cause loss of control or

overturn the machine.

• Use extra care with grass catchers or other

attachments. These can change the stability of

the machine.

3

Safety

Children

Tragic accidents can occur if the operator is not alert

to the presence of children. Children are often

attracted to the machine and the mowing activity.

Never assume that children will remain where you

last saw them. The following requirements must be

followed to prevent injury to children.

1. Keep children out of the mowing area and under

the watchful care of another responsible adult.

2. Be alert and turn the machine off if children

enter the area.

3. Before and while backing, look behind and down

for small children.

4. Never carry children. They may fall off and be

seriously injured or interfere with safe machine

operation.

5. Never allow children to operate the machine.

6. Use extra care when approaching blind corners,

shrubs, trees, the end of a fence or other objects

that may obscure vision.

4. Keep nuts and bolts tight, especially the blade

attachment bolts. Keep equipment in good

condition.

5. Never tamper with safety devices. Check safety

systems for proper operation before each use.

6. Keep the machine free of grass, leaves, or other

debris build-up. Clean up oil or fuel spillage.

Allow the machine to cool before storing.

7. Stop and inspect the equipment if you strike an

object. Repair, if necessary, before restarting.

8. Grass catcher components are subject to wear,

damage and deterioration, which could expose

moving parts or allow objects to be thrown.

Frequently check components and replace with

manufacturer’s recommended parts, when

necessary.

9. Mower blades are sharp and can cut. Wrap the

blade(s) or wear gloves, and use extra caution

when servicing them.

10. Use only genuine replacement parts to ensure

that original standards are maintained.

Service

1. Stop the engine and disconnect spark plug

wire(s) before performing any service, repairs,

maintenance or adjustments.

2. Use extra care when handling gasoline and other

fuels. They are flammable and vapors are

explosive.

A. Use only an approved container.

B. Never remove the gas cap or add fuel when

the engine is running. Allow the engine to

cool before refueling. Do not smoke.

C. Never refuel the machine indoors.

D. Never store the machine or fuel container

inside where there is an open flame, such as

near a water heater or furnace.

3. Never run a machine inside a closed area.

11. Check brake operation frequently. Adjust and

service as required.

12. Battery acid is poisonous and can cause burns.

Avoid contact with skin, eyes and clothing.

Protect your face, eyes and clothing when

working with a battery.

13. Battery gases can explode. Keep cigarettes,

sparks and flames away from battery.

14. Hydraulic fluid escaping under pressure can

penetrate the skin and cause injury. Use

cardboard or paper to find hydraulic leaks.

15. Never modify ROPS (roll over protection)

frames or structures because they are specifically

designed, sized, located and tested for injury

reduction. If a rollover occurs, a modified ROPS

will not provide adequate protection.

4

Slope Chart

Read all safety instructions on pages 2–4.

Safety

5

Safety

Safety and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near

any area of potential danger. Replace any decal that is damaged or lost.

ON INSTRUMENT P ANEL

(Part No. 98–4357)

BELOW FRONT OF SEAT

(Part No. 98–1313)

BELOW FRONT OF SEAT

(Part No. 98–4387)

ON REAR FRAME MEMBER

AND CLUTCH GUARD

(Part No. 93–9198)

6

ON FRONT FRAME MEMBER

(Part No. 98–4361)

ON UTILITY BOX LATCH

(Part No. 98–1306)

Gasoline and Oil

Recommended Gasoline

Use UNLEADED Regular Gasoline suitable for

automotive use (85 pump octane minimum). Leaded

regular gasoline may be used if unleaded regular is

not available.

IMPORTANT: Never use methanol, gasoline

containing methanol, or gasohol containing

more than 10% ethanol because the fuel

system could be damaged. Do not mix oil with

gasoline.

POTENTIAL HAZARD

• In certain conditions gasoline is extremely

flammable and highly explosive.

WHAT CAN HAPPEN

• A fire or explosion from gasoline can burn

you, others, and cause property damage.

HOW TO AVOID THE HAZARD

• Use a funnel and fill the fuel tank outdoors,

in an open area, when the engine is cold.

Wipe up any gasoline that spills.

• Do not fill the fuel tank completely full.

Add gasoline to the fuel tank until the level

is 1/4” to 1/2” (6 mm to 13 mm) below the

bottom of the filler neck. This empty space

in the tank allows gasoline to expand.

• Never smoke when handling gasoline, and

stay away from an open flame or where

gasoline fumes may be ignited by a spark.

• Store gasoline in an approved container

and keep it out of the reach of children.

Never buy more than a 30-day supply of

gasoline.

Stabilizer/Conditioner

Add the correct amount of gas stabilizer/conditioner

to the gas. Using a stabilizer/conditioner in the

machine:

• Keeps gasoline fresh during storage

• Cleans the engine while it runs

• Eliminates gum-like buildup in the fuel system,

which causes hard starting

IMPORTANT: Never use fuel additives

containing methanol or ethanol.

Filling the Fuel Tank

1. Shut the engine off and set the parking brake.

2. Clean around the fuel tank cap and remove the

cap. Add unleaded regular gasoline until the

level is to the bottom of the filler neck. Do not

fill the neck completely full, this space in the

tank allows gasoline to expand.

3. Install fuel tank cap securely. Wipe up any

gasoline that may have spilled.

Check Engine Oil Level

Before you start the engine and use the machine,

check the oil level in the engine crankcase; refer to

Checking Oil Level, page 23.

7

Assembly

Loose Parts

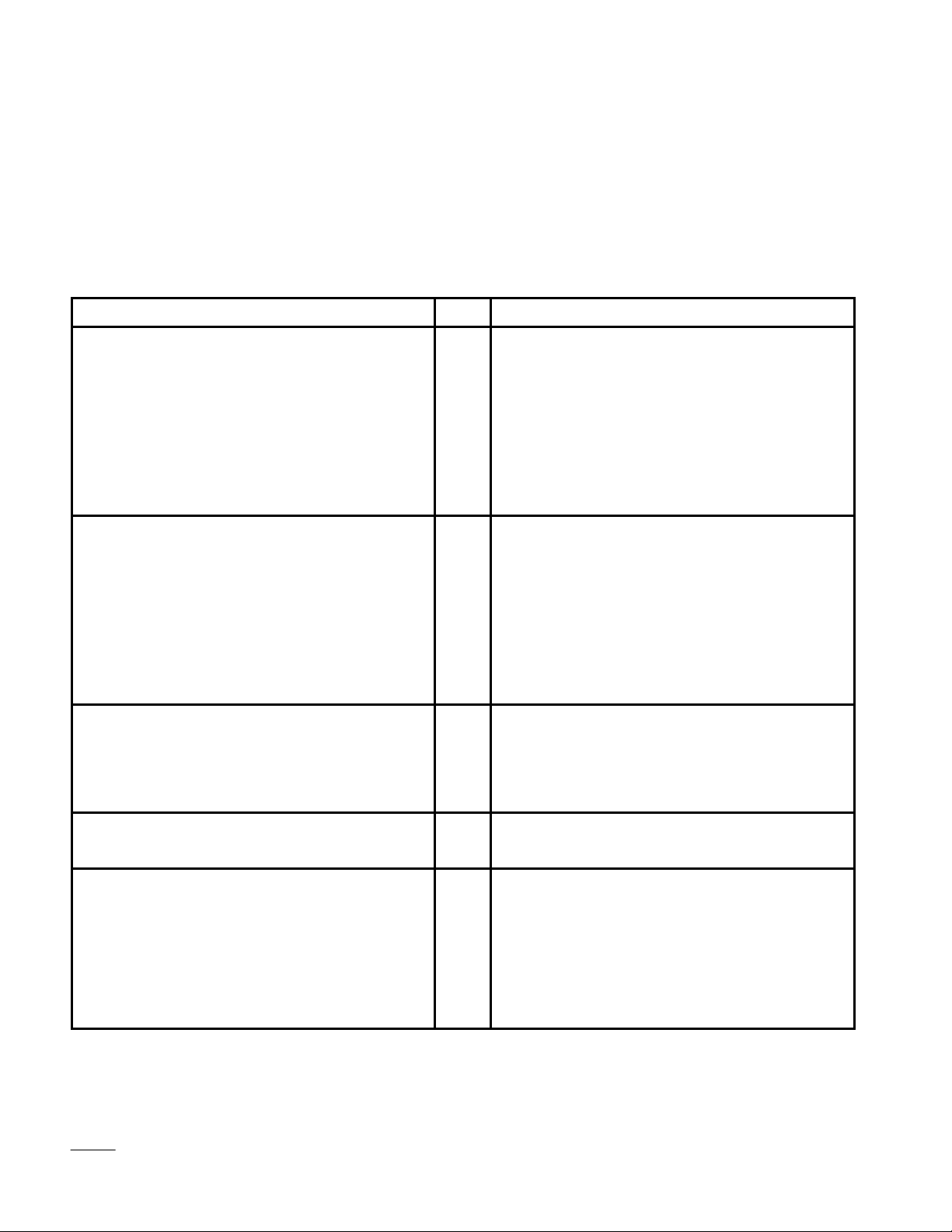

Note: Use the chart below to verify all parts have been shipped.

DESCRIPTION QTY. USE

Wheel assembly–castor

Axle

Locknut 1/2–13

Washer 1/2” (13 mm)

Spacer

Nut 1/2–13

Jam nut 1/2–13

Battery

Battery clamp

Battery support rod

Wing nut 1/4–20

Terminal boot

Bolt 1/4–20 x 3/4” (19 mm)

Washer 1/4”

Drive Shaft

Roll Pin 3/16 x 2” (51 mm)

Bolt 3/8”–16 x 1–5/8” (41.5 MM)

1

1

1

2

1

1

1

1

1

2

4

1

2

2

1

1

2

Install castor wheel

Install battery

Install drive shaft to mower gearbox

Locknut 3/8”–16

Pivot pin assembly

Hairpin cotter

Key

Safety Booklet

Operator’s Manual

Engine Operator’s Manual

Parts Catalog

Registration card

8

2

2

2

2

1

1

1

1

1

Install mower attachment

Read before operating machine

For ordering parts

Fill out and return to Toro

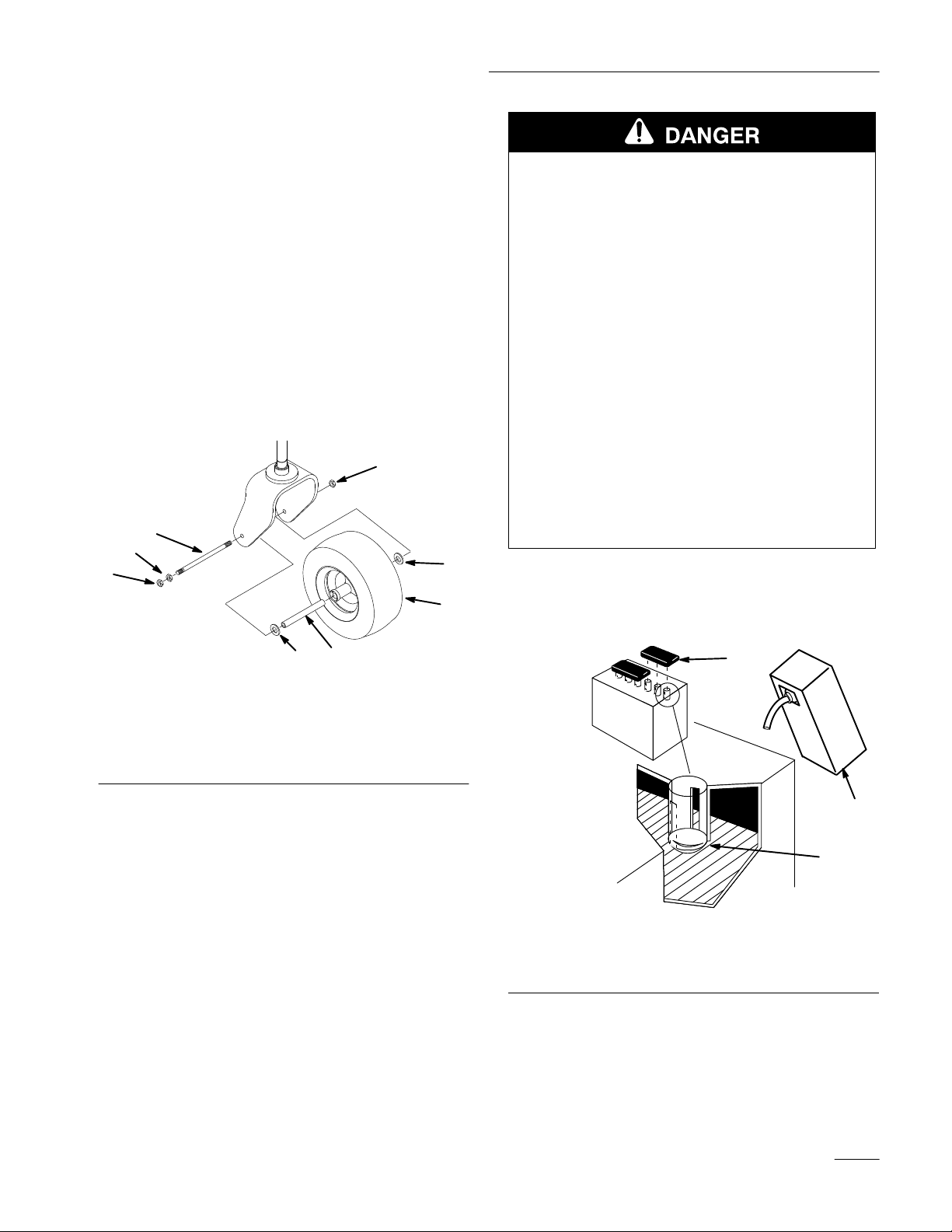

Install Castor Wheel

Assembly

1. Remove nuts, washers, spacer and axle shaft

from fork (Fig. 1).

2. Jack up rear of unit and install rear wheel into

castor fork (Fig. 1).

3. Place wheel between fork and slide axle through

bearings (Fig. 1).

4. Secure axle with

5. Torque nuts to 75 ft–lb (55 N⋅m).

6. Grease castor wheel bearings (Fig. 1).

POTENTIAL HAZARD

• Battery electrolyte contains sulfuric acid

which is a deadly poison and it causes

severe burns.

WHAT CAN HAPPEN

• If you carelessly drink electrolyte you could

die or if it gets onto your skin you will be

burned.

HOW TO AVOID THE HAZARD

• Do not drink electrolyte and avoid contact

with skin, eyes or clothing. Wear safety

glasses to shield your eyes and rubber

gloves to protect your hands.

• Fill the battery where clean water is always

available for flushing the skin.

• Follow all instructions and comply with all

safety messages on the electrolyte container.

2. Remove filler caps from the battery. Slowly pour

electrolyte into each cell until the electrolyte

level is up to the lower part of the tube (Fig. 2).

m–3227

1. Wheel assembly

2. Axle

3. Washer 1/2” (13 mm)

4. Spacer

Figure 1

5. Nut 1/2–13

6. Jam nut 1/2–13

7. Locknut 1/2–13

Check the air pressure in the front and rear tires: refer

to Tire Pressure in Maintenance section.

Activate the Battery

Bulk electrolyte with 1.260 specific gravity must be

purchased from a local battery supply outlet.

1. Remove the battery from the machine.

IMPORTANT: Be careful not to damage the

long vent tube when removing the battery

box.

1

3

m–1262

Figure 2

1. Filler caps

2. Electrolyte

3. Lower part of the tube

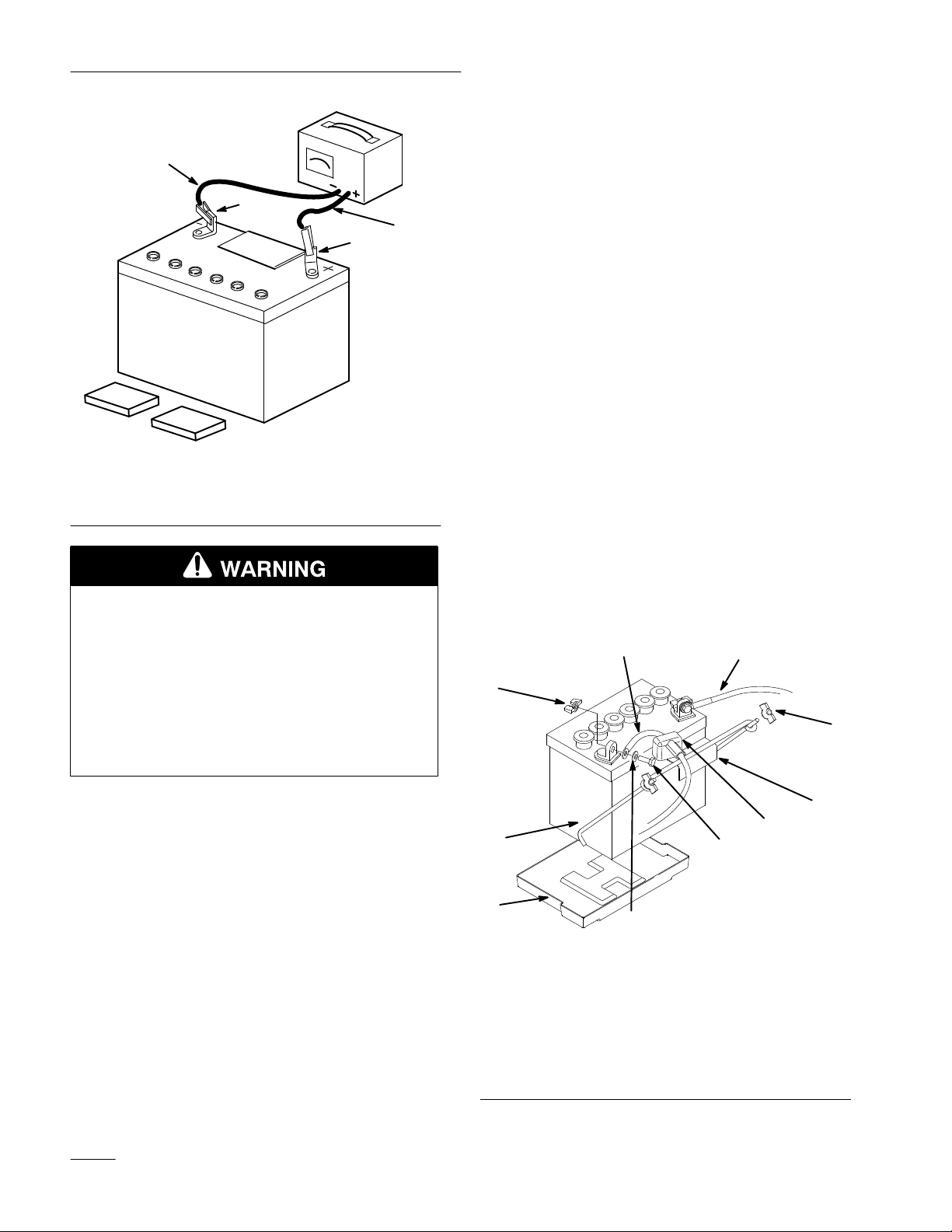

3. Leave the covers off and connect a 3 to 4 amp

battery charger to the battery posts (Fig. 3).

Charge the battery at a rate of 4 amperes or less

for 4 hours (12 volts).

2

9

Assembly

Install Battery

4

2

1

Figure 3

1. Positive post

2. Negative post

3. Charger red (+) wire

4. Charger black (–) wire

POTENTIAL HAZARD

• Charging battery produces gasses.

WHAT CAN HAPPEN

• Battery gasses can explode.

HOW TO AVOID THE HAZARD

• Keep cigarettes, sparks and flames away

from battery.

3

m–1254

1. Fill battery with electrolyte and charge, refer to

BATTERY, page 35.

2. Position battery in tray with terminal posts

toward the engine (Fig. 4).

3. Slide the red terminal boot onto the red battery

cable.

4. Install the positive (red) battery cable to positive

(+) battery terminal then negative battery cable

to the negative (–) battery terminal. Secure

cables with (2) 1/4 x 3/4” (19 mm) bolts 1/4”

washers, 1/4” lock washers and 1/4” locknuts.

IMPORTANT: Route cables so they do not

contact metal edges or frame members.

5. Secure battery with (2) support rods, a battery

clamp and (2) 1/4” wing nuts. Position support

rods in mounting holes (Fig. 4). Tighten wing

nuts so battery is held securely in position and

will not slide. DO NOT OVERTIGHTEN.

3

9

4

9

4. When the battery is fully charged, disconnect the

charger from the electrical outlet then from the

negative and positive battery posts (Fig. 3).

5. Slowly pour electrolyte into each cell until the

level is once again up to the “UPPER” line on

the battery case (Fig. 2) and install covers.

10

7

1

6

1. Battery tray

2. Terminal boot

3. Positive battery cable

4. Negative battery cable

5. Bolt 1/4–20 x 3/4” (19 mm)

8

2

5

m–3224

Figure 4

6. Washer 1/4”

7. Battery support rod

8. Battery clamp

9. Wing nut 1/4”

Assembly

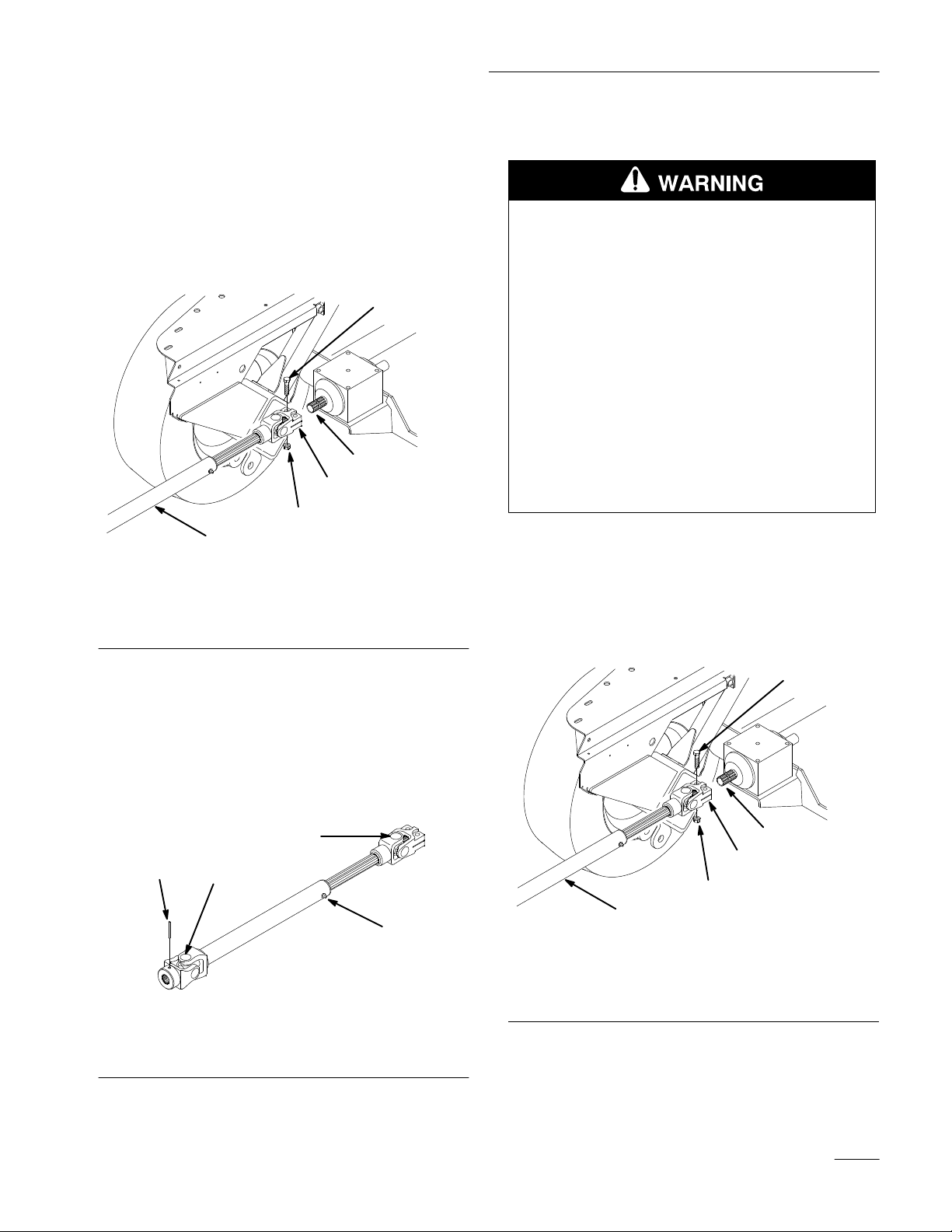

Install Drive Shaft

Install the drive shaft only when ready to attach a

mower deck to the traction unit.

1. Secure universal joint to gearbox shaft with (2)

3/8”–16 x 1-5/8” (41.5 mm) bolts and 3/8”–16

locknuts (Fig. 5).

4

3

2

1. PTO Driveshaft

2. Universal Joint

3. Gearbox shaft

5

1

Figure 5

4. Bolt 3/8”–16 x 1-5/8”

(41.5 mm)

5. Locknut 3/8”–16

m-3198

Remove Drive Shaft

POTENTIAL HAZARD

• If the drive shaft is attached to the tractor

and not to a mower deck or other

attachment, and the tractor is operated, the

drive shaft may flail about dangerously.

WHAT CAN HAPPEN

• If the drive shaft is connected only to the

tractor when the PTO is engaged, the shaft

will flail about and can seriously injure you

or bystanders.

HOW TO AVOID THE HAZARD

• Remove the drive shaft from the tractor

when not using it with an attachment.

1. Remove (2) 3/8”–16 x 1-5/8” (41.5 mm) bolts

and 3/8”–16 locknuts from universal joint and

slide the driveshaft off gearbox shaft (Fig. 5).

Note: Save all hardware for use when

installing mower.

2. Grease the fittings on drive shaft and universal

joints (Fig. 6).

3. Temporarily install the roll pin 3/16” x 2”

part–way into the hole in the end of the

unconnected universal joint to store it until a

mower deck is instaled (Fig. 6).

2

3

1. PTO Driveshaft

2. Universal Joint

2

1

m-3203

Figure 6

3. Roll Pin 3/16” x 2”

(51 mm)

1. PTO Driveshaft

2. Universal Joint

3. Gearbox shaft

1

4

3

2

5

m-3198

Figure 7

4. Bolt 3/8”–16 x 1-5/8”

(41.5 MM)

5. Locknut 3/8”–16

11

Operation

Think Safety First

Please carefully read all the safety instructions on

pages 2–8. Knowing this information could help you,

your family, pets or bystanders avoid injury.

POTENTIAL HAZARD

• Loud sounds can cause ear damage and

loss of hearing.

WHAT CAN HAPPEN

• Ear damage or hearing loss may occur.

HOW TO AVOID THE HAZARD

• Wear ear protection when operating this

machine.

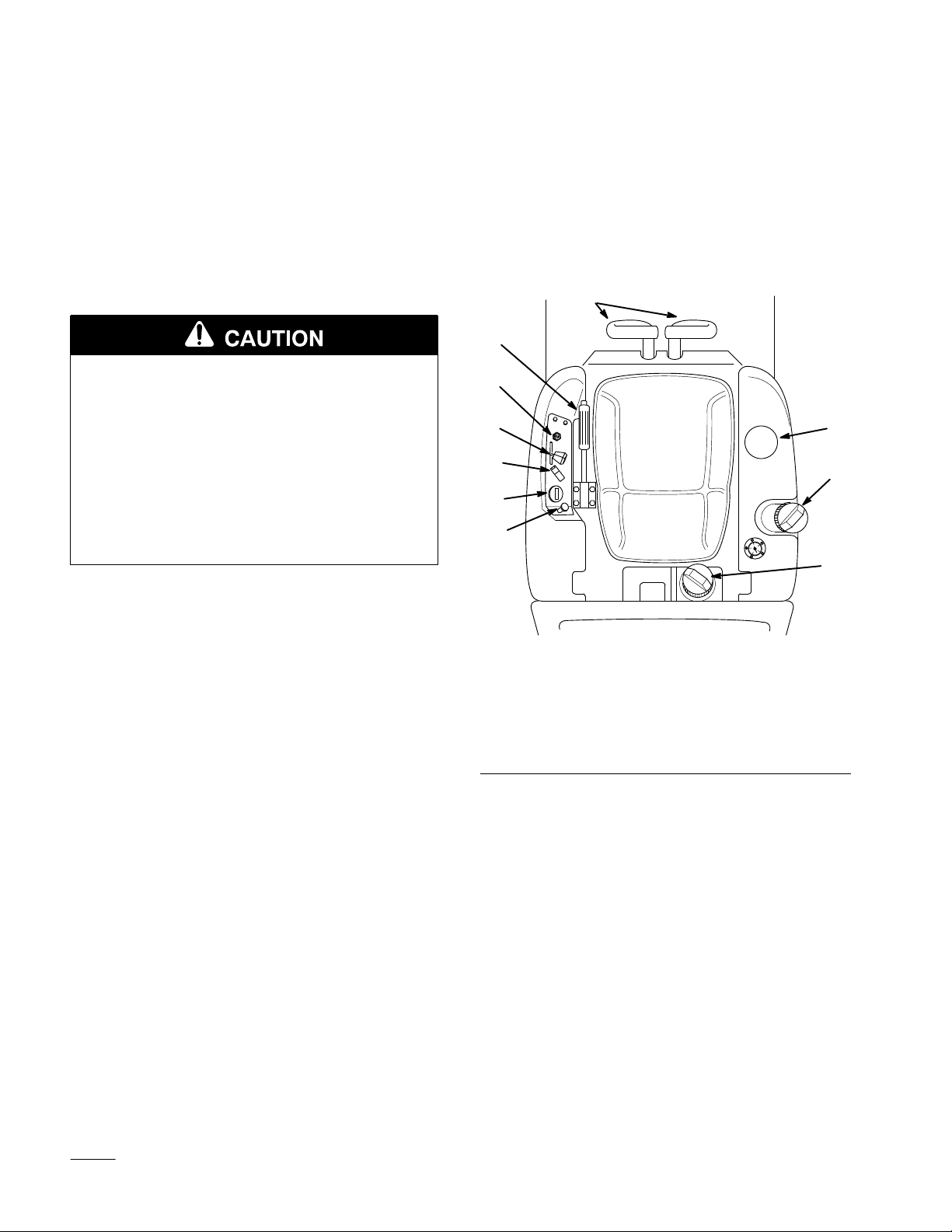

Controls

Become familiar with all the controls (Fig. 1) before

you start the engine and operate the machine.

1

2

3

4

5

6

7

m–3729

8

9

10

1. Motion control lever

2. Parking brake

3. Ignition switch

4. Throttle

5. Power take off (PTO)

Figure 1

6. Hourmeter

7. Choke

8. Drink holder

9. Fuel cap

10. Hydro reservoir cap

12

Loading...

Loading...