Toro 74178, 74197 Operator's Manual

Form No. 3329-519

Z150 and Z153

Z Master with 52 SFS Side Discharge Mower

Model No. 74178—Serial No. 230006001 and Up

Model No. 74197—Serial No. 230006001 and Up

Operator ’s Manual

Domestic English (EN)

Warning

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

Important This engine is not equipped with a spark

arrester muffler. It is a violation of California Public

Resource Code Section 4442 to use or operate this engine

on any forest–covered, brush–covered or grass–covered

land. Other states or federal areas may have similar laws.

This spark ignition system complies with Canadian

ICES-002.

Ce système d’allumage par étincelle de véhicule est

conforme à la norme NMB-002 du Canada.

The enclosed Engine Owner’s Manual is supplied for

information regarding The U.S. Environmental

Protection Agency (EPA) and the California Emission

Control Regulation of emission systems, maintenance

and warranty.

Keep this engine Owner’s Manual with your unit.

Should this engine Owner’s Manual become damaged

or illegible, replace immediately. Replacements may be

ordered through the engine manufacturer.

Contents

Page

Introduction 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safe Operating Practices 3. . . . . . . . . . . . . . . . . . . .

Slope Chart 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety and Instruction Decals 8. . . . . . . . . . . . . . . .

Gasoline and Oil 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Gasoline 13. . . . . . . . . . . . . . . . . . . .

Using Stabilizer/Conditioner 13. . . . . . . . . . . . . . . .

Filling the Fuel Tank 13. . . . . . . . . . . . . . . . . . . . . .

Checking the Engine Oil Level 13. . . . . . . . . . . . . .

Setup 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loose Parts 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Drive Wheels 14. . . . . . . . . . . . . . . . .

Checking the Tire Pressure 14. . . . . . . . . . . . . . . . . .

Installing the Seat Retaining Rod 15. . . . . . . . . . . . .

Installing the Motion Control Levers 15. . . . . . . . . .

Activating the Battery 16. . . . . . . . . . . . . . . . . . . . . .

Installing the Air Cleaner Cap 16. . . . . . . . . . . . . . .

Checking the Hydraulic Fluid 17. . . . . . . . . . . . . . .

Greasing the Bearings 17. . . . . . . . . . . . . . . . . . . . . .

Checking the Leveling of the Mower Deck 17. . . . .

Checking the Side Discharge Chute 17. . . . . . . . . . .

2003 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

Page

Checking the Engine Oil Level 17. . . . . . . . . . . . . .

Operation 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Think Safety First 17. . . . . . . . . . . . . . . . . . . . . . . . .

Controls 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating the Parking Brake 18. . . . . . . . . . . . . . . .

Starting and Stopping the Engine 19. . . . . . . . . . . . .

Operating the Power Take Off (PTO) 20. . . . . . . . . .

The Safety Interlock System 20. . . . . . . . . . . . . . . .

Driving Forward or Backward 21. . . . . . . . . . . . . . .

Stopping the Machine 21. . . . . . . . . . . . . . . . . . . . . .

Adjusting the Height-of-Cut 22. . . . . . . . . . . . . . . . .

Adjusting the Anti-Scalp Rollers 22. . . . . . . . . . . . .

Positioning the Seat 23. . . . . . . . . . . . . . . . . . . . . . .

Pushing the Machine by Hand 23. . . . . . . . . . . . . . .

Operating with Side Discharge 23. . . . . . . . . . . . . . .

Using a Rollover Protection System (ROPS) 23. . . .

Transporting the Machine 24. . . . . . . . . . . . . . . . . . .

Loading Machines 24. . . . . . . . . . . . . . . . . . . . . . . .

Tips for Mowing Grass 25. . . . . . . . . . . . . . . . . . . . .

Maintenance 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Maintenance Schedule 26. . . . . . . . .

Servicing the Cutting Blades 27. . . . . . . . . . . . . . . .

Servicing the Air Cleaner 29. . . . . . . . . . . . . . . . . . .

Servicing the Engine Oil 30. . . . . . . . . . . . . . . . . . .

Servicing the Spark Plug 31. . . . . . . . . . . . . . . . . . .

Replacing the Fuel Filter 32. . . . . . . . . . . . . . . . . . .

Draining the Fuel Tank 32. . . . . . . . . . . . . . . . . . . . .

Cleaning the Cooling Systems 33. . . . . . . . . . . . . . .

Greasing and Lubrication 33. . . . . . . . . . . . . . . . . . .

Checking the Tire Pressure 34. . . . . . . . . . . . . . . . . .

Servicing the Hydraulic System 34. . . . . . . . . . . . . .

Adjusting the Handle Neutral 36. . . . . . . . . . . . . . . .

Setting the Hydraulic Pump Neutral 38. . . . . . . . . . .

Adjusting the Tracking 39. . . . . . . . . . . . . . . . . . . . .

Adjusting the Caster Pivot Bearing 39. . . . . . . . . . .

Checking the Wheel Hub Slotted Nut 40. . . . . . . . .

Adjusting the Mower Level 40. . . . . . . . . . . . . . . . .

Adjusting the Push Arms 41. . . . . . . . . . . . . . . . . . .

Cleaning Under the Deck 41. . . . . . . . . . . . . . . . . . .

Inspecting the Belts 41. . . . . . . . . . . . . . . . . . . . . . .

Replacing the Deck Belt 41. . . . . . . . . . . . . . . . . . . .

Replacing the Pump Drive Belt 42. . . . . . . . . . . . . .

Adjusting the Parking Brake 43. . . . . . . . . . . . . . . .

Servicing the Fuses 43. . . . . . . . . . . . . . . . . . . . . . . .

Servicing the Battery 44. . . . . . . . . . . . . . . . . . . . . .

Replacing the Grass Deflector 46. . . . . . . . . . . . . . .

Waste Disposal 47. . . . . . . . . . . . . . . . . . . . . . . . . . .

Mercury Tilt Switch 47. . . . . . . . . . . . . . . . . . . . . . .

Mercury Tilt Switch Disposal 47. . . . . . . . . . . . . . . .

All Rights Reserved

Printed in the USA

2

Page

Wiring Diagram 48. . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning and Storage 49. . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Toro Total Coverage Guarantee 52. . . . . . . . . . . . .

Introduction

Read this manual carefully to learn how to operate and

maintain your product properly. The information in this

manual can help you and others avoid injury and product

damage. Although Toro designs and produces safe

products, you are responsible for operating the product

properly and safely.

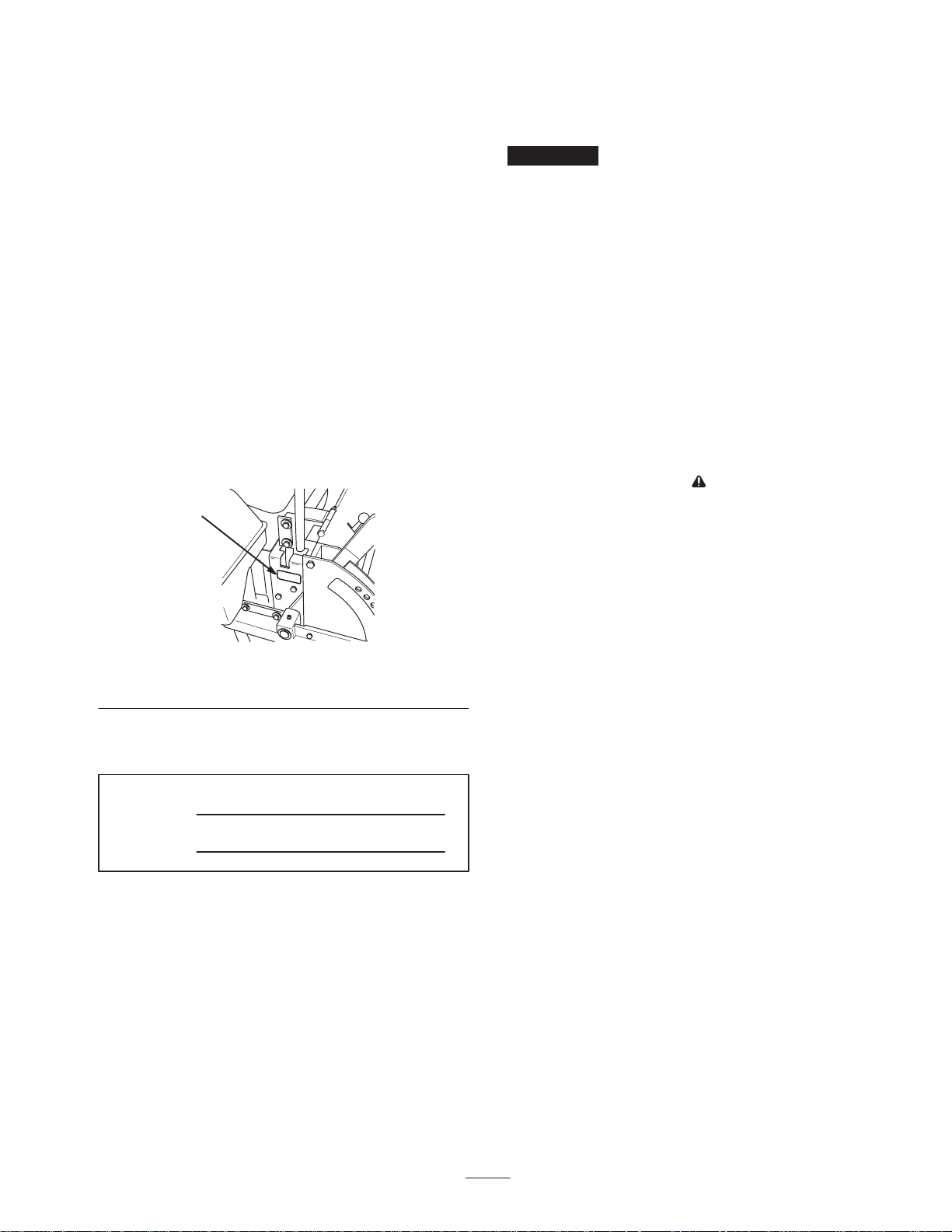

Whenever you need service, genuine Toro parts, or

additional information, contact an Authorized Service

Dealer or Toro Customer Service and have the model and

serial numbers of your product ready. Figure 1 illustrates

the location of the model and serial numbers on the

product.

1

Caution signals a hazard that may cause minor or moderate

injury if you do not follow the recommended precautions.

This manual uses two other words to highlight information.

Important calls attention to special mechanical

information and Note: emphasizes general information

worthy of special attention.

Safety

This machine meets or exceeds the B71.4 1999

specifications of the American National Standards

Institute, in effect at time of production.

Note: The addition of attachments made by other

manufacturers that do not meet American National

Standards Institute certification will cause noncompliance

of this machine.

Improper use or maintenance by the operator or owner

can result in injury. To reduce the potential for injury,

comply with these safety instructions and always pay

attention to the safety alert symbol, which means

CAUTION, WARNING, or DANGER—“personal

safety instruction.” Failure to comply with the

instruction may result in personal injury or death.

m–3648

Figure 1

1. Location of the model and serial numbers

Write the product model and serial numbers in the space

below:

Model No.

Serial No.

This manual identifies potential hazards and has special

safety messages that help you and others avoid personal

injury and even death. Danger, Warning, and Caution are

signal words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

Danger signals an extreme hazard that will cause serious

injury or death if you do not follow the recommended

precautions.

Warning signals a hazard that may cause serious injury or

death if you do not follow the recommended precautions.

This product is capable of amputating hands and feet and

throwing objects. Always follow all safety instructions to

avoid serious injury or death.

This product is designed for cutting and recycling grass or,

when equipped with a grass bagger, for catching cut grass.

Any use for purposes other than these could prove

dangerous to user and bystanders.

Safe Operating Practices

The following instructions are from ANSI standard

B71.4—1999.

Training

• Read the Operator’s Manual and other training material.

If the operator(s) or mechanic(s) can not read English it

is the owner’s responsibility to explain this material to

them.

• Become familiar with the safe operation of the

equipment, operator controls, and safety signs.

• All operators and mechanics should be trained. The

owner is responsible for training the users.

• Never let children or untrained people operate or

service the equipment. Local regulations may restrict

the age of the operator.

3

• The owner/user can prevent and is responsible for

accidents or injuries occurring to himself or herself,

other people or property.

• Keep hands and feet away from the cutting units.

• Never carry passengers and keep pets and bystanders

away.

Preparation

• Evaluate the terrain to determine what accessories and

attachments are needed to properly and safely perform

the job. Only use accessories and attachments approved

by the manufacturer.

• Wear appropriate clothing including hard hat, safety

glasses and hearing protection. Long hair, loose

clothing or jewelry may get tangled in moving parts.

• Inspect the area where the equipment is to be used and

remove all objects such as rocks, toys and wire which

can be thrown by the machine.

• Use extra care when handling gasoline and other fuels.

They are flammable and vapors are explosive.

• Use only an approved container

• Never remove gas cap or add fuel with engine

running. Allow engine to cool before refueling.

Do not smoke.

• Never refuel or drain the machine indoors.

• Check that operator’s presence controls, safety switches

and shields are attached and functioning properly. Do

not operate unless they are functioning properly.

Operation

• Never run an engine in an enclosed area.

• Only operate in good light, keeping away from holes

and hidden hazards.

• Be sure all drives are in neutral and parking brake is

engaged before starting engine. Start the engine only

from the operator’s position.

• Never raise deck with the blades running.

• Never operate without the PTO shield, or other guards

securely in place. Be sure all interlocks are functioning

properly.

• Never operate with the discharge deflector raised,

removed or altered, unless using a grass catcher.

• Do not change the engine governor setting or overspeed

the engine.

• Stop on level ground, lower implements, disengage

drives, engage parking brake, shut off engine before

leaving the operator’s position for any reason including

emptying the catchers or unclogging the chute.

• Stop equipment and inspect blades after striking objects

or if an abnormal vibration occurs. Make necessary

repairs before resuming operations.

• Be alert, slow down and use caution when making

turns. Look behind and to the side before changing

directions.

• Slow down and use caution when crossing roads and

sidewalks. Stop blades if not mowing.

• Be aware of the mower discharge direction and do not

point it at anyone.

• Do not operate the mower under the influence of

alcohol or drugs.

• Use extreme care when loading or unloading the

machine into a trailer or truck.

• Use care when approaching blind corners, shrubs, trees,

or other objects that may obscure vision.

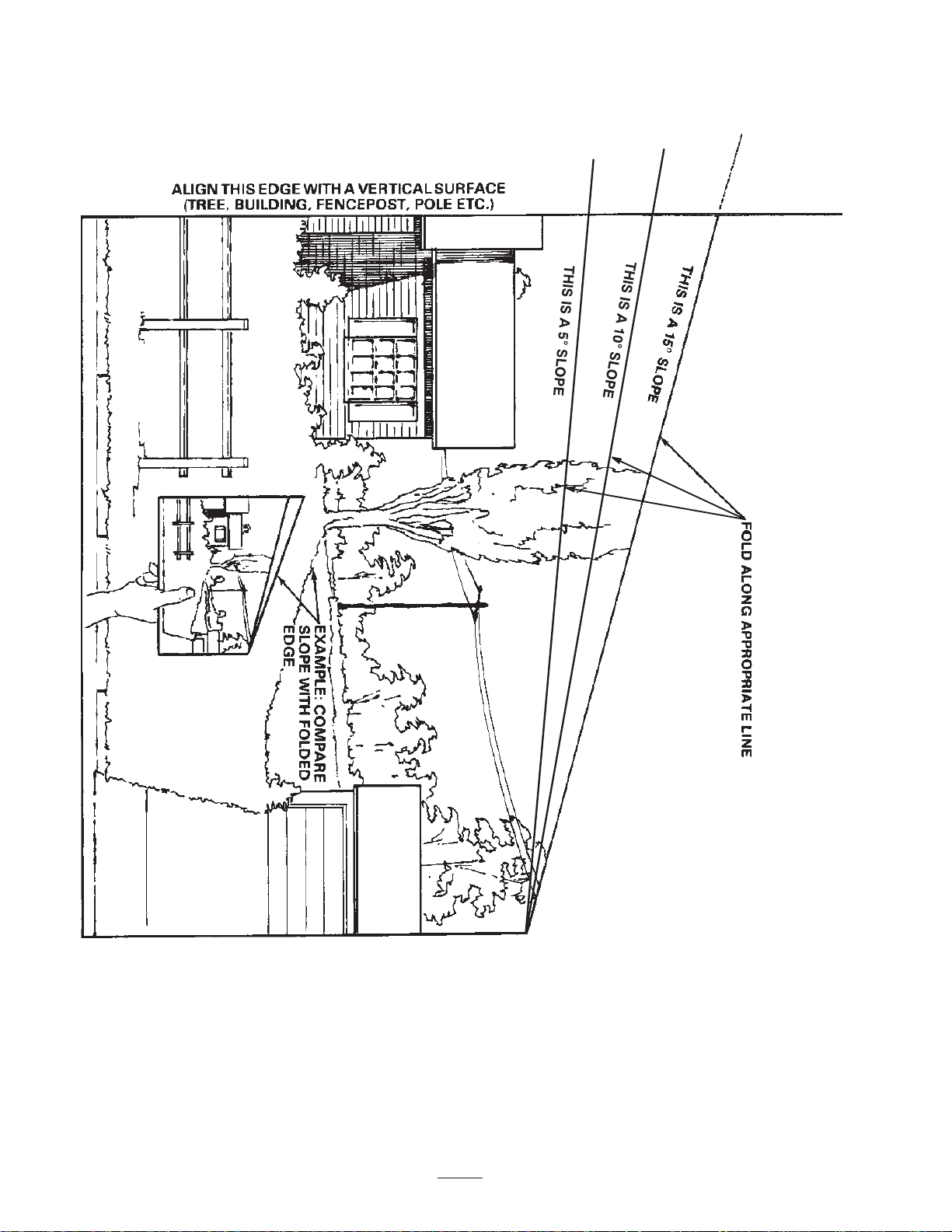

Slope Operation

• Do not mow slopes greater than 15 degrees.

• Do not mow near drop–offs, ditches, steep banks or

water. Wheels dropping over edges can cause rollovers,

which may result in serious injury, death or drowning.

• Do not mow slopes when grass is wet. Slippery

conditions reduce traction and could cause sliding and

loss of control.

• Do not make sudden turns or rapid speed changes.

• Use a walk behind mower and/or a hand trimmer near

drop–offs, ditches, steep banks or water.

• Reduce speed and use extreme caution on slopes.

• Remove or mark obstacles such as rocks, tree limbs,

etc. from the mowing area. Tall grass can hide

obstacles.

• Watch for ditches, holes, rocks, dips, and rises that

change the operating angle, as rough terrain could

overturn the machine.

• Avoid sudden starts when mowing uphill because the

mower may tip backwards.

• Be aware that loss of traction may occur going

downhill. Weight transfer to the front wheels may cause

drive wheels to slip and cause loss of braking and

steering.

• Always avoid sudden starting or stopping on a slope. If

tires lose traction, disengage the blades and proceed

slowly off the slope.

• Follow the manufacturer’s recommendations for wheel

weights or counterweights to improve stability.

4

• Use extreme care with grass catchers or other

attachments. These can change the stability of the

machine and cause loss of control.

Using the Rollover Protection System (ROPS)

• A rollbar is available and its use is recommended for

areas where there are slopes, drop–offs or water.

• When operating a machine with ROPS always use the

seat belt.

• Be certain that the seat belt can be released quickly if

the machine is driven or rolls into ponds or water.

• Check carefully for overhead clearances (i.e. branches,

doorways, electrical wires) before driving under any

objects and do not contact them.

Maintenance and storage

• Disengage drives, lower implement, set parking brake,

stop engine and remove key or disconnect spark plug

wire. Wait for all movement to stop before adjusting,

cleaning or repairing.

• Clean grass and debris from cutting units, drives,

mufflers, and engine to help prevent fires. Clean up oil

or fuel spillage.

• Use only Toro-approved attachments. Warranty may be

voided if used with unapproved attachments.

• Let engine cool before storing and do not store near

flame.

• Shut off fuel while storing or transporting. Do not store

fuel near flames or drain indoors.

• Park machine on level ground. Never allow untrained

personnel to service machine.

• Use jack stands to support components when required.

• Carefully release pressure from components with stored

energy.

• Disconnect battery or remove spark plug wire before

making any repairs. Disconnect the negative terminal

first and the positive last. Reconnect positive first and

negative last.

• Use care when checking blades. Wrap the blade(s) or

wear gloves, and use caution when servicing them.

Only replace blades. Never straighten or weld them.

• Keep hands and feet away from moving parts. If

possible, do not make adjustments with the engine

running.

• Charge batteries in an open well ventilated area, away

from spark and flames. Unplug charger before

connecting or disconnecting from battery. Wear

protective clothing and use insulated tools.

• Keep all parts in good working condition and all

hardware tightened. Replace all worn or damaged

decals.

5

Slope Chart

6

7

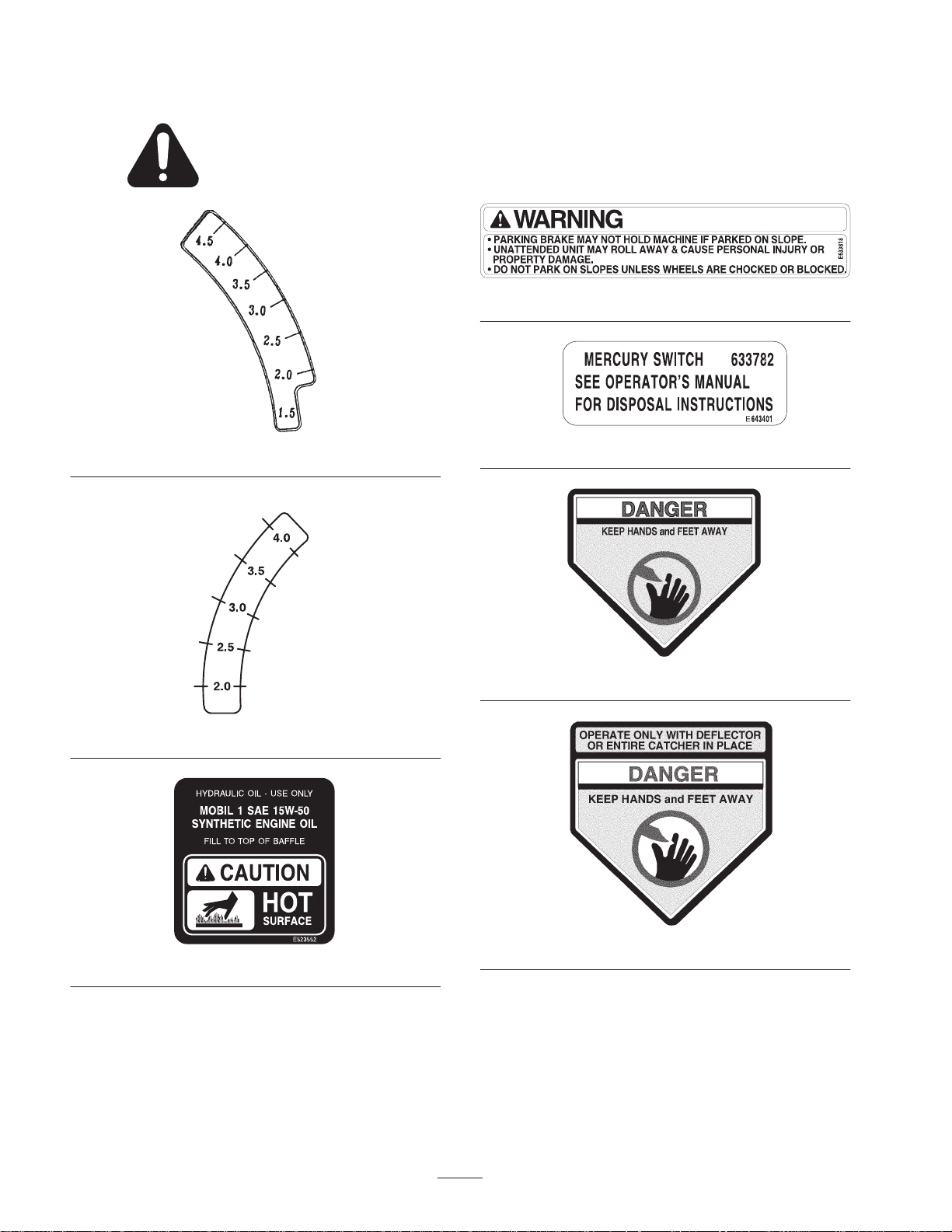

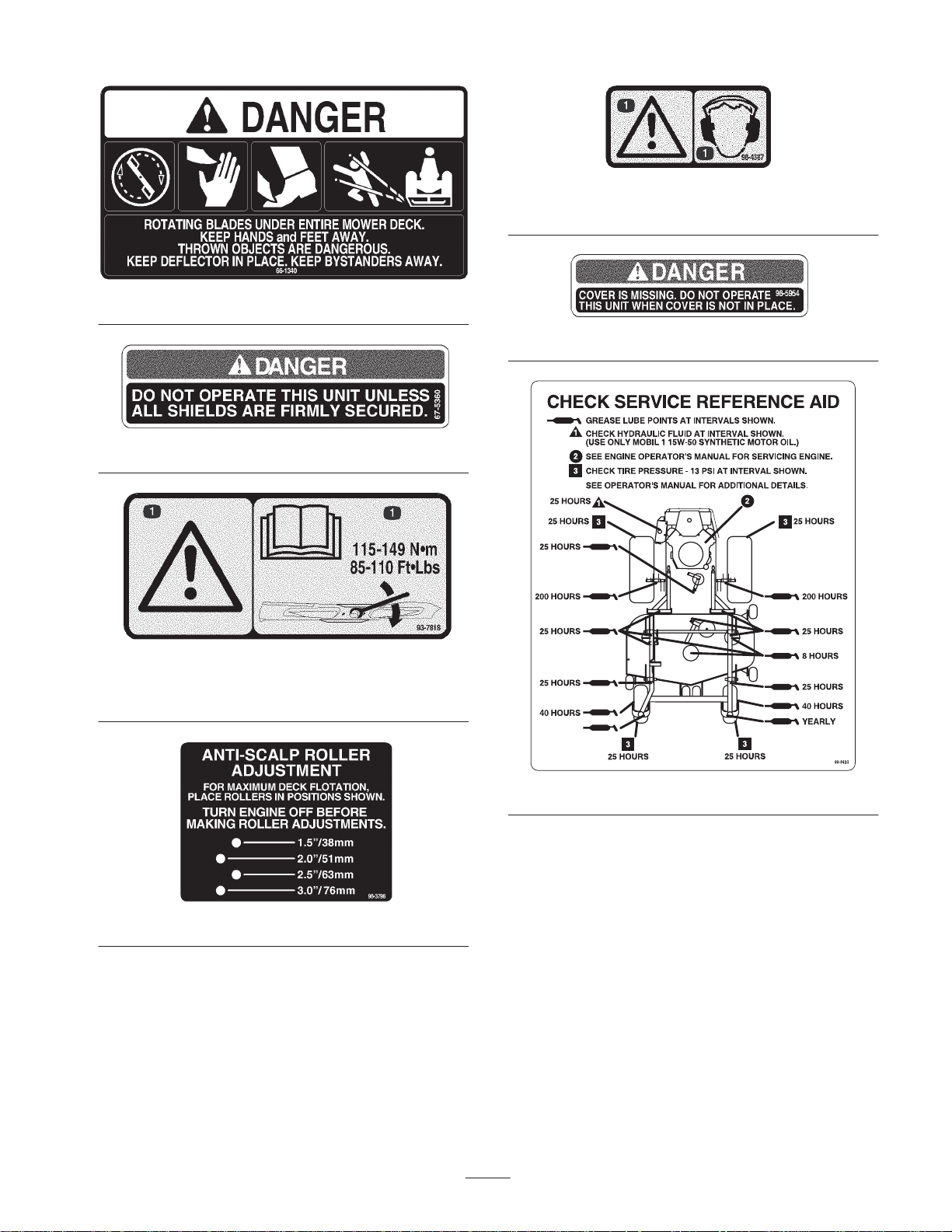

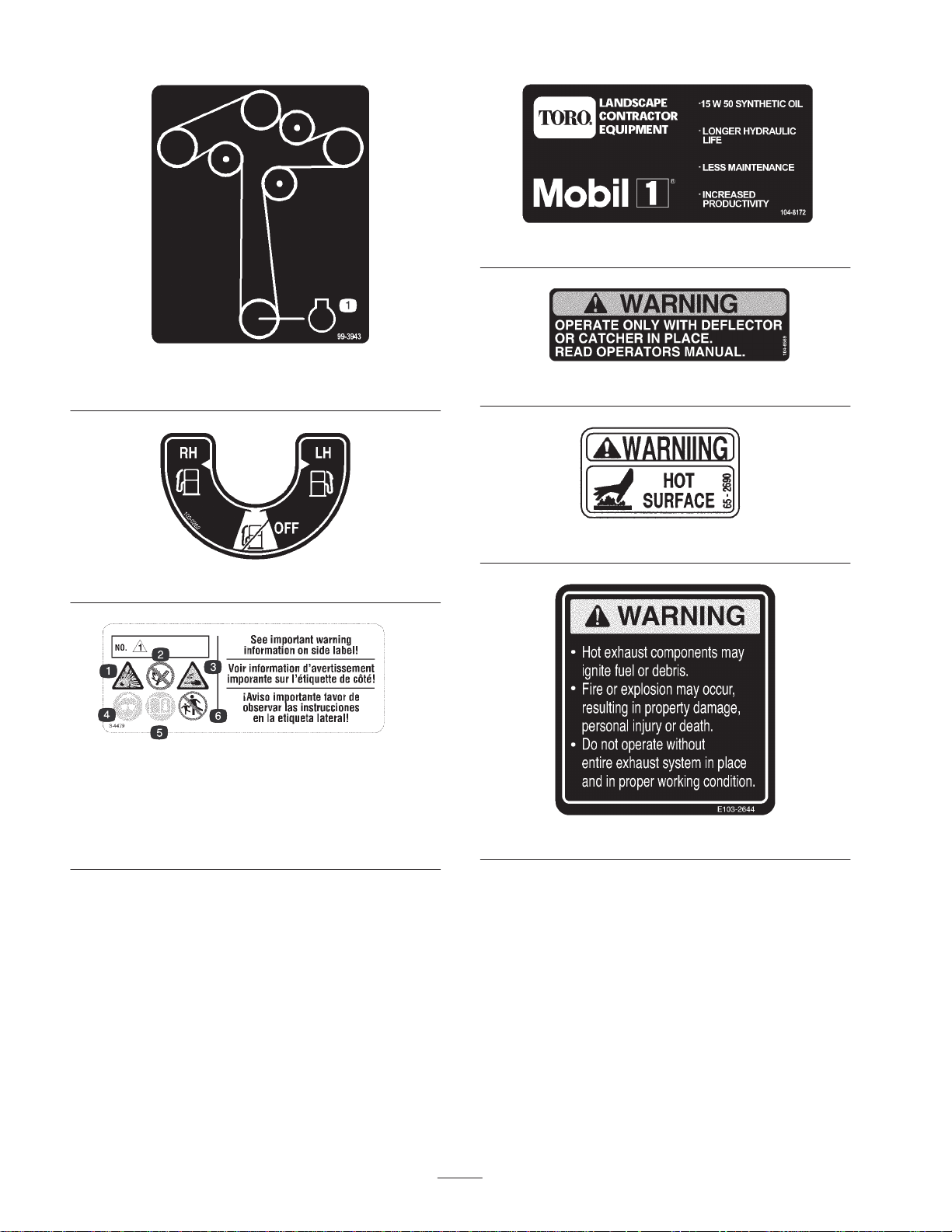

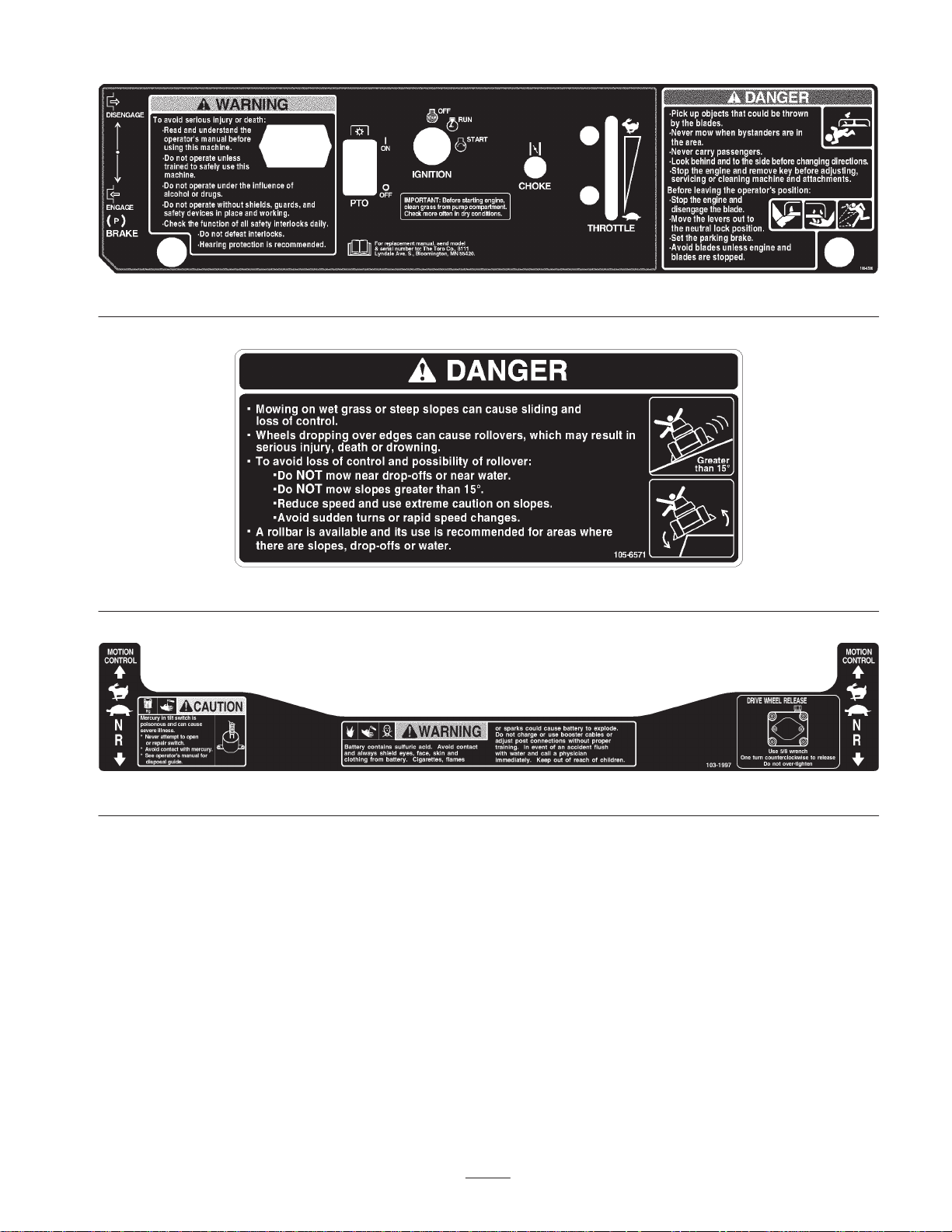

Safety and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near any area

of potential danger. Replace any decal that is damaged or lost.

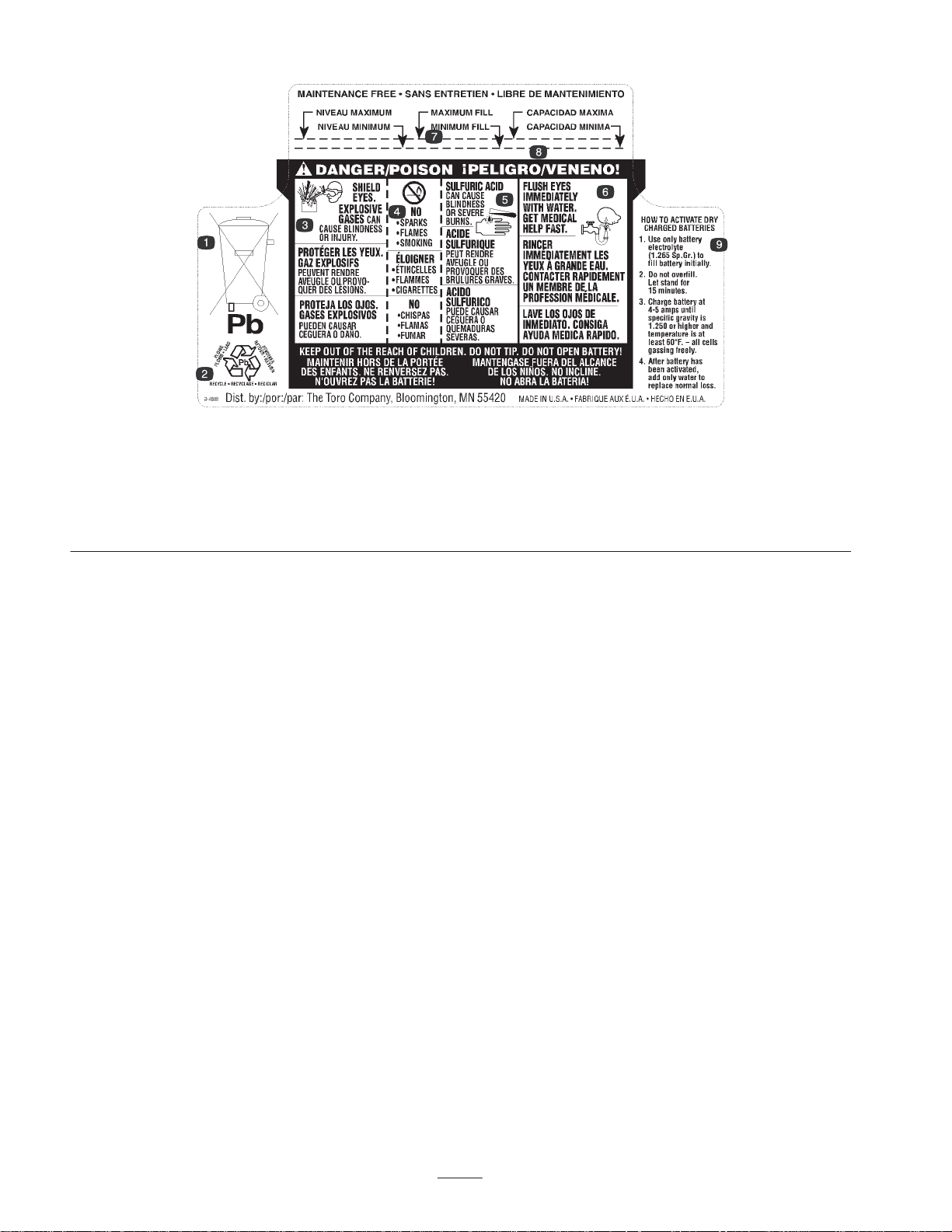

1-633818

1–653140

1–653147

1-643401

43-8480

1-523552

54-9220

8

66-1340

67-5360

98-4387

1. Warning—wear hearing protection.

98-5954

93-7818

1. Warning—read the

torquing the blade bolt/nut to 115–149 N⋅m (85–110 ft–lb).

Operator’s Manual

for instructions on

98-3798

99–3924

9

1. Engine

104-8172

99-3943

104-8569

65–2690

103–0262

1. Explosion hazard

2. No fire, open flames, or

smoking.

3. Caustic liquid/chemical

burn hazard

104-4163

4. Wear eye protection

5. Read the

6. Keep bystanders a safe

Manual.

Operator’s

distance from the battery.

103–2644

10

106-6586

106-6571

103-1997

11

1. Contains lead; do not

discard.

2. Recycle

3. Wear eye protection;

explosive gases can cause

blindness and other injuries

4. No sparks, flame, or

smoking

5. Sulfuric acid can cause

blindness or severe burns.

104-4164

6. Flush eyes immediately with

water and get medical help

fast.

7. Maximum fill line

8. Minimum fill line

9. Instructions for activating the

battery

12

Gasoline and Oil

Recommended Gasoline

Use UNLEADED Regular Gasoline suitable for automotive

use (85 pump octane minimum). Leaded regular gasoline

may be used if unleaded regular is not available.

Important Never use methanol, gasoline containing

methanol, or gasohol containing more than 10% ethanol

because the fuel system could be damaged. Do not mix oil

with gasoline.

Danger

In certain conditions, gasoline is extremely

flammable and highly explosive. A fire or

explosion from gasoline can burn you and others

and can damage property.

• Fill the fuel tank outdoors, in an open area,

when the engine is cold. Wipe up any gasoline

that spills.

• Never fill the fuel tank inside an enclosed trailer.

• Do not fill the fuel tank completely full. Add

gasoline to the fuel tank until the level is 1/4 to

1/2 in. (6 to 13 mm) below the bottom of the

filler neck. This empty space in the tank allows

gasoline to expand.

• Never smoke when handling gasoline, and stay

away from an open flame or where gasoline

fumes may be ignited by a spark.

• Store gasoline in an approved container and

keep it out of the reach of children. Never buy

more than a 30-day supply of gasoline.

• Always place gasoline containers on the ground

away from your vehicle before filling.

• Do not fill gasoline containers inside a vehicle or

on a truck or trailer bed because interior

carpets or plastic truck bed liners may insulate

the container and slow the loss of any static

charge.

• When practical, remove gas–powered

equipment from the truck or trailer and refuel

the equipment with its wheels on the ground.

• If this is not possible, then refuel such

equipment on a truck or trailer from a portable

container, rather than from a gasoline dispenser

nozzle.

• If a gasoline dispenser nozzle must be used, keep

the nozzle in contact with the rim of the fuel

tank or container opening at all times until

fueling is complete.

• Do not operate without entire exhaust system in

place and in proper working condition.

Warning

Gasoline is harmful or fatal if swallowed.

Long-term exposure to vapors can cause serious

injury and illness.

• Avoid prolonged breathing of vapors.

• Keep face away from nozzle and gas tank or

conditioner opening.

• Keep gas away from eyes and skin.

Using Stabilizer/Conditioner

Use a fuel stabilizer/conditioner in the machine to provide

the following benefits:

• Keeps gasoline fresh during storage of 90 days or less.

For longer storage it is recommended that the fuel tank

be drained.

• Cleans the engine while it runs

• Eliminates gum-like varnish buildup in the fuel system,

which causes hard starting

Important Do not use fuel additives containing

methanol or ethanol.

Add the correct amount of gas stabilizer/conditioner to the

gas.

Note: A fuel stabilizer/conditioner is most effective when

mixed with fresh gasoline. To minimize the chance of

varnish deposits in the fuel system, use fuel stabilizer at all

times.

Filling the Fuel Tank

1. Shut the engine off and set the parking brake.

2. Clean around each fuel tank cap and remove the cap.

Add unleaded regular gasoline to both fuel tanks, until

the level is 1/4 to 1/2 inch (6 to 13 mm) below the

bottom of the filler neck. This space in the tank allows

gasoline to expand. Do not fill the fuel tanks completely

full.

3. Install fuel tank caps securely. Wipe up any gasoline

that may have spilled.

Checking the Engine Oil Level

Before you start the engine and use the machine, check the

oil level in the engine crankcase; refer to Checking the

Engine Oil Level, page 30.

13

Setup

Note: Determine the left and right sides of the machine from the normal operating position.

Loose Parts

Note: Use the chart below to verify that all parts have been shipped.

Description Qty. Use

Rear wheels 2 Installing the wheels to the traction unit

Retaining rod

Bolt, 5/16 x 1 in.

Locknut, 5/16 in.

Control lever—right

Control lever—left

Bolt, 3/8 x 1 in.

Spring washer, 3/8 in.

Key

Operator’s Manual

Engine Operator’s Manual

Parts Catalog

Registration card 1 Fill out and return to Toro.

Installing the Drive Wheels

1. Uncrate the mower.

2. Remove the wheel bolts or nuts from the rear wheel

hubs.

3. Align the holes. Mount the drive wheels with the valve

stem to the outside of the traction unit.

4. Secure the wheels using the wheel bolts or nuts

provided. Torque to 95 ft–lb (128 N⋅m).

1

1

1

1

1

4

4

2

1

1

1

Installing the seat retaining rod

Installing the motion control levers

Read before operating the machine.

Checking the Tire Pressure

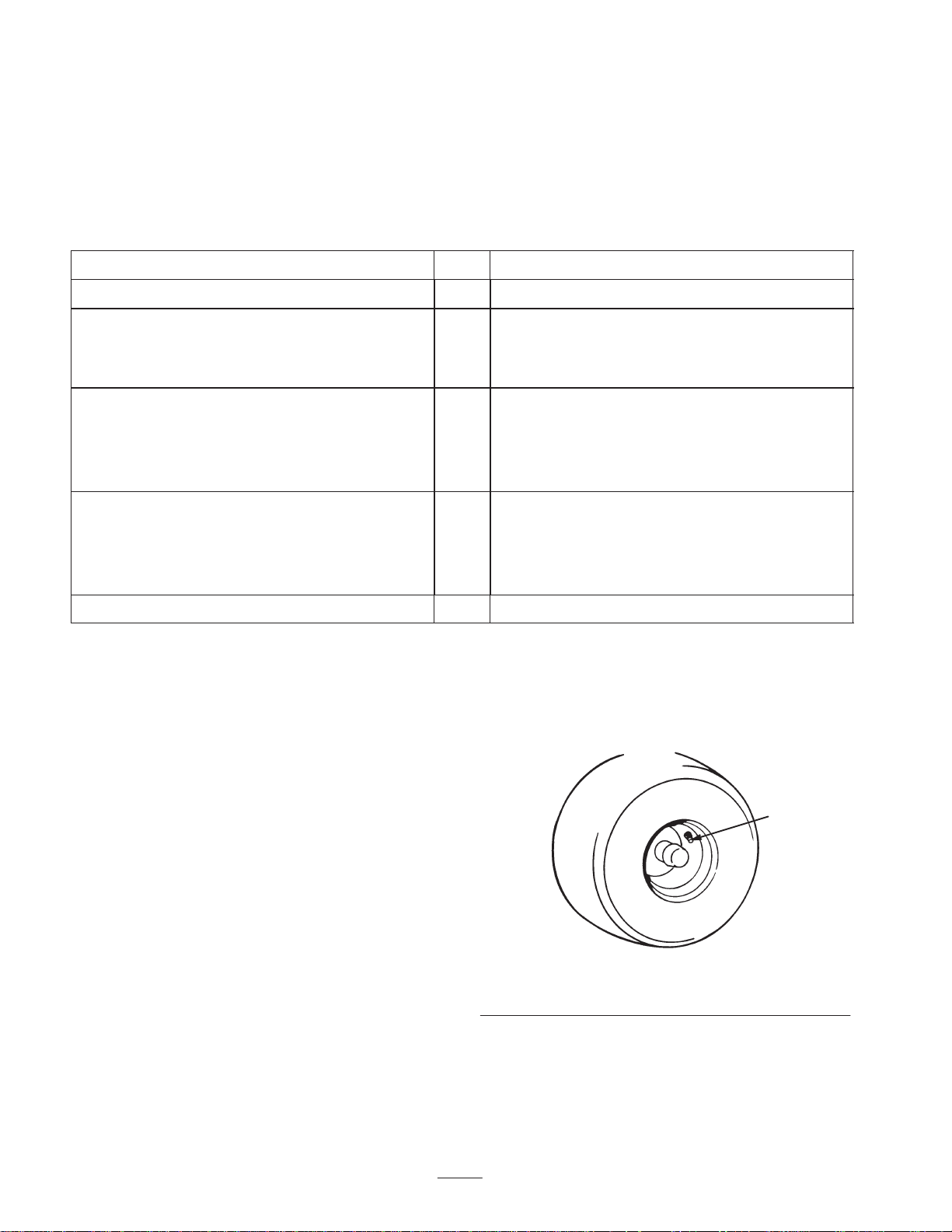

Check the air pressure in the front and rear tires (Fig. 2).

Pressure: 13 psi (90 kPa)

1

1. Valve stem

14

m–1872

Figure 2

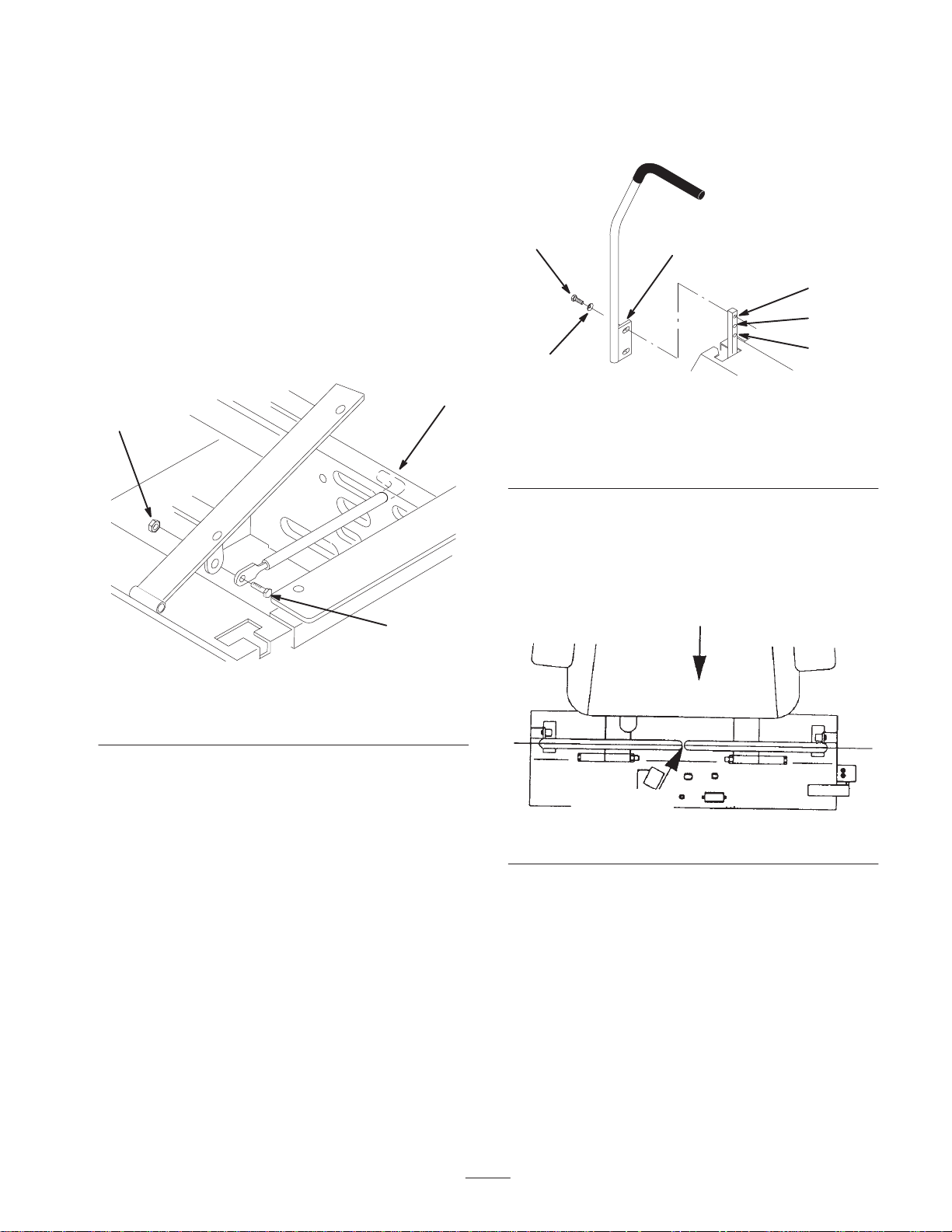

Installing the Seat Retaining

Rod

1. Tilt the seat up. Remove the locknut (5/16 in.) from the

bolt attaching the seat retaining rod to the seat frame

(Fig. 3).

2. Remove the retaining rod from the seat and insert the L

shaped end of the rod into the hole directly above the

left-side hydraulic pump (Fig. 3).

4. Align the front\rear position of the levers, with each

other, in the neutral position. Loosen the hardware and

adjust by sliding/tilting the lever(s) forward or

backward until they are properly aligned (Fig. 4).

2

1

3. Place the seat retaining rod to the outside of the

mounting tab of the seat frame and secure it with the

bolt (5/16 x 1 in.) and locknut (5/16 in.) (Fig. 3).

4. Tighten until snug, then loosen them so that the rod

pivots freely.

2

3

m–3750

Figure 3

1. L end of retaining rod

2. Locknut, 5/16 in.

3. Bolt, 5/16 x 1 in.

4

5

6

3

m–5596

1

1. Mounting plate

2. Bolt, 3/8 x 1 in.

3. Spring washer, 3/8 in.

Figure 4

4. Top hole

5. Middle hole

6. Bottom hole

5. If the ends of the levers hit against each other while in

the drive position (Fig. 5) (levers rotated in as far as

possible), make adjustments by moving the levers

outward to the neutral lock position and carefully bend

them outward. Move them back to the drive position

and check for clearance. Repeat if necessary.

FRONT

OF

UNIT

Installing the Motion Control

Levers

There are two positions to install the control levers: high

and low. Install the levers in the top and middle holes for

the high position. Install the levers in the middle and

bottom holes for the low position.

1. Remove the 4 bolts (3/8 x 1 in.) and 4 spring washers

(3/8 in.) which attach the motion control levers to the

control arm shafts for shipping (Fig. 4).

2. Place the levers (with the mounting plate toward the

rear) on the outside of the control arm shaft and secure

them with 4 bolts (3/8 x 1 in.) and 4 spring washers

(3/8 in.) (Fig. 4).

3. Position the lever so that the bolts are in the center of

the slots on the lever mounting plate and tighten until

snug.

LEVERS IN

ALIGNMENT

Figure 5

15

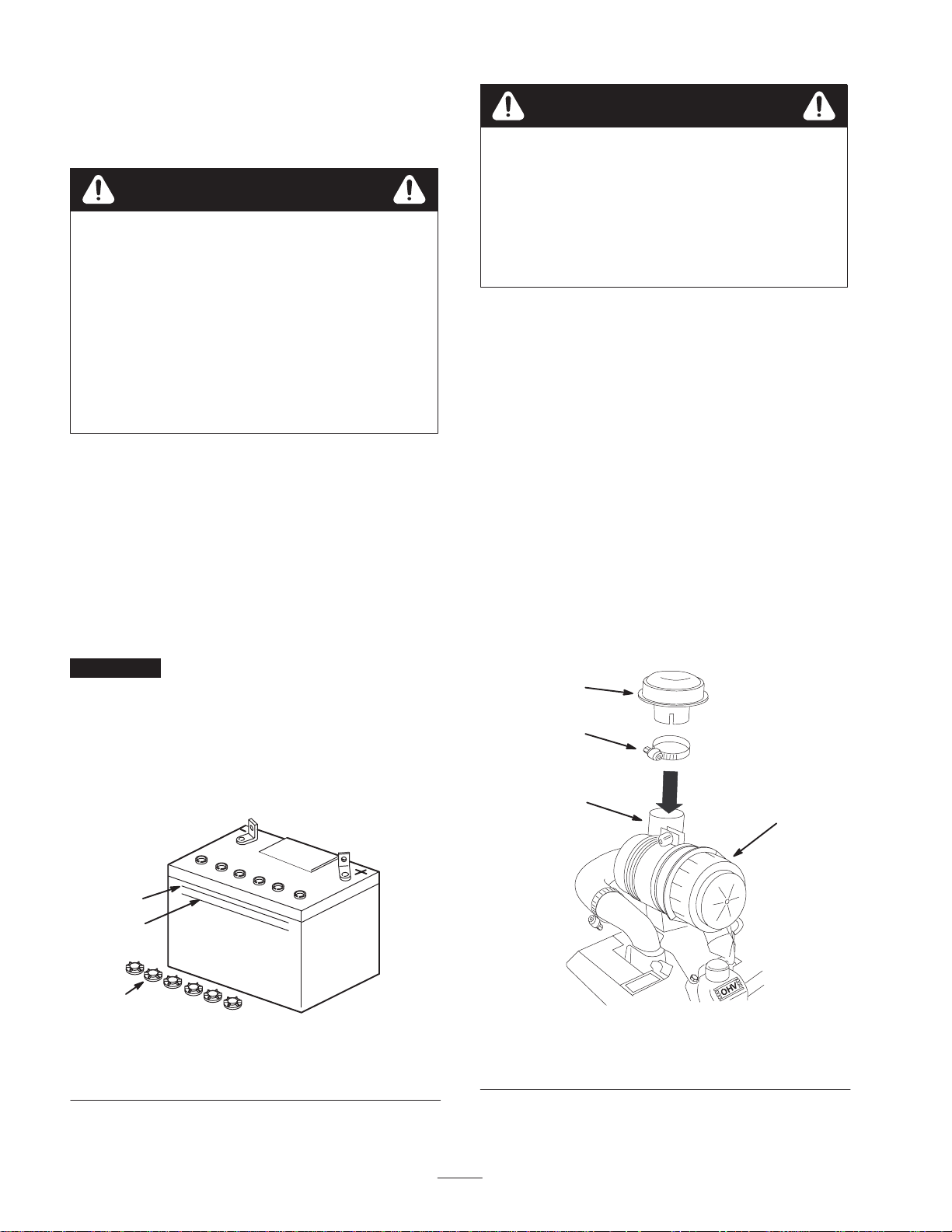

Activating the Battery

Bulk electrolyte with 1.265 specific gravity must be

purchased from a local battery supply outlet.

Danger

Battery electrolyte contains sulfuric acid which is a

deadly poison and causes severe burns.

• Do not drink electrolyte and avoid contact with

skin, eyes or clothing. Wear safety glasses to

shield your eyes and robber gloves to protect

your hands.

• Fill the battery where clean water is always

available for flushing the skin.

• Follow all instructions and comply with all

safety messages on the electrolyte container.

Warning

Charging battery produces gasses that can explode

and cause serious injury.

• Keep cigarettes, sparks and flames away from

battery.

• Make sure the ignition switch is off.

• Ventilate when charging or using battery in an

enclosed space.

7. Charge the battery; refer to Charging the Battery,

page 46.

8. Install the battery into the machine; refer to Installing

the Battery, page 44.

Note: Do not run the machine with the battery

disconnected, electrical damage may occur.

1. Remove the battery from the machine; refer to

Removing the Battery, page 45.

2. Clean the top of the battery with a paper towel.

Note: Never fill the battery with electrolyte while the

battery is installed in the machine. Electrolyte could be

spilled on other parts and cause corrosion.

3. Remove the vent caps from the battery (Fig. 6).

4. Slowly pour electrolyte into each battery cell until the

level is up to the upper line (Fig. 6) on the battery case.

Important Do not overfill the battery because

electrolyte (sulfuric acid) can cause severe corrosion and

damage to the chassis.

5. Wait five to ten minutes after filling the battery cells.

Add electrolyte, if necessary, until the electrolyte level

is up to the upper line (Fig. 6) on the battery case.

6. Reinstall battery filler caps.

2

Installing the Air Cleaner Cap

1. Locate the air cleaner cap (Fig. 7).

2. Remove the plastic plug from the air intake in the air

cleaner canister (Fig. 7).

3. Place the clamp onto the air cleaner cap (Fig. 7).

4. Slide the clamp and air cleaner cap onto air cleaner

canister (Fig. 7).

5. Tighten the clamp to hold the air cleaner cap (Fig. 7).

3

4

2

1

3

1

1. Filler caps

2. Upper line

Figure 6

3. Lower line

m–5004

1. Air cleaner canister

2. Air intake

16

m–6277

Figure 7

3. Air cleaner cap

4. Clamp

Loading...

Loading...