Toro 74165, 74166, 74163, 74167, 74167TE Service Manual

...

TORO MID-MOUNT Z SERVICE MANUAL

Table of Contents – Page 1 of 3

SPECIFICATIONS

ENGINE

Z100 SERIES

Z250 SERIES

Z280 SERIES

UNIT DIMENSIONS

Z100 SERIES

Z250 SERIES

Z280 SERIES

HYDRAULIC SYSTEM

TORQUE SPECIFICATIONS

HYDRAULIC HOSES & FITTINGS

CHASSIS

MAINTENANCE

RECOMMENDED MAINTENANCE SCHEDULE

CHECKING THE OIL LEVEL

CHANGING OIL AND FILTER

SERVICING THE AIR CLEANER

REMOVING THE FILTERS

INSTALLING THE FILTERS

SERVICING MODELS EQUIPPED WITH THE HEAVY-DUTY AIR CLEANER

USING THE FILTER MINDER

REMOVING THE AIR CLEANER

CLEANING THE PRIMARY FILTER

INSTALLING THE FILTERS

SERVICING THE AIR CLEANER LIQUID-COOLED MODELS

REMOVING THE PAPER ELEMENT

CLEANING THE PAPER ELEMENTS

INSTALLING THE PAPER ELEMENTS

CLEANING THE ENGINE FINS

SERVICING THE COOLING SYSTEM

CHECKING THE RADIATOR COOLANT

CLEANING THE COOLING SYSTEM

CHANGING THE ENGINE COOLANT

INSPECTING THE COOLING SYSTEM

SERVICING THE FUEL FILTER

REPLACING THE FUEL FILTER

SERVICING THE SPARK PLUG

REMOVING THE SPARK PLUG(S)

CHECKING THE SPARK PLUG

INSTALLING THE SPARK PLUG(S)

CHECK VALVE CLEARANCE

GREASING AND LUBRICATION

HOW TO GREASE

GREASING THE FRONT CASTOR PIVOTS

WHERE TO ADD GREASE

WHERE TO ADD LIGHT OIL OR SPRAY LUBRICATION

GREASING THE BEARINGS

TORO MID-MOUNT Z SERVICE MANUAL

Table of Contents – Page 2 of 3

ENGINE

EXTERNAL ALTERNATOR REMOVE & REPLACE

ENGINE REMOVE & REPLACE AIR-COOLED

ENGINE REMOVE & REPLACE LIQUID-COOLED

RADIATOR REMOVE & REPLACE LIQUID-COOLED MOWERS

MODELS EQUIPPED WITH ELECTRONIC FUEL INJECTION (EFI)

HYDRAULIC SYSTEMS

HYDRAULIC SYSTEM, TYPICAL

DESCRIPTION

GENERAL HYDRAULIC ASSEMBLY GUIDELINES

REPLACING THE PUMP DRIVE BELT

PUMP REMOVAL

ADJUSTING THE HYDRAULIC PUMP NEUTRAL

WHEEL MOTOR R & R

CHASSIS

MOTION CONTROL LINKAGE - REMOVE AND REPLACE

ADJUSTING THE HANDLE NEUTRAL

REPLACING THE PARKING BRAKE AND LINKAGE

ADJUSTING THE PARKING BRAKE

DESCRIPTION - FUEL SYSTEM

FUEL TANK - REMOVE AND REPLACE

REPLACE FRONT WHEEL BEARINGS

FRONT CASTER BEARINGS - REMOVE & REPLACE

MOWER DECKS

REPLACING THE PTO DRIVE BELT

MOWER DECK REMOVAL

SPINDLE REPAIR

ASSEMBLY

DECK MOUNTING, TYPICAL

LEVELING THE MOWER

CHECKING FOR BENT BLADES

ADJUSTING THE COMPRESSION SPRING

SPINDLE ASSEMBLIES, TYPICAL

ELECTRICAL SYSTEMS

ELECTRICAL SCHEMATICS

ALTERNATOR, KOHLER

PURPOSE

HOW IT WORKS

TESTING

REGULATOR/RECTIFIOR

PURPOSE

HOW IT WORKS

TESTING

CLUTCH, ELECTRIC

PURPOSE

HOW IT WORKS

TESTING

TORO MID-MOUNT Z SERVICE MANUAL

Table of Contents – Page 3 of 3

ELECTRICAL SYSTEMS - CONTINUED

ELECTRIC PTO CLUTCH REMOVAL

SOLENOID

PURPOSE

HOW IT WORKS

TESTING

STARTER, ELECTRIC

PURPOSE

HOW IT WORKS

TESTING

SWITCH, PTO/CLUTCH

PURPOSE

HOW IT WORKS

TESTING

BRAKE SWITCH

PURPOSE

HOW IT WORKS

TESTING

INTERLOCK MODULE

PURPOSE

HOW IT WORKS

TESTING

HOURMETER

PURPOSE

HOW IT WORKS

TESTING

MOTION CONTROL SWITCH

PURPOSE

HOW IT WORKS

TESTING

KEY SWITCH

PURPOSE

HOW IT WORKS

TESTING

SEAT SWITCH

PURPOSE

HOW IT WORKS

TESTING

MERCURY SWITCH

PURPOSE

HOW IT WORKS

TESTING

20 AMP FUSE

PURPOSE

TESTING

WIRING HARNESS, TYPICAL

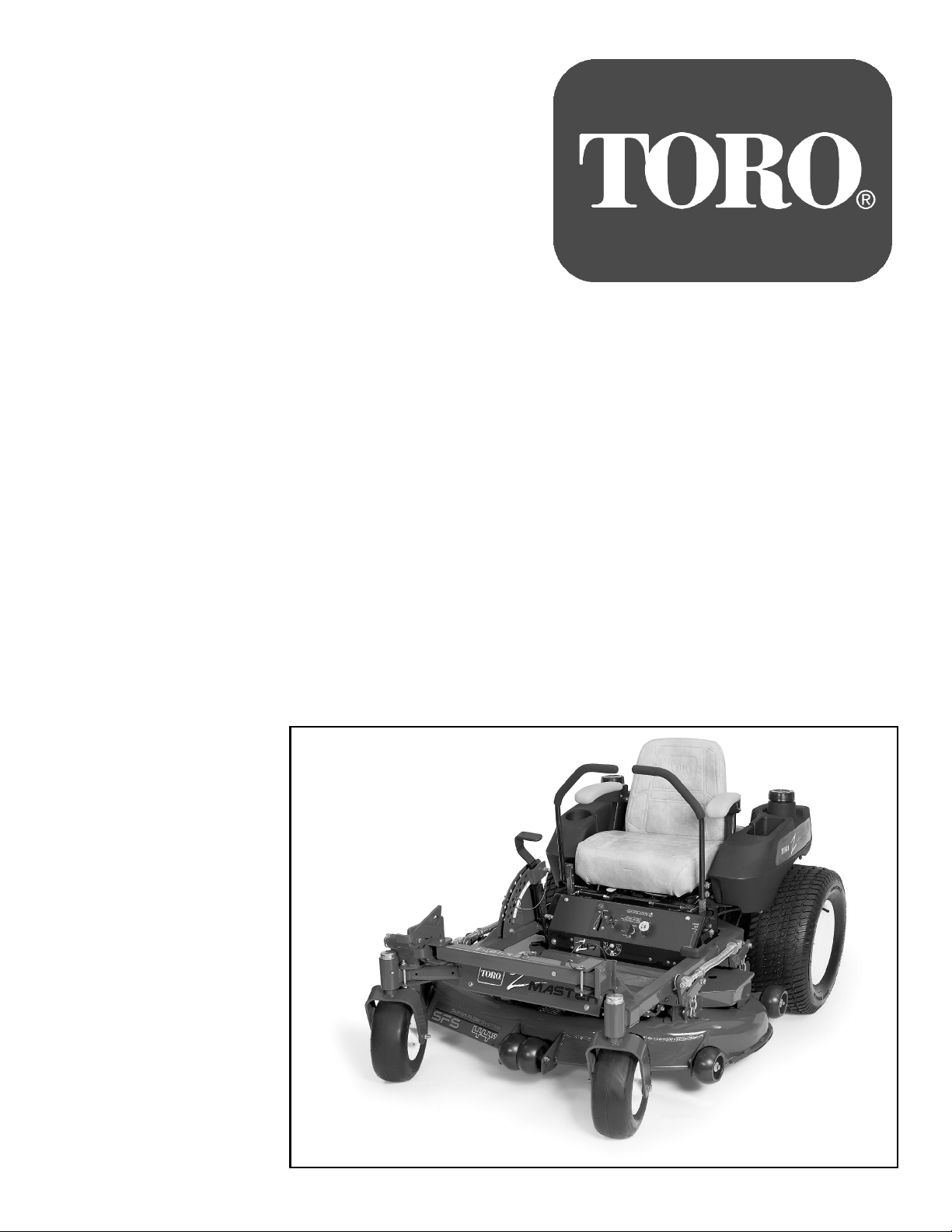

Mid-Mount Z

Service Manual

PREFACE

ABOUT THIS MANUAL

This service manual was written expressly for the Toro Mid-Mount Z product line. The Toro Company has made

every effort to make the information in this manual complete and correct.

This manual was written for the service technician; basic mechanical/electrical skills are assumed. The Table of

Contents lists the systems and the related topics covered in this manual.

For additional information on the electrical systems, please refer to the LCB Electrical Troubleshooting CD (PN

492-4757). For information specific to the engines used on these products, refer to the appropriate engine

manufacturer’s service and repair instructions.

We hope you find this manual a valuable addition to your service shop. If you have any questions or comments

regarding this manual, please contact us at the following address:

The Toro Company

Landscape Contractors Group

8111 Lyndale Avenue South

Bloomington, MN 55420

The Toro Company reserves the right to change product specifications or this manual without notice.

Copyright© All Rights Reserved

©2002 The Toro Company

Bloomington, MN 55420 - U.S.A.

TABLE OF CONTENTS

SPECIFICATIONS

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

Z100 Series. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Z250 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

Z280 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

Unit Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 2

Z100 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 2

Z250 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 2

Z280 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 2

Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 3

Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 3

Hydraulic Hoses & Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 3

Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 3

MAINTENANCE

Recommended Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

Checking the Oil Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 2

Changing Oil and Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 2

Servicing the Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 3

Removing the Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 3

Installing the Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 4

Servicing Models Equipped With the Heavy-Duty Air Cleaner . . . . . . . . . . . . . . . . . . . .2 - 4

Using the Filter Minder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 4

Removing the Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 5

Cleaning the Primary Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 5

Installing the Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 5

Servicing the Air Cleaner Liquid-Cooled Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 5

Removing the Paper Element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 5

Cleaning the Paper Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 6

Installing the Paper Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 6

Cleaning the Engine Fins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 6

Servicing the Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 7

Checking the Radiator Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 7

Cleaning the Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 7

Changing the Engine Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 8

Inspecting the Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 9

Servicing the Fuel Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 9

Replacing the Fuel Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 9

Mid-Mount Z Service Manual i

TABLE OF CONTENTS

Servicing the Spark Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 10

Removing the Spark Plug(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 10

Checking the Spark Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 10

Installing the Spark Plug(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 10

Check Valve Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 10

Greasing and Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 11

How to Grease . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 11

Greasing the Front Castor Pivots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 11

Where to Add Grease . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 11

Where to Add Light Oil or Spray Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 11

Greasing the Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 11

ENGINE

External Alternator Remove & Replace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Engine Remove & Replace Air-Cooled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

Engine Remove & Replace Liquid-Cooled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

Radiator Remove & Replace Liquid-Cooled Mowers . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 8

Models Equipped With Electronic Fuel Injection (EFI) . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 11

HYDRAULIC SYSTEMS

Hydraulic System, Typical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

General Hydraulic Assembly Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

Replacing the Pump Drive Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

Pump Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

Adjusting the Hydraulic Pump Neutral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

Wheel Motor R & R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 5

ii Mid-Mount Z Service Manual

TABLE OF CONTENTS

CHASSIS

Motion Control Linkage - Remove and Replace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 1

Adjusting the Handle Neutral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 2

Replacing the Parking Brake and Linkage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 4

Adjusting the Parking Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 8

Description - Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 9

Fuel Tank - Remove and Replace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 10

Replace Front Wheel Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 12

Front Caster Bearings - Remove & Replace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 14

MOWER DECKS

Replacing the PTO Drive Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 1

Mower Deck Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 3

Spindle Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 4

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 6

Deck Mounting, Typical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 9

Leveling the Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 10

Checking for Bent Blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 11

Adjusting the Compression Spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 12

Spindle Assemblies, Typical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 13

ELECTRICAL SYSTEMS

Electrical Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 1

Alternator, Kohler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 20

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 20

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 20

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 20

Regulator/Rectifior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 21

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 21

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 21

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 21

Clutch,Electric. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 22

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 22

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 22

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 22

Electric PTO Clutch Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 23

Mid-Mount Z Service Manual iii

TABLE OF CONTENTS

ELECTRICAL SYSTEMS (cont’d)

Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 24

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 24

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 24

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 24

Starter, Electric . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 25

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 25

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 25

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 25

Switch, PTO/Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 26

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 26

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 26

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 26

Brake Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 27

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 27

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 27

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 27

Interlock Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 28

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 28

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 28

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 28

Hourmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 29

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 29

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 29

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 29

Motion Control Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 30

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 30

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 30

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 30

Key Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 31

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 31

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 31

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 31

Seat Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 32

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 32

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 32

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 32

iv Mid-Mount Z Service Manual

TABLE OF CONTENTS

ELECTRICAL SYSTEMS (cont’d)

Mercury Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 33

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 33

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 33

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 33

20 Amp Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 34

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 34

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 34

Wiring Harness, Typical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 35

Mid-Mount Z Service Manual v

THIS PAGE INTENTIONALLY LEFT BLANK

vi Mid-Mount Z Service Manual

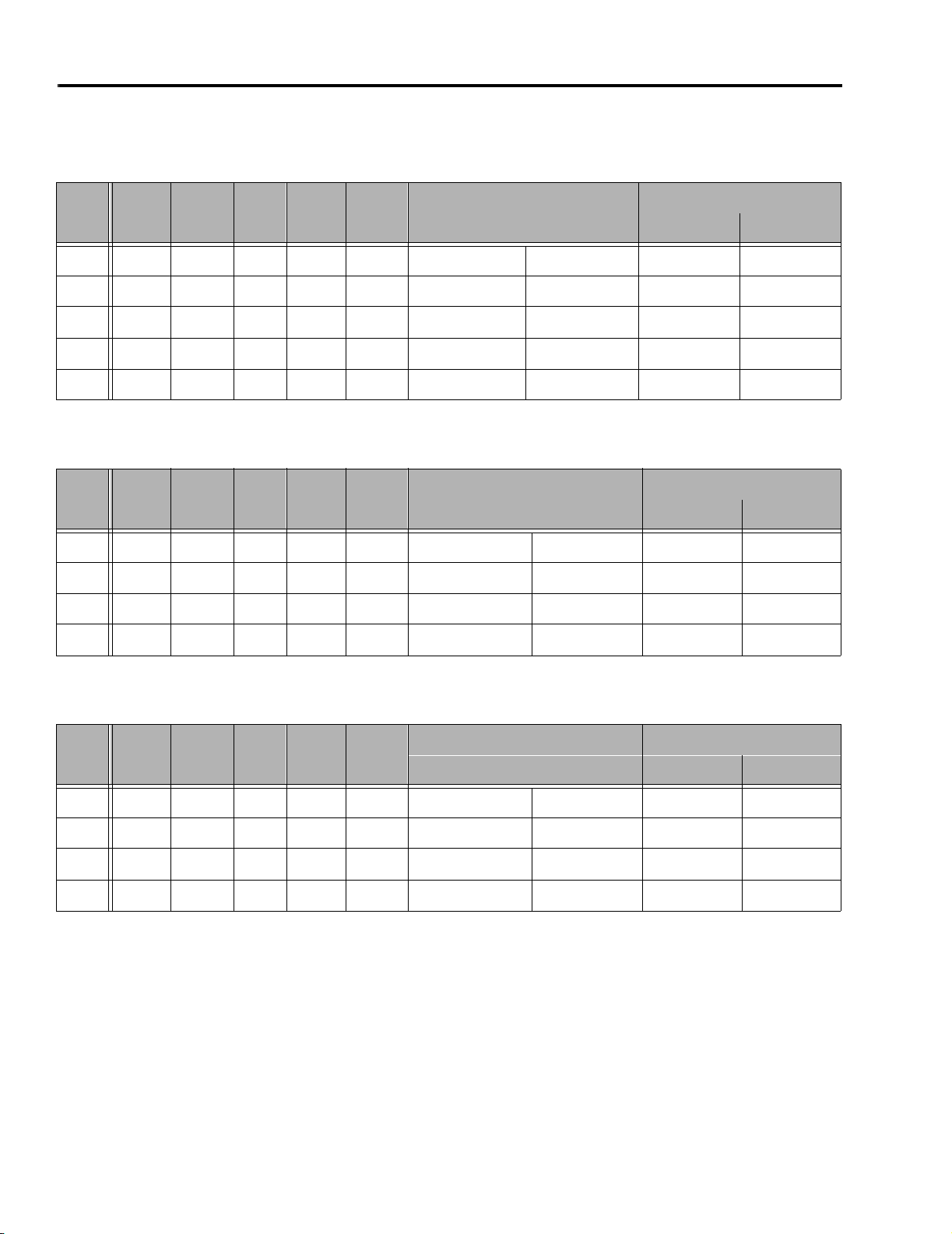

SPECIFICATIONS

ENGINE

Z100 Series

Model Manufacturer HP Oil Capacity High Idle Low Idle Cooling System

74170 Kawasaki 17 1.9 Qts. 3600 ± 100 1500 Air-Cooled

74171 Kohler 22 2 Qts. 3600 ± 100 1500 Air-Cooled

74172 Kohler 20 2 Qts. 3600 ± 100 1500 Air-Cooled

74173 Kawasaki 19 2 Qts. 3600 ± 100 1500 Air-Cooled

74174 Kohler 23 2 Qts. 3600 ± 100 1500 Air-Cooled

74175 Kawasaki 23 2 Qts. 3600 ± 100 1500 Air-Cooled

74176 Kawasaki 17 2 Qts. 3600 ± 100 1500 Air-Cooled

74178 Kohler 20 2 Qts. 3600 ± 100 1500 Air-Cooled

74179 Kawasaki 19 2 Qts. 3600 ± 100 1500 Air-Cooled

74197 Kohler 23 2 Qts. 3600 ± 100 1500 Air-Cooled

74198 Kawasaki 23 2 Qts. 3600 ± 100 1500 Air-Cooled

Z250 Series

Model Manufacturer HP Oil Capacity High Idle Low Idle Cooling System

74200 Kohler 25 2.1 Qts. 3600 ± 100 1500 Air-Cooled

74201 Kohler 25 2.1 Qts. 3600 ± 100 1500 Air-Cooled

74202 Kohler 23 2.1 Qts. 3600 ± 100 1500 Air-Cooled

74203 Kohler 25 2.1 Qts. 3600 ± 100 1500 Air-Cooled

74204 Kohler 25 2.1 Qts. 3600 ± 100 1500 Air-Cooled

74205 Kohler 25 2.1 Qts. 3600 ± 100 1500 Air-Cooled

74209 Kohler 23 2.1 Qts. 3600 ± 100 1500 Air-Cooled

74211 Kawasaki 22 2.1 Qts. 3600 ± 100 1500 Liquid-Cooled

74212 Kawasaki 22 2.1 Qts. 3600 ± 100 1500 Liquid-Cooled

74218 Kohler 26 2.1 Qts. 3600 ± 100 1500 Air-Cooled

74219 Kohler 26 2.1 Qts. 3600 ± 100 1500 Air-Cooled

74228 Kohler 25 2.1 Qts. 3600 ± 100 1500 Air-Cooled

74225 Kohler 23 2.1 Qts. 3600 ± 100 1500 Air-Cooled

74226 Kohler 25 2.1 Qts. 3600 ± 100 1500 Air-Cooled

74227 Kohler 25 2.1 Qts. 3600 ± 100 1500 Air-Cooled

Z280 Series

Model Manufacturer HP Oil Capacity High Idle Low Idle Cooling System

74213 Kawasaki 27 2.1 Qts. 3600 ± 100 1500 Liquid-Cooled

74214 Kawasaki 27 2.1 Qts. 3600 ± 100 1500 Liquid-Cooled

74240 Kohler 26 2.1 Qts. 3600 ± 100 1500 Air-Cooled

74241 Kohler 26 2.1 Qts. 3600 ± 100 1500 Air-Cooled

Mid-Mount Z Service Manual 1 - 1

SPECIFICATIONS

UNIT DIMENSIONS

Z100 Series

Model Wheel

Base

74176 50” 78” 55” 40” 885 23” x 9.50-12” 13” x 5.00”-6” 13 PSI 13 PSI

74178 50” 78” 65” 40” 910 23” x 9.50-12” 13” x 5.00”-6” 13 PSI 13 PSI

74179 50” 78” 65” 40” 910 23” x 9.50-12” 13” x 5.00”-6” 13 PSI 13 PSI

74197 50” 78” 65” 40” 910 23” x 9.50-12” 13” x 5.00”-6” 13 PSI 13 PSI

74198 50” 78” 65” 40” 910 23” x 9.50-12” 13” x 5.00”-6” 13 PSI 13 PSI

Length Width Height Weight

lb.

Tires Tire Pressure

Rear Front Rear Front

Z250 Series

Model Wheel

Base

74228 50” 79.8” 66” 44.5” 1045 23” x 9.5”-12” 13” x 6.50”-6” 13 PSI 13 PSI

74225 53” 81.5” 74” 44.5” 1105 24” x 12.00”-12” 13” x 6.50”-6” 13 PSI 13 PSI

74226 53” 81.5” 74” 44.5” 1105 24” x 12.00”-12” 13” x 6.50”-6” 13 PSI 13 PSI

74227 55.25” 84.5” 85” 44.5” 1170 24” x 12.00”-12” 13” x 6.50”-6” 13 PSI 13 PSI

Length Width Height Weight

lb.

Tires Tire Pressure

Rear Front Rear Front

Z280 Series

Model Wheel

Base

74213 50” 83” 74” 48” 1320 24” x 12.00”-12” 13” x 6.50”-6” 13 PSI 13 PSI

74214 53.12” 84.5” 85” 48” 1320 24” x 12.00”-12” 13” x 6.50”-6” 13 PSI 13 PSI

74240 53” 83” 74” 44.5” 1105 24” x 12.00”-12” 13” x 6.50”-6” 13 PSI 13 PSI

74241 55.25” 84.5” 85” 44.5” 1170 24” x 12.00”-12” 13” x 6.50”-6” 13 PSI 13 PSI

Length Width Height Weight

lb.

Tires Tire Pressure

Rear Front Rear Front

1 - 2 Mid-Mount Z Service Manual

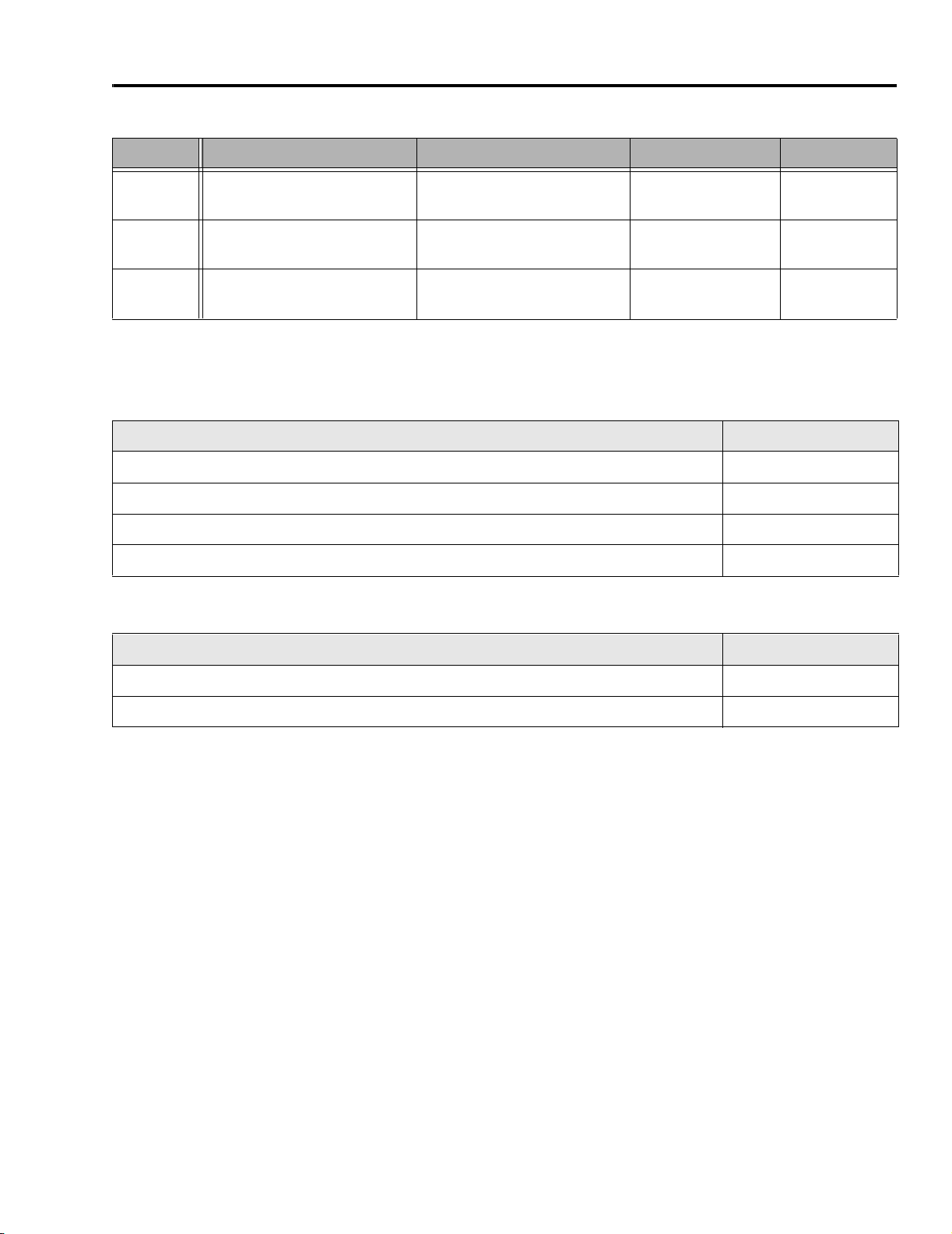

SPECIFICATIONS

HYDRAULIC SYSTEM

Model Pumps Motors Fluid Type Fluid Capacity

Z100

Series

Z250

Series

Z280

Series

(2) Hydro-Gear BDP10A (2) Ross MB15 Torquemotors

(2) Hydro-Gear BDP10A (2) Ross MB15 Torquemotors Mobil 1 15W20

(2) Hydro-Gear BDP10A (2) Ross MB15 Torquemotors Mobil 1 15W20

Mobil 1 15W20

Synthetic

Synthetic

Synthetic

TORQUE SPECIFICATIONS

Hydraulic Hoses & Fittings

Item Torque

Fitting to hydraulic oil tank 50 - 70 ft. lbs.

Fittings to hydraulic pumps 50 - 70 ft. lbs.

Hoses to pump fittings 34 - 41 ft. lbs.

Straight fittings to wheel motors 72 - 82 ft. lbs.

CHASSIS

2.1 Qts.

2.1 Qts.

2.1 Qts.

Item Torque

Wheel lug nuts 45 - 55 ft. lbs.

Rear hubs to drive motors 300 - 400 ft. lbs.

Mid-Mount Z Service Manual 1 - 3

THIS PAGE INTENTIONALLY LEFT BLANK

1 - 4 Mid-Mount Z Service Manual

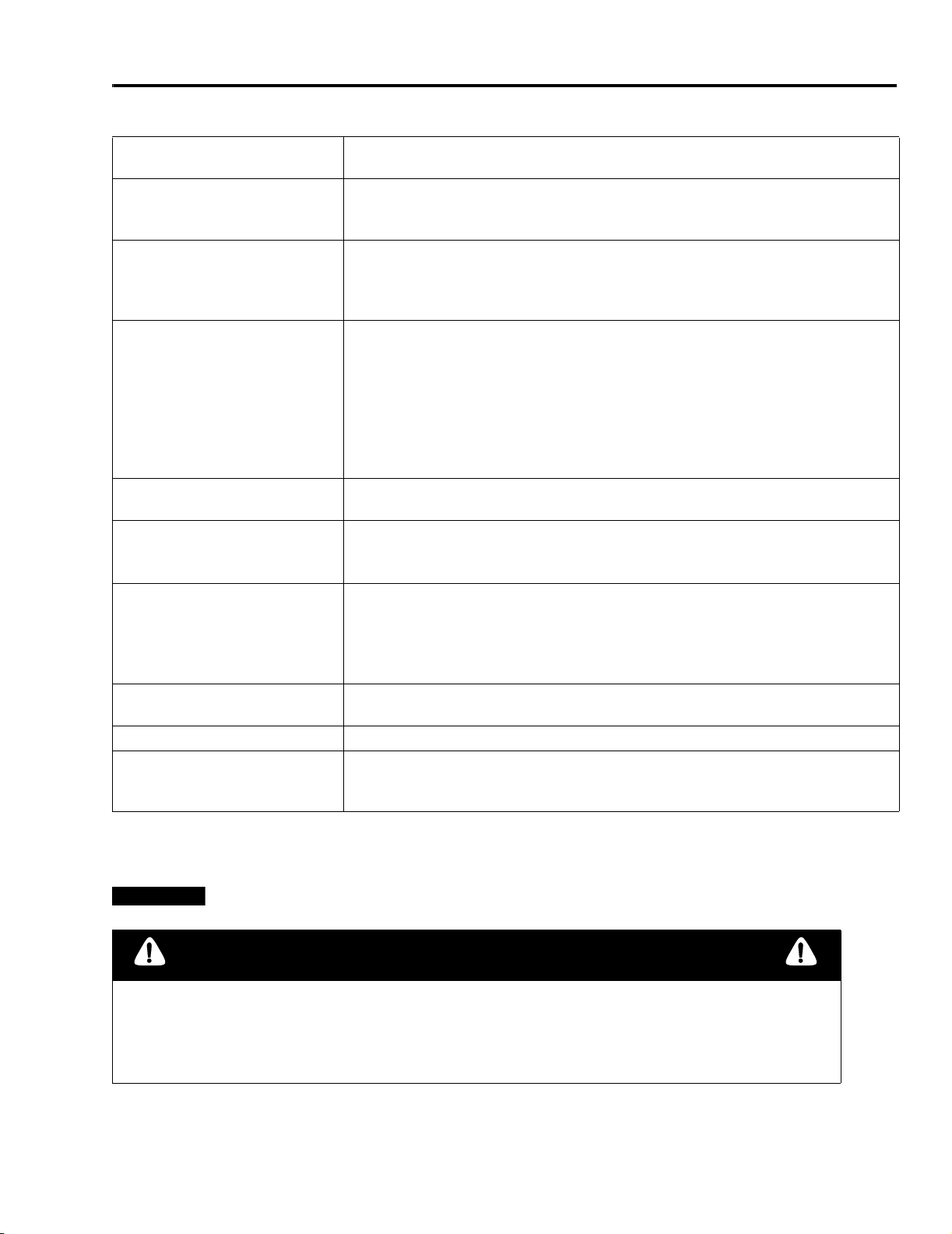

Recommended Maintenance Schedule

Maintenance Service

Interval

After first 5 hours

Each Use

Every 5 Hours

Every 50 Hours

Every 100 Hours

Every 200 Hours

Every 500 Hours or at Storage

Every 600 Hours or at Storage

Before Storage Service

Perform all maintenance procedures listed above before storage.

Maintenance Procedure

• Hydraulic fluid—check level

• Engine Oil—check

• Hydraulic filter—change

• Oil—check level

• Safety System—check

• Mower Housing—clean

• Engine Cooling System—clean

• Cutting Blades—check

• Blade Spindle Bearings—grease

• Every 25 Hours

• Chassis—grease

• Linkage bushings—oil

1

1

• Hydraulic fluid—check level

• Foam Air Cleaner—service

1

• Battery—check electrolyte

• Belts—check for wear/cracks

• Tires—check pressure

• Engine Oil—change

1

• Hydraulic lines—check

• Engine Cooling System—clean

• Oil Filter—change (200 hours or every other oil change)

• Hydraulic filter—change

• Spark Plug(s)—check

• Fuel Filter—replace

• Replace or clean primary air cleaner filter

• Wheel Hub Slotted Nut— adjustment

• Castor Pivot— adjustment

• Replace safety air cleaner

1

• Battery–charge, Disconnect cables

• Gasoline—drain

• Chipped Surfaces—paint

MAINTENANCE

1

1

1

1

1

More often in dusty, dirty conditions.

Important

Refer to your engine operator’s manual for additional maintenance procedures.

CAUTION

If you leave the key in the ignition switch, someone could accidently start the engine and

seriously injure you or other bystanders.

Remove the key from the ignition and disconnect the wire from the spark plug(s) before you do

any maintenance. Set the wire aside so that it does not accidentally contact the spark plug.

Mid-Mount Z Service Manual 2 - 1

MAINTENANCE

Checking the Oil Level

Note: Check oil when engine is cold.

1. Disengage the power take off (PTO) and turn the

ignition key to off. Move levers to neutral locked

position and apply parking brake. Remove the

key.

2. Clean around the oil dipstick so dirt cannot fall into

the filler hole and damage the engine.

3. Pull the oil dipstick and wipe the metal end clean

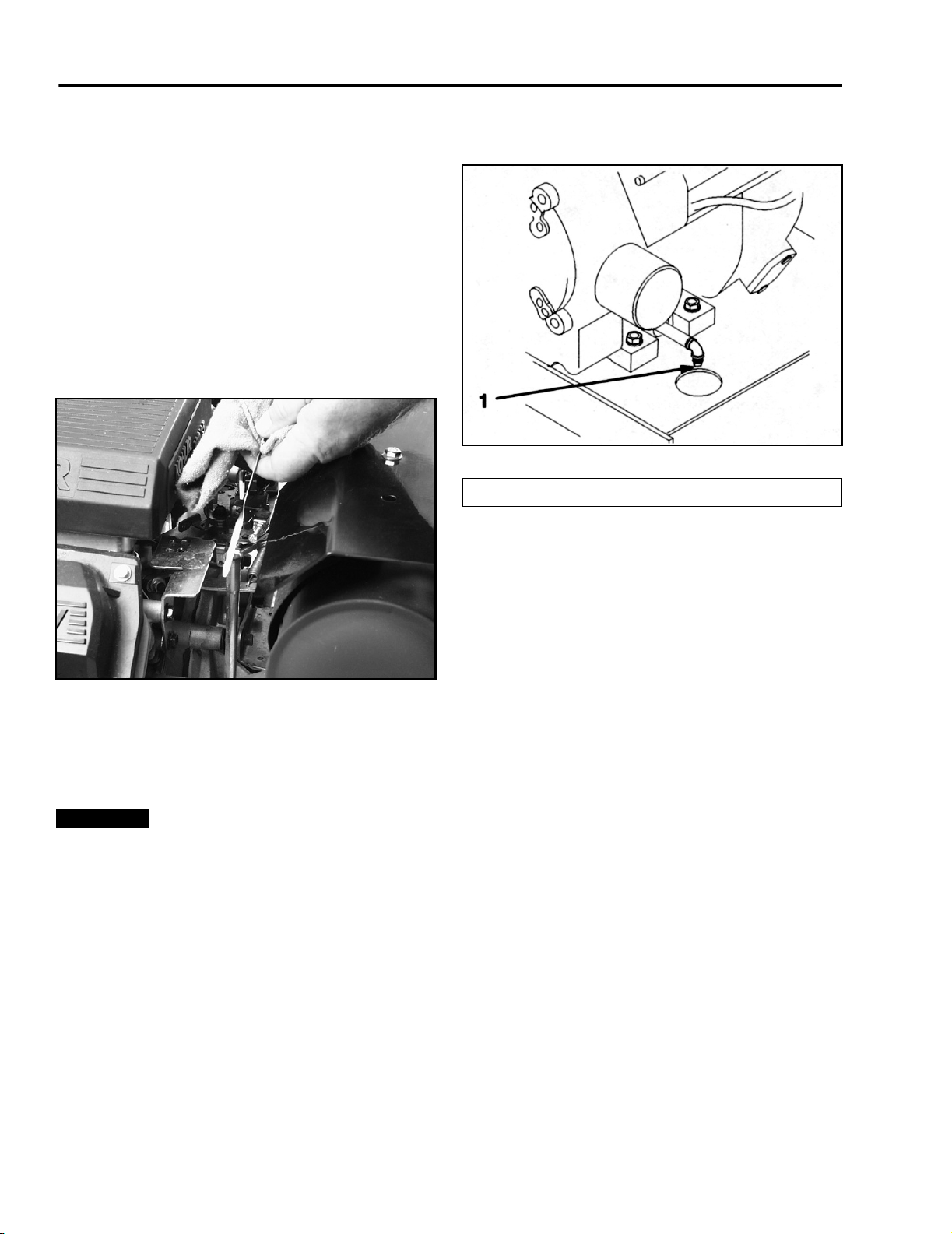

(Figure 1).

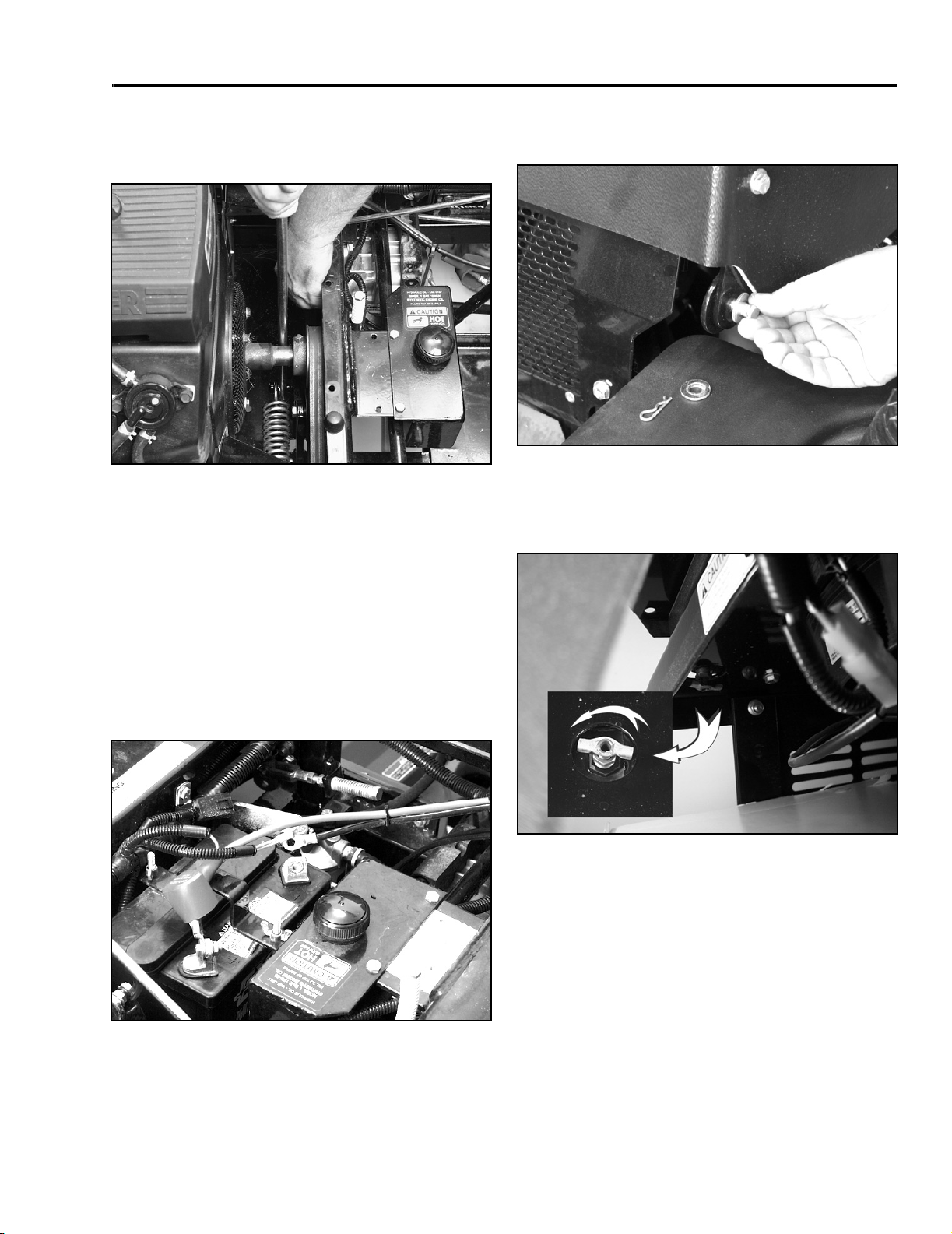

3. Place a pan below the oil drain. Rotate oil drain

valve to allow oil to drain (Figure 2).

Figure 2

(1) Oil Drain Plug

4. When oil has drained completely, close the drain

valve.

m-4386

Figure 1

4. Slide the oil dipstick fully into the filler tube. Pull

the dipstick out and look at the metal end. If oil

level is low, add oil to raise the level to the full

mark.

Important

Do not overfill the crankcase.

1101-015

Changing Oil and Filter

1. Start the engine and let it run five minutes. This

warms the oil so it drains better.

2. Park the machine so that the drain side is slightly

lower than the opposite side to assure the oil

drains completely. Disengage the power take off

(PTO), set the parking brake, and turn the ignition

key to off. Remove the key.

Slowly pour approximately 2 quarts of the specified oil

into the filler tube (Figure 2). Now check the oil level.

Slowly add additional oil to bring it to the “FULL” mark

on the dipstick.

Change oil:

• After the first 8 operating hours.

• After every 100 operating hours.

Note: Change oil more frequently when operating

conditions are extremely dusty or sandy.

Oil Type: Detergent oil (API service SG or SH)

Crankcase Capacity: w/filter, 67 oz. (2.0 l)

2 - 2 Mid-Mount Z Service Manual

MAINTENANCE

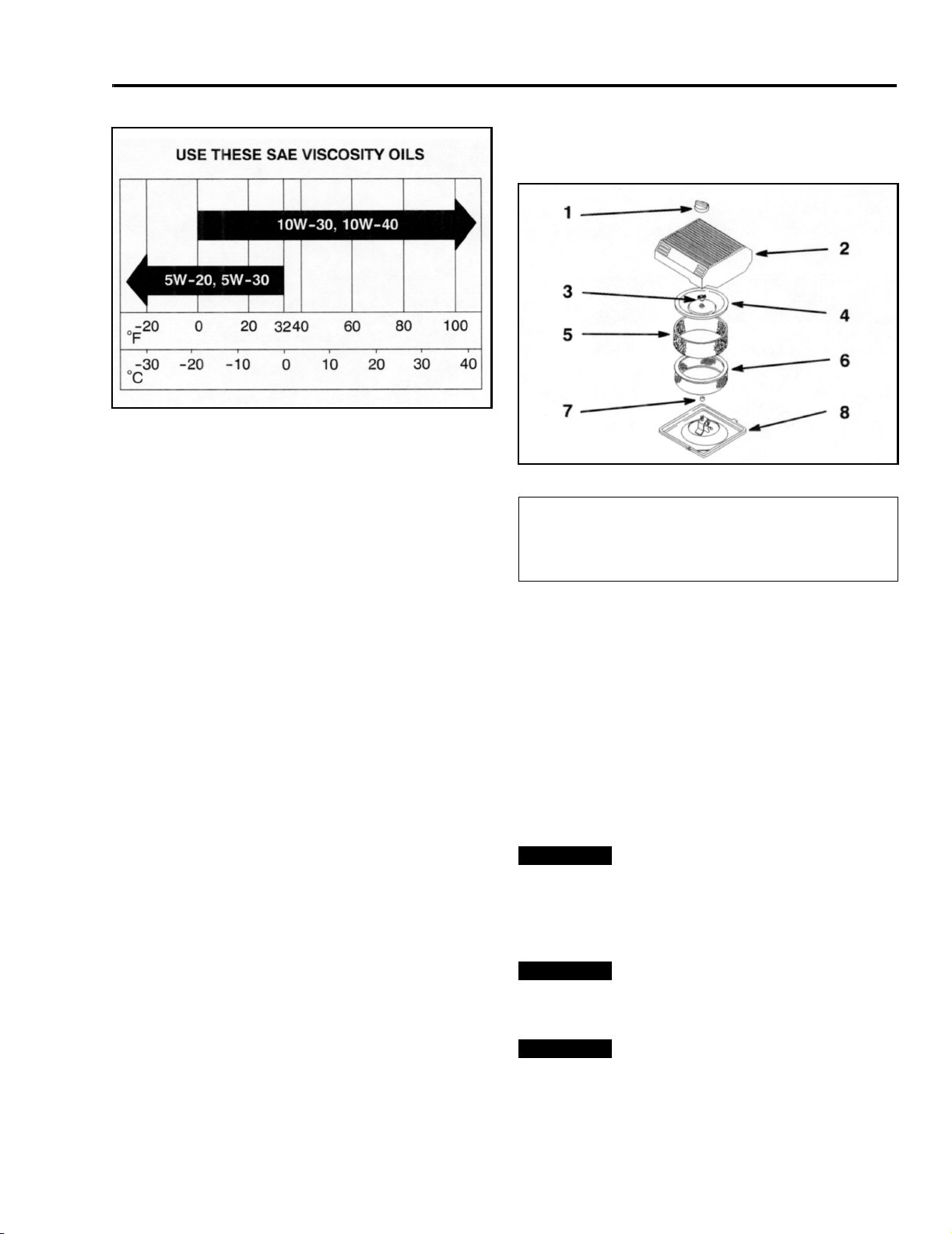

Viscosity: See table below

Servicing the Air Cleaner

Primary Filter: Clean or replace after every 200

operating hours.

Safety Filter: Replace after every 600 operating hours.

Note: Check the filters more frequently if operating

conditions are extremely dusty or sandy.

Removing the Filters

1. Disengage the power take off (PTO), set the

parking brake, and turn the ignition key to off.

Remove the key. Remove spark plug wire(s).

2. Release the latches on the air cleaner and pull the

air cleaner cover off of the air cleaner body (Figure

3).

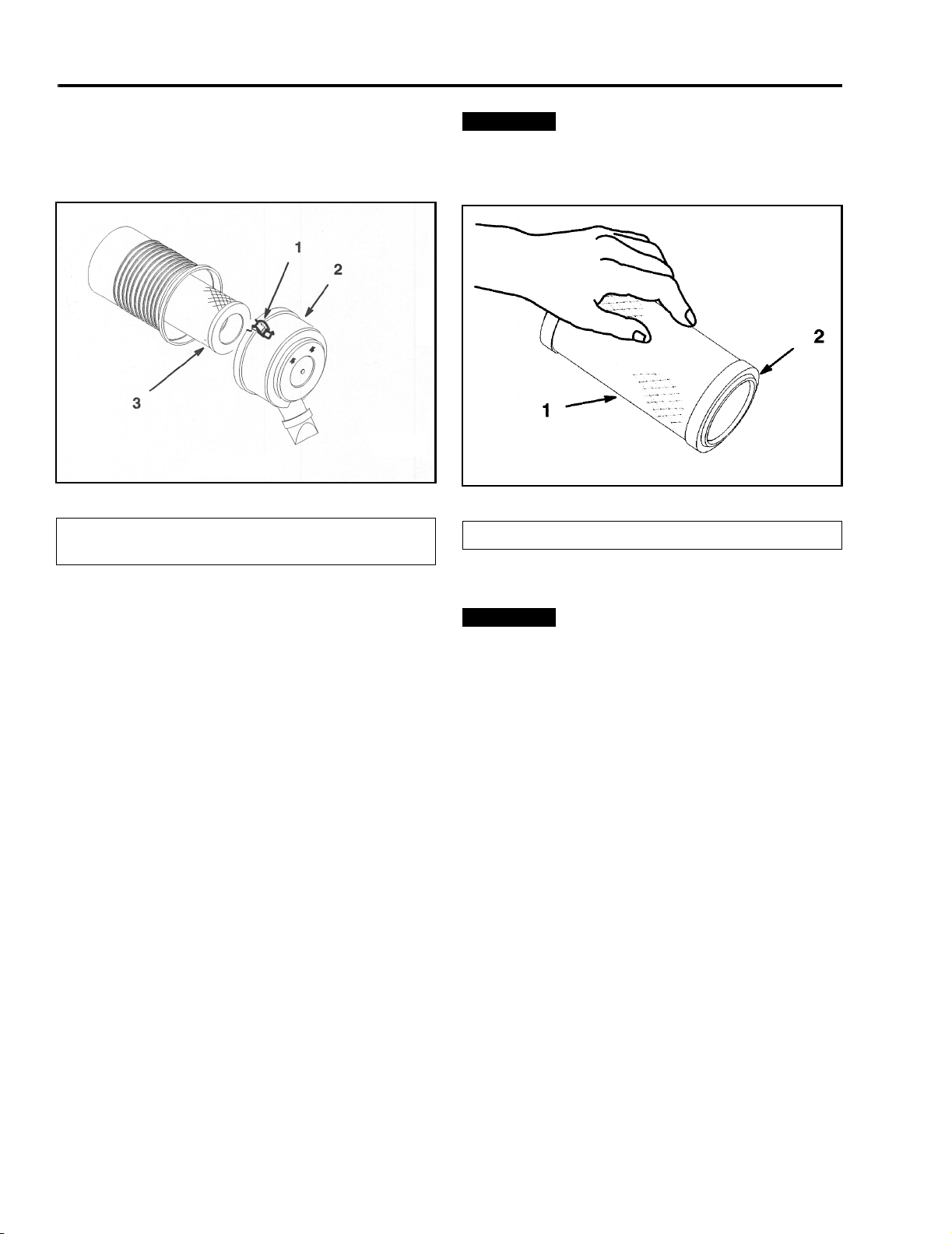

Figure 3

(1) Knob

(2) Air Cleaner Cover

(3) Cover Nut

(4) Cover

3. Clean the inside of the air cleaner cover with

compressed air.

4. Gently slide the primary filter out of the air cleaner

body (Figure 3). Avoid knocking the filter into the

side of the body. Do not remove the safety filter,

unless you intend to replace it as well.

(5) Foam Element

(6) Paper Element

(7) Rubber Seal

(8) Air Cleaner Base

m-3214

5. Inspect the primary filter for damage by looking

into the filter while shining a bright light on the

outside of the filter. Holes in the filter will appear

as bright spots. If the filter is damaged discard it.

Important

the safety filter is dirty, then the primary filter is

damaged and you should replace both filters. Blow

compressed air from the inside to the outside of the

primary filter.

Important

hose at least 2 inches from the filter. Replace air filters

if they are damaged or cannot be cleaned.

Important

600 operating hours.

Mid-Mount Z Service Manual 2 - 3

Never attempt to clean the safety filter. If

Do not exceed 100 psi and keep the

Do not clean safety filter. Replace it after

MAINTENANCE

Installing the Filters

Important

operate the engine with both air filters and cover

installed.

1. If installing new filters, check each filter for

shipping damage. Do not use a damaged filter.

2. If the safety filter is being replaced, carefully slide

it into the filter body (Figure 3).

3. Carefully slide the primary filter over the safety

filter (Figure 3). Ensure that it is fully seated by

pushing on the outer rim of the filter while

installing it.

Important

the filter.

Install the air cleaner cover with the side indicated as

UP facing up and secure the latches (Figure 3).

To prevent engine damage, always

Do not press on the soft inside area of

Servicing Models Equipped With the

Heavy-Duty Air Cleaner

Primary Filter: Clean or replace every 200 operating

hours or when Filter Minder reaches Change Filter

level.

Safety Filter: Replace after every 600 operating hours.

Note: Service the air cleaner more frequently if

operating conditions are extremely dusty or sandy.

1. Start by visually checking the condition of the

primary element. If the element is visually dirty,

replace the primary element. Do not attempt to

clean it.

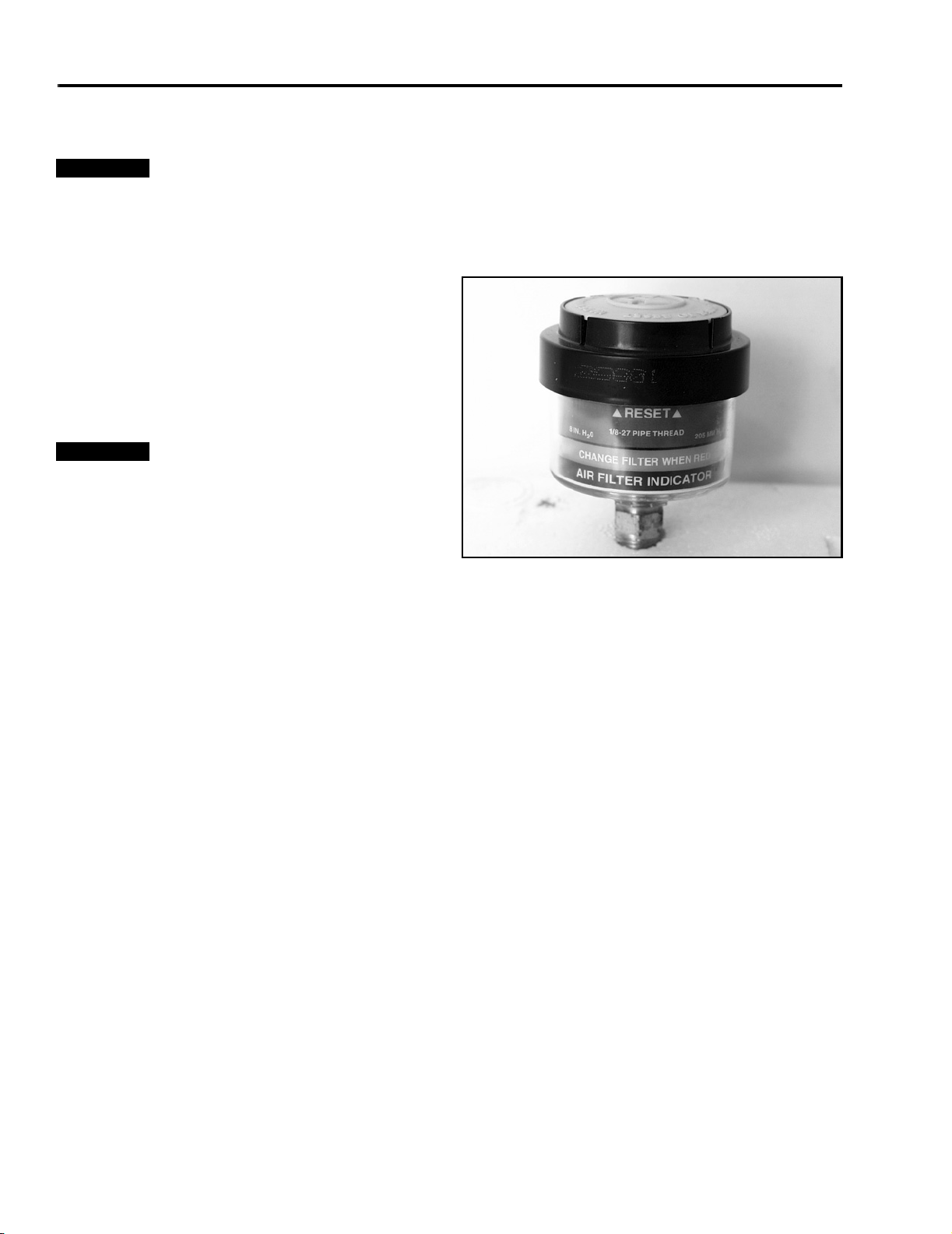

2. Reset the gauge by depressing the button in the

bottom of the canister until the plunger returns to

the lowest point (Figure 4).

Figure 4

3. Test run the engine and recheck the gauge. If the

plunger changes to red, the primary element is

restricted and must be replaced, even though it

may not appear to be dirty.

4. The gauge may be reset at any time, however it

will return to red if correct filter servicing has not

been performed.

0508-001

Using the Filter Minder

This machine contains an air cleaner Filter Minder

gauge.

Filter Minder: Check this daily.

The plunger inside the gauge canister will change to

red when the air cleaner element becomes dirty and

restricted. When it changes red, air cleaner

maintenance is required.

2 - 4 Mid-Mount Z Service Manual

MAINTENANCE

Removing the Air Cleaner

1. Disengage the power take off (PTO), set the

parking brake, and turn the ignition key to off.

Remove the key. Remove spark plug wire(s).

2. Release the latches on the air cleaner and pull the

air cleaner cover off of the air cleaner body (Figure

5).

Important

hose at least 2 inches from the filter. Replace air filters

if they are damaged or cannot be cleaned.

Installing the Filters

Important

operate the engine with both air filters and cover

installed.

1. If installing new filters, check each filter for

shipping damage. Do not use a damaged filter.

2. If the safety filter is being replaced, carefully slide

it into the filter body (Figure 5).

3. Carefully slide the primary filter over the safety

filter (Figure 5). Ensure that it is fully seated by

pushing on the outer rim of the filter while

installing it.

Important

the filter.

Do not exceed 100 psi and keep the

To prevent engine damage, always

Do not press on the soft inside area of

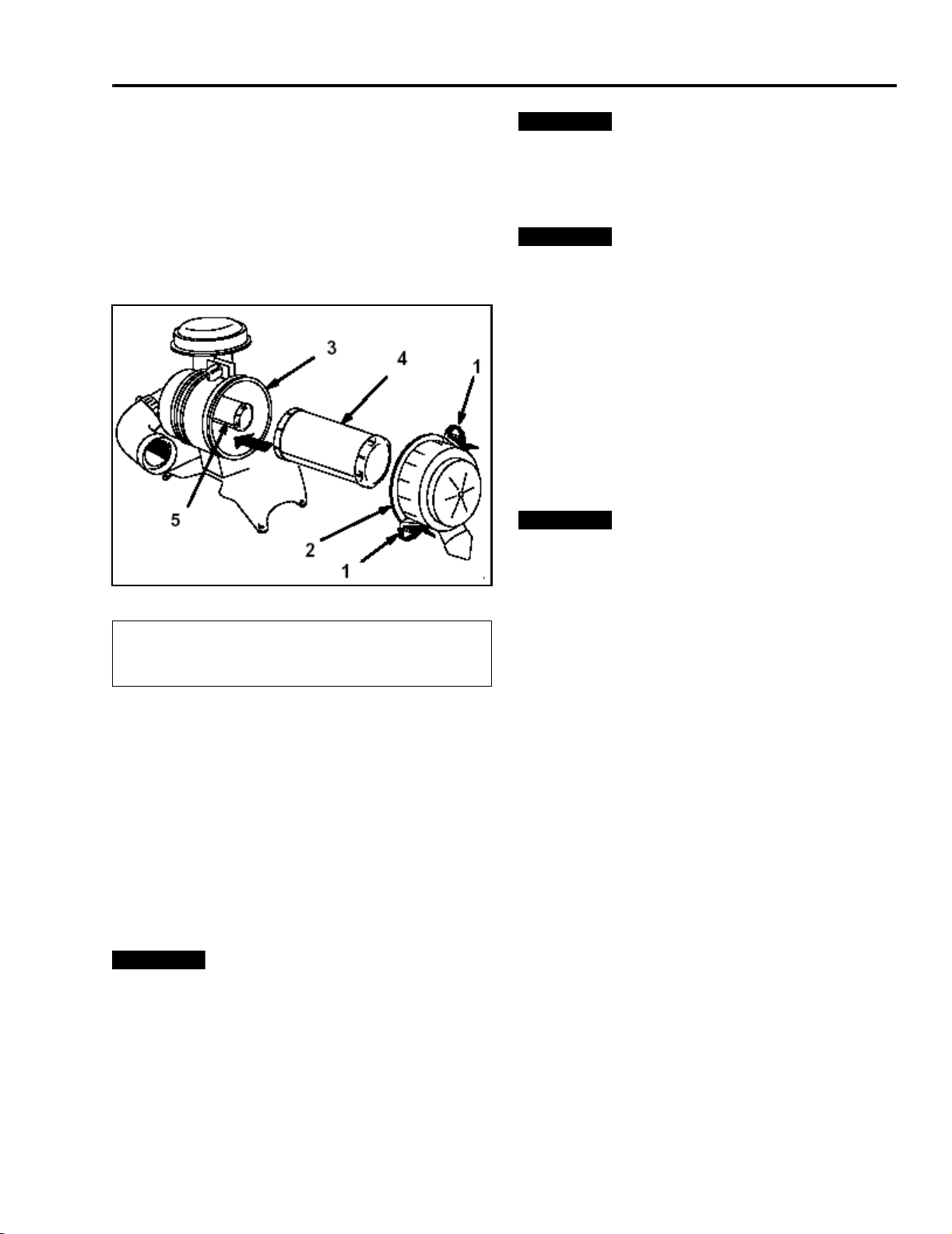

Figure 5

(1) Latches

(2) Air Cleaner Cover

(3) Air Filter Body

3. Clean the inside of the air cleaner cover with

compressed air.

4. Gently slide the primary filter out of the air cleaner

body (Figure 5). Avoid knocking the filter into the

side of the body. Do not remove the safety filter,

unless you intend to replace it as well.

5. Inspect the primary filter for damage by looking

into the filter while shining a bright light on the

outside of the filter. Holes in the filter will appear

as bright spots. If the filter is damaged discard it.

Important

the safety filter is dirty, then the primary filter is

damaged and you should replace both filters.

Never attempt to clean the safety filter. If

(4) Primary Filter

(5) Safety Filter

m-4815

4. Install the air cleaner cover with the side indicated

as UP facing up and secure the latches (Figure 5).

Servicing the Air Cleaner Liquid-Cooled

Models

Paper Element:

• Clean after 50 operating hours.

• Replace after 300 operating hours.

NOTE: Service the air cleaner more frequently (every

few hours) if operating conditions are extremely dusty

or sandy.

Removing the Paper Element

1. Disengage the power take off (PTO), set the

parking brake, stop the engine, and remove the

key.

2. Tilt the seat up and tilt the engine cover forward.

Cleaning the Primary Filter

Blow compressed air from the inside to the outside of

the primary filter.

Mid-Mount Z Service Manual 2 - 5

MAINTENANCE

3. Clean around the air cleaner to prevent dirt from

getting into the engine and causing damage.

Loosen the retaining clips and remove the air

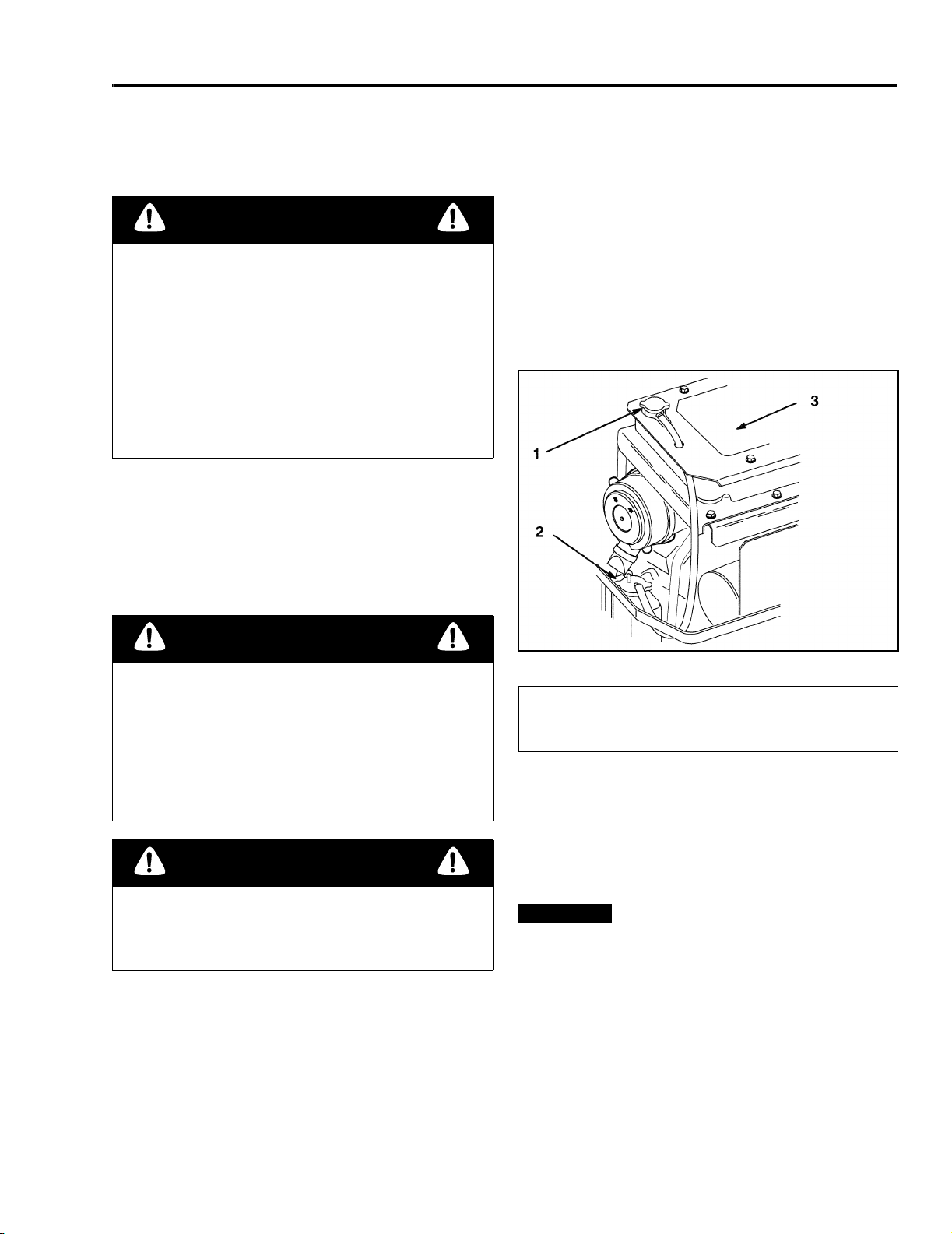

cleaner cover (Figure 6).

(1) Retaining Clip

(2) Air Cleaner Cover

Figure 6

(3) Air Filter

m-4382

Important

pressurized air or liquids, such as solvent, gas, or

kerosene. Replace the paper element if it is damaged,

or cannot be cleaned thoroughly.

(1) Paper Element (2) Rubber Seal

Never clean the paper element with

Figure 7

m-4383

Cleaning the Paper Elements

1. Lightly tap the element on a flat surface to remove

dust and dirt (Figure 7).

2. Inspect the element for tears, an oily film, and

damage to the rubber seal.

Installing the Paper Elements

Important

operate the engine with the paper air cleaner installed.

1. Carefully slide the element into the compartment

(Figure 6).

2. Place the air cleaner cover into the compartment

and latch the retaining clips (Figure 6).

To prevent engine damage, always

Cleaning the Engine Fins

Every 100 hours clean engine cylinder and cylinder

head cooling fins. Also clean around carburetor,

governor levers and linkage. This will make sure

adequate cooling to hydraulic pumps, motors and

engine and will reduce the possibility of overheating

and mechanical damage.

Remove the panels from the engine shroud.

Clean the engine cooling fins.

Install the panels onto the engine shroud.

2 - 6 Mid-Mount Z Service Manual

MAINTENANCE

Servicing the Cooling System

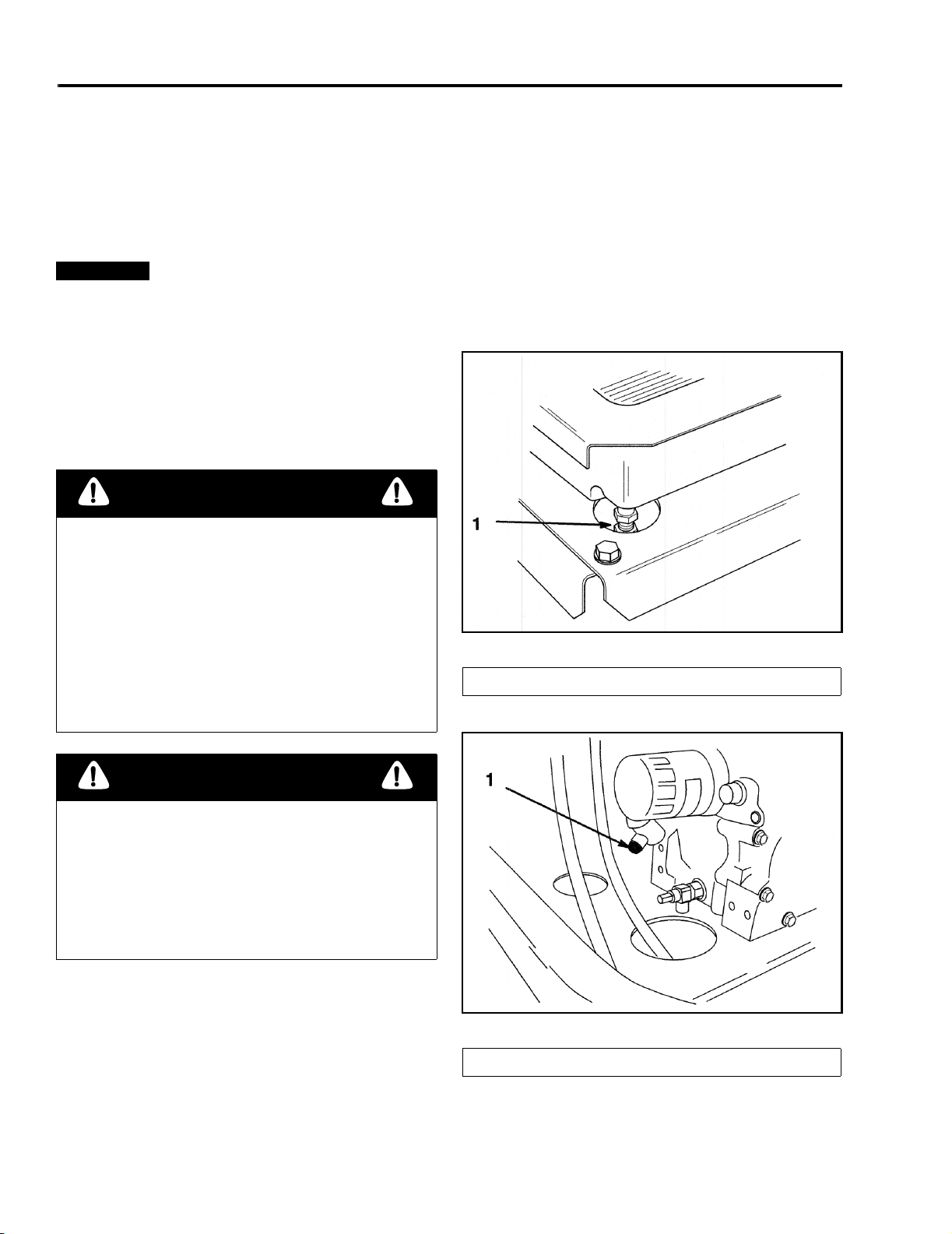

Checking the Radiator Coolant

Danger

Discharge of hot pressurized coolant or touching

hot radiator and surrounding parts can cause

severe burns.

• Do not remove the radiator cap when the

engine is hot. Always allow the engine to cool

at least 15 minutes or until the radiator cap is

cool enough to touch without burning your

hand before removing the radiator cap.

• Do not touch radiator and surrounding parts

that are hot.

Check the cooling system level daily.

Fluid Type: 50/50 mix of permanent antifreeze

(ethylene glycol) and water.

3. With the engine cool, remove the radiator cap

(Figure 8).

4. If the coolant level is low, add a 50/50 mixture of

permanent antifreeze and water until the radiator

is completely full without overflowing.

5. Install the radiator cap. Completely seat the cap

by pushing down and turning it until it stops.

6. Add a 50/50 coolant mix to the overflow bottle and

fill it to the indicator line on the bottle, if required

(Figure 8).

Cooling System Capacity: 128 oz. (3.8 l).

Danger

Rotating shaft and fan can cause personal injury.

• Do not operate the machine without the covers

in place.

• Keep fingers, hands and clothing clear of

rotating fan and drive shaft.

• Shut off the engine and remove the ignition

key before performing maintenance.

Caution

Swallowing engine coolant can cause poisoning.

• Do not swallow engine coolant.

• Keep out of reach from children and pets.

1. Position the machine on a level surface, stop the

engine, and set the parking brake.

2. Tilt the seat up and tilt the engine hood forward.

Figure 8

(1) Radiator Cap

(2) Antifreeze Overflow

Bottle

Cleaning the Cooling System

Clean the cooling system daily before each use.

1. Position the machine on a level surface, stop the

engine, and set the parking brake.

Important

from the pump drive belt compartment. Check more

often in dry conditions.

2. Tilt the seat up and raise the rubber flap above the

drive belt compartment.

3. Remove debris from the drive belt compartment

and hydraulic pumps.

Before starting the engine, clean grass

(3) Radiator Core and

Screen

m-5031-1

Mid-Mount Z Service Manual 2 - 7

MAINTENANCE

4. Remove debris from the screen on the engine

cover.

5. Tilt the engine cover forward.

6. Remove debris from the radiator core and engine

(Figure 8).

Important

7. Inspect the seals on the engine cover and replace

them if needed.

8. Close the engine cover and tilt the seat back.

Changing the Engine Coolant

Change the engine coolant every 400 hours.

Do not damage the radiator cooling fins.

Danger

Discharge of hot pressurized coolant or touching

hot radiator and surrounding parts can cause

severe burns.

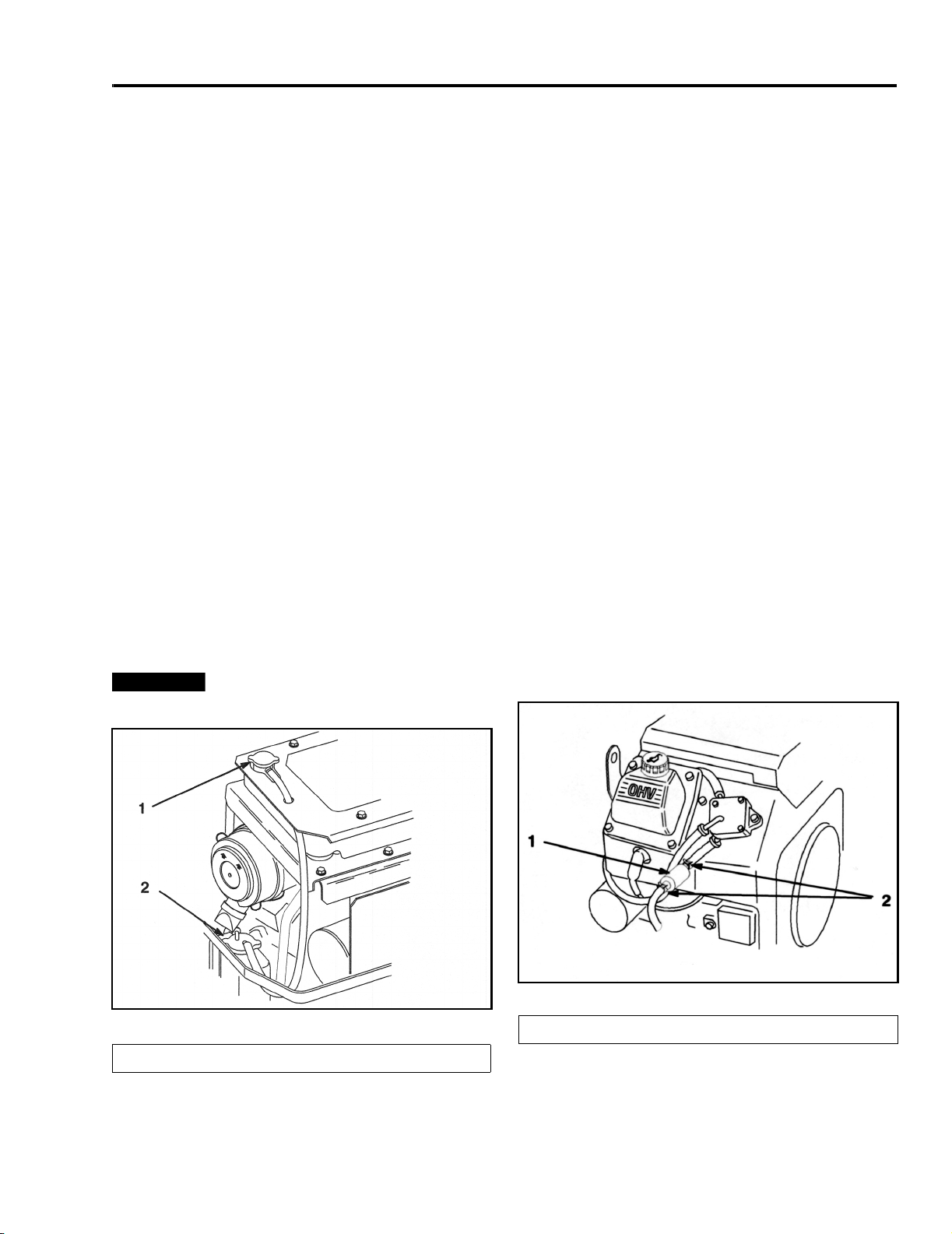

3. With the engine cool, drain the coolant by

loosening the drain cock in the right rear corner

(Figure 9).

4. The engine block must be drained by removing

the drain plug from the engine block (Figure 10).

NOTE: The drain plug is black in color and is located

near the oil filter (Figure 10).

5. Install all drain plugs, the radiator hose, and

tighten the drain cock.

• Do not remove the radiator cap when the

engine is hot. Always allow the engine to cool

at least 15 minutes or until the radiator cap is

cool enough to touch without burning your

hand before removing the radiator cap.

• Do not touch radiator and surrounding parts

that are hot.

Danger

Rotating shaft and fan can cause personal injury.

• Do not operate the machine without the covers

in place.

• Keep fingers, hands and clothing clear of

rotating fan and drive shaft.

• Shut off the engine and remove the ignition

key before performing maintenance.

1. Position the machine on a level surface, stop the

engine, and set the parking brake.

2. Tilt the seat up and tilt the engine hood forward.

Figure 9

(1) Drain Cock (right rear of radiator)

Figure 10 m-5030

(1) Coolant Drain Plug (black in color)

m-4379

2 - 8 Mid-Mount Z Service Manual

MAINTENANCE

6. Drain the coolant from the overflow bottle.

7. Remove the radiator cap and add a 50/50 mixture

of permanent antifreeze and water until the

radiator is completely full.

8. Wait 2 minutes and check if the coolant stays up

to the full level. Add a 50/50 mixture of permanent

antifreeze and water until the radiator is

completely full, if required. Repeat until the

coolant stays up to the full level.

9. With the radiator cap off, tilt the engine cover

down and put the seat down. Start the engine.

Run the engine until it is warm.

10. Tilt the seat up, tilt the engine hood forward, and

keep the engine running. As air is purged from the

engine block and the coolant level drops, add

additional coolant to the radiator it is until full.

11. Install the radiator cap. Completely seat the cap

by pushing down and turning it until it stops.

12. Shut off the engine.

13. Check for any leaks in the cooling system.

14. Close the engine cover and tilt the seat back.

Important

hours of changing the coolant.

Check the coolant level after the first 8

Inspecting the Cooling System

Inspect the radiator and the hoses initially and after the

first 8 operating hours.

Inspect the radiator and the hoses every 200 hours.

Check the hoses and radiator for cracks, dents, and

fractured seams. Repair or replace damaged hoses or

the radiator.

Servicing the Fuel Filter

Replace the fuel filter after every 200 operating hours

or yearly, whichever occurs first.

Replacing the Fuel Filter

Never install a dirty filter if it is removed from the fuel

line.

1. Disengage the power take off (PTO) and turn the

ignition key to off. Move levers to neutral locked

position and apply parking brake. Remove the

key.

2. Close fuel shut-off valve on console.

3. Squeeze the ends of the hose clamps together

and slide them away from the filter (Figure 12).

Figure 12

Figure 11

(1) Radiator Cap (2) Antifreeze Overflow Bottle

Mid-Mount Z Service Manual 2 - 9

m-5031-2

(1) Filter (2) Hose Clamp

4. Remove the filter from the fuel lines.

m-3217

MAINTENANCE

5. Install a new filter and move the hose clamps

close to the filter (Figure 12).

6. Wipe up any spilled fuel.

Open fuel shut-off valve on console.

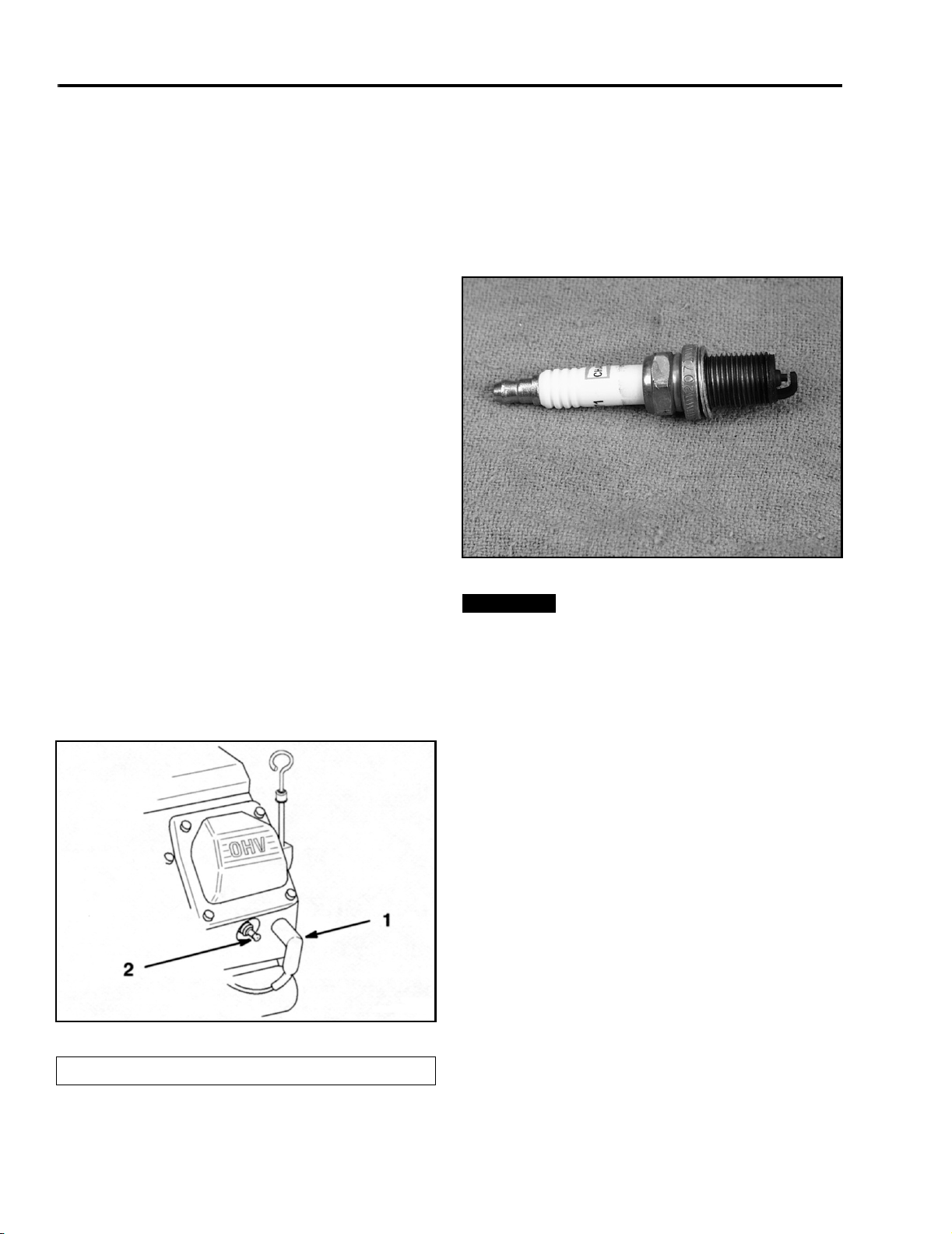

Servicing the Spark Plug

Check the spark plug(s) after every 200 operating

hours. Make sure the air gap between the center and

side electrodes is correct before installing the spark

plug. Use a spark plug wrench for removing and

installing the spark plug(s) and a gapping tool/feeler

gauge to check and adjust the air gap. Install a new

spark plug(s) if necessary.

Type: Champion RC12YC (or equivalent).

Air Gap: 0.030 in. (0.76mm).

Removing the Spark Plug

1. Disengage the power take off (PTO) and turn the

ignition key to off. Move levers to neutral locked

position and apply parking brake. Remove the

key.

2. Pull the wire(s) off the spark plug(s) (Figure 13).

Now clean around the spark plug(s) to prevent dirt

from falling into the engine and potentially causing

damage.

(s)

3. Remove the spark plug(s) and metal washer.

Checking the Spark Plug

1. Look at the center of the spark plug(s) (Figure 14).

If you see light brown or gray on the insulator, the

engine is operating properly. A black coating on

the insulator usually means the air cleaner is dirty.

Figure 14

Important

replace the spark plug(s) when it has: a black coating,

worn electrodes, an oily film, or cracks.

2. Check the gap between the center and side

electrodes (Figure 14). Bend the side electrode

(Figure 14) if the gap is not correct.

Never clean the spark plug(s). Always

1101-020

Installing the Spark Plug

1. Install the spark plug(s). Make sure the air gap is

set correctly.

2. Tighten the spark plug(s) to 20 ft-lb (27 N·m).

3. Push the wire(s) onto the spark plug(s) (Figure

13).

(s)

Check Valve Clearance

Refer to the engine manufacturer’s service manual for

service interval and instructions.

Figure 13

(1) Spark Plug Wire (2) Spark Plug

2 - 10 Mid-Mount Z Service Manual

m-3218

MAINTENANCE

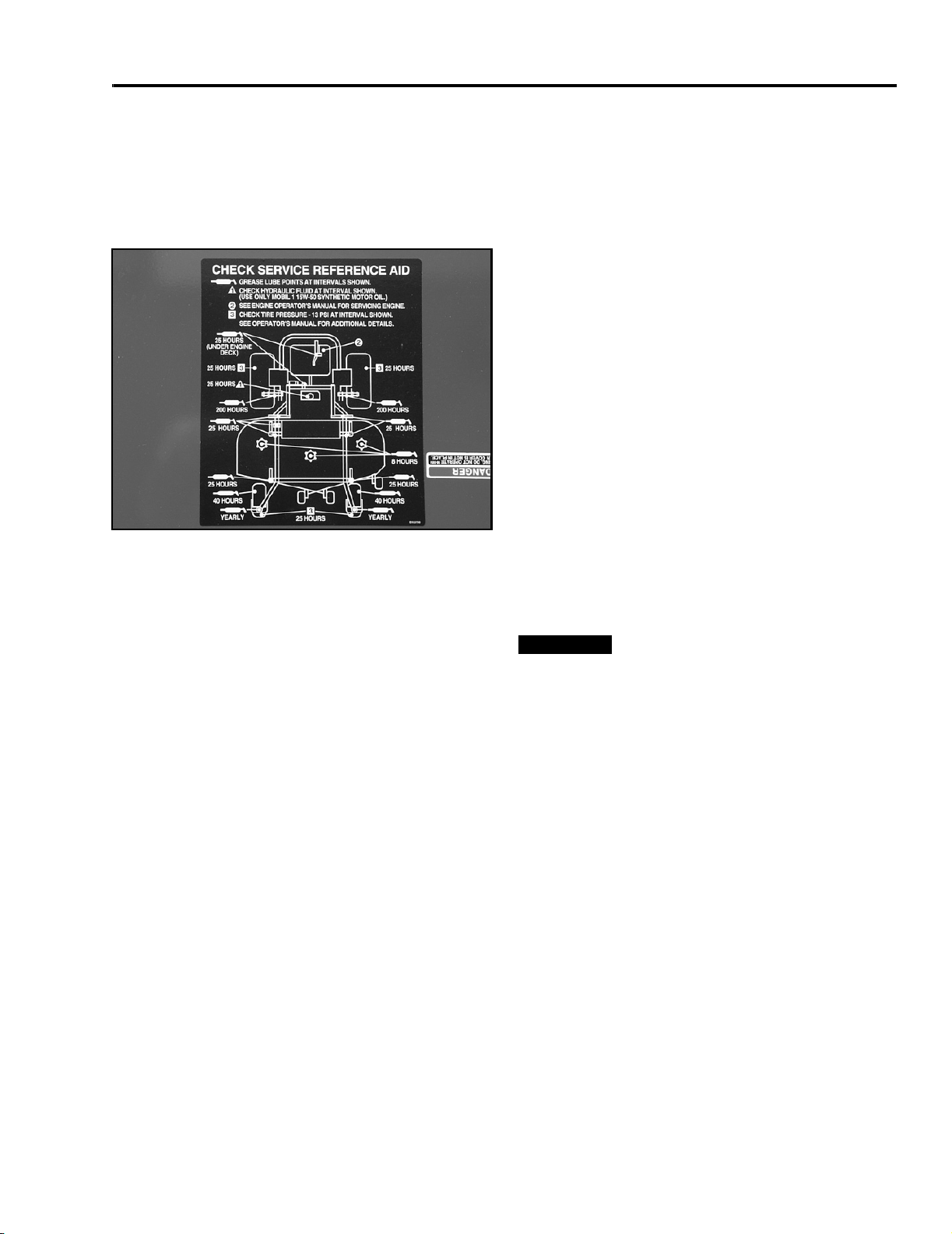

Greasing and Lubrication

Lubricate the machine when shown on the Check

Service Reference Aid decal (Figure 15). Grease

more frequently when operating conditions are

extremely dusty or sandy.

Figure 15

Grease Type: General-purpose grease.

How to Grease

1101-017

3. Remove grease zerk in hole. Reinstall hex plug

and cap.

Where to Add Grease

Lubricate the grease fittings as shown on the Check

Service Reference Aid decal (Figure 15).

Where to Add Light Oil or Spray Lubrication

Lubricate the machine in the following areas with spray

type lubricant or light oil. Lubricate every 160 hours.

• Seat switch actuator.

• Brake handle pivot.

• Brake rod bushings.

• Motion control bronze bushings.

Greasing the Bearings

The cutting unit must be lubricated daily. Refer to the

“Recommended Maintenance Schedule” on page 2 - 1.

Grease with No. 2 general purpose lithium base or

molybdenum base grease.

1. Disengage the power take off (PTO) and turn the

ignition key to off. Move levers to neutral locked

position and apply parking brake. Remove the

key.

2. Clean the grease fittings with a rag. Make sure to

scrape any paint off the front of the fitting(s).

3. Connect a grease gun to the fitting. Pump grease

into the fittings until grease begins to ooze out of

the bearings.

4. Wipe up any excess grease.

Greasing the Front Castor Pivots

Lubricate the front castor pivots once a year.

1. Remove hex plug and cap. Thread a grease zerk

into hole.

2. Pump grease into zerk until it oozes out around

top bearing.

Important

grease daily.

1. Stop the engine, set the parking brake, remove

the key and disconnect the spark plug wire(s) from

the spark plug(s).

2. Grease the fittings on the three spindle bearings

until grease comes out lower seals (Figure 15).

3. Grease the fittings on the push arms (Figure 15).

Make sure cutting unit spindles are full of

Mid-Mount Z Service Manual 2 - 11

THIS PAGE INTENTIONALLY LEFT BLANK

2 - 12 Mid-Mount Z Service Manual

ENGINE

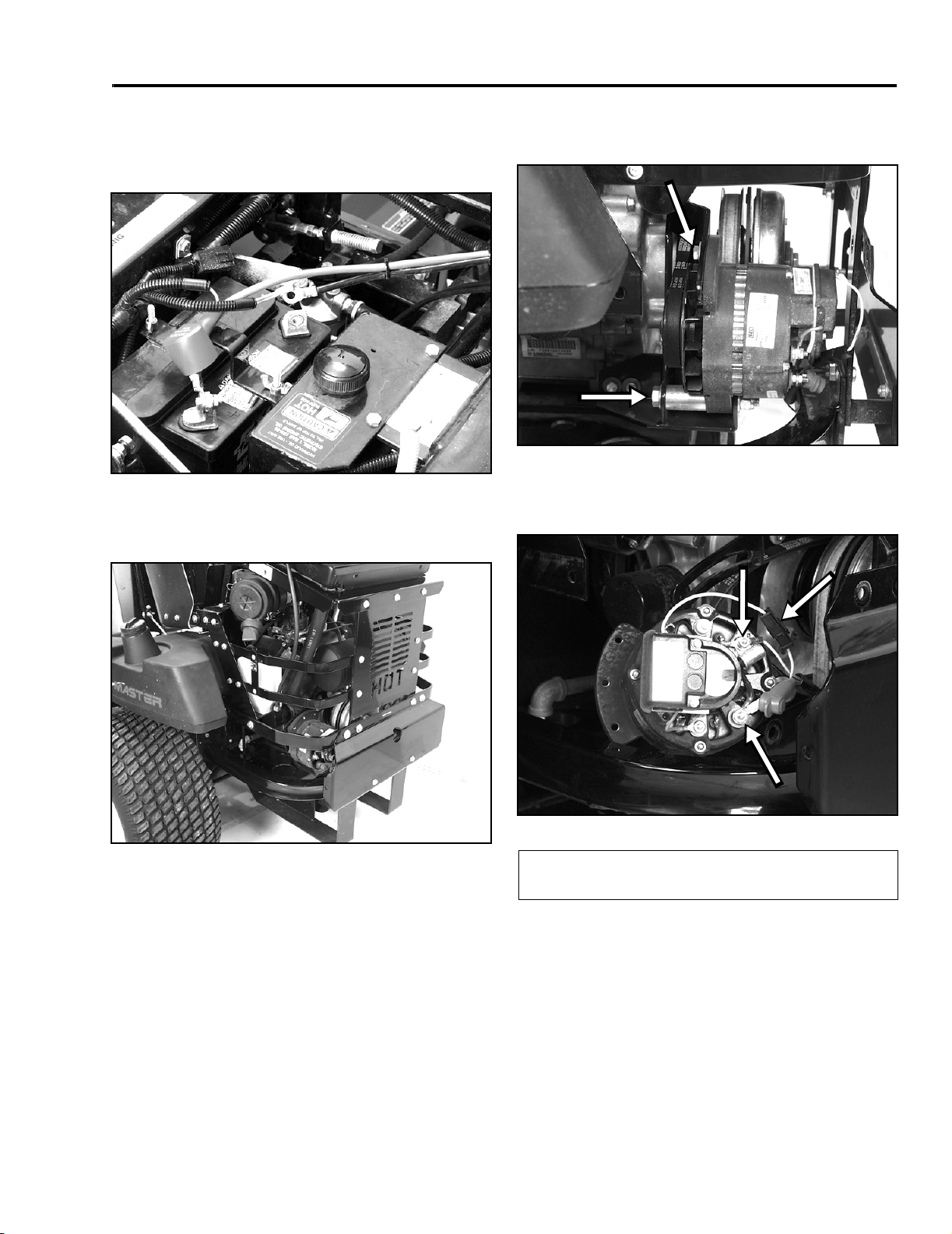

External Alternator Remove & Replace

1. Disconnect the battery negative cable.

Figure 16

2. Remove the lower engine protection bracket and

set the coolant recovery bottle off to the side.

0507-001

3. Remove the alternator adjustment bolt and pivot

bolt.

Figure 18

4. Remove the alternator belt and rotate the

alternator to gain access to the wiring.

A

0508-003

B

C

Figure 19

Figure 17

Mid-Mount Z Service Manual 3 - 1

0508-002

(A) Ground Wire

(B) Exciter Wire

5. Remove the alternator output wire, ground wire,

and exciter wire.

6. Inspect the alternator belt for wear, cracking, or

other damage.

7. Reverse procedure to reinstall.

(C) Output Wire

0508-004

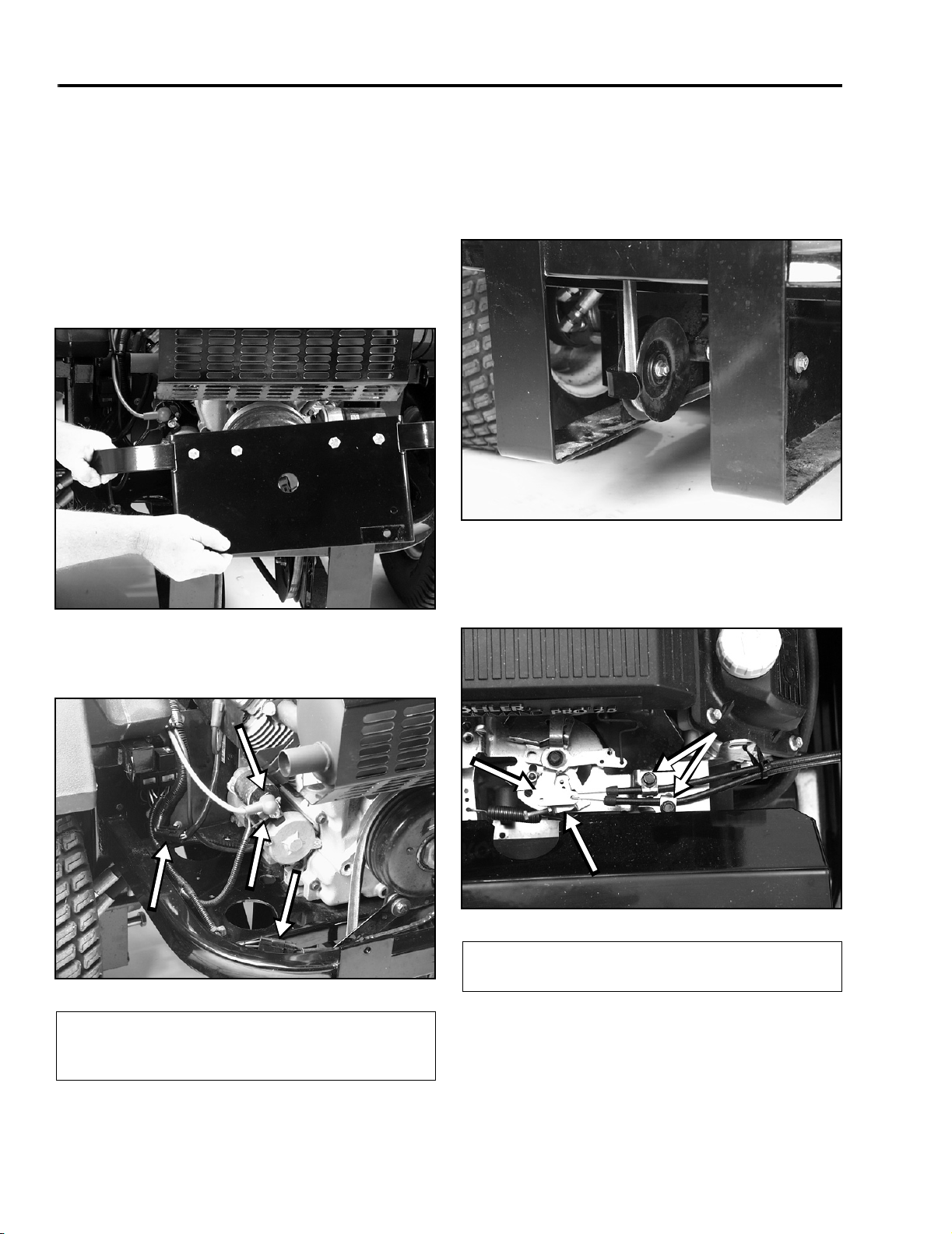

ENGINE

Engine Remove & Replace

Air-Cooled

1. Disconnect the negative battery cable.

2. Remove the PTO clutch anchor bolt from the

clutch guard.

3. Remove the clutch guard and clutch guard

brackets (Figure 20).

Figure 20

1023-011

5. Disconnect the PTO clutch electrical plug and

main wiring harness connector (Figure 21).

6. Release the tension from the drive belt by raising

the lever against the spring tension and remove

the belt from the PTO pulley (Figure 22).

Figure 22

7. Remove the clamps securing the choke and

throttle cables. Then remove the Z bends from

the choke and throttle levers (Figure 23).

1101-011

4. Remove the battery cable, main power feed, and

solenoid wire from the starter solenoid (Figure 21).

A

C

D

(A) Battery Cable/

Power Feed

(B) Solenoid Wire

B

Figure 21

(C) Clutch Plug

(D) Main Harness

Connector

1023-008

A

C

B

Figure 23

(A) Cable Clamps

(B) Throttle Lever

8. Place the fuel tank selector lever in the off position

and disconnect the fuel supply line from the fuel

filter.

(C) Choke Lever

1023-005

3 - 2 Mid-Mount Z Service Manual

ENGINE

9. Using a suitable pry bar, release the idler pulley

spring tension and remove the hydraulic pump

drive belt.

Figure 24

10. Remove the 4 engine mounting bolts.

11. Slide the engine toward the rear of the machine

and rotate it slightly counterclockwise until the

hydraulic pump belt drive pulley clears the

chassis. Then, lift the engine from the chassis.

1023-012

2. Remove the pins from the radiator cover and lift

off the cover.

Figure 26

3. Remove the radiator cap and open the drain

petcock to drain the coolant into a suitable

container.

0507-002

Engine Remove & Replace

Liquid-Cooled

1. Disconnect the negative battery cable.

Figure 25

0507-001

Figure 27

0507-003

Mid-Mount Z Service Manual 3 - 3

Loading...

Loading...