Page 1

Form No. 3329-965

Z100 Series Z Master Mowers

Setup Instructions

Loose Parts

Use steps 1 trough 12 in the following chart to verify all parts have been shipped and as a guide through the

setup.

Step Description Qty. Use

1

2

3

4

5

6

No parts needed – Raising the machine up

Roll bar, right section

Roll bar, left section

Roll bar, center section

Bolt, 3/8 x 1 inch

Curved washer, 3/8 inch

Flange nut, 3/8 inch

Bolt, 1/2 x 3-1/4 inches

Flange nut, 1/2 inch

Lanyard

Wheels 2 Installing the drive wheels

No parts needed – Checking the tire pressure

Seat

Nuts (installed on the seat)

Control lever–right

Control lever–left

Bolt, 3/8 x 1 inch

Curved washer, 3/8 inch

1

1

1

8

8

8

2

2

2

1

4

1

1

4

4

Installing the roll over protection system

(ROPS)

Installing the seat

Installing the motion control levers

7

8

9

10

2003—The Toro Company

8111 Lyndale A ve., Blomington, MN 55420, USA

Bulk electrolyte with 1.265 specific gravity

(Purchase from a battery supply outlet.)

Air cleaner cap

Hose clamp

Number 2 general purpose lithium base or

molybdenum base grease. (Purchase

separately.)

No parts needed – Preparing the side discharge chute

80

ounces

1

1

1 tube Greasing the bearings

Printed in the USA

All Rights Reserved

Activating the battery

Installing the air cleaner cap

Original Instructions (EN)

Register your product at www.Toro.com

Page 2

Step UseQty.Description

2

11

12

No parts needed. – Checking the machine before delivery

Key

Operator’s Manual

Engine Owner’s Manual

Parts Catalog

Safety video

Registration card

Step

1

Raising the Machine Up

Parts needed for this step:

None

2

1

1

1

1

1

Delivering the Machine to the Customer

Procedure

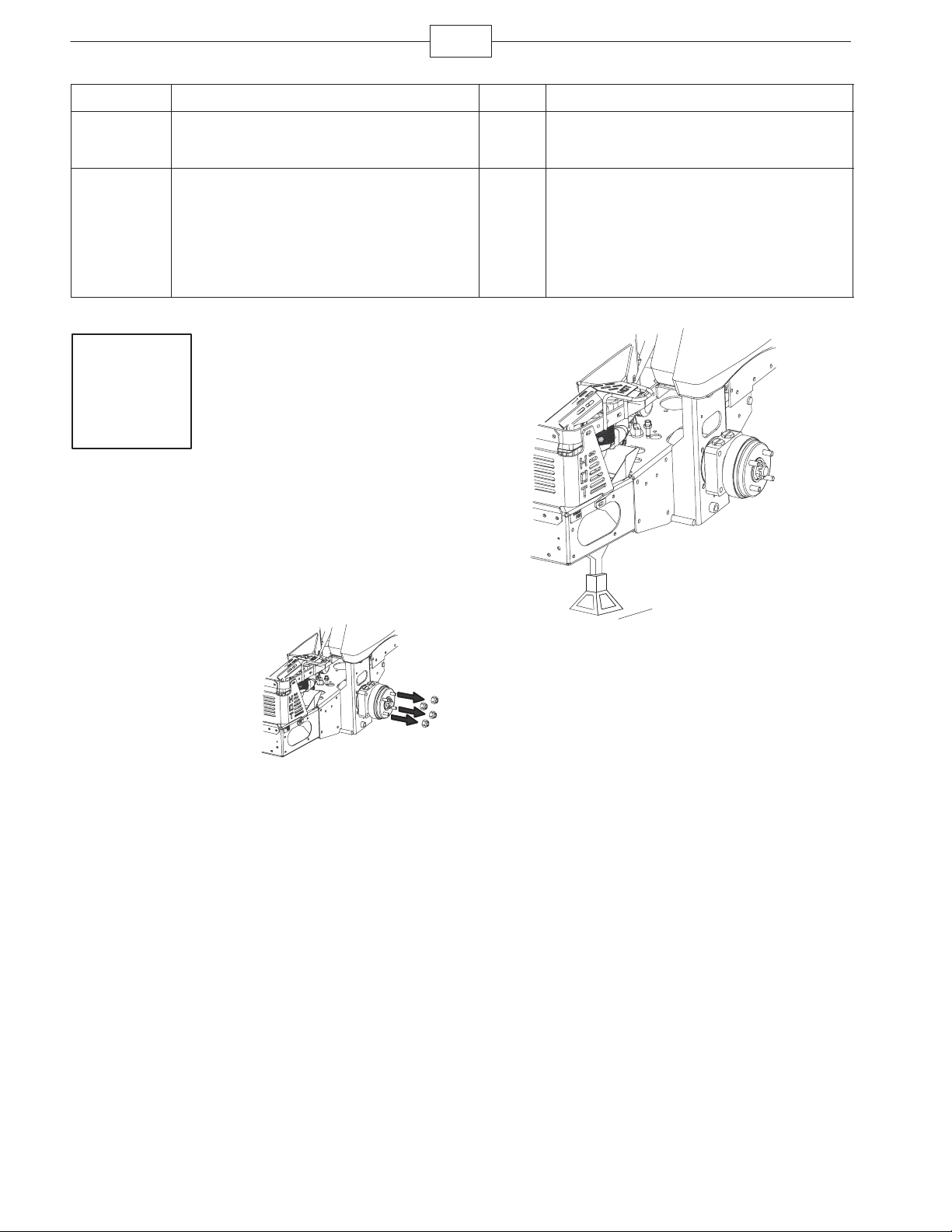

1. Remove the wheel

nuts from both sides of

the vehicle.

2. Remove the right

angle retaining plate

from the crate and the

wheel hub.

3. Raise the back of the machine up and support it

with jack-stands.

m–6918

m–6919

Page 3

Step

2

Installing the Roll Over

Protection System (ROPS)

Parts needed for this step:

Qty. Part

1 Roll bar, right section

1 Roll bar, left section

1 Roll bar, center section

8 Bolt, 3/8 x 1 inch

8 Curved washer

8 Flange nut, 3/8 inch

2 Bolt, 1/2 x 3-1/4 inches

2 Flange nut, 1/2 inch

2 Lanyard

Procedure

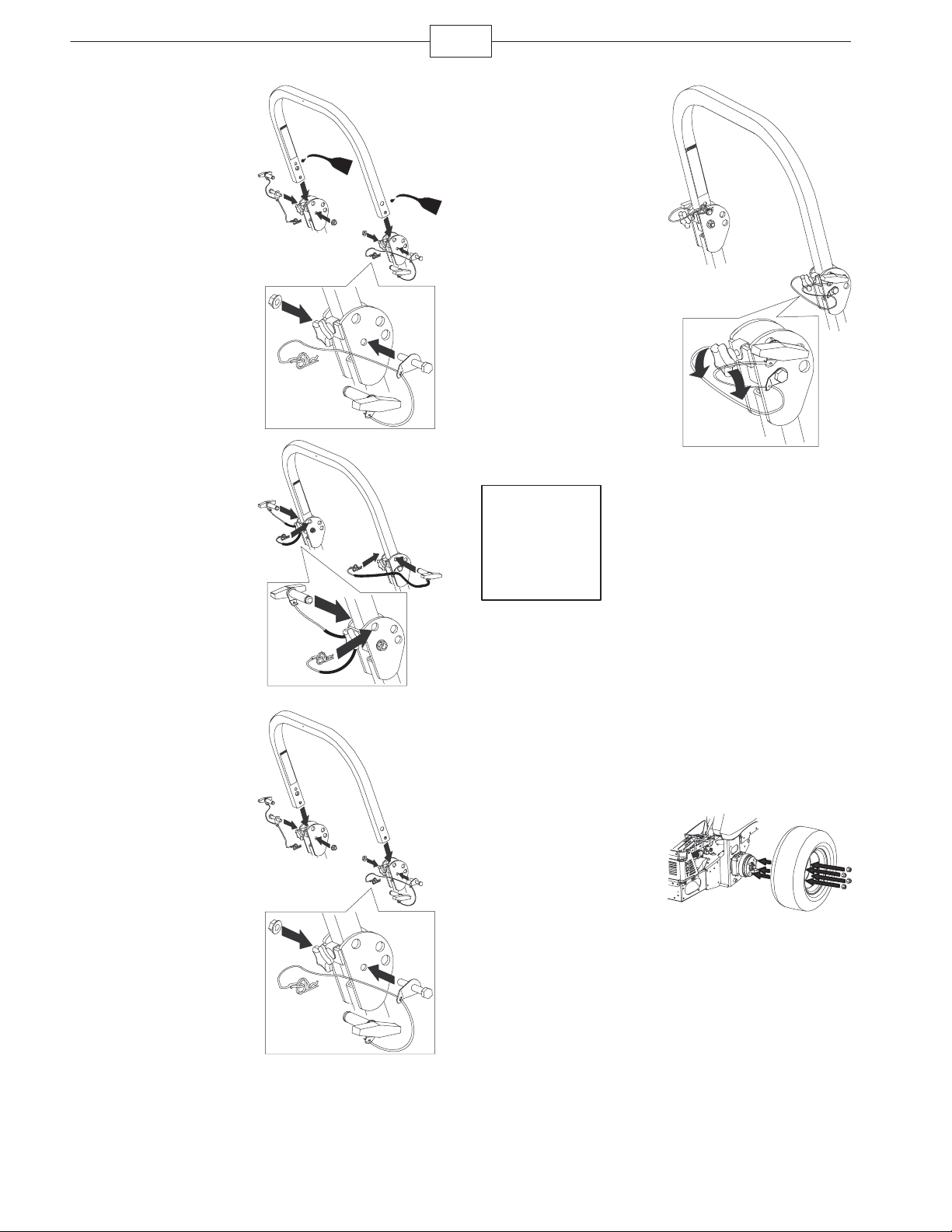

1. Loosely install the right and left roll bar sections

to the frame, using 8 bolts (3/8 x 1 inch), 8 curved

washers, and 8 flange nuts (3/8 inch).

3

m–6916

2. Install the lanyard

clips onto the 2 bolts

(1/2 x 3-1/4 inches).

Note: Make sure the

bent tab points toward

the head of the bolt.

m–6892

Page 4

4

5

3. Lightly oil the ends

of the center roll bar

section.

4. Loosely install the

center roll bar section,

using 2 bolts

(1/2 x 3-1/4 inches) and

2 flange nuts (1/2 inch).

Note: Make sure the

bolts are installed on the

outside of the roll bar.

Note: Make sure the

lanyard tab is install as

shown and points

forward.

5. Raise the roll bar

into the upright position

and secure it with the

pins and hairpin cotter

pins fastened to the

lanyards.

6. Torque all lower

fasteners, attached to

the machine frame, to

30 ft–lb.

m–6891

m–6893

8. Tighten the front

handles against the

center roll bar ends.

m–683

Step

3

Installing the Drive Wheels

7. Tighten the center

roll bar bolts

(1/2 x 3-1/4 inches) so

the roll bar rotates freely

with some resistance.

Note: No more than one

thread should be

exposed outside the nut.

m–6891

Parts needed for this step:

Qty. Part

2 Rear wheels

Procedure

1. Mount the wheels

with the valve stem to

the outside and secure

them with the nuts

previously removed in

Step 1.

2. Torque the nuts to

95 ft-lb (128 N⋅m).

m–6917

Page 5

5

2

Step

4

Checking the Tire Pressure

Parts needed for this step:

None

Procedure

Check the air pressure

in the front and rear

tires.

Pressure: 13 psi

(90 kPa)

m–6873

Step

5

Installing the Seat

Parts needed for this step:

None

Procedure

1. Remove the bolt

and nut from the seat

frame.

2. Secure the seat rod

to the seat with the bolt

and nut.

m–571

Page 6

Step

6

Installing the Motion

Control Levers

Parts needed for this step:

6

Qty. Part

1 Control lever–right

1 Control lever–left

4 Bolt, 3/8 x 1 inch (2 assembled)

4 Curved washer, 3/8 inch (2 assembled)

Procedure

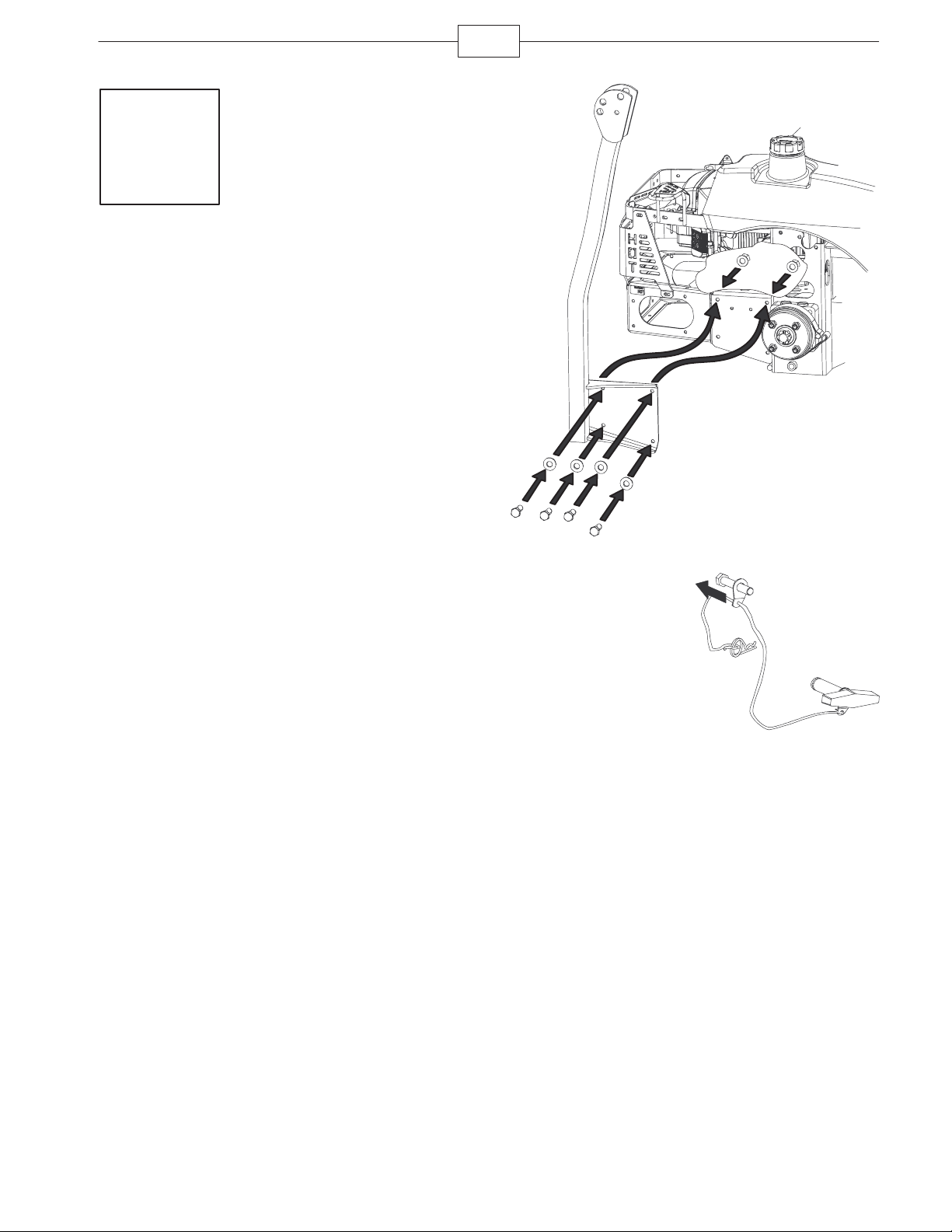

1. Rotate the handles

to the upright position.

2. Loosely install the

levers on the outside of

the posts, using 4 bolts

and curved washers.

Note: Install the levers

in the top and middle

holes for the high

position or the middle

and bottom holes for the

low position, as desired.

3. In the neutral position, raise the levers, bringing

them together, and slide them until they are aligned,

then tighten the bolts.

m–6866

m–6867

m–6868

Page 7

Step

7

Activating the Battery

Parts needed for this step:

Qty. Part

80

Bulk electrolyte with 1.265 specific gravity

ounces

Procedure

(Purchase from a battery supply outlet.)

Danger

7

1. Remove the battery.

Refer to the

Manual

Important: Do not add

electrolyte while the

battery is in the

machine. You could spill

it, causing corrosion.

2. Clean the top of the

battery and remove the

vent caps.

Operator’s

for instructions.

m–6850

Battery electrolyte contains sulfuric acid which is

a deadly poison and causes severe burns.

Do not drink electrolyte and avoid contact

with skin, eyes or clothing. Wear safety

glasses to shield your eyes and rubber gloves

to protect your hands.

Fill the battery where clean water is always

available for flushing the skin.

Follow all instructions and comply with all

safety messages on the electrolyte container.

Warning

CALIFORNIA

Proposition 65 Warning

Battery posts, terminals, and related accessories

contain lead and lead compounds, chemicals

known to the State of California to cause cancer

and reproductive harm.

handling.

Wash hands after

m–6851

3. Slowly pour

electrolyte into each

battery cell until the level

is up to the upper line

on the battery case.

Important: Do not

overfill the battery.

m–6853

4. Wait five to ten minutes, then add electrolyte, if

necessary, until the electrolyte level is up to the

upper line on the battery case.

5. Install battery filler

caps.

6. Charge the battery and then install it on the

machine. Refer to the

instructions.

Operator’s Manual

for

m–6852

Page 8

8

Warning

Charging the battery produces gasses that can

explode and cause serious injury.

Keep cigarettes, sparks and flames away from

the battery.

Make sure the ignition switch is off.

Ventilate when charging or using the battery

in an enclosed space.

Important: Do not run the machine with the battery

disconnected; electrical damage may occur to the

engine computer.

Important: Do not jump start an EFI machine, or you

may damage the electronic control unit.

Step

8

3. Install the hose

clamp onto the air

cleaner cap.

m–6914

4. Install the air

cleaner cap onto the air

cleaner and secure it

with the hose clamp.

Installing the Air Cleaner

Cap

Parts needed for this step:

Qty. Part

1 Air cleaner cap

1 Hose clamp

Procedure

1. Remove the plastic

plug.

m–6913

m–6912

2. Remove the air cleaner cap from the machine.

Page 9

9

Step

9

Checking the Spindles for

Grease

Parts needed for this step:

Qty. Part

1 tube Number 2 general purpose lithium base or

molybdenum base grease. (Purchase

separately.)

Procedure

Important: Check the cutting unit spindles to

make sure they are greased before starting the

engine.

1. Remove the belt covers.

2. Grease the fittings on the three spindle bearings.

Step

10

Preparing the Side

Discharge Chute

Parts needed for this step:

None

Procedure

Remove the plastic tie holding the side discharge

chute up and lower the chute into place.

m–5531

Page 10

10

Step

11

Checking the Machine Before Delivery to the Customer

Parts needed for this step:

None

Procedure

Before delivering the machine to the customer, ensure that you perform or have performed the procedures listed

in the following table and initial each when finished. Refer to the

these procedures.

Initial Check Procedure

Operator’s Manual

for instructions on performing

Check the tire pressure

Check the level of the mower.

Check that all mower spindles are greased.

Check the engine oil level.

Check the hydraulic fluid level.

On liquid cooled machines, check the level of the coolant.

Check the adjustment of the parking brake.

Ensure that the machine tracks (drives) correctly.

Check the safety interlock system.

Ensure that the PTO works.

Check all fasteners you installed to ensure that they are tight.

When you finish setting up the machine, sign and date in the space provided below:

Signature: Date:

Page 11

11

Step

12

Delivering the Machine to the Customer

Parts needed for this step:

Qty. Part

1

Operator’s Manual

1

Parts Catalog

1

Engine Owner’s Manual

1 Registration card

1 Safety video

2 Key

Procedure

At delivery, complete the items listed in the following table and initial each when finished.

Model Number: Serial Number:

Page 12

12

Dealer

Initial

Customer

Initial

Check Procedure

Show the customer where the following features are located and how they function:

• Fuel Tank Caps

• Oil Fill Tube/ Oil dipstick

• Oil Filter

• Oil Drain

• Spark Plug(s)

• Air Filter

• Radiator Coolant

• Hydraulic fluid reservoir

• Hydraulic filter

• Battery

• Ignition Switch

• Throttle Lever

• Choke

• Power Take Off Switch (PTO)

• Motion Control Levers

• Parking Brake

• Mower Height–of–Cut Lever

• Adjustable Seat

• Hydraulic Bypass

• Rollover Protection System (ROPS)

Refer to the operator’s manual to point out safety procedures, operation, and

maintenance procedures.

Review the warranty statement as shown in the

Describe the post sale service procedures for your store.

Assist the customer in filling out and mailing the registration card or register online at

www.Toro.com.

Make sure that the customer receives the

Owner’s Manual, Set Up Instructions

Assist the customer in loading the mower.

, and safety video.

Operator’s Manual

.

Operator’s Manual, Parts Catalog

, and

Engine

Note: When you, the dealer representative, have finished delivering the machine to the customer, sign and date

in the space provided below and keep a copy of this page for dealer records:

Signature: Date:

Signature: Date:

Loading...

Loading...