Page 1

Wheel Horse Lawn Tractor

For Tractors with 32 and 38 Mowers

Loose Parts

Note: Use the chart below to verify that all parts have been shipped.

DESCRIPTION QTY. USE

Form No. 3328-647

Setup Instructions

Bolts—1/4–20 x 3/4 in.

Wing nuts

Spring Hook 1 Installing the lift assist spring

Keys 2 Using in the ignition and KeyChoice switches

Washout Port Adapter 1 Washing the underside of the mower

Operator’s Manual

Engine Operator’s Manual

Safety Booklet

Safety Video

Activating the Battery

Warning

Battery posts, terminals, and related accessories

contain lead and lead compounds, chemicals

known to the State of California to cause cancer

and reproductive harm. Wash hands after

handling.

Purchase bulk electrolyte with 1.260 specific gravity from a

local battery supply outlet.

Important Never fill the battery with electrolyte while

the battery is installed in the tractor. Electrolyte could be

spilled on other parts and corrode them.

2

2

1

1

1

1

Installing the battery cables

Reading and watching before operating the

tractor

1. Remove the battery and battery box from the tractor;

refer to the Operator’s Manual.

Danger

Battery electrolyte contains sulfuric acid, a deadly

poison that can severely burn you and others.

• Do not drink electrolyte and avoid contact with

skin, eyes, or clothing. Wear safety glasses to

shield your eyes and rubber gloves to protect

your hands.

• Fill the battery where clean water is always

available for flushing the skin.

• Follow all instructions and comply with all

safety messages on the electrolyte container.

2. Remove the vent caps from the battery.

2002 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

All Rights Reserved

Printed in the USA

1

Page 2

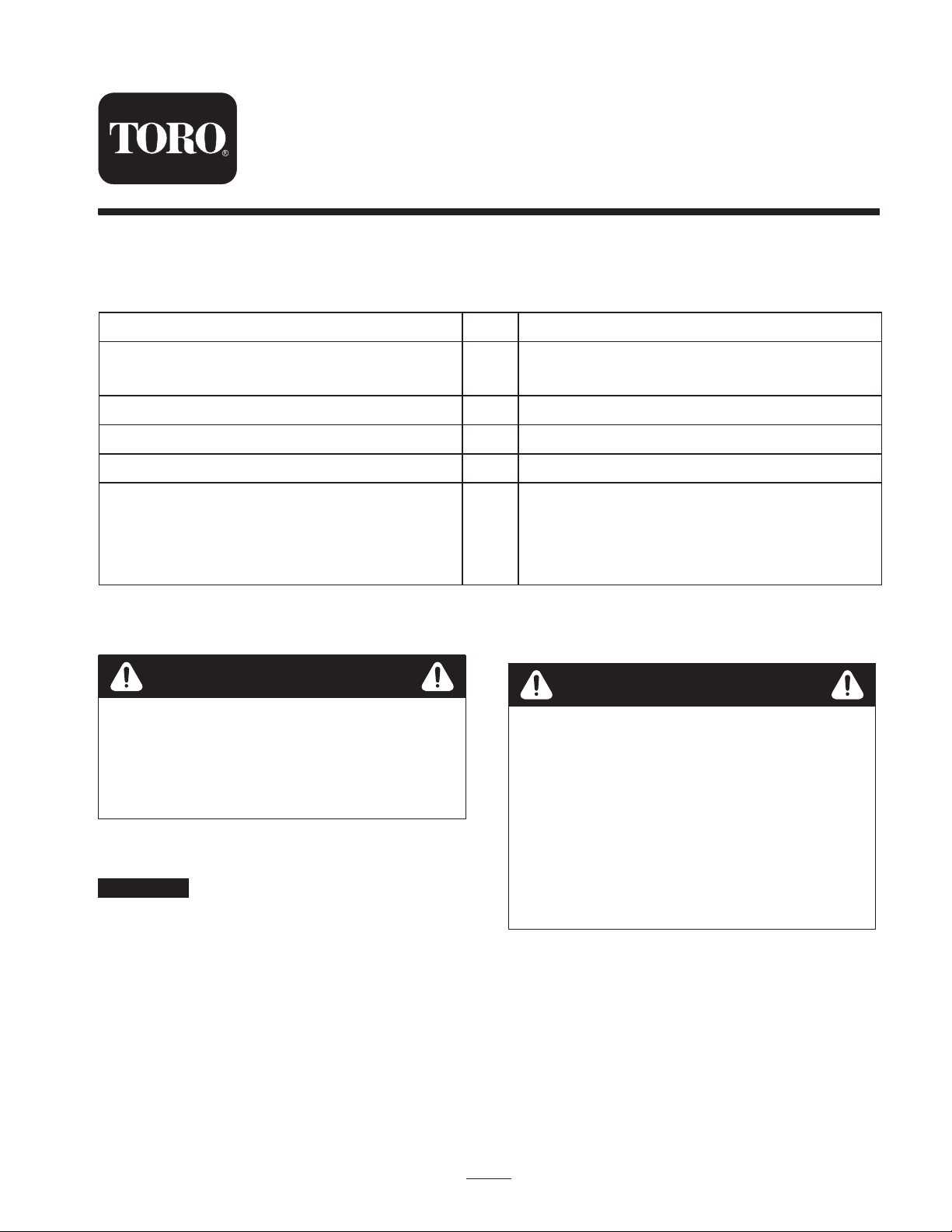

3. Slowly pour electrolyte into each battery cell until the

electrolyte level is up to the Upper line on the battery

case (Fig. 1).

1

9. Install the battery and battery box in the tractor and

connect the battery cables; refer to the Operator’s

Manual.

Checking the Engine Oil Level

2

3

m5004

Figure 1

1. Vent caps

2. Upper line

Important Do not overfill the battery because

electrolyte (sulfuric acid) can severely corrode and damage

the chassis.

4. Wait 5 to 10 minutes after filling the battery cells.

5. Add electrolyte, if necessary, until the electrolyte level

is up to the Upper line (Fig. 1) on the battery case.

6. Install the battery vent caps.

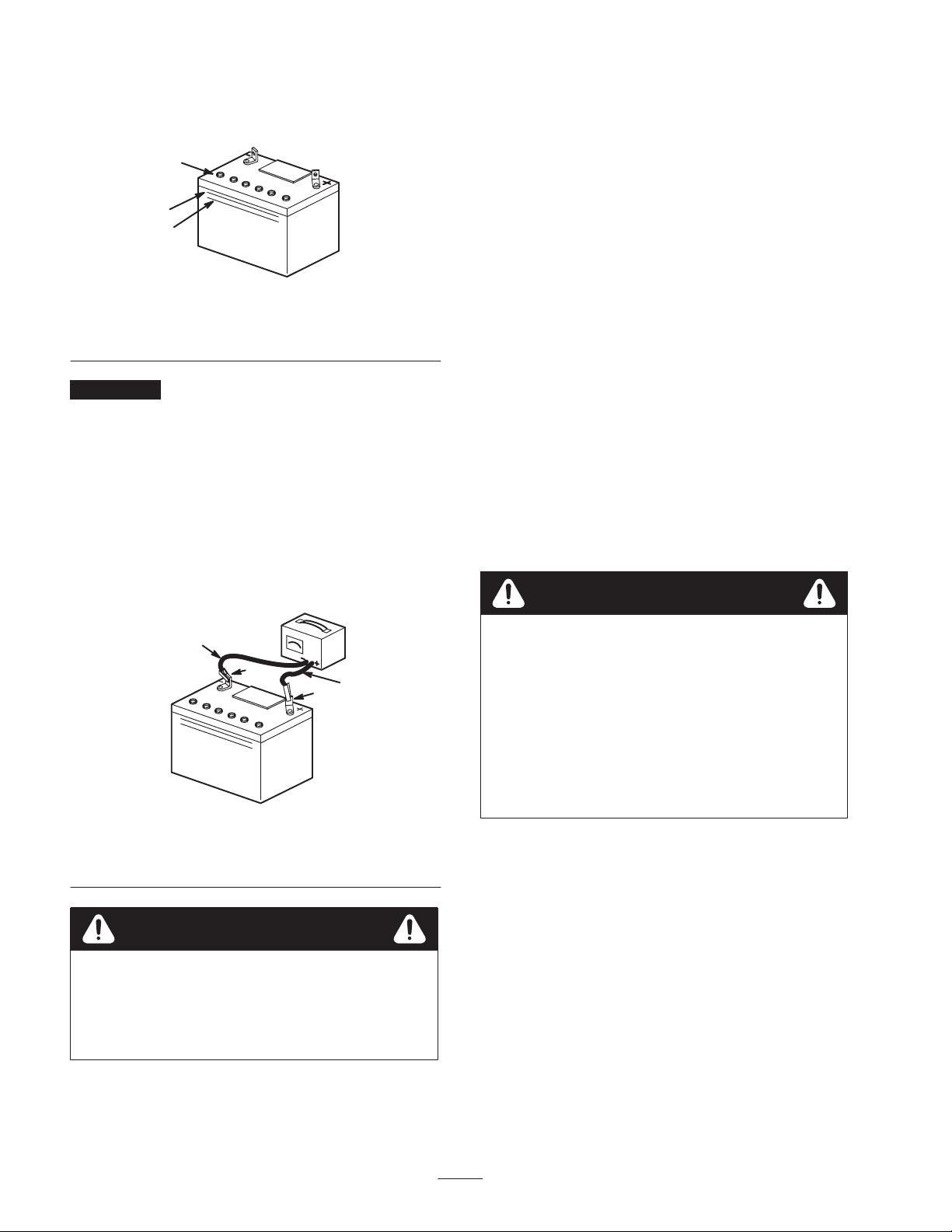

7. Charge the battery for 10 to 15 minutes at 25 to

30 amps or 30 minutes at 4 to 6 amps (Fig. 2).

Do not overcharge the battery.

4

3. Lower line

2

3

1

The tractor comes from the factory with oil in the engine

crankcase; however, you may be need to add oil. Refer to

the Operator’s Manual for oil type, viscosity, and crankcase

capacity. Add only enough oil to raise the level to the Full

mark on the dipstick.

Checking the Tire Pressure

Check the tires to ensure that they are inflated to the proper

level. Refer to the Operator’s Manual.

Checking the Mower

Adjustment

For 32 Mowers only

The mower was leveled at the factory. However, if the

mower is not cutting level, adjust the side-to-side level and

the front-to-rear blade slope. See the Operator’s Manual.

Warning

An improperly adjusted mower can cause the

drive belt to engage the blade at the highest

height-of-cut setting when the blade control (PTO)

lever is in the Disengaged position. Operating the

mower at the highest height-of-cut setting during

or soon after setup may expose you or others to a

rotating blade, causing injury or death.

Figure 2

1. Positive post

2. Negative post

3. Charger red (+) wire

4. Charger black (–) wire

Warning

Charging the battery produces gasses that can

explode.

Never smoke near the battery and keep sparks and

flames away from battery.

8. When the battery is fully charged, unplug the charger

from the electrical outlet, then disconnect the charger

leads from the battery posts (Fig. 2).

Never put your hands or feet under the mower or

through any openings in the mower.

To ensure that the mower is properly functioning at the

highest height-of-cut setting during or soon after setup, do

the following:

1. Raise the mower to the highest height-of-cut setting.

2. Ensure that the blade control (PTO) lever is in the

Disengaged position.

3. Start the engine and have someone check if the drive

belt engages or tries to engage the blade.

4. If the drive belt tries to engage or engages the blade,

operate the mower for several minutes at different

height-of-cut settings.

2

Page 3

Note: The length of the long rod extending out of the front

of the adjusting block on the sides of the chassis (Fig. 3) is

set to 3/4 in. (19 mm) at the factory.

5

1

2

4. Move the drive control in the Operate position (Fig. 4)

and drive the tractor forward and reverse for about

5 feet (1.5 m) each way. Repeat this step 3 times.

Checking the Hydro Neutral

Position

For Hydro Drive Tractors only

3

4

m-1805

Figure 3

1. Adjusting block

2. Long rod

3. Hairpin cotter and washer

4. Mower mount

5. Length of long rod

extending out

Lubricating the Tractor

Ensure that all of the necessary points on the tractor are

lubricated; refer to the Operator’s Manual.

Checking the Safety Interlock

System

Refer to the Operator’s Manual.

Purging the Hydro Transaxle

For Hydro Drive Tractors only

Ensure that the neutral position is set properly. If the tractor

moves when the traction control pedal is not depressed,

adjust the neutral position.

1. Run the engine at a low idle and move the traction

control pedal forward, then release it.

2. Move the traction control pedal to reverse, then release.

If the tractor moves while it is in the Neutral position,

do the following:

3. Run the tractor for 5 to 10 minutes to warm up the

transaxle.

4. Disengage the blade (PTO).

5. Set the parking brake.

6. Stop the engine and wait for all moving parts to stop.

7. Remove the ignition key.

8. Raise the right rear wheel off the ground and support it

with a jack stand.

Note: Ensure that the left rear wheel is on the ground.

Danger

Shipping and handling can introduce air into the hydro

transaxle. For proper performance, remove all trapped air.

1. Move the tractor to a flat, level surface.

2. Move the drive control in the Push position (Fig. 4).

1

2

Figure 4

1. Operate position 2. Push position

3. Run the engine at a low idle and move the traction

control pedal forward for 5 seconds, then reverse for

5 seconds. Repeat this step 3 times.

m-4974

Mechanical or hydraulic jacks may fail to support

the tractor and cause a serious injury.

• Use jack stands when supporting the tractor.

• Do not use hydraulic jacks.

Note: To gain access to the adjusting puck (Fig. 5), you

may need to remove the tire.

1

2

m-4900

Figure 5

1. Adjusting puck screw 2. Adjusting puck

3

Page 4

9. Loosen the adjusting puck screw (Fig. 5).

10.Start the engine and run it at full throttle.

11. Rotate the adjusting puck in both directions until you

find the midpoint where the axle no longer rotates

forward or reverse.

12.Hold the puck with an adjustable wrench so that it will

not move and torque the adjusting puck screw to 21 to

27 ft-lb (28 to 36 N•m).

13.Stop the engine and wait for all moving parts to stop.

14.Remove the ignition key.

15.Lower the tractor from the jack stand.

16.Check the adjustment again by repeating step 1.

Checking the Traction Control

Pedal

For Hydro Drive Tractors only

You can adjust the traction control pedal for optimum

forward and reverse speeds.

1. Loosen the screws below the right footrest.

1

2

m-1879

Figure 7

1. Ground speed lever 2. Numbers

1. If either of the above conditions exist, turn the engine

off and ensure that the belt guides are no more than

1/8 inch away from the engine and the transmission

pulleys.

2. Check the cable tension. The cable should be taught and

have 1/2 in. (13 mm) movement when you apply a

slight pressure to the cable (Fig. 8).

2

1

2. Slide the pedal forward for a faster reverse speed or

backward for a faster forward speed (Fig. 6).

1

2

Figure 6

1. Traction control pedal 2. Adjusting screws

3. Tighten the screws.

4. Check the traction control pedal.

m-1909

Checking the Shift Cable

Adjustment

For Gear Drive Tractors only

1910

Figure 8

1. Cable 2. Cable guide

3. Move the ground speed lever and note the gap between

the lever and the edge of the gate. There should be

about 1/4 in. (6 mm) of free play before the cable is

taught.

4. Adjust the cable tension by loosening the front cable

guide located on tractor brace above the pulley.

5. Slide the guide sideways as needed for proper tension

(Fig. 8).

Test Driving the Tractor

To ensure that all electrical and mechanical systems are

operating properly, see the Operator’s Manual.

Adjust the shift cable if either the ground speed lever does

not shift firmly toward the numbers on the shift plate when

you release the lever or if it is difficult to shift on-the-go

(Fig. 7).

4

Loading...

Loading...